Patents

Literature

171results about How to "Ease of industrial preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing novel polyaspartic ester and application thereof

InactiveCN101817924AHigh reaction conversion rateShort reaction timePolyurea/polyurethane coatingsPolyasparticDicarboxylic acid

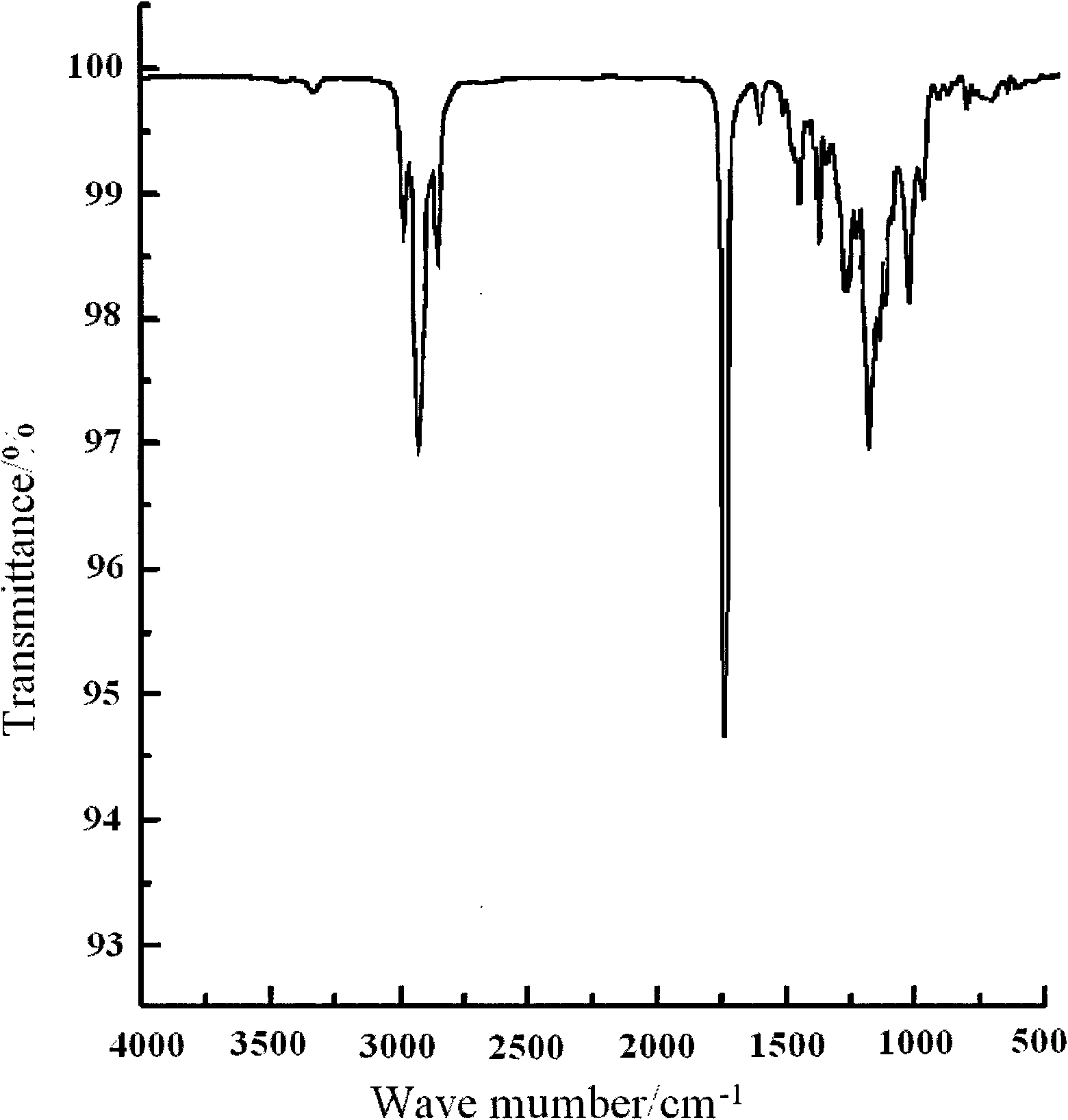

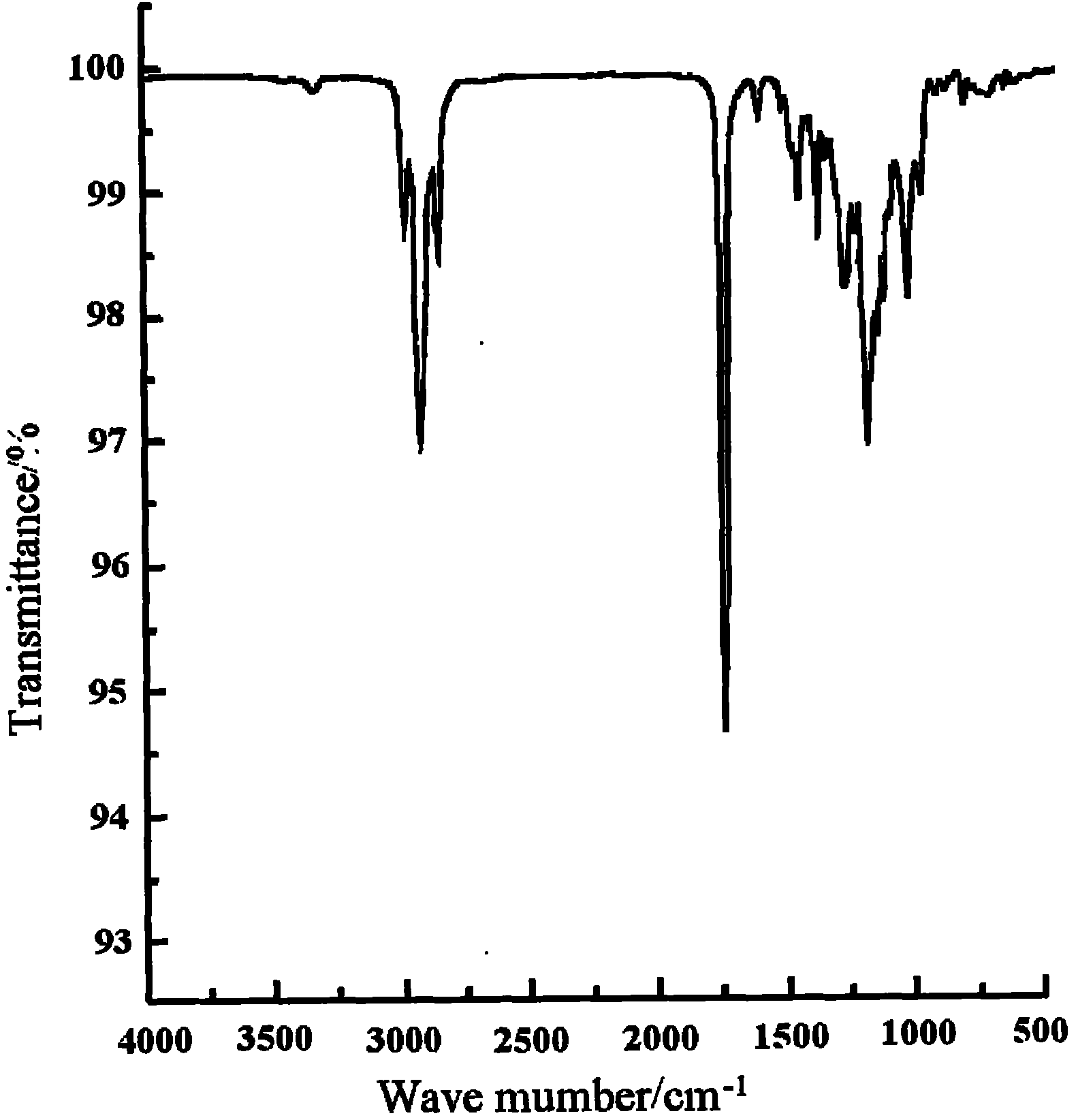

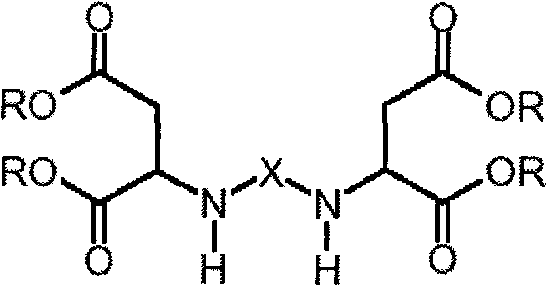

The invention discloses a method for preparing novel polyaspartic ester, in particular a method for preparing a component for slow reaction type polyurea paints. The method comprises the following concrete steps of: 1) performing a catalytic reaction of dicarboxylic ester and primary amine to obtain a Michael additive product; and 2) adding epoxy resin into the product obtained in the step 1) to obtain the novel polyaspartic ester after reaction. The method for preparing the novel polyaspartic ester shortens the reaction time, improves the reaction conversion ratio, and conveniently realizes industrial preparation. Due to the adoption of the method, the problems of low conversion ratio in short time, long synthesis time, failure of timely delivery, difficult industrial production or low product performance after solidification in the prior art are solved. The novel polyaspartic ester has high tensile strength and high elongation rate.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Graphene/titanium dioxide composite porous material, preparation method and application thereof

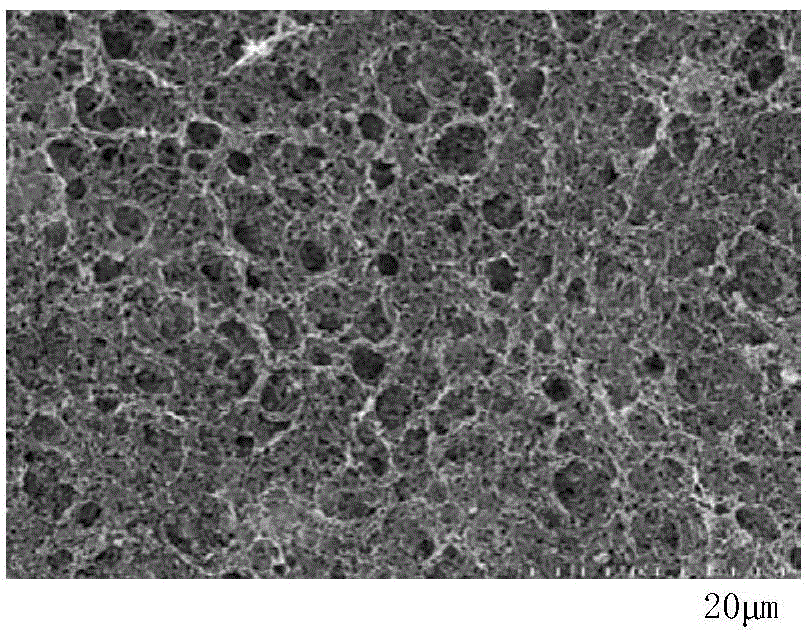

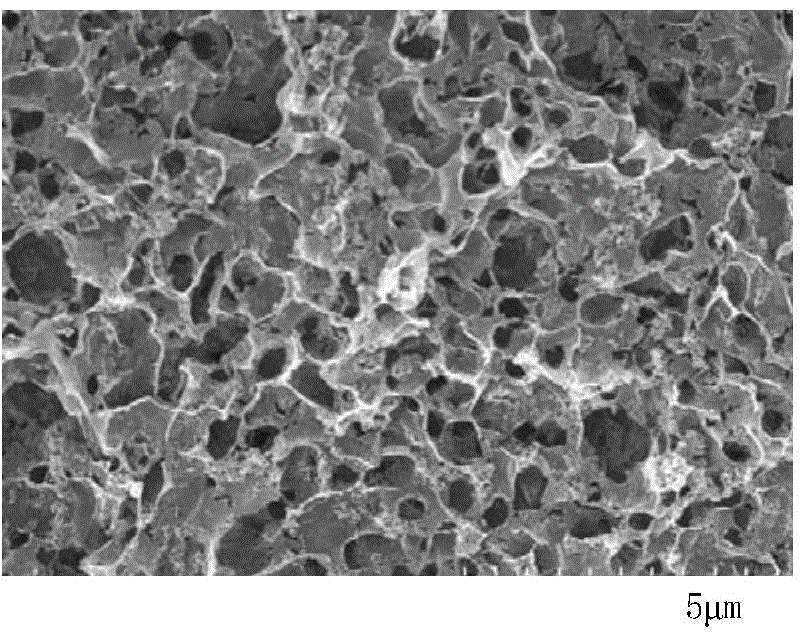

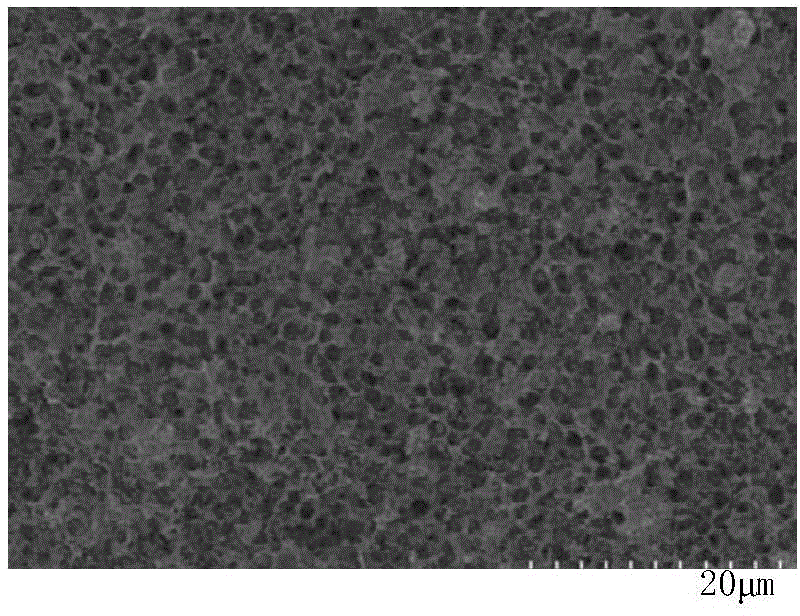

InactiveCN104157833AEasy to prepareLow costHybrid capacitor electrodesCell electrodesScale structureSolvent

A graphene / titanium dioxide composite porous material, a preparation method and an application thereof. The invention relates to porous materials. The composite material has an interpenetrated pore structure with a substrate structure size being 100 nm-5 [mu]m and a pore diameter being 100 nm-5 [mu]m. The composite material is in a three-dimension net-pore structure. A micro-scale structure of the substrate is a continuous phase composed of graphene and nano titanium dioxide is dispersed on a dispersed graphene sheet layer. The graphene / titanium dioxide composite porous material is prepared by following steps including: dissolving a styrene segmented copolymer in a selective solvent to form a polymer micelle solution; adding a graphene oxide solution; adding titanium dioxide after the graphene oxide solution and the polymer micelle solution being mixed uniformly; performing ultrasound wave treatment; performing a curtain coating process on a carrying plate which is placed in a saturated atmosphere of a precipitant to obtain a polymer / graphene oxide / titanium dioxide composite porous material after the solvent being volatilized; performing a carbonizing process in an inert atmosphere with the carrying plate to obtain a product. The composite porous material can be applied in preparation of a graphene / titanium dioxide porous composite electrode which can be used in the fields such as photocatalysis, a lithium ion battery, a super capacitor and the like.

Owner:XIAMEN UNIV

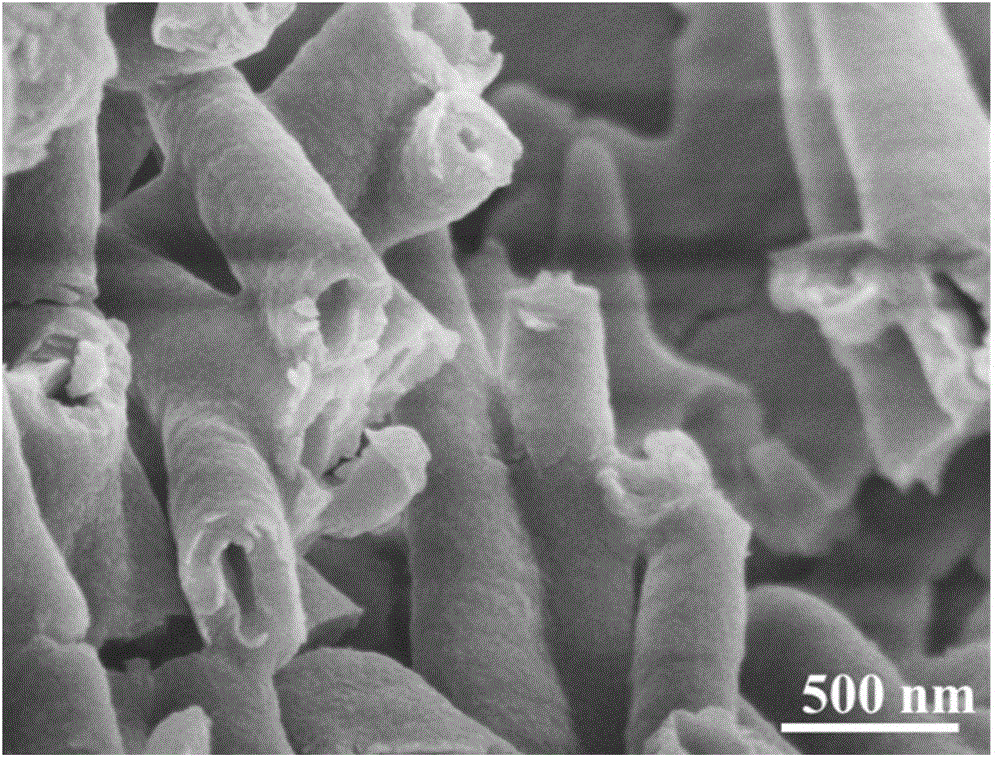

Preparation method of graphite type carbon nitride nanotubes

ActiveCN103601162AWarrantyConducive to vertical ascentNanotechnologyNitrogen and non-metal compoundsNano-deviceFluorescence

The invention discloses a preparation method of graphite type carbon nitride nanotubes. The preparation method comprises the following steps: adding melamine powder into a high temperature-resistant container, and placing the high temperature-resistant container on a vibrator for vibration treatment; then adding a cover on the high temperature-resistant container, placing the high temperature-resistant container into a program heating control device, heating to a first preset temperature at a relatively high heating rate and keeping for a period of time; further heating the program heating control device to a second preset temperature at a relatively low heating rate and keeping for a period of time; and cooling an obtained product to room temperature, and then grinding to form powder so as to obtain the graphite type carbon nitride nanotubes disclosed by the invention. In the synthesis process of the preparation method, the addition of a template or additional organic matters is not required, the preparation method has the advantages of low price, high yield, good repeatability, no impurity interference of products and the like, is simple and easy to operate, and the prepared carbon nitride nanotubes have good fluorescence performance and photocatalytic performance, and have broad application prospects in the fields of nano devices, photocatalysis and the like.

