Patents

Literature

1768 results about "Dimethyl benzene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

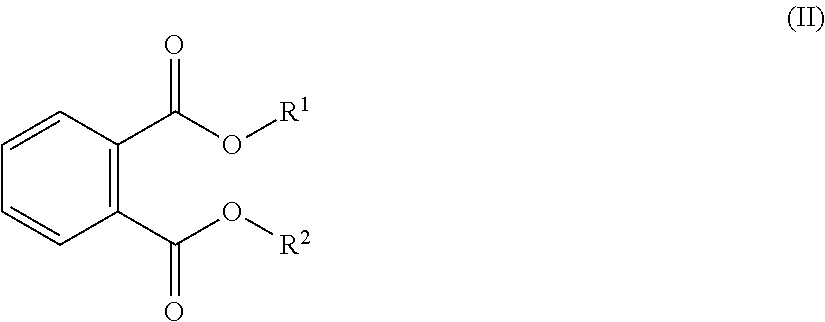

Xylene (from Greek ξύλο, xylo, wood), xylol or dimethylbenzene is any one of three isomers of dimethylbenzene, or a combination thereof. With the formula (CH3)2C6H4, each of the three compounds has a central benzene ring with two methyl groups attached at substituents.

Catalyst for preparing aromatic hydrocarbon through methanol conversion as well as preparation method and application thereof

InactiveCN102416342AHigh yieldHigh activityMolecular sieve catalystsHydrocarbon from oxygen organic compoundsLiquid productGas phase

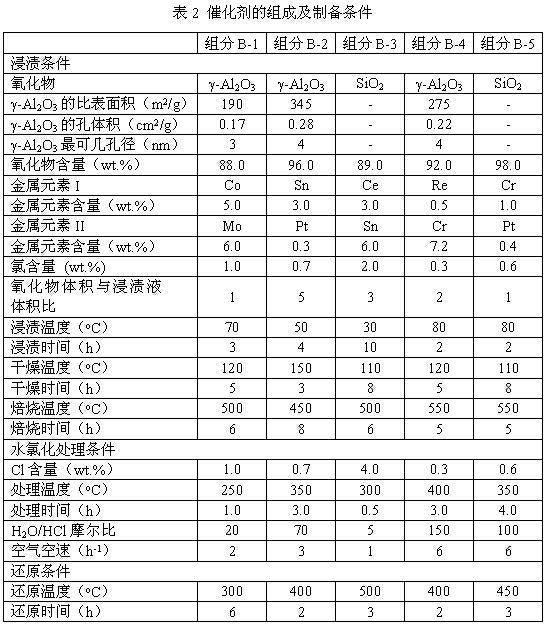

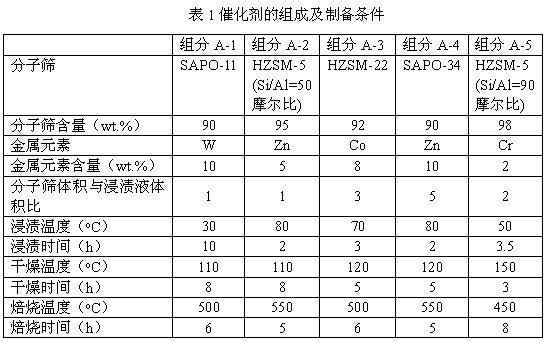

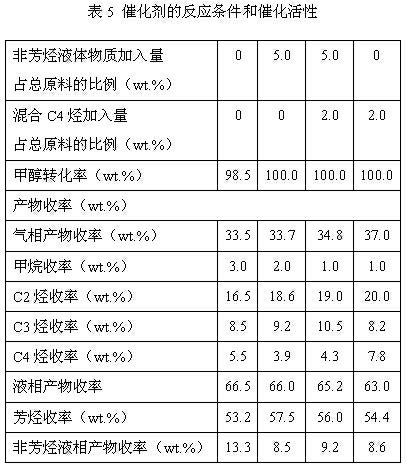

The invention discloses a catalyst for preparing aromatic hydrocarbon through methanol conversion. The catalyst comprises a component A and components B, wherein the mass ratio of component A to components B is 0.25-4; the component A is a modified zeolite molecular sieve and comprises 80-99wt% of molecular sieves and 1-20wt% of molecular sieve modifiers; the components B are oxide loaded metallic elements and halogen and comprise 85-95wt% of oxide, 0.5-10wt% of total metallic elements and 0.1-5wt% of halogen; and the component A and the components B are formed through squashing or extruding after being mixed uniformly. The catalyst has the following characteristics that: (1) the total recovery of benzene, toluene and xylene is higher and selectivity is high; (2) the raw material treatment capacity is large; (3) the non-aromatic hydrocarbon liquid product can serve as the solvent oil or gasoline component; (4) C4 hydrocarbon and non-aromatic hydrocarbon liquid phase products in the gas phase product can circularly enter into the catalyst bed layer, thus not only balancing the reaction heat but also improving the total recovery of the aromatic hydrocarbon; and (5) the catalyst has high activity and long life.

Owner:NORTHWEST UNIV

Tough composition for food applications

Heterophasic polypropylene composition comprising:—a polypropylene matrix (M) and—an elastomeric copolymer (E) being dispersed in the matrix (M), wherein the elastomeric copolymer (E) comprises units derived from—propylene and—ethylene and / or C4 to C20 α-olefin, and wherein further,—the intrinsic viscosity of the xylene cold soluble fraction (XCS) of the heterophasic polypropylene composition is above 2.1 dl / g measured according to ISO 1628-1 (at 135° C. in decaline) and / or—Mz / Mw of the xylene cold soluble fraction (XCS) of the heterophasic polypropylene composition is more than 2.6, preferably 2.7, wherein the Mz is the z-average molecular weight measured according to ISO 16014-4:2003 and Mw is the weight average molecular weight measured according to ISO 16014-4:2003.

Owner:BOREALIS AG

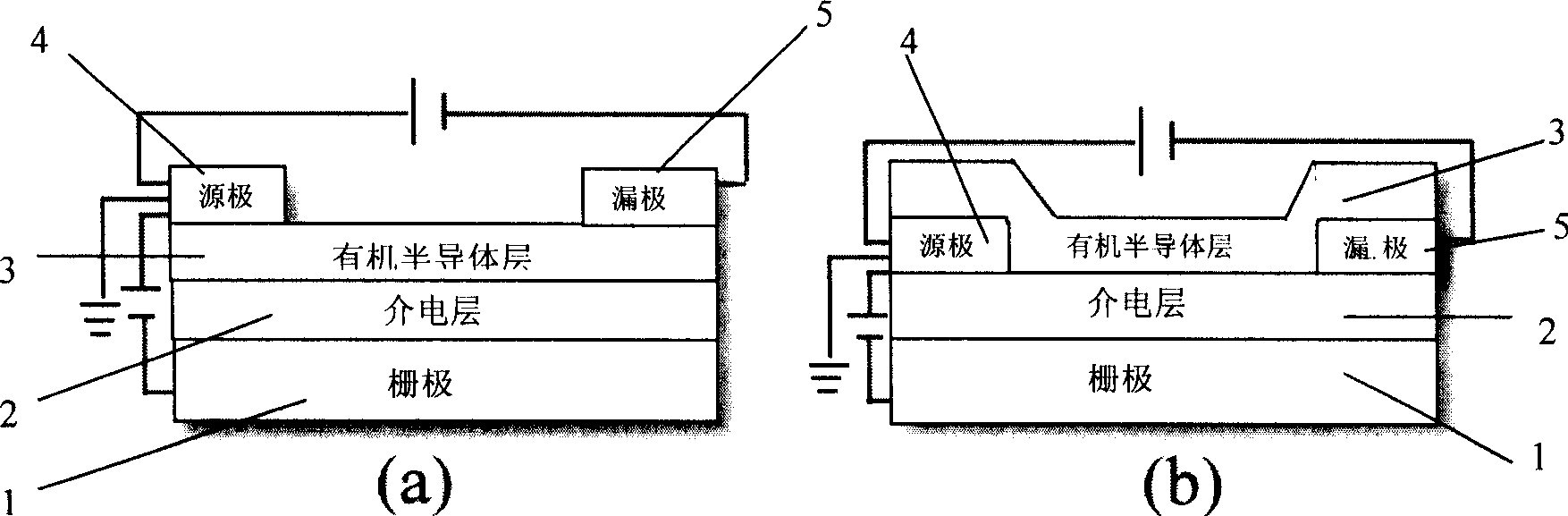

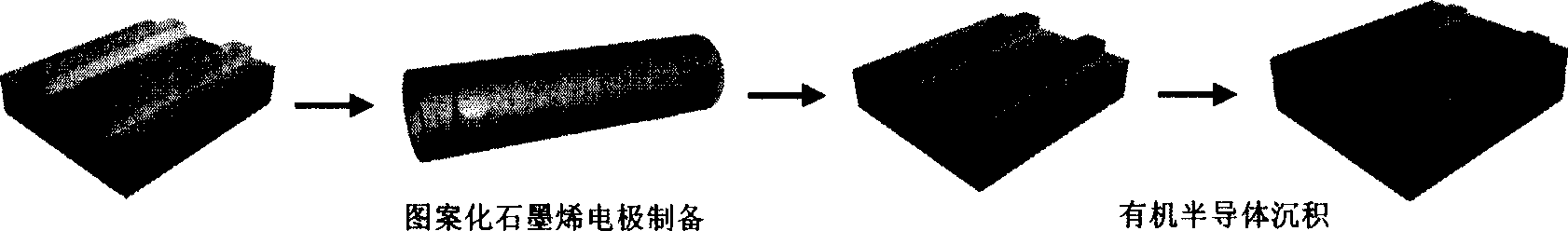

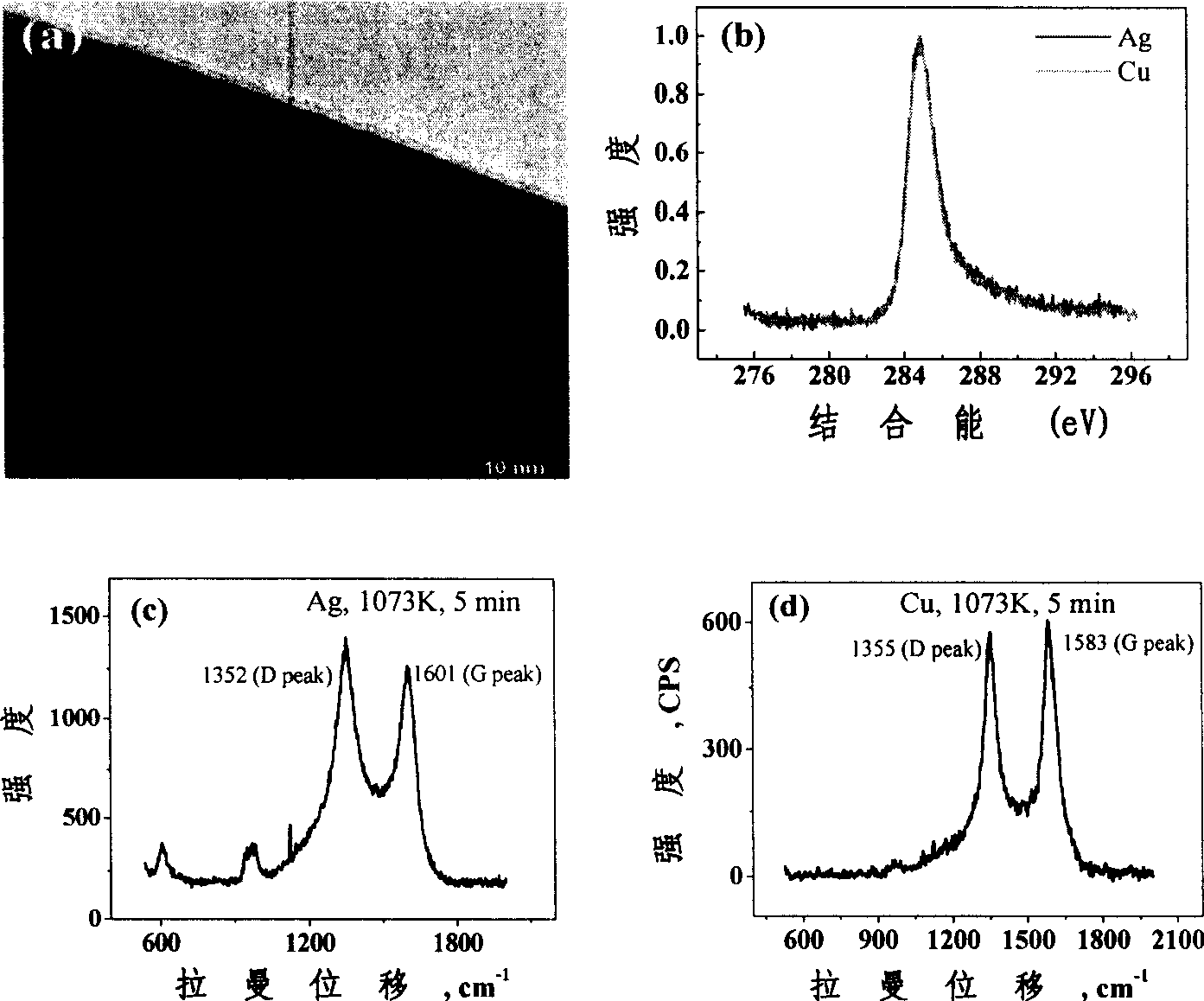

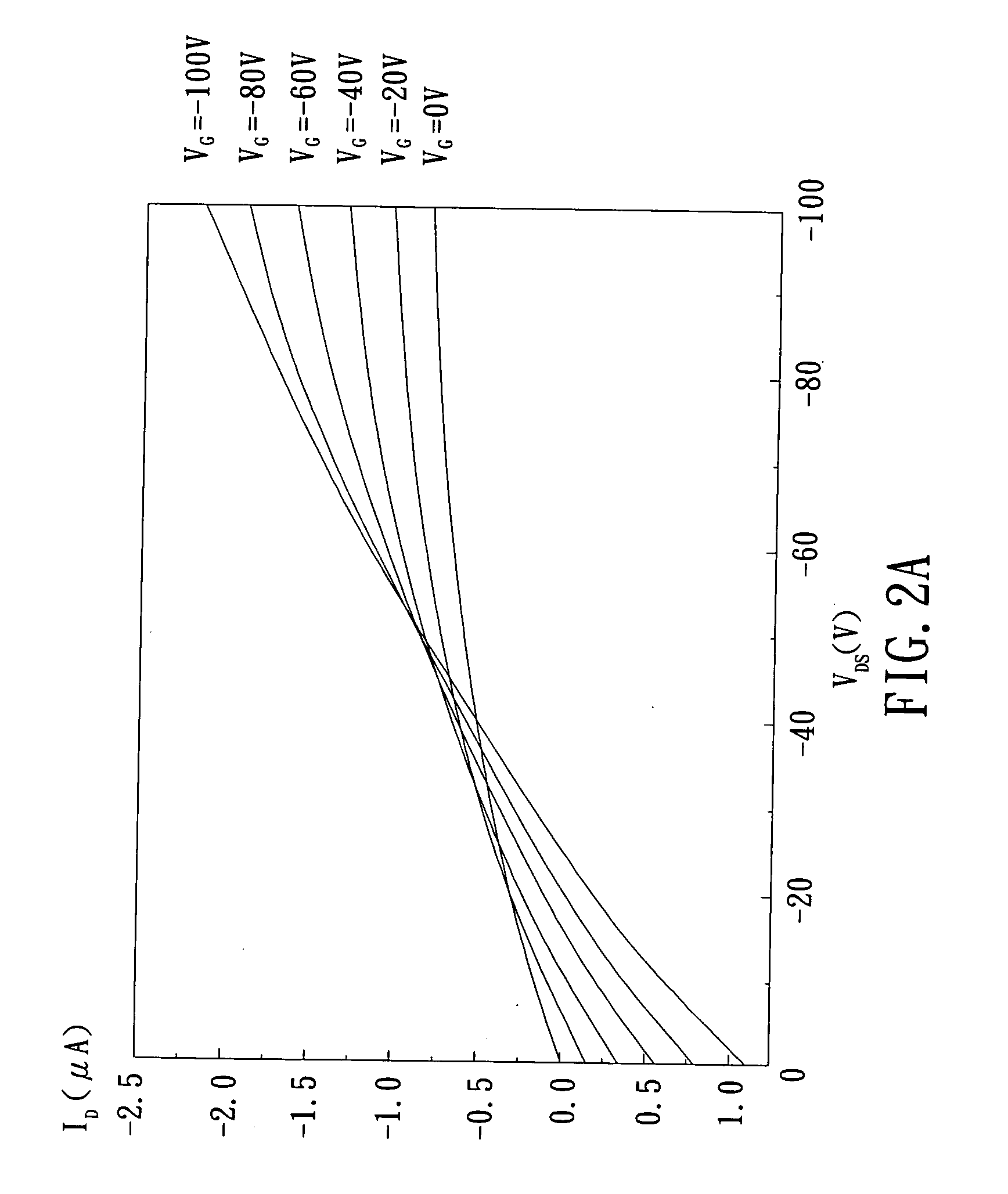

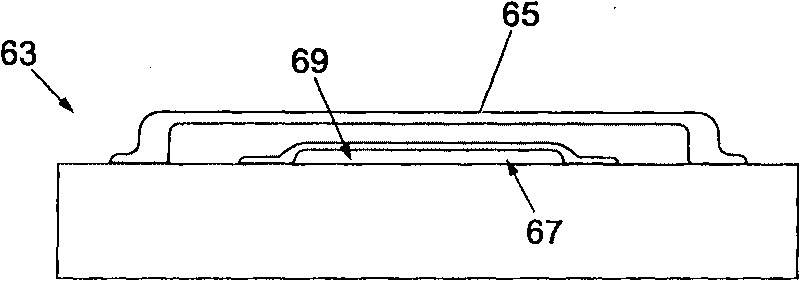

Organic field effect transistor and special source/drain electrode and preparation method thereof

InactiveCN101442105ALow costImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingOrganic field-effect transistorGas phase

The invention discloses an organic field effect transistor (FET), as well as a special source-drain electrode and a preparation method thereof. The organic FET with an electrode structure comprises a gate electrode, a dielectric layer, an organic semiconductor layer, a source electrode and a drain electrode, wherein the source electrode and the drain electrode are patterned Graphene electrodes. The method for preparing the patterned Graphene electrodes comprises the following steps: 1) a metal film is deposited on a substrate and is patterned; and 2) the substrate on which the patterned metal film is deposited is placed in a chemical vapor deposition system, and chemical vapor Graphene deposition is performed on the surface of a patterned metal electrode material, so as to obtain the patterned Graphene electrodes, wherein a carbon source used in chemical vapor deposition is methanol, ethanol, propanol, pentanol, benzene, toluene, xylene, methane and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Preparation method of micro-emulsion absorption liquid used for processing organic exhaust gas

The invention relates to a preparation method of an organic exhaust gas micro-emulsion absorption liquid, and a method for applying the micro-emulsion absorption liquid for cleaning industrial organic exhaust gas comprising benzene, toluene, xylene, and the like. The invention belongs to the technical field of atmosphere pollution control. The absorption liquid is prepared from the components of, by mass, 80-90% of water, 0.5-3% of a surfactant, 7-19.5% of a coupling agent, and 0.02-0.06% of an auxiliary agent. The surfactant is sufficiently mixed with water, such that a surfactant solution is obtained; the auxiliary agent is dissolved in water, such that an auxiliary agent solution is obtained; the two solutions are combined and uniformly mixed; and the coupling agent is added, and the obtained solution is stirred, such that the organic exhaust gas micro-emulsion absorption liquid is obtained. The organic exhaust gas micro-emulsion absorption liquid is suitable to be used for controlling exhaust gas containing benzene-series volatiles, and has the advantages of convenient raw material source, low cost, mild and stable property, low toxicity, environment-friendliness, no absorption tower corrosion or blocking phenomena, no severe influence to human health, high removal rate to organic exhaust gas, no need of pretreatment upon exhaust gas, and low investment and running cost. Saturated absorption liquid and absorbed organics can be recycled, such that waste can be turned useful.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

