Patents

Literature

487 results about "Formation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surfactant process for promoting gas hydrate formation and application of the same

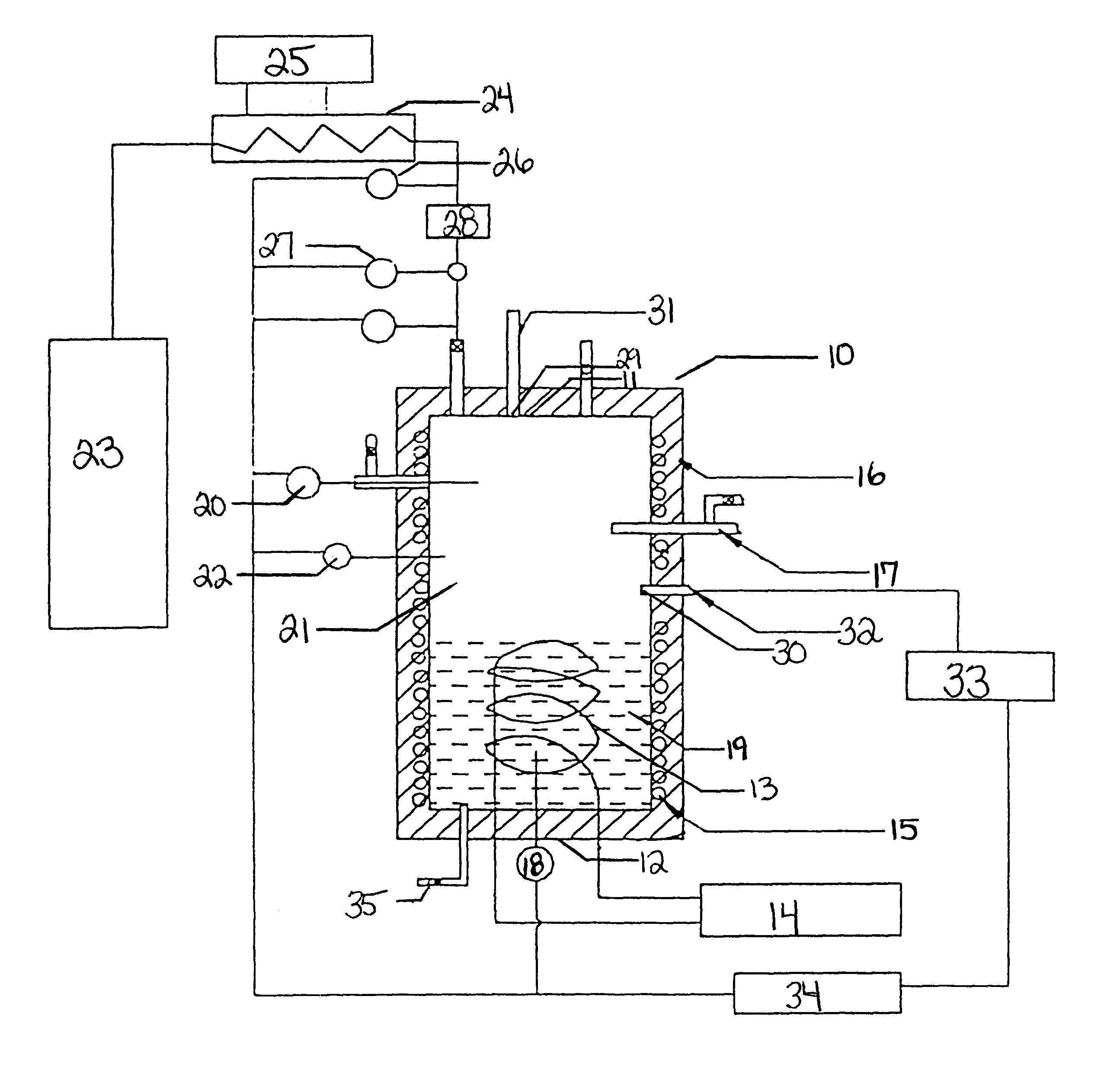

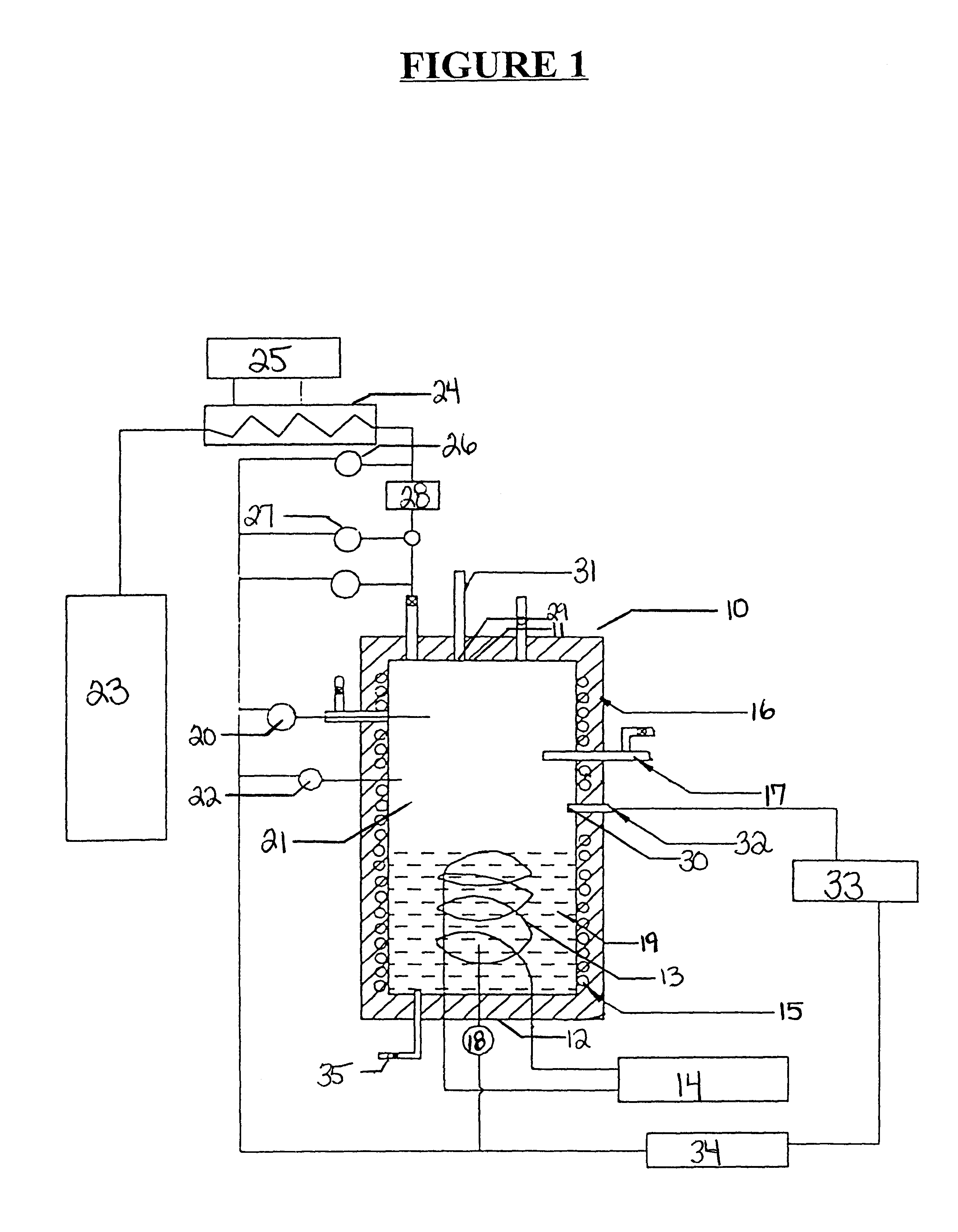

This invention relates to a method of storing gas using gas hydrates comprising forming gas hydrates in the presence of a water-surfactant solution that comprises water and surfactant. The addition of minor amounts of surfactant increases the gas hydrate formation rate, increases packing density of the solid hydrate mass and simplifies the formation-storage-decomposition process of gas hydrates. The minor amounts of surfactant also enhance the potential of gas hydrates for industrial storage applications.

Owner:MISSISSIPPI STATE UNIVERSITY

Self-hardening calcium phosphate materials with high resistance to fracture, controlled strength histories and tailored macropore formation rates

InactiveUS6955716B2Strong and tough self-hardeningHigh strengthPhosphatesOther chemical processesFiberHigh resistance

A bone replacement material and therapy comprises the combination of calcium phosphate compounds and two or more soluble fillers in the form of fibers, mesh or other materials which have the dual functions of reinforcing an in vivo implant while dissolving at a programmed rate to form macropores capable of receiving natural bone ingrowth.

