Patents

Literature

35results about How to "Long reaction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

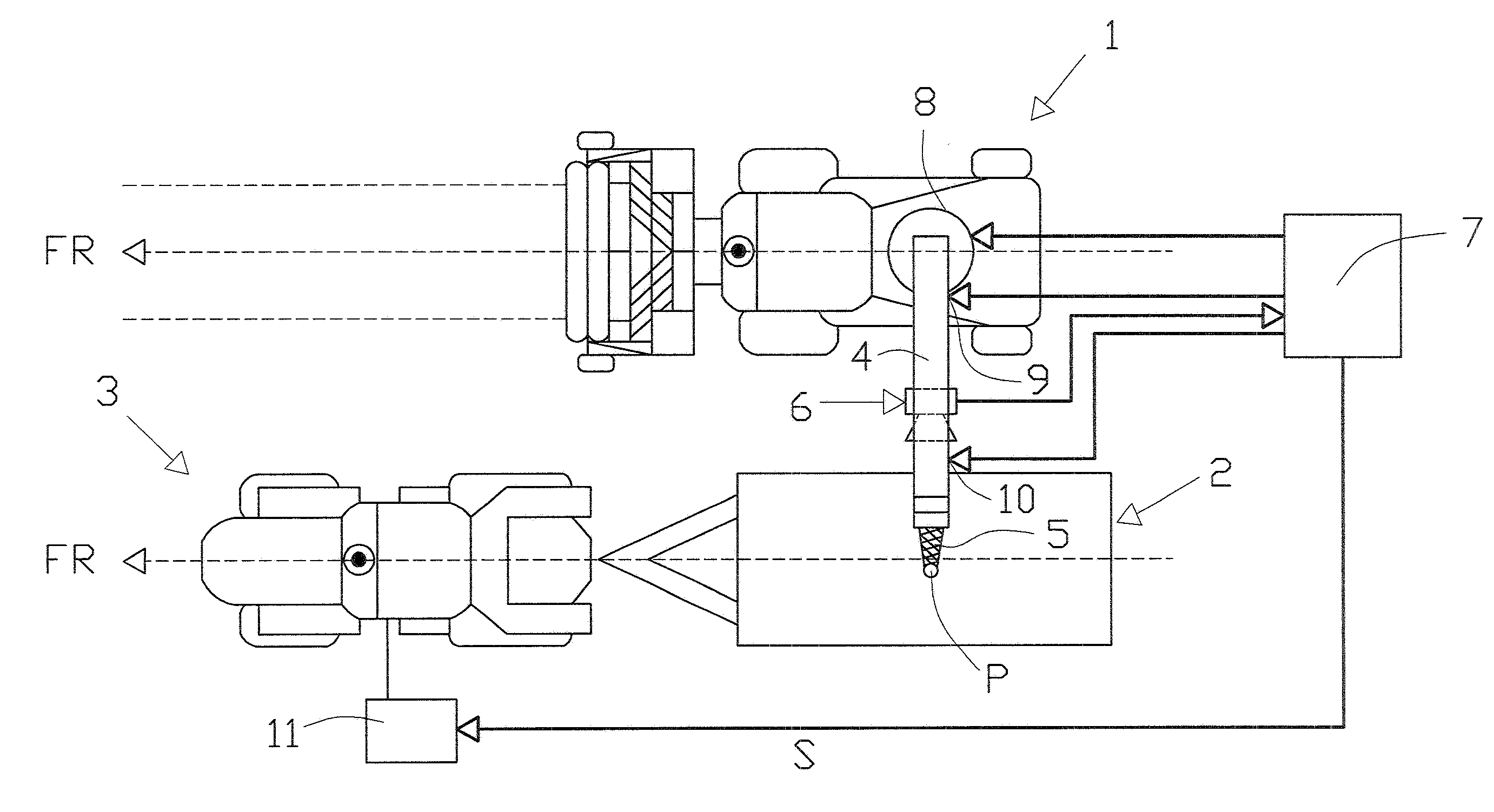

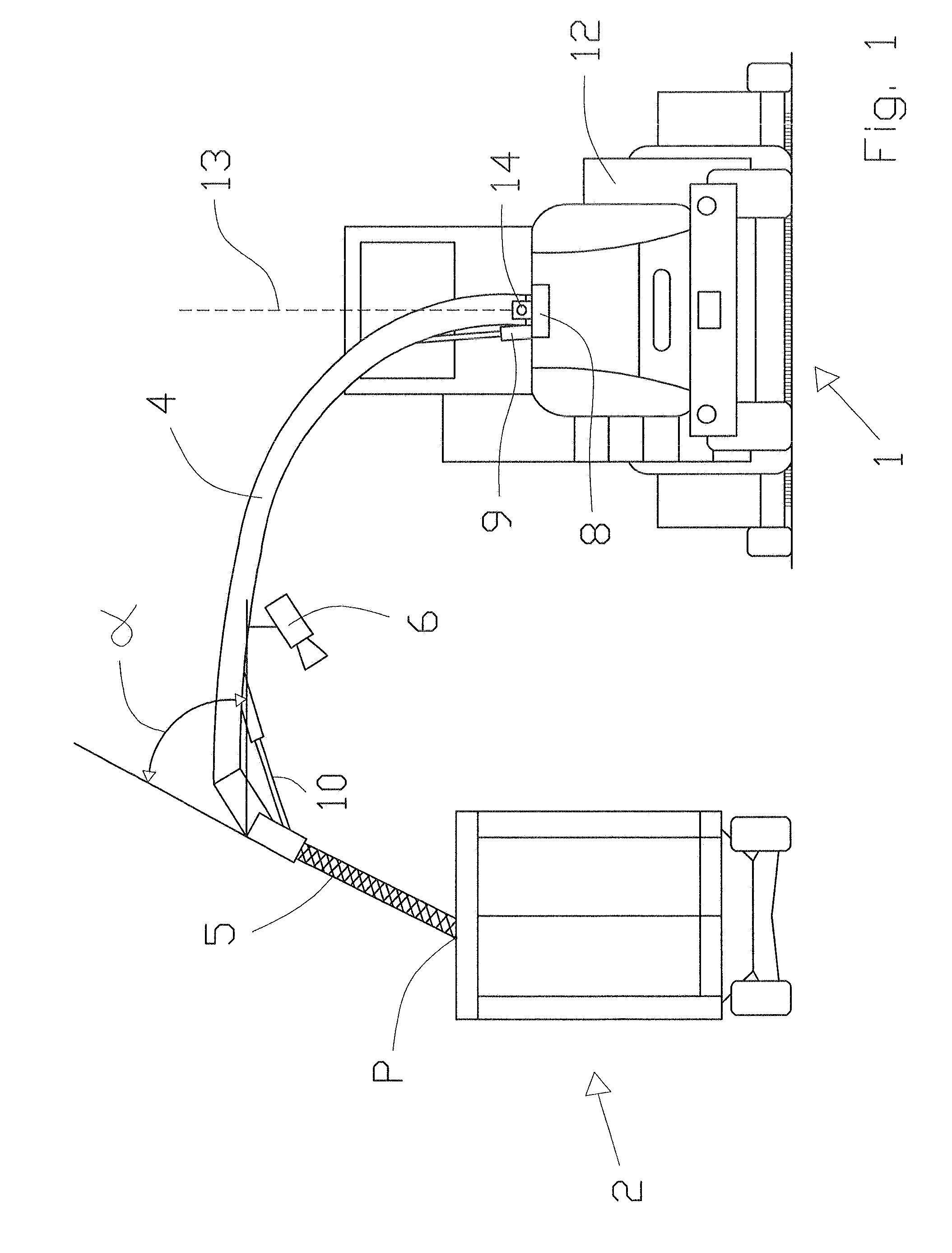

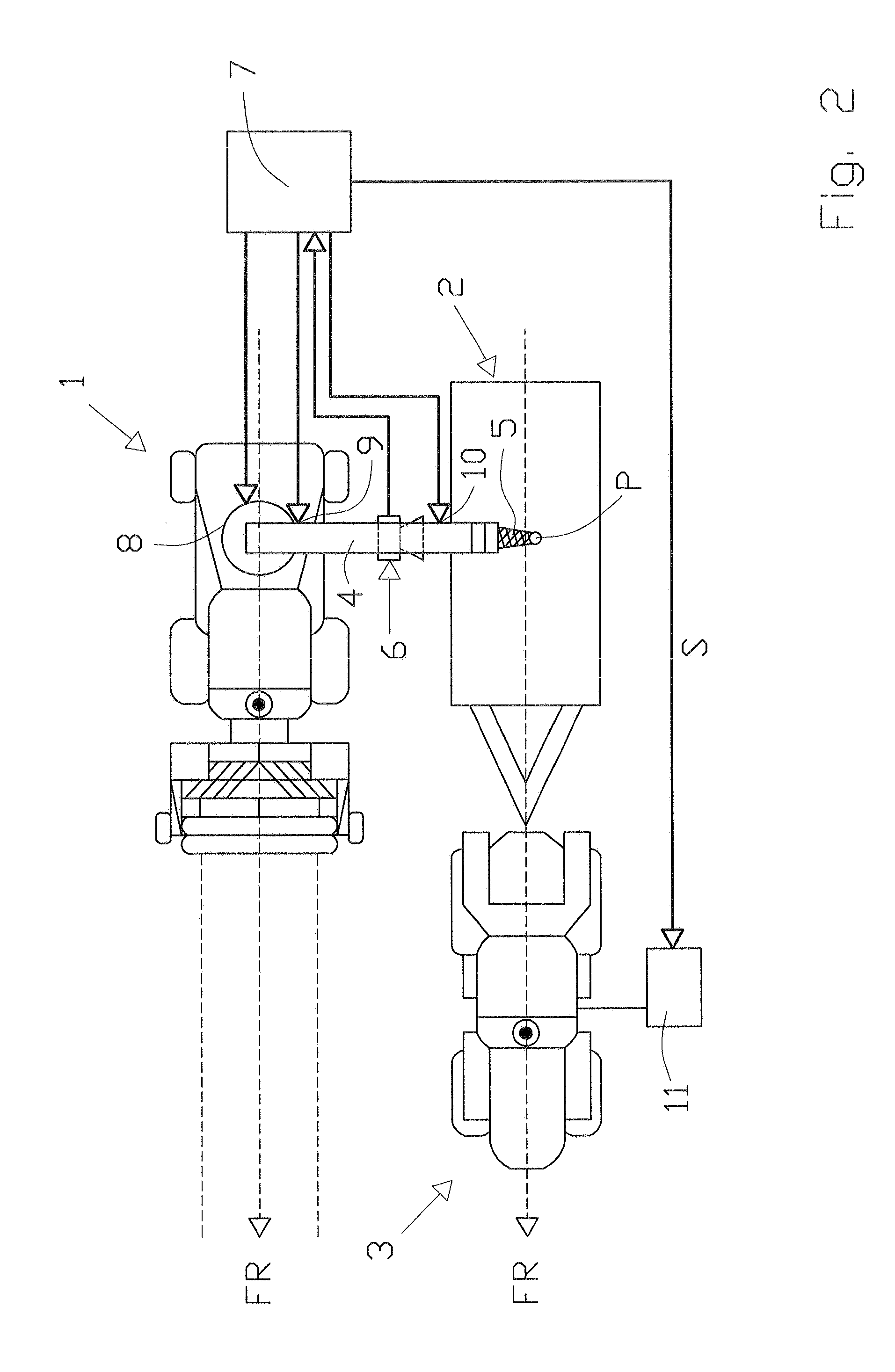

System and method for controlling crop transfer

InactiveUS20120263560A1Good reliefFast influenceMowersStorage devicesAgricultural scienceControl signal

A system for controlling crop transfer from a self-propelled agricultural harvesting machine into the loading container of a hauling vehicle includes a transfer device assigned to the harvesting machine from which the crop emerges in the form of a crop discharge flow and a detection device which detects the position of the loading container relative to the harvesting machine and transmits it to a control unit. The control unit actuates at least one actuator assigned to the transfer device in such a way that the crop discharge flow lands within the loading container in order to fill it with crop. The control unit generates a control signal (S) for the hauling vehicle that specifies a position of the hauling vehicle relative to the harvesting machine that is suitable for transfer into the loading container.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

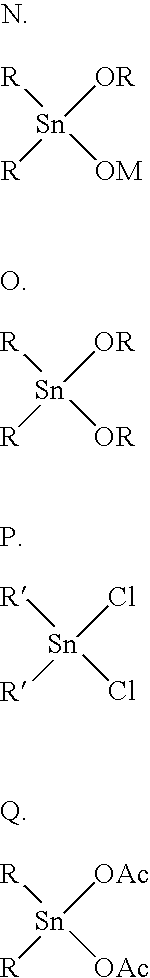

Certain polyester compositions which comprise cyclohexanedimethanol, moderate cyclobutanediol, cyclohexanedimethanol, and high trans cyclohexanedicarboxylic acid

InactiveUS20070232779A1Good chemical resistanceLess reactiveSynthetic resin layered productsOptical articlesPolyesterCyclohexanedimethanol

Described as one aspect of the invention are polyester compositions A polyester composition comprising at least one polyester which comprises:(A) a dicarboxylic acid component comprising:i) 70 to 100 mole % of cyclohexanedicarboxylic acid residues or an ester thereof comprising:(a) 80 to 99 mole % trans-cyclohexanedicarboxylic acid residues or an ester thereof; and(b) 1 to 20 mole % cis-cyclohexanedicarboxylic acid residues or an ester thereof;ii) 0 to 30 mole % of aliphatic dicarboxylic acid residues, other than cyclohexanedicarboxylic acid residues, having up to 16 carbon atoms or esters thereof, other than cyclohexanedicarboxylic acid residues; andiii) 0 to 10 mole % of aromatic dicarboxylic acid residues having up to 20 carbon atoms; and(B) a glycol component comprising:i) 5 to 35 mole % of 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; andii) 65 to 95 mole % of 1,4-cyclohexanedimethanol residues, 1,3-cyclohexanedimethanol residues, 1,2-cyclohexanedimethanol residues or esters thereof or mixtures thereof,wherein the total mole % of said dicarboxylic acid component is equal to 100 mole %;the total mole % of said glycol component is equal to 100 mole %;wherein the inherent viscosity of said polyester is from 0.35 to 1.2 dL / g as determined in 60 / 40 (wt / wt) phenol / tetrachloroethane at a concentration of 0.5 g / 100 ml at 25° C.; and wherein said polyester has a Tg of from 66 to 120° C. The polyesters may be manufactured into articles.

Owner:EASTMAN CHEM CO

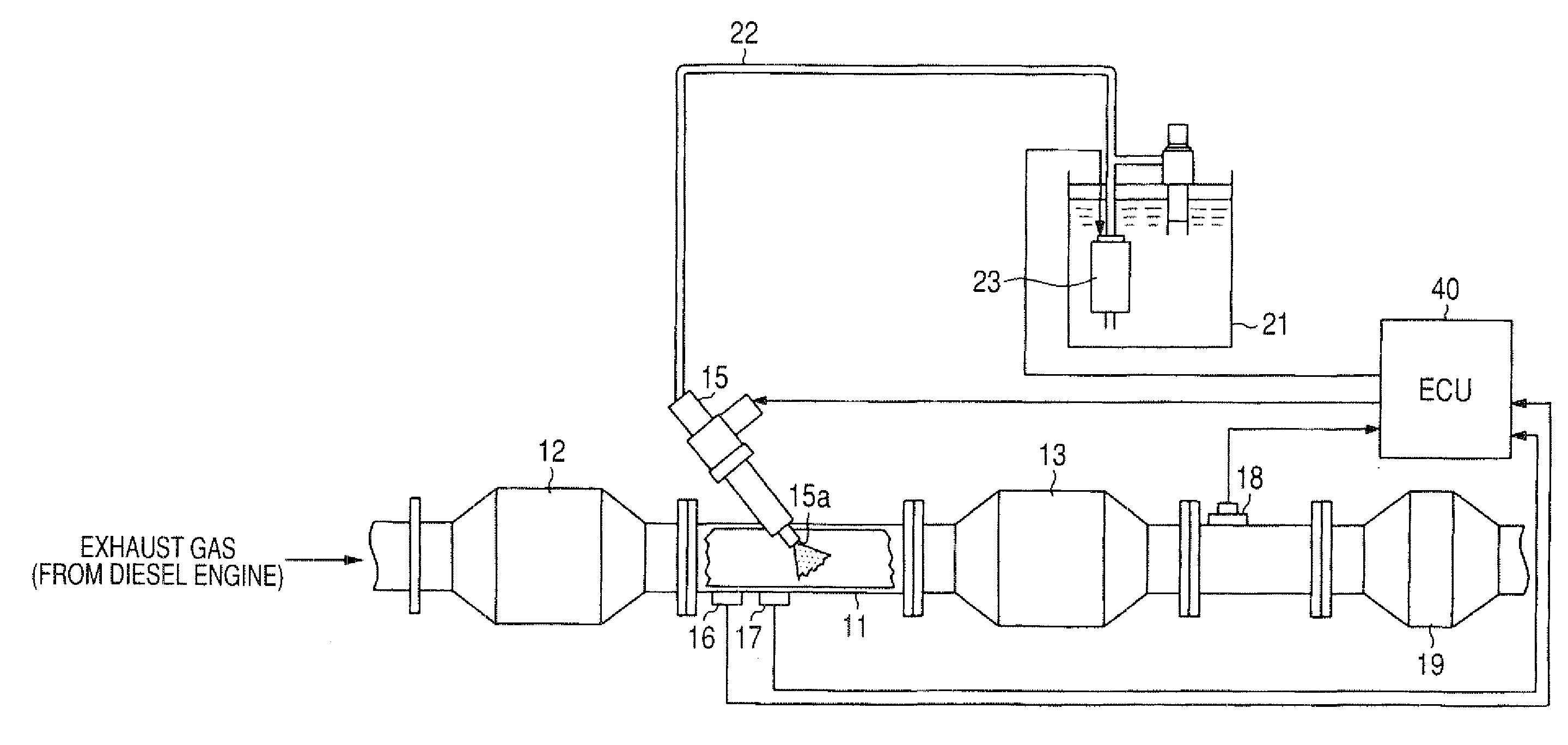

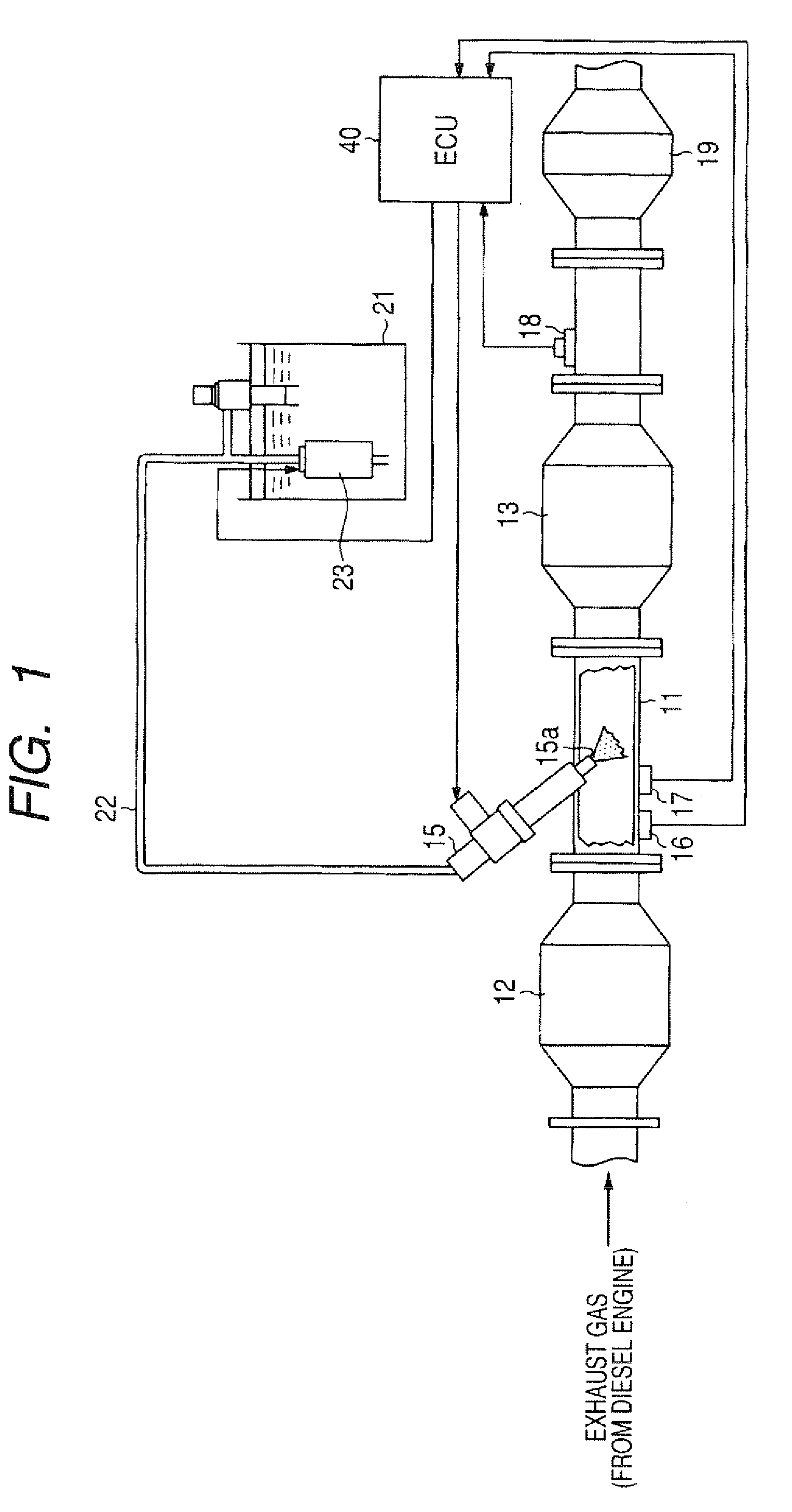

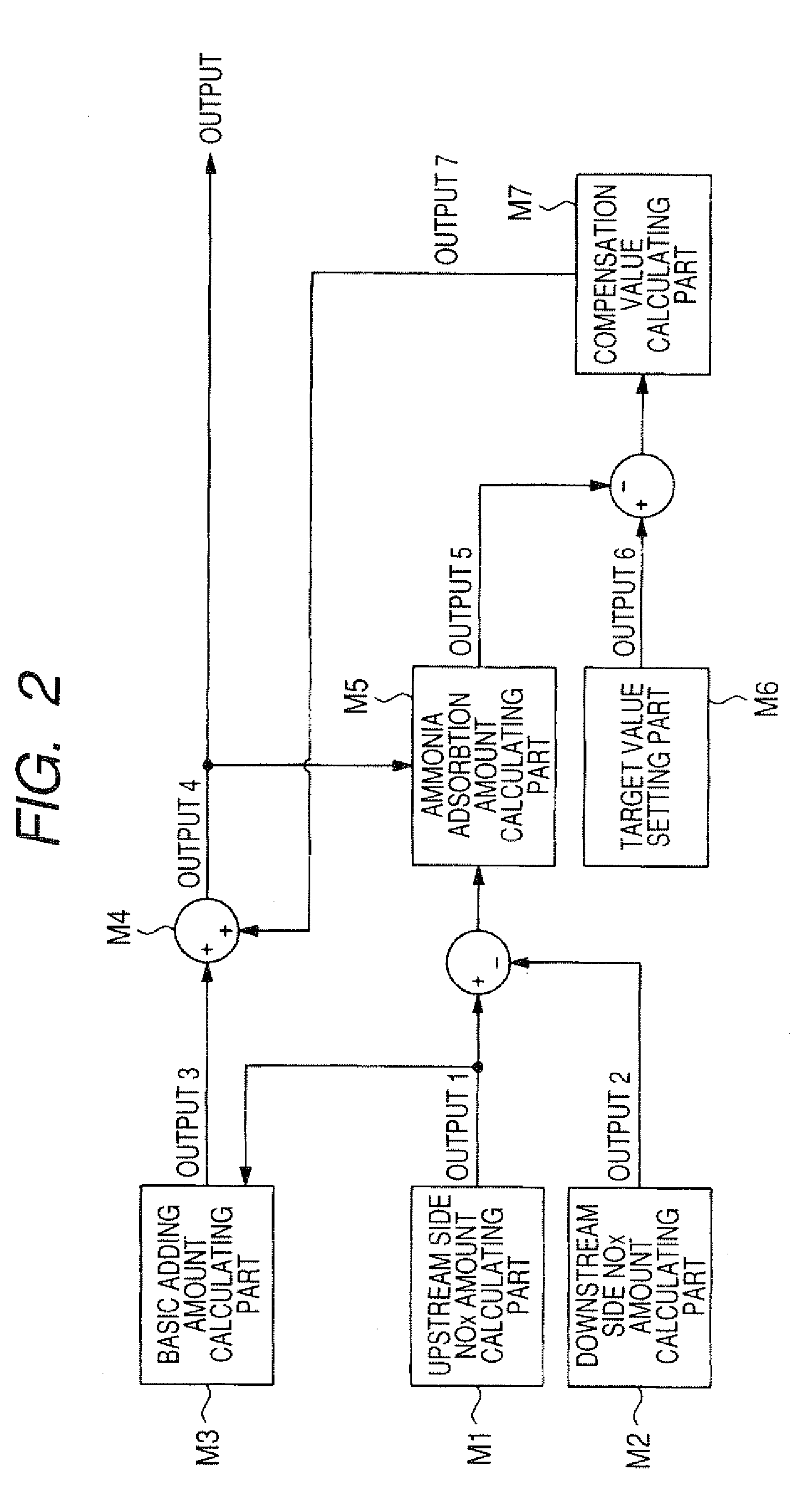

Exhaust gas purifying device for internal combustion engine

ActiveUS20100257844A1Long reaction timeLong response timeInternal combustion piston enginesExhaust apparatusExternal combustion engineExhaust fumes

An exhaust gas purifying system for a diesel engine has an ECU, a passage of exhaust gas, a unit having SCR catalyst, a NOx sensor placed at a downstream side of the unit, and a urea water adding valve placed at an upstream side of the unit. The SCR catalyst in the unit selectively adsorbs ammonia, and selectively purifies NOx contained in an exhaust gas emitted from the diesel engine by the adsorbed ammonia. The ECU changes the urea water adding amount, and performs abnormality diagnosis based on the detection result of the NOx sensor while changing an adding amount of the urea water. The ECU uses a first condition to indicate the presence of an excess NOx amount in the exhaust gas, and a second condition to indicate there is no error cause by the ammonia adsorption on the SCR catalyst.

