Patents

Literature

37results about How to "Long run time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

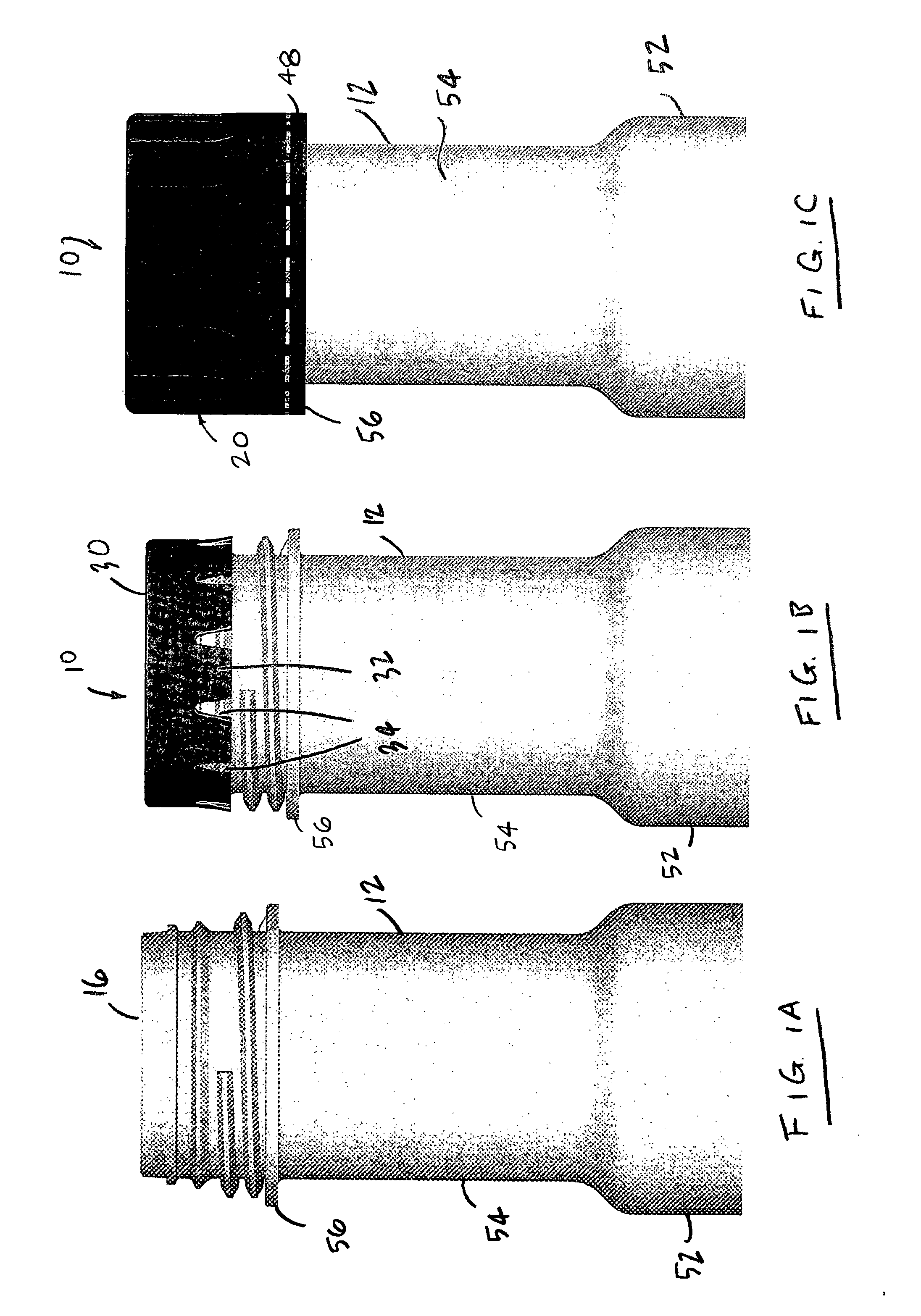

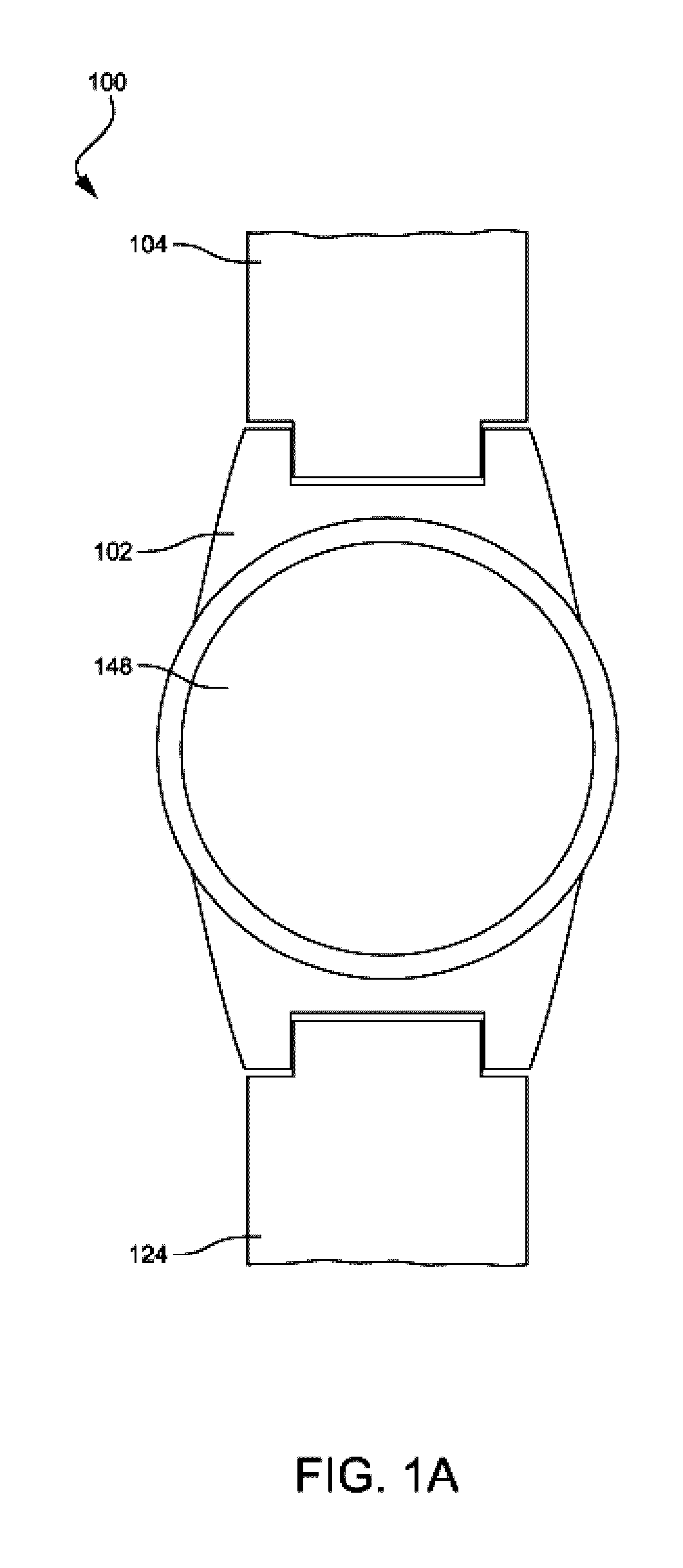

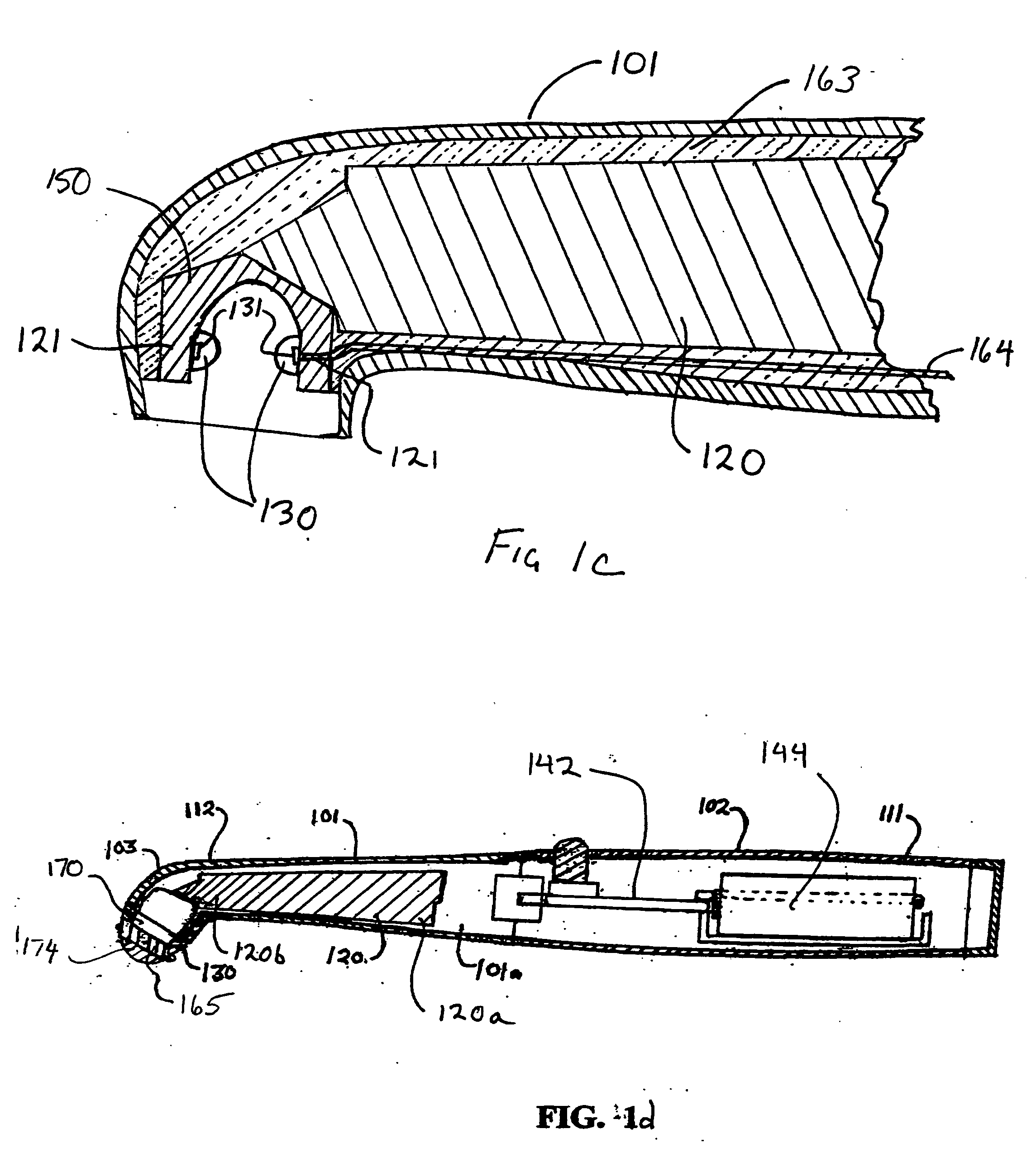

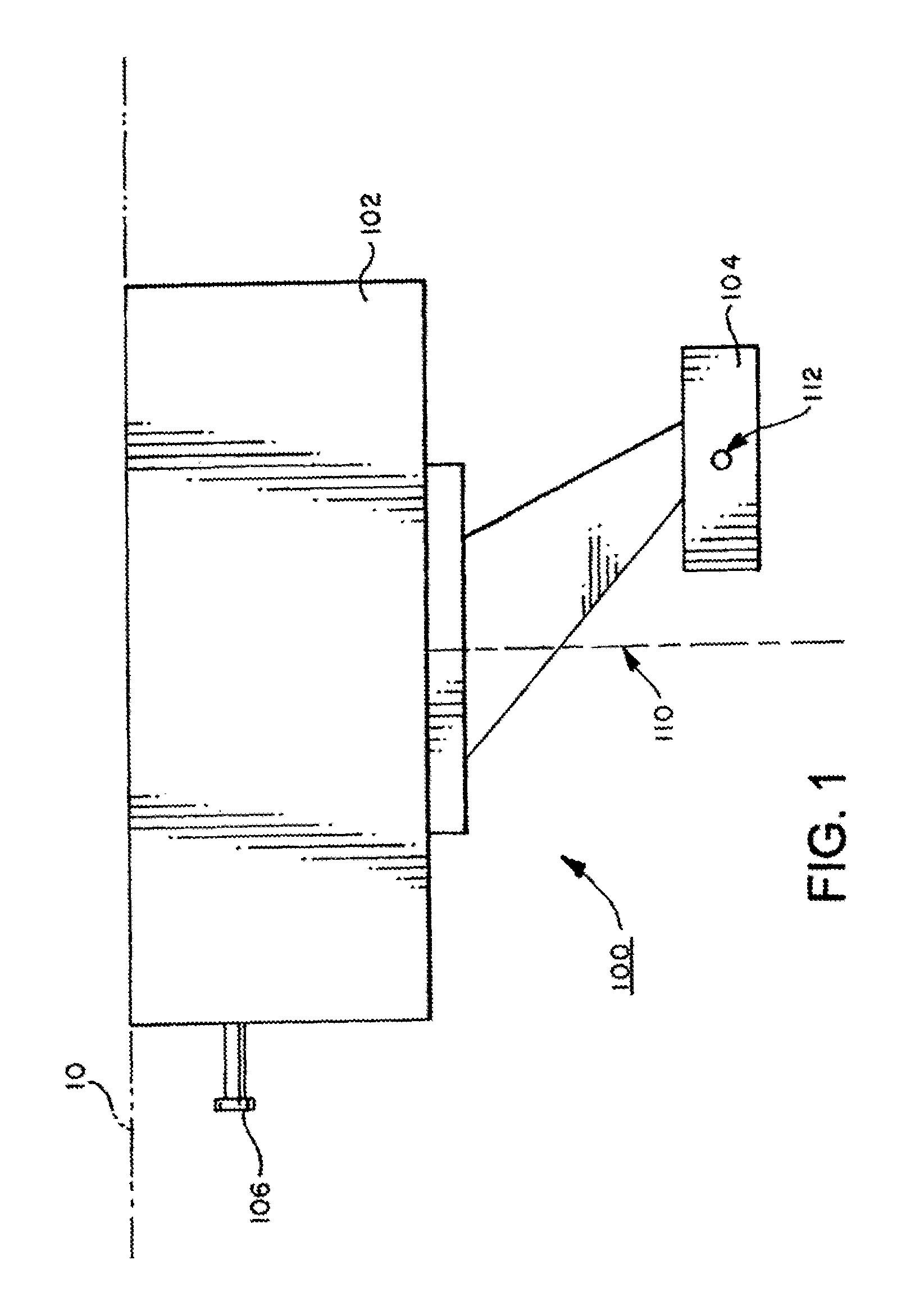

Container closure with overlying needle penetrable and thermally resealable portion and underlying portion compatible with fat containing liquid product, and related method

InactiveUS20060231519A1Avoiding seal integrity problemGood product containmentCapsLiquid fillingLiquid productFormulary

A container and method are provided for storing fat containing liquid products, such as infant or baby formula, or other milk-based products. The container includes a body defining a storage chamber for receiving the aseptic fat containing liquid product, and a first aperture in fluid communication with the storage chamber. The body does not leach more than a predetermined amount of leachables into the fat containing liquid product and does not undesirably alter a taste profile of the fat containing liquid product. A container closure assembly includes a stopper receivable within the first aperture for hermetically sealing the storage chamber. The stopper includes a first material portion defining an internal surface in fluid communication with the storage chamber forming at least most of the surface area of the container closure that can contact any fat containing liquid product within the storage chamber and that does not leach more than a predetermined amount of leachables into the fat containing liquid product or undesirably alter a taste profile of the fat containing liquid product. A second material portion of the stopper either (i) overlies the first material portion and cannot contact any product within the storage chamber, or (ii) forms a substantially lesser surface area of the container closure that can contact any product within the storage chamber in comparison to the first material portion. The second material portion is needle penetrable for filling the storage chamber with product, and a resulting needle aperture formed in the second material portion is thermally resealable such as by the application of laser energy to seal the product within the storage chamber. A sealing portion of the container closure is engageable with the body prior to needle filling the storage chamber to thereby form a substantially dry hermetic seal between the container closure and body.

