Patents

Literature

545results about How to "Reduce excavation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

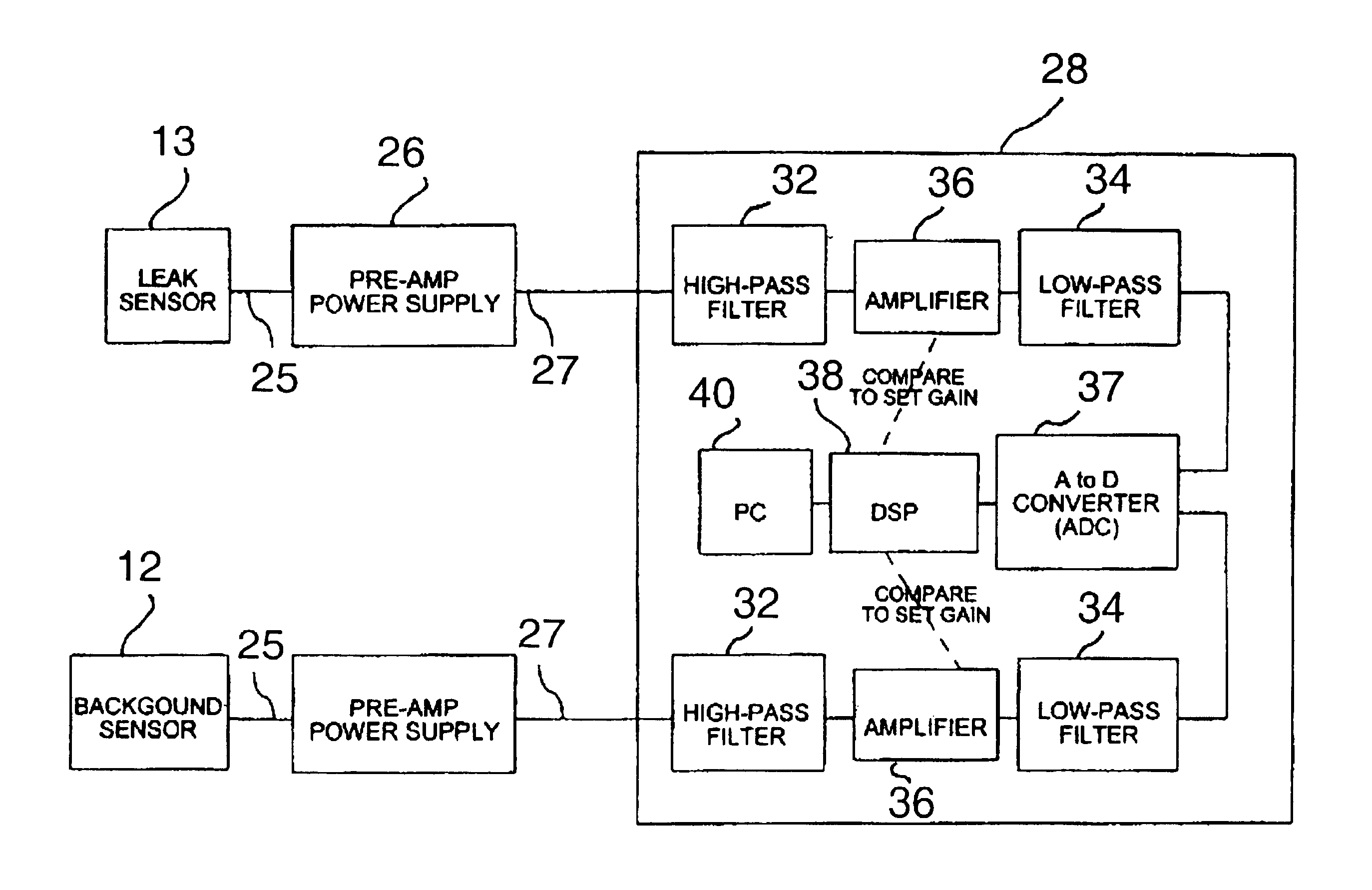

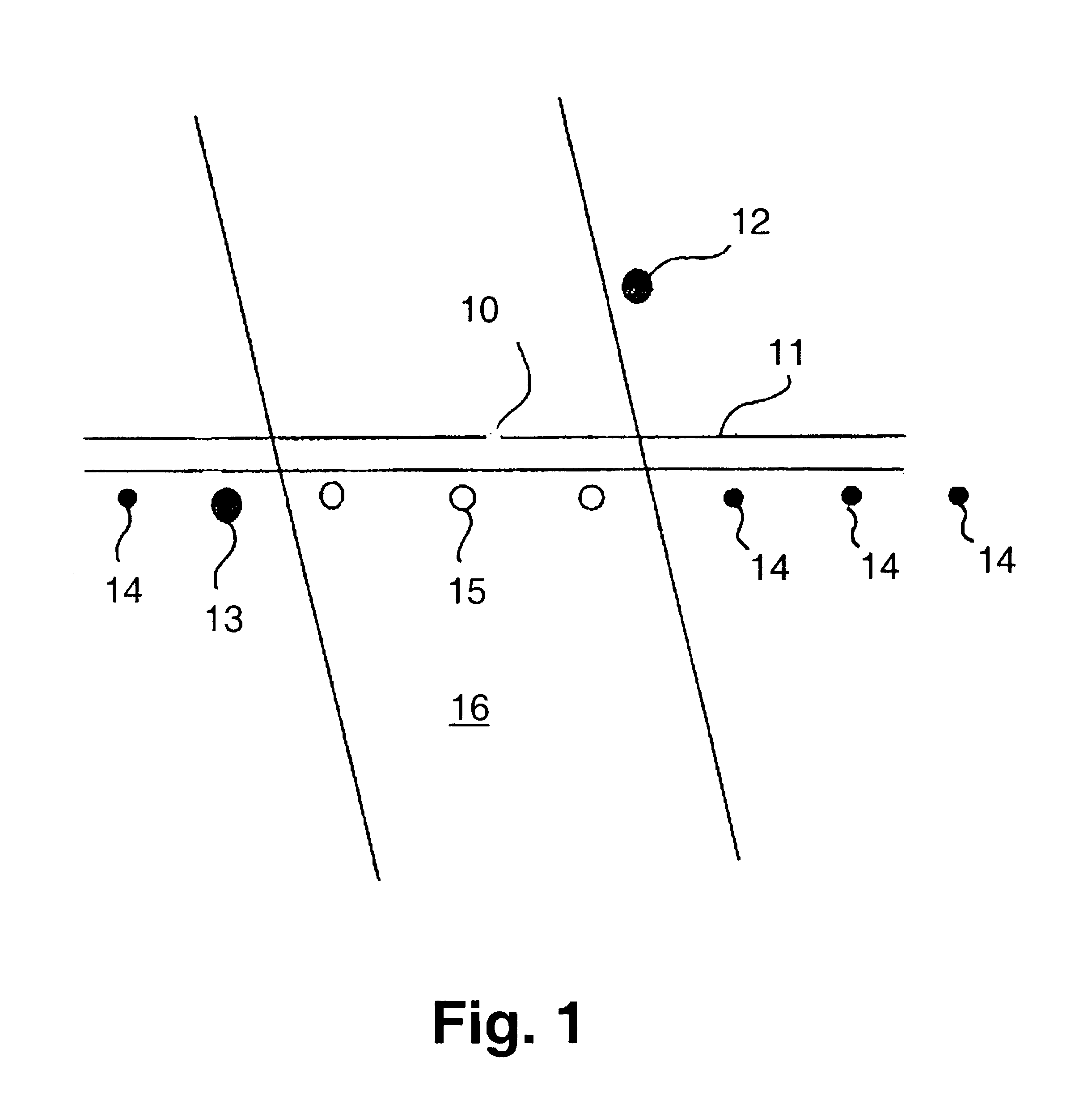

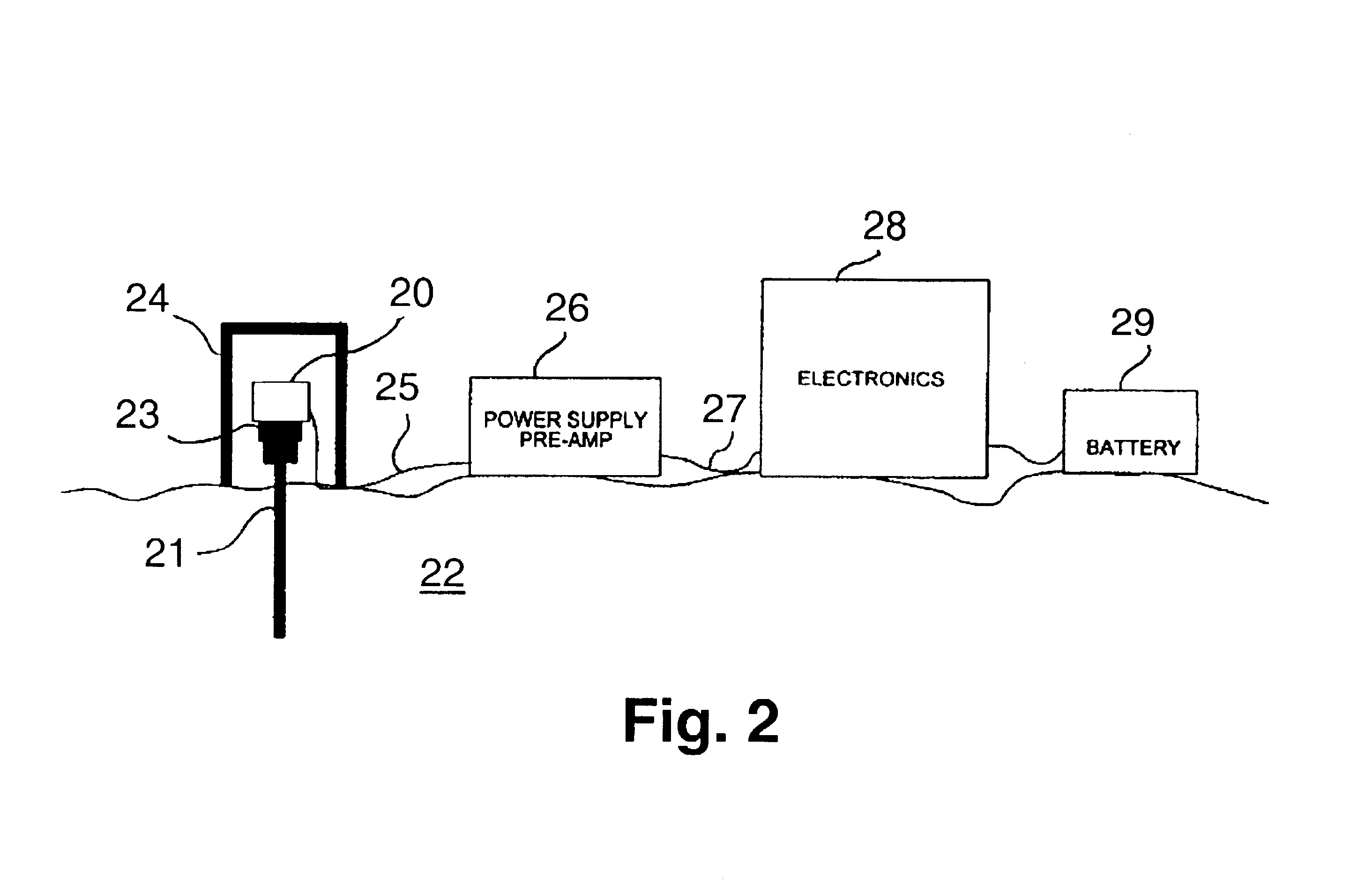

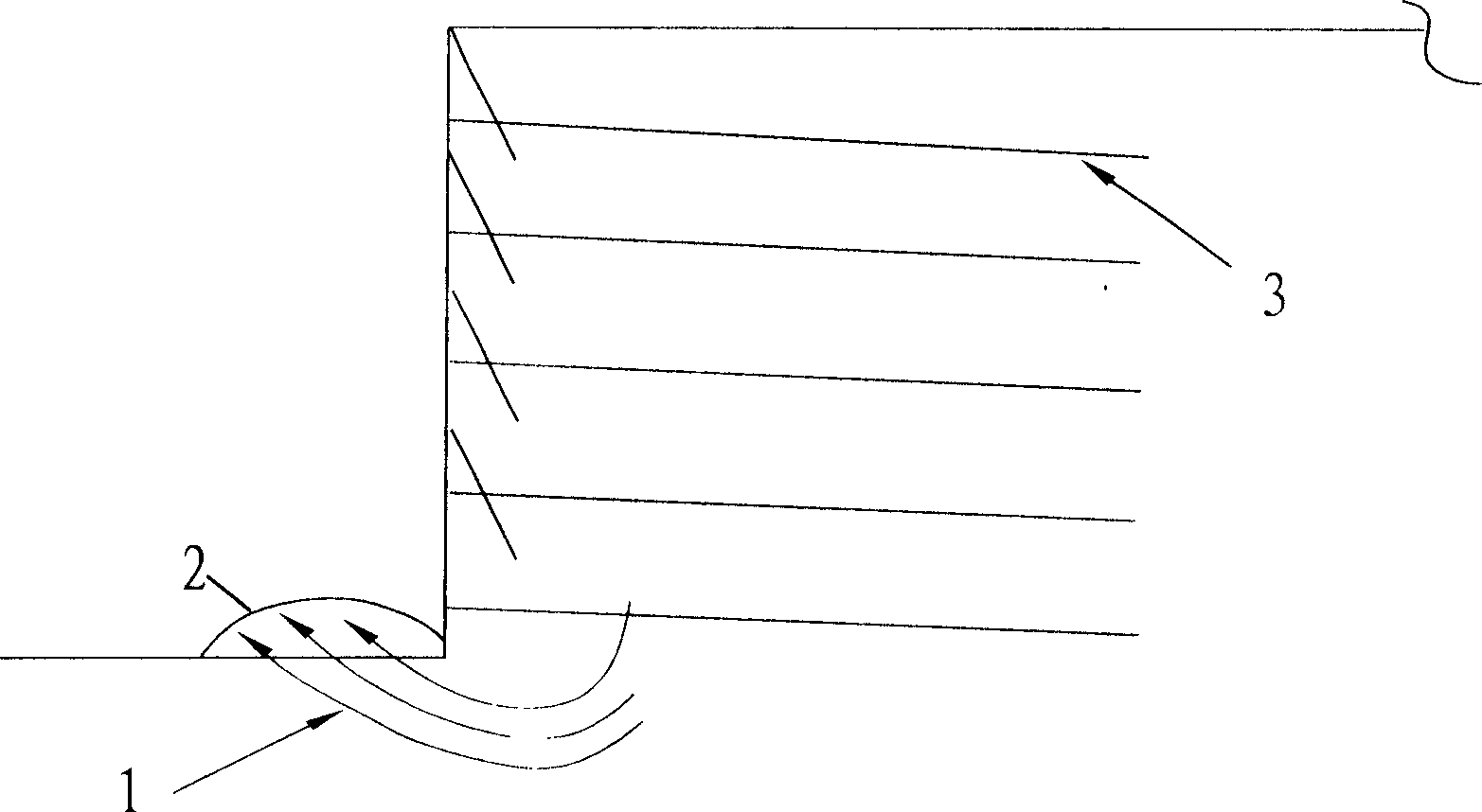

Enhanced acoustic detection of gas leaks in underground gas pipelines

InactiveUS6725705B1Improve efficiencyIncrease the lengthDetection of fluid at leakage pointMaterial analysis using sonic/ultrasonic/infrasonic wavesGas leakEngineering

A method for locating gas leaks from underground gas pipelines in which a first acoustic sensor having a first signal output is positioned in ground disposed substantially above or at a distance from the underground gas pipeline. At least one second acoustic sensor having a second signal output is positioned in the ground at a plurality of locations substantially above the underground gas pipeline. The output signals from the acoustic sensors are measured for each location of the second acoustic sensor and the signals are adaptively filtered to remove common noise signal components. The statistical minima of these rms voltages are determined for both the first output signal and the adaptively filtered second output signals and the differences determined. The location of the second acoustic sensor corresponding to the largest positive said difference is the location closest to the leak site.

