Patents

Literature

138results about How to "Improve coalescence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wet-skin treatment compositions

InactiveUS6645511B2Better behavedFast absorptionCosmetic preparationsToilet preparationsSkin treatmentsDermatology

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

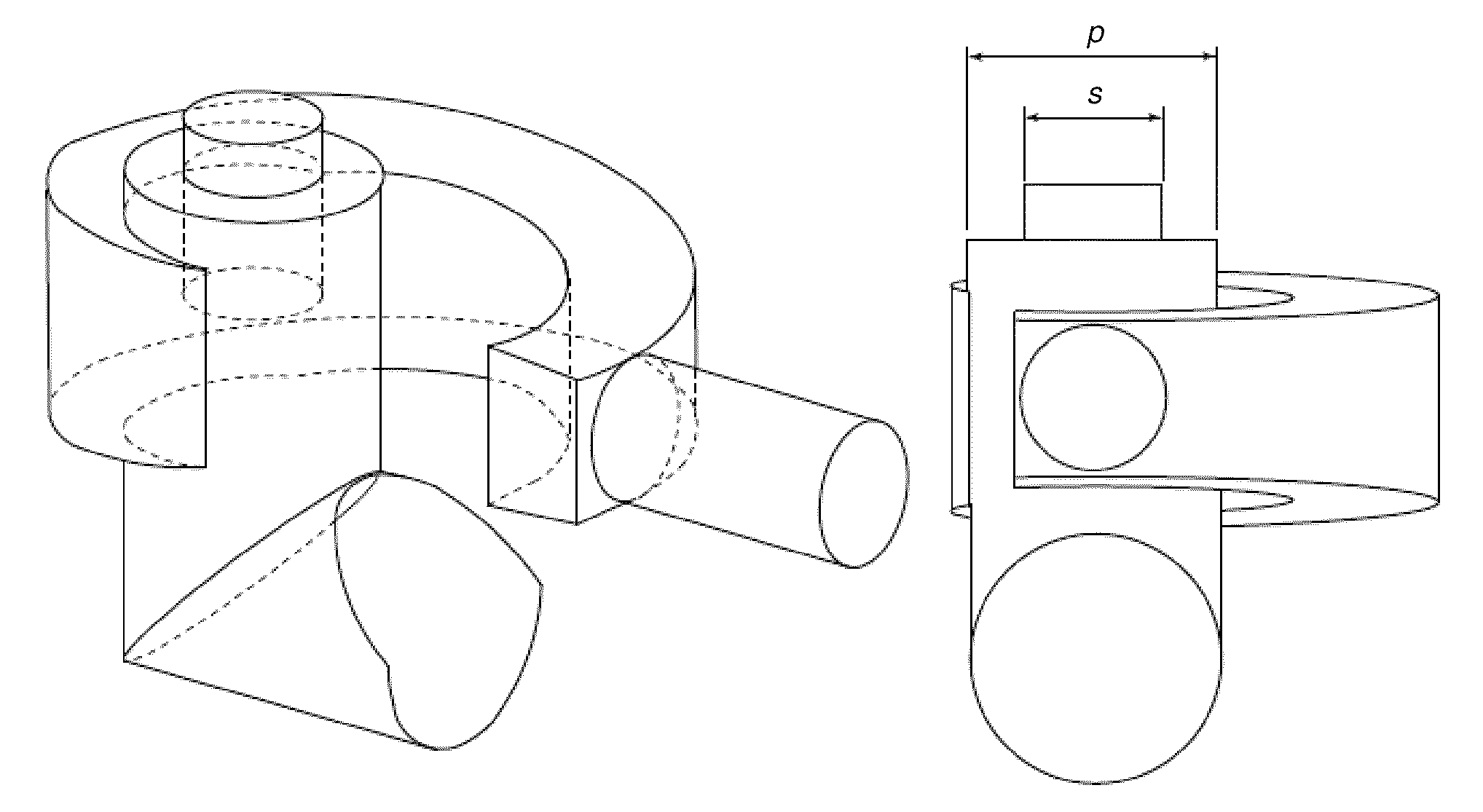