Owner:TIANJIN UNIV

Preparation method of yttria-stabilized zirconia tetragonal nano powder with high specific surface area

ActiveCN103524128ASolve serious sintering and agglomerationSolution areaMaterial nanotechnologyZirconium hydrideSolution combustion

A preparation method of an yttria-stabilized zirconia tetragonal nano powder with high specific surface area. The method is characterized by comprising the following steps: (1) respectively weighing zirconium oxychloride octahydrate?and an yttrium raw material according to a stoichiometric ratio of zirconium and yttrium in (Y2O3)x(ZrO2) 1-2x (0.005<=x<=0.150), according to the amount of a target product, converting the yttrium raw material into an yttrium nitrate solution by dissolving, and then completely dissolving the zirconium oxychloride octahydrate; (2) respectively adding a soluble salt and organic fuel to the solution obtained in the step (1), heating for dissolving, continuing heating and concentrating to a sticky state, igniting in a heating furnace chamber at 400-1000 DEG C, and taking out the powder after complete combustion; and (3) washing, filtering and drying the powder obtained in the step (2). The invention effectively solves the problems of serious particle sintering agglomeration and small specific area in the process of solution combustion for synthesis of zirconium oxide; the powder has specific surface area as high as 378 m<2> / g and particle size about 2.8 nm; and the materials are more accessible and cheaper, so as to facilitate industrialized preparation.

Owner:赣州点金新材料科技有限公司

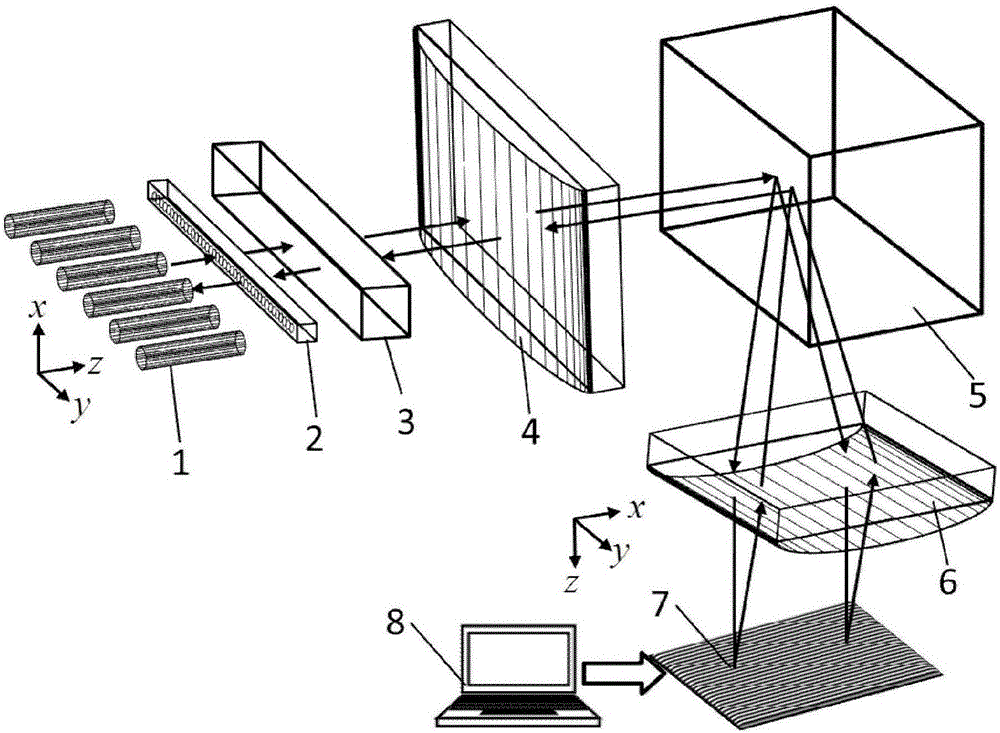

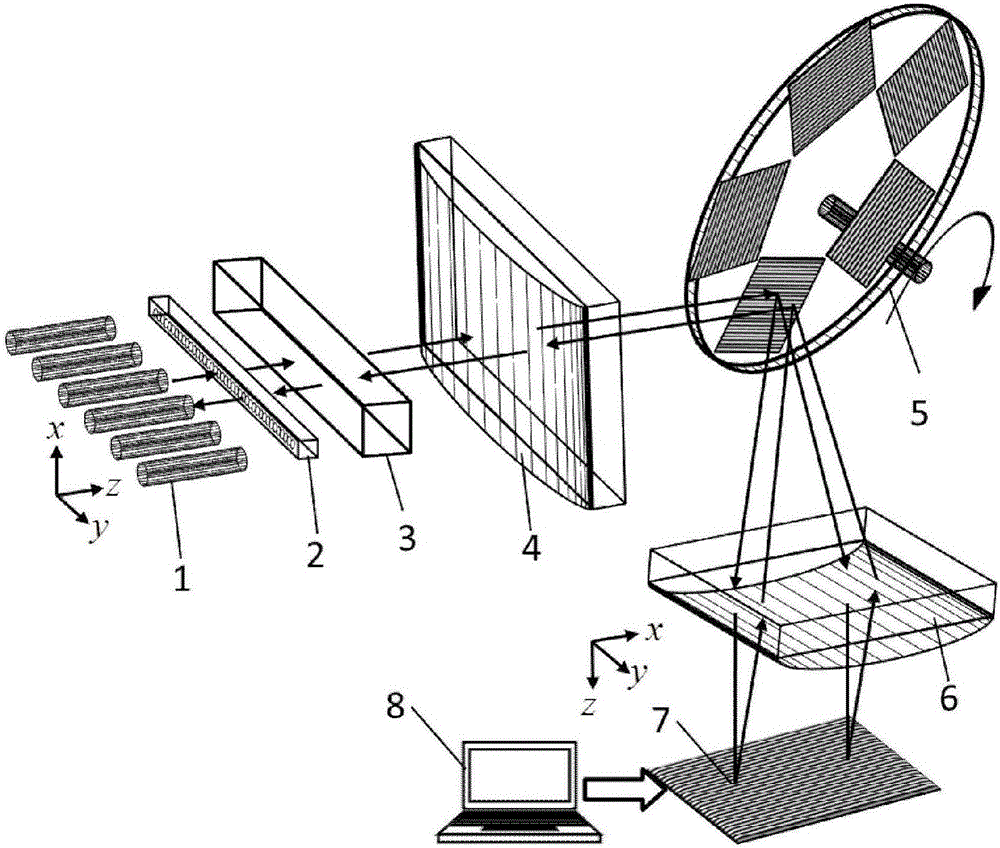

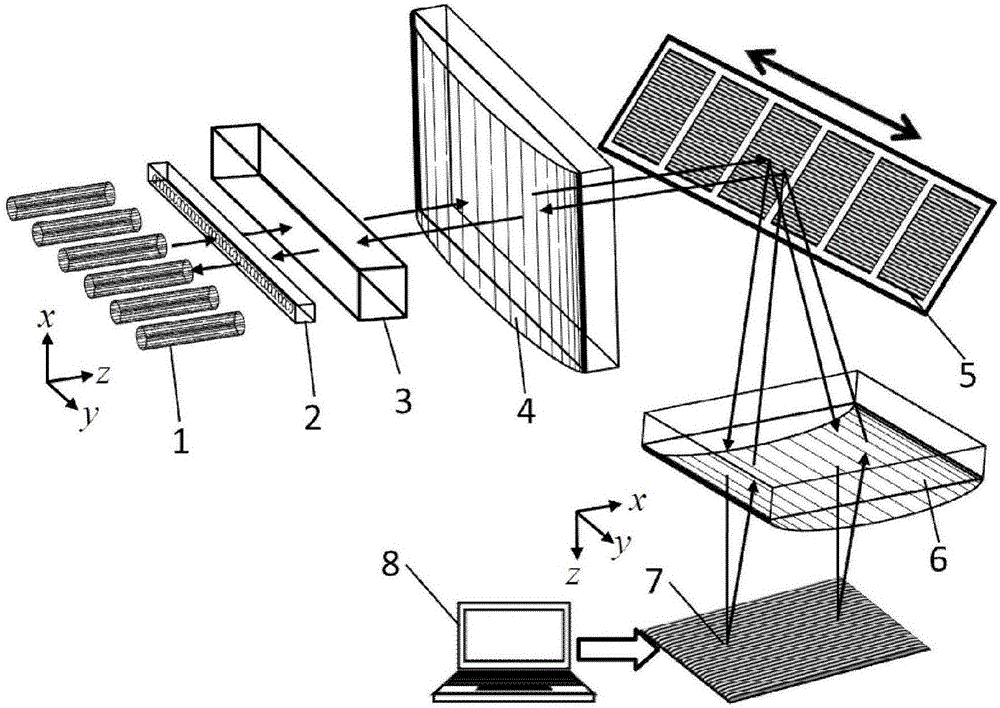

Resolution-adjustable wavelength selection switch based on phase grating array and control method

PendingCN106772813AEasy to assembleEasy to adjustCoupling light guidesNon-linear opticsFiber arrayPrism

The invention discloses a resolution-adjustable wavelength selection switch based on a phase grating array and a control method. The resolution-adjustable wavelength selection switch comprises a one-dimensional single mode fiber array, a microlens array, a polarization adjusting prism, a double-glued optical Fourier transformation lens, a transmissive phase diffraction grating array, a cylindrical mirror, a liquid crystal spatial light modulator and a graph loading control system. The transmissive phase diffraction grating array is adopted, difference in chromatic dispersivity of transmissive phase diffraction gratings different in period is utilized, and wavelength range of parallel beams finally imaged on the liquid crystal spatial light modulator and wavelength control accuracy determined by a single pixel unit can be changed by switching the transmissive phase diffraction gratings having different periods, so that switching and adjusting of working wavelength range and wavelength resolution of the wavelength selection switch are realized, and the wavelength selection switch can be used for processing large-bandwidth high-speed signals in backbone networks.

Owner:MINZU UNIVERSITY OF CHINA

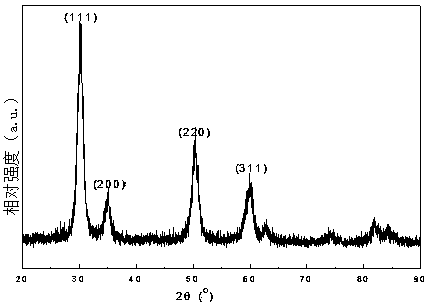

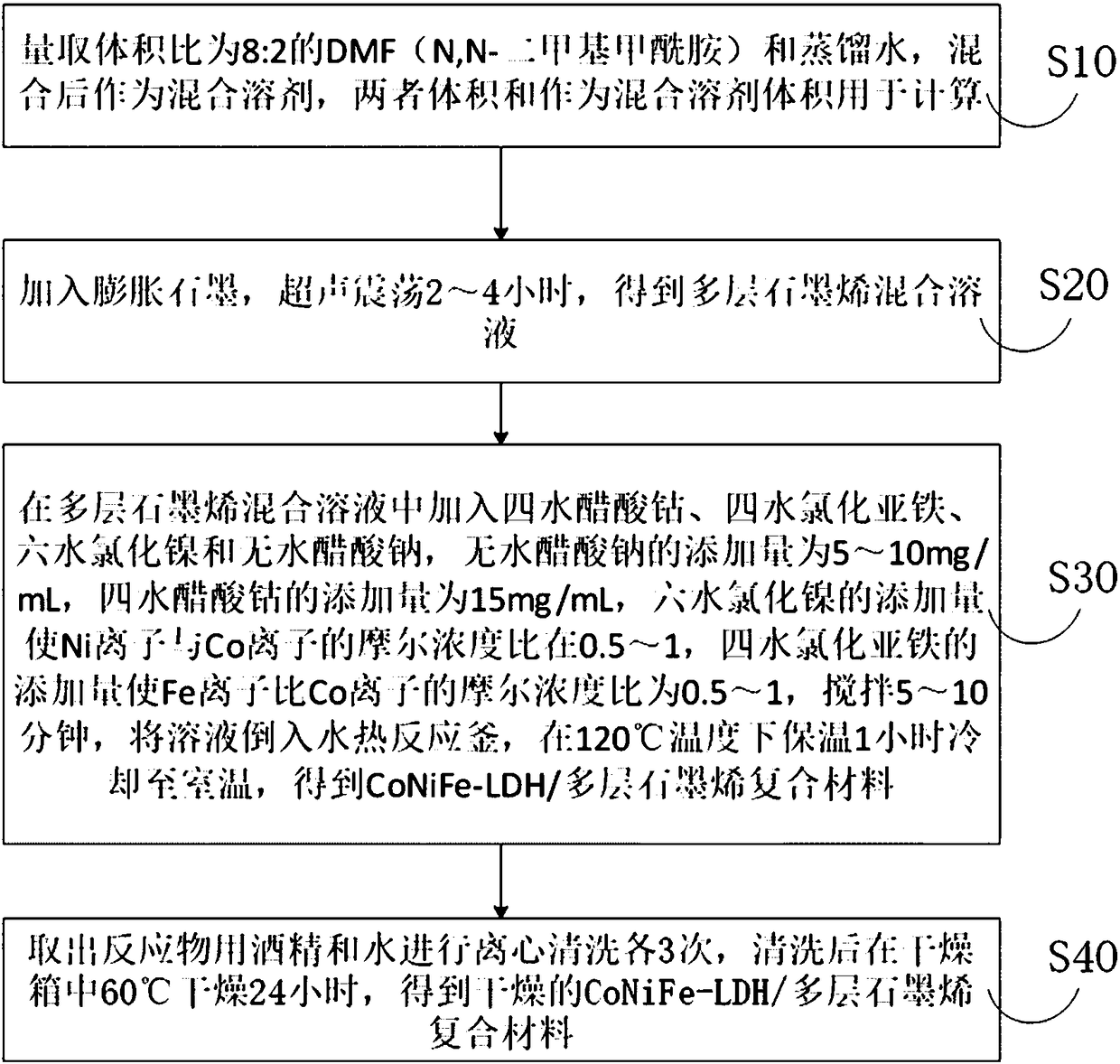

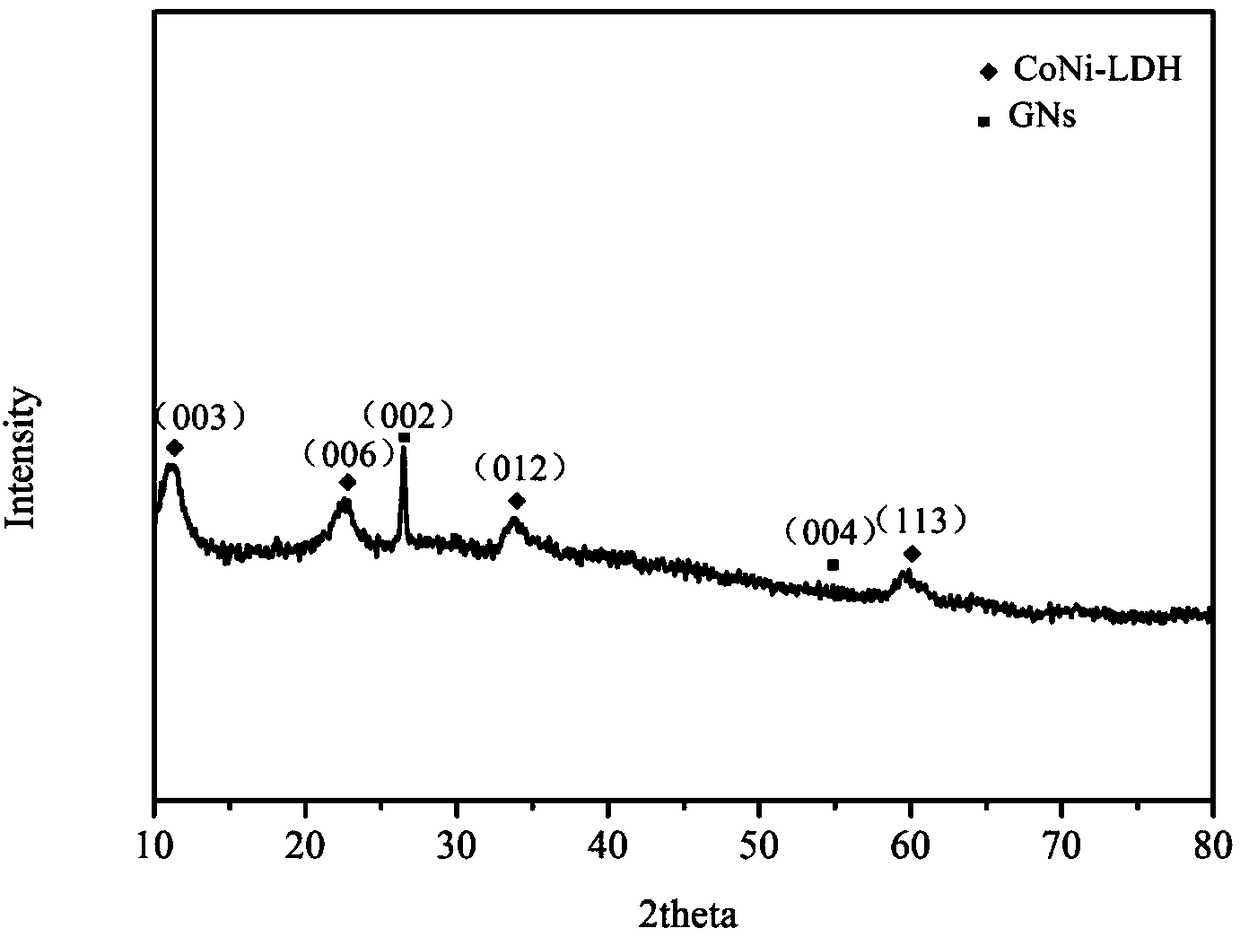

CoNiFe-LDH/multilayer graphene high-performance composite energy storage material and preparation method thereof

