Patents

Literature

56 results about "Ionising radiation source" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

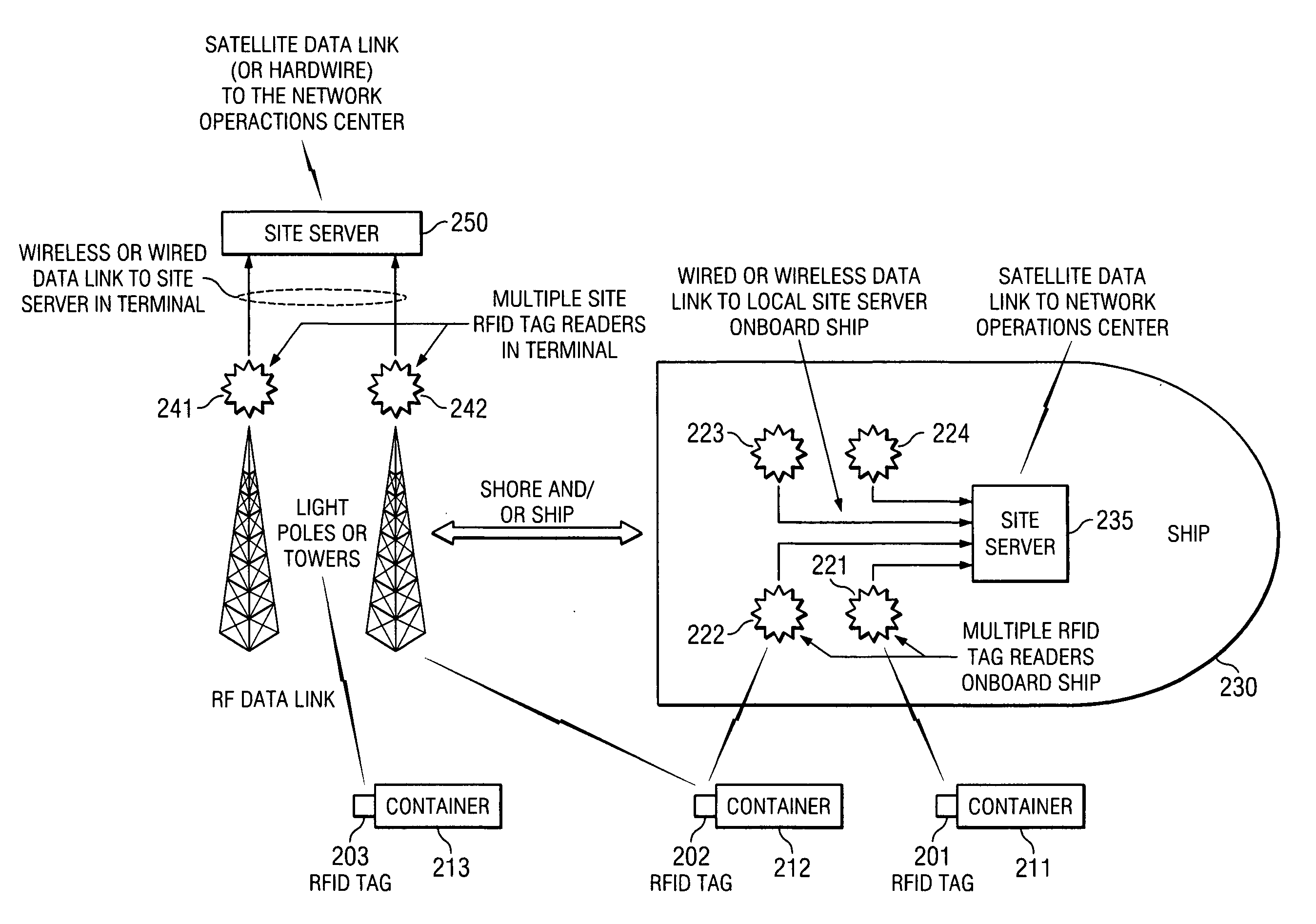

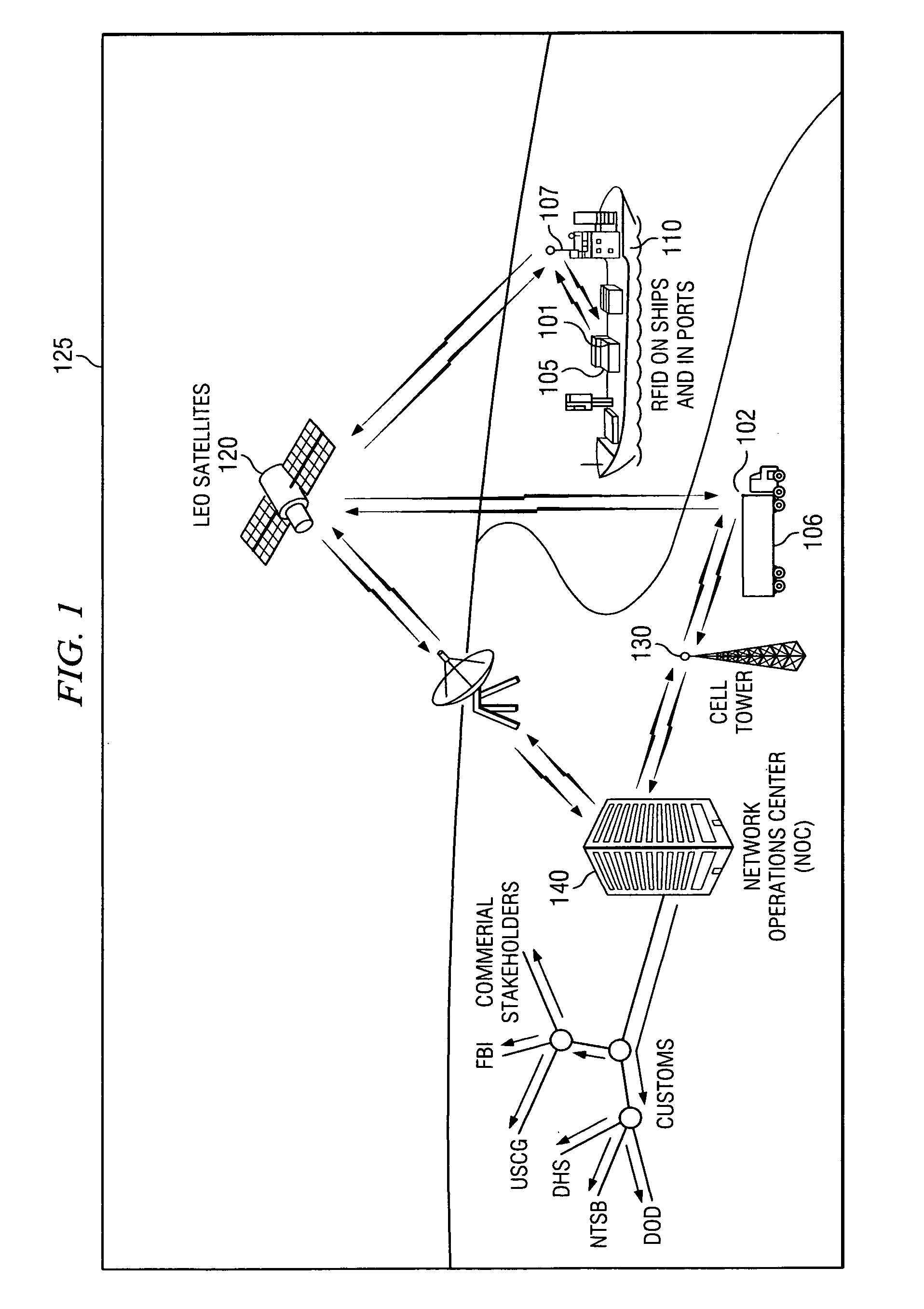

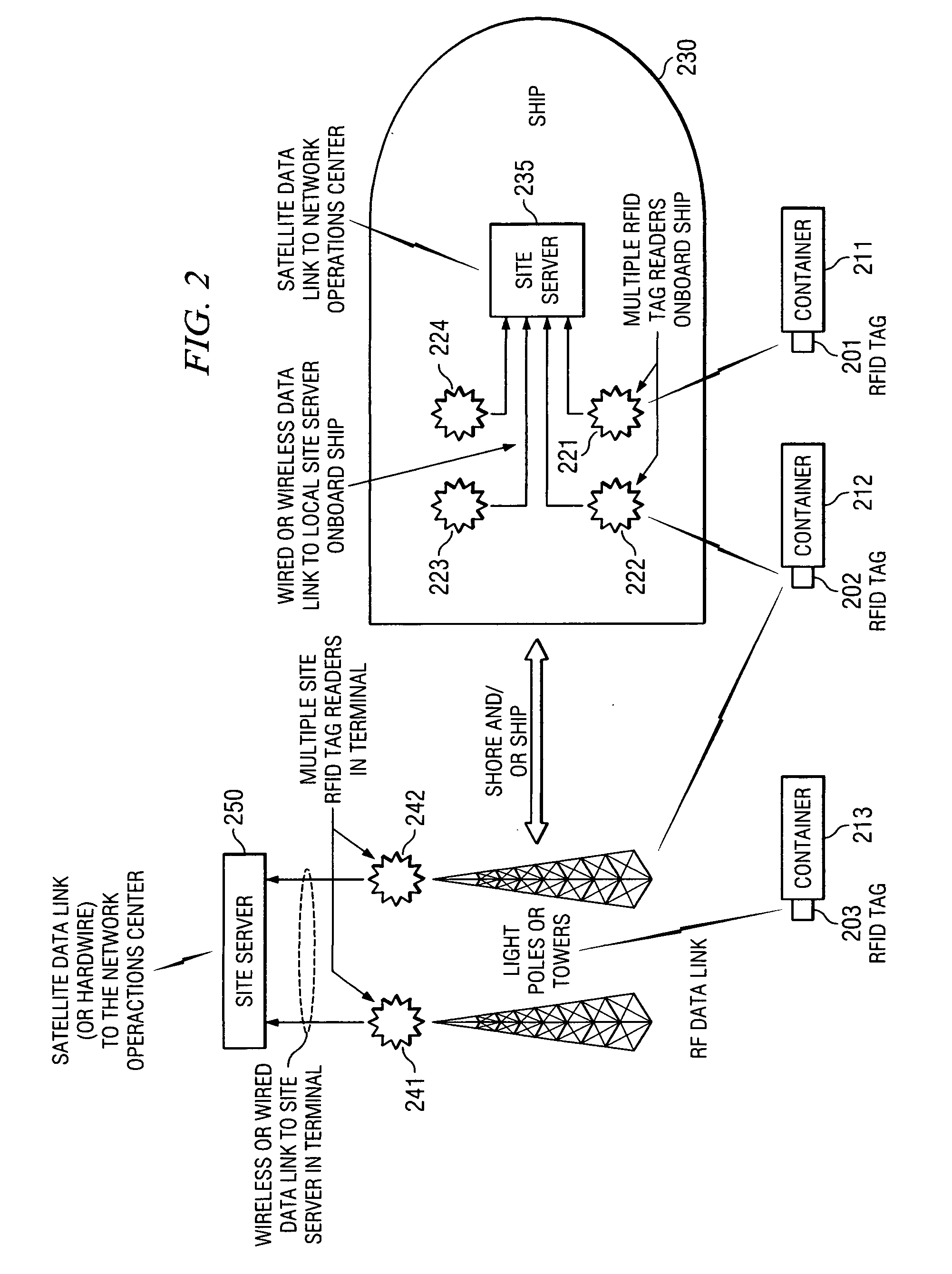

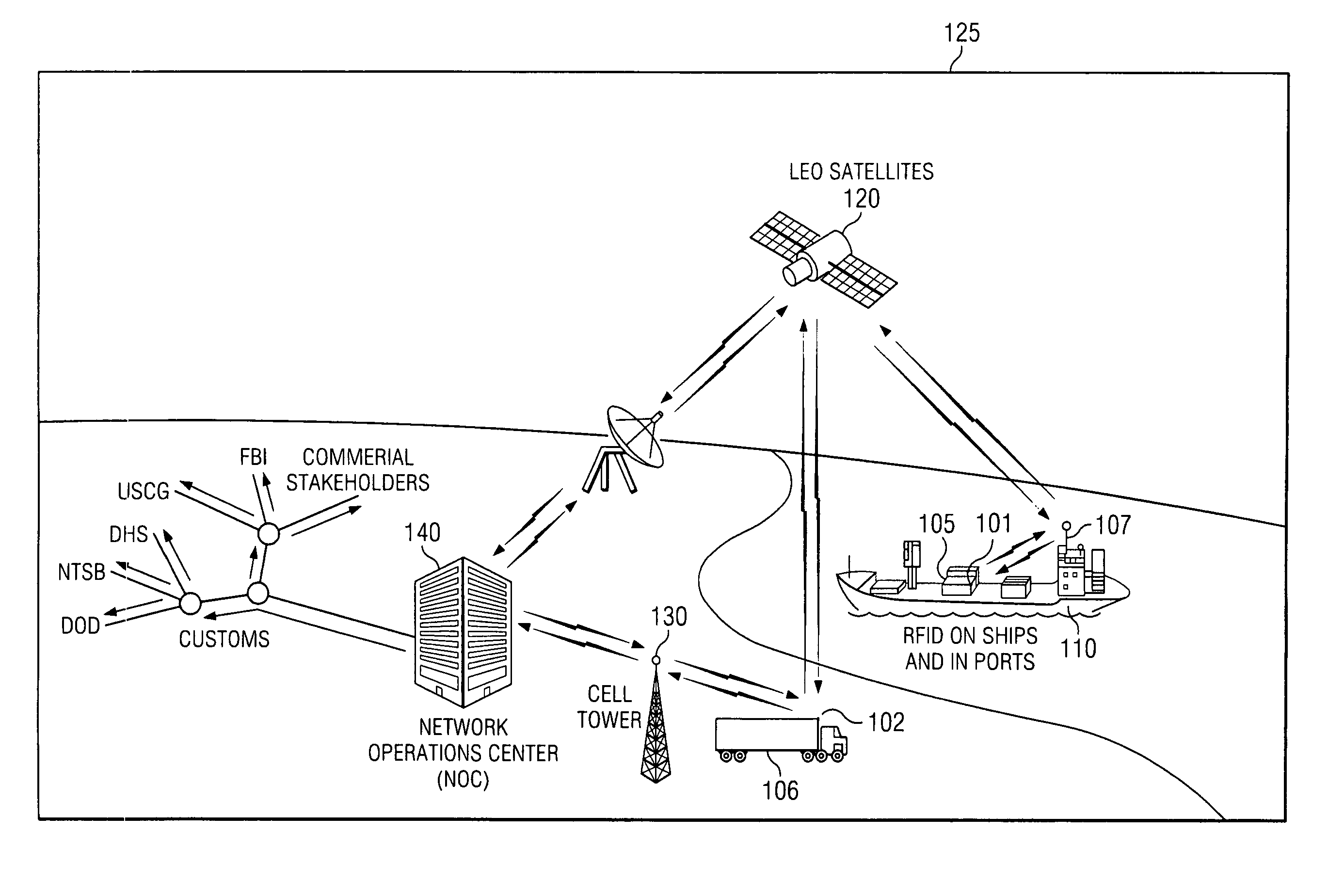

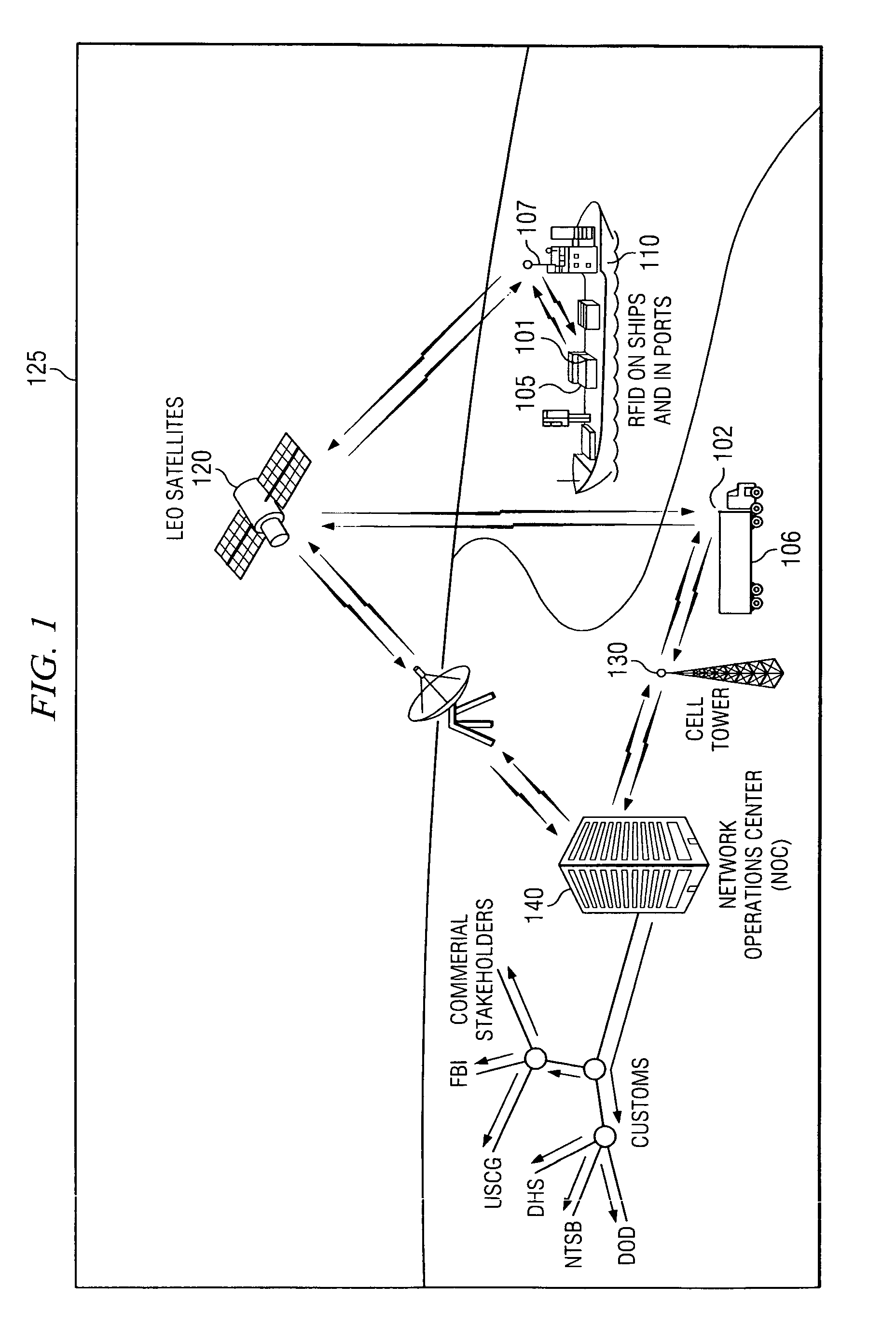

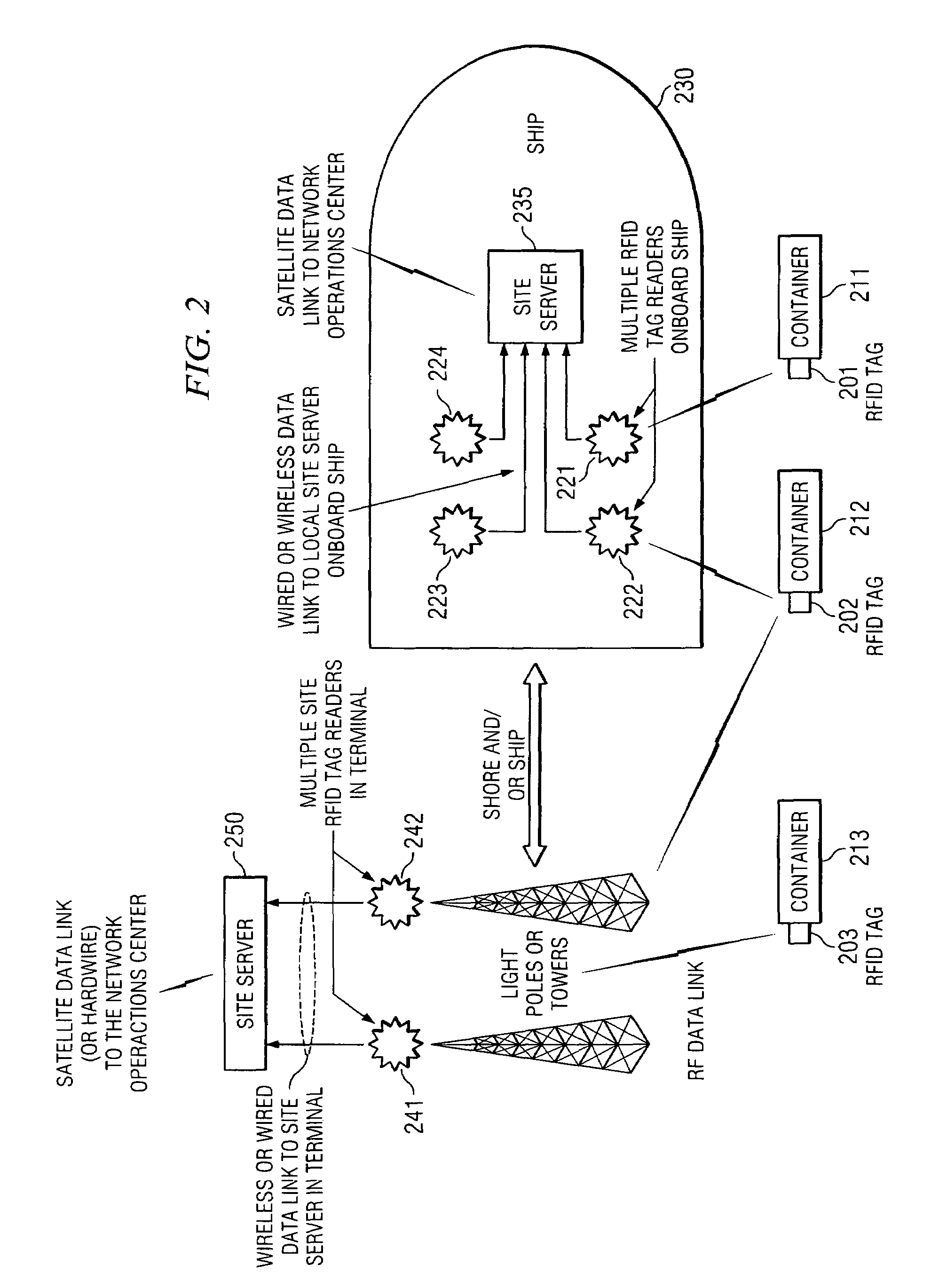

Space charge dosimeters for extremely low power measurements of radiation in shipping containers

InactiveUS20050248456A1Electric signal transmission systemsSolid-state devicesDosimeterRadiation sensor

Methods and apparatus are described for space charge dosimeters for extremely low power measurements of radiation in shipping containers. A method includes insitu polling a suite of passive integrating ionizing radiation sensors including reading-out dosimetric data from a first passive integrating ionizing radiation sensor and a second passive integrating ionizing radiation sensor, where the first passive integrating ionizing radiation sensor and the second passive integrating ionizing radiation sensor remain situated where the dosimetric data was integrated while reading-out. Another method includes arranging a plurality of ionizing radiation sensors in a spatially dispersed array; determining a relative position of each of the plurality of ionizing radiation sensors to define a volume of interest; collecting ionizing radiation data from at least a subset of the plurality of ionizing radiation sensors; and triggering an alarm condition when a dose level of an ionizing radiation source is calculated to exceed a threshold.

Owner:UT BATTELLE LLC

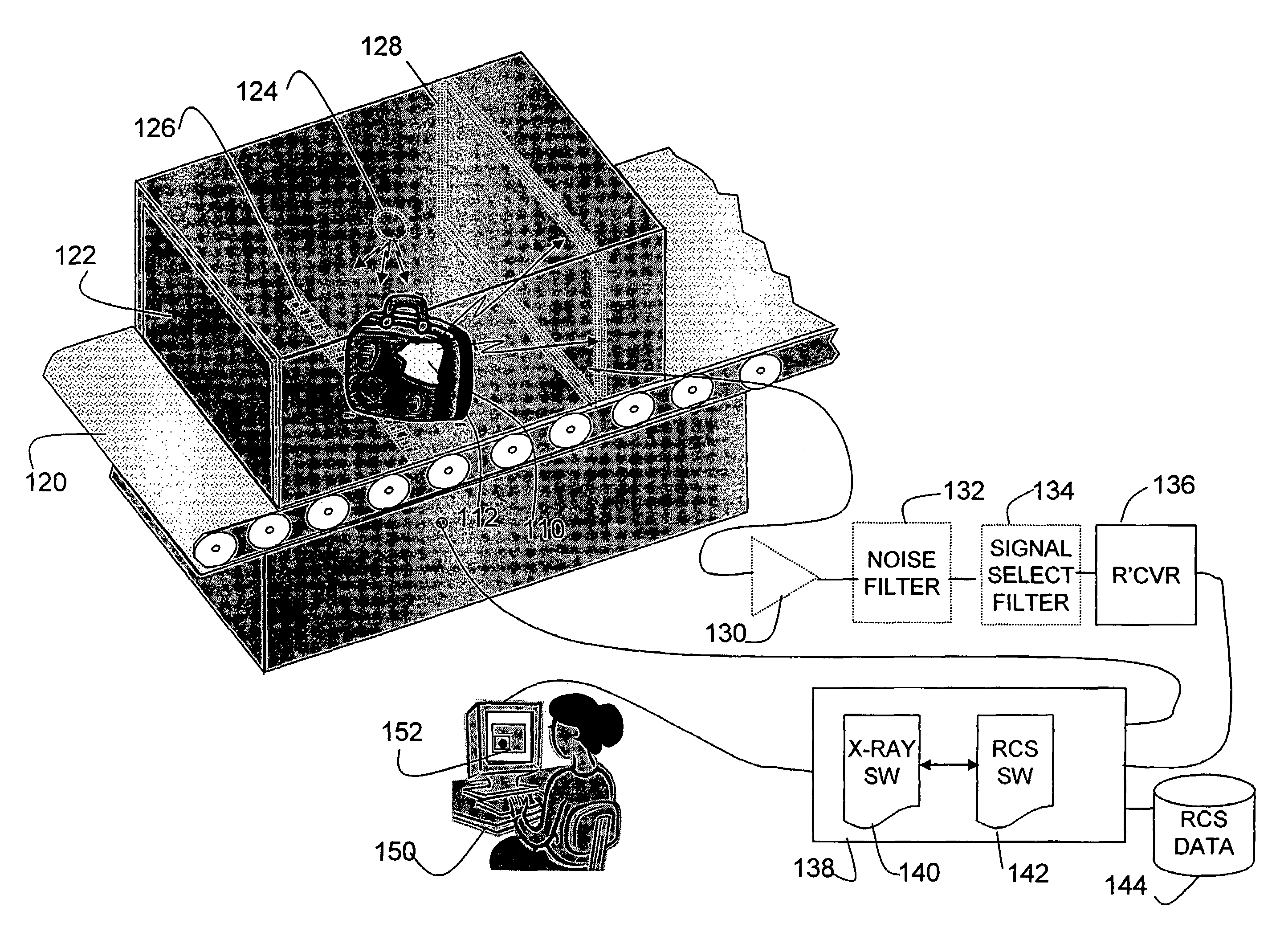

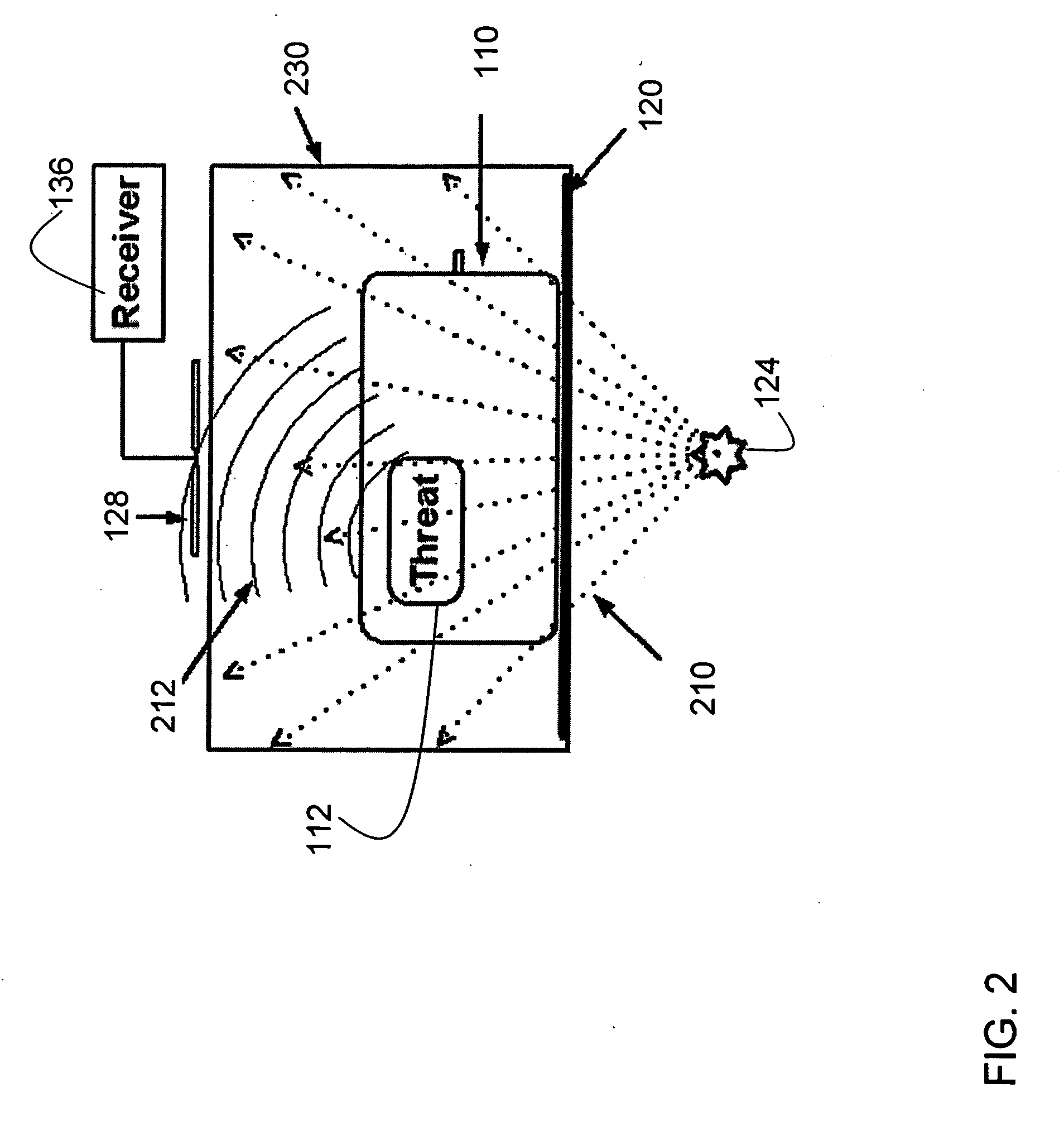

Method and apparatus for detecting contraband using radiated compound signatures

InactiveUS7251310B2Electric/magnetic detectionMaterial analysis by transmitting radiationSecondary analysisIonization

An system for detecting contraband, particularly explosives or other energetic materials. The system includes a source of ionizing radiation that irradiates an item under inspection. The radiation stimulates the emission of RF energy from objects within the item under inspection. The characteristics of the emitted RF energy reveals information about the material composition of the objects. The system detects this emitted RF energy and comparers it to a signature of RF emissions from contraband objects. Apparatus to detect and analyze RF emissions may be constructed as a stand-alone unit or may be incorporated into an imaging system in which the ionizing radiation is used to form an image of the item under inspection. Similarly, the RF analysis may be used, in the first instance, to determine whether an object contains a contraband item or may be used as a second level analysis to clear alarms generated by analysis of images formed by the imaging system.

Owner:L3 COMMUNICATIONS SECURITY & DETECTION SYSTEMS CORPORATION

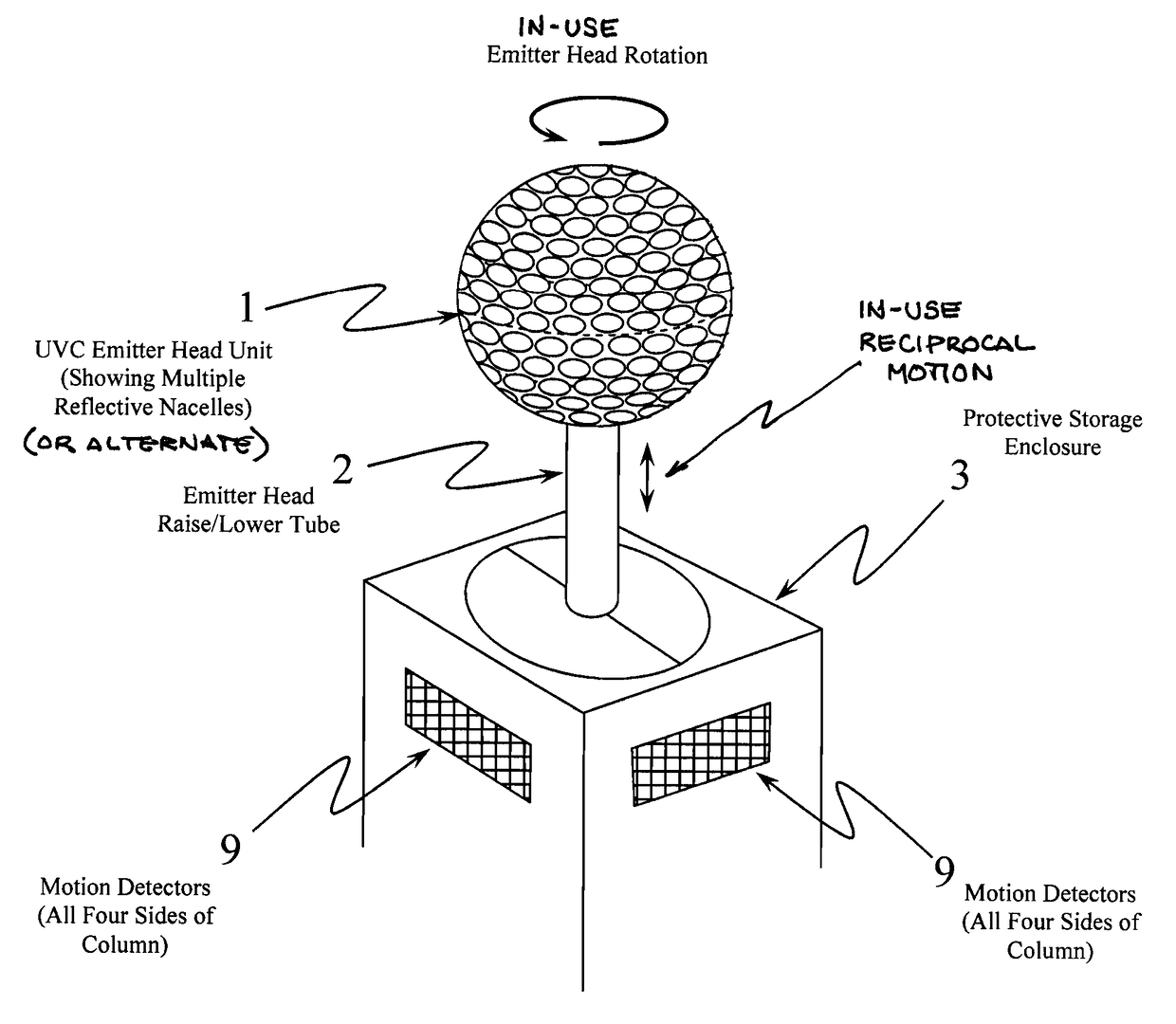

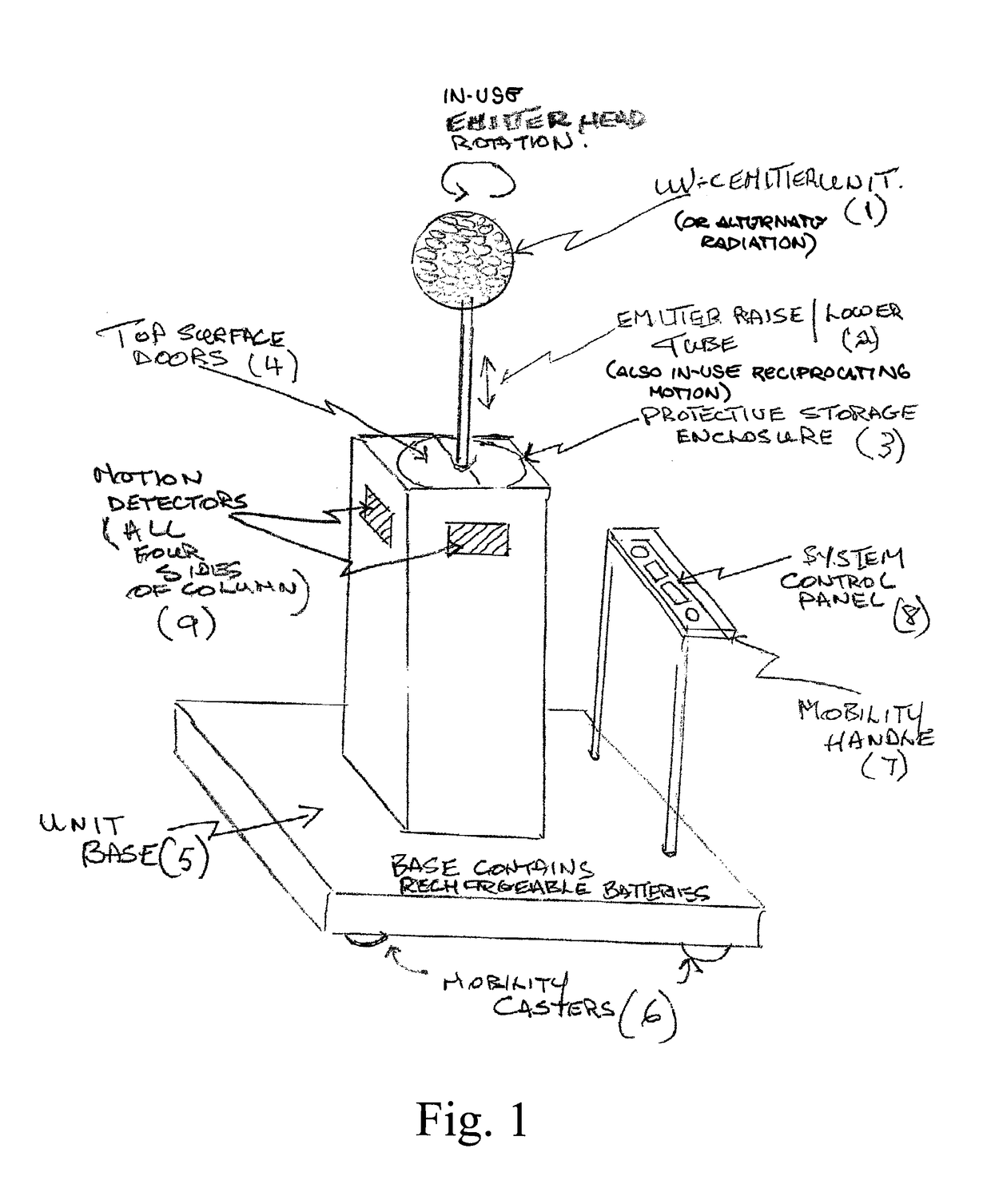

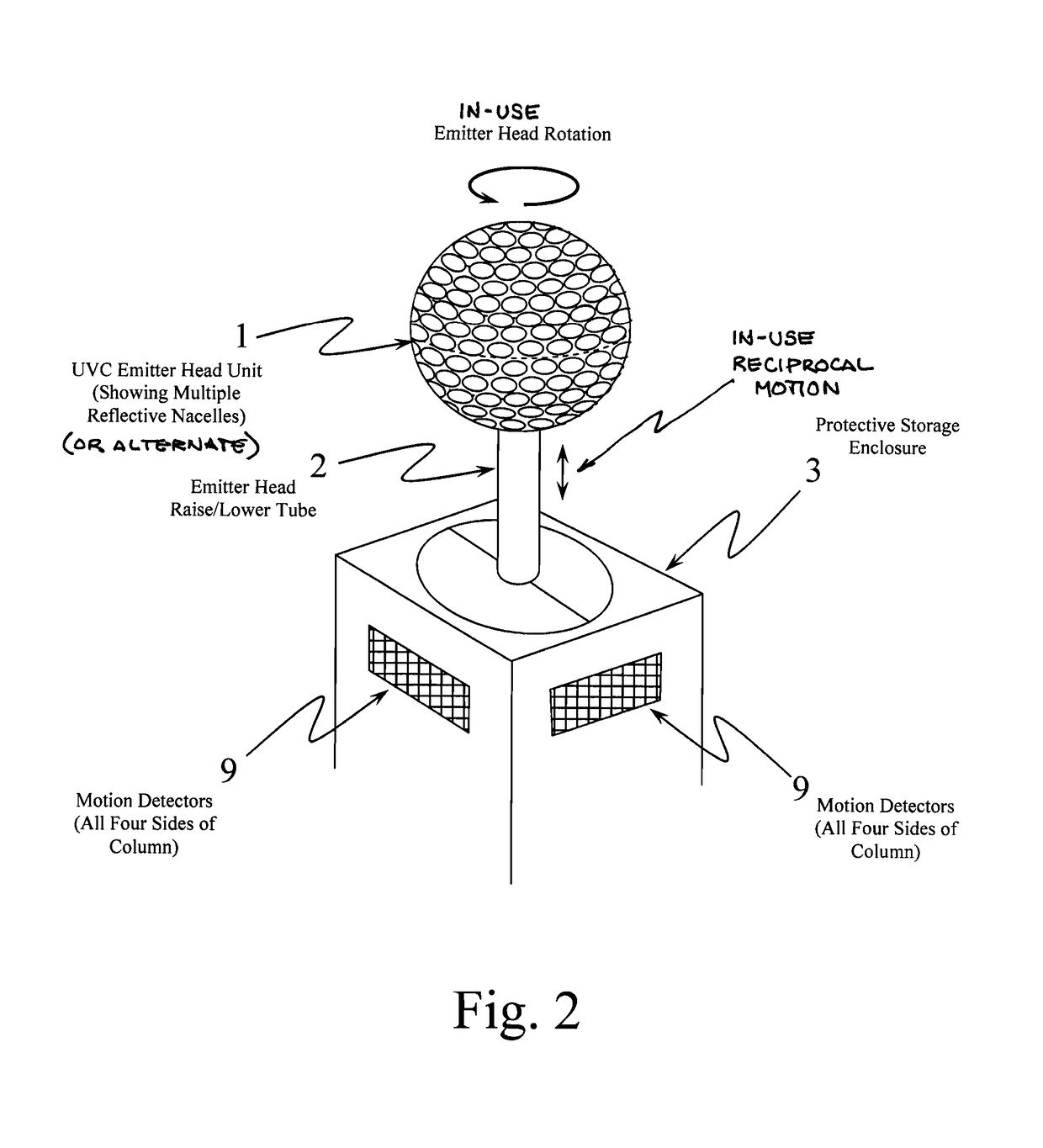

Dynamic enhanced and diffuse broad spectrum UVC or alternative controlled ionizing radiation source emitters for mobile and fixed placement disinfection of clinical surfaces

InactiveUS9603956B2High energySpread evenlyElectric discharge tubesDiffusing elementsAlternative controlHigh intensity

A system providing effective, broad spectrum UV-C or other ionizing radiation clinical surface disinfection, high intensity UV-C light emitting diodes (LEDs) of incrementally differing wavelengths are sequentially embedded in densely packed reflective nacels (cups or pockets) forming the surface of a rotating spherical or hemispherical structure. A combination of UV-C emitter component location and activation with the rotational and reciprocal elevation functions of such structures produces complete and continuous environmental overlapping UV-C energy scattering.

