Patents

Literature

234 results about "Self hardening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air Dry & Self-Hardening. Self-hardening clay, also known as air-dried, air-hardening or non-firing clay, is perfect for beginners or anyone without a kiln. It can be used for handbuilding, throwing and sculpting. Self-hardening clay usually dries hard within several days to a durable surface, which may be painted with acrylic paints...

Injectable bone-replacement mixture

InactiveUS20060041033A1Optimal radio-opacityGood biocompatibilityImpression capsSurgical adhesivesInjectable boneRadiographic contrast media

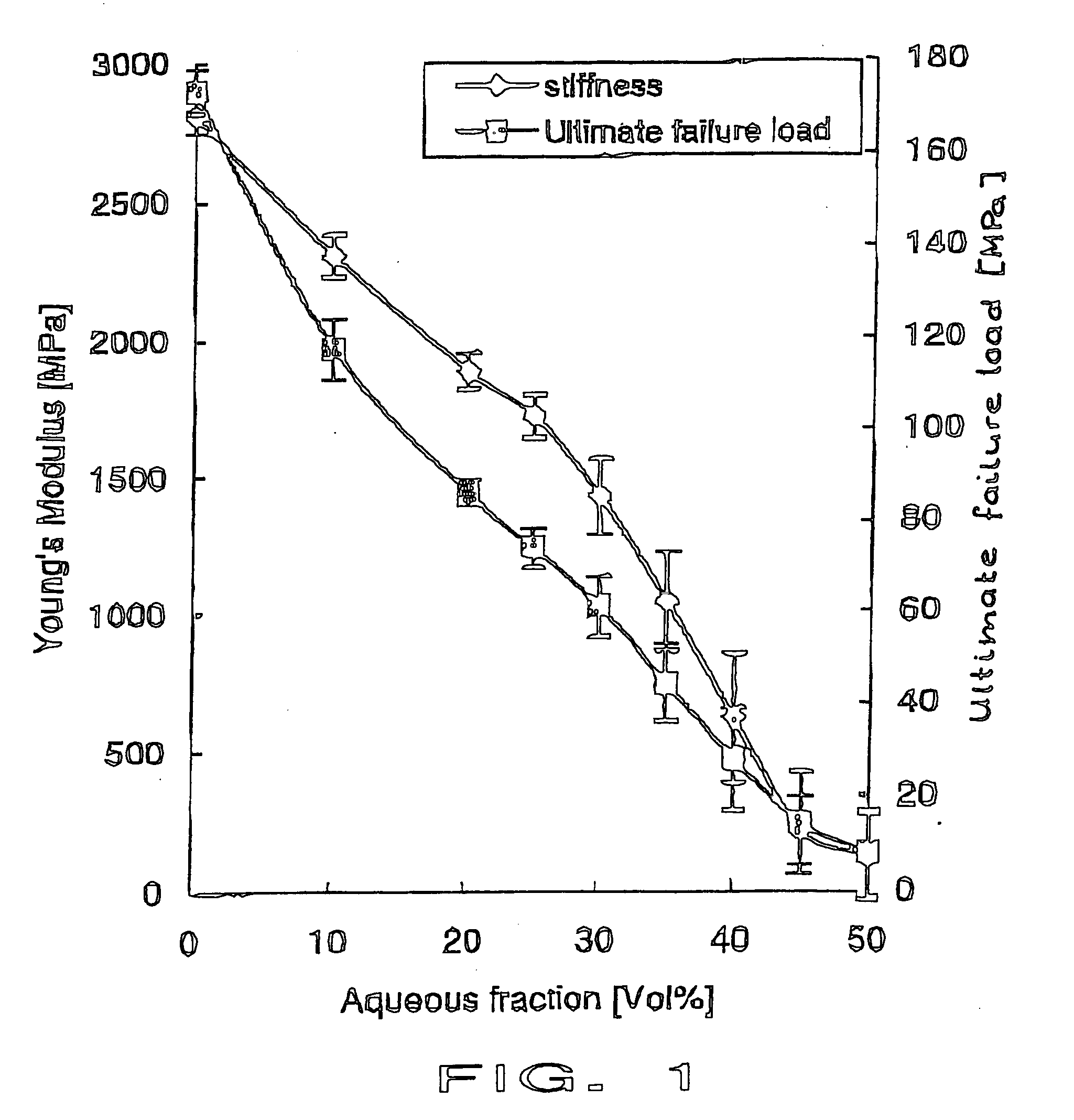

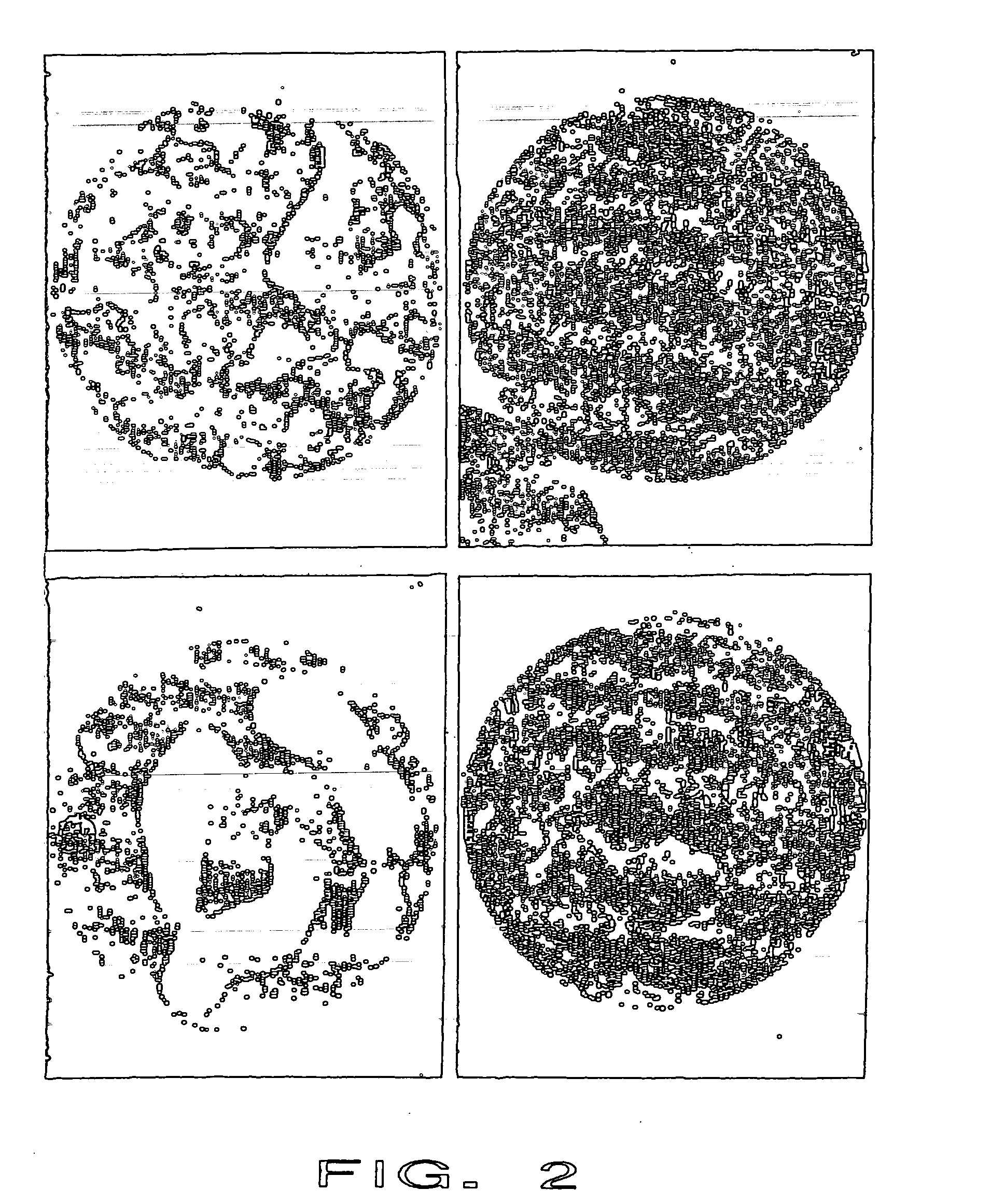

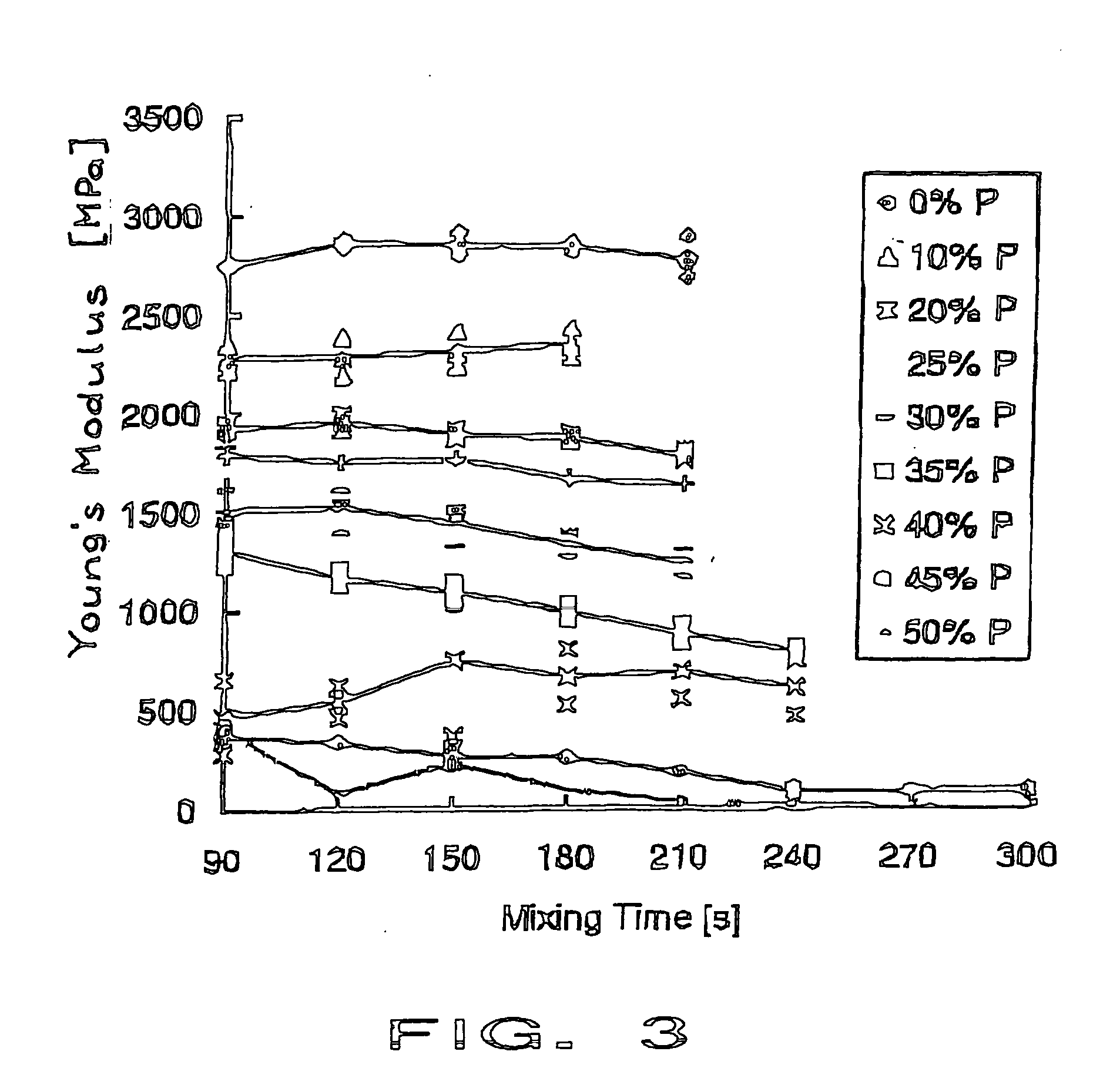

An injectable mixture for substituting bone tissue in situ comprises: A) a two-component powder / liquid bone cement which upon mixing forms a self-hardening cement paste; and B) a third component consisting of a liquid which essentially is non-miscible with the cement paste and which is suitable to be washed out after hardening of said mixture in situ, resulting in a porous bone substituting material; and C) an X-ray contrast agent which is an organic substance. The injectable bone substitute material for bone augmentation has adaptable mechanical properties, an optimal radio-opacity without any inorganic X-ray contrast agent and therefore good biocompatibility.

Owner:SYNTHES USA

Self-hardening calcium phosphate materials with high resistance to fracture, controlled strength histories and tailored macropore formation rates

InactiveUS6955716B2Strong and tough self-hardeningHigh strengthPhosphatesOther chemical processesFiberHigh resistance

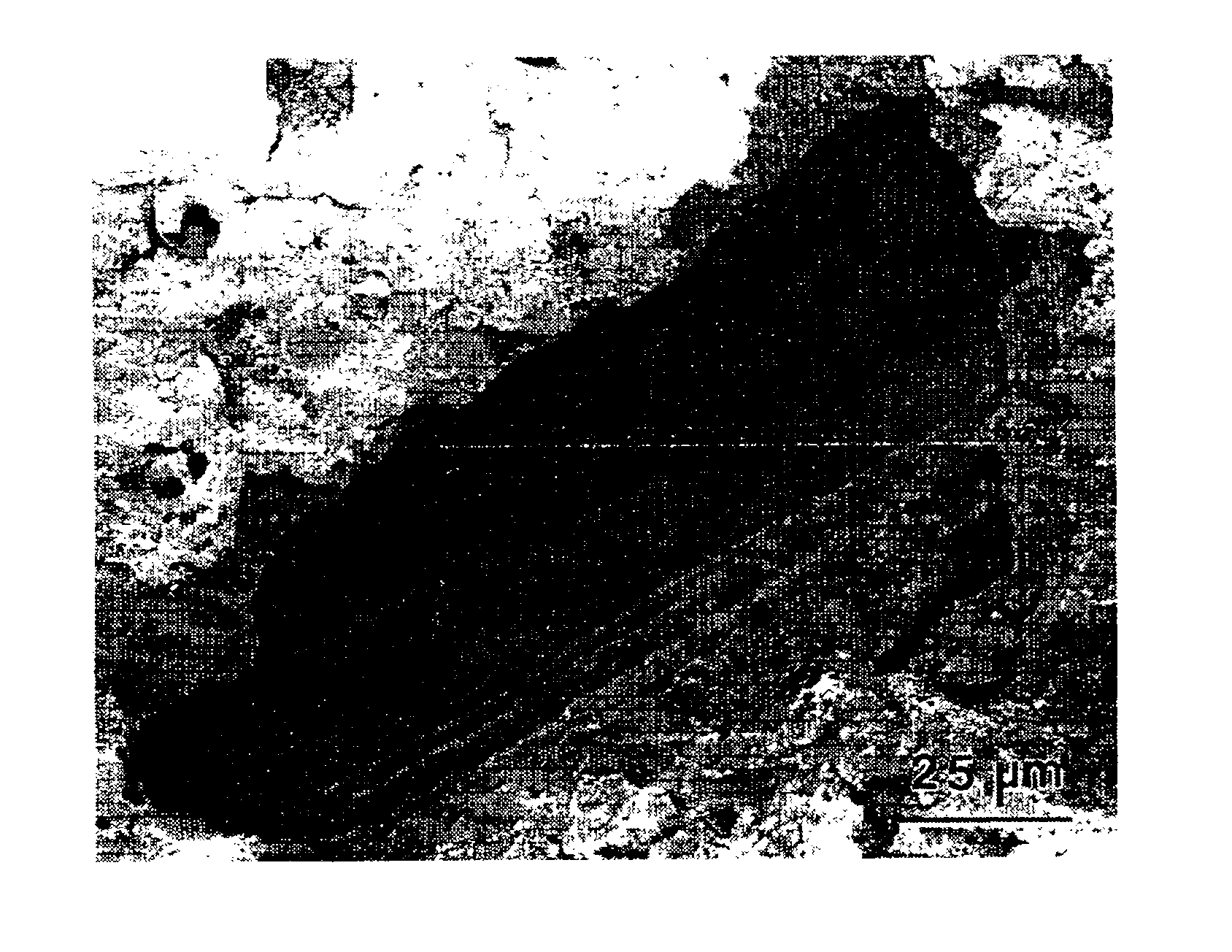

A bone replacement material and therapy comprises the combination of calcium phosphate compounds and two or more soluble fillers in the form of fibers, mesh or other materials which have the dual functions of reinforcing an in vivo implant while dissolving at a programmed rate to form macropores capable of receiving natural bone ingrowth.

