Epoxy ester modified aqueous alkyd resin and preparation method thereof

A technology of water-based alkyd resin and alkyd resin, applied in the direction of coating, etc., can solve the problems of easy gelation, increased viscosity, and darkened resin color, etc., and achieve the effect of good yellowing resistance, good hardness, and not easy to stick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

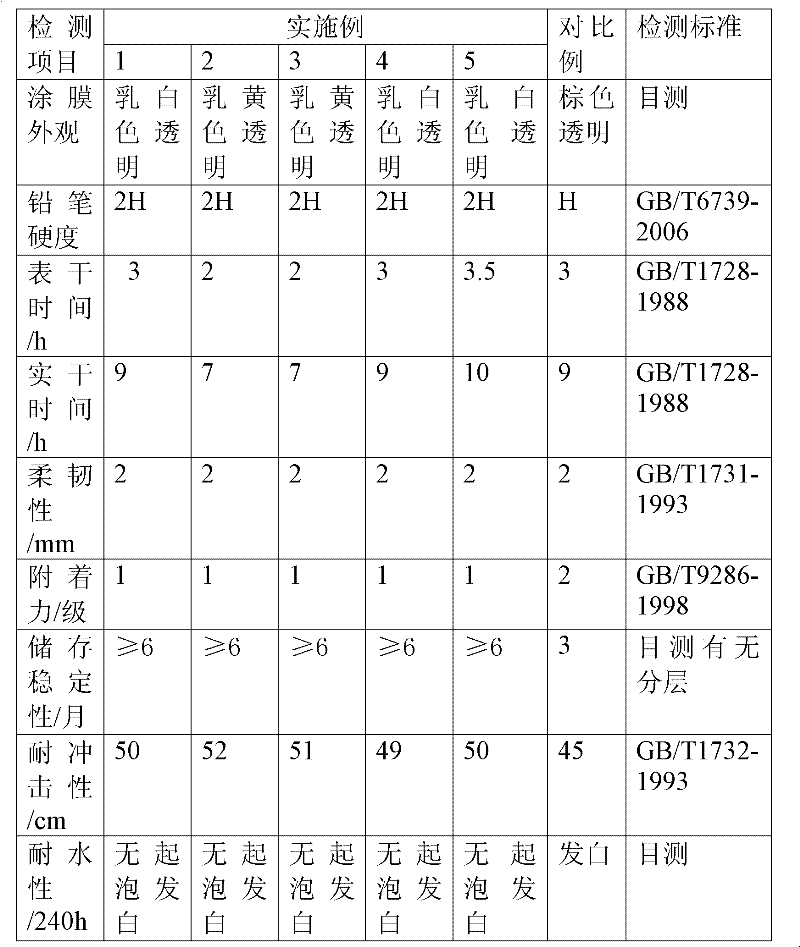

Examples

Embodiment 1

[0031] (1) Add 55g of soy oil, 20g of phthalic anhydride, 30g of trimethylolpropane, 0.28g of organotin catalyst BC-98, 7g of xylene, heat to 180°C, reflux reaction for 1h, at 10°C / h Raise the temperature to 230°C, hold the temperature for 40 minutes, and stop the reaction when the acid value drops to 31mgKOH / g;

[0032] (2) Put 28g of soybean oil fatty acid, epoxy resin E-2015g, and 3.4g of triphenylphosphine into another reactor, heat up to 180°C, keep the temperature for 1 hour, and record the acid value less than 5mgKOH / g; The epoxy resin molar ratio is 2.7g of maleic anhydride of 1: 1, catalyst benzoyl peroxide BPO 0.92g, heat preservation copolymerization at 180 ℃ for 2h, generate epoxy ester;

[0033] (3) Add 10g of xylene, 1.5g of BC-98, and the above-mentioned epoxy ester into the reactor with alkyd resin, and reflux at 180°C for 1h. When the acid value is lower than 7mgKOH / g, stop stirring and filter with suction Remove the solvent, lower the temperature to 110°C; a...

Embodiment 2

[0035] (1) Add 70g of linolenic acid, 20g of adipic acid, 25g of trimethylolpropane, BC-980.34g, 8.41g of xylene, heat to 180°C, reflux for 1h, and heat up to 230°C at a rate of 10°C / h , heat preservation reaction for 35min, stop the reaction when the acid value drops to 33mgKOH / g;

[0036] (2) Put 18g of linolenic acid, epoxy resin E-2032g, and 0.4g of triphenylphosphine into another reactor, heat up to 180°C, keep the temperature for 1 hour, and record the acid value less than 5mgKOH / g; The epoxy resin molar ratio is 3.14g of maleic anhydride of 1:1, catalyst benzoyl peroxide BPO 1.06g, heat preservation copolymerization at 180 ℃ for 2.5h, generate epoxy ester;

[0037] (3) Add 12g of xylene, 1.8g of BC-98, and the above-mentioned epoxy ester into the reactor with alkyd resin, and reflux at 180°C for 1h. When the acid value is lower than 7mgKOH / g, stop stirring and filter with suction Remove the solvent, lower the temperature to 110°C; add 13.28g of 2-acrylamide-2-methylpro...

Embodiment 3

[0039](1) Add 60g of linolenic acid, 30g of phthalic anhydride, 25g of pentaerythritol, BC-980.36g, 8.94g of xylene, heat to 180°C, reflux for 1h, heat up to 230°C at a rate of 10°C / h, and keep warm React for 40min, stop the reaction when the acid value drops to 30.2mgKOH / g;

[0040] (2) Put 35.22g of linolenic acid, 24.78g of epoxy resin E-5124.78g, and 0.48g of triphenylphosphine into another reactor, raise the temperature to 180°C, keep the temperature for 1 hour, and the measured acid value is less than 5mgKOH / g; add 3.77g of maleic anhydride and 1.28g of catalyst benzoyl peroxide BPO with a molar ratio of 1:1 to the epoxy resin were incubated at 180°C for 2 hours to generate epoxy ester;

[0041] (3) Add 10g of xylene, 1.5g of BC-98, and the above-mentioned epoxy ester into the reactor with alkyd resin, and reflux at 180°C for 1.5h. When the acid value is lower than 7mgKOH / g, stop stirring and pump The solvent was filtered off, and the temperature was lowered to 110°C; 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com