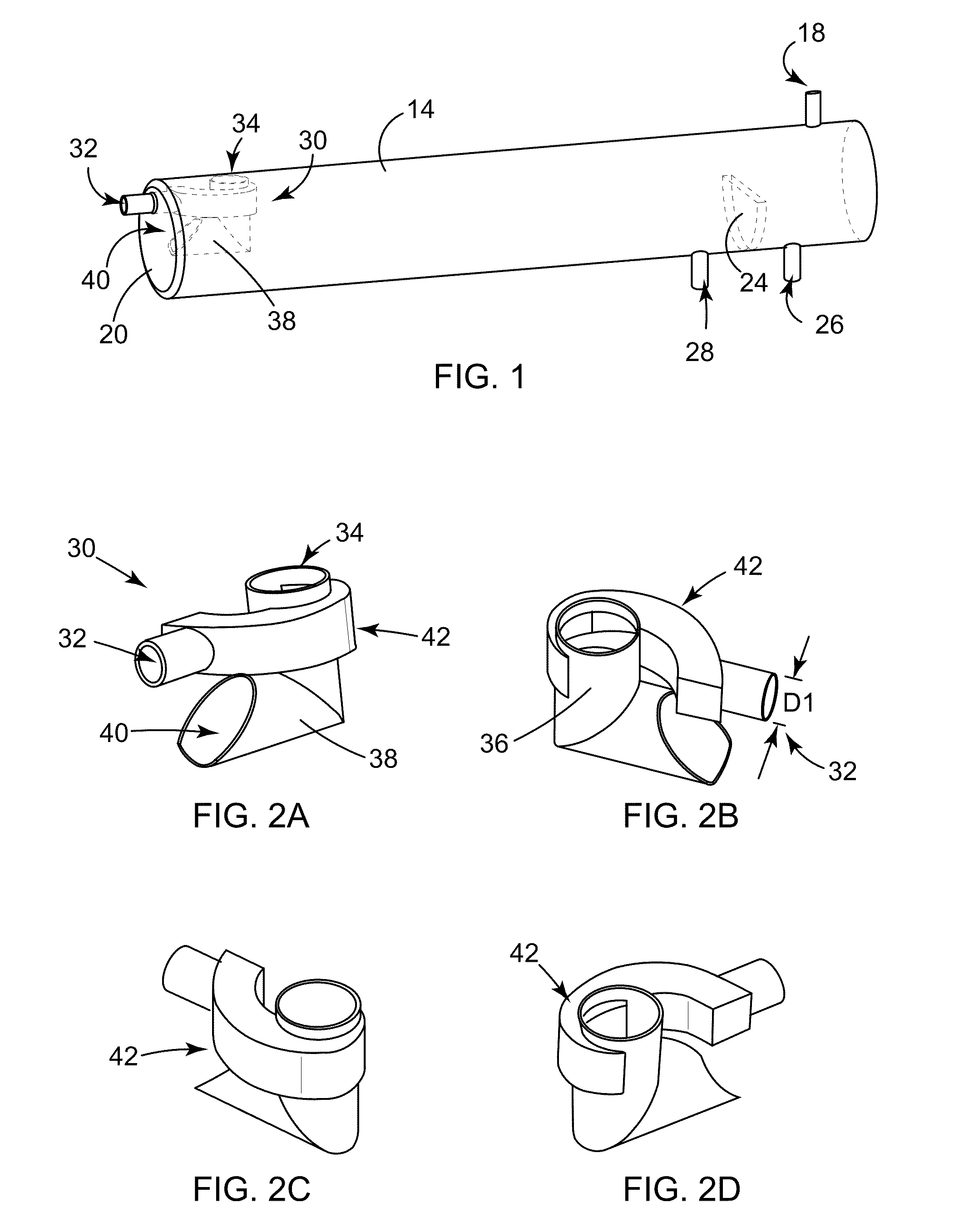

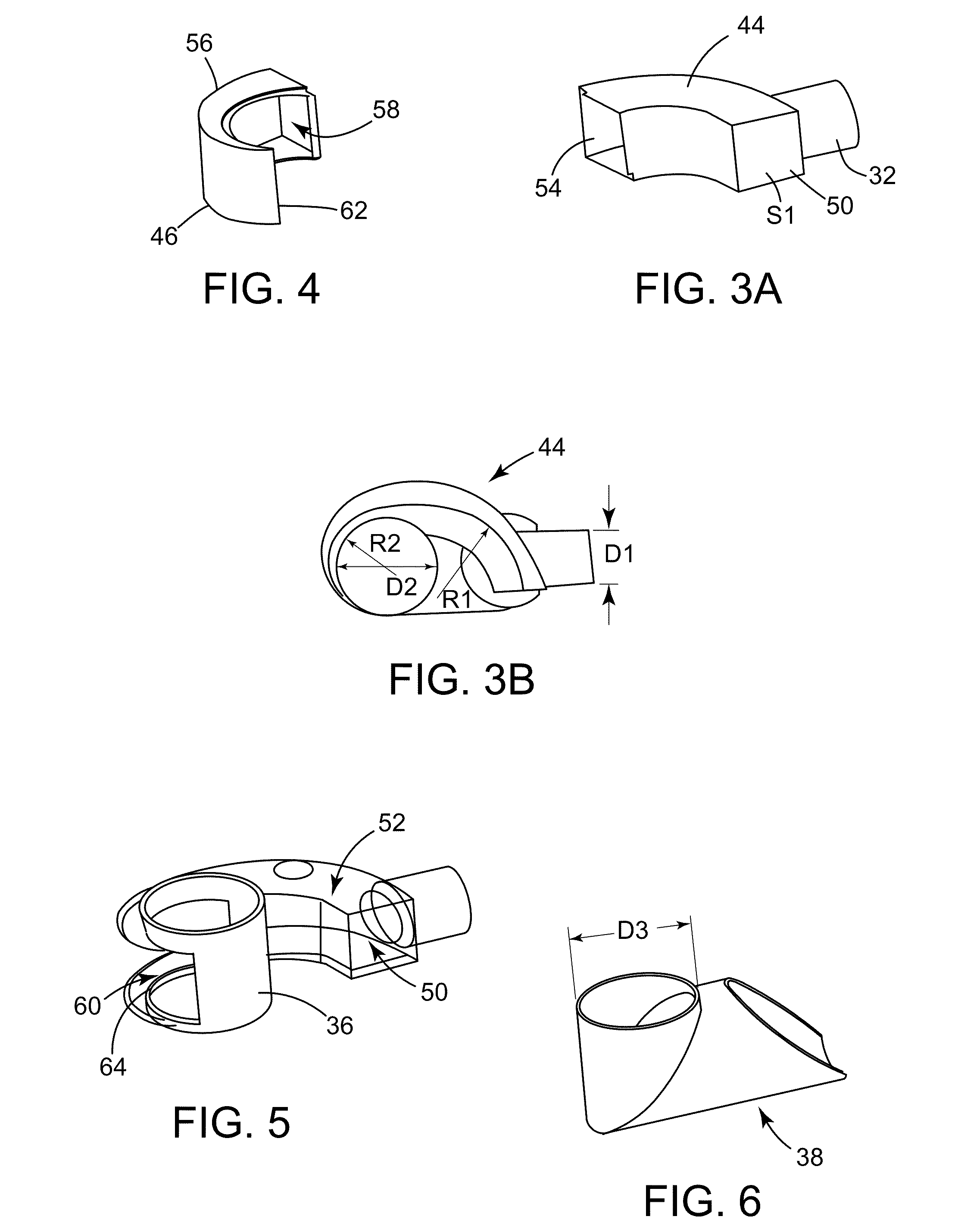

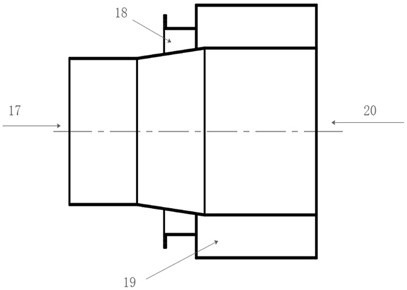

Apparatus for separation of gas-liquid mixtures and promoting coalescence of liquids

ActiveUS20110247500A1Reduce momentumPromote droplet coalescenceLiquid degasificationReversed direction vortexChemical physicsOil separation

