Coal mine dust removal system and dust removal method

A dust removal system and technology for coal mines, which are applied in drilling, mine safety comprehensive management projects, fully mechanized mining dust removal and tunnel construction, and mine mining fields, can solve the problems of inability to meet safety regulations, large water consumption, and low dust removal efficiency. Achieve the effect of saving transportation equipment, reducing water consumption, and long operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

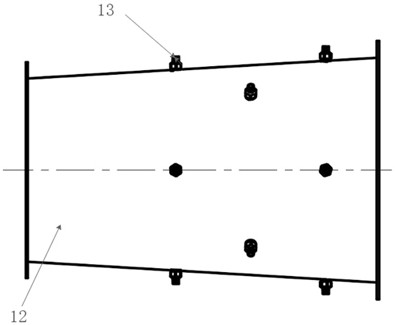

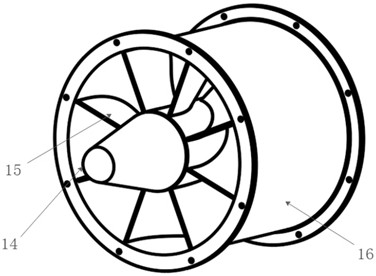

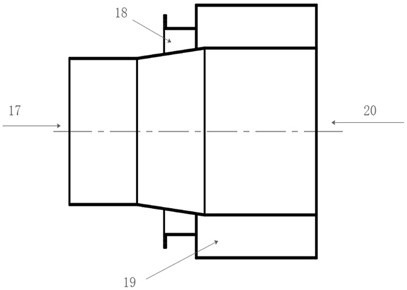

[0041] Such as Figure 1 to Figure 8 As shown, the coal mine dust removal system according to the present embodiment 1 includes a collection device, a pneumatic suction device 2, a mist dust removal device 3, a cyclone separation device 4, a multiphase flow splitting device 5 and a dust collector 6 connected in sequence, The trapping device, the pneumatic suction device 2, the mist dedusting device 3, the cyclone separation device 4 and the multi-phase flow splitting device 5 are all tubular structures and between two adjacent devices It is an integrated structure through flange connection, the pneumatic suction device 2 is softly connected to the coal mine ventilation pipe through a telescopic hose, and the slag discharge port of the multiphase flow diversion device 5 is softly connected to the coal mine slag discharge system through a telescopic pipe , the mist dedusting device 3 is connected to the coal mine water supply system through a hose, and shut-off valves are respec...

Embodiment 2

[0057] According to the coal mine dedusting method of present embodiment 2, may further comprise the steps:

[0058] Step (1) Move the construction equipment carrying the coal mine dust removal system to the working area, and place the capture device in the designated dust removal area through the telescopic pipe;

[0059] Step (2) Open the nozzle 13 of the mist dust removal device 3 and the valve of the shut-off valve of the coal mine water supply system;

[0060] Step (3) Gradually open the coal mine ventilation pipe of the coal mine ventilation system and the cut-off valve of the ejector 1 in the pneumatic suction device 2, start the ejector 1, and the dust-laden gas enters the pneumatic suction device 2 through the suction chamber;

[0061] Step (4) The water curtain formed by the nozzle 13 of the mist dedusting device 3 absorbs, wets, and condenses the dust in the dusty gas, depressurizes at the outlet of the mist dedusting device 3 , and accelerates into the cyclone sepa...

Embodiment 3

[0069] The coal mine dedusting system of this embodiment 3 is applied to a certain coal mine working face for dedusting, and the conditions of the working face are:

[0070] Table 1 Working face environmental conditions of the present embodiment 3

[0071]

[0072] By calculating the air volume of the working face, the coal mine dust removal system composed of four pneumatic suction devices 2 is selected to deal with the working flour dust.

[0073]When in use, place the collector on the designated dust removal work surface through the telescopic pipe, and connect the coal mine dust removal system with the coal mine air supply and water supply system pipes; after opening the nozzle 13 of the mist dust removal device 3 and the coal mine supply water valve, gradually open The shut-off valve of the ejector 1 of the coal mine ventilation system and the pneumatic suction device 2, the high-pressure air of the coal mine ventilation is introduced into the pneumatic suction device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com