Patents

Literature

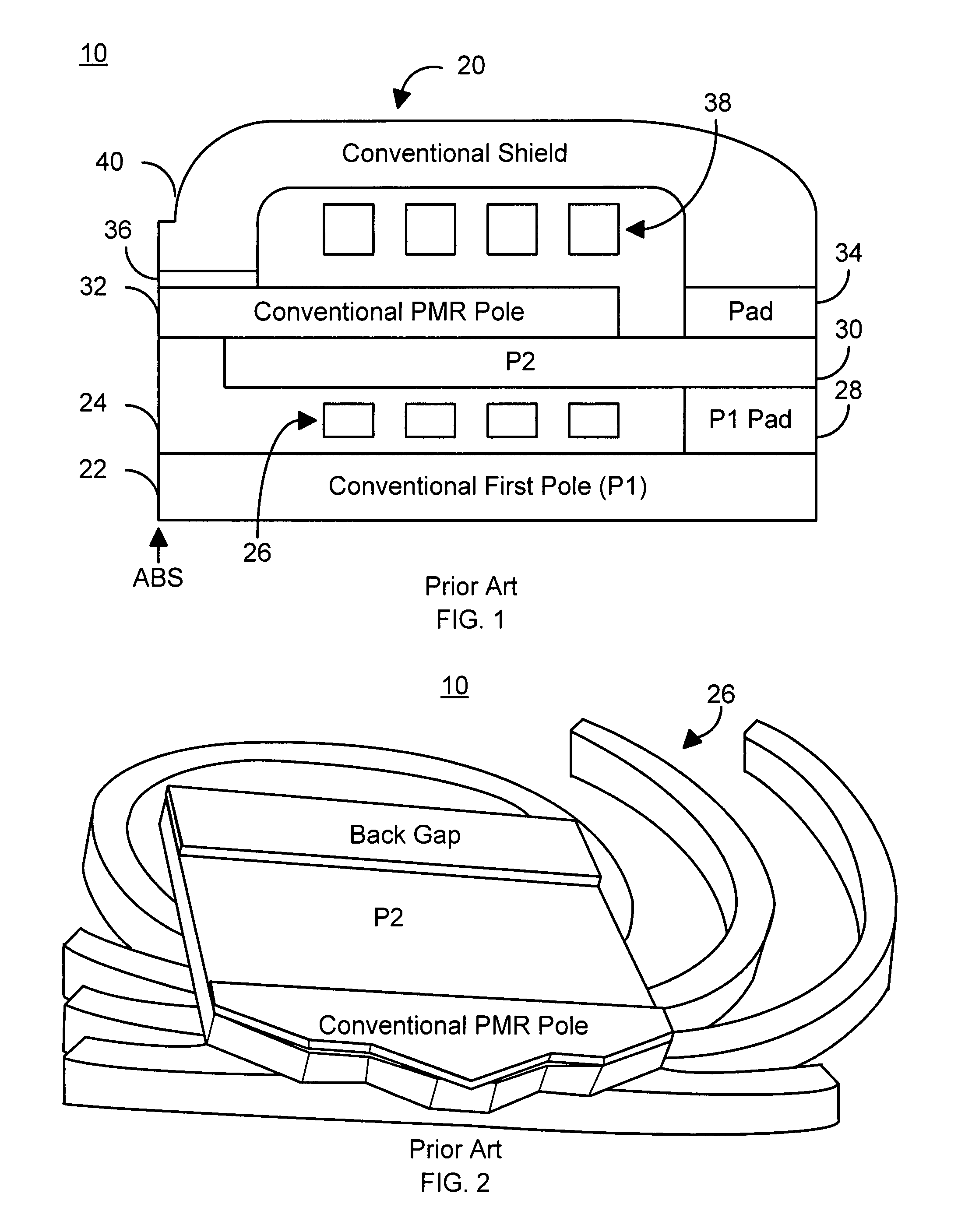

261 results about "Magnetic transducers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

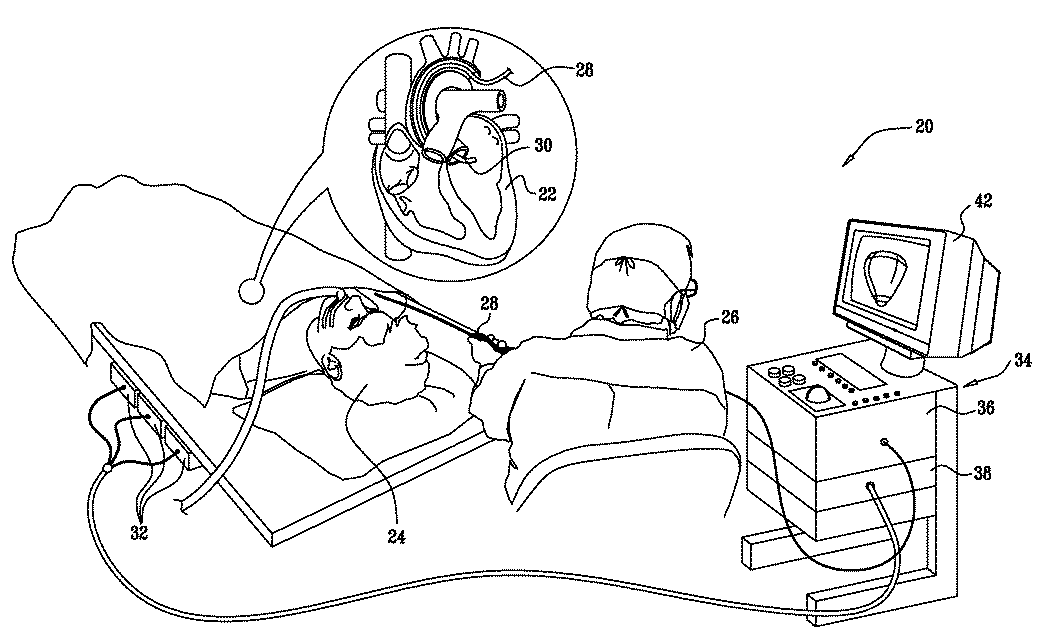

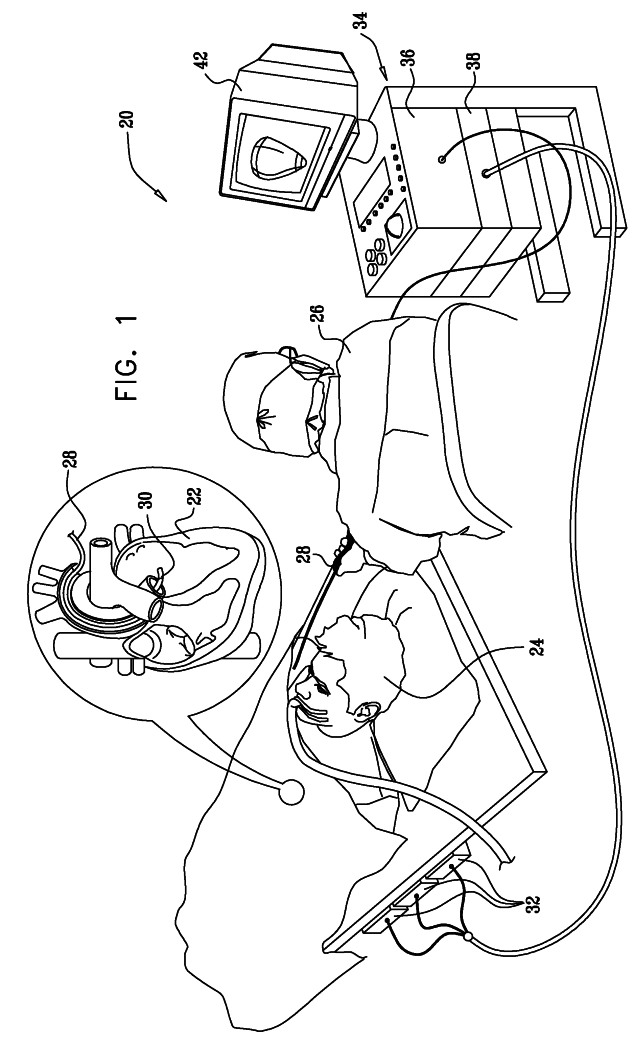

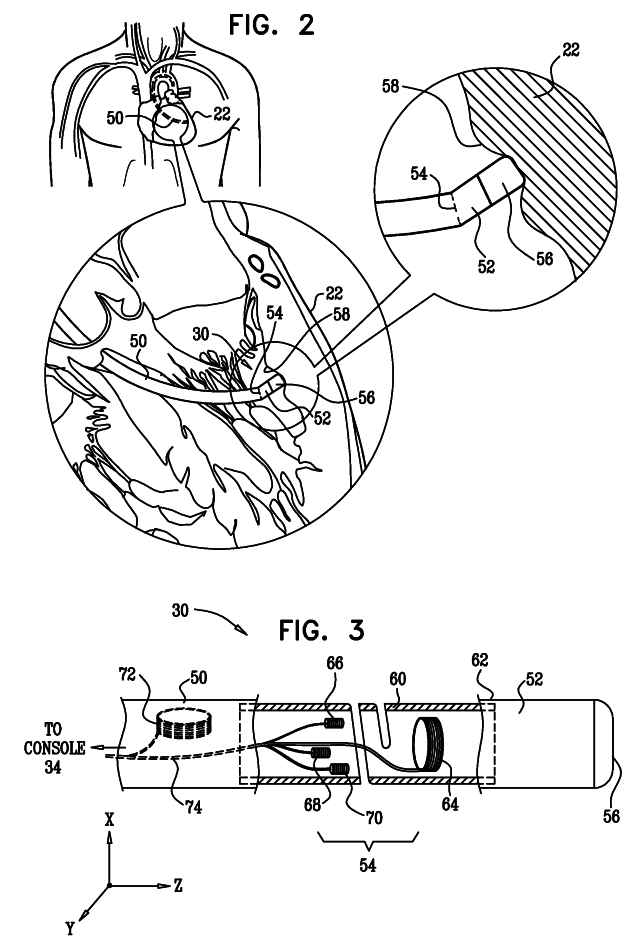

High-sensitivity pressure-sensing probe

ActiveUS20090138007A1Accurate inductionTransvascular endocardial electrodesEndoscopesMagnetic transducersSacroiliac joint

A medical probe includes an insertion tube, having a longitudinal axis and having a distal end. A distal tip is disposed at the distal end of the insertion tube and is configured to be brought into contact with a body tissue. A joint couples the distal tip to the distal end of the insertion tube. A joint sensor, contained within the probe, senses a position of the distal tip relative to the distal end of the insertion tube. The joint sensor includes first and second subassemblies, which are disposed within the probe on opposite, respective sides of the joint and each include one or more magnetic transducers.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

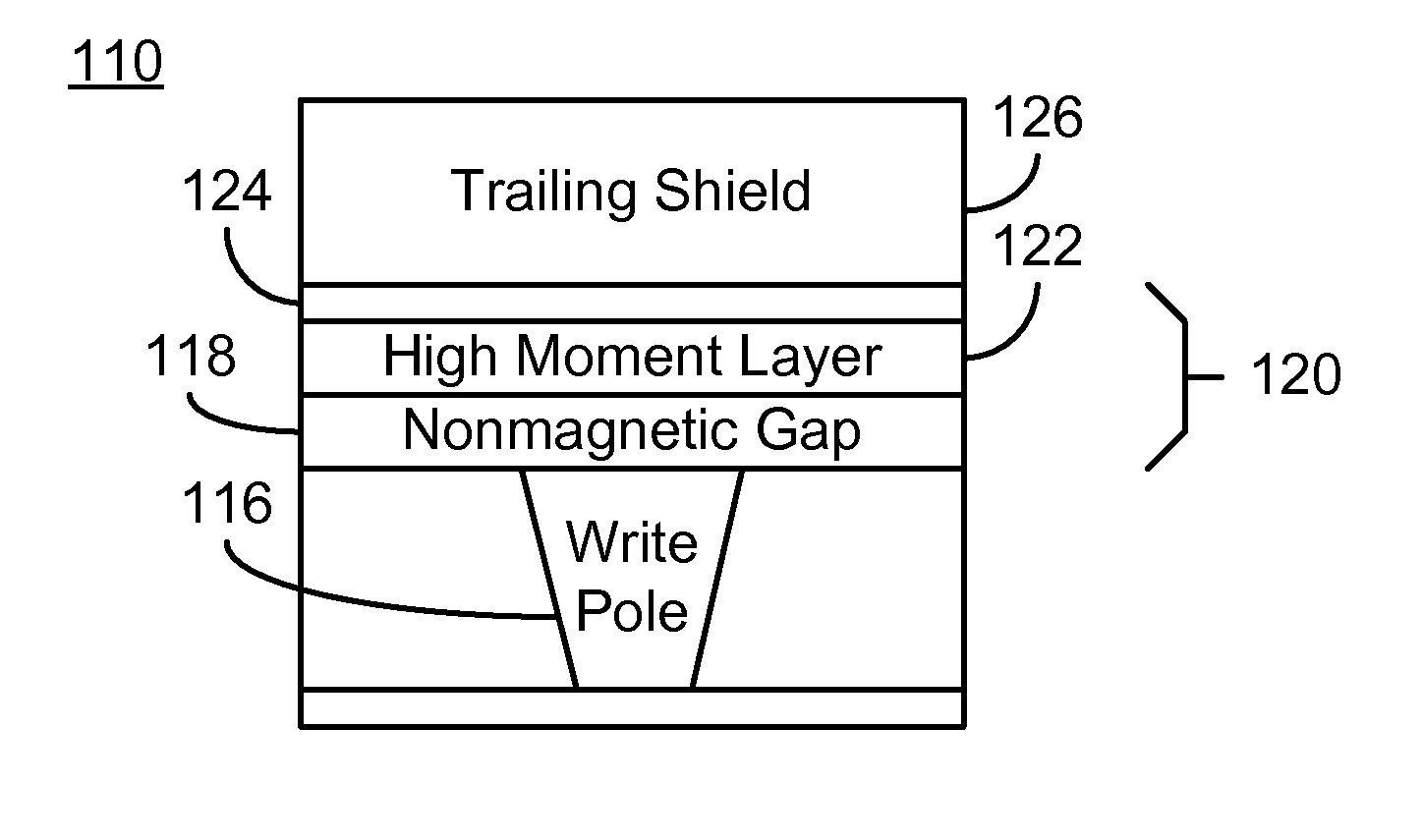

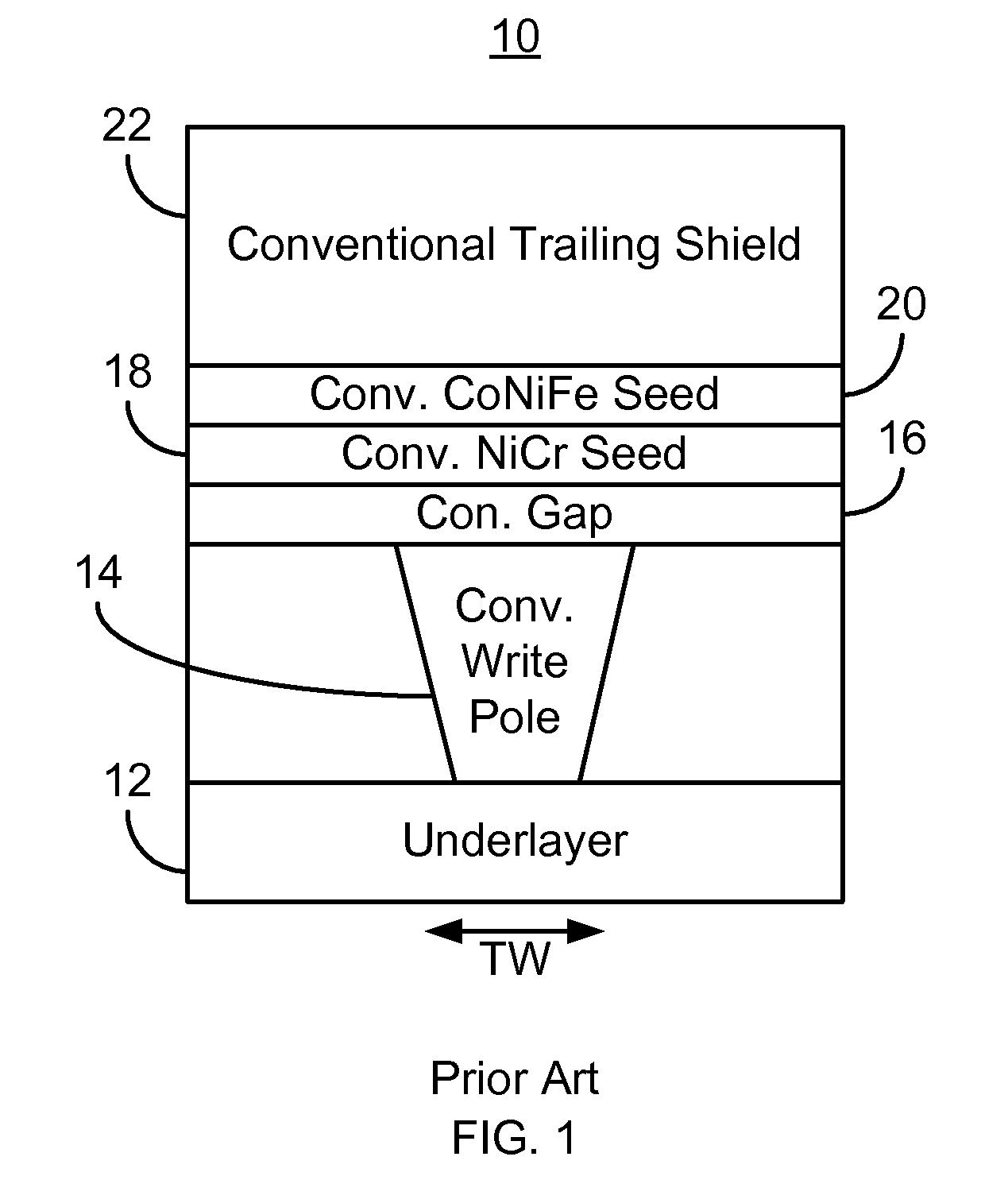

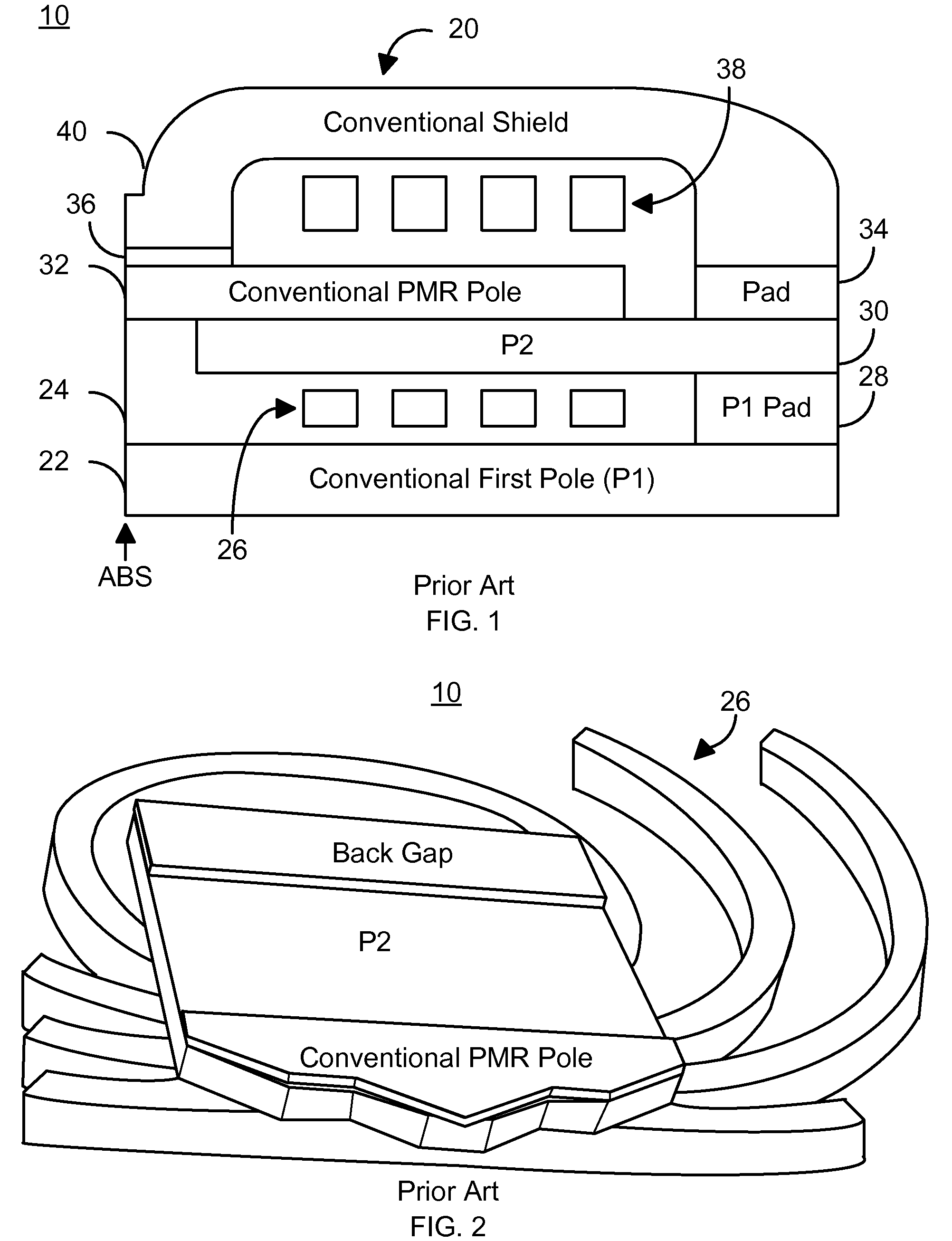

Method and system for providing a magnetic transducer having a high moment bilayer magnetic seed layer for a trailing shield

ActiveUS8582241B1Record information storageHeads for perpendicular magnetisationsMagnetic transducersMagnetization

A method and system for providing a magnetic read transducer is described. The magnetic recording transducer includes a write pole, a nonmagnetic gap, a magnetic seed layer, a trailing shield and coil(s) that energize the write pole. The write pole is configured to write to a media. The nonmagnetic gap is between the write pole and the magnetic seed layer. The magnetic seed layer includes a high moment layer and a magnetic buffer layer. The high moment layer is between the nonmagnetic gap and the magnetic buffer layer. The high moment layer has a saturation magnetization greater than 2.3 T and a first corrosion potential. The magnetic buffer layer has a second corrosion potential less than the first corrosion potential. The magnetic seed layer is between the trailing shield and the nonmagnetic gap layer. The magnetic buffer layer is between the trailing shield and the high moment layer.