Owner:DENSO CORP

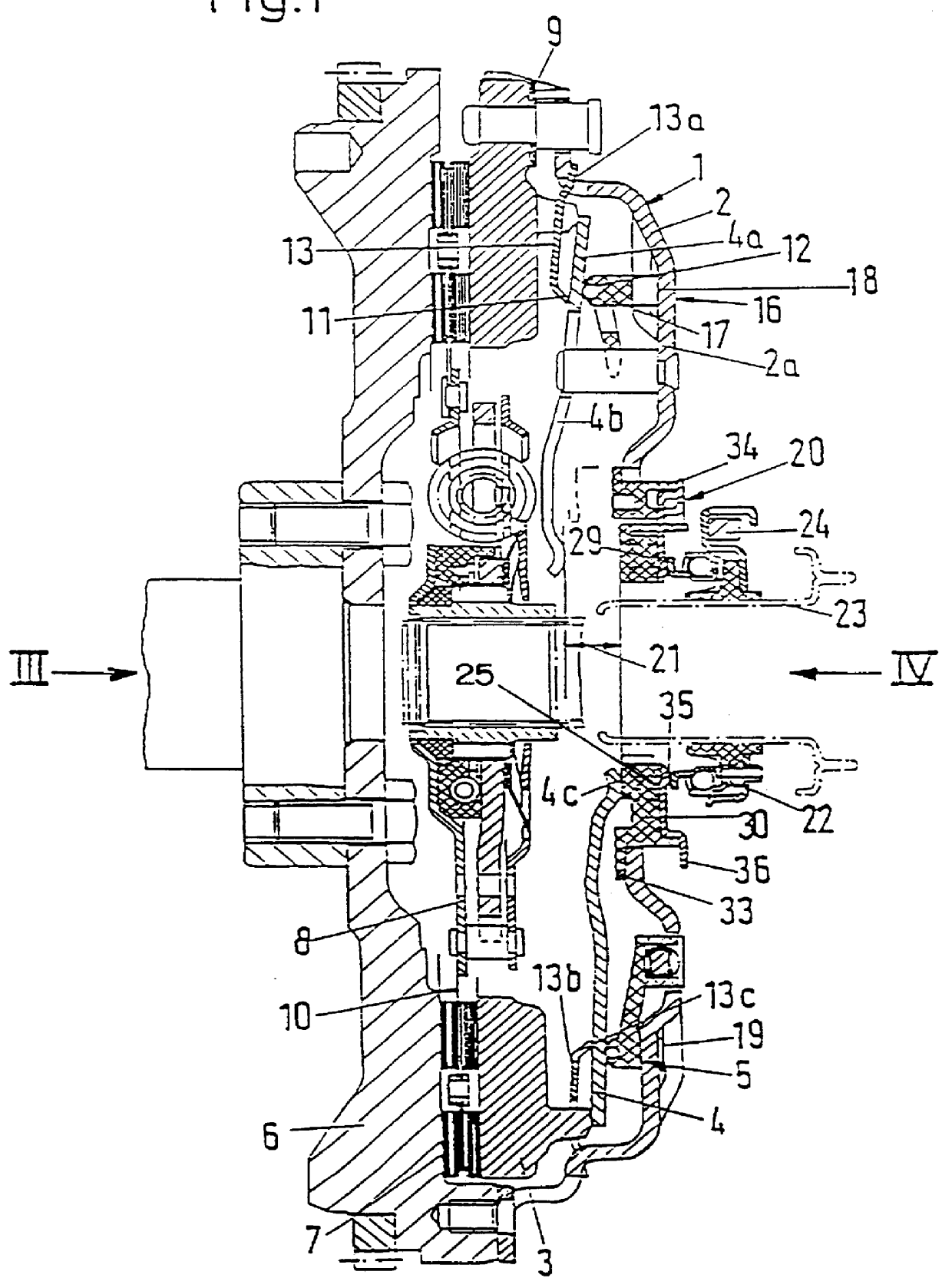

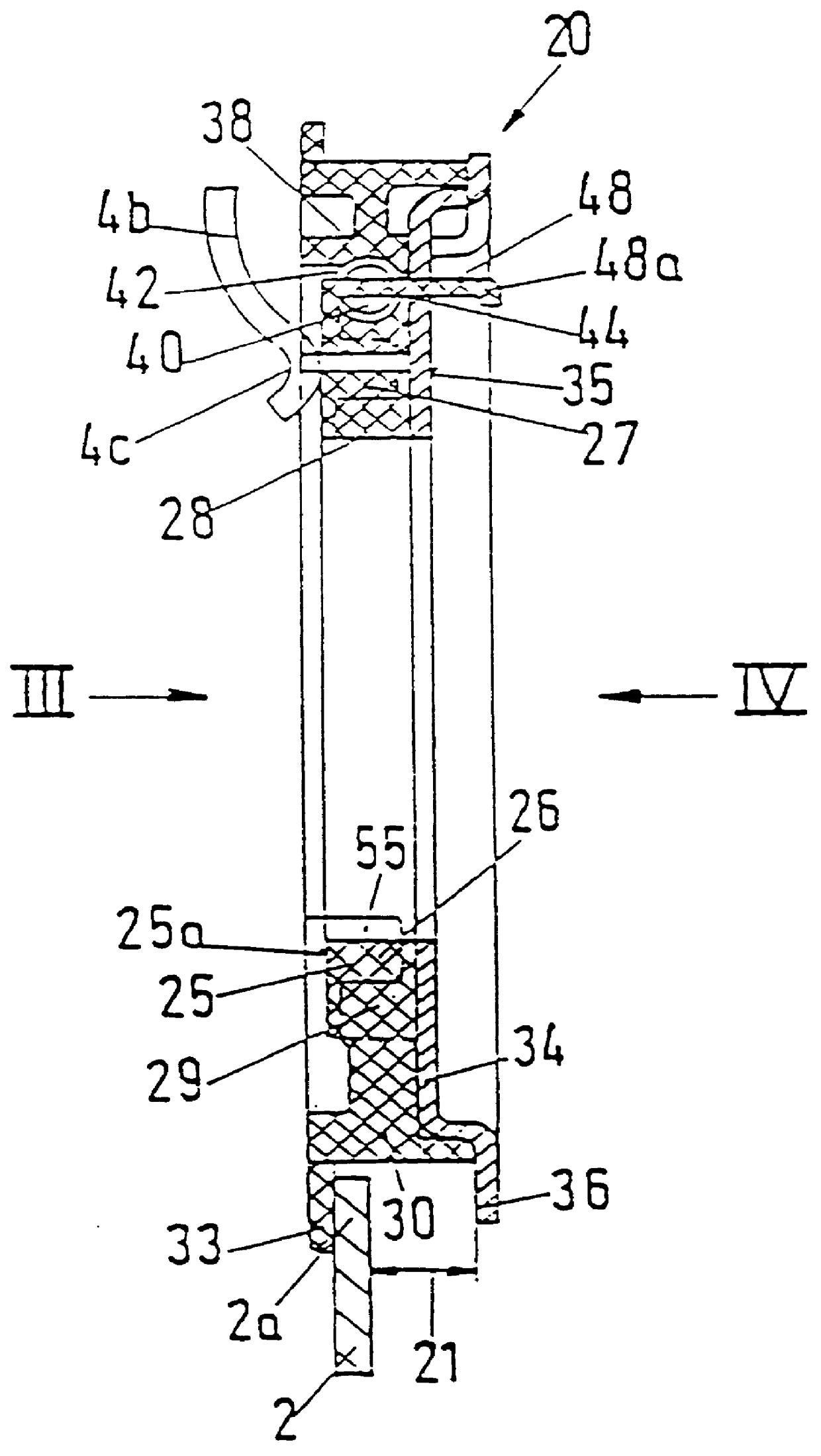

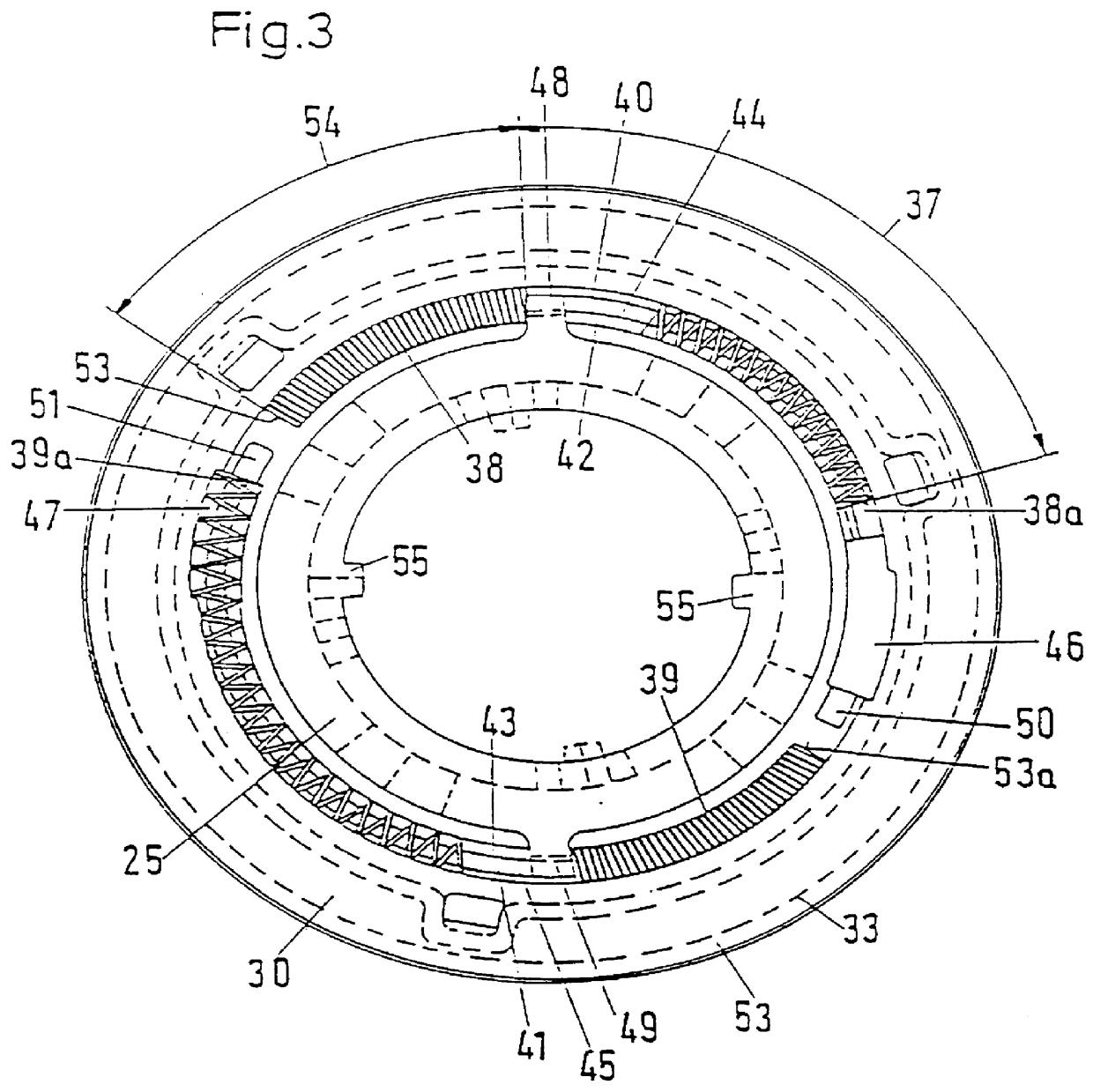

Self-adjusting friction clutch

InactiveUS6098772ASimple and inexpensive mannerAccurate operationFriction clutchesInterengaging clutchesEngineeringClutch

A friction clutch wherein an adjusting device serves to compensate for wear at least upon the friction linings of the clutch disc between the driven counterpressure plate and the axially movable pressure plate. The purpose of the adjusting device is to ensure that the bias of the clutch spring upon the pressure plate remains at least substantially unchanged. The adjusting device satisfies such requirement due to the provision of a device which compensates for departures of the actual position of the clutch actuating unit from an optimum position or which compensates for the departures of those portions of the actuating unit relative to a clutch disengaging member from an optimum position which are acted upon by the actuating unit.

Owner:LUK LAMELLEN & KUPPLUNGSBAU BETEILIGUNGS KG

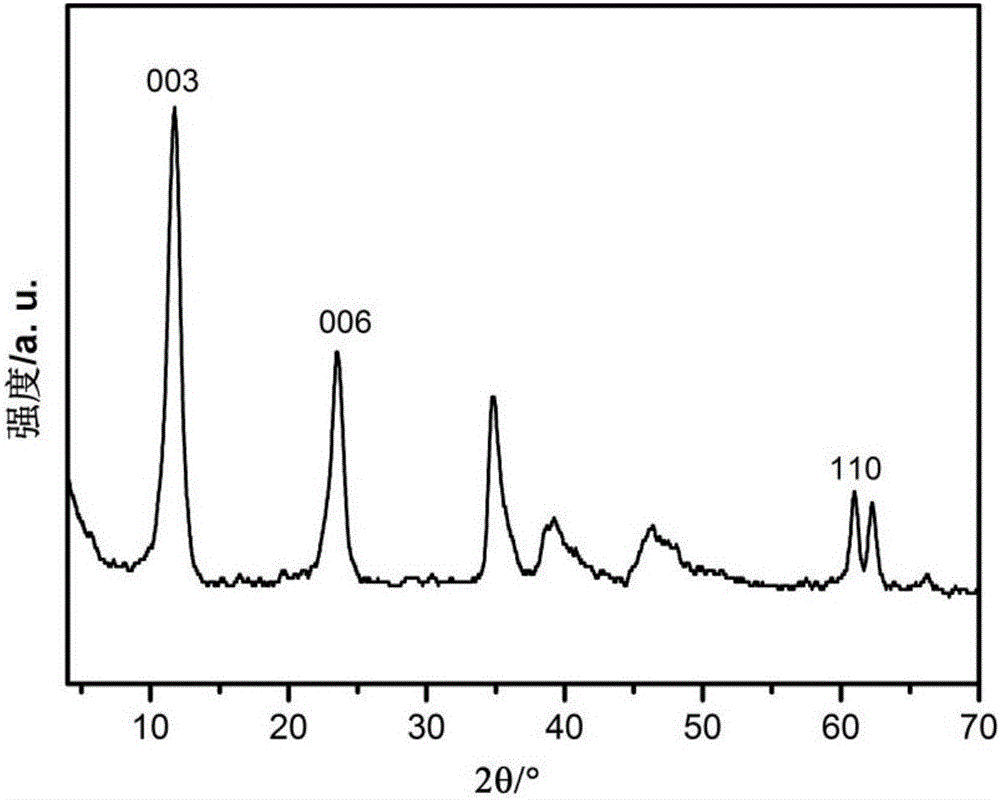

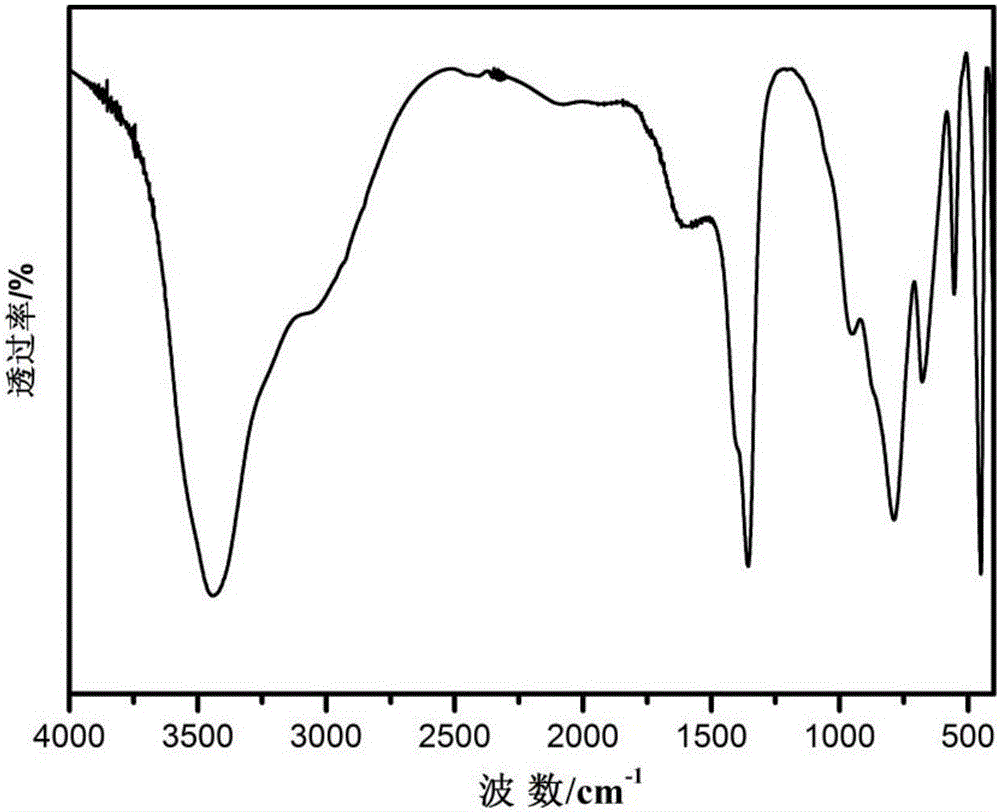

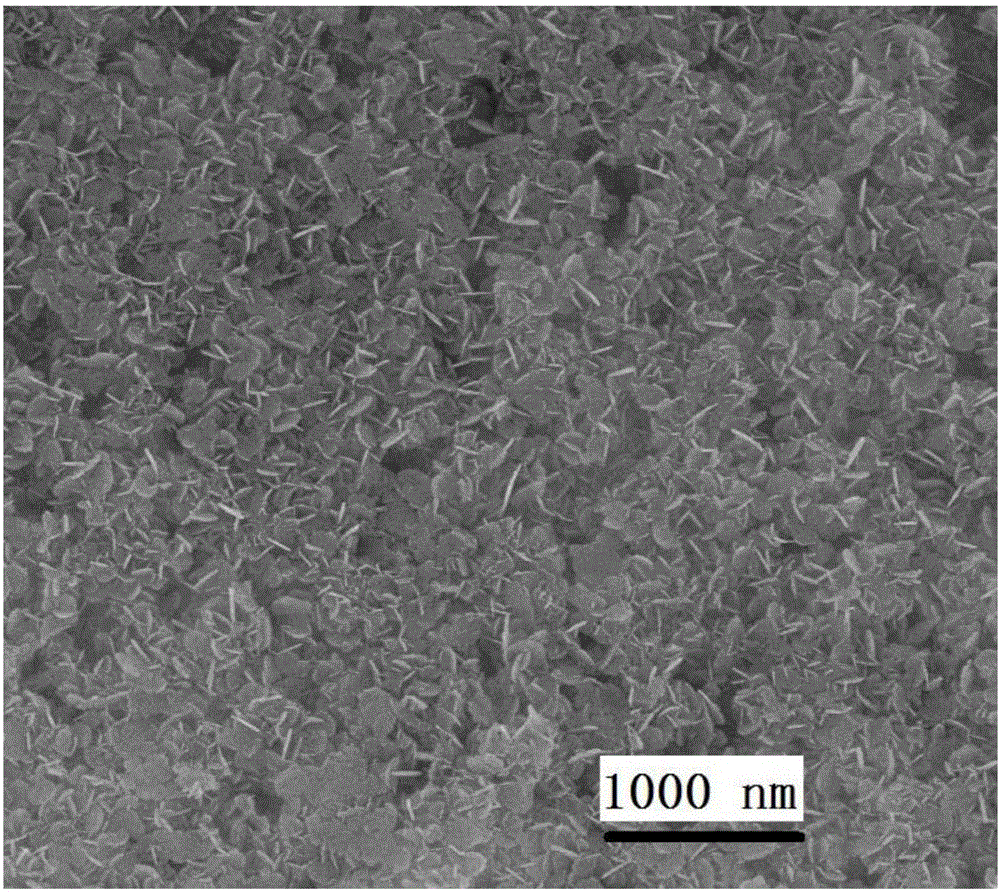

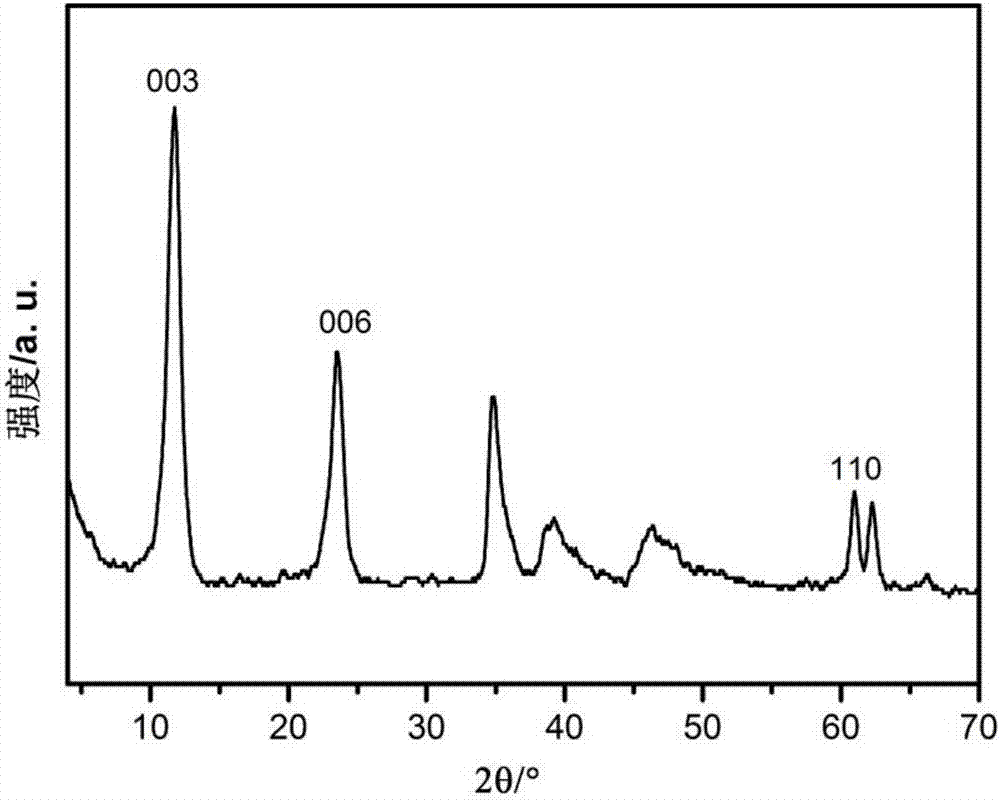

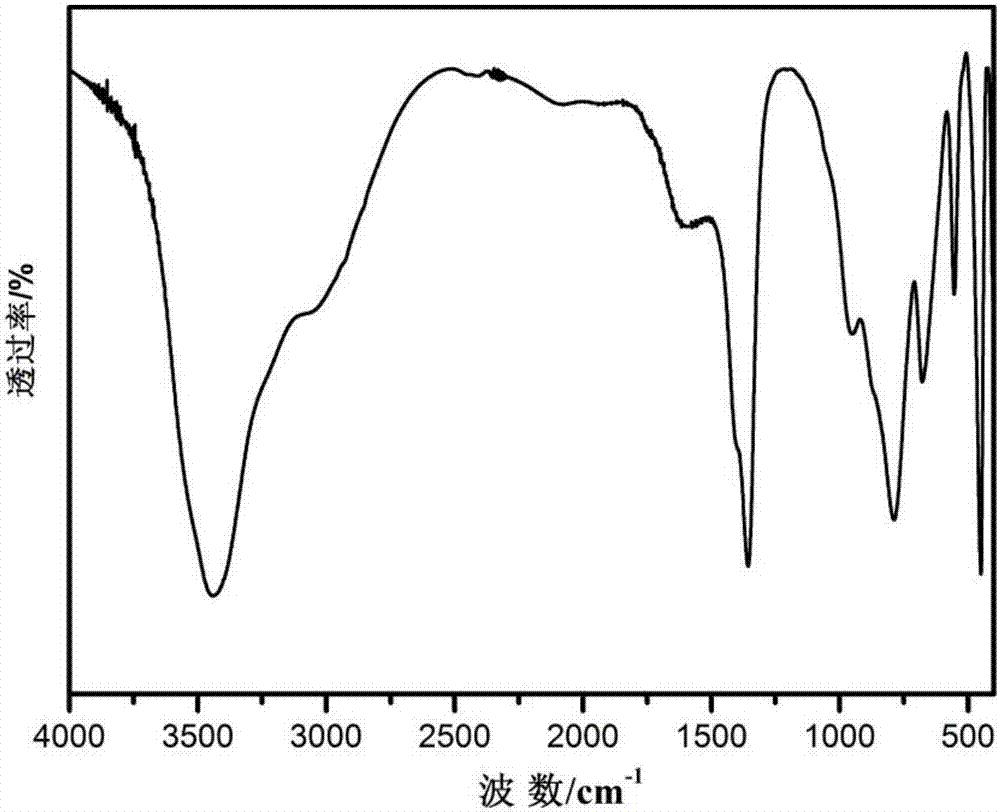

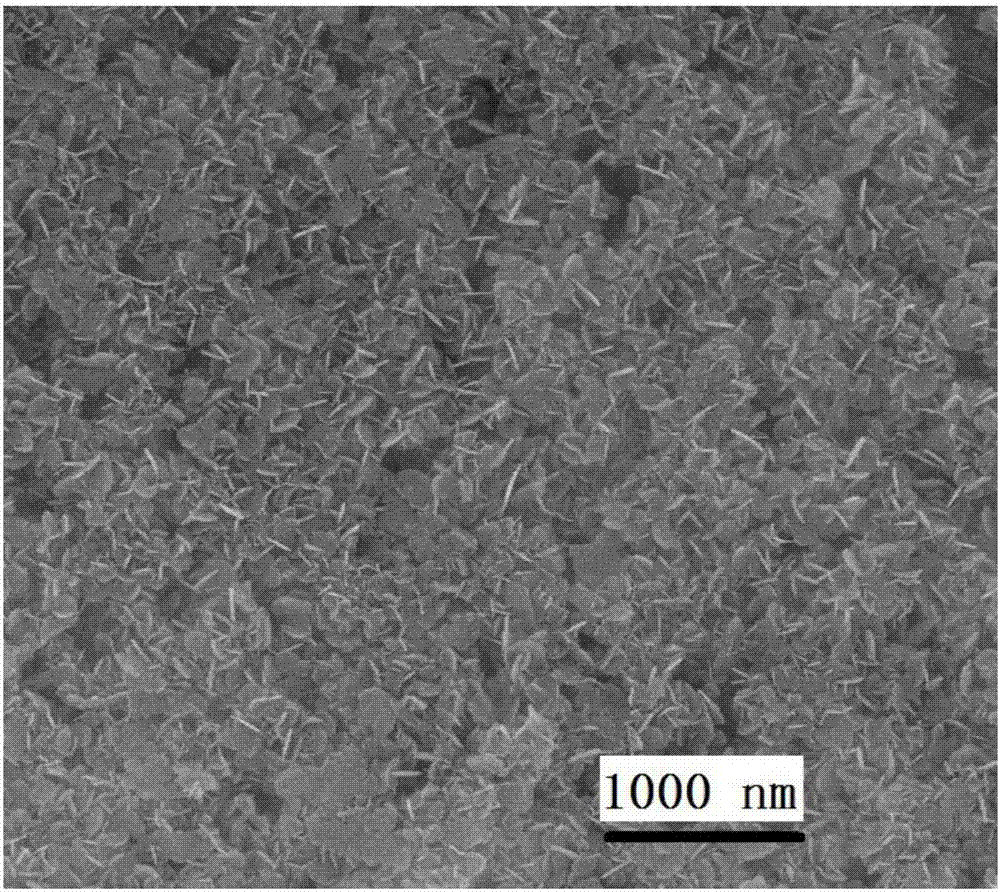

Clean preparation method of magnalium based laminated composite hydroxide

ActiveCN105836769ARich sourcesIncrease spawn rateAluminium compoundsZinc compoundsEnvironmental resistanceReaction temperature

The invention provides a clean preparation method of a magnalium based laminated composite hydroxide. The method uses magnesium hydroxide, magnesium oxide, pseudo boehmite, inorganic acid and a material containing functional anions as raw materials, uses magnesium chloride or magnesium nitrate as a circulation medium, and uses the property of peptization under acidic condition of boehmite to improve the reaction activity of pseudoboehmite; the concentration of magnesium ions in solution is increased by using magnesium chloride or magnesium nitrate. The method accelerates the formation rate of laminated composite hydroxide, promotes the dissolution of magnesium hydroxide and magnesium oxide, shortens the reaction time, overcomes the defects of high reaction temperature and long time consumption in hydrothermal method for synthesis of laminated composite hydroxide, and can rapidly prepare magnalium based laminated composite hydroxide under mild conditions. Magnesium chloride and magnesium nitrate can be recycled; and the preparation process has no waste discharge, and is green and environment-friendly. The method has the advantages of abundant raw materials, low cost, simple preparation process, mild reaction conditions, and easiness to industrial production.

