Automatic constant-temperature ink filling device for printer

A technology for automatic inking and printer use. It is used in general parts of printing machinery, printing presses, rotary printing presses, etc. It can solve the problems of oil black adding ink oxidation drying, time, waste of ink substrate, and unstable printing effect. , to achieve better printing effect, improve the quality of printed matter, and improve the effect of ink utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following describes the embodiments of the present invention in detail with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways defined and covered by the claims.

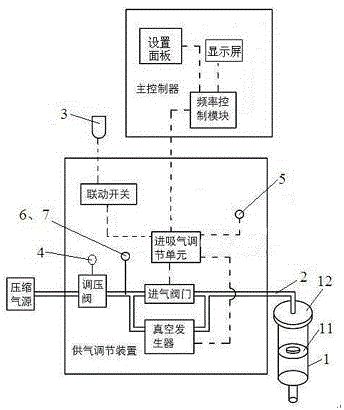

[0019] See figure 1 A constant temperature automatic ink refilling device for a printer includes an air supply adjusting device, a main controller electrically connected to the air supply adjusting device, and an ink storage cylinder 1 connected to the air supply adjusting device through a ventilation pipe. The ink storage cylinder 1 is The inner cavity of the cylinder is plugged with a syringe structure of a piston 11. The piston 11 can prevent ink from entering the ventilation pipe 2. One end of the ink storage cylinder 1 is connected with the ventilation pipe 2, and the air supply regulator blows the ink storage cylinder 1 through the ventilation pipe 2 Air or suction, the other end of the ink storage cylinder 1 is provided with an ink outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com