Patents

Literature

129 results about "Magnetic image" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

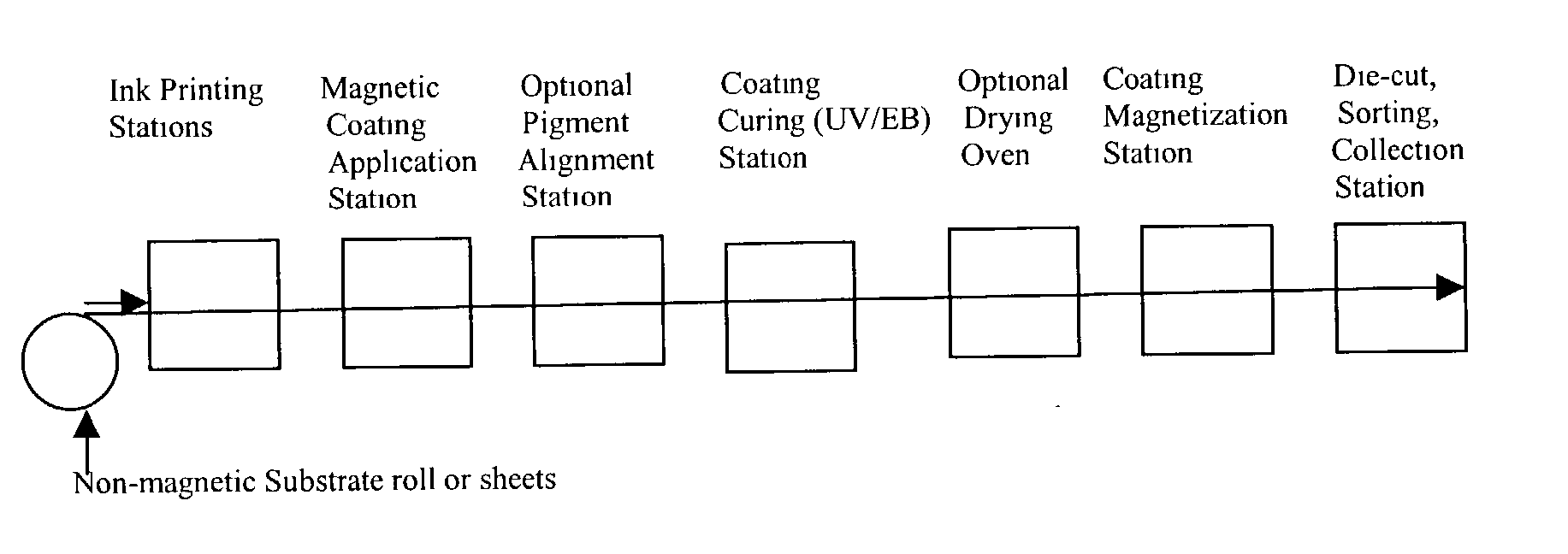

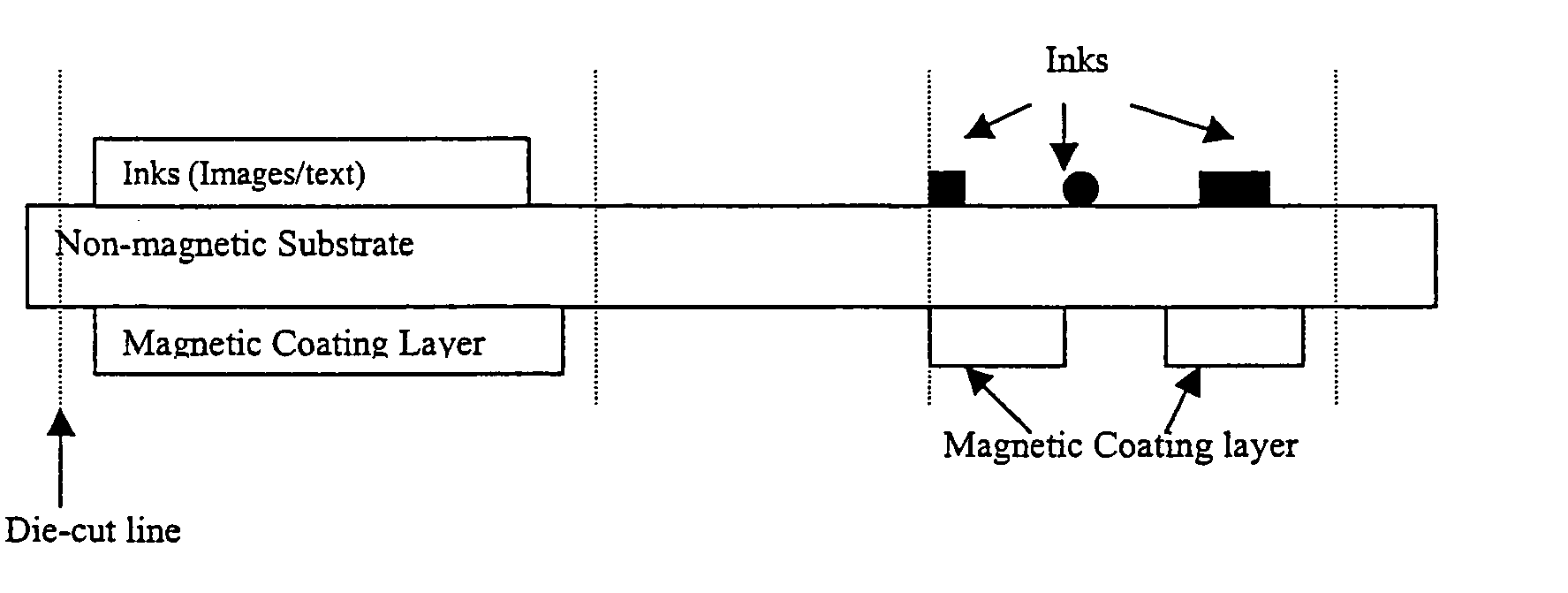

UV/EB cured integrated magnets-composition and method of fabrication

The present invention comprises a radiation curable composition for in-line printing containing magnetic pigments capable of being magnetized to possess permanent magnetic properties after the composition is cured. The composition is cured by an ionizing radiation source, preferably by UV light or electron beam radiation (UV / EB). The present invention is also directed to an in-line process for printing magnetic images on non-magnetic substrate, comprising: pattern applying the above mentioned radiation curable composition on the substrate opposite to a print side, pre-aligning the magnetic pigment particles (if necessary) of the applied composition, curing the composition by ionizing radiation source (UV / EB), magnetizing the cured composition, then finishing the final piece. The finishing step could involve delivering the final piece in a simple sheet with die cut magnets or creating an "integrated magnet" format involving plow folding over the magnet panel, pattern coating or flood coating an adhesive that will only adhere the non-magnet matrix areas between die cut magnets, thus, allowing for the individual magnets to be "popped" out of the carrier by the final end user. The resulting magnetized pieces will possess holding power like magnets (refrigerator and office magnets) and are capable of carrying personalized, Scitex imaged and direct marketing information (including redemption value for coupons, local public service access numbers, etc.)

Owner:SOVEREIGN SPECIALTY CHEM +1

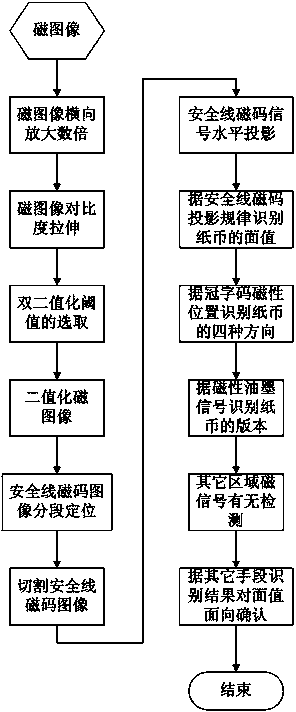

Paper currency face value identification method and device based on magnetic image

InactiveCN104346858AImprove counterfeiting abilityImprove recognition ratePaper-money testing devicesCharacter and pattern recognitionMagnetic imageEngineering

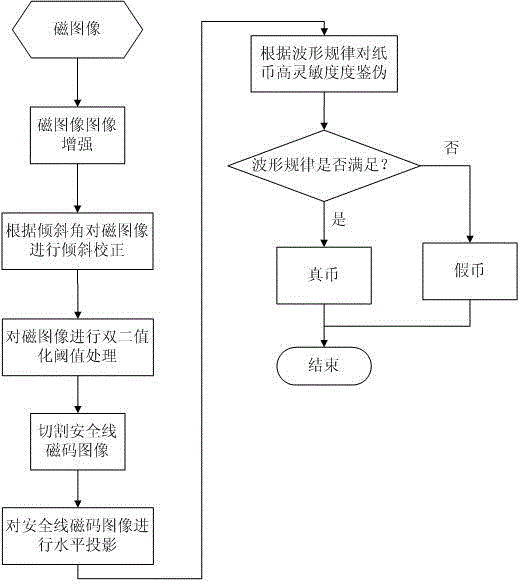

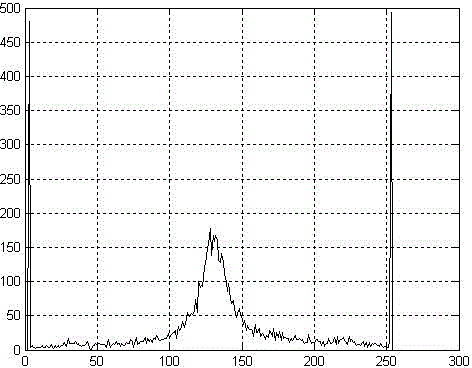

The invention discloses a paper currency face value identification method and device based on a magnetic image. The paper currency face value identification method comprises the following steps: laterally magnifying the magnetic image by multiple times, carrying out contrast stretching, high-low threshold binaryzation, safety line and magnetic code image positioning section by section and safety line and magnetic code cutting, drawing a safety line and magnetic code horizontal projection curve, identifying the face value of paper currency according to the safety line and magnetic code curve rule, identifying four directions of the paper currency according to the position of a magnetic signal of a crown character code, identifying the version of the paper currency according to whether magnetic ink exists, verifying the face value direction, and the like. According to the paper currency face value identification method and device, a safety line and magnetic code image is cut by adopting a sectional positioning method and is further verified by using the face value of the paper currency, which is identified by utilizing the safety line and magnetic code projection curve rule, and the face value direction identified by other identification measures, so that the face value direction error probability of the paper currency is greatly reduced, relatively high face value direction rate is achieved and the paper currency processing level of financial self-service equipment is improved.

Owner:NDT SCI & TECH

Paper currency authentic identification method and device based on magnetic images

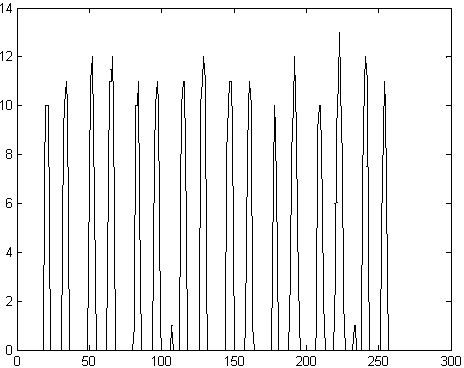

InactiveCN104091388AIncrease credibilityPaper-money testing devicesCharacter and pattern recognitionMagnetic imagePulse waveform

The invention discloses a paper currency authentic identification method and device based on magnetic images. Magnetic images of paper currency obtained by a magnetic image sensor are processed, after image enhancement processing, tilt correction pre-processing and the like are carried out on the magnetic images, a magnetic image histogram is calculated, binarization processing is carried out, two binaryzation magnetic images of safety lines are cut out, horizontal projection is carried out on the two cut binaryzation magnetic images, whether the features of impulse waveforms of the horizontal projection curve of the two binaryzation magnetic images of the safety lines conform to set regulations is judged, and the paper currency is judged to be real currency if all the features conform to the set regulations. According to the method and device, due to the fact that a high threshold value and a low threshold value are adopted for carrying out binaryzation on the magnetic images, the binaryzation magnetic images of safety lines are cut out, the features of the two binaryzation magnetic images of safety lines are recognized, and the paper currency is judged to be the real currency if all the features conform to the set regulations.

Owner:NDT SCI & TECH

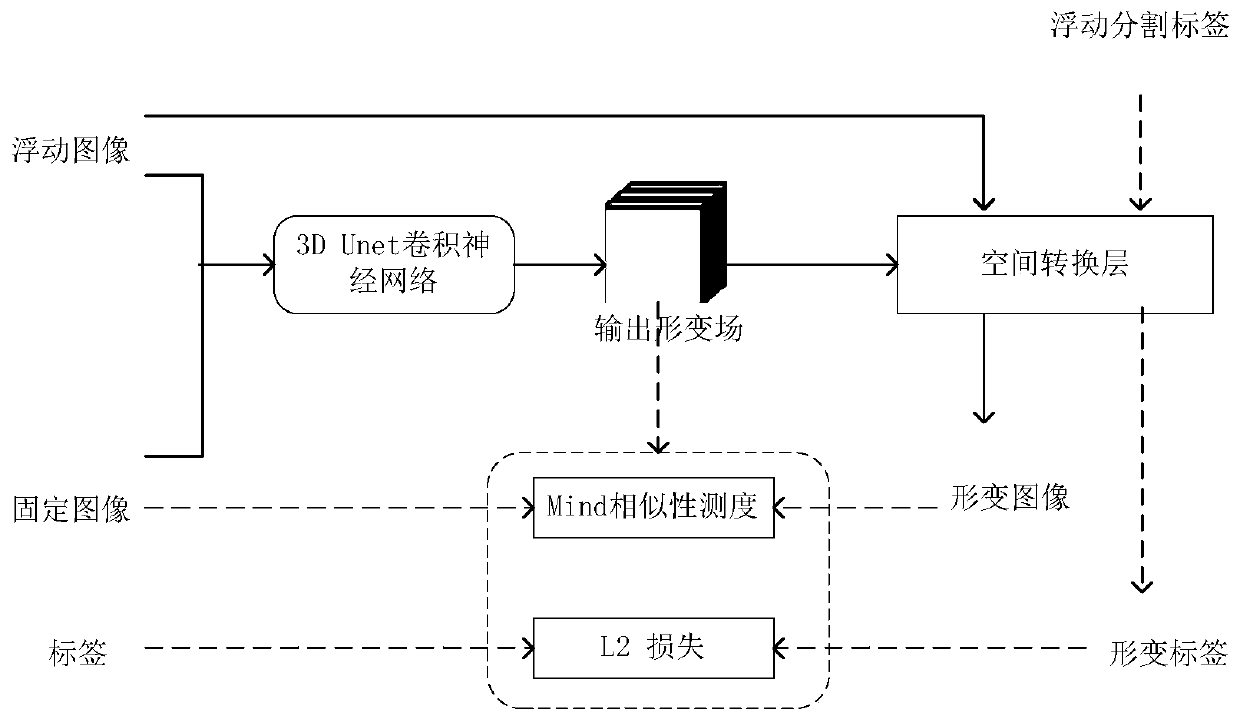

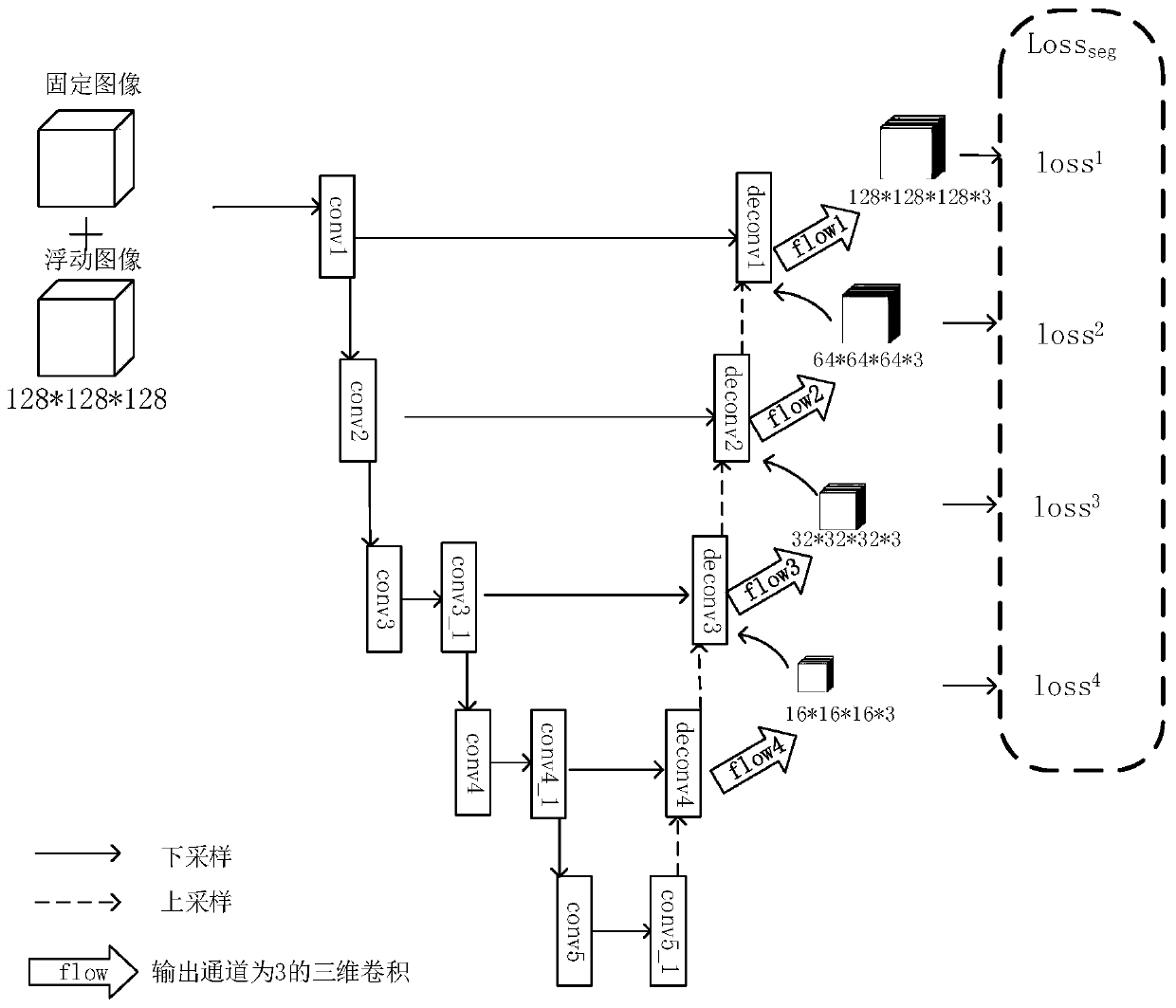

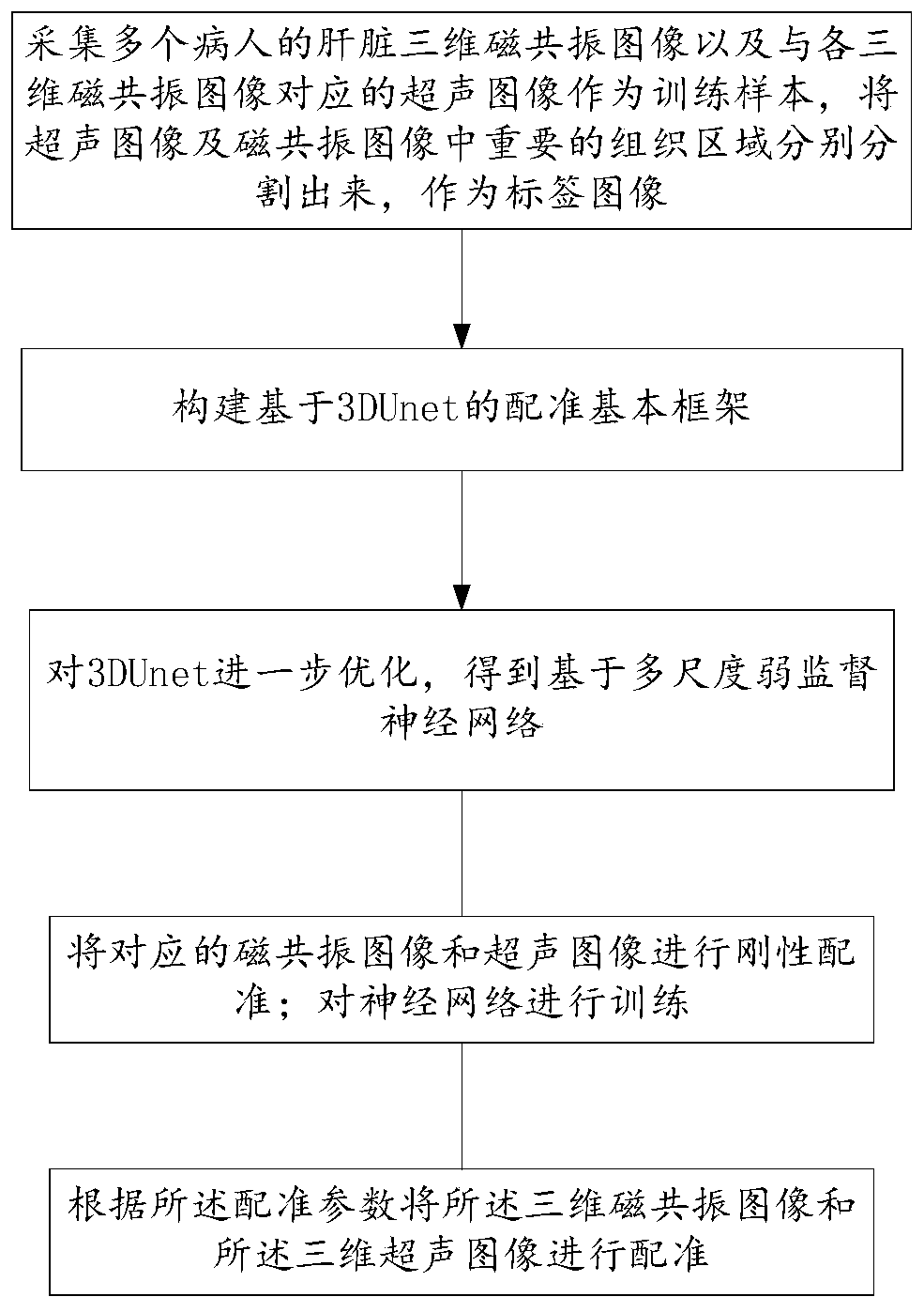

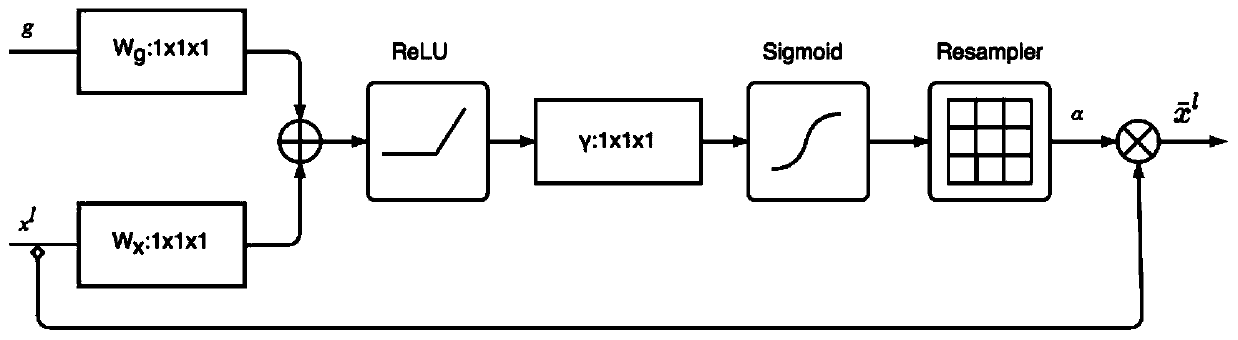

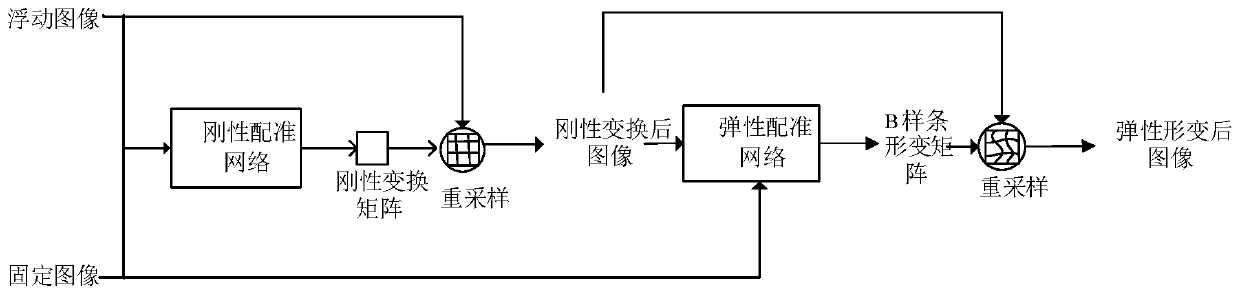

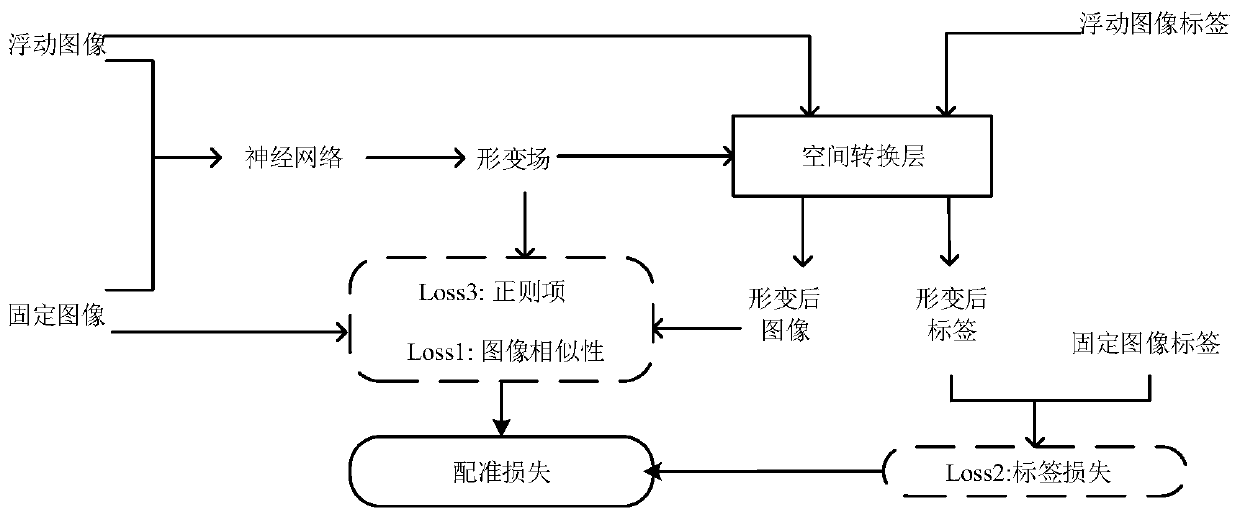

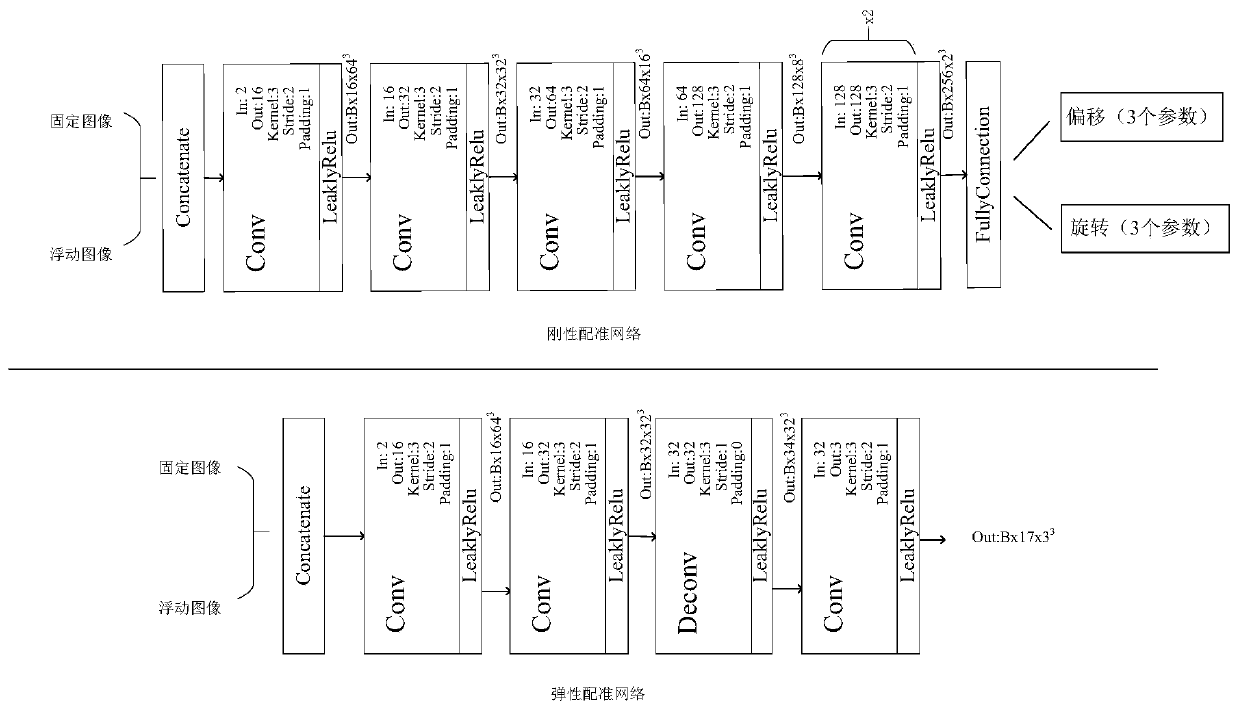

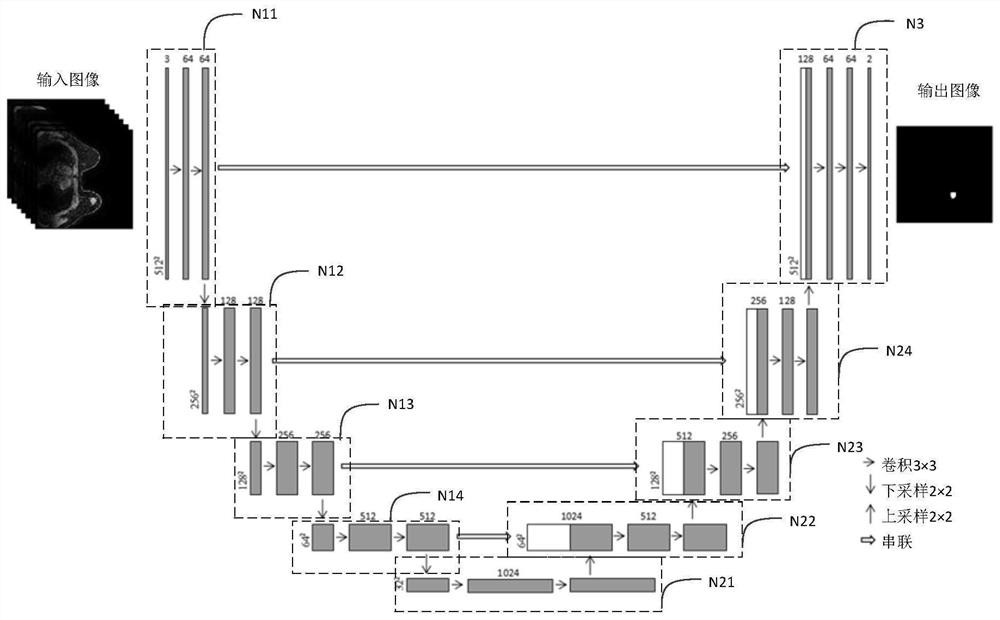

Ultrasonic and nuclear magnetic image registration method and device based on multi-scale supervised learning