Owner:WESTERN DIGITAL TECH INC

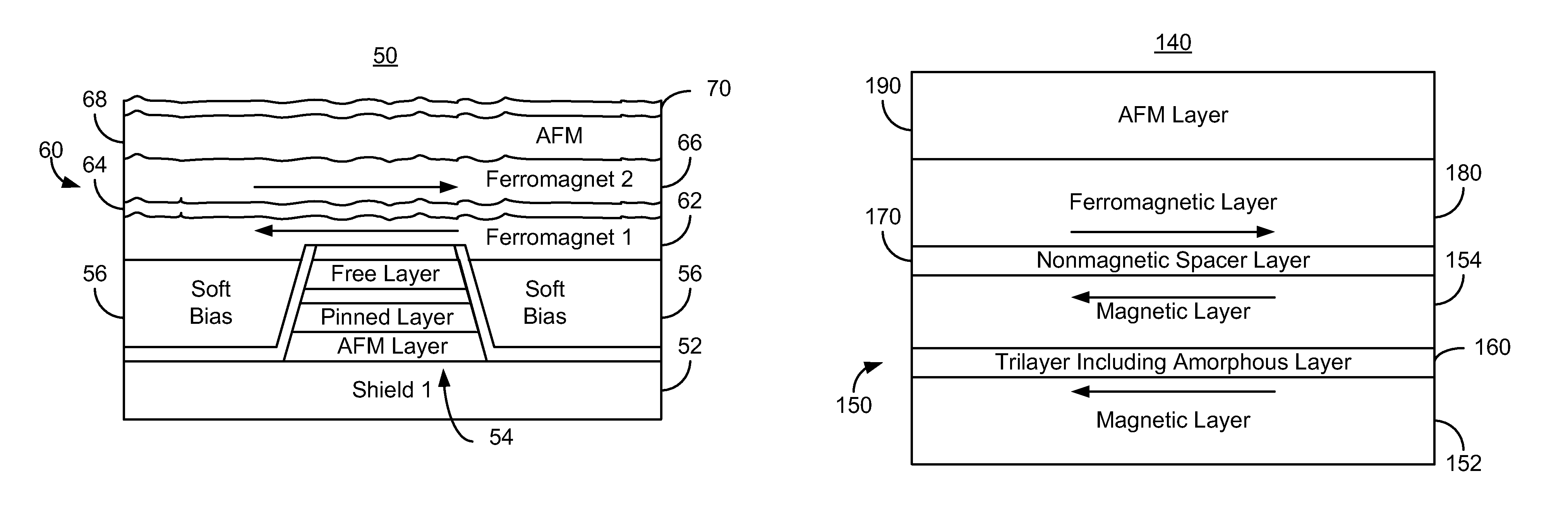

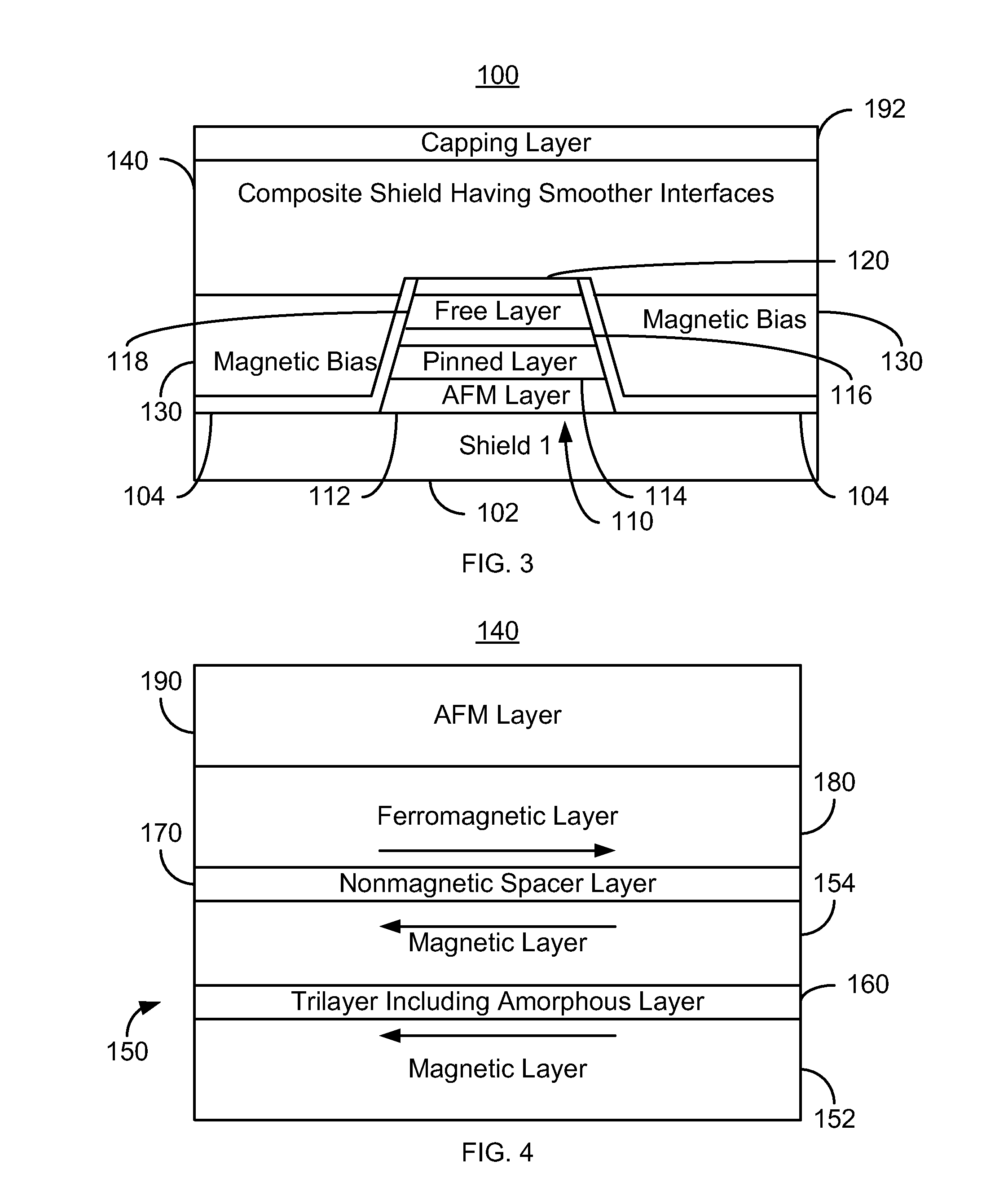

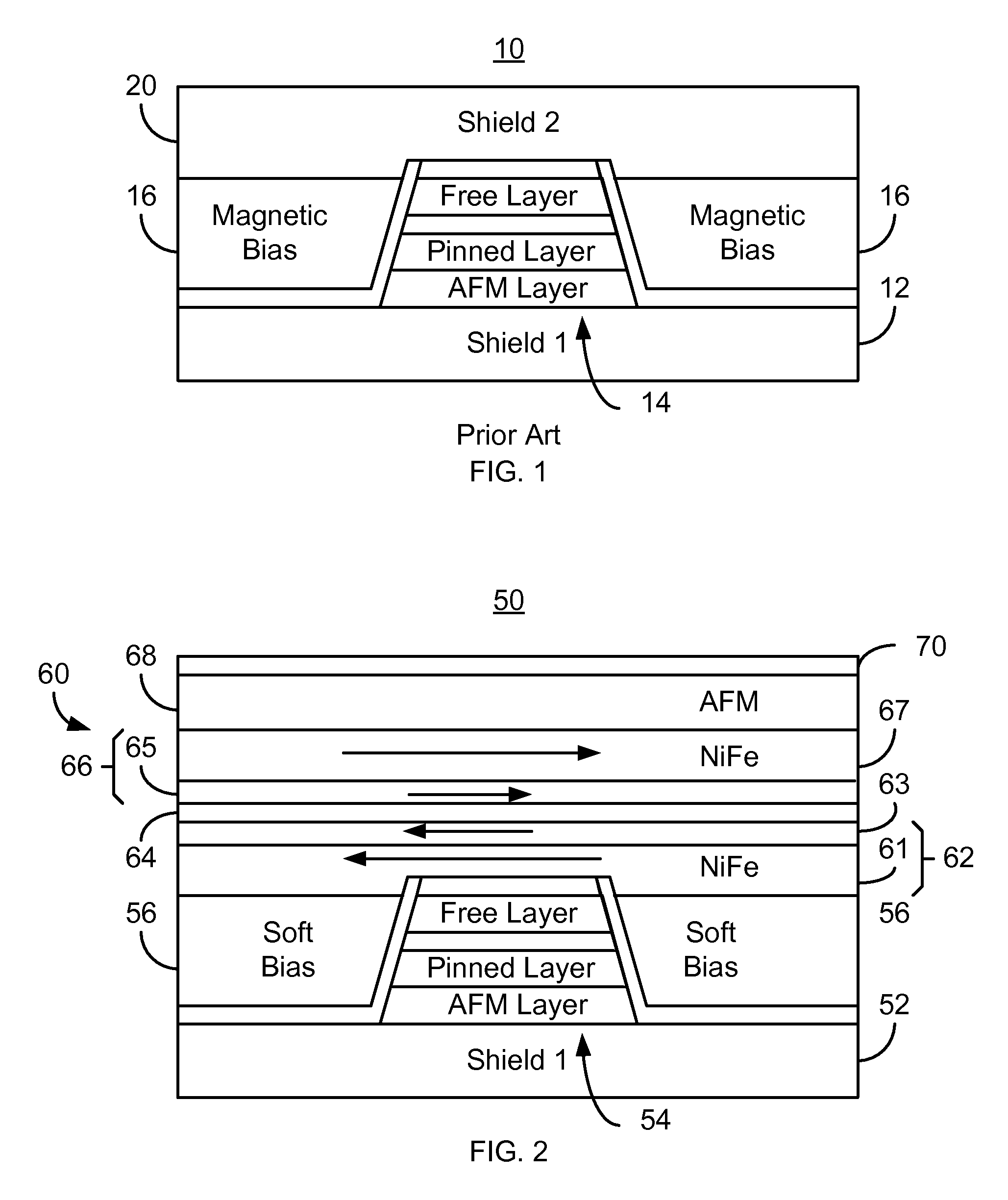

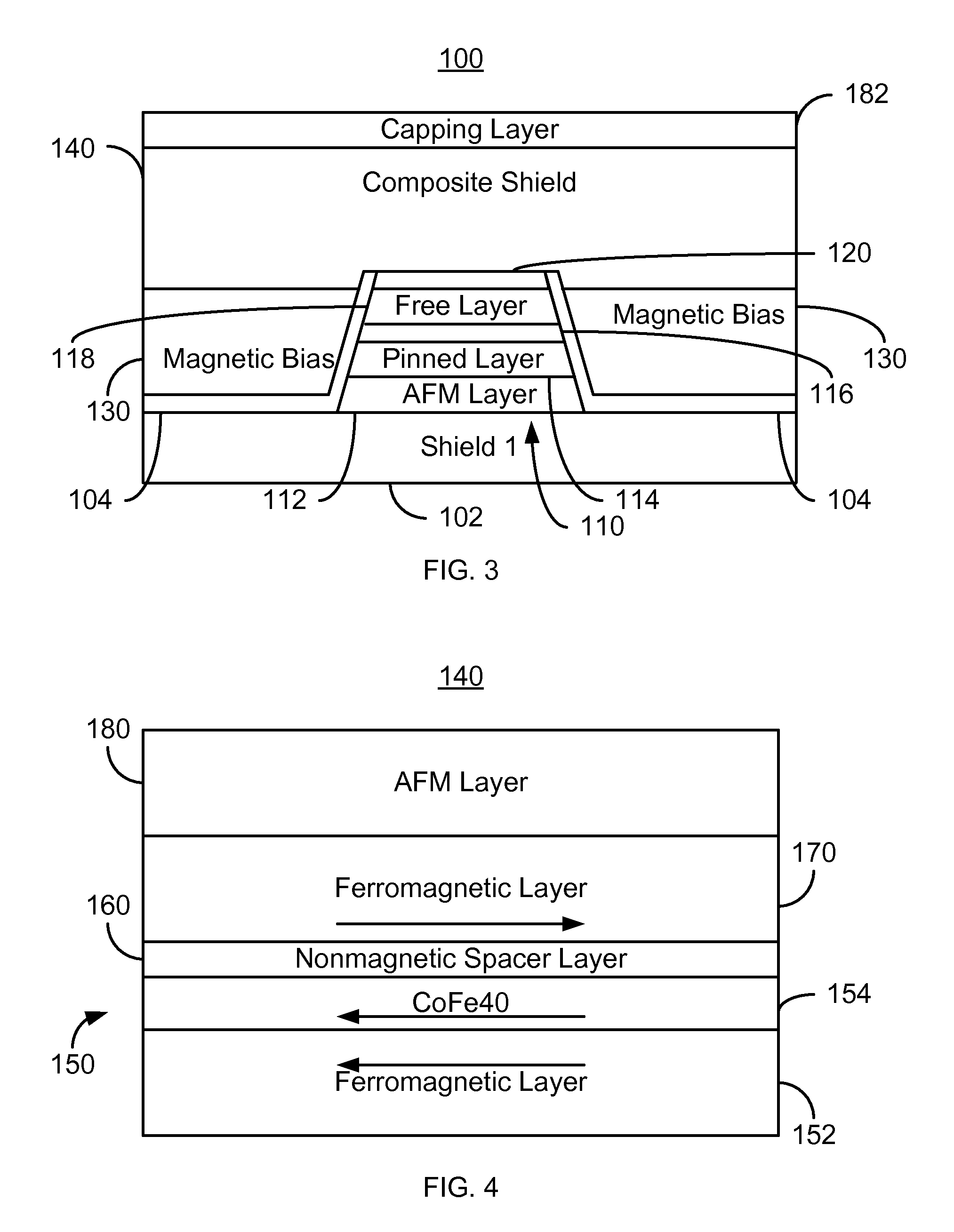

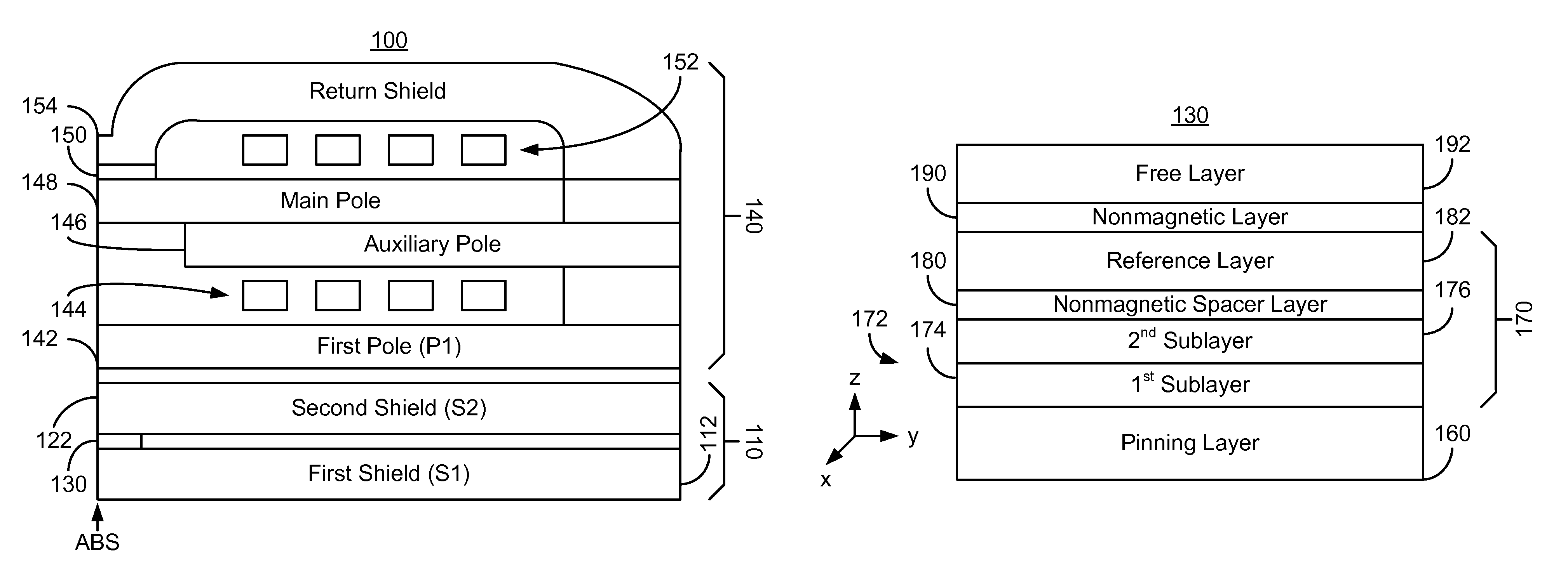

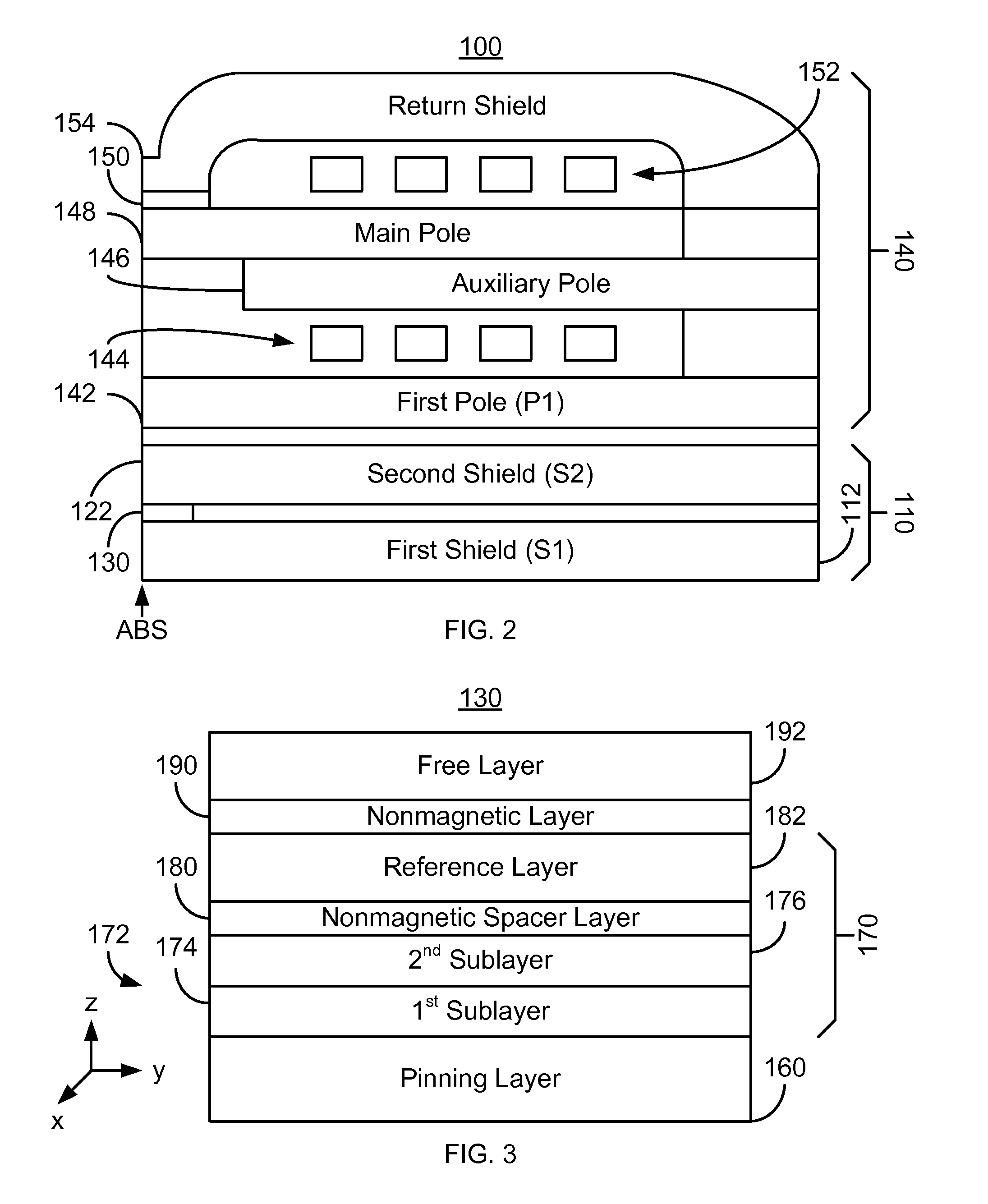

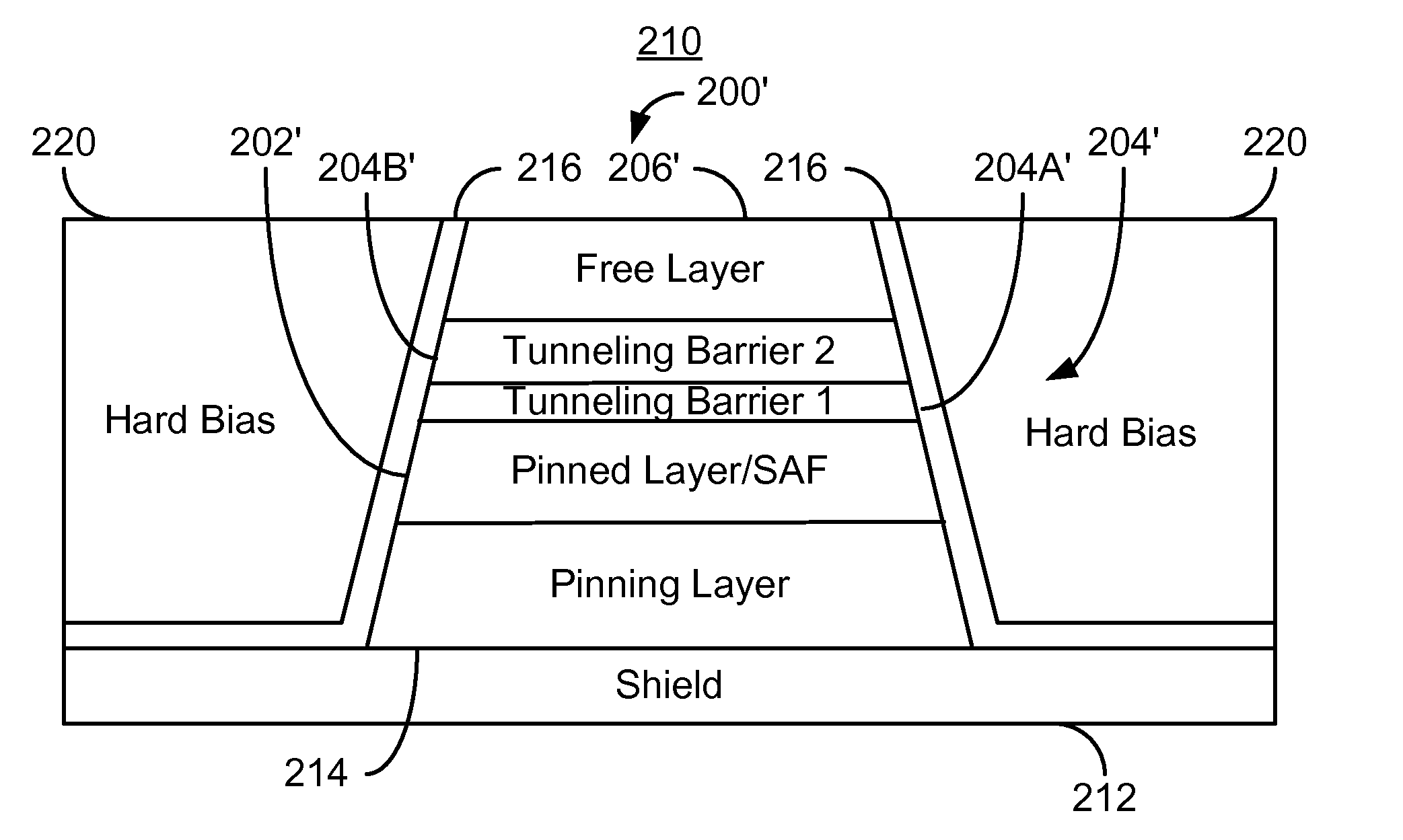

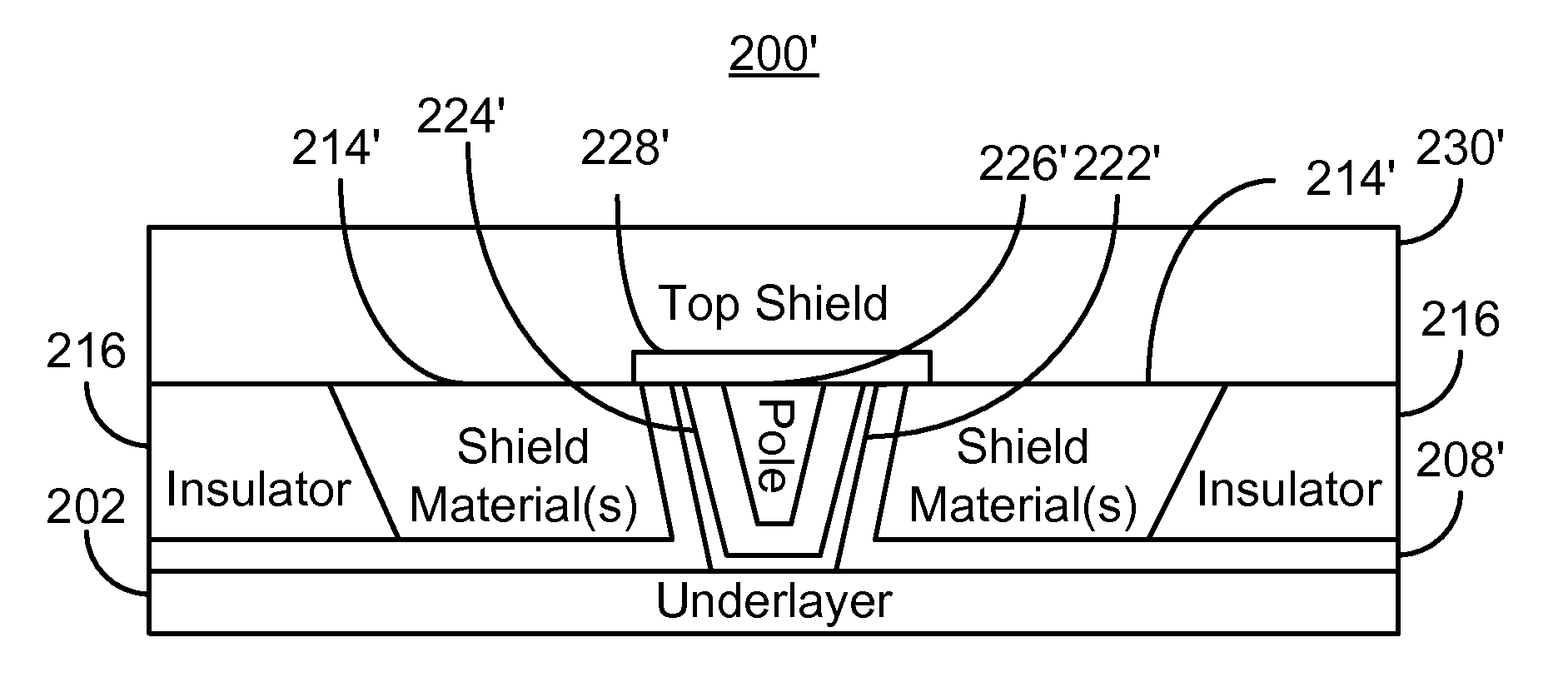

Method and system for providing a read transducer having a composite magnetic shield with smooth interfaces

A method and system provide a magnetic transducer including first and second shields, a read sensor, and magnetic bias structure(s) adjacent to the read sensor. The read sensor and magnetic bias structure(s) are between the shields. The second shield includes first and second ferromagnetic layers, a nonmagnetic spacer layer and a pinning layer. The nonmagnetic spacer layer is between the first and second ferromagnetic layers. The first ferromagnetic layer is between the read sensor and the nonmagnetic spacer layer. The pinning layer is adjacent to the second ferromagnetic layer. The first and second ferromagnetic layers are coupled antiparallel. The first ferromagnetic layer includes magnetic layers interleaved with trilayer(s). Each magnetic layer includes crystalline grains. The trilayer(s) include an amorphous nonmagnetic layer less than three Angstroms thick. Thus, the magnetic layers are ferromagnetically coupled but the crystalline grains in different magnetic layers are decoupled.

Owner:WESTERN DIGITAL TECH INC

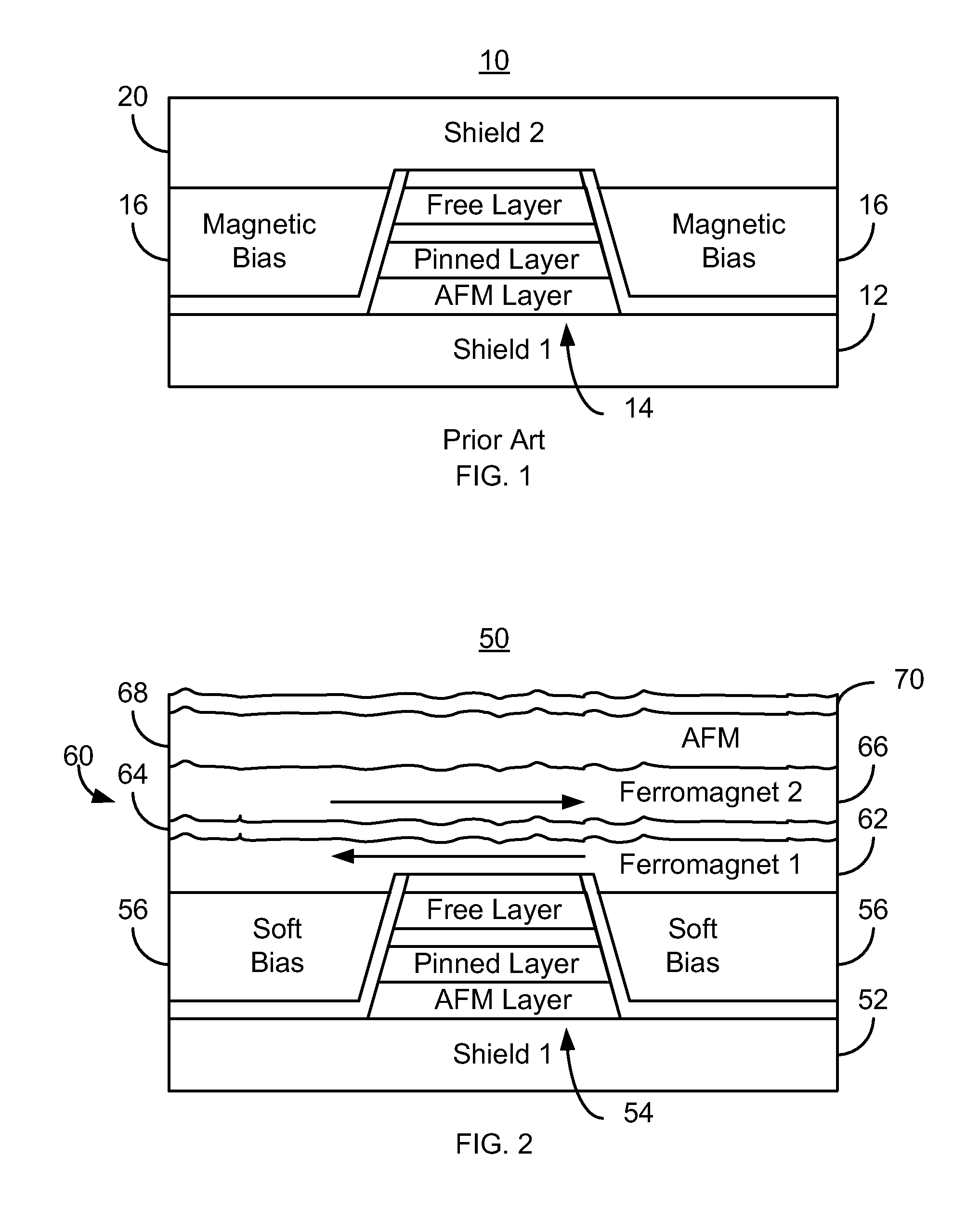

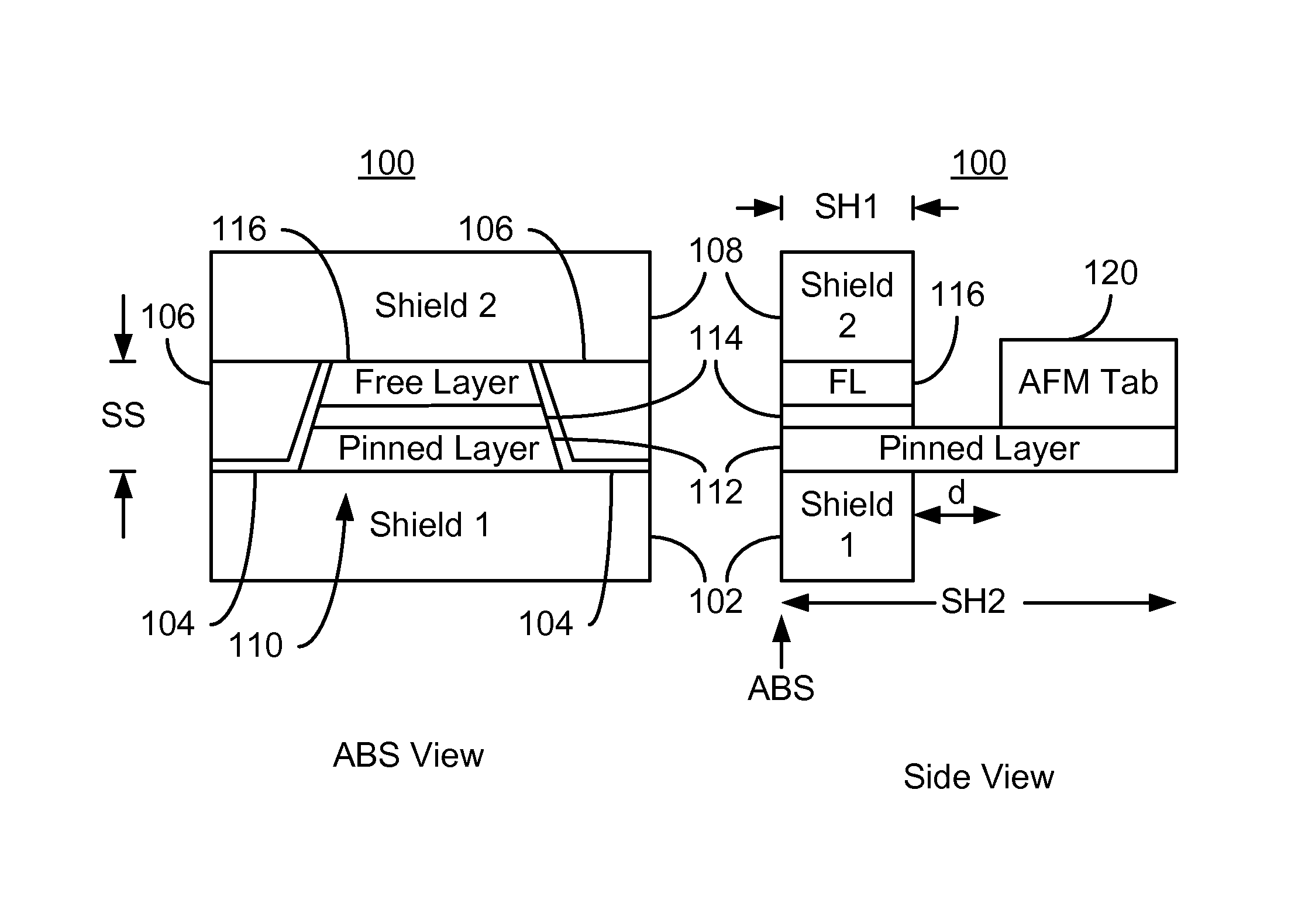

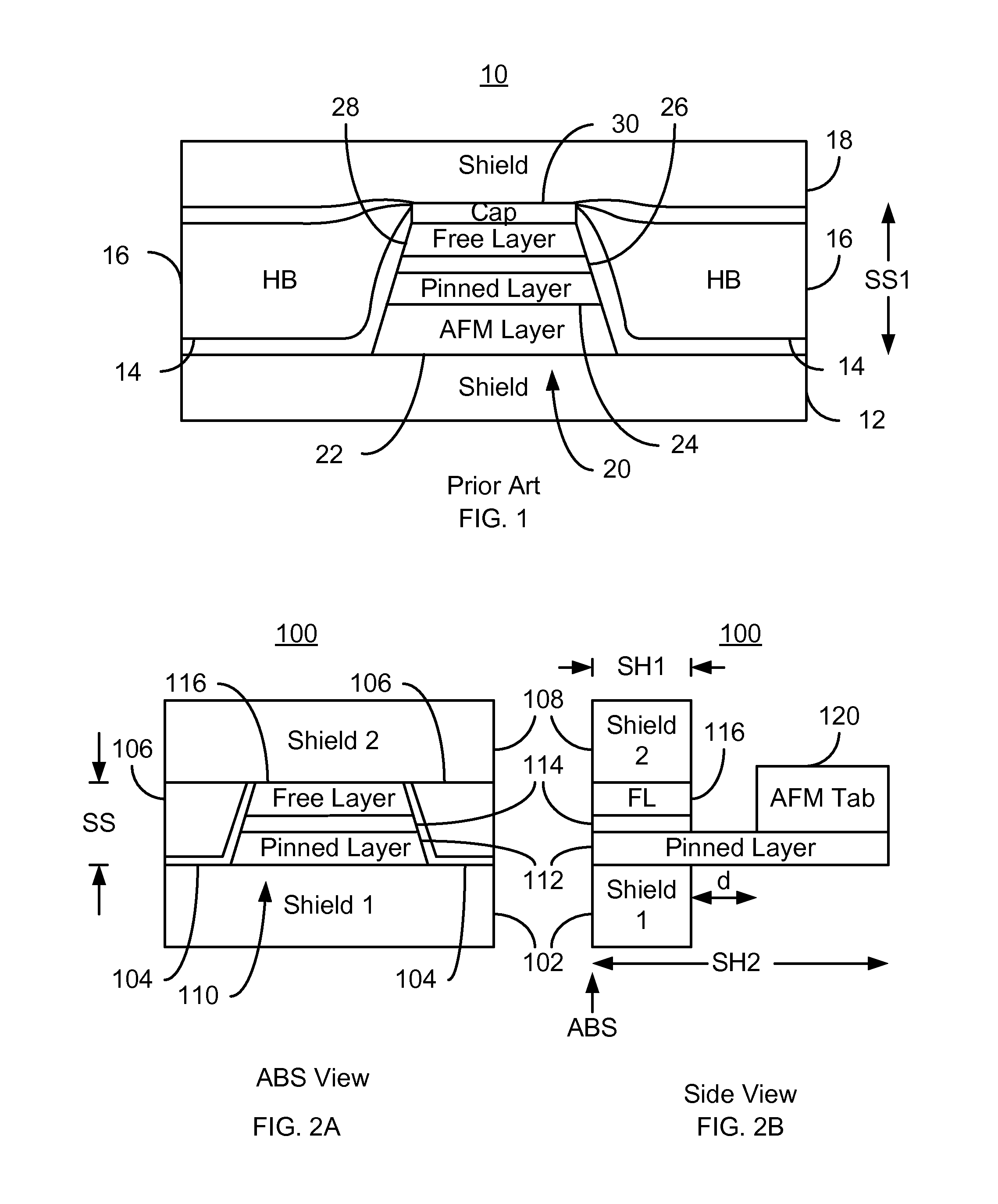

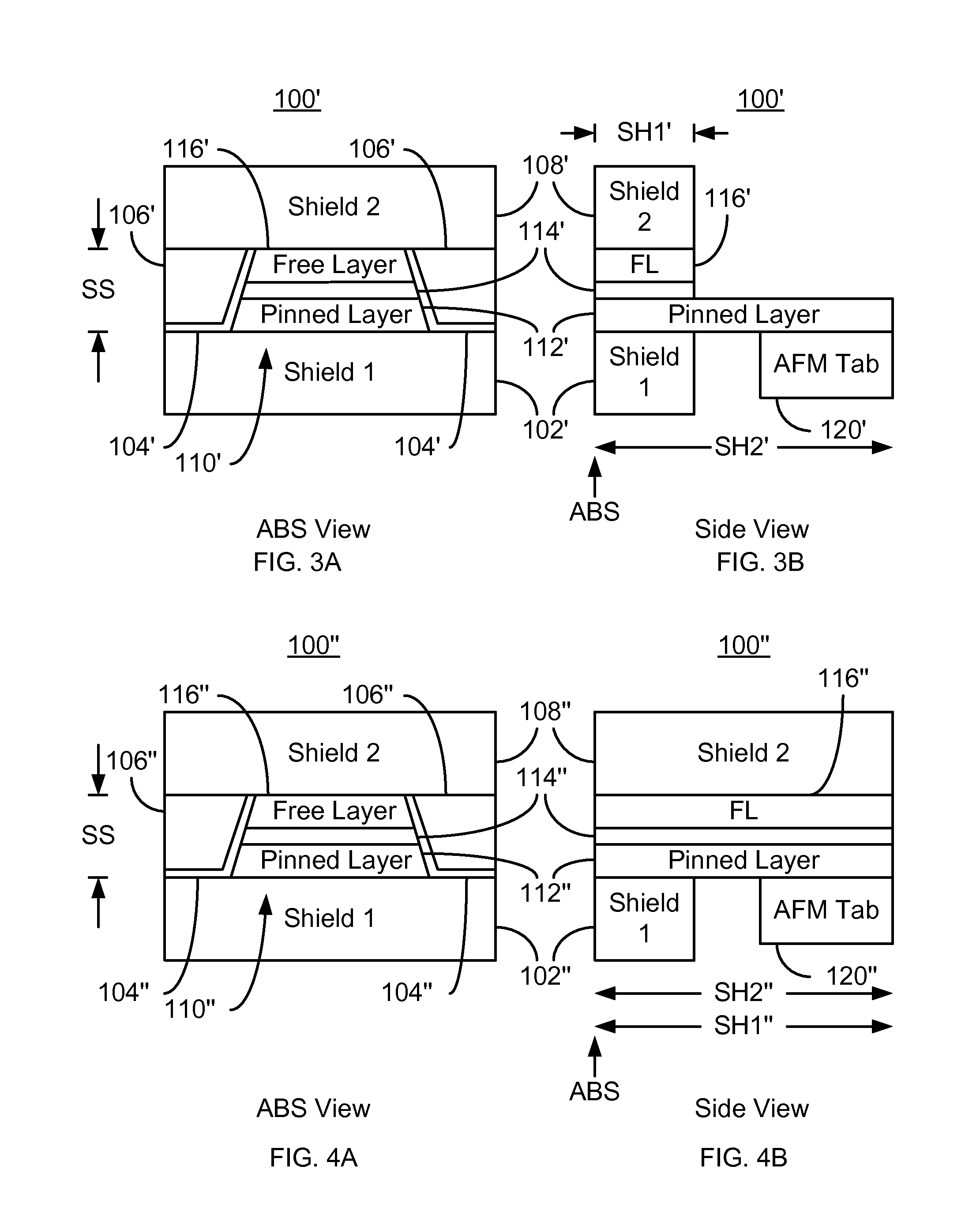

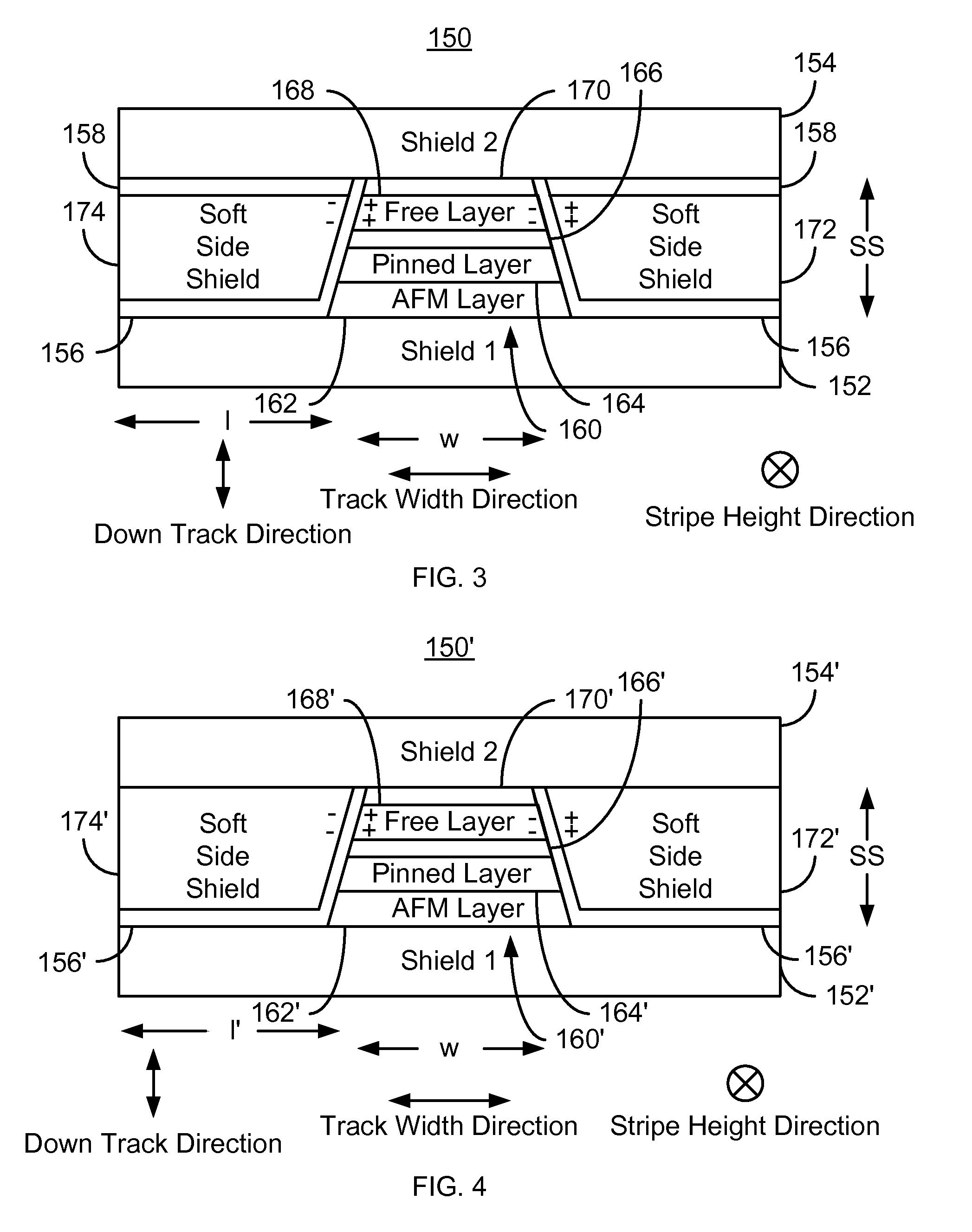

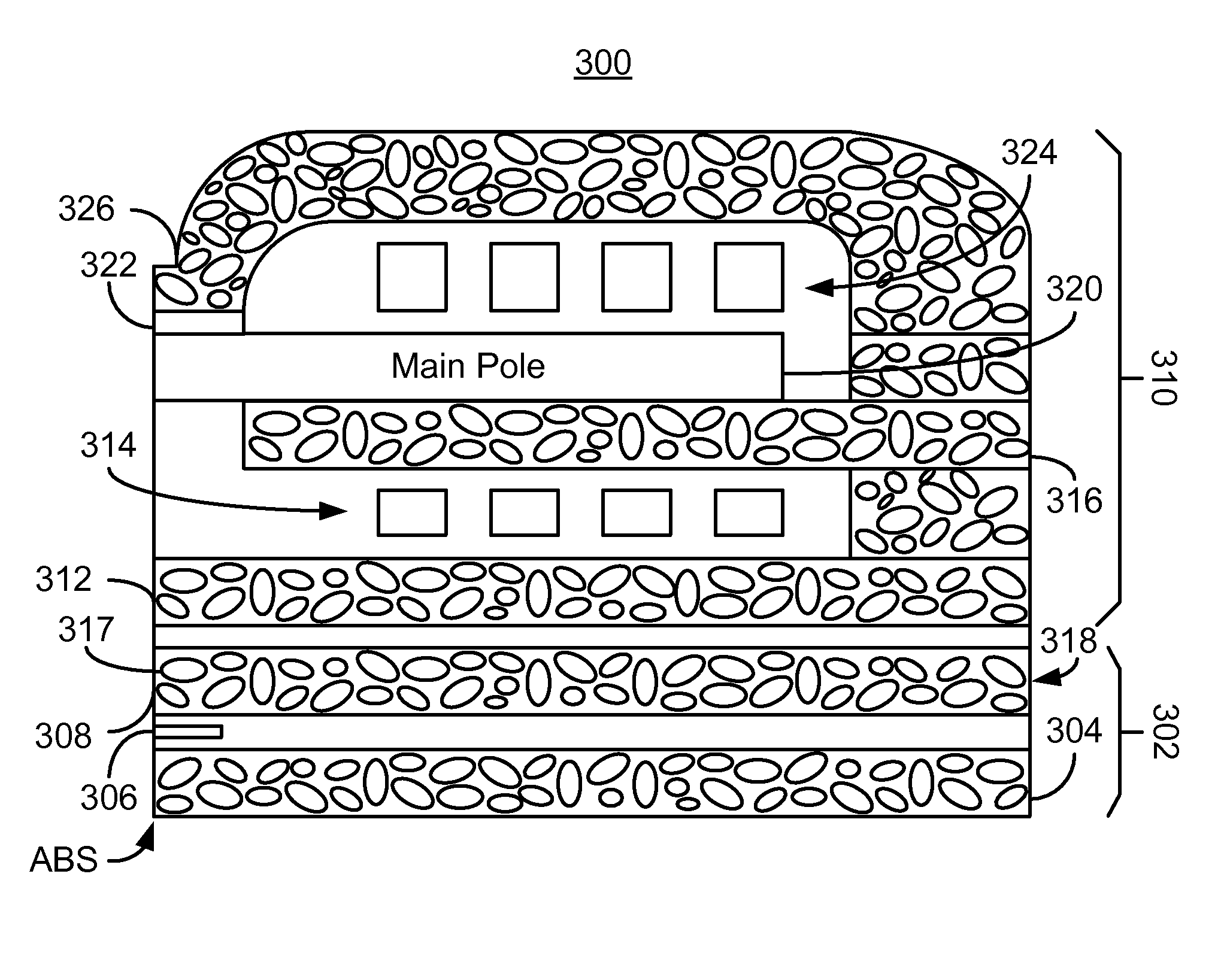

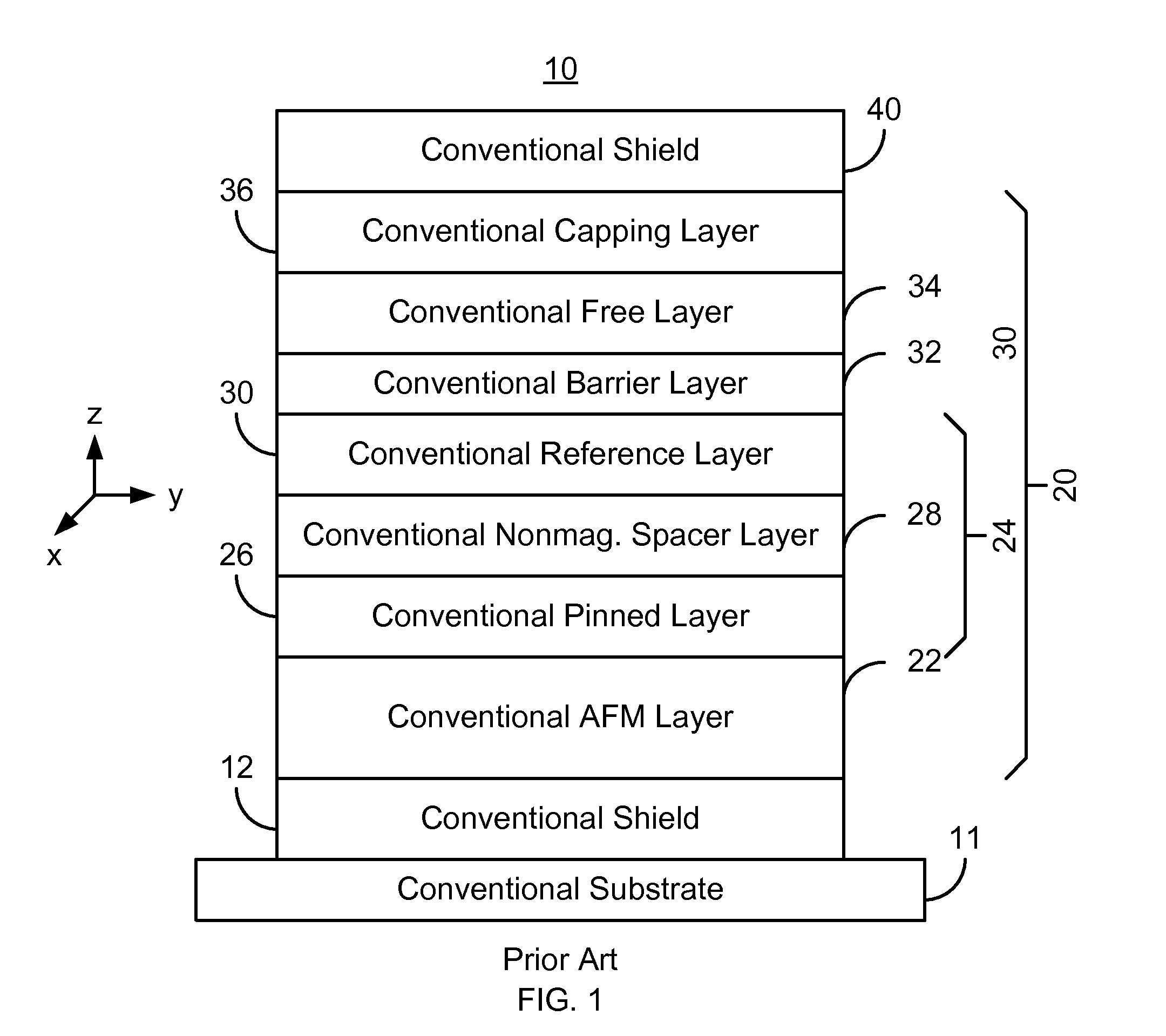

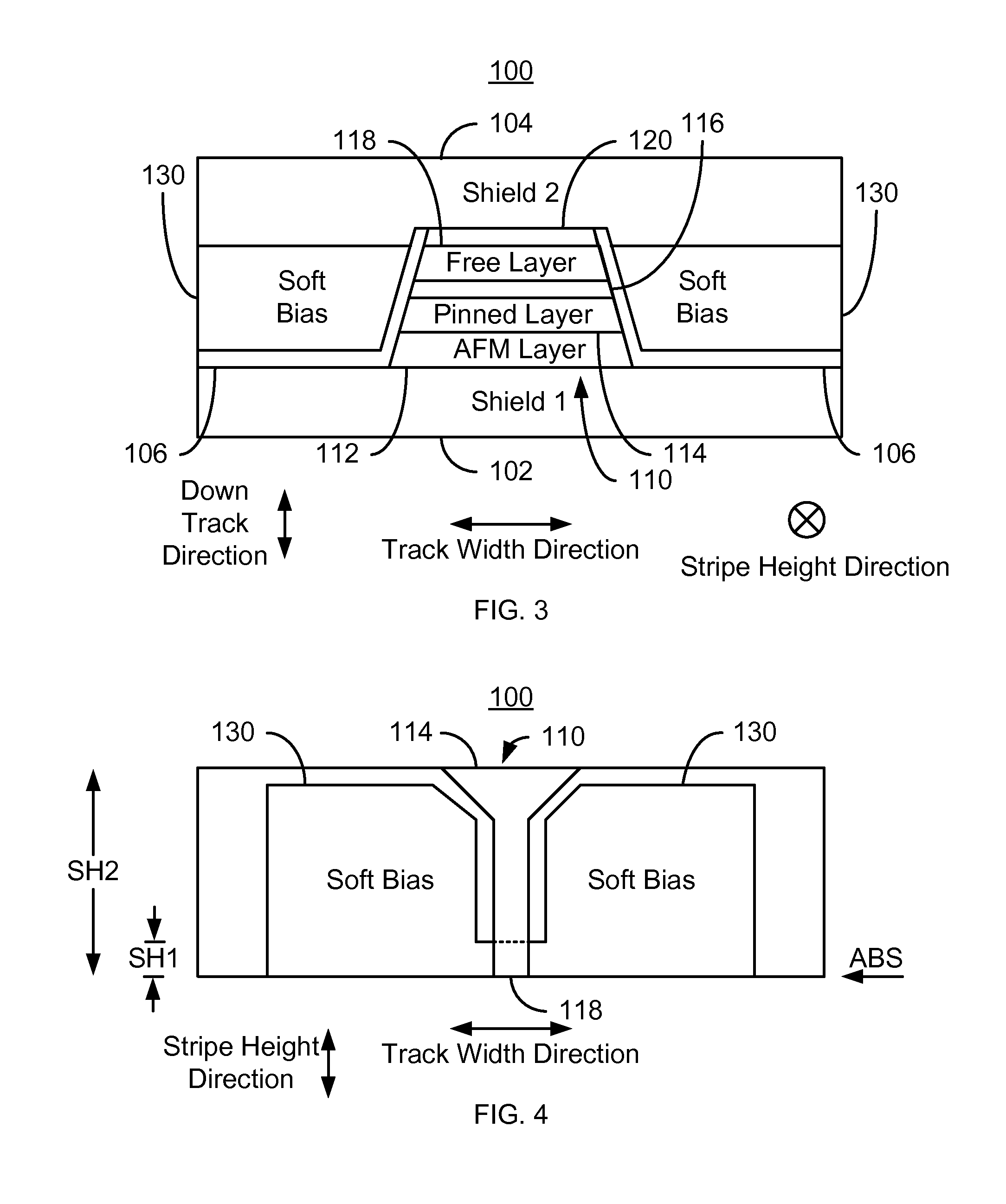

Method and system for providing a read transducer having a reduced shield-to-shield spacing

ActiveUS8675318B1Record information storageManufacture of flux-sensitive headsMagnetic transducersComputer science

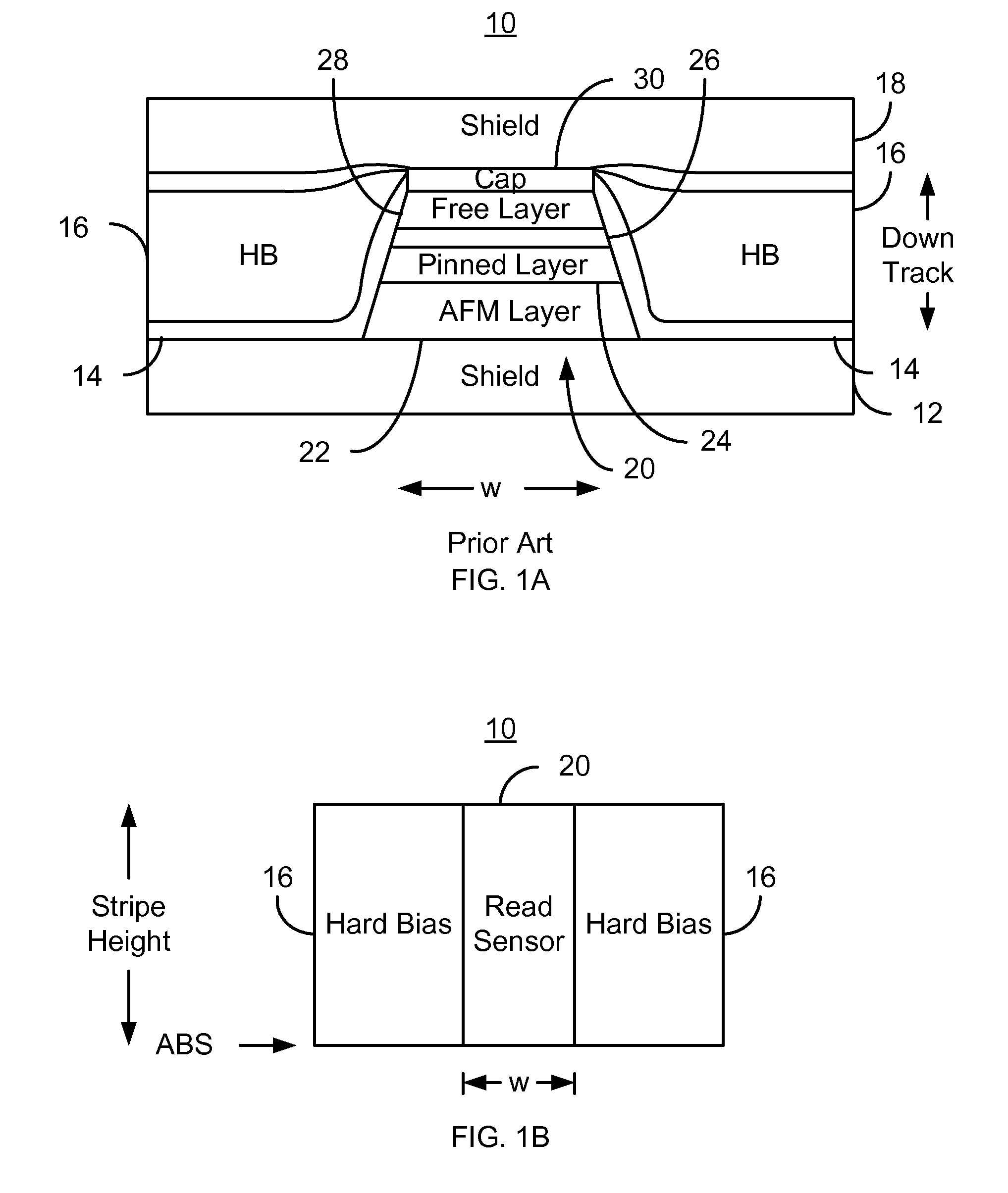

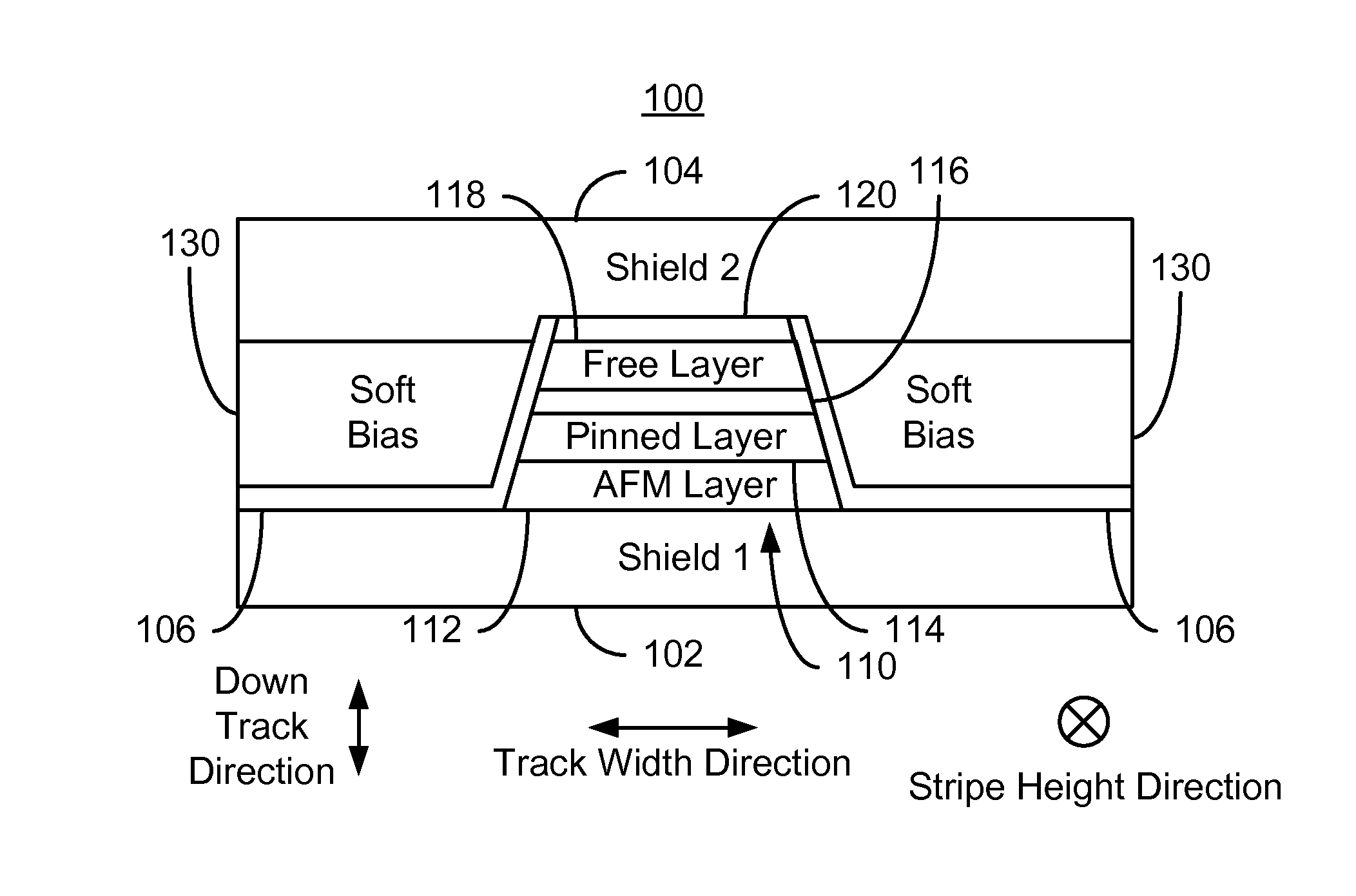

A method and system for providing a read magnetic transducer having an air-bearing surface (ABS) is described. The magnetic read transducer includes a first shield, a read sensor stack, an antiferromagnetic (AFM) tab, and a second shield. The read sensor stack includes a pinned layer, a spacer layer, and a free layer. The spacer layer is nonmagnetic and between the pinned layer and the free layer. A portion of the read sensor stack is at the ABS. The AFM tab is recessed from the ABS and adjacent to a portion of the pinned layer. The read sensor resides between the first shield and the second shield.

