Patents

Literature

238results about How to "Improve stress conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

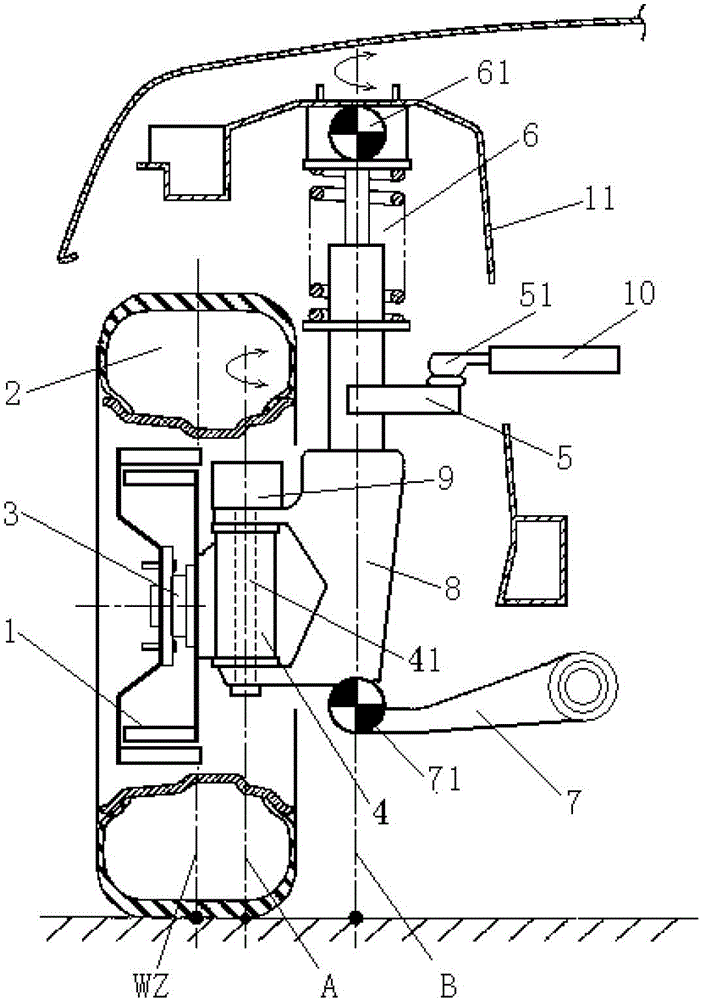

Independent driving, steering and suspending system

InactiveCN102717696ALow steering effortExcellent suspension dynamicsSteering linkagesMotor depositionActuatorControl theory

The invention provides an independent driving, steering and suspending system which comprises an in-wheel motor, a wheel hub unit, a first steering knuckle, a spring shock absorber, a lower cross arm, a second steering knuckle, a first steering actuator and a second steering actuator, wherein the in-wheel motor is used for driving a wheel to rotate; the wheel hub unit is used for supporting the rotation of the wheel and the in-wheel motor; the first steering knuckle is used for supporting the wheel hub unit, and can rotate around a first king pin axis formed by a first king pin; the spring shock absorber is used for supporting the wheel to jump up and down; the lower cross arm is used for guiding when the wheel jumps up and down; the second steering knuckle is used for supporting the first king pin, and can rotate around a second king pin axis formed by an upper fulcrum of the spring shock absorber and a spherical hinge of the lower cross arm; the first steering actuator is used for driving the first steering knuckle to rotate; and the second steering actuator is used for driving the second steering knuckle to rotate.