Owner:NEWHAM PAUL

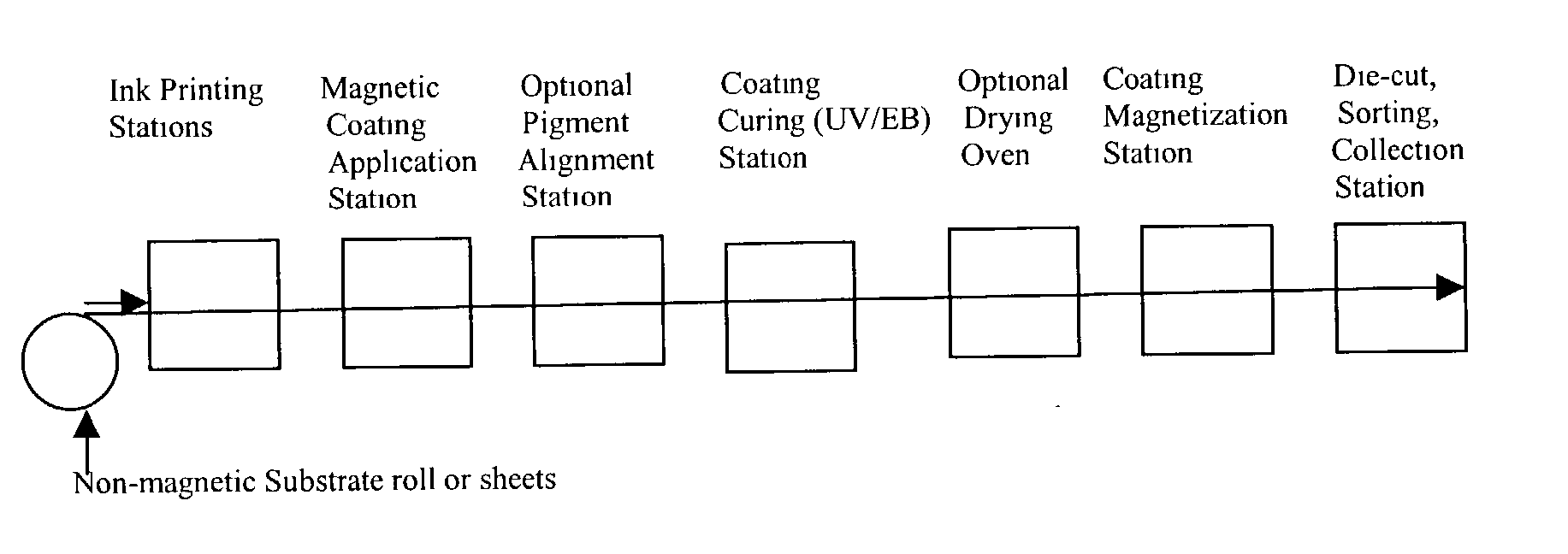

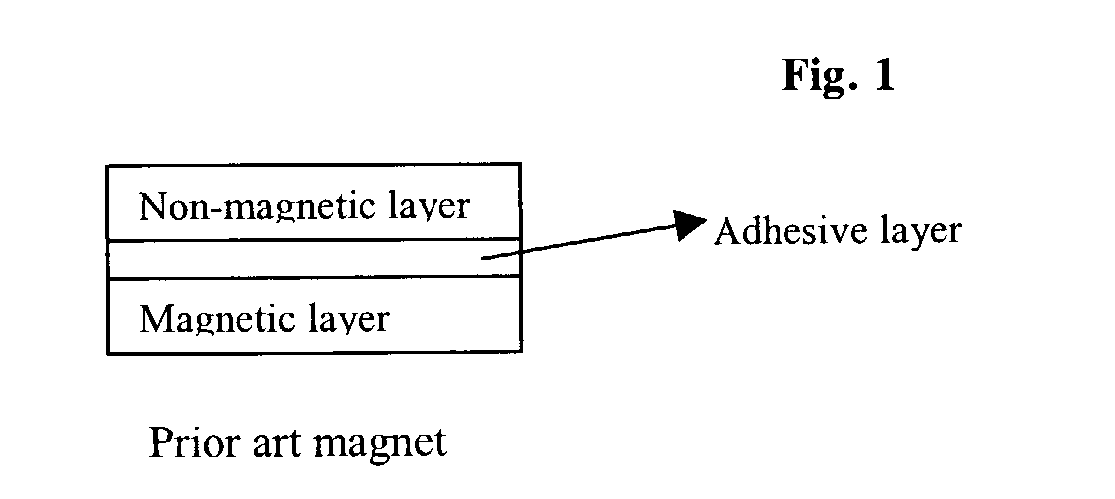

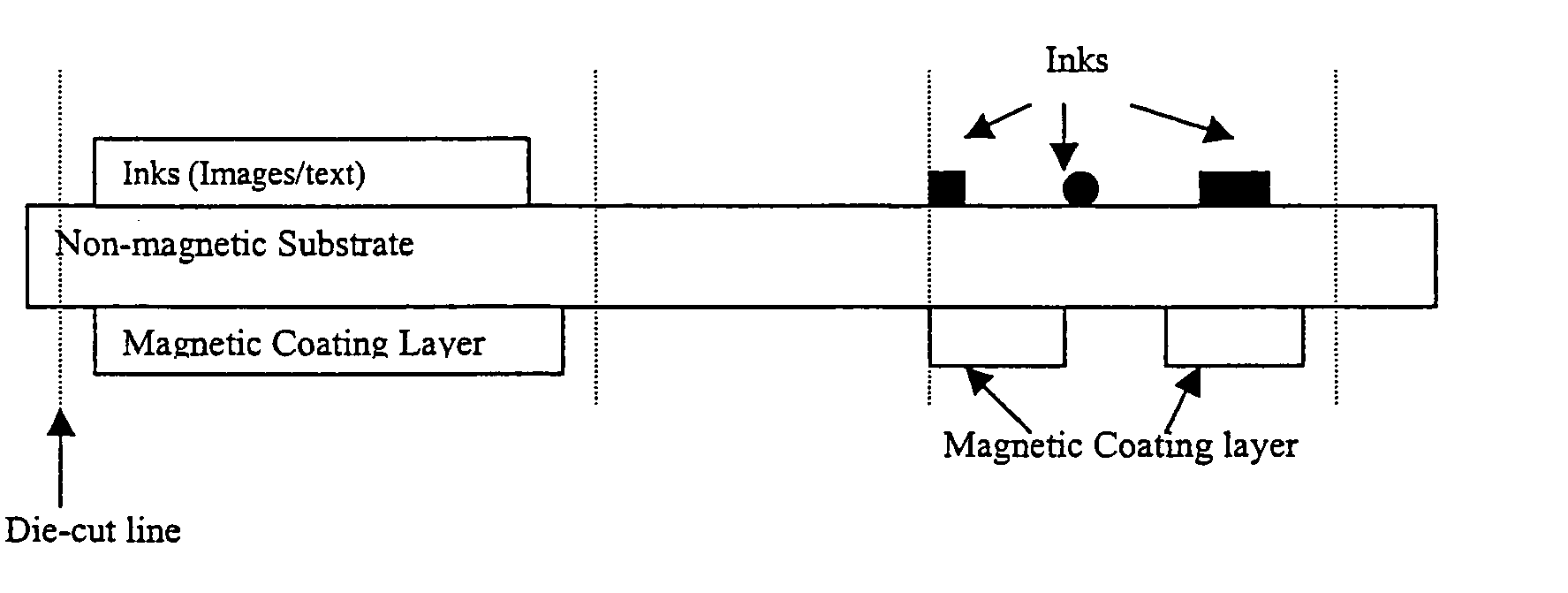

UV/EB cured integrated magnets-composition and method of fabrication

The present invention comprises a radiation curable composition for in-line printing containing magnetic pigments capable of being magnetized to possess permanent magnetic properties after the composition is cured. The composition is cured by an ionizing radiation source, preferably by UV light or electron beam radiation (UV / EB). The present invention is also directed to an in-line process for printing magnetic images on non-magnetic substrate, comprising: pattern applying the above mentioned radiation curable composition on the substrate opposite to a print side, pre-aligning the magnetic pigment particles (if necessary) of the applied composition, curing the composition by ionizing radiation source (UV / EB), magnetizing the cured composition, then finishing the final piece. The finishing step could involve delivering the final piece in a simple sheet with die cut magnets or creating an "integrated magnet" format involving plow folding over the magnet panel, pattern coating or flood coating an adhesive that will only adhere the non-magnet matrix areas between die cut magnets, thus, allowing for the individual magnets to be "popped" out of the carrier by the final end user. The resulting magnetized pieces will possess holding power like magnets (refrigerator and office magnets) and are capable of carrying personalized, Scitex imaged and direct marketing information (including redemption value for coupons, local public service access numbers, etc.)

Owner:SOVEREIGN SPECIALTY CHEM +1

Space charge dosimeters for extremely low power measurements of radiation in shipping containers

Methods and apparatus are described for space charge dosimeters for extremely low power measurements of radiation in shipping containers. A method includes insitu polling a suite of passive integrating ionizing radiation sensors including reading-out dosimetric data from a first passive integrating ionizing radiation sensor and a second passive integrating ionizing radiation sensor, where the first passive integrating ionizing radiation sensor and the second passive integrating ionizing radiation sensor remain situated where the dosimetric data was integrated while reading-out. Another method includes arranging a plurality of ionizing radiation sensors in a spatially dispersed array; determining a relative position of each of the plurality of ionizing radiation sensors to define a volume of interest; collecting ionizing radiation data from at least a subset of the plurality of ionizing radiation sensors; and triggering an alarm condition when a dose level of an ionizing radiation source is calculated to exceed a threshold.

