Construction method of large-span subway station main body by using arched cover method and station main body structure

A construction method and technology of the main structure, which are used in earthwork drilling, underground chambers, mining equipment, etc., can solve the problems of difficult to guarantee the verticality of the enclosure piles, disturbed strata frequently, and weak support systems, etc., and achieve waterproof quality. Excellent effect, less blasting times and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

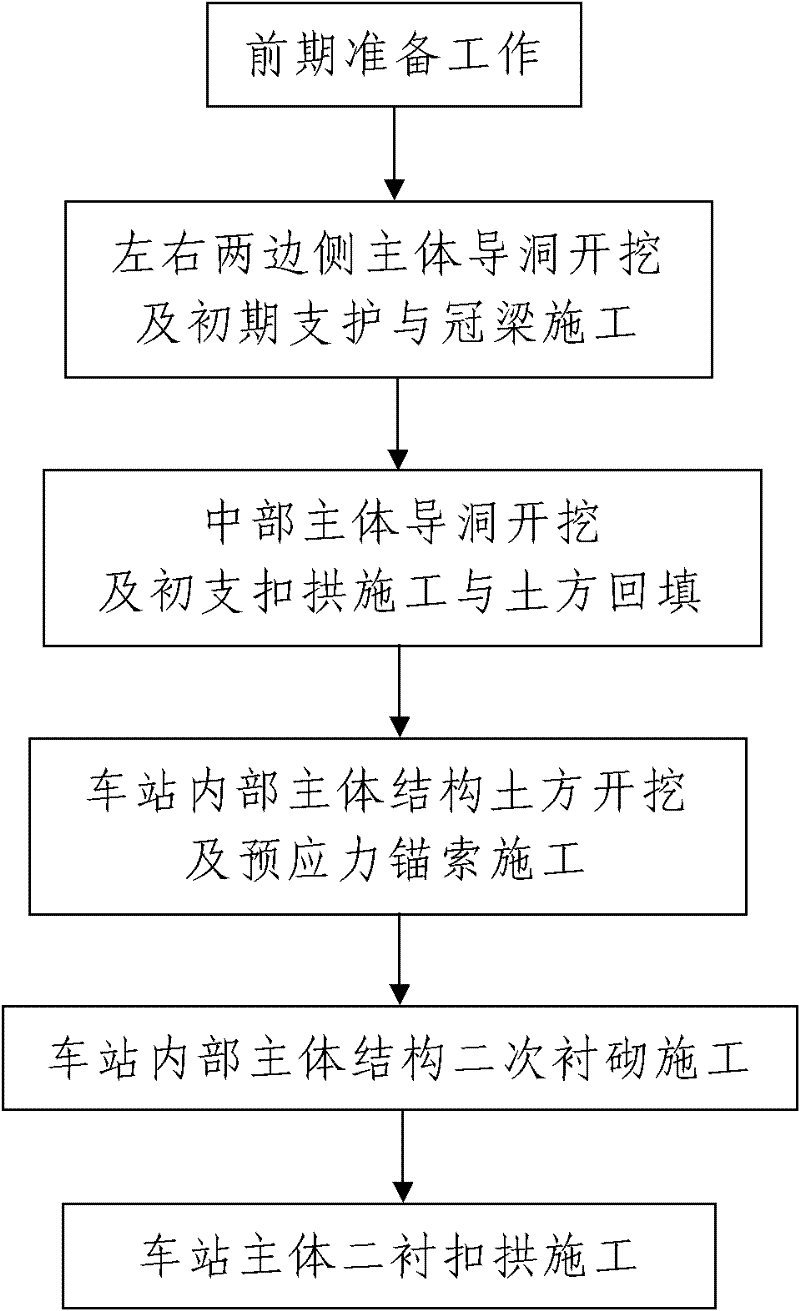

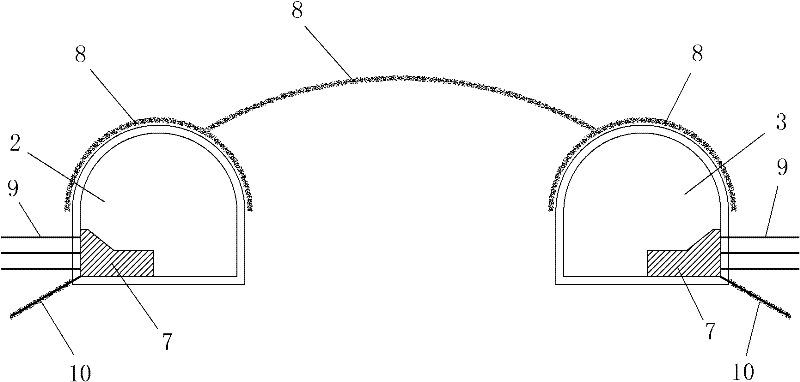

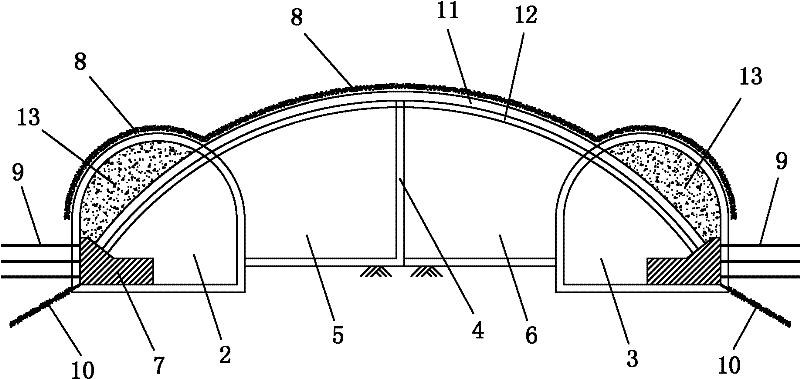

[0052] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Shown, the subway large-span station main body arch cover method construction method of the present invention comprises the following steps:

[0053] Step 1. Preparatory work: Use conventional construction measurement methods and carry out construction measurement at the construction site according to the design drawings, and measure and set the peripheral edge and center line of the main arch of the large-span station to be constructed, as well as the left and right sides of the main arch. The layout positions of the two arch feet on the side; then at the layout positions of the two arch feet, the centerlines of the main guide hole 1 2 and the main guide hole 2 3 and the respective peripheral edge lines at the entrance of the hole are respectively measured, and corresponding The peripheral edge lines of two crown beams 7 on the left and right are measured and arranged on the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com