Rock-soil pressure sensor embedding device and embedding method thereof

A technology of earth pressure sensor and pressure sensor, which is applied in the field of geotechnical engineering, can solve the problems of low quality of protective layer, low embedding efficiency, and large size of protective layer, so as to reduce the size of sensor protective layer, cushion size and excavation The effect of reducing the amount and improving the quality of the protective layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

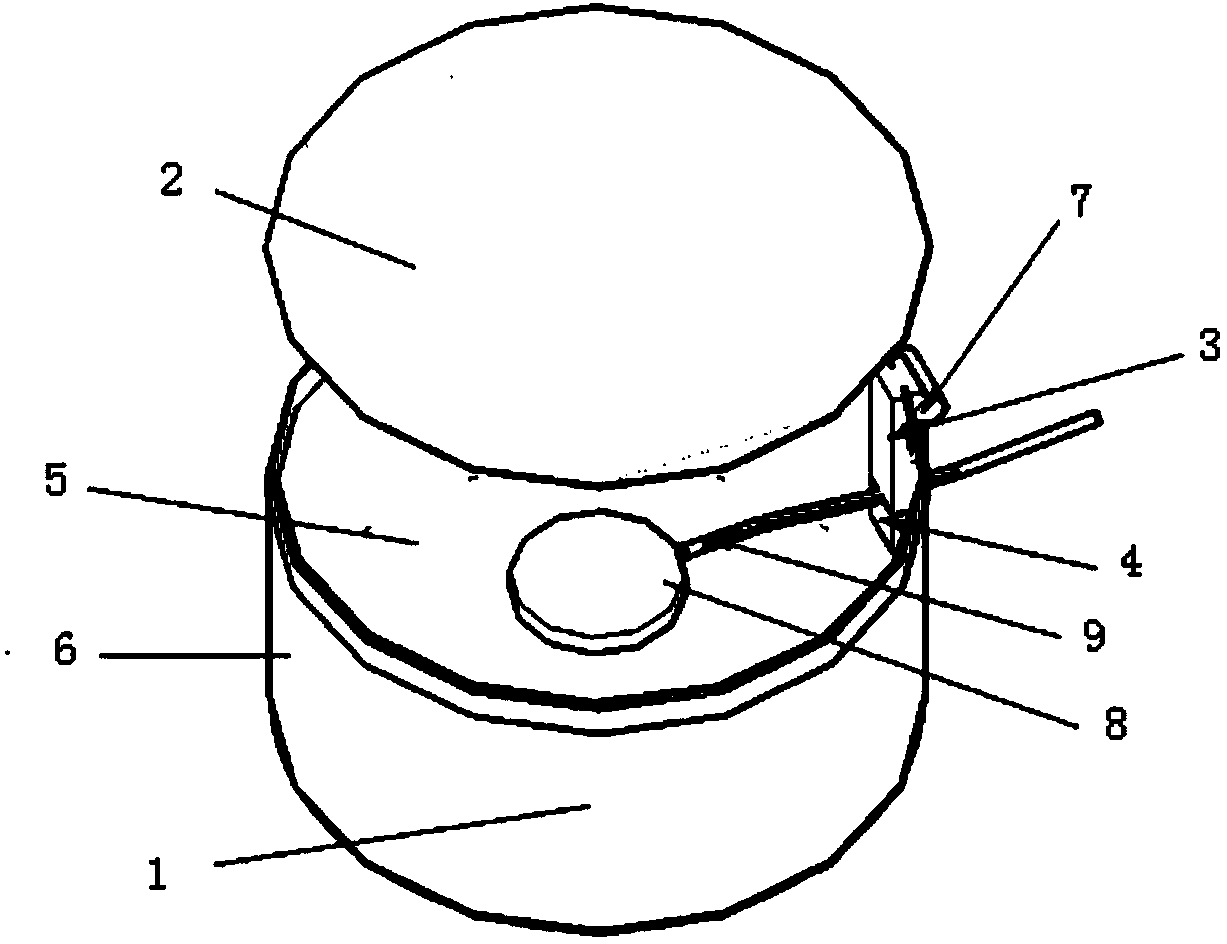

[0051] A device for embedding a rock-earth pressure sensor, comprising a cylindrical thin-walled container 1, a top seat 2, an upper sealing strip 3, a lower sealing strip 4, an inner lining 5, an outer lining 6, a belt 7 and a pressure sensor 8, and the top seat 2 Located on the top of the cylindrical thin-walled container 1, the inside of the cylindrical thin-walled container 1 is provided with a protective layer material, the inner liner 5 is arranged between the cylindrical thin-walled container 1 and the protective layer material, and the outer lining 6 is arranged on the cylindrical thin-walled container 1 outside; the cylindrical thin-walled container 1 is composed of a bottom plate and a side wall, the side wall is provided with a notch, the pressure sensor 8 is located between the protective layer materials, the pressure sensor 8 is connected with the sensor cable 9, and the sensor line The cable 9 extends to the outside through the inner liner 5, the notch on the side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com