Owner:ADA FOUND

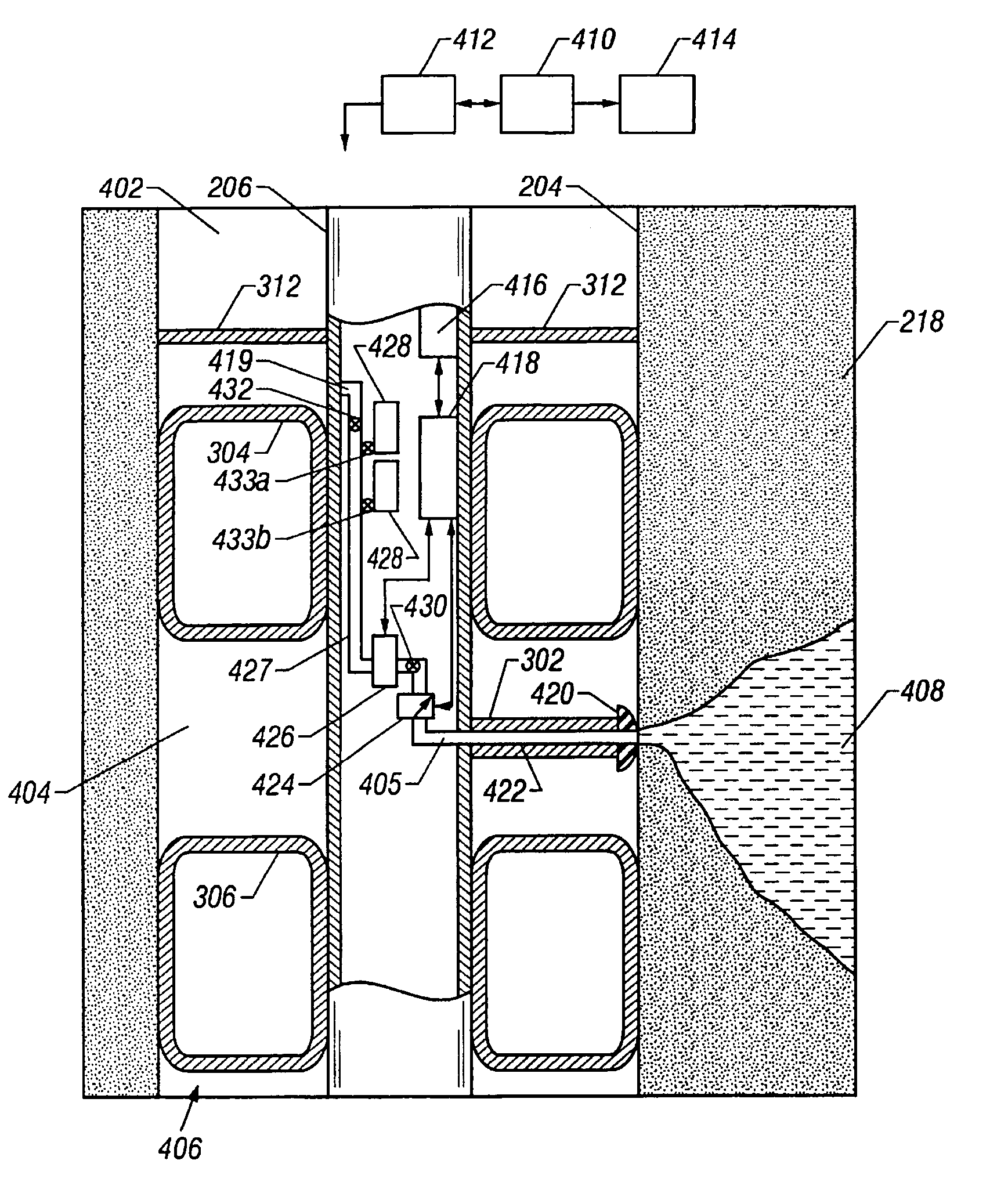

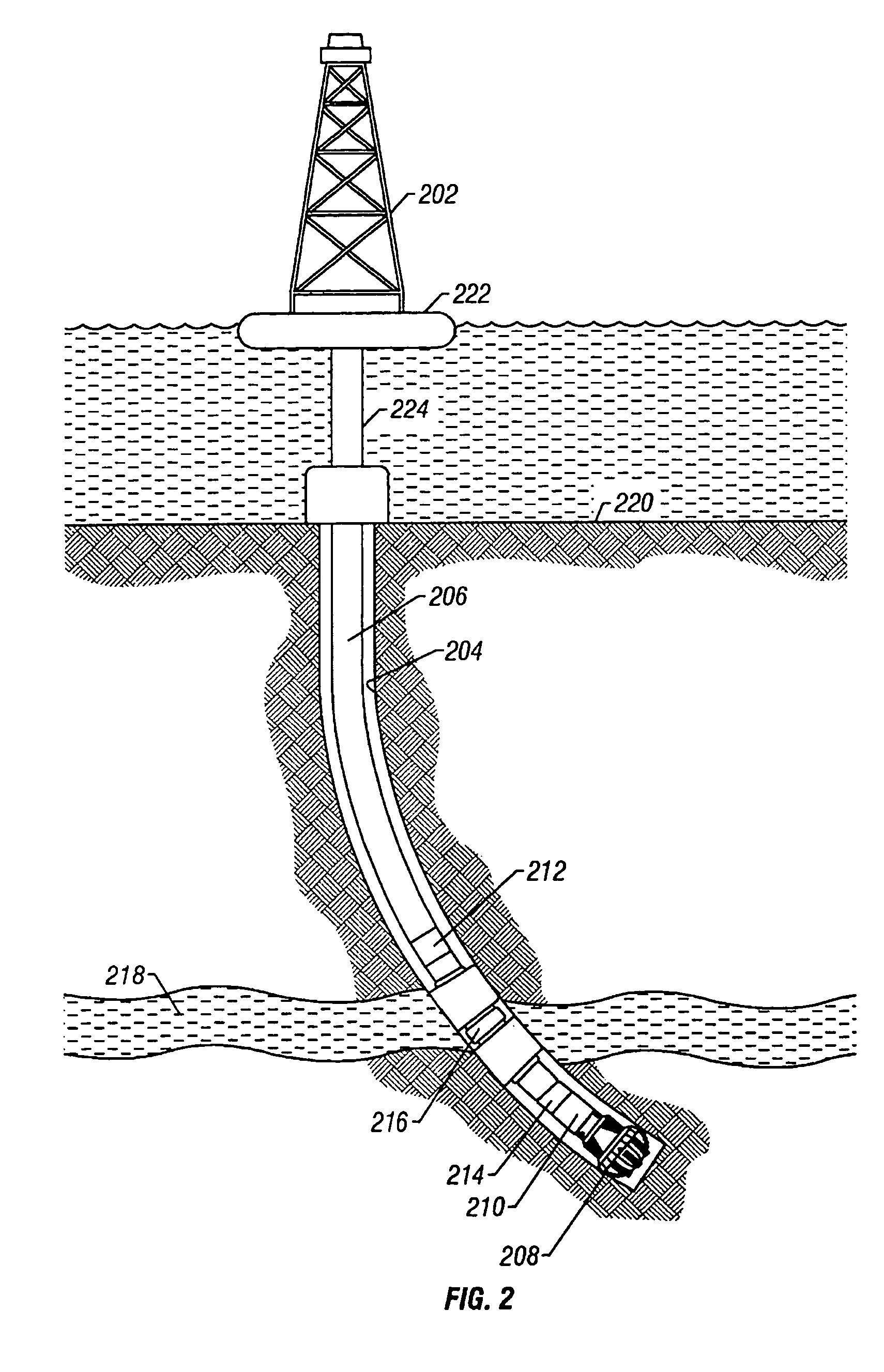

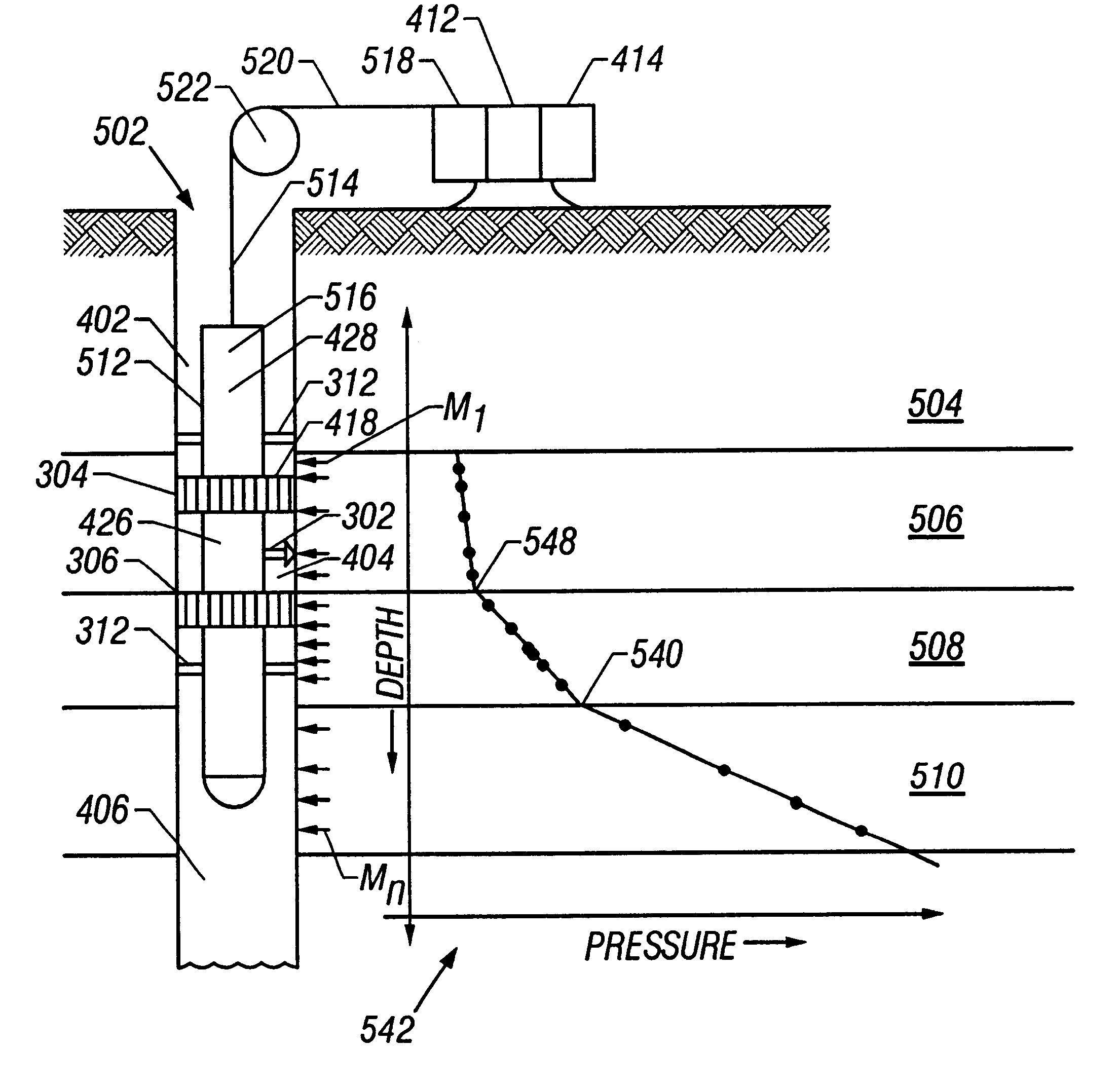

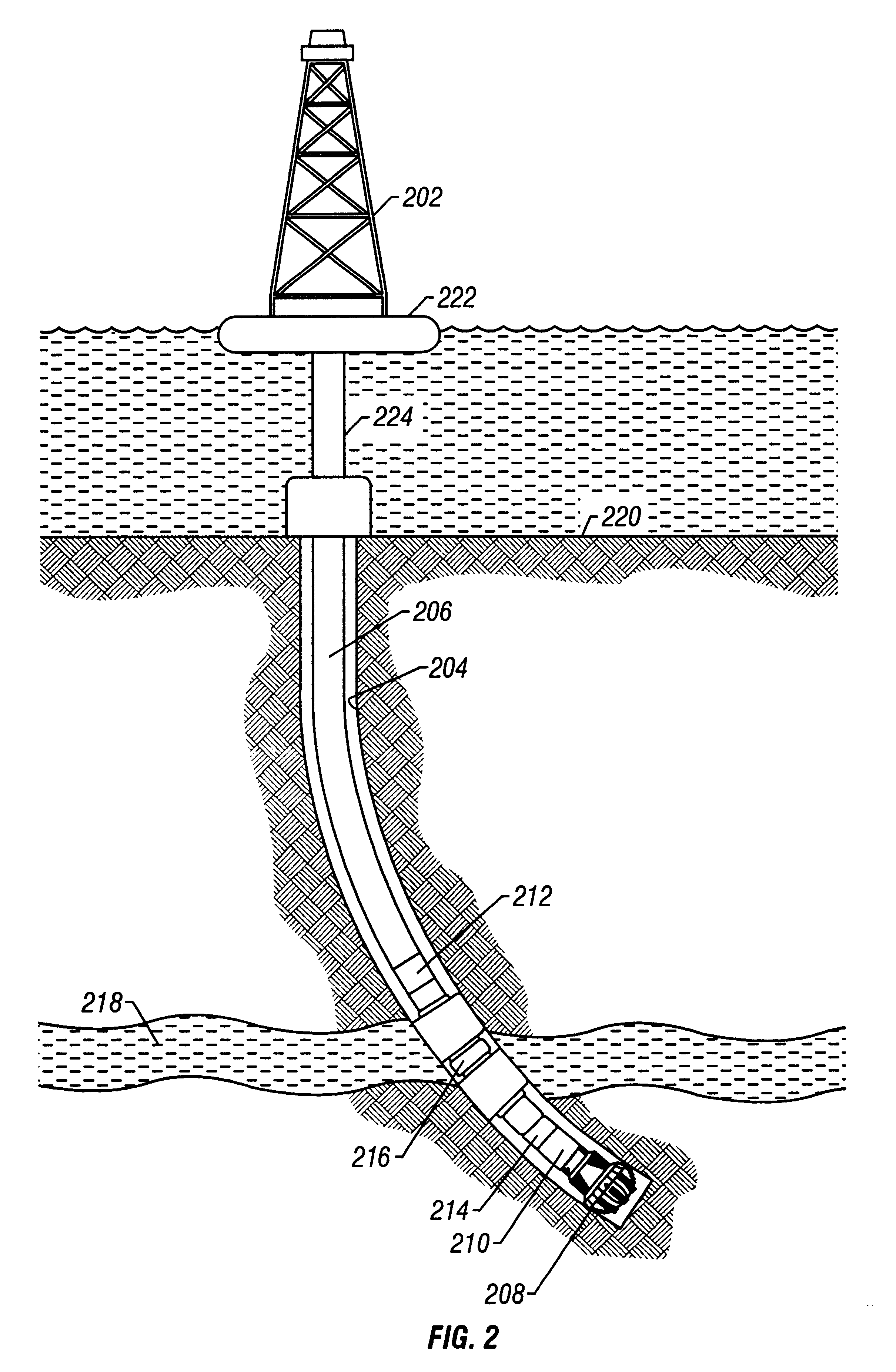

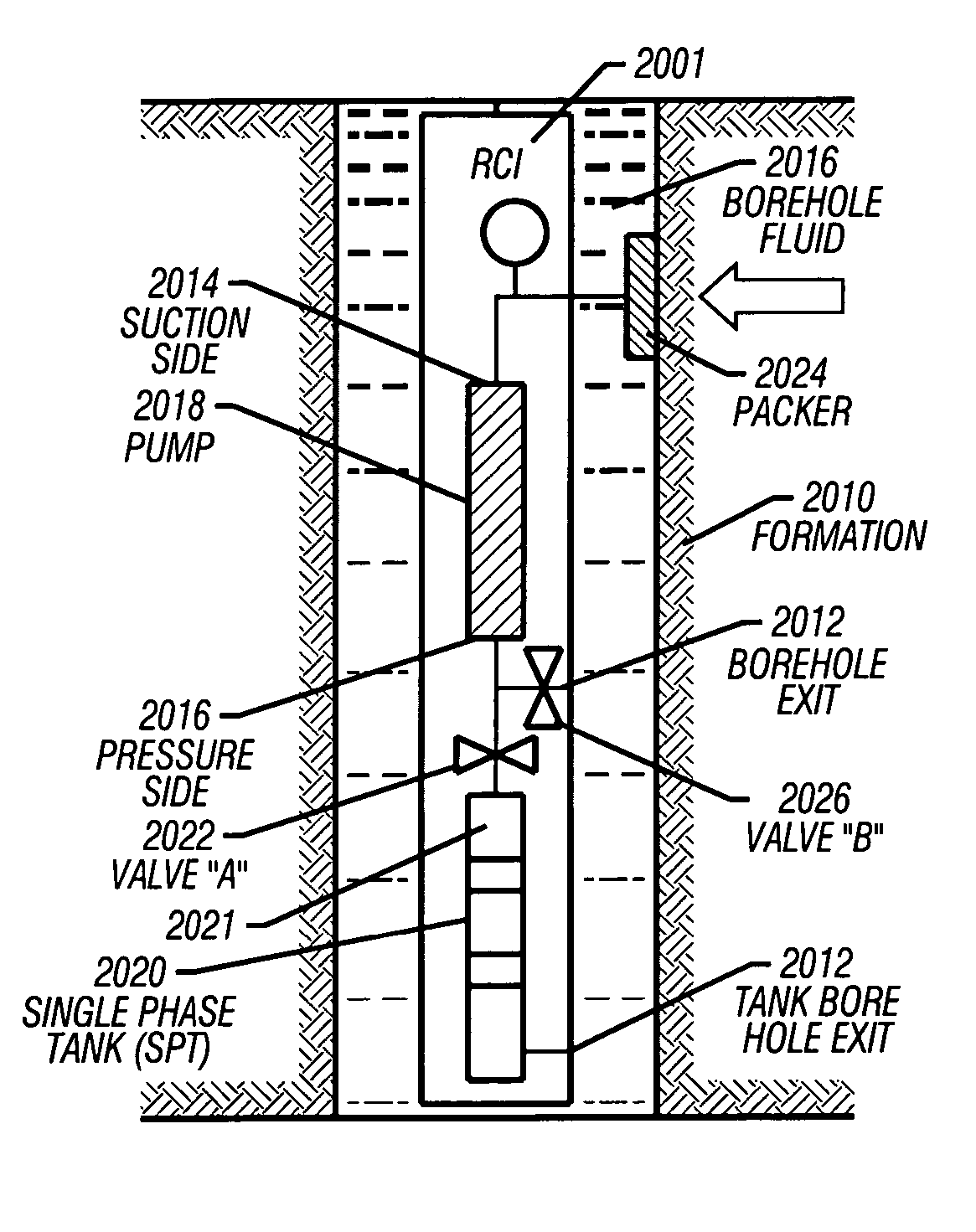

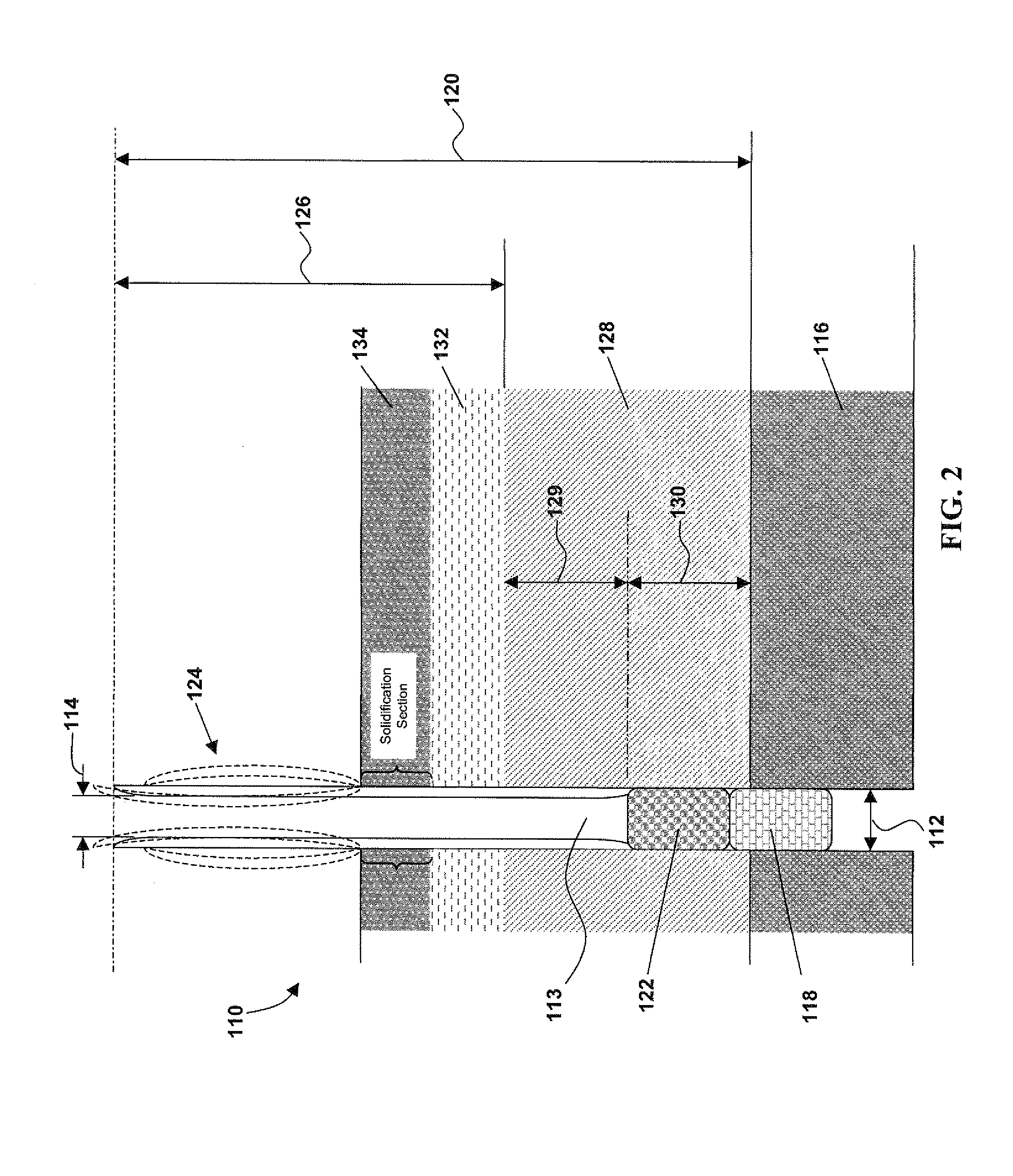

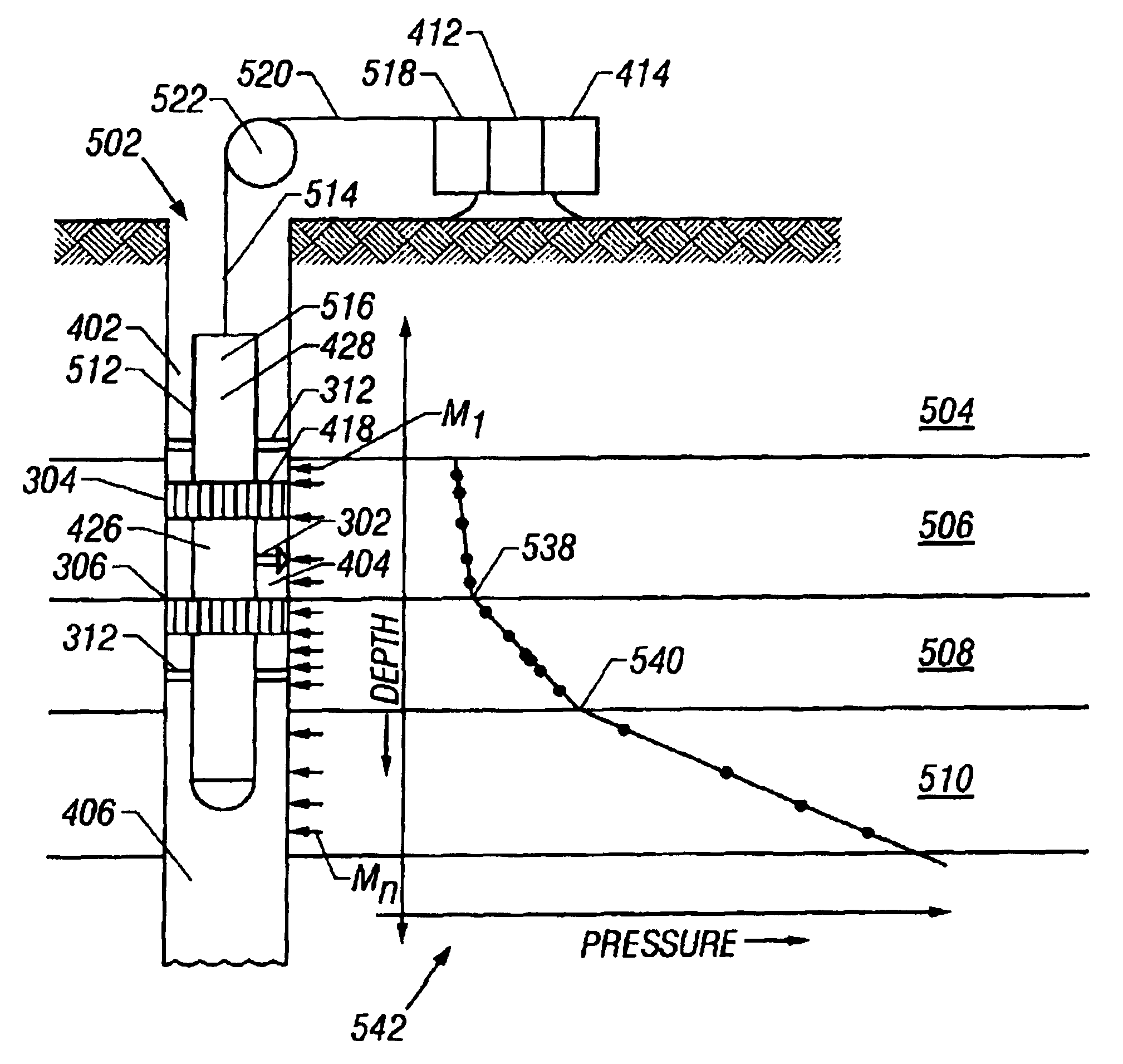

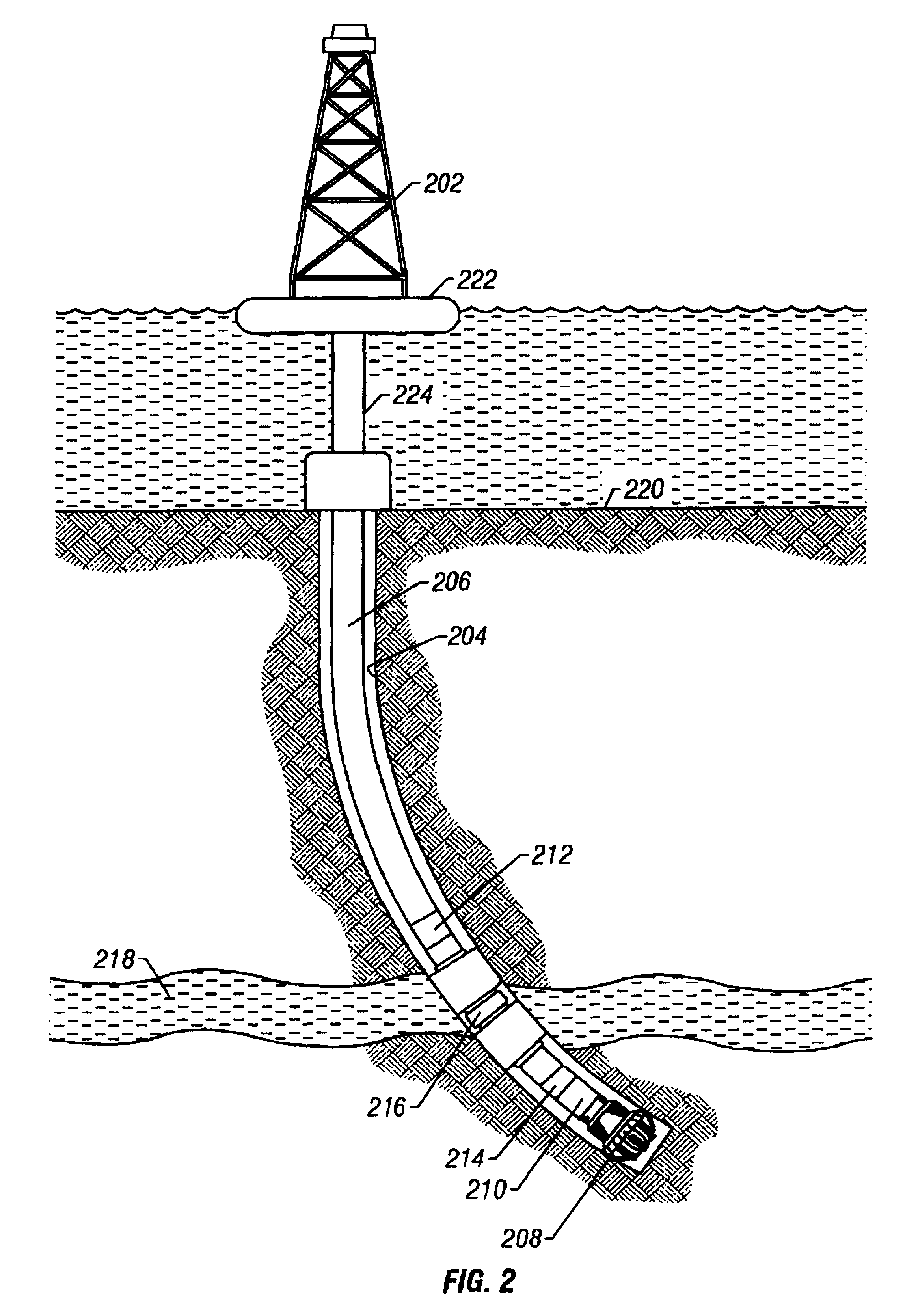

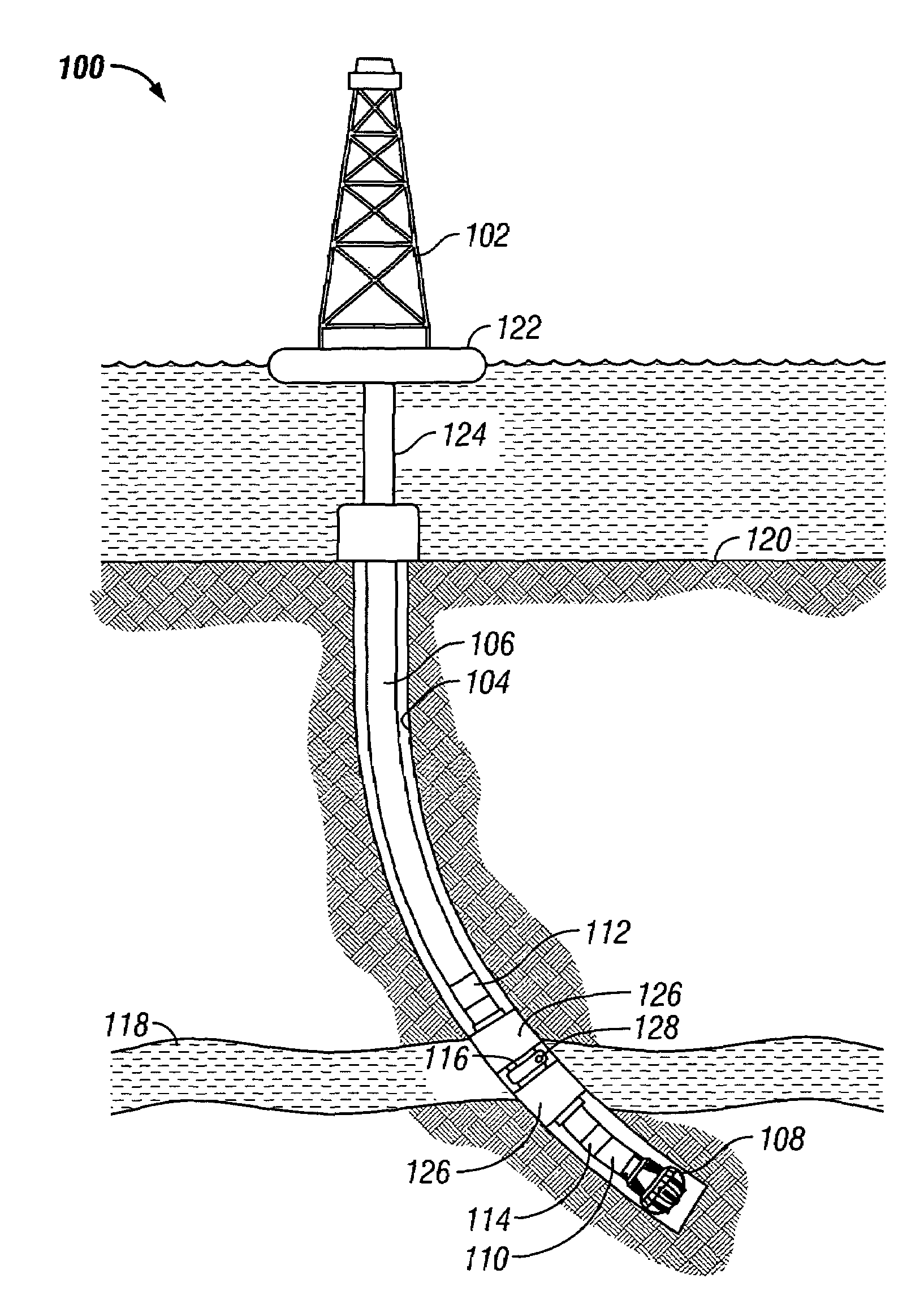

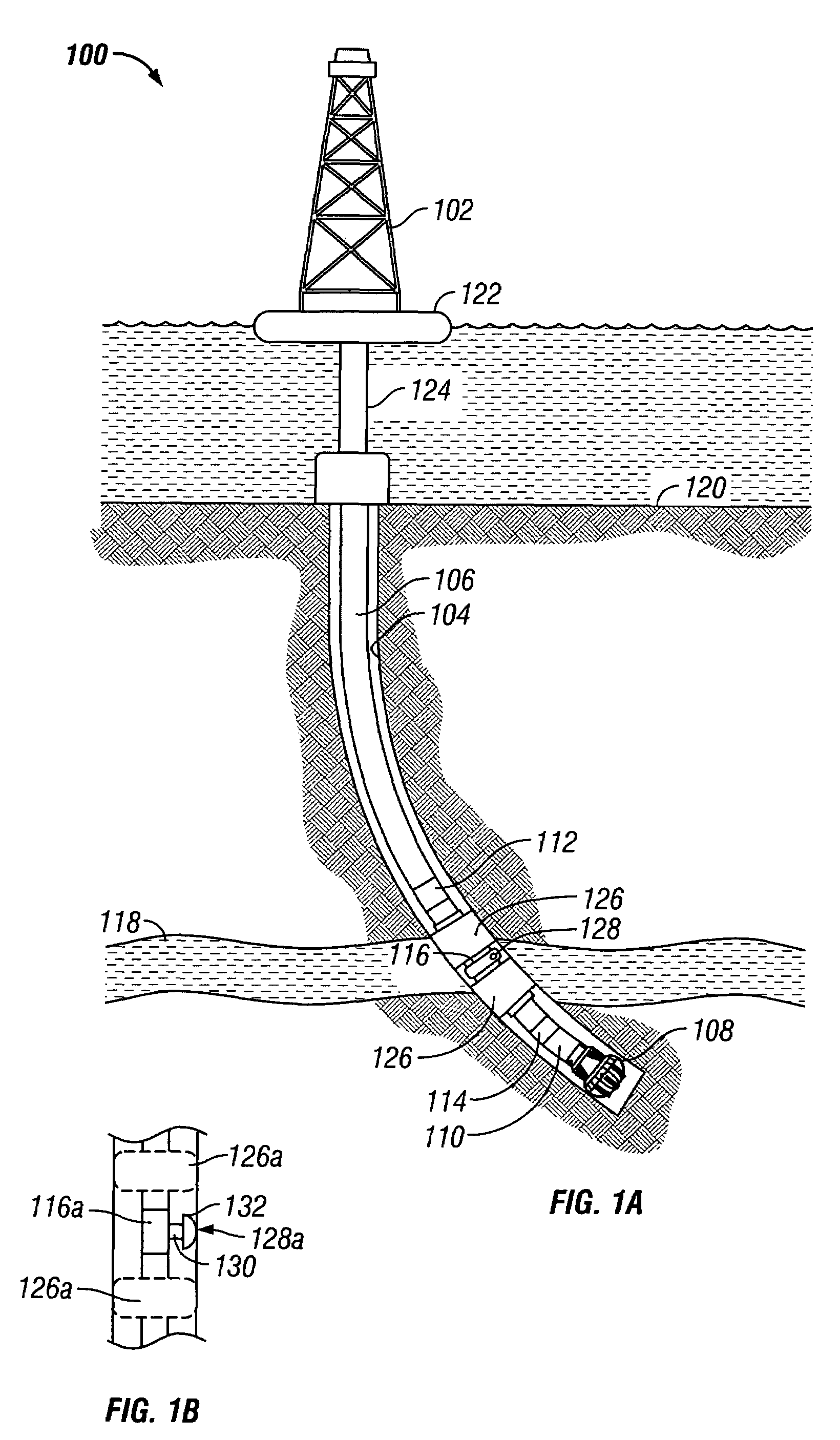

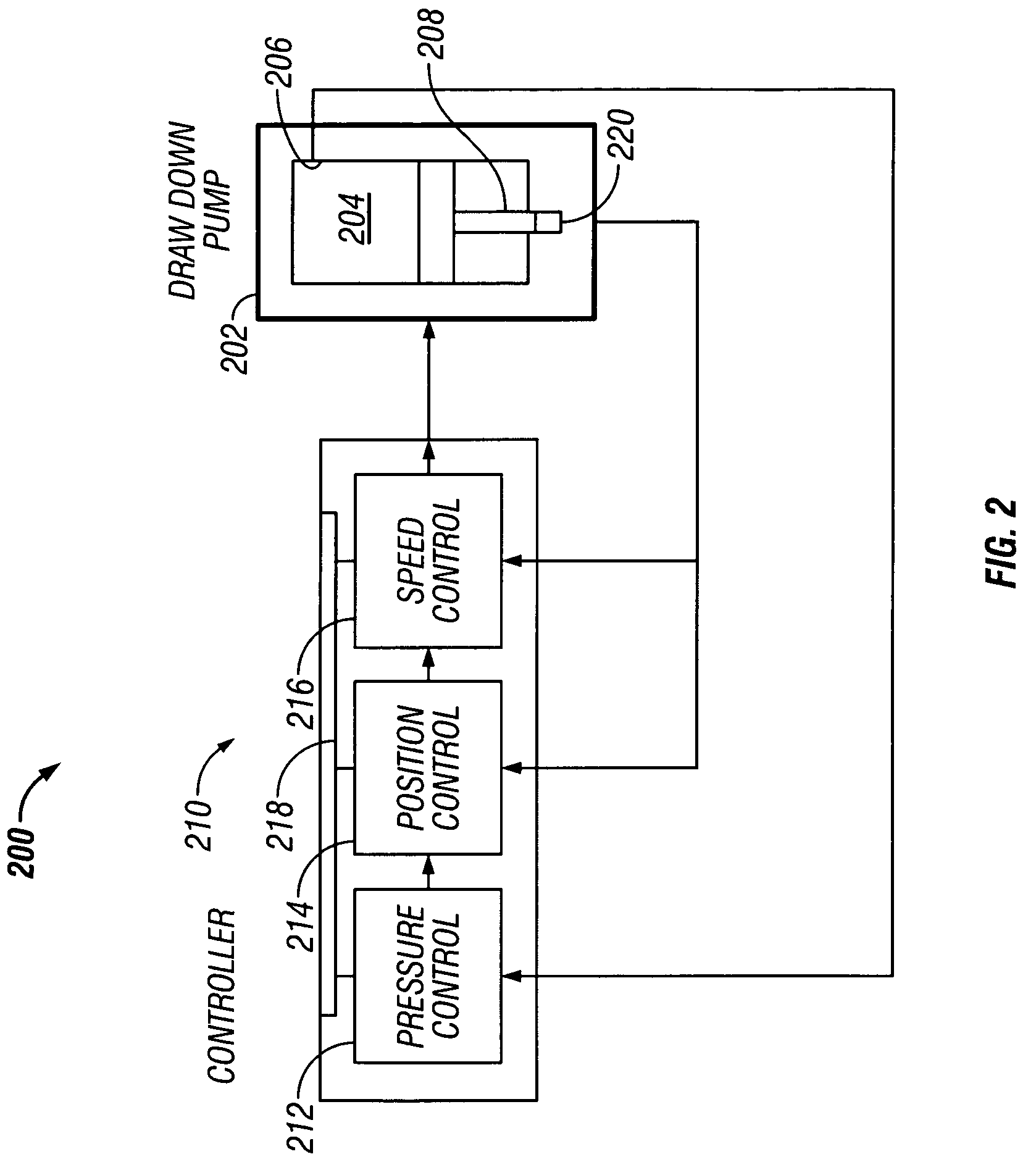

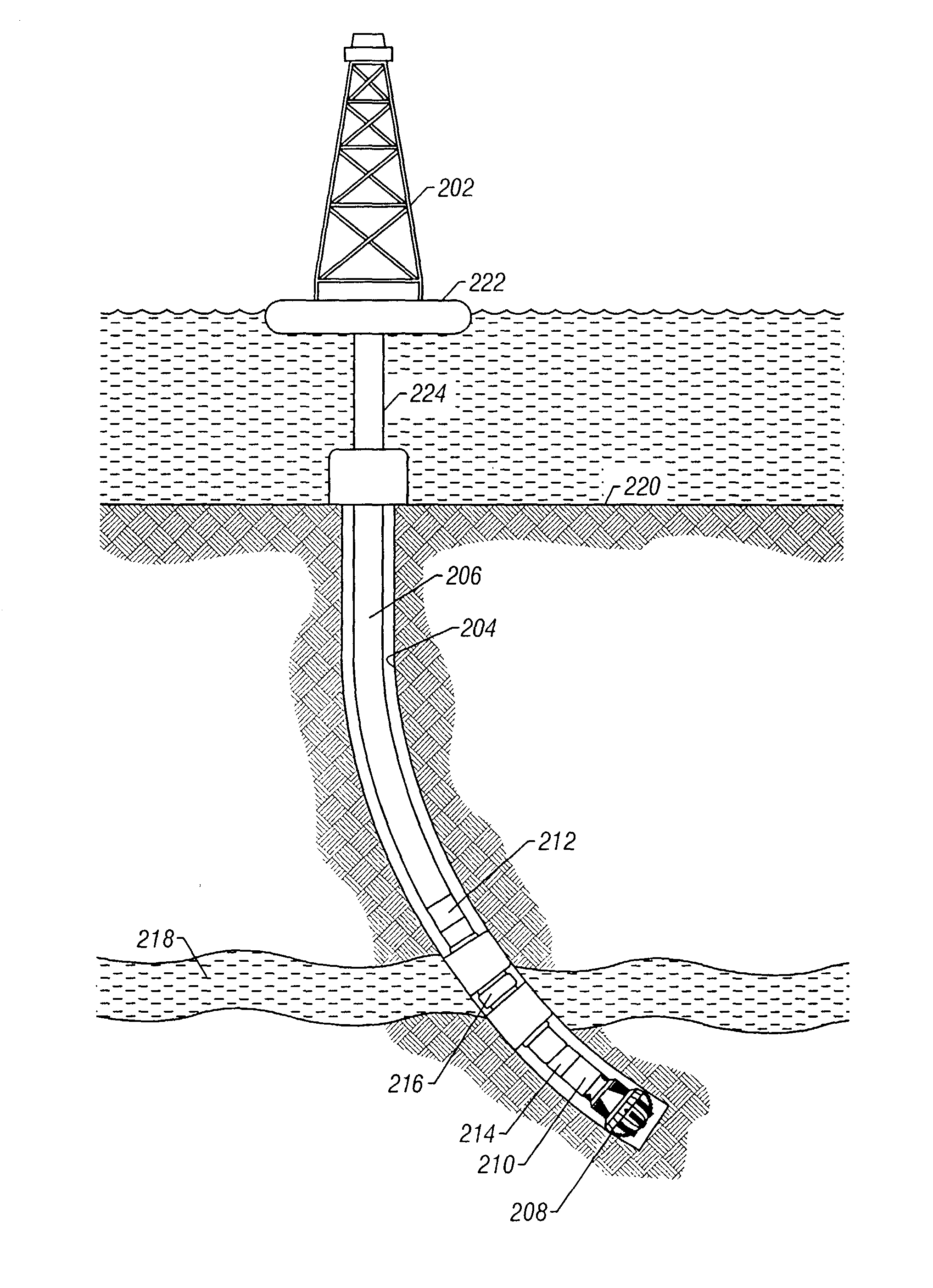

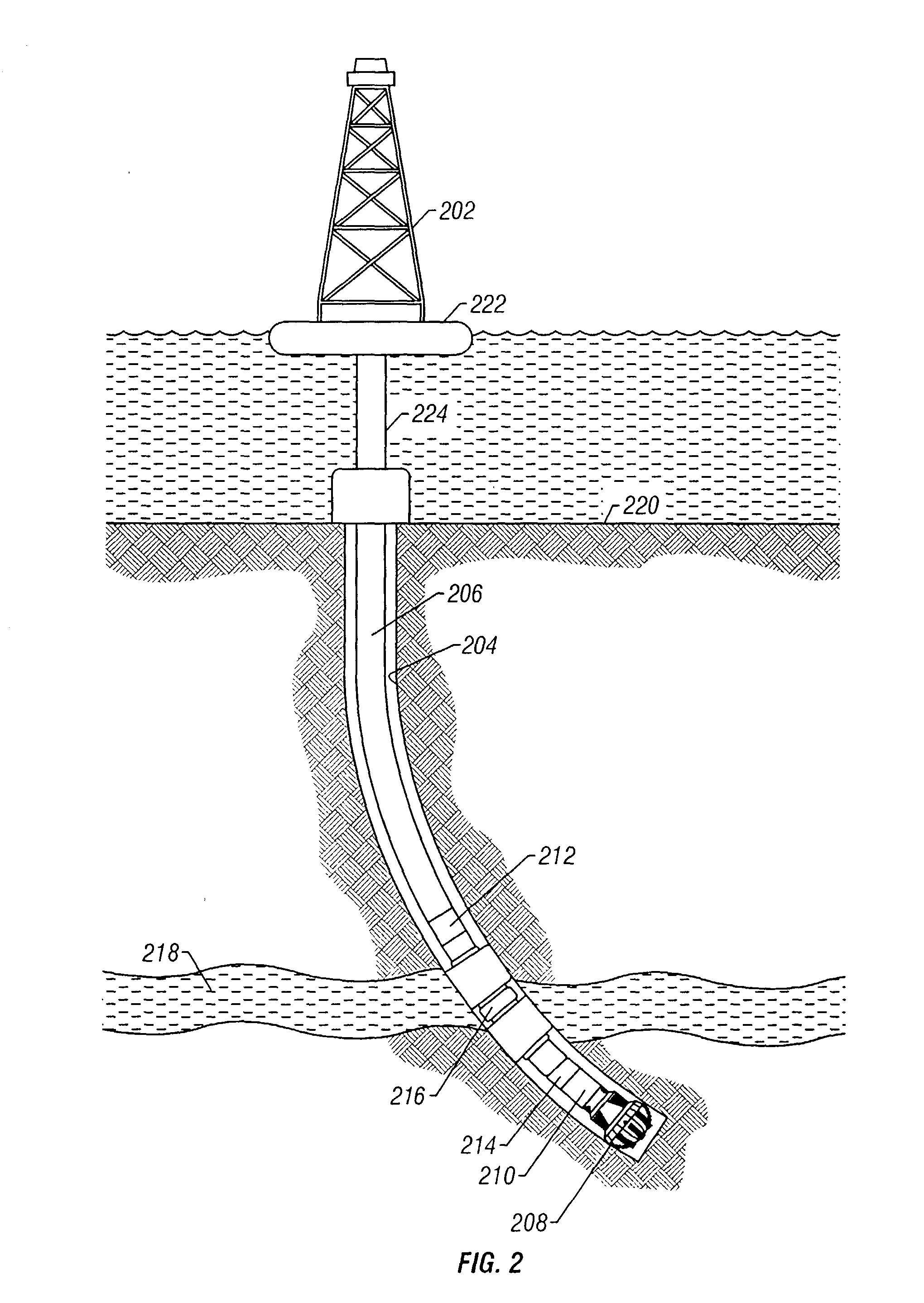

Method and apparatus for pumping quality control through formation rate analysis techniques

InactiveUS20040231842A1Enhance well operation efficiencyImprove securitySurveyFluid removalMinimum timeQuality control

The present invention provides a method and apparatus for determination of the quality of a formation fluid sample including monitoring permeability and mobililty versus time to determine a filtrate contamination level, single phase state without gas and solids in the formation fluid, as it existed in the formation and the determination of laminar flow from the formation. The present invention also enables determination of an optimal pumping rate to match the ability of a subsurface formation to produce a single phase formation fluid sample in minimum time. The method and apparatus also detect pumping problems such as sanding and loss of seal with borehole.

Owner:BAKER HUGHES INC

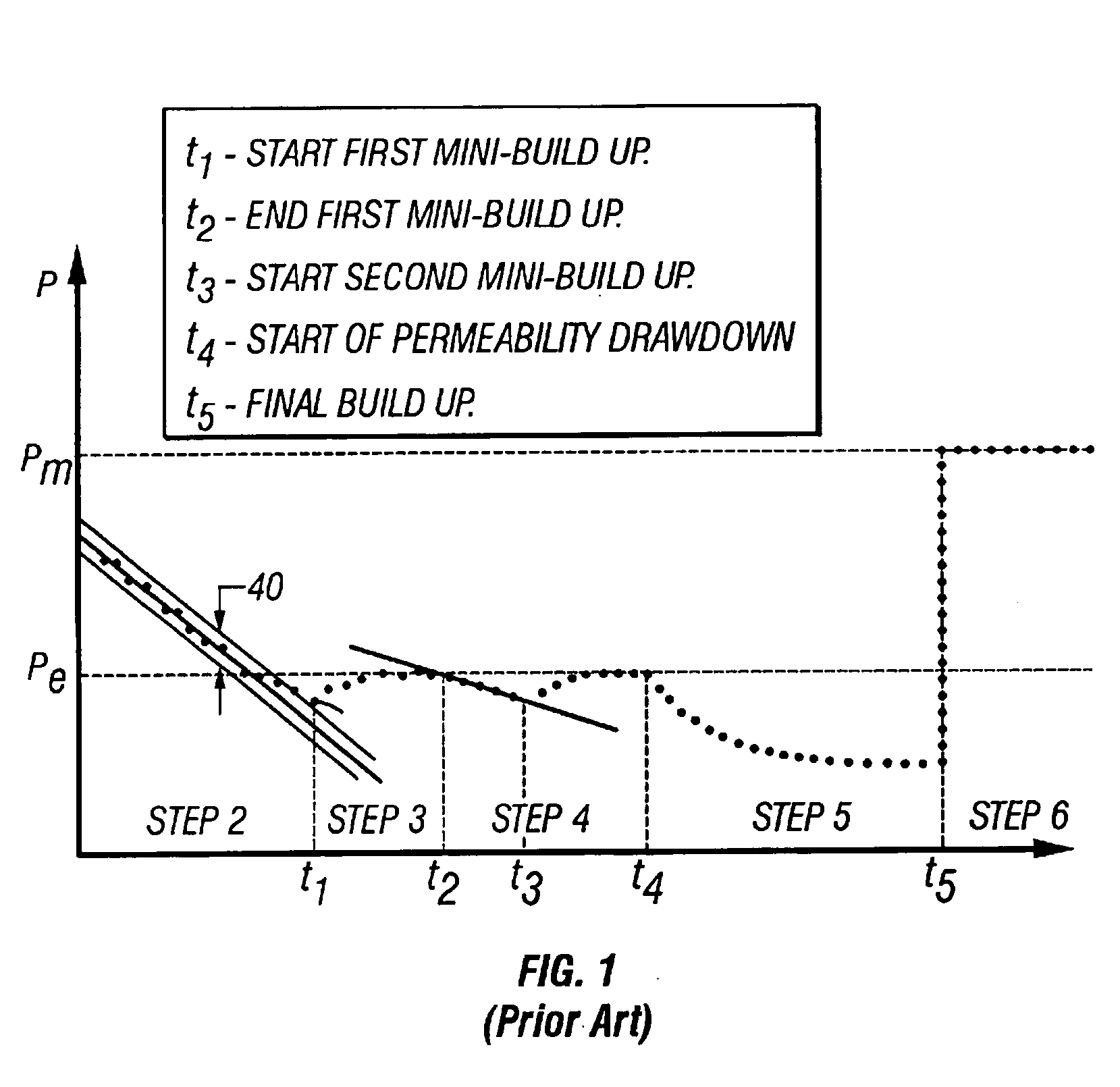

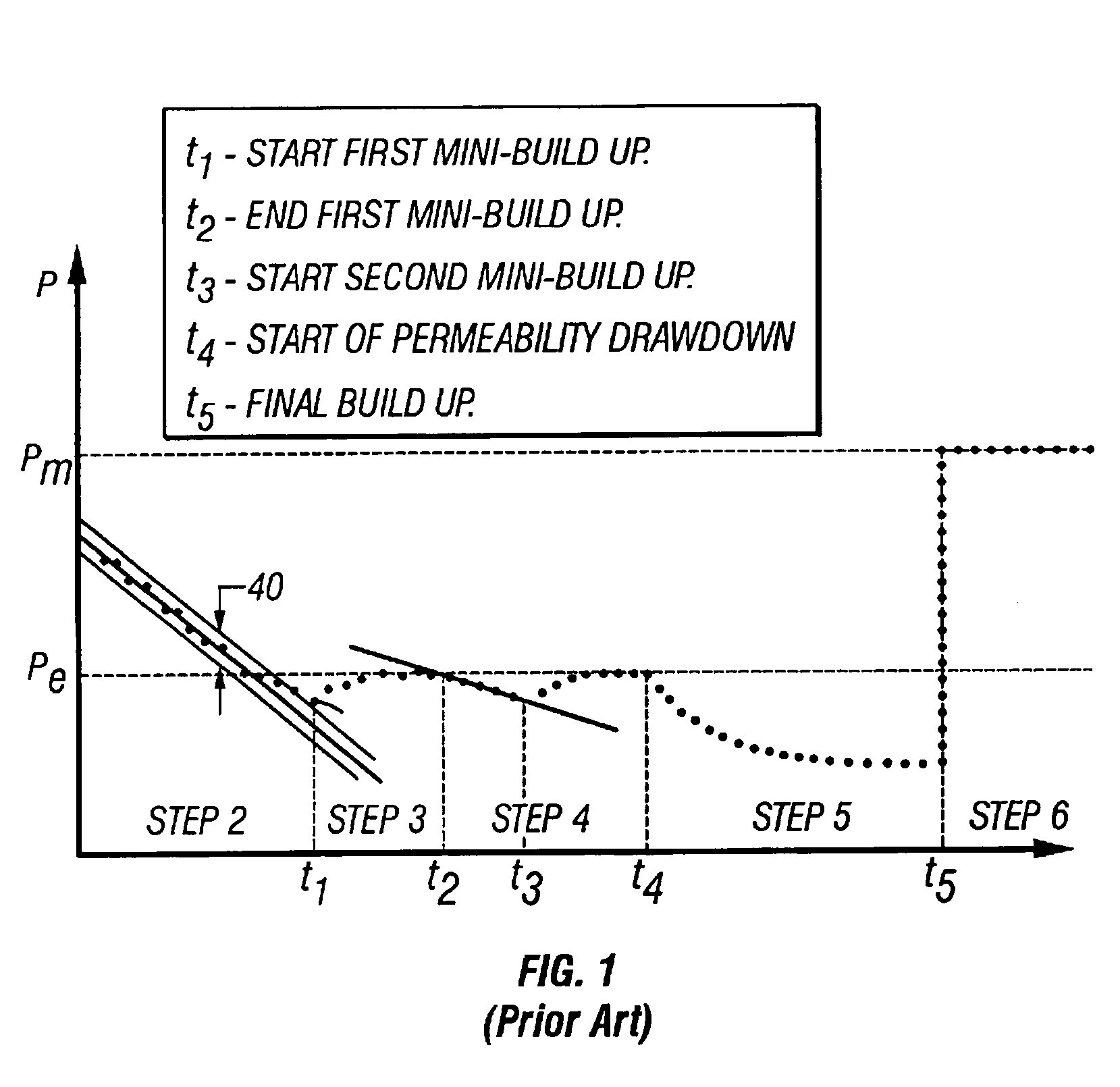

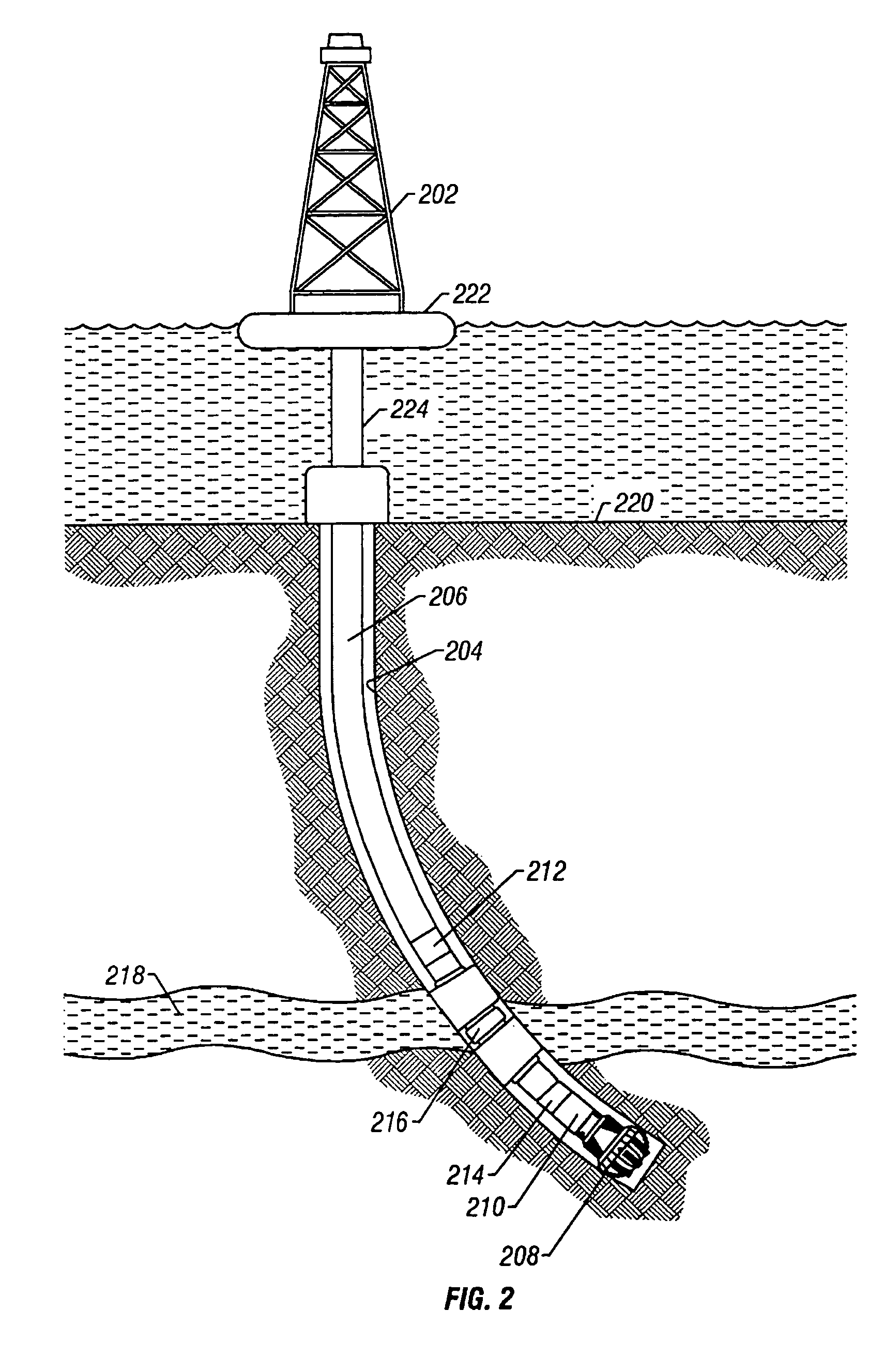

Method for in-situ analysis of formation parameters

A method of performing a formation rate analysis from pressure and formation flow rate data. Pressure and flow rate data are measured as fluid is withdrawn from a formation. Variable system volume is accounted for. The pressure and flow rate data are correlated using a multiple linear regression technique. Time derivative terms related to pressure and flow rate are smoothed using a summation technique, thereby providing better correlations than using the time derivatives directly. Formation parameters comprising formation permeability, formation pressure, and fluid compressibility may be determined from the correlation.