Owner:ADA FOUND

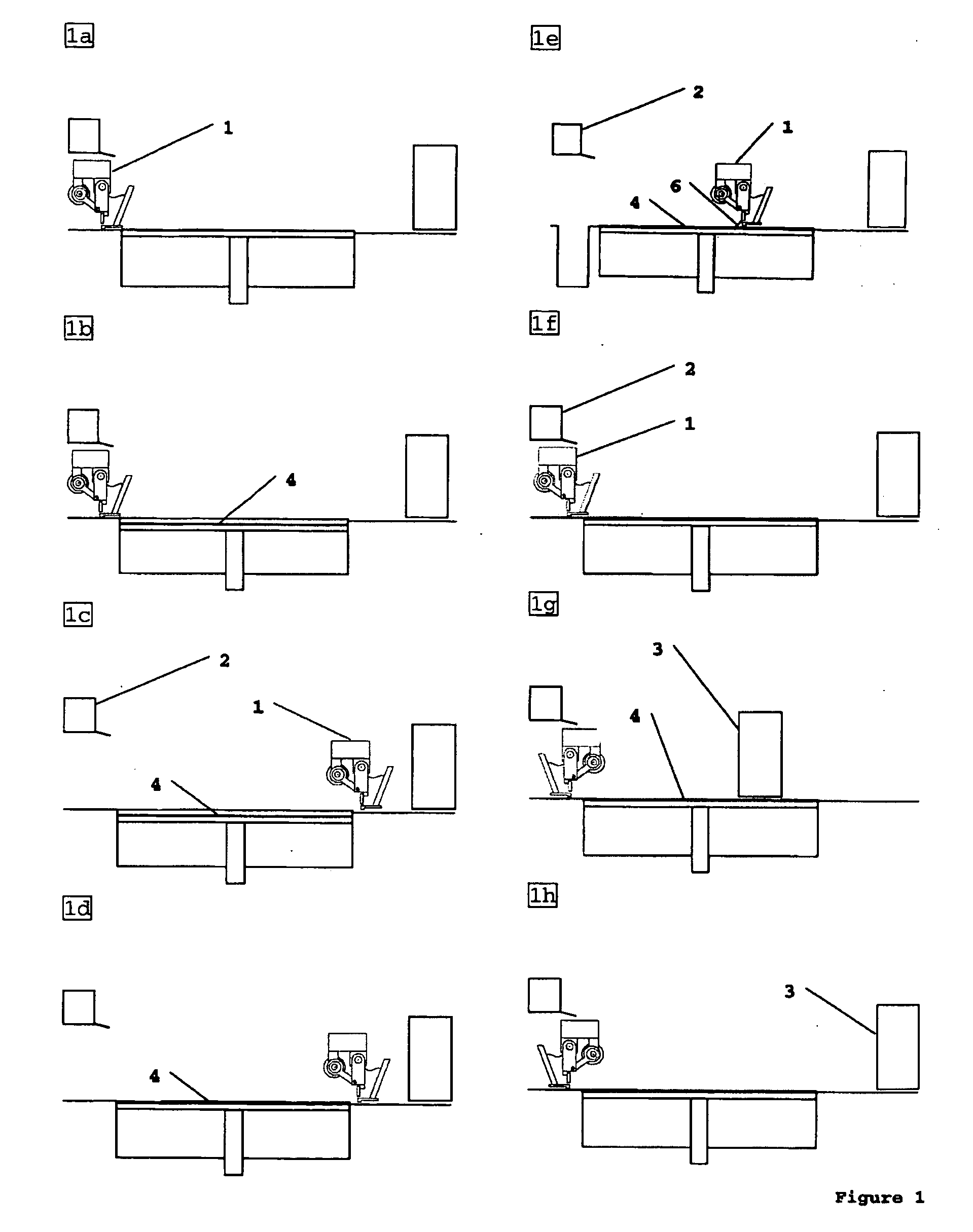

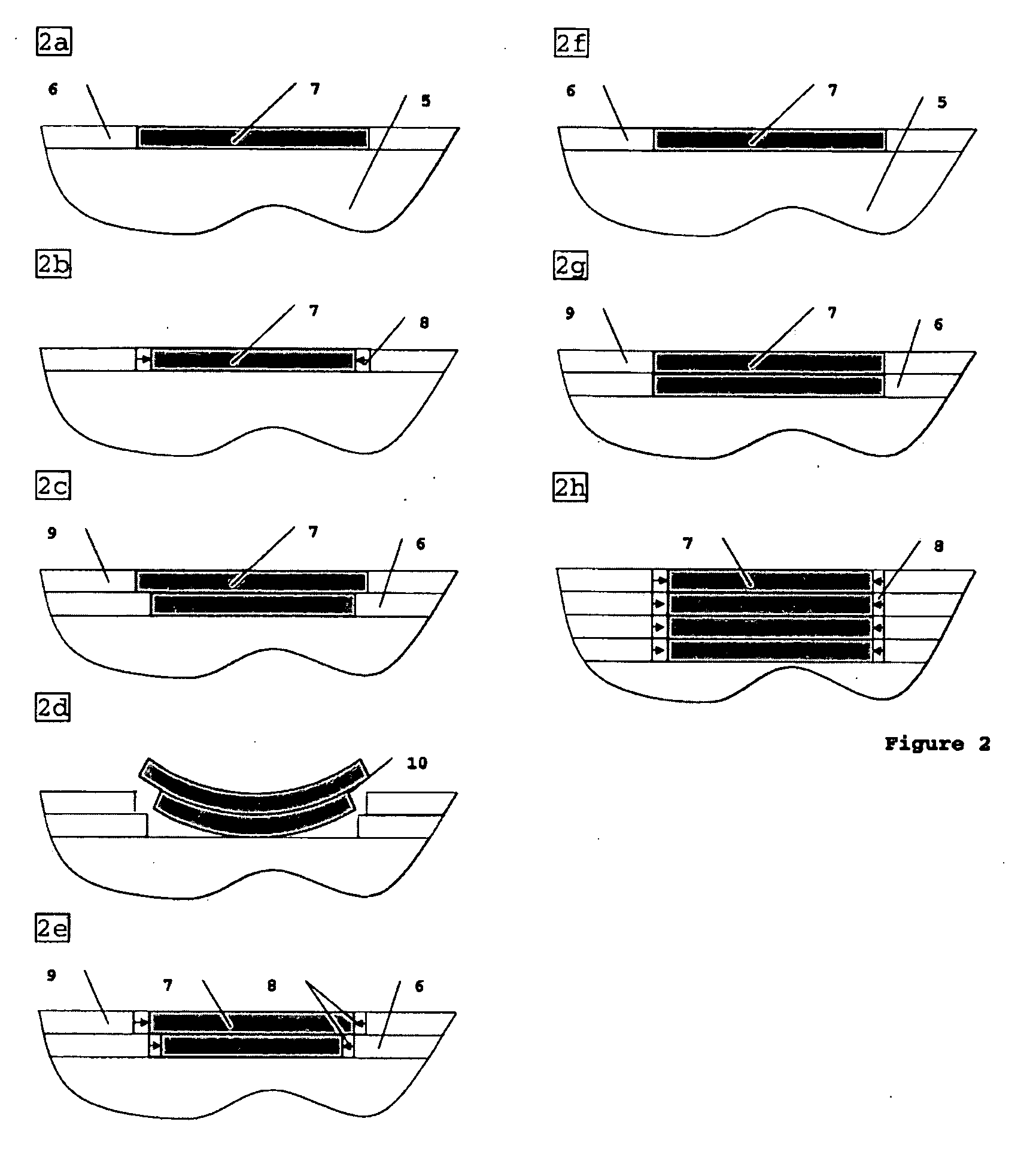

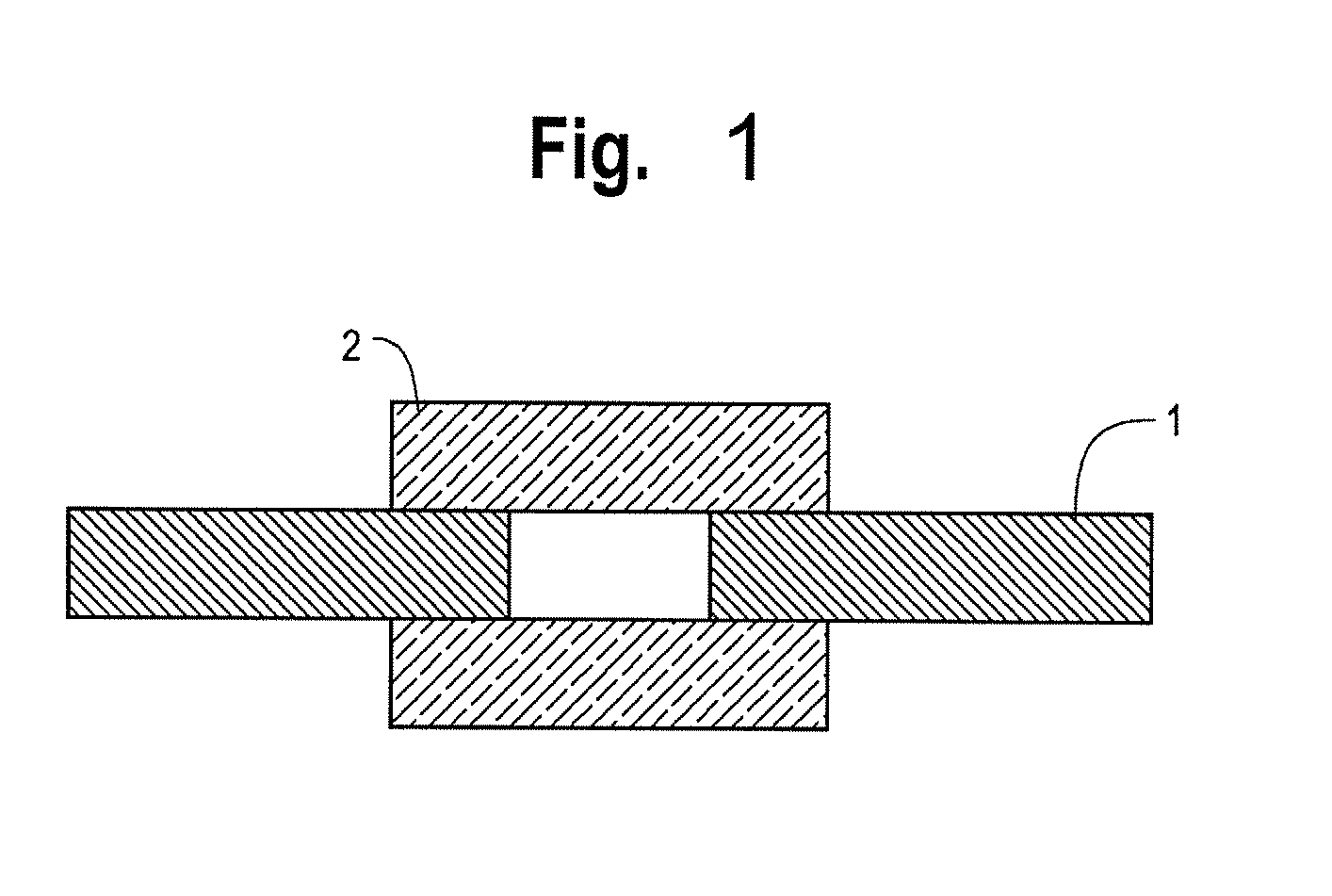

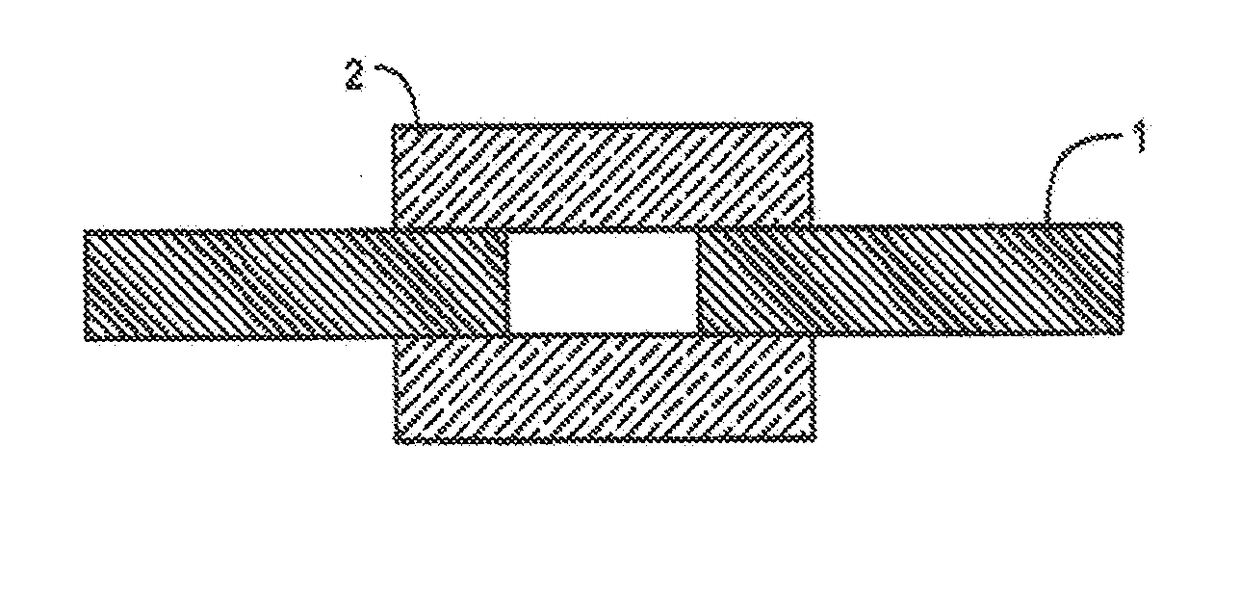

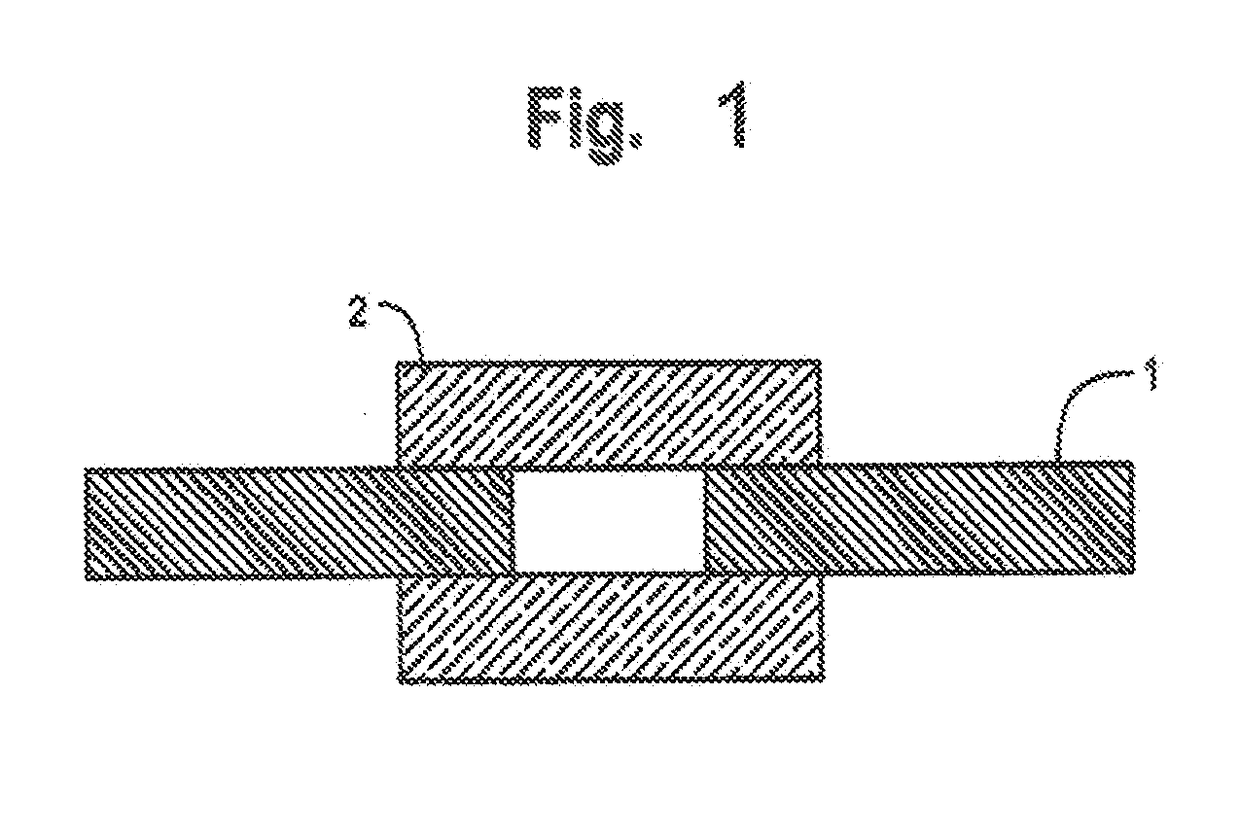

Self-hardening material and process for layerwise formation of models

ActiveUS20100291314A1Additive manufacturing apparatusPretreated surfacesParticulatesApplication time

The invention relates to a self-hardening material for layerwise construction of three-dimensional components, whereby the material comprises at least one particulate material and a separately applied bonding agent for bonding the particulate material, and has a setting time which is at least several times as long as the application time of a particulate layer.

Owner:VOXELJET AG

Premixed self-hardening bone graft pastes

A bone or dental implant material in the form of a paste includes a mixture of calcium phosphate and / or calcium-containing powders, liquid glycerol, organic acid and gelling agent. The paste is stable, resistant to washout and will harden upon exposure to water. Physical characteristics of the paste, including consistency, porosity, and hardening time, are controlled by the choice and ratio of constituents.

Owner:ADA FOUND

Geopolymer grouting material

InactiveCN101712546AImprove early strengthImprove liquiditySolid waste managementCement productionSlagGeopolymer

The invention discloses a geopolymer grouting material, which is prepared from the following components in parts by weight: 10-30 parts of waste concrete powder, 5-15 parts of desulfurization gypsum, 10-20 parts of steel slag powder, 20-40 parts of scoria powder, 3-8 parts of high calcium fly ash, 20-50parts of coal ash and 5-10 parts of alkali-activator. The geopolymer grouting material has the advantages of high early strength, good flowing property, low production cost, and the like; moreover, the geopolymer grouting material has self-hardening property, can react with soil, and enable soil bodies to become a plate-shaped structure, thereby improving the bearing capacity of a soil roadbed.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Self-hardening calcium phosphate materials with high resistance to fracture, controlled strength histories and tailored macropore formation rates

InactiveUS20050081750A1Encourage bone ingrowthHighly integratedImpression capsPhosphatesHigh resistanceFiber

A bone replacement material and therapy comprises the combination of calcium phosphate compounds and two or more soluble fillers in the form of fibers, mesh or other materials which have the dual functions of reinforcing an in vivo implant while dissolving at a programmed rate to form macropores capable of receiving natural bone ingrowth.

Owner:ADA FOUND

Dental and Endodontic Filling Materials and Methods

Disclosed are endodontic filling materials and methods. A method for filling a dental root canal may include providing a hydrosetting filling material and inserting the hydrosetting filling material into the dental root canal, the material setting in the root canal to form a biocompatible filling. The hydrosetting filling material comprises a hydrogel former and a filler. The hydrogel former is at least one of a reactive organic hydrogel formers, an inorganic hydrogel formers, and a non-reactive organic hydrogel formers, and the filler is at least one of a self-hardening and a non-hardening filler. Plural filling material precursor compositions that collectively contain hydrogel formers and fillers may be provided.

Owner:ADA FOUND

Modified phosphate casting binder and preparation method and application thereof

InactiveCN103302232AHigh bonding strengthGood chemical stabilityFoundry mouldsFoundry coresChemical reactionPhosphate

The invention discloses a modified phosphate casting binder and a preparation method and application thereof. The modified phosphate casting binder is synthesized and prepared by a chemical reaction from the following components in percentage by weight: 9-15% of aluminum hydroxide, 60-65% of phosphoric acid, 1-5% of boric acid, 1-3% of borax, 1-5% of citric acid, 10-20% of water and 4-15% of ethanol. The obtained binder has good chemical stability, strong moisture absorption resistance and high bonding strength. The binder disclosed by the invention is suitable for preparing a self-hardening sand mould and has the characteristics of high bonding strength, long service time of a sand mould, good performance stability of the sand mould, easy collapse of the sand mould, normal-temperature regeneration of old sand and easy sand clearing of castings, and has broad application prospects in the casting industry.

Owner:HUBEI UNIV OF TECH

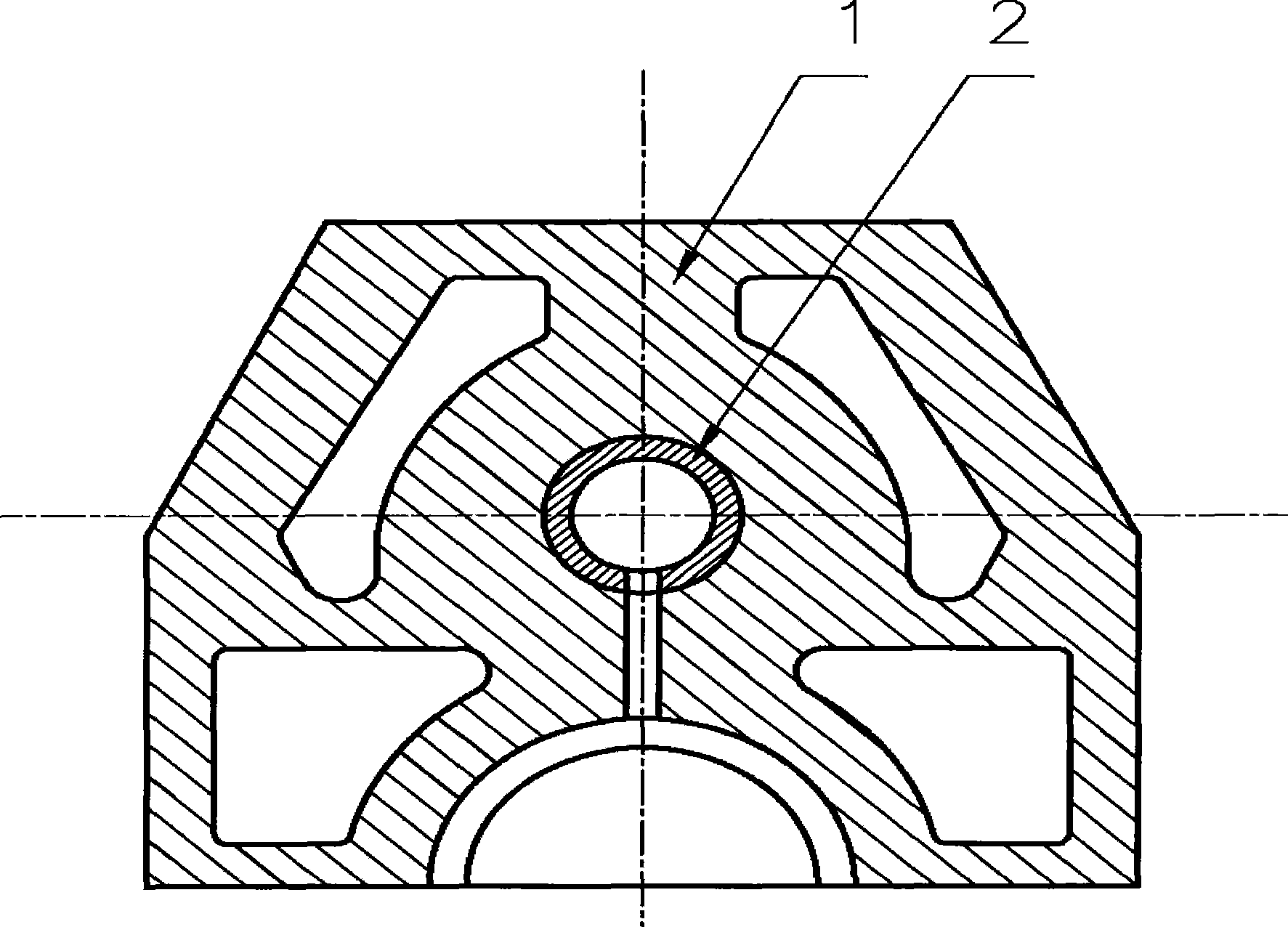

Furan self-hardening resin sand mold for producing integral casting axle case

The invention relates to a furan self-hardening resin sand mold for producing an integral casting axle case, which is characterized in that raw sand, furan resin, and curing agent are molded by weight part according to the following methods of: stirring the raw sand and the furan resin sufficiently in a sand mixer, wherein the furan resin is 1.0-1.5% of the weight part of the raw sand, and the furan resin is cementing agent; adding boric acid, and mixing equally, wherein the boric acid is 0.5-0.75% of the weight part of the raw sand, and the boric acid is curing agent; putting the mixed molding sand in a sand box during the molding; and curing and molding for about 20-30 minutes by utilizing a chemical method of the reaction between the resin and the curing agent. The furan self-hardening resin sand mold for producing the integral casting axle case can improve the quality and the service life of the casting, stably produce qualified castings, and reduce the cost of the axle case assembly.