Owner:MEDINSTILL DEV

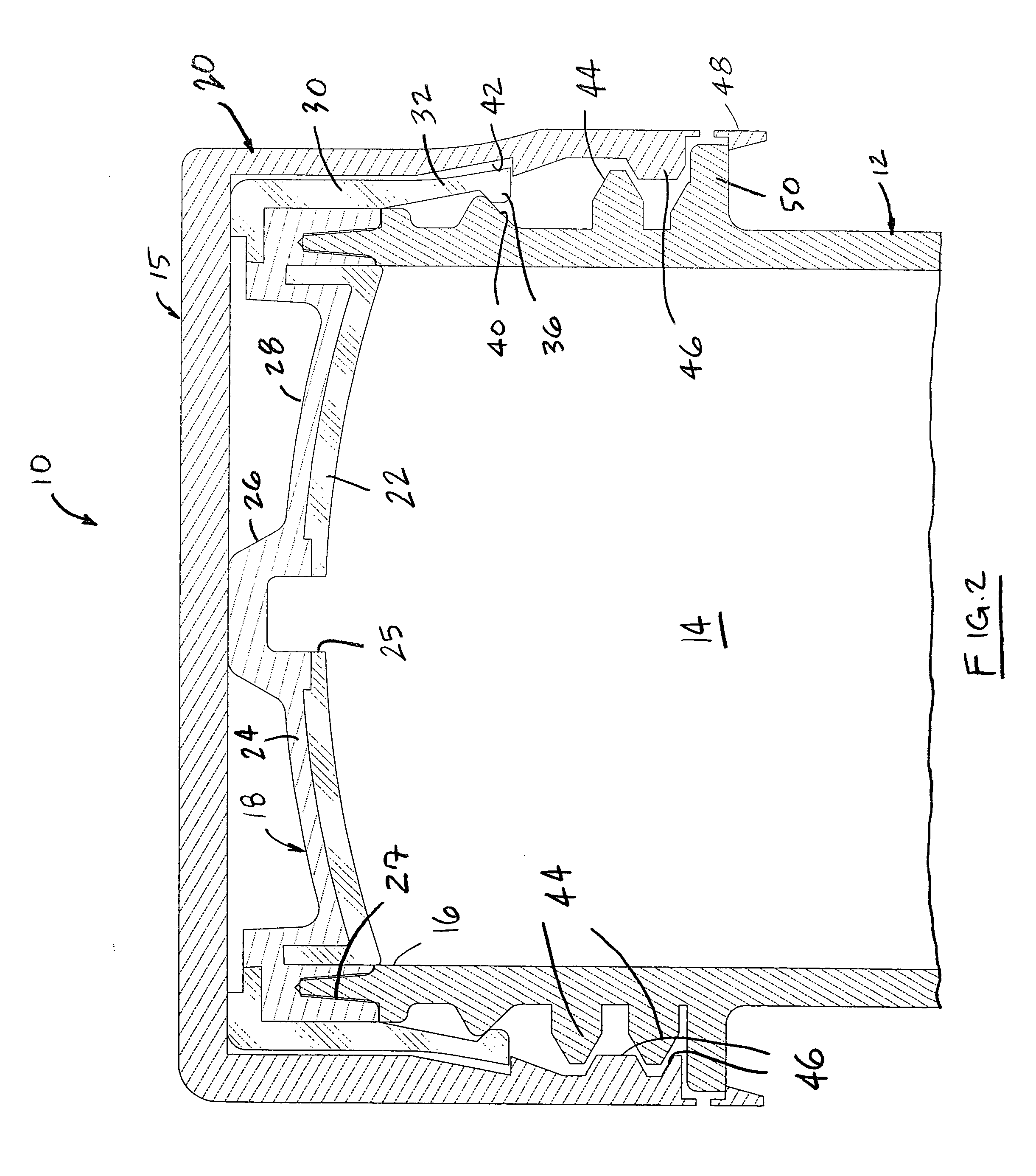

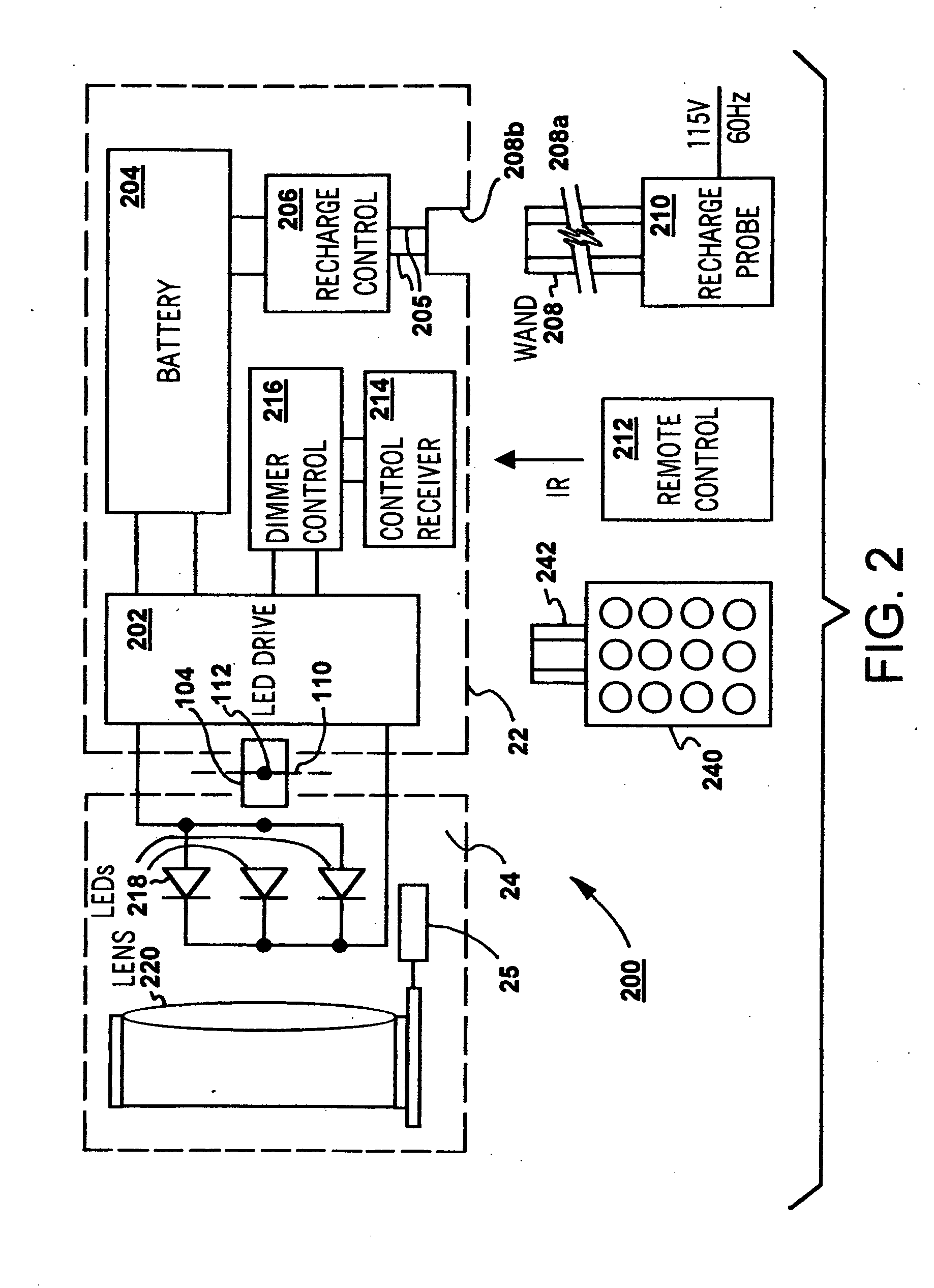

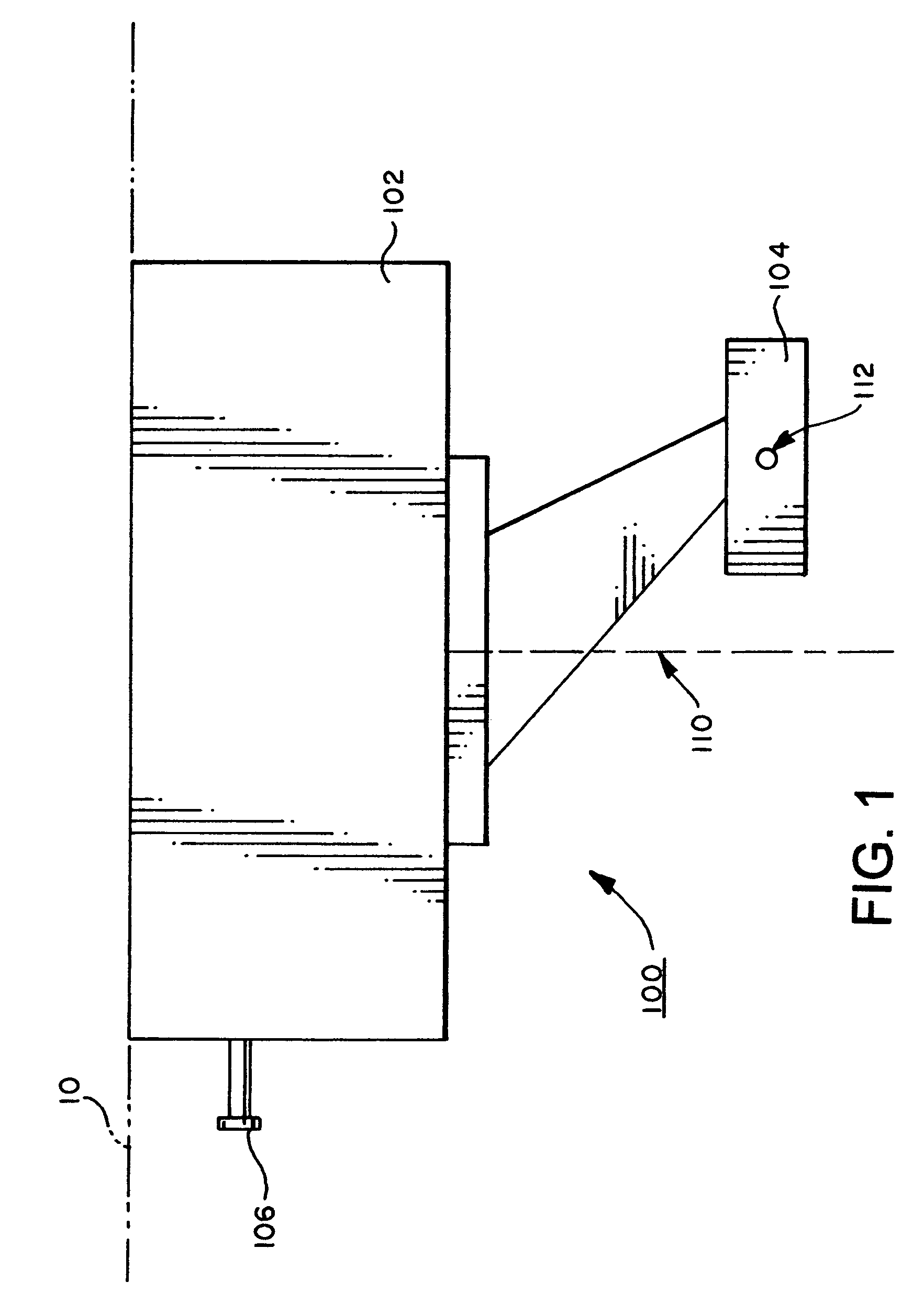

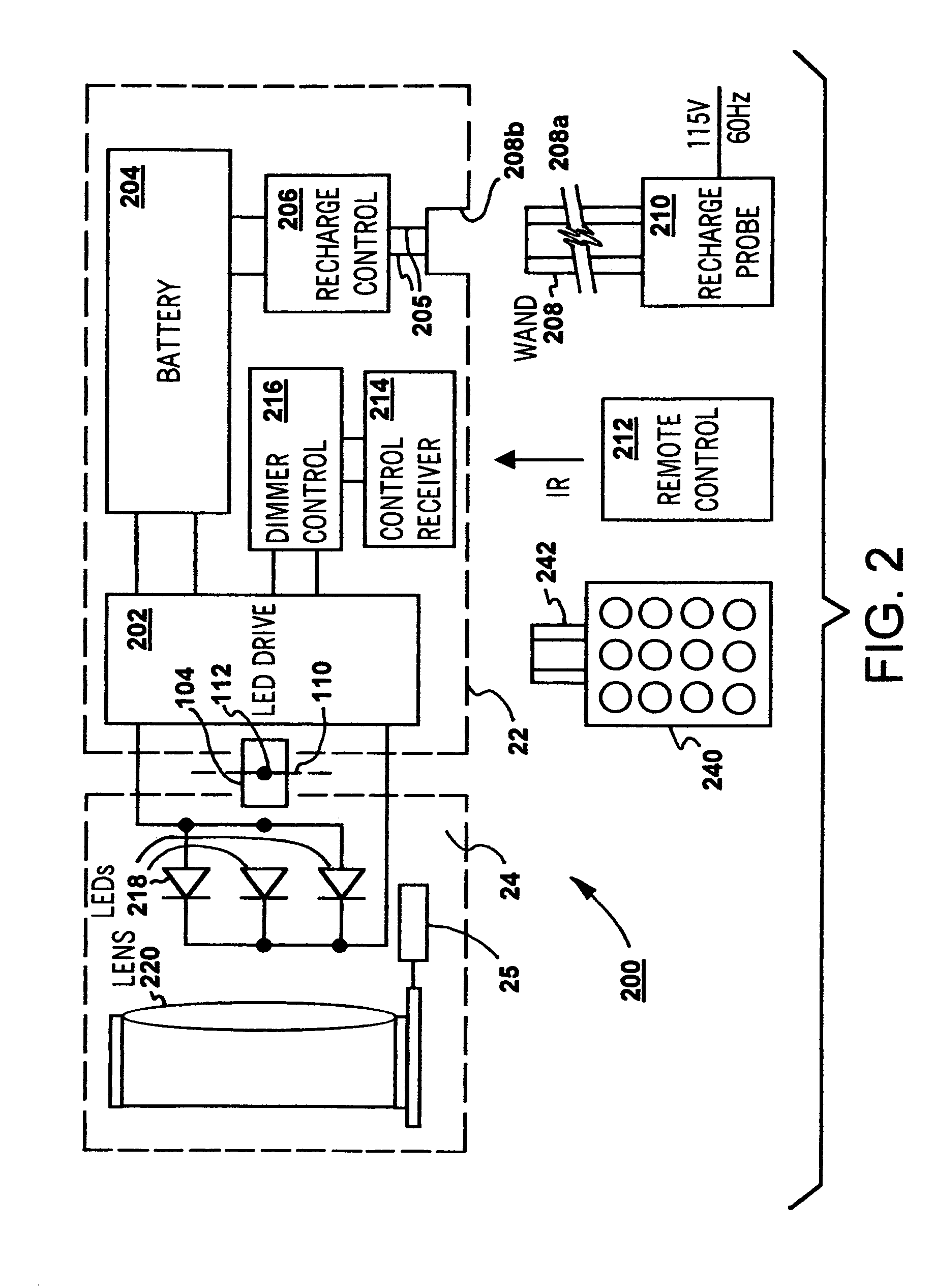

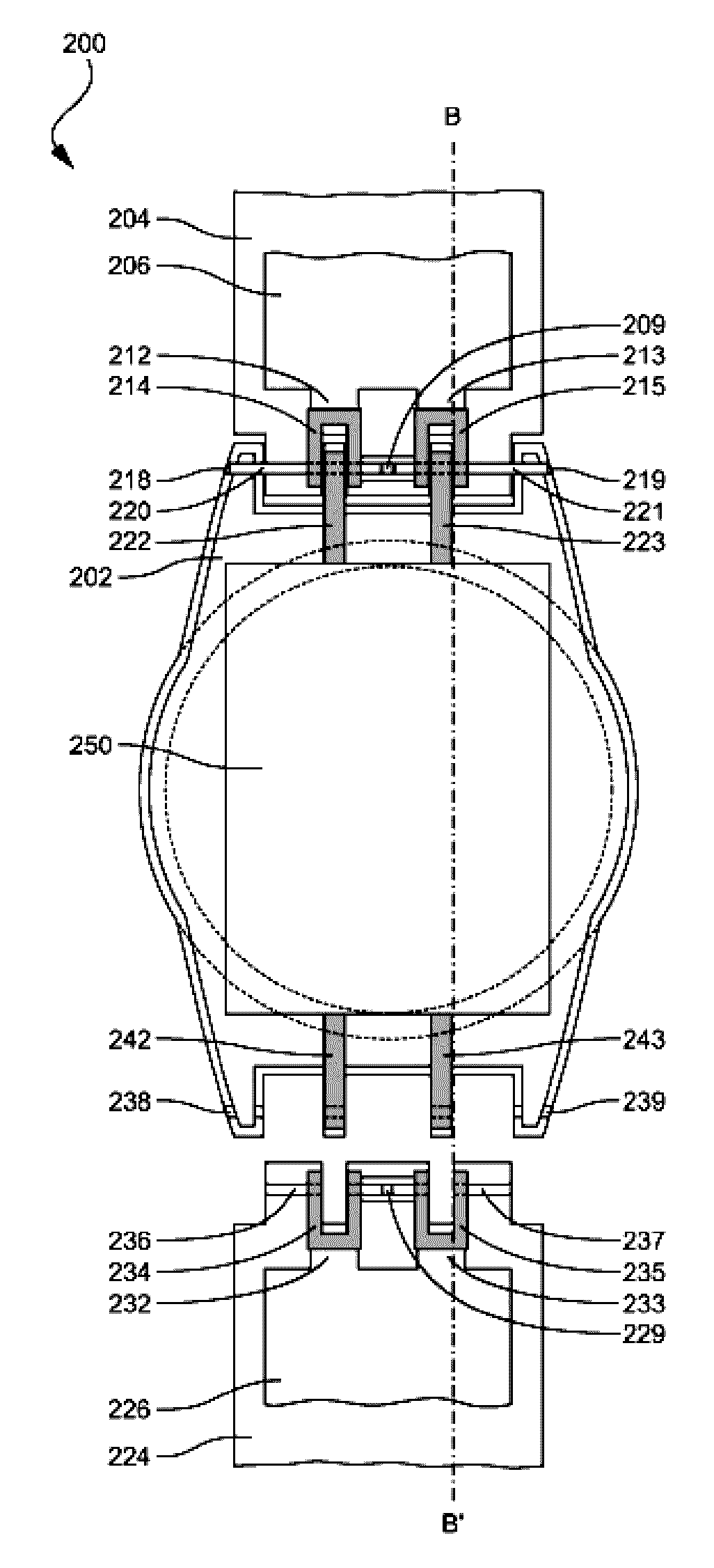

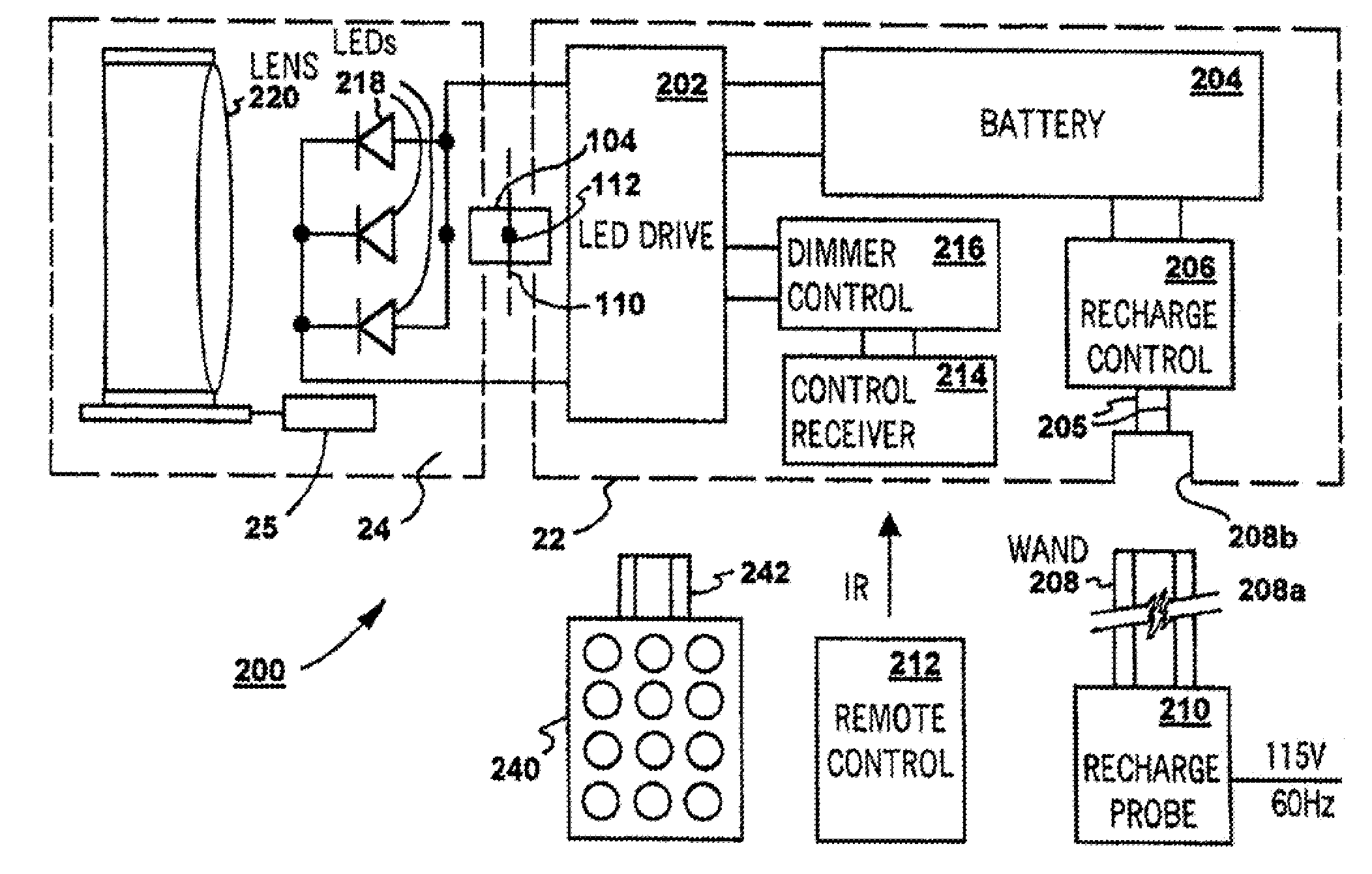

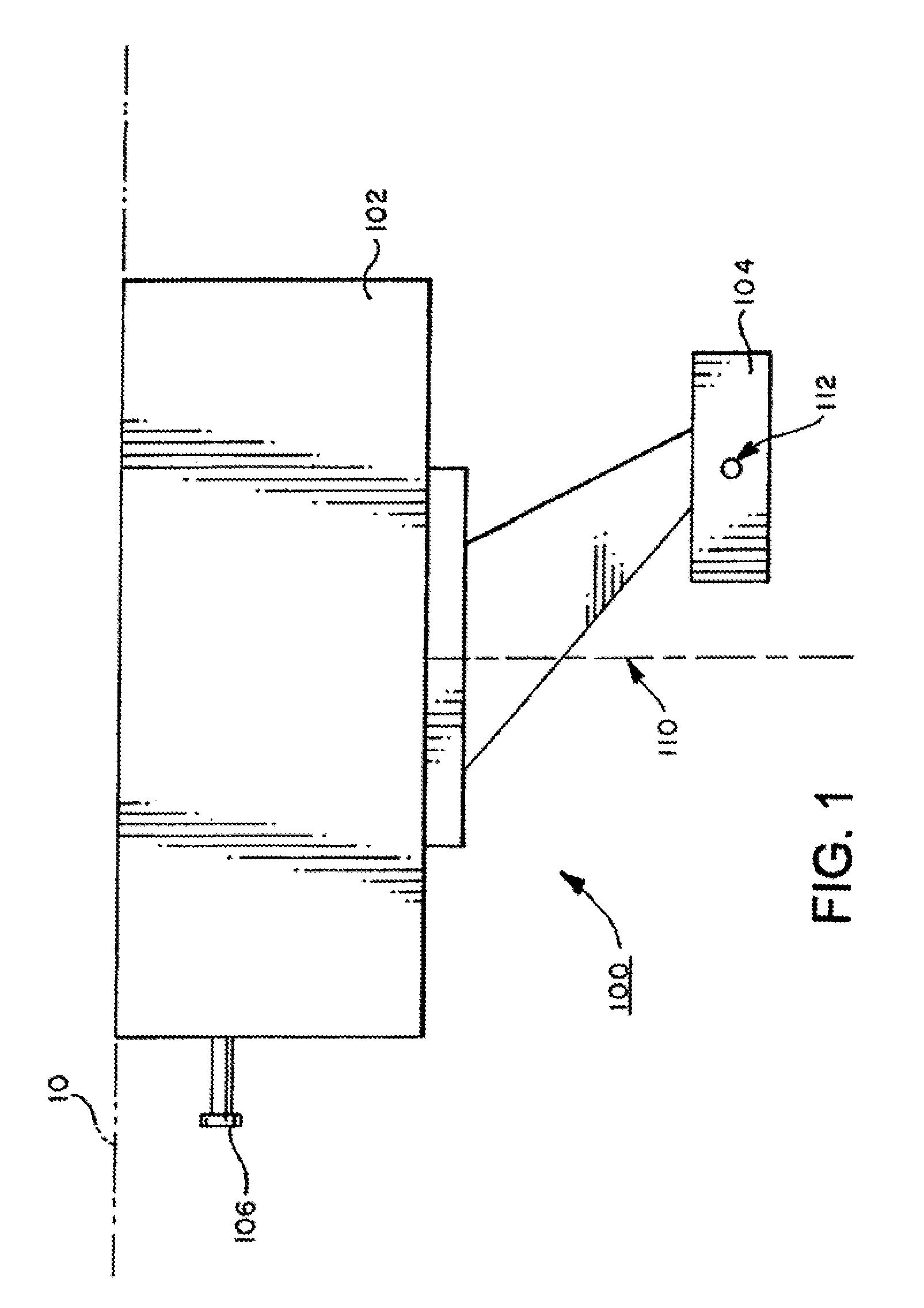

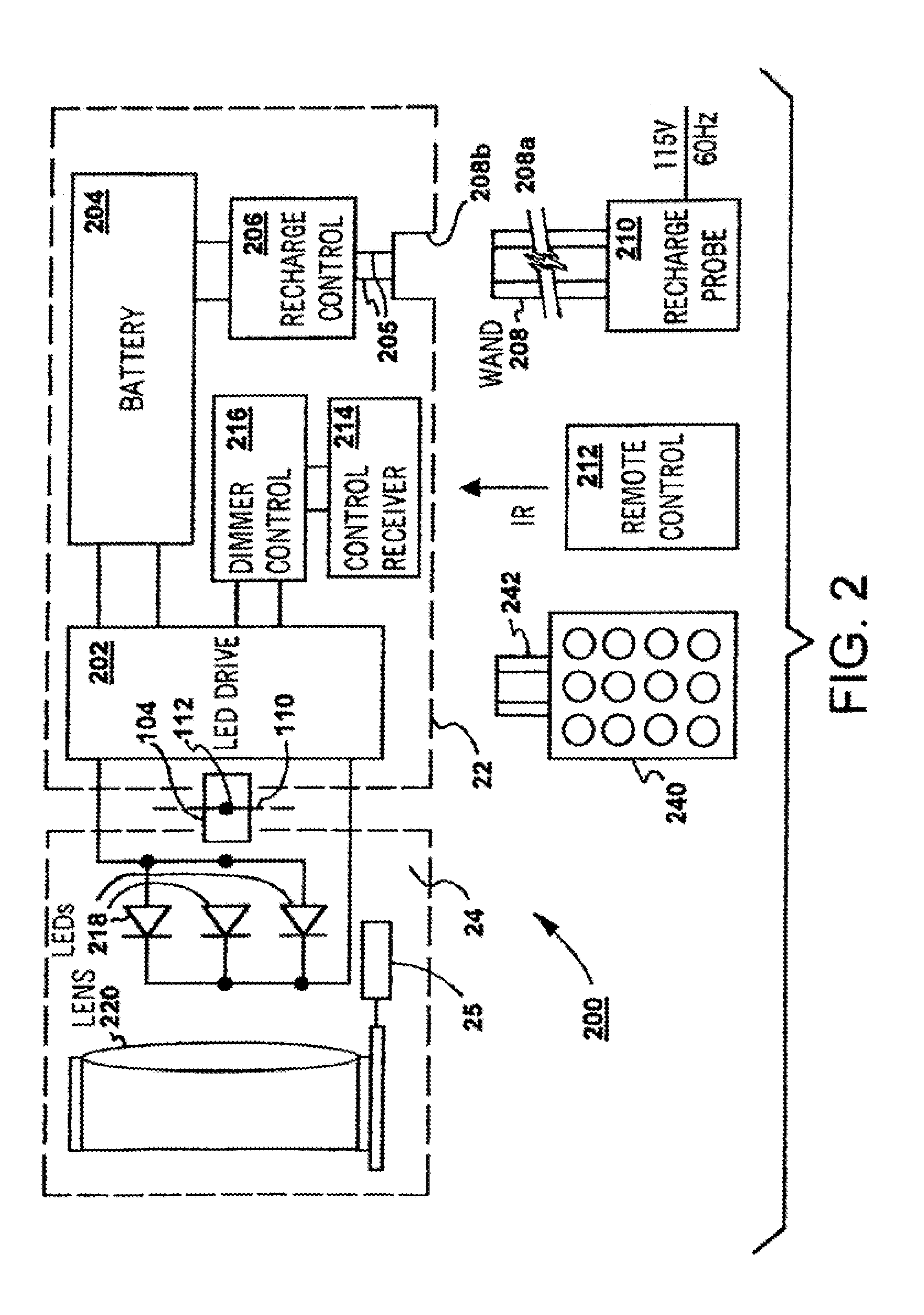

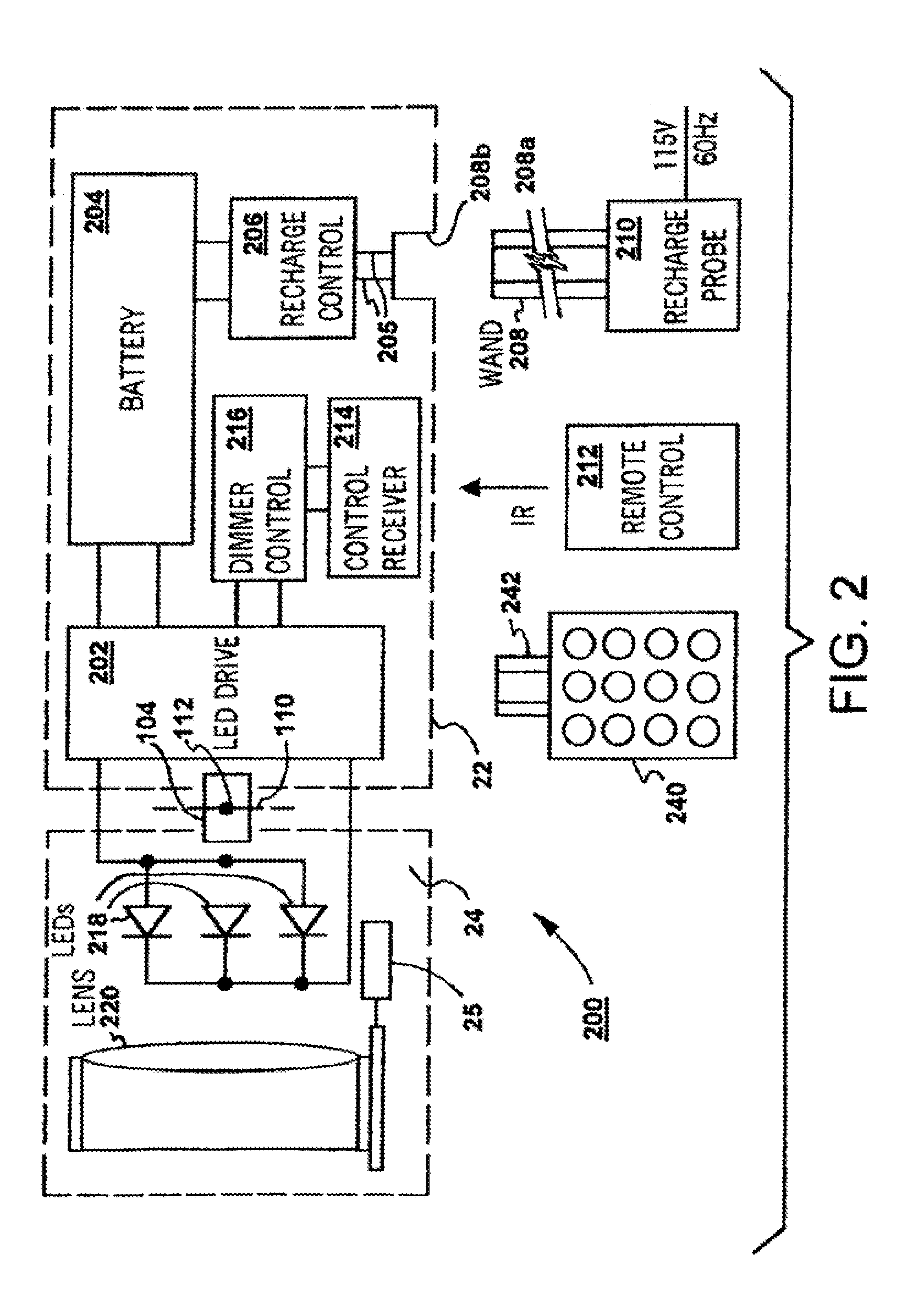

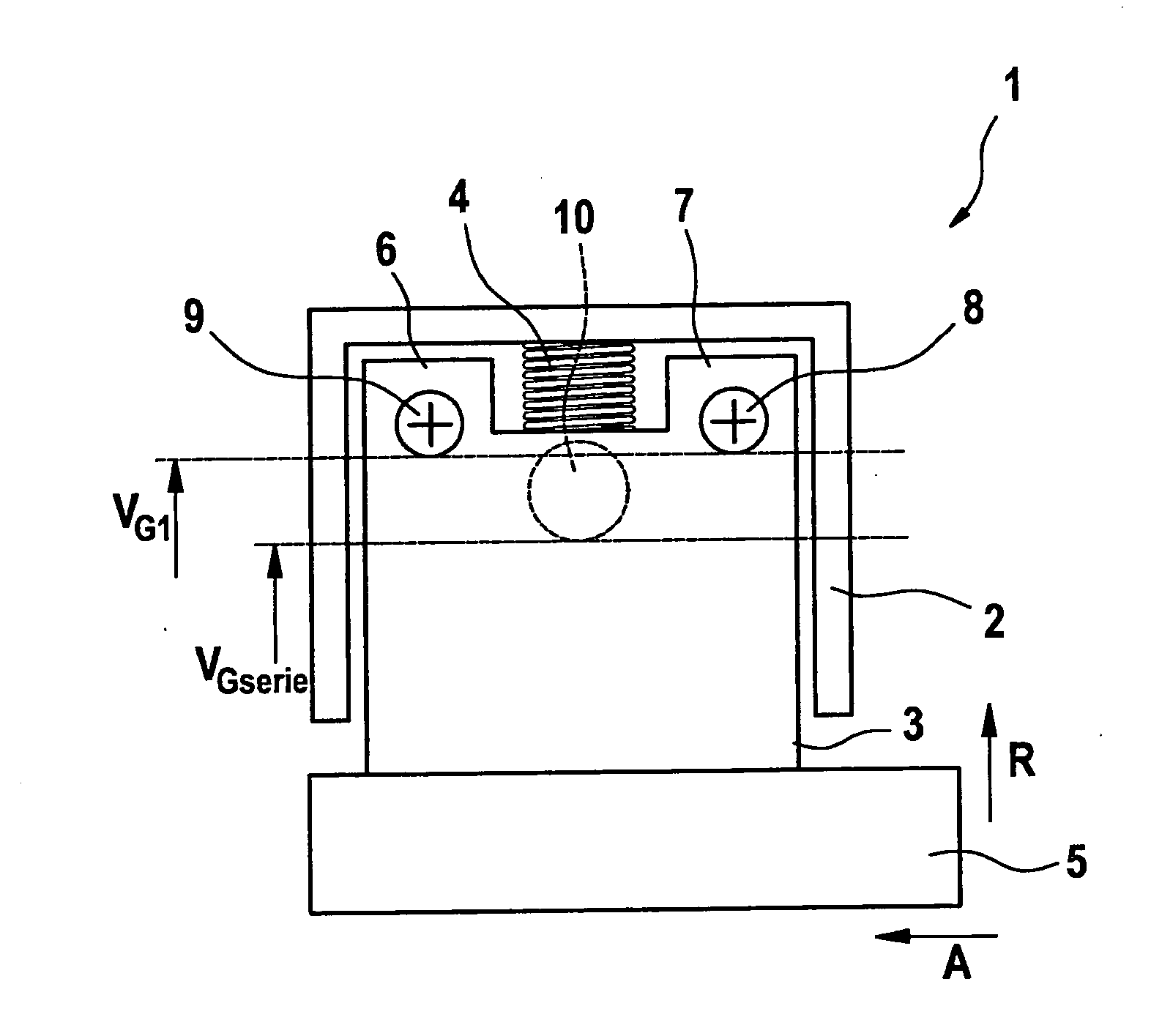

Versatile lighting device

InactiveUS20060176689A1Overcome deficienciesLong run timeMechanical apparatusDomestic lightingLight equipmentElectrical battery

A wall or ceiling mountable lighting device comprises a self-contained single or multiple LED light source for emitting warm yellow-white light corresponding to halogen or incandescent light and a control circuit controlled by a remote control unit to energize and deenergize the light source and control light intensity. A rechargeable battery power source mounted on the lighting device is connectable to apparatus for charging the battery without removing the battery from the device. The apparatus includes an elongated probe assembly releasably connectable to the lighting device to perform the recharging process. The lighting device is particularly adapted for ease of placement of a light source for decorative purposes and / or illuminating artifacts in locations which would require substantial structural modifications to install conventional lighting.

Owner:VERSALITE ASSOCS

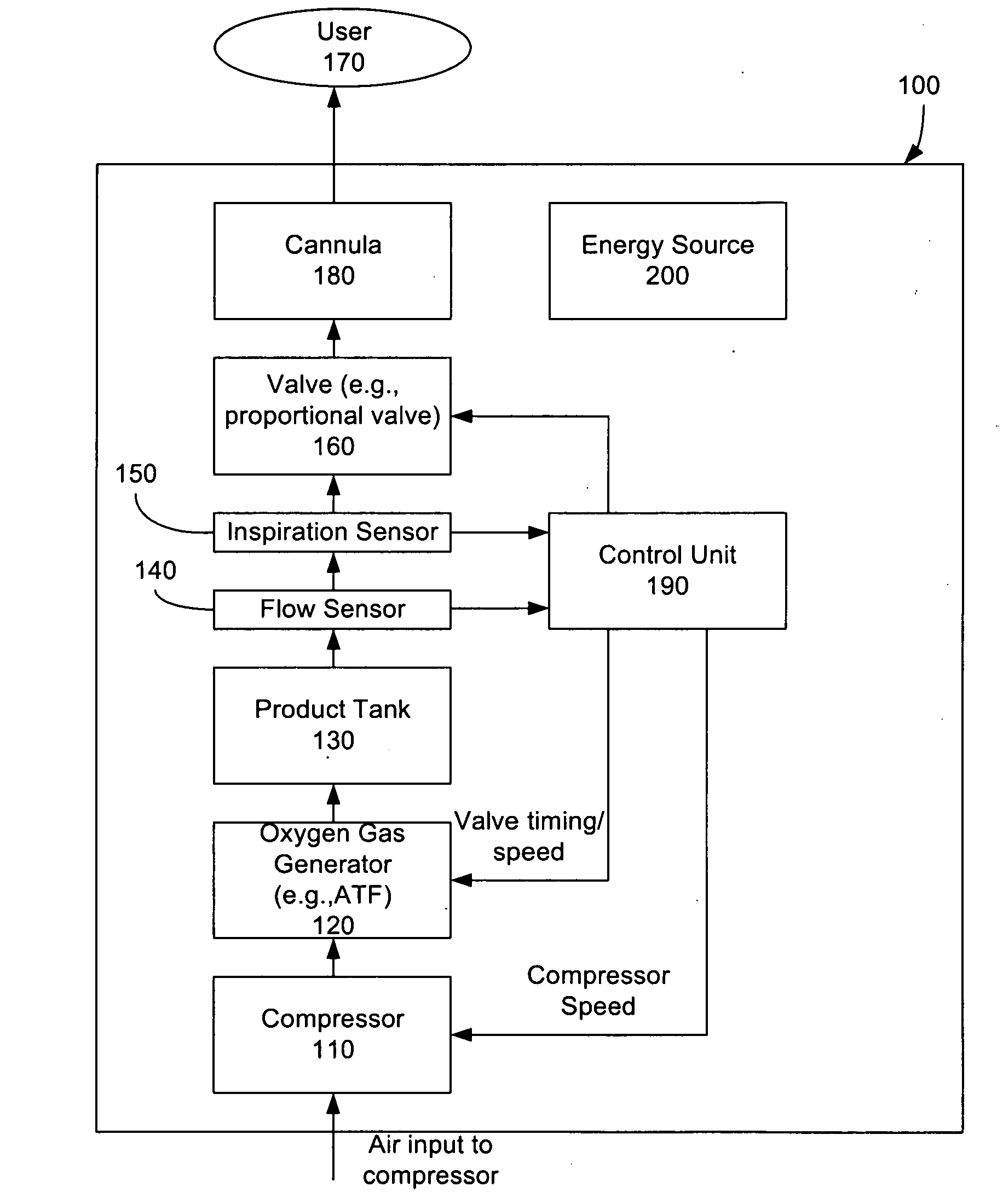

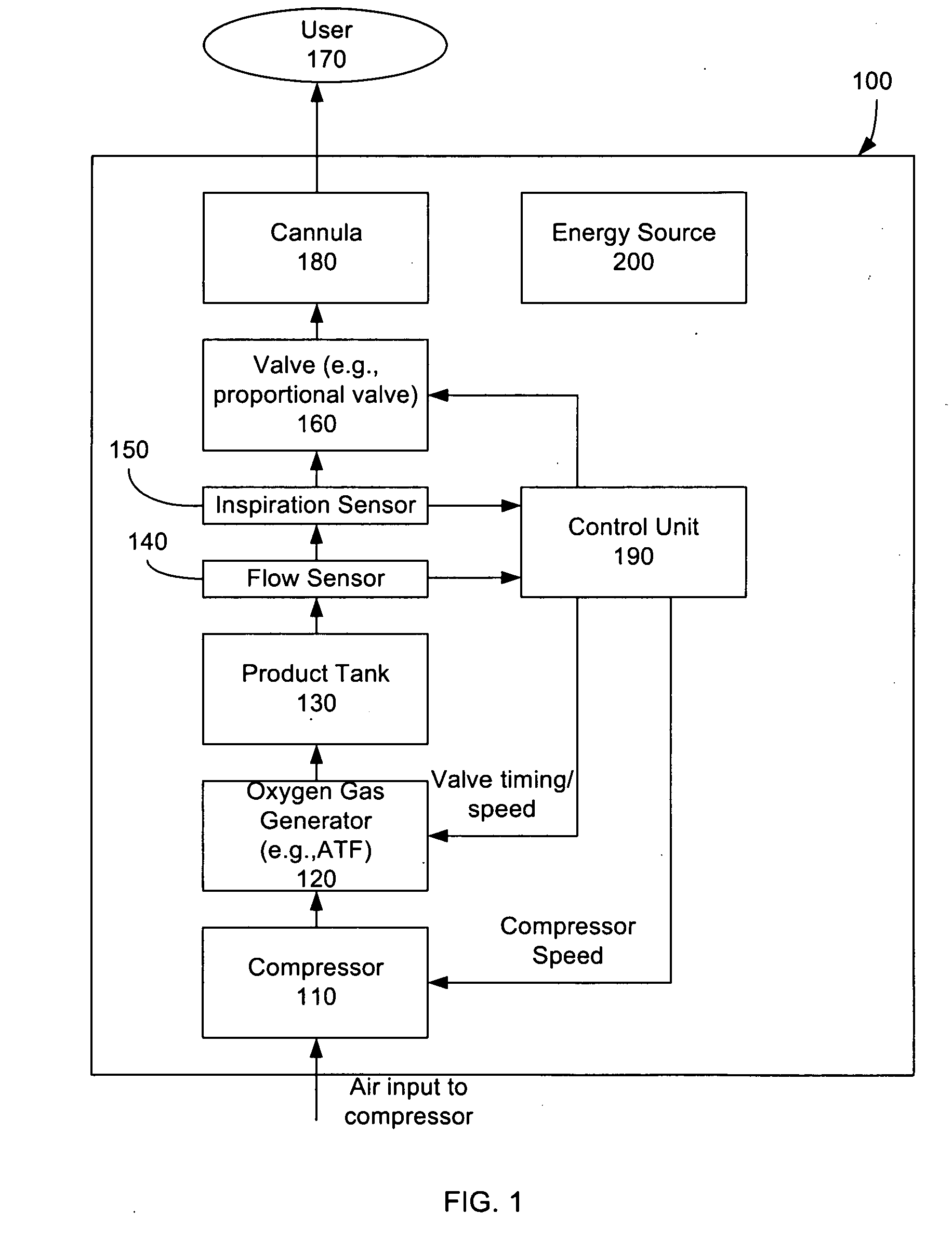

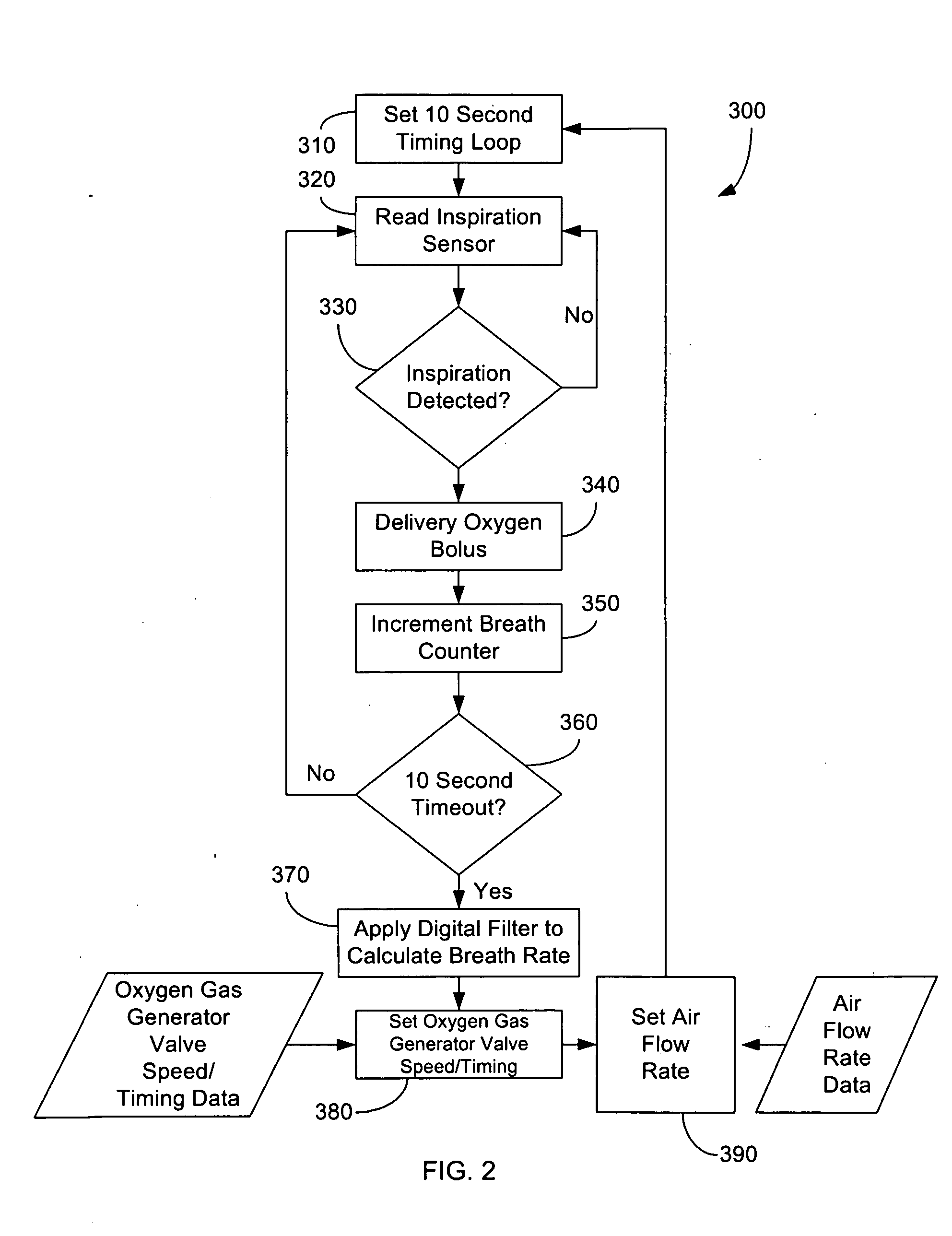

System and Method for Controlling Supply of Oxygen Based on Breathing Rate

A portable oxygen concentrator system weighing 4-20 pounds that is adapted to be readily transported by a user and deliver oxygen to the user includes a rechargeable energy source; a concentrator powered by said energy source and adapted to convert ambient air into concentrated oxygen gas for the user; an inspiration sensor that senses respiratory activity of the user, and produces a signal in response thereto; and a control unit that receives the signal in response to sensed respiratory activity, determines a breath rate based in part on the received signal in response to sensed respiratory activity and controls the portable oxygen concentrator system to deliver oxygen flow sufficient to meet oxygen demand of the user based at least in part on the determined breath rate.

Owner:SILICON VALLEY BANK

Versatile lighting device

InactiveUS7604370B2Long run timeShort charging timeMechanical apparatusDomestic lightingRemote controlElectrical battery

A wall or ceiling mountable lighting device comprises a self-contained single or multiple LED light source for emitting warm yellow-white light corresponding to halogen or incandescent light and a control circuit controlled by a remote control unit to energize and deenergize the light source and control light intensity. A rechargeable battery power source mounted on the lighting device is connectable to apparatus for charging the battery without removing the battery from the device. The apparatus includes an elongated probe assembly releasably connectable to the lighting device to perform the recharging process. The lighting device is particularly adapted for ease of placement of a light source for decorative purposes and / or illuminating artifacts in locations which would require substantial structural modifications to install conventional lighting.

Owner:VERSALITE ASSOCS

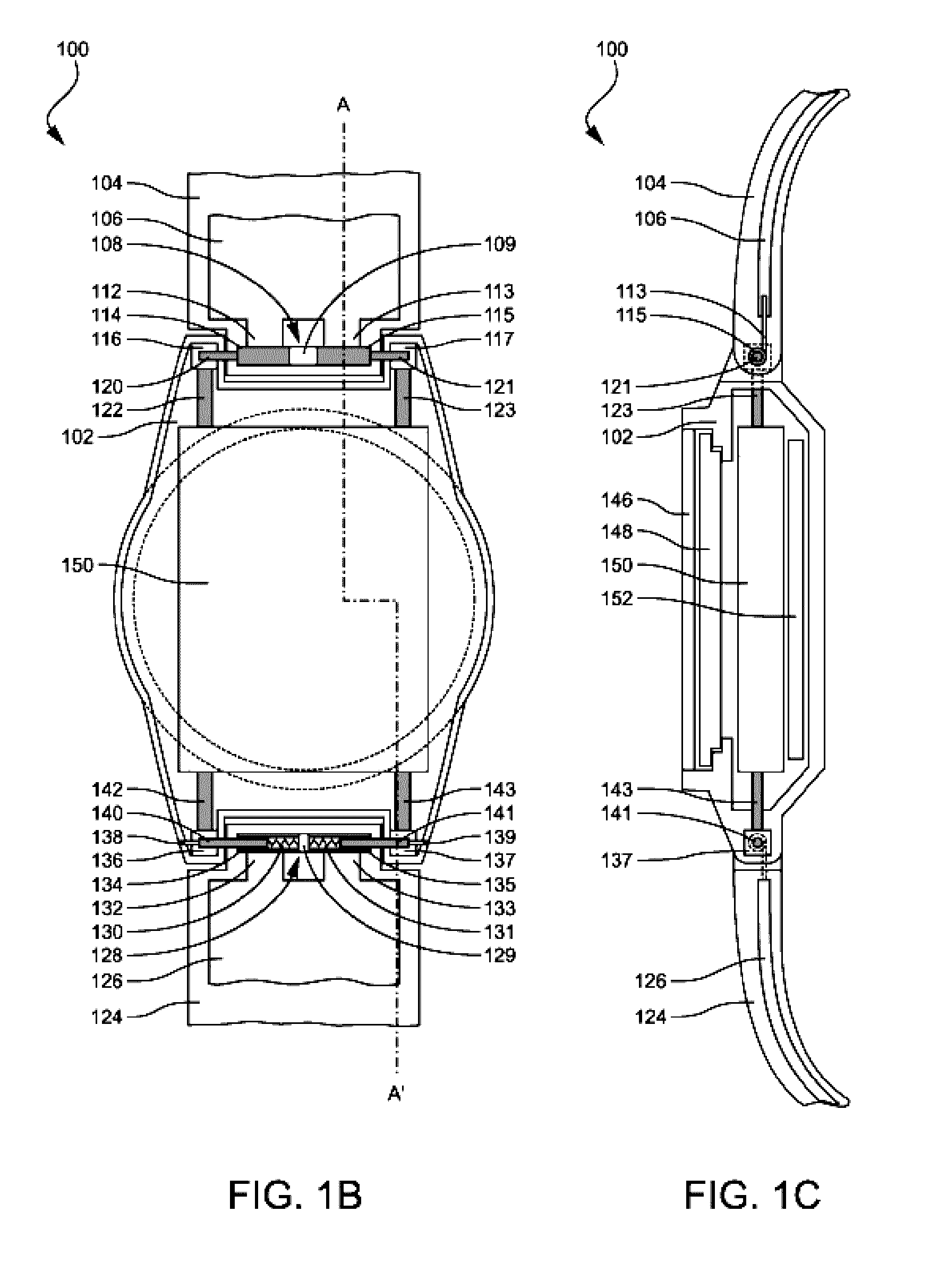

Wearable computer with electronic strap and attachment therefor

InactiveUS20160363957A1Reliable and durable overtimeLong run timeBatteries circuit arrangementsElectronic time-piece structural detailsElectrical energy storageElectric energy

Embodiments of a wearable computer are disclosed. The wearable computer comprises an electronic module, a central portion for housing the electronic module, a strap for wearing the portable electronic device on a body part of a user, at least one electrical energy storage device embedded within the strap, and an attachment for mechanically fastening and electrically coupling the electronic strap to the central portion. In some embodiments, the wearable computer can have a display, a means for wirelessly charging the energy storage device, different materials for the electronic strap, and a clasp means. In some embodiments, the wearable electronic device can be removably coupled to the electronic strap. This permits the wearable computer to provide a long runtime and to assume novel configurations.

Owner:STROETMANN CHRISTIAN

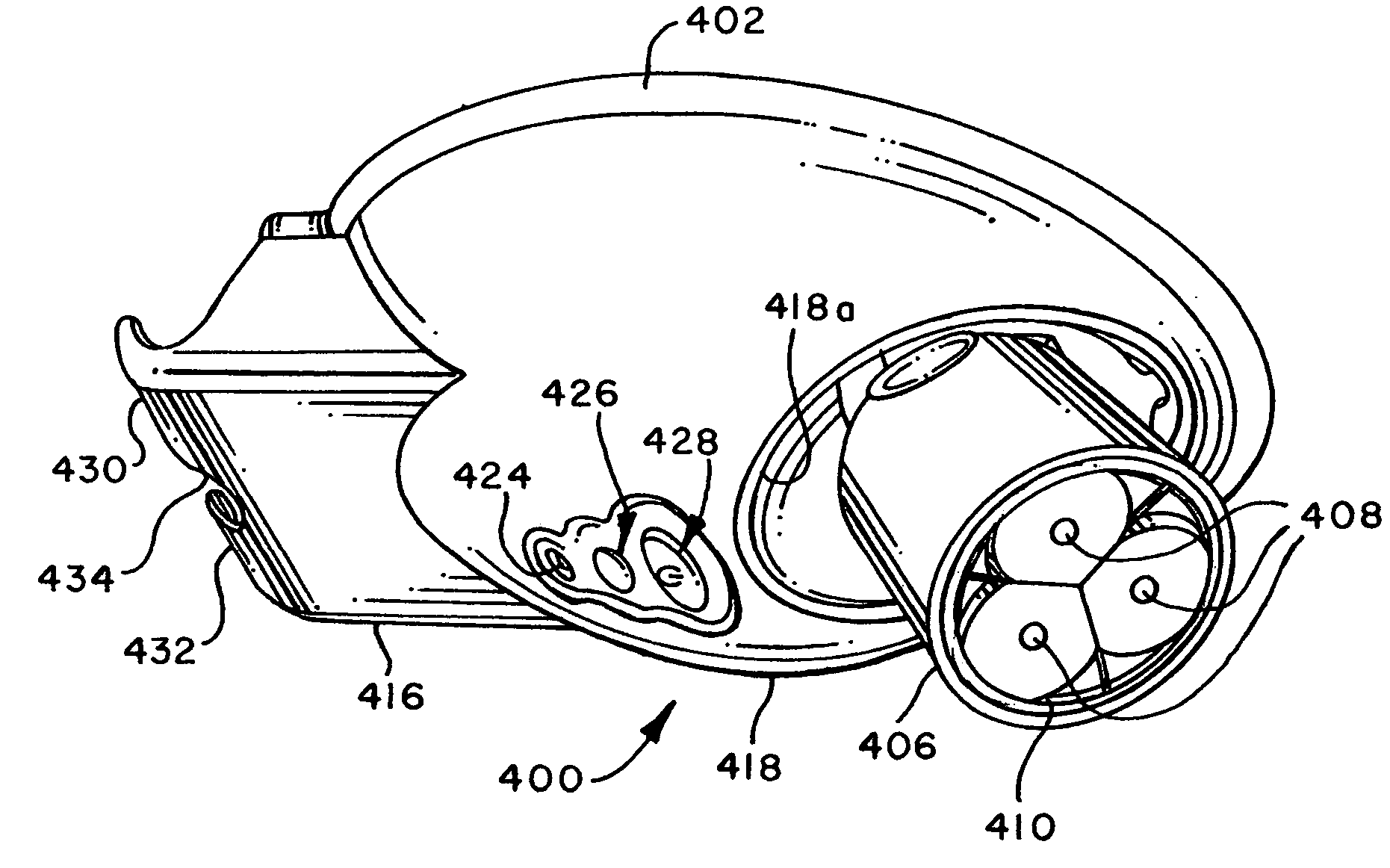

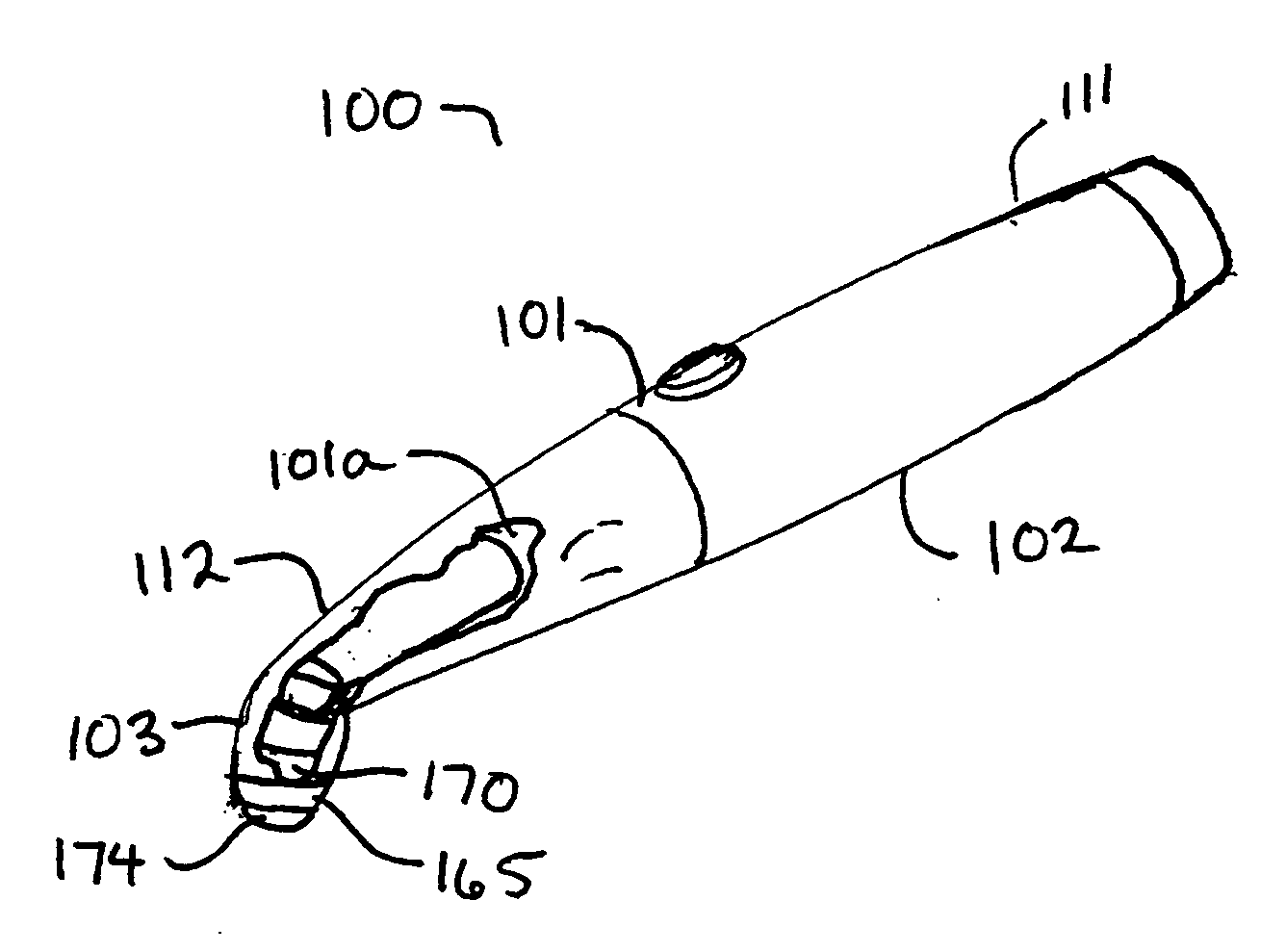

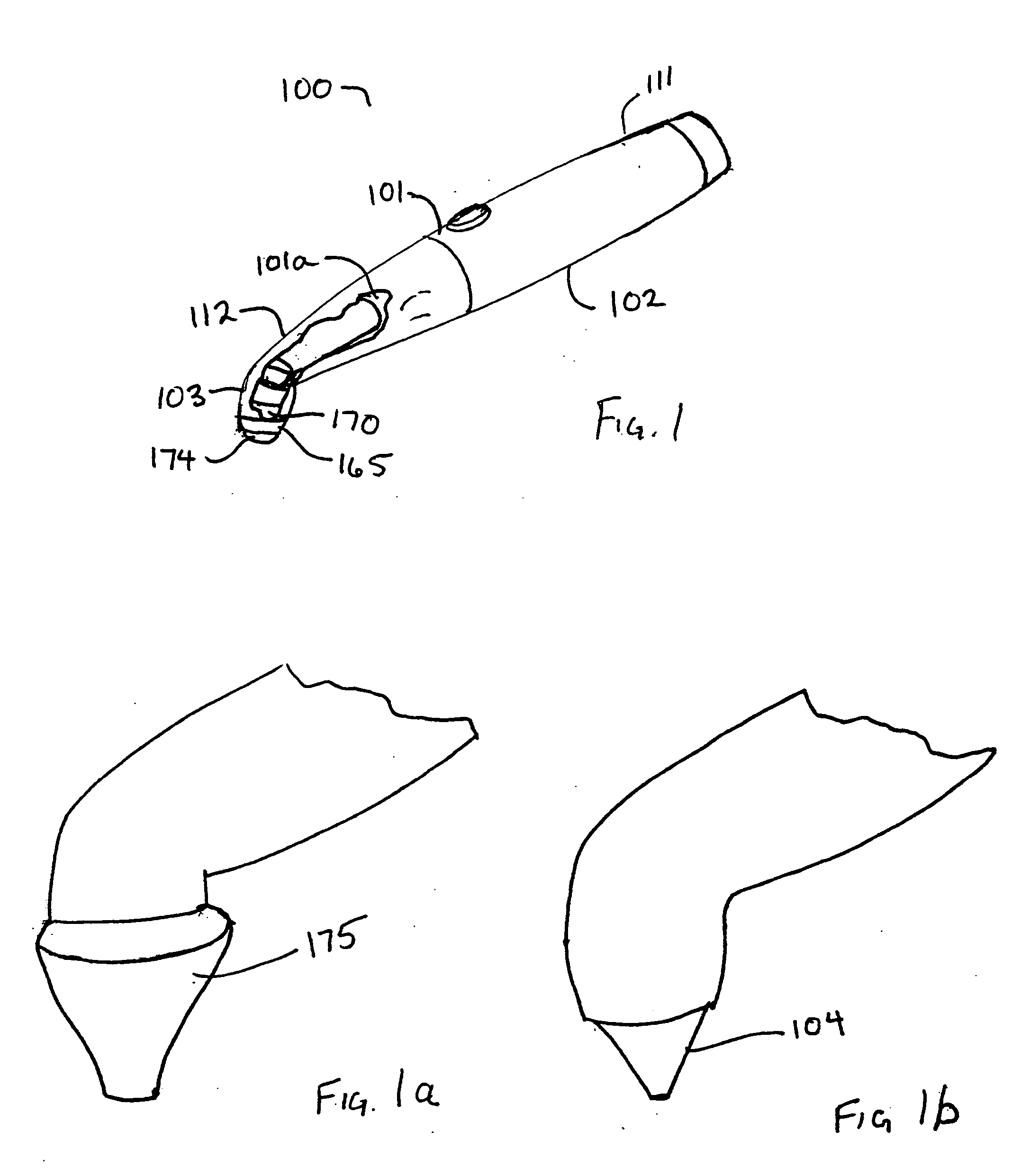

Curing light

ActiveUS20060024638A1Long run timeConvenient ArrangementCosmetic preparationsToilet preparationsLight sourceHeat spreader

The present invention relates to a curing light suitable for curing light curable dental composite materials. The curing light device has a light module housing having at least one heat sink located therein. The heat sink has at least two mounting platforms arranged in different geometric arrangements. More than two light sources may be used, emitting at least two different wavelengths. The curing light includes at least one heat sink having various geometric shapes, which facilitate the arrangement of the light sources in the curing light and minimizing the concentration.

