Flexible pipe for transporting fluid and associated method

A flexible tube and fluid technology, applied in the field of flexible tubes, can solve problems such as complicated operation, increased cost, and large storage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

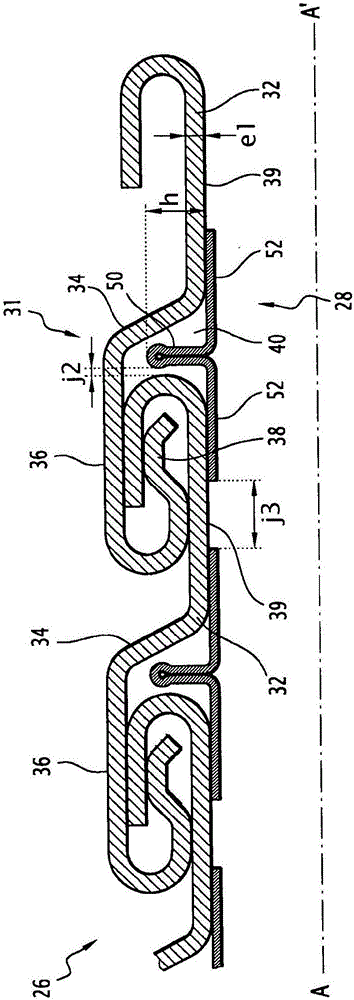

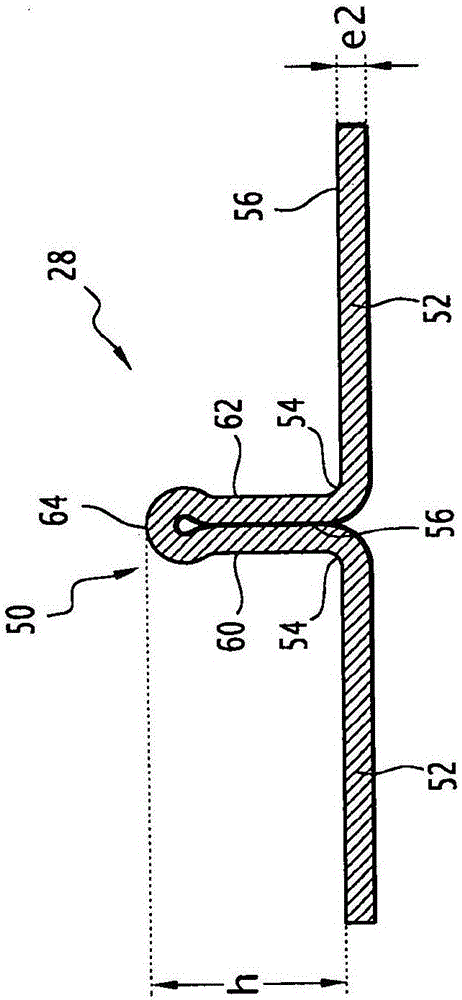

[0055] In the rest of this document, the terms "outer" and "inner" are generally understood radially with respect to the axis AA' of the pipe, the term "outer" is understood as being relatively radially farther from the axis AA' and The term "inner" is understood as being relatively radially closer to the axis AA' of the tube.

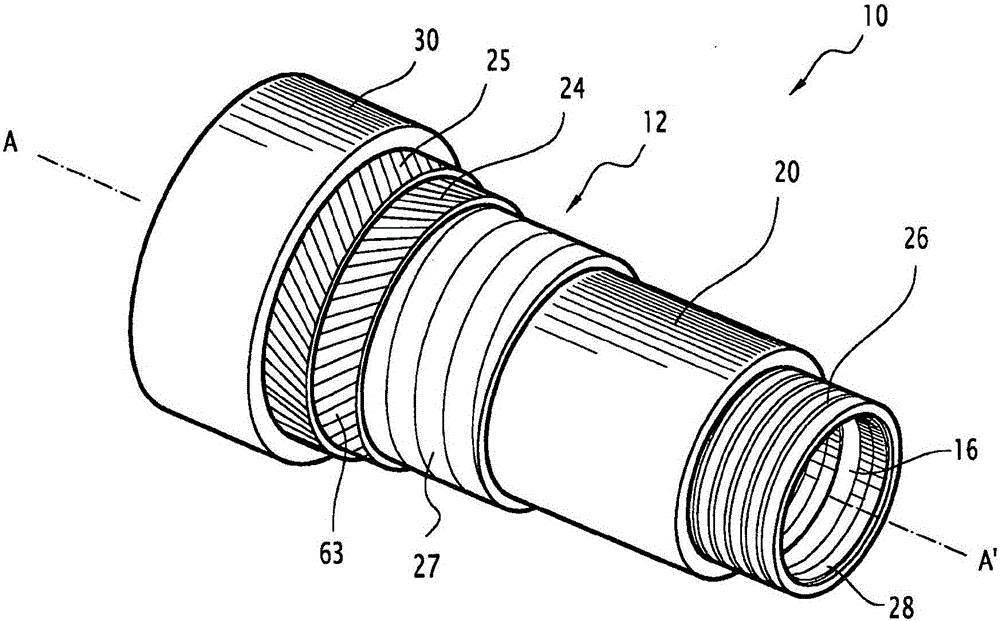

[0056] The first flexible pipe 10 according to the present invention is figure 1 partially shown in.

[0057] The flexible pipe 10 includes a central section 12 . It comprises end pieces (not shown) at each axial end of the central section 12 .

[0058] refer to figure 1 , the tube 10 delimits a central channel 16 for the flow of a fluid, advantageously an oil fluid. A central channel 16 extends along axis AA' between the upstream and downstream ends of the tube 10 .

[0059] The coiled pipe 10 is designed to be positioned through a body of water (not shown) in a fluid production facility, particularly for hydrocarbons.

[0060]A body of water is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com