Owner:SHANGHAI ZHONGKE SHENJIANG ELECTRIC VEHICLE

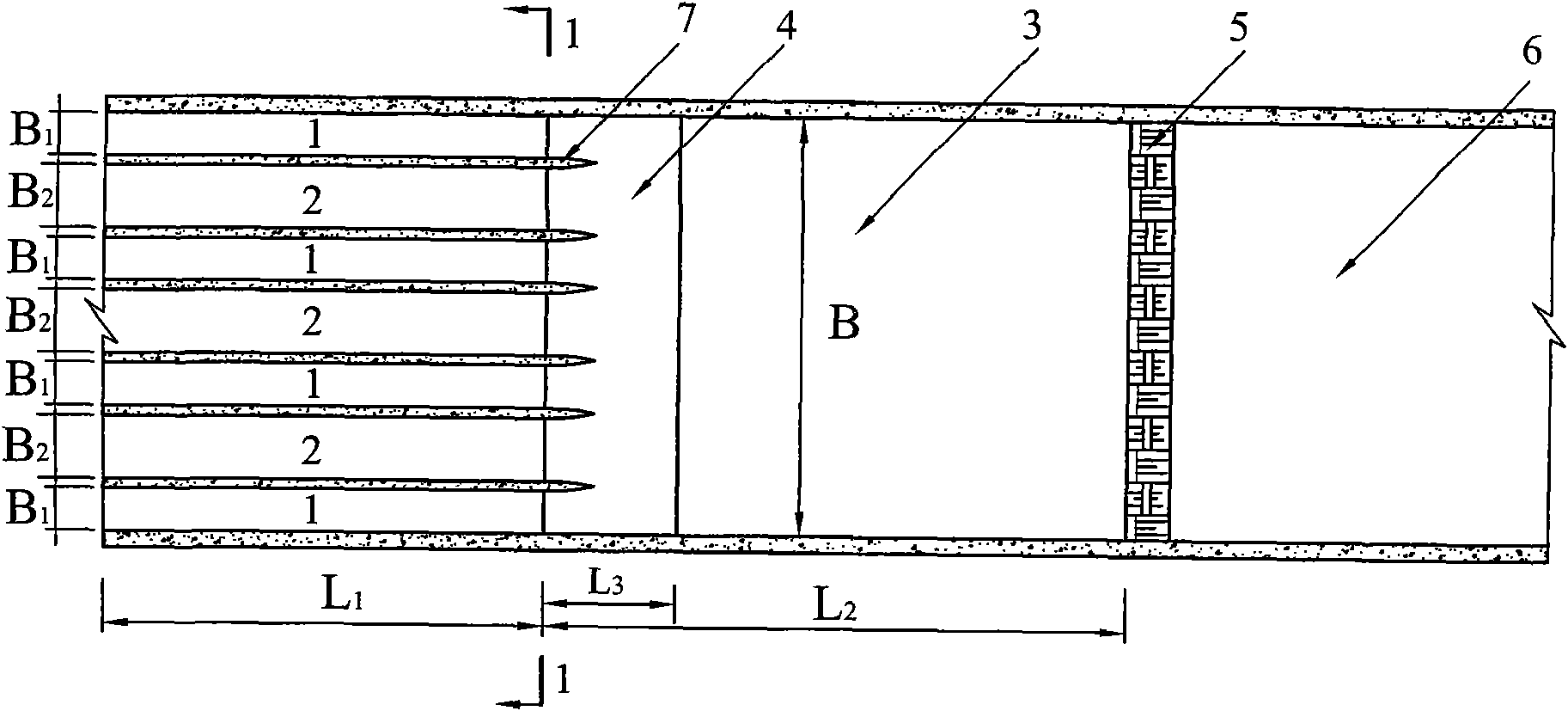

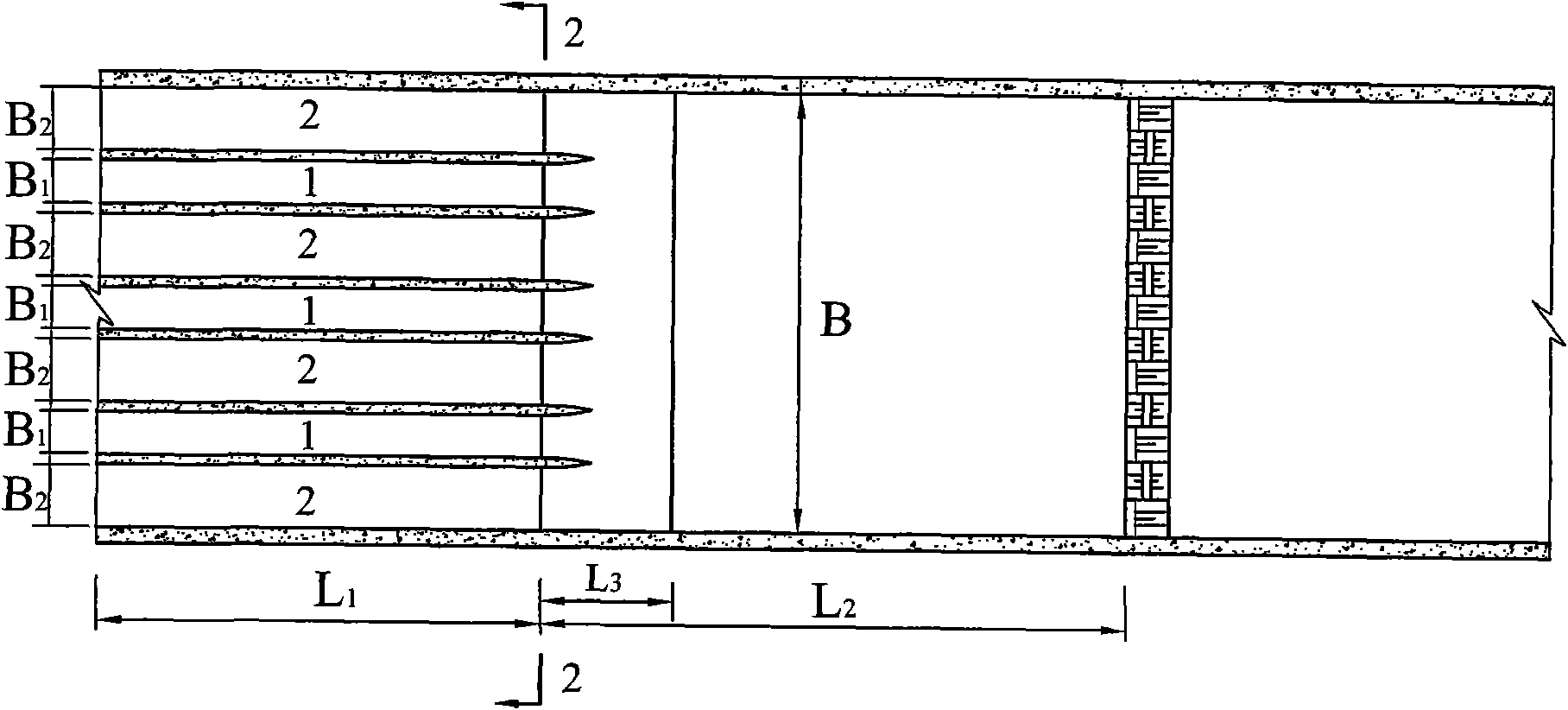

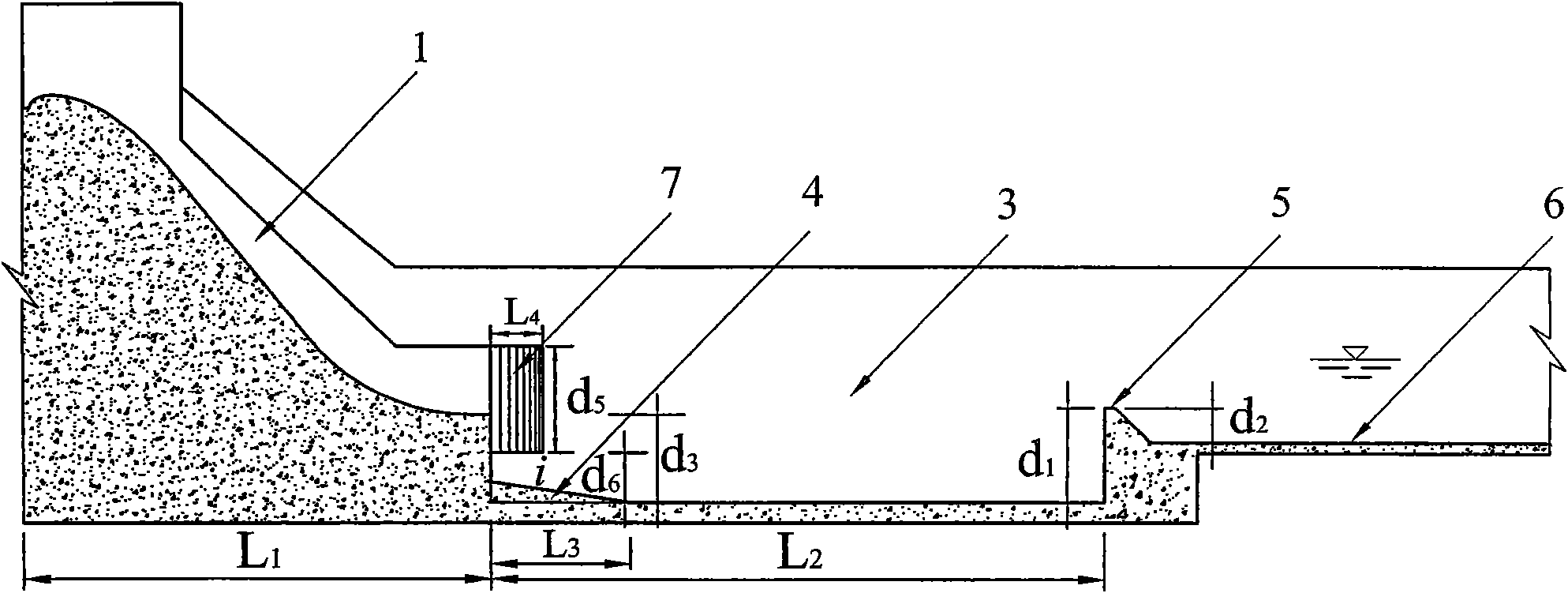

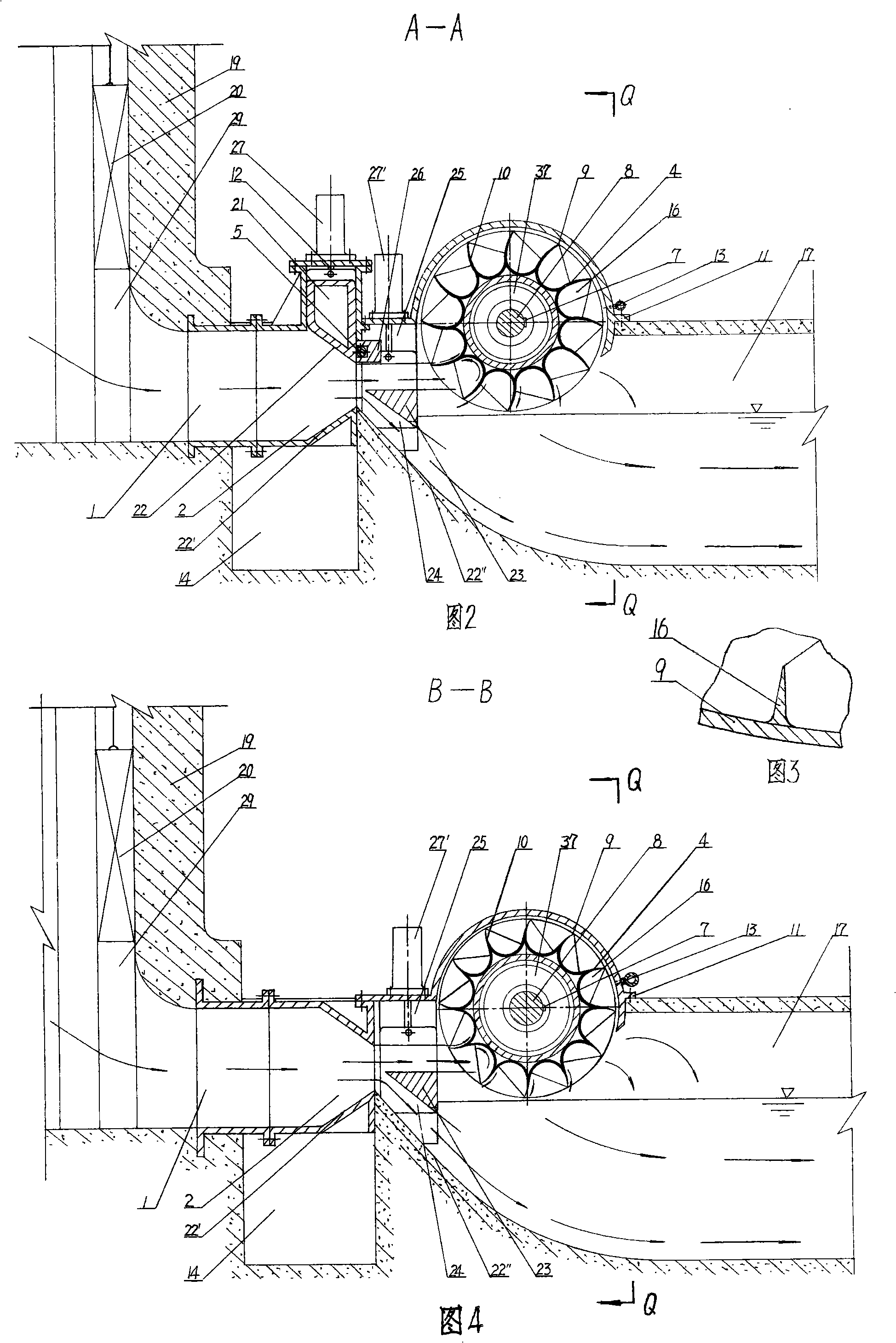

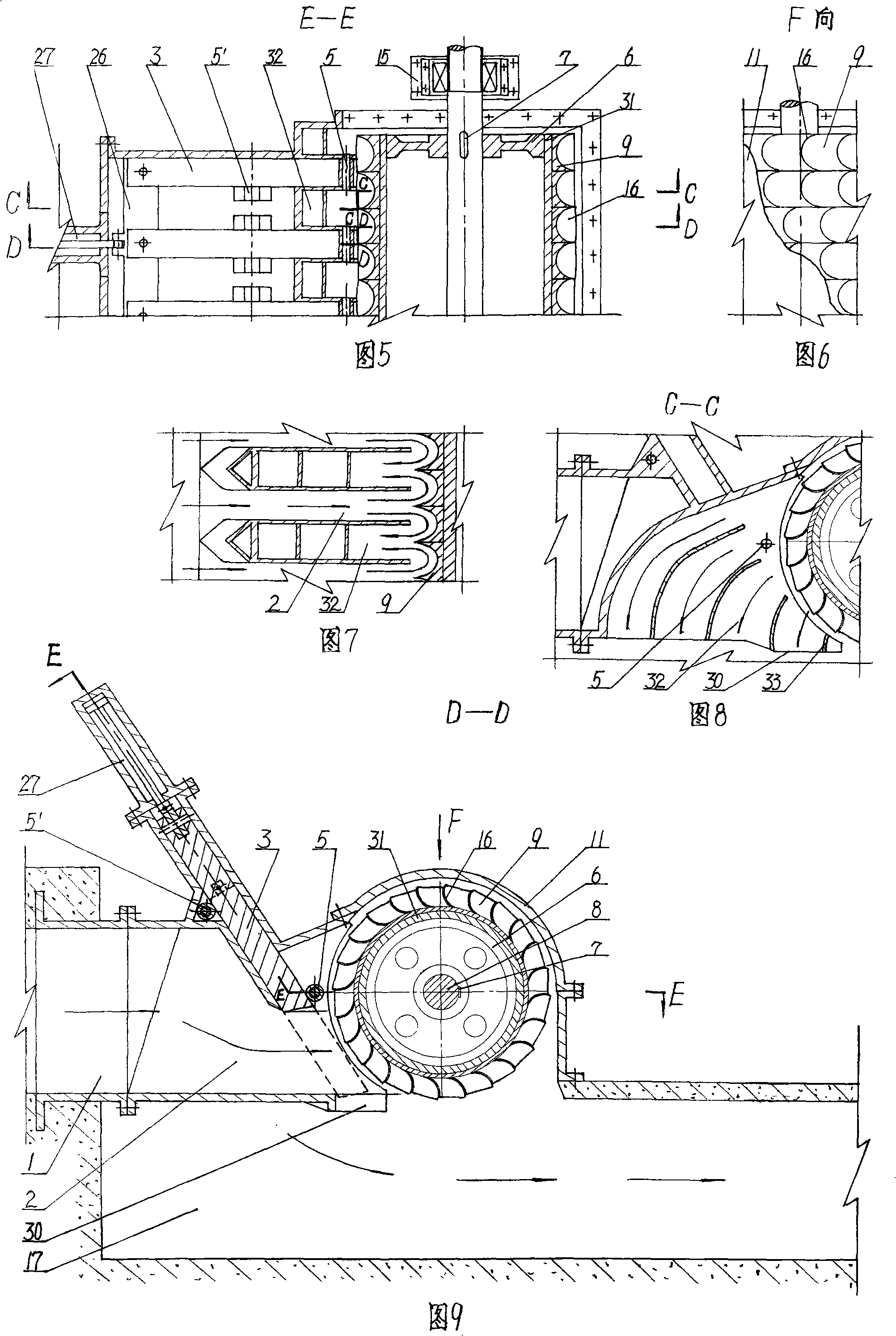

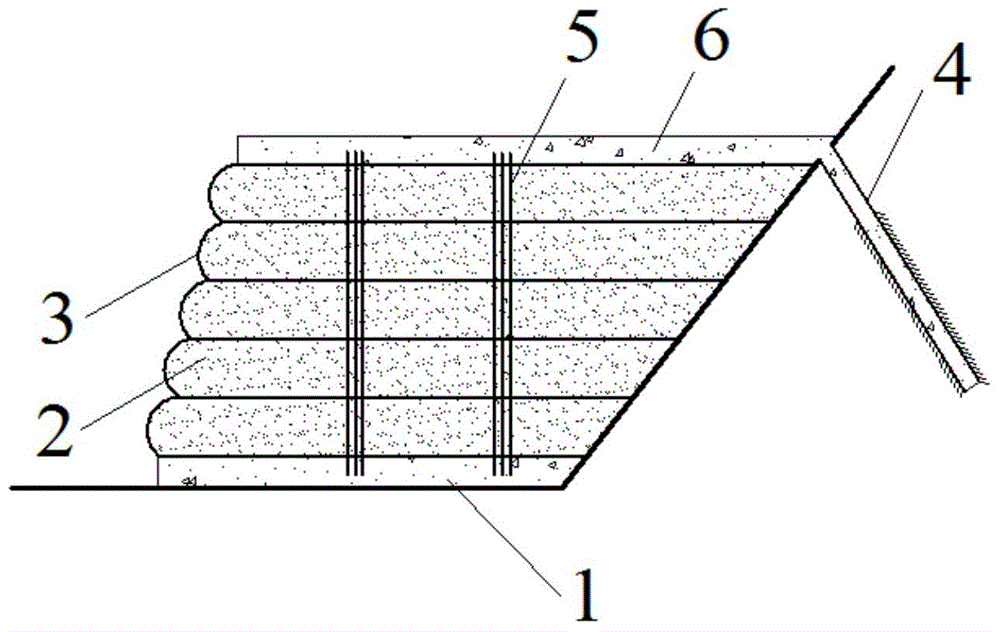

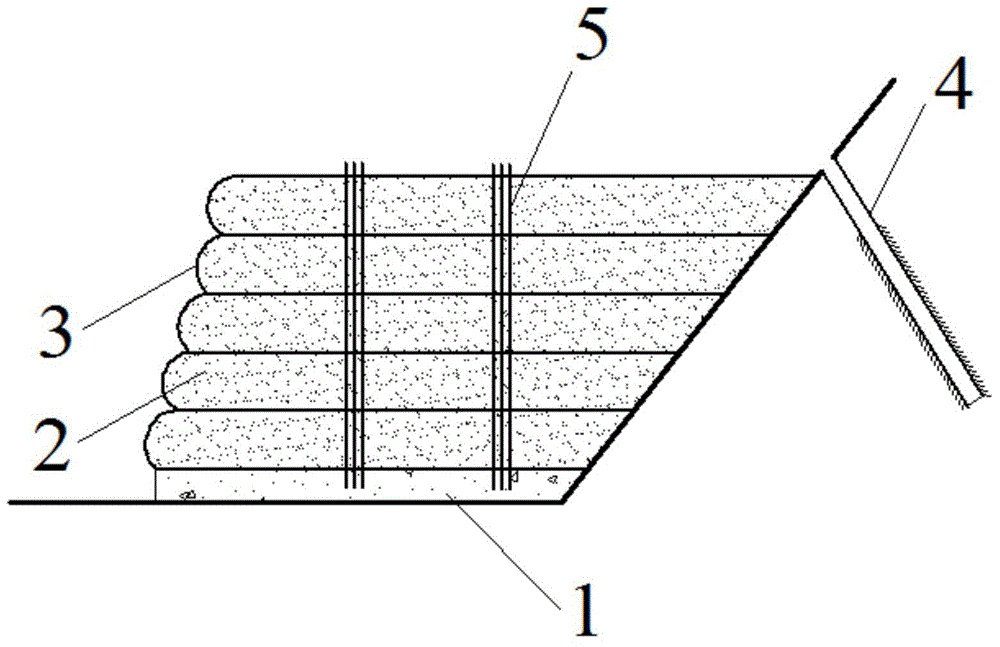

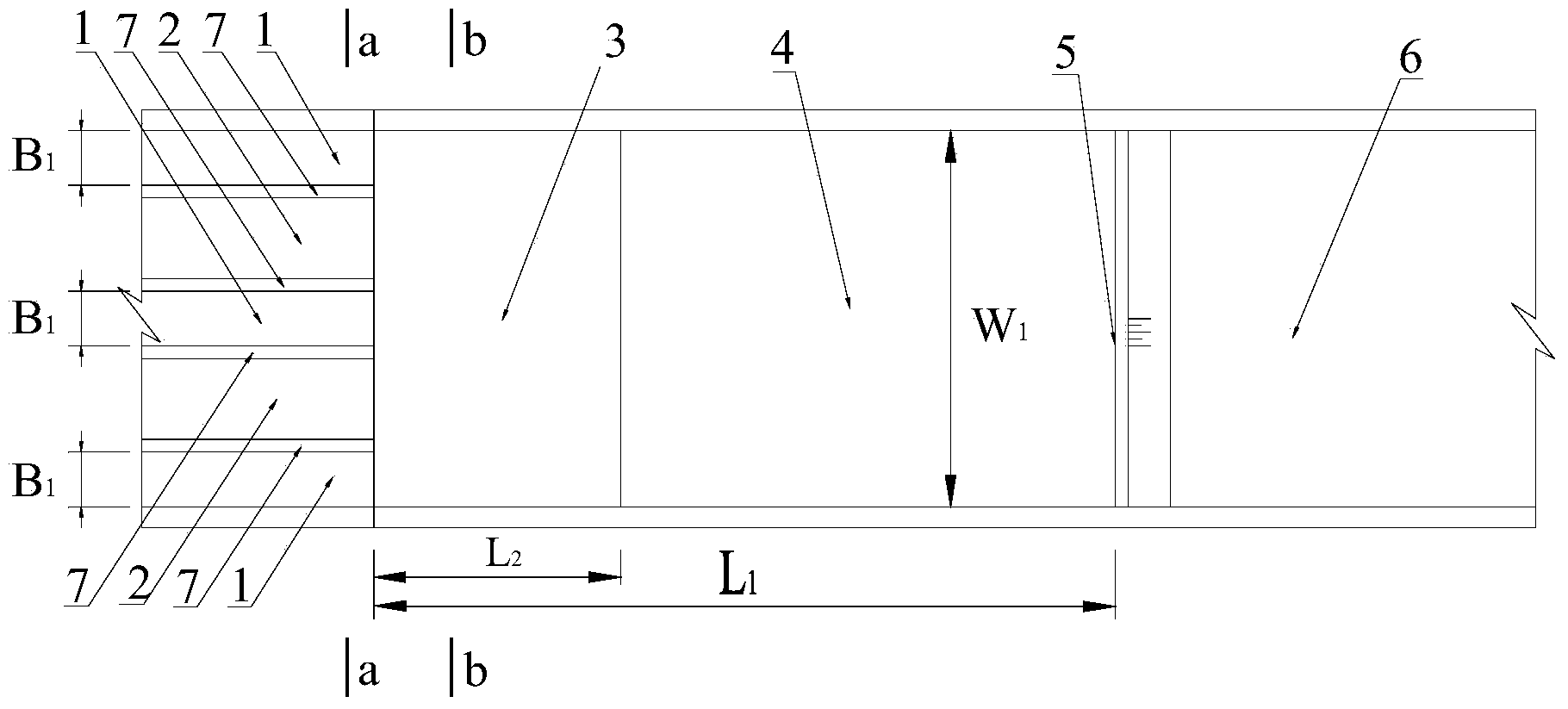

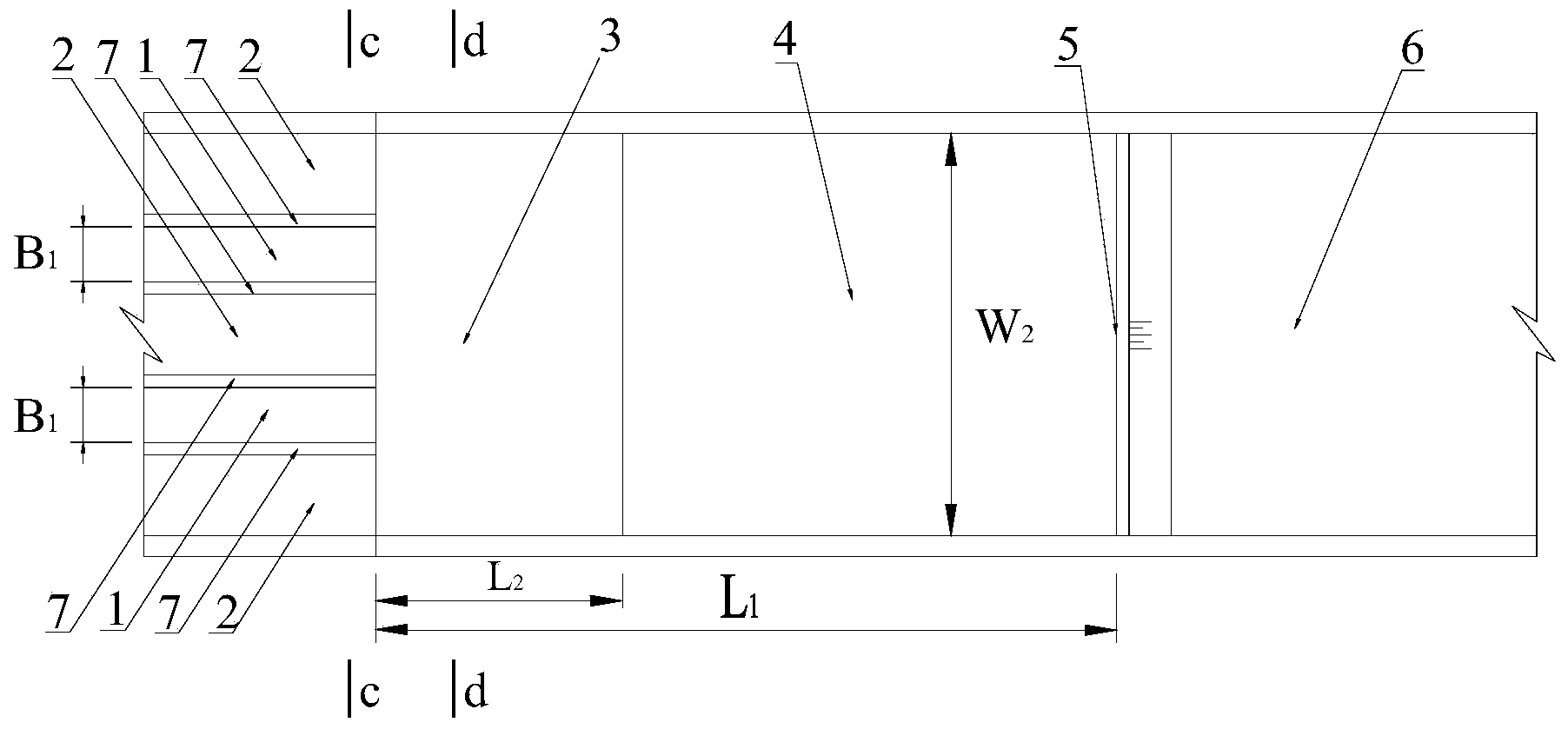

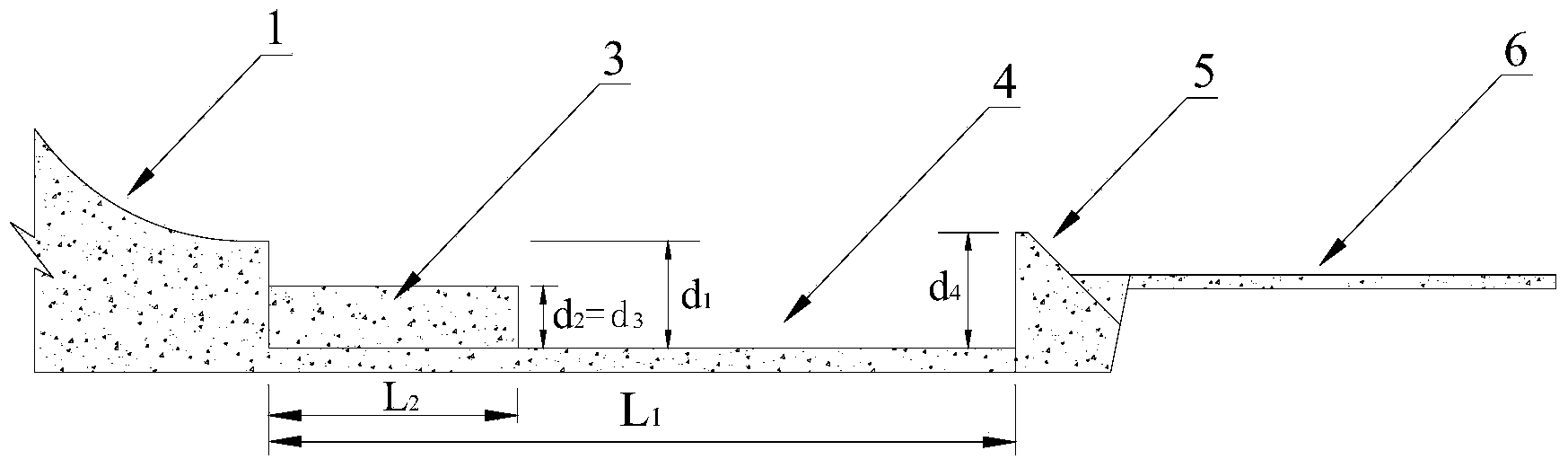

Differential column-splitting inlet energy dissipater

InactiveCN101624818AIncreasing the thicknessImprove stress conditionsBarrages/weirsWater flowEngineering

The invention relates to a differential column-splitting inlet energy dissipater, comprising a water current inlet section, a stilling pool connected with the water current inlet section, and an apron connected with the stilling pool; the water current inlet section is composed of a high-level drainage channel (drainage hole) and a lower-level drainage channel (drainage hole) which are arrayed alternatively, a slim is arranged at the boundary position of a drop-sill of the outlet end part of the high-level drainage channel of the water current inlet section and the lower-level drainage channel and a bottom plate of the stilling pool, the slim is a right-angle wedge shape, the bottom surface of the right-angle wedge shape is arranged on the bottom plate of the stilling pool, and the side surface vertical to the bottom surface of the right-angle wedge shape is attached to the drop-sill of the outlet end part of the high-level drainage channel of the water current inlet section and the lower-level drainage channel, a tail sill of the stilling pool is a differential tail sill, and the top surface of the differential tail sill is formed by a combined surface unit I and a combined surface II which have different structures and are arrayed alternatively; a middle isolated pier tail between the high-level drainage channel and the lower-level drainage channel is a cantilever type streamline pier tail. The energy dissipater can improve the service life and reduces scouring damage of water current to downstream river channels.

Owner:SICHUAN UNIV

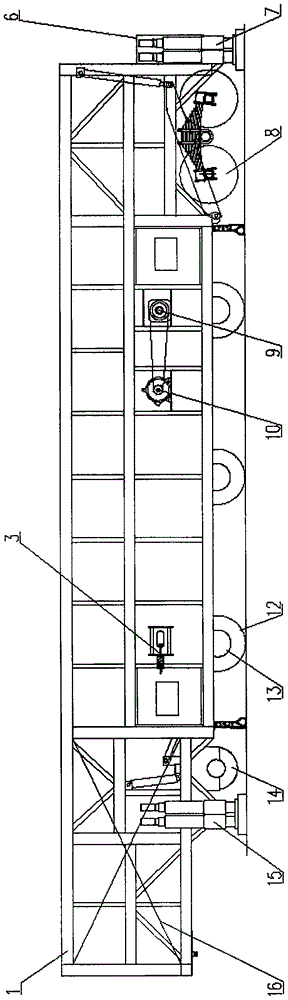

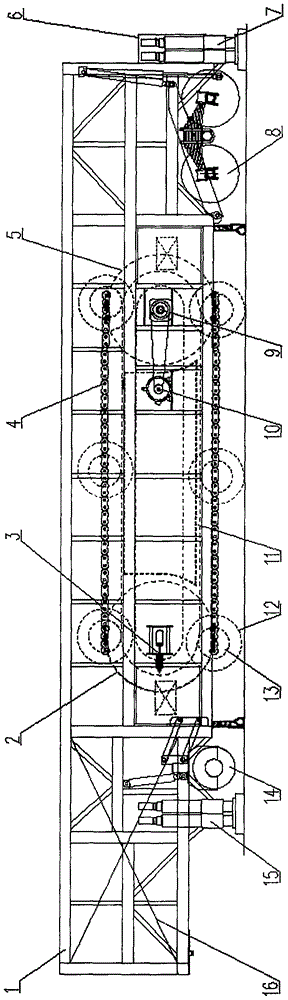

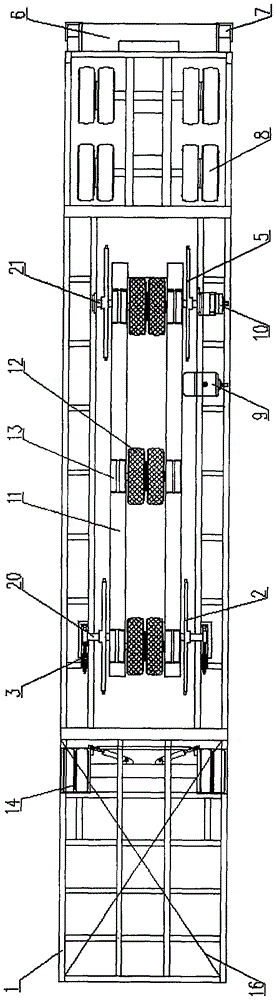

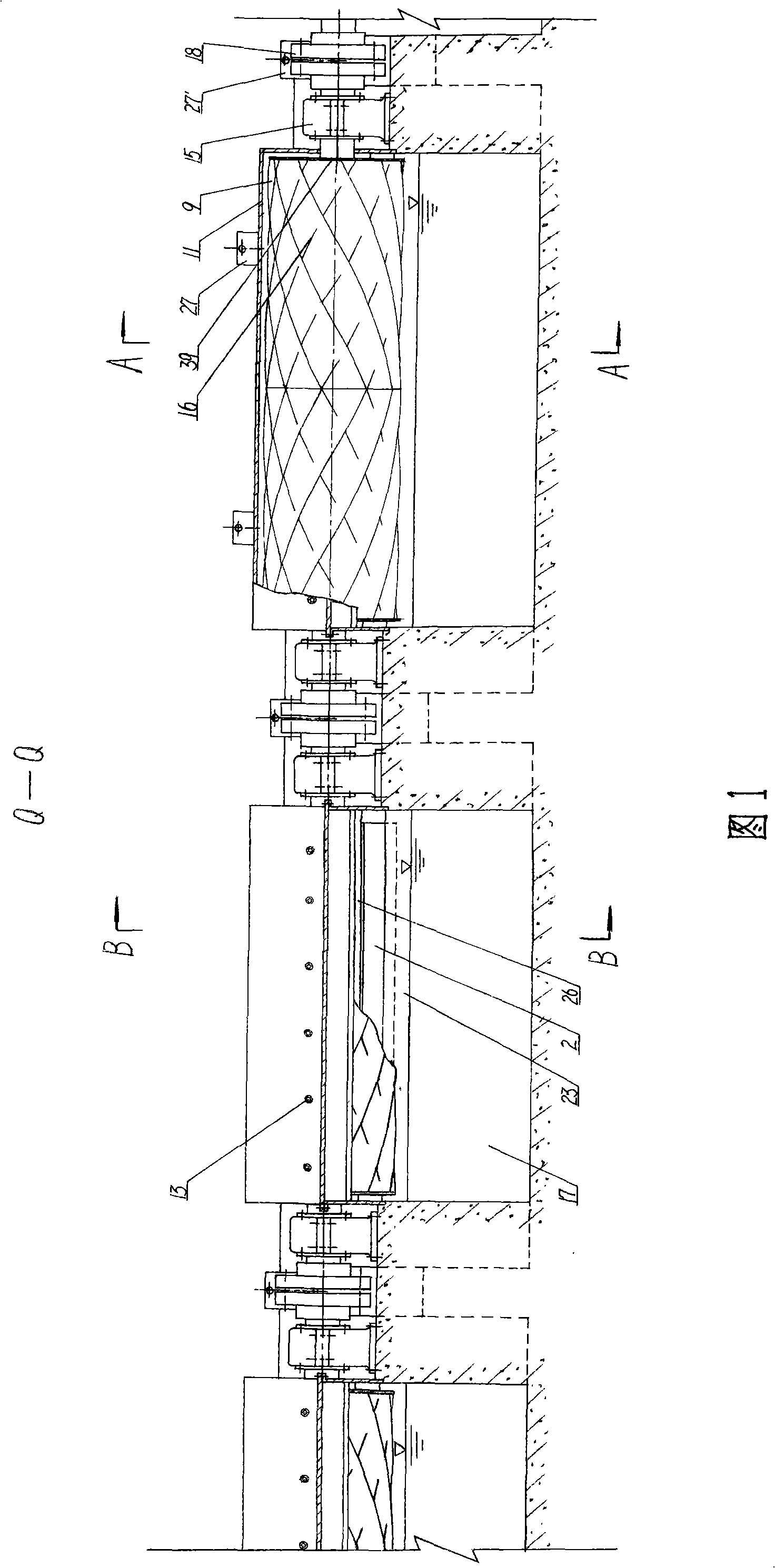

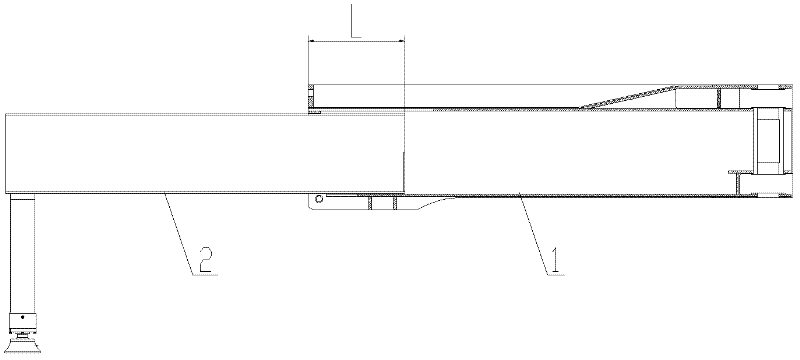

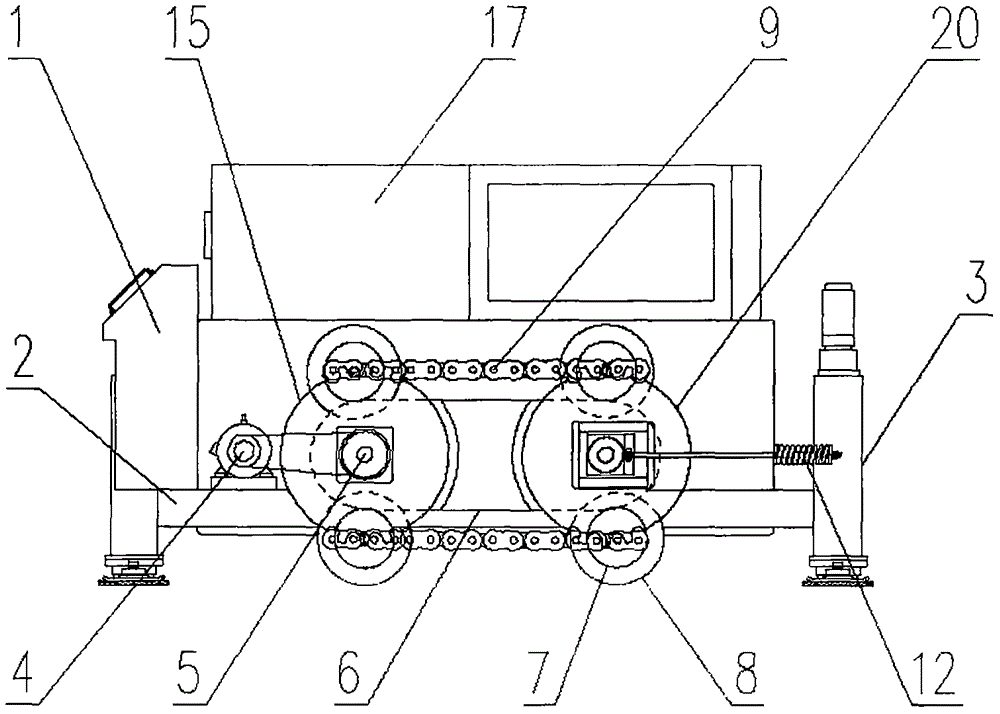

Full-scale-movement linear circulating accelerated loading test system

PendingCN106769558AImprove efficiencyReduce distanceMaterial strength using repeated/pulsating forcesShock testingStress conditionsFull scale

The invention provides a full-scale-movement linear circulating accelerated loading test system. The full-scale-movement linear circulating accelerated loading test system comprises a machine frame, a guide rail, two or more rolling wheel sets and two chain transmission pairs, wherein a front walking and guiding wheel and a back walking wheel are fixed to the lower part of the machine frame through a lifting mechanism; the guide rail is arranged on the machine frame; the upper loading surface of the guide rail is a linear section; the lower loading surface of the guide rail is shaped like a boat bottom; the two ends of the upper loading surface and the lower loading surface are connected in smooth transition through curved sections; the guide rail adopts a box-type structure and is internally filled with a shock-absorbing material; each rolling wheel set comprises two loading wheels and a rolling wheel; the rolling wheel is positioned between the two loading wheels and is coaxial with the loading wheels. The full-scale-movement linear circulating accelerated loading test system adopts a design scheme that the chain transmission pairs drive the rolling wheel sets, a chain and the rolling wheel sets are assembled together through chain pin shafts and connecting components, and the axes of wheel axles of the rolling wheel sets are vertical to and intersected with the longitudinal centerline of the chain; the full-scale-movement linear circulating accelerated loading test system is simple in structure, high in reliability and low in using cost and maintenance cost; the distance from the loading wheel to the rolling wheel is small, the stress condition is good, noise is low, and the efficiency is high.

