Patents

Literature

142results about How to "Advanced and reasonable technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting platinum, rhodium and palladium from failed platinum alloy gauze

ActiveCN102586607AAdvanced and reasonable technologyAdvancedProcess efficiency improvementAlloySodium nitrite

The invention relates to a method for extracting platinum, rhodium and palladium from a failed platinum alloy gauze, which comprises the following steps of: separating to extract precious metals such as the platinum, the rhodium and the palladium from the failed platinum alloy gauze; dissolving through hydrochloric acid and nitric acid; removing nitro group, transforming sodium and leaching; obtaining platinum, rhodium and palladium complexing solution; adopting an ammonium chloride precipitation method to separate the platinum; adopting a sodium nitrite complexometry to separate the palladium and the rhodium; adopting a six nitroso rhodium acid ammonium method to purify the rhodium; adopting a dichlorodiamminopalladium method to purify the palladium; carrying out reduction to obtain spongy platinum, spongy palladium and rhodium powder through adding hydrazine hydrate; vacuum drying and roasting; and purifying again. The extracting method has advanced and reasonable process, and accurate and detailed parameters; the purity of the extracted spongy platinum, spongy palladium and rhodium powder is great than 99.9 percent, and the quality is stable; and the method is a very ideal method for extracting the precious metals such as the platinum, the rhodium and the palladium from the failed platinum alloy gauze.

Owner:太原瑞麟贵金属回收有限公司

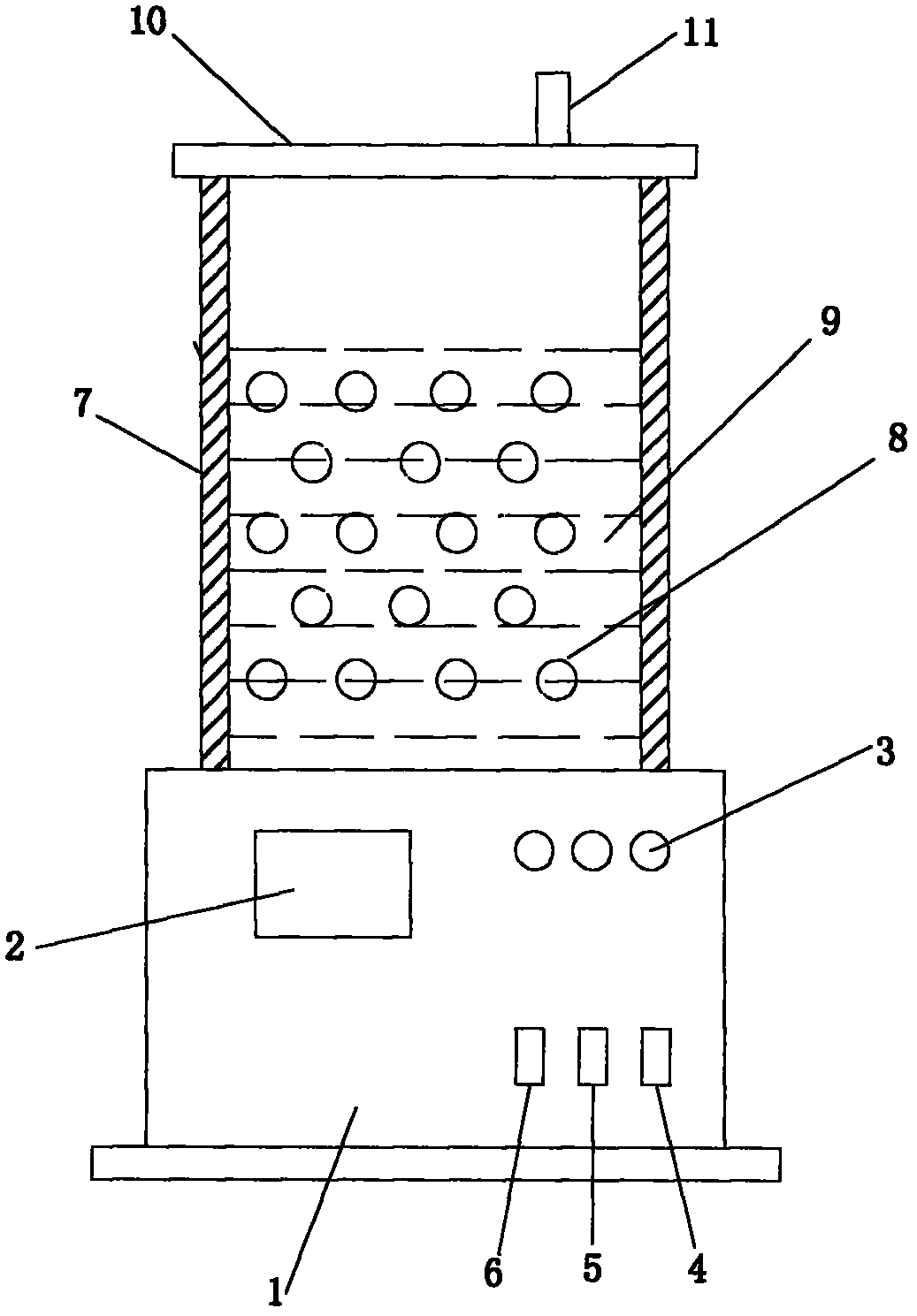

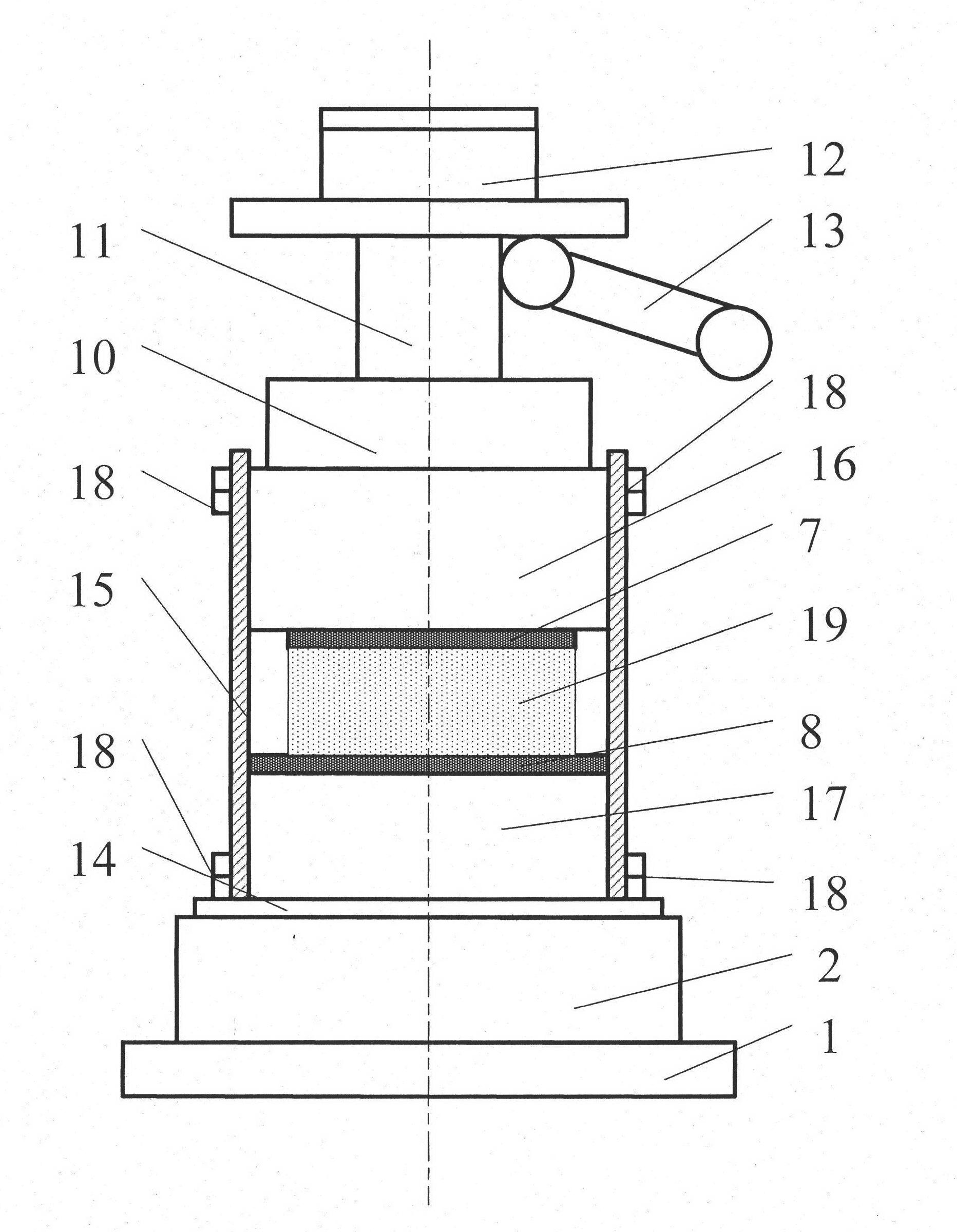

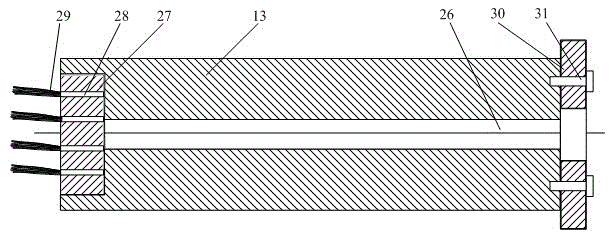

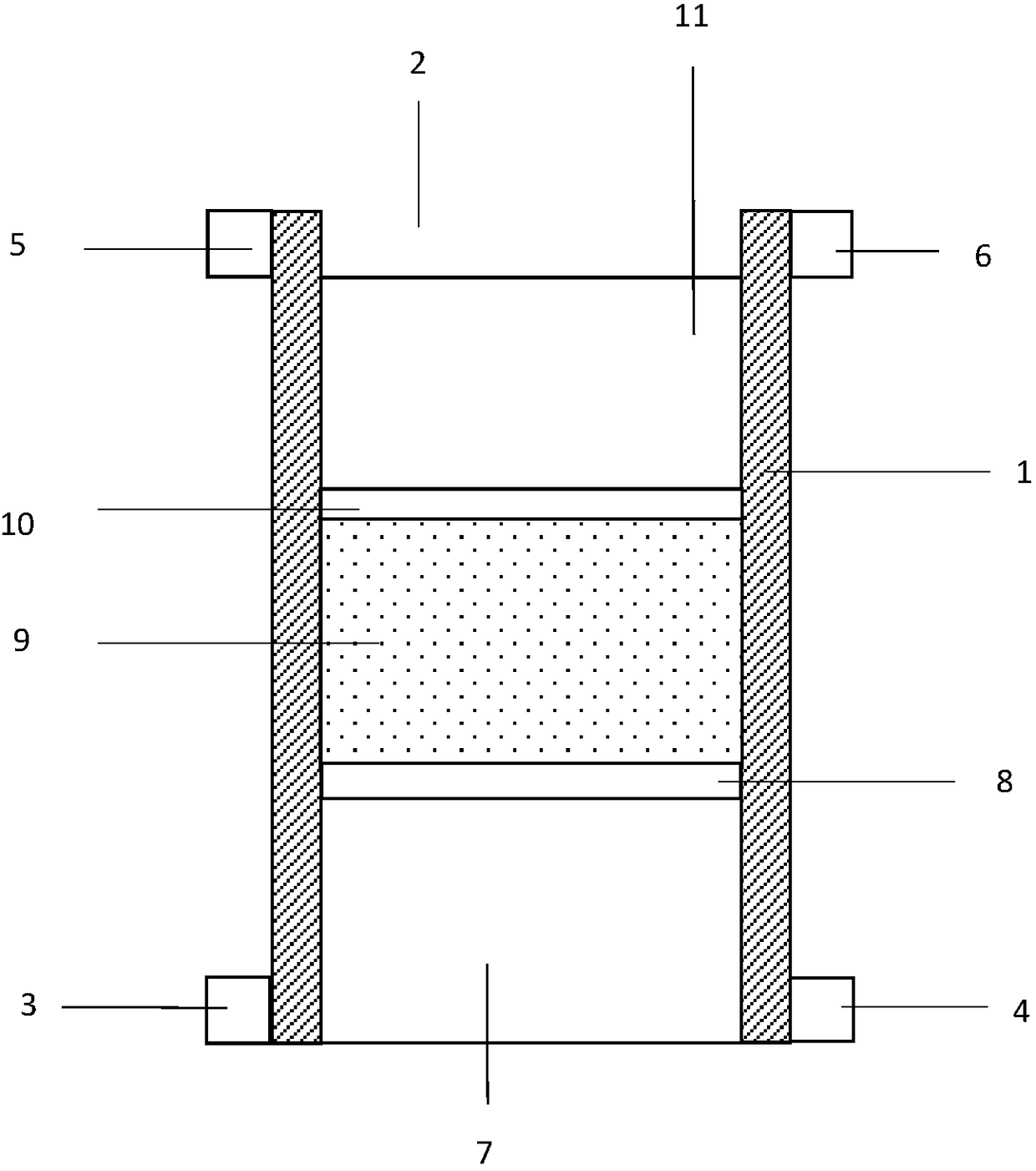

A kind of preparation method of aluminum-based boron carbide neutron absorbing plate

The invention relates to a method for preparing an aluminum-based boron carbide neutron absorption board. According to a requirement on nuclear device protection, the compact aluminum-based boron carbide neutron absorption board is formed by mixing aluminum powder, boron carbide powder, silicon powder, titanium powder and boracic acid crystal, performing powder metallurgy to make a rectangular board, and performing hot extrusion molding on the rectangular board on a pressing machine in a die in a heating state; the compound neutron absorption board is grey white; the neutron absorption rate is more than or equal to 90 percent, the boron carbide is distributed uniformly, and particles and a base body are tightly combined together; the micro hardness of the base body is up to 185.8HV and the micro hardness of the particles is up to 2,022.2HV; a corrosion resistance level on the surface of the board is -0.45 voltage, the anti-bending angle is more than or equal to 10 degrees, the tensilestrength is more than or equal to 200 MPa, the fracture elongation rate is 1.8 percent and the fracture contractibility rate is more than or equal to 1.0 percent. The preparation method is advanced and rational in process, and is full and accurate in parameter; and the preparation method is an ideal method for preparing the aluminum-based boron carbide neutron absorption board.

