External-installed triggering type anti-sink device

An anti-falling and triggering technology, which is applied in the directions of construction, housing structure support, scaffolding supported by housing structure, etc., can solve the problems of increased processing and installation costs, dismantling of the anti-fall device 100, low reliability, etc. Cost of machining and installation, improved safety and reliability, effect of wide range of clearance adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

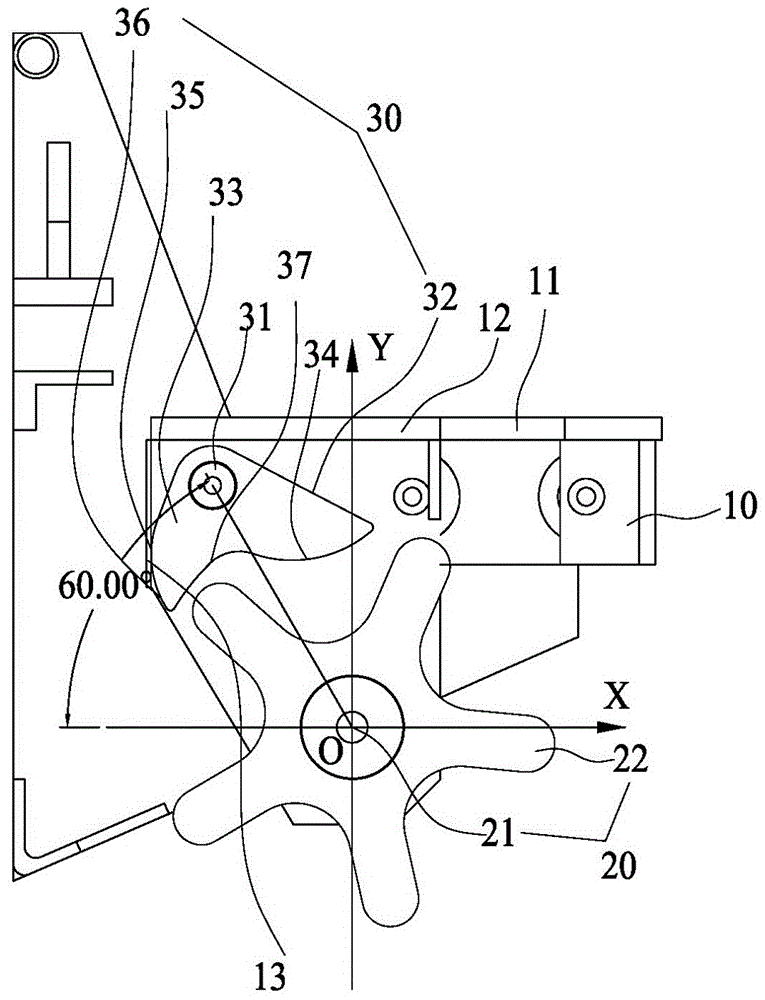

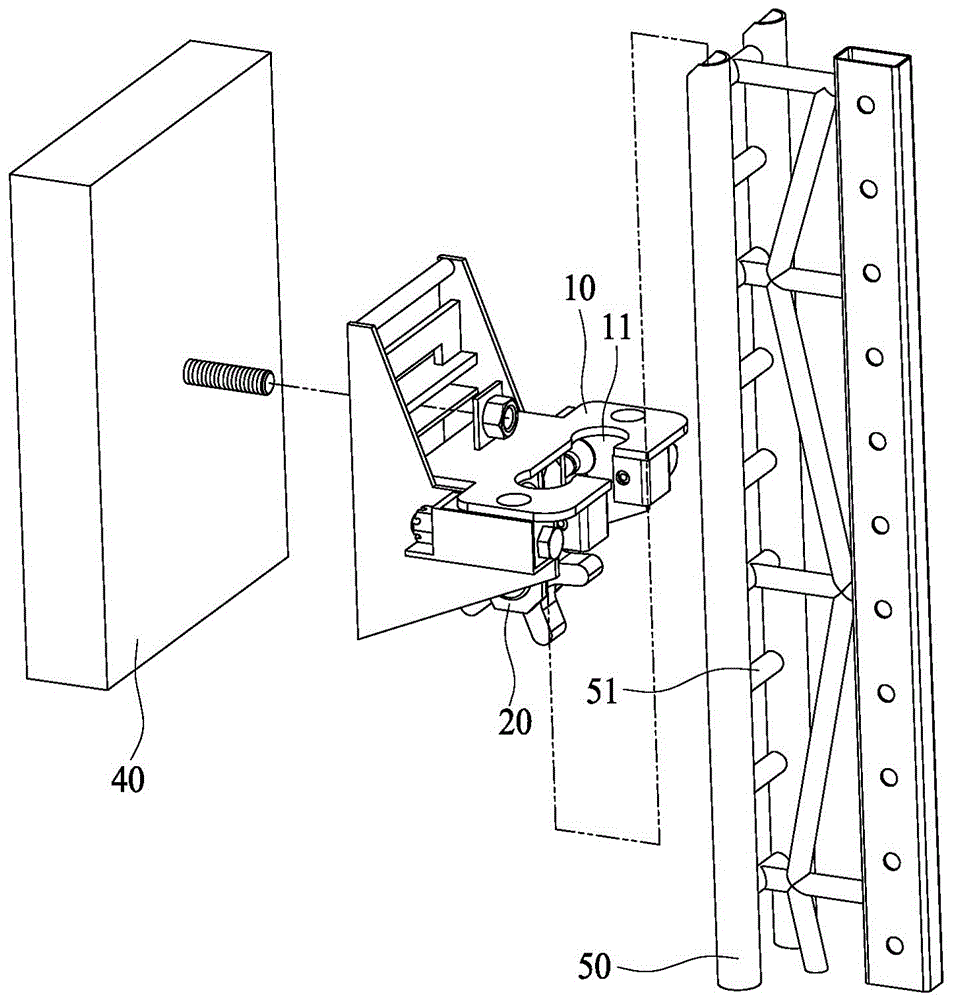

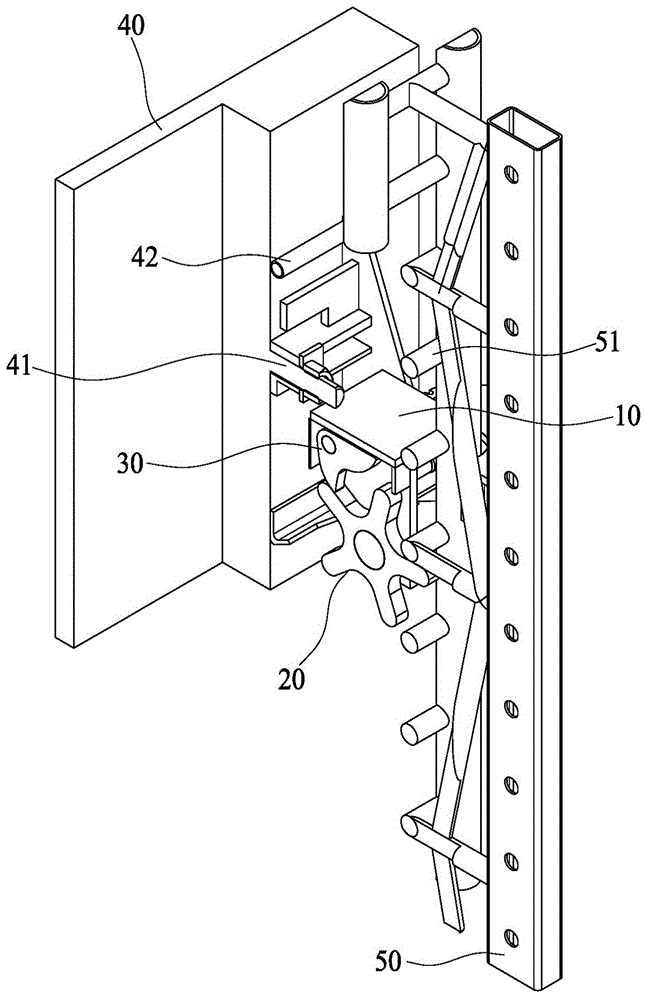

[0070] see Figure 1 to Figure 19 As shown, an external trigger type fall arrester 100 disclosed in the present invention has a base 10 with a lifting rail 11 guiding it.

[0071] The multi-claw rotor 20 is rotatably installed in the base body 10 through a pin shaft 21 . The so-called multi-claw rotor 20 may have 4-6 claws 22 evenly arranged.

[0072] The special-shaped clip 30 is rotatably installed in the base body 10 through a pin shaft 31 . The special-shaped clip 30 has a transmission part 32 and a brake part 33 arranged in an L shape. One end of the transmission part 32 and the brake part 33 near the pin shaft 31 is connected together, and the other end extends to the distance respectively. The inner surface of the transmission part 32 The arc counterweight 34 is formed by arching. Correspondingly, the outer surface corresponding to the transmission part 32 on the base body 10 forms an upper limit plate 12 for limiting the upward rotation of the special-shaped clip 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com