Owner:BAKER HUGHES HLDG LLC

Method and apparatus for pumping quality control through formation rate analysis techniques

The present invention provides a method and apparatus for determination of the quality of a formation fluid sample including monitoring permeability and mobililty versus time to determine a filtrate contamination level, single phase state without gas and solids in the formation fluid, as it existed in the formation and the determination of laminar flow from the formation. The present invention also enables determination of an optimal pumping rate to match the ability of a subsurface formation to produce a single phase formation fluid sample in minimum time. The method and apparatus also detect pumping problems such as sanding and loss of seal with borehole.

Owner:BAKER HUGHES INC

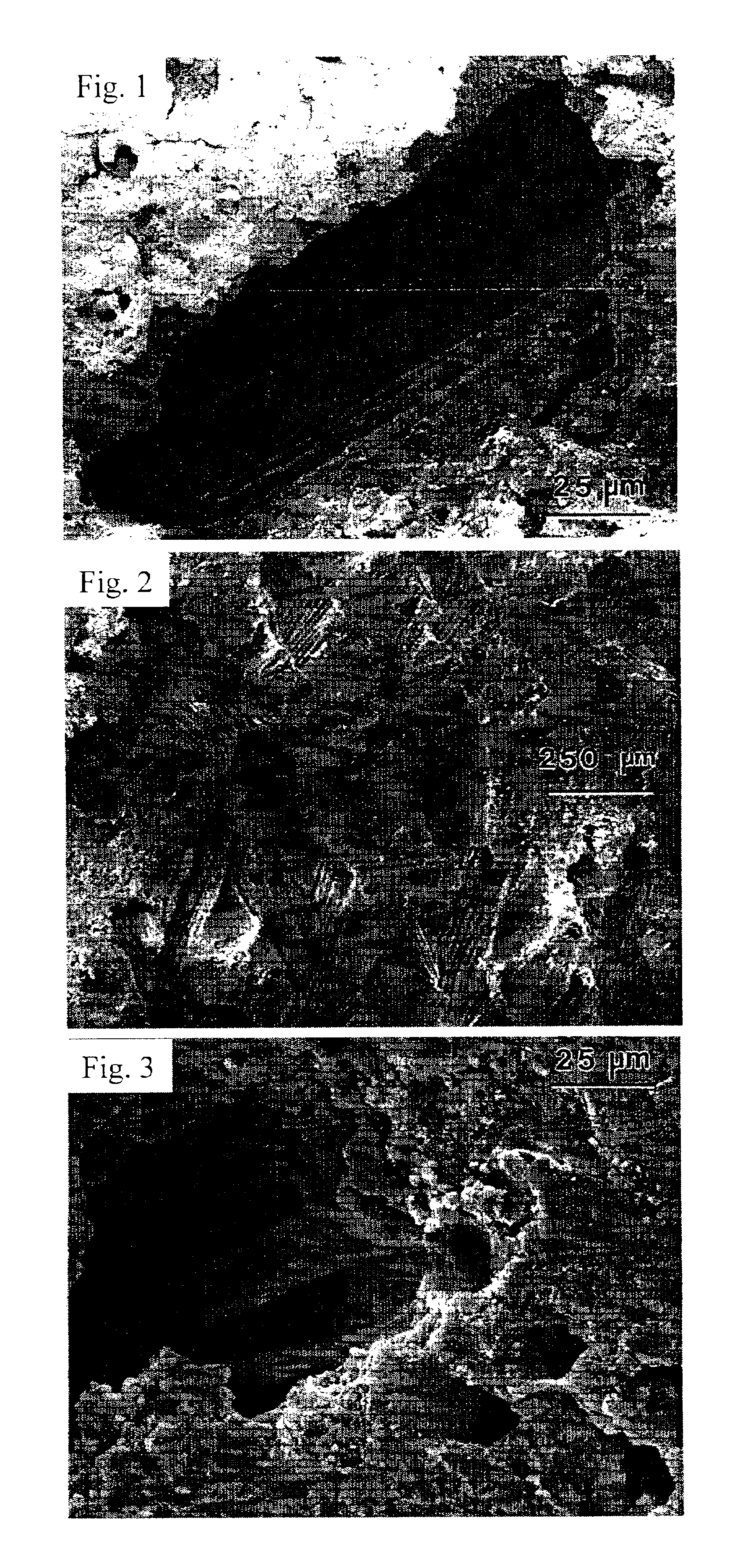

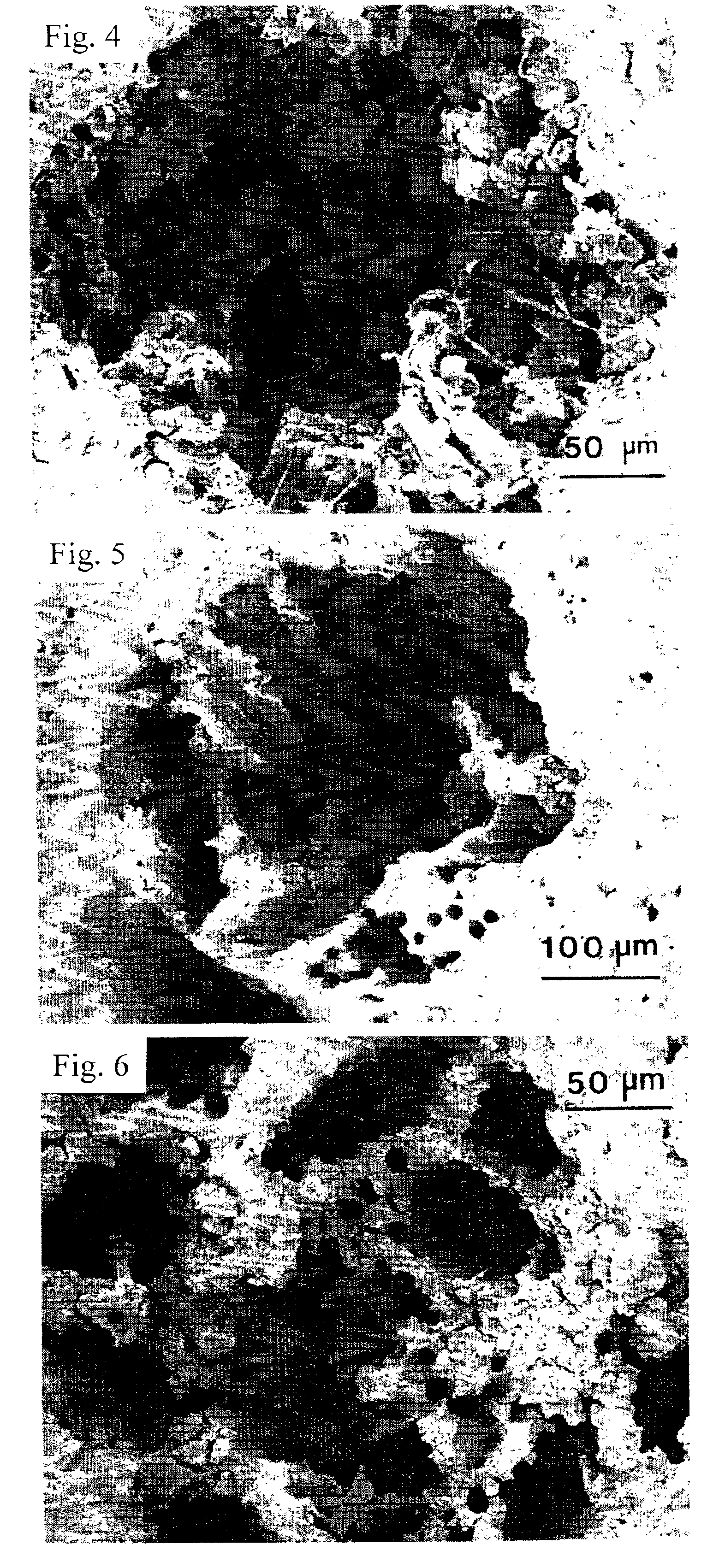

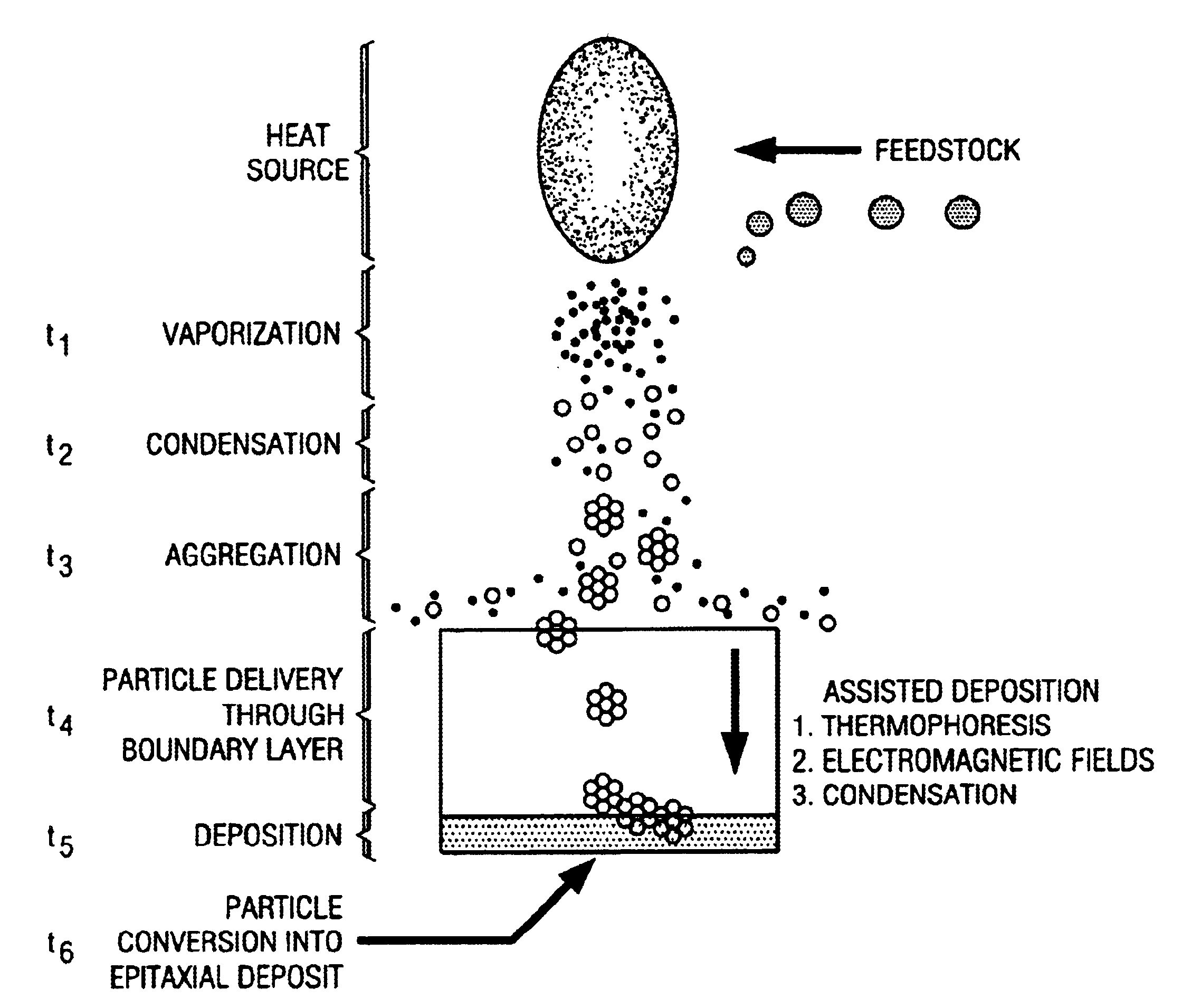

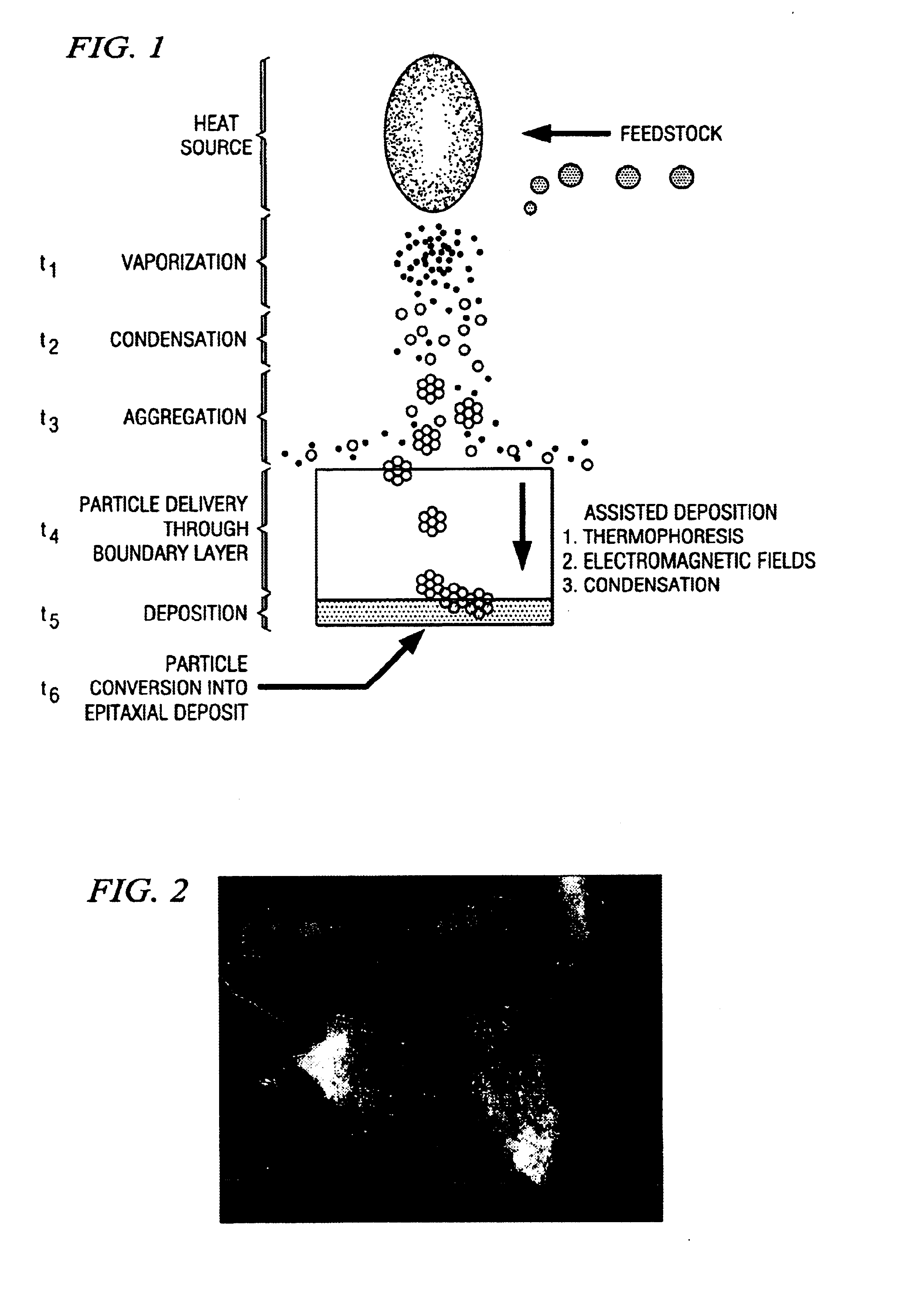

Condensed phase conversion and growth of nanorods instead of from vapor

Compositions, systems and methods are described for condensed phase conversion and growth of nanorods and other materials. A method includes providing a condensed phase matrix material; and activating the condensed phase matrix material to produce a plurality of nanorods by condensed phase conversion and growth from the condensed chase matrix material instead of from vacor. The compositions are very strong. The compositions and methods provide advantages because they allow (1) formation rates of nanostructures necessary for reasonable production rates, and (2) the near net shaped production of component structures.

Owner:UT BATTELLE LLC

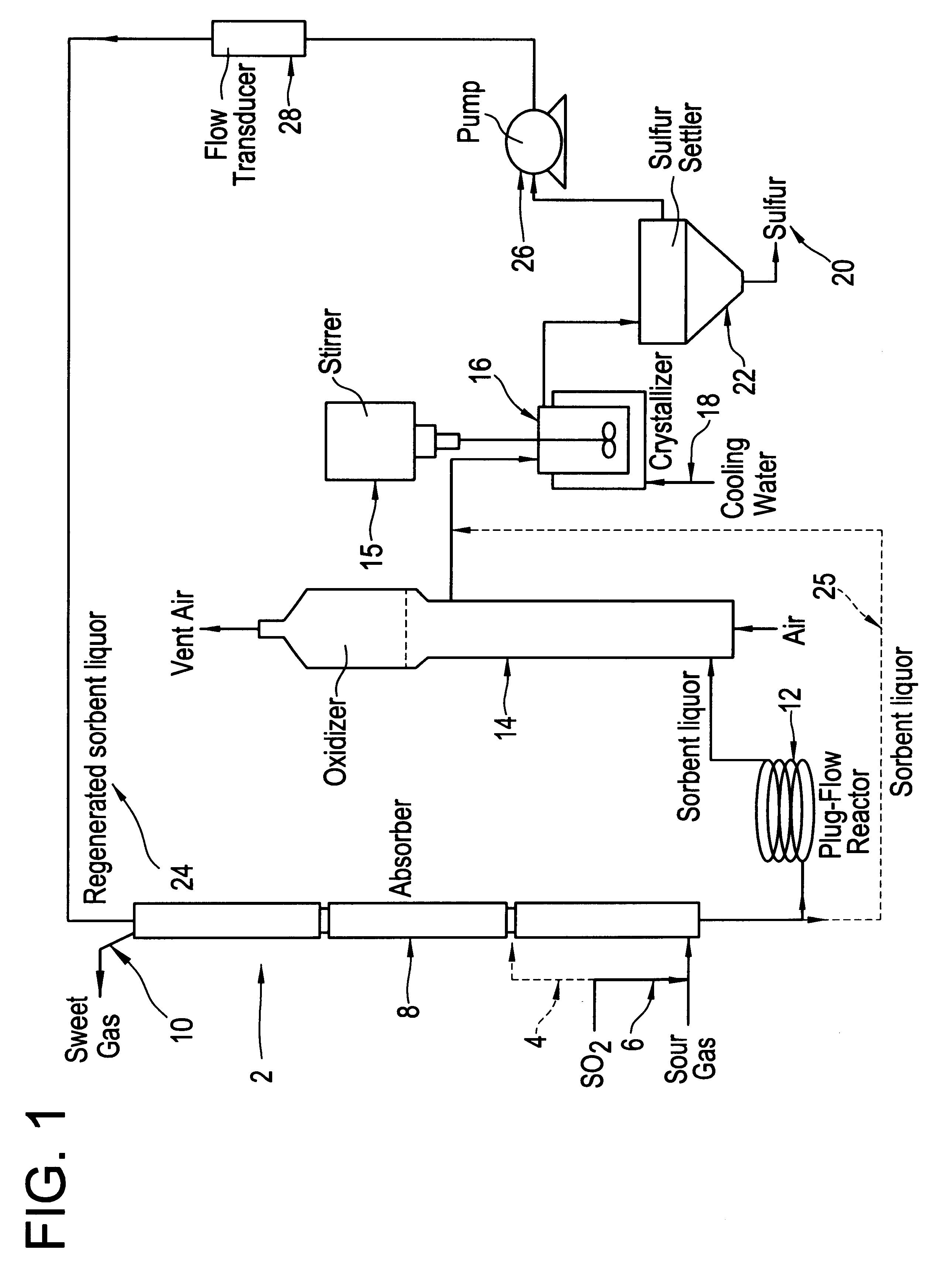

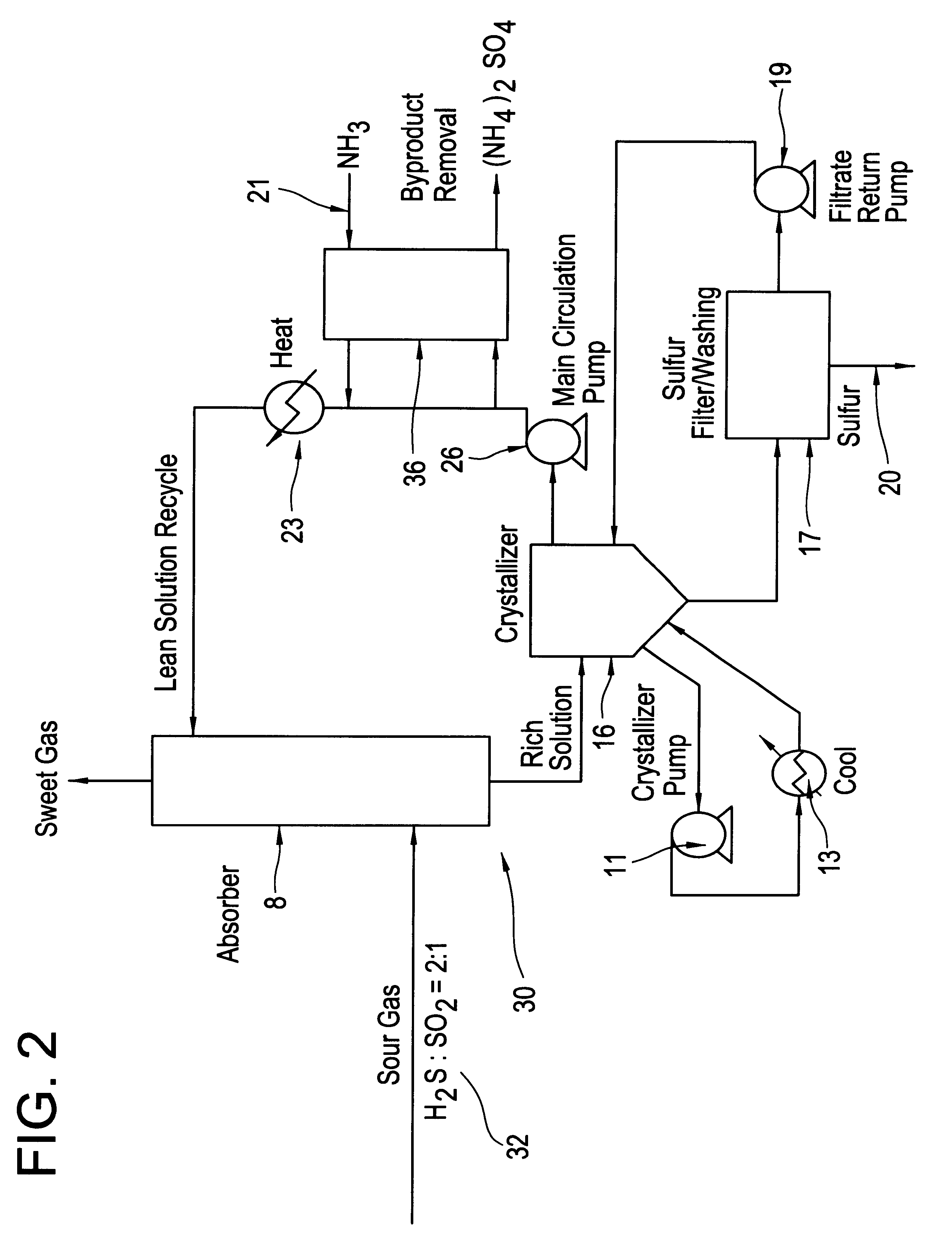

Process for removing hydrogen sulfide from gas streams which include or are supplemented with sulfur dioxide

InactiveUS6416729B1Good removal effectReduce degradationDispersed particle separationSulfur preparation/purificationOrganic solventSorbent

In a known process and system wherein hydrogen sulfide is removed from a gaseous stream, using a non-aqueous scrubbing liquor which can be an organic solvent for elemental sulfur such as a phenylxylyl ethane in which are dissolved sulfur and a reaction-promoting amine base such as a tertiary amine, sulfur dioxide is added to the sulfur-amine nonaqueous sorbent (or advantage is taken of SO2 which may already be present in the gas stream) to obtain better H2S removal, lower chemical degradation rates, and lower rates of formation of byproduct sulfur salts such as sulfates.

Owner:URS

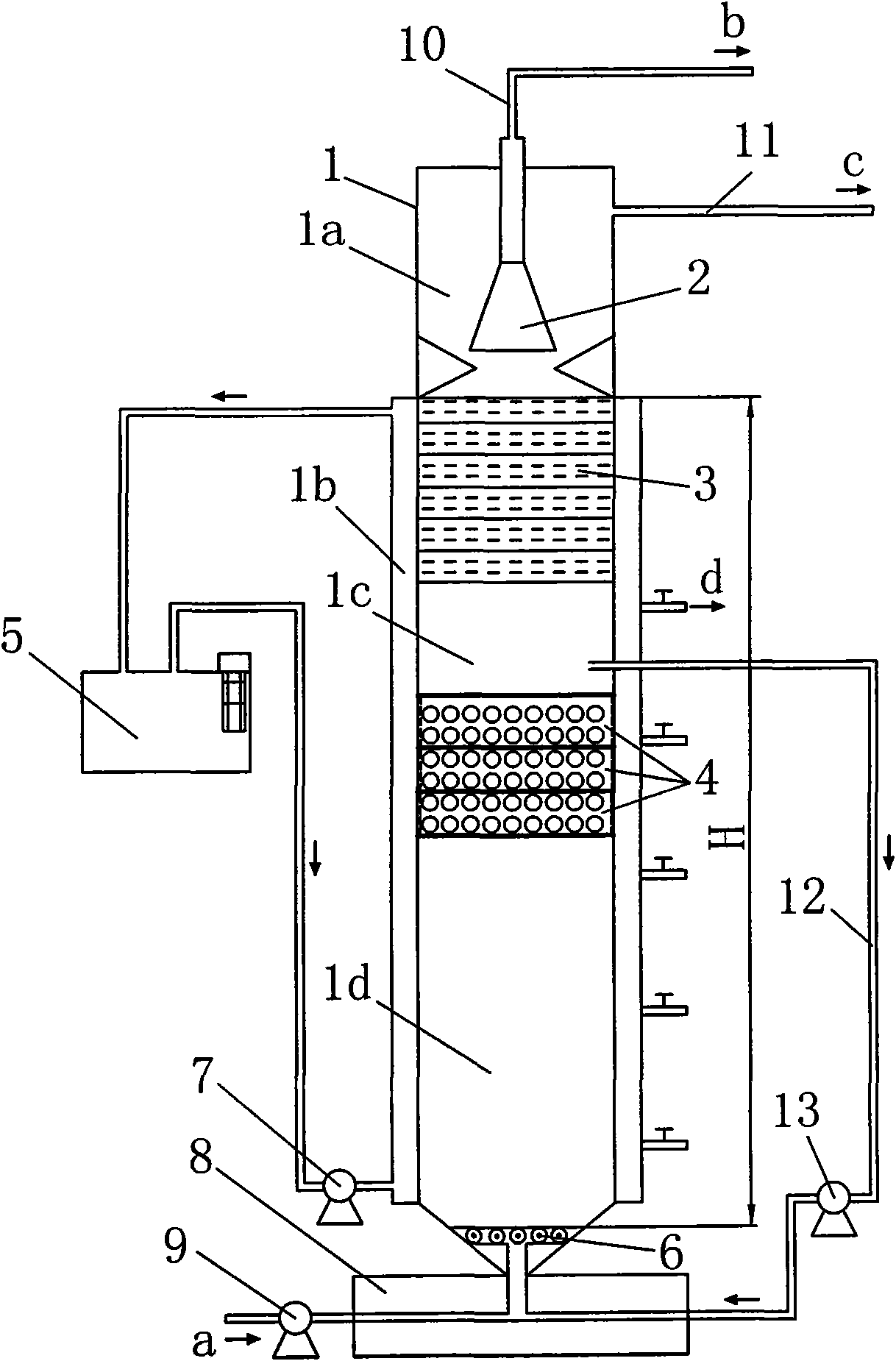

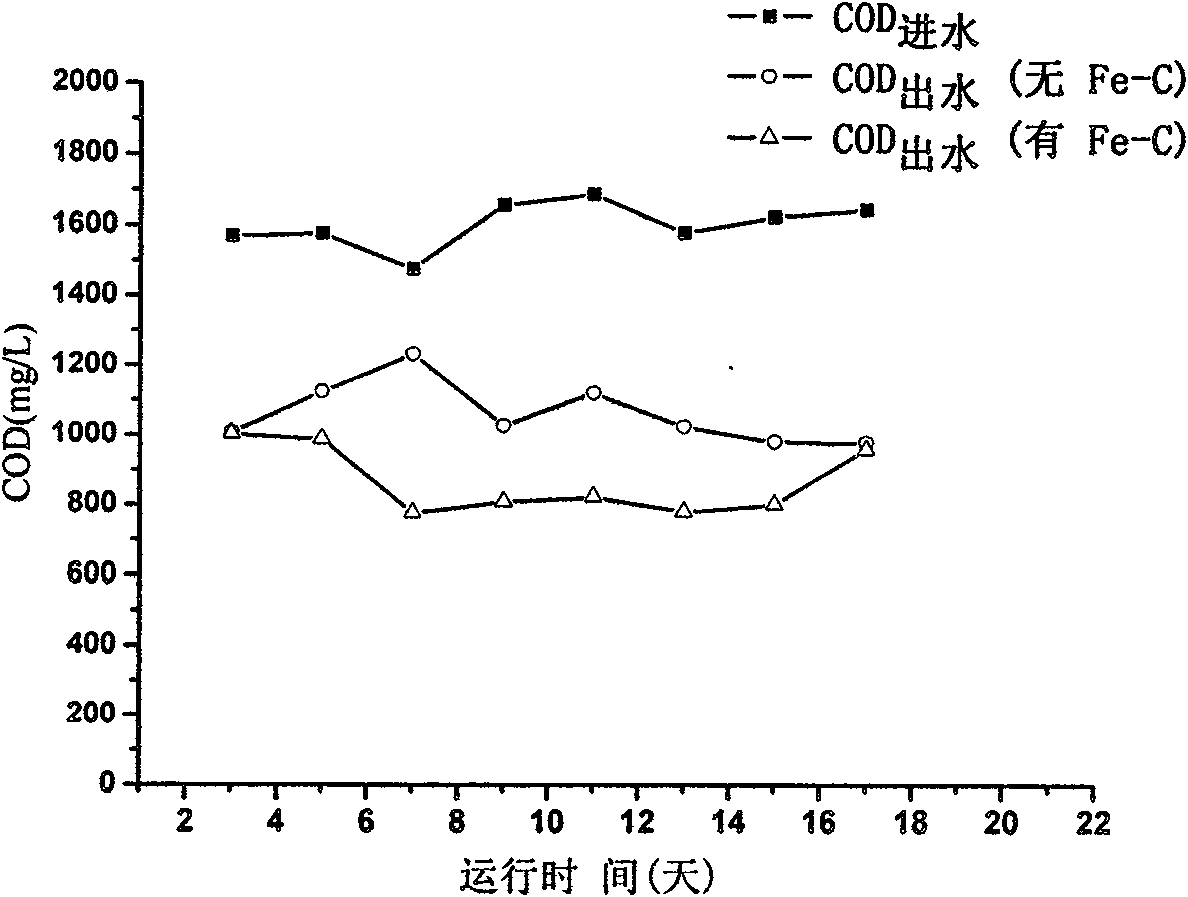

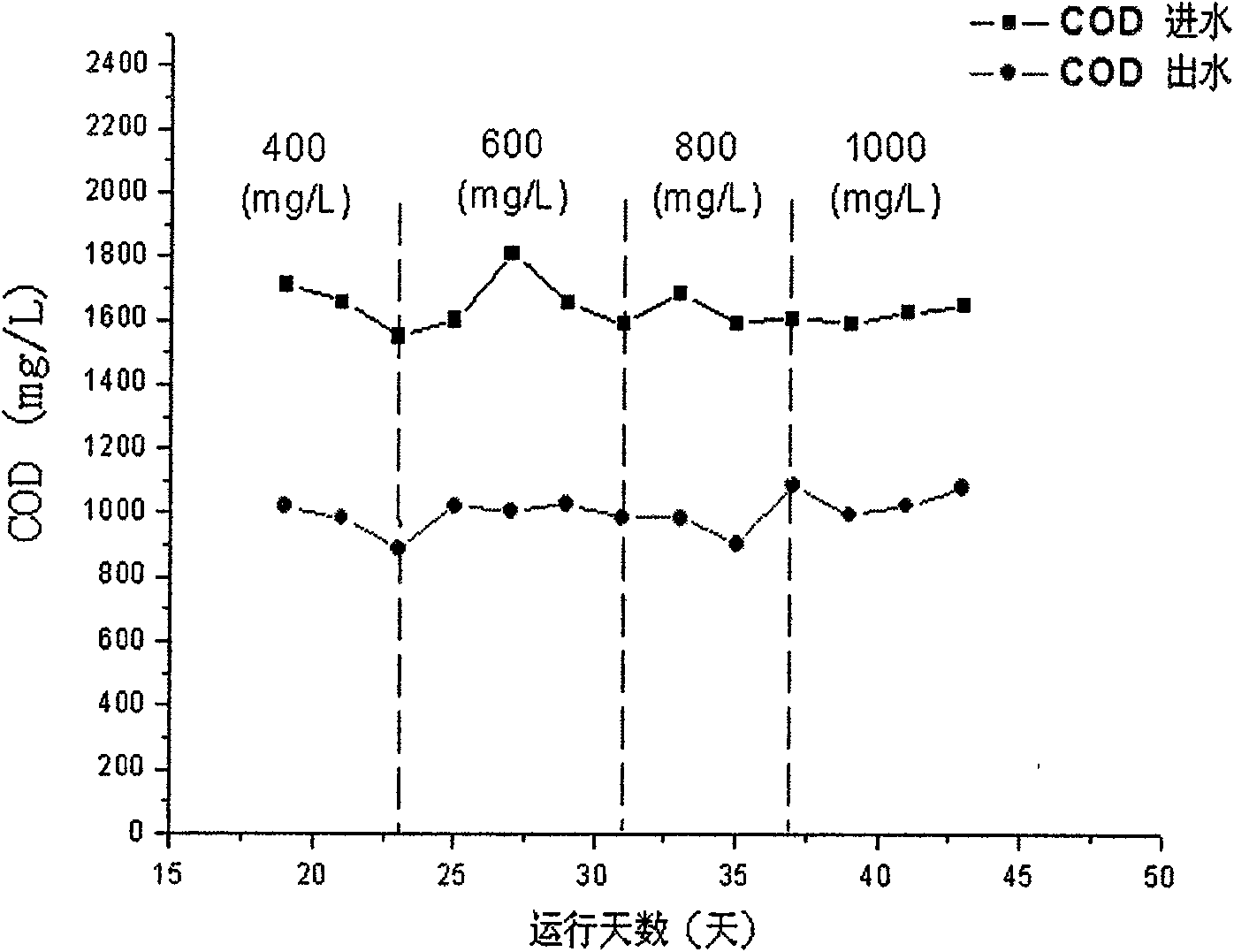

Anaerobic zero-valent iron sewage treatment method

ActiveCN101624250AImprove responseAvoid formingWaste based fuelTreatment with anaerobic digestion processesAnaerobic reactorDyeing wastewater

The invention relates to an anaerobic zero-valent iron sewage treatment method, belonging to the sewage treatment technical field. The anaerobic zero-valent iron sewage treatment places zero-valent iron in an anaerobic reactor and utilizes the environmental conditions of the anaerobic isolated air to largely reduce the formation rate of the rust of zero-valent iron and avoid the formation of hardening; meanwhile, the method uses the reducing action of metal iron to increase the anaerobic reductive atmosphere, balance the pH and increase the effect of the anaerobic organism. A circulating pump is adopted for sewage backflow so as to increase the overflow load of an iron / activated carbon layer and the reaction effect of zero-valent iron, improve the fluidization effect of sludge to increase the anaerobic process efficiency. In a sewage treatment system, ferrous iron contained in the discharged sewage is oxidized to Fe(OH)3 with the air and the coagulation generated in the process can further purify the sewage. Long-term experiment research shows that the decolorizing rate of the sewage treatment method for dye wastewater can teach 85%-95%, the COD can be reduced by more than 50% and the biodegradability can be increased to more than 0.3.

