Polyurethane grouting water plugging-reinforcing material, and preparation method and application method thereof

A reinforcement material and polyurethane chemical technology, applied in mining equipment, shaft equipment, earthwork drilling and mining, etc., can solve problems such as difficulty in adapting to safety, fast and efficient production, etc., to achieve easy control of product quality, significant water blocking effect, and production process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

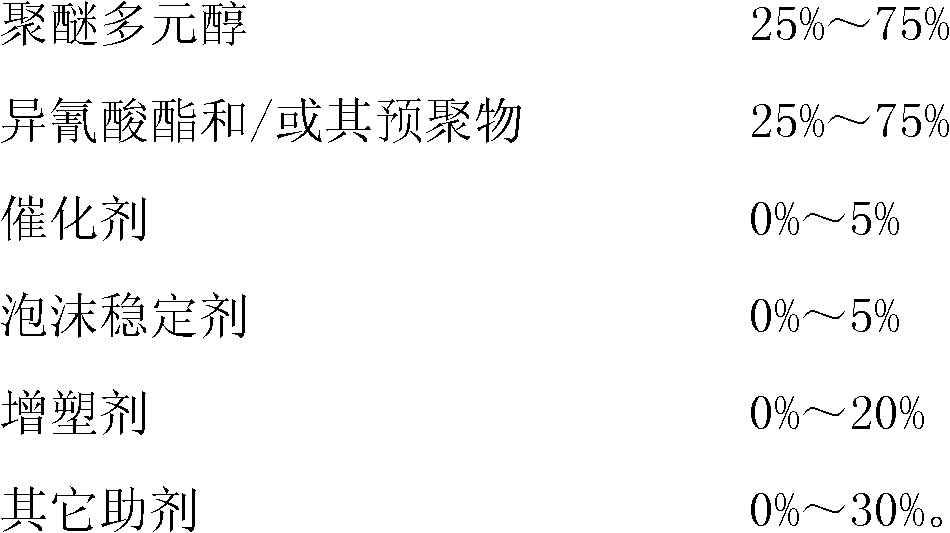

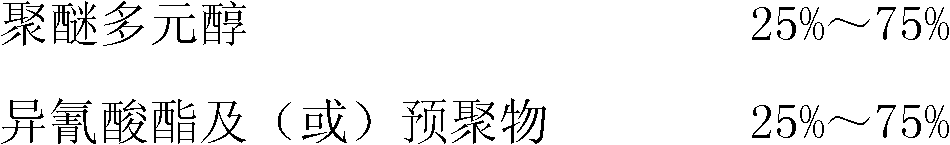

[0035] Component A:

[0036]

[0037]

[0038] Component B:

[0039] Isocyanate 45

[0040] Plasticizer 10

[0041] water remover 1

[0042] The polyurethane chemical grouting water blocking-reinforcement material prepared according to the aforementioned process has a fast reaction speed and a foaming ratio greater than 15 times, and is suitable for large-area water seepage or water gushing treatment.

Embodiment 2

[0044] Component A:

[0045]

[0046] Component B:

[0047] Isocyanate 45

[0048] Plasticizer 9

[0049] The polyurethane chemical grouting water blocking-reinforcement material prepared according to the aforementioned process has high compressive strength and a foaming ratio of about 3 times, and is suitable for water seepage and reinforcement treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com