Pit pile anchor breast wall concrete breast beam structure and construction method thereof

A construction method and concrete technology, which is applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve the problems of steel waist beams affecting construction safety, long construction time, high construction cost, etc., and achieve shortened construction time, simple construction method, The effect of simplifying the construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

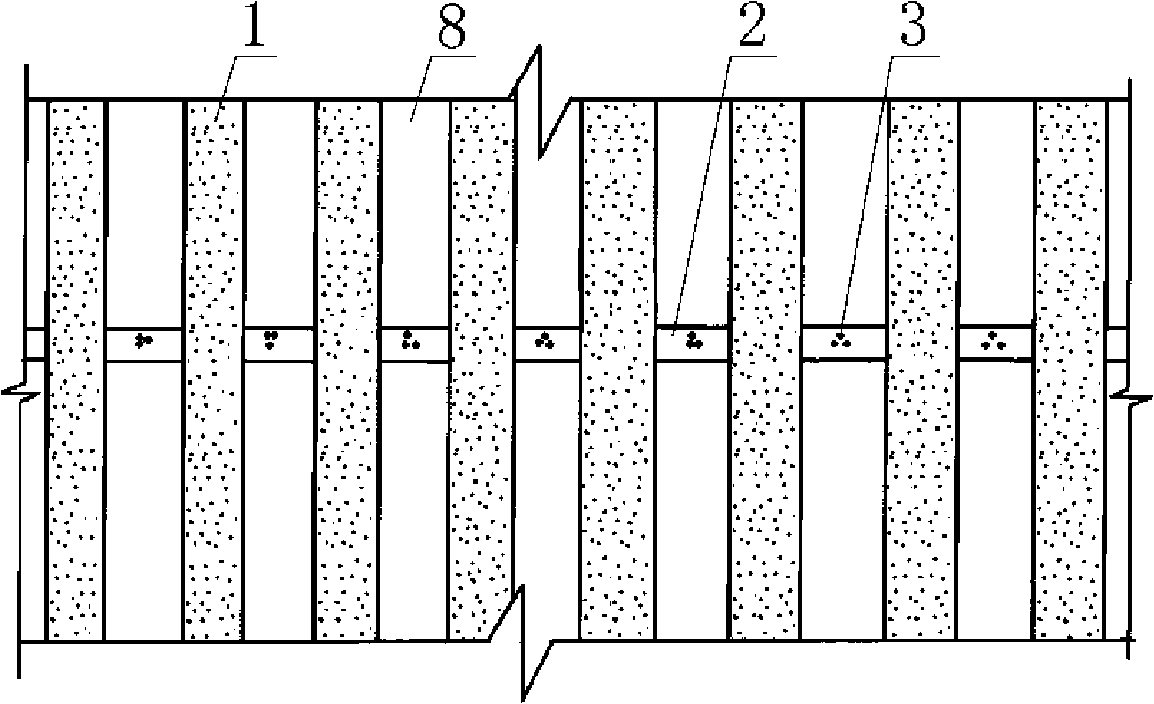

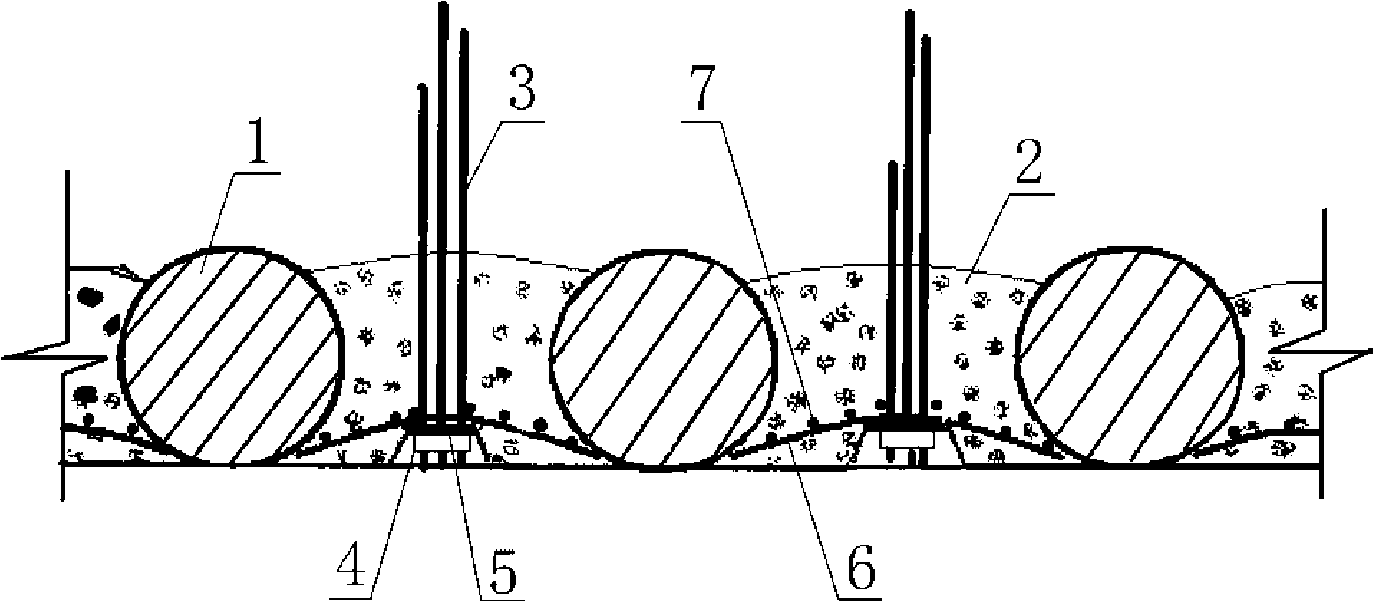

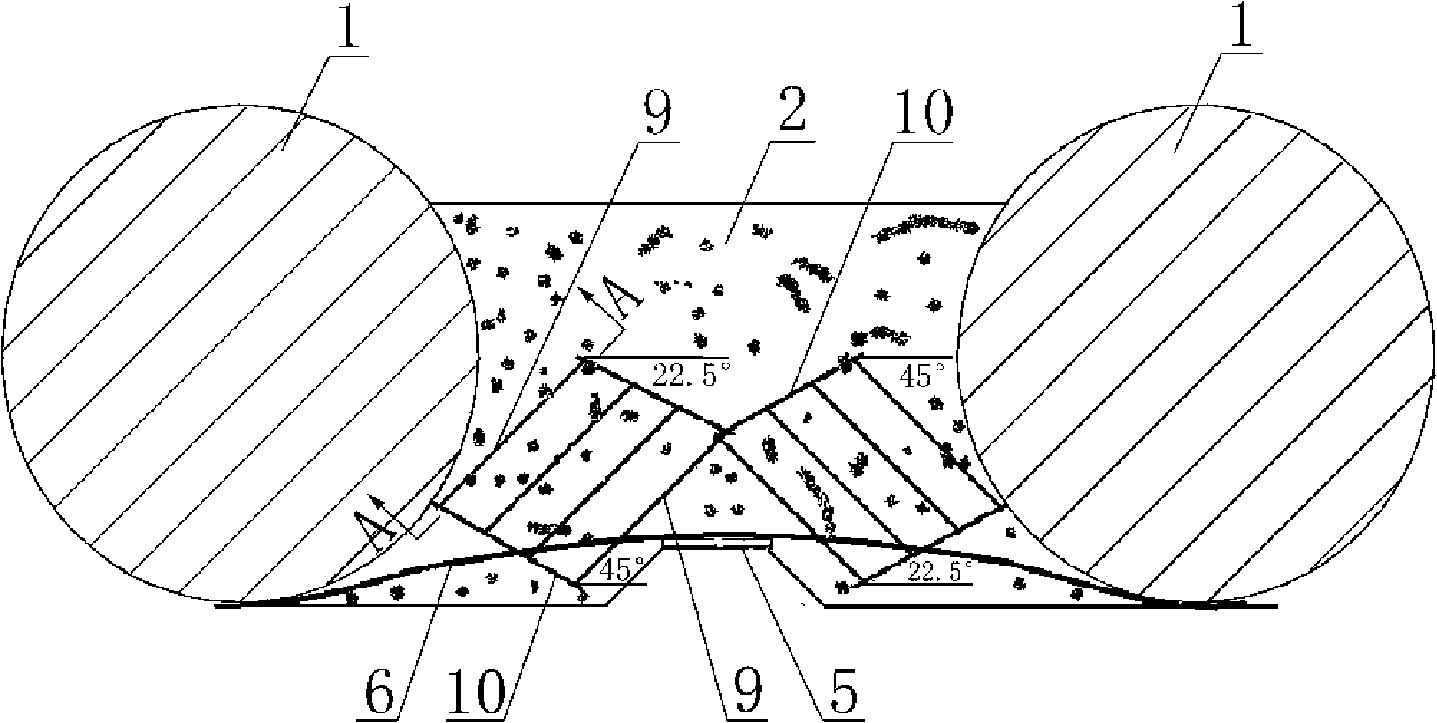

[0045] Examples see figure 1 , figure 2 As shown, this kind of foundation pit pile anchor protection wall concrete waist beam structure has a row of slope protection piles 1 arranged at intervals in the side wall of the foundation pit, and the prestressed anchors are fixed and fixed into the soil 8 between the piles of the slope protection piles. Bar 3, a lateral waist beam is also arranged on the side wall of the foundation pit. The above waist beam is a concrete waist beam 2. The concrete waist beam 2 is located between the piles of the concrete slope protection pile 1, and is connected to the prestressed anchor 3 by pouring. The outer side of the waist beam 2 is flush with the outer skin of the concrete slope protection pile 1, the inner side of the concrete waist beam is close to the inner end of the concrete slope protection pile, and the inner side of the concrete waist beam is distributed near the outer side. The sheet is wrapped on the outside of the pile body of the row...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com