Curing agent of self-hardening furan resin sand and preparation method thereof

A technology of furan resin and curing agent, which is applied in the manufacture of tools, casting molding equipment, metal processing equipment, etc., and can solve the problem of mismatch between model and sand temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

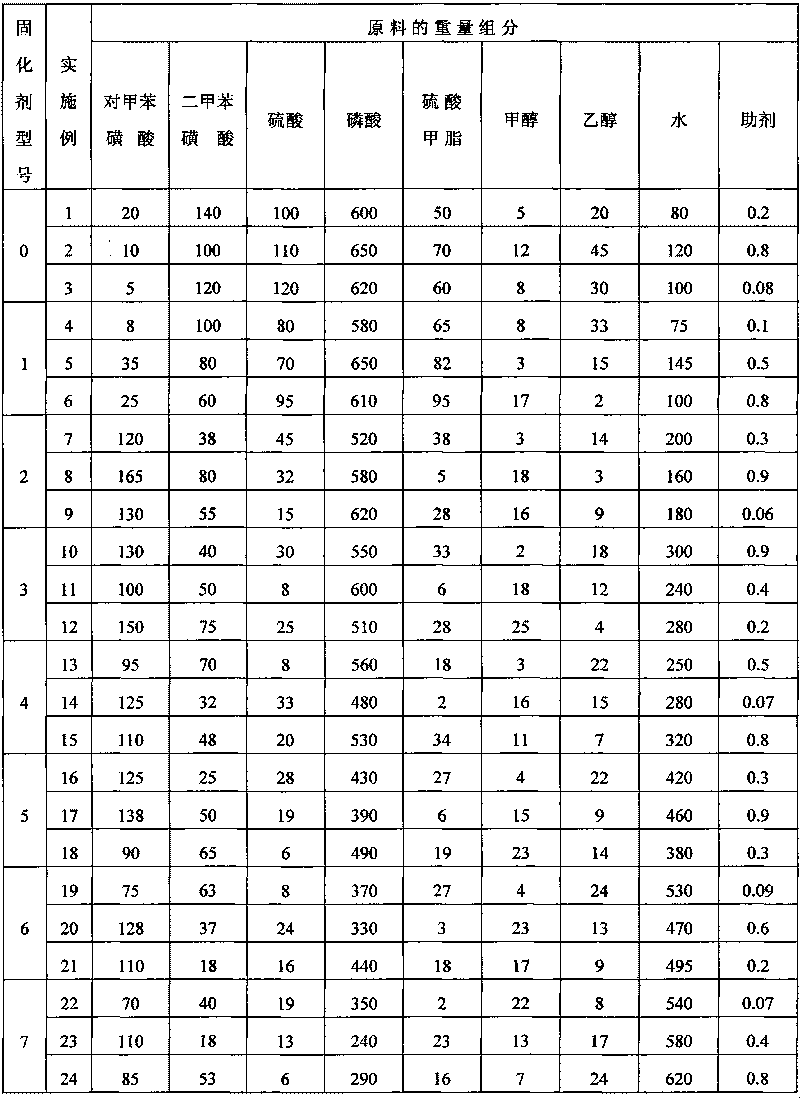

Examples

Embodiment Construction

[0063] Two-step synthesis:

[0064] First prepare toluenesulfonic acid, xylenesulfonic acid, methyl sulfate, and the concrete method is:

[0065] ●Prefabrication of toluenesulfonic acid raw material:

[0066] Determine the ratio of toluene and sulfuric acid according to the required toluene consumption of toluenesulfonic acid, then add sulfuric acid to the toluene solution, and react at a temperature of 105 to 120 °C for 2.0 hours;

[0067] ●Prefabrication of xylene sulfonic acid raw material:

[0068] Determine the ratio of xylene and sulfuric acid according to the required xylene consumption of xylene sulfonic acid, then add sulfuric acid to the xylene solution, and react at a temperature of 105 to 120 ° C for 2.0 hours;

[0069] ●Prefabrication of methyl sulfate raw materials:

[0070] Determine the ratio of methanol and sulfuric acid according to the amount of methanol required for methyl sulfate, then add sulfuric acid to the methanol solution, and react at a temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com