Owner:SHANDONG JIAOTONG UNIV

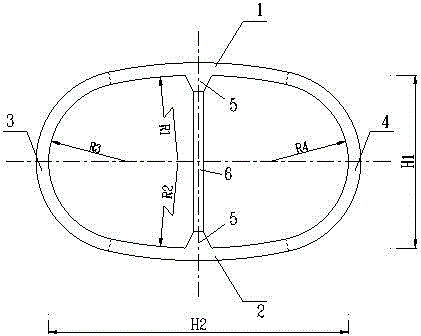

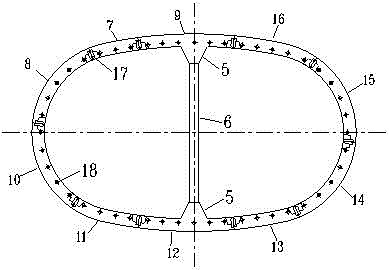

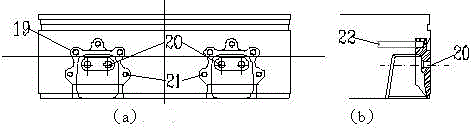

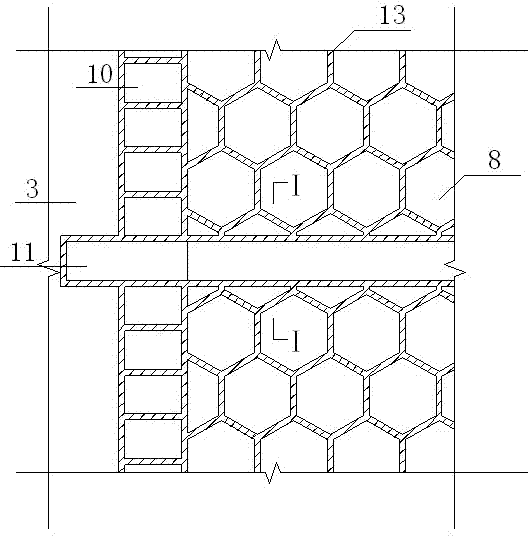

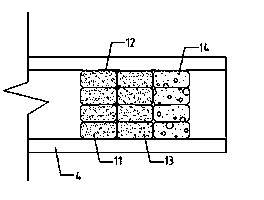

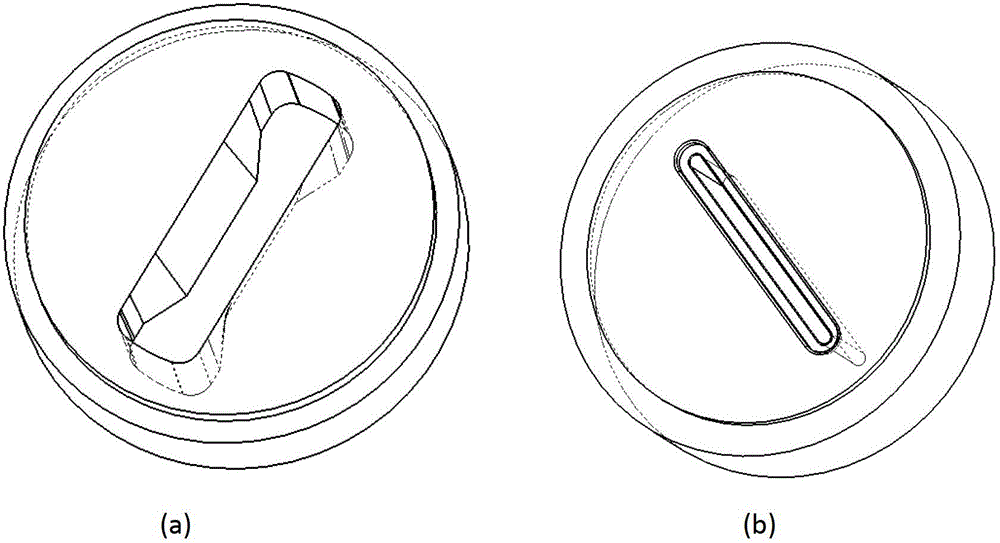

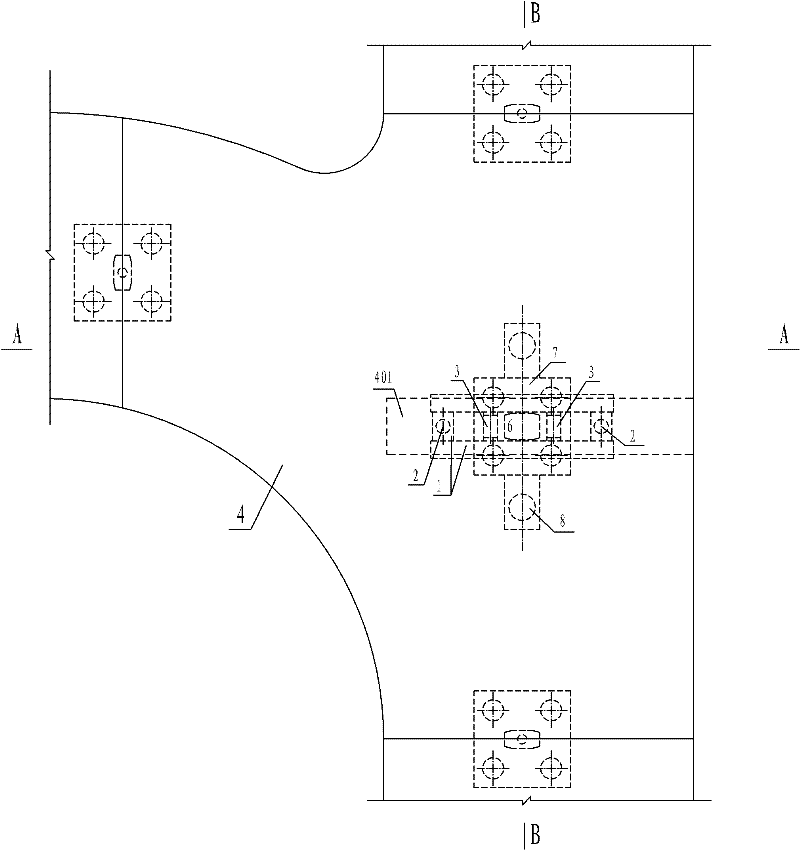

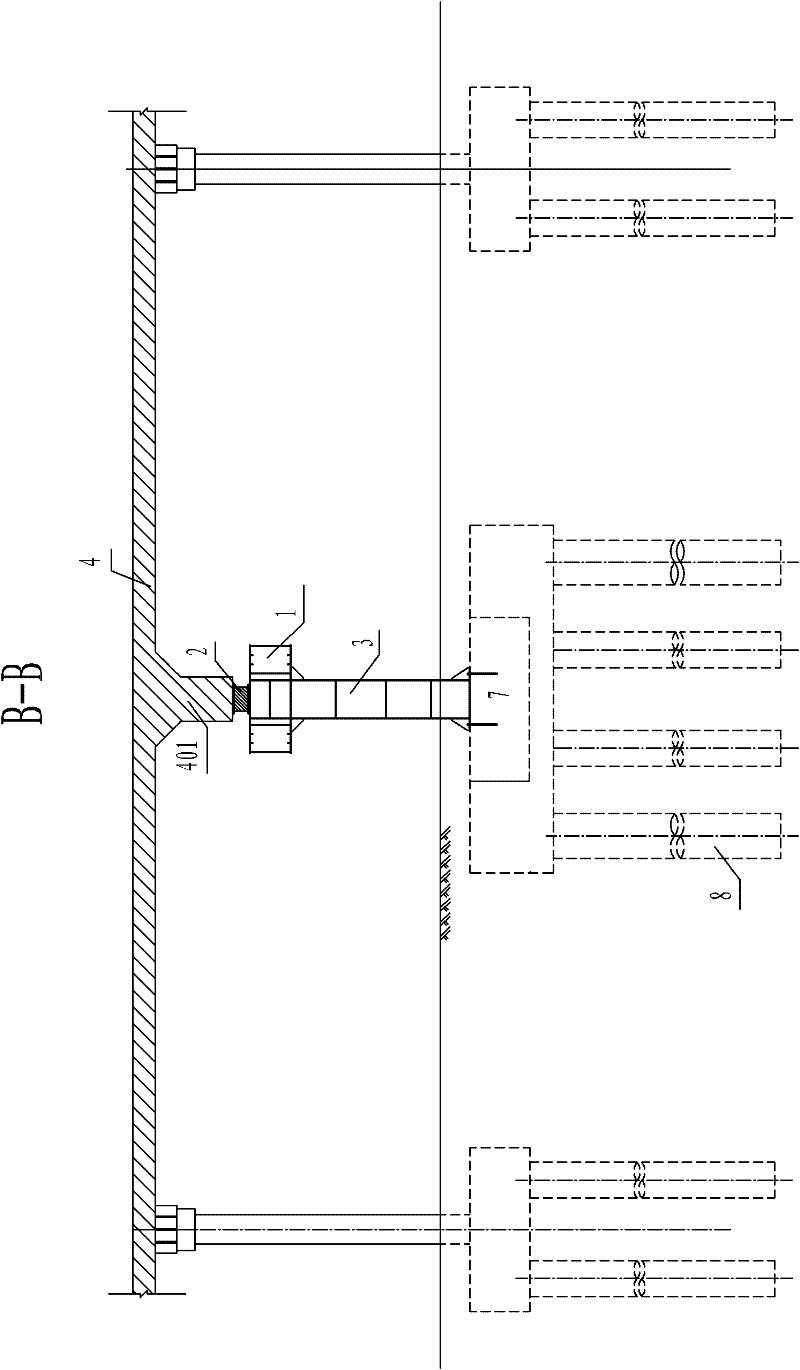

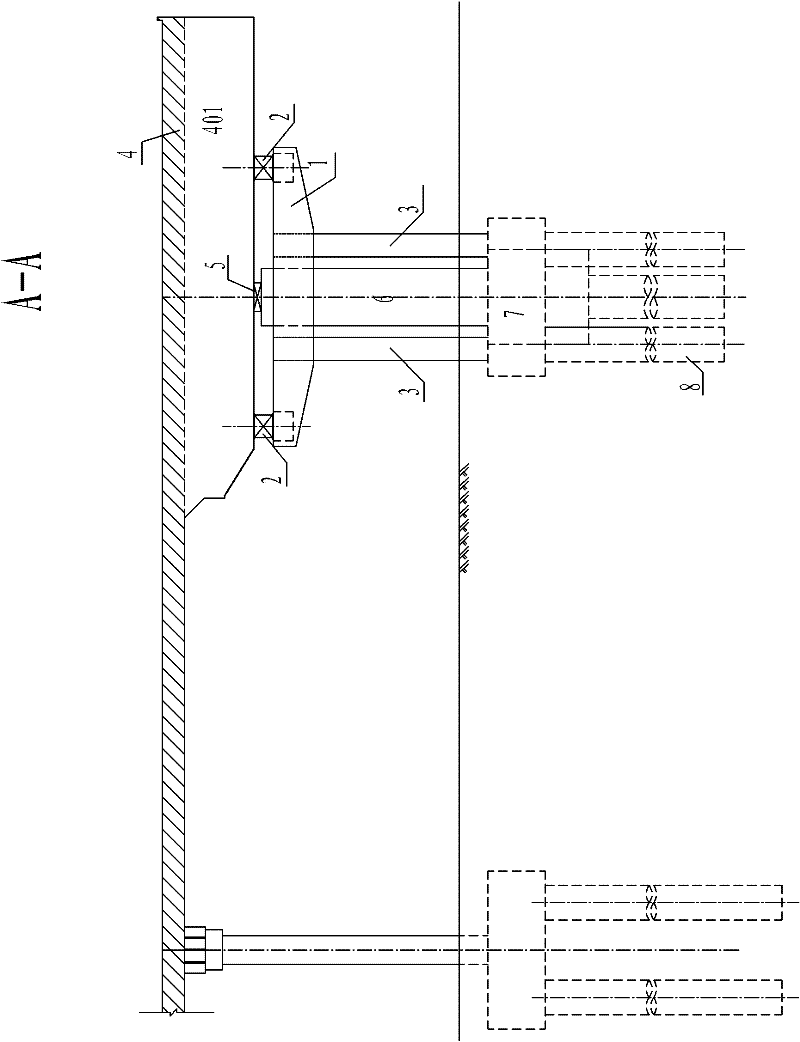

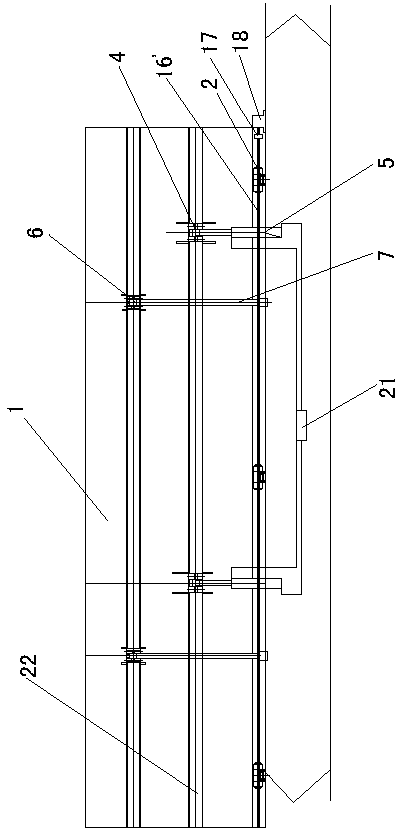

Splicing structure for pipe pieces of ellipse-like shield tunnel with stand column

InactiveCN104612724AOptimal Geometry DesignReduce in quantityUnderground chambersTunnel liningEllipseEngineering

The invention relates to a splicing structure for pipe pieces of an ellipse-like shield tunnel with a stand column. An integral ring is formed by enclosing and splicing the pipe pieces. The adjacent integral ring pipe pieces are spliced to form the splicing structure for the pipe pieces of the shield tunnel. The splicing structure is characterized in that the cross section of the splicing structure for the pipe pieces of the shield tunnel is a double-axis symmetric smooth ellipse-like part provided with the center stand column and formed by four sections of inferior arcs, the double-axis symmetric smooth ellipse-like part comprises a top arc, a bottom arc, a left side arc and a right side arc, the top arc with the large radius and the bottom arc with the large radius are arranged vertically and symmetrically in the opposite directions, and the left side arc with the small radius and the right side arc with the large radius are transversely and symmetrically arranged in the opposite directions. The spliced joints of the adjacent integral ring pipe pieces on the cross section keep away from the most unfavorable stress part of the tunnel structure, and the adjacent integral ring pipe pieces are spliced through staggered joints. Annular connectors and the longitudinal connectors of the pipe pieces are connected through bolts and hand holes, plane contact pulling and anchoring type lacework box type hand holes are adopted in the annular connectors, and high bearing force is achieved. The splicing structure has the advantages that a tunnel arc bearing structure and the high rectangular structure space utilization rate are combined; the longitudinal hand holes are in double-axis symmetric arrangement, and one set of pipe pieces can meet the requirement for staggered joint splicing.