According to an ultrasonic and nuclear magnetic image registration method and device based on multi-scale supervised learning, a deformation field from ultrasonic to magnetic resonance can be predicted only by inputting ultrasonic and magnetic resonance images in a test stage, registration from ultrasonic to magnetic resonance is completed, iteration of a traditional algorithm is not needed, and the speed and accuracy are greatly improved. The method comprises the following steps: (1) collecting liver three-dimensional magnetic resonance images of a plurality of patients and ultrasonic imagescorresponding to the liver three-dimensional magnetic resonance images as training samples, and segmenting important tissue regions as label images; (2) constructing a registration basic framework based on 3DUnet; (3) obtaining a neural network based on multi-scale supervision; (4) rigidly registering the corresponding magnetic resonance and ultrasonic images; inputting the processed magnetic resonance and ultrasonic images as two channels into a neural network, and training the neural network by using three loss functions of MIND similarity measurement, segmentation label loss and deformationfield smoothing term; and (5) registering the magnetic resonance images and the ultrasonic images according to the registration parameters.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

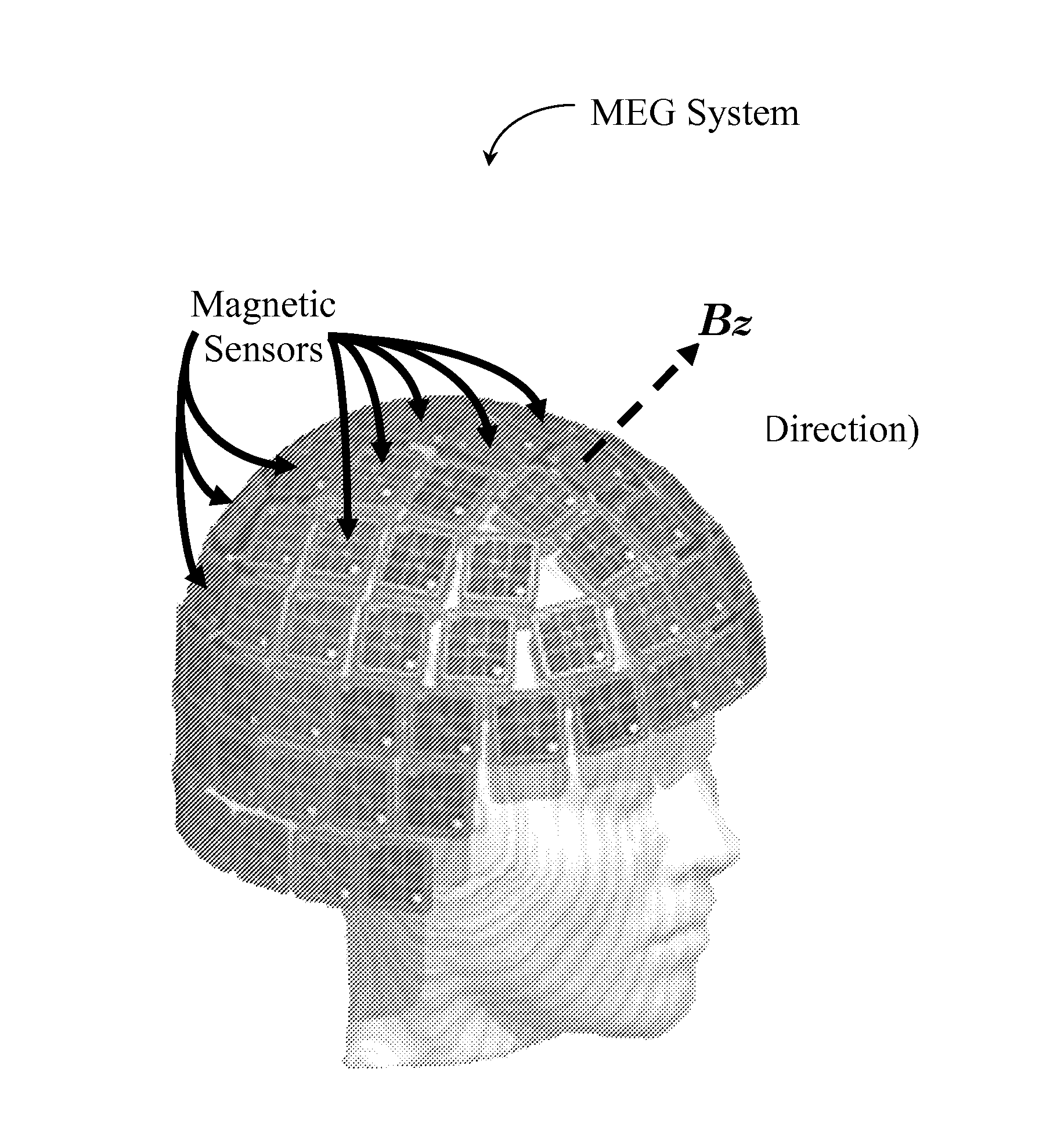

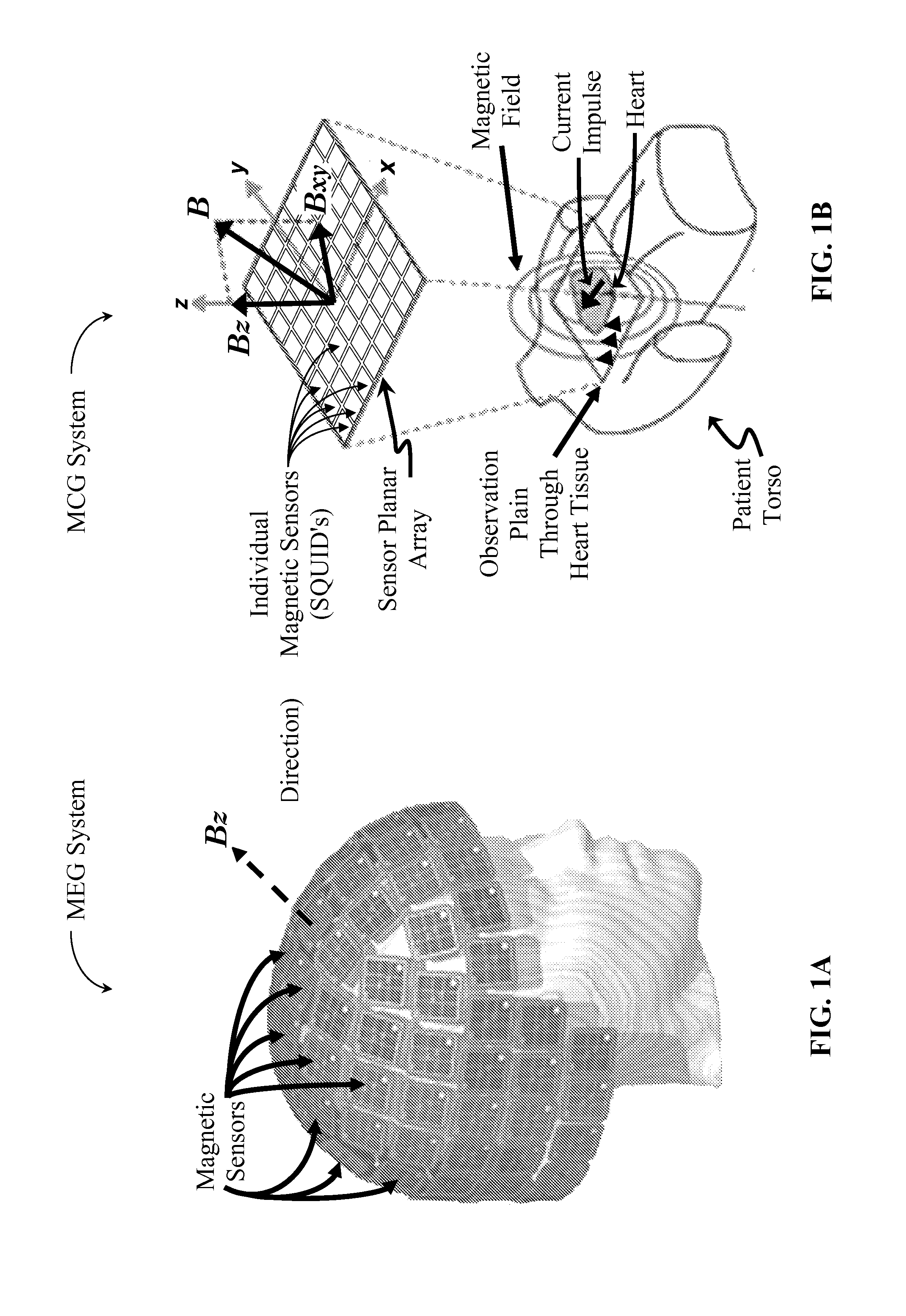