Owner:DALIAN UNIV OF TECH

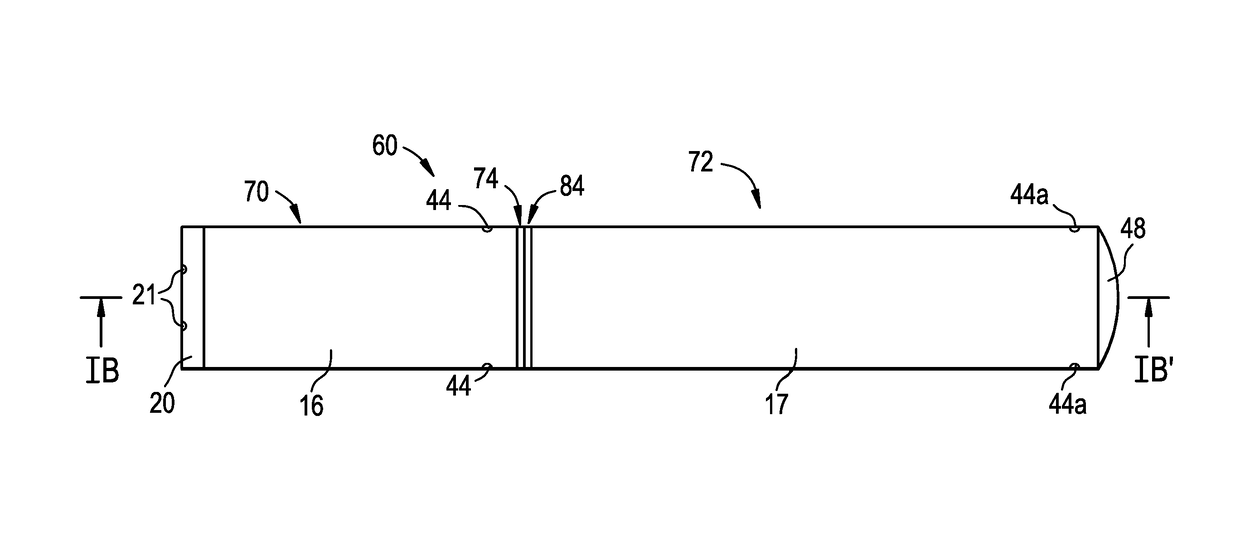

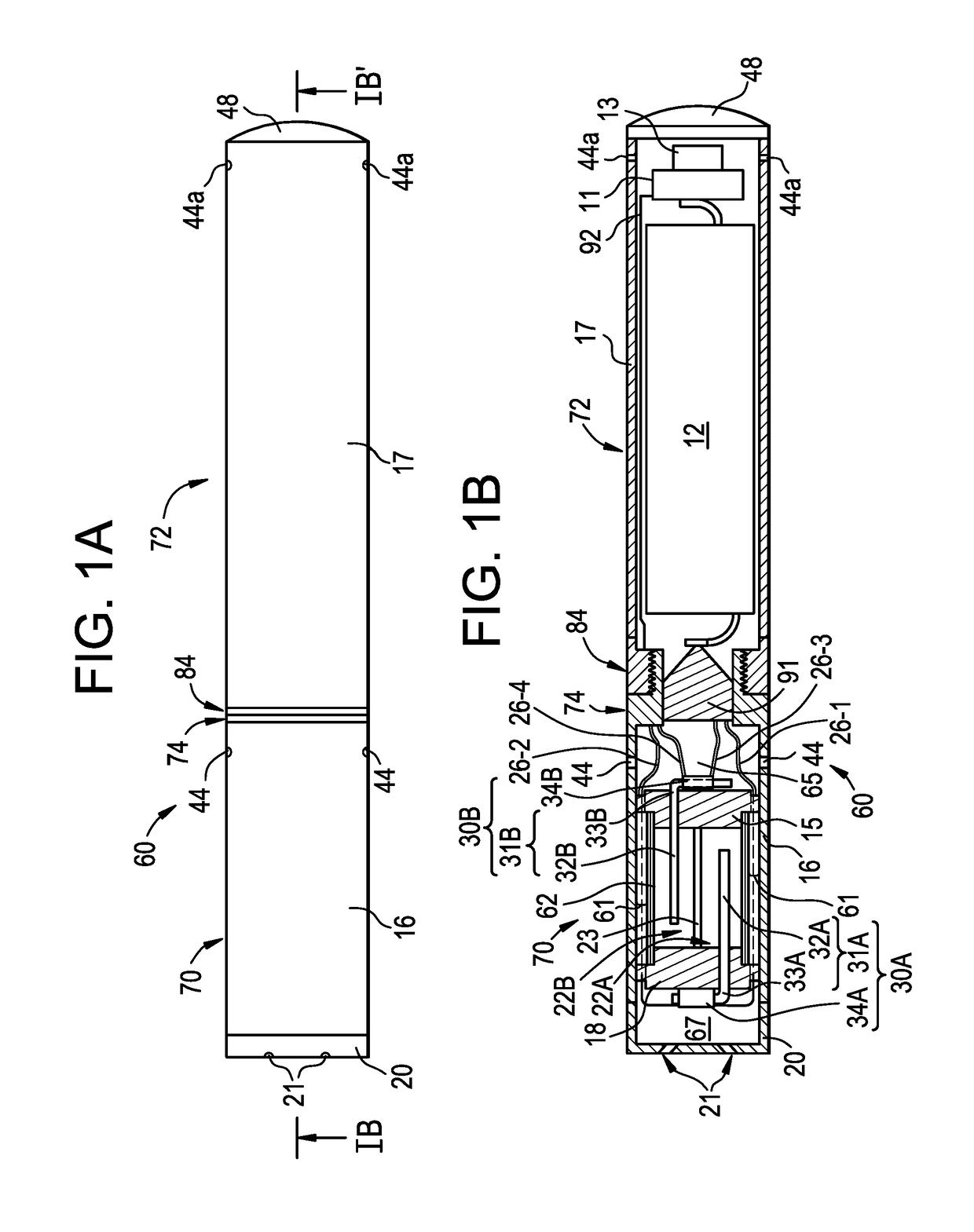

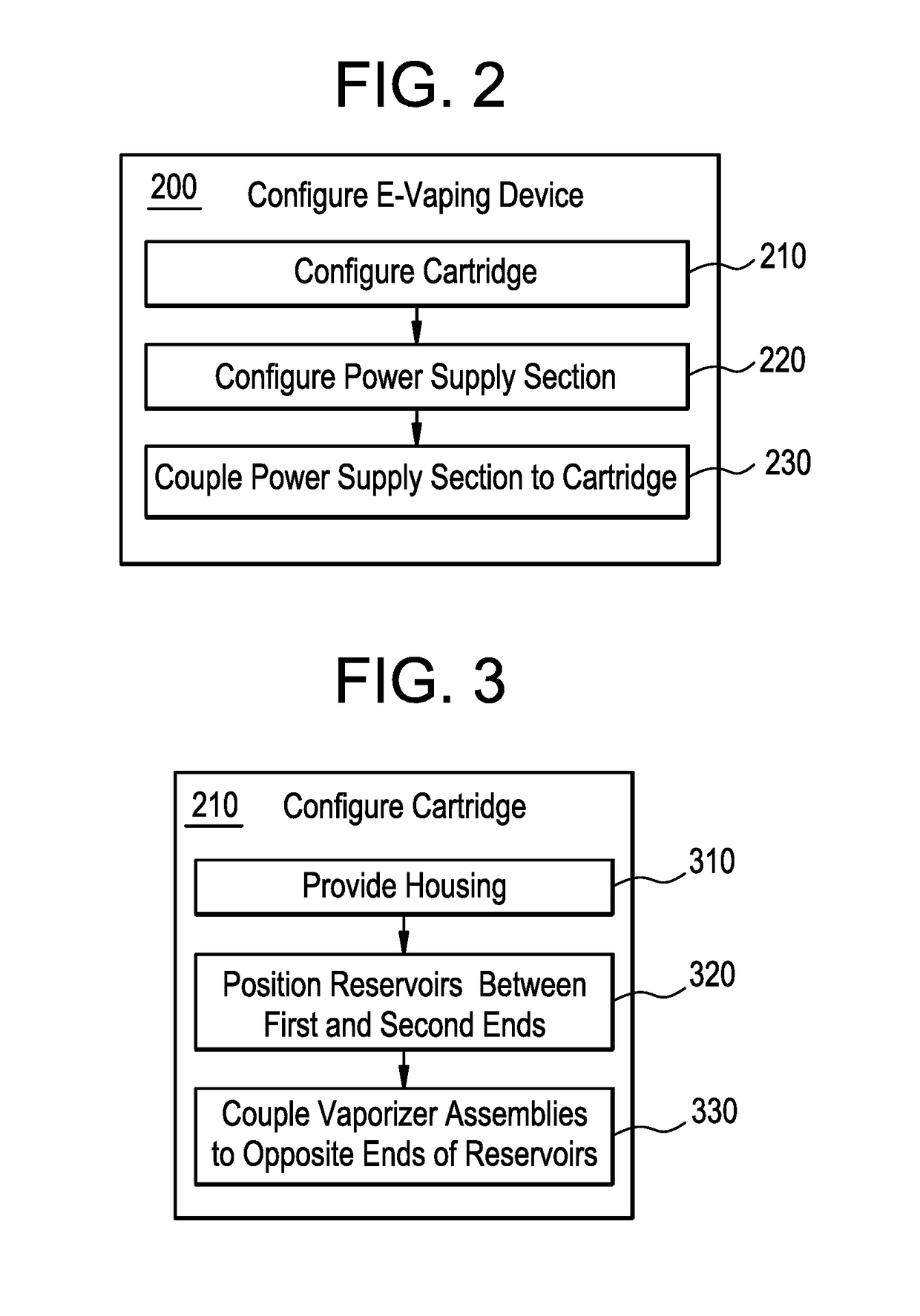

Cartridge for electronic vaping device

A cartridge for an e-vaping device enables separate vapors to be formed proximate to separate, respective ends of the cartridge. The cartridge includes multiple reservoirs and separate vaporizer assemblies coupled to separate reservoirs on opposite ends of the reservoirs. The separate reservoirs may hold separate pre-vapor formulations. The separate vaporizer assemblies may draw separate pre-vapor formulations from separate reservoirs towards opposite ends of the cartridge and vaporize the separate pre-vapor formulations via operation of separate heaters proximate to the separate ends. The separate heaters may be independently controlled to independently control vapor formation at the separate ends. The heaters may be controlled to independently control vapor formation rates proximate to the separate ends. The heaters may be controlled to form separate vapors at least one of simultaneously, concurrently, and at different times.

Owner:AKRIA CLIENT SERVICES LLC

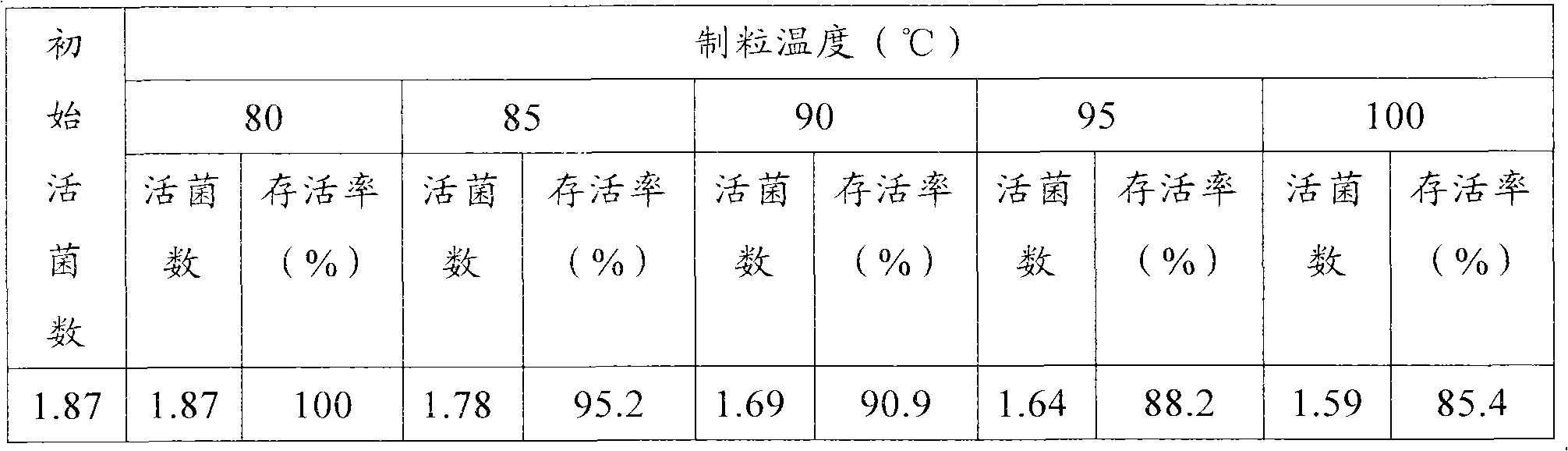

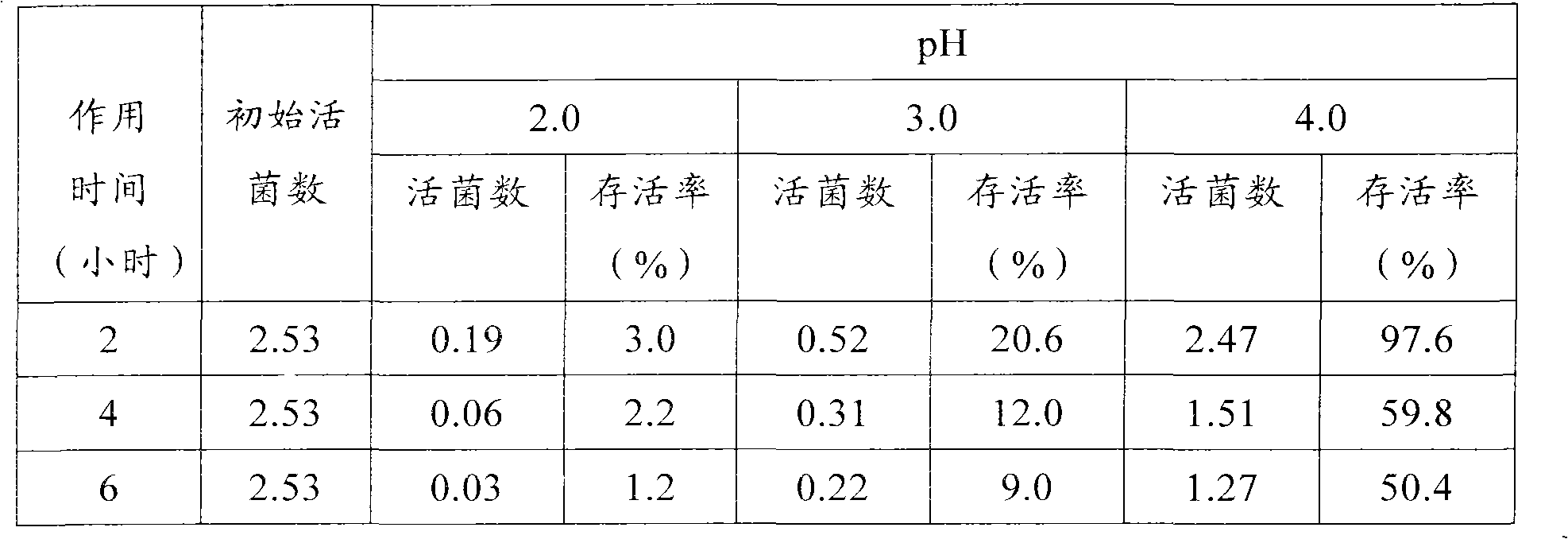

Bacillus subtilis preparation and preparation method thereof

ActiveCN102168045AHigh content of live bacteriaGuaranteed validityBacteriaAnimal feeding stuffBacillus subtilisFermentation broth

The invention discloses a bacillus subtilis preparation and preparation method thereof. The bacillus subtilis preparation is prepared by bacillus subtilis fermentation broth prepared by the following steps: accessing bacillus subtilis seed liquid into fermentation medium with 0.5 to 5% (weight ratio) of inoculation amount, and conducting fermentation for 20 to 40 hours, with pressure being 0.02 to 0.15 MPa, agitation speed being 100 to 300 r / m, and ventilation ratio being 1:0.3-1.5(volume ratio). The advantages of the invention: the invention adopts liquid deep fermentation method instead of solid fermentation method to improve efficiency of preparation technology, and further optimizes composition of the mediums used in various steps and fermentation technological conditions to substantially increase live bacteria content of the bacillus subtilis in final product; the bacillus subtilis preparation is acid resistant and cholate resistant, and keeps high efficiency and stability in intestinal tract environment; and gemma formation rate is high, the bacillus subtilis is more high-temperature resistant and convenient for processing and preservation.

Owner:北京科为博生物科技有限公司

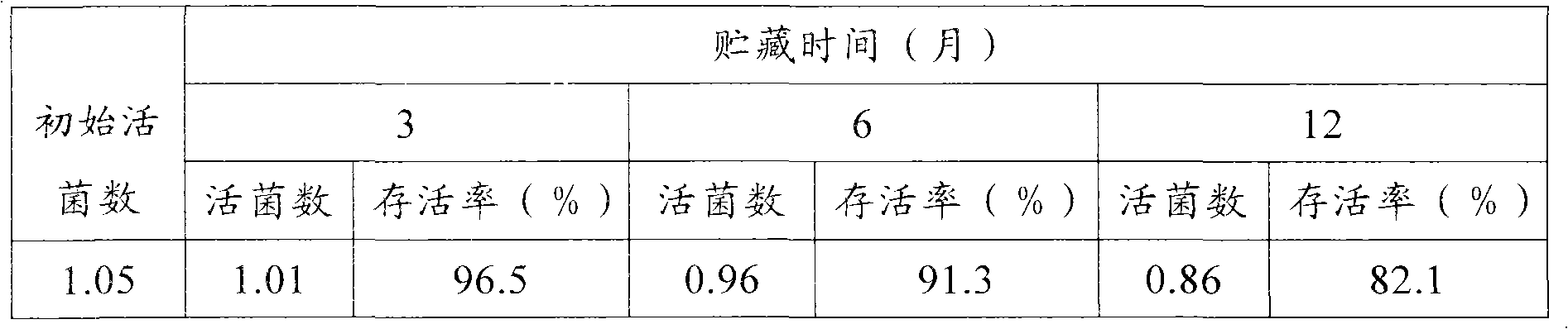

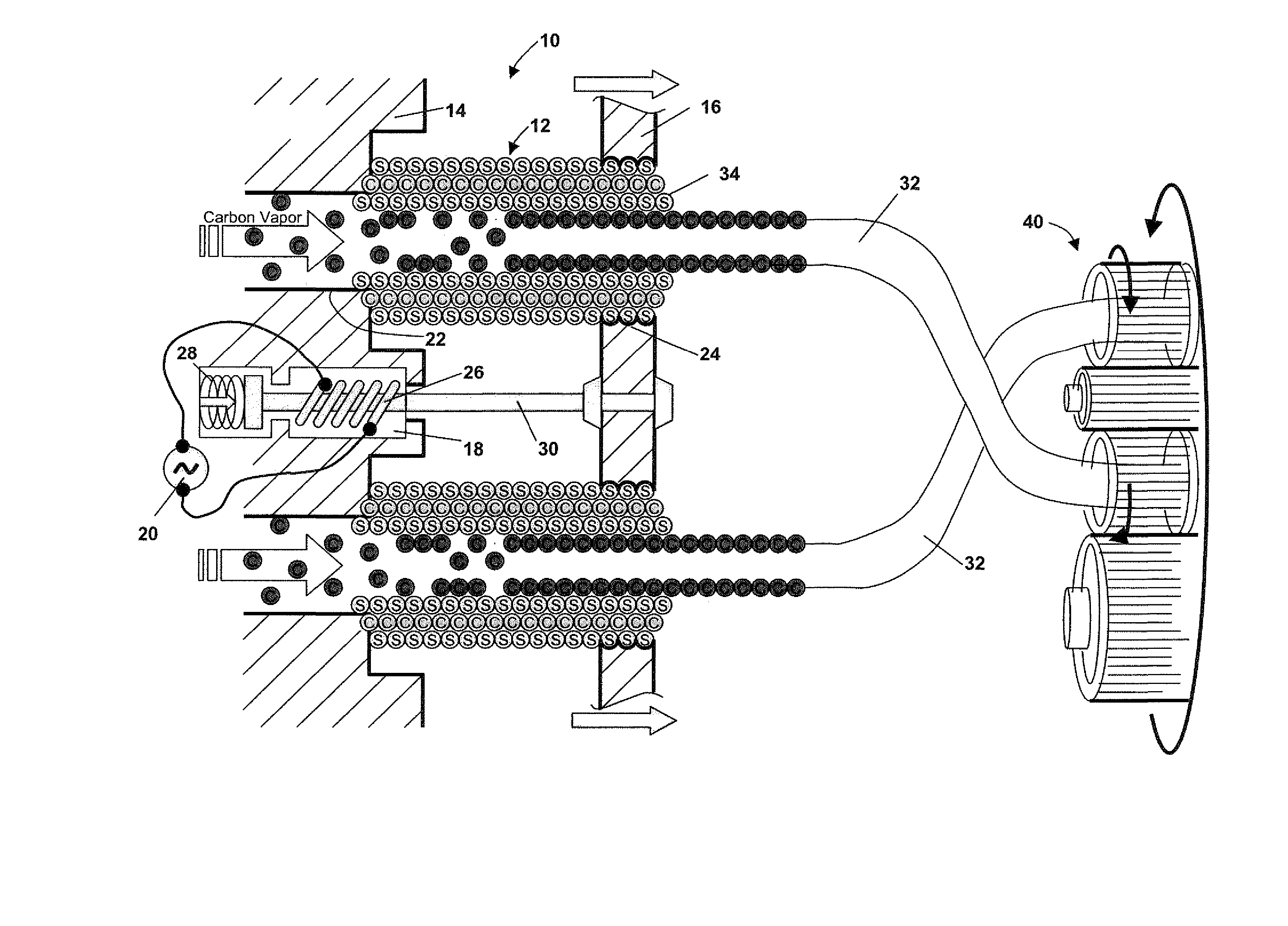

Carbon Nanotube (CNT) Extrusion Methods And CNT Wire And Composites

A carbon nanotube (CNT) extrusion system includes a carbon source, an extrusion die having a baseplate having a plurality of die sets, each die set has a plurality of through-holes in fluid communication with the carbon source and a corresponding plurality of template tubes connected at one end to the baseplate and coaxial with the through-holes, each template tube includes a catalyst for forming a CNT structure in combination with the carbon source. An oscillating mechanism operatively associated with the free end of each template tube axially oscillates the template tubes to alternately form and release the CNT structure within each template tube in a continuous manner. The oscillating mechanism can be an alternating electric field or magnetic field applied to the template tubes, the frequency of the electric or magnetic field being synchronized with a formation rate of the CNT within the template tubes.

Owner:CAPIZZO PETER DAVID

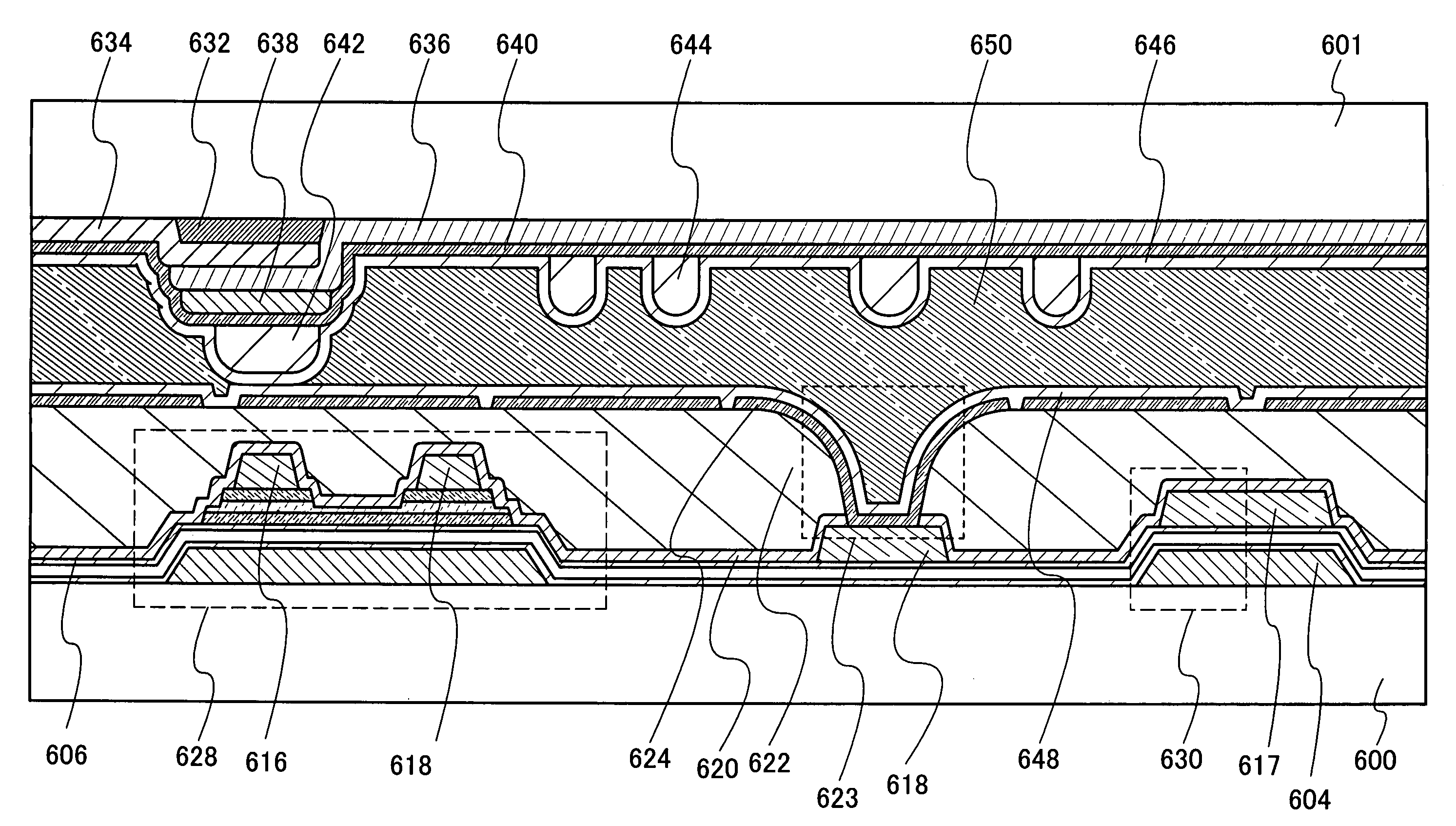

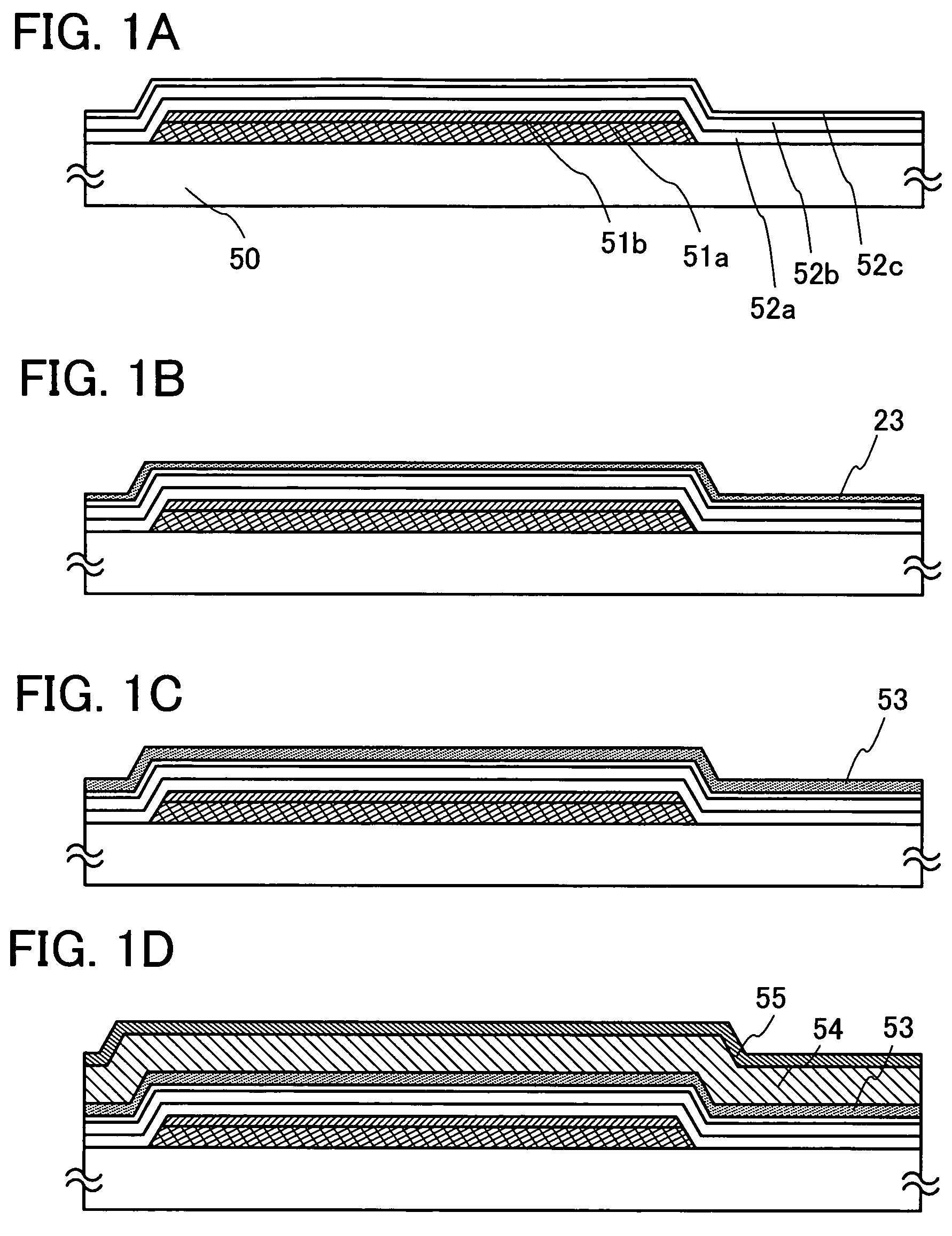

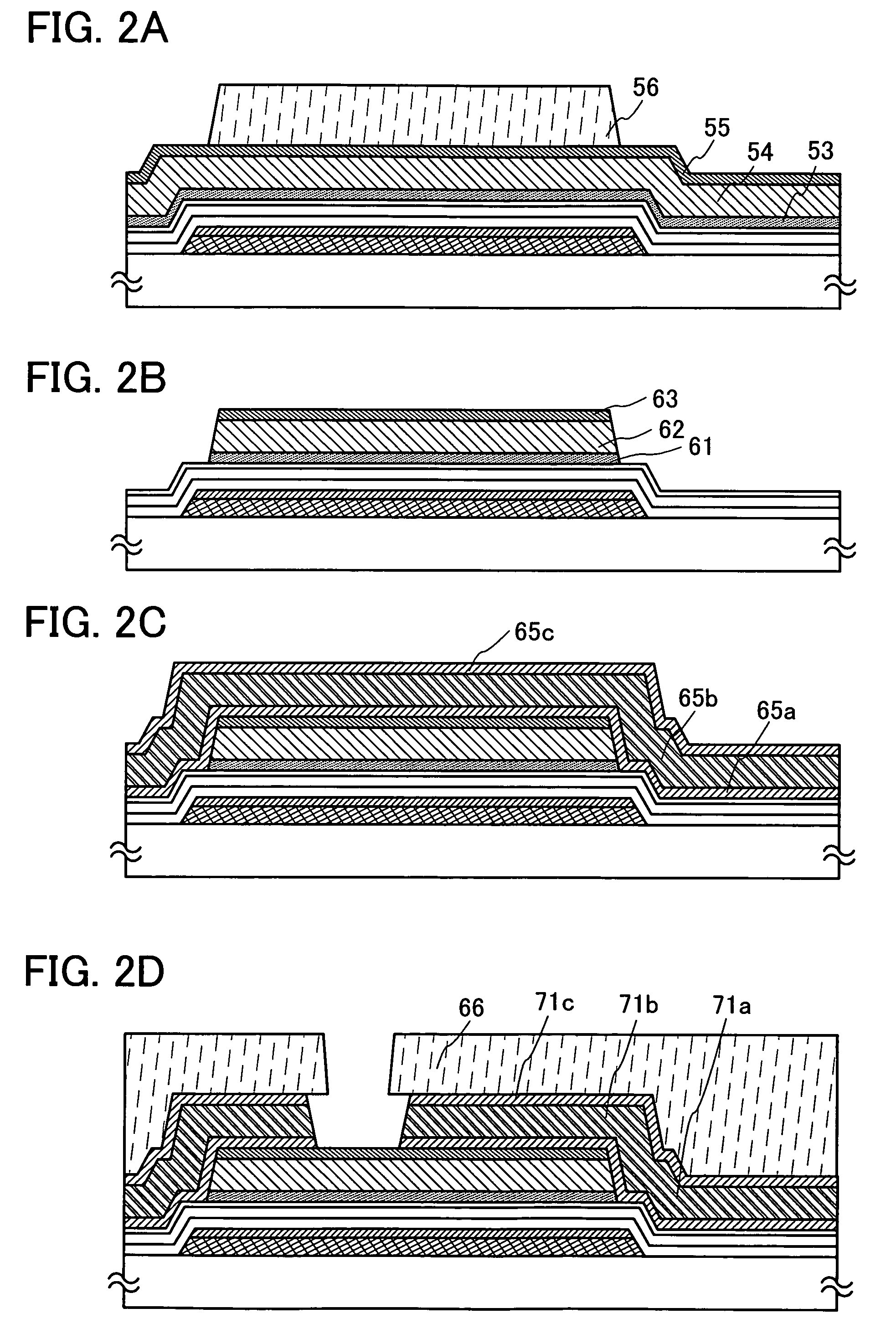

Manufacturing method of semiconductor device

InactiveUS7833845B2Low costIncrease in sizeSolid-state devicesSemiconductor/solid-state device manufacturingHigh frequency powerEngineering

An object is to provide a manufacturing method of a microcrystalline semiconductor film with favorable quality over a large-area substrate. After forming a gate insulating film over a gate electrode, in order to improve quality of a microcrystalline semiconductor film formed in an initial stage, glow discharge plasma is generated by supplying high-frequency powers with different frequencies, and a lower part of the film near an interface with the gate insulating film is formed under a first film formation condition, which is low in film formation rate but results in a good quality film. Thereafter, an upper part of the film is deposited under a second film formation condition with higher film formation rate, and further, a buffer layer is stacked on the microcrystalline semiconductor film.

