Patents

Literature

68results about How to "Improve mold life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

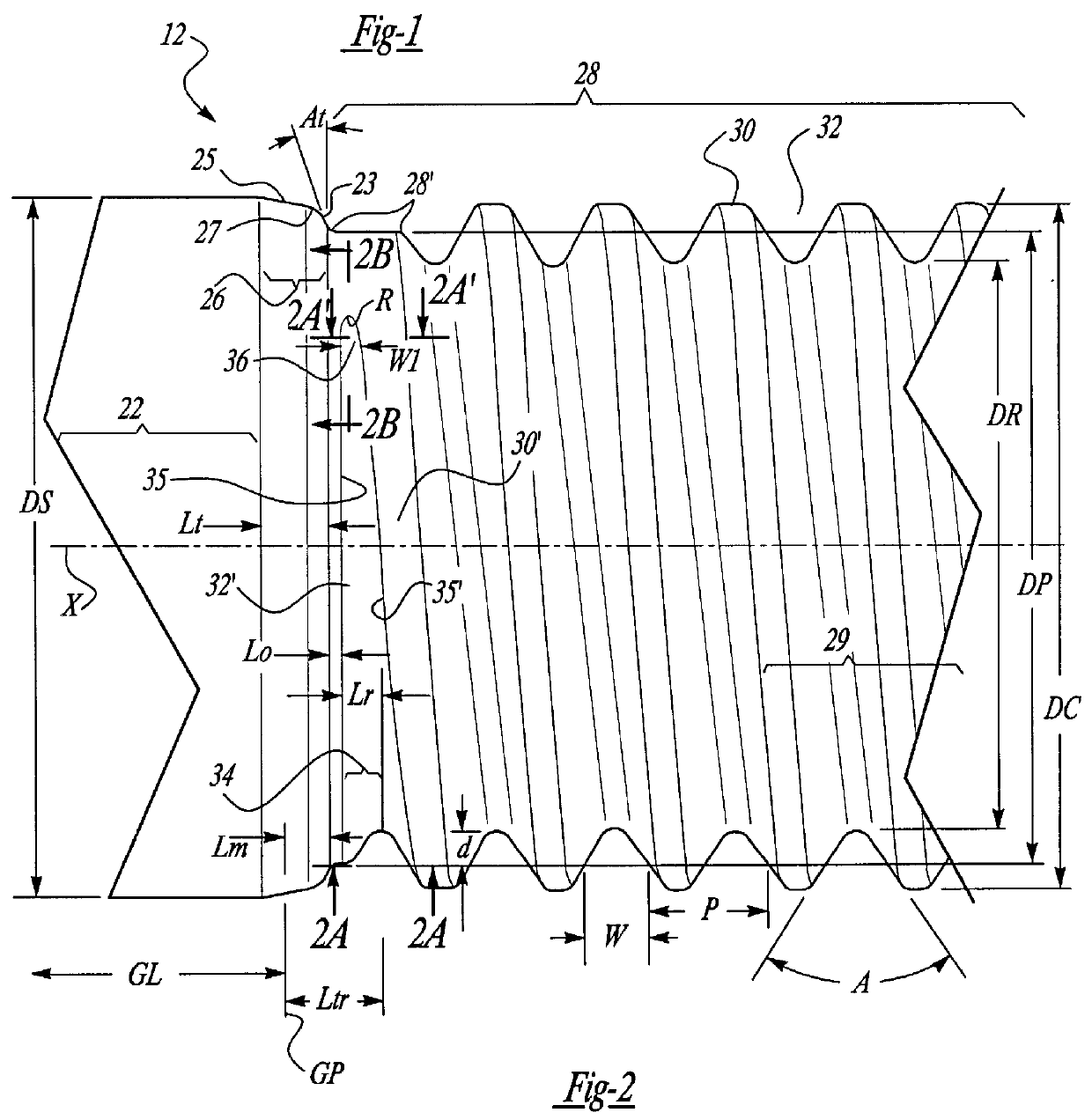

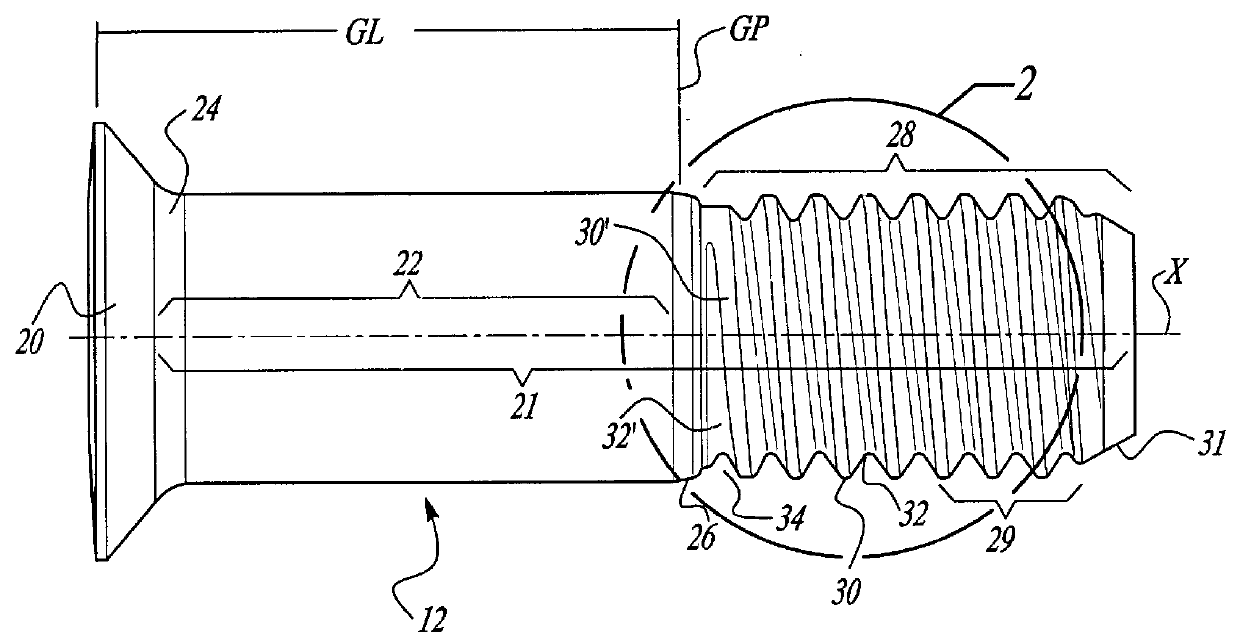

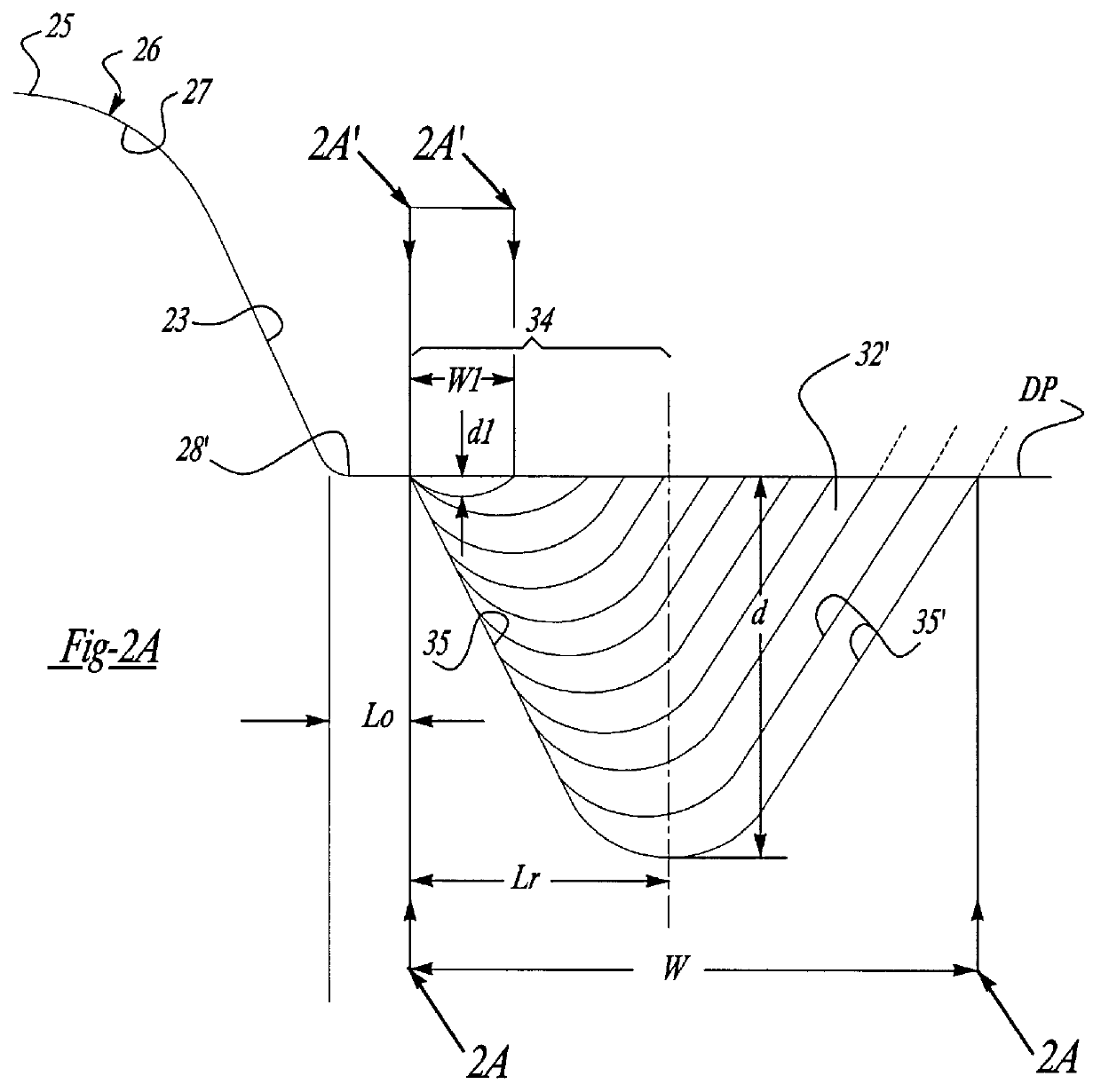

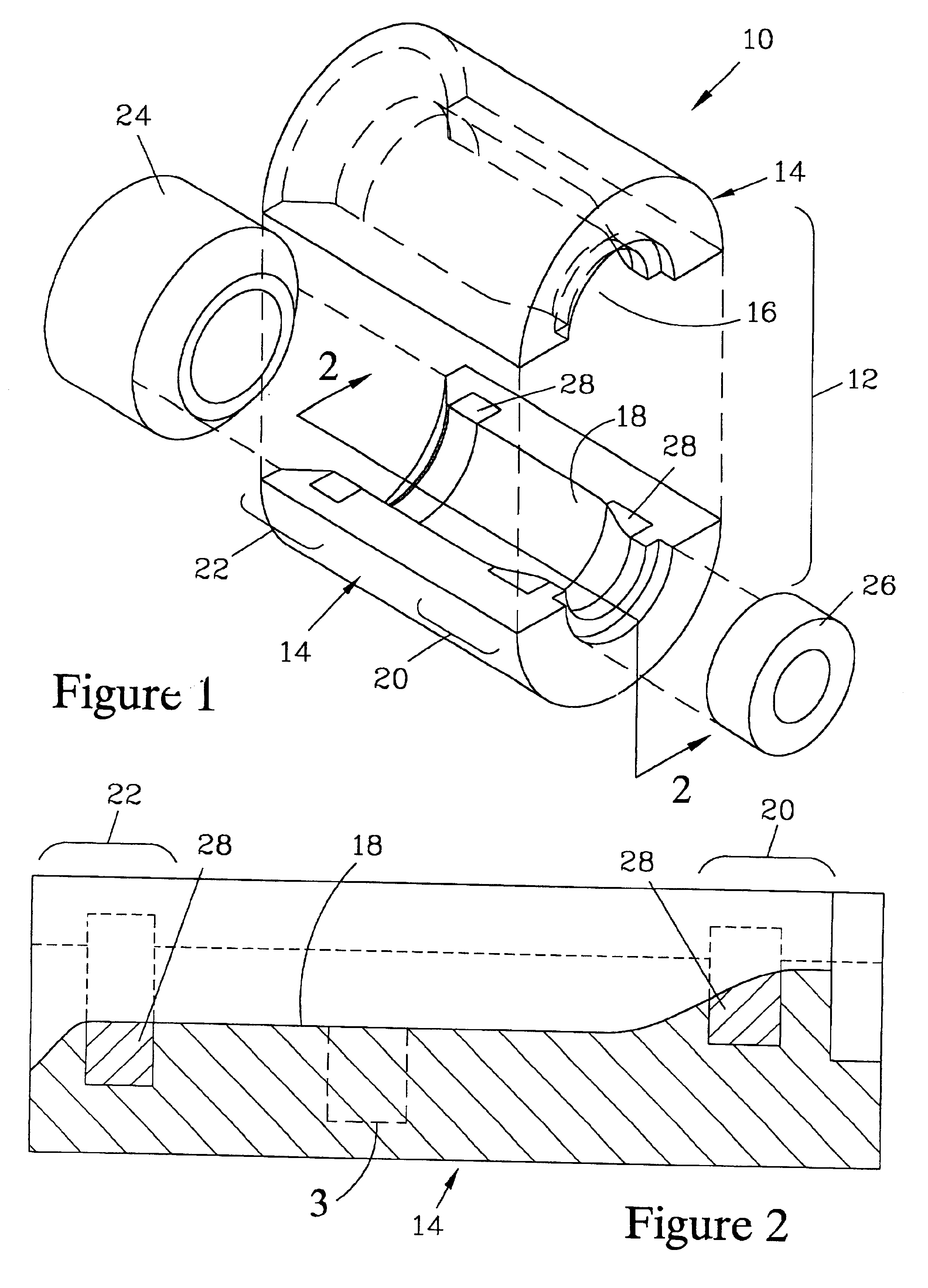

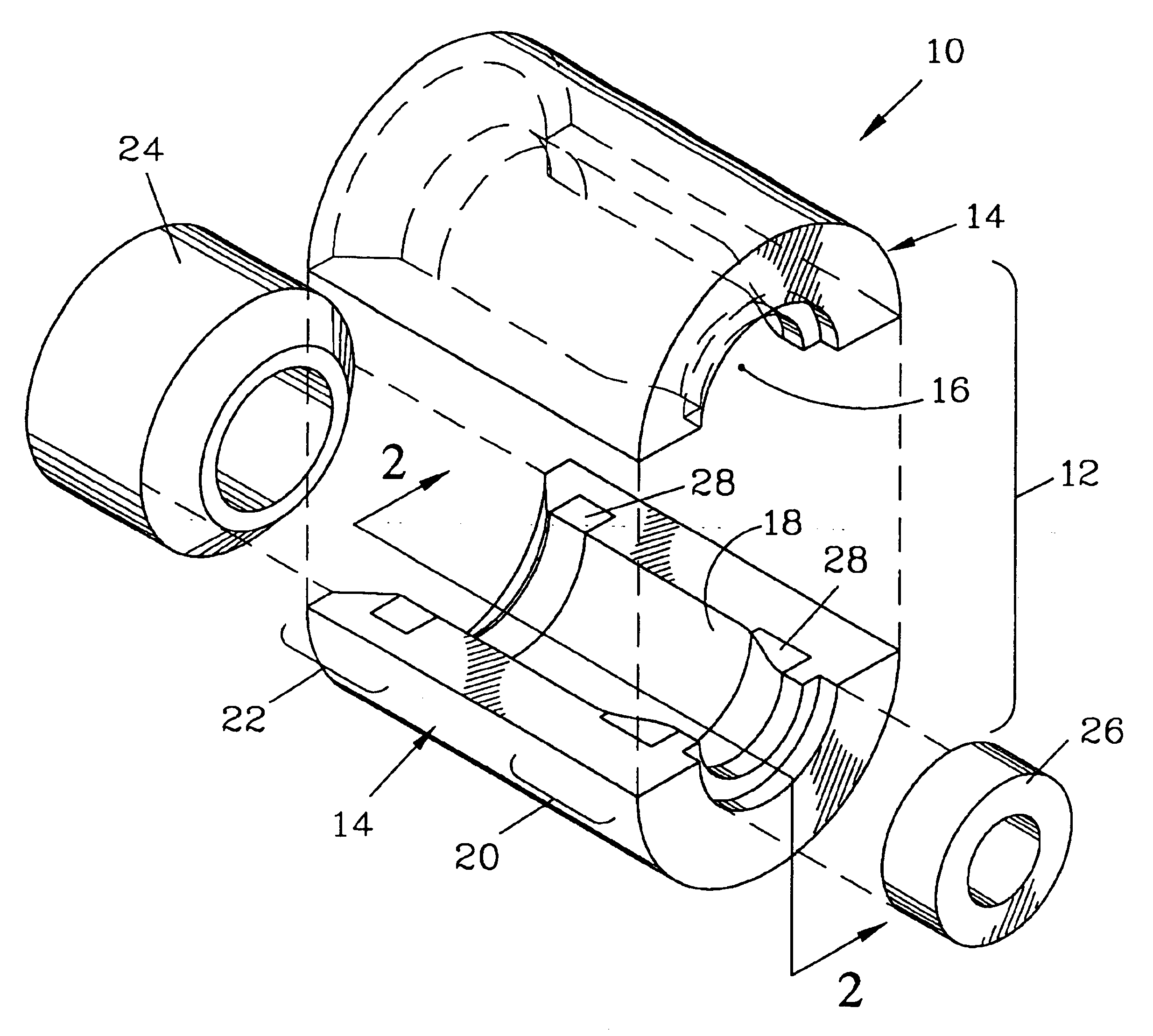

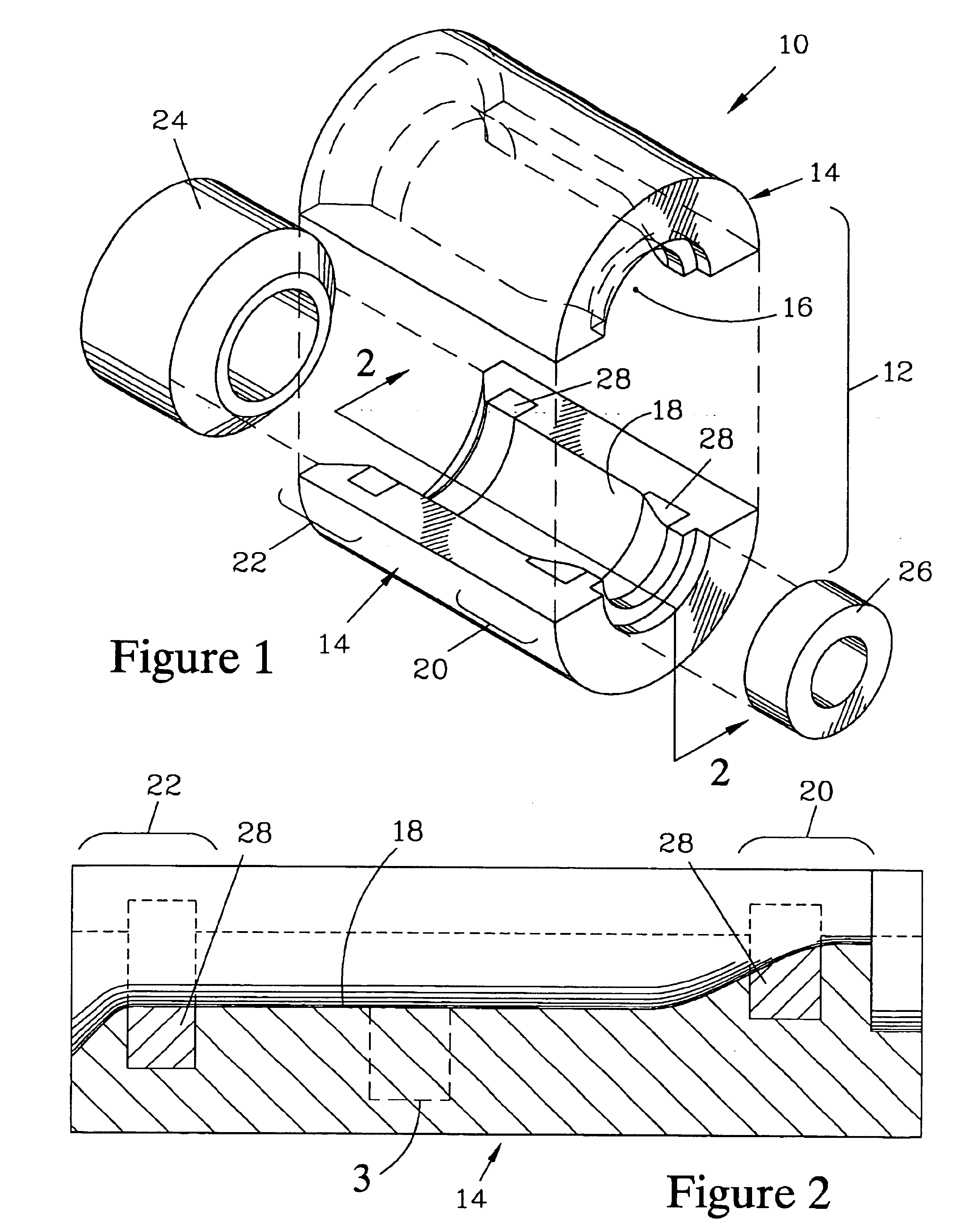

Lightweight threaded fastener and thread rolling die

InactiveUS6149363AImprove fatigue performanceImprove wear resistanceNutsBoltsEngineeringScrew thread

The present invention is to a lightweight threaded bolt type fastener having a shank with a large diameter portion and small diameter portion connected by a transition portion; a thread is roll formed on the small diameter portion and terminates in a run-out section where the thread gradually decreases in root depth and width and with the run-out section being of minimal axial length and being located closely adjacent the transition portion to produce a run-out zone of minimal axial length. A rolling die for forming the thread with minimal thread run-out having ridge segments with tapered end surfaces for providing the run-out thread with an end wall parallel to the transition portion and a method of making the bolt type fastener.

Owner:HUCK INT INC

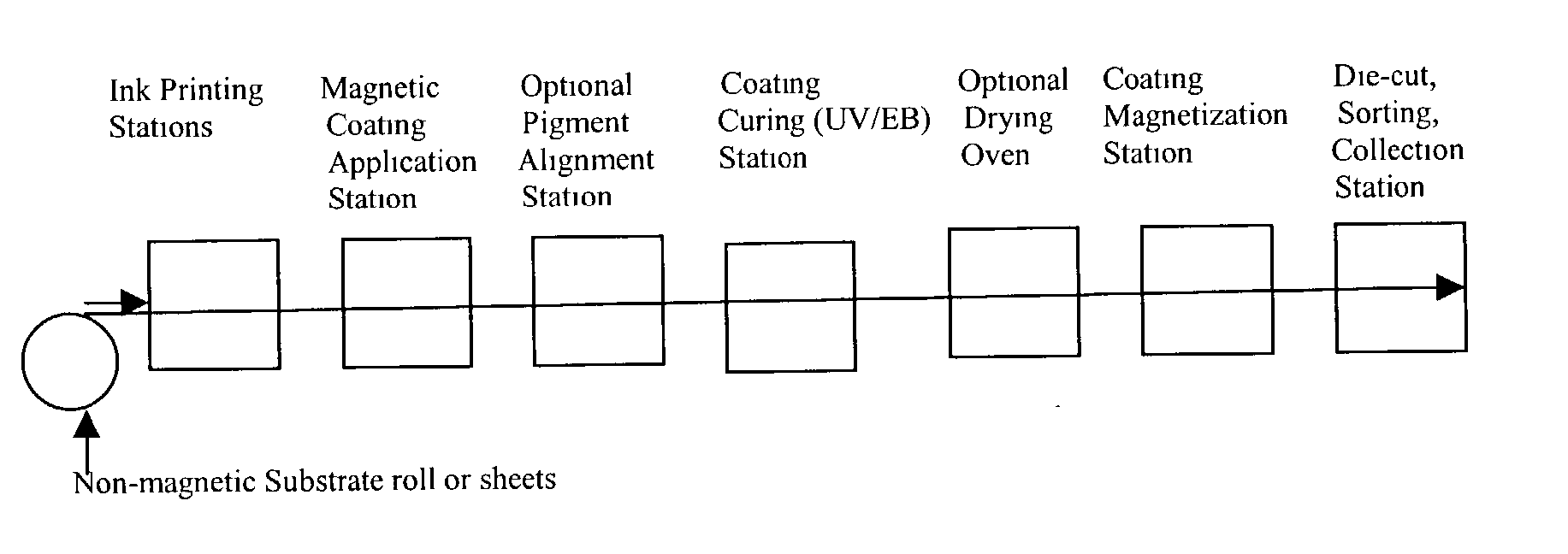

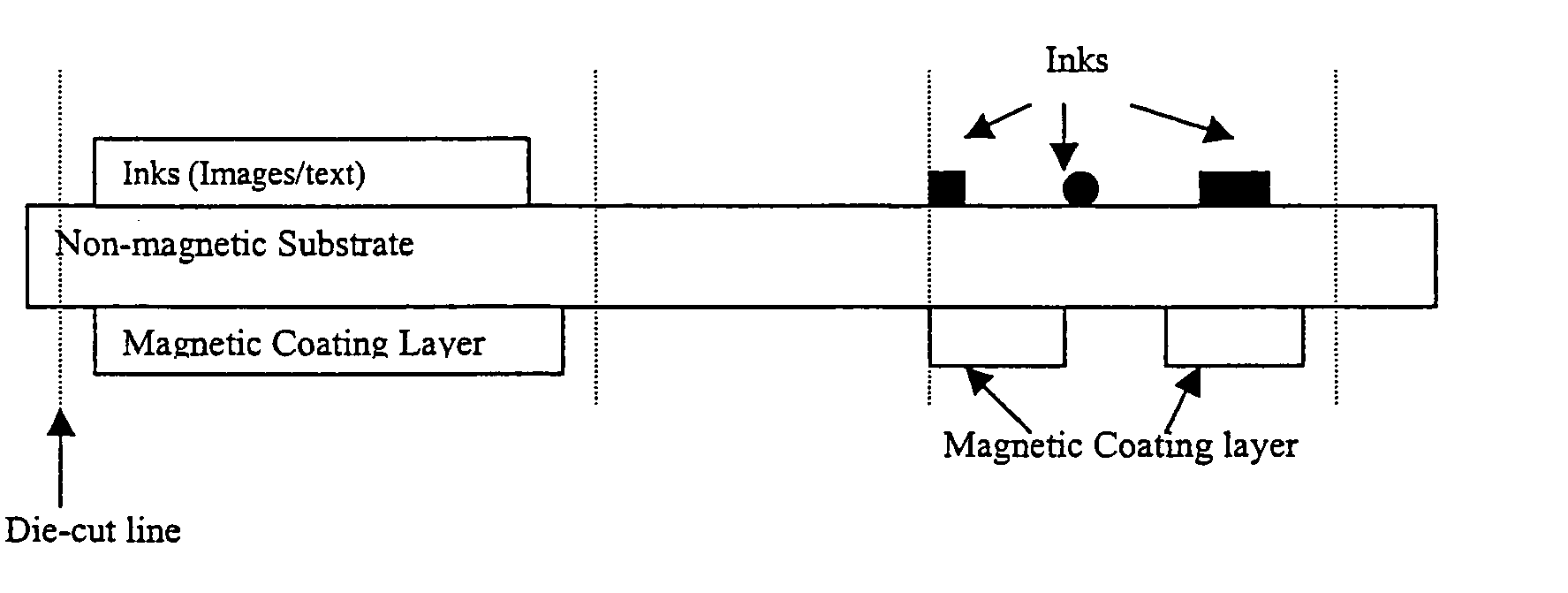

UV/EB cured integrated magnets-composition and method of fabrication

The present invention comprises a radiation curable composition for in-line printing containing magnetic pigments capable of being magnetized to possess permanent magnetic properties after the composition is cured. The composition is cured by an ionizing radiation source, preferably by UV light or electron beam radiation (UV / EB). The present invention is also directed to an in-line process for printing magnetic images on non-magnetic substrate, comprising: pattern applying the above mentioned radiation curable composition on the substrate opposite to a print side, pre-aligning the magnetic pigment particles (if necessary) of the applied composition, curing the composition by ionizing radiation source (UV / EB), magnetizing the cured composition, then finishing the final piece. The finishing step could involve delivering the final piece in a simple sheet with die cut magnets or creating an "integrated magnet" format involving plow folding over the magnet panel, pattern coating or flood coating an adhesive that will only adhere the non-magnet matrix areas between die cut magnets, thus, allowing for the individual magnets to be "popped" out of the carrier by the final end user. The resulting magnetized pieces will possess holding power like magnets (refrigerator and office magnets) and are capable of carrying personalized, Scitex imaged and direct marketing information (including redemption value for coupons, local public service access numbers, etc.)