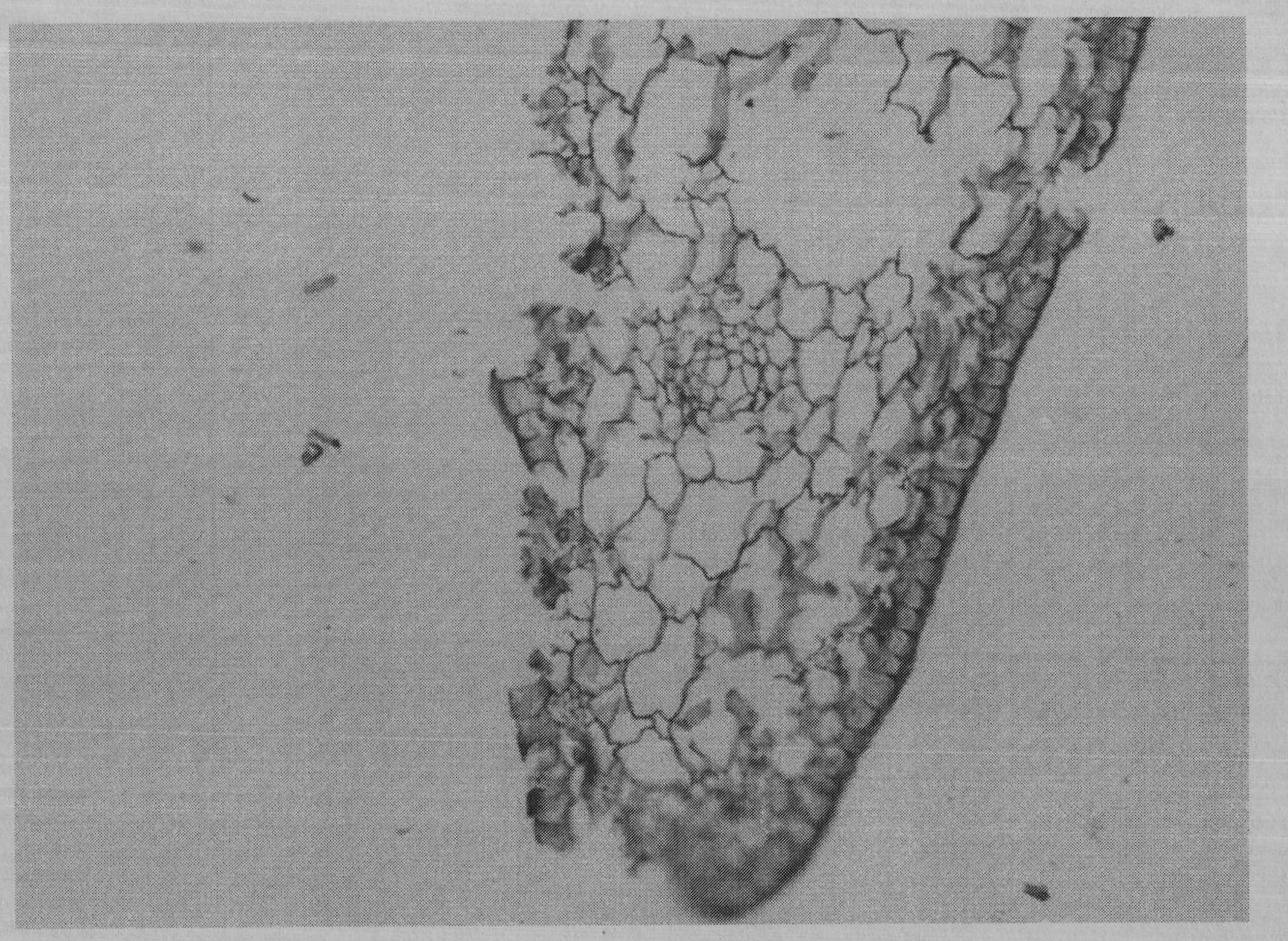

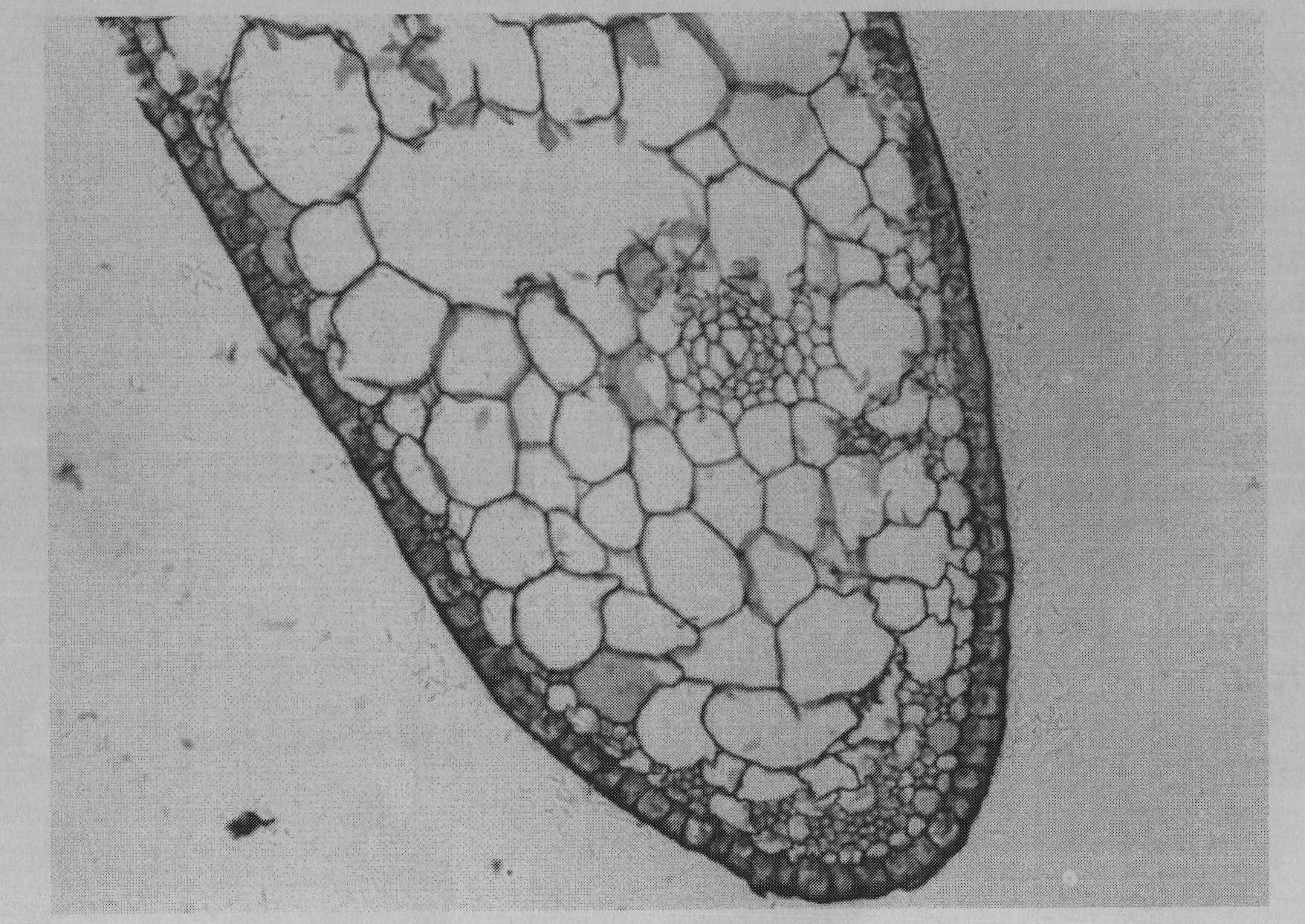

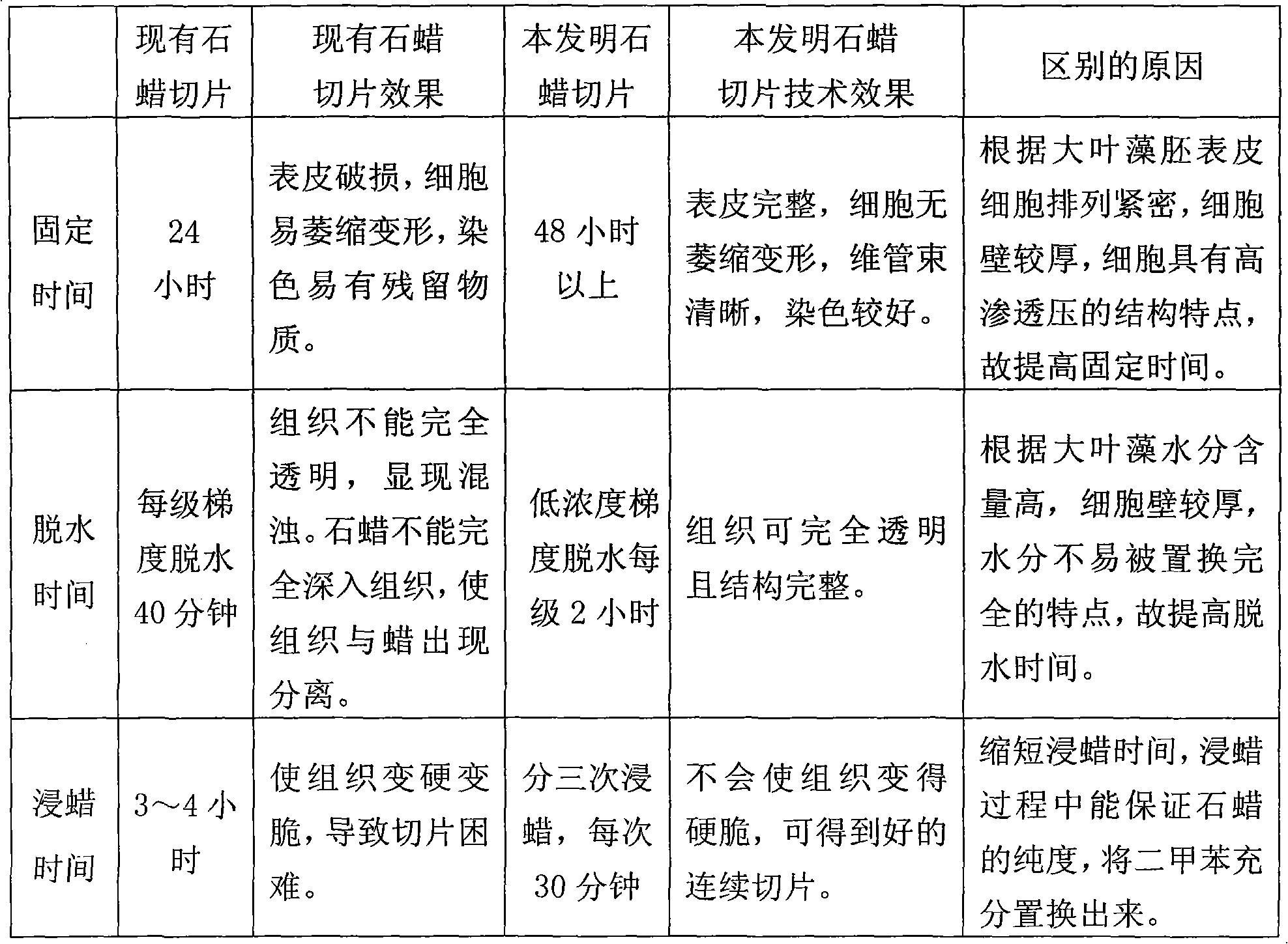

Manufacturing method of paraffin sections of zostera marina embryo

ActiveCN102116711AAvoid deformationModerate hardnessWithdrawing sample devicesPreparing sample for investigationParaffin waxEmbryo

The invention discloses a manufacturing method of paraffin sections of zostera marina embryo, comprising the following steps: (1) material drawing and fixation: zostera marina seeds are taken and the fruit skin is stripped, and after endosperm is removed, an integral zostera marina embryo is soaked in FAA (free amino acids) fixing solution and is fixed for more than 48 hours; (2) dehydration: the zostera marina embryo is taken out from the fixing solution and is soaked in alcohol for dehydration; (3) waxing and embedding: paraffin is added gradually in a vessel containing the zostera marina embryo and dimethylbenzene, and conventional paraffin embedding is carried out to obtain the wax blocks containing the zostera marina embryo; (4) slicing, spreading and drying: the wax blocks coated with the zostera marina embryo is fixed on a wheel rotation type slicing machine for carrying out continuous slicing of the paraffin, so as to obtain wax bands and enable the wax bands to be attached to an object slide; (5) dewaxing, rehydration and dyeing of hematoxylin dye solution; (6) slicing, dehydration and dyeing of eosin and alcohol; and (7) transparence and mounting are carried out to manufacture a permanent section. In the manufacturing method disclosed by the invention, the paraffin sections of the zostera marina embryo, which have clear dyeing and an integral texture structure, can be obtained.

Owner:SHANDONG ORIENTAL OCEAN SCI TECH

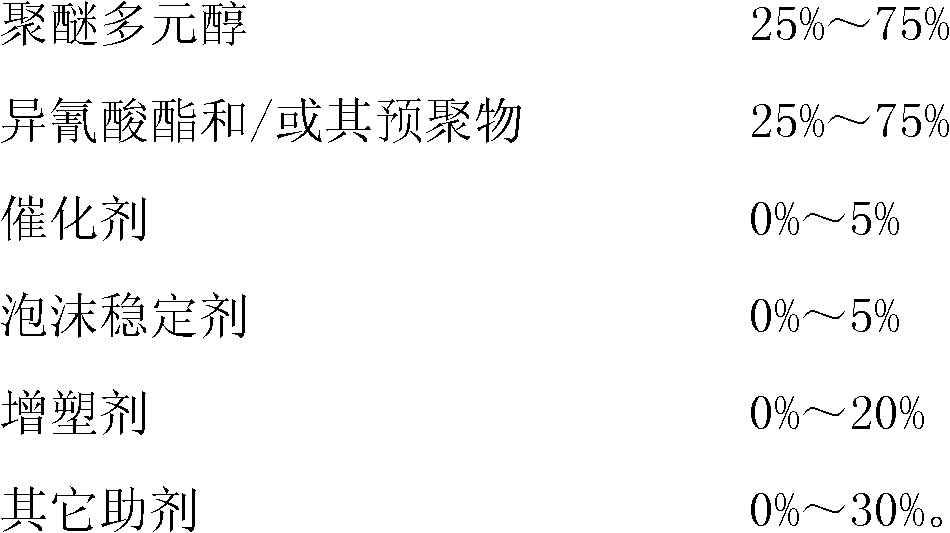

Polyurethane grouting water plugging-reinforcing material, and preparation method and application method thereof

InactiveCN102702728AQuick responseQuick treatment of seepage waterUnderground chambersTunnel liningWater leakageChemical grouting

The invention discloses a polyurethane chemical grouting water plugging-reinforcing material which comprises a component A and a component B. The invention is characterized in that the component A is composed of polyether glycol and auxiliary materials, and the component B is composed of isocyanate and / or prepolymer thereof and auxiliary materials; and the auxiliary materials comprise catalyst, foam stabilizer and other assistants. The polyurethane chemical grouting water plugging-reinforcing material disclosed by the invention does not contain benzene, xylene, acetone and other solvents and does not influence the water quality after curing, and the solid content is 100%, thereby being environment-friendly and pollution-free; and when in use, the reaction speed of the double components is very high, the reaction starts after 20 seconds and basically finishes after 90 seconds, the reaction time is adjustable according to the engineering demands, and thus, the polyurethane chemical grouting water plugging-reinforcing material can effectively and quickly solve the problems of water leakage and water inflow of mines.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

