Device and method for the non destructive testing of tyres by tomography

A technology of tomography and tires, applied in the field of non-destructive inspection, representation of tomography images, and devices implementing the method, which can solve problems such as slow tire inspection, parameterization and setup of extended equipment, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

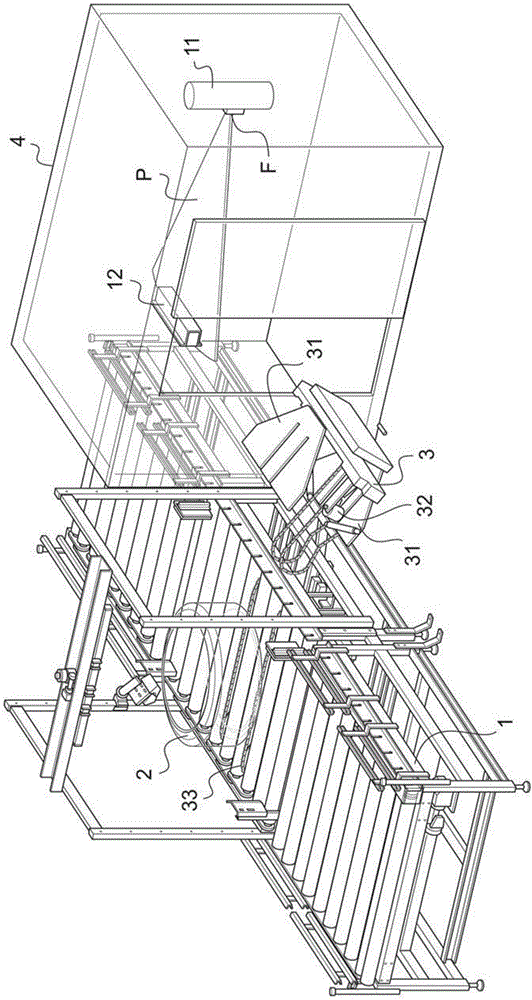

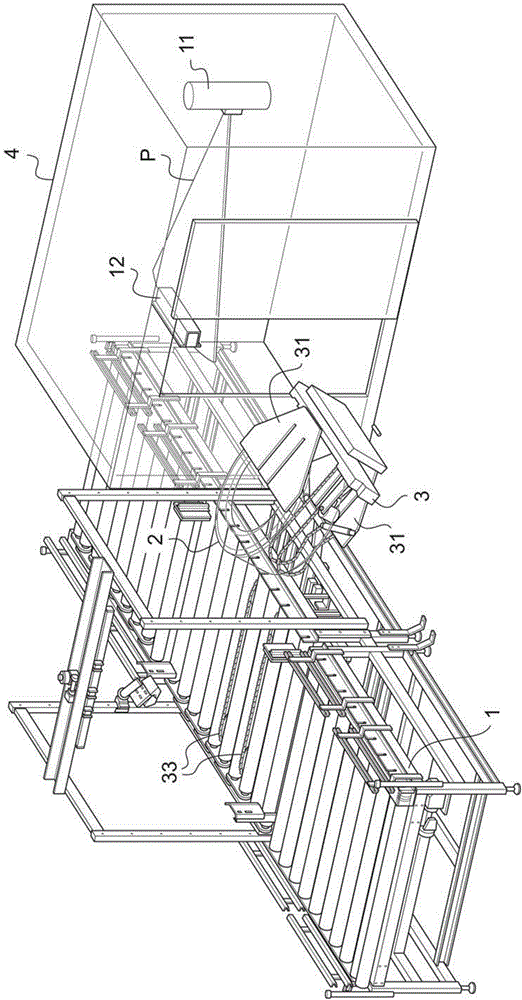

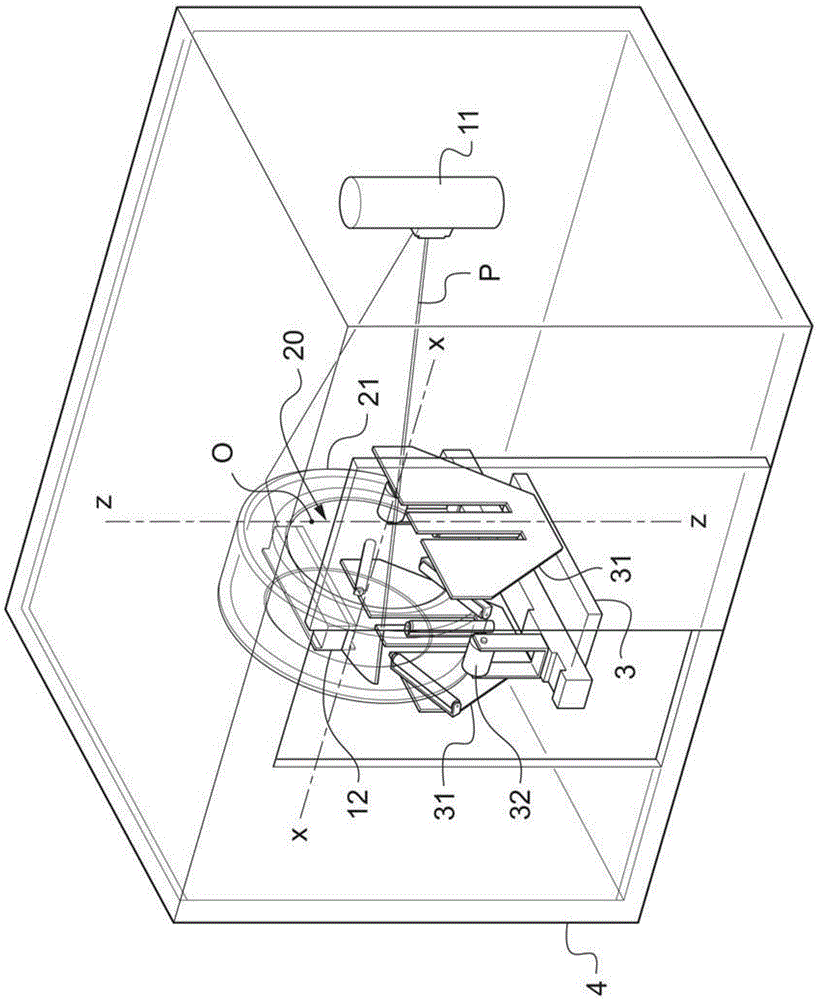

[0039] The device for inspecting tires by tomography according to the invention is incorporated into a tire production line. The infeed conveyor 1 for the tire 2 cooperates with the steering stand 3 to transfer the tire 2 from the infeed conveyor 1 to the examination chamber 4, which has an X-ray impermeable wall, in which the X-ray source 11 and the X-ray detector 12. This detector 12 may be a linear or matrix detector and is arranged horizontally in the examination chamber 4 facing the source 11 . The source 11 is preferably equipped with a collimator such that the radiation is emitted in the form of a planar beam of horizontal axis, which defines a cross-sectional plane P, also called the emission plane, which passes through the focal point F of the source 11 and the horizontally positioned detector 12 .

[0040] The steering stand 3 of the tyres, comprising a frame supporting the motor drive system, is available for the stand 3 so that it can be placed on rails (not show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com