Owner:FAW GROUP

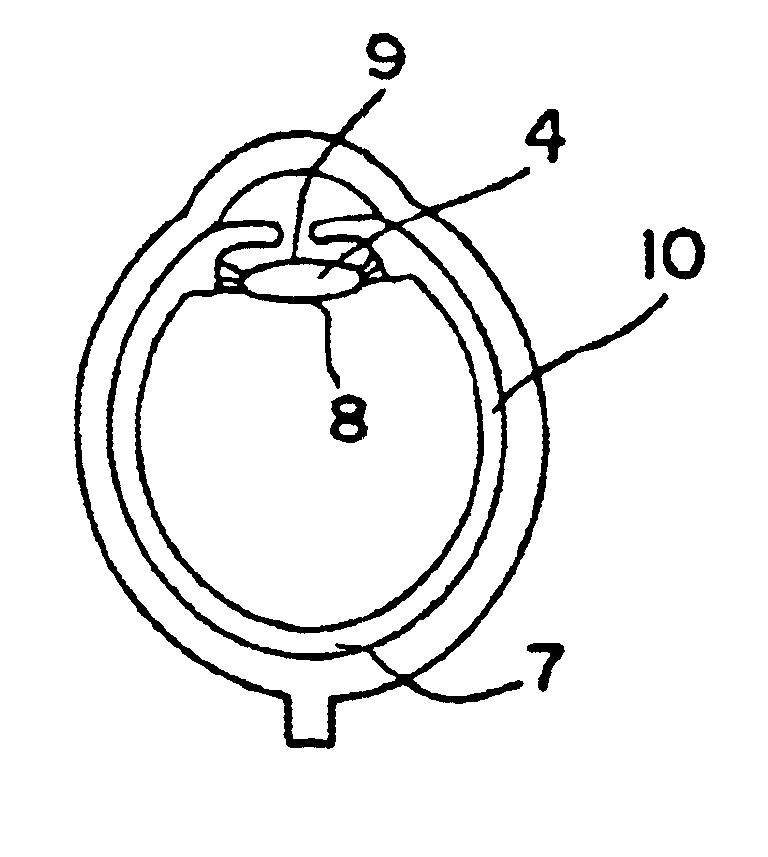

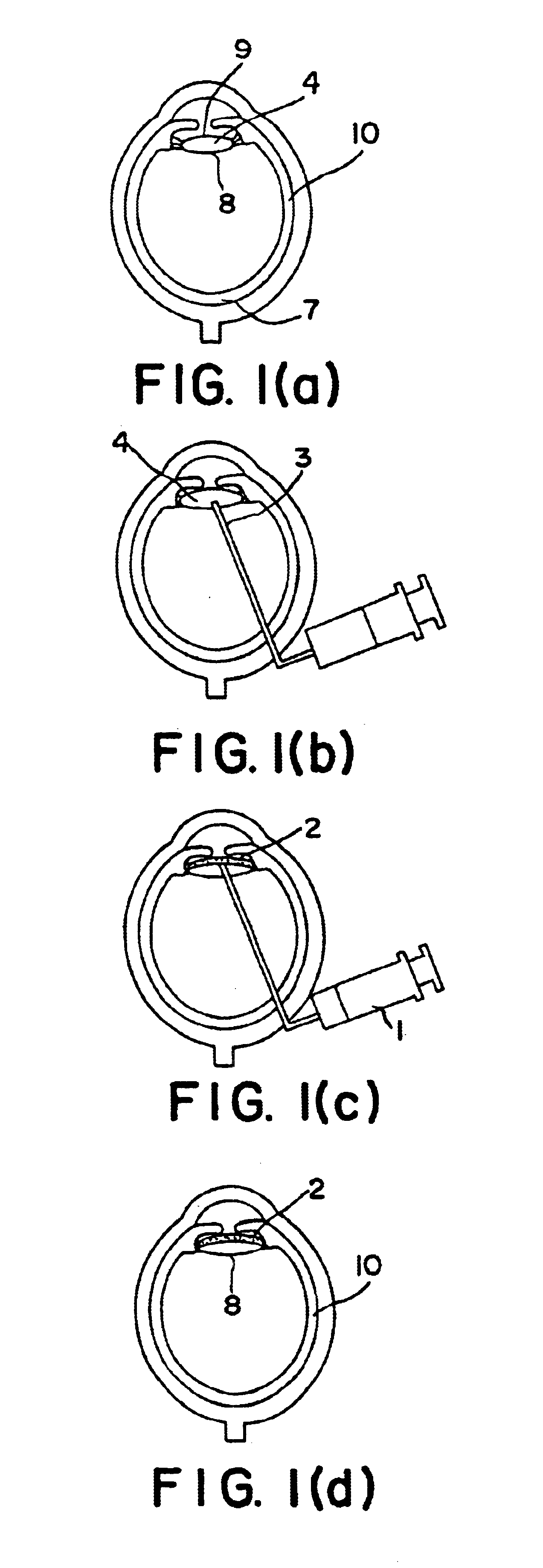

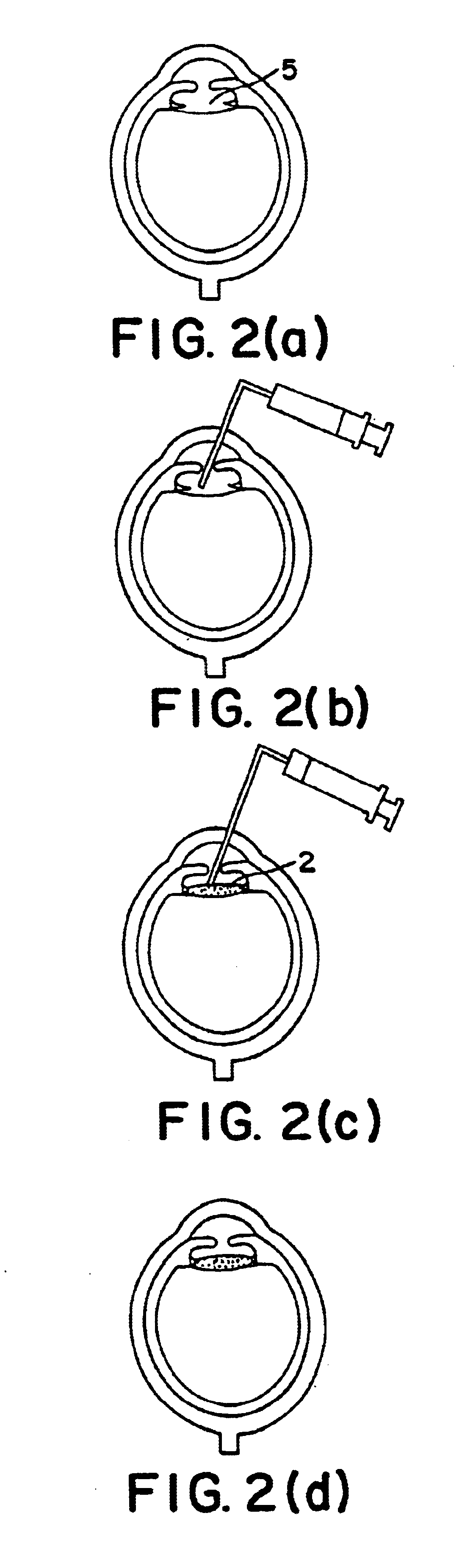

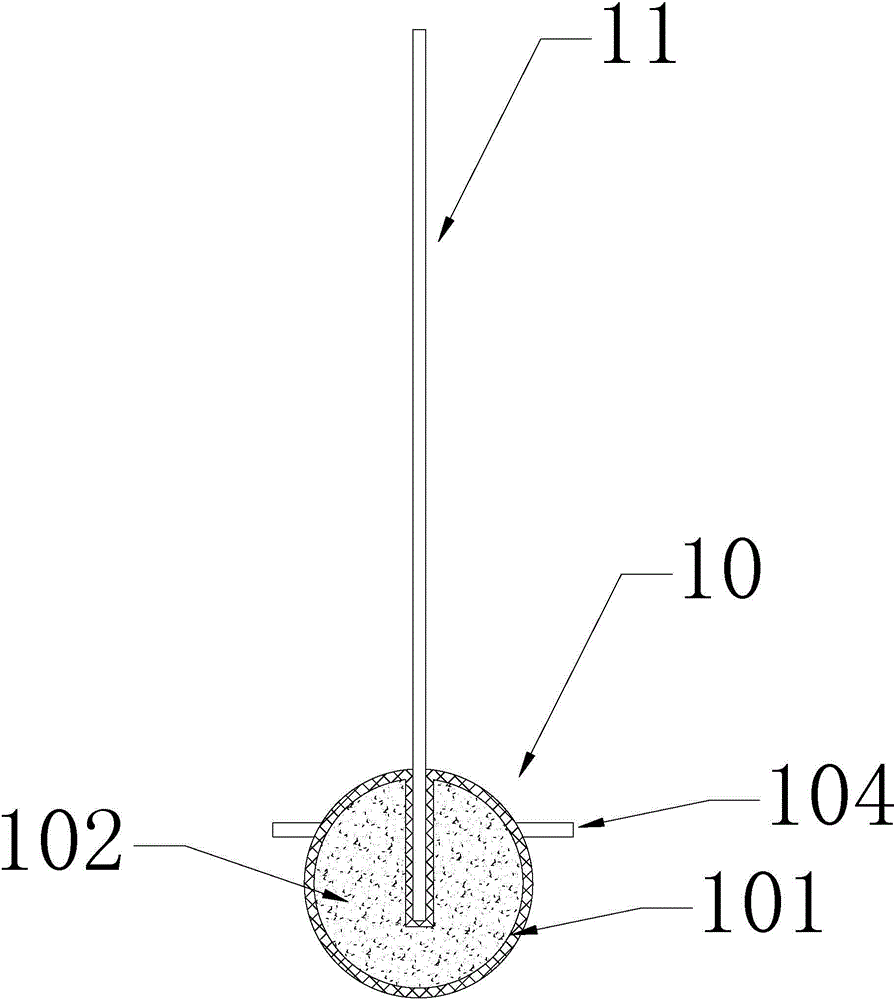

Model for training of surgical operation of cataract

The present invention relates to a model for surgical operation for an eye with cataract comprising a pig's eye which is prepared by injecting self hardening type chemicals into a crystalline lens capsule or into an empty crystalline lens capsule of said pig's eye, further relates to a model for an enucleating operation of a fallen nucleus lens which is prepared by falling the hardened chemicals into corpus vitreum by breaking posterior capsule of crystalline lens consciously.

Owner:UMEYAMA HIDEKI +1

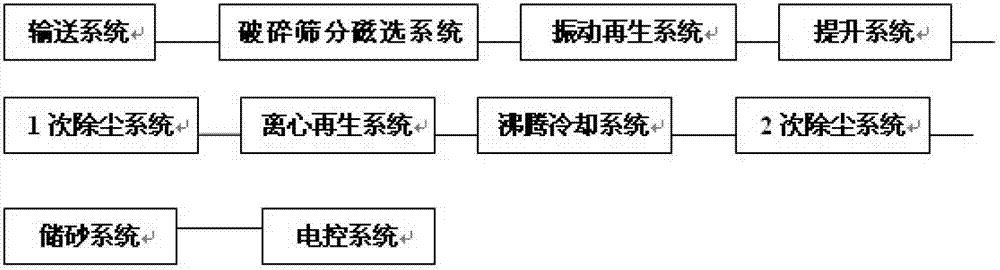

Foundry self-hardening sand recycling system process

ActiveCN102873268AReduce manufacturing costSimple processMould handling/dressing devicesFoundryElectric control

The invention discloses a foundry self-hardening sand recycling system process, which comprises a delivery system, a crushing, screening and magnetic separation system, a vibrating regeneration system, a hoisting system, a primary dedusting system, a centrifugal regeneration system, a boiling cooling system, a secondary dedusting system, a sand storage system and an electric control system. The invention overcomes the defects of the prior art, waste sand is recycled, the production cost is saved, energy is saved, emission is reduced, environment is protected, and the pollution is avoided.

Owner:ANHUI CHENGUANG HIGH WEAR RESISTANCE TECH CO LTD

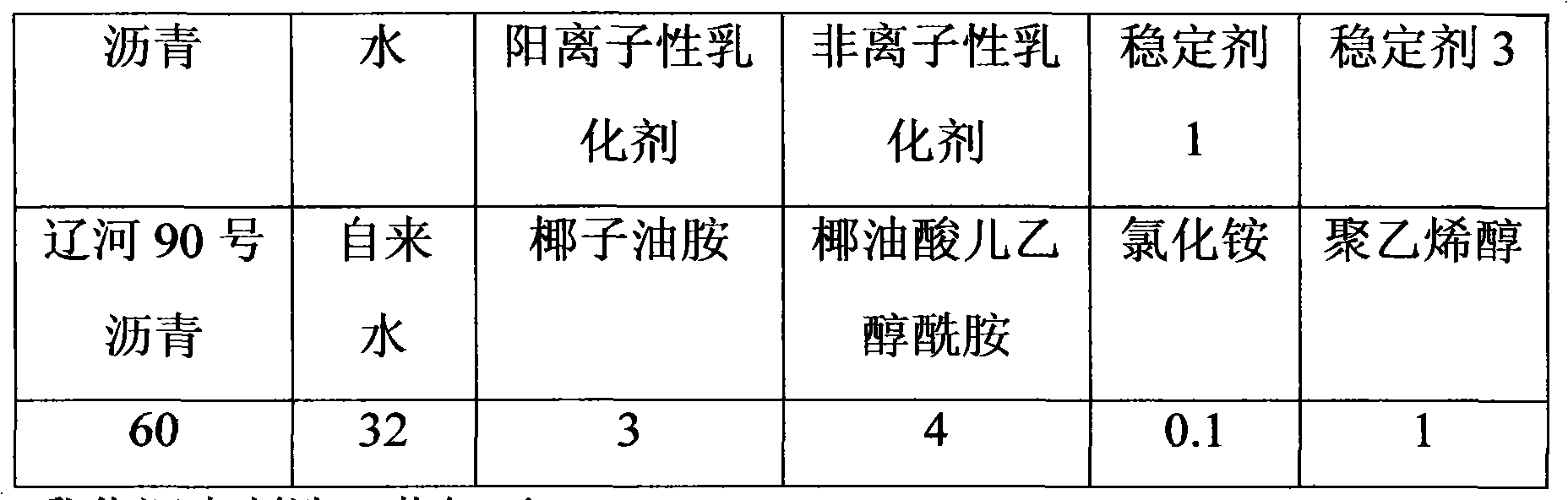

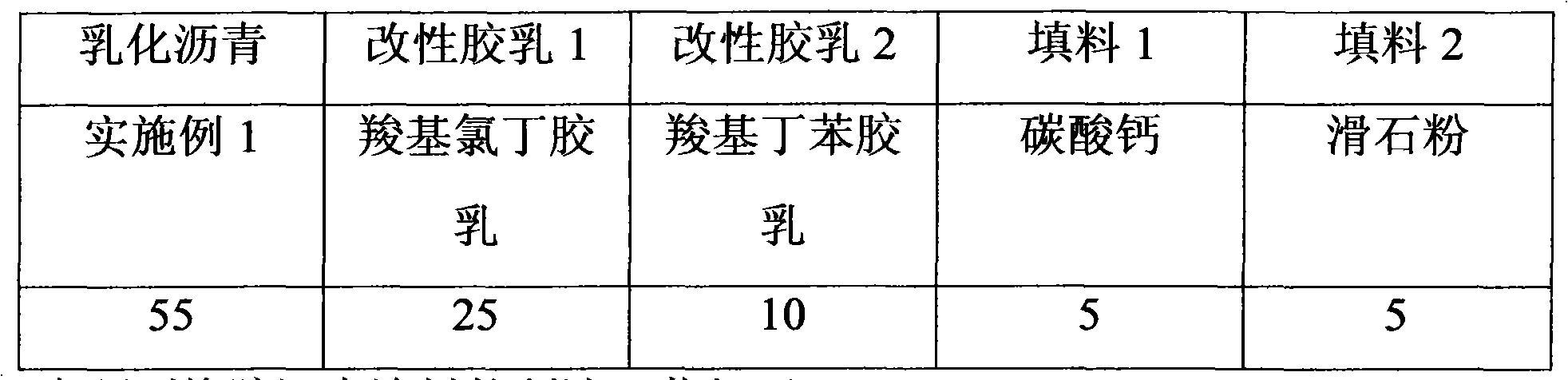

Self-hardening rubber asphalt paint

InactiveCN102108257AEliminates prone to low cloud point problemsLow densityConjugated diene hydrocarbon coatingsNatural rubber coatingsEmulsionSpray coating

The invention provides self-hardening rubber asphalt paint which comprises the following components by weight percent: 50%-65% of asphalt, 3%-6% of cationic emulsifier, 3%-6% of nonionic emulsifier, 25%-35% of modified latex, 1%-3% of stabilizer and 5%-10% of filler. The invention further provides a preparation method of the self-hardening rubber asphalt paint, the rubber asphalt paint is modified through normal-temperature self-crosslinking emulsion, has the prominent characteristics of normal temperature spray coating, manual scrape-coating, instant shaping, perfect joint, high elastic force, zero joints and the like, and can fundamentally solve the technical difficulty of leakages at side angles, gaps and junction of irregular structures and the like, thereby thoroughly updating the traditional construction process and the method of waterproof material.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

Furan resin self-hardening sand and preparation method thereof

The invention discloses furan resin self-hardening sand and a preparation method thereof. The self-hardening sand is prepared from the following raw materials: silica sand, furan resin, epoxy resin, glycerin water solution, a silane coupling agent, titanium dioxide, boron carbide, hydroxypropyl-beta-cyclodextrin and pyralene. The preparation method comprises the following steps of mixing silica sand with the size of larger than 200 meshes with pyralene, sequentially feeding the silane coupling agent, titanium dioxide, boron carbide, hydroxypropyl-beta-cyclodextrin, glycerin water solution, epoxy resin and furan resin, and rapidly stirring until the raw materials are fully mixed, wherein the stirring speed is 120r / min. The preparation method is simple; all the raw materials are matched and act; the silica sand can achieve good bonding property and curing effect by virtue of furan resin, epoxy resin, silane coupling agent and pyralene, and glycerin water solution, titanium dioxide, boron carbide and hydroxypropyl-beta-cyclodextrin are capable of improving the humidity resistance, the fluidity and the compressive strength of the silica sand.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

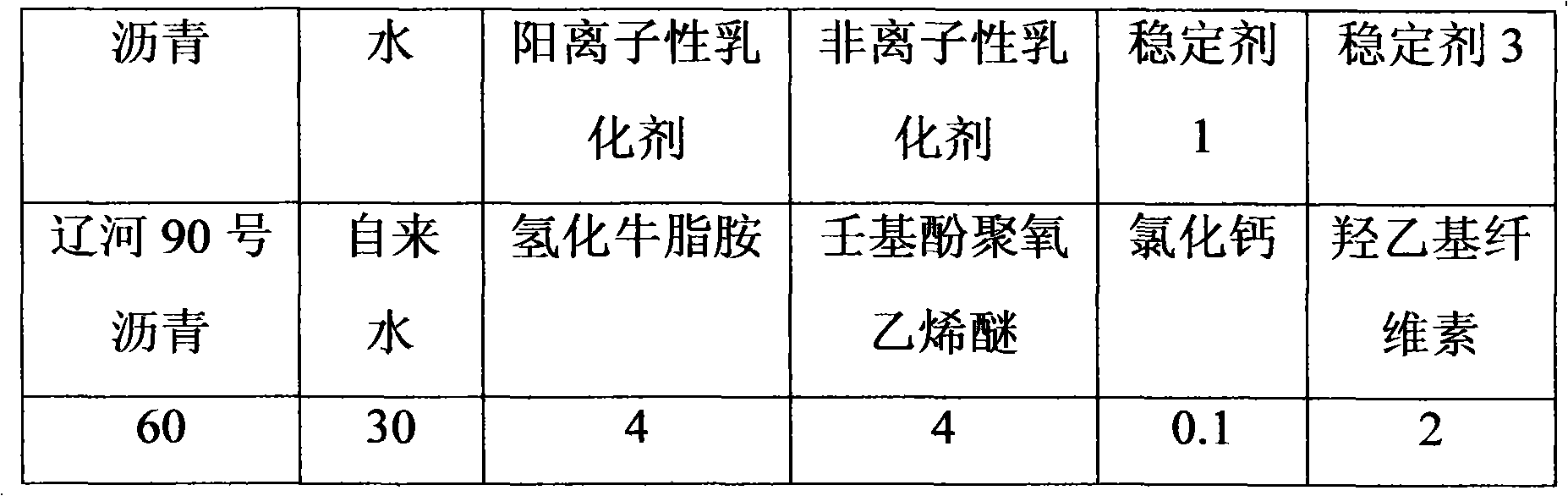

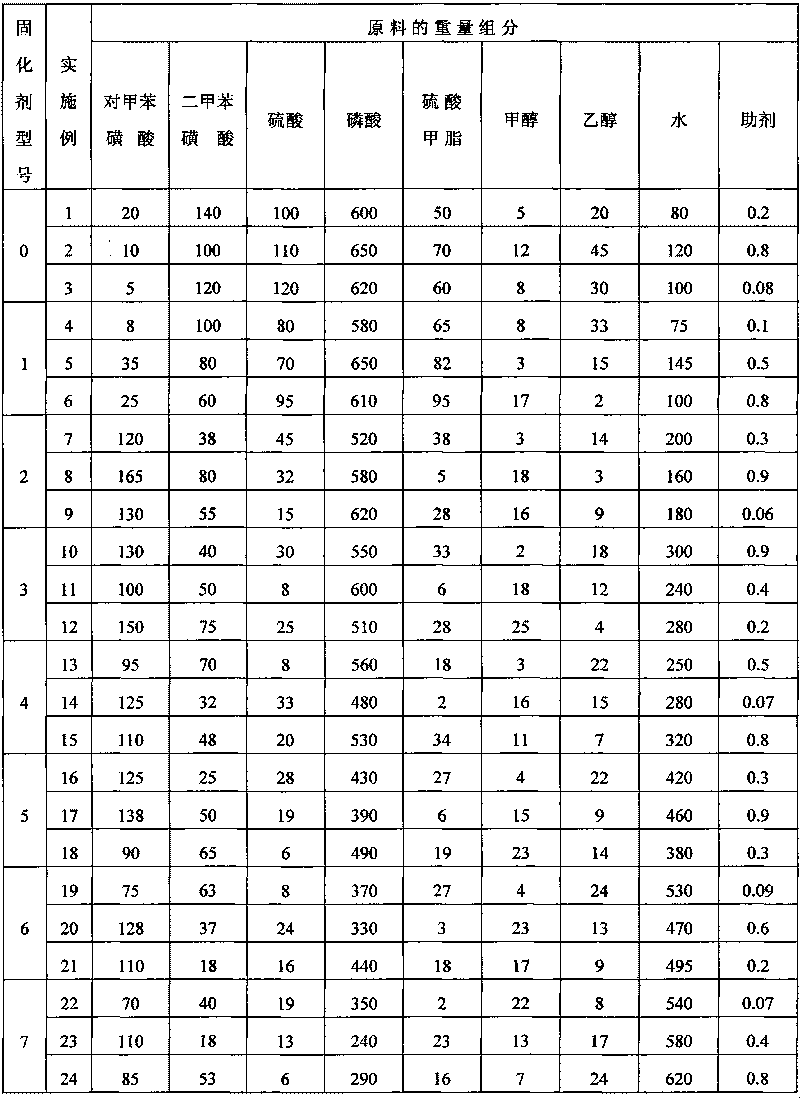

Curing agent of self-hardening furan resin sand and preparation method thereof

ActiveCN101722272ASolve the problem that the usable time is too shortSolve the difficult problems of productionFoundry mouldsFoundry coresFuranPhosphoric acid

The invention relates to a curing agent of self-hardening furan resin sand, which comprises the following components in portions by weight: 1-300 portions of toluenesulfonic acid, 10-300 portions of xylene monosulfonic acid, 1-170 portions of sulfuric acid, 200-800 portions of phosphoric acid, 1-200 portions of methyl sulfate, 1-50 portions of ethanol, 1-50 portions of methanol, 40-900 portions of water and 0.05-1.0 portion of assistant. The preparation method comprises the following steps: (1) prefabricating the toluenesulfonic acid, the xylene monosulfonic acid and the methyl sulfate; (2) preparing all the raw materials according to the proportion of the curing agent; and (3) synthesizing the curing agent by the following steps: (a) mixing the toluenesulfonic acid, the xylene monosulfonic acid, the methyl sulfate and the sulfuric acid to react for 1.0 hour; (b) cooling to 55 DEG C, adding the mixture of methanol and ethanol to react at 50-70 DEG C for 1.0 hour; (c) adding the phosphoric acid to react at 55-70 DEG C for 1.0 hour; and (d) cooling to 50 DEG C, and adding water and assistant; and discharging after evenly mixing. The curing agent can adapt to the long (super long) use time in the molding process of large castings at high air temperature (above 28 DEG C) and high sand temperature (30-50 DEG C), and solves the problem that the large (super long and large) castings are difficult to produce since the temperature of the reclaimed sand can not drop to the designed value due to various reasons in the foundry corporations.