Owner:TONGJI UNIV

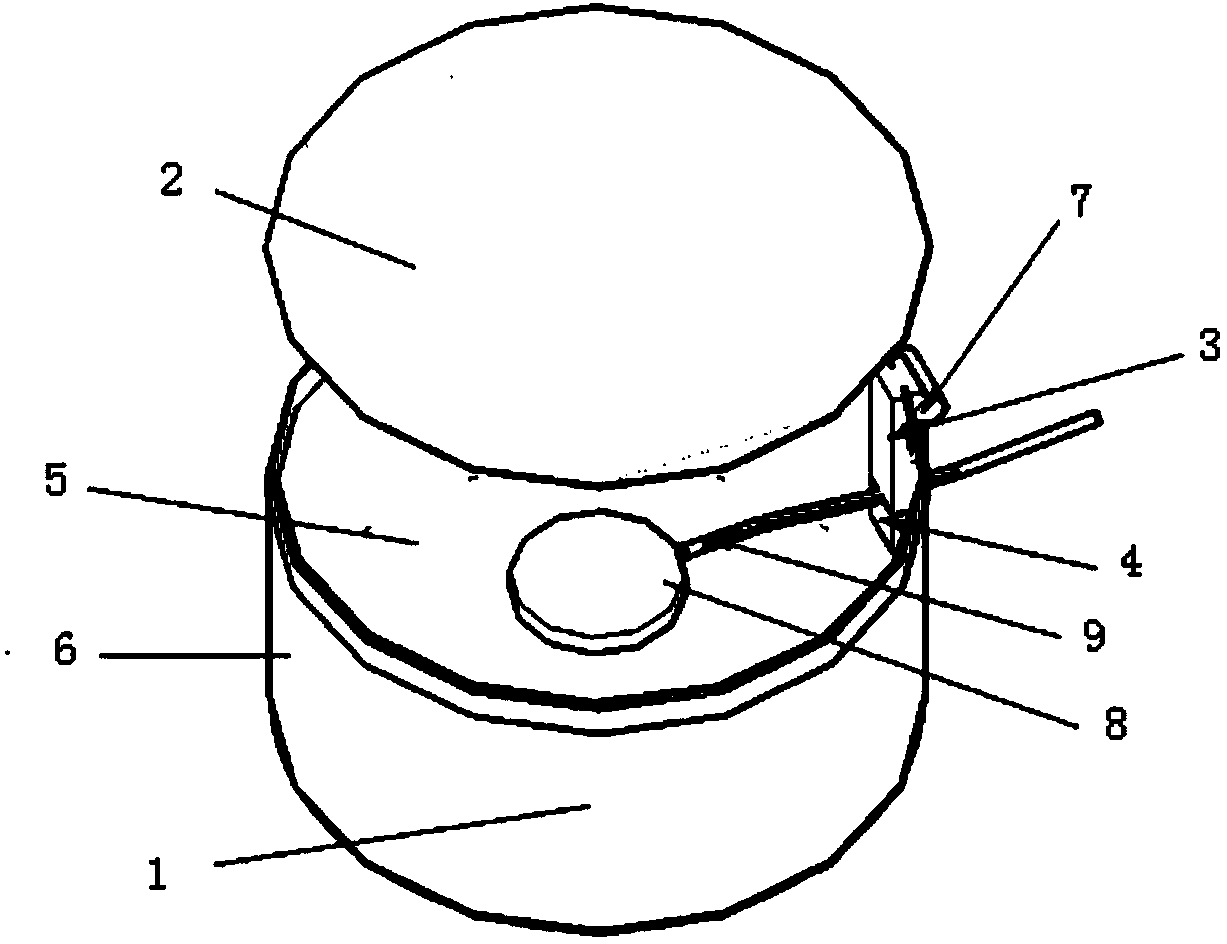

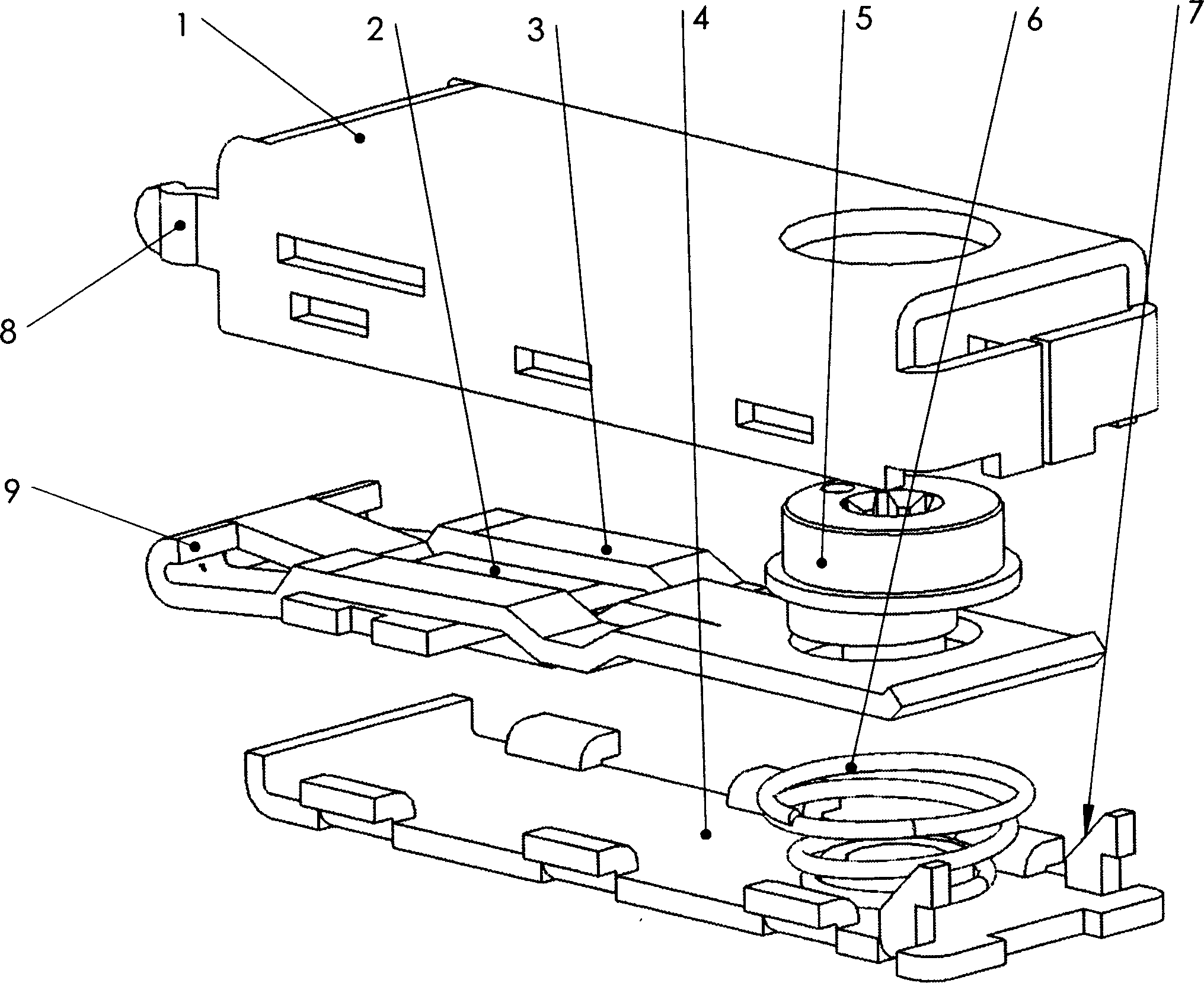

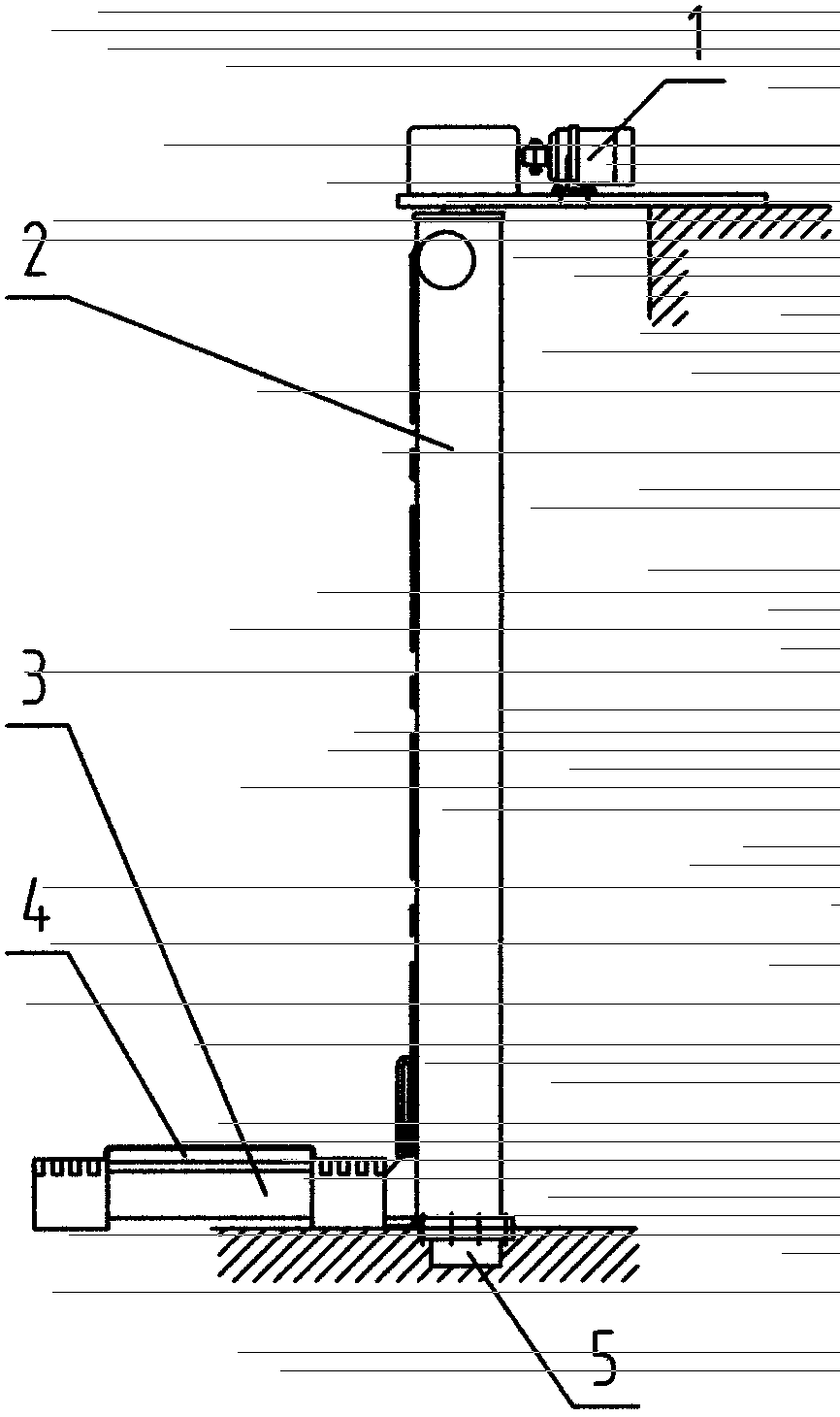

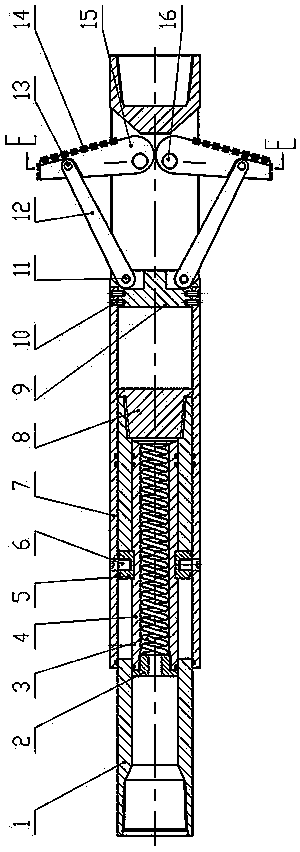

Rock-soil pressure sensor embedding device and embedding method thereof

ActiveCN103808435AHigh measurement accuracySmall sizeFoundation testingForce measurementEngineeringSoil material

The invention discloses a rock-soil pressure sensor embedding device and an embedding method thereof. The rock-soil pressure sensor embedding device comprises a cylindrical thin-wall vessel, a base, an upper sealing strip, a lower sealing strip, a lining, an outer lining, a band and a pressure sensor. The embedding method includes: arranging the soil pressure sensor embedding device, digging an embedding hole, levelling the basal plane of the sensor, inverting the pressure sensor embedding device, backfilling the original soil material, extracting the cylindrical thin-wall vessel, and backfilling and so on. By means of the rock-soil pressure sensor embedding device and the embedding method thereof, the digged pit slot is small, the size of a protecting layer needed for the sensor is small, the embedding efficiency is improved, the measuring precision is improved, the protecting layer is avoided from loosening in vibration rolling, and the problem of embedding the sensor in coarse granular materials is solved.

Owner:JSTI GRP CO LTD

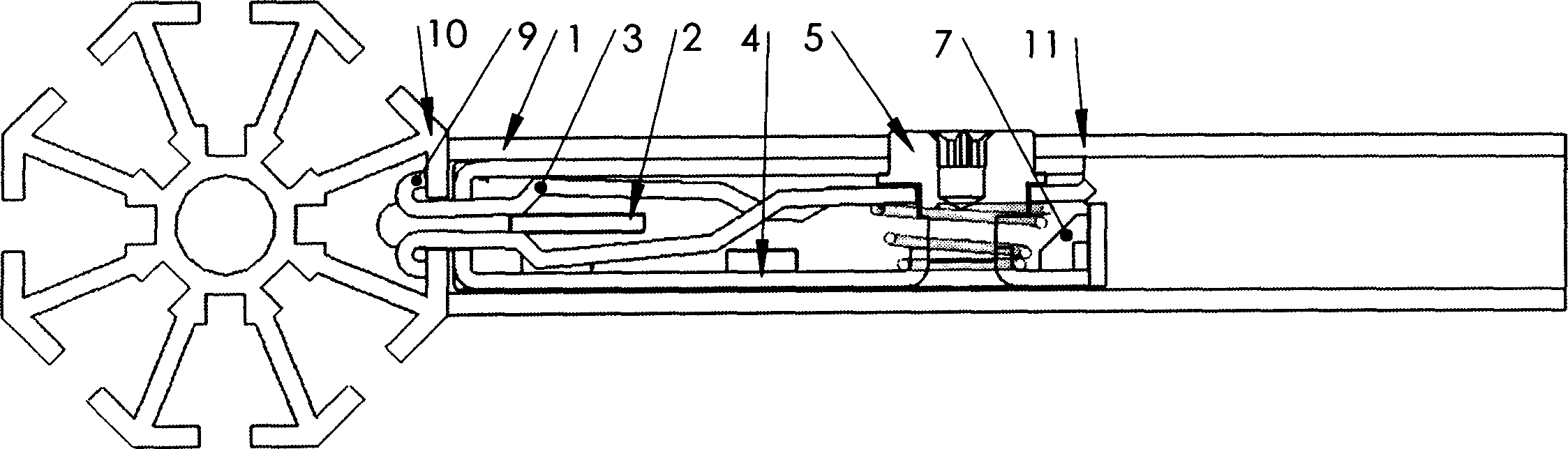

All-purpose hydroturbine

InactiveCN101354004ASmall lossSelf lossHydro energy generationEngine componentsHydro energyWater turbine

A universal water-turbine engine pertains to an impact water-turbine engine which converts pressure energy of current to kinetic energy and converts the kinetic energy to rotating mechanical energy in the hydraulic machinery; the water-turbine engine consists of a or a plurality of jet orifices, a device corresponding to the jet orifices, a or a plurality of turning wheels arranged on a main axis for the universal water-turbine engine, a tailrace arranged under the turning wheel, a speed governor, a driving device and other parts. The water-turbine engine can develop and exploit all waterpower resources and has high efficiency, large capacity, safe and reliable performance, simple and reasonable structure as well as low manufacturing cost; the application of the water-turbine engine significantly promotes the current development and exploitation of the waterpower resource, thus being capable of marking a new epoch of rapid development of the hydroelectric power industry.

Owner:黄国宏

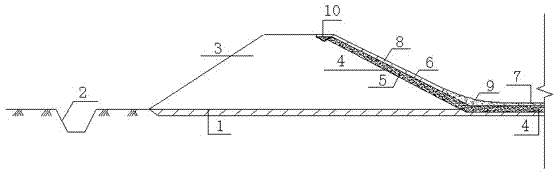

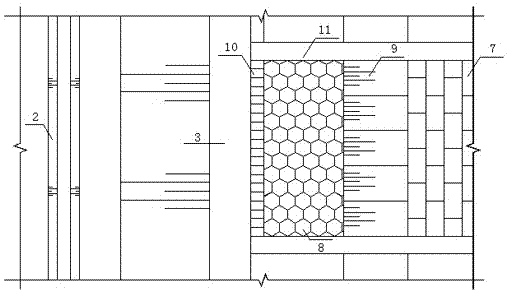

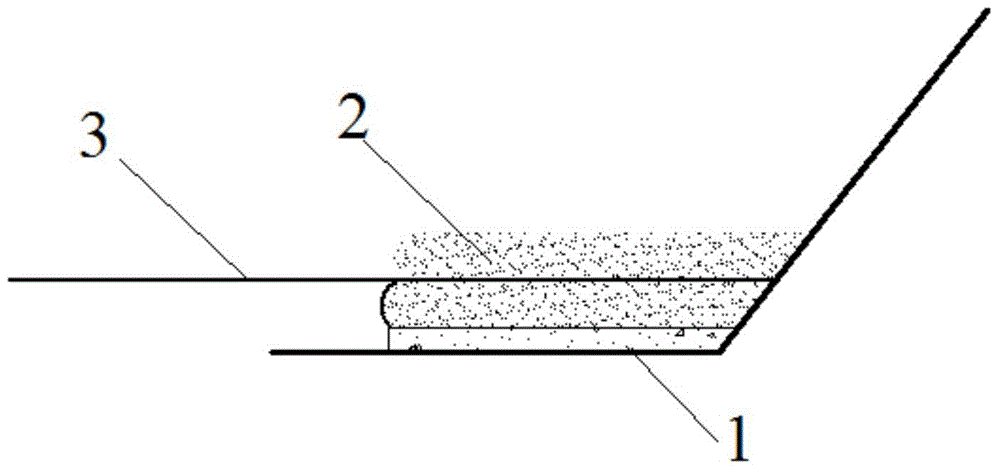

Fill channel anti-frost heaving and anti-seepage structure and construction method

ActiveCN104514216AGuaranteed compactnessGuaranteed StrengthIrrigation ditchesMarine site engineeringStress concentrationStress conditions

The invention discloses a fill channel anti-frost heaving and anti-seepage structure and a construction method. The structure is characterized in that drainage channels are arranged on the two sides of the channel; a wind-blown sand layer is arranged on the bottom and two sides of an embankment of the channel; a plastic film is arranged on the wind-blown sand layer; a slope toe on a connection position of the bottom and the embankment of the channel is cast-in-place concrete; prefabricated concrete blocks are laid on the plastic film; and a capping concrete board is arranged on the top of the embankment of the channel. The construction method comprises the following steps: digging a drainage open channel; clearing channel base earth; carrying out filling to form the embankment of the channel; laying wind-blown sand; laying the plastic film; casting the arc channel-bottom concrete in place; laying the prefabricated concrete blocks; and laying the capping concrete board. The problems of the common channel design such as seepage, frost heaving and destruction, and not stable quality are eliminated, the wind-blown sand layer is arranged on the bottom and the two sides of the embankment of the channel, the foundation bearing force is increased, the frost heaving is lightened; the polyethylene plastic film is laid on the wind-blown sand layer to prevent seepage of the channel; concrete is arranged on the film to prevent water flow from scouring and seeping; the concrete arc channel bottom is cast in place, the stress condition is good and the stress concentration is prevented; and the drainage open channel prevents underground water retention and eliminates frost heaving.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

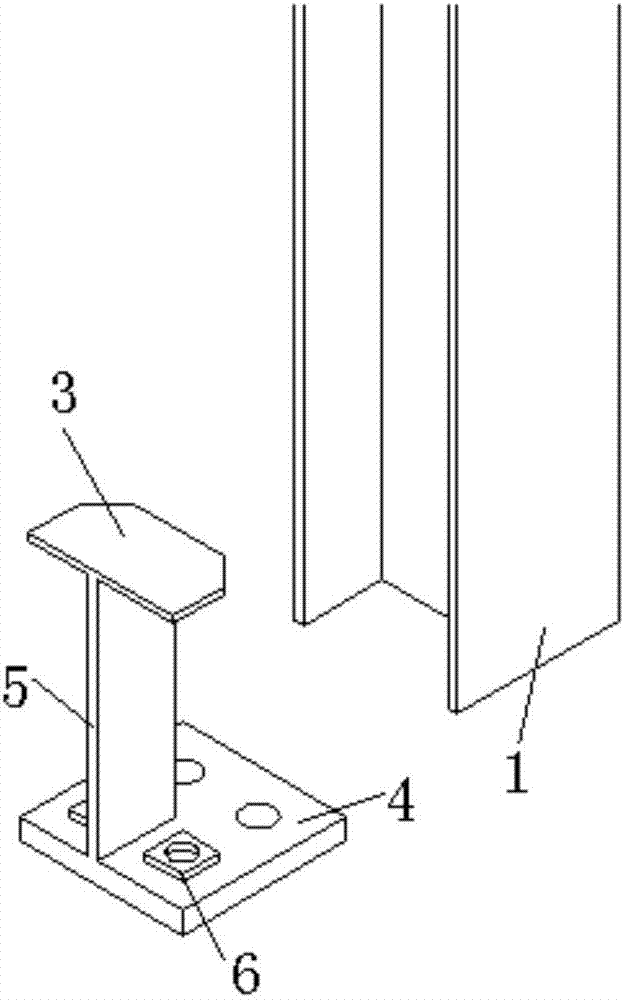

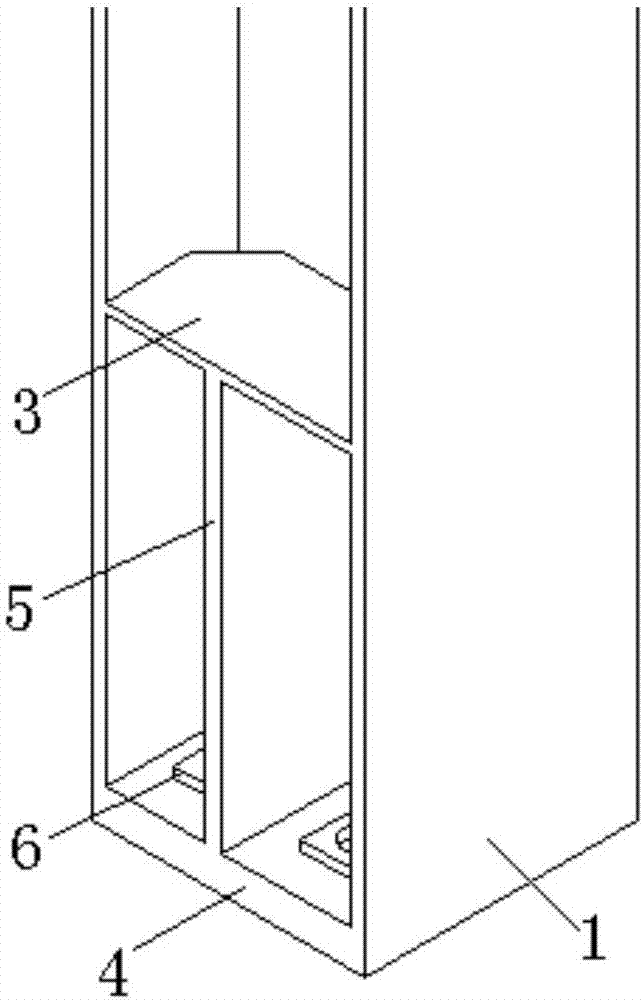

High rigid exhibition table fastener for rapid connection of members

ActiveCN1865719ARigid enoughImprove stress conditionsRod connectionsFurniture joiningFastenerEngineering

Owner:金元安

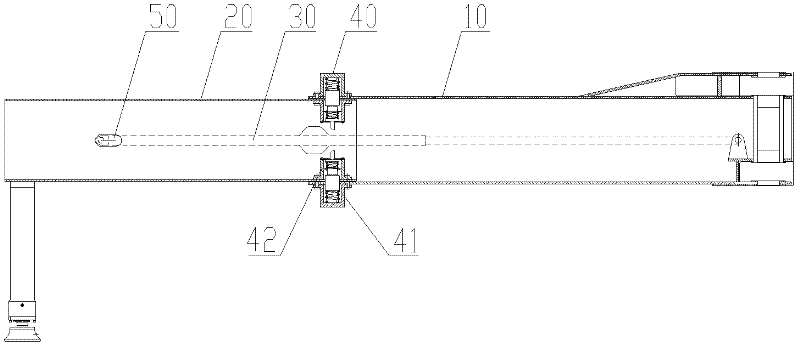

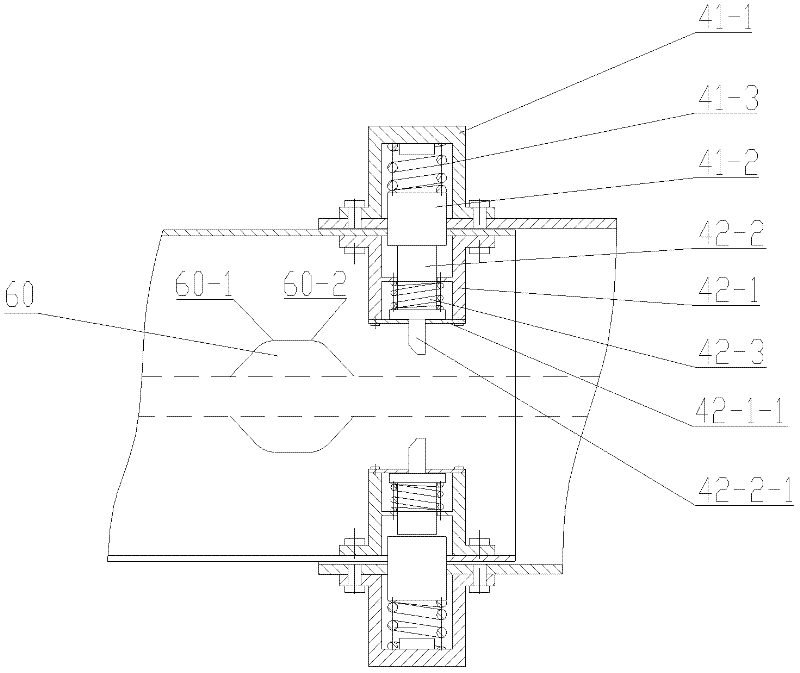

Retractable support leg and engineering machine with same

ActiveCN102381291AIncrease spread spanMake full use of the expansion spaceVehicle fittings for liftingCranesStructural reliabilityEngineering

