High-conductivity aluminum alloy plate extrusion forming device and technology

An aluminum alloy plate, extrusion forming technology, applied in the direction of metal extrusion dies, etc., can solve problems such as cracks, achieve the effects of improving stress conditions, increasing deformation texture, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

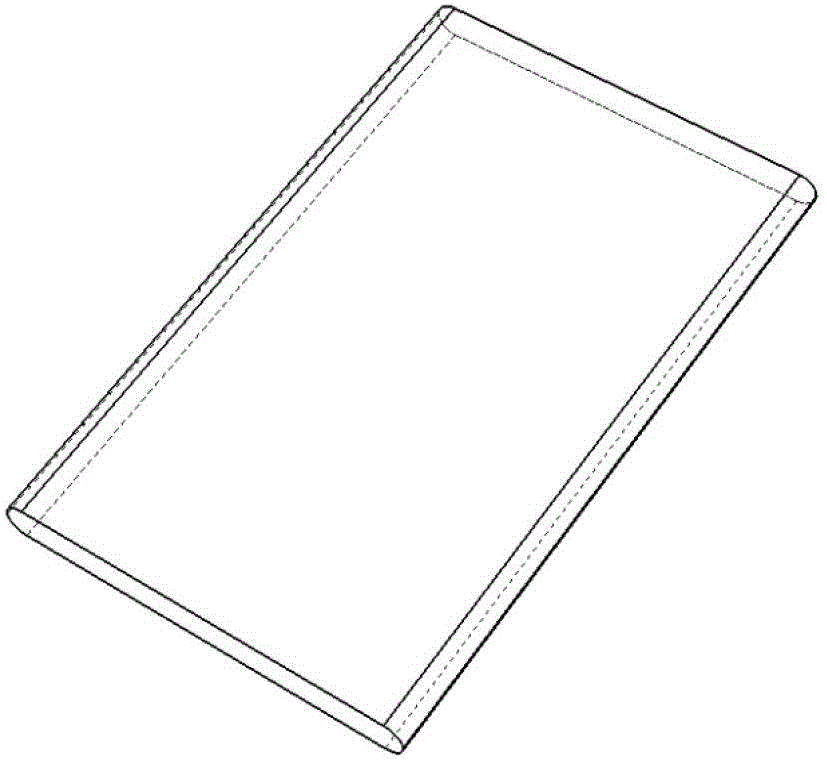

[0021] Using 6061 / 6063 aluminum alloy as the matrix to prepare such as figure 1 The conductivity shown is greater than 57% IACS aluminum alloy sheet.

[0022] First, melt the 6061 / 6063 aluminum alloy ingot with a melting furnace suitable for melting aluminum-silicon alloy, put the dried aluminum alloy ingot into the crucible with tongs, and put the crucible into the melting furnace. When heated to 690°C, an Al-B alloy with a B content of 3% is put in, wherein the B element content is 0.05% (mass percentage) of the total alloy content. Press the Al-B alloy into the molten aluminum. After the molten aluminum is completely melted, stir fully to make the ingredients uniform. Let stand for 45 minutes to ensure that impurity elements are removed by precipitation. When the temperature of the molten aluminum reaches 710°C, remove the smelting scum in the crucible, and add Al-Ti-B alloy (the main component is AlTi5B1) as a refiner, and the amount added is 0.1%-0.3% of the aluminum ...

Embodiment 2

[0024] Using 6061 / 6063 aluminum alloy as the matrix to prepare such as figure 1 The conductivity shown is greater than 57% IACS aluminum alloy sheet.

[0025] First, melt the 6061 / 6063 aluminum alloy ingot with a melting furnace suitable for melting aluminum-silicon alloy, put the dried aluminum alloy ingot into the crucible with tongs, and put the crucible into the melting furnace. When heated to 700°C, an Al-B alloy with a B content of 3% is put in, wherein the B element content is 0.06% (mass percentage) of the total alloy content. Press the Al-B alloy into the molten aluminum. After the molten aluminum is completely melted, stir fully to make the ingredients uniform. Let stand for 60 minutes to ensure that impurity elements are removed by precipitation. When the temperature of the molten aluminum reaches 720°C, remove the smelting scum in the crucible, and add Al-Ti-B alloy (the main component is AlTi5B1) as a refiner, and the amount added is 0.1%-0.3% of the aluminum ...

Embodiment 3

[0027] Using 6061 / 6063 aluminum alloy as the matrix to prepare such as figure 1 The conductivity shown is greater than 57% IACS aluminum alloy sheet.

[0028] First, melt the 6061 / 6063 aluminum alloy ingot with a melting furnace suitable for melting aluminum-silicon alloy, put the dried aluminum alloy ingot into the crucible with tongs, and put the crucible into the melting furnace. When heated to 720°C, an Al-B alloy with a B content of 3% is put in, wherein the B element content is 0.08% (mass percentage) of the total alloy content. Press the Al-B alloy into the molten aluminum. After the molten aluminum is completely melted, stir fully to make the ingredients uniform. Let stand for 75 minutes to ensure that impurity elements are removed by precipitation. When the temperature of the molten aluminum reaches 730°C, remove the smelting scum in the crucible, and add Al-Ti-B alloy (the main component is AlTi5B1) as a refiner, and the amount added is 0.1%-0.3% of the aluminum al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com