Owner:四川东树新材料有限公司

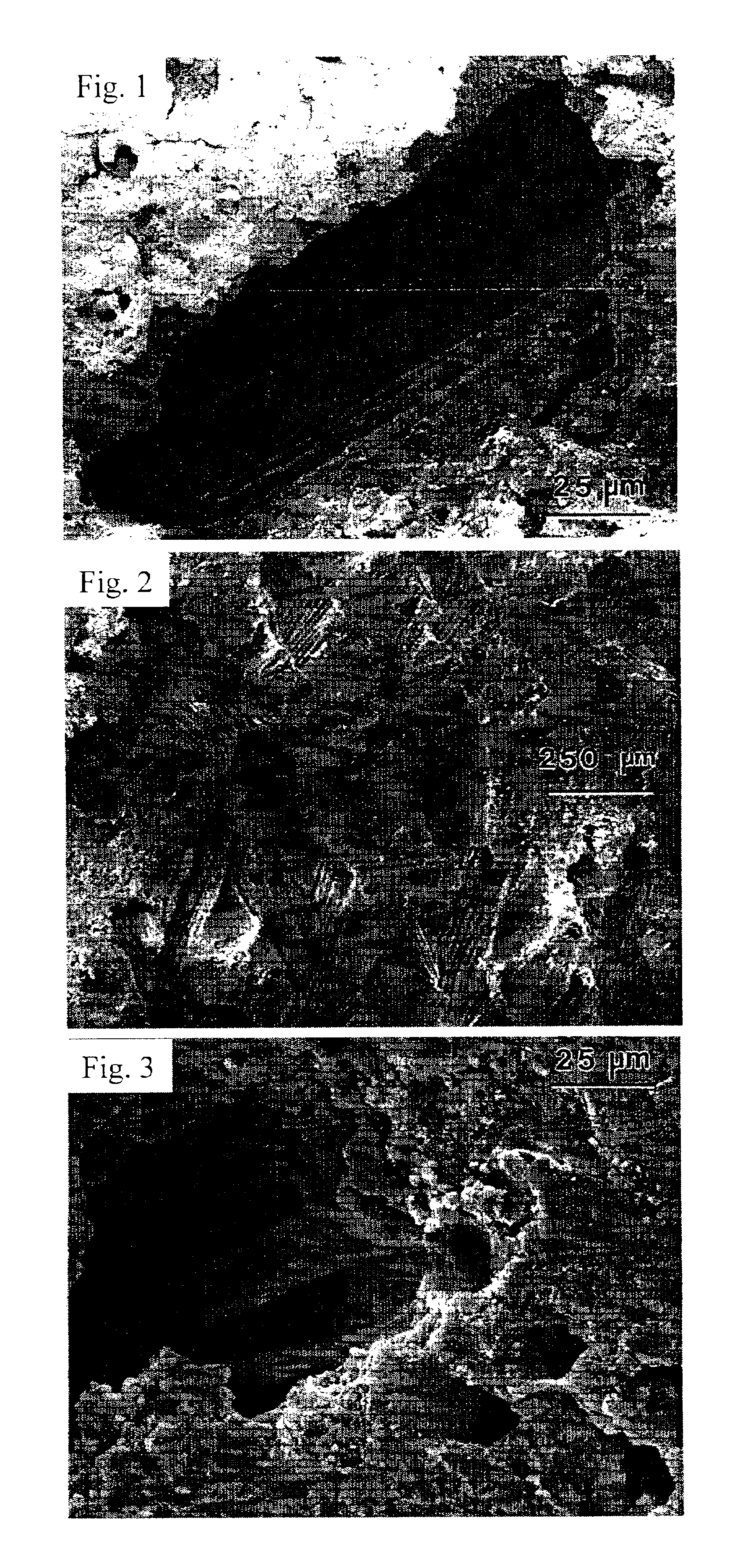

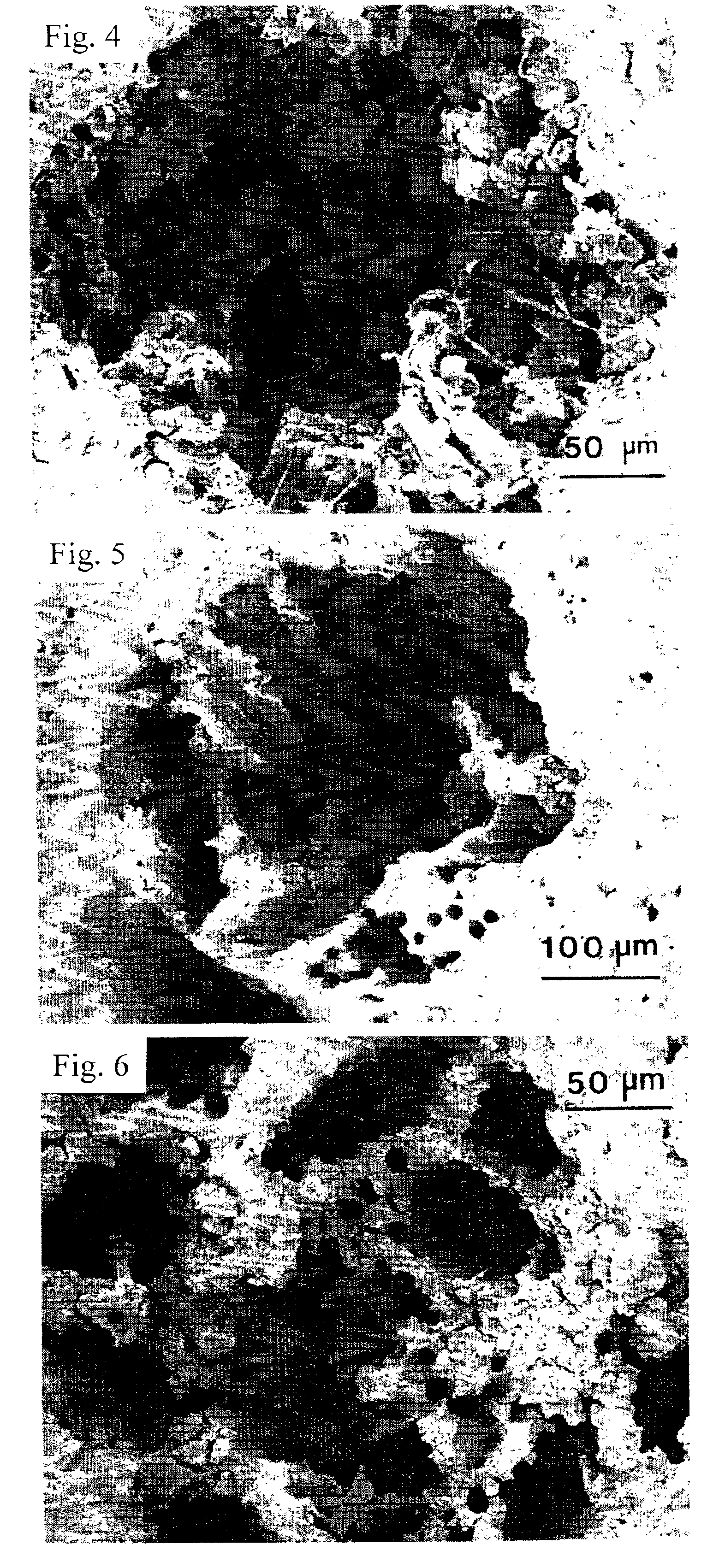

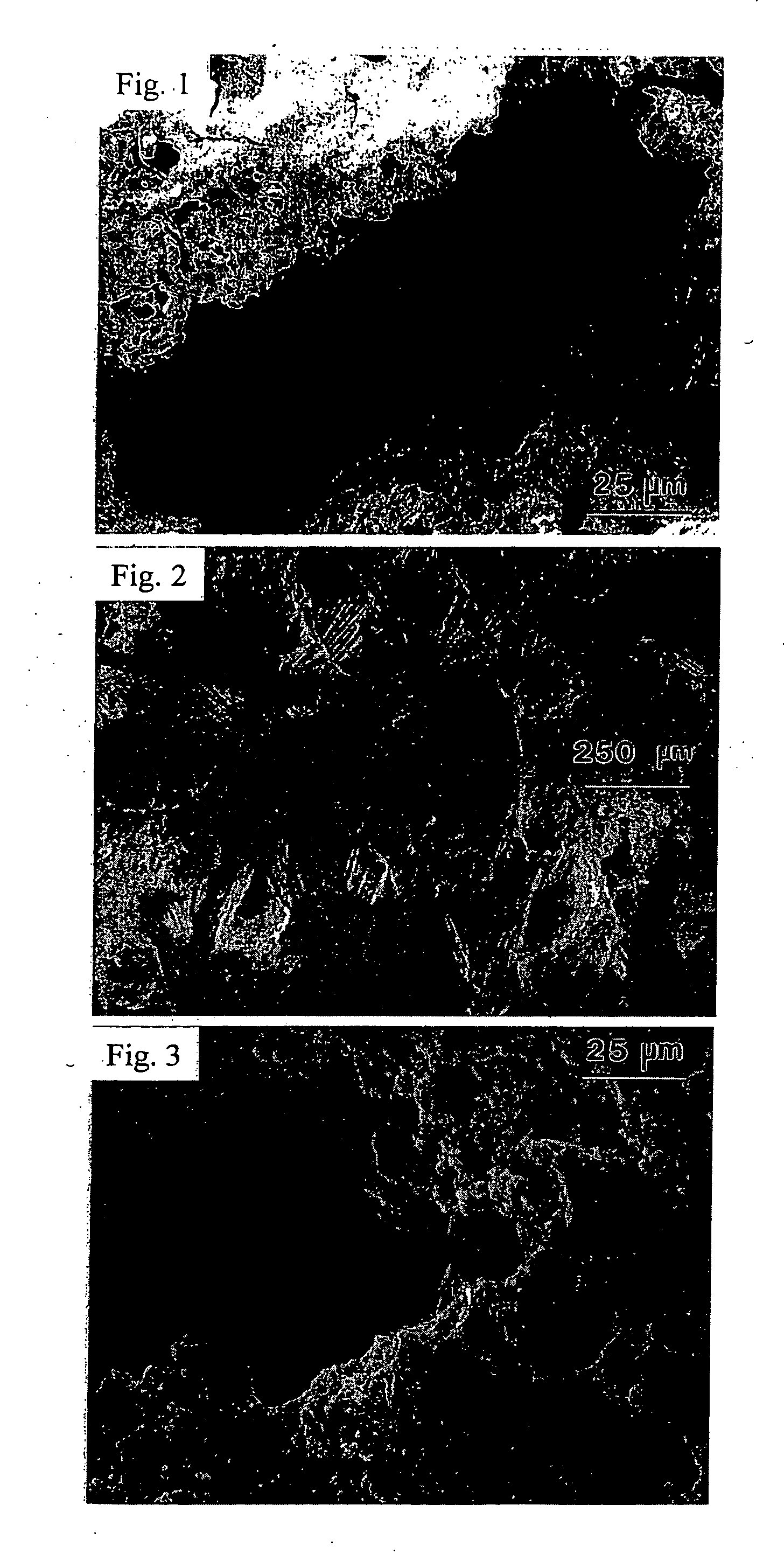

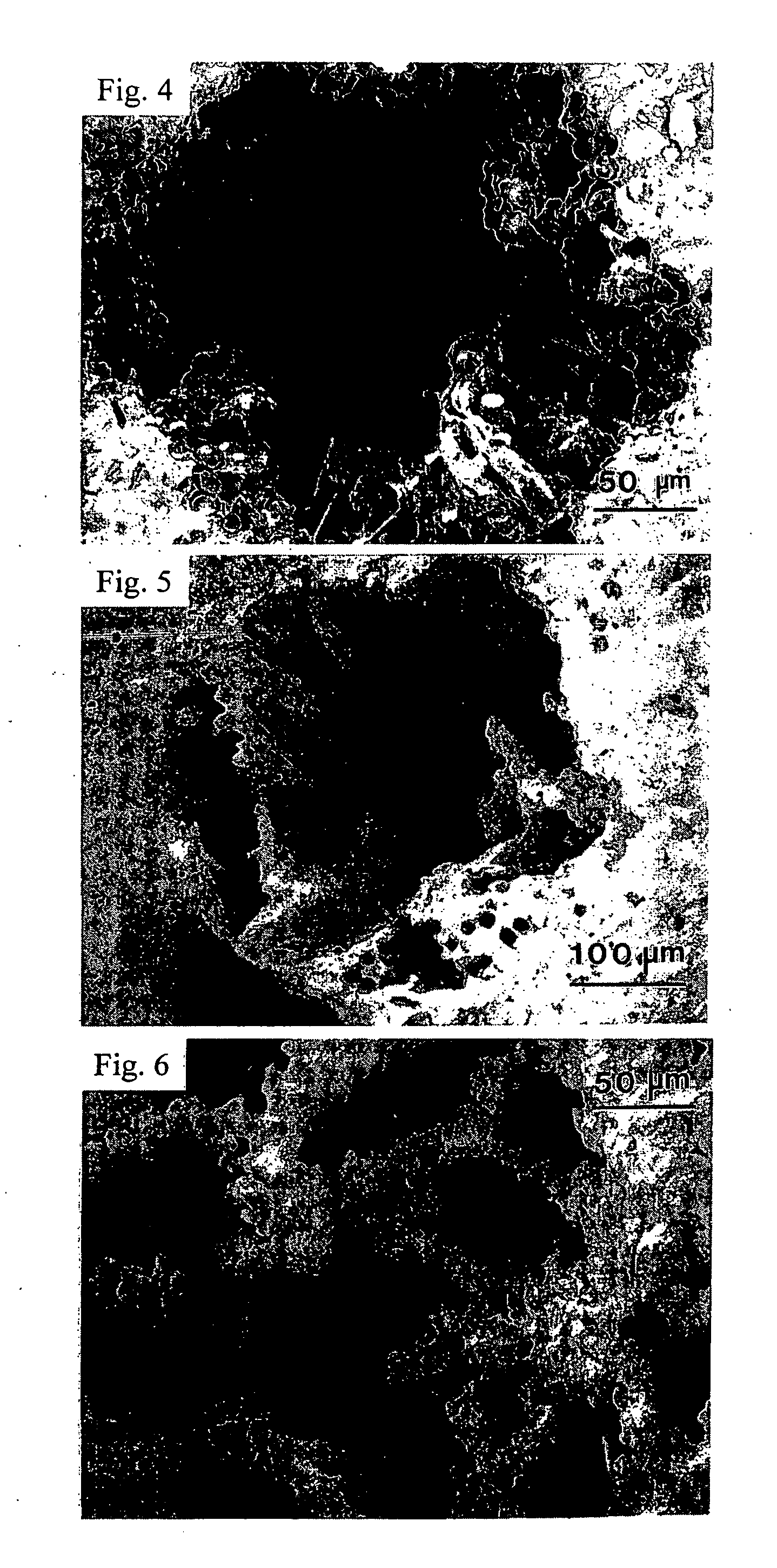

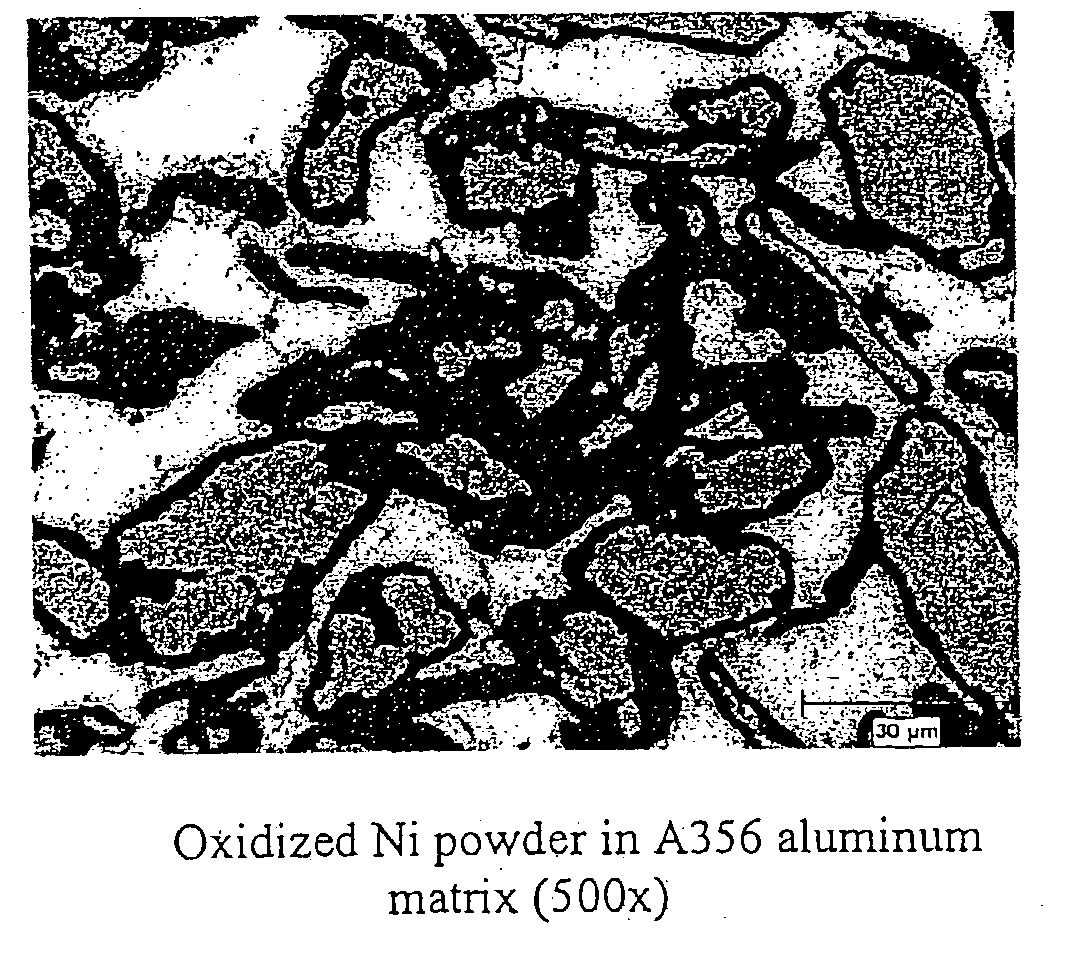

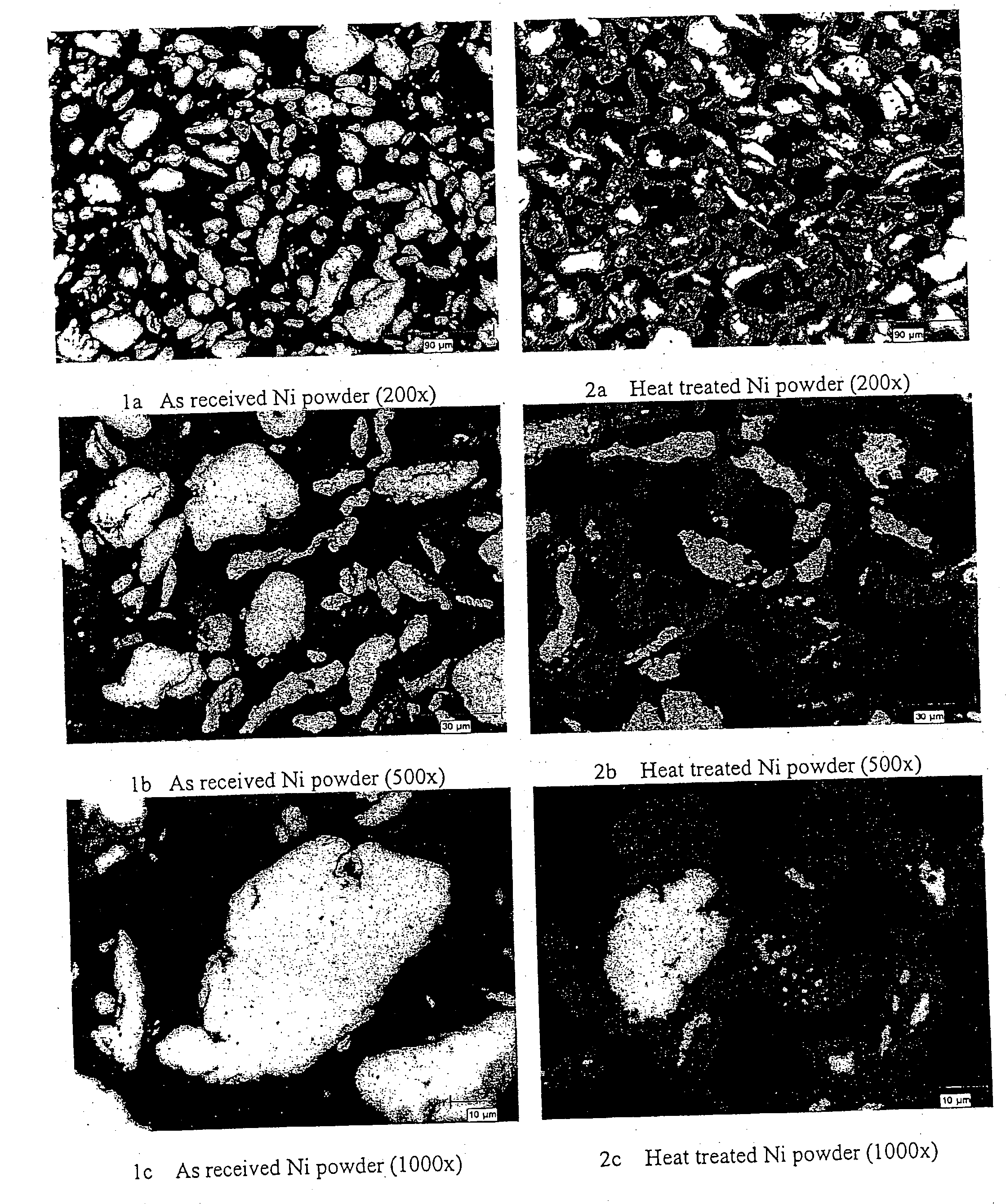

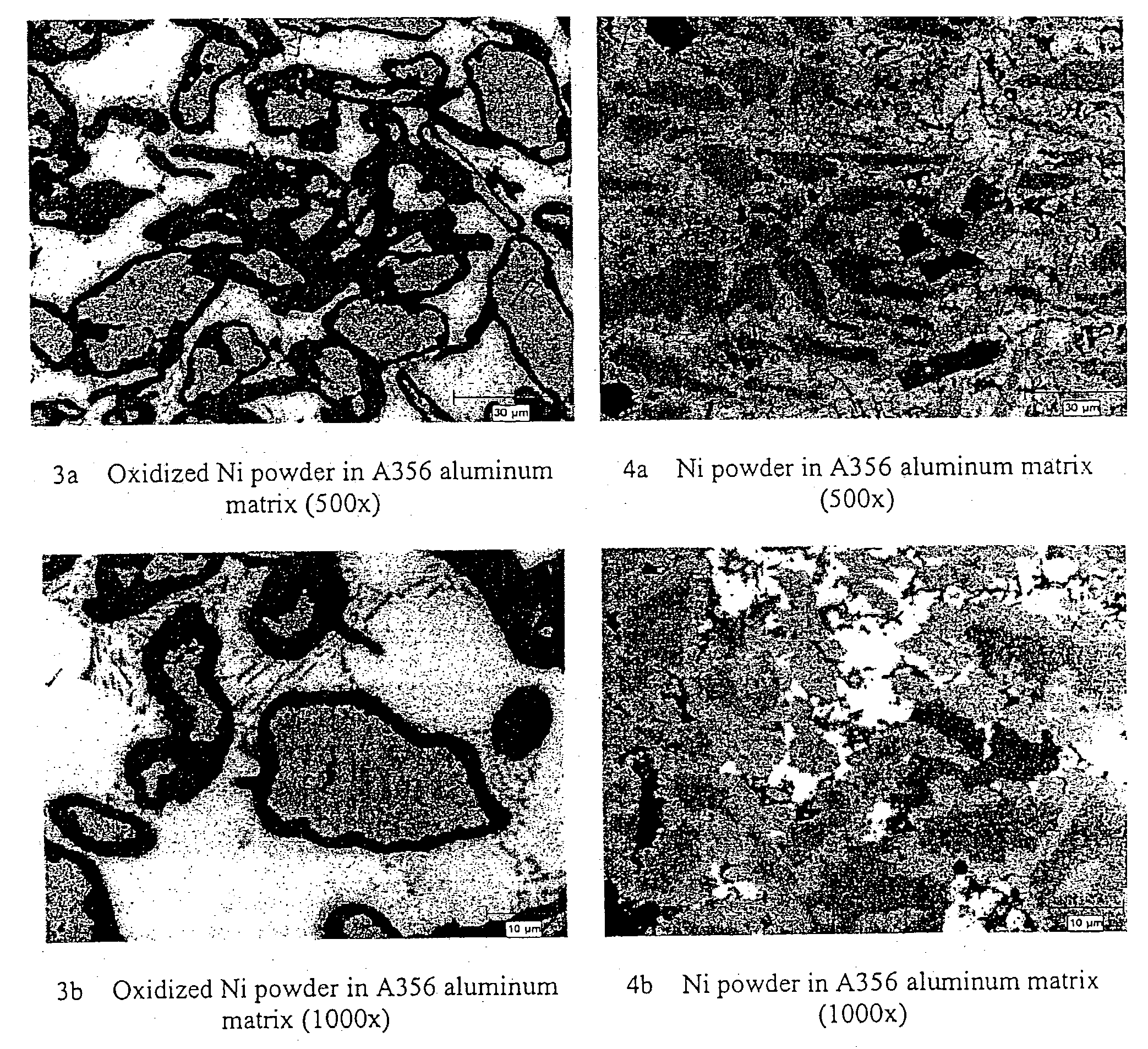

Hybrid metal matrix composites

A hybrid composite reinforced metal matrix in which the metal is aluminum, aluminum alloy, or a magnesium alloy containing a relatively high percentage of aluminum. In addition to the reinforcement, which is typically alumina, the metal matrix also includes a hardening agent which is at least one intermetallic compound of aluminum with at least one second metal chosen from iron, nickel, titanium, zirconium, cobalt and niobium. The intermetallic compound(s) can be added as a powder to the metal matrix during formation of the composite, or can be created in the composite by adding the at least one second metal as a powder to the molten metal matrix during composite preparation. When the intermetallic compound(s) are created in the composite, during the addition step the second metal powder should be protected from oxidation. If the intermetallic compound is created in the composite, the composite when made initially can be readily machined and is self hardening through repeated heating cycles. The composite finds use in brake parts, such as brake rotors and brake drums as a replacement for the commonly used grey cast iron and exhibits adequate strength and compression properties up to a working temperature of at least about 450° C.