ActiveCN108364793AStrong ion capacityEasy to makeMaterial nanotechnologyHybrid capacitor electrodesSolventOxygen

The invention discloses a CoNiFe-LDH / multilayer graphene high-performance composite energy storage material and a preparation method thereof. the preparation method comprises the steps of: measuring DMF and distilled water with a volume ratio of 8:2, and mixing the DMF and the distilled water to serve as a mixed solvent; adding expanded graphite into the mixed solvent, carrying out ultrasonic processing on the solution for 2 to 4 hours to obtain a multi-layer graphene mixed solution; adding cobalt acetate tetrahydrate, ferrous chloride tetrahydrate, nickel chloride hexahydrate and anhydrous sodium acetate into the mixed solution, stirring the solution for 5 to 10 minutes, pouring the solution into a hydrothermal reaction kettle, maintaining the temperature of the solution at 120 DEG C for1 hour, and then cooling the solution to room temperature; taking out a reactant and centrifugally washing the reactant with alcohol and water for three times, and drying the reactant in a 60 DEG C oven for 24 hours to obtain a dry CoNiFe-LDH / multilayer graphene composite material. According to the CoNiFe-LDH / multilayer graphene high-performance composite energy storage material and the preparation method thereof, a method of complexing metal by means of organic molecules is adopted for preparing laminar multi-element metal hydroxide ont eh surface of multilayer graphene which does not containoxygen functional groups, and the process is simple and suitable for production.

Owner:嘉善县国创新能源研究院

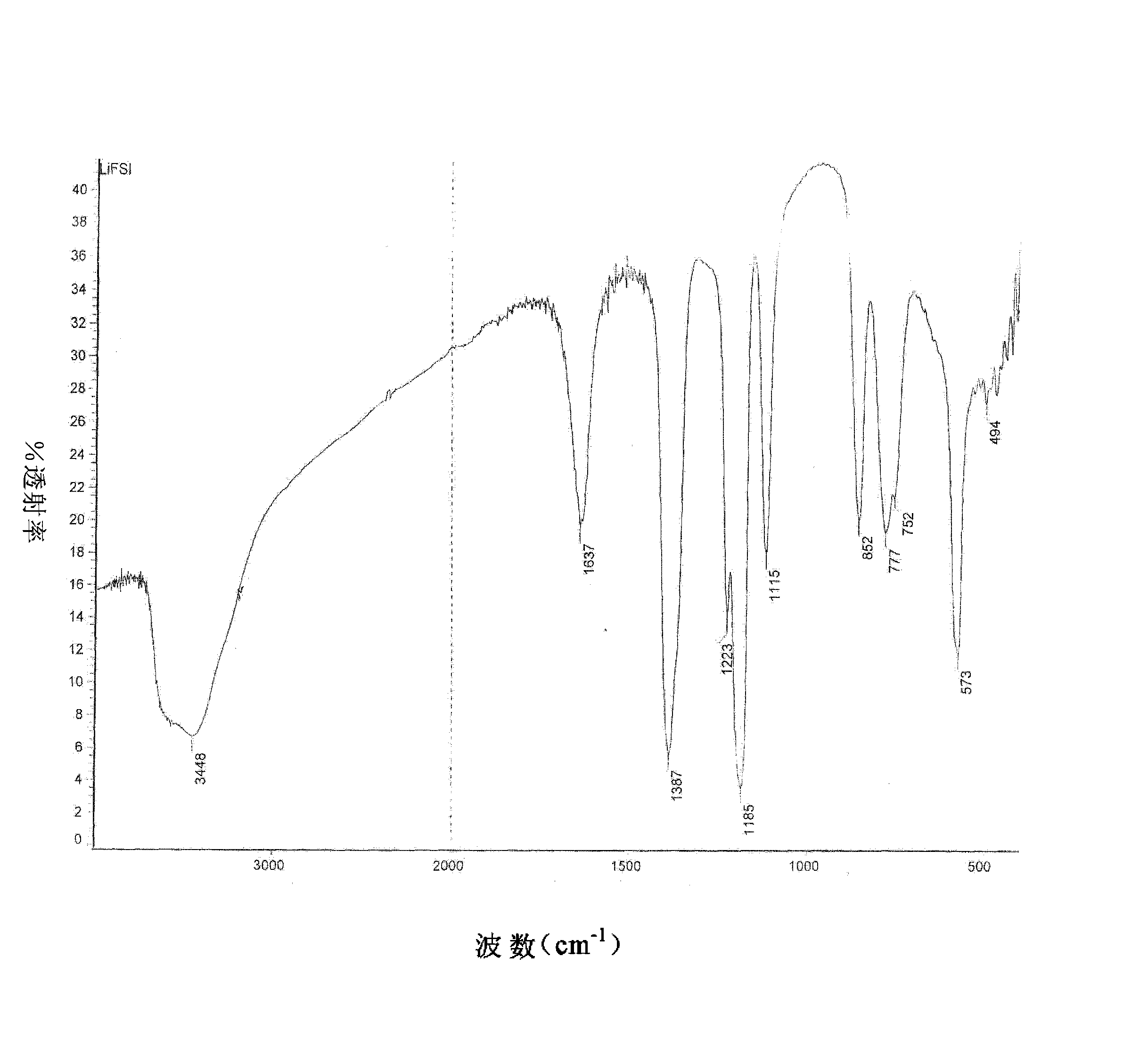

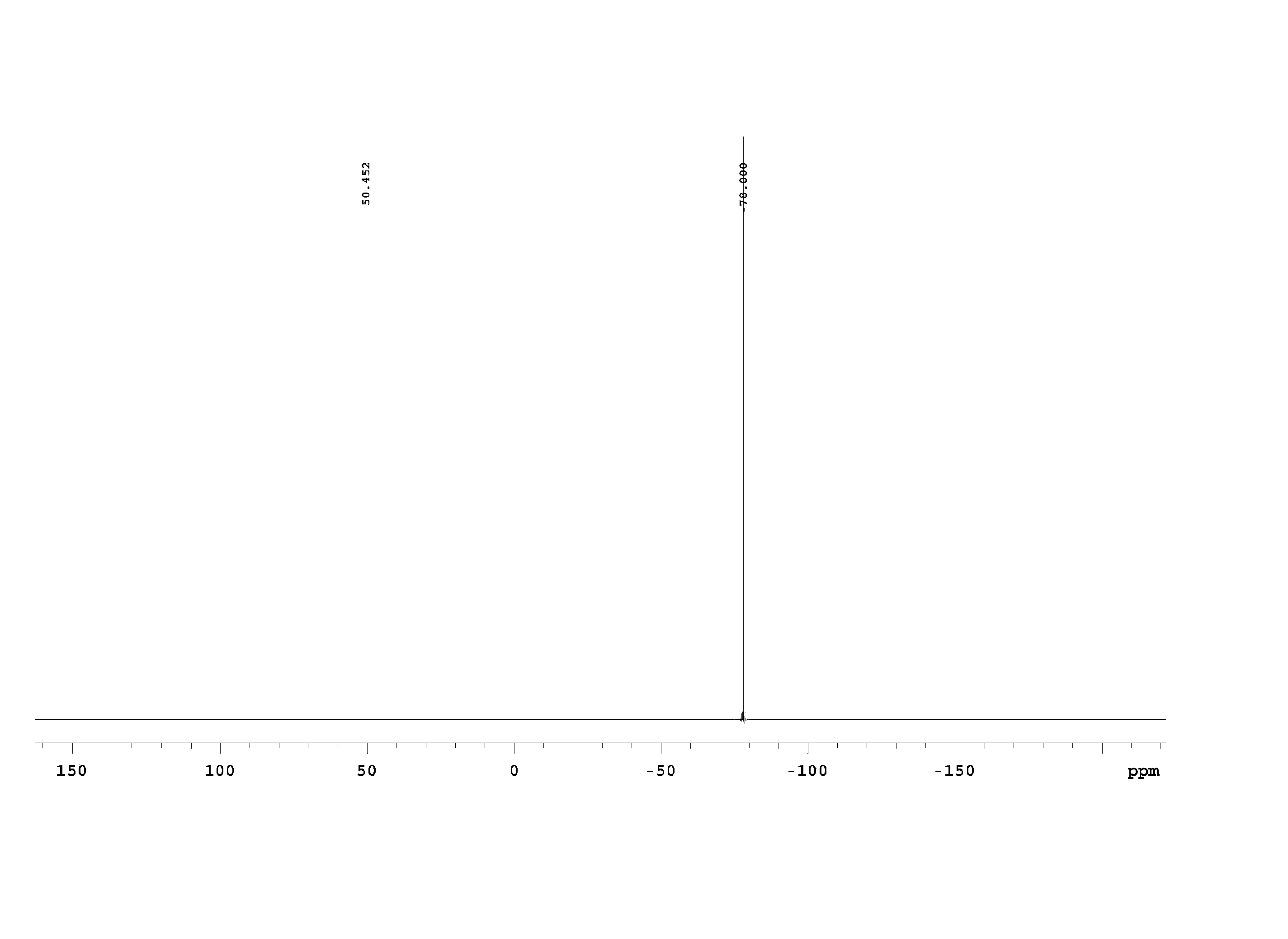

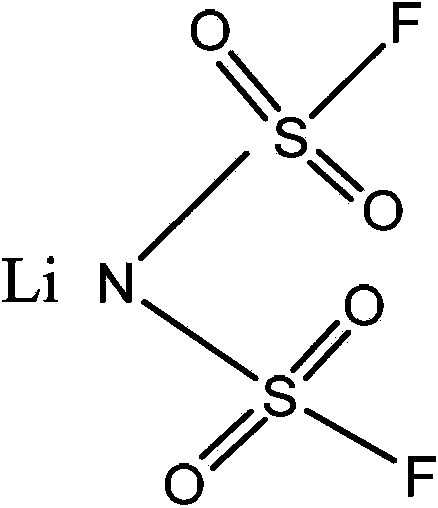

Method for preparing bis(fluorosulfonyl)imide

ActiveCN103910346ASimple process routeEase of industrial preparationImidodisulfonic/nitrilotrisulfonic acidFluoboric acidSolvent

The invention relates to a method for preparing bis(fluorosulfonyl)imide, which is characterized in that double oxalate lithium borate or oxalate fluoboric acid lithium enables a metathesis exchange reaction with double fluorine sulfonyl imide potash to obtain the bis(fluorosulfonyl)imide product. The method for preparing bis(fluorosulfonyl)imide has a simple process route, and the industrialized production is easy to realize.

Owner:浙江盛美リ電材料有限公司

Nanometer striking pin capable of intensifying micro-power on surfaces of substance

InactiveCN105771001AExtensive expansionHighlight substantiveSurgeryPharmaceutical non-active ingredientsSynthetic materialsEngineering

The invention provides a nanometer striking pin capable of intensifying micro-power on the surfaces of substances. The nanometer striking pin is characterized by being a polymer molecule composed of an artificial synthetic material.

Owner:于杰

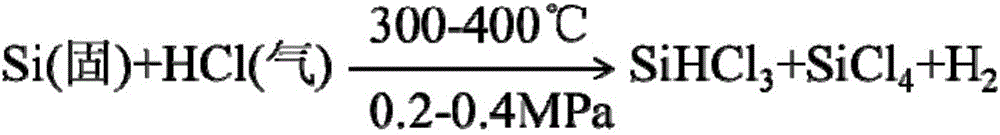

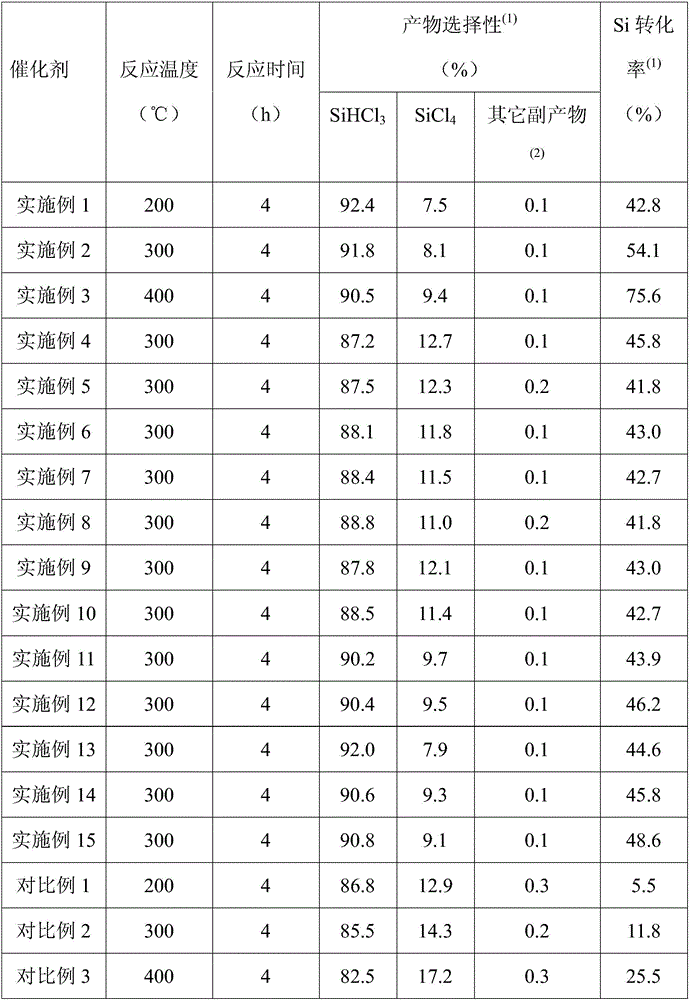

Catalyst for producing trichlorosilane with silicon-hydrogen chlorination process, preparation method of catalyst and method for catalytically producing trichlorosilane

InactiveCN106378133AHigh catalytic activityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsMetal/metal-oxides/metal-hydroxide catalystsHydrogenAdditive ingredient

The invention provides a catalyst for producing trichlorosilane with a silicon-hydrogen chlorination process, a preparation method of the catalyst and a method for catalytically producing the trichlorosilane. The catalyst is prepared from copper-based active ingredients and selectable additives; or the catalyst is prepared from a copper elementary substance and additives; the copper-based active ingredients comprise coppery oxide and / or copper salt, or the combination of the copper elementary substance and the coppery oxide and / or the copper salt; and the particle size of the catalyst is 0.5 to 100 microns. According to the catalyst, the selectivity of the trichlorosilane and the conversion rate of silica powder raw material can be obviously improved, the ingredients are simple, the catalyst is easy for industrial preparation and is free of pollution to the environment, reaction conditions for catalytically producing the trichlorosilane with the silicon-hydrogen chlorination process is mild, and a reaction is easy to control.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