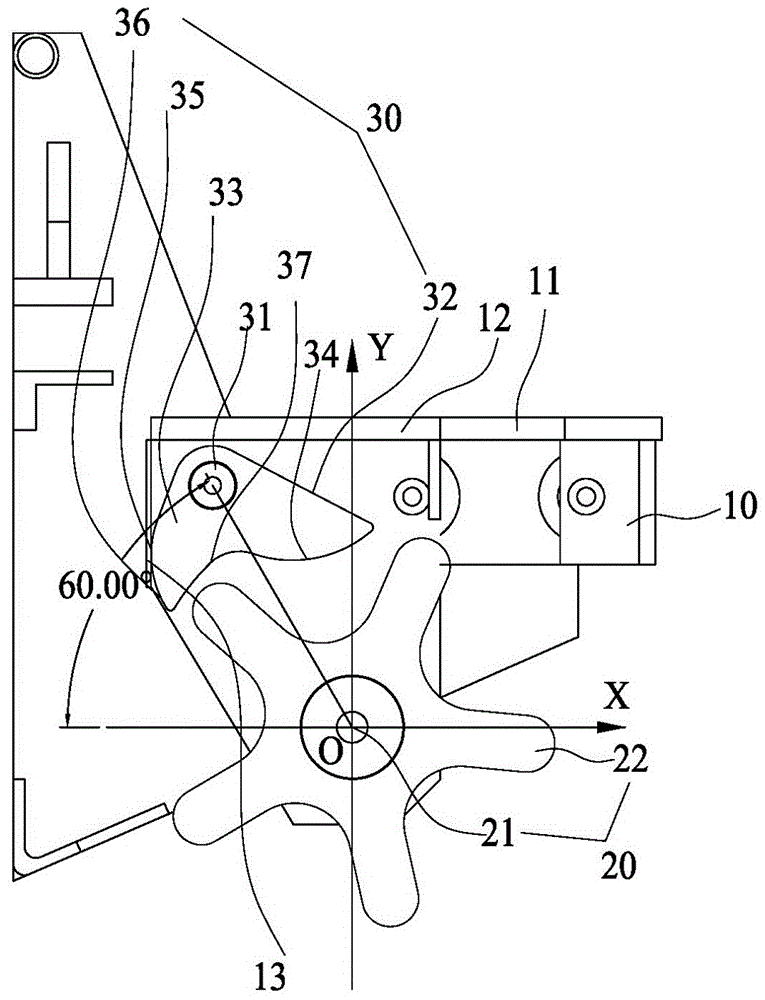

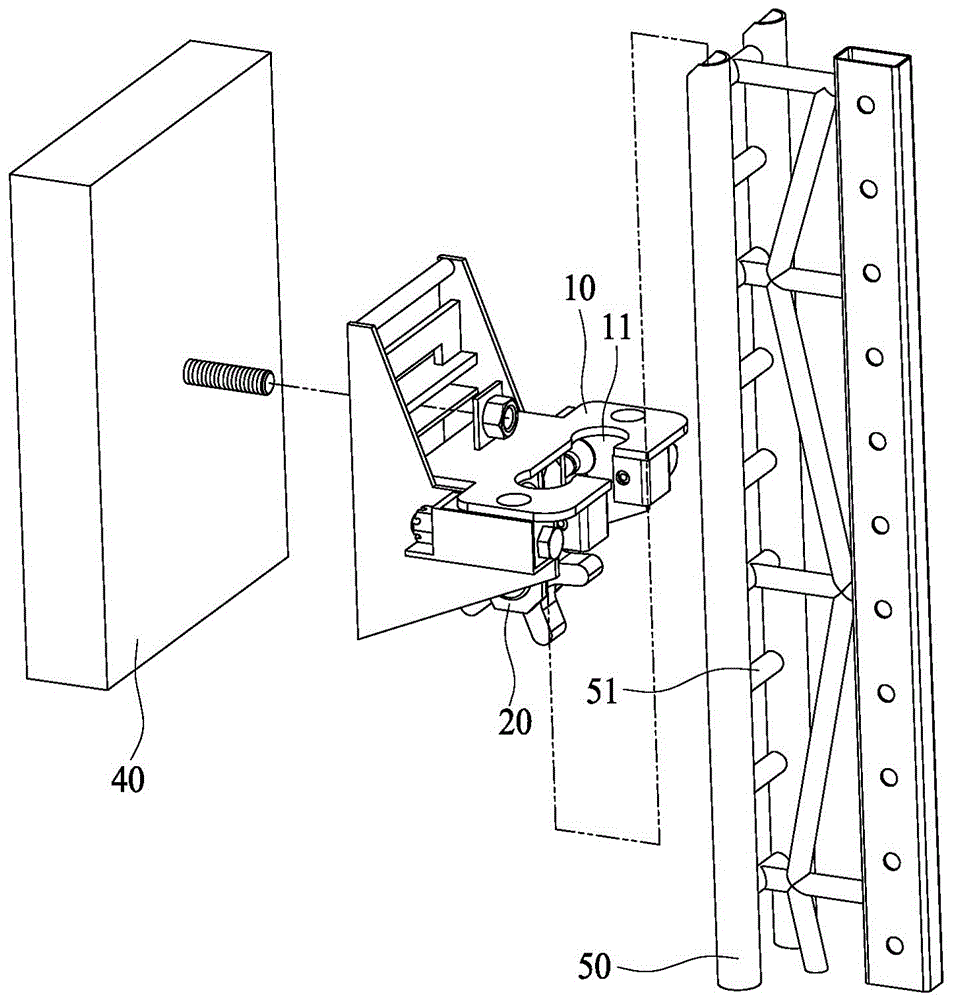

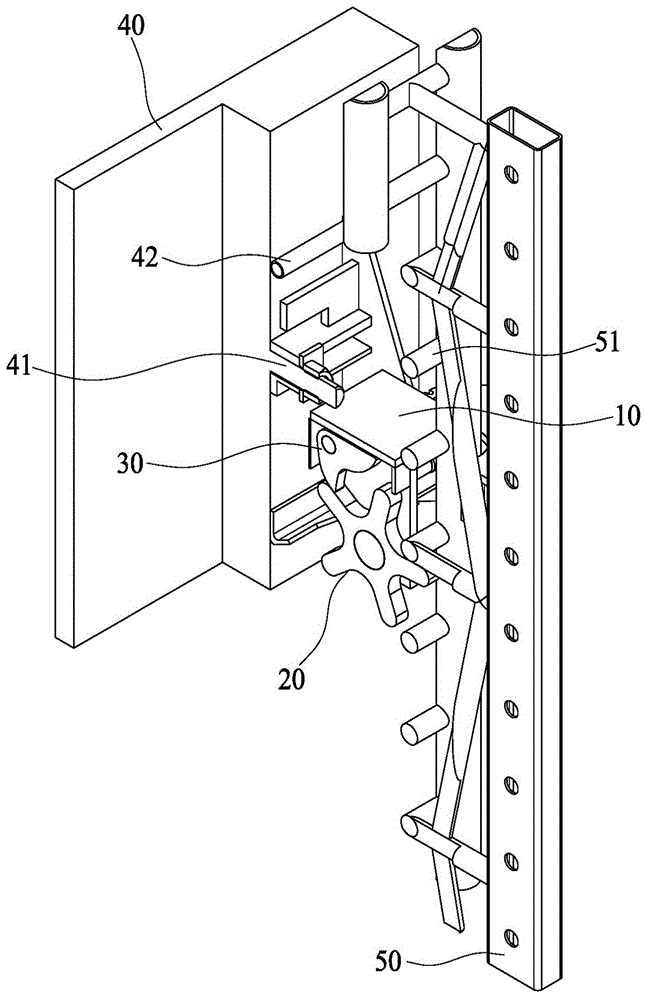

The invention discloses a retractable support leg, which comprises a fixed support leg (10) and a movable support leg (20). When the movable support leg (20) stretches in place, coincidence portions of the movable support leg (20) and the fixed support leg (10) which are nested mutually are positioned and connected by a movable hinge pin, both the movable support leg (20) and the fixed support leg (10) are provided with pin holes, a retractable cylinder (30) of the movable support leg (20) can slide within small displacement range along a stretching and retracting direction, and is provided with a transmission component, and the movable hinge pin is driven to be inserted or withdrawn from the pin holes via the transmission component when the retractable cylinder (30) slides. Coincidence lengths of the movable support leg and the fixed support leg of the support leg are shorter, spreading span of the support leg can be increased, stability of an integral vehicle can be further improved, simultaneously, a stressed manner of the support leg can be improved, and structural reliability is enhanced. The invention further discloses an engineering machine comprising the retractable support leg.

Owner:SANY AUTOMOBILE MFG CO LTD

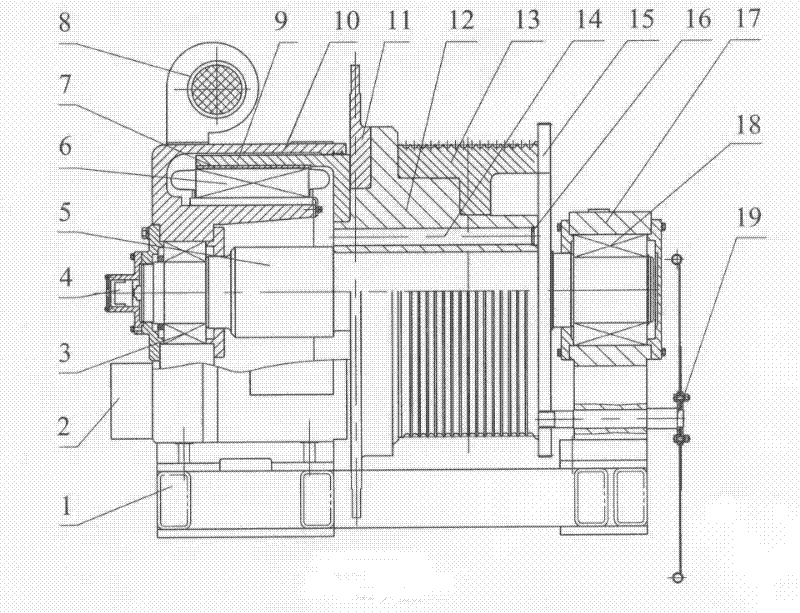

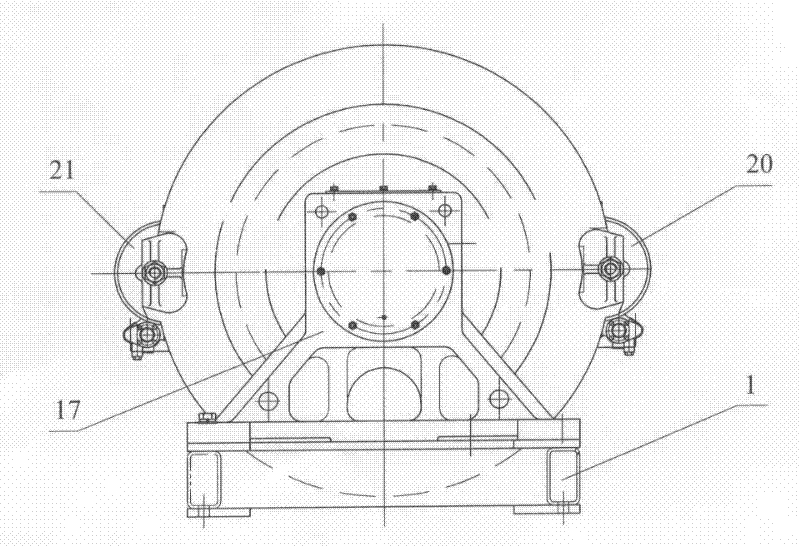

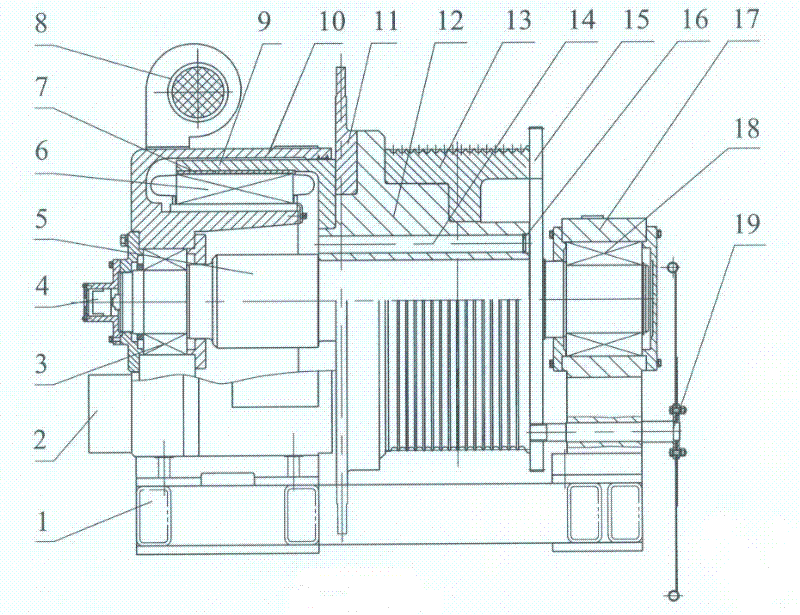

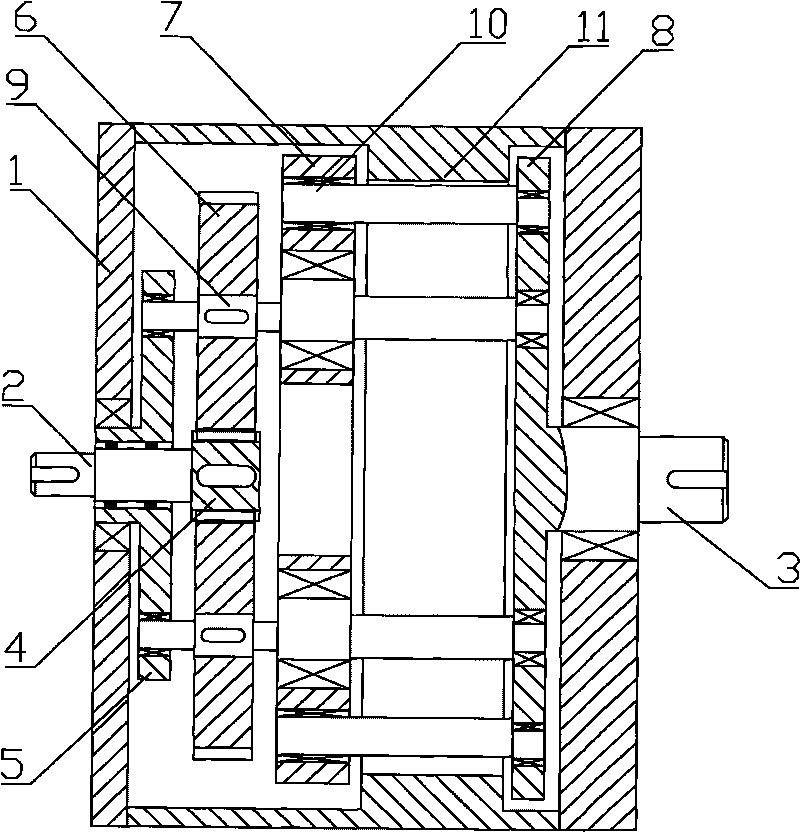

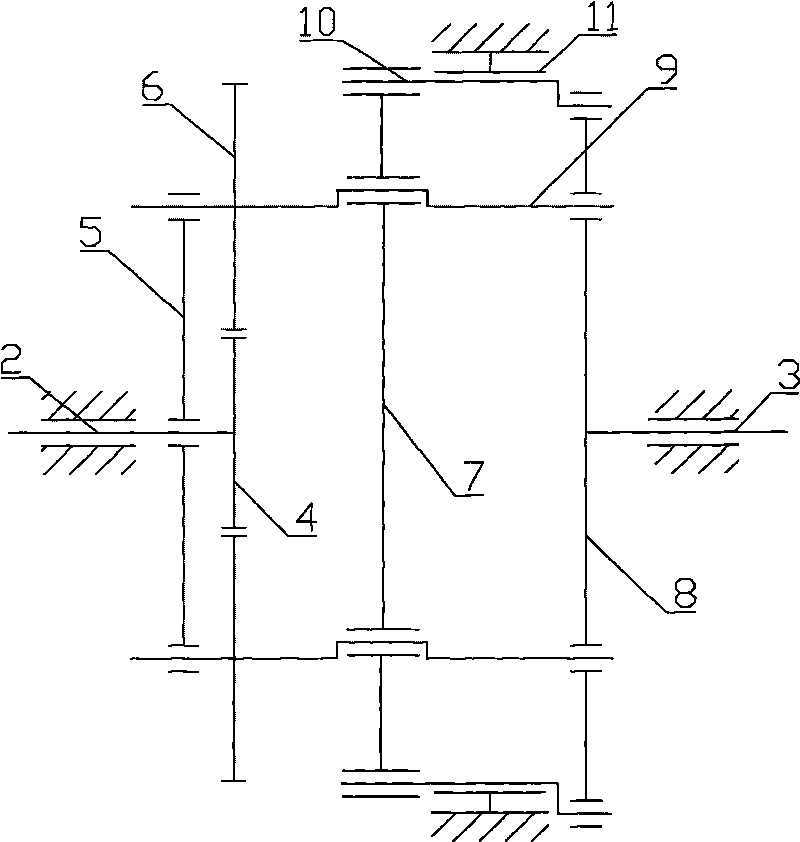

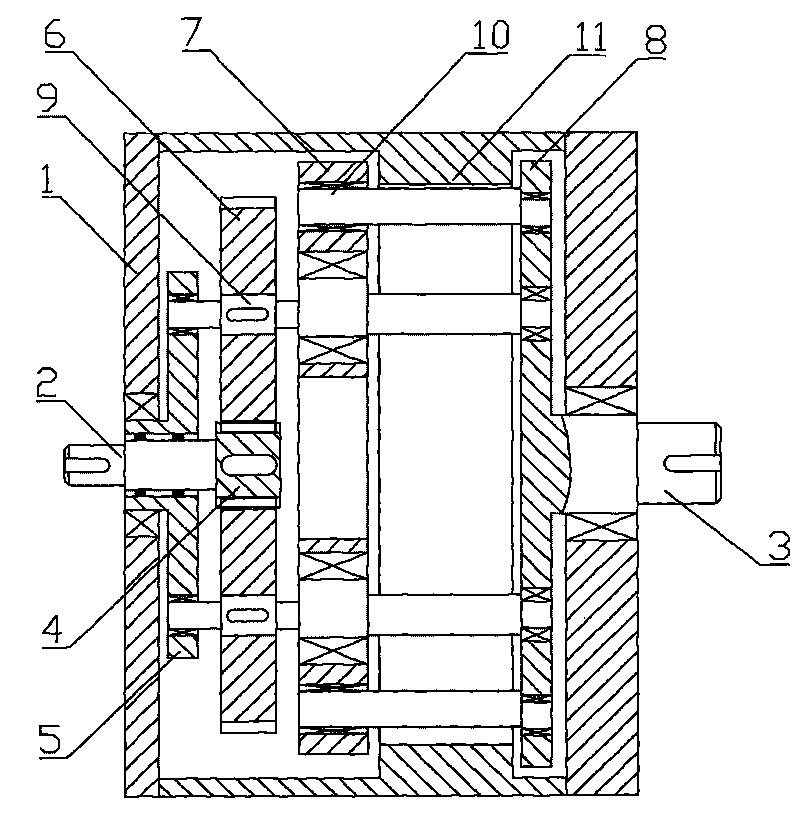

Ultra-high-speed heavy-loading outer-rotor permanent magnet synchronous traction machine

ActiveCN101973479BCompact structureImprove stress conditionsMagnetic circuit rotating partsBuilding liftsStress distributionUltra high speed

The invention relates to an ultra-high-speed heavy-loading outer-rotor permanent magnet synchronous traction machine solving the problems of service life influence and the like in the prior art. The ultra-high-speed heavy-loading outer-rotor permanent magnet synchronous traction machine comprises a stand, a main shaft, a stator coil, a rotor sleeve, a rotor body, a traction wheel, a disc-type brake device and an encoder, wherein the main shaft is assembled on the stand; the rotor body, the traction wheel and the disc-type brake device are fixed on the rotor sleeve; and the encoder is assembled on the rear end of the main shaft. The invention puts a technical emphasis on that a machine base with a rear bearing and a front support with a front bearing are respectively fixed on both ends of the stand; the main shaft supports between the machine base and the front support through the front bearing and the rear bearing, and an internal circumference is attached to the rotor body of a permanent magnet and arranged outside the stator coil; the rotor sleeve is provided with a ventilation hole used for ventilation and heat dissipation and a dustproof rubber plug positioned on an outer sideend, and the rotor body, a brake disc and the traction wheel are respectively connected and fixed with the main shaft to form an integral type structure through the rotor sleeve. The invention has compact structure and design and reasonable stress distribution; and in addition, compared with a similar product, the ultra-high-speed heavy-loading outer-rotor permanent magnet synchronous traction machine has the advantages of small occupying area, material saving, little energy consumption, high operation efficiency, safe and reliable use, convenient installation and maintenance, and the like.