Owner:DALIAN BAOYUAN NUCLEAR EQUIP +2

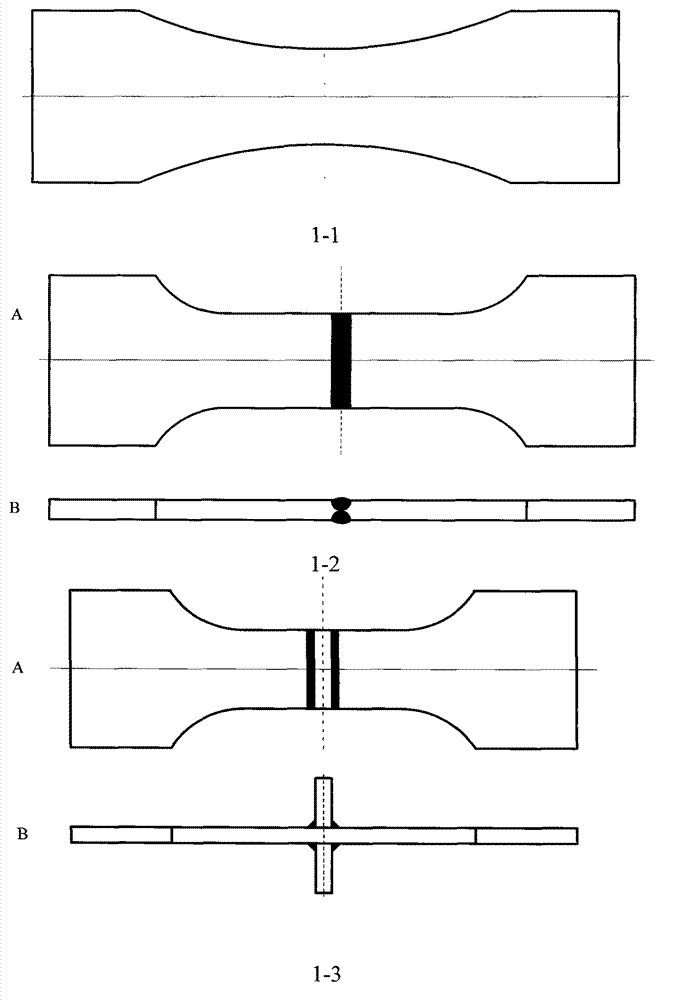

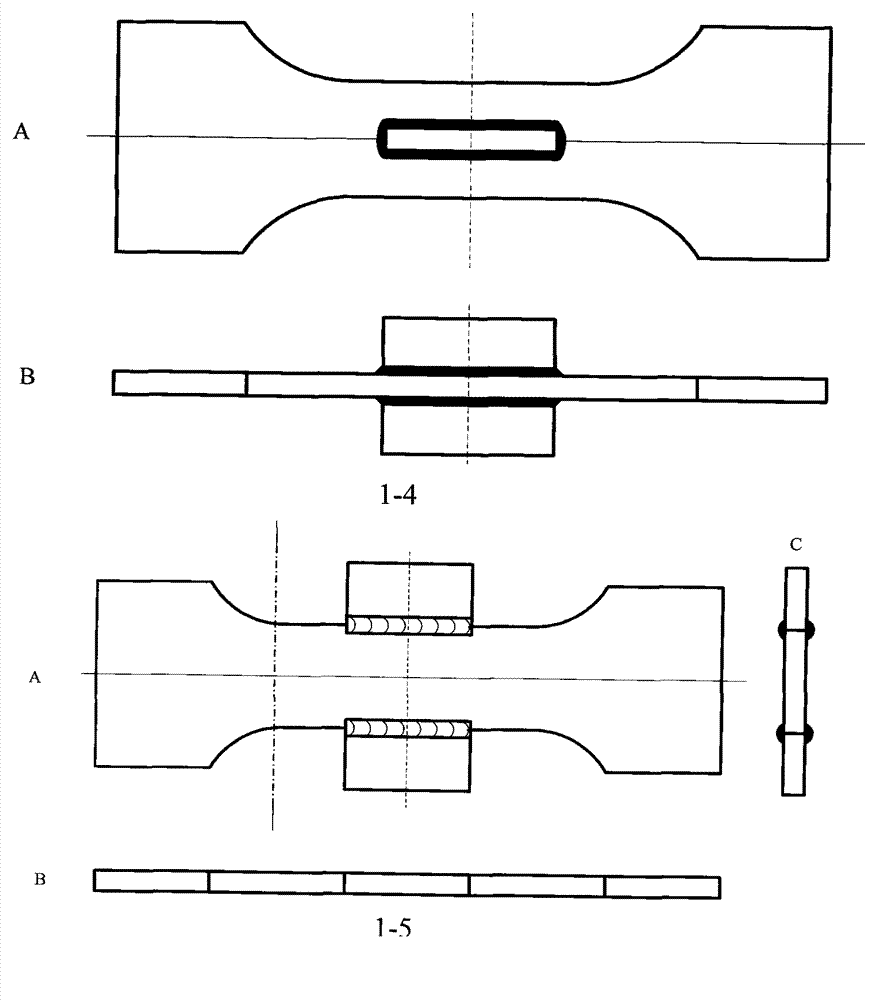

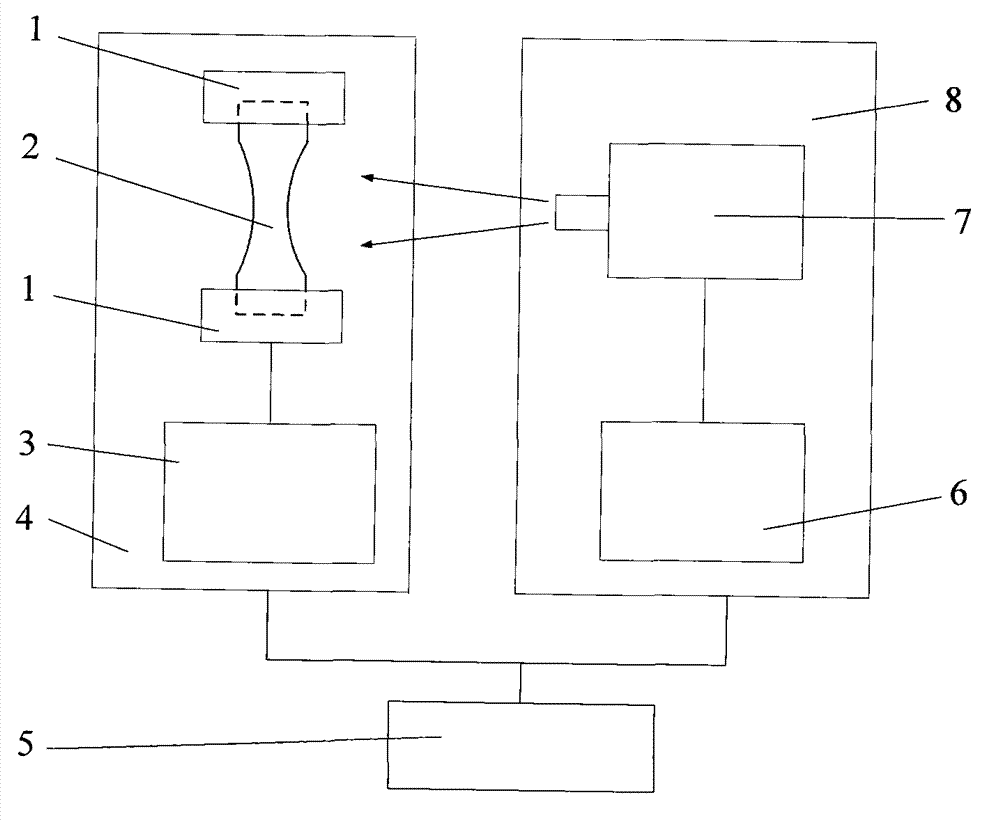

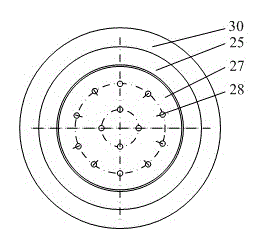

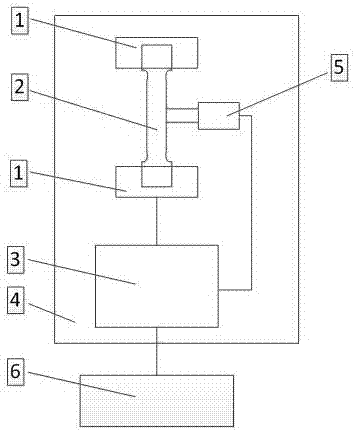

System for predicting fatigue limit of magnesium alloy member based on infrared thermal imaging, and method thereof

InactiveCN103076243ADetermining the fatigue limitAdvancedMaterial strength using repeated/pulsating forcesControl systemFatigue testing

The invention discloses a system for predicting the fatigue limit of a magnesium alloy member based on infrared thermal imaging, and a method thereof. The system comprises: fatigue tester jigs (1); a fatigue test piece (2) comprising a magnesium alloy base material and a welded joint test piece; a fatigue test control system (3); a fatigue test system (4) used for the fatigue test of the magnesium alloy base material and the welded joint test piece to obtain a magnesium alloy fatigue limit under a cycle frequency of 10<7 >; an infrared temperature measurement system (8) for obtaining the surface temperature change curve of the fatigue test piece (2) in the fatigue test process and recording the temperature change data of the fatigue test piece (2) in the fatigue process; and a comprehensive analysis system (5) applying origin software to compare the obtained magnesium alloy fatigue limit with a fatigue limit obtained through routine fatigue tests in order to judge the measurement accuracy. The system and the method can be used for estimating the dangerous point and the fatigue limit of a welding structure in service.

Owner:TAIYUAN UNIV OF TECH

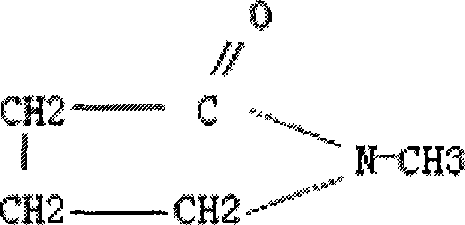

Purification method of N-methyl pyrrolidone

InactiveCN101508667AHigh yield and purityAdvanced and reasonable technologyOrganic chemistryVacuum distillation separationIonChemistry

The invention relates to a method for purifying N-methylpyrrolidone, which is a method for producing a heterocyclic compound. The method comprises the following steps: adding a water repellent agent accounting for 0.1 to 2 percent of a crude product into crude product solution, and then continuously throwing the mixture into a three-tower combined rectifying system. By adopting good-quality stuffing and three-tower continuous pressure reduced rectification, adopting an advanced rectifying operation method according to the optimal principle of reflux separation effect, and adopting a reflux ratio of 1.5 to 3 to extract a product, the method effectively controls the contents of impurities such as metal ions and the like.

Owner:MAIQI CHEM CO LTD

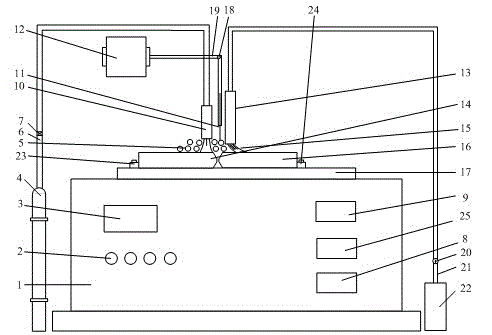

Method for welding ferritic stainless steel with trailing intense cooling

ActiveCN102941401AAdvancedAvoid grain growthArc welding apparatusHeat-affected zoneSS - Stainless steel

The invention relates to a method for welding ferritic stainless steel with trailing intense cooling and aims at the problem that a crystal grain grows and is brittle in the welding process of the ferritic stainless steel. A argon tungsten-arc welding machine is adopted, liquid nitrogen is used in the welding process to conduct welding with trailing intense cooling, and argon is used for protection, so that the problem that the crystal grain grows and is brittle in the welding heat affected zone is effectively prevented, the data are full and accurate, the quality of a welding joint is good, a welding line is good in fusion property and is not easily cracked, the strength of extension of the welding line is up to 481.5MPa, and therefore, the method is a quite ideal method for welding ferritic stainless steel.

Owner:太原理工技术转移有限公司

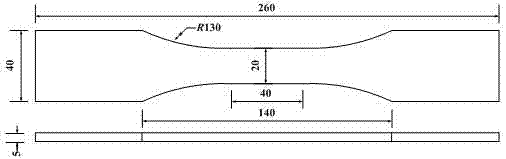

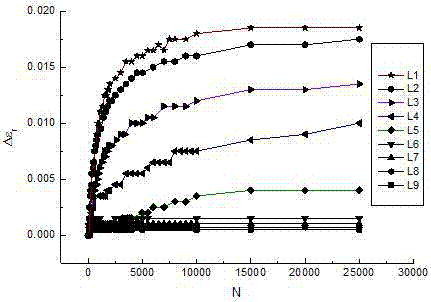

Method for predicting fatigue limit of magnesium alloy component

InactiveCN106872299AAdvancedAdvanced and reasonable technologyPreparing sample for investigationMaterial strength using tensile/compressive forcesLinearityMechanical property

The invention relates to a method for predicting thefatigue limit of a magnesium alloy component, and belongs to the technical field of magnesium alloy material mechanical properties. The method is characterized by comprising the following steps: by aiming at a deformation process of magnesium alloy under action of a cyclic load, obtaining an average cyclic strain curve along with a regular change of strain since a magnesium alloy sample can generate irreversible deformation under higher cyclic stress; through analyzing a linear relation between an average cyclic strain curve stabilization value and the cyclic load, determining an intersection point of two straight lines, and thus obtaining the fatigue limit of the magnesium alloy. The method does no need experimenters to observe the sample all the time, and has the advantages of convenience, quickness, accuracy and the like.

Owner:TAIYUAN UNIV OF TECH

Handling method for using aluminum sulfate slag as cement ingredient

InactiveCN101041562AImproved performance such as wear resistanceLow costCement productionAluminium sulfateSlag

The invention discloses a disposing method to supply aluminum sulfate slag as cement dosage, which comprises the following steps: mixing aluminum sulfate slag and acetylene gas slag and coal ash as finite ratio; producing blank independently; disposing mature blank block with high-temperature roasting steps; grinding into powder separately; using to cement or concrete; or grinding mature blank block and cement clinker to cement. This invention is a good disposing method, which can improve the antiwear property of cement markedly.

Owner:谭纪林

Method for synthesizing aliphatic alcohol polyethenoxy ether carboxylate

InactiveCN101497564AImprove conversion rateSimple processOrganic compound preparationTransportation and packagingEfficient catalystFatty alcohol

The invention provides a method for synthesizing fatty alcohol-polyoxyethyleneether carboxylate, which belongs to the technical field of synthesis of an anion surfactant in organic chemistry. The method uses fatty alcohol-polyoxyethyleneether and chloracetate as raw materials, leads the fatty alcohol-polyoxyethyleneether to perform a carboxy methylation reaction by a new catalyst under protection of inert gas, adds an ethanol solution of an alkali metal hydroxide after reaction so as to adjust the range of pH, and filters the pure fatty alcohol-polyoxyethyleneether carboxylate obtained after inorganic salt is dried in the ethanol, wherein the new catalyst can be sodium alcoholate and / or kalium alcoholate; and a ratio of the catalyst to the pure fatty alcohol-polyoxyethyleneether by weight can be 1:1.0-2.0. The method adopts the new high-efficiency catalyst with high conversion rate of the product, and can obtain the pure fatty alcohol-polyoxyethyleneether carboxylate. Compared with the prior method, the method has a more advanced and reasonable process, and saves equipment investment.