Owner:DEN MAT HLDG

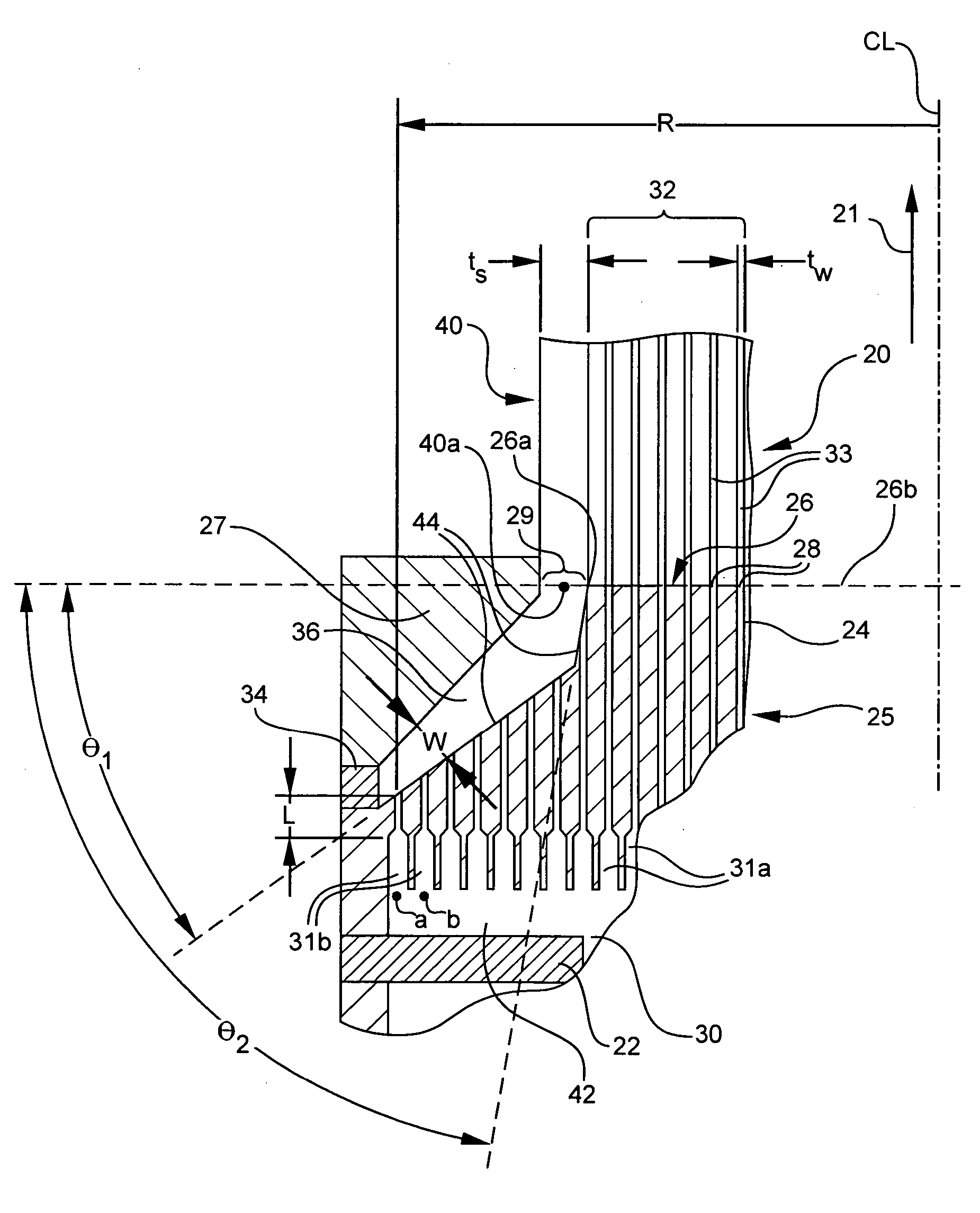

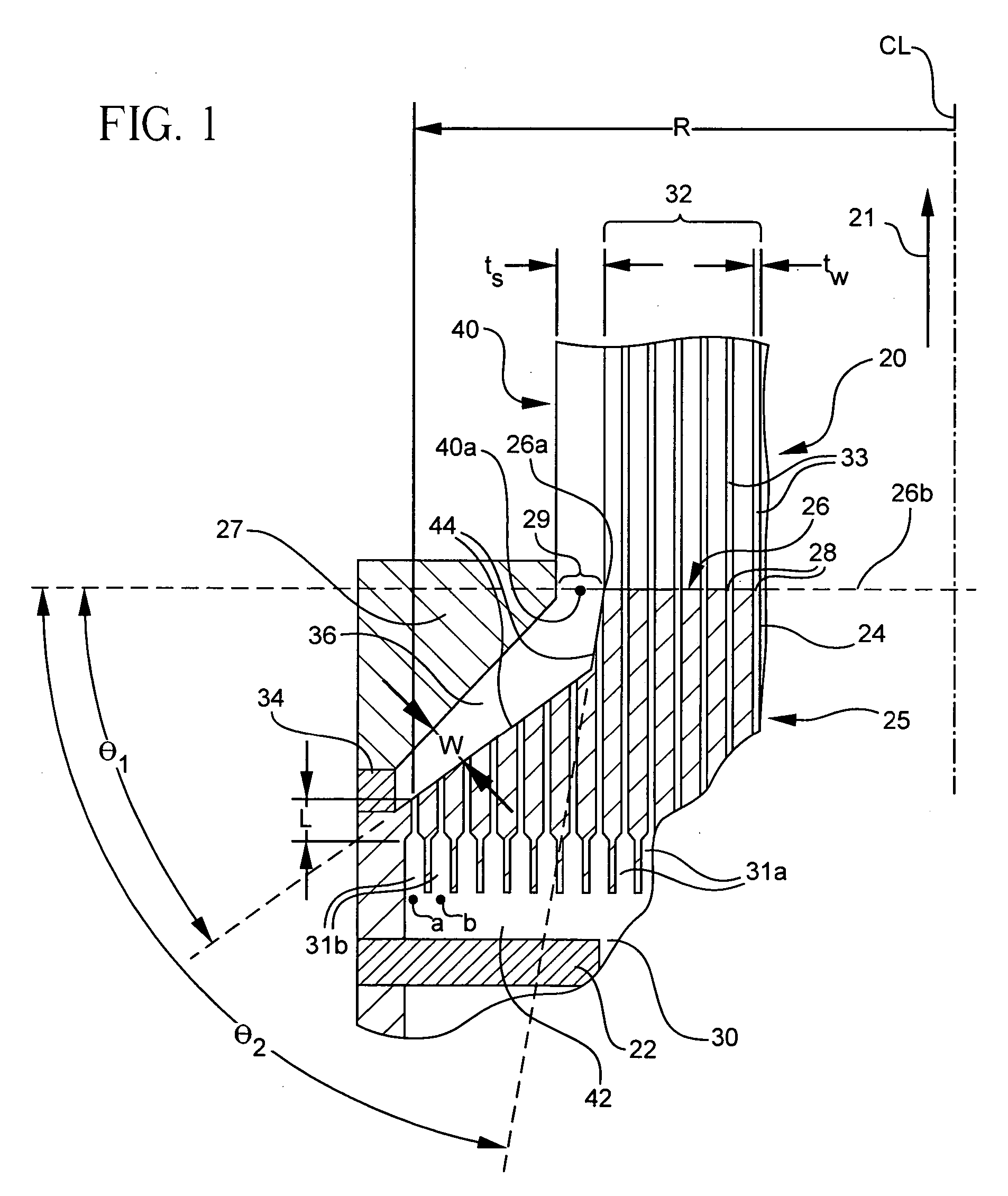

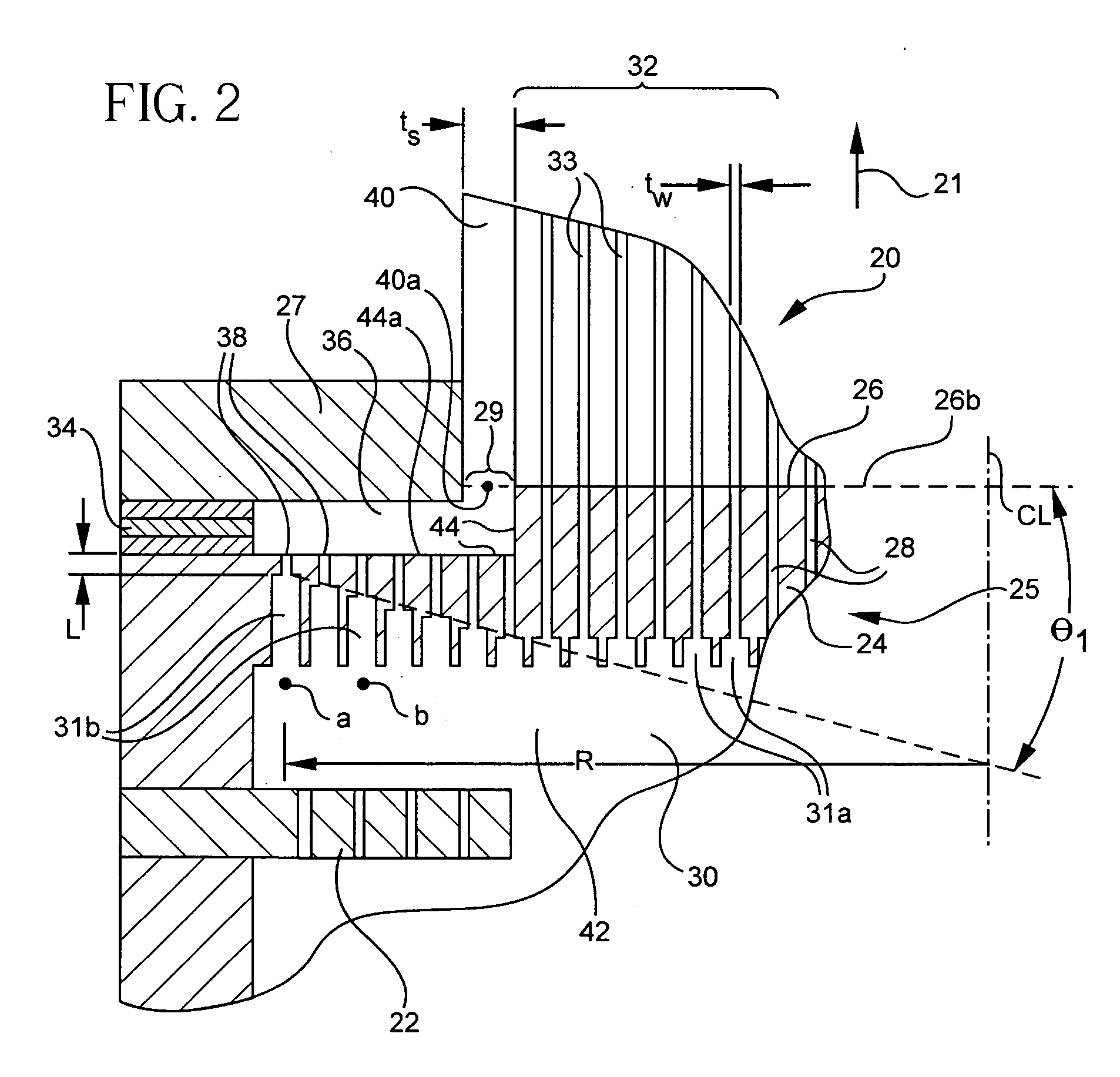

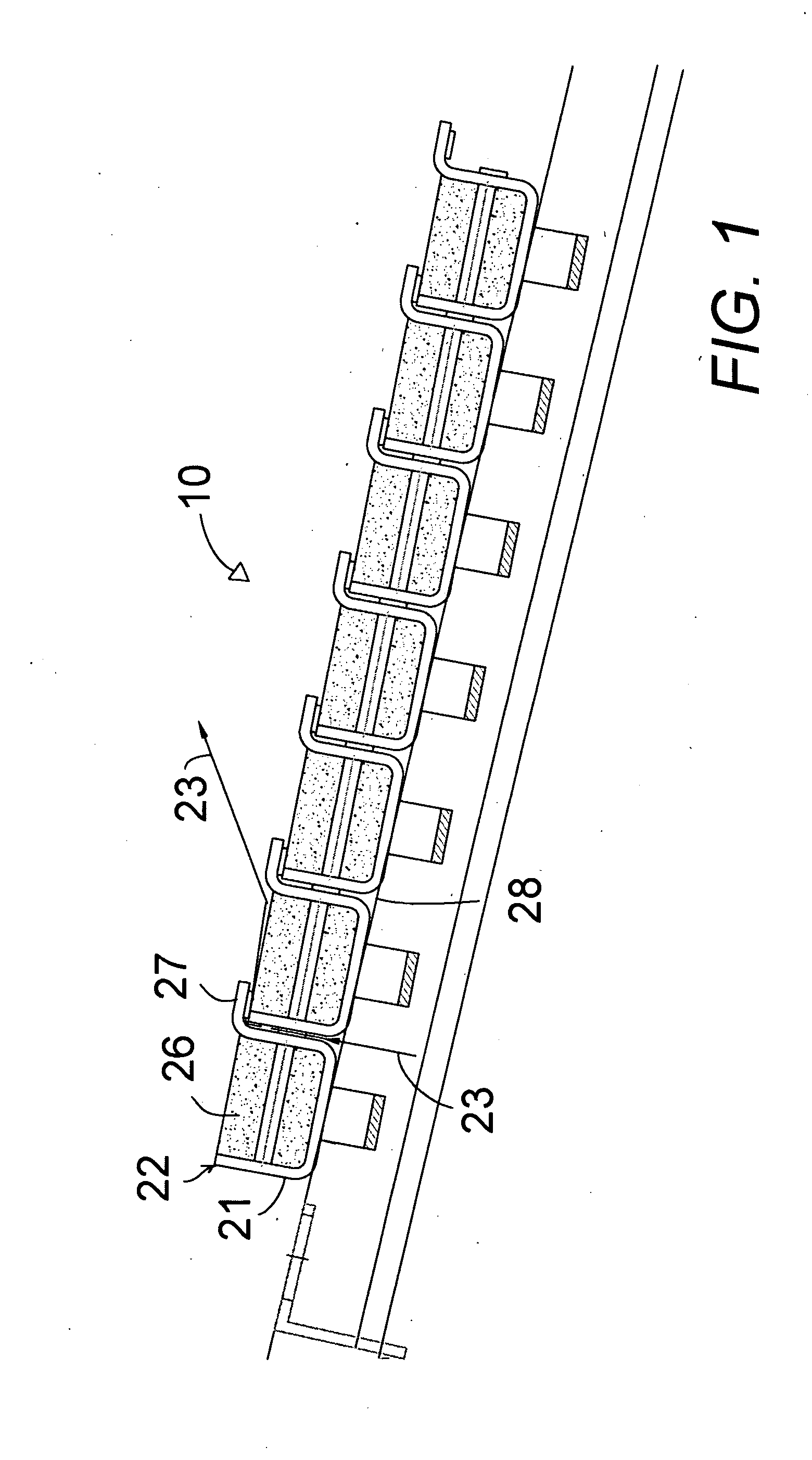

Method and apparatus for extruding honeycomb articles and thick-skinned ceramic honeycomb articles manufactured thereby

ActiveUS20070026188A1Reduction tendencyEasy alignmentLayered productsConfectioneryParticle alignmentMaterials science

Disclosed is a method and apparatus for forming a circumferential skin surrounding a central cellular structure of an extruded honeycomb article. The method and apparatus may be used to produce defect-free skins and / or skins having large thickness and a high degree of particle alignment thereby preferably exhibiting CTE comparable to the extruded webs. These benefits are achieved by providing a die and method wherein a flow, Q, exiting any two active ones of a plurality of peripheral slots forming the skin is substantially equal. Also disclosed is a thick-skinned ceramic article having a thick extruded skin (ts′>5 tw′) with an I-value comparable to the webs.

Owner:CORNING INC

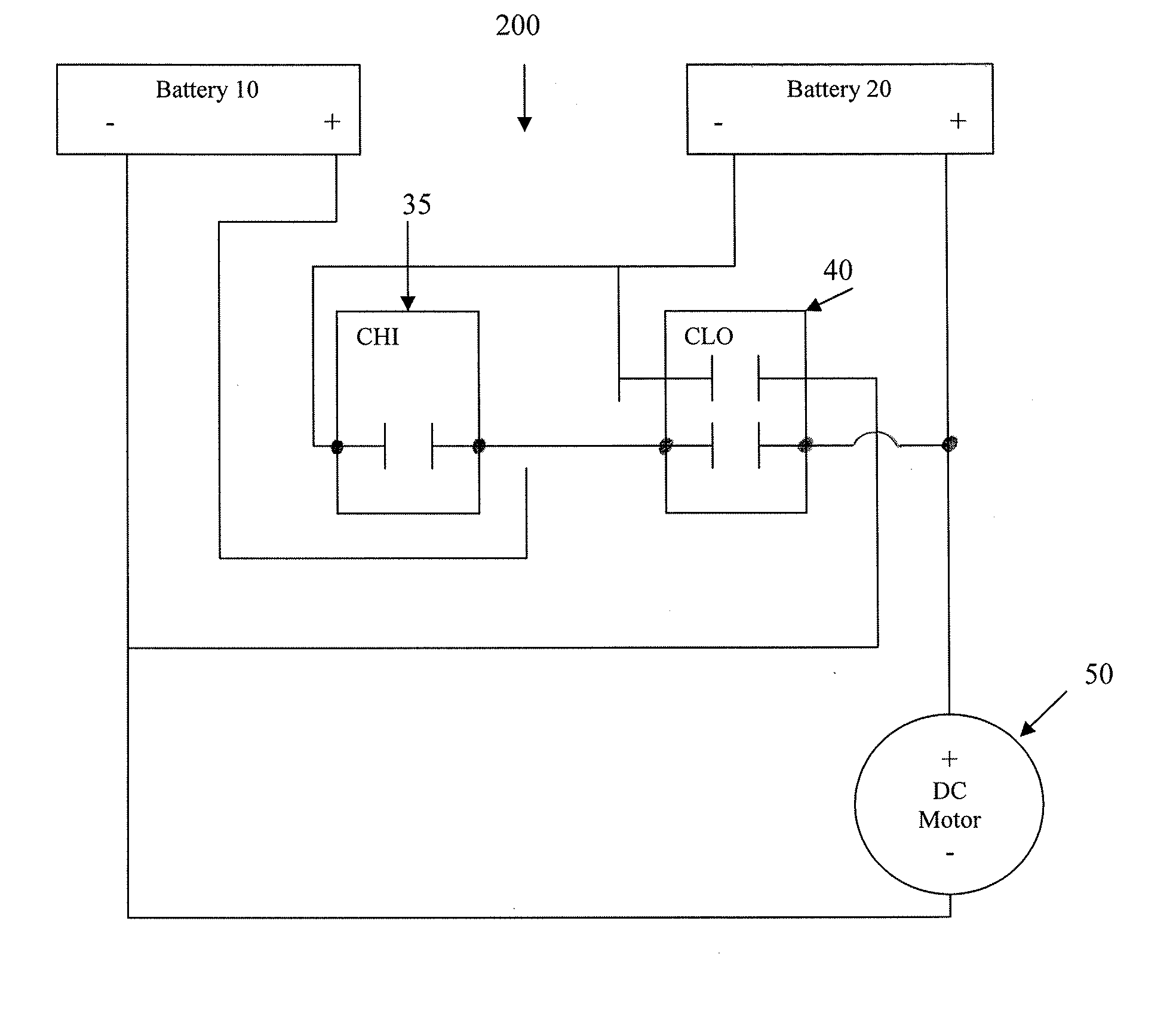

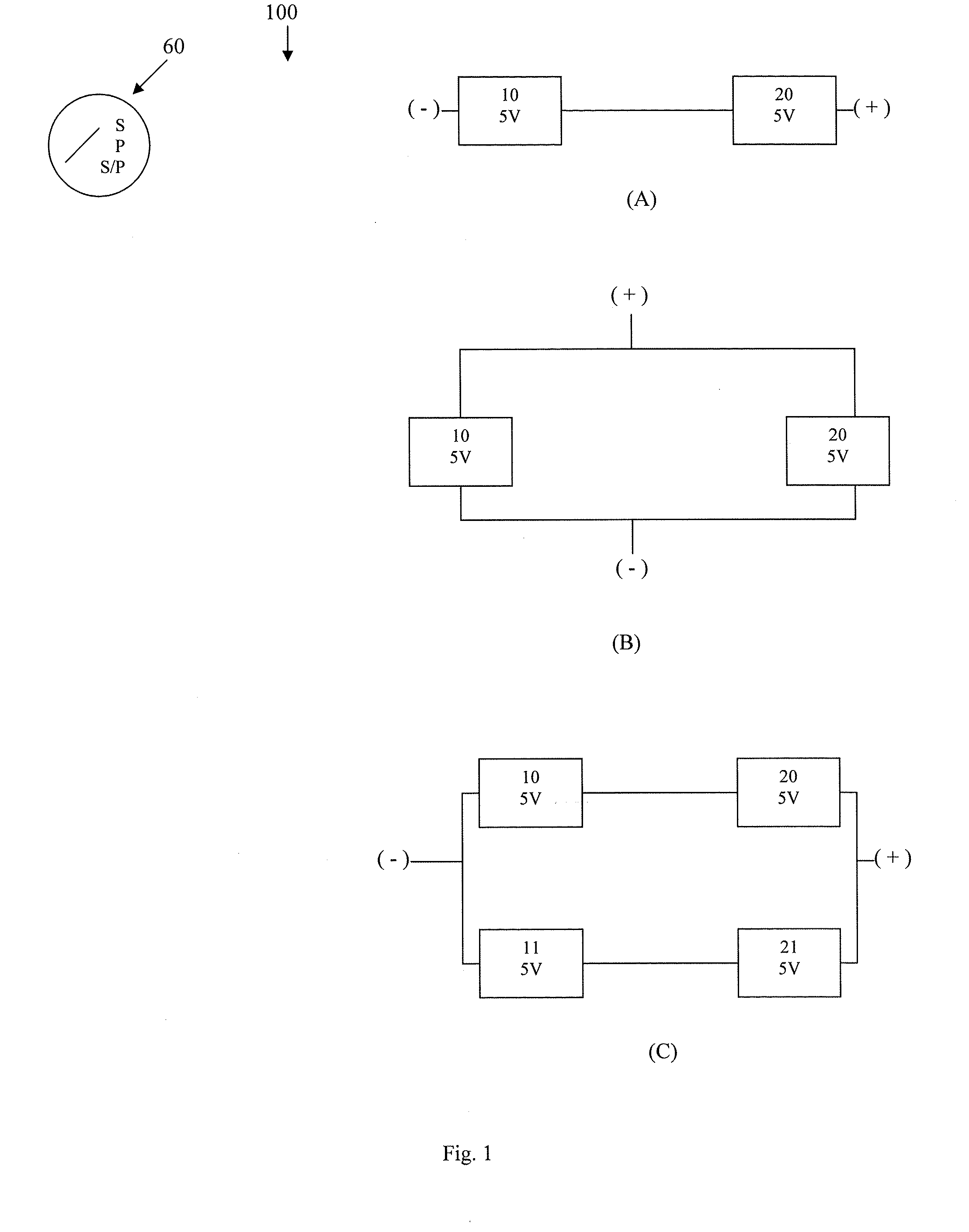

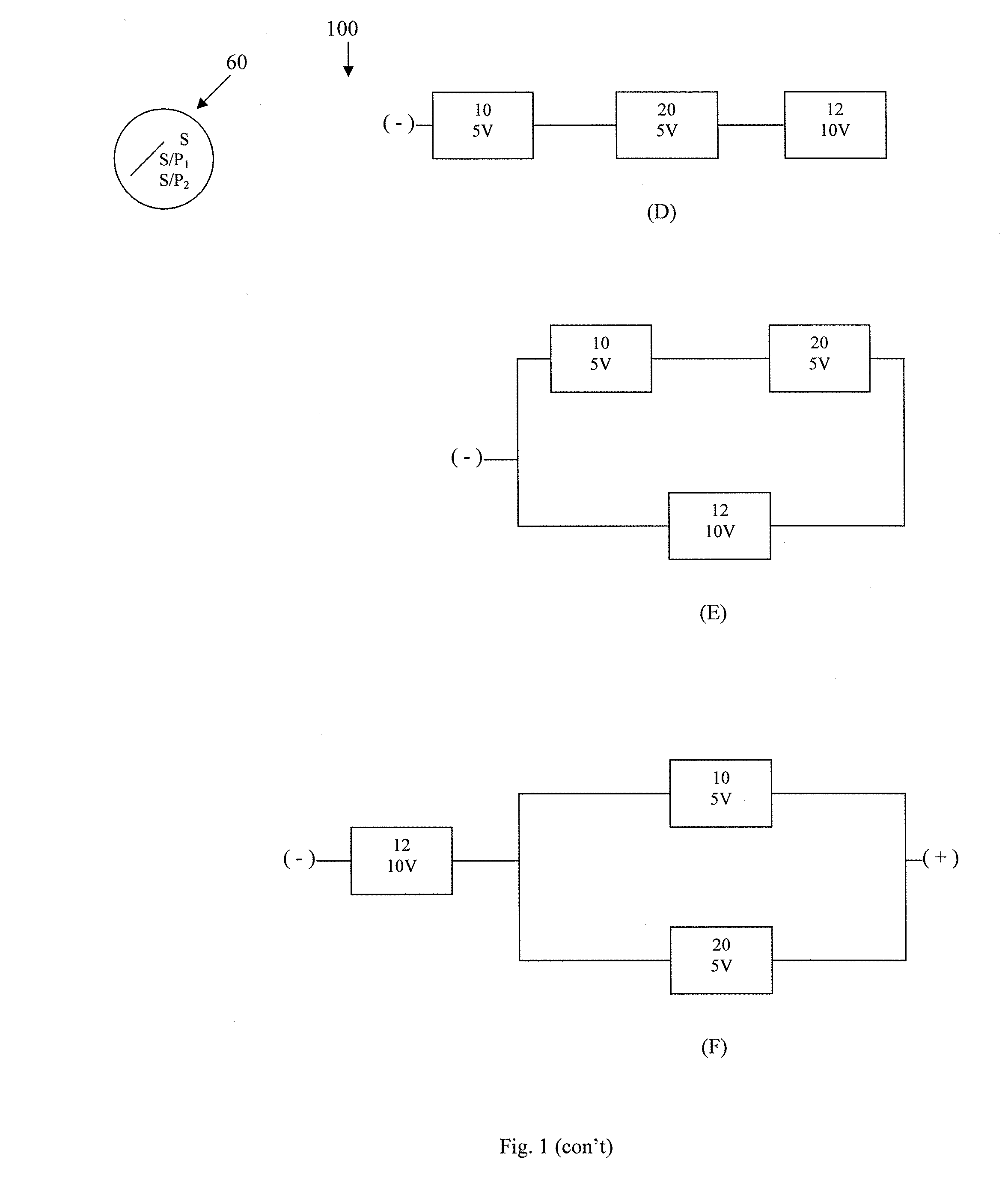

Speed and Power Control Mechanisms for Battery Powered DC Motor

InactiveUS20110043143A1Long run timeSave battery powerField or armature current controlStarter detailsPower controlElectrical battery

A speed and power control mechanisms for battery powered DC motors including a plurality of batteries structured to be configured in series, parallel, or series / parallel wiring configurations / combinations, a selectable switch, relay, or contractor structured to wire the batteries in the series, parallel, or series / parallel wiring configurations / combinations based on the setting of the selectable switch, relay, or contractor to deliver various selected voltage levels, and thus various selected power and speed levels to a motor.

Owner:ALTER DANIEL J

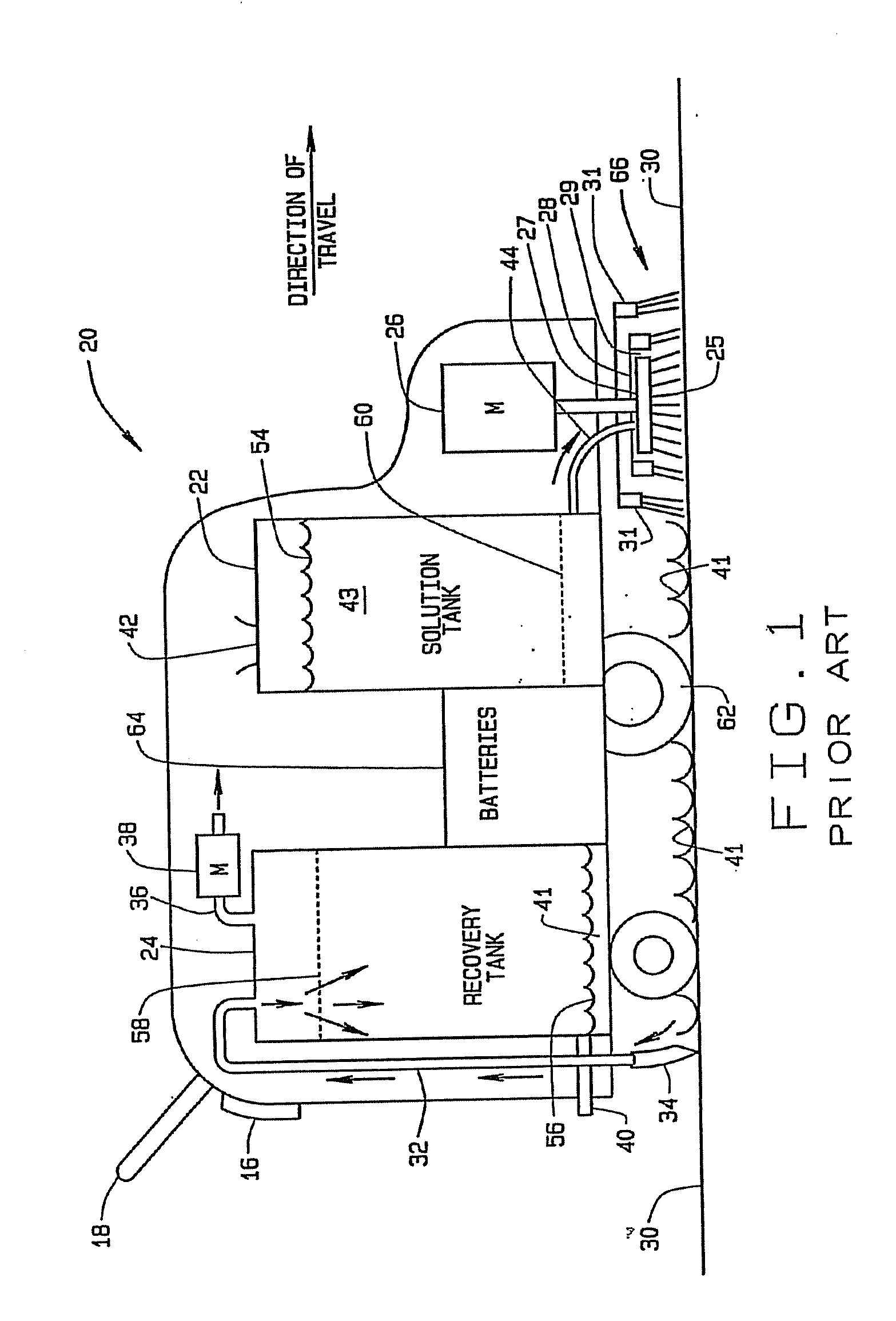

Orbital scrubber with stabilizer element

InactiveUS20080078041A1Long run timeGood for cleaningCarpet cleanersFloor cleanersScrubberEngineering

Vibration dampening elements that are made of rubber and / or an elastomer may fail when subjected to vertical and / or horizontal stresses caused by repeated lifting of the cleaning head assembly and / or unintentional bumping of the cleaning head assembly into door frames, walls or other non-movable objects. The present invention includes, among other things, at least one stabilizer element and preferably two stabilizer elements to reduce damage to certain vibration dampening elements caused by vertical and / or horizontal stress. Alternative embodiments of the stabilizer element are also disclosed.