Owner:浙江蓝光驱动技术有限公司

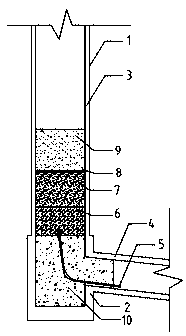

Rigid plugging method for mine tailings pond drainage well

InactiveCN103741702AAvoid pollutionImprove protectionFoundation engineeringStress conditionsWater flow

A rigid plugging method for a mine tailings pond drainage well includes: casting in situ to form a concrete plugging block at the junction of the drainage well and a drainage channel, embedding a drainage steel pipe in the casting process, setting a pebble layer on the concrete plugging block, setting a gravel layer on the pebble layer, setting a nonwoven geotextile layer I on the gravel layer, setting a coarse tail sand layer on the nonwoven geotextile layer I, wrapping the entry end of the drainage steel pipe with multiple layers of nonwoven geotextile, placing the entry end in the pebble layer above the concrete plugging block at a drainage well section, and placing the exit end of the steel pipe outside the concrete plugging block at a drainage channel segment; at the exit of the drainage channel, setting a bagged coarse tail sand layer I in the water flow direction, setting a nonwoven geotextile layer II outside the bagged coarse tail sand layer I, setting a bagged coarse tail sand layer II outside the nonwoven geotextile layer II, and setting a bagged gravel layer outside the bagged coarse tail sand layer II. According to the method, by improving stress conditions of a plugging member, plugging failure can be effectively avoided, and construction is simple, fast, economical and environmentally friendly.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

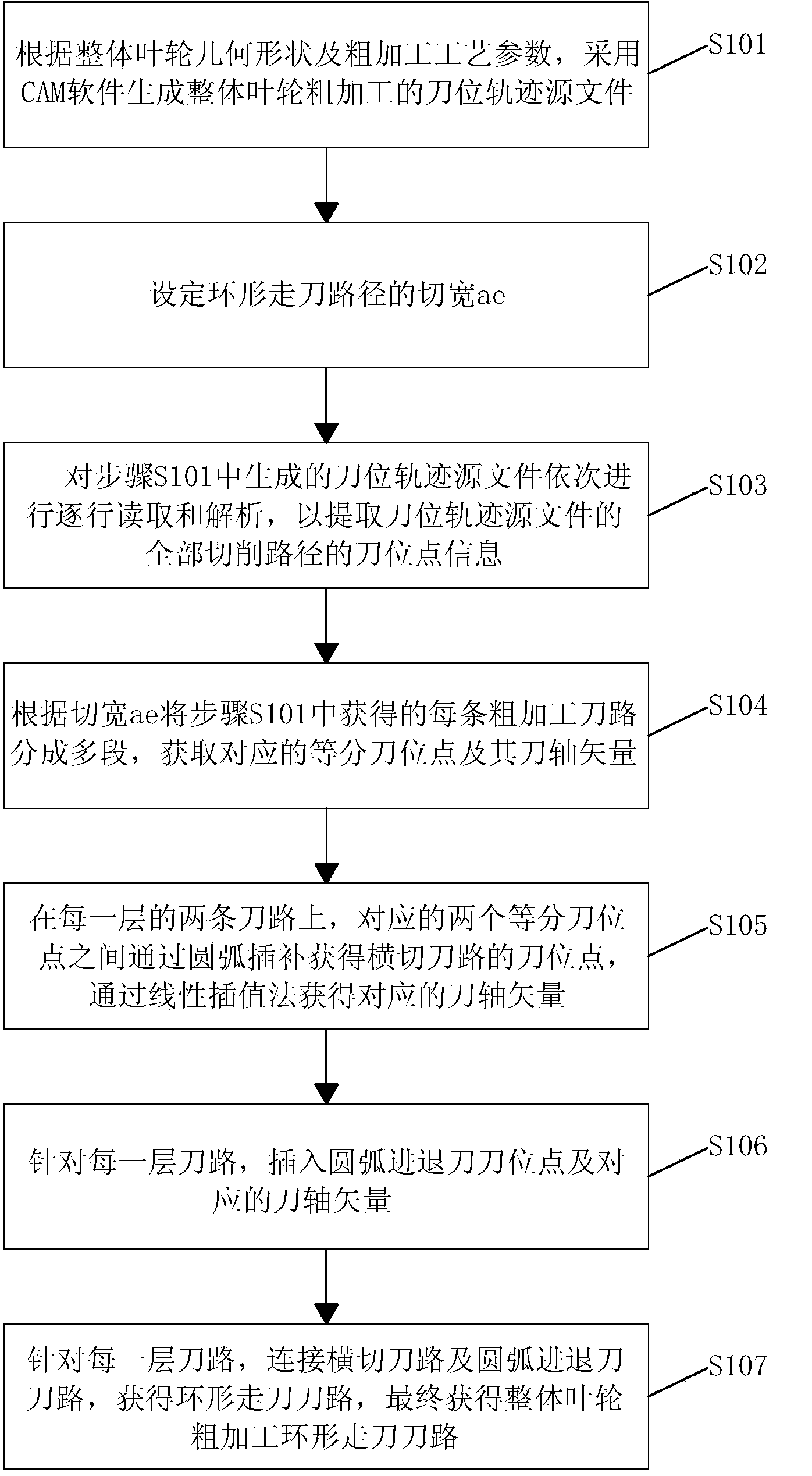

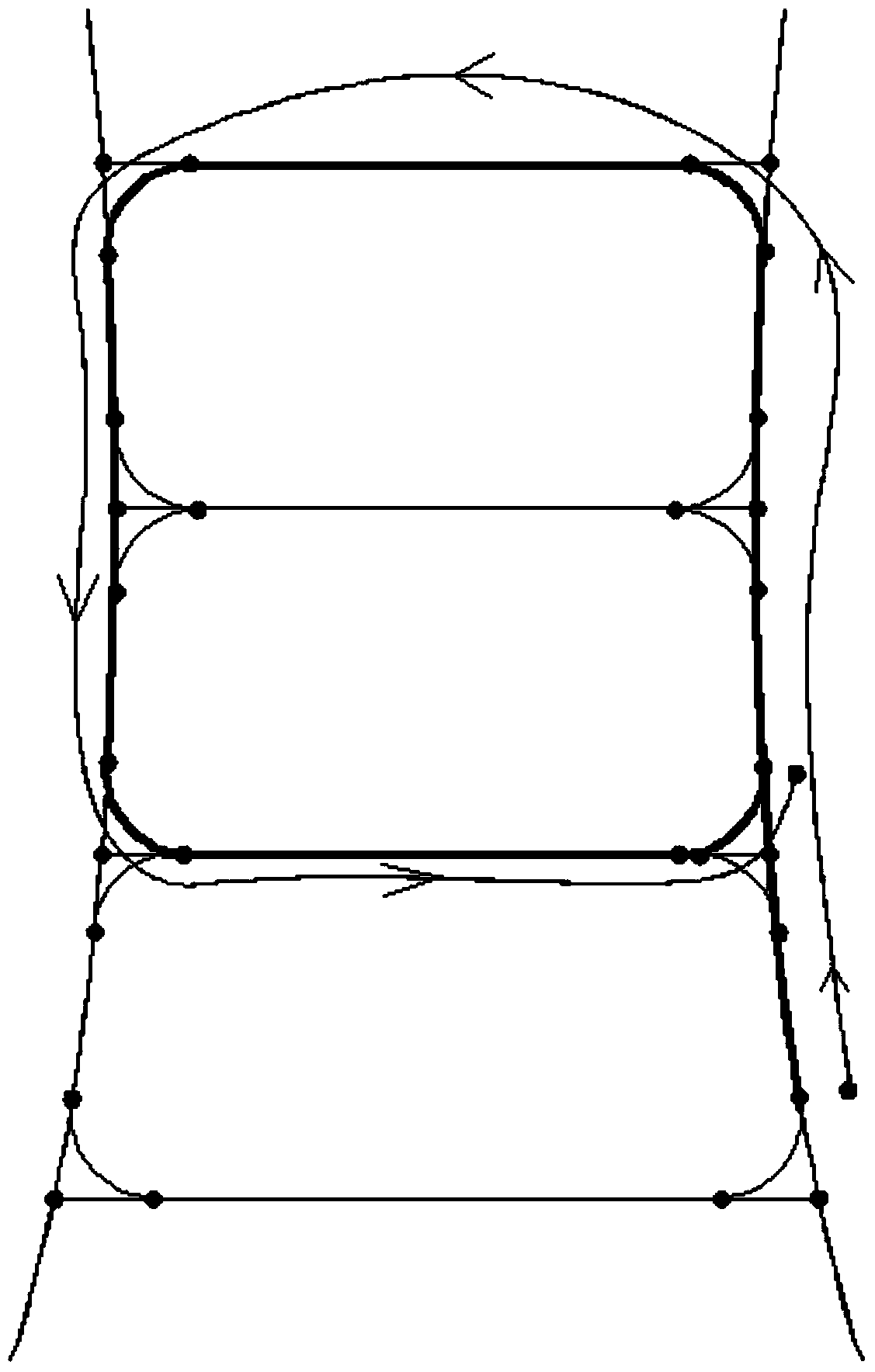

Annular feed path planning method of integral impeller rough machining

ActiveCN104181865AReasonable distributionReduce wearProgramme controlComputer controlImpellerControl theory

The invention discloses an annular feed path planning method of integral impeller rough machining. According to the method, an existing bilateral-offset feed mode is replaced by the feed mode perpendicular to the impeller axial direction, each transverse cutting path perpendicular to the impeller axial direction is connected through an arc feeding and retracting cutter to form an annular cutting path, and a layer of rough machining path is composed of a plurality of annular cutting paths. By means of the method, through reasonable machining feed path planning, the total length of the feed paths is shortened, and the problem of the low machining efficiency caused by redundant machining feed paths existing in a traditional integral impeller rough machining method is solved.

Owner:JIANGSU JITRI HUST INTELLIGENT EQUIP TECH CO LTD

Water turbine

InactiveCN105370478AAuto excludeSignificant progressHydro energy generationSafety/regulatory devicesWater turbineWater flow

The invention relates to an impact type water turbine in the technical field of hydraulic electrogenerating. The water turbine is mainly composed of an ejection device and a rotation device, wherein the ejection device is mainly composed of a base plate, a top plate, lateral plates on the two sides and components such as an ejection opening formed by a rotary valve hinged to the water outlet end of the top plate or the base plate and a transmission component of the rotary valve; and the rotation device is formed by components such as a wheel disc or hub arranged on a main shaft, a plurality of blades which are arranged on the outer surface of the wheel disc or hub, the shape of the surface between the two sides is a groove, outer end guide plates arranged on the outer end faces of the groove-shaped blades, inner end guide plates arranged on the inner end faces of the groove-shaped blades and the like, wherein the shape of the surface between the two sides of each blade is in a groove shape. By means of the water turbine, the water flow pressure energy can be efficiently converted into rotary mechanical energy, and the water turbine can be suitable for low-water-head large-flow water energy resources.

Owner:黄国宏

Hypocycloid RV transmission device

InactiveCN101718329ARealize large transmission ratio transmissionImprove stress conditionsToothed gearingsStress conditionsGear wheel

The invention discloses a hypocycloid RV transmission device comprising a shell, a power input shaft and a power output shaft. The power input shaft and the power output shaft are coaxially arranged and are in running fit with the shell; a support disc, a driven gear, a pin tooth installation disk and an output disk are axially juxtaposed in the shell in sequence; and the shell is provided with a hypocycloid gear. The hypocycloid RV transmission device retains the advantage of the RV transmission and improves and overcomes the disadvantages of the RV transmission. A pinwheel is adopted by the hypocycloid RV transmission device to do planetary motion, and only one pin tooth installation disk provided with a lightening hole is used by the hypocycloid RV transmission device, thus the weight of the hypocycloid RV transmission device is effectively reduced. Two ends of the pinwheel are respectively arranged on the pin tooth installation disk and the output disk, thus the vibration of the hypocycloid RV transmission device is effectively decreased, and the dynamic performance of the hypocycloid RV transmission device is improved. The hypocycloid RV transmission device adopts a crankshaft and the pinwheel to output simultaneously, thus the stressing condition of a rotating arm bearing is improved, and the bearing capacity of the rotating arm bearing is enhanced. Due to the appropriate tooth choose and pinwheel diameter increase, the bearing capacity of the rotating arm bearing can be further enhanced. The invention has simple and compact structure and low manufacturing cost and is convenient to maintain.

Owner:CHONGQING UNIV

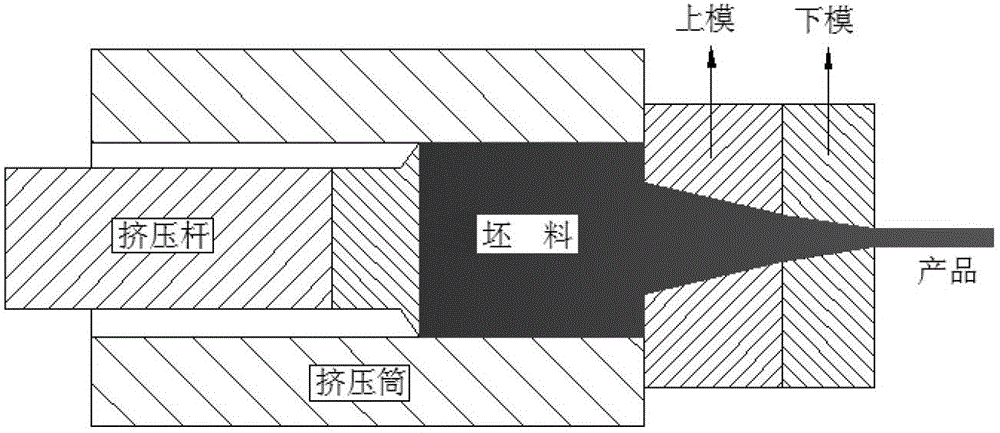

High-conductivity aluminum alloy plate extrusion forming device and technology

InactiveCN103143582AImprove stress conditionsImprove yieldExtrusion diesExtrusion mouldingElectrically conductive

The invention provides a high-conductivity aluminum alloy plate extrusion forming device and technology. The forming device is an extrusion mold which comprises an extrusion rod, an extrusion cylinder, a flow guide mold and a forming mold; an extrusion groove of the flow guide mold is designed to be inverted conical; and the shapes of the extrusion groove of the forming mold and a forming element are keep to be consistent. The forming technology comprises the steps of preparing aluminum alloy blanks, preheating a mold, spraying graphite, and extruding and forming an aluminum alloy plate. Metal materials provided by the invention are not formed once in the forming process, and are subjected performing and final forming; stress produced in the forming process is reduced; the deformation texture in the aluminum alloy plate is increased; and the conductivity performance and heat conduction capability of products are improved greatly.

Owner:安徽皖北铝基新材料技术研究院有限公司

Earth and rockfill dam core wall hydraulic fracture test device

ActiveCN102928298AImprove stress conditionsGuaranteed Authenticity and AccuracyMaterial strength using tensile/compressive forcesEmbankment damTest sample

The invention relates to an earth and rockfill dam core wall hydraulic fracture test device. Specifically, a water inlet hole is additionally arranged on a base of an ordinary triaxial apparatus pressure chamber corresponding to the test sample center position, a vertical sleeve with threads is fixed on the water inlet hole, a rotary hollow cylindrical steel member with the barrel wall is positioned in the sleeve, a water spray hole is previously arranged at the certain position between the sleeve and the barrel wall of the member, hydraulic pressure can be injected through the water inlet hole additionally arranged on the base, and a fracture water head is arranged at the position of the water spray hole. The earth and rockfill dam core wall hydraulic fracture test device overcomes the defects of presently using a hollow test sample directly to carry out hydraulic fracture tests, solves the problem that centrifugal hydraulic fracture tests are not obvious in soil arch effect, reasonably reflects hydraulic fracture conditions and action methods, and is suitable for determine earth and rockfill dam core wall hydraulic fracture tests and fracture water heads.

Owner:POWERCHINA ZHONGNAN ENG

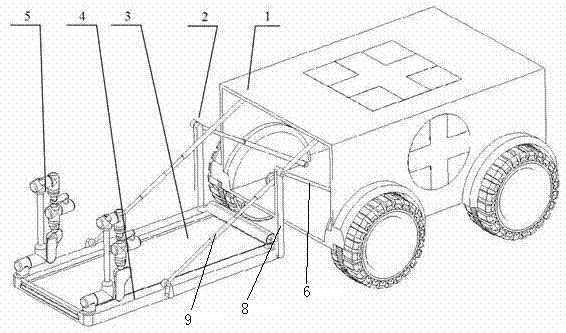

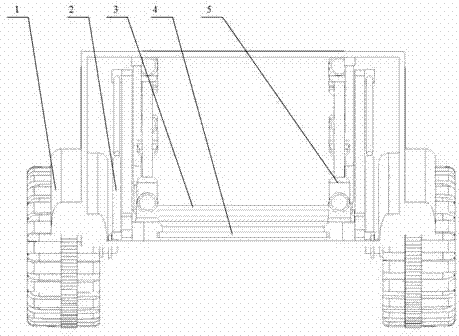

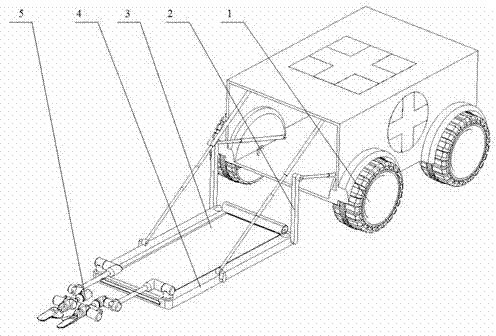

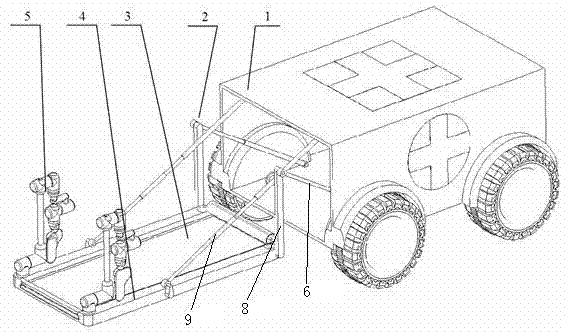

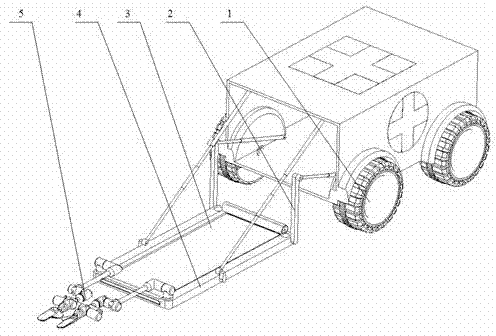

Fracture patient rescue robot

InactiveCN103083142AThe folded volume to unfolded volume ratio is minimizedReduce volumeAmbulance serviceSix degrees of freedomFirst aid

The invention discloses a fracture patient rescue robot which is composed of a vehicle body and an actuating mechanism. The actuating mechanism comprises a lifting mechanism, a sliding stretcher and two operating arms of six degrees of freedom. The sliding stretcher has an upper layer and a lower layer, the lower layer is a protective shell and the upper layer is a belt drive device. The lifting mechanism is composed of a vehicle body telescopic connecting bar fixed with the vehicle body, a stretcher connecting bar fixed with a lower layer movable stretcher and a telescopic bar. One end of the vehicle body telescopic connecting bar is movably connected with one end of the stretcher connecting bar, both ends of the telescopic bar are respectively connected with the lower layer movable stretcher and the vehicle body, and the vehicle body telescopic connecting bar and the telescopic bar are respectively driven by a worm and gear. The two operating arms of six degrees of freedom are installed symmetrically at the front portion of the sliding stretcher. According to the sliding stretcher, full consideration is given to human body structure and injury particularity, the operational process of the double-position automatic registration and fusion scanning board meets standards of human body first-aid operations, and damage to the human body in an operational process is reduced to the maximum extent.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

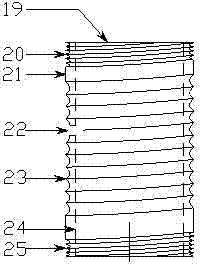

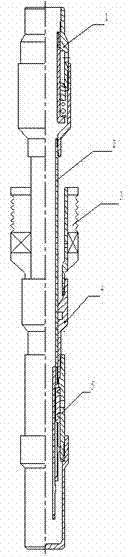

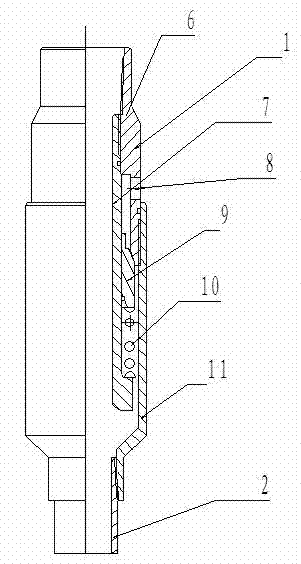

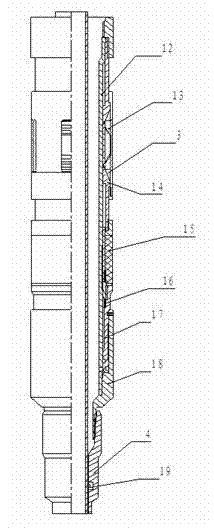

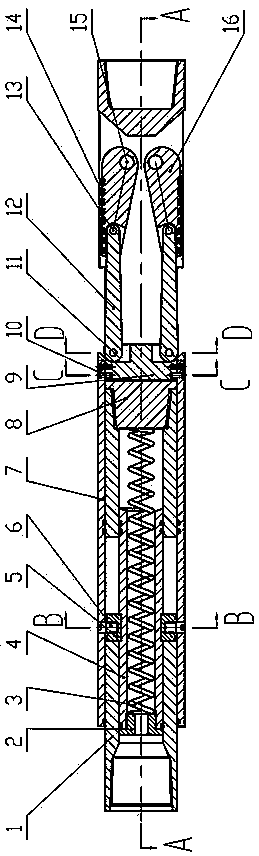

Down-hole steam injection string of thick-oil thermal production well

The invention discloses a down-hole steam injection string of a thick-oil thermal production well. The down-hole steam injection string is capable of protecting a casing in a steam injected well, improving the dryness of steam at the bottom of the well, and improving the steam injection heat efficiency and the steam injection effect. The steam injection string comprises a heat insulation pipe and a wall-hook packer; the heat insulation pipe, a backwashing valve and a sealed telescopic pipe are orderly connected to form an internal steam injection string; the wall-hook packer is orderly connected with a sealing sleeve and a switch assembly to form an external steam injection string; the wall-hook packer of the external steam injection string is down and sealed and hung on the inner wall of the casing; the sealed telescopic pipe of the internal steam injection string is inserted in the switch assembly of the external steam injection string and is capable of sliding in the sealing sleeve. The down-hole steam injection string of the thick-oil thermal production well can be reused after being put down once; the steam injection quality is obviously improved, the oil-steam ratio is increased, and an obvious oil increasing effect is achieved. The down-hole steam injection string of the thick-oil thermal production well is simple in structure and reliable in working; besides, the swept volume of the steam and multi-turn steam injection efficiency are improved, the energy source is thoroughly saved, the casing is effectively protected, and the defect of leakage at the wellhead casing head of the existing steam injection string is eliminated.