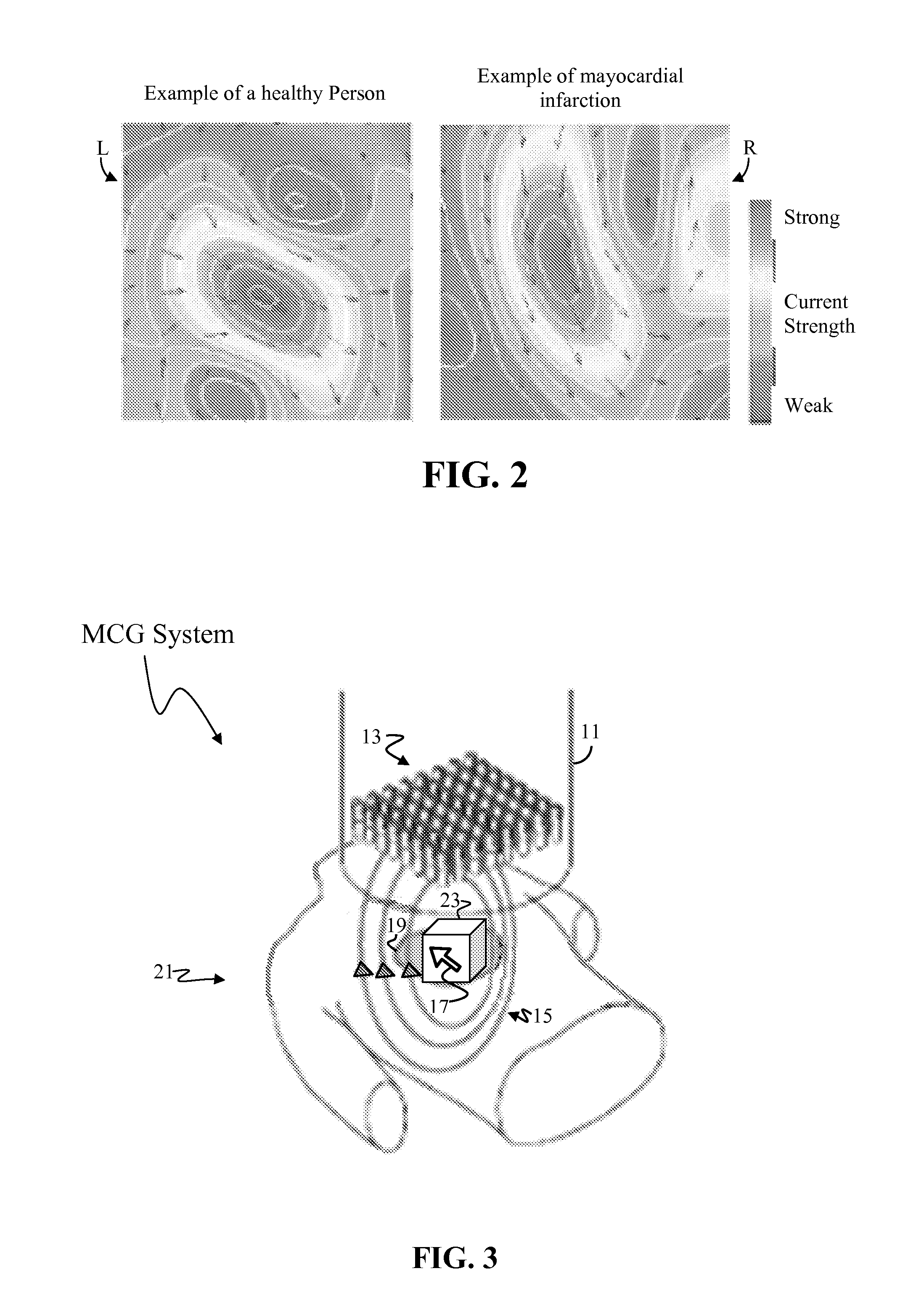

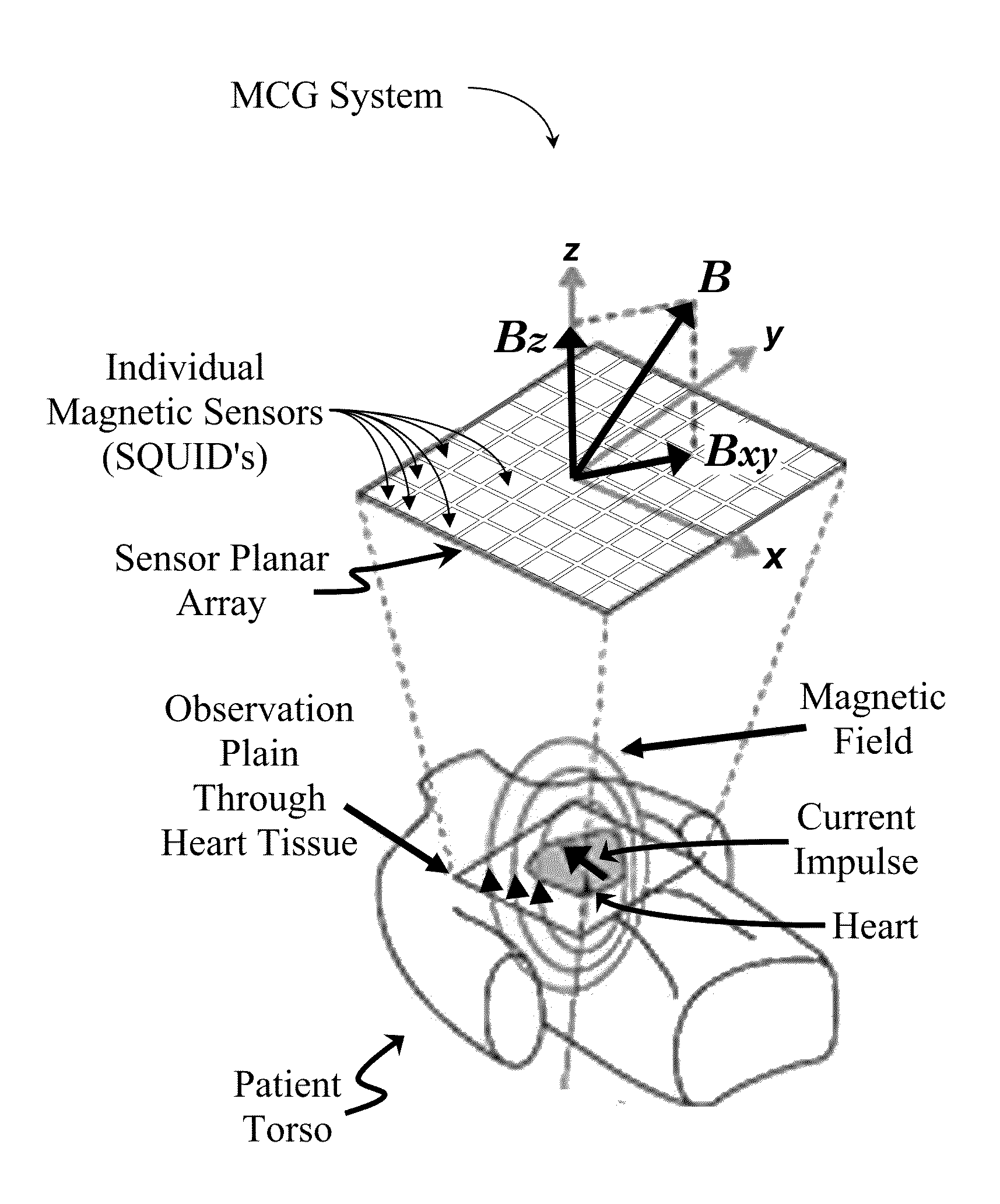

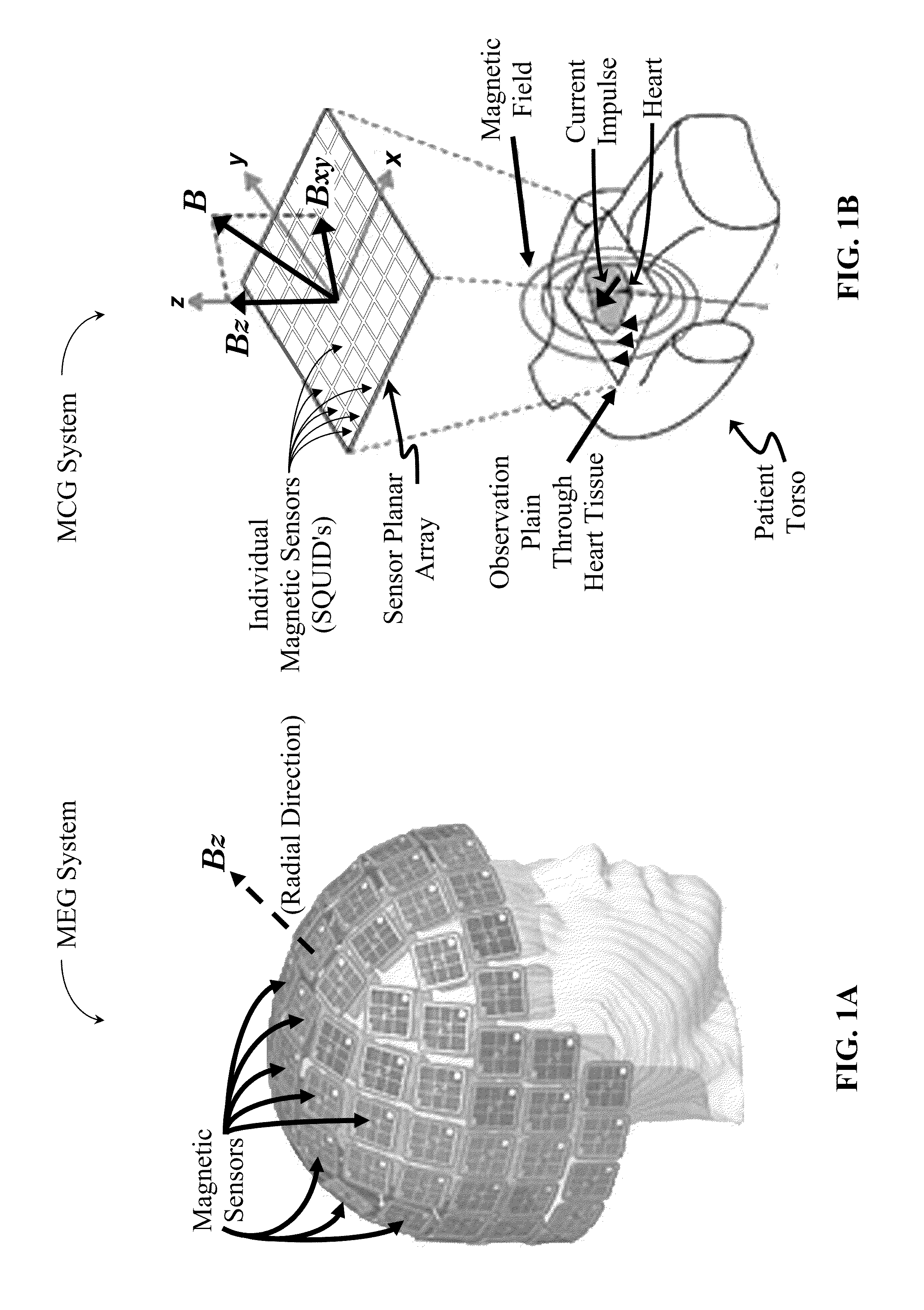

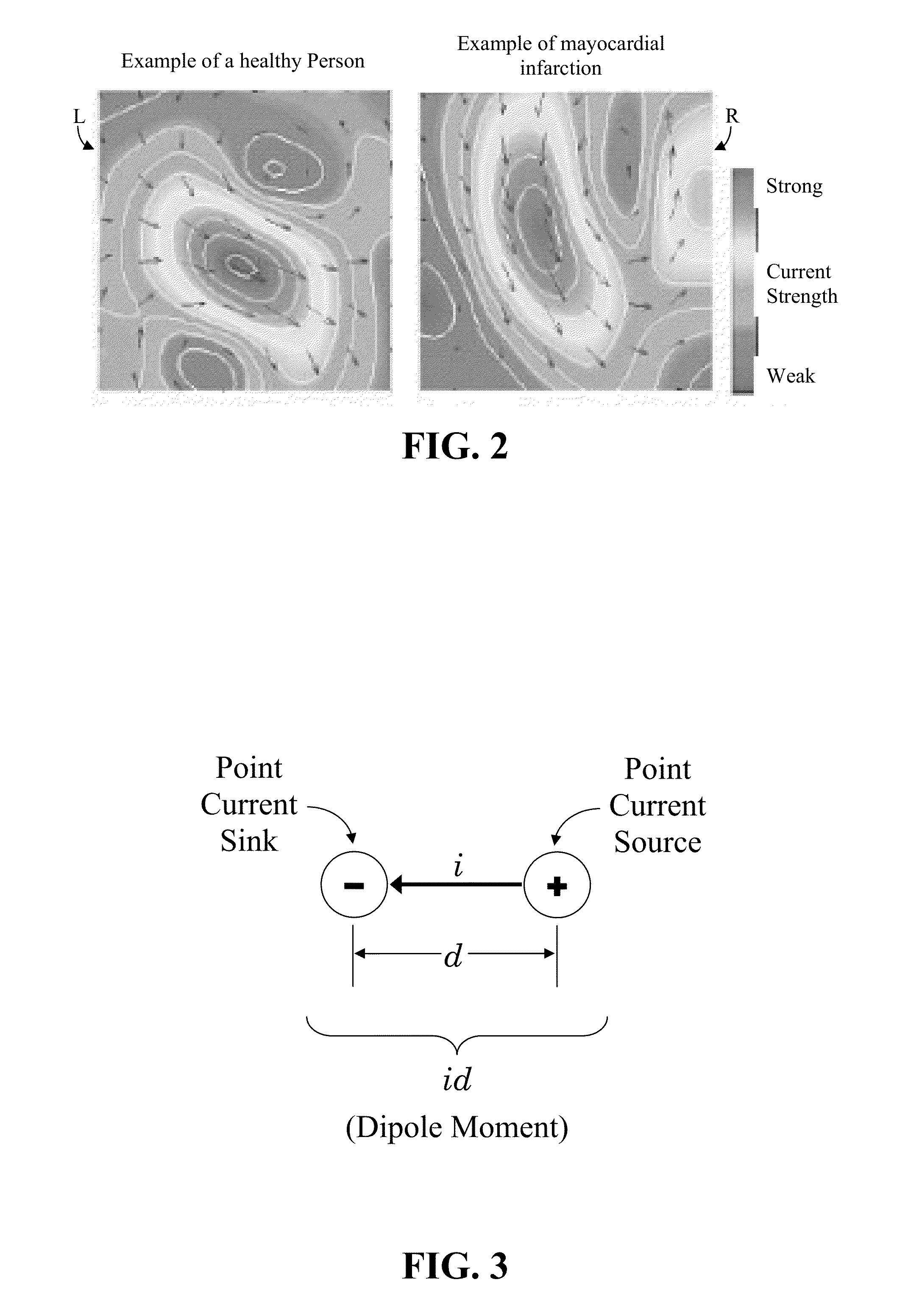

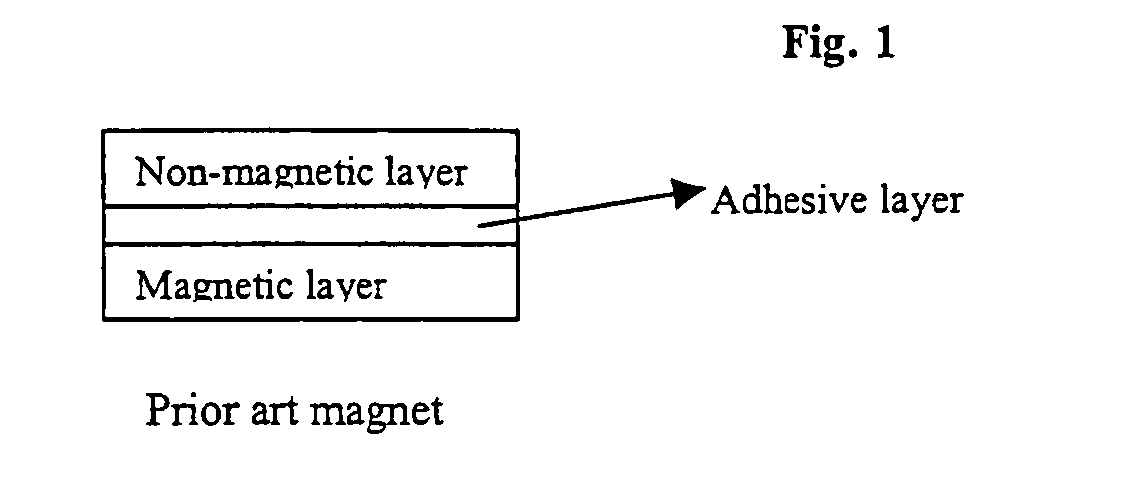

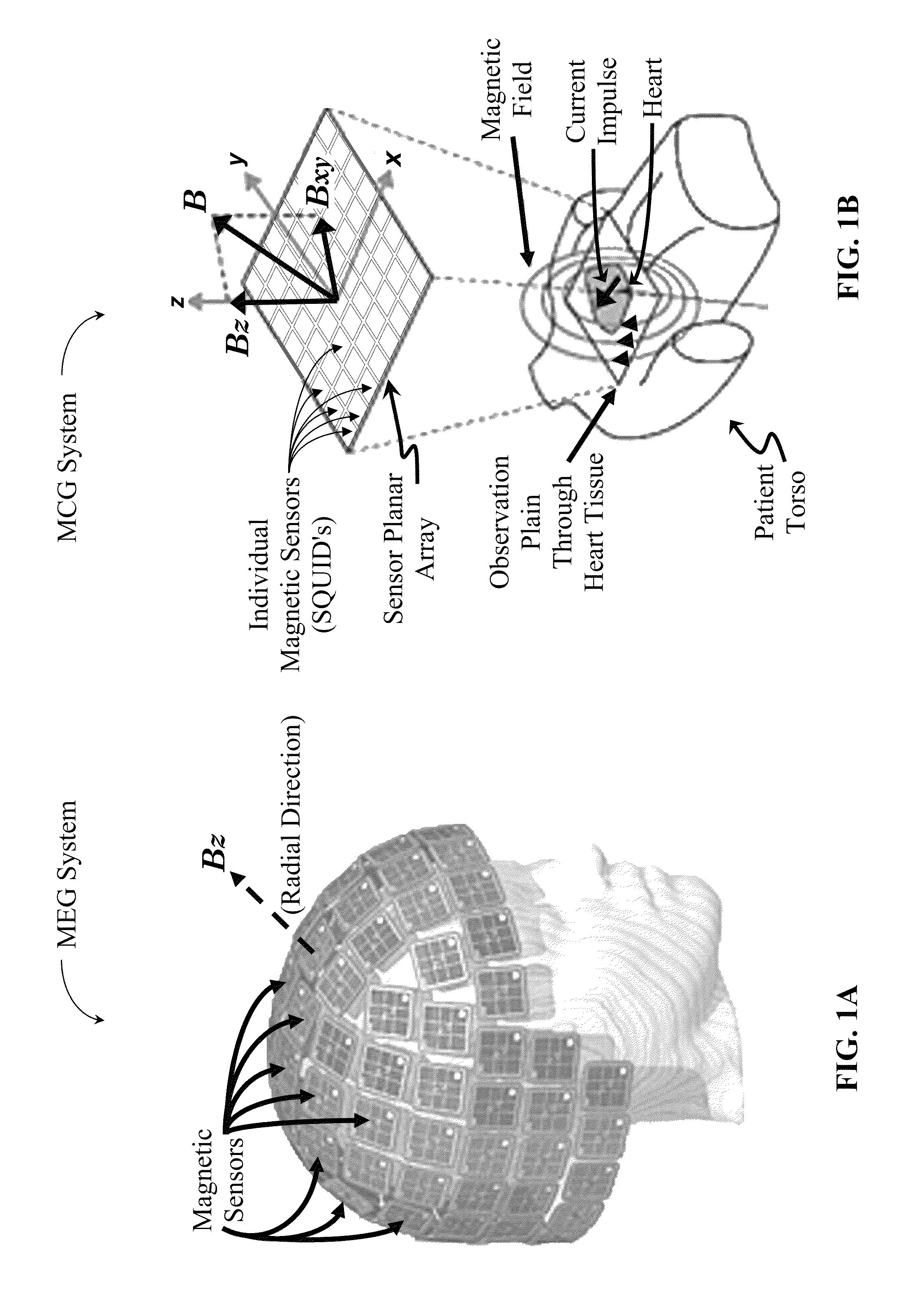

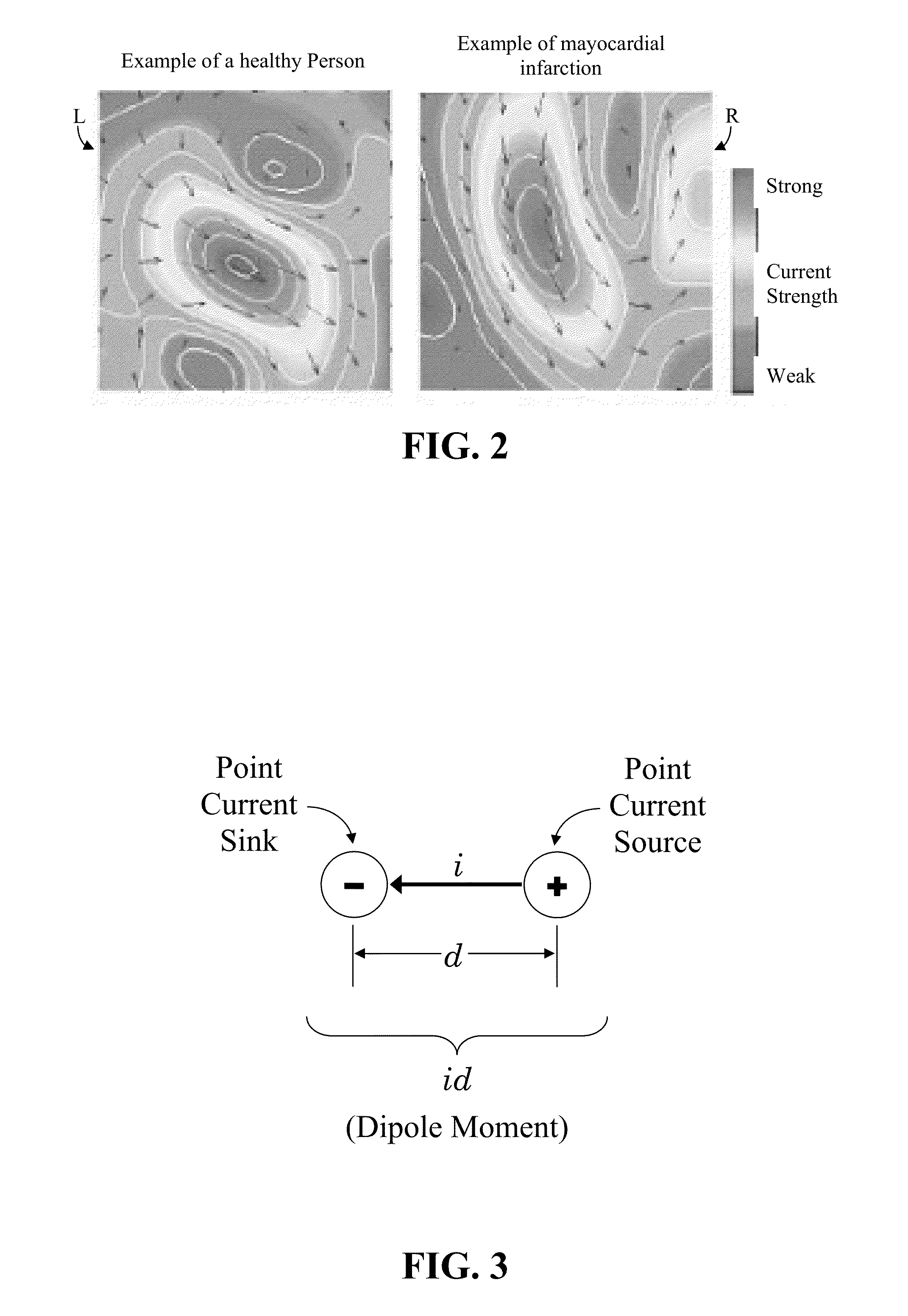

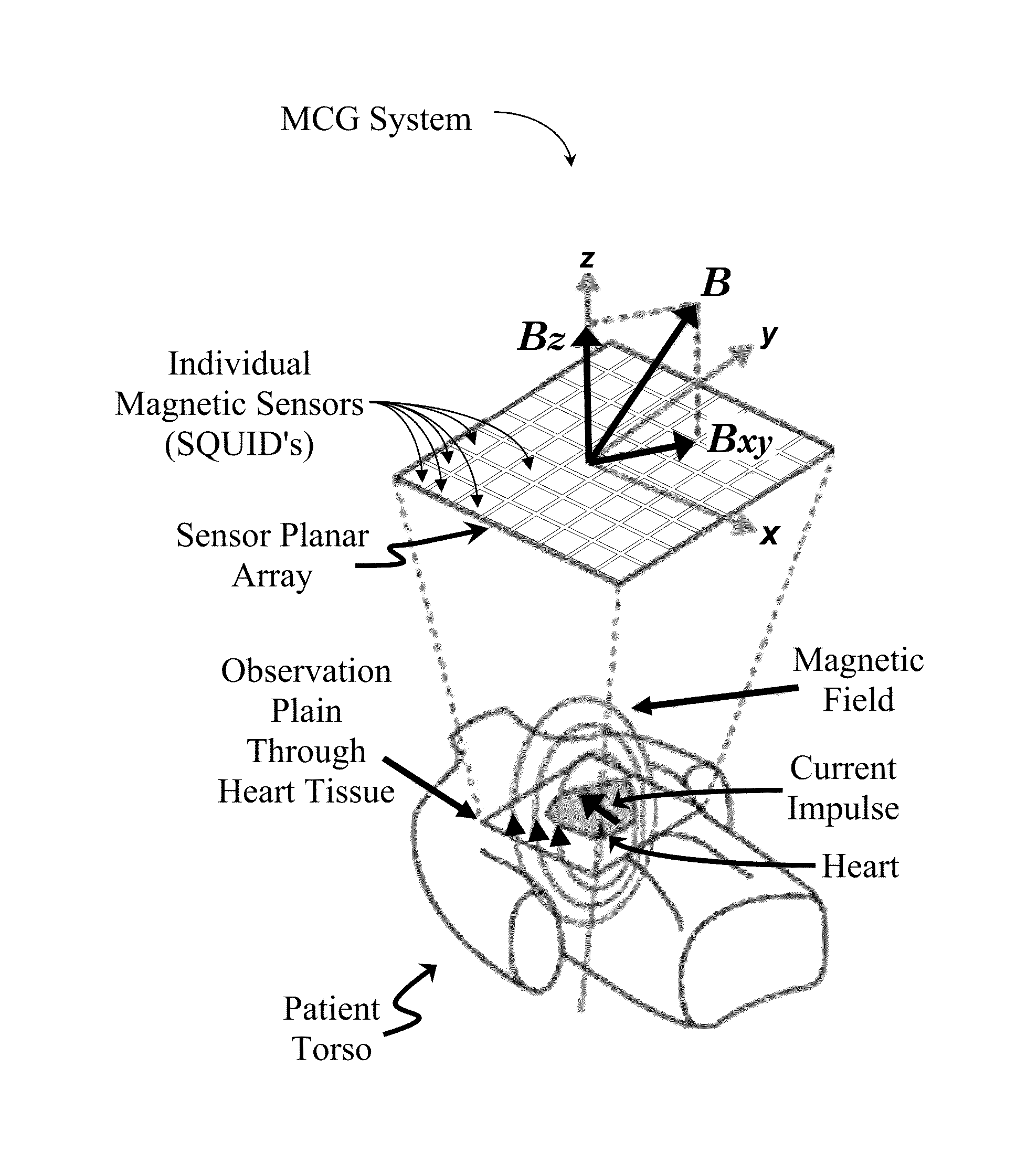

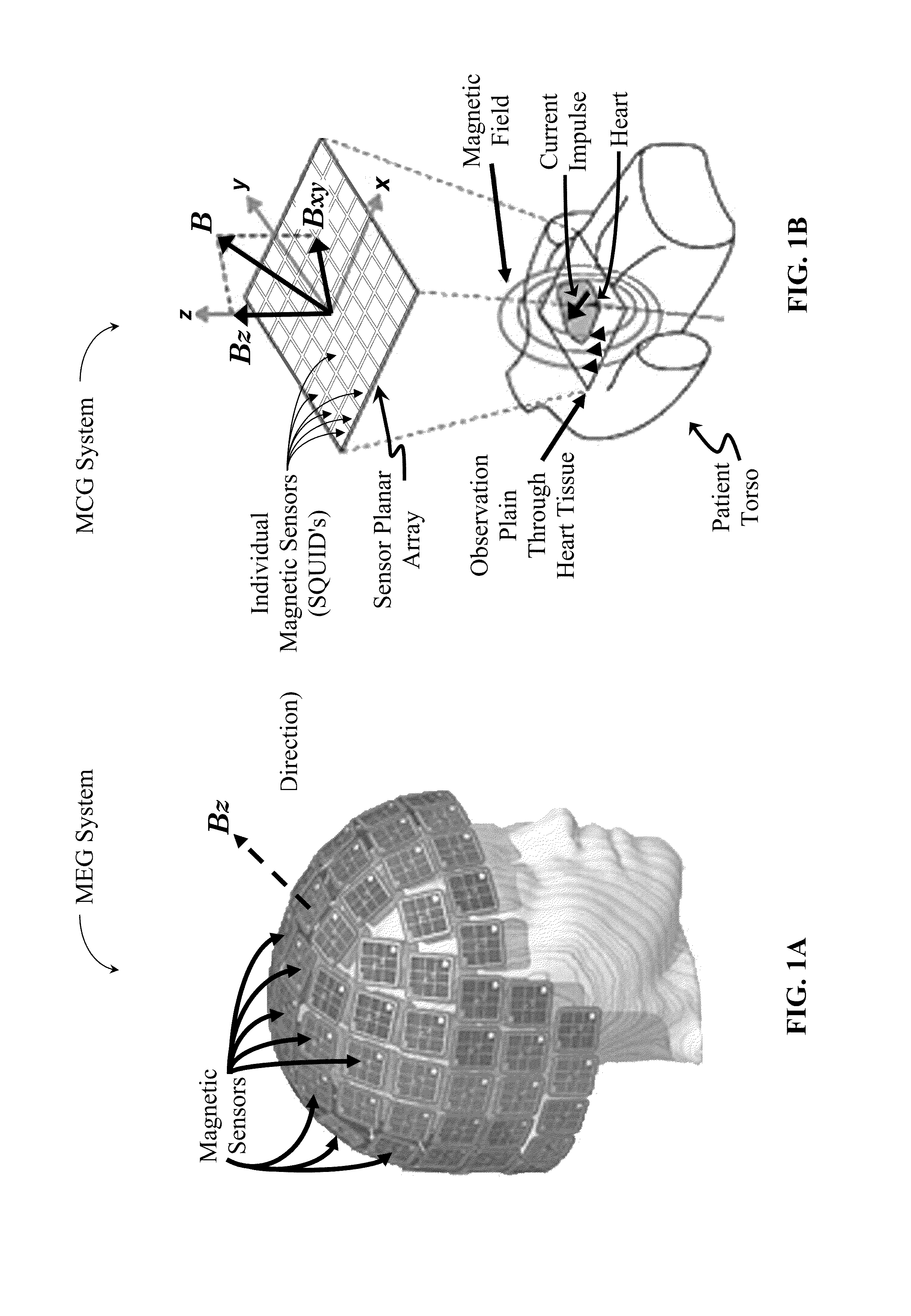

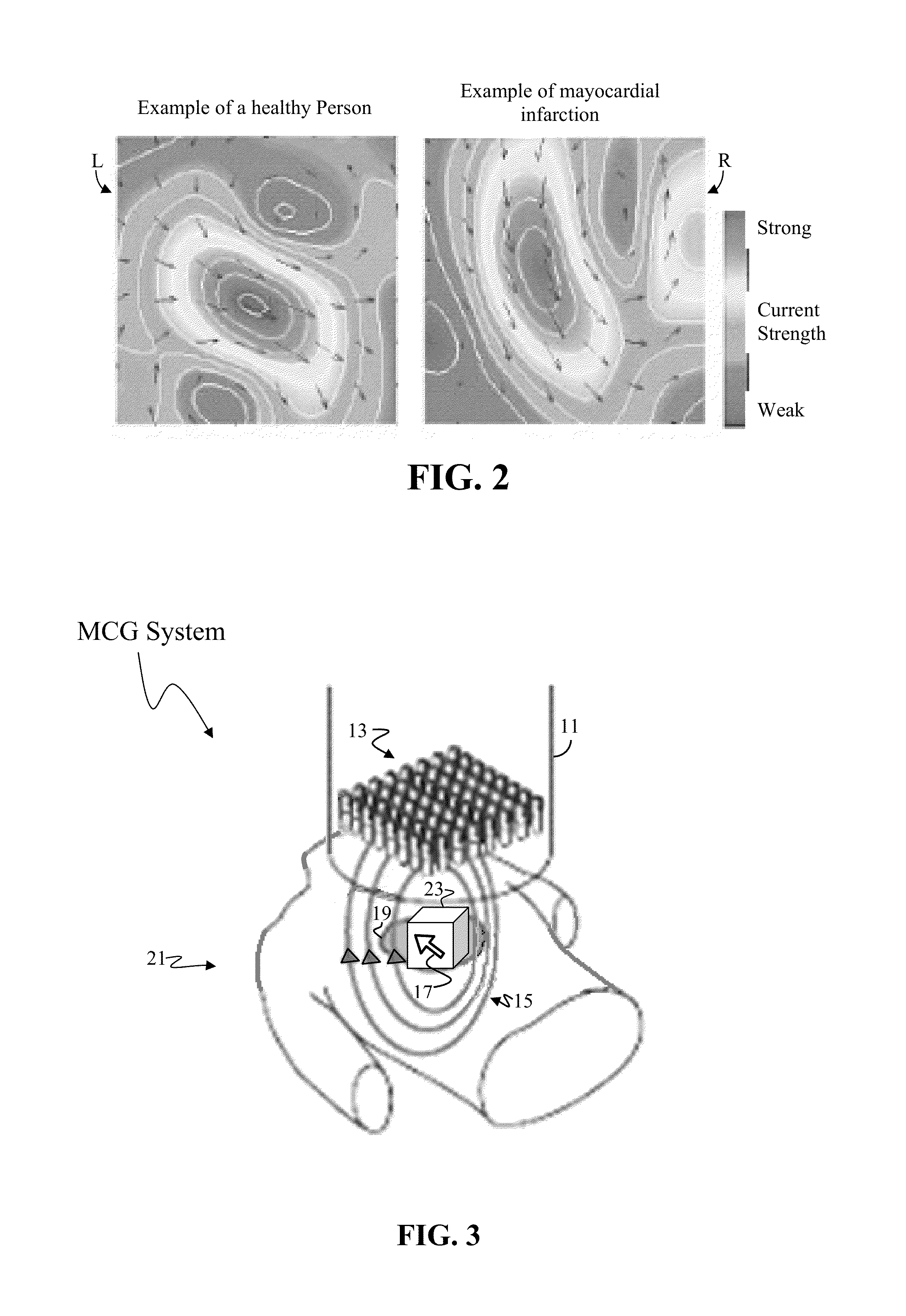

2D Dipole Localization Using Absolute Value of MCG Measurements

A magnetic imaging systems produces magnetic magnitude images using magnetic sensors capable of determining only the absolute value of a detected magnetic field and provide no information regarding the positive or negative sign of the detected magnetic image. A 2D dipole location is determines the 2D location of a dipole within a magnetic magnitude image by finding the minimum of the derivative of the absolute value of the magnetic field. This 2D dipole location is then used to determine the 3D position and momentum of a current dipole responsible for the observed magnetic magnitude image. The current dipole is used to generate a magnetic image that incorporate positive and negative sign information.

Owner:SEIKO EPSON CORP

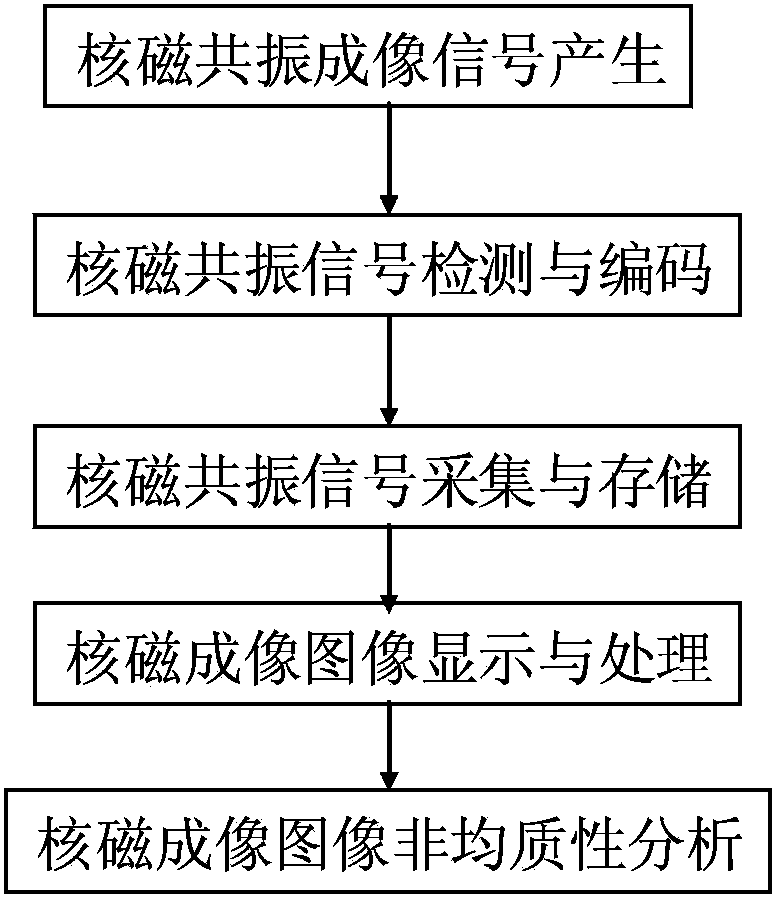

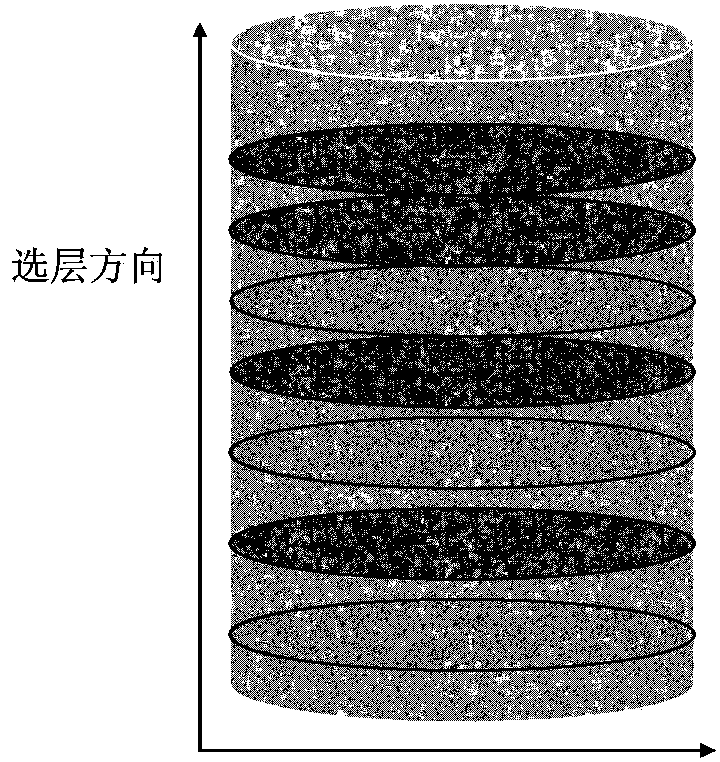

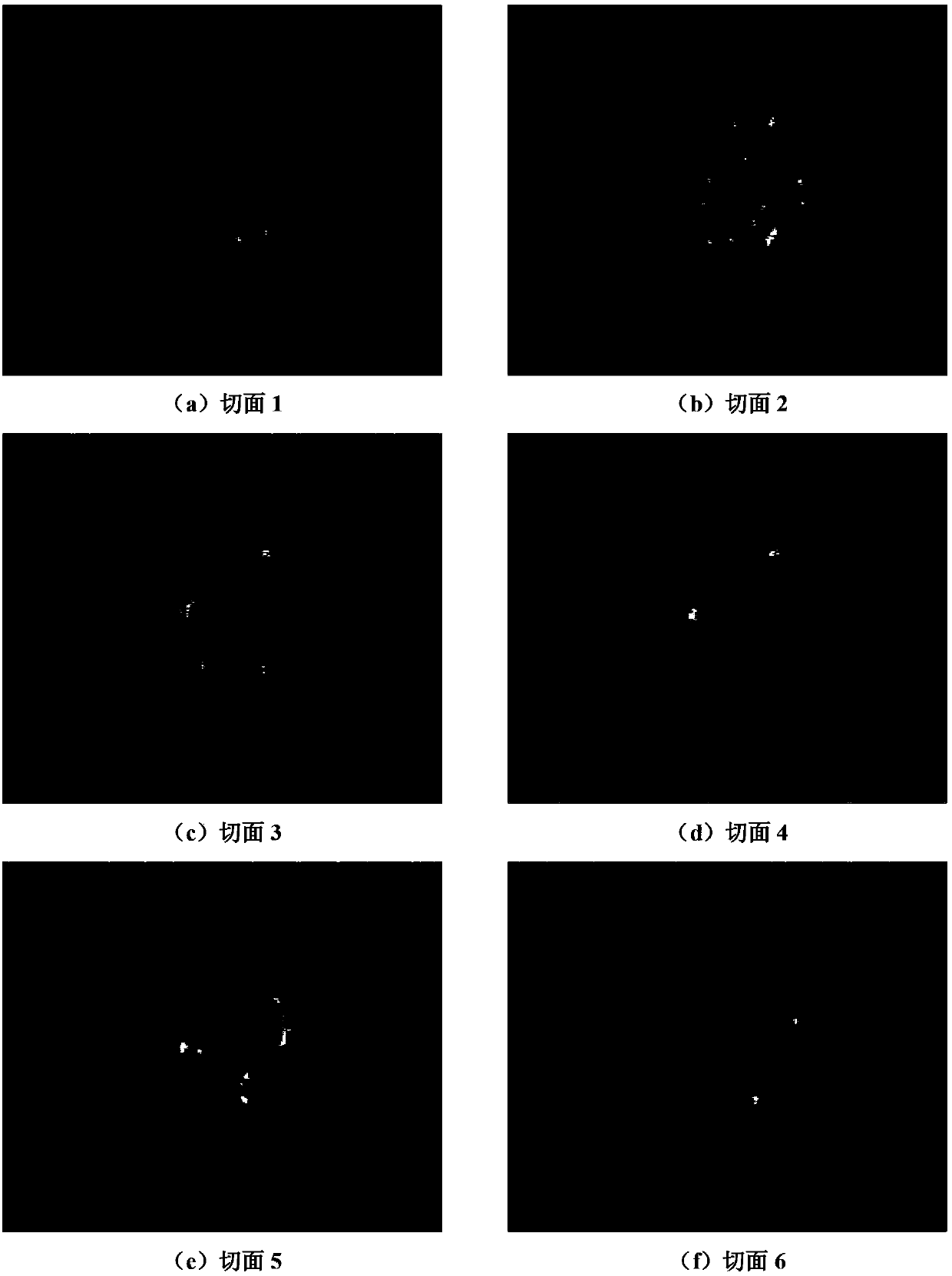

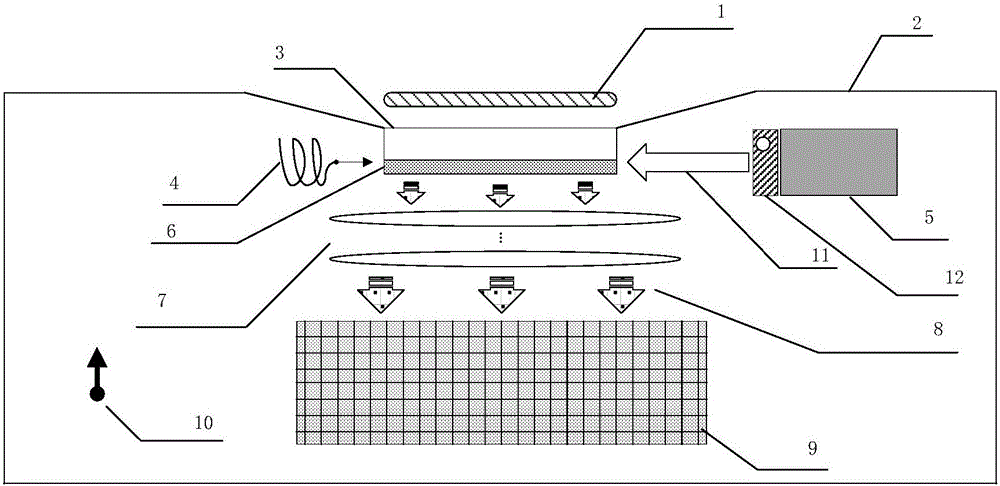

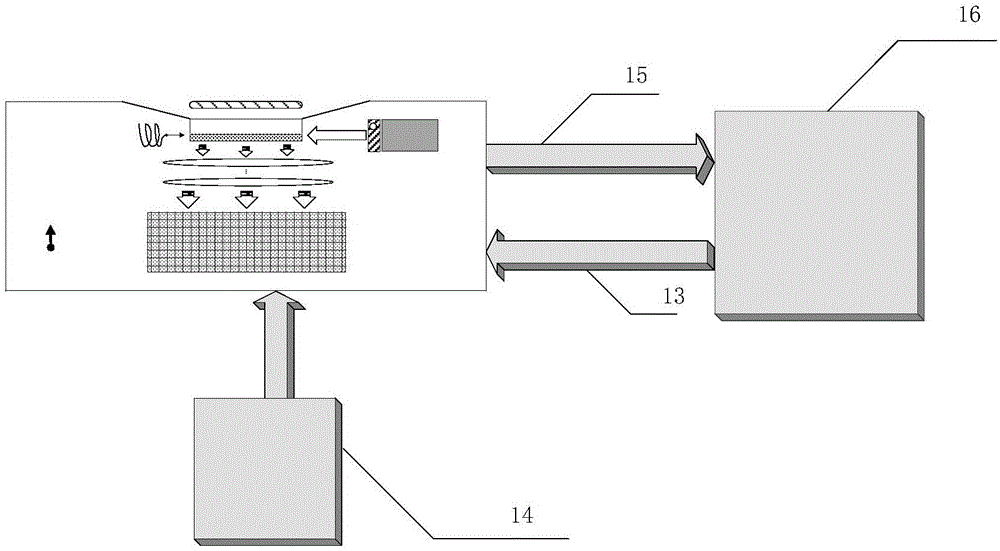

Rock heterogeneous quantitative evaluation method based on magnetic resonance imaging