Owner:ZHEJIANG HUANGMA TECH

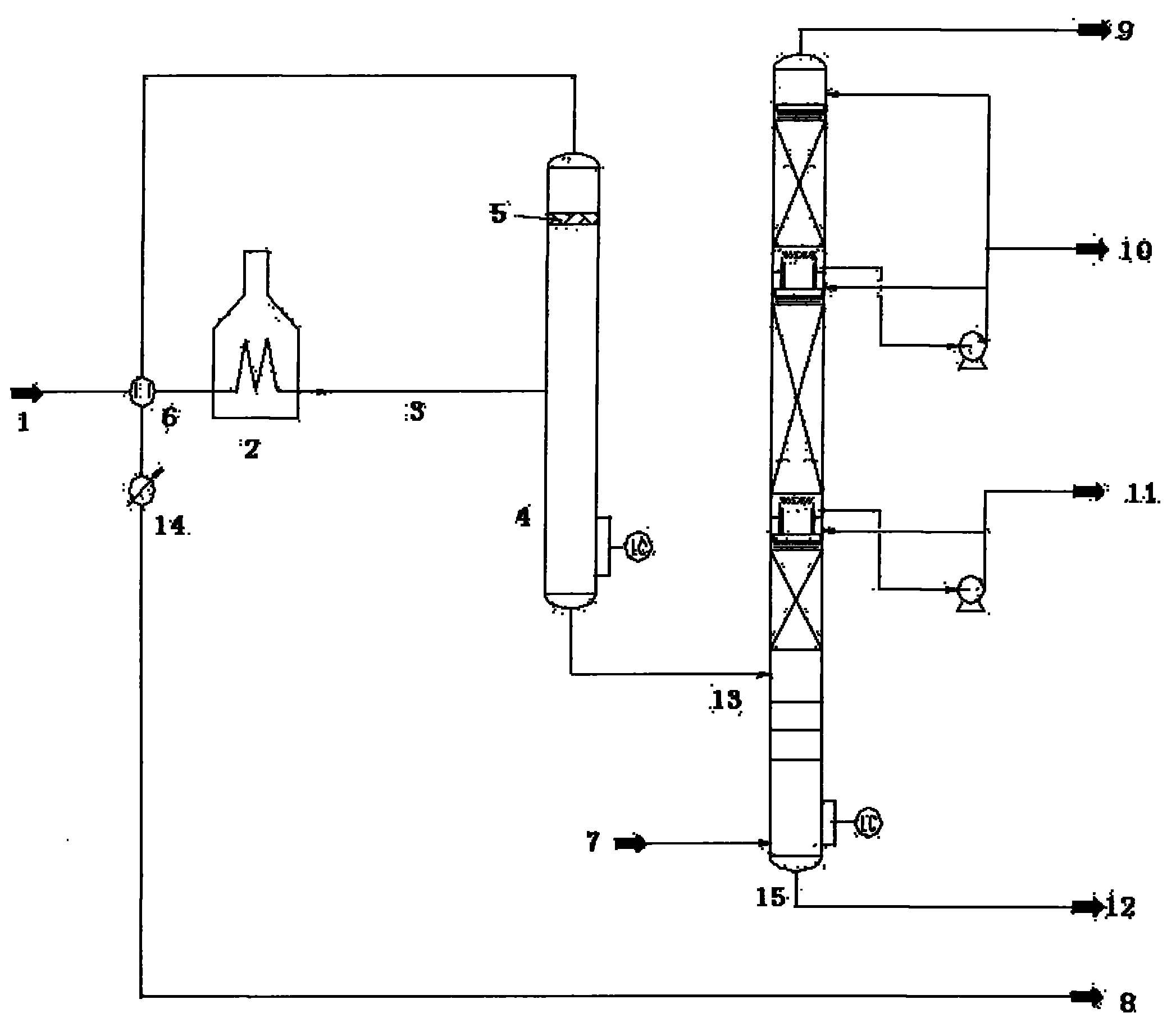

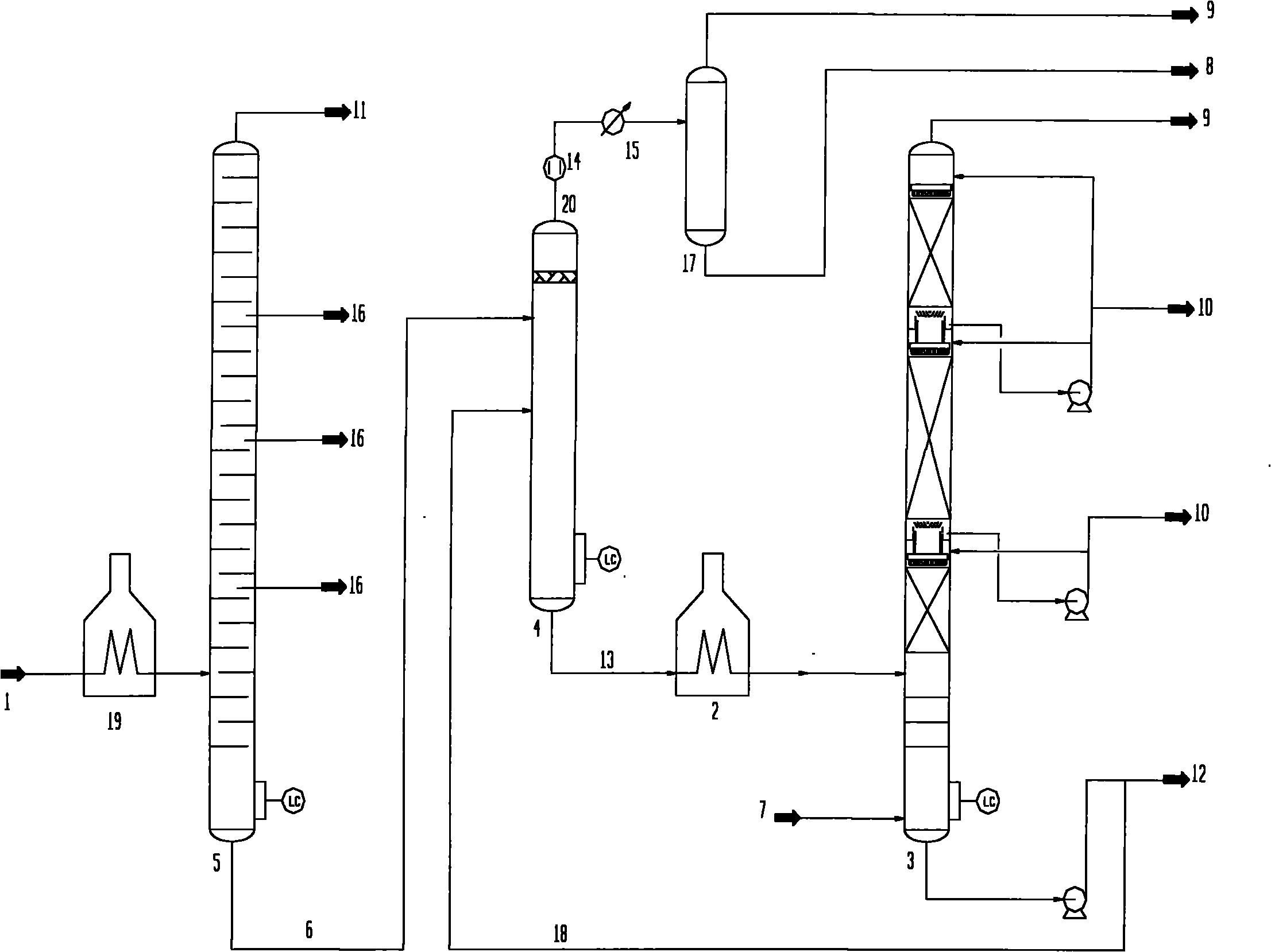

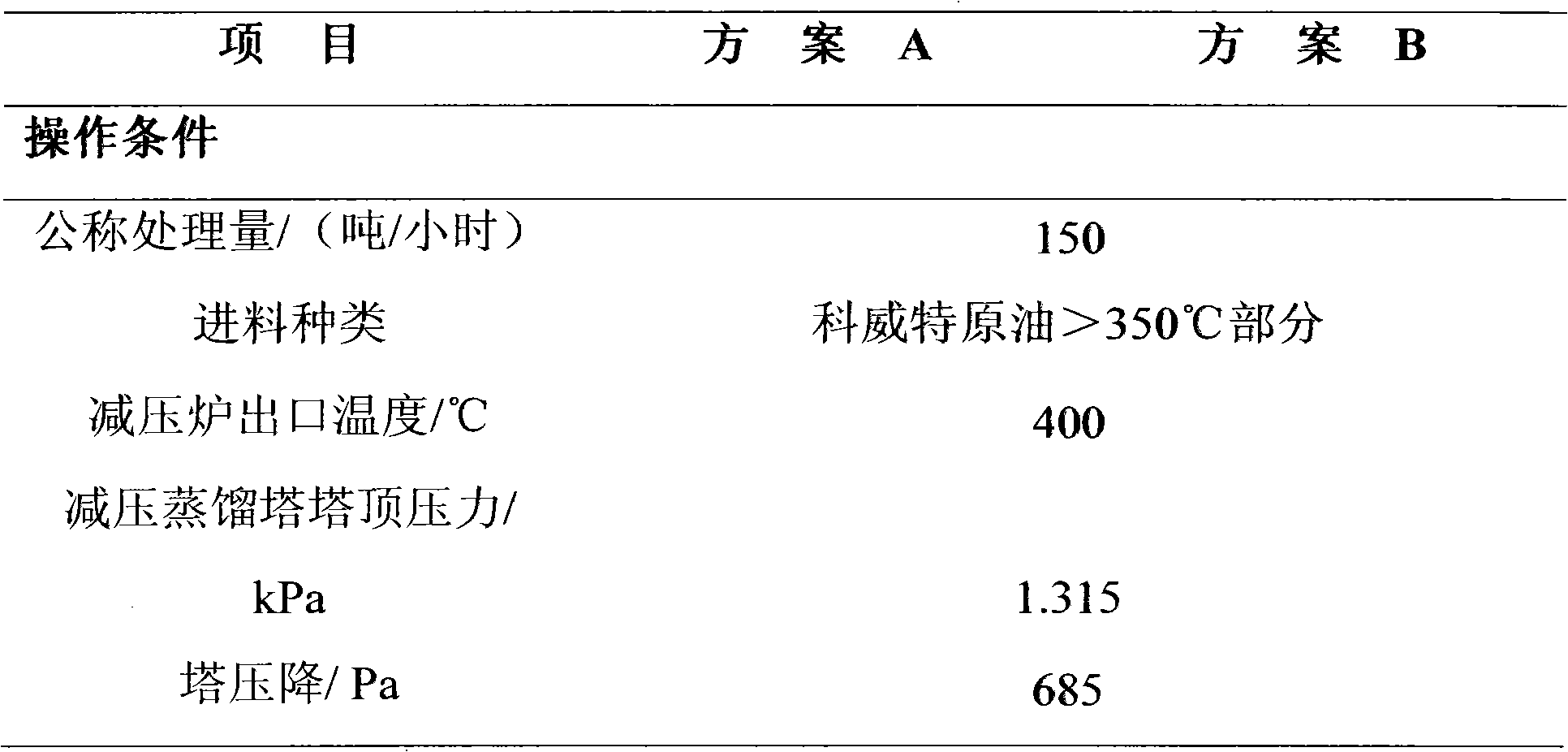

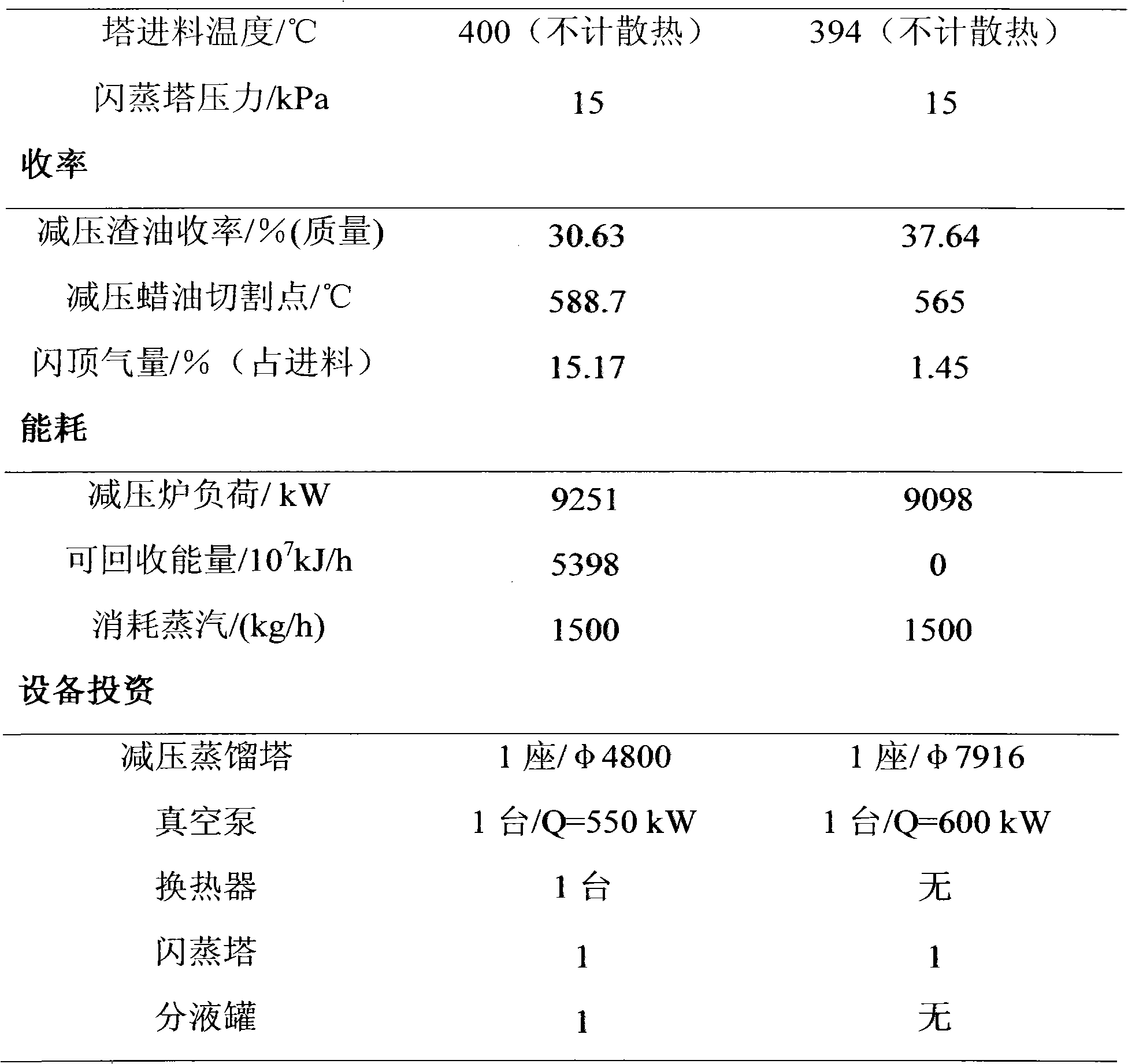

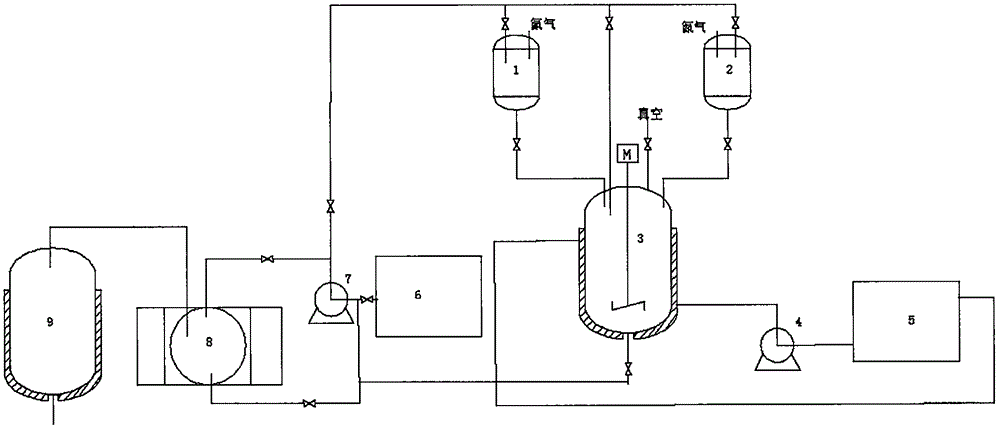

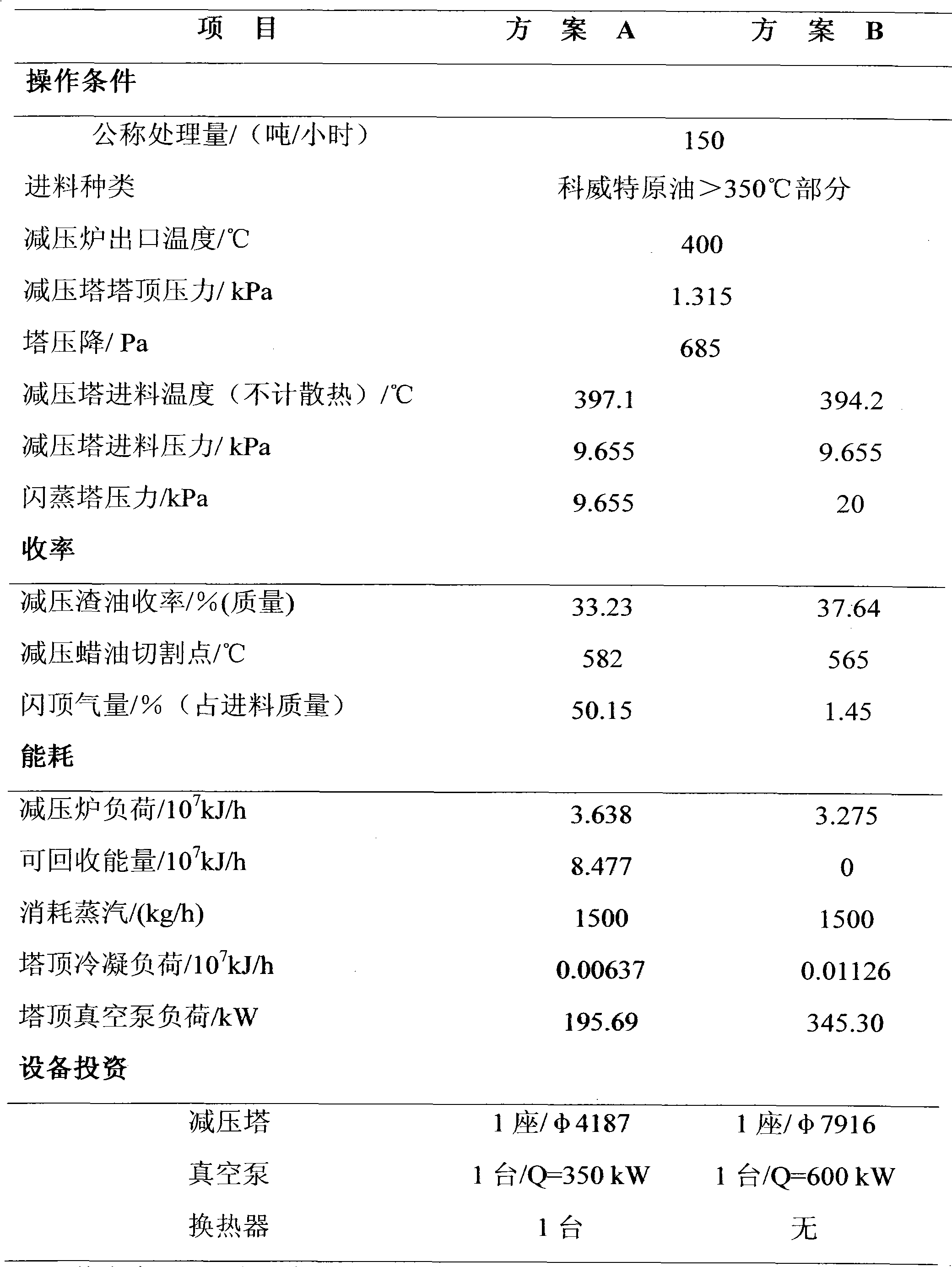

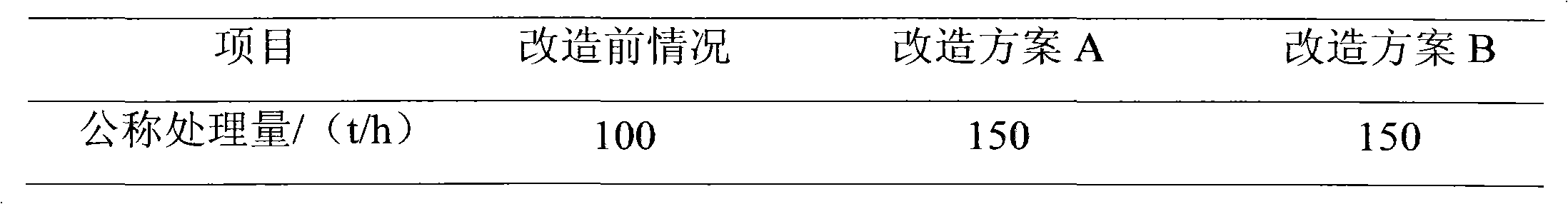

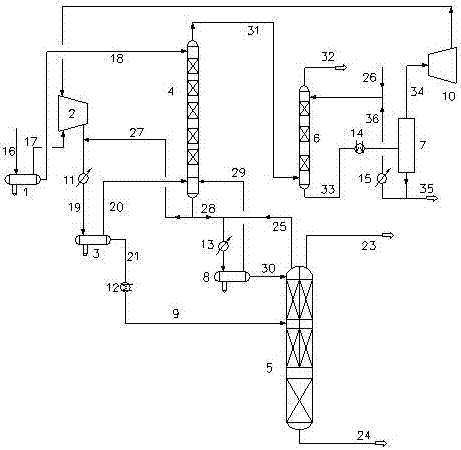

Distillate yield improving vacuum distillation method and device

ActiveCN102311772AAvoid lateral thermal displacementEasy to separateVacuum distillationHydrocarbon oils treatmentLow speedVaporization

The invention discloses a distillate yield improving vacuum distillation method and device. A flash vaporization vessel is arranged on an oil transfer line between a vacuum furnace and a vacuum distillation tower. Vacuum distillation raw materials enter the oil transfer line and the flash vaporization vessel after being heated by the vacuum furnace. Gas liquid separation is carried out in the flash vaporization vessel: liquid discharged from the bottom of the flash vaporization vessel, namely flash bottom oil, is introduced into the vacuum distillation tower; and gas discharged from the top of the flash vaporization vessel, namely flash top gas, is led out of the device after being condensed into liquid. According to the vacuum distillation method and device with the flash vaporization vessel arranged behind the vacuum furnace, on one hand, the yield of vacuum distillate is increased, on the other hand, a conventional decompression oil transfer line low-speed section is omitted, the operation load of the vacuum tower is reduced, and the diameter of the vacuum tower can be appropriately reduced, so equipment investment is saved, and the operating cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