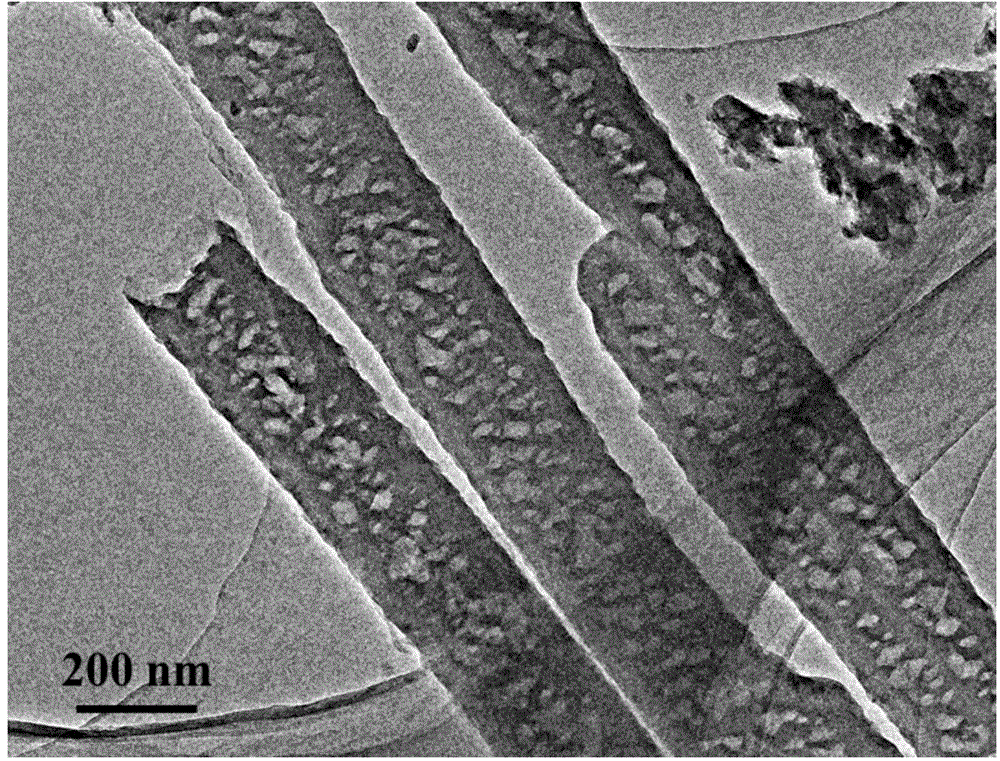

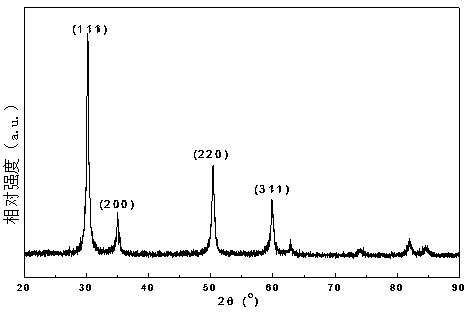

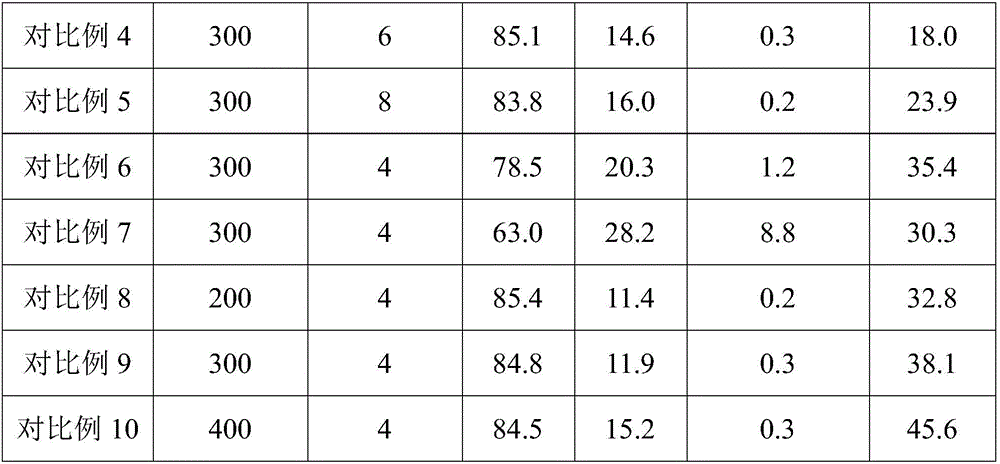

Porous copper oxide microsphere/multilayer graphene composite material, and preparation method thereof

ActiveCN108346782AEasy to prepareConducive to industrial preparationHybrid capacitor electrodesCell electrodesIonCvd graphene

The invention discloses a preparation method of a porous copper oxide microsphere / multilayer graphene composite material. The preparation method comprises following steps: DMF and distilled water at avolume ratio of 8:2 are taken, and are mixed so as to obtain a mixed solvent; expandable graphite is added, ultrasonic vibration is carried out for 2 to 7h so as to obtain a multilayer graphene solution; copper acetate monohydrate is added into the multilayer graphene solution, stirring is carried out for 3 to 6h, an obtained mixed solution is introduced into a hydro-thermal reaction vessel, is subjected to thermal insulation treatment at 100 to 130 DEG C for 2h, and is cooled to room temperature; an obtained reaction product is subjected to centrifugal cleaning with alcohol for three times,and centrifugal cleaning with water for three times so as to obtain the dried porous copper oxide microsphere / multilayer graphene composite material. According to the preparation method, organic molecules are adopted for complexation of metal ions, so that porous copper oxide microspheres are prepared on the surface of multilayer graphene containing no oxygen functional groups, the obtained porouscopper oxide microsphere / multilayer graphene composite material possesses a special morphology.

Owner:嘉善县国创新能源研究院

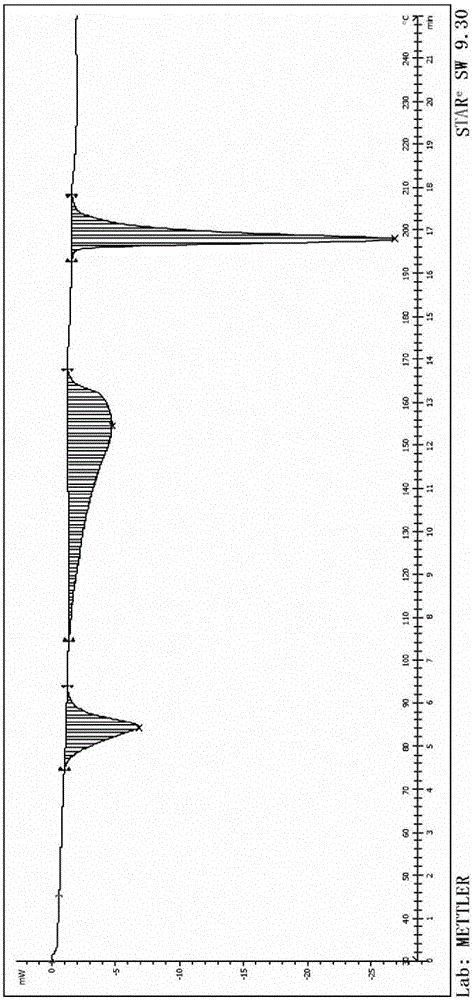

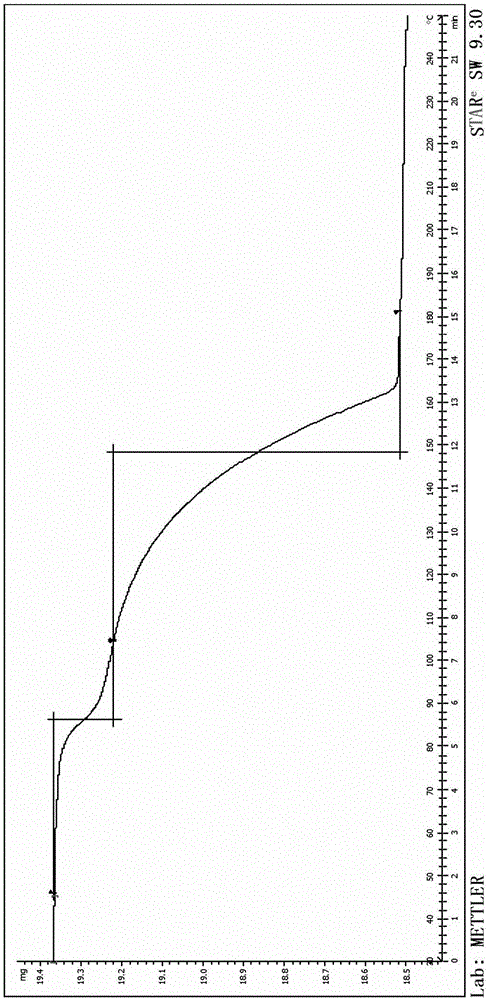

Gefitinib glycol solvate and its preparation method and use

ActiveCN104693127BEasy to manufactureEase of industrial preparationOrganic chemistry methodsSolventMedicinal chemistry

The invention belongs to the technical field of medicinal chemistry and in particular relates to a gefitinib ethylene glycol solvate, a preparation method of the solvate, and a method for preparing a high-purity gefitinib Form 1 crystal form by adopting the gefitinib ethylene glycol solvate. The gefitinib ethylene glycol solvate is simple in large-scale preparation, easy to operate, high in stability and high in purity and can be used for preparing the high-purity gefitinib Form 1 crystal form.

Owner:QILU PHARMA CO LTD +1

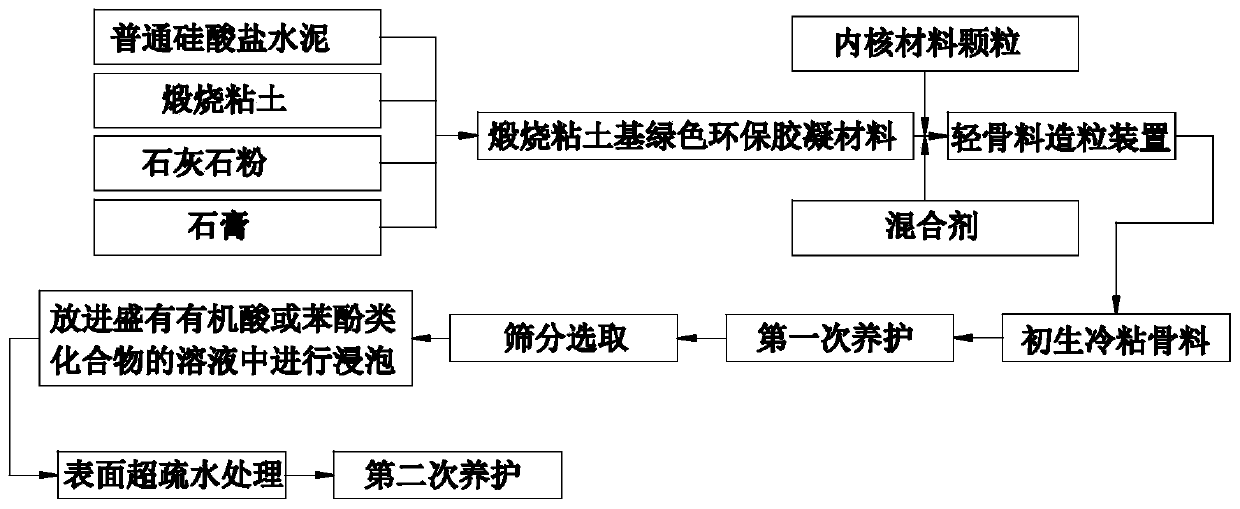

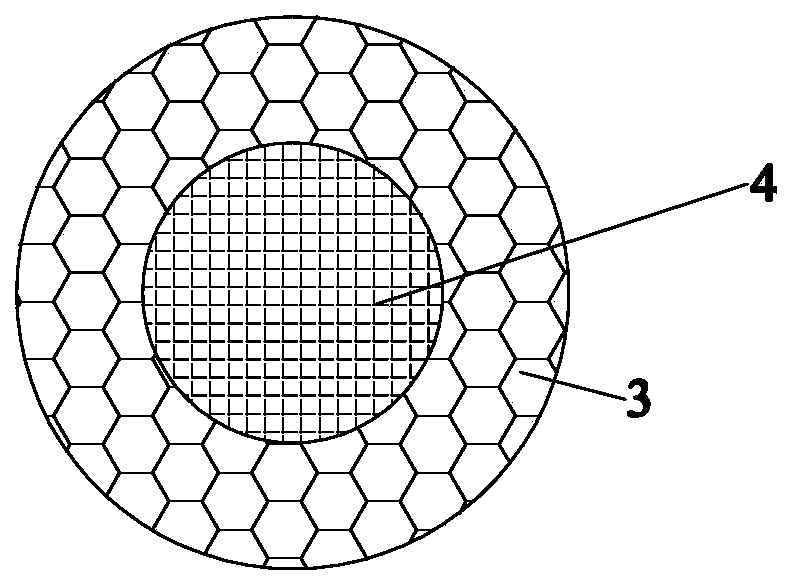

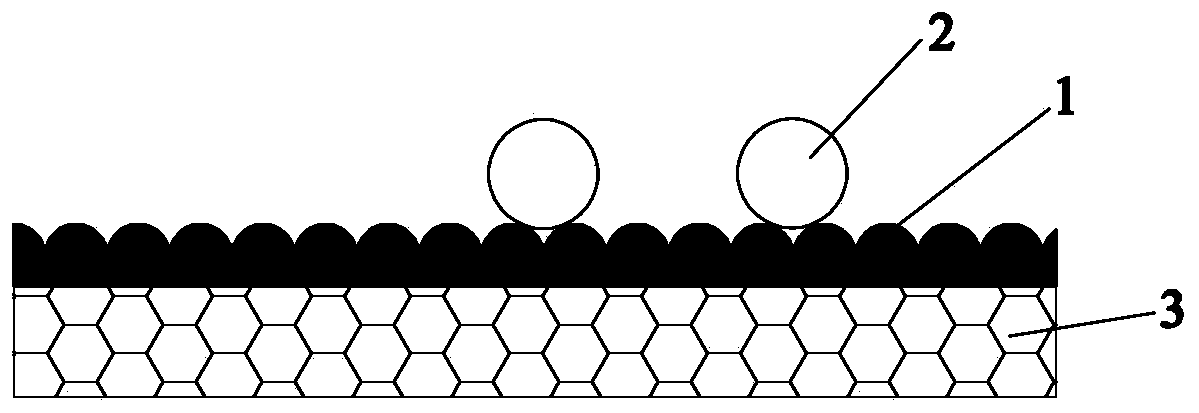

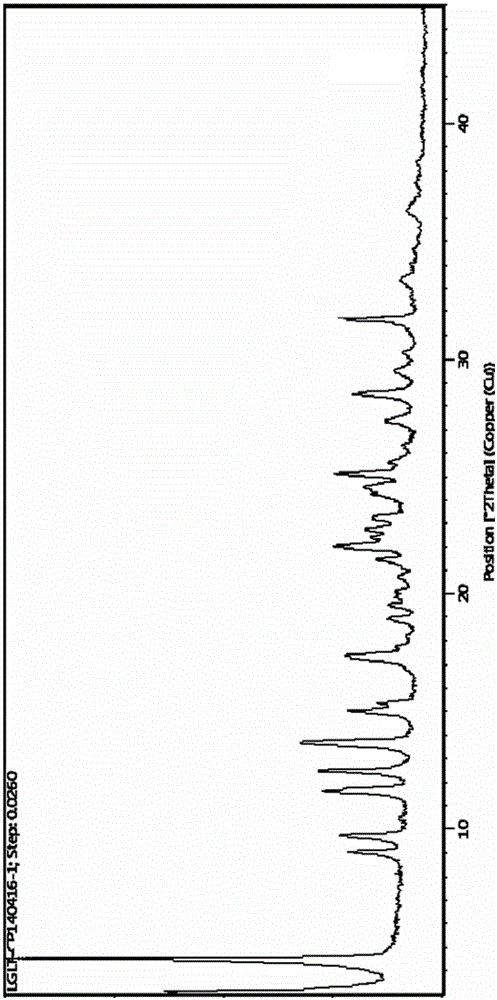

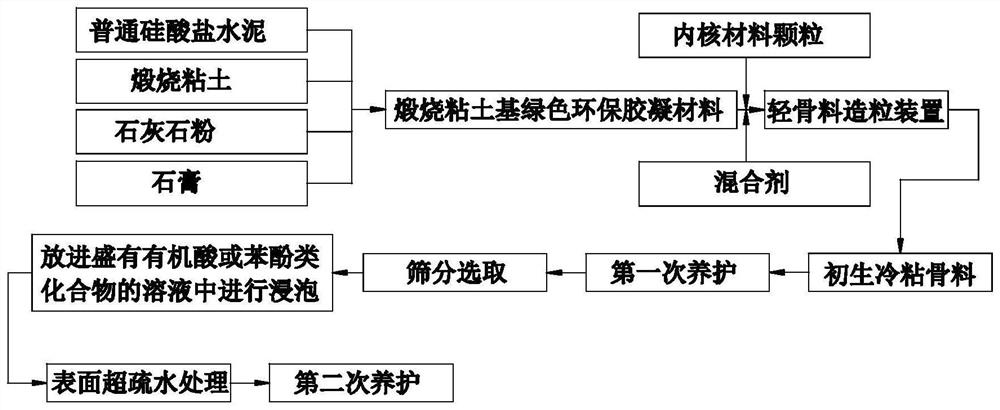

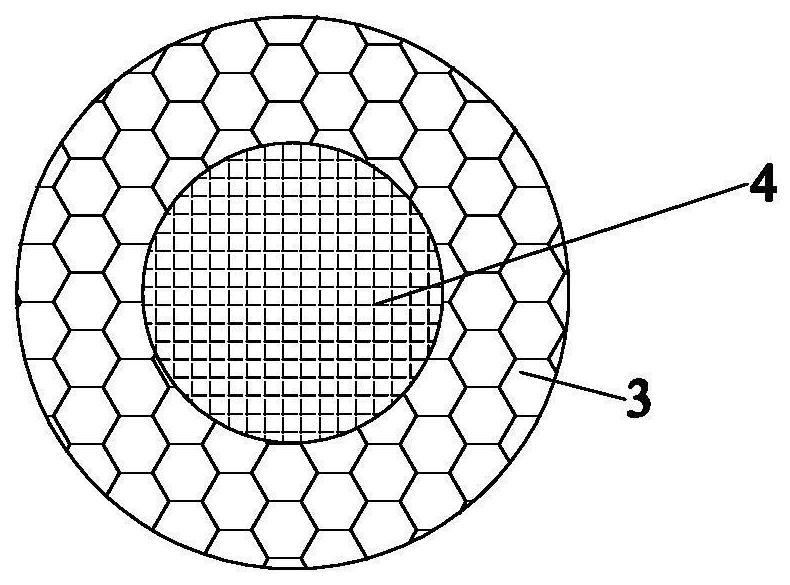

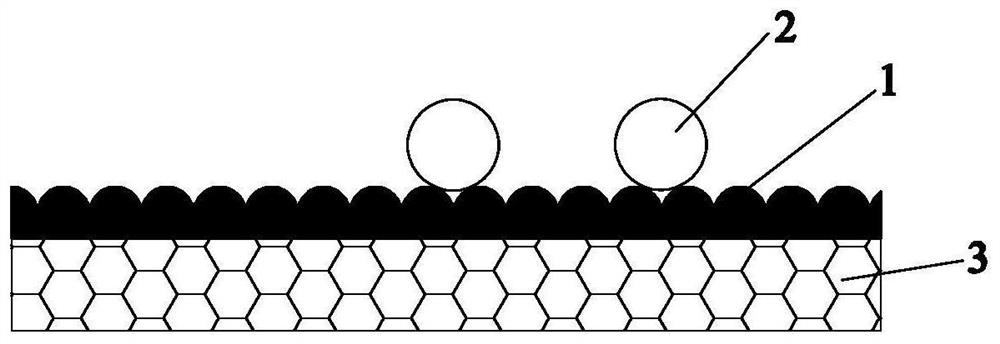

Core-shell-structure lightweight aggregate prepared by cold bonding method and preparation method thereof

The invention discloses a core-shell-structure lightweight aggregate prepared by a cold bonding method and a preparation method thereof. The preparation method comprises the following steps: preparinga calcined clay-based environment-friendly cementing material from ordinary Portland cement, calcined clay, limestone powder and gypsum in proportion; putting core material particles into a lightweight aggregate granulation device, then adding the calcined clay-based environment-friendly cementing material, and uniformly spraying a mixture for granulation to form primary cold-bonded aggregate; carrying out primary maintenance on the primarily-generated cold-bonded aggregate, soaking the primarily-generated cold-bonded aggregate in a solution containing organic acid or phenol compounds, takingout the primarily-generated cold-bonded aggregate, airing, and repeatedly spraying a calcium hydroxide aqueous solution on the surface of the aggregate to form aggregate with a super-hydrophobic surface; and subjecting the aggregate with the super-hydrophobic surface to water for secondary maintenance to produce the super-hydrophobic high-strength lightweight aggregate. According to the core-shell structure lightweight aggregate and the preparation method thereof, energy is saved, consumption is low, the processing flow is simplified, solid waste recycling can be achieved, the water absorption rate is low, and the single bearing capacity is high.

