Zirconia ceramic ferrule and production process thereof

A technology of zirconia ceramics and production process, which is applied in the field of zirconia ceramic ferrule and its production process, which can solve the problems of high raw material cost, gradual blackening of ferrule blanks, and low production efficiency, and achieve strong environmental adaptability, The effect of overcoming the blank shape of the ferrule and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] Example 1 A zirconia ceramic ferrule and its production process

[0081] This embodiment is a zirconia ceramic ferrule and its production process, wherein the ingredients of the zirconia ceramic ferrule are embodied in the process steps, and the specific production process is carried out according to the following steps:

[0082] (11) dry

[0083] Dry 80kg of nano-sized zirconia ceramic powder to obtain A1;

[0084] (12) Mixing

[0085] Divide A1 into two parts, one part is A11, the other part is A12, adjust the temperature of the mixer to 180°C, add A11 into the mixer, and add 3kg ethylene-vinyl acetate copolymer, 4kg Oleic acid, 3kg polymethacrylate, 2kg random polypropylene, 5kg paraffin, and A12 were added into the mixing chamber in four stages. When adding zirconia ceramic powder in each stage, the materials in the mixing chamber in the previous stage were After mixing evenly, add 20kg in the first stage, 10kg in the second stage, 5kg in the third stage, 5kg in...

Embodiment 2-6

[0103] Example 2-6 Zirconia ceramic ferrule and its production process

[0104] Examples 2-6 are respectively a zirconia ceramic ferrule and its production process. The raw materials and ingredients used in them are shown in Table 1. The production process of the zirconia ceramic ferrule is the same as that of Example 1, the only difference being: The corresponding technical parameters in the production process are different, and the specific values are shown in Table 2.

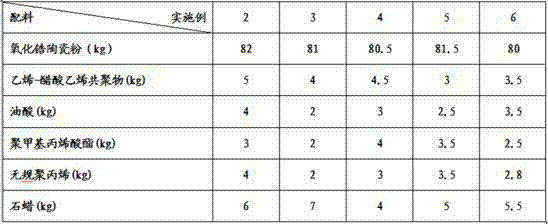

[0105] Table 1 Ingredients list of zirconia ceramic ferrule

[0106]

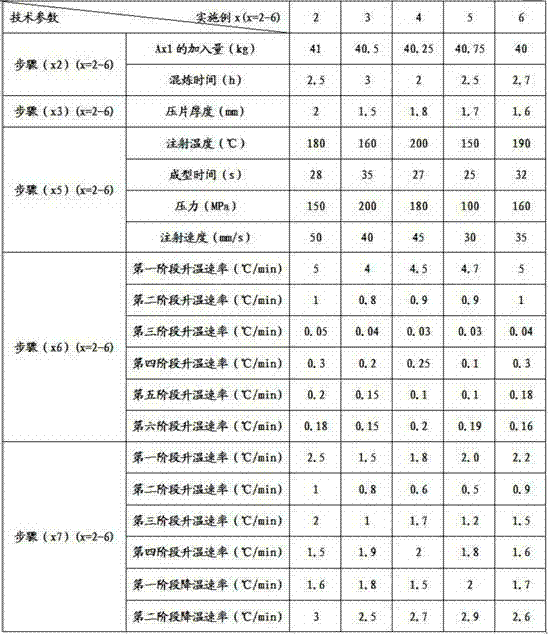

[0107] Table 2 Control parameters in the production process of zirconia ceramic ferrule

[0108]

[0109] In the preparation process of the above-mentioned zirconia ceramic ferrule, the mixing process of step (x2) (x=2-6) is:

Embodiment 2

[0110] In Example 2, A22 was added into the mixing chamber in four stages, 20.5kg was added in the first stage, 10.25kg was added in the second stage, 5.125kg was added in the third stage, and 5.125kg was added in the fourth stage;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com