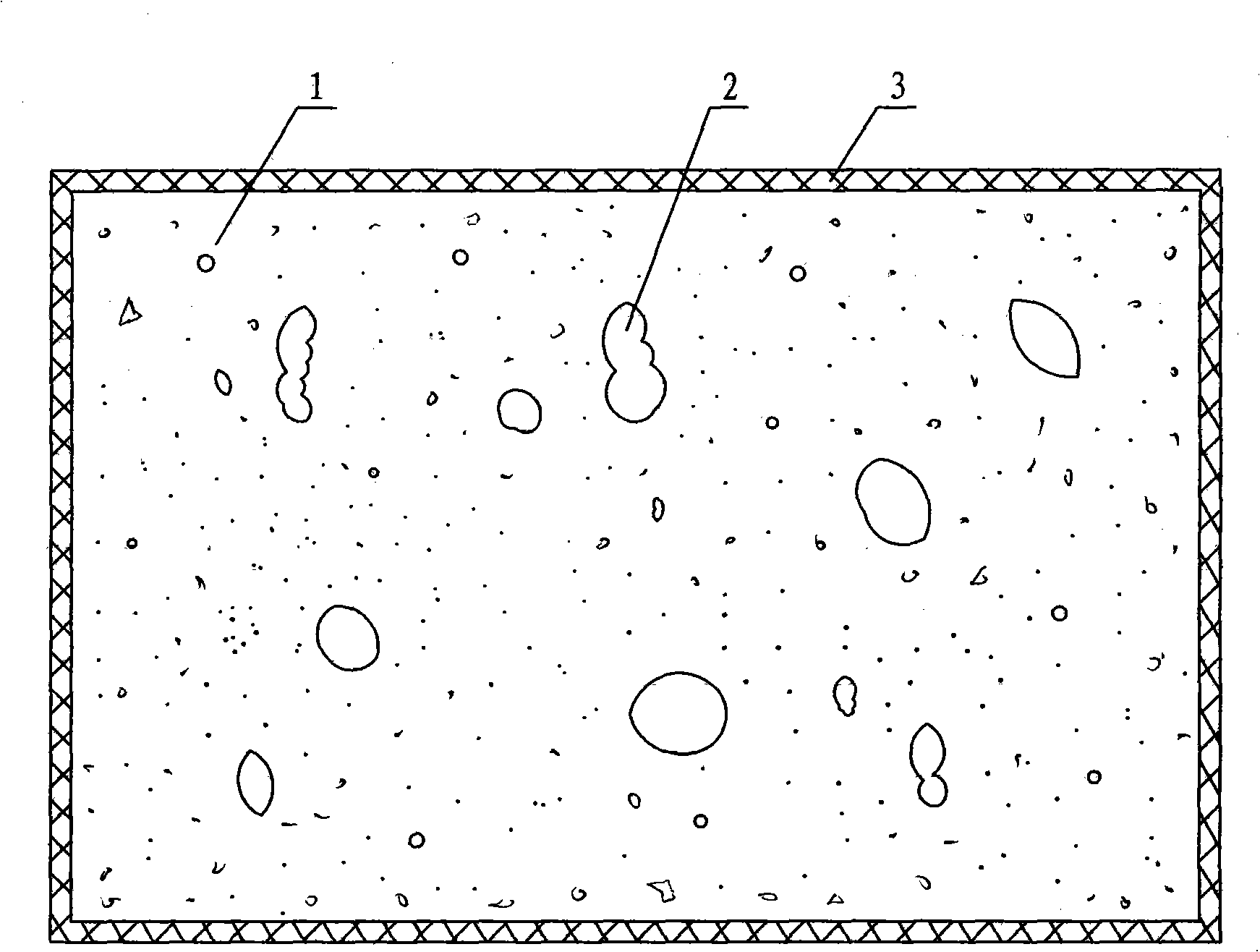

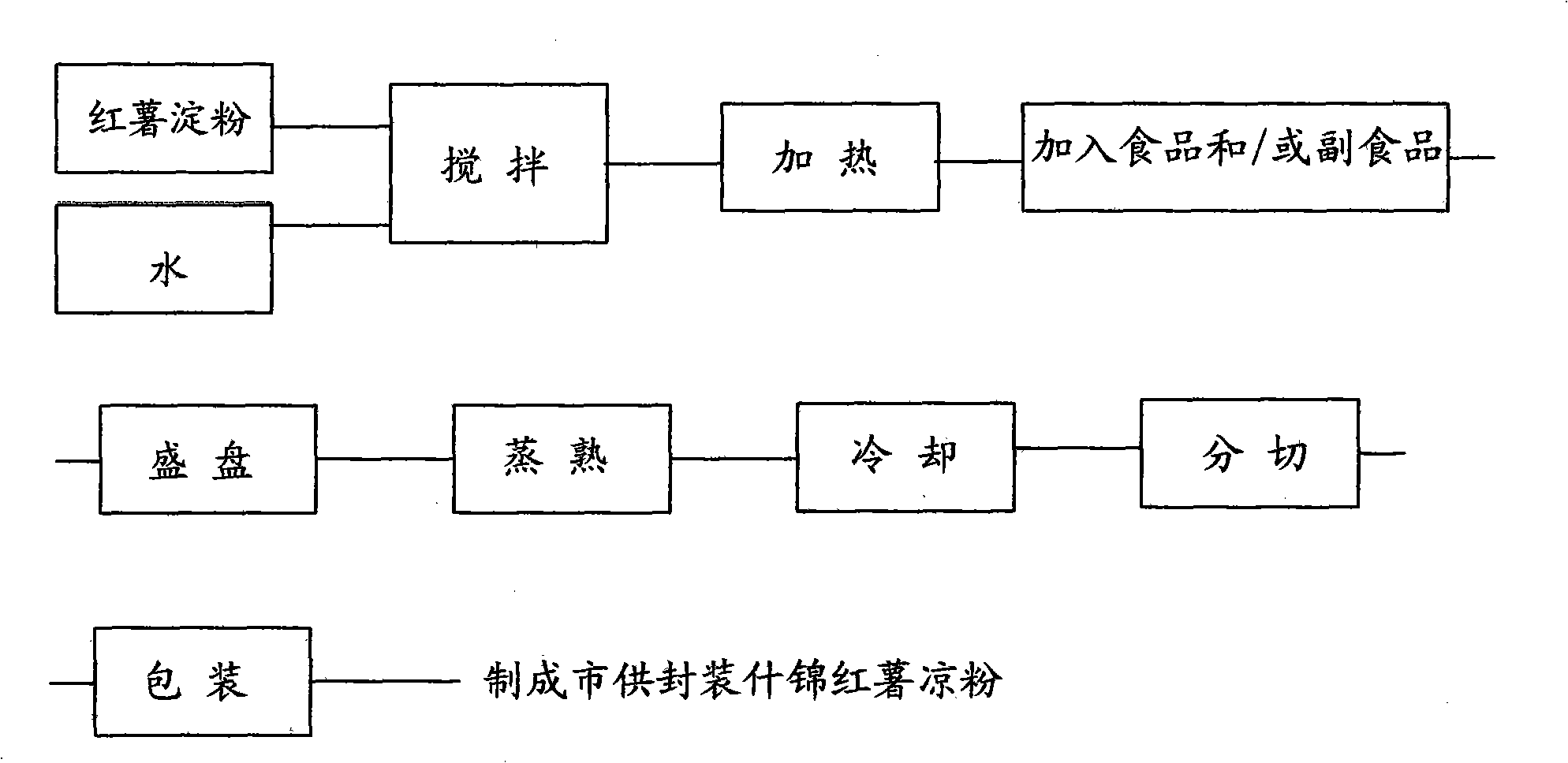

Mixed sweet potato bean jelly and method of preparing the same

InactiveCN101401631APleasing colorGreat tasteDough treatmentFood preparationPotato starchPotato-bean

The invention discloses an assoeted sweet potato agar-agar jelly and a preparation method thereof. The assoeted sweet potato agar-agar jelly is mainly characterized in that an agar-agar jelly body (1) of the assoeted sweet potato agar-agar jelly contains one or more than one food and / or subsidiary foodstuff (2), and the blocky or sheet or bar-shaped agar-agar jelly body (1) is sterilized and packaged in a packing bag (3). The preparation method of the assoeted sweet potato agar-agar jelly takes sweet potato starch as a main material, and is mainly characterized in that the sweet potato starch is performed according to eight steps: stirring, heating, adding of auxiliary material food and / or the subsidiary foodstuff, plate loading, steaming, cooling, cutting, and packing. The assoeted sweet potato agar-agar jelly has the characteristics of good taste, high edible value, good sanitary conditions, convenient storage and transportation, long quality guarantee period and so on. The preparation method of the assoeted sweet potato agar-agar jelly has the characteristics of reasonable and advanced process, high production efficiency, capability of ensuring the quality of a finished product of the assoeted sweet potato agar-agar jelly and so on. The invention develops a novel finished product and provides a novel preparation method for a traditional food sweet potato agar-agar jelly in our country.

