Continuous wall milling machine

A milling machine and milling technology, which is applied to sheet pile walls, earth movers/excavators, construction, etc., can solve the problems of wall strength influence, complicated maintenance, and low construction efficiency, so as to improve construction safety performance, Simple and convenient maintenance and high working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

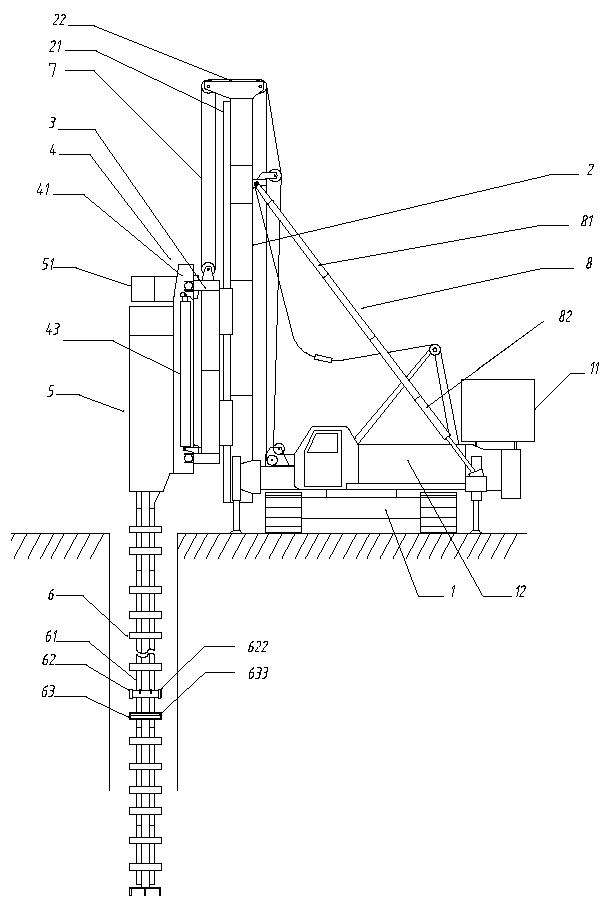

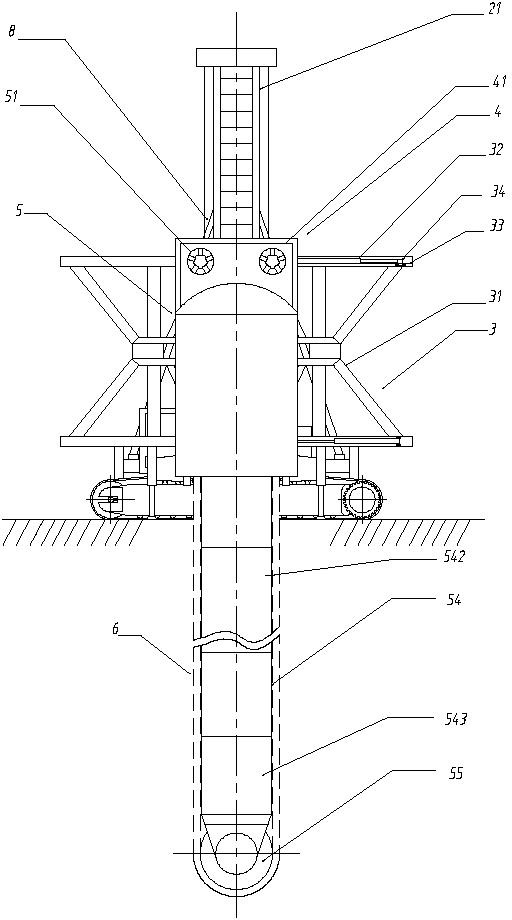

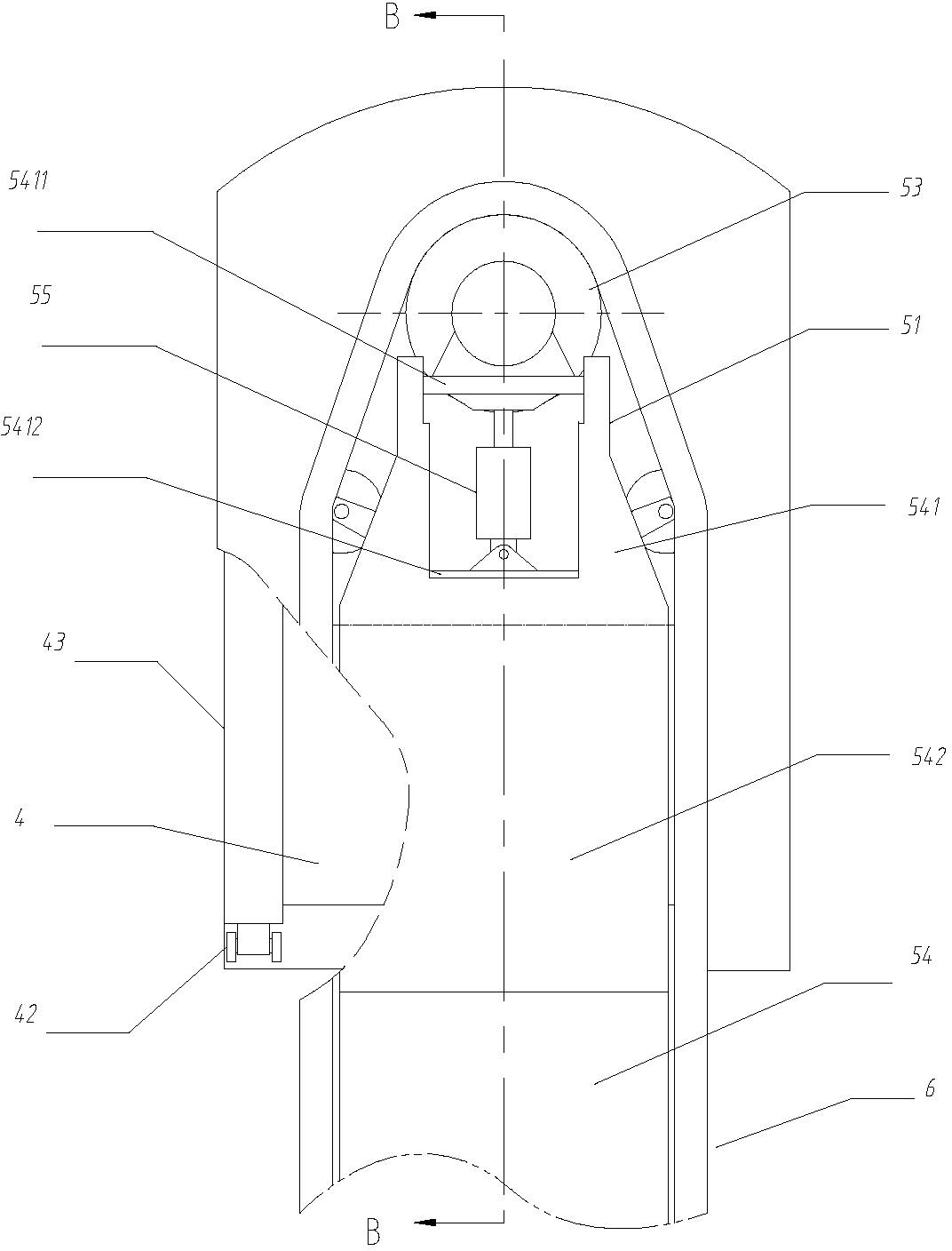

[0043] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a continuous wall milling machine includes: a host chassis 1, including a power source 11 and a hoist unit 12; a column 2, including a guide rail 21 and a top pulley frame 22; a door frame 3, including a frame body 31, and a horizontally moving oil cylinder 32. Transverse rail 33 and guide seat 34; guide frame 4, including frame body 41 with upper and lower rails, guide slider 42 and vertical jacking cylinder 43; milling box 5, including drive head 51 containing motor and planetary reducer , gearbox 52, driving sprocket 53, milling frame 54, tensioning oil cylinder 55, driven sprocket 56 and grouting pipe 57; milling frame 54 adopts box-type structure, including upper section 541, connecting member 542 and lower section 543 in turn Milling and stirring chain 6, comprising chain 61, some groups of milling cutter bodies 62 and some groups of stirring bodies 63 fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com