Synthesis method of polycarbosilane capable of being used for thermosetting crosslinking

A technology of polycarbosilane and synthesis method, applied in the field of polycarbosilane synthesis, can solve problems such as difficulty in obtaining pyrolysis ceramic product properties, excellent polycarbosilane, etc., achieve easy implementation, improve ceramic yield, and avoid melting outflow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

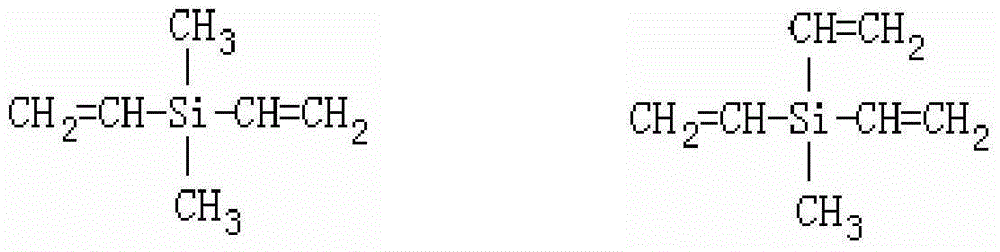

[0024] Synthesis of PVCS-1 from PCS-1 and Dimethyldivinylsilane (DVS)

[0025] Add PCS-1 and DVS to the autoclave at a weight ratio of 1:0.3, add xylene at a ratio of 10ml / g to xylene / PCS-1 for uniform miscibility, and then add xylene at a ratio of 100ppm (weight of PCS-1 is Calculation basis) Add chloroplatinic acid catalyst, vacuumize and replace high-purity nitrogen, pre-fill nitrogen pressure to 10MPa, heat to 120°C, keep warm for 20 hours, stop the reaction, cool to room temperature, and place the product solution in a distillation device , under the protection of high-purity nitrogen, after heating to 160 ° C to distill off the solvent and unreacted DVS, the light yellow solid product PVCS-1 was obtained.

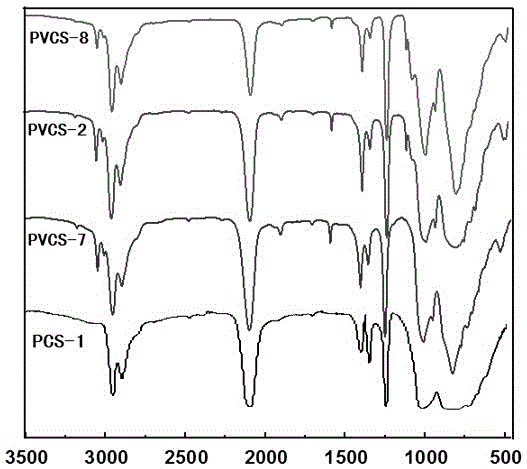

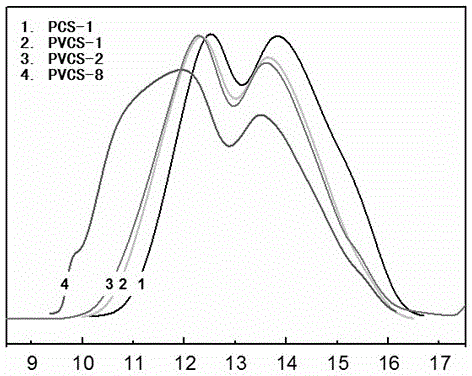

[0026] The light yellow solid product PVCS-1 of present embodiment gained, record its number average molecular weight In 1951, its molecular weight distribution coefficient The gel permeation chromatography (GPC) figure of raw material PCS-1 and product PVCS-1 is ...

Embodiment 2

[0028] Synthesis of PVCS-2 from PCS-2 and DVS

[0029] Using substantially the same method as in Example 1, LPCS-2 and DVS were co-dissolved in xylene at a ratio of 1:0.4 and then mixed into the autoclave. The reaction conditions different from Example 1 and the characteristics of the product PVCS-2 are shown in the table. 1 and Table 2.

Embodiment 3

[0031] Synthesis of PVCS-3 from PCS-2 and DVS

[0032] Using substantially the same method as in Example 1, LPCS-2 and DVS were co-dissolved in xylene at a ratio of 1:0.5 and then mixed into the autoclave. The reaction conditions different from Example 1 and the characteristics of the product PVCS-3 are shown in the table. 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com