Fill channel anti-frost heaving and anti-seepage structure and construction method

A construction method and channel technology, applied in marine engineering, water conservancy projects, irrigation pipelines, etc., can solve the problem that the anti-seepage technology cannot take into account the requirements of anti-scour, anti-seepage and anti-frost heave at the same time, so as to improve the stress conditions of frost heave, The effect of reducing freeze-thaw damage, method reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

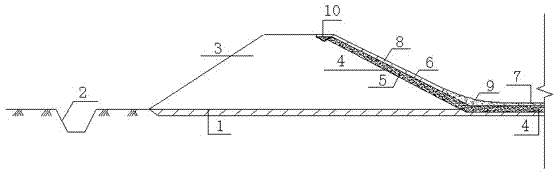

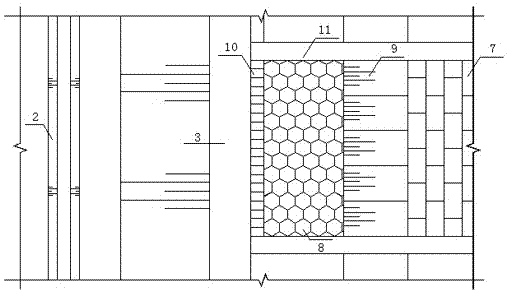

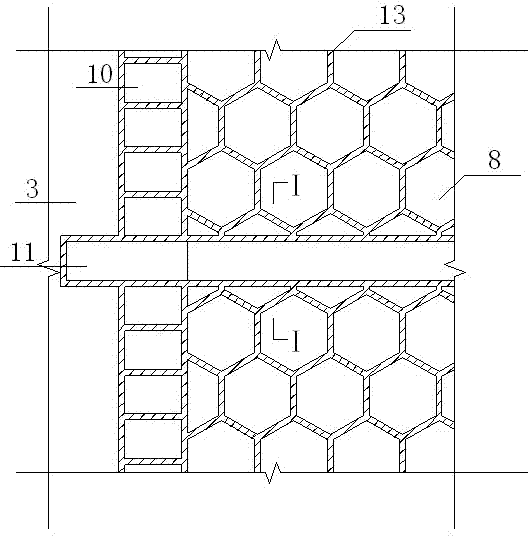

[0019] Describe the specific embodiment of the present invention in detail below in conjunction with technical scheme and accompanying drawing, as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 shown. The protection scope of the present invention is not limited only to the description of this embodiment.

[0020] Such as figure 1 , 2 , 3, 4 and 5, a kind of anti-frost-heave anti-seepage structure and construction method of the channel, consists of aeolian sand cushion 4, geotechnical anti-seepage plastic film 5, prefabricated concrete block 8, arc-shaped concrete slope foot 9 and drainage The ditch 2 is composed of a geotechnical anti-seepage plastic film 5, a concrete ditch bottom 7, a prefabricated concrete block 8 and a curved concrete slope foot 9, and a cement mortar cushion 6 is provided.

[0021] An anti-frost heaving and anti-seepage structure and construction method of a channel, the construction steps of which are as follows:

[0022] (1) Use a bulld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com