Owner:CHINA PETROLEUM & CHEM CORP +1

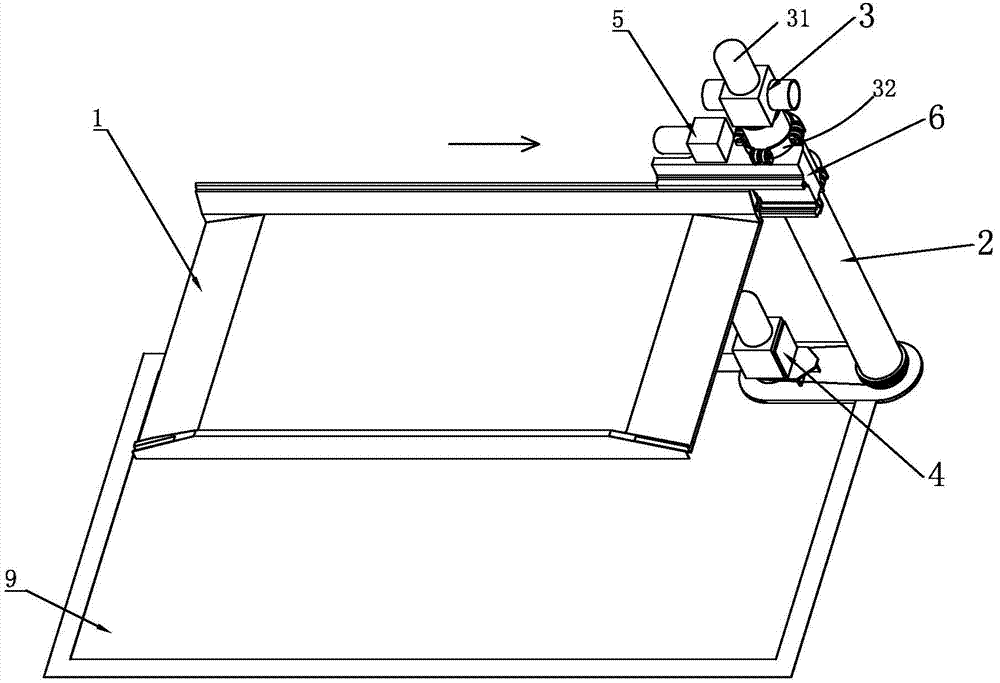

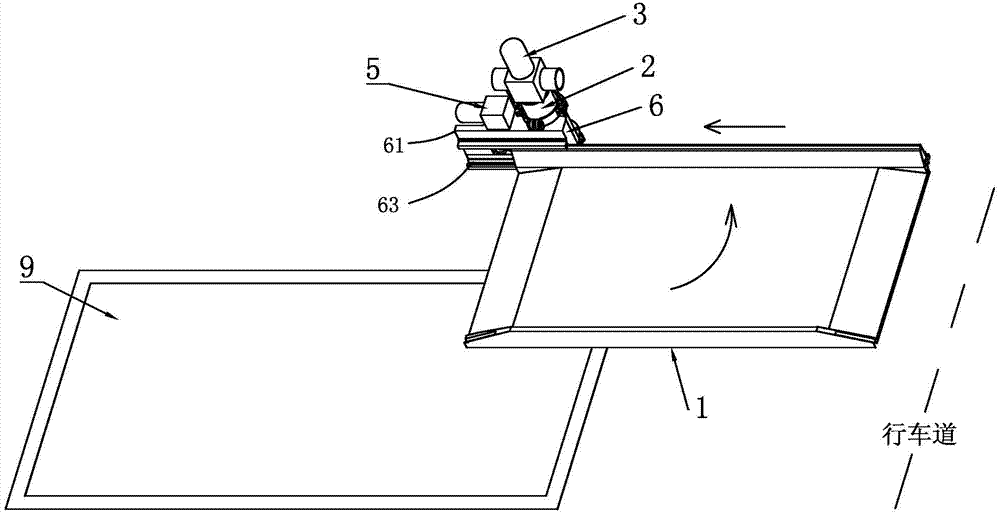

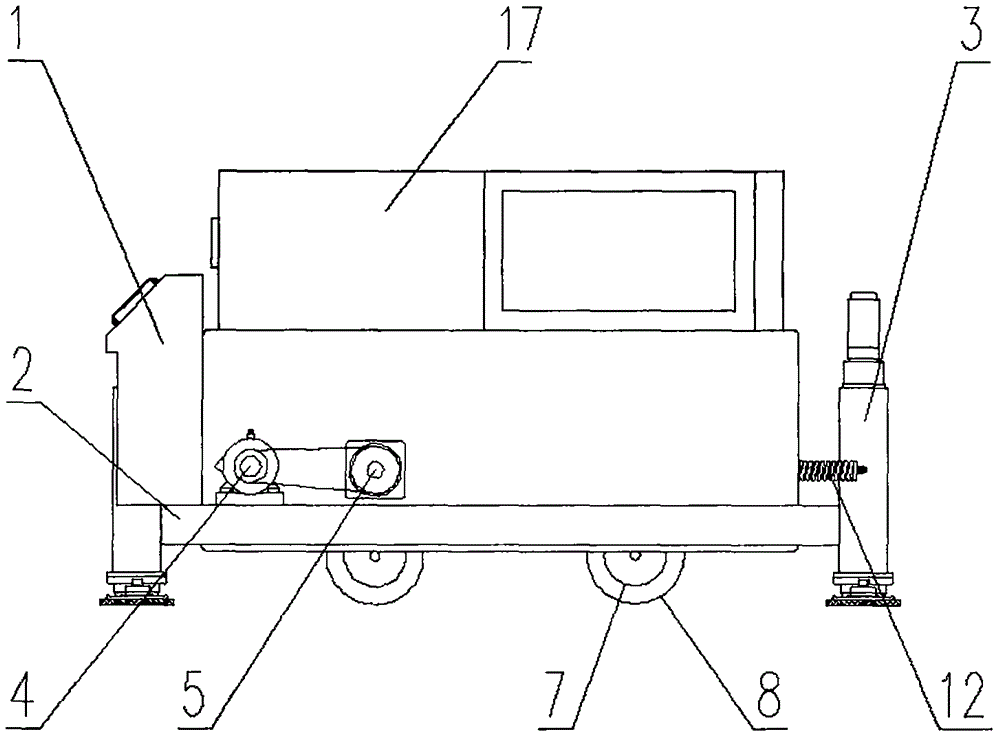

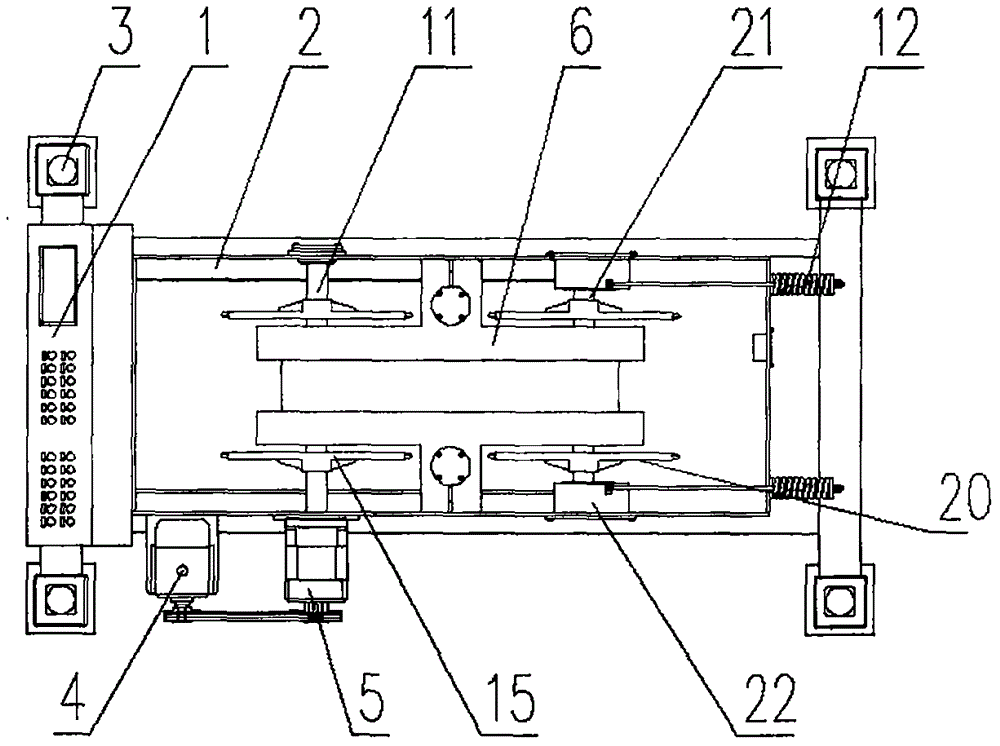

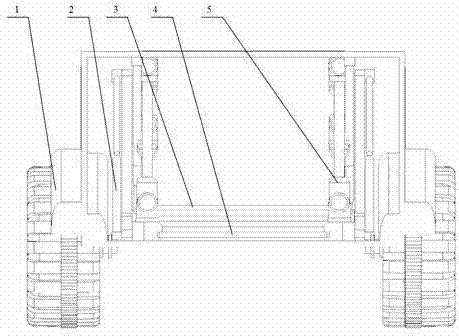

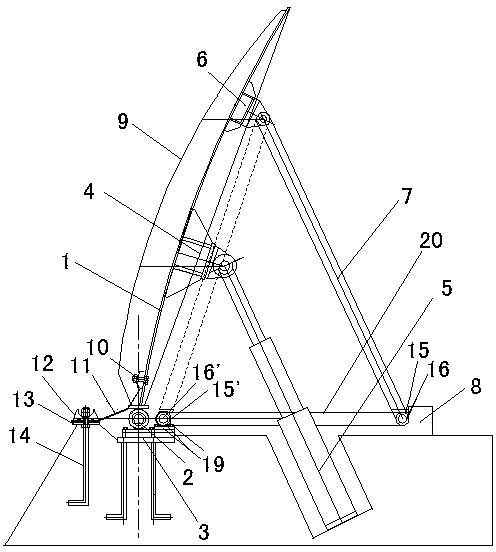

Mobile linear circulating-type acceleration loading test system

PendingCN106596304AImprove efficiencyReduce distanceMaterial strength using repeated/pulsating forcesEngineeringMechanical engineering

The invention provides a mobile linear circulating-type acceleration loading test system. The mobile linear circulating-type acceleration loading test system comprises a frame, a guide rail, more than one of rolling wheel groups and two chain transmission pairs. The guide rail is arranged on the frame, an upper loading surface on the guide rail is a straight-line segment, a lower loading surface is in a hull bottom shape, two ends of the upper loading surface and the lower loading surface are connected through curve segments in a smooth and transition mode, the guide rail is in a box type, and is filled with a damping material; each rolling wheel group comprises two loading wheels and a rolling wheel, and the rolling wheel is positioned between the loading wheels and coaxially arranged. The system employs a design scheme for driving the rolling wheel groups by the chain transmission pairs, a chain is assembled with the rolling wheel groups together through a chain pin and a connecting piece, the wheel shaft axis of the rolling wheel group and the longitudinal center line of the chain vertically intersect, the structure is simple, reliability is high, usage maintenance cost is low; loading wheelspan rolling wheel distance is short, the bearing condition is good, the noise is little, and the efficiency is high.

Owner:SHANDONG JIAOTONG UNIV

Integral prestress reinforced earth retaining wall construction method

ActiveCN104790429ADevelop tensile strengthPlay coordinationArtificial islandsUnderwater structuresPre stressRebar

The invention discloses an integral prestress reinforced earth retaining wall construction method. The method comprises the steps of excavating an earth retaining wall foundation trench, pouring a concrete floor of an earth retaining wall, arranging vertical rebars, laying geogrids and geotechnical cloth, refilling a backfill material by certain thickness, overturning the geogrids and geotechnical cloth to wrap the backfill material inside, refilling the backfill material multiple times to the designed height of the earth retaining wall, pouring a top plate, tensioning and locking the rebars, and driving a pre-stressed anchor cable to a side slope from the edge of a concrete cover plate. According to the method, by arranging ribs in the horizontal direction and applying prestress in the vertical direction, cost is lower compared with a reinforced concrete retaining wall; the mechanical property of reinforcement materials is fully utilized, the integral type earth retaining wall is formed, and pouring of a concrete panel is not needed. The method has the advantages that construction is easy, economic effectiveness is high, and implementation effect is good.

Owner:CHONGQING UNIV

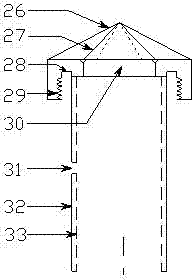

High-low ridge stilling pool achieving double-layer disperse energy dissipation

The invention relates to a high-low ridge stilling pool achieving double-layer disperse energy dissipation. The high-low ridge stilling pool comprises a falling-ridge water flow inlet section, a stilling pool body, a stilling pool tail ridge and an apron; the falling-ridge water flow inlet section is composed of high-ridge flow drainage holes, low-ridge flow drainage holes and partition walls, wherein the high-ridge flow drainage holes and the low-ridge flow drainage holes are arranged in a combined mode, and the partition walls are located between the high-ridge flow drainage holes and the low-ridge flow drainage holes; the stilling pool body comprises an upper stilling pool body and a lower stilling pool body, the upper stilling pool body is connected with the water flow inlet section, the floor elevation of the upper stilling pool body is equal to the elevations of the outlet ends of the low-ridge flow drainage holes, the lower stilling pool body is located behind the upper stilling pool body, and the floor elevation of the lower stilling pool body is lower than that of the upper stilling pool body; the stilling pool tail ridge is located at the tail portion of the stilling pool body, and the apron is connected with the stilling pool body. The high-low ridge stilling pool can reduce impact to the front portion of the high-low ridge stilling pool caused by discharged flow and homogenize the concentrated energy dissipation region of the front half portion of the high-low ridge stilling pool, the effect of double-layer disperse energy dissipation is achieved, and the phenomena of violent water flow turbulent fluctuation and great water surface fluctuation of the concentrated energy dissipation region are eliminated.

Owner:CHINA THREE GORGES CORPORATION

Spring-propped bridge reinforcing structure

ActiveCN102251490AEasy to useReduce consumptionBridge erection/assemblyBridge strengtheningPre stressCushion

The invention relates to a spring-propped bridge reinforcing structure. In the structure, an intact pillar is fixed on a middle cushion cap and supports the slab cross beam of an irregular bridge slab by a support; the structure is characterized in that at least one unit spring-propped reinforcing structure is arranged at the periphery of the intact pillar and comprises two symmetrical pier columns, an n-shaped steel bent cap and two symmetrical dynamometry-adjustable supports; the lower bottom slabs of the two symmetrical pier columns are in threaded connection with the middle cushion cap, the n-shaped steel bent cap is of a symmetrical n-shaped structure and is symmetrically and fixedly arranged at the tops of the two symmetrical pier columns, and the two ends of the upper part of the n-shaped steel bent cap are supported at the lower part of the slab cross beam by the two symmetrical dynamometry-adjustable supports. The structure is used for reinforcement under the condition that key parts of the irregular slab crack seriously and have insufficient bearing force; a loaded reinforcing method is implemented, construction process is simple, and complicated prestress steel bundle construction process and the anchoring structure are avoided, and a good reinforcement effect is achieved.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