Owner:BEIJING UNIV OF CHEM TECH

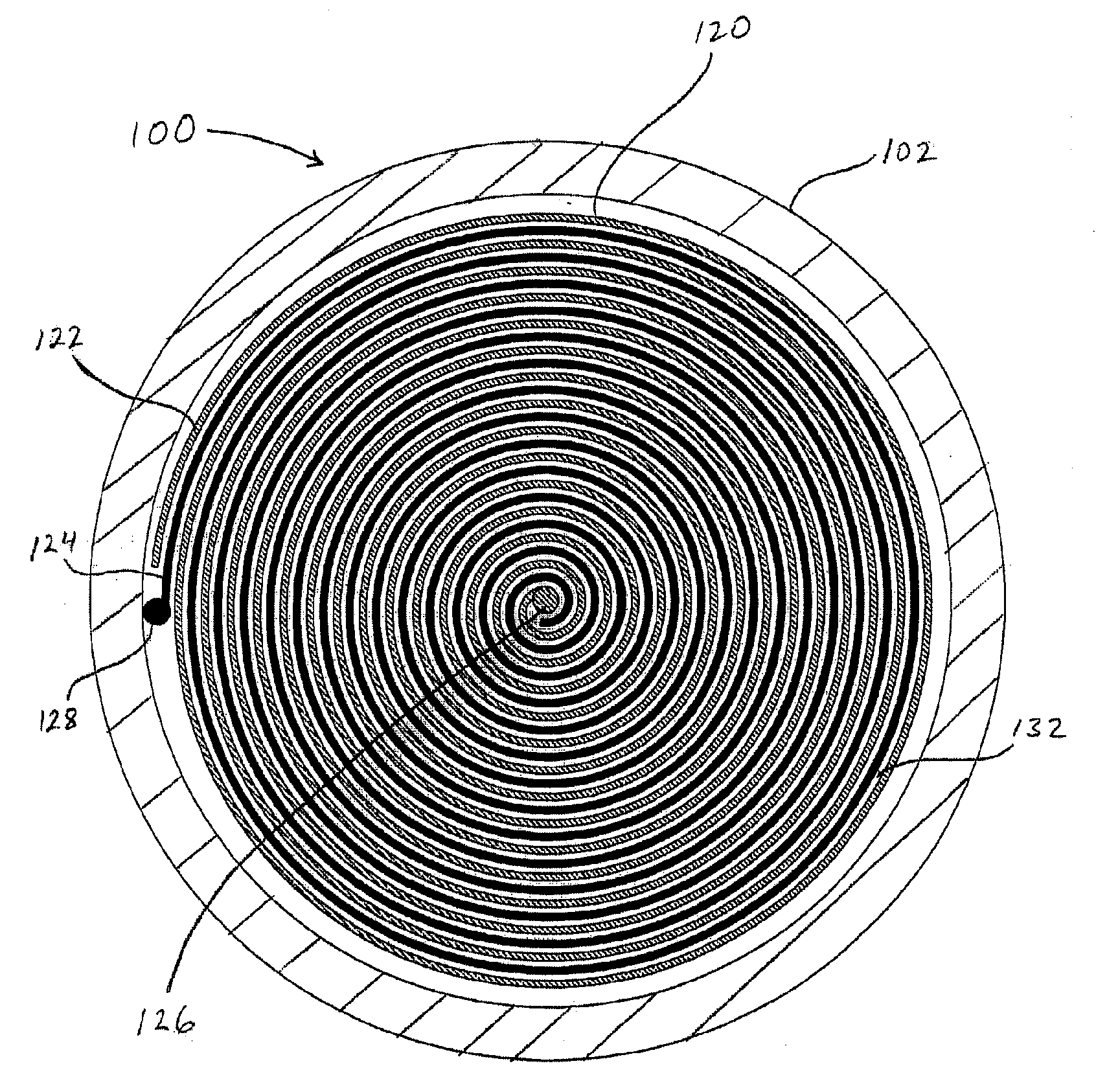

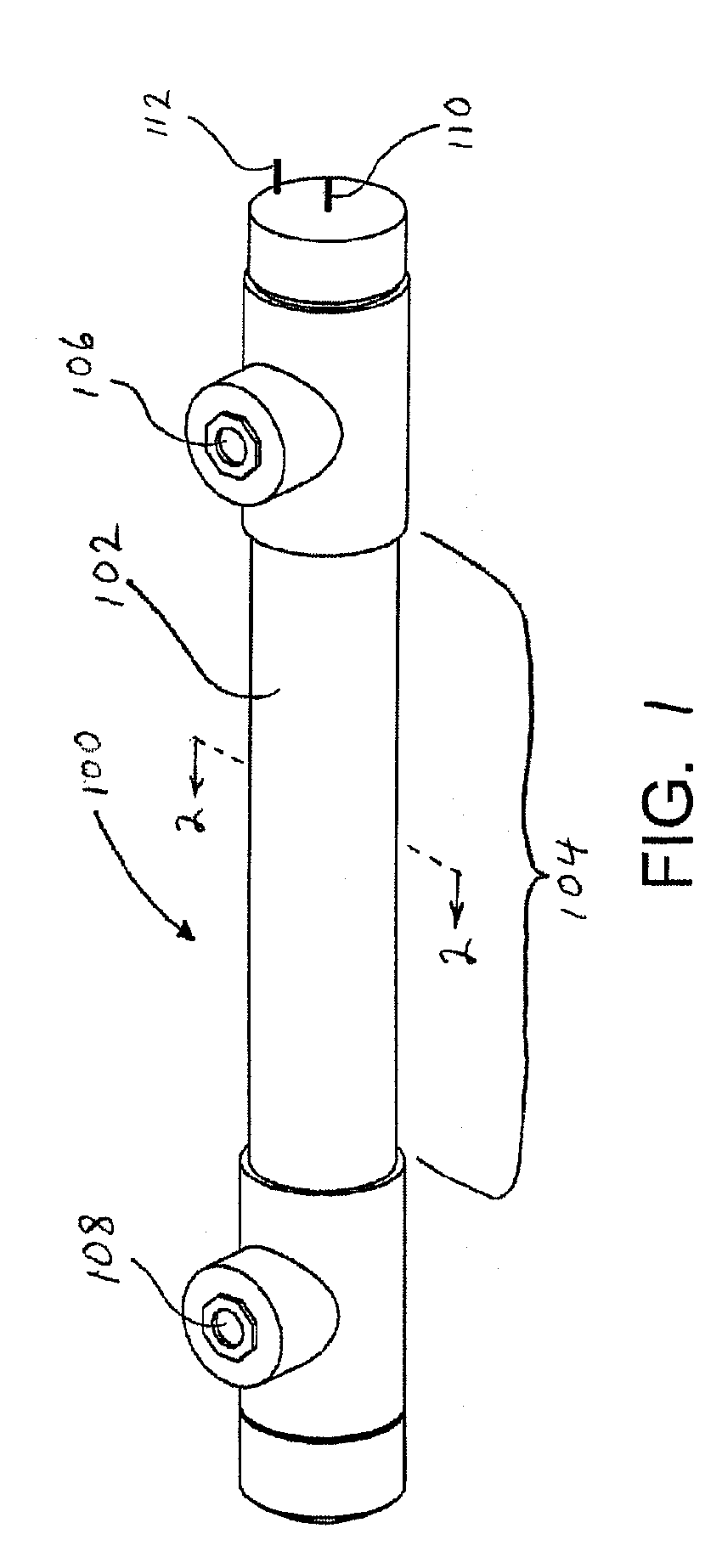

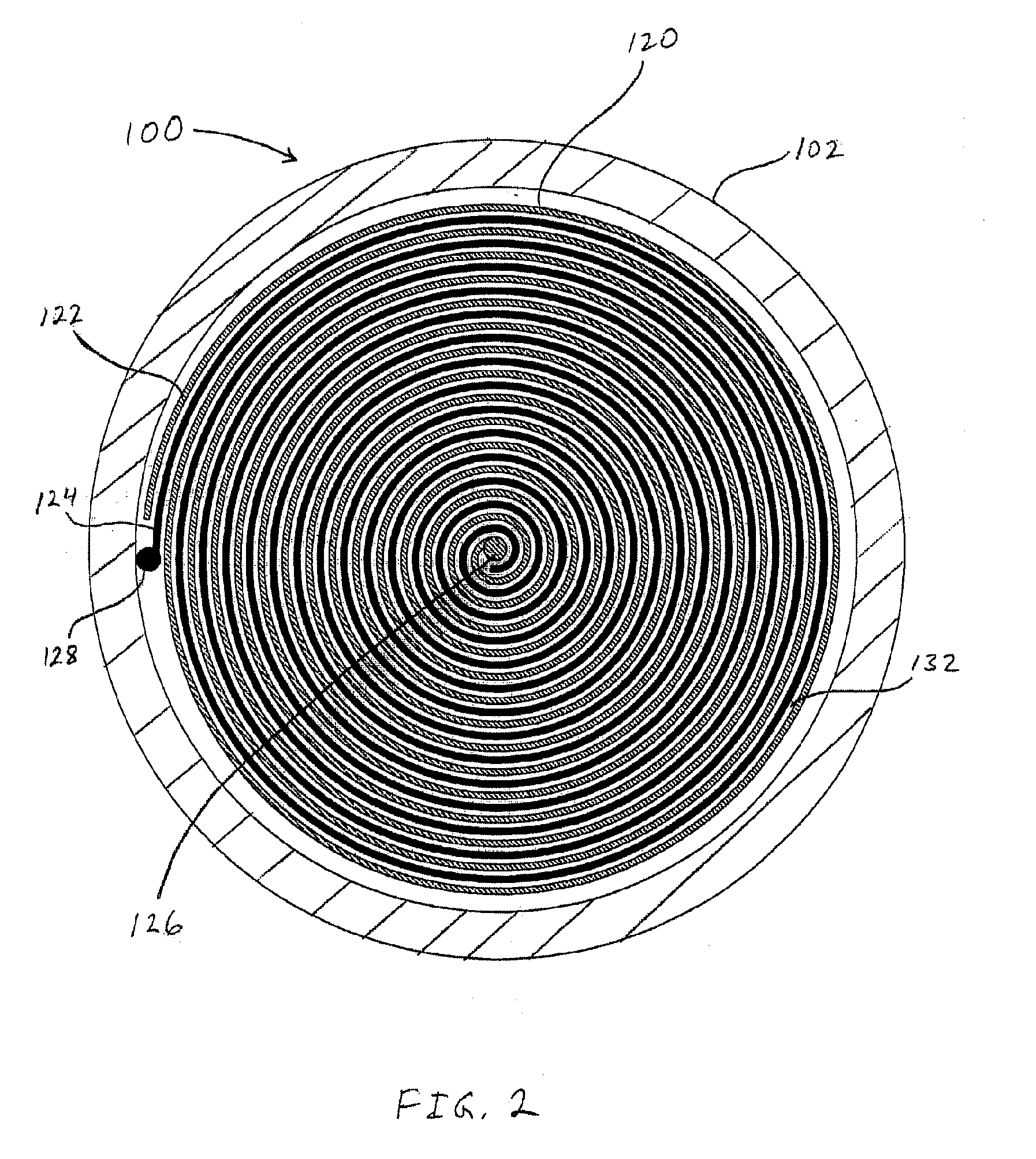

Electrocoagulation reactor and water treatment system and method

InactiveUS20090008269A1Increase electrode surface areaSimple designCellsTreatment involving filtrationElectrocoagulationWater treatment system

An electrocoagulation reactor, and water purification systems and methods using the reactor, are provided. The electrocoagulation reactor has a spirally wound assembly in which electrocoagulation treatment takes place. The spirally wound assembly includes electrode sheets spirally wound in spaced relation with an area for fluid flow in the space between the electrode sheets.

Owner:POWELL WATER SYST

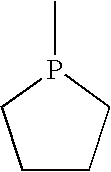

Preparation of polyisocyanates of the trimer type

ActiveUS20090234091A1Low average NCO functionalityReduced suitability requirementsOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsPhotochemistryPhosphorus

The invention relates to the use of heterocycles containing trivalent phosphorus as a ring member as catalysts for isocyanate modification and to a process for preparing polyisocyanates of the trimer type.

Owner:COVESTRO DEUTSCHLAND AG

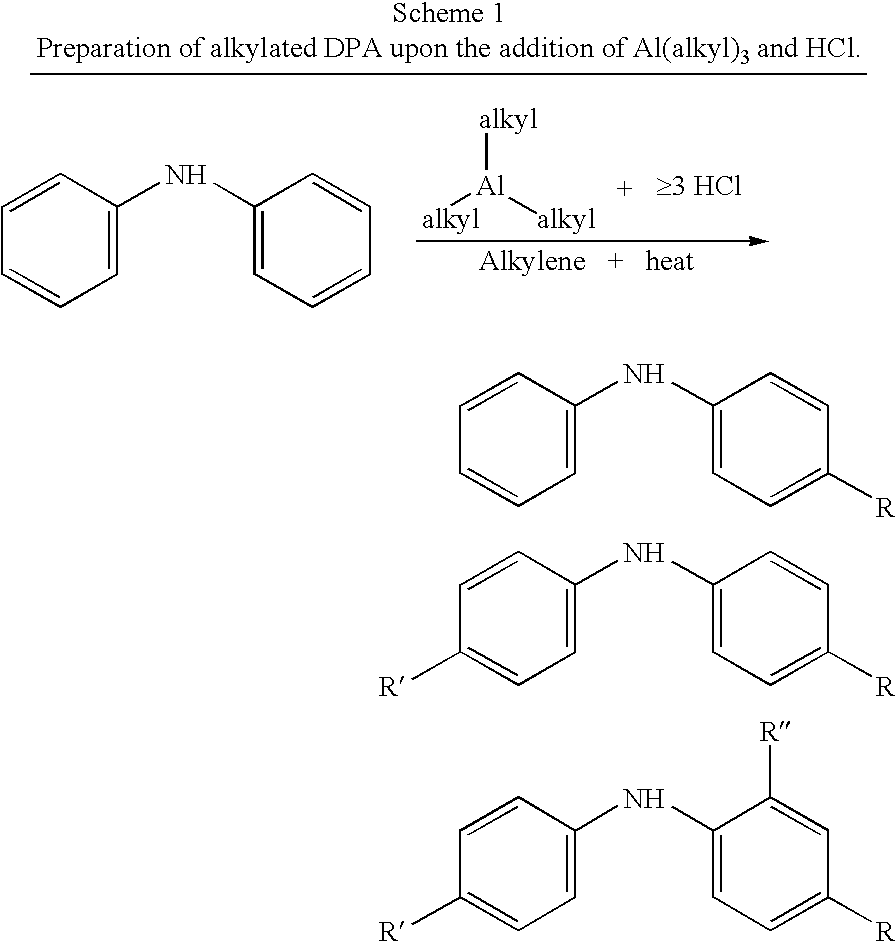

Process for synthesizing alkylated arylamines

InactiveUS20060276677A1Maximize high conversionMaximizing conversionAmino preparation from aminesOrganic compound preparationHydrogen halideOrganic chemistry

An improved process and novel catalyst system for alkylating arylamines generally comprising the combination of an arylamine and an alkylating agent in the presence of a trialkyl aluminum compound and a hydrogen halide. The improved process and new catalyst system allows for higher total conversion of the arylamine feedstock without sacrificing substitution product selectivity and also allows for the reaction of recycled alkylene feedstock.

Owner:ALBEMARLE CORP

Method for quickly extracting bacteria cellulose from mother liquor

InactiveCN1837460AReduce the temperatureLong reaction timePaper material treatmentDistilled waterMagnetic stirrer

This invention discloses a process for the separation and purification of bacteria cellulose from mother liquid, which comprises the following steps: putting wet bacteria cellulose film into distilled water, formulating 1-9% alkali liquor and 1-10% acid solution by concentration,separetly holding temperature to 20-60 degrees with digital display thermostatic and magnetic stirrer; putting wet bacteria cellulose film into alkali liquor formulated for swelling for 3-10min, then taking it out and putting it into acid solution formulated, steeping it for 4-8min with magnetic stirrer whose revolution rate is 100- 700rpm; taking the wet bacteria cellulose film and rinsing it for 2-3 times, then conserving it in fridge. The invention comprises the following good effects: (1) using not only alkali liquor, but also acid solution; (2) the temperature isn't high and the reaction time isn't long in purification process; (3) the solution used is nonvolatile, so the process is nontoxic; (4) the solution can be used repeatedly, so the extraction cycle is shortened.

Owner:DONGHUA UNIV +1

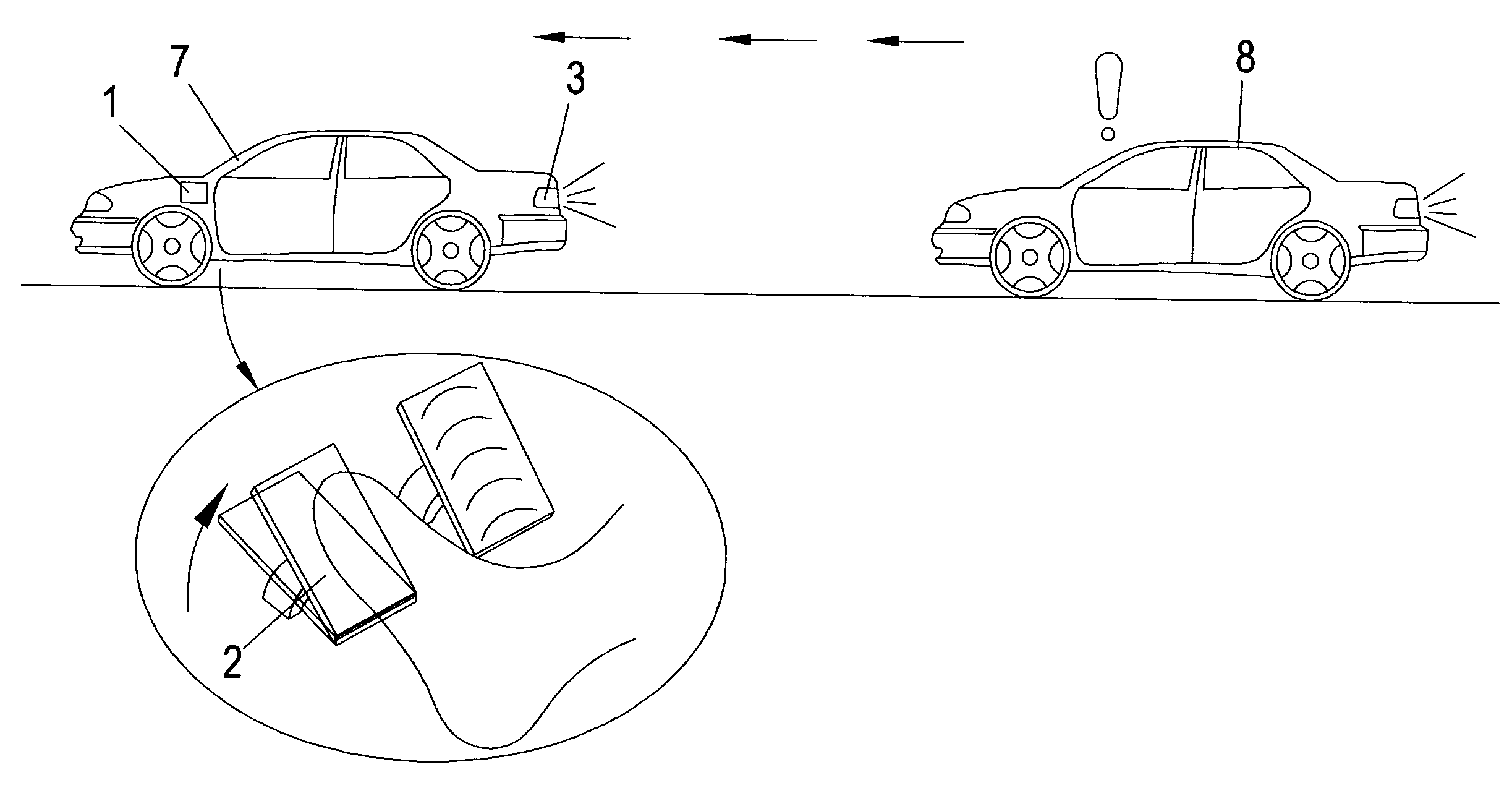

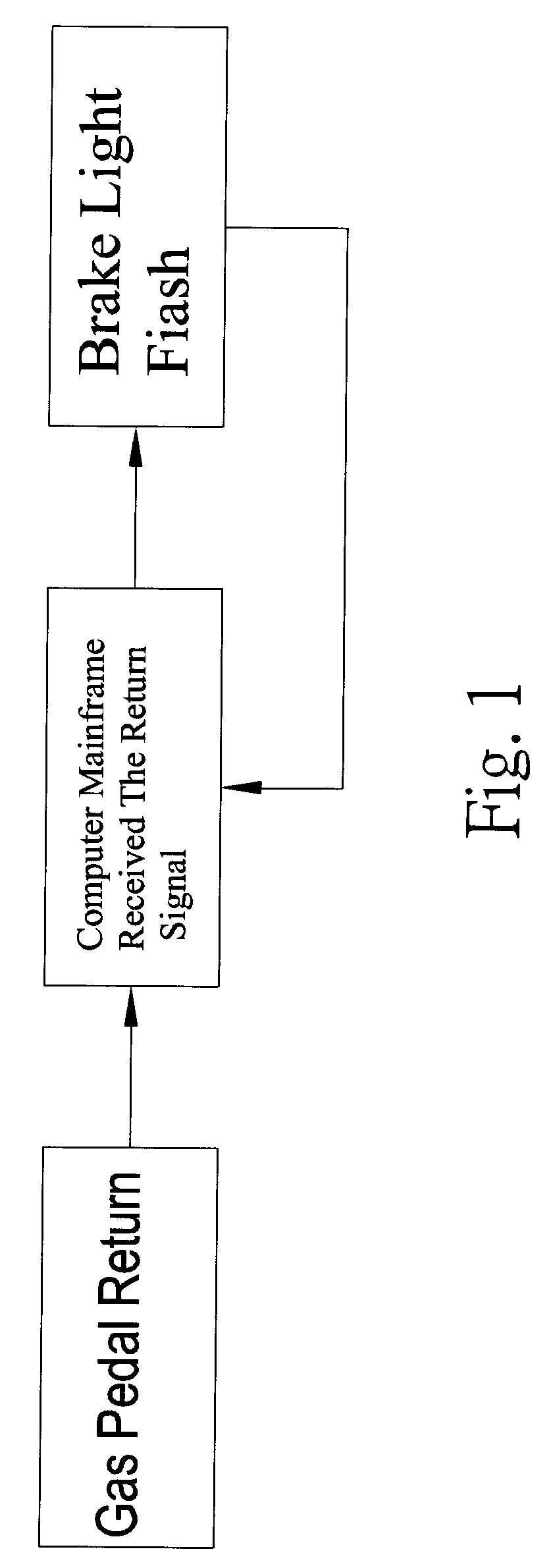

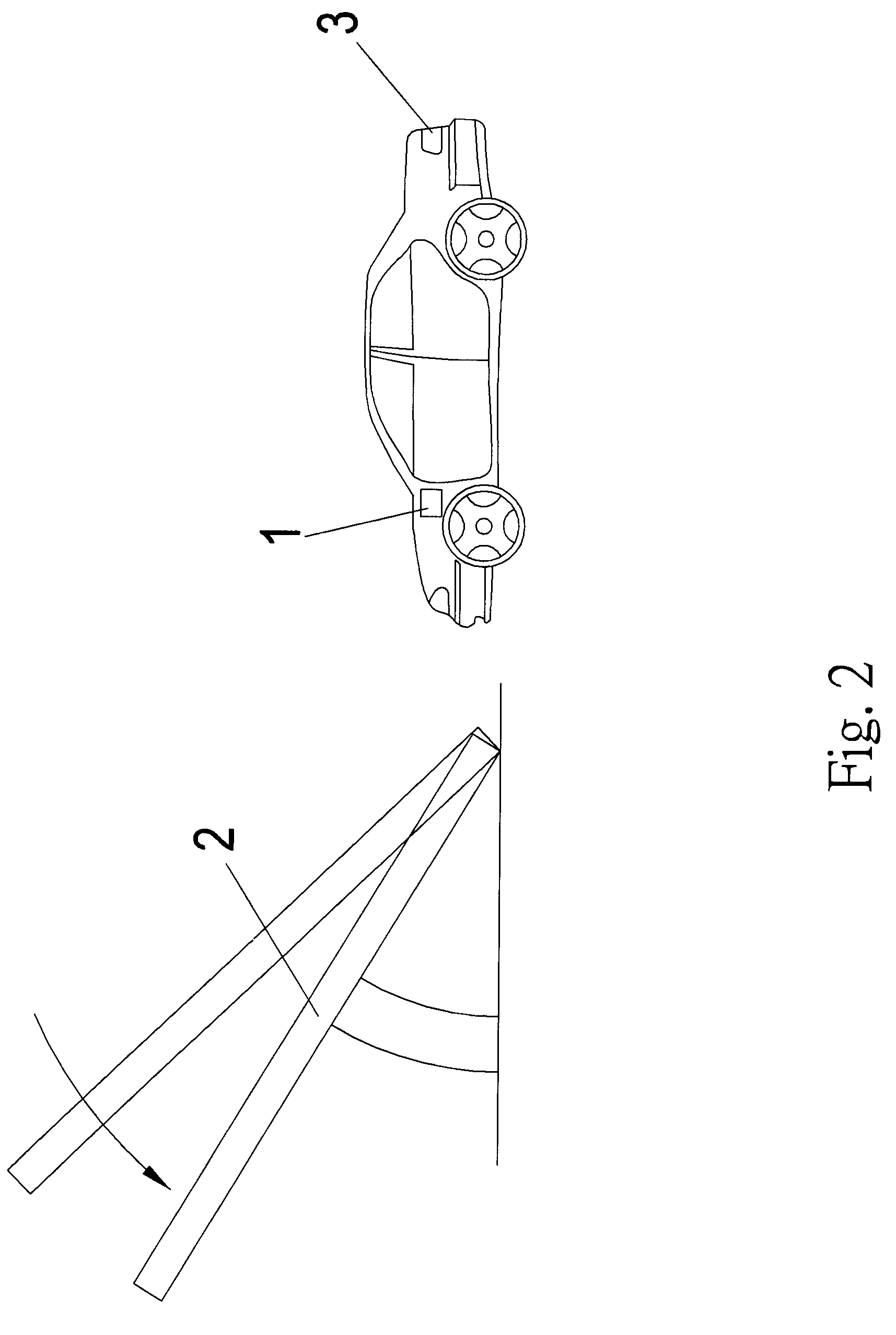

Speed-reduction alert device

InactiveUS20100117818A1Long reaction timeKeep for a long timeOptical signallingDriver/operatorAlarm device