Owner:GAS TECH INST

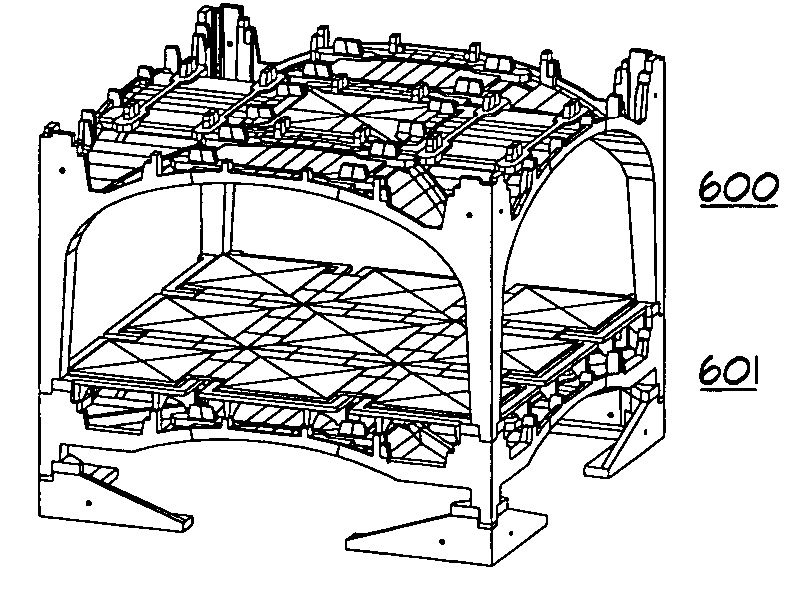

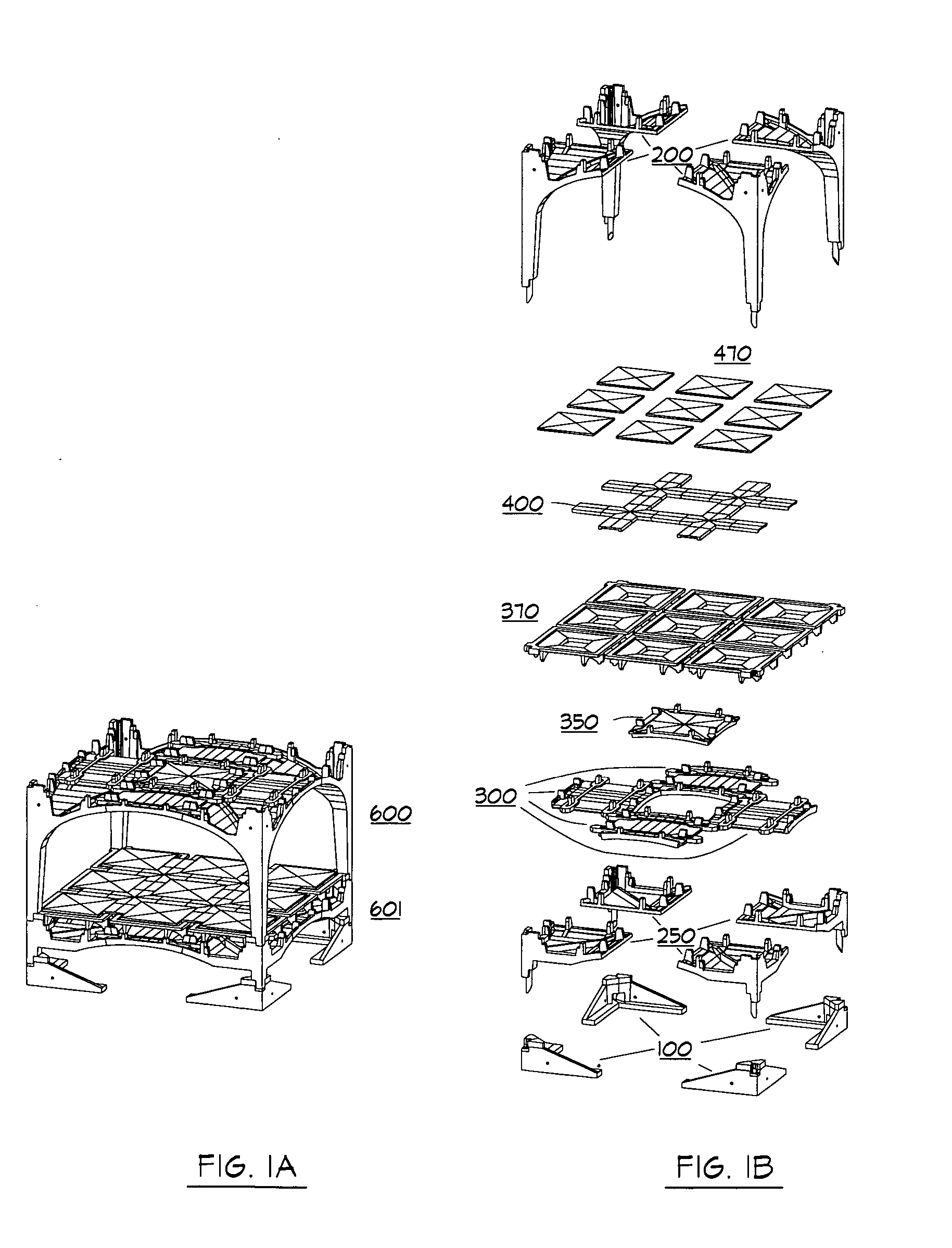

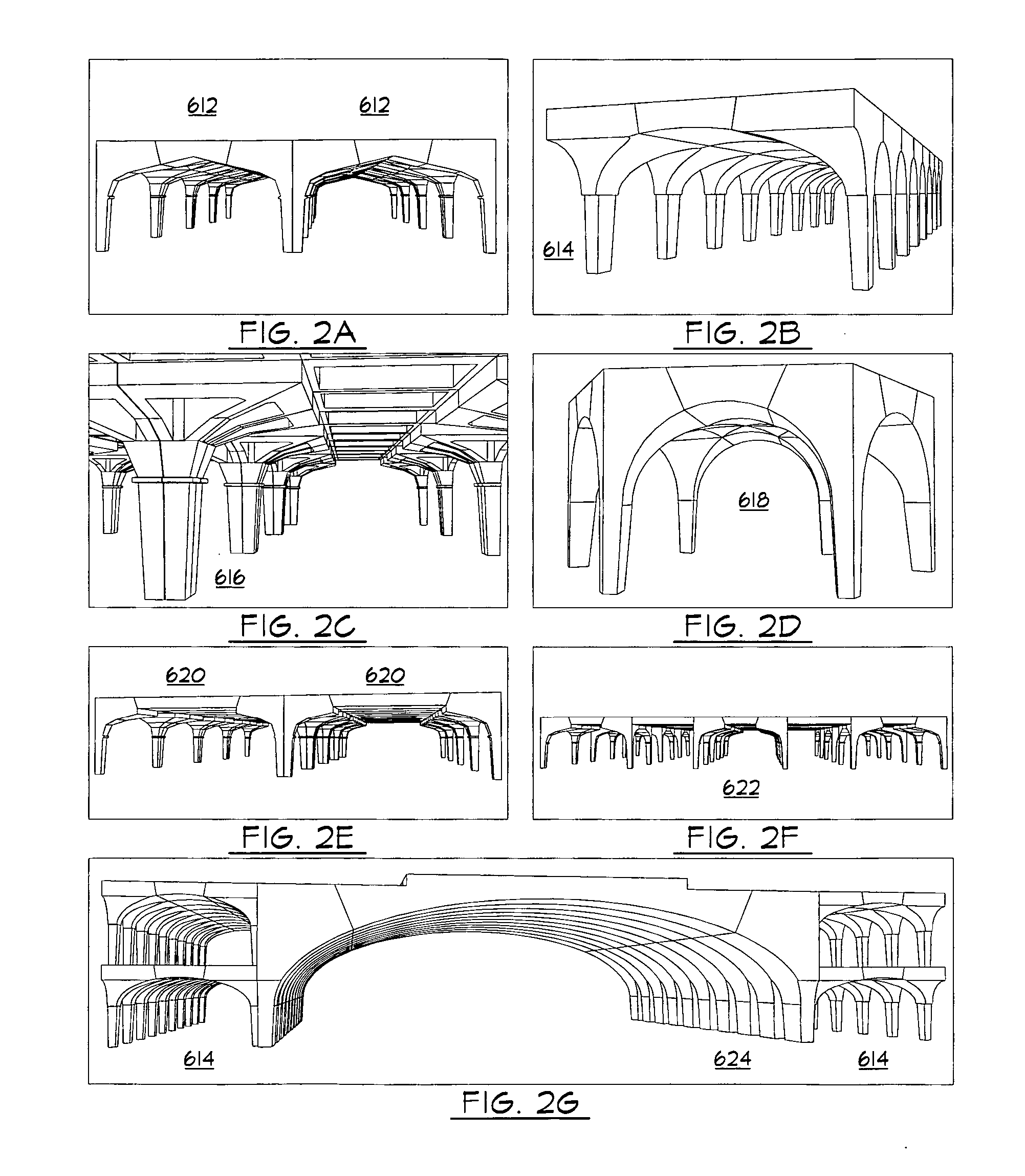

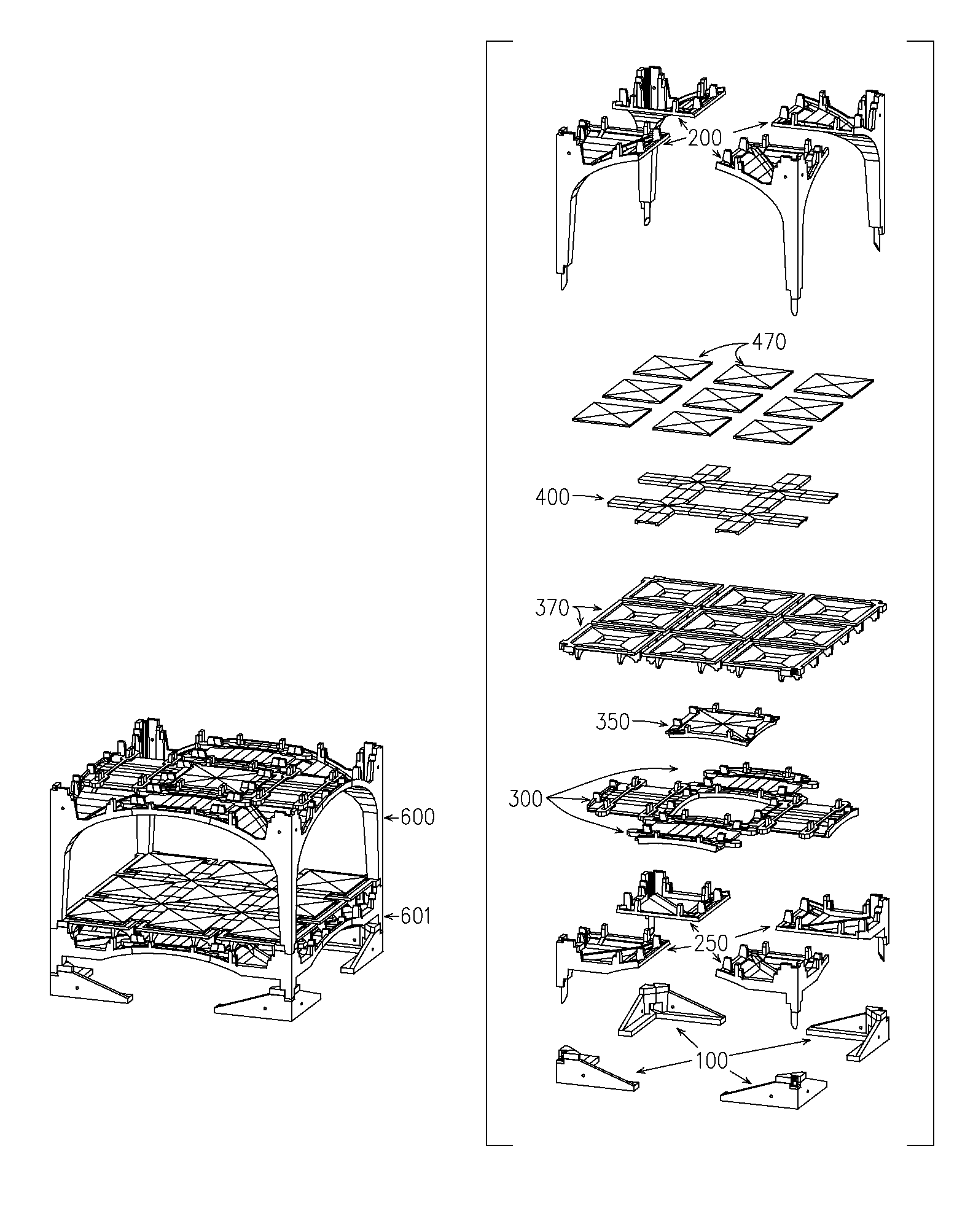

Method and system for prefabricated construction

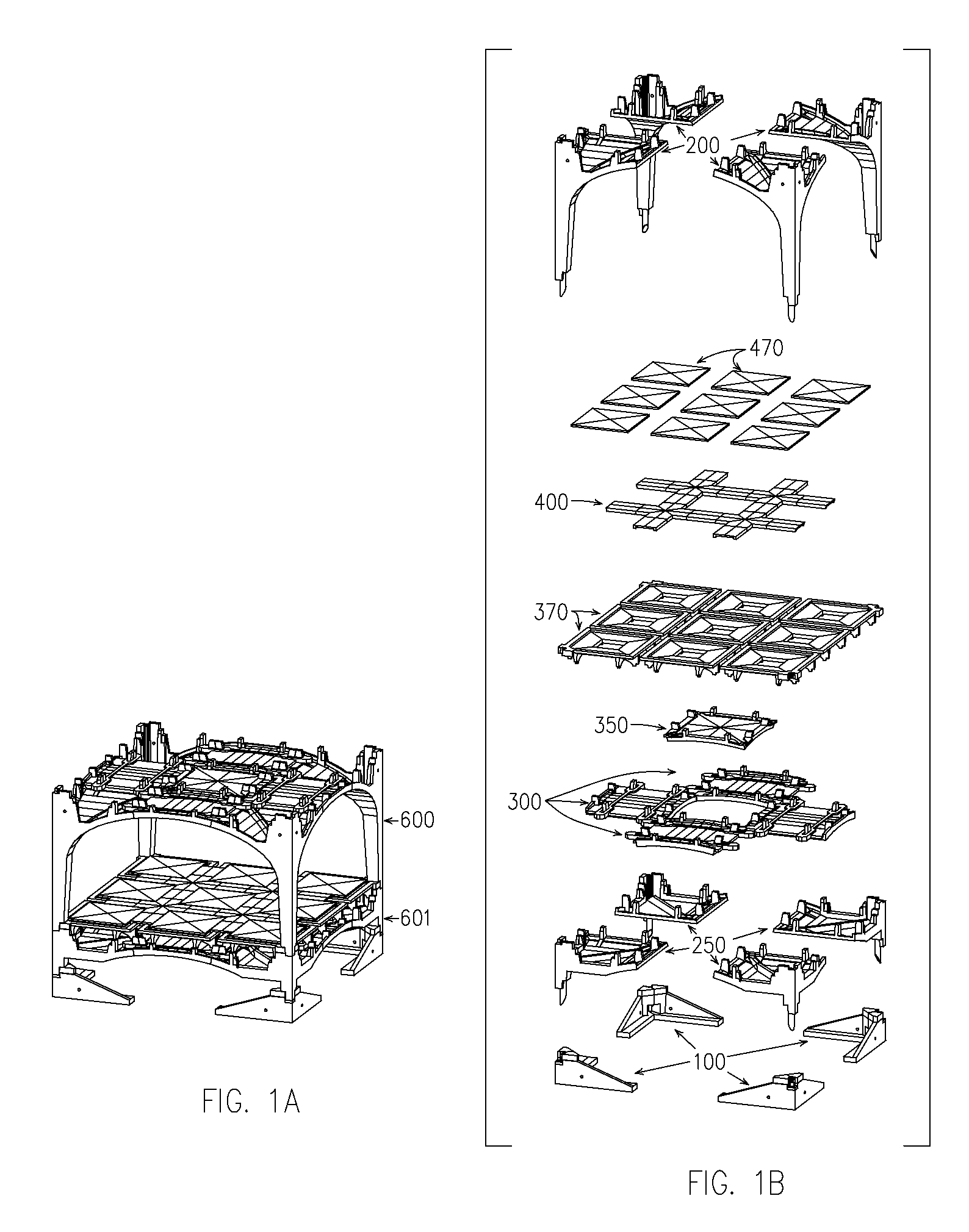

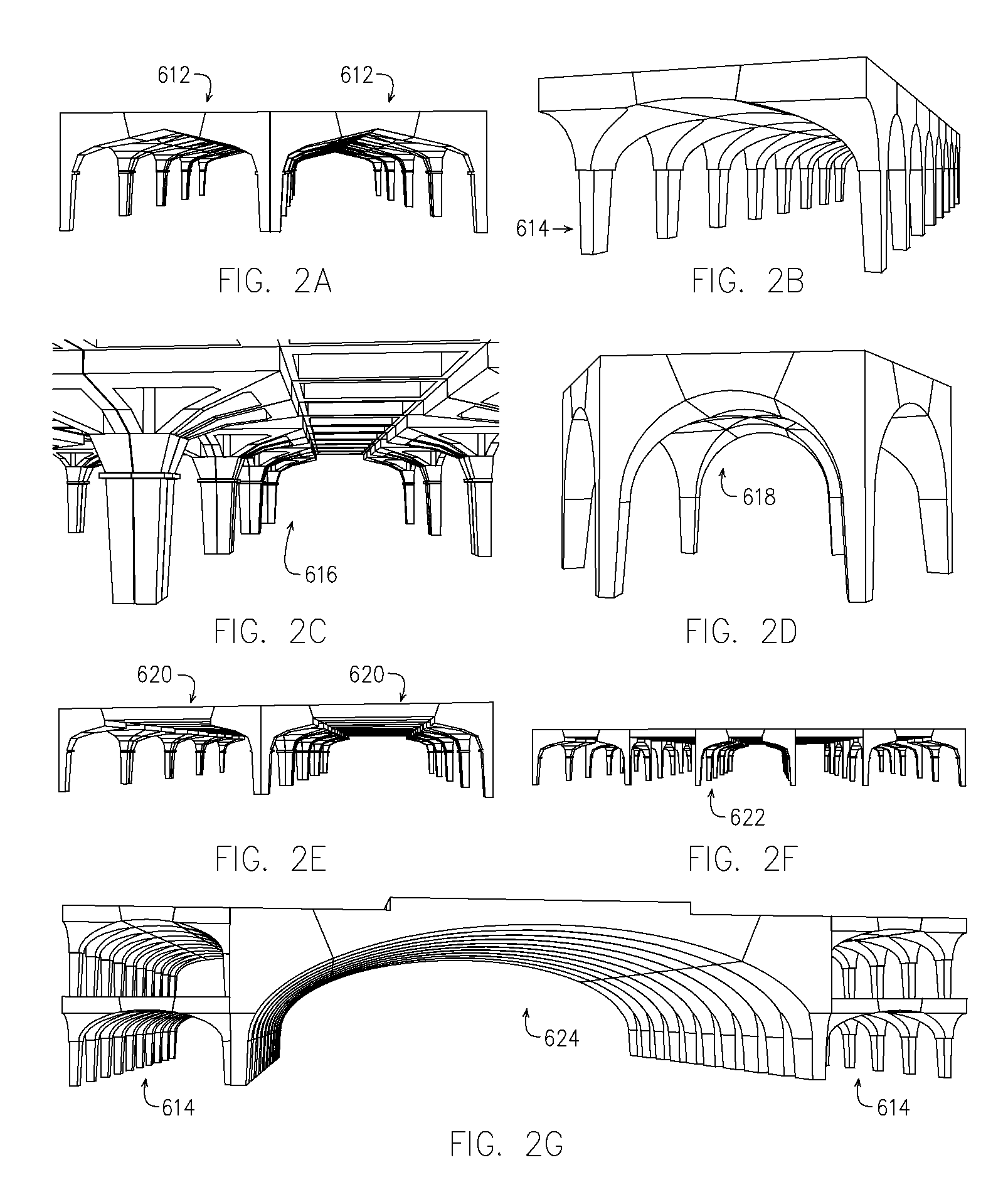

A structure assembled from a combination of stackable modules, each module assembled from multiple prefabricated, transportable blocks. The blocks are typically reinforced cast concrete formed in reusable molds. Module framing blocks may include arched corner blocks, key blocks that interlock with a pair of corner blocks, and optional center blocks. Other structural elements include roof, floor, and wall components that interlock with the framing modules. Modules may be stacked or nested to form structures including buildings, elevated roadways, and parking garages. Utilities may be provided through optional conduits formed in the corner elements. The framing supports raised floor modules for ease in mechanical system installation and modification. The roof elements support usable terraces and rainwater collection. The blocks are demountable and reusable. The modules are self-supporting during erection, and may be assembled without fasteners.

Owner:POWELL DAVID W

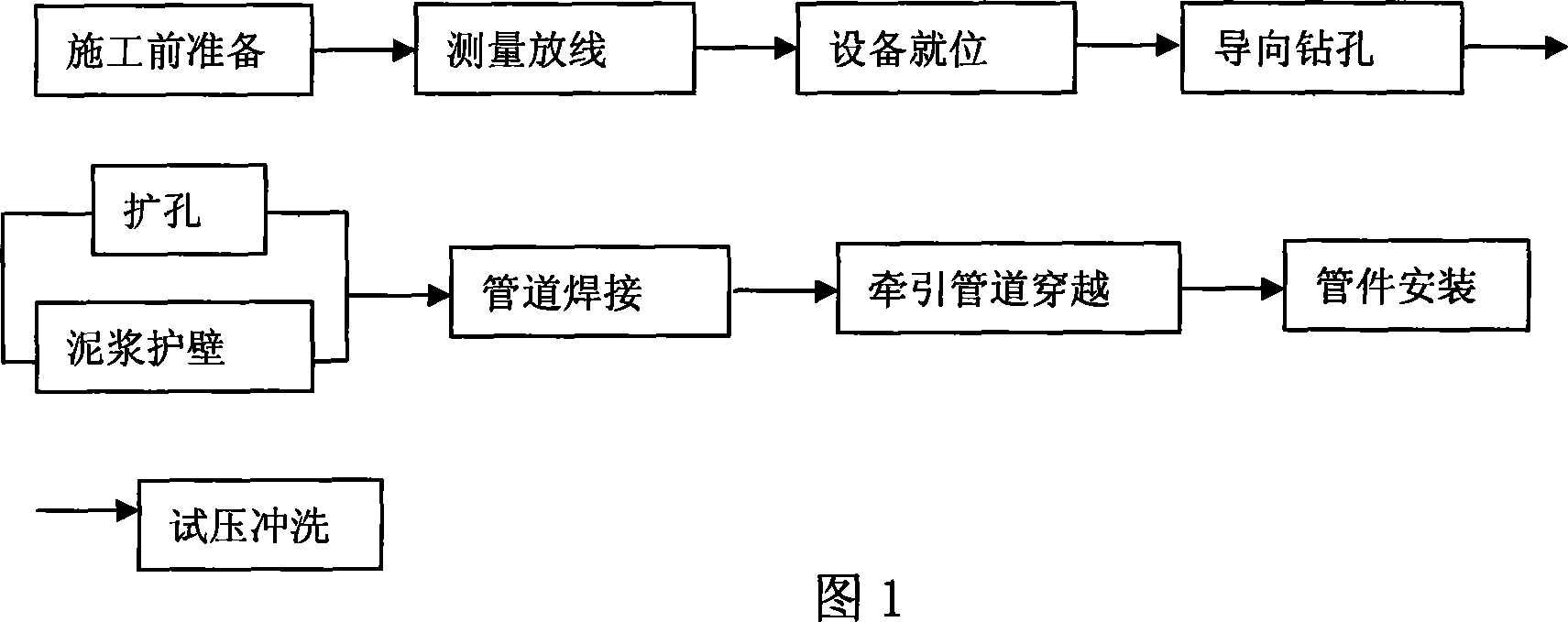

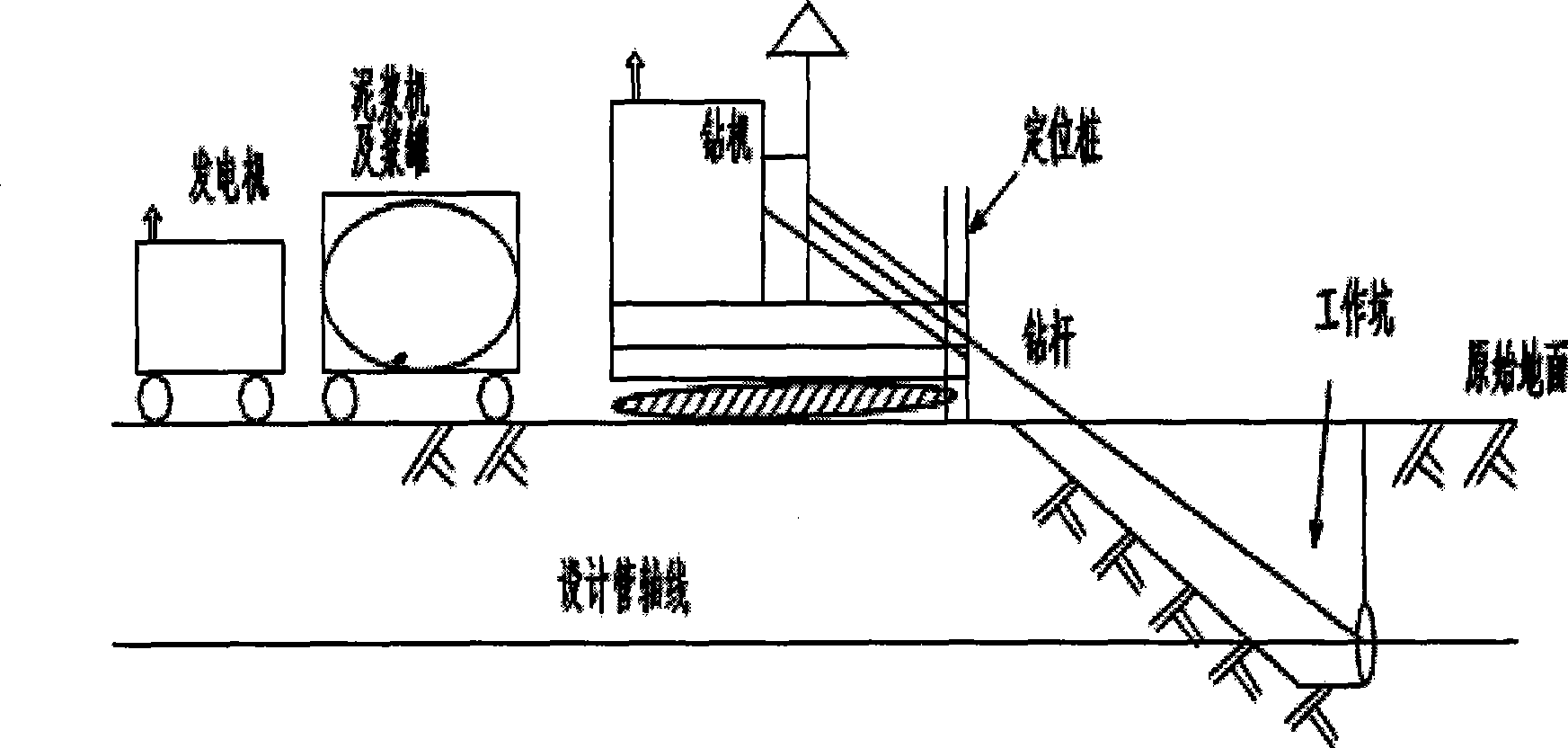

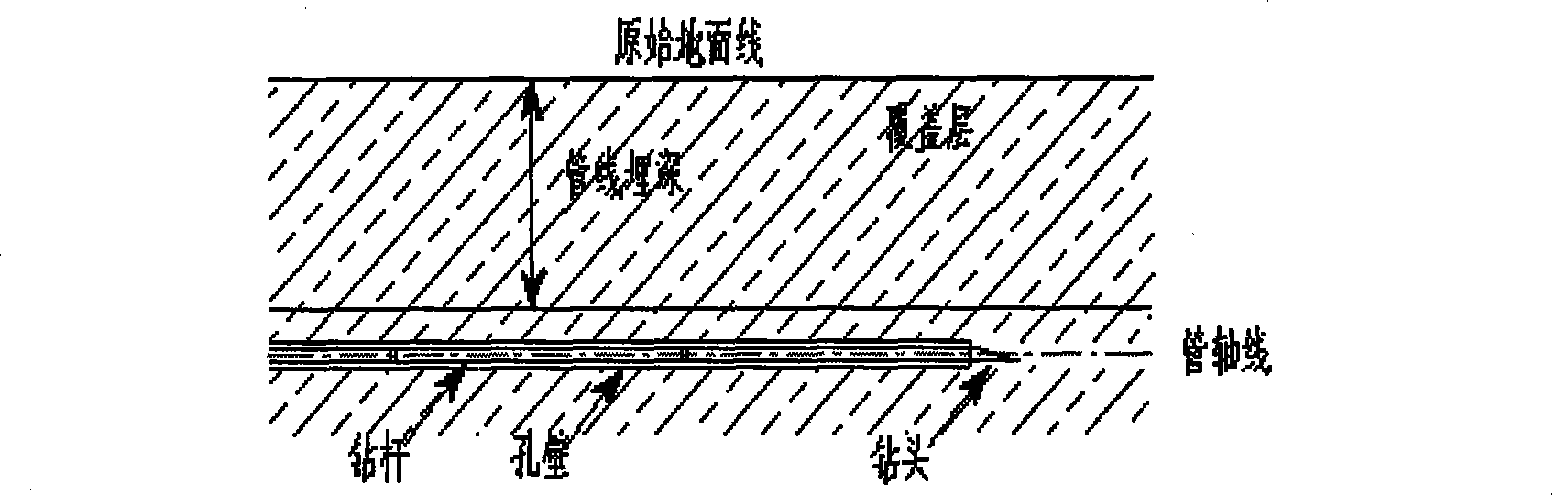

Non-digging tube-pulling construction method

InactiveCN101457853AReduce excavationReduce backfill workloadPipe laying and repairSocial benefitsGeomorphology

The invention relates to a non-excavation tube pulling construction method which comprises the following steps: (1) preparation work: understanding stratum and underground condition, calculating the number of chambering and the size of a return compandor, and formulating the control data of a pipeline midline and elevation and correction measures; (2) measuring plane surface, controlling payingoff, and measuring the elevation of each pile; (3) setting an active well, and receiving and setting a drilling machine; (4) preparing drilling fluid; (5) drilling pilot holes,; (6) adopting the compandor to chambering, cleaning the hole at the same time, and protecting walls with slurry; (7) welding the pipeline; (8) pulling the tube, and simultaneously pulling a steel tube with the same length as that of the tube; (9) casting slip and fixing; (10) mounting tubes; (11) testing pressure and flushing. The invention can effectively increases economical benefit and social benefit, and has the advantages of environmental protection and energy saving.

Owner:江苏广宇建设集团有限公司

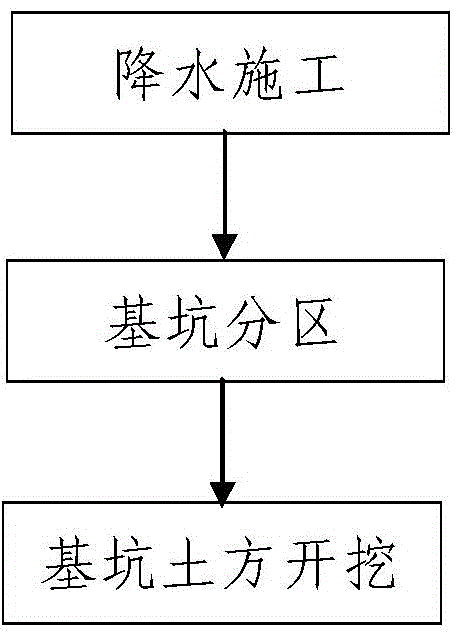

Subway station deep foundation pit excavation construction method

ActiveCN104612162AThe method steps are simpleReasonable designExcavationsReinforced concreteSubway station

The invention discloses a subway station deep foundation pit excavation construction method, wherein the upper portion of an excavated foundation pit is a sandy gravel stratum, and the lower portion of the excavated foundation pit is a mud rock stratum. The method includes the steps of 1, precipitation construction, wherein precipitation construction is conducted on the sandy gravel stratum through a precipitation well and 2, foundation pit excavation, wherein the foundation pit excavation includes the following steps of foundation pit partition and foundation pit earthwork excavation; the excavated foundation pit is divided into a plurality of small foundation pit bodies to conduct excavation respectively; the small foundation pits comprise first foundation pit bodies and second foundation pit bodies; excavation is conducted on the divided small foundation pit bodies; an open-cut method is adopted for the first foundation pit bodies and the second foundation pit bodies; the first foundation pit bodies are supported by fender posts, reinforced concrete supports and steel pipe inner supports; the second foundation pit bodies are supported by the fender posts, pre-stressed anchor cables and the steel pipe inner supports. The subway station deep foundation pit excavation construction method is simple in step, reasonable in design, convenient to construct, faster in construction process, good in construction effect and capable of easily conveniently and fast to finish deep foundation pit excavation construction process, and the influences on the surrounding environment by the excavation construction process are smaller.

Owner:中铁二十局集团第三工程有限公司

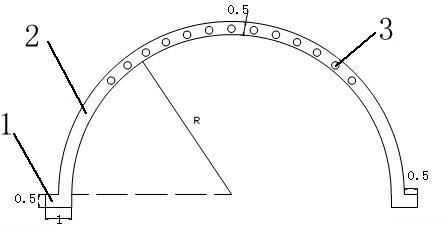

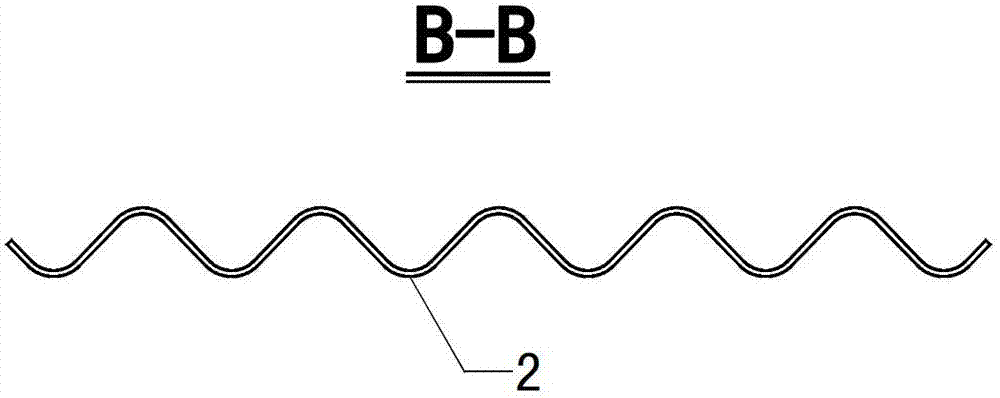

Method for primary support with corrugated steel plate and concrete combined structure taking place of steel grating

InactiveCN104863614AImprove the force characteristicsReduce disturbanceUnderground chambersTunnel liningSheet steelGrating

The invention discloses a method for primary support with a corrugated steel plate and concrete combined structure taking the place of a steel grating. The corrugated steel plate and concrete combined structure is formed by assembling and connecting an upper supporting corrugated plate, a side wall corrugated plate and an inverted arch corrugated plate into a ring; two arch feet of an upper step of a cavern are fixedly provided with two pieces of H-section steel, and the upper end of the upper supporting corrugated plate and the upper end of the side wall corrugated plate are supported and fixed through the H-section steel; two arch feet of a lower step are fixedly provided with two pieces of channel steel, the lower end of the side wall corrugated plate is supported and fixed through the channel steel, and an inverted arch lap joint is reserved on the lower end of the side wall corrugated plate; the upper supporting corrugated plate, the side wall corrugated plate and the inverted arch corrugated plate are sequentially connected through flanges in the longitudinal direction; concrete is poured among the upper supporting corrugated plate, the side wall corrugated plate, the inverted arch corrugated plate and surrounding rock. The structure is manufactured through the structure mixing a corrugated steel plate and the concrete, stress is balanced through the structure and the surrounding rock, strength of the primary support is guaranteed, and the structure has the advantages that construction is facilitated, the period is short, efficiency is high, stability is high, and cost is low.