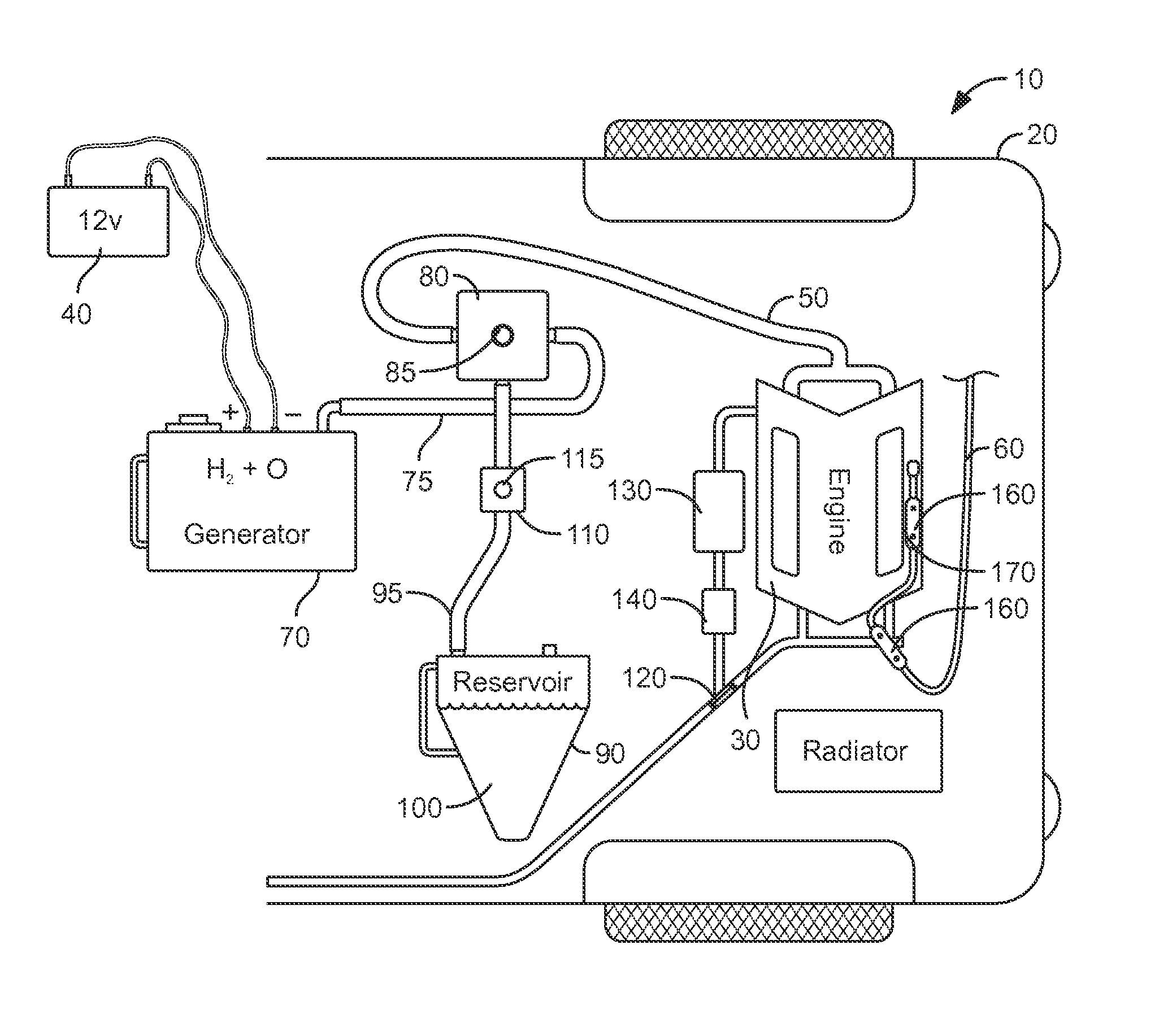

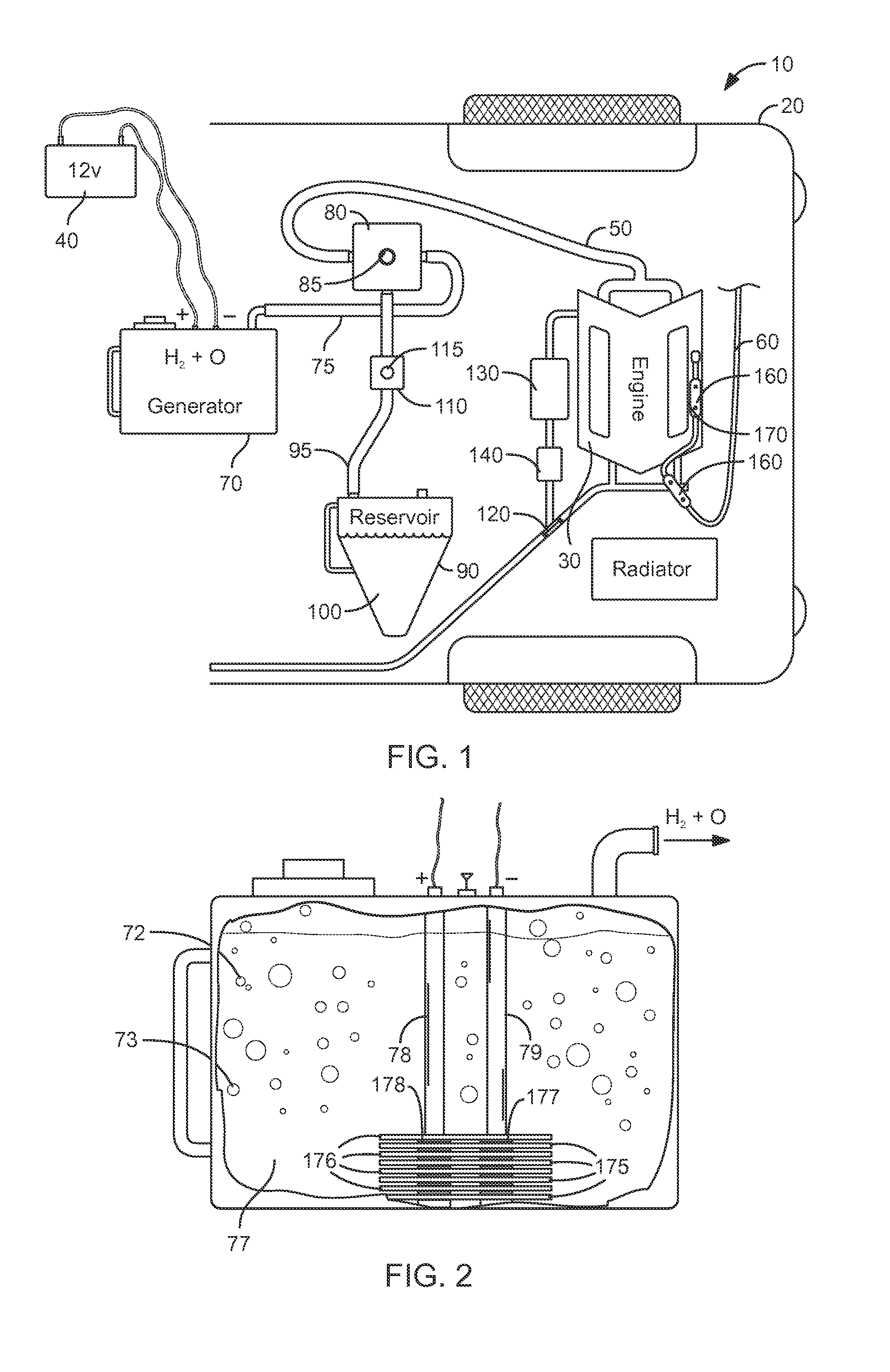

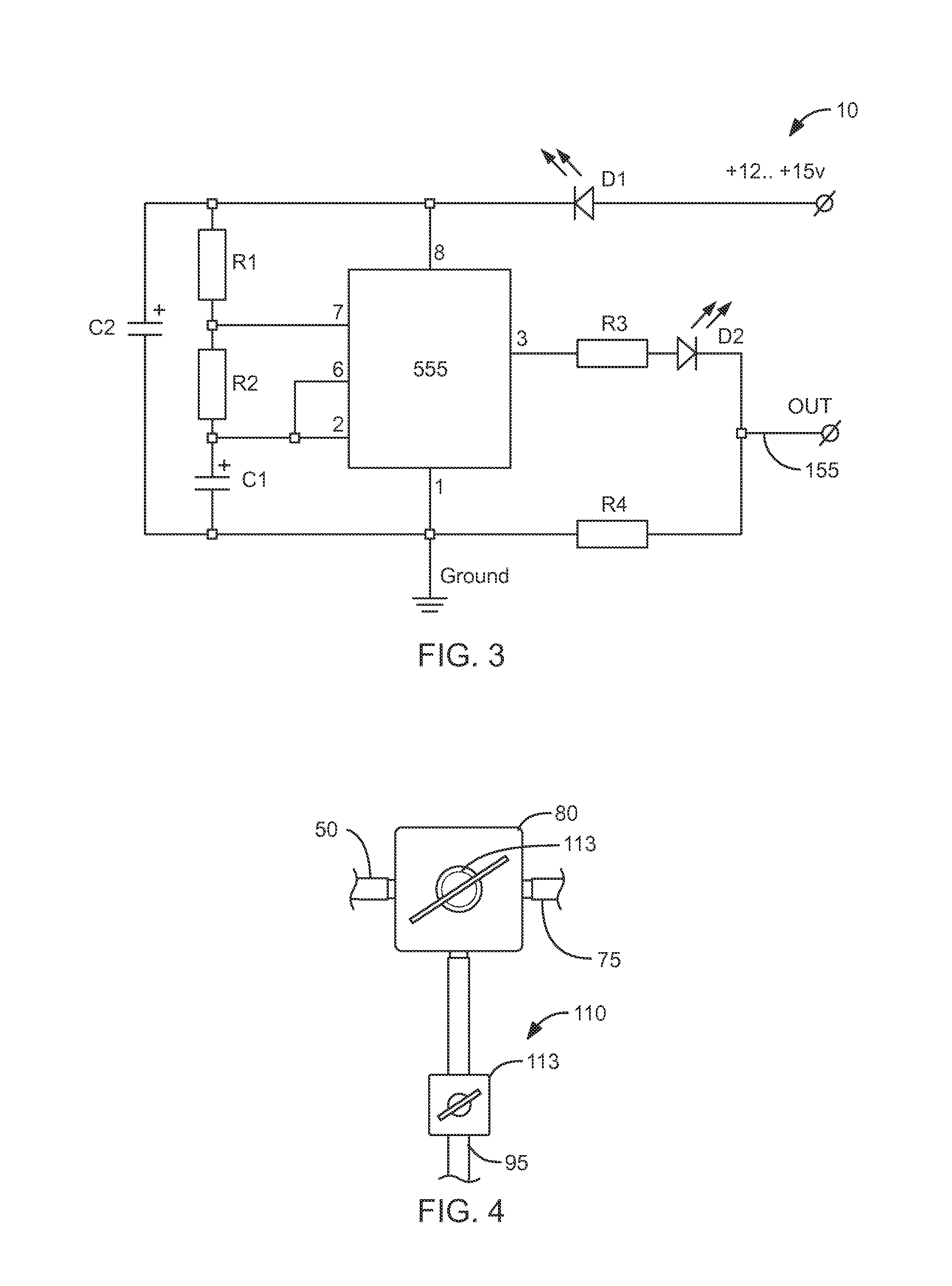

Engine fuel efficiency improvements

InactiveUS7458368B1Good fuel atomizationEfficient combustionPhotography auxillary processesNon-fuel substance addition to fuelFuel efficiencyInternal combustion engine

The present invention is a system for increasing the fuel efficiency of a vehicle of the type having an internal combustion engine, a battery, a vacuum line, and a fuel line that feeds fuel to the engine. The system comprises a hydrogen gas generator and a vacuum regulator. A vacuum regulator is in fluid communication with the vacuum line of the vehicle and an output line of the gas generator. The vacuum regulator includes a vacuum pressure adjustment means for controlling the amount of hydrogen gas that is introduced into the vacuum line of the vehicle. In use, hydrogen gas is introduced into the vehicle vacuum line and then into the engine where it is mixed with the fuel from the fuel line and ambient air. The hydrogen gas increases the atomization of the fuel for more efficient burning thereof in the engine. A fuel additive including an acetone-based compound, a xylene-based compound, and an upper cylinder lubricant may be mixed with the hydrogen gas to further atomize the fuel. An oxygen sensor signal generator that generates a bypass signal replicates the output of a vehicle oxygen sensor under normal operating conductions to keep the air mixture of the engine unaffected. The system may additional include at least one fuel heating means fixed to a high-temperature portion of the engine, such that the fuel is heated before being introduced into the engine so as to further increase atomization of the fuel for more efficient burning thereof in the engine.

Owner:HUFFMAN DANIEL

Routine paraffin wax flaking HE dyeing non-xylol whole-course treatment liquid for biological organization sample

InactiveCN101344467AThoroughly dehydratedSpeed up productionPreparing sample for investigationParaffin waxNon toxicity

The invention aims at providing a pathological diagnosis reagent, which is mainly used for processing various tissue samples in the pathology department in all levels of hospitals, can satisfy the requirements of a global non-xylene HE dyeing treating fluid of routine paraffin slices of biological tissue samples that is required in the slicing technique of the tissue samples with manual operation or operation of an automatic dehydrator and in the HE dyeing technique of cast-off cells, and is separated into two parts of tissue dehydration and section staining. As a novel conservation-conscious environmental protection technique, the pathological diagnosis reagent quickens splicing speed and simultaneously leads the tissue not to become over shrunk, hardened, split and crisp and leads the cells and the tissue structure to be closer to original patterns; the pathological diagnosis reagent has more complete tissue dehydration and adopts various novel mixed reagents that are pure analyzing organic chemical reagents with low volatility or non-volatility, non-toxicity and non-pollution, thus replacing originally widely used xylene reagents that have toxicity and heavy environmental pollution and eliminating occupational diseases that are caused by the xylene reagents in the global slicing of tissue sample preparation and tissue slice HE dyeing.

Owner:赵晓辉

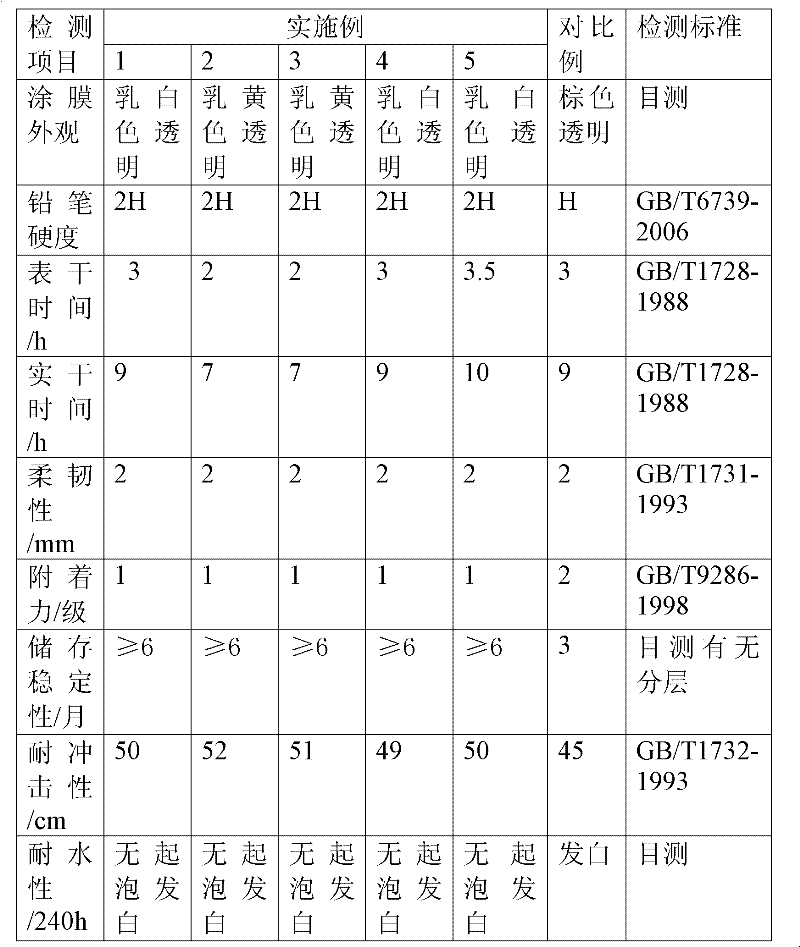

Epoxy ester modified aqueous alkyd resin and preparation method thereof

The invention discloses an epoxy ester modified aqueous alkyd resin and a preparation method thereof. The method comprises the following steps of: preparing alkyd resin, synthesizing epoxy ester, and synthesizing the epoxy ester modified aqueous alkyd resin: stirring and mixing epoxy ester and basic alkyd resin in mass ratio of 0.2:1-0.5:1, 1-3 parts of organic tin catalyst and 5-15 parts of dimethyl benzene, and performing reflux reaction at the temperature of 180 DEG C for 1-2 hours until the acid value is measured to be less than 7mgKOH / g; and water-dissolving the modified alkyd resin. A product provided by the invention keeps superior performances of paint dryness, glossiness, durability, flexibility, hardness, higher solubility and the like of the alkyd resin, has superior cohesive property, salt fog resistance and good self-drying property of the epoxy resin, and can keep that a coating has superior solvent resistance and chemical resistance.

Owner:SOUTH CHINA UNIV OF TECH

Production method for paraffin section of paeonia lactiflora mature embryo

InactiveCN103630421AComplete structureClear structureWithdrawing sample devicesPreparing sample for investigationWater bathsParaffin wax

The invention discloses a production method for a paraffin section of a paeonia lactiflora mature embryo. The production method comprises the following steps: drawing materials and fixing: stripping a seed coat, cutting a seed, immersing the seed top part containing the embryo or part endosperm into a FAA stationary liquid, and fixing for more than 24 hours; dehydrating: washing in ethyl alcohol with the concentration of 70% for 3 to 5 times, and performing gradient dehydration from the ethyl alcohol with the concentration of 70%; performing hyalinization: carrying out five level hyalinization by using dimethyl benzene as a transparent reagent; waxing and embedding: pouring out one half volume of dimethyl benzene, adding wax crumbs in a bottle until saturation, staying overnight at the temperature of 40 DEG C; then changing a wax liquid every two hours for three times per day, repeating for three days, and carrying out conventional paraffin embedding; slicing; flattening and bonding: flattening a linoleum tape on an iron plate of a water bath kettle at the constant temperature of 50 DEG C, dewaxing, rehydrating, dyeing through safranine and fast green and performing hyalinization; mounting. According to the invention, the paeonia lactiflora mature embryo paraffin section of which the tissue structure is integrated and clear can be obtained, so that accurate technical support can be provided for researching paeonia lactiflora seed dormancy and germination.

Owner:SHENYANG AGRI UNIV

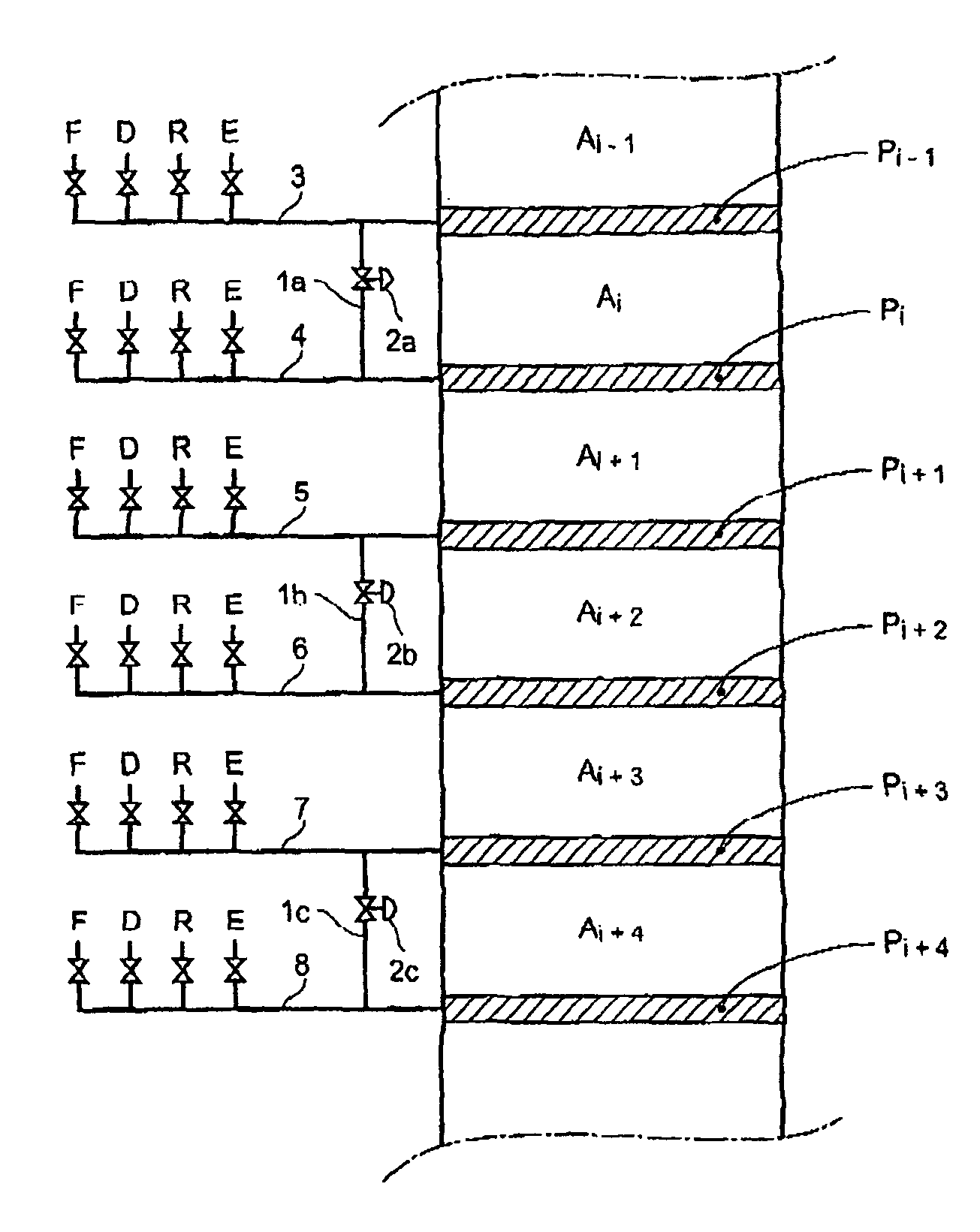

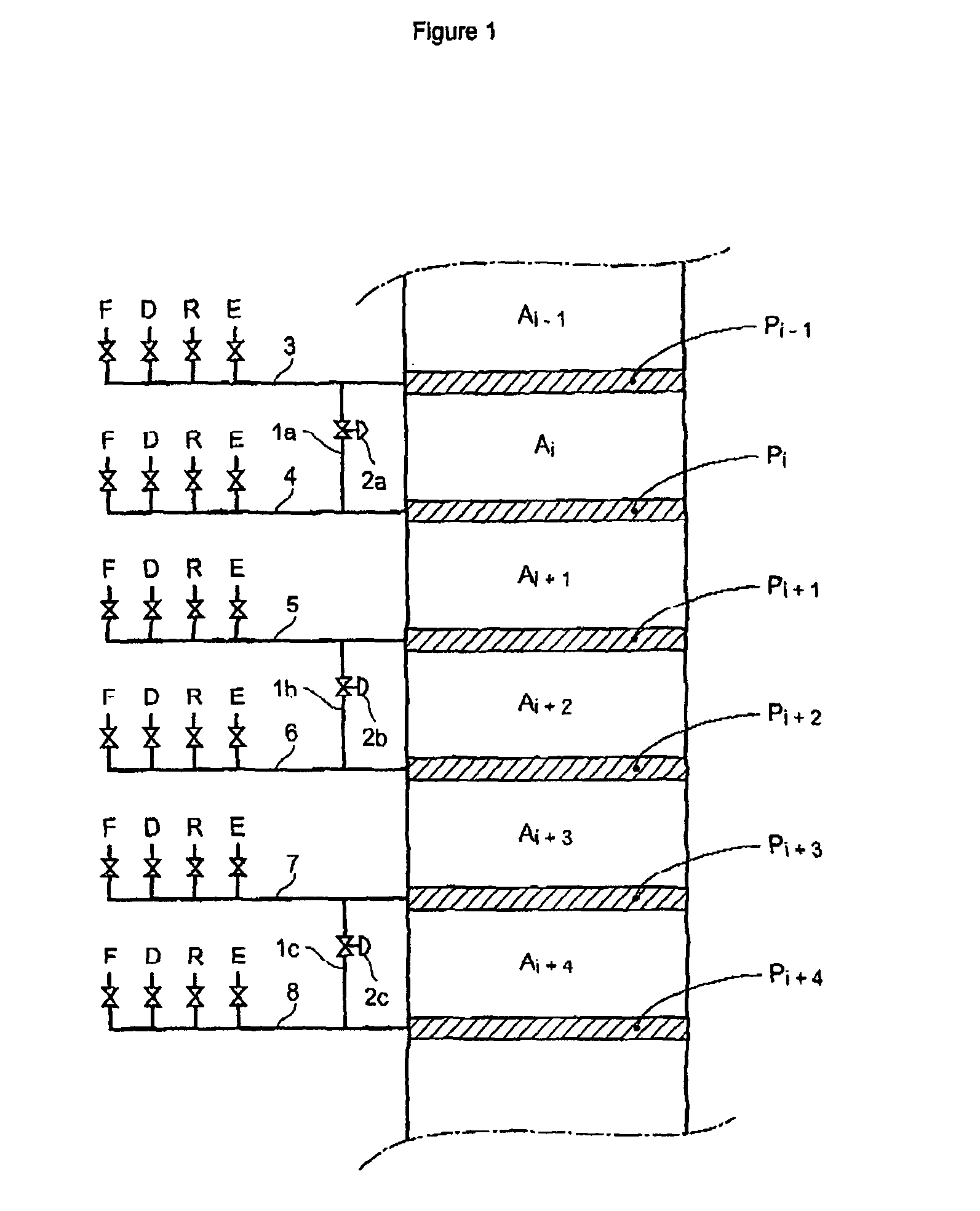

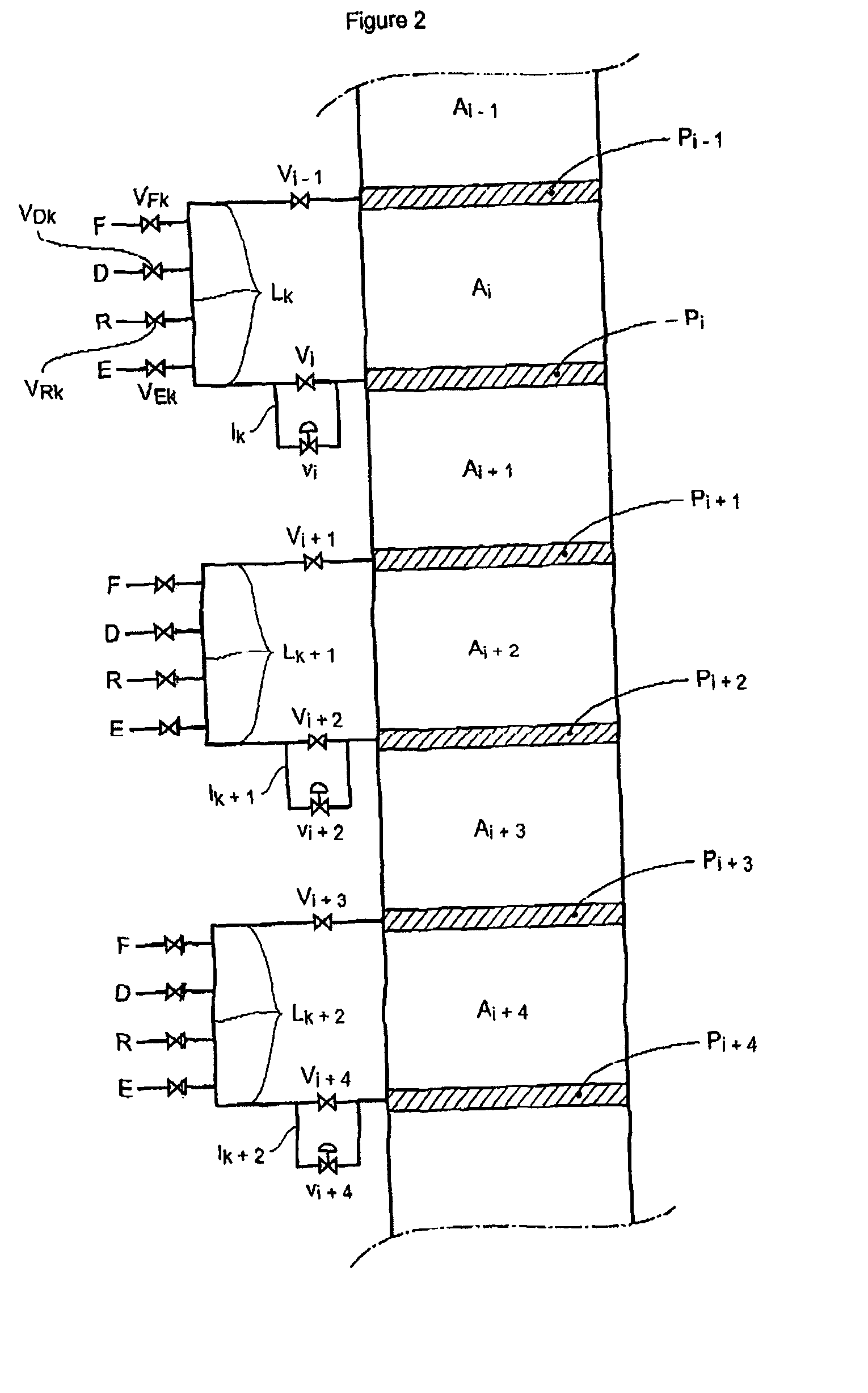

Process and device for simulated moving bed separation with a reduced number of valves and lines