Owner:NILFISK

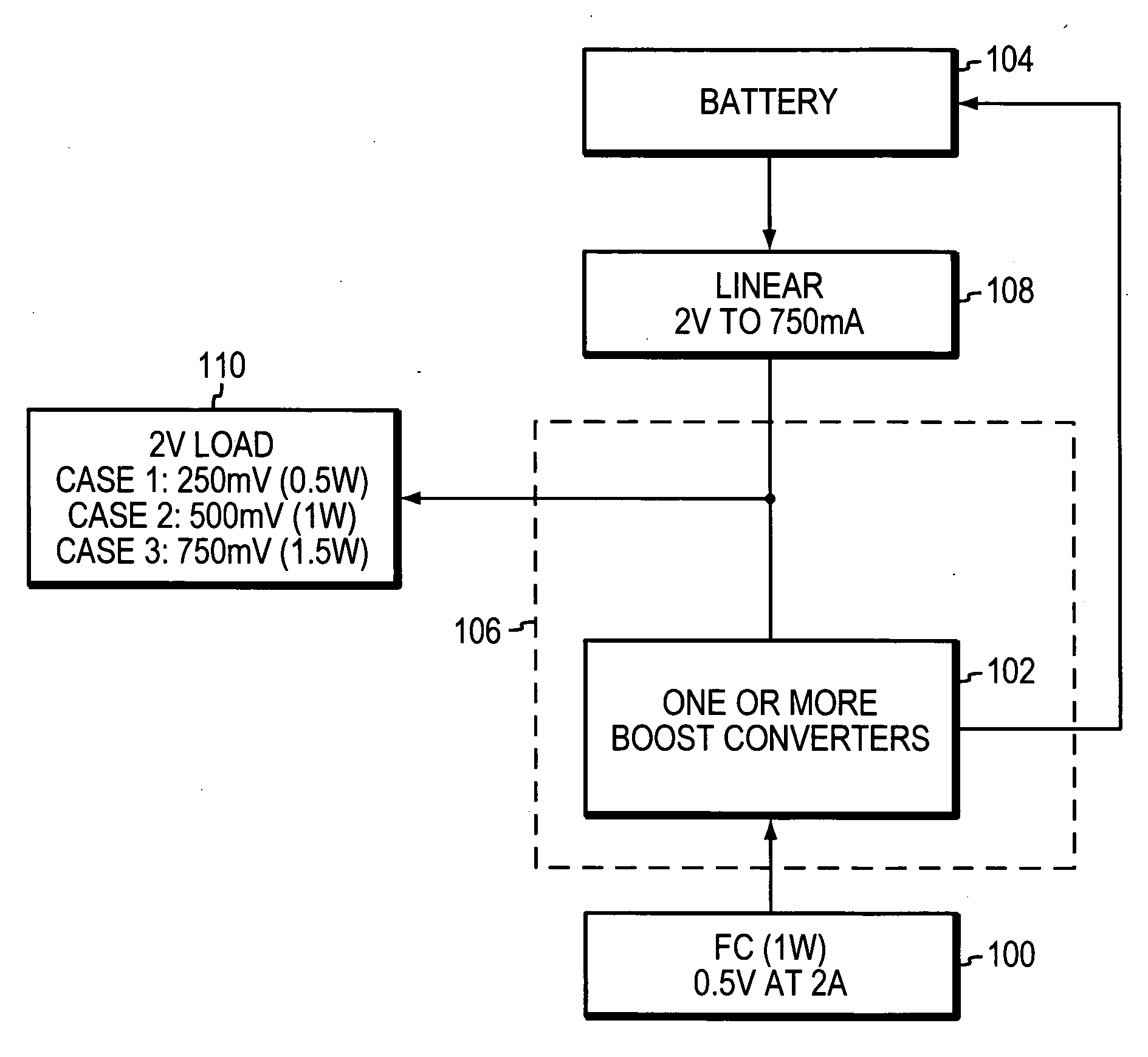

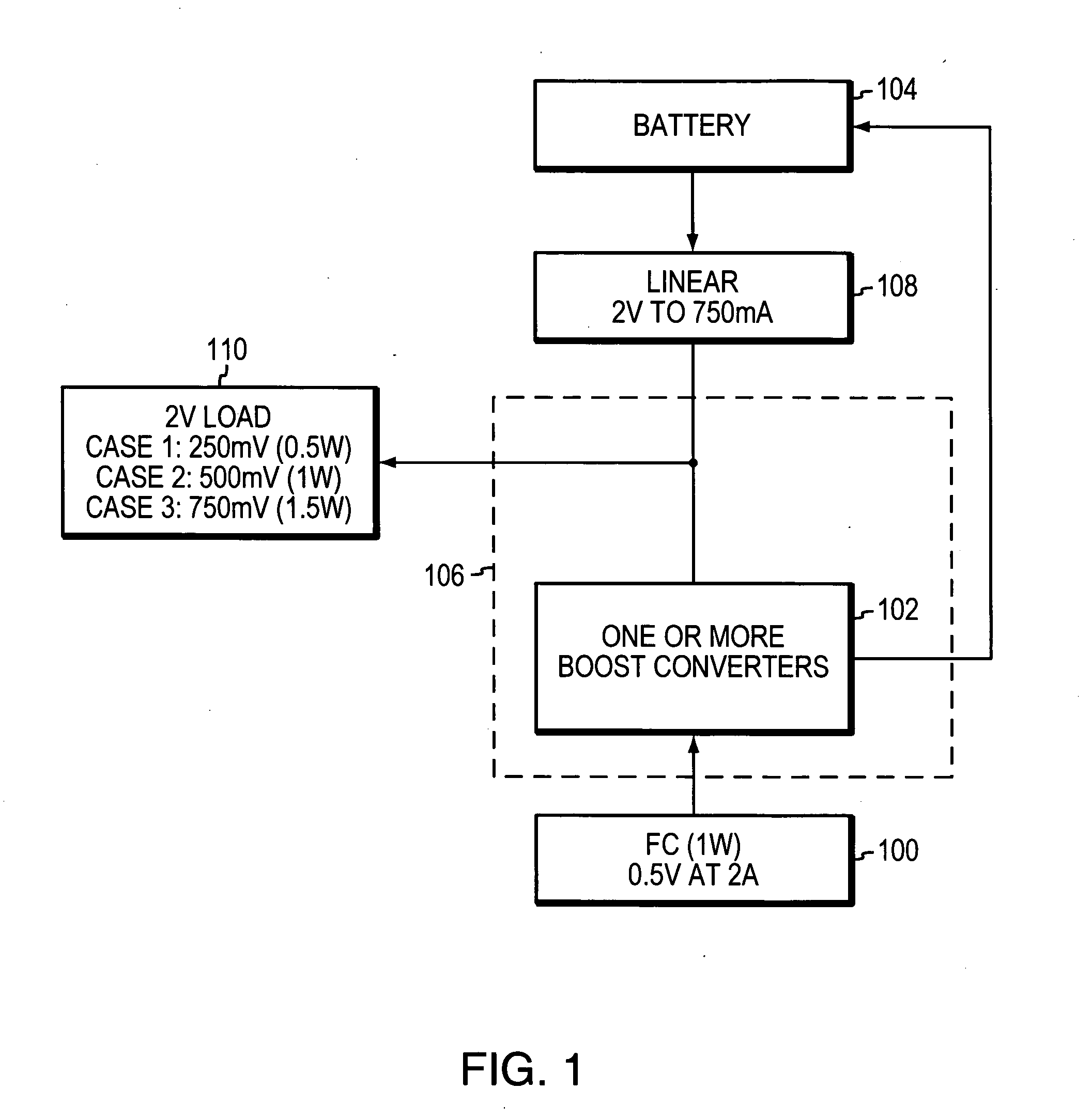

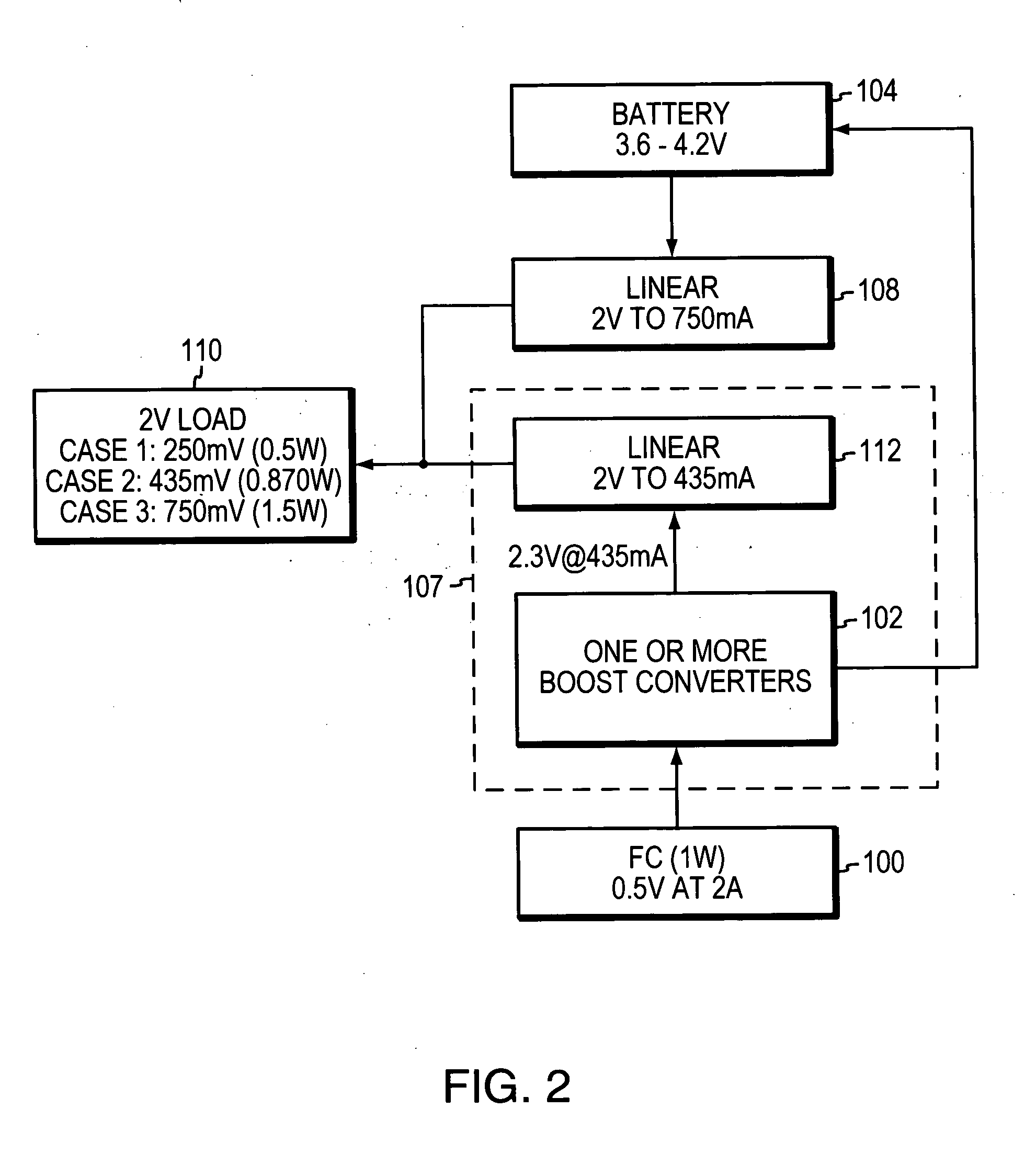

Fuel cell charger interface with multiple voltage outputs for portable devices

InactiveUS20070285048A1Fast powerSecondary loss is either eliminated or lessenedDc source parallel operationSecondary cells charging/dischargingDc dc converterFuel cells

A fuel cell-based powerpack for use with an electronic device that requires multiple voltages is provided. The power pack includes an interface between a direct oxidation fuel cell and one or more rechargeable batteries coupled to supply power to the electronic application device. The interface is connected to receive the output of the fuel cell and includes one or more DC-DC converters that not only boost power to said one or more batteries, but are further coupled to the electronic device such that the fuel cell can be used to directly provide one or more subvoltages, at required voltage rails, directly to said electronic device. The output voltage can also be linearly regulated if needed in a particular application.

Owner:MTI MICROFUEL CELLS

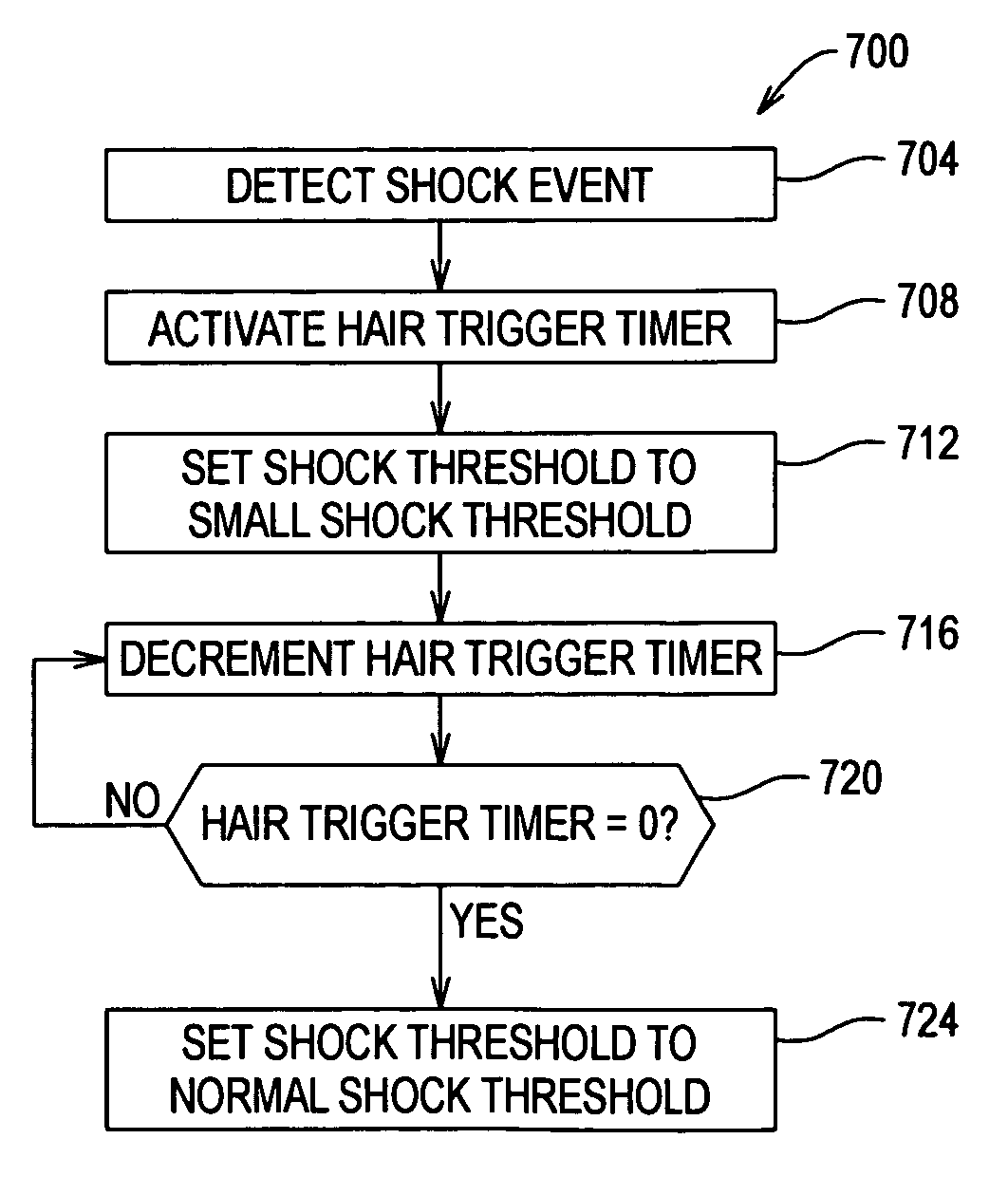

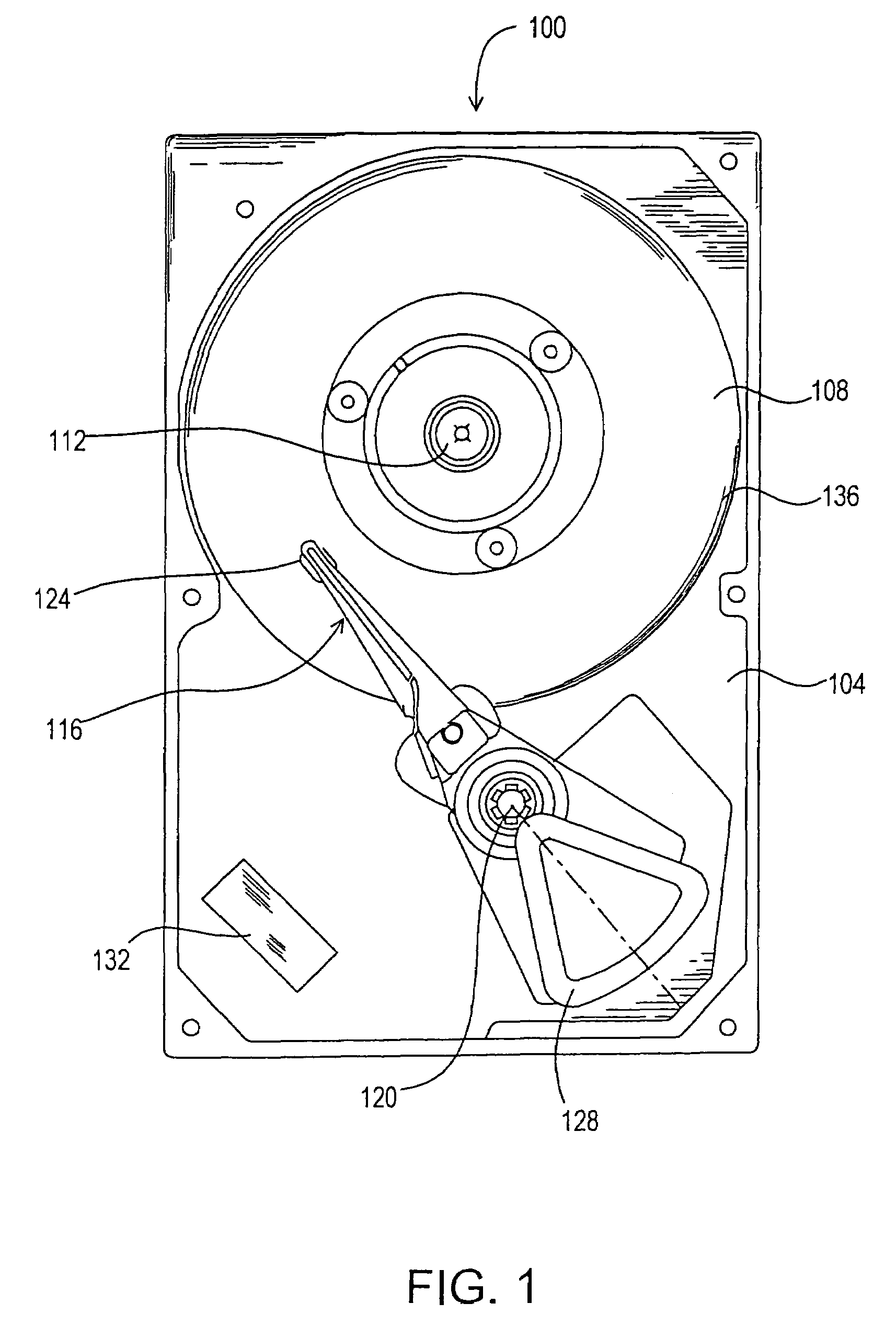

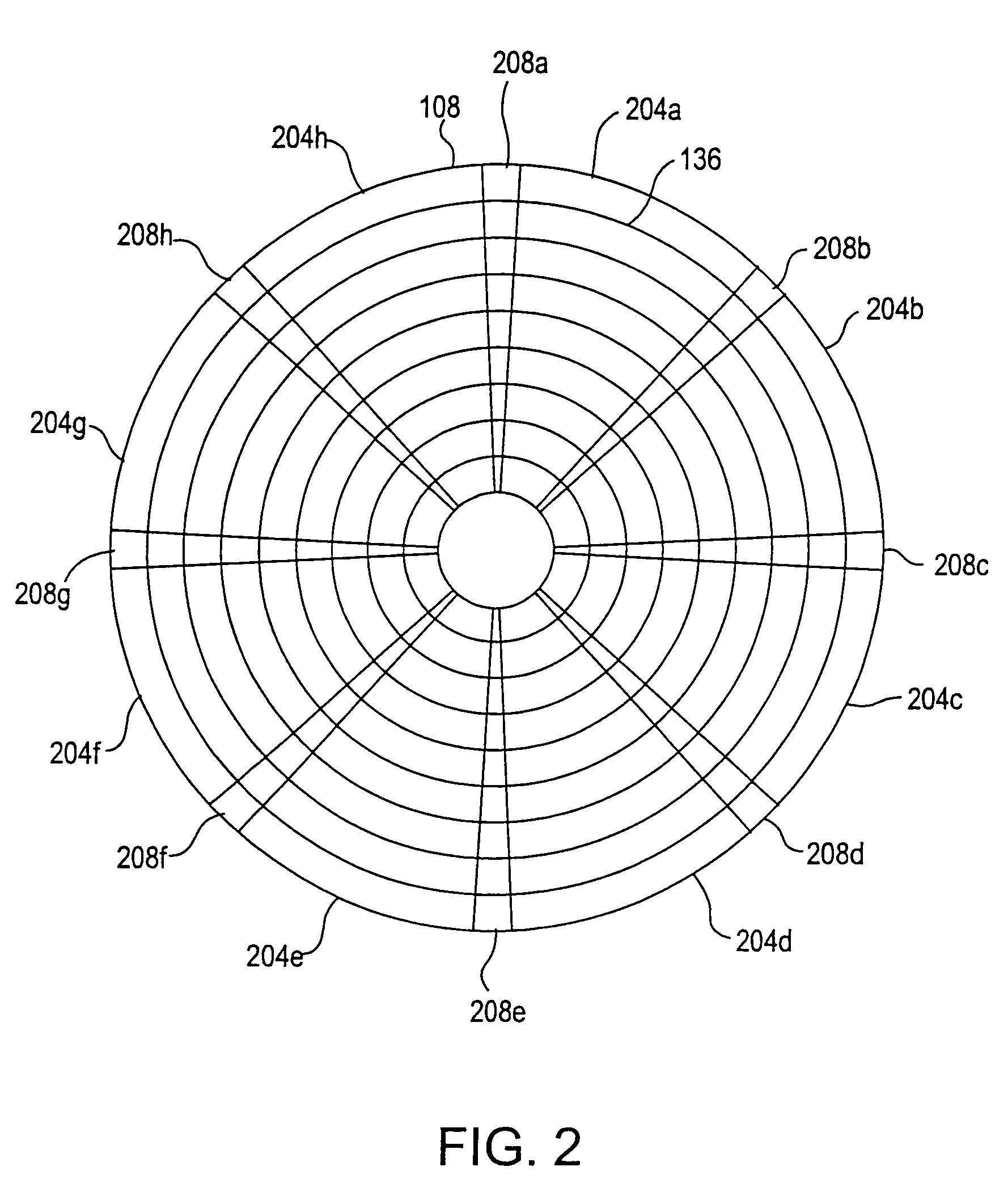

Dynamic shock detection in disk drive using hair trigger timer

InactiveUS7253982B1Long run timeImprove protectionDriving/moving recording headsRecord information storageTransducerEngineering

Dynamically detecting off-track errors in a disk drive by adjusting transducer head position control parameters in response to shock events. In an embodiment, shock events with large magnitude trigger a severe shock timer which lengthens the write fault before write operations resume. In another embodiment, a lower shock threshold is used following an initial shock event. In yet another embodiment, a lower shock threshold is used if an accumulated average position error of the transducer head is large.

Owner:MAXTOR

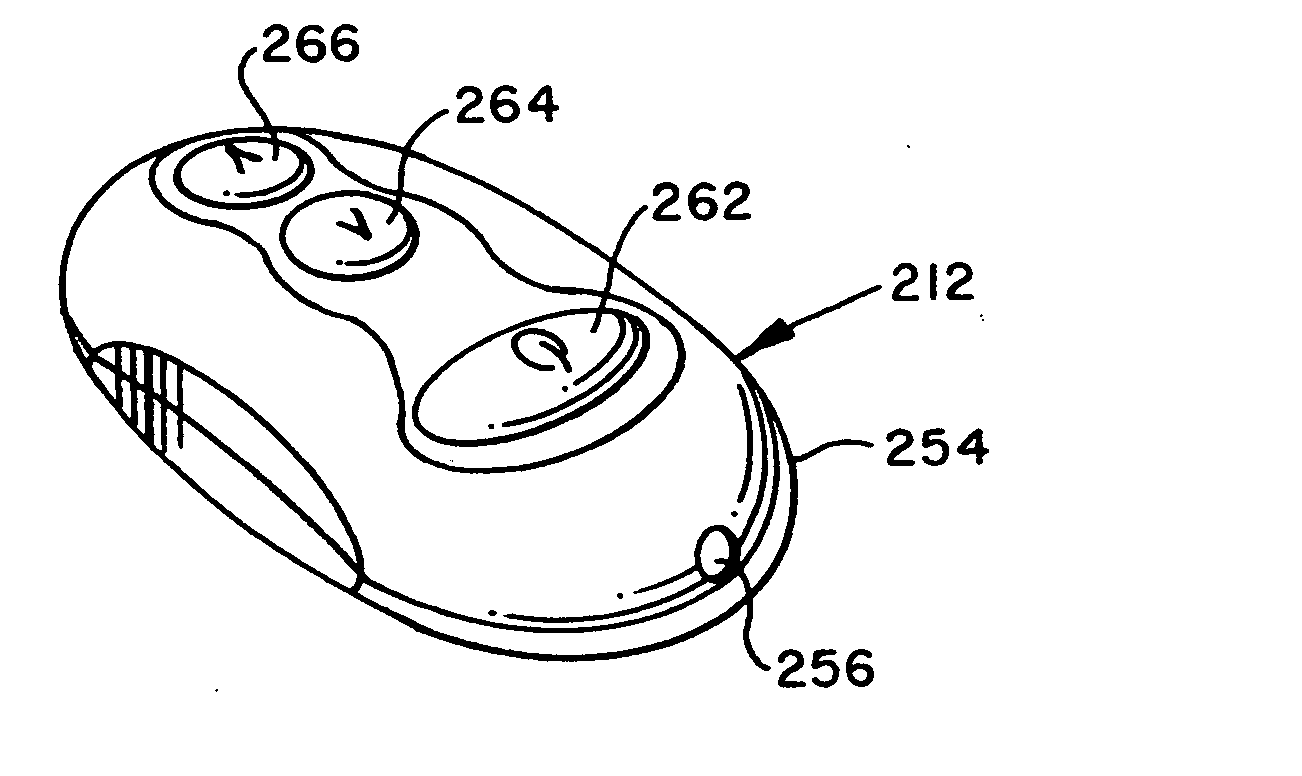

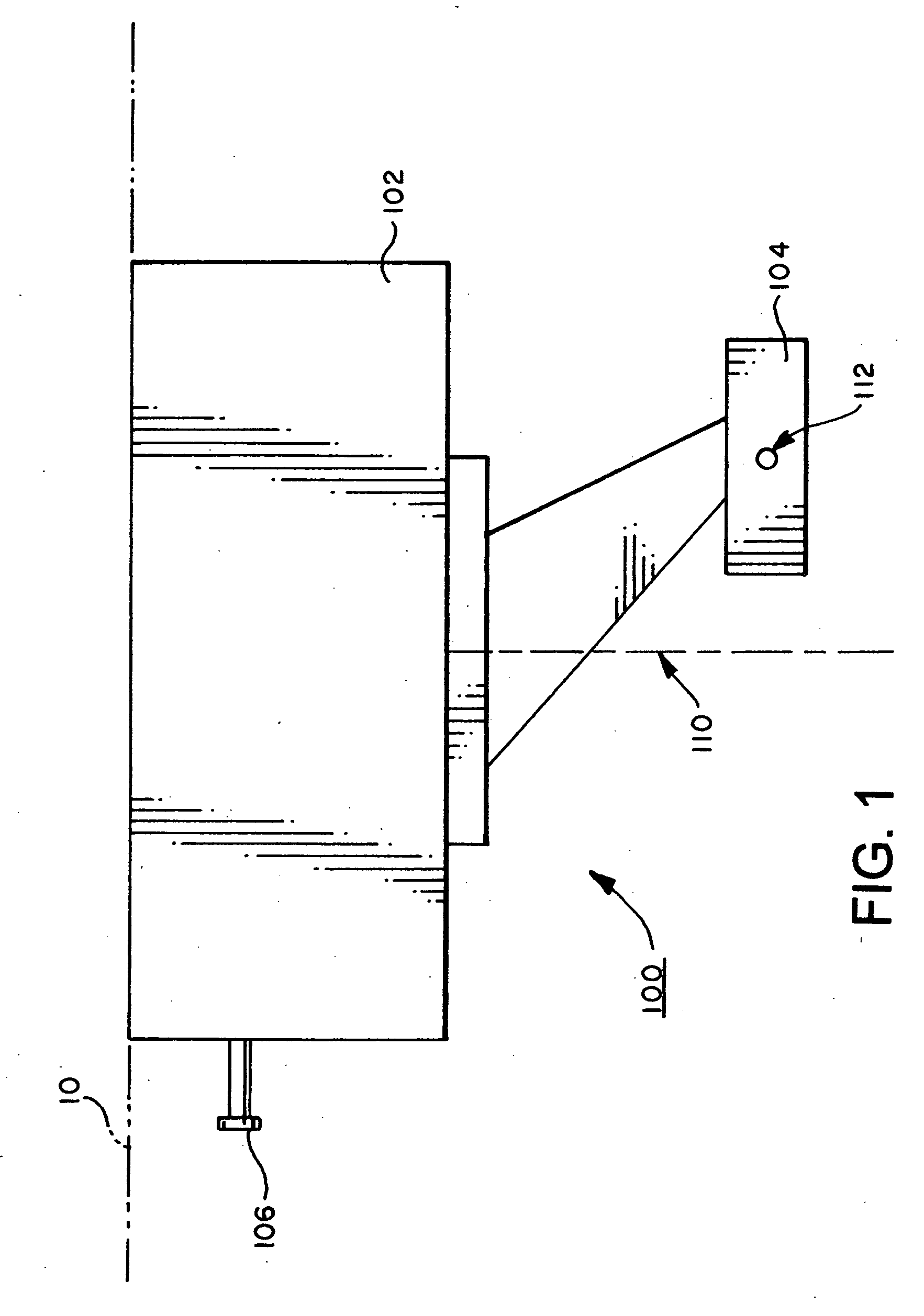

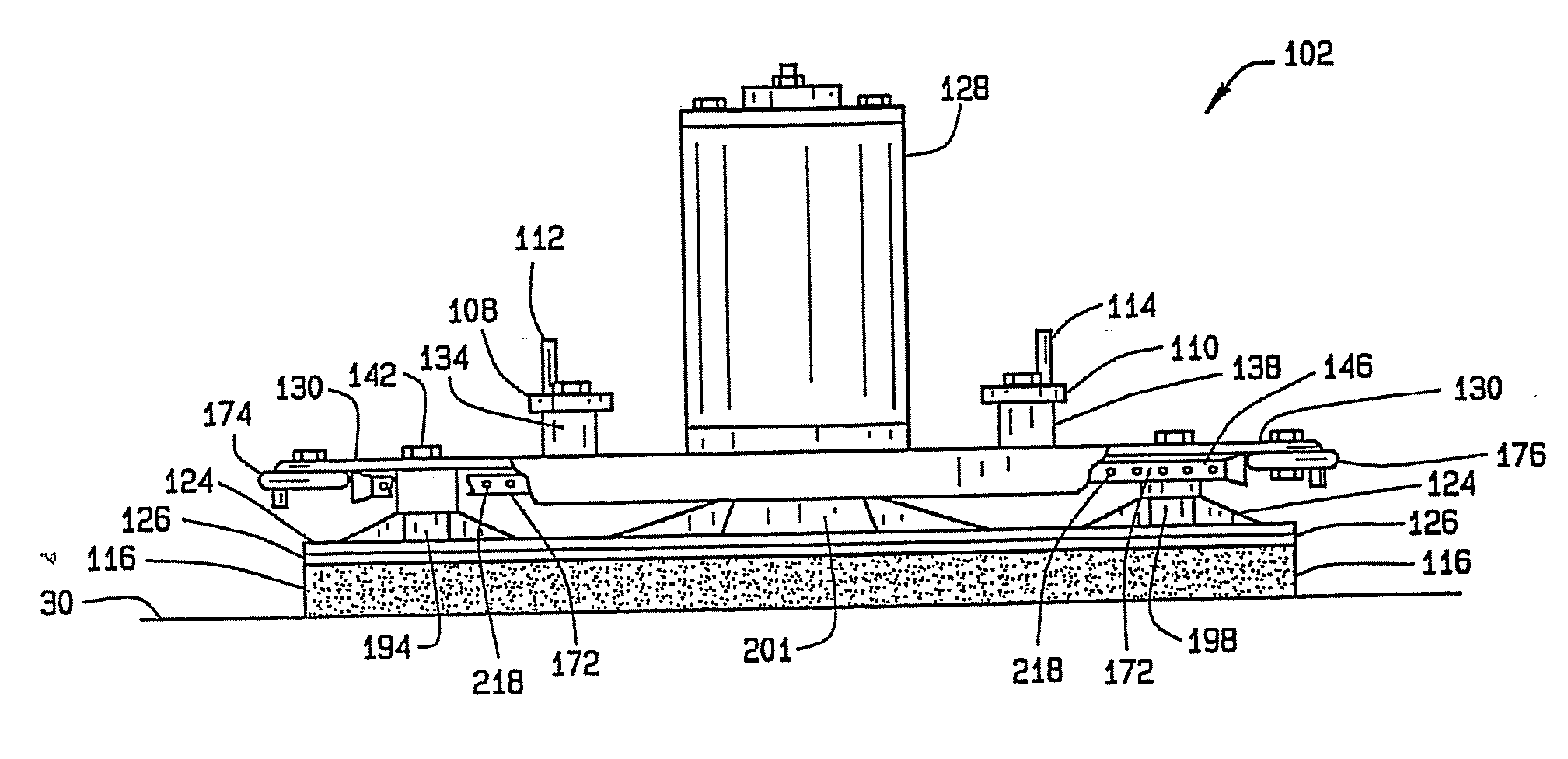

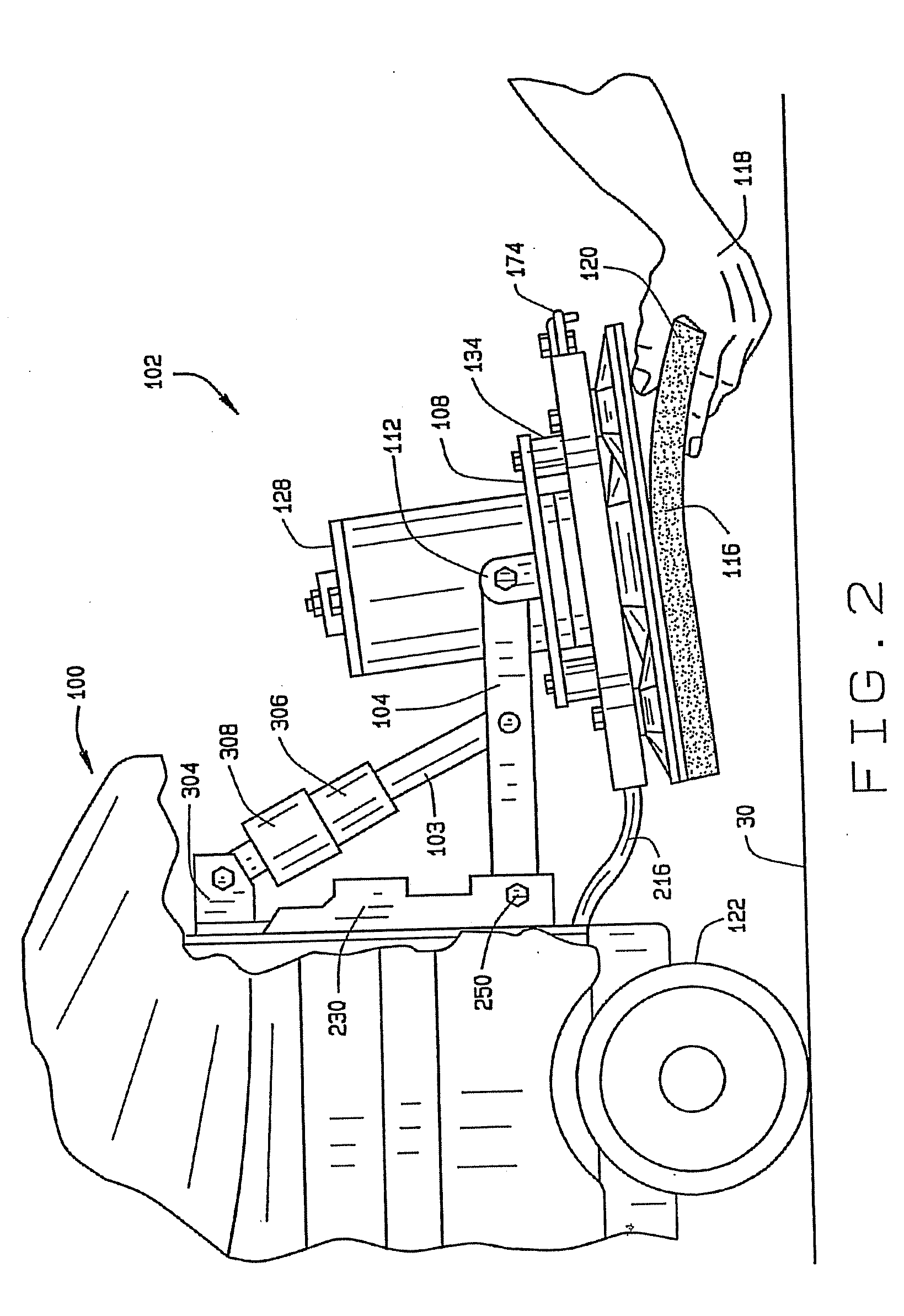

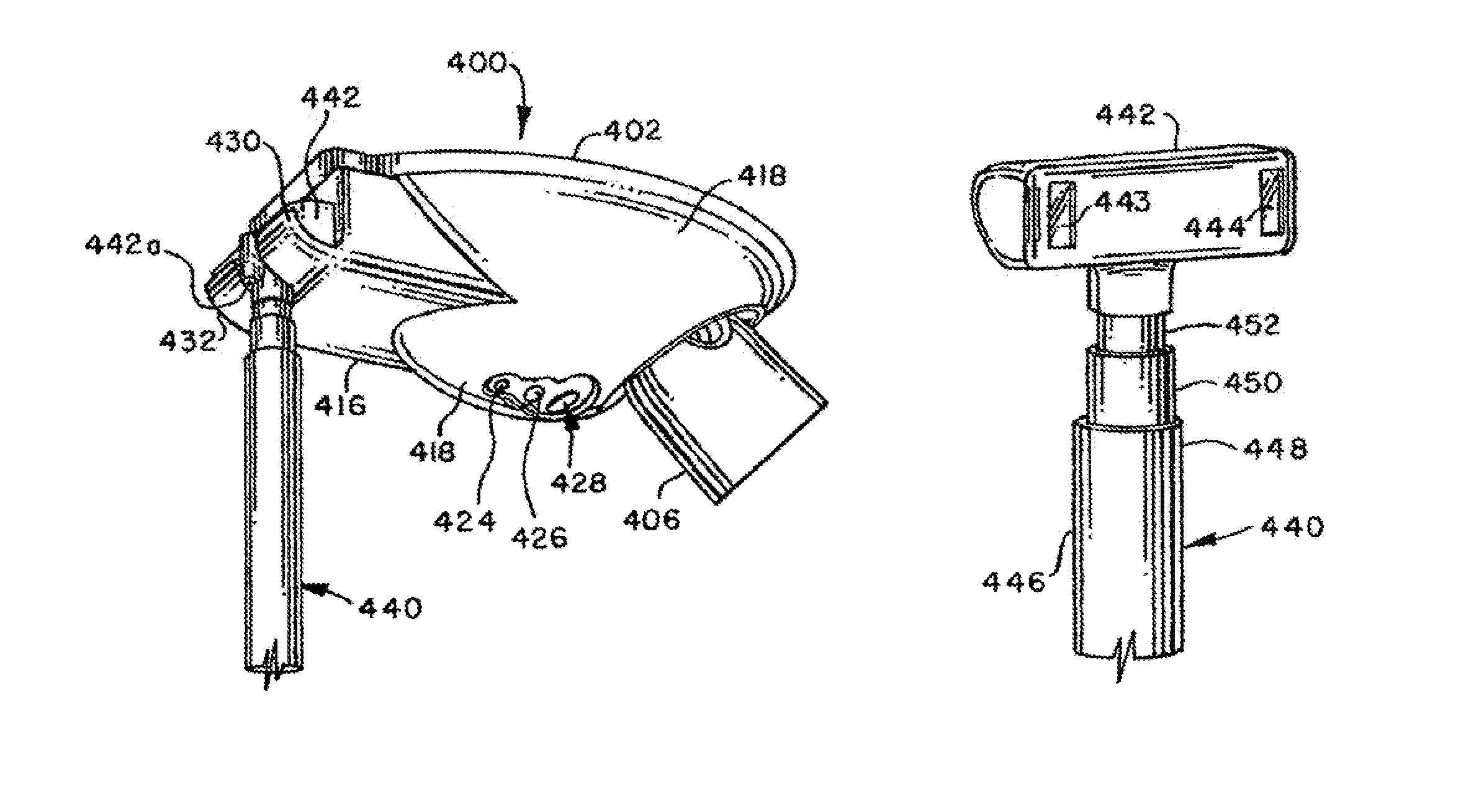

Extended reach battery charging system

ActiveUS20110001455A1Long run timeShort charging timeBatteries circuit arrangementsLighting support devicesElectricityLight equipment

A charging system for use in charging a battery includes an elongate handle with a working length sufficient to reach a battery that is out of reach of a user. The charging system includes a charging apparatus coupled to the elongate handle. A head member is configured to mechanically engage with and electrically connect to a battery unit and also mechanically disengage and electrically disconnect from the battery unit by manually grasping and applying mechanical force to the elongate handle. The charging system also includes a power supply configured to provide electrical power to the charging apparatus. The charging system can be used to recharge the battery of a wall or ceiling mounted device (e.g., a battery powered lighting device) that is out of reach of the user without having to remove the device or use a ladder to reach the device.

