Patents

Literature

83 results about "Every Two Hours" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Every two hours. (NCI)

Peritoneal Dialysis System

InactiveUS20100312174A1Reduces chance of malnutritionGood for healthMedical devicesPeritoneal dialysisGlucose polymersD-Glucose

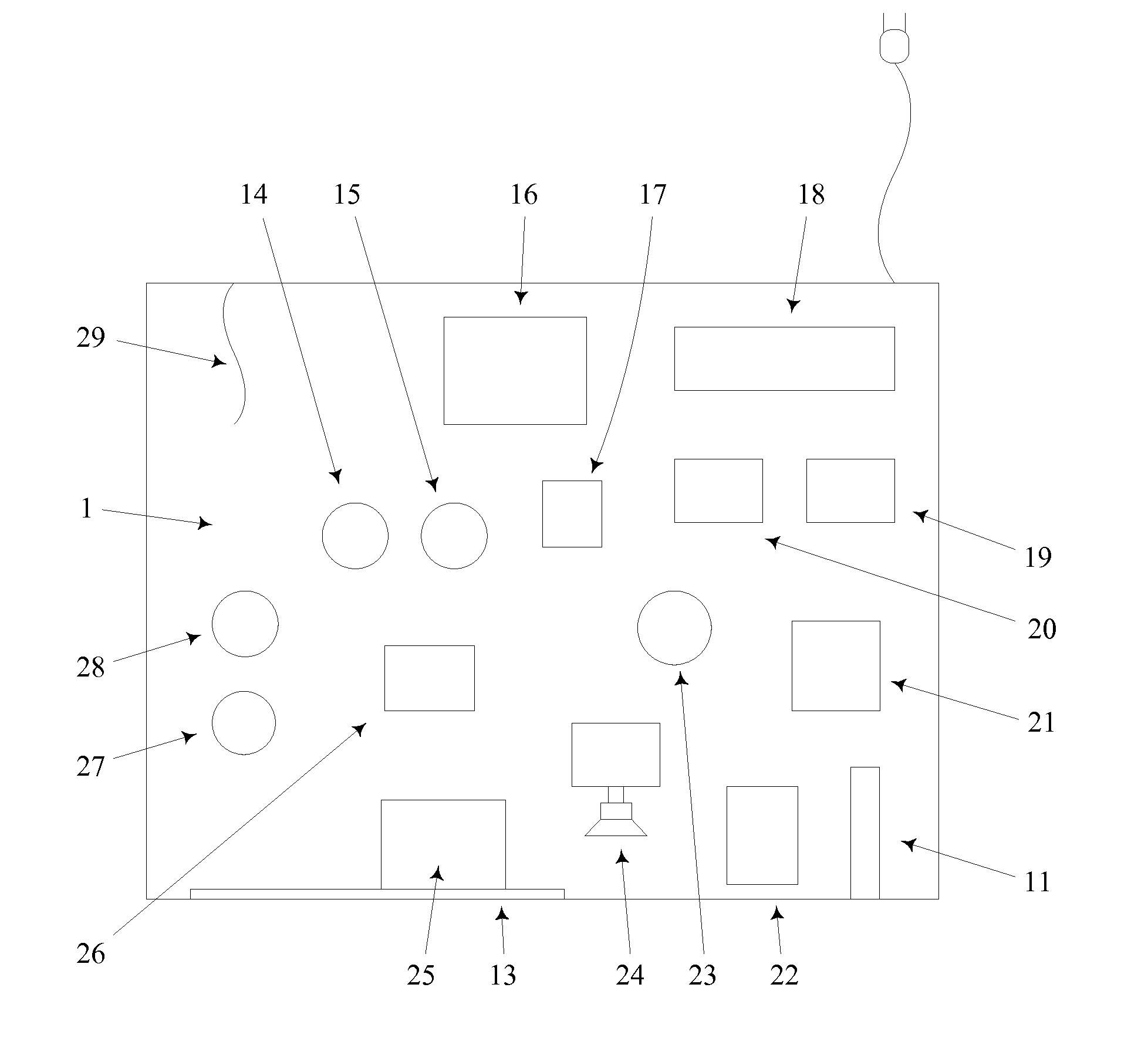

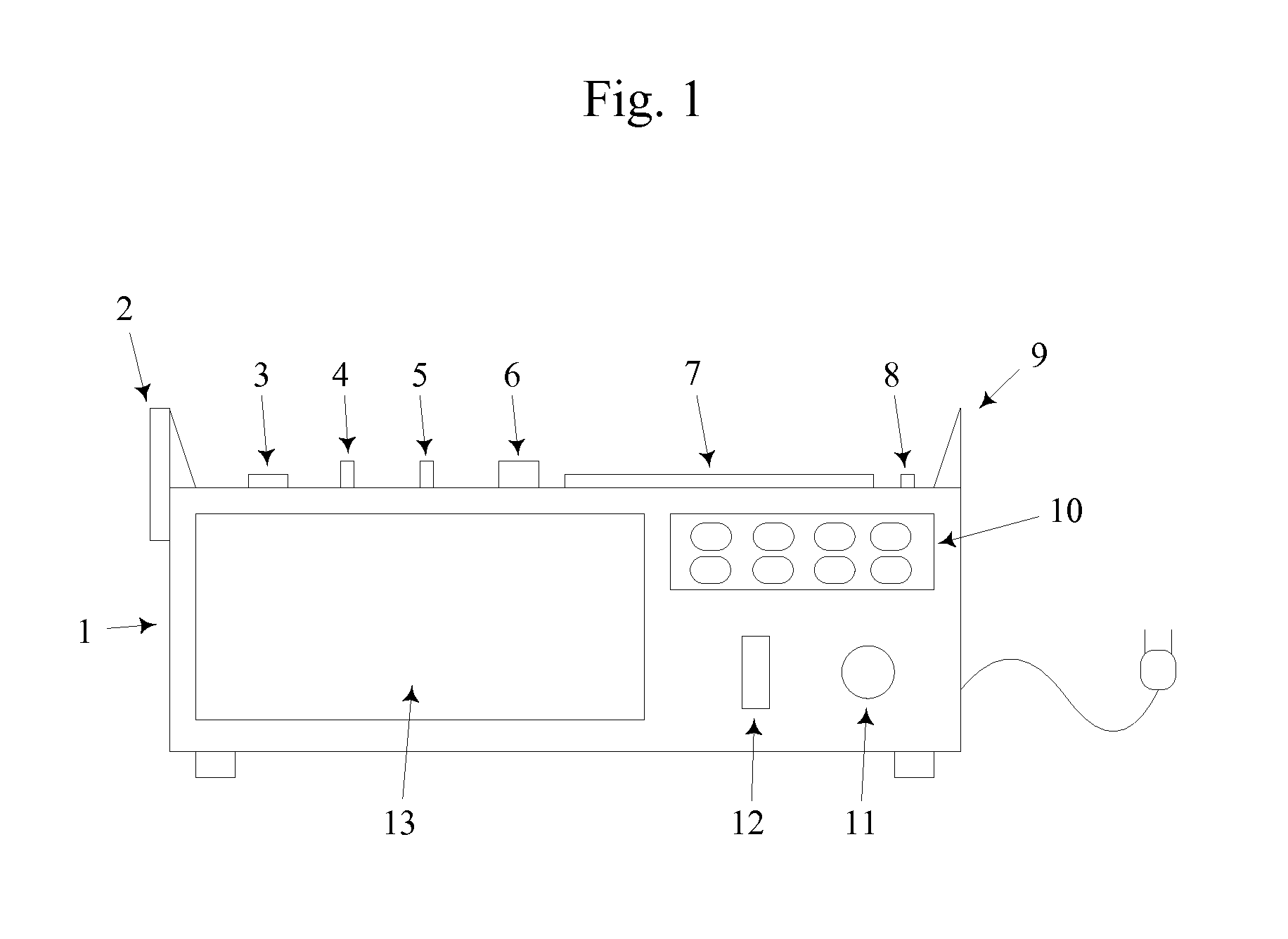

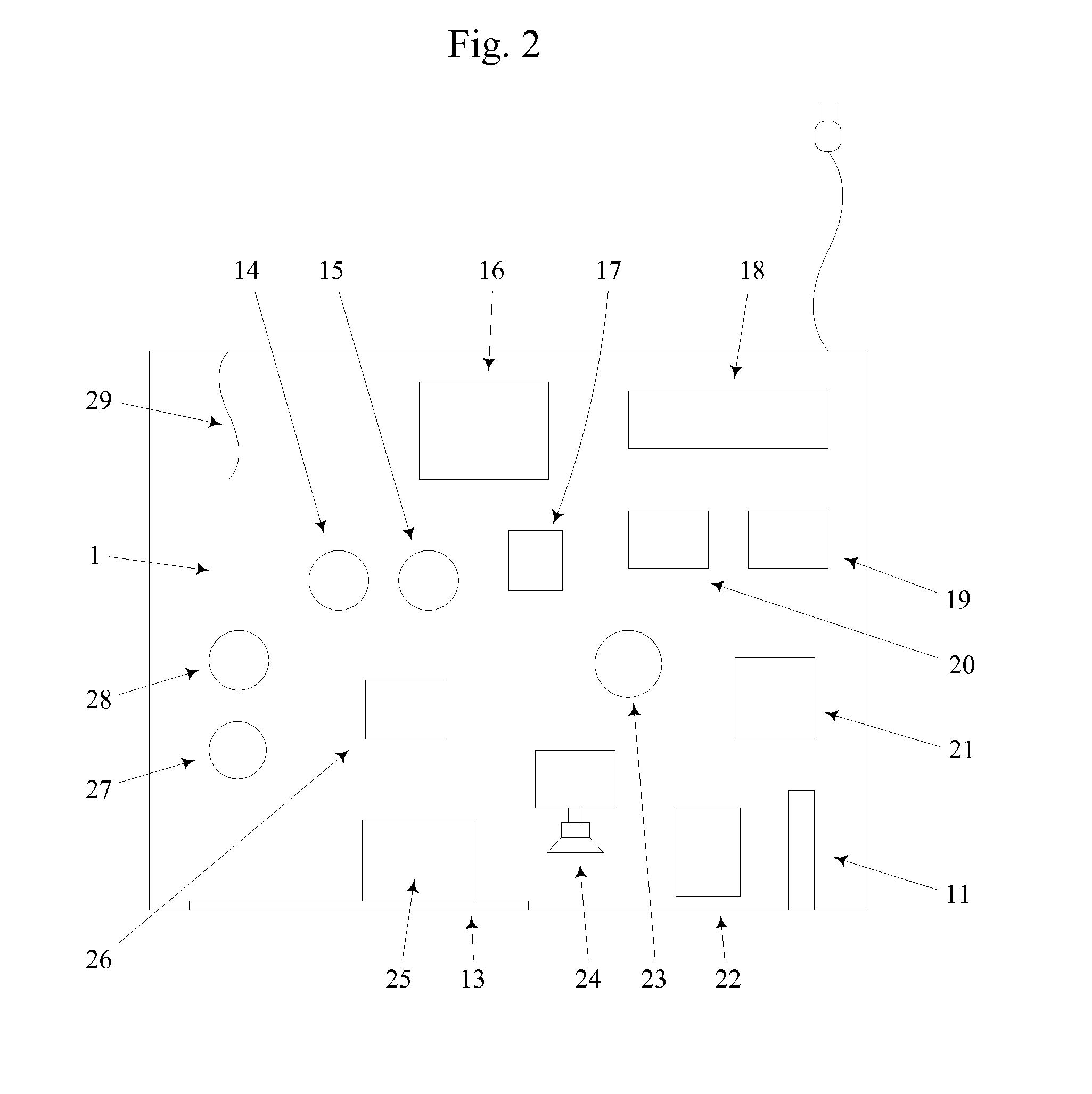

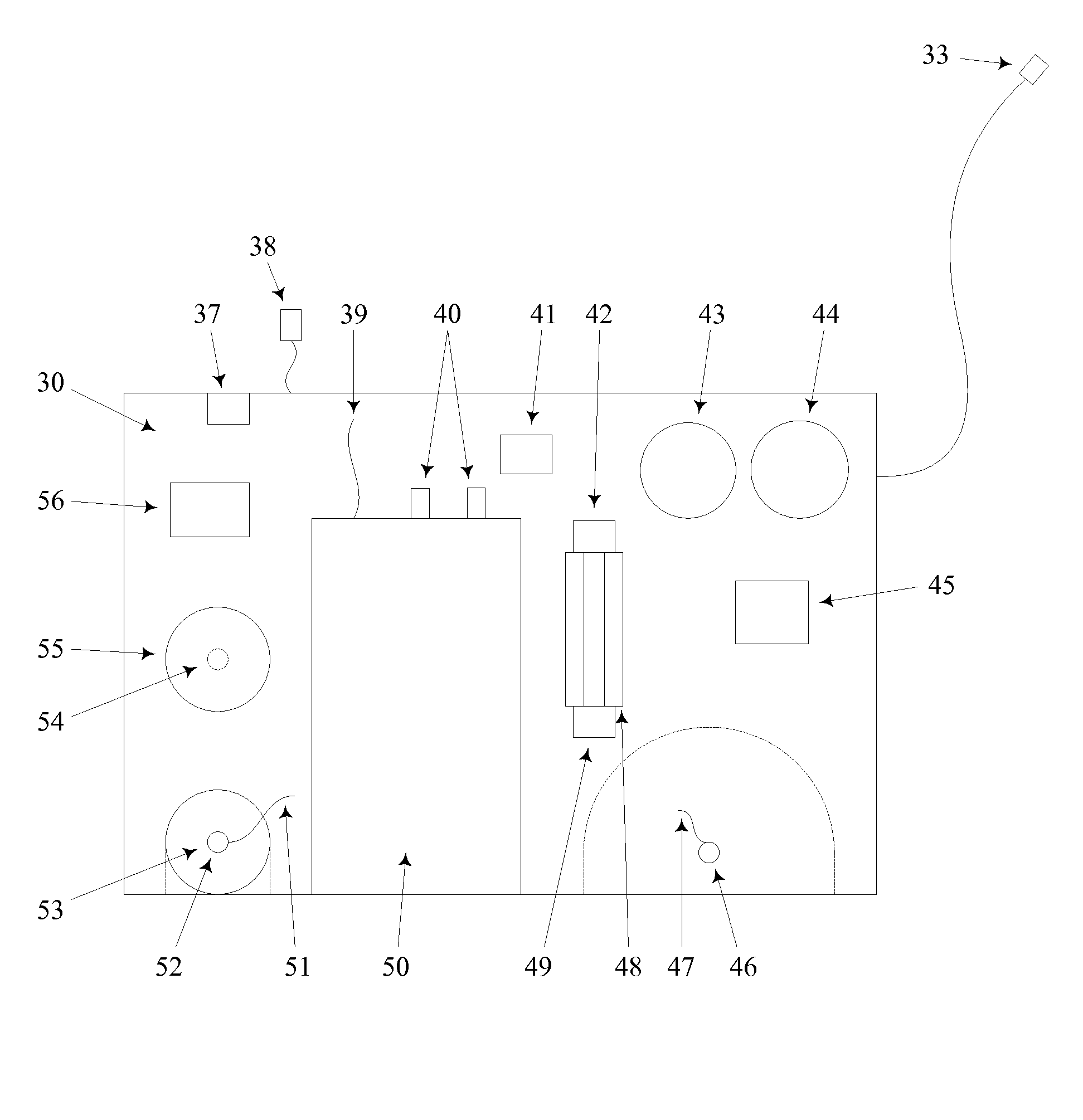

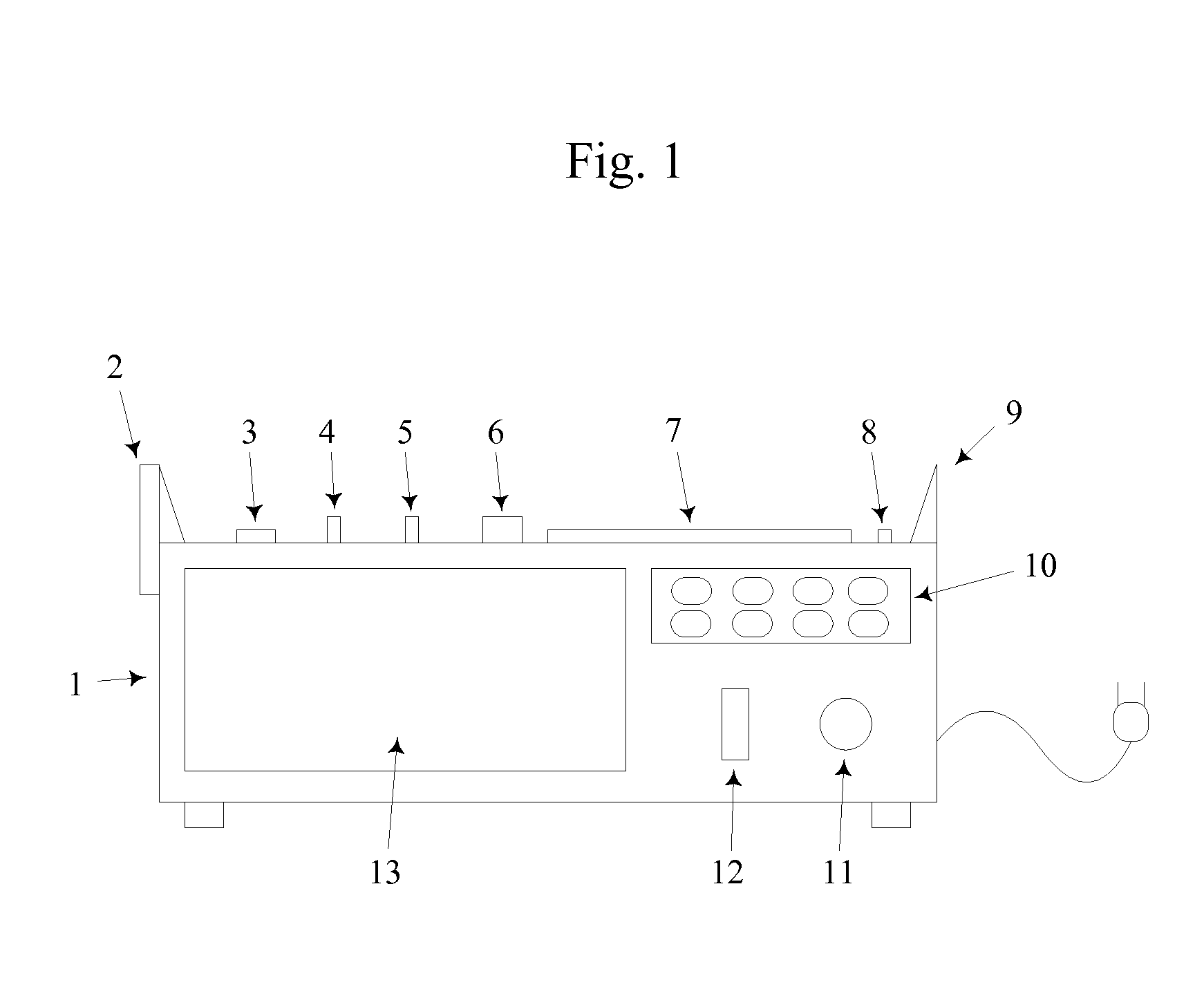

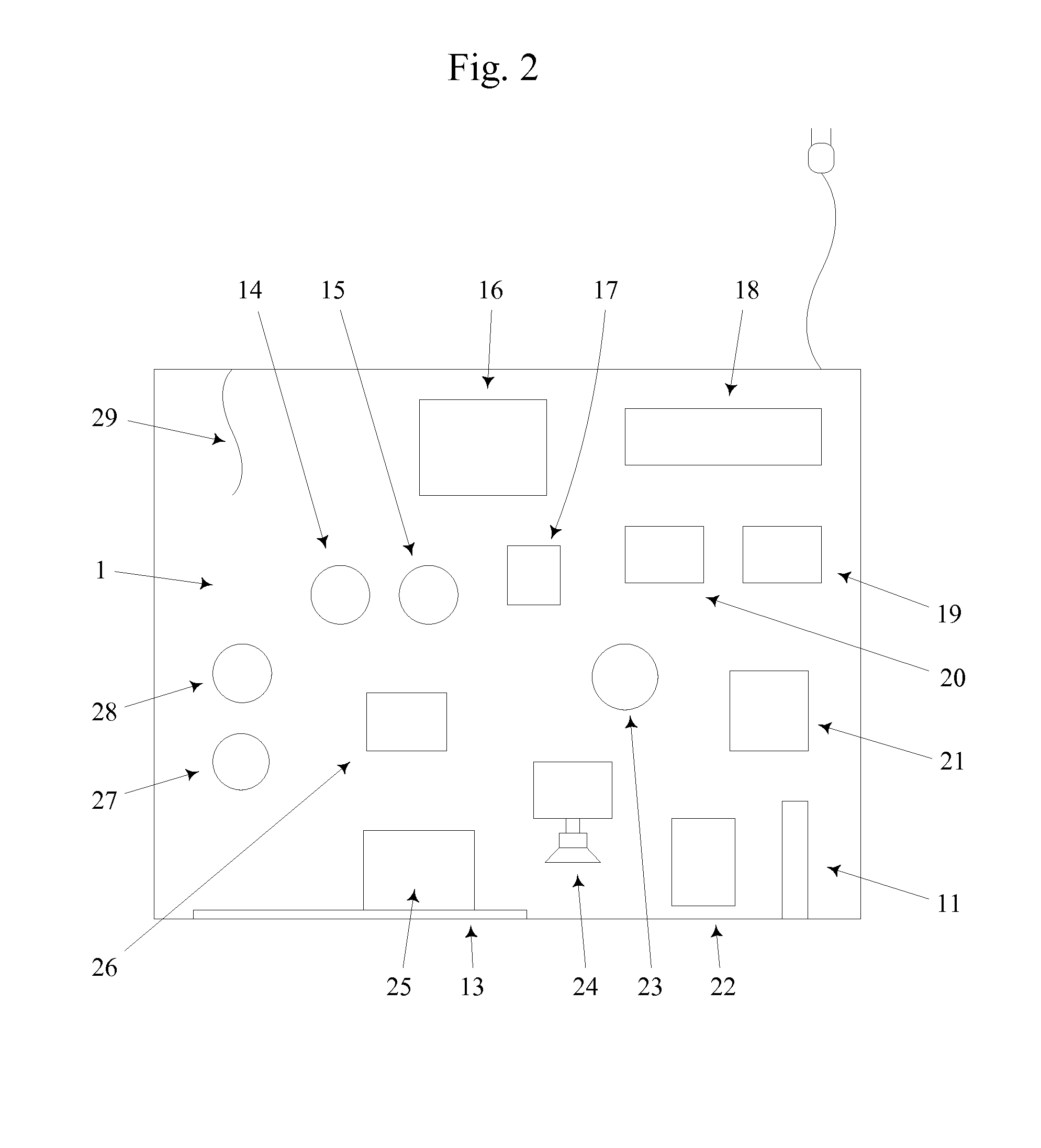

The present invention is a sorbent-based portable peritoneal dialysis system that uses 2.5 liters of tap water per day. The system comprises a control unit, a sterilized disposable cassette, a sterilized disposable glucose solution cartridge and a sterilized sorbent cartridge, and a three liter removable fluid storage container. A supply of concentrated electrolytes solution and a venting sterilizing dialysate filter are contained in the cassette. The glucose and sorbent cartridges snap into the cassette, which snaps onto the control unit. The cartridges are replaced daily, and the cassette is replaced weekly. During use (typically while the patient sleeps at night), the system removes all spent dialysate from the patient every two hours. The system then returns two liters of regenerated, sterilized dialysate to the patient. The patient discards the spent dialysate in the morning.

Owner:HOFFMAN JOSEF C A

Method of Peritoneal Dialysis

InactiveUS20100312172A1Reduces chance of malnutritionGood for healthPeritoneal dialysisGlucose polymersD-Glucose

The present invention is a sorbent-based portable peritoneal dialysis system that uses 2.5 liters of tap water per day. The system comprises a control unit, a sterilized disposable cassette, a sterilized disposable glucose solution cartridge and a sterilized sorbent cartridge, and a three liter fluid storage container. A supply of concentrated electrolytes solution and a venting sterilizing dialysate filter are contained in the cassette. The glucose and sorbent cartridges snap into the cassette, which snaps onto the control unit. The cartridges are replaced daily, and the cassette is replaced weekly. During use (typically while the patient sleeps at night), the system removes all spent dialysate from the patient every two hours. The system then returns two liters of regenerated, sterilized dialysate to the patient. The patient discards the spent dialysate in the morning.

Owner:HOFFMAN JOSEF C A

Production method for paraffin section of paeonia lactiflora mature embryo

InactiveCN103630421AComplete structureClear structureWithdrawing sample devicesPreparing sample for investigationWater bathsParaffin wax

The invention discloses a production method for a paraffin section of a paeonia lactiflora mature embryo. The production method comprises the following steps: drawing materials and fixing: stripping a seed coat, cutting a seed, immersing the seed top part containing the embryo or part endosperm into a FAA stationary liquid, and fixing for more than 24 hours; dehydrating: washing in ethyl alcohol with the concentration of 70% for 3 to 5 times, and performing gradient dehydration from the ethyl alcohol with the concentration of 70%; performing hyalinization: carrying out five level hyalinization by using dimethyl benzene as a transparent reagent; waxing and embedding: pouring out one half volume of dimethyl benzene, adding wax crumbs in a bottle until saturation, staying overnight at the