Owner:HEBEI TENGSHIDA METAL STRUCTURE +1

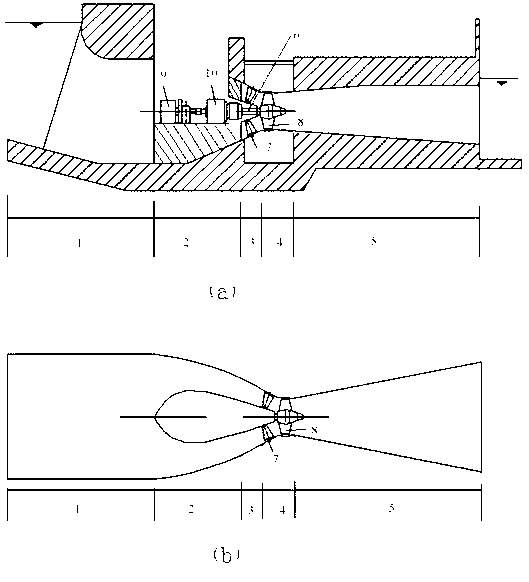

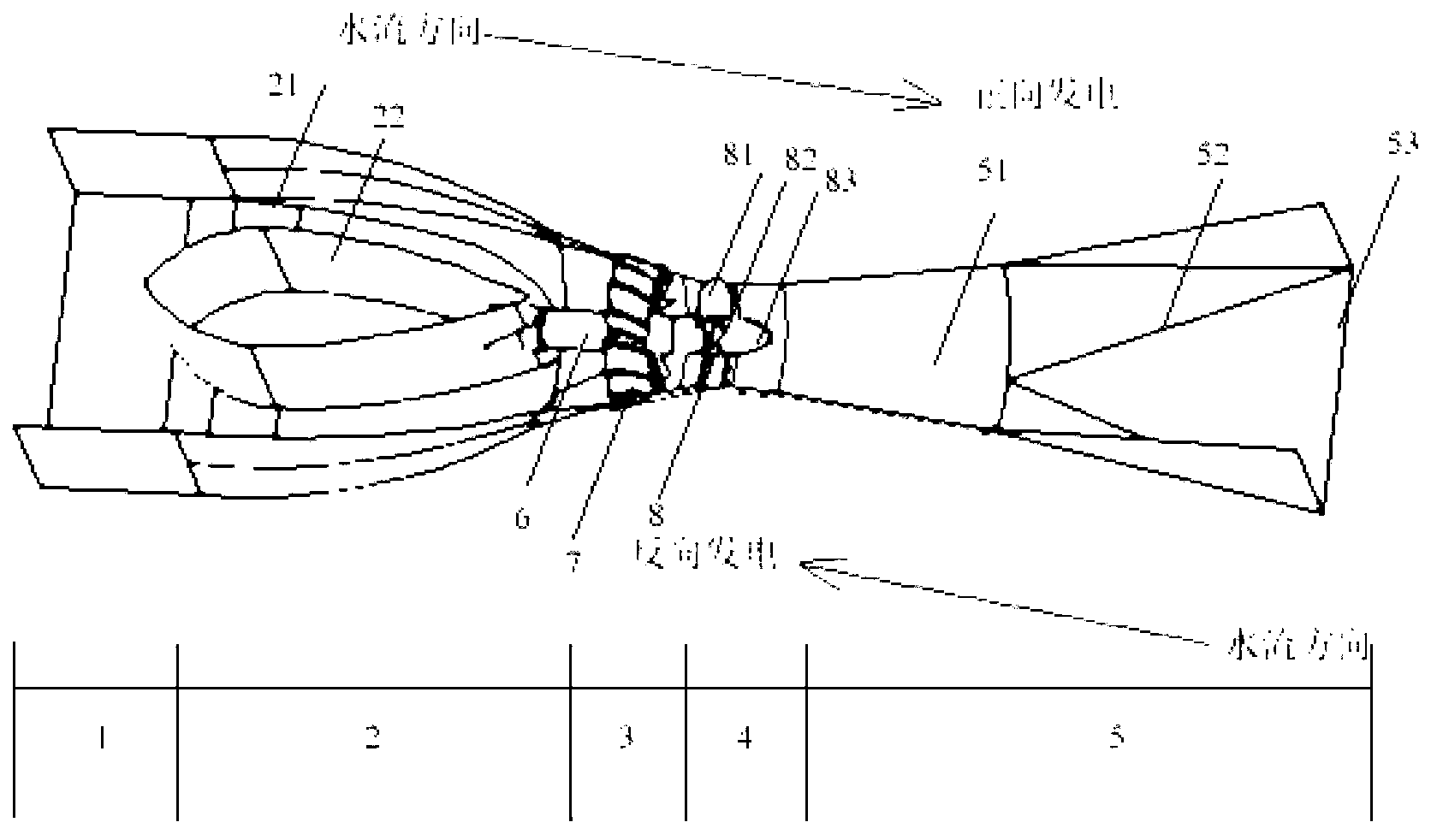

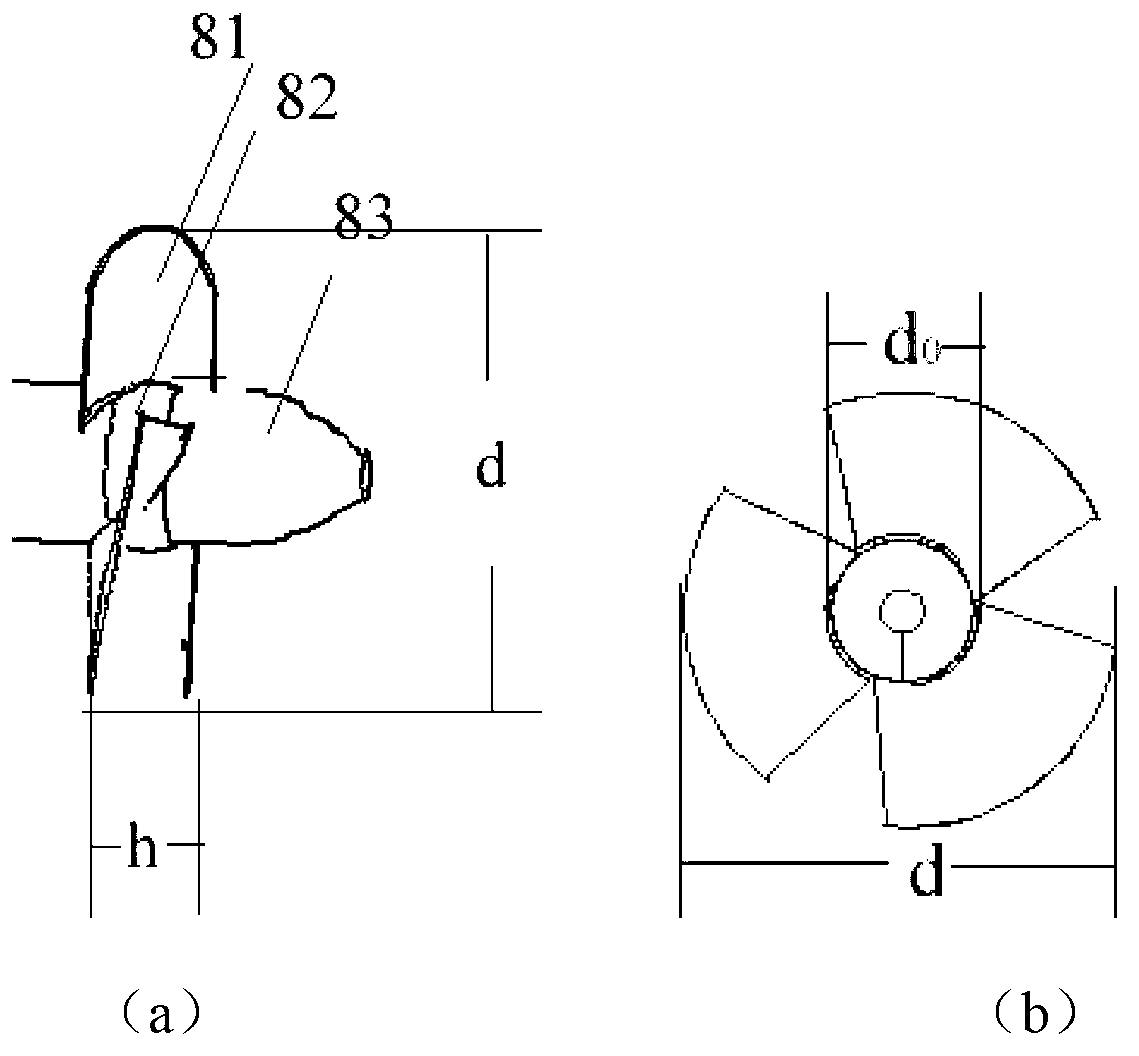

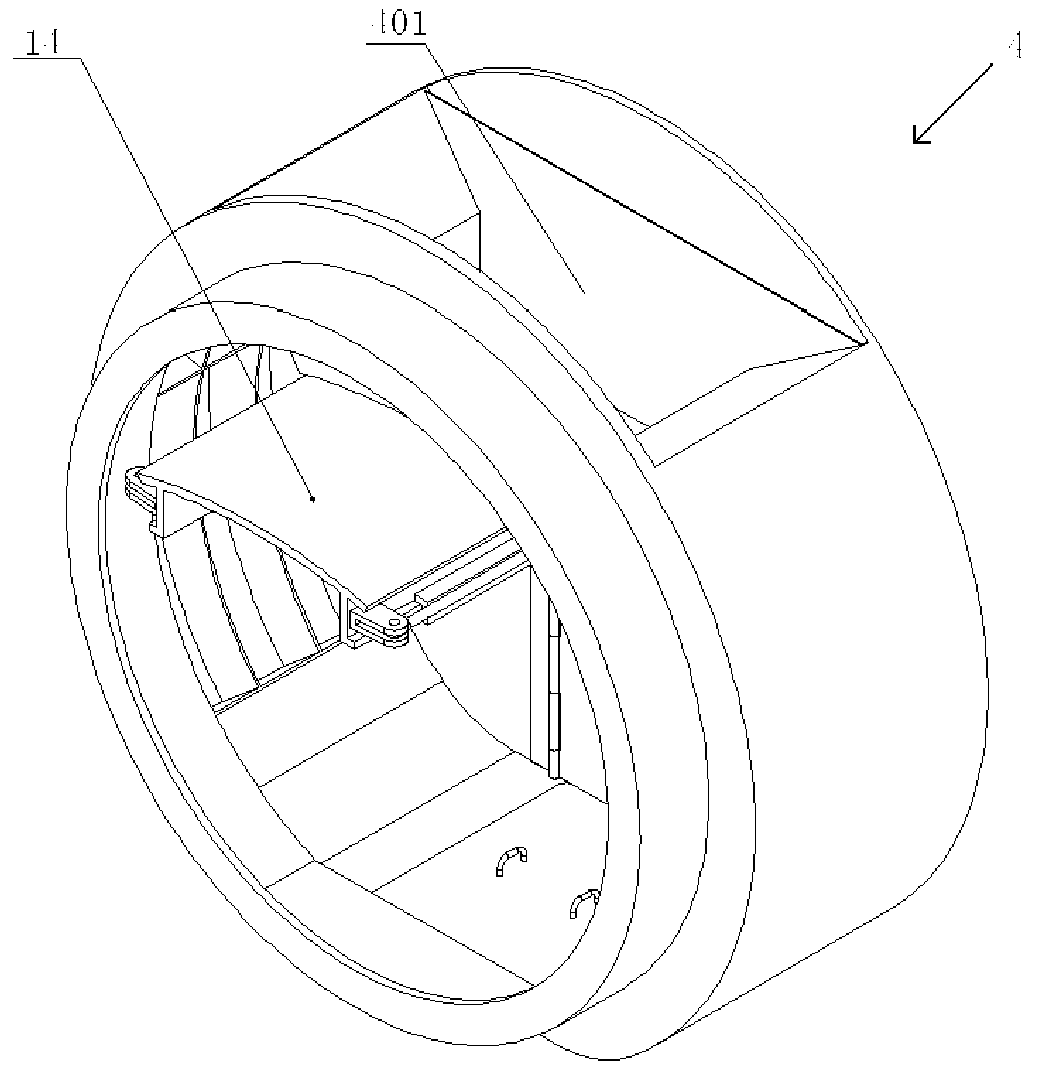

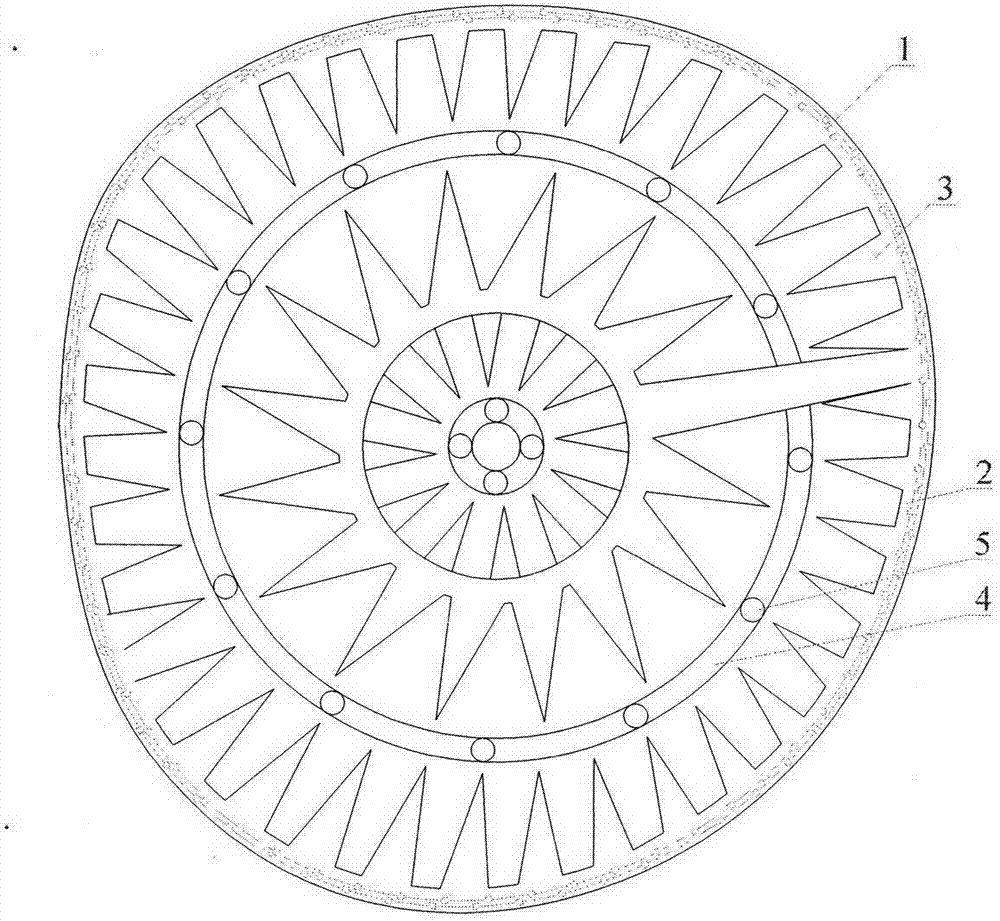

Low water head vertical shaft through-flow bi-directional efficient turbine runner as well as electromechanical device and mated flow passage thereof

InactiveCN103233846AImprove efficiencyTake advantage ofReaction enginesEngine componentsWater turbineTurbine

The invention relates to a low water head vertical shaft through-flow bi-directional efficient turbine runner as well as an electromechanical device and a mated flow passage thereof. The turbine runner comprises a flow passage and an electromechanical part; the flow passage comprises a water inlet section, a vertical shaft section, a guide vane section, a runner section and a draft tube section; the electromechanical part mainly comprises an electric generator, a speed increaser, a movable guide vane, a main shaft and a water turbine; the runner comprises blades, a runner hub and a runner cone; the blades are uniformly arranged on the runner hub in the circumference direction; the section of each blade takes the shape of a symmetrical wing; the structure of the blade is that the middle part is thicker and the two ends are thinner; the ratio of the minimum thickness b1 to the maximum thickness b2 of the blade is 0.28 to 0.35; meanwhile, the wing-shaped bending angle of the blade ranges from 90 to 95 degrees; the initial placing angle of the blade is 66 degrees, and the adjusting value is within negative 3 degrees and positive 3 degrees. The turbine runner, the electromechanical device and the mated flow passage can operate bi-directionally, have better energy conversion performance, and are low in cost.

Owner:HOHAI UNIV

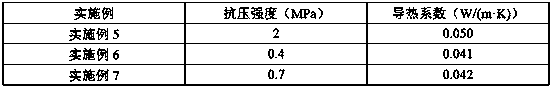

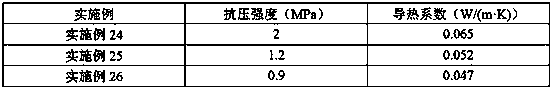

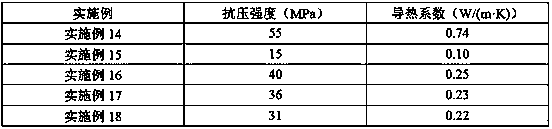

Manufacturing method for microorganism heat-insulation building material

PendingCN108530013ASolve the strength problemSolve insulation problemsBacteriaMicroorganism based processesNutrient solutionMechanical property

The invention discloses a manufacturing method for a microorganism heat-insulation building material. The manufacturing method for the microorganism heat-insulation building material comprises the following steps: taking a bacteria solution which has a mineral deposition function and is prepared from microorganisms and a corresponding nutrient solution as raw materials; directly carrying out mineral deposition on various lightweight aggregates or compounding inorganic or organic cementing materials; and carrying out microorganism inactivation and pore forming to obtain novel microorganism heat-insulation plates, heat-insulation blocks, heat-insulation concrete, heat-insulation mortar and the like. By the method, the physical and mechanical properties of an existing traditional heat-insulation material can further be improved through a microorganism mineralization function and an inactivation process. Microorganism mineral deposition products are used as cementing material manufacturingand modifying building heat-insulation materials, contradiction between strength and heat insulation of the heat-insulation materials can be solved effectively, cementing materials such as cement arereduced and are even prevented from being used, resource consumption are reduced remarkably, mine excavation frequency is reduced, pollution emission is eliminated, and environment stress and haze influence are relieved. The manufacturing method for the microorganism heat-insulation building material is an environmentally friendly building material manufacturing method, and has good economic benefit, environment benefit and social benefit.

Owner:李珠

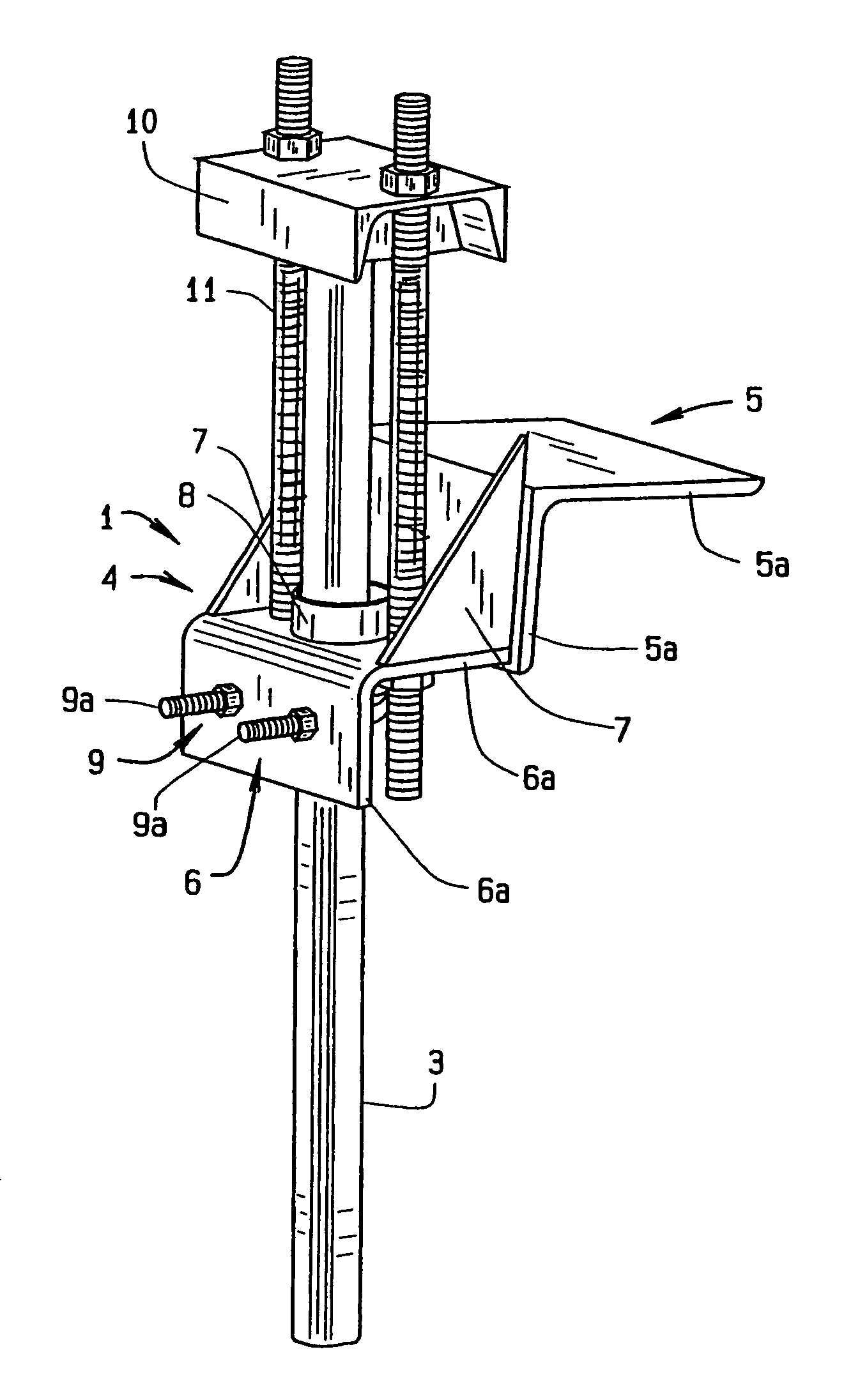

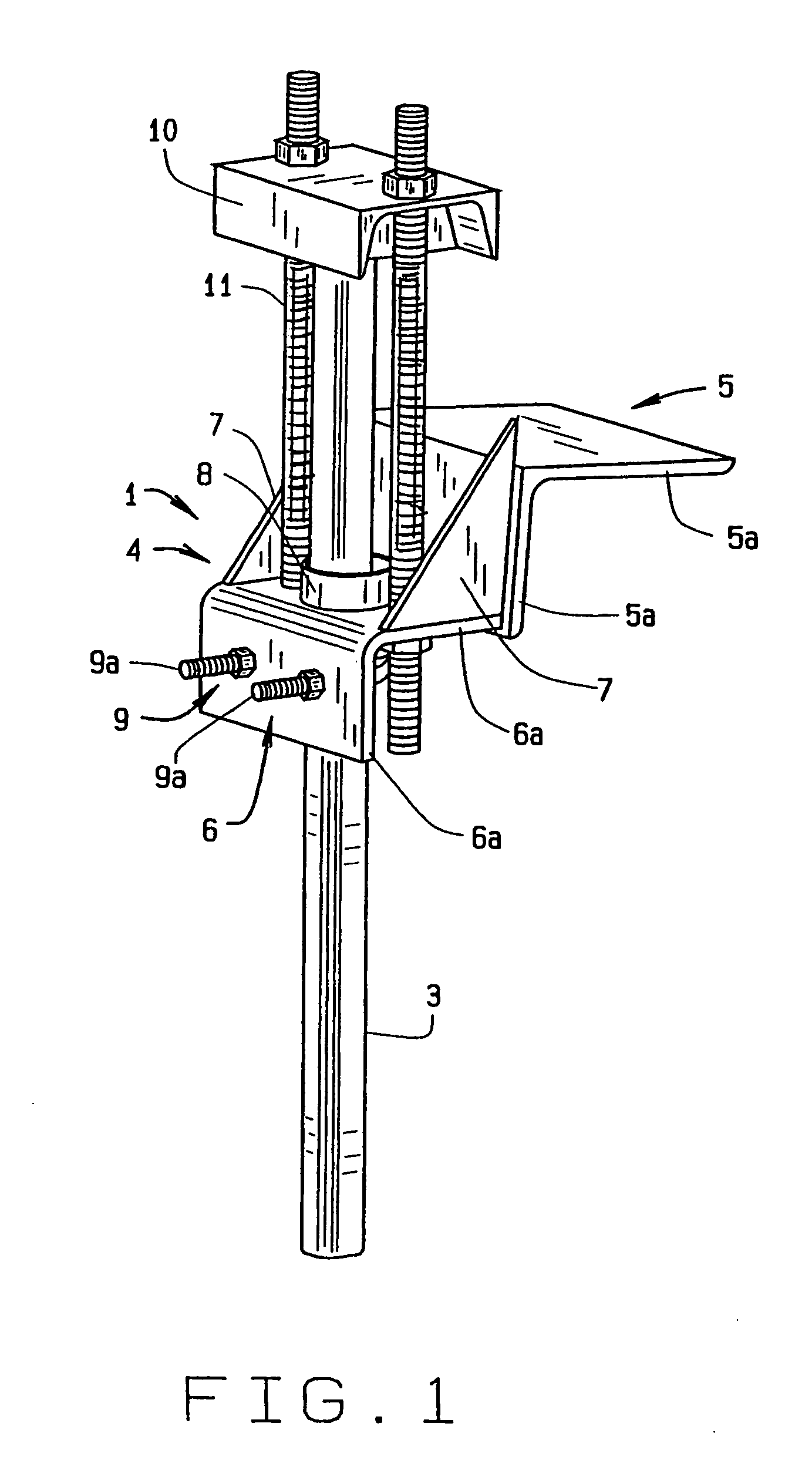

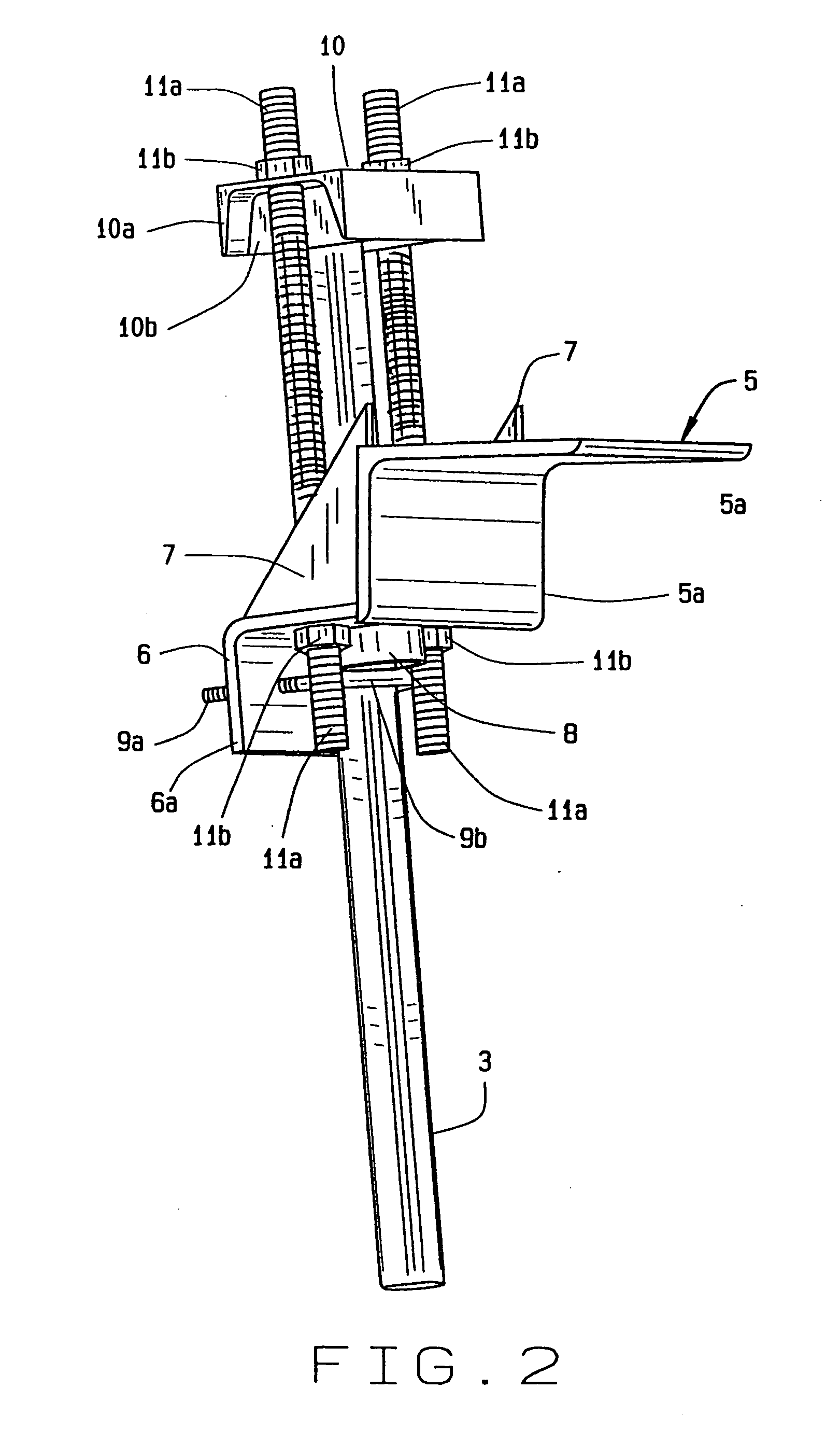

Bracket assembly for lifting and supporting a lightweight foundation

A bracket assembly rests upon a pile or deep foundation pier set adjacent to a lightweight structure or foundation element such as a porch. The bracket slides upon a pile or deep foundation pier and adjusts from the side of the pile or deep foundation pier. The bracket assembly has a weldment with bearing and guide members. The bearing member supports the lightweight structure or foundation element while the guide member raises the bearing member on the pile or deep foundation pier. The guide member has a sleeve and U-shaped bolt to grasp the pile or deep foundation pier. A cap plate atop the pile or deep foundation pier connects to the guide member through rods. Turning nuts on the upper end of the rods pulls them and thus the lightweight structure or foundation element upwards. The bracket assembly is lightweight and supports approximately five thousand pounds.