Owner:SOVEREIGN SPECIALTY CHEM +1

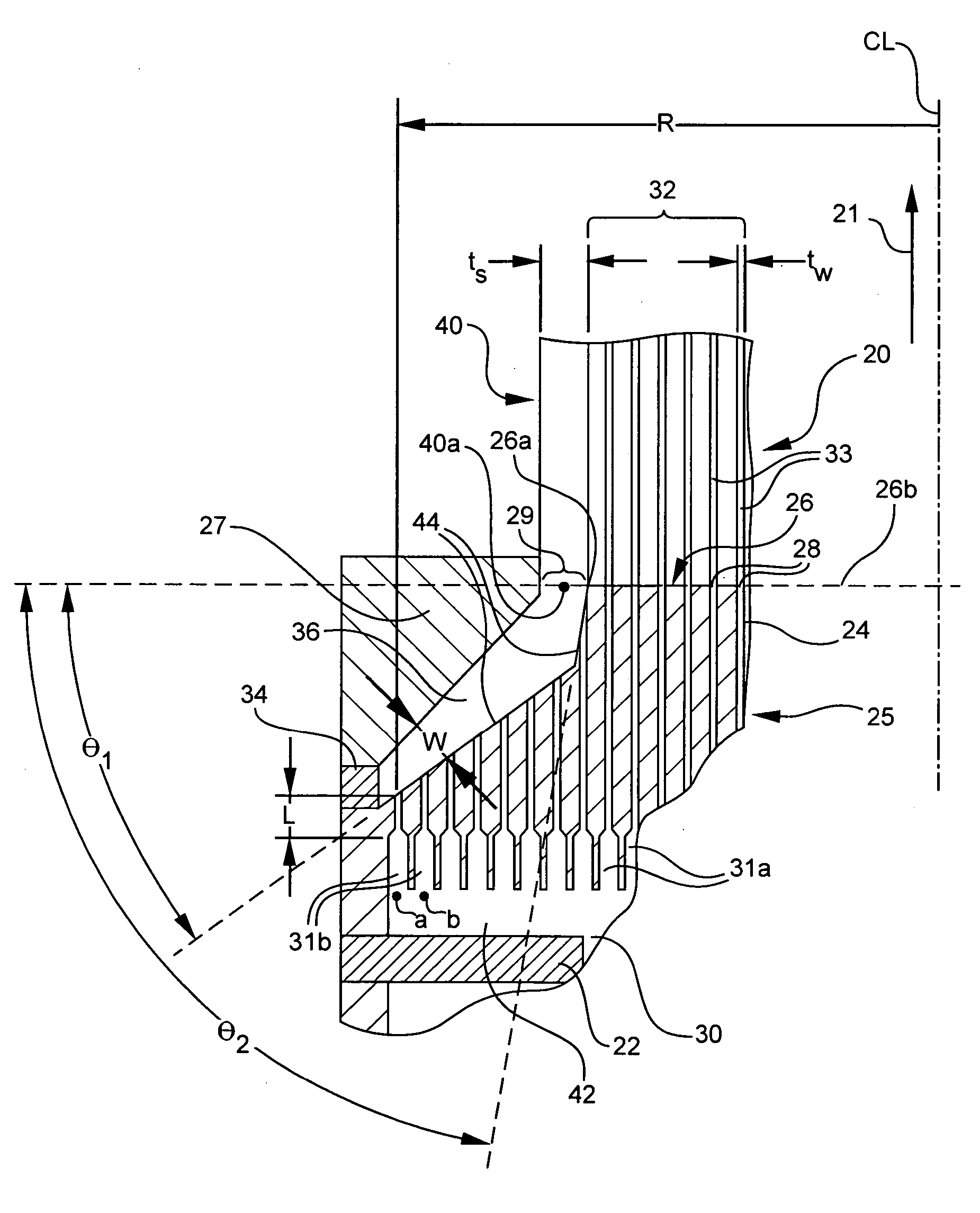

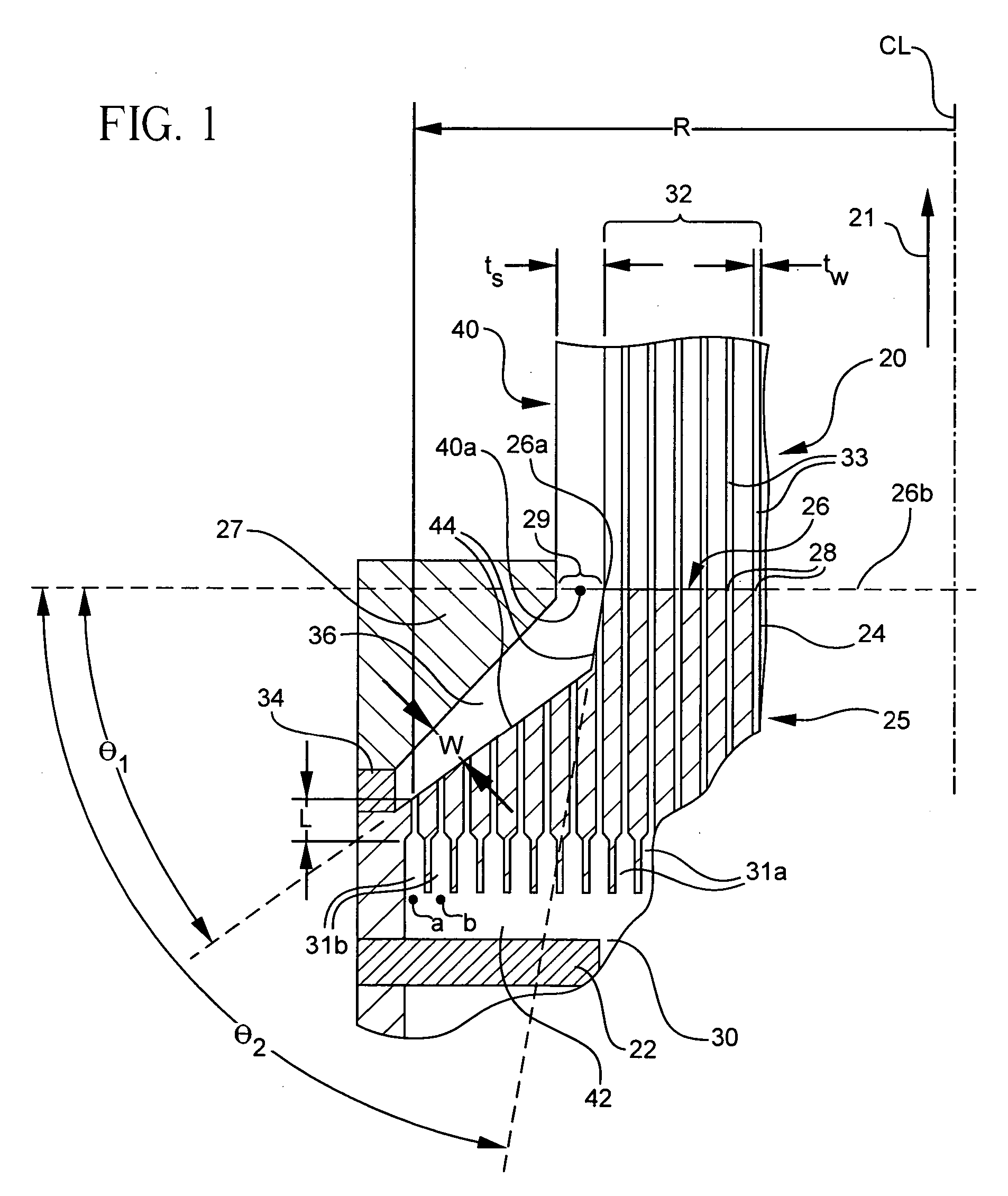

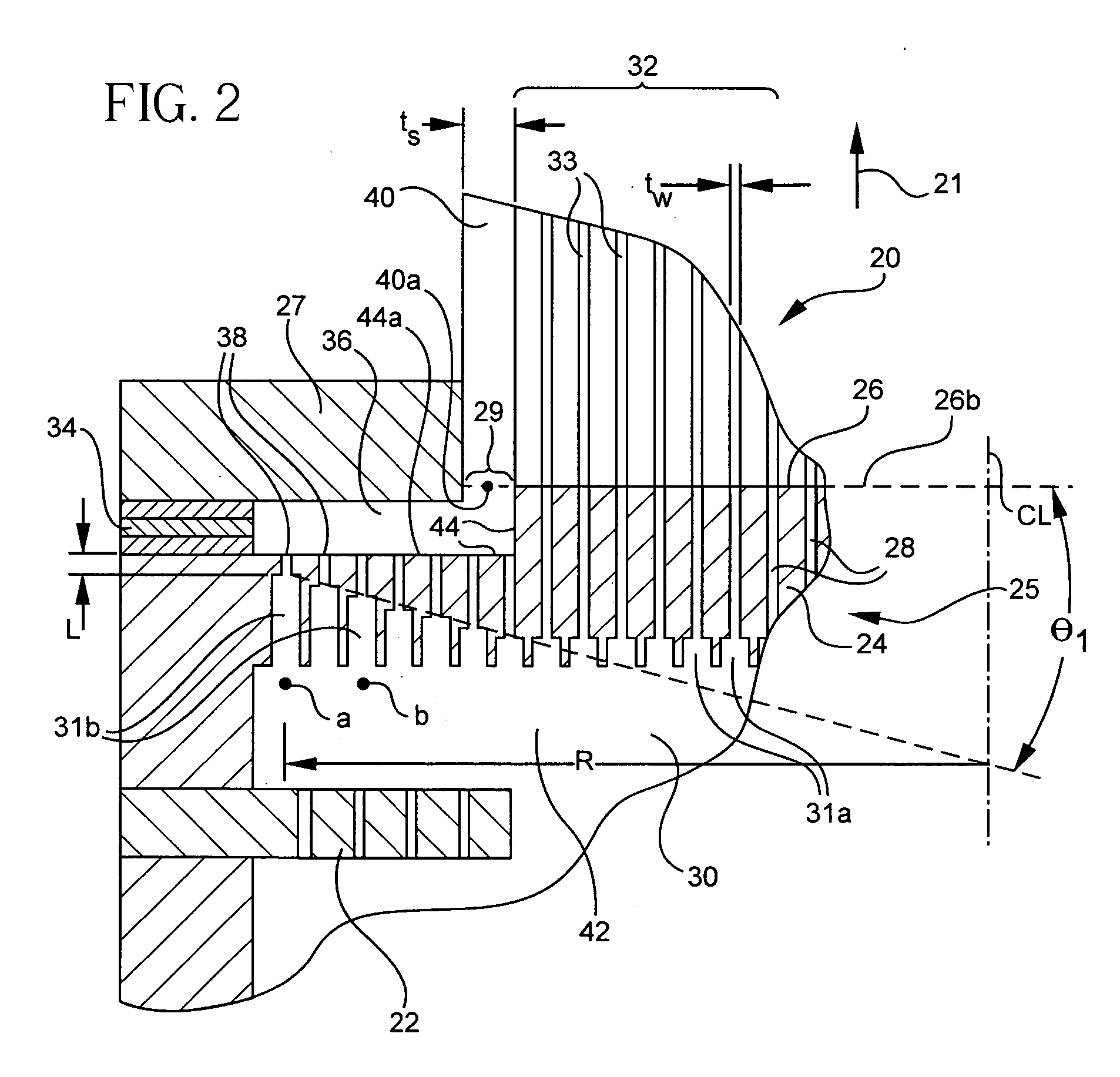

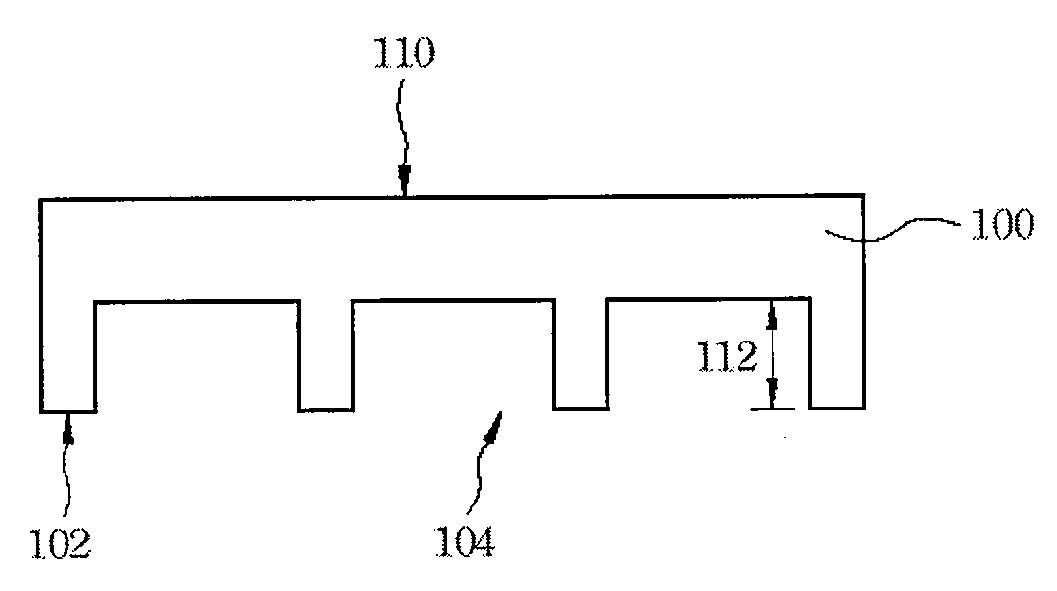

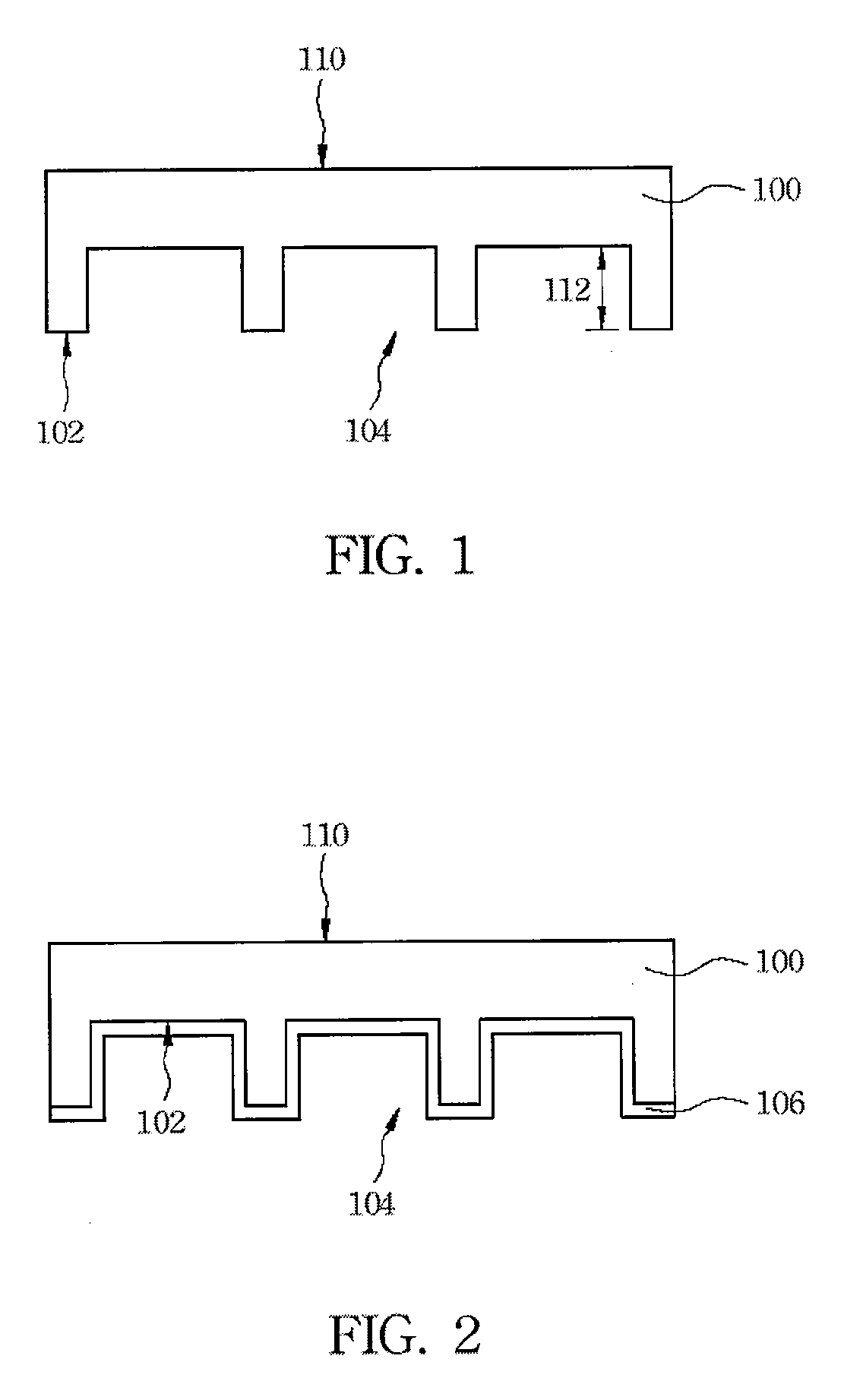

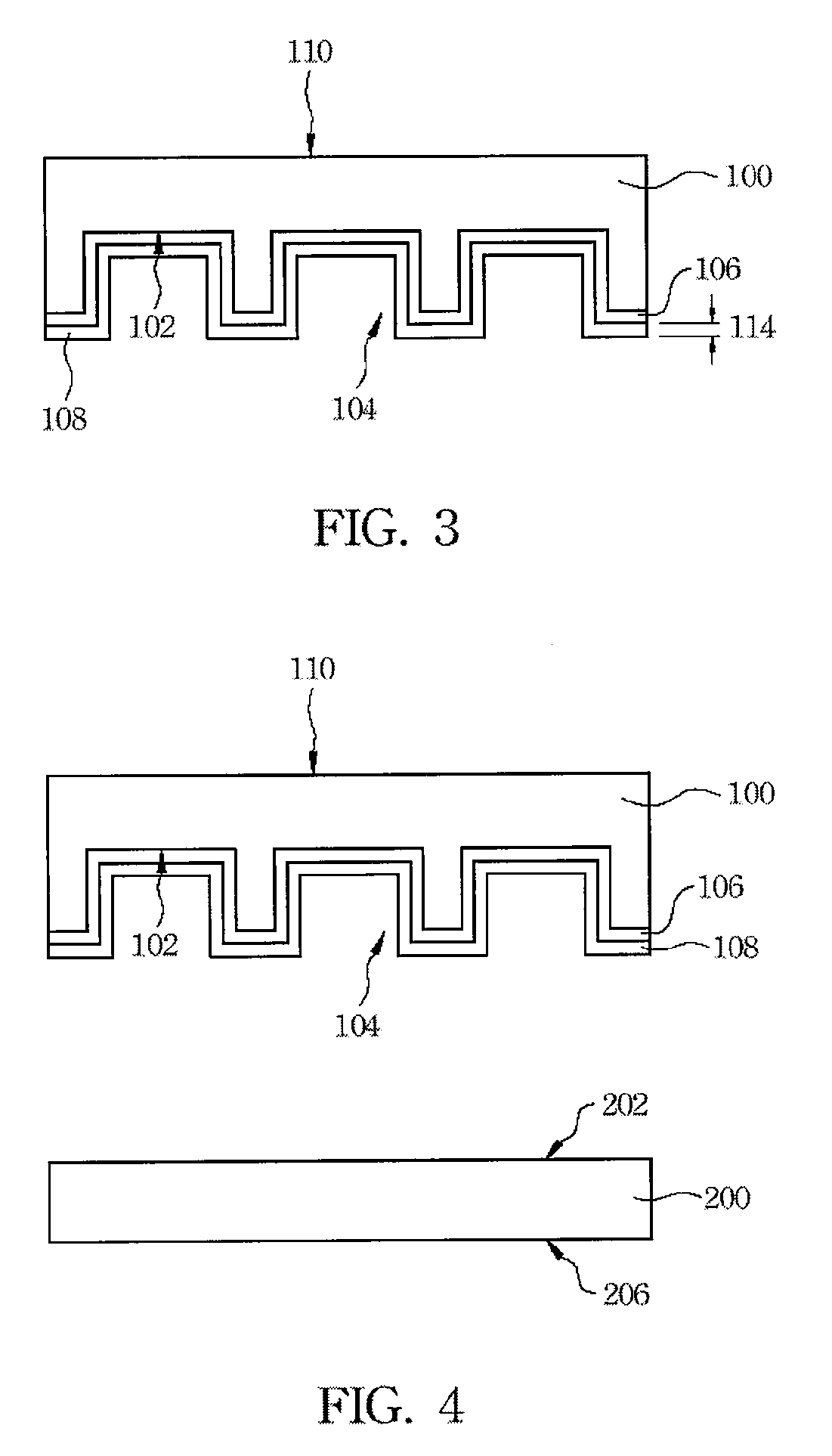

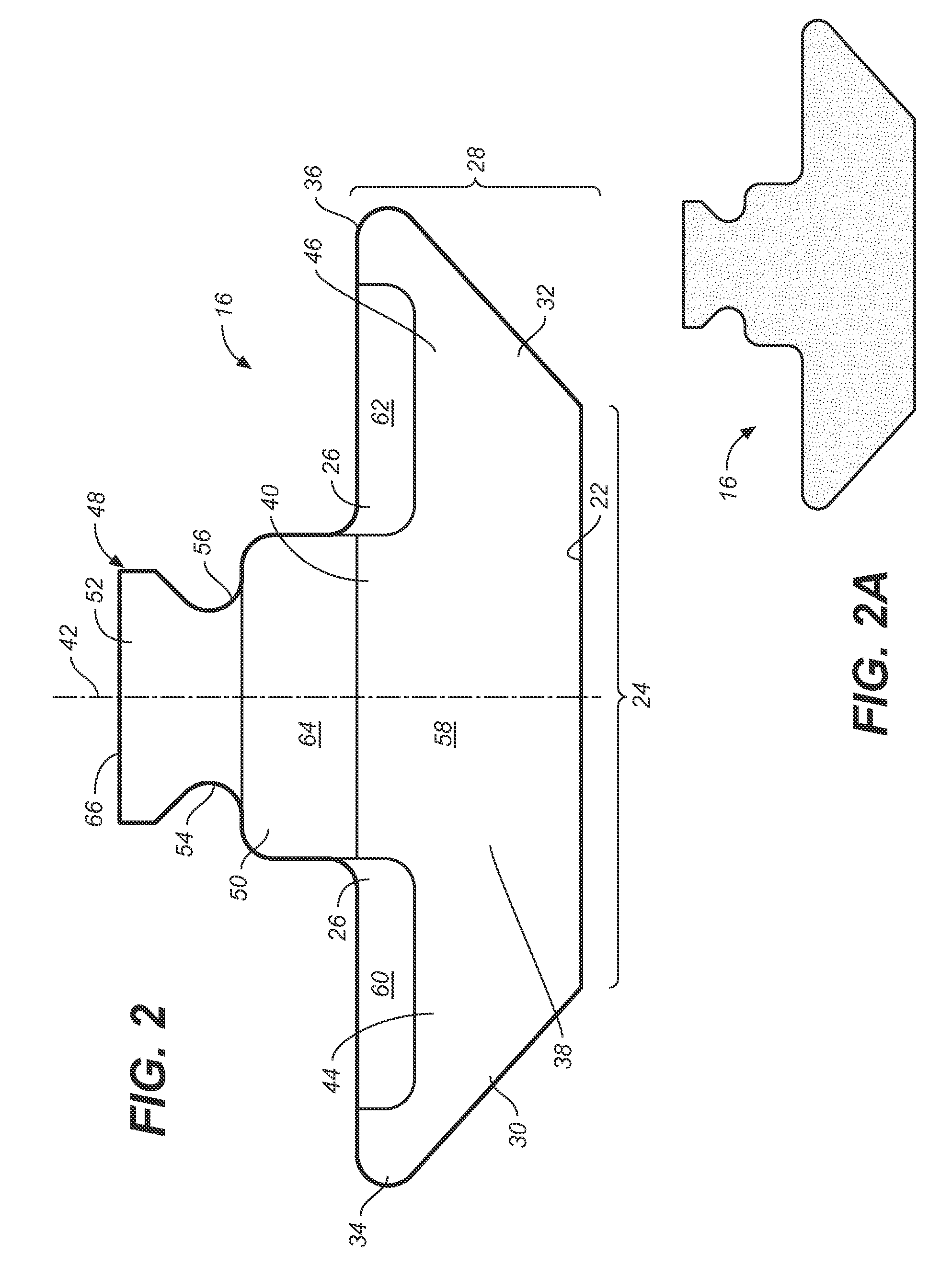

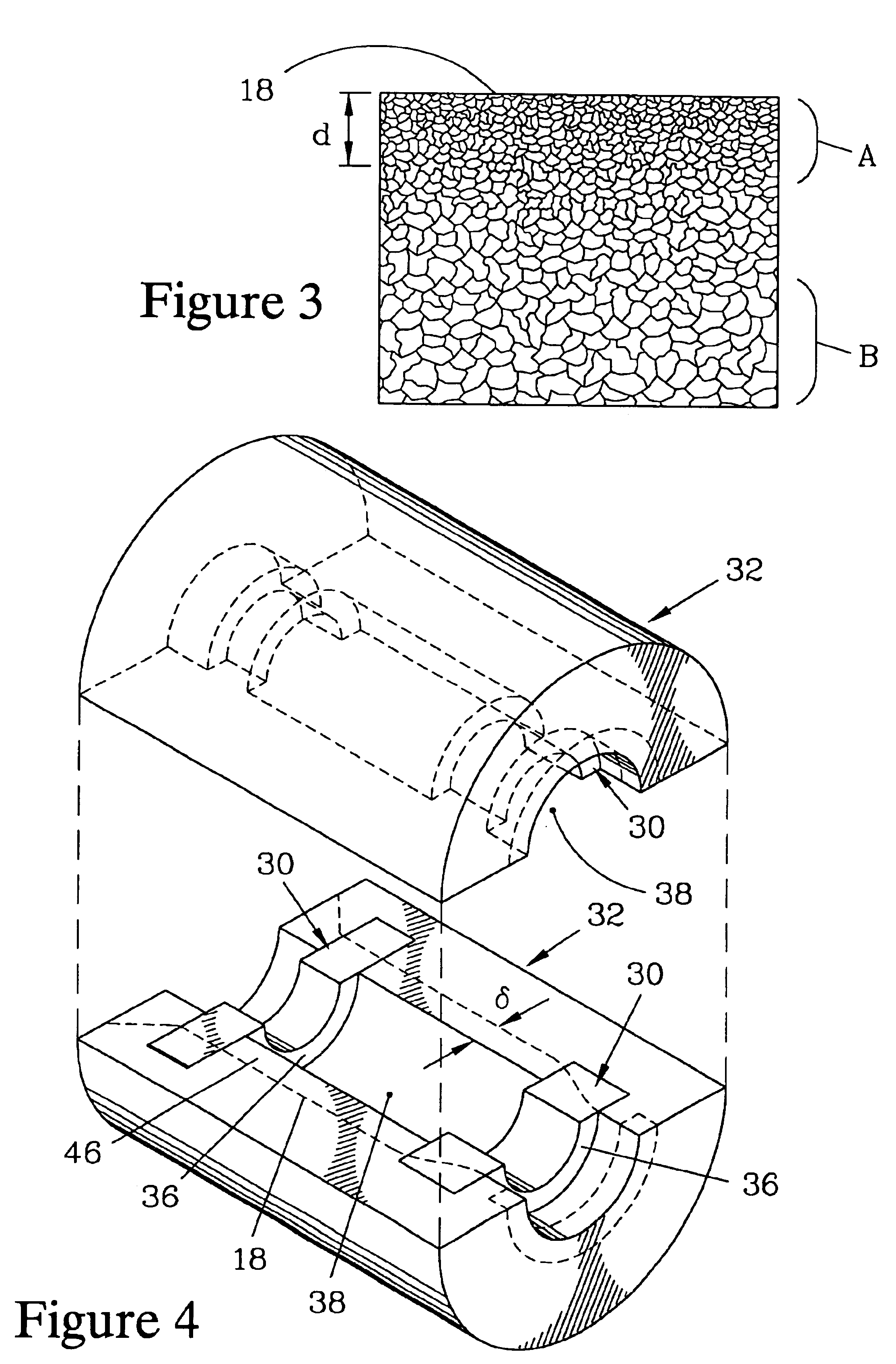

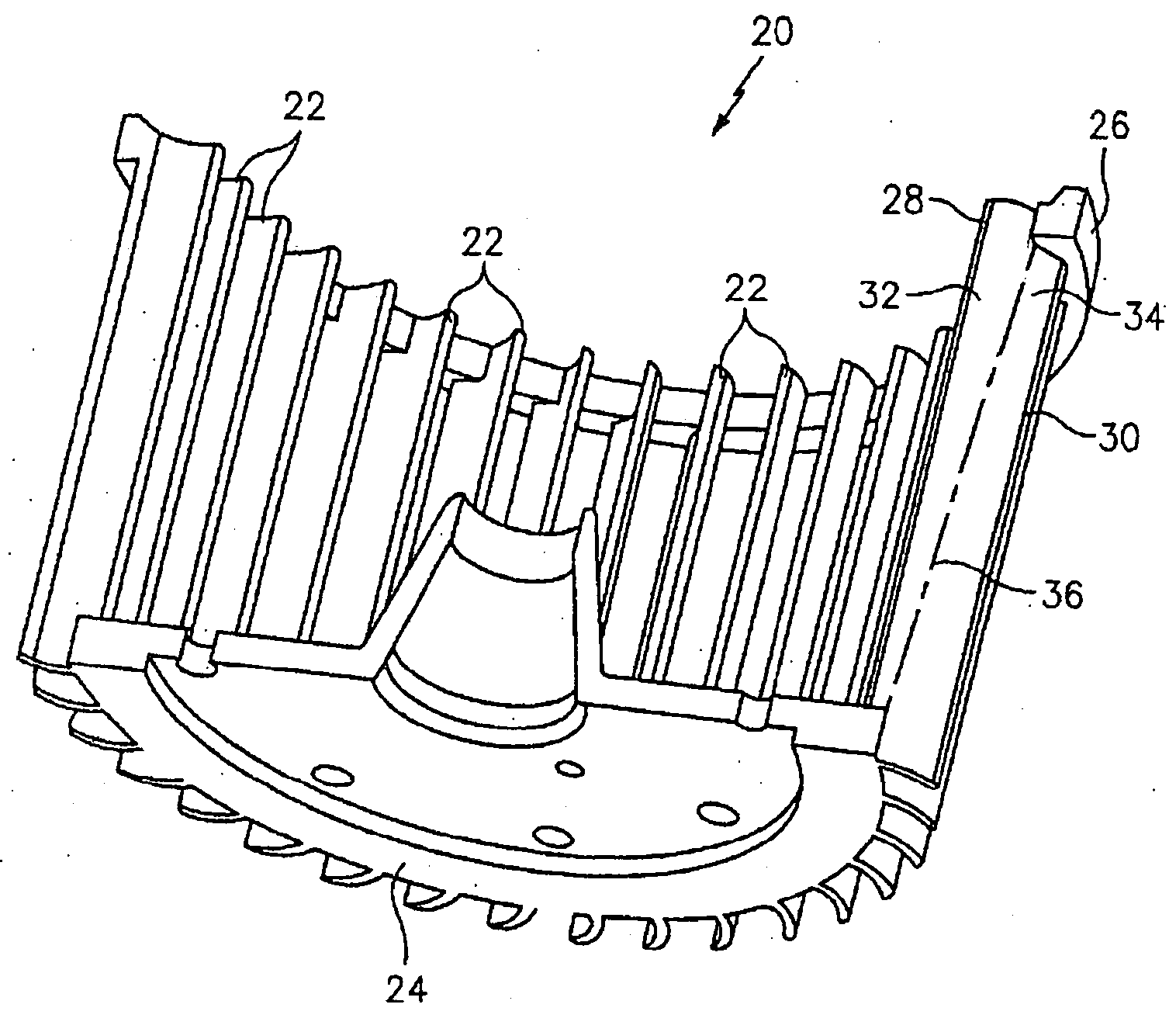

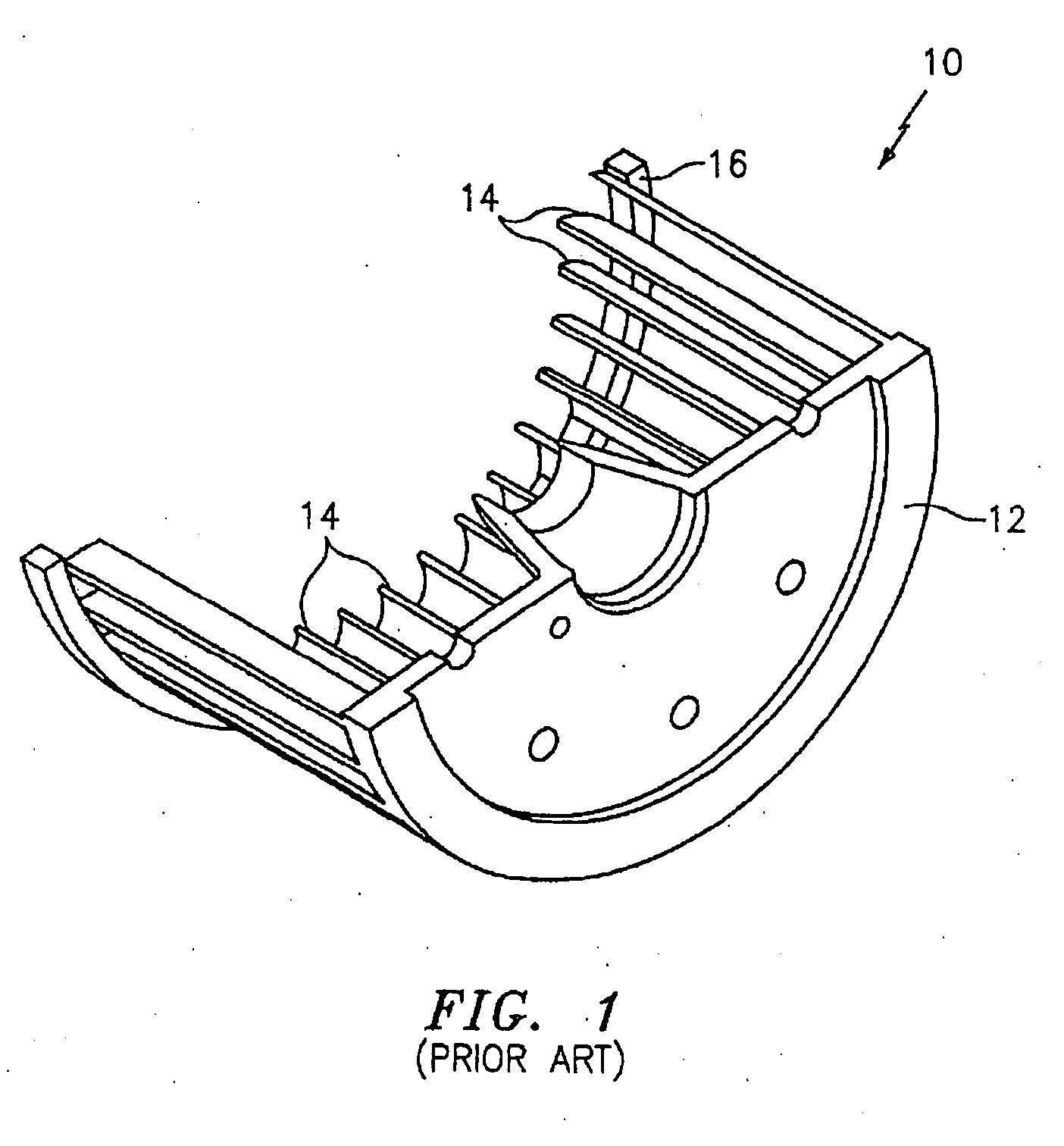

Method and apparatus for extruding honeycomb articles and thick-skinned ceramic honeycomb articles manufactured thereby