temperature of 40 DEG C; then changing a wax liquid every two hours for three times per day, repeating for three days, and carrying out conventional paraffin embedding; slicing; flattening and bonding: flattening a linoleum tape on an iron plate of a water bath kettle at the constant temperature of 50 DEG C, dewaxing, rehydrating, dyeing through safranine and fast green and performing hyalinization; mounting. According to the invention, the paeonia lactiflora mature embryo paraffin section of which the tissue structure is integrated and clear can be obtained, so that accurate technical support can be provided for researching paeonia lactiflora seed dormancy and germination.

Owner:SHENYANG AGRI UNIV

Method for processing fast cooking germination husked rice and germination dehusked rice maded thereout

The invention relates to a processing method of quick cooking germinated brown rice and the germinated brown rice made by the method. The control starts from paddy which is stored in a cryogenic thermostat warehouse after the dried in a drying tower. Afterward, the paddy was processed into brown rice which is used as raw material by cleaning, stoning, deshelling, rolling by a vertical rice mill, polishing and color-selecting. The brown rice is processed in sequence in the steps as follows: preparing phytase operating fluid, adding the brown rice in accordance with a particularly mixture of 1 to 1 brown rice and phytase pressure fluid, immersing the mixed liquid of brown rice in an ultrasonic field for 45 to 75 minutes; the brown ice germinates on a tunnel germinating bed in the temperature of 30 to 35 DEG C, which needs to be sprayed automatically with the gibberellin liquid every two hours; the germinated brown rice which is cooked in the high temperature for 30 minutes and then is dried in low temperature for 4 to 6 hours, after microwave sterilizing and subpackaging, is formed into the finished products of germinated brown rice. The invention particularly relates to that the germinated brown rice has better taste by the control of the germinating, is easier for cooking in the home and boiled with the rice simultaneously, and has higher safety for the microbial contamination.

Owner:刘来法

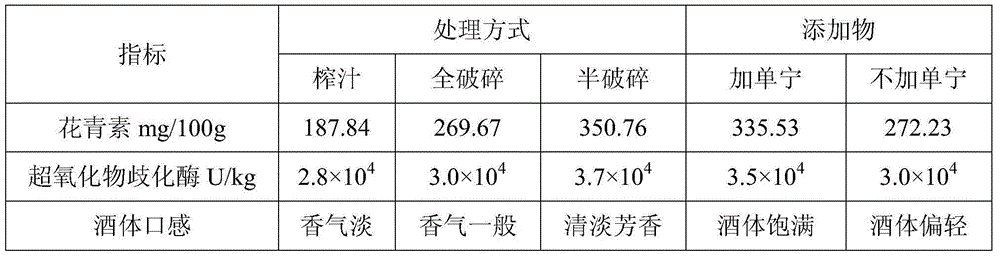

Brewing method of fermented blueberry wine

InactiveCN105087277AKeep the flavorElegant and soft aromaAlcoholic beverage preparationPectinaseGrape wine

The invention discloses a brewing method of fermented blueberry wine. The brewing method comprises the following steps: selecting Bluecrop blueberries and Duke blueberries; crushing moderately till the blueberries are in half-grain state; adding potassium metabisulfite and tannin into the half-grain blueberries, and mixing the potassium metabisulfite and tannin with the half-grain blueberries uniformly; adjusting the temperature to 20-30 DEG C, and adding pectinase into the mixture; inoculating by adopting wine brewer's yeast; fermenting under stirring every two hours till the content of residual sugar is not larger than 4g / L wherein the fermentation temperature is not higher than 30 DEG C; carrying out mechanical extruding after fermentation is finished for separating skin dregs from wine liquid; carrying out fining and clarification; carrying out stability analysis; regulating the concentration of free sulfur dioxide and the alcoholic strength; and filtering and storing. According to the brewing method, the proper blueberry variety is selected for producing the blueberry wine, thus the taste of a product is guaranteed; through the half-broken and half-grain fermentation method, the prepared blueberry wine is soft and elegant in aroma; and through color protection of tannin, the colour and luster, the taste and the nutrition of the product are guaranteed, and the wine body is relatively mature and plump.