Owner:AGRI & AGRI FOOD

Method for molding large ring piece by casting blank ring rolling

The invention relates to a method for molding a large ring piece by casting blank ring rolling, belonging to a method for processing and molding a large metal ring piece. The invention mainly solves the technical difficulty of more material waste and serious energy waste of the existing ring rolling method. The method has the technical scheme that the method for molding the large ring piece by casting blank ring rolling comprises the steps of alloy melting, refining, casting ring blank, casting blank ring rolling, rough processing, heat treatment and finishing; the refining means that an LF furnace is used for external refining, molten steel content and temperature are rapidly homogenized by argon blowing stirring, so that molten steel with high purity can be obtained; the casting ring blank means that when the temperature of the refined molten steel is reduced to 1580-1600 DEG C, self-hardening sand molding pouring is adopted to obtain a ring-shaped casting blank; and the casting blank ring rolling means that the ring-shaped casting blank is heated to 1100-1200 DEG C and is treated by ring rolling on a ring rolling machine, the feeding amount is controlled, and the ring rolling ratio is 2-3.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

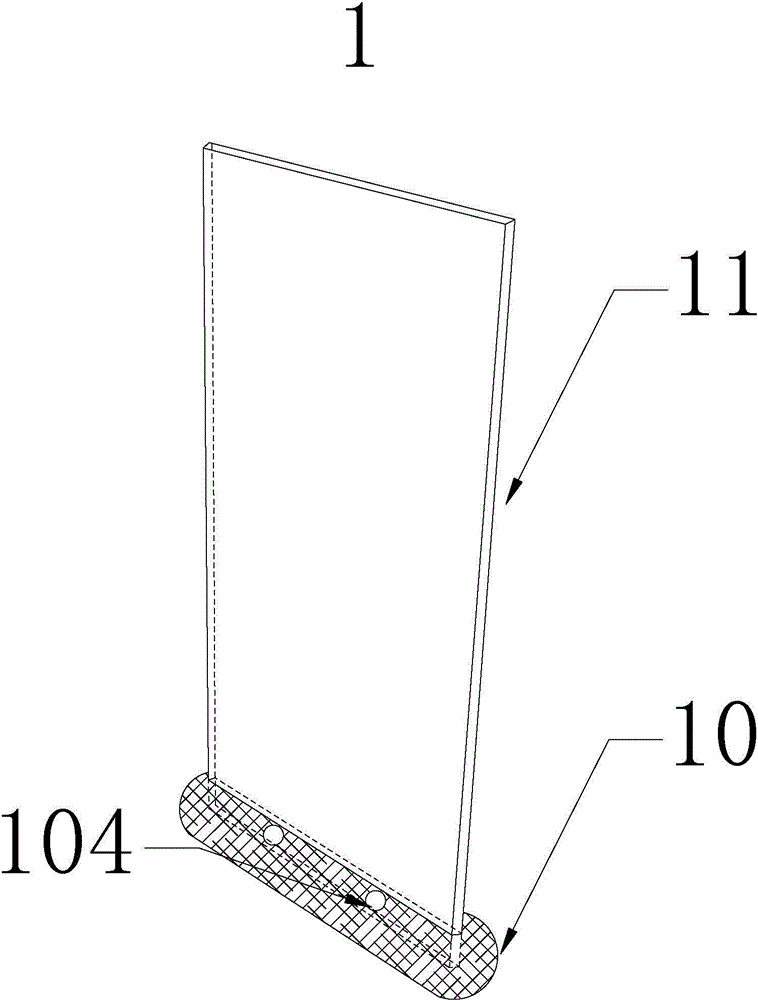

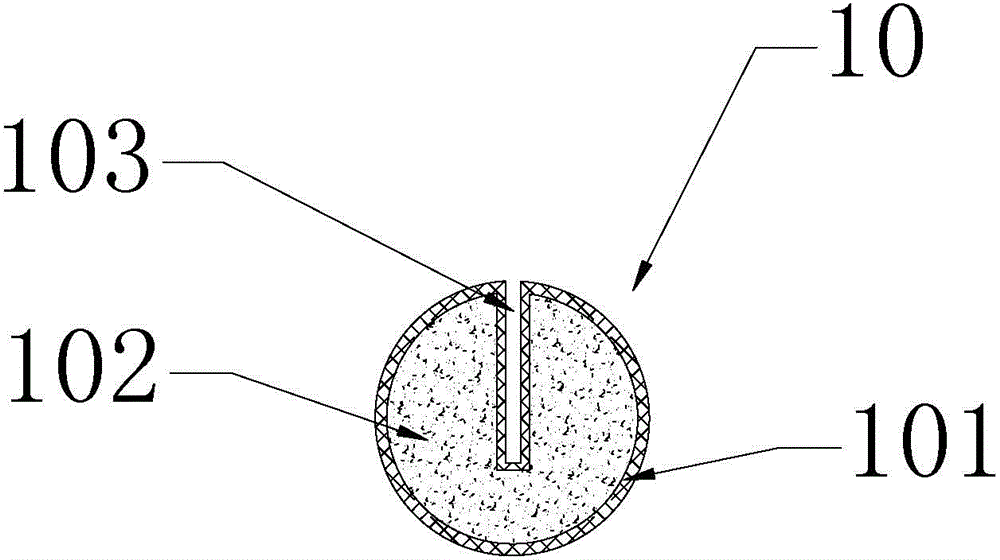

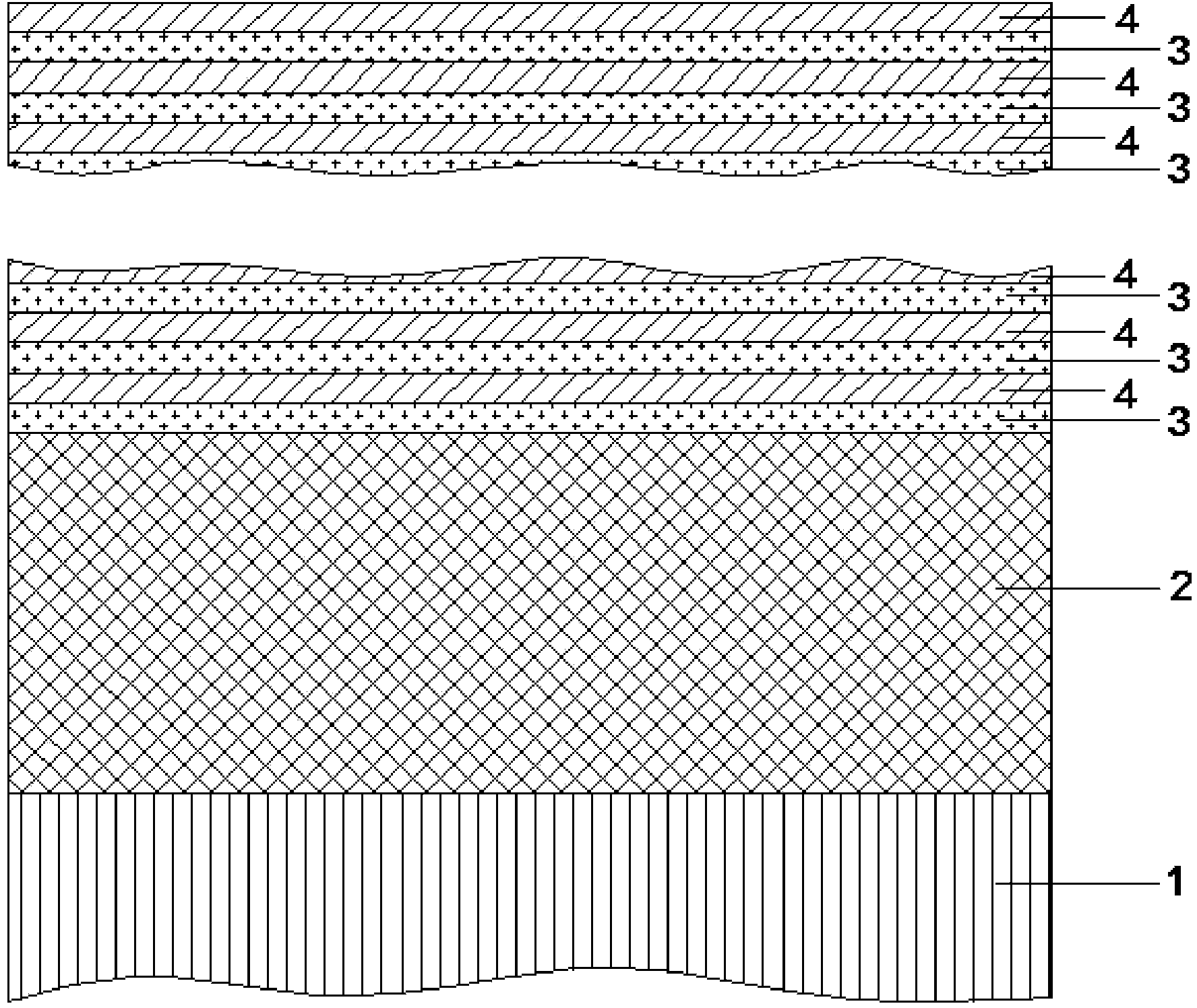

Compound type perpendicular seepage-proofing screen and application thereof

InactiveCN104805871ASolve the problem of circumventionEasy constructionProtective foundationGeomembraneMedicine

The invention discloses a compound type perpendicular seepage-proofing screen which is used for preventing horizontal seepage of pollutants in soil or underground water. The compound type perpendicular seepage-proofing screen comprises a perpendicular flexible seepage-proofing part and a by-pass seepage preventing part, wherein the perpendicular flexible seepage-proofing part comprises a rectangular HDPE (high-density polyethylene) geomembrane; the by-pass seepage preventing part comprises a by-pass seepage preventing supporting part and self-hardening mud which coats the by-pass seepage preventing supporting part; the by-pass seepage preventing supporting part comprises gridding cloth and sodium-based bentonite encapsulated in the gridding cloth, and a groove is formed in the surface of the by-pass seepage preventing supporting part; the bottom of the perpendicular flexible seepage-proofing part is embedded and inserted into the groove of the by-pass seepage preventing supporting part, and the bottom of the perpendicular flexible seepage-proofing part is fixed with the by-pass seepage preventing supporting part through a bolt. The compound type perpendicular seepage-proofing screen has the advantages of being simple in construction, good in seepage-proofing effect, and the like, and can be used for solving the by-pass seepage problem on a joint of the HDPE geomembrane and an underground water-impermeable layer.

Owner:BEIJING GEOENVIRON ENG & TECH

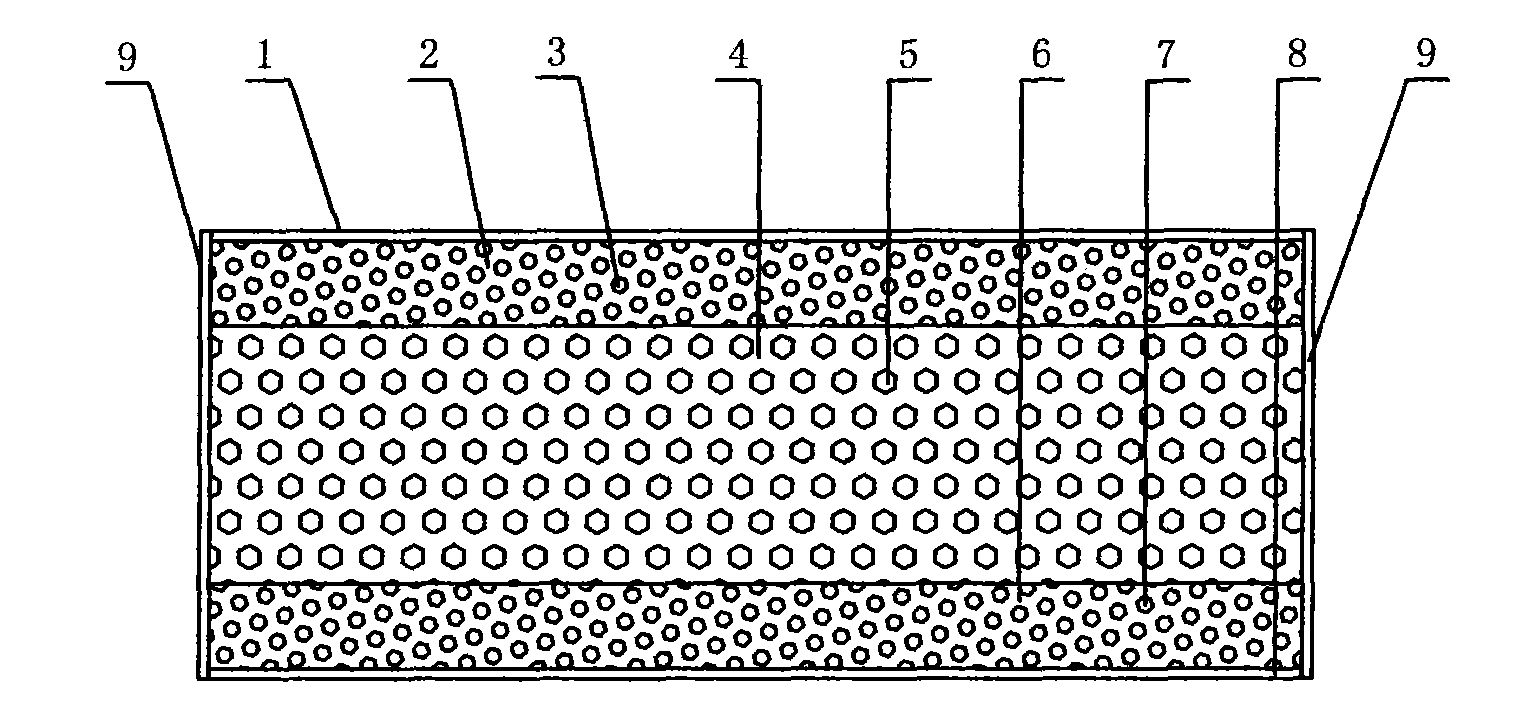

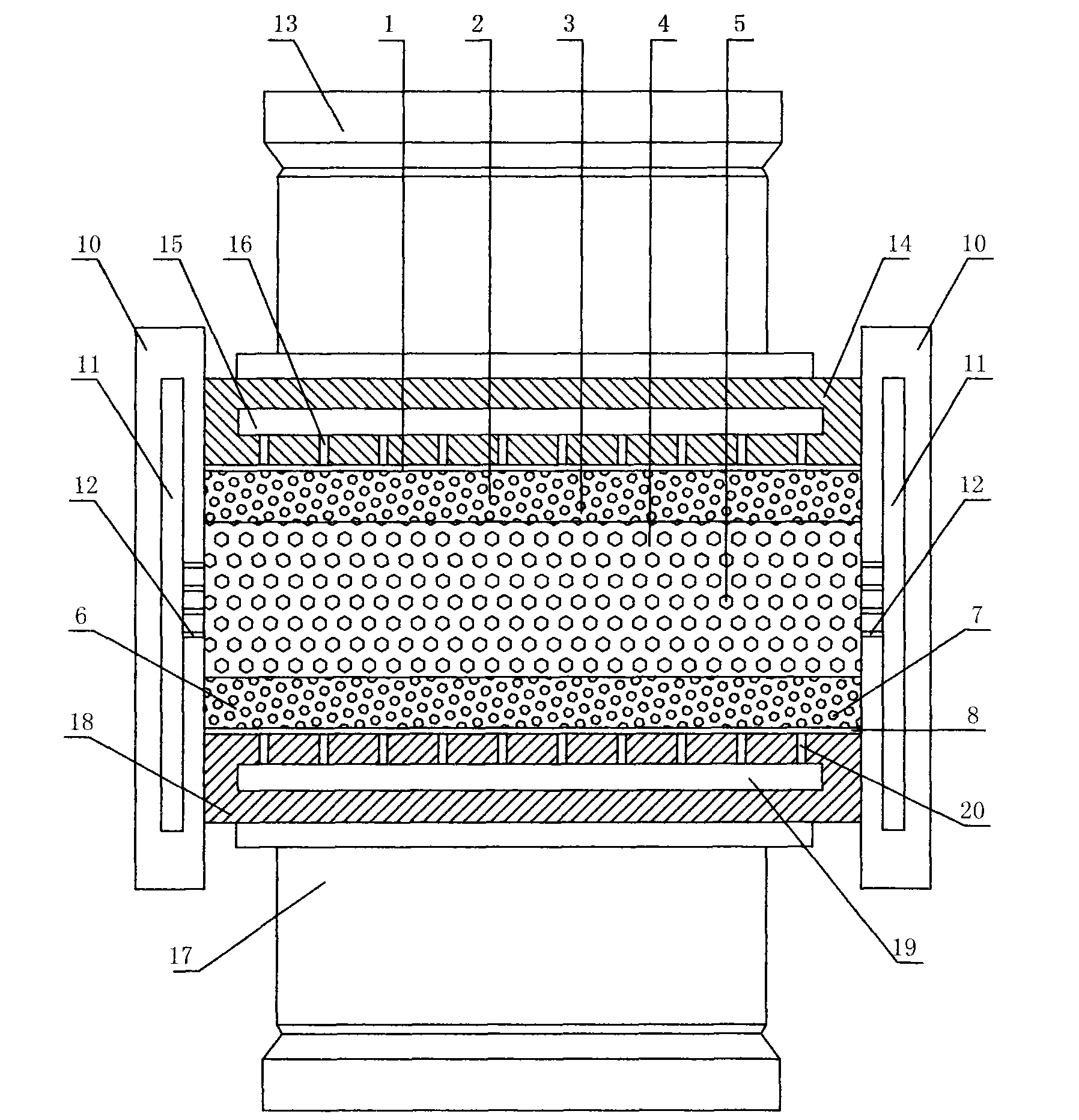

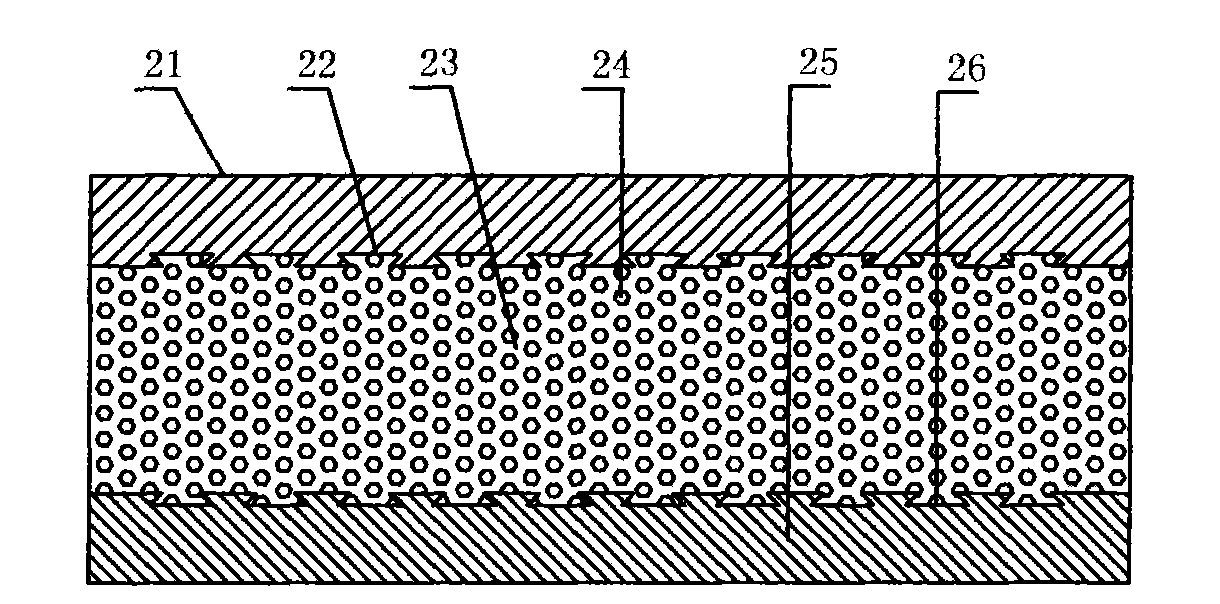

Self-hardening resin insulation board or building block and manufacturing method thereof

InactiveCN101929205AAvoid enteringImprove insulation effectConstruction materialClimate change adaptationYarnCalcium silicate

The invention relates to a self-hardening resin insulation board or a building block. The insulation board or the building block consists of a surface layer material, a self-hardening resin, a curing agent and a core layer material formed by mixing single or various materials, wherein the surface layer material, the self-hardening resin, the curing agent and the core layer material are molded by pressing; the surface layer material comprises plaster, cement, plant fiber reinforced cement, calcium silicate, an organic resin film, an organic resin plate, a stone plate, a ceramic plate, a wood-plastic plate, a metal plate and release paper; the core layer material comprises expanded perlite, vermiculite, wood flour, bamboo powder, plant straw, pulverized fuel ash, rock wool, glass yarn, glass beads, graphite and a phase-change energy storage material; the upper surface or upper and lower surfaces or four sides of the core layer material made by mixing the self-hardening resin and the curing agent are surface layer materials; a vacuum machine sucks gas and moisture in the mixed self-hardening resin core layer material; and the surface layer material is bonded integrally with the core layer material made by mixing the self-hardening resin and the curing agent.