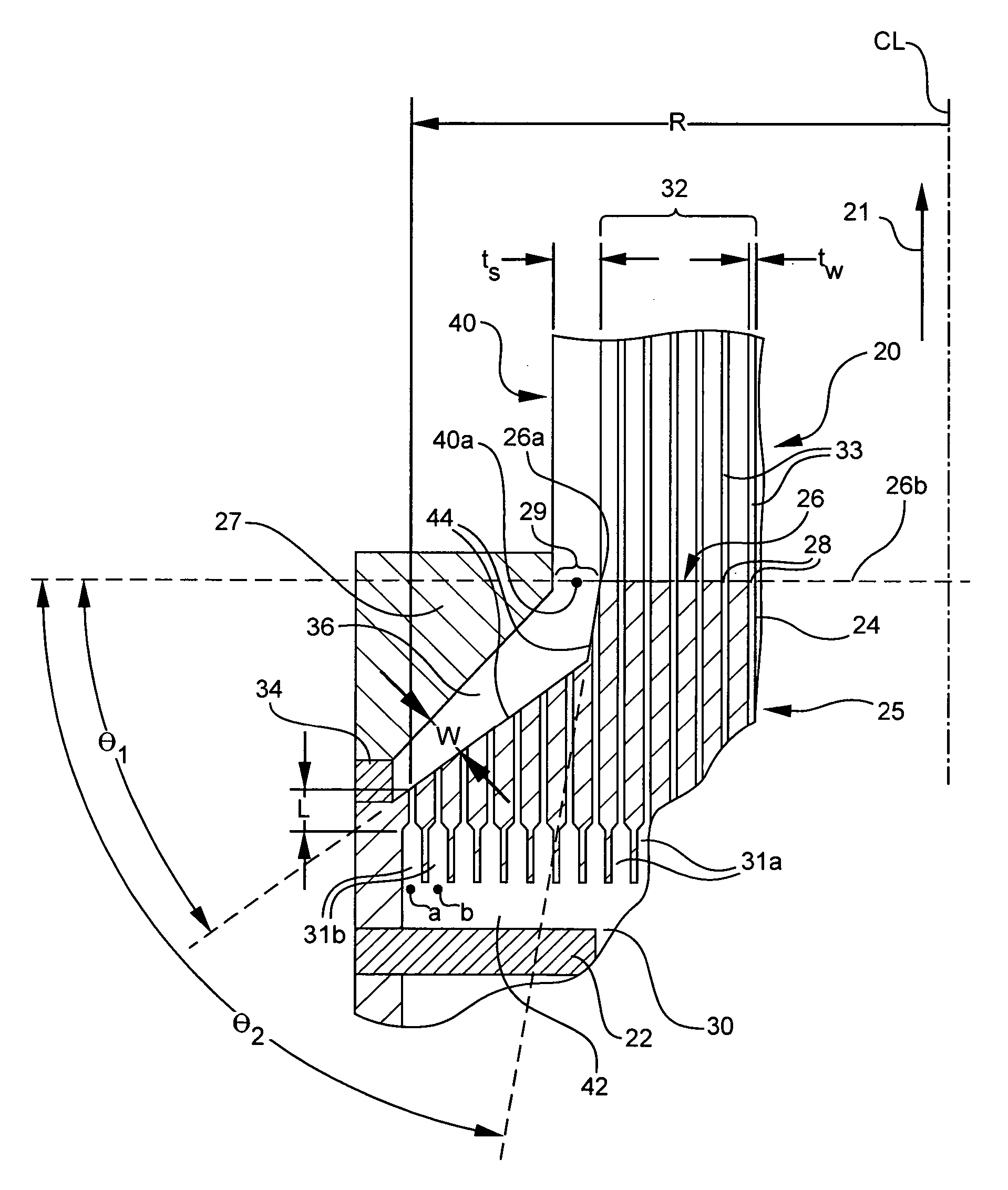

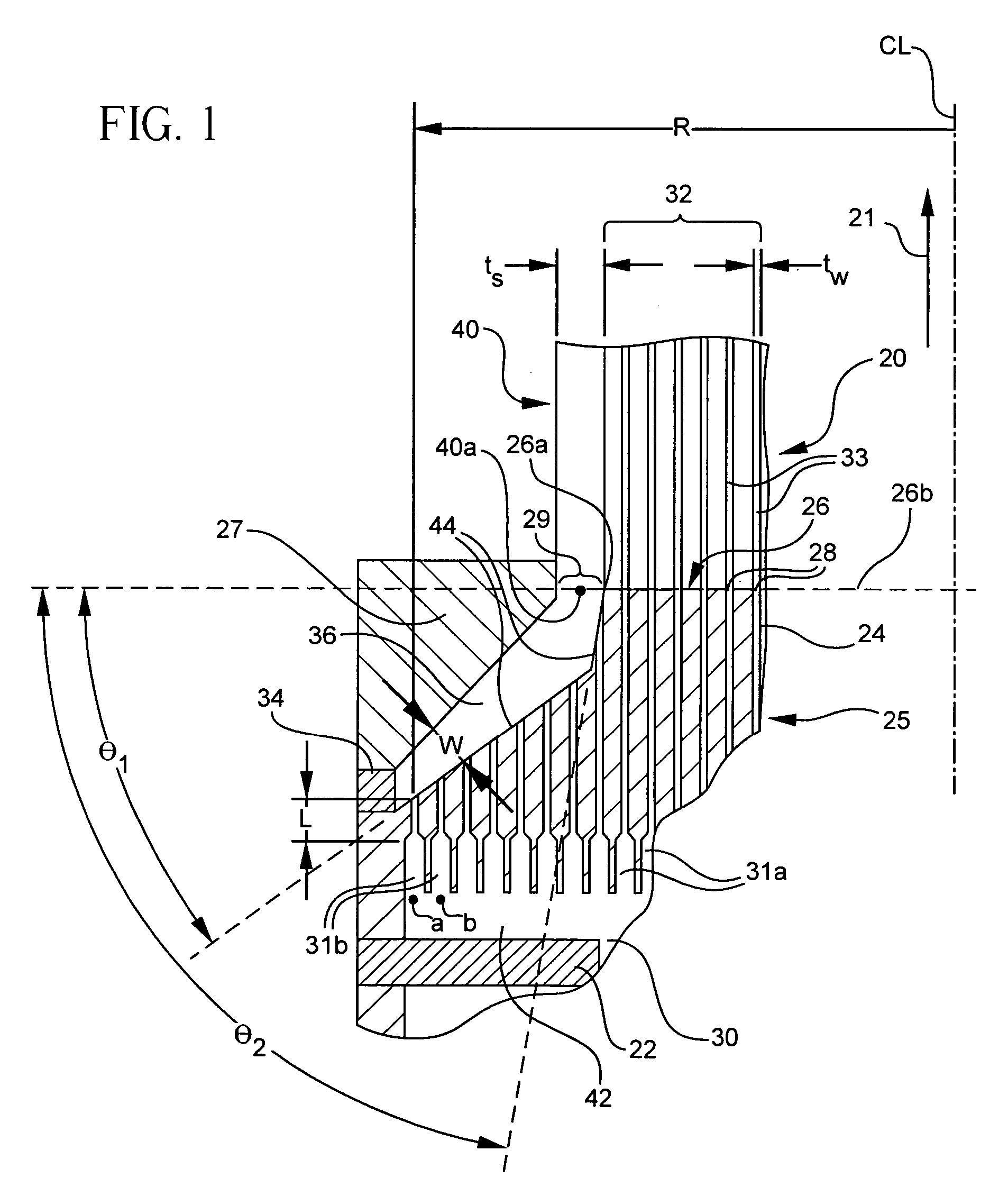

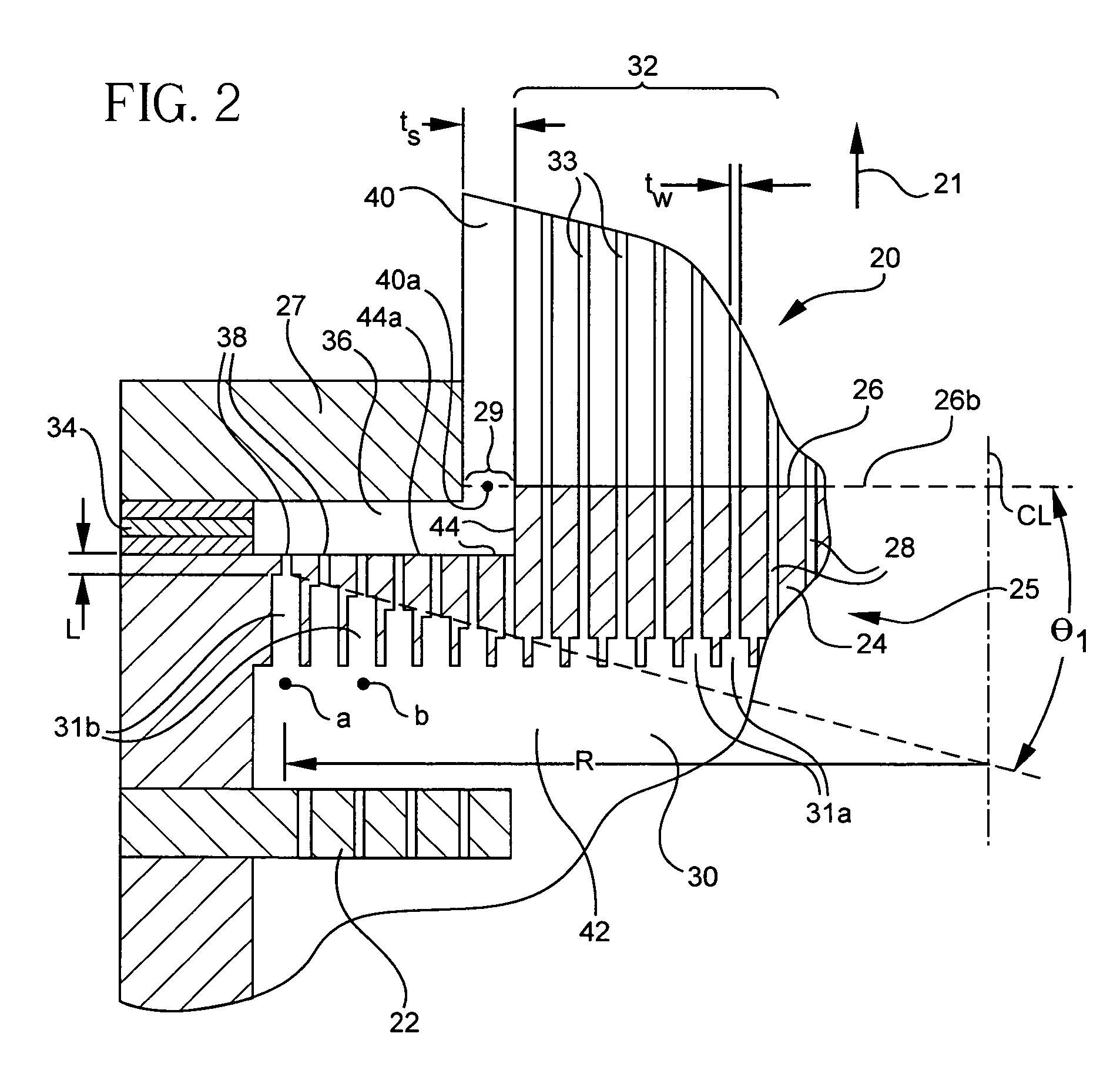

ActiveUS20070026188A1Reduction tendencyEasy alignmentLayered productsConfectioneryParticle alignmentMaterials science

Disclosed is a method and apparatus for forming a circumferential skin surrounding a central cellular structure of an extruded honeycomb article. The method and apparatus may be used to produce defect-free skins and / or skins having large thickness and a high degree of particle alignment thereby preferably exhibiting CTE comparable to the extruded webs. These benefits are achieved by providing a die and method wherein a flow, Q, exiting any two active ones of a plurality of peripheral slots forming the skin is substantially equal. Also disclosed is a thick-skinned ceramic article having a thick extruded skin (ts′>5 tw′) with an I-value comparable to the webs.

Owner:CORNING INC

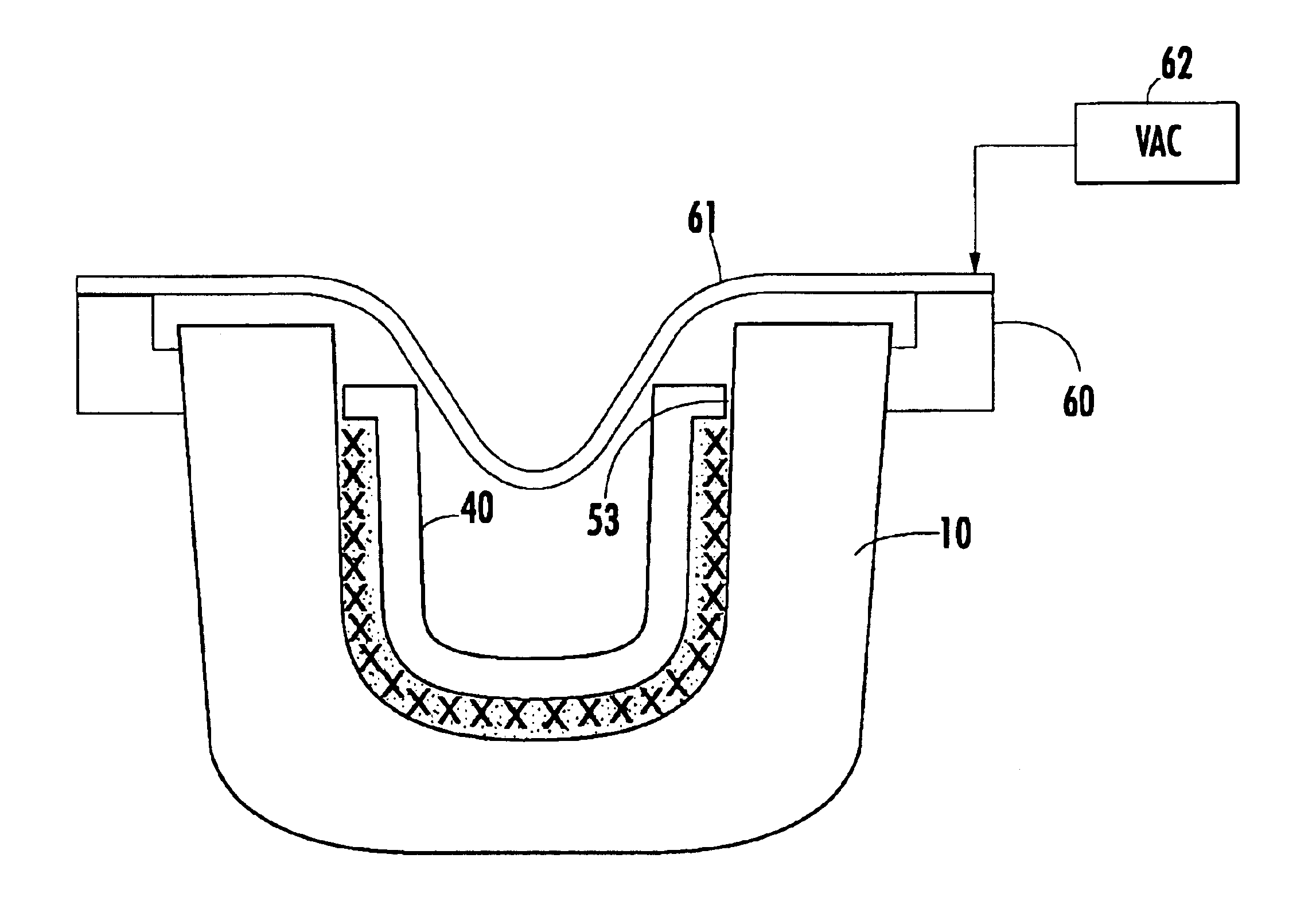

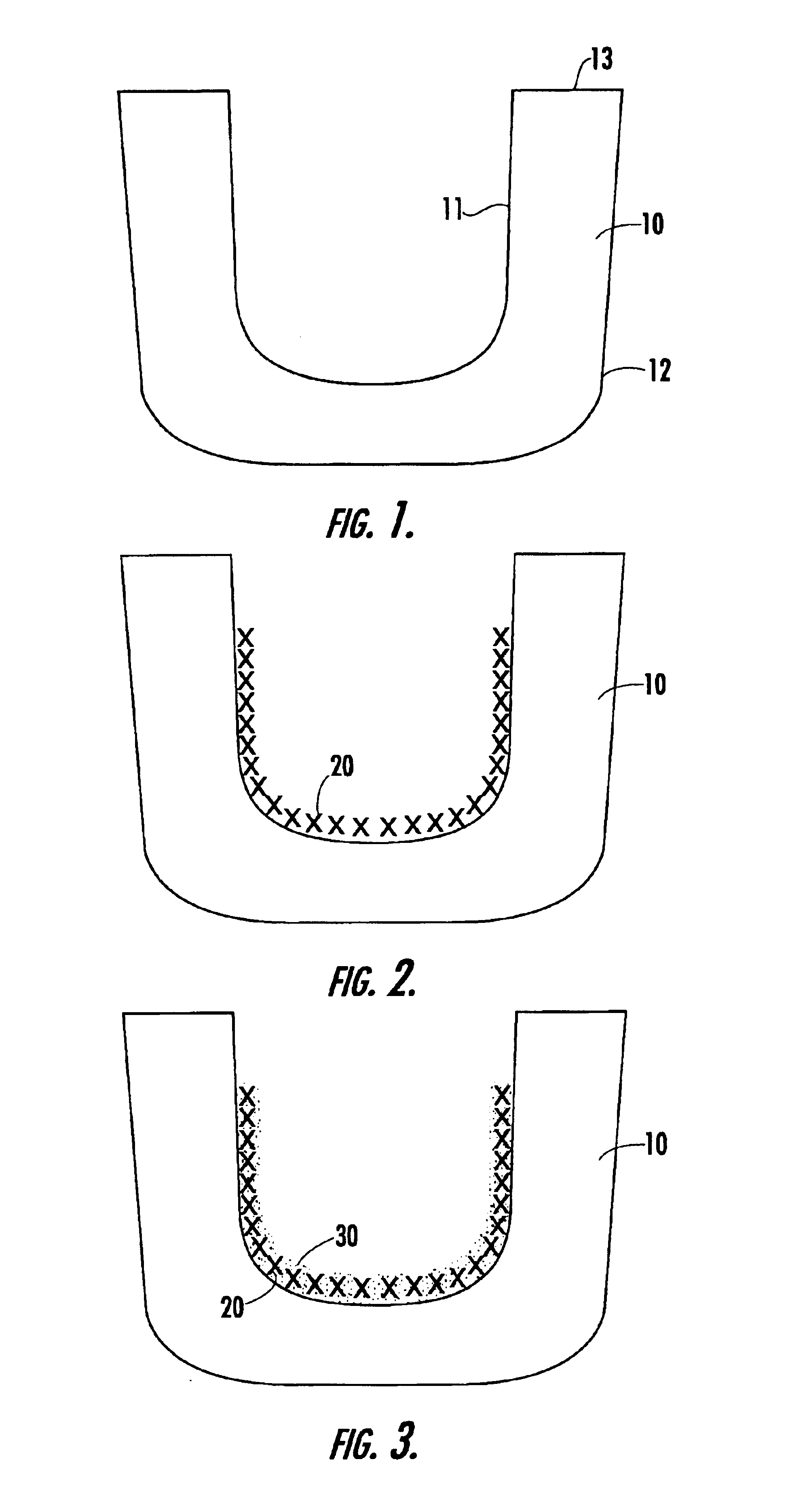

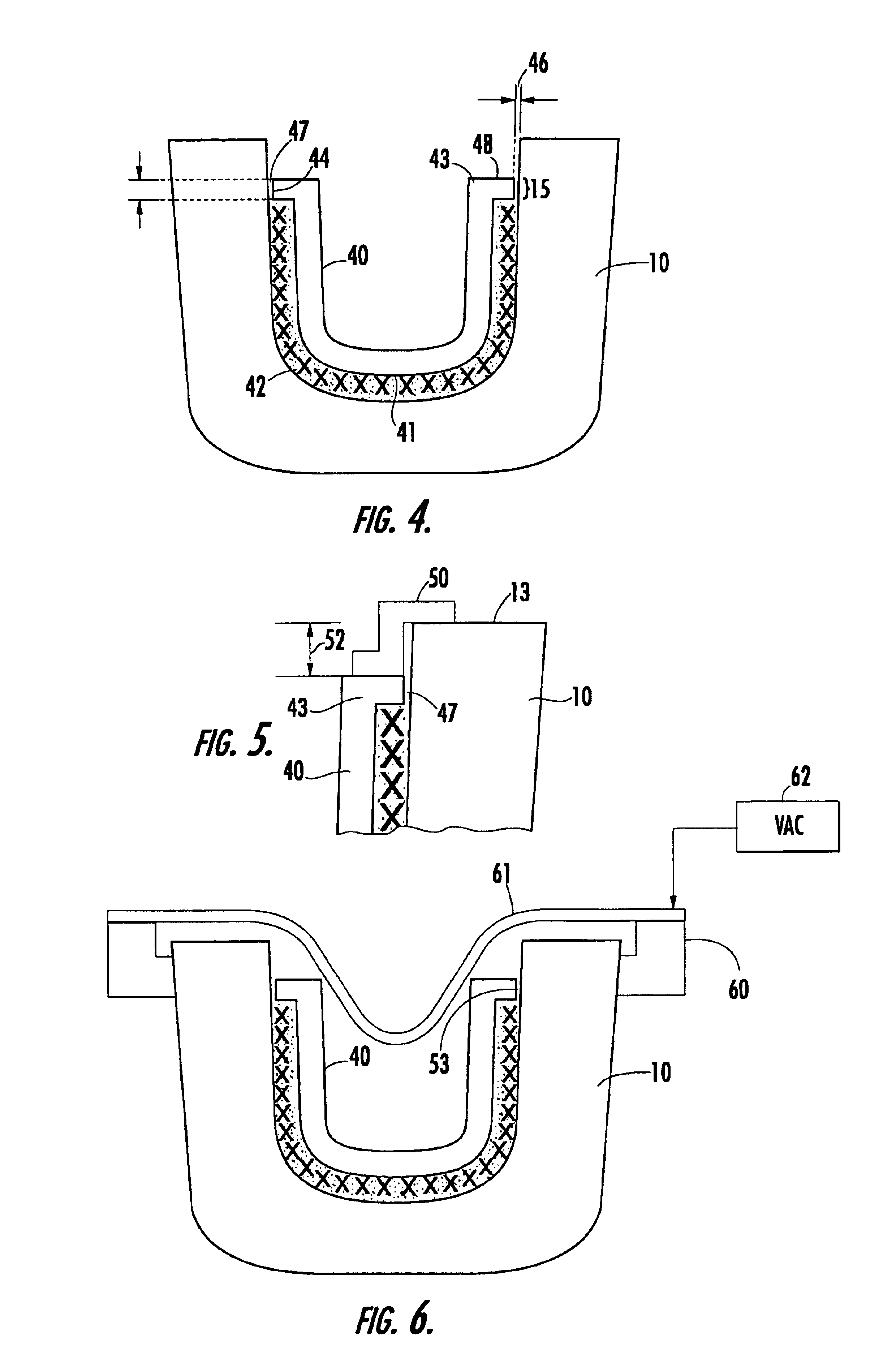

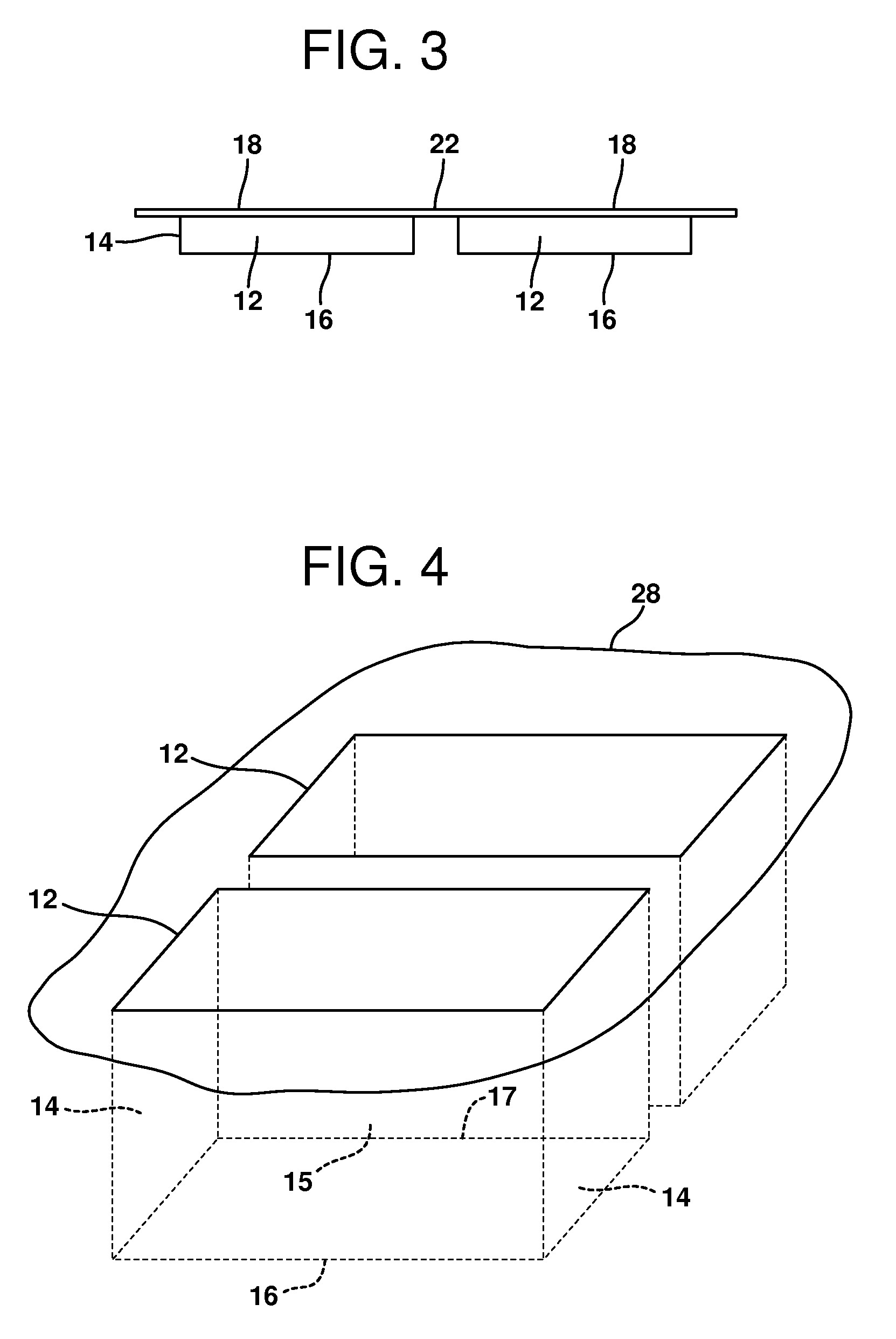

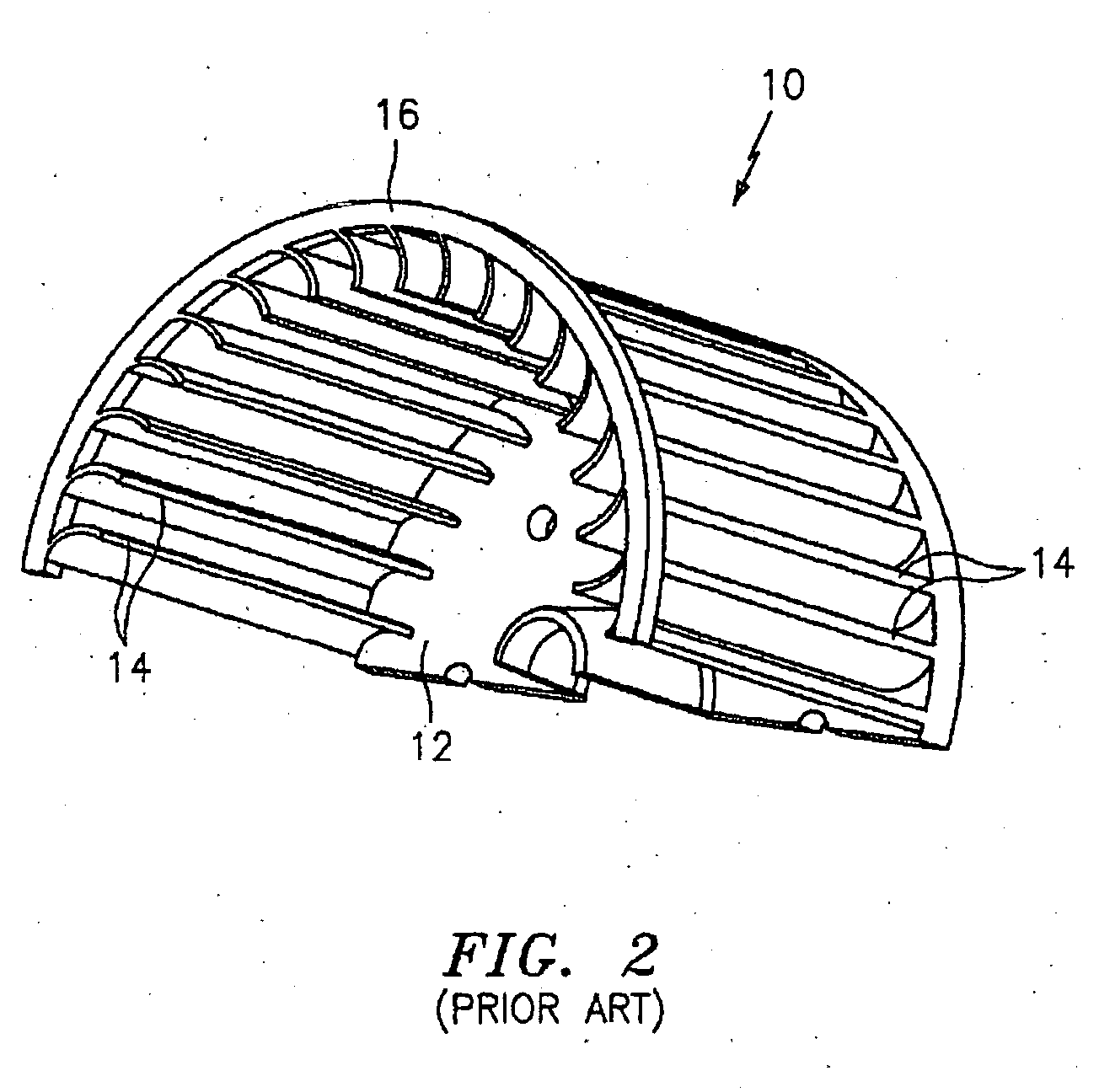

Mandrel-assisted resin transfer molding process employing resin outflow perimeter channel between male and female mold elements

InactiveUS6929770B2Augments outflowPrecise definitionConfectioneryWood working apparatusShell moldingTransfer molding

A mandrel-assisted resin transfer molding process and apparatus therefor provides a generally continuous, narrow annular channel between the perimeter of an inner male mold element and an outer female mold element. This channel allows air, heat and vapor to evenly escape and resin to outflow from the mold cavity everywhere around the edge of the part being molded. A very thin resin band forms in the channel is easily trimmed away, leaving the article completely finished on both sides and having a well defined edge that does not require shaping.

Owner:CALDWELL DESIGN & FABTION

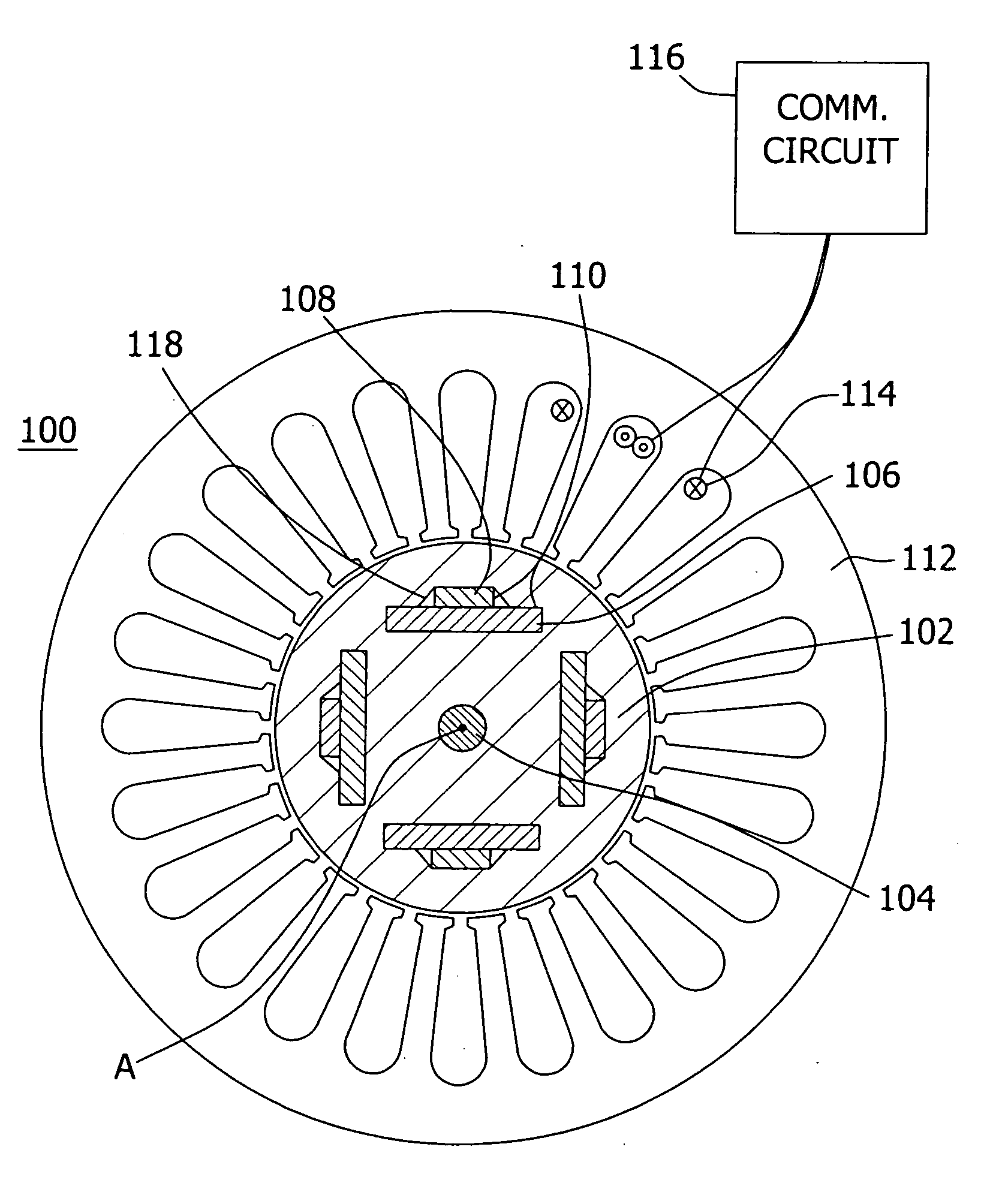

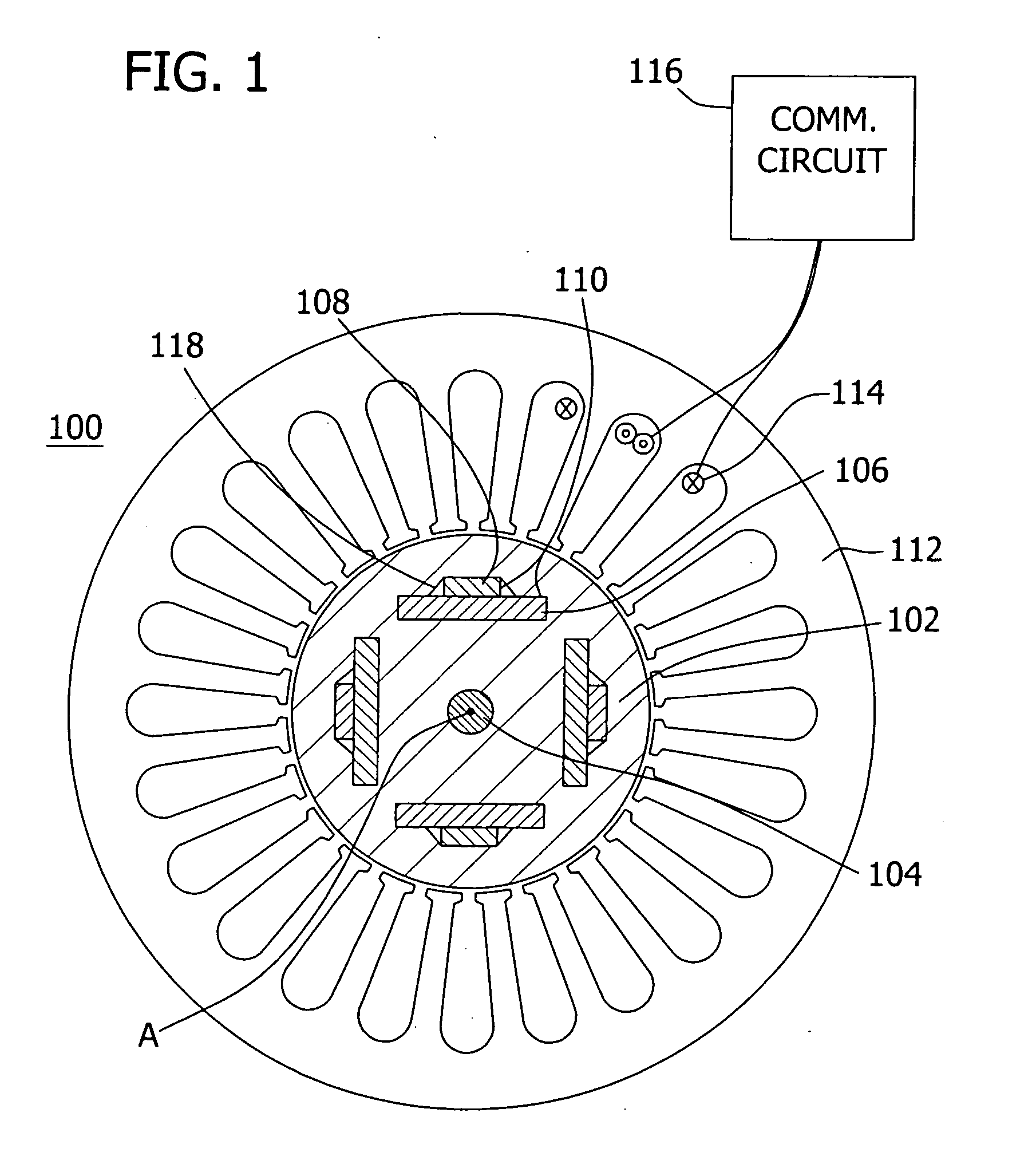

Composite magnet structure for rotor

InactiveUS20070159021A1Quiet motorImprove mold lifeMagnetic circuitSynchronous machines with stationary armatures and rotating magnetsPermanent magnet motorMagnet

An interior permanent magnet electric motor. A rotor comprising a slot radially spaced from its longitudinal axis of rotation extending parallel to the axis. First and second magnets are positioned in the slot and extend parallel to the axis. A first magnet is positioned between a second magnet and the axis.