Owner:WOLIN QINGDAO FOOD CO LTD

Chicken manure organic fertilizer and production method thereof

InactiveCN101723714APromote absorptionLow costBio-organic fraction processingClimate change adaptationMicroorganismOxygen

The invention discloses a chicken manure organic fertilizer and a production method thereof. The chicken manure organic fertilizer is produced by the following raw materials of fresh chicken manure with 75-80% of water content, power straw mixture with 2-5% of water content and high-efficiency decomposed bacteria according to the weight ratio of 80-88:10.5-19.5:0.5-1.5. The preparation method of the high-efficiency decomposed bacteria comprises the following steps: weighing chicken manure which contains 25-35% of water content and is piled and stored for 30-60 days; adding 0.3-0.7wt% of agar, 0.3-0.7wt% of beef extract, 1-3wt% of brown sugar and 1-3wt% of fried bean flour, wherein, the agar and the beef extract are used after being dissolved by boiling with hot water; evenly mixing the above materials; adjusting the water content to be 50-60%; adjusting the pH value to be 5-8; improving the temperature to be 50-65 DEG C; introducing oxygen to lead the oxygen concentration to reach 18-19%; manually turning over once at every two hours; and taking out 5 days later. The chicken manure organic fertilizer of the invention is easily absorbed and utilized by plants, contains various multi-functional microorganisms and rich organic matters, and has low cost and quick effect.

Owner:GUIZHOU LIUJIANG ANIMAL & POULTRY

Laying pigeon artificial incubation method

The invention relates to an egg pigeon artificial incubation method, which belongs to avian hatching. The invention is characterized by six steps: firstly, pigeon eggs, which are yielded at the same period, are disinfected, and then put into a hatching machine; secondly, the hatching machine is started, and the temperature inside an incubation room is controlled within 38.2 DEG C to 38.5 DEG C, and the humidity is controlled within 60 percent to 65 percent; thirdly, the eggs are turned over, and the eggs are turned over once every two hours in the process of incubating, and the turning over of the eggs should be stopped one day before squeakers are hatched; fourthly, the eggs are checked, and the first check should be carried after the eggs are incubated for 4-5 days, and the second check should be carried after the eggs are incubated for 9-10 days, and the unfertilized eggs and the addle eggs should be winkled; fifthly, the breeding eggs are shifted from incubation room to hatching room when the eggs are incubated for 16 days; sixthly, the eggs are hatched, and the breeding eggs can be hatched when the breeding eggs are incubated for 18 days, and the temperature inside the hatching room should be 38 DEG C, and the humidity should be within 70 percent to 75 percent. The invention improves the incubation rate and creates condition for pigeon eggs breeding squabs in bulk. The invention shortens the egg product period of egg pigeons. The natural incubation period is 45 days, the artificial incubation period is shortened to about 15 days and the period is improved 66.67 percent.