Owner:凌才新

Synthetic method of trimethylolpropane tricaprylate

ActiveCN101445453AHigh selectivityAdvanced and reasonable technologyPreparation by caroxylic acid/anhydride-hydrocarbon reactionMetal/metal-oxides/metal-hydroxide catalystsSTANNOUS OXIDEFiltration

The invention relates to a synthetic method of trimethylolpropane tricaprylate, which belongs to the technical field of esters compound synthesizing in organic chemistry. Taking trimethylolpropane and isocaprylic acid as material, an esterification reaction is preformed in nitrogen gas under the action of metallic oxide catalyst, the trimethylolpropane tricaprylate is obtained after depickle and filtration; the mass ratio of the trimethylolpropane and the isocaprylic acid is 1:3.15-3.95; the metallic oxide catalyst is stannous oxide or ferric oxide or magnesia, and the like, and the adding amount of the catalyst accounts for 0.03 to 0.10 percent by weight of the total weight of the trimethylolpropane and the isocaprylic acid. The invention reasonably selects metal oxide as the catalyst, and the metal oxide does not erode equipment, can be removed by filtration after the reaction is finished and can be recovered for recycle use; and the invention has advanced and reasonable process and less equipment investment through reasonable regulation of the adding amount of the trimethylolpropane and the isocaprylic acid and the proportion of the metal oxide catalyst and the optimal selection of reaction temperature and reaction time.

Owner:ZHEJIANG HUANGMA TECH

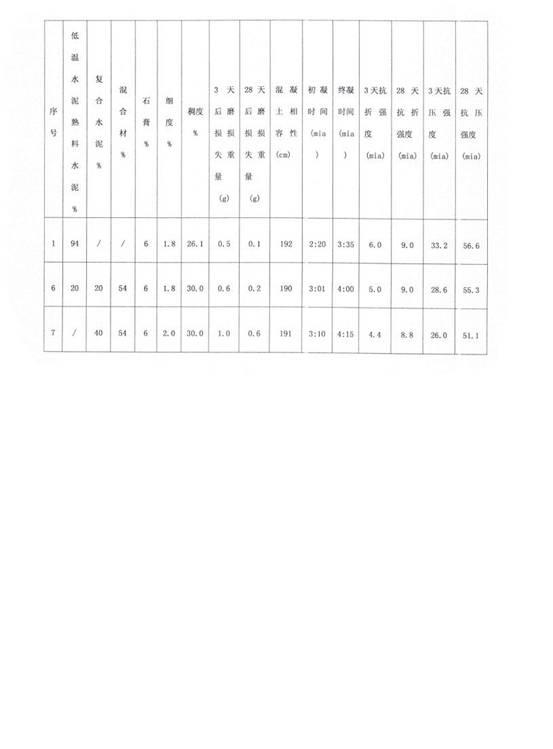

Method for producing low-temperature cement clinker from straw ash

InactiveCN102584043AReduce heat of hydrationImprove wear resistanceCement productionSlagToxic industrial waste

The invention relates to a method for producing low-temperature cement clinker from straw ash, which mainly comprises the following steps of: feed preparation, burdening, pelletizing, steam curing, low-temperature calcining, grinding and the like. Cement of the low-temperature cement clinker, which can be comparable to the cement of Portland cement clinker, is produced by taking dry and wet strawash as a main raw material and steel slag and aluminum slag as auxiliary materials, and the cement of the low-temperature cement clinker has various characteristics of high cement strength, high concrete compatibility, good abrasion resistance, low hydration heat, minimum inflation, freezing resistance, corrosion resistance and the like. The low-temperature cement clinker can be directly used forengineering construction of dams, underwater constructions, roads, bridges, civil constructions and the like. The method for producing the low-temperature cement clinker from the straw ash also has the advantages of simple and reasonable process, low energy consumption, high benefit, investment saving, no secondary pollution, environmental protection and the like. Compared with regular cement produced by traditional methods, the investment is saved by 80 percent, the cement cost is reduced by 60 percent, the energy consumption is reduced by 80 percent, the carbon dioxide emission is reduced by 80 percent, the straw ash and other industrial waste residues can be largely digested, and the environmental pollution is reduced. The method for producing the low-temperature cement clinker from the straw ash is a good method which is favor of protecting environment and is capable of turning waste into wealth.

Owner:淮安市水泥厂有限公司 +1

Crude oil processing method

The invention discloses a crude oil processing method, which comprises normal-pressure distillation and reduced-pressure distillation, wherein the heavy oil at the bottom of a normal-pressure distillation tower, namely normal bottom oil, is mixed with part of circular reduced-pressure residual oil at the bottom of a reduced-pressure distillation tower, the mixture enters a flash tower, and a top gas phase, namely flash top gas, of the flash tower undergoes heat exchange and is condensed into a liquid phase to be discharged out of the device as a product; and bottom oil, namely flash bottom oil, of the flash tower, is heated in a reduced-pressure furnace to 390 to 420 DEG C, the heated bottom oil is intruded into a flash section of the reduced-pressure distillation tower from a reduced-pressure oil transfer line for reduced-pressure distillation, proper distillate product is drawn from a side line of the reduced-pressure distillation tower, part of reduced-pressure residual oil drawn out from the bottom of the reduced-pressure distillation tower is circulated, and another part of the reduced-pressure residual oil is discharged of the device. Compared with the prior art, the method can effectively improve the drawing rate of a reduced-pressure distillation process and can reduce the load of the reduced-pressure furnace and the reduced-pressure distillation tower at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for sodium fatty acyl methyl taurate

InactiveCN106588709ASolve environmental problems of emissionsSolve environmental problemsOrganic compound preparationSulfonic acids salts preparationSolubilityAcyl group

The invention discloses a preparation method for sodium fatty acyl methyl taurate. According to the method, an organic solvent is not used for performing crystallization and re-crystallization, and a byproduct-centrifugal filter liquor in a reaction process is recycled, so that the environment and health problems caused by use of the solvent and the environmental protection problem of salt-containing and acid-containing wastewater discharge in a purification process in the past are solved. A frozen recovered filter liquor is added in a freezing crystallization process, so that the temperature is reduced; and sodium chloride in the filter liquor is used for performing seeding, and the effects of crystal seeds and crystal nucleuses are achieved, so that the graining in the process is quick, wrapped impurities due to non-crystal agglomeration are reduced, and the prepared product is higher in purity and higher in content. The freezing crystallization is combined with the freezing centrifugation, so that the crystal solubility is reduced and the product yield is increased. Through optimized selection of a process route, the process is advanced and rational, can be realized by using a general device, and is simple in operation, relatively high in economic benefit and relatively low in environmental pollution.

Owner:ZHANGJIAGANG GREAT CHEM

Method for manufacturing laser direct plating tipping paper

InactiveCN101100833AAdvanced and reasonable technologySolve environmental problemsSpecial paperPaper/cardboardPaper manufacturingCinnamic acid

The invention discloses radium irradiating direct plating Chinese water pine paper manufacturing method. It includes the following steps: mixing cinnamic acid latex with hydrophilic thickening agent in weight percentage of 97%-99% and 1%-3%, standing more then 12 hours to form hydrophilic paint; coating hydrophilic paint on BOPP film with 8-10g / sq m wet coating weight; jointing the base paper with the coating surface; mill finish; drying to make the water content be 5%-8%; peeling off the BOPP film; aluminum plating in vacuum to obtain the finished product. The invention has the advantages of simple, reasonable, scientific select material, good for increasing cigarette grade, reducing its influence for people's health.

Owner:扬州海克赛尔新材料有限公司

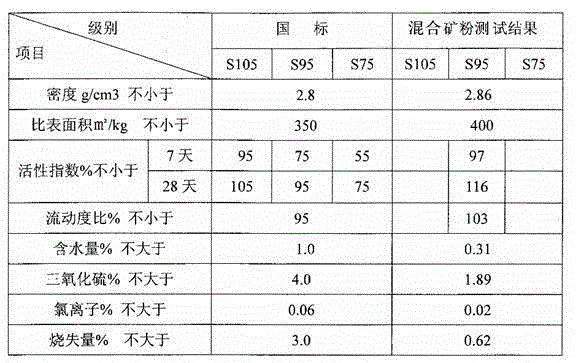

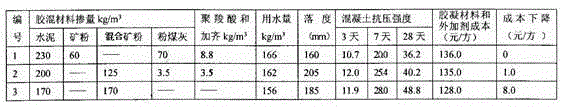

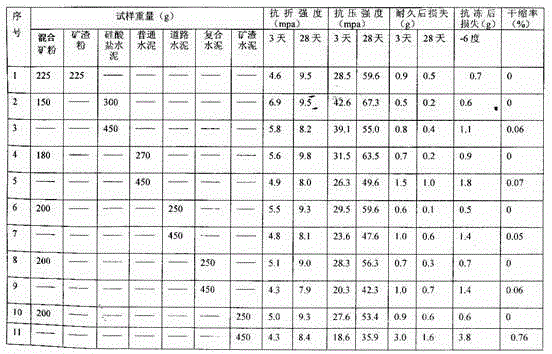

Preparation method of industrial waste residue mixed ore powder

ActiveCN104016603AAdvanced and reasonable technologyLess investmentSolid waste managementCement productionSlagGypsum

The invention relates to a preparation method of industrial waste residue mixed ore powder, which mainly comprises the following steps: proportionally mixing and forming waste alkali residue discharged after producing industrial crystal soda in salinization plants, waste steel residue discharged by steel plants, waste residue straw ash discharged by straw power plants and waste residue titanium gypsum discharged by titanium white plants, drying at 250 DEG C, and the like. The method can change piled unmanageable alkali residue (which pollutes the underground water resources) and other industrial waste residues into valuable substances to obtain the industrial waste residue mixed ore powder product which can completely substitute the resources-short price-increasing slag powder. Various properties of the produced mixed ore powder product can achieve or exceed quality indexes for slag powder, and thus, the mixed ore powder product is a high-quality concrete admixture; the maximum doping amount of the mixed ore powder product in the concrete is up to 50%, and thus, the method can change wastes into valuable substances and perform harmless and decrement treatment on the industrial waste residues; and the method has the advantages of advanced and reasonable technique, low investment, low cost, high benefit, no pollution or waste residue emission in the production process, and the like.

Owner:淮安市水泥厂有限公司

Method for preparing pentaerythrite oleic ester used in cold-rolling oil

InactiveCN102050735AReduce non-target componentsImprove performanceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzenePentaerythritol

A method for preparing pentaerythrite oleic ester used in cold-rolling oil belongs to the technical field of ester compound synthesis in organic chemistry. Pentaerythrite and oleinic acid are adopted as raw materials and p-toluenesulfonic acid or / and tributyl phosphate is / are adopted as catalyst; toluene or benzol is adopted as a water carrier, and esterification reaction lasting 4 to 6 hours is performed under the protection of high-purity nitrogen and under the temperature of 140 to 180 DEG C; after the reaction, continuous vacuumization lasting 40 to 60 mins is performed under the high-vacuum condition with a vacuity of 40 to 60Pa; and pentaerythrite oleic ester is obtained after the filtration of remains after vacuumizing. The pentaerythrite oleic ester prepared by adopting the method provided by the invention is specially used in cold-rolling oil, and has the advantages of excellent lubricity, temperature characteristics, annealing detergency and excellent mill housing cleanness.

Owner:LUOYANG XINZHONG PETROCHEM

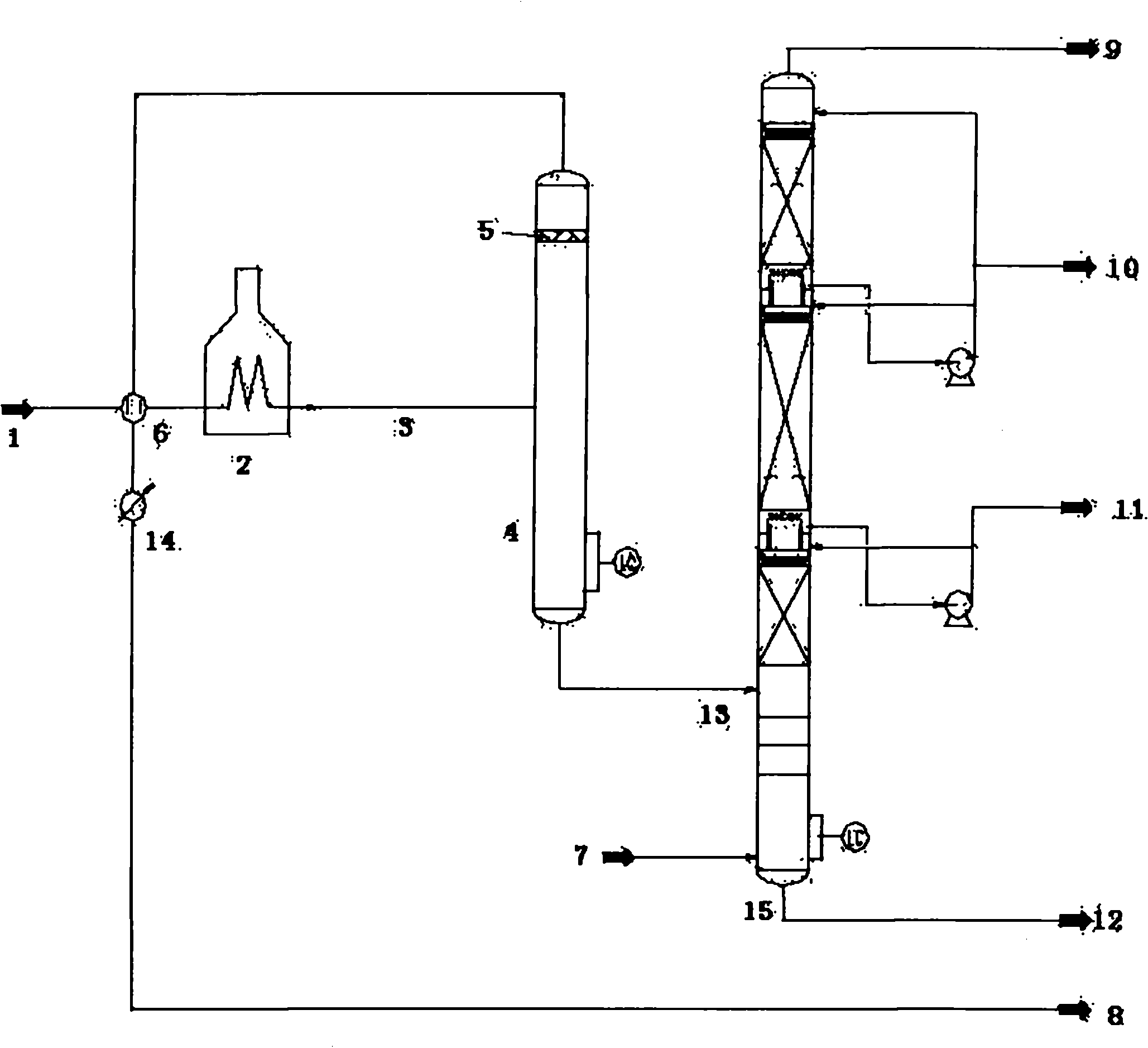

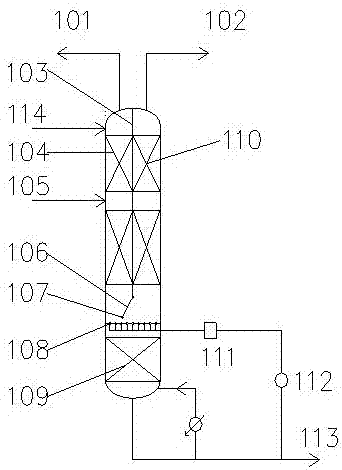

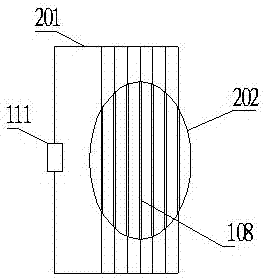

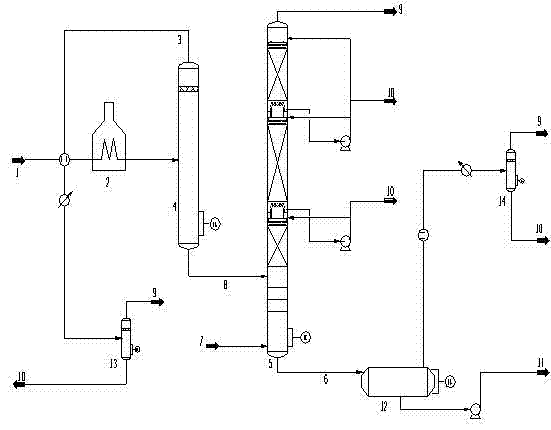

Crude oil pressure-reduced distillation method and device

InactiveCN102311754AEasy to separateGood stripping effectVacuum distillation separationVacuum distillationHydrogenGas phase