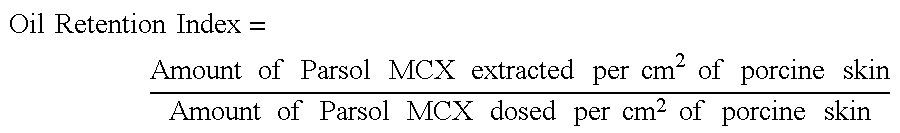

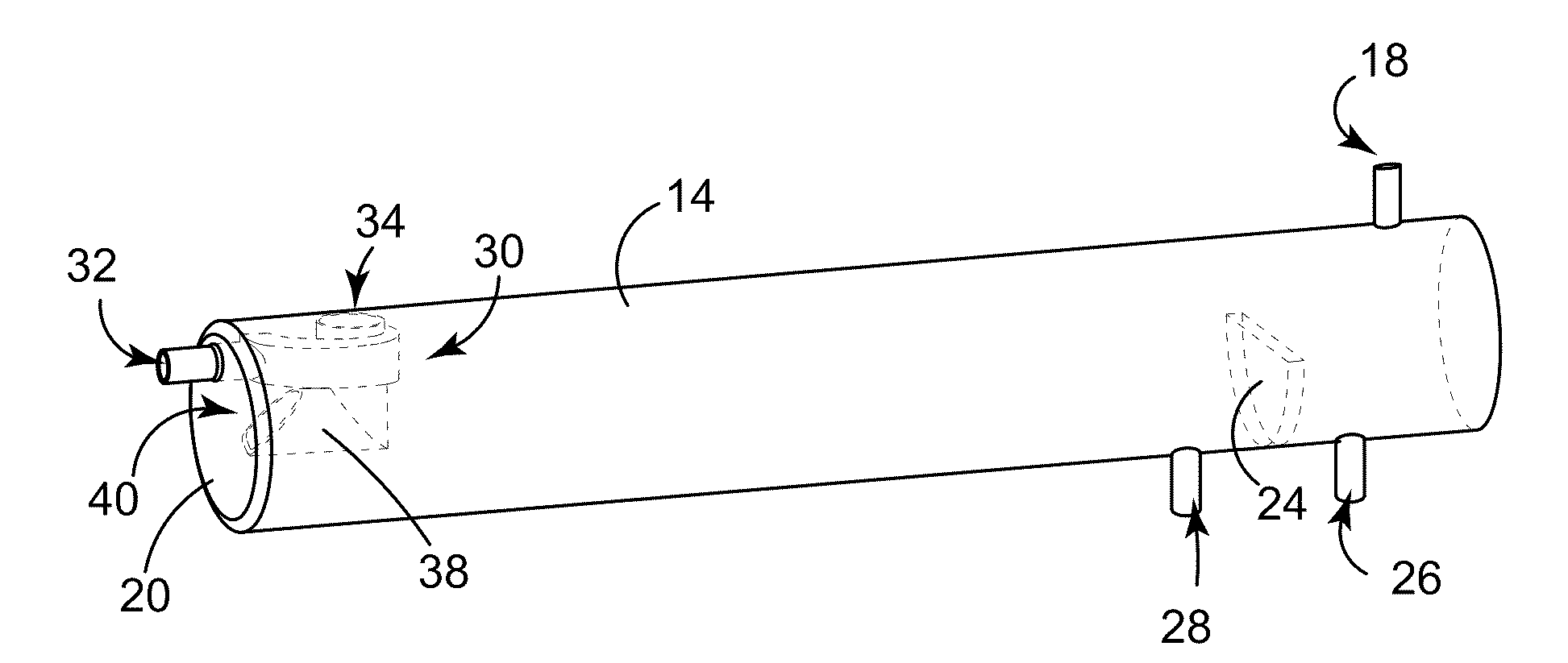

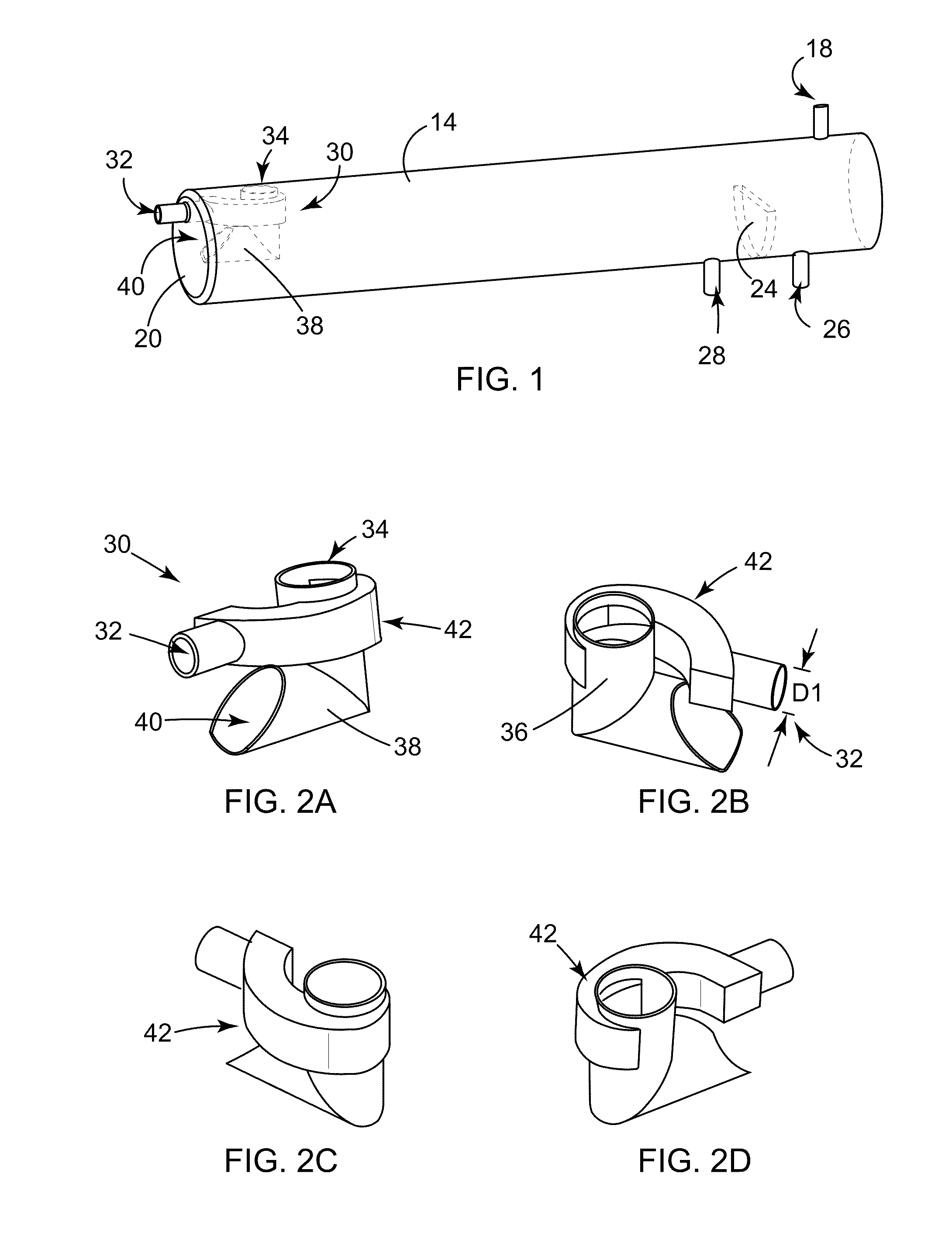

Provided herein is a conditioning apparatus that includes a geometrical configuration having an inlet flow deceleration conduit and a cyclonic tube to effectuate both liquid-gas separation and droplet coalescence. The apparatus is typically positioned at the inlet of a separator vessel used for removing water and gas from extracted crude oil containing entrained water and gas. The apparatus promotes droplet coalescence and gas separation for mixed fluids flowing into an existing water and oil separation device.