Owner:温积辉

Green shell egg incubation method

Owner:GUIZHOU GEILI ECOLOGICAL AGRI DEV CO LTD

Novel method for preparing organic fertilizer from crop residual bodies by microbial fermentation technology

InactiveCN104478568APromote growthFull of nutritionExcrement fertilisersBioloigcal waste fertilisersBiotechnologyMicroorganism

The invention relates to a novel method for preparing an organic fertilizer from crop residual bodies by a microbial fermentation technology. The novel method comprises the following steps of (1) proportioning raw materials; (2) feeding the materials in the step (1) into a sterilization device for sterilizing; (3) feeding the materials sterilized in the step (2) into a tumbling machine for tumbling; (4) feeding the materials tumbled in the step (3) into a fermentation device; (5) carrying out seal fermentation on the materials sprayed in the step (4), by controlling the initial fermentation temperature at about 70 DEG C, reducing the temperature by 5 DEG C every two hours, stirring once until the temperature reaches 20 DEG C, maintaining the temperature at 20 DEG C and fermenting for 2 hours; (6) taking the materials fermented in the step (5) and feeding the materials to a drying device for drying the materials in an air-drying manner until the moisture content of the materials is less than 15% by controlling the temperature of the hot air in the drying device at 50-60 DEG C; and (7) feeding the materials dried in the step (6) into a granulator for granulating and packaging.

