Magnetic plate for printing of optical effects

一种印刷板、薄板的技术,应用在用于印刷光学效果的磁板领域,能够解决防伪文件不可行等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

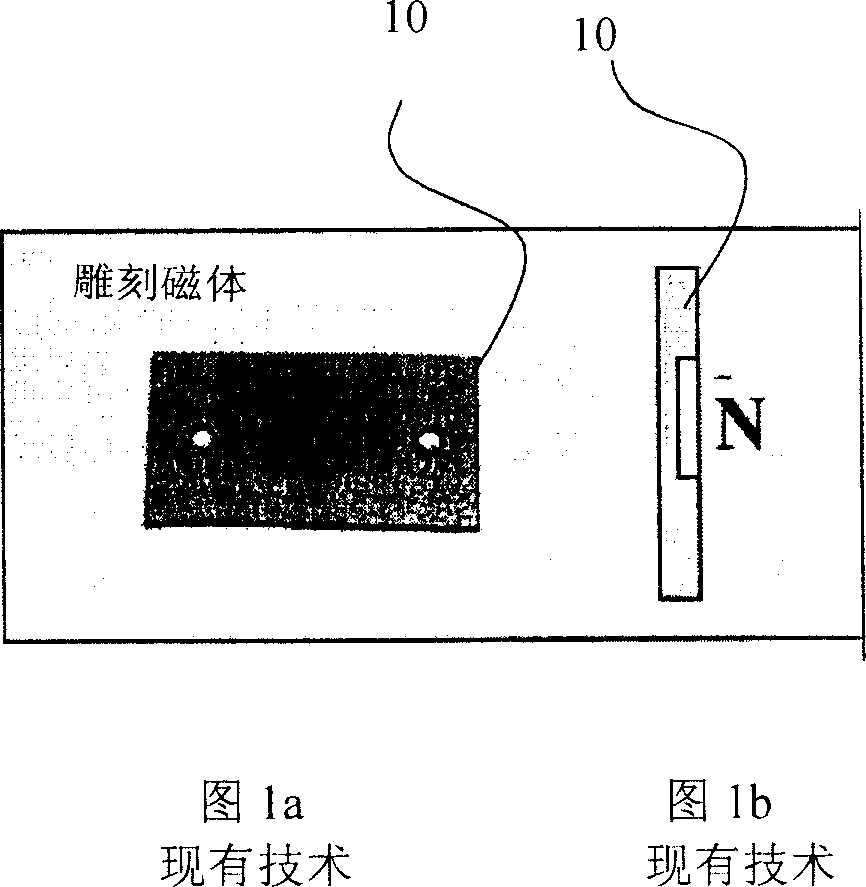

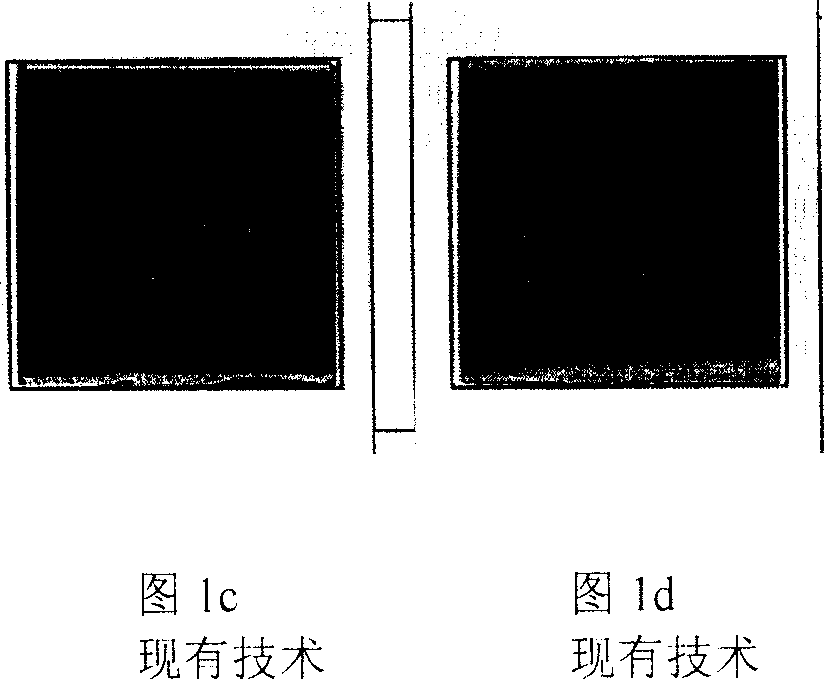

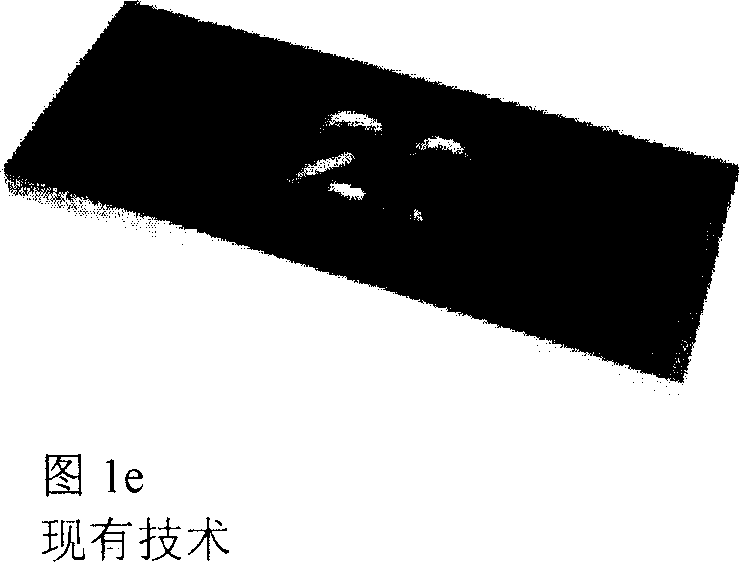

[0075] [75] Referring now to prior art Figures 1a through 1f, Figure 1a shows an engraved magnet for forming a print in a substrate coated with wet ink or paint comprising magnetically aligned Granules or flakes. After the substrate is coated with ink or paint, a magnet 10 is placed under the substrate and the flakes in the ink or paint align along the field lines to form the numeral "20". In Figure 1c, reflective flakes, such as Ni, have a silver-like appearance in a blue carrier vehicle, and the reflective flakes are arranged to form the number "20". The flakes appear to be a moldy color, and the flakes in the background of the "20" and in the number itself have a dark appearance. This is because the flakes are upright and all that is visible in the spaces between the upright flakes is the dark blue carrier medium. A similar effect is illustrated in Figure 1d, where color-changing flakes are applied. The magnetic field in Figure 1f radiates from the engraving magnet and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com