Owner:UT BATTELLE LLC

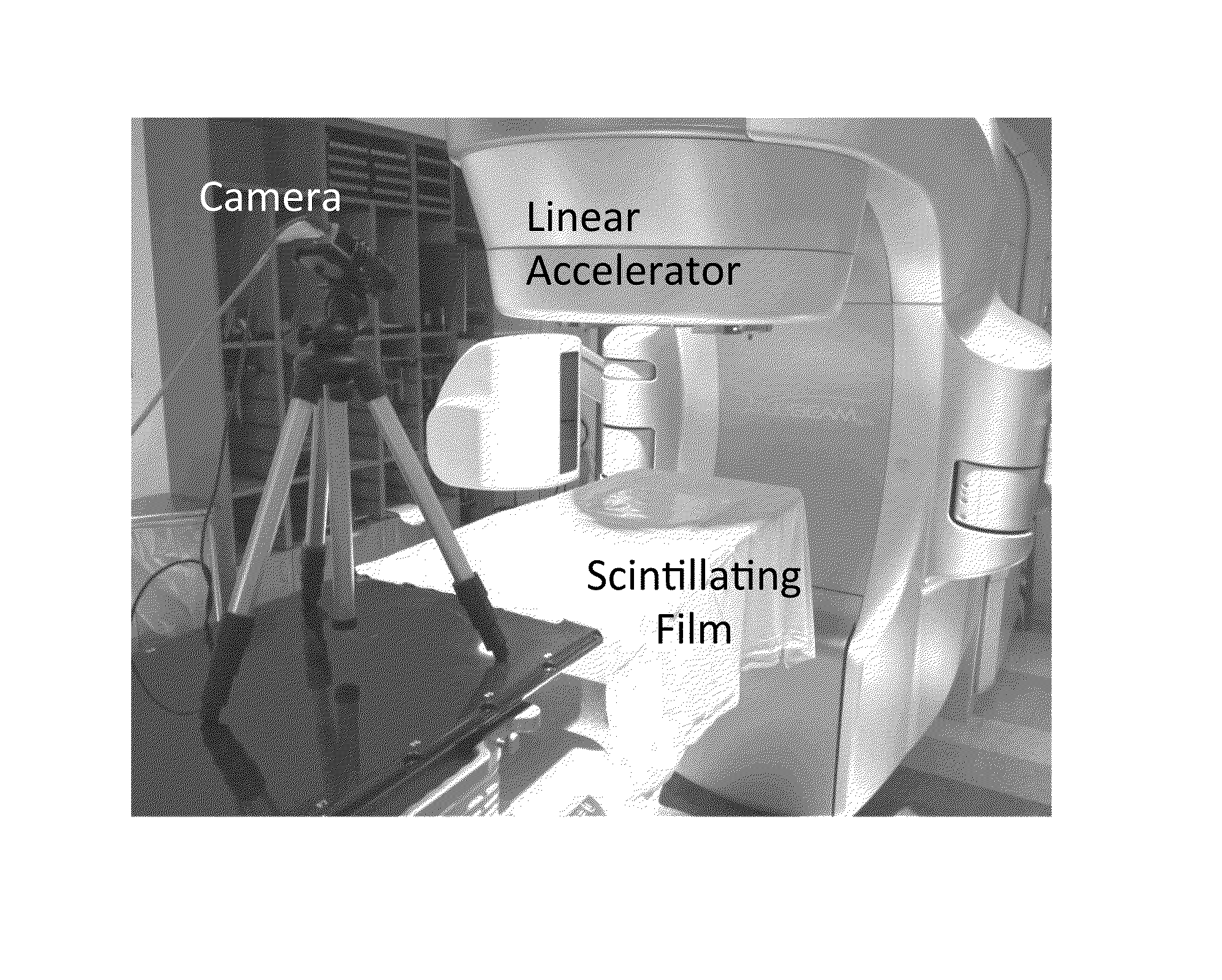

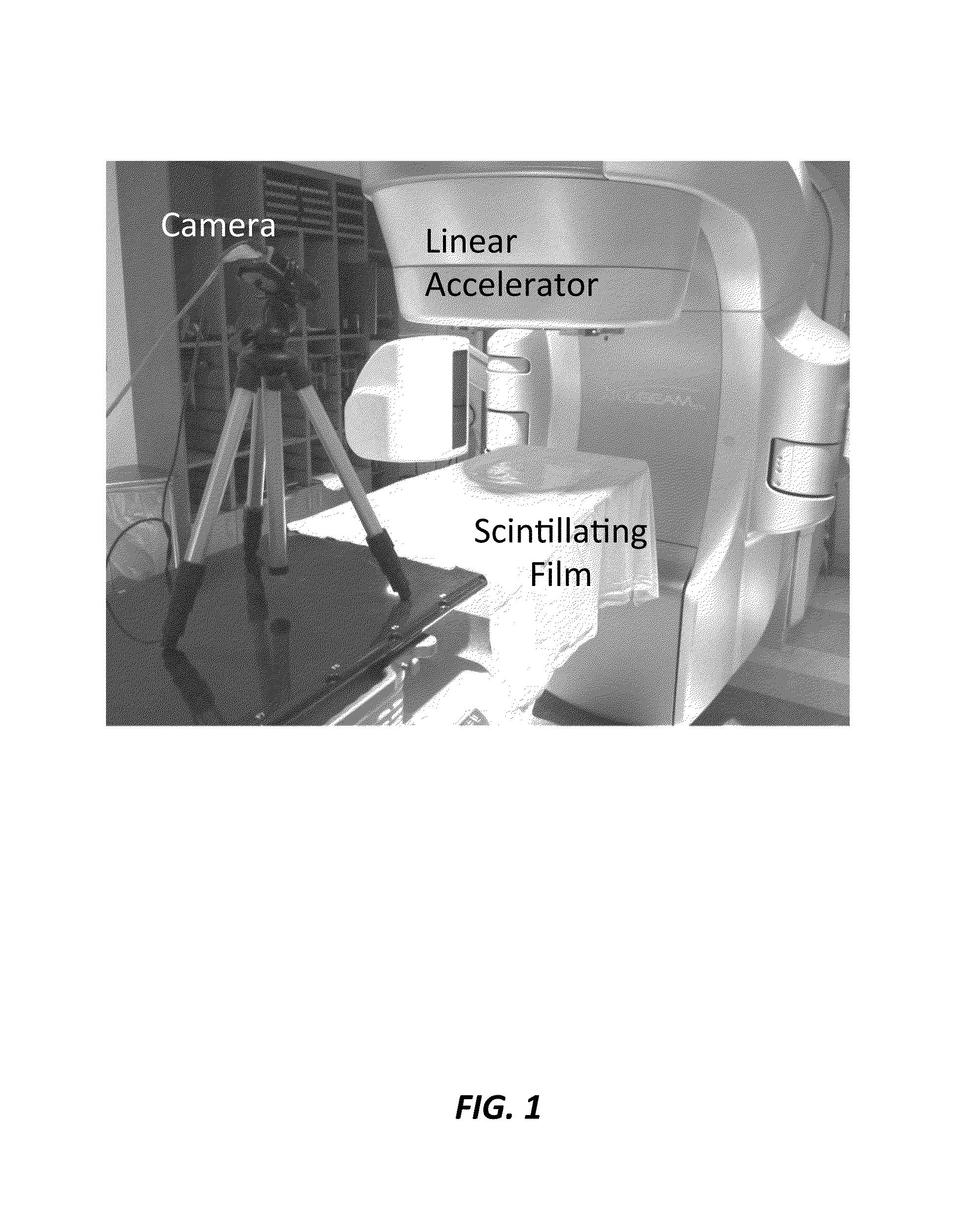

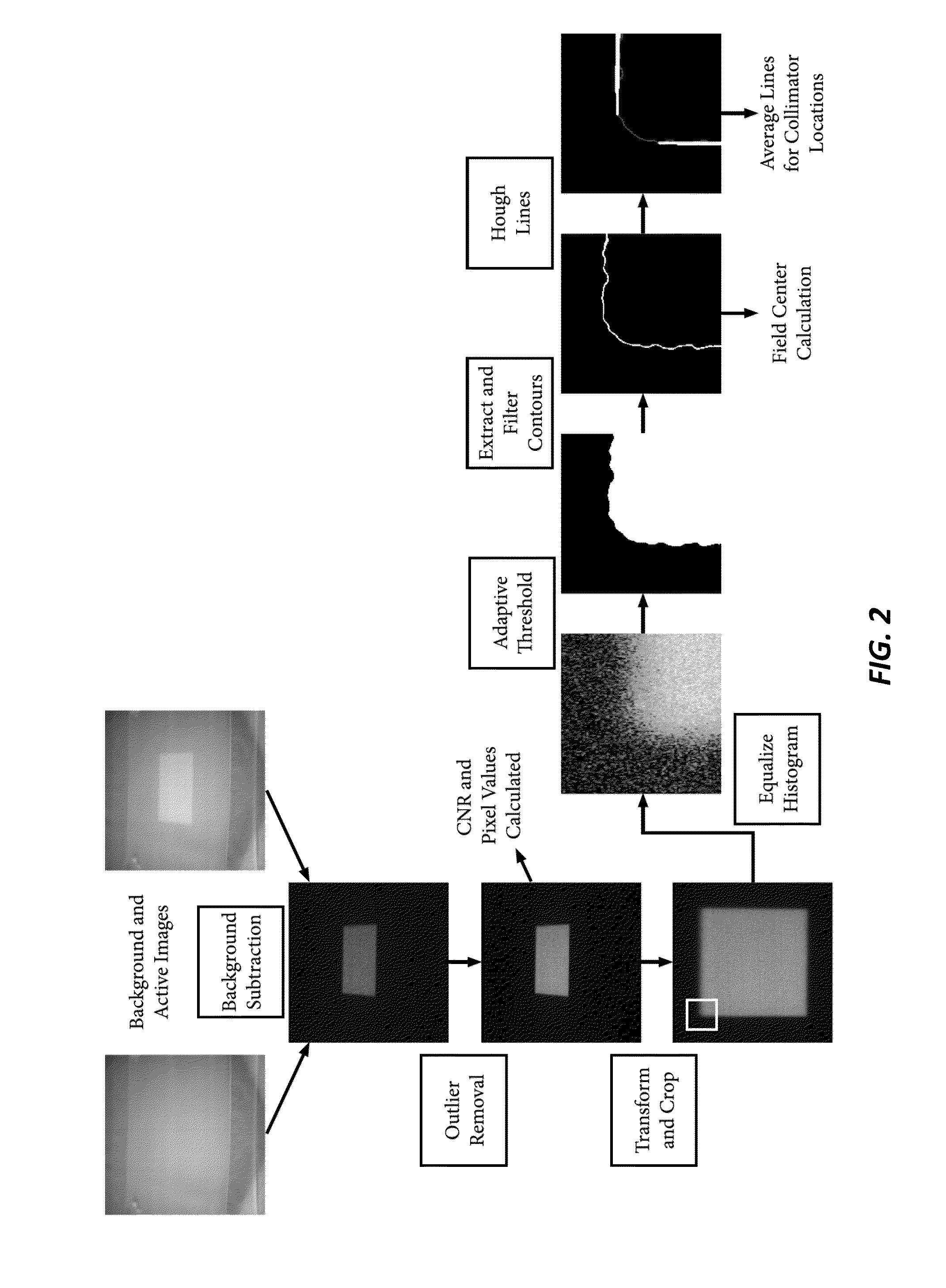

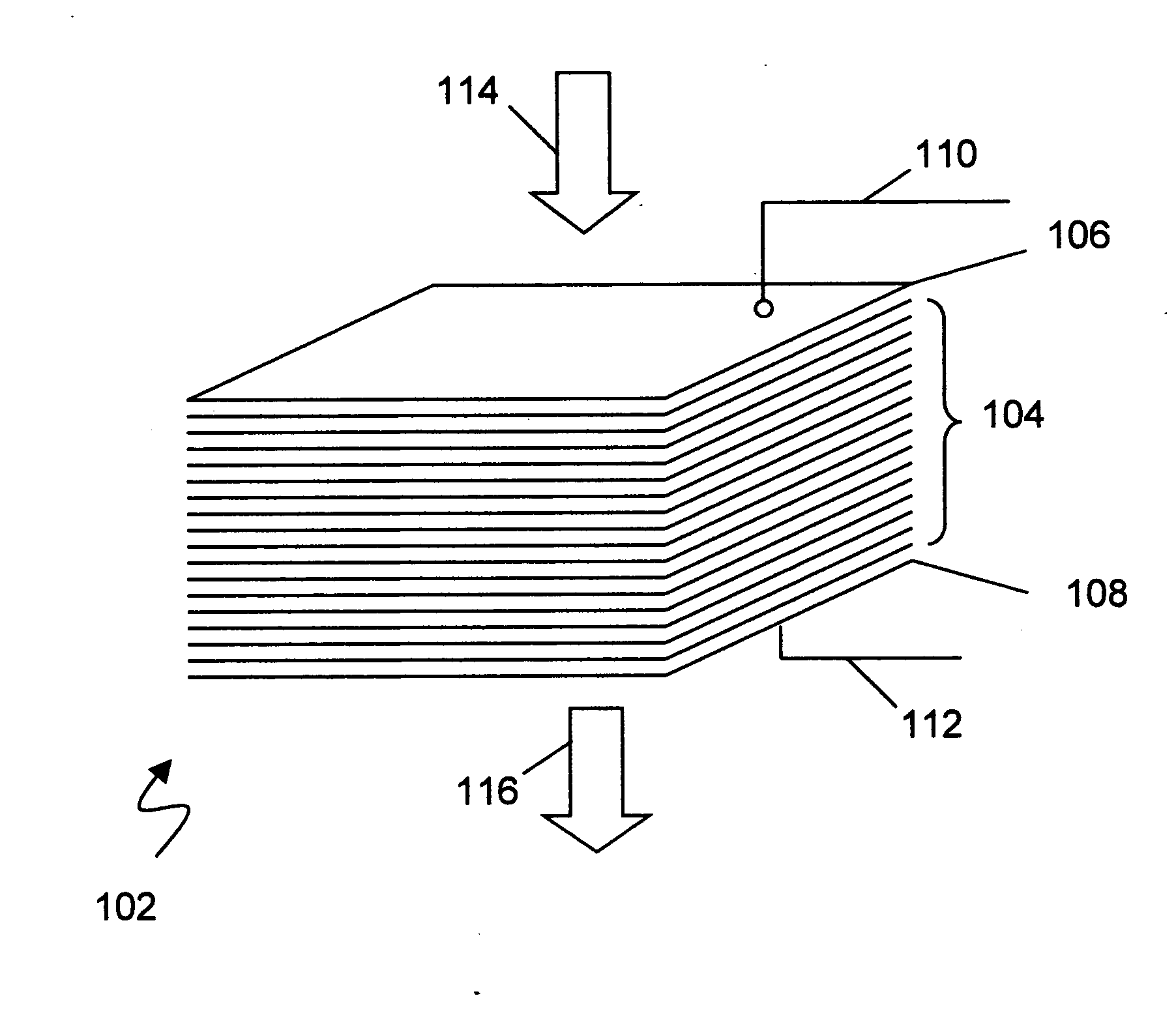

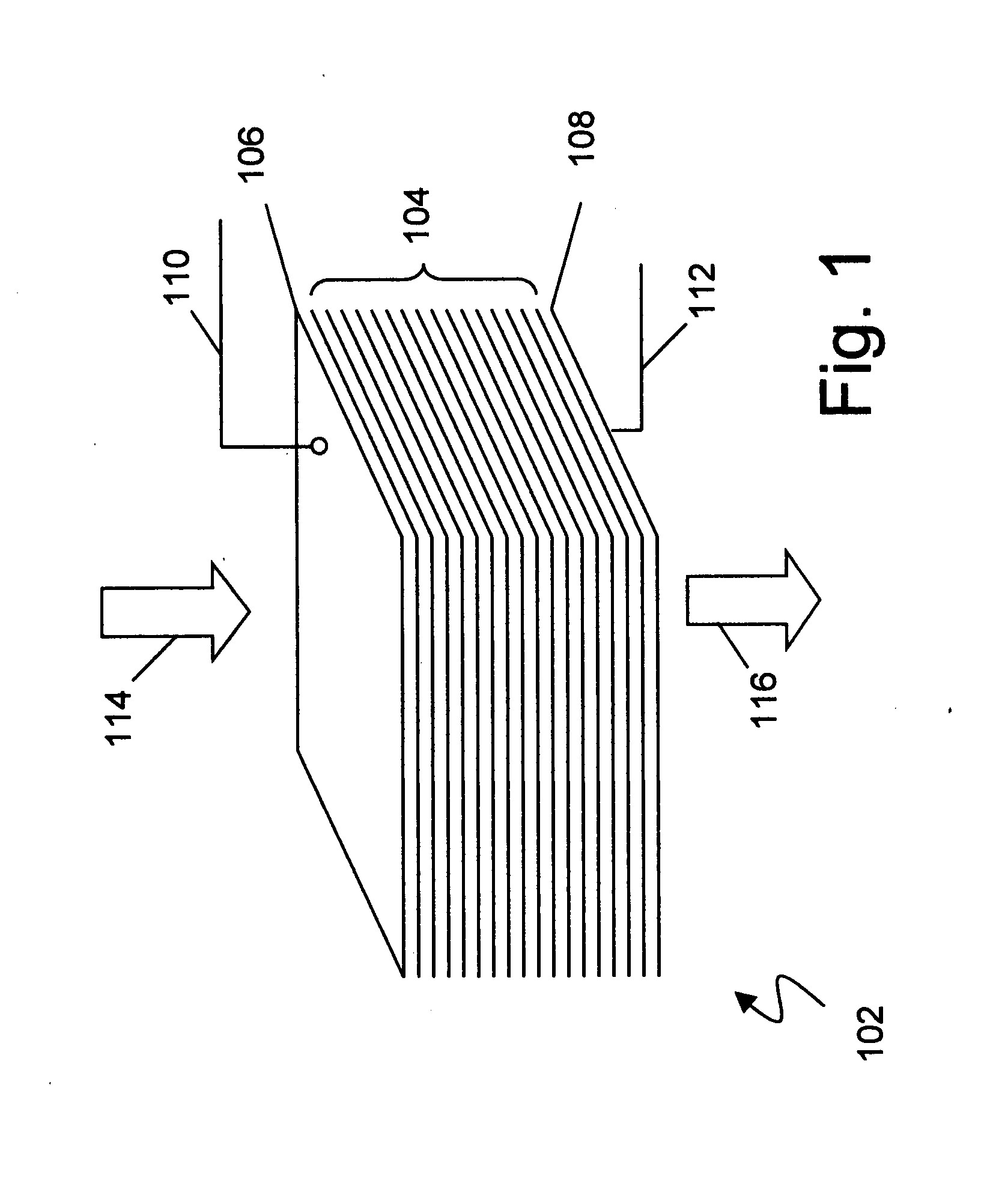

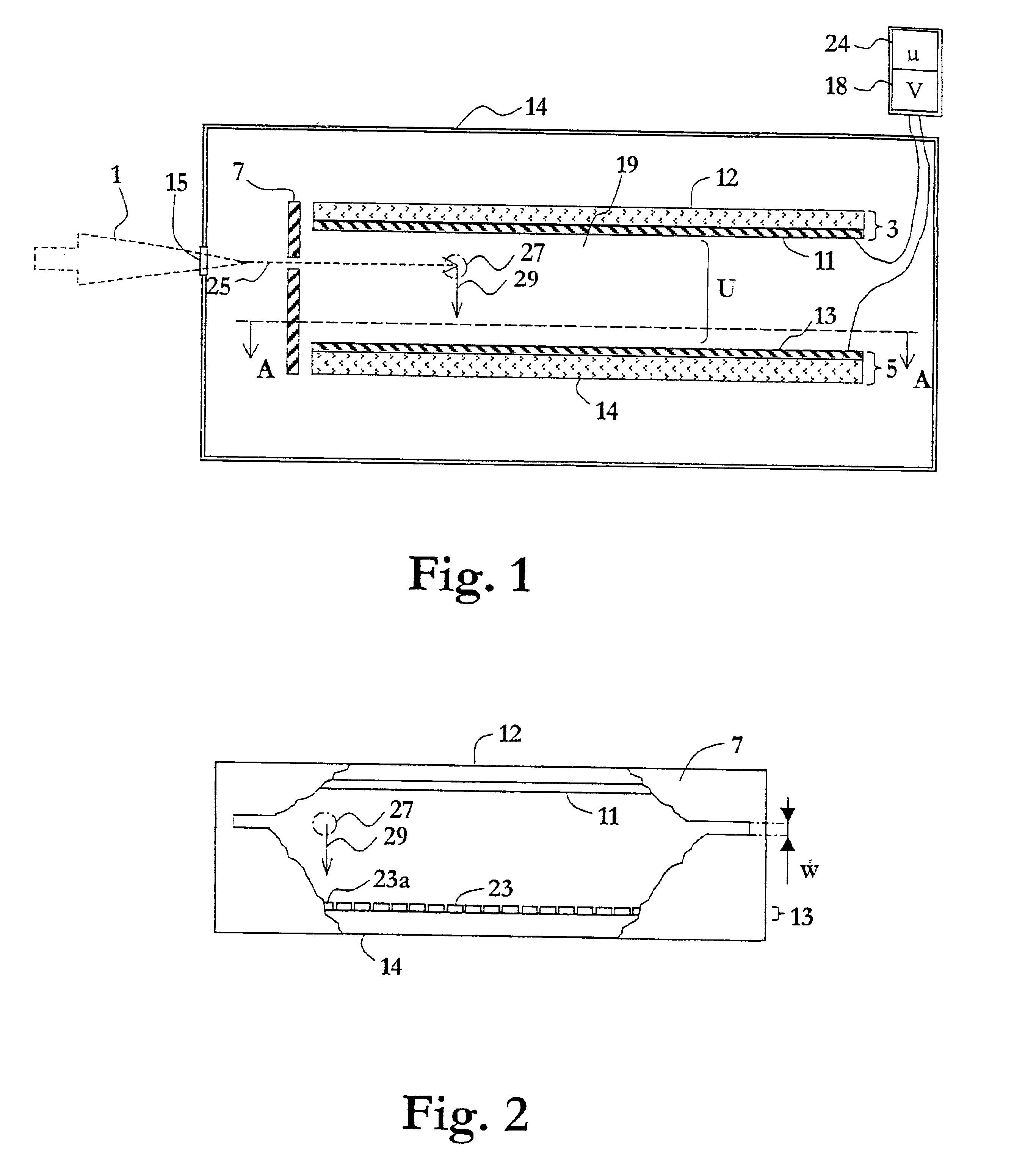

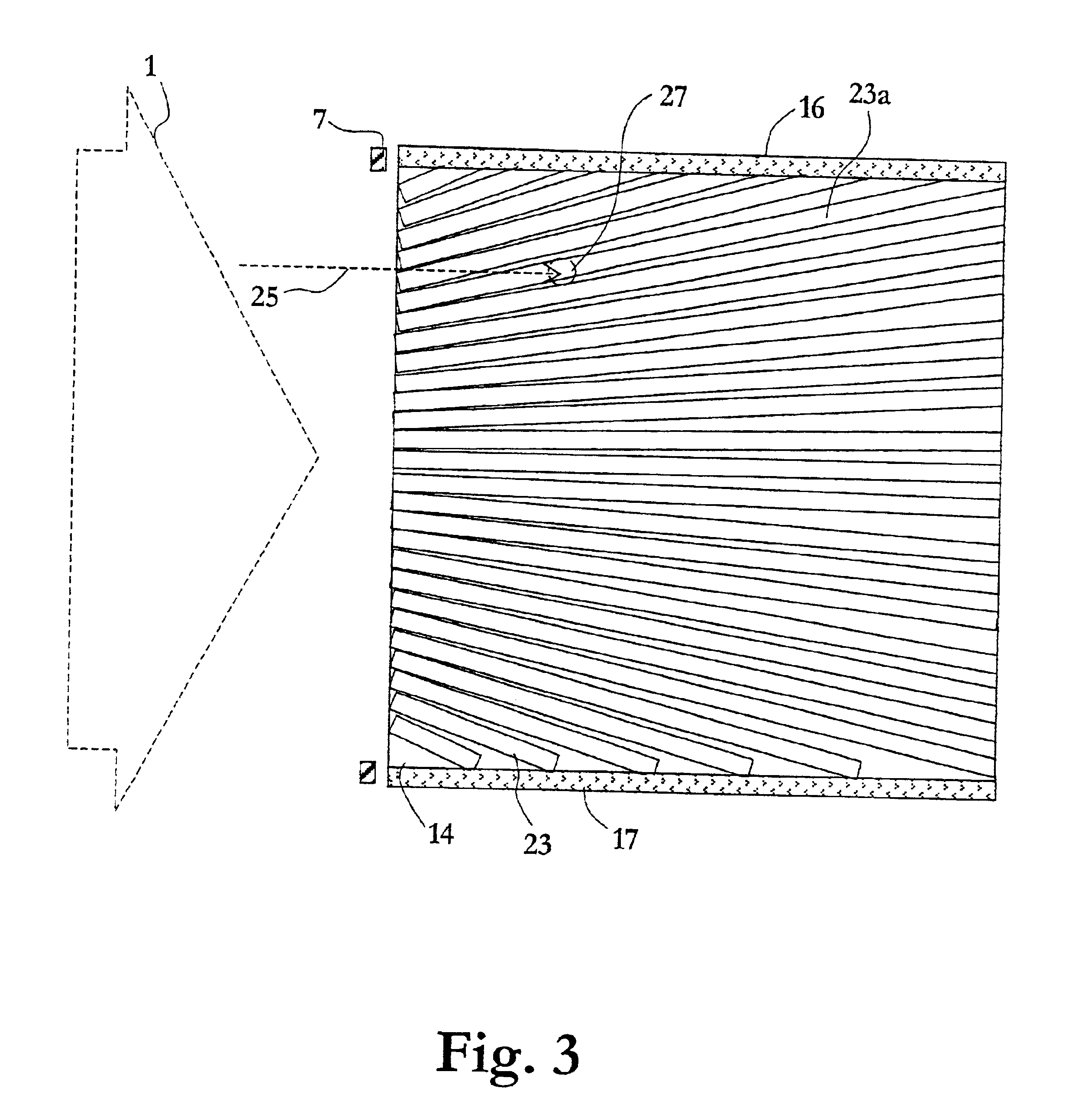

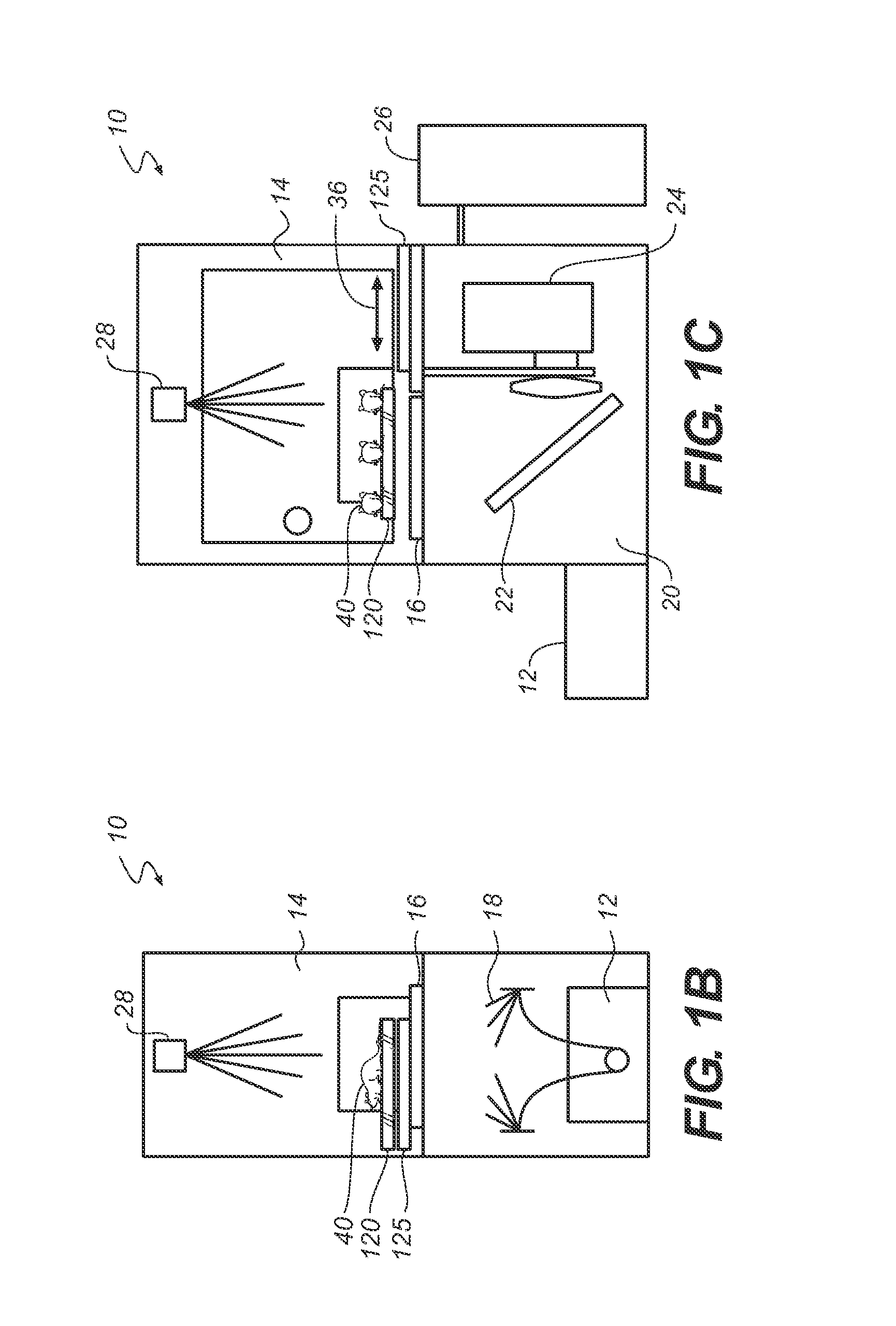

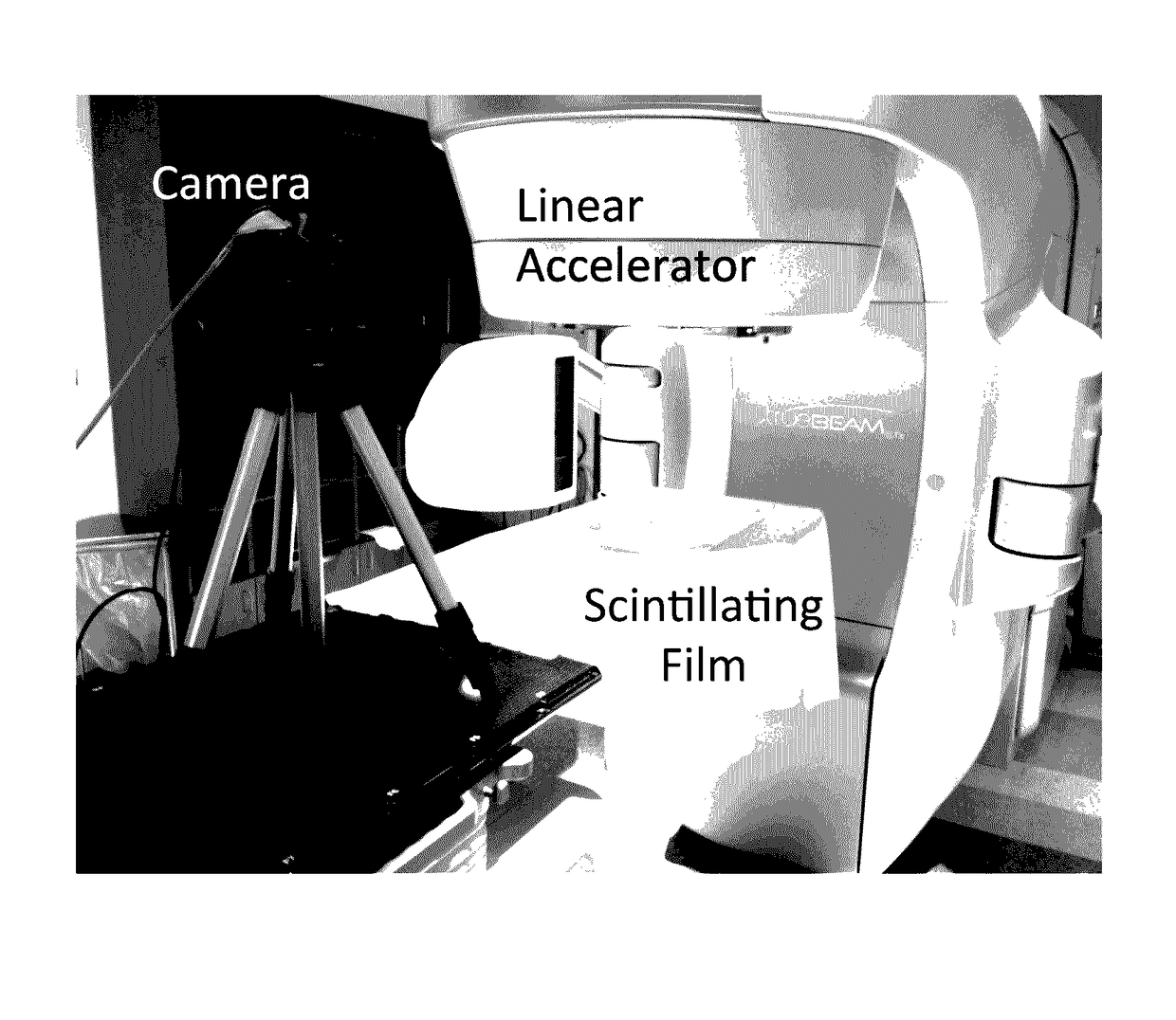

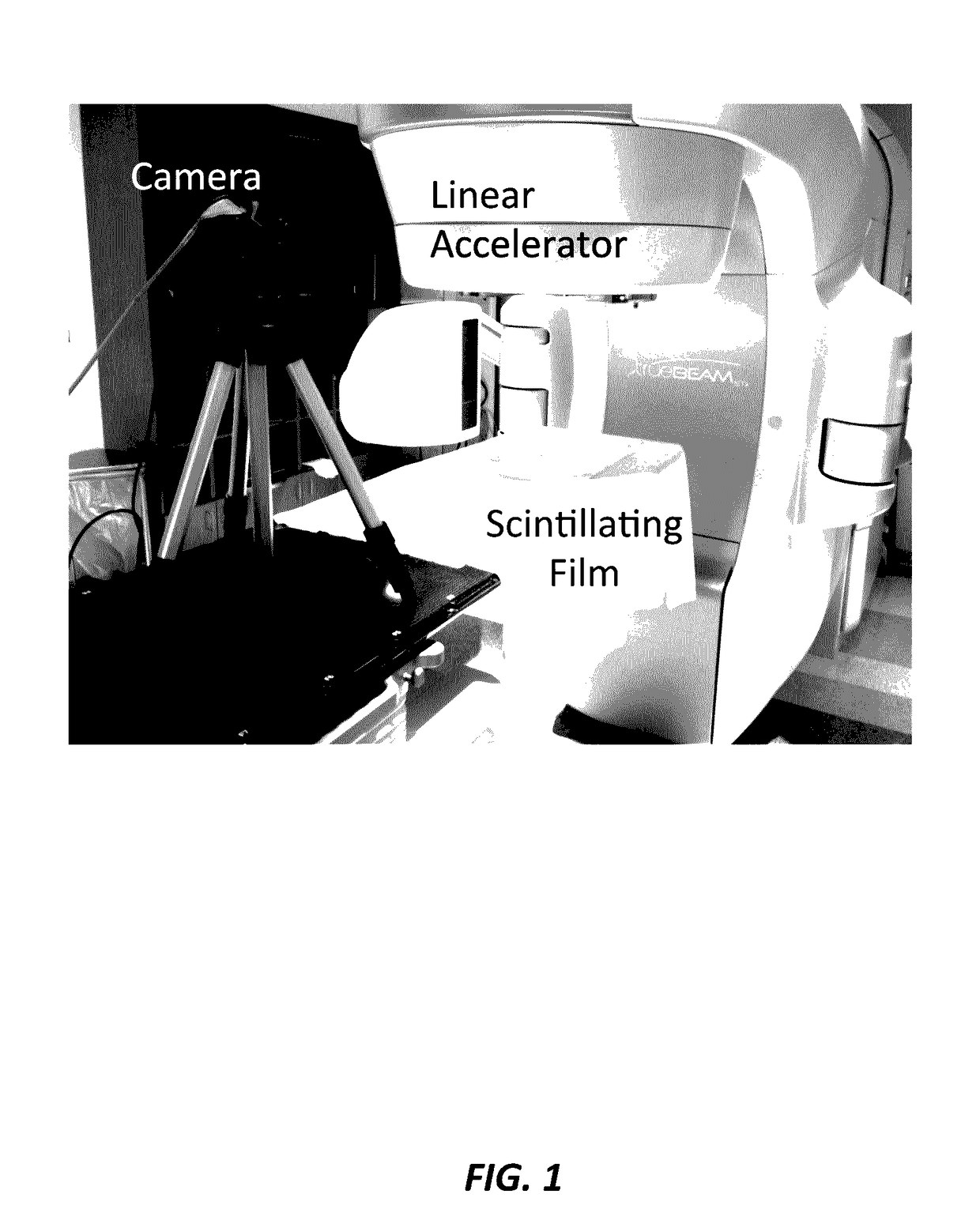

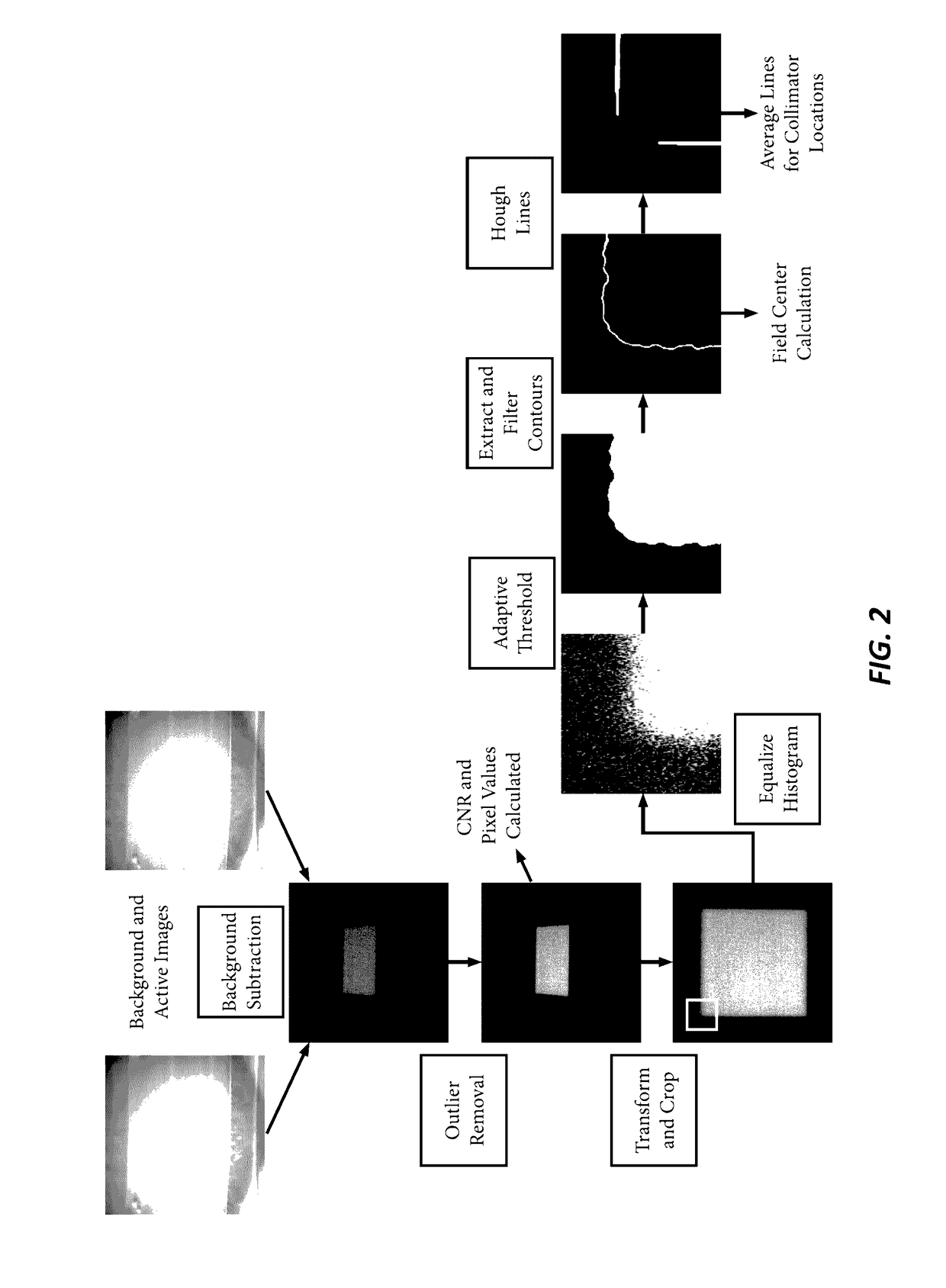

Visualizing Radiation Therapy Beam in Real-Time in the context of Patient's Anatomy

ActiveUS20150360056A1Material analysis by optical meansX-ray/gamma-ray/particle-irradiation therapyReal time validationTreatment delivery

A method of real-time radiotherapy beam visualization is provided that includes disposing a free-form flexible scintillating sheet on a subject of interest, irradiating the subject of interest with a source of ionizing radiation, where the free-forming flexible scintillating sheet emits light when irradiated by the therapeutic photon beam, collecting the emitted light and collecting ambient light reflected from the subject of interest and surrounding objects using a camera, where the collected light is converted to image data by the camera, where the image data is communicated to an appropriately programmed computer, and processing the image data to determine beam characteristics and the characteristics of the subject of interest, using the appropriately programmed computer, where the beam characteristics and the characteristics of the subject of interest are displayed in real-time to a machine operator enabling real-time verification of treatment delivery.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

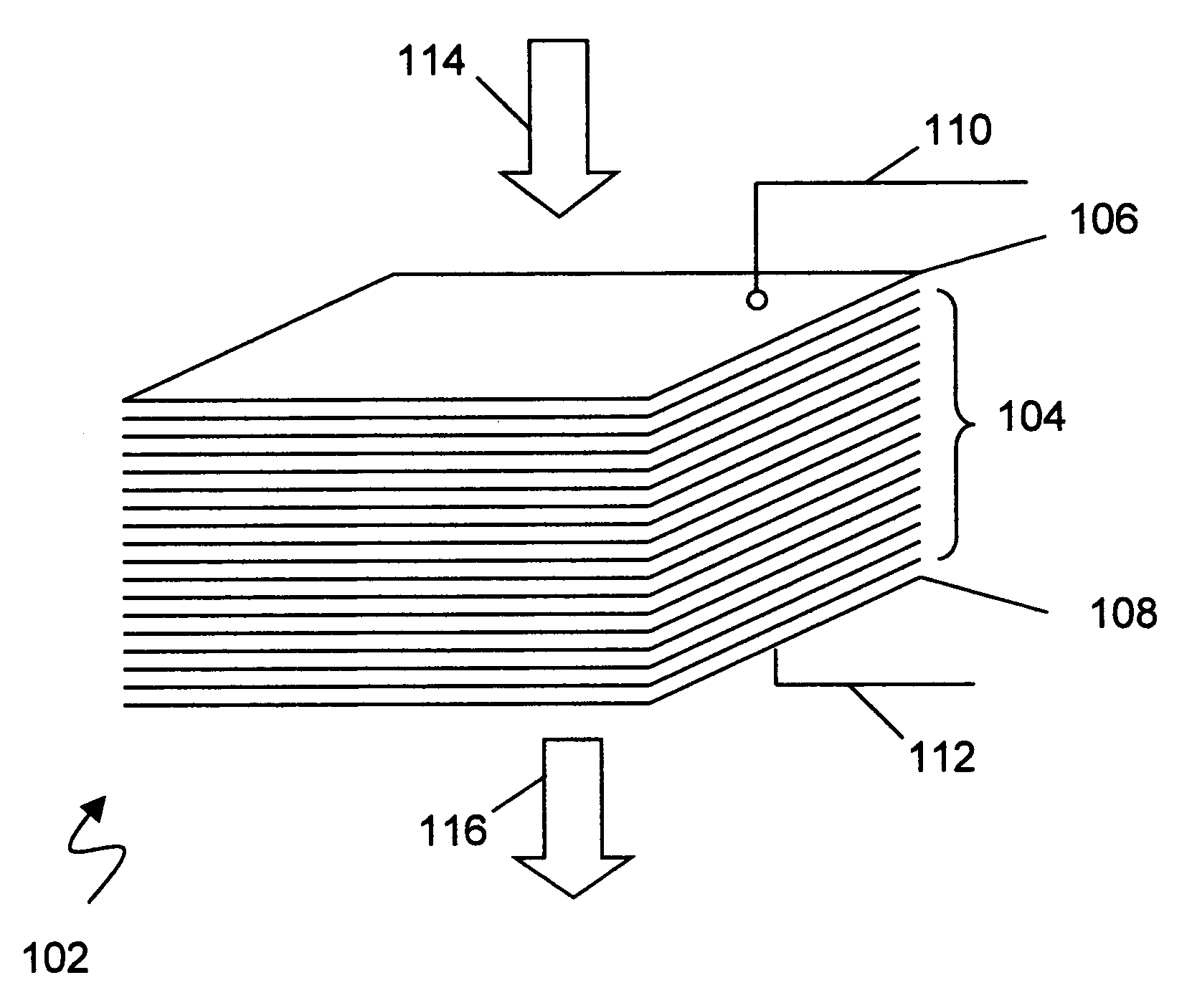

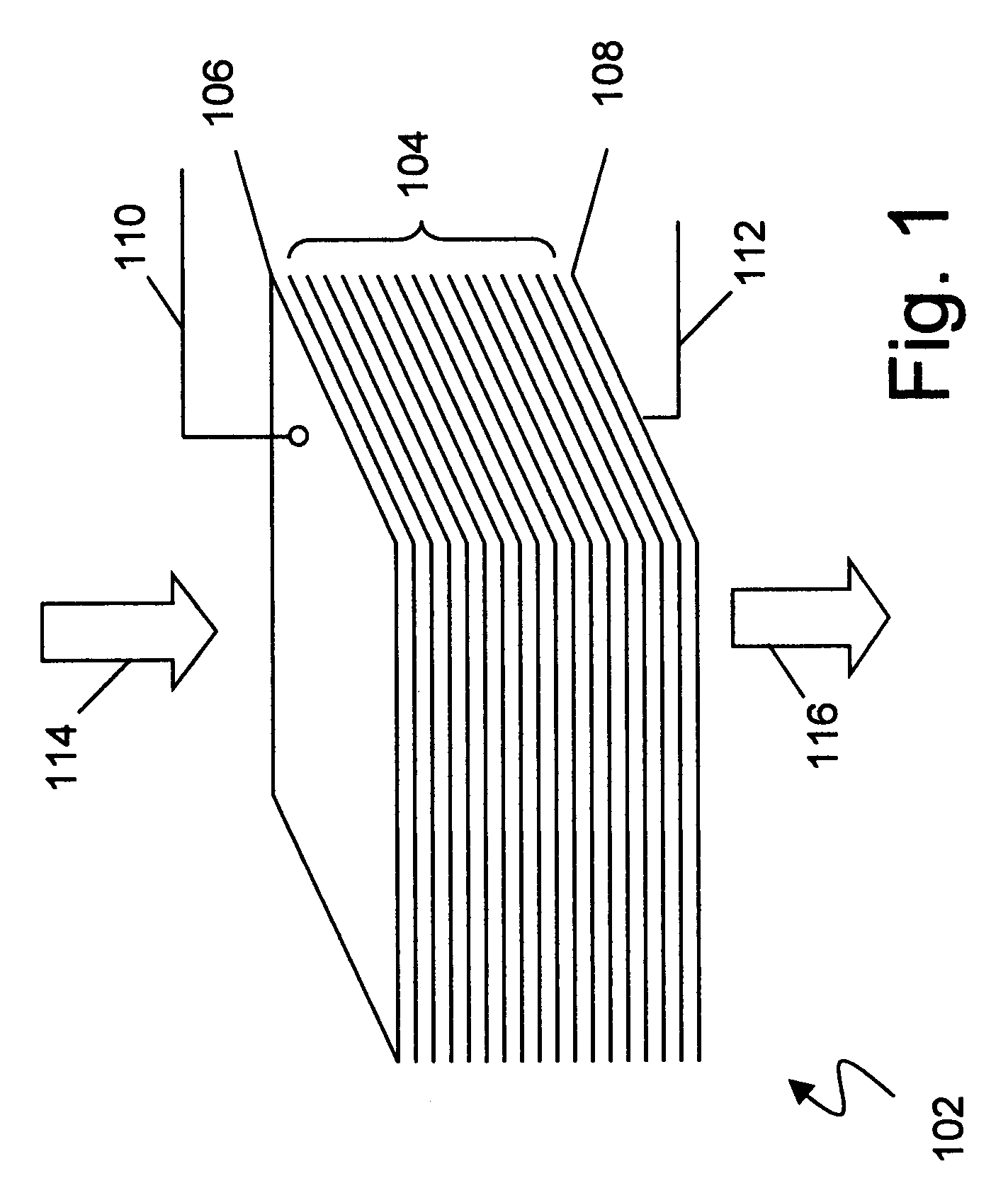

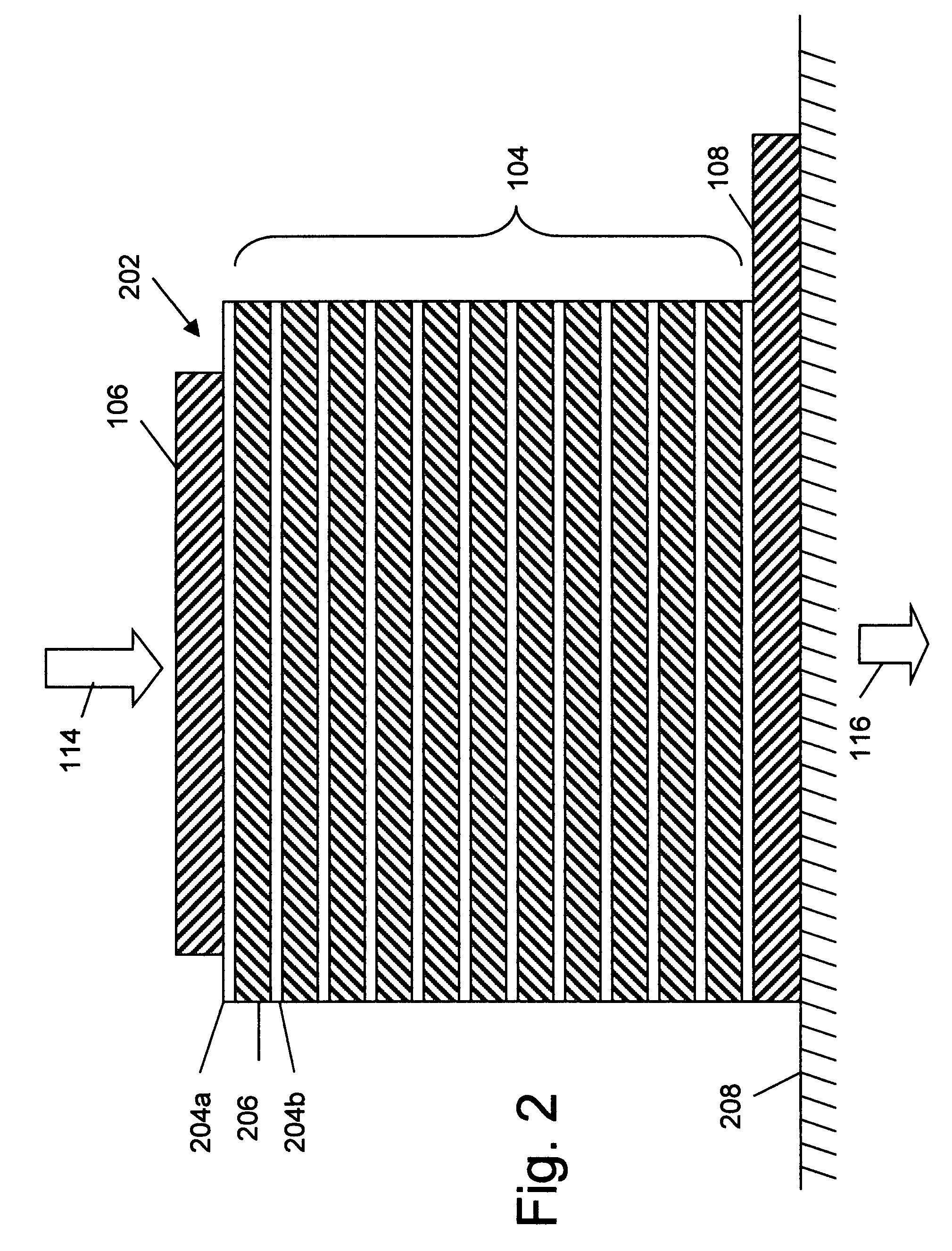

Efficient thermoelectric device

InactiveUS20070235070A1Increasing thermoelectric figureImprove efficiencyThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentMetallic materialsFigure of merit

A high efficiency thermo electric device comprising a multi nanolayer structure of alternating insulator and insulator / metal material that is irradiated across the plane of the layer structure with ionizing radiation. The ionizing radiation produces nanocrystals in the layered structure that increase the electrical conductivity and decrease the thermal conductivity thereby increasing the thermoelectric figure of merit. Figures of merit as high as 2.5 have been achieved using layers of co-deposited gold and silicon dioxide interspersed with layers of silicon dioxide. The gold to silicon dioxide ratio was 0.04. 5 MeV silicon ions were used to irradiate the structure. Other metals and insulators may be substituted. Other ionizing radiation sources may be used. The structure tolerates a wide range of metal to insulator ratio.

Owner:AAMU RES INST

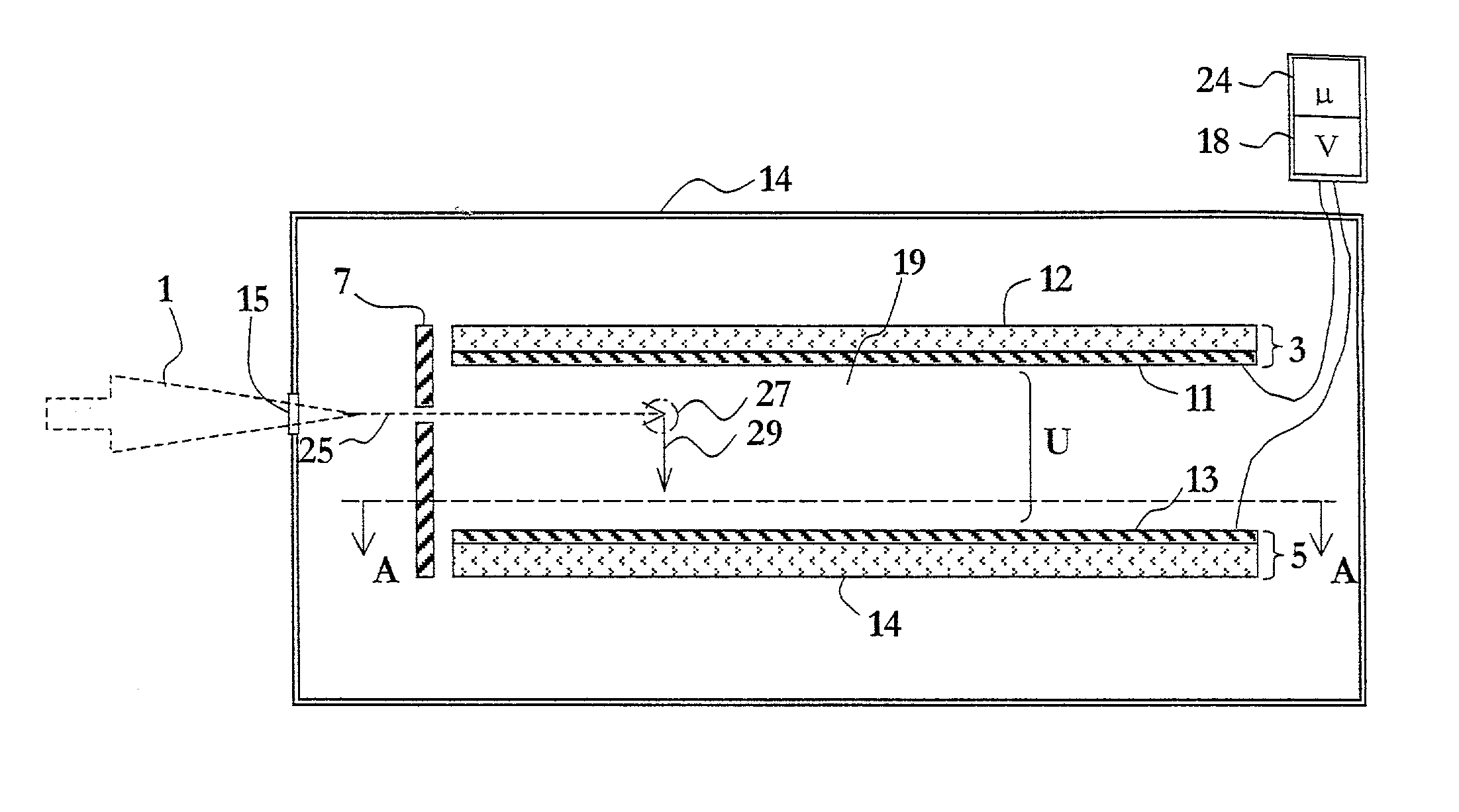

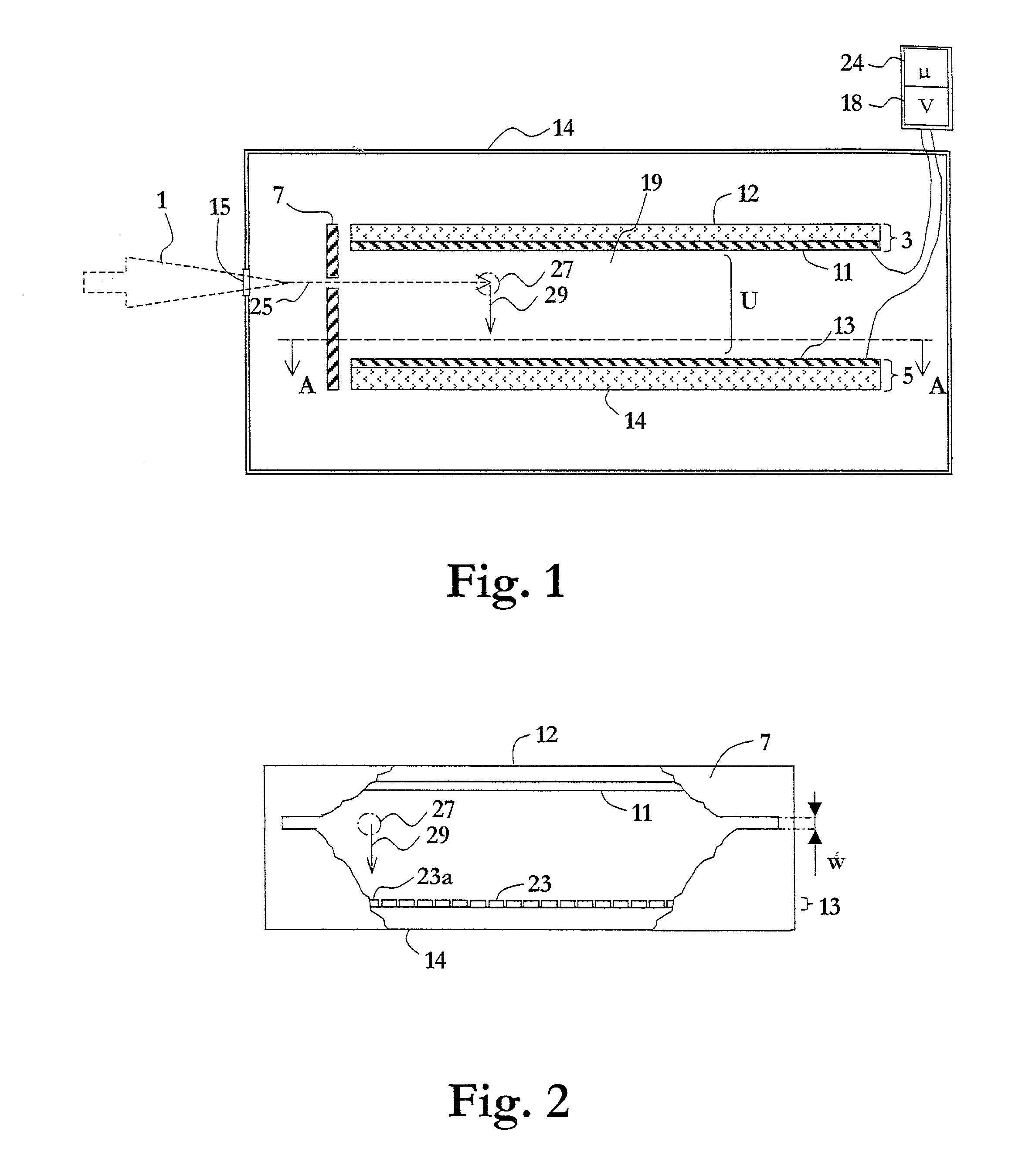

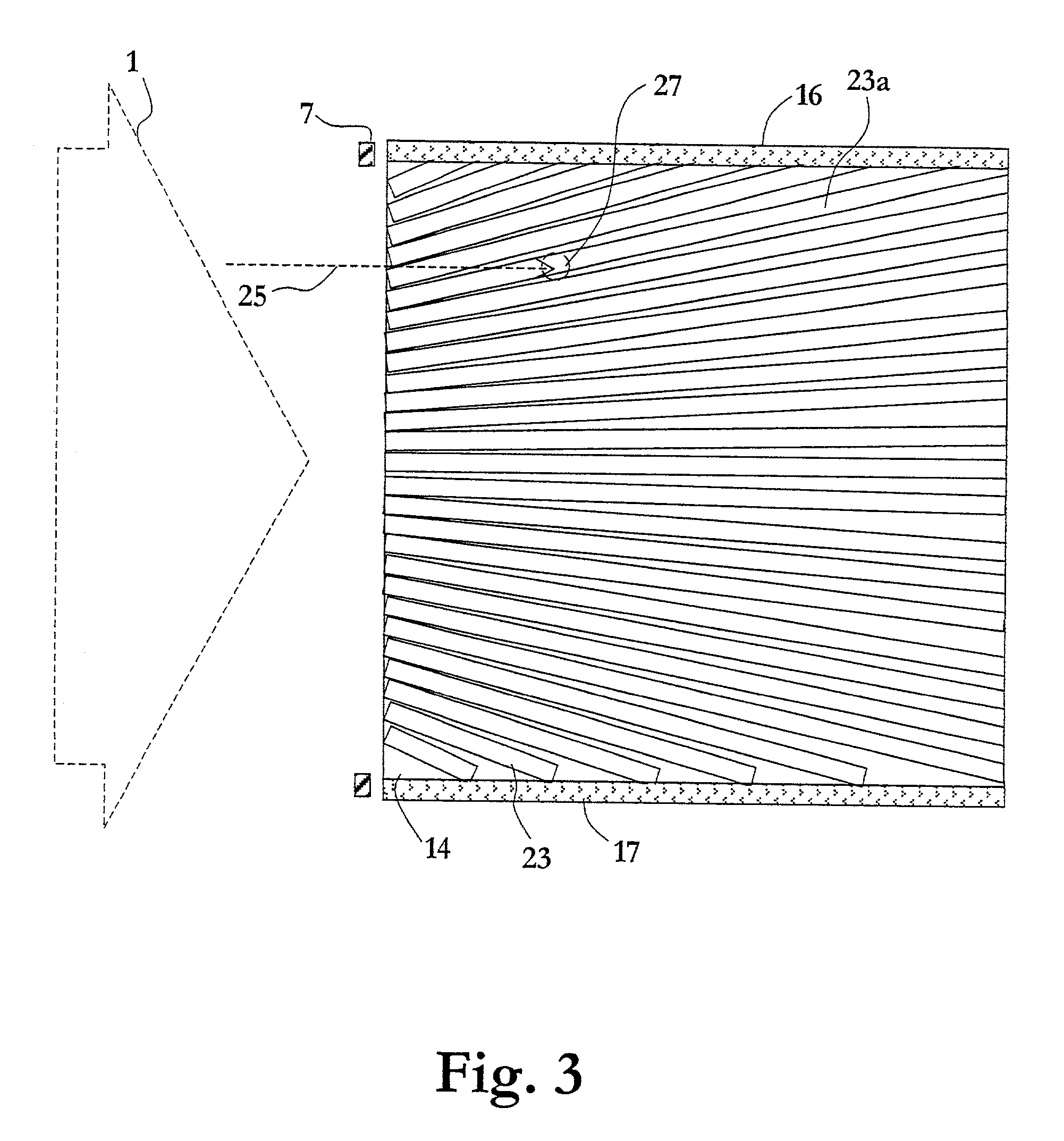

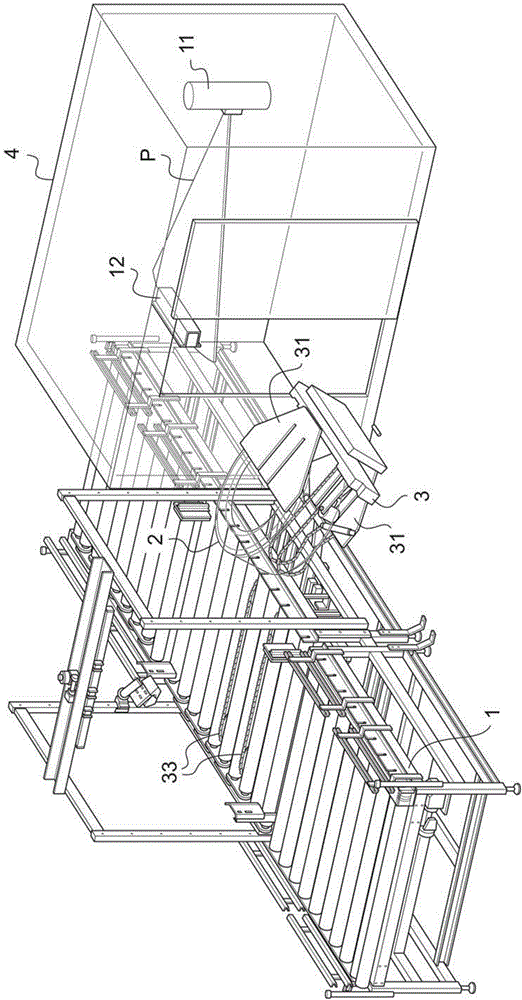

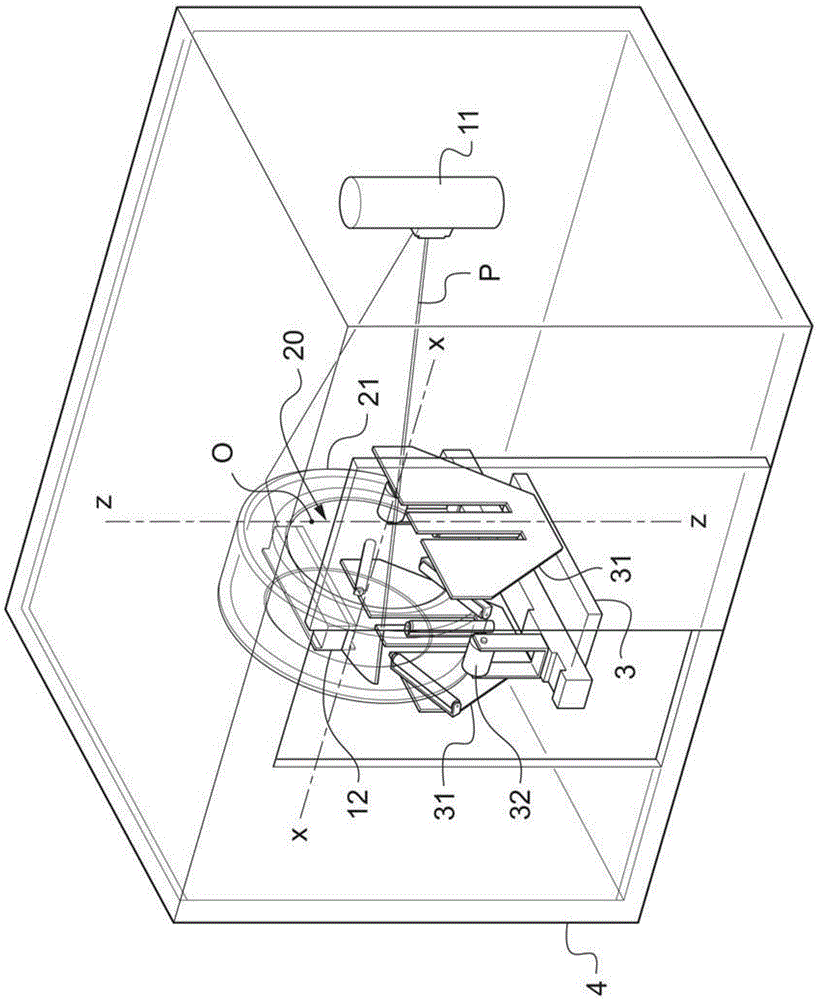

Radiation detector arrangement

InactiveUS6794656B2Shorten scanning time and distanceLong lastingTelevision system detailsElectric discharge tubesIonising radiation sourceTwo dimensional imaging

