Construction method of single-side mould supporting system

A single-sided formwork and construction method technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of large construction site area, high construction cost, and many turnover materials, etc., to achieve a small construction site area, The effect of reducing earthwork excavation and earthwork backfilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

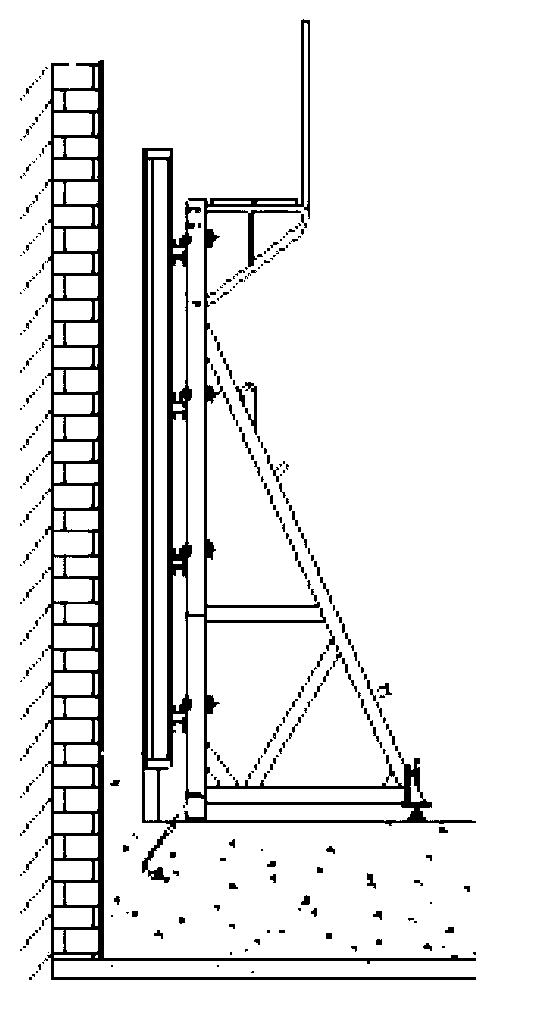

[0024] The invention provides a construction method of a single-side formwork system, which has simple procedures, improved work efficiency, good appearance quality of poured exterior wall concrete, no phenomenon of mold expansion and runaway, and strong applicability.

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

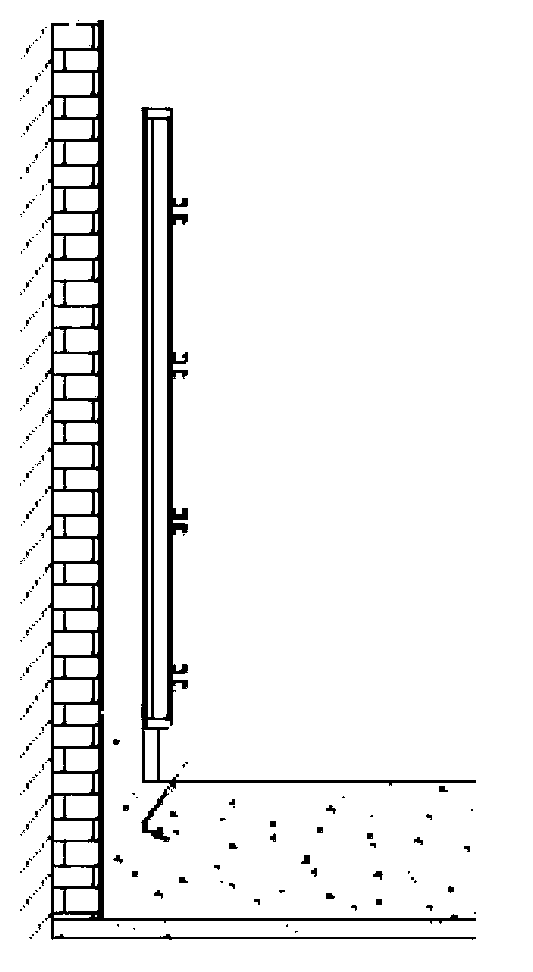

[0026] The embodiment of the present invention provides a construction method for a unilateral formwork system, the formwork system includes an embedded system, a wall formwork and a unilateral support, and is characterized in that it includes:

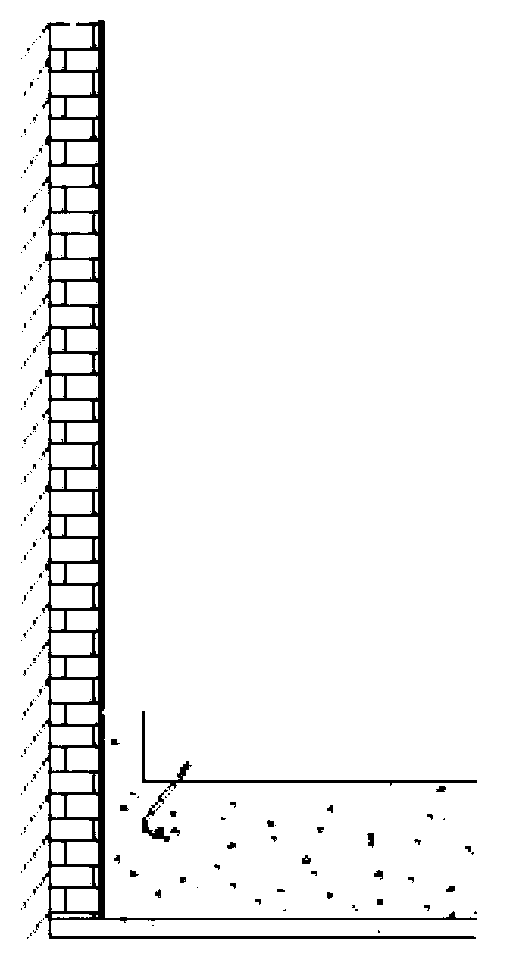

[0027] Step 1: Determine where the anchor bolts of the embedded parts system come out of the ground according to the position of the adjacent wall, and pre-emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com