High-efficiency quick green preparation method of zeolite molecular sieve

A technology of zeolite molecular sieve and precursor solution, which is applied in molecular sieve and alkali exchange compound, molecular sieve and alkali exchange phosphate, chemical instrument and method, etc., can solve the problems of high requirement of reaction equipment, long synthesis cycle, long product crystallization time, etc. , to achieve the effect of low cost, extremely short synthesis cycle and fast product crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The synthesis of embodiment 1Na-A type zeolite molecular sieve

[0033] (1) Precursor solution preparation: 6.11g of Na 2 SiO 3 9H 2 O was added to 10 g of deionized water, and heated in an oven at 60°C for 3-5 minutes to obtain a clear sodium silicate solution A. 2.5g NaAlO 2 Soluble in 10.0g H 2 O obtains the clarified sodium metaaluminate solution, then takes by weighing 4.7g NaOH and adds in the sodium metaaluminate solution to make solution B;

[0034] (2) Aging: Weigh 8.0 g of tetrapropylammonium bromide and add it to solution A, then add solution B dropwise to solution A under stirring, and then stir the mixture at room temperature for 12 hours of aging.

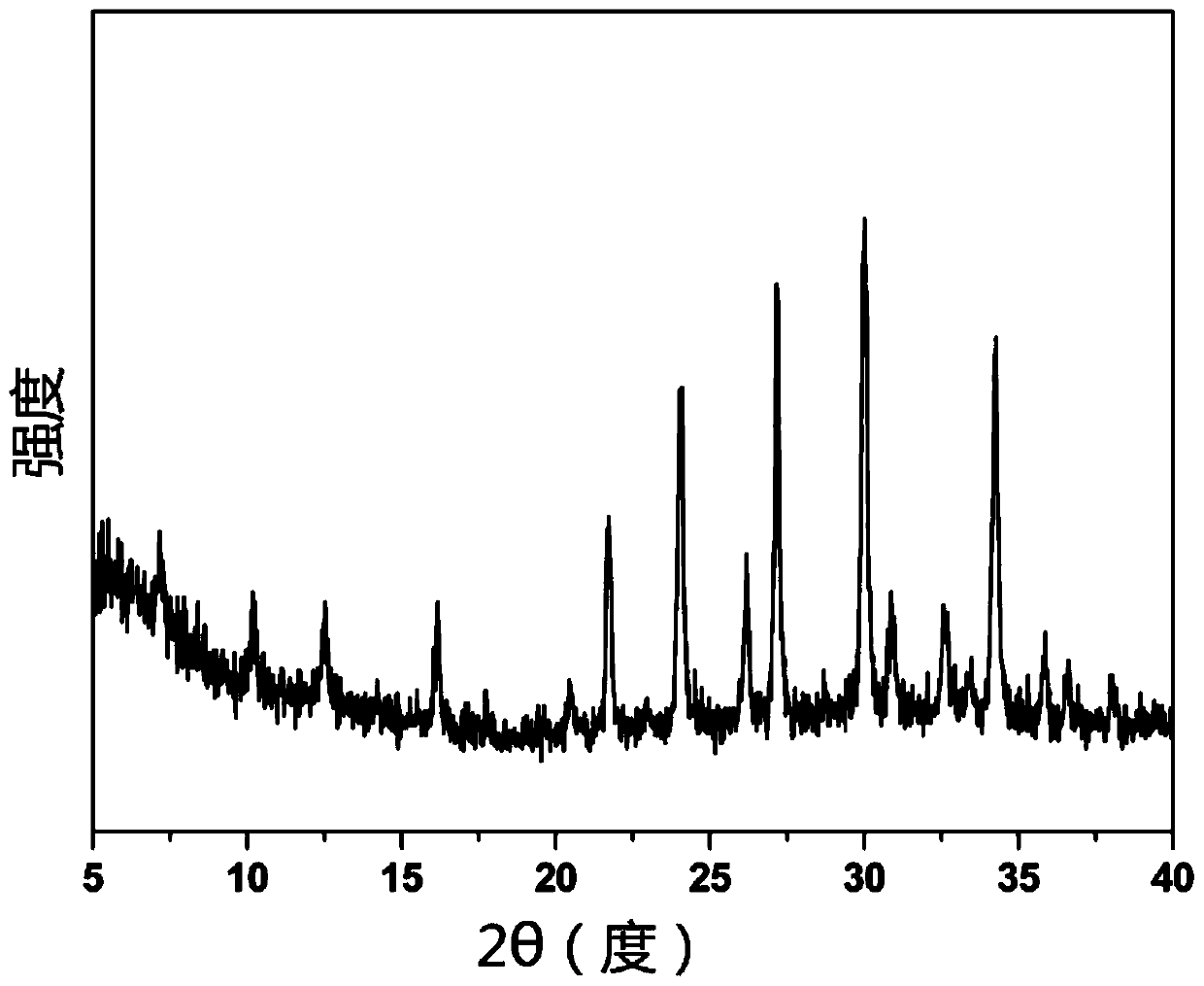

[0035] (3) Electron beam irradiation: Use a 1mL pipette to pipette 0.5mL of the cured mixed solution into a 3mL glass scintillation vial, and then place the sample under electron accelerator irradiation with an absorbed dose of 500kGy and an irradiation time of 800s. The white solid produced after irradia...

Embodiment 2

[0036] The synthesis of embodiment 2 Na-A type zeolite molecular sieve

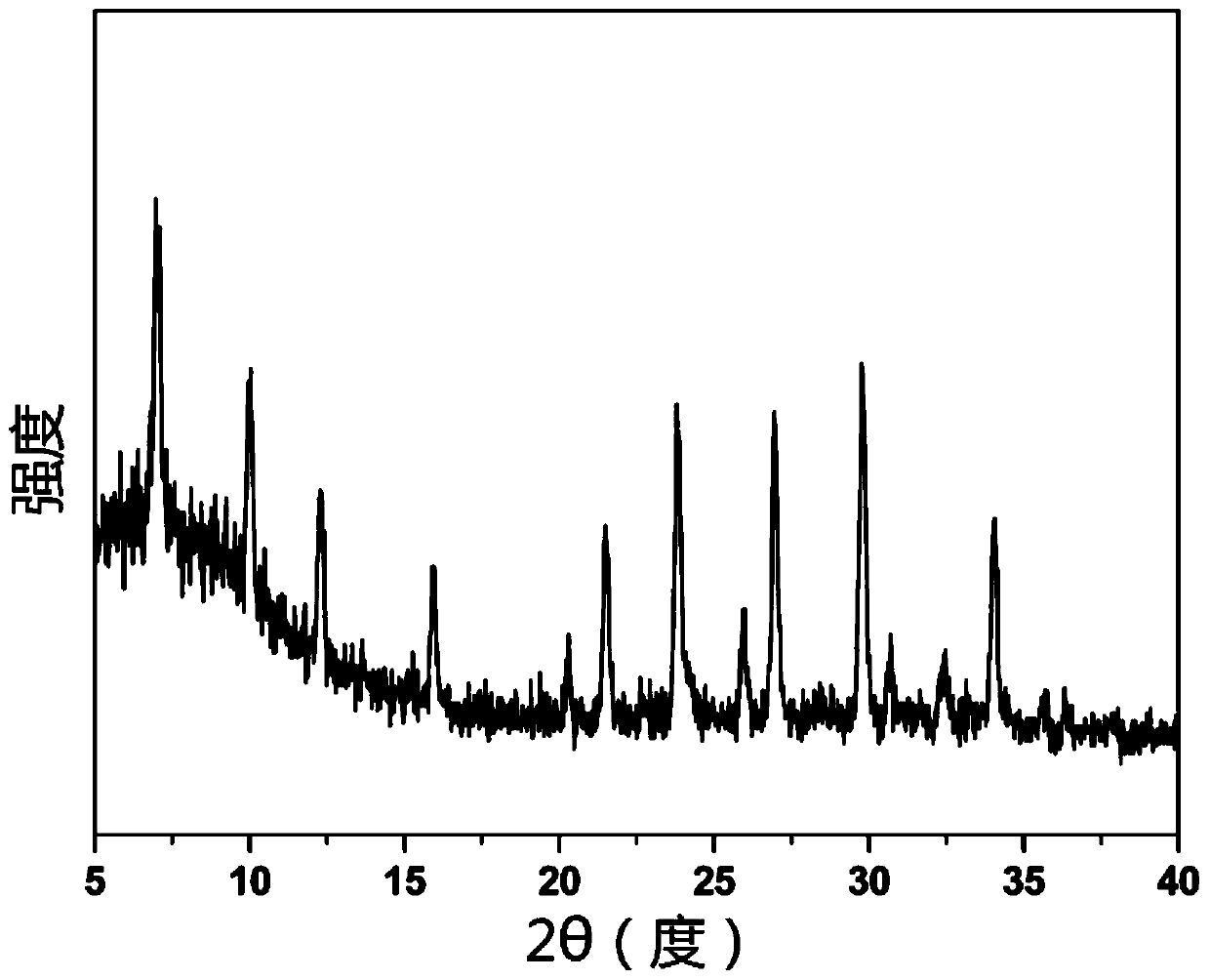

[0037] The Na-A type zeolite molecular sieve was prepared according to the method of Example 1, except that the absorbed dose was 700 kGy and the irradiation time was 1120 s. Adopt polycrystalline powder diffractometer (PXRD) to determine the crystal structure of product, test result is as follows figure 2 shown.

