Prestressed mud jacking trolley and circulating mud jacking method

A grouting trolley and prestressing technology, applied in the direction of erecting/assembling bridges, bridge materials, bridges, etc., can solve the problem of uncompact grouting of prestressed pipelines, and achieve the effect of ensuring the quality of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

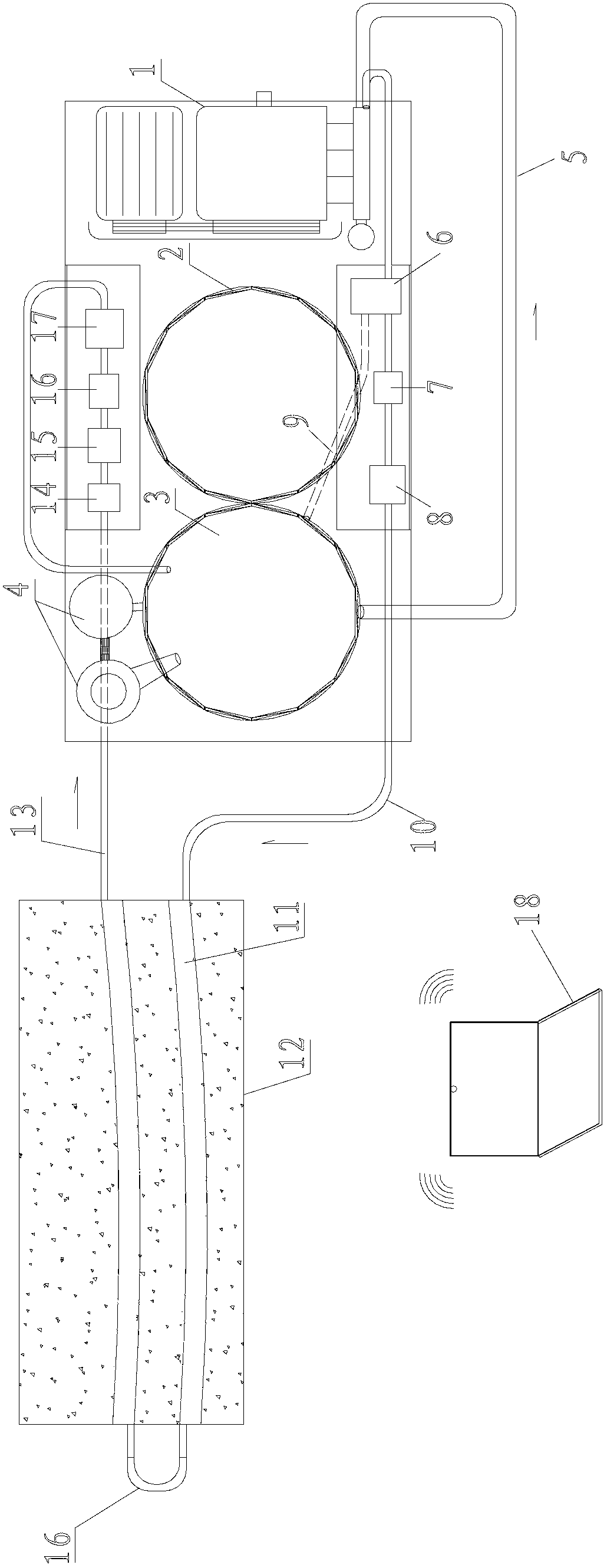

[0041] see figure 1 , a prestressed grouting trolley, including a mortar pump 1, a low-speed slurry storage tank 3, a water-binder ratio tester 4, a pressure sensor (7, 15), an electromagnetic flowmeter (8, 17), a slurry inlet-overflow Valve 6, slurry return valve 14, pressure regulating valve 16 and computer 18.

[0042] The water-binder ratio tester 4 is connected with the low-speed slurry storage tank 3 to facilitate the measurement of the water-binder ratio of the slurry in the low-speed slurry storage tank 3 at any time. The low-speed slurry storage tank 3 is connected to the mortar pump 1 through the slurry suction pipe 5, and the mortar pump 1 is connected to the prestressed pipeline 11 of the object to be constructed 12 through the slurry inlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com