Owner:FAIRES GUY L +2

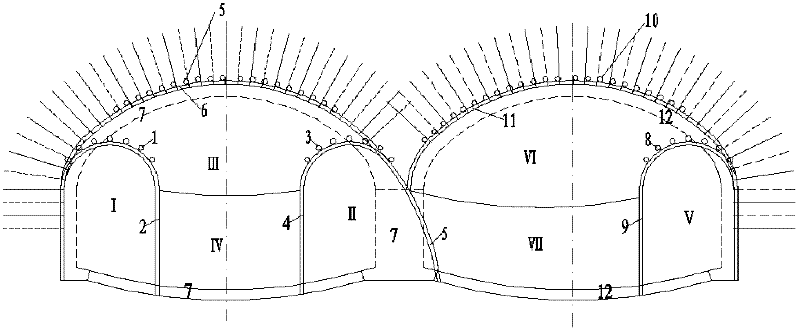

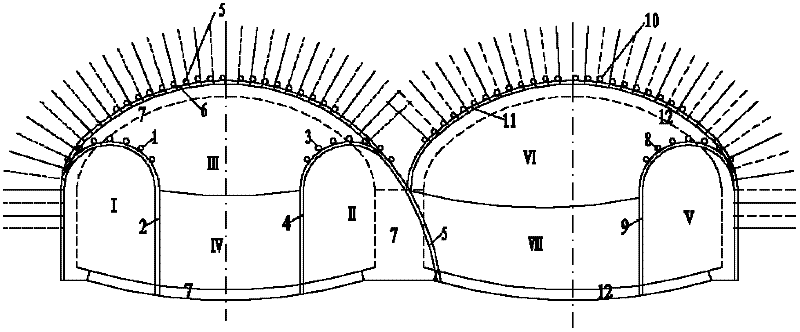

Rapid construction method of weak surrounding rock large-section multi-arc tunnel

InactiveCN102373930AImprove construction progressShorten the construction periodUnderground chambersTunnel liningStructure of the EarthRapid construction

The invention discloses a rapid construction method of a weak surrounding rock large-section multi-arc tunnel. According to the invention, in tunnel construction, the main tunnel on one side of the multi-arc tunnel and the place of a partition wall are synchronously excavated; the tunnel excavation is implemented by using a double side-wall heading method; then, a primary support and the partition wall are constructed before the secondary lining of the tunnel; and finally, the main tunnel on the other side of the multi-arc tunnel is excavated by using a single side-wall heading method, and a corresponding support structure is built. Compared with the traditional multi-arc tunnel construction method, the construction method disclosed by the invention does not need to cut through a middle guide tunnel and build the partition wall before excavating the main tunnels on the two sides, thereby greatly accelerating the construction of the multi-arc tunnel, shortening the construction period and properly lowering the construction cost.

Owner:CENT SOUTH UNIV

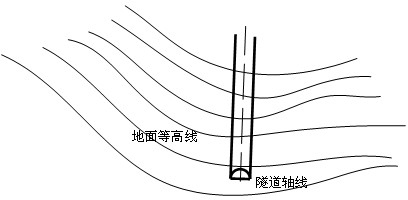

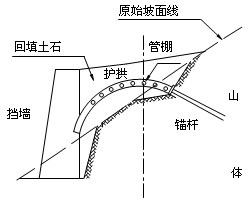

Tunnel-entering construction method for tunnel

InactiveCN102182465ASuitable for hole construction methodFast holeUnderground chambersTunnel liningStructural stabilityContour line

The invention relates to a tunnel-entering construction method for a tunnel, which can reduce the construction difficulty when being applied to construction, and is beneficial to ensuring the construction safety and the structural stability. The tunnel entering method is determined according to an intersected angle of the axis of a tunnel entrance and a ground contour line, and includes orthogonal tunnel entering construction, oblique crossing tunnel entering construction, lateral tunnel entering construction and single-direction tunnel entering construction. The application condition of the orthogonal tunnel entering construction is that the intersected angle of the axis of the tunnel entrance and the ground contour line is larger than 40 degrees; and the application condition of the oblique crossing tunnel entering construction is that the intersected angle of the axis of the tunnel entrance and the ground contour line is smaller than 40 degrees. When the oblique crossing angle is 20 to 40 degrees, a half protective arch method is adopted; and when the intersected angle of the axis of the tunnel entrance and the ground contour line is smaller than 20 degrees, a shed tunnel method is adopted.

Owner:CHANGAN UNIV

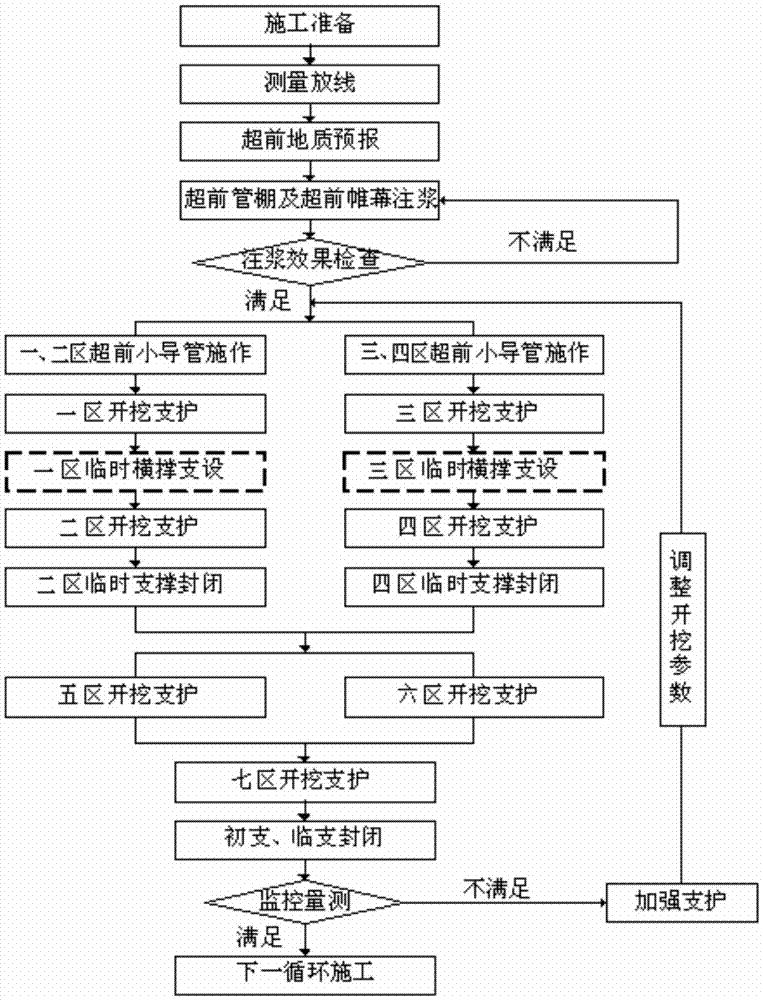

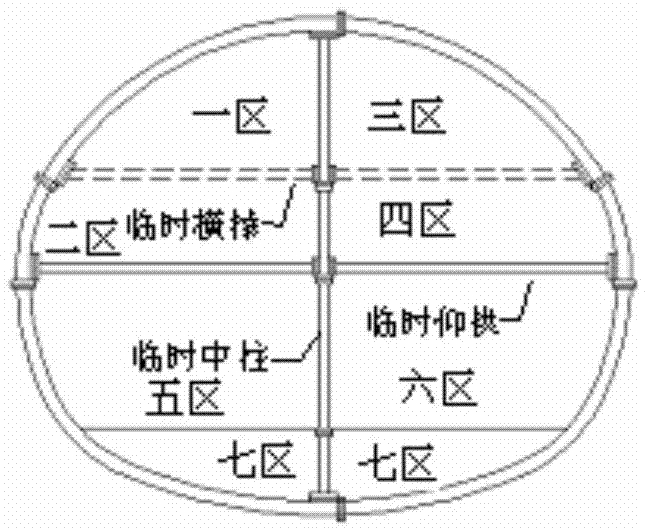

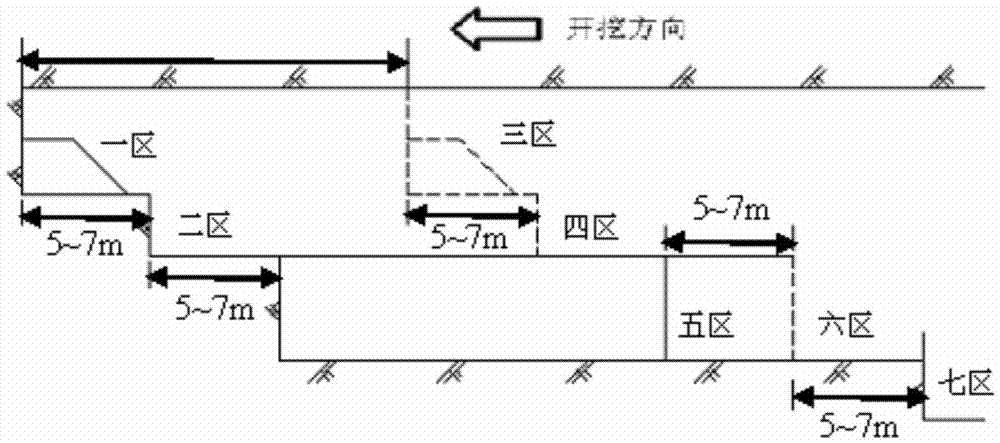

Construction method of shallow-buried subsurface-excavated cross-shaped cross-strut tunnel

ActiveCN105443132AEasy to operateQuality is easy to controlUnderground chambersTunnel liningConstruction designEnvironmental geology

The invention discloses a construction method of a shallow-buried subsurface-excavated cross-shaped cross-strut tunnel. The method includes the following steps of conducting construction preparation, conducting measurement and pay-off on a tunnel advanced support and the tunnel contour line according to construction design requirements, conducting advanced geological forecasting through the geophysical prospecting advanced geological forecasting and drilling advanced geological forecasting combined mode, conducting advanced pipe shed grouting and advanced curtain grouting, checking the grouting effect, entering the next procedure if the grouting effect meets the construction requirement, conducting advanced pipe shed and advanced curtain grouting again if the grouting effect does not meet the construction requirement, conducting excavation support construction on construction areas on by one from top to bottom and from left to right, conducting primary support and temporary support sealing and conducting monitoring and measuring after the primary tunnel transverse end face construction is completed, repeatedly executing the steps for the next circulation of construction if the design requirement is met, conducting support strengthening if the design requirement is not met, and regulating excavation parameters to conduct excavation support construction again till the design requirement is met.

Owner:ZHONGJIAN SUIDAO CONSTR CO LTD

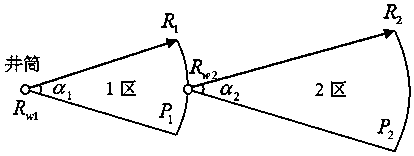

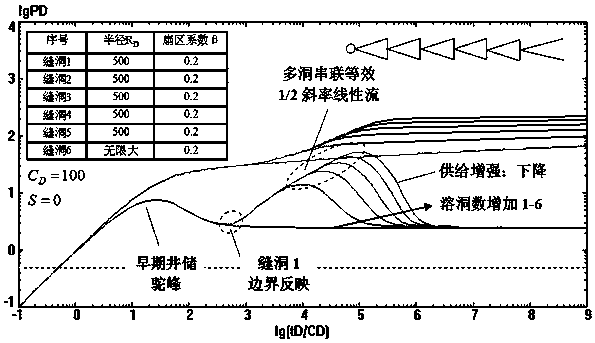

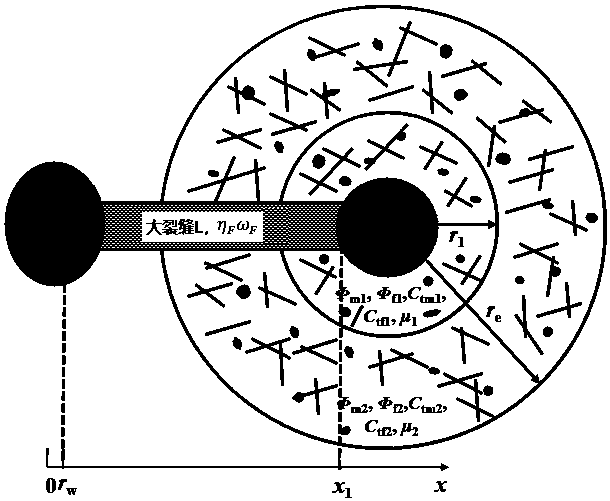

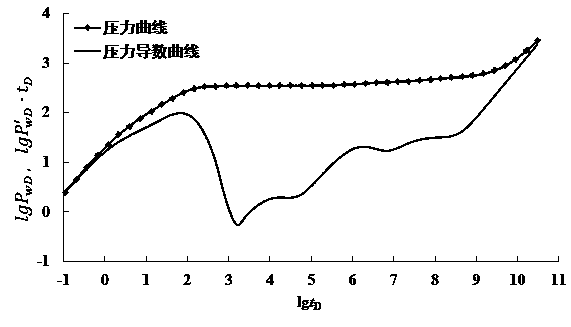

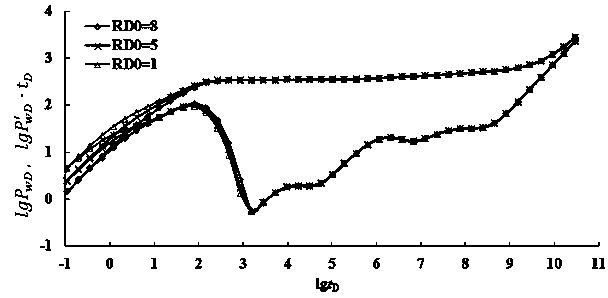

Well-testing interpretation model used for analyzing series structure of multiple fracture-cave units and methods

ActiveCN107563027AMonitor production statusReduce excavationSpecial data processing applicationsBorehole/well accessoriesCarbonate rockKarst

The invention discloses a well-testing interpretation model used for analyzing a series structure of multiple fracture-cave units and methods. The model includes: merging fracture-karst-cave reservoirbodies in fracture-cave-type oil reservoirs into the fracture-cave units; merging fracture-corrosion-hole reservoir bodies in the fracture-cave-type oil reservoirs into the fracture-cave units; for carbonate-rock fracture-cave-type oil reservoirs, using the fracture-cave units and fracture-hole units to approximate radial sector structure bodies; and regarding connection areas between sectors aspressure conducting areas with no pressure dropping, namely being equal to boundary pressure of the preceding sector by pressure of an outflow end of the subsequent sector, and being equal to a boundary inflow amount of the preceding sector by an outflow amount of the subsequent sector. One of the methods includes applying the model to analysis and interpretation technology of the fracture-cave-type oil reservoirs. According to the well-testing technology solution used for analyzing the fracture-cave-type oil reservoirs provided by the invention, a well-testing technology blank of the fracture-cave-type oil reservoirs is filled, a utilization rate of well-testing data is increased, and a well-testing analysis means is provided for knowing and evaluating fracture-cave-type oil reservoir structures.

Owner:SOUTHWEST PETROLEUM UNIV

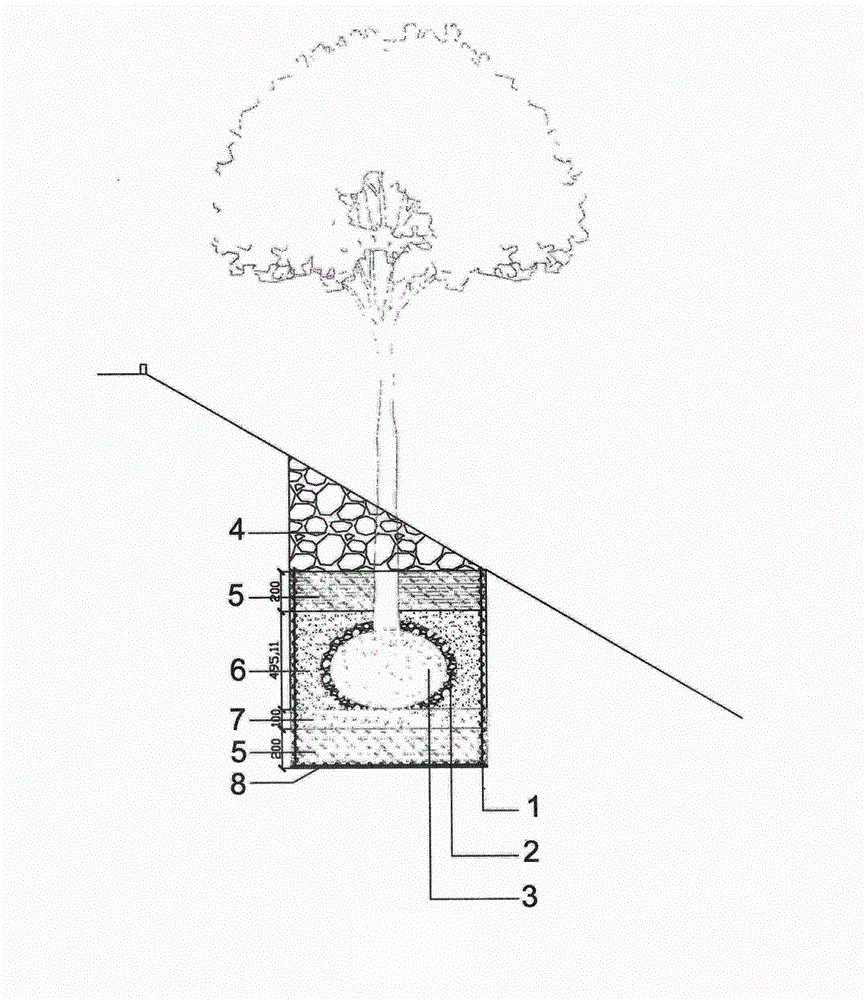

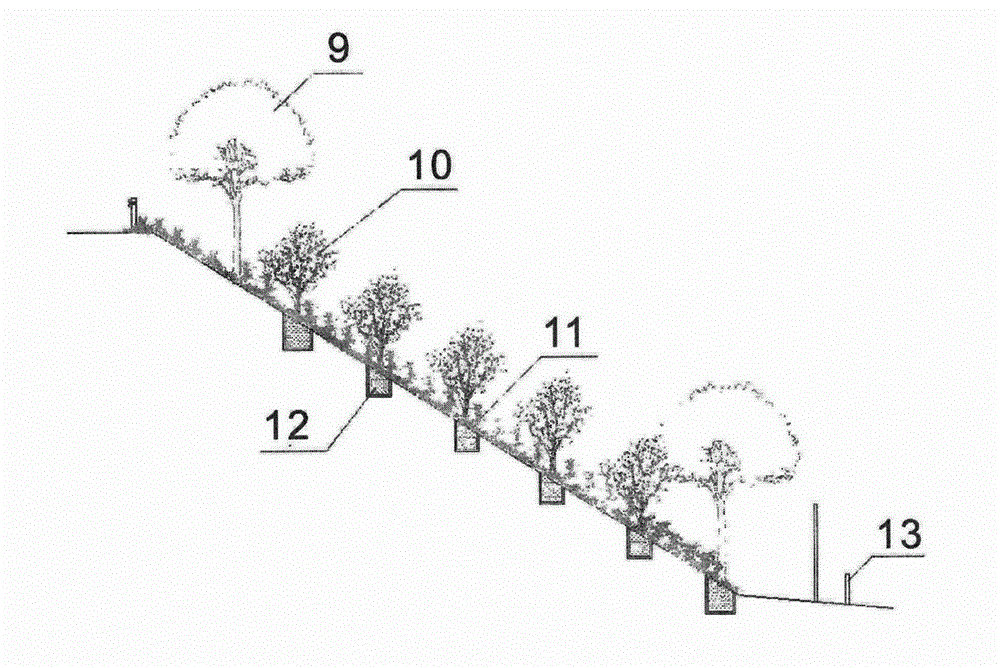

Stone side slope biological control method

ActiveCN103931371AReduce excavationImprove slope stabilityExcavationsCultivating equipmentsEngineeringBiological pest control

The invention discloses a stone side slope biological control method which comprises the following steps of (1) side slope status analysis and safety evaluation, (2) nursery stocks pre-cultivating, (3) bird nest type layout, (4) bionic nest building, (5) formula planting and (6) community forming. The stone side slope biological control method integrates the engineering mechanics, the ecology, the aesthetics, the biotechnology and other disciplines and fields, a stable and ecological three-dimensional side slope can be quickly formed, the landscape effect is good, the ecological benefit is lasting and stable, maintenance cost is low, maintenance difficulty is low, the slope fixing effect is obvious, a protection function is outstanding, and the method is used for side slope protection of roads, railways, dams and the like, and also can be used for ecological management of desertification and stony desertification.