Owner:界首市聚丰家庭农场

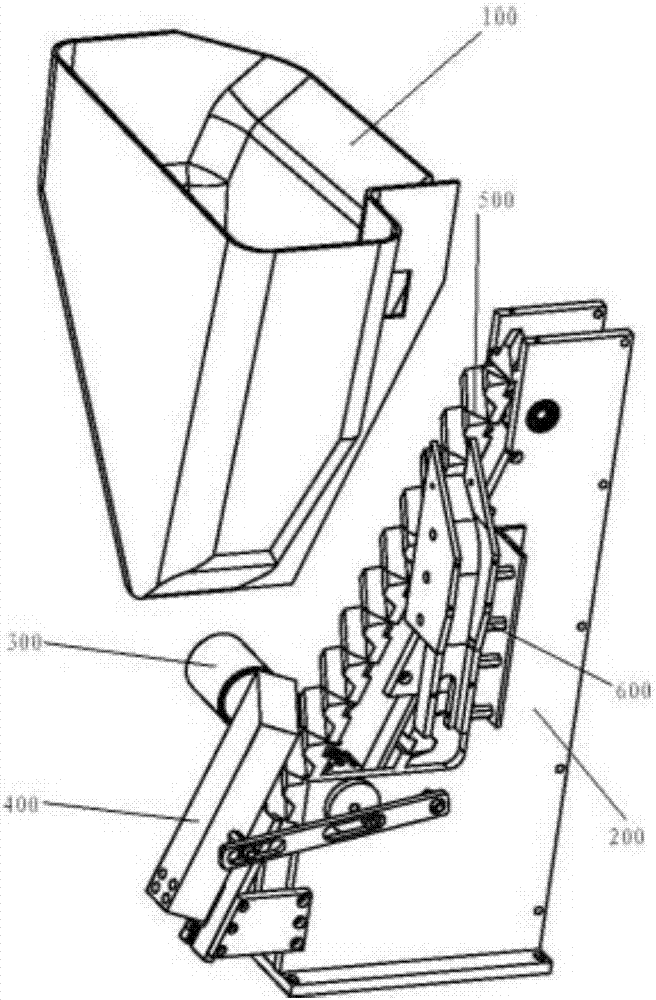

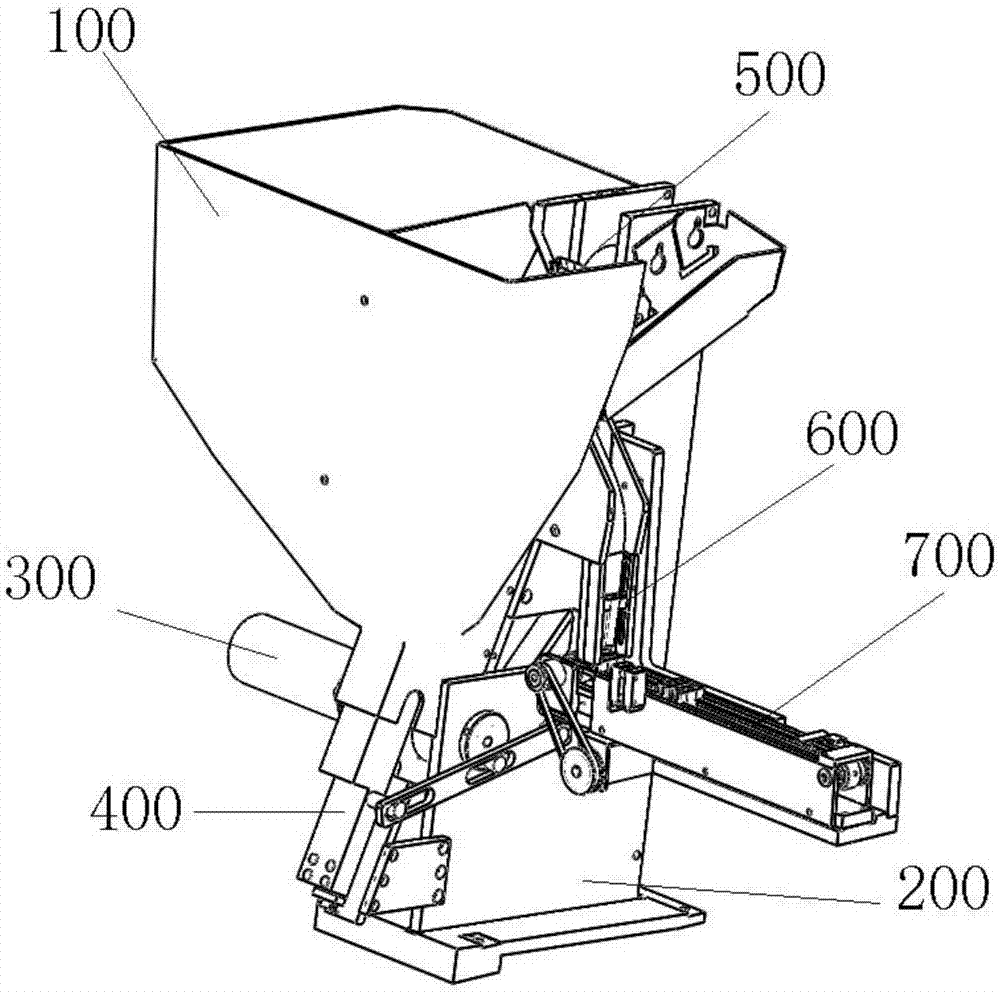

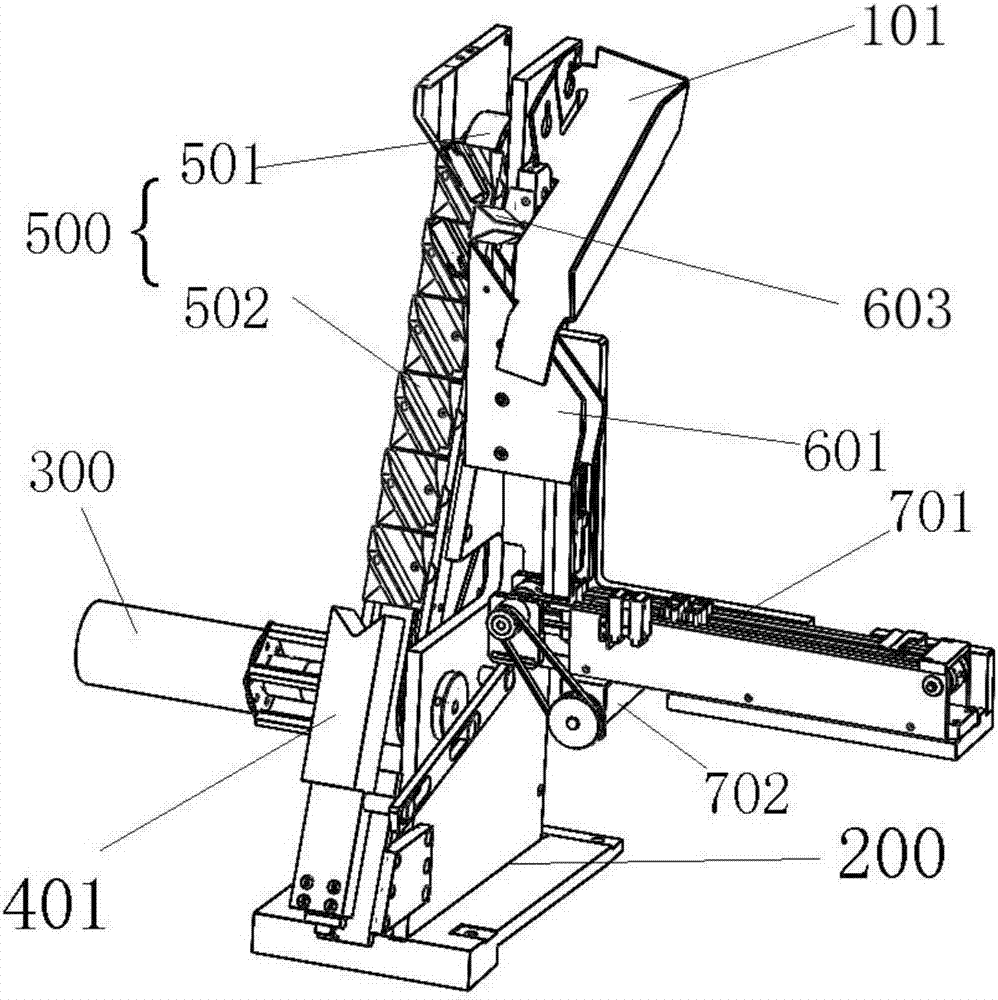

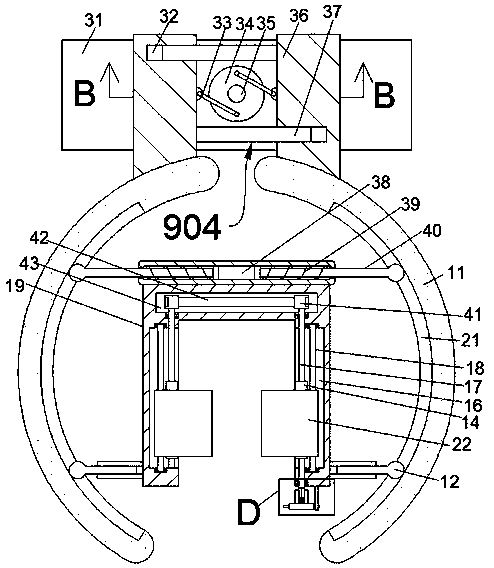

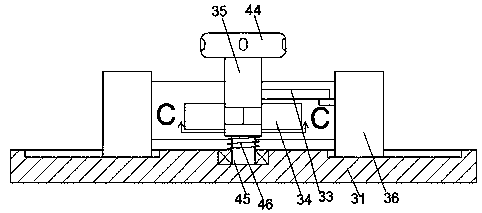

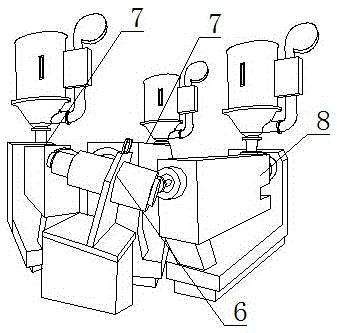

Full-automatic cup embedding feeding mechanism

The invention relates to a full-automatic cup embedding feeding mechanism which comprises a support assembly, a discharging barrel, a cup pushing assembly, a vertical conveying assembly, a cup outlet assembly and a horizontal conveying assembly. The cup outlet assembly is provided with a cup outlet channel, shape changes of a bottom block enable the cup outlet channel to be provided with a first inclined section, a second inclined section and the vertical section sequentially from a cup inlet to a cup outlet, the included angle between the axle wire of the bottom face of the first inclined section and the horizontal face ranges from 65 degrees to 70 degrees, and the included angle between the bottom face of the first inclined section and the vertical side face ranges from 50 degrees to 60 degrees. Through tests of the full-automatic cup embedding feeding mechanism, a conveying block and the cup outlet channel are subject to comprehensive consideration and special design, the angle cooperation relationship is used, under joint effects of a power device and gravity, disordered reaction cups finally enter the horizontal conveying assembly from the discharging barrel, and therefore in the continuous running process, the cup clamping condition happens every 24 hours averagely, but manual cleaning needs to be carried out every two hours in the full-automatic cup embedding feeding mechanism, and therefore reliability is greatly improved.

Owner:SUZHOU HYBIOME BIOMEDICAL ENG CO LTD

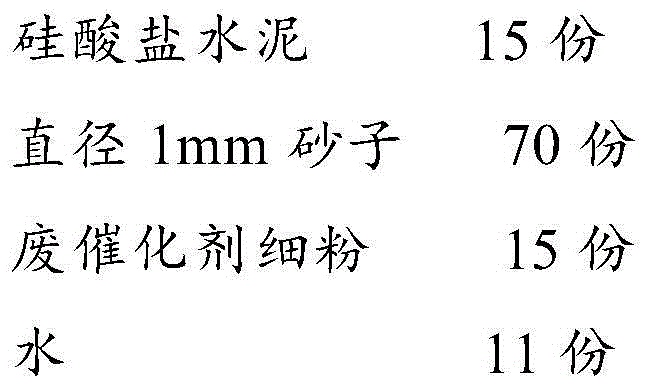

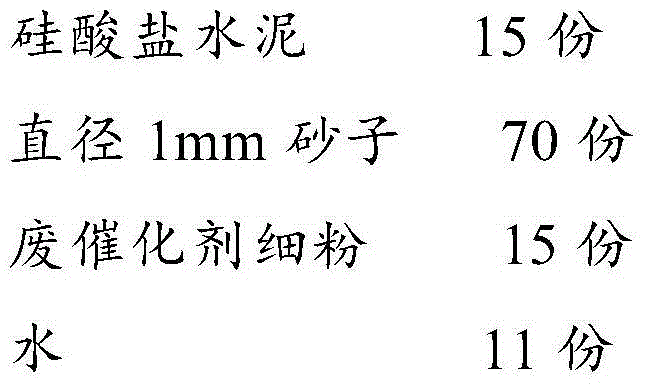

Treating and curing method before scrapped SCR denitration catalyst burying

ActiveCN104926235ANo pollutionAvoid pollutionSolid waste managementCeramic shaping apparatusPortland cementCrusher

The invention provides a treating and curing method before scrapped SCR denitration catalyst burying. The treating and curing method is characterized by comprising the following steps: (1) making a mould for casting concrete through steel plates; (2) smashing scrapped catalyst through a crusher, and then grinding the scrapped catalyst into scrapped catalyst fine powder through a ball mill; (3) mixing the scrapped catalyst fine powder, Portland cement, sand and water, and fully stirring into concrete to be poured into the mould in the step (1); (4) demoulding the concrete after 3-4 h; (5) placing the demoulded concrete cube blocks in single layer, spraying water once every two hours, and covering with a straw mattress to realize moisture retention and maintenance; (6) when the strength of the concrete cube blocks is not less than 30 mpa, conducting plastic package respectively with thick plastic cloth and then burying, wherein the concrete comprises the following ingredients in parts by weight: 10-15 parts of Portland cement, 60-80 parts of sand, 10-15 parts of scrapped catalyst fine powder and 10-15 parts of water. The method is relatively efficient and environment-friendly in treating the scrapped catalyst.

Owner:北京济元紫能环境科技有限公司

Method for increasing pulullan output through fed-batch fermentation

InactiveCN104911231AHigh substrate conversion rateAids in synthesisMicroorganism based processesFermentationPullulanAnimal science

The invention relates to a method for increasing pulullan output through fed-batch fermentation, which comprises the following steps: culturing seeds, performing fermentation culture and separating pulullan; continuously feeding a fed-batch solution after fermenting for 24-28 hours, controlling the residual sugar of a broth to maintain at 6-12g / L, supplementing 0.5-2g / L of amino acid solution for once by every two hours, wherein the total fermentation period is 65-67 hours. Aiming at defects of long period and low substrate conversion rate during a process of fermentation of aureobasidium pullulans with a preservation number of No. 7055 to produce pulullan, a proper amount of amino acid is continuously fed during the fermentation process for synthesis of pullulan, substrate conversion rate is increased, operation is convenient, effect is obvious, fermentation period is greatly shortened, and cost of pullulan can be reduced.

Owner:天津北洋百川生物技术有限公司

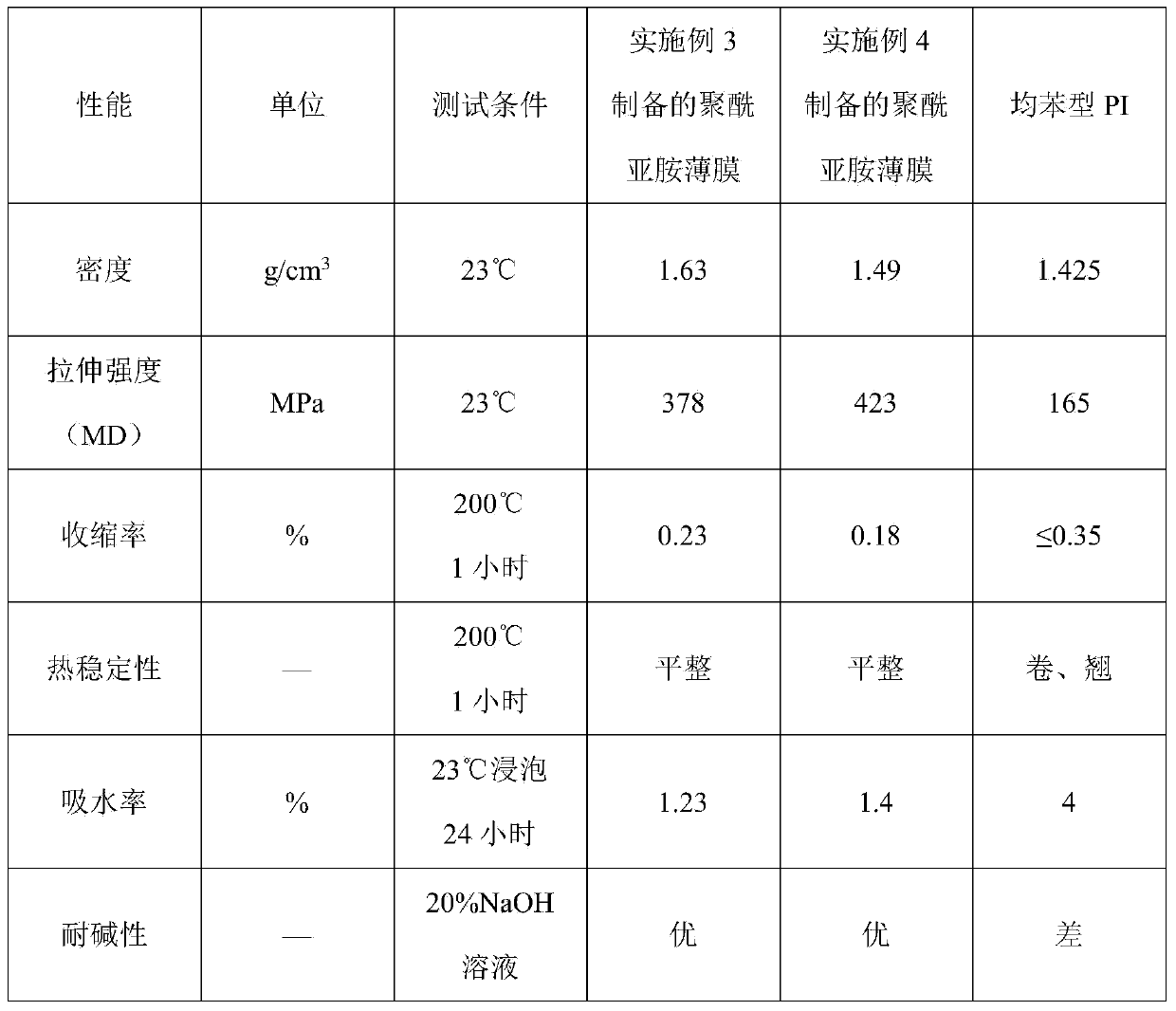

Polyamide acid copolymer and polyimide film prepared from polyamide acid copolymer

The invention discloses a polyamide acid copolymer and a polyimide film prepared from the polyamide acid copolymer. The polyamide acid copolymer is prepared by the following concrete experiment steps: firstly, dissolving diamine into an aprotic solvent at 30 DEG C, and then reducing the temperature to 15 DEG C; adding diamine for the first time, and quickly reducing the temperature to 5 DEG C; adding the diamine once every two hours, and adding the diamine in three times; after a dianhydride monomer is added, immediately transferring a reactor to an ultra-low constant temperature tank containing ethylene glycol and water cooling liquid, controlling the temperature between -5 DEG C and -20 DEG C, and reacting for a period of time, so as to obtain a viscous polyamide acid solution; and carrying out de-solvent and heat imidization on the synthetic polyamide acid, so as to obtain the polyimide film, wherein the obtained polyimide material has the advantages of excellent mechanical property, low hot-shrinkage rate, low water absorption rate, excellent alkaline resistance and the like.