Owner:XCOUNTER

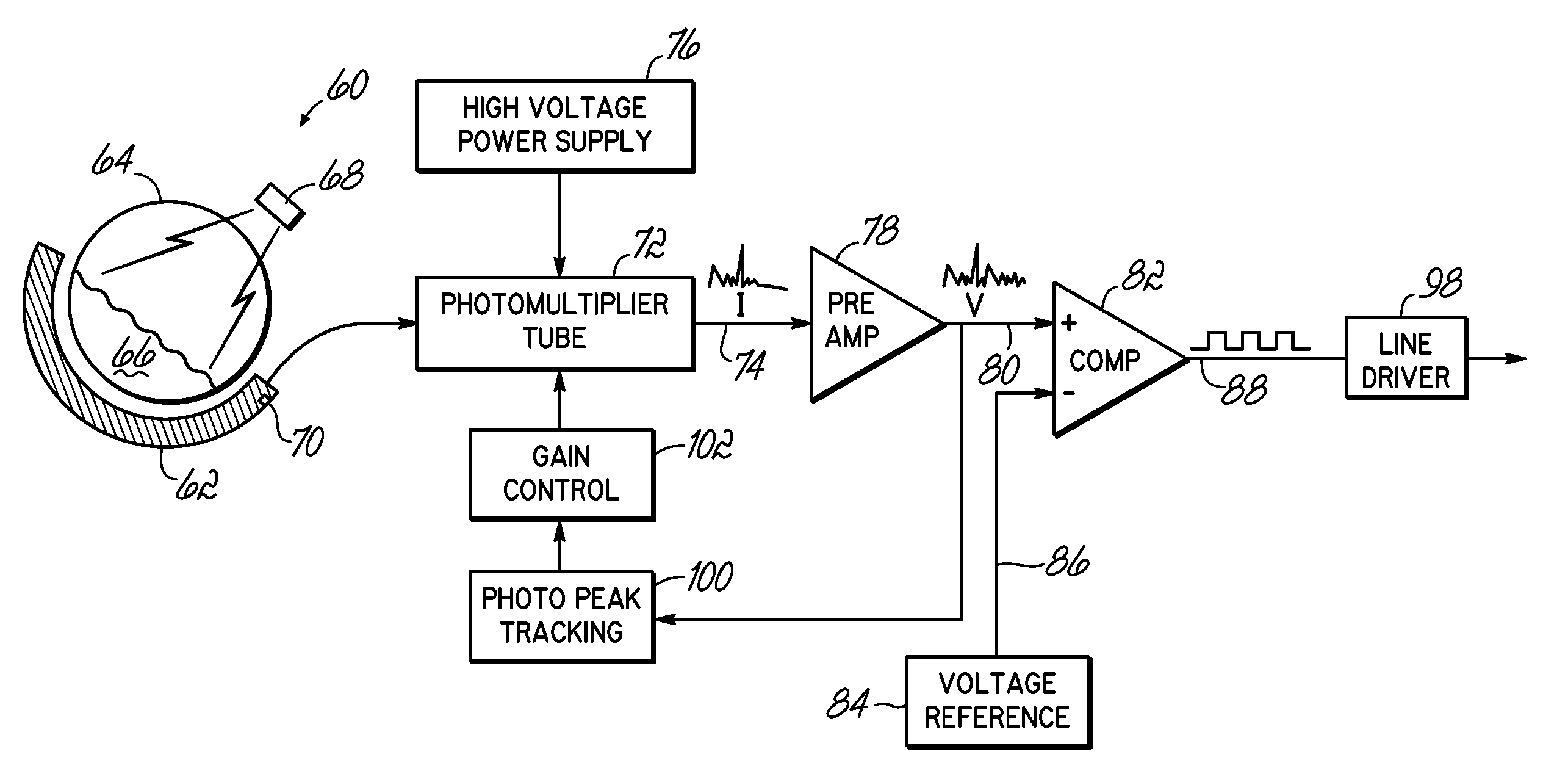

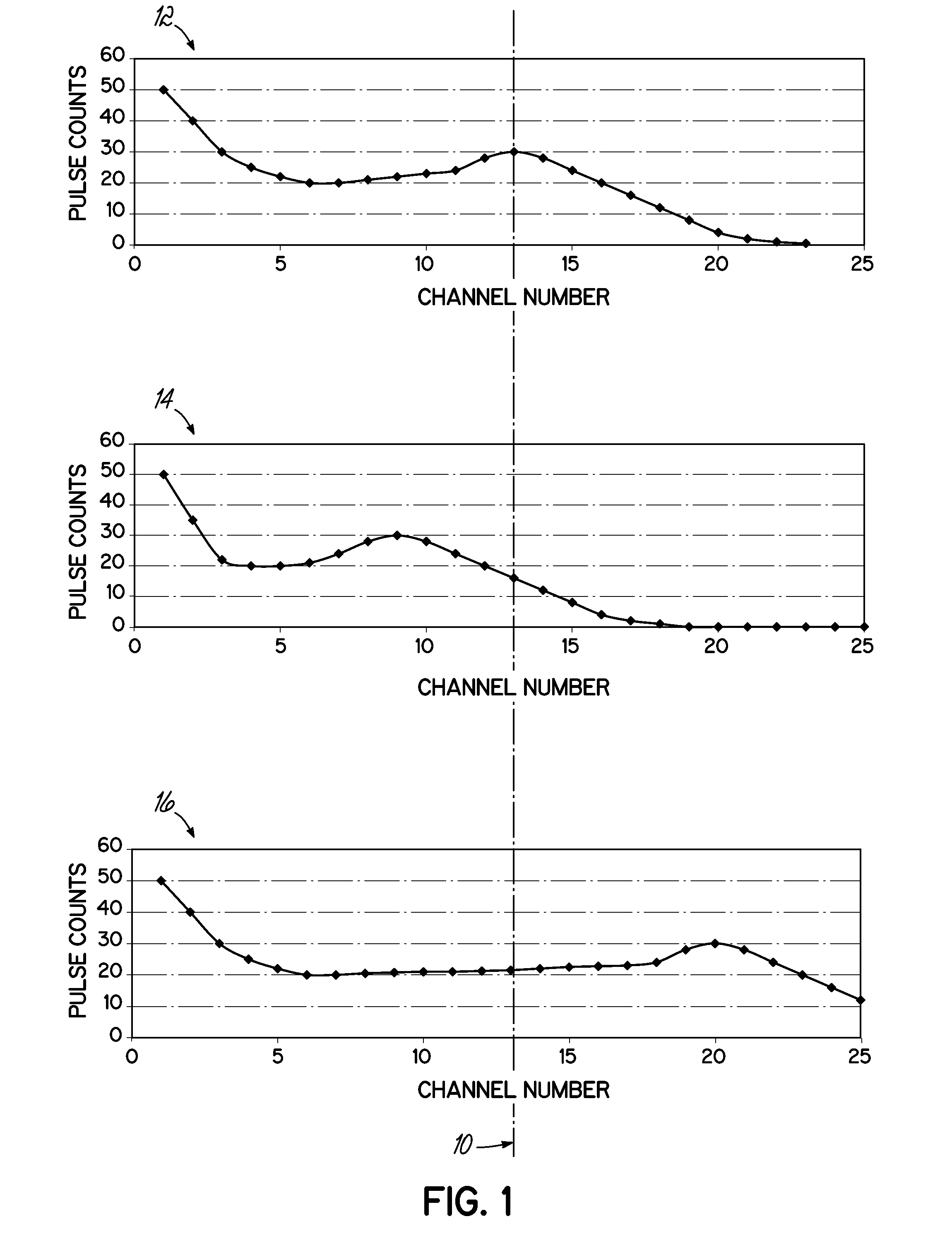

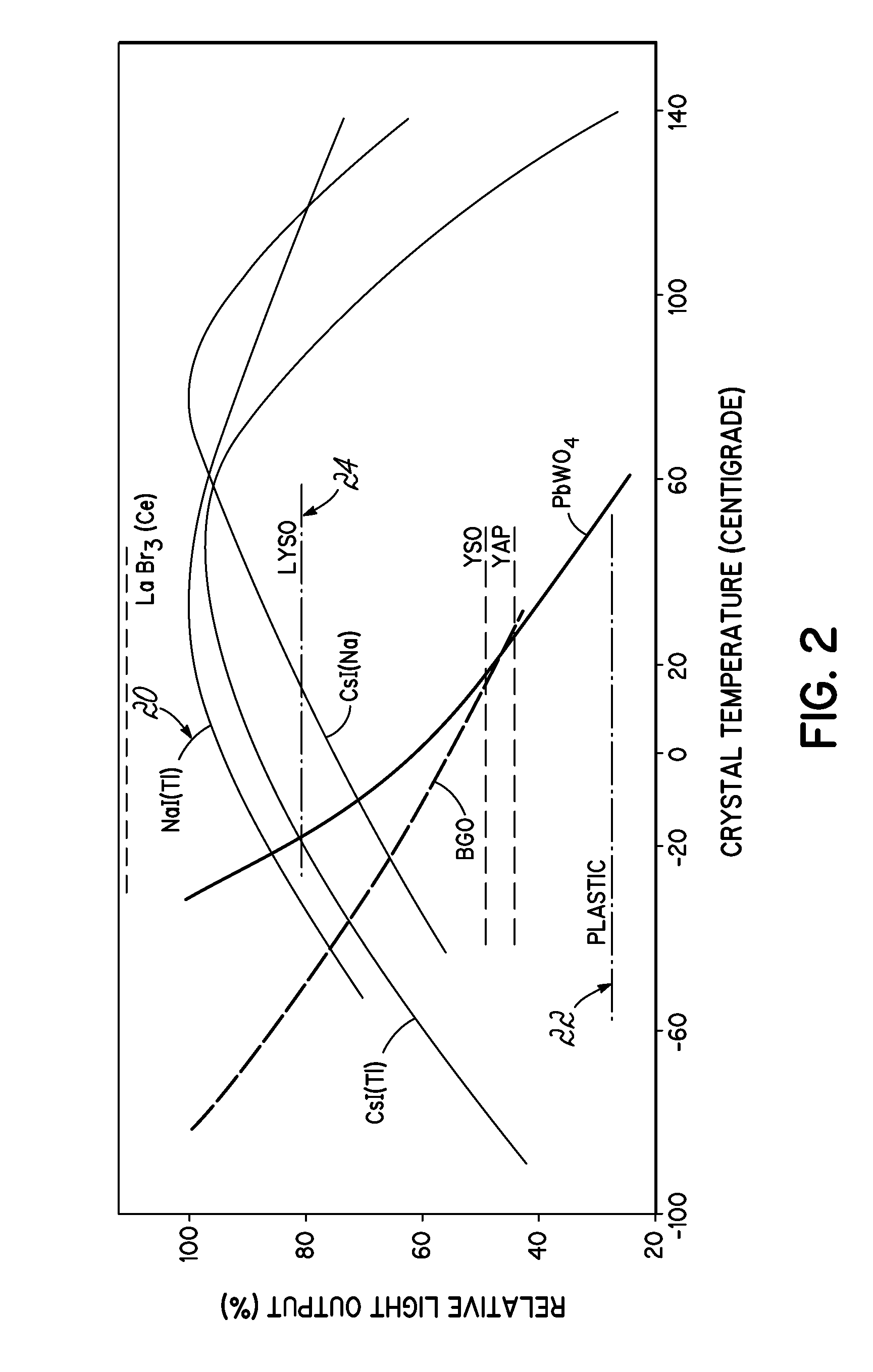

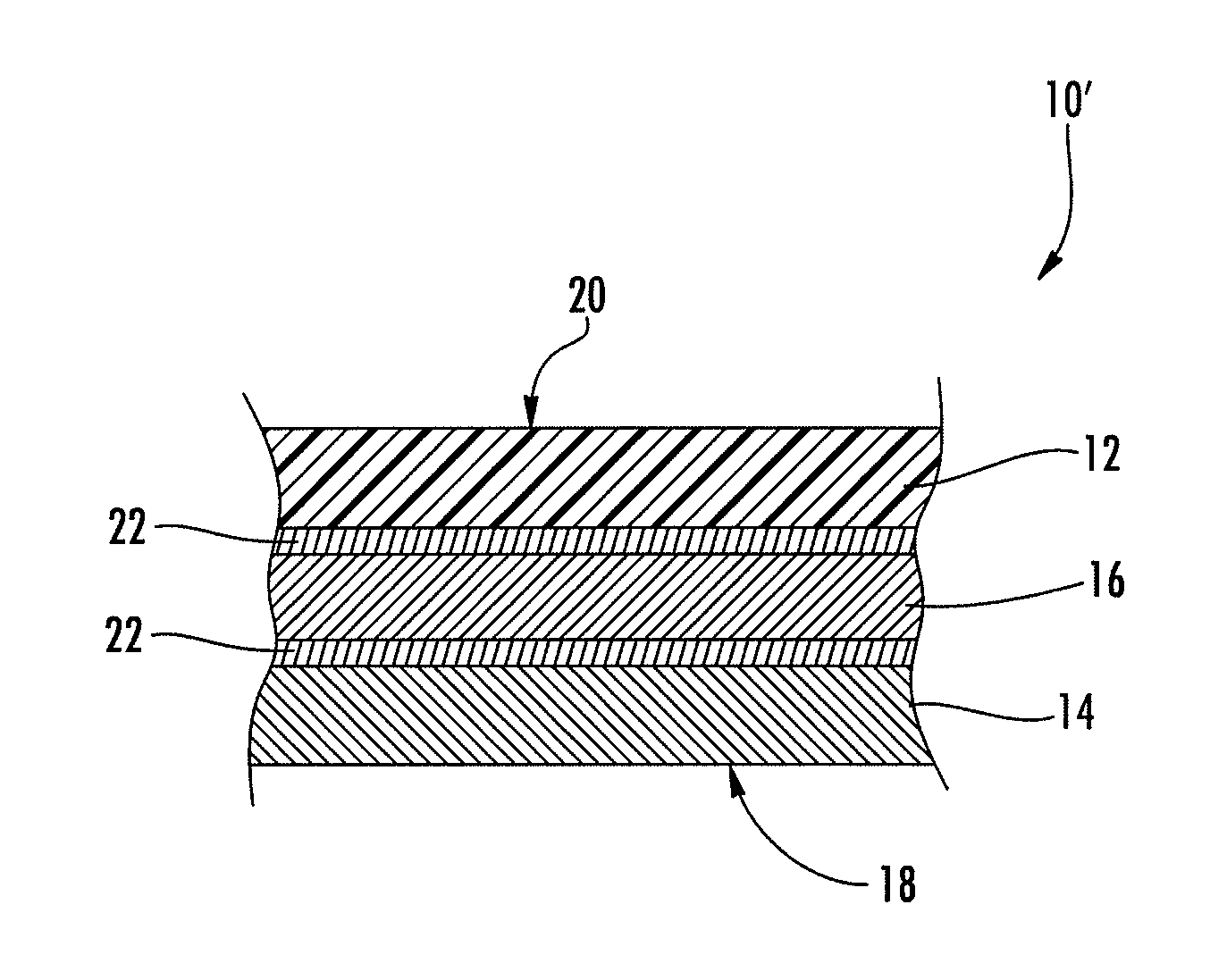

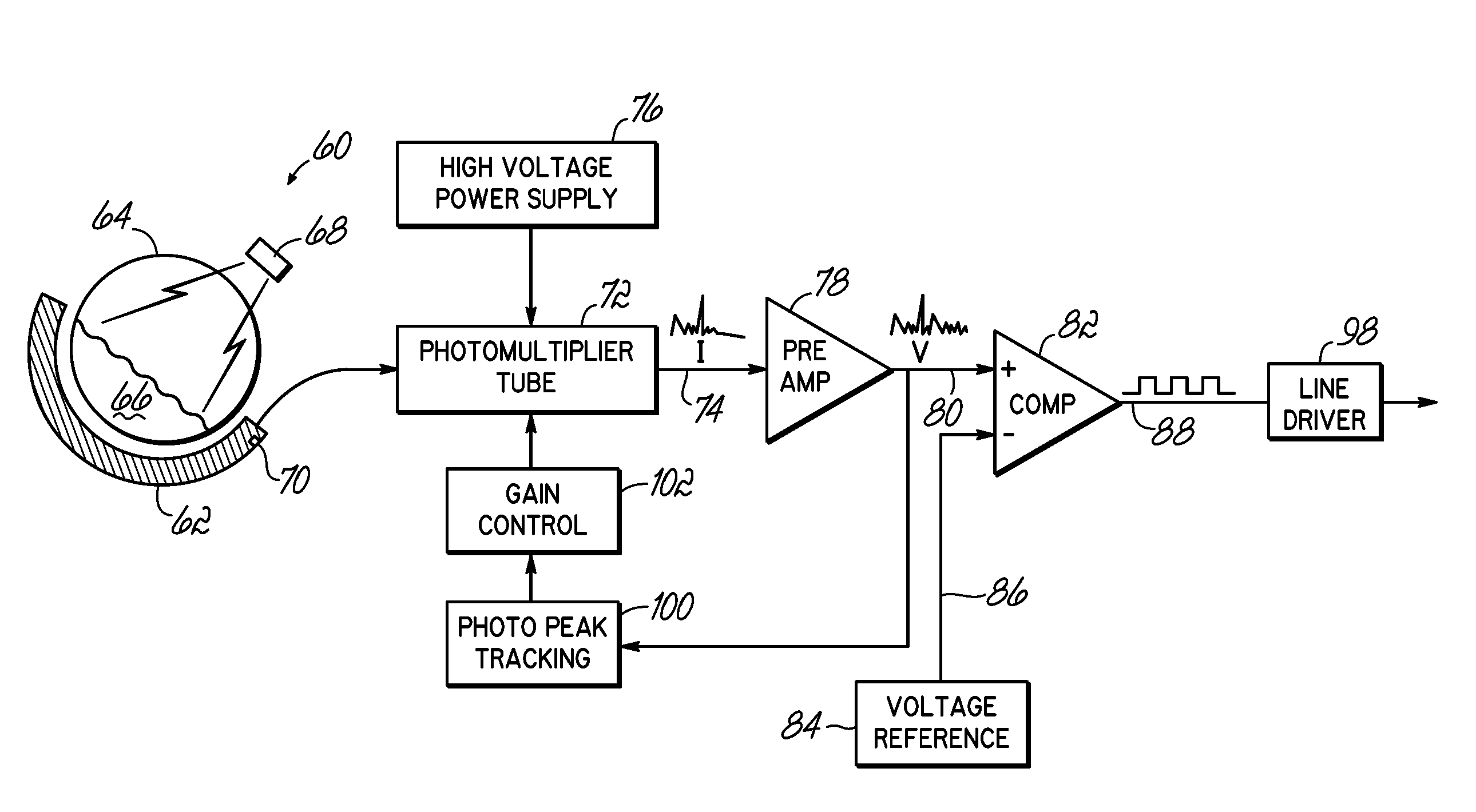

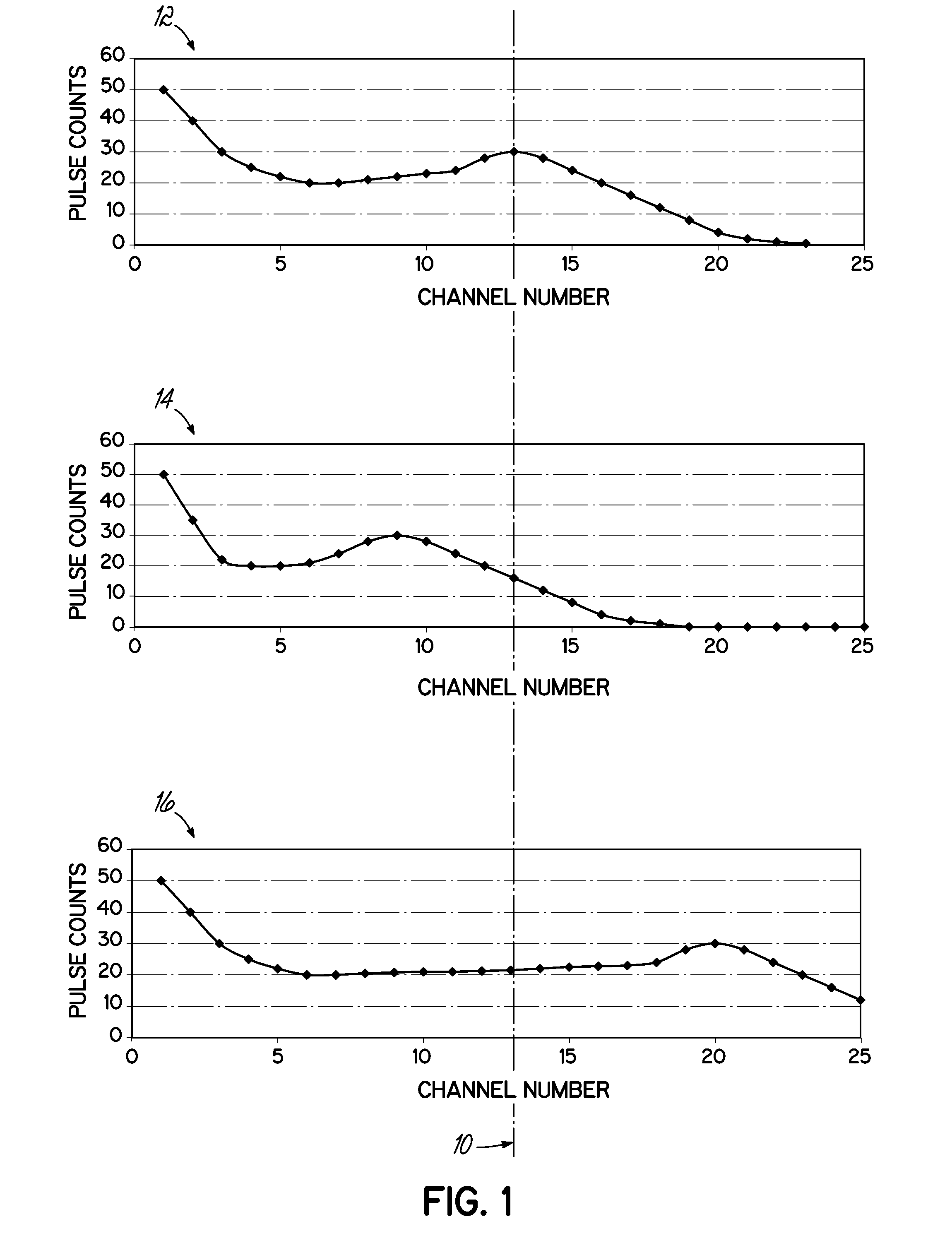

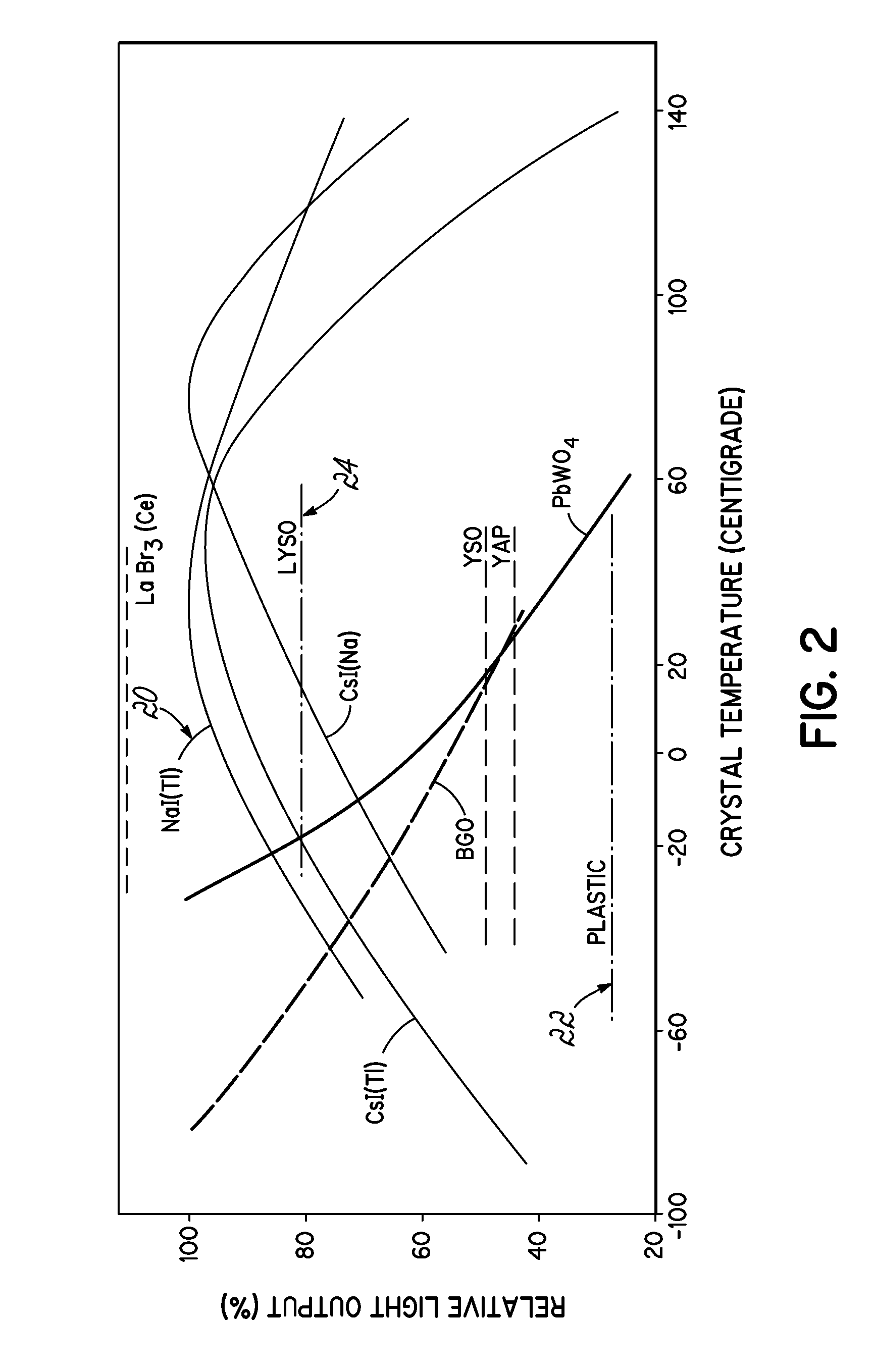

Automatic gain stabilization and temperature compensation for organic and/or plastic scintillation devices

ActiveUS20110192979A1X-ray spectral distribution measurementMaterial analysis by optical meansElectrical impulsePhotomultiplier

A detector and associated method are provided including a first scintillation material having a light yield temperature dependence and an output at a first energy level, a second scintillation material having a light yield temperature dependence similar to the first material and an output at a second energy level, and detection circuitry. The first and second outputs are responsive to radiation emitted from an ionizing radiation source. The detection circuitry includes a photo multiplier tube configured to convert photon outputs from the first and second scintillating materials to electrical pulses, a counter circuit configured to count the electrical pulses generated in the photo multiplier tube by the first and second materials, and a gain control circuit configured to monitor the electrical pulses generated in the photomultiplier tube by the second material and adjust a gain of the detector upon detecting a drift in the output of the second material.

Owner:VEGA GRIESHABER GMBH & CO

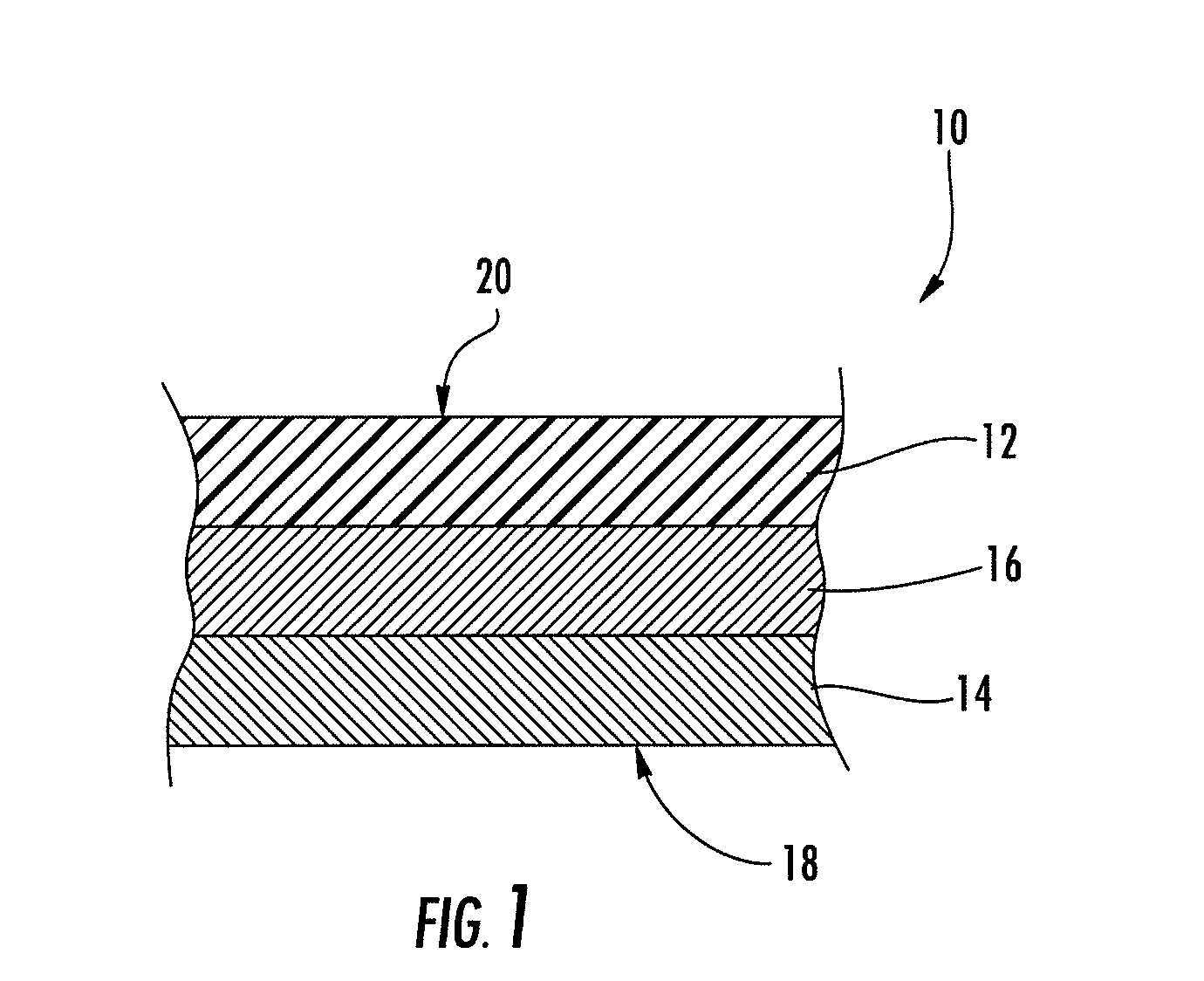

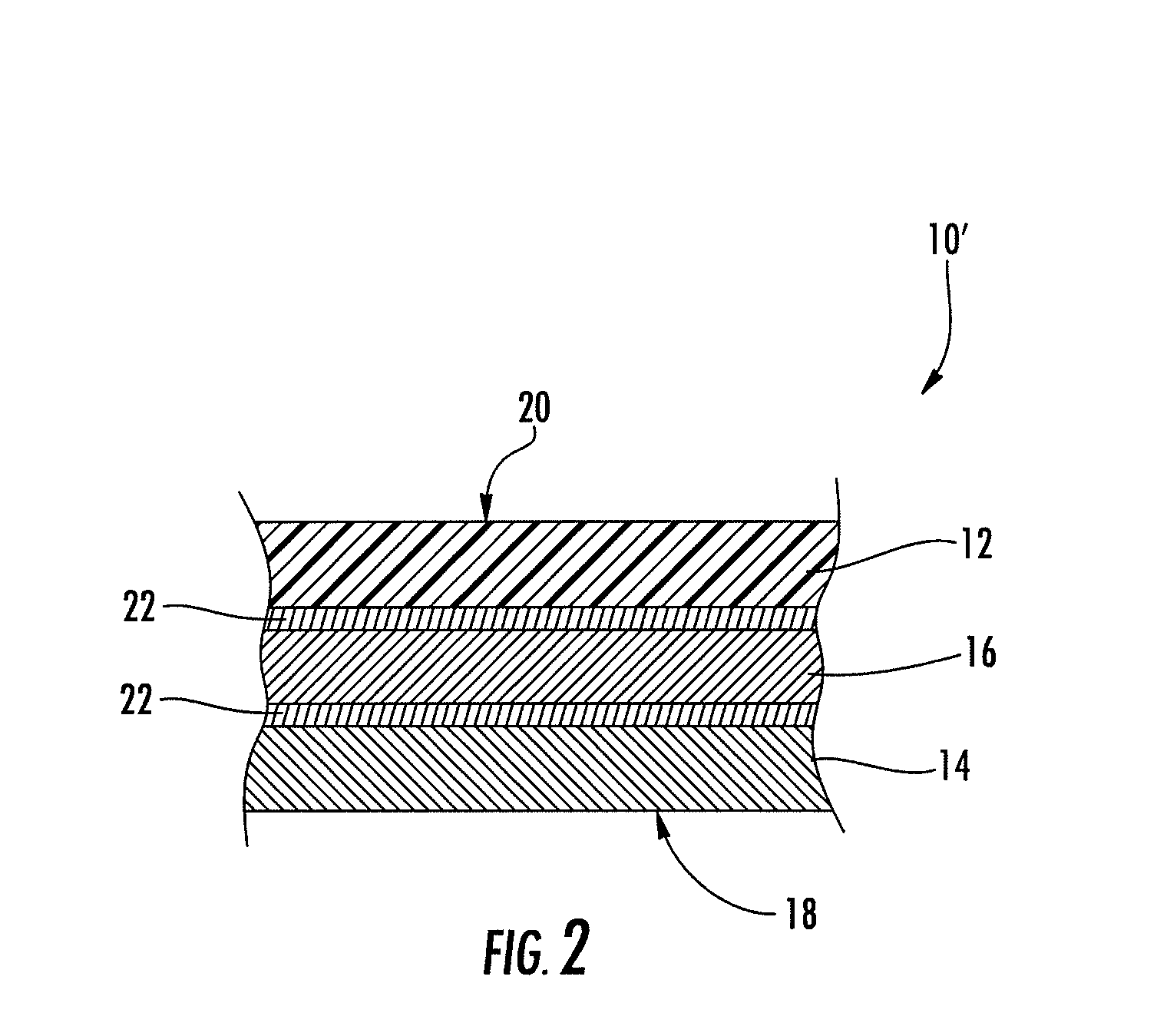

Multilayer Film Having an Active Oxygen Barrier Layer With Radiation Enhanced Active Barrier Properties

ActiveUS20090061057A1Improves oxygen scavenging abilityImproved active barrier propertyMilk preservationFatty substance preservation using additivesDouble bondOxygen barrier

The present invention is directed to a multilayer film having an active oxygen barrier layer that comprises an oxygen scavenging composition that is a blend of a thermoplastic resin (A) having carbon-carbon double bonds substantially in its main chain, a transition metal salt (B), and an oxygen barrier polymer (C) having oxygen barrier properties that can be further enhanced by exposing the composition to a source of ionizing radiation e.g., electron beam radiation. Irradiation improves the oxygen scavenging abilities of the oxygen scavenging composition so that oxygen can be intercepted and scavenged as it passes through the film. The resulting irradiated multilayer film has improved active barrier properties in comparison to the same film prior to irradiation. As result, the multilayer film of the present invention can be used in packaging applications to help maintain a low oxygen atmosphere in the interior of a package.