A speed-reduction alert device comprises a speed-reduction alert unit installed below a gas pedal for detecting swinging operation of the gas pedal so as to transfer a swing signal outwards; a computer main frame connected to the speed-reduction alert unit for receiving the swinging signals and controlling the flash frequencies, flash periods and change of signals of a brake light in a first car to show a deceleration of the first car to a driver of a second car so that the driver of the second car will alert the deceleration of the first car. When the gas pedal is pressed downwards for acceleration, the computer main frame will determine that it is an accelerating signal and the brake light is not actuated; and when the gas pedal is released to move upwards for deceleration, the computer main frame will determine that it is a deceleration signal.

Owner:WAN JEE

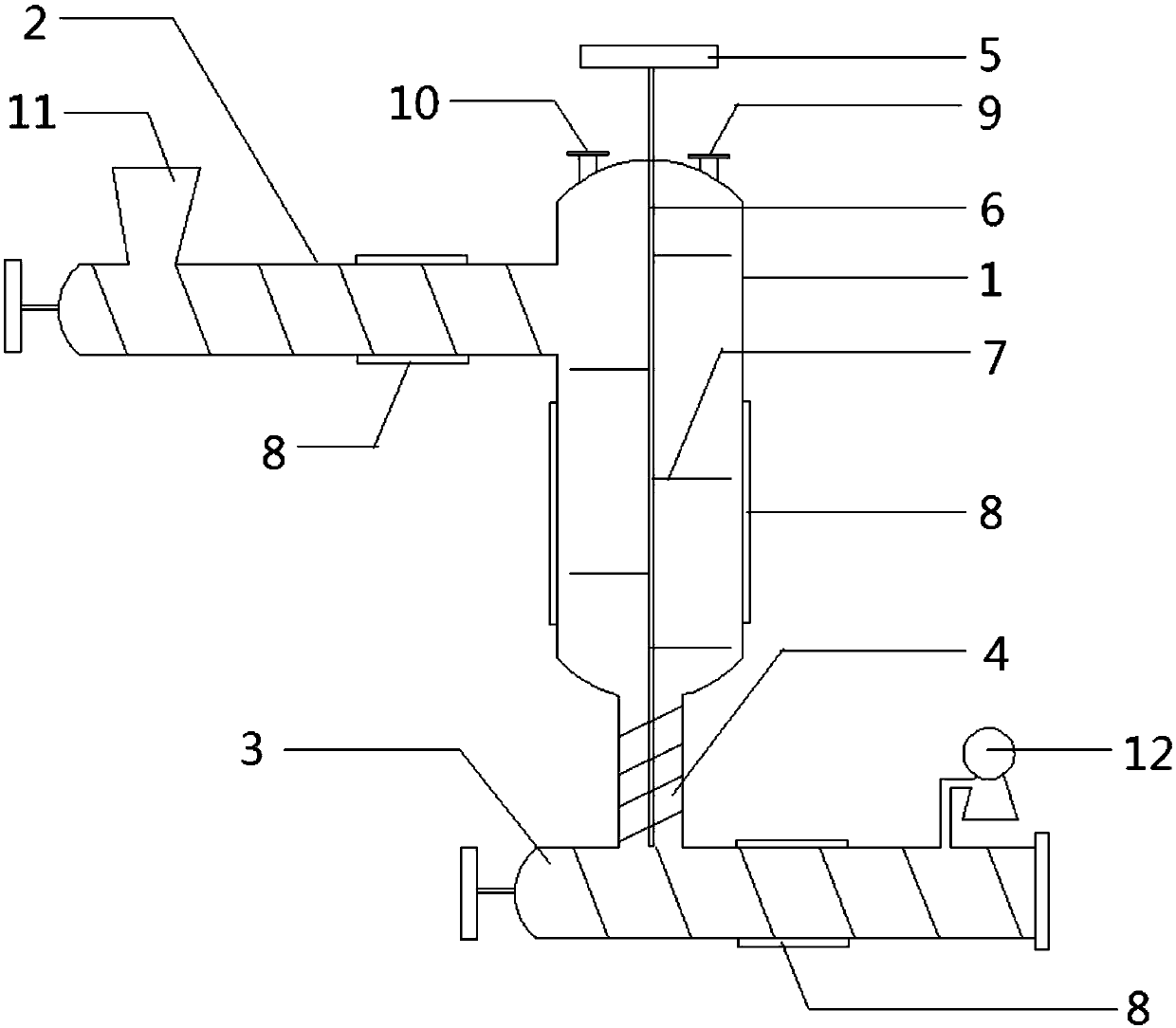

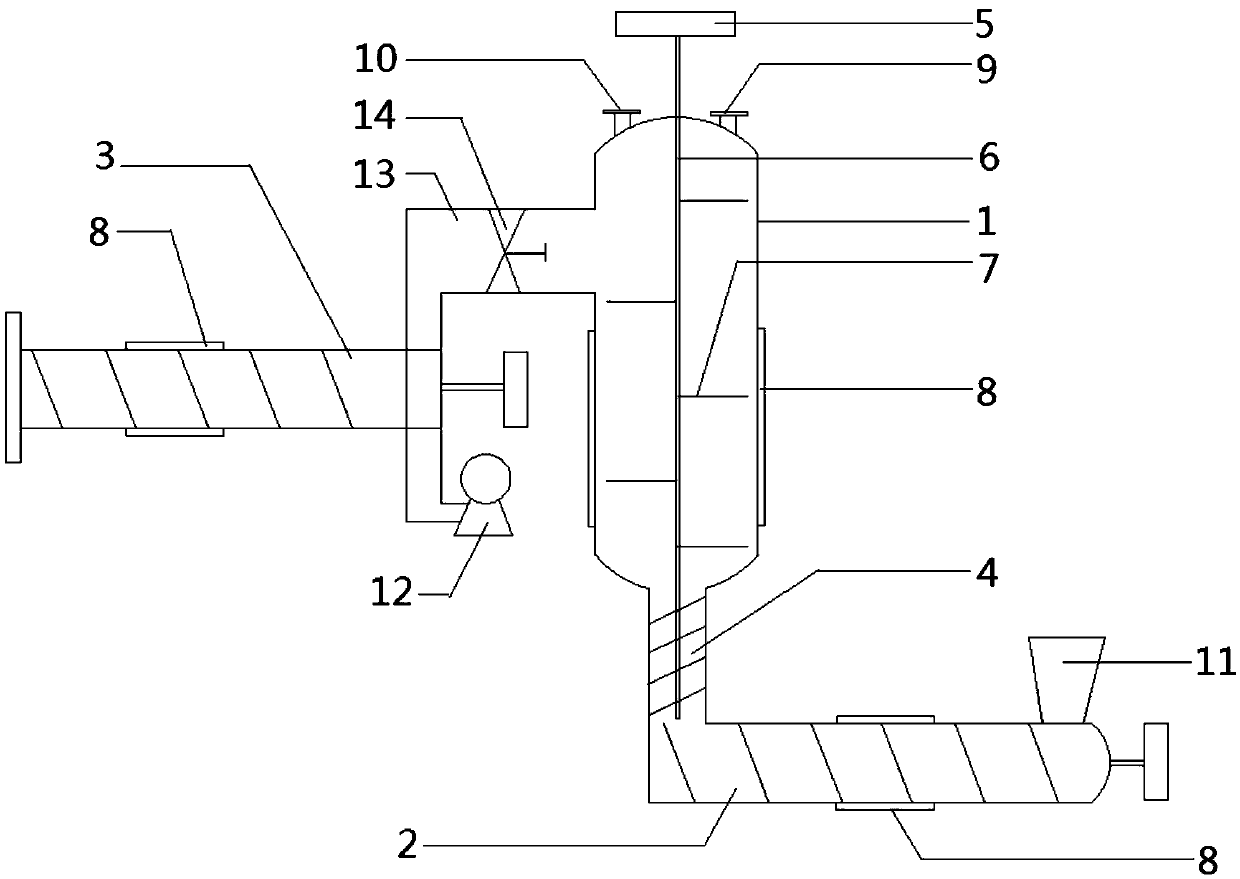

Screw extrusion-kettle type stirred combined reactor and application thereof

InactiveCN109569477AGood modification effectHigh grafting rateChemical/physical/physico-chemical stationary reactorsFeed devicesEngineeringResidence time

The invention relates to a screw extrusion-kettle type stirred combined reactor and application thereof. The screw extrusion-kettle type stirred combined reactor comprises a reaction kettle, a first screw extruder and a second screw extruder. The first screw extruder is connected with a feed inlet of the reaction kettle, and the second screw extruder is connected with a discharge outlet of the reaction kettle; the reaction kettle is provided with a stirring motor, the stirring motor is provided with a stirring shaft, and the stirring shaft is provided with stirring blades; a conveying screw isarranged at the bottom of the reaction kettle and is connected with the stirring shaft, so that the stirring shaft can rotate to drive the conveying screw to rotate. The screw extrusion-kettle type stirred combined reactor and the application have the advantages that long reaction residence time can be provided by the screw extrusion-kettle type stirred combined reactor to chemically modifying high-viscosity resin, and accordingly good modification effects such as high graft ratios can be realized by the aid of the screw extrusion-kettle type stirred combined reactor.

Owner:杨建强

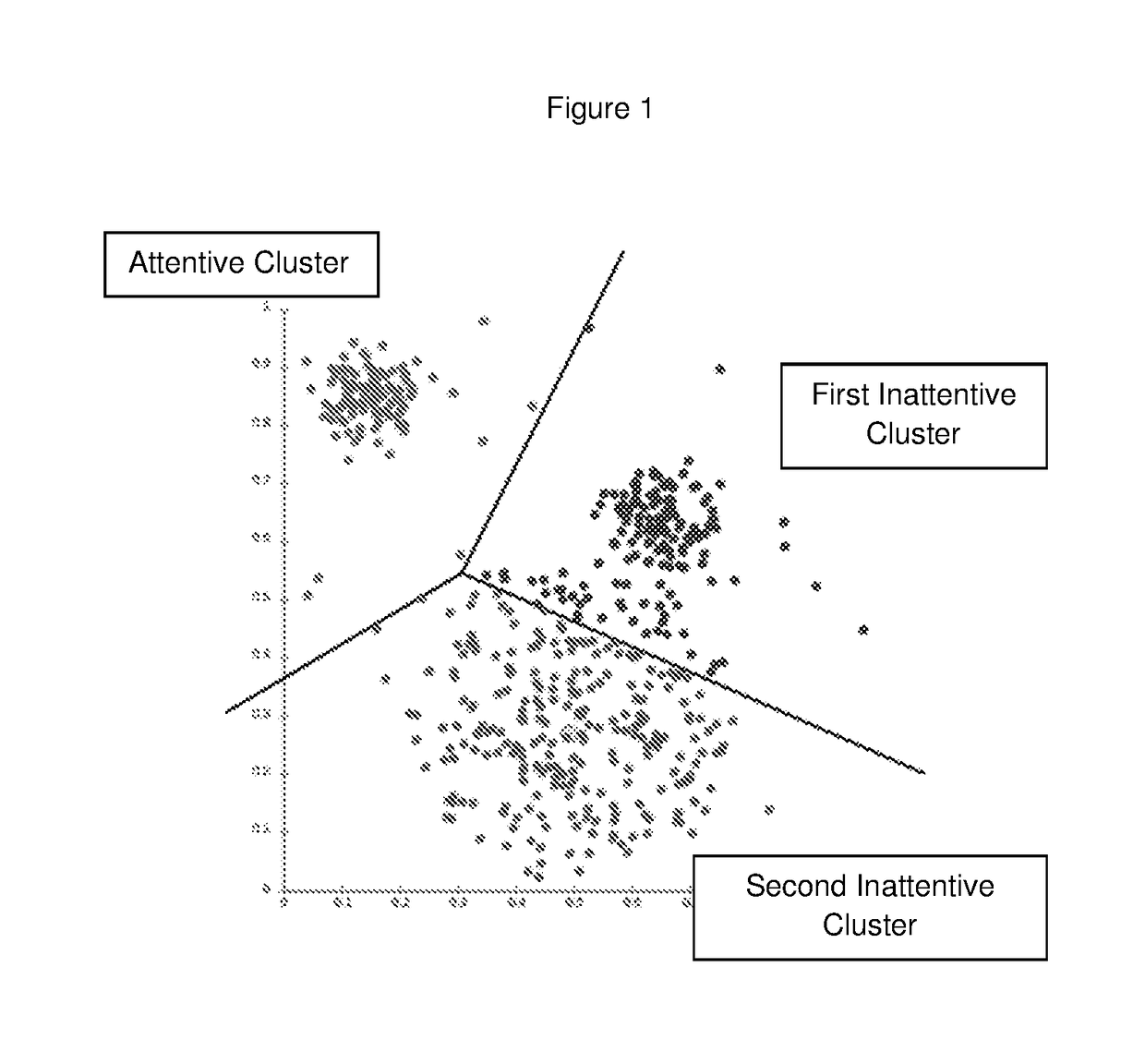

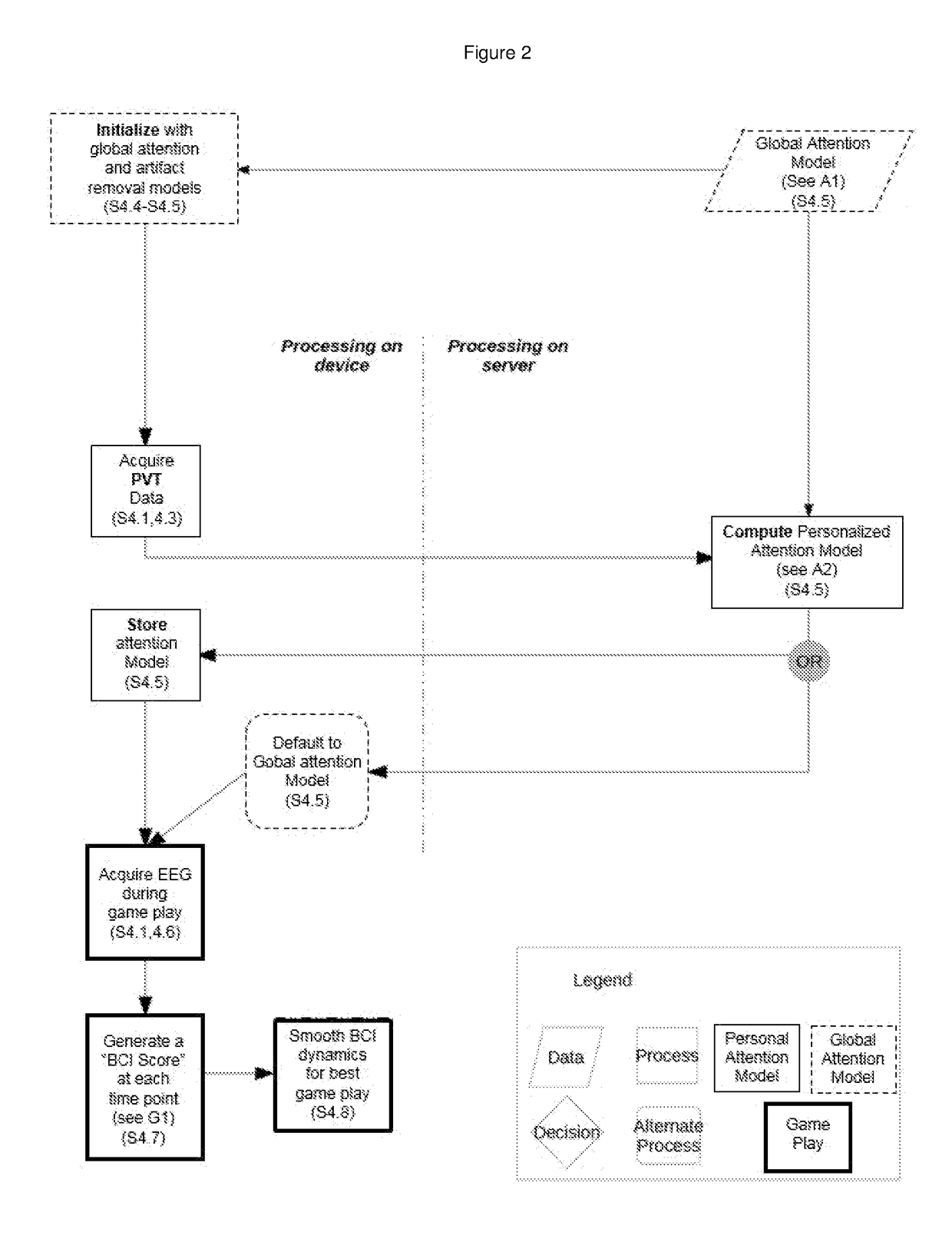

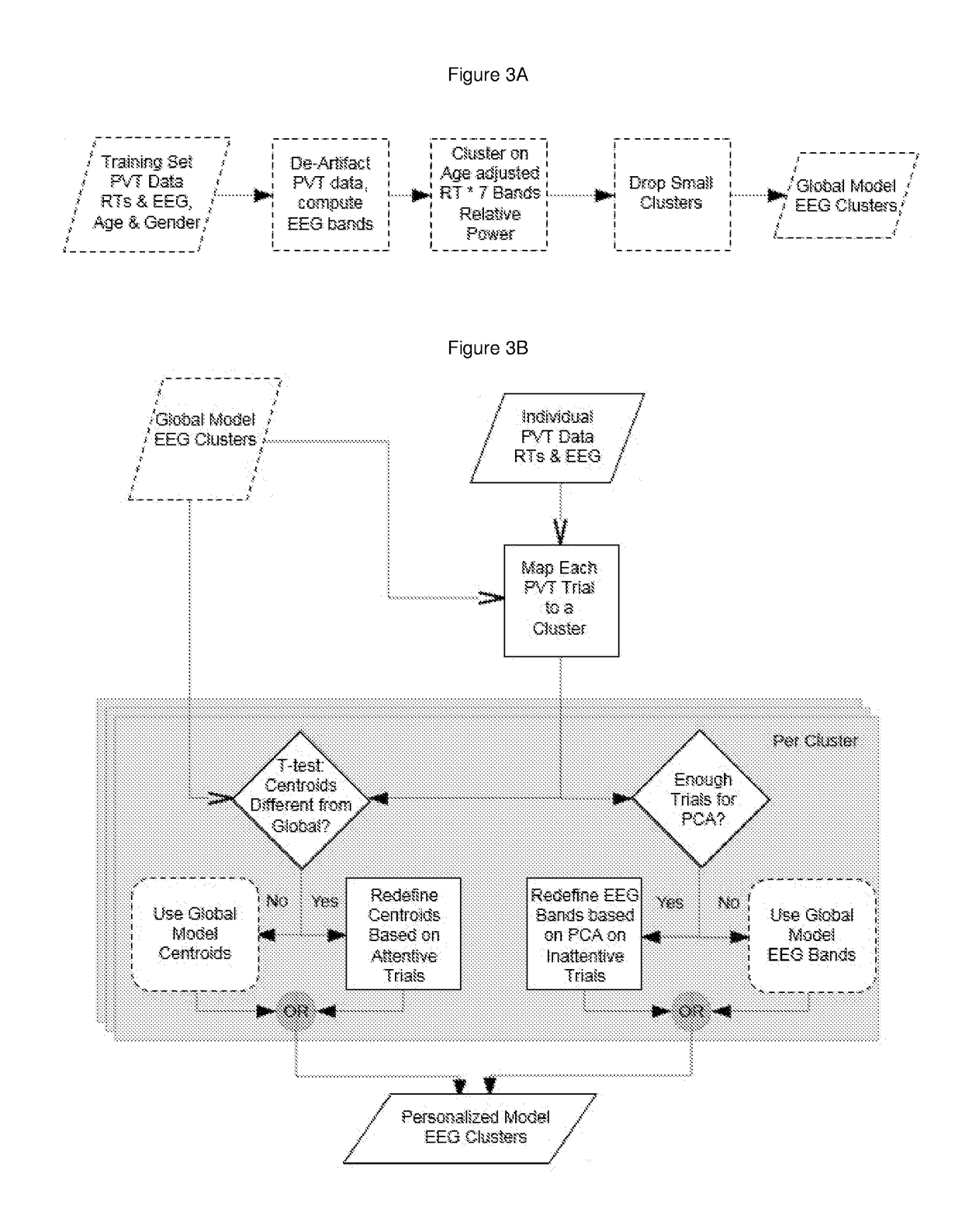

Method and system for monitoring and improving attention

PendingUS20190008436A1Encourage vigilanceIncrease powerElectroencephalographyMedical automated diagnosisComputer sciencePhysical medicine and rehabilitation

Owner:ATENTIV LLC

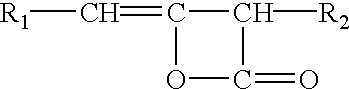

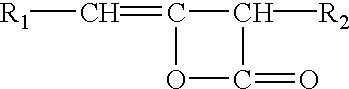

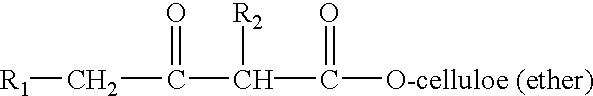

Method for the preparation of modified cellulose ethers

InactiveUS20030040622A1The process is simple and fastLong reaction timeDetergent compounding agentsWater basedTO-18

The invention relates to the preparation of a cellulose ether that is hydrophobically modified with an alkyl or alkenylketene dimer the general formula of which is in which R1 and R2 are alkyl or alkenyl chain, such as one having 5 to 22, preferably 13 to 20, most preferably 14 to 18 carbons. The product can be used in water-based products to control the rheological properties, for example. Objects of use include, for example, detergents, paper coating mixtures, paints, dispersing agents, and oil drilling muds.