Owner:NANJING UNIV OF SCI & TECH

Method for preparing high-strength transparent cellulose film material in low-temperature and normal-pressure cooking manner and application thereof

InactiveCN109262783AEasy to prepareEase of industrial preparationPressure wood treatmentWood treatment detailsFiberCellulose

The invention relates to a method for preparing a high-strength transparent cellulose film material in a low-temperature and normal-pressure cooking manner and application thereof. The preparation method comprises the following steps: adding wood sheets into a cooking chemical solution prepared from sodium chlorite, acid and water, removing lignin in a cooking manner at the temperature less than or equal to 100 DEG C, adding an equal amount of chemical every two hours until the wood sheet becomes white, and thus obtaining the lignin-removed wood sheet; and washing the lignin-removed wood sheetby using water, removing the residual cooking chemical solution, pressurizing and drying, and thus obtaining the high-strength transparent cellulose film material. The cellulose film material prepared in the invention has excellent mechanical properties due to the reservation of orderly-arranged structure characteristics of fibers in the wood and high polymerization degree of the fibers, and thetensile strength is 8 to 15 times of the original wood sheet; and meanwhile, since the air in the internal pore is removed in the pressurizing process, the optical performance is good.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

Method for preparing food from chicken byproduct

InactiveCN101803750AUnique formulaUnique formula unique, no coloring addedFood preparationPreservativeGlucose polymers

The invention discloses a method for preparing food from chicken byproduct, which includes the steps of washing the chicken byproduct, and then boiling, stripping and slicing the chicken byproduct, adding cooking wine and rice vinegar to remove the fishy smell of the chicken byproduct, stir-frying dry red chilli and pepper through hot oil, then adding clear water, adding pickled Japanese pepper, edible glucose, gourmet powder, chicken extract and edible salt for seasoning, stirring every two hours and repeating for four times. After that, the food is edible. The formula of the food is unique; no pigment or antiseptic is added to the food; the food has golden colour and luster, crisp and tender taste, is hot and spicy, and has unique luster, flavor and taste; the food is rich in nutrition; and the green pickled Japanese pepper added to the food has the efficacy of stimulating appetite. The method is simple, convenient and low in cost, so the method has a broad application prospect.

Owner:李敬

Oral liquid for preventing and treating gastric cancer and preparation method thereof

ActiveCN103083550AAvoid instabilityMask direct contactDigestive systemPharmaceutical delivery mechanismHas active ingredientAreca palm

The invention relates to an oral liquid for preventing and treating a gastric cancer and a preparation method thereof. According to the preparation method, the oral liquid is prepared from spina gleditsiae, Indian iphigenia bulb, radix helicteris, dried Chinese jujubes, lucid ganoderma, rhizoma cyperi, rhizoma polygoni cuspidati, radix actinidiae chinensis and areca catechu through digestion, sterilization, fermentation, filling, and sterilization. In the fermentation, with the adoption of a lactobacillus casei strain, the inoculation proportion is 0.5-0.8g / 100kg; and fermentation conditions are as follows: carrying out heat preservation and fermenting for 12 hours at 30-40 DEG C, stirring for 5-8 minutes every two hours in a fermenting process, and controlling the stirring speed to be 60-70rpm. According to the invention, a plurality of traditional Chinese medicine extracts for supporting the healthy energy are fermented by lactic acid bacteria to obtain the oral liquid for preventing and treating the gastric cancer. A fermented culture generates lactobacillus viscous polysaccharides in a metabolic process, so that the unstable phenomenon caused by placing and precipitating effective pharmaceutical components for a long time can be avoided; in addition, compared with the existing similar medicaments, the oral liquid disclosed by the invention has the characteristics of high effective component content, good taste and remarkable efficacy.

Owner:HARBIN MEDICAL UNIVERSITY

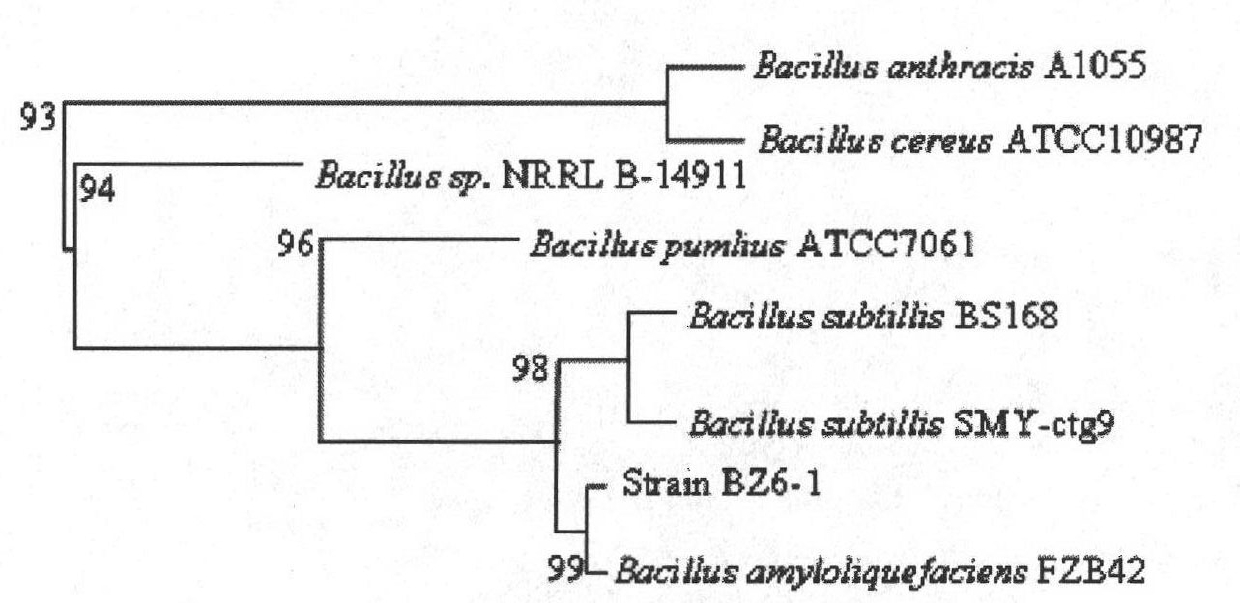

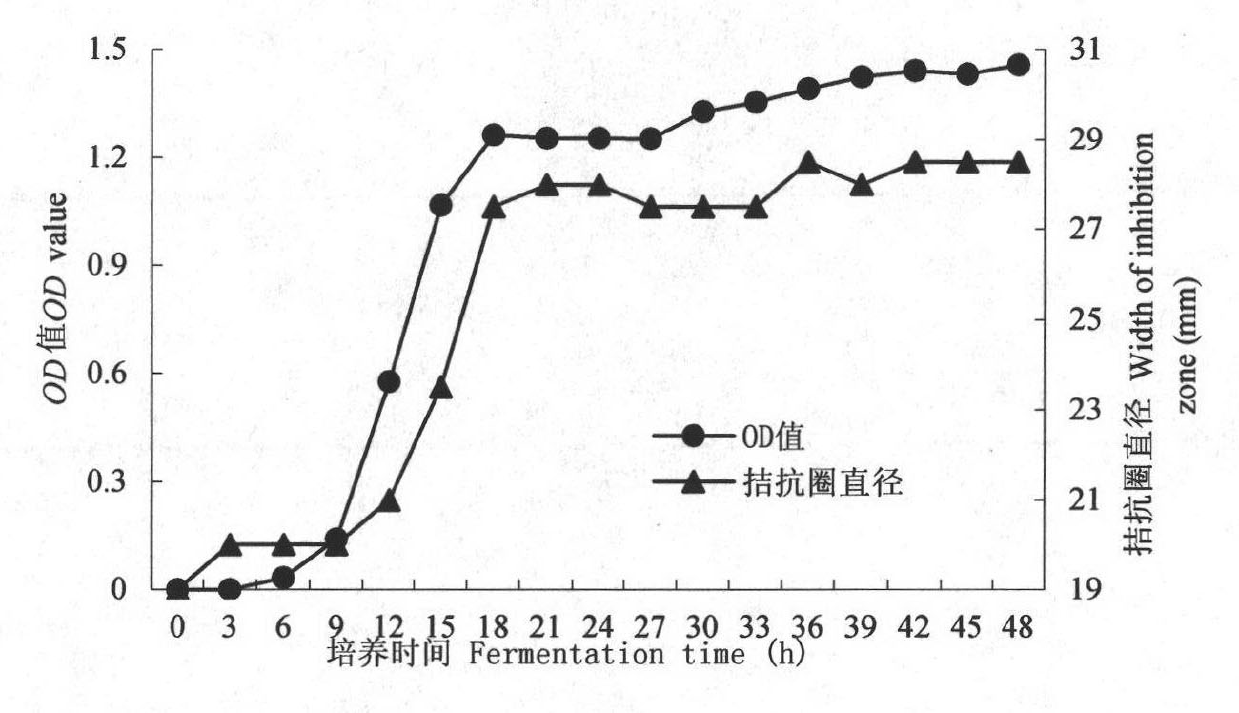

Application of BZ6-1 bacterial strain in preparing drugs for treating plant peanut bacterial wilt

The invention relates to an application of BZ6-1 bacterial strain in preparing drugs for treating plant peanut bacterial wilt, comprising the following steps of: inoculating the plate activated BZ6-1 to 100mL of YGPA liquid culture mediums, carrying out overnight culture at 30 DEG C for 18 hours; inoculating to 250mL of YGPA culture solutions according to the volume ratio of 1 percent; carrying out shaking culture for 18 hours, and then carrying out spore staining every two hours; checking the formation of spores; and when the quantity of thalli reaches 1*109cfu<mL-1> and the formation rate of the spores reaches 80 percent, adsorbing into a matrix according to the proportion of 50 percent (V / M, unit: mL / g) to prepare a solid inoculant. The BZ6-1 bacterial strain has higher inhibiting effect on peanut ralstonia solanacearum.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

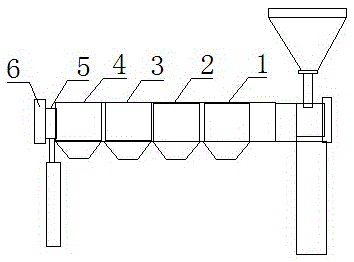

Control method for a variety of ore grinding media during ore grinding

InactiveCN103599840AImprove grinding efficiencyReduce unit energy consumptionGrain treatmentsBall millEnergy consumption

The invention relates to a control method for a variety of ore grinding media during ore grinding. The method includes: firstly classifying 5 ore grinding media with different diameters according to particle size and storing them in a ball storage bin before adding them into a ball grinder, calculating the proportions of the ore grinding media with different diameters according to the nature, ore grinding particle size and ratio requirements of ore, starting an ore grinding device, conducting ore grinding for 12-15h, carrying out sampling every two hours to conduct particle size detection four times, calculating the mass of the ore grinding media according to a proportion of maximum content of particle size in the total proportion under the condition of the ore grinding particle size in the normal distribution, and converting the mass into the corresponding quantity of the ore grinding media with different diameters. According to different effects of the ball grinding media with different thicknesses on minerals, the method provided in the invention adopts a variety of ball grinding media to conduct ball grinding on the minerals in two stages. The needed ball grinding media are re-calculated every time according to the detection results, so that the ratio of the ore grinding media added into the ball grinder can reach an optimal state, thus improving the ore grinding efficiency of the grinder and reducing the unit energy consumption of the grinder.