Owner:VERSALITE ASSOCS

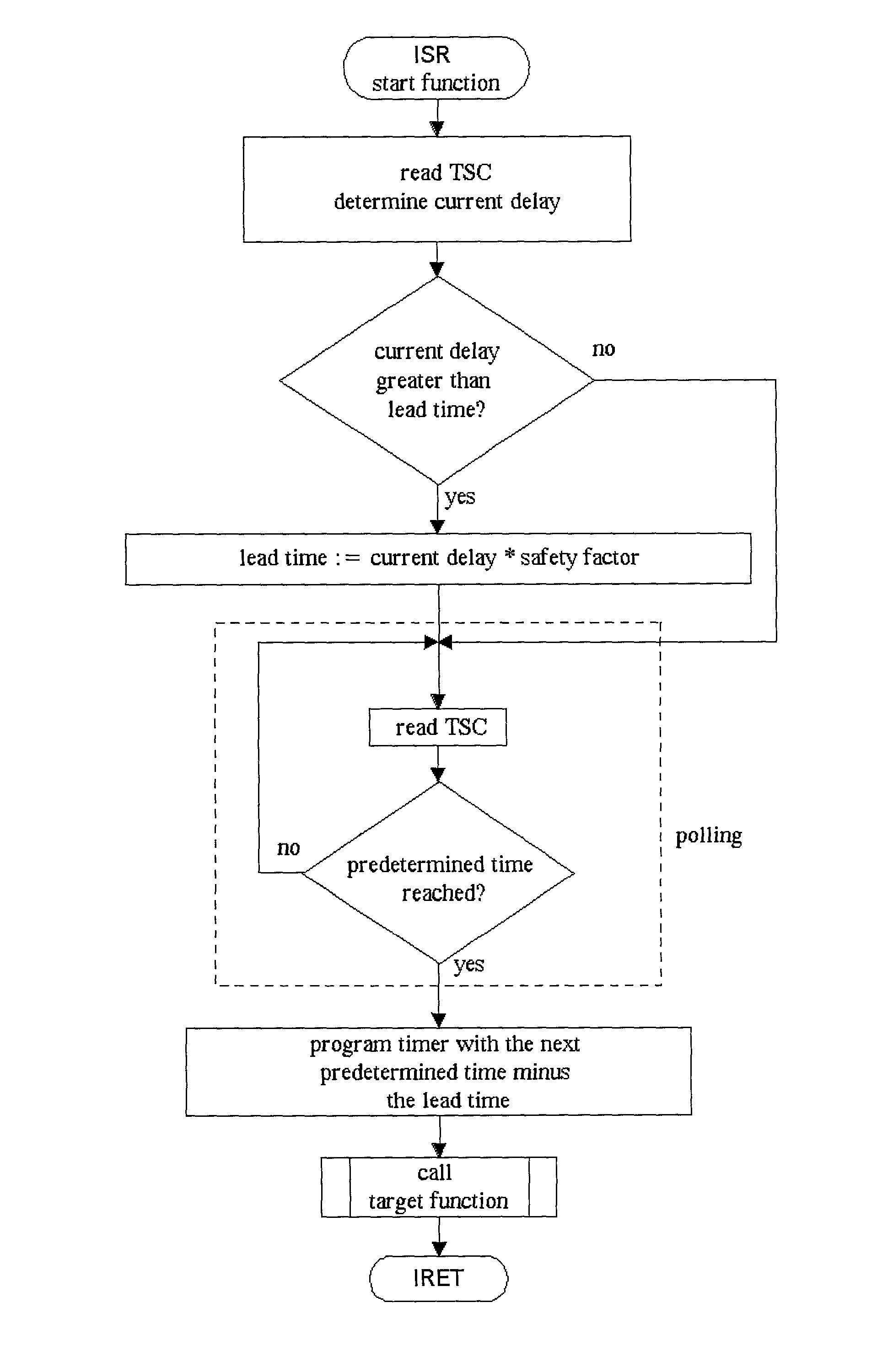

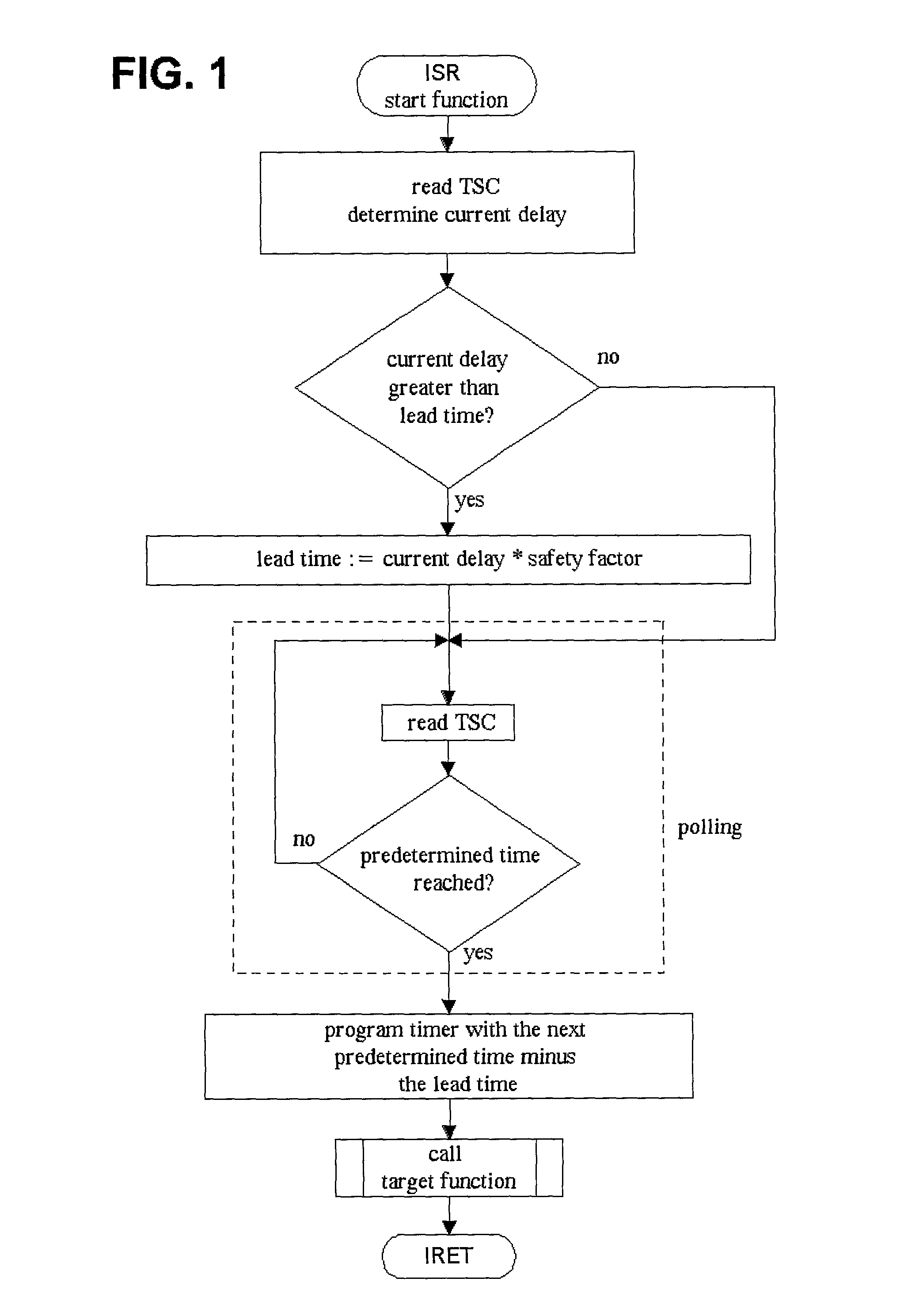

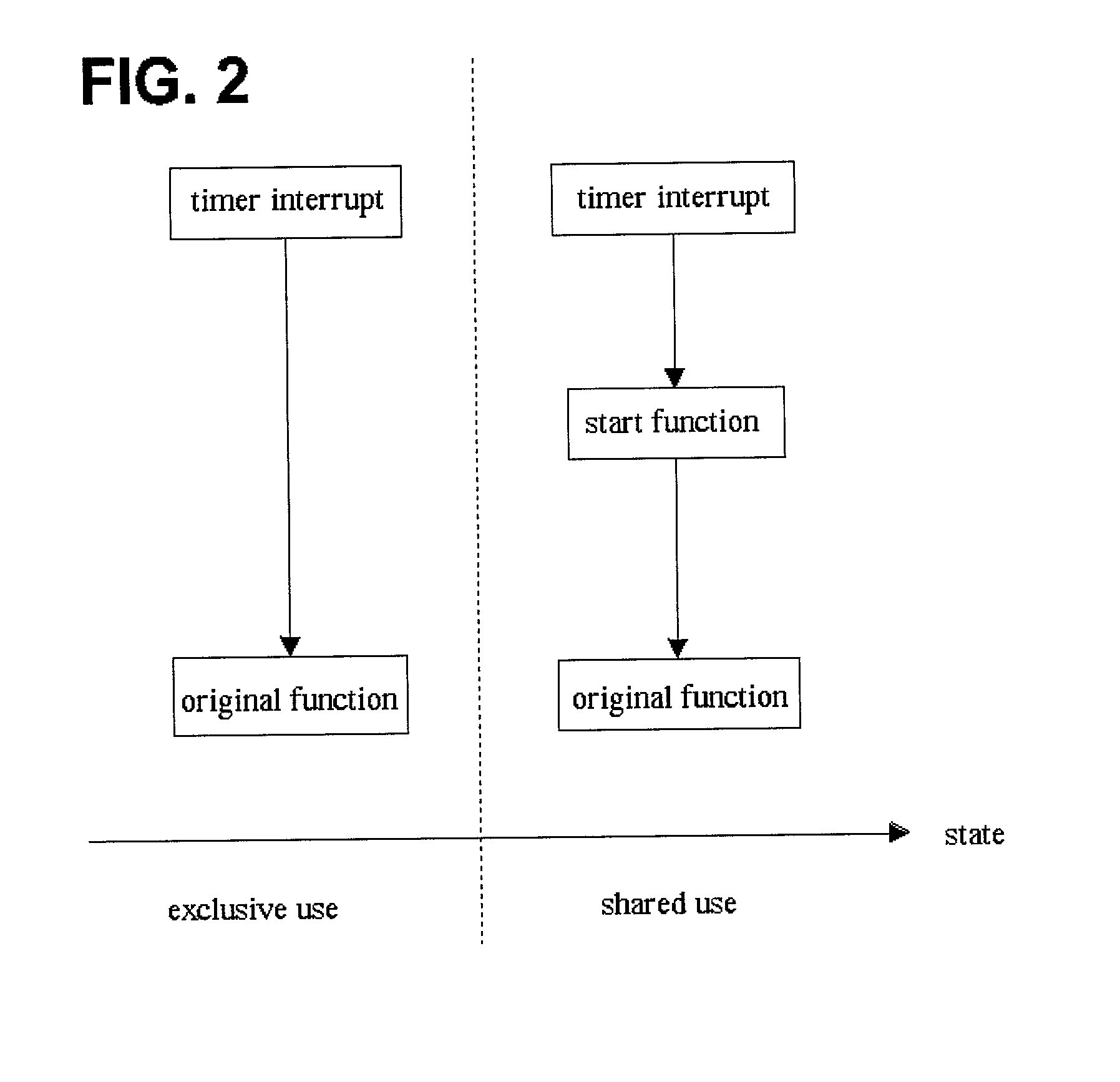

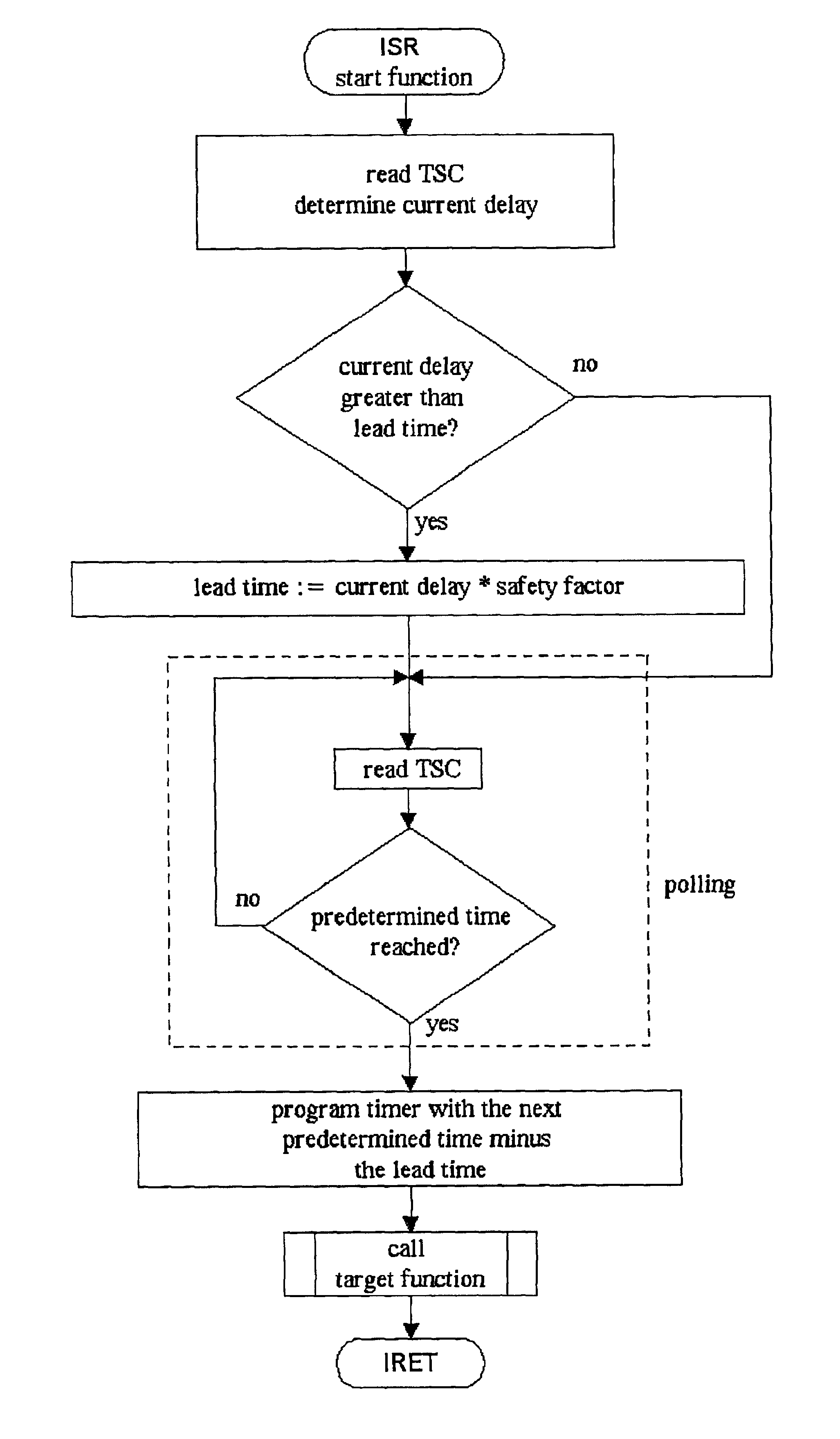

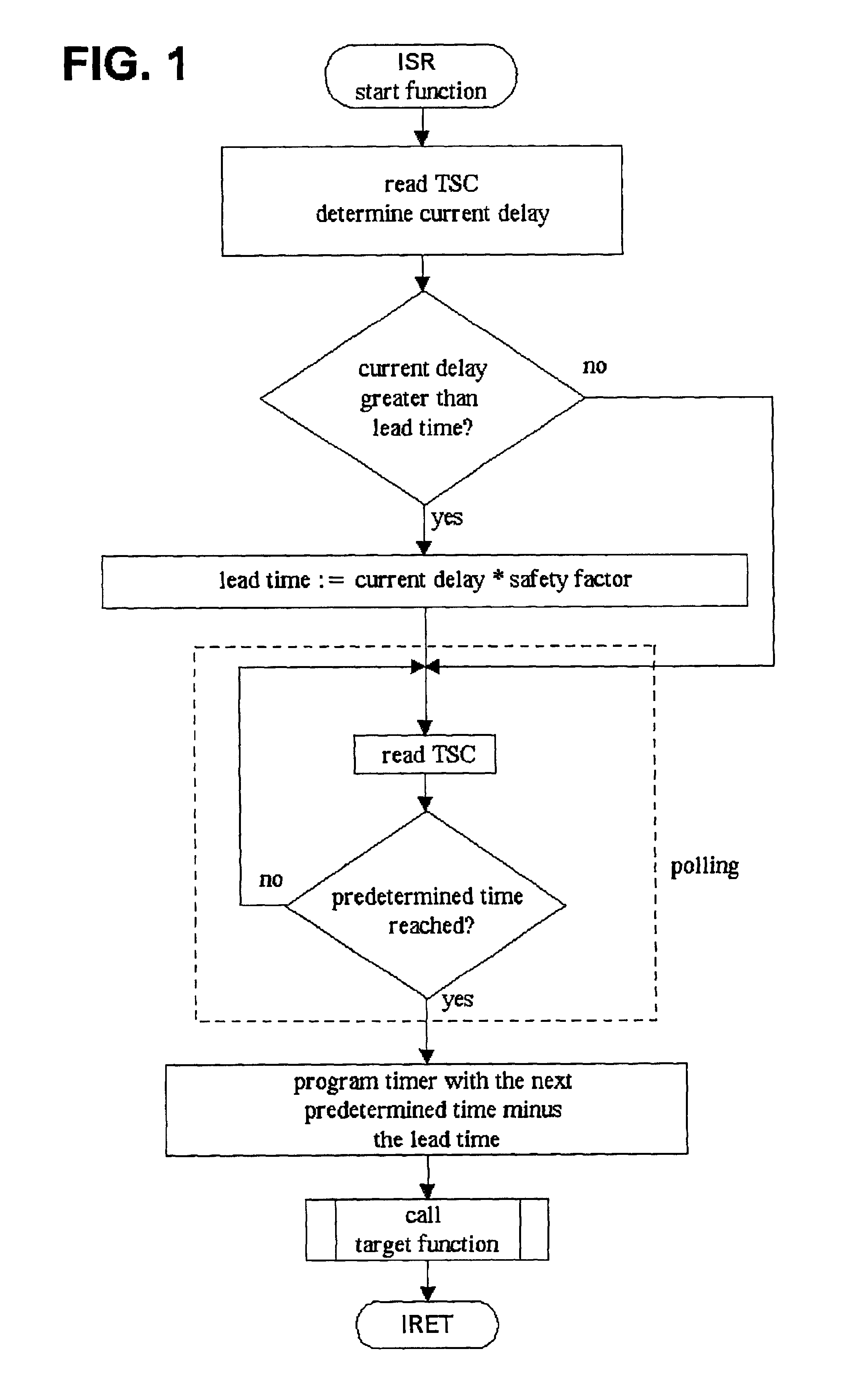

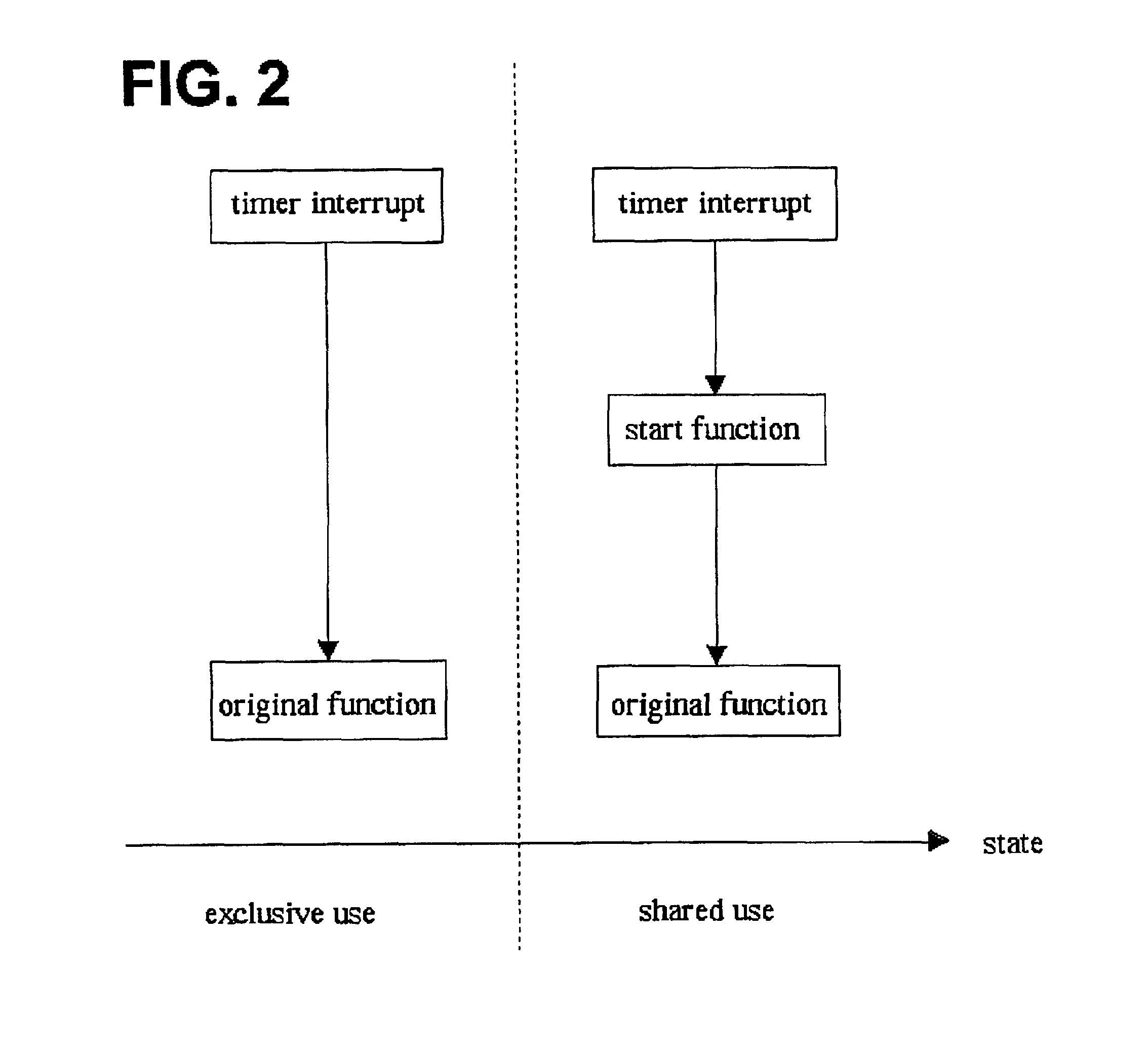

Method for the scheduled execution of a target function

InactiveUS20020069233A1Long run timeLittle computing timeProgram initiation/switchingMemory systemsProcessor registerProgram planning

A method for the scheduled execution of program steps (target function) by the processor of a computer at predetermined times, in which a register of the computer is read repeatedly and this value is compared with a reference value representing the predetermined time, wherein when the read value corresponds to the reference value, the target function is executed in the processor. In the described method, a technique is used that is known by the English term "polling." The disadvantage of the polling method is that it is not suitable for multitasking. This disadvantage is overcome by the present invention. This task is solved such that the reading of the register is performed within a start function that is executed by the processor as an interrupt service routine.

Owner:NAT INSTR IRELAND RESOURCES

Extended reach battery charging system

ActiveUS8358101B2Long run timeShort charging timeBatteries circuit arrangementsPoint-like light sourceElectricityElectrical battery

A charging system for use in charging a battery includes an elongate handle with a working length sufficient to reach a battery that is out of reach of a user. The charging system includes a charging apparatus coupled to the elongate handle. A head member is configured to mechanically engage with and electrically connect to a battery unit and also mechanically disengage and electrically disconnect from the battery unit by manually grasping and applying mechanical force to the elongate handle. The charging system also includes a power supply configured to provide electrical power to the charging apparatus. The charging system can be used to recharge the battery of a wall or ceiling mounted device (e.g., a battery powered lighting device) that is out of reach of the user without having to remove the device or use a ladder to reach the device.

Owner:VERSALITE ASSOCS

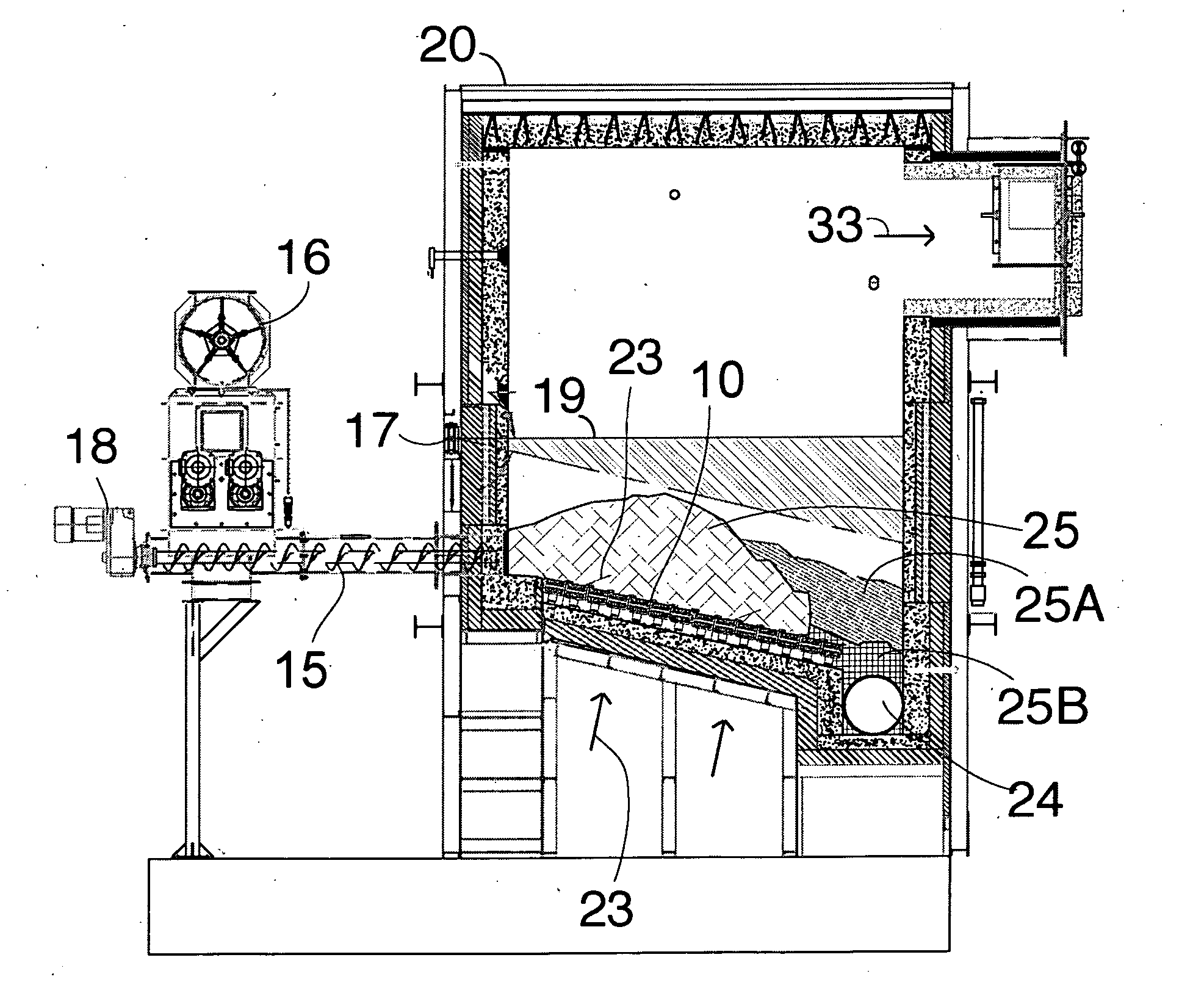

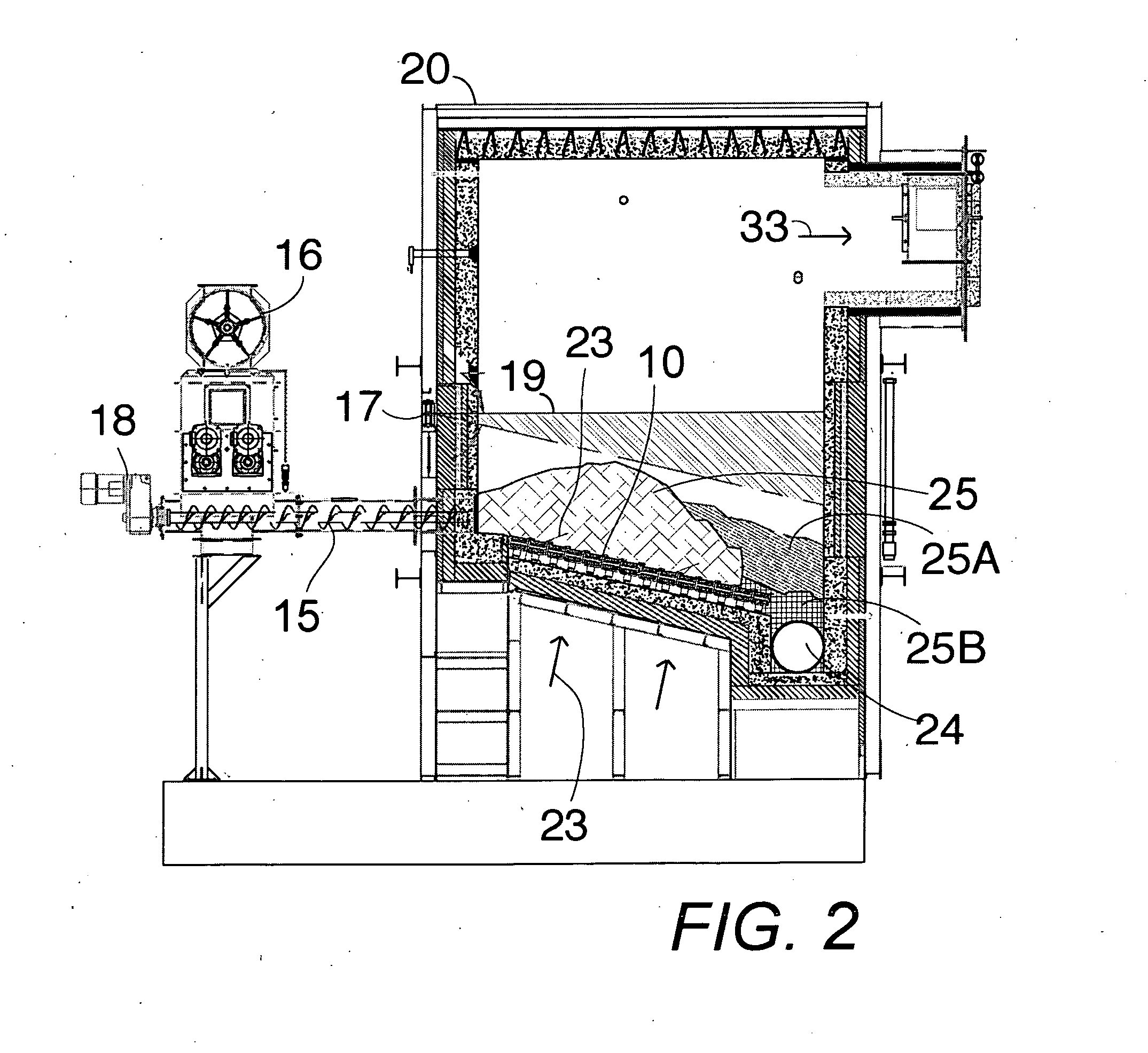

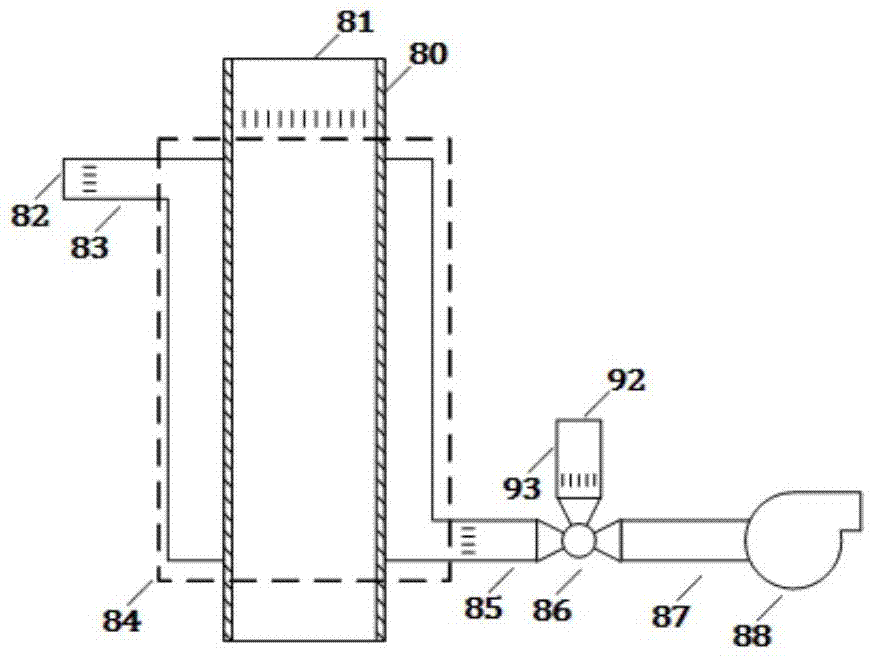

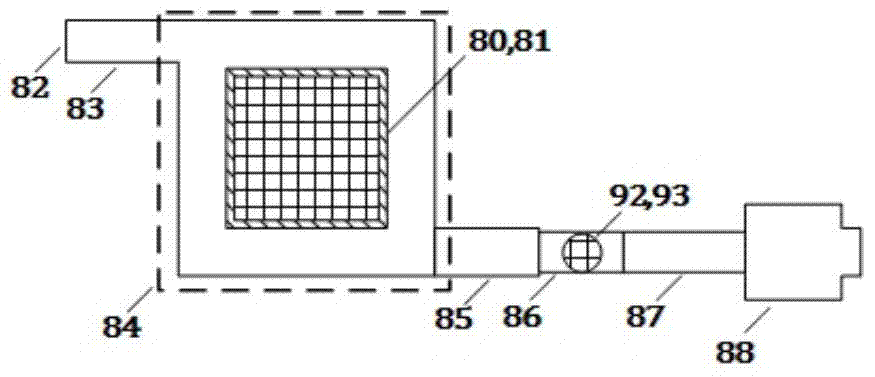

Grate clearing and ash removal system for gasification furnace

A relatively level fuel grate surface angle cooperates with multiple feed screws that press solid fuel material into and across the grate surface to continually clear off the grate. Air spaces between each pair of adjacent grate elements for under fire air each have a ninety degree deflector flange at the top of the air space extending from one grate element across the air space and up and over an adjacent grate element to deflect under fire airflow across the adjacent grate element to act as a grate sweeper. The smooth curved surface of the deflector flange between grate elements facilitates movement of the fuel and ash material and prevents from one grate element to the next and prevents clogging of the airflow space.