Owner:METSA SPECIALTY CHEM

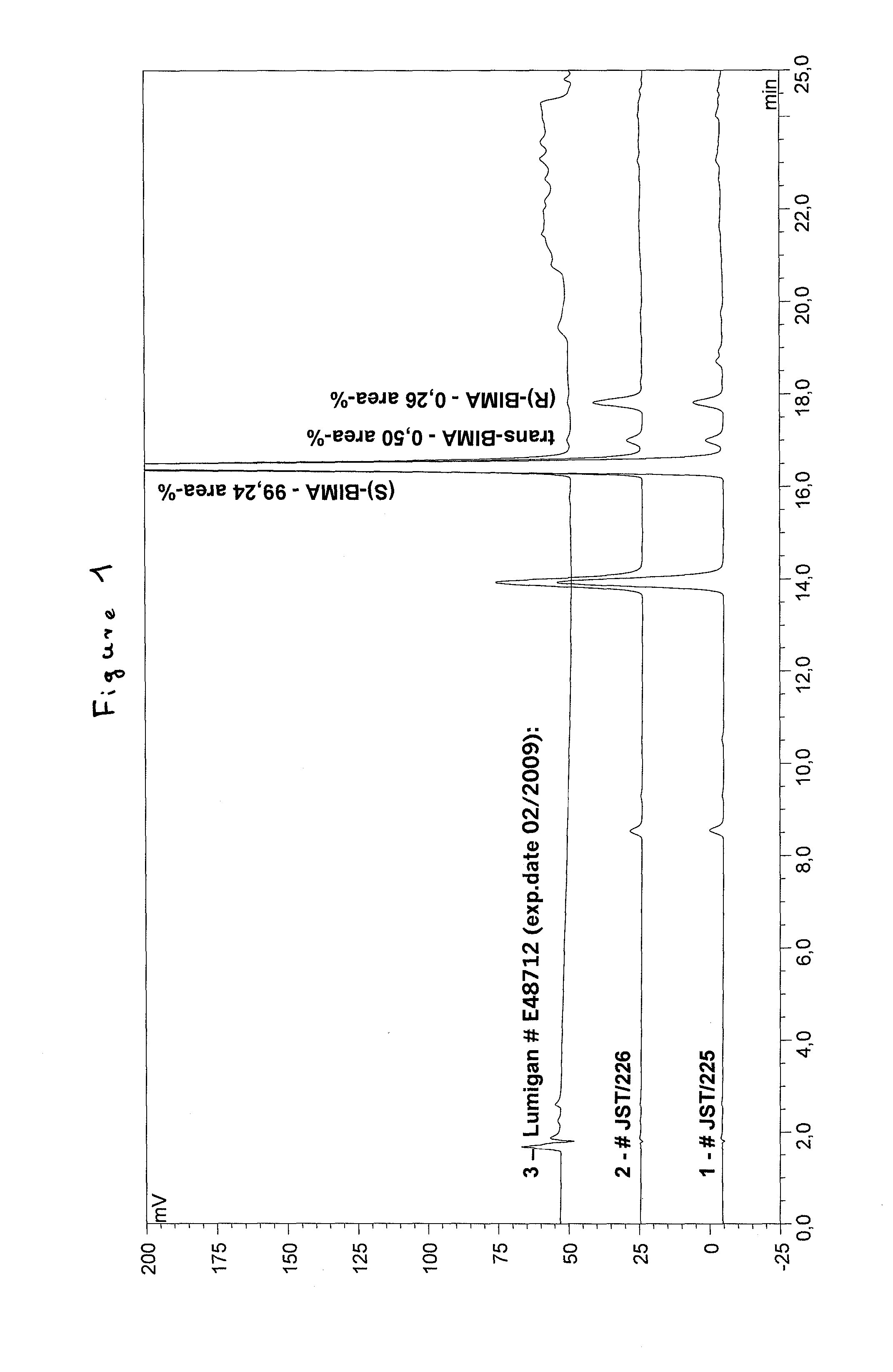

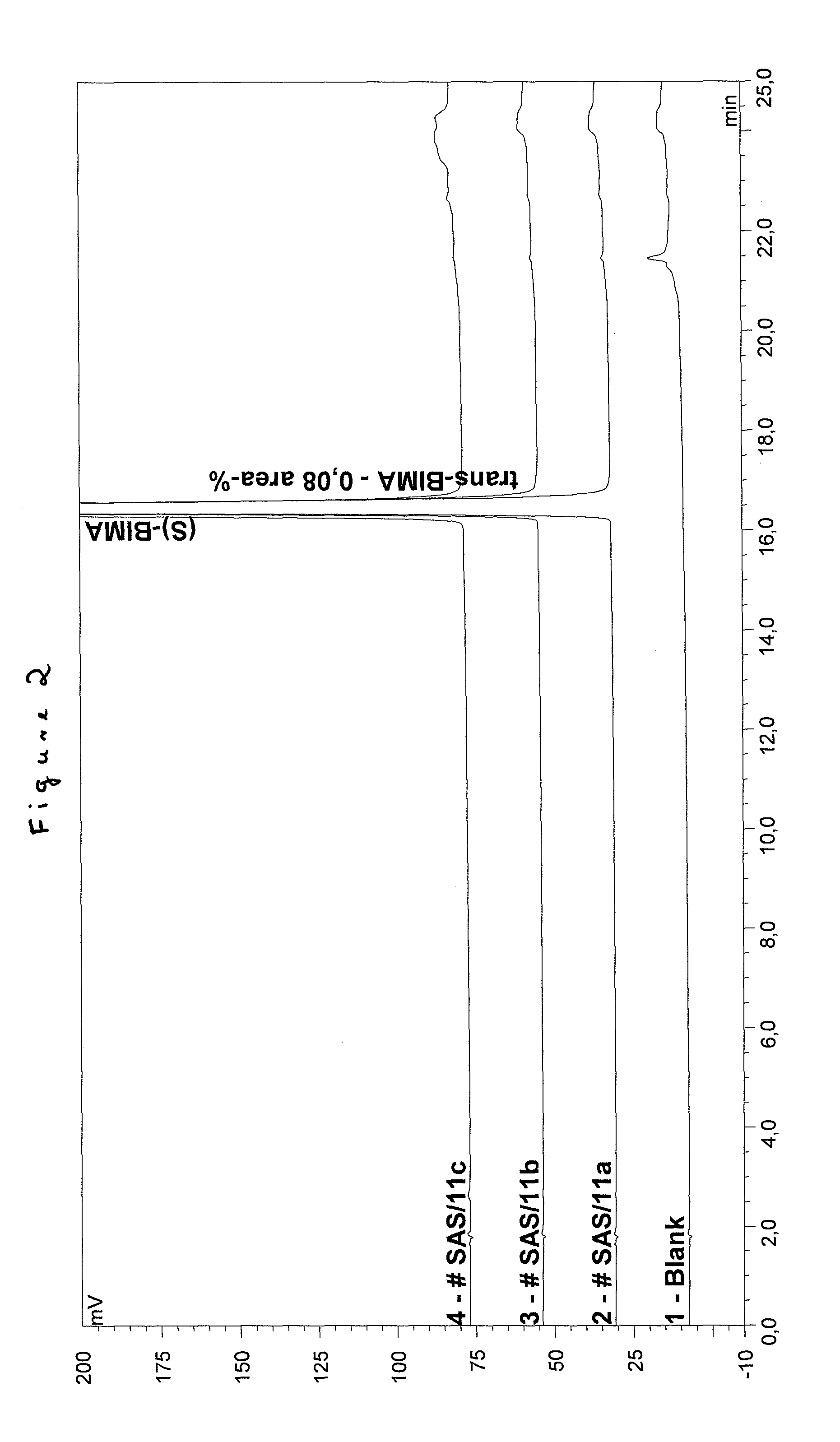

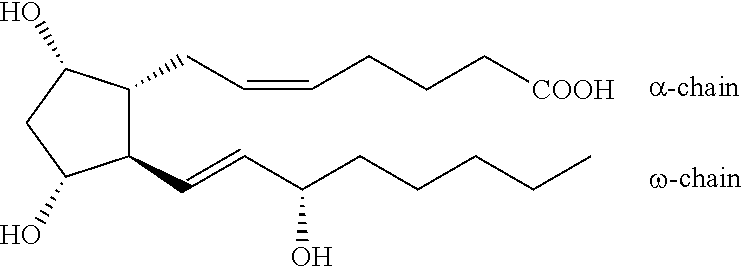

Improved process for the production of bimatoprost

InactiveUS20110178340A1Long reaction timeHigh yieldOrganic compound preparationCarboxylic acid amide separation/purificationAlcoholSolvent

The present invention relates to a process for the purification of crude bimatoprost to obtain pure bimatoprost comprising a chromatography, preferably a chromatography using an achiral stationary phase and an eluent comprising an alcohol and an apolar solvent; and crystallisation of the product obtained the chromatography to obtain pure bimatoprost.

Owner:SANDOZ AG

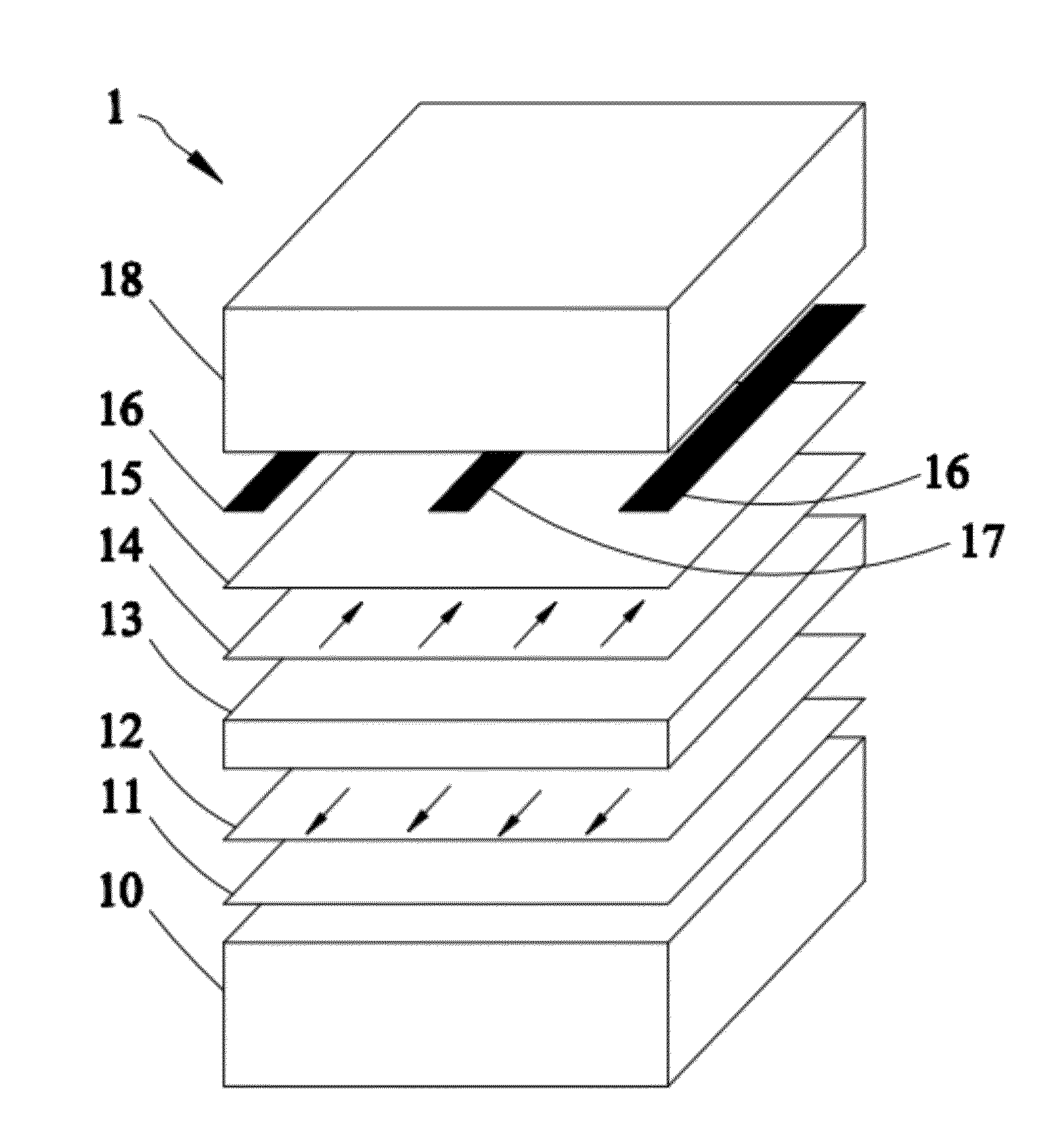

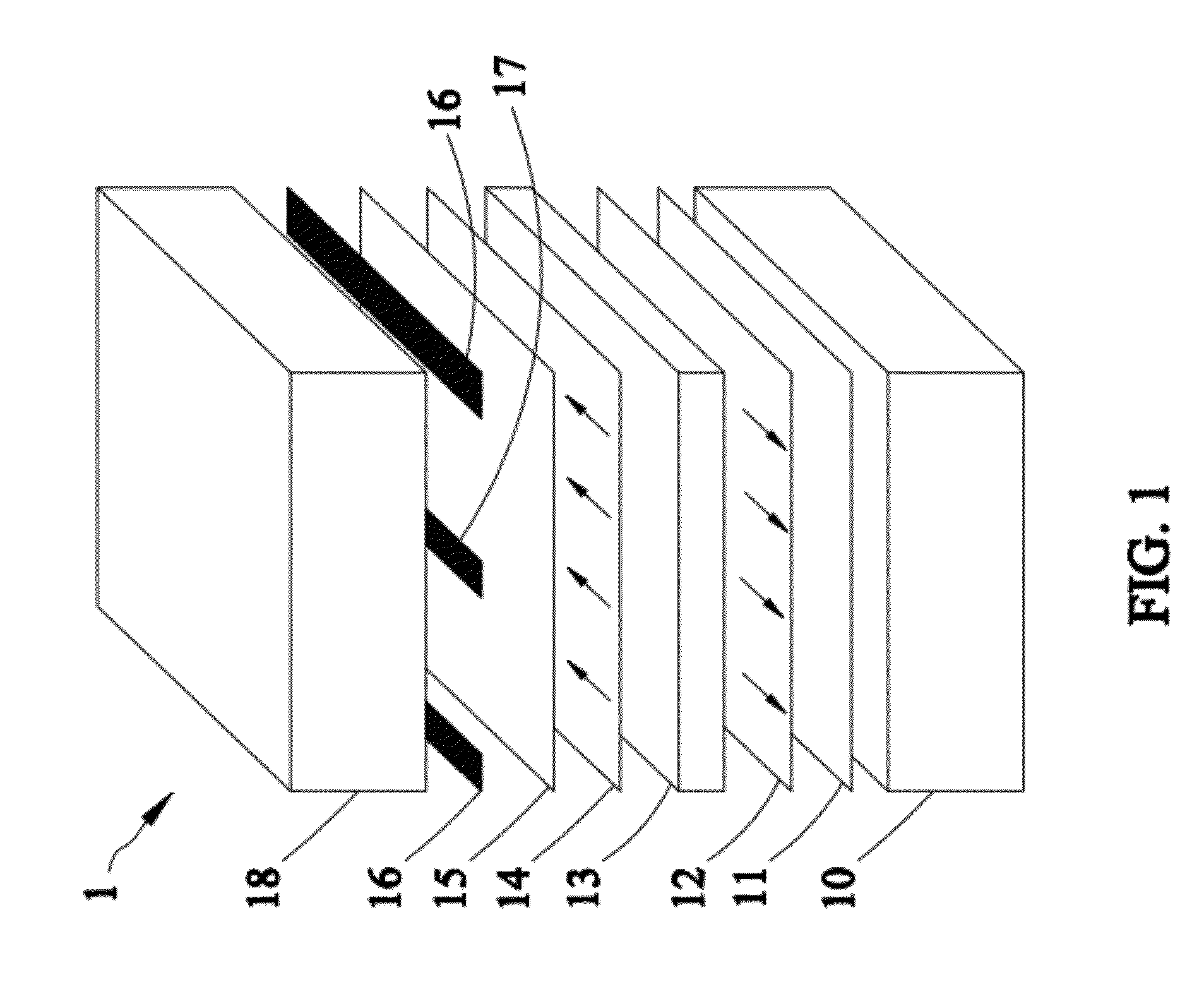

Liquid crystal lens and manufacturing method thereof

ActiveUS20120033174A1Long reaction timeIncrease working voltageNon-linear opticsLiquid-crystal displayLiquid crystal

The present invention discloses a liquid crystal lens and a manufacturing method thereof. At least one first electrode is disposed on a first substrate, a first alignment layer is disposed on the first electrode, a liquid crystal layer is disposed on the first alignment layer, a second alignment layer is disposed on the liquid crystal layer, an electric field uniformization layer is disposed on the second alignment layer, at least one second electrode and at least one third electrode are disposed on the electric field uniformization layer, and the second electrode is arranged around the third electrode. A second substrate is disposed on the second electrode and the third electrode. The third electrode which matches up with the second electrode produces an electric field gradient and the liquid crystal layer is affected uniformly by the electric field uniformization layer so as to achieve rapid focus purpose by the liquid crystal.

Owner:NAT CHIAO TUNG UNIV

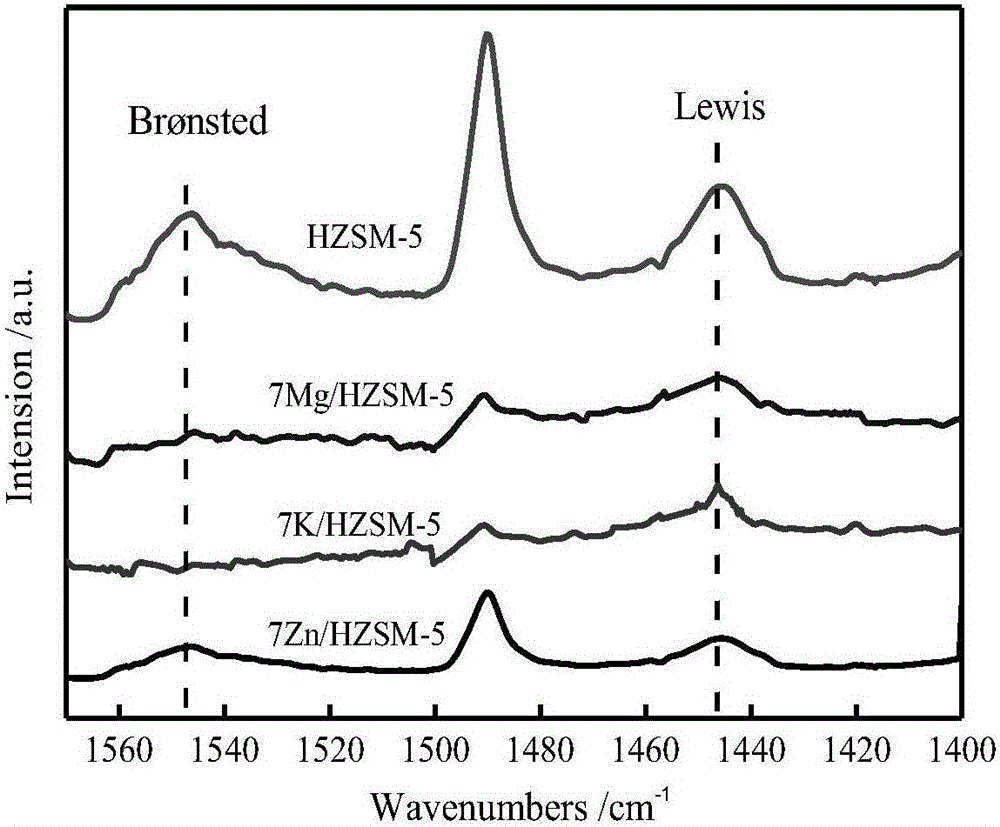

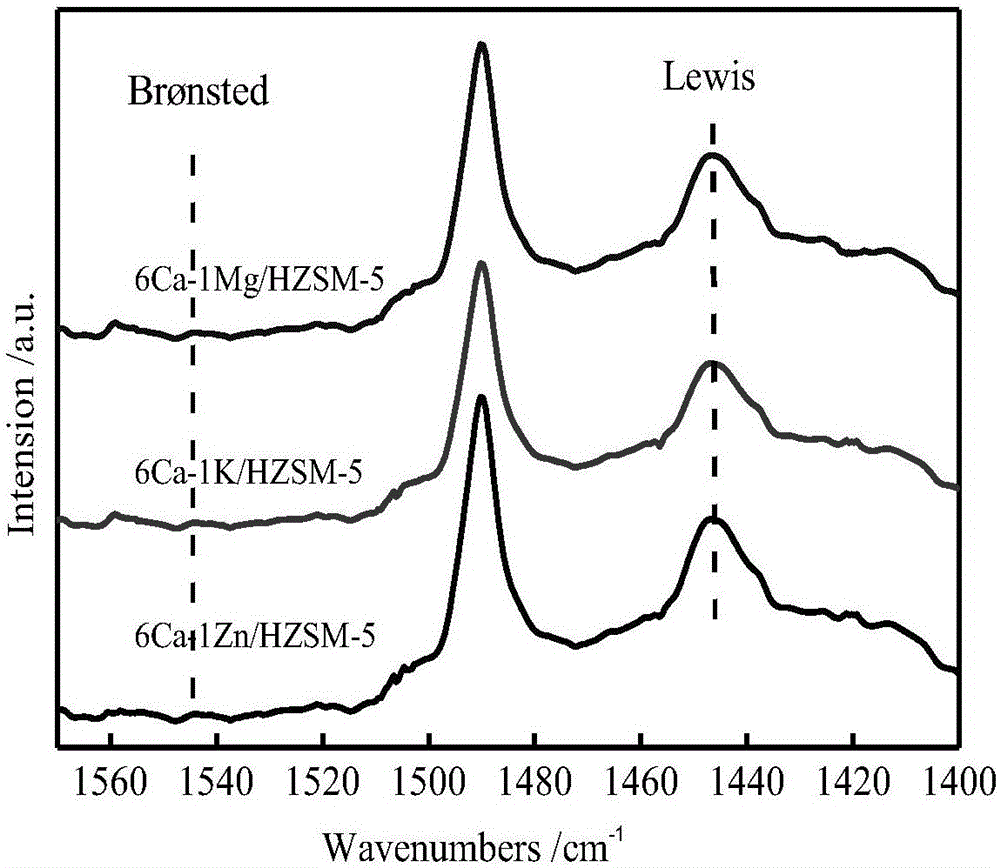

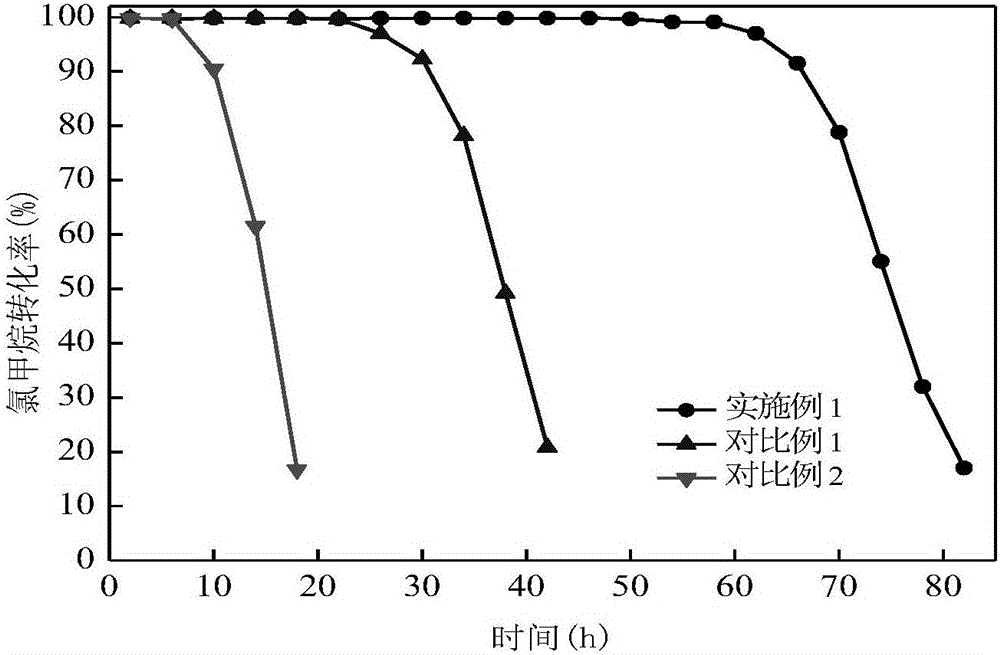

Supported composite metal molecular sieve catalyst for coupling preparation of low-carbon olefin by catalyzing chloromethane