Owner:CRYOVAC INC

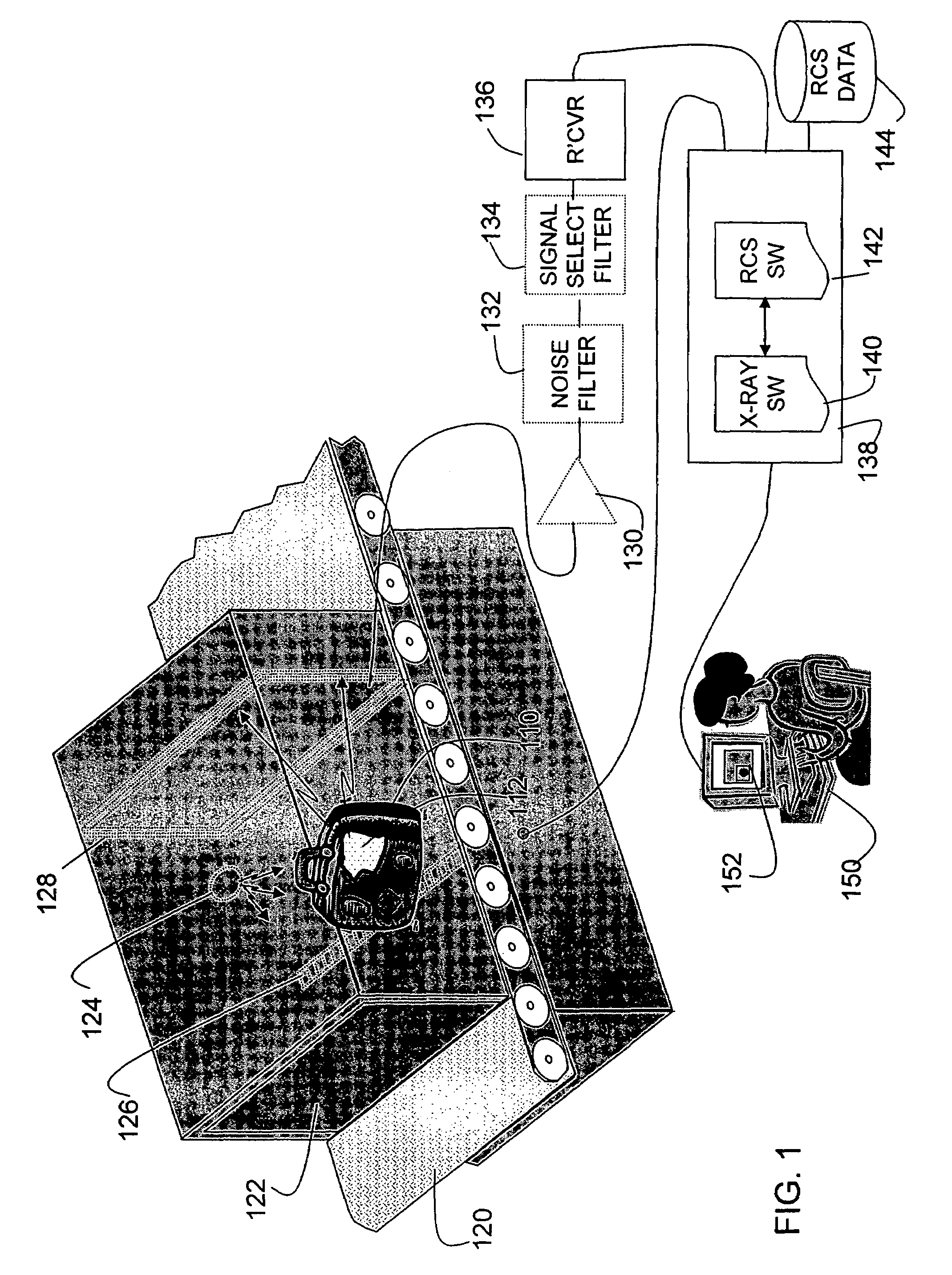

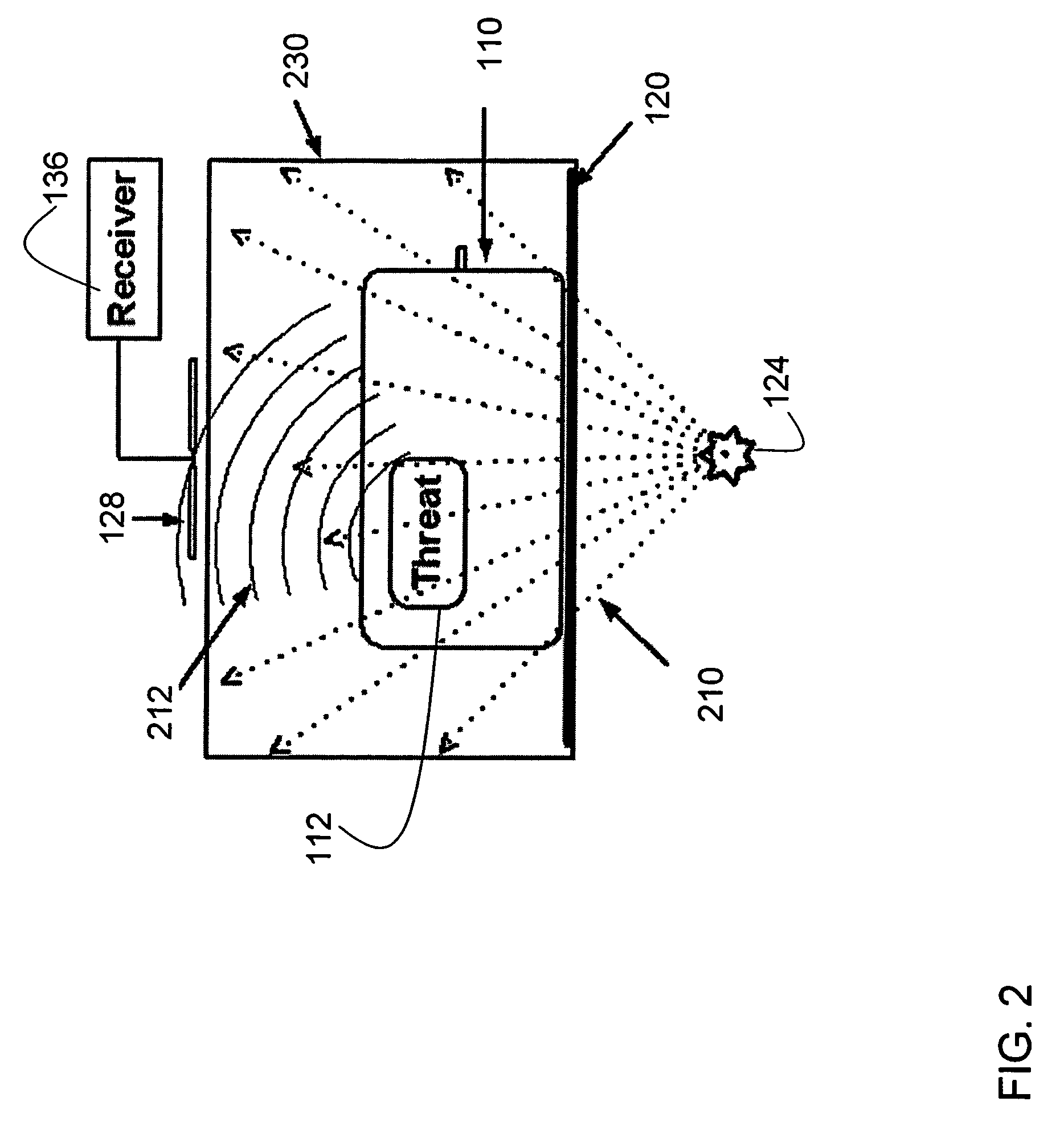

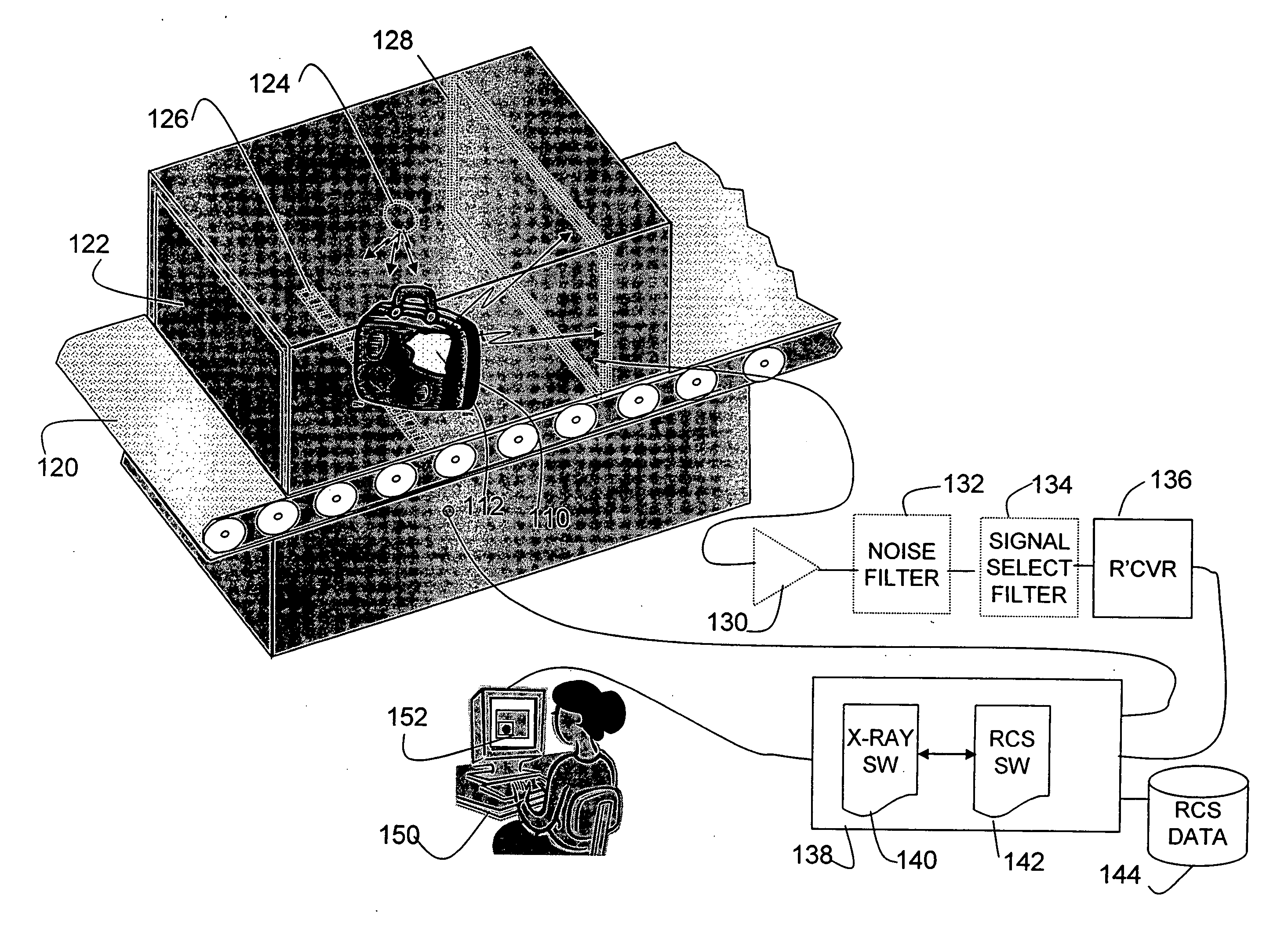

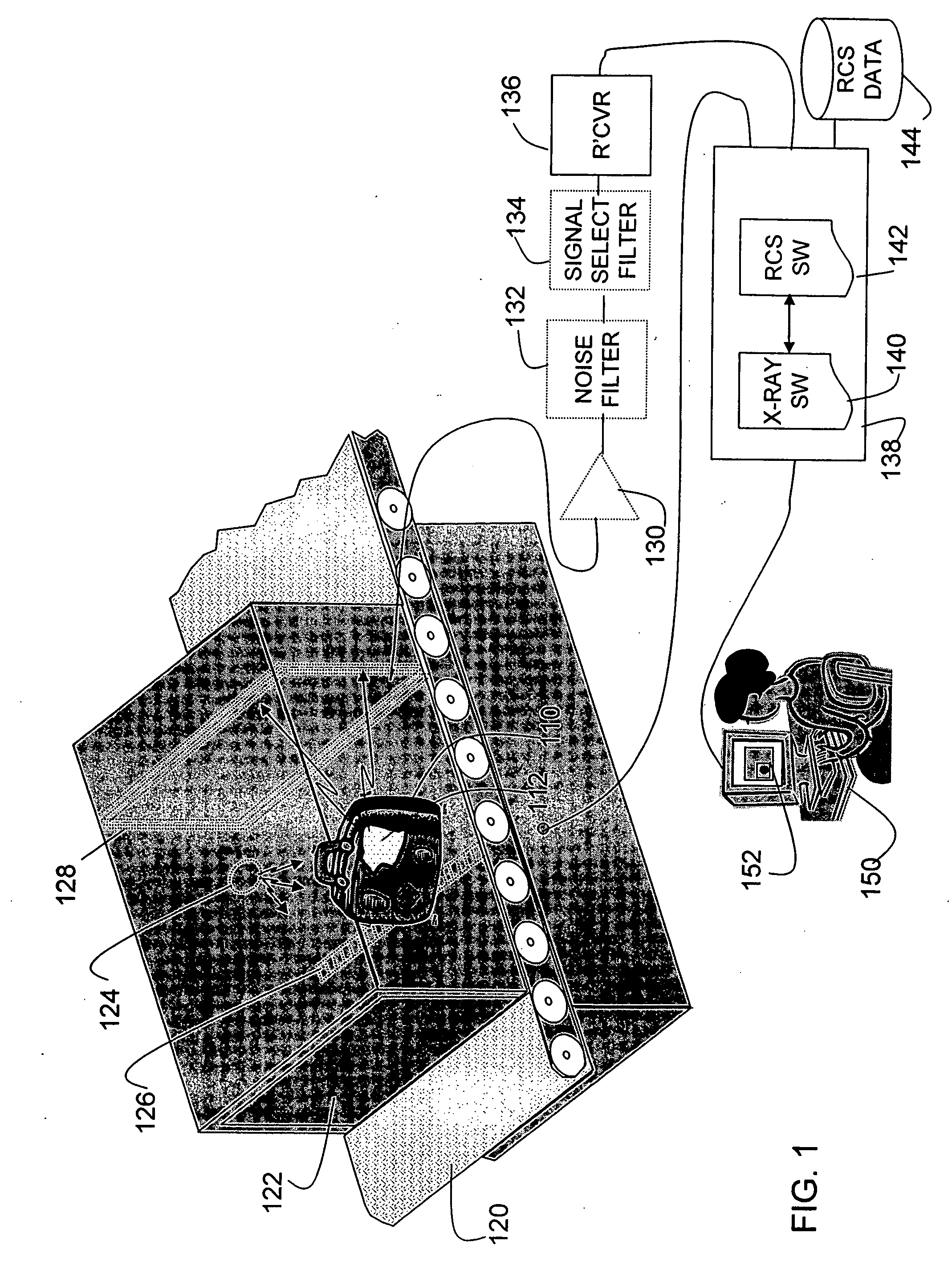

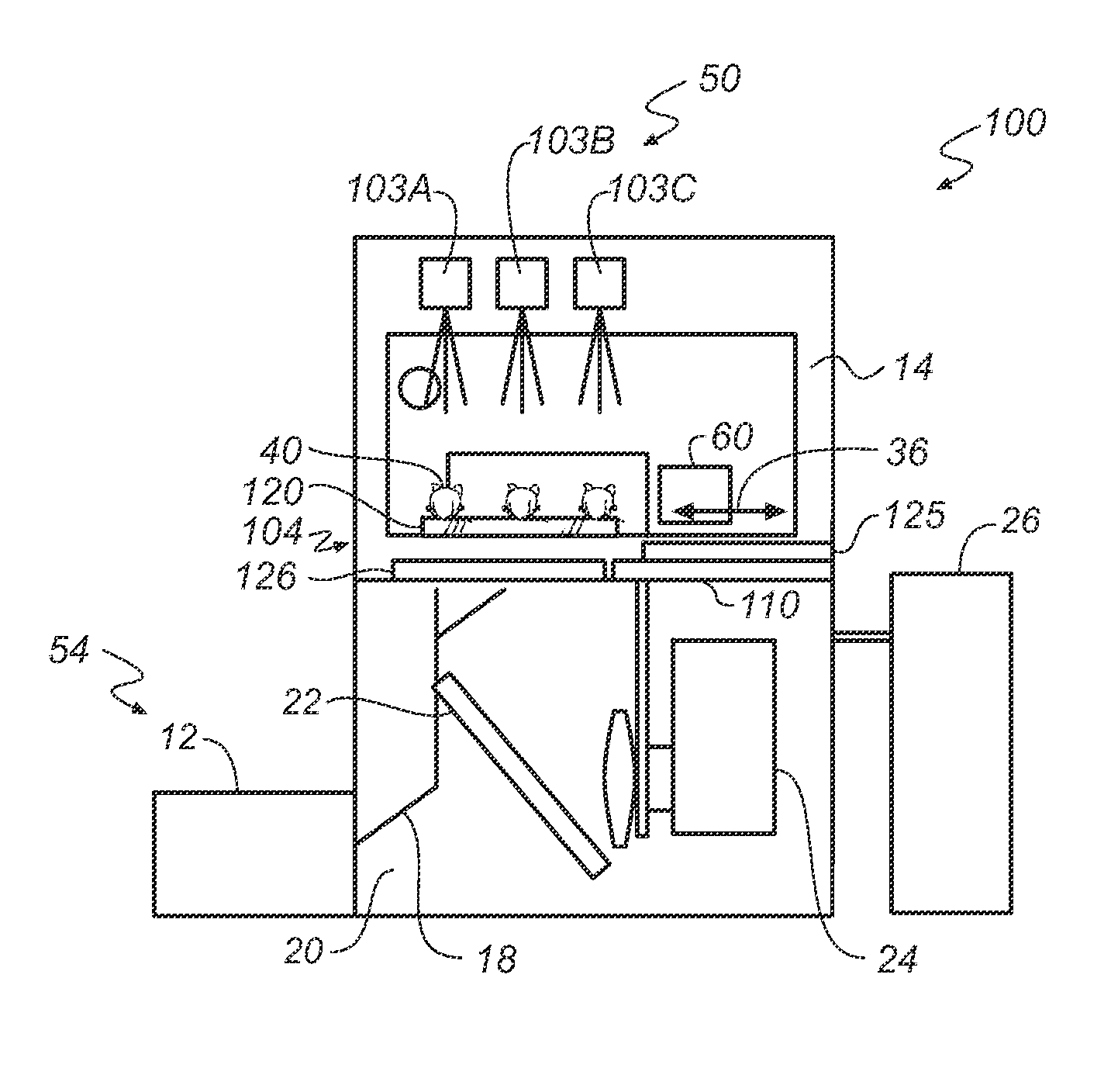

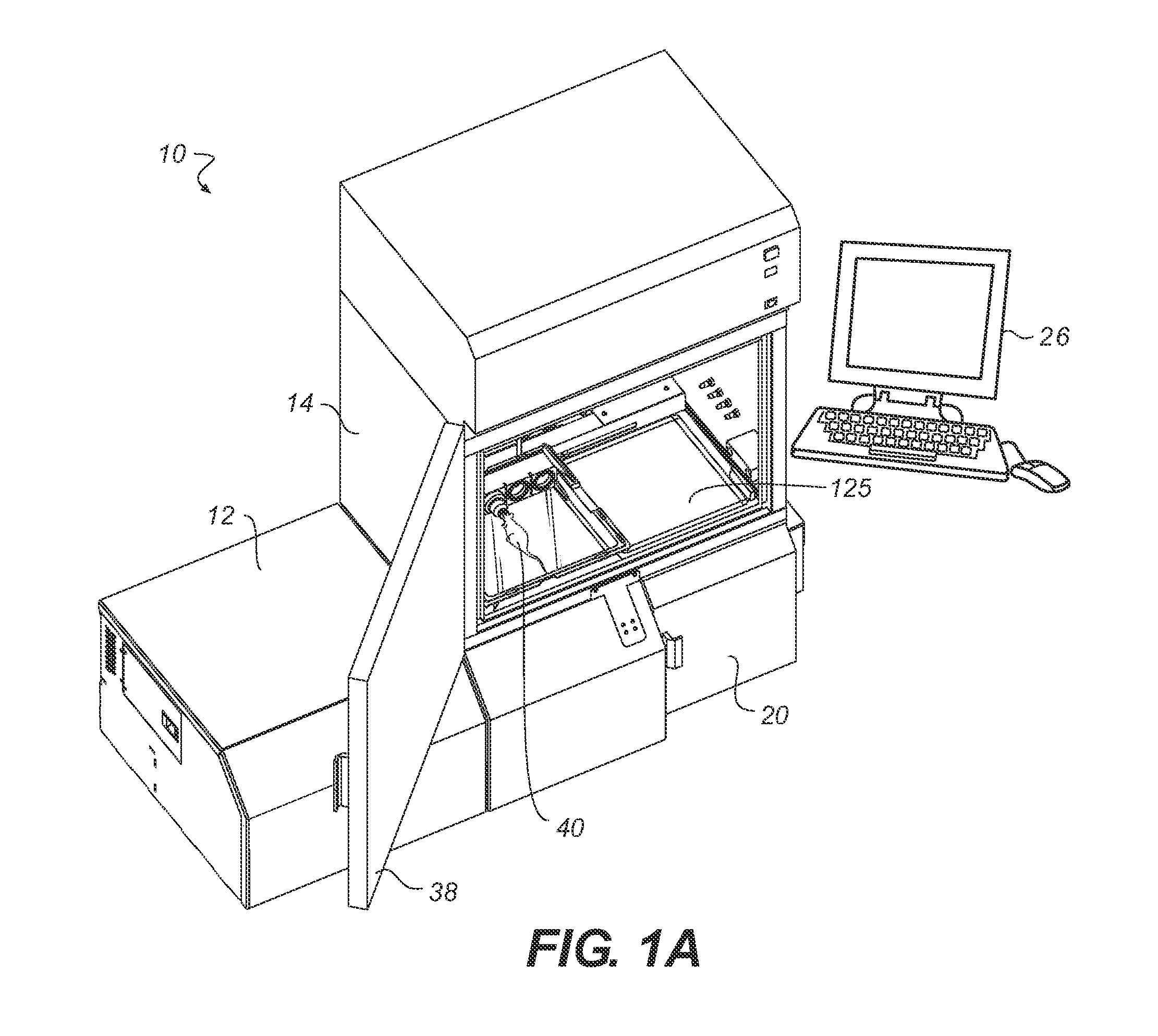

Method and apparatus for detecting contraband using radiated compound signatures

InactiveUS20070153974A1Electric/magnetic detectionMaterial analysis by transmitting radiationImage systemInformation system

An system for detecting contraband, particularly explosives or other energetic materials. The system includes a source of ionizing radiation that irradiates an item under inspection. The radiation stimulates the emission of RF energy from objects within the item under inspection. The characteristics of the emitted RF energy reveals information about the material composition of the objects. The system detects this emitted RF energy and comparers it to a signature of RF emissions from contraband objects. Apparatus to detect and analyze RF emissions may be constructed as a stand-alone unit or may be incorporated into an imaging system in which the ionizing radiation is used to form an image of the item under inspection. Similarly, the RF analysis may be used, in the first instance, to determine whether an object contains a contraband item or may be used as a second level analysis to clear alarms generated by analysis of images formed by the imaging system.

Owner:L3 COMMUNICATIONS SECURITY & DETECTION SYSTEMS CORPORATION

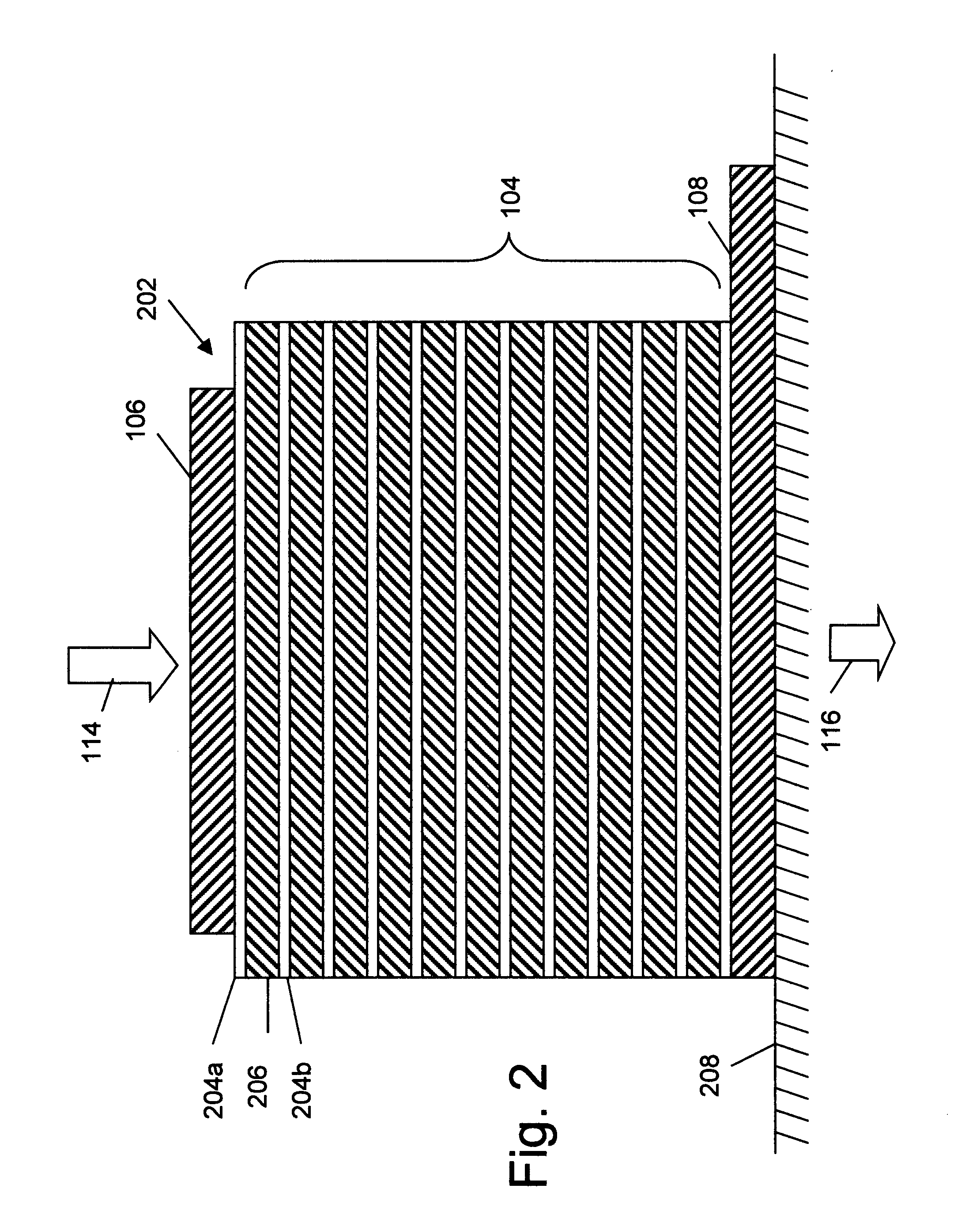

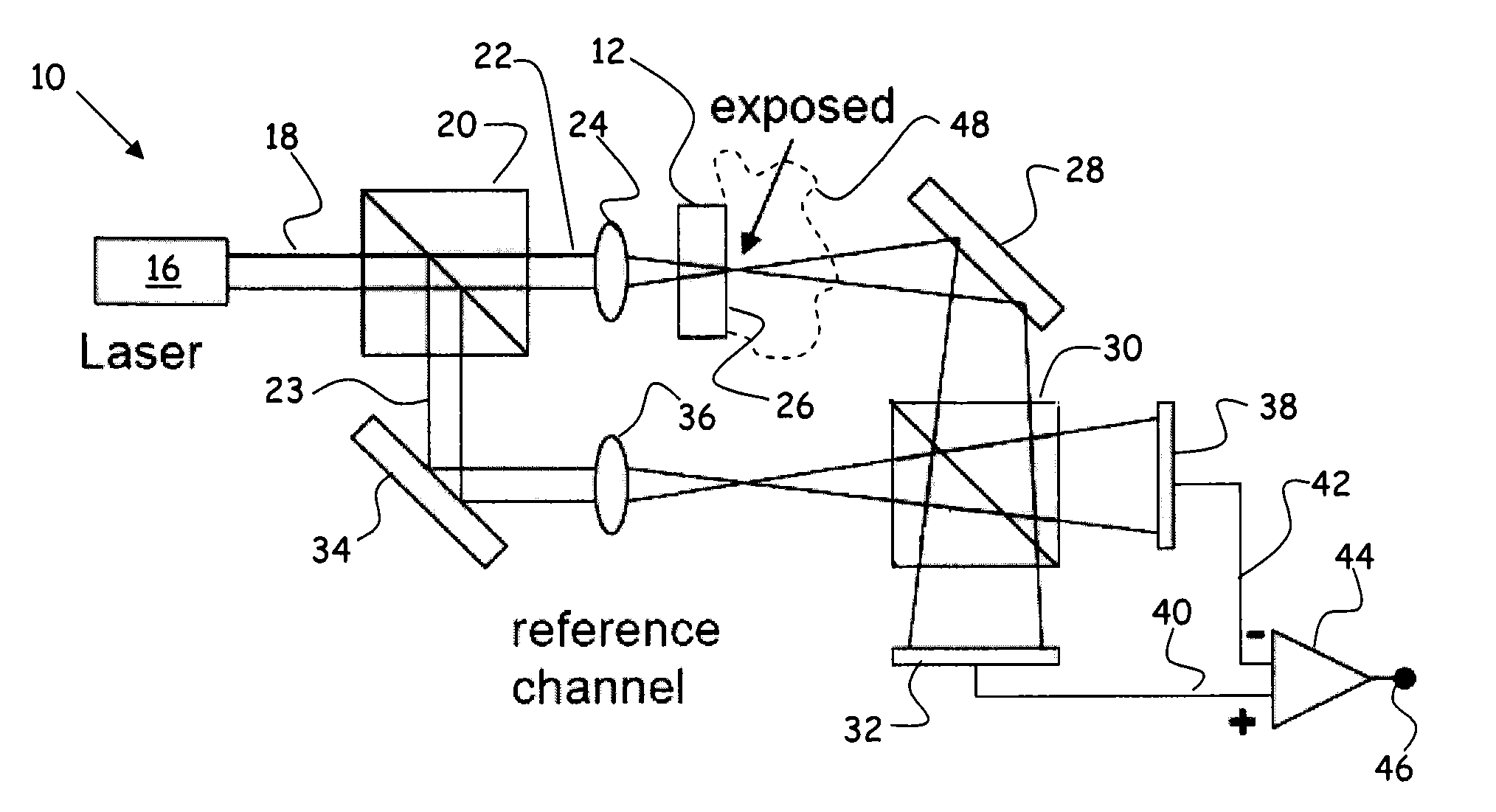

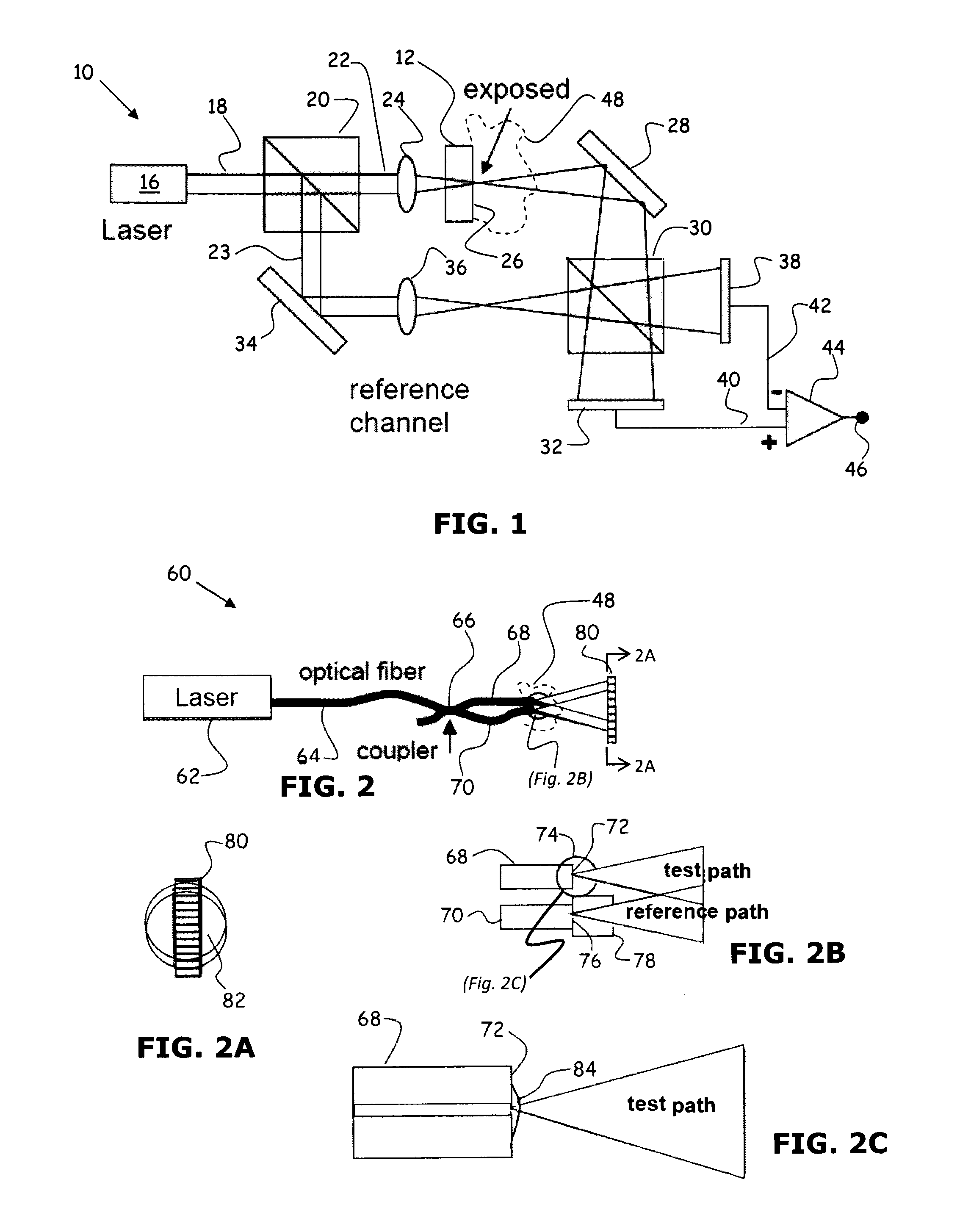

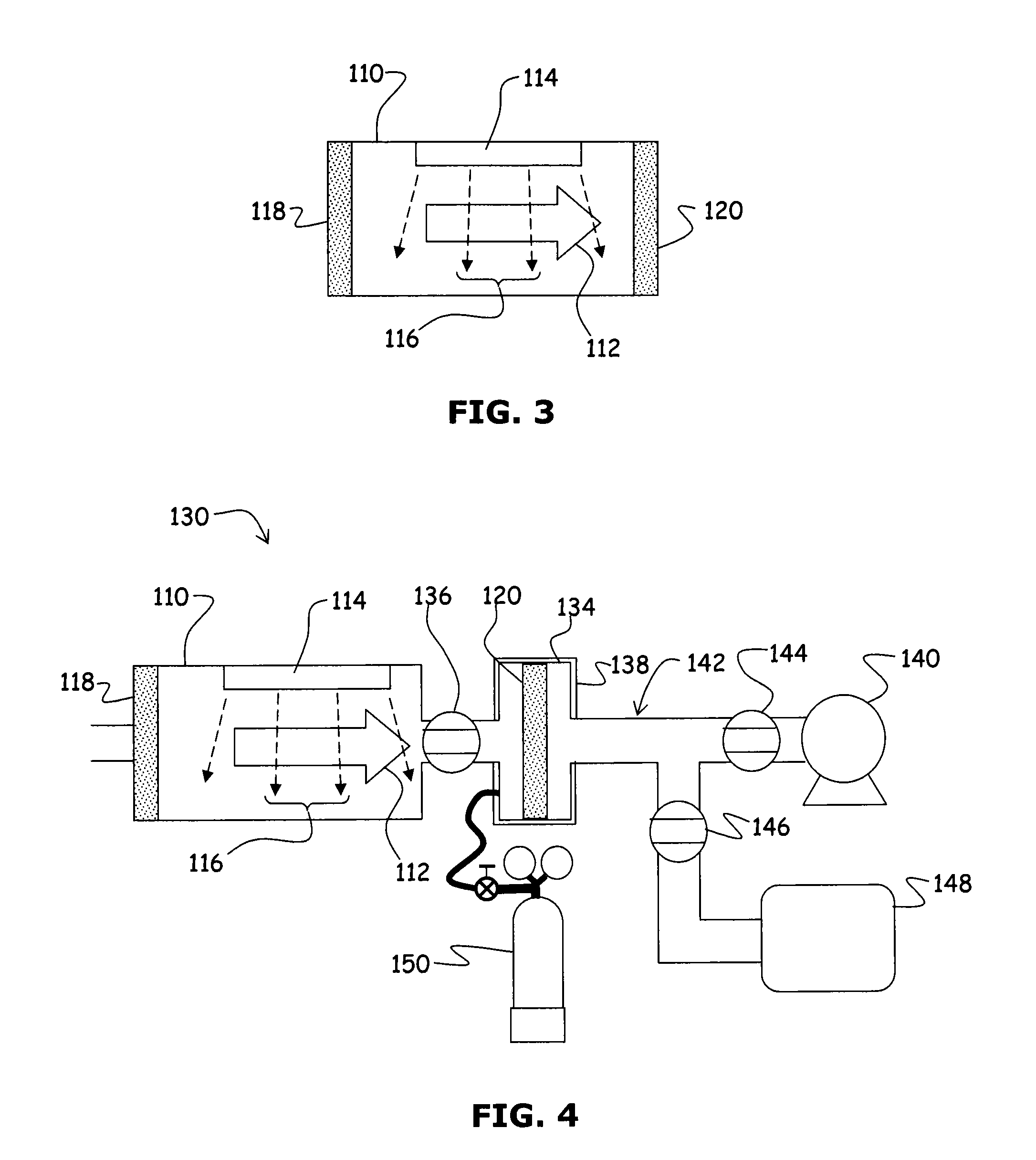

Methods and apparatus for detecting airborne molecular contaminants

ActiveUS20120241601A1High analytical sensitivityLow costPhase-affecting property measurementsIsotope separationHigh concentrationFiltration

Methods and apparatuses for the removal, analysis and / or detection of harmful airborne molecular contaminants (AMCs). In one embodiment, an ionizing radiation source is utilized to remove the harmful AMCs from a flow stream via radiolytic particle generation and subsequent capture by filtration. The captured particles may be released, for example, by re-gasification for analysis at much higher concentrations. In another embodiment, the ionizing radiation source is utilized with a particle detector to sense when harmful AMCs are present. In one embodiment, a solid optical medium is exposed to a monitored environment so that the AMCs are in contact with a surface of the solid optical medium. A focused light beam is arranged to emerge from a solid optical medium at an energy density sufficient to cause the AMCs to form deposits on the exposed surface of the solid optical medium, which can be detected using an interferometric technique.

Owner:TSI INC

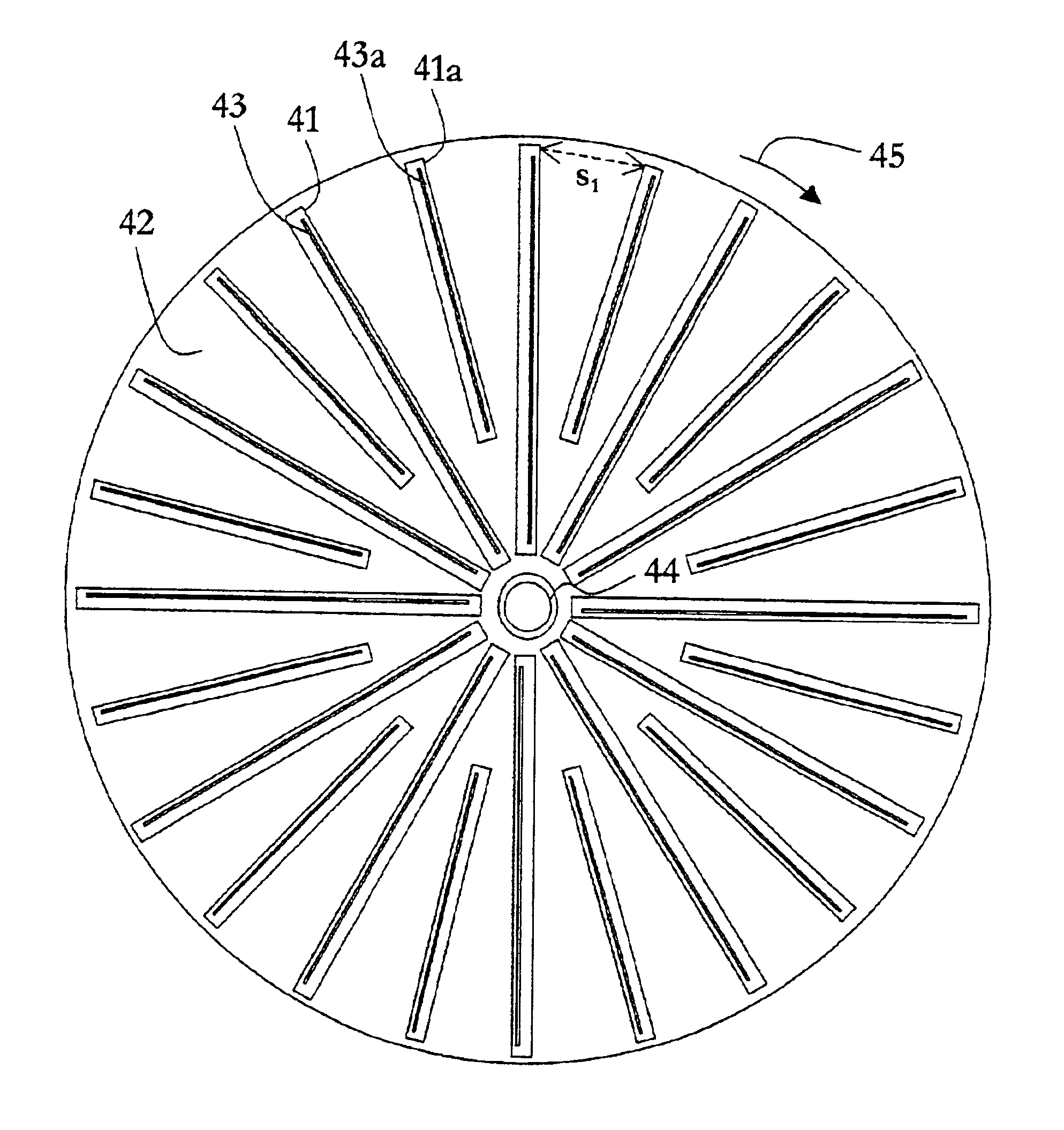

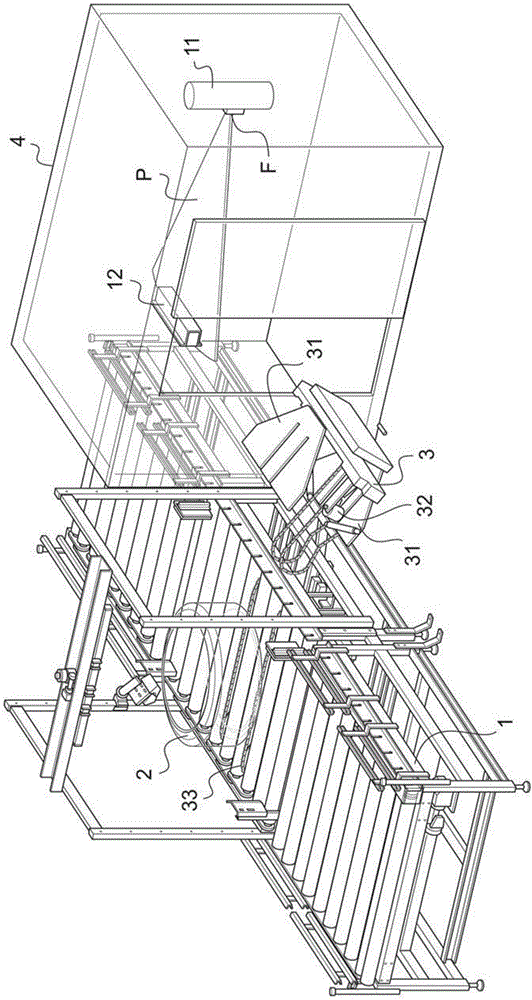

Radiation detector arrangement

InactiveUS20030155519A1Television system detailsElectric discharge tubesIonising radiation sourceTwo dimensional imaging

A scanning-based radiation detector arrangement for two-dimensional imaging of an object comprises a plurality of one-dimensional detector units, each comprising an entrance slit, through which ionizing radiation as transmitted through the object is entered, and being arranged for one-dimensional imaging of the ionizing radiation, wherein the detector units are arranged in an array on a support with their respective entrance slits being parallel with each other and facing the source of the ionizing radiation. The detector arrangement further includes a rotating device for rotating the detector unit array in a plane perpendicular to the direction of the ionizing radiation, while the detector units are arranged to repeatedly detect, hence creating a series of two-dimensional images of the object.