Owner:WESTERN DIGITAL TECH INC

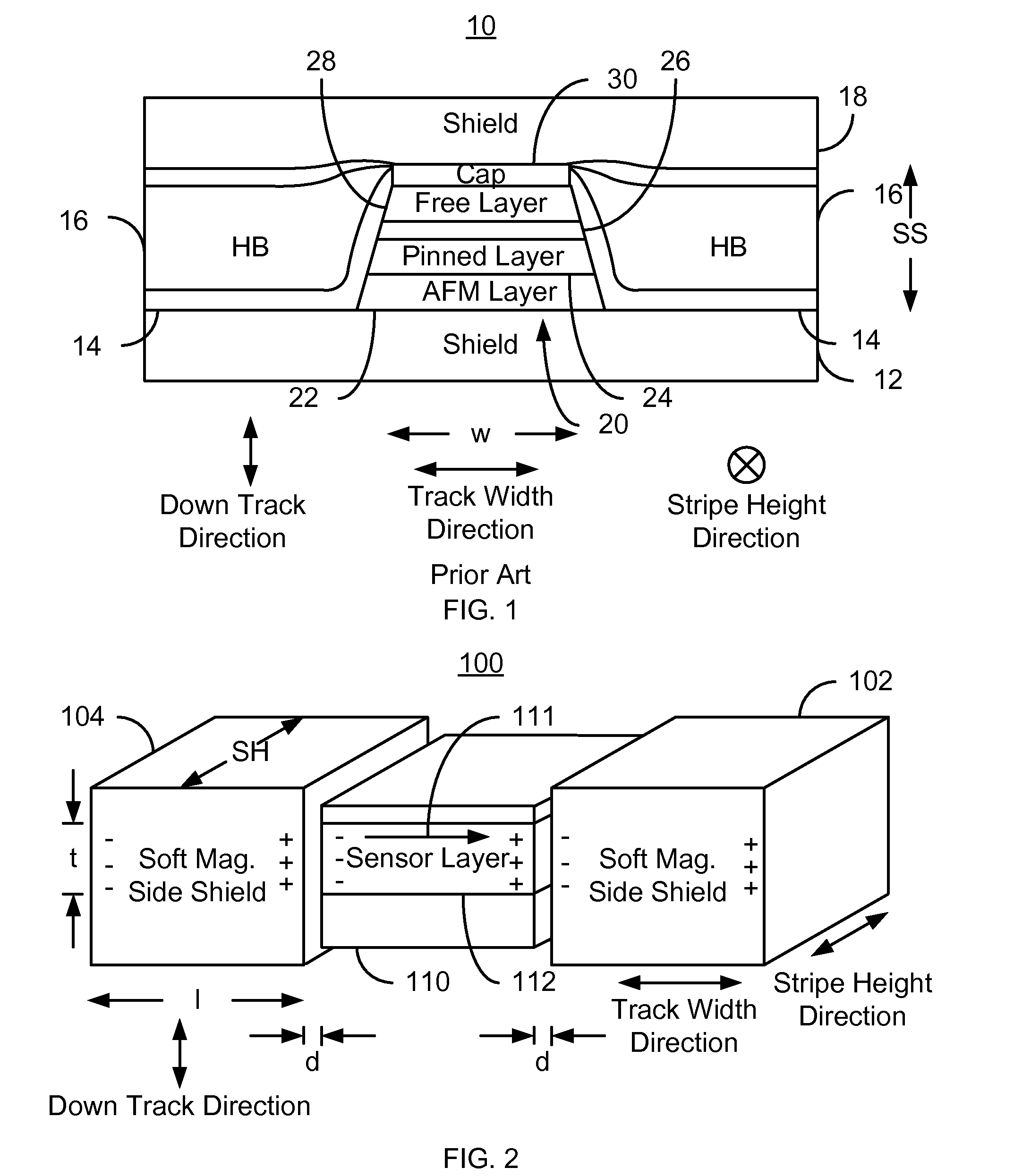

Method and system for providing a side shielded read transducer

A method and system for providing a magnetic transducer having an air-bearing surface (ABS) is described. The magnetic read transducer includes a first shield, a magnetoresistive sensor, at least one soft magnetic side shield, and a second shield. The magnetoresistive sensor includes a sensor layer having at least one edge in the track width direction along the ABS. The at least one soft magnetic side shield is adjacent to the at least one edge of the sensor layer. The at least one soft magnetic side shield has a full film permeability of at least ten. The magnetoresistive sensor is between the first shield and the second shield and free of an in-stack hard bias layer.

Owner:WESTERN DIGITAL TECH INC

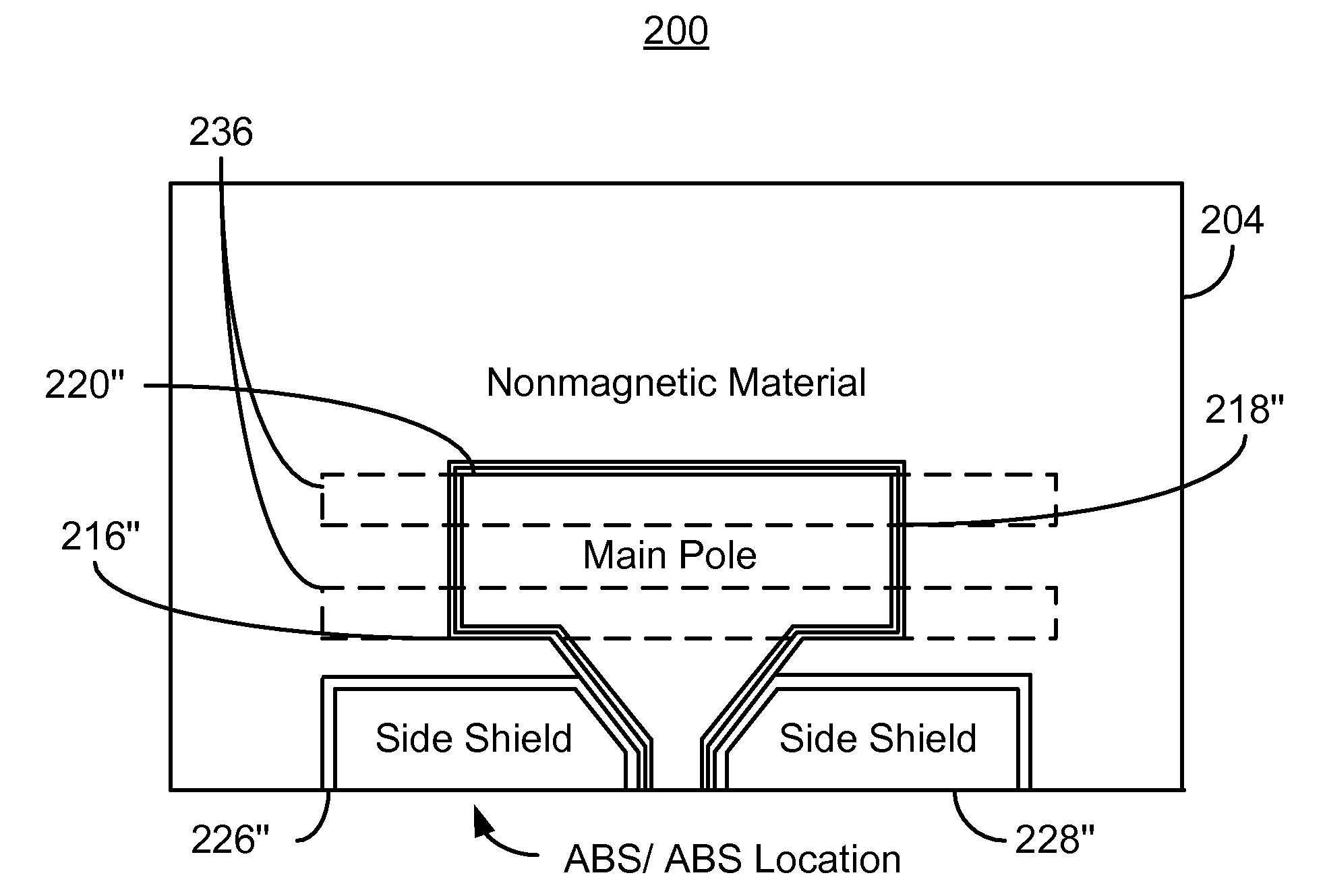

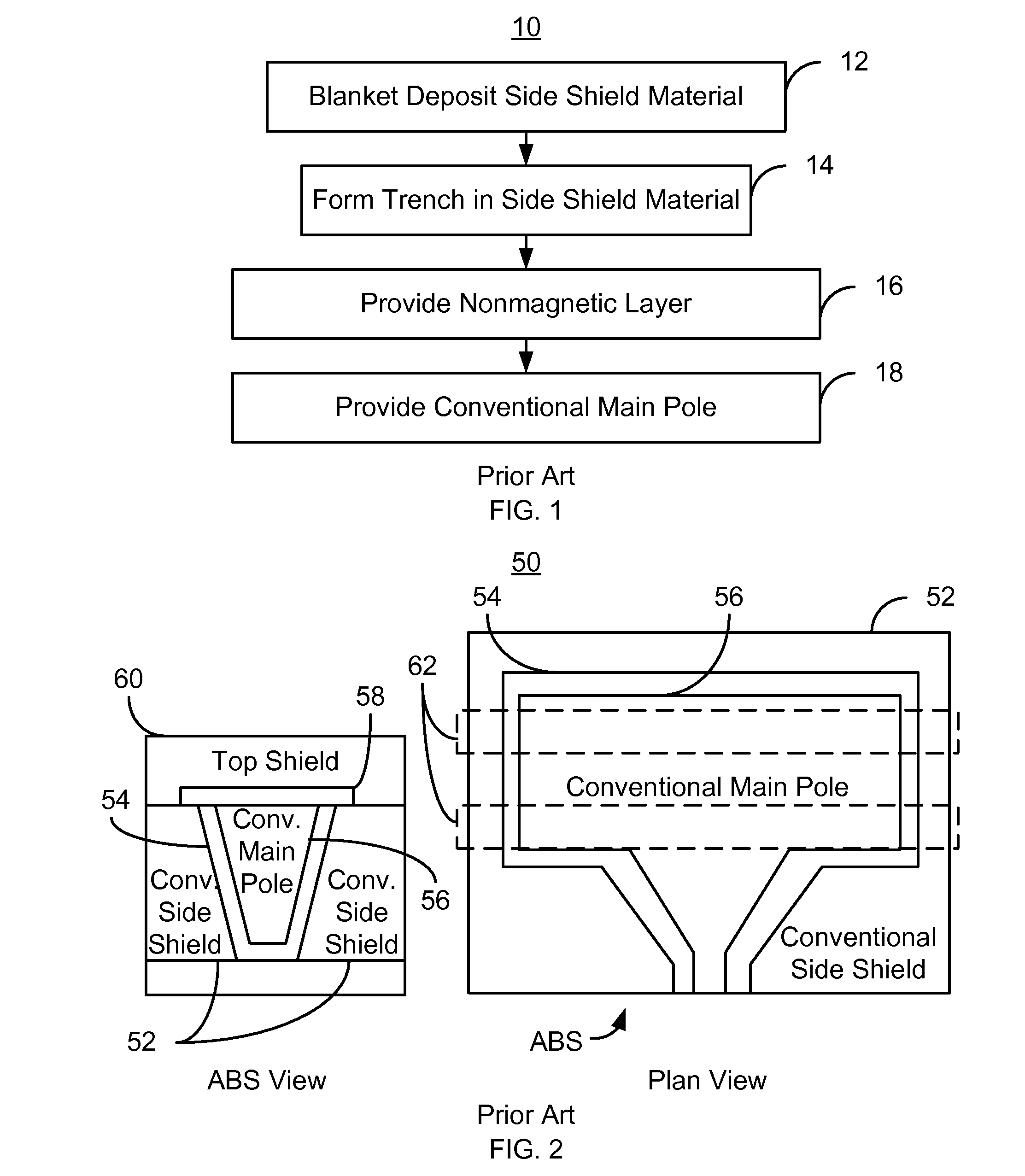

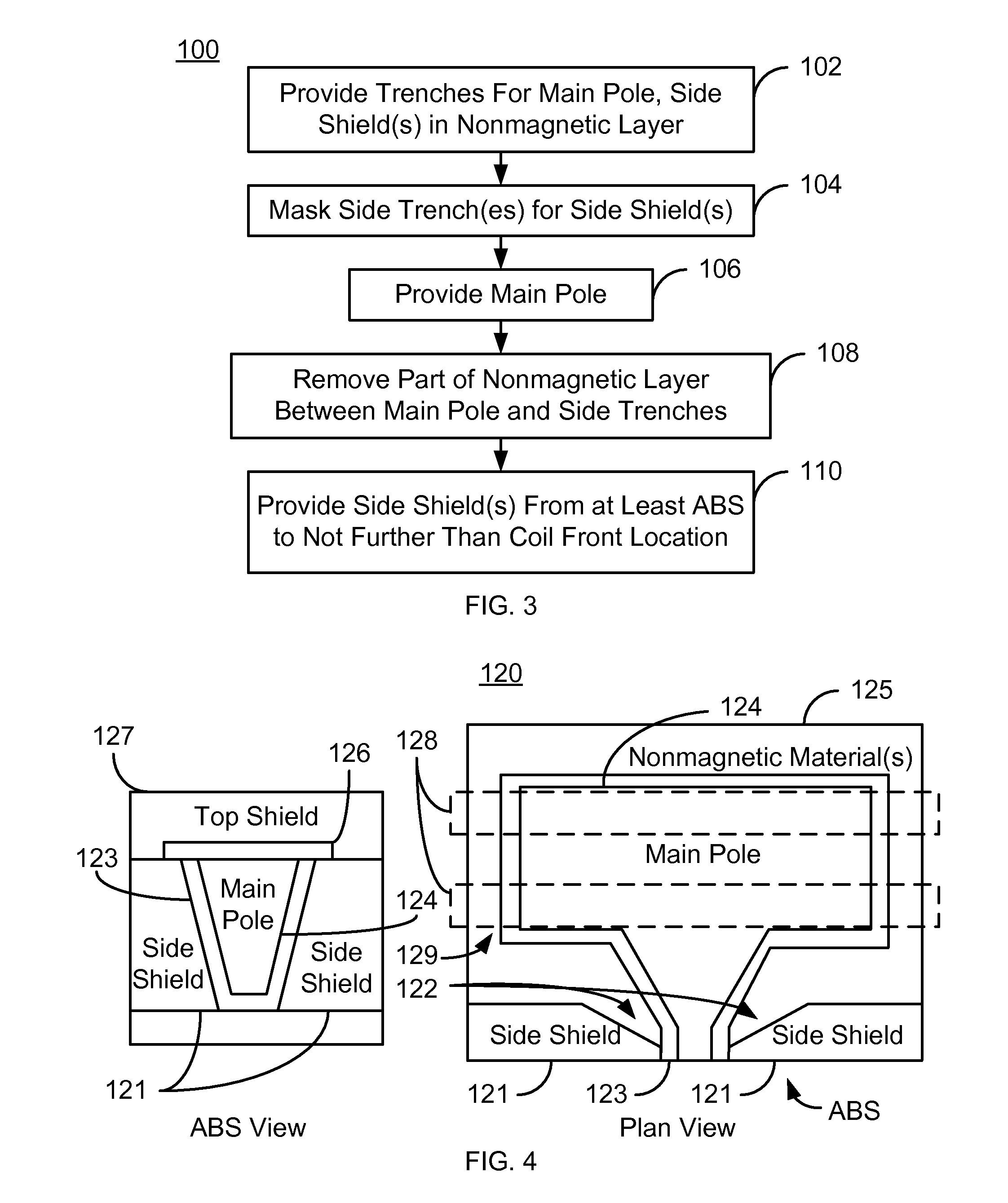

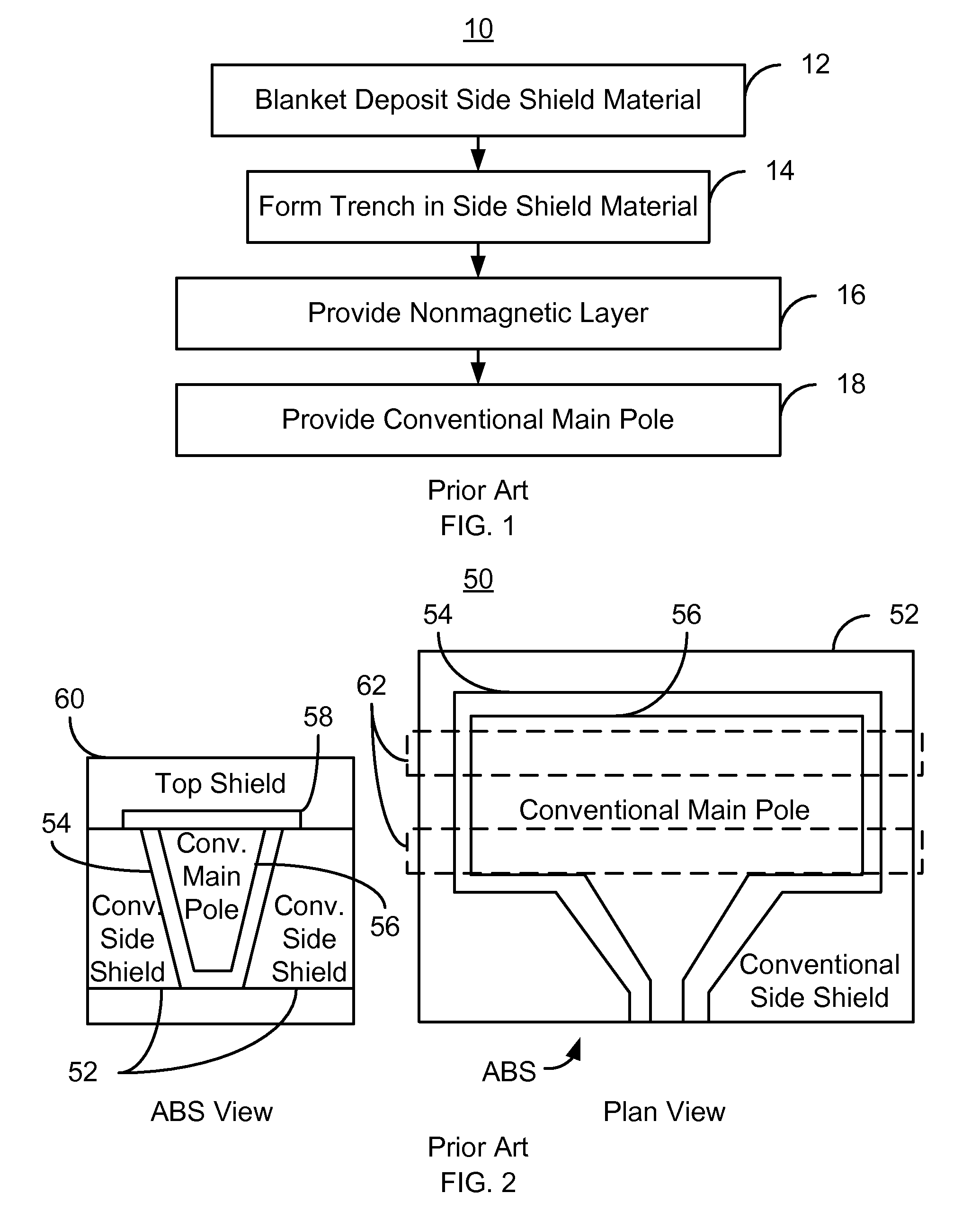

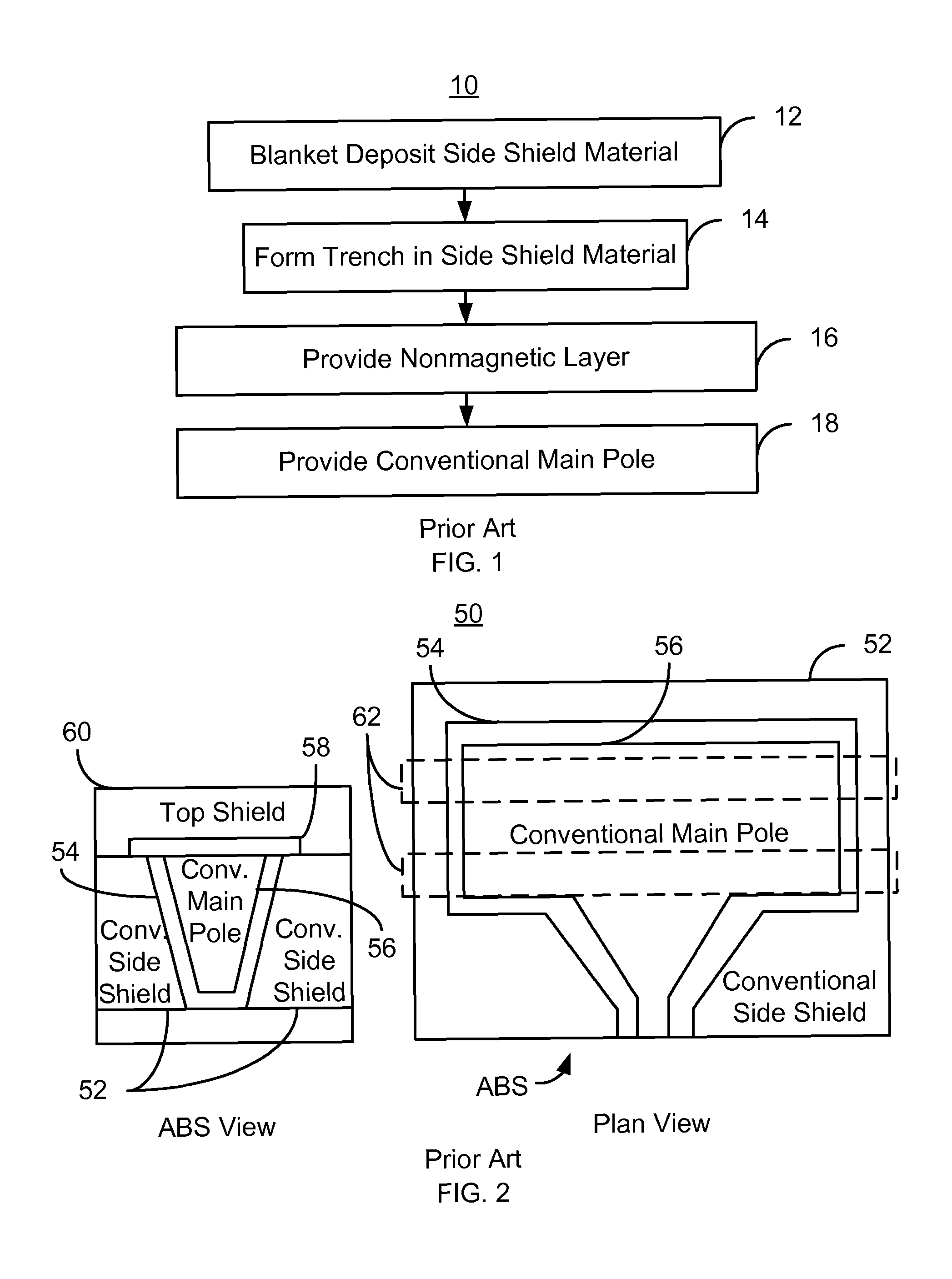

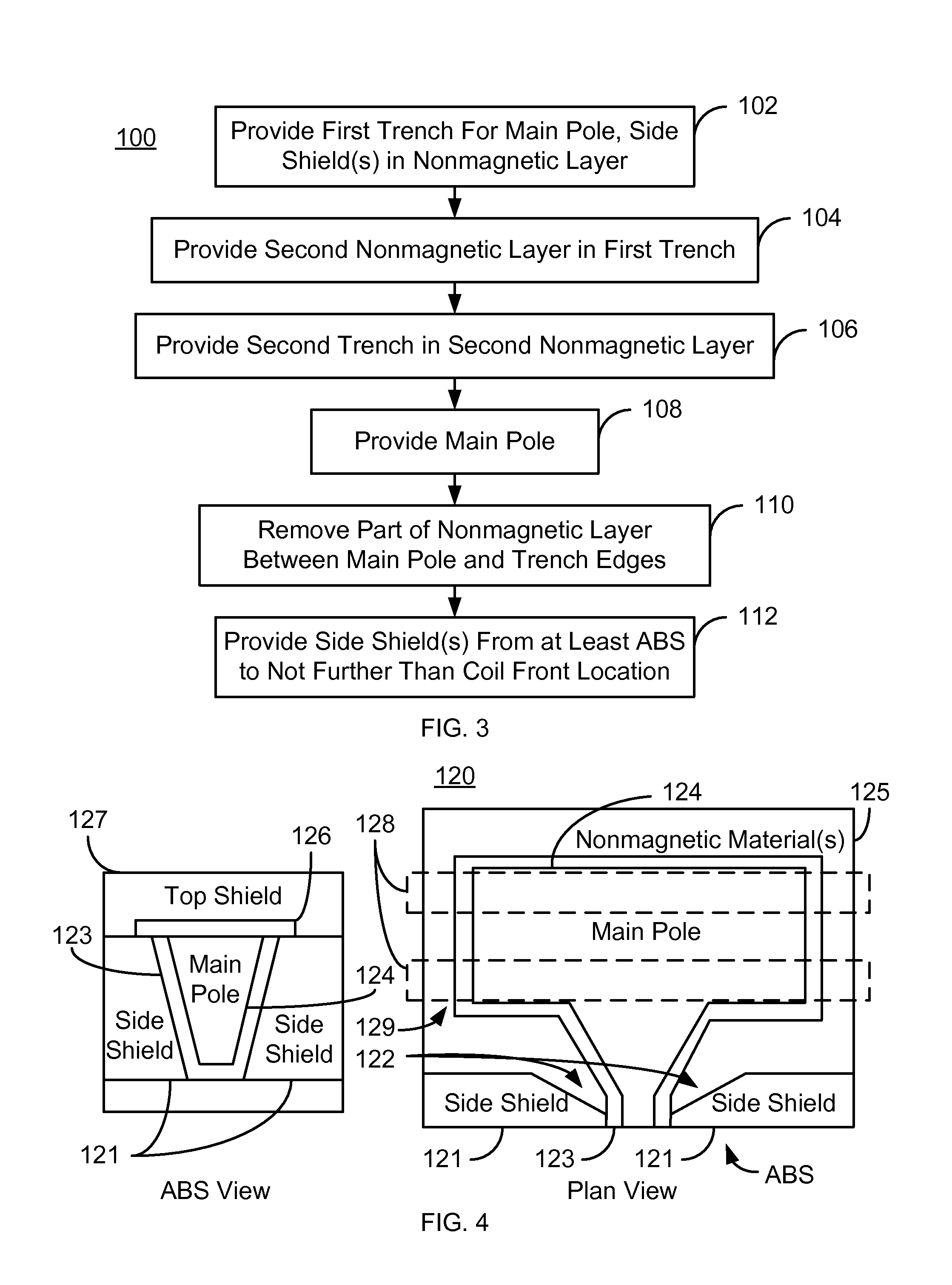

Method for fabricating a magnetic recording transducer having side shields

A method provides a magnetic transducer that includes an underlayer and a nonmagnetic layer on the underlayer. The method includes providing a plurality of trenches in the nonmagnetic layer. A first trench of corresponds to a main pole, while at least one side trench corresponds to at least one side shield. The method also includes providing mask covering the side trench(es) and providing the main pole. At least a portion of the main pole resides in the first trench. The method also includes removing at least a portion of the nonmagnetic layer residing between the side trench(es) and the main pole. The method also includes providing at least one side shield. The shield(s) extend from at least an air-bearing surface location to not further than a coil front location.

Owner:WESTERN DIGITAL TECH INC

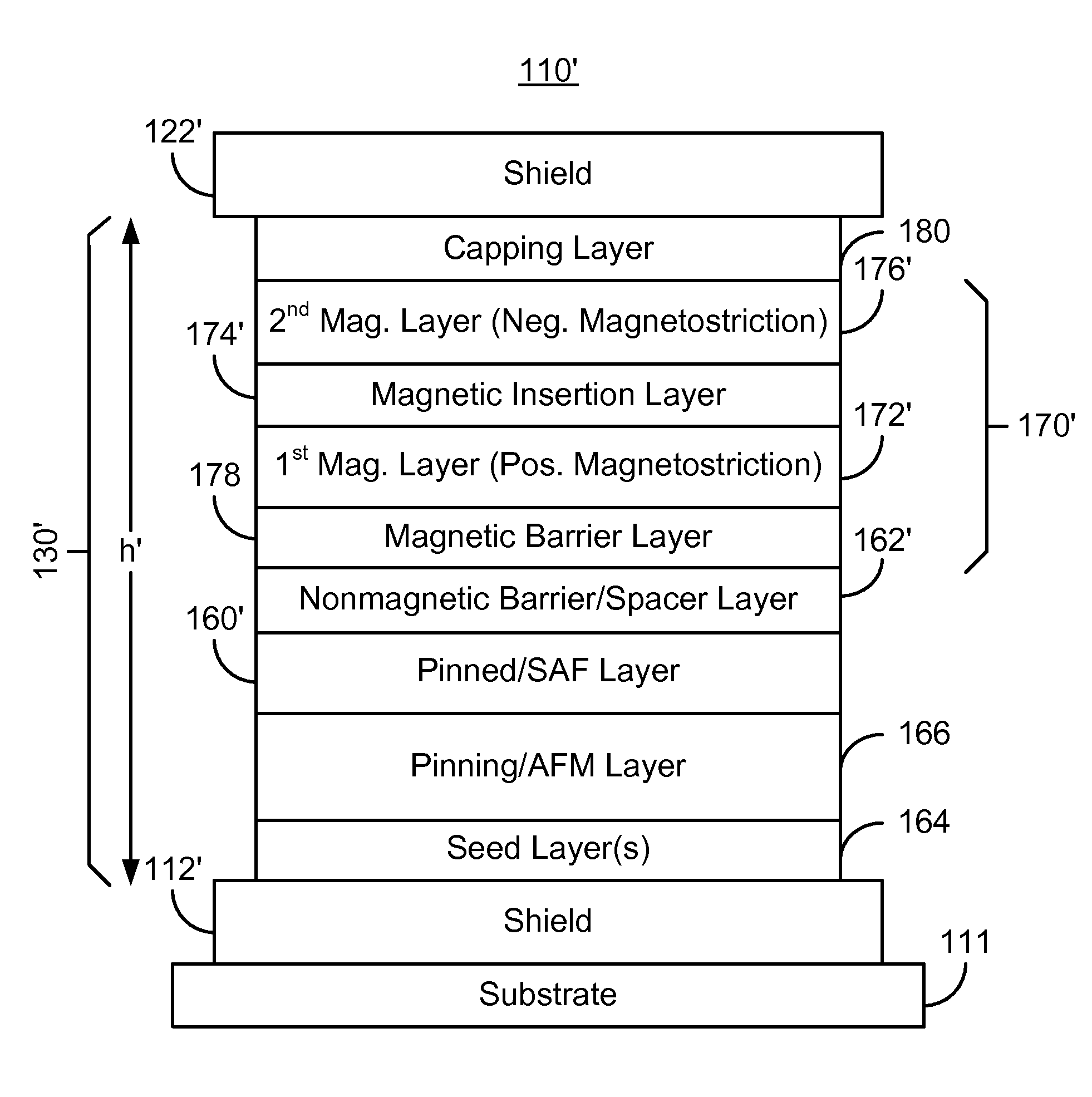

Method and system for providing a read sensor having a low magnetostriction free layer

ActiveUS8194365B1Magnetic measurementsMagnetic-field-controlled resistorsMagnetic transducersMagnetic layer

A method and system for providing a magnetic structure in magnetic transducer is described. The magnetic structure includes a pinned layer, a nonmagnetic spacer layer, and a free layer. The nonmagnetic spacer layer is between the pinned layer and the free layer. The free layer includes a first magnetic layer, a second magnetic layer, and a magnetic insertion layer between the first magnetic layer and the second magnetic layer. The first magnetic layer has a first magnetostriction. The second magnetic layer has a second magnetostriction opposite to the first magnetostriction. The magnetic insertion layer provides a growth texture barrier between the first magnetic layer and the second magnetic layer.