Owner:BENDER ROBERT J +2

Method for the scheduled execution of a target function

InactiveUS6934783B2Long run timeLittle computing timeProgram initiation/switchingMemory systemsProgram planningProcessor register

Owner:NAT INSTR IRELAND RESOURCES

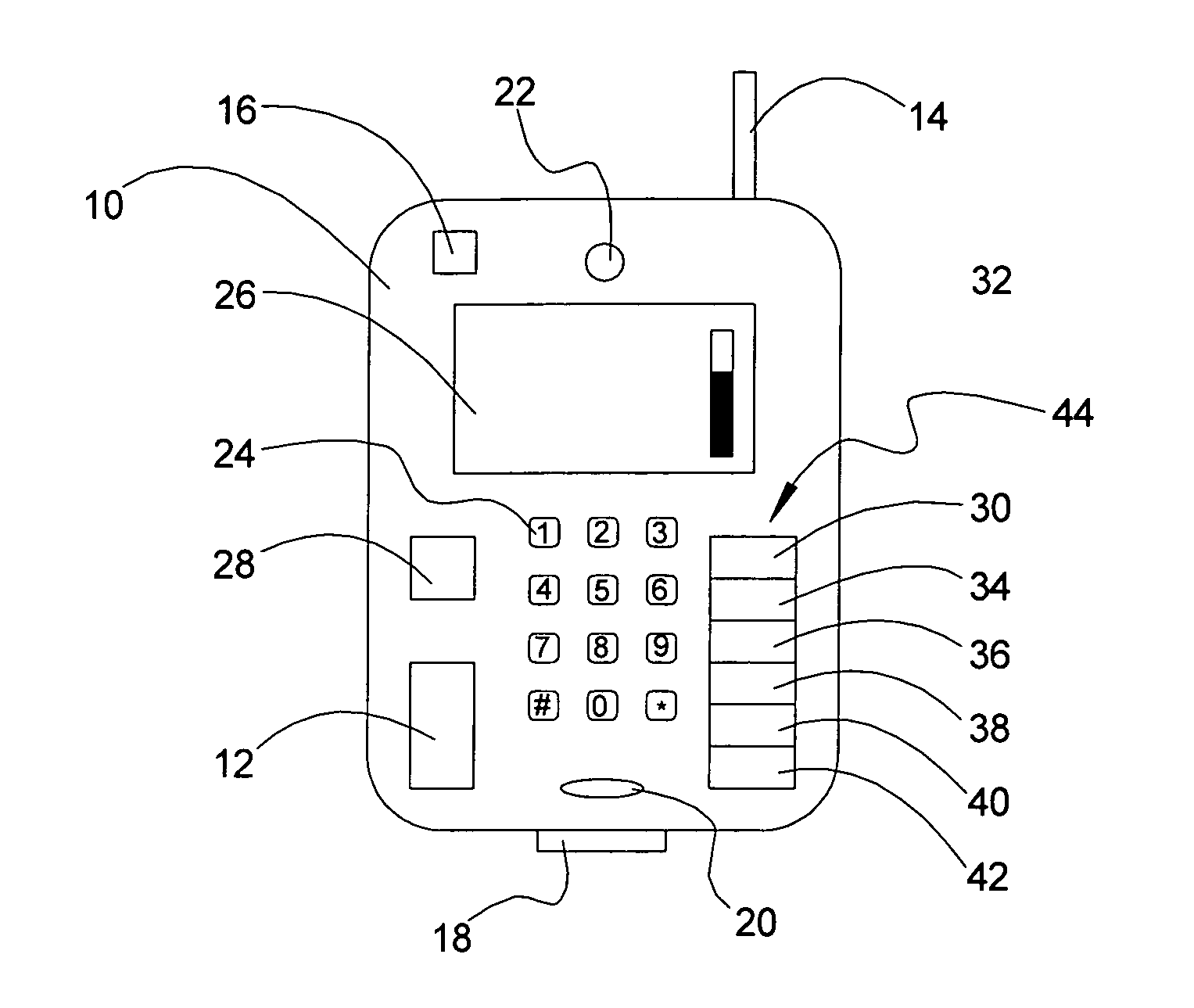

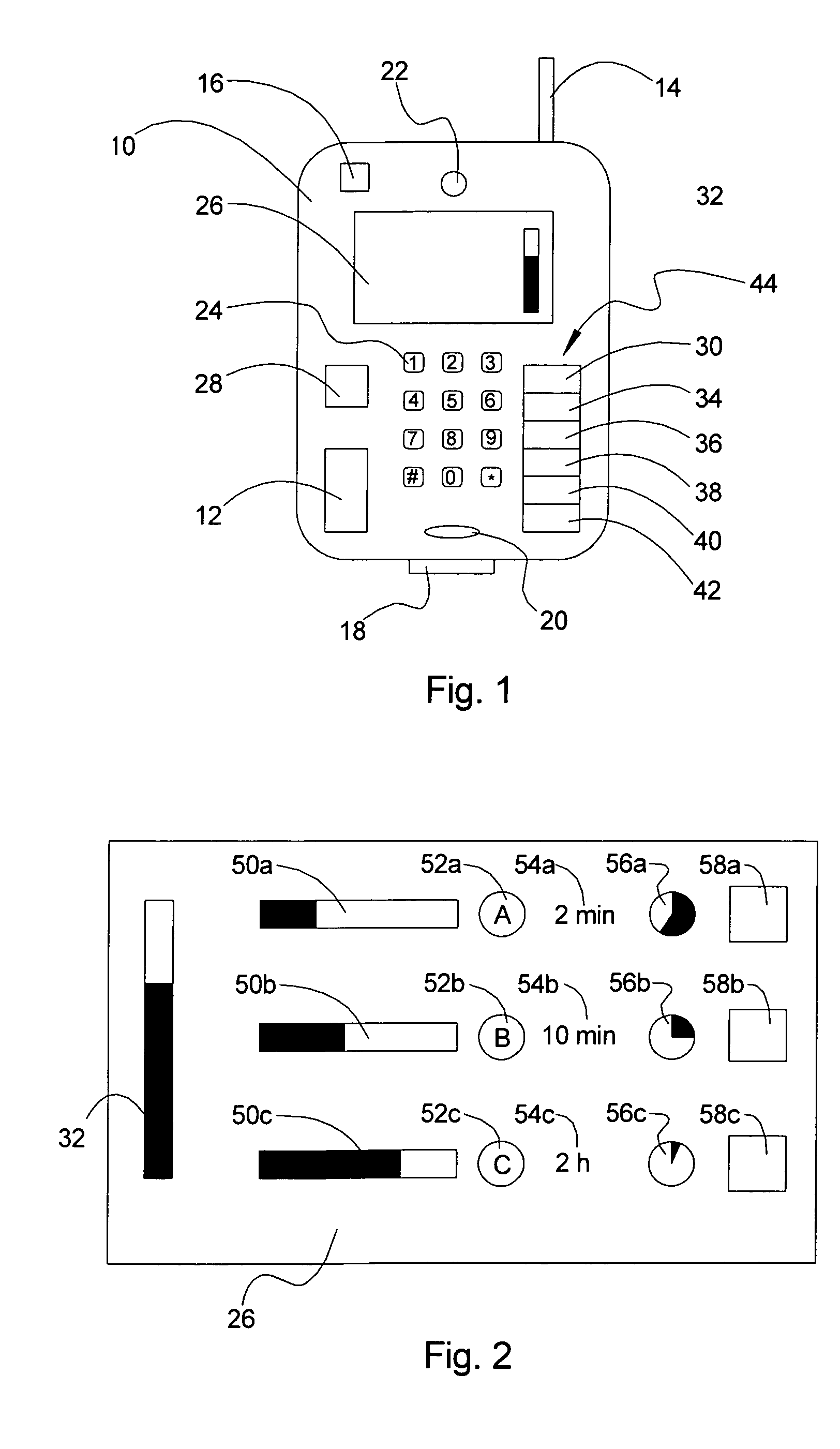

Battery charge status indicator for user terminal device

ActiveUS8482259B2Performed easily and quicklyQuick and easy determinationBatteries circuit arrangementsElectrical testingBattery state of chargeBattery charge

The invention relates to an indicator device for displaying a battery charge status of an electronic battery powered user terminal device, which is adapted to provide a plurality of applications to a user. The user terminal device comprises a plurality of electric components performing the applications, a battery supplying power to the electric components and a power supply control deactivating the electric components of individual applications at a predetermined battery charge status respectively. The indicator device comprises a detection device for detecting the battery charge status of the user terminal device and a display for displaying the battery charge status. A charging state arrangement is provided for determining and displaying an application-specific battery charge state of at least one of the applications.

Owner:VODAFONE HLDG GMBH

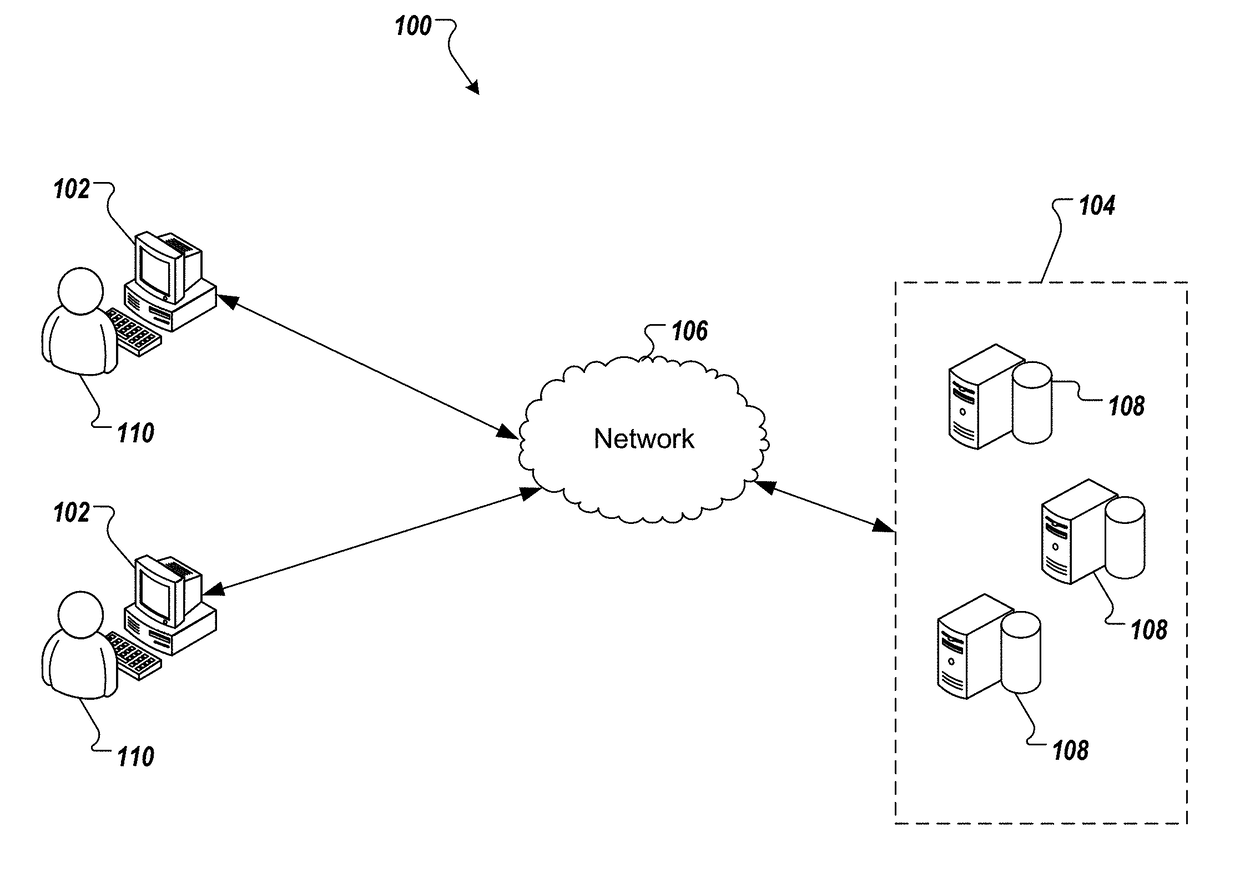

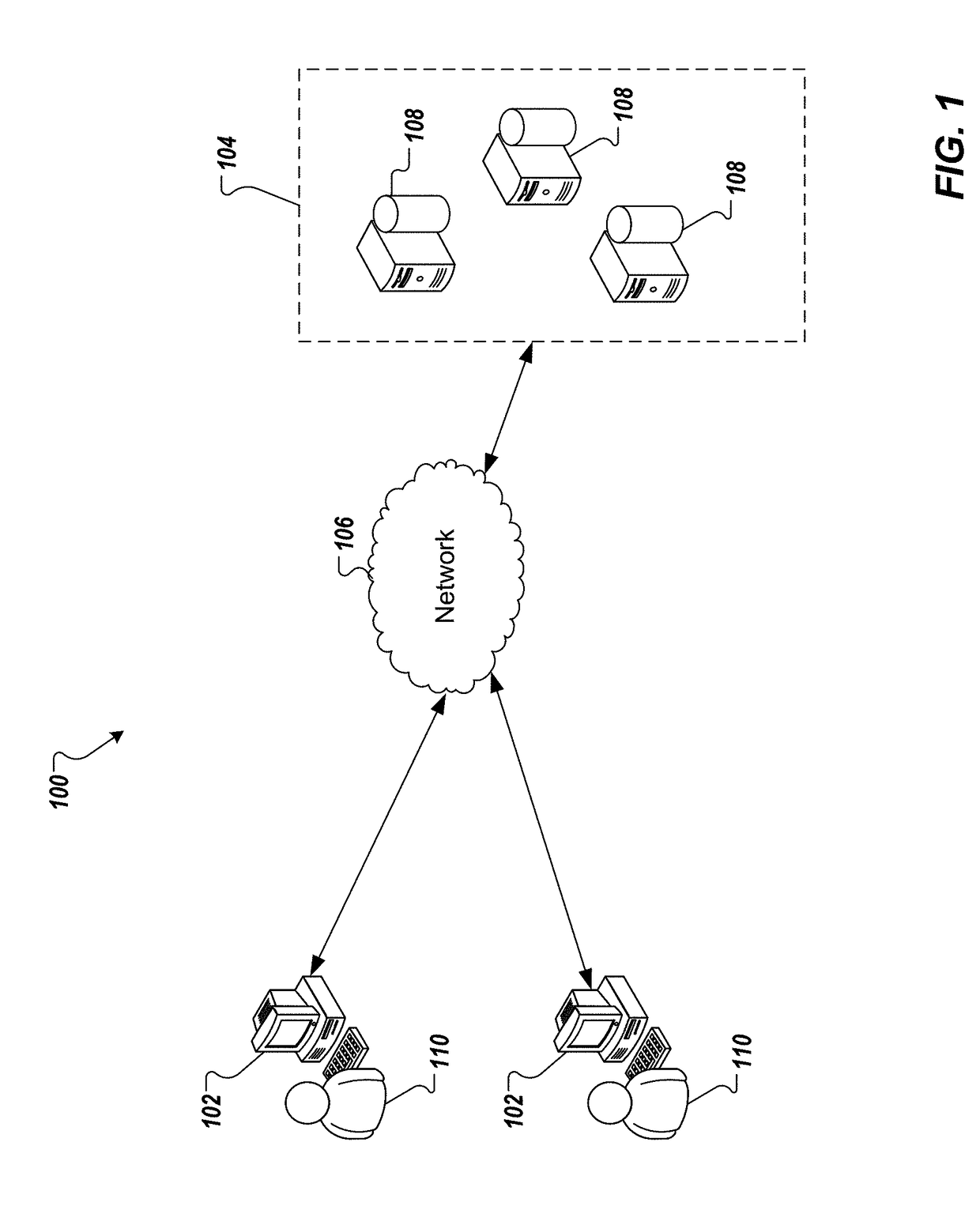

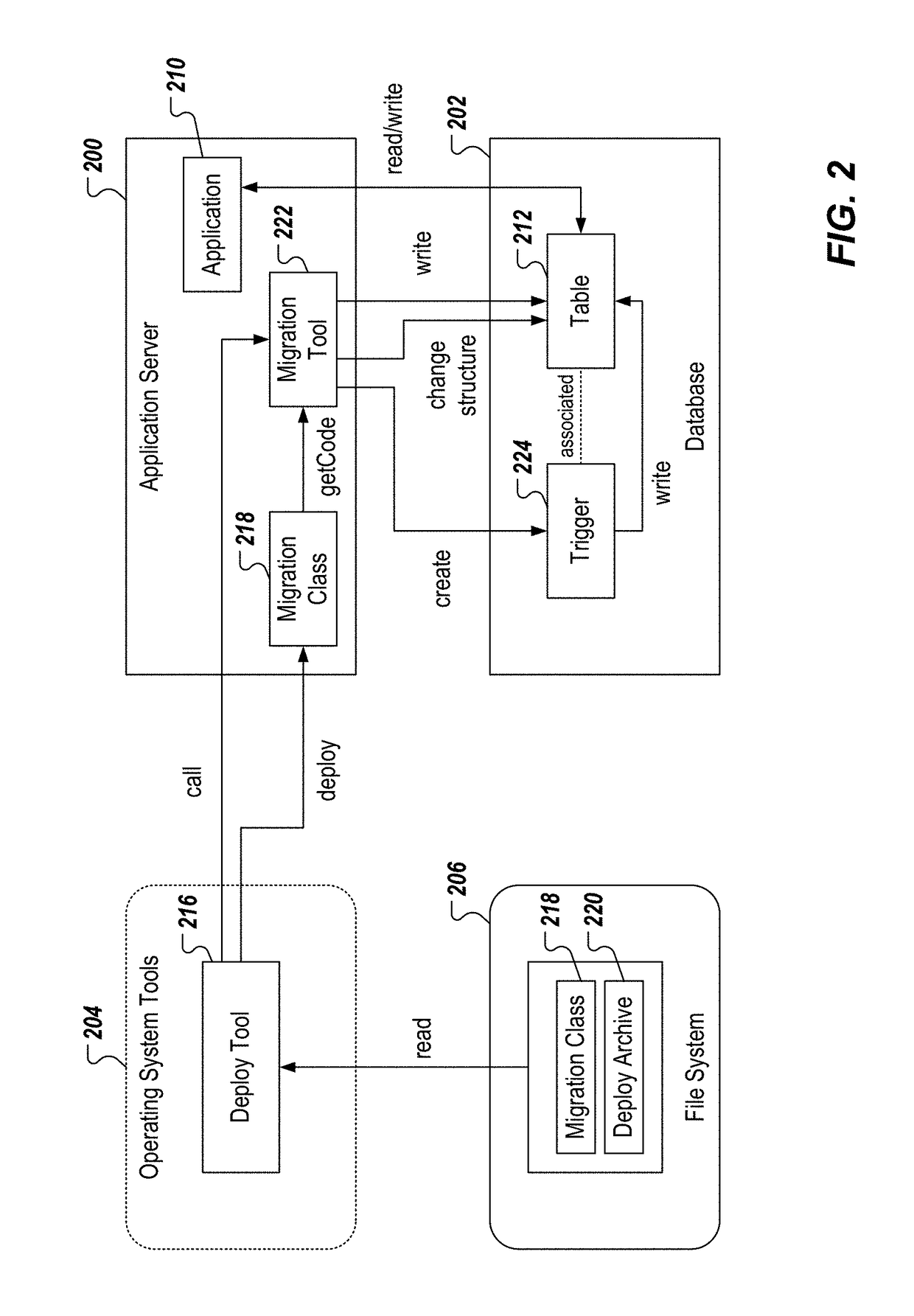

Multi-procedure support in data migration

ActiveUS20180232382A1Reduce running timeLong run timeDigital data information retrievalSpecial data processing applicationsProgramming languageBridge pattern

Implementations include actions of initiating a procedure on an application that interacts with a database system having a start schema, through which a first version of the application interacts with tables, providing a bridge schema including table views to each table of the start schema, switching a first version of the application to interact through the bridge schema, creating a shadow field in a table, the shadow field corresponding to a field of the table that is to undergo a change during an upgrade from the first version to a second version, providing a trigger in the start schema, the trigger executing a transformation between the field and the shadow field during the upgrade, modifying the table in the start schema to a target structure to change a parameter of the shadow field or the field of the table, and switching the second version to interact through the start schema.

Owner:SAP AG

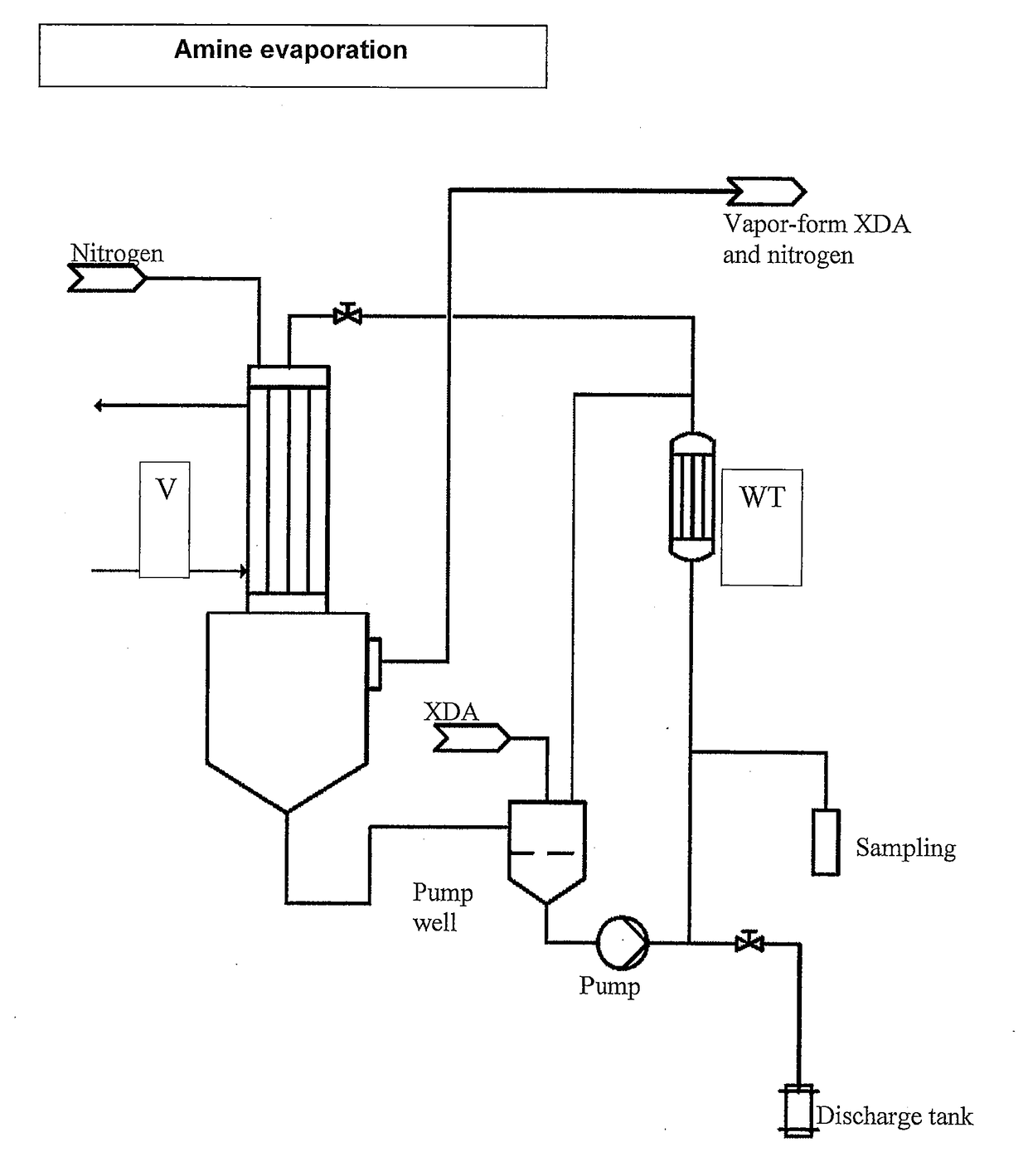

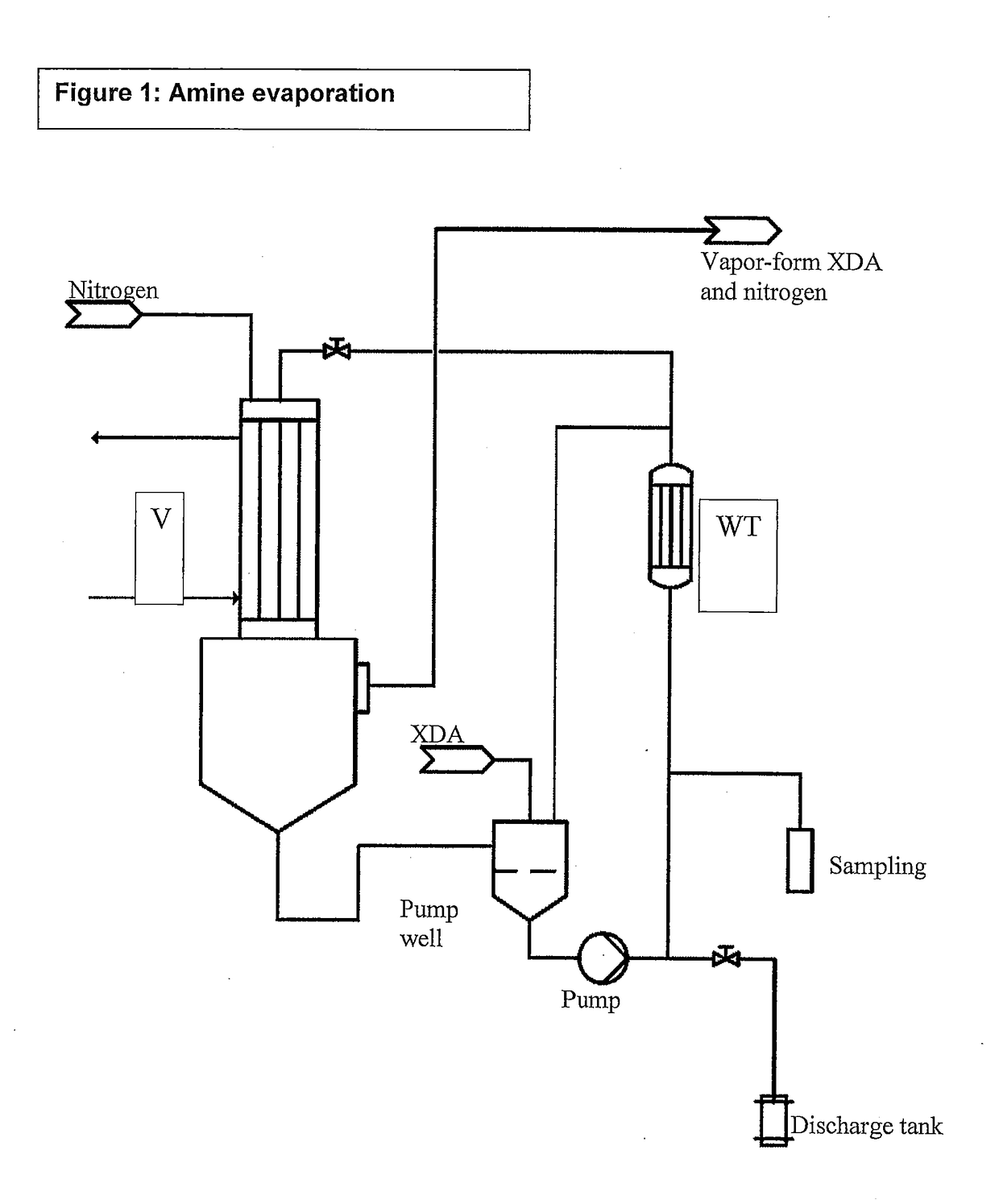

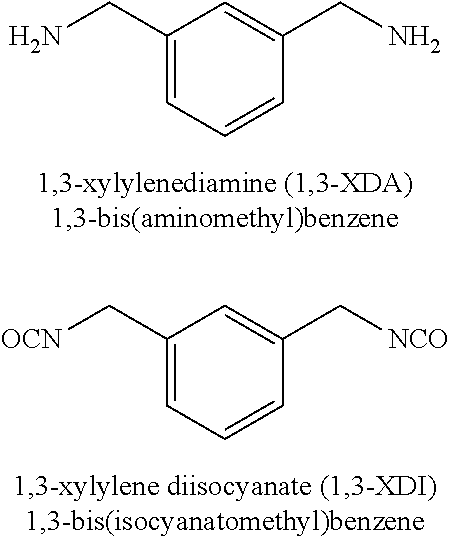

Method for producing xylylene diisocyanates in the gaseous phase

ActiveUS20170210702A1Long run timeKeep for a long timeIsocyanic acid derivatives preparationOrganic compound preparationChemistryIsocyanate compound

Owner:COVESTRO DEUTSCHLAND AG

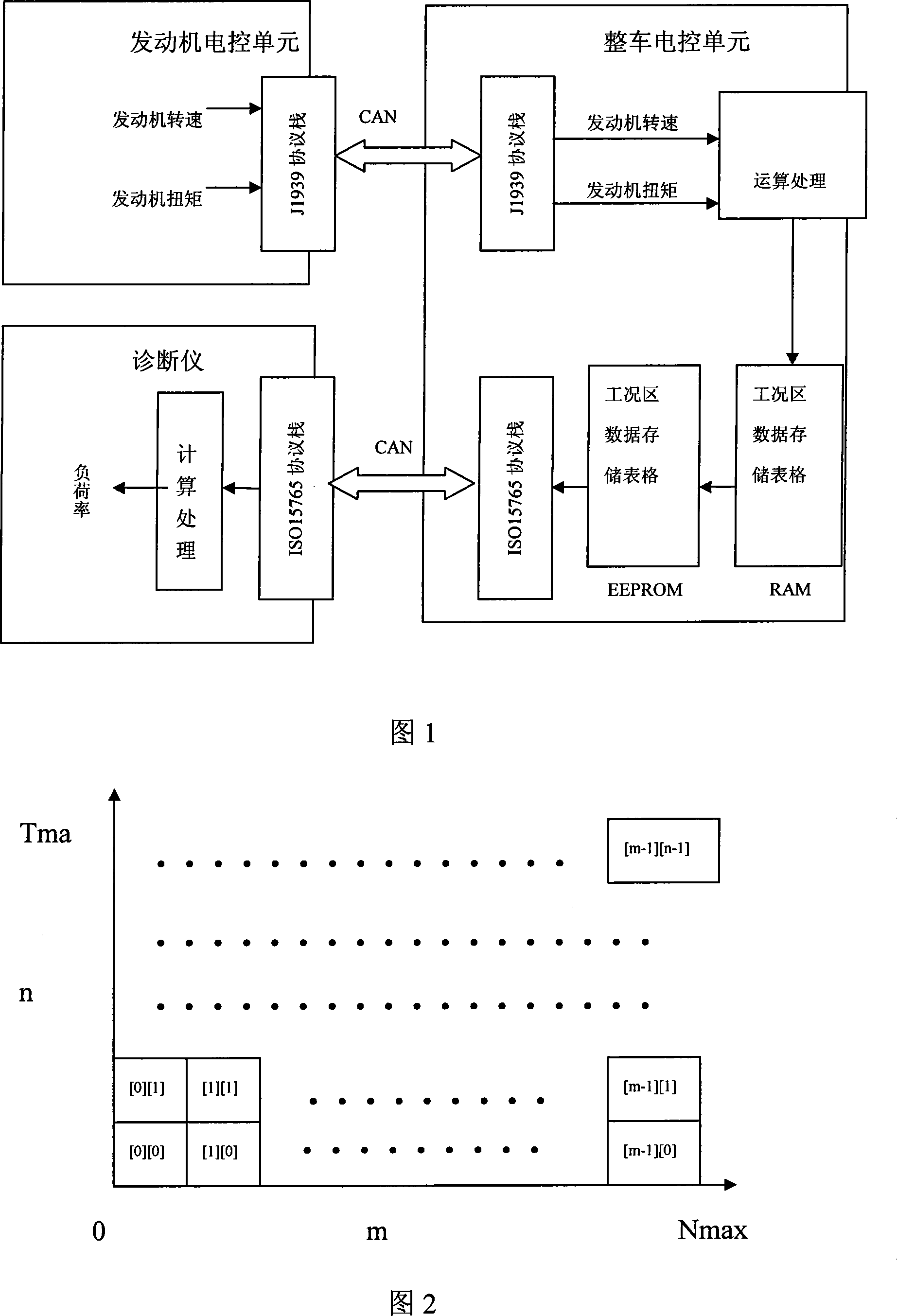

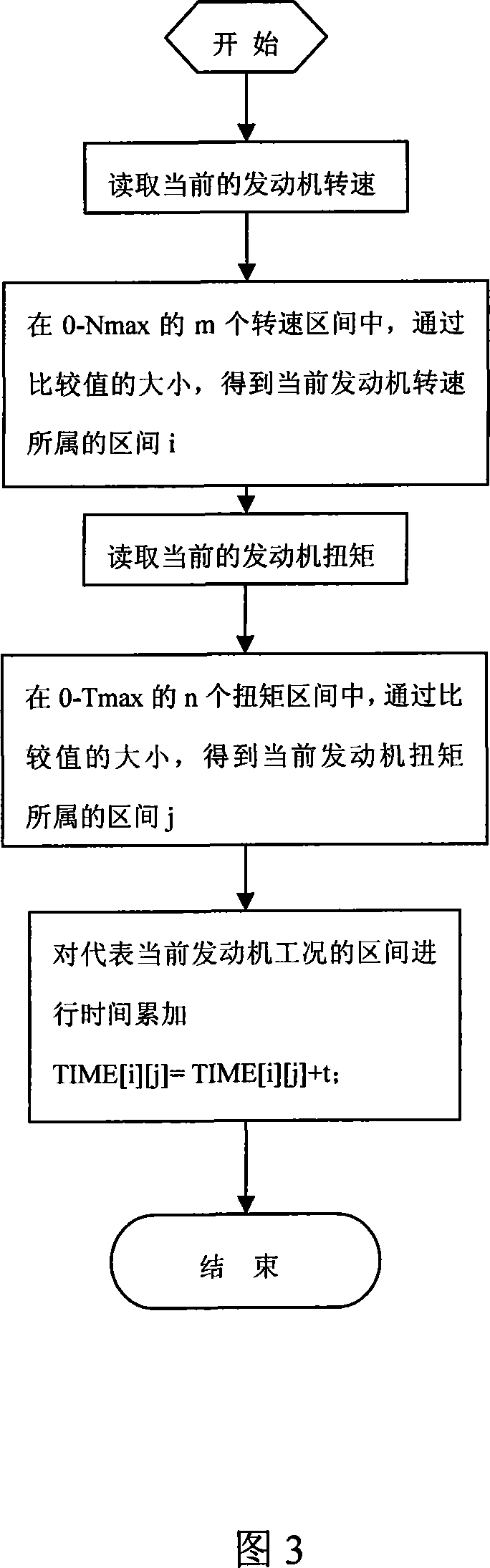

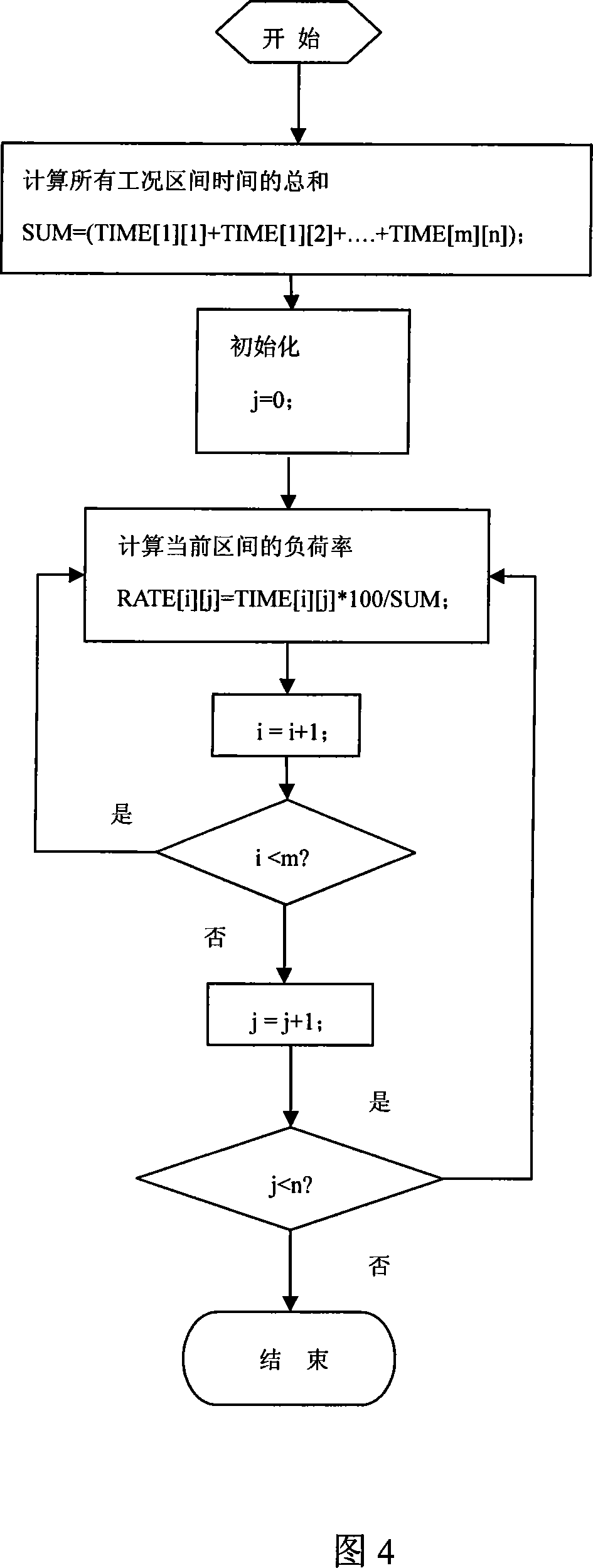

Car borne real time statistical method for load factor of engine

ActiveCN101092912ALearn about runtimeLong run timeEngine controllersMachines/enginesRate parameterAutomotive engineering

This invention provides a car-carrying real time statistic method for load rate of engines including: 1, dividing the rotation speed of an engine into m points from bottom to high, dividing a torque to n points from bottom to high to compose a data table storing operating time of m*n duty regions to be stored in a RAM of a car electric control unit, 2, when the engine operates, the control unit collects data of rotation speed and torque of the engine sent by the control unit by a CAN bus line and accumulates the operation time of the duty regions by looking up two corresponding elements, 3, before the control unit is turned off, the data table stored in the RAM is copied in EEPROM and stored, 4, when the control unit is re-turned on, the RAM is initialized based on the data table read in the EEPROM, 5, a diagnosis device reads the data table stored in the RAM and computes the load rate parameters of the duty regions.

Owner:DONGFENG MOTOR CORP HUBEI

Method for producing phosphoric acid from phosphate ore by displacement method

A method for producing phosphoric acid through a phosphate ore displacement method comprises the following steps: adding silicon dioxide and phosphate rock powder into an eddy kiln to carry out a high-temperature melting displacement reaction so as to displace P2O5 gas; obtaining an industrial-grade or food-grade phosphoric acid product through hydration, absorption, refining and purification of the displaced P205 gas; and adding alkali metal oxides or salts of kalium and sodium into melted slag to obtain a slag wool product through blowing and drawing. Compared with the prior kiln method phosphoric acid process, the method omits the reduction of phosphate ore, the oxidization reaction of phosphorus and the processes and equipment for the ball forming and drying of ore charge, and saves carbon for reduction. The method saves investment on equipment by about 60 percent, reduces furnace gas dust by 90 percent, and improves the unit kiln volume and the productivity in the unit time by more than 50 times and the reaction speed by more than 20 times. The method is characterized by simplified flow, simple and feasible operation and control, reliability and stability. During the technical process, no waste residue or water is produced and discharged; and the discharged end gas basically has no impact on the atmosphere. The method is suitable for phosphoric acid manufacturers with an annual output of 1,000 to 800,000 tons industrial grade phosphoric acid.

