Preparation method of precious metal/graphene nanocomposite

A technology of nanocomposite materials and precious metals, applied in the field of preparation of carbon-based nanocomposite materials, can solve unsatisfactory problems and achieve the effects of simple implementation, uniform and controllable particle size, and easy industrial preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

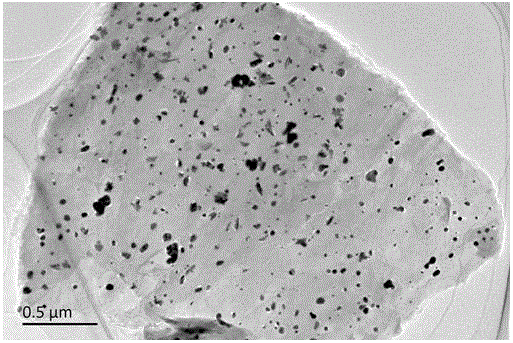

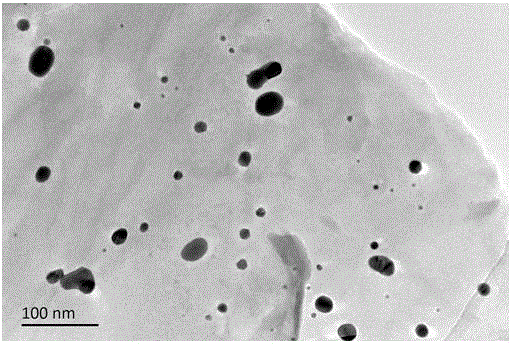

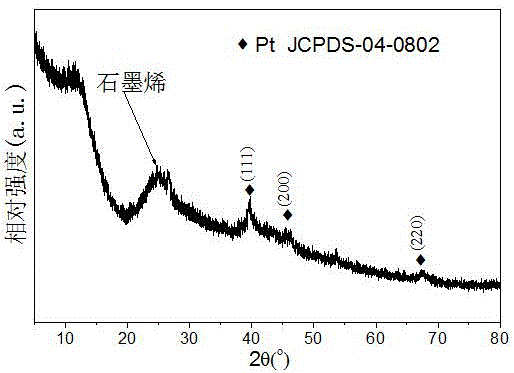

[0022] Weigh 0.4258 g K 2 PtCl 4 Dissolved in a small amount of water, added to 400 ml of graphene oxide water dispersion with a concentration of 0.5 g / L, then added 0.1346 g of ammonium nitrate and 0.3435 g of glycine, stirred evenly and ultrasonicated for 30 minutes to obtain a uniform dispersion, heated and concentrated When it becomes thick, put it into a muffle furnace at 500°C to ignite. After the combustion is complete, cool it to room temperature, and wash the product with deionized water and ethanol until the conductivity of the washing liquid is lower than 10 μs / cm 2 After drying, the platinum / graphene nanocomposite material is obtained.

Embodiment 2

[0024] Weigh 0.3709 g NaAuCl 4 Dissolved in a small amount of water, added to 400 ml of graphene oxide water dispersion with a concentration of 0.5 g / L, then added 0.1346 g of ammonium nitrate and 0.2748 g of urea, stirred evenly and ultrasonicated for 30 minutes to obtain a uniform dispersion, heated and concentrated When it becomes thick, put it into a muffle furnace at 500°C to ignite. After the combustion is complete, cool it to room temperature, and wash the product with deionized water and ethanol until the conductivity of the washing liquid is lower than 10 μs / cm 2 After drying, the gold / graphene nanocomposite material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com