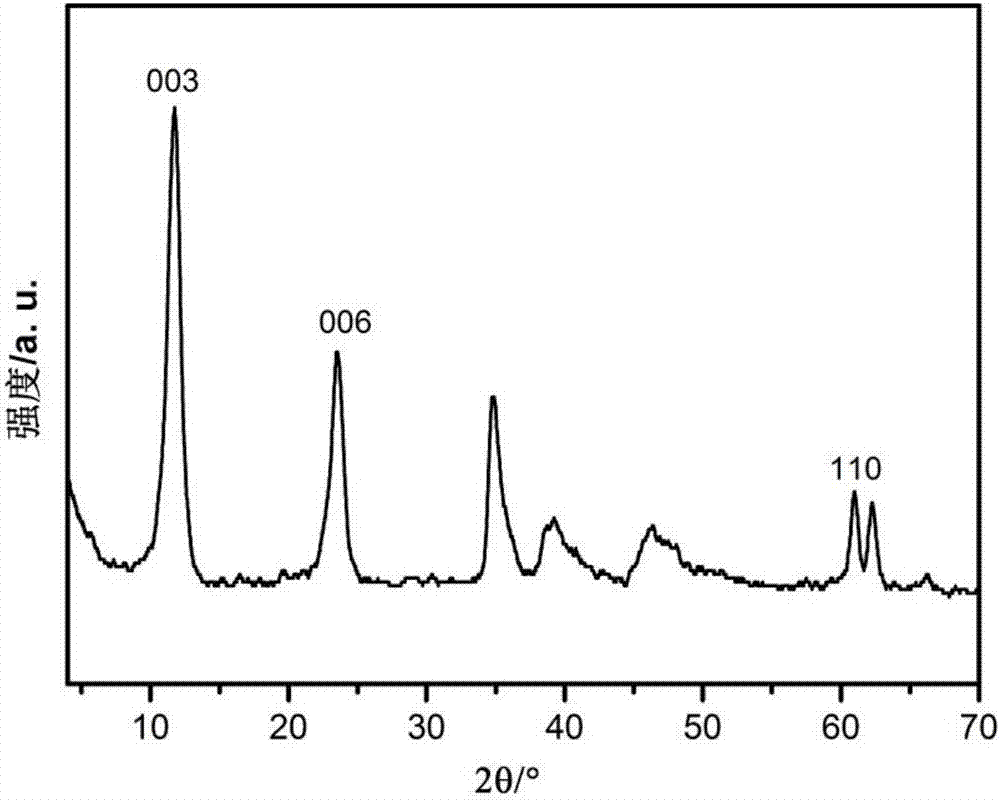

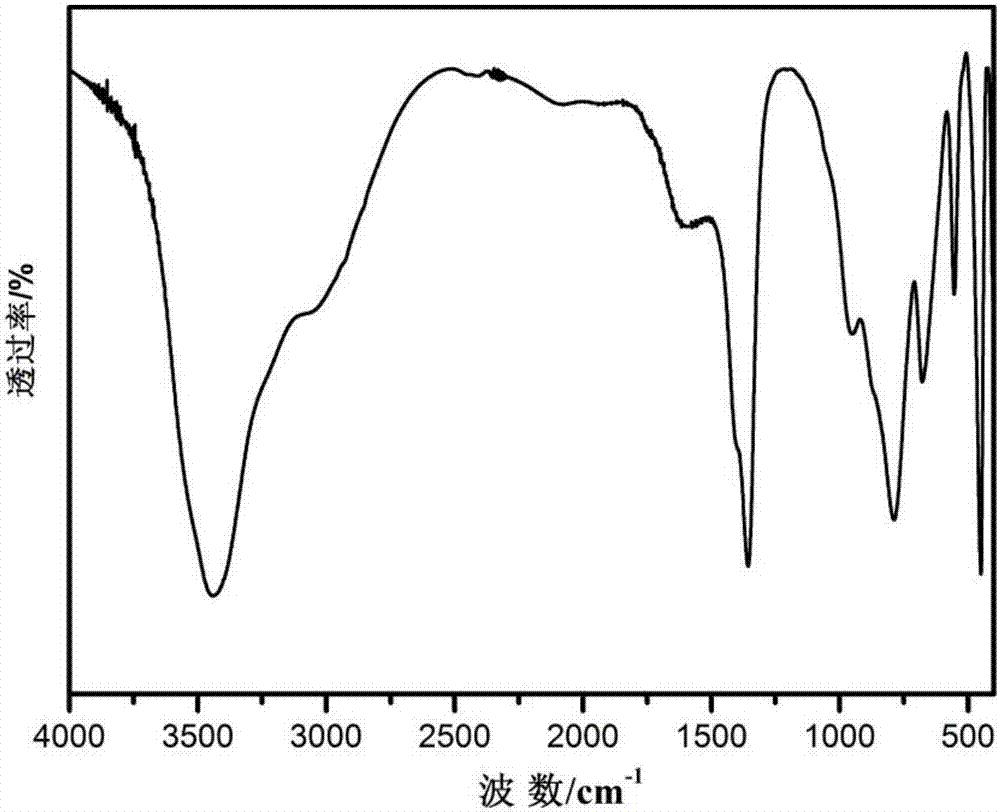

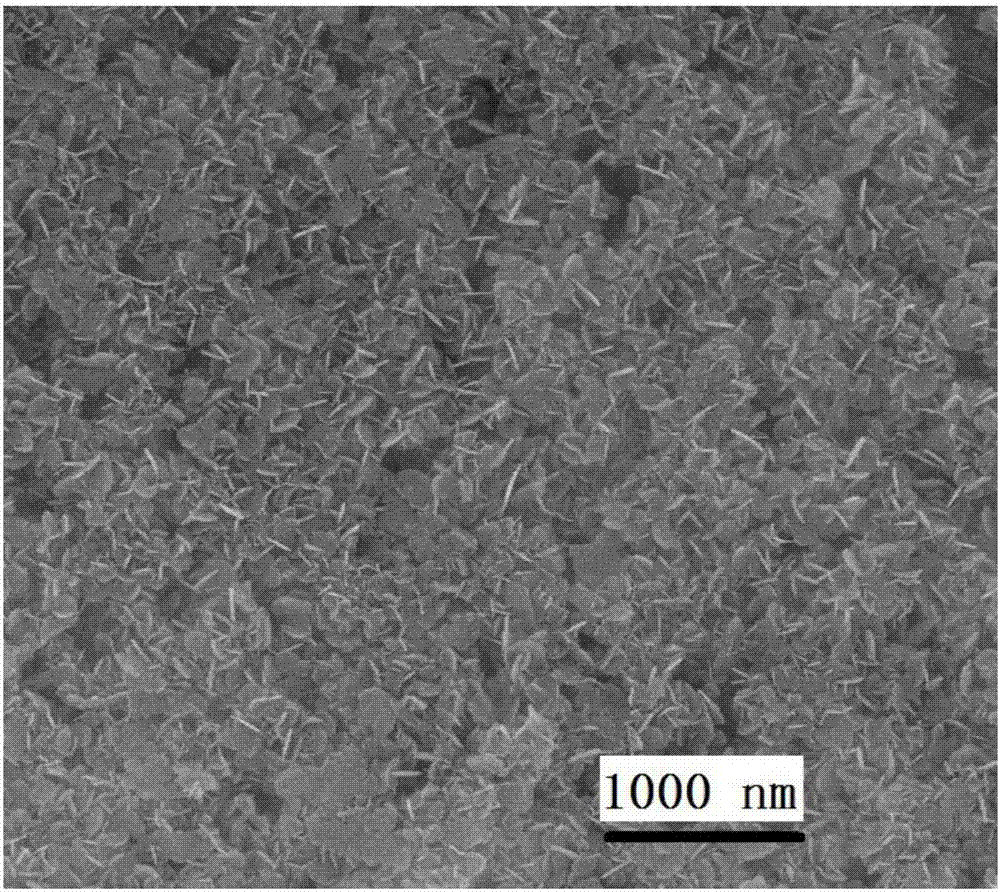

A clean preparation method of magnesium-aluminum-based layered composite hydroxide