Owner:SEMICON ENERGY LAB CO LTD

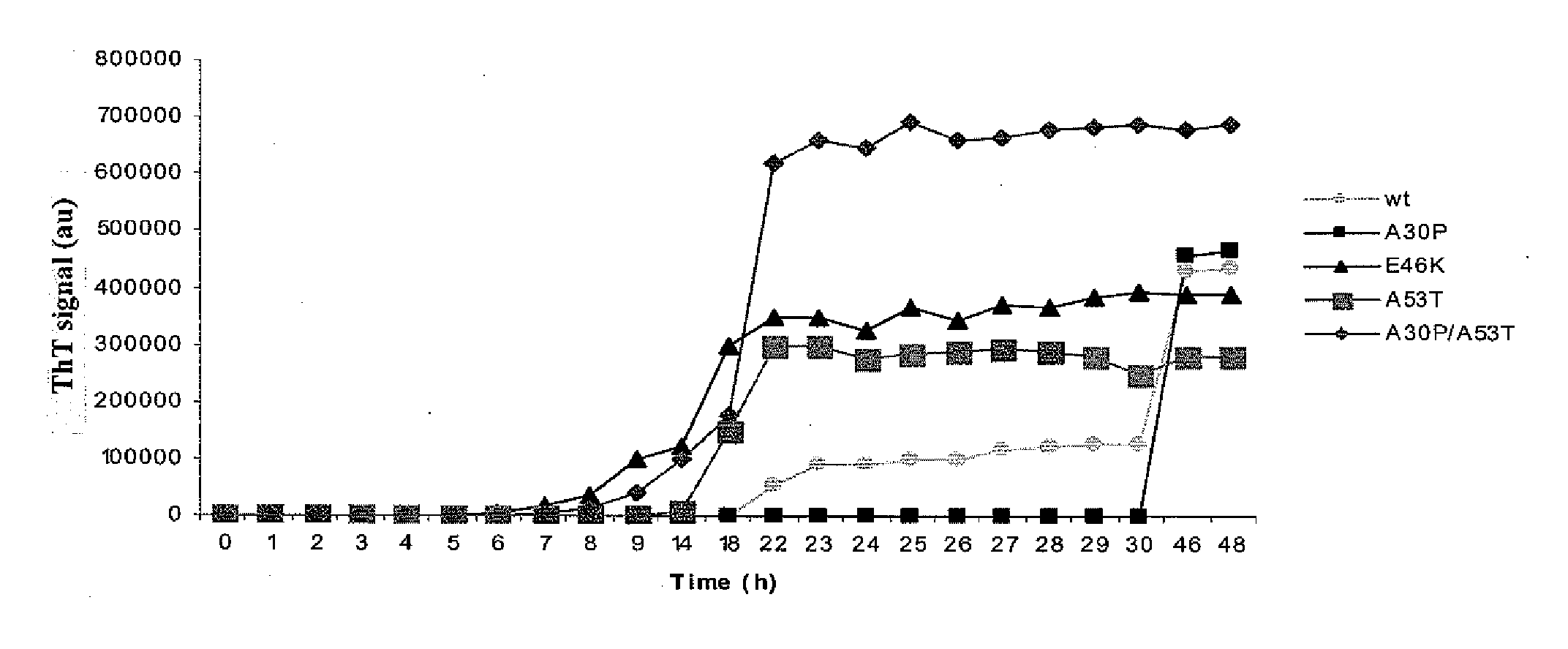

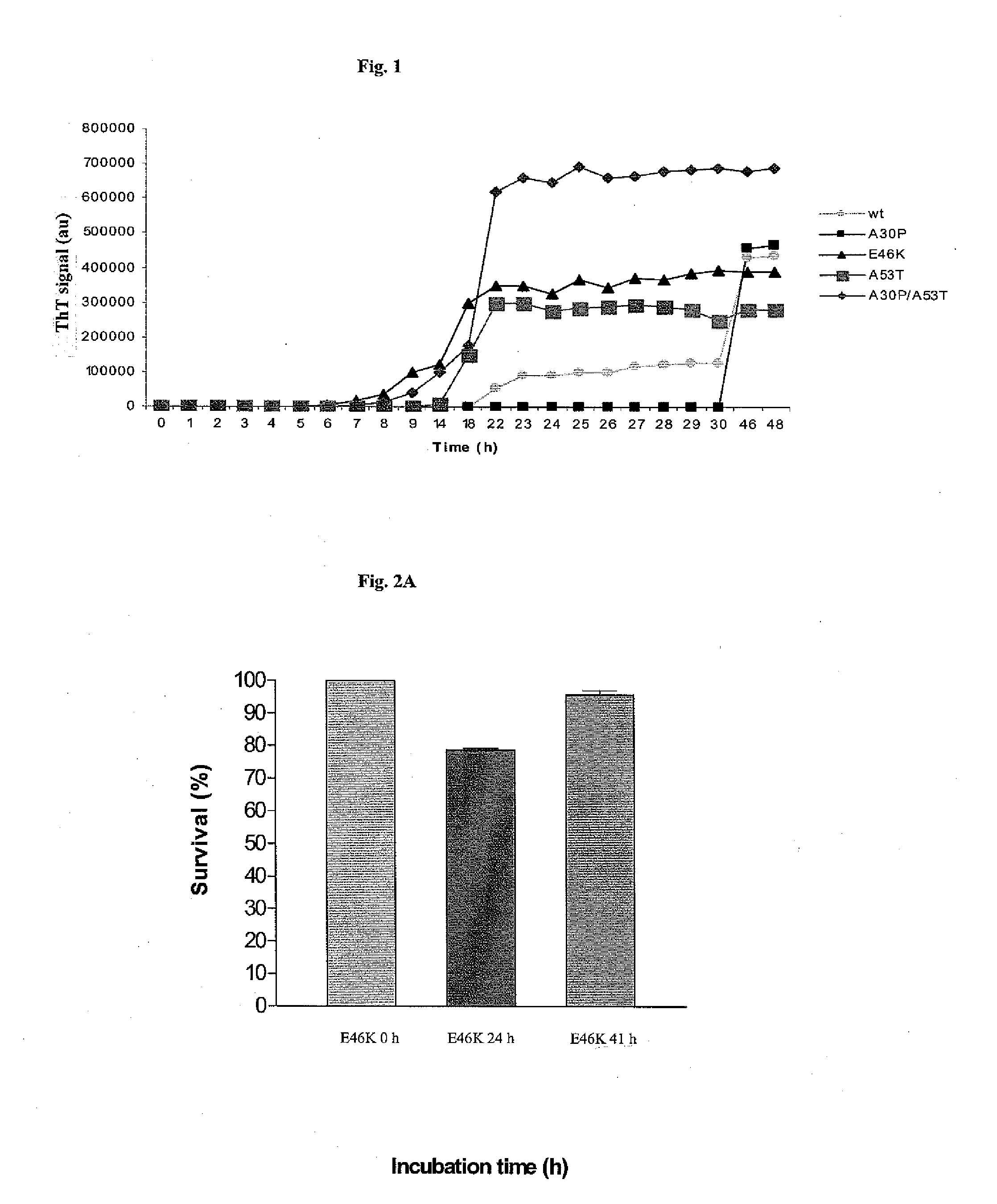

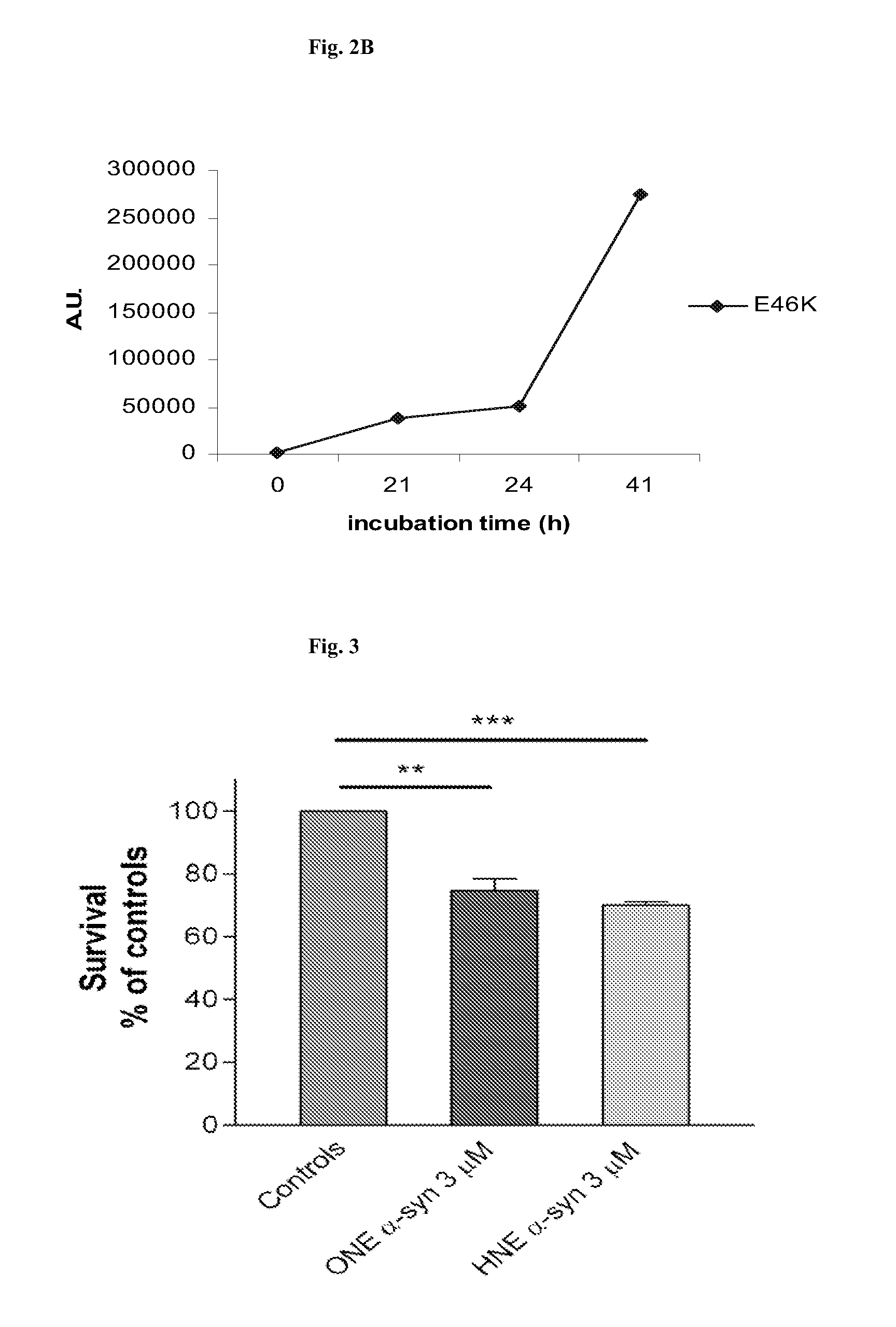

Antibodies and Vaccines for Use in Therapeutic and Diagnostic Methods for Alpha-Synuclein-Related Disorders

A vaccine for delaying an onset of or for treatment of an α-synuclein-related disorder in an individual comprises a therapeutically effective amount of isolated stabilized soluble α-synuclein oligomer having a lower formation rate to a non-soluble aggregated form than a non-stabilized oligomer of the α-synuclein. An antibody for delaying an onset of or for treatment of an α-synuclein-related disorder in an individual binds soluble α-synuclein. Methods for delaying an onset of for treatment or for prevention of an α-synuclein-related disorder employ the vaccine or antibody. Methods of detecting α-synuclein oligomers employ the antibody.

Owner:BIOARCTIC NEUROSCI AB

Self-hardening calcium phosphate materials with high resistance to fracture, controlled strength histories and tailored macropore formation rates

InactiveUS20050081750A1Encourage bone ingrowthHighly integratedImpression capsPhosphatesHigh resistanceFiber

A bone replacement material and therapy comprises the combination of calcium phosphate compounds and two or more soluble fillers in the form of fibers, mesh or other materials which have the dual functions of reinforcing an in vivo implant while dissolving at a programmed rate to form macropores capable of receiving natural bone ingrowth.

Owner:ADA FOUND

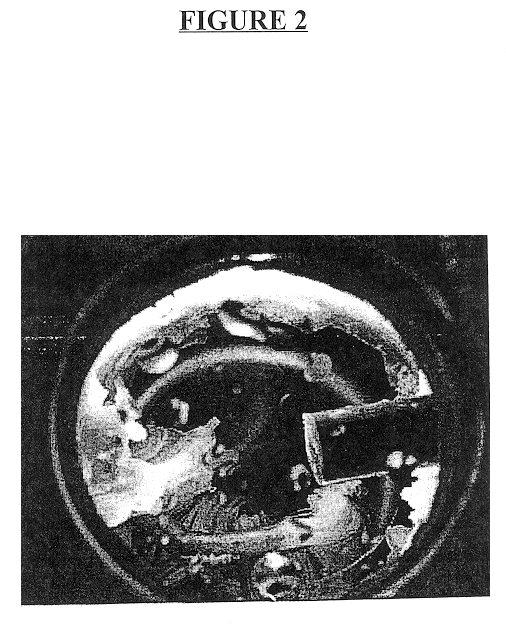

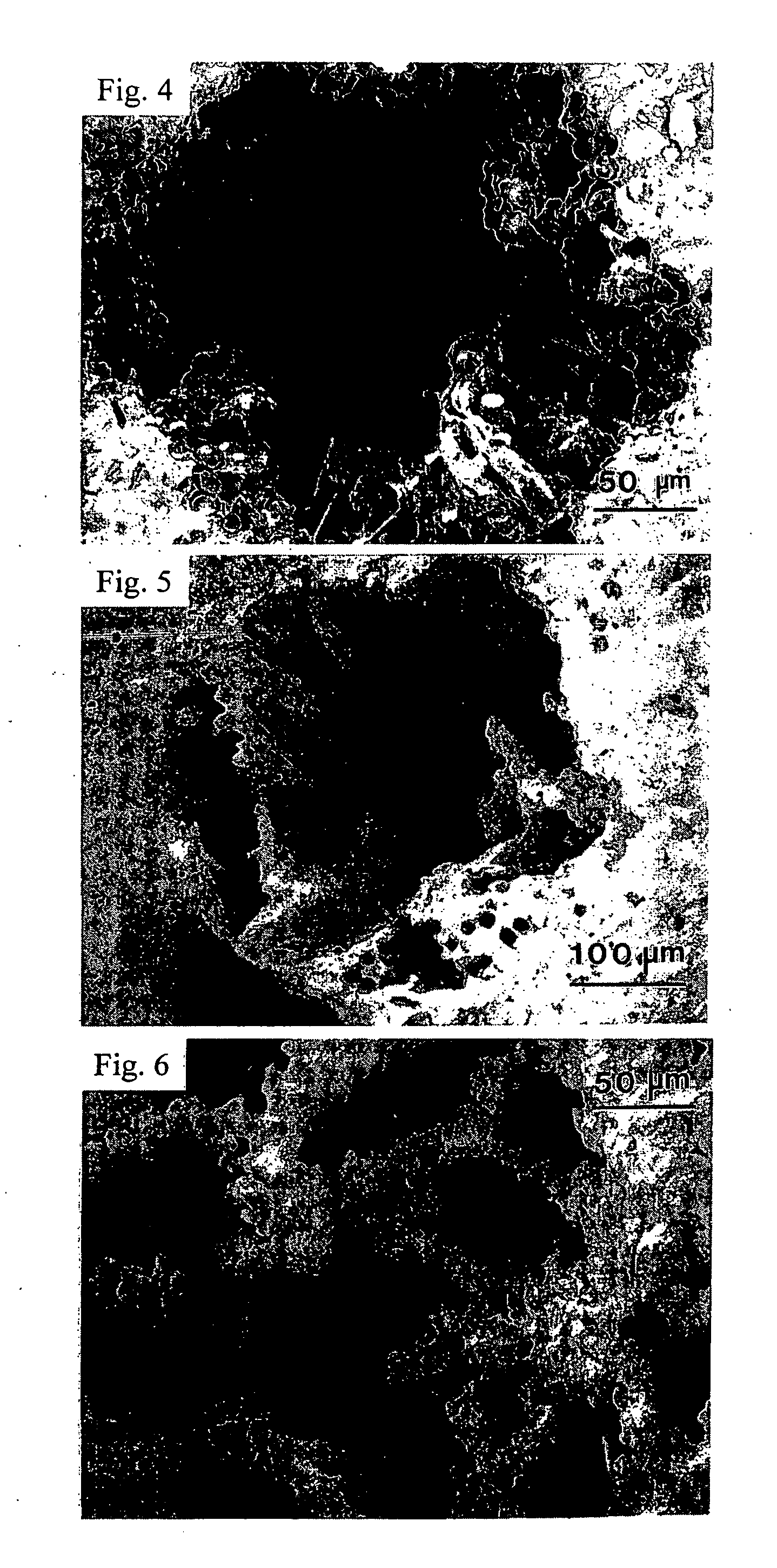

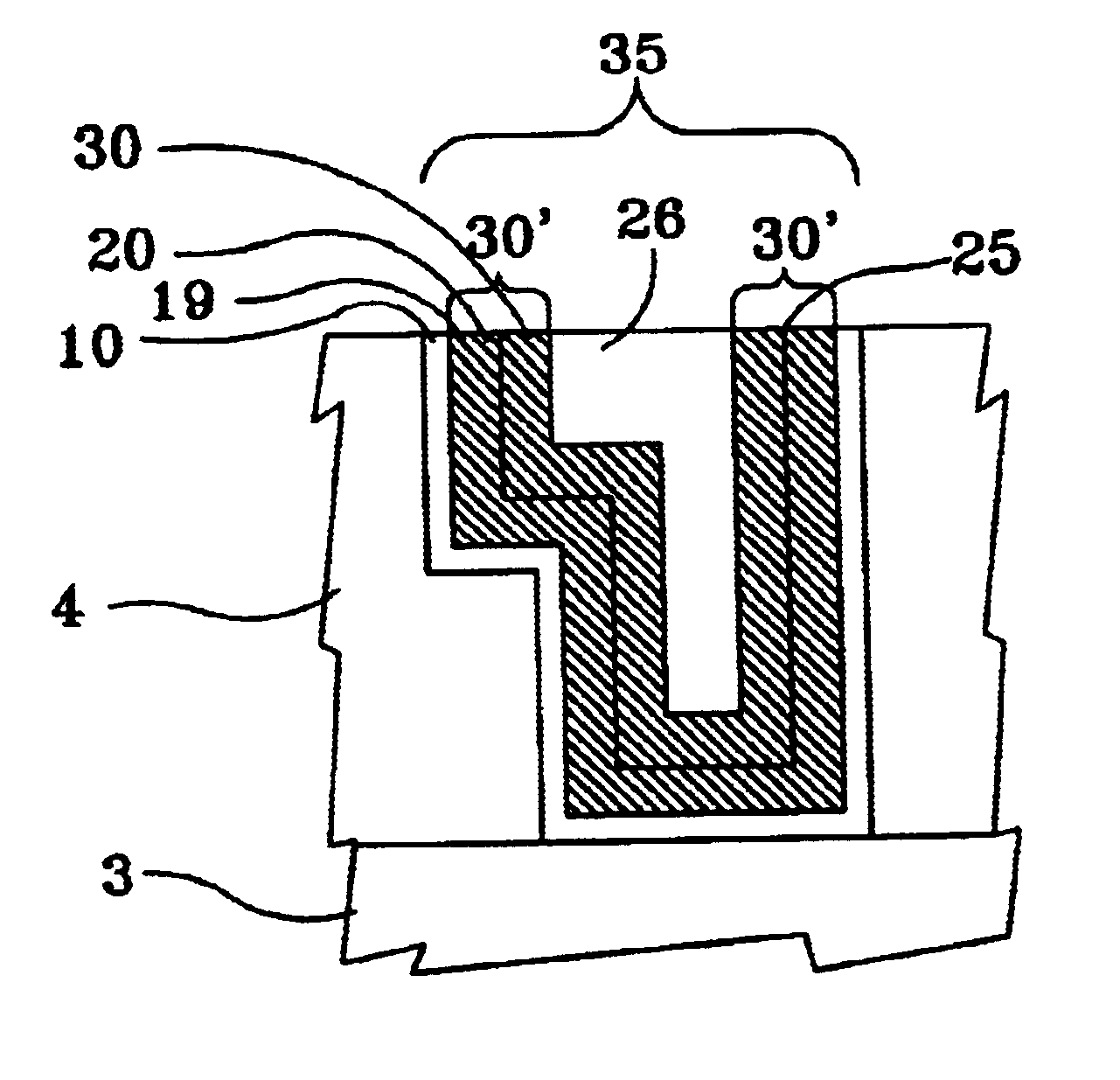

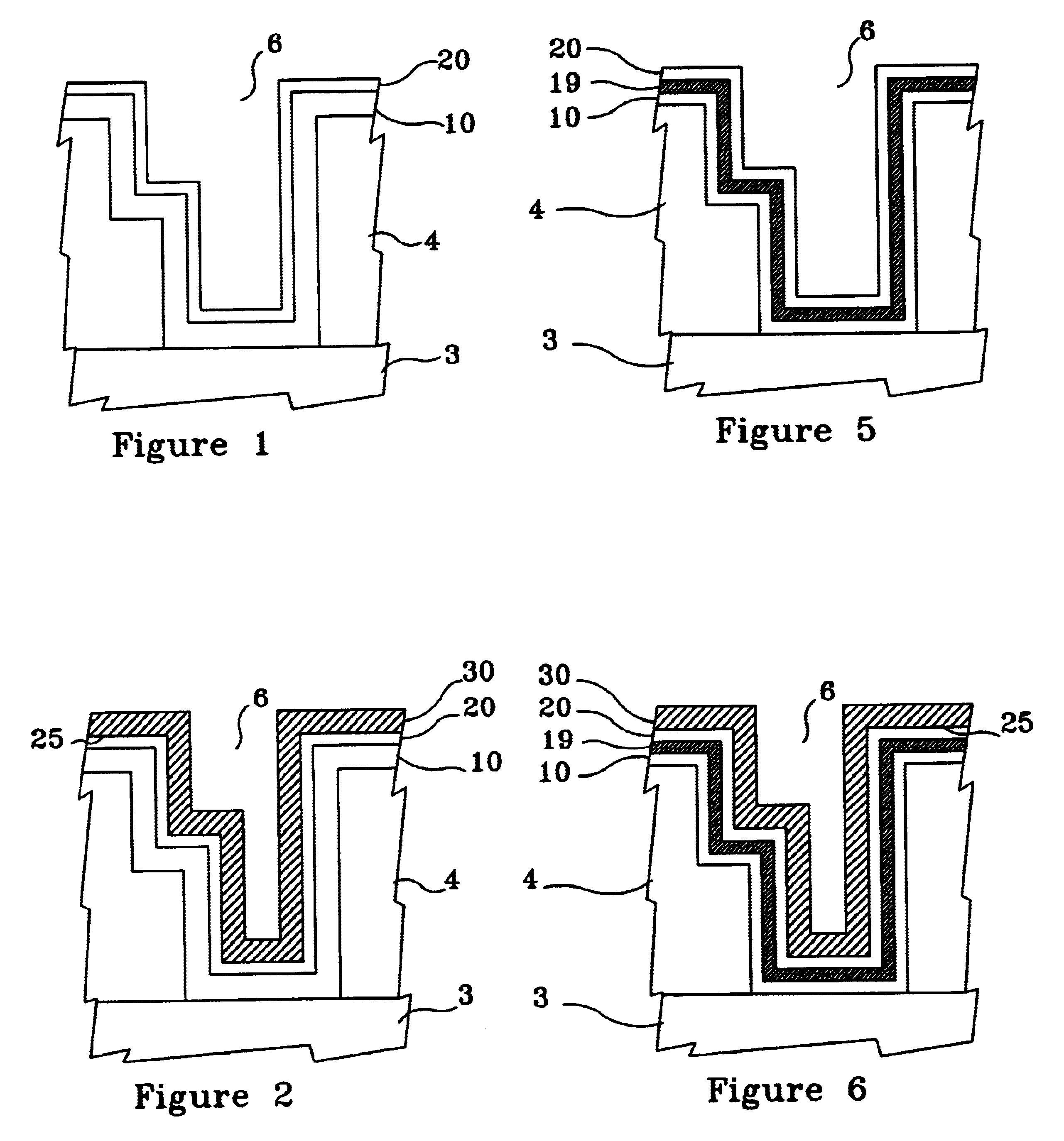

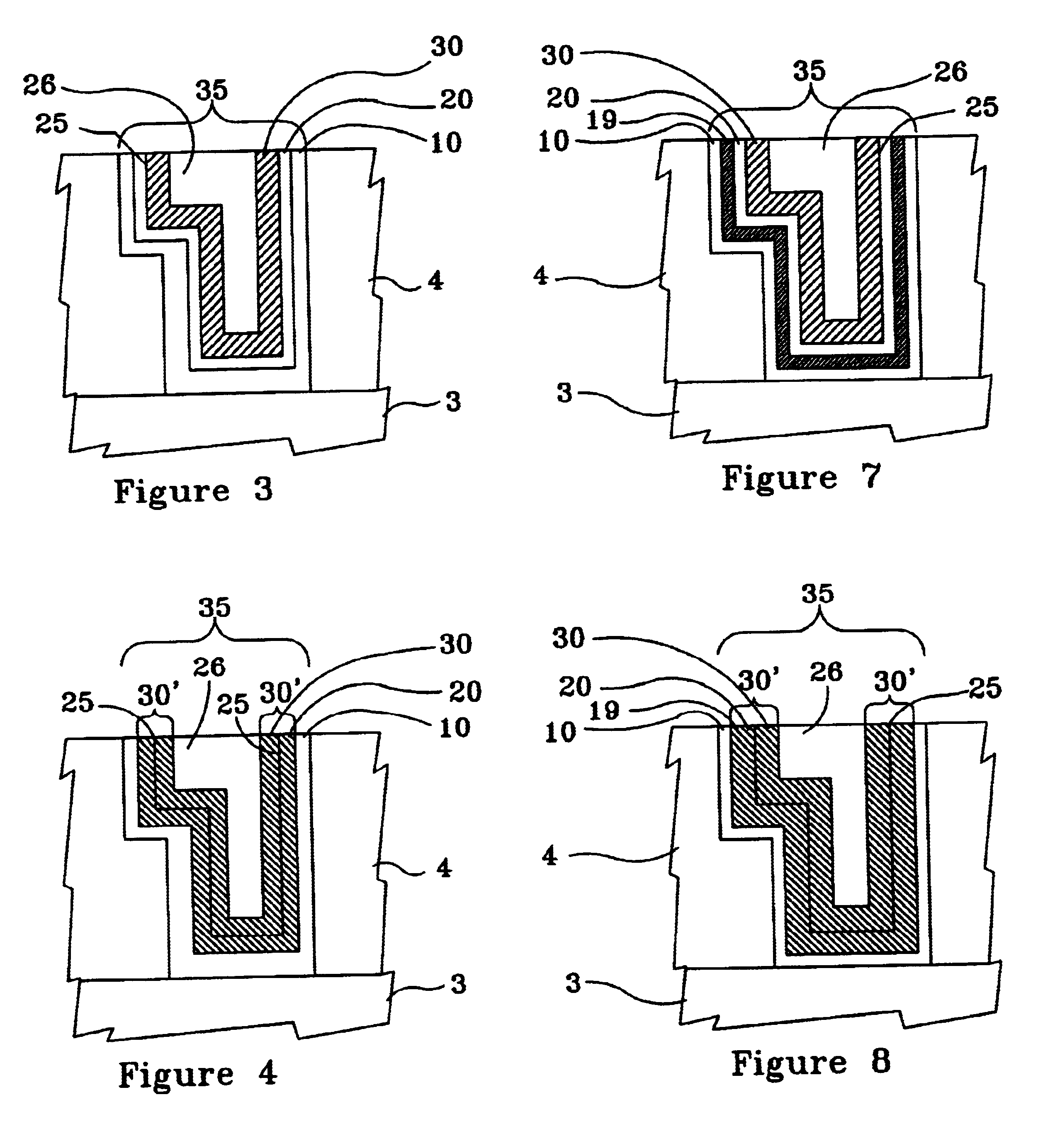

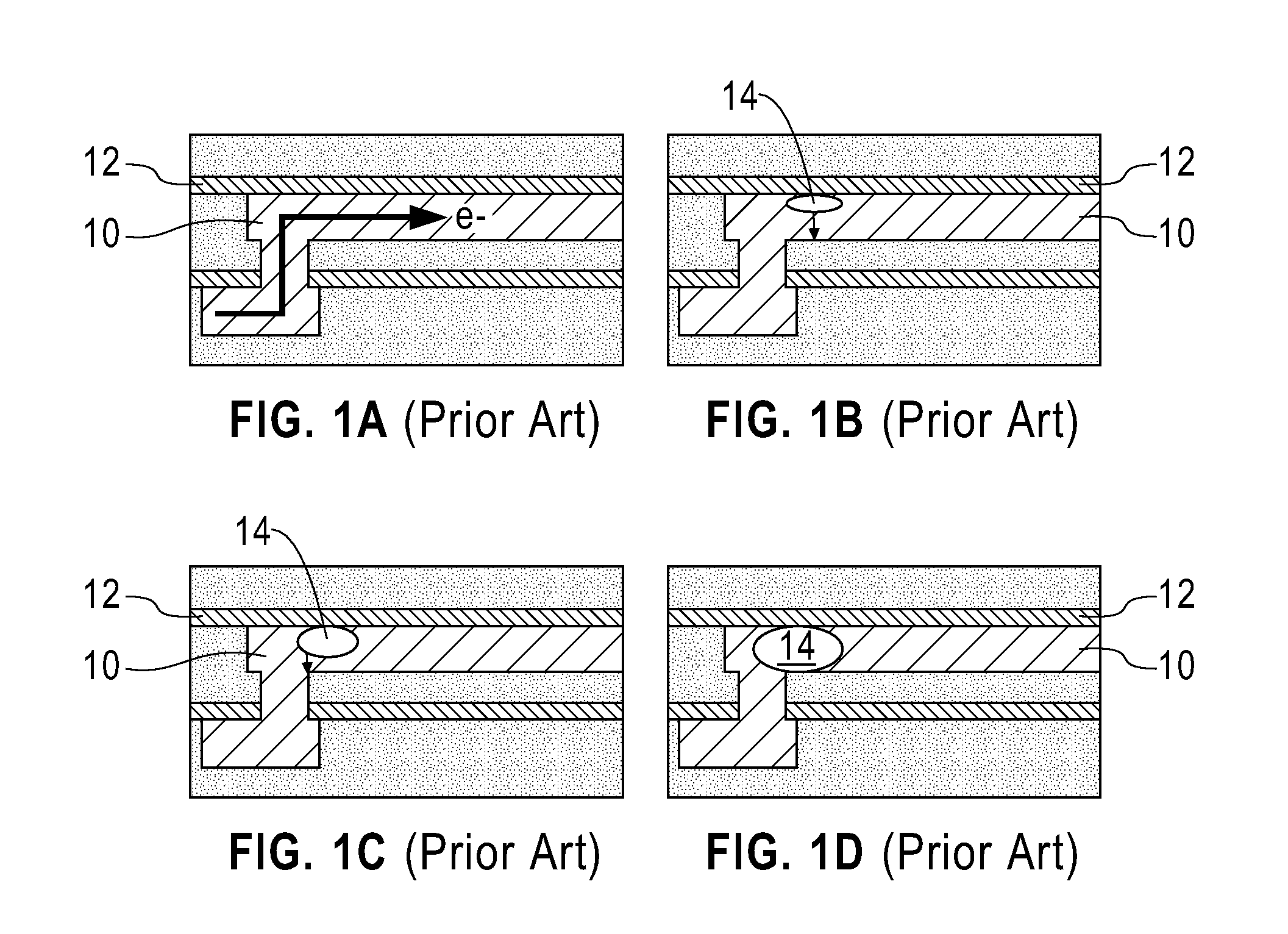

Method of reducing electromigration in a copper line by electroplating an interim copper-zinc alloy thin film on a copper surface and a semiconductor device thereby formed

InactiveUS6660633B1Improves Cu interconnect reliabilityReduce manufacturing costElectrolysis componentsSolid-state devicesCopper interconnectChemical solution

A method of fabricating a semiconductor device, having an interim reduced-oxygen Cu-Zn alloy thin film (30) electroplated on a blanket Cu surface (20) disposed in a via (6) by electroplating, using an electroplating apparatus, the Cu surface (20) in a unique chemical solution containing salts of Zn and Cu, their complexing agents, a pH adjuster, and surfactants; and annealing the interim electroplated Cu-Zn alloy thin film (30); filling the via (6) with further Cu (26); annealing and planarizing the interconnect structure (35); and a semiconductor device thereby formed. The reduction of electromigration in copper interconnect lines (35) is achieved by decreasing the drift velocity in the copper line (35) / via (6), thereby decreasing the copper migration rate as well as the void formation rate, by using an interim conformal Cu-rich Cu-Zn alloy thin film (30) electroplated on a Cu surface (20) from a stable chemical solution, and by controlling the Zn-doping thereof, which improves also interconnect reliability and corrosion resistance.