Owner:黄璞

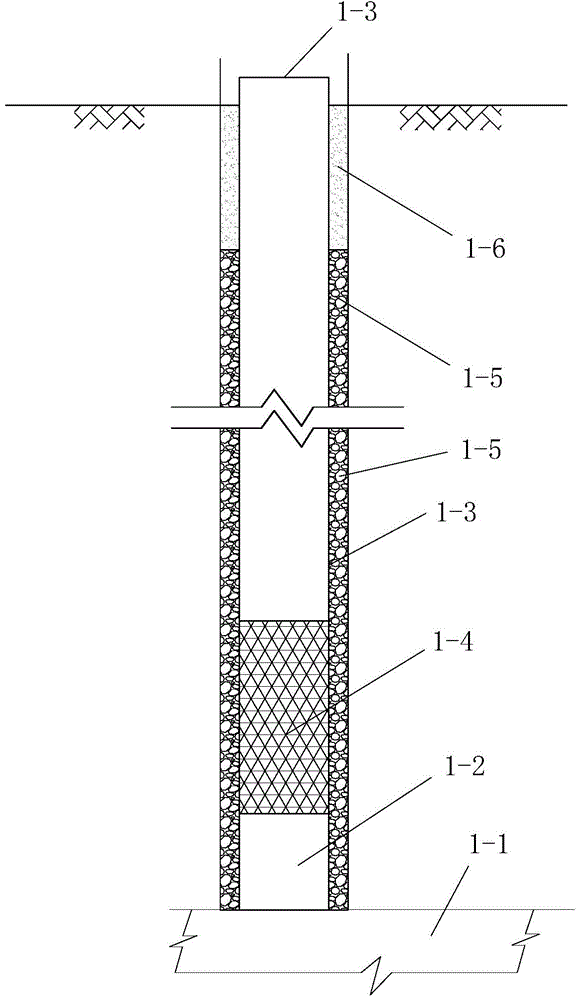

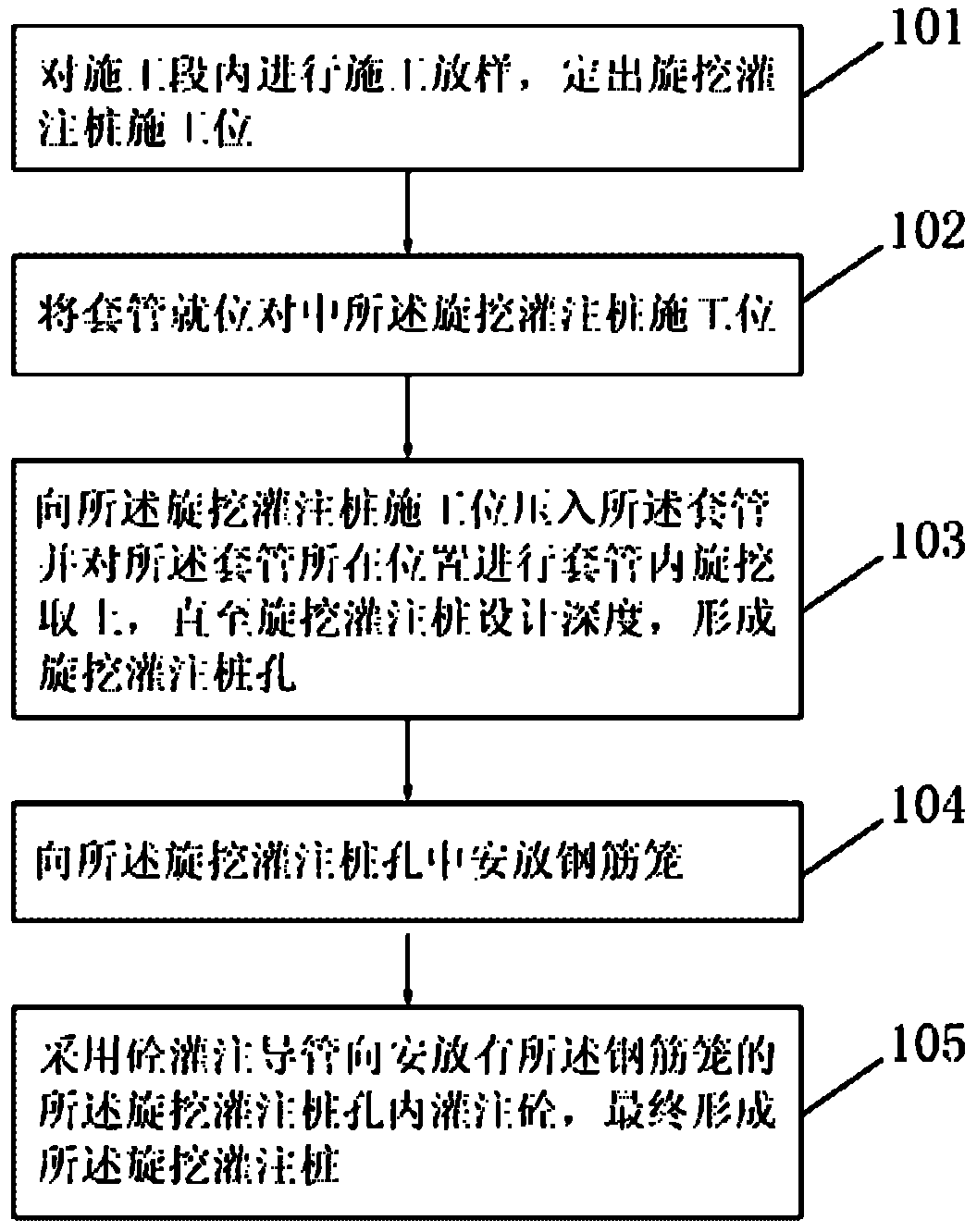

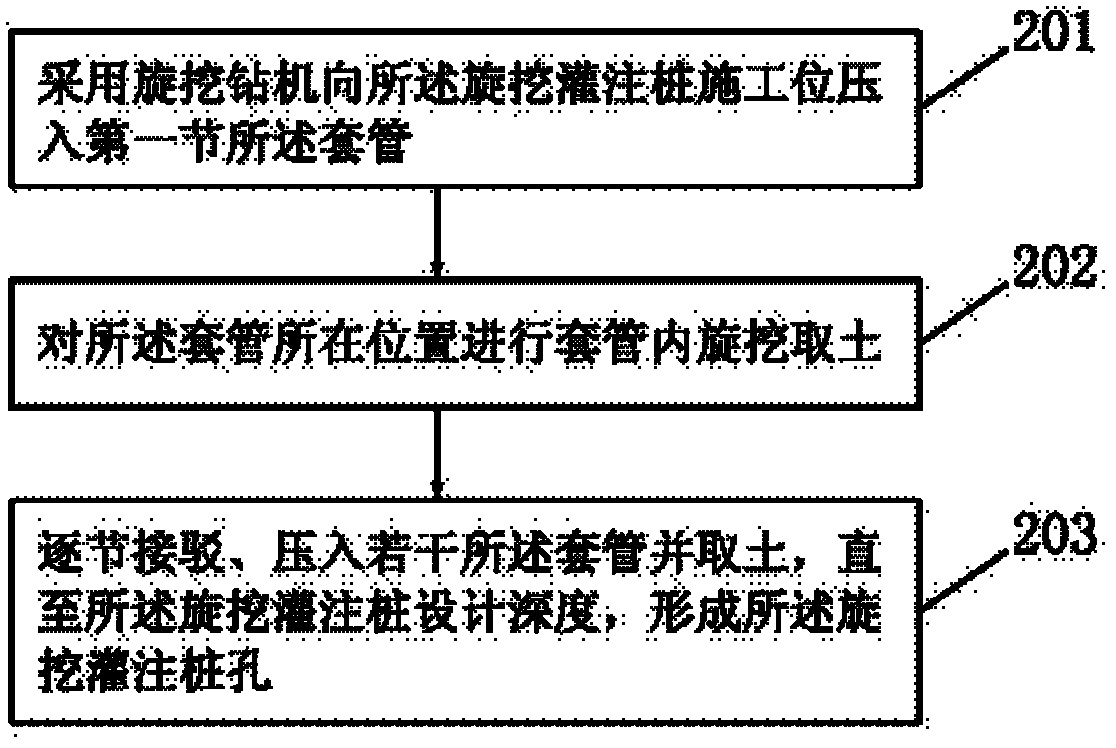

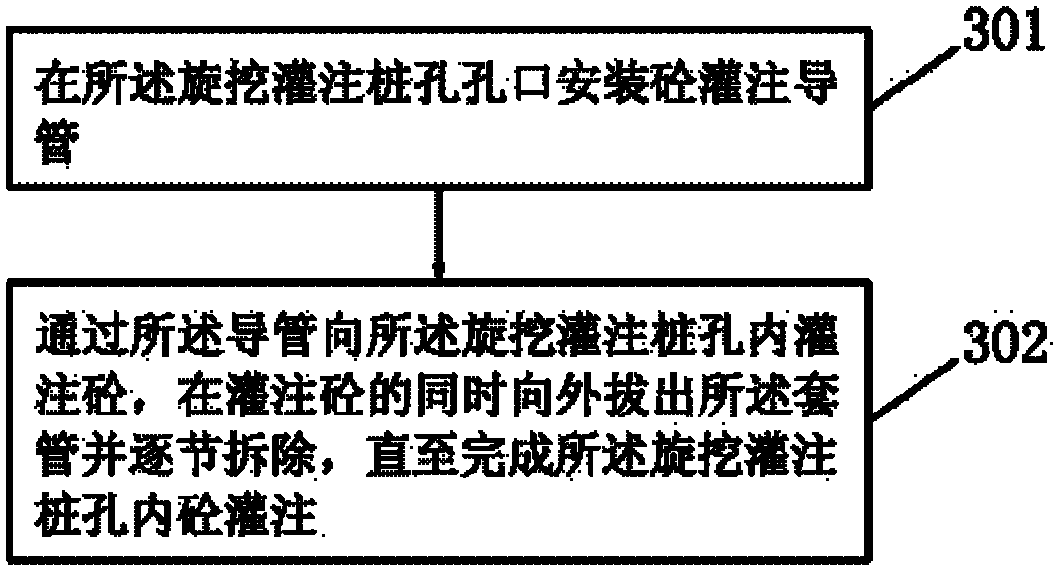

Construction method for revolving digging cast-in-place pile

An embodiment of the invention discloses a construction method for a revolving digging cast-in-place pile. A case pile is used for holing and protecting a wall, a revolving digging machine is used for taking soil and holing from the inside of the case pile, soil excavated volume of the construction method is lower as compared with a traditional wall protecting method by the aid of mud, a peripheral soil structure cannot be damaged, influences to surrounding environments and pollution due to construction are low, the speed for removing slag in end holes is fast, quality is high, and the problem that the mud skin on a side of a mud wall protecting and holing technical pile reduces bearing capacity of the engineering pile is avoided effectively. The construction method effectively stops common quality drawbacks of other types of punched and bored cast-in-place piles, such as hole collapse, necking and the like. Operation is safe, pile forming speed is faster, cost is lower, and construction efficiency and construction quality are greatly improved.

Owner:深圳市润信建设工程有限公司 +1

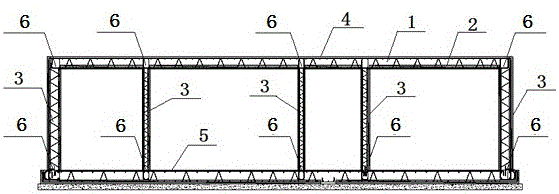

Construction and manufacturing process of total-prefabricated superimposed assembly type underground pipe gallery

ActiveCN105839667AOutstanding FeaturesHighlight significant effectArtificial islandsUnderwater structuresPrefabricationBuilding construction

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

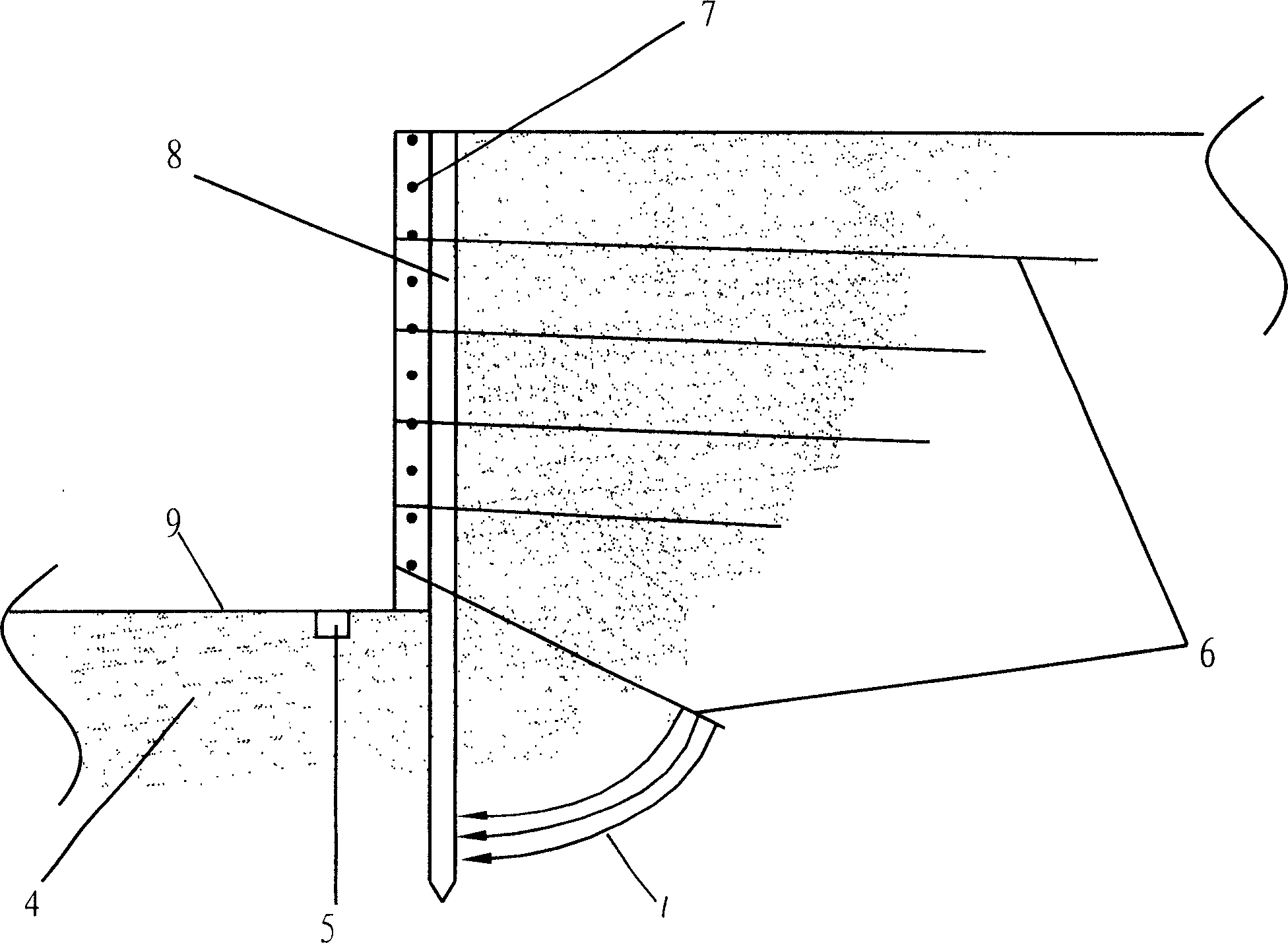

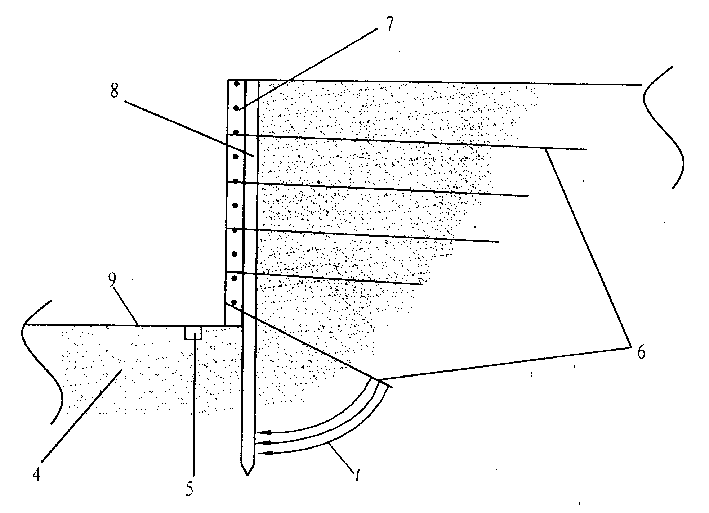

Operation method for supportins soft border by using earth slope nails

InactiveCN1540107AImprove physical and mechanical propertiesAvoid bumpingExcavationsBulkheads/pilesShotcreteSlurry

An earth nail method for protecting the soft-earth slope includes measuring and drawing lines, vertically driving the anchor tubes with grouting hole into earth, grouting, vertically digging down along the internal side of each anchor tube, arranging net, spraying cement, slurry, driving earth nails in the earth, grouting, rigidly fixing the earth nails, net ribs and anchor tubes, and spraying concrete. Said steps are repeated layer by layer undtil foundation. The drain ditch is dug on the foundation.

Owner:曾宪明

Well testing interpretation model for analyzing fracture-cave series mode double-hole composite reservoir

ActiveCN111581786AReduce utilizationReduce excavationDesign optimisation/simulationCAD numerical modellingBottom hole pressureMathematical model

The invention relates to a well testing interpretation model for analyzing a fracture-cave series mode double-hole composite reservoir, which comprises the following steps of: 1, establishing a corresponding physical model according to reservoir characteristics of a certain type of oil reservoir; 2, establishing a mathematical model, wherein the mathematical model is used for describing a physicalmodel; 3, solving the mathematical model to obtain a real space bottom hole pressure solution; and 4, drawing a real space well testing theoretical curve by utilizing a real space well bottom pressure solution, analyzing the well testing theoretical curve, performing curve fitting on theoretical pressure data and actually measured pressure recovery data to obtain a fitting result, and obtaining interpretation parameters which comprise fracture conductivity, fracture length, karst cave volume and karst cave storage capacity ratio. By solving the well testing mathematical model of the fracture-cavity series mode, the well bottom pressure solution of the fracture-cavity series mode is obtained, the typical well testing curve is drawn, the stratum parameters are obtained, the well testing interpretation method of the fracture-cavity series mode double-hole composite reservoir is determined, and the fracture-cavity type oil reservoir is accurately evaluated and effectively developed.

Owner:NORTHEAST GASOLINEEUM UNIV

High-sublevel multi-layer mining method of ultrathin copper ore body

InactiveCN102086765ALow cost of industrializationThe pit rate is reducedUnderground miningTunnel/mines ventillationResource protectionCopper mine

The invention discloses a high-sublevel multi-layer mining method of an ultrathin copper mine body. Mining channels are reclaimed to be connected with an upper middle section and a lower middle section based on the high-sublevel that the altitude difference of the middle section of the ore body is 50 meters, wherein, the thickness of the ore body bed is 0.4-1m, and the inclined angle of the ore body is above 25 degrees; the ore blocks between the middle sections are divided into extraction ore blocks with 50 meters square; a layered communication channel with small specification the altitude difference of which is 13-17m is reclaimed between the mining channels; the extraction ore blocks between the mining channel are divided into three extraction units; the ores mined by each extraction unit is centralized to the mining channel uniformly; and the ores are sent out from a trench after being transported to a transportation road. The method disclosed by the invention has the advantages that the copper ore resource mining recovery rate is effectively improved, cost is low, land is saved, unification of the resource protection and the environment protection is realized, and use is safe.

Owner:DAYAO GUIHUA COPPER SMELTING YONGREN ZHIJU BRANCH

System for construction of a compression structure with corner blocks, key blocks, and corner block supports

A structure assembled from a combination of stackable modules, each module assembled from multiple prefabricated, transportable blocks. The blocks are typically reinforced cast concrete formed in reusable molds. Module framing blocks may include arched corner blocks, key blocks that interlock with a pair of corner blocks, and optional center blocks. Other structural elements include roof, floor, and wall components that interlock with the framing modules. Modules may be stacked or nested to form structures including buildings, elevated roadways, and parking garages. Utilities may be provided through optional conduits formed in the corner elements. The framing supports raised floor modules for ease in mechanical system installation and modification. The roof elements support usable terraces and rainwater collection. The blocks are demountable and reusable. The modules are self-supporting during erection, and may be assembled without fasteners.

Owner:POWELL DAVID W

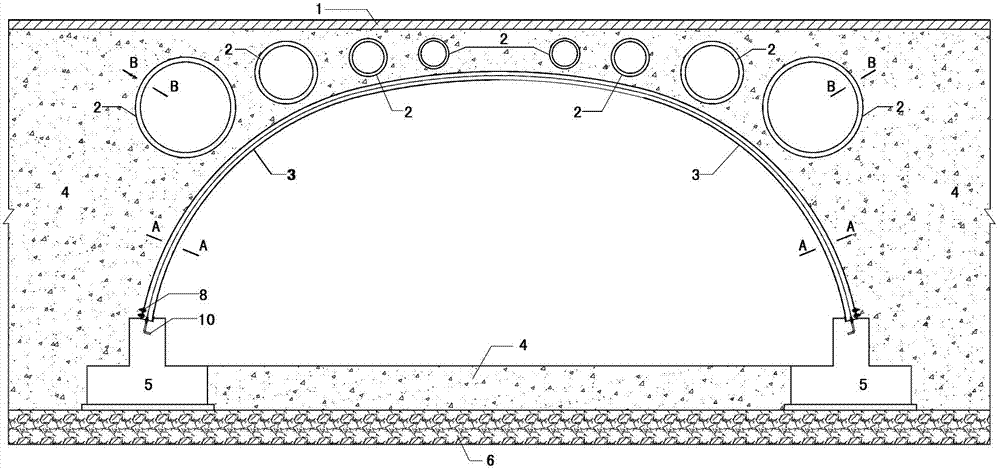

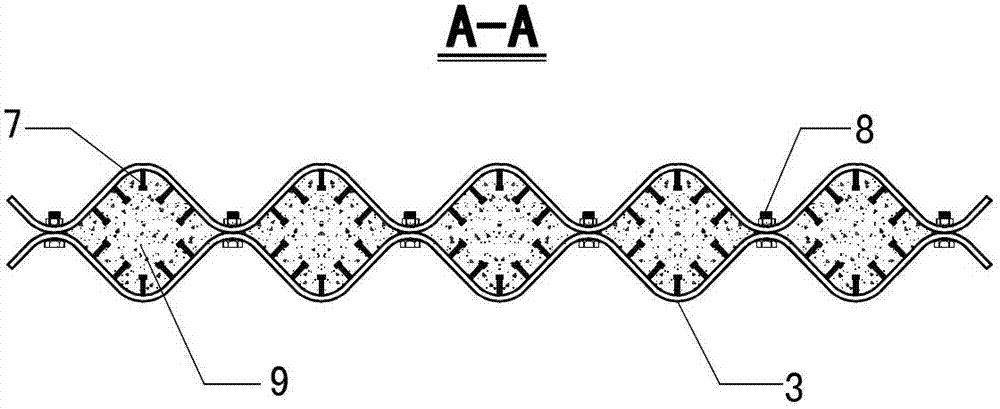

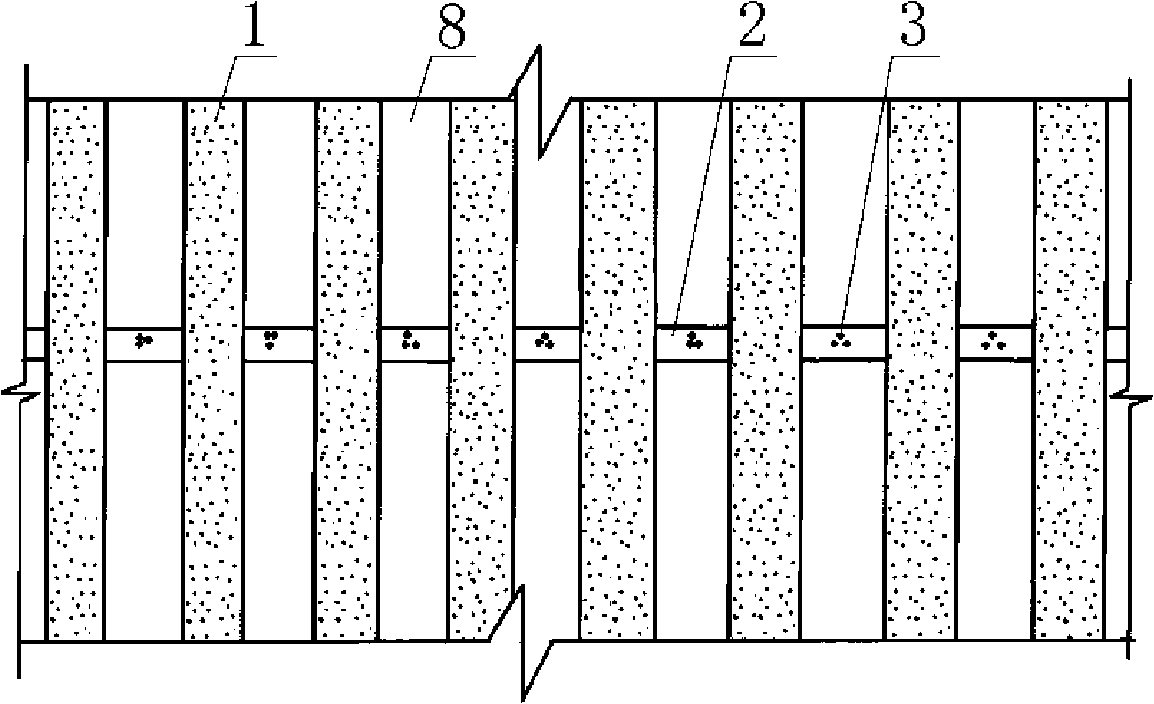

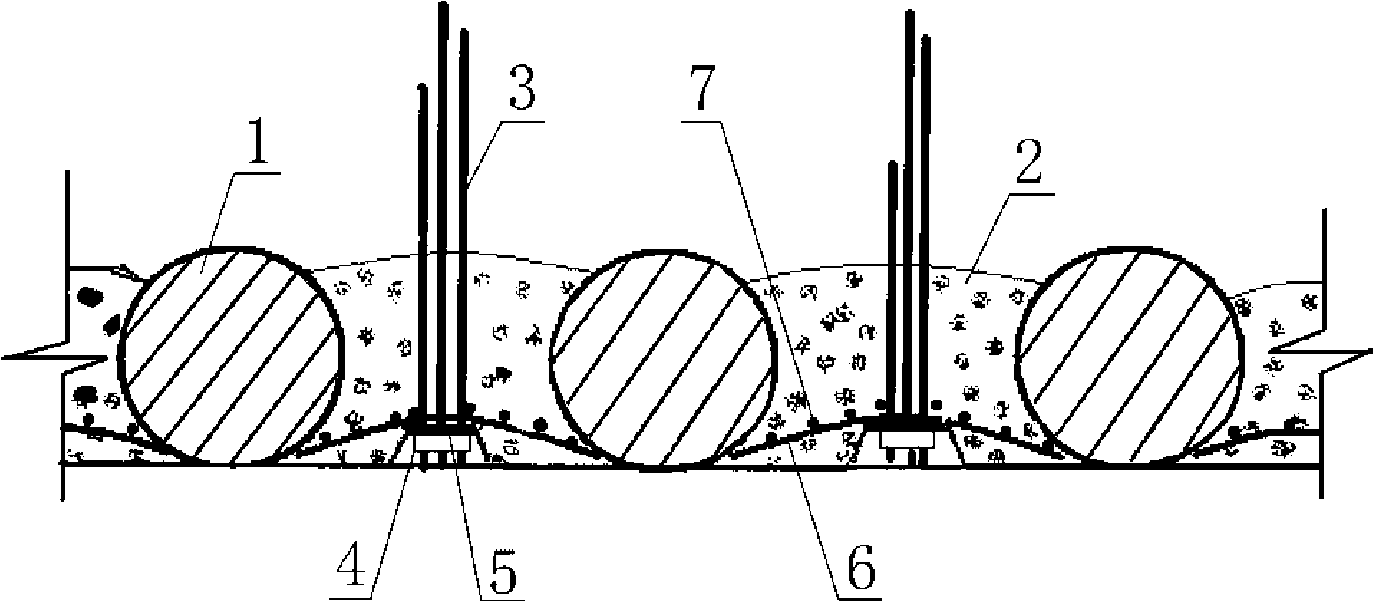

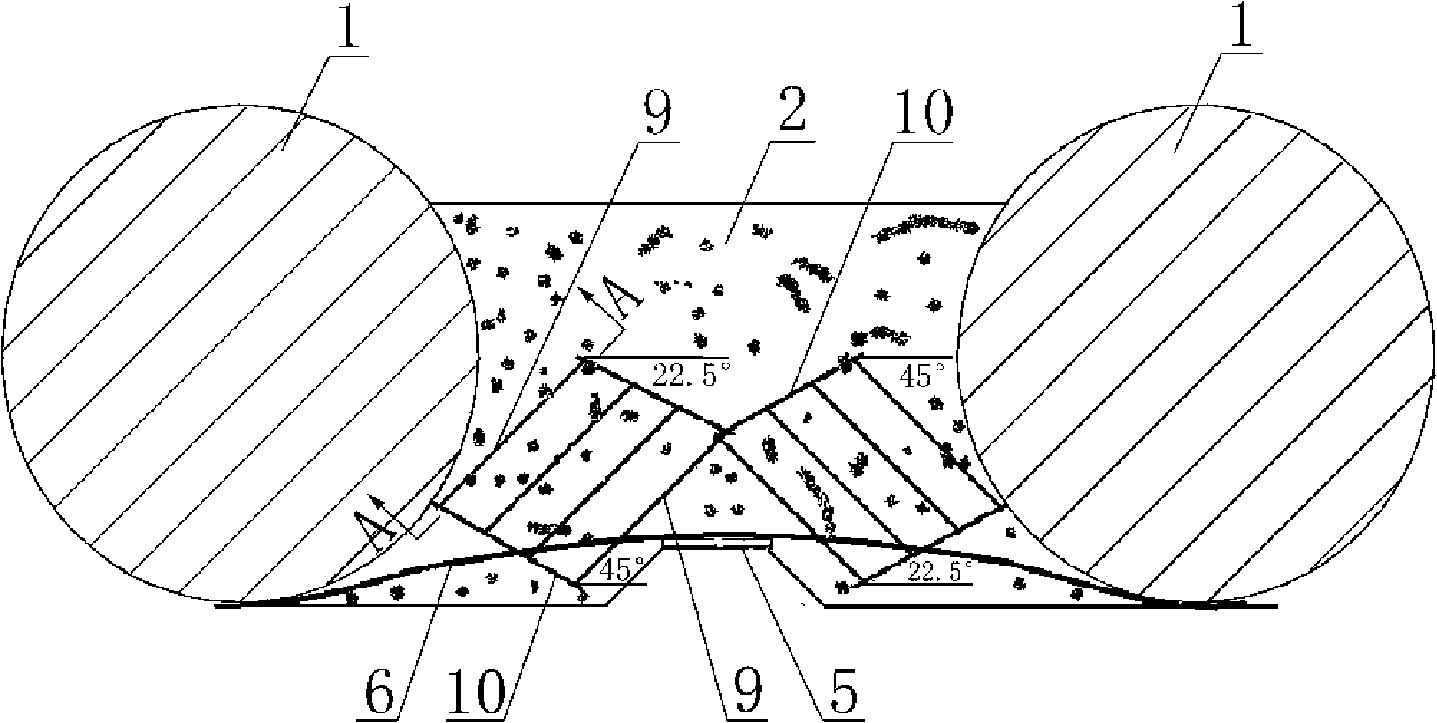

Lattice-type large-span soil-filling composite corrugated steel arch bridge structure

InactiveCN103114520ASimplify the assembly processReduce weightBridge erection/assemblyArch-type bridgeReinforced concreteEconomic benefits

The invention relates to a novel composite arc bridge structure, and particularly discloses a lattice-type large-span soil-filling composite corrugated steel arch bridge structure. Sandwich mortar composite corrugated steel plates are adopted as large-span main arch rings of the composite structure. The corrugated steel plates are connected to form a reversely arranged double-layer plate through bolts, studs are arranged in an interlayer, and filled high-strength mortar forms an integral sandwich composite corrugated steel plate. Corrugated steel tubes are adopted by gastropore. Load is conveyed between the main arch rings and the gastropore by filling soil. The lattice-type large-span soil-filling composite corrugated steel arch bridge structure has the advantages of being low in weight, durable, high in strength, good in flexibility, high in performance, rapid in construction, good in economic benefit and the like, is an ideal alternative to reinforced concrete bridges, can be widely used in the construction of middle-sized bridges (20-50m), and can certainly generate good social economic benefit.