Owner:WESTERN DIGITAL TECH INC

Method and system for providing a magnetic recording transducer having side shields

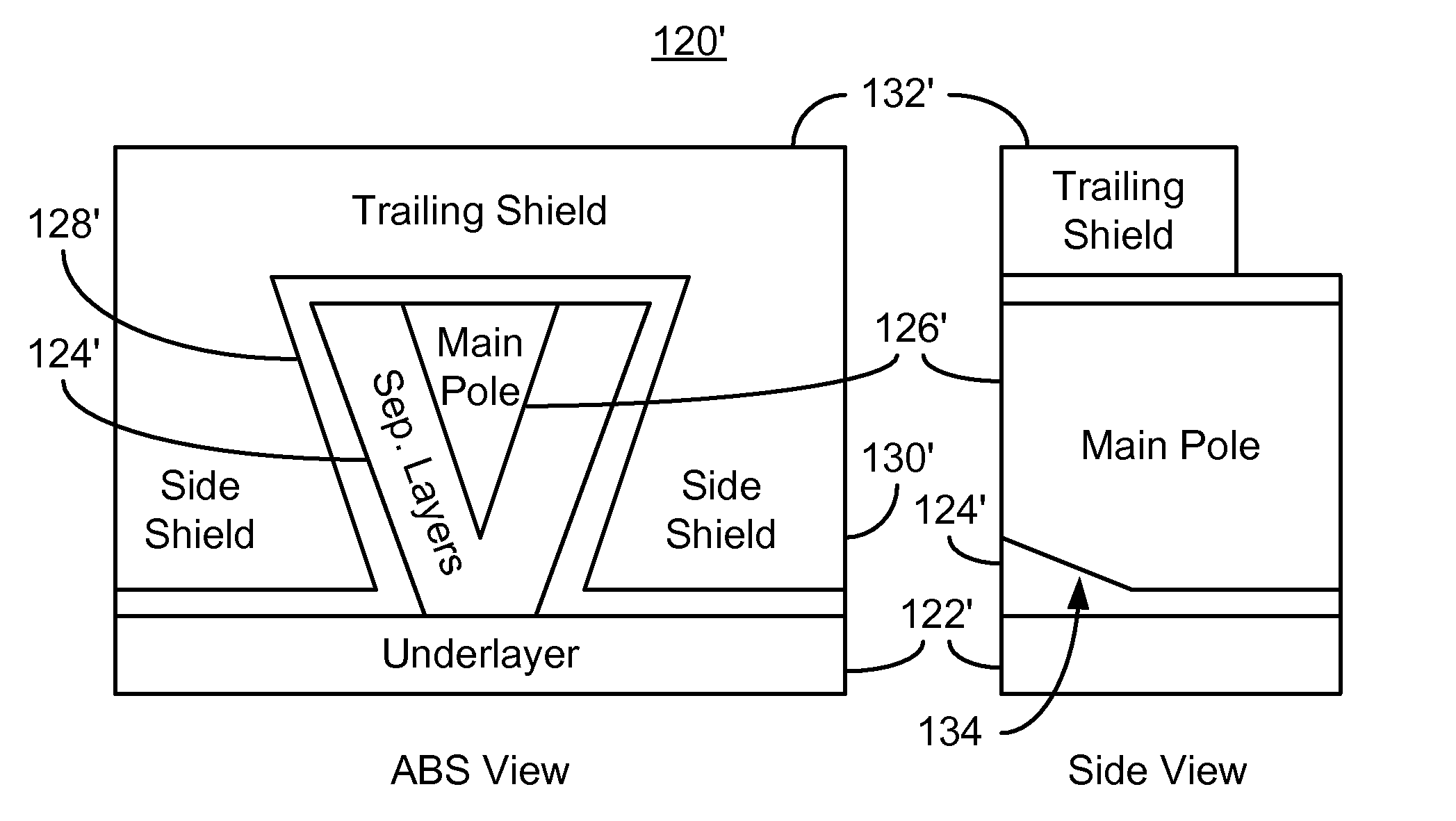

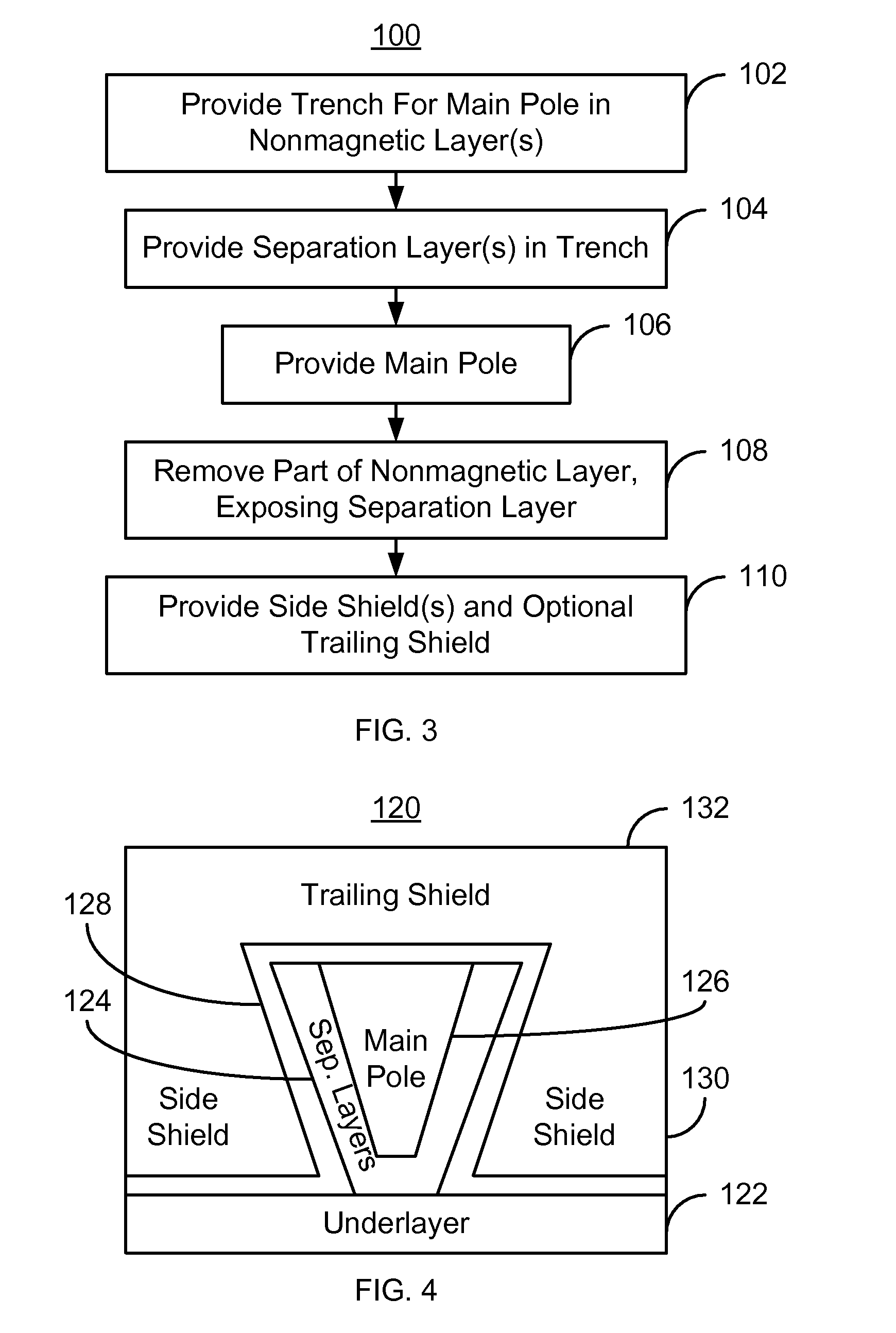

ActiveUS8231796B1Decorative surface effectsRecord information storageMagnetic transducersNon magnetic

A method and system provide a magnetic transducer that includes an underlayer and a nonmagnetic layer on the underlayer. The method and system include providing a trench in the nonmagnetic layer. The trench has a plurality of sides. The method and system also include providing a separation layer in the trench. A portion of the separation layer resides on the sides of the trench. The method and system include providing the main pole. At least part of the main pole resides in the trench on the portion of the separation layer and has a plurality of pole sides. The method and system further include removing at least a portion of the second nonmagnetic layer, thereby exposing the portion of the separation layer. The method and system also include providing a side shield. The separation layer magnetically separates the pole sides from the side shield.

Owner:WESTERN DIGITAL TECH INC

Method and system for providing a read transducer having an improved composite magnetic shield

A method and system provide a magnetic transducer including a first shield, a read sensor, and a second shield. The read sensor is between the first shield and the second shield. The second shield includes a first ferromagnetic layer, a nonmagnetic spacer layer, a second ferromagnetic layer and a pinning layer. The nonmagnetic spacer layer is between the first ferromagnetic layer and the second ferromagnetic layer. The first ferromagnetic layer is between the read sensor and the nonmagnetic spacer layer. The pinning layer is adjacent to the second ferromagnetic layer. The first ferromagnetic layer is coupled antiparallel with the second ferromagnetic layer. At least one of the first ferromagnetic layer and the second ferromagnetic layer includes a CoFe portion adjacent to the nonmagnetic spacer layer. The CoFe portion includes at least twenty-five atomic percent and not more than fifty atomic percent Fe.

Owner:WESTERN DIGITAL TECH INC

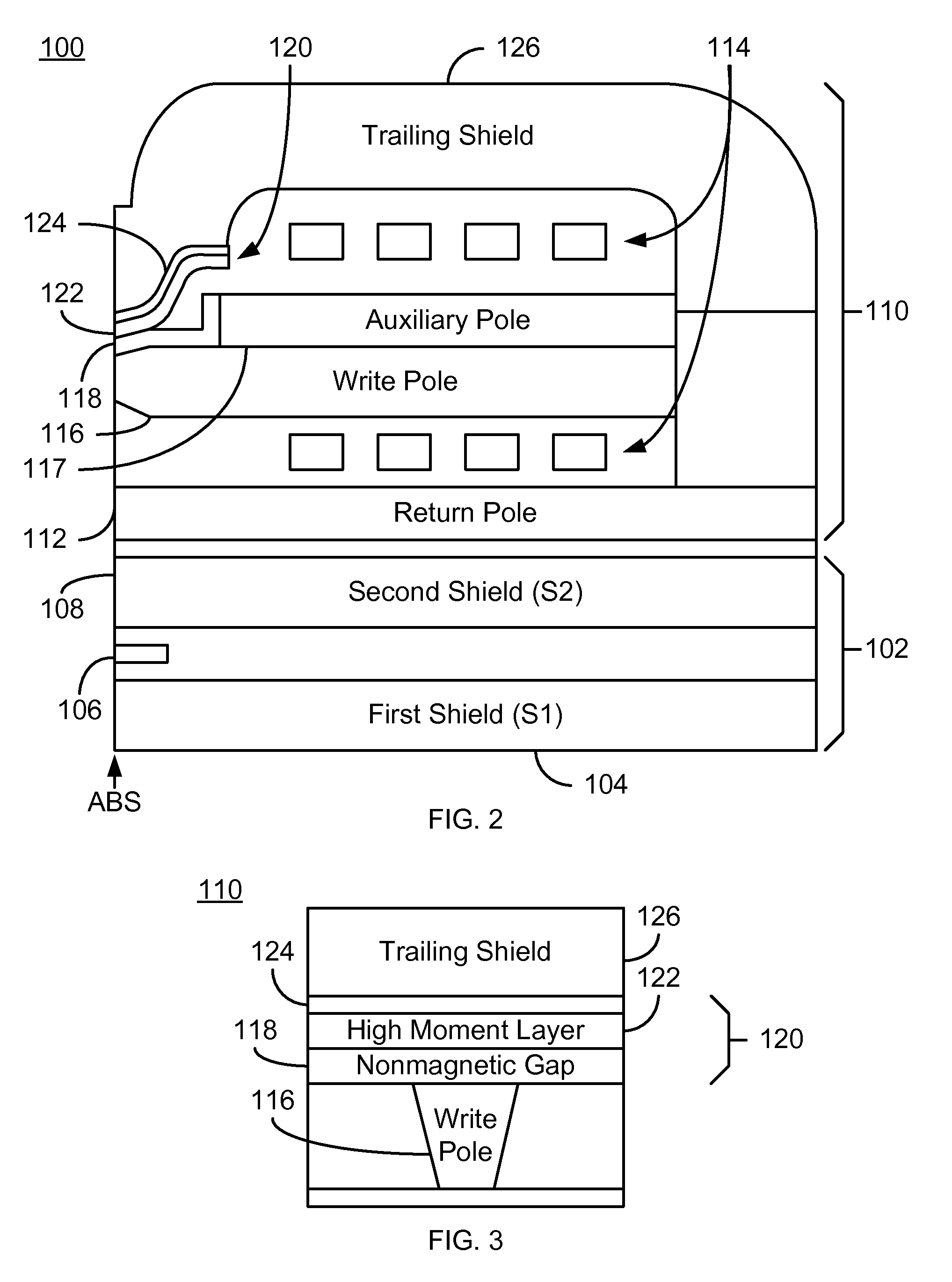

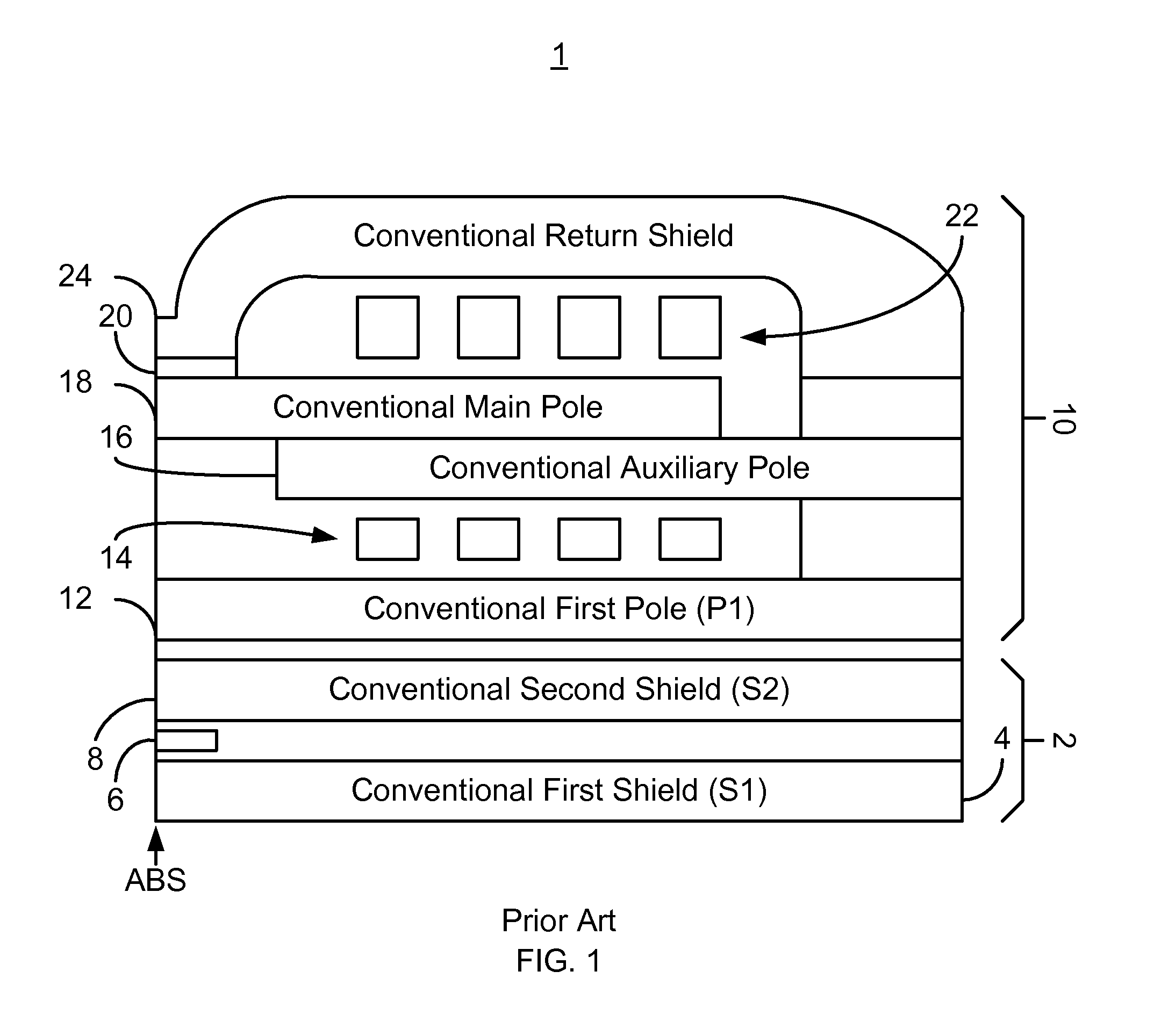

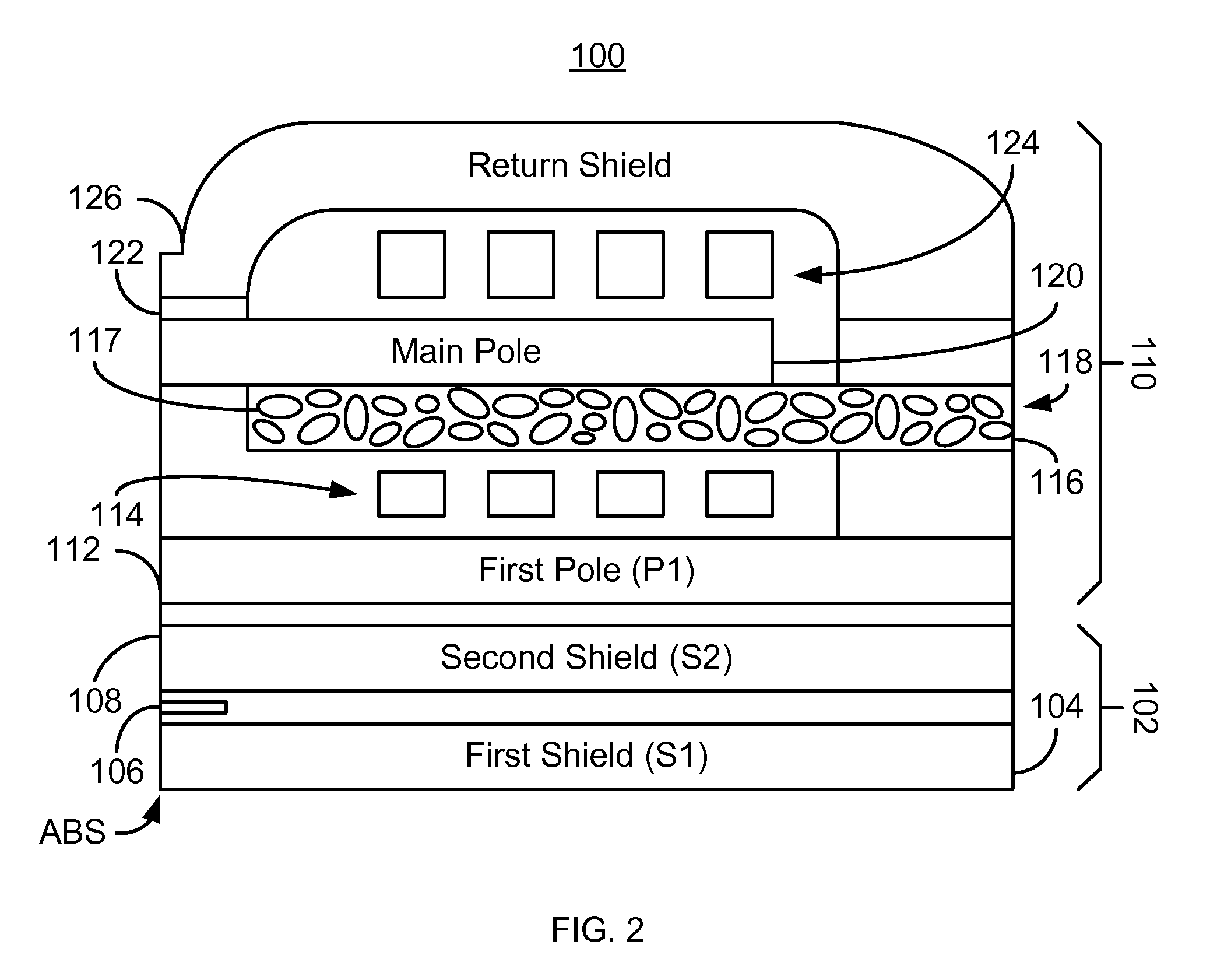

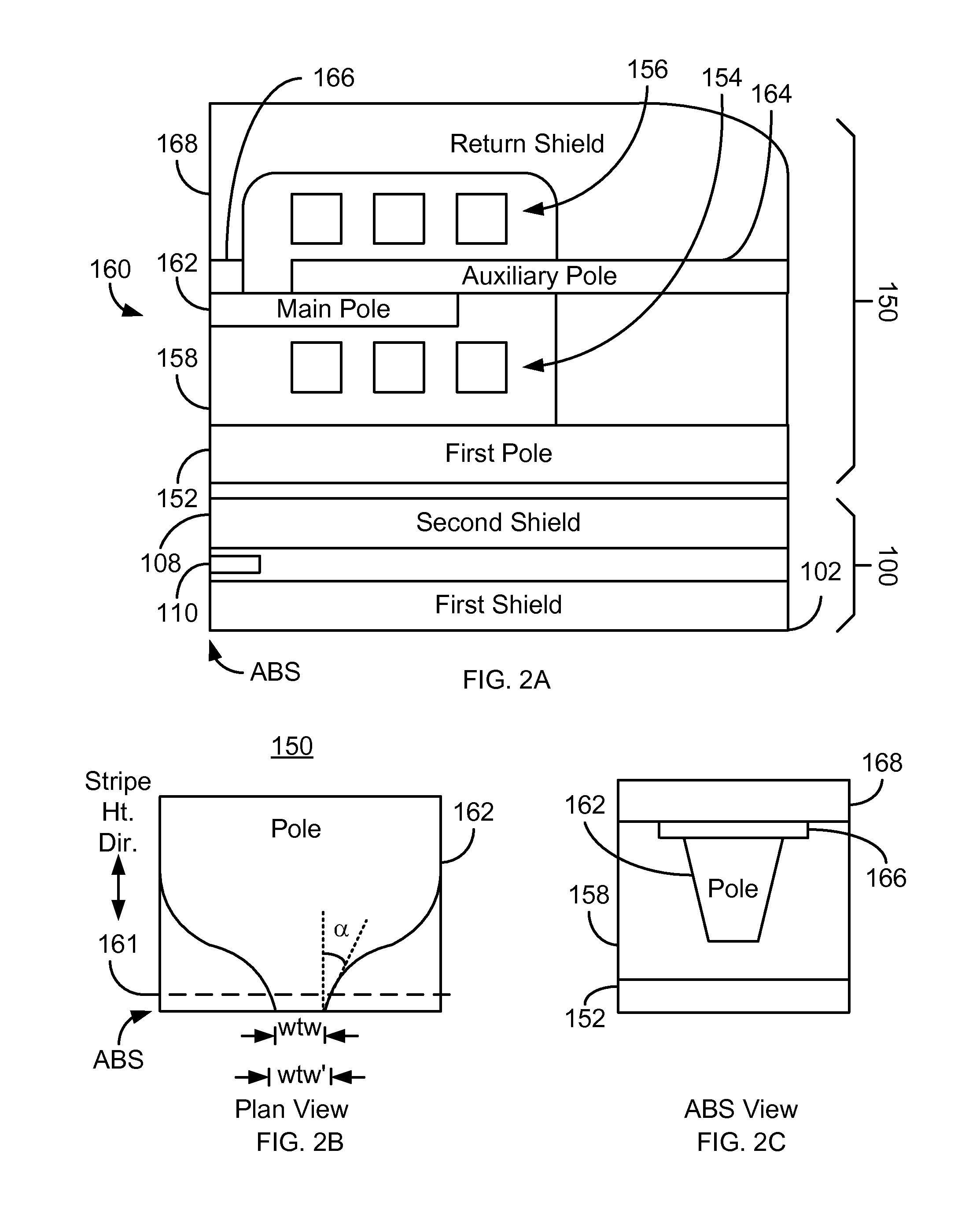

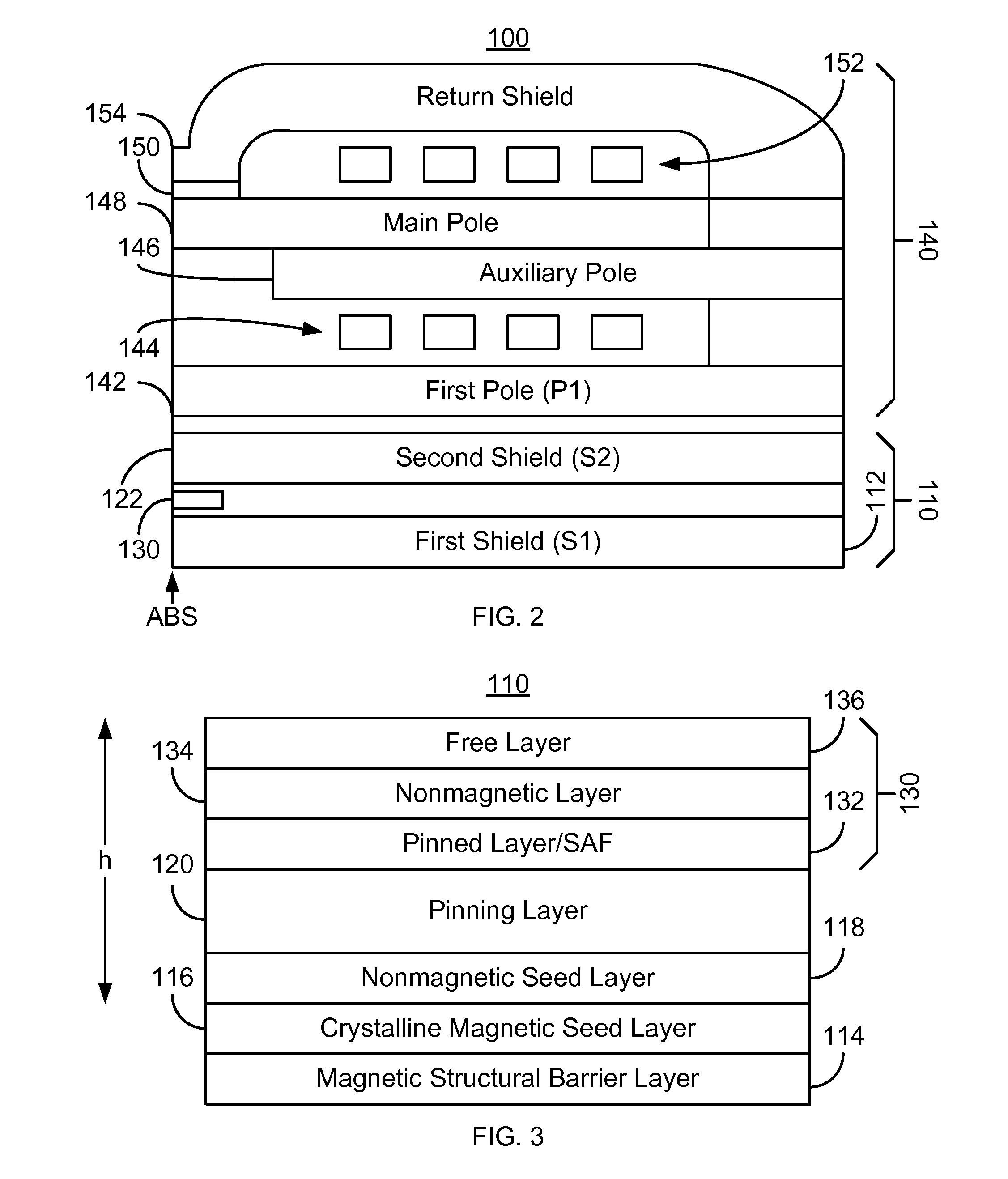

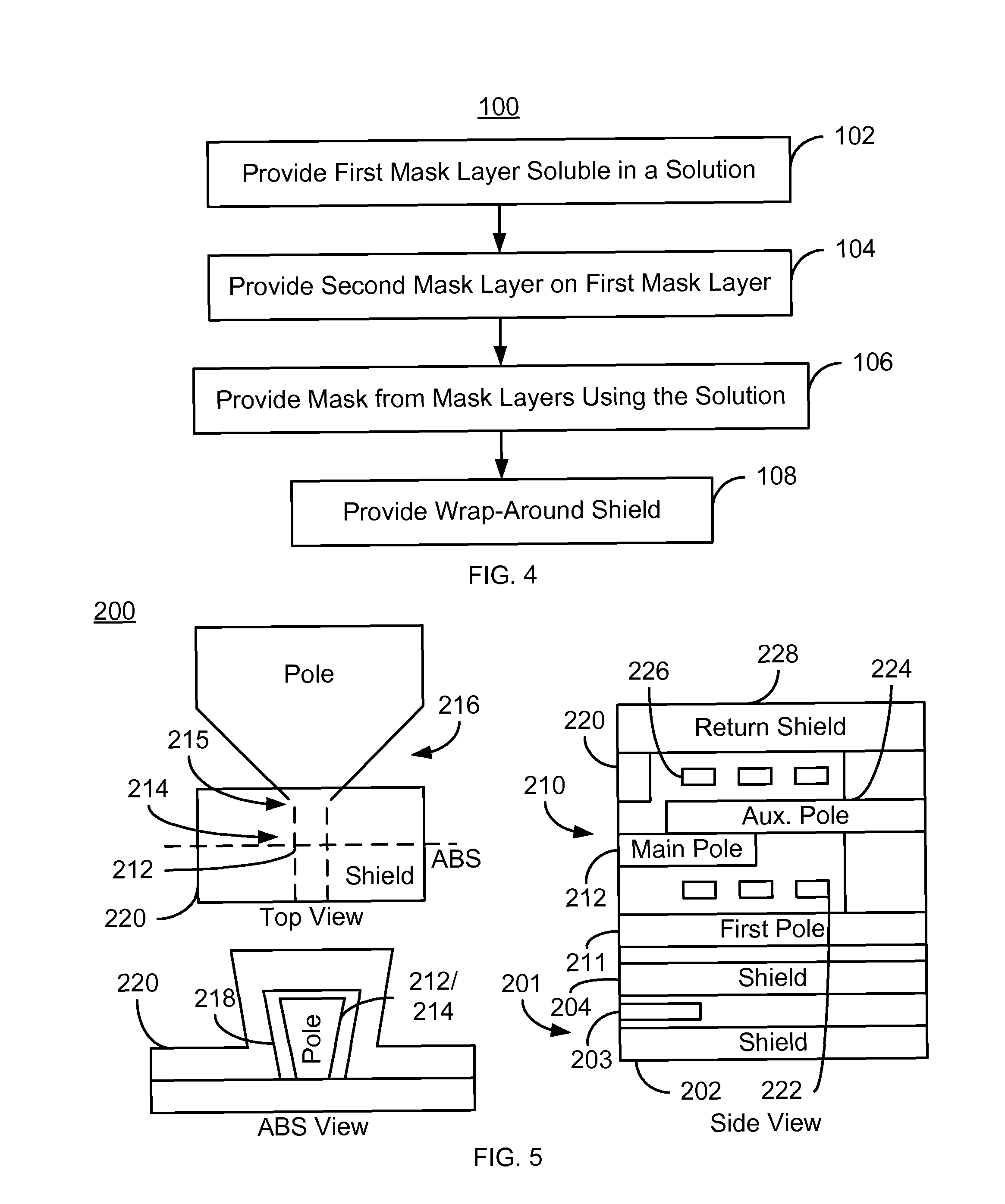

Method and system for providing a magnetic head using a composite magnetic material in the recording transducer

A method and system for providing a magnetic transducer for recording to media is described. The method and system include providing a first pole, a main pole, at least one coil and at least one auxiliary pole. The main pole is for providing a magnetic field for recording to the media. The coil(s) are for energizing the main pole. The auxiliary pole is magnetically coupled with the main pole. The shield(s) are for magnetically isolating a portion of the magnetic transducer. At least one of the first pole, the auxiliary pole, and the at least one shield includes a composite magnetic material including a plurality of ferromagnetic grains in an insulating matrix.