Owner:XCOUNTER

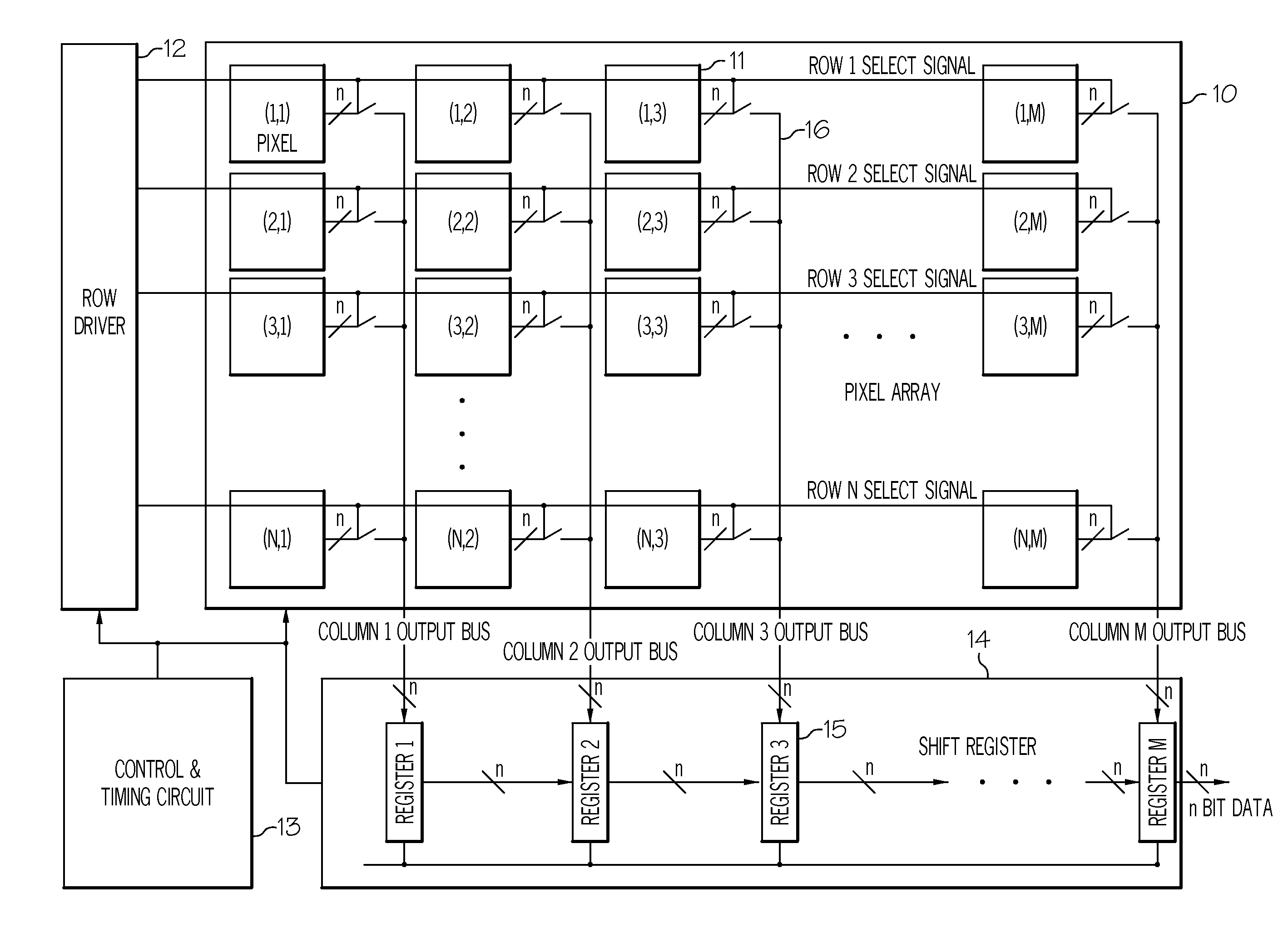

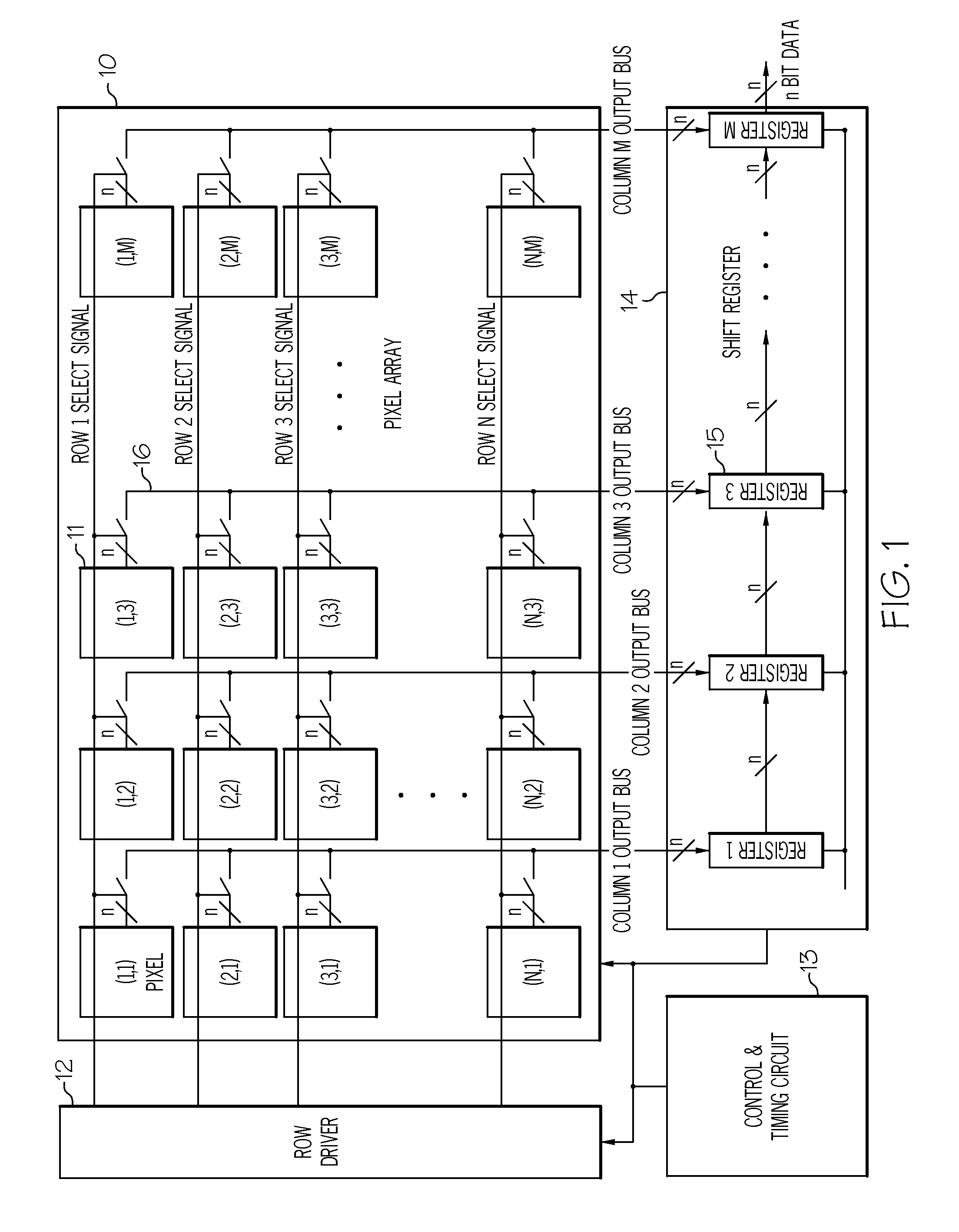

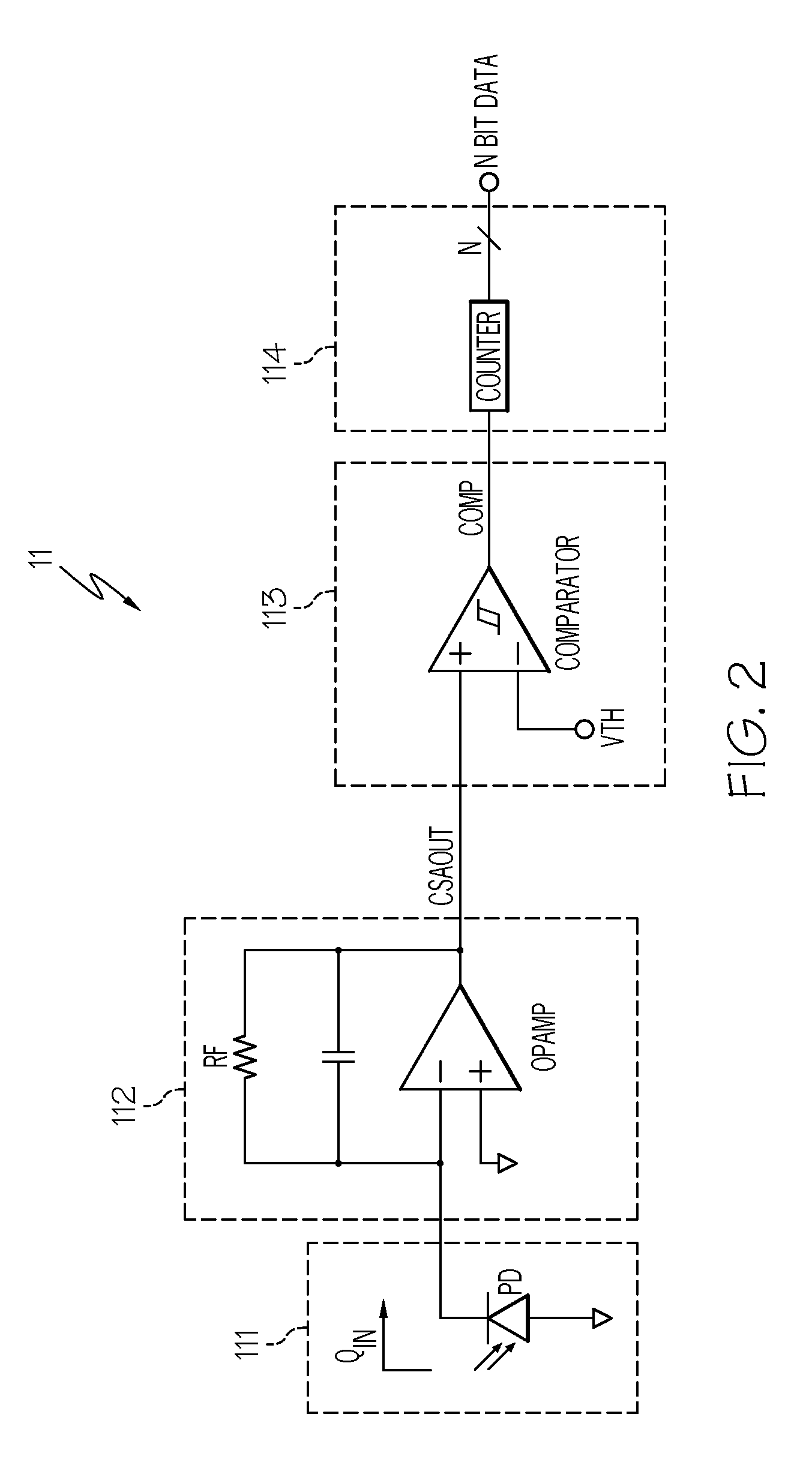

Programmable readout integrated circuit for an ionizing radiation sensor

InactiveUS20130256542A1Television system detailsSolid-state devicesControl signalReadout integrated circuit

Embodiments of the present invention provide a computer-implemented method for setting an amplification gain of a pixel array. Specifically, among other things, embodiments of the present invention provide a computer-implemented infrastructure comprising: receiving an electrical signal from an ionizing radiation source at one or more pixel sensors of a plurality of pixel sensors within the pixel array; setting an amplification gain of the electrical signal at a charge sensitive amplifier by turning a switch on or off, wherein the switch connects the at least one or more pixel sensors to a respective capacitor; scanning the pixel array to determine the ionizing radiation source intensity; and generating a gain control signal based on the ionizing radiation source intensity.

Owner:LUXEN TECH +1

Apparatus and method for multi-modal imaging using multiple x-ray sources

InactiveUS20120106702A1Reduce errorsDiagnostics using lightMaterial analysis by transmitting radiationX-rayImage system

Owner:BRUKER BIOSPIN

Visualizing radiation therapy beam in real-time in the context of patient's anatomy

ActiveUS9604077B2X/gamma/cosmic radiation measurmentX-ray/gamma-ray/particle-irradiation therapyTreatment deliveryFree form

A method of real-time radiotherapy beam visualization is provided that includes disposing a free-form flexible scintillating sheet on a subject of interest, irradiating the subject of interest with a source of ionizing radiation, where the free-forming flexible scintillating sheet emits light when irradiated by the therapeutic photon beam, collecting the emitted light and collecting ambient light reflected from the subject of interest and surrounding objects using a camera, where the collected light is converted to image data by the camera, where the image data is communicated to an appropriately programmed computer, and processing the image data to determine beam characteristics and the characteristics of the subject of interest, using the appropriately programmed computer, where the beam characteristics and the characteristics of the subject of interest are displayed in real-time to a machine operator enabling real-time verification of treatment delivery.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

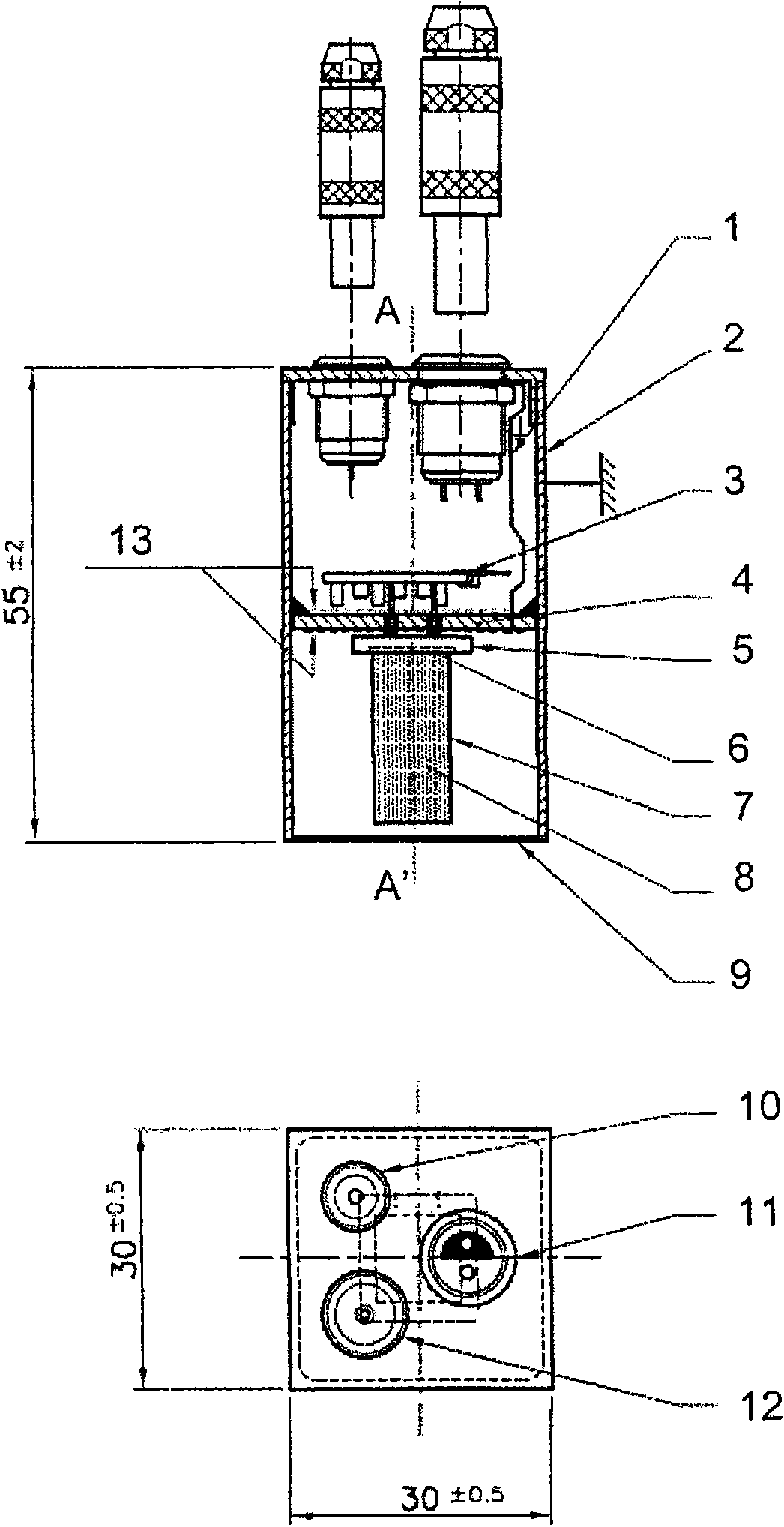

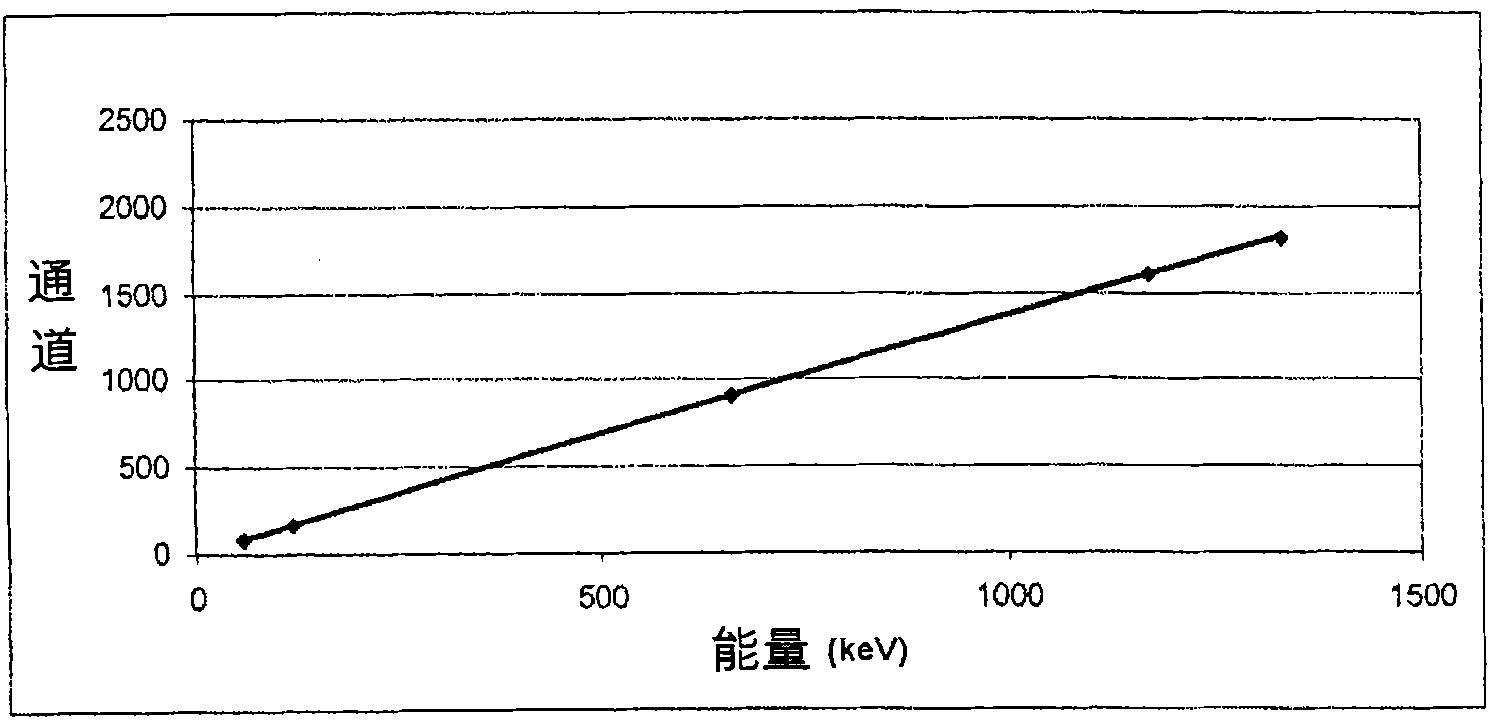

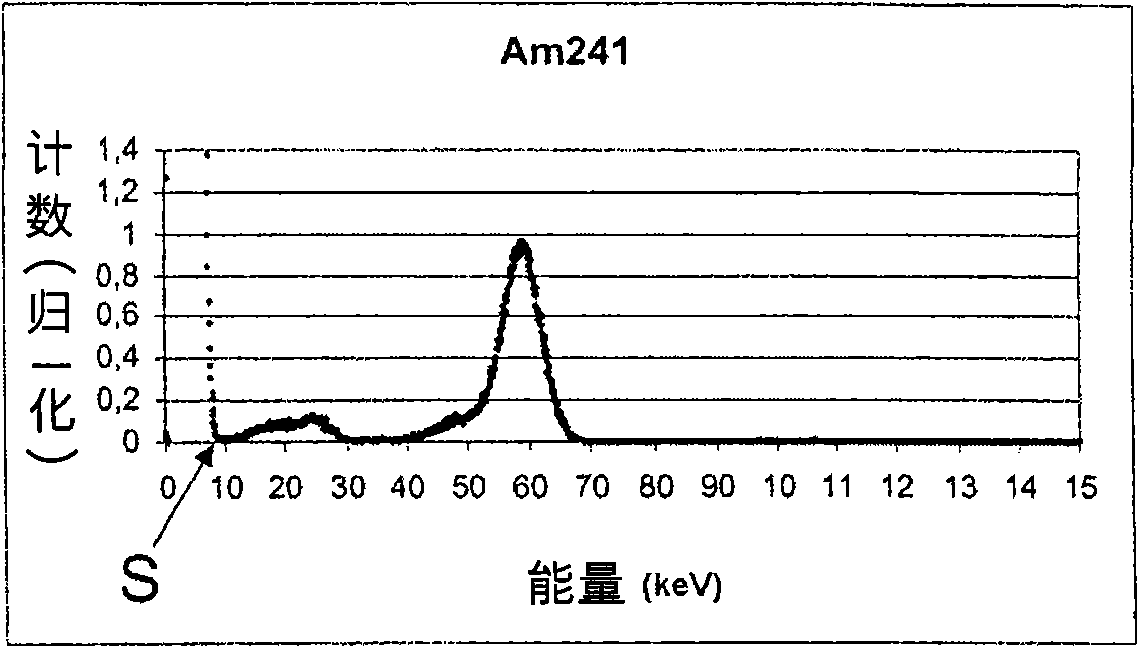

Ionising radiation detector

InactiveCN101971053AReduce weightRadiation intensity measurementAudio power amplifierImage resolution

The invention relates to an ionising radiation detector that comprises a housing including an avalanche photodiode having its photosensitive surface in contact with the scintillating material via an optical coupler, and a preamplifier of the electric signal of the avalanche photodiode. The detector is compact, portable and very sturdy. It is capable of detecting X or gamma radiation with an excellent resolution that can be lower than 3% at 662 keV.

Owner:SAINT GOBAIN CRISTAUX & DETECTEURS

UV/EB cured integrated magnets-composition and method of fabrication

The present invention comprises a radiation curable composition for in-line printing containing magnetic pigments capable of being magnetized to possess permanent magnetic properties after the composition is cured. The composition is cured by an ionizing radiation source, preferably by UV light or electron beam radiation (UV / EB). The present invention is also directed to an in-line process for printing magnetic images on non-magnetic substrate, comprising: pattern applying the above mentioned radiation curable composition on the substrate opposite to a print side, pre-aligning the magnetic pigment particles (if necessary) of the applied composition, curing the composition by ionizing radiation source (UV / EB), magnetizing the cured composition, then finishing the final piece. The finishing step could involve delivering the final piece in a simple sheet with die cut magnets or creating an "integrated magnet" format involving plow folding over the magnet panel, pattern coating or flood coating an adhesive that will only adhere the non-magnet matrix areas between die cut magnets, thus, allowing for the individual magnets to be "popped" out of the carrier by the final end user. The resulting magnetized pieces will possess holding power like magnets (refrigerator and office magnets) and are capable of carrying personalized, Scitex imaged and direct marketing information (including redemption value for coupons, local public service access numbers, etc.)

Owner:SOVEREIGN SPECIALTY CHEM

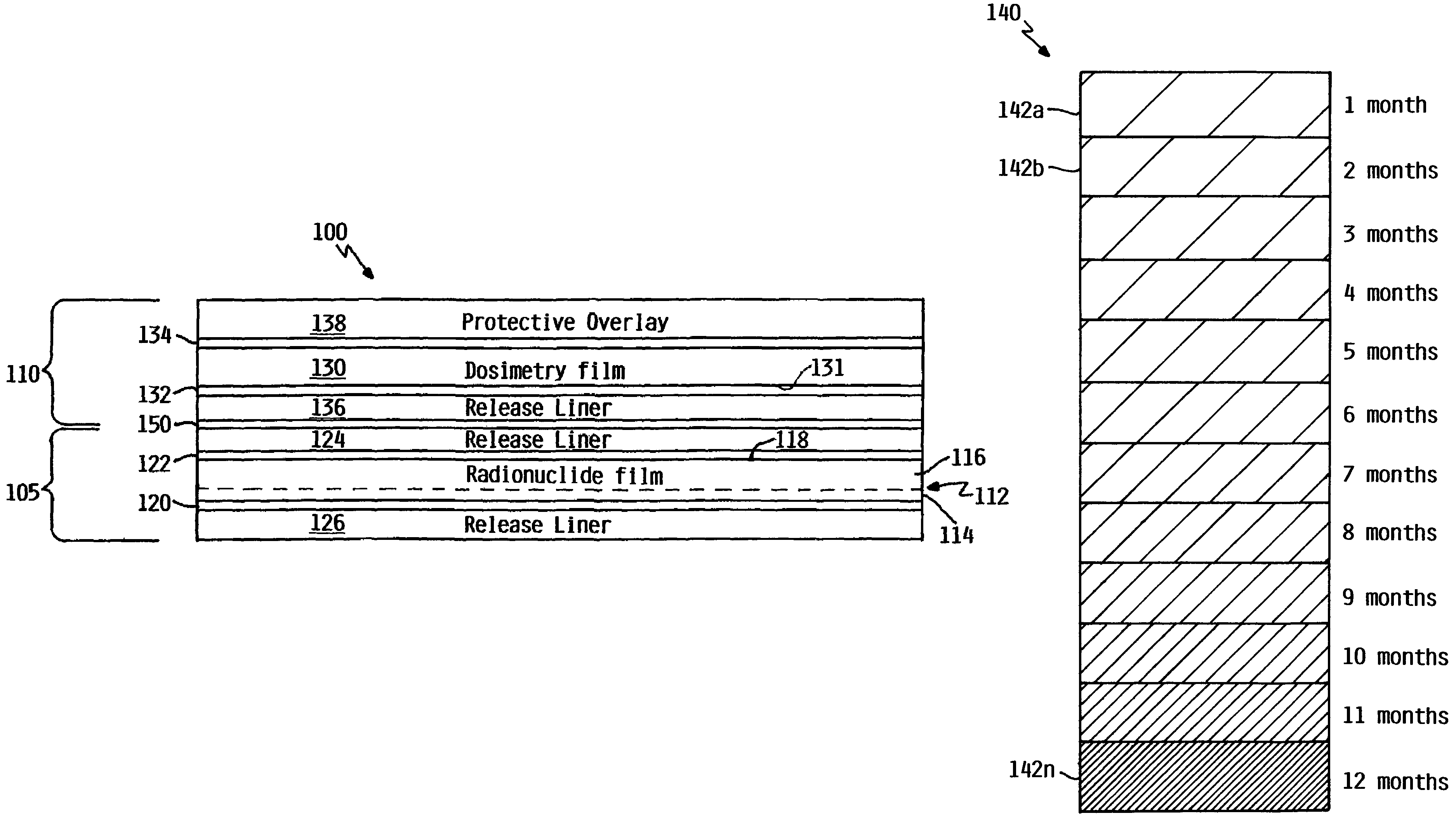

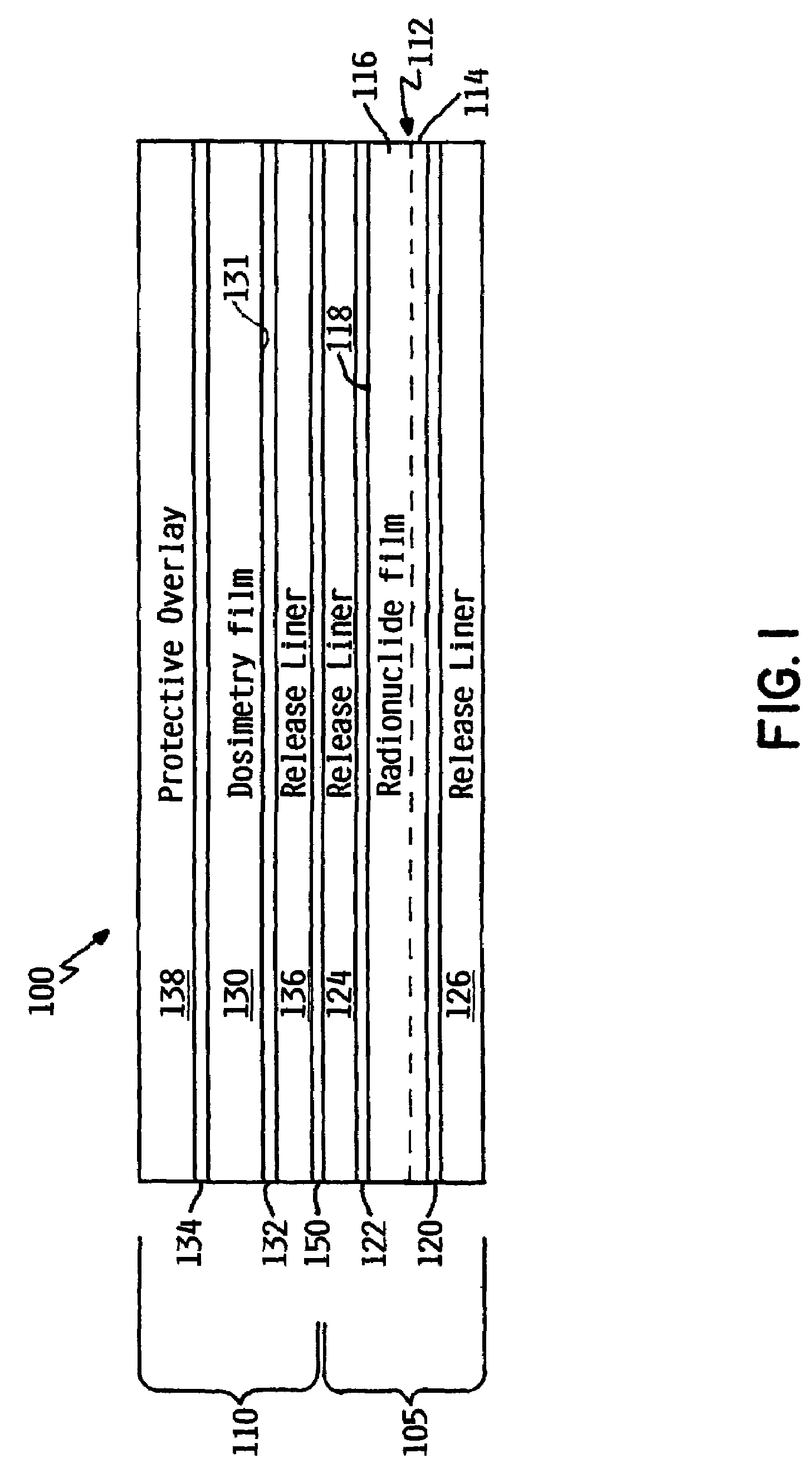

Methods and apparatus capable of indicating elapsed time intervals

InactiveUS7489596B2Non-power consumingImprove reliabilityMechanical unknown time interval measurementElectromechanical unknown time interval measurementStart timeIonising radiation source

Owner:INT BUSINESS MASCH CORP

Efficient thermoelectric device

InactiveUS7687705B2Increasing thermoelectric figureImprove efficiencyThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentMetallic materialsFigure of merit

A high efficiency thermo electric device comprising a multi nanolayer structure of alternating insulator and insulator / metal material that is irradiated across the plane of the layer structure with ionizing radiation. The ionizing radiation produces nanocrystals in the layered structure that increase the electrical conductivity and decrease the thermal conductivity thereby increasing the thermoelectric figure of merit. Figures of merit as high as 2.5 have been achieved using layers of co-deposited gold and silicon dioxide interspersed with layers of silicon dioxide. The gold to silicon dioxide ratio was 0.04. 5 MeV silicon ions were used to irradiate the structure. Other metals and insulators may be substituted. Other ionizing radiation sources may be used. The structure tolerates a wide range of metal to insulator ratio.

Owner:AAMU RES INST

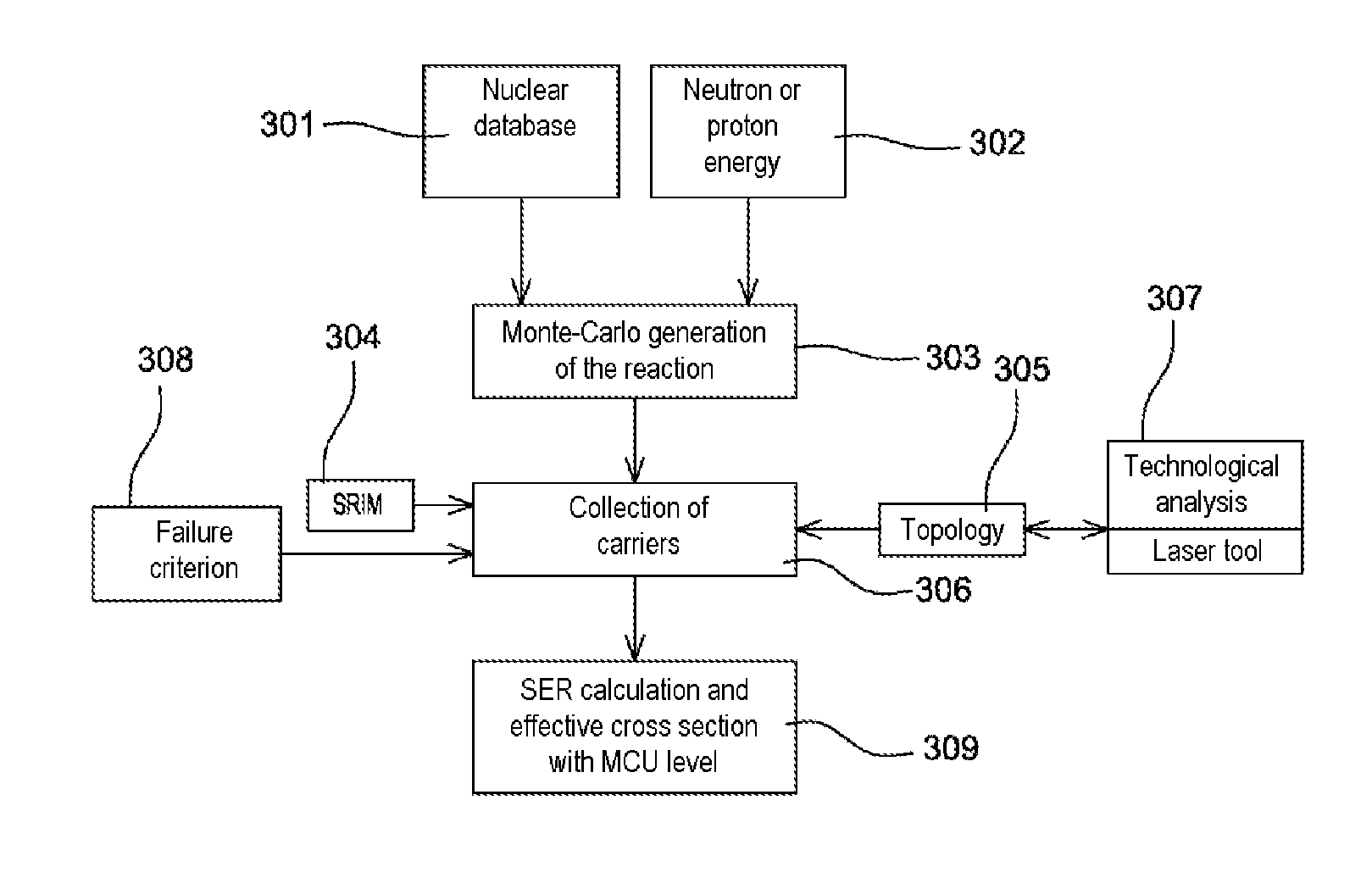

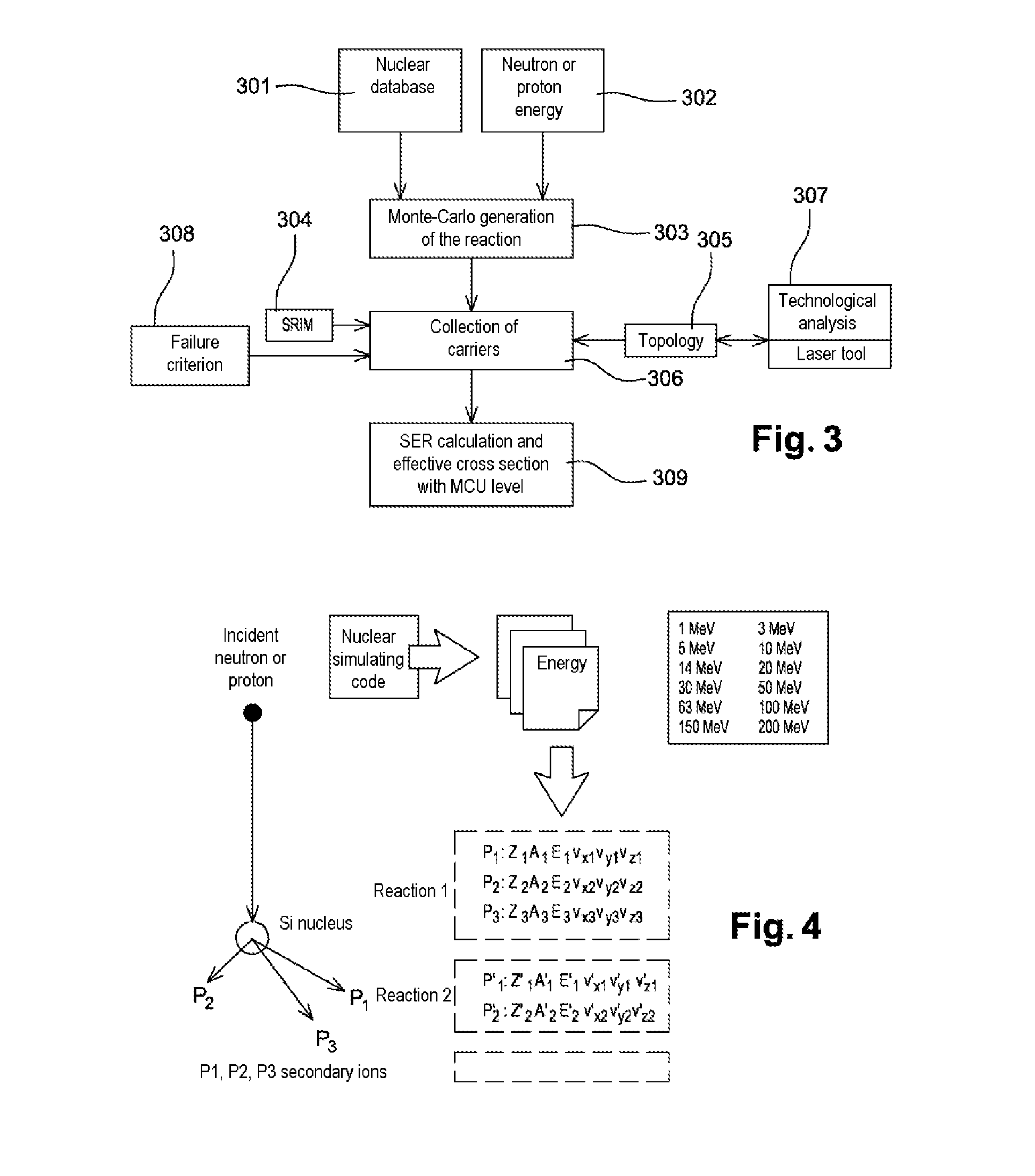

Method of characterizing the sensitivity of an electronic component subjected to irradiation conditions

InactiveUS20140203836A1Increase flexibilityLow costTesting electric installations on transportMeasuring interference from external sourcesElectronic componentElectron

A method of selecting a piece of electronic equipment subjected to irradiation conditions comprising at least one electronic component by characterizing a sensitivity parameter of the electronic component to the irradiation conditions listed in a predetermined specifications. The electronic component is irradiated with a source of ionizing radiation having the known irradiation characteristics and geometry. A set of operating values of the electronic component are measured during the irradiation of the electronic component. The sensitivity of the electronic component are measured for a number of irradiation conditions lower than all of the conditions listed in the specifications. The measured results are extrapolated to the other irradiation conditions of the specifications.