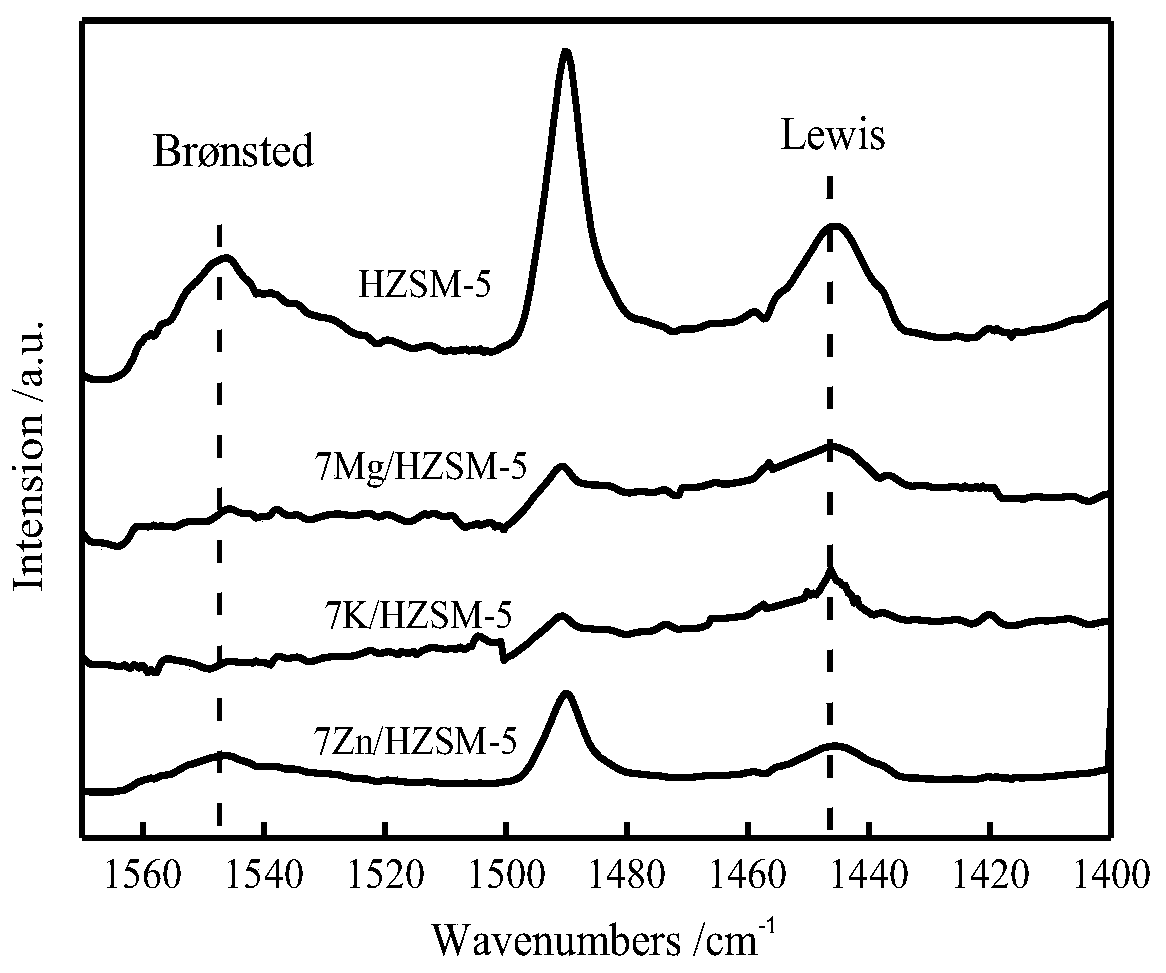

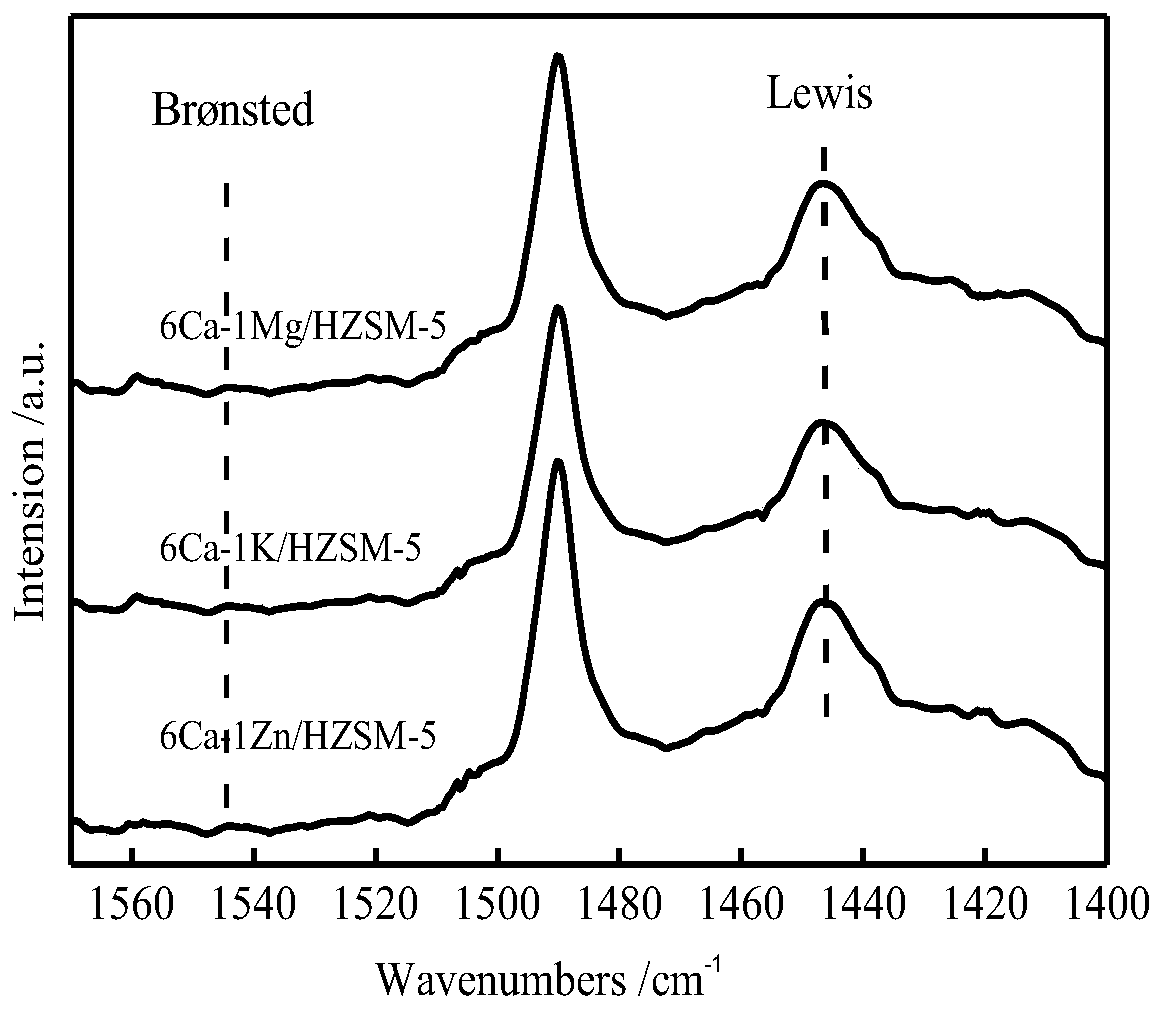

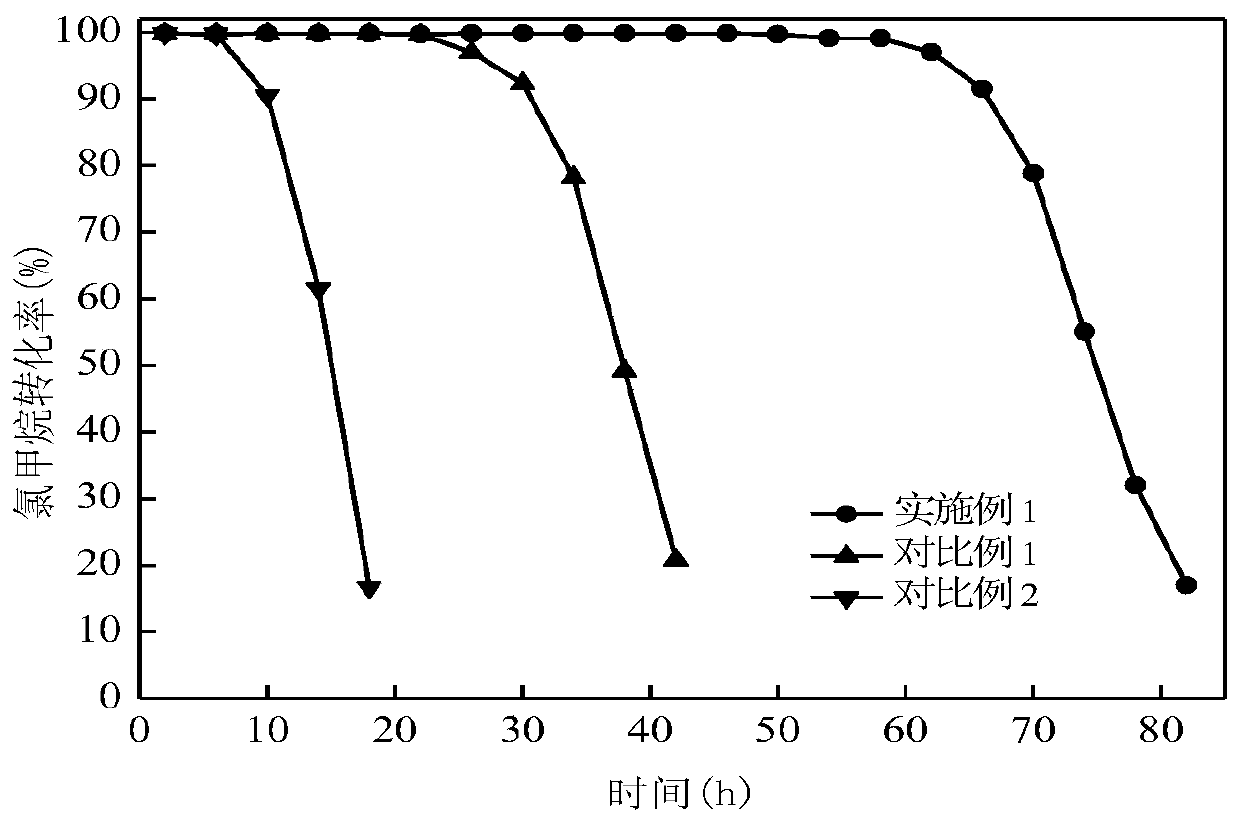

ActiveCN107175127ASimple preparation processLow priceMolecular sieve catalystsMolecular sieve catalystMolecular sieveIncipient wetness impregnation

The invention discloses a supported composite metal molecular sieve catalyst. The catalyst takes an HZSM-5 molecular sieve as a carrier, a composite metal oxide is supported on the HZSM-5 molecular sieve by an incipient-wetness impregnation method, the composite metal oxide is Ca-M, and M is Mg, Zn or K. The invention further discloses an application of the supported composite metal molecular sieve catalyst to coupling preparation reaction of low-carbon olefin (MeXTO) by catalyzing chloromethane. Composite metal is modified, Bronsted acid can disappear, Lewis acid is basically unaffected, and carbon deposition is relieved by inhibiting secondary reaction such as hydrogen transfer in MeXTO catalysis reaction, so that reaction stability is prolonged. The catalyst is low in preparation cost and has good industrial application prospect, the conversion rate of the chloromethane is high, the selectivity of the low-carbon olefin is good, and the reaction stability is prolonged in the MeXTO catalysis reaction.

Owner:NANJING UNIV OF TECH

Spatially-controlled modified porous membrane

InactiveUS7919178B2Long reaction timeInhibition of polymerizationBioreactor/fermenter combinationsBiological substance pretreatmentsPorous membraneChemistry

This invention relates to a general method to surface modify porous membranes with a free radical polymerized polymer coating in a layer which is less than the thickness of the membrane. Another object of this invention relates to a general method to surface modify porous membranes with a free radical polymerized polymer coating to a predetermined and controlled depth from a first facial surface. Another object of this invention is to provide a general method to surface modify porous membranes with a free radical polymerized polymer coating into a pattern on one or both facial surfaces, the pattern maintaining its form to a controlled depth into the membrane. Membrane modification is spatially controlled through the use of a polymerization preventing agent (PPA), which prevents modification from occurring in defined spatially volumes of the membrane. The invention relates to porous membranes surface modified by the methods described.

Owner:MILLIPORE CORP

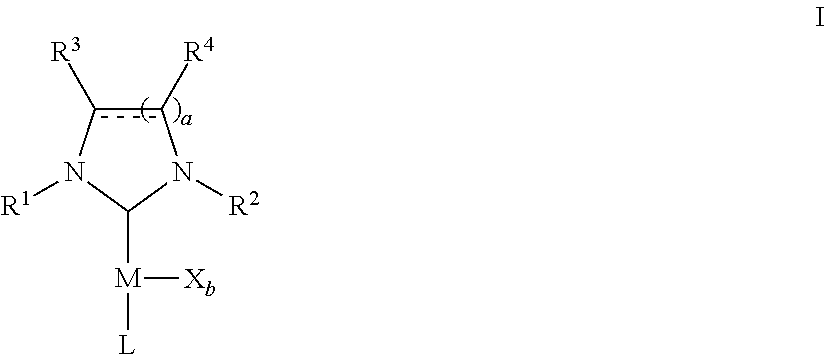

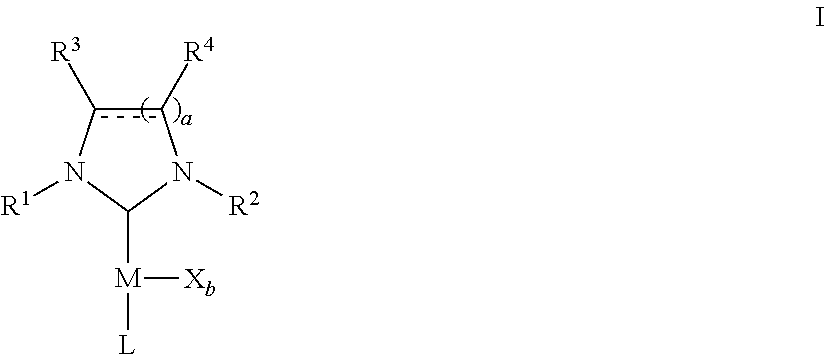

Microwave-assisted synthesis of n-heterocyclic carbene transition metal complexes

InactiveUS20130131343A1Long reaction timeRuthenium organic compoundsIndium organic compoundsCarbeneChemistry

Microwave heating is used to synthesize NHC-transition metal complexes. Reaction times for the formation of NHC-transition metal complexes is greatly reduced. The speed of the reactions allows for otherwise problematic air handling of reagents. Apparatus for carrying out the reactions is less complex than conventional apparatus and requires less energy to achieve the desired temperatures. Methods utilize salts of NHC's which overcomes the oftentimes difficult preparation of free carbenes for formation of the corresponding transition metal complexes.

Owner:UNIV OF HAWAII

Process For Extracting Values from Lithium Slag

A process for extracting values from lithium slag comprising: (a) hydrothermally treating lithium slag with an aqueous solution of an alkaline compound at selected temperature and duration; (b) performing an ion exchange step on the alkaline treated lithium slag; and (c) recovering values selected from the group consisting of aluminium compounds, silicon compounds and compounds containing silicon and aluminium.

Owner:TIANQI LITHIUM KWINANA PTY LTD

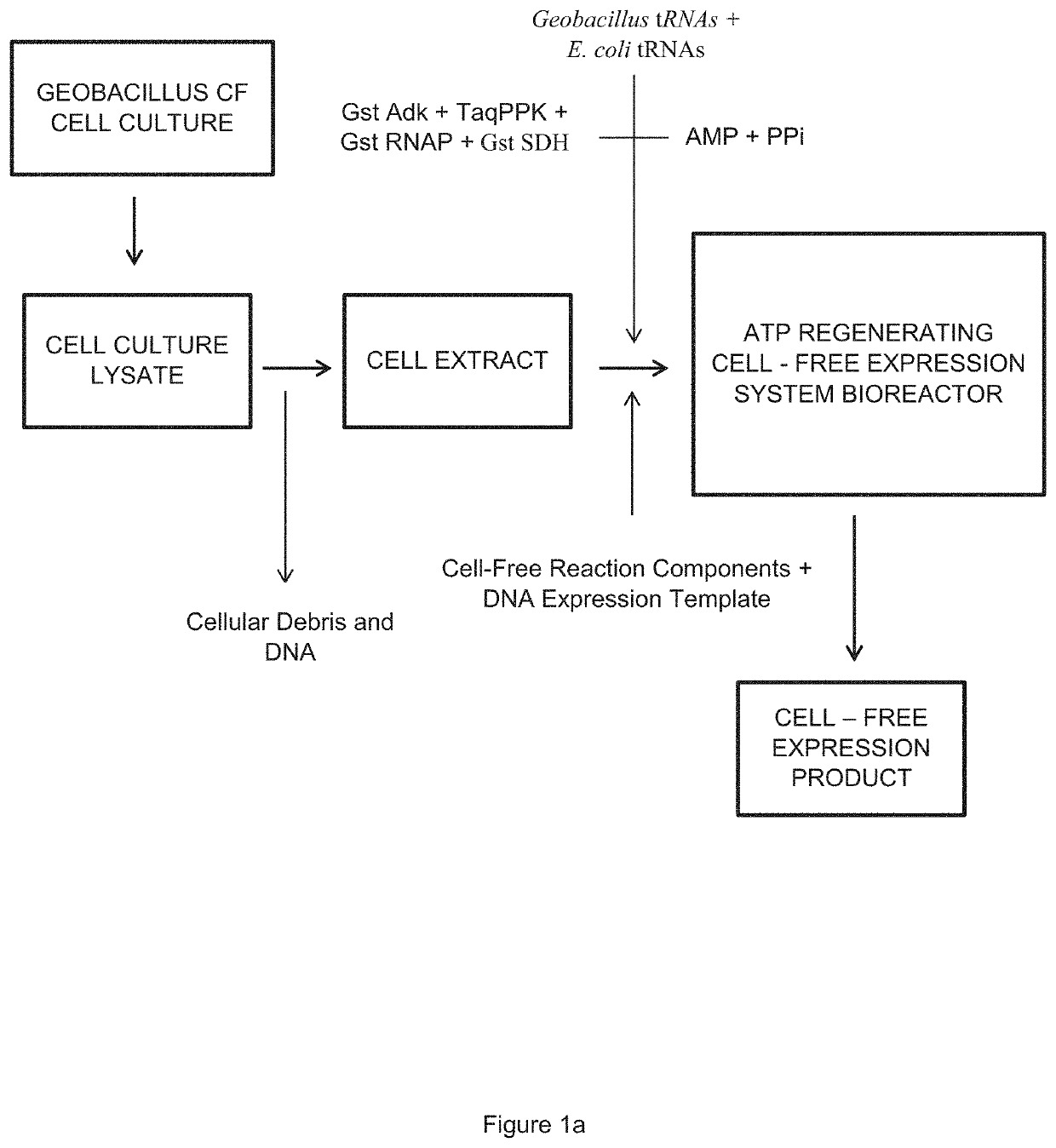

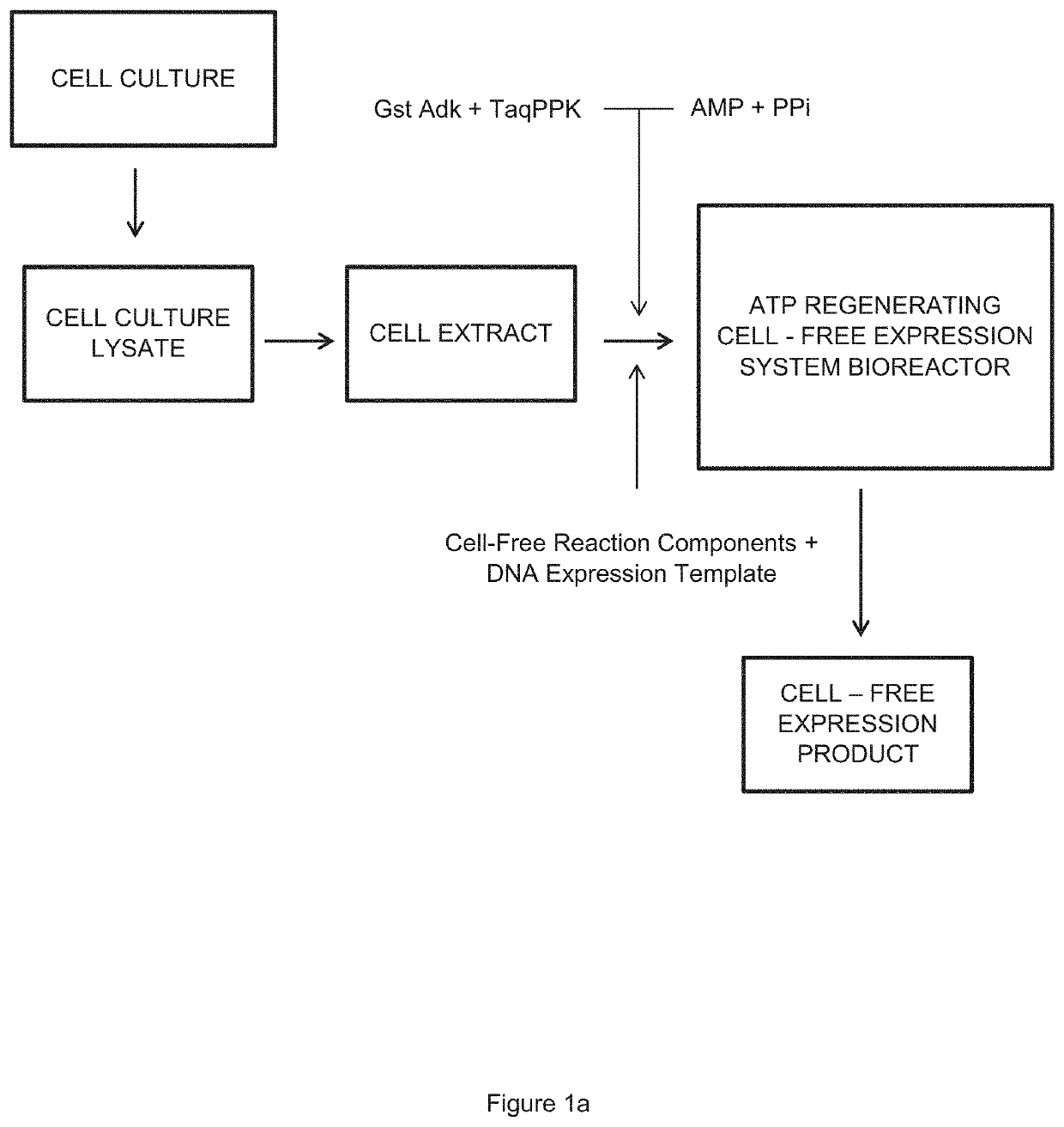

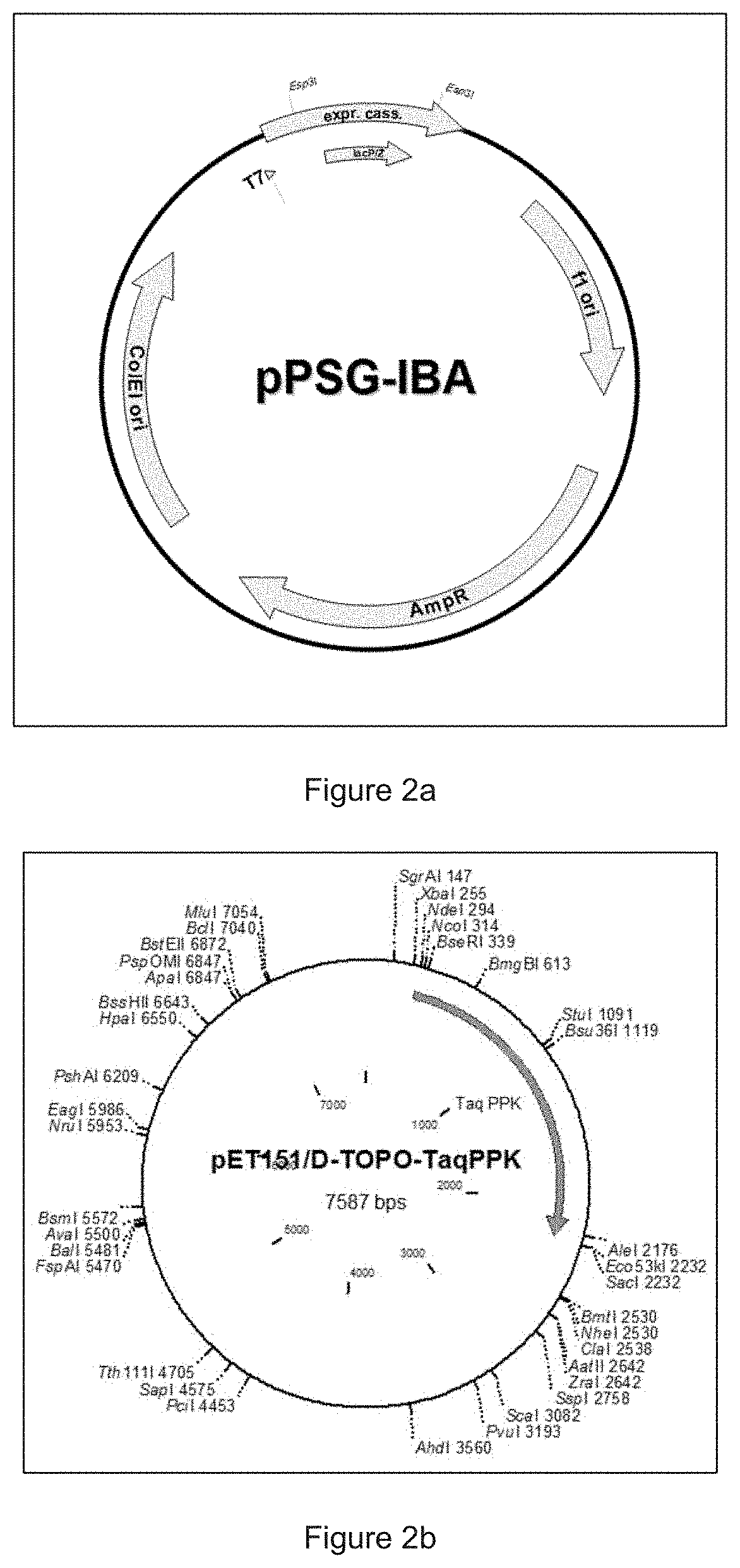

Cell-Free Expression System Having Novel Inorganic Polyphosphate-Based Energy Regeneration

PendingUS20210024912A1Long reaction timeImprove reaction efficiencyTransferasesOxidoreductasesCell freeEnzyme system

The invention relates to an in vitro cell-free expression system incorporating a novel inorganic polyphosphate-based energy regeneration system. In certain embodiments, the invention includes a cell-free expression system where the cellular energy source, ATP, is regenerated from inorganic polyphosphate using a dual enzyme system. In this embodiment, this dual enzyme system may include thermostable Adenosyl Kinase, and / or Polyphosphate Kinase enzymes.