InactiveUS20080237132A1Reduce in quantityReduce disadvantagesComponent separationIon-exchanger regenerationSimulated moving bedMeta-xylene

The invention concerns a simulated moving bed adsorption separation device comprising a limited number of valves. According to the invention, the device comprises a column with a plurality of sectors Sk with 2 superimposed plates Pi with a single distribution network, each sector Sk comprising an external principal bypass line Lk connected to each plate Pi of Sk via a plate valve Vi. Each line Lk comprises a flow limitation means and is connected to each of the fluid networks via a single valve.Further, the connectors of lines Lk onto the column are offset by at most 20° inside Sk to limit the volume of lines Lk, and are offset by a mean angle in the range 70° to 110° between two neighbouring sectors Sk and Sk+1 so as not to weaken the column mechanically. The plates preferably comprise panels DMEi,j with parallel segments the direction of which varies from plate to plate or per group of 2 plates.The invention also concerns a separation process using said device, in particular to separate para-xylene or meta-xylene from an aromatic C8 cut.

Owner:INST FR DU PETROLE

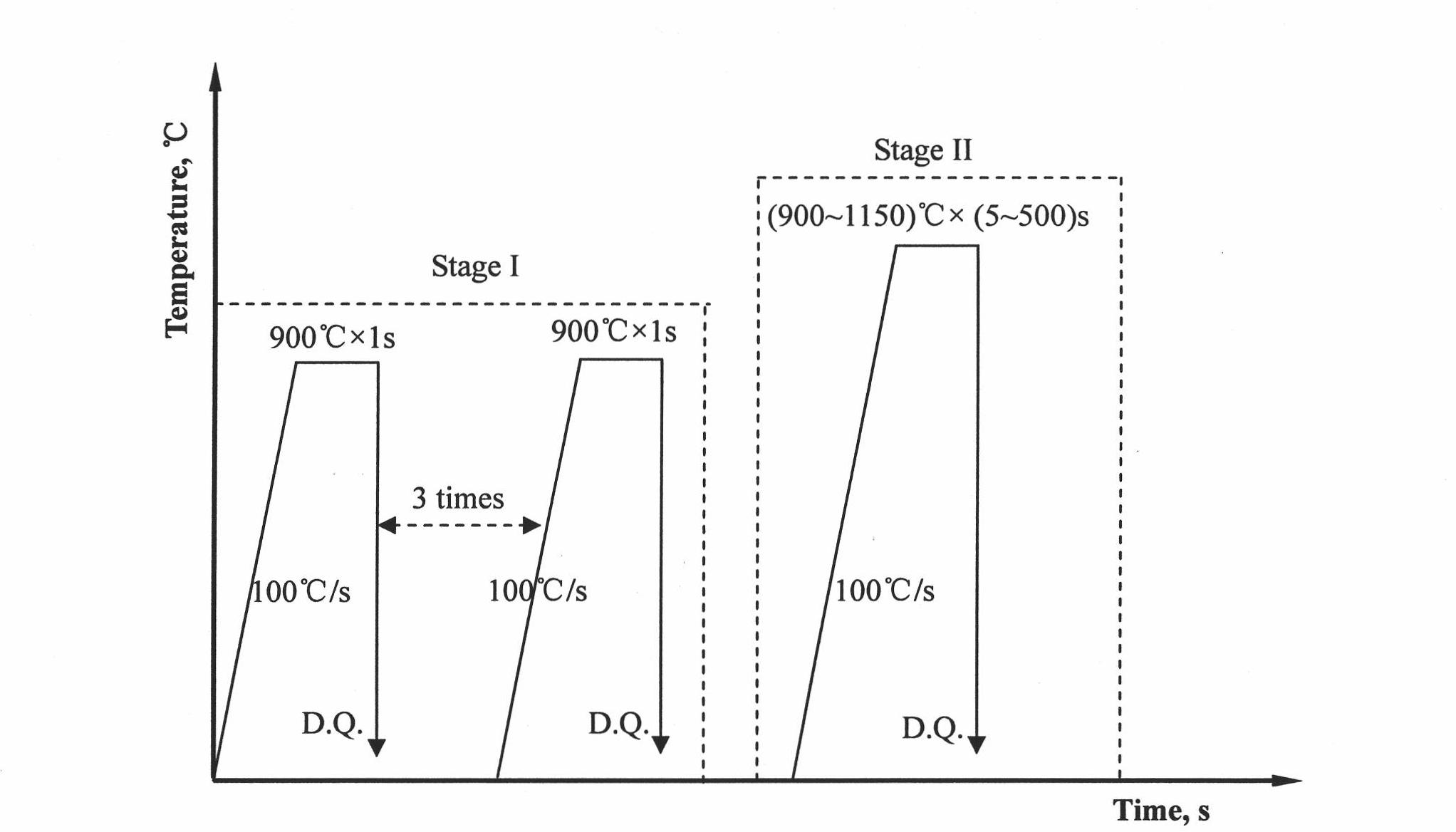

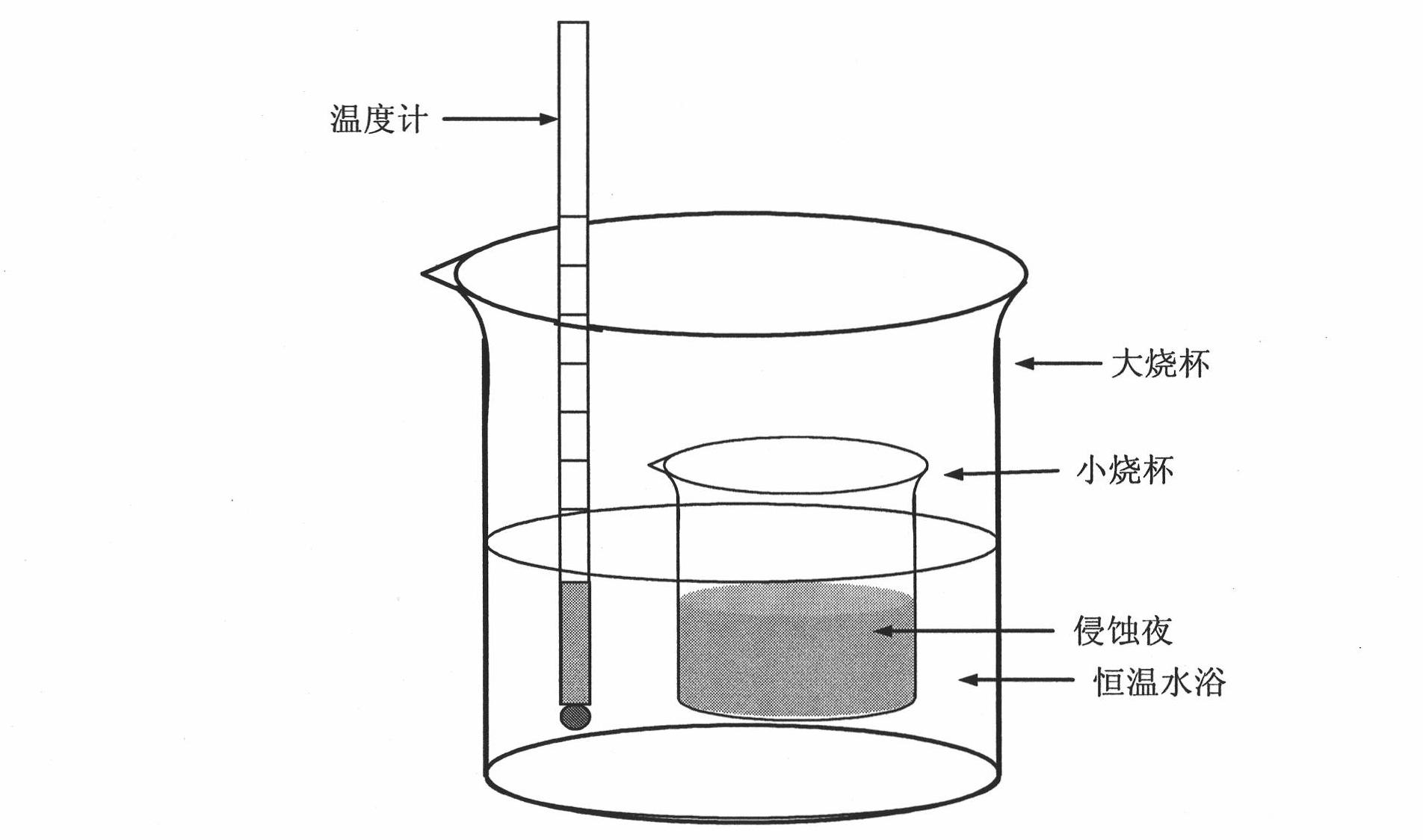

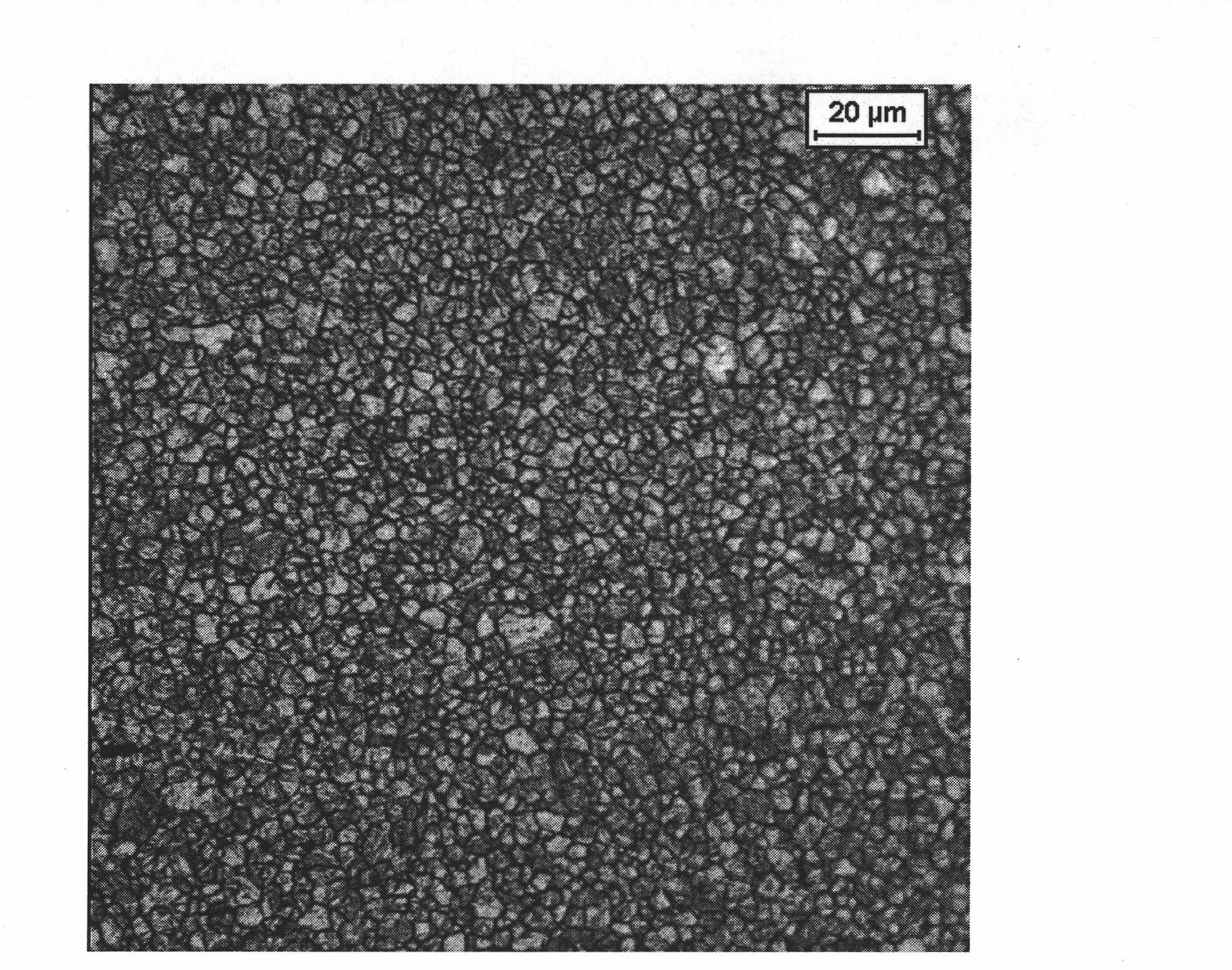

Etching agent for rapidly displaying ultrafine austenite grains and thermal erosion method thereof

InactiveCN102400146AQuick and clear displayAccurately measure grain sizePreparing sample for investigationAlcoholAustenite grain

The invention discloses an etching agent for rapidly displaying ultrafine austenite grains and a thermal erosion method thereof. The etching agent comprises a saturated aqueous solution of picric acid, a saturated aqueous solution of CuCl2, HF acid and xylene, wherein, the volume ratio of the ingredients is 100-200:1-1.5:0.5-1.5:1-2. The thermal erosion method comprises the following steps: grinding and polishing a sample, then immersing the section in a 60-70 DEG C etching liquid for carrying out thermal erosion with the erosion time of 5-15 s, and then cleaning the section through wiping with anhydrous alcohol, and drying. According to the invention, the rapid and clear display of ultrafine-grained austenite can be realized by using a formula of a few reagents and reasonable assembly, and the invention provides reliable conditions for accurately measuring the grain size of ultrafine-grained austenite.