Owner:EMERSON ELECTRIC CO

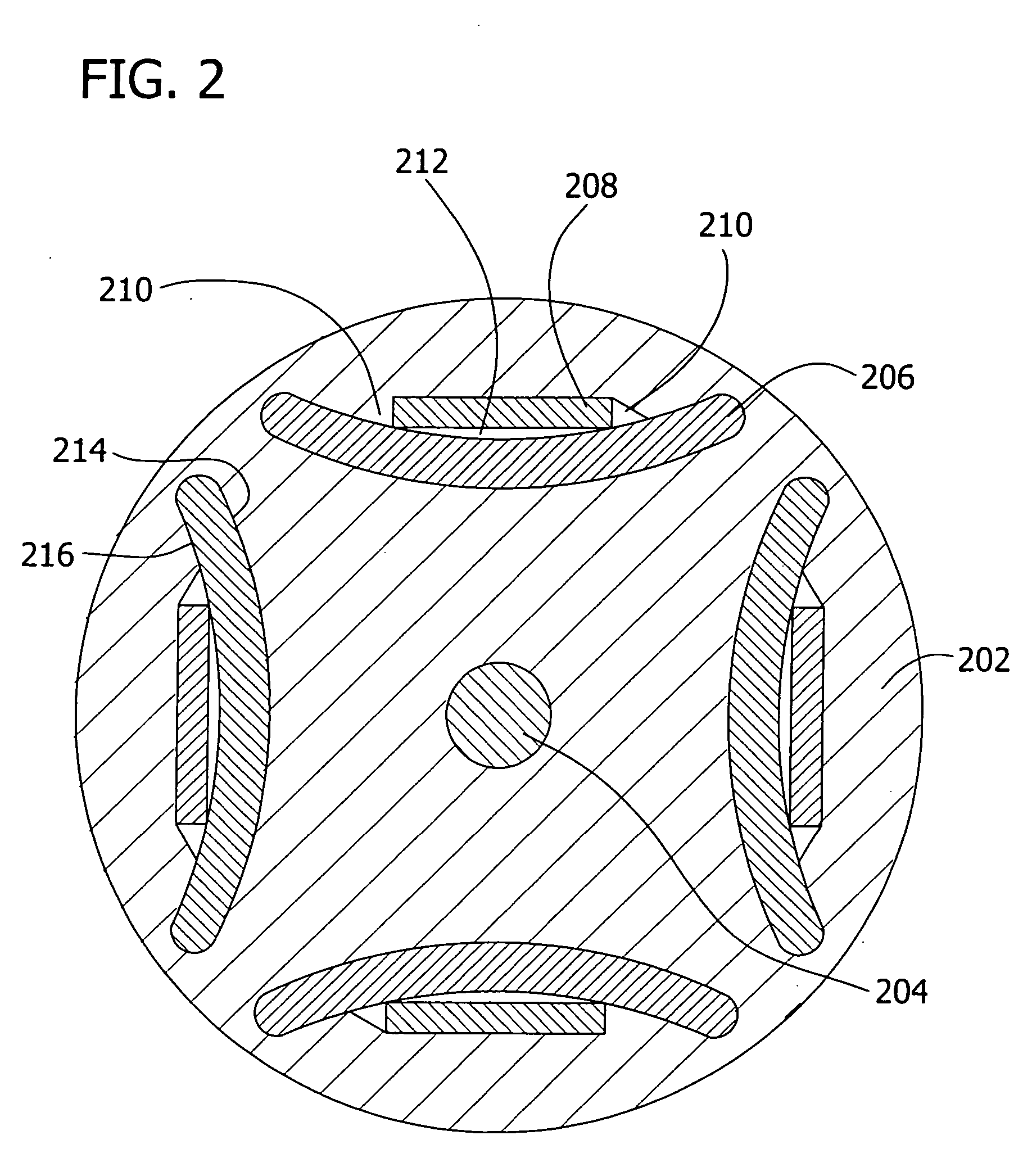

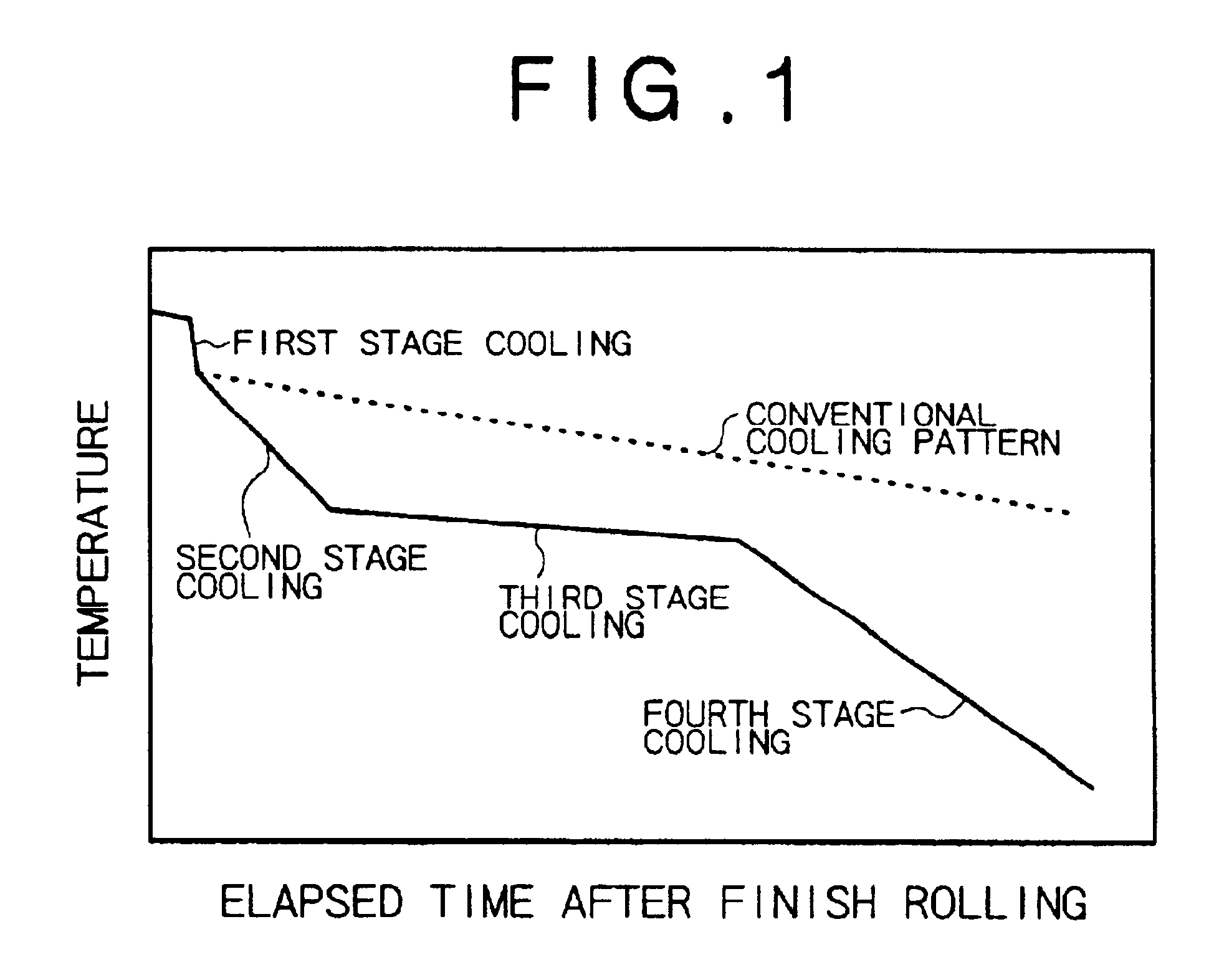

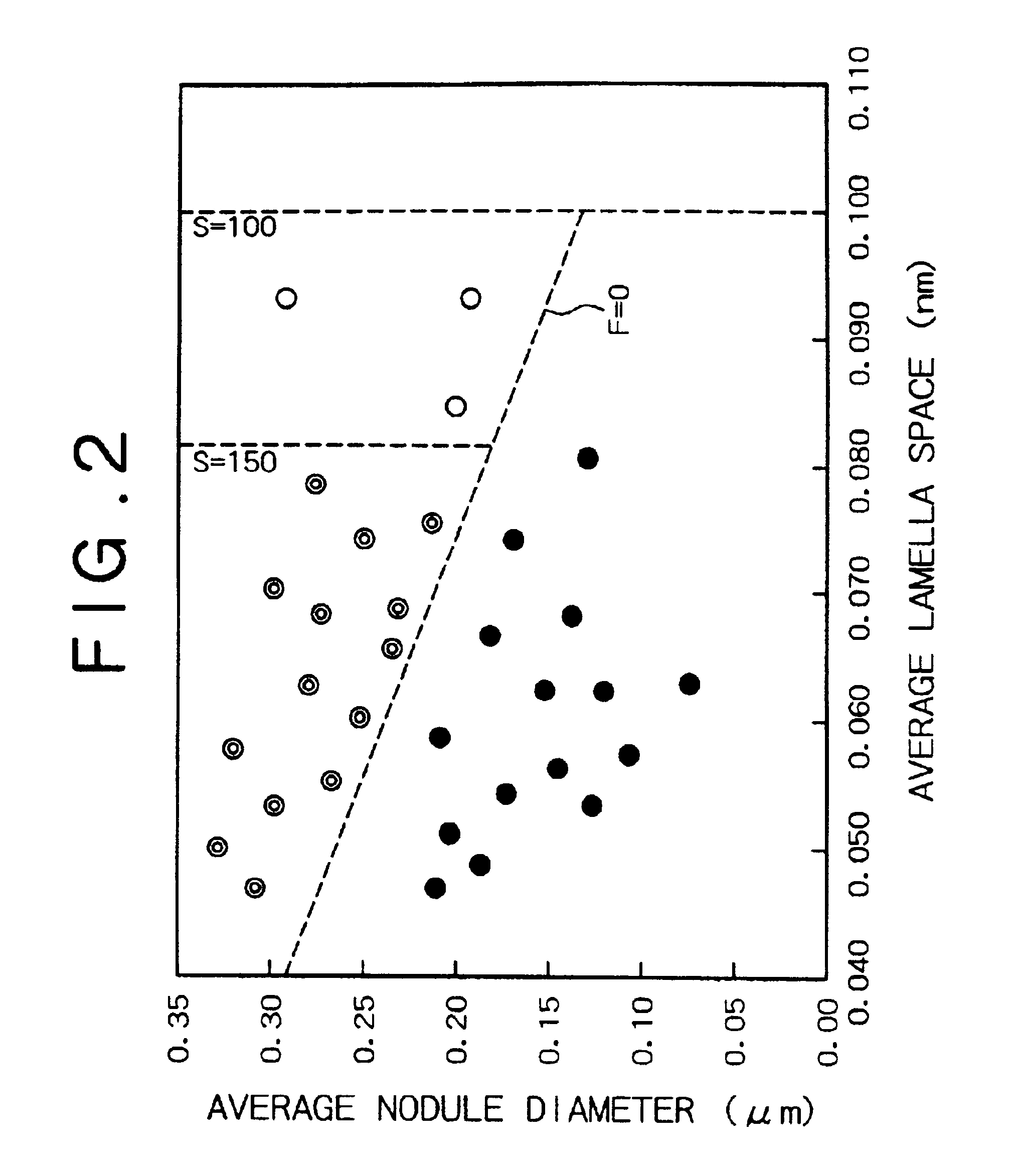

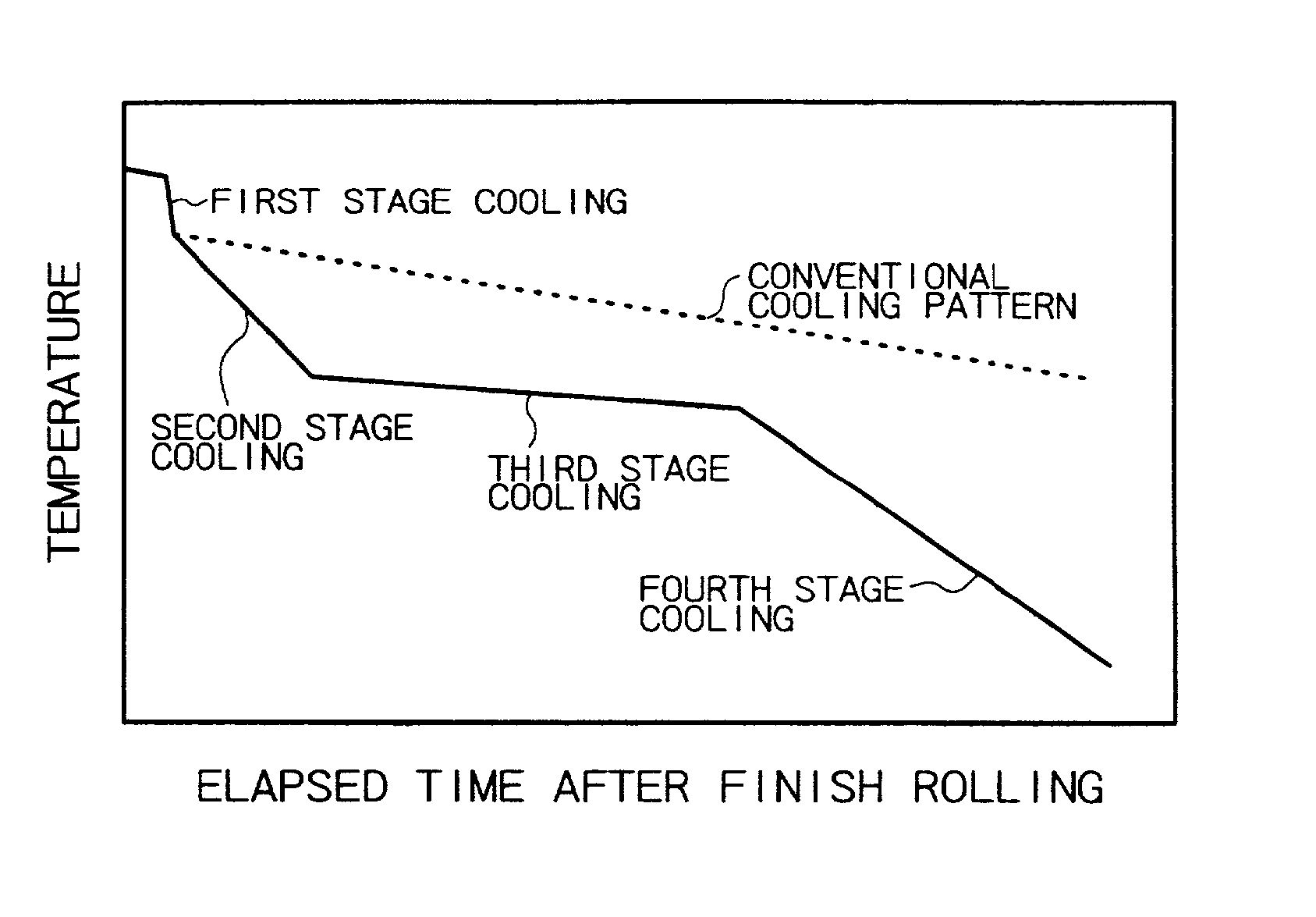

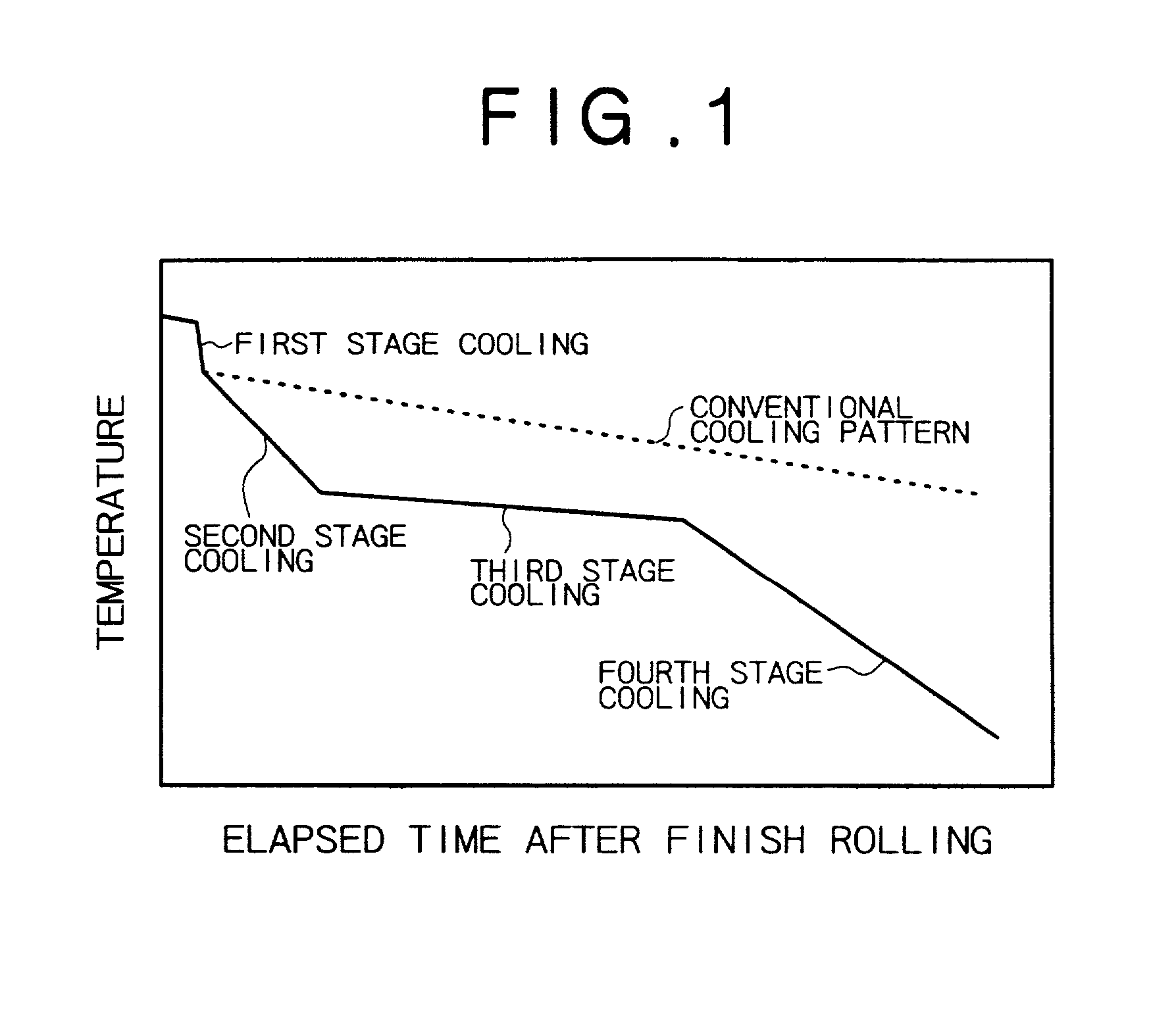

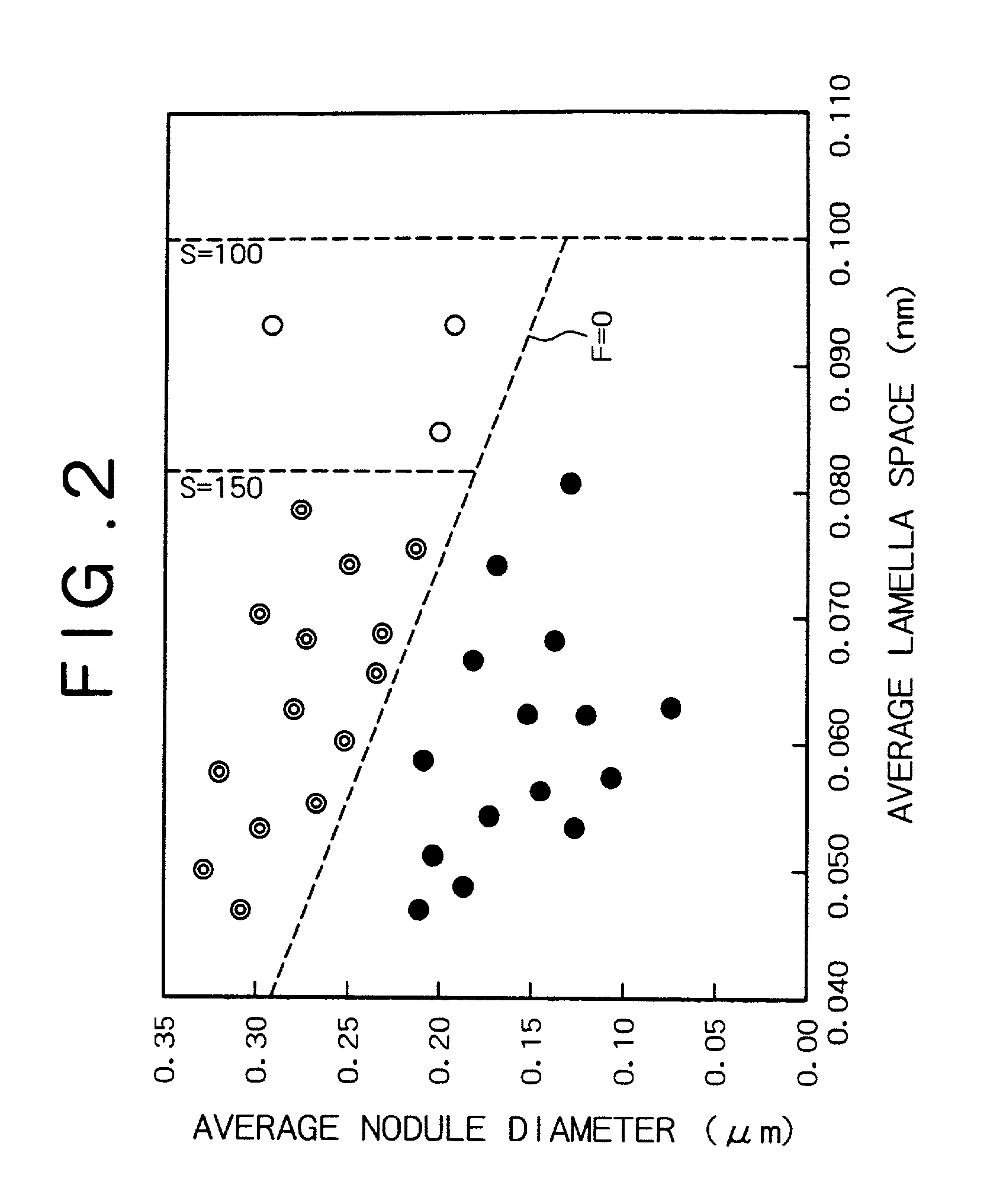

High-carbon steel wire rod with superior drawability and method for production thereof

InactiveUS6783609B2Good stretchabilityImprove fracture resistanceFurnace typesHeat treatment furnacesWire rodChemical composition

A high-carbon steel wire rod with superior drawability which has the chemical composition (in mass %) of C: 0.6-1.0%, Si: 0.1-1.5%, Mn: 0.3-0.9%, P: no more than 0.02%, S no more than 0.03%, N: no more than 0.005%, (optional Nb: 0.020-0.050% and V: 0.05-0.20%), with the remainder being Fe and inevitable impurities, and the structure which is characterized in that pearlite accounts for no less than 95 area % and pearlite has an average nodule diameter (P mum) no larger than 30 mum and an average lamella space (S nm) no smaller than 100 nm such that the value of F calculated by the formula below is larger than zero