Owner:HUNAN UNIV

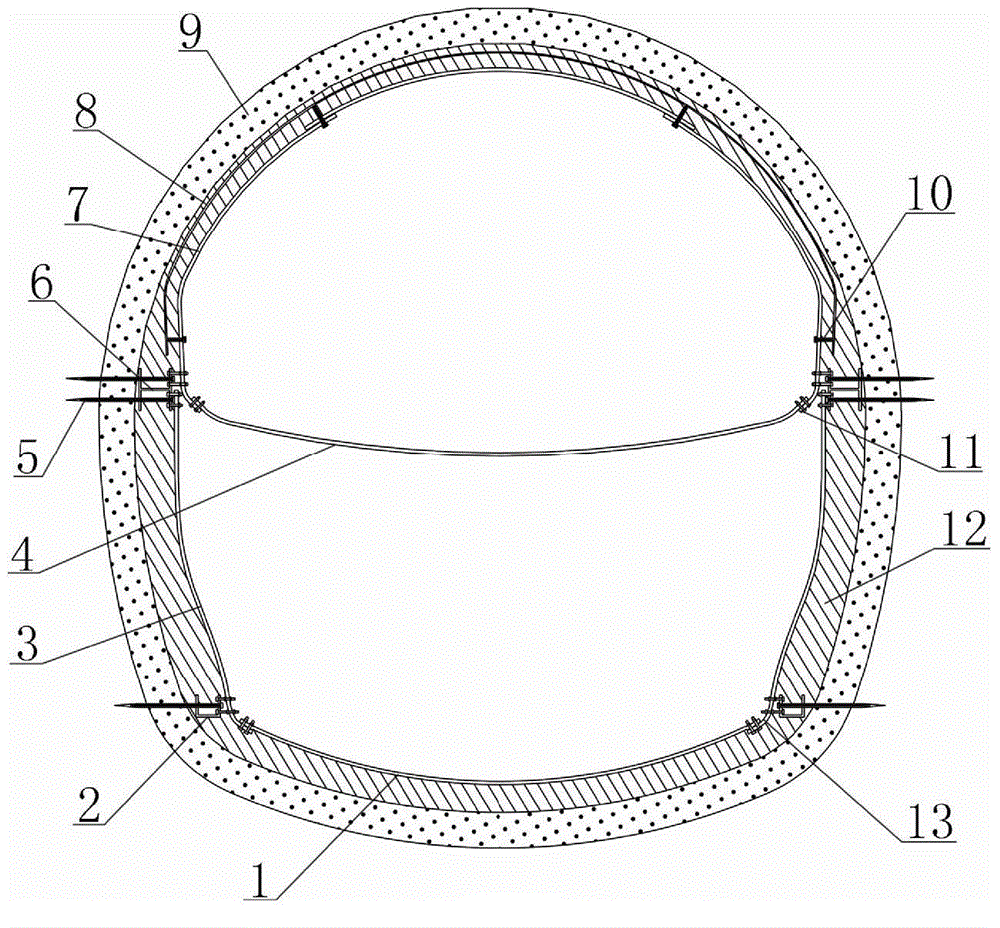

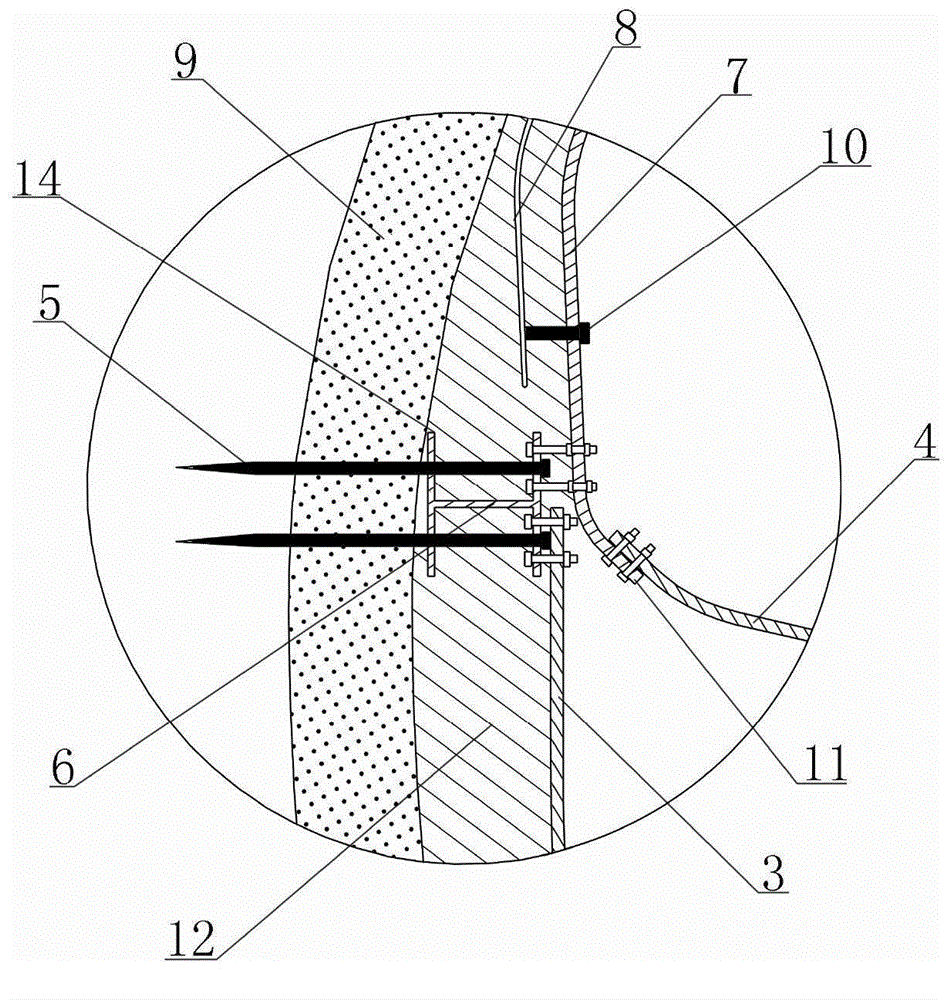

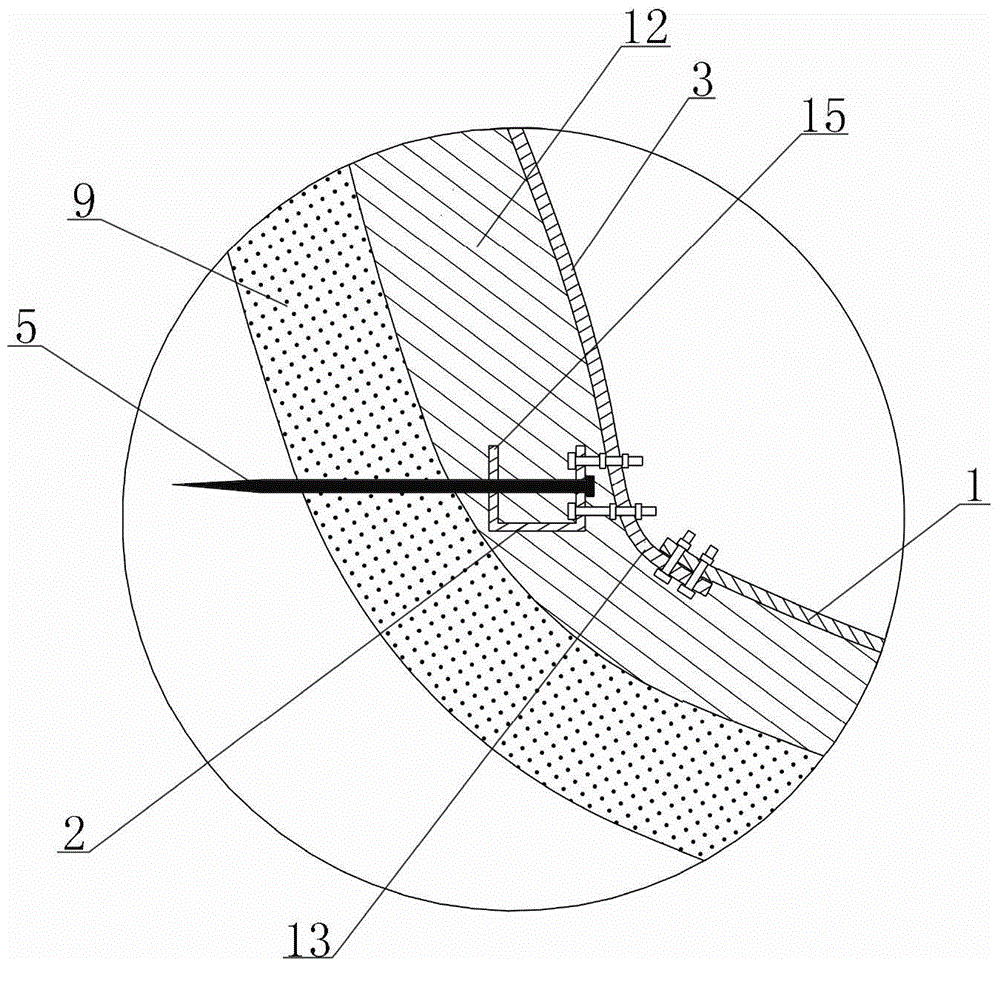

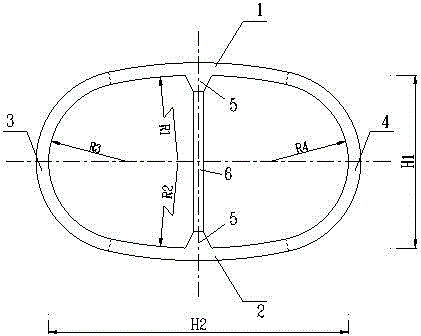

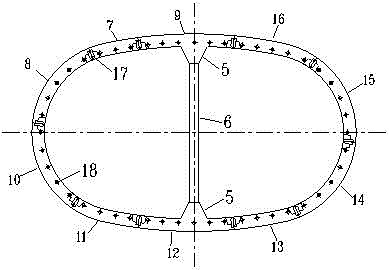

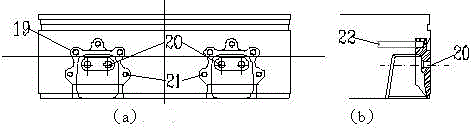

Splicing structure for pipe pieces of ellipse-like shield tunnel with stand column

InactiveCN104612724AOptimal Geometry DesignReduce in quantityUnderground chambersTunnel liningEllipseEngineering

The invention relates to a splicing structure for pipe pieces of an ellipse-like shield tunnel with a stand column. An integral ring is formed by enclosing and splicing the pipe pieces. The adjacent integral ring pipe pieces are spliced to form the splicing structure for the pipe pieces of the shield tunnel. The splicing structure is characterized in that the cross section of the splicing structure for the pipe pieces of the shield tunnel is a double-axis symmetric smooth ellipse-like part provided with the center stand column and formed by four sections of inferior arcs, the double-axis symmetric smooth ellipse-like part comprises a top arc, a bottom arc, a left side arc and a right side arc, the top arc with the large radius and the bottom arc with the large radius are arranged vertically and symmetrically in the opposite directions, and the left side arc with the small radius and the right side arc with the large radius are transversely and symmetrically arranged in the opposite directions. The spliced joints of the adjacent integral ring pipe pieces on the cross section keep away from the most unfavorable stress part of the tunnel structure, and the adjacent integral ring pipe pieces are spliced through staggered joints. Annular connectors and the longitudinal connectors of the pipe pieces are connected through bolts and hand holes, plane contact pulling and anchoring type lacework box type hand holes are adopted in the annular connectors, and high bearing force is achieved. The splicing structure has the advantages that a tunnel arc bearing structure and the high rectangular structure space utilization rate are combined; the longitudinal hand holes are in double-axis symmetric arrangement, and one set of pipe pieces can meet the requirement for staggered joint splicing.

Owner:TONGJI UNIV

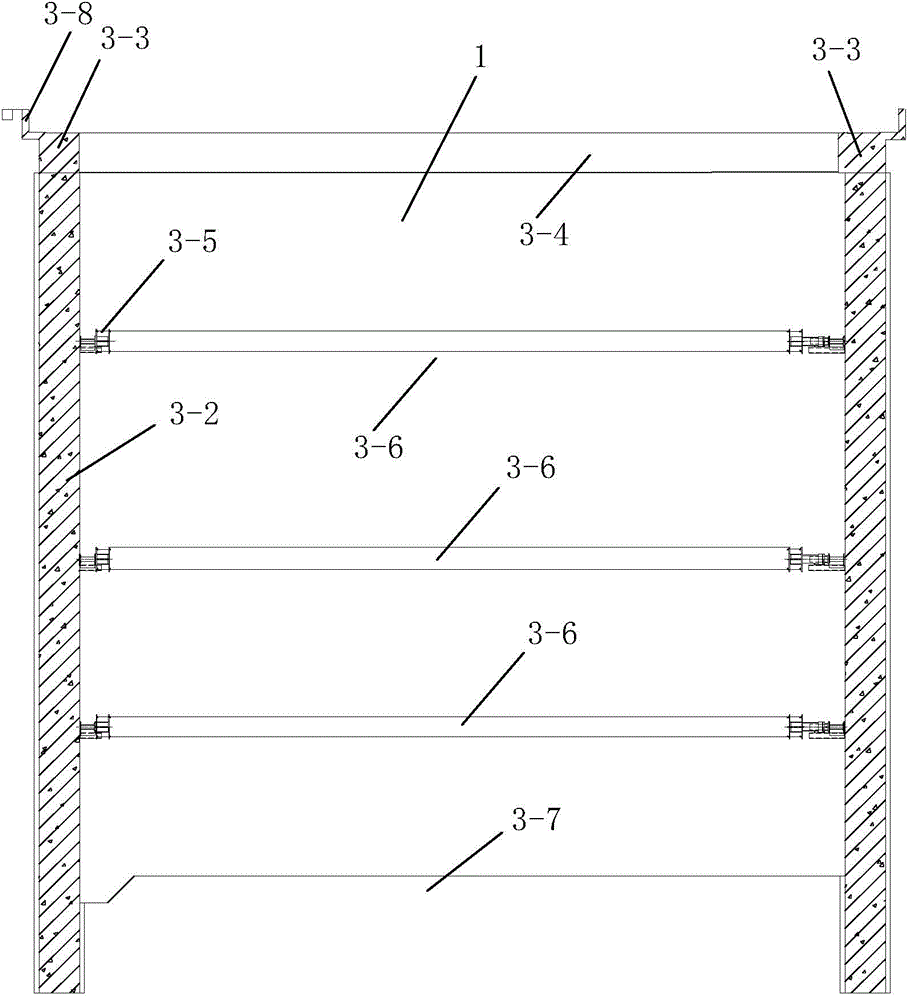

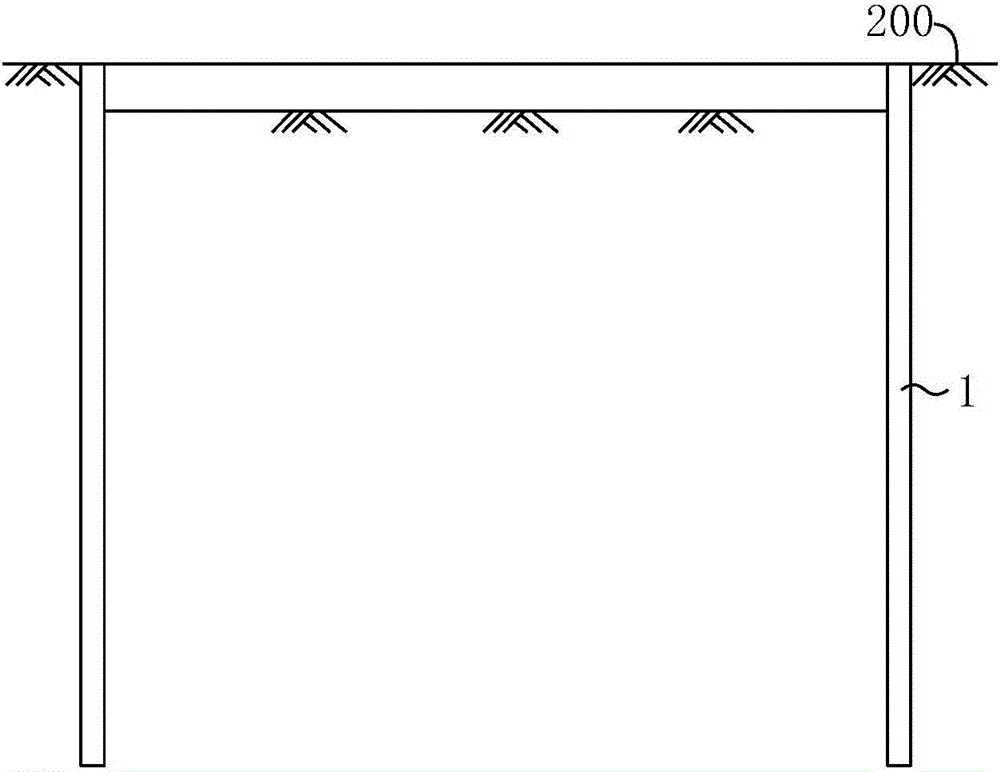

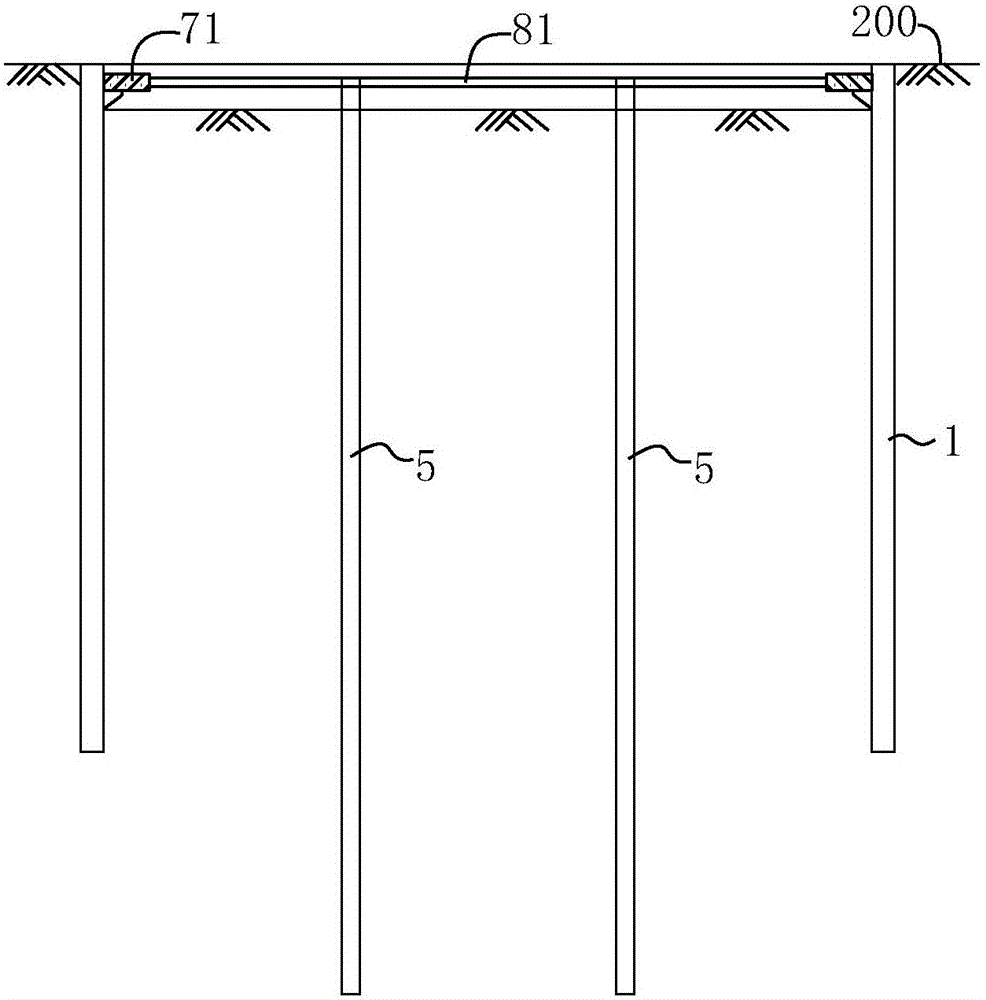

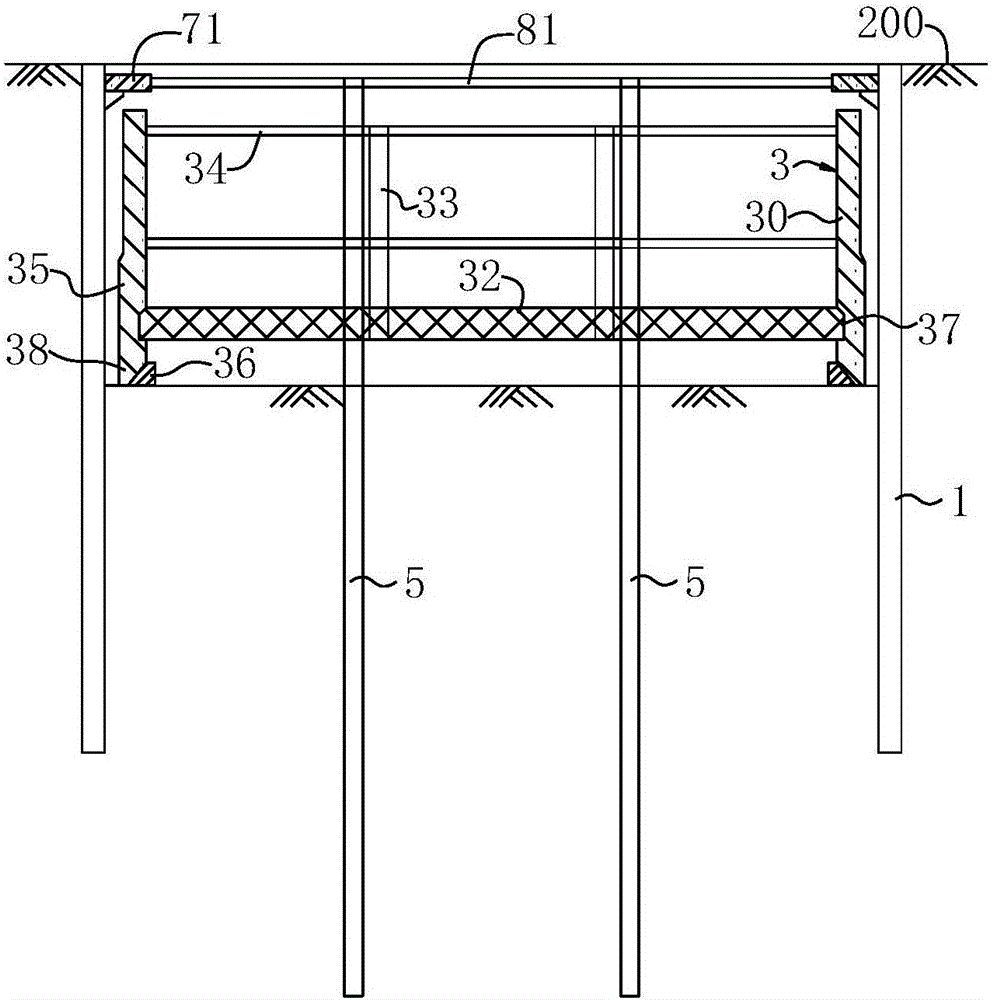

Steel sheet pile and open caisson combined underground garage and construction method thereof

ActiveCN106013052AHigh strengthTightly boundArtificial islandsExcavationsReinforced concreteEngineering

The invention discloses a steel sheet pile and open caisson combined underground garage. A body structure of the underground garage comprises an external wall and an external wall supporting structure; the external wall is composed of an upper external wall body and a lower external wall body which are connected in an up-down manner; the upper external wall body is a steel plate pile wall formed by connecting steel plate piles with one another; the lower external wall body is a reinforced concrete well wall of an open caisson; and the external wall supporting structure serves as a supporting structure of a parking platform of the underground garage at the same time. The external wall of the underground garage adopts a compounded external wall composed of the steel plate pile wall and the well wall of the open caisson, and the beneficial effects of the steel plate pile wall and the well wall of the open caisson are combined. The invention further discloses a construction method of the underground garage. According to the construction method, firstly, the steel plate piles sink to form the steel plate pile wall; and then the open caisson is poured in the steel plate pile wall and sinks. By means of the construction method, the building cost of the underground garage is successfully reduced, and the building time of the underground garage is successfully shortened.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