Owner:SHENZHEN UNIV

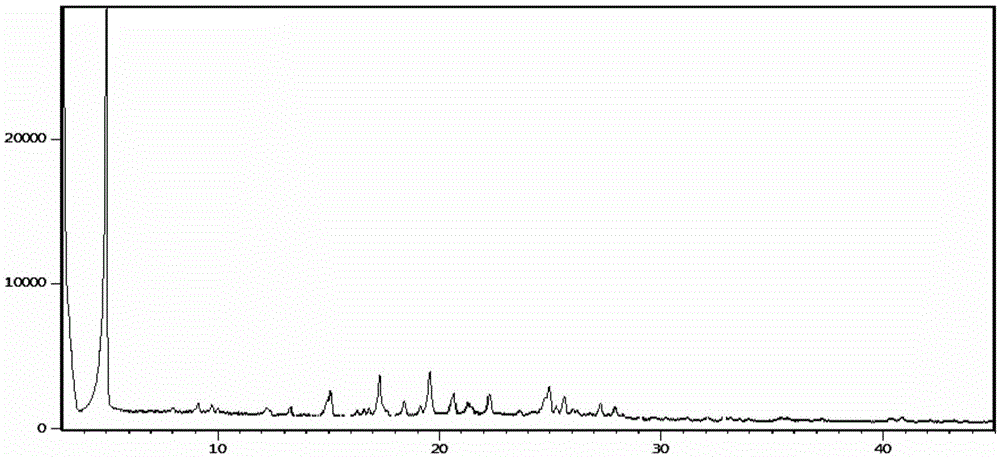

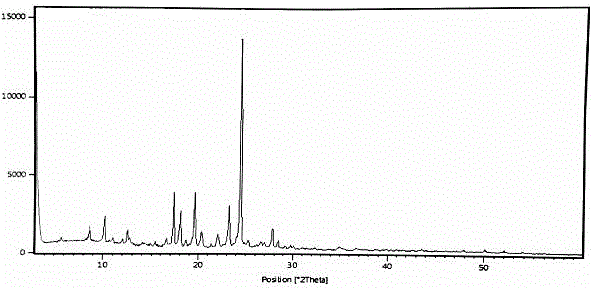

New Trajenta crystal form and preparation method thereof

ActiveCN105272982AHigh purityCrystal stableOrganic chemistry methodsPharmaceutical formulationMedicinal chemistry

The invention belongs to the technical field of pharmaceutical chemistry and particularly relates to a new Trajenta crystal form and a preparation method thereof. The crystal form has good chemical stability and crystal form purity and is easy to prepare on a large scale, operation is easy, and the crystal form can be better suitable for preparation of pharmaceutical preparations and large-scale production, and has a broad application prospect.

Owner:QILU PHARMA HAINAN +1

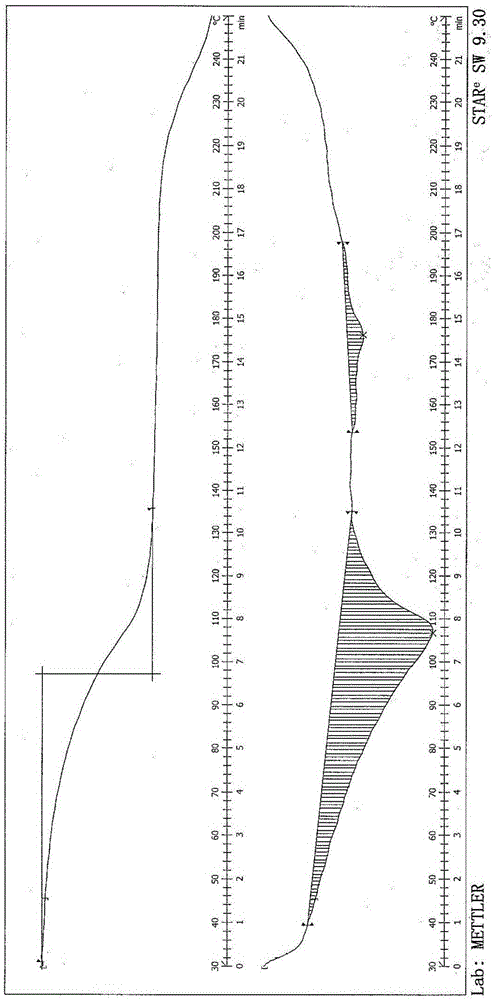

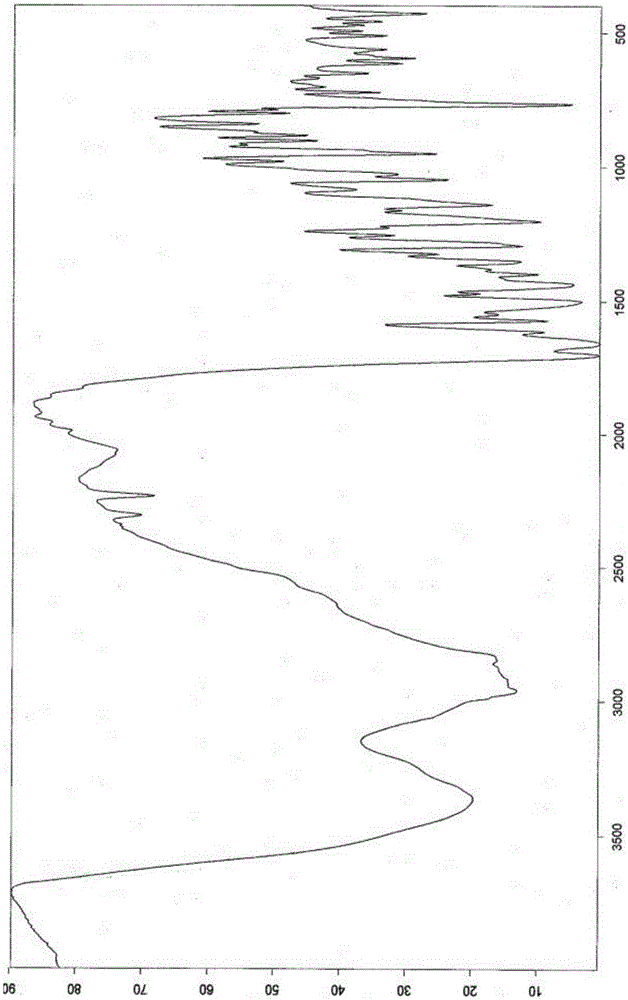

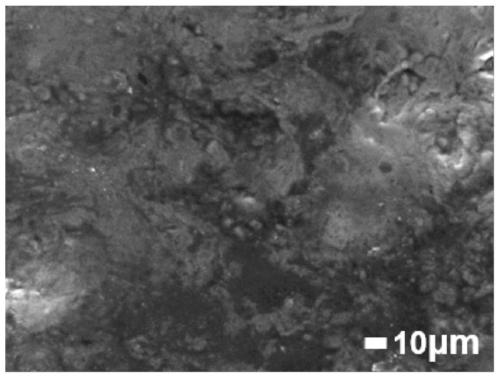

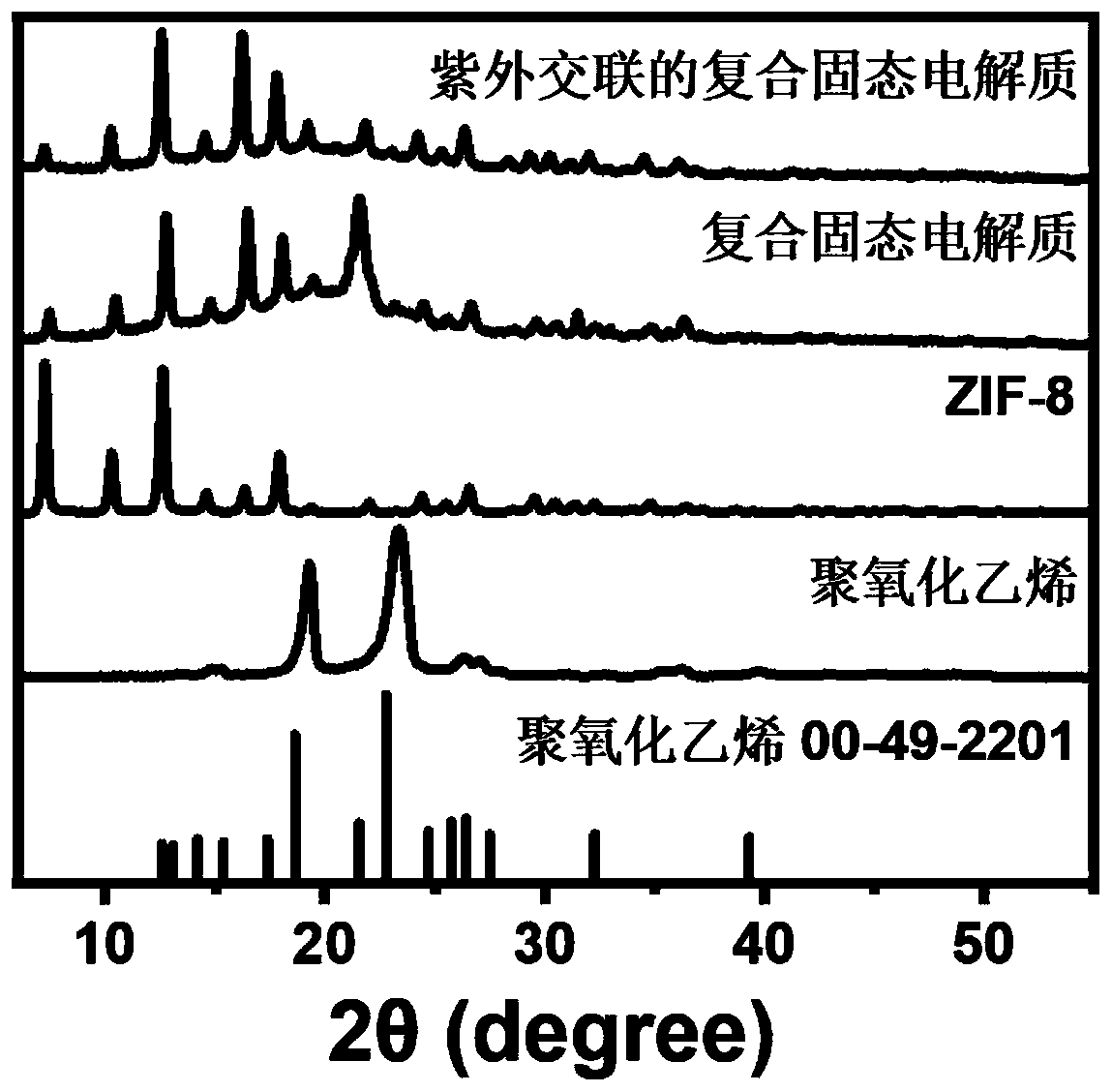

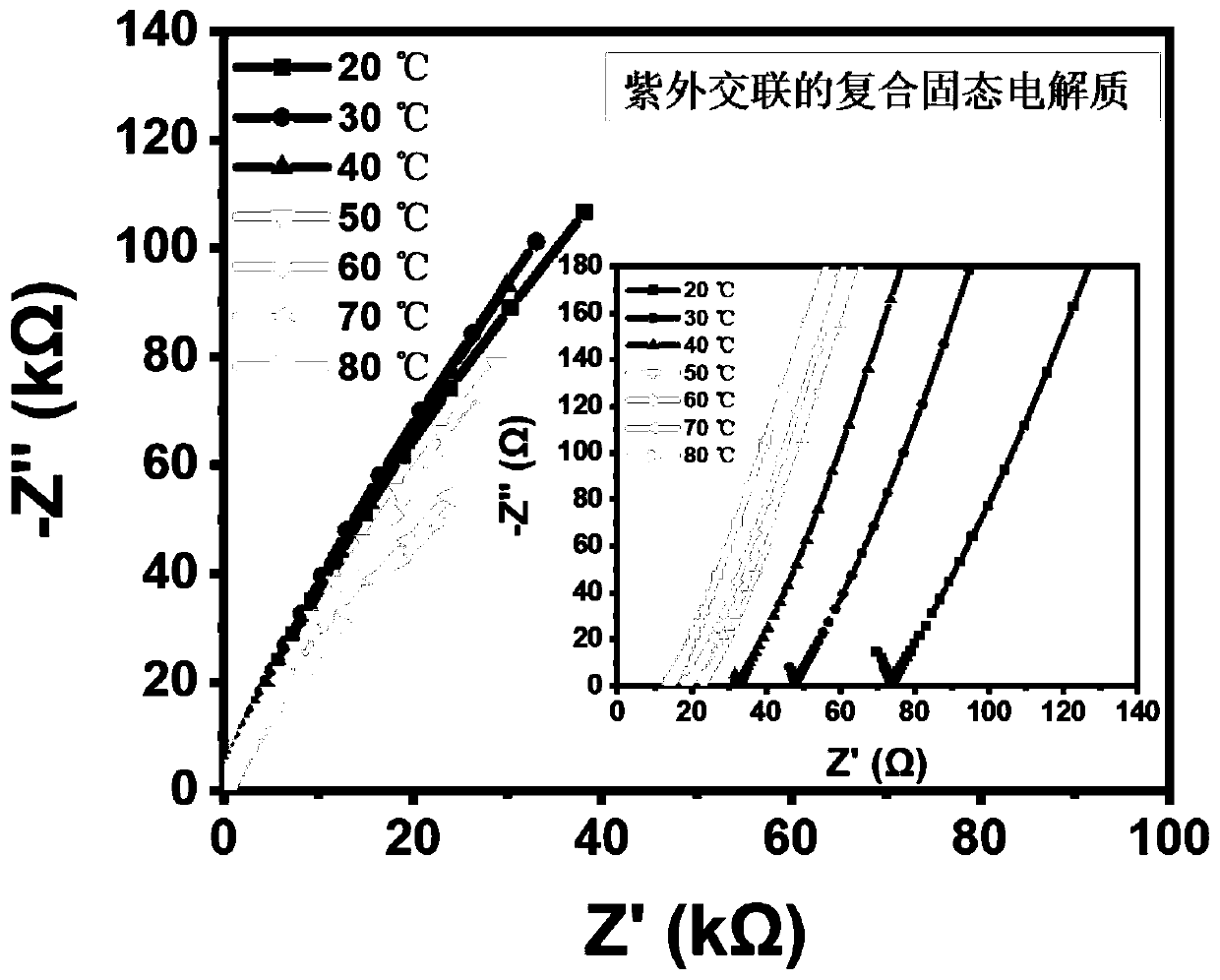

Preparation method of ionic conductor/polyoxyethylene composite solid electrolyte based on ultraviolet crosslinking

ActiveCN111313089AImprove performanceImprove ionic conductivityFinal product manufactureElectrolyte accumulators manufactureSolid state electrolyteCompression molding

The invention relates to a preparation method of an ionic conductor / polyoxyethylene composite solid electrolyte based on ultraviolet crosslinking. The method comprises the following steps: 1) dissolving a lithium salt in an ionic liquid, and magnetically stirring to obtain an ionic liquid containing the lithium salt; 2) adding an ionic liquid containing a lithium salt into the activated MOFs material, uniformly grinding, and drying at high temperature to obtain an MOFs-based ionic conductor; 3) mixing polyoxyethylene, a lithium salt and the MOFs-based ion conductor in the step 2), carrying outball milling, and carrying out compression molding to obtain a compact composite solid electrolyte film; 4) uniformly coating the cross-linking liquid on the surface of the obtained composite solid electrolyte film; and 5) irradiating the composite solid electrolyte film in the step 4) with ultraviolet light after the composite solid electrolyte film is fully absorbed to prepare the ionic conductor / polyoxyethylene composite solid electrolyte. The beneficial effects of the present invention are that the material has excellent comprehensive performance and can be used as a solid electrolyte material in solid batteries.