Owner:ANGANG STEEL CO LTD

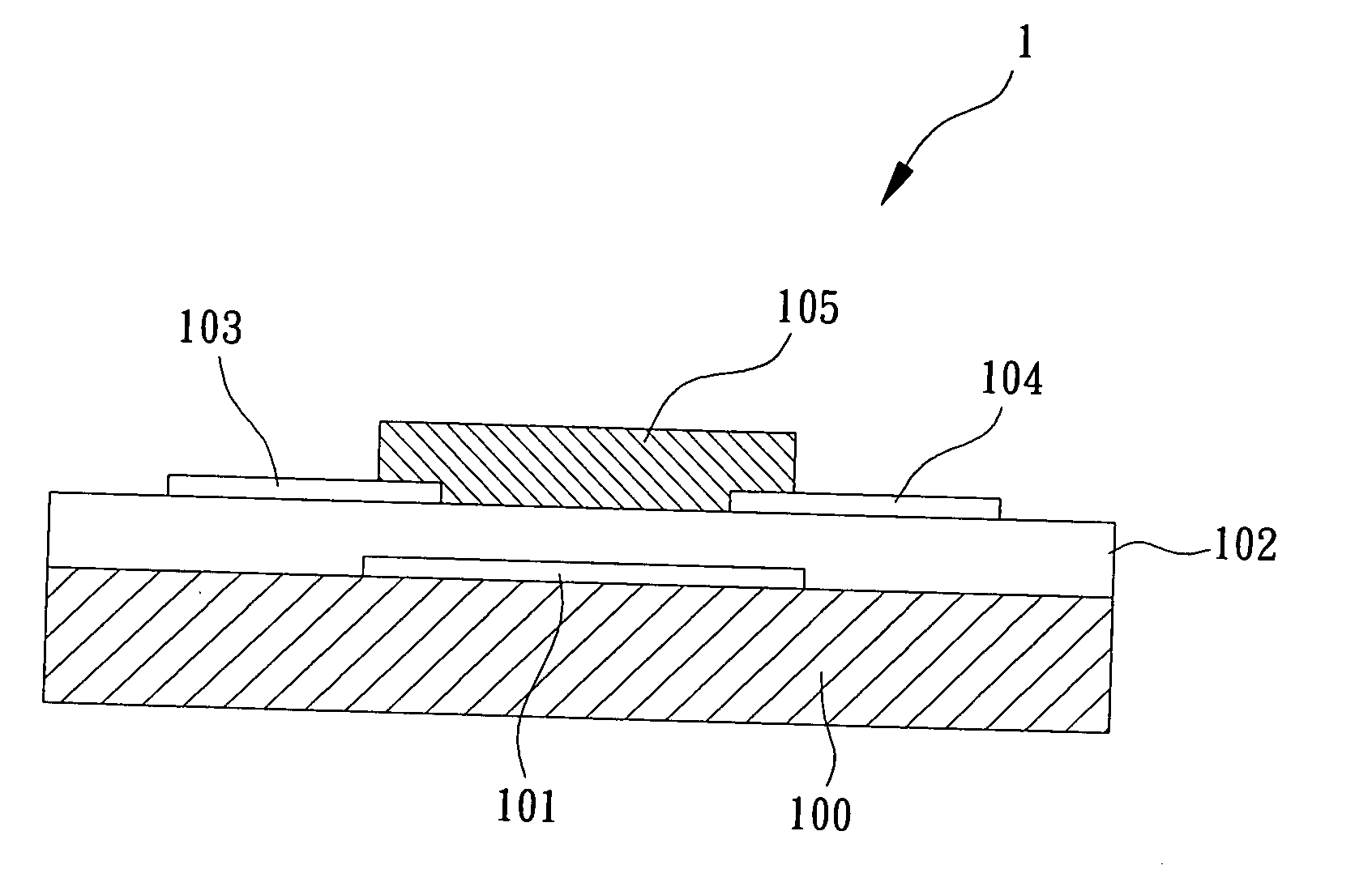

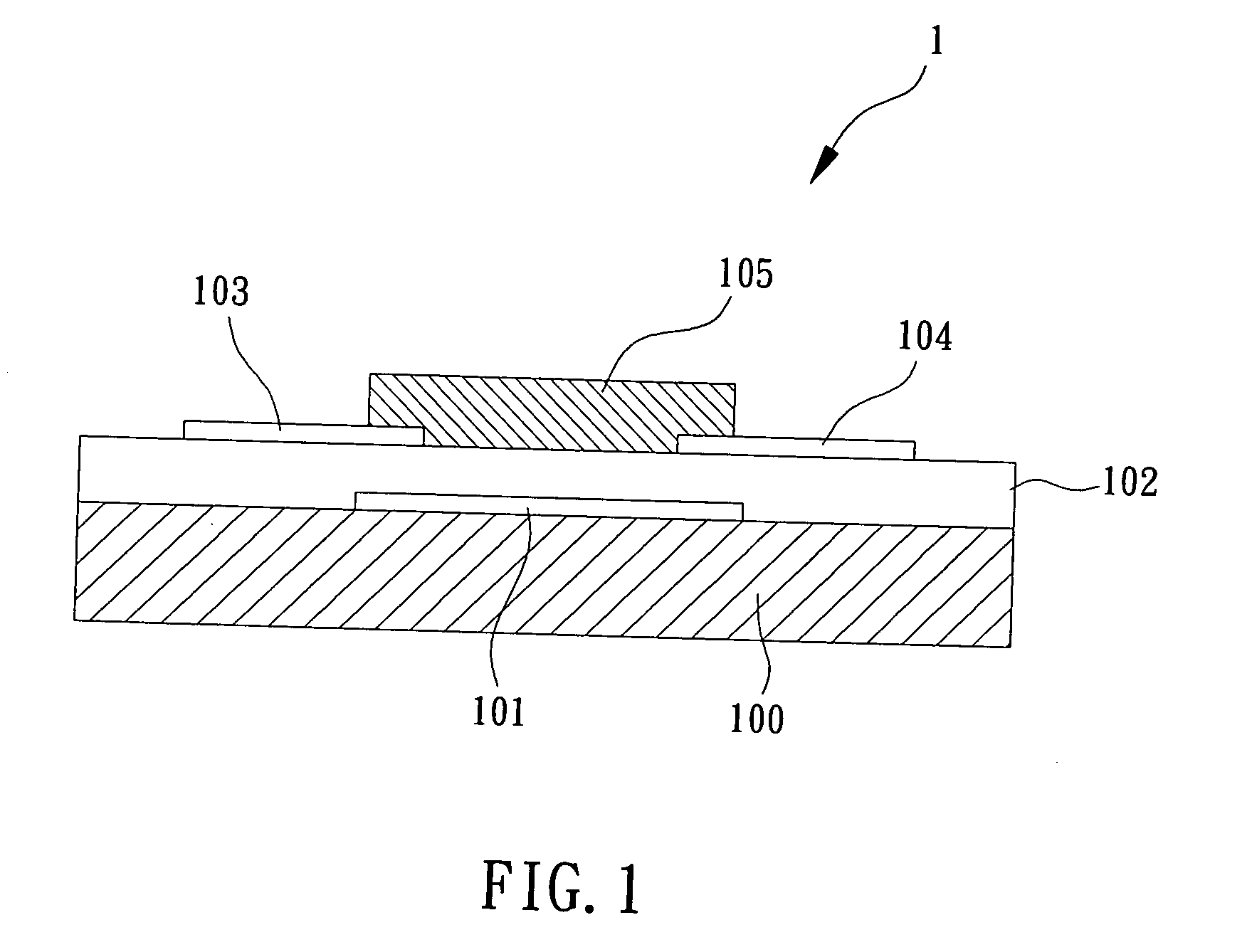

Method for enhancing electrical characteristics of organic electronic devices

InactiveUS20050221530A1Improve electrical characteristicsThe process is simple and fastTransistorMaterial nanotechnologyPolytetramethylene terephthalateCarbon nanotube

The present invention provides a method for enhancing electrical characteristics of organic electronic devices, especially for an organic thin-film transistors, comprising the steps of: providing a substrate with a gate and an insulator layer formed thereon; preparing an organic solution by mixing materials of an organic semiconductor polymer, an organic insulator polymer, a conducting particle and a solvent; forming an organic semiconductor layer on top of the insulator layer between the source and the drain using the organic solvent. Wherein, the organic semiconductor polymer can be a polymer selected from the group consisting of poly(3-alkylthiophene) (P3AT) with different alkyl side groups of 2, 4, 6, 8, 10, 12, and 18, as the P3HT is a P3AT with alkyl side group of 6, and the organic insulator polymer can be a polymer selected from the group consisting of poly(methylmethacrylate) (PMMA), and polybutylene terephthalate (PBT), etc. and the conducting particle can be a kind of particle selected from the group consisting of carbon nanotubes (CNTs), C60, and nano silver particle, and so on, and the solvent can be a solvent selected from the group consisting of xylene, toluene, and THF, and so forth.

Owner:IND TECH RES INST

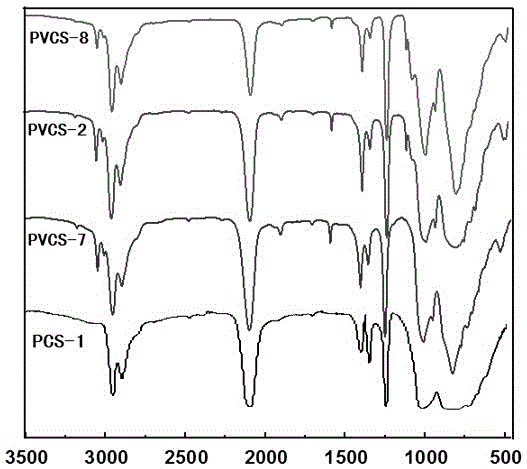

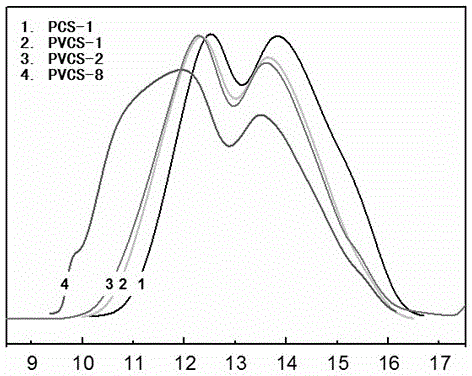

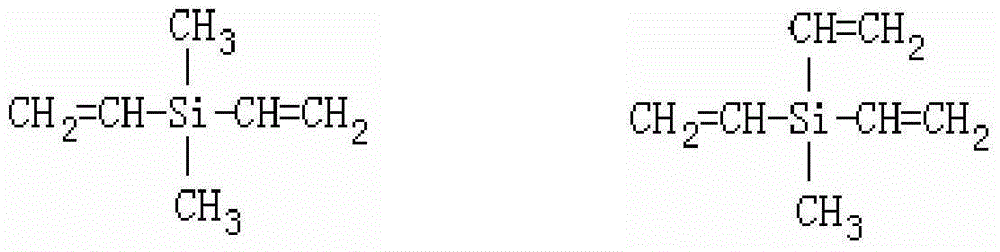

Synthesis method of polycarbosilane capable of being used for thermosetting crosslinking

A synthesis method of polycarbosilane capable of being used for thermosetting crosslinking comprises the following steps: taking polycarbosilane used for preparing a composite material as a raw material; placing the polycarbosilane used for preparing the composite material and an organosilan compound containing 2 to 3 -C=C- groups into a reaction vessel; adding dimethyl benzene; mixing uniformly for dissolving; adding a Si-H additive reaction catalyst; vacuumizing; carrying out replacing with high-purity nitrogen; carrying out an Si-H additive reaction under a normal-pressure or high-pressure heating condition and the protection of the high-purity nitrogen. The synthesis method is simple and convenient, and easy to implement; the product PVCS can be used for self-setting crosslinking under an inert atmosphere after being treated at 400 DEG C; the smelting outflow of PCS during heat treatment can be avoided; the ceramic yield can be improved remarkably; the polycarbosilane synthesized according to the synthesize method can be used as a precursor polymer of ceramic-based composite materials such as Cf / SiC, and SiCf / SiC.

Owner:NAT UNIV OF DEFENSE TECH

Green making technology of animal tissue paraffin section

A green making technology of animal tissue paraffin section disclosed in the invention aims at providing a technique of making a paraffin section of animal tissue applied to the agricultural university medicine and other majors, characterized by that the type of chemical reagents that are used is limited, the chemical reagents have no toxicity, and dehydrate the tissue thoroughly, accelerate making sections but not lead to excessive contraction and increasement of hardness of the tissue, and substitute dimethyl benzene used in the traditional making technology of the paraffin section which isharmful to human body, so as to eliminate the occupational diseases and environmental pollution caused by dimethyl benzene. The making technology comprises the following steps: carrying out fixation with a fixative solution (100ml of the fixative solution comprises 91 ml 85% alcohol, 4 ml methanol and 5 ml glacial acetic acid ), dehydrating the tissue with graded ethanol, then putting the fixative and dehydrated tissue in a mixed transparent reagent (comprising 14wt% of analytically pour n-butanol, 29wt% of acetone and 57wt% of absolute alcohol ) for standing for 3 hours, then carrying out normal waxing and embedding, using analytically pour turpentine (60 DEG C) for section staining, carrying out dewaxing twice, carrying out hydration under normal temperature, using haematoxylin for staining nuclei, decoloration and bluing, and using eosin for staining, dehydrating until get absolute alcohol, then carrying out air drying, and directly using the gum diluted by turpentine to sealing the section.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Nano-wollastonite modified adhesive for packaging

InactiveCN102965036AHigh bonding strengthImprove water resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolyvinyl chlorideEthyl acetate

The invention discloses a nano-wollastonite modified adhesive for packaging. The adhesive is prepared from the following raw materials in parts by weight: The adhesive is prepared from the following raw materials in parts by weight: 100-120 parts of styrene, 100-150 parts of ethyl acetate, 20-25 parts of duprene rubber CR121, 15-20 parts of xylene, 1-2 parts of 4,4'-diphenyl methane diisocyanate, 8-12 parts of polyisobutylene, 2-3 parts of (3-aminopropyl)trimethoxysilane, 2-3 parts of polytetramethylene ether glycol, 3-5 parts of SG-2 PVC (polyvinyl chloride) resin, 1-2 parts of ferrocene, 10-15 parts of 704 silicon rubber, 8-12 parts of butyl rubber CBK139, 3-5 parts of epoxidized soybean oil, and the like. The adhesive is excellent in heat resistance heat resistance and cold resistance, high in cohesive strength, water-resistant, moisture-proof, good in storage stability, good in environment friendliness, good in using effect and convenient.

Owner:TONGLING XIANGYUN FIRE FIGHTING TECH

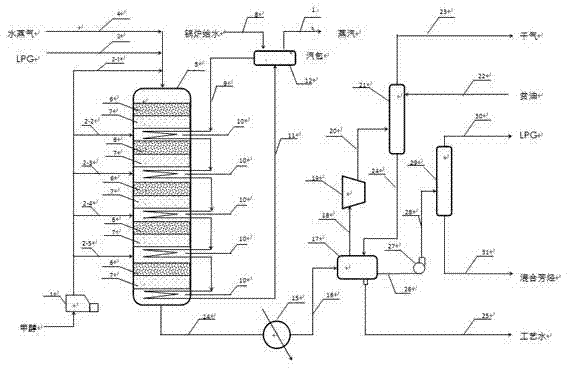

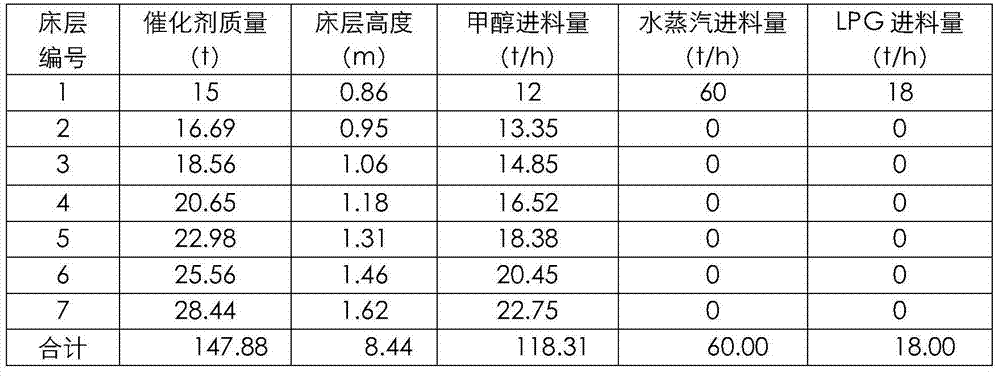

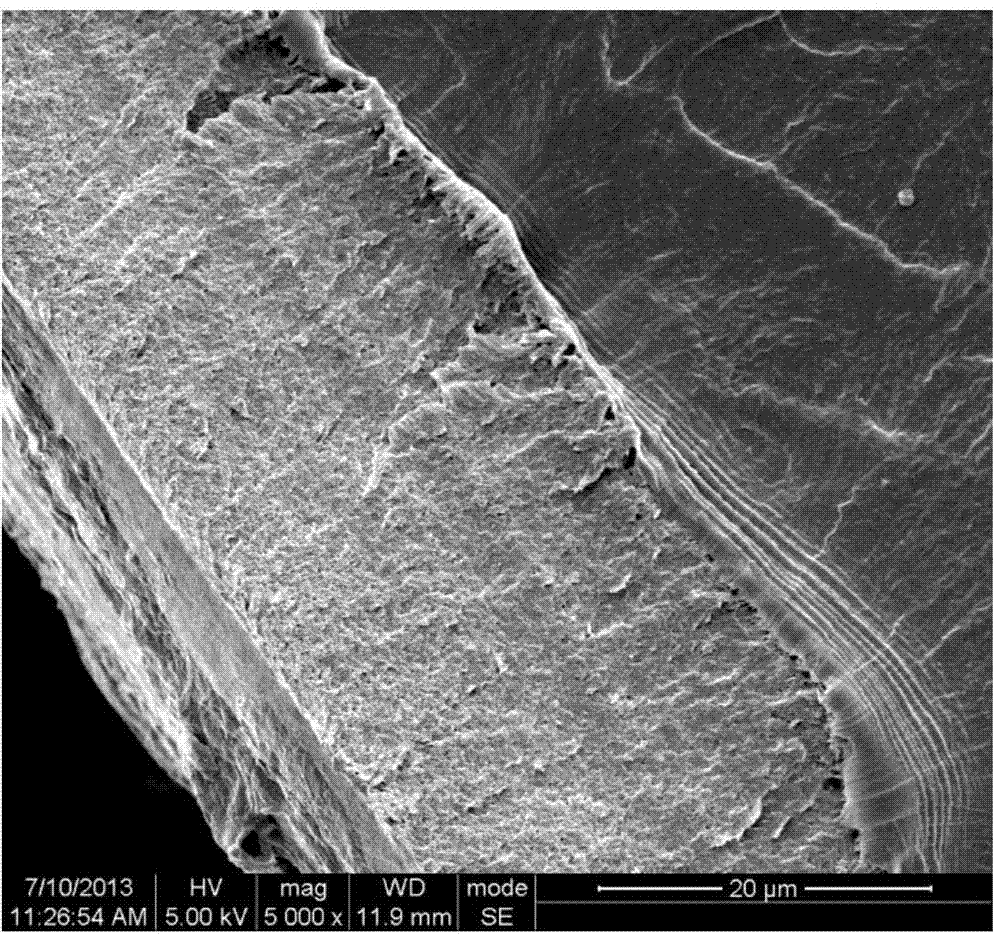

Method for preparing aromatic hydrocarbon mixture rich in benzene, toluene and xylene (BTX) by conversion of methanol in fixed bed reactor

ActiveCN104496743AActual usage is smallReduce operating energy consumptionHydrocarbon from oxygen organic compoundsHydrocarbon by hydrocarbon condensationBenzeneAromatization

The invention relates to a method for preparing an aromatic hydrocarbon mixture rich in benzene, toluene and xylene (BTX) by conversion of methanol in a fixed bed reactor. The method comprises the following steps of feeding a catalyst for preparation of low-carbon olefin by conversion of methanol and a catalyst for aromatization of low-carbon olefin in the same fixed bed reactor to form a catalyst combined unit in which the lower layer is the catalyst for aromatization of low-carbon olefin and the upper layer is catalyst for preparation of low-carbon olefin by conversion of methanol; dividing methanol steam into a plurality of blasts, mixing one blast of the methanol steam, circulating LPG and water steam to obtain a mixture, feeding the mixture into the fixed bed reactor from a material inlet formed in the top of the fixed bed reactor, feeding the residual methanol steam into the fixed bed reactor from a material inlet formed in the side wall of the reactor to obtain the aromatic hydrocarbon mixture rich in BTX. The method has the advantages that the process is simple, the cost is low and the large-scale production can be achieved.

Owner:SHANXI FEISHI TECH +1

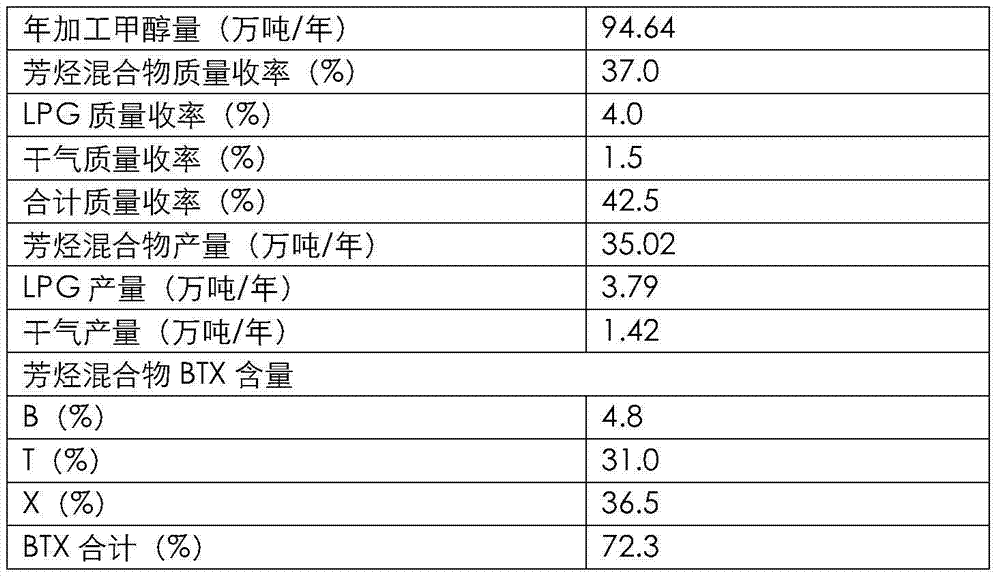

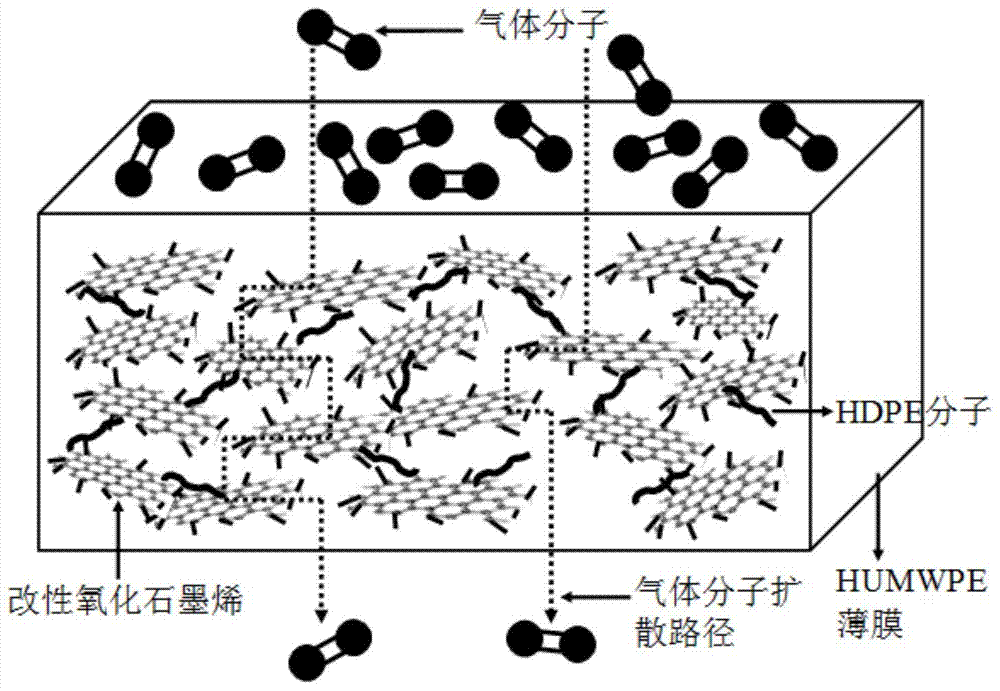

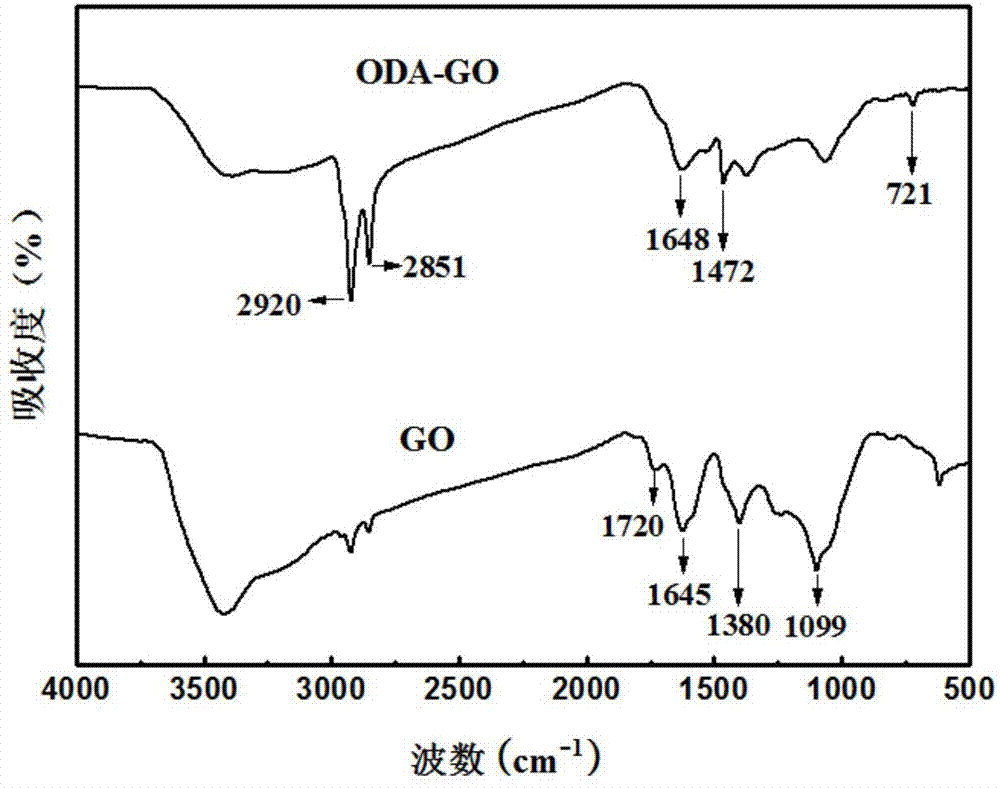

Method for preparing high-barrier graphene oxide-polyethylene nano composite film

ActiveCN103897244AImprove securityPromote environmental protectionLaminationLamination apparatusPolymer scienceComposite film

The invention discloses a method for preparing a high-barrier graphene oxide-polyethylene nano composite film. The method comprises the following steps: ultrasonically dispersing modified graphene oxide into xylene and heating; then adding high-density polyethylene and stirring so as to obtain an ODA-GO / HDP mixed solution; cleaning an ultra-high molecular weight polyethylene film by xylene; after xylene is evaporated, soaking a UHMWPE film into a hot ODA-GO / HDPE mixed solution in a dipping manner; drying; and repeating the above steps until the required layer quantity is reached. The high-barrier graphene oxide-polyethylene nano composite film prepared by the method is high in safety and good in environmental protection property; the oxygen permeating coefficient is reduced by about 49%; the nano composite film has ultra-high oxygen barrier property, can meet the packaging requirements of a plurality of foods and drugs and use of other products, is simple in process and low in cost, and has broad practicability and promotional value.