Owner:GLOBALFOUNDRIES US INC

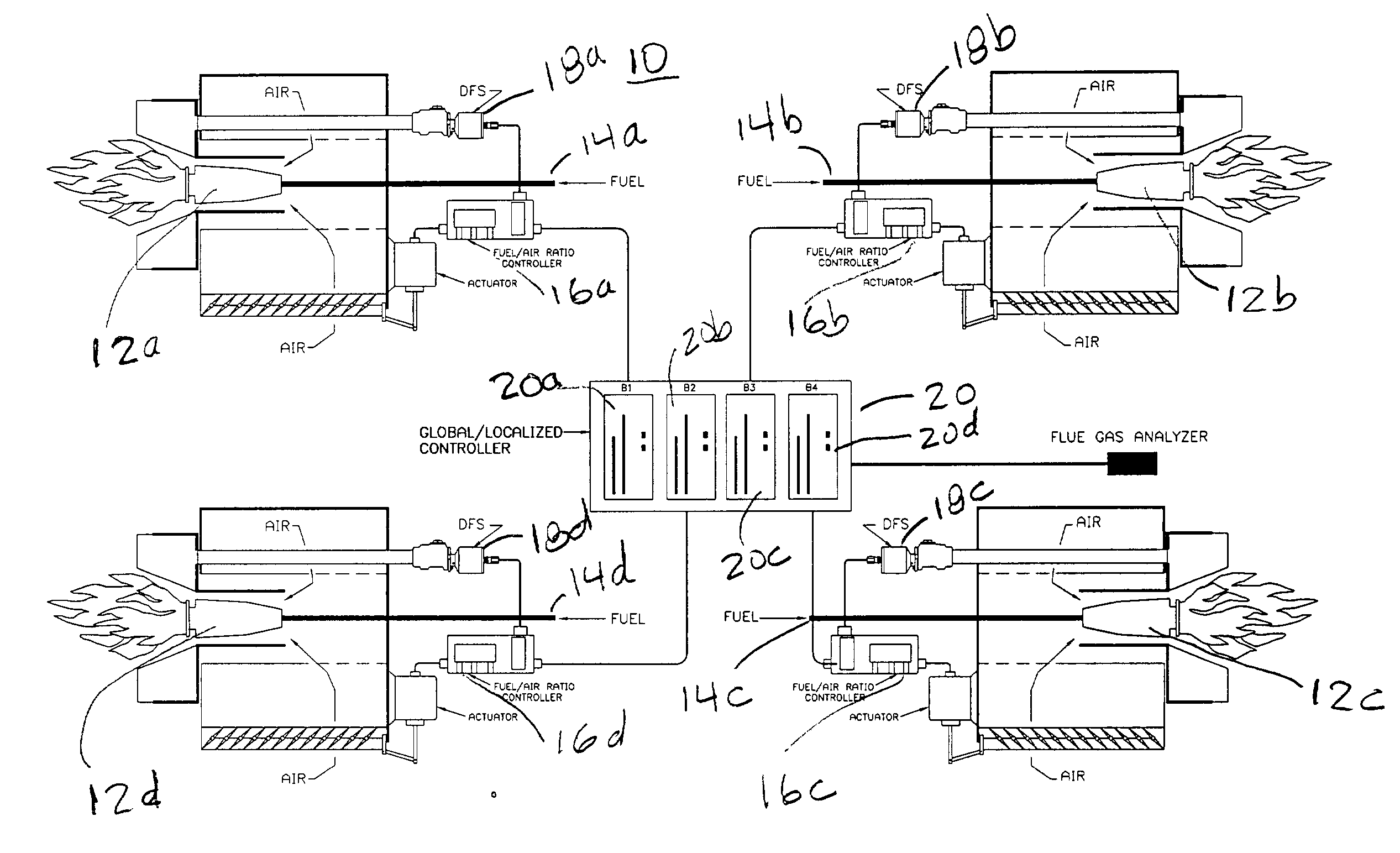

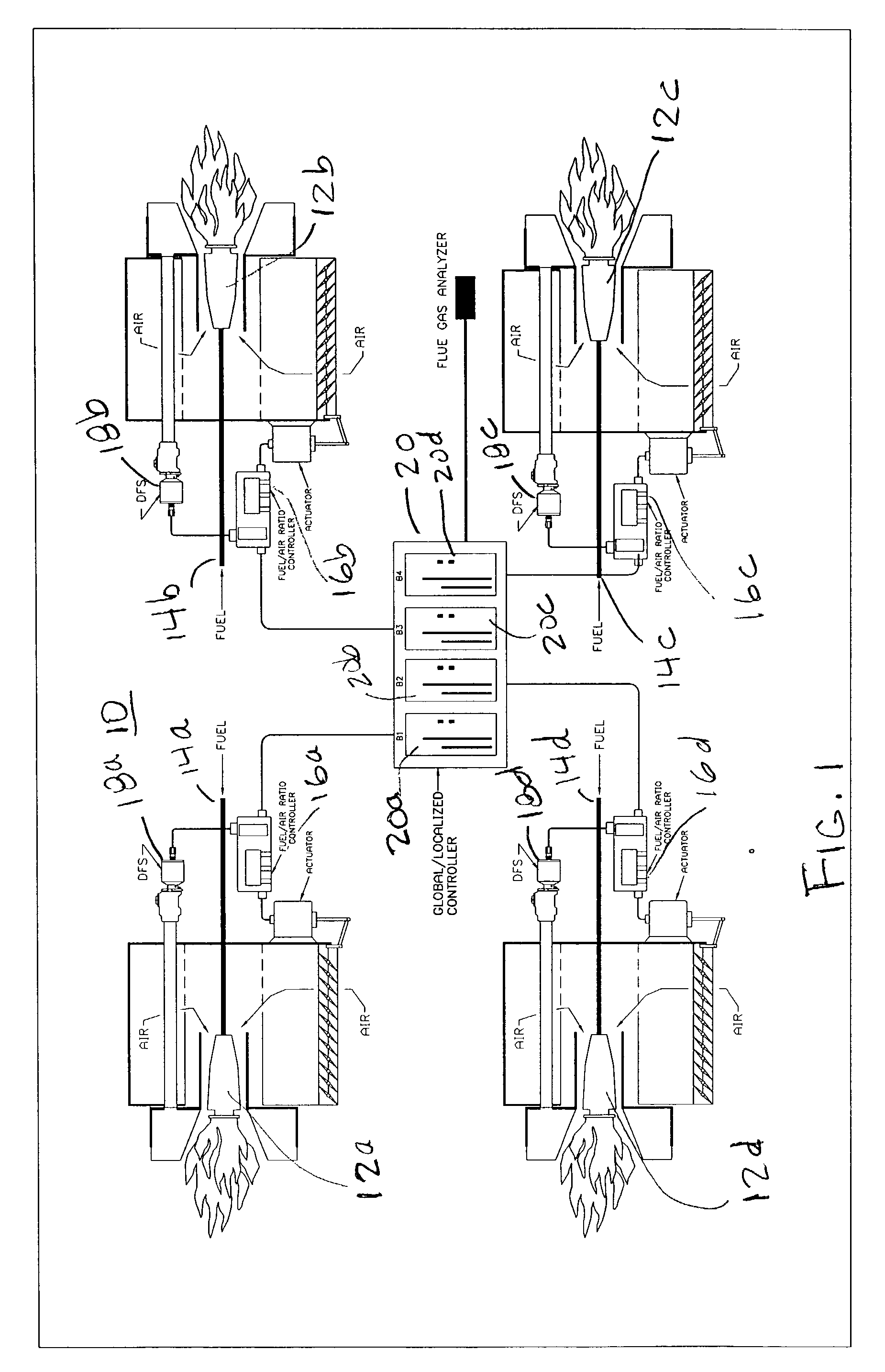

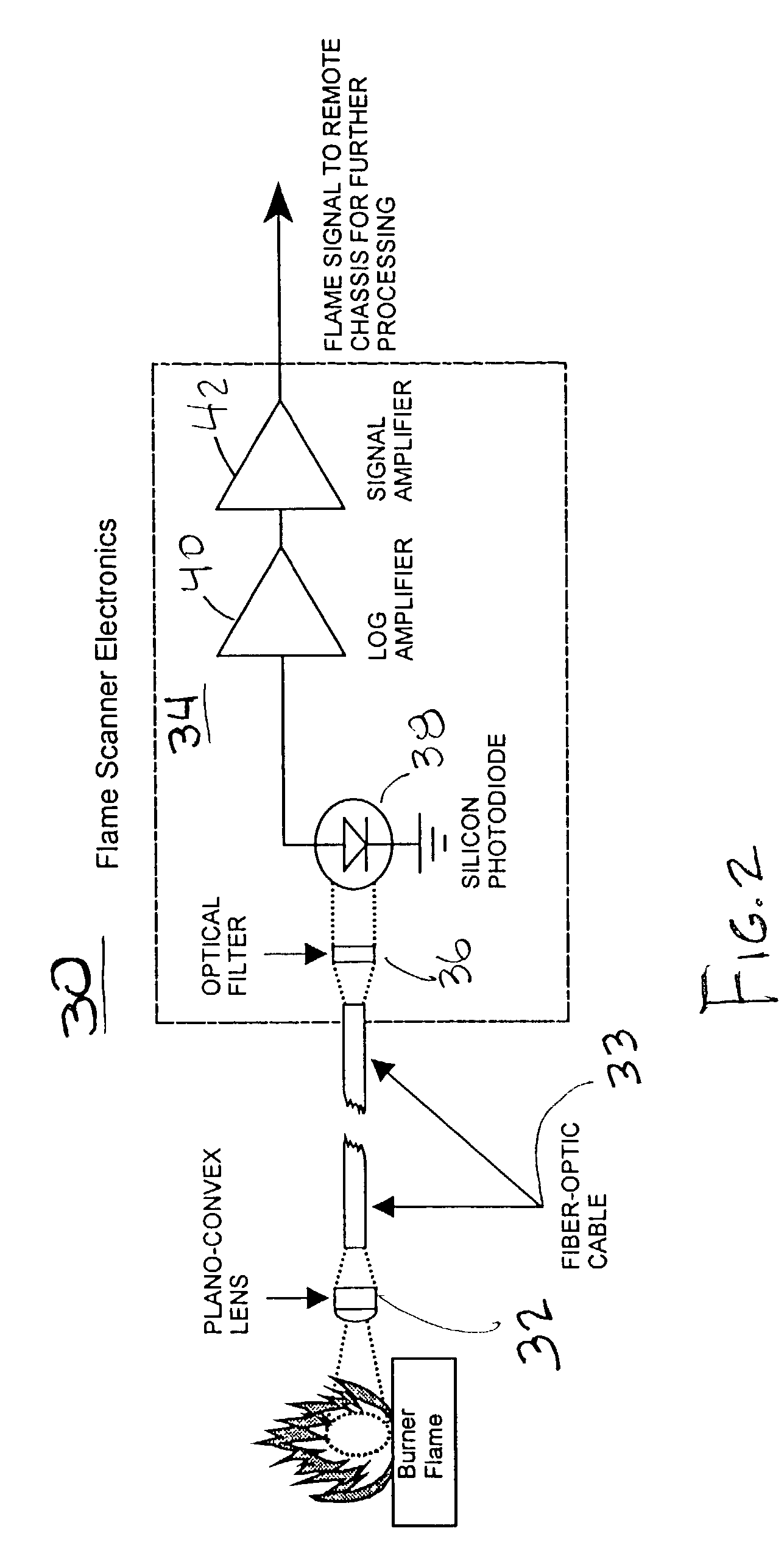

Combustion emission estimation with flame sensing system

InactiveUS20040033457A1High frequencyAddressing Insufficient SensitivityFuel supply regulationPilot flame ignitersCombustorEngineering

There is described a method and apparatus for controlling the combustion by-product formation rate in at least one burner of a fossil fuel fired power plant. The burner has an associated flame scanner which is focused on a small area of the burner flame to obtain an image signal of the flame. A flame signal that represents properties of temporal combustion in the visible light spectrum of the burner is generated from the image signal. Combustion turbulence at the burner is analyzed from the flame signal by a dynamic invariant that has a relationship to the combustion by-product values and different combustion by-product levels at the burner and the combustion turbulence is correlated to the combustion by-product formation rate at the burner. The method and apparatus can also be used to correlated the combustion turbulence at a multiplicity of burners to the associated combustion by-product formation rate.

Owner:ABB INC

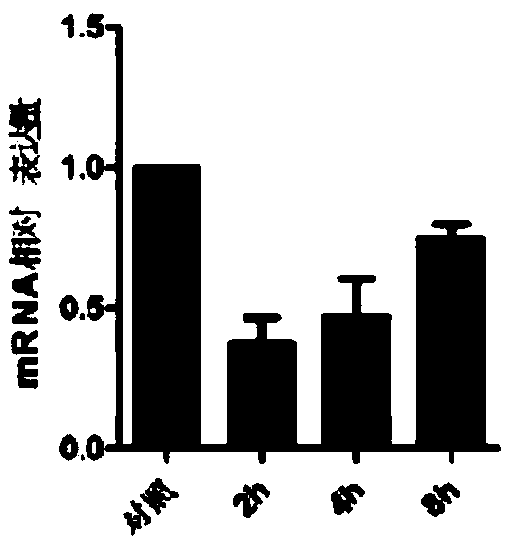

Application of crRNA mediated CRISPR/Cas13a gene editing system in tumor cells

ActiveCN108546718ALower indexInhibition of tumor formation rateStable introduction of DNADNA/RNA fragmentationSingle strandMouse tumor

The invention discloses application of a crRNA mediated CRISPR / Cas13a gene editing system in tumor cells. According to the invention, in a U87 glioma cell system, a Cas13a protein can be mediated ontocomplementary target RNA by single-stranded crRNA and is cut. Meanwhile, the Cas13a protein can also trigger a joint shearing effect in eucaryotic cells, i.e., after starting to cut a first piece oftarget RNA, the Cas13a protein carries out aimless random cutting on other encountered RNA so as to take effects of inhibiting and killing tumors, such as effects of reducing a tumor cell index, inhibiting a mouse tumor formation rate and a tumor size. The invention provides a novel method for inhibiting or killing the tumor cells so as to lay a foundation for application of a random shearing effect of the CRISPR-Cas13 system in eukaryotic cells.

Owner:GENERAL HOSPITAL OF TIANJIN MEDICAL UNIV

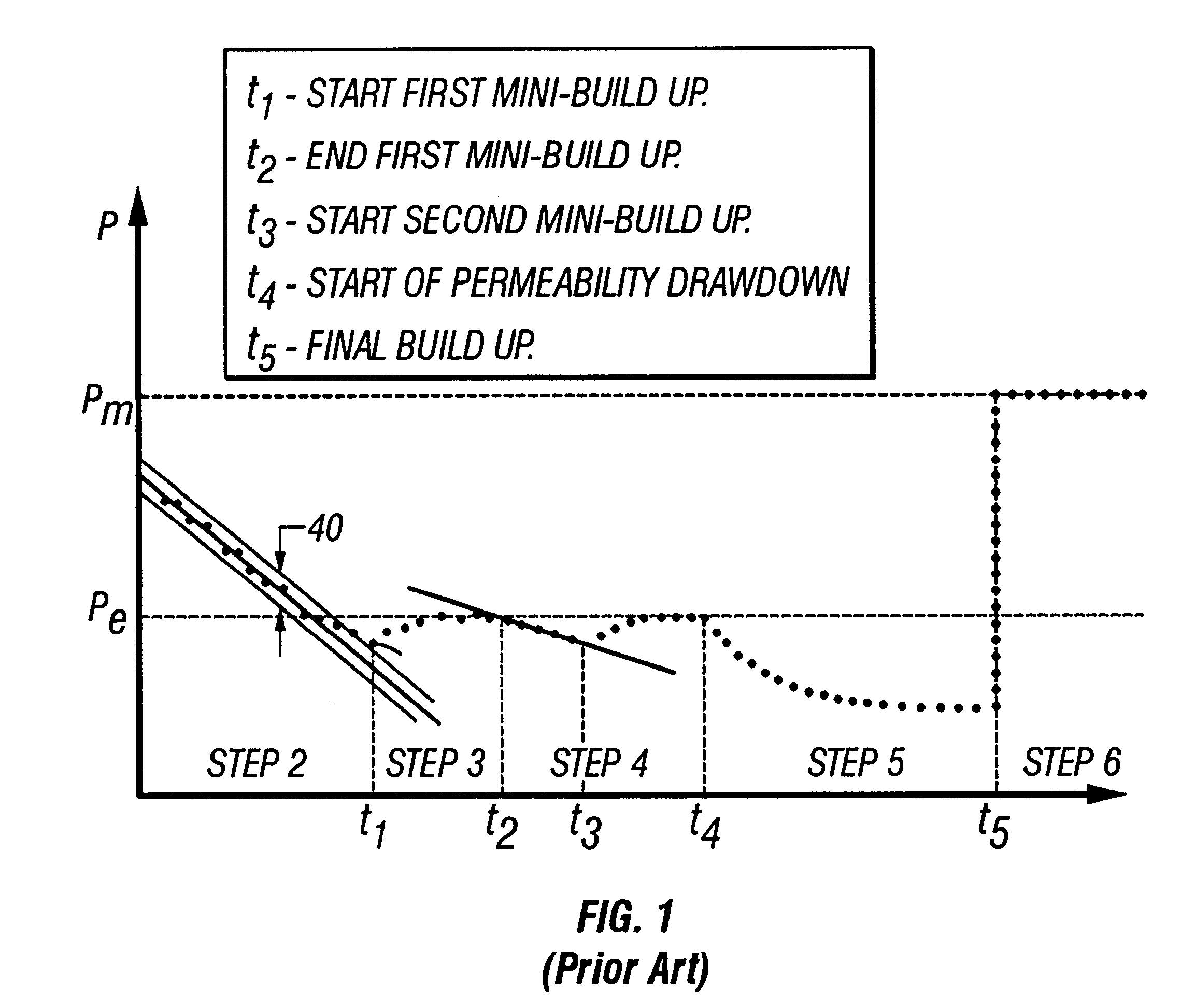

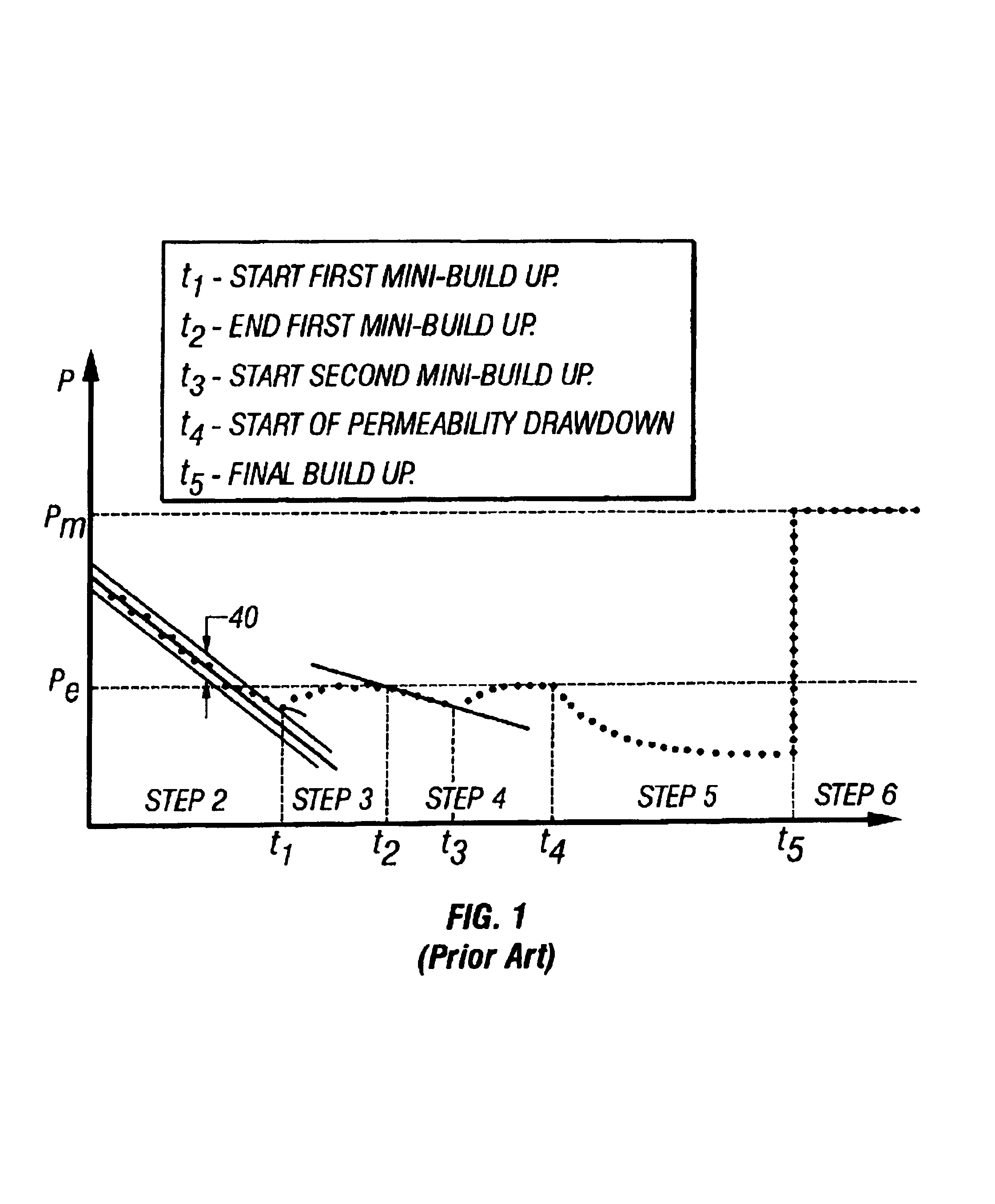

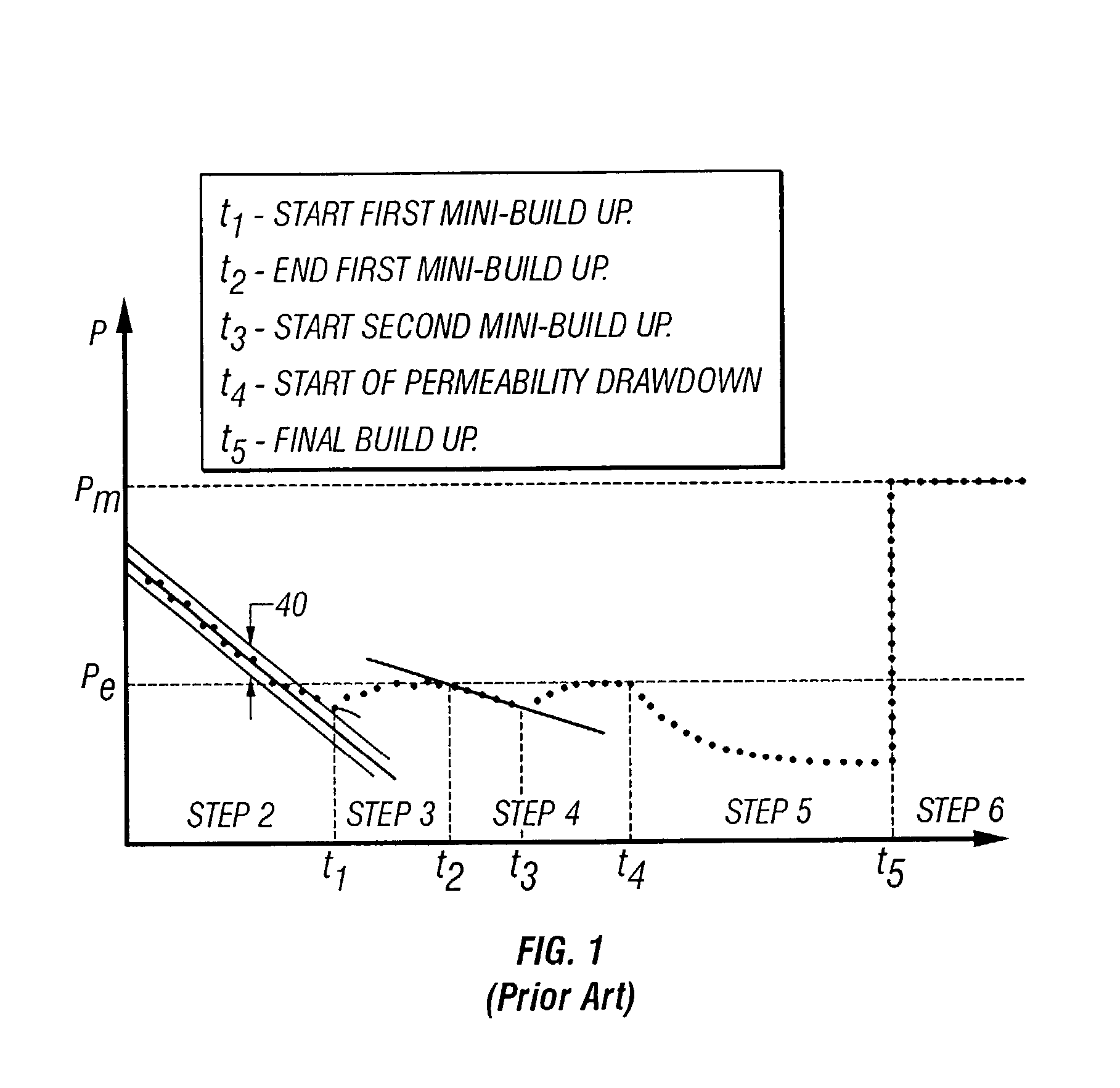

Methods to detect formation pressure

Methods for estimating formation pressure from data taken during the drawdown cycle are presented. In one aspect, a method of determining a formation pressure during drawdown of a formation comprises sampling fluid from a formation using a downhole tool having a sample volume and a fluid sampling device. At least one time dependent parameter of interest related to the fluid is determined during the drawdown. The at least one time dependent parameter is analyzed using a plurality of calculation techniques to determine the formation pressure. The techniques include (i) a first pressure derivative technique; (ii) a second pressure derivative technique; (iii) a formation rate analysis technique; (iv) a dp / dt-ratio technique; and (v) a stepwise drawdown technique.

Owner:BAKER HUGHES INC

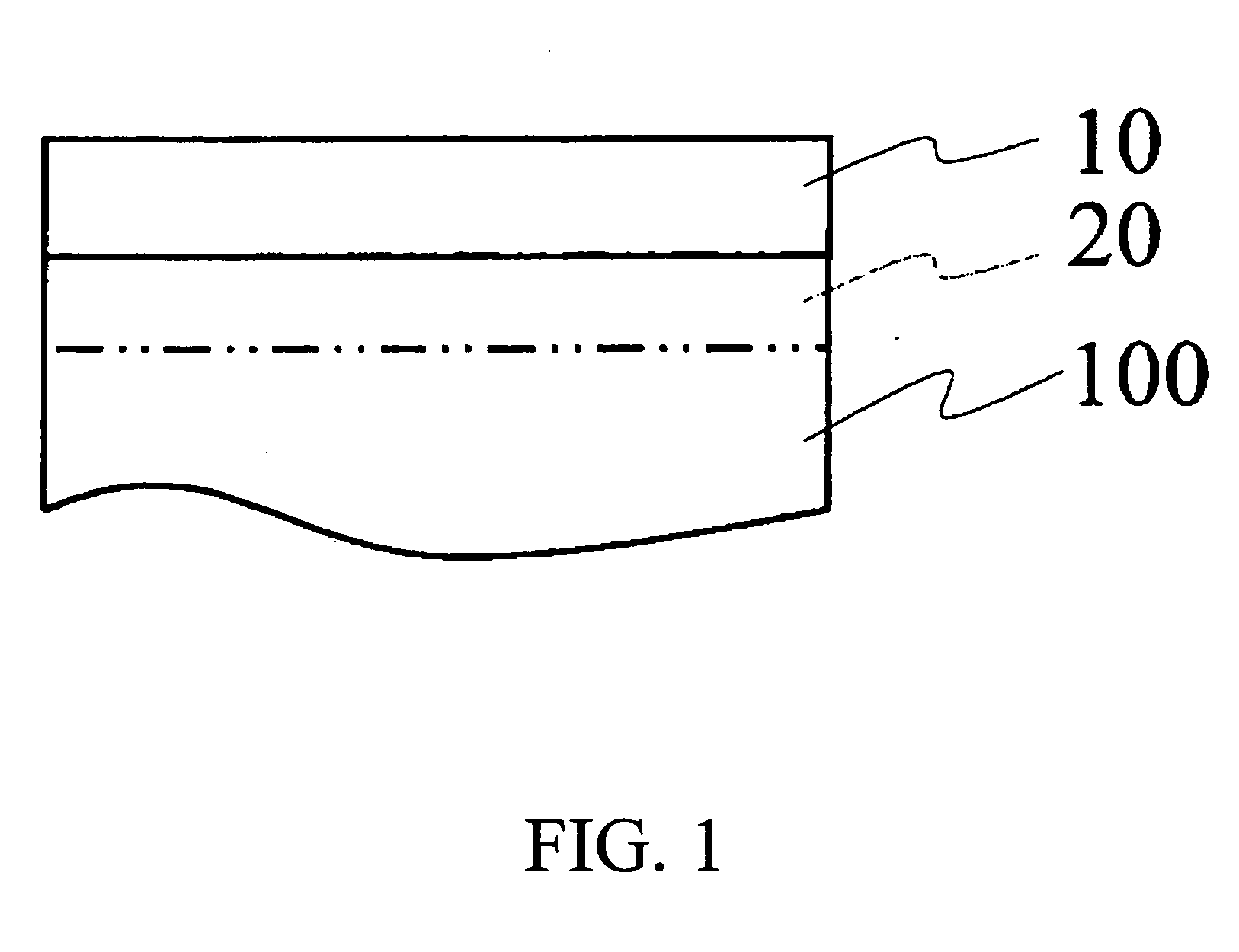

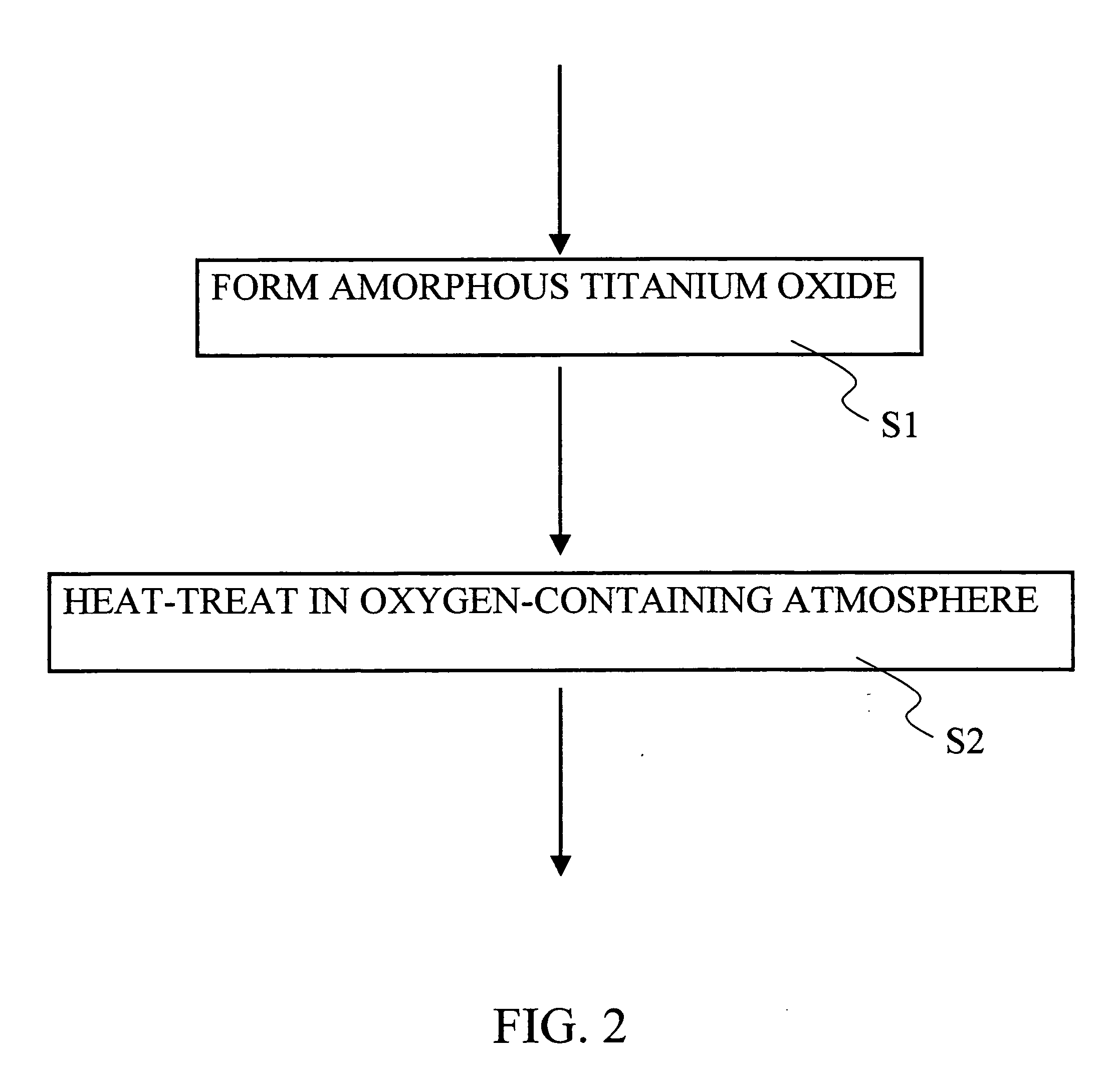

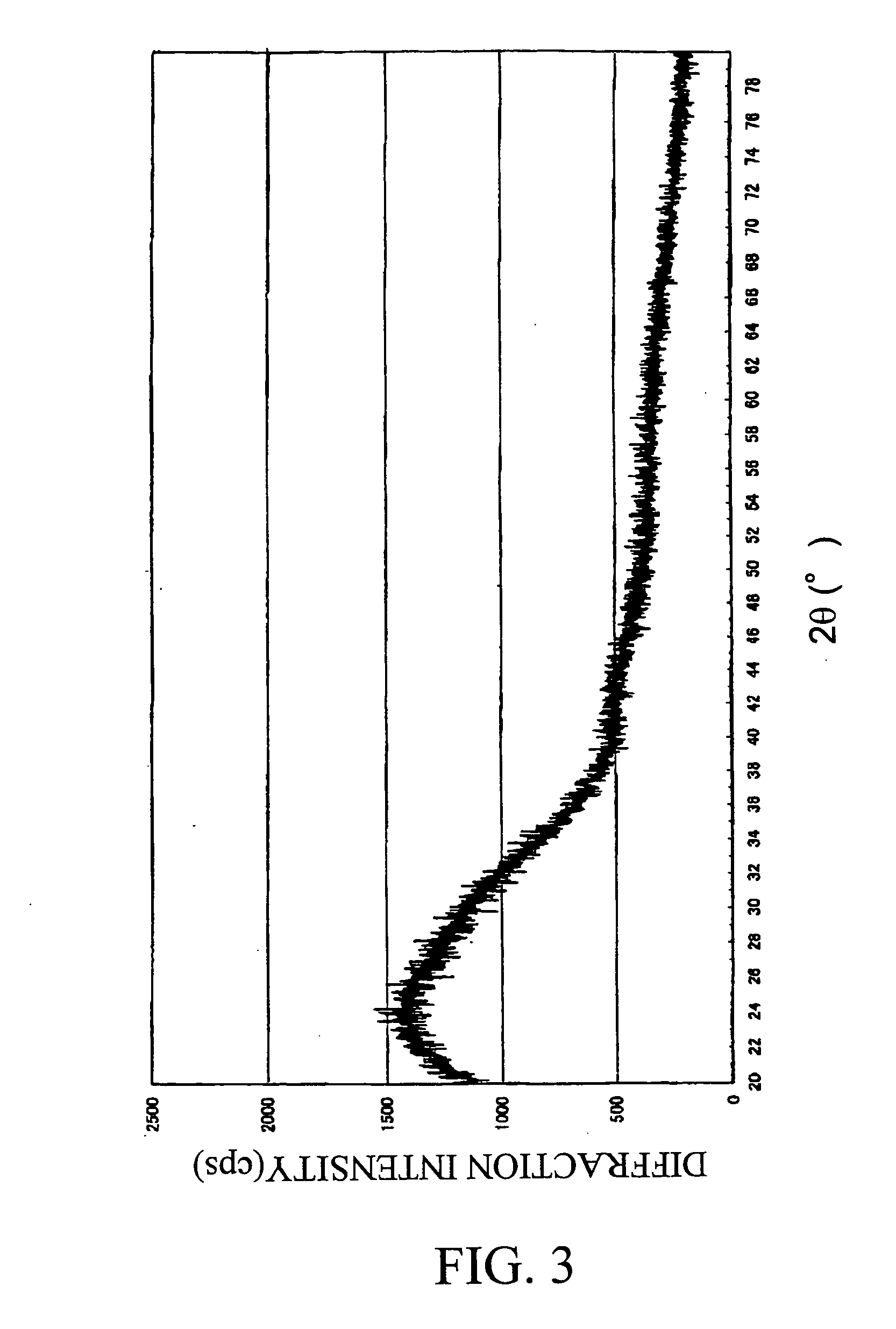

Method and apparatus for producing photocatalyst

A method of producing a photocatalyst according to the invention comprises forming an amorphous titanium oxide and heat-treating it in an atmosphere containing oxygen, whereby a photocatalyst having a good photocatalysis can be obtained. In particular, the amorphous titanium oxide is obtained by using the reactive sputtering method and via deposition at a low temperature and at a high film formation rate. This apparatus can be provided with cooling means to allow enhancement of the throughput of the film formation process.