InactiveCN103353462AOvercoming the Difficulties of Unrepresentative SamplingSimple processing capacityAnalysis using nuclear magnetic resonancePorosityPhase Code

The invention discloses a rock heterogeneous quantitative evaluation method based on magnetic resonance imaging. Three-dimensional space orientation of rock can be realized by layer selection pulse, phase coded pulse and frequency coded pulse. An imaging signal can be obtained by applying a spin-echo sequence, and optimization selection of imaging experimental parameters can be carried out through experimental scale. On the basis, a nuclear magnetic imaging signal obtained by experimental measurement is subjected to digital image processing so as to generate a pseudo color graph. By means of the relationship between the porosity and nuclear magnetic imaging signal intensity of a stand sample, the total porosity and porosity and distribution spectrum of a single layer can be obtained. Multi-layer imaging results are compared and a porosity heterogeneous coefficient is defined, so that the longitudinal porosity distribution characteristic and heterogeneity of rock can be obtained. In addition, by applying a first-order spherical variation function model and a grid search method, characteristic parameters of a variation function can be obtained. Heterogeneous coefficients and relative heterogeneous coefficients can be defined to realize longitudinal and horizontal heterogeneous quantitative characterization of rock.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

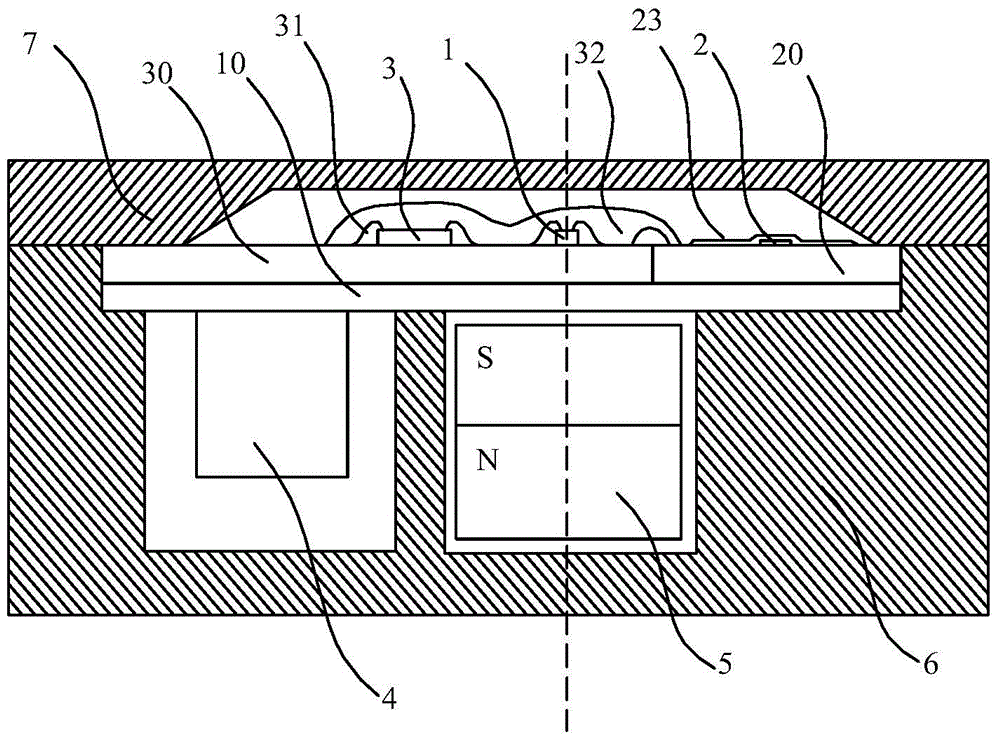

Chip-level diamond NV-color center magnetic imaging device and method

ActiveCN105137371AReduce volumeQuick responseMagnetic measurementsDiagnostic recording/measuringMedical diagnosisElectromagnetic shielding

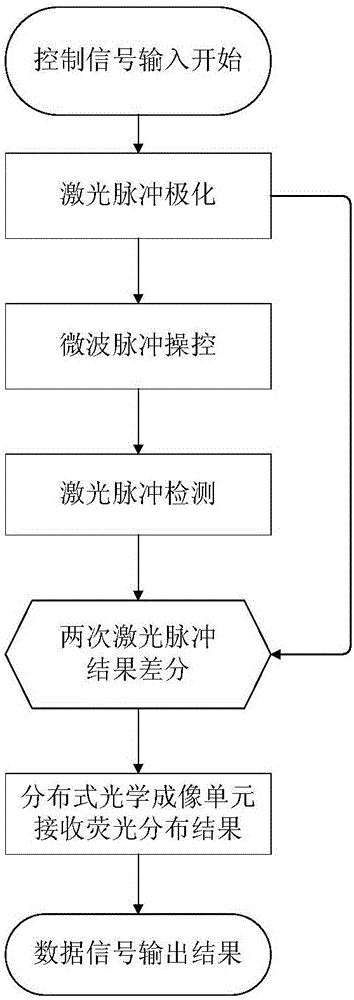

The invention discloses a chip-level diamond NV-color center magnetic imaging device and method, and the method achieves the hyperfine magnetic field imaging of the two-dimensional surface of an object, such as a magnetic image of a biological cell. The method comprises the steps: carrying out the polarization of a laser pulse and a microwave pulse; generating fluorescent light generated at the NV-color center of a diamond in an external magnetic field; employing the laser pulse to generate fluorescent light again, wherein the difference result of fluorescent light of two times can reflect the magnetic field intensity of the NV-color center, thereby achieving the conversion of magnetic field information to optical information; and employing a nano-level convex lens group and a distributed optical imaging unit to convert an optical signal into an electric signal. The invention also relates to a packaging method for enabling a whole system to be packaged in a manner of chip level, and the method comprises temperature control and electromagnetic shielding. The method is great in value in the fields of biomedical research and medical diagnosis.

Owner:BEIHANG UNIV +1

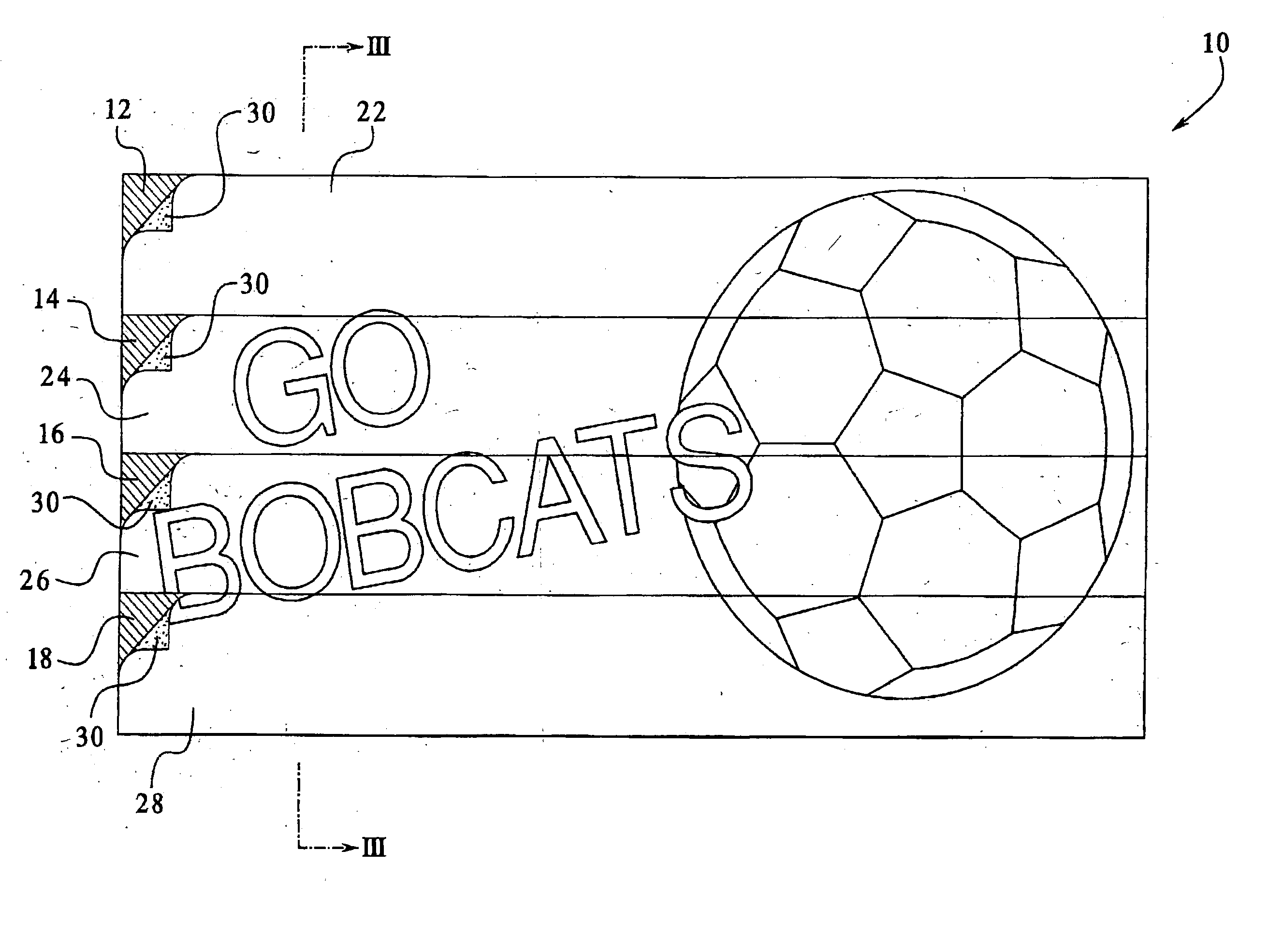

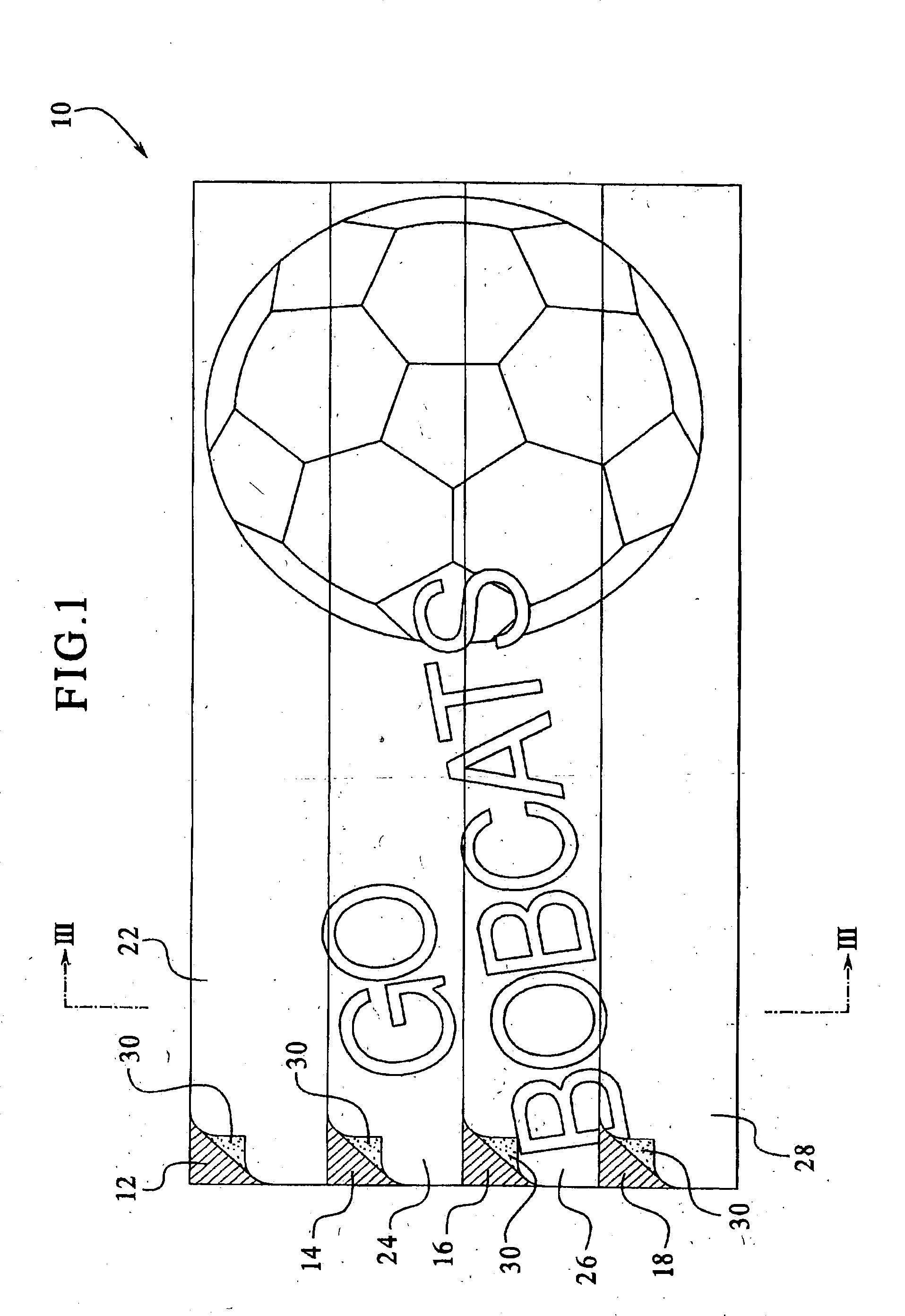

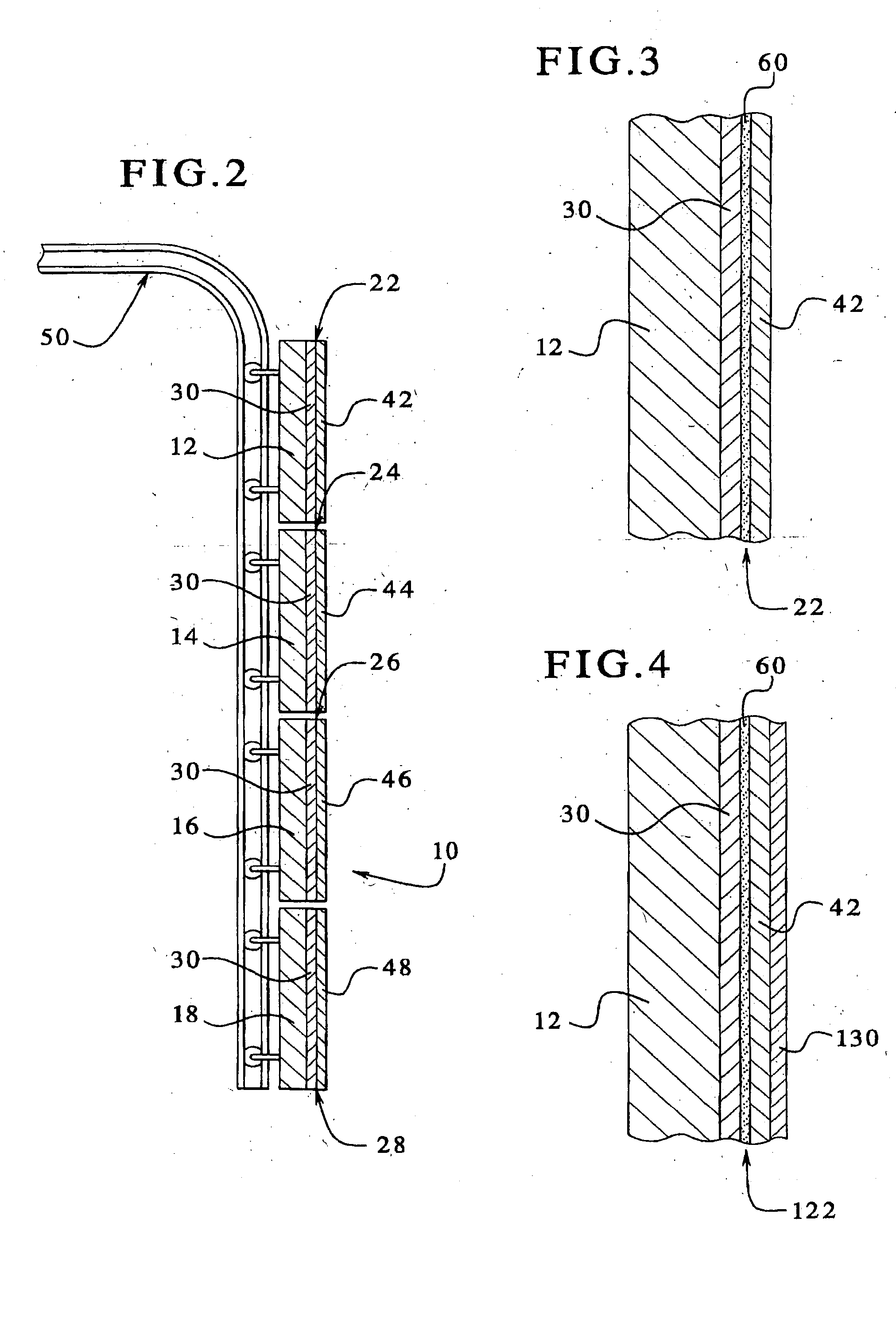

Magnetic image assembly to mount on garage door panels and a system and a method for decorating a garage door

InactiveUS20050076591A1Keep energy smallLittle timeCovering/liningsDecorative surface effectsLight reflectionMagnetic image

An assembly, a system and a method provide a magnetic image assembly to mount on a garage door having printed designs, pictures and / or indicia wherein the use of more than one of the covers creates an image on the garage door. The assembly, the system and the method create images which may be seasonal or festive themes, celebratory salutations and / or personal messages. The magnetic cover assembly provides an image which forms a decorative design and / or a personal message on the garage door panels. The magnetic image assembly has a magnetic backside for attaching to the garage door and a front side for receiving printed designs, pictures and / or indicia. The front side of the magnetic image assembly may have glow in the dark material creating a magnetic image assembly which may be more visible in dark surroundings. The front side of the magnetic image assembly may have a light reflective material creating a magnetic image assembly which is visible when light is directed upon the light reflective material.