Owner:WESTERN DIGITAL TECH INC

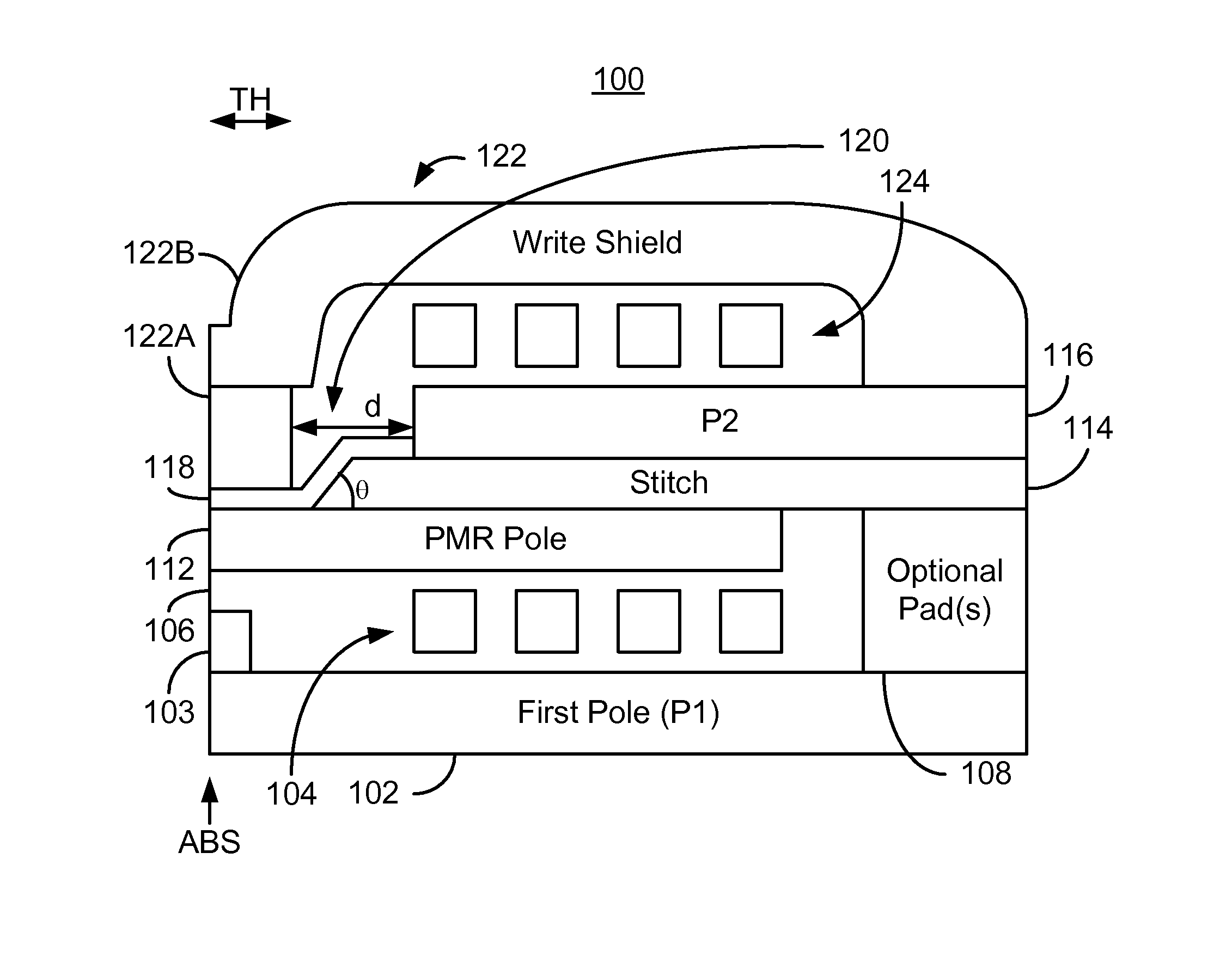

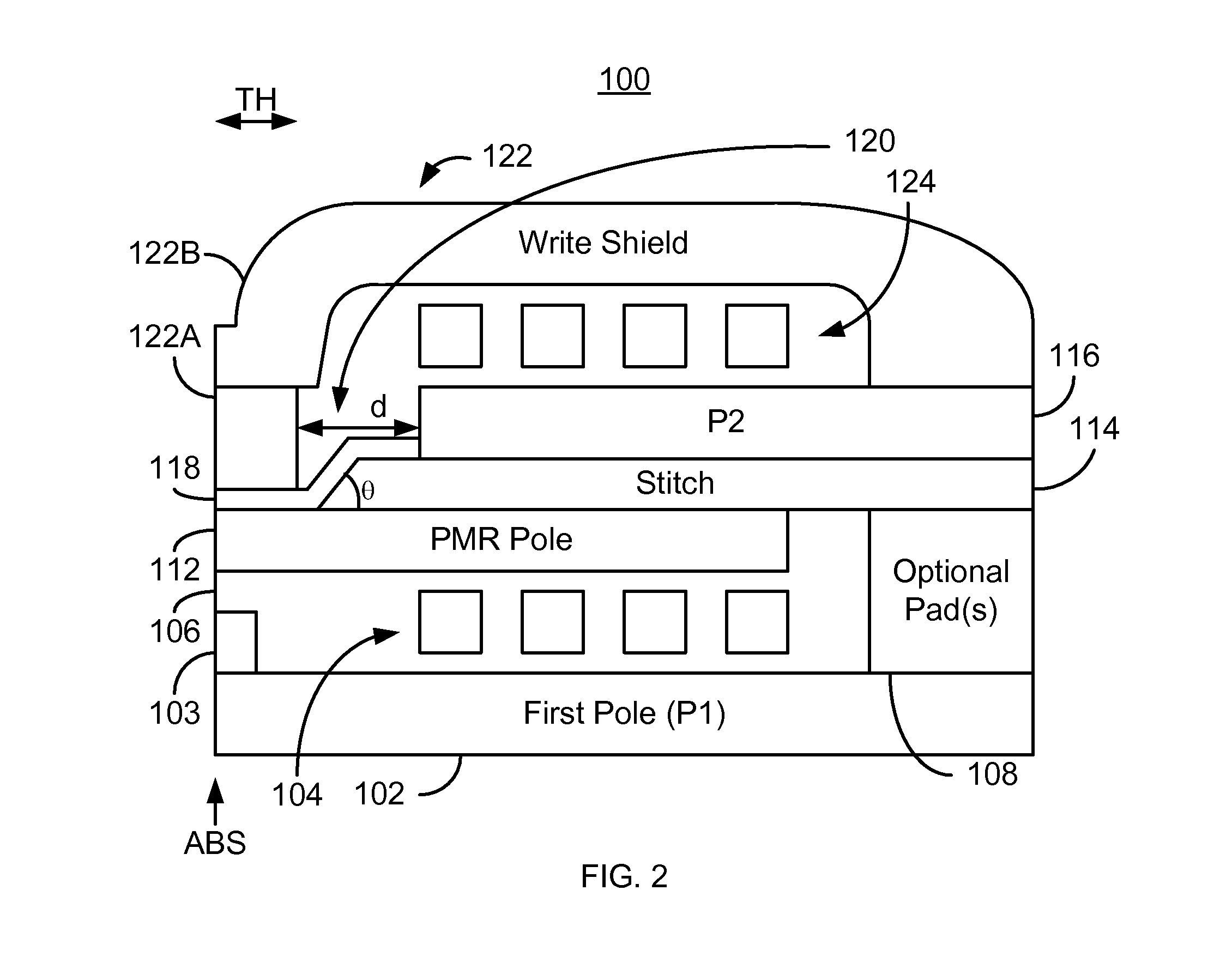

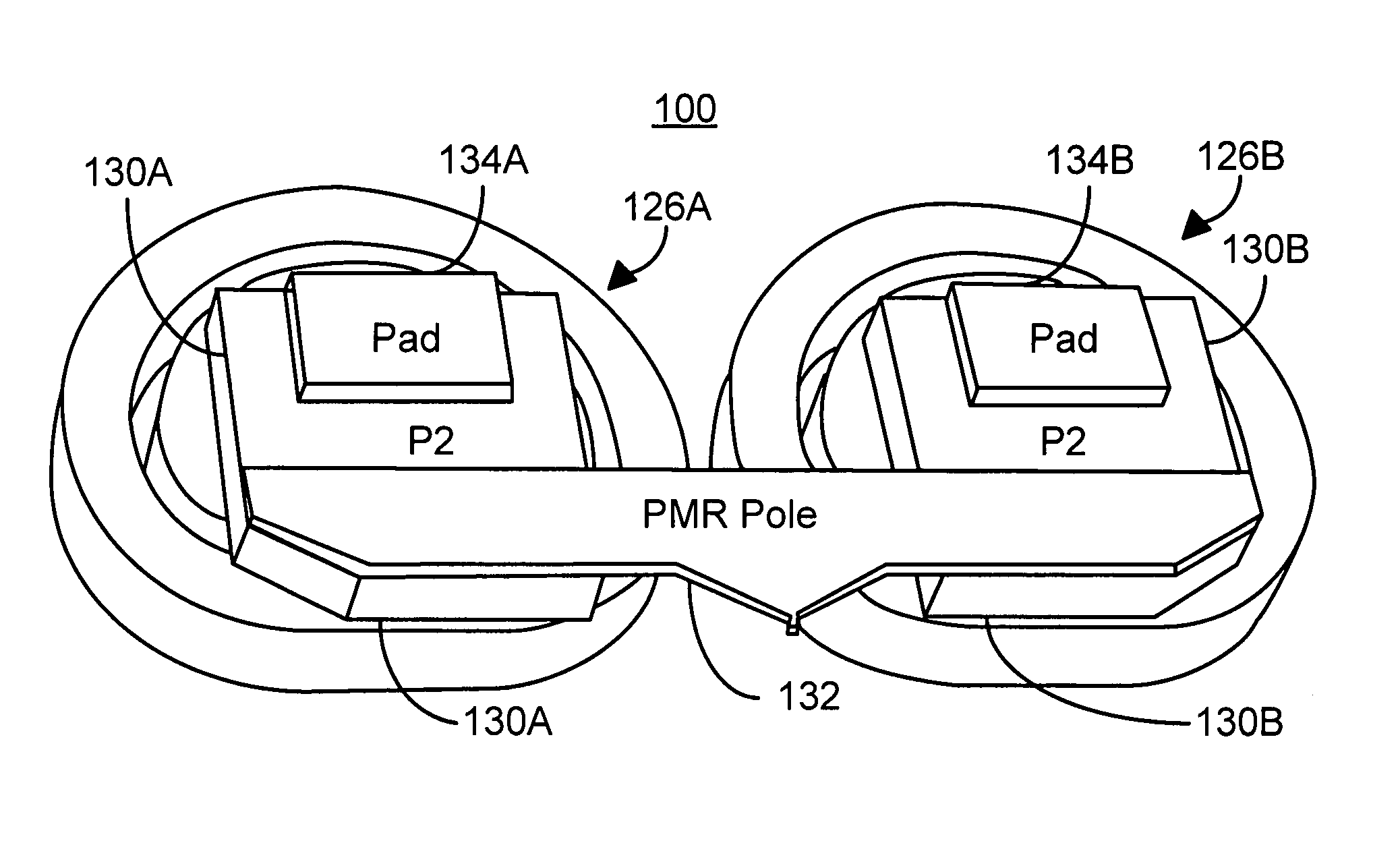

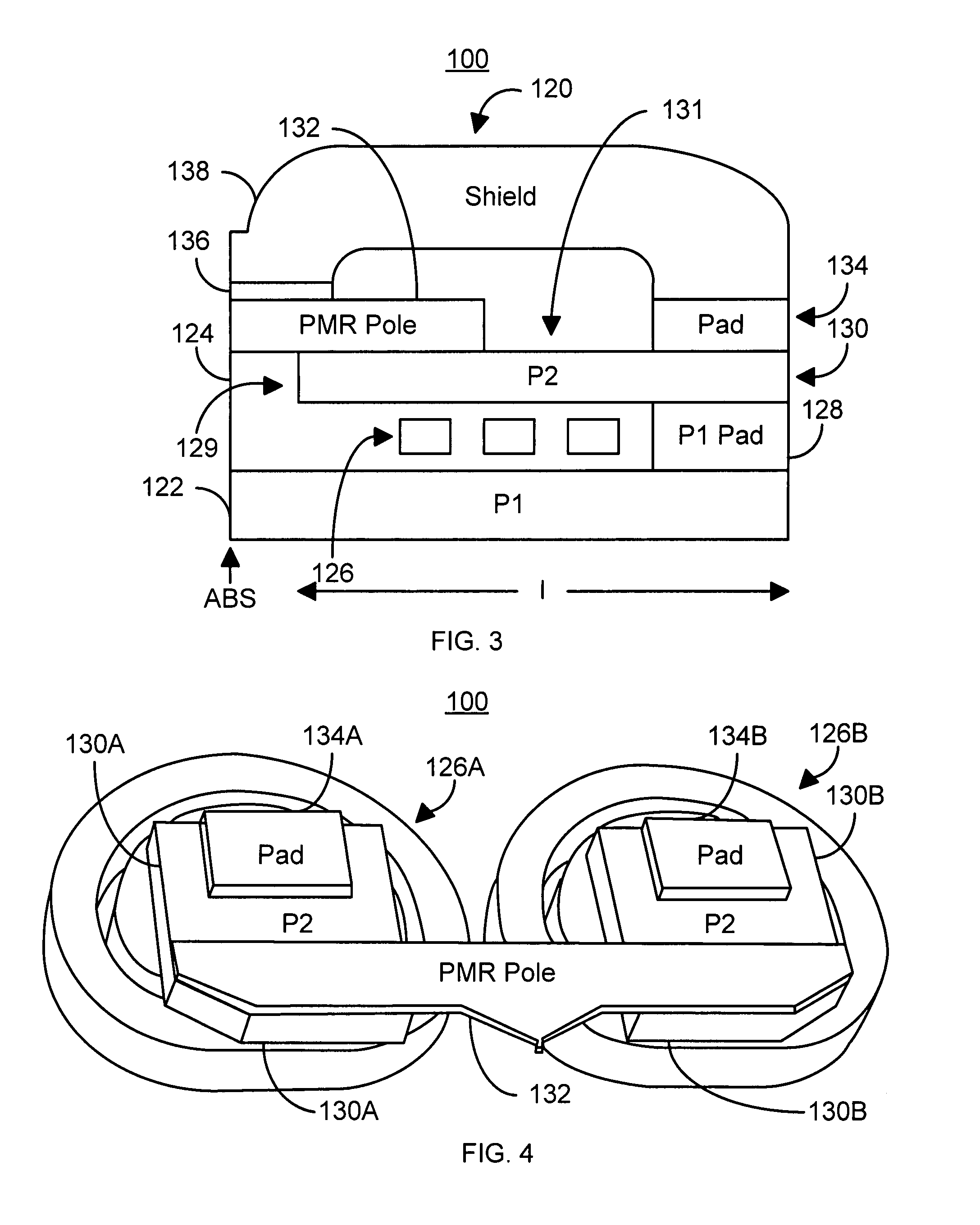

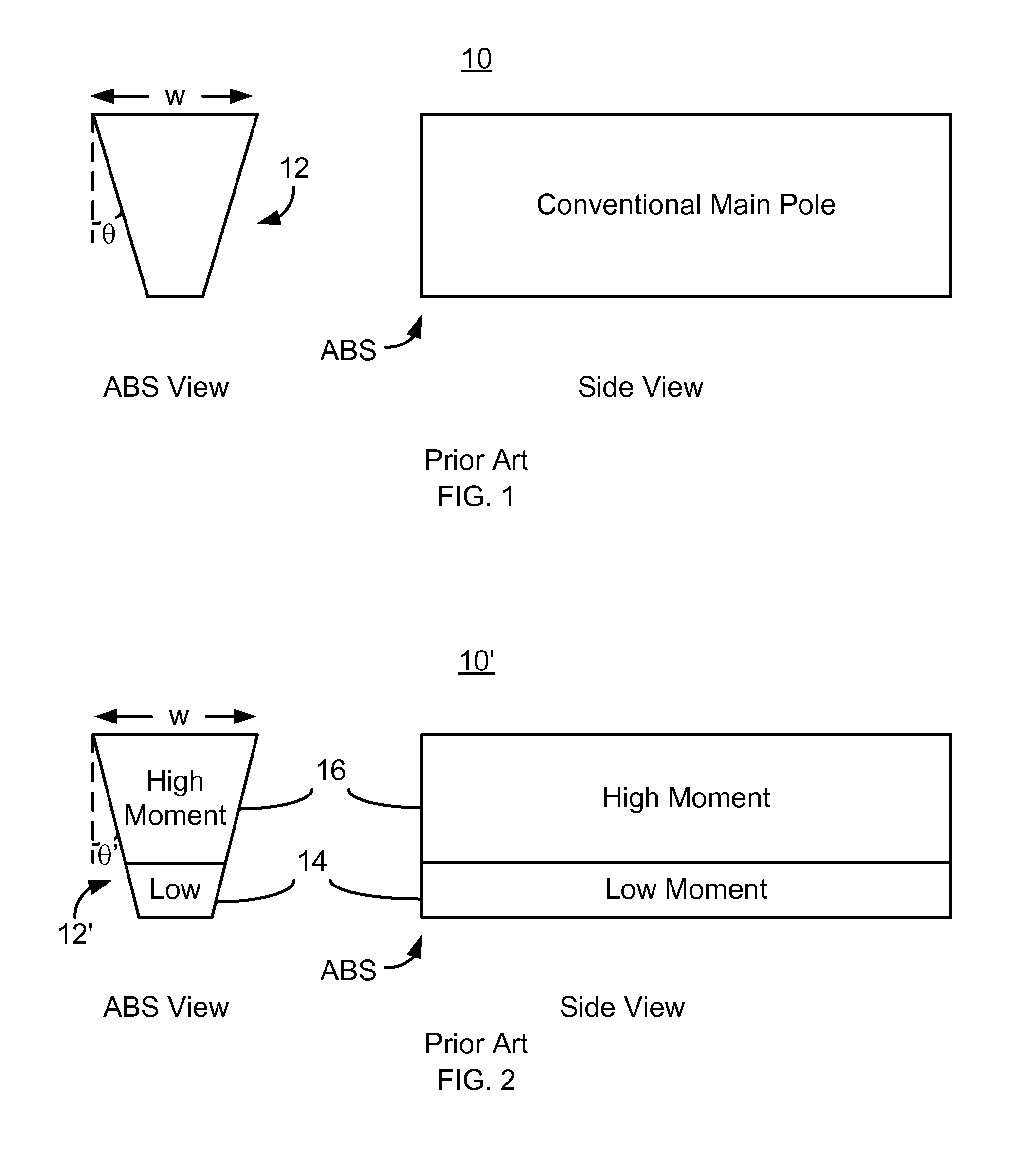

PMR head with an angled stitch layer

ActiveUS8537494B1Record information storageHeads for perpendicular magnetisationsMagnetic transducersAir bearing

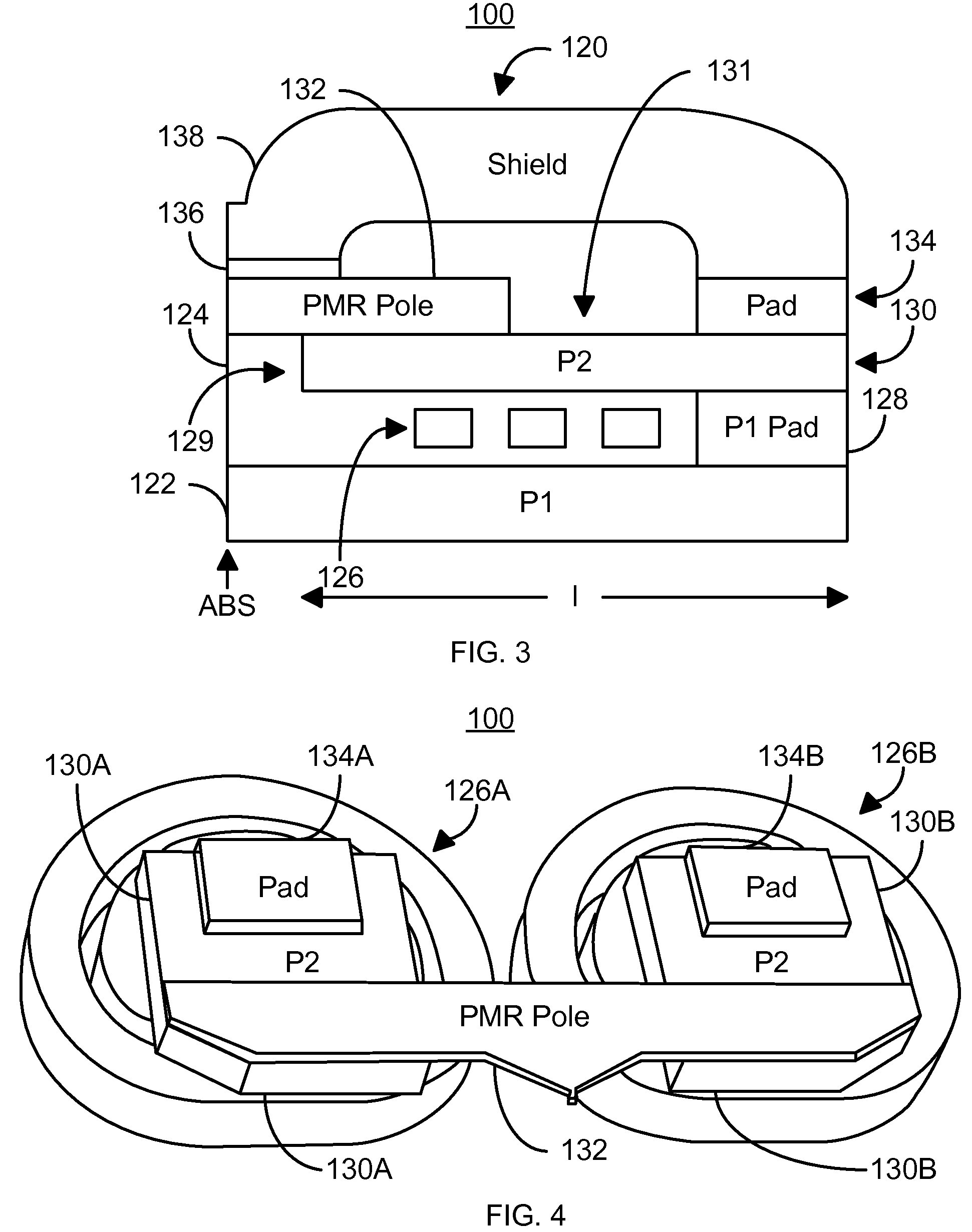

A method and system for providing a magnetic transducer having an air-bearing surface (ABS) are described. The magnetic transducer includes a perpendicular magnetic recording (PMR) pole, an additional pole, a stitch, a shield, a write gap between the PMR pole and a portion of the shield, and at least one coil that energizes at least the additional pole. The PMR pole has a first front portion proximate to the ABS, while the additional pole is recessed from the ABS. The stitch resides between the PMR pole and the additional pole and has a stitch front portion between the front portion of the PMR pole and the additional pole. At least a portion of the write gap resides on the front portion of the PMR pole. At least a portion of the additional pole resides between the PMR pole and the shield.

Owner:WESTERN DIGITAL TECH INC

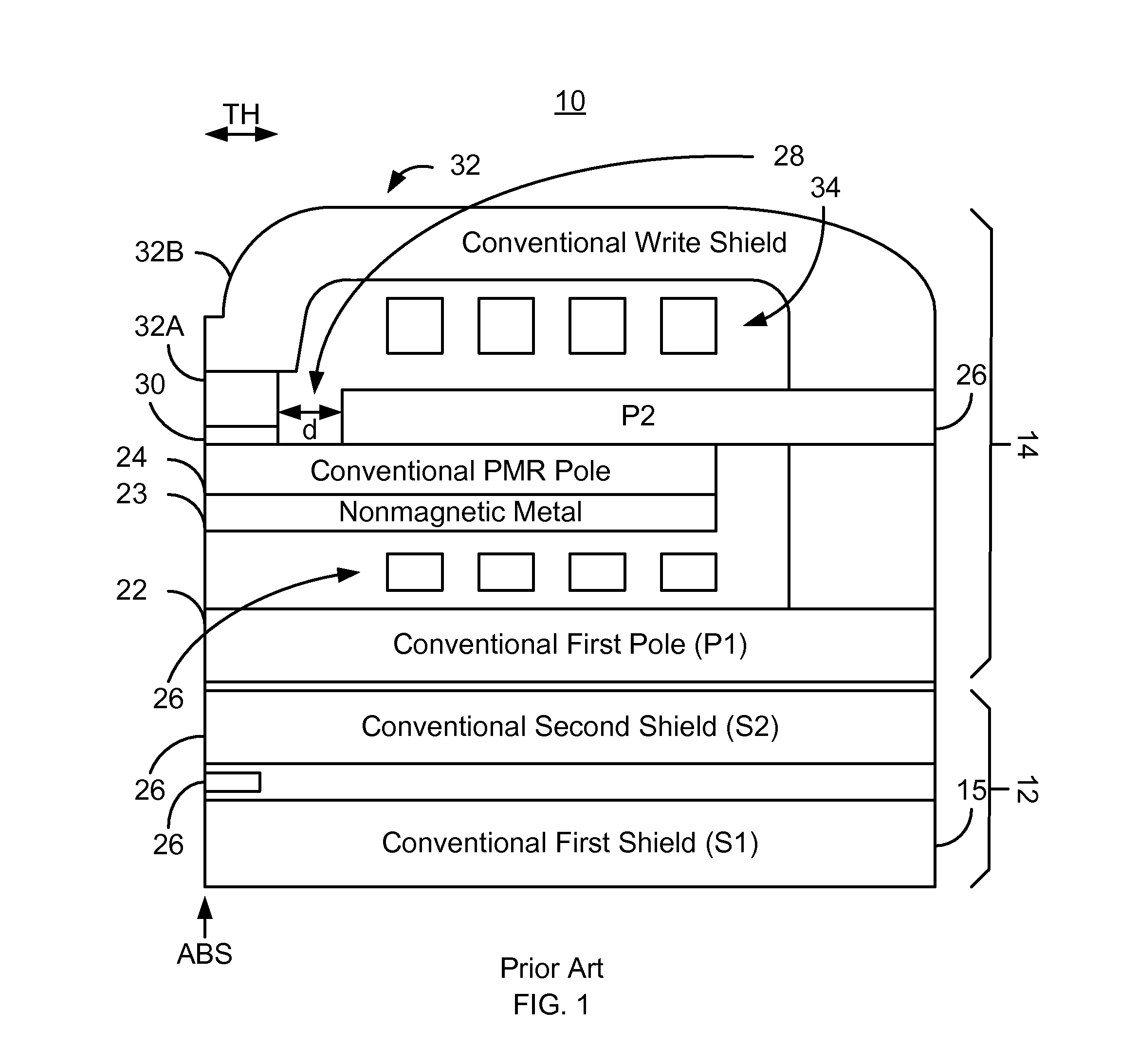

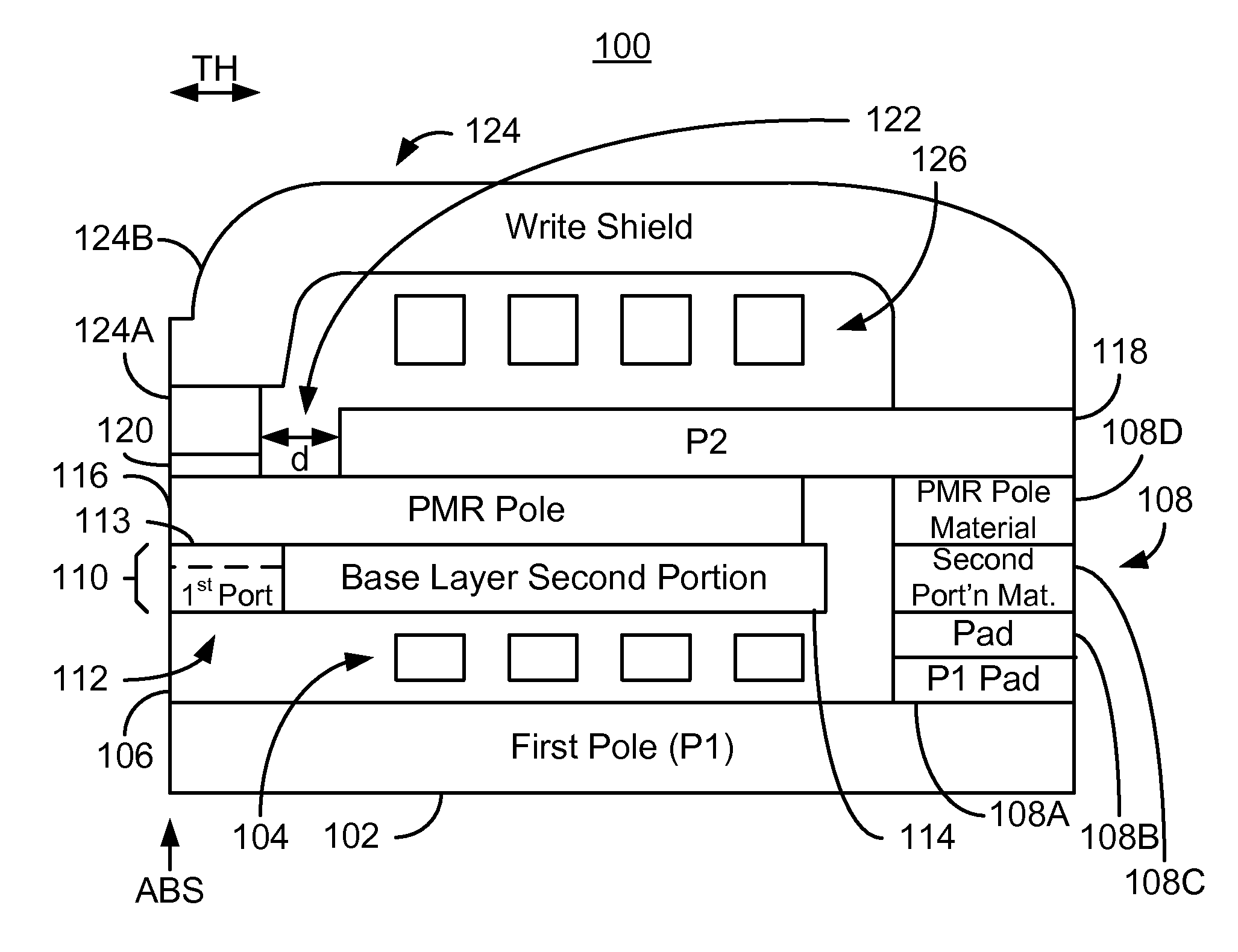

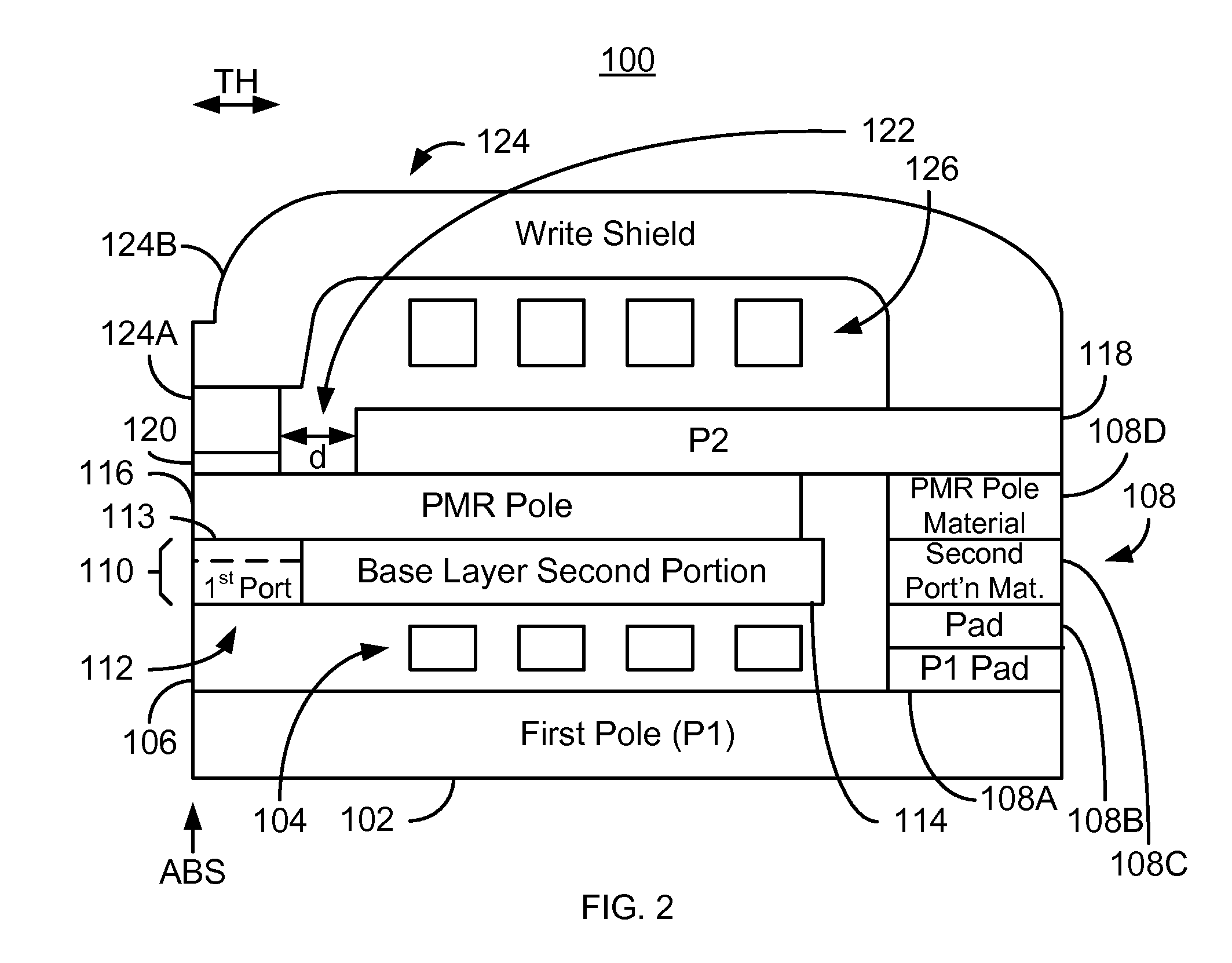

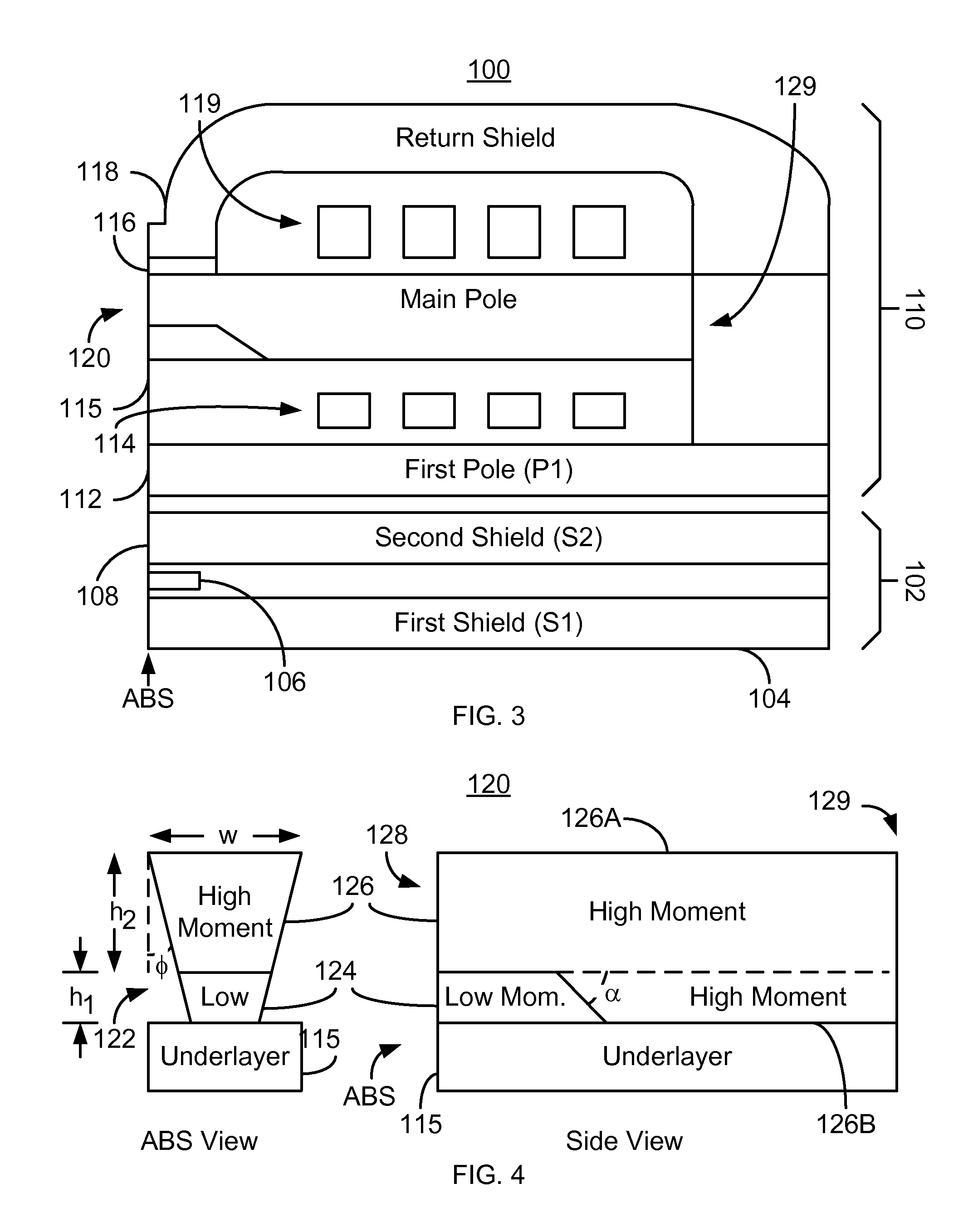

Perpendicular magnetic recording head having a recessed magnetic base layer

ActiveUS8077434B1Record information storageHeads for perpendicular magnetisationsMagnetic transducersEngineering

A method and system for providing a magnetic transducer having an air-bearing surface (ABS) are described. The magnetic transducer includes a base layer, a perpendicular magnetic recording (PMR) pole on the base layer, an additional pole, a write shield, a write gap between the PMR pole and a portion of the write shield, and coil(s) that energize at least the additional pole. The base layer includes a first portion proximate to the ABS and a second portion recessed from the ABS. The first portion is nonmagnetic, while the second portion is magnetic. The PMR pole has a first front portion proximate to the ABS. The additional pole has a second front portion recessed from the ABS. At least a portion of the additional pole resides between the PMR pole and write shield. At least a portion of the write gap resides on the front portion of the PMR pole.

Owner:WESTERN DIGITAL TECH INC

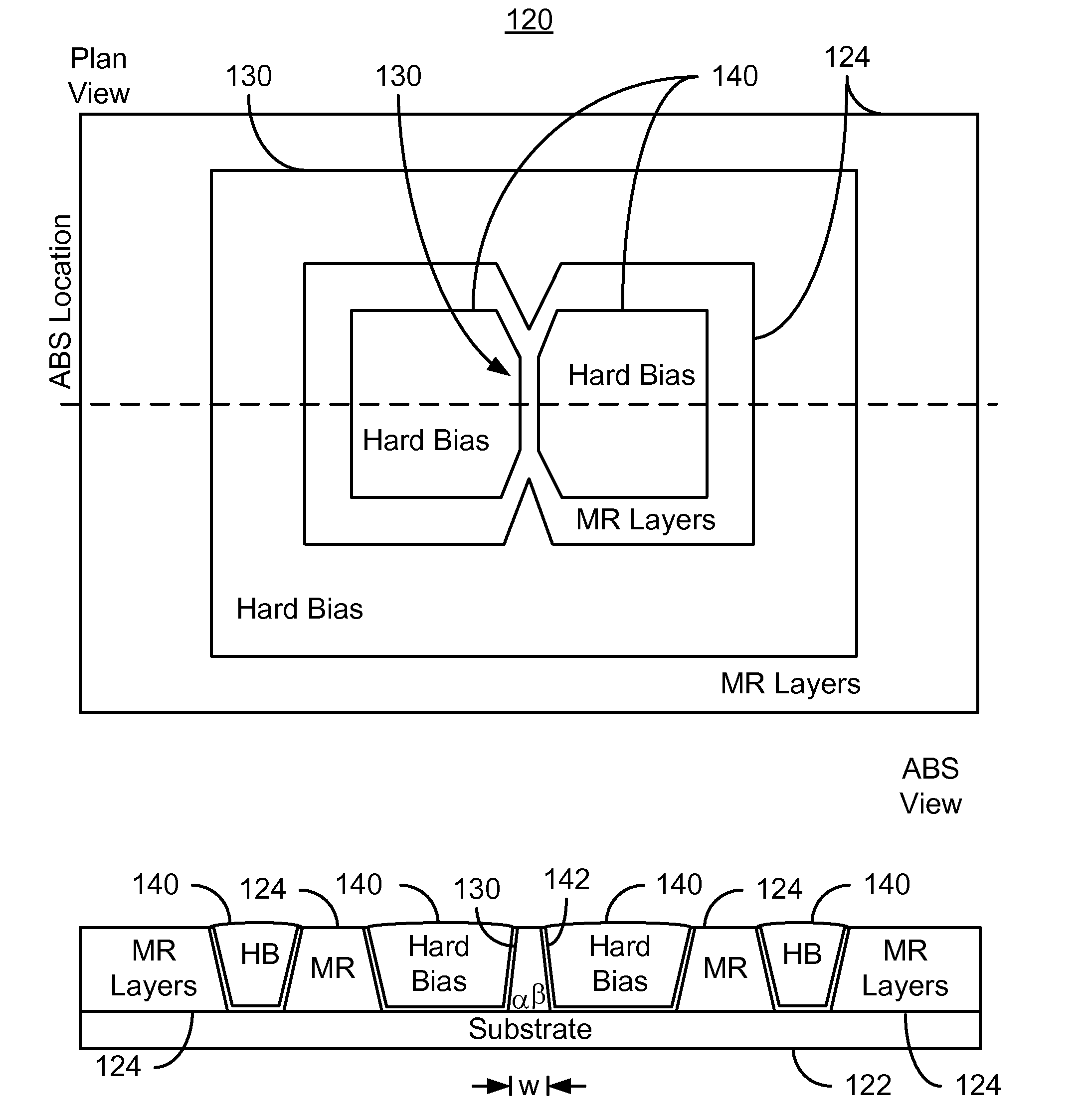

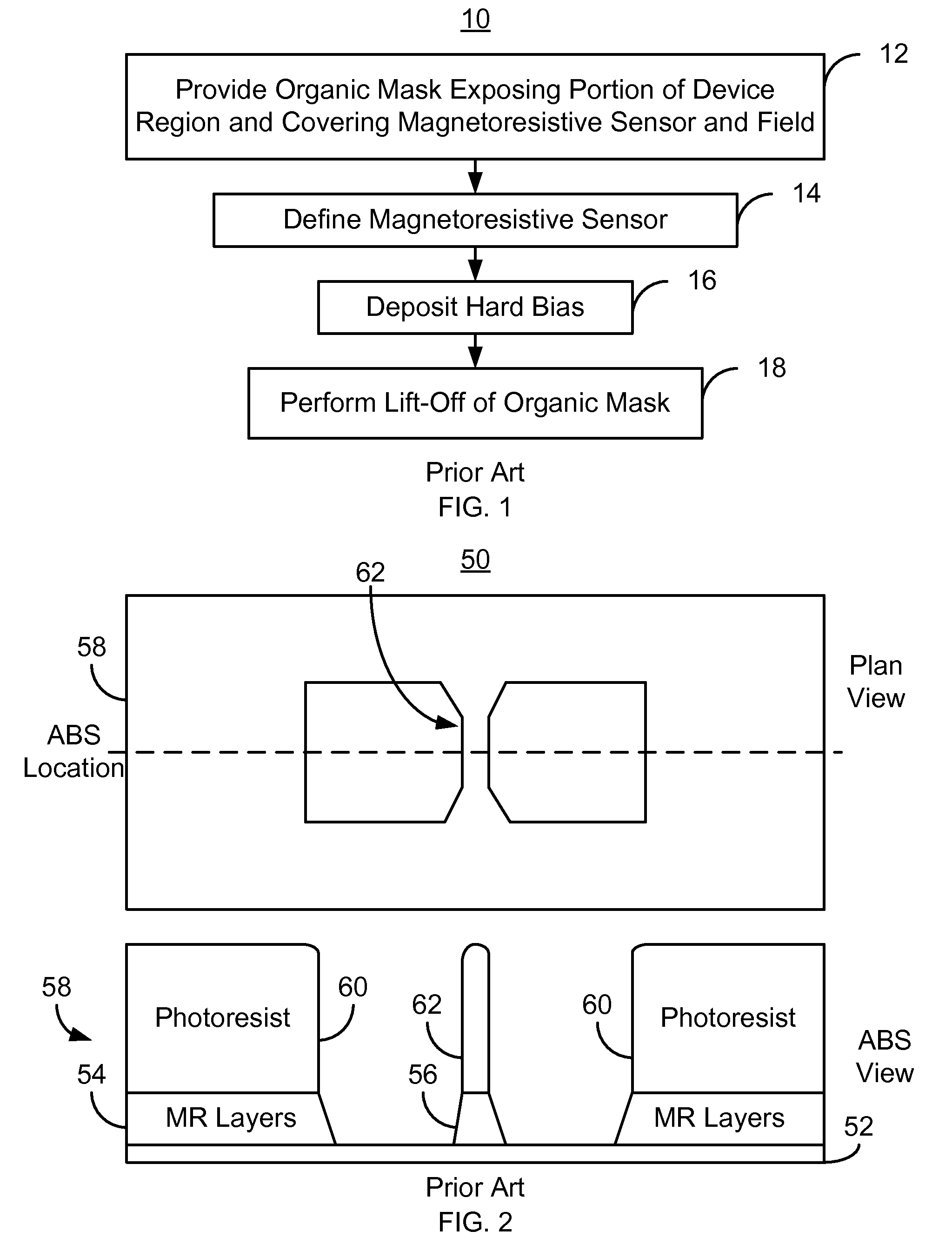

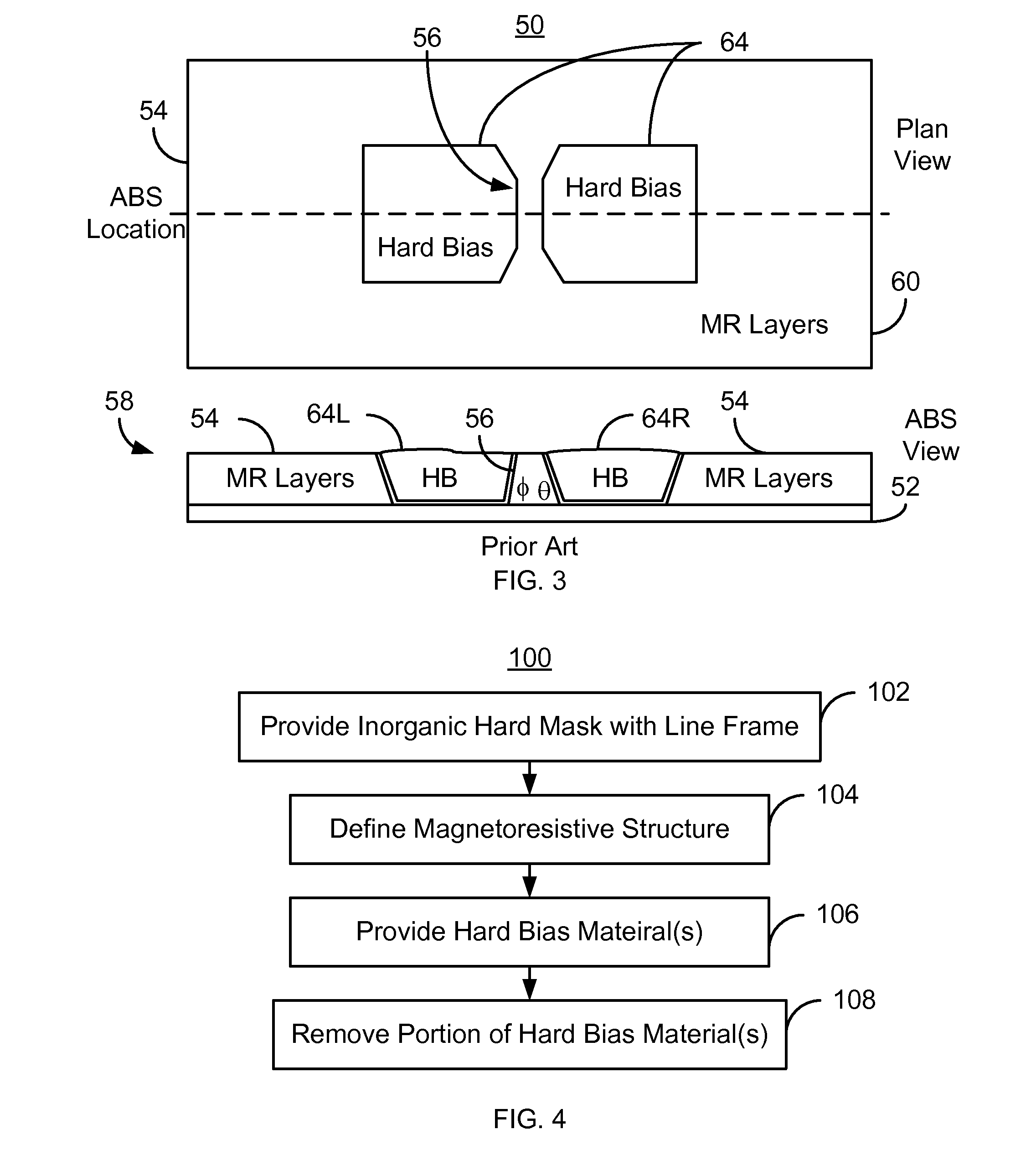

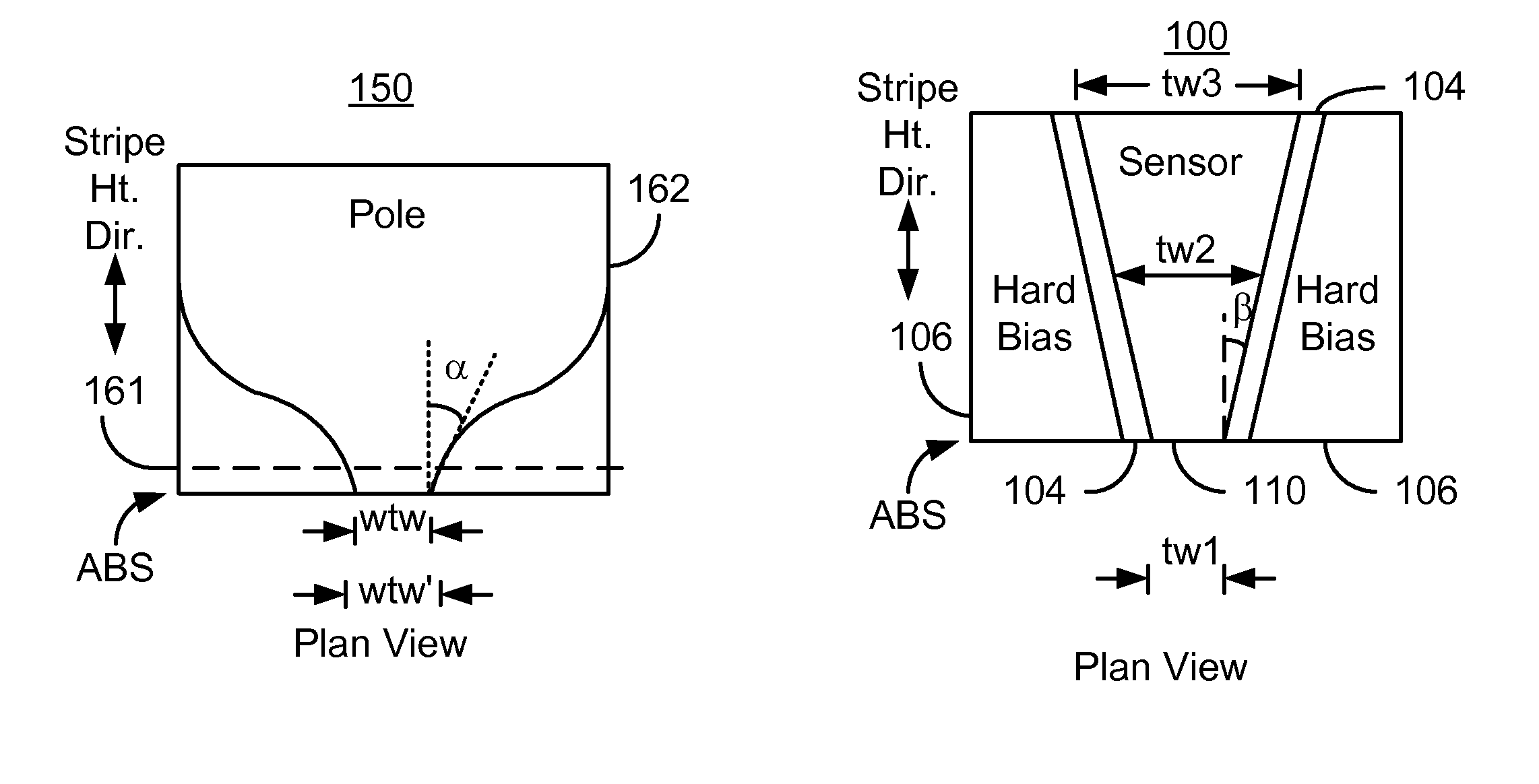

Method and system for providing a magnetic recording transducer using a line hard mask

InactiveUS8233248B1Electrical transducersMagnetic measurementsMagnetic transducersMagnetic reluctance

A method and system for fabricating a magnetic transducer is described. The transducer has a device region, a field region, and a magnetoresistive stack. The method and system include providing a hard mask on the magnetoresistive stack. The hard mask is inorganic and includes a sensor portion and a line frame. The sensor portion covers a first portion of the magnetoresistive stack corresponding to a magnetoresistive structure. The line frame covers a second portion of the magnetoresistive stack in the device region. The method and system include defining the magnetoresistive structure in a track width direction using the hard mask and providing at least one hard bias material after the magnetoresistive structure is defined. A first portion of the hard bias material(s) is substantially adjacent to the magnetoresistive structure in the track width direction. The method and system also include removing a second portion of the hard bias material(s).