Owner:CENT SOUTH UNIV

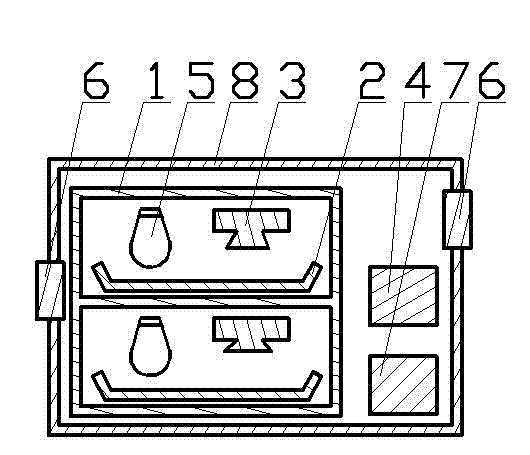

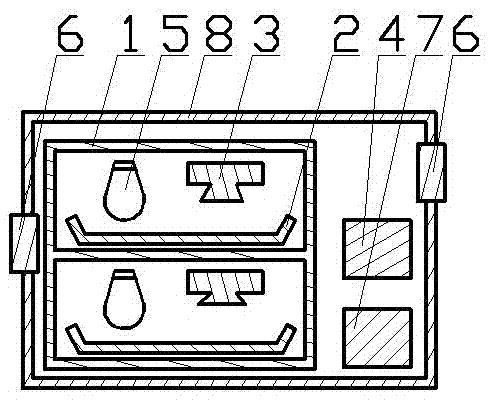

Vegetable sprout cultivation chamber

InactiveCN102511370ABreeding method is simpleEasy to breedAgriculture gas emission reductionCultivating equipmentsFresh airEngineering

The invention discloses a vegetable sprout cultivation chamber and a sprout cultivation control method. A temperature control chamber (8) of the vegetable sprout cultivation chamber is provided with a window, and a fan is disposed at the window. A temperature sensor, a resistor heater, a refrigerating device, a timing and temperature adjustment controller, a timing switch, an indoor air circulation device (7) and a nursery system are mounted inside the temperature control chamber (8). A nursery tray (2) is disposed on each nursery holder (1), a mist nozzle and a light (5) are arranged above each nursery tray (2), and the mist nozzles are connected with a spray time controller. Misty water is automatically sprayed from the mist nozzles for seconds every two hours to guarantee growth of sprouts. An automatic temperature control system controls change and time of low and high temperature to guarantee nutrients in air for the sprouts to absorb. The lights are turned on at the high temperature, and turned off at the low temperature, so that normal photosynthesis of the sprouts is guaranteed and synthesis of amino acids is promoted. Foul air in the chamber is exhausted and replaced with fresh air every three hours through an indoor-outdoor automatic ventilation system, so that sufficient nutrients in the air for the sprouts to absorb are guaranteed. The indoor air circulation device is used with the automatic temperature control system to control and balance indoor temperature. By using the vegetable sprout cultivation chamber simple in cultivation and convenient in large-scale peanut seedling cultivation, the cultivated nutritious peanut seedlings are green and tender, have light fragrance, are rich in nutrients such as vitamins, amino acids and the like, are environment-friendly nutritious health vegetable, and can be continuously supplied to vegetable markets all year round.

Owner:徐浩钟

Extraction method of fish glue from scale

InactiveCN103040028AReduce consumptionReduce manufacturing costFood preparationHeating timeFresh fish

The invention provides an extraction method of fish glue from scale. The method includes steps of washing fresh fish scale and drying; grinding; dissolving in water; mixing evenly; and placing in a constant temperature bath for heating, wherein the heating time is 6 hours, and the heating temperatures are 70 DEG C, 75 DEG C and 80 DEG C respectively every two hours. The extraction method is a production technology suitable for industrialized extraction of the fish glue from the scale, the technology can be simplified, the cost can be reduced, and the added value of aquatic products is improved.

Owner:QINGDAO SHENGHAN CHROMATOGRAPH TECH CO LTD

Improved variety breeding method of green-eggshell chicken

InactiveCN104855337AMeet humidity requirementsImprove hatchabilityAnimal husbandryComing outEggshell

The invention discloses an improved variety breeding method of green-eggshell chicken, wherein the method comprises mating, selecting eggs, naturally pre-heating in a hatching house and arranging a hatching machine sensor; after hatching from the first day to the twentieth day, the eggs should be turned over at every two hours and the turned angle is 90 degree so as to make each part of the embryo be heated uniformly and avoid the embryo stick to the shell; after hatching, at the seventh say, shell less eggs and addle eggs are elected out through lighting; after hatching to the eighteenth day, living breed eggs should be placed on a disc; at the twentieth day, the breed eggs begin to give berth to young chicken and finish at the twenty-first day; and after the young chicken coming out of the eggshells, the young chickens should be selected out every two hours. According to the invention, each process from selecting eggs to hatching is effectively controlled; part of bad quality eggs can be prevented from hatching by the selection of eggs at the first step, so the continuation of good quality green-eggshell chicken is ensured; at the same time, the hatching process is effectively controlled and the humidity requirement of the breed eggs during the hatching process is satisfied, thus the hatching rate of the green-shell eggs are improved and the hatched young chicken are healthy.

Owner:施秉县丽康生态农业科技发展有限公司

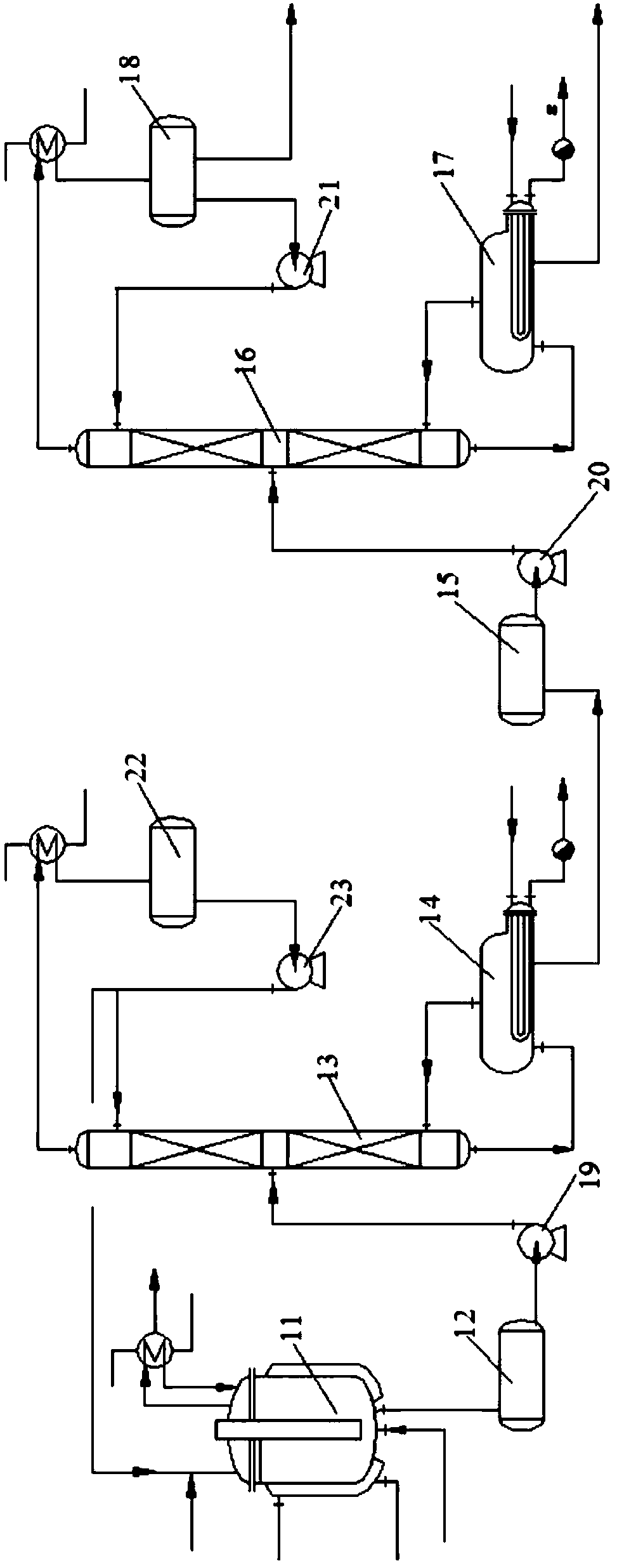

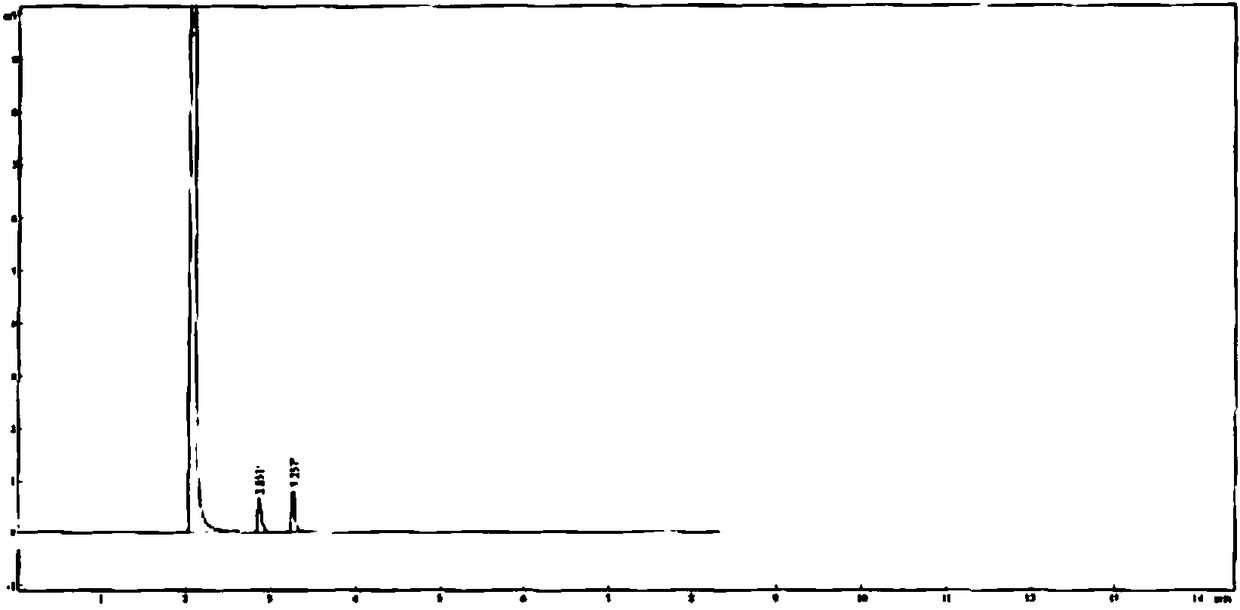

Environmentally-friendly benzyl chloride production method and device

The embodiment of the invention discloses an environmentally-friendly benzyl chloride production method. The method comprises the following steps: feeding chlorine and methylbenzene into a chlorination reactor; performing optical chlorination; conveying the obtained chlorination liquid into a chlorination liquid storing tank for storing; conveying the chlorination liquid from the chlorination liquid storing tank into the middle part of a defluvium unguium rectifying tower; performing defluvium unguium rectifying; conveying the crude benzyl chloride product subjected to defluvium unguium rectifying into a crude product storing tank for temporary storing; conveying the crude benzyl chloride product from the crude product storing tank into the middle part of a finished product rectifying tower for rectifying the finished product; sampling and analyzing at every two hours; collecting the materials on the top of the tower when the benzyl chloride content is beyond 99.5wt%, the chlorotoluenecontent is less than 0.02wt%, and the 2, 4-dichlorotoluene content is less than 0.002wt%; and then feeding into a finished product packing system. With the adoption of the method, the benzyl chloridegoods containing chlorotoluene less than 300ppm and 2, 4-dichlorotoluene less than 20ppm can be continuously produced; and the demand of a dye company on environmentally-friendly benzyl chloride canbe met.