Owner:李兴德

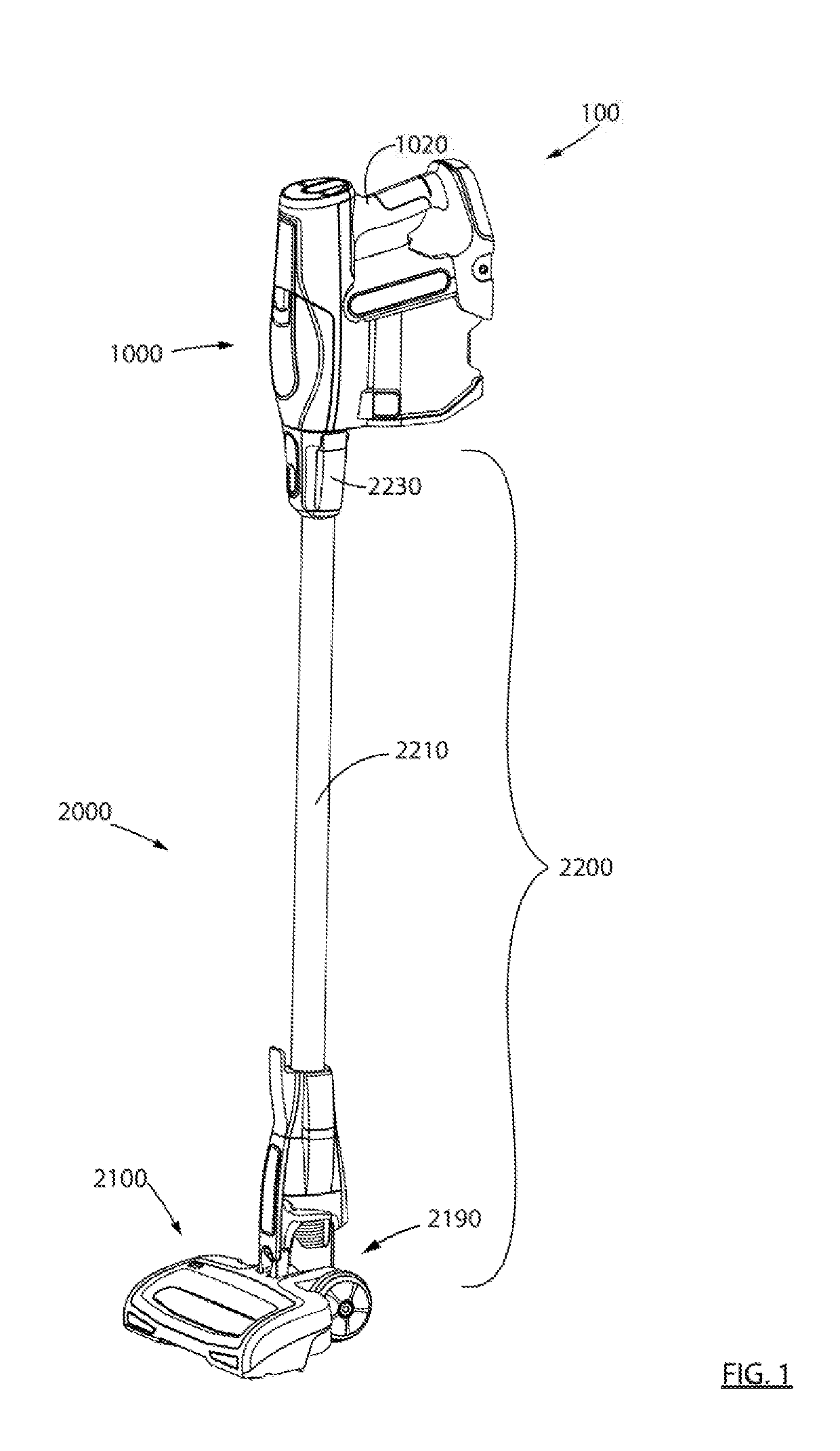

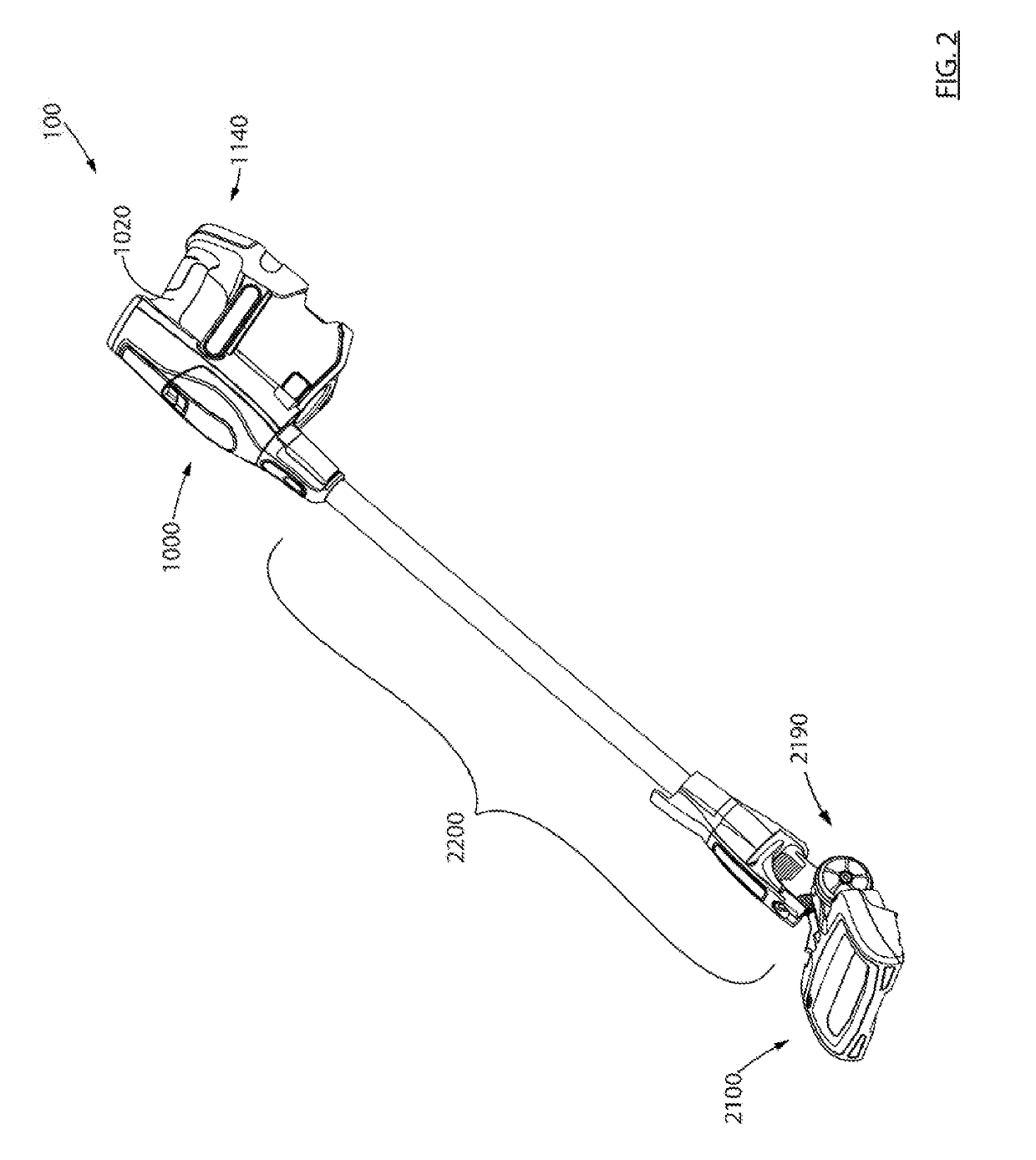

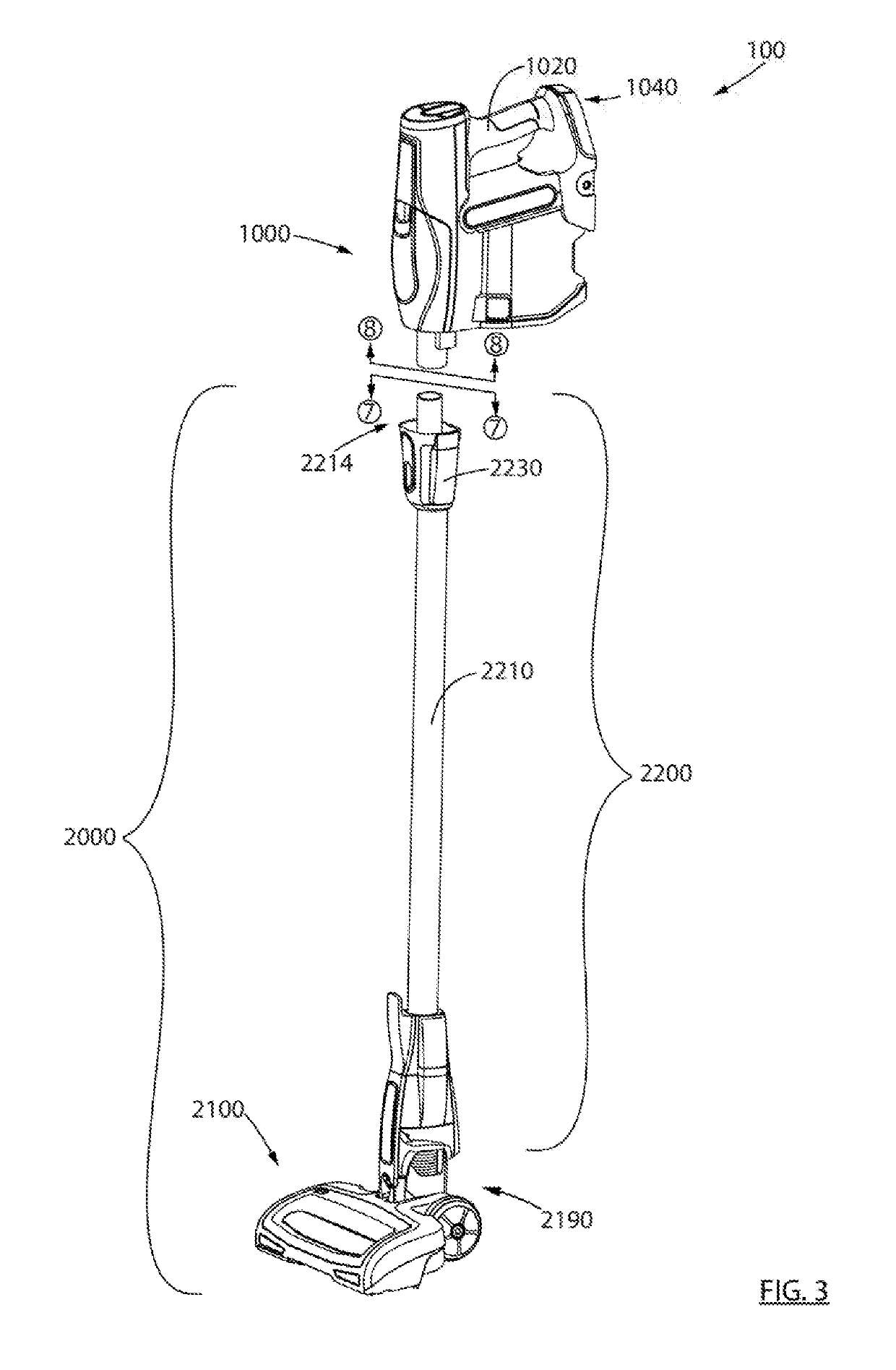

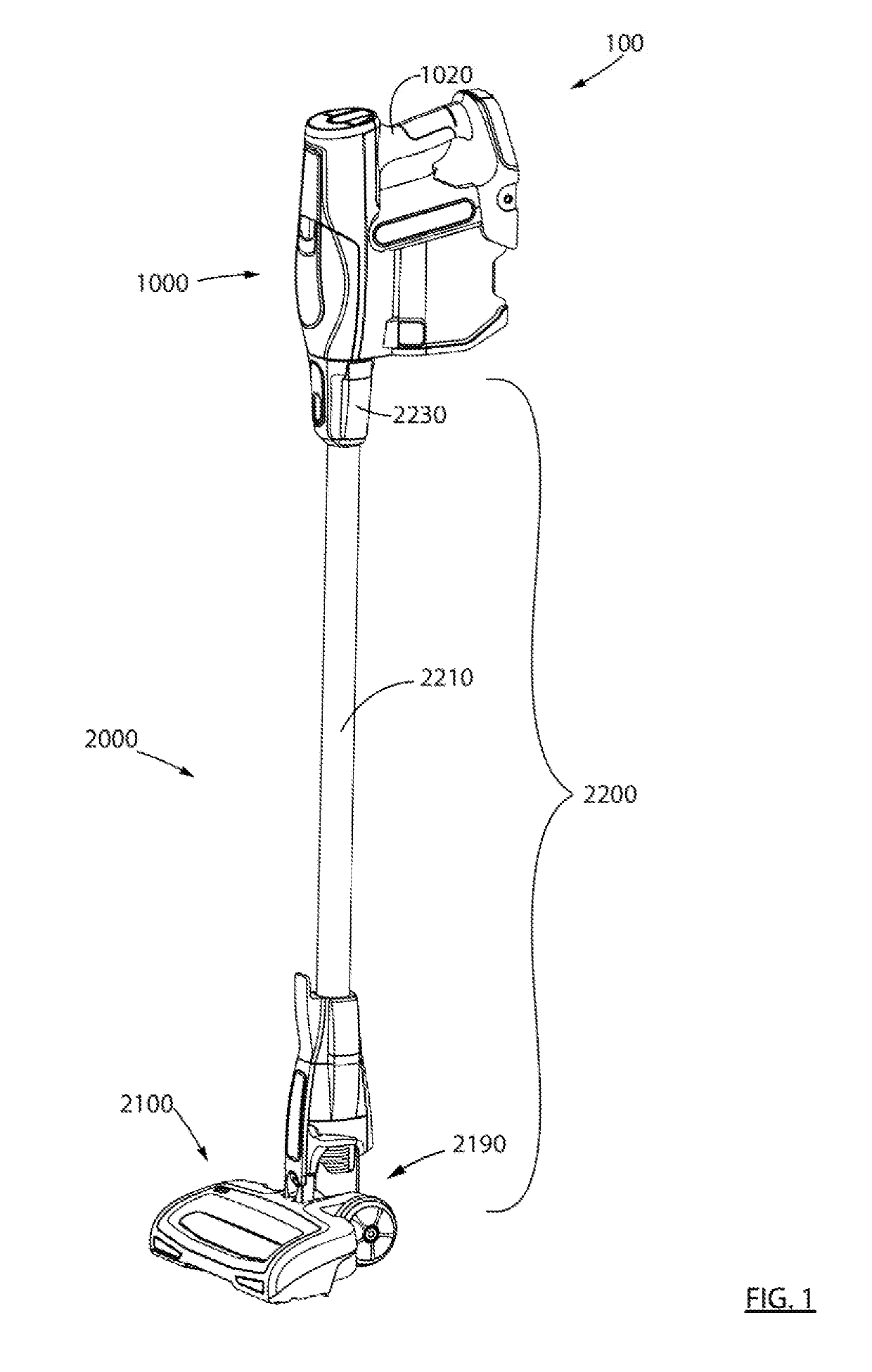

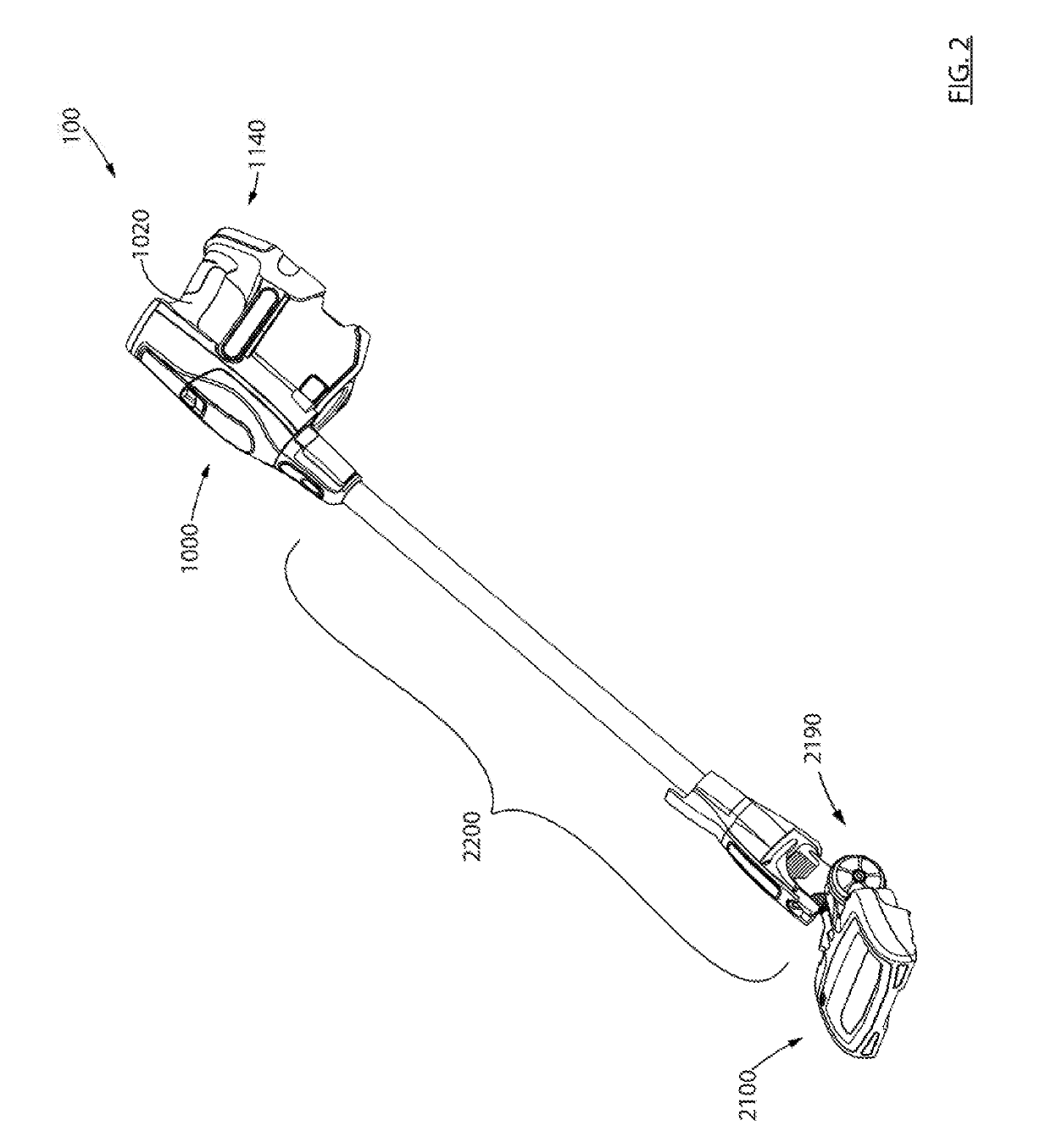

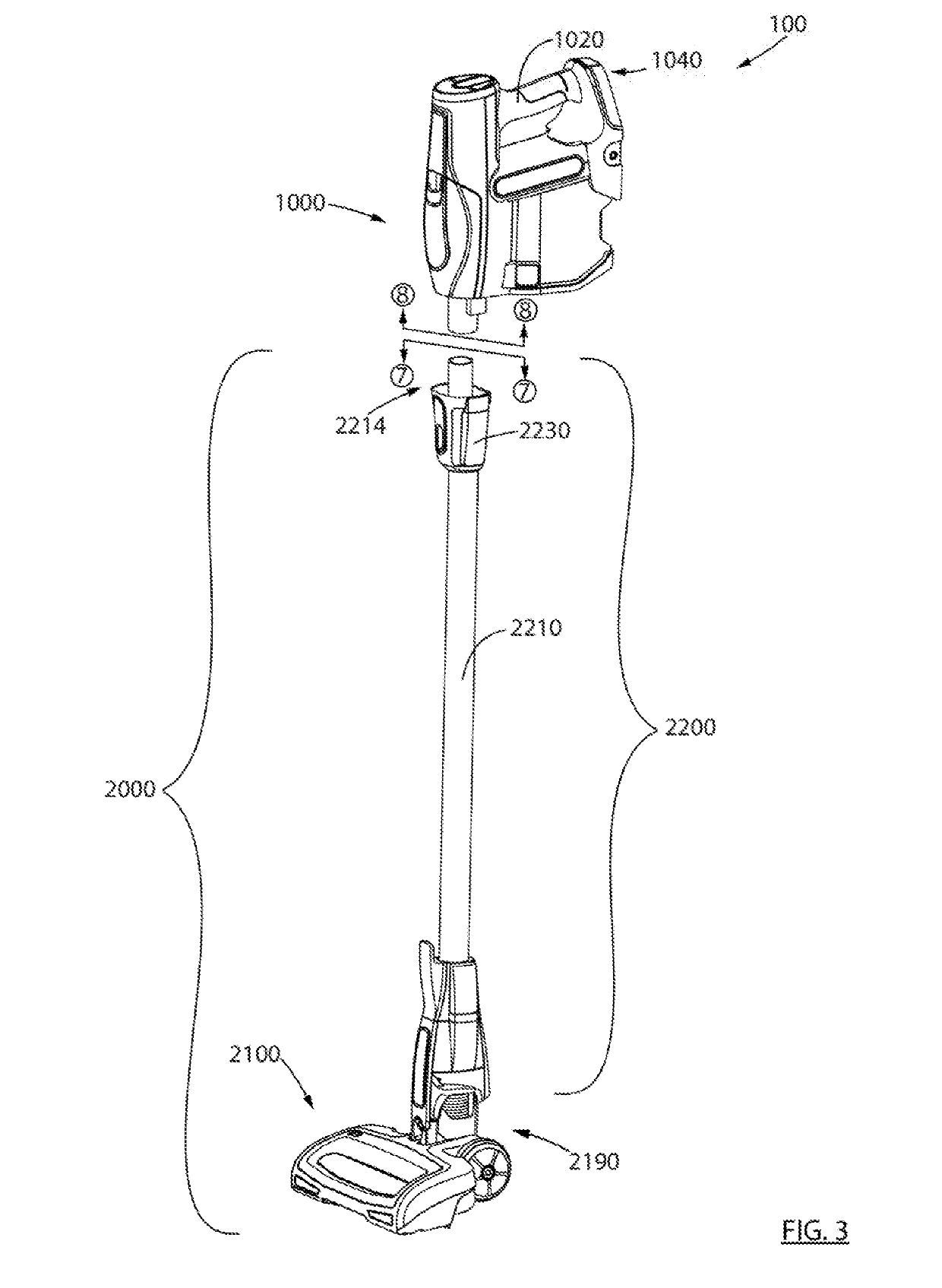

Surface cleaning apparatus

A reconfigurable surface cleaning apparatus includes a floor cleaning unit comprising a surface cleaning head, and a portable cleaning unit comprising an energy storage member and an inverted cyclone. The reconfigurable surface cleaning apparatus is operable in an above floor cleaning mode in which the portable cleaning unit is removed from the floor cleaning unit and in a floor cleaning mode in which the portable cleaning unit is mounted to the floor cleaning unit. In the floor cleaning mode. In the floor cleaning mode, the cyclone air inlet is located up to 20 inches above the floor.

Owner:OMACHRON INTPROP

Tetrafluoroethylene/hexafluoropropylene copolymers with higher drawability

A tetrafluoroethylene / hexafluoropropylene copolymer with high drawability is provided. Also provided is a process employing the polymer and an article coated with the polymer.

Owner:3M INNOVATIVE PROPERTIES CO

Surface cleaning apparatus with a variable inlet flow area

A reconfigurable surface cleaning apparatus includes a floor cleaning unit comprising a surface cleaning head, and a portable cleaning unit. The reconfigurable surface cleaning apparatus is operable in an above floor cleaning mode in which the portable cleaning unit is removed from the floor cleaning unit and in a floor cleaning mode in which an upflow duct is received in the portable cleaning unit and defines the air flow passage upwardly through the portable cleaning unit to a cyclone chamber air inlet.