A composite hydroxide and base layer technology, applied in the directions of aluminum compounds, chemical instruments and methods, nickel compounds, etc., can solve the problems of accelerating the formation rate of layered composite hydroxides, shortening the reaction time, and high reaction temperature, and achieving easy industrialization. The effect of production, shortened reaction time, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step A: Weigh 3.48g of magnesium hydroxide into 50g of deionized water, grind in a ball mill for 10 minutes to prepare A slurry.

[0024] Step B: Weigh out 2.564g Mg(NO 3 ) 2 .6H 2 O was added to 20ml deionized water to make a solution, and Mg(NO 3 ) 2 The solution is added to A slurry and stirred evenly to obtain B slurry.

[0025] Step C: Weigh 2.4 g of pseudo-boehmite, add it to 50 g of deionized water, grind in a colloid mill for 10 minutes, and prepare a pseudo-boehmite slurry. Prepare 5g of dilute nitric acid solution with a mass fraction of 5%, and add the prepared dilute nitric acid solution dropwise to the pseudo-boehmite slurry under stirring. The dripping is completed in 5 minutes, and then the pseudo-boehmite slurry is heated to 90 C sol was obtained by stirring for 1 hour at ℃.

[0026] Step D: Weigh out 5.128g Mg(NO 3 ) 2 .6H 2 O was added to 50ml of deionized water to prepare a solution, added to C sol, and stirred uniformly to obtain D sol; heat the B slurry t...

Embodiment 2

[0028] Steps A and B: same as in Example 1.

[0029] Step C: Weigh 2.4 g of pseudo-boehmite, add it to 40 g of deionized water, grind in a colloid mill for 15 minutes, and prepare a pseudo-boehmite slurry. Prepare 8g of dilute nitric acid solution with a mass fraction of 3%, and add the configured dilute nitric acid solution dropwise to the pseudo-boehmite slurry under stirring. The dripping is completed in 6 minutes, and then the pseudo-boehmite slurry is heated to 95 C sol is obtained by stirring for 1 hour at ℃.

[0030] Step D: Weigh 1.686g MgCO 3 Add it to 50ml of deionized water to prepare a solution, add it to C sol, stir evenly to obtain D sol; heat the B slurry to 95°C, add the D sol to the B slurry dropwise within 3 hours under stirring, After the dripping is completed, heating and stirring are continued for 3 hours; after the reaction, the slurry is filtered and washed 3 times to obtain a layered composite hydroxide filter cake, and the filter cake is dried in an oven a...

Embodiment 3

[0032] Steps A and B: Same as Example 1, except that the weight of magnesium hydroxide weighed in Step A is 4.64 g.

[0033] Step C: Weigh 2.4 g of pseudo-boehmite, add it to 60 g of deionized water, grind in a ball mill for 20 minutes, and prepare a pseudo-boehmite slurry. Prepare 6g of dilute nitric acid solution with a mass fraction of 4%, add the configured dilute nitric acid solution dropwise to the pseudo-boehmite slurry under stirring, and the dripping is completed in 8 minutes, and then heat the pseudo-boehmite slurry to 100 C sol is obtained by stirring for 1 hour at ℃.

[0034] Step D: Weigh 2.07g of salicylic acid and add it to 60ml of deionized water to prepare a solution, add it to C sol, stir evenly to obtain D sol; heat the B slurry to 100°C, and mix under stirring to obtain D sol was added dropwise to B slurry within 4 hours. After the addition, heating and stirring were continued for 3 hours; after the reaction, the slurry was filtered and washed 3 times to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com