Rigid plugging method for mine tailings pond drainage well

A technology for drainage wells and tailings ponds, which is applied in construction, infrastructure engineering, etc., and can solve problems such as plugging failure, construction quality defects, and high thrust of the plugging body, so as to reduce the possibility of leakage, and the implementation is simple and fast. Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

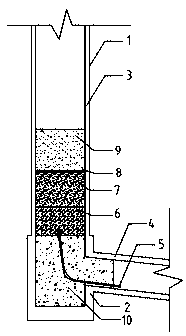

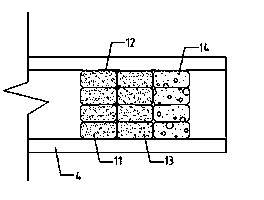

[0025] Referring to the accompanying drawings, the rigid sealing method for drainage wells of mine tailings ponds in this embodiment is to cast in-situ concrete blocking blocks 10 at the junction of drainage well 1 (including well base 2 and derrick 3) and drainage tunnel 4, during the pouring process Pre-buried the drainage steel pipe 5, and set a pebble layer 6 on the concrete block 10, set a sand and gravel layer 7 on the pebble layer 6, set a non-woven geotextile layer Ⅰ8 on the sand and gravel layer 7, and set a non-woven geotextile layer Ⅰ8. A thick tailing sand layer 9 is set, and the inlet end of the drainage steel pipe 5 is wrapped with 3 layers of non-woven geotextiles, placed in the pebble layer 6 above the concrete block in the drainage well section, and the outlet end of the drainage steel pipe 5 is wrapped with 2 layers of non-woven geotext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com