Owner:上海追得新材料科技有限公司

Process for covering water transfer printing on wood plastic, plastic and metallic products

The invention discloses a water-coated transfer printing process for wood, plastic, and metal products, which comprises the following steps: according to the necessary background color, spraying oil paint on the surfaces of the wood, the plastic, and the metal products; spreading a water-coated transfer printing film on the water surface by putting the surface with printing ink patterns to face upwards; spraying an activator on the water-coated transfer printing film evenly through a spray gun when the water-coated transfer printing film is softened and spread levelly; and according to the positions of the patterns floating on the water surface, pressing an obtained product downwards into the water for 2 to 10 seconds and taking out the product, and transferring the patterns on the water-coated transfer printing film to the surface of the product under the action of water pressure. The process further comprises the following steps: washing the obtained product clean by water and then putting the product into a drying furnace to be dried at a temperature between 50 and 70 DEG C; or using a blowing gun to blow off the water, drying the product at room temperature, spraying a layer of transparent oil paint on the surface of the product, putting the product in the drying furnace and curing the product at a temperature between 50 and 160 DEG C. The compositions of the activator are as follows according to percentage by weight: 33 percent of xylene, 15 percent of butyl acetate, 15 percent of methyl acetate, 10 percent of methyl isobutyl ketone, 5 percent of isobutanol, 8 percent of isophorone, 5 percent of methyl methacrylate, 7 percent of cyclo ethyl ketone, and 2 percent of nitrocellulose resin.

Owner:张艳 +1

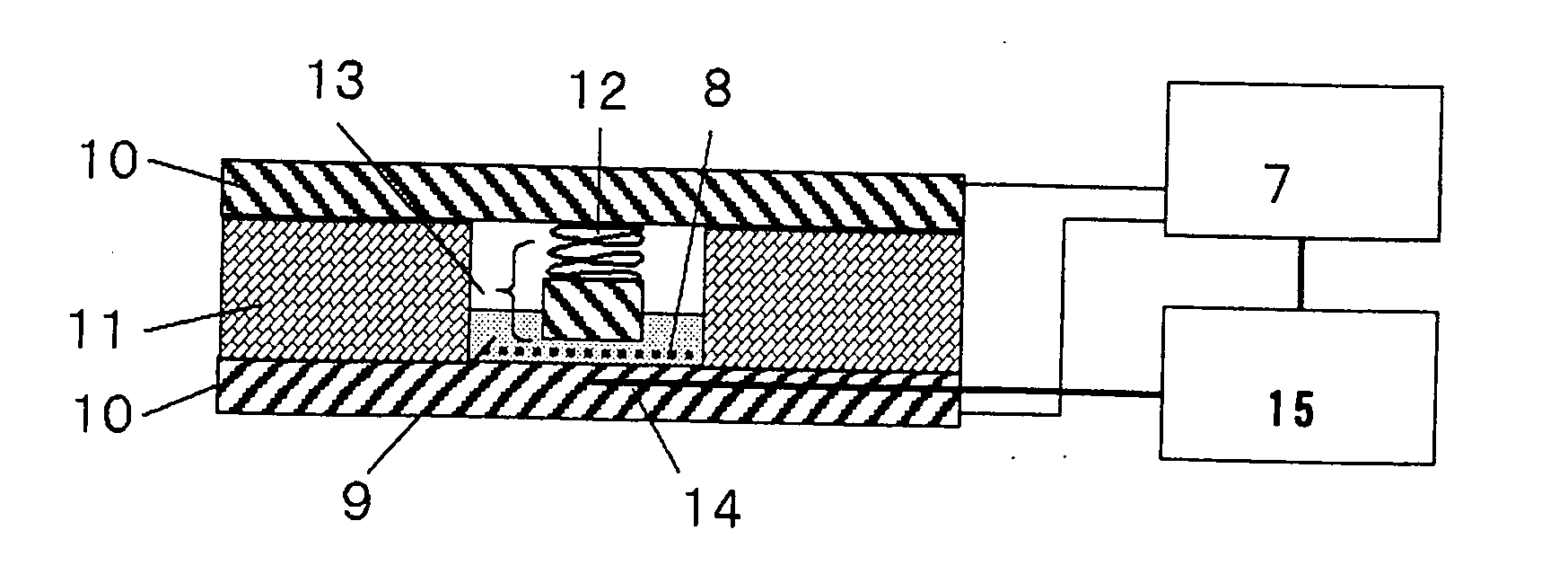

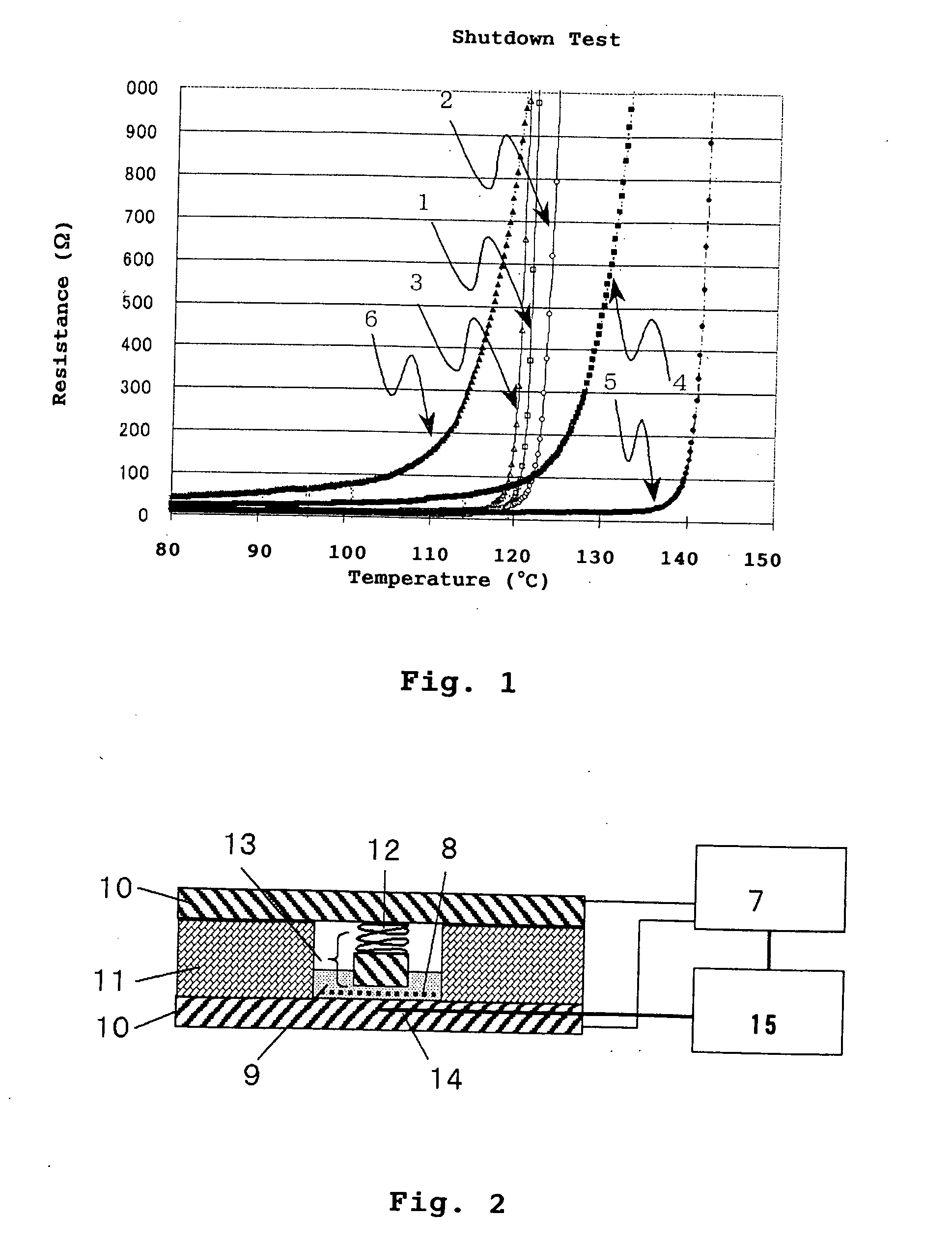

Porous film, and production method and applications thereof

InactiveUS20060234031A1Improve ion permeabilityExcels in ion permeabilitySynthetic resin layered productsSecondary cellsPolyolefinAlpha-olefin

Disclosed is a porous film formed of a polyolefin resin comprising an ethylene-α-olefin copolymer (A) which comprises structural units originating from ethylene and structural units originating from one or more sorts of monomers selected from α-olefins having 4-8 carbon atoms and which satisfies the requirements (I) the intrinsic viscosity [η] is 9.0 to 15.0 dl / g; (II) the melting point Tm is not lower than 115° C. but lower than 130° C.; (III) the content of cold-xylene-soluble components included in the ethylene-α-olefin copolymer (A) is 3% by weight or less; and (IV) Tm≦0.54×[η]+114. A battery separator including the porous film and a method for the preparation of the porous film are also disclosed.

Owner:SUMITOMO CHEM CO LTD

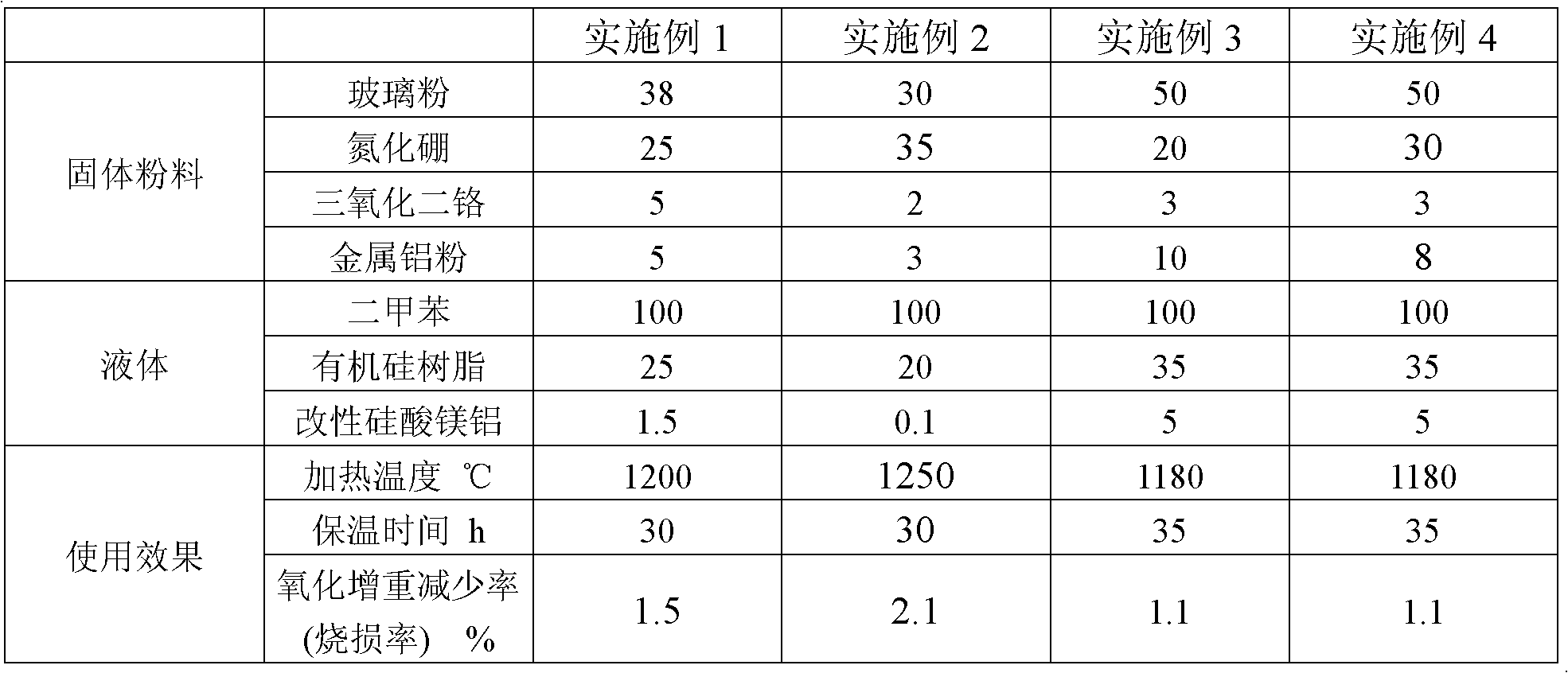

Anti-oxidation coating for heat treatment of iron and preparation method thereof

ActiveCN102585568AImprove performanceWide variety of sourcesSpecial surfacesCoatingsBoron nitrideOxidation resistant

The invention belongs to the technical field of the preparation of high-temperature anti-oxidation coatings, in particular to an anti-oxidation coating used in a long-time heat treatment process of iron, and the like at high temperature. The coating comprises solid powder and liquid, and is characterized in that the solid powder comprises following components by weight part: 30 to 50 parts of glass powder, 10 to 50 parts of boron nitride, 2 to 5 parts of chromic oxide and 3 to 10 parts of metal aluminum powder; and the liquid comprises following components by weight part: 0.1 to 5 parts of modified magnesium aluminosilicate, 20 to 35 parts of organic silicone resin and 100 parts of xylene. Through the adoption of the coating, oxydic weight gain of carbon steel or alloy steel can be guaranteed to be reduced by more than 80 percent in the heat treatment process for a long time (larger than 30 hours) at temperature of 1200 DEG C and above.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

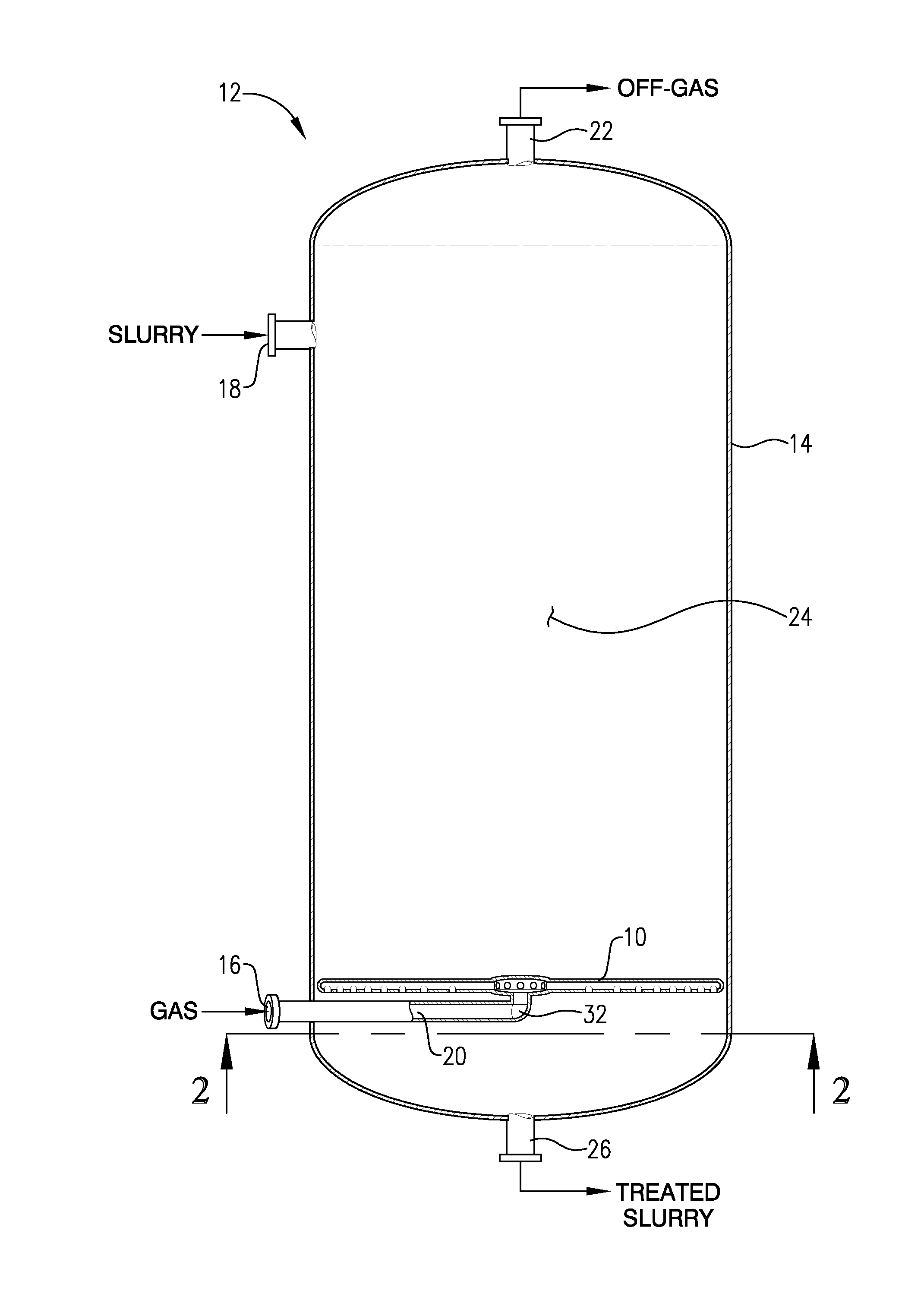

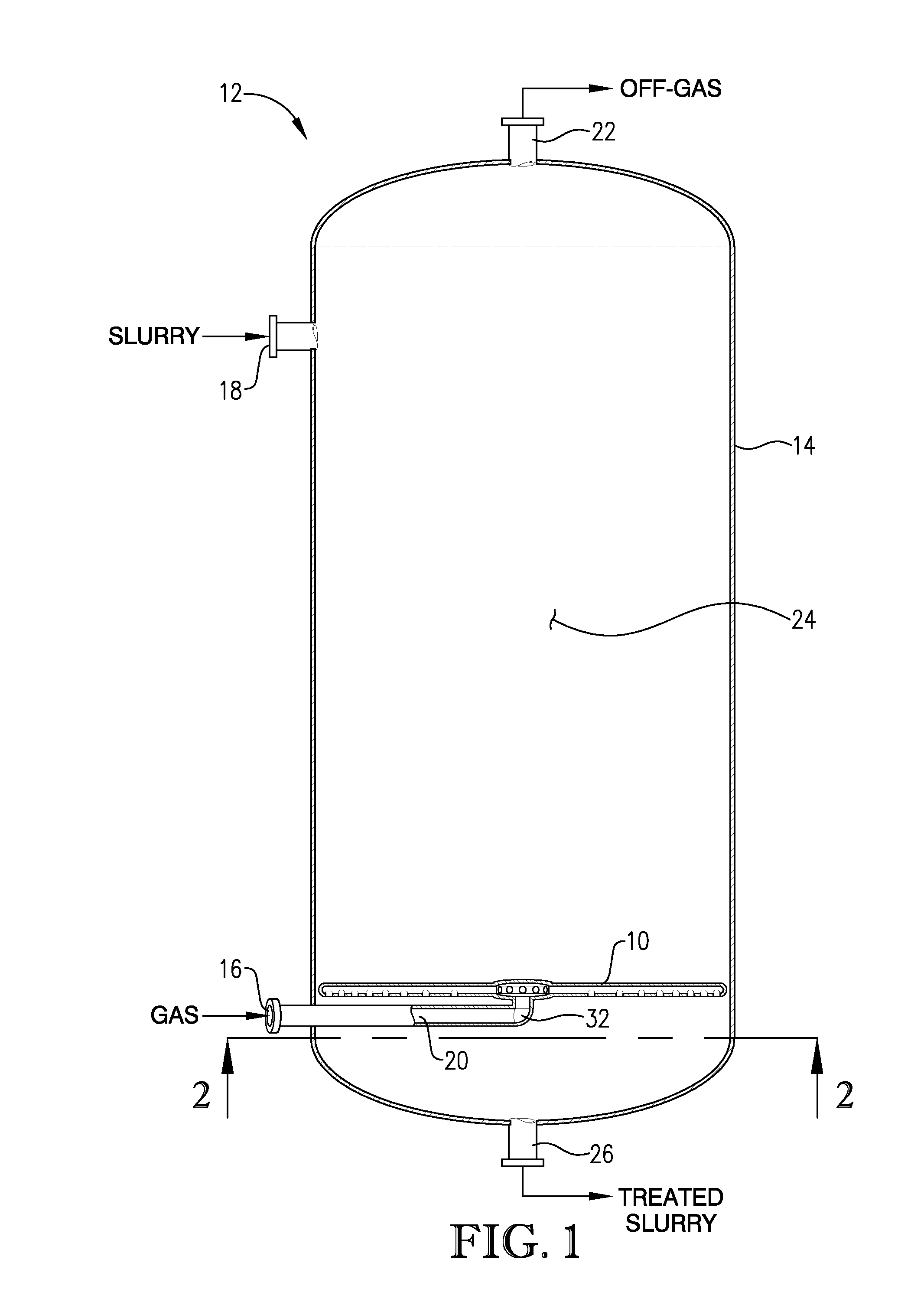

Methods and Apparatus for Enhanced Gas Distribution

ActiveUS20120068111A1Low costLiquid degasificationTransportation and packagingDistribution methodReaction zone