Owner:OMACHRON INTPROP

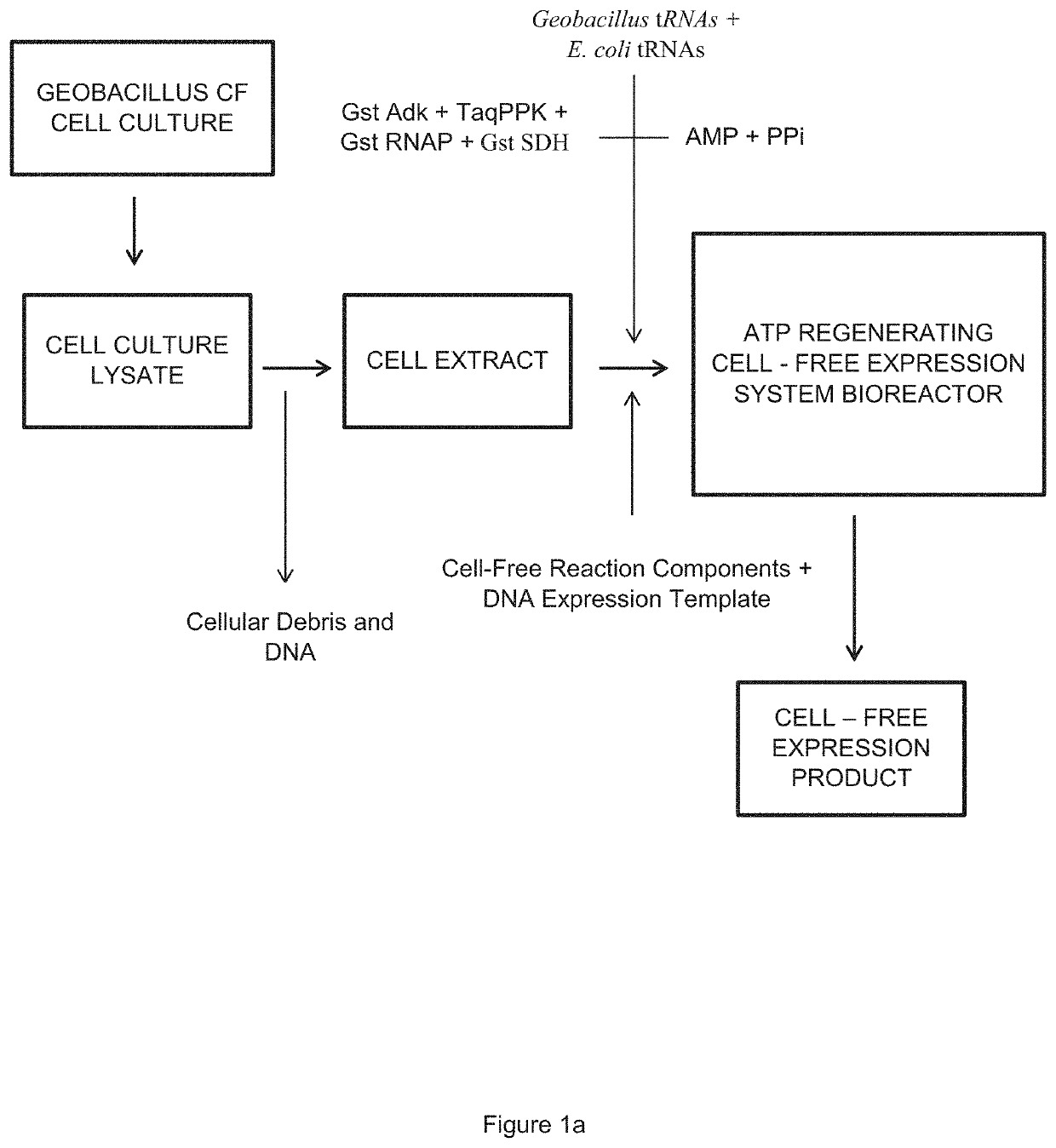

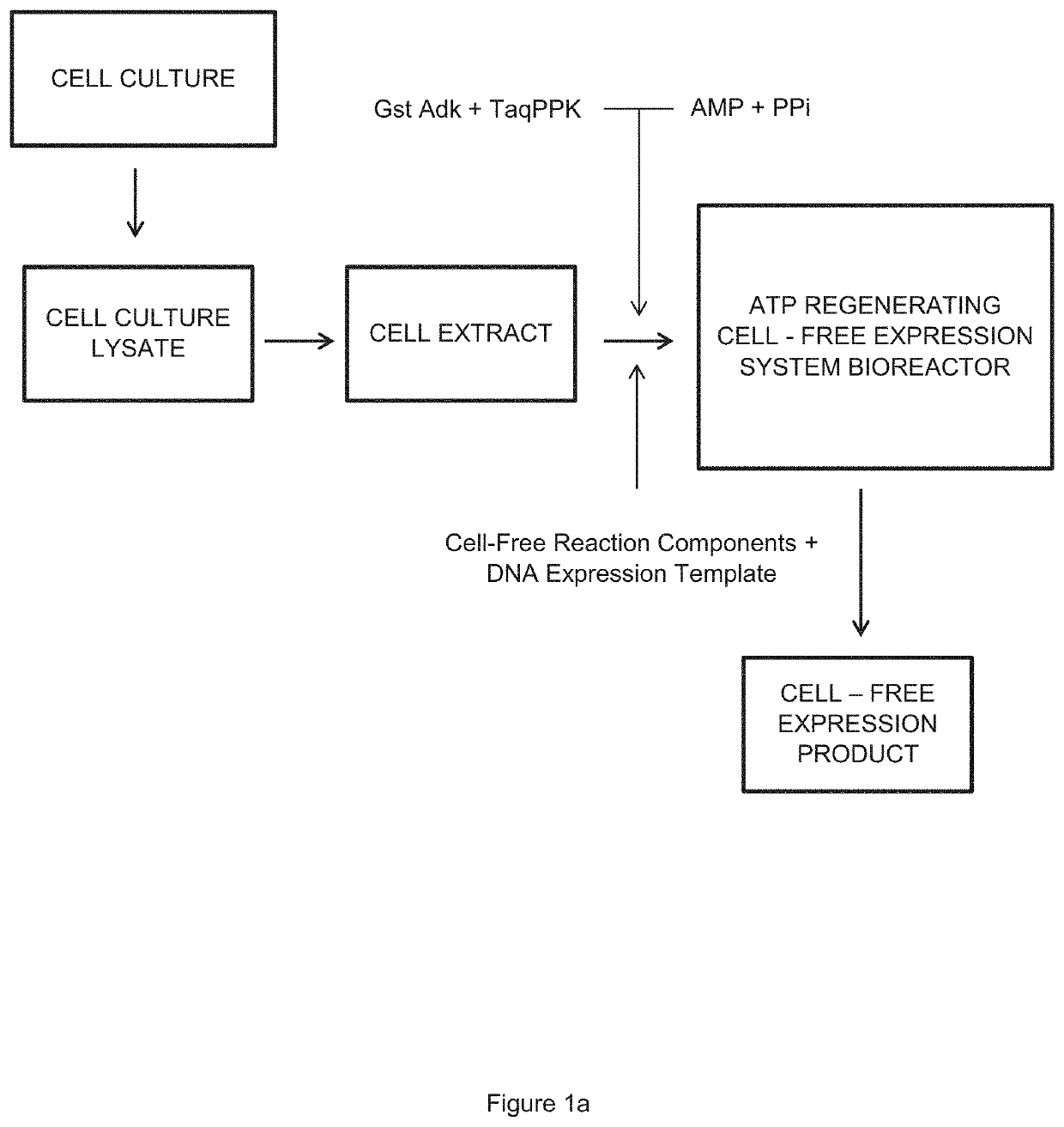

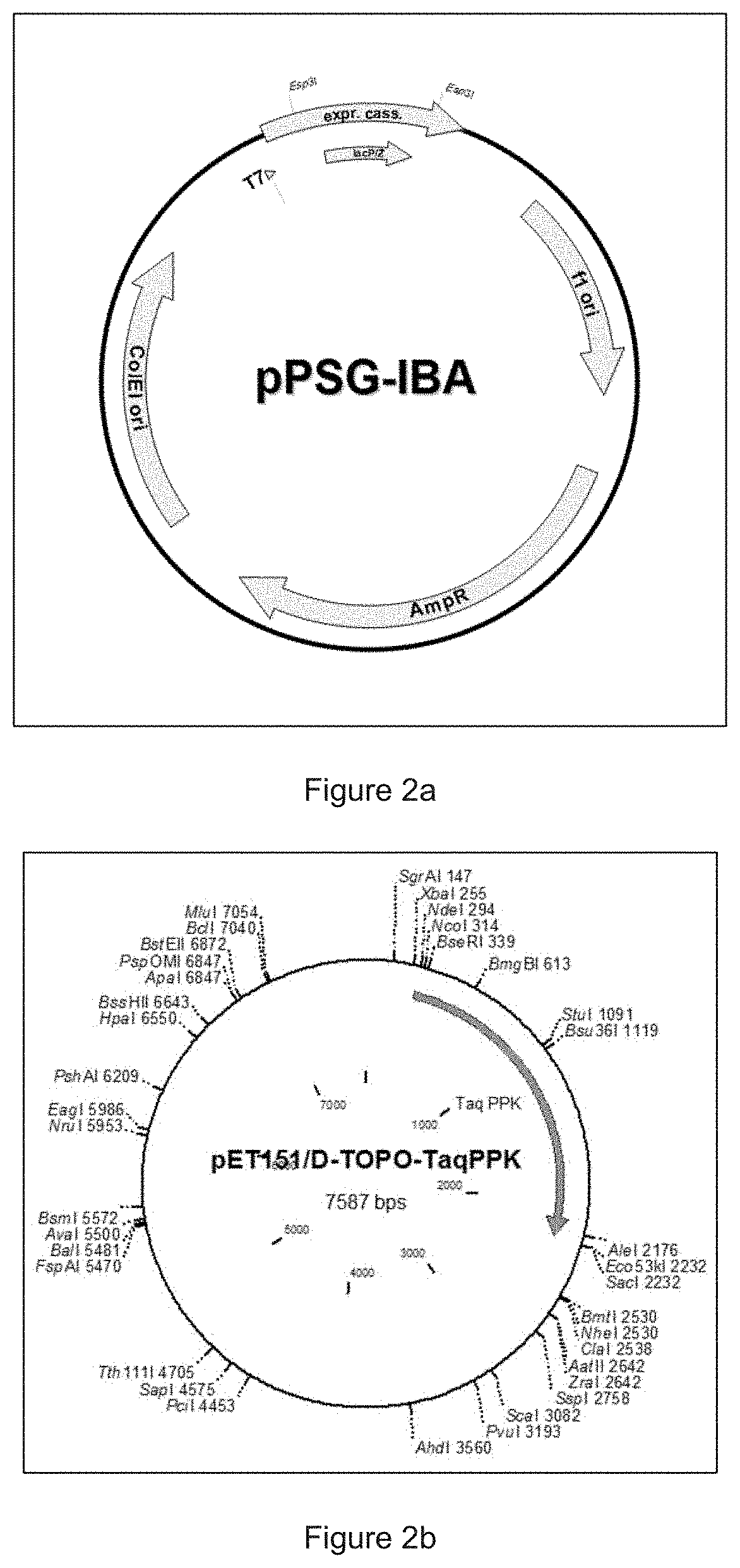

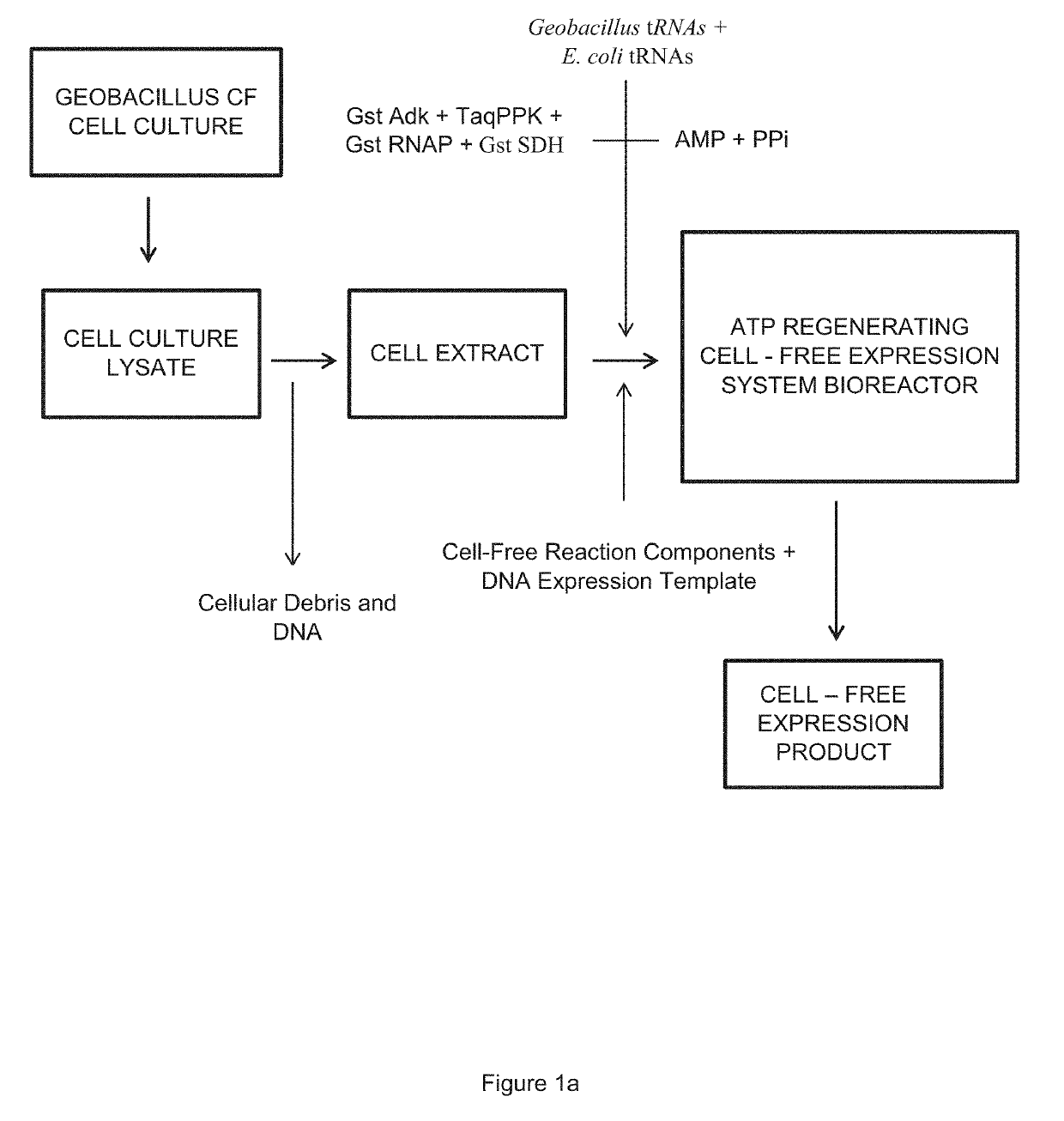

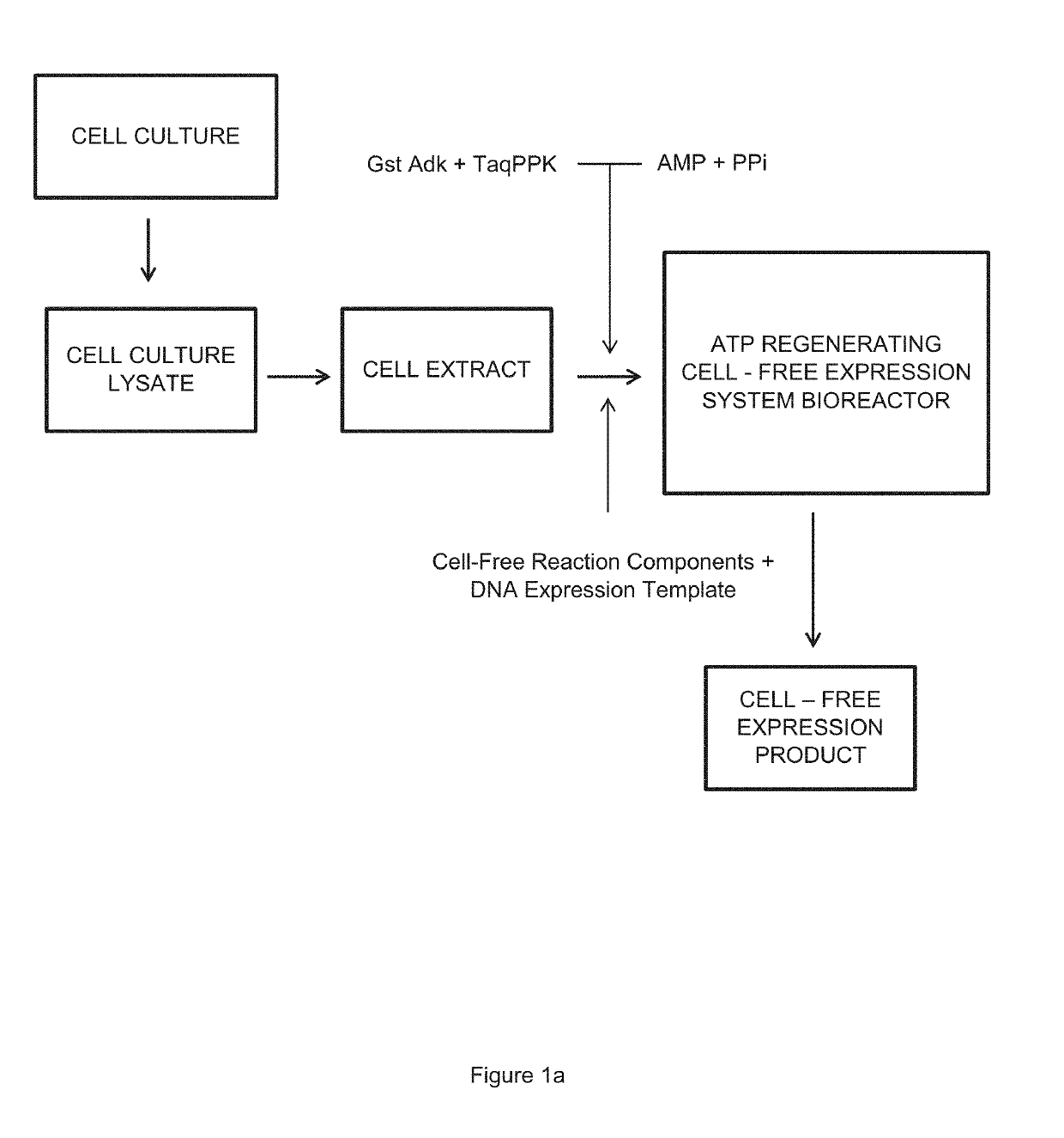

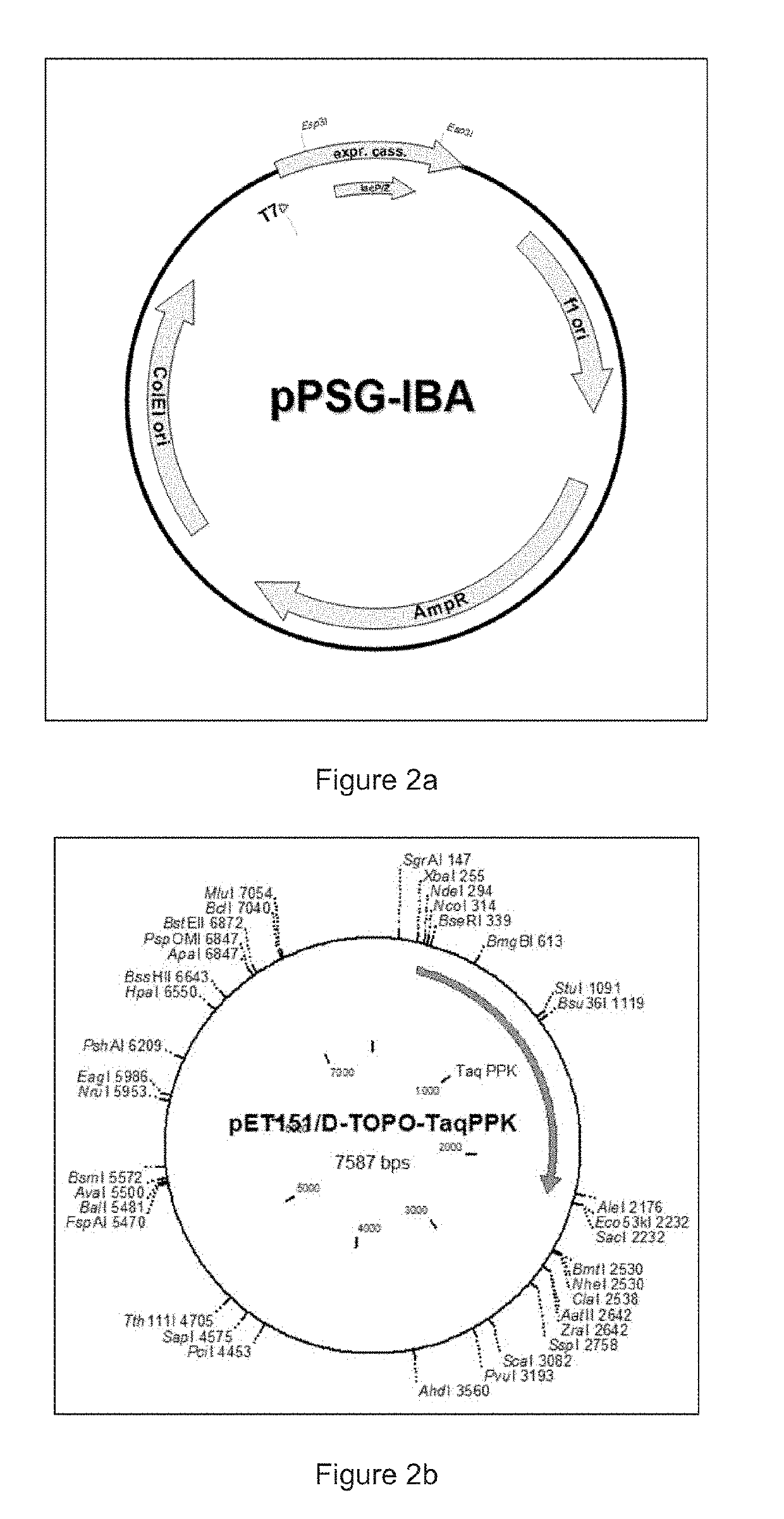

Cell-Free Expression System Having Novel Inorganic Polyphosphate-Based Energy Regeneration

PendingUS20210024912A1Long reaction timeImprove reaction efficiencyTransferasesOxidoreductasesCell freeEnzyme system

The invention relates to an in vitro cell-free expression system incorporating a novel inorganic polyphosphate-based energy regeneration system. In certain embodiments, the invention includes a cell-free expression system where the cellular energy source, ATP, is regenerated from inorganic polyphosphate using a dual enzyme system. In this embodiment, this dual enzyme system may include thermostable Adenosyl Kinase, and / or Polyphosphate Kinase enzymes.

Owner:NATURES TOOLBOX INC

Cell-Free Expression System Having Novel Inorganic Polyphosphate-Based Energy Regeneration

ActiveUS20190309311A1Long reaction timeImprove reaction efficiencyBacteriaHydrolasesCell freeEnzyme system

The invention relates to an in vitro cell-free expression system incorporating a novel inorganic polyphosphate-based energy regeneration system. In certain embodiments, the invention includes a cell-free expression system where the cellular energy source, ATP, is regenerated from inorganic polyphosphate using a dual enzyme system. In this embodiment, this dual enzyme system may include thermostable Adenosyl Kinase, and / or Polyphosphate Kinase enzymes.

Owner:NATURES TOOLBOX INC

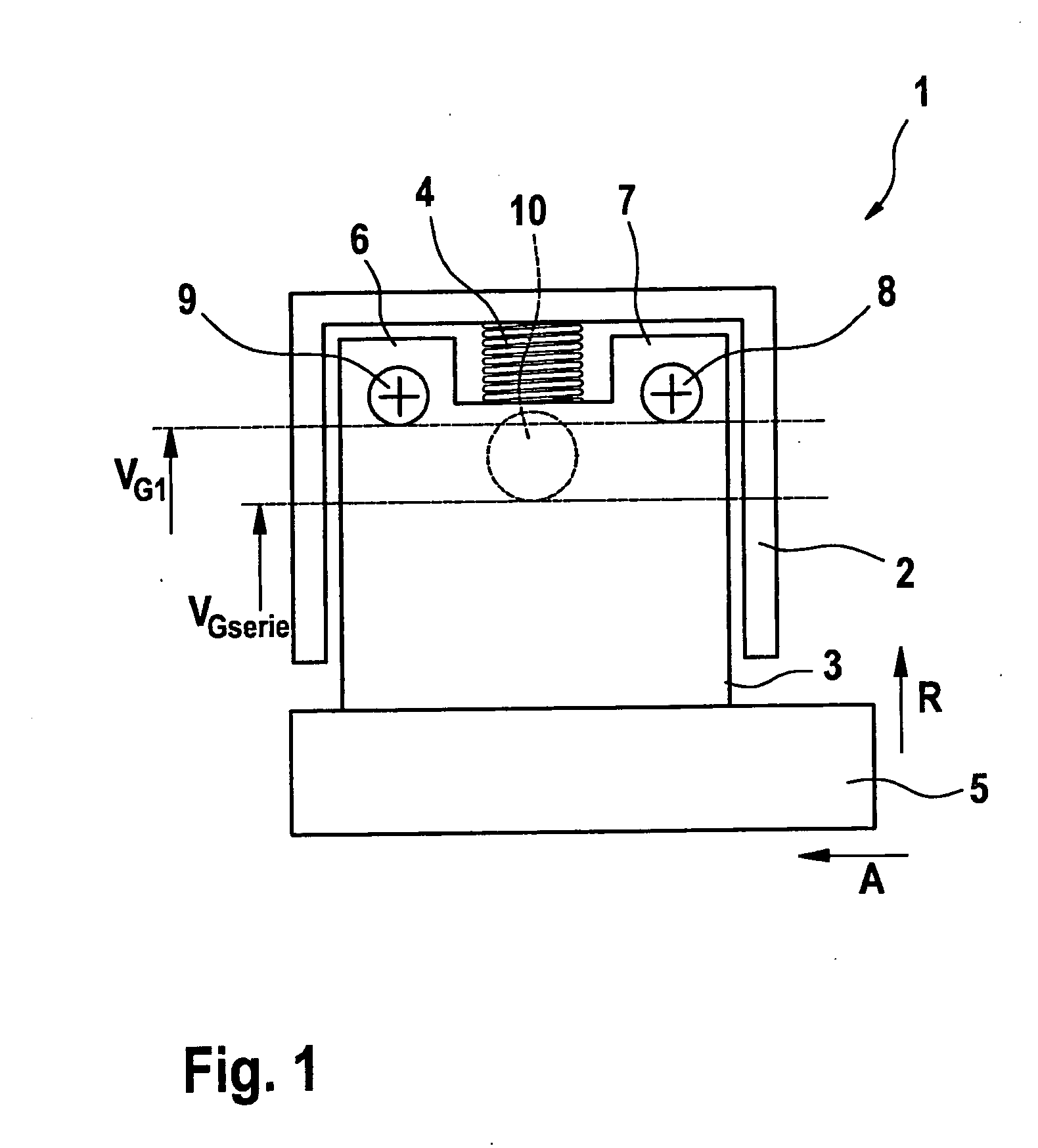

Brush device having a litz wire for an electric machine

InactiveUS20120025666A1Increase the number ofLong run timeRotary current collectorSupports/enclosures/casingsLitz wireElectric machine

A brush device for an electric machine is described, having a brush mount that has a brush which is accommodated in it and having a first integrated litz wire, having a first spring, which prestresses the brush against a commutator. In order to create an E machine having an improved service life, at least one second litz wire is developed integrated into the brush.

Owner:ROBERT BOSCH GMBH

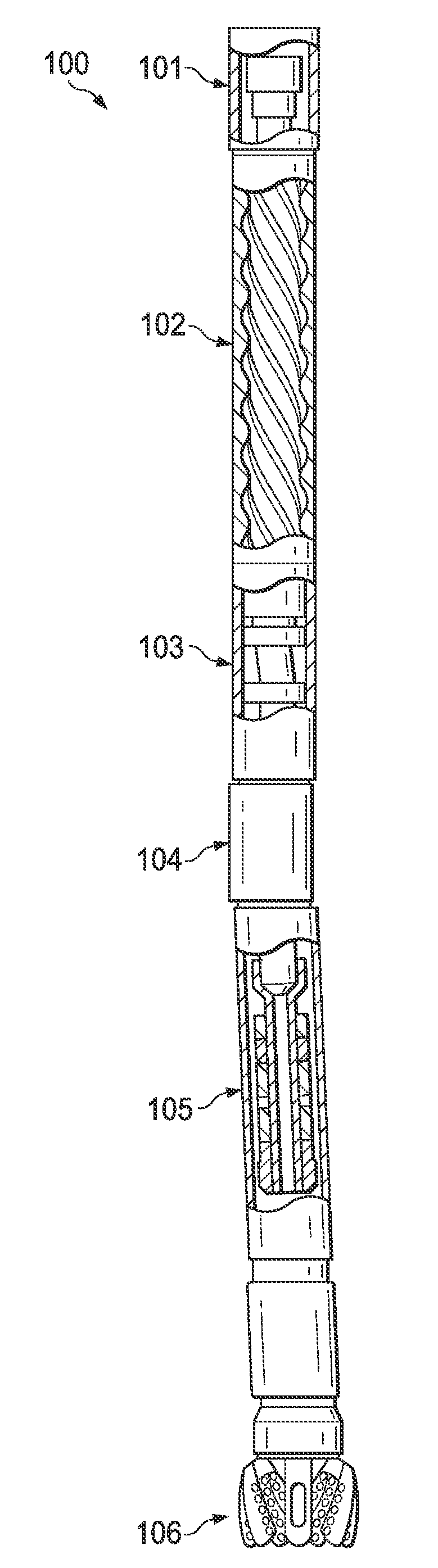

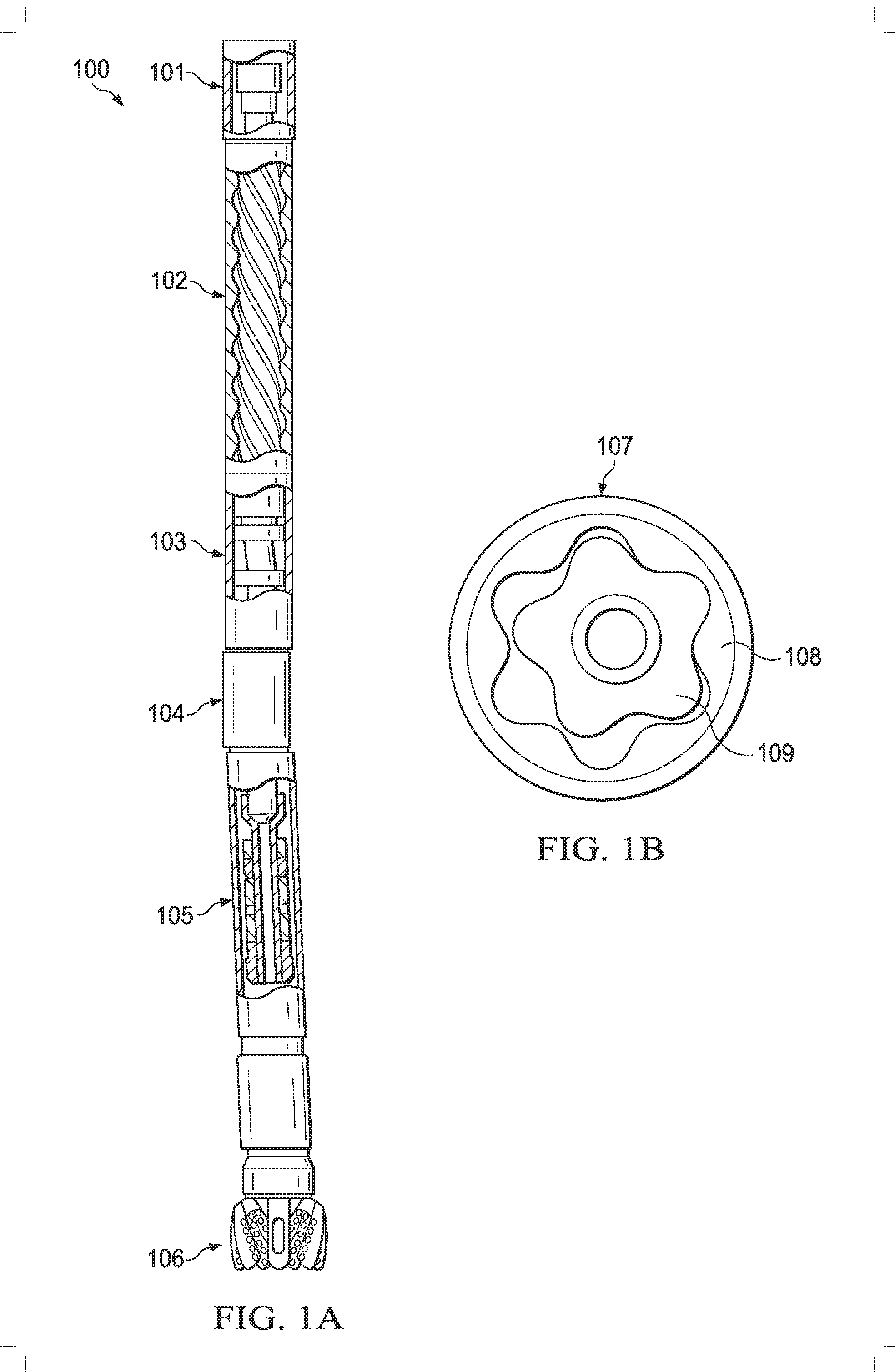

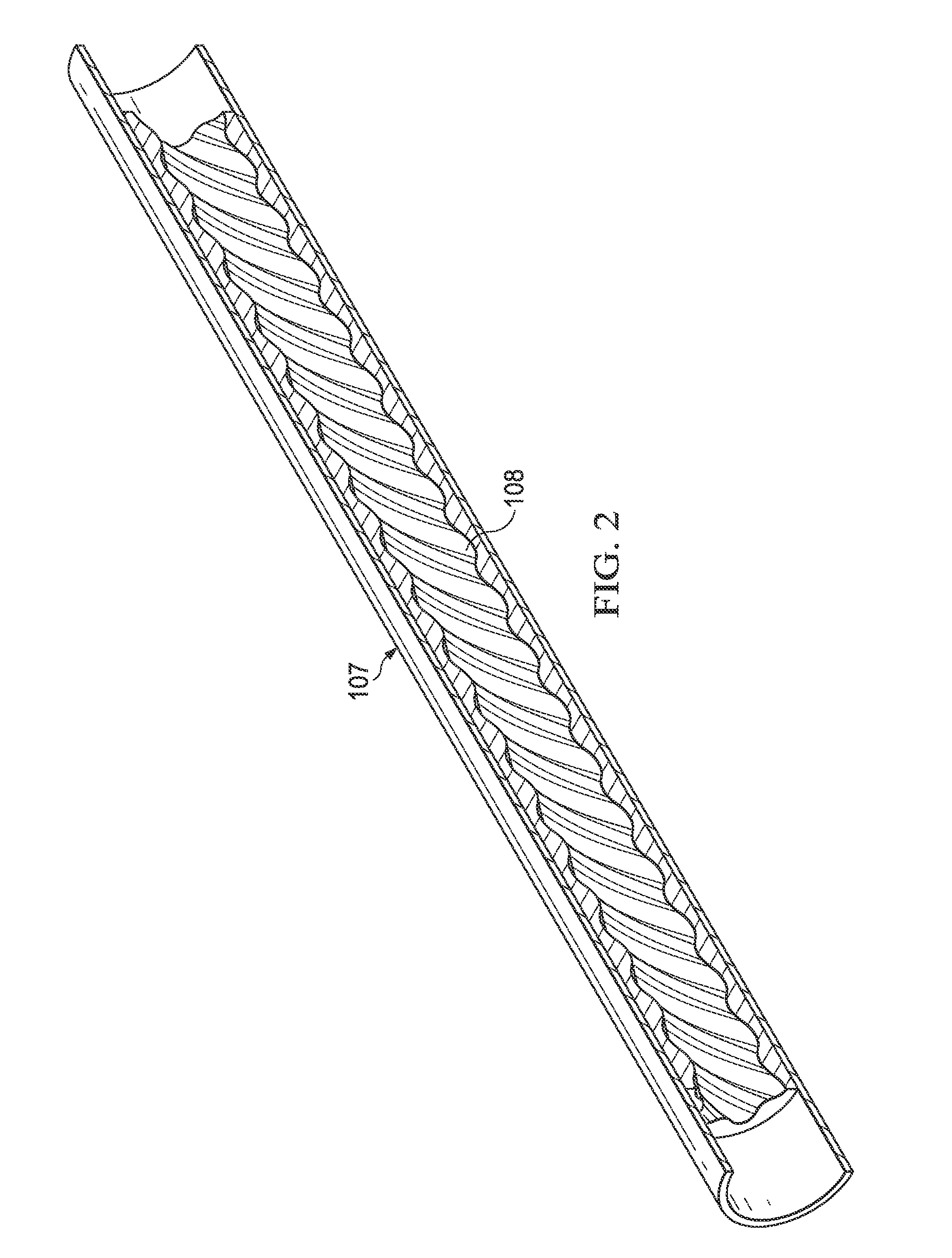

Stator compound having an nbir terpolymer elastomeric base and stators and downhole motors using the same

A stator compound including an acrylonitrile butadiene isoprene rubber (NBIR) terpolymer elastomeric base.

Owner:ABACO DRILLING TECH LLC

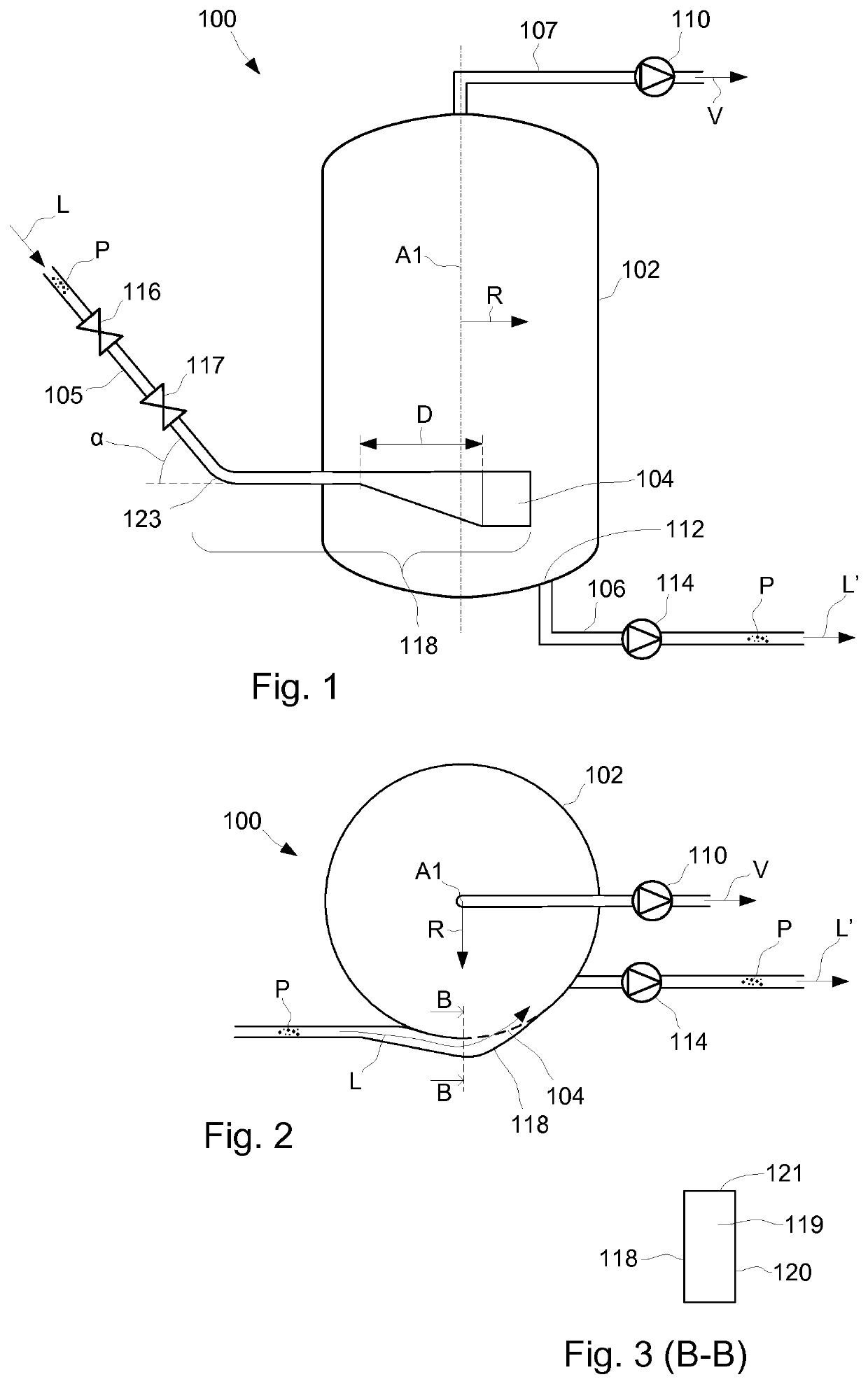

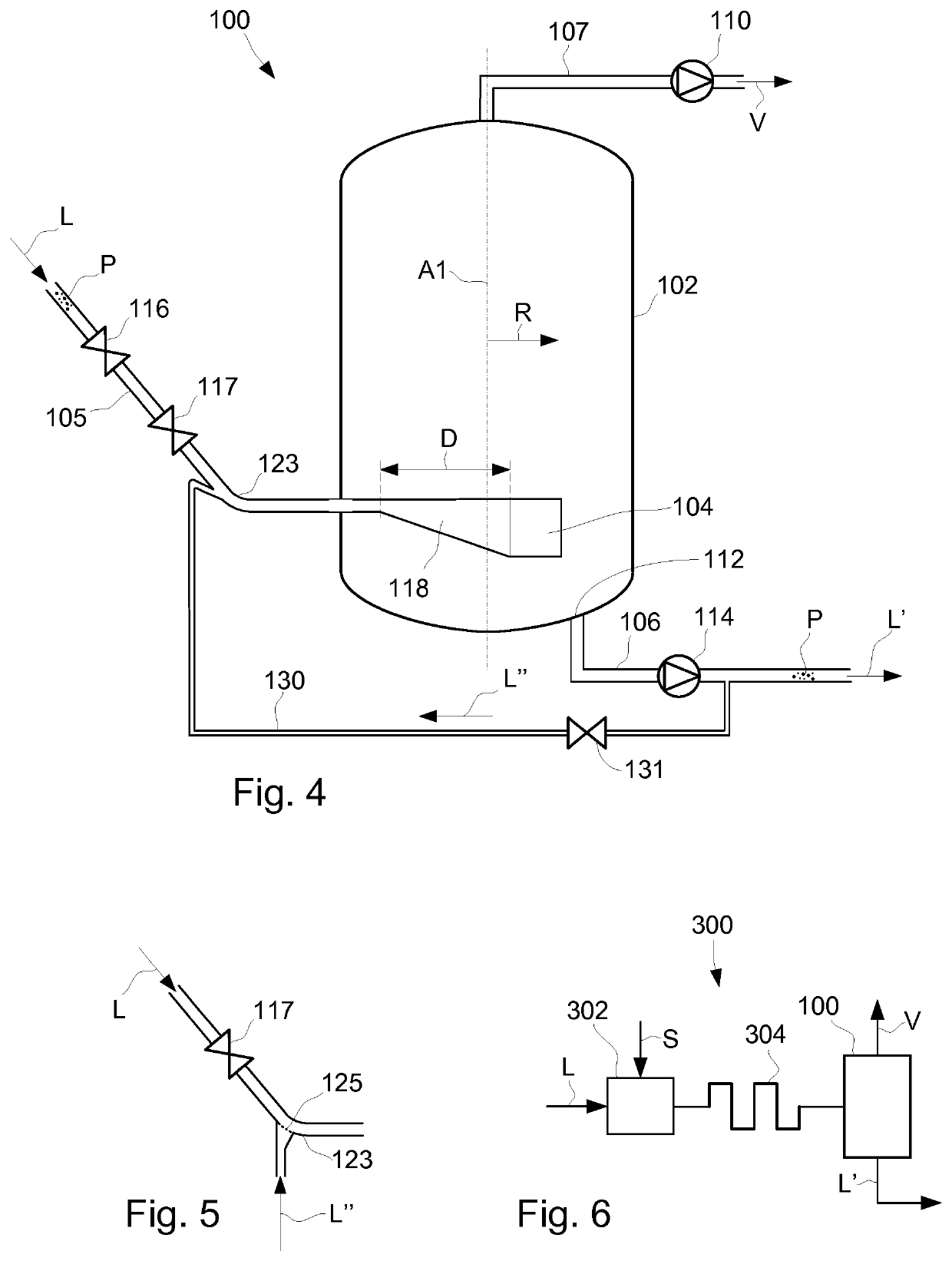

Flash boiling apparatus

ActiveUS20200008450A1Long run timeKeep for a long timeMilk preservationFood preservationLiquid foodRelief valve

A flash boiling apparatus for a liquid food product that includes particles, the apparatus including a vacuum vessel provided with a product inlet and a product outlet for liquid food product, a pressure relief valve arranged upstream the product inlet for providing a pressure drop that results in flash boiling of the liquid food product, and an inlet section arranged between the pressure relief valve and the product inlet, for conveying the liquid food product from the pressure relief valve to the product inlet. The inlet section includes a through-flow area that increases in a direction from the pressure relief valve to the product inlet, such that a flow velocity of the liquid food product decreases when it passes the inlet section.

Owner:TETRA LAVAL HLDG & FINANCE SA

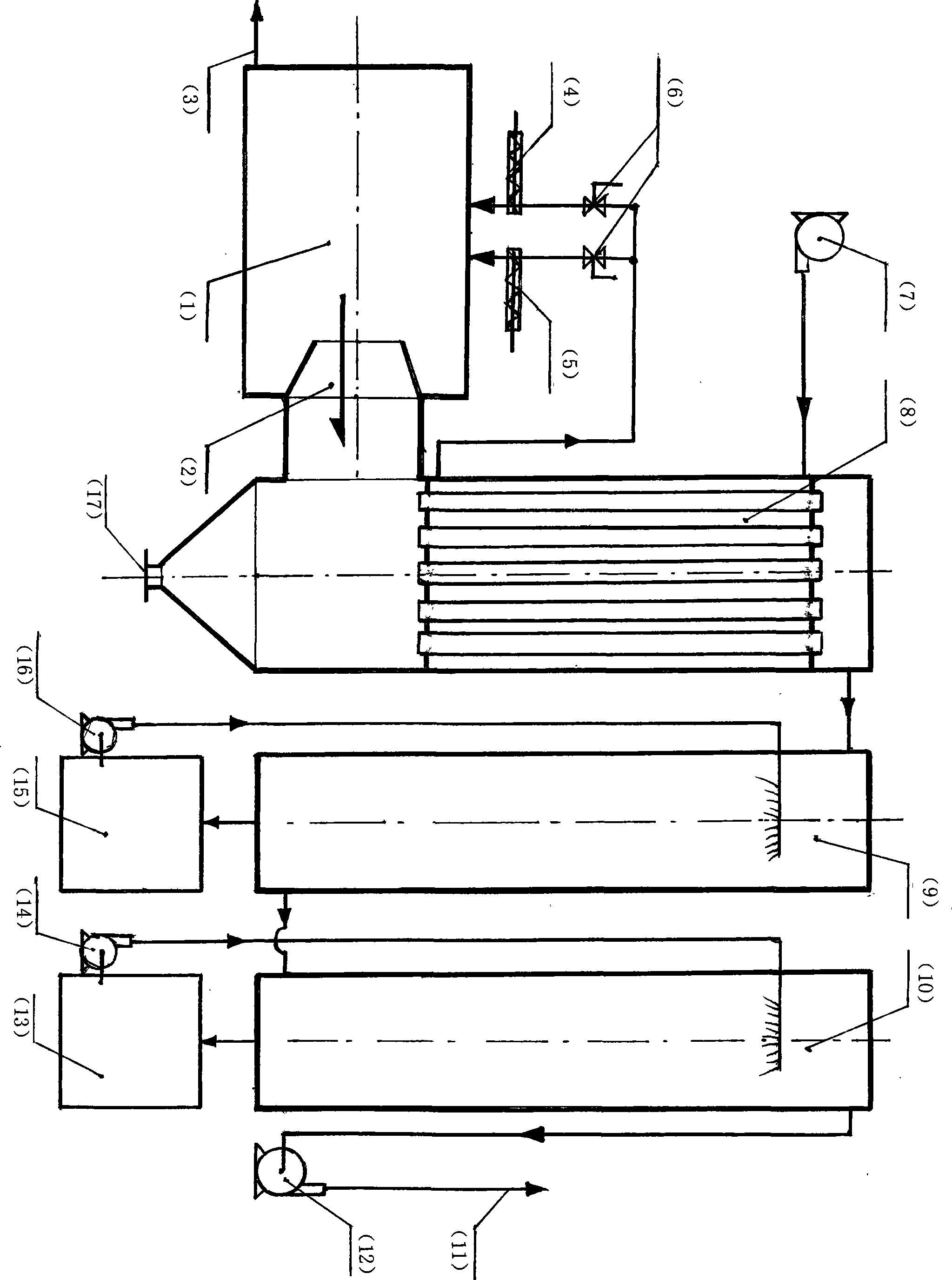

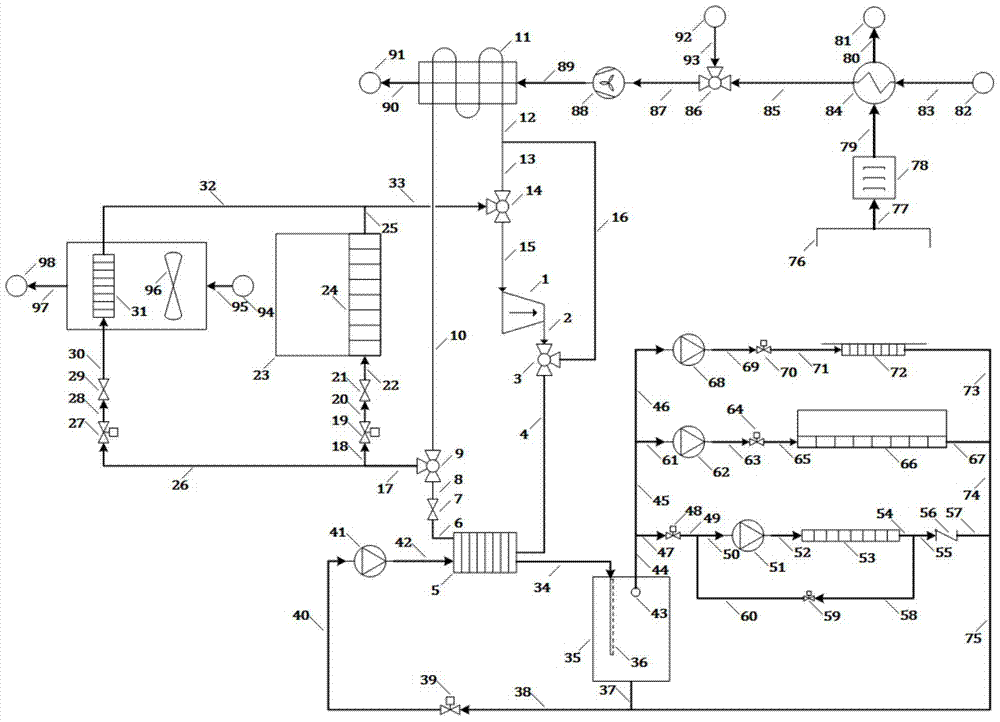

A Central Cooling and Heating System for Canteens Based on Vapor Compression Heat Pump Technology

InactiveCN104930745BDecrease productivityMeet heating needsClimate change adaptationCompression machines with several evaporatorsThermal energyPlate heat exchanger

The invention relates to a centralized cooling and heating system for canteens based on vapor compression heat pump technology, which mainly includes compressors, outdoor heat exchangers, indoor condensers, canteen heating equipment, canteen cooling equipment, oil fume purifiers, casing type Heat exchangers, evaporators in refrigerators, evaporators in air conditioners, etc. Compared with the prior art, the present invention can significantly increase the heat production of the system and meet the heating demand of the canteen in winter. In winter, the central heating system is adopted, and the vapor compression heat pump technology is used to recover the waste heat from kitchen exhaust, which greatly improves the heating efficiency. At the same time, the capillary heat exchanger is used to improve the heat utilization efficiency of the terminal. In summer, a central cooling system is adopted to meet the cooling demand of the canteen and avoid heat dissipation from the refrigerator in the storage room to the room. The system has high efficiency, remarkable energy-saving effect, and fully considers the heating and cooling requirements of the cafeteria. It has many functions, flexible configuration, and strong practicability.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com