Owner:SHIBAURA MECHATRONICS CORP

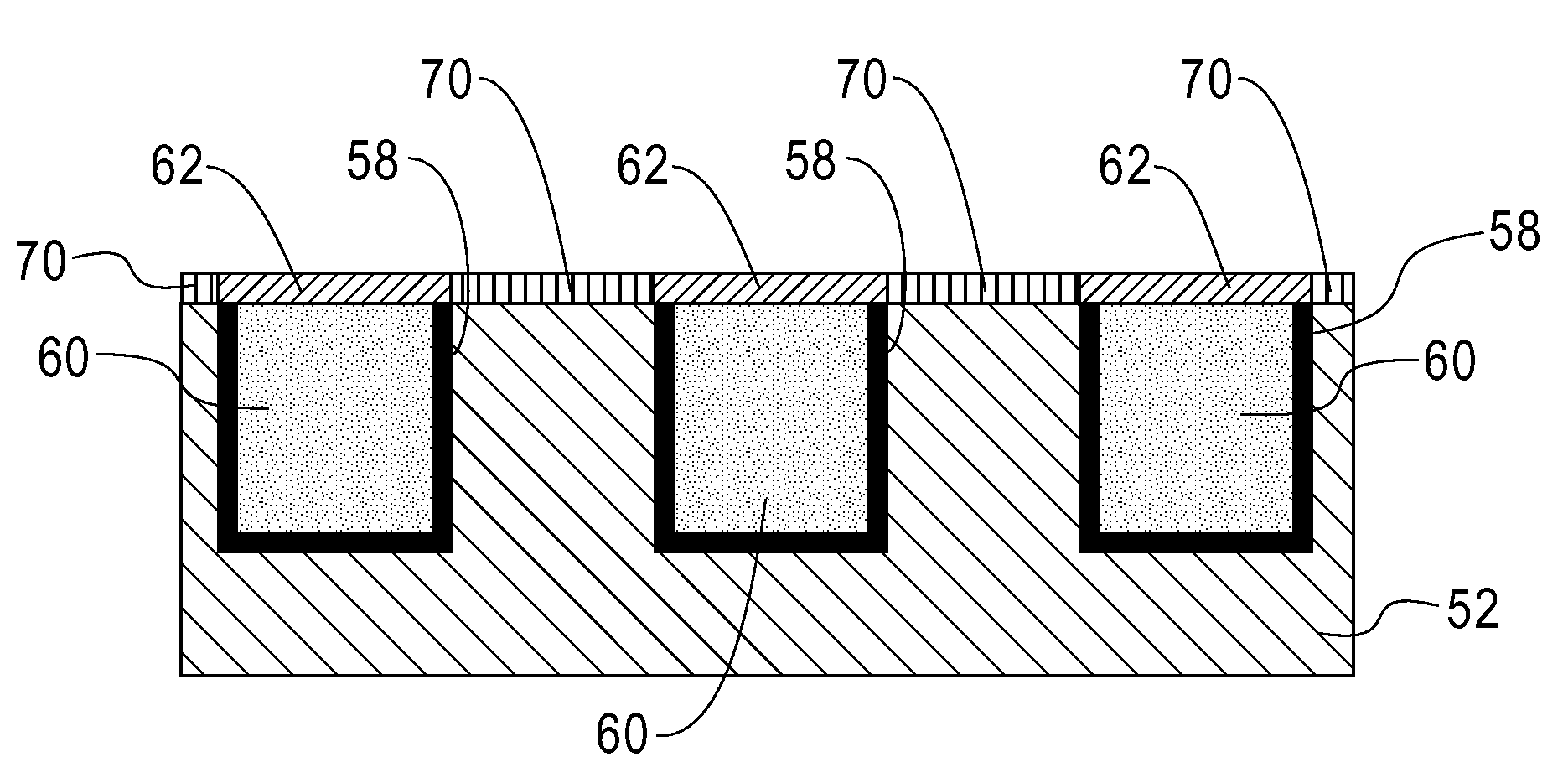

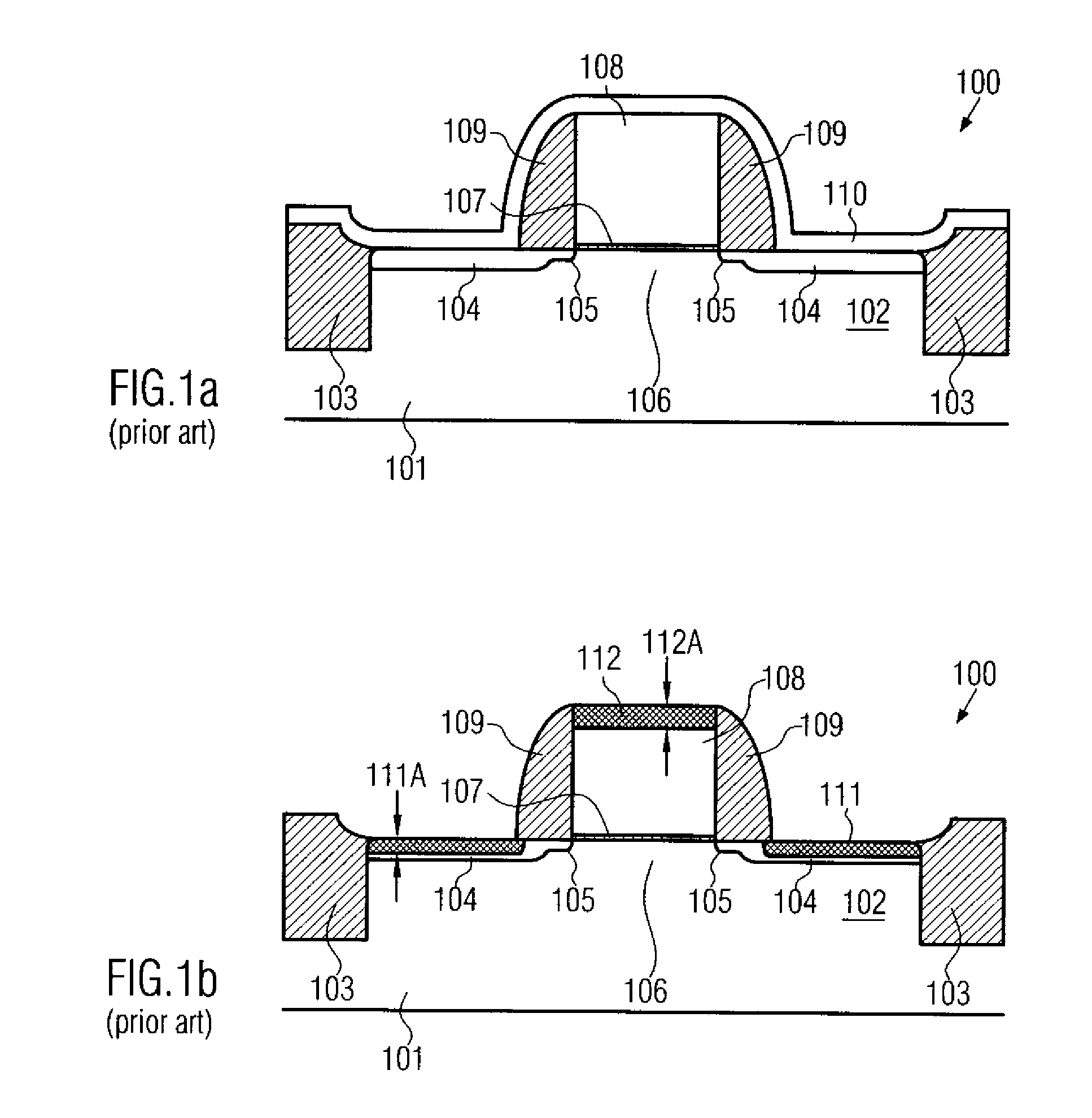

Surface treatment for selective metal cap applications

ActiveUS20090250815A1Improved EM reliabilityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesConductive materialsSelective deposition

Interconnect structures in which a noble metal-containing cap layer is present directly on a non-recessed surface of a conductive material which is embedded within a low k dielectric material are provided. It has been determined that by forming a hydrophobic surface on a low k dielectric material prior to metal cap formation provides a means for controlling the selective formation of the metal cap directly on the non-recessed surface of a conductive material. That is, the selective formation of the metal cap directly on the non-recessed surface of a conductive material is enhanced since the formation rate of the metal cap on the non-recessed surface of a conductive material is greater than on the hydrophobic surface of the low k dielectric material. It is observed that the hydrophobic surface may be a result of treating a damaged surface of the dielectric material with a silylating agent prior to the selective formation of the noble metal cap or, as a result of forming a hydrophobic polymeric layer on the surface of the dielectric material prior to the selective deposition of the noble metal cap. The hydrophobic polymeric layer typically includes atoms of Si, C and O.

Owner:GLOBALFOUNDRIES INC

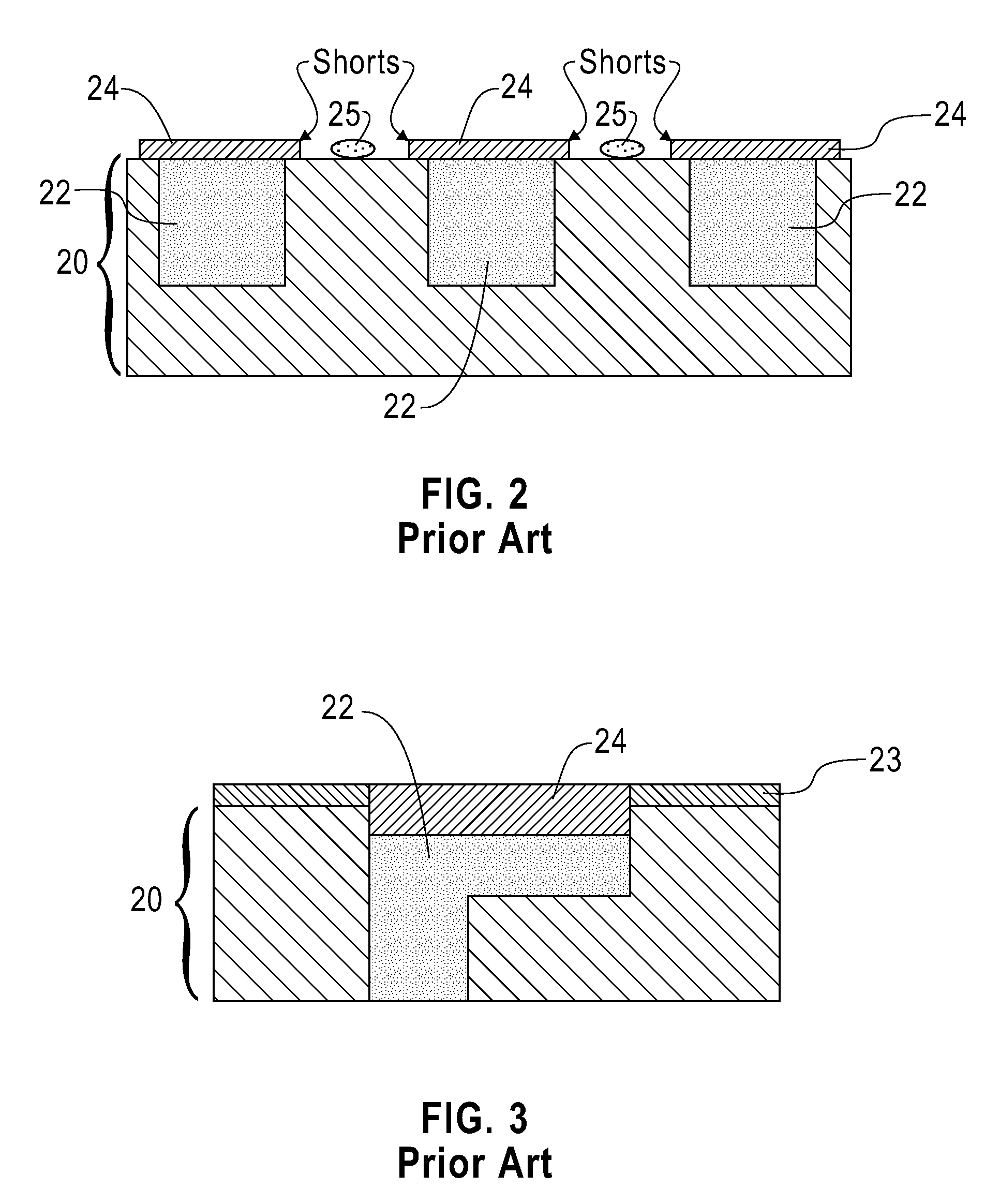

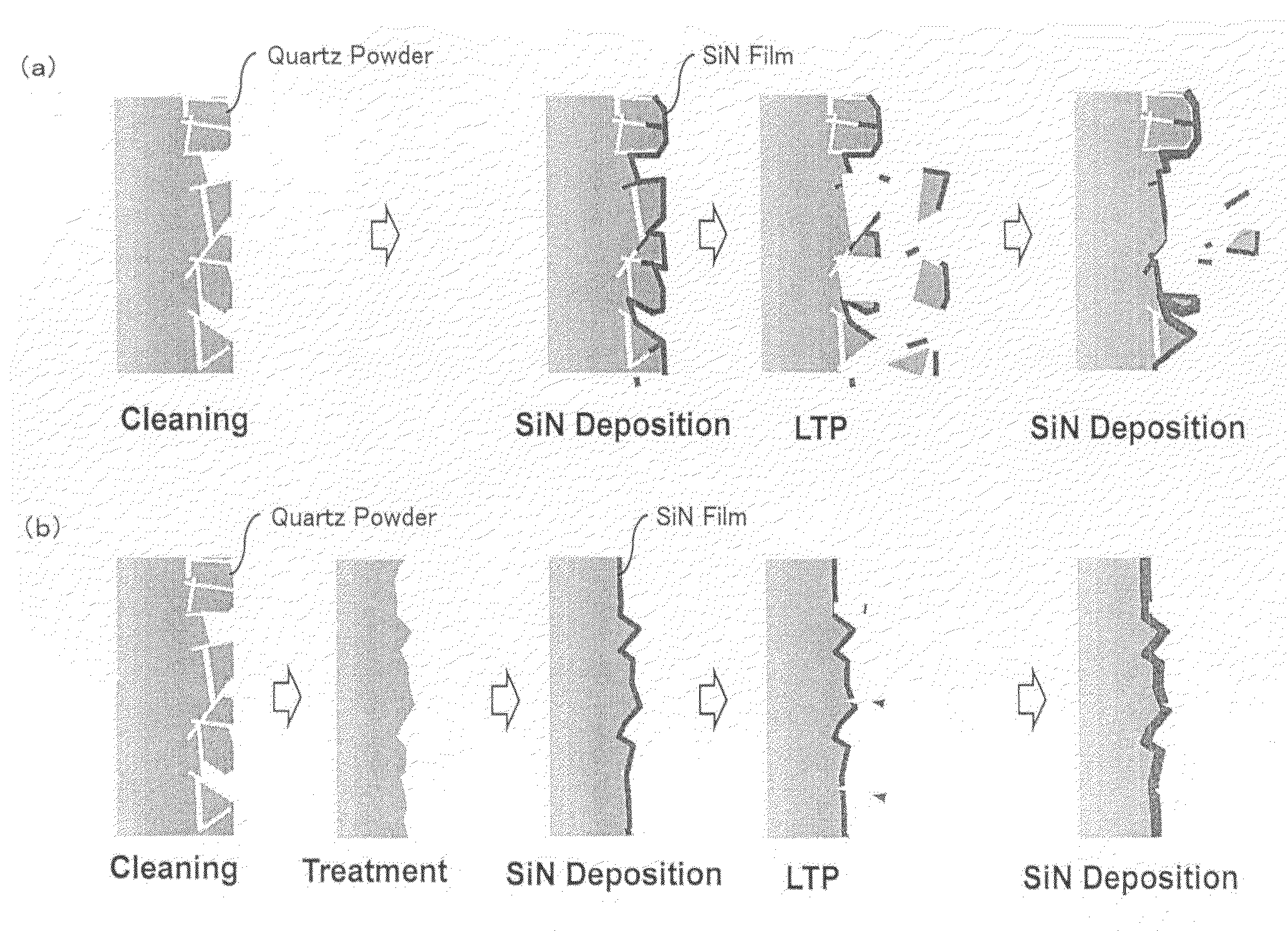

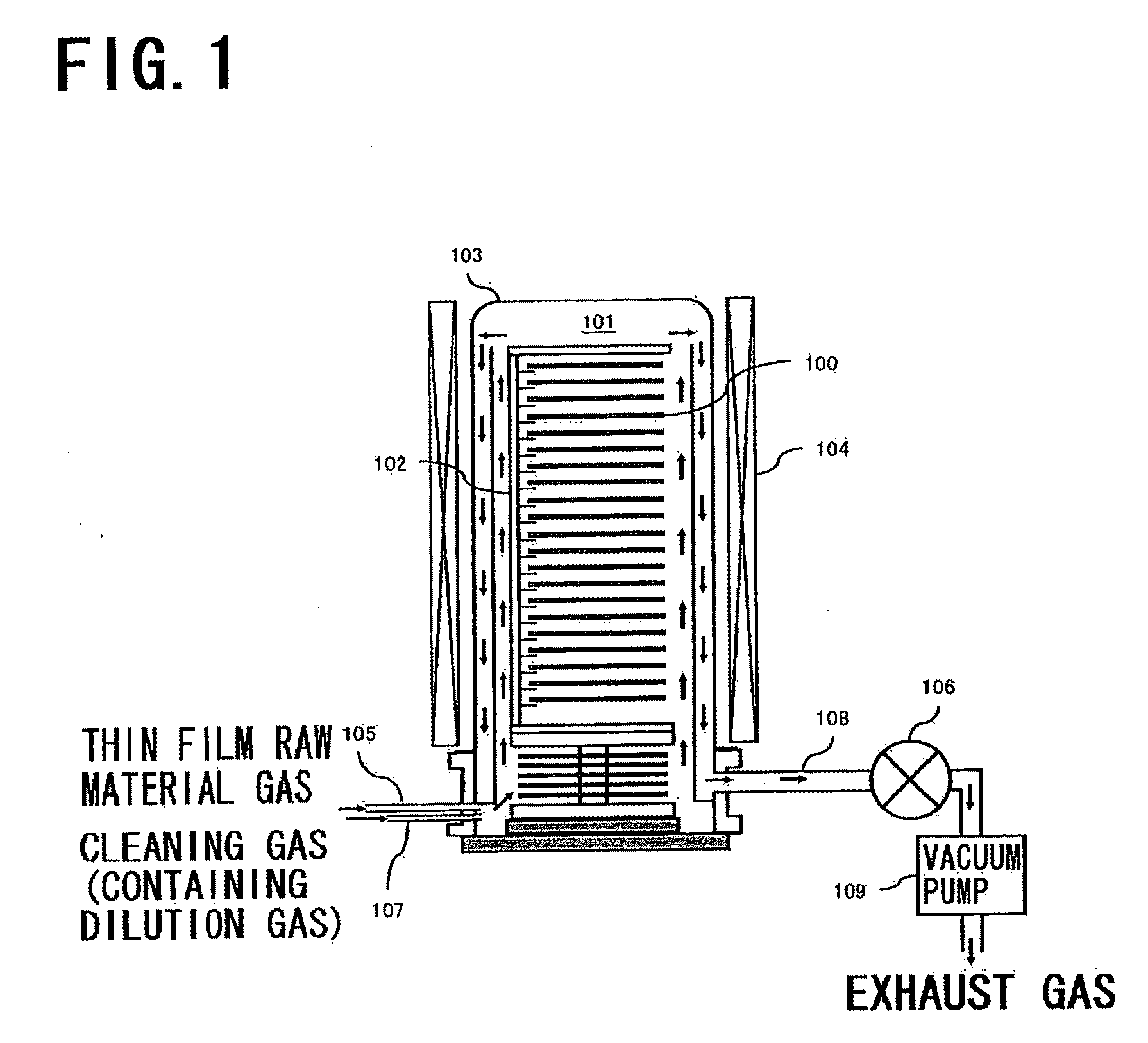

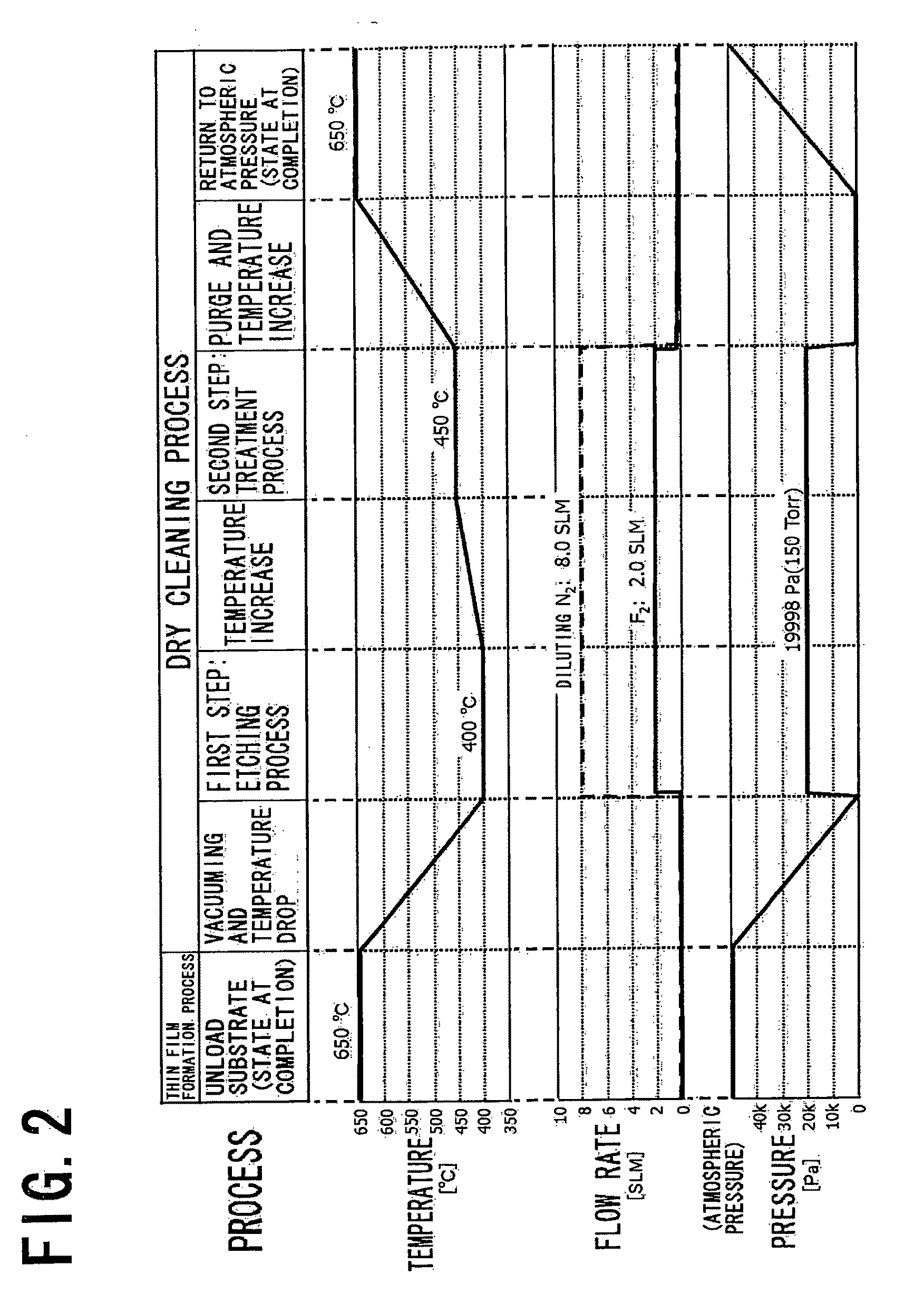

Method for manufacturing semiconductor device and substrate processing apparatus

InactiveUS20090149032A1Sufficient etching rateLiquid surface applicatorsSemiconductor/solid-state device manufacturingProduct gasInert gas dilution

The present invention suppresses metallic contamination in a processing chamber and a breakage of a quartz member, while suppressing decrease in film formation rate in a thin film formation process immediately after dry cleaning of the inside of the processing chamber, and enhances the operation rate of a apparatus. The method according to the invention includes the steps of: removing the thin film on the inside of the processing chamber by supplying a fluorine gas solely or a fluorine gas diluted by an inert gas solely, as the cleaning gas, to the inside of the processing chamber heated to a first temperature; and removing an adhered material remaining on the inside of the processing chamber after removing the thin film by supplying a fluorine gas solely or a fluorine gas diluted by an inert gas solely, as the cleaning gas, to the inside of the processing chamber heated to a second temperature.

Owner:KOKUSA ELECTRIC CO LTD

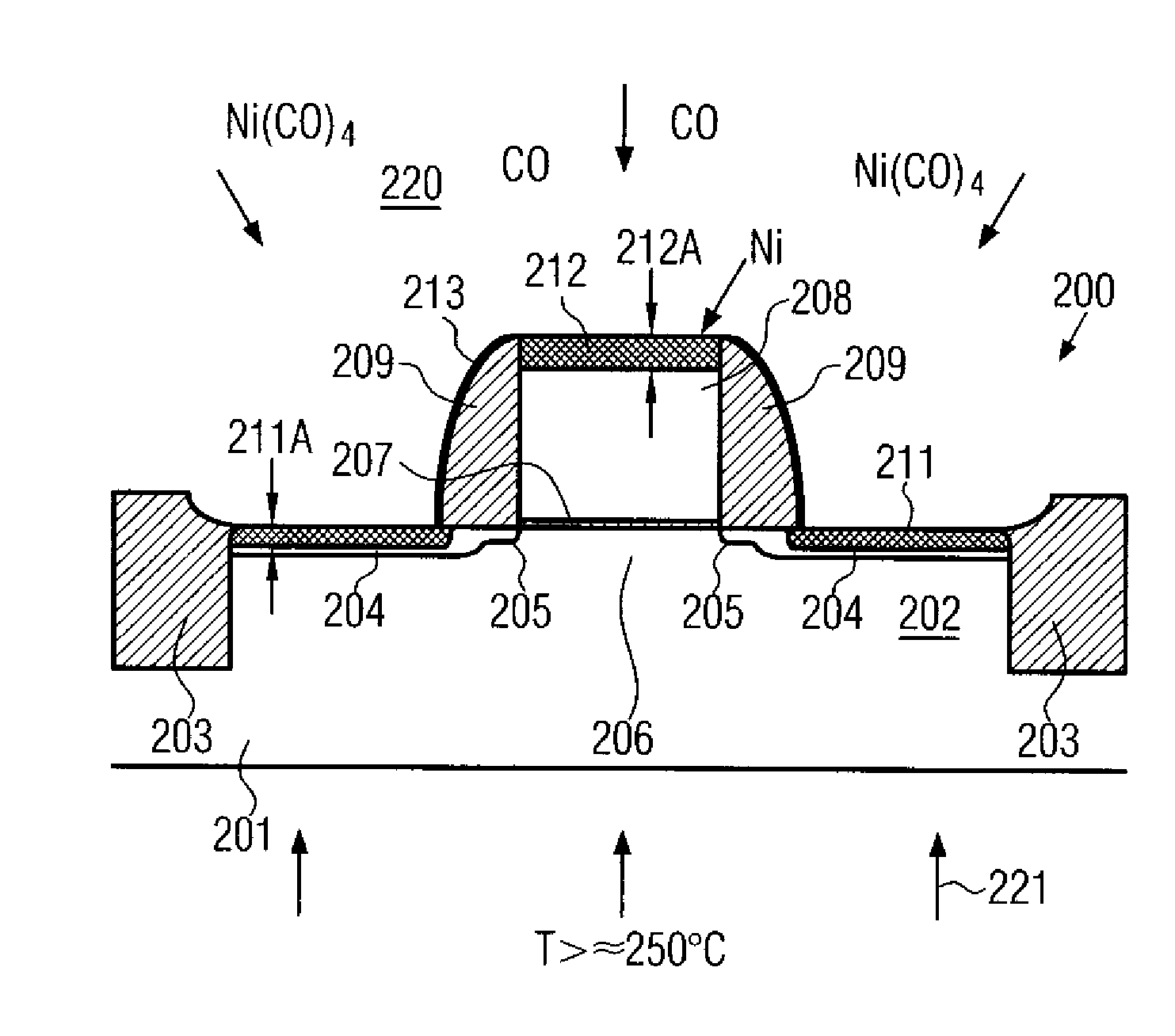

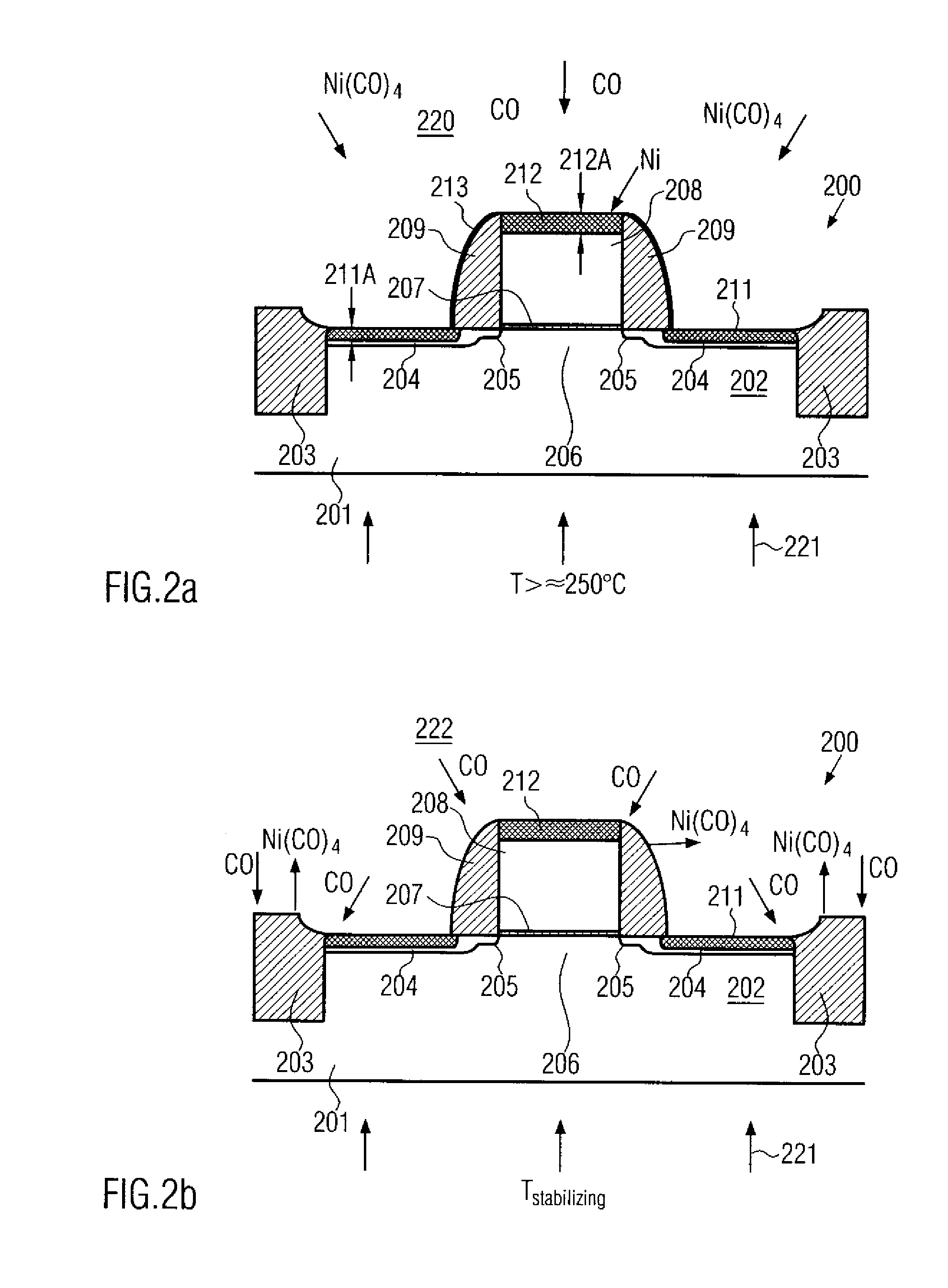

Technique for forming nickel silicide by depositing nickel from a gaseous precursor

Nickel silicide is formed on the basis of a gaseous precursor, such as nickel tetra carbonyl, wherein the equilibrium of the decomposition of this gas may be controlled to obtain a highly selective nickel silicide formation rate. Moreover, any etch step for removing excess nickel may be avoided, since only minute amounts of nickel may form on exposed surfaces, which may then be effectively removed by correspondingly shifting the equilibrium. Consequently, reduced process complexity, enhanced controllability and enhanced tool lifetime may be obtained.