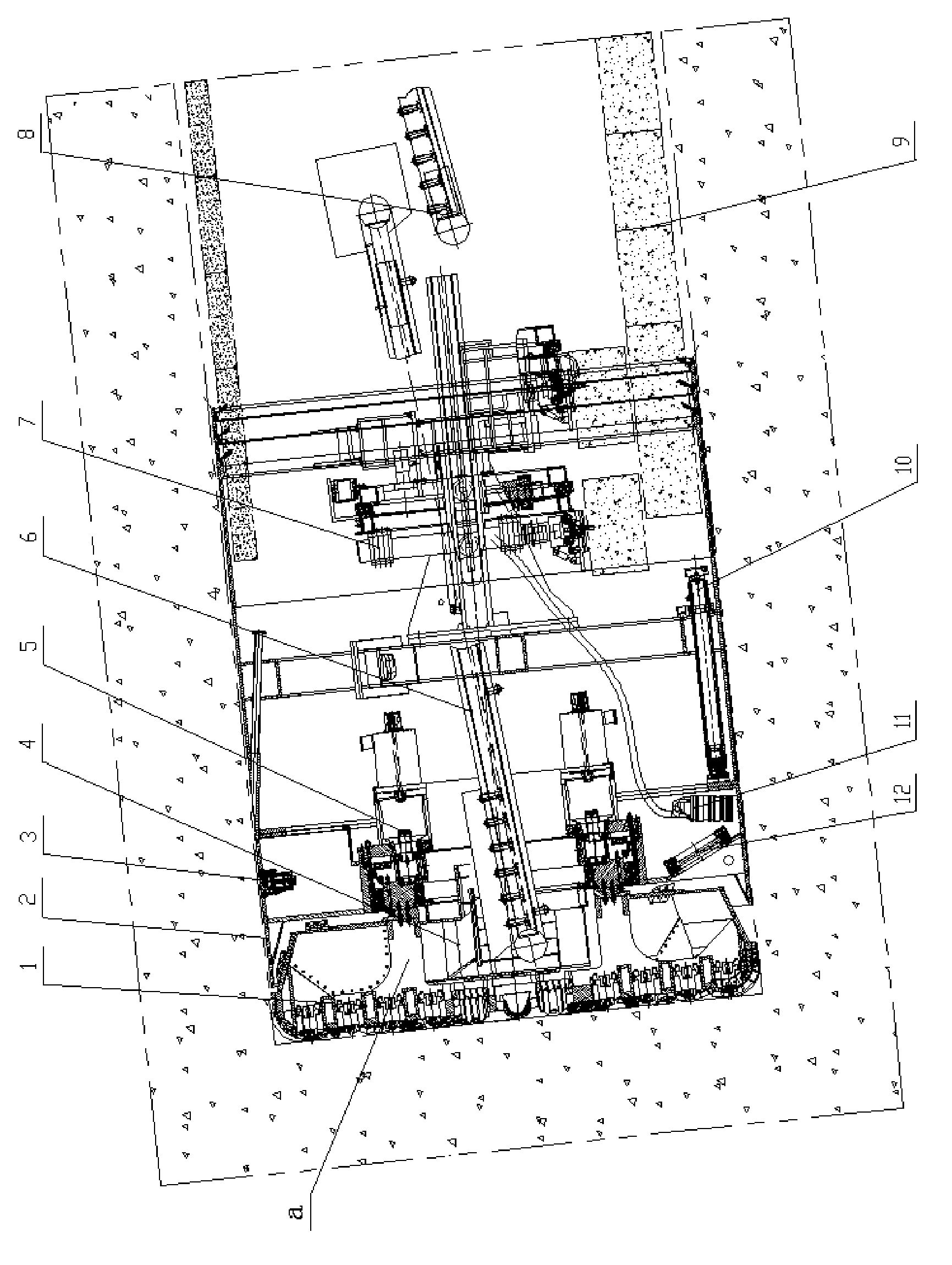

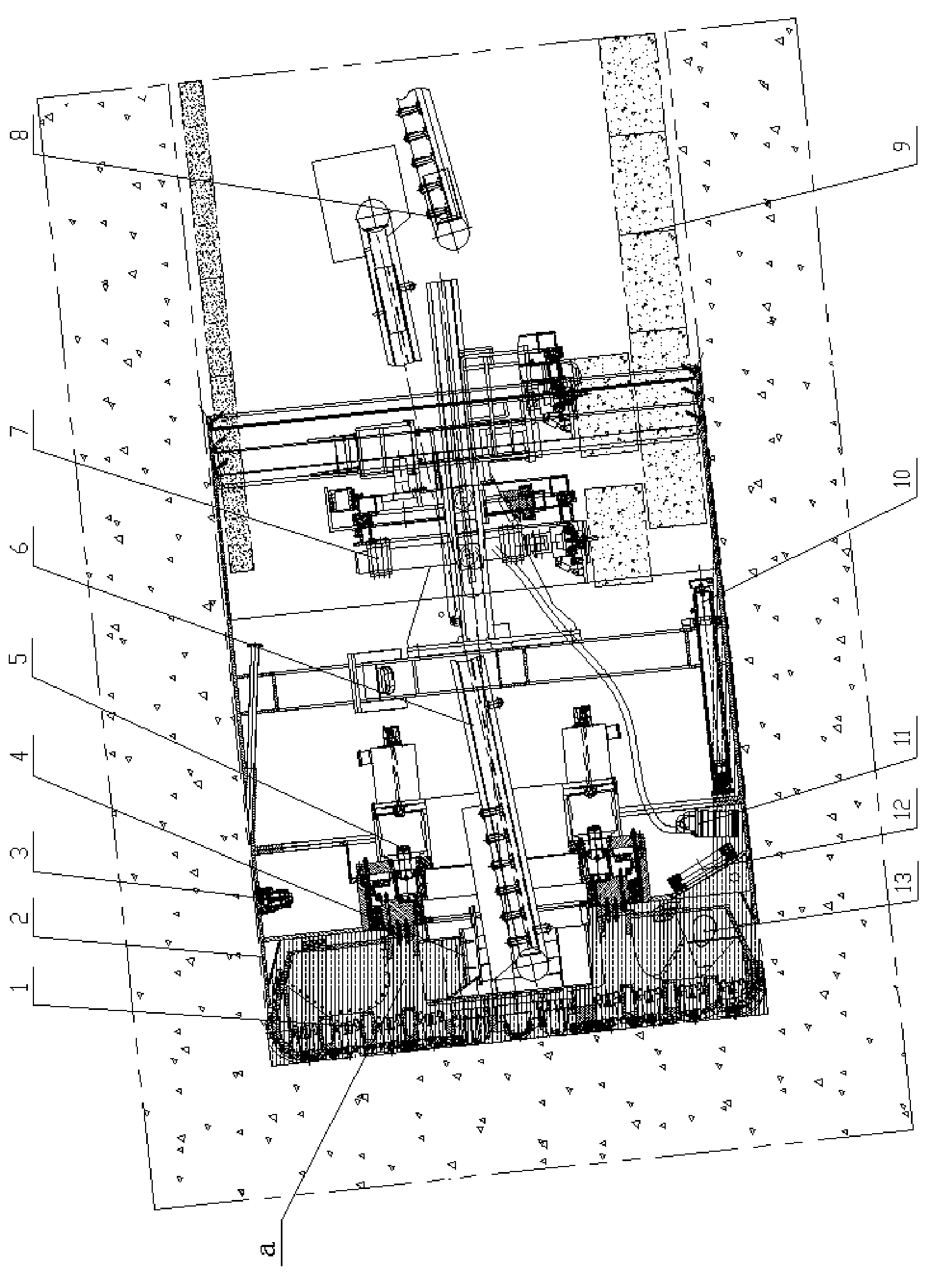

Full-section rock ripper for long-distance heavy-gradient inclined shaft

ActiveCN102704945AEnsure safetySolve a lot of water gushingUnderground chambersTunnel liningSlagEngineering

The invention discloses a full-section rock ripper for a long-distance heavy-gradient inclined shaft. The full-section rock ripper comprises a shield body, a handpiece arranged on the front end of the shield body and composed of a cutterhead and a main driving system, a cutterhead capable of rotating in two directions to discharge slag, an excavation cabinet located behind the cutterhead, a sealable slag receiving hopper and an anti-surge door, which are arranged in the excavation cabinet, a stabilizer arranged at the top part in the shield body, a propelling oil cylinder arranged in the shield body and hinged with the handpiece, an explosion proof drainage system, an explosion proof ventilating and dedusting system and a mainframe belt conveyor, wherein the full-section rock ripper further comprises a duct piece assembling machine arranged at the back end of the shield body, an assorted back belt conveyor connected with the mainframe belt conveyor and a quick material pouring and conveying system. The full-section rock ripper disclosed by the invention can effectively solve such problems in the long-distance heavy-gradient inclined shaft as burst of massive water and harmful gases, tunneling speed and efficiency, auxiliary material transport, mainframe overturning and lateral rolling of mainframe.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Pit pile anchor breast wall concrete breast beam structure and construction method thereof

InactiveCN101280564AReduce processing costsChange the situationExcavationsBulkheads/pilesPre stressRock bolt

Disclosed is a concrete middle beam structure with foundation pit piles and anchor breast wall and the construction method thereof. Prestressed anchor rods are fixed between slope protection piles towards the soil between piles, and side wall of the foundation pits is also provided with transverse concrete middle beams which are between concrete slope protection piles and are in casting connection with the prestressed anchor rods; the outer lateral surface of the transverse concrete middle beams is as parallel and level as the sheath of the pile bodies of the concrete slope protection piles; the inner lateral surface is close to the inner end of the pile bodies of the concrete slope protection piles, and the inner part close to the outer lateral surface is distributed with reinforced nets which are coated at the outer lateral surface of the pile bodies of the row of the concrete slope protection piles and connected with anchor plates of the prestressed anchor rods; the prestressed anchor rods are embedded into the soil between piles from the side wall of the foundation pits, wherein, the anchor heads are positioned in the inner side of the connecting surface at the outer lateral surface of the row of the concrete slope protection piles. The structure of the invention changes the middle beams of section steel and the state that the prestressed anchor heads extrude the pile bodies, can reduce the excavation volume of foundation pits and needs no hoisting equipment to lift section steel middle beam, thereby greatly shortening construction time, simplifying construction steps and reducing construction cost.

Owner:BEIJING CONSTR ENG GRP CO LTD +1

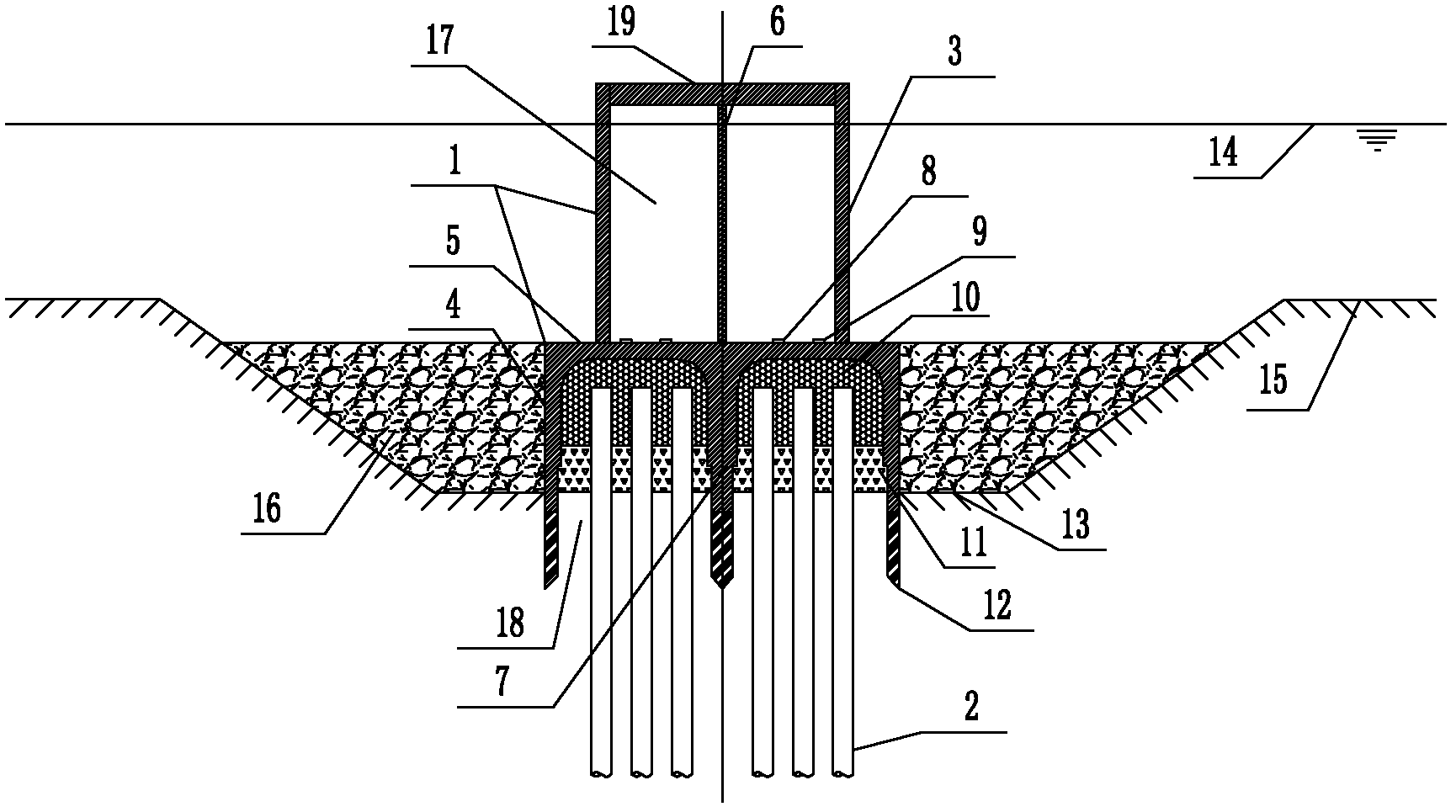

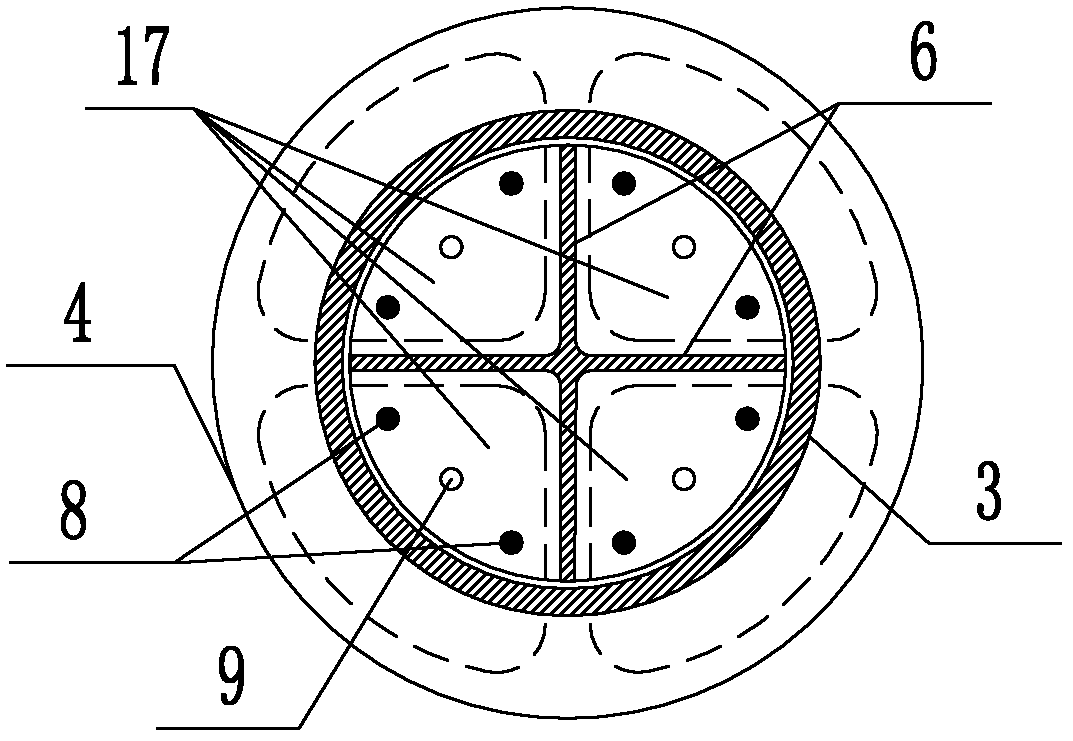

Pile foundation bucket foundation and construction method thereof

ActiveCN102644293AWith air stabilityAir flotationFoundation engineeringOffshore constructionBuilding construction

The invention discloses a construction method of the pile foundation bucket foundation. The foundation consists of a bucket body and a pile foundation; the bucket body comprises an upper wall body, a lower wall body, a cover plate, an upper baffle and a lower baffle. The cover plate is arranged at the upper part of the lower wall body, and the lower baffle is arranged inside the lower wall body, so as to form a lower wall body cavity. The upper wall body is arranged on the cover plate, the upper baffle is arranged inside the cover plate, so as to form an upper wall body cavity. A water-air valve and a concrete pouring valve which are communicated with the upper wall body cavity and the lower wall body cavity are arranged on the cover plate. The bucket body is sunk after the construction of the pile foundation, injecting water into the upper wall body cavity and absorbing water by the lower wall body cavity are main sinking means, and when the bucket body reaches a designed penetrating depth, bottom sealing concrete and in-bucket concrete are poured into the lower wall body cavity, so that a pile is connected with the bucket body. The pile foundation bucket foundation is suitable for being served as a deep-water bridge foundation on the condition of a thick covering layer, gives full play to the characteristics of high vertical bearing capability of the file foundation and convenience in construction of the bucket foundation, has high applicability, simple construction technology, small post-construction settlement, and lower requirement on offshore construction equipment, does not require the building of large construction auxiliary facilities, and is low in construction cost.

Owner:CCCC SECOND HARBOR ENG

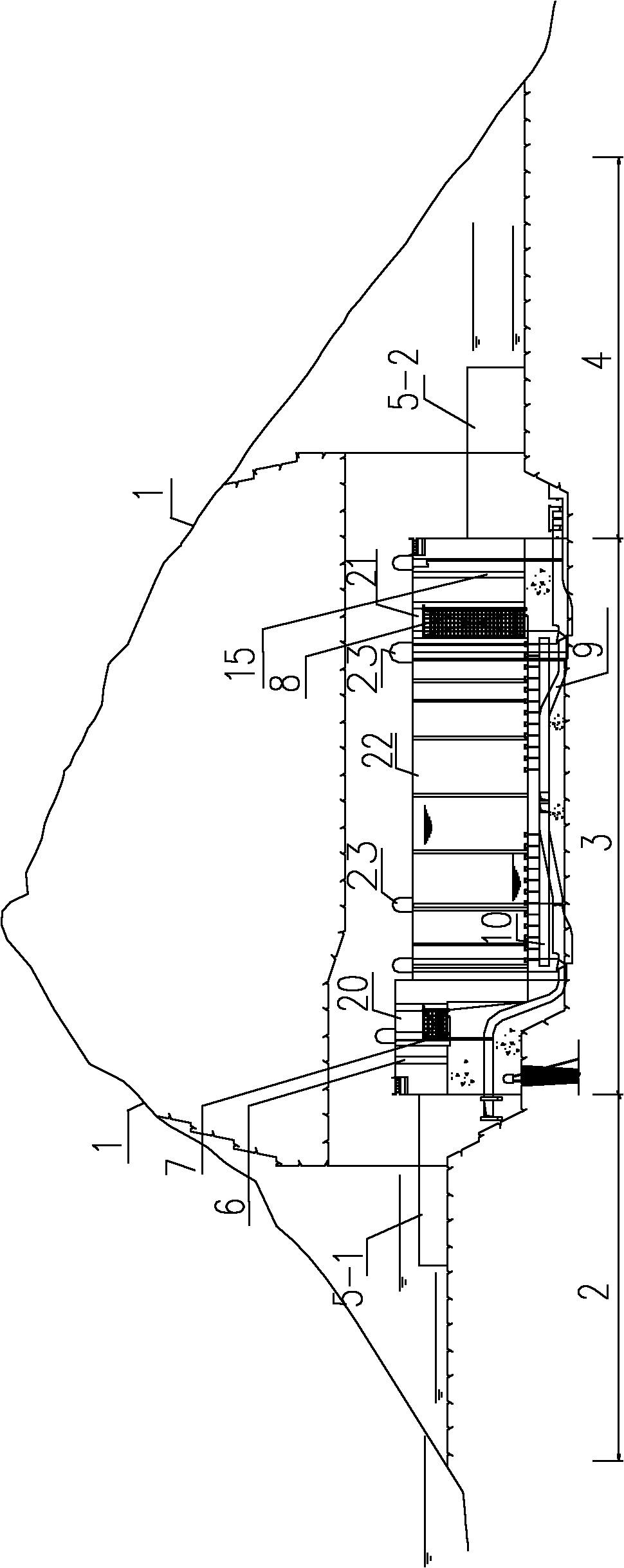

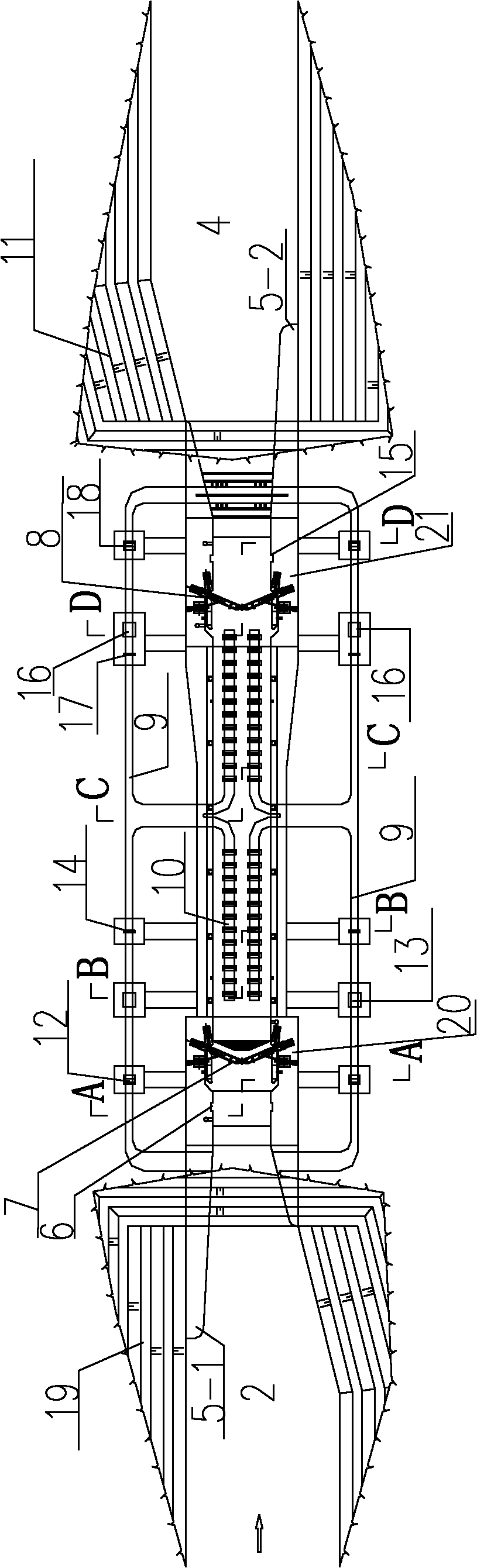

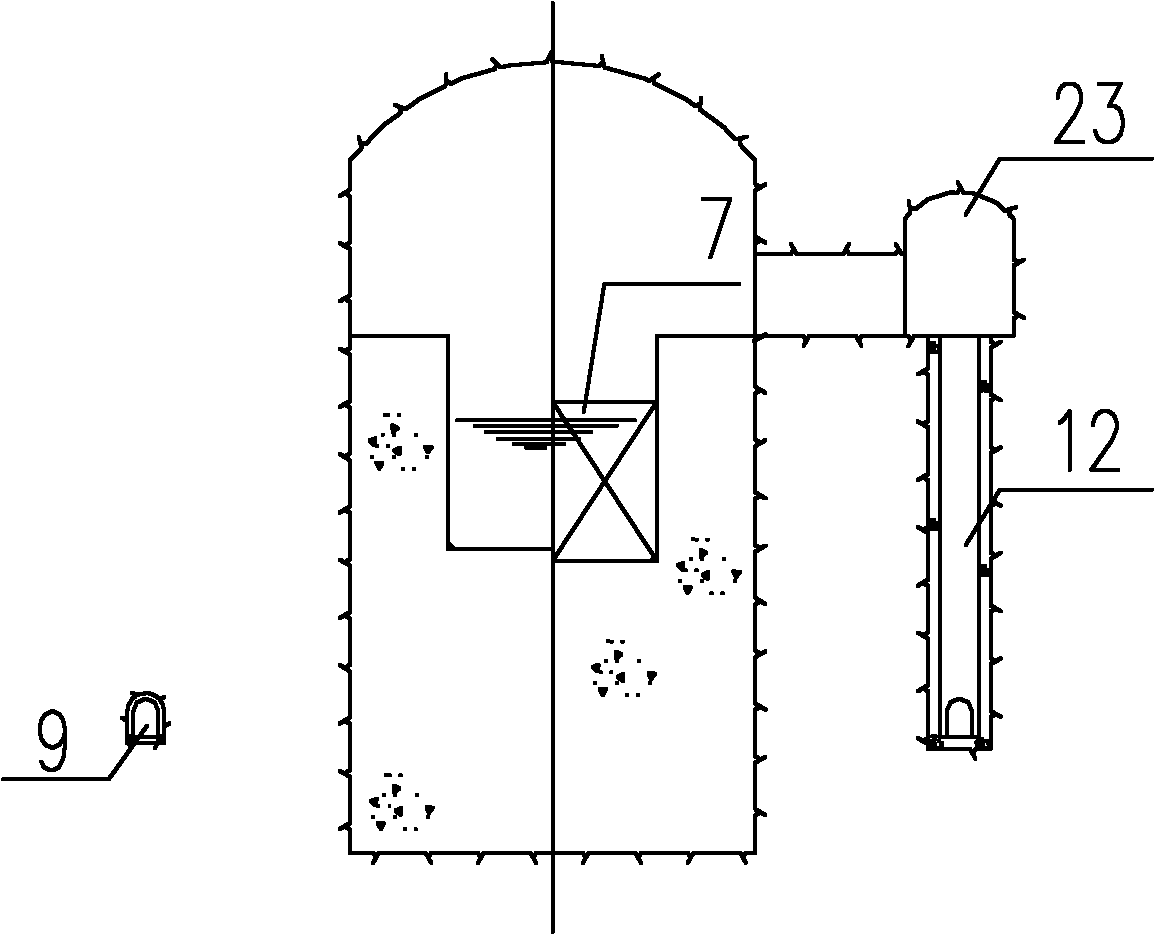

Underground shiplock arranged in mountain body

ActiveCN102134846AReduce support costsWill not form artificialDry-docksClimate change adaptationReinforced concreteWater block

The invention relates to an underground shiplock arranged in a mountain body, which comprises an upstream approach channel (2) and a downstream approach channel (4) for connecting a shiplock main body section (3), wherein the shiplock main body section (3) comprises an upper lock head (20), a lock chamber (22) and a lower lock head (21), an upstream water-blocking door slot (6) is arranged at theupper lock head (20) of the shiplock, an upstream working door (7) is arranged behind the upstream water-blocking door slot (6), a downstream working door (8) is arranged at the lower lock head (21) of the shiplock, a downstream access door slot (15) is arranged behind the downstream working door (8), and the shiplock adopts a reinforced concrete lining structure. When the shiplock is built on a water conservancy and hydropower junction in a high mountain and valley area, hole excavation is used for replacing open excavation, thereby greatly saving engineering quantity and cost of the shiplock; by matching with construction of a dam, the navigation conditions of an upstream river course and a downstream river course are improved, and a bright future is provided for enabling the river courses to expand the navigable mileage upstream and developing water transportation traffic in mountain areas.