The invention discloses a crude oil pressure-reduced distillation method and a crude oil pressure-reduced distillation device. A flash tower is arranged between a reduced-pressure furnace and a reduced-pressure distillation tower, an oil transfer line is eliminated, a reduced-pressure distillation raw material is heated in the reduced-pressure furnace and directly enter the flash tower, a small amount of stripping gas is introduced into the flash tower, and the liquid phase, namely flash bottom oil, obtained by gas-liquid separation in the flash tower is introduced into the reduced-pressure distillation tower; and a gas phase, namely flash top gas, discharged from the top of the flash tower is condensed into a liquid phase to be led out of the device. A high-temperature hydrogen or inert gas is introduced into the bottom of the flash tower. When the pressure-reduced distillation method and the pressure-reduced distillation device, in which the flash tower for high-temperature hydrogen or inert gas stripping flash tower is arranged behind the reduced-pressure furnace, are used, the yield of a reduced-pressure fraction oil is increased, the conventional reduced-pressure oil transfer line is not used, the operation load of the reduced-pressure furnace is lowered, and the tower diameter of the reduced-pressure tower can be reduced properly; therefore, equipment investment is reduced, and operation cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Absorption-stabilization technology and system for refining

ActiveCN107298988AReduce the amount of gas phaseReduce loadGaseous mixture working upGas compressorDesorption

The invention provides an absorption-stabilization technology and system for refining. The absorption-stabilization system comprises a gas-liquid balance tank, a rich gas compressor, a rich gas balance tank, an absorption tower, a desorption-stabilization dividing wall tower, a re-absorption tower, a regeneration tank, a desorption gas balance tank and a vacuum pump. The invention further provides the absorption-stabilization technology utilizing the absorption-stabilization system. By adopting the absorption-stabilization technology and system, provided by the invention, the concentration of liquefied gas in dry gas is greatly reduced; and meanwhile, the yield of catalytic gasoline and the liquefied gas can be improved and the energy consumption of the system is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Synthetic method for sorbitan octoate emulsifier

ActiveCN106588830AHigh selectivityHigh purityOrganic chemistryTransportation and packagingHydroxyl valueSaponification value

The invention discloses a synthetic method for a sorbitan octoate emulsifier. The synthetic method is characterized by being prepared from commercially available D-sorbitol, caprylic acid, a metal tin catalyst, a basic catalyst and a granular magnesium silicate adsorbent, which serve as raw materials, through processes of etherification, etherate refinement, esterification, deacidification, ester refinement and the like. According to the method, the metal tin catalyst is rationally selected and used; a product in the etherification process is subjected to adsorption and refinement treatment by utilizing the granular magnesium silicate adsorbent; unreacted caprylic acid is removed in vacuum at a high temperature; and a final product is subjected to adsorption and refinement treatment by utilizing the granular magnesium silicate adsorbent, so that the sorbitan octoate emulsifier which has the acid value less than 2.0 mgKOH / g, the color luster less than or equal to 100 Hazen, the hydroxyl value equal to 230-300 mgKOH / g and the saponification value equal to 180-210 mgKOH / g, is light in smell, high in transparency, low in fatty acid residue content, difficult in acid backflow and high in stability, and has good solubilizing, emulsification-facilitating, tackifying and anticorrosion-enhancing effects and safe and mild performance is obtained; and the method is suitable for the fields of daily chemicals and cosmetics, and the like.

Owner:ZHANGJIAGANG GREAT CHEM

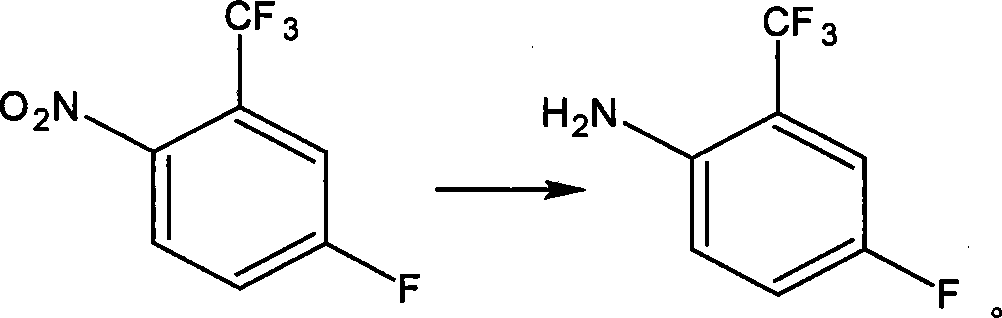

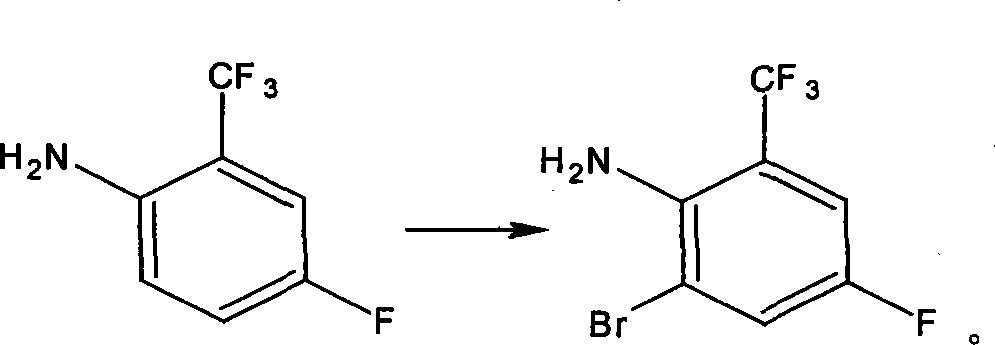

Preparation technique of 3-fluorine -5 bromine benzotrifluoride

InactiveCN101157597AAdvanced and reasonable technologyEase of industrial preparationHalogenated hydrocarbon preparationBromineMedicinal chemistry

The invention discloses a technique of preparing 3-fluorin-5-bromobenzotrifluoride which is an intermediate for novel medicine, belonging to the technical field of fine chemicals intermediate. The technique of preparing 3-fluorin-5-bromobenzotrifluoride takes 4-fluorin-6-nitrobenzotrifluoride as the initial material,and the 3-fluorin-5-bromobenzotrifluoride is prepared by reduction, bromination and deamination in sequence. The invention has reasonable and advanced technology, each involving reaction is regular unit reaction, and the 3-fluorin-5-bromobenzotrifluoride is an intermediate for the novel medicine; besides, the invention is easy in industrial production and ensures high yield.

Owner:高邮市光明化工厂

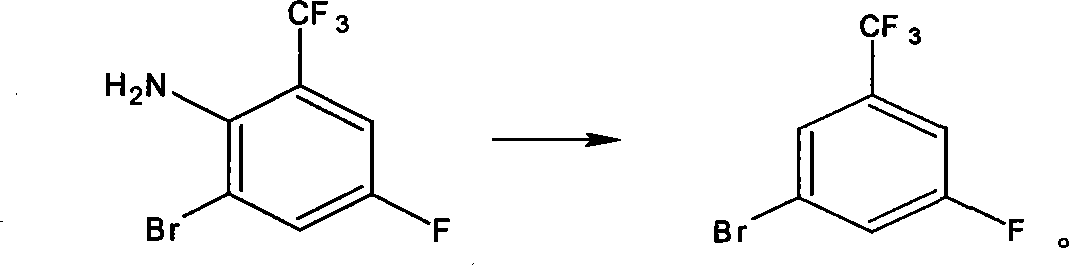

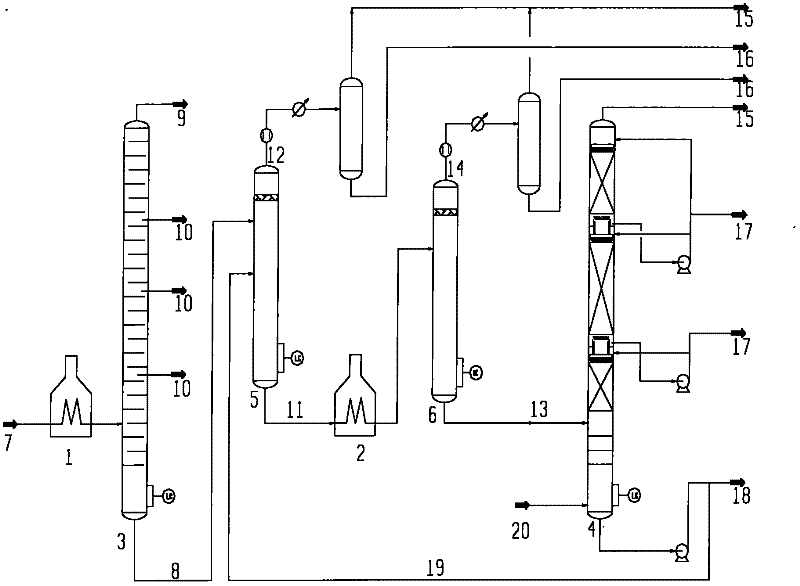

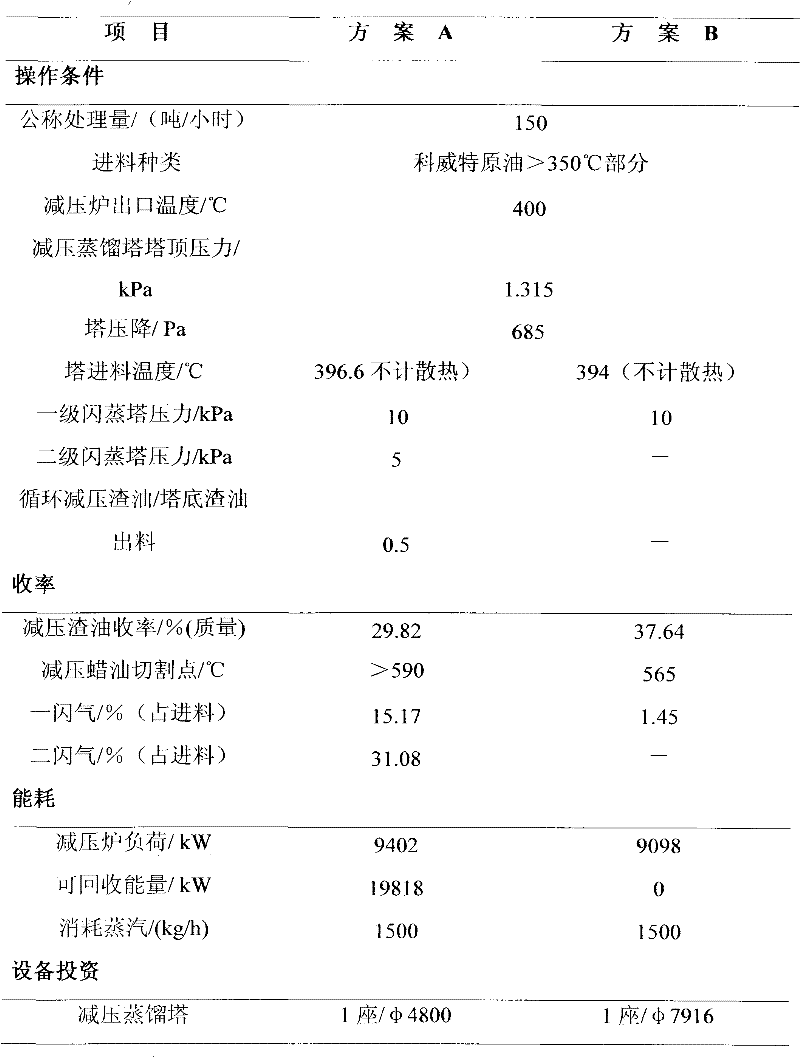

Crude oil distillation method

The invention discloses a crude oil distillation method. A primary flash distillation tower is arranged between a normal pressure distillation tower and a pressure reduction furnace, a pressure reduction oil line from an outlet of the pressure reduction furnace to a pressure reduction distillation tower is omitted, a secondary flash distillation tower is arranged between the pressure reduction furnace and the pressure reduction distillation tower, tower bottom heavy oil of the normal pressure distillation tower, i.e. normal bottom oil enters the primary flash distillation tower after being mixed with cyclic pressure reduction slag oil, the tower top gas phase of the primary flash distillation tower is converted into a liquid phase to be used as products through heat exchange and condensing, bottom oil of the primary flash distillation tower enters the secondary flash distillation tower through being heated by the pressure reduction furnace, the tower top gas phase of the secondary flash distillation tower is converted into a liquid phase to be used as products through heat exchange and condensing, and bottom oil of the secondary flash distillation tower is introduced into a flash distillation section of the pressure reduction distillation tower for pressure reduction distillation. Compared with the prior art, the method has the advantages that on one hand, the yield of the pressure reduction slag oil is reduced, and the economic benefits of devices are improved; and on the other hand, the load of the pressure reduction furnace and the pressure reduction distillation tower is reduced, the device investment is saved, and the energy consumption of the devices is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