Owner:WESTERN DIGITAL TECH INC

Method and system for providing a read transducer having an adaptive read sensor track width

ActiveUS8599520B1Manufacture head surfaceMagnetic measurementsMagnetic transducersAir bearing surface

A method and system provide a magnetic read transducer having an air-bearing surface (ABS). The magnetic transducer includes a first shield, a second shield, and a read sensor between the first shield and the second shield. The read sensor extends along a stripe height direction perpendicular to the ABS. A first portion of the read sensor at the ABS has a first width in a track width direction parallel to the ABS. A second portion of the read sensor is recessed from the ABS along the stripe height direction and has a second width in the track width direction. The second width is greater than the first width.

Owner:WESTERN DIGITAL TECH INC

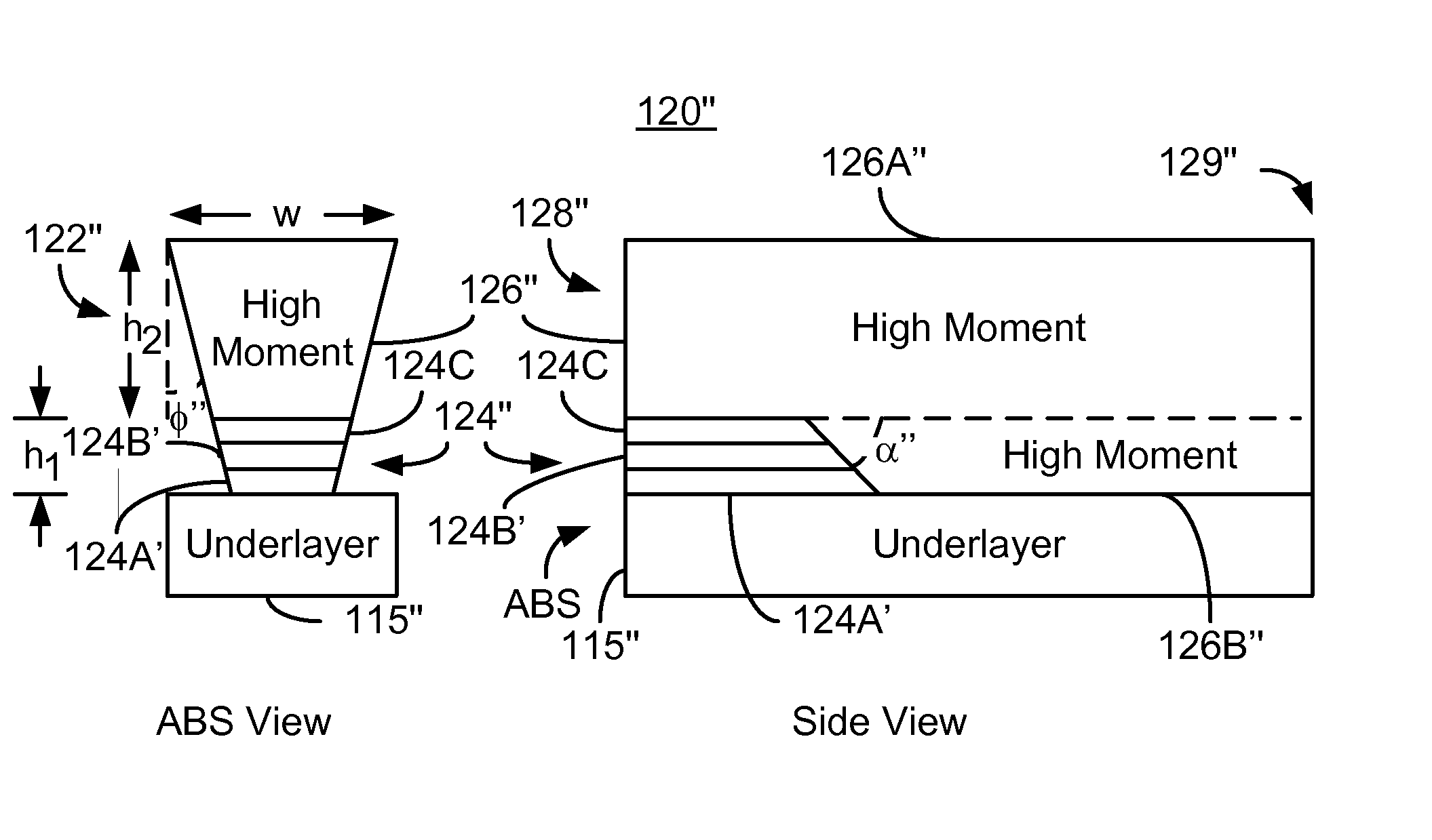

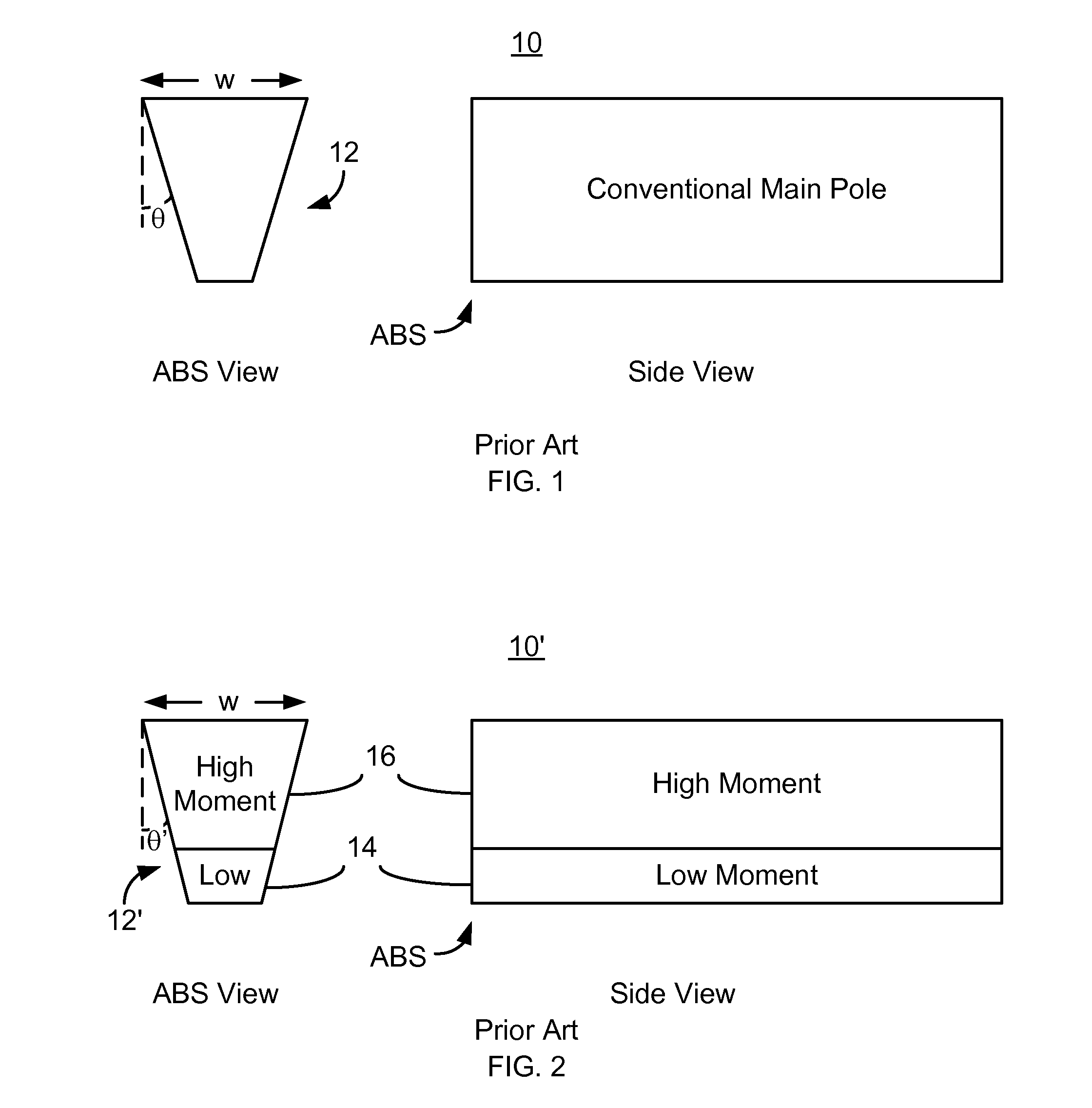

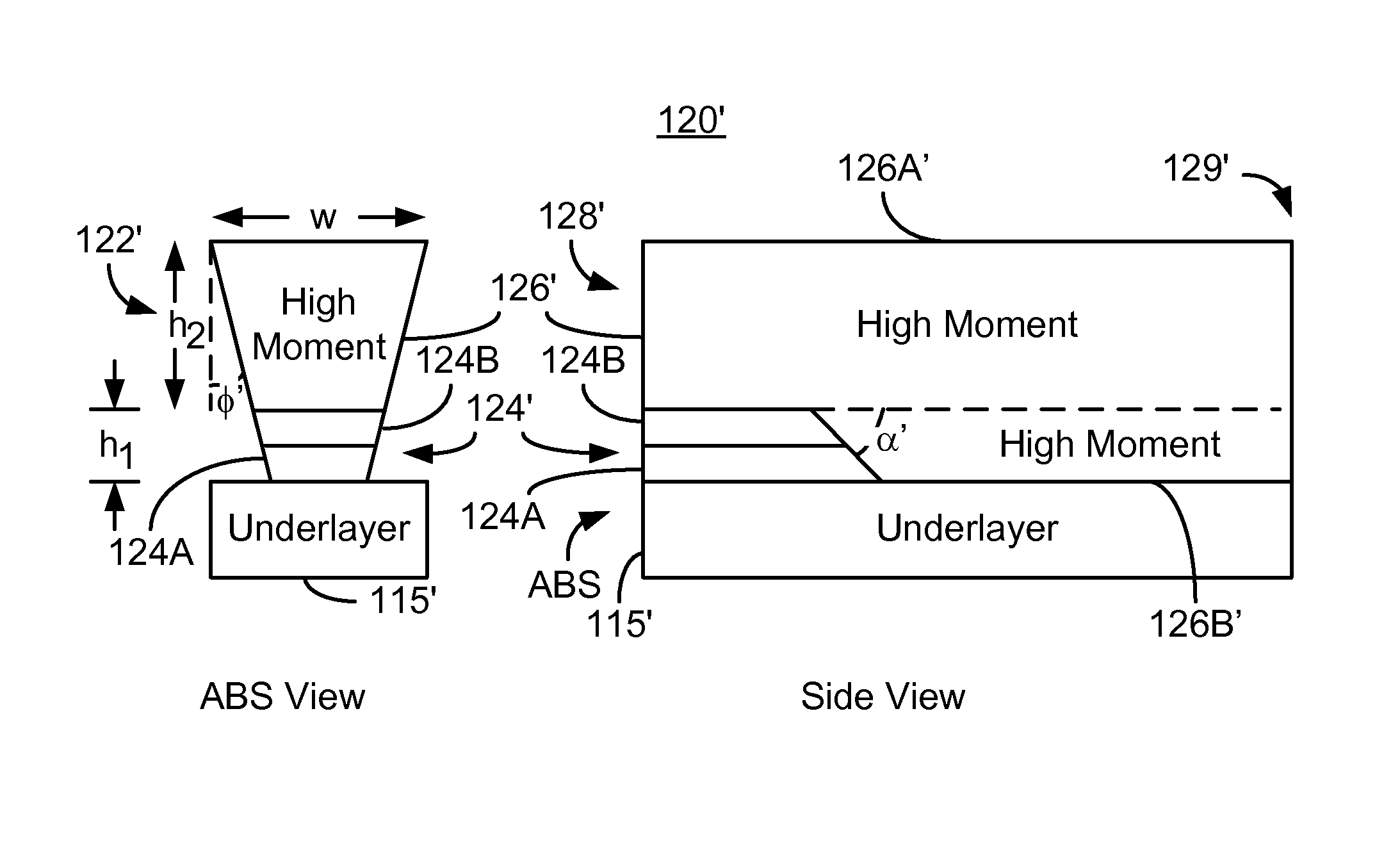

Method and system for providing a magnetic recording transducer having a hybrid moment pole

ActiveUS8228633B1Manufacture head surfaceRecord information storageMagnetic transducersMagnetic moment

A method and system provide a magnetic transducer that includes an air-bearing surface (ABS). The magnetic transducer includes an underlayer and a main pole residing on the underlayer. The main pole includes a front and a rear. The front resides at the ABS, while the rear is distal from the ABS. The main pole also includes a first portion having a first magnetic moment and a second portion having a second magnetic moment. The first portion has a front face at the ABS and terminates between the ABS and the rear of the main pole. A part of the second portion resides on the first portion, while another part of the second portion resides between the first portion of the main pole and the rear of the main pole. The first magnetic moment is less than the second magnetic moment.

Owner:WESTERN DIGITAL TECH INC

Magnetic writer having a split yoke

InactiveUS8537495B1Heads using thin filmsRecord information storageMagnetic transducersElectrical and Electronics engineering

A method and system for providing a magnetic transducer are described. The magnetic transducer includes a first pole, a write gap, a second pole, a first coil, and a second coil. The first pole has a front portion on which at least a portion of the write gap resides. The second pole includes a split yoke that includes a first portion and a second portion. At least a portion of the first coil resides between the first portion of the split yoke and the first pole. At least a portion of the second coil resides between the second portion of the split yoke and the first pole.

Owner:WESTERN DIGITAL TECH INC

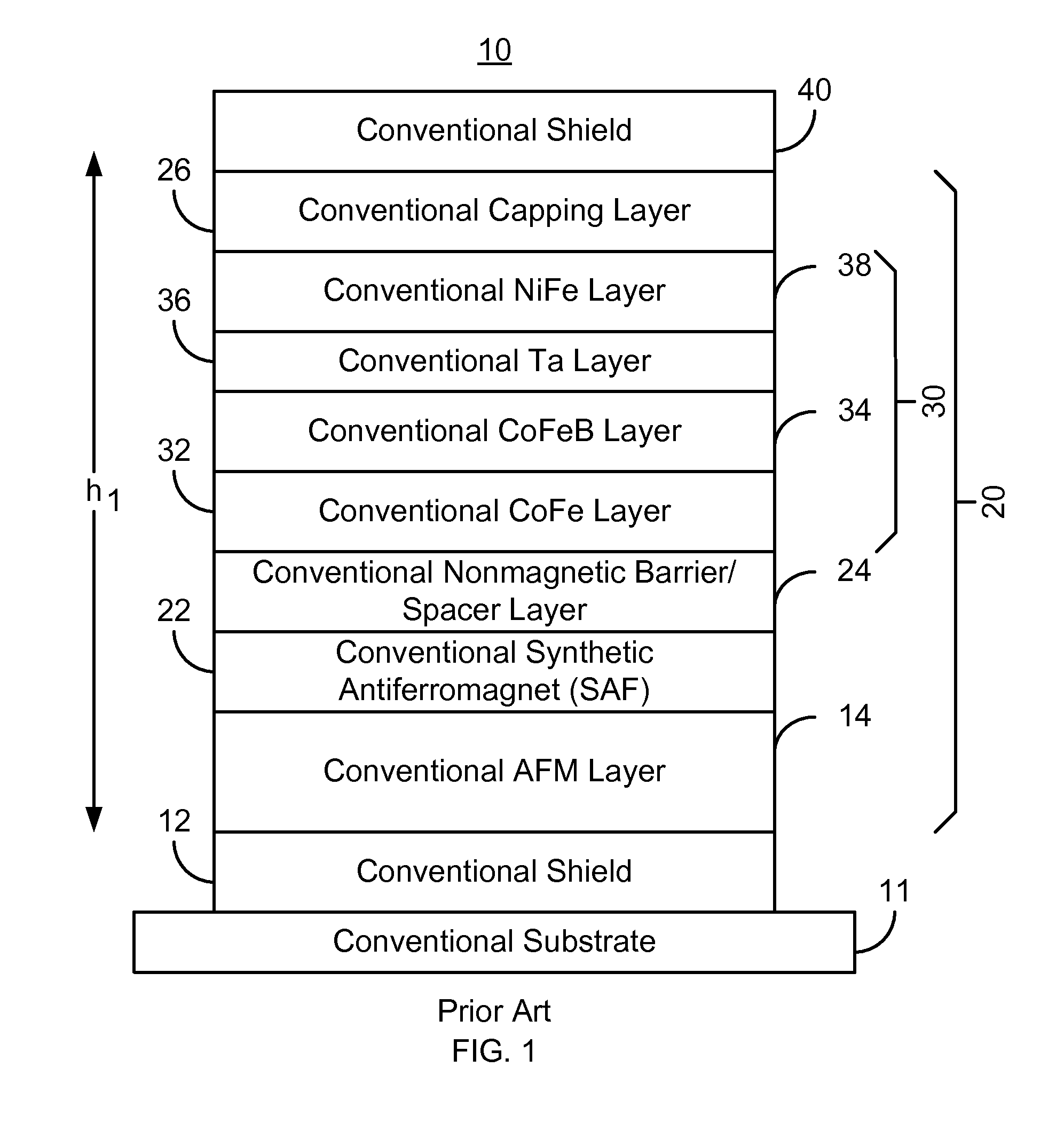

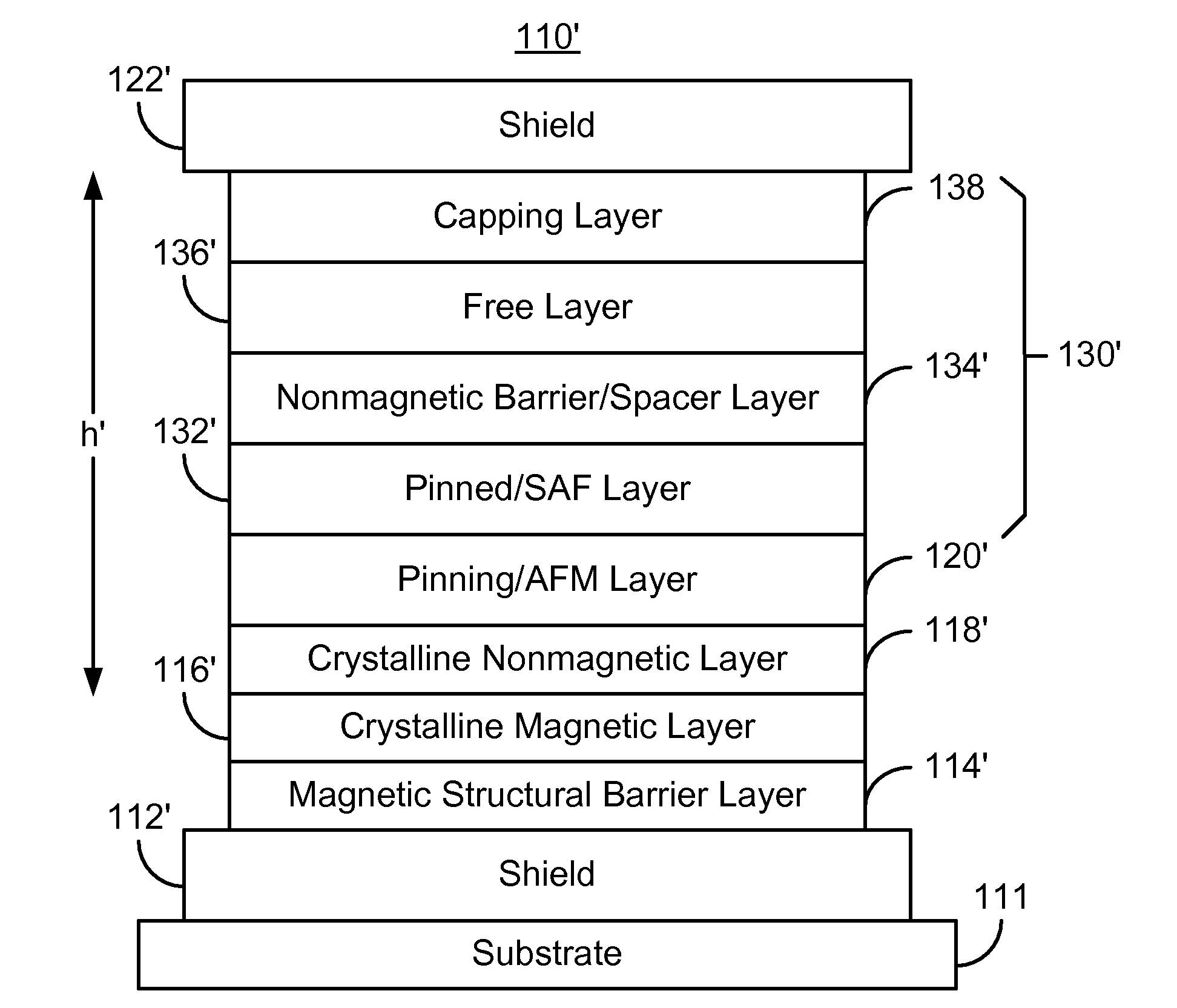

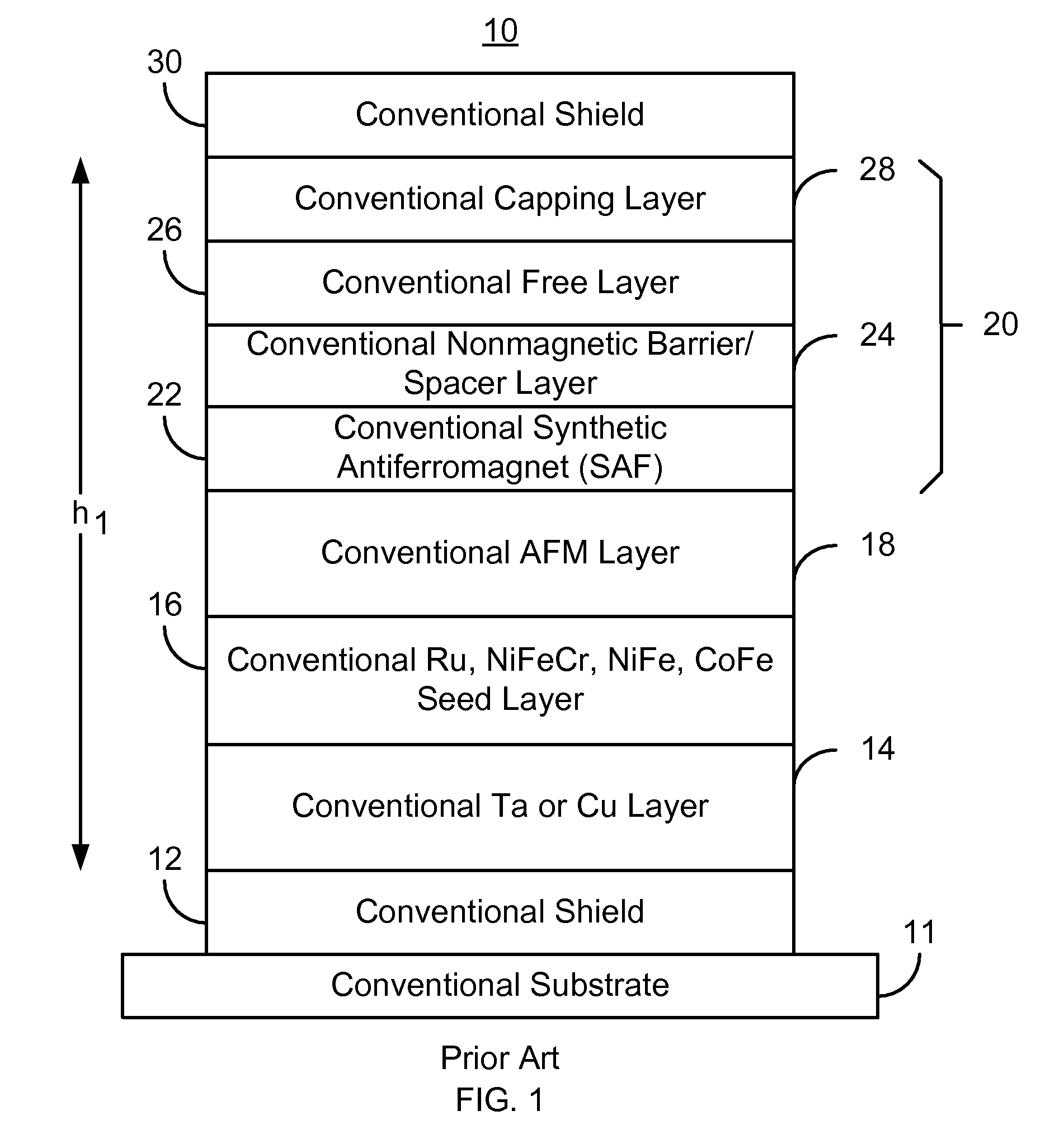

Method and system for providing a magnetic transducer having improved shield-to-shield spacing

InactiveUS8537502B1Magnetic measurementsMagnetic-field-controlled resistorsMagnetic transducersNon magnetic

A method and system for providing a magnetic transducer is described. The method and system include providing a magnetic structural barrier layer and a crystalline magnetic layer on the magnetic structural barrier layer. The magnetic structural barrier layer may reside on a shield. The method and system also include providing a nonmagnetic layer on the crystalline magnetic layer. A pinning layer is provided on the nonmagnetic layer. Similarly, a pinned layer is provided on the pinning layer. The pinning layer is magnetically coupled with the pinned layer. The method and system also include providing a free layer and a nonmagnetic spacer layer between the pinned layer and the free layer.

Owner:WESTERN DIGITAL TECH INC

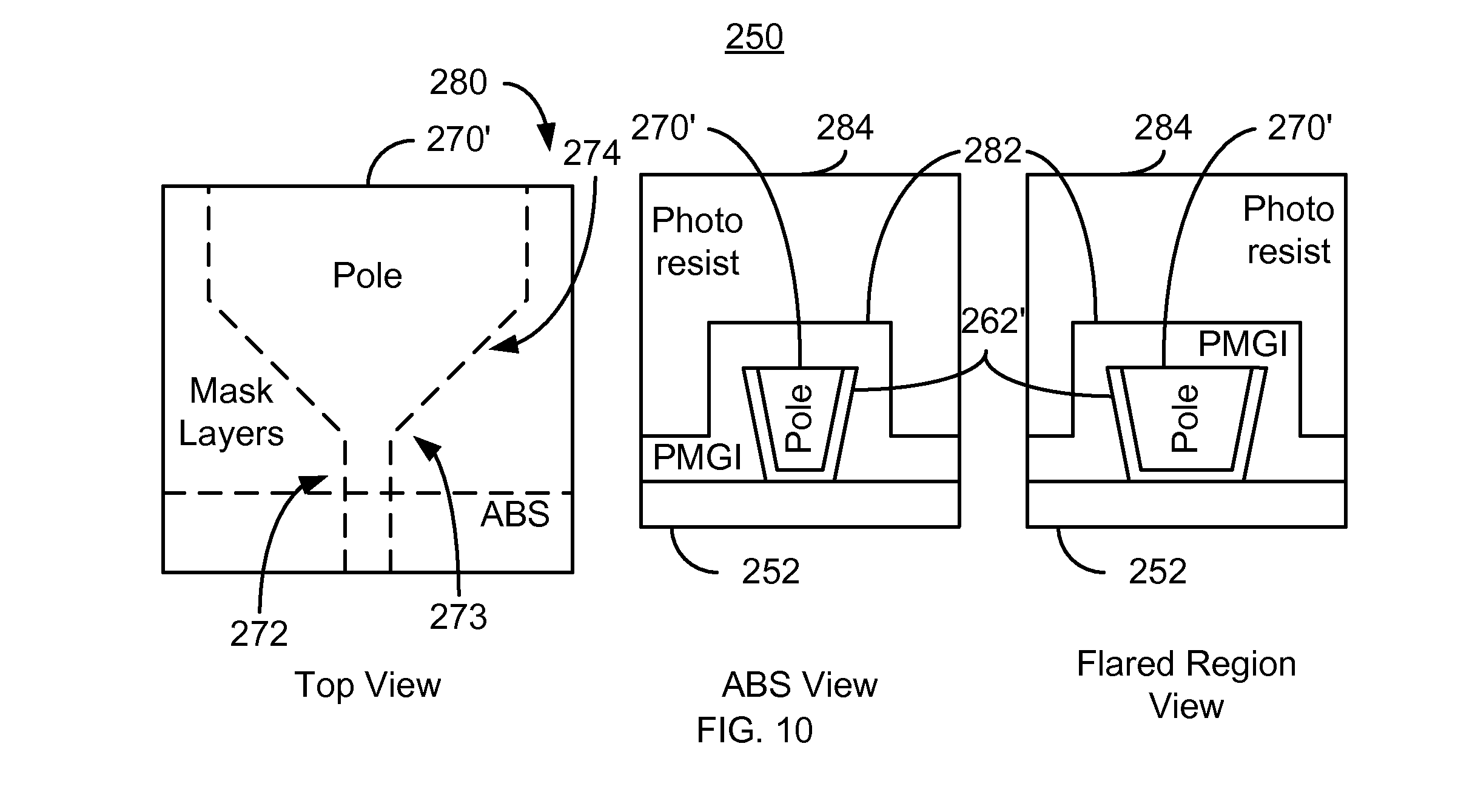

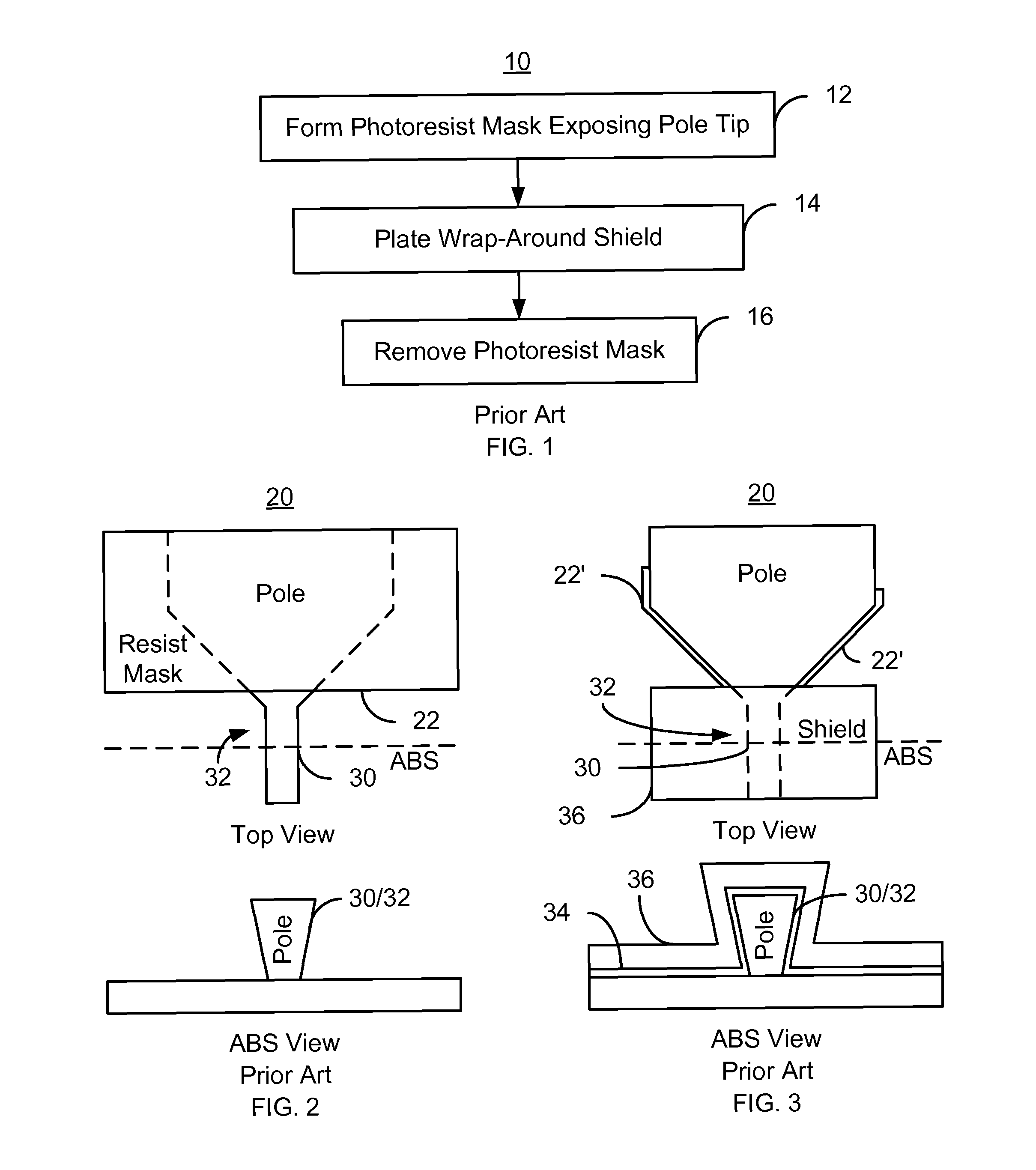

Method for providing a wrap-around shield for a magnetic recording transducer

A method for fabricating a magnetic transducer is described. The magnetic transducer includes a pole having a pole tip and a flared region. The method Includes providing a first mask layer on the pole and providing a second mask layer on the first mask layer. The first mask layer is soluble in a predetermined solution and has a first thickness. The second mask layer has a second thickness greater than the first thickness. The method also includes forming a mask from the first mask layer and the second mask layer. The step of forming the mask layer includes using the predetermined solution. The mask has a pattern that exposes a portion of the pole tip and covers a portion of the flared region. The method also includes providing a wrap-around shield on at least the pole tip.

Owner:WESTERN DIGITAL TECH INC

Magnetic writer having a split yoke

A method and system for providing a magnetic transducer are described. The magnetic transducer includes a first pole, a write gap, a second pole, a first coil, and a second coil. The first pole has a front portion on which at least a portion of the write gap resides. The second pole includes a split yoke that includes a first portion and a second portion. At least a portion of the first coil resides between the first portion of the split yoke and the first pole. At least a portion of the second coil resides between the second portion of the split yoke and the first pole.

Owner:WESTERN DIGITAL TECH INC

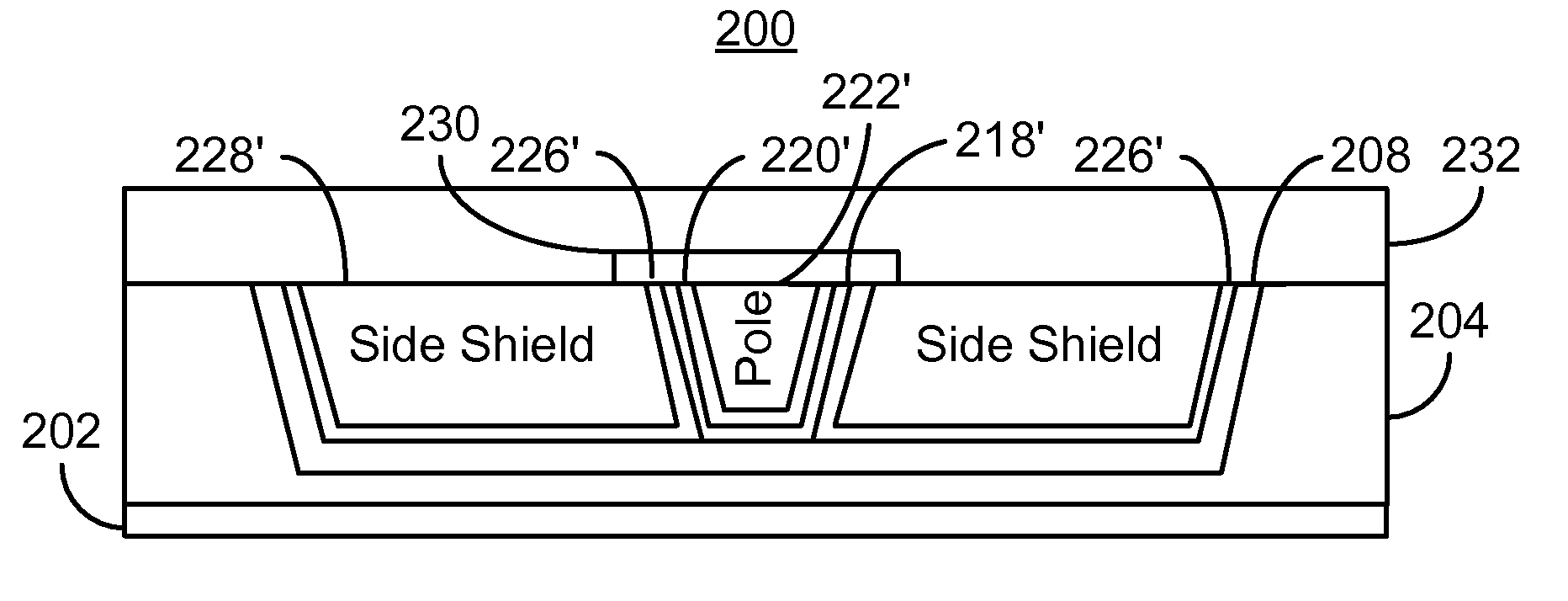

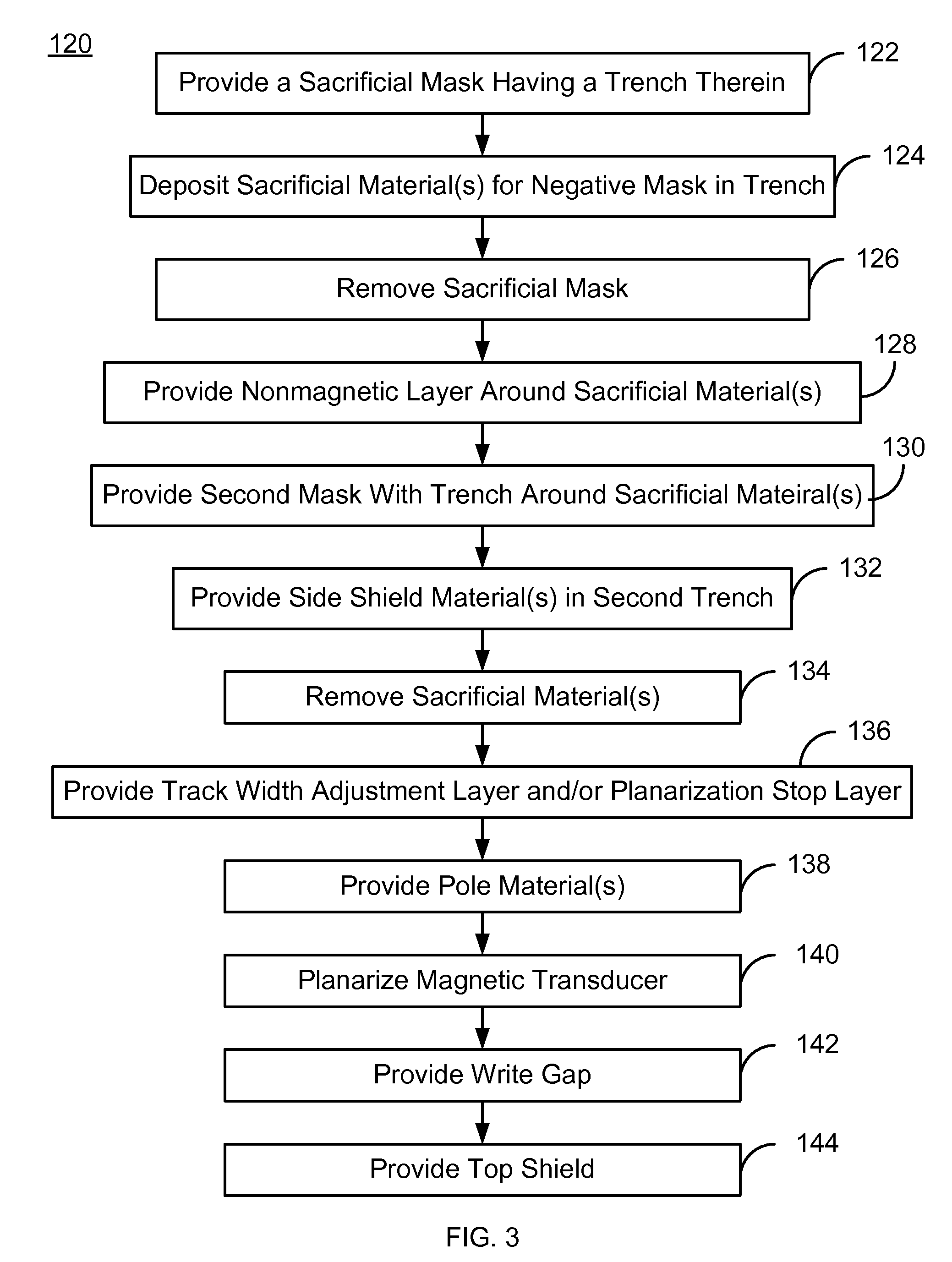

Method for fabricating a magnetic recording transducer

ActiveUS8276258B1Manufacture head surfaceElectrical transducersMagnetic transducersAir bearing surface

A method and system provide a magnetic transducer that includes an underlayer and a first nonmagnetic layer on the underlayer. The method and system include providing a first trench in the first nonmagnetic layer. The first trench has at least one edge corresponding to at least one side shield. The method and system also include providing a second nonmagnetic layer in the first trench and providing a second trench in the second nonmagnetic layer. The method and system include providing the main pole. At least part of the main pole resides in the second trench. The method and system further include removing at least a portion of the second nonmagnetic layer between the edge(s) and the main pole. The method and system also provide the side shield(s) in the first trench. The side shield(s) extend from at least an air-bearing surface location to not further than a coil front location.