Owner:王广武

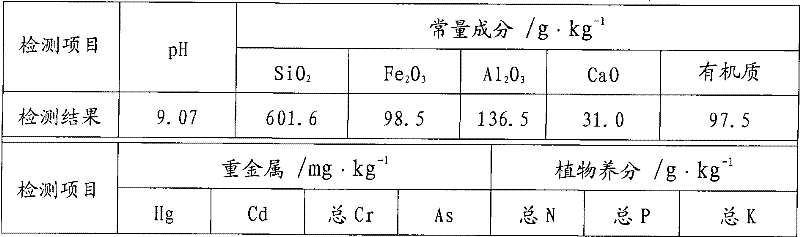

Mineral admixture as well as preparation method and application thereof

The invention discloses a mineral admixture as well as preparation and application thereof. The mineral admixture contains superfine solid sulfur ash, the D50 of the superfine solid sulfur ash is 0.5 to 15mum, and the D90 of the superfine solid sulfur ash is less than or equal to 30mum. The invention also provides a preparation method for the mineral admixture. The method comprises the following step of: mixing the superfine solid sulfur ash, fly ash and slag powder, wherein the mineral admixture contains 50-70wt% of superfine solid sulfur ash, 10-30wt% of fly ash and 10-30wt% of slag powder, the D50 of the superfine solid sulfur ash is 0.5 to 15mum, the D90 of the superfine solid sulfur ash is less than or equal to 30mum, the specific surface area is 450 to 1,500m<2> / kg, the 28d activity index is more than or equal to 75 percent, and the 28d self-hardening compressive strength is 7 to 15MPa. Compared with the common fly ash or slag powder in the prior art, the mineral admixture has the advantages that when concrete is prepared, the filling effect of fine particles can be fully exerted, the internal structure of the concrete is optimized, micro cracks produced by dry shrinkage or chemical shrinkage are inhibited to a certain degree, and the durability such as freezing resistance of the concrete can also be improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Dental and endodontic filing materials and methods

Disclosed are endodontic filling materials and methods. A method for filling a dental root canal may include providing a hydrosetting filling material and inserting the hydrosetting filling material into the dental root canal, the material setting in the root canal to form a biocompatible filling. The hydrosetting filling material comprises a hydrogel former and a filler. The hydrogel former is at least one of a reactive organic hydrogel formers, an inorganic hydrogel formers, and a non-reactive organic hydrogel formers, and the filler is at least one of a self-hardening and a non-hardening filler. Plural filling material precursor compositions that collectively contain hydrogel formers and fillers may be provided.

Owner:ADA FOUND

Phenolic resin self-hardening sand and preparation method thereof

ActiveCN104139154AImprove moisture resistanceHigh compressive strengthFoundry mouldsFoundry coresPolyamideHardening effect

The invention discloses phenolic resin self-hardening sand and a preparation method thereof. The self-hardening sand is made of roughing sand, phenolic resin, a silane coupling agent, methyl formate, calcium carbonate, aluminic acid ester, ethylene glycol, bentonite and polyamides. The rough sand passing through a 250-mesh screen and the bentonite passing through a 300-mesh screen are mixed, then the phenolic resin, the silane coupling agent, the polyamide, the calcium carbonate, the aluminic acid ester, the ethylene glycol and the methyl formate are added in sequence, rapid stirring is carried out until the materials are mixed fully, and the stirring speed is 129 r / min. The preparation method is simple, the prepared phenolic resin self-hardening sand is small in gas generating amount and does not contain harmful elements of nitrogen, phosphorus, sulphur or the like, the hardening effect is good, and under the condition that the roughing sand is at ambient temperature, the hardening time is 15 to 20 min; the intensity is high, after hardening is conducted for 24 hours, the compressive strength is 7.4 to 8.5 MPa, compared with the self-hardening sand in the prior art, the occurrence rate of the heat crack phenomenon is reduced by 18 percent, and the phenolic resin self-hardening sand is especially suitable for casting of steel castings.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

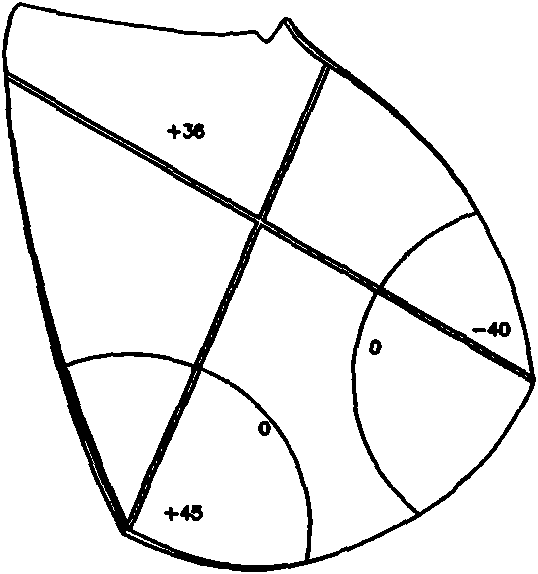

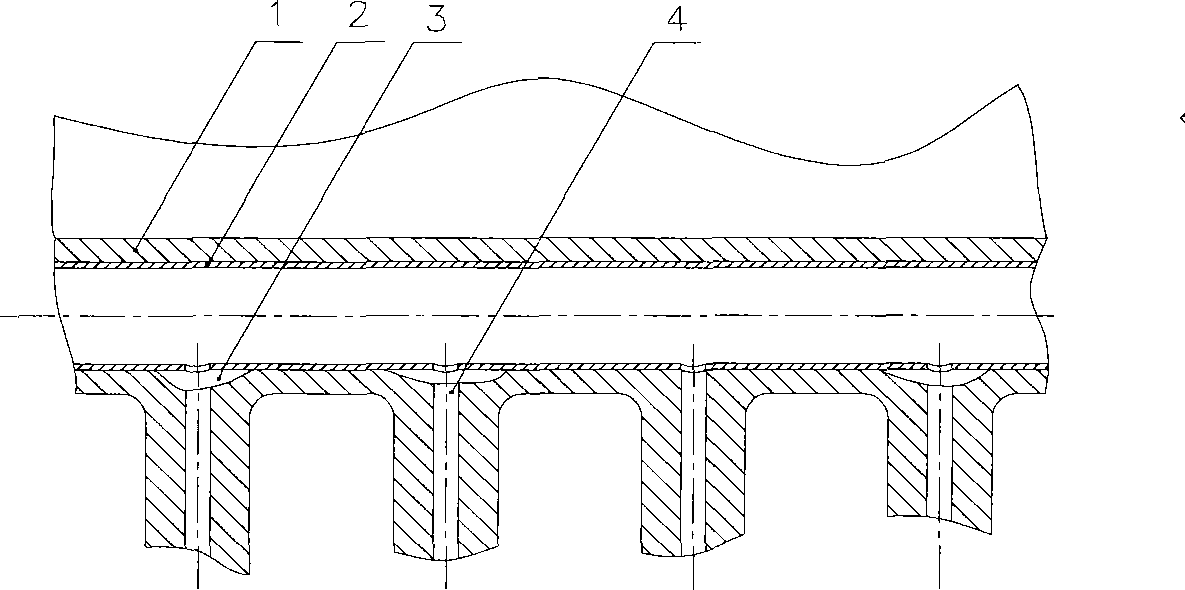

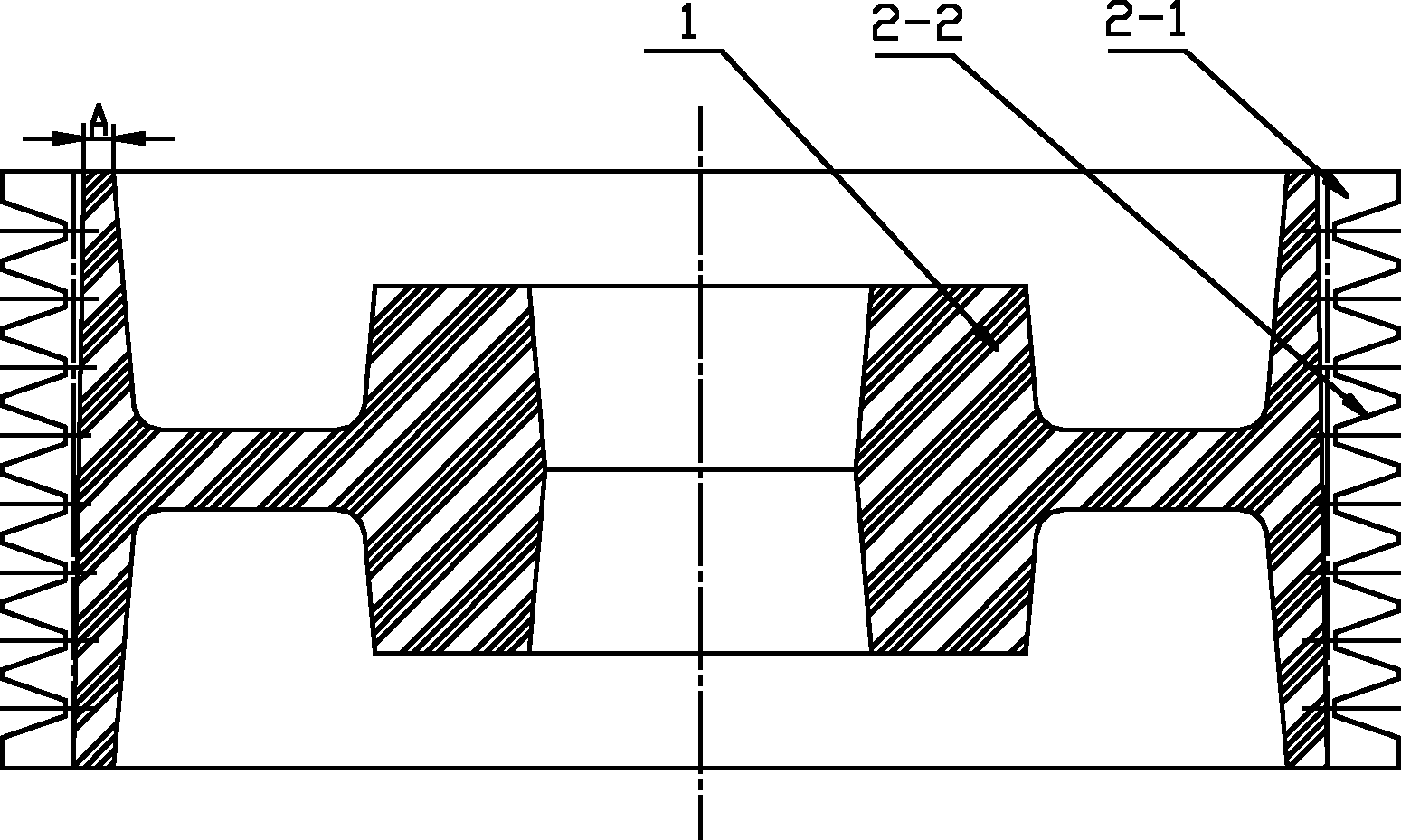

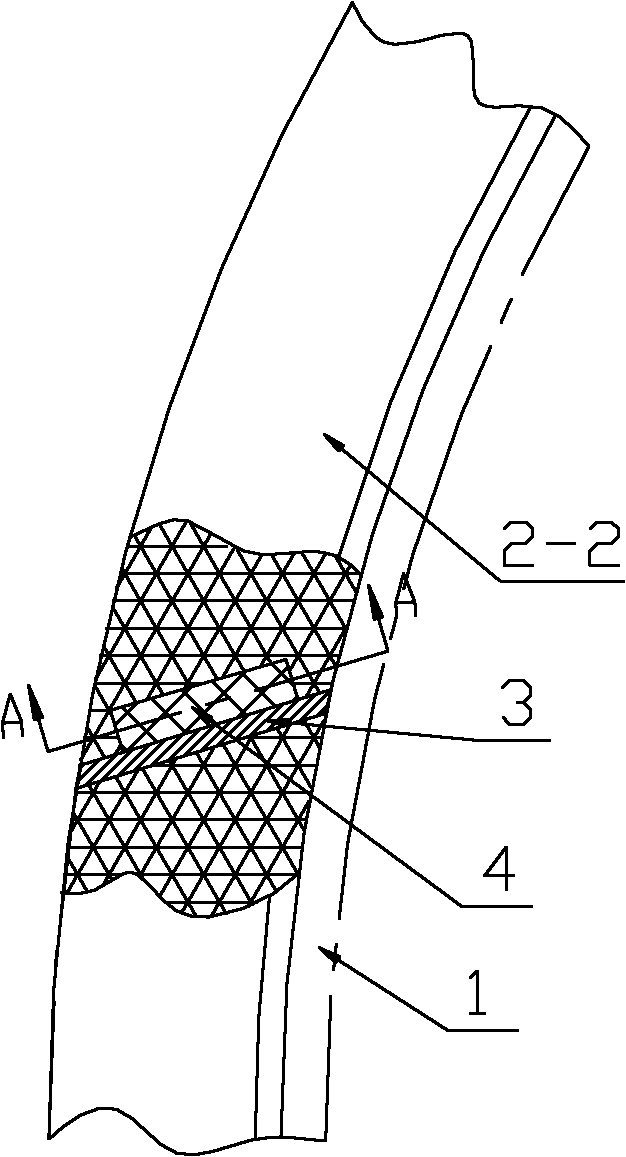

Anti-deformation method for casting vane of ultra-large mixed flow type water turbine

ActiveCN101716653AReduced deformation tendencyEliminate deformationFoundry mouldsFoundry coresWater turbineRebar

The invention relates to an anti-deformation casting method, in particular to an anti-deformation method for casting a vane of an ultra-large mixed flow type water turbine, which comprises the steps of mould manufacturing, molding, mould assembling, pouring, sand falling, cleaning and heat treatment. The method is characterized in that: the manufactured mould adopts a steel-wood mesh-shaped frame as aggregate which is filled with resin; a support is manufactured according to a molded line; a three-box T-type assembling, real pattern molding, flat building and vertical casting, combined sand boxes and resin self-hardening sand are adopted; facing sand adopts chromite sand; the inside of the molding sand is provided with a framework of steel reinforcement; the heat treatment adopts a vertical type charging method and uses a U-shaped supporting frock; and a dead head is cut and provided with a leveled dead head neck; the direction of the dead head neck is downward for supporting the vane; and two sides of the dead head neck are provided with a clamp for ensuring the vertical direction of the vane. The process method is unique, reduces the machining amount, reduces the ratio of gross and weight, shortens production period, reduces the cost, and solves the problems of deformation in vane production and manufacturing, and fat head and big ears caused by overlarge vane machining amount.

Owner:KOCEL EQUIP

Composite material used for casting aluminum alloy box body oil duct and method thereof

InactiveCN103480794AContinuous adjustment of thermophysical parametersAvoid the hidden danger of entering the oil passageFoundry mouldsFoundry coresBodies oilSurface finish

The invention belongs to the field of casting technologies, and particularly relates to a composite material used for casting an aluminum alloy box body oil duct and a method of the composite material used for casting the aluminum alloy box body oil duct. In order to solve the deep hole casting technical problem which is difficult to solve through an original casting technique, avoid the phenomenon that drilling is performed after hole-forming through an inlaying-cast steel pipe, and thus the oil duct is not homocentric and the aluminum base face is scratched, and solve the problem that a box body oil duct made of a common sand core can not meet the requirement for leakproofness, the composite material comprises metal pills, iron powder, roughing sand and a self-hardening resin sand binding agent, the oil duct core is made from the composite material to take place of an oil duct hole made of a steel pipe, interlayer defects can not be generated between the steel pipe and an aluminum substrate, and the potential hazard that steel scrapes enter the oil duct is avoided. According to the oil duct core made from the composite material, a compact chilling layer can be formed around the oil duct and meet the requirement for the leakproofness of the oil duct and is easy to scatter and low in gas forming, the surface of the oil duct is good in smoothness, and the oil duct can meet use requirements even if the oil duct is not subjected to machining.