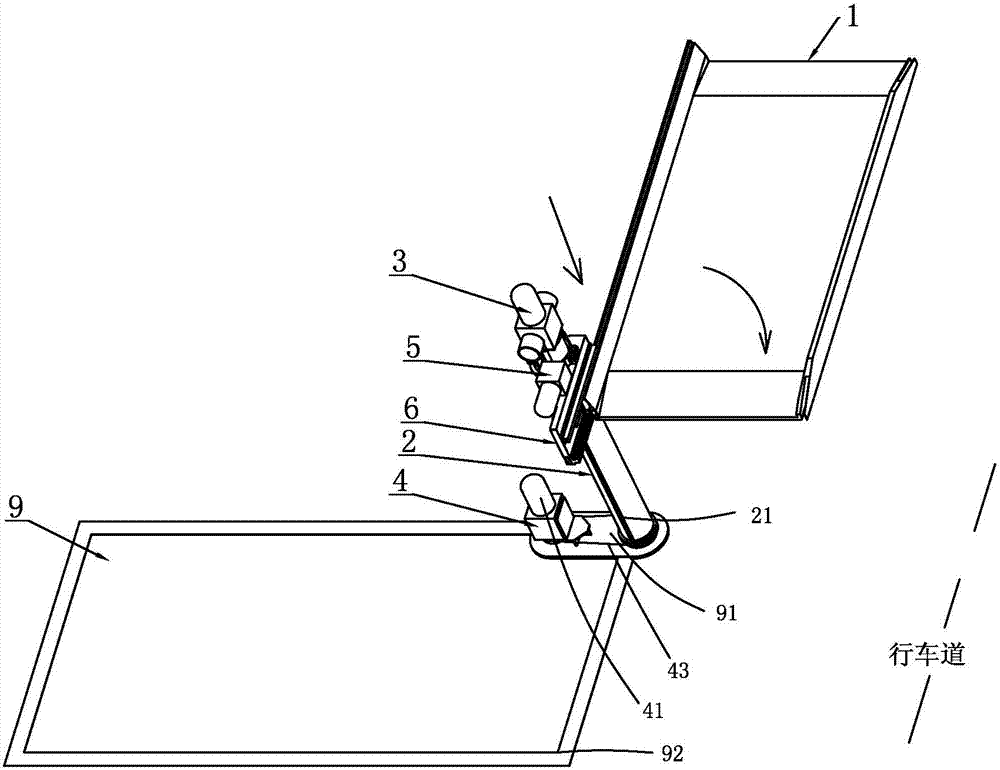

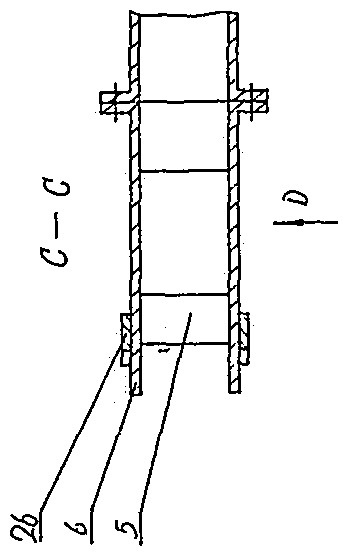

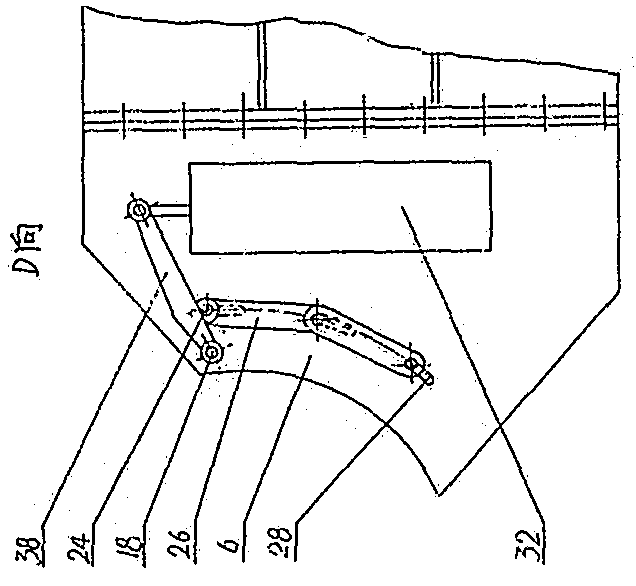

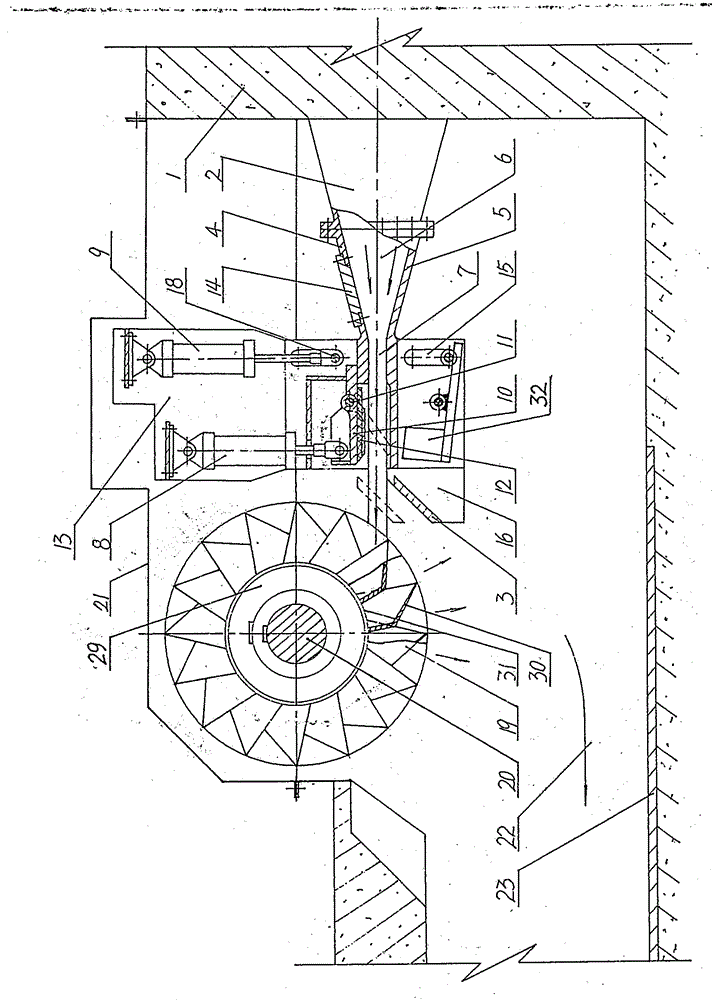

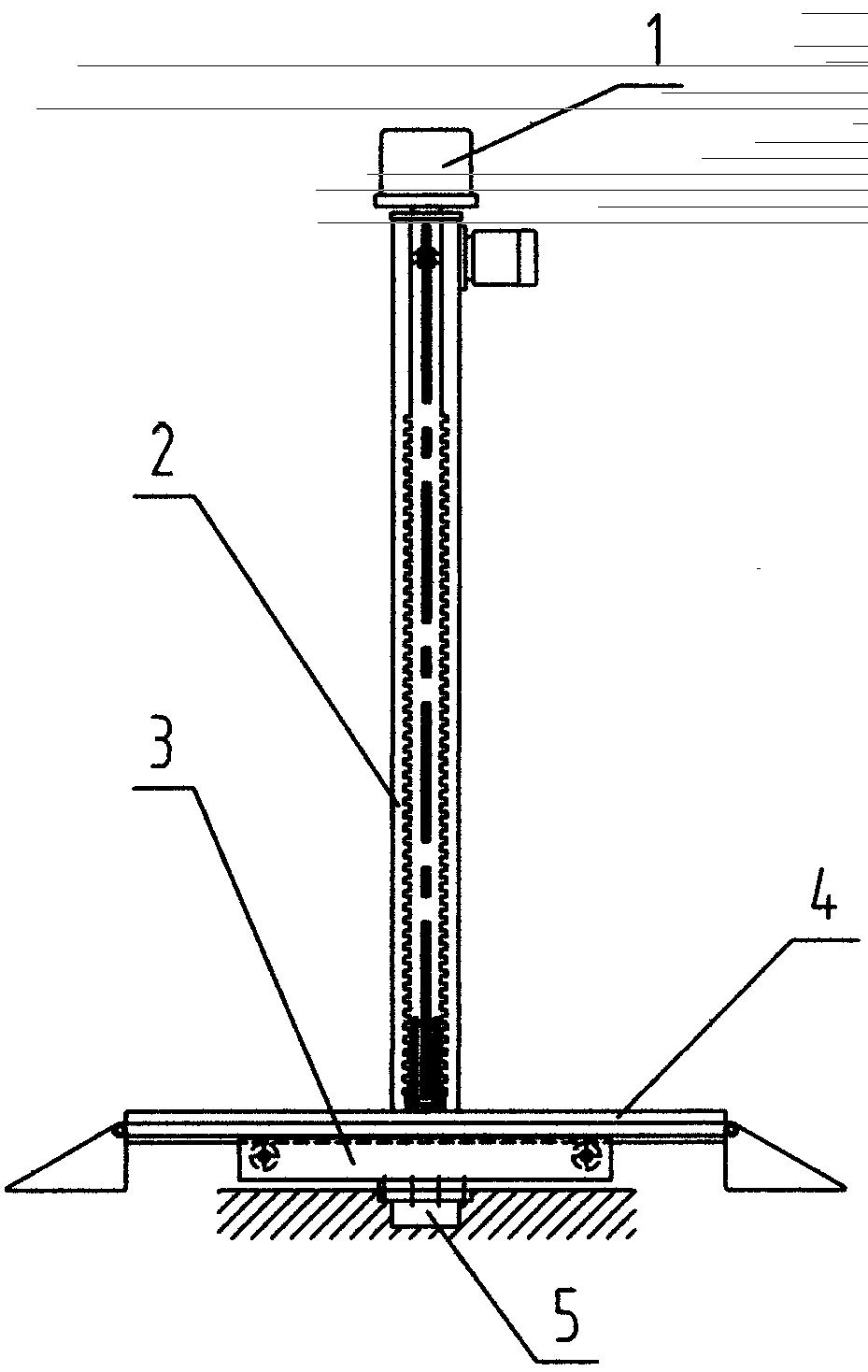

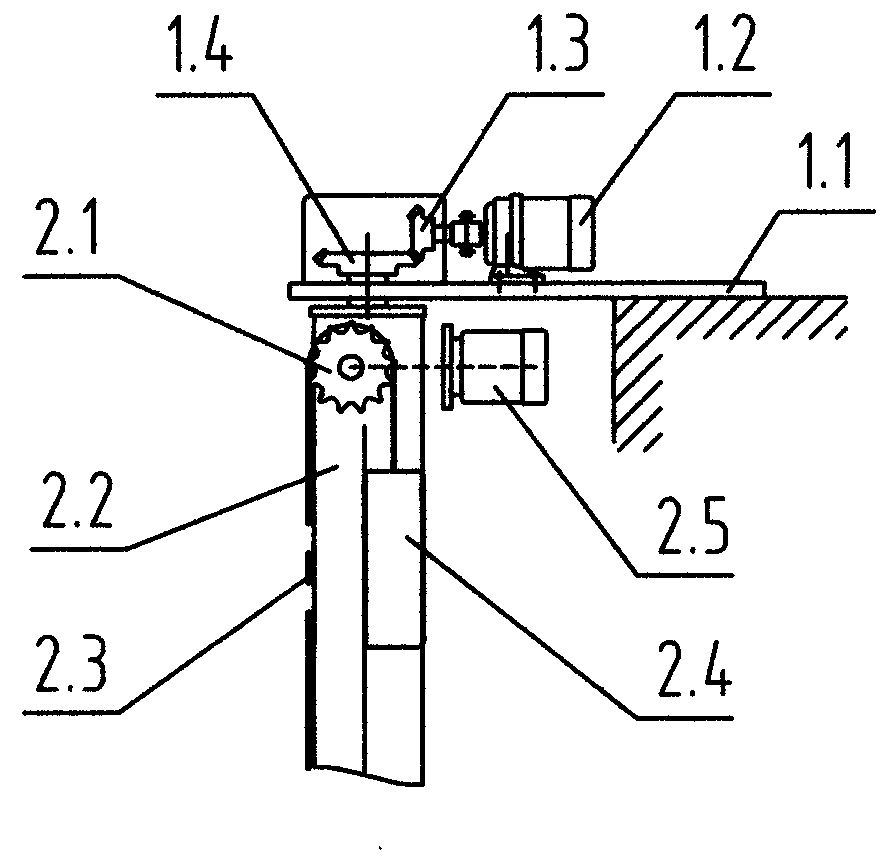

Vehicle storing and taking mechanical hand

A vehicle storing and taking mechanical hand is used for storing and taking sedans, small vans and other small vehicles for a mechanical parking device. The vehicle storing and taking mechanical hand is composed of a rotating driving device, a function column, a mechanical hand, vehicle loading plates and a control system. The invention relates to the technical field of steel structures, mechanical transmission and automatic control and the like. The function column rotates in situ, the mechanical hand and the vehicle loading plates are of an independent structure, the mechanical hand performs lifting by simple transmission and is provided with the novel unique driving device, a supporting mode and anti-dropping measures are adopted, and vehicles can be stored in or taken out of parking spaces on two sides of the function column through a plurality of vehicle loading plates.

Owner:蓝家瑞

Rescue robot executing mechanism for person with fracture

InactiveCN103110482AEffective protectionCause secondary damageAmbulance serviceRescue robotEngineering

The invention discloses a rescue robot executing mechanism for a person with fracture. The executing mechanism comprises a lifting mechanism, a sliding stretcher and two operation arms with six degrees of freedom. The sliding stretcher is divided into an upper layer and a lower layer, the lower layer is a protective cover shell, and the upper layer is a belt type transmission device. The lifting mechanism is composed of a vehicle body stretchable connection rod fixed with a vehicle body, a stretcher connection rod fixed with a lower layer movable stretcher and a stretchable rod. One end of the vehicle body stretchable connection rod is movably connected with one end of the stretchable rod, and two ends of the stretchable rod are respectively connected with the lower layer movable stretcher and the vehicle body. The vehicle body stretchable connection rod and the stretchable rod are respectively driven by a worm and a gear, and the two operation arms with six degrees of freedom are symmetrically arranged on the front portion of the sliding stretcher. Each operation arm with six degrees of freedom is of a separation movement decoupling structure composed of six rotational joints. According to the rescue robot executing mechanism for the person, human body structure and particularity of damage are taken into full consideration, operation procedures are in accordance with human body rescue operation specifications, and damage to a human body in an operation process is greatly reduced.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

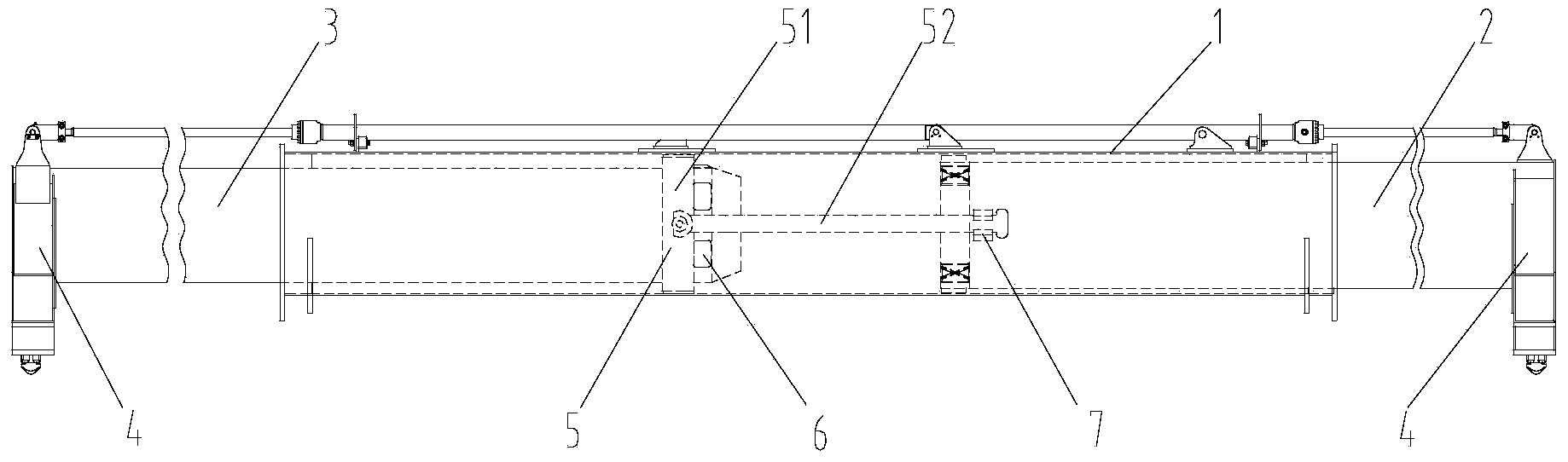

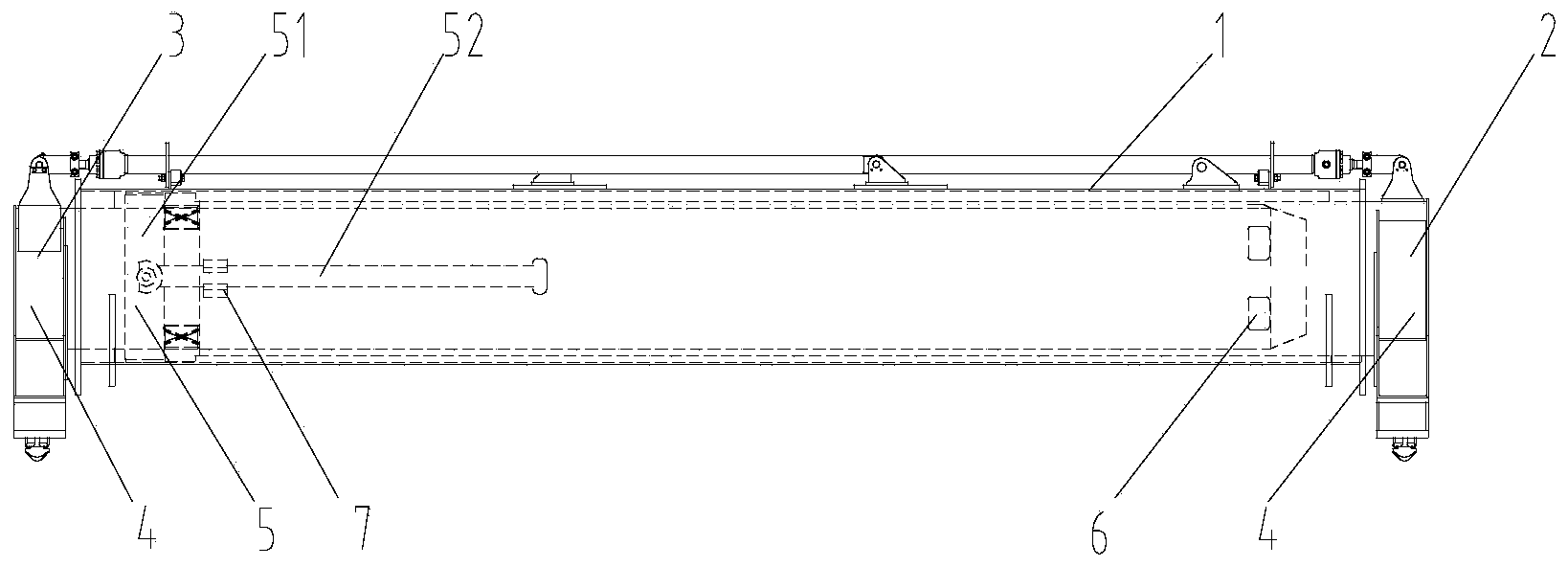

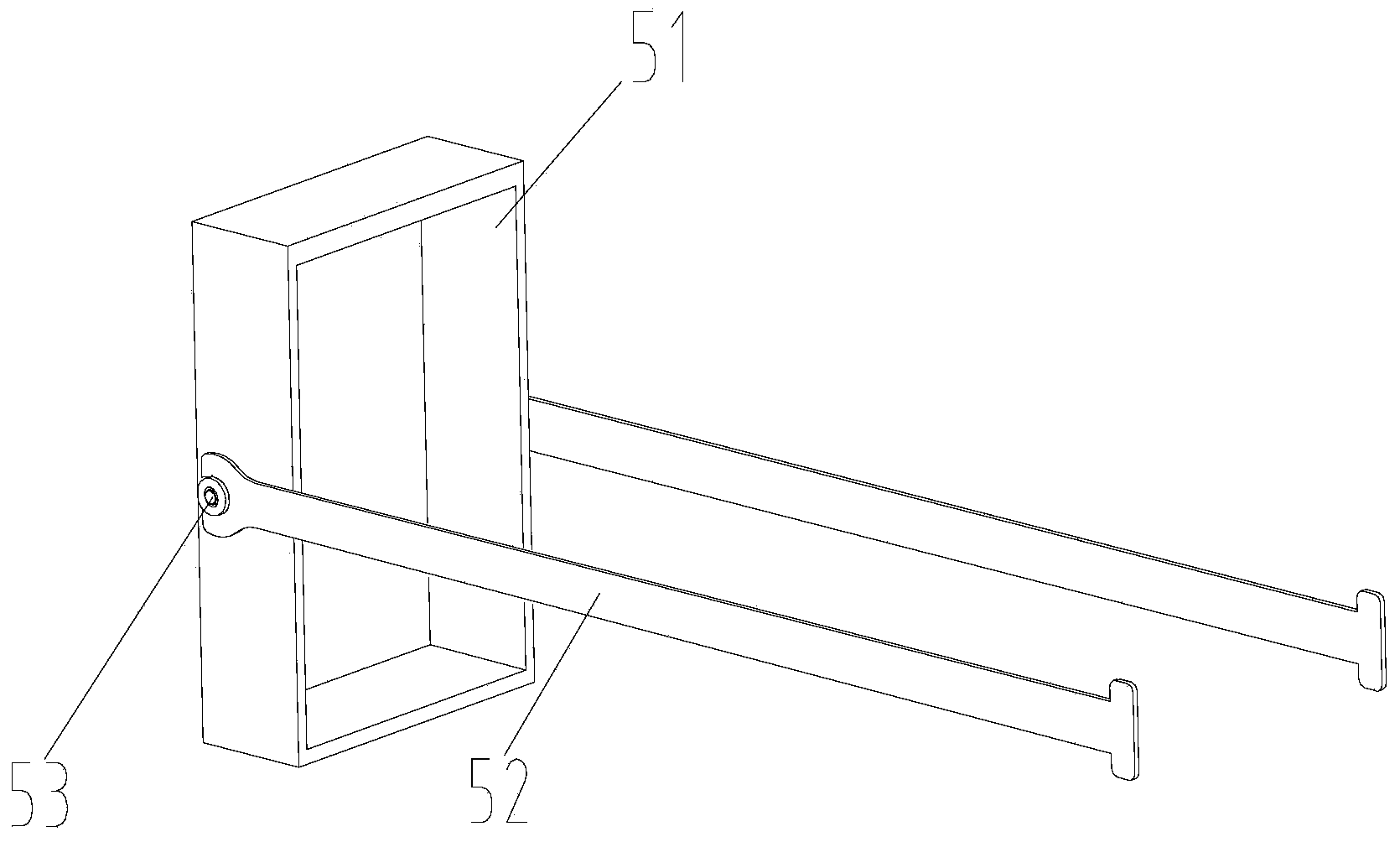

Single-girder hanger and reach stacker

The invention provides a single-girder hanger which comprises a girder (1), a large telescopic beam (2), a small telescopic beam (3), cross beams (4), a follow-up supporting mechanism (5), a first limiting mechanism (6) and a second limiting mechanism (7), wherein the large telescopic beam (2) and the small telescopic beam (3) are located in the girder (1), and the small telescopic beam (3) is nested in the larger telescopic beam (2); the cross beams (4) are located at free ends of the large telescopic beam (2) and the small telescopic beam (3); one end of the follow-up supporting mechanism (5) is connected with the large telescopic beam (2), the other end of the follow-up supporting mechanism (5) is nested on the small telescopic beam (3), the outer wall of the follow-up supporting mechanism (5) is propped against the inner surface of the girder (1), and the inner wall of the follow-up supporting mechanism (5) is propped against the outer surface of the small telescopic beam (3); the first limiting mechanism (6) is located at the fixed end of the small telescopic beam (3); and the second limiting mechanism (7) is located on the large telescopic beam (2). According to the single-girder hanger, the follow-up supporting mechanism is arranged between the girder and the telescopic beams, follow-up supporting for the small telescopic beam is realized, and supporting moment arms of the two telescopic beams are prolonged, so that the stress condition of a mechanical structure is improved, the requirement for carrying capacity of a mechanical material is reduced, the carrying capacity of the single-girder hanger is improved, and the single-girder hanger can lift a heavy load container weighing up to 20 ft.

Owner:SANY MARINE HEAVY IND +1

External-installed triggering type anti-sink device

PendingCN106677514ALess componentsReduce processing costsBuilding support scaffoldsElectrical and Electronics engineering

Owner:厦门安科科技有限公司

Supporting-rod two-blade large-diameter changing reaming tool

InactiveCN104481404AWide range of variable diameterSimple controlDrilling machines and methodsEngineeringDriving mode

The invention relates to a supporting-rod two-blade large-diameter changing reaming tool for mineral resource exploiting and oil-gas well underground reaming and solves the problem of underground large diameter changing reaming. According to the technical scheme, a main cylinder is in threaded connection with a blade seat, and three through grooves are formed uniformly in the main cylinder peripherally. A water nozzle is in threaded connection with a central tube, and three sliding blocks penetrate the three through grooves to be mounted in an inner central tube circular groove. The middle of an outer central tube is fixedly connected with a sliding block through screws a, and the lower portion is fixedly connected with a supporting rod seat through screws b. Cutting teeth are inlaid in the outsides of the blade wings, and the blade wings are hinged to the blade wing seat through bolts. The ends of supporting rods are hinged to the supporting rod seat, and the other ends are hinged to the blade wings. By means of the tool, the largest diameter after diameter changing can be more than three times of the largest diameter before diameter changing, the mechanical structure is reliable, and a hydraulic drive mode is used, so that the tool is simple to control and is used for underground reaming.

Owner:SOUTHWEST PETROLEUM UNIV

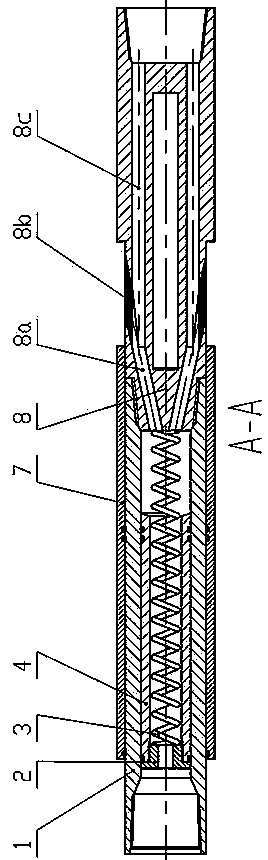

Hinge movable dam

InactiveCN103422475AAvoid damageActivities are fully synchronizedBarrages/weirsHydraulic motorSynchronous motor

The invention discloses a hinge movable dam, which consists of a plurality of movable dam units, wherein the lower end of the water retaining dam face (1) of each movable dam unit is connected with a gate bottom tilting fillet (3) through a gate hinge (2). The hinge movable dam is characterized in that a hydraulic oil cylinder (5) is connected to the middle part of the inner side of each water retaining dam face (1); the hydraulic oil cylinders (5) are connected through synchronous motors (21); a support rod (7) is connected to the upper part of the inner side of each water retaining dam face (1); a chain (20) is connected to the lower end of each support rod (7), and is connected to a driving chain wheel (15) and a driven chain wheel (15'); each driving chain wheel (15) is connected with a driving shaft (16); each driven chain wheel (15') is connected with a driven shaft (16'); each driving chain wheel (16) is connected with a hydraulic motor (18). The hinge movable dam is simple and practical in structure, convenient to use, high in damage prevention capability, long in service life, safe and reliable, and has a good floodwater draining effect, water blocking is avoided, and good stress conditions are ensured.

Owner:YANTAI TIANSHENG RUBBER

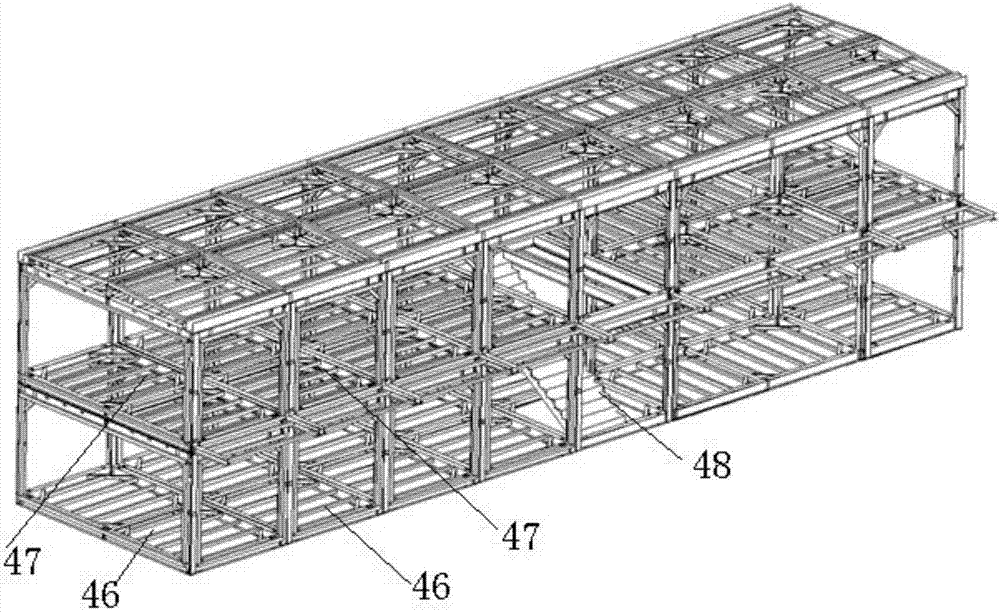

Fabricated box structure building

PendingCN107386451AFirmly connectedImprove mechanical propertiesBuilding constructionsArchitectural engineeringMechanical engineering

The invention belongs to the technical field of box structure building structures, and particularly relates to a fabricated box structure building. The fabricated box structure building comprises box units used for being spliced to form a fabricated box structure building body. The box units comprise a plurality of standard layer box units arranged on a first layer, a plurality of top layer box units arranged on a second layer and staircase box units used for communicating the first layer with the second layer. When a house is built by adopting a steel structure box component of the fabricated box structure building, the construction process of the box units is completed in a factory, assembly of the box units, pipe lines communicating and a small amount of decoration work are only needed on a site, the degree of assembly is high, the working efficiency is improved, the construction cycle is shortened greatly, the degree of industrialization is high, the product quality is easy to control, and the production efficiency is improved; and because the box units are completed in the factory, the fabricated box structure building is less affected by climate, and the fabricated box structure building is suitable for extensive industrialization production.

Owner:天水大成精工制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com