Owner:KOBE STEEL LTD

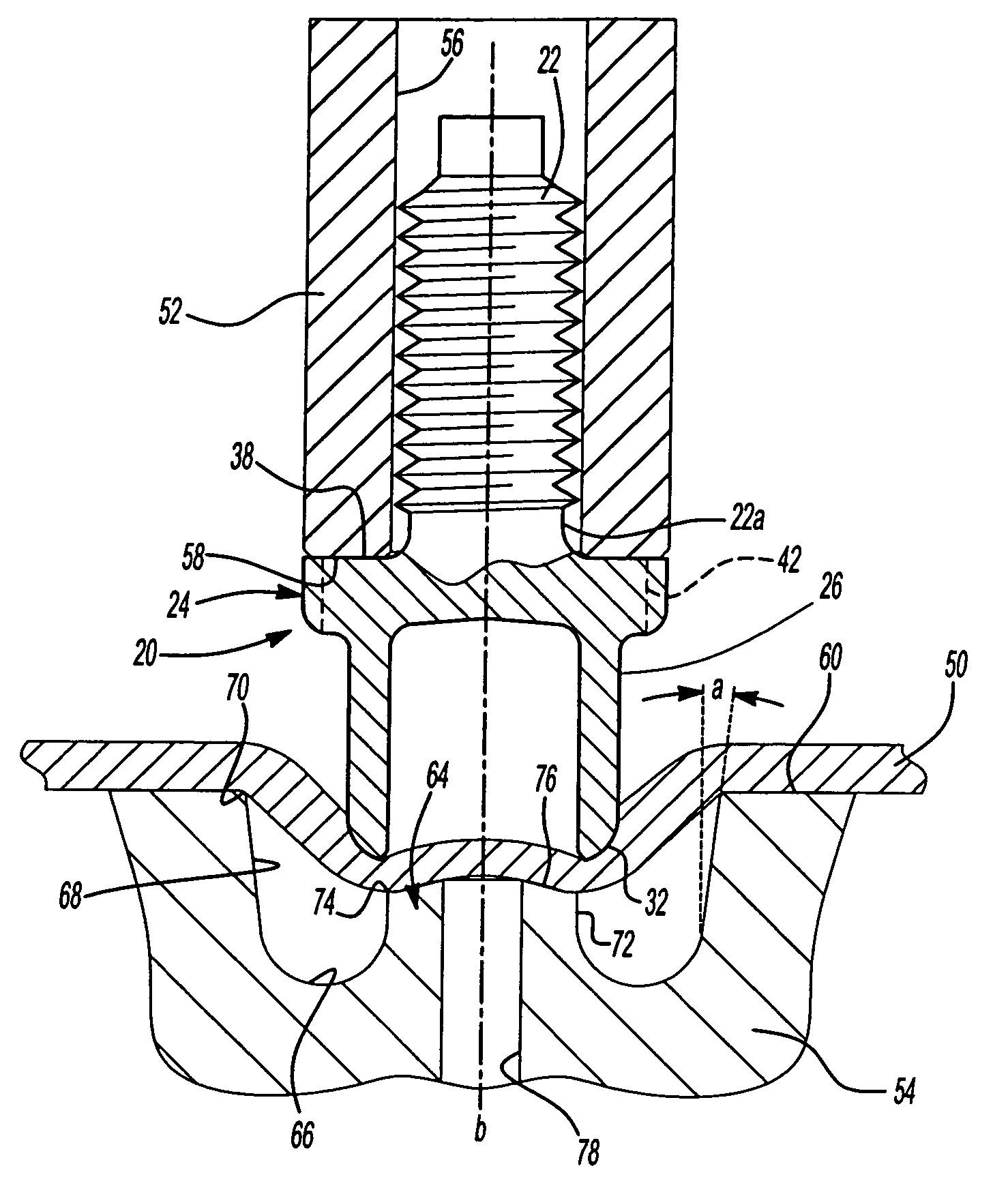

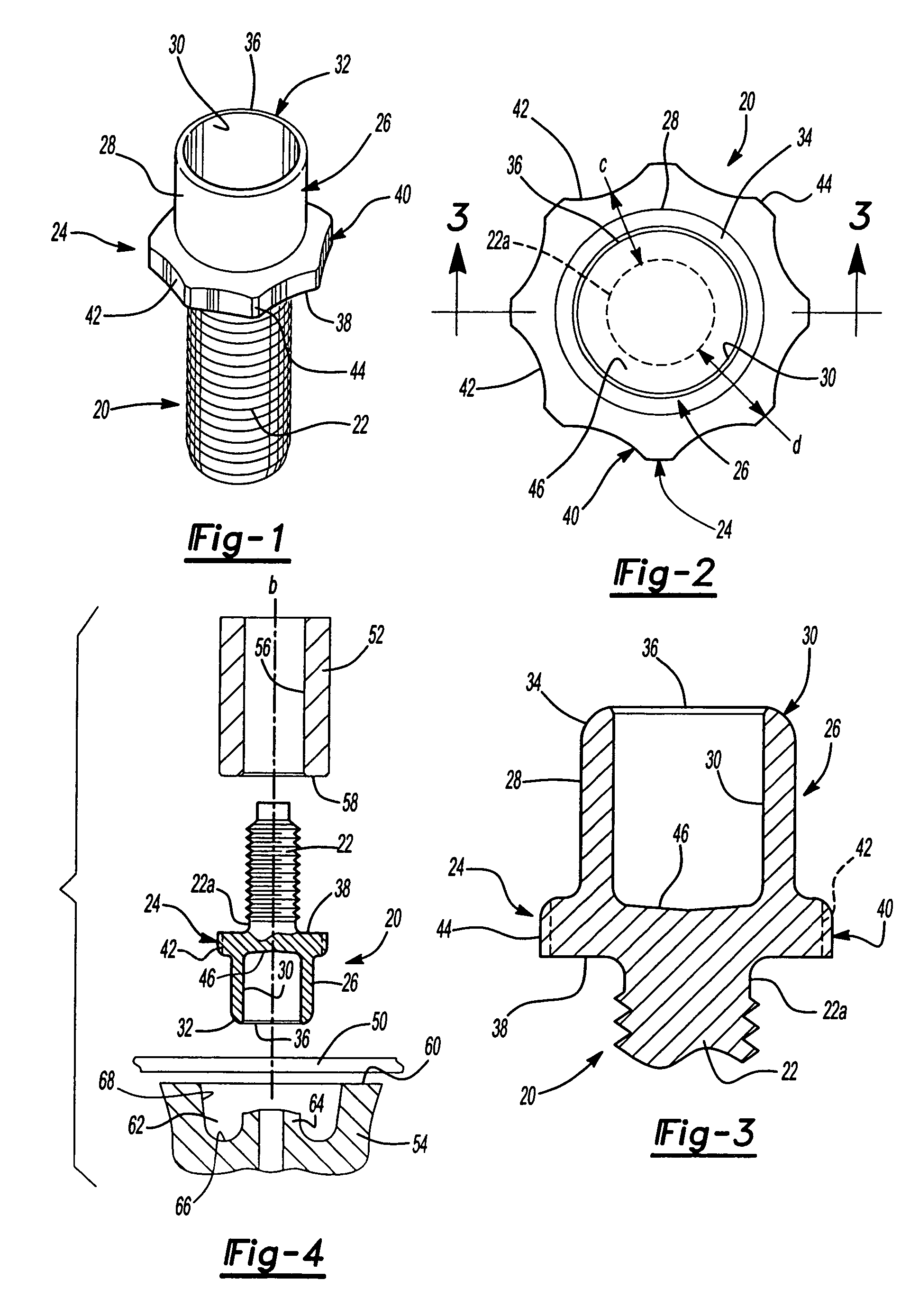

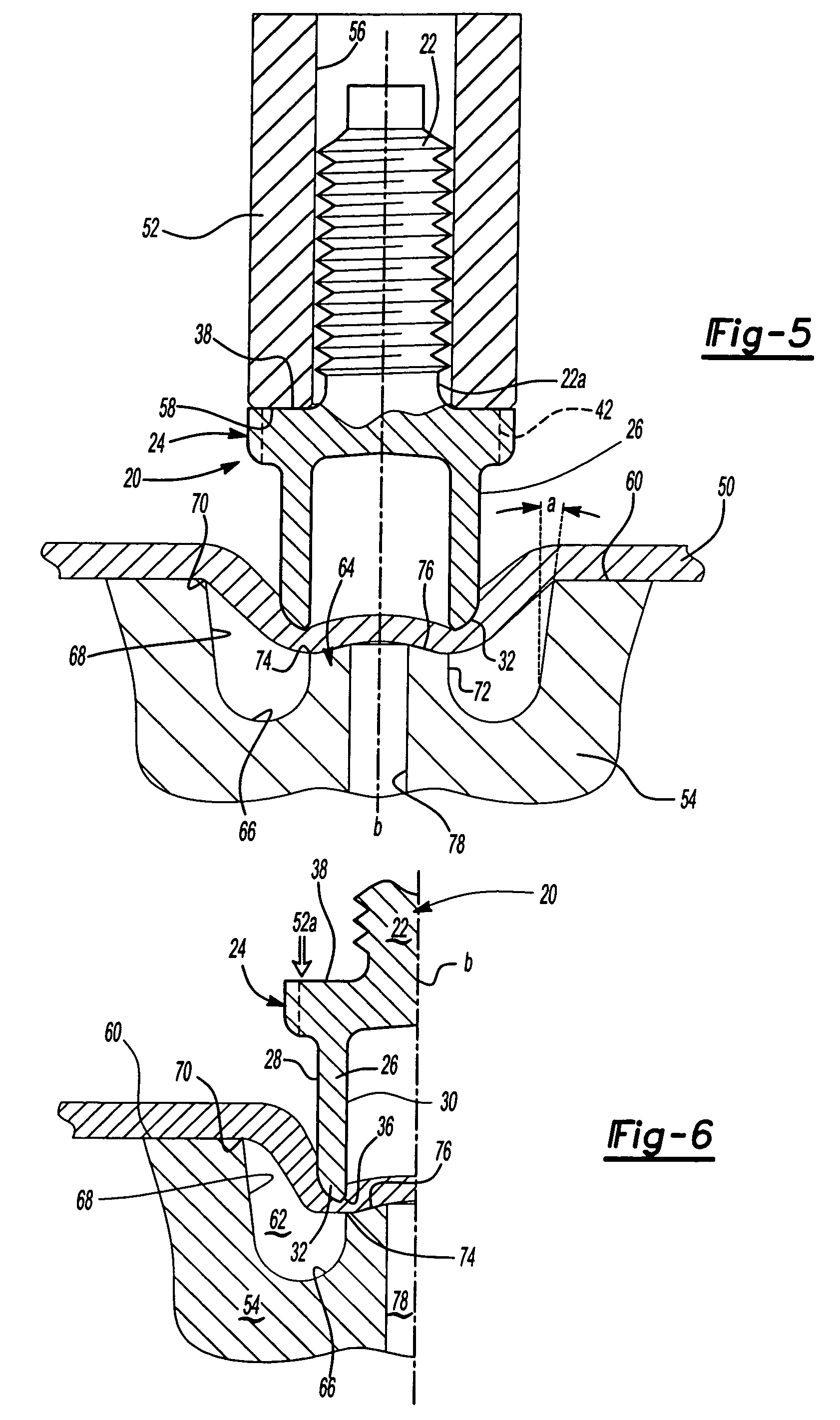

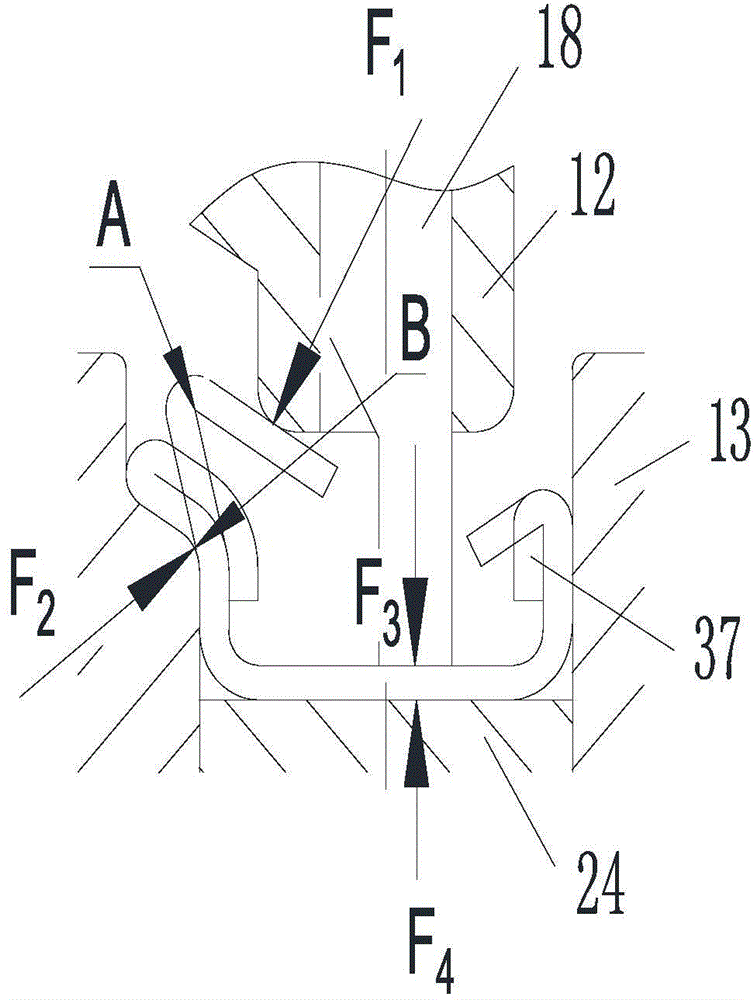

Method of attaching a self-piercing element in a panel and die member

A self-piercing element including a shank, a radial flange and a tubular barrel. The flange includes spaced concave surfaces and the annular bearing surface has an area at least four times the concave surfaces. The element is installed in a panel supported on a female die including a central die post, wherein the outer side wall is a frustoconical having an included angle between five and twelve degrees. During installation, the tubular barrel pierces an opening in the panel and the panel is drawn against the outer surface of the tubular barrel and the barrel is deformed into a U-shape. The flange is simultaneously received in the die cavity and the panel is incrementally deformed radially into the concave surfaces between the frustoconical side wall and the flange portion providing improved torque resistance.

Owner:WHITESELL FORMED COMPONENTS

Steel for carburizing, carburized steel component, and method of producing the same

InactiveUS20130146181A1Little resistanceLarge critical working ratioSolid state diffusion coatingFurnace typesChemical compositionHardness

A steel for a carburizing and a carburized steel component having a steel portion and a carburized layer with a thickness of more than 0.4 mm to less than 2 mm which is formed on an outside of the steel portion. A chemical composition of the steel for the carburizing and the steel portion of the carburized steel component satisfies simultaneously equations of a hardness parameter, a hardenability parameter, and an AlN precipitation parameter.

Owner:NIPPON STEEL CORP

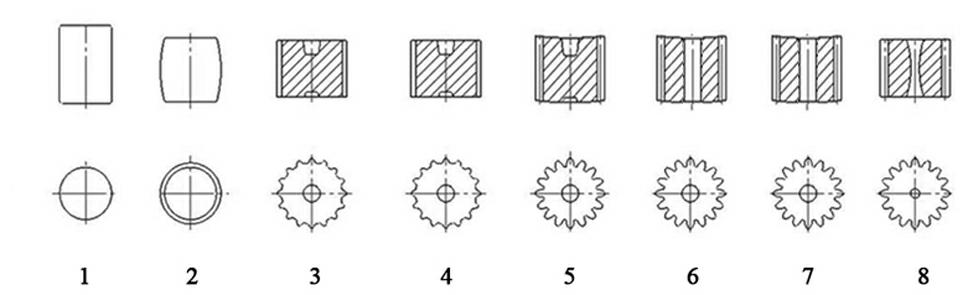

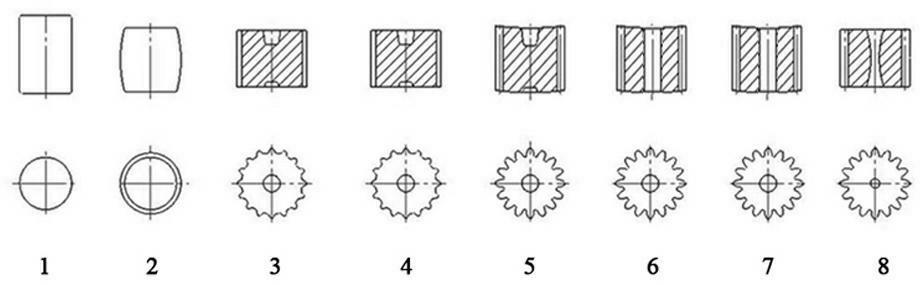

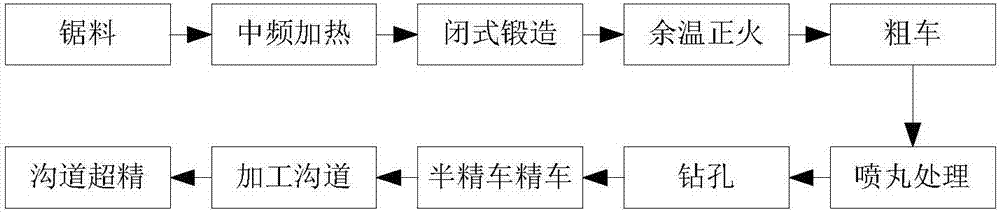

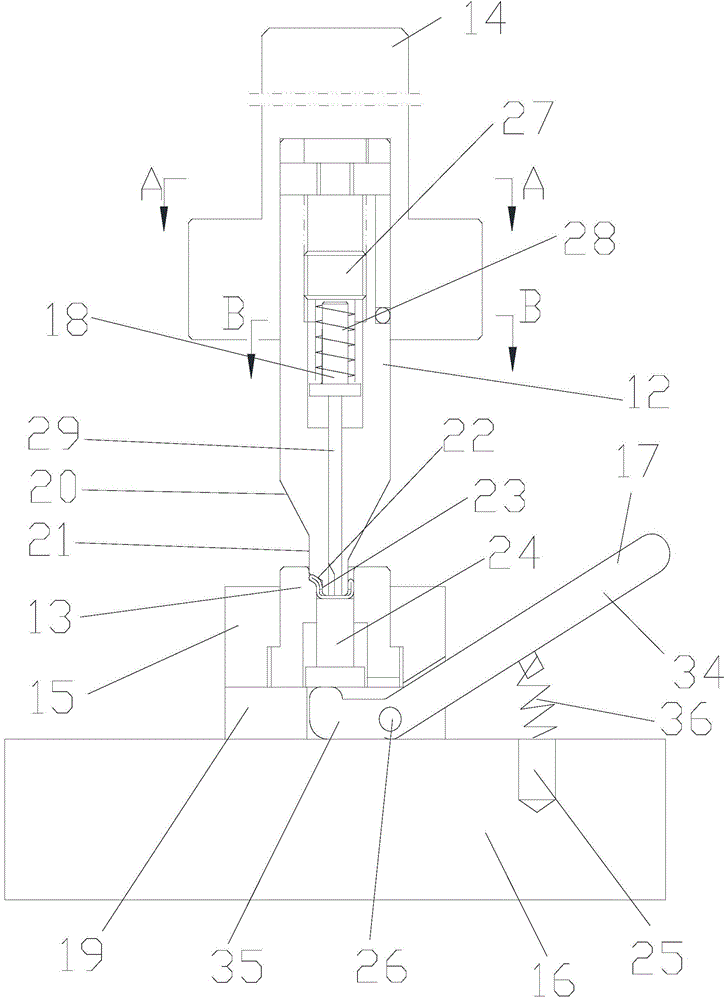

Hot and cold composite precision forging forming method of great-modulus high-thickness straight-tooth cylindrical gear

InactiveCN102489978AReduce stress concentrationImprove mold lifeMetal-working apparatusPlastic propertyMaterial flow

The invention provides a hot and cold composite precision forging forming method applied to a great-modulus high-thickness straight-tooth cylindrical gear, and belongs to the technical field of metal plastic processing. The hot and cold composite precision forging forming method adopts the following steps of: baiting, upsetting after heating, hot die forging, annealing middle treatment, cold forward extrusion, center hole processing, annealing middle treatment and cold finishing, wherein the deformation quantity is reasonably distributed in three forming work procedures, certain tooth shapes are formed by the hot die forging work procedure, then, the cold forward extrusion process is adopted for further forming complete tooth shapes, and better surface quality is formed through radial and axial material flowing. Through the center hole processing work procedures, the stress concentration phenomenon during the closed cold finishing can be effectively reduced, and the service life of a mold is improved. Through the cold finishing work procedure, the tooth surface precision can be further improved, simultaneously, the defect of imperfect gear sectional surface filling generated in the cold extrusion work procedure is eliminated, and finally, the tooth-shaped surface of a forge element can directly reach gear hobbing and gear milling precision.

Owner:BEIJING RES INST OF MECHANICAL&ELECTRICAL TECH +1

High-carbon steel wire rod with superior drawability and method for production thereof

InactiveUS20030079815A1Good stretchabilityImprove fracture resistanceFurnace typesHeat treatment furnacesWire rodChemical composition

A high-carbon steel wire rod with superior drawability which has the chemical composition (in mass%) of C: 0.6 -1.0%, Si: 0.1-1.5%, Mn: 0.3-0.9%, P: no more than 0.02%, S no more than 0.03%, N: no more than 0.005%, (optional Nb: 0.020-0.050% and V: 0.05-0.20%), with the remainder being Fe and inevitable impurities, and the structure which is characterized in that pearlite accounts for no less than 95 area % and pearlite has an average nodule diameter (P mum) no larger than 30 mum and an average lamella space (S nm) no smaller than 100 nm such that the value of F calculated by the formula below is larger than zero.F=350.3 / {square root}{overscore (S +130.3 / {square root}{overscore (P -51.7

Owner:KOBE STEEL LTD

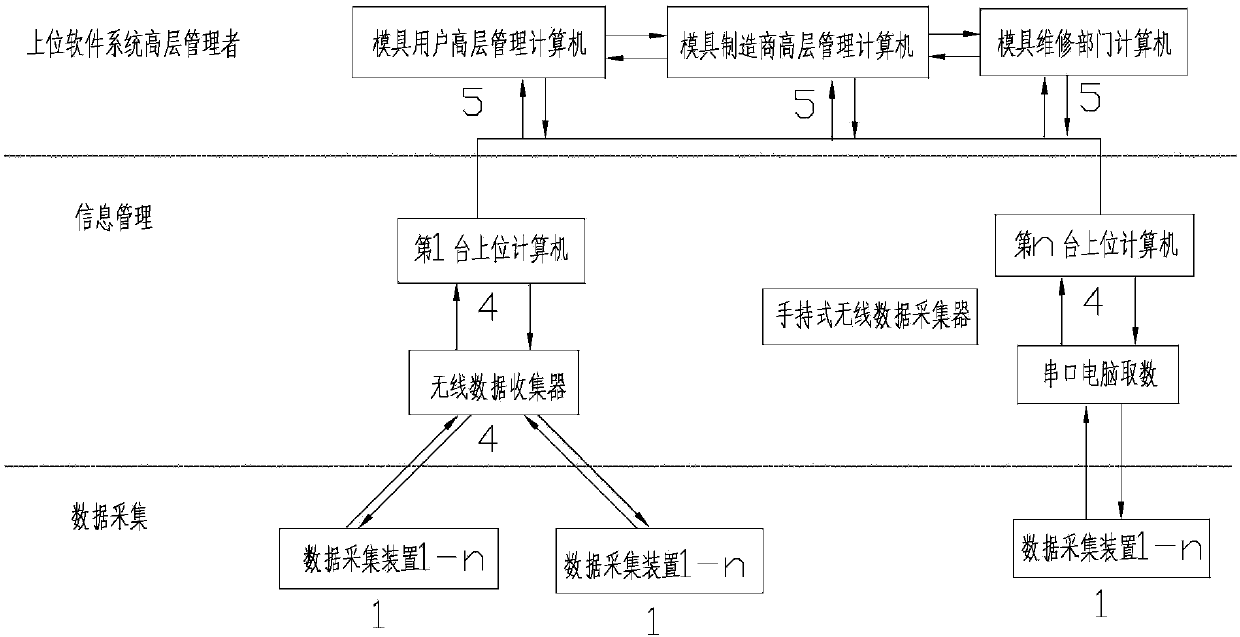

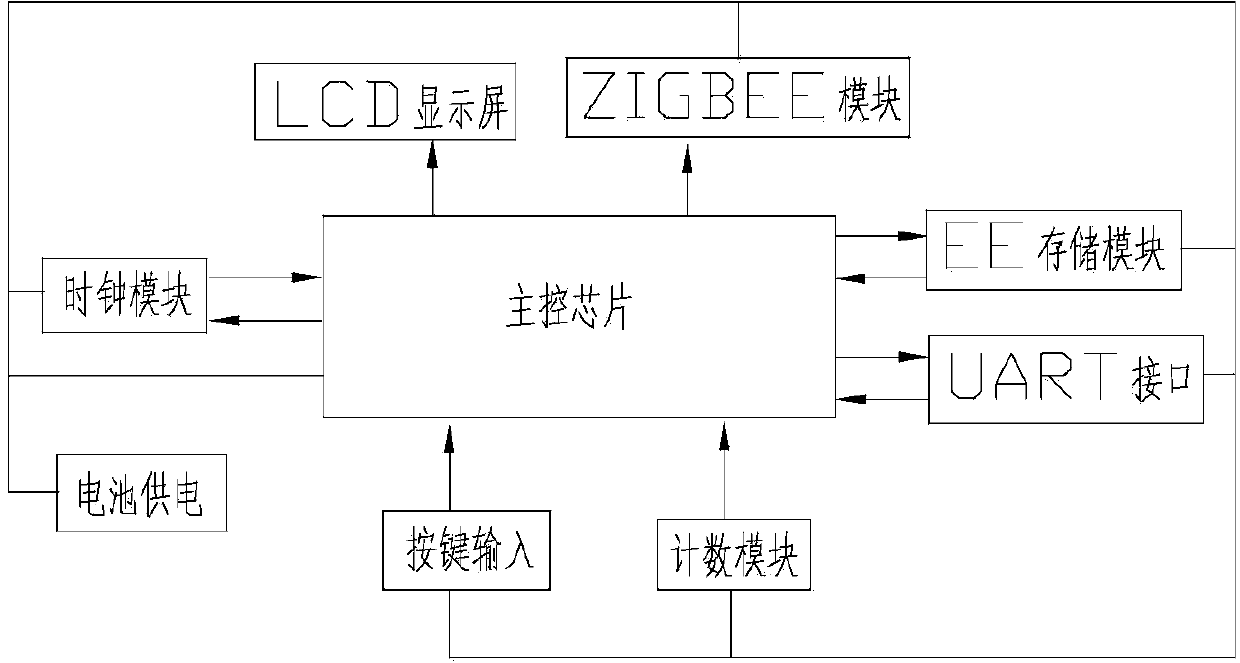

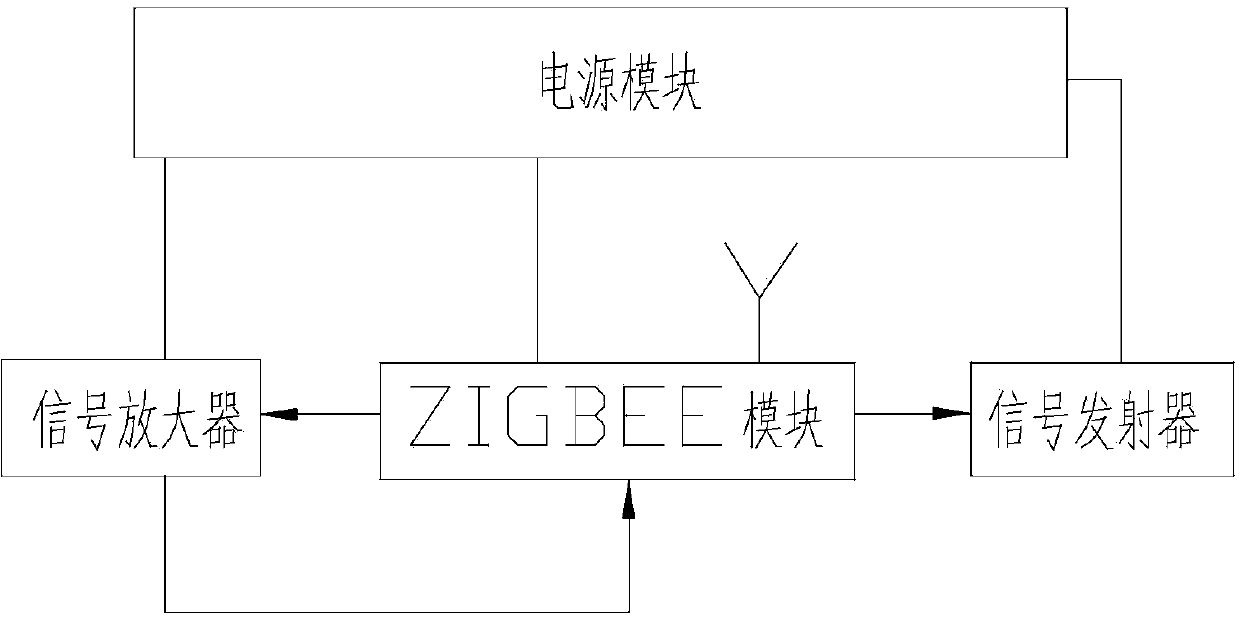

Die management method and die management system

ActiveCN103996092AImprove mold lifeLow investment costResourcesManufacturing computing systemsRemote computerData collector

The invention relates to a die management method and a die management system. According to the die management method, data collection devices arranged at dies are used for collecting die station information; information data of all dies in a specific area are sent to a data collector of the specific area by transmission paths; the data collector sends the data to a host computer, a database is established at the host computer, and a die management information file that can be checked is formed; a die using situation of the area is estimated; host computers in all specific areas send data to remote computers of a higher management layer, a die manufacturer and a die maintenance department by the internet; the remote computers carry out comprehensive estimation on states of all dies; and heavy maintenance time of all dies is predicted, early warning information is sent out in advance and a maintenance instruction is issued, and the die manufacturer and the die maintenance department send workers to carry out heavy maintenance on the dies. According to the invention, the die manufacturer and the die maintenance department can obtain die information comprehensively in real time and thus maintenance can be carried out on the die timely, thereby prolonging the service lives of dies.

Owner:QINGDAO HAIER ROBOT CO LTD +2

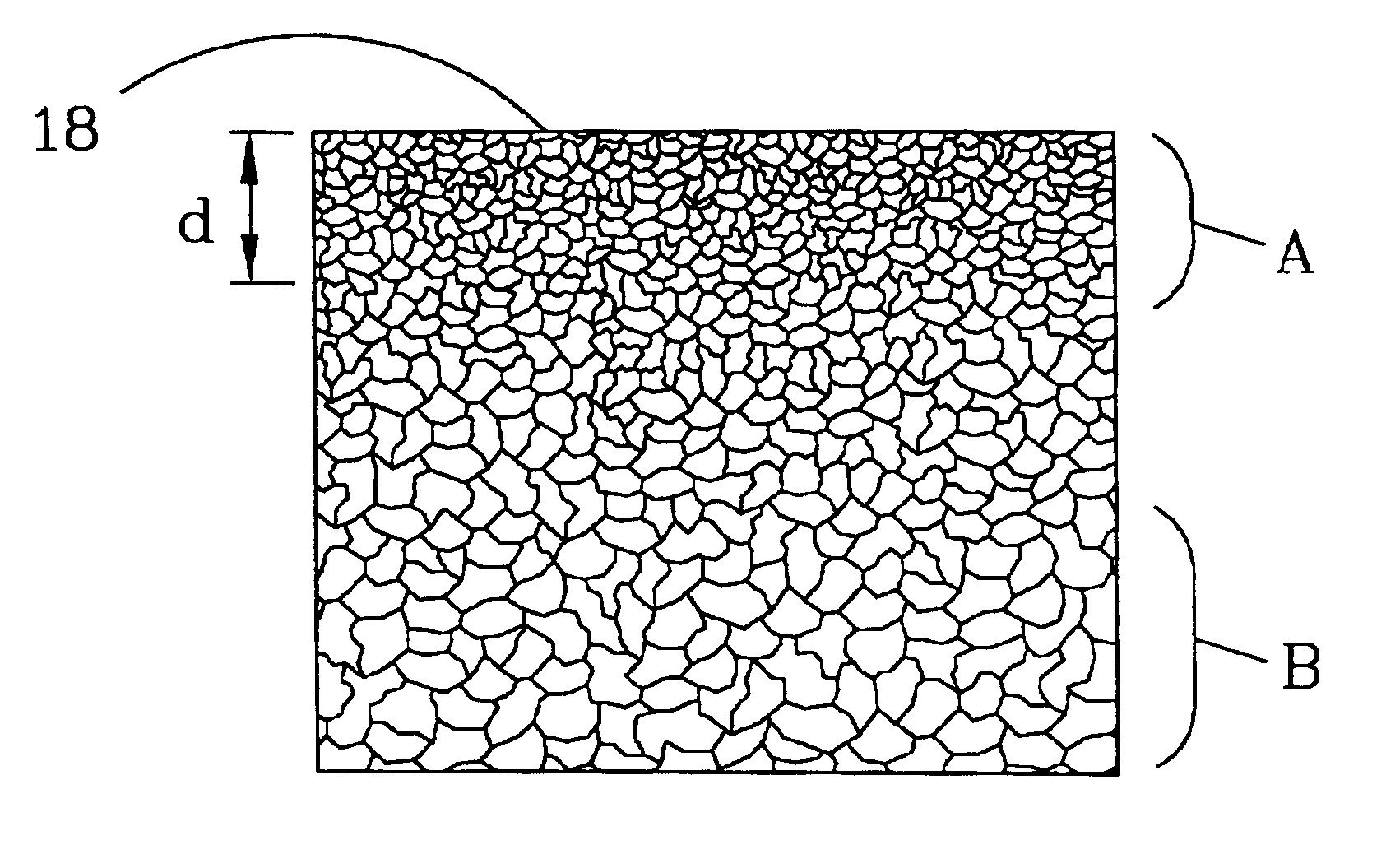

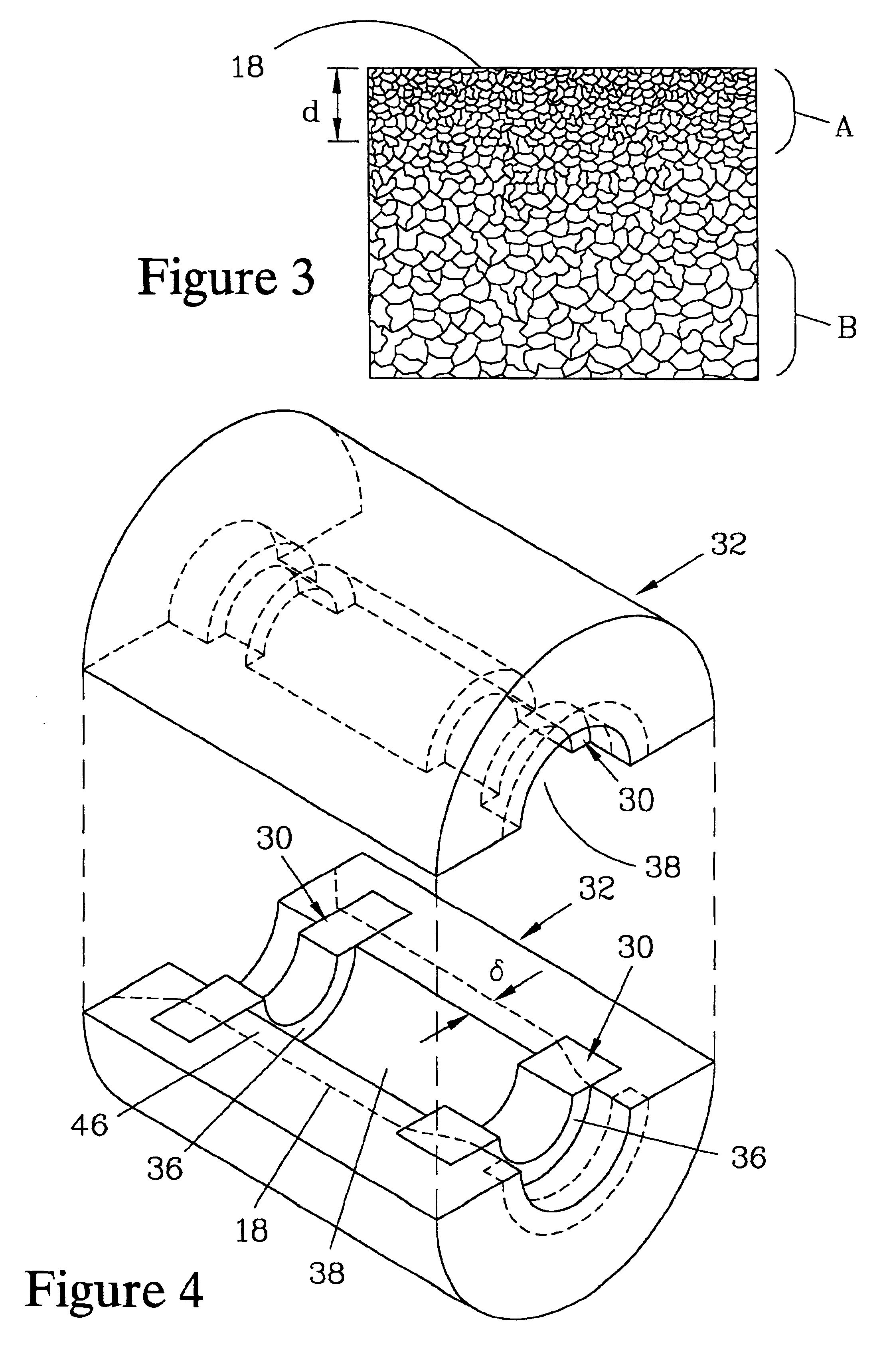

Glass bottle molds and method for making the same

InactiveUS6840062B1Improve mold lifeAdded fabricationGlass pressing apparatusBlowing mouldsBottleMachining

The bottle mold has dissimilar metal inserts embedded in regions where the bottle mold is most subject to attack by hot glass, such as the neck region and the baffle region, and has a glass contact surface with refined grain size. To fabricate the bottle mold, rough castings are made by pouring cast-iron into a composite mold having dissimilar metal insert blanks fixably positioned therein. The dissimilar metal insert blanks become embedded in the cast-iron matrix to form rough dissimilar metal inserts in the rough casting. The composite mold has regions which are formed by metal chills that are partially embedded in a sand mix. The chills and the exposed surfaces of the rough dissimilar metal inserts define a cavity surface of the rough casting, which is subsequently machined to provide the glass contact surface of the bottle mold. The chills serve to refine the grain size of the cast iron at the glass contact surface. Preferably the dissimilar metal insert blanks have protrusions to assure that they become fixably engaged in the resulting rough casting.

Owner:KELLY MACHINE & FOUNDRY

Micro/Nano-Pattern Film Contact Transfer Process

InactiveUS20080217819A1Avoid high pressureImprove mold lifeNanoinformaticsPhotomechanical apparatusMaterials science

Owner:NAT CHENG KUNG UNIV

UV/EB cured integrated magnets-composition and method of fabrication

The present invention comprises a radiation curable composition for in-line printing containing magnetic pigments capable of being magnetized to possess permanent magnetic properties after the composition is cured. The composition is cured by an ionizing radiation source, preferably by UV light or electron beam radiation (UV / EB). The present invention is also directed to an in-line process for printing magnetic images on non-magnetic substrate, comprising: pattern applying the above mentioned radiation curable composition on the substrate opposite to a print side, pre-aligning the magnetic pigment particles (if necessary) of the applied composition, curing the composition by ionizing radiation source (UV / EB), magnetizing the cured composition, then finishing the final piece. The finishing step could involve delivering the final piece in a simple sheet with die cut magnets or creating an "integrated magnet" format involving plow folding over the magnet panel, pattern coating or flood coating an adhesive that will only adhere the non-magnet matrix areas between die cut magnets, thus, allowing for the individual magnets to be "popped" out of the carrier by the final end user. The resulting magnetized pieces will possess holding power like magnets (refrigerator and office magnets) and are capable of carrying personalized, Scitex imaged and direct marketing information (including redemption value for coupons, local public service access numbers, etc.)

Owner:SOVEREIGN SPECIALTY CHEM

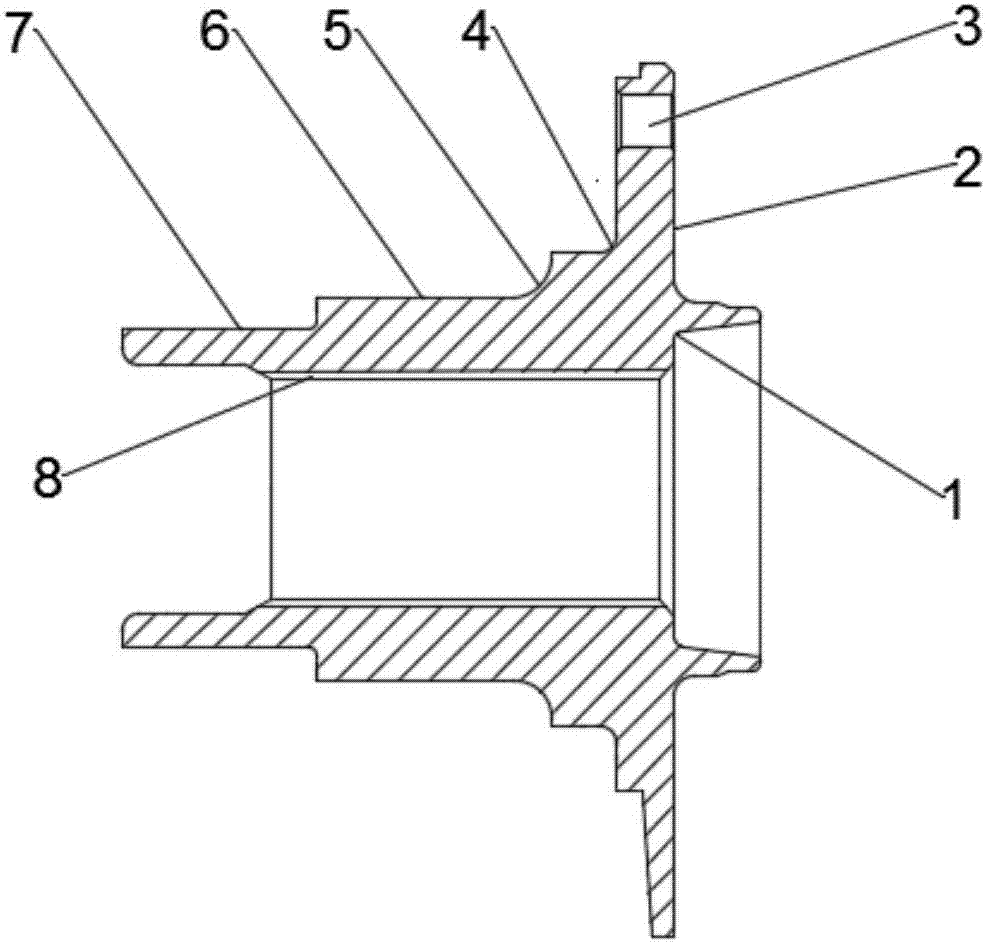

Method for machining high-rigidity inner ring flange of automobile hub bearing unit

Owner:江苏昊鹏机械有限公司 +1

Methods for extruding a honeycomb article with a skin surrounding a central cellular structure

ActiveUS7914724B2Reduction tendencyEasy alignmentLayered productsConfectioneryHoneycombBiomedical engineering

Disclosed is a method and apparatus for forming a circumferential skin surrounding a central cellular structure of an extruded honeycomb article. The method and apparatus may be used to produce defect-free skins and / or skins having large thickness and a high degree of particle alignment thereby preferably exhibiting CTE comparable to the extruded webs. These benefits are achieved by providing a die and method wherein a flow, Q, exiting any two active ones of a plurality of peripheral slots forming the skin is substantially equal. Also disclosed is a thick-skinned ceramic article having a thick extruded skin (ts′>5 tw′) with an I-value comparable to the webs.