Owner:STATE RUN NO 616 FACTORY

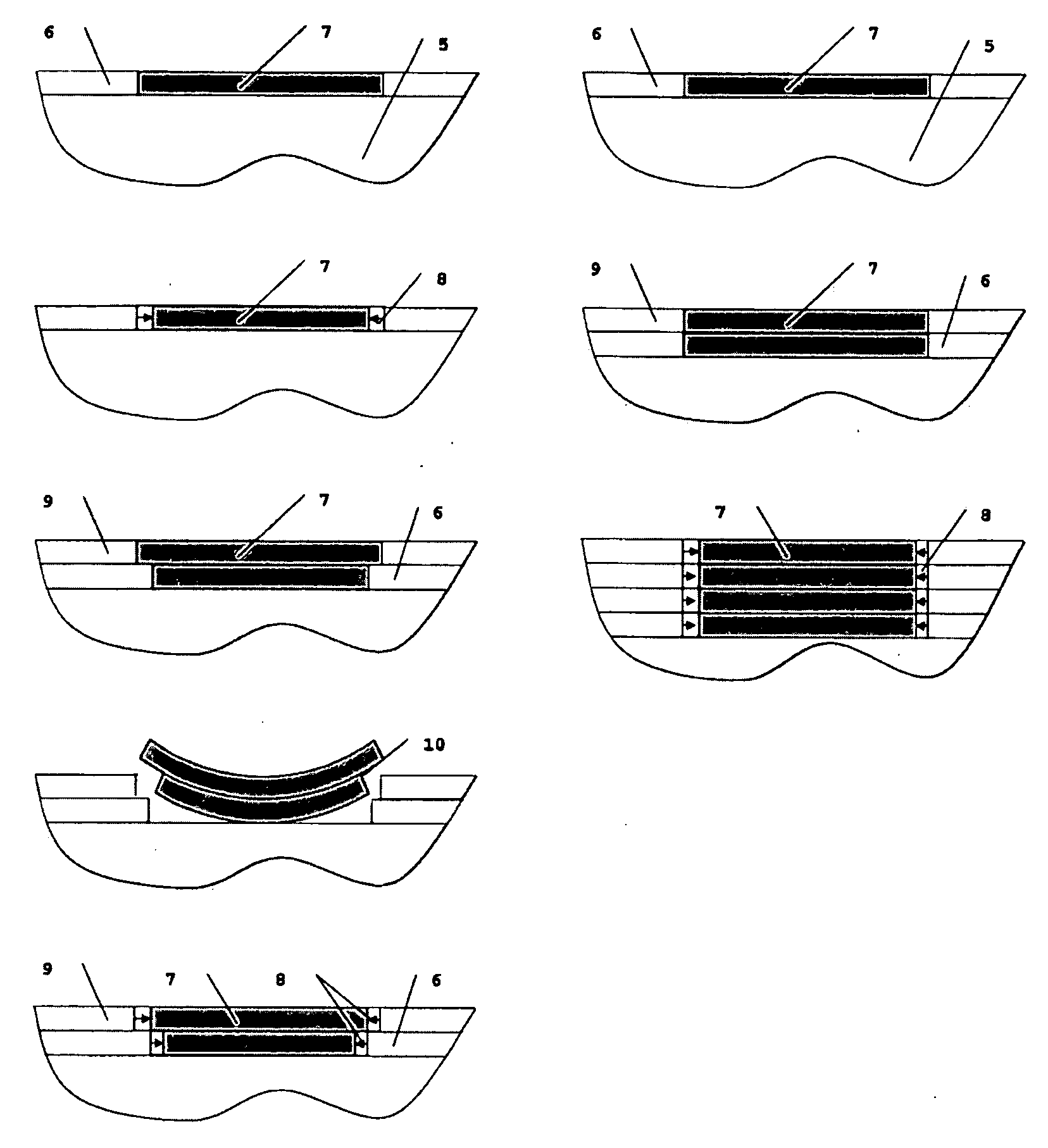

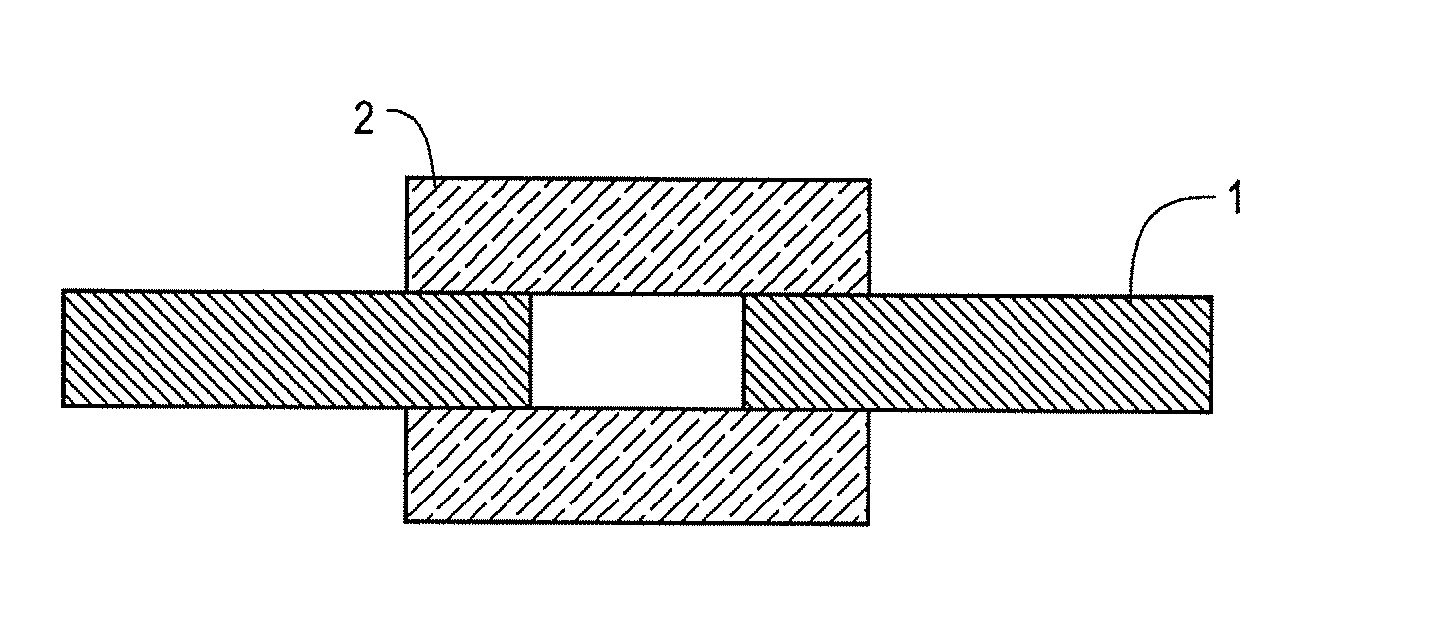

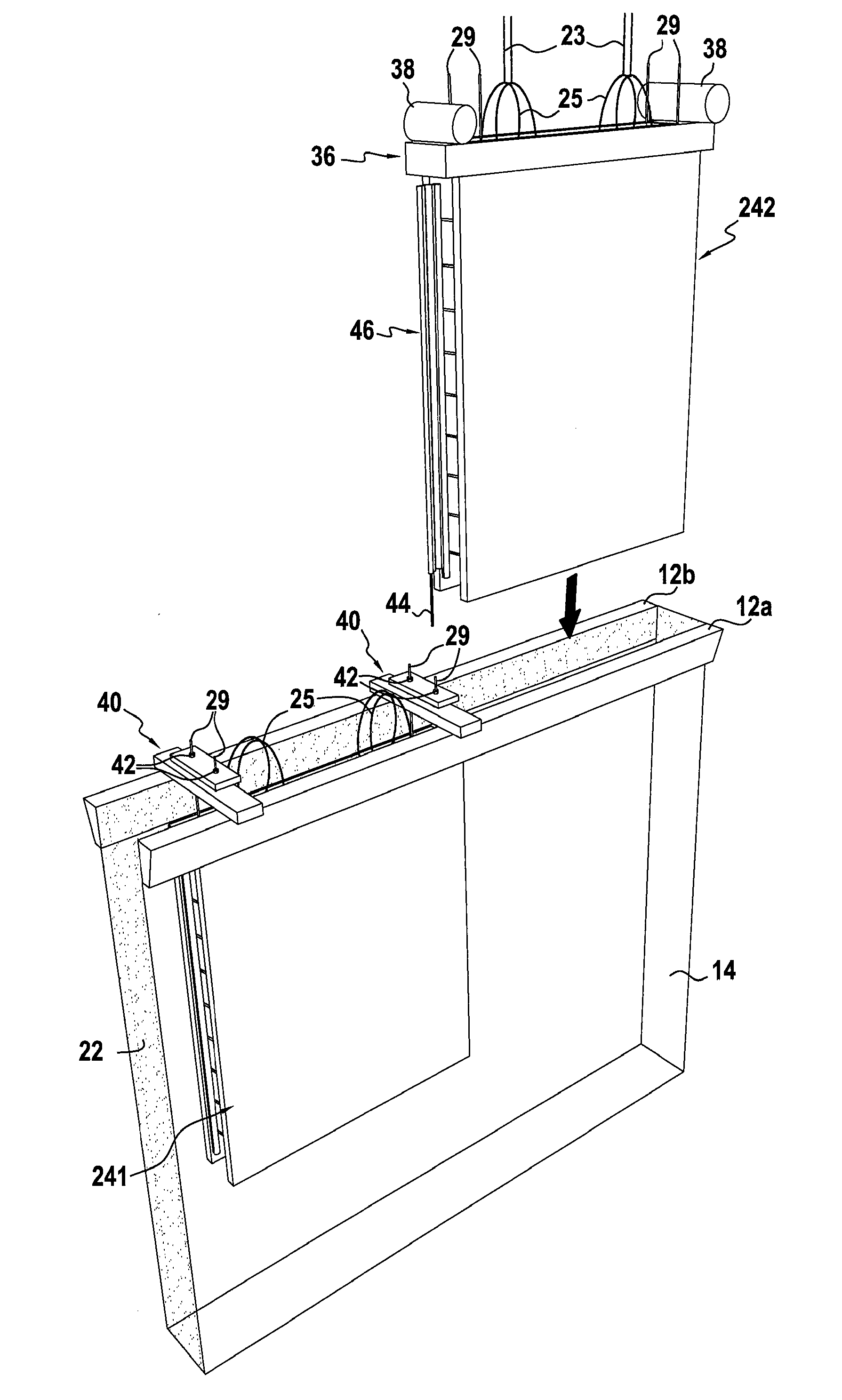

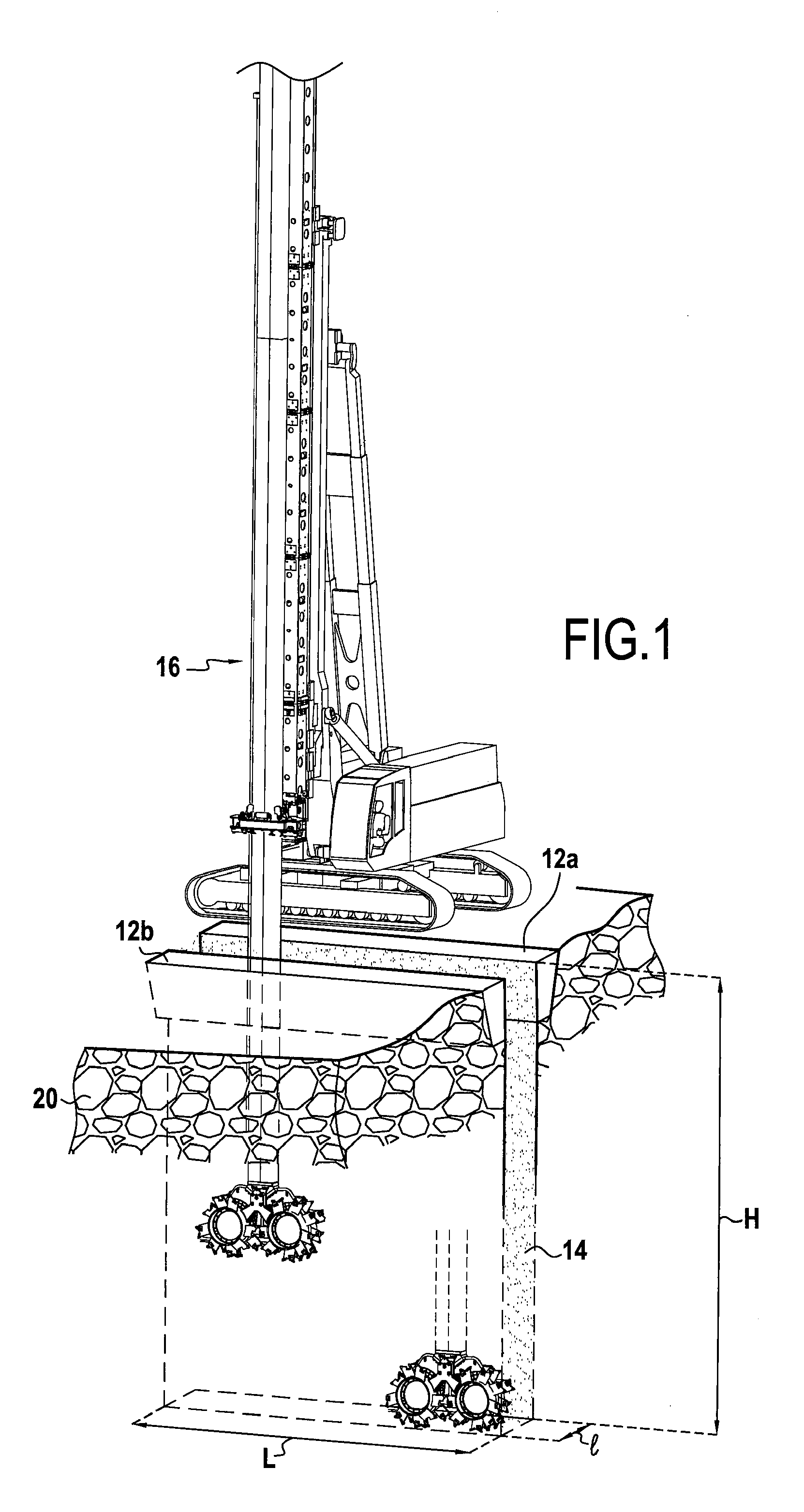

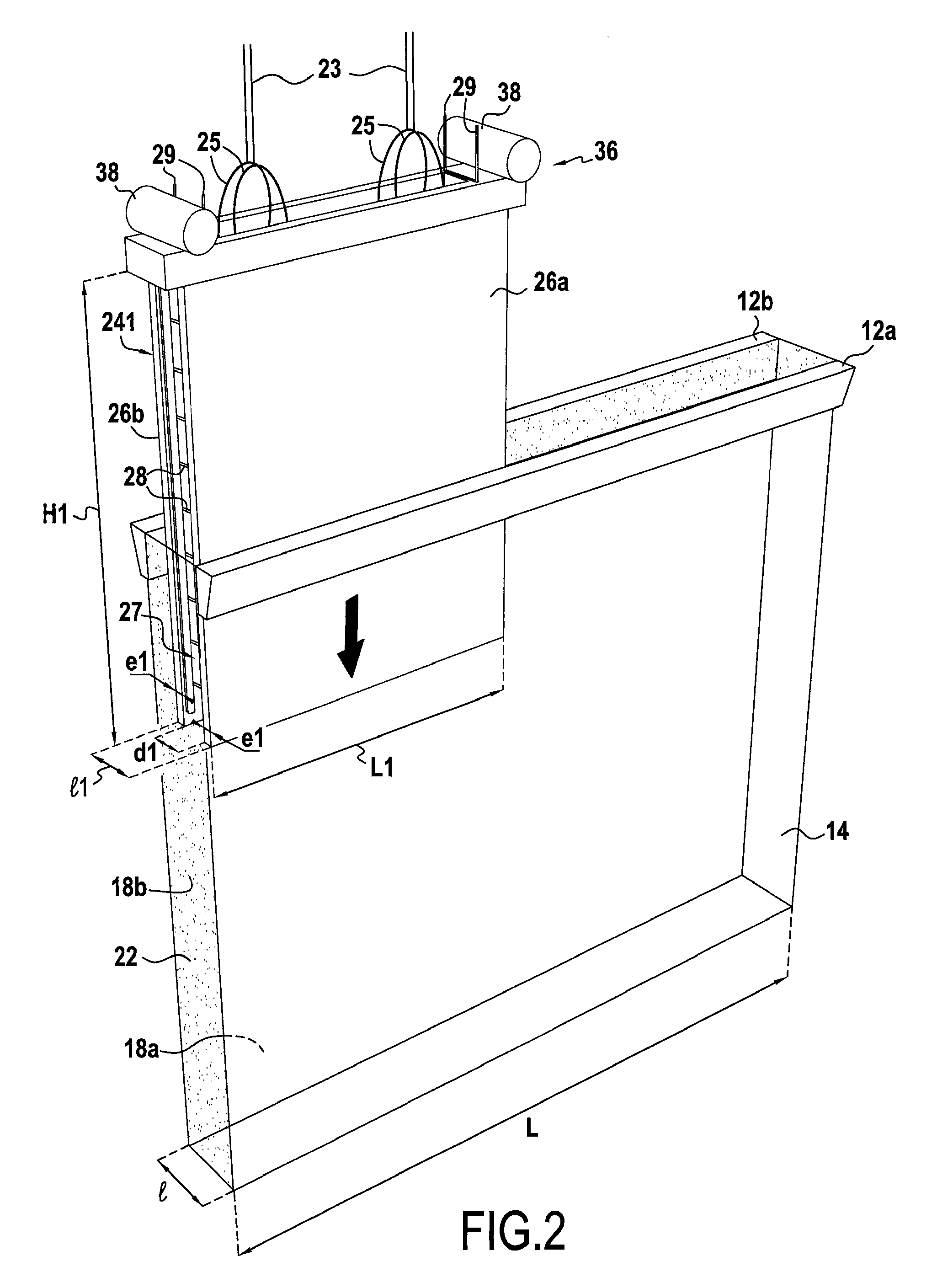

Wall formed in soil, the wall including a hollow prefabricated element, and a method of making such a wall

ActiveUS9212462B2Low costConstraint is somewhat limitingArtificial islandsBuilding repairsMechanical engineeringSelf hardening

Owner:SOLETANCHE FREYSSINET SAS

Metal component casting process

ActiveCN102806310AExcellent recycling rateGood collapsibilityFoundry mouldsFoundry coresWaxPlaster mold casting

The invention discloses a metal component casting process, which comprises the following steps: (1) manufacturing a mold sample, (2) manufacturing a silica gel outer mold, (3) manufacturing a wax mold, (4) molding, and (5) carrying out casting, shaking-out and finishing, wherein the molding process adopts combination of a lost-wax precision casting process, a plaster mold casting process and a self-hardening resin sand mold casting process to carry out modification grafting on a casting mold system so as to successfully develop a metal component casting process. Results of process performance tests, technical analysis and production applications of the new process show that the new casting method has the following characteristics that a casting surface is fine, casting quality is good, a specification size is large, flatness is good, cost is low, a production cycle is short, molding is rapid, collapsibility is good, the material can be subjected to dry regeneration and recovery utilization, pollution is less, energy sources are saved, and the bottleneck of metal component casting is solved. In addition, the process of the present invention is applicable for molding of various alloy castings.

Owner:上海浦宇铜艺装饰工程股份有限公司

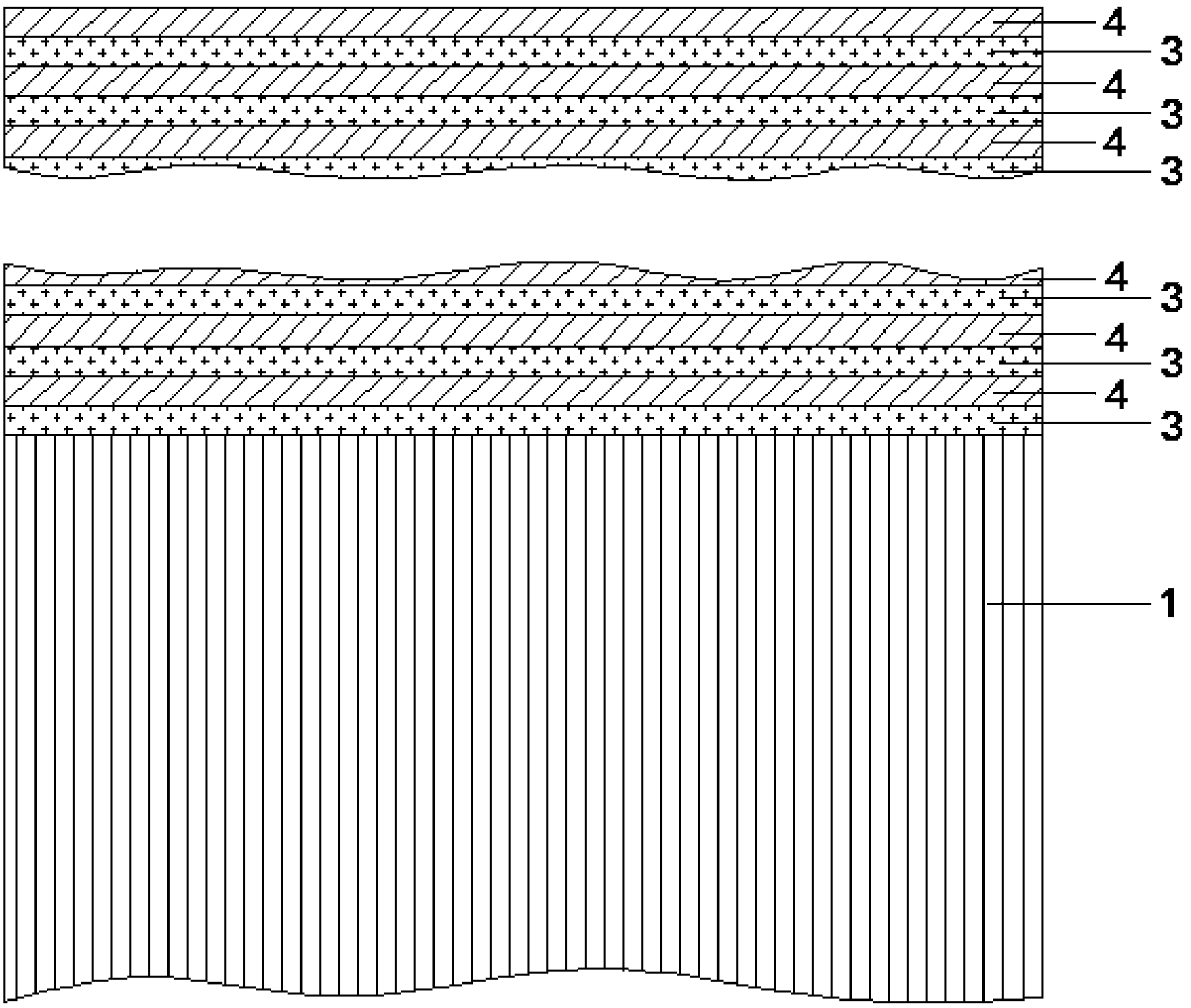

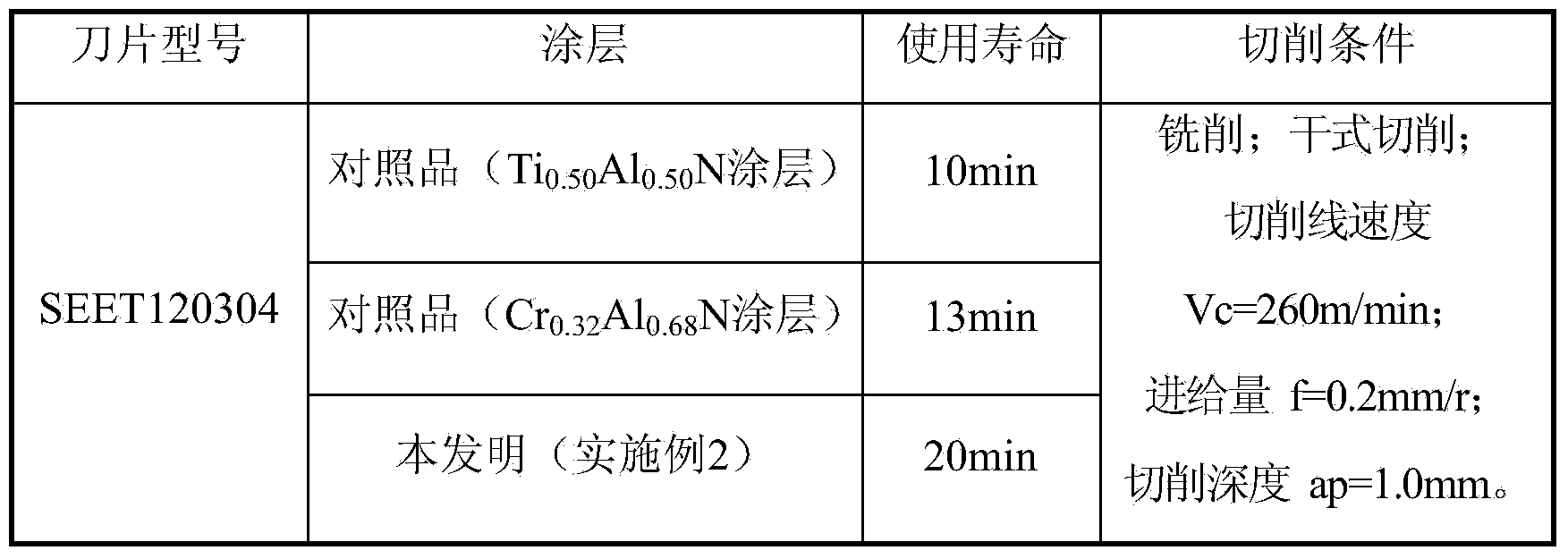

Self-hardening TiAlN/CrAlN multi-layer coated cutter and preparation method thereof

ActiveCN104175682AImprove thermal stabilityGood high temperature oxidation resistanceLayered productsTurning toolsHeat stabilityPre treatment

The invention discloses a self-hardening TiAlN / CrAlN multi-layer coated cutter and a preparation method of the self-hardening TiAlN / CrAlN multi-layer coated cutter; the multi-layer coated cutter comprises a cutter base body and multiple-layer coatings deposited on the cutter base body; the multiple-layer coatings comprise multi-period coatings, on which a Til-xAlxN layer and a Crl-yAlyN layer are alternatively deposited, wherein x is more than or equal to 0.35 and less than or equal to 0.67; y is more than or equal to 0.50 and less than or equal to 0.70; and the thickness ratio of the Til-xAlxN layer to the Crl-yAlyN layer is more than or equal to 1.5. The preparation method disclosed by the invention comprises the following steps: pre-processing the cutter base body, selectively depositing a transition layer, alternatively depositing the multi-period coatings including the Til-xAlxN layer and the Crl-yAlyN layer, and then, obtaining the multi-layer coated cutter. The multi-layer coated cutter disclosed by the invention has excellent heat stability and high-temperature oxidation resistance and can be hardened in an ageing manner; and the preparation method is simple in process, conventional in equipment and low in production cost.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Clear slurry dewatering and solidifying integrated treatment method

ActiveCN101746942ASelf-hardening abilityRationalizeSludge treatment by de-watering/drying/thickeningSulfateEngineering

The invention relates to an integrated treatment method for dewatering and solidifying clear slurry, which comprises the following steps: conveying slurry in river, sea and lake ponds to a settling pond through a dredging pump, a slurry pump and a pipeline and flowing into a slurry storage pond after the slurry is filtered by a combined grid device; conveying the slurry with 80 percent of moisture content in the slurry storage pond to a slurry compounding pond by using the pump, adding inorganic macromolecule conditioning agents of 0.01 kilogram (35 percent of polymeric ferric silicate sulfate PFSS plus 65 percent of poly aluminum chloride PAC) in the slurry per cube to condition and then adding FSA flocculating-settling agents of 0.05 kilograms in the slurry per cub to condition again; adding HEC high-strength high-water resistant soil body consolidating agents of 5-20 kilograms in the slurry per cube and uniformly mixing; pressing the slurry after being treated in above steps into slurry consolidating soil by using a filter press, discharging clear water and obtaining a mud cake with 30 percent or below moisture content as engineering soil. The slurry has a certain self-hardening capacity after being dewatered and solidified, the formed consolidated soil has the air permeability and the bearing capacity, and the PH value thereof is equivalent to that of common soil, so that the rationalization, the resource, innocuous disposal and the economic treatment of the slurry are really realized.