Owner:KOELLER DAVID

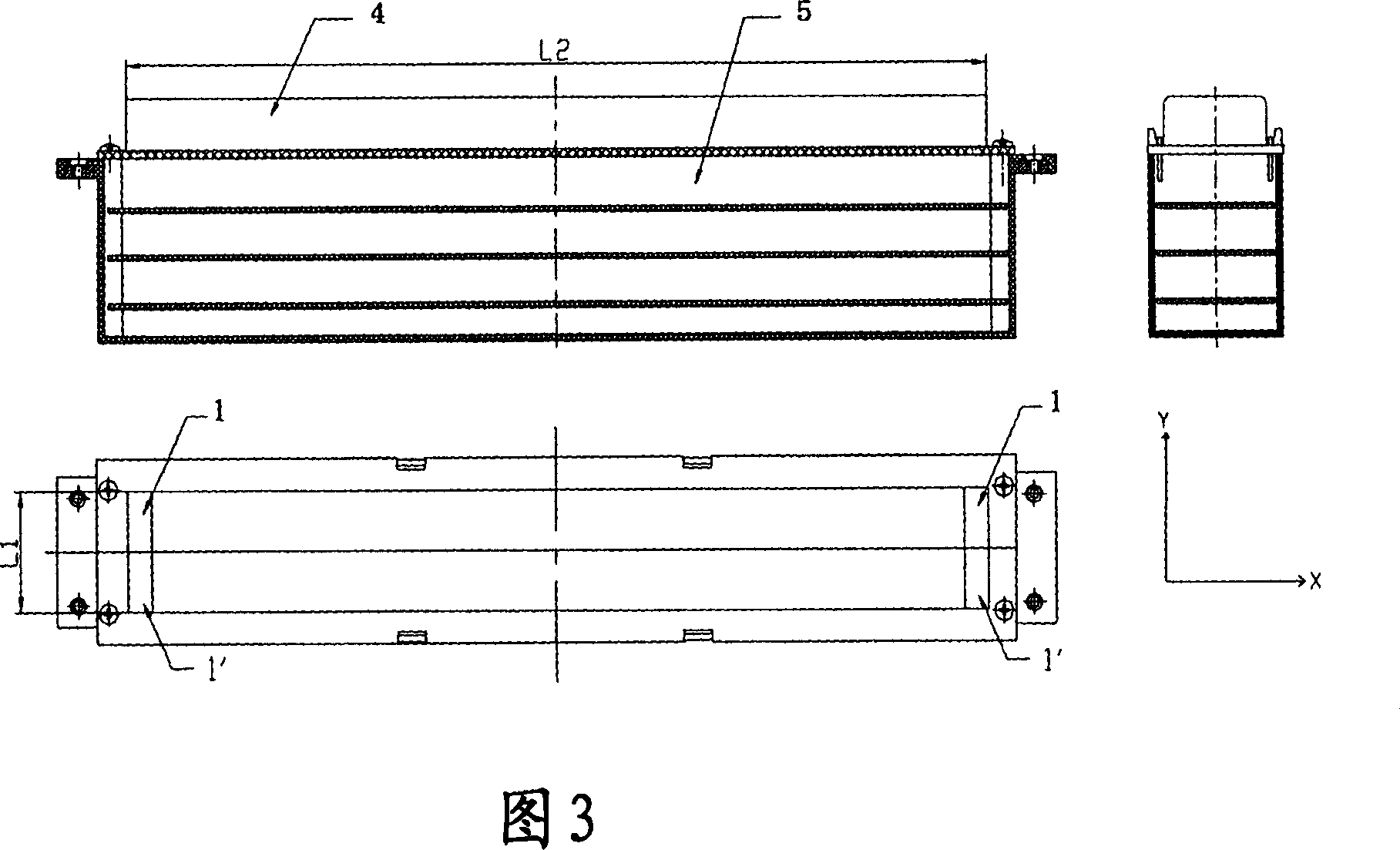

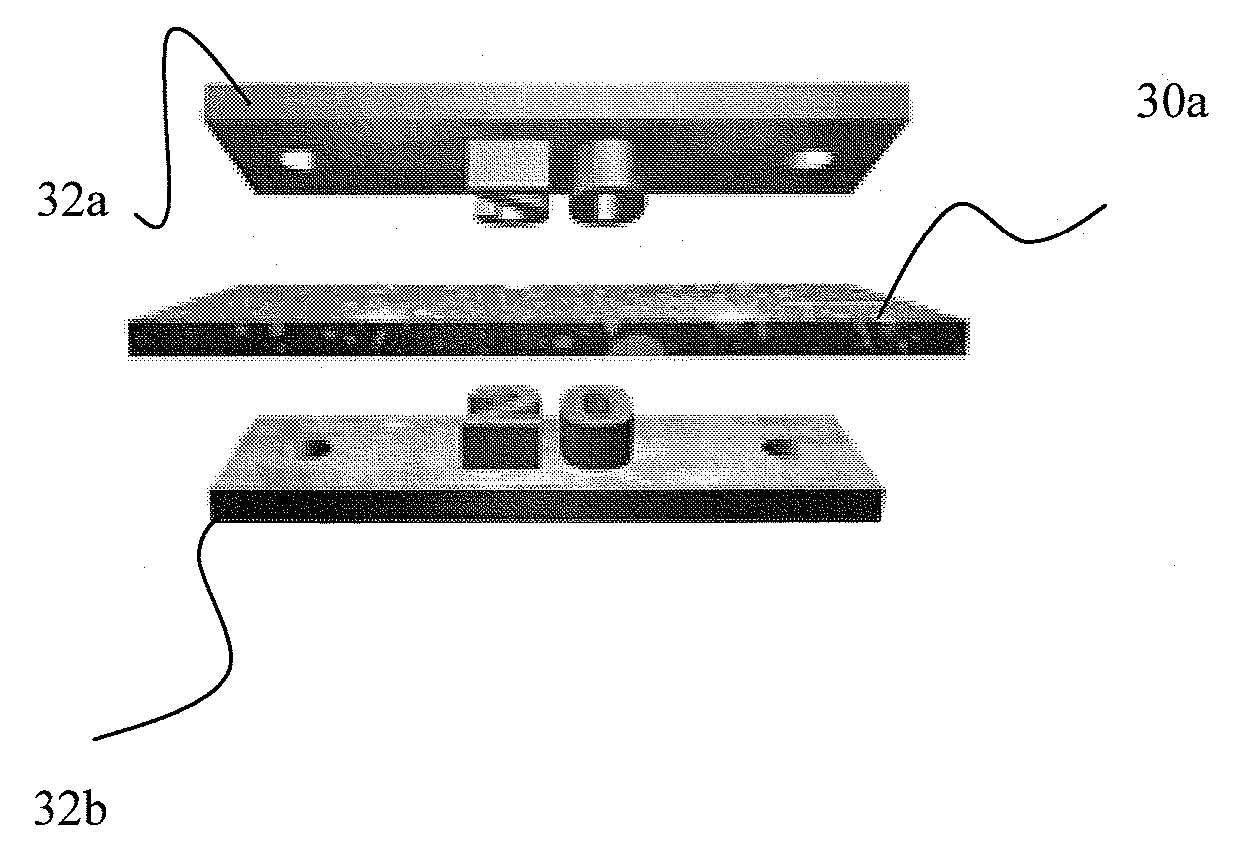

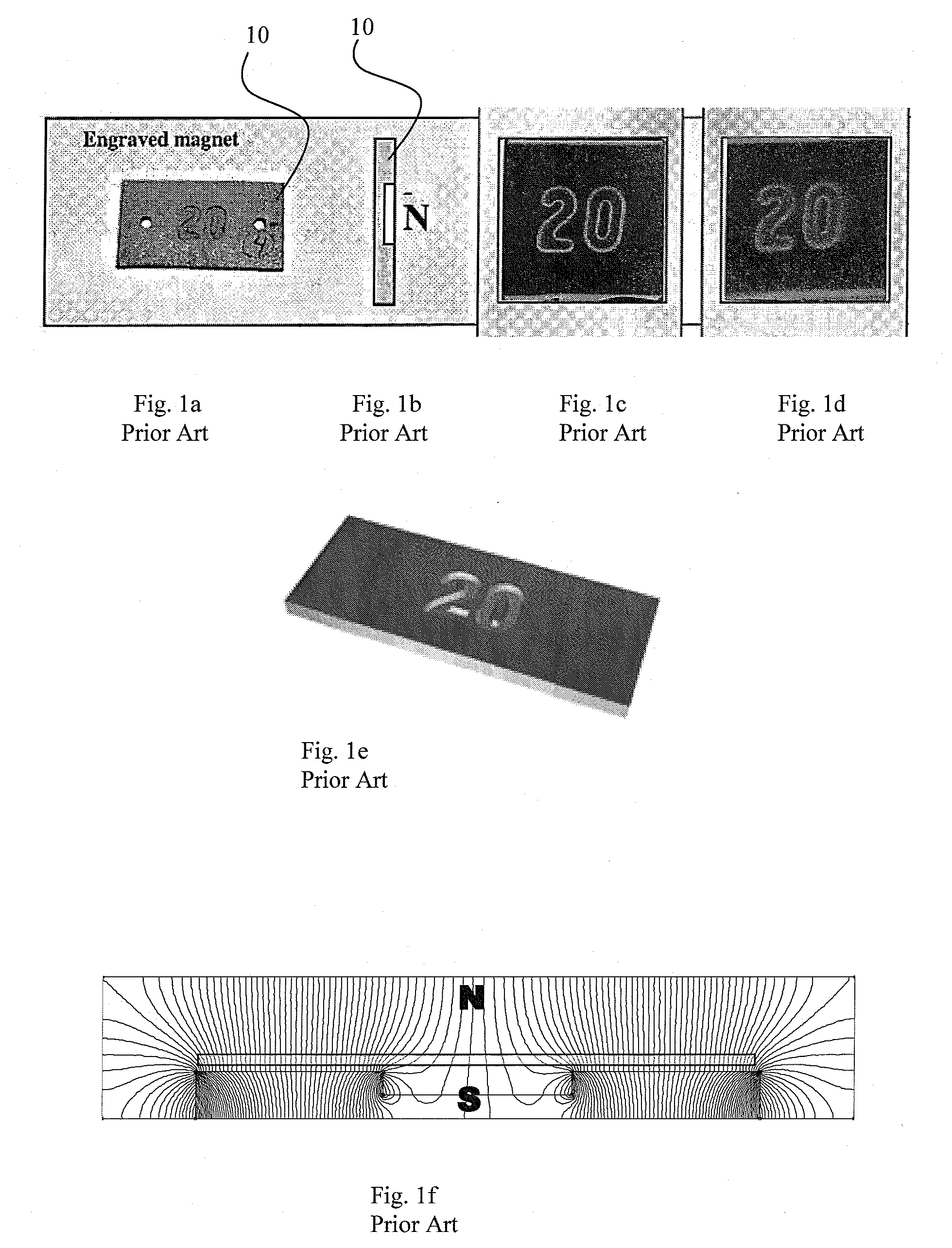

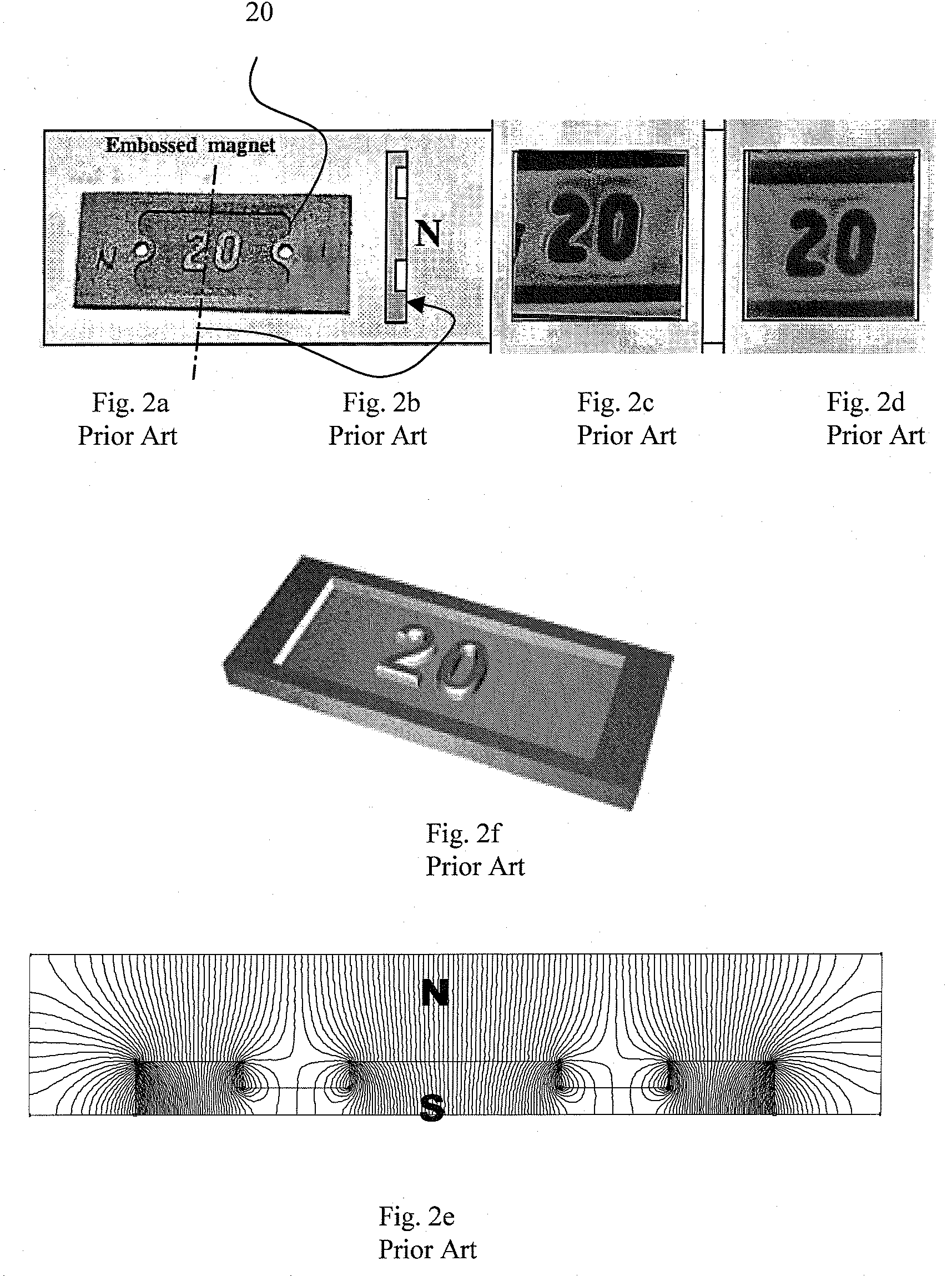

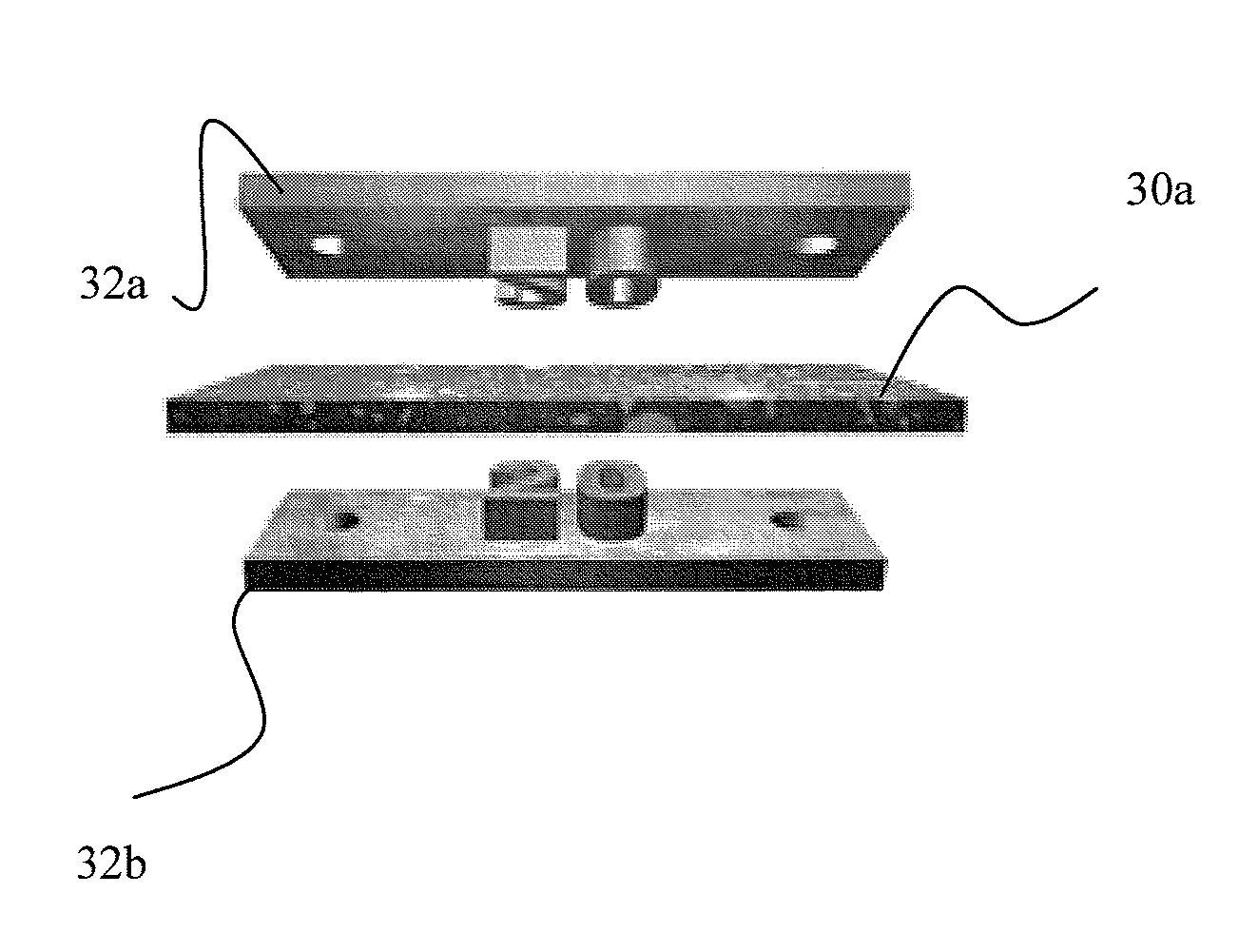

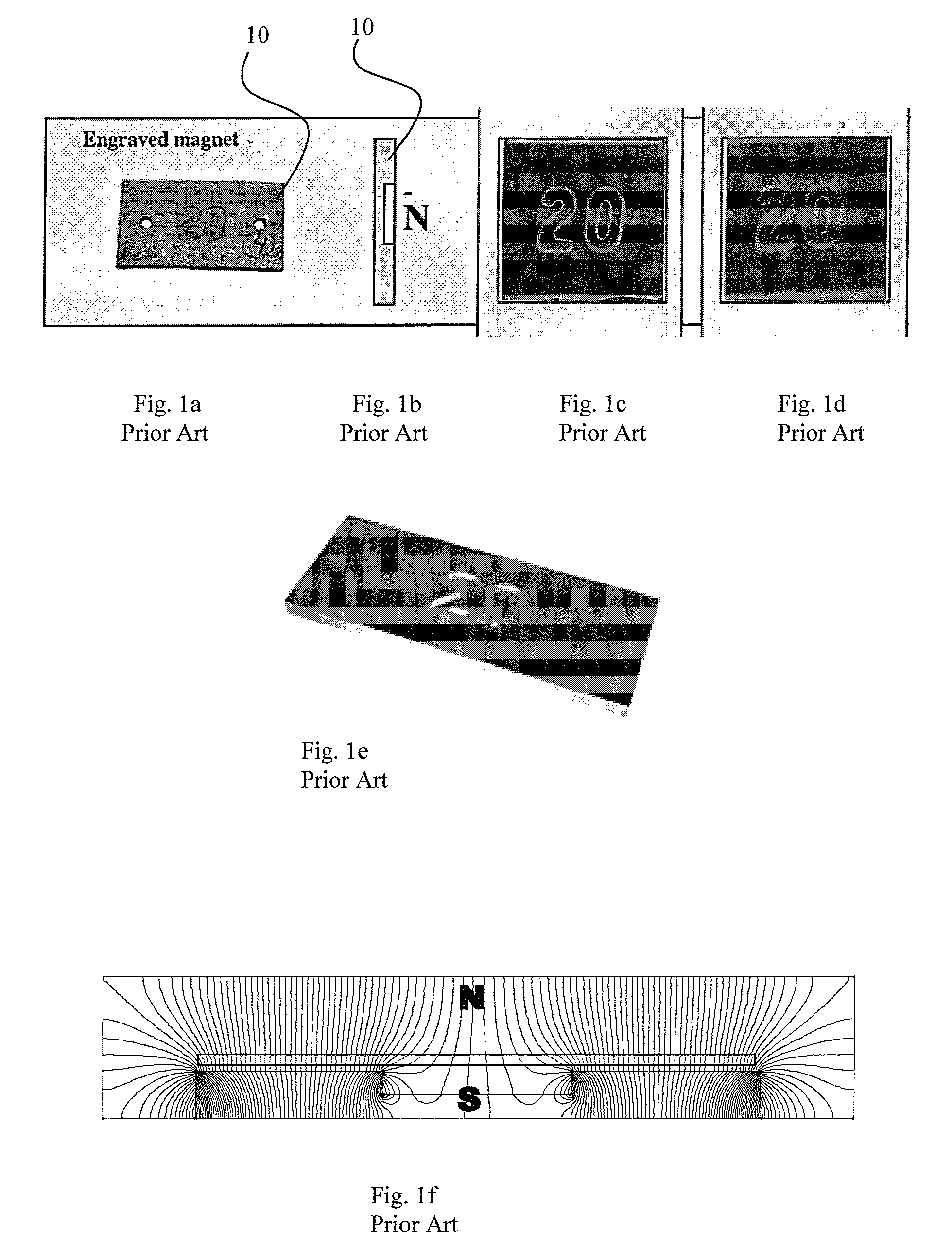

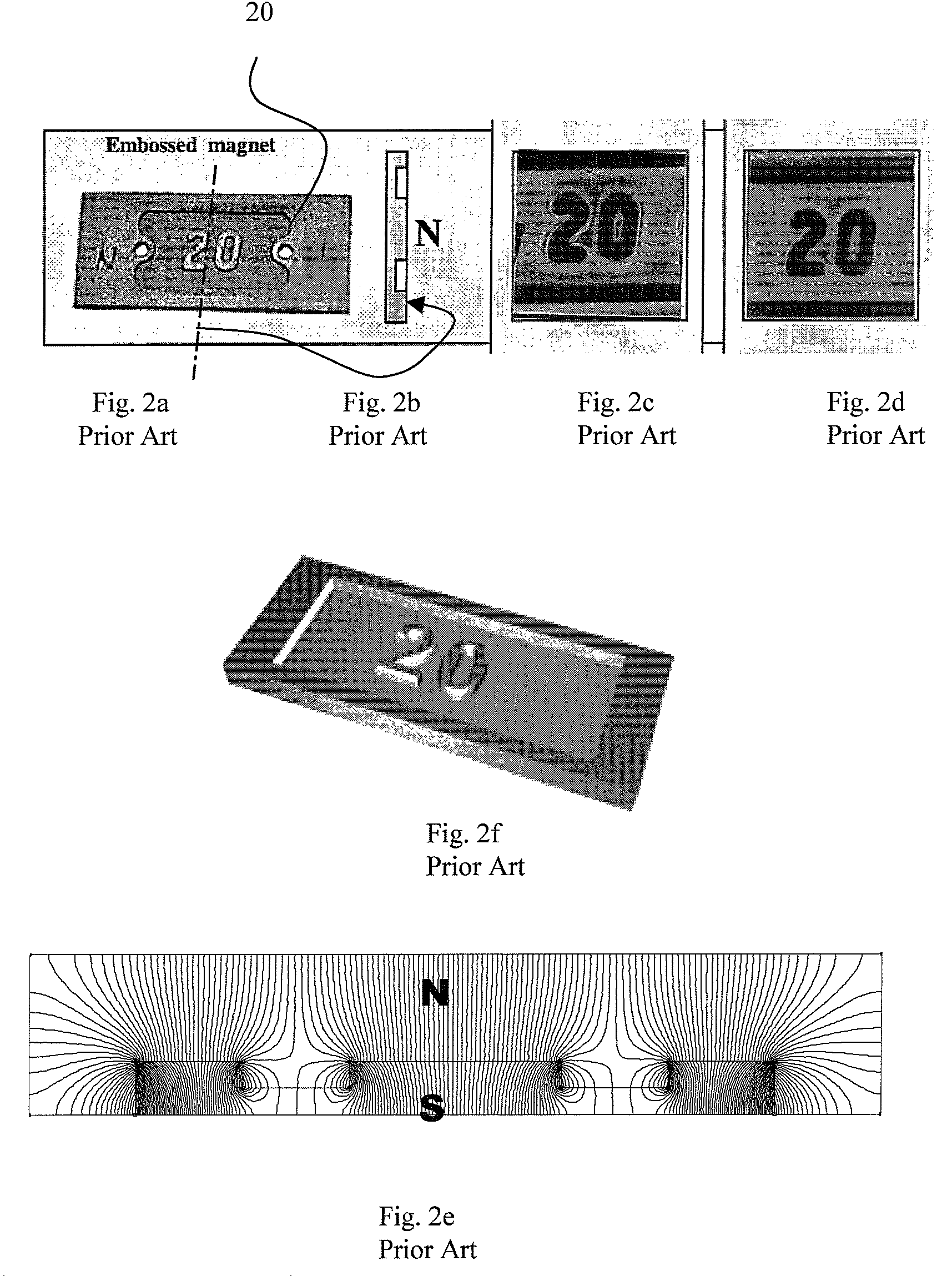

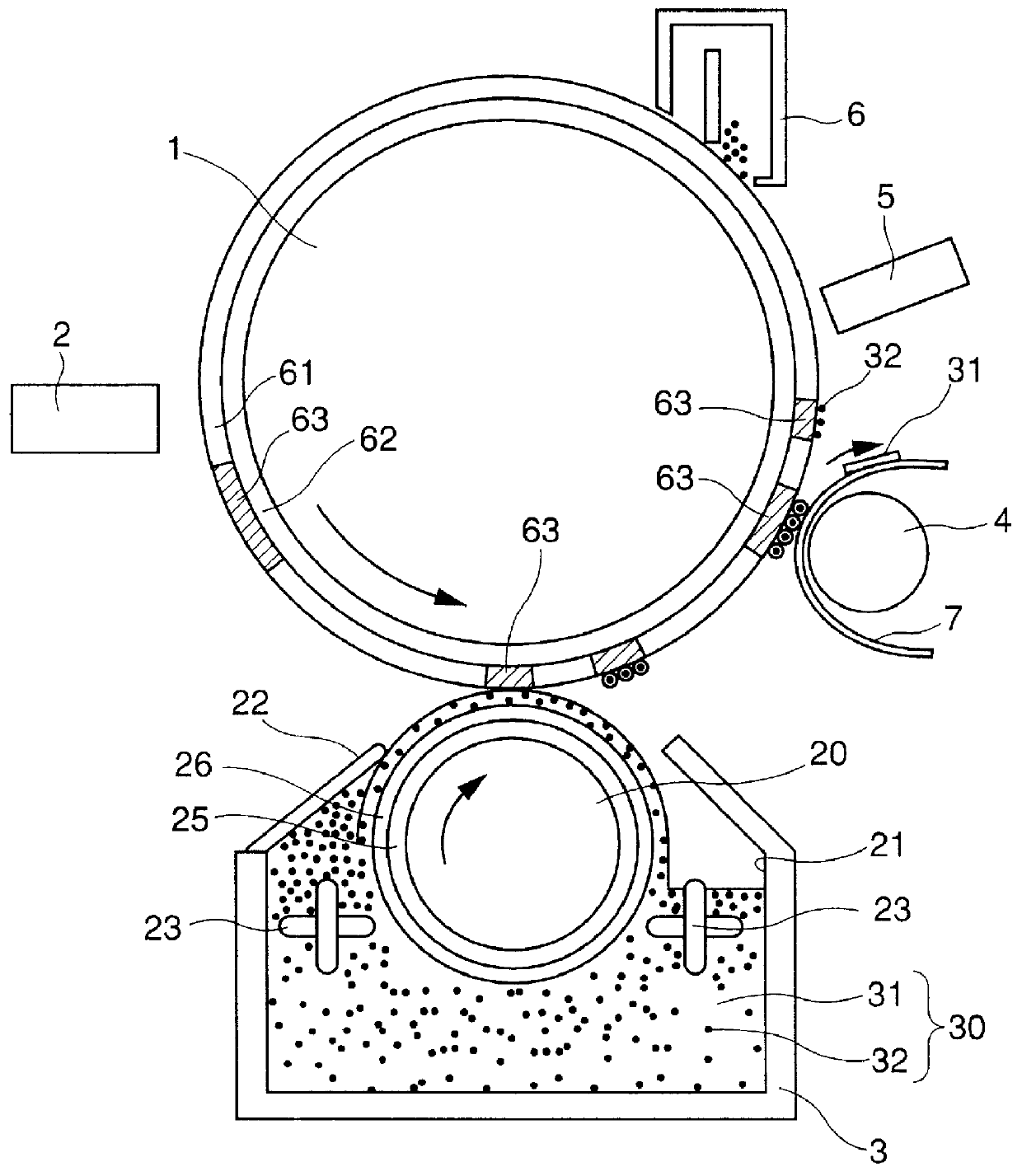

Magnetic plate for printing of optical effects

This invention discloses a magnet for use as a printing plate or printing head that is used for aligning flakes or particles in a paint or ink. A composite sheet or block of magnetizable material is selectively magnetized so that a magnet is formed within the sheet or block that has a shape of a predetermined image, logo, or indica. Dies are used to magnetize the magnetizable material and preferably the does contact the material to be magnetized. A pre-magnetized sheet such as a refrigerator magnet may be re-magnetized differently so that a magnetic image is encoded therein for use as a printing plate. Preferably the printing plate is flexible so that it can be formed to a curved surface of a cylinder or drum for printing. Conveniently these flexible magnets can be changed for other deisgins and placed on the same drum for use in printing.

Owner:VIAVI SOLUTIONS INC

Continuous Modeling for Dipole Localization from 2D MCG Images with Unknown Depth

A system identifies double-layer dipoles in a magnetic image by defining two-dimensional patches of distributed point charges that simulate the double-layer dipoles. The geometric center of a two-dimensional patch is used as the location of an equivalent dipole moment of the double-layer dipole. The momentum of the equivalent dipole moment is determined by submitting the magnetic image to a dipole construction system that identifies the location and momentum based on the submitted magnetic image.