Owner:WESTERN DIGITAL TECH INC

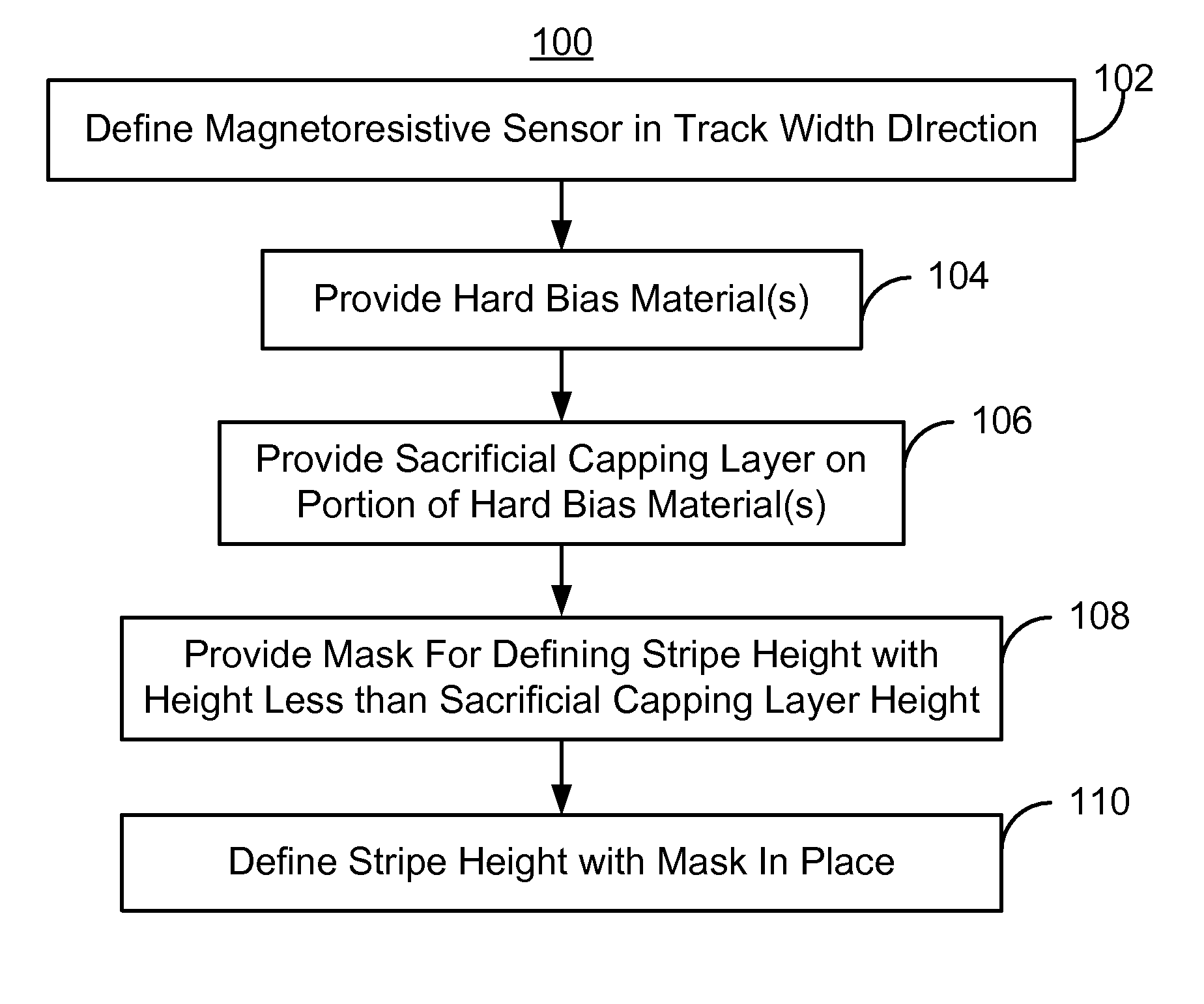

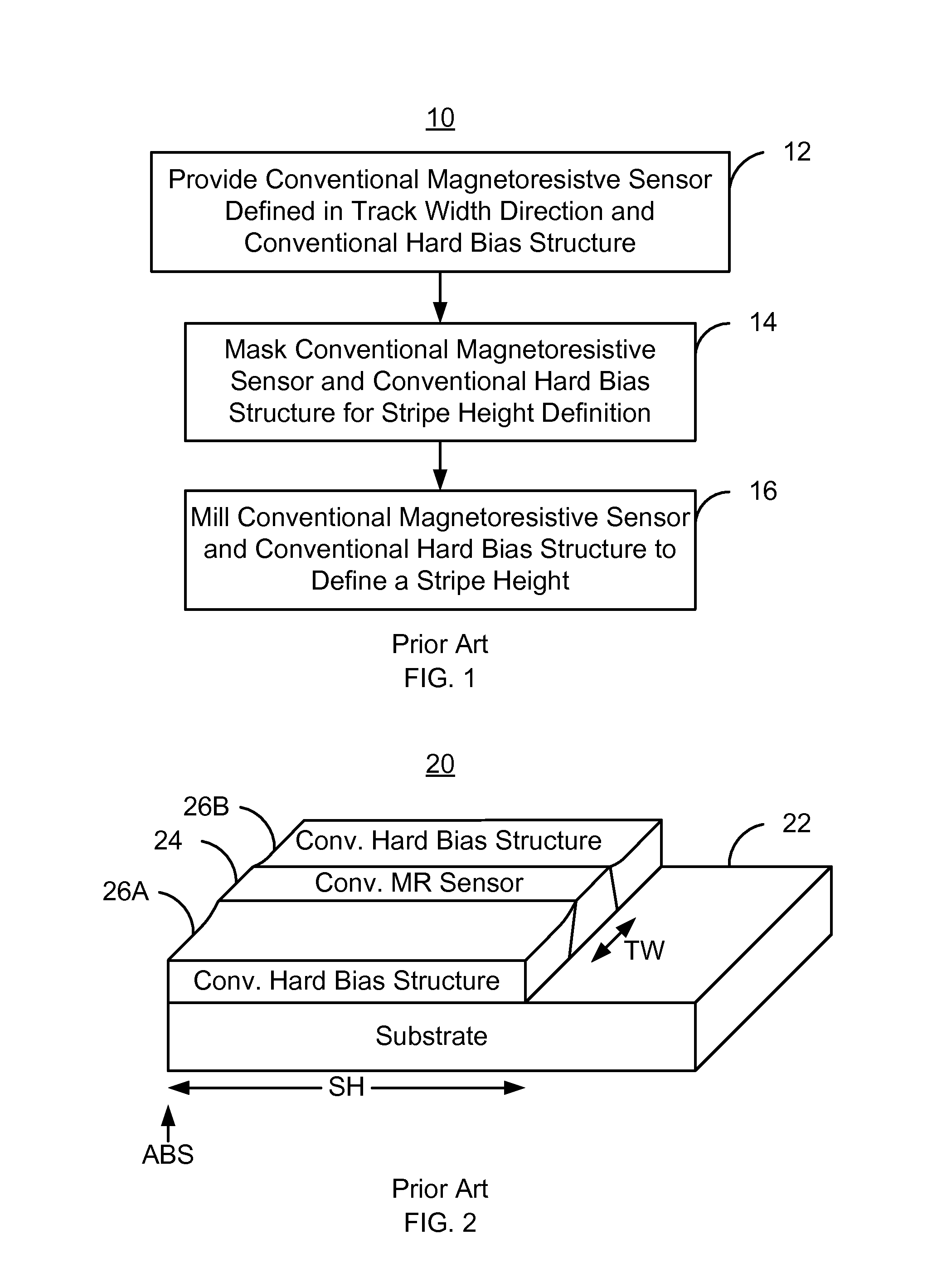

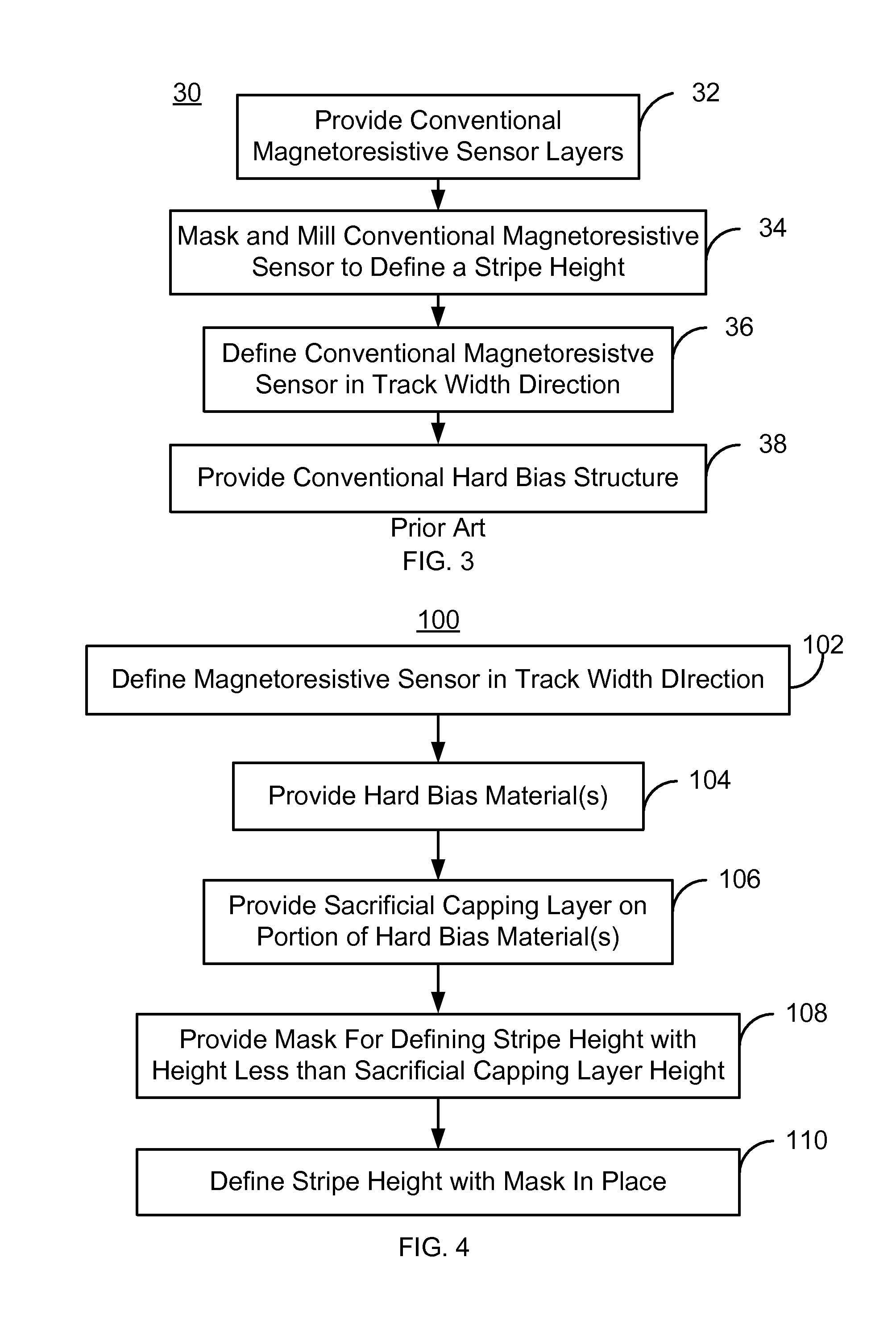

Method and system for providing an improved hard bias structure

InactiveUS8343319B1Prevent removalDecorative surface effectsVacuum evaporation coatingMagnetic transducersSystem definition

A method and system for providing a magnetic transducer is described. The method and system define a magnetoresistive sensor in a track width direction, provide hard bias material(s) adjacent to the sensor in the track width direction, and provide sacrificial capping layer(s) on a portion of the hard bias material(s). The sacrificial capping layer(s) have a first height in a stripe height direction. The method and system also provide a mask for defining a stripe height of the sensor. The mask covers at least part of the sensor and has a second height in the stripe height direction. The second height is less than the first height. The method and system define the stripe height of the sensor while the mask covers the sensor. The sacrificial capping layer(s) are configured to prevent removal of the portion of the hard bias material(s) while the stripe height is defined.

Owner:WESTERN DIGITAL TECH INC

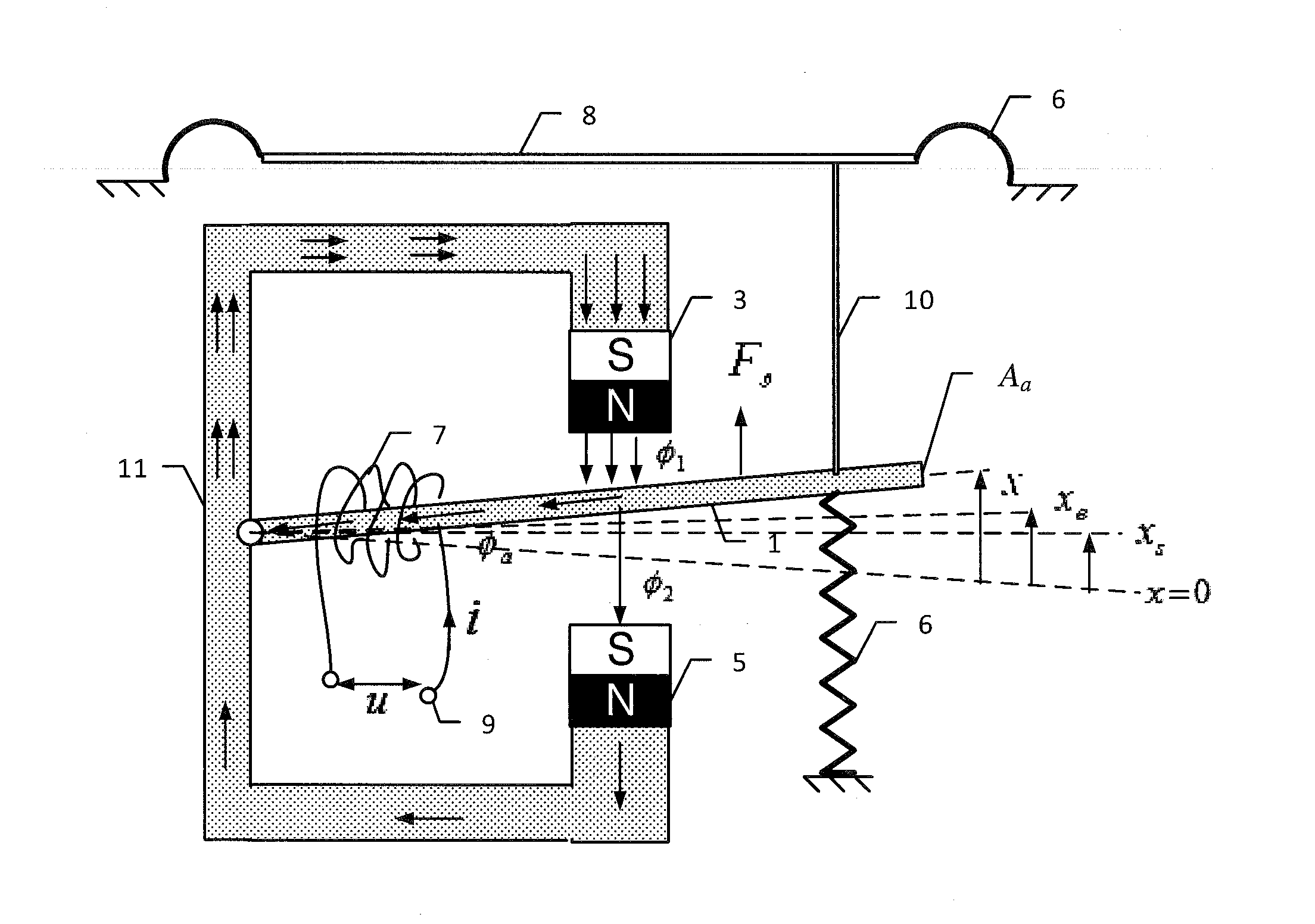

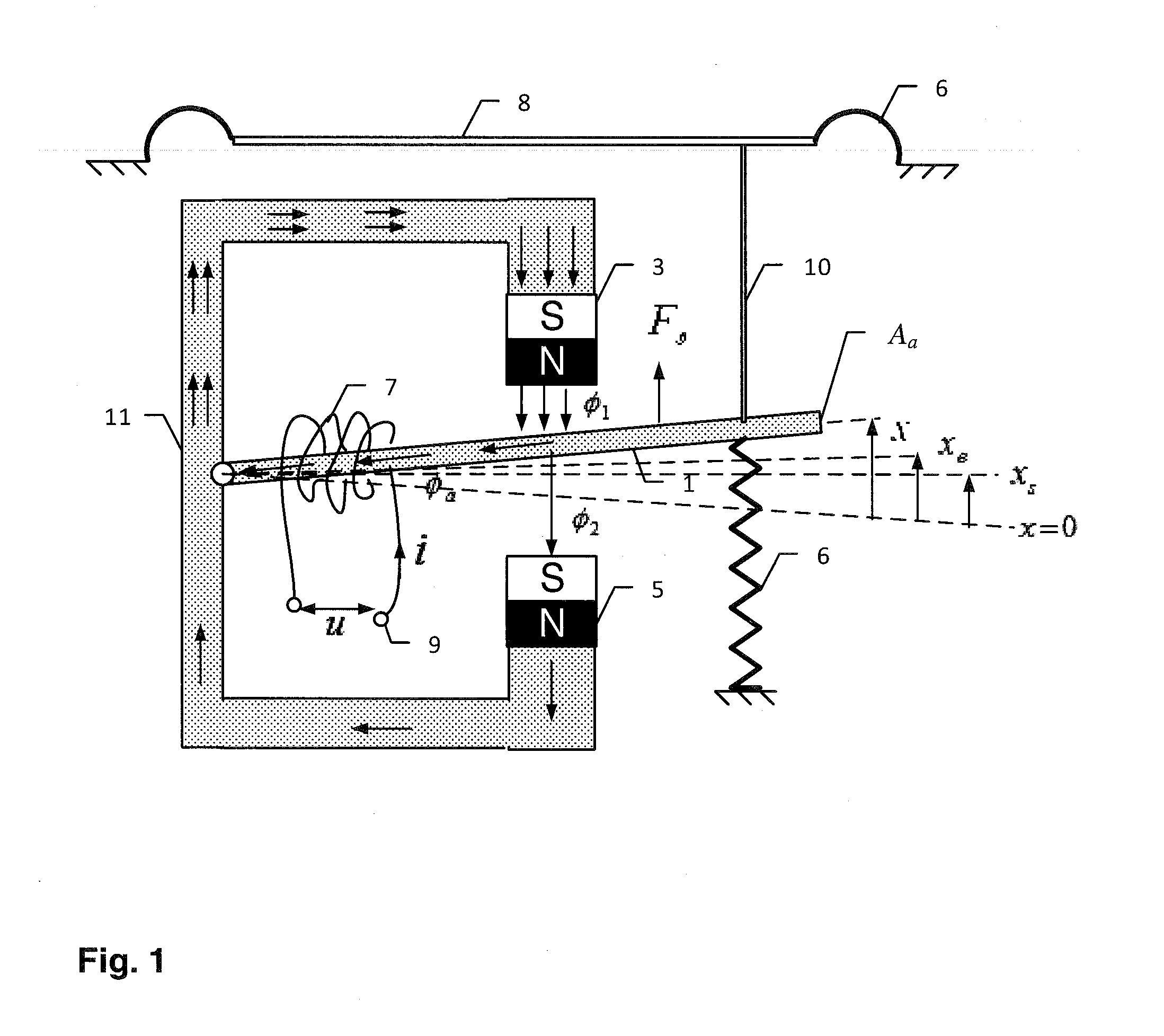

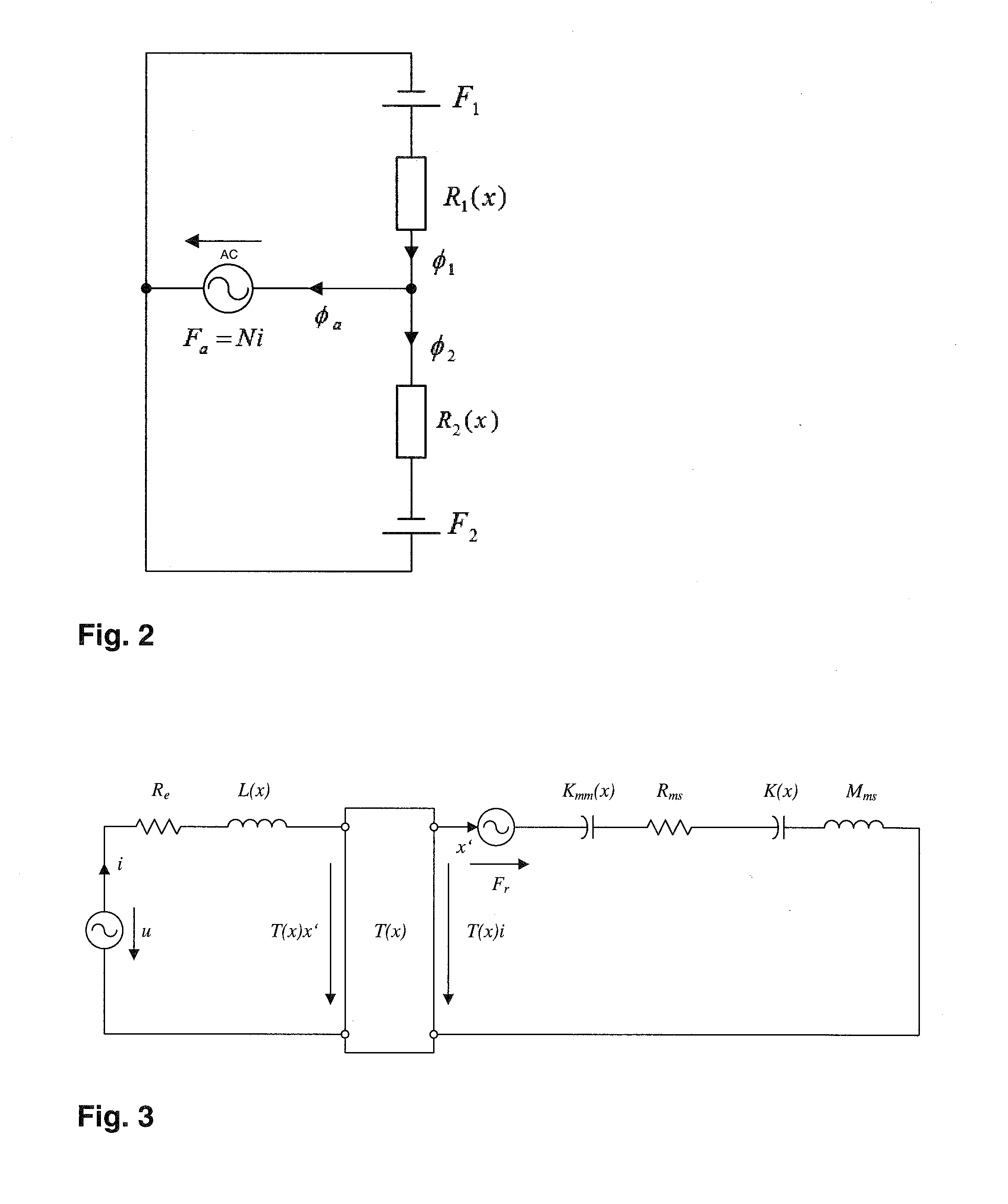

Arrangement and method for converting an input signal into an output signal and for generating a predefined transfer behavior between said input signal and said output signal

ActiveUS20150036831A1Cost effectiveLow hardware requirementsTransducer protection circuitsLimiting amplitudeRest positionMagnetic transducers

An arrangement and method for converting an input signal z(t) into a mechanical or acoustical output signal p(t) comprising an electro-magnetic transducer using a coil at a fixed position and a moving armature, a sensor, a parameter measurement device and a controller. The parameter measurement device identifies parameter information P of an nonlinear model of the transducer considering and the saturation and the geometry of the magnetic elements. A diagnostic system reveals the physical causes of signal distortion and generates information for optimizing the design and manufacturing process of this transducer. The controller compensates for nonlinear signal distortion, stabilizes the rest position of the armature and protects the transducer against mechanical and thermal overload.

Owner:KLIPPEL WOLFGANG

Method and system for providing a magnetic transducer having an improved read sensor synthetic antiferromagnet

A method and system for providing a magnetic structure in magnetic transducer is described. The method and system include providing a pinning layer, a synthetic antiferromagnetic (SAF) adjacent to the pinning layer, a nonmagnetic layer, and a sensor layer. The SAF resides between the nonmagnetic and pinning layers. The nonmagnetic layer is between the SAF and the sensor layer. The SAF includes a pinned layer, a reference layer, and a nonmagnetic spacer layer between the pinned and reference layers. The pinned layer is magnetically coupled with the reference layer and includes sublayers. A first sublayer has a first blocking temperature distribution (TBD) and a first exchange energy. A second sublayer has a second TBD and a second exchange energy. The first sublayer is between the pinning layer and second sublayer. The first TBD is greater than the second TBD. The first exchange energy is less than the second exchange energy.

Owner:WESTERN DIGITAL TECH INC

Method for providing a magnetic recording transducer having a hybrid moment pole

ActiveUS8339738B1Record information storageHeads for perpendicular magnetisationsMagnetic transducersMagnetic moment

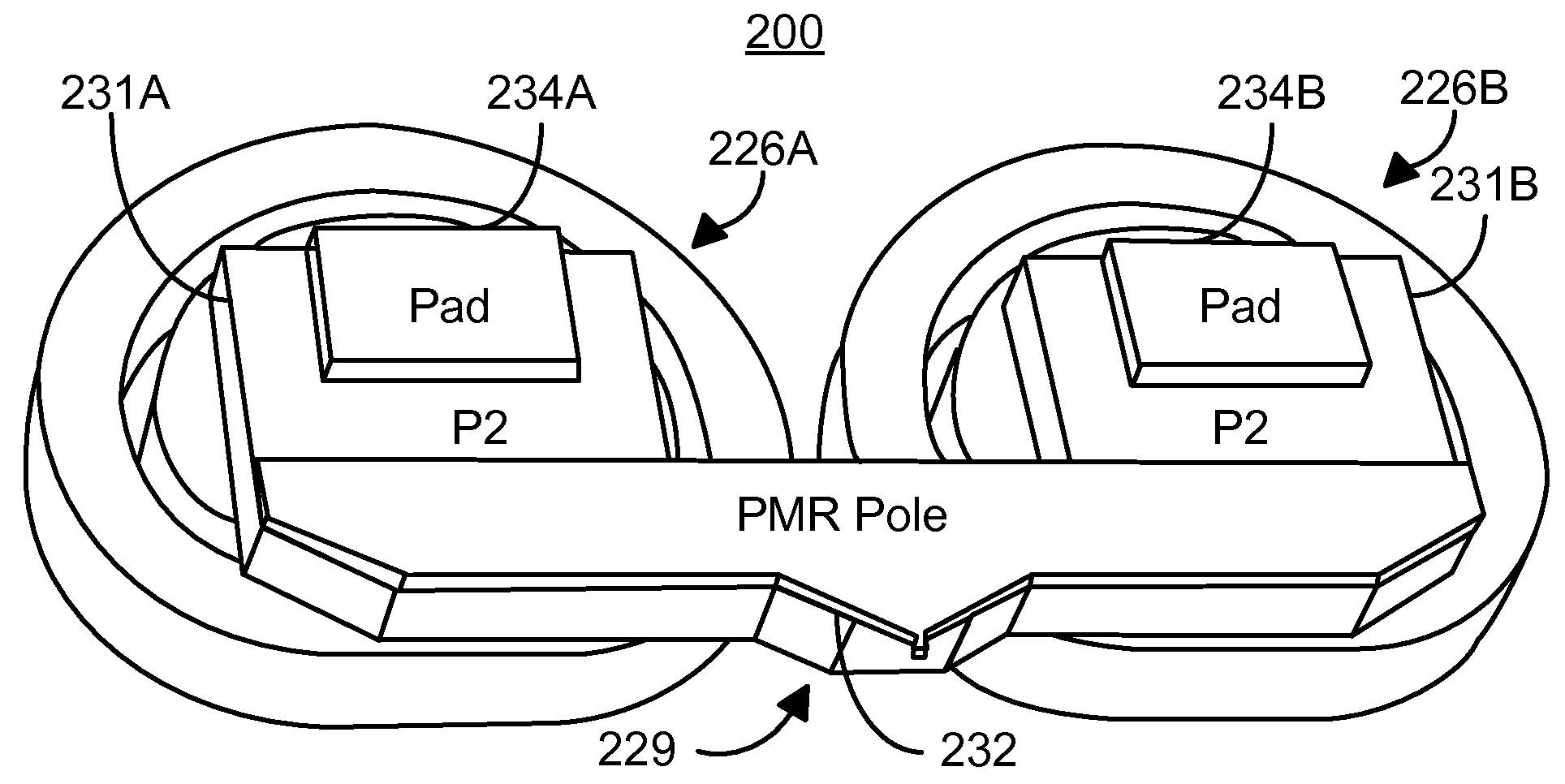

A method for fabricating a magnetic transducer having an air-bearing surface (ABS) is provided. The method comprises providing an underlayer, and providing a main pole residing on the underlayer and having a front and a rear. The step of providing a main pole further includes providing a first portion having a first magnetic moment, the first portion having a front face at the ABS and terminating between the ABS and the rear of the main pole, and providing a second portion having a second magnetic moment. A part of the second portion resides on the first portion, and another part of the second portion resides between the first portion of the main pole and the rear of the main pole. The first magnetic moment is less than the second magnetic moment.

Owner:WESTERN DIGITAL TECH INC

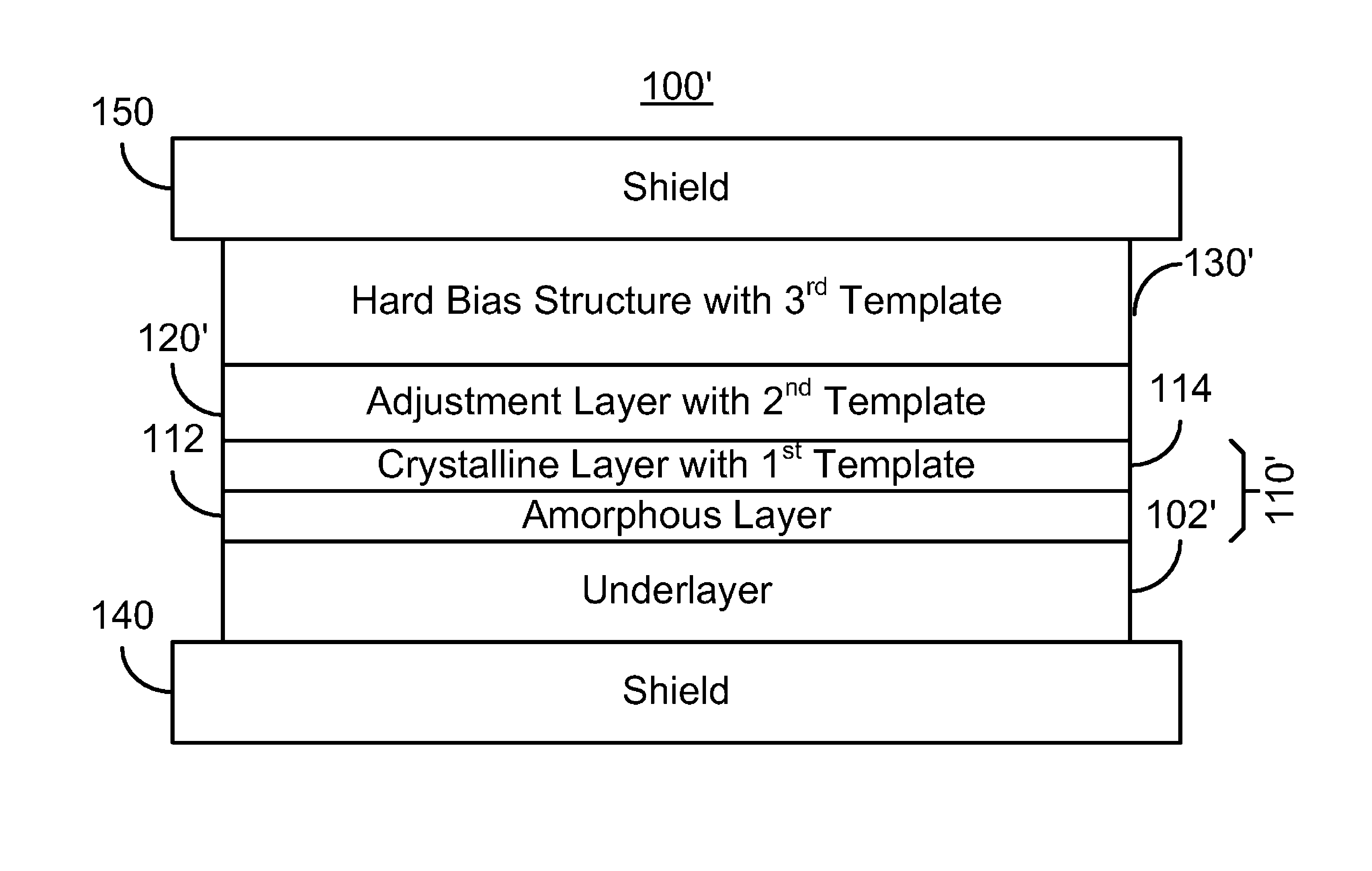

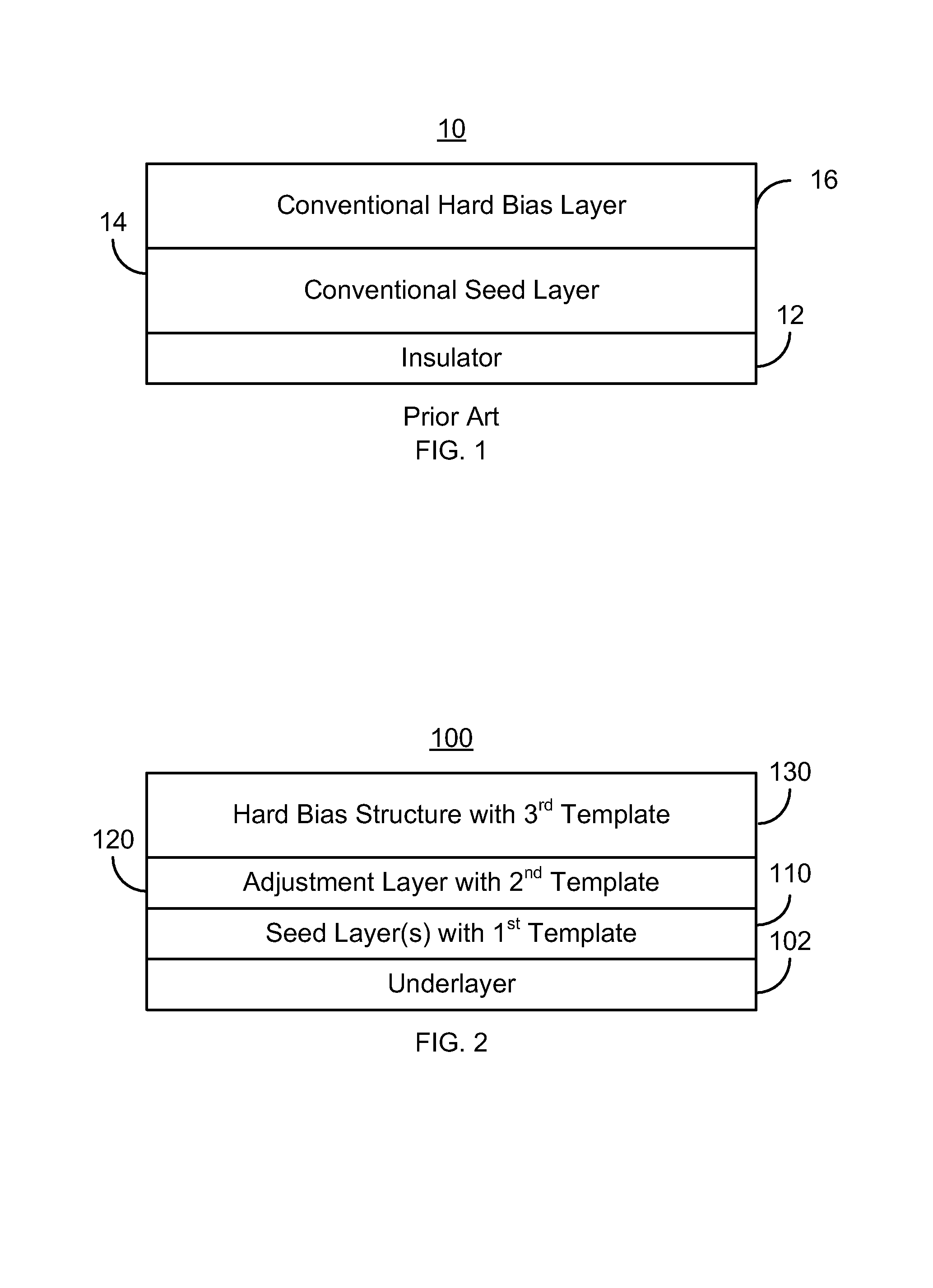

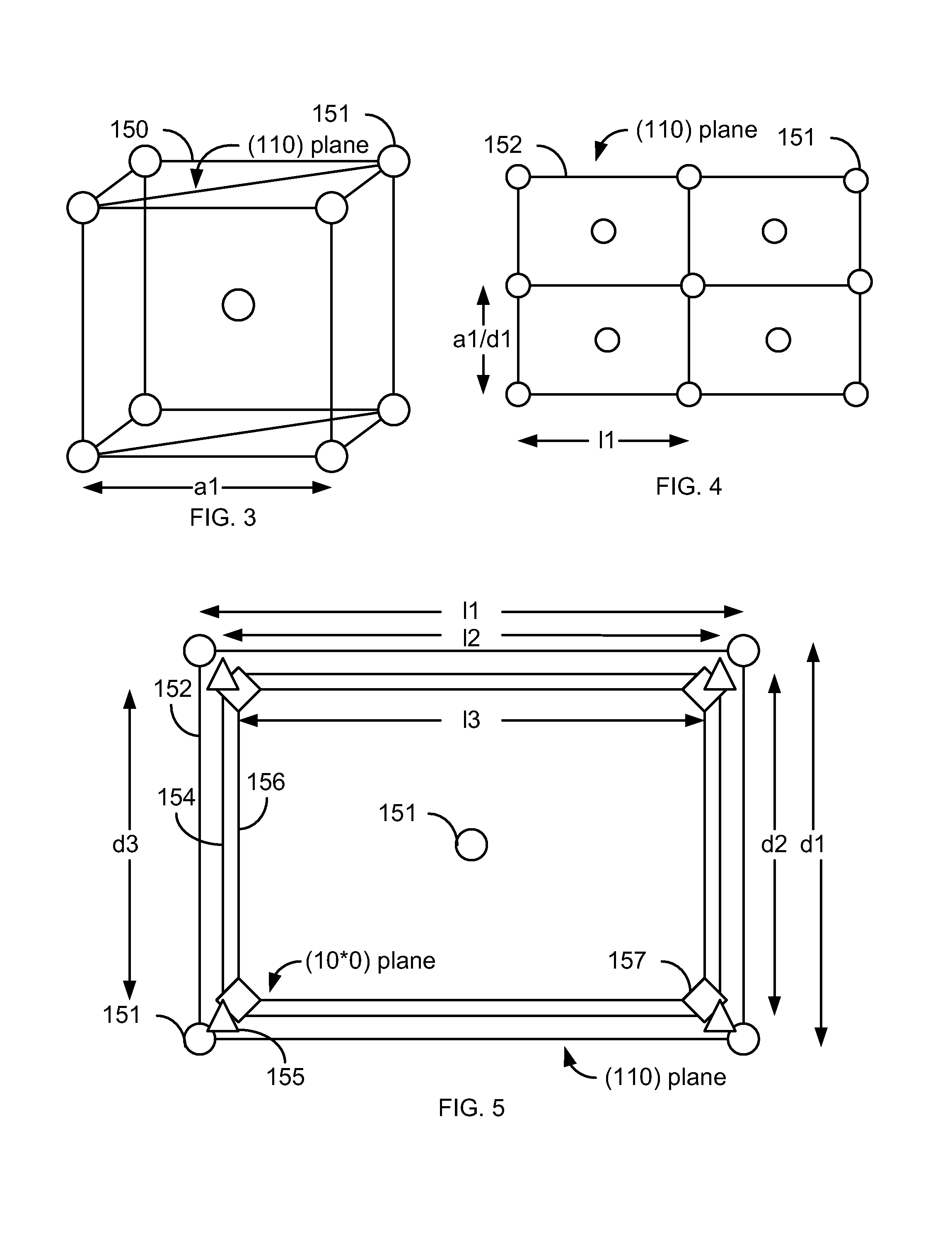

Method and system for providing a hard bias structure in a magnetic recording transducer

InactiveUS8547667B1Record information storageManufacture of flux-sensitive headsMagnetic transducersComputer science

A method and system for providing a magnetic transducer is described. The method and system include providing a seed layer and providing at least one adjustment layer on the seed layer. The method and system also include providing a hard bias structure on the at least one adjustment layer. The seed layer has a first template including a first template dimension and a first texture. The at least one adjustment layer has a second template including a second template dimension and a second texture. The hard bias structure has a third template including a third template dimension and a third texture. The second template is between the first template and the third template.