Owner:ROAD ENVIRONMENT TECH

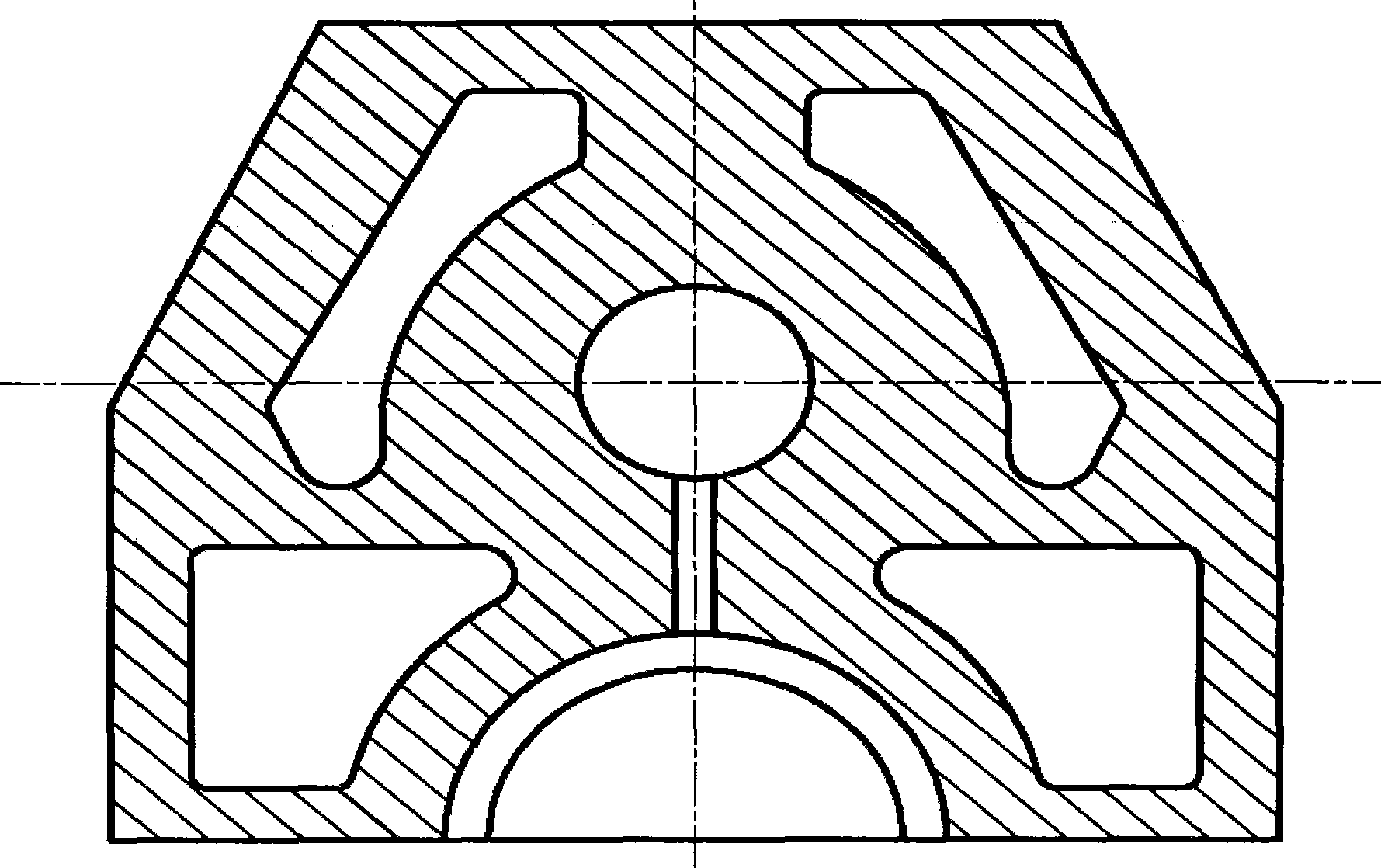

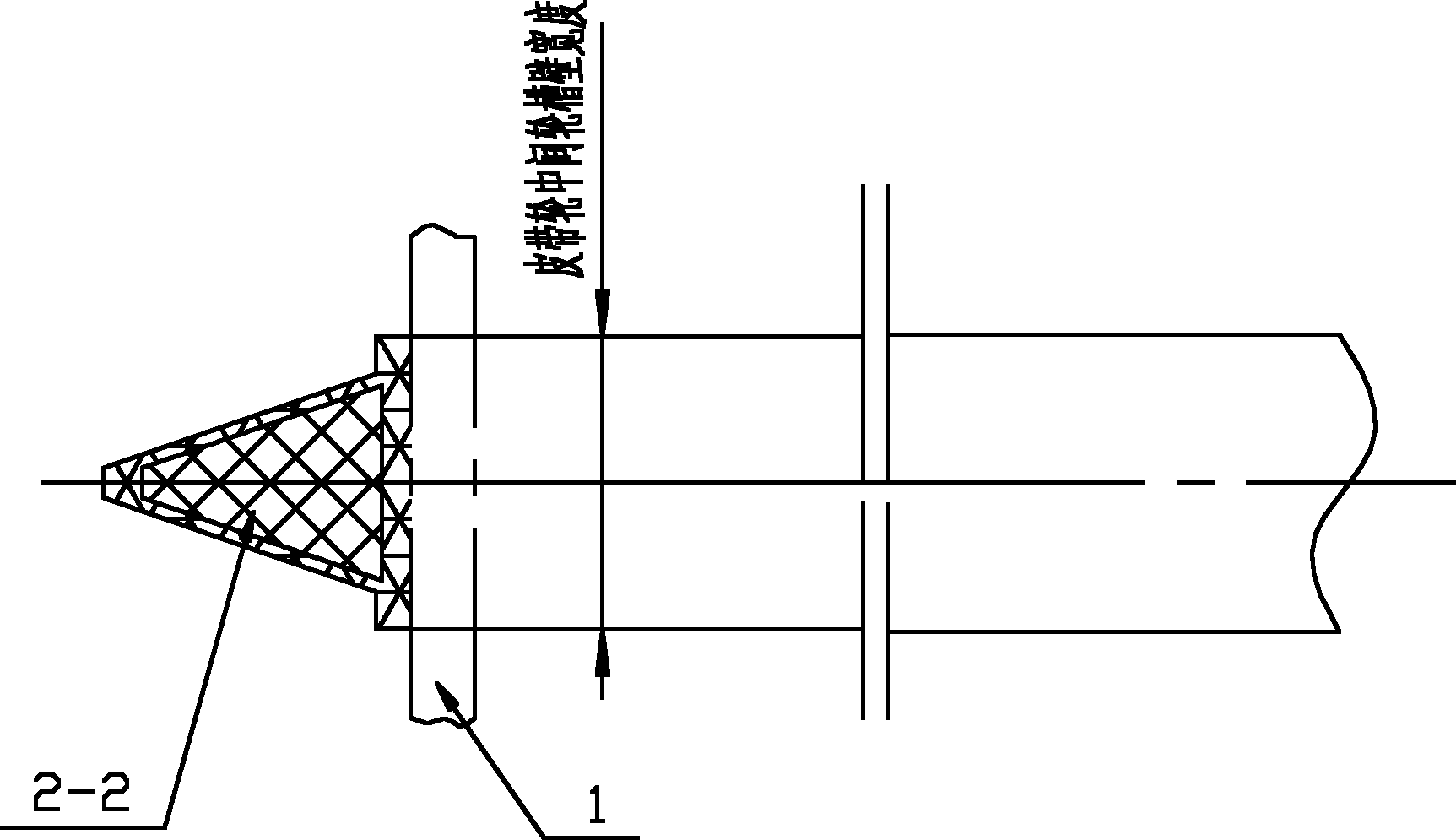

Groove casting technique for large belt pulley

InactiveCN102179479AReduce heat junction thicknessImprove shrinkageFoundry mouldsFoundry coresMaterial consumptionEngineering

The invention discloses a groove casting technique for a large belt pulley, comprising the following steps of: firstly, manufacturing a model for forming a cavity, which comprises a belt pulley matrix model and opened annular flexible movable blocks in which the number is corresponding to that of the groove walls of the belt pulley; secondly, forming a middle sand mould, wherein a belt pulley groove-casting combined model formed by the belt pulley matrix model and the opened annular flexible movable blocks is arranged inside the middle sand mould; thirdly, forming an upper sand mould; fourthly, turning over a box; fifthly, forming a lower sand mould; and sixthly, forming a belt pulley groove-casting cavity. Based on self-hardening sand technique, an inner locating three-box shape is adopted, the opened annular flexible movable blocks form groove profiles, and the thickness of the thermal center of the rim part of the belt pulley can be effectively decreased by relying on the combined mould technique located for belt pulley matrix mould so that the groove-bottom shrinkage porosity and shrinkage cavity tendency are obviously improved; and simultaneously, 15-25% of material consumption is reduced, the machining cost is obviously reduced, and the technique has high production efficiency. The groove casting technique is suitable for being used for the casting of a large belt pulley groove with a diameter of larger than 400 mm.

Owner:天津凯普特动力传输机械有限公司

Alkaline phenolic resin self-hardening sand

ActiveCN101941044AQuality assuranceIncrease alkalinityFoundry mouldsFoundry coresAdhesivePotassium hydroxide

The invention discloses alkaline phenolic resin self-hardening sand, which comprises crude sand, an adhesive, a curing agent, a coupling agent and a lubricant, wherein the using amount of the curing agent is 30 to 50 percent based on that of the adhesive; the using amount of the coupling agent is 1 to 5 percent based on that of the adhesive; the using amount of the adhesive is 3 to 5 percent based on that of the crude sand; the using amount of the lubricant is 1 to 3 percent based on that of the crude sand; the coupling agent comprises the following components in percentage by weight: 80 to 90 percent of silane coupling agent and 10 to 20 percent of celluosic resin; the adhesive comprises the following components in percentage by weight: 60 to 70 percent of phenolic resin, 20 to 40 percent of alkaline solution and the balance of water; the solute of the alkaline solution is potassium hydroxide, sodium hydroxide or a mixture thereof; and the mass percentage concentration of the alkaline solution is more than or equal to 30 percent. The alkaline phenolic resin self-hardening sand has relatively lower hardening speed, is difficult to influence by an acid environment and can ensure the quality of iron and steel castings.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

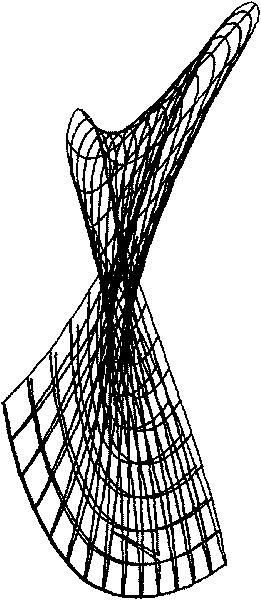

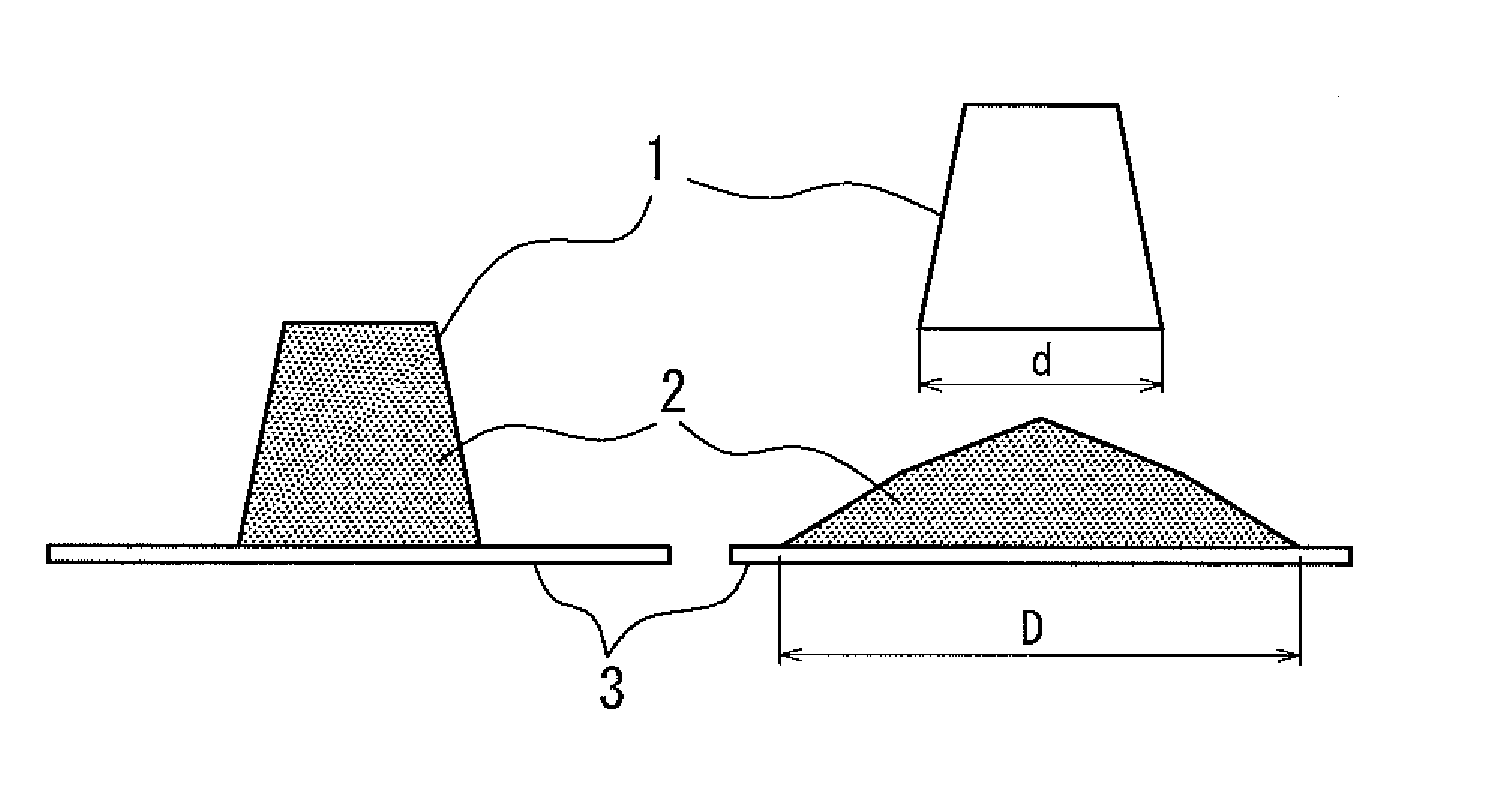

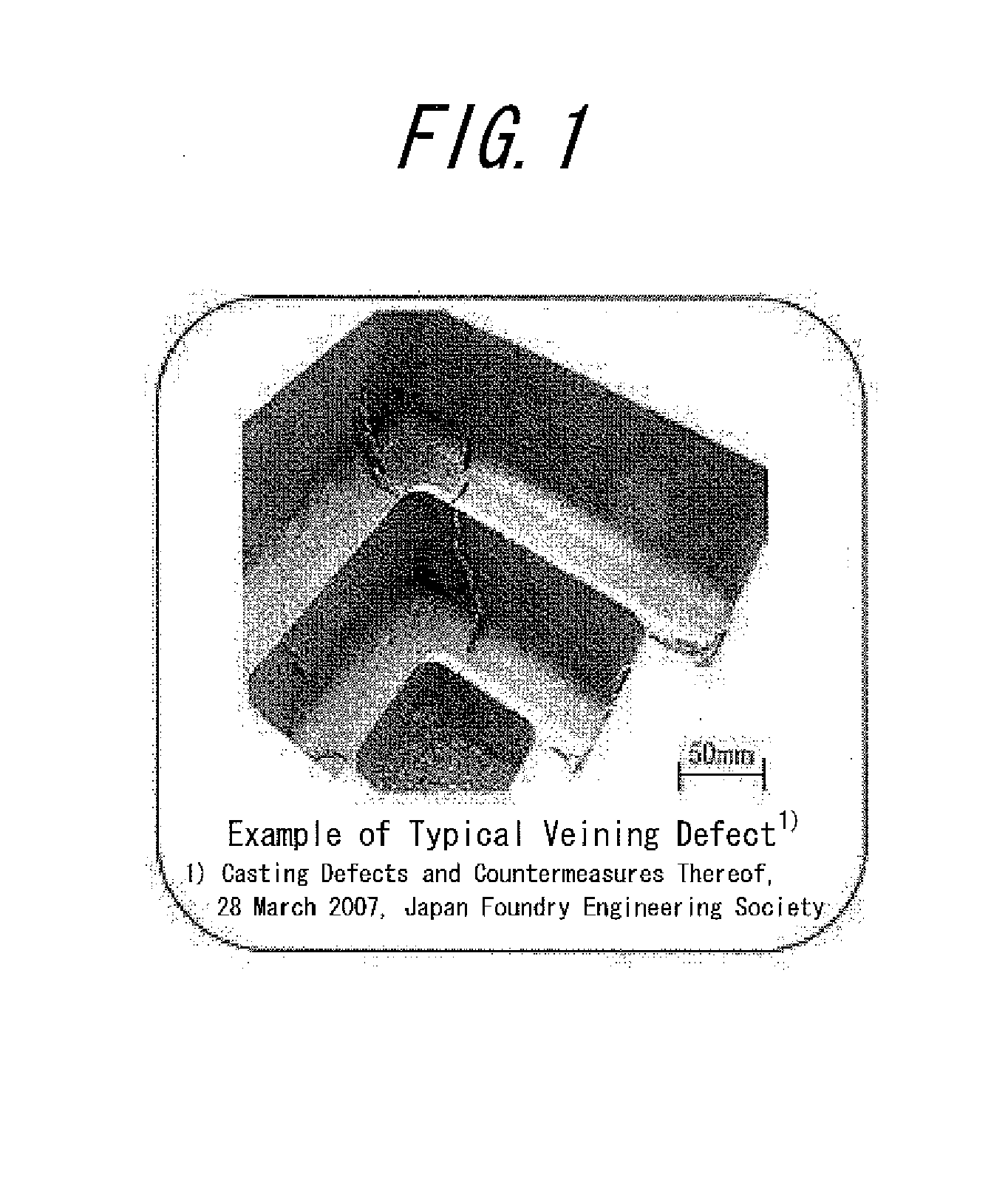

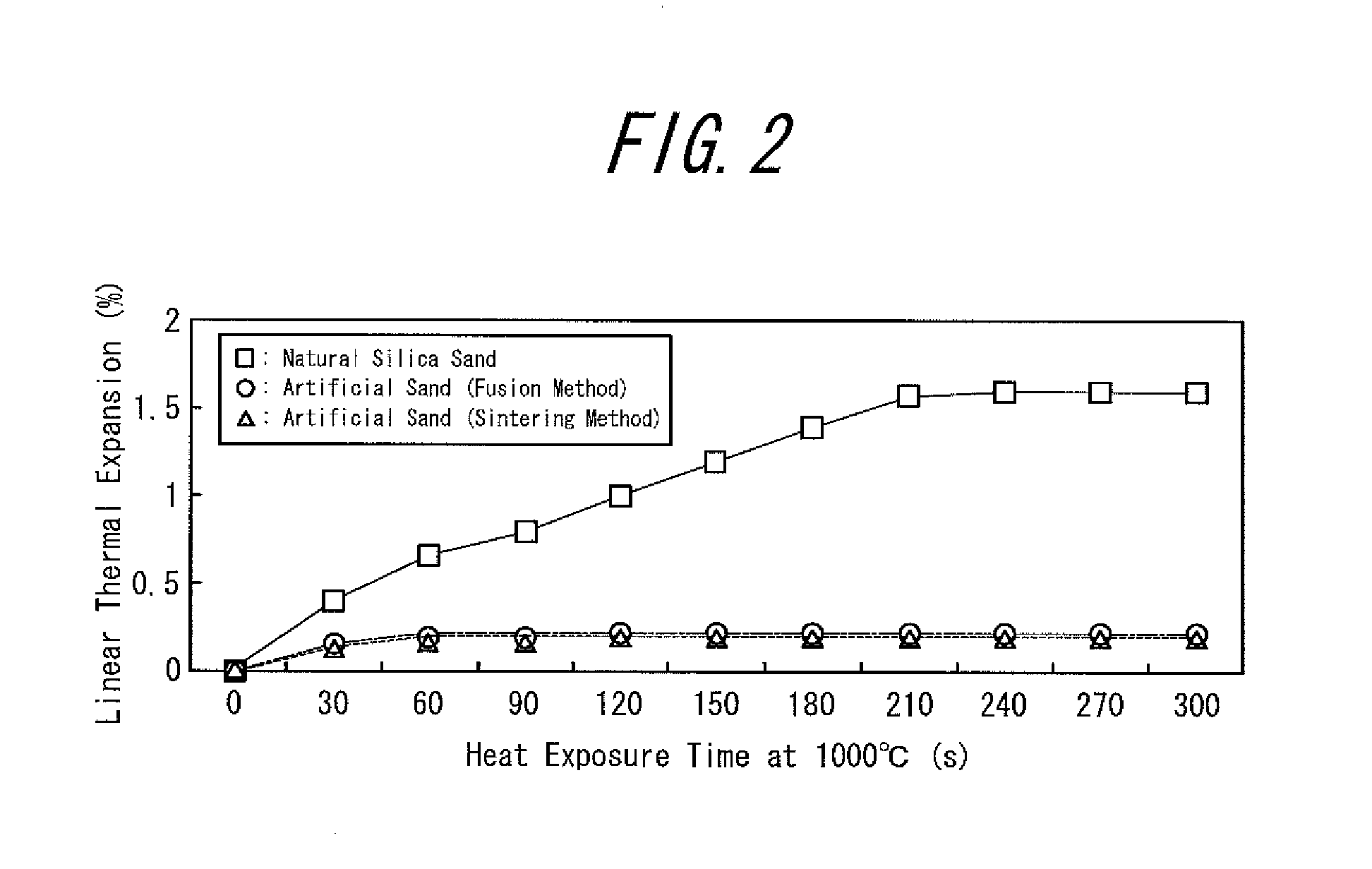

Molding sand for three dimensional laminate molding

ActiveUS20140224152A1Large and complicated shapeAvoid it happening againAdditive manufacturing apparatusFoundry mouldsRoom temperatureThermal expansion

According to the invention, by setting the linear thermal expansion amount when a mold made of a molding sand is heated from a room temperature to 1000° C. to be not more than 0.9%, and the ratio (D / d) between the diameter of a slump (D) and the diameter of a slump cone (d) in a slump test of the molding sand having a hardening agent kneaded to be not less than 1.65, a molding sand preferable for use in a mold produced using the self-hardening type of three dimensional laminate molding sand mold, having low thermal expansibility preventing occurrence of a veining defect, and capable of forming a large and complicated shape can be obtained.

Owner:KIMURA CHUZOSHOKK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com