Owner:QIANJIANG XINYIHONG ORGANIC CHEM

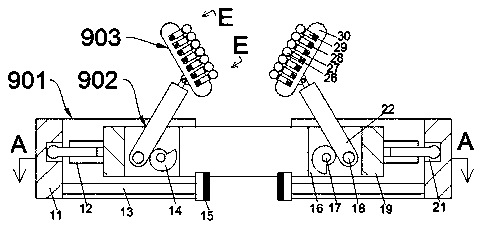

Stability maintaining device used after mandibular face plastic surgery

InactiveCN110623787ASatisfy the thick and thin needsAccelerated reattachmentRestraining devicesRoller massageMassageEngineering

The invention discloses a stability maintaining device used after mandibular face plastic surgery. The device comprises a displacement plate, the displacement plate is slidably connected to symmetrical left and right connection blocks, a fixing device is arranged on the front side of the connecting blocks, and the fixing device comprises an arc-shaped neck ring fixed at the front end of the connecting blocks, a supporting rod fixed at the side, close to the symmetric center, of the arc-shaped neck ring, and a sponge mat fixed on the supporting rod. The invention device adopts a necklace type wearing mode, abandons a mode of an elastic head sleeve, is convenient to wearing and taking process, reduces the pain in the required relaxation process every two hours, adopts the neck ring with theadjustable horizontal distance, meets the requirements for different neck thicknesses, utilizes a double-face clamping plate which is provided with massage balls with the elasticity, gives a reactingforce to the face while adapting to the concave-convex positions of the face, conducts stable keeping, and accelerates muscle reattachment.

Owner:绍兴埔洋美容仪器有限公司

Method for producing organic fertilizer by using high-temperature anaerobic sludge, pig manure and chicken manure as raw materials

InactiveCN102850096AIncrease and update organic matterImprove physical and chemical propertiesBio-organic fraction processingOrganic fertiliser preparationRoom temperatureOrganic matter

The invention discloses a method for producing organic fertilizer by using high-temperature anaerobic sludge, pig manure and chicken manure as raw materials. The method is characterized by comprising the following steps: first mixing the raw materials comprising high-temperature anaerobic sludge, pig manure and chicken manure by a mass ratio of 1.5-2.5:0.5-1.5:0.5-1.5; inoculating fermentation deodorization strains 1-3% of the total weight of the raw materials; fermenting at room temperature for 3-7 d; and inoculating fermentation composting strains 2-4% of the total weight of the raw materials; controlling a fermentation temperature at 20-30 DEG C, and relative humidity at 30-40%; flipping the materials every two hours; and fermenting for 3-7 d, wherein a mass fraction of organic matters in the fertilizer, calculated by dry substances, achieves higher than 45%, and a mass fraction of the total nutrients, calculated by dry substances, reaches higher than 5%, and a mass fraction of water, calculated by fresh sample meter, is less than 30%; and finally packing and storing. The invention has advantages that the produced organic fertilizer is rich in beneficial substances, can provide comprehensive nutrition of crops, has long fertilizer efficiency, and is the main nutrients for green food production.

Owner:温志明

Cress planting method

InactiveCN104904573AImprove germination rateIncrease productionCultivating equipmentsSoilless cultivationGreenhouseNutrient solution

The invention discloses a cress planting method, and relates to the field of agricultural planting. The method comprises the steps that seeding substrates are laid in a seeding plate; cress seeds are evenly sown on the seeding substrates, and the seeding plate sown with the cress seeds is placed in a greenhouse with full sunshine; in the first day after the cress seeds are sown, water is sprayed for 60 seconds every two hours; in the second day to the tenth day, the water is sprayed for 60 seconds every six hours; in the 11th day to the 35th day, nutrient solutions are sprayed for 60 seconds every five hours, cress is preliminarily bred after 35 days, and then field planting is performed to increase the survival rate.

Owner:TONGCHENG GUNIUBEI AGRI DEV

Externally applied preparation for treating acute mastitis

The invention discloses an externally applied preparation for treating acute mastitis. The base method is as follows: a dough is prepared from 300 parts of wheat flour, 1 part of yeast and 100 parts of water by weight, the dough is kneaded to prepare a wheat flour yeast cake with smooth surface and thickness of about 2-3cm, the wheat flour yeast cake is externally applied to the position with mastitis and is 2-3cm beyond the diameter range of mastitis, the wheat flour yeast cake is covered by a preservative film to be protected, the wheat flour yeast cake is turned once every two hours, will be fermented 6-8 hours after absorbing the heat of the position with mastitis symptom and has fluffy meshes, and at the moment, the wheat flour yeast cake is replaced by the new wheat flour yeast cake for external application. The processes are repeated in such a way until the symptom disappears and the breast milk is smooth. Clinically applied to treat mastitis, the wheat flour yeast cake is simple and practicable, is low in price, has no toxic or side effects, has cure rate of about 90% and has reliable curative effects.

Owner:冯英

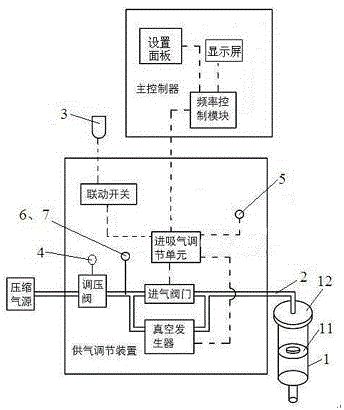

Automatic constant-temperature ink filling device for printer

InactiveCN105620032AAvoid cakingPrevent oxidation from drying outScreen printersPrinting press partsScreen printingElectricity

The invention discloses an automatic constant-temperature ink filling device for a printer. The automatic constant-temperature ink filling device comprises an air supply adjusting device, a main controller and an ink storage cartridge, wherein the main controller is electrically connected with the air supply adjusting device; the ink storage cartridge is connected with the air supply adjusting device through an air pipe; the ink storage cartridge is of a needle cylinder type structure that a piston is plugged in an inner cavity of a cartridge body; one end of the ink storage cartridge communicates with the air pipe, and the air supply adjusting device blows air to the ink storage cartridge or generates suction negative-pressure through the air pipe; the other end of the ink storage cartridge is provided with an ink outlet, and the ink outlet is connected with a screen printing machine and supplies ink for the screen printing machine; an electric constant temperature system and a stirring system are arranged in the ink storage cartridge; the electric constant temperature system is used for controlling the temperature of the ink in the ink storage cartridge to be within the range of 25-30 DEG C; the stirring system is used for stirring the ink in the ink storage cartridge every two hours. By adopting the automatic constant-temperature ink filling device, the printing effect of the printer is stable and does not change with the environmental temperature.

Owner:邓泳安

Production method of tea and wine

The invention discloses a production method of tea wine, tea water is added in low-alcohol wine, the production method is characterized in that: the volume ratio of the low-alcohol wine and the tea water is 50 to 60: 30 to 40, syrup water with the volume ratio of 10 to 20 percent and honey with the volume ratio of 1 to 3 percent are further added therein, the tea water soaks teas with the weight ratio of 20 to 40 percent in water, the stirring is carried out once every two hours, the stirring is carried out for more than 5 times, the syrup water is solution which is prepared by using sugar and water and has the concentration of 30 to 40 percent, the wine can be drunk as a cold or hot drink, the wine can activate the blood circulation, strengthen the body, improve the eyesight and resuscitate the brain; when in drinking, the wine is not intoxicating and has mellow taste.

Owner:傅斌

Cable extrusion technology

ActiveCN105551691AGood quality heat shrinkage testLow heat shrinkageInsulating conductors/cablesShrinkage rateEngineering

The invention discloses a cable extrusion technology, which comprises the following steps: selecting corresponding screw diameters according to cables with different specifications, carrying out warming and preheating after determining machine equipment to be intact, heating various parts of an extruder to corresponding temperatures according to the screw diameters and different materials, detecting the temperatures every two hours, and beginning to charge and start up the machine; placing a filter plate and two wire meshes in front of a machine head, and using a copper mesh and one wire mesh when impurities are excessive; ensuring that the added plastic is clean and dry during charging, starting a main engine, penetrating into a conducting wire core, starting traction, correcting a shifting core according to the trend of a rubber compound, and then measuring the wire diameter for more than six times every 30 minutes by a vernier caliper, and loading a spool for start-up when conforming to a tolerance range of the process; and simultaneously, starting a spark inspection machine, fully cooling an insulating wire core, and frequently adjusting the tension of a pay-off spool. According to the cable extrusion technology, the temperatures of different parts of the extruder are adjusted, so that the hot-shrinkage rate of the cable is reduced; the physical property is improved; and the quality of the cable is ensured.

Owner:浙江五丰电缆有限公司

Pickling method of hot and sour chicken feet

The invention discloses a pickling method of hot and sour chicken feet which are produced from chicken feet, cassia bark, star anise, onion, ginger, vinegar, soy sauce, sugar, garlic bulb and pickled chilli. The pickling method comprises the following steps of: 1, cleaning the chicken feet, soaking for 4h with water, changing water once every two hours; 2, adding water to just cover the chicken feet, boiling water in a pot, placing the chicken feet, the star anise, the cassis bark, the onion and the ginger, continuously boiling for 8min after the water is boiled, fishing the chicken feet out and cleaning, placing in a container capable of enabling the water to fall, and then placing the container below a faucet, washing for 30min with water in the faucet with small flow, fishing out, and airing to remove surface colloid so as to avoid being turbid during soaking; and 3, pouring the soy sauce, the sugar, the vinegar, the garlic bulb and the pickled chilli in the container, uniformly mixing, and placing the aired chicken feet in the container for being soaked for 60min so as to be eaten.

Owner:庄景阳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com