Methods and apparatus for introducing a gas into the reaction zone of a reactor. Such methods and apparatus can more evenly distribute the gas throughout the reaction zone. Spargers for introducing a gas into the reaction zone of a reactor can be employed in systems and methods for carrying out the liquid-phase oxidation of an oxidizable compound, such as para-xylene.

Owner:ALPEK POLYESTER SA DE CV

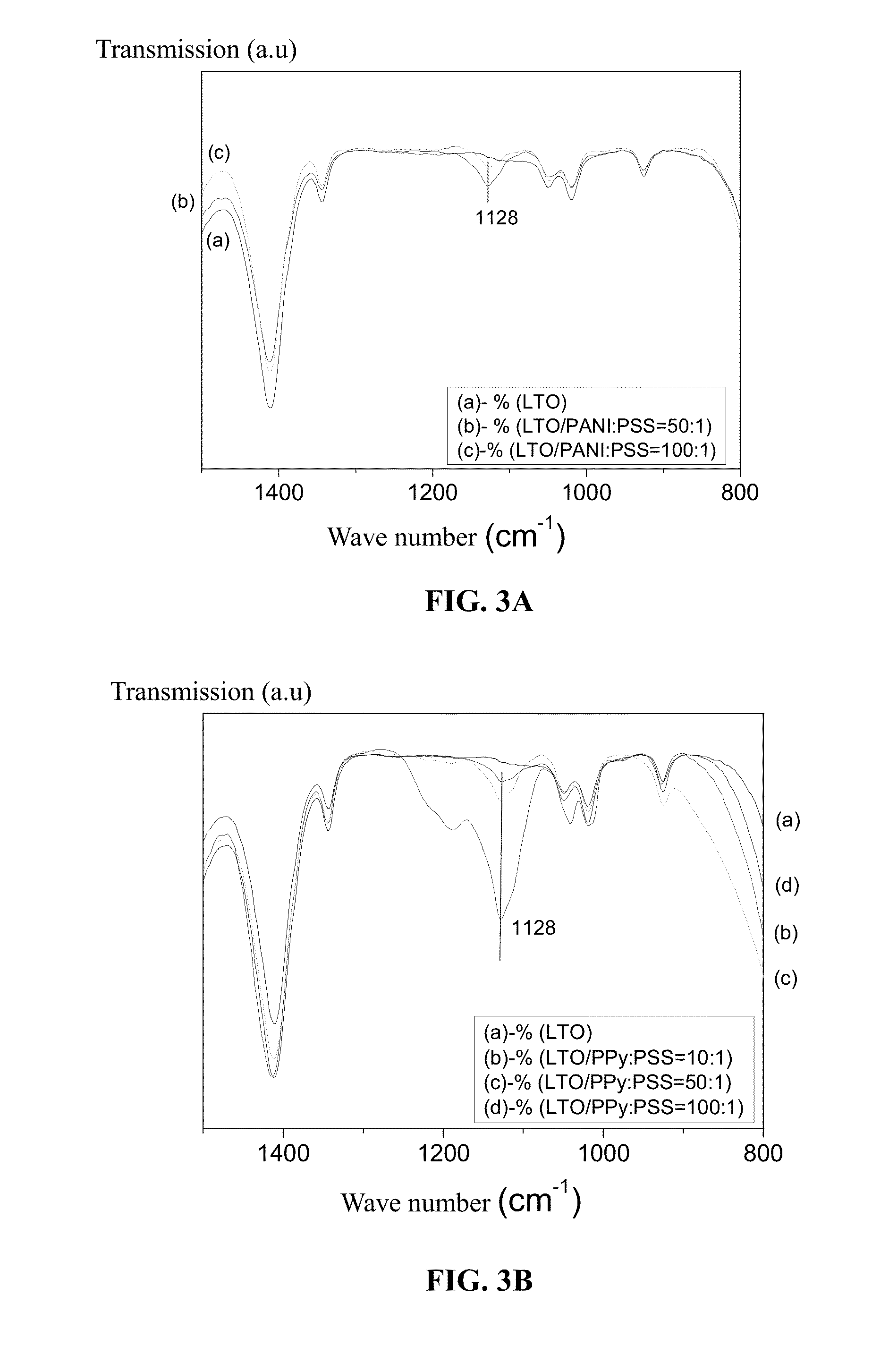

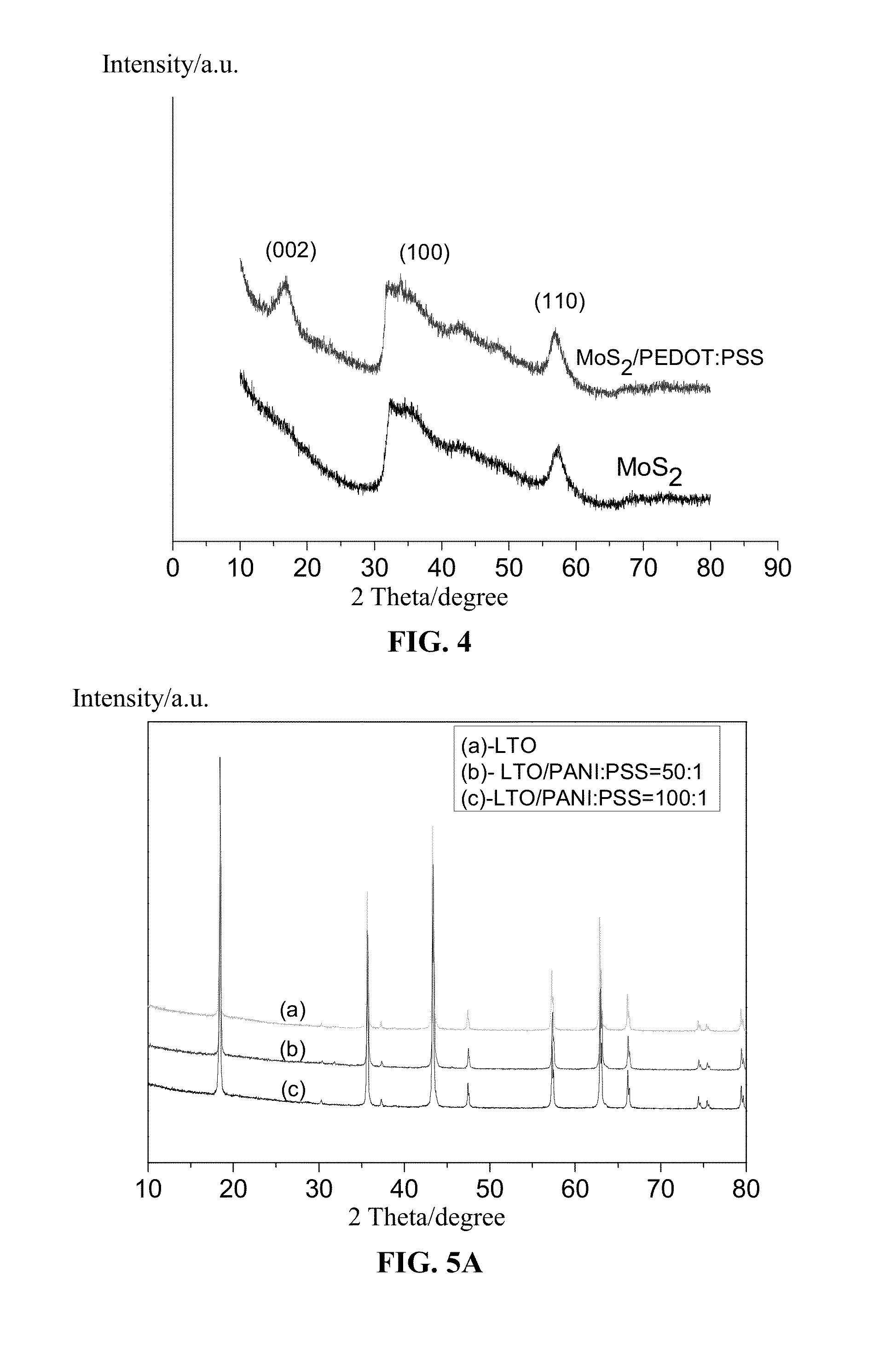

Composite electrode material for lithium ion battery and preparation method thereof

InactiveUS20140315081A1Simple processLow costHybrid capacitor electrodesMechanical vibrations separationPolypyrroleConductive polymer

The invention provides a composite electrode material for a lithium ion battery. The composite electrode material includes an electrode material and a conductive polymer. The conductive polymer coats the surface of the electrode material with a thickness of several nano-meter level. The electrode material is a positive electrode material or a negative electrode material, and the conductive polymer tends to disperse in an aqueous solution or an organic solution in the presence of a doping and dispersing agent and a dispersing medium. The conductive polymer is selected from poly(3,4-ethylenedioxythiophene) (PEDOT), polyaniline (PANT), or polypyrrole (PPy), the doping and dispersing agent is polystyrene sulfonic acid (PSS), and the dispersing medium is water; or the conductive polymer is polyaniline(emeraldine salt), and the dispersing medium is xylene. A method for preparing the composite electrode material for a lithium ion battery is also provided.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

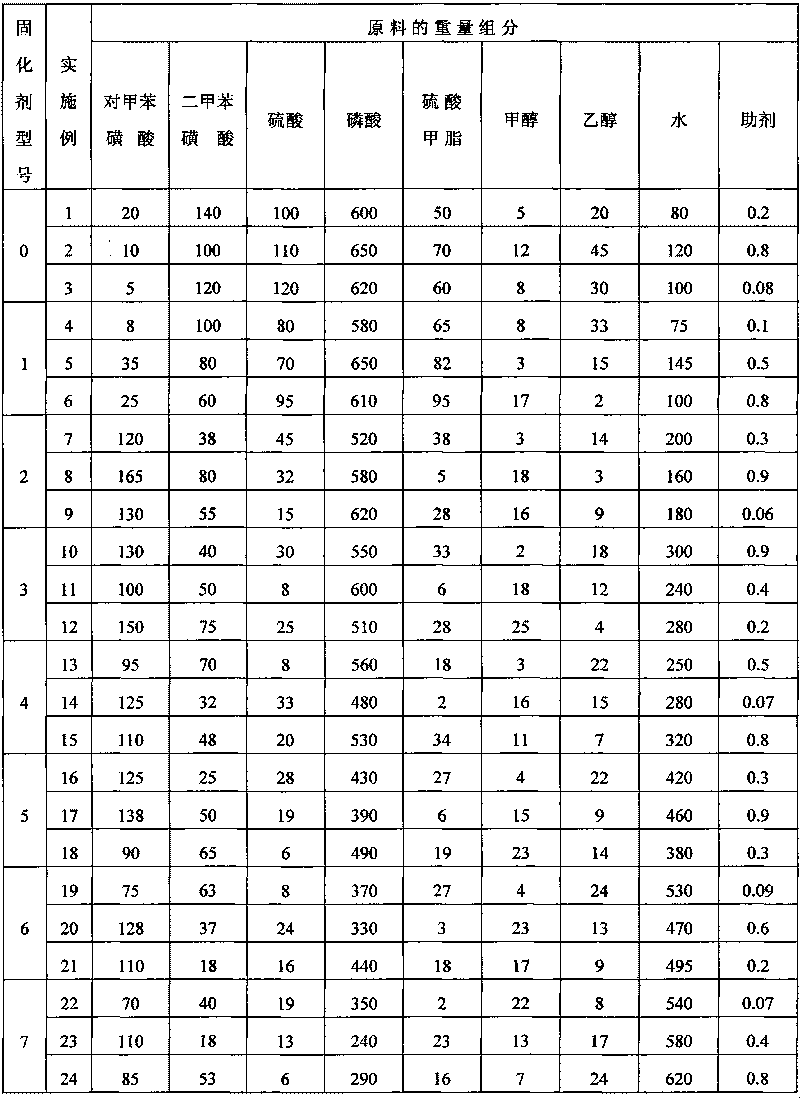

Curing agent of self-hardening furan resin sand and preparation method thereof

ActiveCN101722272ASolve the problem that the usable time is too shortSolve the difficult problems of productionFoundry mouldsFoundry coresFuranPhosphoric acid

The invention relates to a curing agent of self-hardening furan resin sand, which comprises the following components in portions by weight: 1-300 portions of toluenesulfonic acid, 10-300 portions of xylene monosulfonic acid, 1-170 portions of sulfuric acid, 200-800 portions of phosphoric acid, 1-200 portions of methyl sulfate, 1-50 portions of ethanol, 1-50 portions of methanol, 40-900 portions of water and 0.05-1.0 portion of assistant. The preparation method comprises the following steps: (1) prefabricating the toluenesulfonic acid, the xylene monosulfonic acid and the methyl sulfate; (2) preparing all the raw materials according to the proportion of the curing agent; and (3) synthesizing the curing agent by the following steps: (a) mixing the toluenesulfonic acid, the xylene monosulfonic acid, the methyl sulfate and the sulfuric acid to react for 1.0 hour; (b) cooling to 55 DEG C, adding the mixture of methanol and ethanol to react at 50-70 DEG C for 1.0 hour; (c) adding the phosphoric acid to react at 55-70 DEG C for 1.0 hour; and (d) cooling to 50 DEG C, and adding water and assistant; and discharging after evenly mixing. The curing agent can adapt to the long (super long) use time in the molding process of large castings at high air temperature (above 28 DEG C) and high sand temperature (30-50 DEG C), and solves the problem that the large (super long and large) castings are difficult to produce since the temperature of the reclaimed sand can not drop to the designed value due to various reasons in the foundry corporations.

Owner:四川东树新材料有限公司

Acoustic wool with high impact resistance and preparation method thereof

InactiveCN105506857AIncreased durabilityImprove featuresNon-woven fabricsMonocomponent polyolefin artificial filamentHazardous substancePolyethylene glycol

The invention discloses acoustic wool with high impact resistance. The acoustic wool is prepared from, by weight, 1-2 parts of barium stearate, 0.5-1 part of sodium xylene sulfonate, 5-10 parts of zircon powder, 3-5 parts of silicon carbide, 1-2 parts of ethylene bis stearamide, 80-100 parts of polypropylene, 2-4 parts of styrene, 1-2 parts of epoxy rice bran oleic acid butyl ester, 3-5 parts of butyl methacrylate, 1-2 parts of polyethylene glycol, 0.05-0.1 part of azodiisobutyronitrile, 0.5-1 part of castor oil and 3-5 parts of functional powder. The acoustic wool is good in sound absorption effect and mechanical performance, high in durability, high in impact resistance, less prone to deformation, good in processing performance, capable of absorbing harmful substances in air, effectively purifying the air and protecting human health, high in comprehensive value and high in practicality.

Owner:WUHU HUANRUI AUTO INTERIOR DECORATION

Nano-Structured Composite Material and Process of Making for Enclosed Space Air Detoxing and Deodoring

ActiveUS20150126357A1Improve efficiencyLower resistanceMolecular sieve catalystsDispersed particle separationNanoporous carbonToxic chemical

The present invention is related to a nano-structured composite material and process of making for air detoxing and deodoring in enclosed spaces to prevent harmful chemicals in the air from damaging human health. The nano-structured composite material consists of nano-porous carbon, zeolites with sub nano-size pores and at least 1 other component chosen from nano-porous rare earth oxides and nano-sized catalysts, and is made into highly efficient configurations with high geometric surface and low resistance air flow channels. The synergetic action of those nano-structured components can effectively remove toxic chemicals including, but not limited to formaldehyde, benzene, toluene, xylene, propene, butadiene, acetone, carbon monoxide, nitric oxide, nitrogen dioxide, sulfur dioxide, hydrogen sulfide, ammonia, alcohols, chlorine, mercaptans, as well as bad odors, such cigarette smoke and bathroom / toilet smells.

Owner:QI XIWANG +1

Improvements in and relating to reconfigurable antenna

ActiveCN101743665ALow powerReduce weightAntenna arraysRadiating elements structural formsReconfigurable antennaGround plane

A micro electromechanical (MEMS) antenna (36) is positioned on one side of a substrate and is connected to a MEMS switch comprising a capacitor bridge (46) and to a transmission line (42) by means of a thru hole or via (48) which forms an electrically conducting path through the substrate. This arrangement provides a common ground plane for the antenna and switch and shields the switch from the electromagnetic radiation received or transmitted from the antenna. The switch may comprise a topmost metal layer which extends across a bridge structure formed by a polymer layer (19). The polymer layer comprises poly-monochloro-para-xylene (parylene-C). Homogeneous or heterogeneous antenna array structures are implemented. The antenna arrays may include one or more different type of antennas with for example different shapes, rotations and reflections.