Owner:CORNING INC

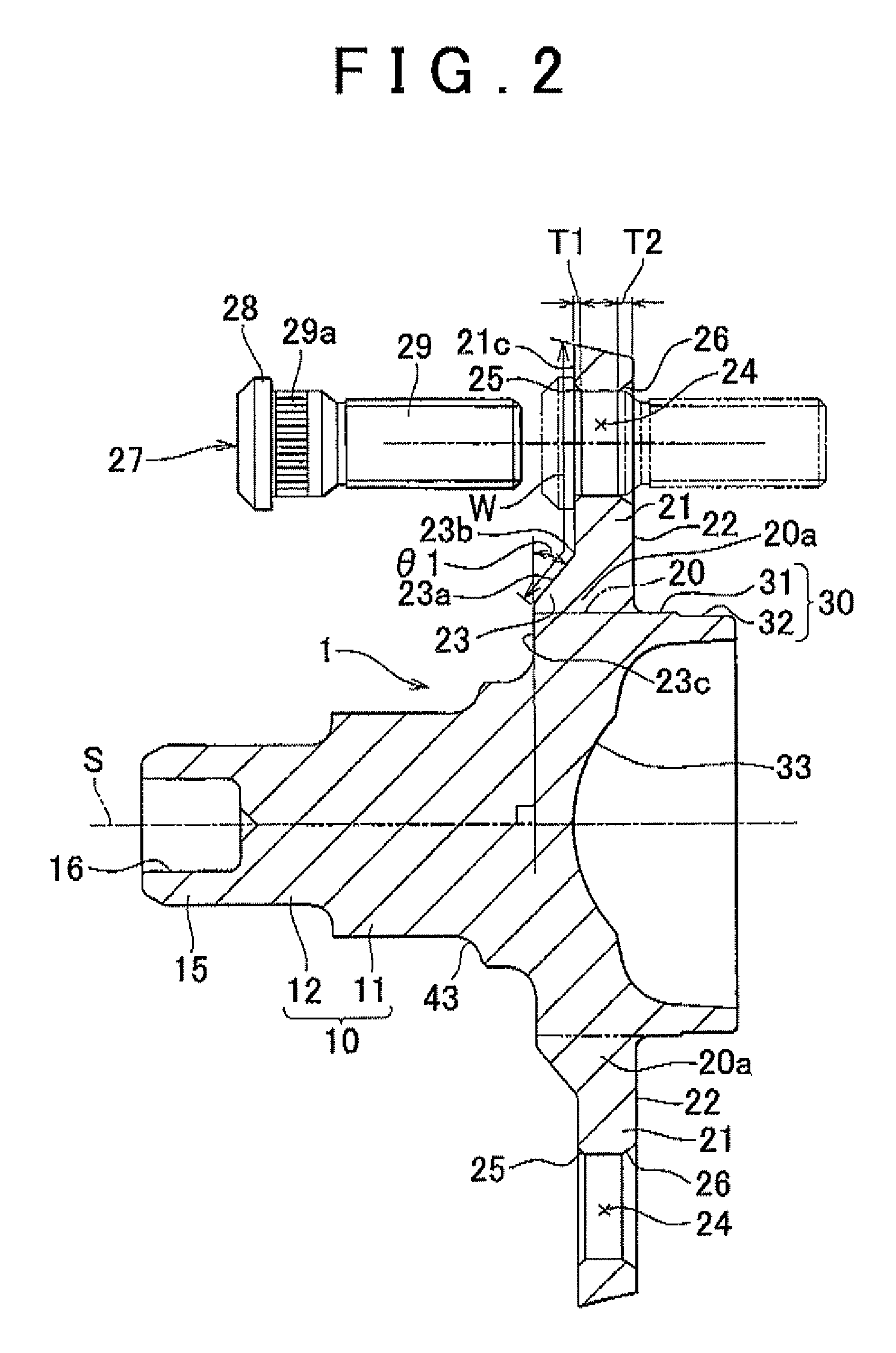

Wheel bearing device and manufacturing method therefor

A wheel bearing device of the invention includes a flanged shaft member that includes a shaft portion to which a rolling bearing is assembled, a fitting shaft portion that is formed on one end side of the shaft portion and that is fitted to a center hole of a wheel, and a plurality of flange portions that extend radially outward on an outer peripheral surface located between the shaft portion and the fitting shaft portion and each of which has a through bolt hole in which a hub bolt for fastening the wheel is arranged. Each flange portion of the wheel bearing device is formed by side extrusion when a forged recess is formed at a center of an end surface of the fitting shaft portion by cold forging. An edge portion of a cross-sectional shape taken perpendicularly to a longitudinal direction of each flange portion is formed in an R-chamfered shape.

Owner:JTEKT CORP

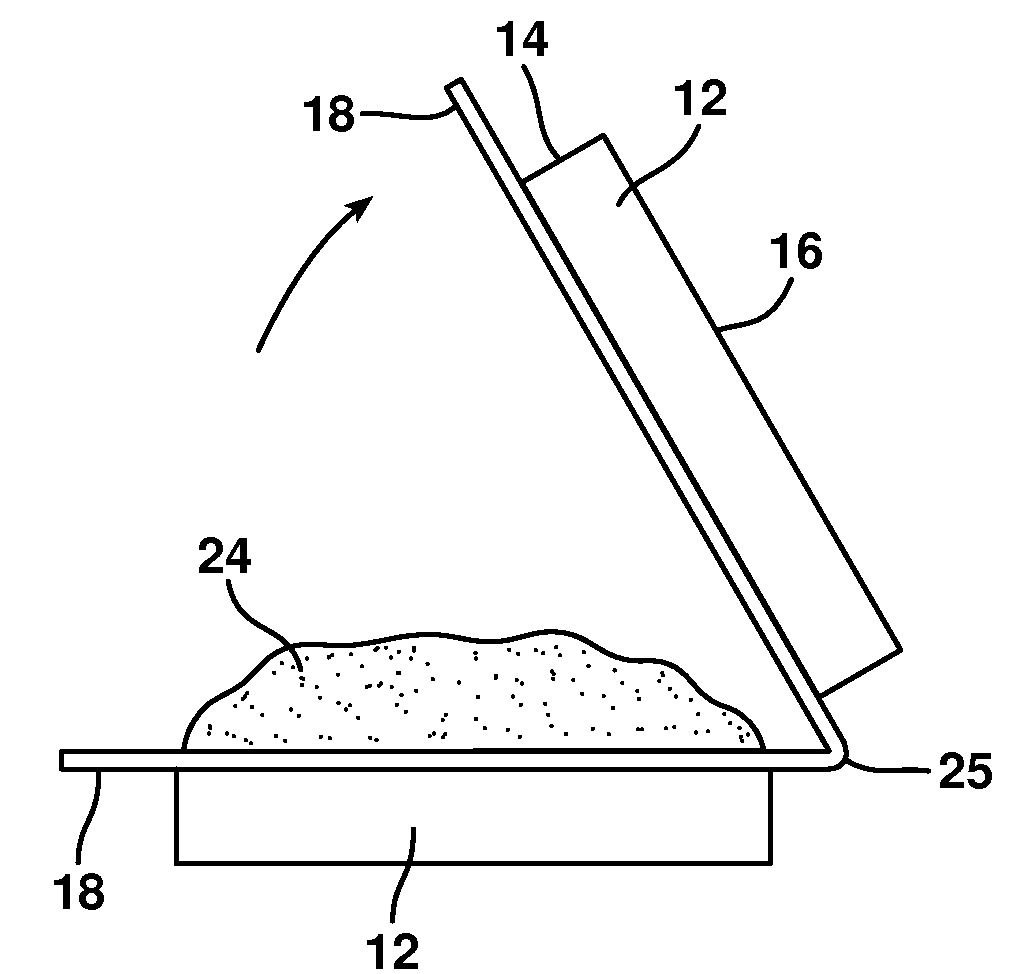

Mold With Reinforced Hinge

InactiveUS20100133725A1Inexpensive materialsImprove mold lifeMouldsConfectioneryEngineeringArtificial stone

Flexible, reinforced polymeric molds for Corning simulated stone veneers is provided. The molds are formed of a single solitary unit containing a plurality of contoured wells. A flange forms an outer portion of the mold and provides a means for grasping the mold so that the mold can be folded and flipped for the extraction of the artificial stones. One or both hinge portions located transversely across the central portion of the mold may be reinforced with an embedded nylon mesh scrim. The scrim increases the tear and tensile strength of the hinge portion. Additionally, the incorporation of the nylon mesh scrim at the hinge portions increases the life of the mold and reduces the occurrence of scrap molds. The polymeric mold advantageously retains its shape after the mold has been removed from the simulated stones, which permits the mold to be used in subsequent stone-molding operations.

Owner:BORAL STONE PRODS

Special die for stamping inward bending part and stamping method

ActiveCN104475579AHigh fillet strengthImprove mold lifeShaping toolsEngineeringMechanical engineering

The invention discloses a special die for stamping an inward bending part and a stamping method. The special die for stamping the inward bending part is provided with a first die component and a second die component, a bottom round angle of a blank is precisely bent through the first die component, and the second die component bends the blank into the part shape which conforms to size requirements based on keeping the bottom round angle. The special die for stamping the inward bending part has high practical value.

Owner:山东省未来人才科技有限公司

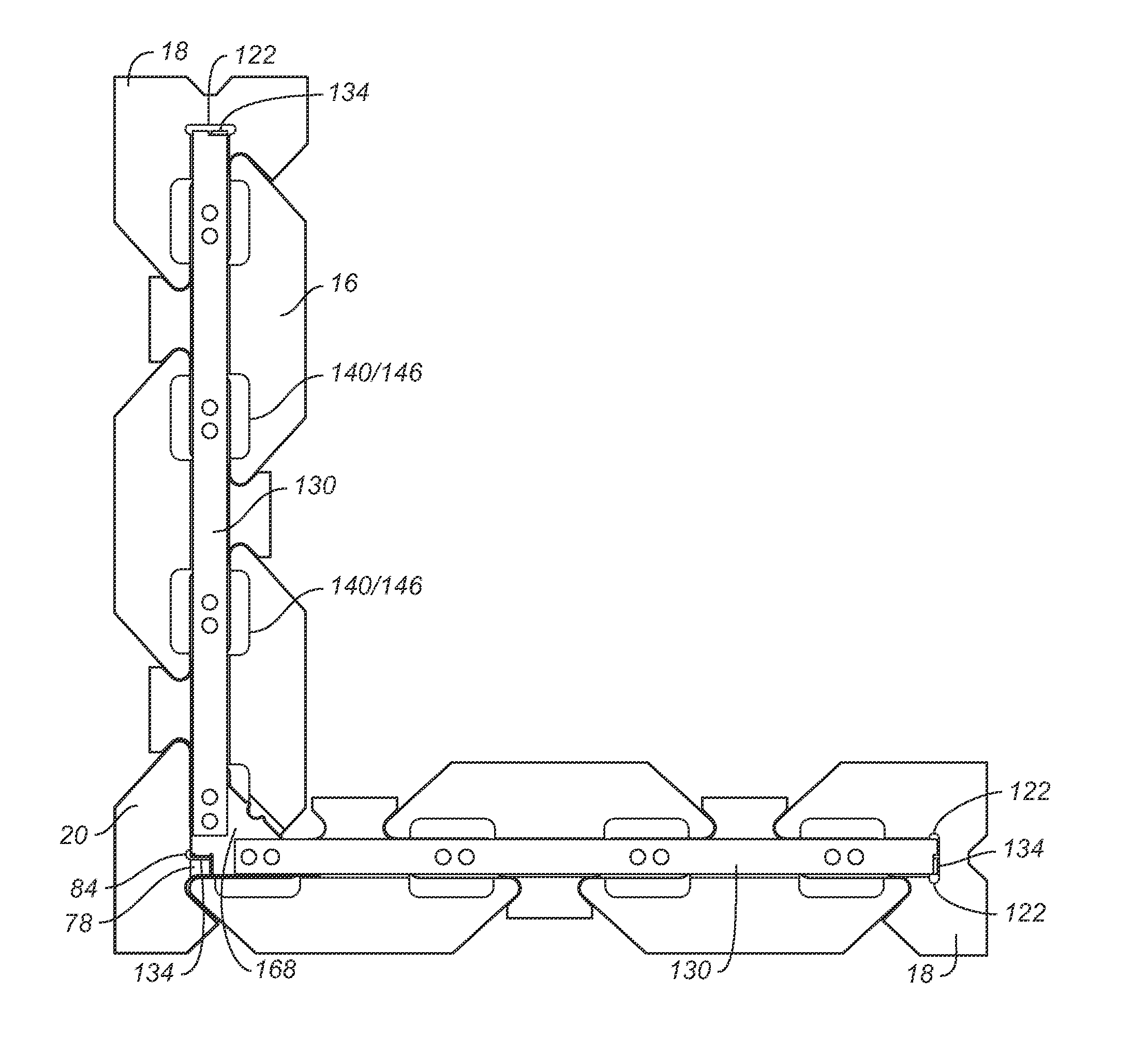

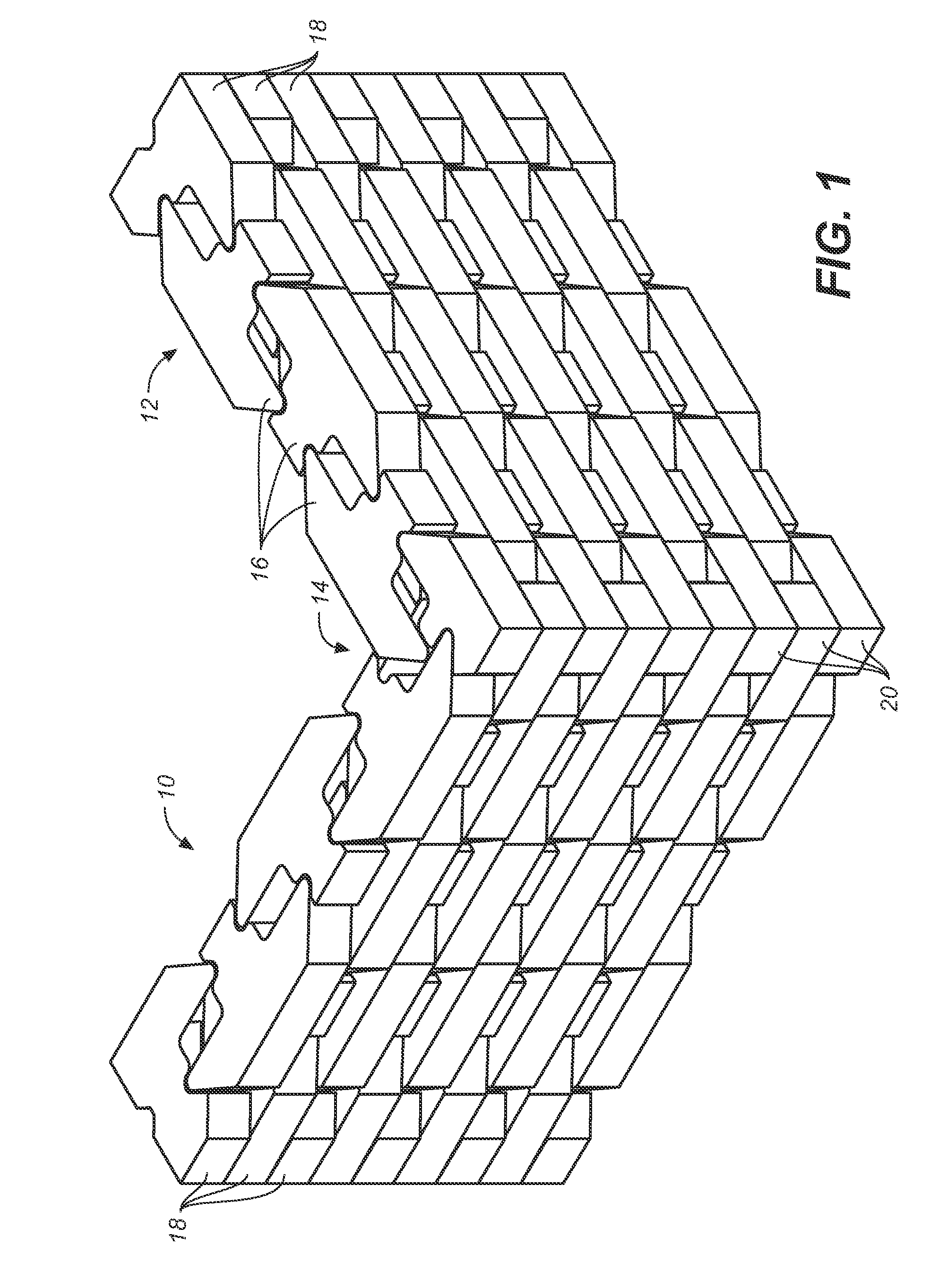

Dry-stack masonry system

ActiveUS20110047921A1Economical and simplifiedImprove mold lifeConstruction materialStrutsEngineeringMechanical engineering

Owner:WITCHER STEVE D

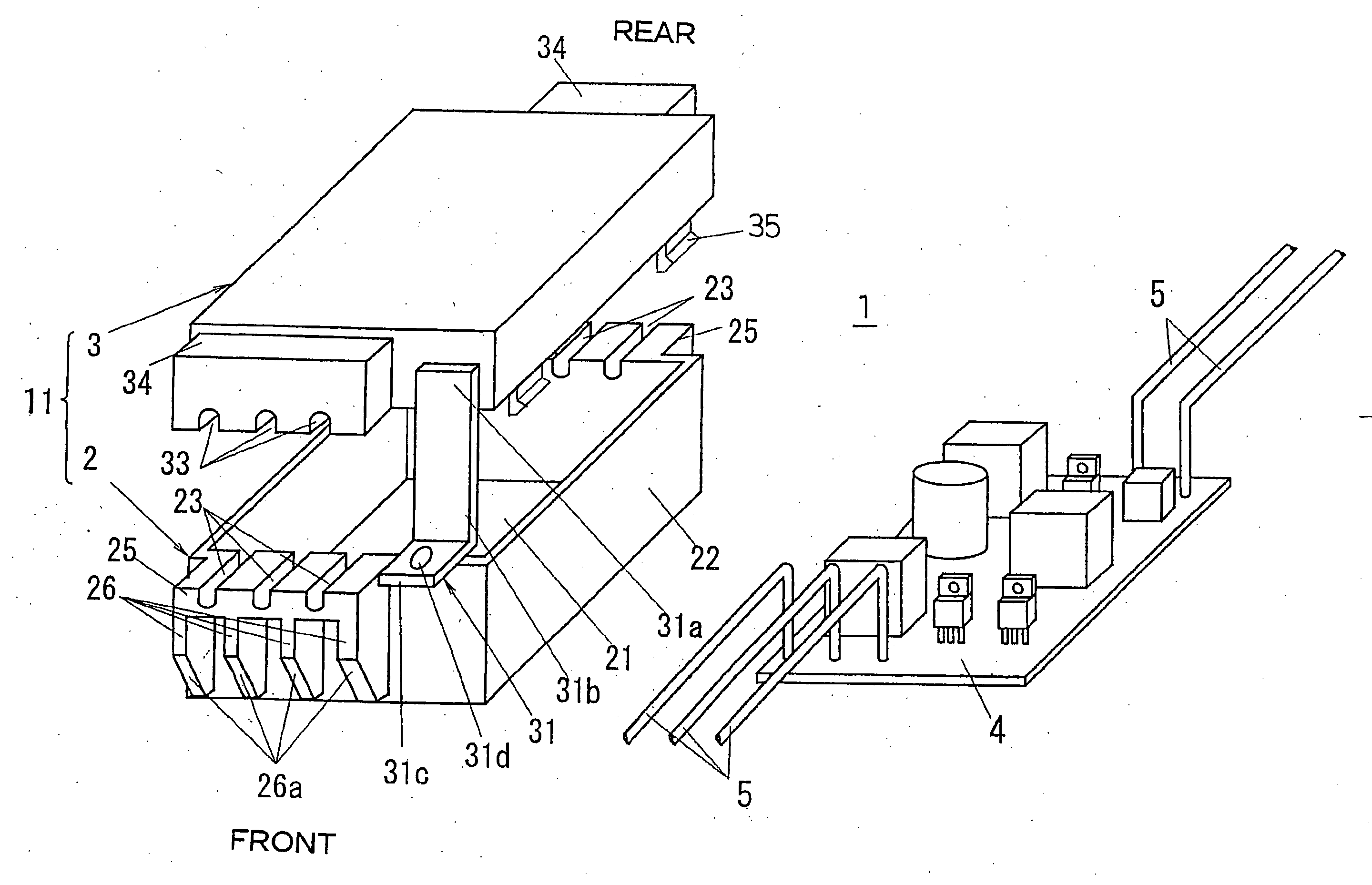

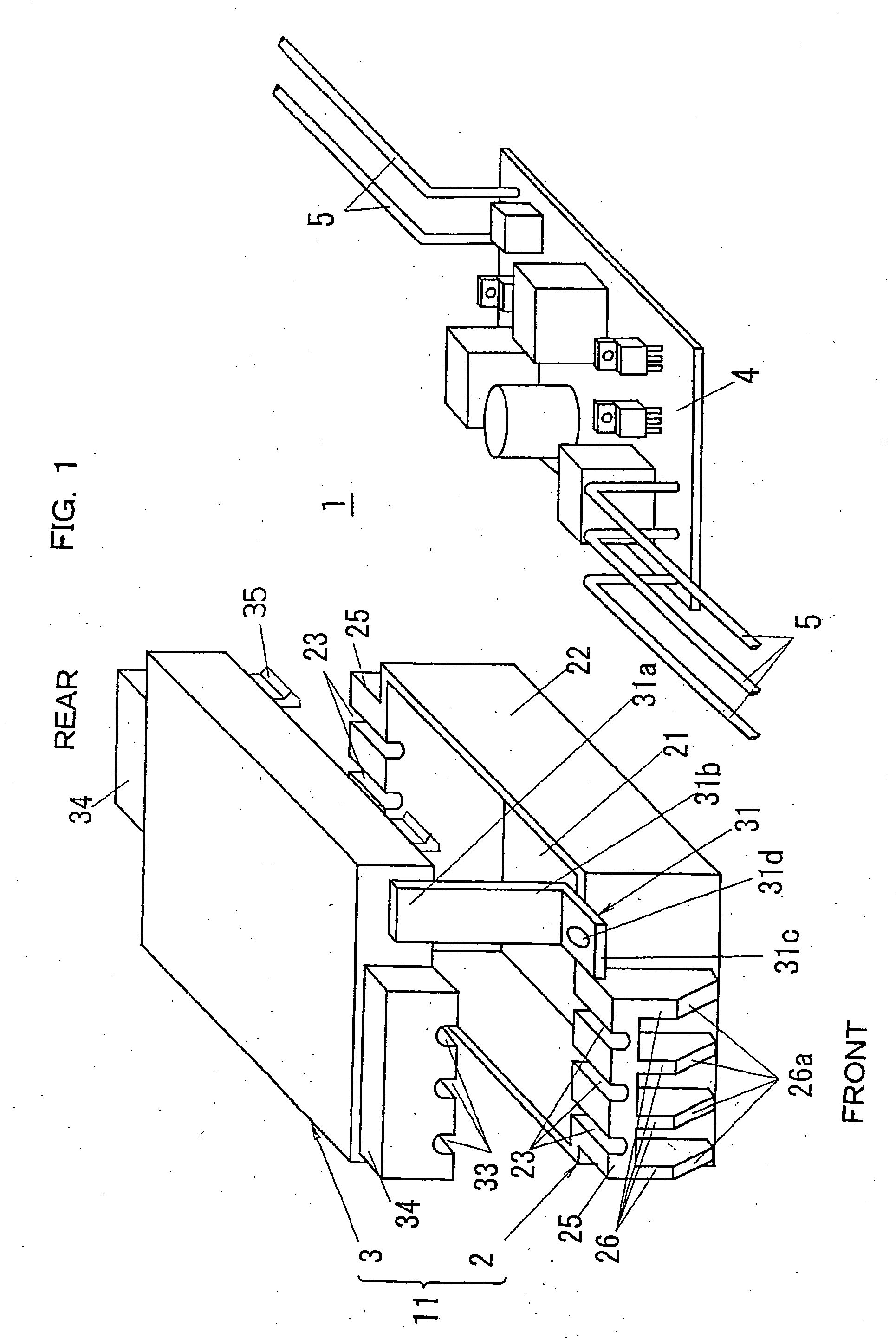

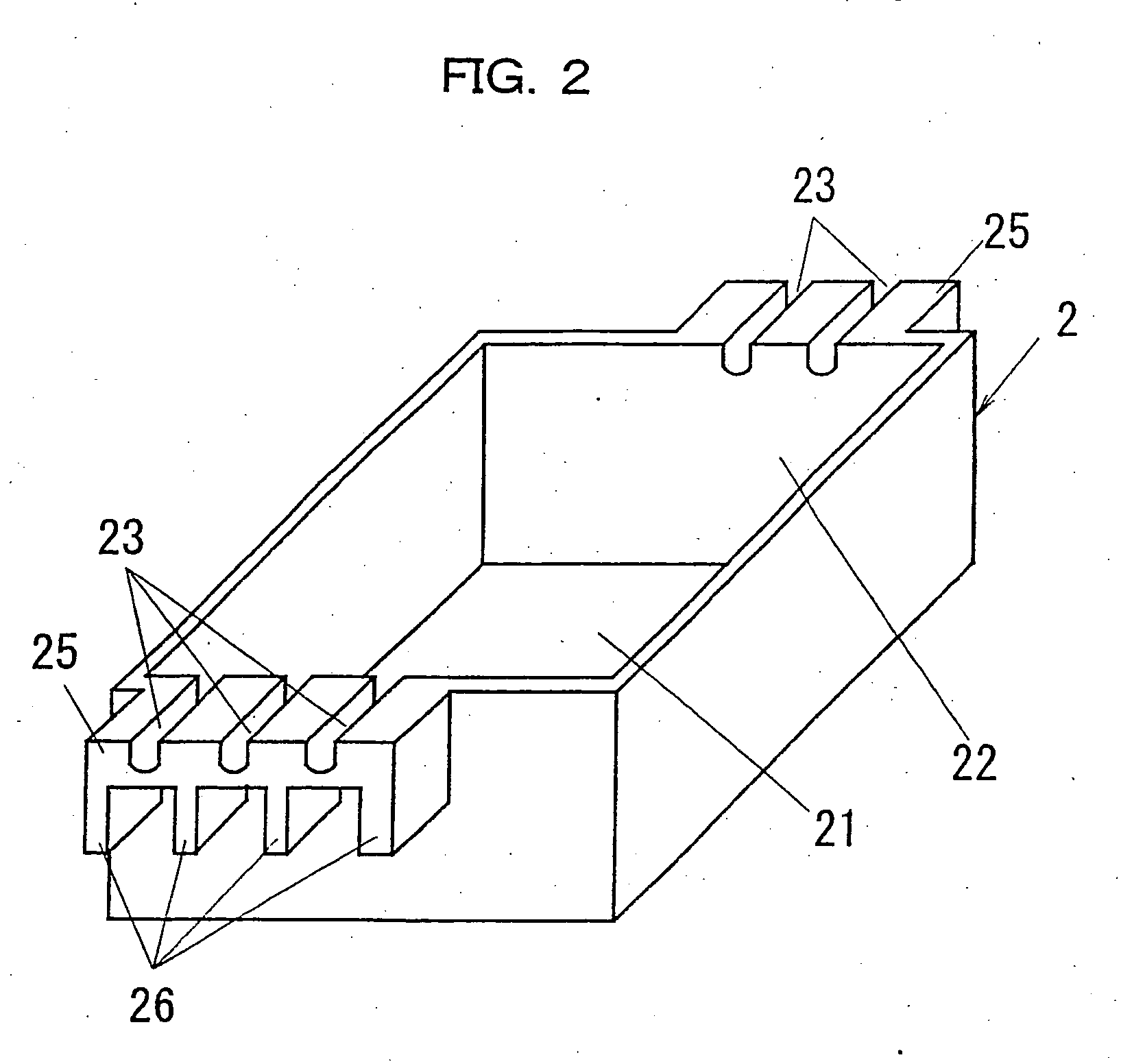

Discharge lamp lighting device and illiminator

InactiveUS20060164842A1Reduce manufacturing costReduce lighting costsClosed casingsElongate light sourcesEffect lightLighting system

In a discharge lamp lighting apparatus for lighting a lighting system using a discharge lamp, a housing used for containing a printed circuit board on which a discharge lamp lighting circuit is mounted is formed by resin molding. In order to put out wires connected to the printed circuit board from an inside to outside of the housing, protruding portions are protruded outward from upper end portions of a front face and a rear face of side walls of a base member which constitute the housing, and wire putting grooves are formed on upper faces of the protruding portions. Furthermore, reinforcing ribs are provided for coupling the protruding portions and portions of the side walls except the protruding portions so as to reinforce mechanical strength of the protruding portions by the reinforcing ribs.

Owner:MATSUSHITA ELECTRIC WORKS LTD

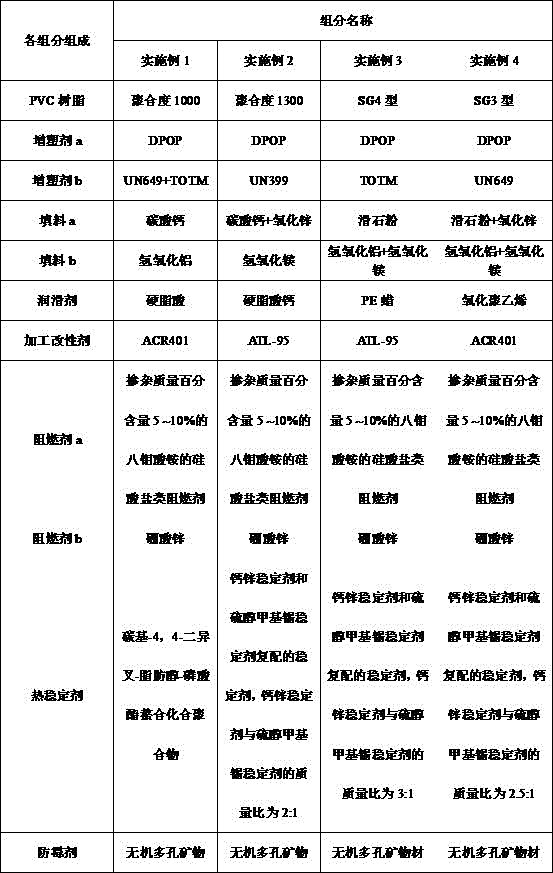

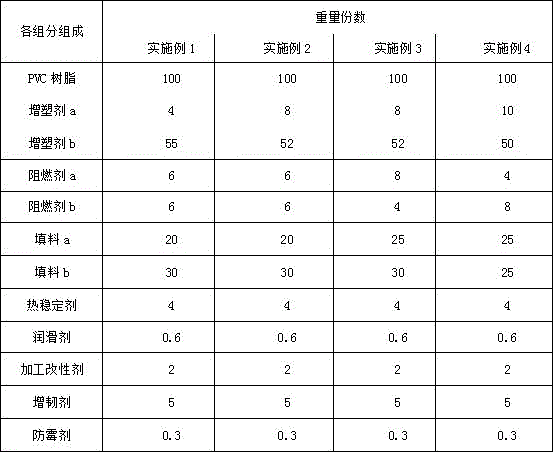

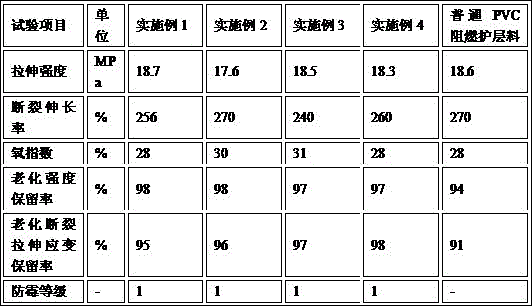

Novel environmental-friendly anti-mold flame-retardant polyvinyl chloride protection layer material

ActiveCN106496863AGood compatibilityGood weather resistancePlastic/resin/waxes insulatorsPlasticizerPolyvinyl chloride

The invention discloses a novel environmental-friendly anti-mold flame-retardant polyvinyl chloride protection layer material which is characterized by being prepared from the following raw materials in parts by weight: 100 parts of PVC resin, 2-8 parts of a plasticizer a, 30-55 parts of a plasticizer b, 5-10 parts of a flame retardant a, 5-10 parts of a flame retardant b, 10-40 parts of packing a, 20-30 parts of packing b, 2-10 parts of a thermal stabilizer, 0.5-2 parts of a lubricant, 1-3 parts of a processing modifier, 0.2-0.4 part of an anti-mold agent and 5-10 parts of a toughening agent, wherein the anti-mold agent is an antibacterial anti-mold agent which is compounded from an inorganic porous mineral material loaded with inorganic antibacterial factors and organic anti-mold factors. Compared with a common PVC flame-retardant protection layer material, the novel environmental-friendly anti-mold flame-retardant polyvinyl chloride protection layer material disclosed by the invention is very good in anti-mold property, and the service life of the protection layer material is greatly prolonged.