Owner:WUHAN UNIV OF TECH

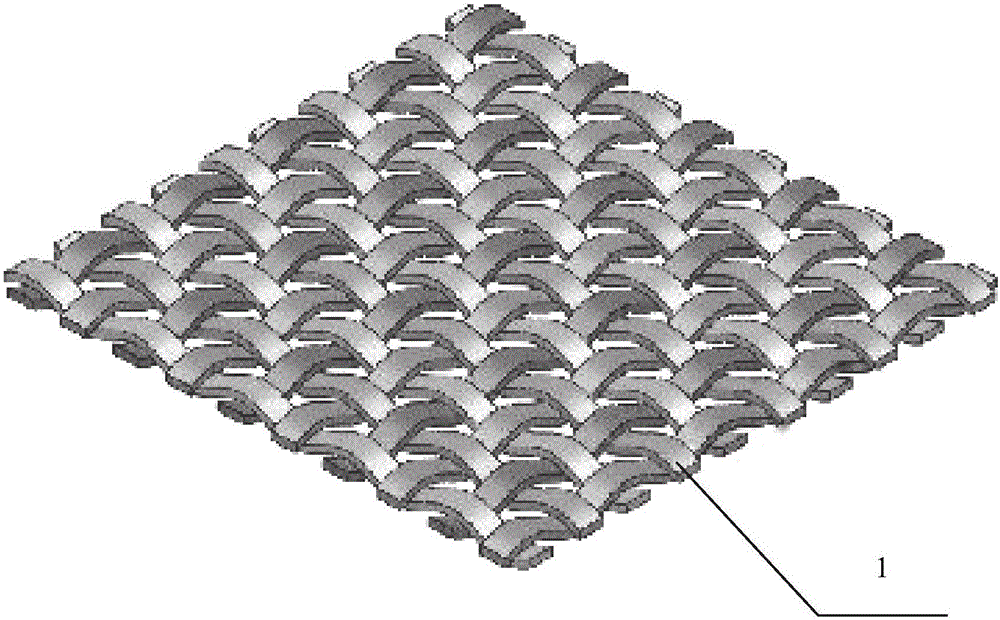

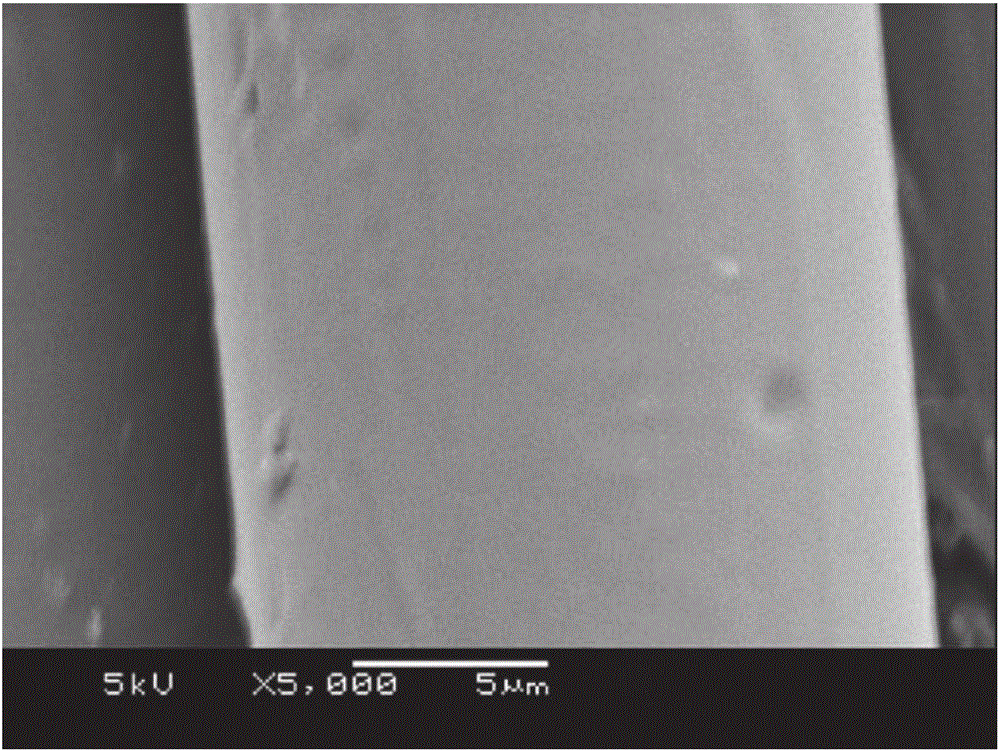

Composite type artificial dura mater and preparation method

The invention relates to a composite type artificial dura mater, comprising two hydrogel layers and a woven layer, wherein the woven layer is arranged between the two hydrogel layers, the woven layer is a degradable polymer material, and cell growth factors are contained in the hydrogel layers. The composite type artificial dura mater disclosed by the invention has the following beneficial effects: (1) the artificial dura mater is made from the degradable polymer material and biological protein which are easily available, and has good biocompatibility; (2) atmospheric pressure plasma jet treatment increases the fiber surface area of the woven layer, decreases a contact angle of a material surface, and improves water transmissibility, degradation speed and cellular affinity; (3) regulation on physical characteristics of the artificial dura mater, such as malleability, toughness, mechanical strength and the like can be realized by regulating a weaving method; and 4) the composite type artificial dura mater is favorable for wound repair, and silver ions enable artificial skin to have good antibacterial performance, so that toxic and side effects on a human body due to the use of a chemical antibacterial medicine are avoided, and storage life of the artificial skin is prolonged.

Owner:ZHEJIANG PROVINCIAL PEOPLES HOSPITAL

Method for preparing porous polyvinylidene fluoride super-hydrophobic coating layer

ActiveCN110564227AStrong anti-icing abilityStrong weather resistanceCoatingsWeather resistanceTriethoxysilane

The invention discloses a method for preparing a porous polyvinylidene fluoride super-hydrophobic coating layer. The method comprises the following steps: mixing polyvinylidene fluoride and N,N-dimethyl formamide, performing stirring, mixing the obtained transparent solution with perfluordecyl triethoxy silane, performing stirring, mixing the obtained perfluordecyl triethoxy silane mixed solutionwith composite nano titanium dioxide granules, performing stirring, performing ultrasonic treatment, and smearing or spraying the obtained porous polyvinylidene fluoride super-hydrophobic coating to asubstrate, so as to obtain a porous polyvinylidene fluoride super-hydrophobic coating layer. The method disclosed by the invention has the advantages of being simple in process, convenient to operate, cheap in raw material, easy in industrial production, and the like, and the super-hydrophobic coating layer which is excellent in super-hydrophobic performance, good in ice resistance and wind resistance, good in weather resistance and good in adaptability can be prepared in a large scale, can be widely applied to anti-ice treatment on fan blades, has great significances for improving the performance and increasing the power generation capacity of a wind turbine generator, and has high use value and good application prospects.

Owner:国家能源集团龙源江永风力发电有限公司

Production process of crystalline silicon double-sided solar battery

InactiveCN102664217AEliminates thermal diffusion stepLeave out the edgeFinal product manufactureSemiconductor devicesTrappingOptoelectronics

The invention relates to a production process of a crystalline silicon double-sided solar battery, comprising the following steps of: etching to enable a silicon substrate to have an etched face; manufacturing a window which accords with an electrode pattern on a backlight face of the silicon substrate; carrying out heat treatment on the silicon substrate to form a PN junction in the window; washing the silicon substrate; plating at least two layers of antireflection films on a light reflective face of the silicon substrate; plating the antireflection film on a backlight face of the silicon substrate; printing electrode slurry on a silk screen; and sintering to obtain a metal electrode so as to finish the manufacturing of a battery cell. The production process disclosed by the invention is ingenious in concept, is compatible with a conventional industrial battery production line and is easy for industrial manufacture; compared with the conventional solar battery, an electrode grid line is not arranged on the light reflective face of the double-sided solar battery so as to prevent the electrode grid line of the light reflective face from shielding sunlight; the backlight face is provided with a light trapping structure and an antireflection film layer so that the backlight face of the battery also can absorb and utilize the sunlight; and the antireflection films of the light reflective face and the backlight face can passivate the solar battery, so as to be good for improving the efficiency of the battery.

Owner:杨正刚

Room-temperature-curable organopolysiloxane composition, and moulded product comprising cured product of said room-temperature-curable organopolysiloxane composition

ActiveCN106459586AEase of industrial preparationEasy to manufactureOther chemical processesCoatingsPolymer scienceSilylene

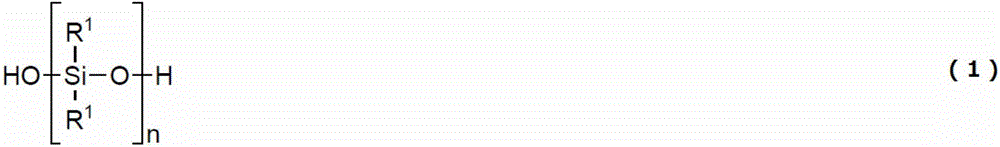

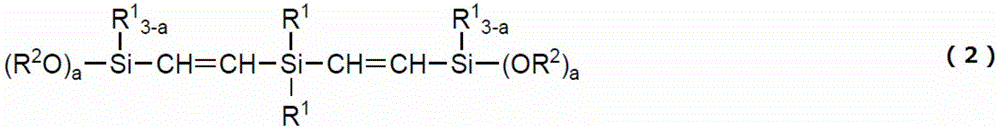

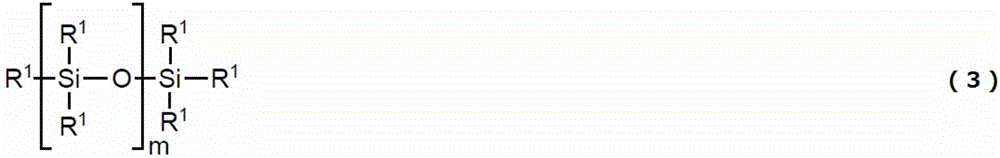

This room-temperature-curable organopolysiloxane composition includes: component (A); 0.1-30 parts by mass of component (B) per 100 parts by mass of component (A); and 0.001-20 parts by mass of component (D) per 100 parts by mass of component (A). Component (A) is an organopolysiloxane represented by general formula (1) (in general formula (1): R1 represents hydrogen, or a substituted or unsubstituted C1-20 monovalent hydrocarbon group; the plurality of R1s may be the same or different; and n represents an integer of at least 1). Component (B) is an organic silicon compound which is represented by general formula (2), and which is characterized by having two silyl-vinylene groups provided to the same silicon atom (in general formula (2): R1 represents hydrogen, or a substituted or unsubstituted C1-20 monovalent hydrocarbon group; the plurality of R1s may be the same or different; R2 represents a substituted or unsubstituted C1-20 alkyl group, or a substituted or unsubstituted C3-20 cycloalkyl group; and a represents an integer from 1 to 3). Component (D) is a curing catalyst.

Owner:SHIN ETSU CHEM CO LTD

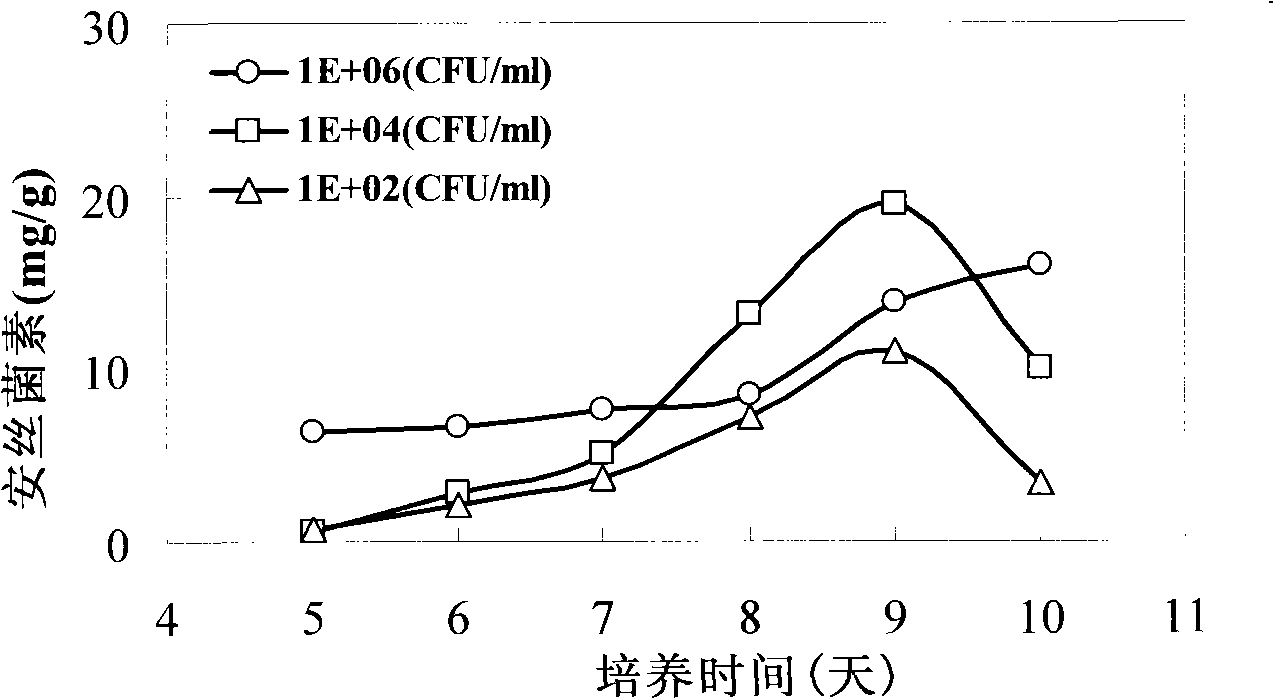

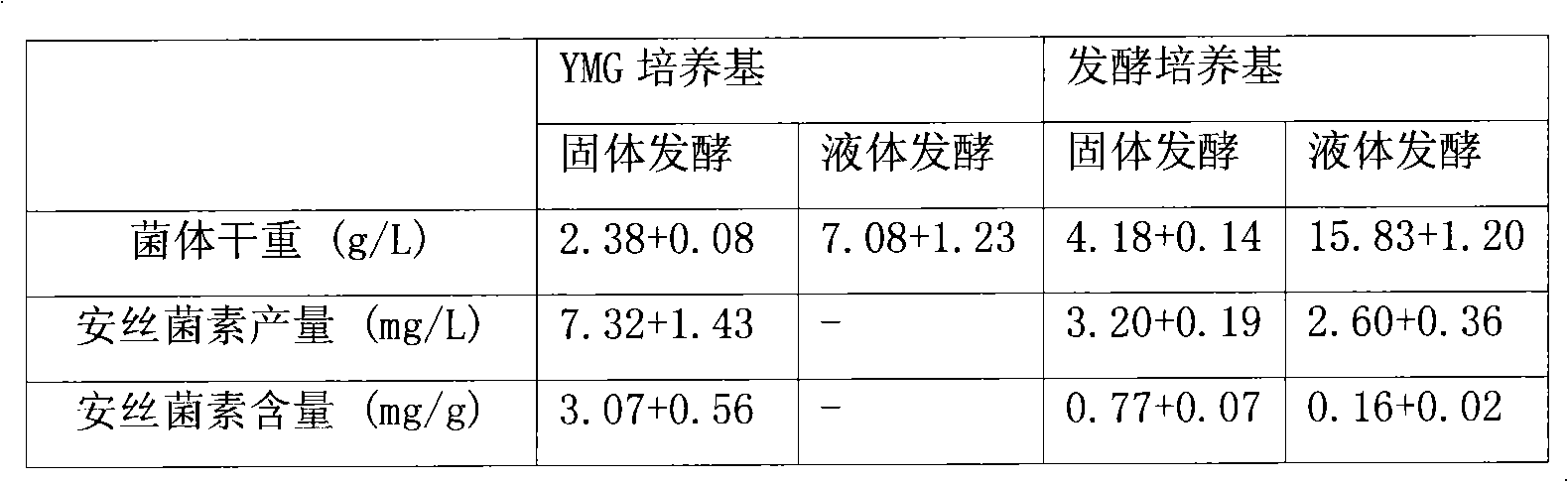

Solid fermentation method of ansamitocin

InactiveCN101319241AHigh unit cell contentEasy to handleMicroorganism based processesFermentationSaccharophagus degradansMicrobiology

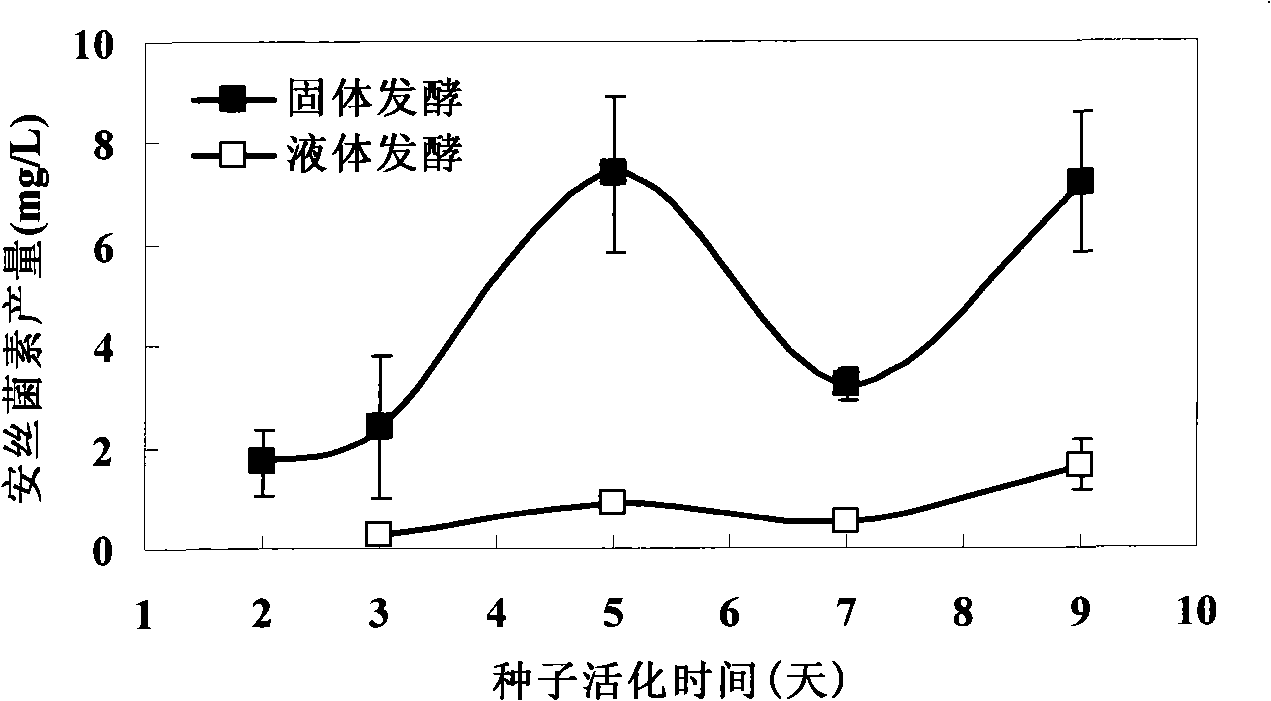

The invention discloses a solid fermentation method for ansamitocin. The method comprises the following steps of: step one, seed culture: a thallophytic streak culture medium plate which is freezingly preserved in a saccharose solution and produces the ansamitocin is subject to inversion activation for 2 to 9 days at a temperature of 28 DEG C and then is transferred to a seed culture medium, and a seed liquid is cultured at a temperature of 28 DEG C; and step two, solid fermentation: the seed liquid obtained in the step one is diluted to a concentration between 10<2> and 10<6>CFU / ml and is coated to a fermentation culture medium plate paved with a regenerative cellulose membrane support to be cultured for 7 to 10 days at a temperature of 28 DEG C. Compared with the prior liquid fermentation method, the method has the advantages that: the output of the ansamitocin is more than 2 times higher, and the unit cell content is near 4 times higher; at the same time, the solid fermentation has small energy consumption, the treatment of a sample is simple, thereby contributing to the industrialized preparation of the ansamitocin.

