Low water head vertical shaft through-flow bi-directional efficient turbine runner as well as electromechanical device and mated flow passage thereof

A water turbine, low head technology, applied in the directions of hydroelectric power generation, machine/engine, tidal flow/damless hydropower, etc., can solve problems such as shortage, and achieve the effect of high energy conversion performance, improved efficiency, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

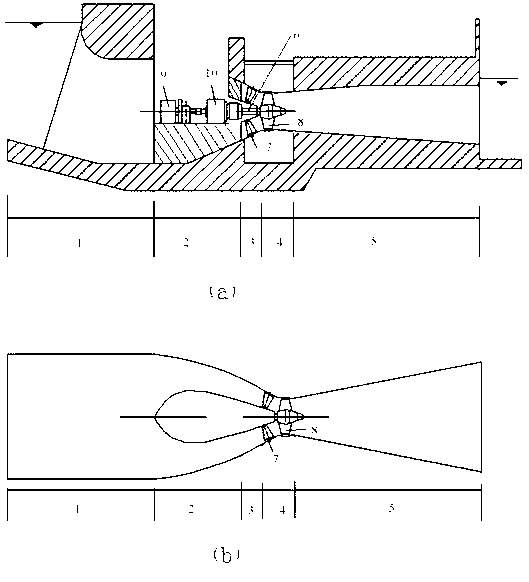

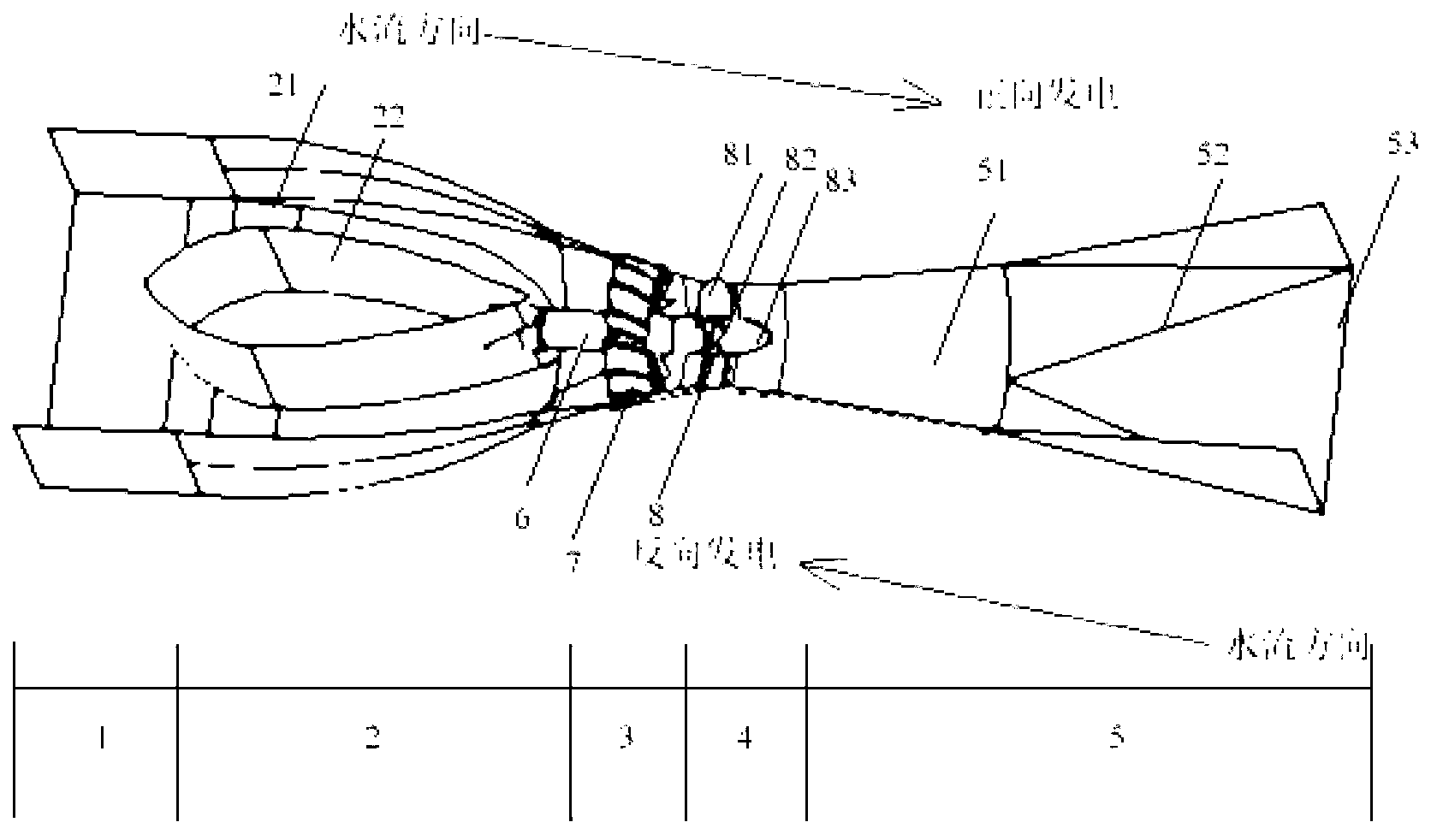

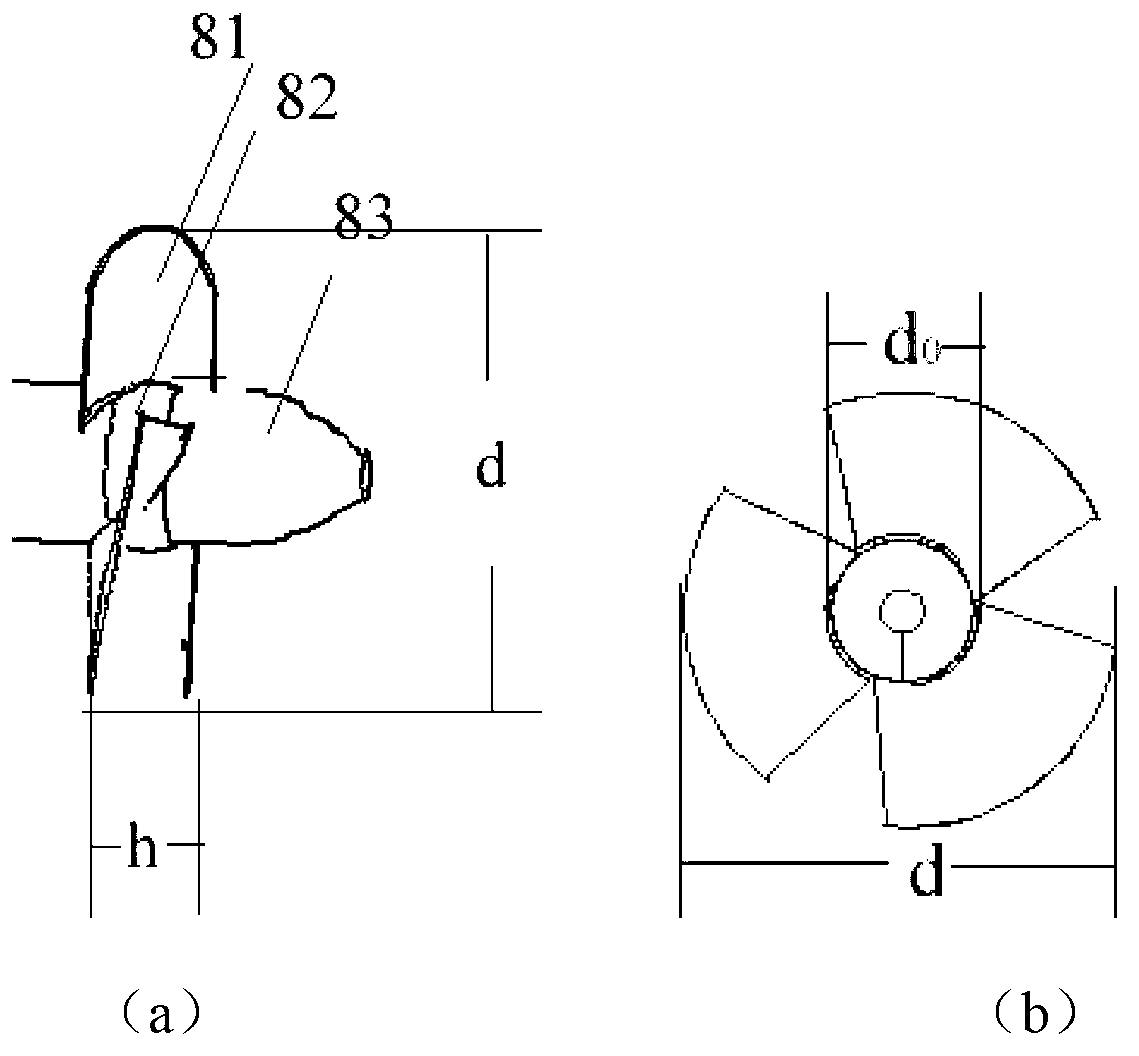

[0021] The two-way tidal power station of this embodiment is such as Figure 1-6 As shown in the figure, a low-head vertical shaft cross-flow two-way high-efficiency water turbine runner includes a runner hub and a water discharge cone. A discharge cone is installed on one side of the water discharge; the shape of the blade is thick in the middle and thin on both sides, and the ratio of the minimum thickness b1 to the maximum thickness b2 of the blade is 0.28-0.35, and the bending angle of the blade is between 90° and 95° between; the initial placement angle of the blade is 66°, and the adjustment value is at + between 3°.

[0022] The blades are three symmetrical airfoil blades arranged uniformly along the circumference of the hub of the runner.

[0023] The ratio of the runner height h to the turbine diameter d is 0.26, and the runner hub diameter d 0 The ratio to the turbine diameter d is 0.35.

[0024] The rotational speed of the runner is 200-300 rpm.

[0025] as att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com