Neutron irradiation preventing low-hydration-heat barite concrete

A technology for preventing neutron radiation and low heat of hydration, applied in the field of concrete, can solve the problems of inability to prevent neutron radiation, difficult-to-protect structure, and high heat of hydration, and achieve a good effect of preventing neutron radiation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

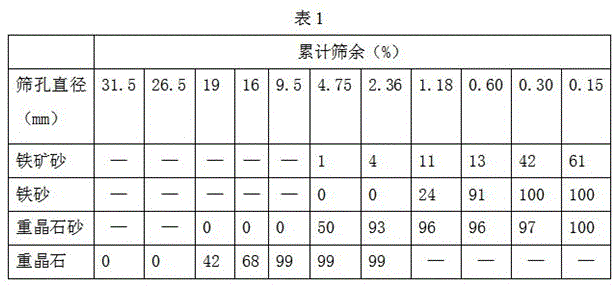

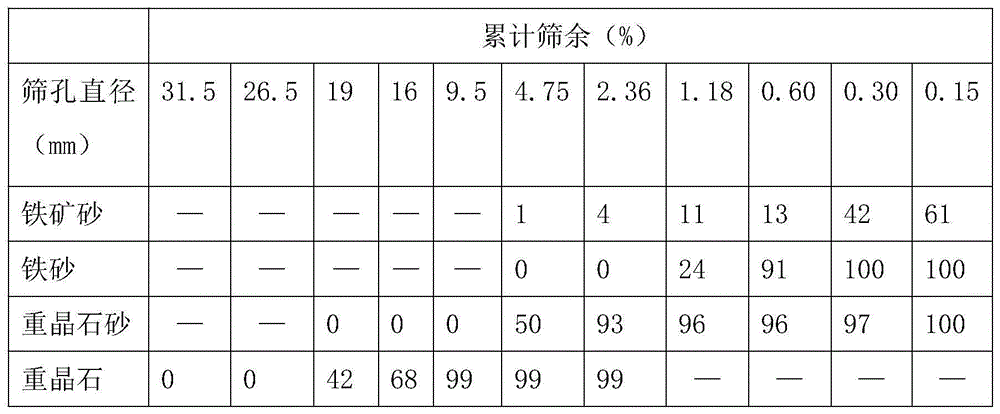

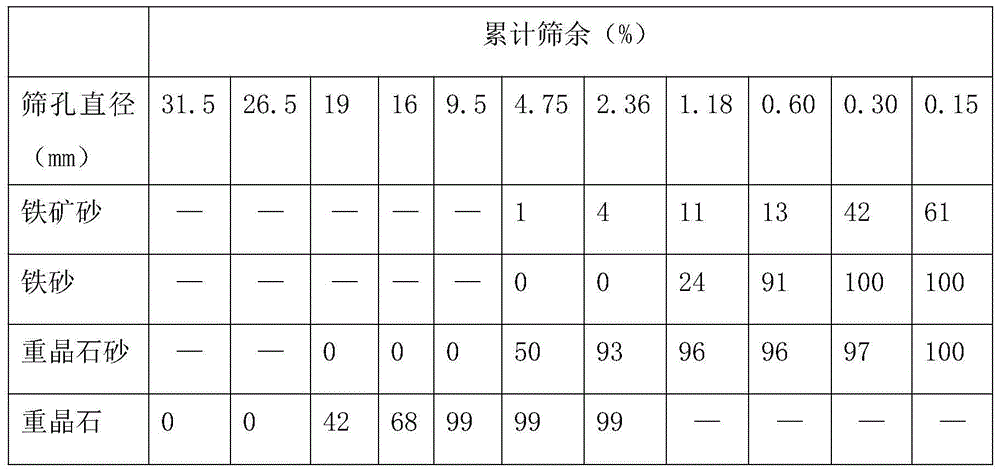

[0021] A kind of anti-neutron radiation barite concrete with low heat of hydration, including water, P·O42.5R cement, S95 grade granulated blast furnace slag powder, boron glass powder with a particle size of 320#, iron ore, iron sand, heavy spar, barite sand, polypropylene fiber, polycarboxylate water reducing agent, wherein barite, barite sand, iron ore, iron sand are aggregates; wherein, the water content of the iron ore is between Between 2.1% and 21.2%, the apparent density is 3104kg / m 3 , the mud content is 19.64%, the mud content is 9.9%, and the fineness modulus is 1.29; the apparent density of the iron sand is 7460kg / m 3 , the fineness modulus is 3.15; the apparent density of the barite sand is 4303kg / m 3 , the mud content is 2.78%, the mud content is 1.5%, and the fineness modulus is 4.58; the barite is 5-25mm continuous gradation, and the apparent density is 4137kg / m 3 , the mud content is 0.27%, the mud content is 0.2%, the needle flake particles are 0%, and the ...

Embodiment 2

[0024] The material that present embodiment adopts is similar to embodiment 1, difference is: described water, cement, slag powder, boron glass powder, iron ore, iron sand, barite, barite sand, polypropylene fiber, polycarboxylic acid The component contents of the superplasticizer are: water 163.8kg / m 3 , cement 250kg / m 3 , slag powder 90kg / m 3 , boron glass powder 10kg / m 3 , iron ore 900kg / m 3 , iron sand 350kg / m 3 , Barite 1558kg / m 3 , barite sand 330kg / m 3 , polypropylene fiber 0.9kg / m 3 , Polycarboxylate water reducer 16.32kg / m 3 ; Among them, the thickness gradation of the aggregate conforms to the attached figure 1 Requirements shown in Table 1.

[0025] The apparent density of the low heat of hydration barite concrete of the present embodiment to prevent neutron radiation is 3669.02kg / m 3 , (R28) strength is 43.6MPa, retained crystal water is 113kg / m 3 , can achieve a better anti-neutron radiation effect; when used in a mass concrete structure with a minimum ...

Embodiment 3

[0027] The material that present embodiment adopts is similar to embodiment 1, difference is: described water, cement, slag powder, boron glass powder, iron ore, iron sand, barite, barite sand, polypropylene fiber, polycarboxylic acid The component contents of the superplasticizer are: water 163.8kg / m 3 , cement 280kg / m 3 , slag powder 90kg / m 3 , boron glass powder 10kg / m 3 , iron ore 850kg / m 3 , iron sand 350kg / m 3 , Barite 1600kg / m 3 , barite sand 300kg / m 3 , polypropylene fiber 0.9kg / m 3 , polycarboxylate water reducer 18.5kg / m 3 ; Among them, the thickness gradation of the aggregate conforms to the attached figure 1 Requirements shown in Table 1.

[0028] The apparent density of the low-heat-of-hydration barite concrete against neutron radiation in this embodiment is 3663.2kg / m 3 , (R28) strength is 44.2MPa, retained crystal water is 112kg / m 3 , can achieve a better anti-neutron radiation effect; when used in a mass concrete structure with a minimum geometric si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com