Earth and rockfill dam core wall hydraulic fracture test device

A test device and hydraulic splitting technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of deviation of soil mechanical parameters, inconspicuous arching effect, unreliable centrifugal test results, etc., and achieve improvement. Stress conditions, effects to ensure authenticity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Such as figure 1 As shown, a hydraulic splitting test device for the core wall of an earth-rock dam includes a pressure chamber 2 and a base 8 in the pressure chamber 2 for supporting a sample 11, and a water injection hole 18 is provided in the base 8.

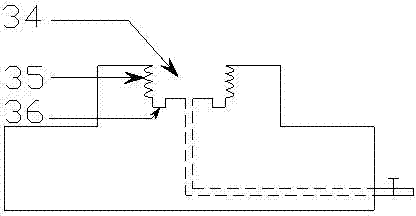

[0028] Such as Figure 4 As shown, the center of the base 8 is provided with a cylindrical groove 34, the diameter of the cylindrical groove 34 is 1 / 5 of the diameter of the sample 11, and the inner wall of the cylindrical groove 34 is provided with a base thread 35, and the water injection One end of the hole 18 extends to the bottom of the cylindrical recess 34;

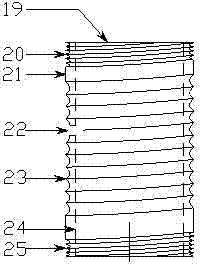

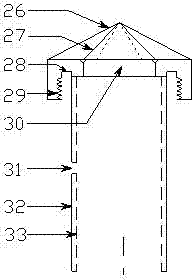

[0029] Such as figure 2 As shown, the test device also includes a water injection device placed inside the sample 11 and injecting water into the sample 11, which is made of steel, and the water injection device includes a hollow sleeve 19 and a hollow cylindrical member sleeved in the sleeve 19 26. The outer diameter of the sleeve 19 and the inner diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com