Owner:CGN DELTA (ZHONGSHAN) POLYMER CO LTD

Method for processing spinning cup by using Al-Cu-Mn-Mg hard aluminum alloy as material

InactiveCN103667831AImprove thermal conductivityRapid coolingFoundry mouldsContinuous wound-up machinesChemical treatmentLow speed

The invention discloses a method for processing a spinning cup by using Al-Cu-Mn-Mg hard aluminum alloy as a material, belonging to the technical field of spinning machineries. The spinning cup is processed by the following steps of preparing a blank through injection molding; normalizing; heavy boring; induction hardening, carrying out chemical treatment on surface; depositing; and coating on surface. The spinning cup prepared by the method is easy to process, is of a more reasonable structure, has long service life, good wear resistance, mechanical property, sealing performance, corrosion resistance and oxidation resistance, does not overflow lubricating grease, prevents rubber rollers and cotton silver from being contaminated, further meets the lubricating requirement of a bearing, further prolongs the service life of the bearing, and is applicable to high speed and low speed spinning machineries.

Owner:WUXI FUMEI LIGHT ALLOY TECH

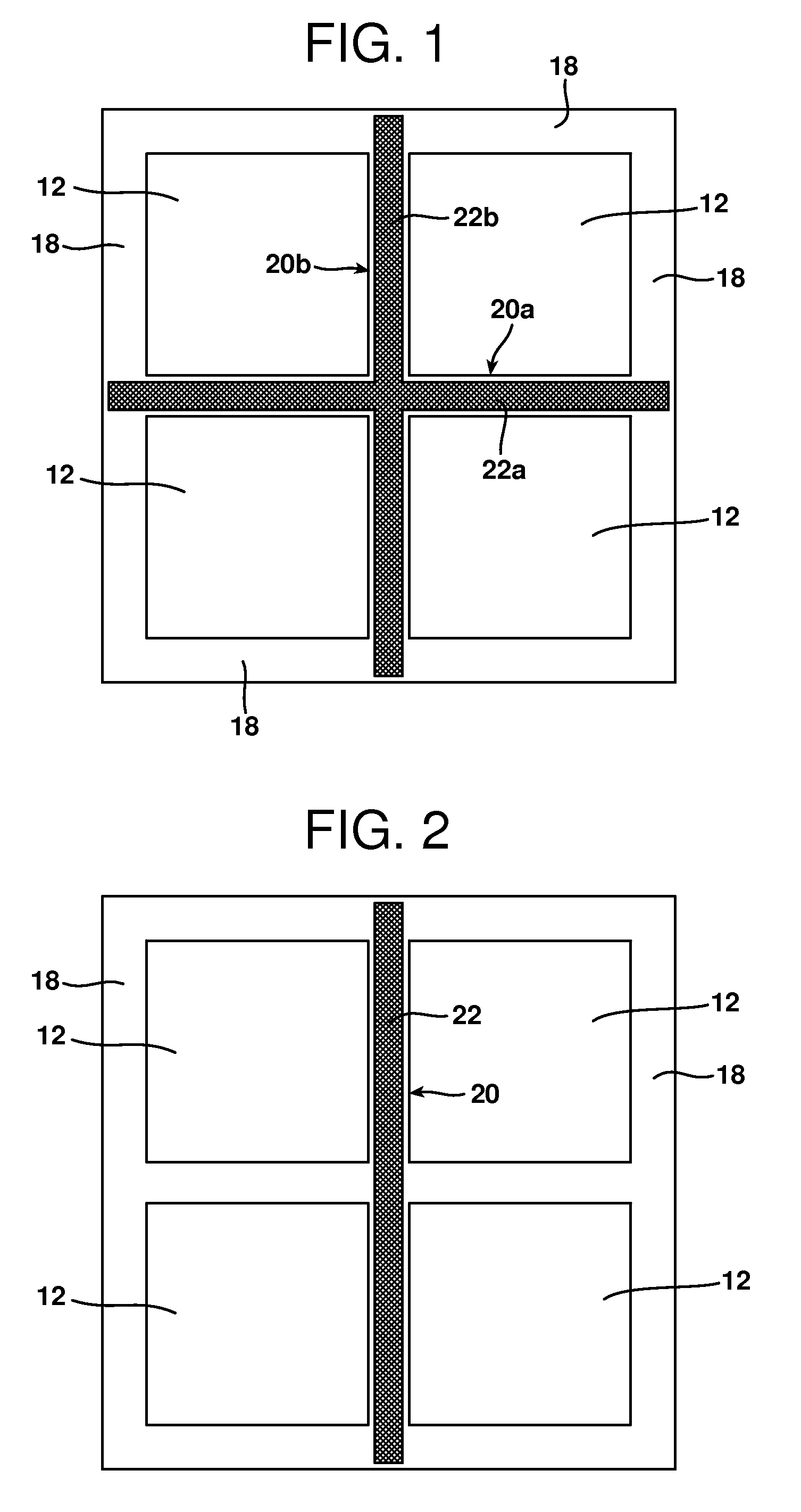

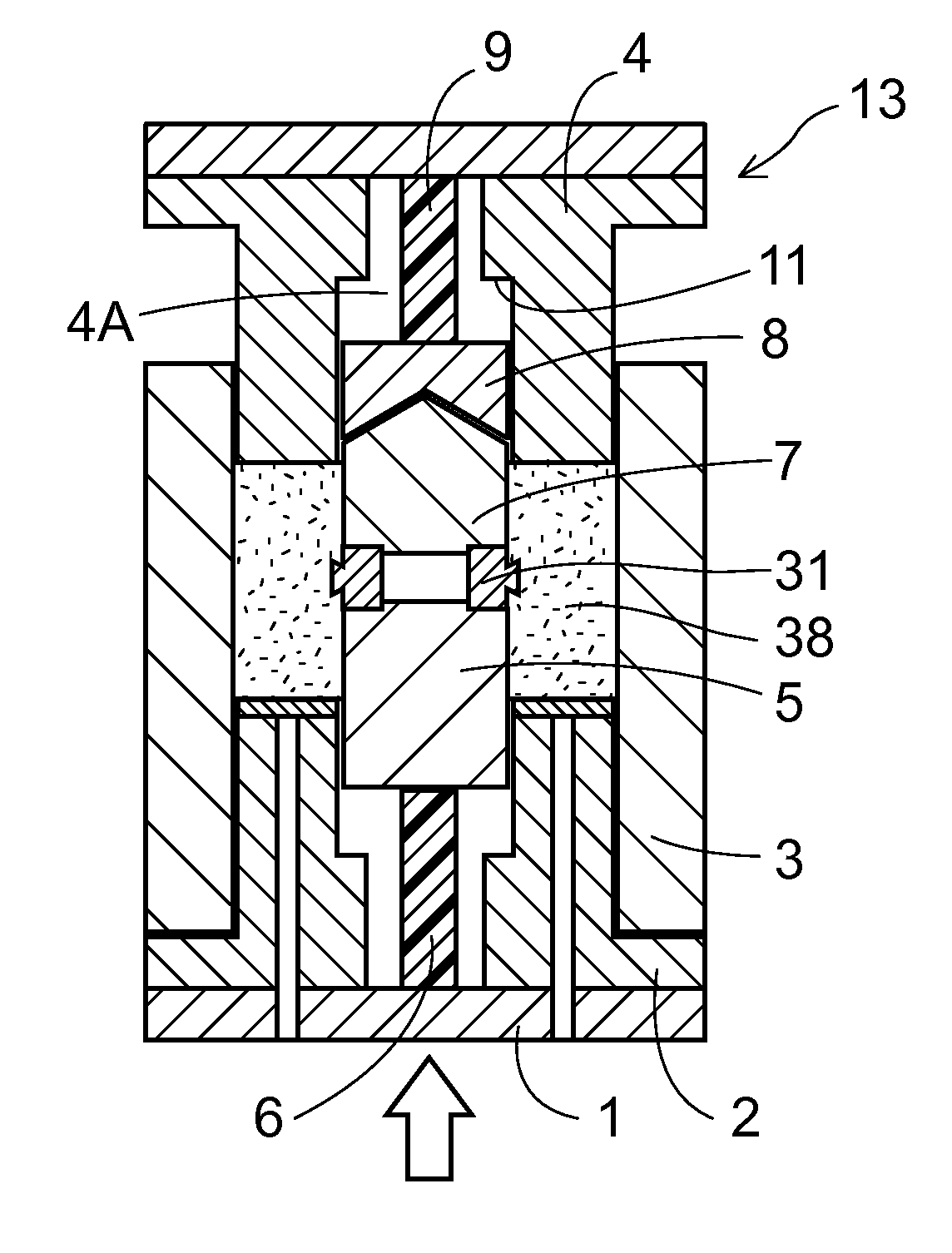

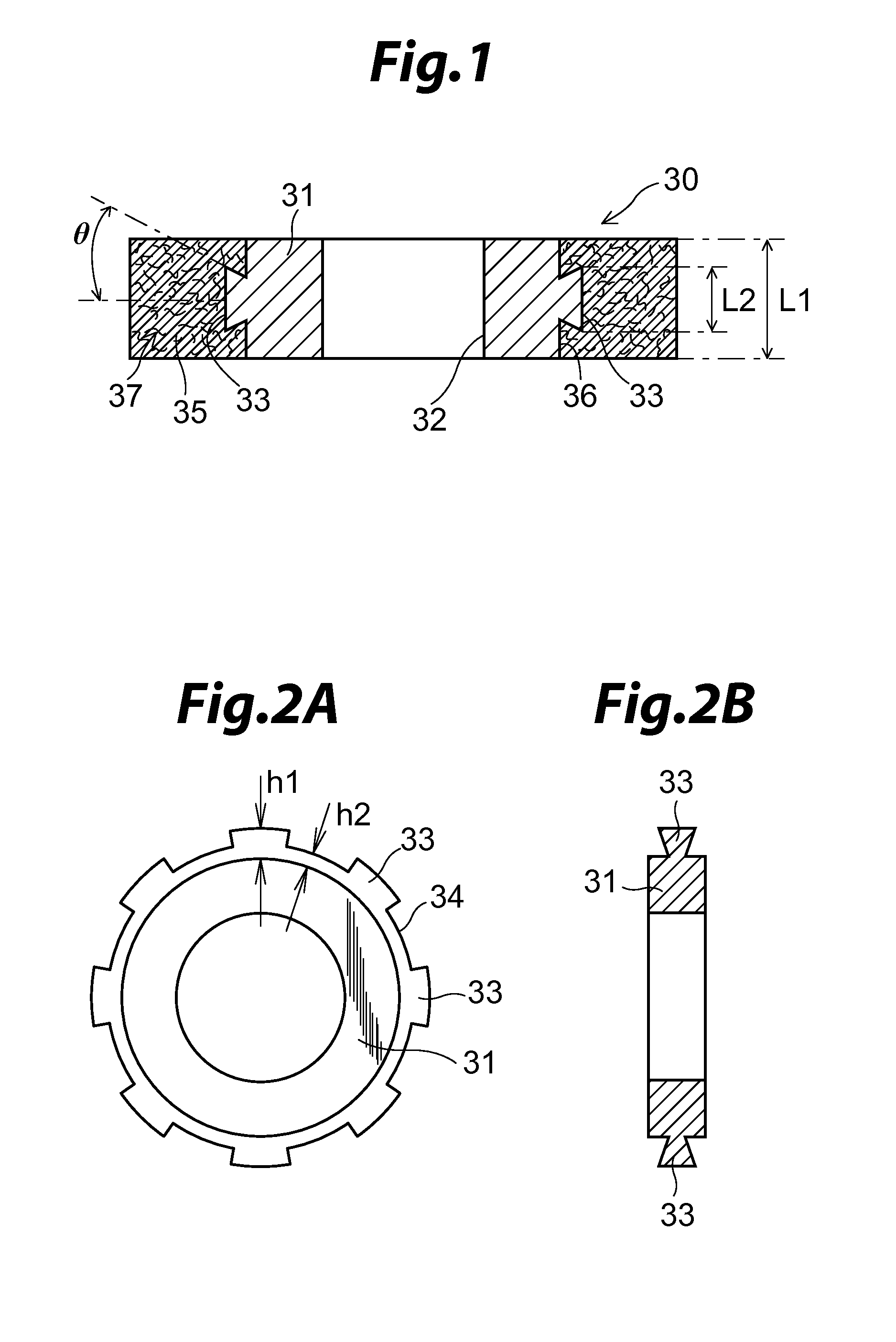

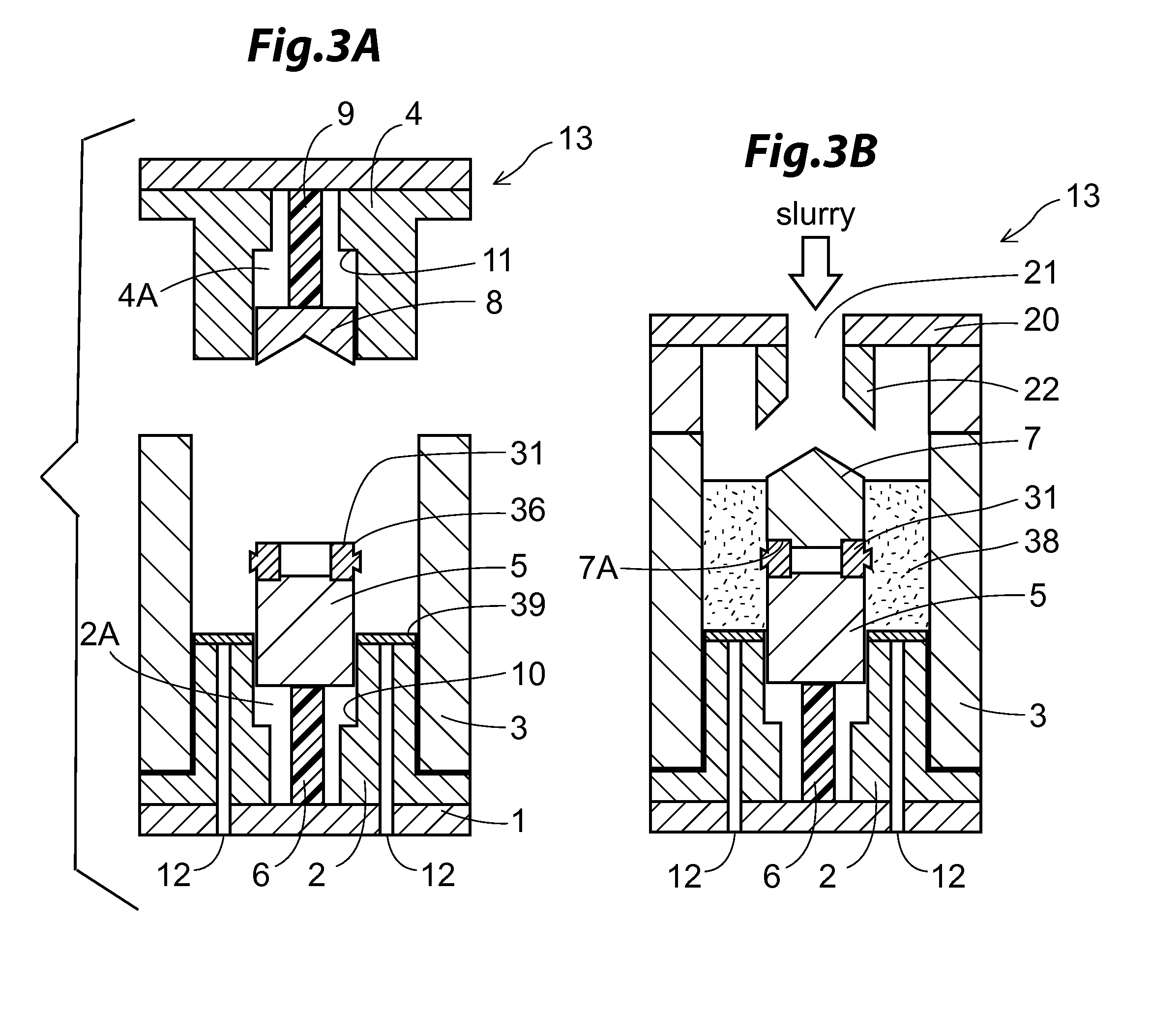

Method of manufacturing fiber substrate and method of manufacturing resin rotator

ActiveUS20160016367A1Uniformly manufacturedImprove mold lifeCeramic shaping apparatusGear wheelsFiberOptoelectronics

There is little fluctuation in amount of short fibers among individual products of fiber substrate. No damage is caused to a mold for the fiber substrate. Continuous production of the fiber substrates is possible. A method of manufacturing a fiber substrate includes the steps of: preparing slurry by dispersing short fibers in a dispersion medium; pouring the slurry into a cylindrical mold from above the cylindrical mold, the slurry being directed to a slurry diffusion member disposed in the center of the cylindrical mold and having an upward pointing conical or pyramidal shape; pouring the dispersion medium or water onto the slurry diffusion member from above the slurry diffusion member to cause the short fibers adhering to the slurry diffusion member to fall down, after the step of pouring the slurry; and discharging the dispersion medium from the cylindrical mold to accumulate the short fibers in the cylindrical mold to obtain a fiber aggregate.

Owner:RESONAC CORP

Method for fabricating bottle molds

InactiveUS6837297B1Promotes local meltingEnhance mechanical interlockingBlowing mouldsBottleMachining

The method allows fabricating a bottle mold having dissimilar metal inserts embedded in regions where the bottle mold is most subject to attack by hot glass, and has a glass contact surface with refined grain size. To fabricate the bottle mold, rough castings are made by pouring cast-iron into a composite mold having dissimilar metal insert blanks fixably positioned therein. The dissimilar metal insert blanks become embedded in the cast-iron matrix to form rough dissimilar metal inserts in the rough casting. The composite mold has regions formed by metal chills that are partially embedded in a sand mix. The chills and the exposed surfaces of the rough dissimilar metal inserts define a cavity surface of the rough casting, which is subsequently machined to provide the glass contact surface of the bottle mold. The chills refine the grain size of the cast iron at the glass contact surface.

Owner:KELLY MACHINE & FOUNDRY

Wheel bearing device and manufacturing method therefor

A wheel bearing device of the invention includes a flanged shaft member that includes a shaft portion to which a rolling bearing is assembled, a fitting shaft portion that is formed on one end side of the shaft portion and that is fitted to a center hole of a wheel, and a plurality of flange portions that extend radially outward on an outer peripheral surface located between the shaft portion and the fitting shaft portion and each of which has a through bolt hole in which a hub bolt for fastening the wheel is arranged. Each flange portion of the wheel bearing device is formed by side extrusion when a forged recess is formed at a center of an end surface of the fitting shaft portion by cold forging. An edge portion of a cross-sectional shape taken perpendicularly to a longitudinal direction of each flange portion is formed in an R-chamfered shape.

Owner:JTEKT CORP

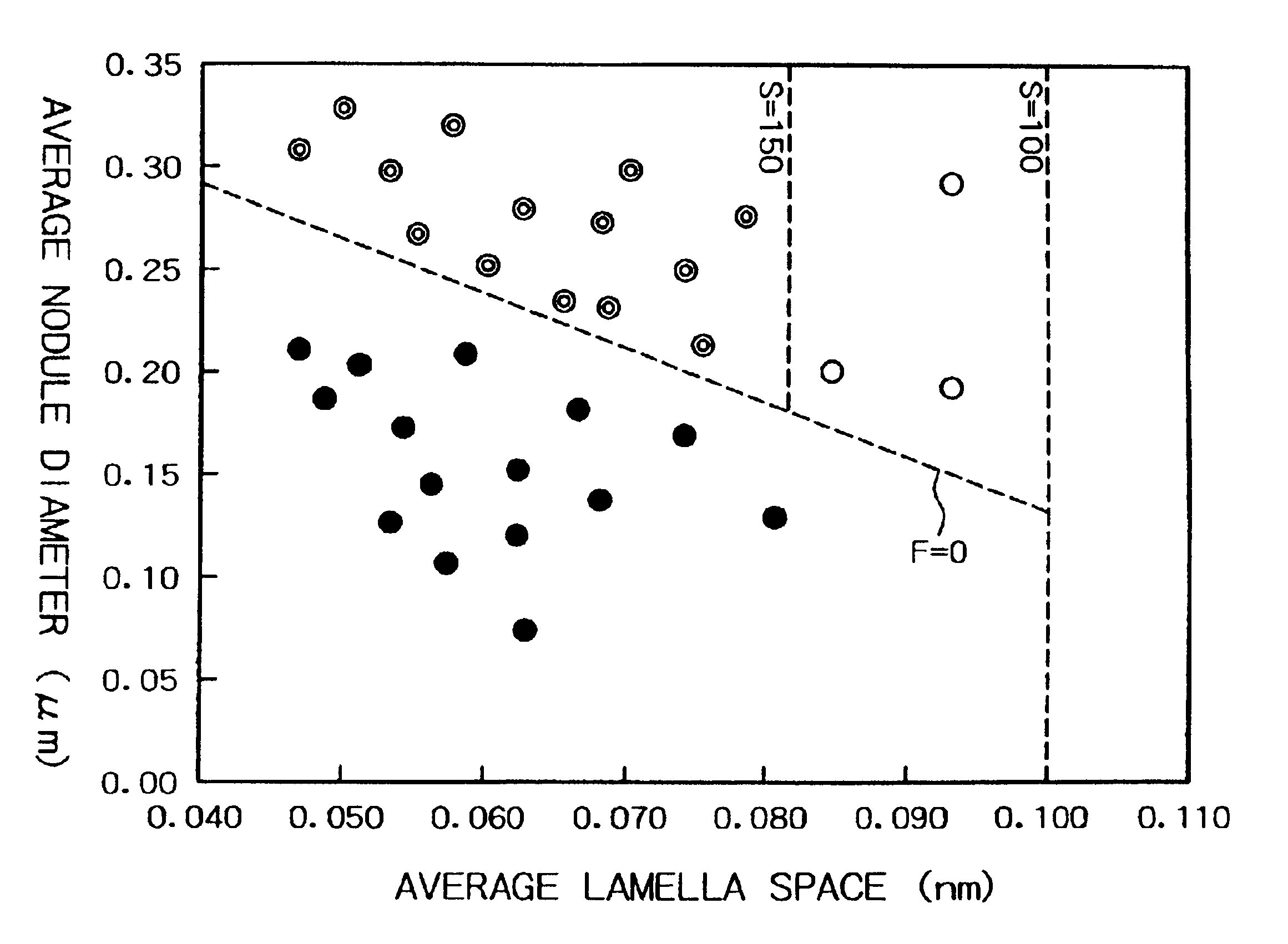

Injection molded centrifugal air impeller

InactiveUS20050095133A1Reduce the possibilityMinimizes mold wearPropellersPump componentsImpellerInjection moulding

A centrifugal air impeller designed for injection molding has a mold parting line extending intermediate the sides of the blades thus permitting optimum configurations of the inner and outer blade edges and enhanced impeller performance. The impeller inlet ring has an inner diameter less than that of the outer edges of the blades and an outer diameter greater than the outer diameter of the blades. The backplate has a diameter greater than that of the inner diameter of the blades.