Owner:SAUDI ARABIAN OIL CO

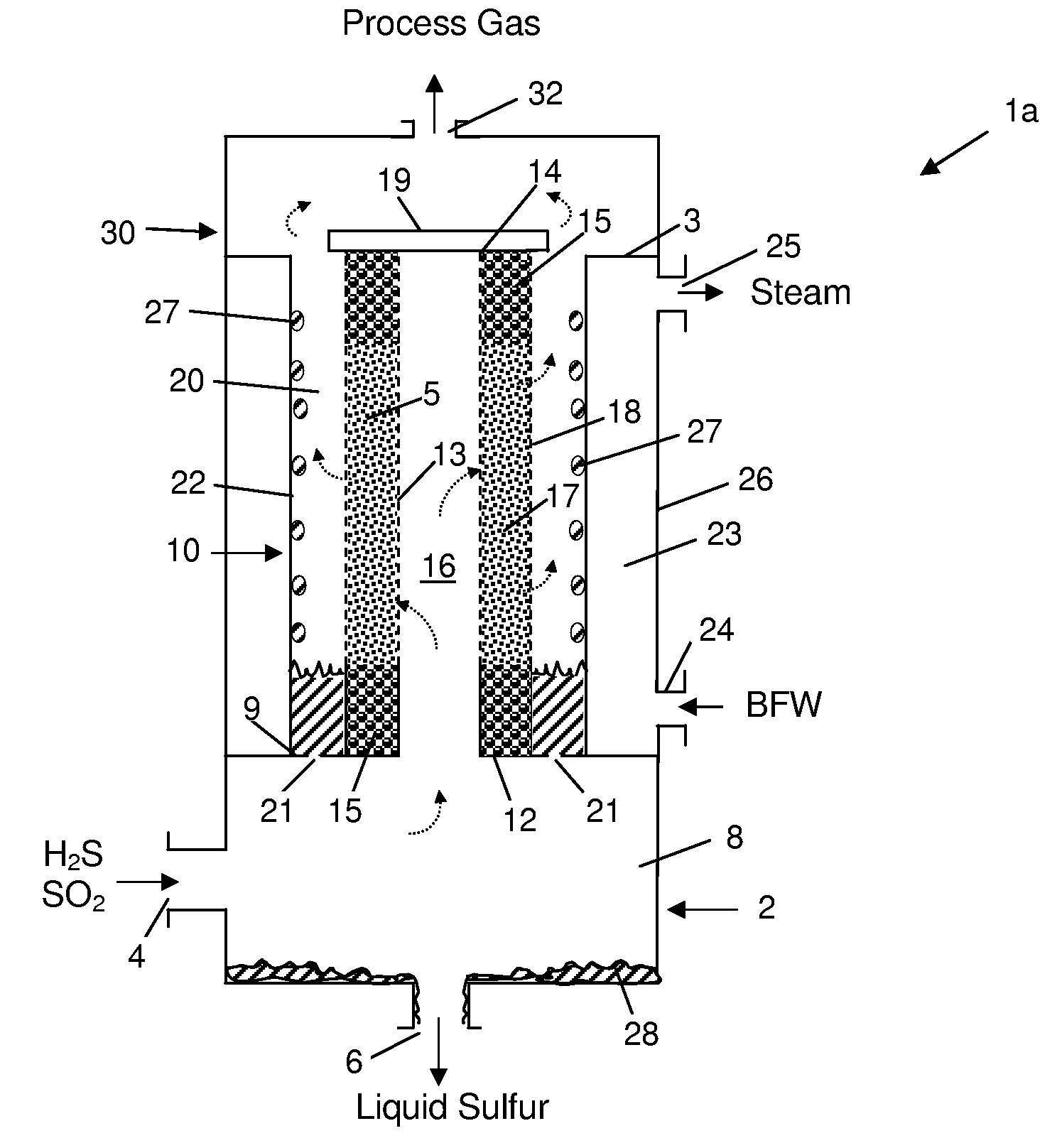

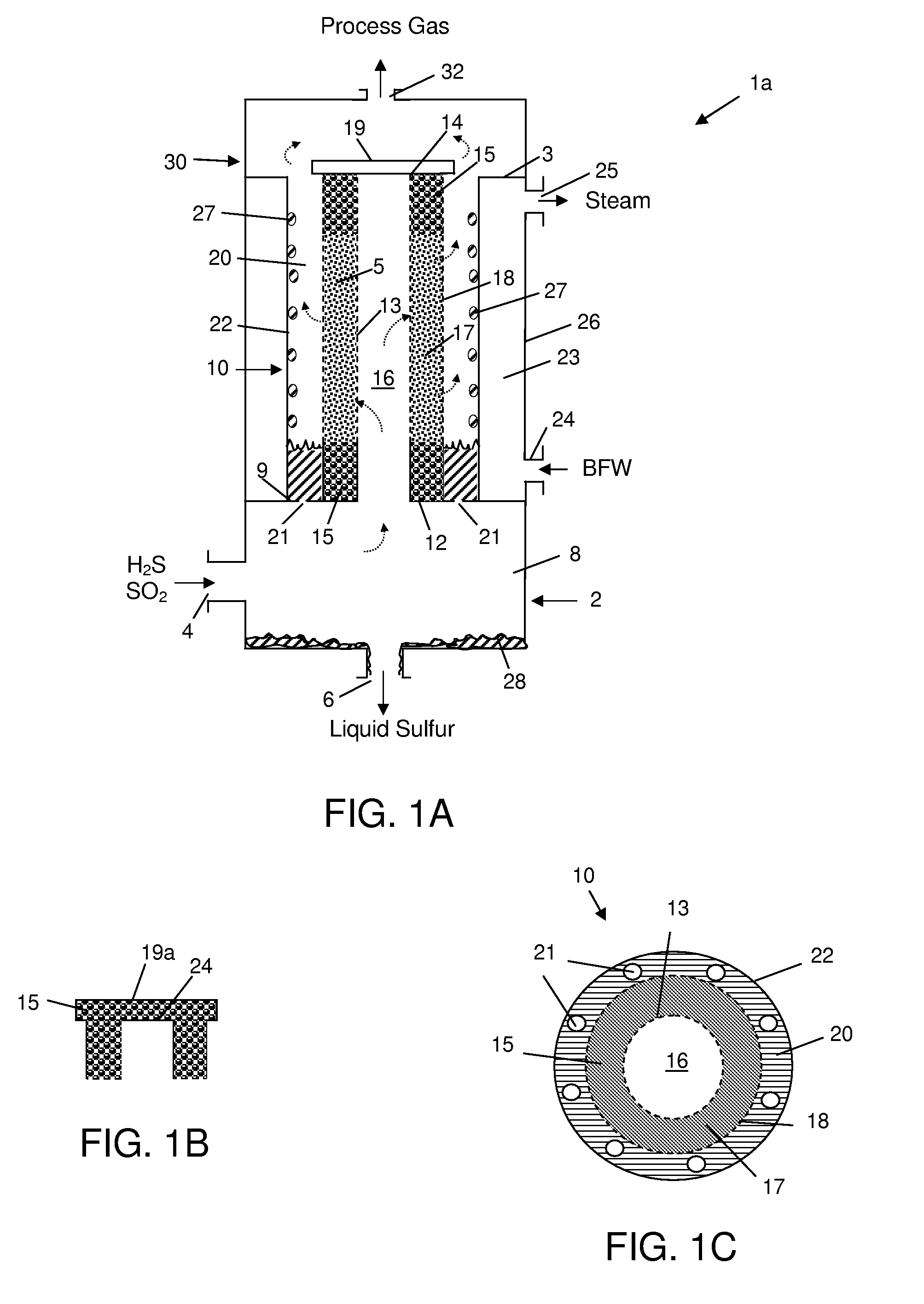

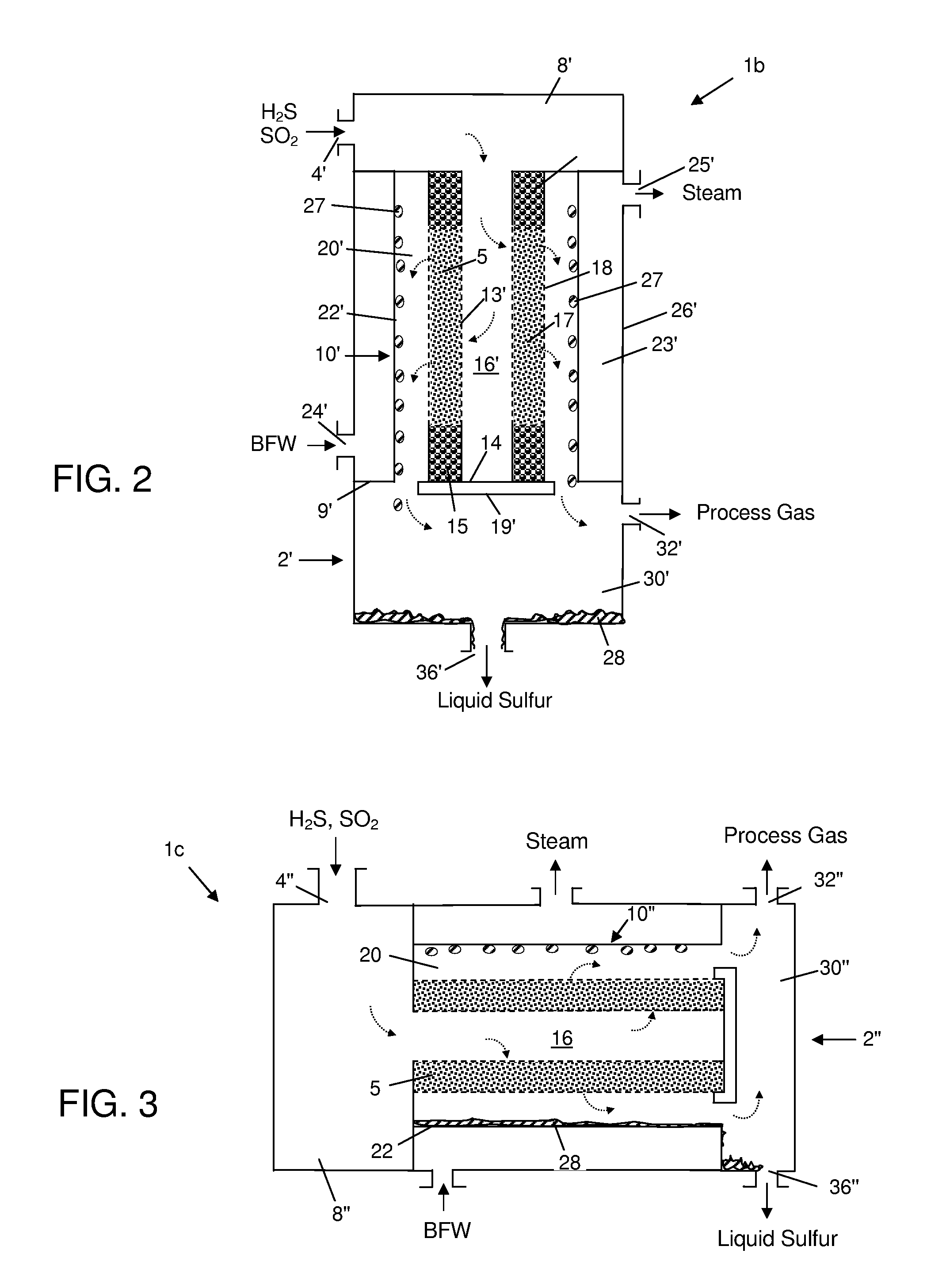

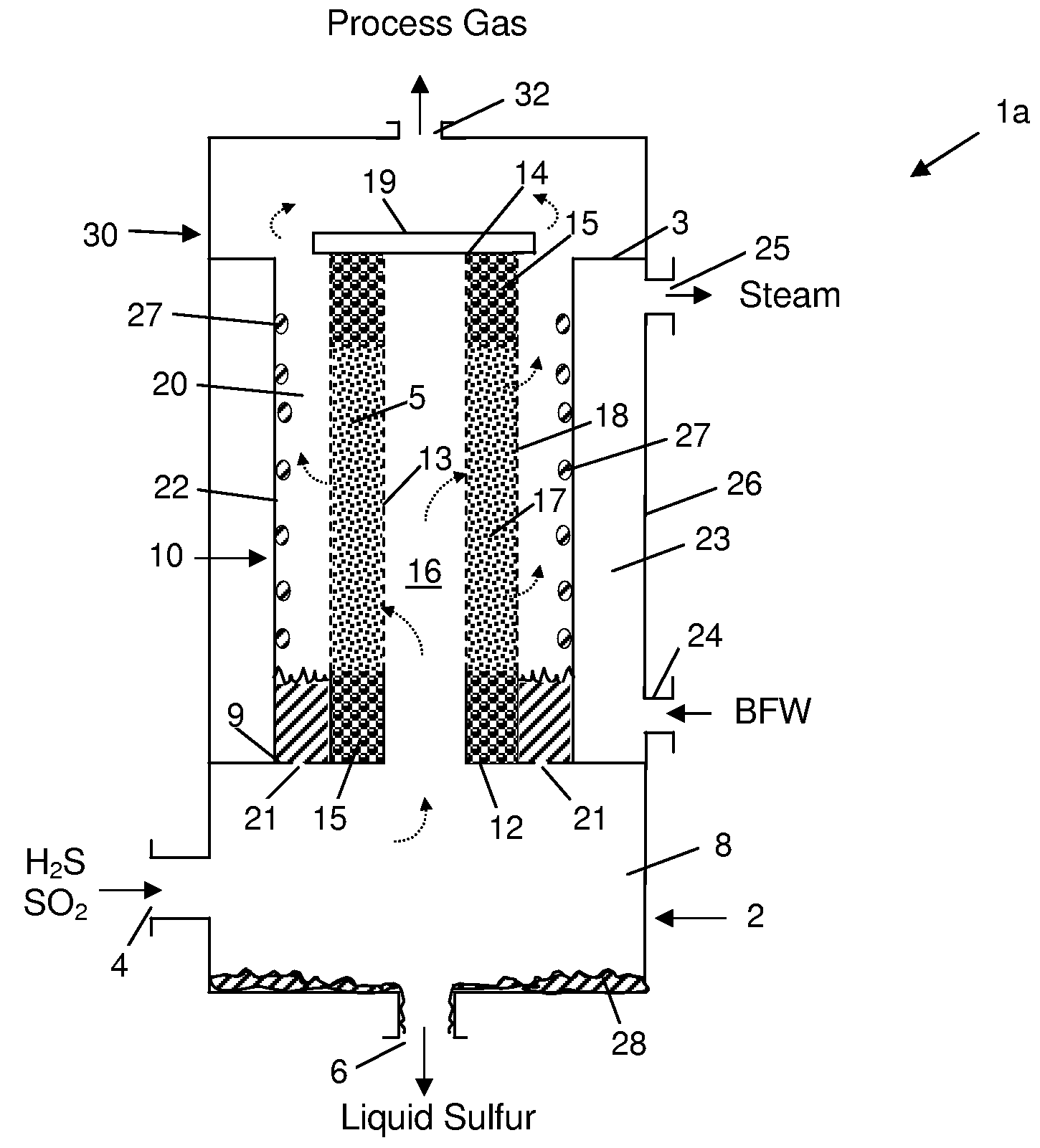

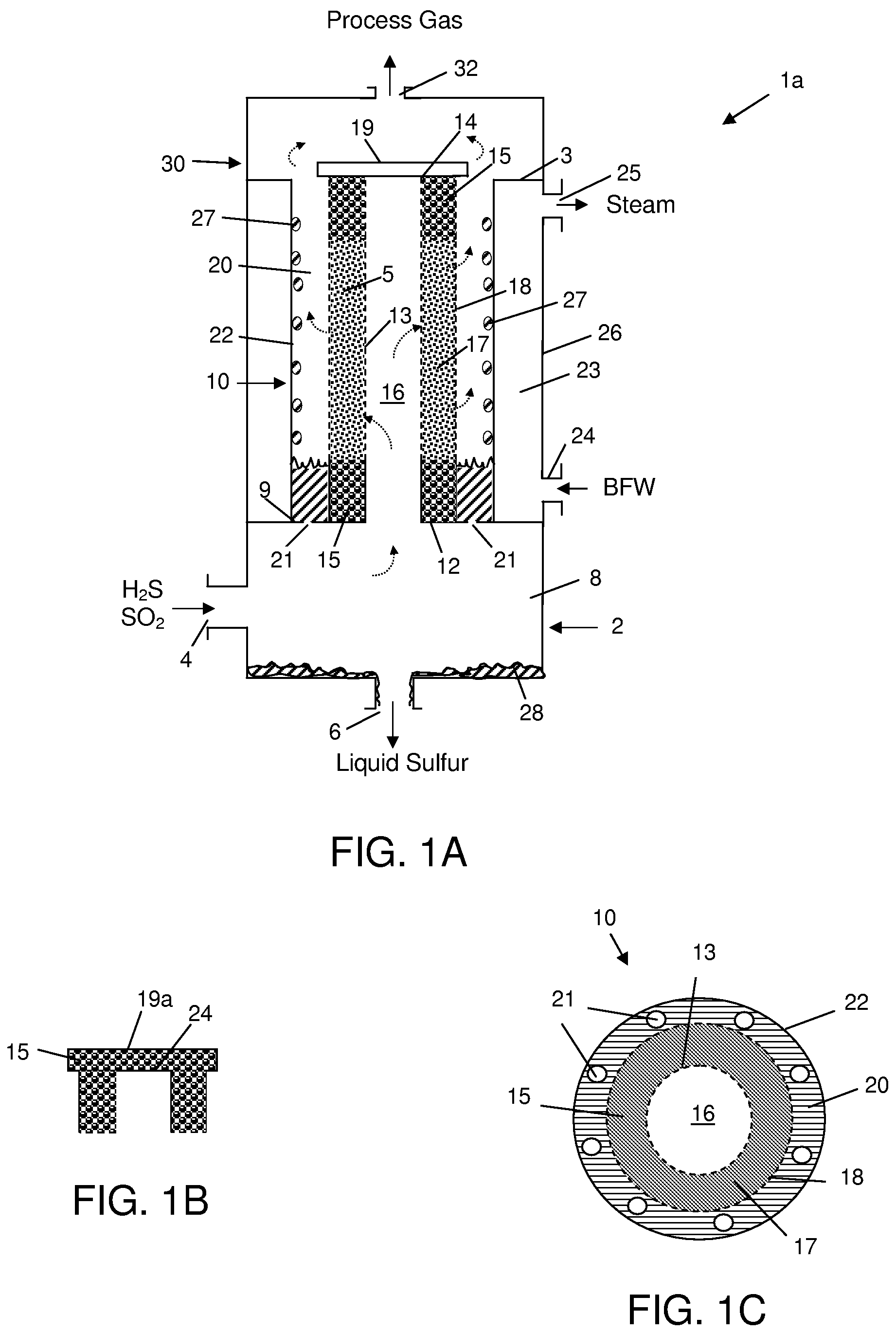

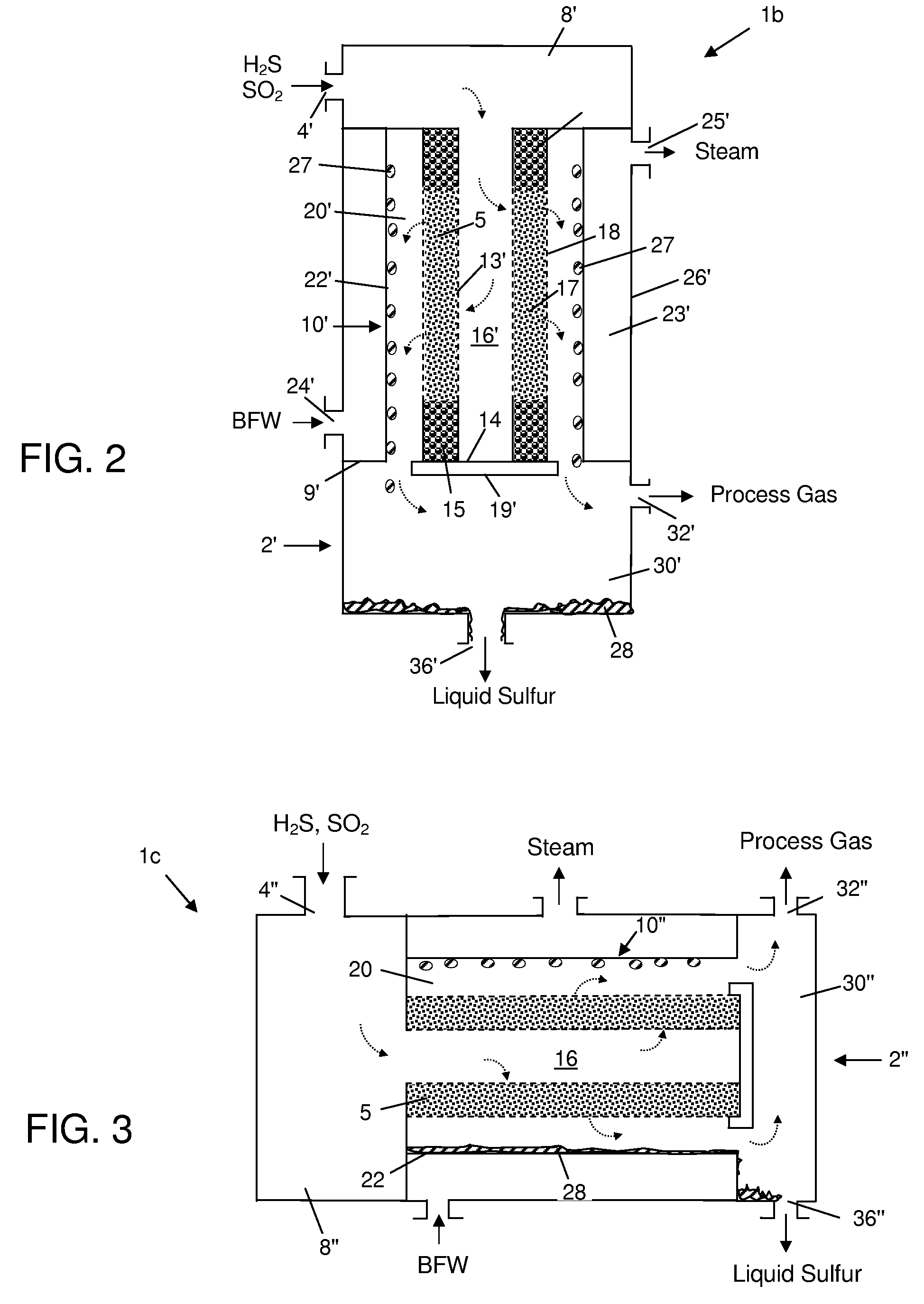

Increased Capacity Sulfur Recovery Plant and Process for Recovering Elemental Sulfur

ActiveUS20080050306A1Eliminate needIncreasing sulfur recovery capacityCombination devicesTeeth fillingSingle stageMicro heat exchanger

Claus sulfur recovery plants that include one or more single-stage or multi-stage compact tubular Claus catalytic reactor-heat exchanger units are disclosed. In some instances, these new or improved Claus plants additionally include one or more compact heat exchanger containing cooling tubes that are filled with a heat transfer enhancement medium. The new compact tubular Claus catalytic reactor-heat exchanger units and HTEM-containing heat exchangers are also disclosed. A process for recovering sulfur from a hydrogen sulfide-containing gas stream, employing the new tubular Claus catalytic reactor-heat exchanger unit, and in some instances a HTEM-containing heat exchanger, are also disclosed.