Owner:WESTERN DIGITAL TECH INC

Method for providing a magnetic recording transducer

Owner:WESTERN DIGITAL TECH INC

Head for perpendicular magnetic recording with a shield structure connected to the return pole piece

An embodiment of the invention is a head for perpendicular recording that has a trailing shield and side shields that are connected to the return pole piece by two studs of ferromagnetic material. The studs extend parallel to the track direction and are located a sufficient distance away from the main pole piece to reduce the flux flow from the main pole piece to the studs. Optionally the studs can be recessed behind the air-bearing surface. The preferred embodiment of the invention is a magnetic transducer with separated read and write heads for perpendicular recording.

Owner:WESTERN DIGITAL TECH INC

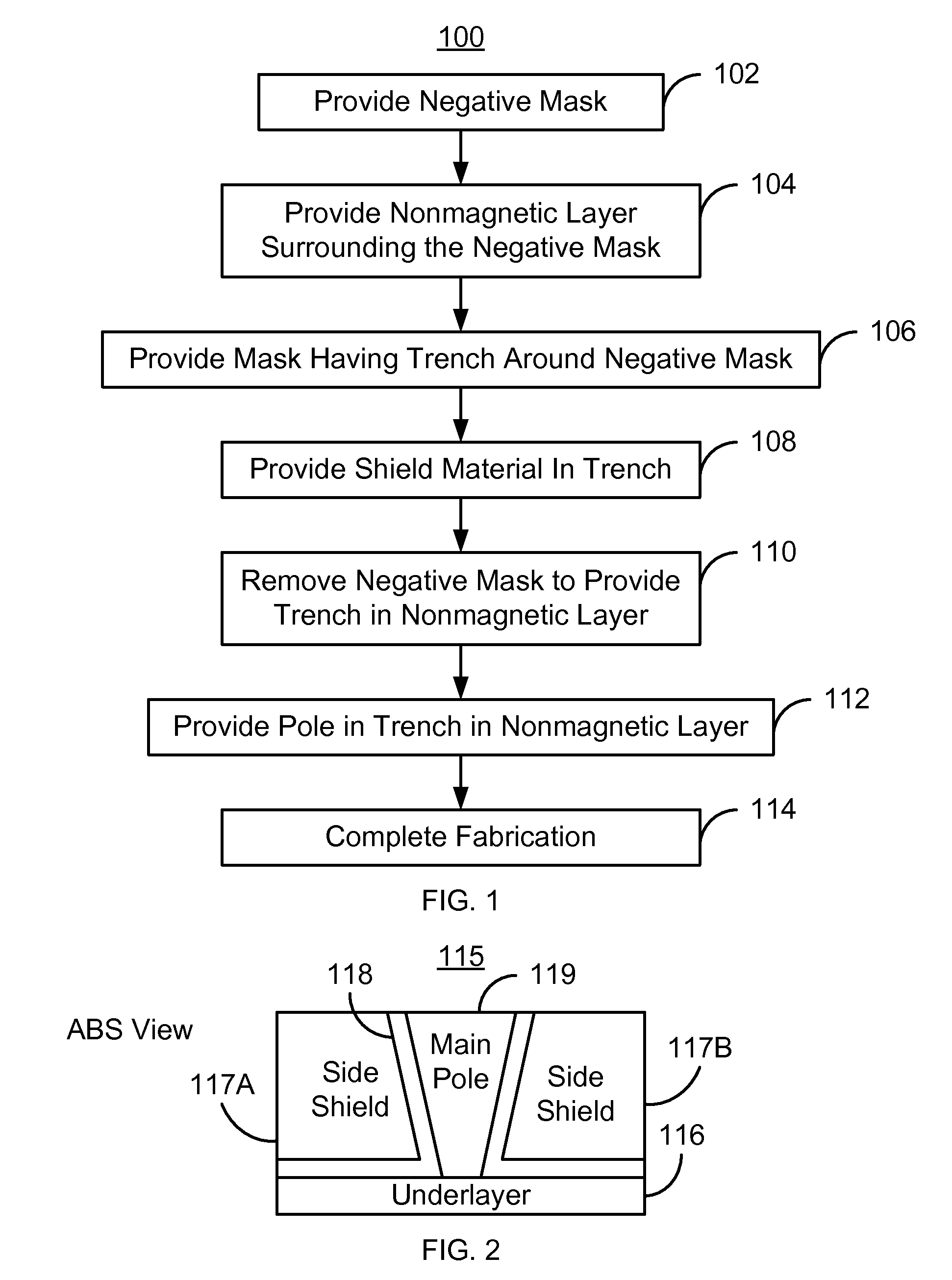

Method for manufacturing a magnetic recording transducer having side shields

A method for manufacturing a magnetic transducer is described. The method includes providing a negative mask having a bottom, a plurality of sides, and a top wider than the bottom. The method also includes depositing a nonmagnetic layer on the negative mask. The nonmagnetic layer has a plurality of portions covering the plurality of sides of the negative mask. The method also includes providing a first mask having a first trench therein. The negative mask resides in the first trench. The method further includes depositing side shield material(s), at least a portion of which resides in the first trench. The method further includes removing the negative mask to create a second trench between the plurality of portions of the nonmagnetic layer and form a pole, at least a portion of which resides in the second trench.

Owner:WESTERN DIGITAL TECH INC

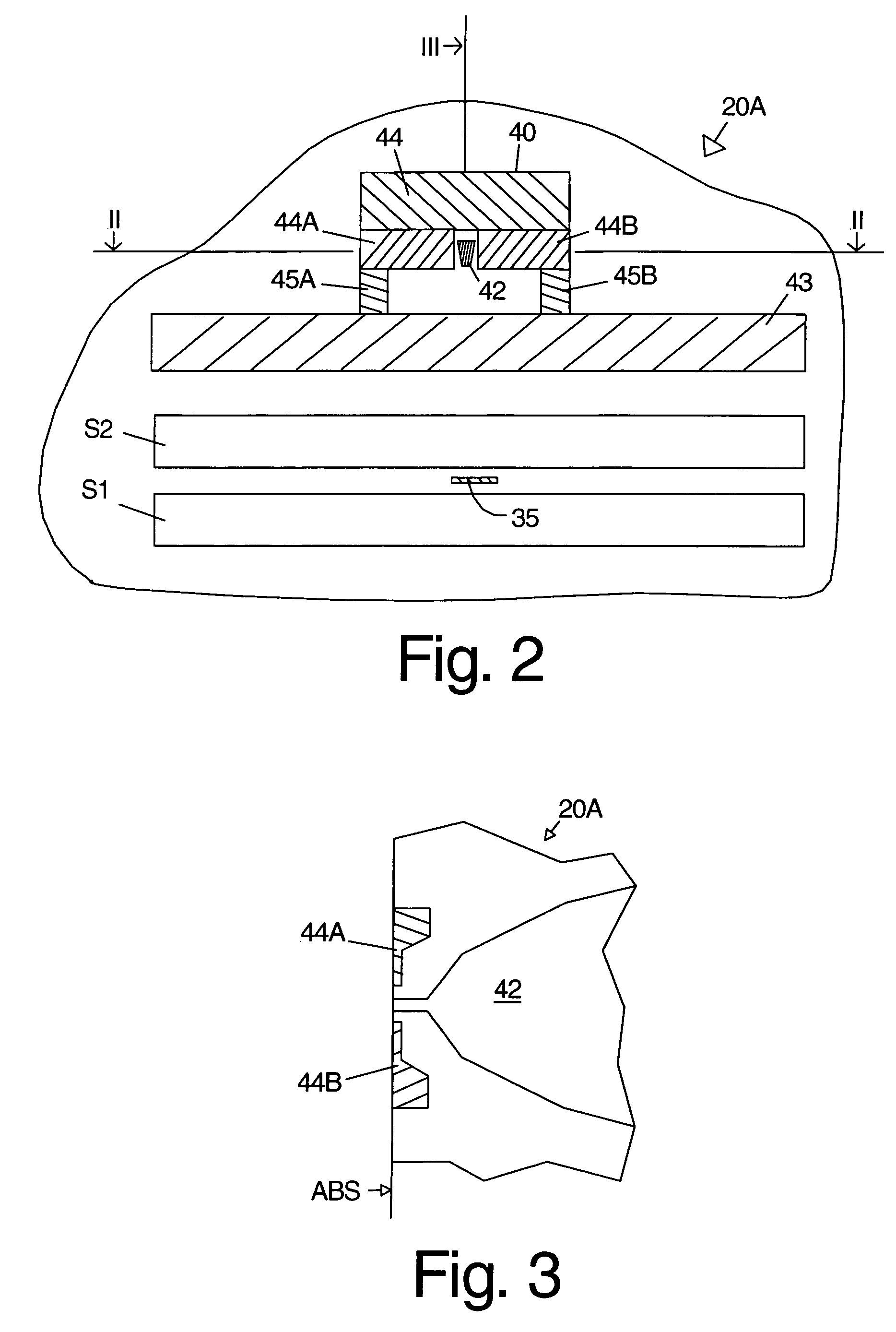

Magnetic recording head with dynamic fly height heating and having thermally controlled pole tip protrusion to control and protect reader element

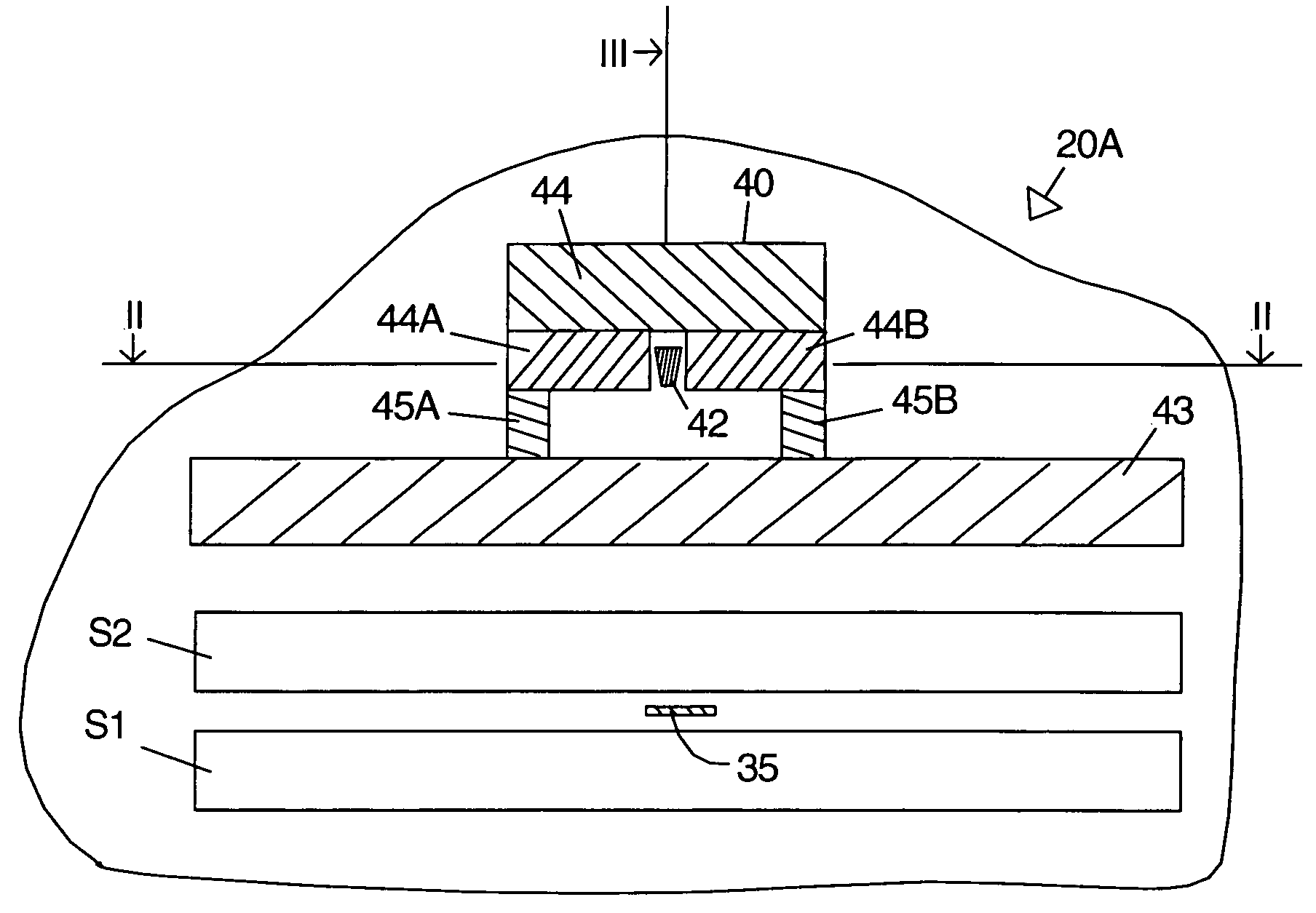

ActiveUS8749920B1Record information storageHeads for perpendicular magnetisationsHard disc driveMagnetic transducers

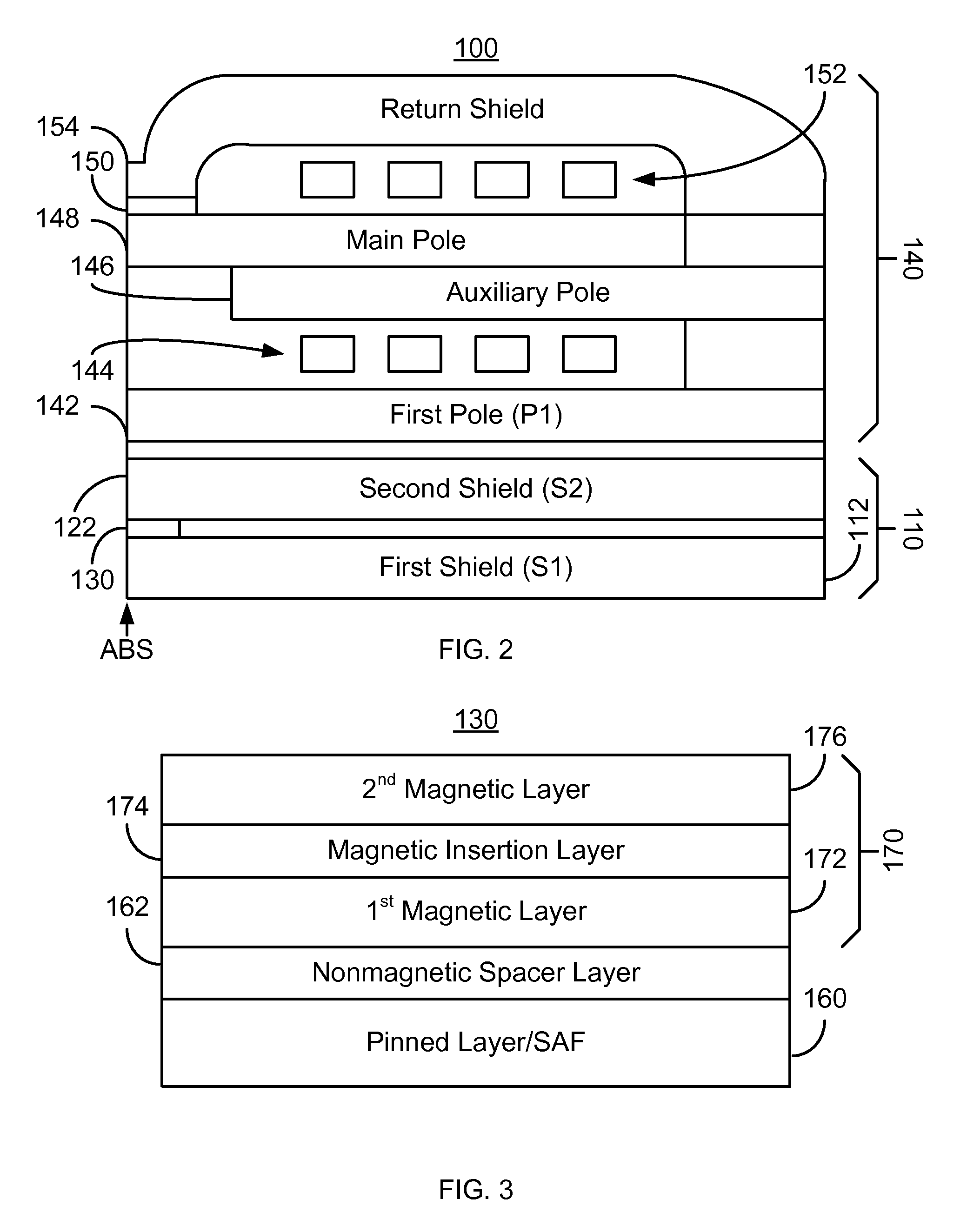

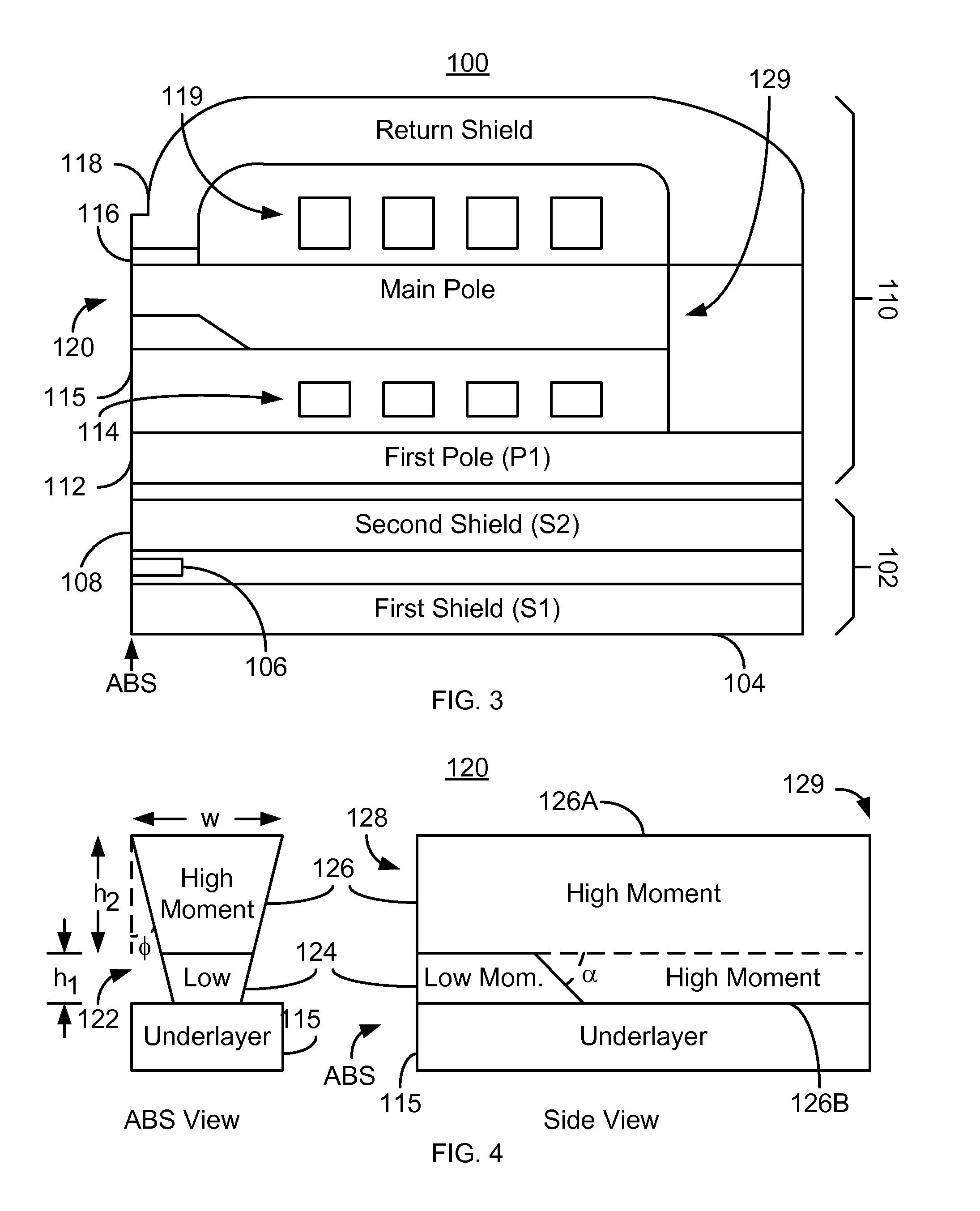

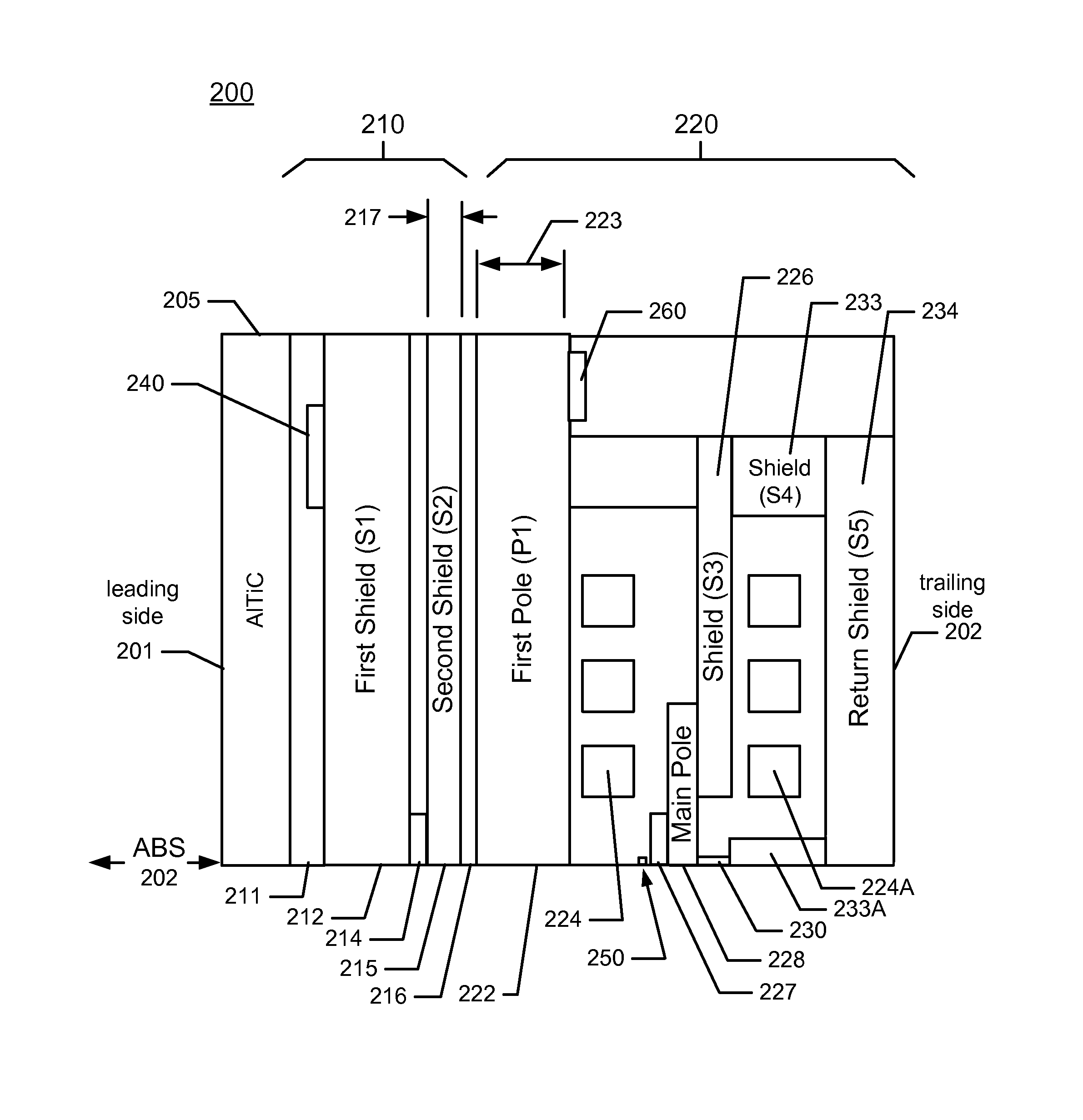

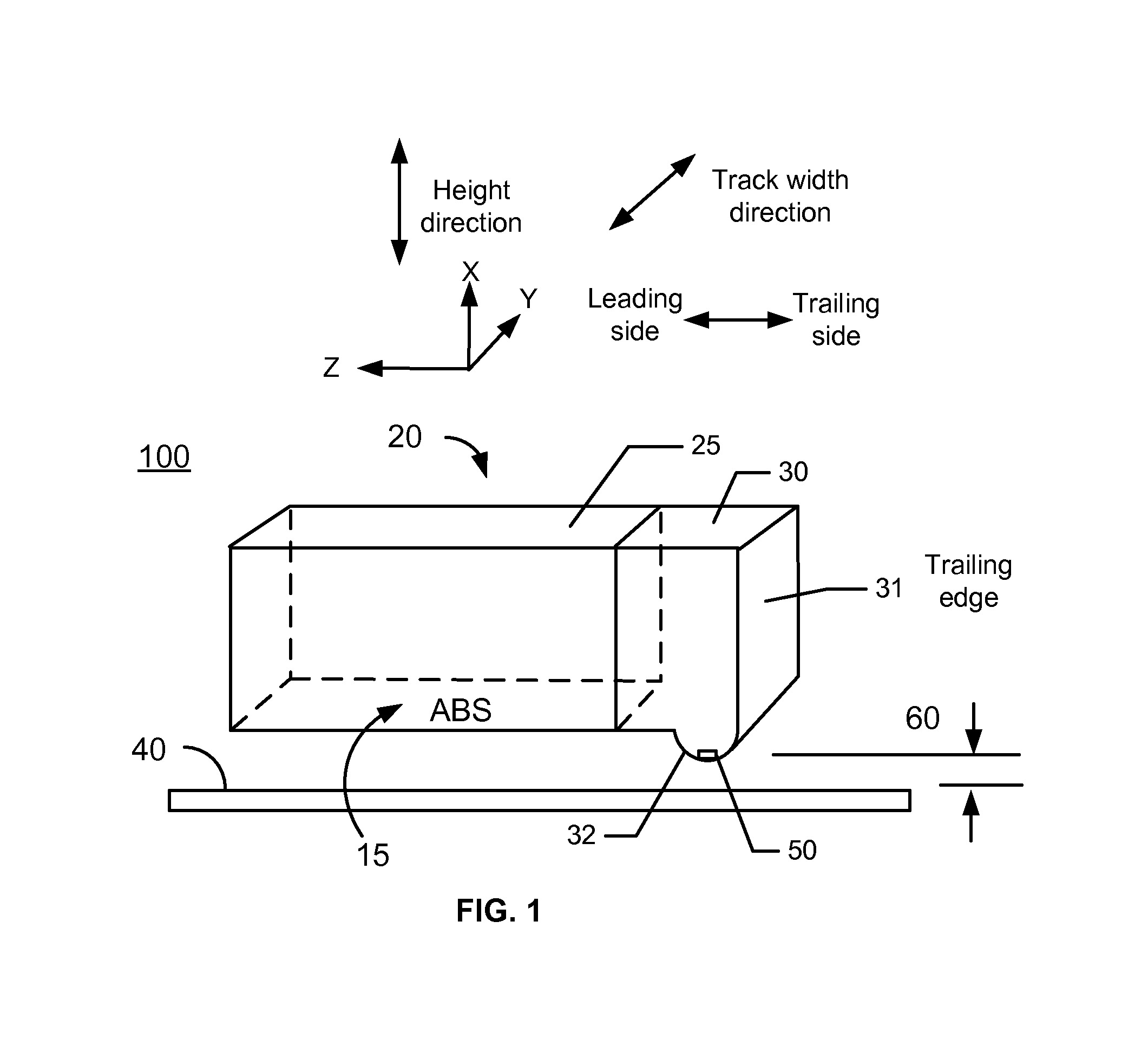

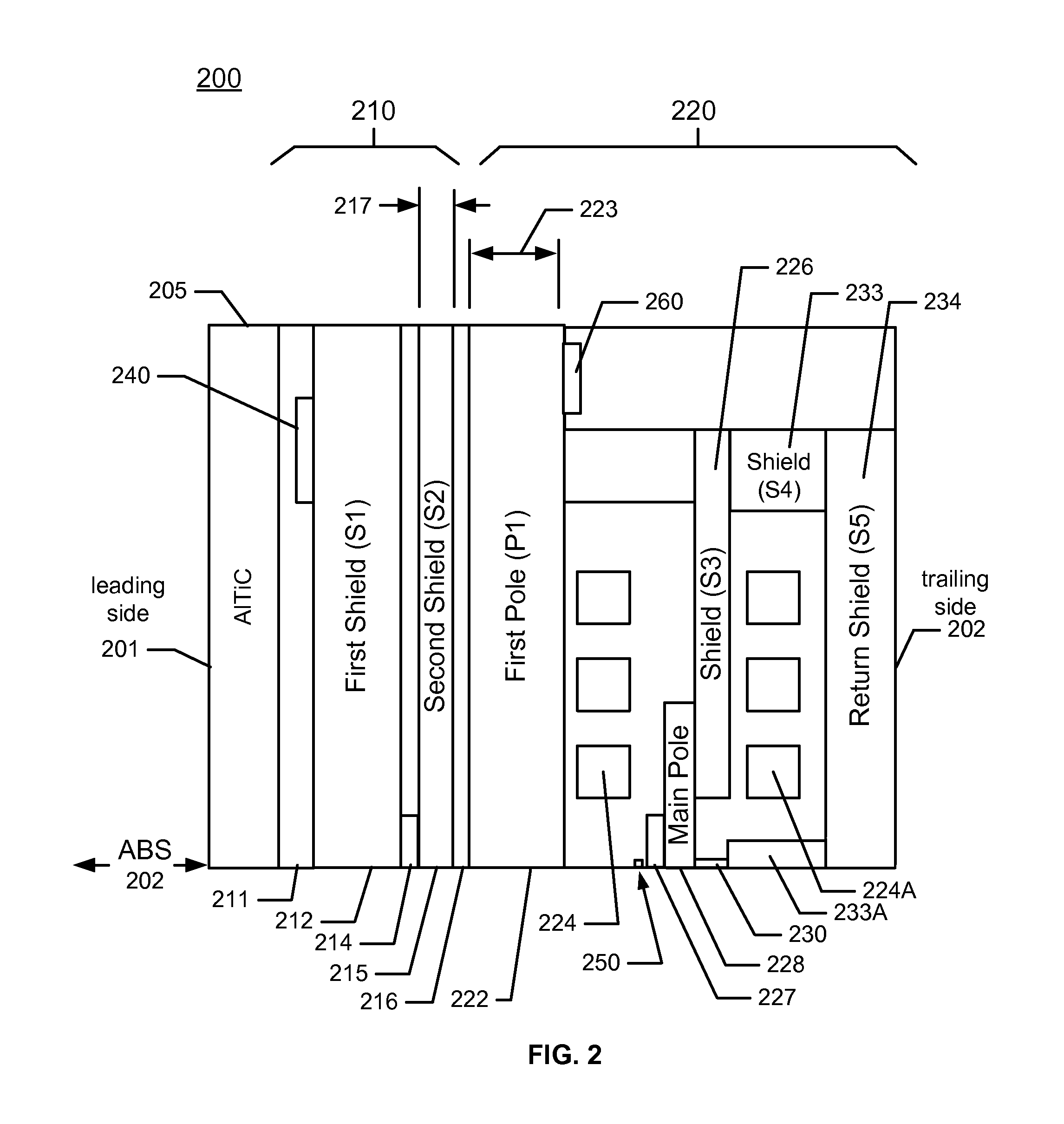

A magnetic recording device includes a slider having an air bearing surface (ABS), a leading side, and a trailing side and a head residing on the slider. The head has a first magnetic transducer and a first heater for heating an area proximal to the first magnetic transducer. A first shield (S1) comprising a first material is on the leading side of the first magnetic transducer and a second shield (S2) comprising the first material is on the trailing side of the first magnetic transducer. A first pole (P1) comprising the first material is on the trailing side of the second shield (S2), and the first pole (P1) is between 0.6 micron and 2.0 micron thick; and the second shield (S2) is less than 0.6 micron thick. A hard disk drive includes the magnetic recording device.

Owner:WESTERN DIGITAL TECH INC

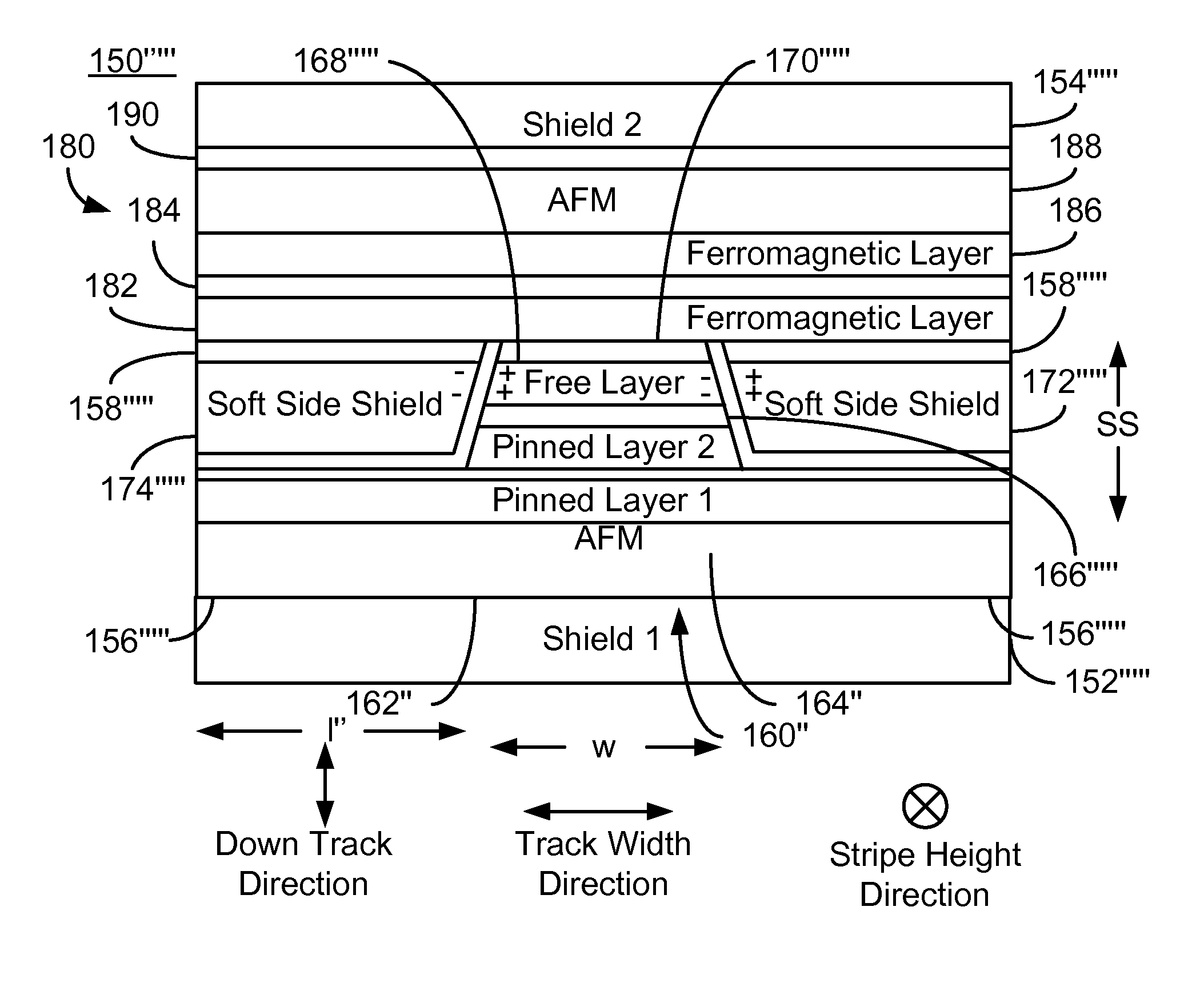

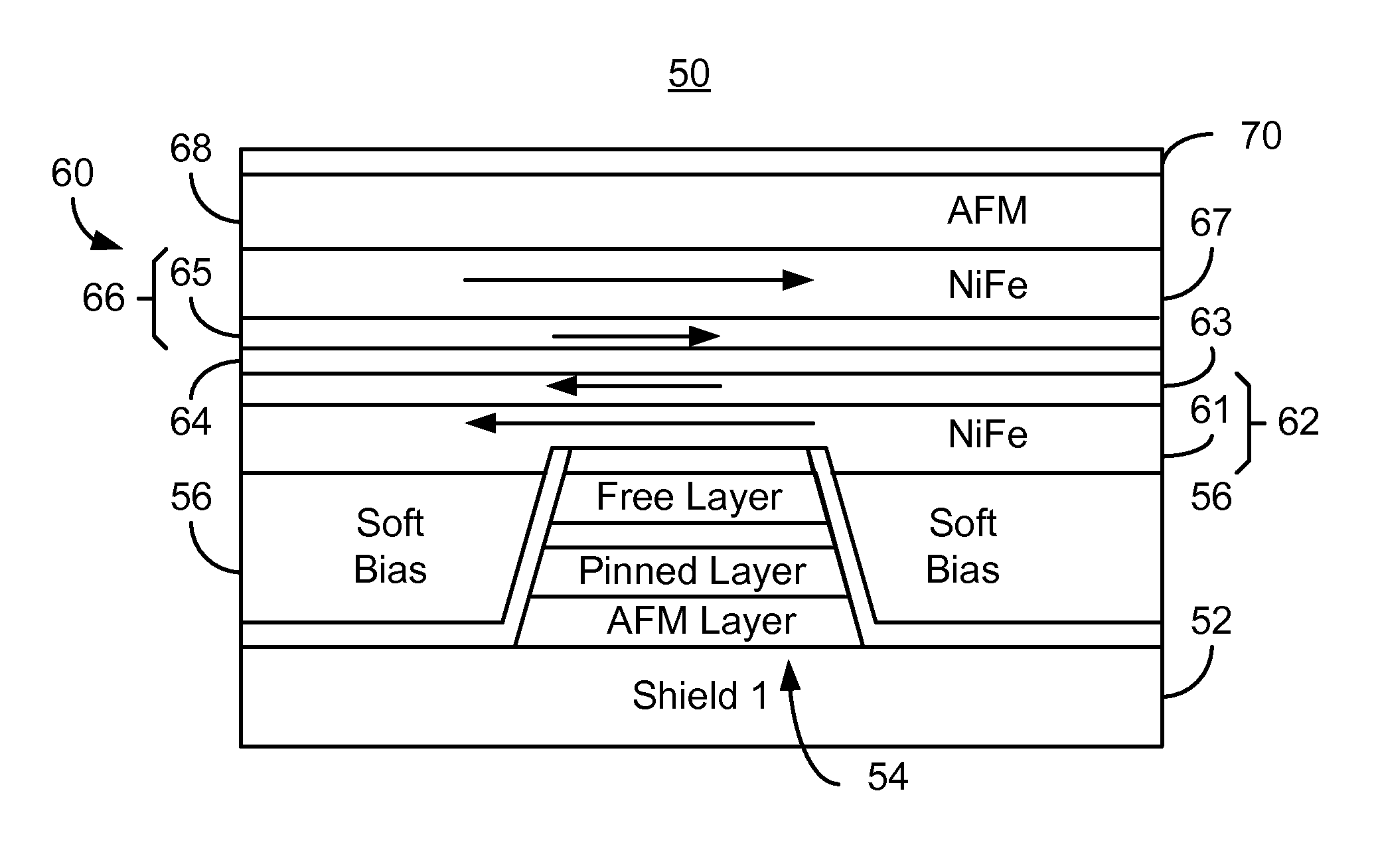

Method and system for providing a read transducer having an extended pinned layer and soft magnetic bias structures with improved stability

ActiveUS8760822B1Magnetic-field-controlled resistorsRecord information storageMagnetic transducersAir bearing surface

A method and system provide a magnetic transducer having an air-bearing surface (ABS). The magnetic transducer includes a first shield, a read sensor, at least one soft magnetic bias structure and a second shield. The read sensor includes a sensor layer, a pinned layer and edge(s). The sensor layer has a first stripe height in a stripe height direction perpendicular to the ABS. The pinned layer has a second stripe height in the stripe height direction. The second stripe height is greater than the first stripe height. The soft magnetic bias structure(s) are adjacent to the edge(s) of the sensor. A portion of the soft magnetic bias structure(s) is further from the ABS than the first stripe height. The read sensor is between the first shield and the second shield. The soft magnetic bias structure(s) extend to the second shield.

Owner:WESTERN DIGITAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com