Owner:NATURES TOOLBOX INC

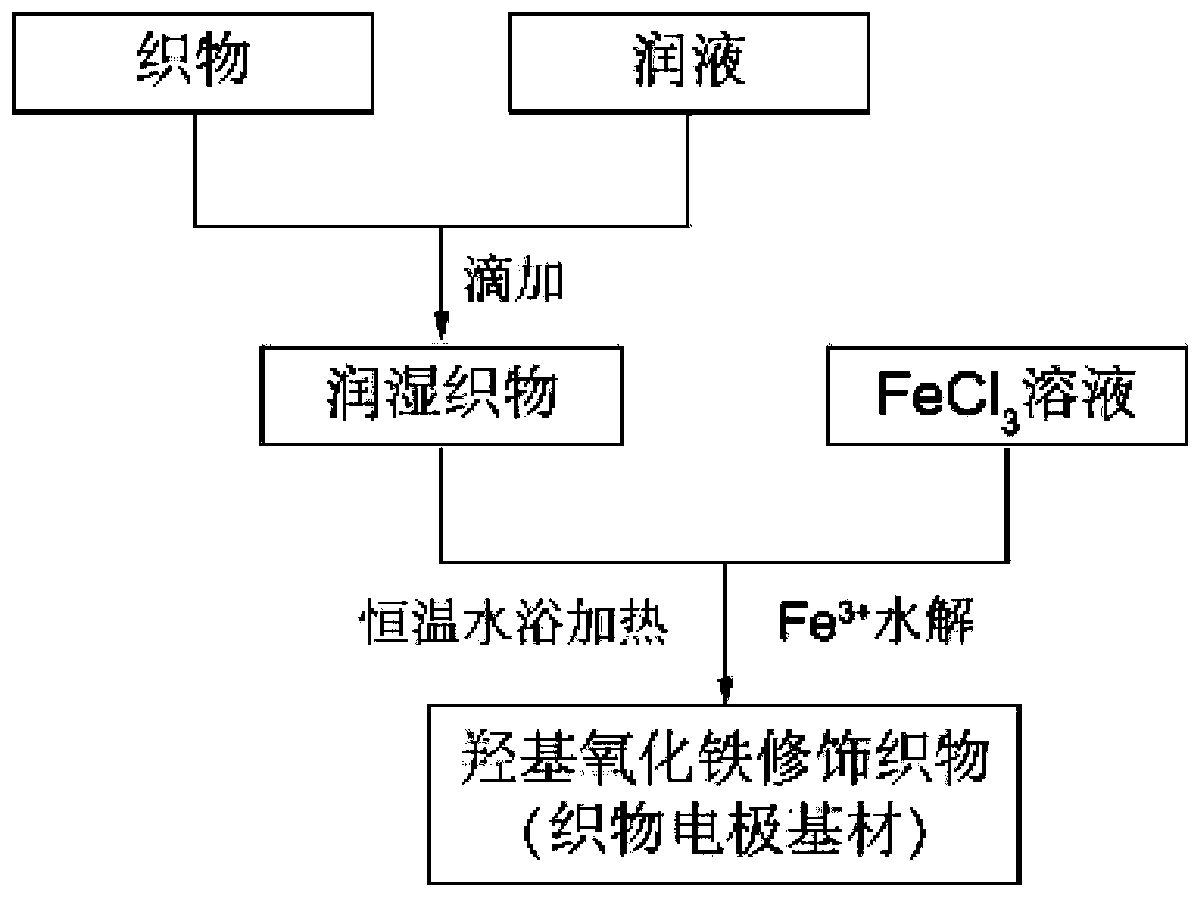

Fabric electrode substrate and application and preparation method thereof

The invention discloses a fabric electrode substrate and application and a preparation method thereof. The fabric electrode substrate comprises a fabric modified with hydroxyl oxidize iron, and the fabric is a cotton fabric or a polyester fabric. According to the application, the fabric electrode substrate is used for preparing a fabric electrode with polypyrrole or polyaniline as a main active material. The preparation method comprises the following steps that a, the wetted fabric is placed in a FeCl3 water solution, soaked with the FeCl3 water solution and stirred; b, the mixture obtained inthe step a is stirred in a temperature-constant water bath; c, the product obtained in the step b is cooled, thoroughly cleaned and dried in sequence, and then the hydroxyl oxidize iron modified fabric electrode substrate is obtained. The preparation process of the hydroxyl oxidize iron modified fabric electrode substrate is relatively simple, the reaction time is not long, the cost is low, and large-scale production can be achieved; the single reagent FeCl3 6H2O is used as the raw material, acid or alkali or an oxidizing agent are not needed, and hydroxyl oxidize iron is directly deposited on the surface of the fabric through the hydrolysis reaction of Fe<3+> within a short time.

Owner:JIANGNAN UNIV

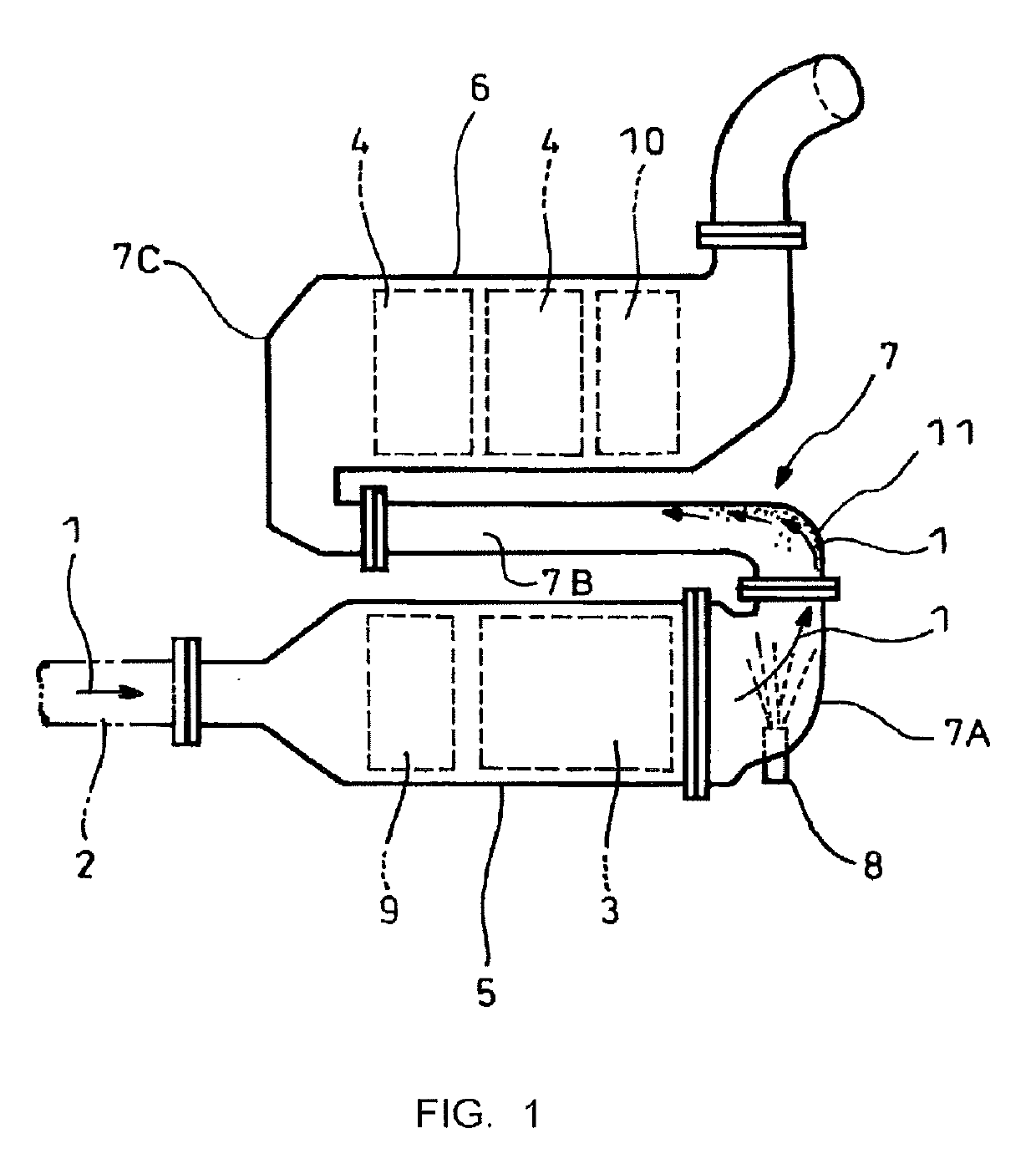

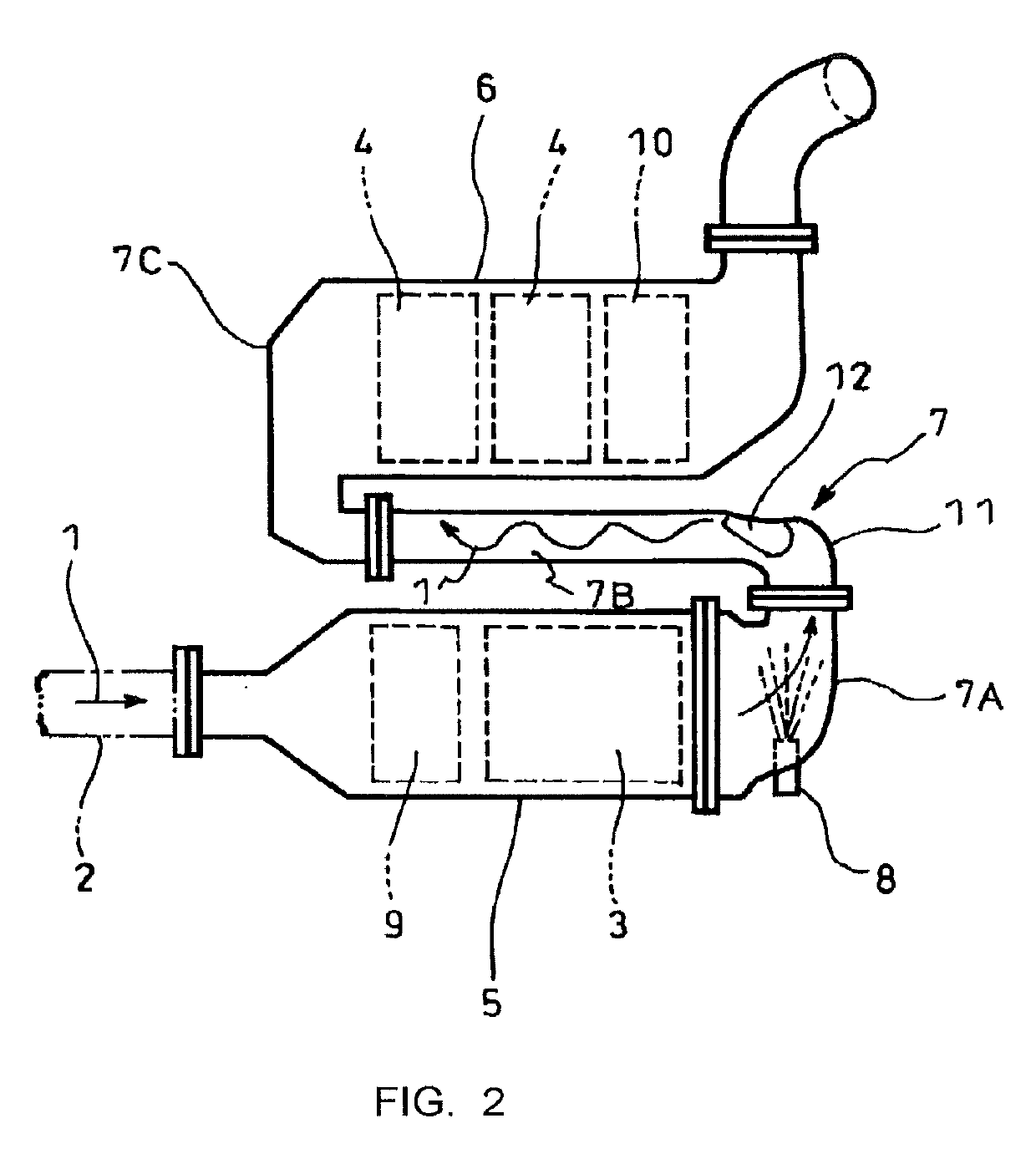

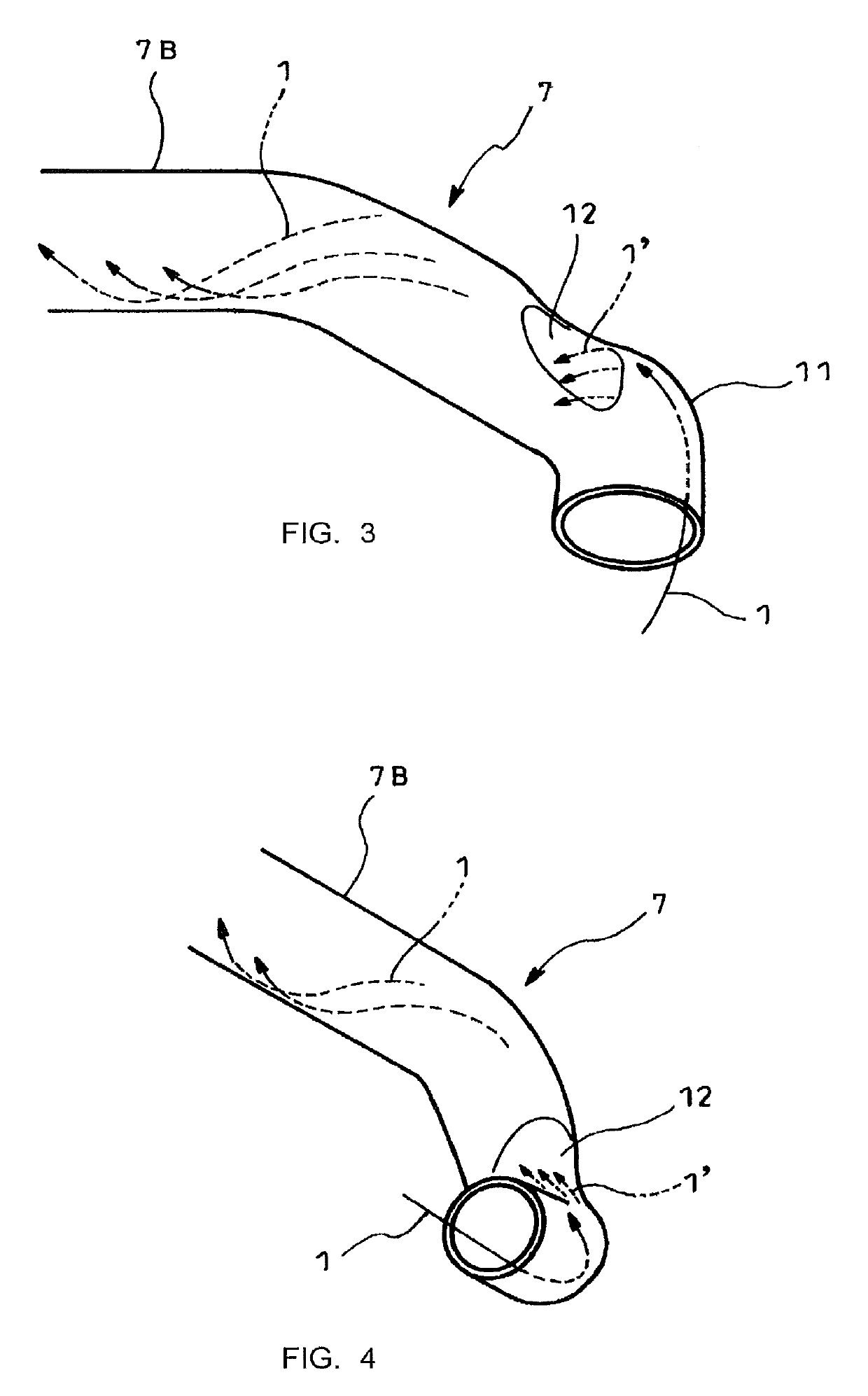

Mixing structure

ActiveUS20190292966A1High exhaust depuration effectLong reaction timeInternal combustion piston enginesFlow mixersExhaust gasUrea

Disclosed is a mixing structure for spraying and mixing urea water (additive agent) into and with exhaust gas 1 flowing through a communication passage 7 (exhaust flow passage). The mixing structure is provided with a curved portion 11 in the communication passage 7 downstream of a sprayed position of the urea water as well as a depression 12 on an exit side of the curved portion 11 and formed on only one of sides of the curved portion 11 bisected by a plane into plane symmetry.

Owner:HINO MOTORS LTD

A supported composite metal molecular sieve catalyst for catalyzing the coupling of methyl chloride to prepare low-carbon olefins

ActiveCN107175127BSimple preparation processLow priceMolecular sieve catalystsMolecular sieve catalystMolecular sieveCoupling

The invention discloses a supported composite metal molecular sieve catalyst. The catalyst takes an HZSM-5 molecular sieve as a carrier, a composite metal oxide is supported on the HZSM-5 molecular sieve by an incipient-wetness impregnation method, the composite metal oxide is Ca-M, and M is Mg, Zn or K. The invention further discloses an application of the supported composite metal molecular sieve catalyst to coupling preparation reaction of low-carbon olefin (MeXTO) by catalyzing chloromethane. Composite metal is modified, Bronsted acid can disappear, Lewis acid is basically unaffected, and carbon deposition is relieved by inhibiting secondary reaction such as hydrogen transfer in MeXTO catalysis reaction, so that reaction stability is prolonged. The catalyst is low in preparation cost and has good industrial application prospect, the conversion rate of the chloromethane is high, the selectivity of the low-carbon olefin is good, and the reaction stability is prolonged in the MeXTO catalysis reaction.

Owner:NANJING TECH UNIV

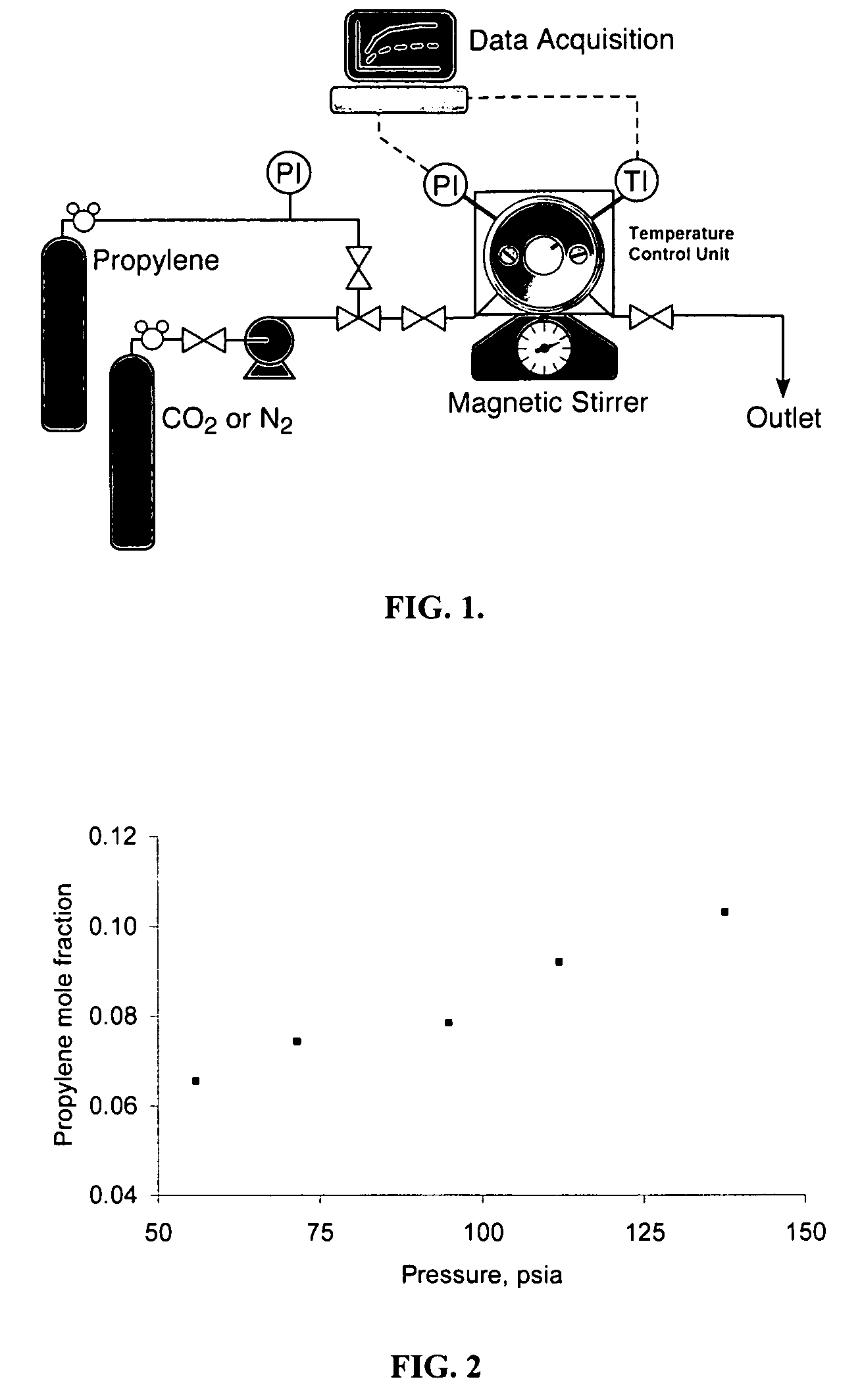

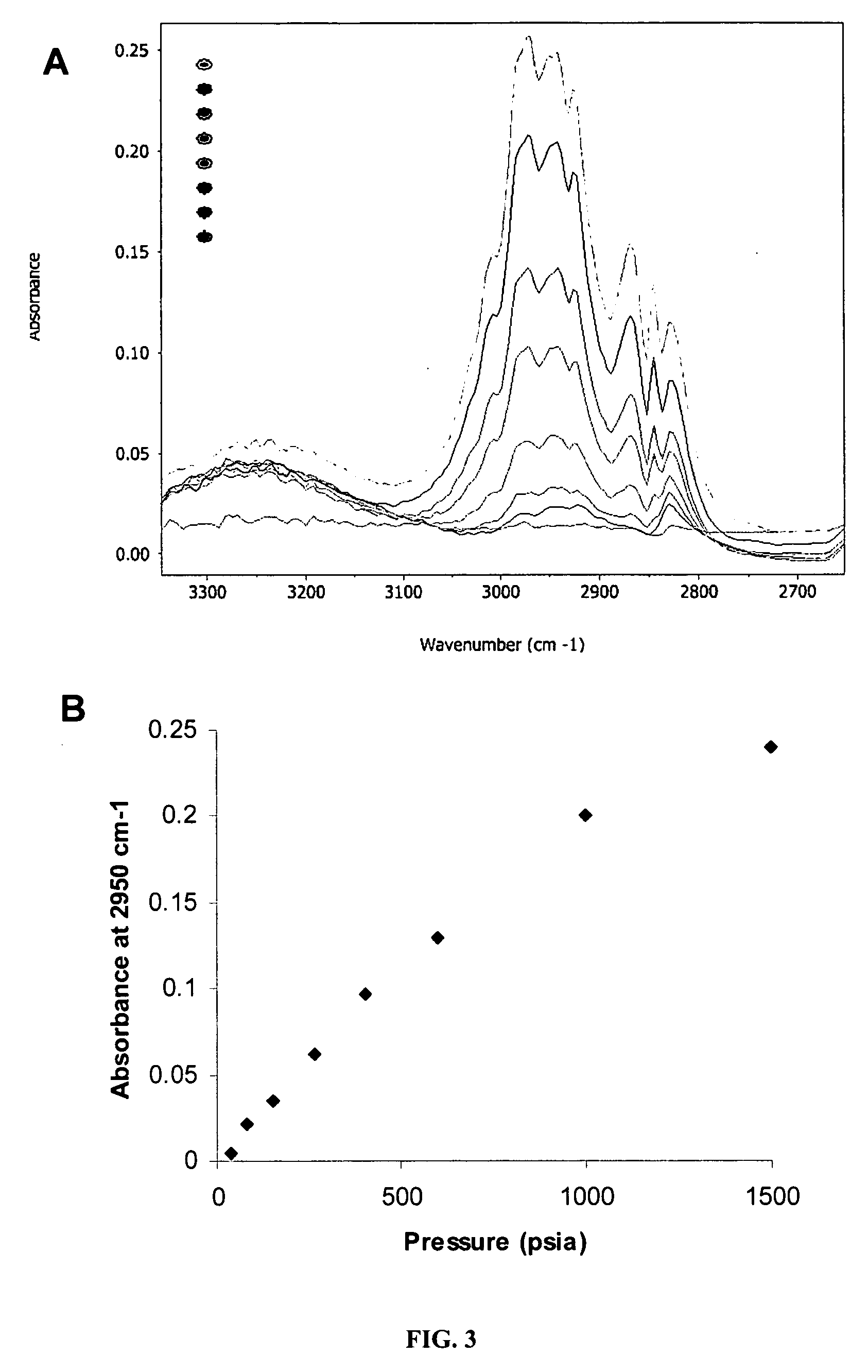

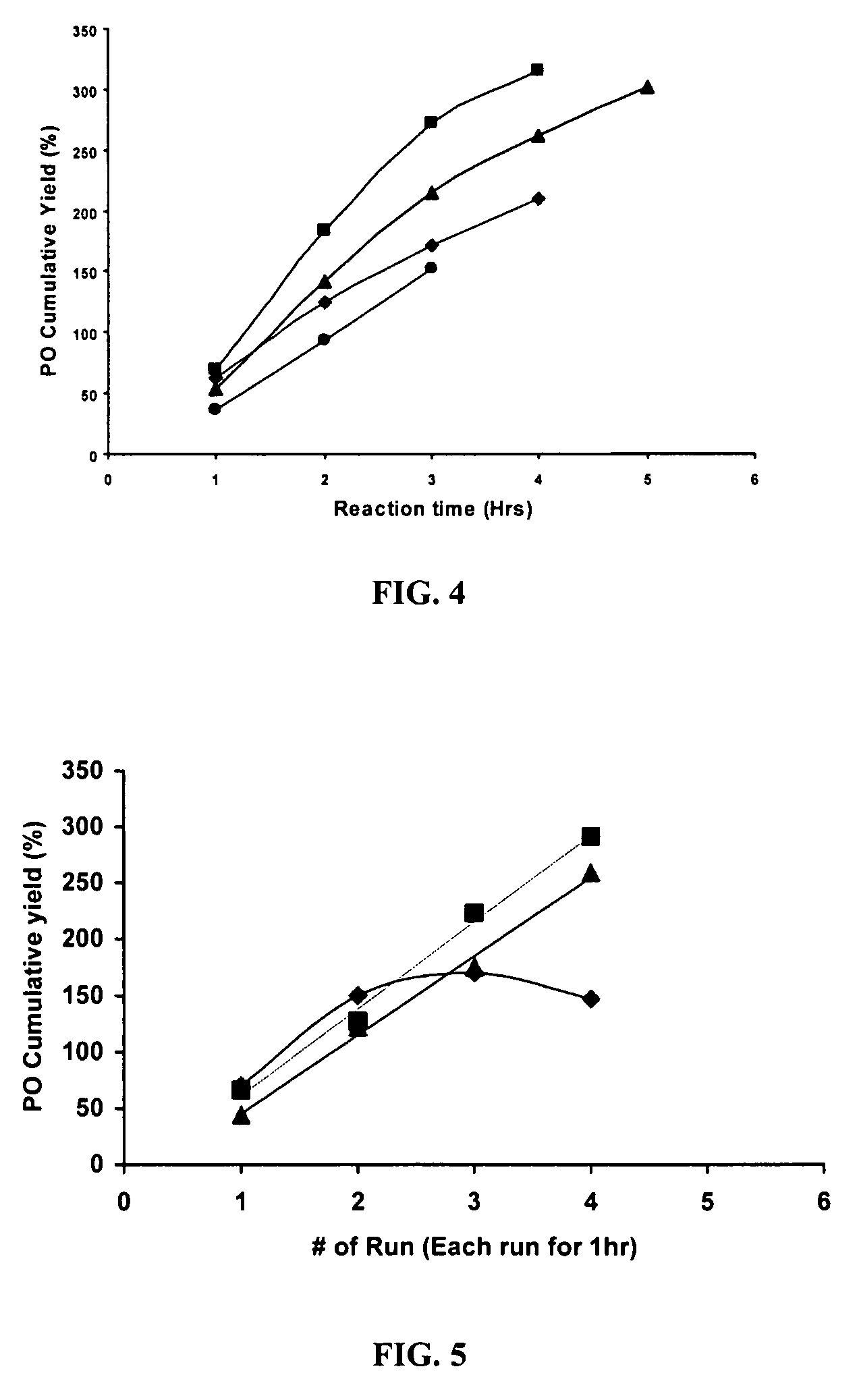

Process for selective oxidation of olefins to epoxides

ActiveUS20070093666A1Improve catalytic performanceHigh activityOrganic chemistryChemical recyclingOrganic baseNitrogen gas

A process for the selective oxidation of olefins to epoxides comprising the step of contacting the olefin (propylene) with an oxidant (hydrogen peroxide) in the presence of a Lewis acid oxidation catalyst (MTO), organic base (pyridine or its N-oxide), in a solvent system comprising an organic water-miscible solvent (methanol); and adding a pressurizing gas (nitrogen) to increase the pressure, whereby olefin is further dissolved in organic solvent system to increase the selectivity and yield of the desired epoxide (propylene oxide).