Owner:SHANGHAI JIAO TONG UNIV

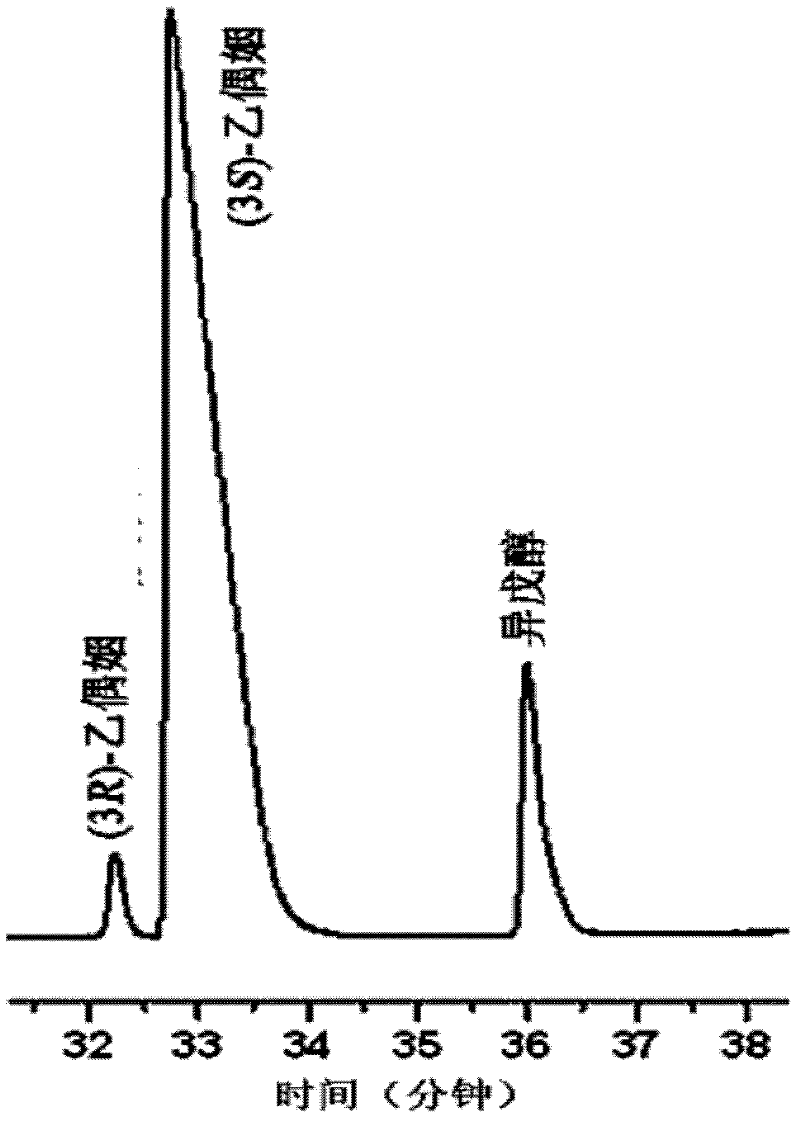

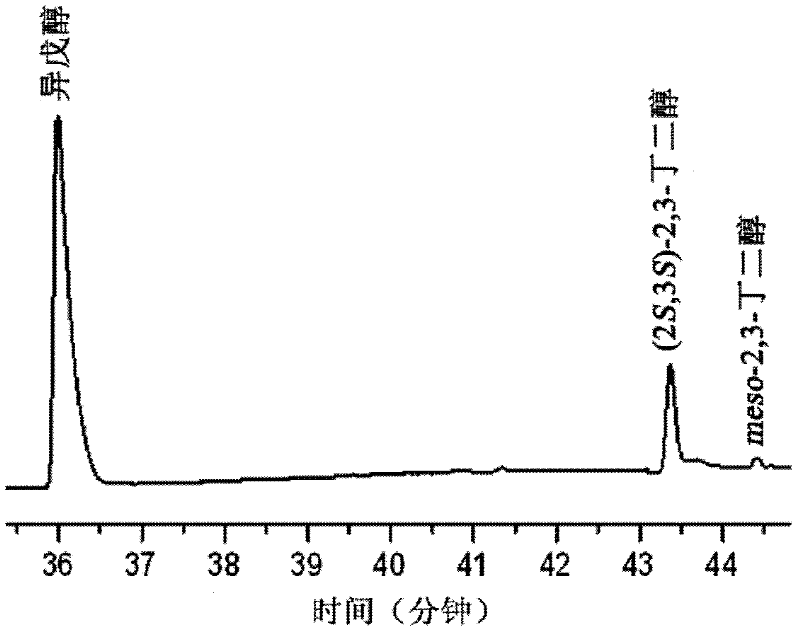

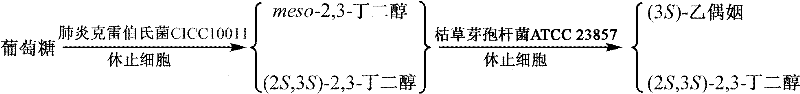

A method for preparing (2s,3s)-2,3-butanediol and (3s)-acetoin from glucose

ActiveCN102296094AReduce manufacturing costLow environmental requirementsMicroorganism based processesFermentationK pneumoniae2,3-Butanediol

The invention discloses a method for prepared (2S,3S)-2,3-butanediol and (3S)-acetoin from glucose. The method comprises the following steps that glucose is converted into a mixture of (2S,3S)-2,3-butanediol and meso-2,3-butanediol by a Klebsiella pneumoma CICC 10011 resting cell biocatalyst; the mixture of (2S,3S)-2,3-butanediol and meso-2,3-butanediol is split by a bacillus subtilis ATCC 23857 resting cell biocatalyst; and (2S,3S)-2,3-butanediol and (3S)-acetoin are prepared simultaneously. The concentration of (2S,3S)-2,3-butanediol prepared by the method reaches 2.5g / L (wherein the optical purity is 96.9%). The concentration of (3S)-acetoin prepared by the method reaches 29.3g / L (wherein e.e. is 96.2%). Therefore, the method has great industrial application prospects.

Owner:上海肆芃科技有限公司

Core-shell structure lightweight aggregate prepared by cold bonding method and preparation method thereof

The invention discloses a core-shell structure lightweight aggregate prepared by a cold bonding method and a preparation method thereof. The method comprises the steps: preparing a calcined clay-basedgreen environment-friendly cementing material from ordinary Portland cement, calcined clay, limestone powder and gypsum in proportion; putting core material particles into a lightweight aggregate granulation device, then putting the calcined clay-based green environment-friendly cementing material, and uniformly spraying a mixture for granulation to form primarily-generated cold-bonded aggregate;carrying out primary maintenance on the primarily-generated cold-bonded aggregate, soaking the primarily-generated cold-bonded aggregate in a solution containing organic acid or phenol compounds, taking out the primarily-generated cold-bonded aggregate, airing the primarily-generated cold-bonded aggregate, and repeatedly spraying a calcium hydroxide aqueous solution on the surface of the aggregate to form aggregate with a super-hydrophobic surface; and continuously putting the aggregate with the super-hydrophobic surface into water for secondary maintenance, and thus producing the super-hydrophobic high-strength lightweight aggregate. According to the core-shell structure lightweight aggregate and the preparation method thereof, energy is saved, consumption is low, the processing flow issimplified, solid waste recycling can be achieved, the water absorption rate is low, and the single bearing capacity is high.

Owner:SHENZHEN UNIV

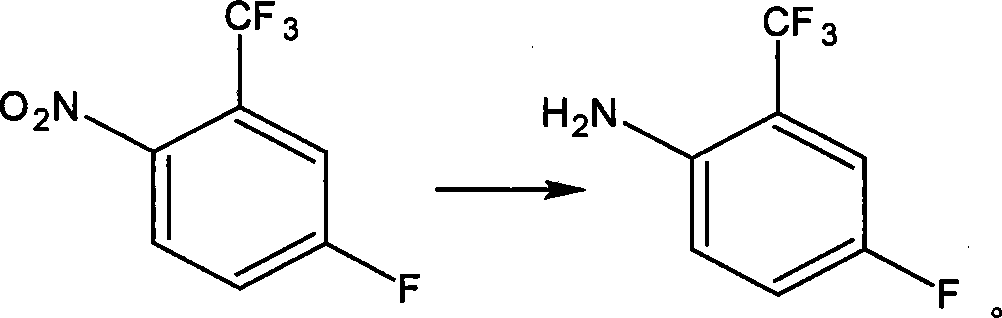

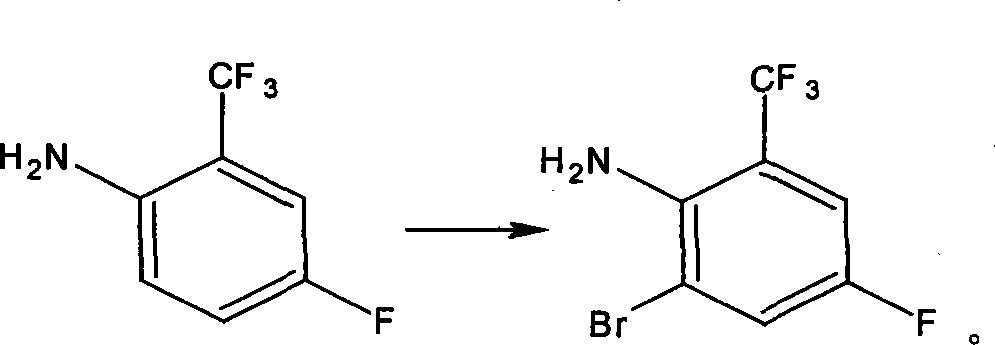

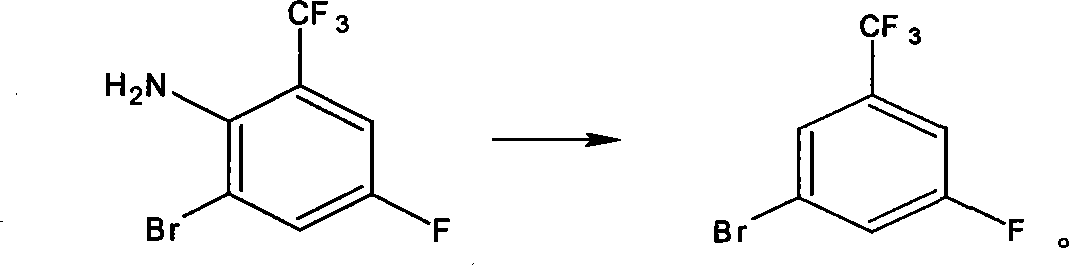

Preparation technique of 3-fluorine -5 bromine benzotrifluoride

InactiveCN101157597AAdvanced and reasonable technologyEase of industrial preparationHalogenated hydrocarbon preparationBromineMedicinal chemistry

The invention discloses a technique of preparing 3-fluorin-5-bromobenzotrifluoride which is an intermediate for novel medicine, belonging to the technical field of fine chemicals intermediate. The technique of preparing 3-fluorin-5-bromobenzotrifluoride takes 4-fluorin-6-nitrobenzotrifluoride as the initial material,and the 3-fluorin-5-bromobenzotrifluoride is prepared by reduction, bromination and deamination in sequence. The invention has reasonable and advanced technology, each involving reaction is regular unit reaction, and the 3-fluorin-5-bromobenzotrifluoride is an intermediate for the novel medicine; besides, the invention is easy in industrial production and ensures high yield.

Owner:高邮市光明化工厂

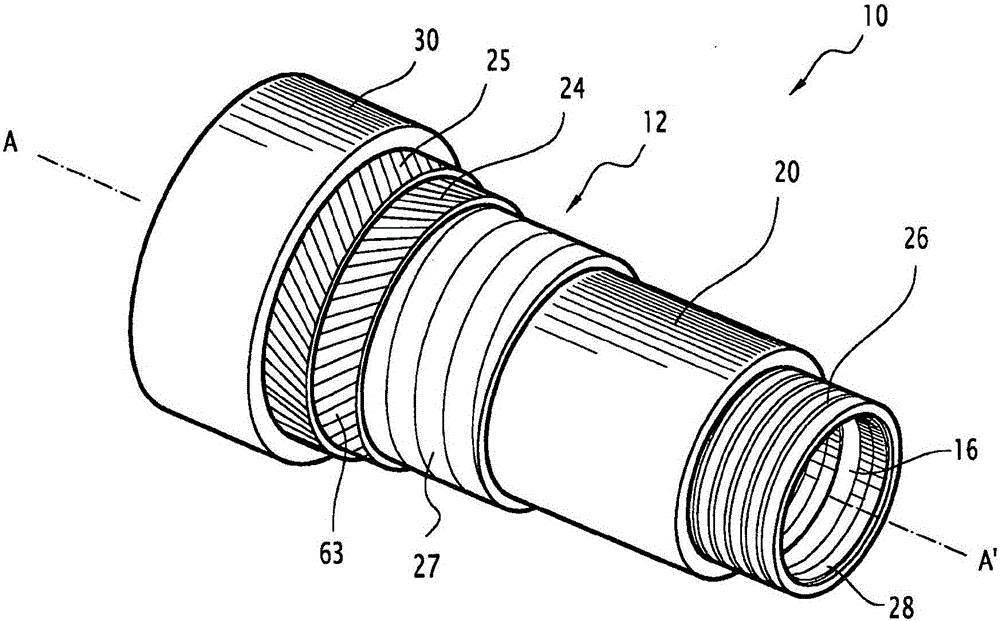

Flexible pipe for transporting fluid and associated method

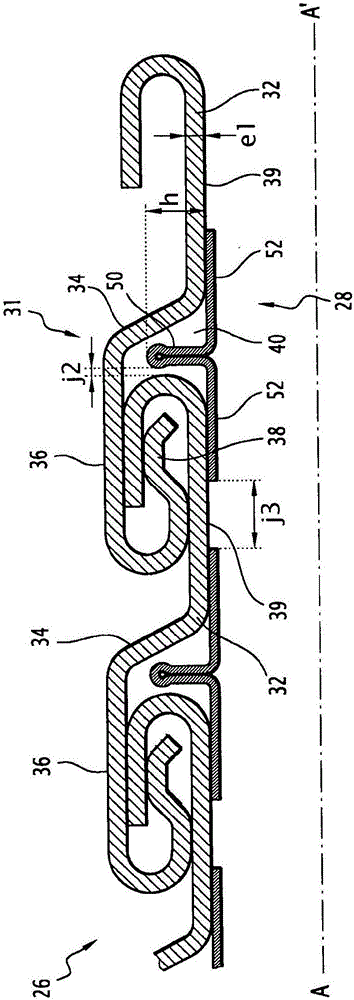

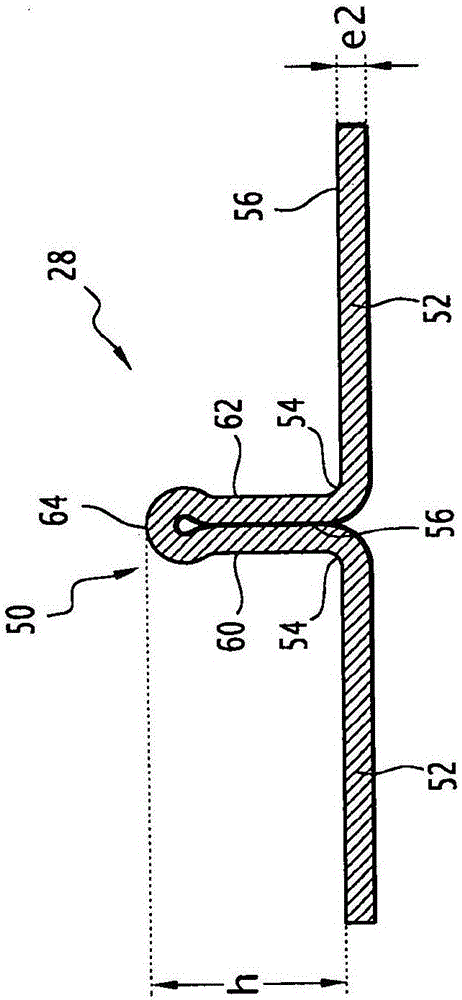

ActiveCN105992899AEase of industrial preparationCost-effectivePipe elementsFlexible pipesEngineeringMechanical engineering

This flexible pipe for transporting fluid comprises a polymer internal sheath for limiting a fluid flow passage of central axis (A-A '); at least one armour layer arranged on the outside of the internal sheath; an internal carcass (26), arranged in the internal sheath, the internal carcass (26) comprising a first folded tape (31) limiting a helical gap (40) opening towards the central axis (A-A '). The pipe comprises a helicoidal insert (28) of T-shaped cross section comprising a leg (50) inserted in the helicoidal gap (40) and two wings (52) projecting one on each side of the leg (50) to close off the helicoidal gap (40) toward the inside. The helicoidal insert (28) is formed of a second folded tape.