Owner:EURON AERONAUTIC DEFENCE & SPACE

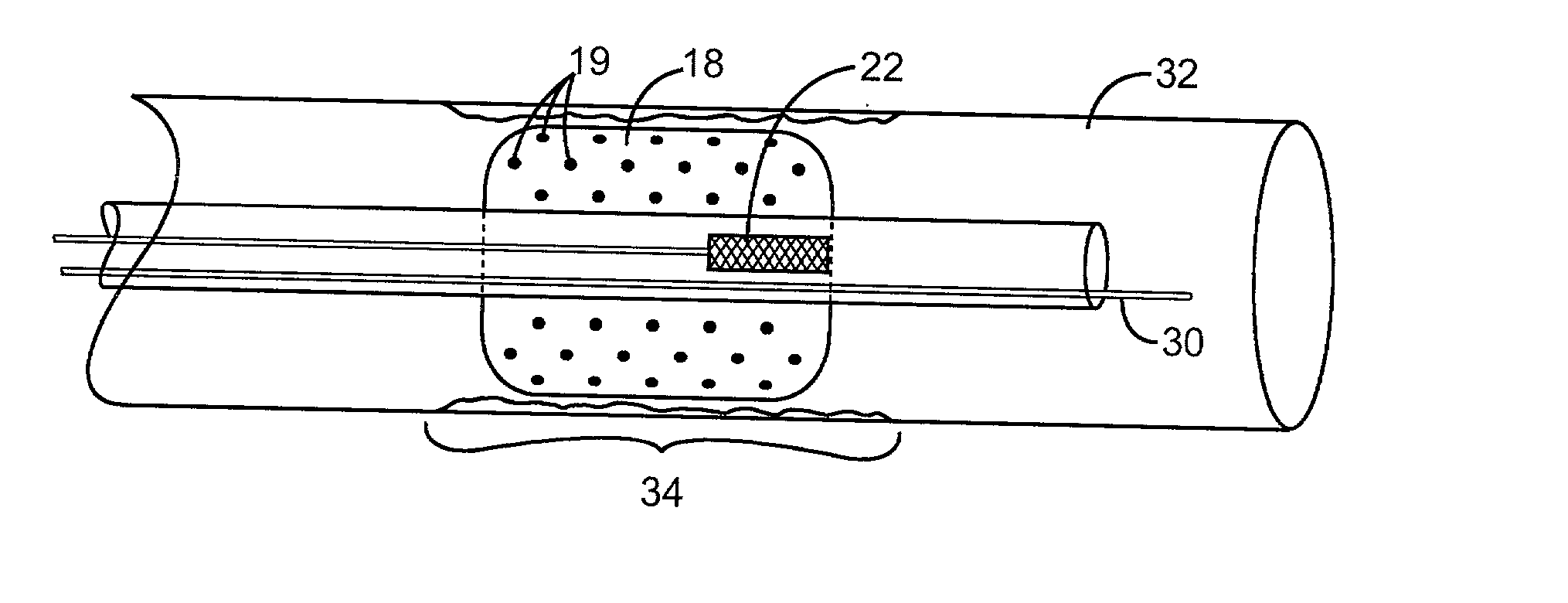

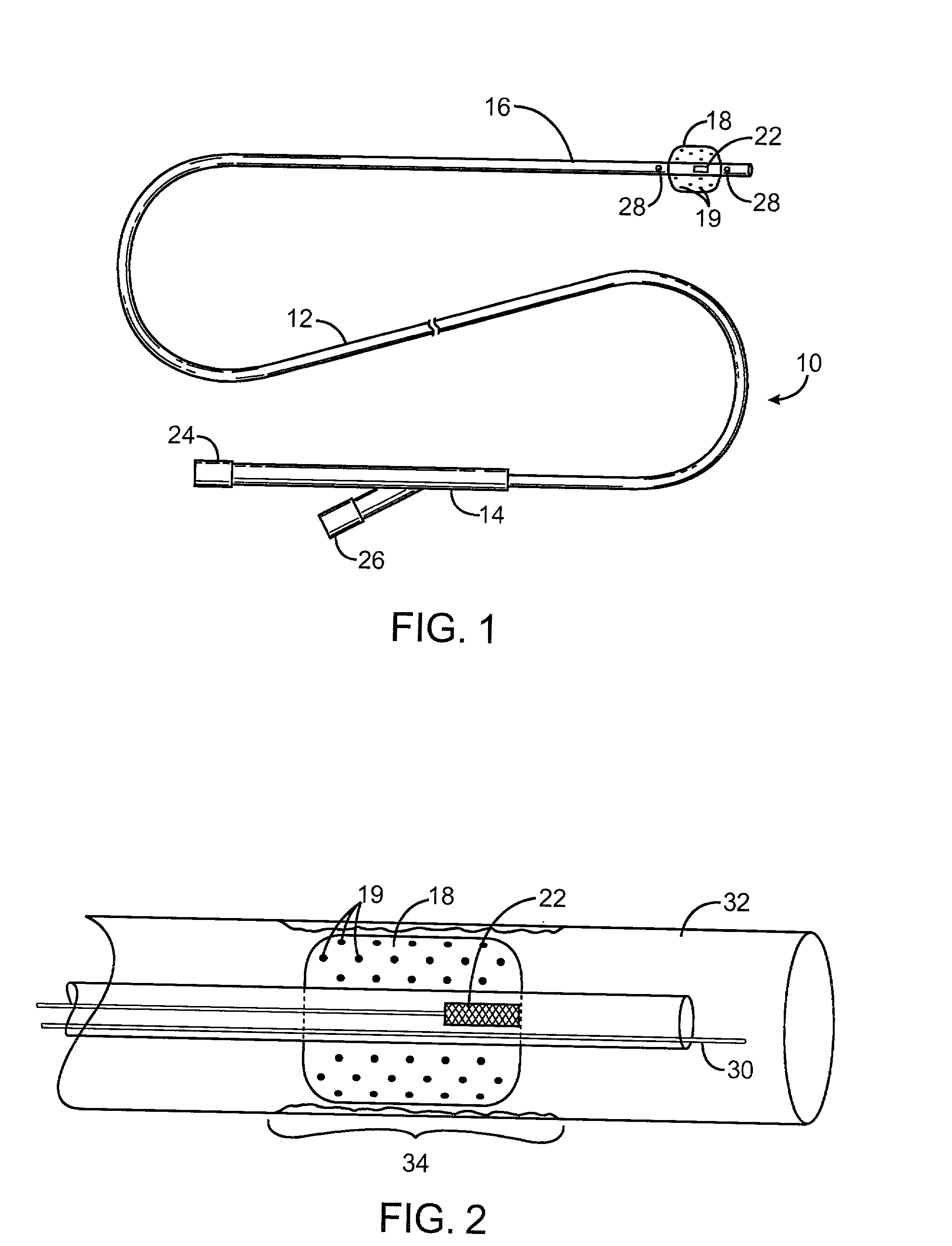

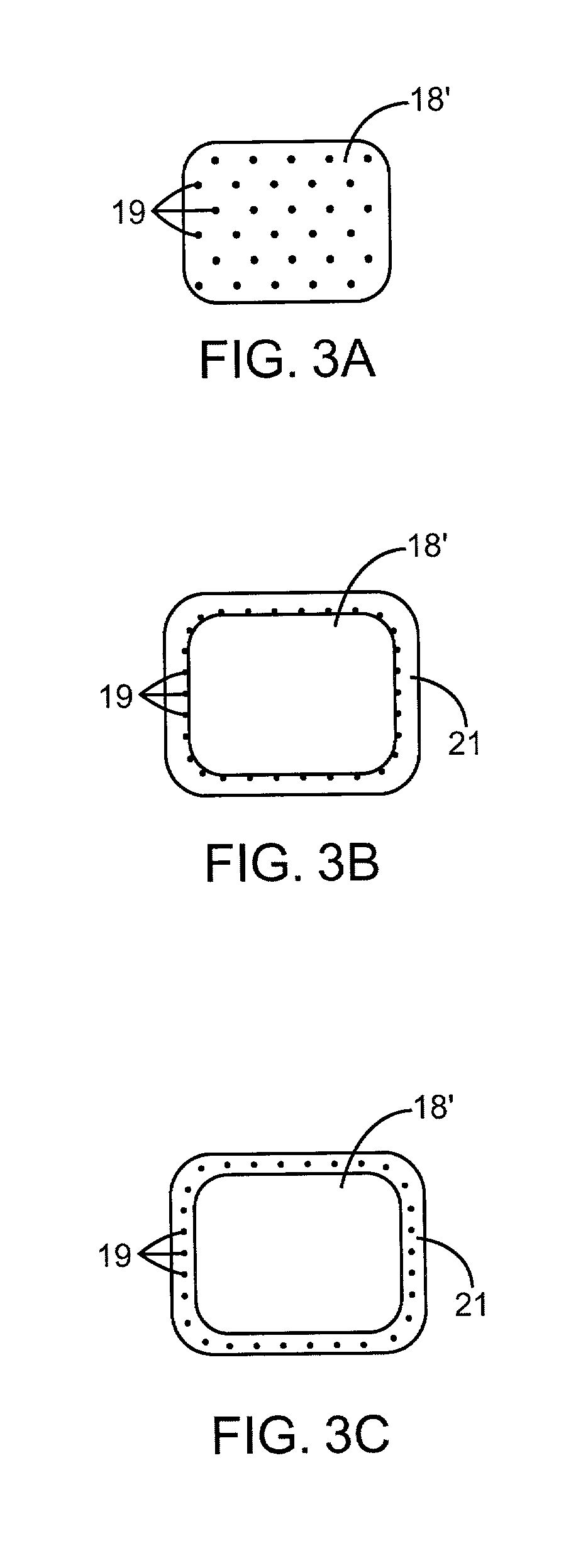

Combination ionizing radiation and radiosensitizer delivery devices and methods for inhibiting hyperplasia

InactiveUS20020165520A1Dosing is convenientTurn easilyStentsBalloon catheterRadiation sensitizersPercent Diameter Stenosis

The present invention provides improved devices, methods, and kits for inhibiting restenosis and hyperplasia after intravascular intervention. In particular, the present invention provides controlled radiosensitizer delivery in combination with ionizing radiation to selected locations within a patient's vasculature to reduce and / or inhibit restenosis and hyperplasia rates with increased efficacy. In one embodiment, the combination radiation and radiosensitizer delivery catheter for inhibiting hyperplasia comprises a catheter body having a proximal end and distal end, an ionizing radiation source coupleable to the catheter body for applying a radiation dose to a body lumen, and means coupleable to the catheter body or the radiation source for releasing a radiosensitizer to the body lumen.

Owner:XOFT INC

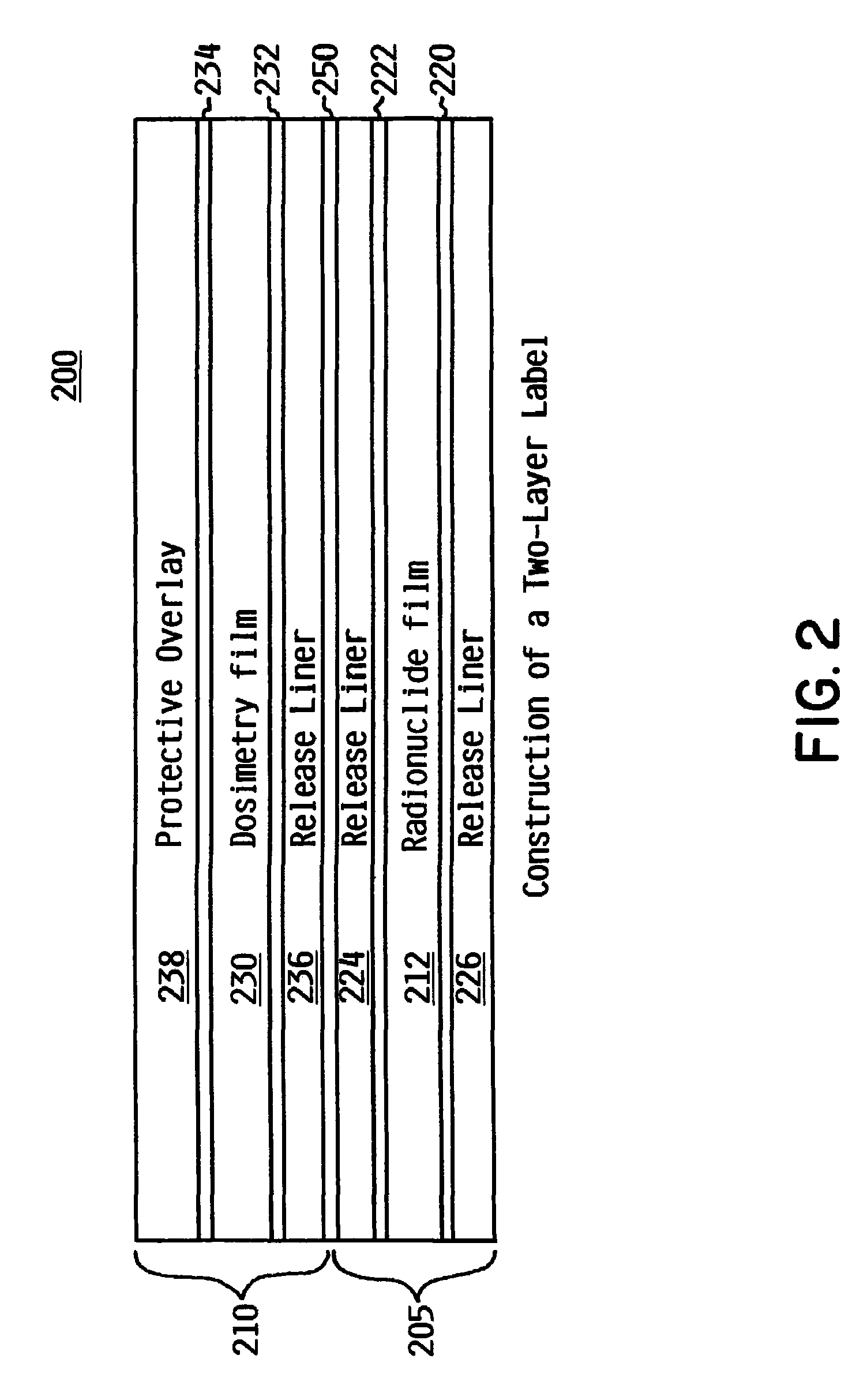

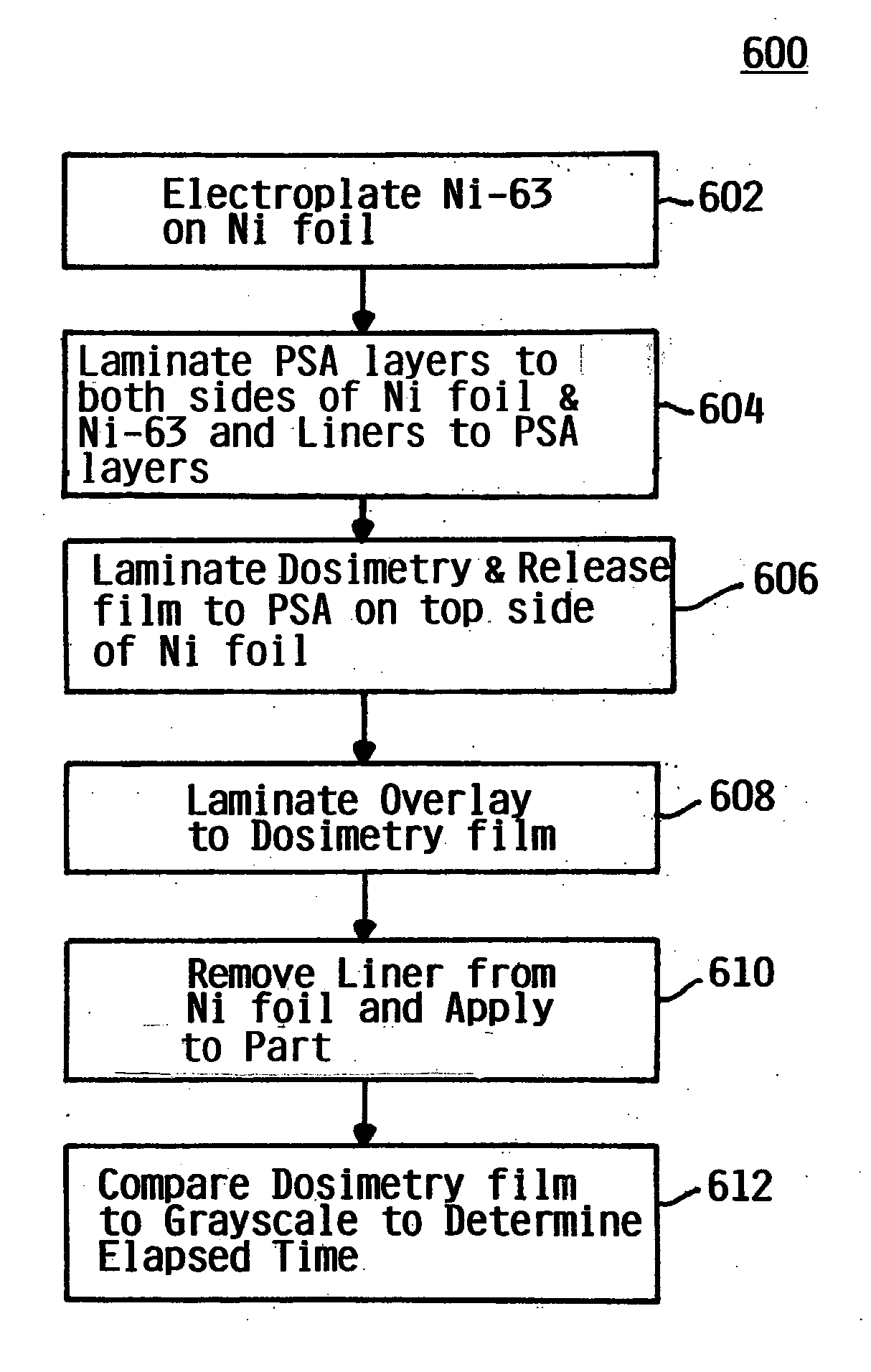

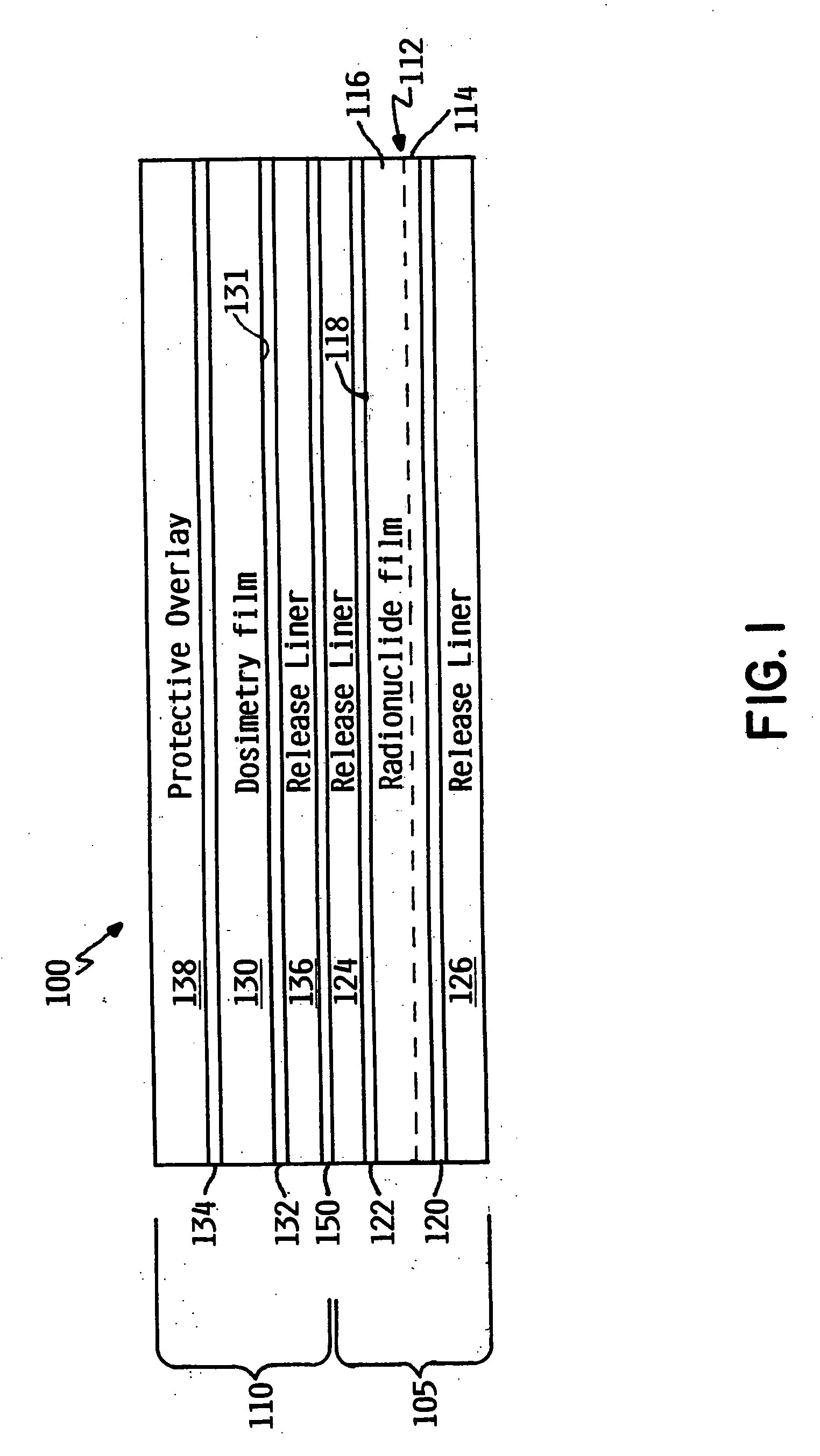

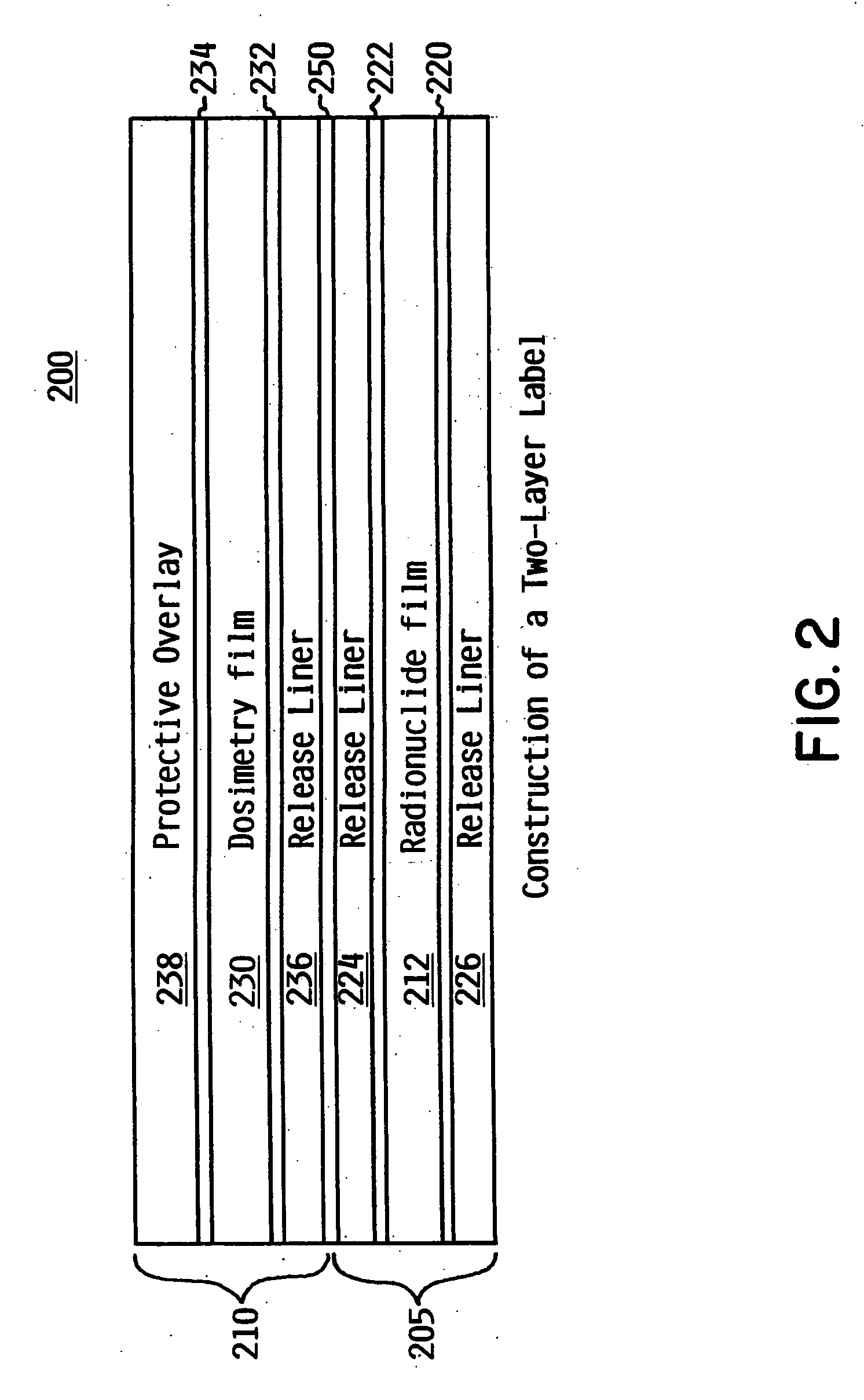

Methods and apparatus capable of indicating elapsed time intervals

InactiveUS20070058493A1Strong specificityImprove reliabilityElectromechanical unknown time interval measurementMaterial analysis by optical meansStart timeIonising radiation source

A method and apparatus of defining a time interval includes providing a source of ionizing radiation that radiates emissions thereof; placing a radiation sensitive display material responsive to ionizing radiation in a close proximity relationship to the source of ionizing radiation whereby the radiated emissions of the source strike the radiation sensitive display material, thereby commencing a time interval; and, measuring changes in characteristics of the radiation sensitive display material that are indicative of the elapsed time.

Owner:IBM CORP

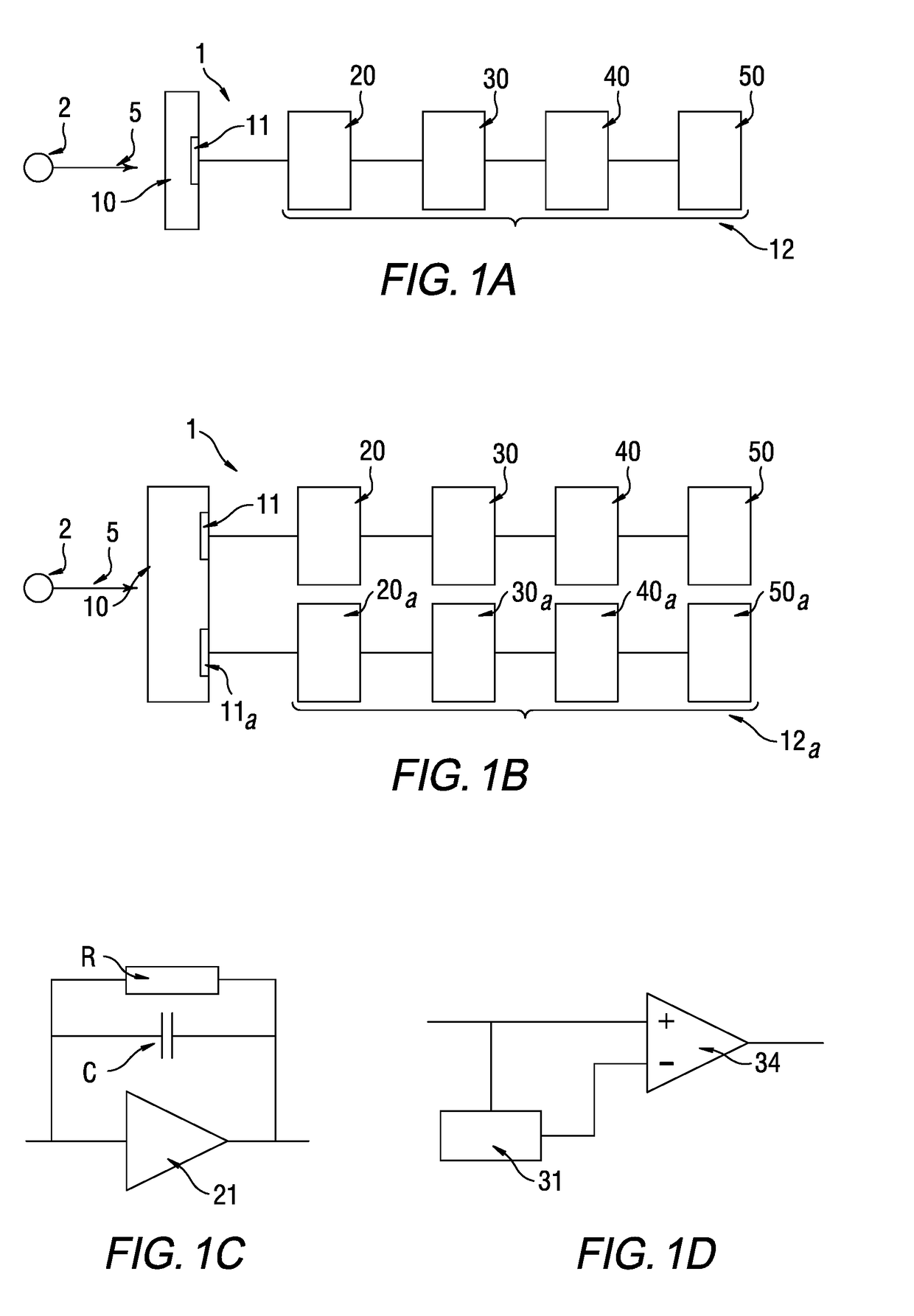

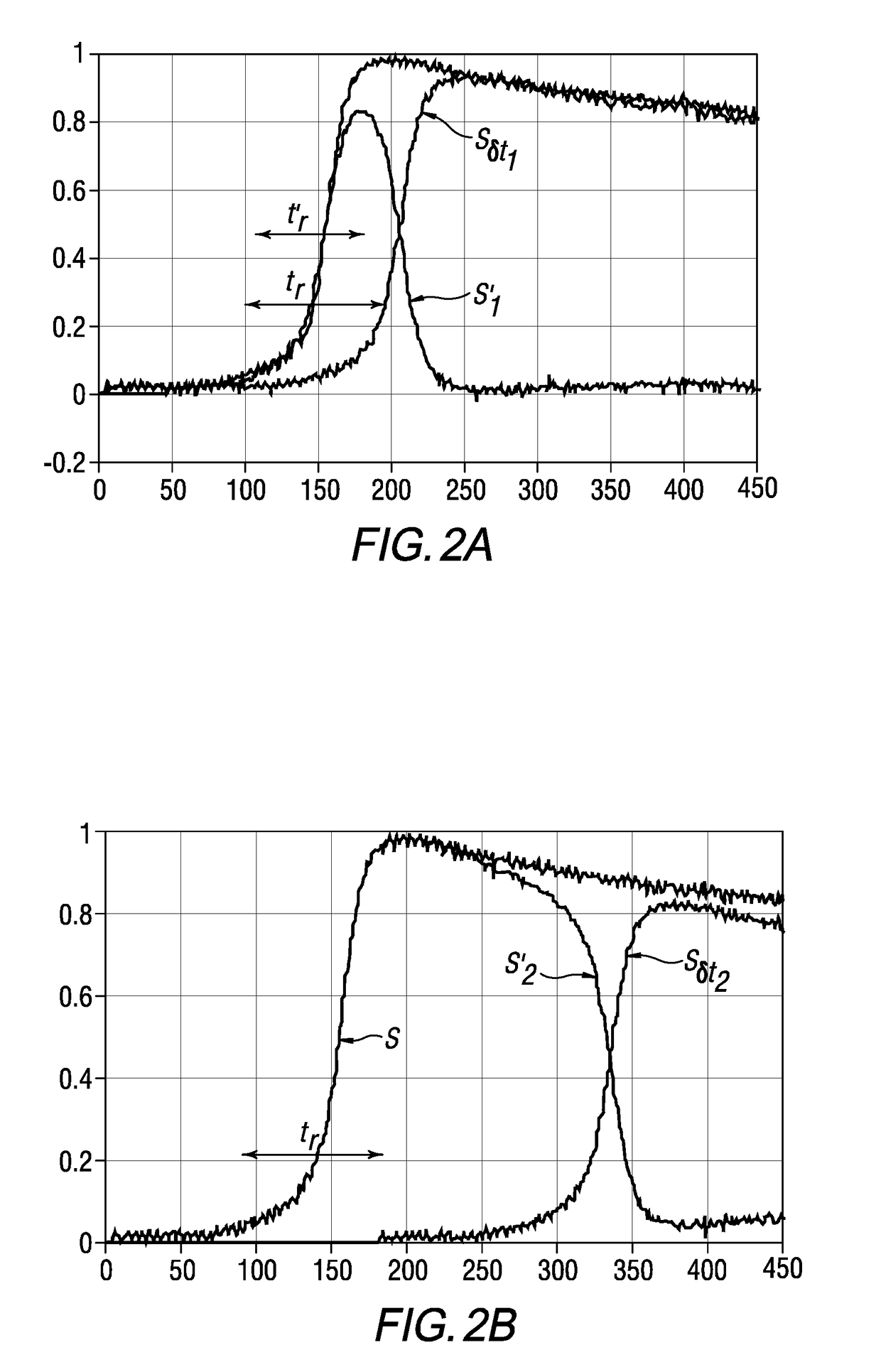

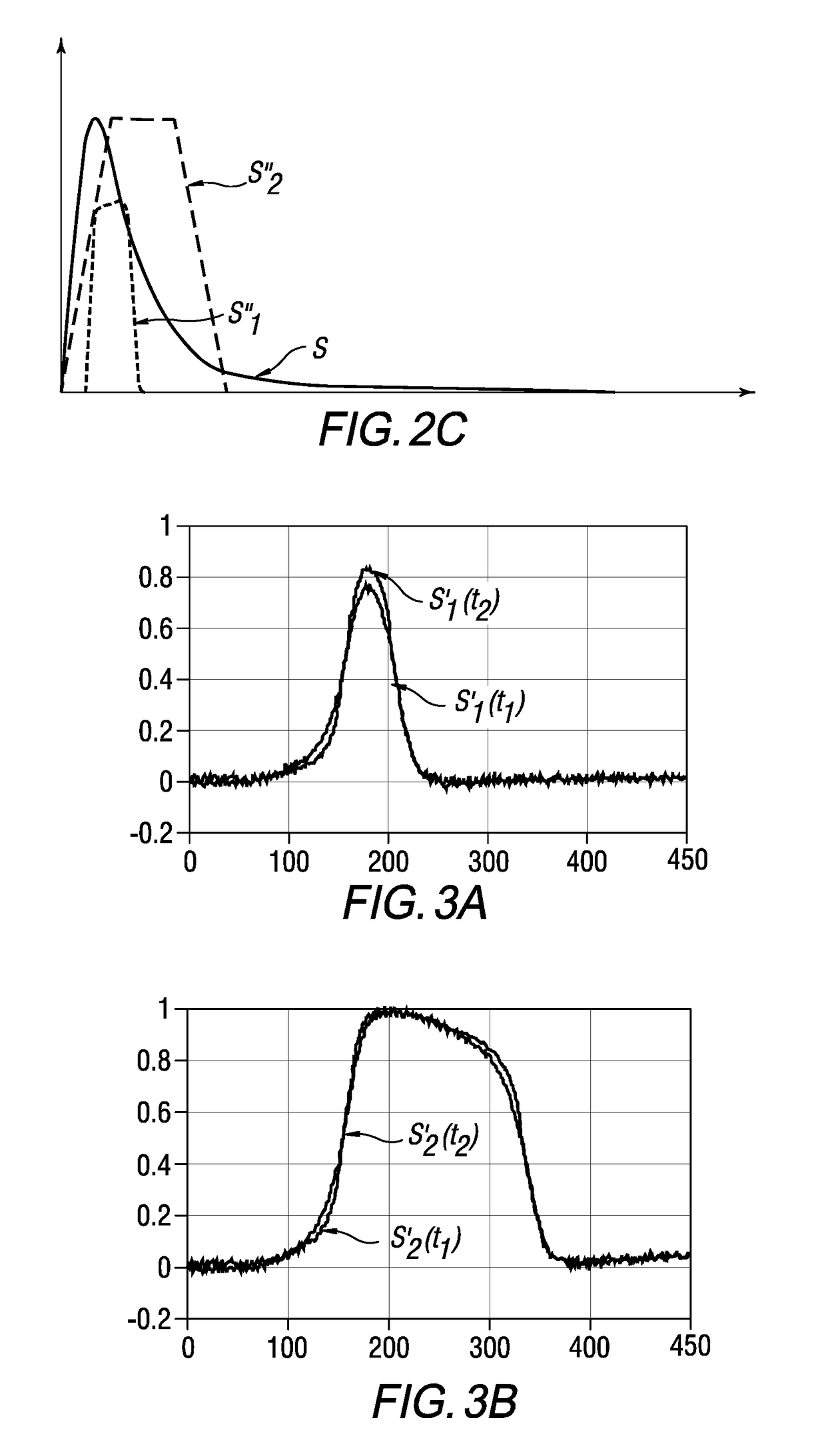

Method for processing a pulse generated by a detector of ionizing radiation

The invention is a method for processing a pulse generated by a detector of ionizing radiation, the detector being configured to interact with ionizing radiation in order to generate said pulse, the amplitude of which depends on an energy liberated by the ionizing radiation during its interaction in the detector, the method including the following steps:a) exposing the detector to a source of ionizing radiation so as to obtain, at a measurement time, a pulse called the measurement pulse;b) shaping the measurement pulse, using a first shaping time, and determining a first amplitude of the measurement pulse thus shaped; andc) correcting the first amplitude measured in step b), by taking into account a correction factor;the correction factor being determined by taking into account pulses, called pulses of interest, formed by the detector during an exposure to the source or to a calibration source, during a time range of interest.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Automatic gain stabilization and temperature compensation for organic and/or plastic scintillation devices

ActiveUS8426827B2X-ray spectral distribution measurementMaterial analysis by optical meansPhotomultiplierElectrical impulse

A detector and associated method are provided including a first scintillation material having a light yield temperature dependence and an output at a first energy level, a second scintillation material having a light yield temperature dependence similar to the first material and an output at a second energy level, and detection circuitry. The first and second outputs are responsive to radiation emitted from an ionizing radiation source. The detection circuitry includes a photo multiplier tube configured to convert photon outputs from the first and second scintillating materials to electrical pulses, a counter circuit configured to count the electrical pulses generated in the photo multiplier tube by the first and second materials, and a gain control circuit configured to monitor the electrical pulses generated in the photomultiplier tube by the second material and adjust a gain of the detector upon detecting a drift in the output of the second material.