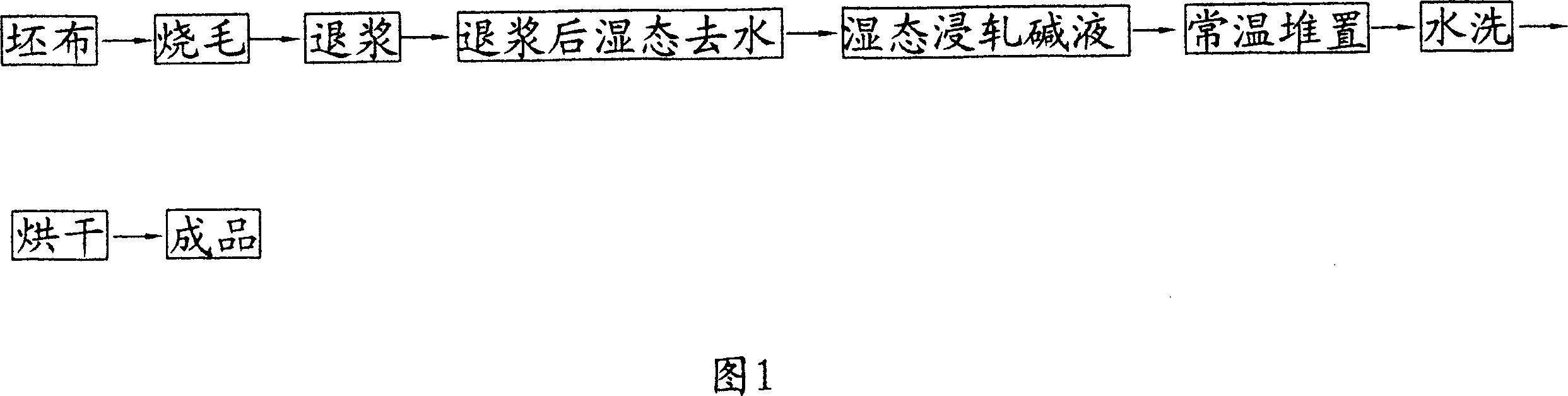

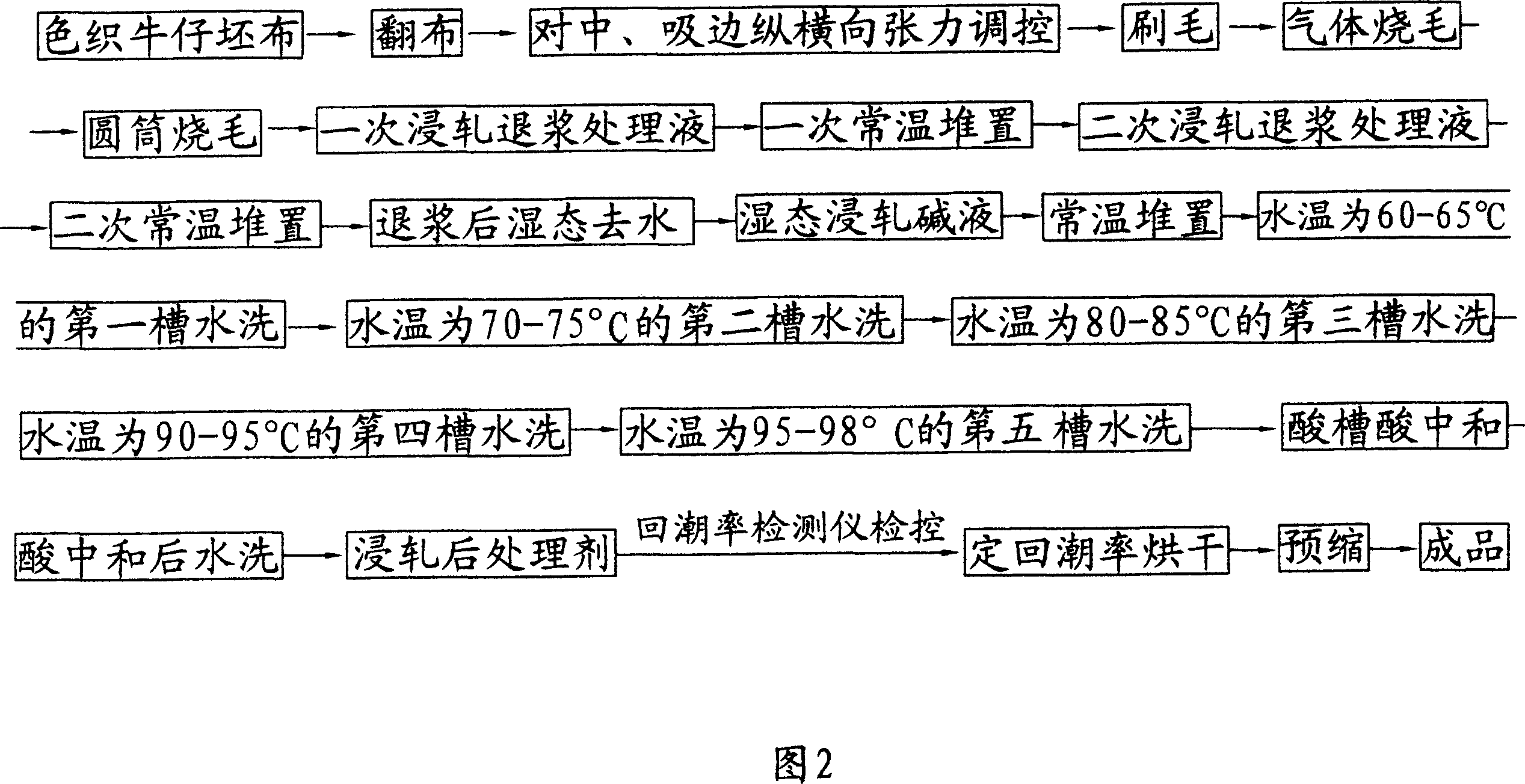

Mercerized denim manufacturing technique

The invention relates to a mercerised denim production, wherein it uses colored woven denim as raw material; and the production comprises: burning hair of blank cloth, desizing, mercerizing, tensioning, and contracting; said mercerizing is characterized in the wet mercerizing step which immerging it with alkali liquid and stacking at normal temperature; and the production comprises: desizing and dewatering in wet state; immerging and rolling it with alkali liquid in wet state; stacking in normal temperature; washing and drying. The invention has high mercerized degree and high barium value.

Owner:常州市东高染整有限公司

Reduced pressure distillation method with low energy consumption and deep total distillation rate

ActiveCN103242896AIncrease gasification rateReduce pressure drop lossTreatment with plural serial refining stagesThermodynamicsEconomic benefits

The invention discloses a reduced pressure distillation method with low energy consumption and deep total distillation rate. By arranging a reduced pressure flashing tower behind a reduced pressure heating furnace, light fractions vaporized by heat are separated out, load of a reduced pressure distillation tower is reduced and energy consumption of an apparatus is reduced; by arranging a reduced pressure flashing tank behind the reduced pressure distillation tower, relatively light fractions in reduced pressure residues can be further flashed under a vacuum degree higher than that of the bottom of a reduced pressure distillation tower, yield of reduced pressure distillate oil is increased, and thus a reduced pressure distillation operation with low energy consumption and deep total drawing rate can be realized. With the reduced pressure distillation method, the content of fractions with a temperature lower than 500 DEG C in the reduced pressure residues can be reduced to the minimum, so that the distillation rate of the reduced pressure distillation is increased and economic benefits of the apparatus can be increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manufacturing method of nanometer silicon-aluminium composite material

The preparation process of nanometer composite Si-Al material with pyrophyllite as material includes soaking pyrophyllite powder in water, adding silane coupling agent and hydrophobic treatment, coating with surfactant, and dispersing in corresponding solvent to prepare nanometer dispersed emulsion. The said pyrophyllite contains aluminum in 10-30 wt%, and the temperature of water for soaking pyrophyllite powder is 60-95 deg.c. The prepared nanometer composite Si-Al material has high dispersivity, small size effect of nanometer material and excellent modifying effect. The preparation process is advanced, low in cost, less in environmental pollution and suitable for industrial production.

Owner:章浩龙

Preparation method of aluminum base gadolinium oxide neutron absorbing plate

The invention relates to a preparation method of an aluminum base gadolinium oxide neutron absorbing plate. The compact aluminum base gadolinium oxide neutron absorbing plate is prepared to meet a protection requirement of neutron radiation shielding for a spent fuel storage rack of a nuclear power station, and is prepared with aluminum powder, gadolinium oxide powder and copper powder as raw materials after powder metallurgy is performed and rolling is performed. The neutron absorbing plate is silver white. The neutron absorption rate is 95%. The gadolinium oxide distributes uniformly. Particles are closely connected with a matrix. The tensile strength is 170MPa and the elongation is 12%. The preparation method is advanced and reasonable in technology and accurate and full in parameter, and is an advanced method for preparing the aluminum base gadolinium oxide neutron absorbing plate.