Owner:TORRINGTON RES CO ASSIGNEE +1

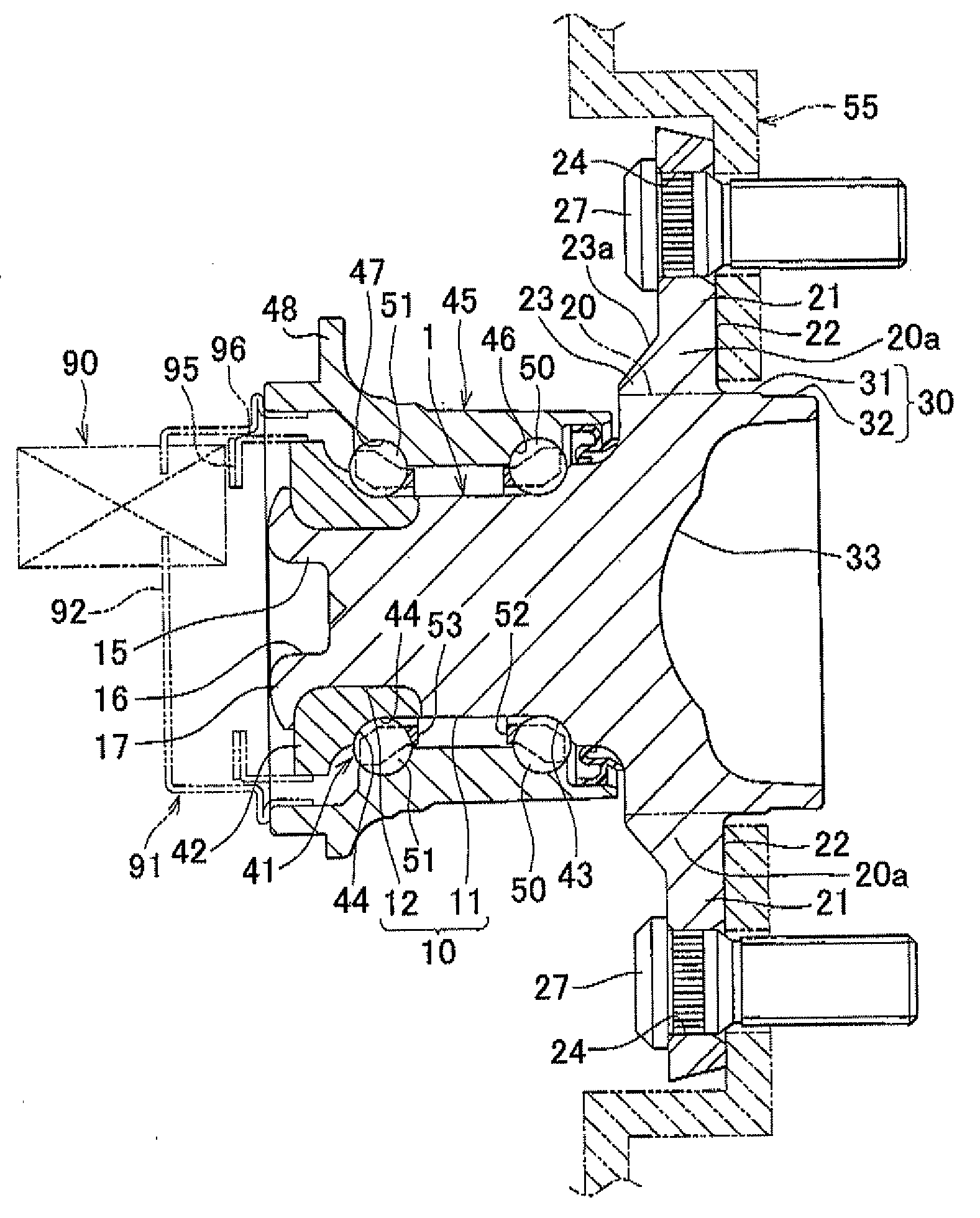

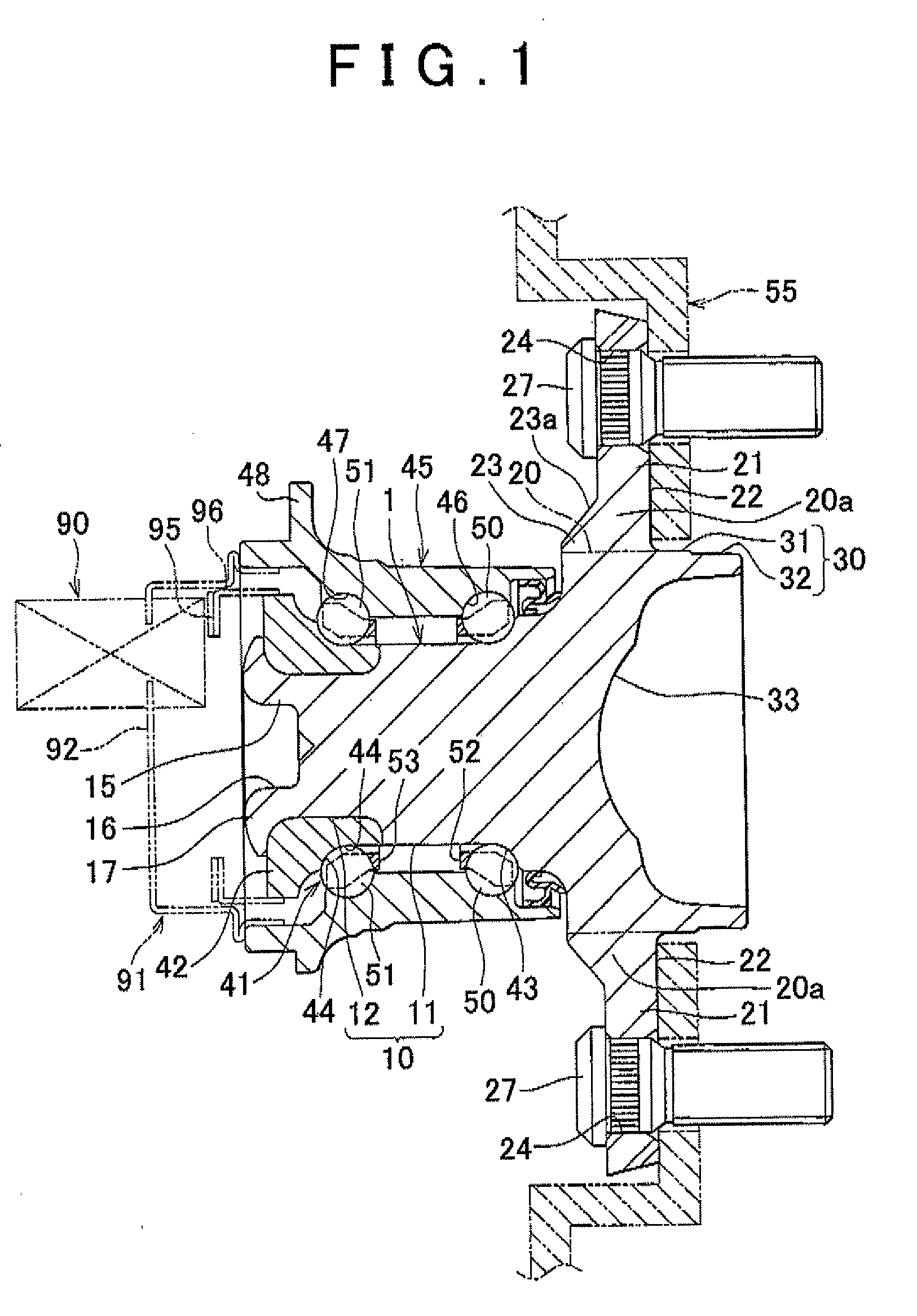

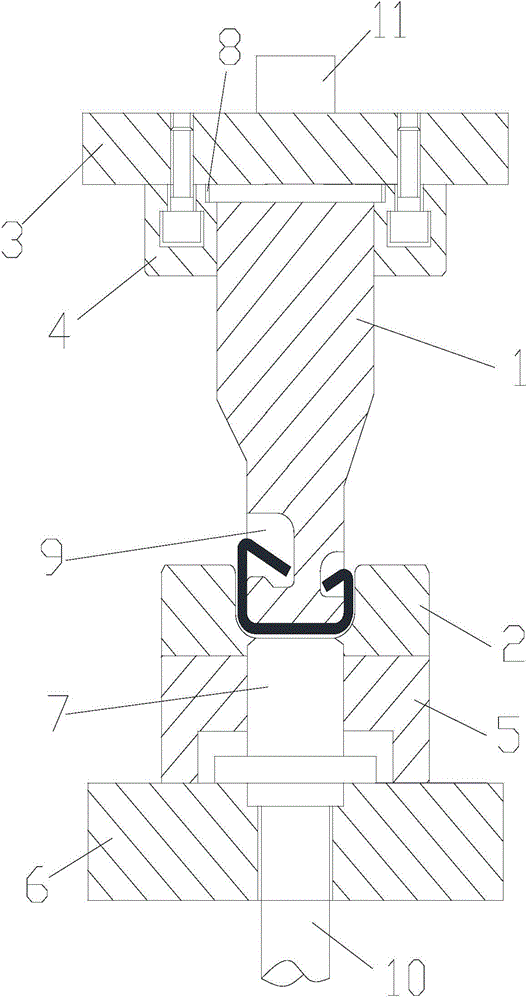

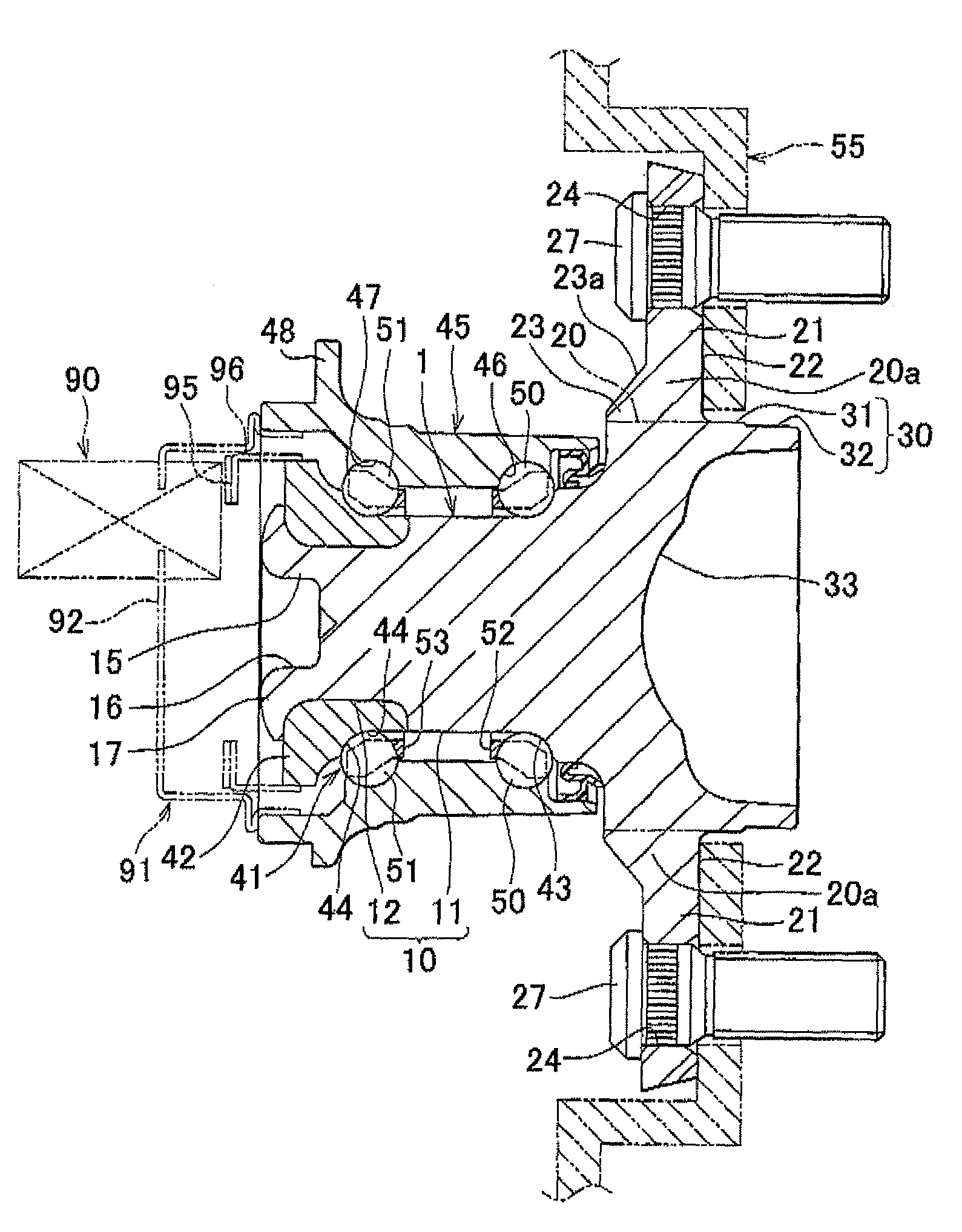

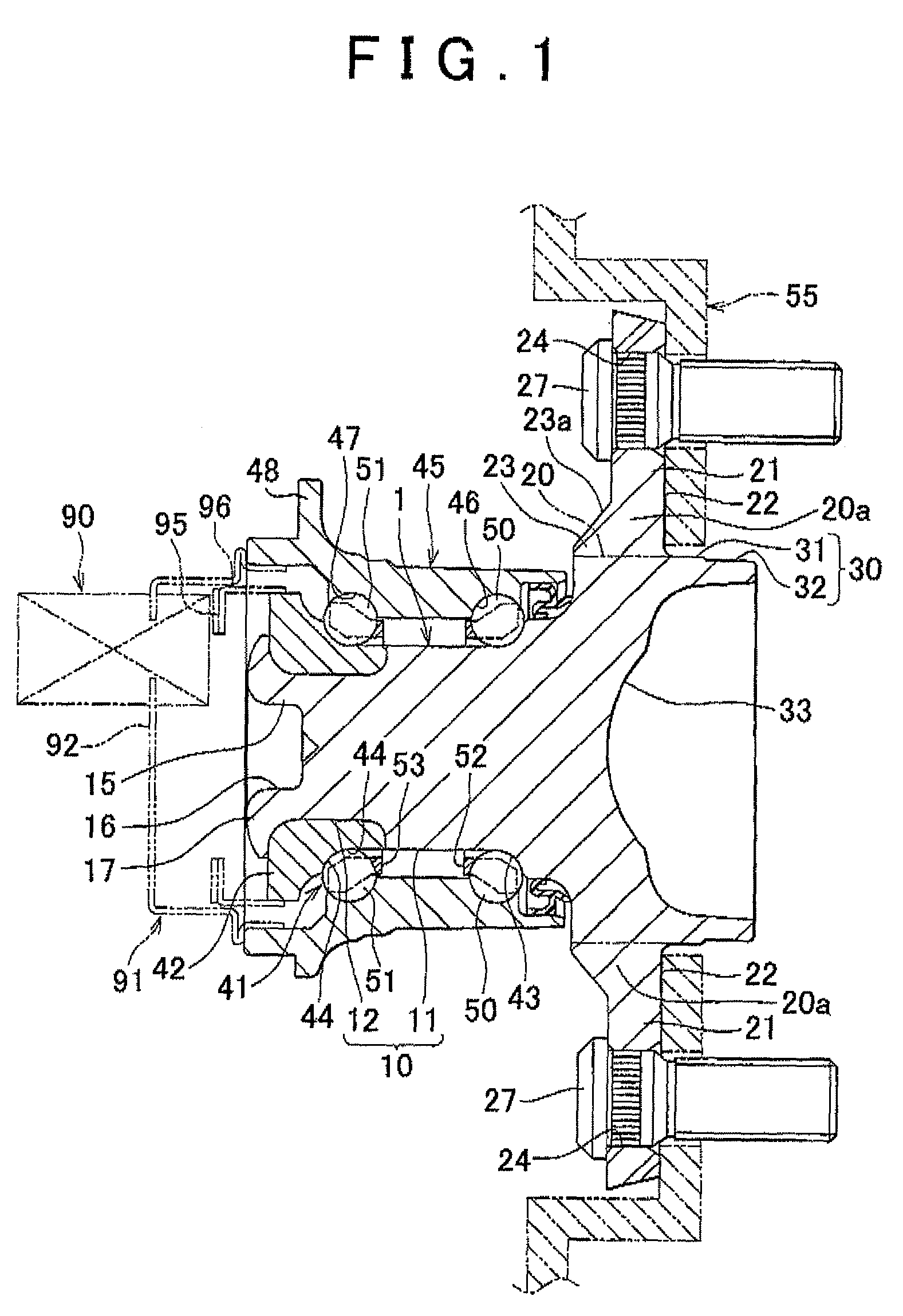

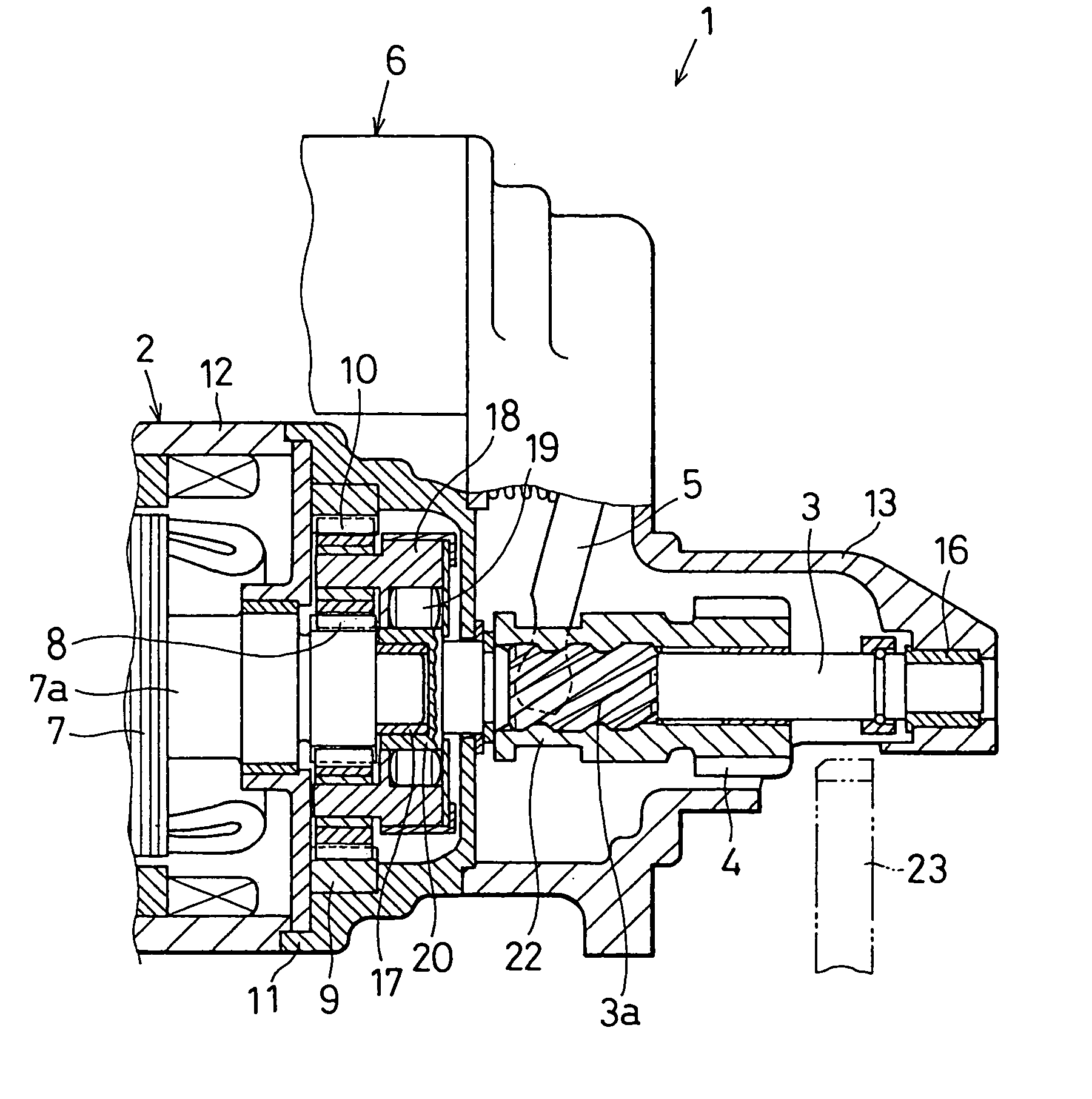

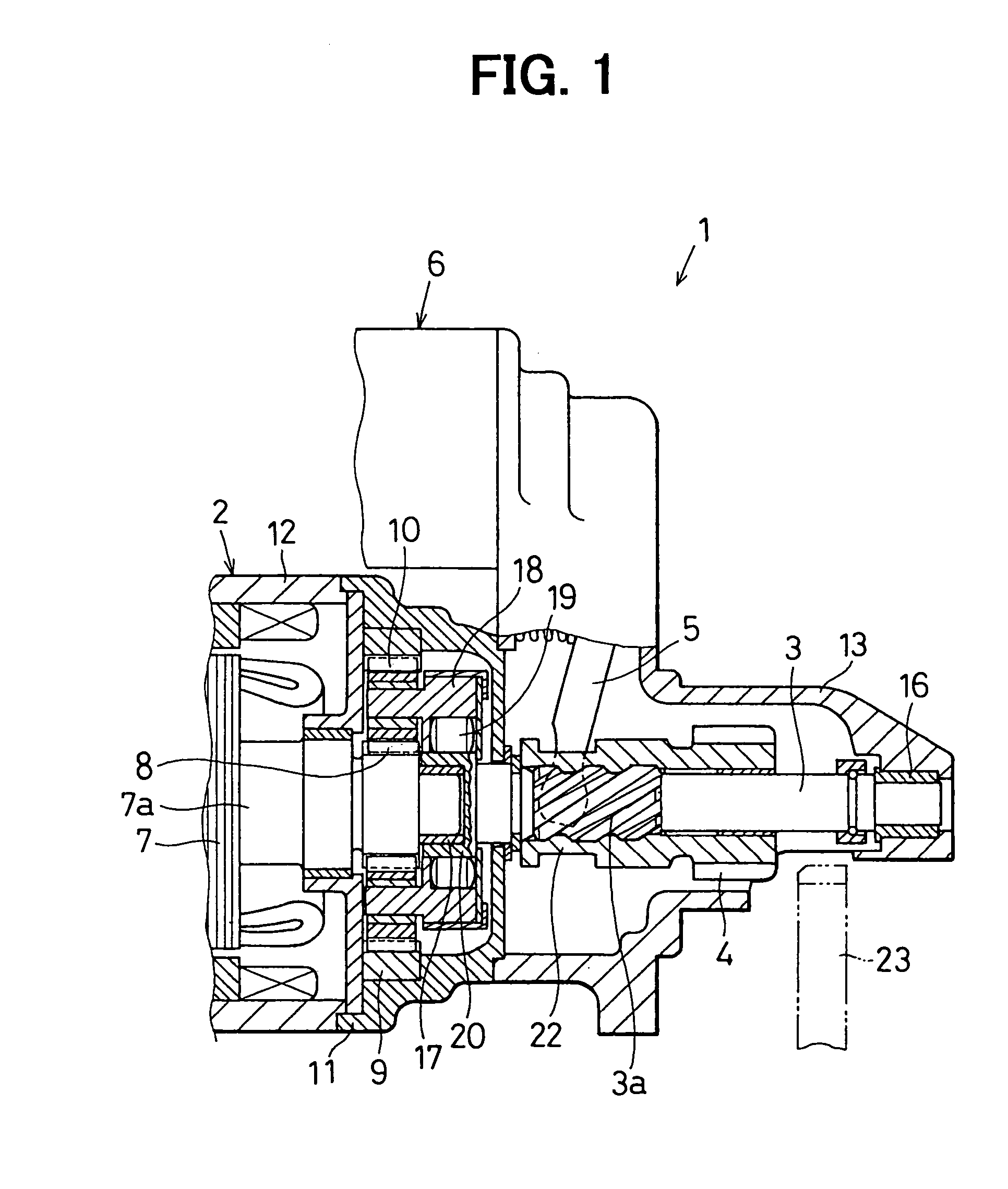

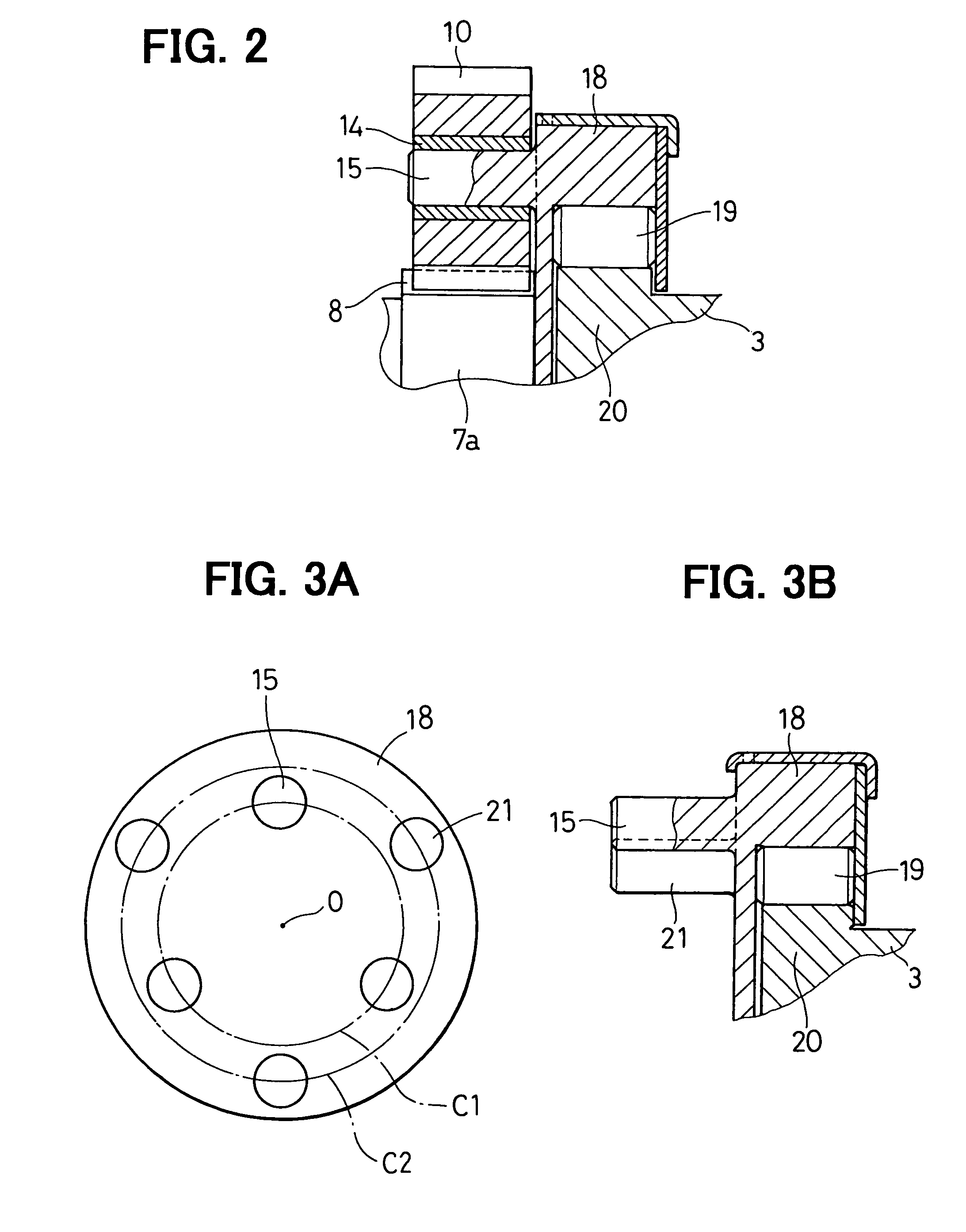

Starter with planetary reduction gear device

ActiveUS7101299B2Reduce speedImprove mold lifePower operated startersToothed gearingsGear wheelEngineering

In a planetary reduction gear device of a starter, a planet carrier forms gear shafts and planetary gears are rotatably supported by the gear shafts through bearings. The planet carrier further forms waste shafts projecting in a direction same as that of the gear shafts. The waste shafts are arranged on a circle having a center coincident with a rotation axis of the clutch outer portion at regular intervals in a circumferential direction. The circle on which the waste shafts are arranged has a diameter different from that of a circle on which the gear shafts are arranged. A speed reduction ratio can be changed by mounting planetary. gears having a gear specification different from that of the planetary gears supported on the gear shafts on the waste shafts. The planet carrier can be integrally formed with a clutch outer portion of a one-way clutch.

Owner:DENSO CORP

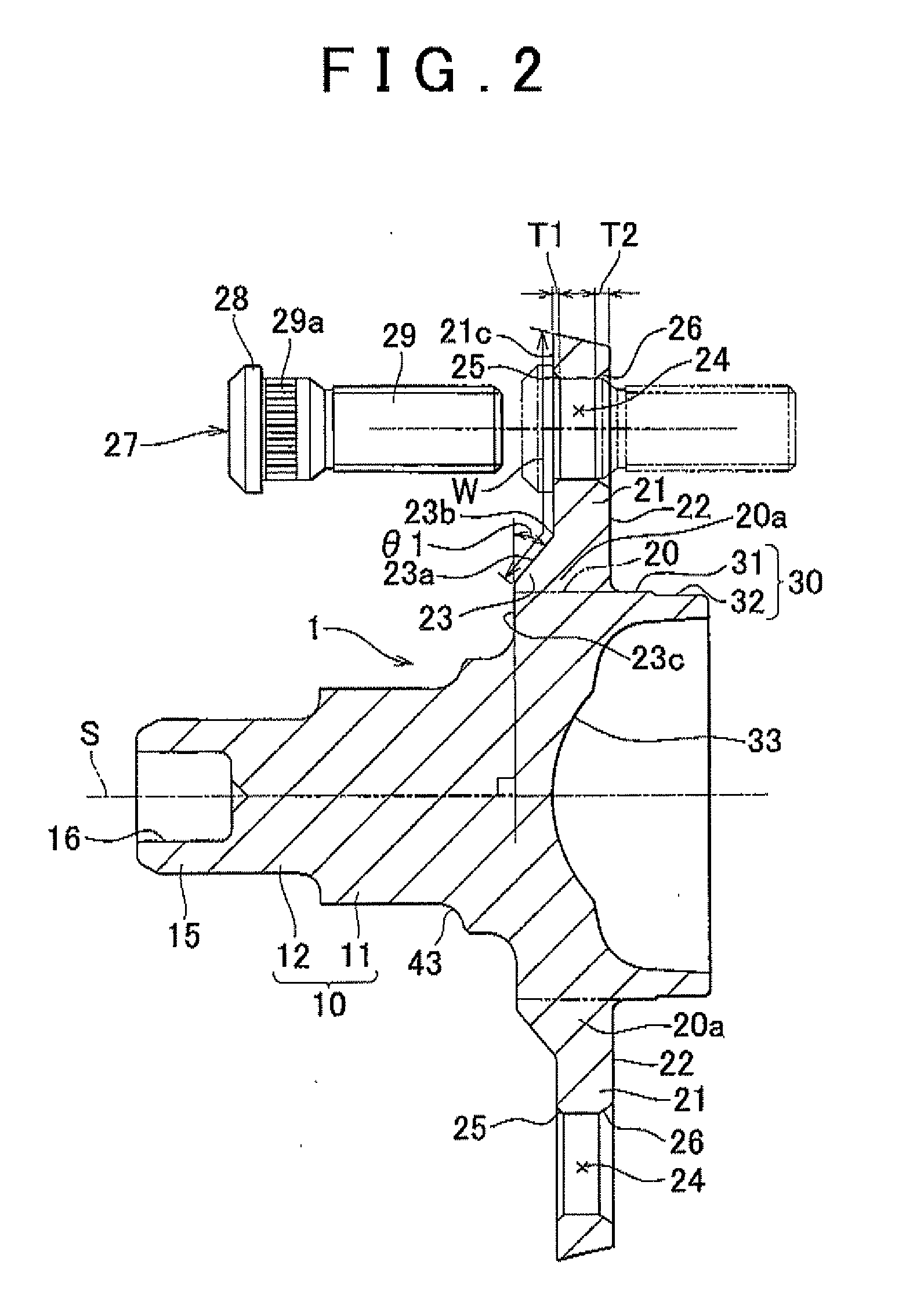

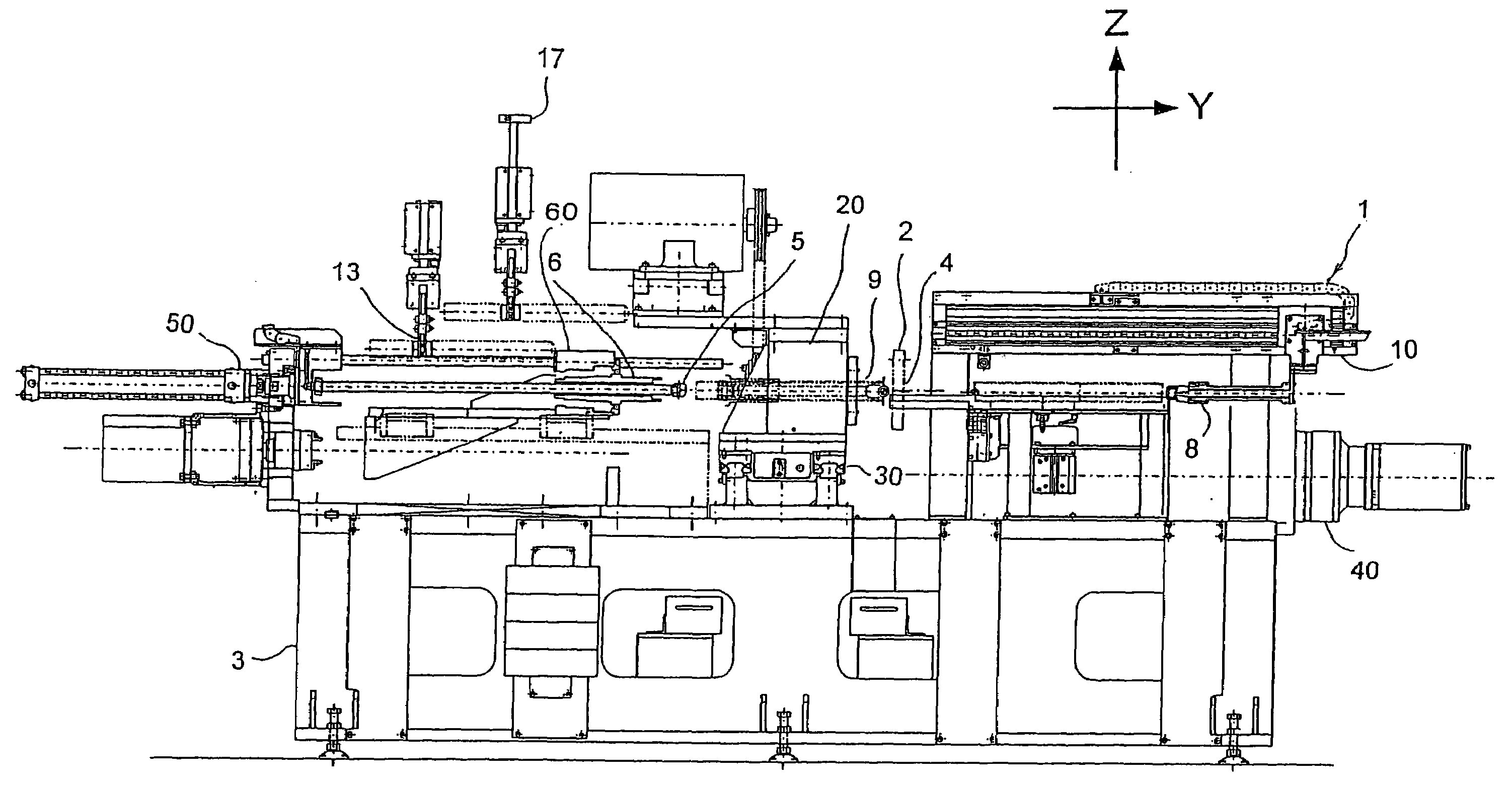

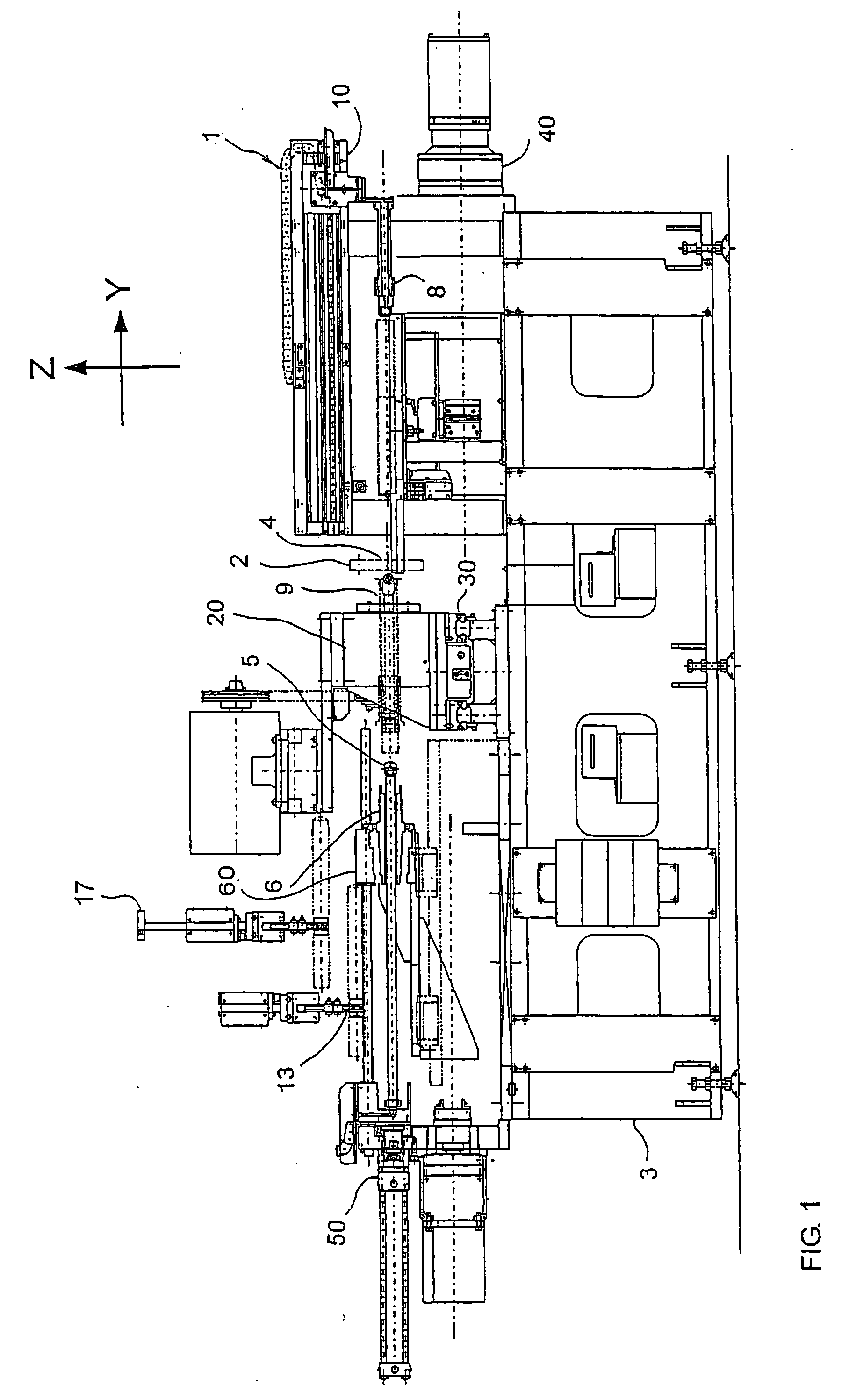

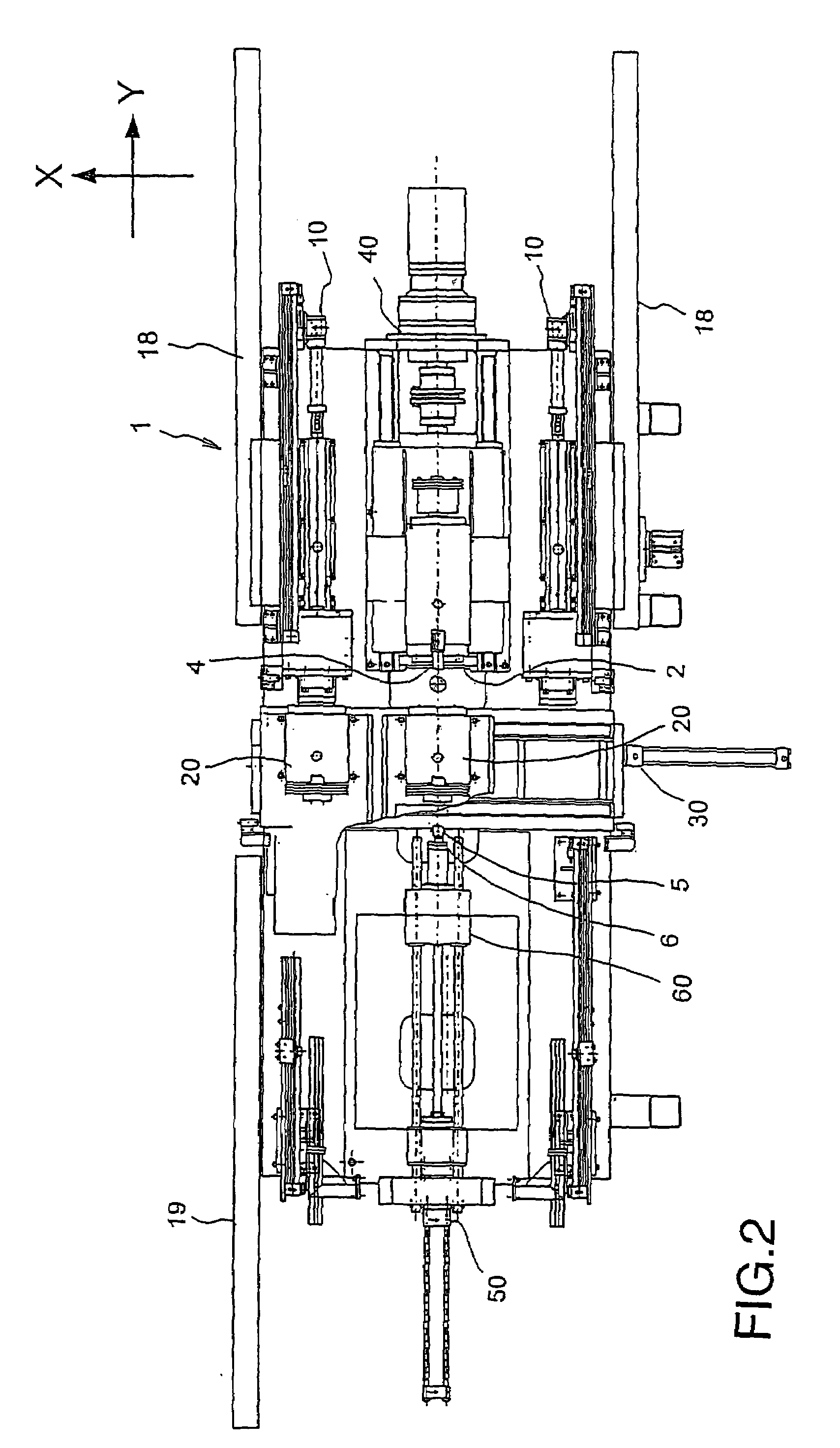

Closing Method and Closing Machine

InactiveUS20090272170A1Improve wear resistanceImprove mold lifeShaping toolsHollow articlesAlloyEngineering

In a closing machine (1) for closing an open end of a work piece (9) by pressing a die (4) heated by a high frequency heating device (2) against the work piece (9) rotating about an axial center, the die (4) comprises a die main body (601) which contacts the work piece (9) and a holder (611) which surrounds the die main body (601). The die main body (601) is formed from cemented carbide whereas the holder (611) is formed from a steel material. The holder (611) is subjected to induction heating by the high-frequency heating device (2), whereas the die main body (601) is heated by heat transfer from the holder (611).

Owner:KYB CORP

Heat treatment technology for die Cr12MoV steel

A heat treatment process for mold Cr12MoV steel. The main chemical composition of the mold steel is: C: 1.45-1.70; Si: ≤0.40; Mn: ≤0.40; S: ≤0.03; P: ≤0.03; Cr: 11-12.5 ; Ni: ≤0.25; Cu: ≤0.30; V: 0.15~0.30; After cooling to a certain temperature, take it out of the furnace and air-cool it, then put it into the heating furnace to heat and then keep it warm; C. Cool in the furnace and then keep it warm; D. Put the mold steel into the quenching oil to cool; E. Put the mold steel into the furnace Heating, then heat preservation, then cooling, and finally taking out the furnace and air cooling; the present invention makes the mold steel have high hardness, high strength and sufficient toughness through repeated heating, heat preservation and cooling.

Owner:HENGYANG FENGSHUN AXLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com