Owner:SOFANT TECH

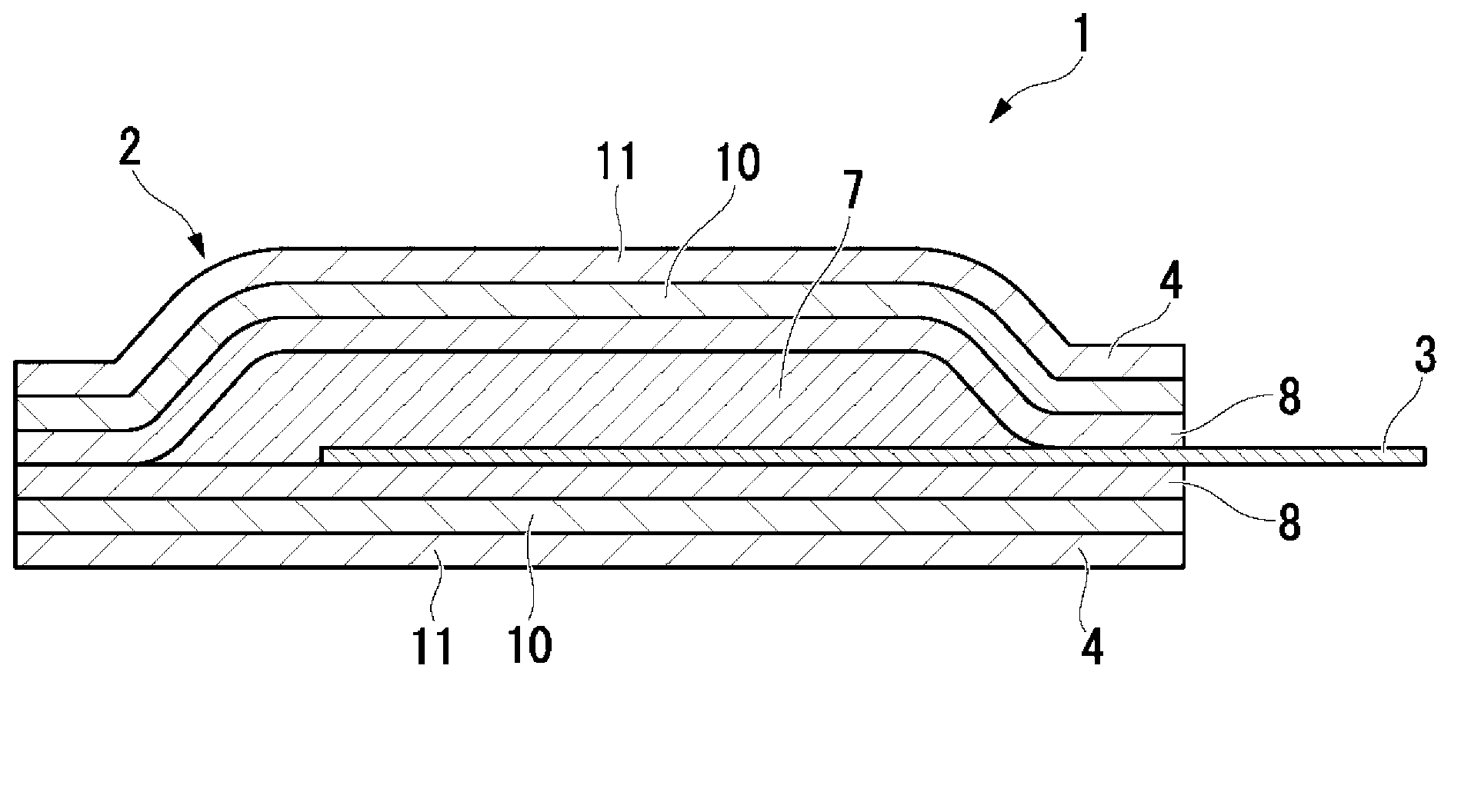

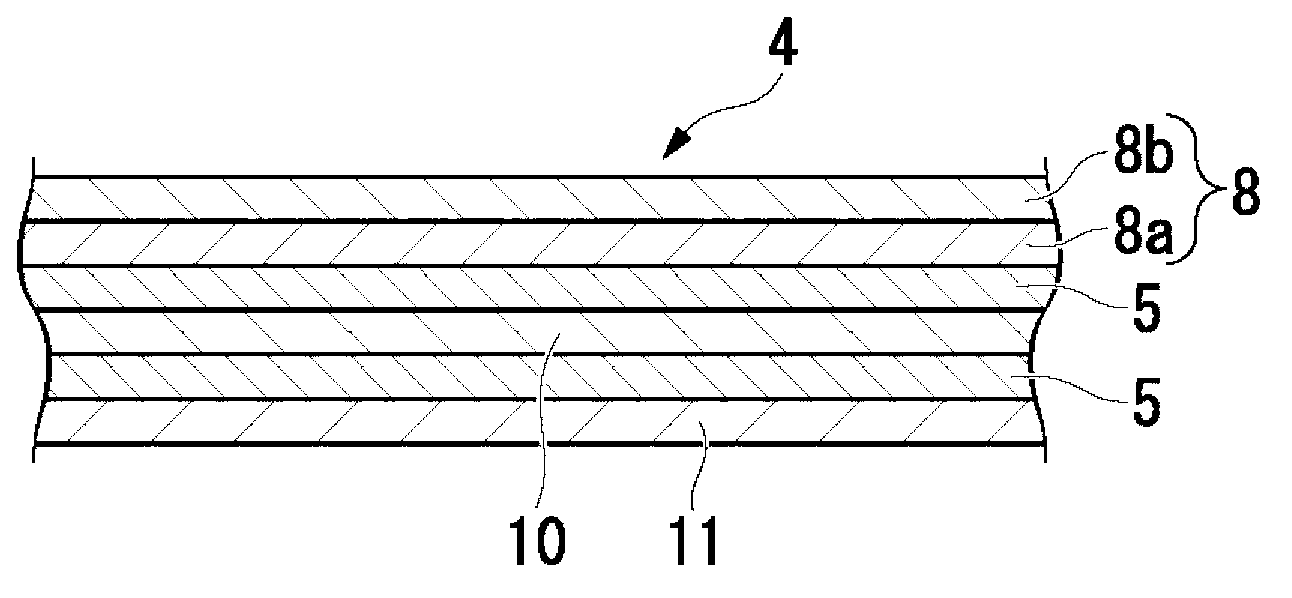

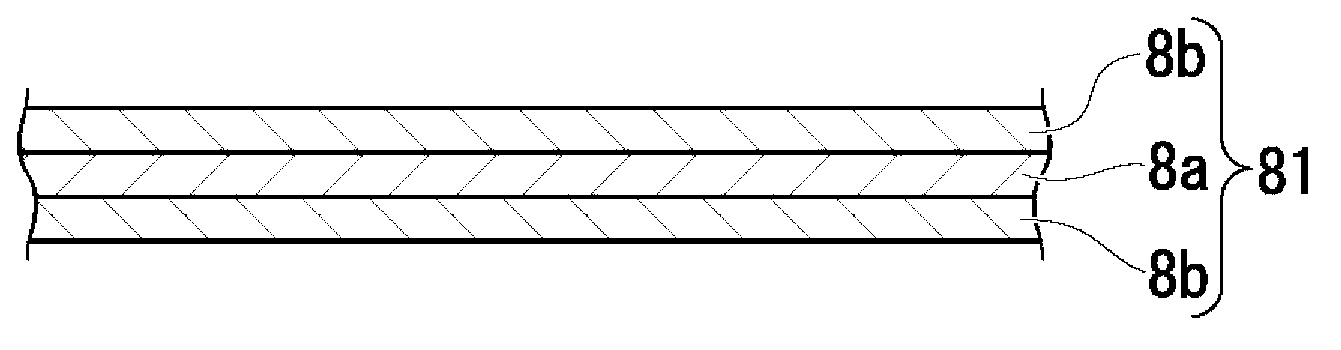

Outer casing material for battery and lithium secondary battery

ActiveCN103227296AImprove insulation performanceLi-accumulatorsCell component detailsElastomerMetal foil

An outer casing material for a battery 4 is provided, wherein an outer layer 11, a metal foil layer 10 and an inner layer 8 are laminated via an adhesive layer 5; the inner layer 8 comprises a sealant layer 8b and a base material layer 8a; the sealant layer 8b is made from a propylene-ethylene random copolymer wherein a melt flow rate at 230 DEG C. thereof is in a range of 3 to 30 g / 10 minutes; the base material layer 8a is made of a resin composition wherein a melt flow rate at 230 DEG C. thereof is in a range of 0.1 to 15 g / 10 minutes, xylene-soluble component Xs thereof satisfies the predetermined conditions, and the resin composition comprises 50 to 80% by mass of a propylene component (A) and 50 to 20% by mass of a copolymer component (B) which is an elastomer of a copolymer of propylene and ethylene and / or alpha-olefin having 4 to 12 carbons and includes 50 to 85% by mass of a polymerization unit originated from propylene.

Owner:LISSENOK PACKAGING CO LTD

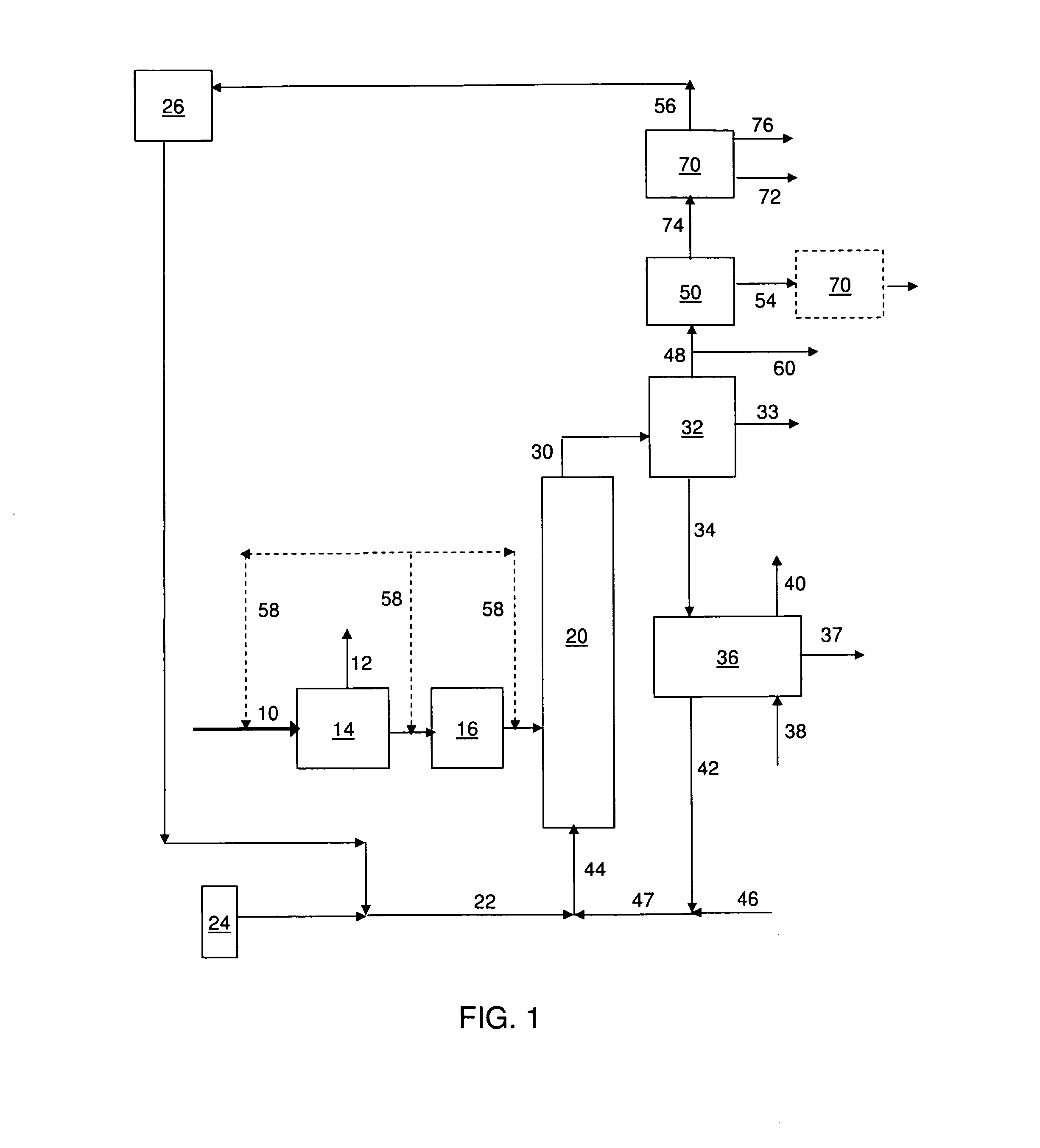

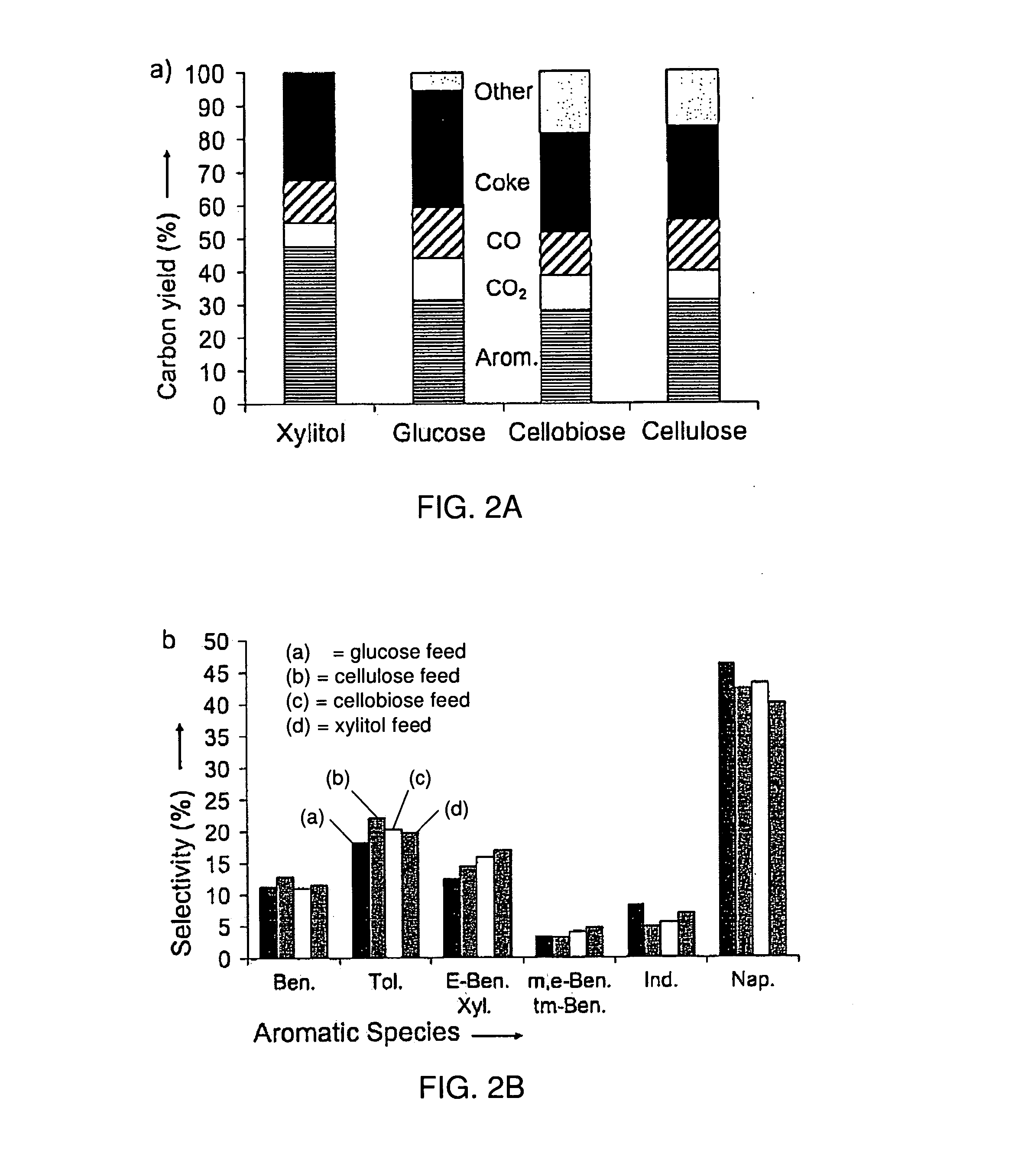

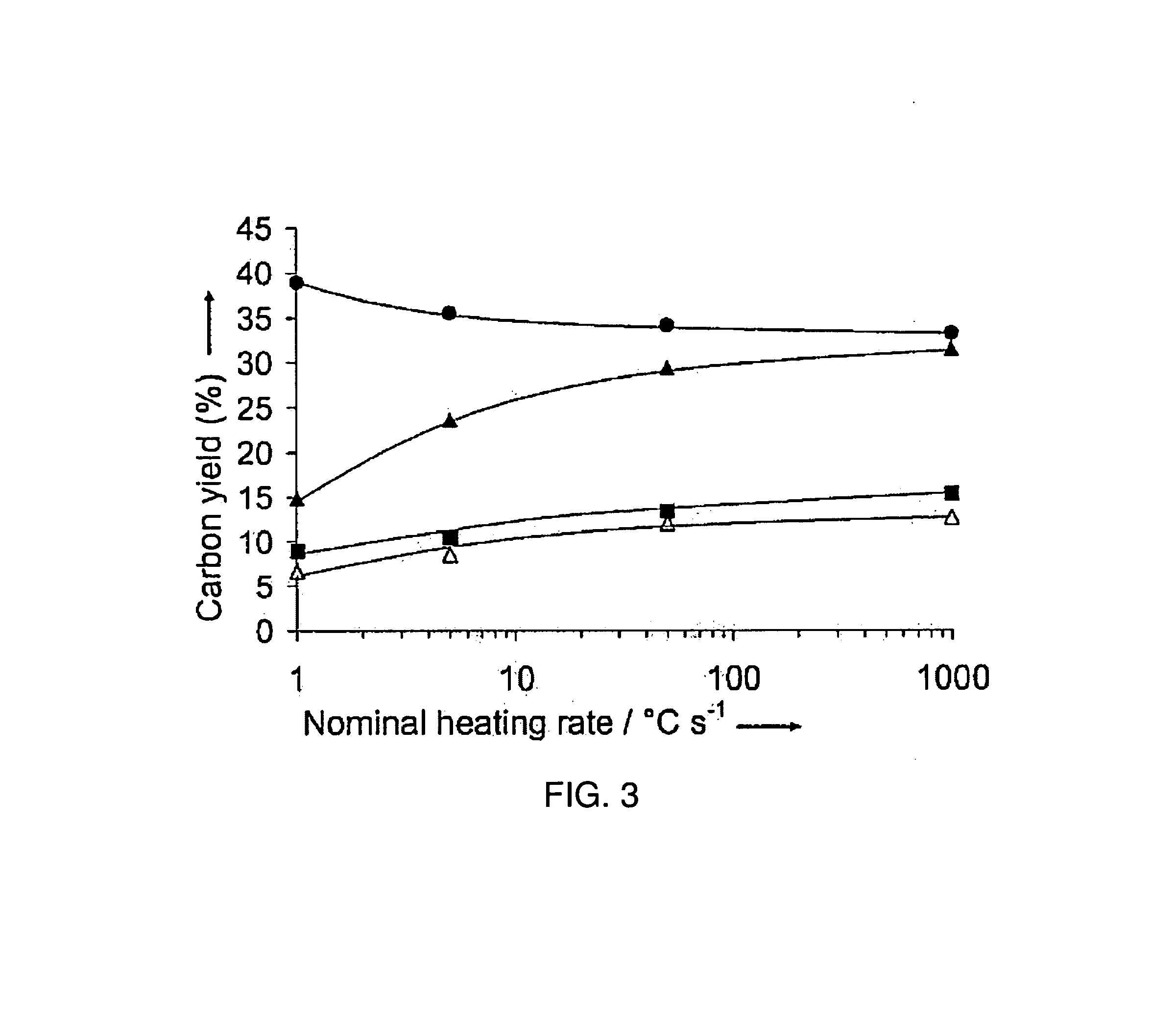

Catalytic pyrolysis of solid biomass and related biofuels, aromatic, and olefin compounds

ActiveUS20130023706A1Minimize coke productionHydrocarbon from oxygen organic compoundsLiquid hydrocarbon mixture productionBenzeneCatalytic pyrolysis

This invention relates to compositions comprising fluid hydrocarbon products, and to methods for making fluid hydrocarbon products via catalytic pyrolysis. Some embodiments relate to methods for the production of specific aromatic products (e.g., benzene, toluene, naphthalene, xylene, etc.) via catalytic pyrolysis. Some such methods involve the use of a composition comprising a mixture of a solid hydrocarbonaceous material and a heterogeneous pyrolytic catalyst component. The methods described herein may also involve the use of specialized catalysts. For example, in some cases, zeolite catalysts may be used.

Owner:UNIV OF MASSACHUSETTS

Catalyst for converting alcohol ether into high p-xylene content aromatic hydrocarbon, preparation method and reaction process thereof

ActiveCN103272633AHigh strengthNot easy to fall offMolecular sieve catalystsHydrocarbon from oxygen organic compoundsChemical industryFixed bed

The invention belongs to the technical field of chemical industry catalysis, and particularly relates to a catalyst for converting an alcohol ether into a high p-xylene content aromatic hydrocarbon, a preparation method and a reaction process thereof. According to the present invention, a molecular sieve loading a metal, phosphorus and rare earth and other reinforcing components are adopted to form high mechanical strength particles, and the surface acid sites are 0.01-1% (molar fraction) of the total acid sites of the catalyst; the preparation method relates to a method for forming composite particles through multiple forming and controlling acid of the surface of the composite particles; and the catalyst can be applicable for fixed beds, moving beds and fluidized beds, and can be provided for converting methanol or dimethyl ether raw materials containing water and a small amount of high carbon alcohol and ester, wherein one-time conversion efficiency of the methanol or the dimethyl ether at a temperature of 450-520 DEG C and a space velocity of 0.2-30 h <-1> is more than 99.9%, the total (carbon-base) yield of the aromatic hydrocarbon is more than 60%, and the mass fraction of the p-xylene in the xylene is more than 90%.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com