Owner:ADVANCED MICRO DEVICES INC

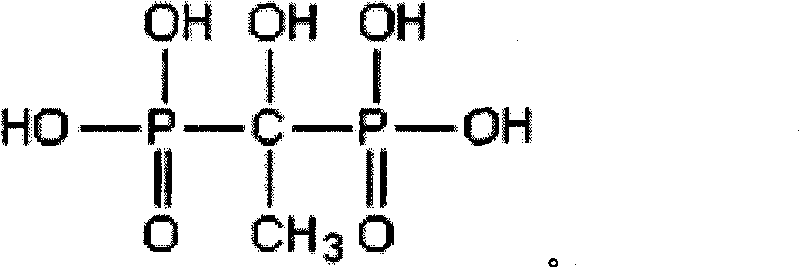

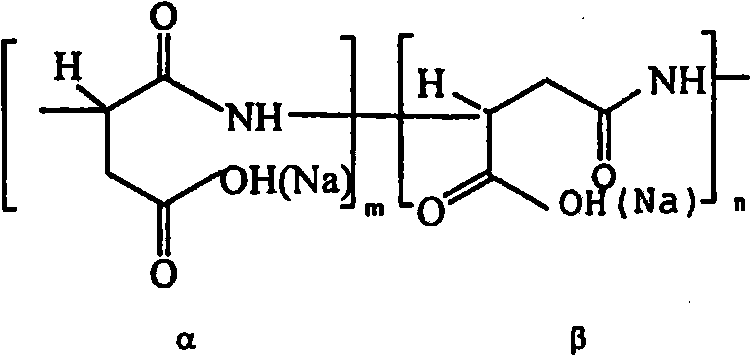

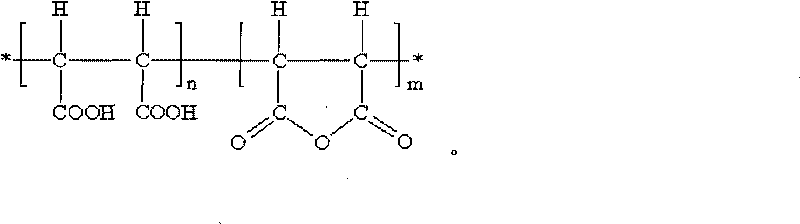

Composite scale inhibitor

InactiveCN101700937AGood anti-scaling effectDoes not accelerate corrosionScale removal and water softeningWastewaterHardness

The invention discloses a composite scale inhibitor which is applicable to high-hardness high-alkali industrial circulating water, and the scale inhibitor consists of HEDP, polyaspartic acid, polymaleic anhydride, polyacrylic acid dispersant and the like. Wherein, the polyacrylic acid dispersant can be one or more of polyacrylic acid ternary dispersants or quaternary dispersants. The composite scale inhibitor has excellent scale inhibition performance and very low formation rate of calcium carbonate scale during the using process, the discharged waste water under the use of the formula can not cause the nutrition-rich pollution to the environment, thereby belonging to environment-friendly products and being particularly applicable to processing the circulating water with high calcium hardness and high alkaline hardness. The cost of using the formula for processing the industrial circulating water is very low, and the cost of a medicament added for processing each ton of water is less than 0.7 yuan, thereby having very high economic value.

Owner:SHENZHEN NANFENG WATER TREATMENT SERVICE

Formation testing apparatus and method for smooth draw down

A method and apparatus for of determining a formation parameter of interest. The method includes placing a tool into communication with the formation to test the formation and drawing down a test volume at an increasing draw rate during a first draw period and decreasing the draw rate during a second draw period to create a smooth draw down cycle. The draw down can be step-wise or continuous. The formation parameter is determined using formation rate analyis and characteristics determined during the draw down cycle.

Owner:BAKER HUGHES INC

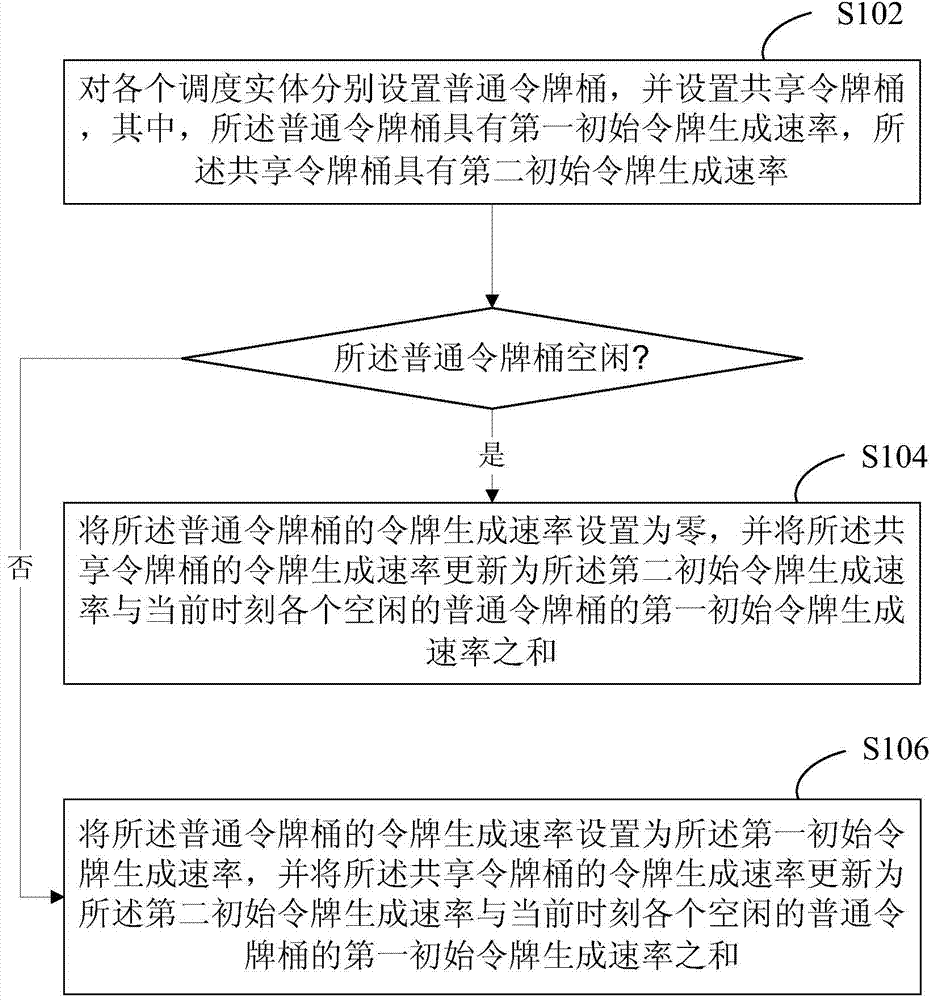

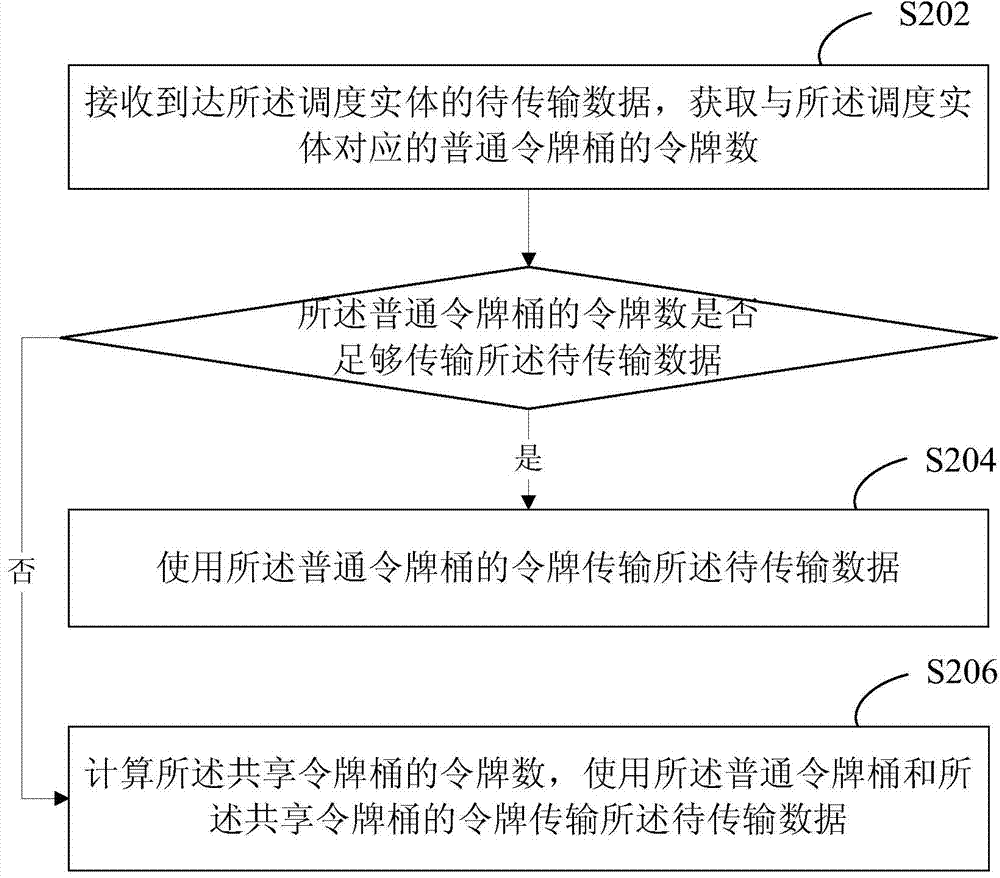

Data transmission flow scheduling method and system based on token buckets

ActiveCN104734989ABuild Rate RestorationReduce consumptionData switching networksHigh level techniquesTimerFlow scheduling

The invention provides a data transmission flow scheduling method and system based on token buckets. Common token buckets are set for all scheduling entities respectively, and a token bucket shared by the scheduling entities is set; each common token bucket records the number of tokens distributed to the corresponding scheduling entity; when one common token bucket is idle, the token formation rate of the common token bucket is transferred and added to that of the shared token bucket by adjusting the token formation rate of the common token bucket and the token formation rate of the shared token bucket; when all the common token buckets are not idle, the token formation rate transferred to the shared token bucket is transferred back to the common token bucket, and the number of overflowing tokens does not need to be calculated. In this way, the shared token bucket can distribute the idler bandwidth resources of all the scheduling entities, the situation that a counter is set to calculate the numbers of the overflowing tokens of the common token buckets is avoided, the calculation amount of setting of the counters of the common token buckets is greatly reduced, and the consumption of the resource processing is reduced.

Owner:TENCENT DIGITAL TIANJIN

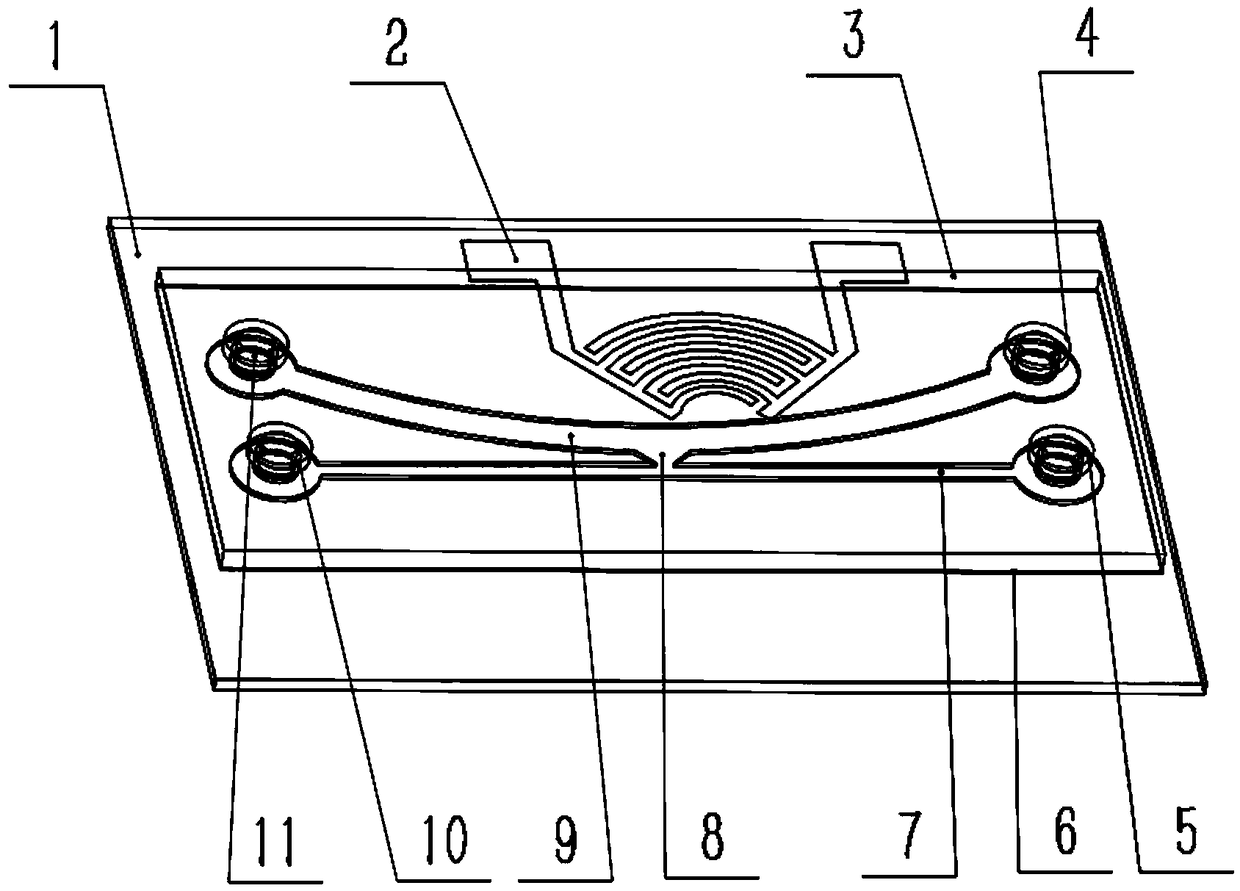

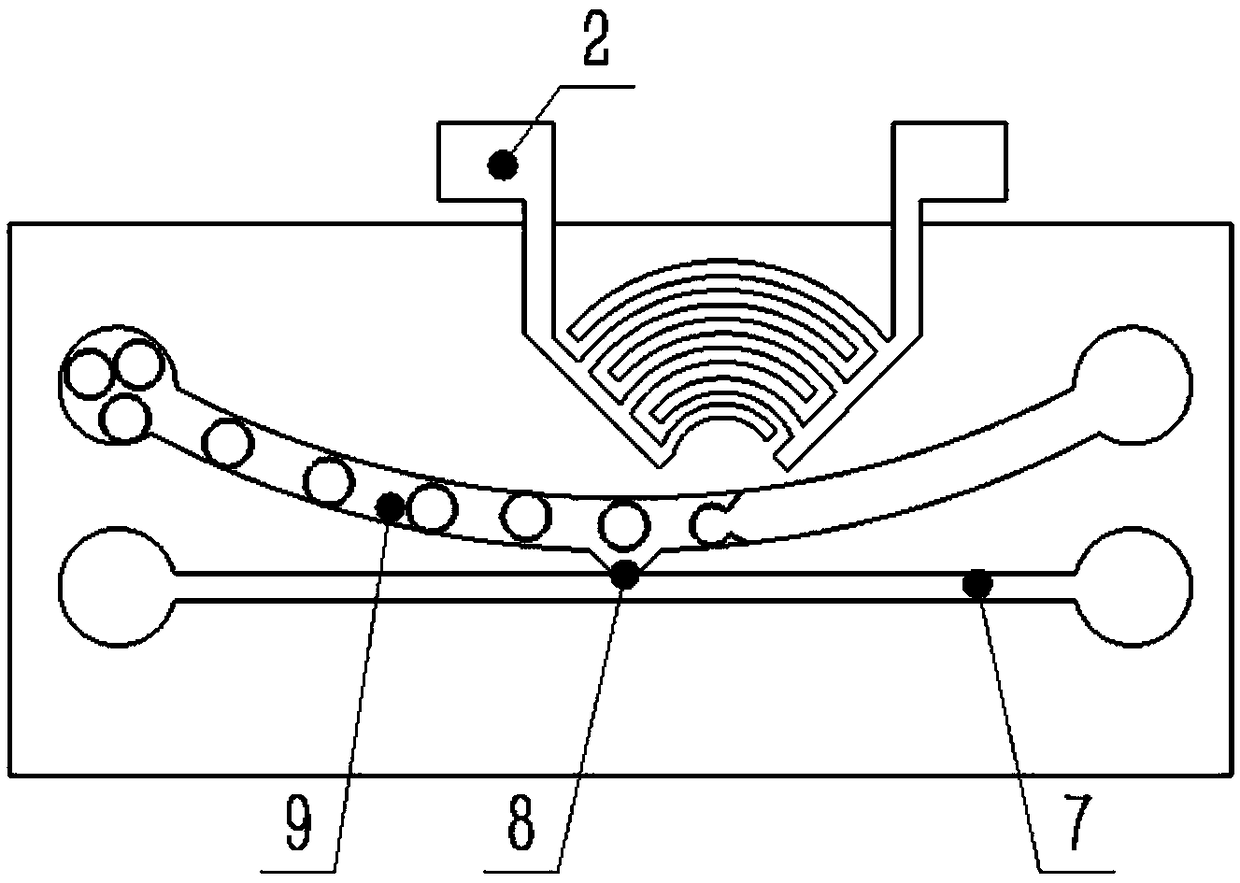

Device and method for generating micro-fluidic droplets based on surface acoustic waves

ActiveCN109012769ARealize electronic controlAchieve continuous generationLaboratory glasswaresFluid controllersEngineeringElectric control

The invention discloses a device and a method for generating micro-fluidic droplets based on surface acoustic waves. The device comprises a piezoelectric substrate, a set of curved interdigital transducers is arranged on the piezoelectric substrate, a closed PDMS micro-channel system is applied to the upper part of the piezoelectric substrate, and the closed PDMS micro-channel system is formed bytop PDMS and a PDMS sealing film. The method comprises the following steps: fixing the micro-fluidic droplet generating device on the objective table of a microscope, switching in the micro-fluidic droplet generating device, and setting the pressures of a dispersed phase inlet joint and a continuous phase inlet joint; and connecting a signal generator with the curved interdigital transducers, adjusting the output signal of the signal generator, turning on a syringe pump, adjusting and stabilizing the two-phase interface position of a dispersed phase and a continuous phase, and generating the micro-fluidic droplets. The device and the method realize the electric control of the formation rate and the size of the droplets; and the device has a small size and can be integrated with other devices, so the repeatability is enhanced, and cracks between channels, caused by overlarge pressure of an input fluid, are reduced.

Owner:XI AN JIAOTONG UNIV

Sunlight greenhouse hot pepper seedling culturing substrate and preparation method thereof

InactiveCN102211966AImprove conductivityIncrease the frequency of irrigationAgriculture gas emission reductionCultivating equipmentsHot peppersGreenhouse

The invention discloses a sunlight greenhouse hot pepper seedling culturing substrate and a preparation method thereof. The preparation method comprises the following step of: performing plug seedling by taking decomposed maize straws, dairy manure, vermiculite and grass carbon as materials, using 5 kinds of compound substrates with different volume mixture ratios and taking hot pepper (Longjiao No.2) as a test material, wherein when the volume ratio of the decomposed maize straws to the decomposed dairy manure to the grass carbon to the vermiculite is 2:4:2:2 according to a screened substrate formula, an optimal seeding culturing effect can be achieved. The seedling culturing substrate has the advantages of scientific formula, simple process, high plug seedling formation rate, good weight, physicochemical indexes meeting the requirement of a seeding culturing substrate and good seeding culturing effect. After the seedling culturing substrate is applied, the production cost of a cultivating substrate can be lowered remarkably, the yield and the quality of hot pepper are improved, the incomes of peasants are increased, and the popularization and the application of an organic ecological soilless seedling culturing technology are accelerated.

Owner:GANSU AGRI UNIV

Artificial crystal with antiproliferous medicine coating for preventing and treating after-cataract forming

InactiveCN101053680AGrowth inhibitionGood treatment effectIntraocular lensTreatment effectAntiproliferative Agents

An artificial lens having stents coated with antiproliferative agents for prevention and treatment of the posterior capsule opacification, the invention relates to an artificial lens having stents coating for solving problems of time of present artificial lens loaded with medicine acting on cornea is short. The artificial lens having stents coated with antiproliferative agents for prevention and treatment of the posterior capsule opacification is prepared by ordinary artificial lens and coating with antiproliferative agents, wherein the coating with antiproliferative agents adheres on surface of ordinary artificial lens, thickness of the coating is 3 to 20 mum. The invention adopts macomolecule coating material to coat antiproliferative agents on artificial lens, slowly releases agents in capsules and ambitus cells, represses generation of lens epithelial cell, prevents and cures formation of the posterior capsule opacification. The agents of the invention act on cornea long time, capable of releasing effectively 90 to 120 days, have good therapeutic, patients use the artificial lens of the invention, formation rate of the posterior capsule opacification reduced greatly from more than 60% to 10% and without untoward reaction.

Owner:刘红玲

Methods to detect formation pressure

Methods for estimating formation pressure from data taken during the drawdown cycle are presented. In one aspect, a method of determining a formation pressure during drawdown of a formation comprises sampling fluid from a formation using a downhole tool having a sample volume and a fluid sampling device. At least one time dependent parameter of interest related to the fluid is determined during the drawdown. The at least one time dependent parameter is analyzed using a plurality of calculation techniques to determine the formation pressure. The techniques include (i) a first pressure derivative technique; (ii) a second pressure derivative technique; (iii) a formation rate analysis technique; (iv) a dp / dt-ratio technique; and (v) a stepwise drawdown technique.

Owner:BAKER HUGHES INC

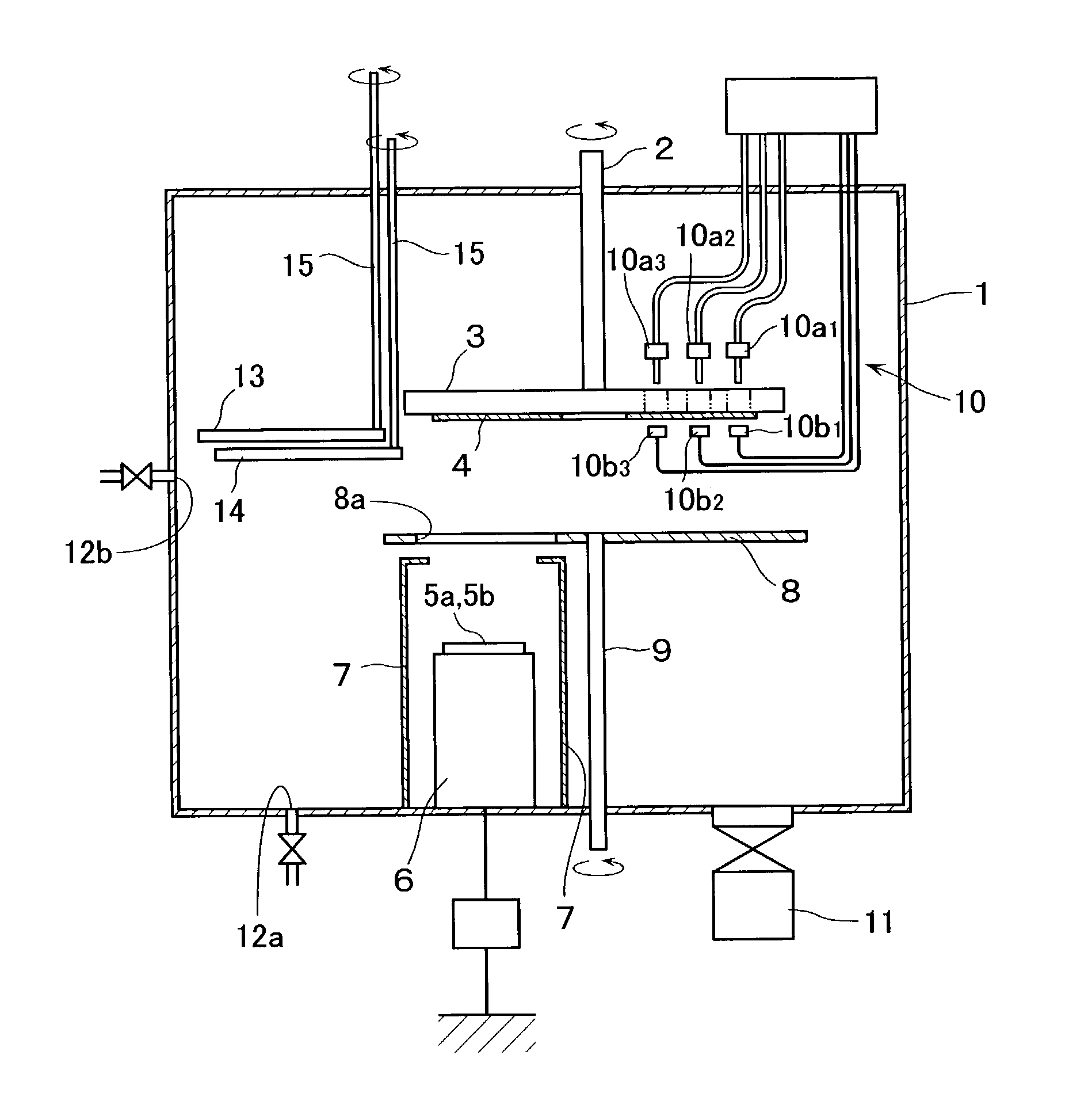

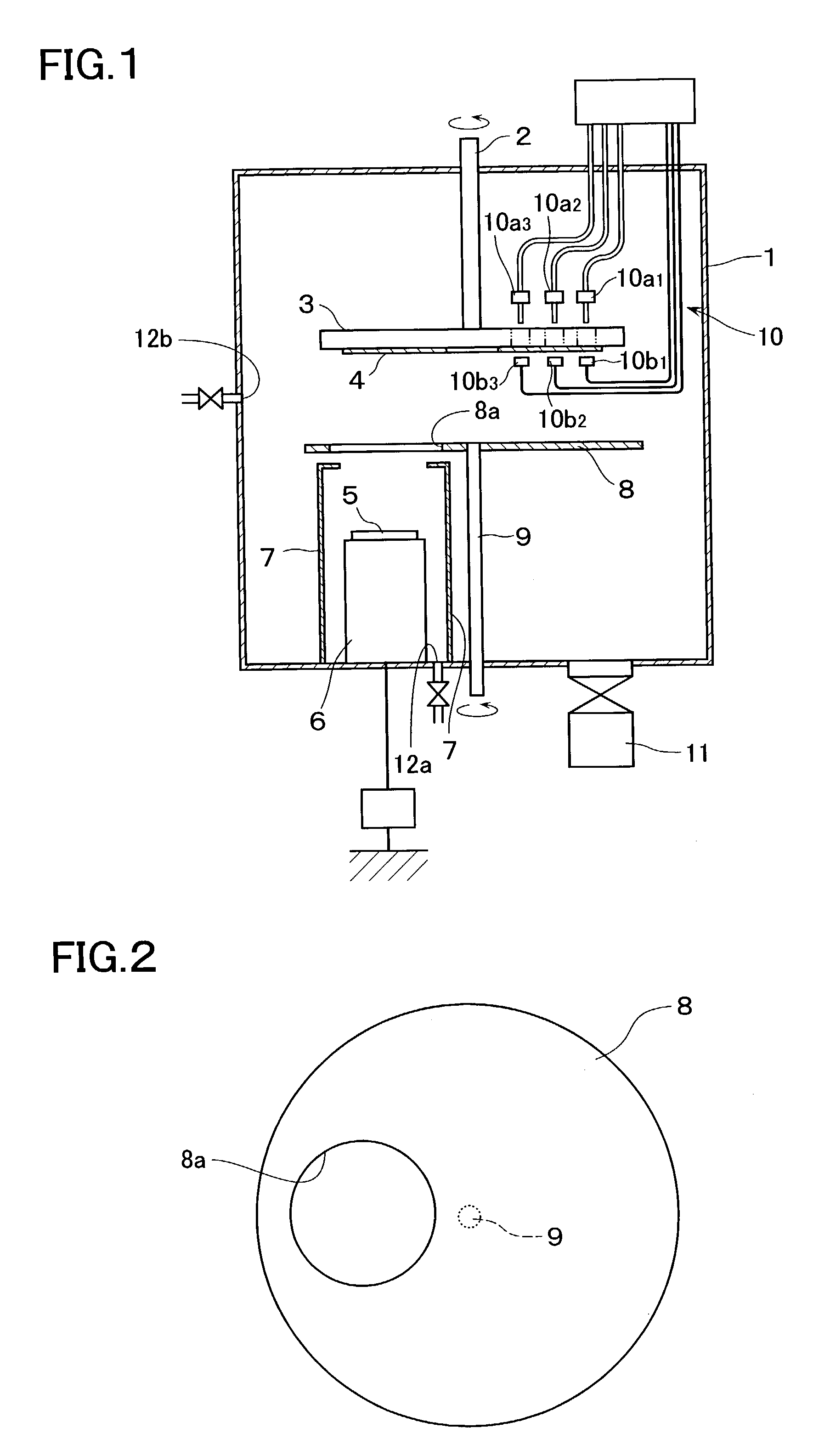

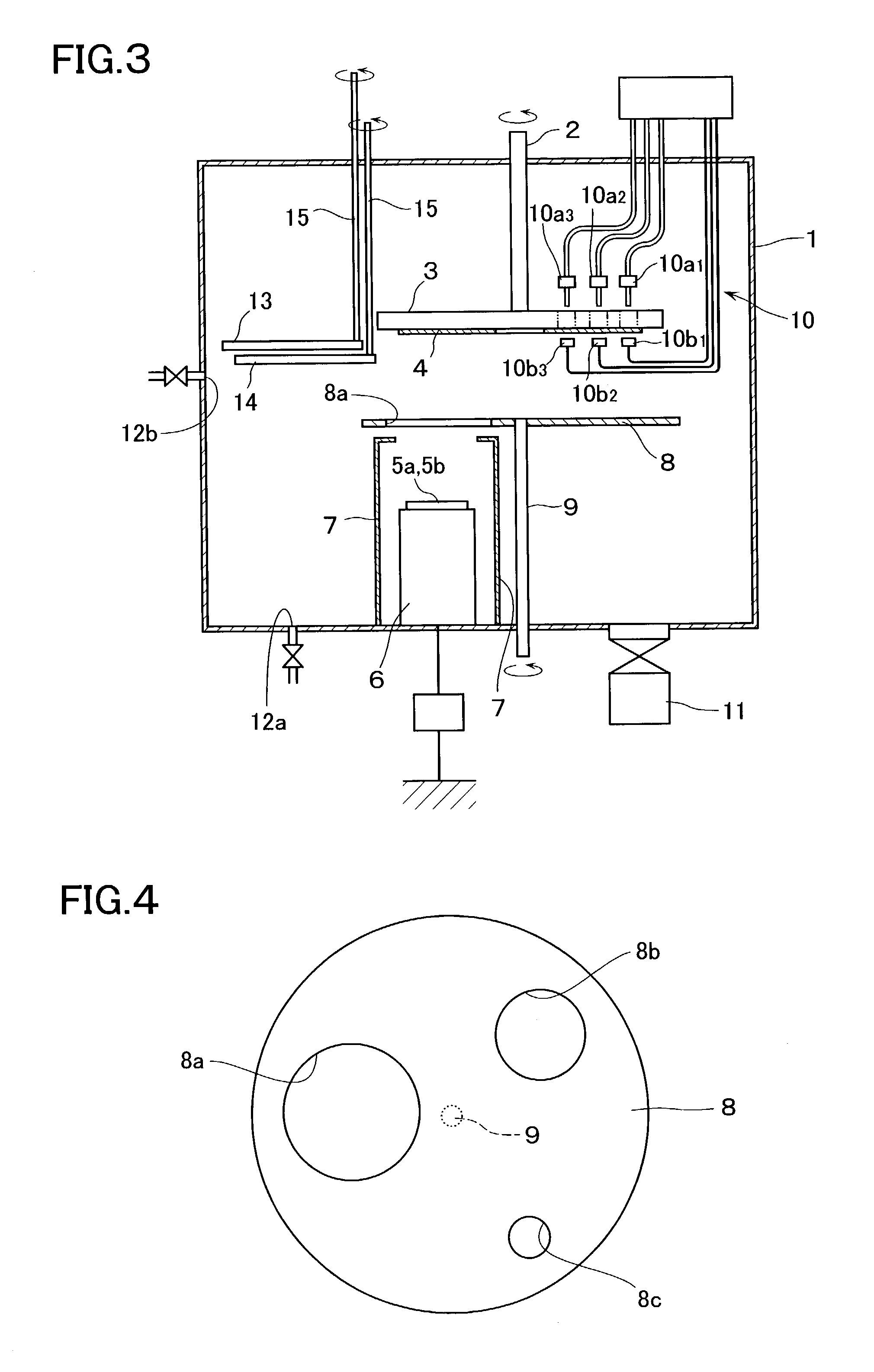

Thin film forming apparatus and method

InactiveUS7033461B2Effective controlEfficiently formedCellsSemiconductor/solid-state device testing/measurementOptoelectronicsFormation rate

The present invention provides an efficient thin film forming apparatus which is capable of correcting a film thickness so as to take care of a variation in distribution in the film thickness and to take care of the circumferential distribution of the film thickness, as well as a method for forming a thin film using this film forming apparatus. The method comprises the first step of first forming a thin film to a predetermined percentage out of thickness through an opening 8a in a shutter 8, the second step of then using a film thickness monitor 10 to measure the distribution of the thickness of the thin film formed in the first step, and the third step of reducing a film formation rate by an opening 8b in the shutter 8 between a substrate 4 and a sputtering cathode 6 as compared to that of the first step and correcting the thickness of the thin film by an opening 13a in the first film thickness correcting plate 13 between the substrate 4 and the sputtering cathode 6 corresponding to the distribution of the film thickness measured by the film thickness monitor 10 in the second step. Then, the second step is carried out again, during which the film thickness monitor 10 is used to measure the distribution of the thickness of the thin film formed in the third step. Further, the third and second steps are repeatedly carried out.

Owner:ULVAC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com