Owner:COLUMBIA PEAK VENTURES LLC

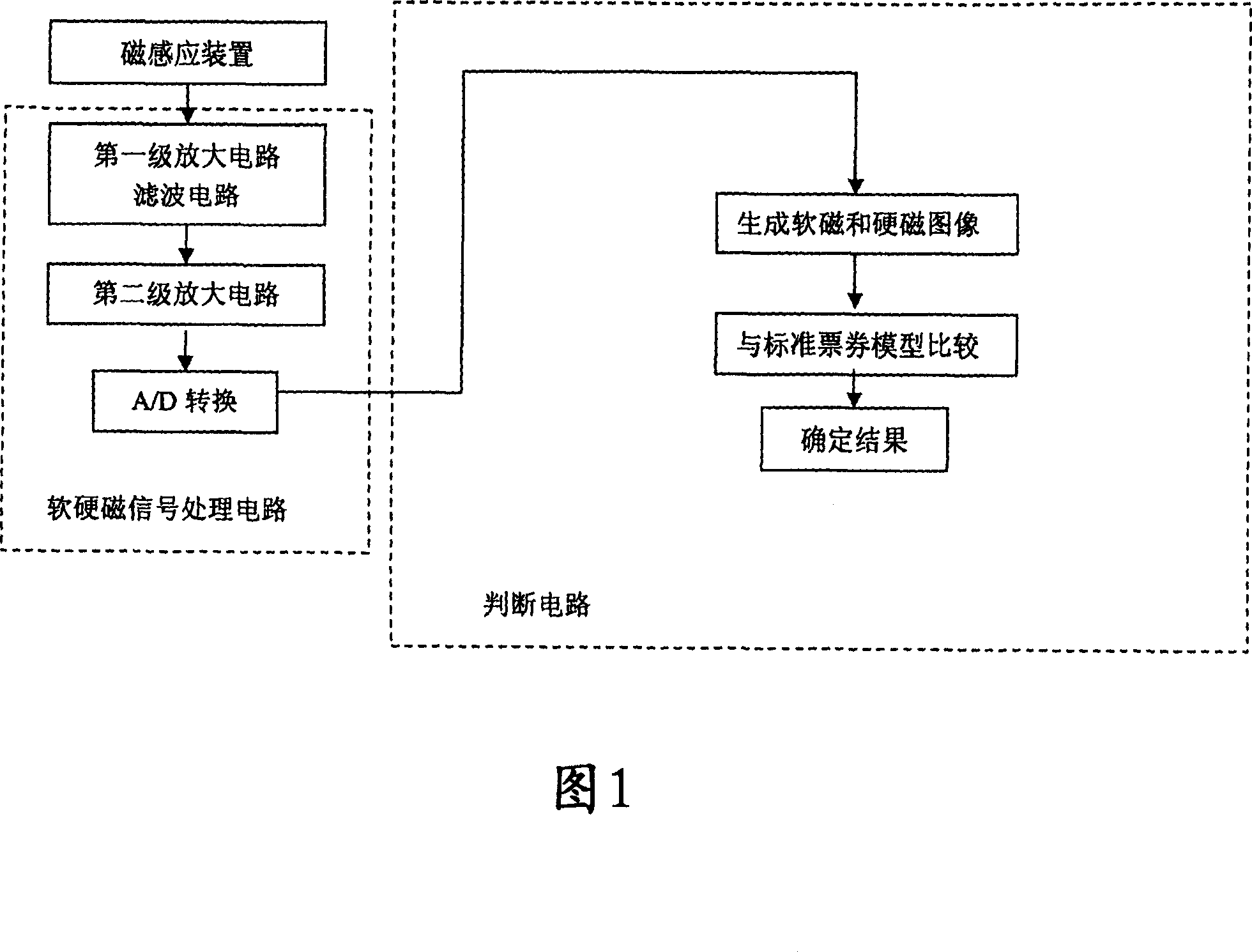

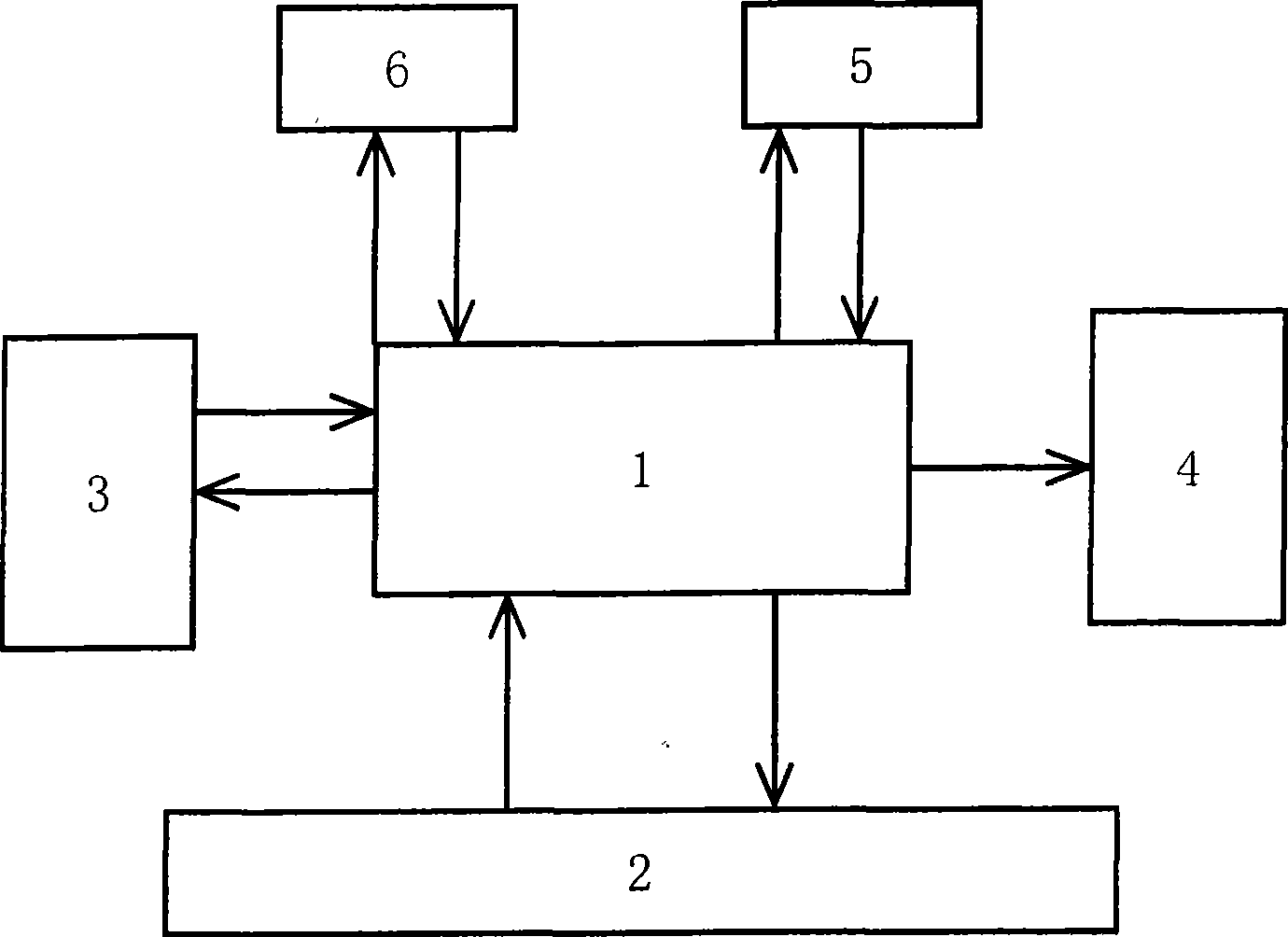

Magnetic induction device, and finance bills detection system of using the device

A ticket detection system comprises magnetic induction unit for obtaining soft / hard magnetic signal, soft / hard magnetic signal processing circuit for amplifying and filtering said signal and for converting said signal to be digital signal, judgment circuit for converting digital signal to be soft / hard magnetic image and for comparing said magnetic image with standard ticket model to identify true or false of ticket. The said magnetic induction unit consists of magnetic transducer with a magnetic head being exerted with external magnetic field and with another magnetic head free of external magnetic field.

Owner:CHINA BANKNOTE PRINTING & MINTING

Magnetic Plate For Printing Of Optical Effects

This invention discloses a magnet for use as a printing plate or printing head that is used for aligning flakes or particles in a paint or ink. A composite sheet or block of magnetizable material is selectively magnetized so that a magnet is formed within the sheet or block that has a shape of a predetermined image, logo, or indica. Dies are used to magnetize the magnetizable material and preferably the does contact the material to be magnetized. A pre-magnetized sheet such as a refrigerator magnet may be re-magnetized differently so that a magnetic image is encoded therein for use as a printing plate. Preferably the printing plate is flexible so that it can be formed to a curved surface of a cylinder or drum for printing. Conveniently these flexible magnets can be changed for other designs and placed on the same drum for use in printing.

Owner:VIAVI SOLUTIONS INC

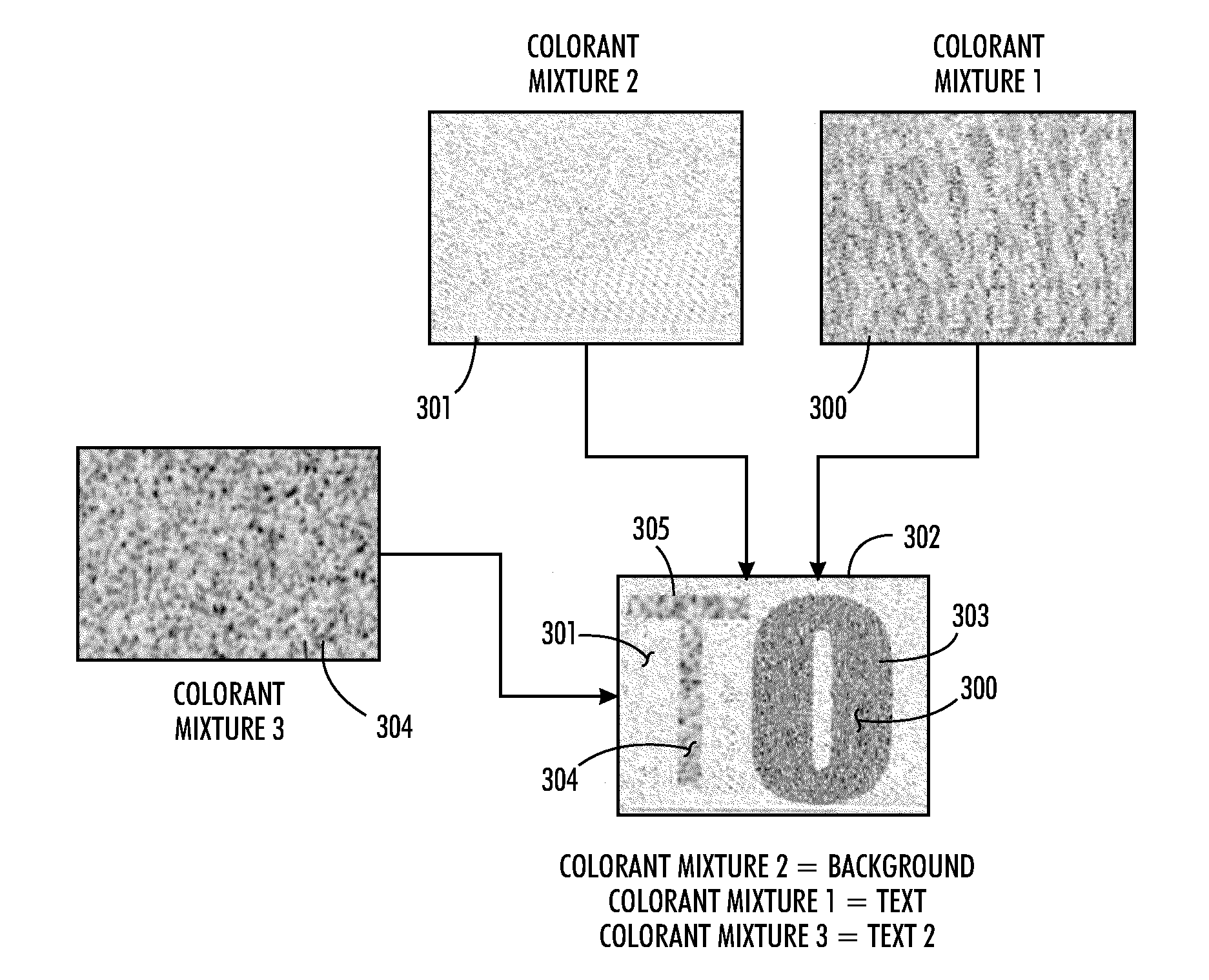

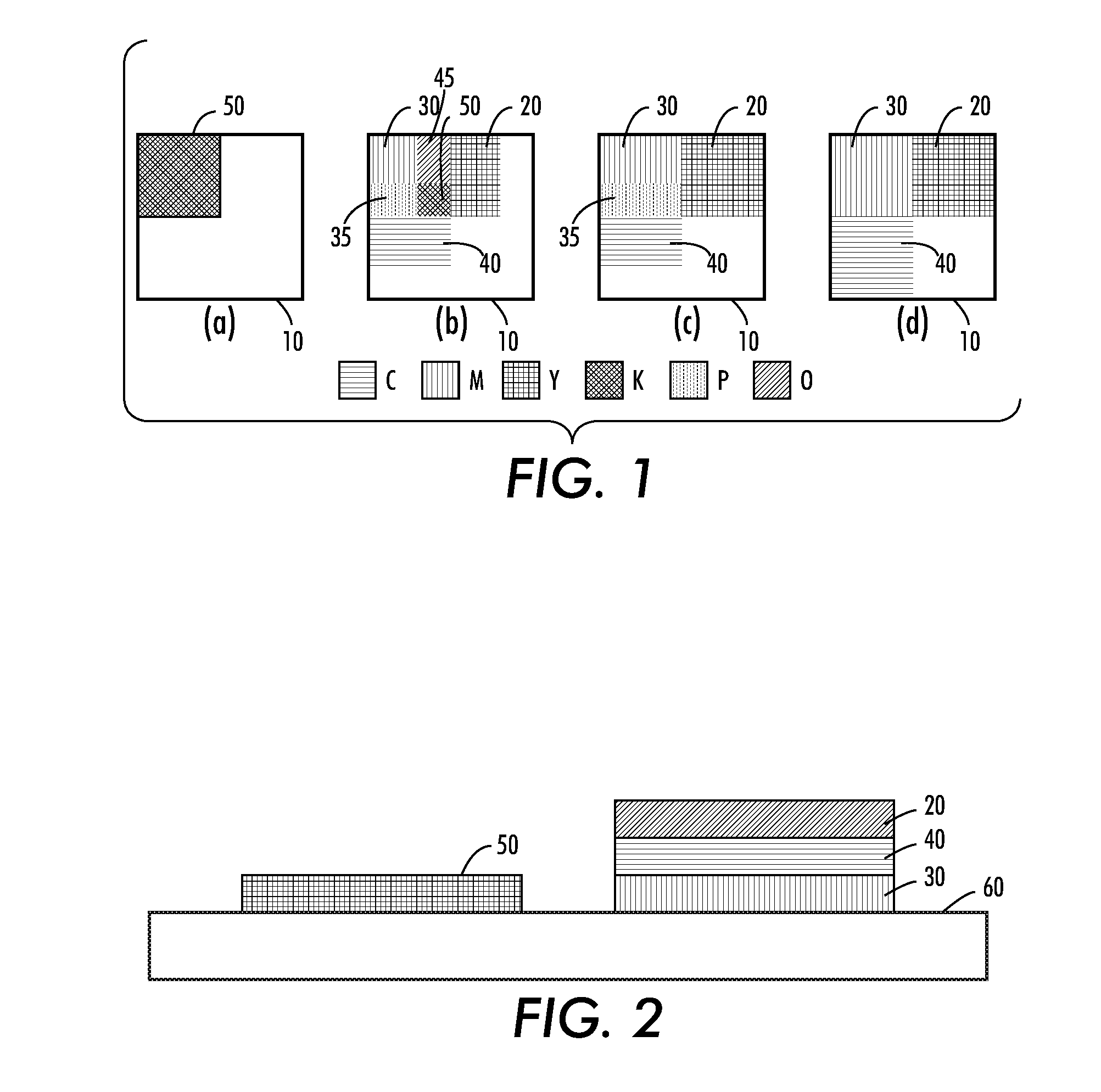

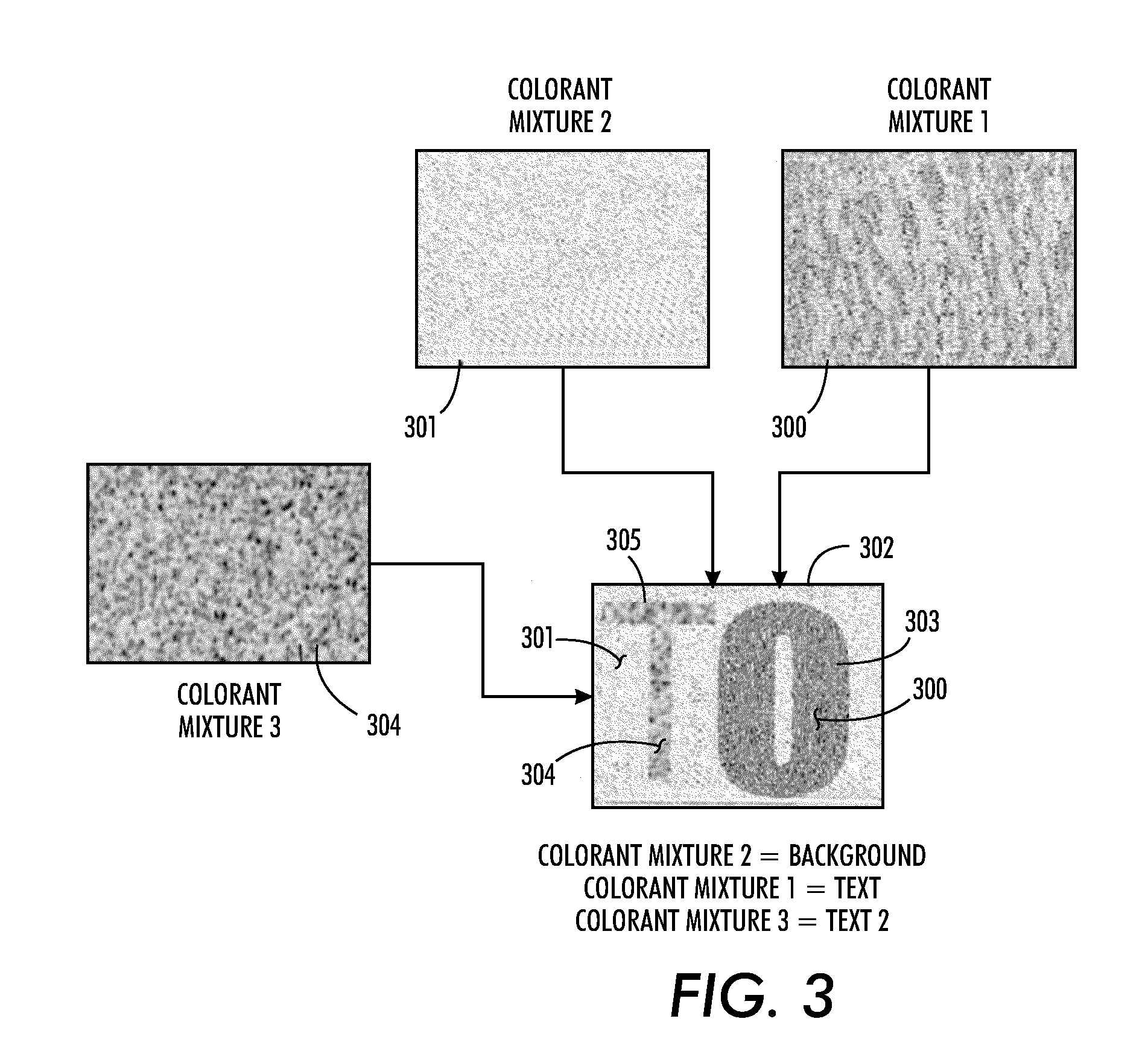

Magnetic watermarking of a printed substrate by metameric rendering

ActiveUS20110052888A1Reduce contrastNon-fibrous pulp additionPaper-money testing devicesMagnetic imageNon magnetic

A document may include a non-magnetic substrate, a first colorant mixture printed as a first image upon the substrate, the first colorant mixture including a magnetic ink, and a second colorant mixture printed as a second image upon the substrate in substantially close spatial proximity to the printed first colorant mixture. The second colorant mixture may consist essentially of one or more non-magnetic inks and exhibit properties of both low visual contrast and high magnetic contrast against the first colorant mixture, such that the resultant printed substrate does not reveal the first image to the human eye, but will reveal the first image to a magnetic image reader.

Owner:XEROX CORP

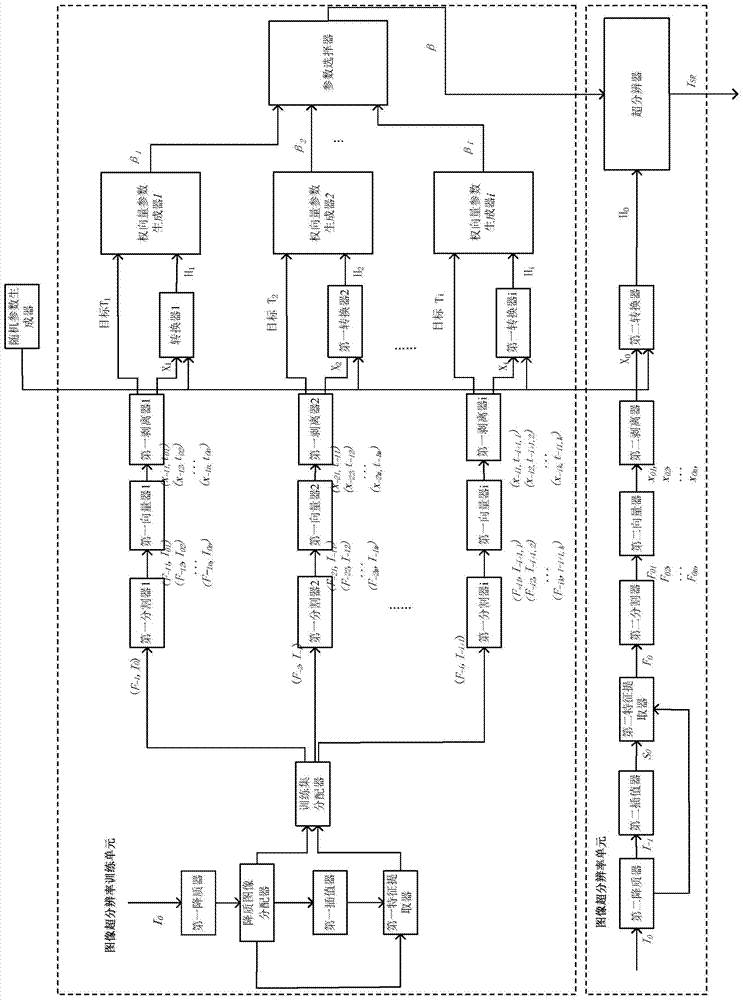

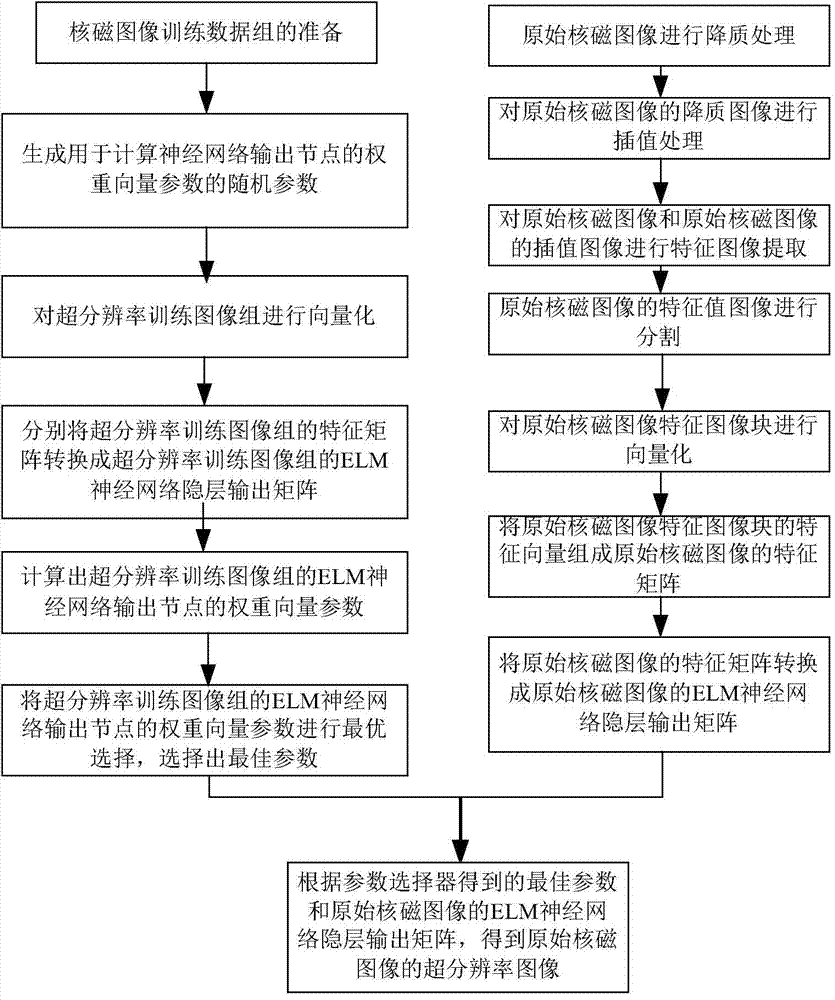

Nuclear magnetic image super-resolution system and method

ActiveCN104123722AHigh-resolutionGood for Medical DiagnosisImage enhancementImage analysisLearning machineImage extraction

The invention relates to a nuclear magnetic image super-resolution system and method. The system comprises an image super-resolution training unit, an image super-resolution unit and a random parameter generator. The method includes performing degradation, interpolation and feature image extraction on an original nuclear magnetic image to obtain a feature image set, performing partition and vectorization on images in the feature image set to obtain a feature matrix and a target matrix of an image super-resolution training set, calculating weight vector parameters of neural network output nodes through the ELM (Extrem Learning Machine) principle, and selecting the optimal parameters from the weight vector parameters of the neural network output nodes to complete the image super-resolution training. According to the nuclear magnetic image super-resolution system and method, the original nuclear magnetic image is subjected to the degradation, interpolation, feature image extraction, partition and vectorization to obtain the feature matrix of the original nuclear magnetic image, and the ELM principle and the optimal parameters are used for obtaining super-resolution images of the original nuclear magnetic image through the feature matrix of the original nuclear magnetic image.

Owner:NORTHEASTERN UNIV

Magnetic plate for printing of optical effects

This invention discloses a magnet for use as a printing plate or printing head that is used for aligning flakes or particles in a paint or ink. A composite sheet or block of magnetizable material is selectively magnetized so that a magnet is formed within the sheet or block that has a shape of a predetermined image, logo, or indica. Dies are used to magnetize the magnetizable material and preferably the does contact the material to be magnetized. A pre-magnetized sheet such as a refrigerator magnet may be re-magnetized differently so that a magnetic image is encoded therein for use as a printing plate. Preferably the printing plate is flexible so that it can be formed to a curved surface of a cylinder or drum for printing. Conveniently these flexible magnets can be changed for other designs and placed on the same drum for use in printing.

Owner:VIAVI SOLUTIONS INC

UV/EB cured integrated magnets-composition and method of fabrication

The present invention comprises a radiation curable composition for in-line printing containing magnetic pigments capable of being magnetized to possess permanent magnetic properties after the composition is cured. The composition is cured by an ionizing radiation source, preferably by UV light or electron beam radiation (UV / EB). The present invention is also directed to an in-line process for printing magnetic images on non-magnetic substrate, comprising: pattern applying the above mentioned radiation curable composition on the substrate opposite to a print side, pre-aligning the magnetic pigment particles (if necessary) of the applied composition, curing the composition by ionizing radiation source (UV / EB), magnetizing the cured composition, then finishing the final piece. The finishing step could involve delivering the final piece in a simple sheet with die cut magnets or creating an "integrated magnet" format involving plow folding over the magnet panel, pattern coating or flood coating an adhesive that will only adhere the non-magnet matrix areas between die cut magnets, thus, allowing for the individual magnets to be "popped" out of the carrier by the final end user. The resulting magnetized pieces will possess holding power like magnets (refrigerator and office magnets) and are capable of carrying personalized, Scitex imaged and direct marketing information (including redemption value for coupons, local public service access numbers, etc.)

Owner:SOVEREIGN SPECIALTY CHEM

Continuous modeling for dipole localization from 2D MCG images with unknown depth

A system identifies double-layer dipoles in a magnetic image by defining two-dimensional patches of distributed point charges that simulate the double-layer dipoles. The geometric center of a two-dimensional patch is used as the location of an equivalent dipole moment of the double-layer dipole. The momentum of the equivalent dipole moment is determined by submitting the magnetic image to a dipole construction system that identifies the location and momentum based on the submitted magnetic image.