Embodiment 3

[0038] The synthesis of embodiment 3 Na-A type zeolite molecular sieve

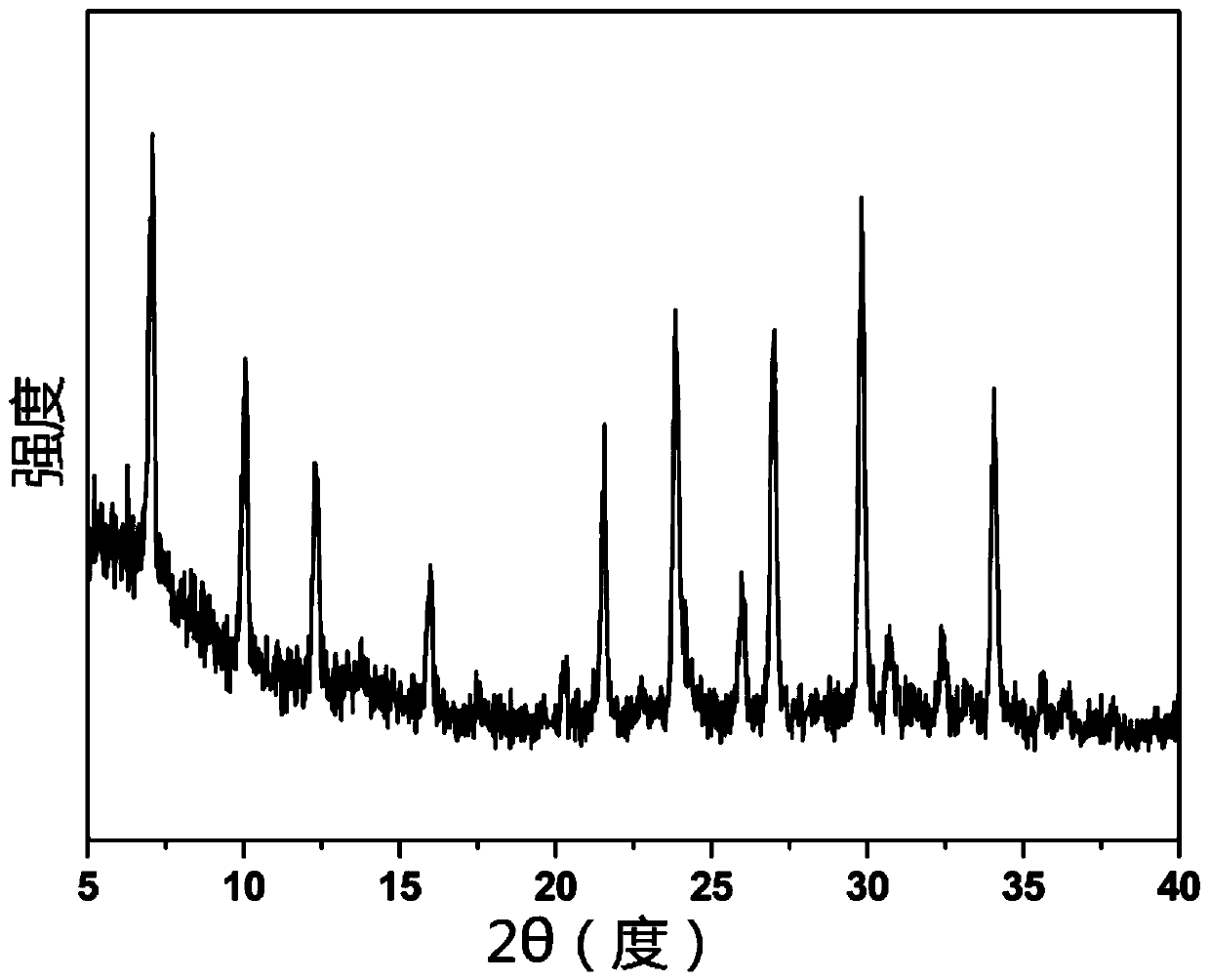

[0039] The Na-A type zeolite molecular sieve was prepared according to the method of Example 1, except that the absorbed dose was 1200 kGy, and the irradiation time was 1920 s. Adopt polycrystalline powder diffractometer (PXRD) to determine the crystal structure of product, test result is as follows image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com