Owner:长江设计集团有限公司

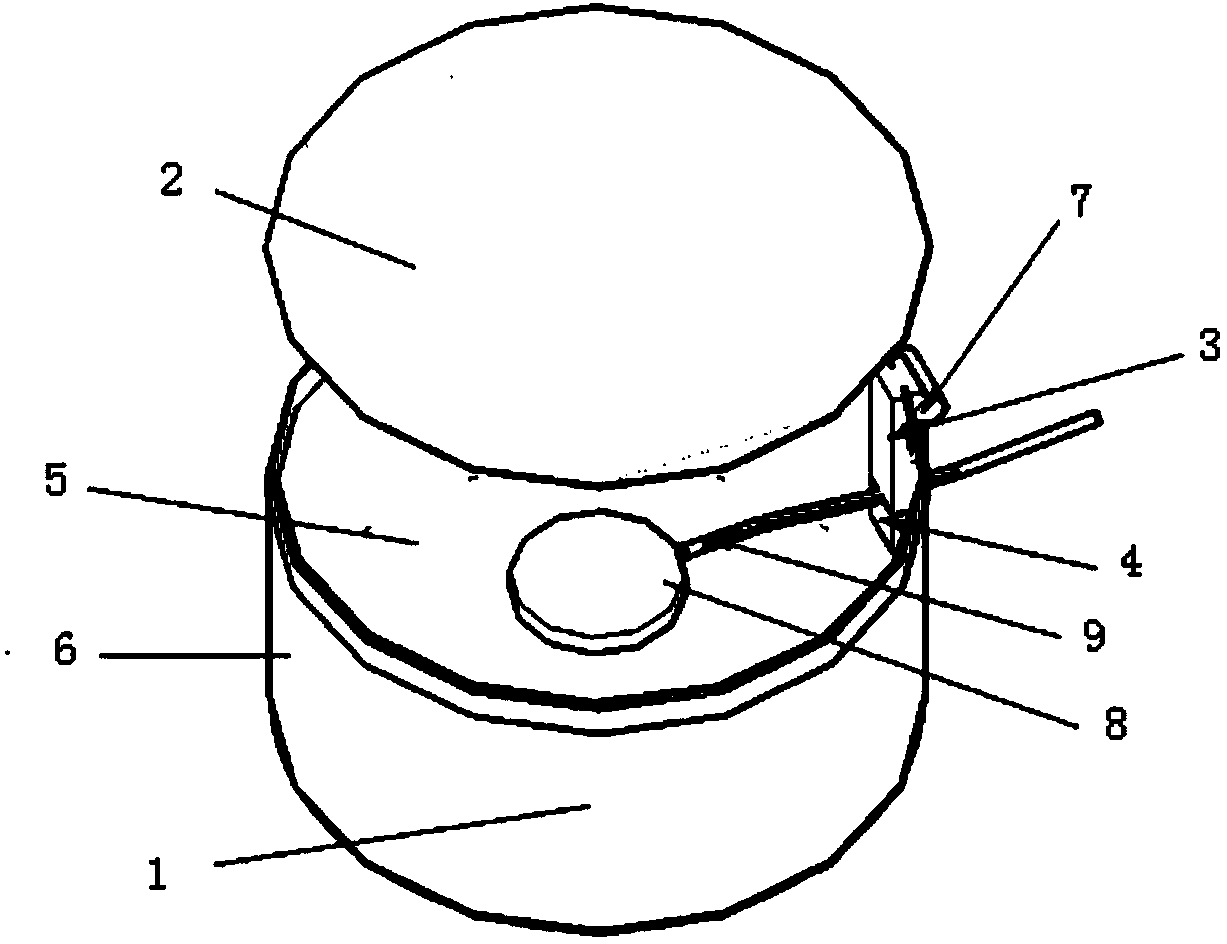

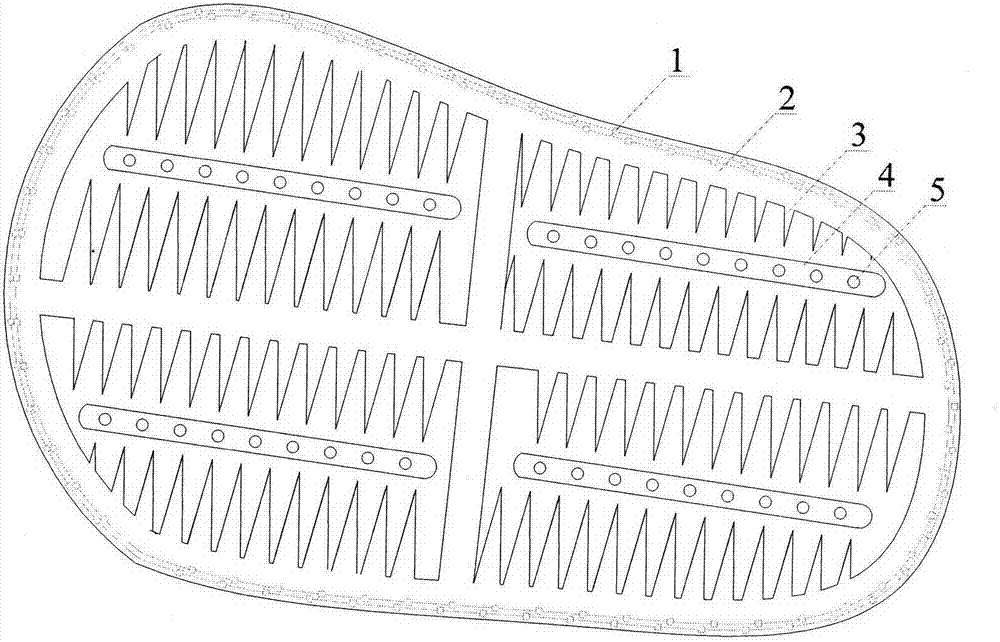

Rock-soil pressure sensor embedding device and embedding method thereof

ActiveCN103808435AHigh measurement accuracySmall sizeFoundation testingForce measurementEngineeringSoil material

The invention discloses a rock-soil pressure sensor embedding device and an embedding method thereof. The rock-soil pressure sensor embedding device comprises a cylindrical thin-wall vessel, a base, an upper sealing strip, a lower sealing strip, a lining, an outer lining, a band and a pressure sensor. The embedding method includes: arranging the soil pressure sensor embedding device, digging an embedding hole, levelling the basal plane of the sensor, inverting the pressure sensor embedding device, backfilling the original soil material, extracting the cylindrical thin-wall vessel, and backfilling and so on. By means of the rock-soil pressure sensor embedding device and the embedding method thereof, the digged pit slot is small, the size of a protecting layer needed for the sensor is small, the embedding efficiency is improved, the measuring precision is improved, the protecting layer is avoided from loosening in vibration rolling, and the problem of embedding the sensor in coarse granular materials is solved.

Owner:JSTI GRP CO LTD

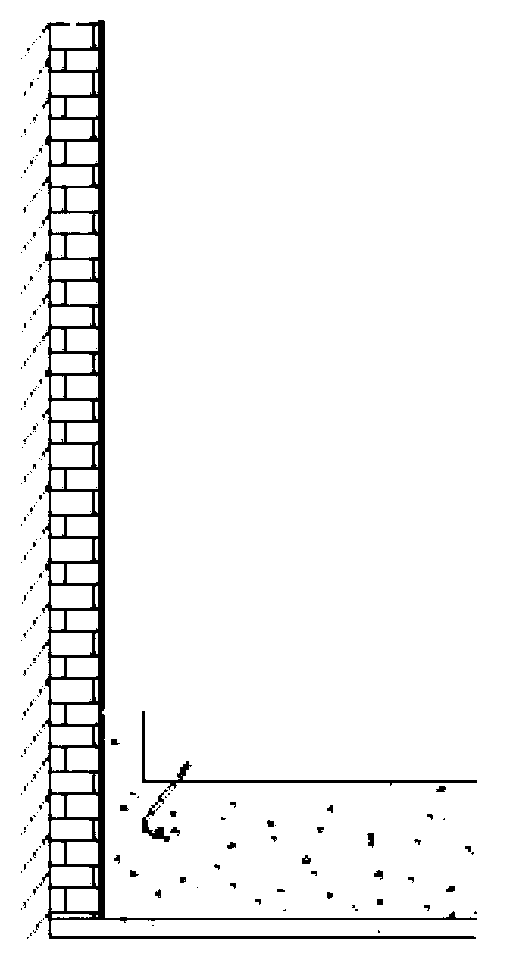

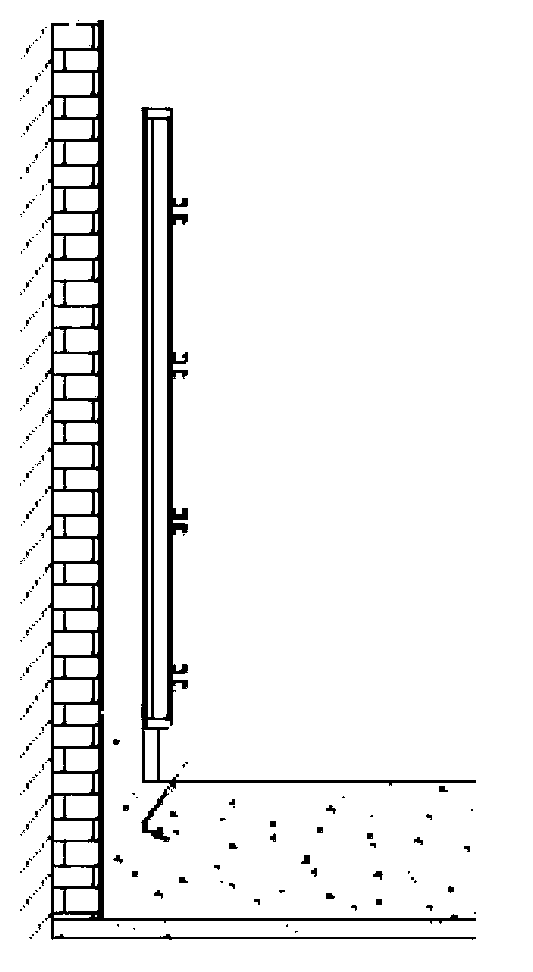

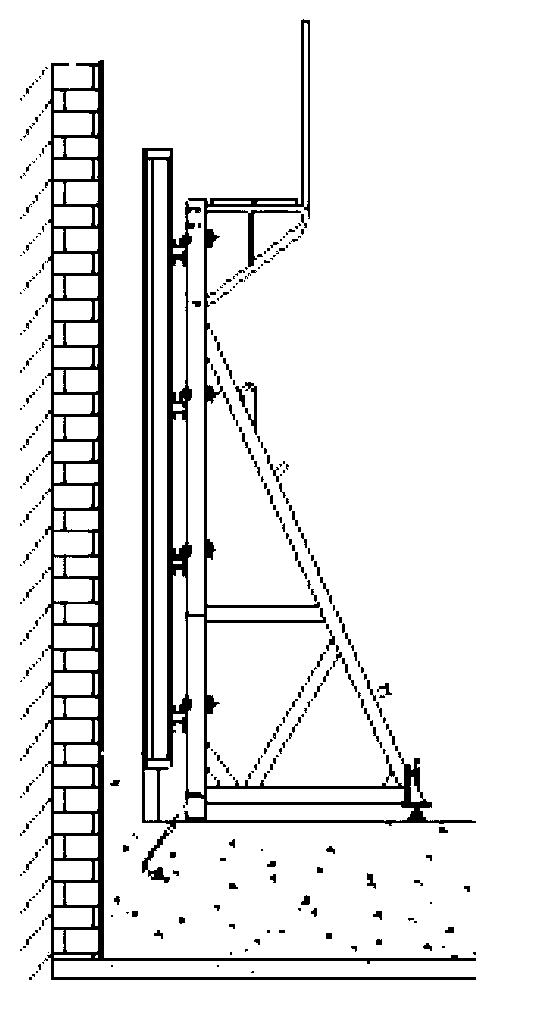

Construction method of single-side mould supporting system

InactiveCN102797357ASolve the problem of no construction work surfaceReduce excavationBuilding material handlingSupporting systemUltimate tensile strength

The invention provides a construction method of a single-side mould supporting system. The single-side mould supporting system comprises an embedded part system, wall body templates and a single-side support frame. The construction method of the single-side mould supporting system is characterized by comprising the following steps of: (1) embedding one end of a foundation bolt, and enabling the other end of the foundation bolt to be protruded out of the ground and form an angle of 45 degrees with the ground; (2) selecting and splicing the wall body templates, and sealing edge seams by using sealing strips; (3) erecting the triangular single-side support frame, installing a steel pipe, and fixing the steel pipe of the single-side support frame with a connecting rod of the embedded part system, which is connected with the upper end of the foundation bolt; (4) connecting the wall body templates and the vertical rod part of the single-side support frame by using a connecting device; (5) adjusting a rear supporting seat positioned on the lower end of the single-side support frame up and down so that an upper ports of the wall body templates are slight inclined into a wall; (6) pouring concrete between the wall body templates and wall bodies of adjacent buildings; and (7) after a concrete wall achieves mould disassembling strength, disassembling the single-side mould supporting system. The construction method of the single-side mould supporting system has simple process and increased work efficiency; and in addition, poured outer wall concrete has good appearance quality and higher applicability.

Owner:发达控股集团股份有限公司

Contaminated soil organized seepage in situ forced purification method

InactiveCN102728609AReduce areaGuaranteed approximationContaminated soil reclamationPurification methodsSoil horizon

A contaminated soil organized seepage in situ forced purification method comprises the following steps: arranging vertical waterproof curtains at the periphery of contaminated sites to isolate and avoid seepage, excavating seepage channels, excavating water collecting wells, preparing leaching solution, and leaching contaminated soil. The method adopts seepage open channels to divide contaminated site leaching units and overcomes the shortcoming that difference of soil quantity of large-area contaminated sites is large so as to result in an unstable leaching effect. The contaminated soil organized seepage in situ forced purification method adopts layered excavating of main open channels, branch open channels and water collecting channel, thereby shortening vertical seepage distance of leaching solution and reducing excavated volume of contaminated site soil during construction. The leaching solution performs submerging, immersing, seepage and leaching in layered mode, thereby promoting sufficient reaction between the leaching solution and contaminant. By means of re-purification of remained contaminant in soil layers after leaching through subsequent leaching, residual quantity of the contaminant in soil is greatly reduced, leaching effect is improved, operation is convenient and fast, controllability of the contaminant is strong, and actual engineering quantity is small.

Owner:武汉致衡环境安全工程技术有限公司

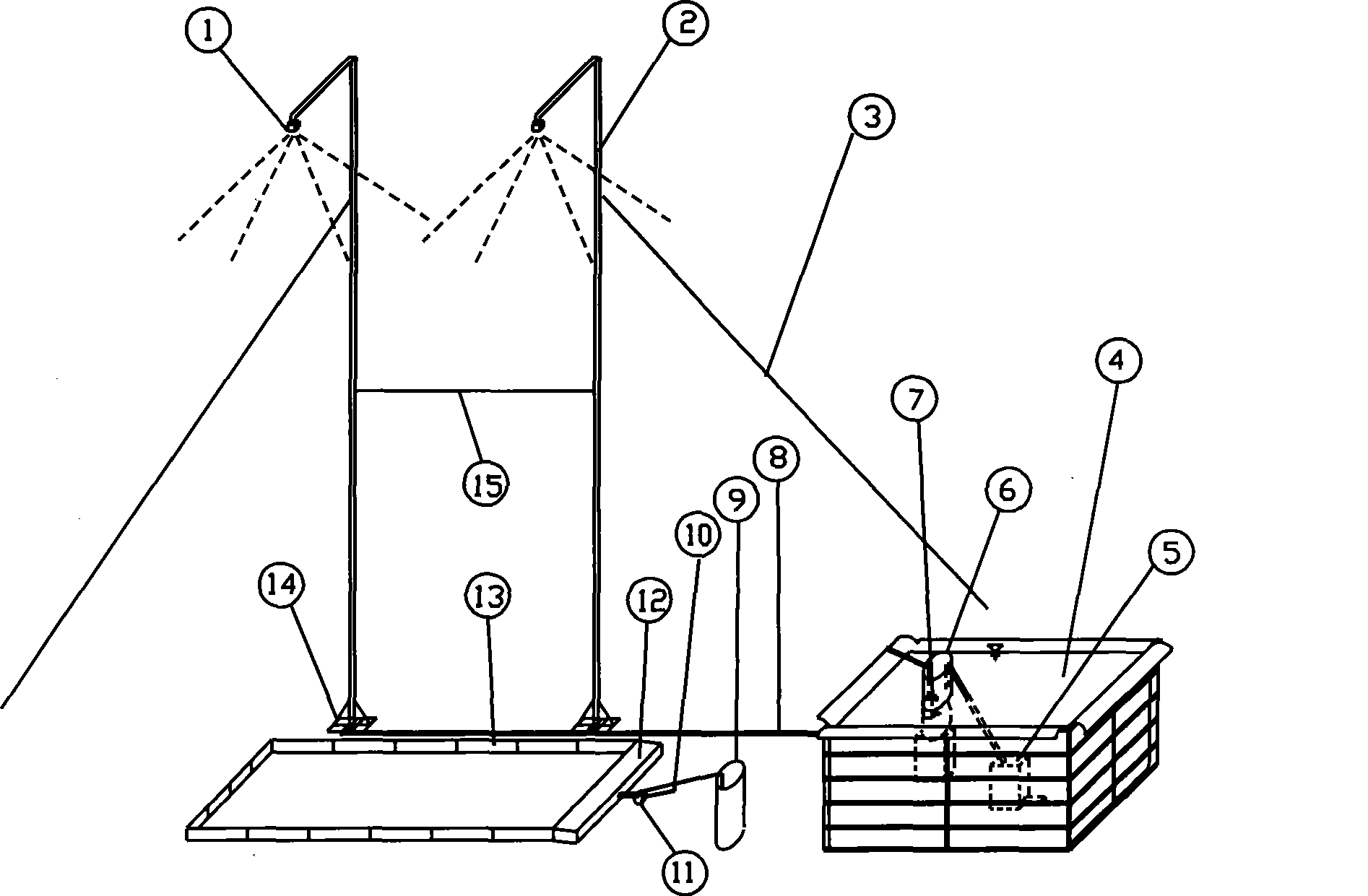

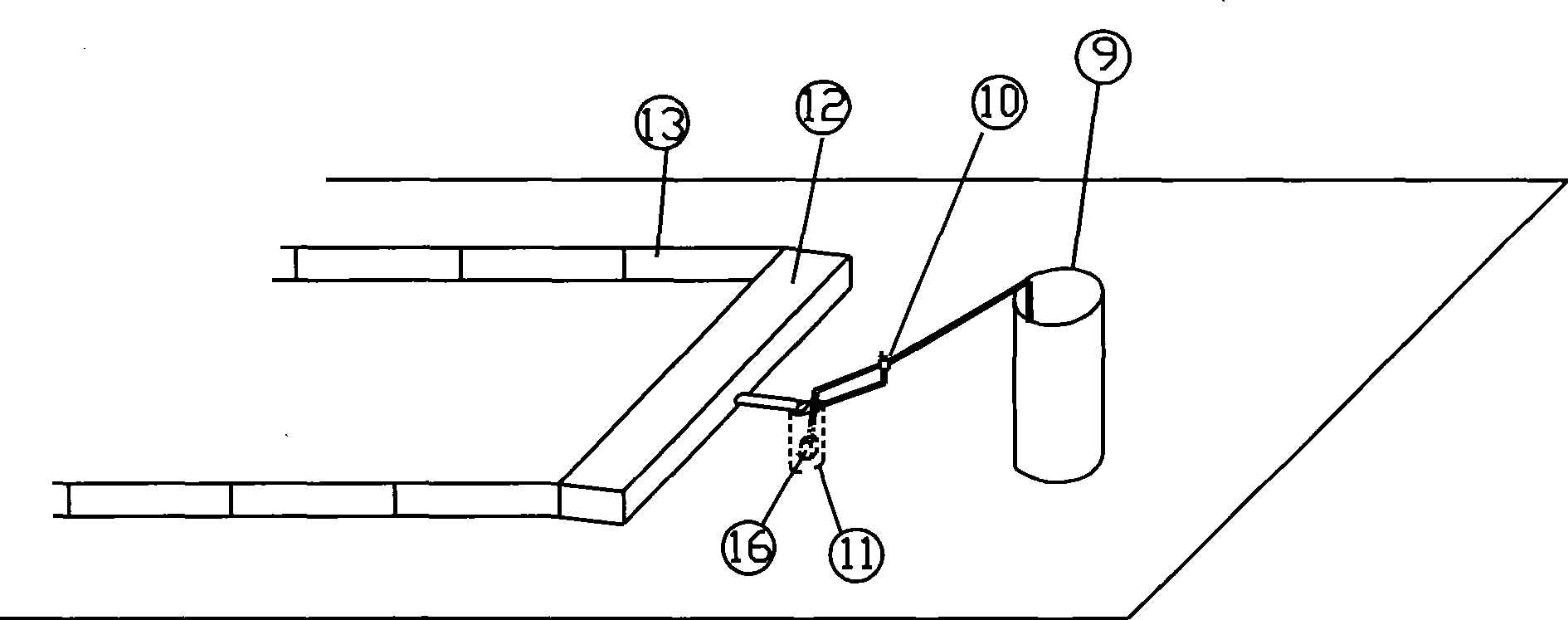

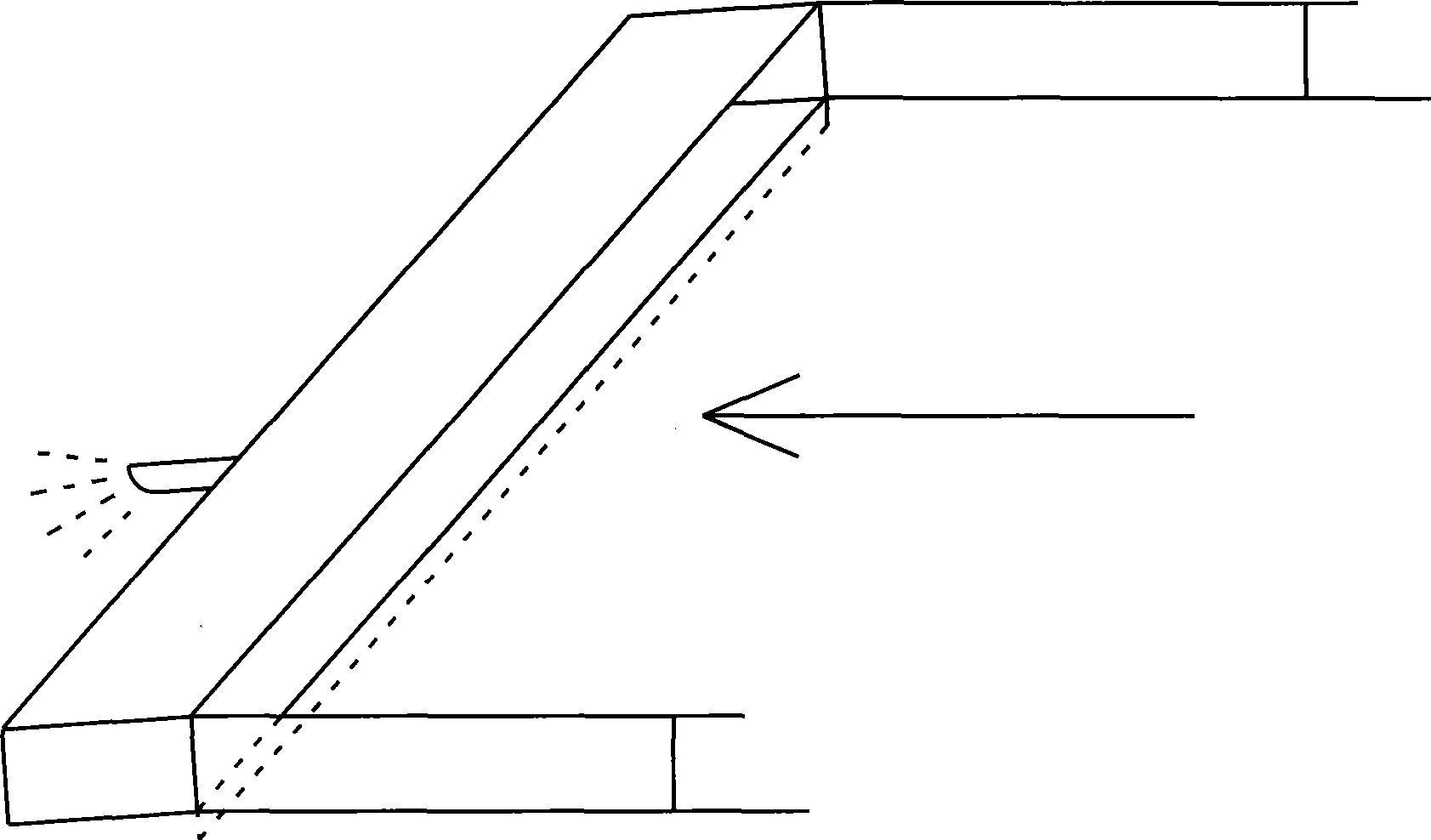

Apparatus for establishing urban water-through surface water collection effect test

The invention belongs to the technical field of research devices for water and soil conservation, and discloses a device for establishing a water-collecting effect test for urban water permeable surfaces. The device is characterized by mainly comprising a radial flow measuring device, a rainfall infiltration test surface and a rainfall simulator. The radial flow measuring device comprises a collecting groove, a collecting tank, a synchronous micro diving pump, a radial flow tank, an adjustable water control valve and a stop watch part, and adopts a transfer type measuring method to measure radial flow. The rainfall infiltration test surface uses a combined steel plate pile as a side wall to separate out an observation surface; the rainfall simulator comprises a rainfall spray head, an adjustable flat base and a water supply system; and a base bracket can keep horizontal through adjusting three lead screws respectively, so that the device is suitable for various sloping surfaces. The water supply system mainly comprises a water control valve, a water supply tank with primary and secondary structures, a first diving pump and a second diving pump. The secondary tank is positioned in the primary tank. The device has the effects and advantages of little influence on surrounding environment, accuracy and flexibility, little water usage, and low cost.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com