Owner:COLUMBIA PEAK VENTURES LLC

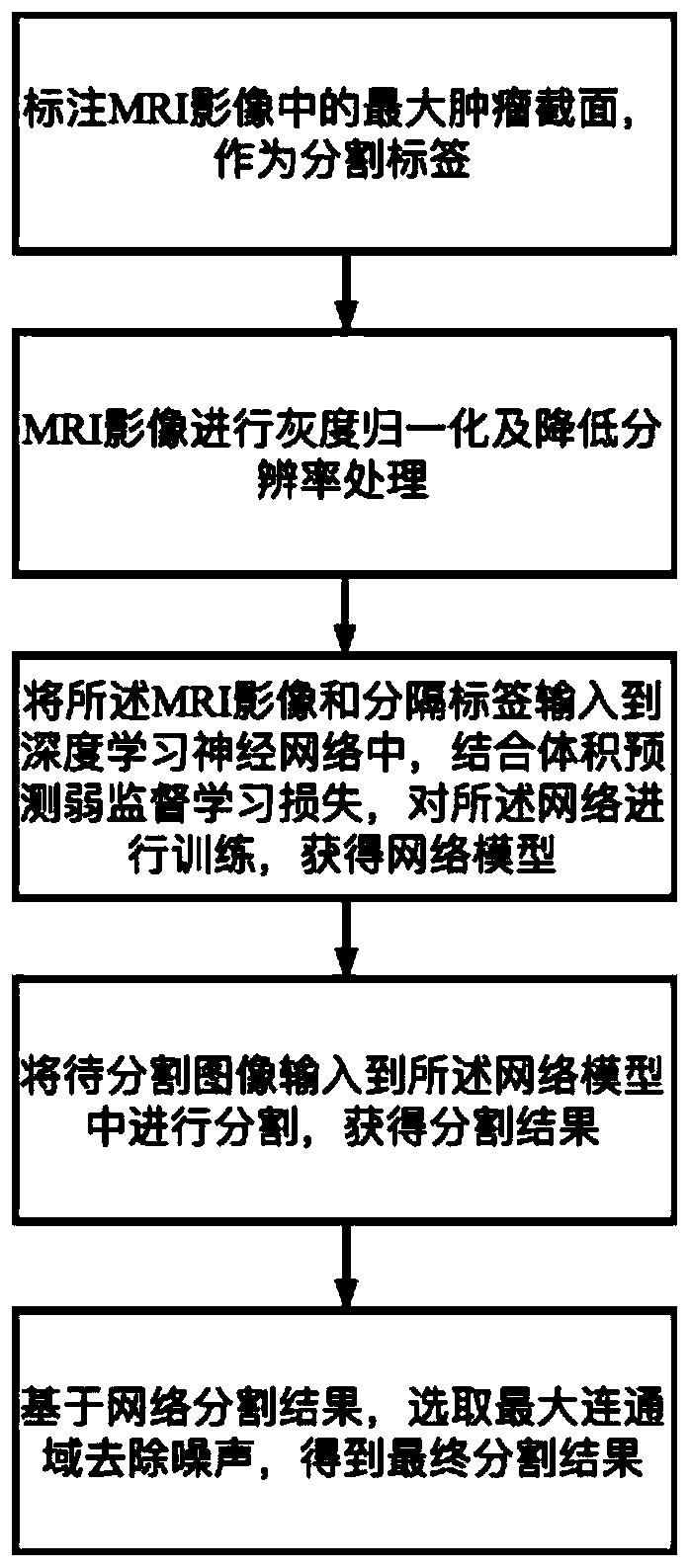

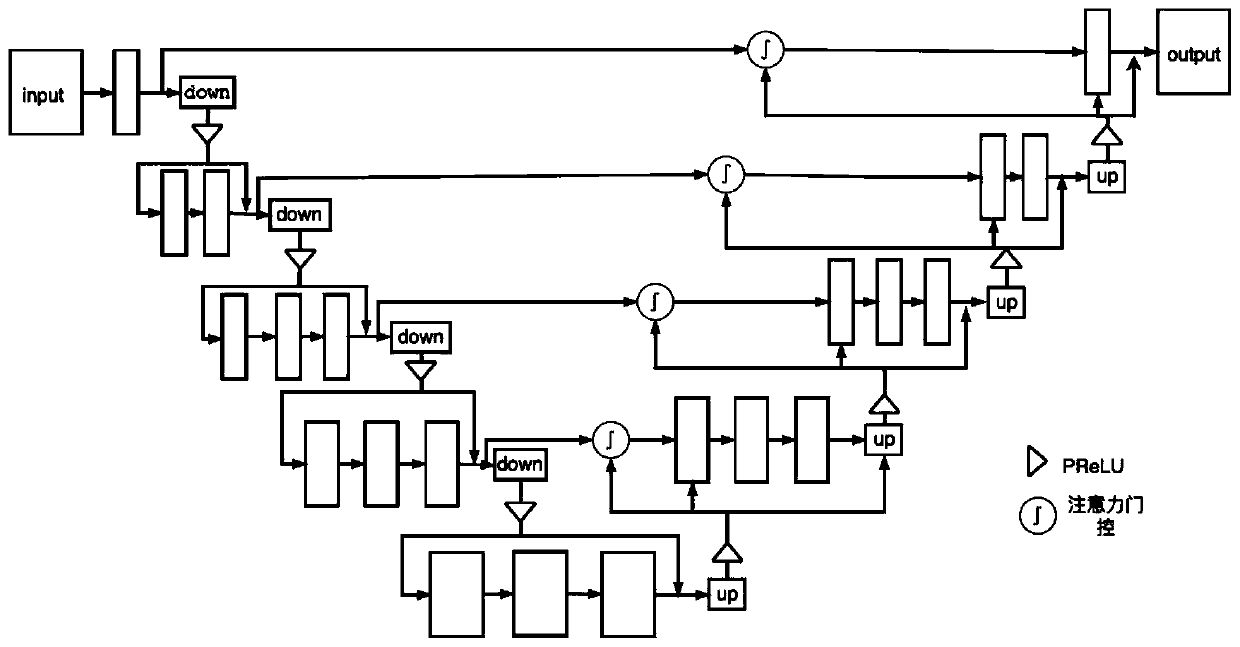

Mammary gland nuclear magnetic image tumor segmentation method and device based on weak supervised learning

PendingCN111563897AGuaranteed accuracyImprove segmentation efficiencyImage enhancementImage analysisImage resolutionRadiology

According to the mammary gland nuclear magnetic image tumor segmentation method and device based on weak supervised learning, the incomplete annotation information can be utilized to train a segmentation model, and the segmentation efficiency is greatly improved while the precision is ensured. The method comprises the following steps: (1) marking a maximum tumor section in an MRI image as a segmentation label; (2) performing gray normalization and resolution reduction processing on the MRI image; (3) inputting the processed MRI image and the segmentation label into a deep learning neural network, and training the deep learning neural network in combination with volume prediction weak supervision loss to obtain a network model; (4) inputting a to-be-segmented image into the network model for segmentation to obtain a segmentation result; and (5) based on the segmentation result in the step (4), selecting a maximum connected domain to remove noise to obtain a final segmentation result.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

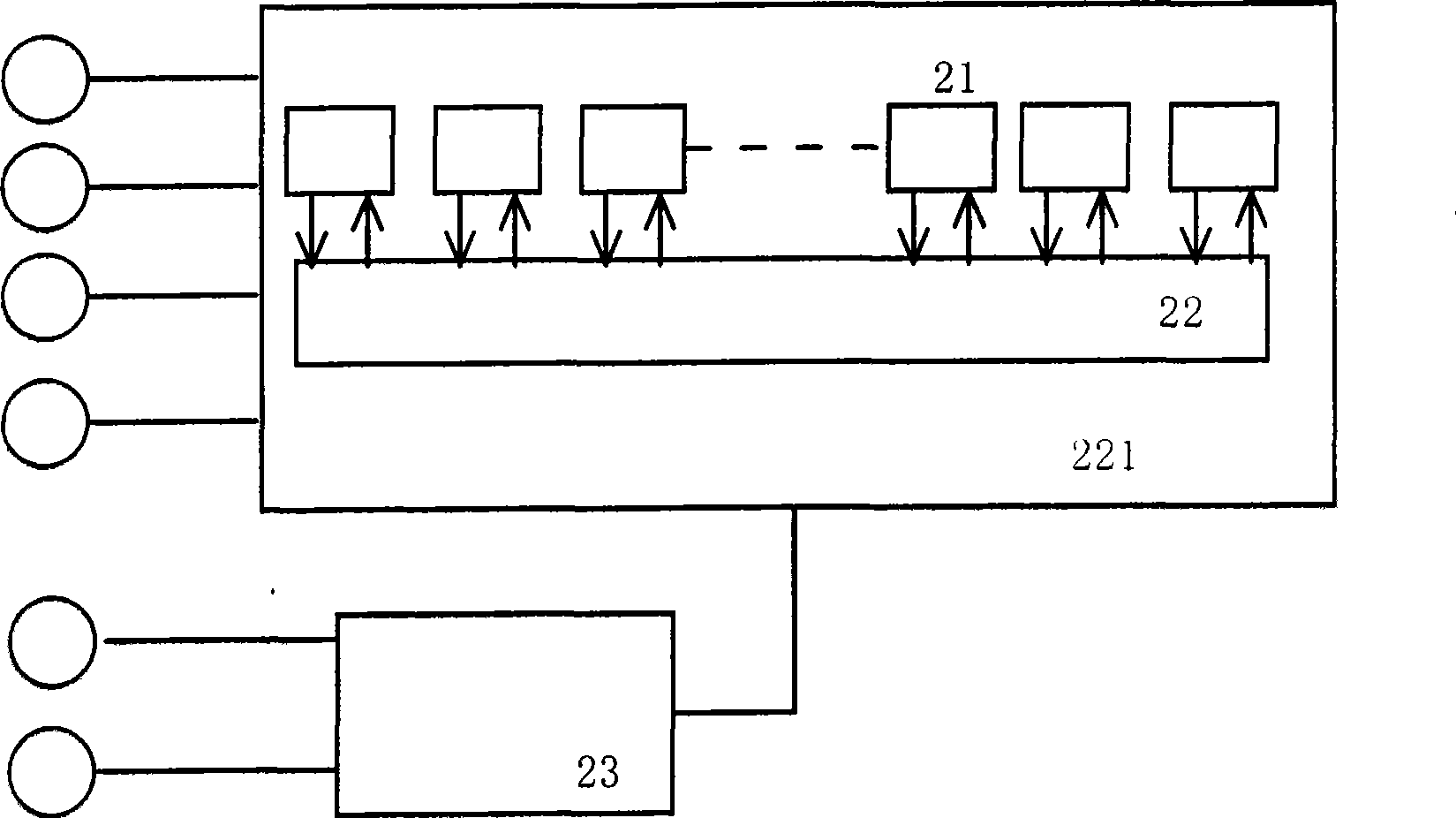

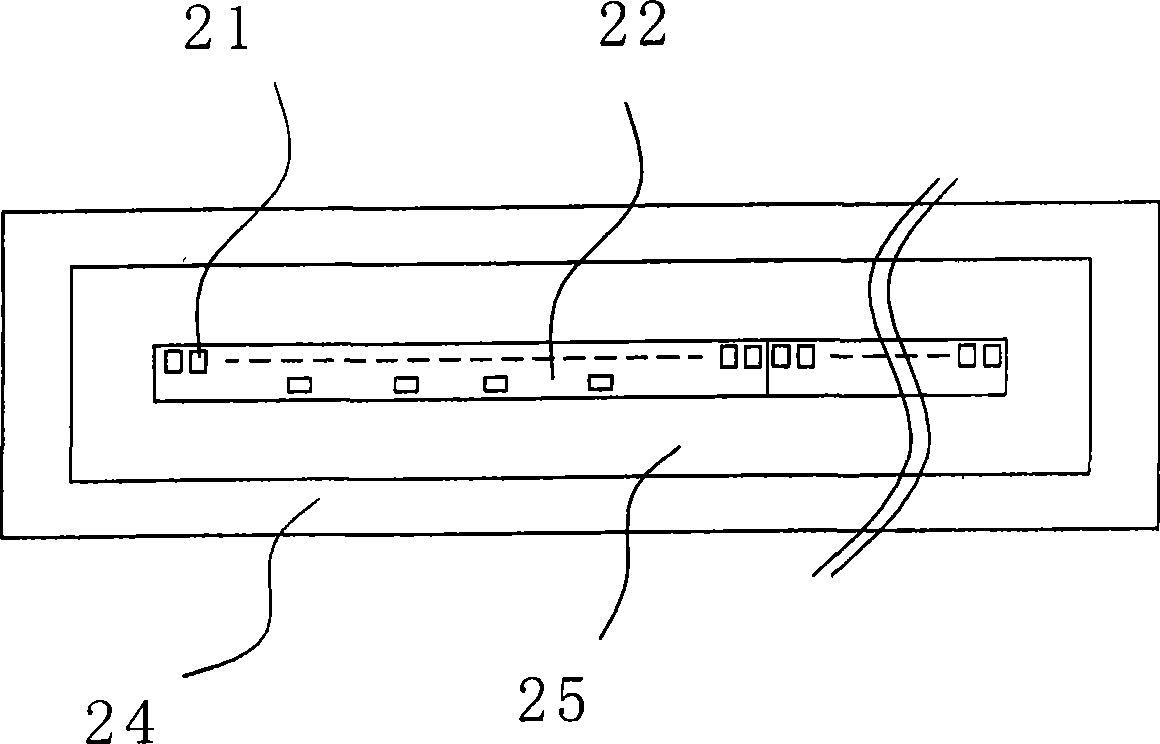

Magnetic image reading apparatus

InactiveCN101382993ALarge amount of informationThe discrimination method is intuitivePaper-money testing devicesCharacter and pattern recognitionGraphicsMagnetic image

The invention discloses a magnetic image reading device which is characterized in that a magnetic image sensor unit is a magnetic linear array sensor. The magnetic image sensor unit solves the defects of low data quantity and non-intuitive judgment since the existing monomer magnetic detection unit can only judge the existence of magnetism or identify simple magnetic numeric characters by means of MICR, and can not only identify magnetic data provided by standard magnetic characters as well as non-standard magnetic characters, but also identify various magnetic pictures. Therefore, such an identification method can have large identifiable data quantity and intuitive judgment and ensure that most of acquired data can be understood by people and are very convenient for use.

Owner:WEIHAI HUALING OPTO ELECTRONICS CO LTD

Single component toner for improved magnetic image character recognition

InactiveUS6696212B2High line and solid area densityReduce the recognition rateDevelopersElectrographic processes using charge patternMagnetic imageVolume average

Magnetic toner particles are disclosed. The magnetic toner particles contain at least one polymeric binder and at least one magnetic additive, wherein the surface of the toner particle contains particles of positively chargeable inorganic fine powder particles. The inorganic fine powder particles have a mean volume average particle size of from about 0.5 to about 7 mum, and a cleaning ratio of from about 0.1 to about 5.0 and a cleaning ratio being the volume fraction of particles between 0 and 1.0 mum, divided by the volume fraction of particles greater than 1.0 mum; and the toner particles having on the surface thereof a flowability improving agent having a BET surface area of at least about 30 m<2> / g. Methods of forming electrostatic images are further disclosed. Also, images formed from the magnetic toner particles are further disclosed and have excellent character void frequency, total void area, and suitable magnetic signal strengths. Developers containing the magnetic toner particles of the present invention are also disclosed.

Owner:EASTMAN KODAK CO +1

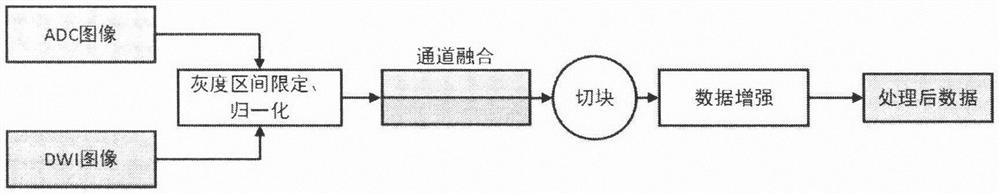

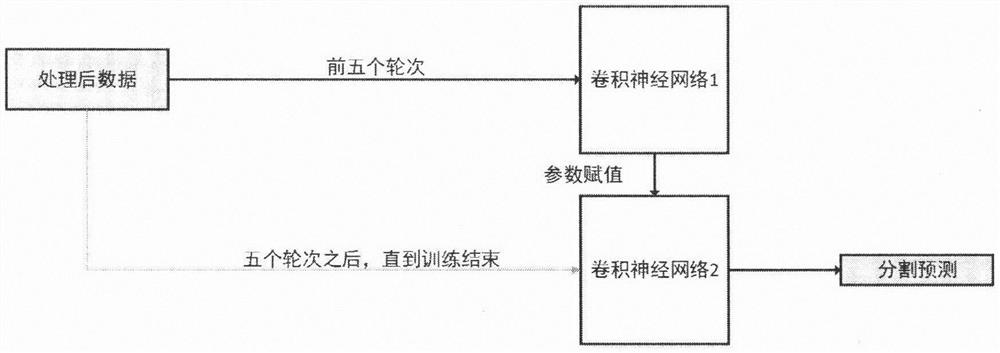

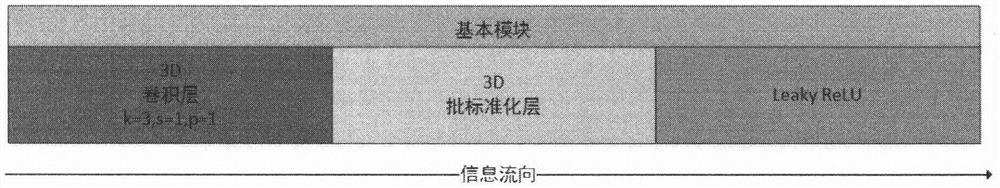

Multi-modal nuclear magnetic image cerebral arterial thrombosis lesion segmentation method based on convolutional neural network

InactiveCN111862136AEffective segmentationShorten the timeImage enhancementImage analysisCerebral arterial thrombosisTest set

The invention discloses a multi-mode nuclear magnetic image cerebral arterial thrombosis lesion segmentation method based on a convolutional neural network. The method comprises the steps of designinga deep convolutional neural network 1 based on an original framework of a 3D U-Net network; basic modules based on a 3 * 3 * 3 convolution layer and a batch standardization layer; a 3D deformable convolution module based on a 3 * 3 * 3 convolution layer and trilinear interpolation; a cascade deformation module based on the 3D deformable convolution module and the basic module; constructing a deepconvolutional neural network 2 based on the 3D U-Net network and the cascaded deformation module; inputting the processed data into a neural network 1 for pre-training; assigning a weight obtained bypre-training to a neural network 2 for training; and verifying the segmentation effect on the test set of the pixel-level label. The invention provides an automatic labeling method for ischemic stroke lesion segmentation, so that the cost of labeling data is greatly reduced, the engineering operability is enhanced to a certain extent, and doctors are assisted in clinical diagnosis of ischemic stroke patients.

Owner:NANKAI UNIV

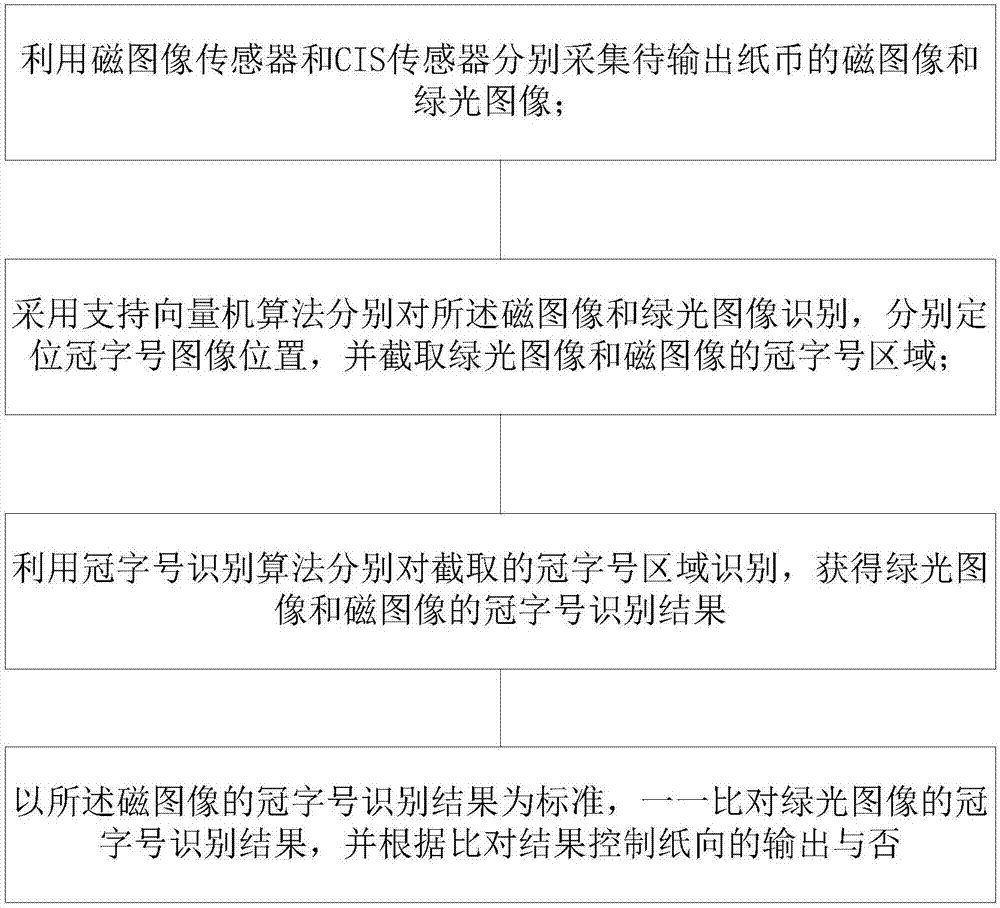

Banknote serial number identification and authentication method

InactiveCN107393115AAccurate identificationImprove recognition accuracyPaper-money testing devicesCharacter and pattern recognitionMagnetic imageGreen-light

The invention discloses a banknote serial number identification and authentication method, which comprises the following steps: collecting a magnetic image and a green light image of a banknote to be output through a magnetic image sensor and a CIS sensor; carrying out identification on the magnetic image and the green light image through a support vector machine algorithm to locate serial number image positions and intercept serial number areas of the green light image and the magnetic image respectively; carrying out identification on the intercepted serial number areas through a serial number identification algorithm to obtain serial number identification results of the green light image and the magnetic image respectively; and with the serial number identification results of the magnetic image being as reference, comparing the serial number identification results of the green light image one by one, and controlling whether to output the banknote or not according to the comparison results. Through one-by-one comparison between the serial numbers of the green light image and the serial numbers of the magnetic image, the method can still identify the serial numbers when the serial numbers are smeared and stained, thereby improving identification accuracy.

Owner:CASHWAY FINTECH CO LTD

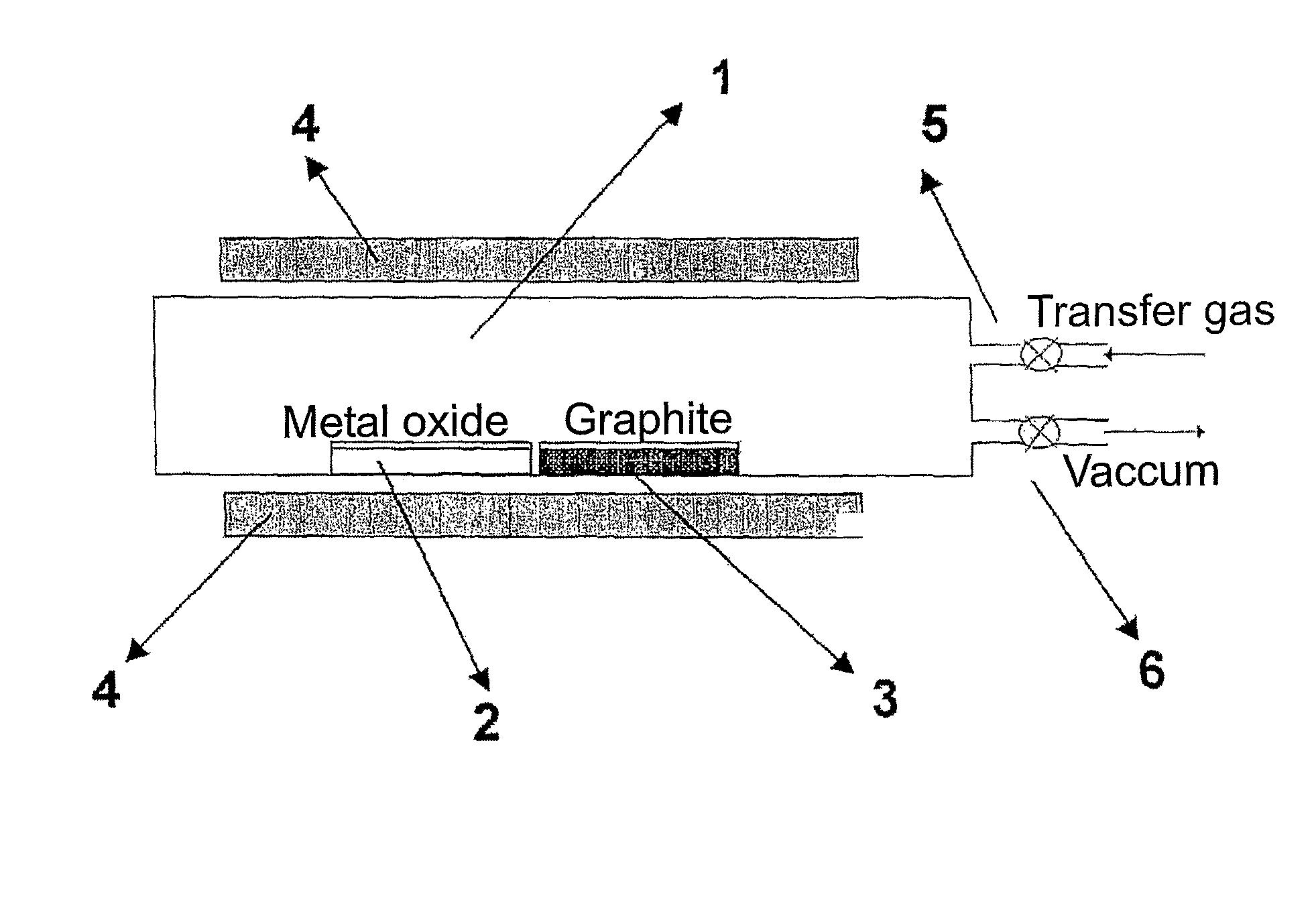

Process for preparing magnetic graphitic materials, and materials thereof

Owner:UNIVE FEDERAL DE SAO CARLOS +1

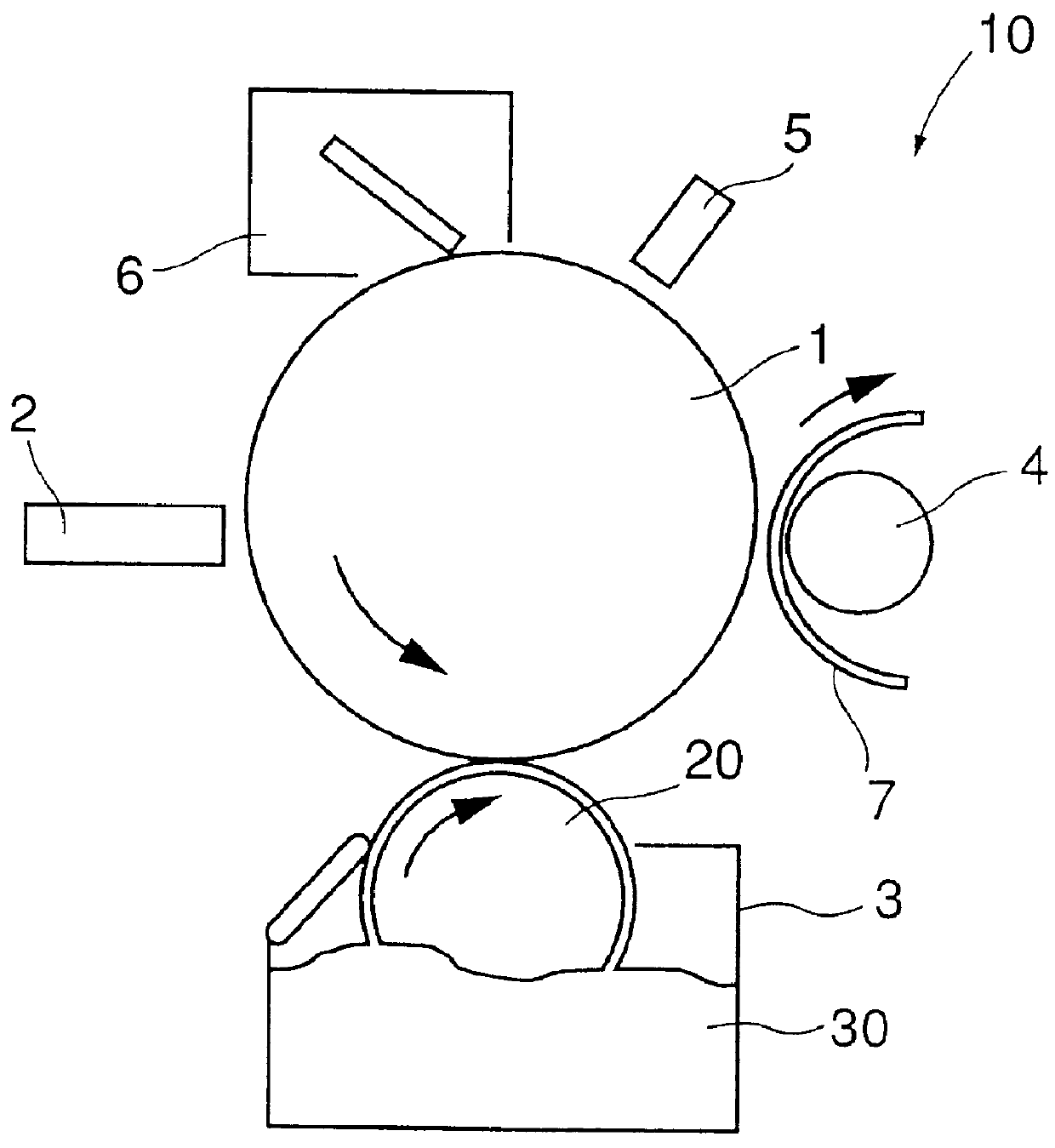

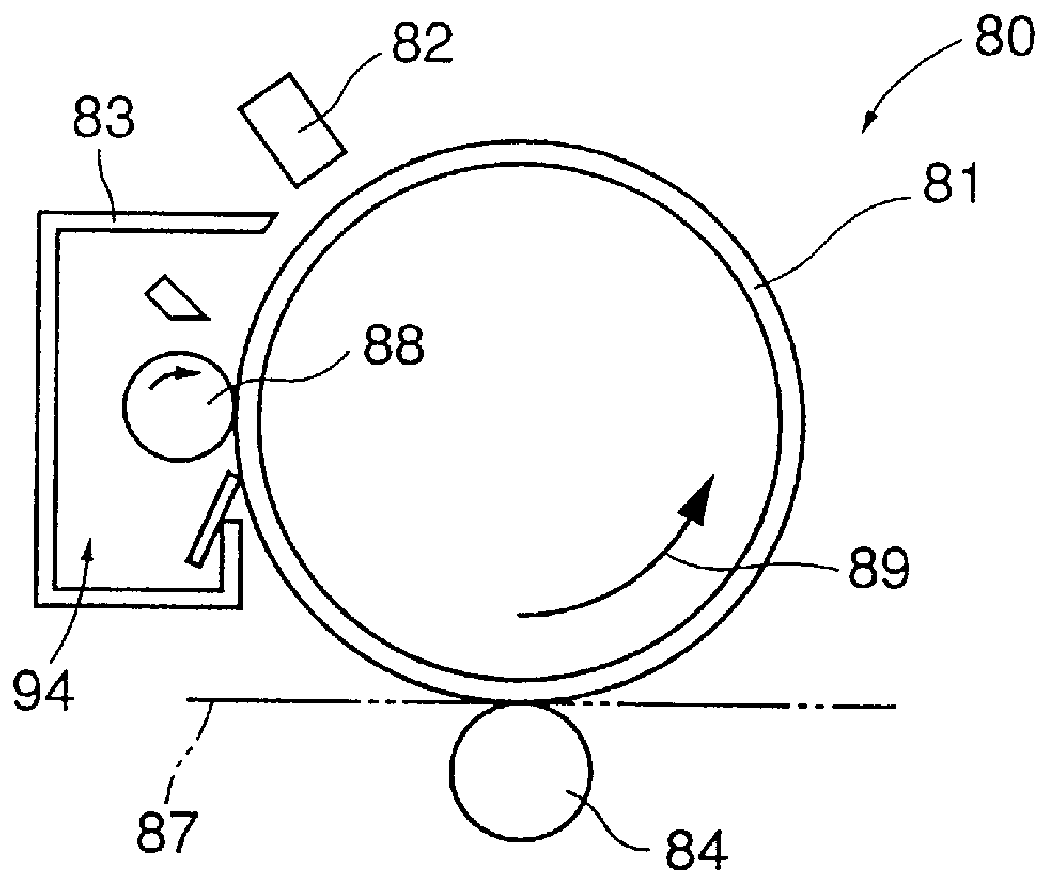

Developer and magnetic image formation apparatus using the same

InactiveUS6108506AGood reproducibilityMangetographic processRecord information storageLatent imageImage formation

A magnetic image forming apparatus includes a developer for developing a magnetic latent image. The developer has a liquid ink and particles of a resin to be dispersed in the liquid ink. The particles contain magnetic powder formed of plural parts dispersed in each of the particles of the resin. The apparatus also includes a stirrer for stirring the developer in a storage device. Also, there is a restrictor for limiting an amount of developer to be supplied.