Owner:UNIVERSITY OF KANSAS

A clean preparation method of magnesium-aluminum-based layered composite hydroxide

ActiveCN105836769BRich sourcesIncrease spawn rateAluminium compoundsZinc compoundsAluminateStrong acids

A clean preparation method of magnesium-aluminum-based layered composite hydroxide. The present invention uses magnesium hydroxide and magnesium oxide, pseudo-boehmite, inorganic strong acid, and functional anion-containing substances as raw materials, uses magnesium chloride or magnesium nitrate as a circulating medium, and utilizes the property that pseudo-boehmite can be peptized under acidic conditions Improve the reactivity of pseudo-boehmite, use magnesium chloride or magnesium nitrate to increase the concentration of magnesium ions in the solution, accelerate the formation rate of layered composite hydroxide and promote the dissolution of magnesium hydroxide and magnesium oxide, shorten the reaction time, overcome the water The preparation of layered composite hydroxide by thermal method has the disadvantages of high reaction temperature and long time consumption, but magnesium-aluminum-based layered composite hydroxide can be rapidly prepared under mild conditions. Magnesium chloride and magnesium nitrate can be recycled, and there is no waste discharge in the preparation process, which is green and environmentally friendly. The method has the advantages of rich source of raw materials, low price, simple preparation process, mild reaction conditions, easy industrial production and the like.

Owner:BEIJING UNIV OF CHEM TECH

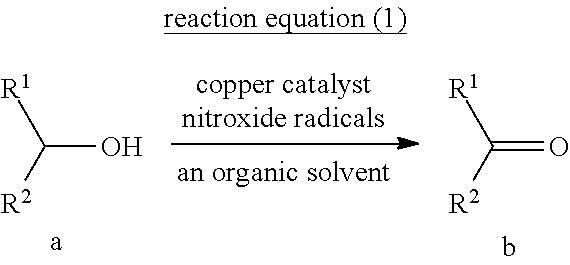

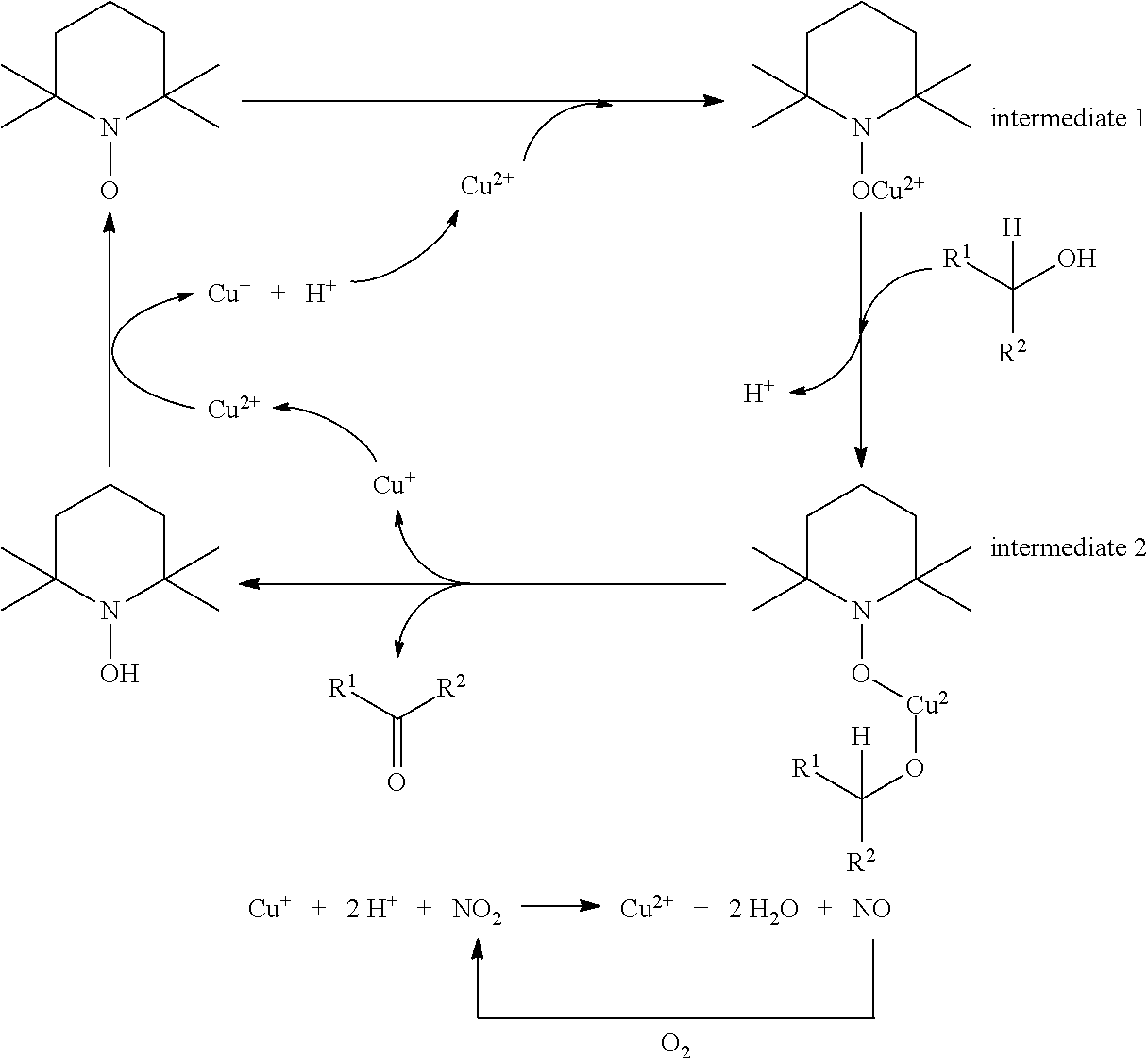

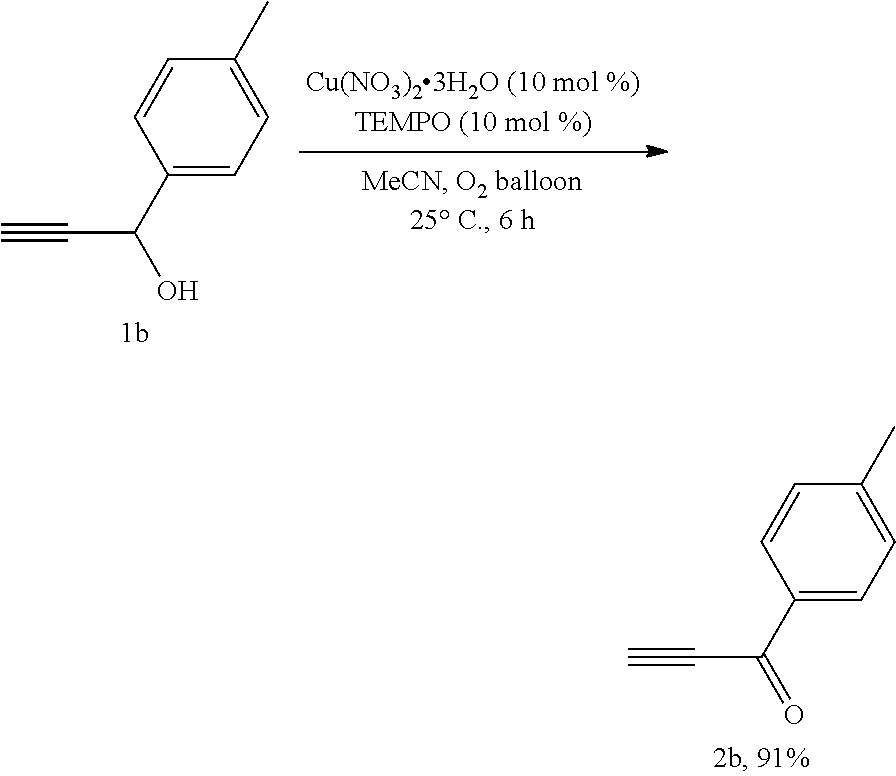

A copper-catalyzed method and application for preparing aldehydes or ketones by oxidizing alcohols with oxygen as an oxidant

InactiveUS20220127215A1Wide substrate universalityHigh catalytic efficiencyGroup 4/14 element organic compoundsCarboxylic acid nitrile preparationPtru catalystKetone

The present invention discloses a method for preparing aldehydes or ketones via aerobic oxidation of alcohols with the copper salts and nitroxide radicals as catalysts. Both oxygen and air could be used as oxidants, after 4 to 48 hours of reaction in an organic solvent at room temperature, the alcohols are efficiently oxidized to the corresponding aldehydes or ketones. The present invention has the following advantages: easy to operate, refraining from using chlorides which are corrosive to equipment, readily available raw materials and reagents, mils reaction conditions, the broad substrate scope, good functional group tolerance, convenient purification, environmentally friendly and no pollution. Thus, the method is suitable for industrial production.

Owner:FUDAN UNIV

Ink for ink-jet recording

ActiveUS20070186809A1Short reaction timeLong reaction timeDuplicating/marking methodsInksAmmoniumNuclear chemistry

Owner:BROTHER KOGYO KK

Method for producing calcium dipropionate

ActiveUS20180186717A1Long reaction timeLack of homogeneityProcess control/regulationOrganic compound preparationCalcium hydroxidePropanoic acid

The invention relates to a solid-material method for producing calcium dipropionate in a pressure-resistant solid-state mixing reactor by charging calcium oxide, calcium hydroxide or calcium carbonate or mixtures of these calcium compounds, and adding propionic acid by a reaction directly in the solid phase under a pressure that is increased above normal pressure.

Owner:ADDCON EURO

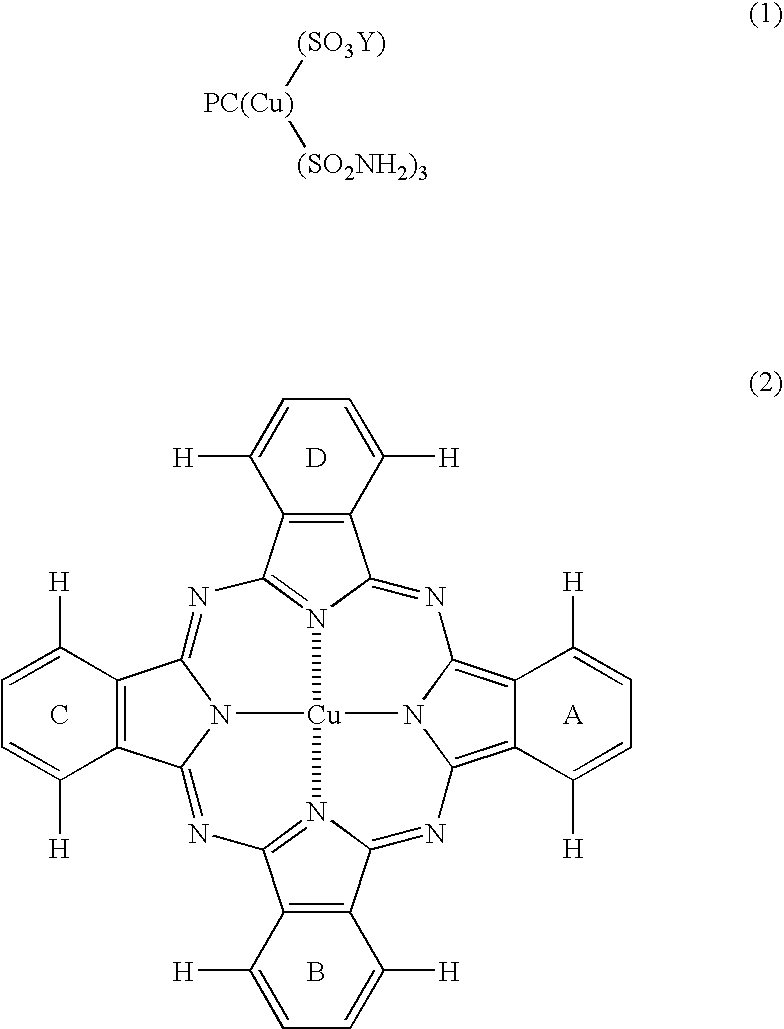

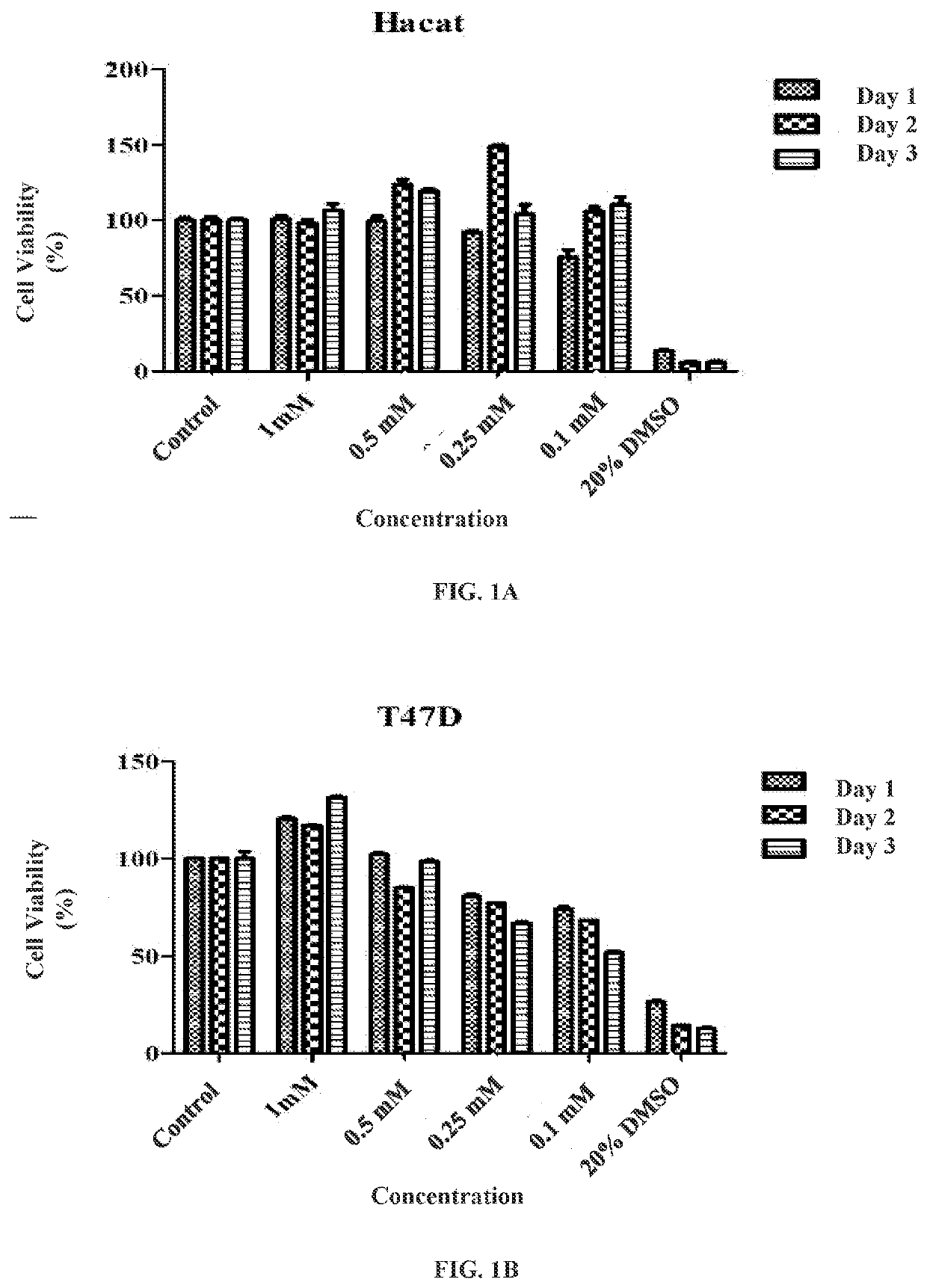

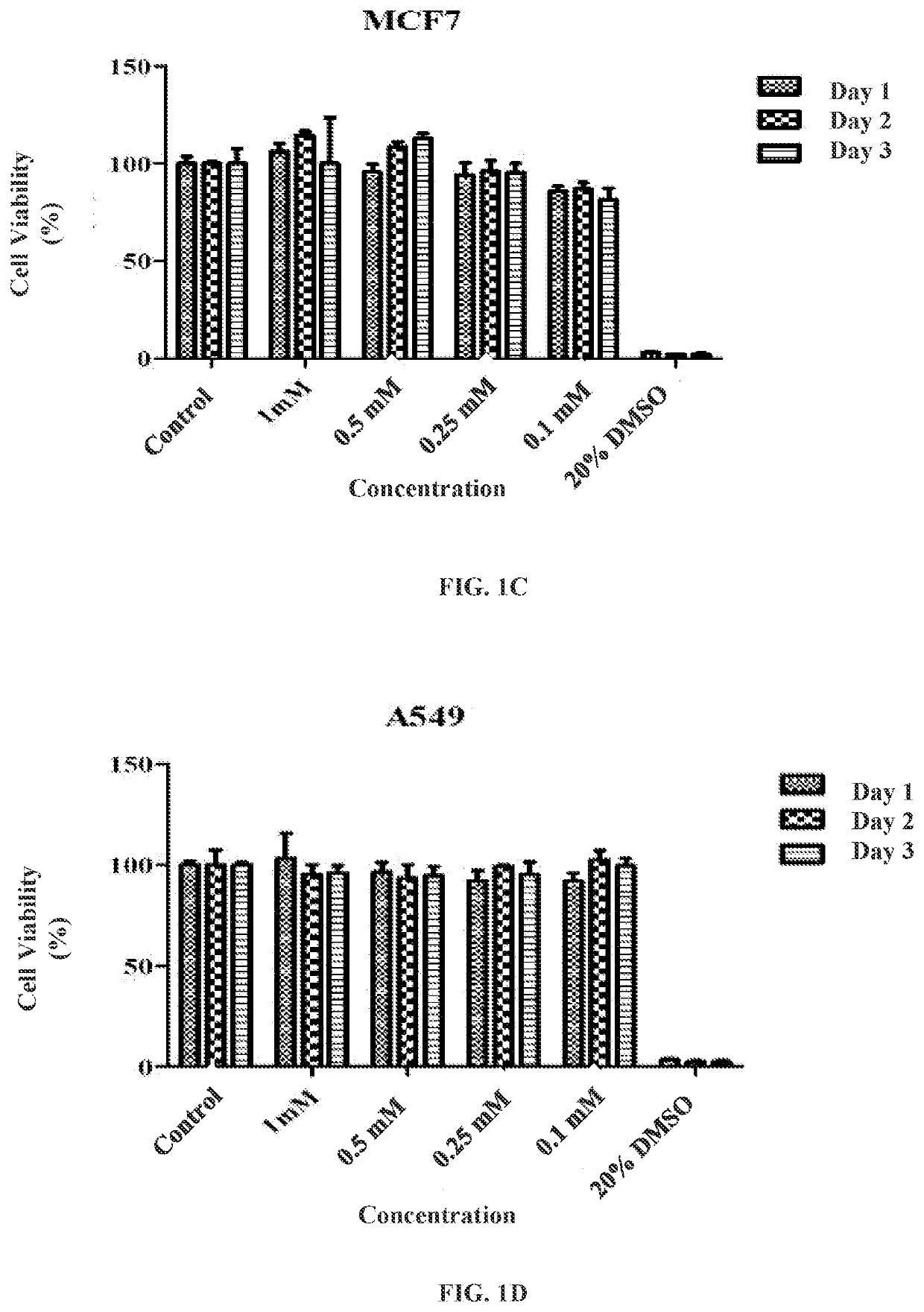

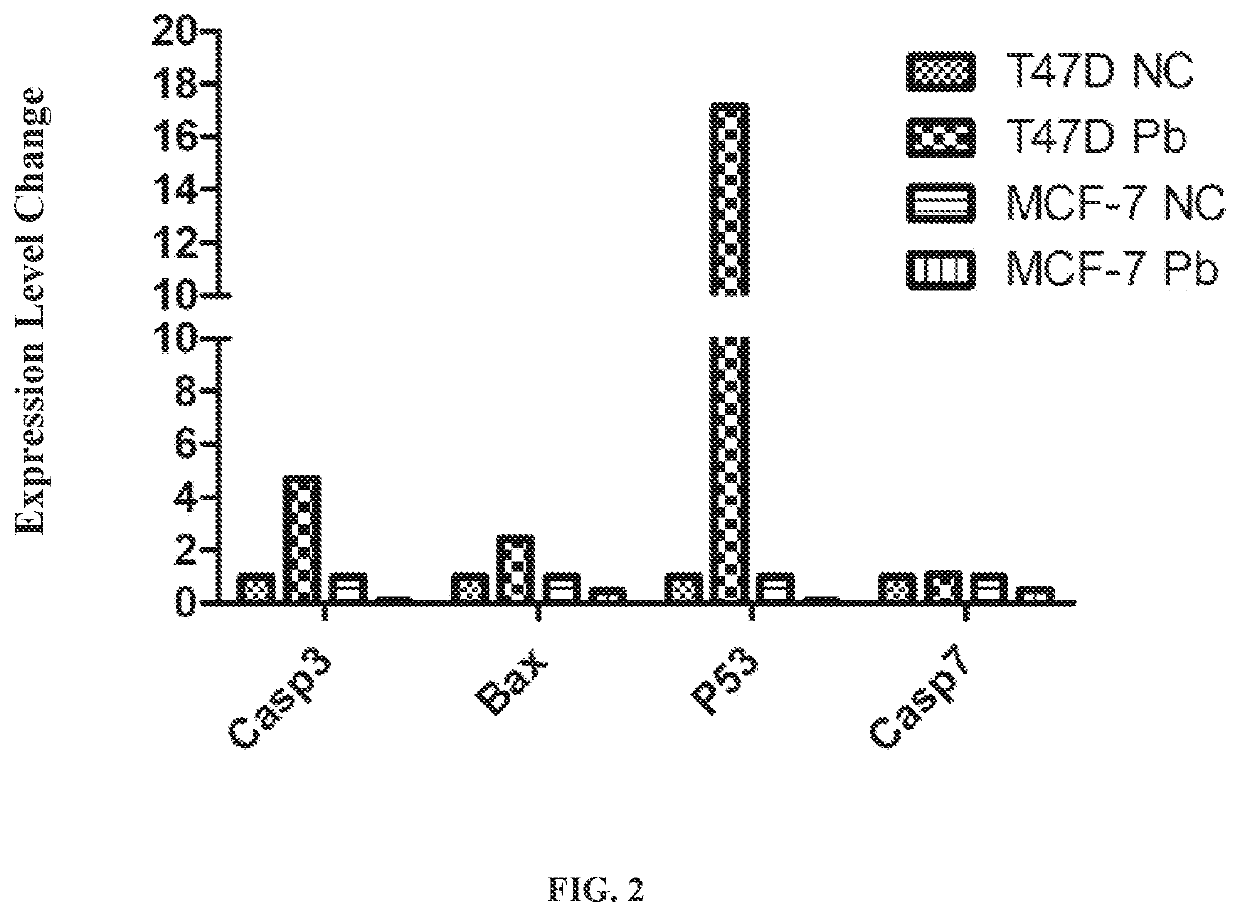

Use of mutant p53 gene targeted lead borate nanoparticles in cancer treatment and production method of these nanoparticles

PendingUS20220000910A1Easy and economical and suitable for fabricationLong reaction timePowder deliveryInorganic active ingredientsLead nitrateGene targeting

Use of nano-sized lead borate compounds for treatment purposes due to their selective anticancer activity on p53 mutant breast cancer cell line, T47D is disclosed. The method of synthesizing nano-sized lead borates of the present invention comprises the steps of preparing a borate buffer solution by sodium hydroxide and boric acid, dissolving lead nitrate (and preferably PEG) in distilled water by stirring, mixing the borate buffer solution with the lead nitrate (and preferably PEG) solution, washing the resulting solution with distilled water and drying to remove the impurities.

Owner:YEDITEPE UNIVSI

A Method for Enzymatic Resolution of Chiral Substances

PendingUS20220017935A1Low costReduce reaction efficiencyHydrolasesMicroorganism based processesChiral selectivityFood technology

The invention belongs to the field of bioengineering and food technology, and discloses a method for enzymatic resolution of chiral substances, including the following steps: (1) preparing an enzyme solution with a lipase concentration of 1-3000 U / mL, and adding a soluble salt, a hydrophilic solvent and a hydrophobic solvent to the enzyme solution to form a three-liquid phase system; the hydrophobic solvent contains esters or amide compounds composed of racemic chiral compounds; (2) subjecting the three-liquid phase system to enzyme-catalyzed reaction under stirring condition; after the reaction is completed, standing or centrifuging the three-liquid phase system to divide it into three layers, which are a upper liquid layer, a middle liquid layer and a lower liquid layer from top to bottom. The optically pure chiral product after hydrolysis is mainly rich in the middle liquid layer or the lower liquid layer, while the upper liquid layer product is another ester or amide product containing an optically pure chiral product. The method has the advantages of low energy consumption, high raw material utilization rate, and mild reaction conditions, and solves the problems of low chiral resolution efficiency, poor chiral selectivity, low recovery rate, and difficulty in industrialization in the existing enzymatic method.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com