Owner:TECH FRANCE SA

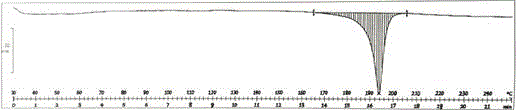

Crystal form alpha of vonoprazan fumarate and the preparation method thereof

The invention belongs to the technical field of pharmaceutical chemistry, in particular to a crystal form alpha of vonoprazan fumarate and the preparation method of the new crystal form. The crystal form has high purity as well as favorable chemical stability and crystal form stability; the crystal form can be prepared through mass production, of which the process is simple and the cost is low, so the potential applications are fantastic.

Owner:YICHANG HUMANWELL PHARMA +1

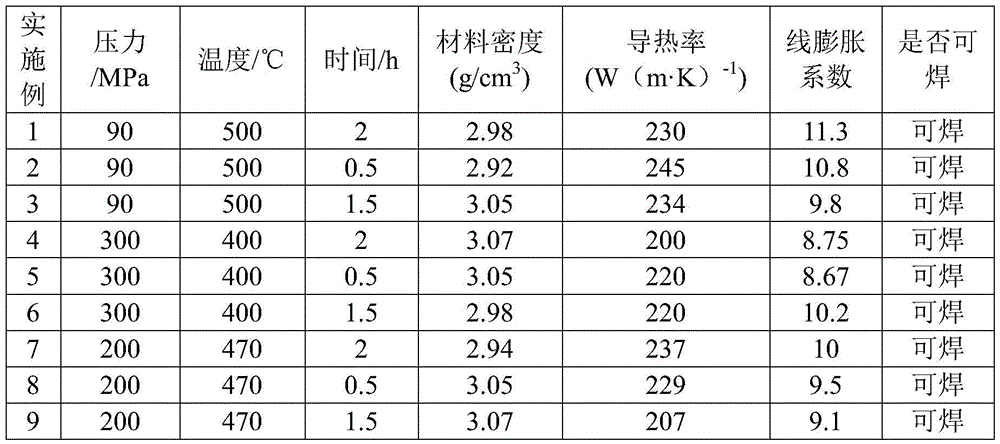

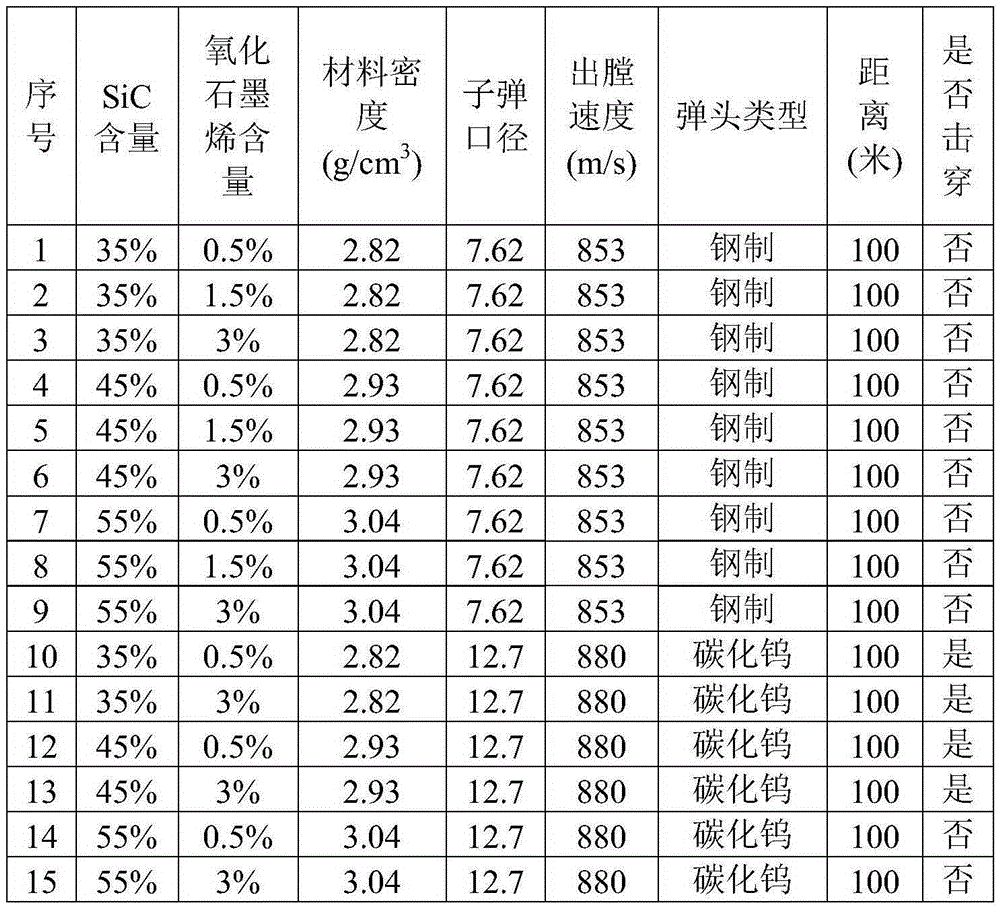

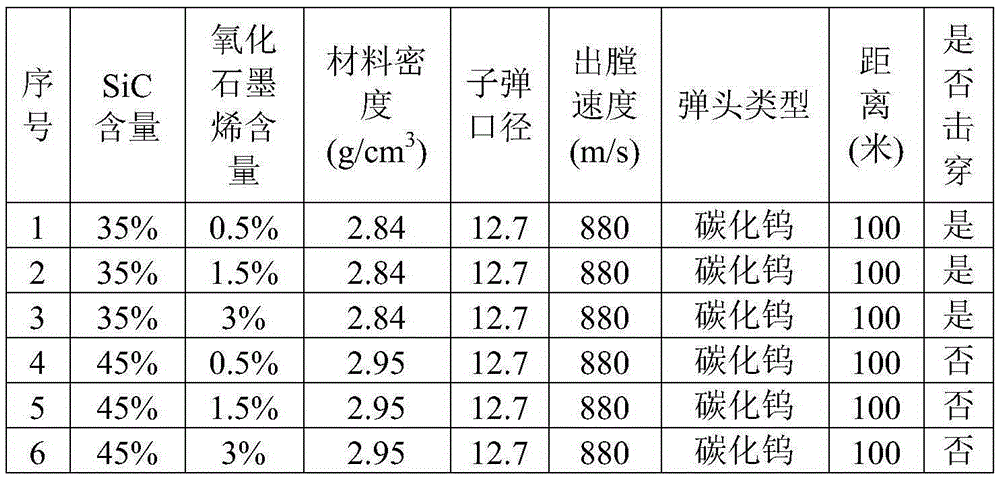

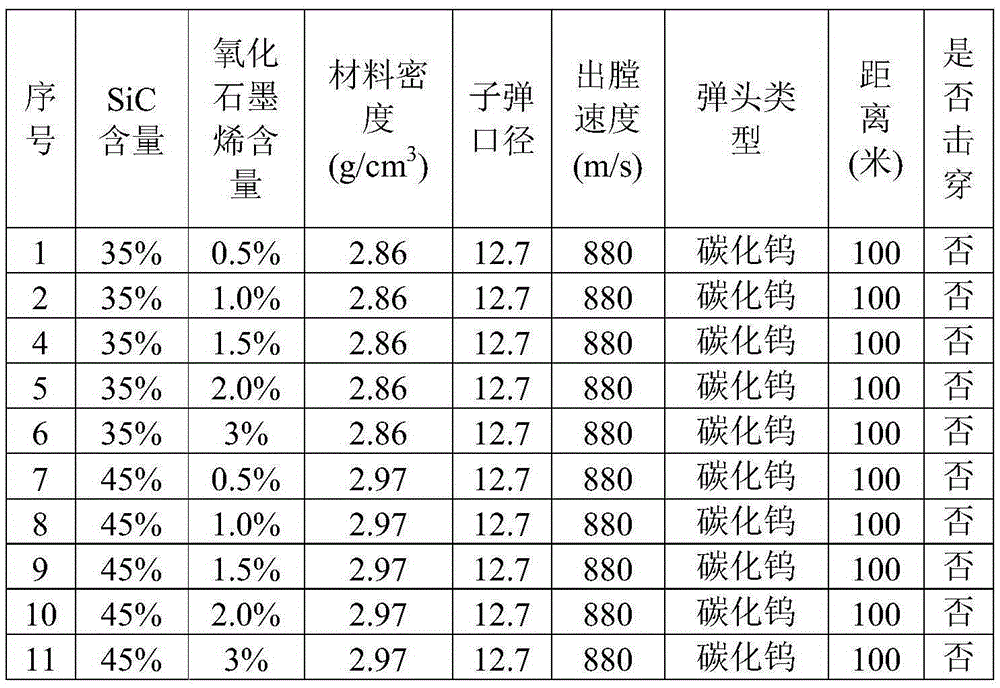

Preparing method of electronic packaging material

The invention provides a preparing method of an electronic packaging material. The electronic packaging material is composed of a base body and a reinforcement body; the base body comprises an aluminum alloy, and the reinforcement body comprises graphene oxide and SiC particles and comprises, by mass percentage, 2% of graphene oxide, 50% of SiC particles and the balance aluminum alloy powder; and the aluminum alloy powder comprises 70% of Al-Si, 10% of Al-Ti-B, 10% of Al-Be and 10% of Al powder. By the adoption of the method, the light electronic packaging material with the density lower than 3.1g / cm<3> and thermal conductivity larger than 180 W / (m K) can be prepared, and therefore the comprehensive performance of a military electronic device can be greatly improved; and the preparing method is suitable for producing and preparing of packaging materials of portable devices, military power hybrid circuits of aerospace and other fields sensitive to weight, carriers of microwave tubes, and heat-sink and super-power modules of a multi-chip assembly.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Solid lucid ganoderma strain and application thereof in submerged fermentation of lucid ganoderma

InactiveCN107177515AReduce manufacturing costNo significant decline in fermentation performanceFungiMicroorganism based processesDispersityBottle

The invention discloses a solid lucid ganoderma strain and an application thereof in submerged fermentation of lucid ganoderma. Peanut shell powder and bran powder or fine rice bran are taken as raw materials and are prepared into compost, an activated lucid ganoderma slant strain is taken as a stock strain and the dark culture is performed in a strain bottle or a polypropylene plastic strain bag, so as to acquire the solid lucid ganoderma strain. Compared with the traditional liquid strain (primary in mycelium pellet), the solid lucid ganoderma strain disclosed by the invention has the advantages of low strain cost, long preservation time and direct application to liquid fermentation; the frequent preparation for the fermentation strain can be avoided and the increasing of the working efficiency is benefited; when the solid lucid ganoderma strain is used as the strain for the submerged fermentation culture of lucid ganoderma, the dispersity is high and a large amount of hypha growing points can be formed, so that the fermentation efficiency of the lucid ganoderma can be greatly promoted, the extracellular polysaccharide and biomass of the lucid ganoderma are obviously increased, the fermentation pollution rate can be reduced and the application prospect is extremely wide.

Owner:NINGDE NORMAL UNIV

Method for preparing high-strength transparent cellulose film material in low-temperature and normal-pressure cooking manner and application thereof

InactiveCN109262783AEasy to prepareEase of industrial preparationPressure wood treatmentWood treatment detailsFiberCellulose

The invention relates to a method for preparing a high-strength transparent cellulose film material in a low-temperature and normal-pressure cooking manner and application thereof. The preparation method comprises the following steps: adding wood sheets into a cooking chemical solution prepared from sodium chlorite, acid and water, removing lignin in a cooking manner at the temperature less than or equal to 100 DEG C, adding an equal amount of chemical every two hours until the wood sheet becomes white, and thus obtaining the lignin-removed wood sheet; and washing the lignin-removed wood sheetby using water, removing the residual cooking chemical solution, pressurizing and drying, and thus obtaining the high-strength transparent cellulose film material. The cellulose film material prepared in the invention has excellent mechanical properties due to the reservation of orderly-arranged structure characteristics of fibers in the wood and high polymerization degree of the fibers, and thetensile strength is 8 to 15 times of the original wood sheet; and meanwhile, since the air in the internal pore is removed in the pressurizing process, the optical performance is good.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

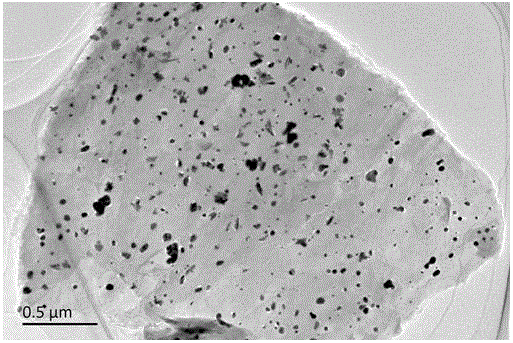

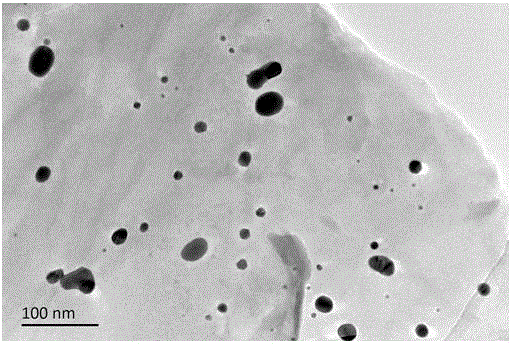

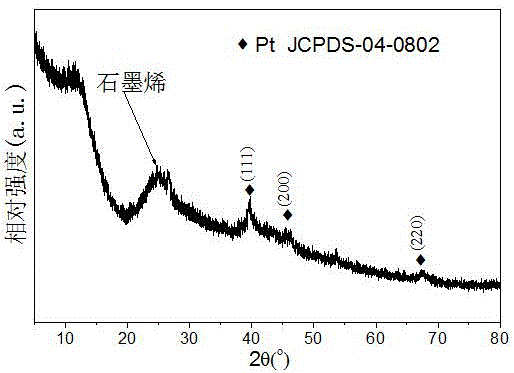

Preparation method of precious metal/graphene nanocomposite

ActiveCN106311223AAvoid uneven loadLarge particle sizeMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsDispersityGraphene nanocomposites

The invention discloses a preparation method of a precious metal / graphene nanocomposite. The method comprises the following steps that 1, according to the loading capacity of precious metal on graphene and the preparation quantity of target products, a corresponding quantity of precious metal soluble compounds are weighed and dissolved in a small amount of water, and the mixture is added into a corresponding volume of graphene oxide aqueous dispersion liquid with the concentration of 0.5-5 g / L; 2, a proper amount of organic fuel and ammonium nitrate are added into the dispersion liquid in step 1, and the mixture is stirred and subjected to ultrasound treatment for 15-90 minutes; 3, the mixed dispersion liquid in step 2 is heated and concentrated to be thick and then placed in a heating furnace at the temperature of 300-900 DEG C for ignition, and after combustion is completed, the product is cooled to room temperature, washed and dried. The preparation method is short in synthesis time and easy to implement, a poisonous and harmful reducing agent or stabilizing agent does not need to be added, the particle sizes of platinum nano-particles are uniform and controllable, the platinum nano-particles are uniform in dispersity on graphene, and the preparation method is a new method which is fast and efficient and makes industrial preparation of the platinum / graphene nanocomposite easy.

Owner:NANCHANG UNIV

Spherical active carbon and process for producing the same

InactiveCN1956919AReduce dust generationDustyCarbon compoundsOther chemical processesActivated carbonSolid carbon

Owner:KURARAY CO LTD

Preparation method for novel light-weight and high-strength protection armor plate

The invention provides a preparation method for a novel light-weight and high-strength protection armor plate. The armor plate material is of a multi-layer sandwich biscuit type composite structure. The middle of the composite structure is connected with single-edge interlayer metal plates of different materials and thicknesses through thermal diffusion. The preparation method for the armor plate includes the steps that firstly, raw materials are mixed; secondly, bag covers used for containing powder are prepared; thirdly, sample mixed powder is contained in the prepared bag covers; fourthly, powder physical sintering and metal plate thermal diffusion connection are conducted; fifthly, solid solution heat treatment is conducted; and sixthly, ageing thermal treatment is conducted. The preparation method is suitable for bulletproof armor layers adopted for attacks of fighting light arms such as light armored cars and gunships and anti-material weapons, and production and preparation of the bulletproof armor layers.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com