Owner:VEGA GRIESHABER GMBH & CO

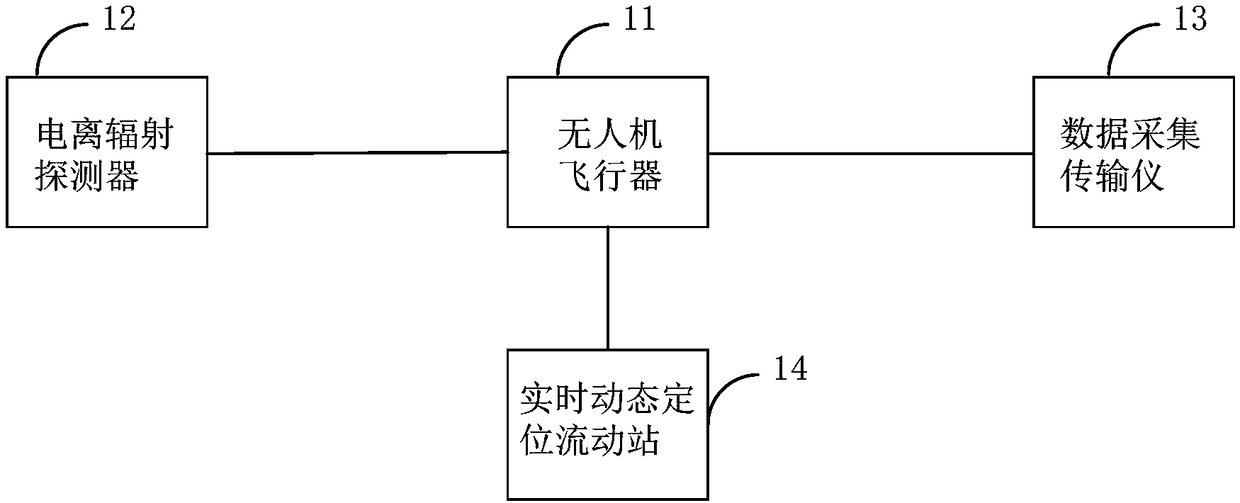

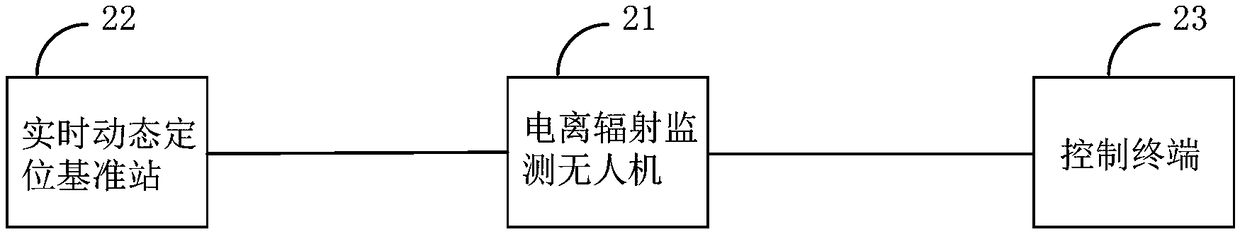

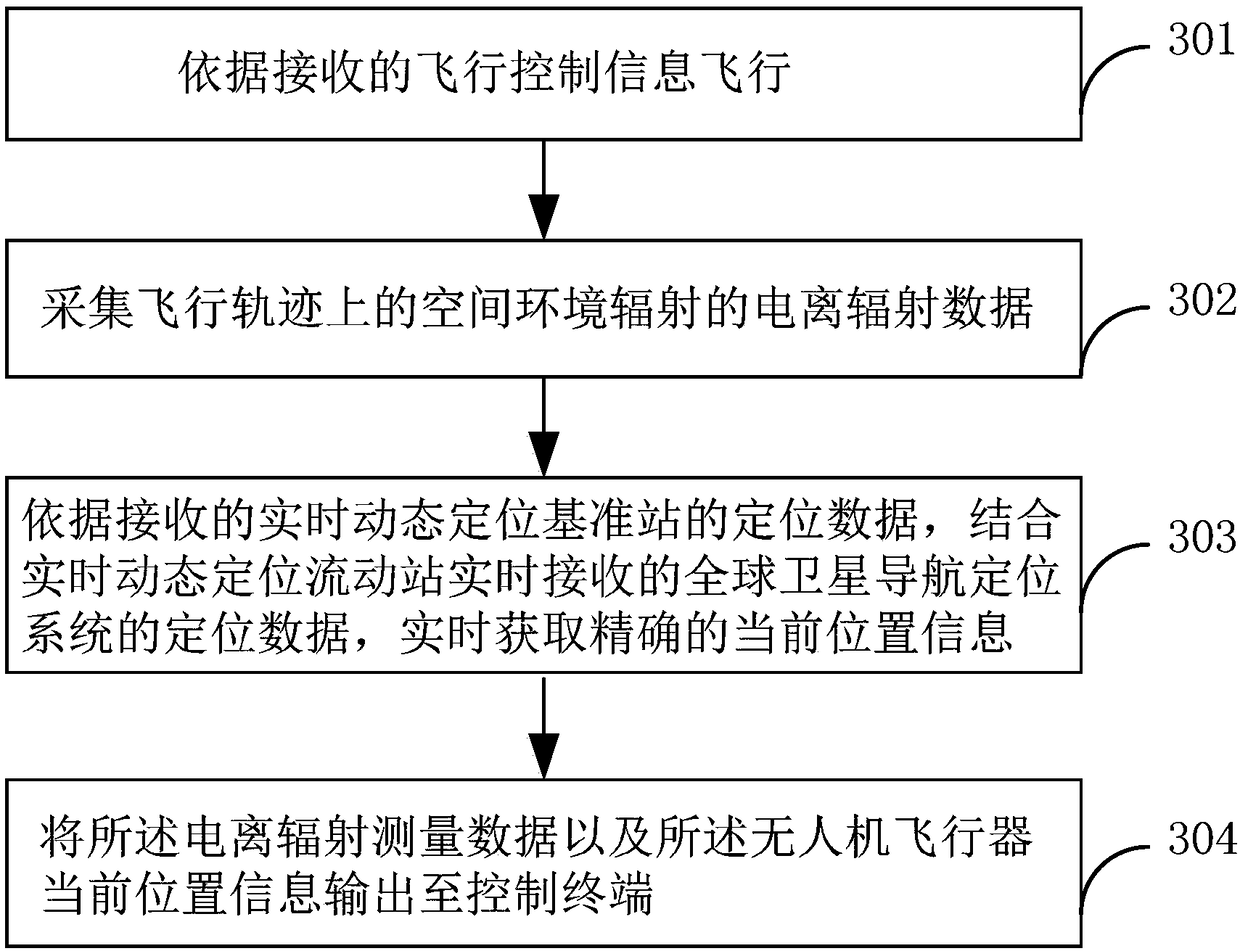

Ionization radiation monitoring unmanned aerial vehicle, system and ionization radiation monitoring method

The invention provides an ionization radiation monitoring unmanned aerial vehicle, a system and an ionization radiation monitoring method. The flight control stability and positioning precision of anunmanned aerial vehicle can be improved, and accurate space ionization radiation monitoring and ionization radiation source searching are conducted. The ionization radiation monitoring unmanned aerialvehicle comprises an unmanned aerial vehicle aircraft, an ionization radiation detector, a data collecting and transmission instrument and real-time dynamic positioning moving stations. The ionization radiation detector, the data collecting and transmission instrument and the real-time dynamic positioning moving stations are carried on the unmanned aerial vehicle aircraft, and the ionization radiation detector and the real-time dynamic positioning moving stations are in signal connection with the data collecting and transmission instrument. The ionization radiation detector is mounted on thelower portion of a fuselage of the unmanned aerial vehicle aircraft. The data collecting and transmission instrument is mounted between the ionization radiation detector and the fuselage of the unmanned aerial vehicle aircraft. The real-time dynamic positioning moving stations are mounted on the two sides of the top of the unmanned aerial vehicle aircraft.

Owner:BEIJING SENFU SCI & TECH CO LTD

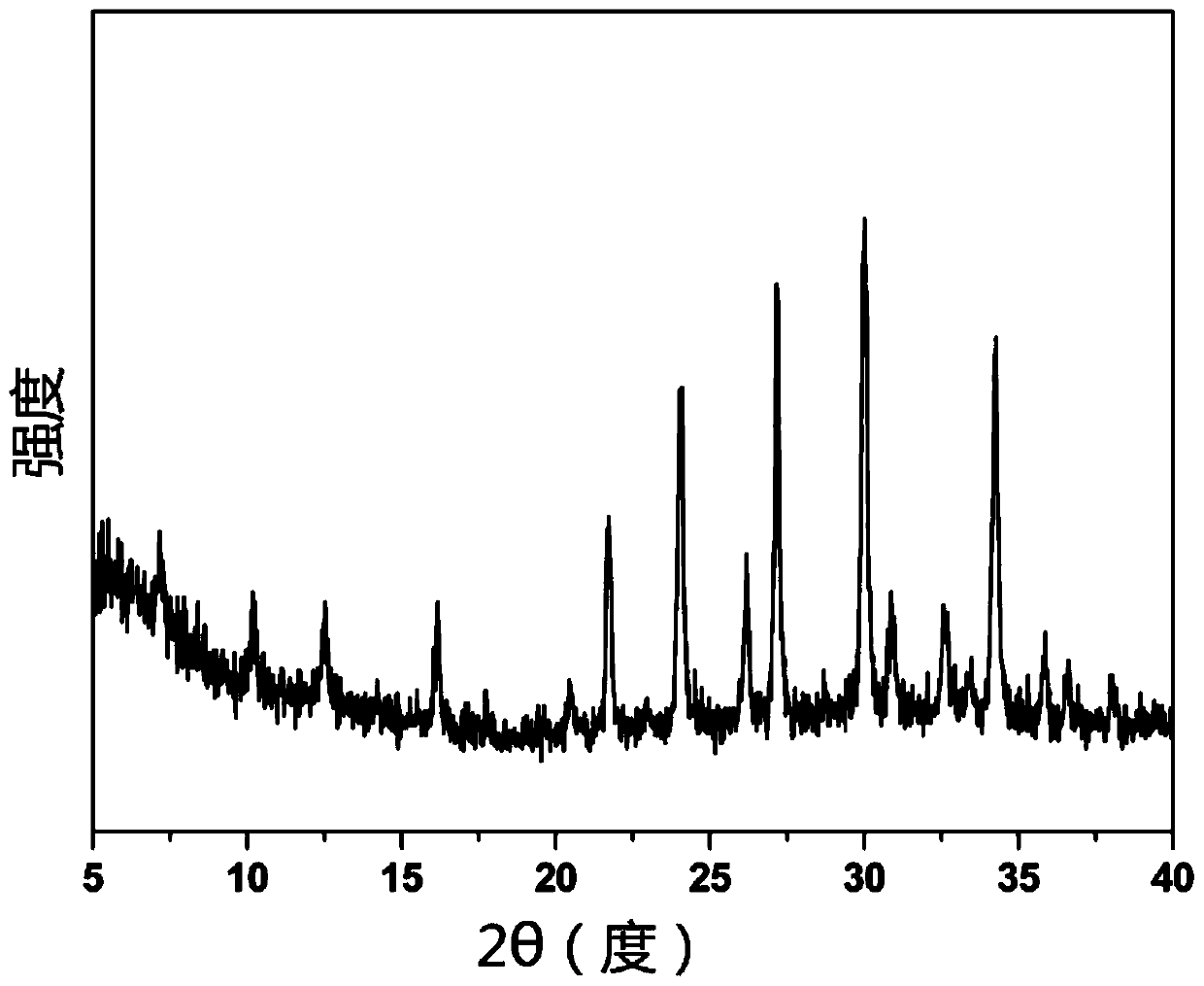

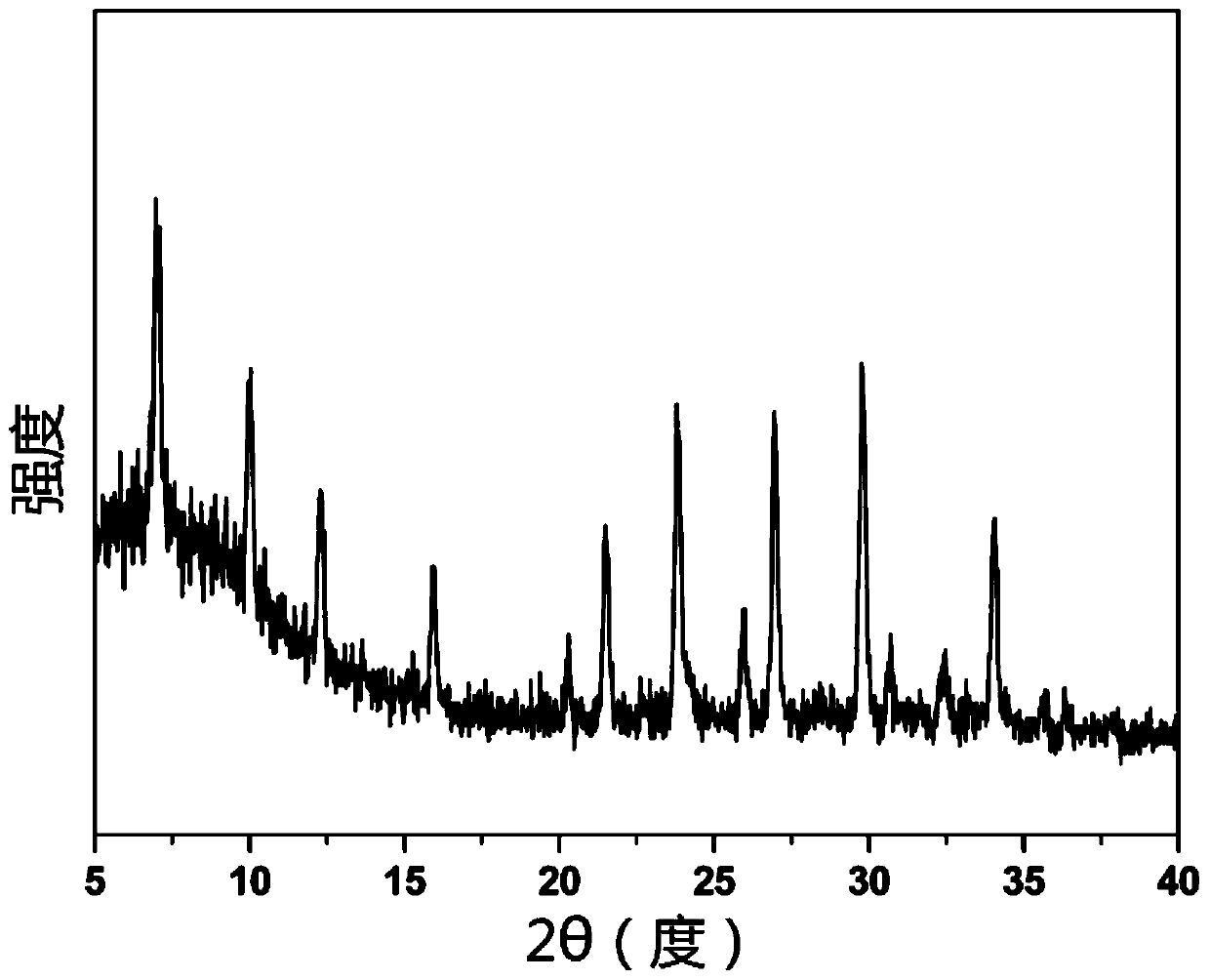

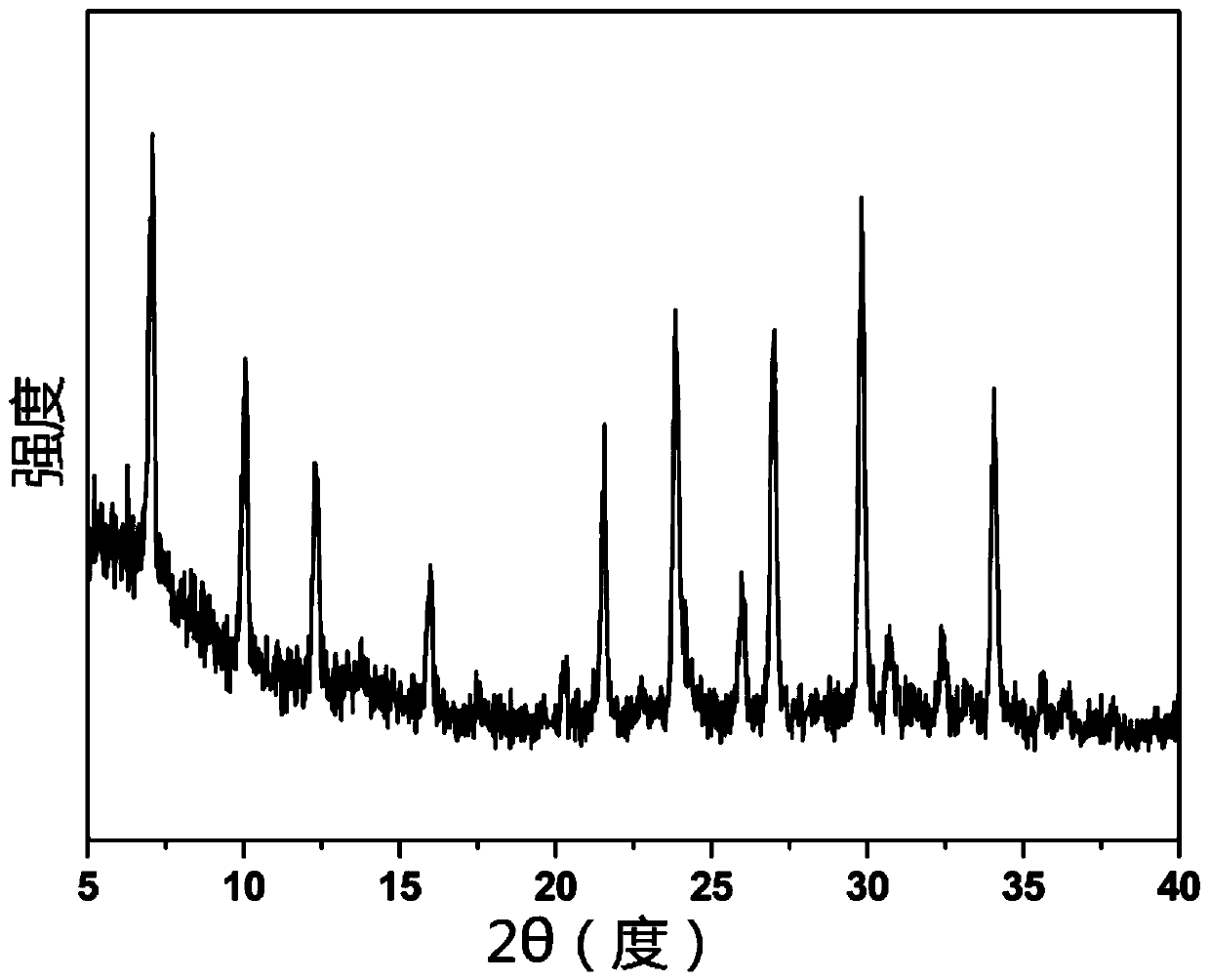

High-efficiency quick green preparation method of zeolite molecular sieve

ActiveCN110156039ALower requirementFast preparationCatalyst activation/preparationFaujasite aluminosilicate zeoliteMolecular sieveHigh pressure

The invention relates to a preparation method of a zeolite molecular sieve. The method comprises the following steps: uniformly mixing at least one of a silicon source, an aluminum source and a phosphorus source, a basic substance, a templating agent and water to obtain a zeolite molecular sieve precursor solution, wherein the zeolite molecular sieve precursor solution comprises at least the silicon source; performing curing on the zeolite molecular sieve precursor solution at 20-30 DEG C for 10-15 h; and performing ionizing radiation on the cured solution, washing the obtained solid to be neutral, and performing drying to obtain the zeolite molecular sieve. The preparation method provided by the invention is green and simple and has extremely-low costs; and under irradiation of an ionizing radiation source, the synthetic cycle of the zeolite molecular sieve is short, heating is not needed in the preparation process, the energy consumption is reduced, and a high-pressure system is avoided.

Owner:SUZHOU UNIV

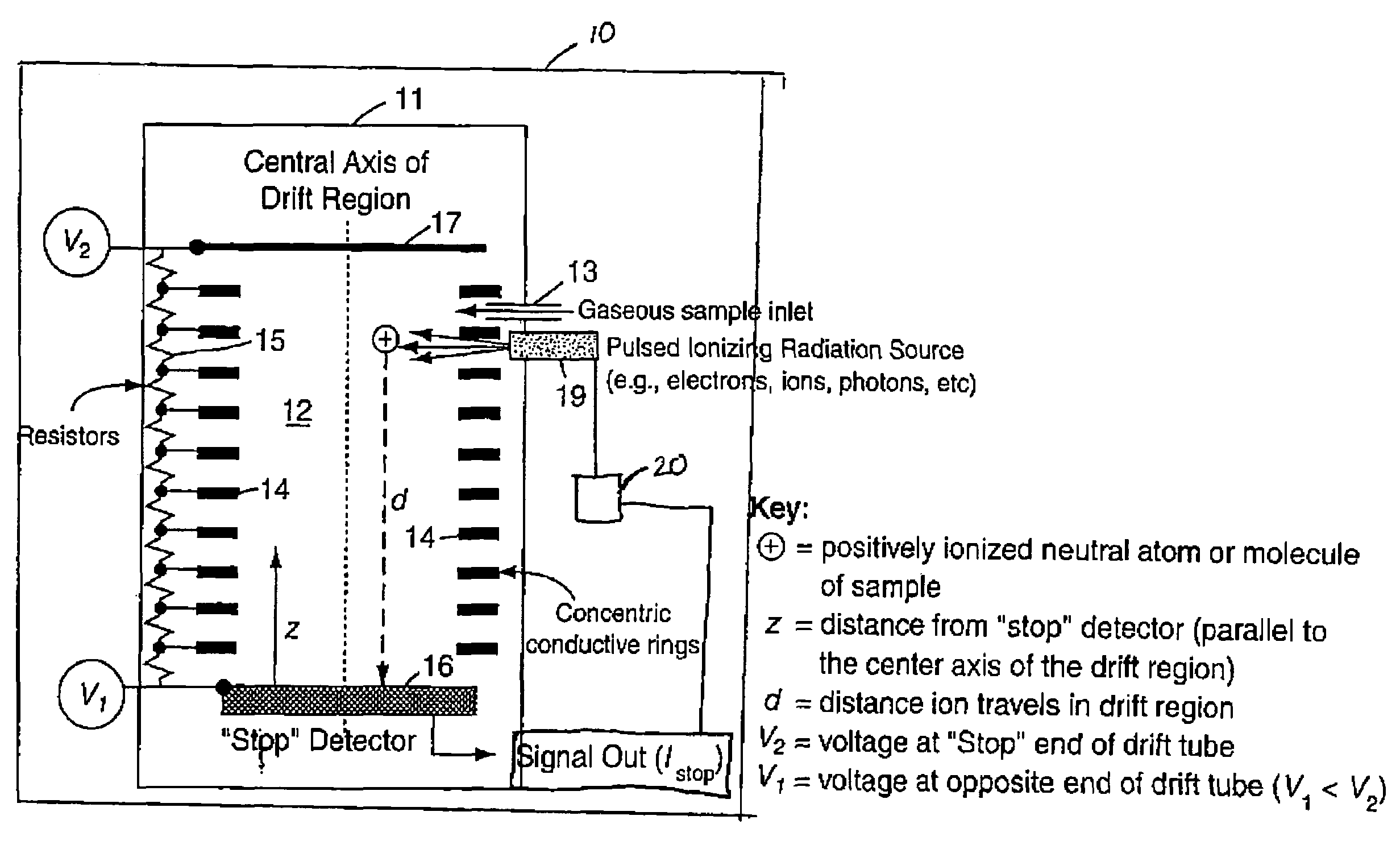

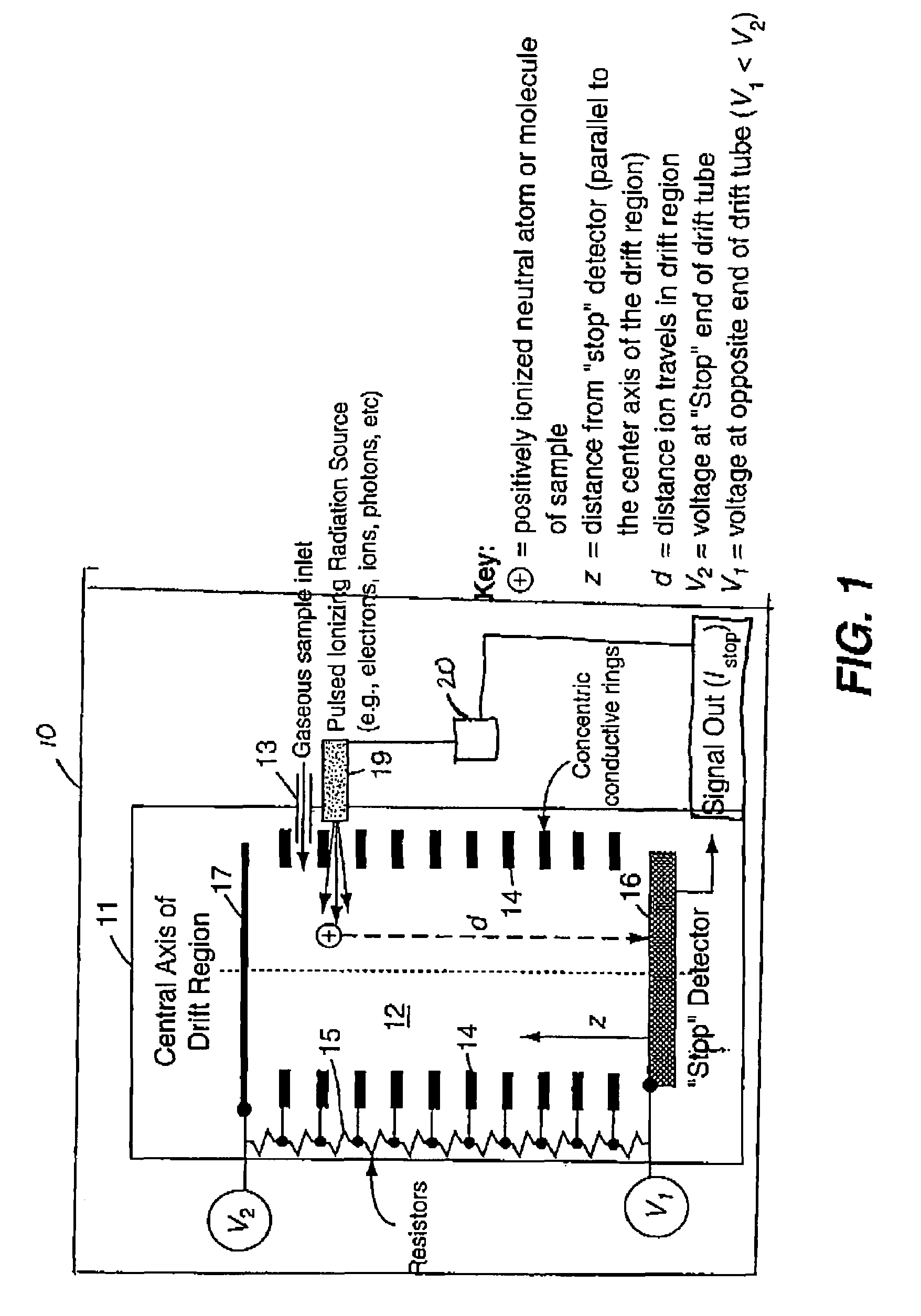

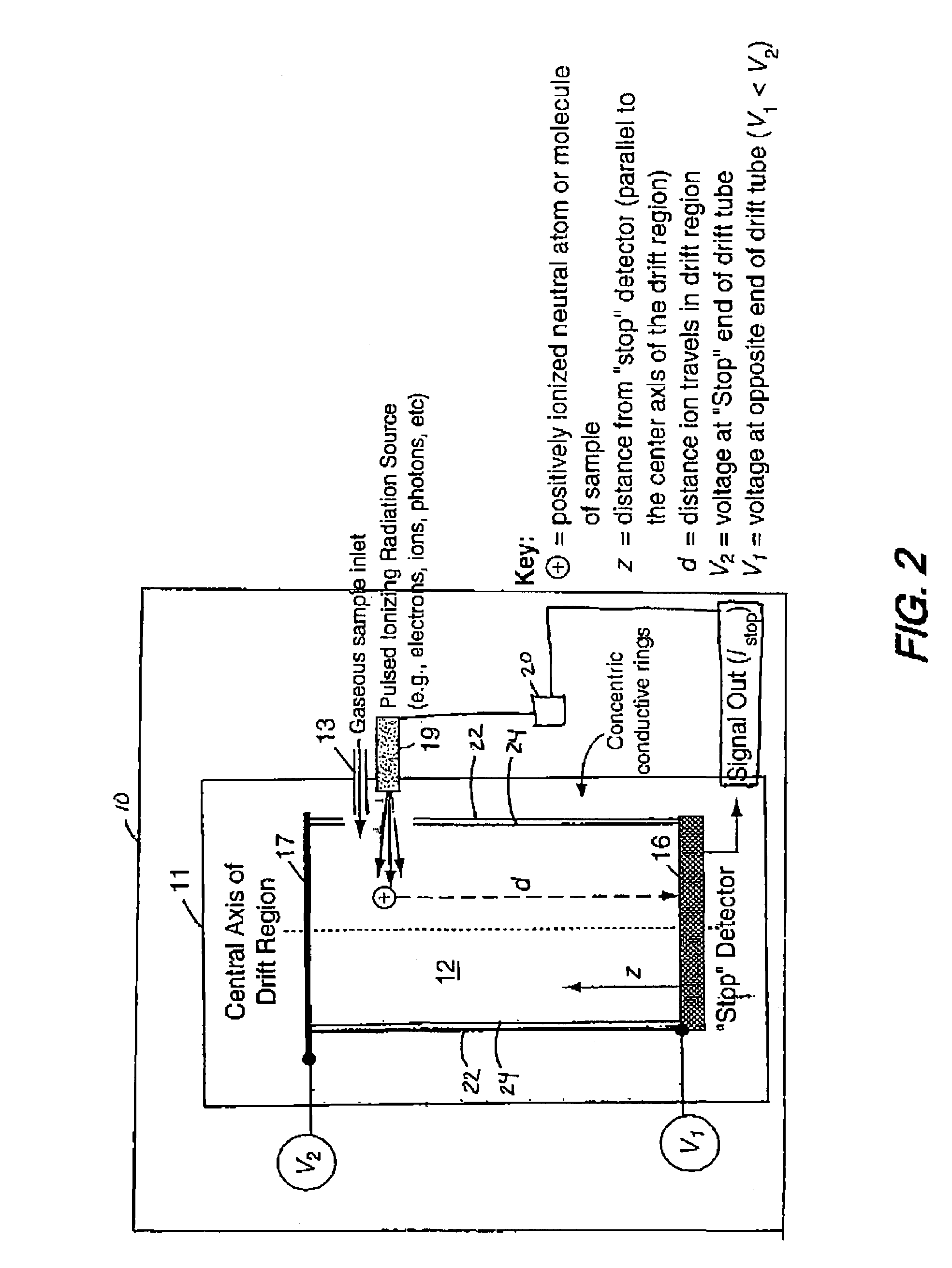

Linear electric field time-of-flight ion mass spectrometer

A linear electric field ion mass spectrometer having an evacuated enclosure with means for generating a linear electric field located in the evacuated enclosure and means for injecting a sample material into the linear electric field. A source of pulsed ionizing radiation injects ionizing radiation into the linear electric field to ionize atoms or molecules of the sample material, and timing means determine the time elapsed between ionization of atoms or molecules and arrival of an ion out of the ionized atoms or molecules at a predetermined position.

Owner:RGT UNIV OF CALIFORNIA

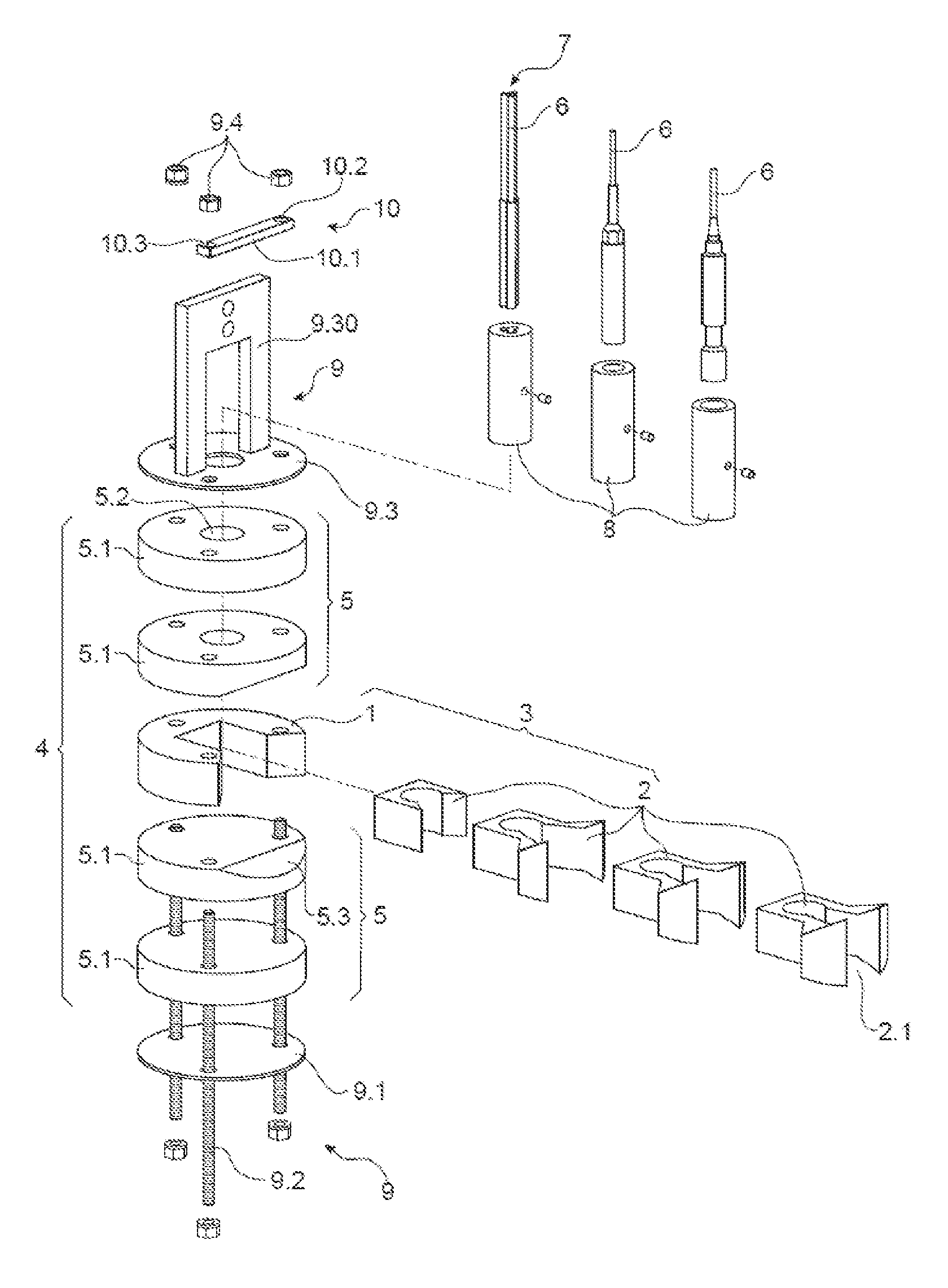

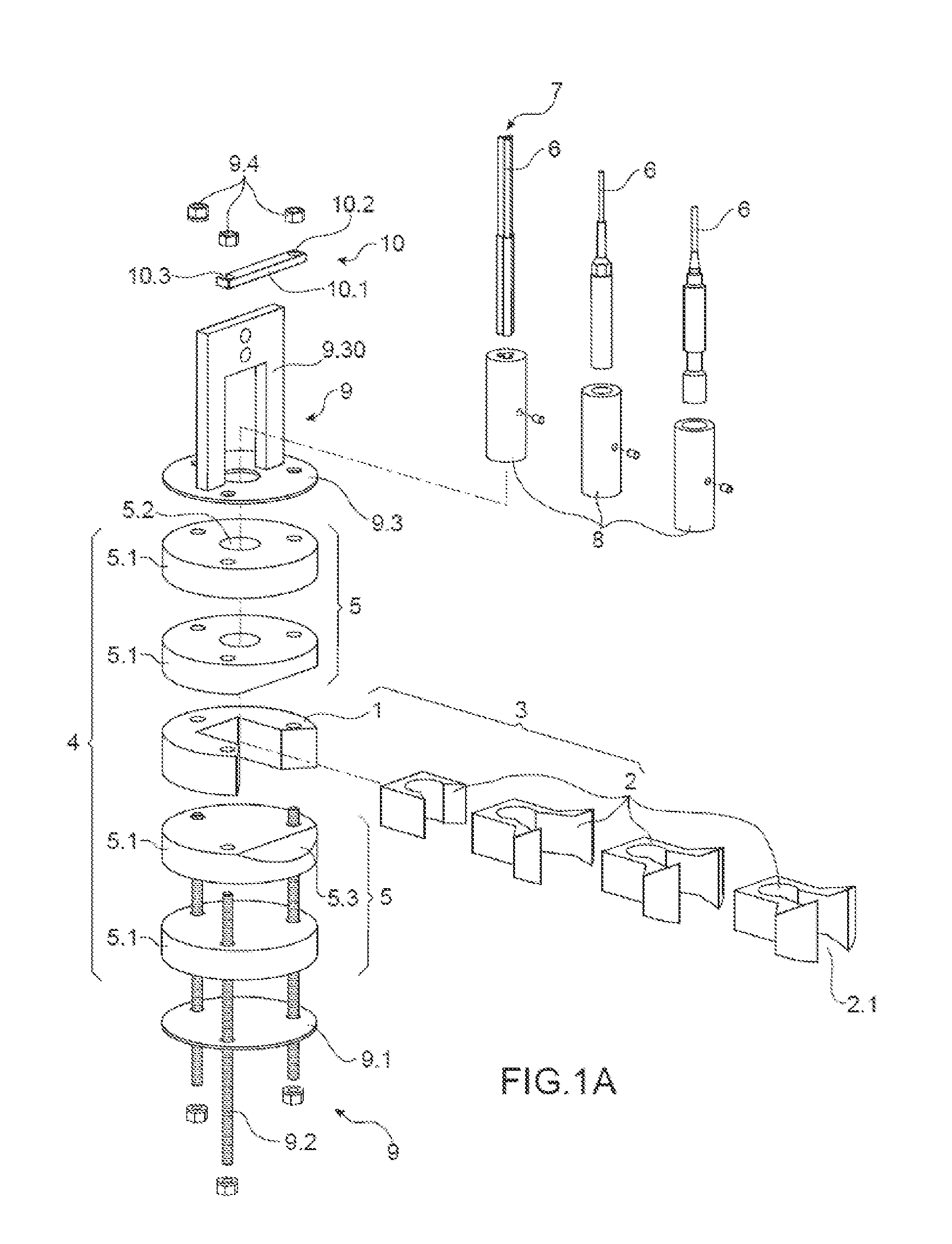

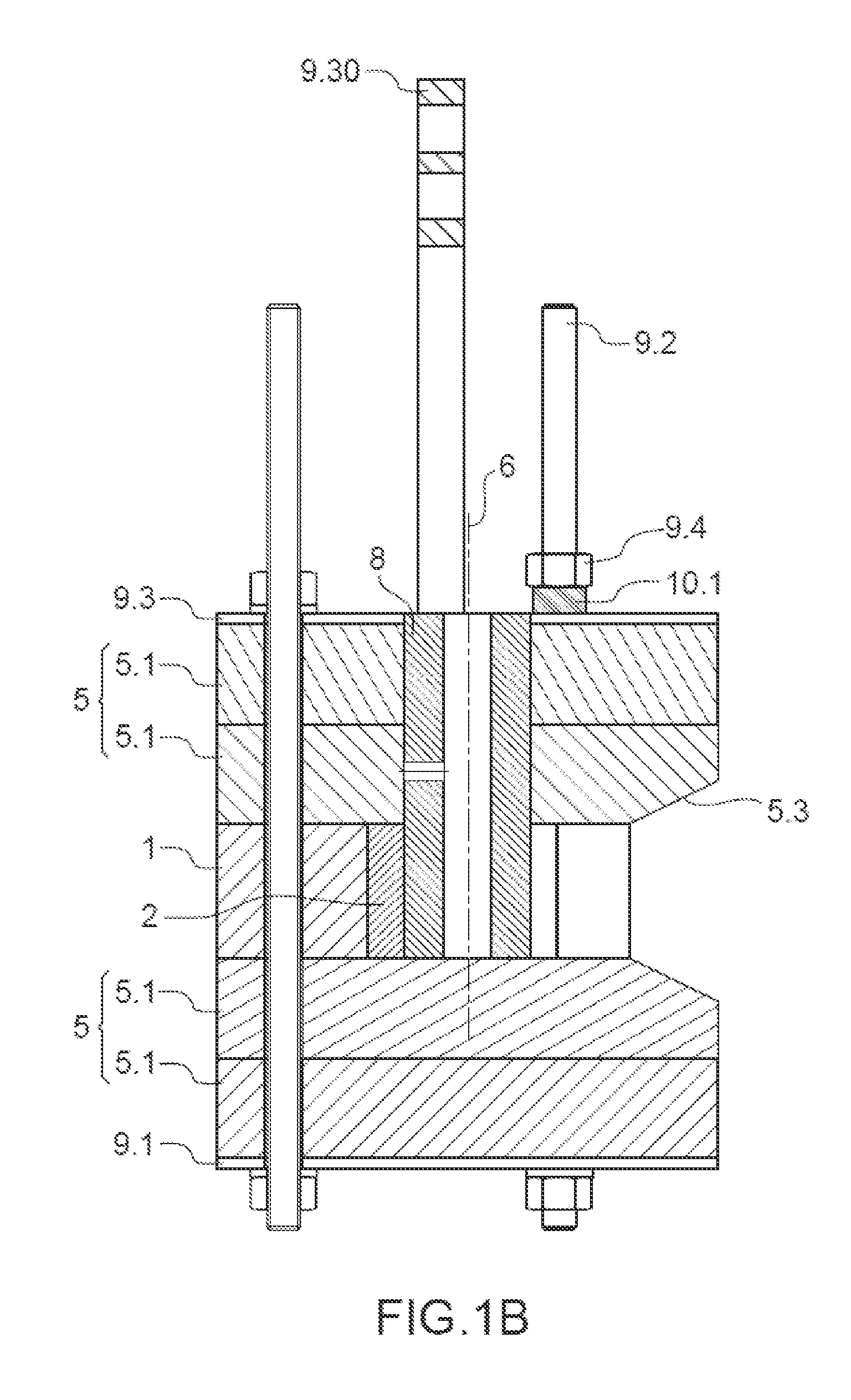

Radiological characterization device protected against parasitic ionizing radiation sources

A radiological characterization device comprising at least one collimated radiological measuring probe, a sensitive end of which is placed in an exchangeable collimator having an opening and a field of observation. The collimator is carried by a collimator holder, the assembly consisting of collimator and collimator holder being inserted in a stack between two shielding screens, the shielding screens being exchangeable so as to adjust the thickness thereof, the assembly consisting of collimator and collimator holder and the shielding screens providing protection for the probe vis-à-vis parasitic ionizing radiation coming from ionizing radiation sources situated outside the field of observation of the collimator.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com