Owner:SHARP KK

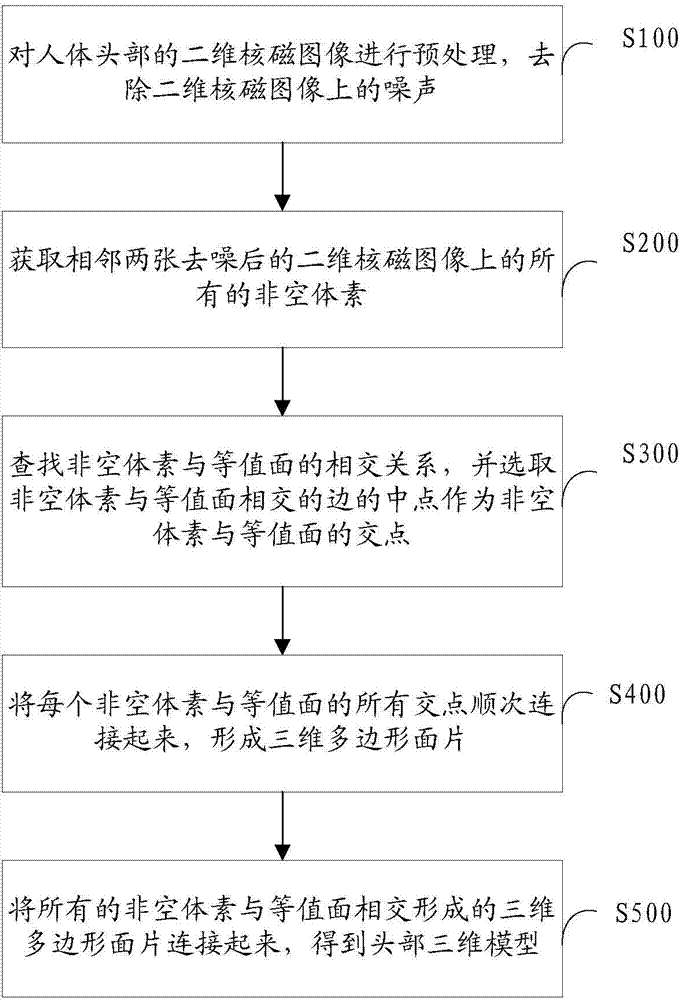

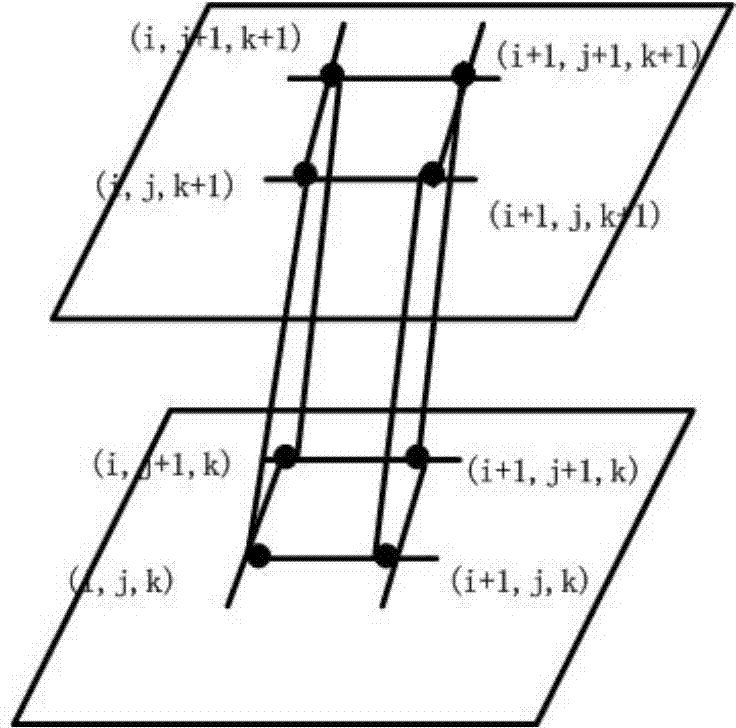

Method and system for rebuilding three-dimensional head model by two-dimensional nuclear magnetic images

InactiveCN103679808AQuality improvementImprove reconstruction accuracyDiagnostic recording/measuringSensorsVoxelMagnetic image

The invention discloses a method and a system for rebuilding a three-dimensional head model by two-dimensional nuclear magnetic images. The method includes the steps: preprocessing the two-dimensional nuclear magnetic images of a human head, and removing noise on the two-dimensional nuclear magnetic images; acquiring all non-empty voxels on two adjacent denoised two-dimensional nuclear magnetic images; searching intersection relations among the non-empty voxels and contour surfaces, and selecting middle points of intersection edges of the non-empty voxels and the contour surfaces to serve as intersection points of the non-empty voxels and the contour surfaces; sequentially connecting all intersection points of each non-empty voxel and the contour surfaces to form a three-dimensional polygonal facet; connecting the three-dimensional polygonal facets formed by intersecting the non-empty voxels and the contour surfaces to form the three-dimensional head model. The method and the system for rebuilding the three-dimensional head model by the two-dimensional nuclear magnetic images are high in rebuilding accuracy and efficiency and small in calculated amount, and the rebuilding performance of the three-dimensional model of the human head is integrally improved.

Owner:CRSC COMM & INFORMATION GRP CO LTD +1

2D dipole localization using absolute value of MCG measurements

A magnetic imaging systems produces magnetic magnitude images using magnetic sensors capable of determining only the absolute value of a detected magnetic field and provide no information regarding the positive or negative sign of the detected magnetic image. A 2D dipole location is determines the 2D location of a dipole within a magnetic magnitude image by finding the minimum of the derivative of the absolute value of the magnetic field. This 2D dipole location is then used to determine the 3D position and momentum of a current dipole responsible for the observed magnetic magnitude image. The current dipole is used to generate a magnetic image that incorporate positive and negative sign information.

Owner:SEIKO EPSON CORP

Ultrasonic and nuclear magnetic image registration fusion method and device based on hybrid supervised learning

PendingCN110838140AReduce the amount of parametersReduced Quantity RequirementsImage enhancementImage analysisRadiologyMagnetic image

According to an ultrasonic and nuclear magnetic image registration fusion method and device based on hybrid supervised learning, the task requirements are met, the training difficulty and time cost are greatly reduced, and meanwhile the requirements for the number and precision of artificial tags are reduced. The method comprises the steps that (1) a global rigid registration network is connectedwith a local B spline registration network in series, rigid deformation serves as a global deformation model, and a B spline serves as an elastic deformation model; wherein the rigid network is drivenby the vessel label to ensure that the ultrasound and nuclear magnetic images are rigidly aligned spatially; and (2) the deformation relationship between the MR and 3D ultrasonic images is predictedby using the training of an elastic registration network jointly supervised by the blood vessel label and MIND similarity measurement, wherein the MIND similarity measurement is mainly used, and theartificially segmented blood vessel label is used as auxiliary supervision.

Owner:ARIEMEDI SCI SHIJIAZHUANG CO LTD

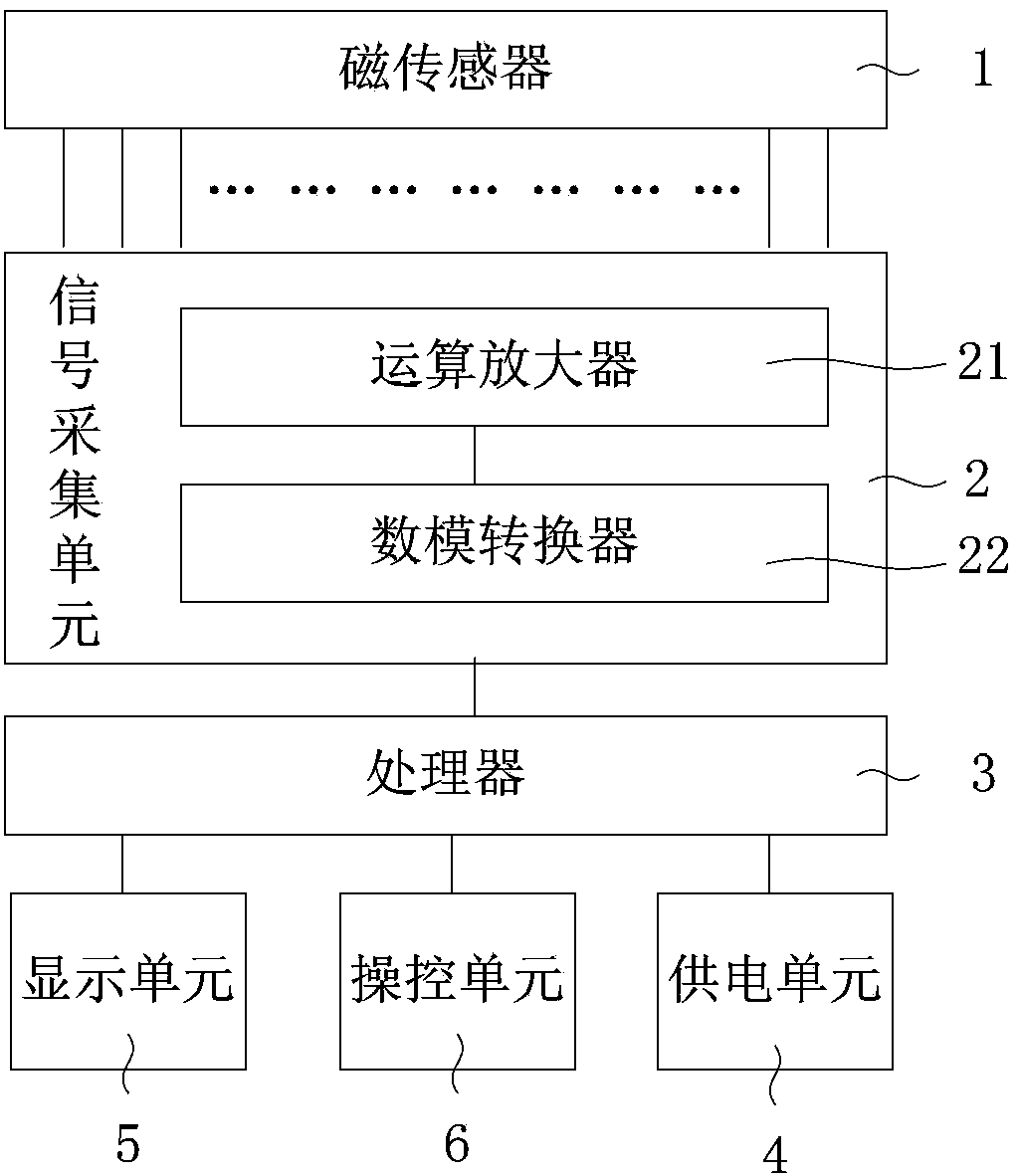

Magnetic image sensor

ActiveCN105701904ASolve the problem of relatively large noise signalReduce noise signalPaper-money testing devicesMagnetic property measurementsComputational physicsMagnetic image

The invention provides a magnetic image sensor. The magnetic image sensor includes: magnetic induction resistors which are arranged along a scanning direction and used for detecting magnetic signal changes in a range to be detected; configuration resistors connected with the magnetic induction resistors, the configuration resistors being resistors with adjustable valves of resistance; and a drive circuit connected with the magnetic induction resistors and used for performing output control on signals detected by the magnetic induction resistors. Through the magnetic image sensor provided by the invention, the problem in related technologies that noise signals of a magnetic image sensor are relatively large due to deviation of magnetic resistance is solved.

Owner:WEIHAI HUALING OPTO ELECTRONICS CO LTD

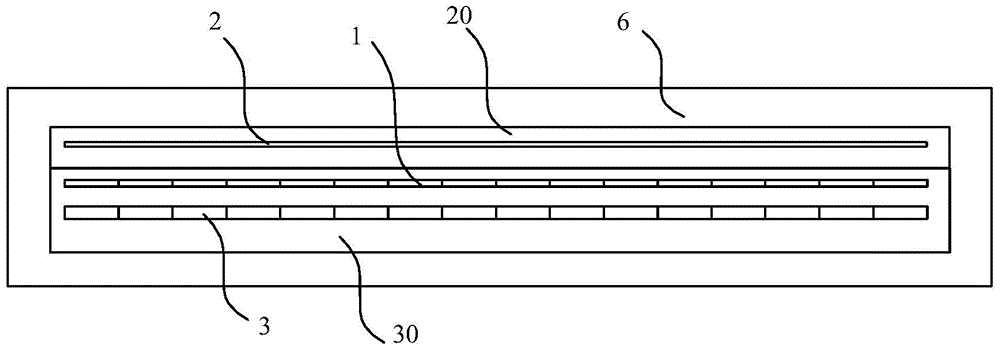

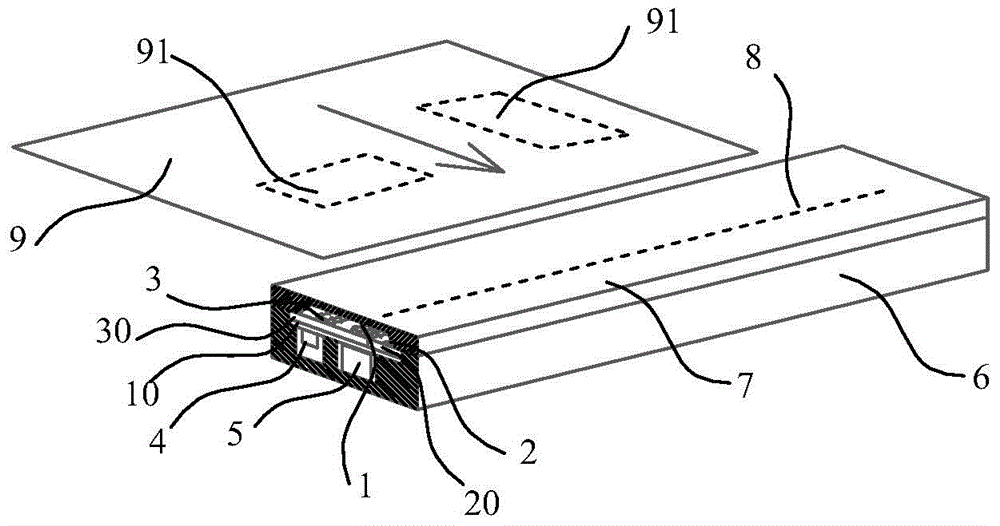

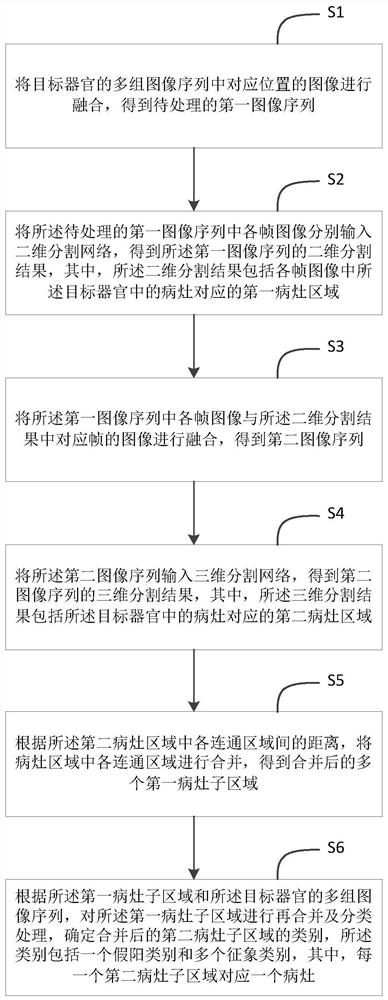

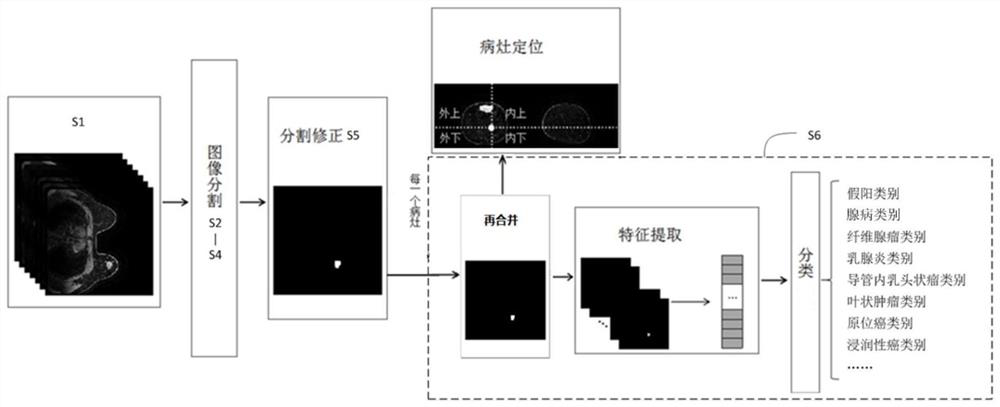

Breast focus classification and positioning method and device based on nuclear magnetic image

ActiveCN113222038ASave time watching moviesImprove work efficiencyImage enhancementImage analysisRadiology3d segmentation

The invention relates to a breast focus classification and positioning method and device based on a nuclear magnetic image, and the method comprises the steps: carrying out the two-dimensional segmentation of a to-be-processed first image sequence, which is obtained through the fusion of a plurality of image sequences of a target organ, and then carrying out the three-dimensional segmentation of the to-be-processed first image sequence; combining the connected regions in the obtained three-dimensional segmentation result to obtain a plurality of combined first focus sub-regions; and finally, according to the first focus sub-regions and the multiple groups of image sequences of the target organ, recombining and classifying the first focus sub-regions, and determining the category of the combined second focus sub-regions, wherein the category comprises a false positive category and a plurality of sign categories. According to the embodiment of the disclosure, the focus can be quickly and accurately identified from the mammary gland nuclear magnetic image sequence, and the reference type of the focus is given, so that the film viewing time of a doctor can be greatly saved, and the working efficiency and accuracy of the doctor can be improved.

Owner:BEIJING ANDE YIZHI TECH CO LTD

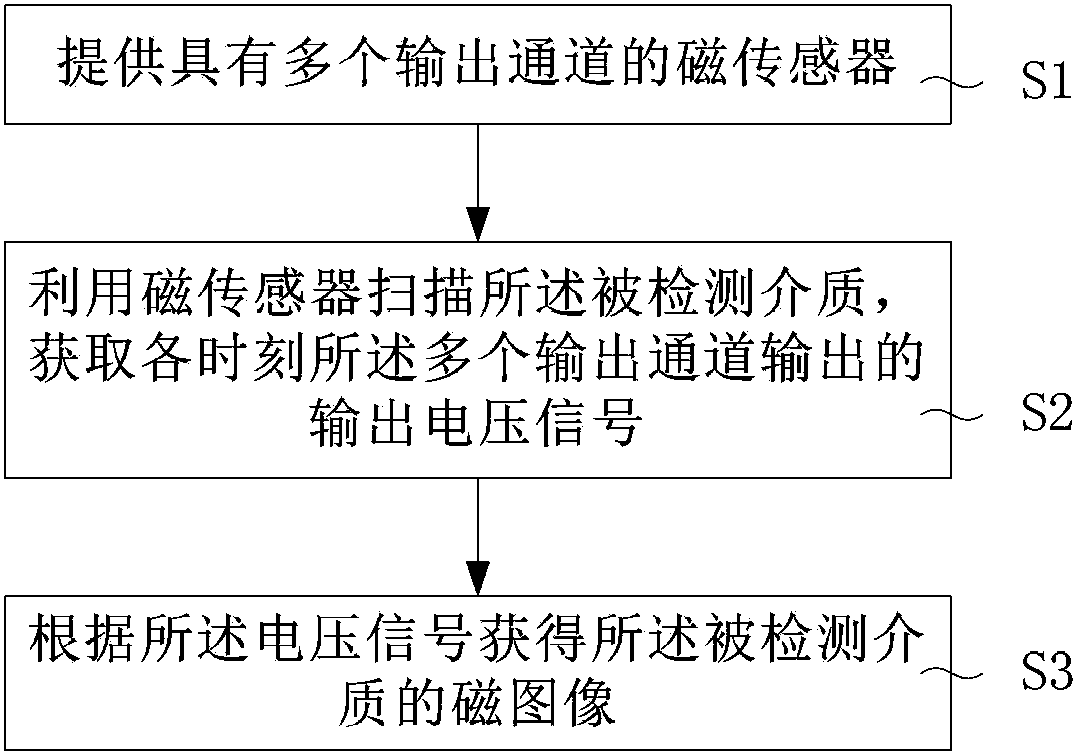

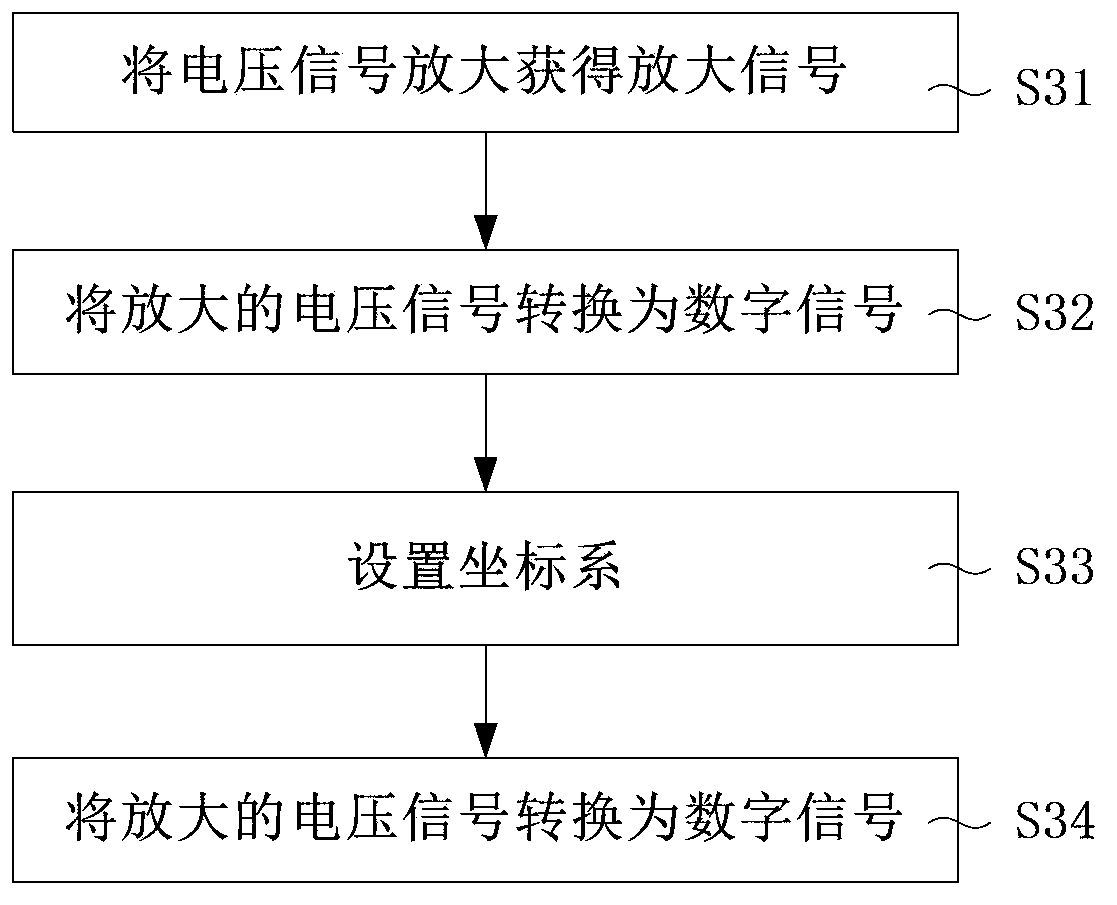

Magnetic imaging method and device

InactiveCN104346857AReduce false positivesReduce false positive ratePaper-money testing devicesCharacter and pattern recognitionMagnetic imageMagnetic imaging

The invention provides a magnetic imaging method used for obtaining a magnetic image of a detected medium in which magnetic identifications are arranged. The method includes the following steps: providing a magnetic sensor with a plurality of output channels; using the magnetic sensor to scan the detected medium so as to obtain output voltage signals output by the plurality of output channels at each time; and according to the voltage signals, obtaining the magnetic image of the detected medium. The magnetic imaging method is capable of reducing a probability of error erroneous judgment and misjudgment so that the authenticity identification precision is improved. The invention also provides a magnetic imaging device.

Owner:BEIJING JIAYUE TONGLEJI ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com