Owner:TAIYUAN UNIV OF TECH

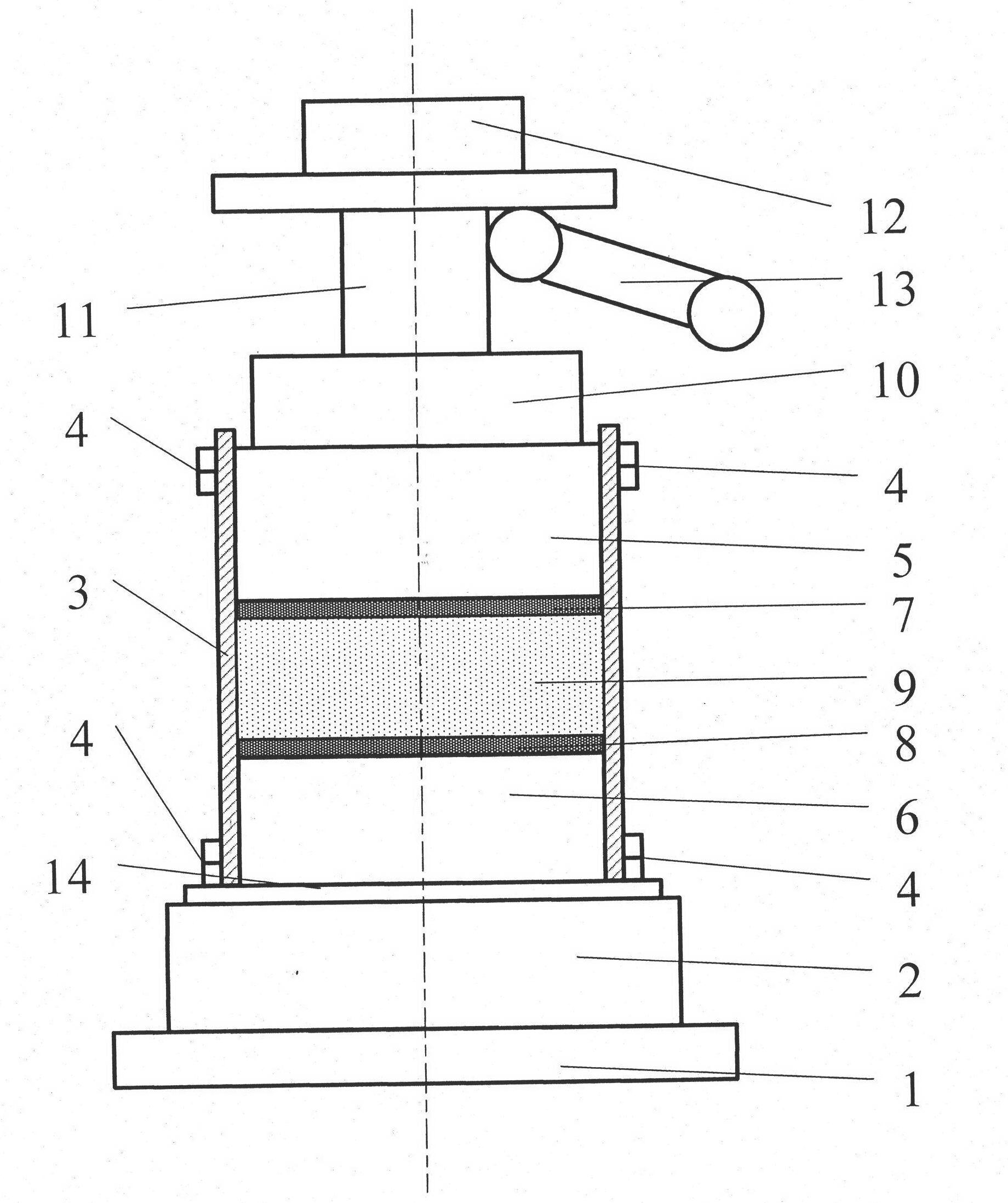

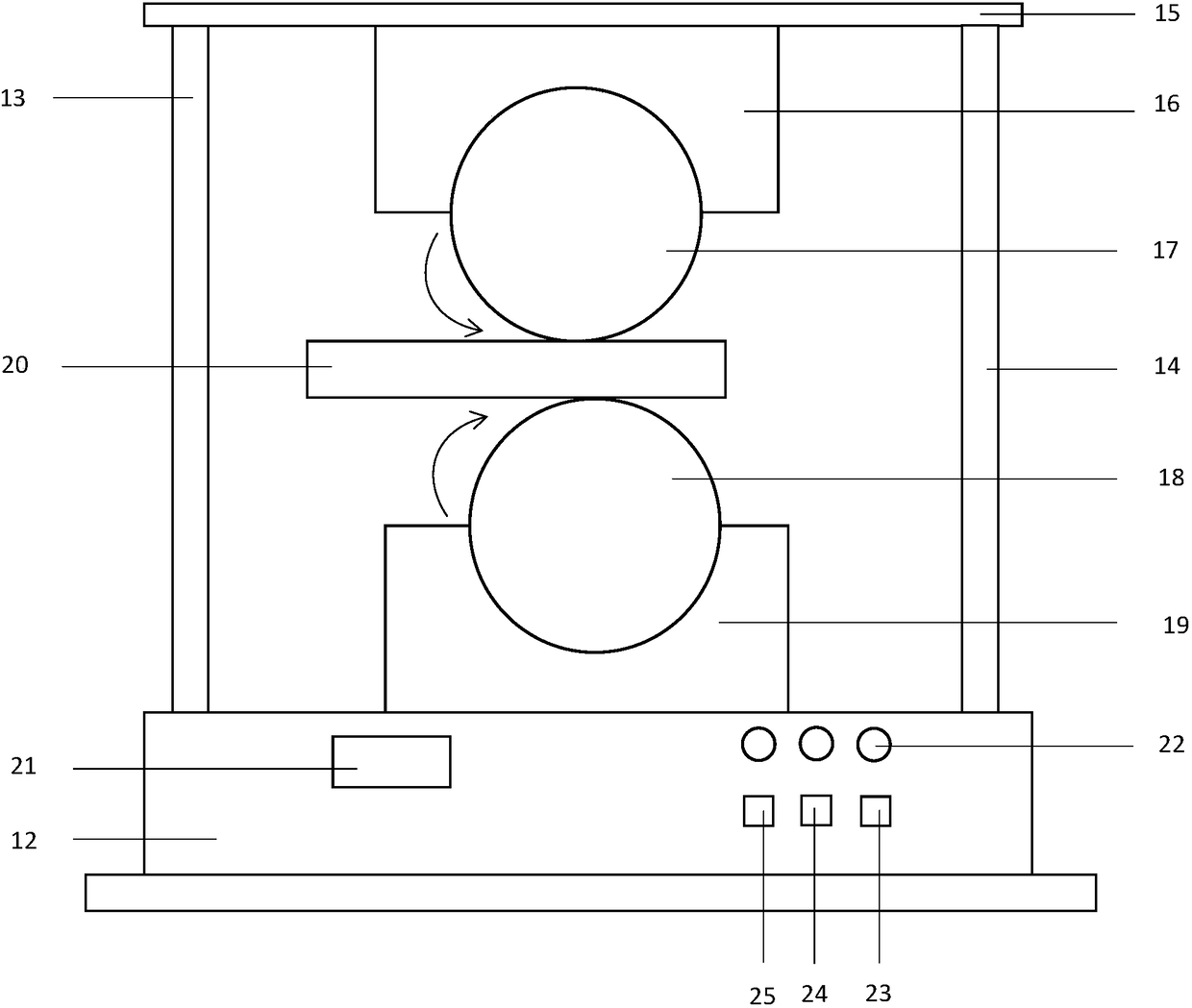

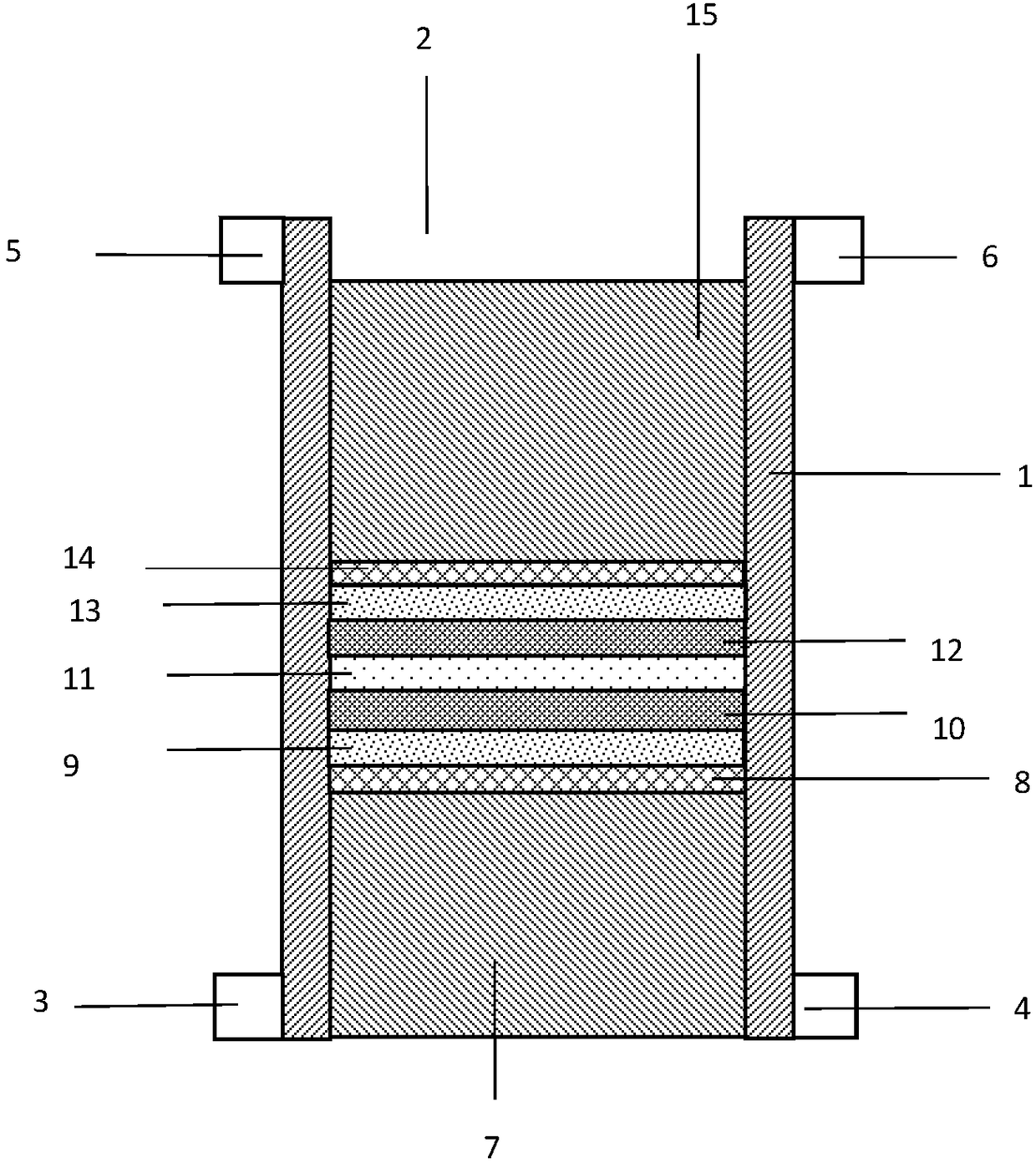

Preparation method for layered aluminum-based neutron absorption plate

The invention relates to a preparation method for a layered aluminum-based neutron absorption plate. The preparation method aims to meet the protection requirement for neutron radiation shielding in aspent fuel storage grillage of a nuclear power station. According to the technical scheme, aluminum powder, boron carbide powder, copper powder, silicon powder, boric acid and carbon fibers are adopted and taken as raw materials, a compact layered aluminum-based neutron absorption plate is manufactured through powder metallurgy blank making and rolling, the neutron absorption plate is silver white, the neutron absorption rate reaches 99%, the interface between all layers is obvious, all the layers are mutually infiltrated, particles are tightly connected with a base body, the tensile strengthreaches 240 MPa, and the elongation is 7%. According to the preparation method, the process is advanced and reasonable, parameters are accurate and detailed, and the preparation method is an advancedmethod for preparing the layered aluminum-based neutron absorption plate.

Owner:TAIYUAN UNIV OF TECH

Coal mine dust removal system and dust removal method

ActiveCN111878153AReasonable matchingReduce volumeHuman health protectionCombination devicesMining engineeringSlag

The invention discloses a coal mine dust removal system and dust removal method. The coal mine dust removal system comprises a trapping device, a pneumatic suction device, an entrainment dust removaldevice, a cyclone separation device, a multi-phase flow division device and a dust exhauster which are connected in sequence, wherein the trapping device, the pneumatic suction device, the entrainmentdust removal device, the cyclone separation device and the multi-phase flow division device are all of tubular structures, every two adjacent devices are integrally connected through a flange, and the pneumatic suction device is connected with a coal mine ventilation pipe through a telescopic hose; a slag discharge port of the multi-phase flow division device is connected with a coal mine slag discharge system through a telescopic pipeline, the entrainment dust removal device is connected with a coal mine water supply system through a hose, and stop valves are arranged on the telescopic hoseand a pipeline of the hose. The coal mine dust removal system is reasonable in unit combination design and small in size, and has the advantages of being small in investment, small in occupied area, low in energy consumption, high in dust removal rate and the like, and the coal mine dust removal method has the advantages of being short in process, low in operation cost and the like.

Owner:DALIAN EAST REFRIGERATION EQUIP

Method for synthesizing N-methylpyrrolidone

ActiveCN101514178BHigh selectivityHigh boiling pointOrganic chemistryMolecular sieve catalystsPtru catalystPyrrolidinones

Owner:MAIQI CHEM CO LTD

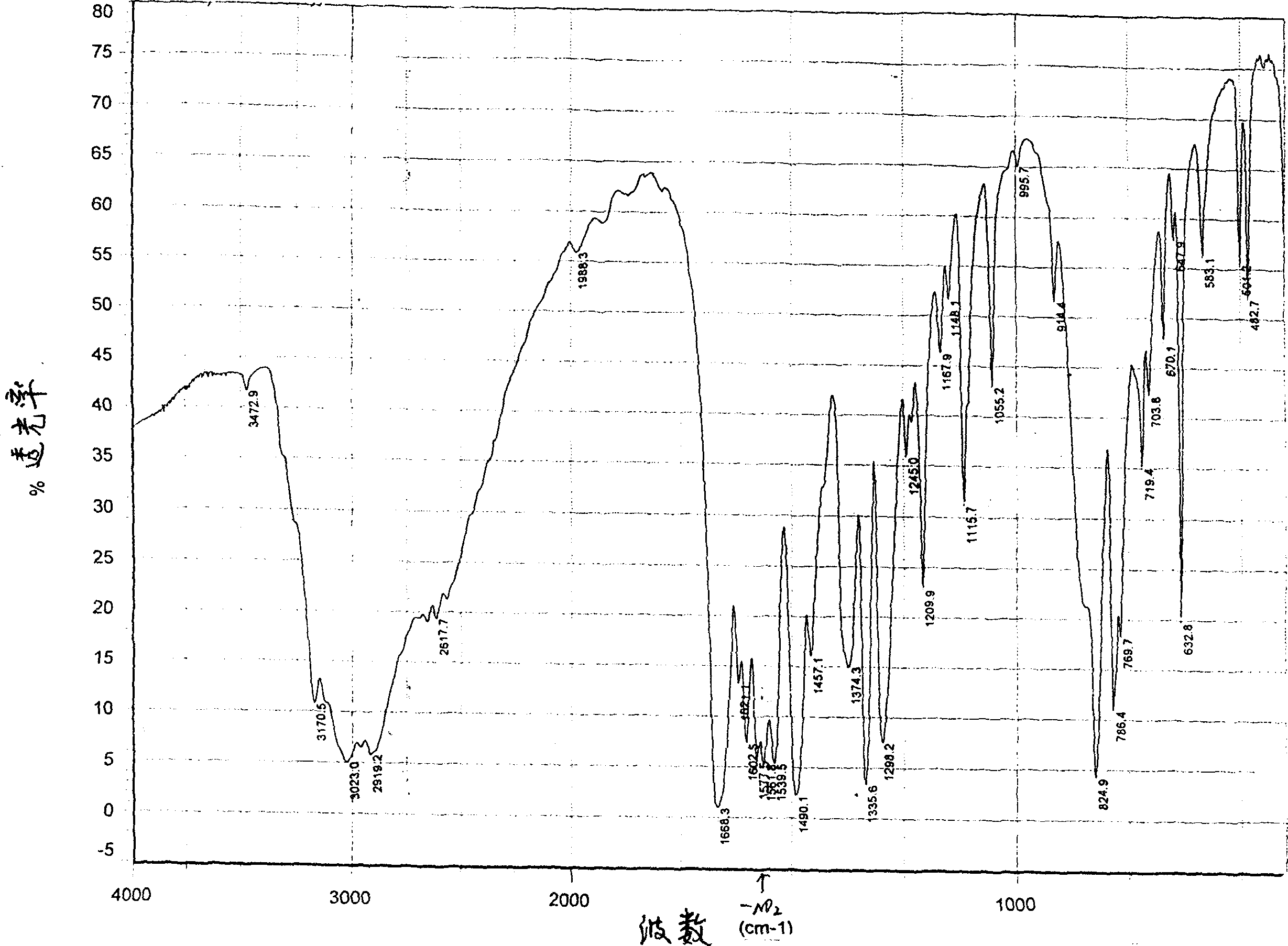

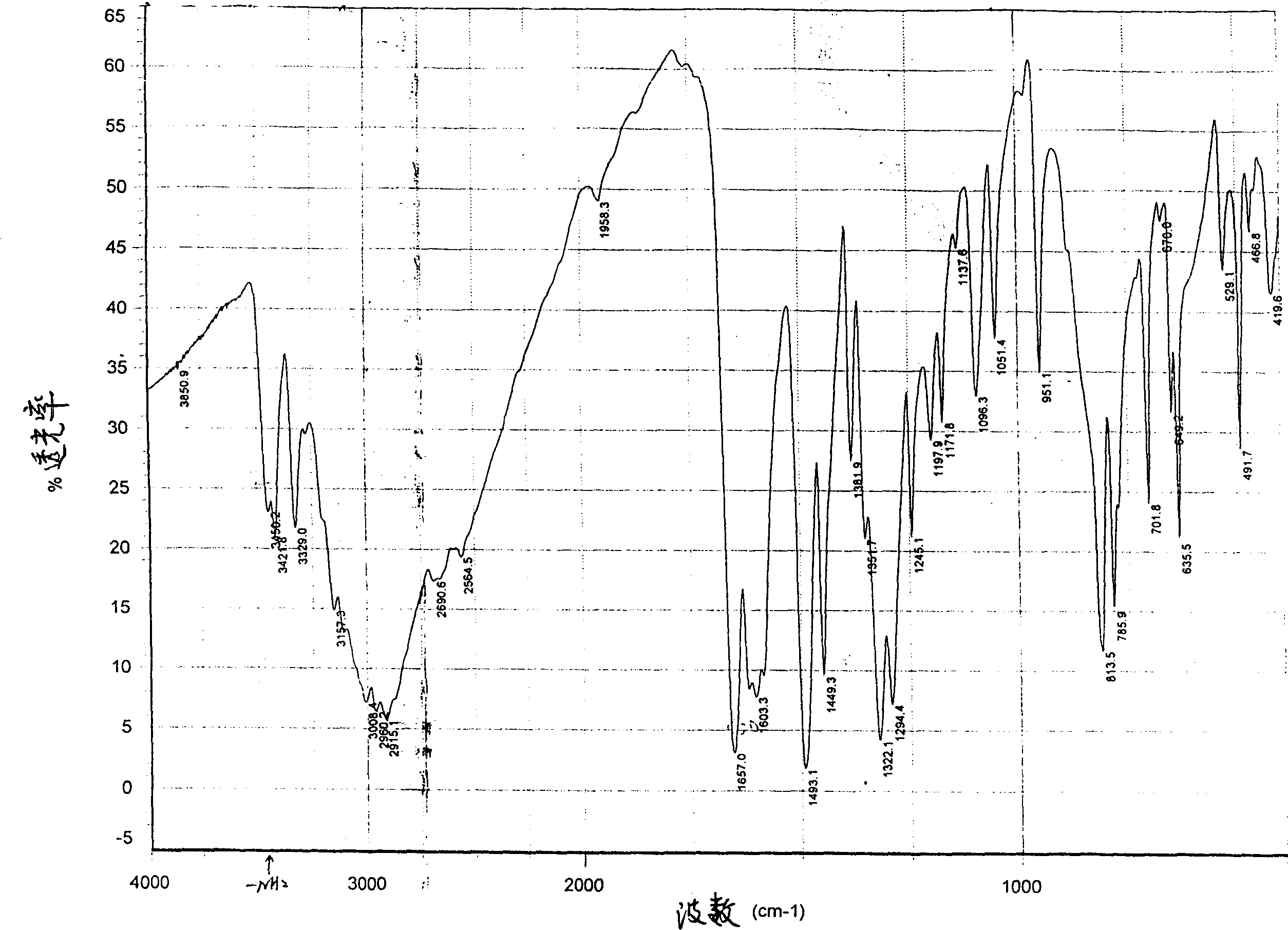

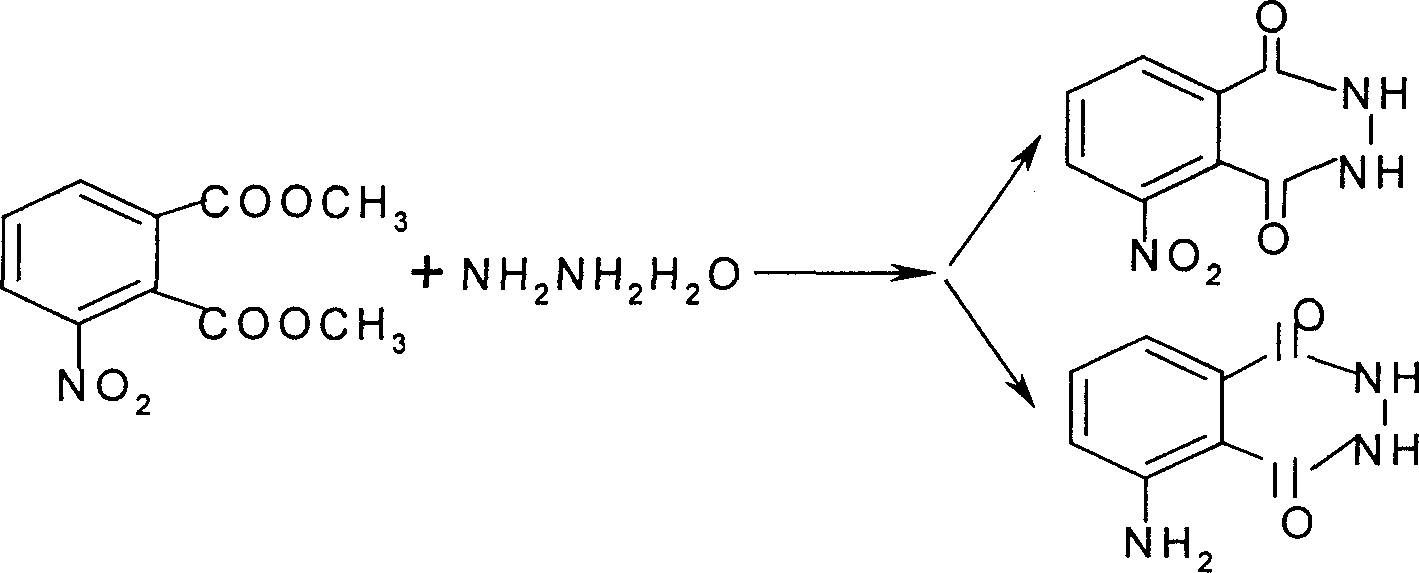

Method for synthesizing 3-nitro or 3-amino phthalyl hydrazine

InactiveCN1821230AAdvanced and reasonable technologySimple and fast operationOrganic chemistryAlcoholHydrazine compound

The method of synthesizing 3-nitro phthalyl hydrazine or 3-amino phthalyl hydrazine is to react 3-nitro dimethyl phthalate and hydrazine hydrate in the weight ratio of 1 to 0.25-1.05 inside ethyl alcohol or methyl alcohol in the amount of 0.8-4 times the weight of 3-nitro dimethyl phthalate at 80-85 deg.c in the presence or absence of catalyst for 2-6 hr before cooling to crystallize and filtering to obtain crude 3-nitro phthalyl hydrazine or 3-amino phthalyl hydrazine product.

Owner:潘健

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com