Owner:PHILLIPS 66 CO

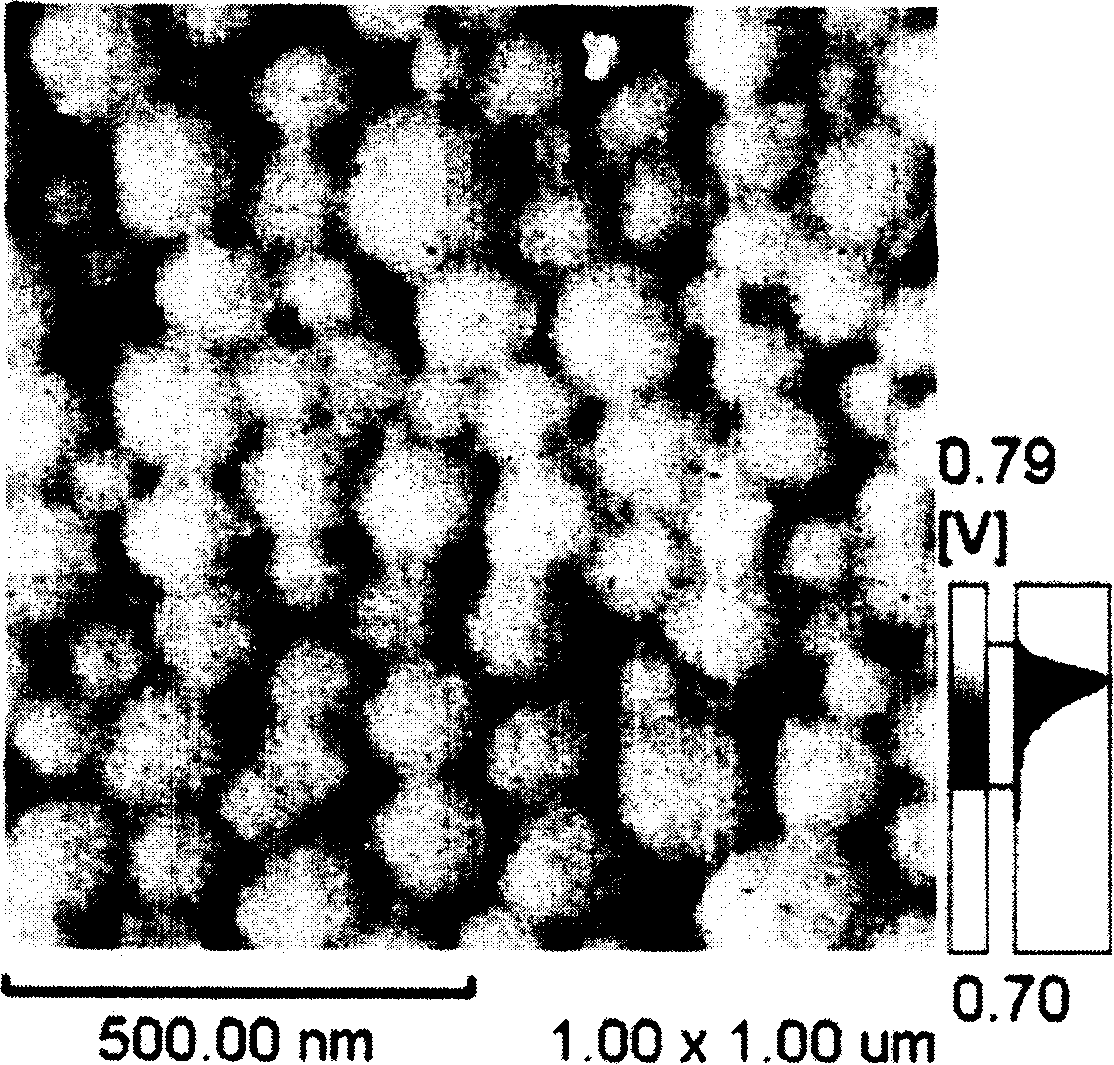

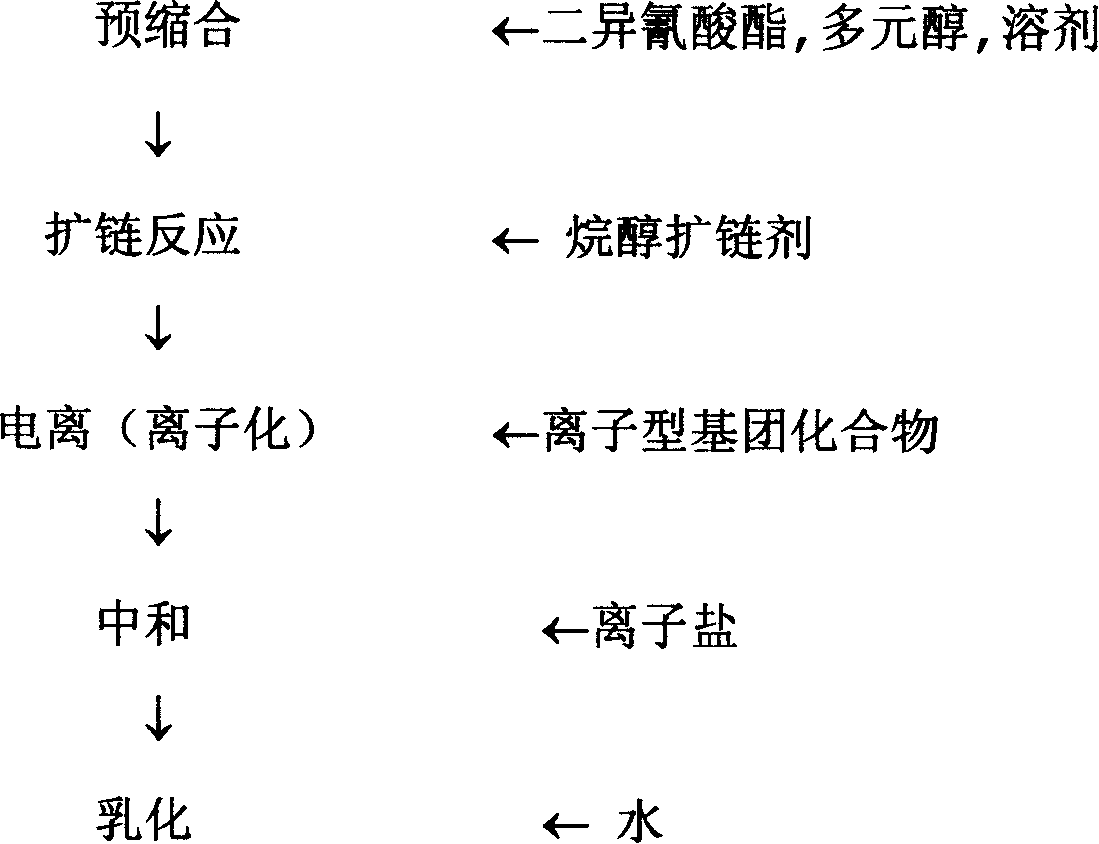

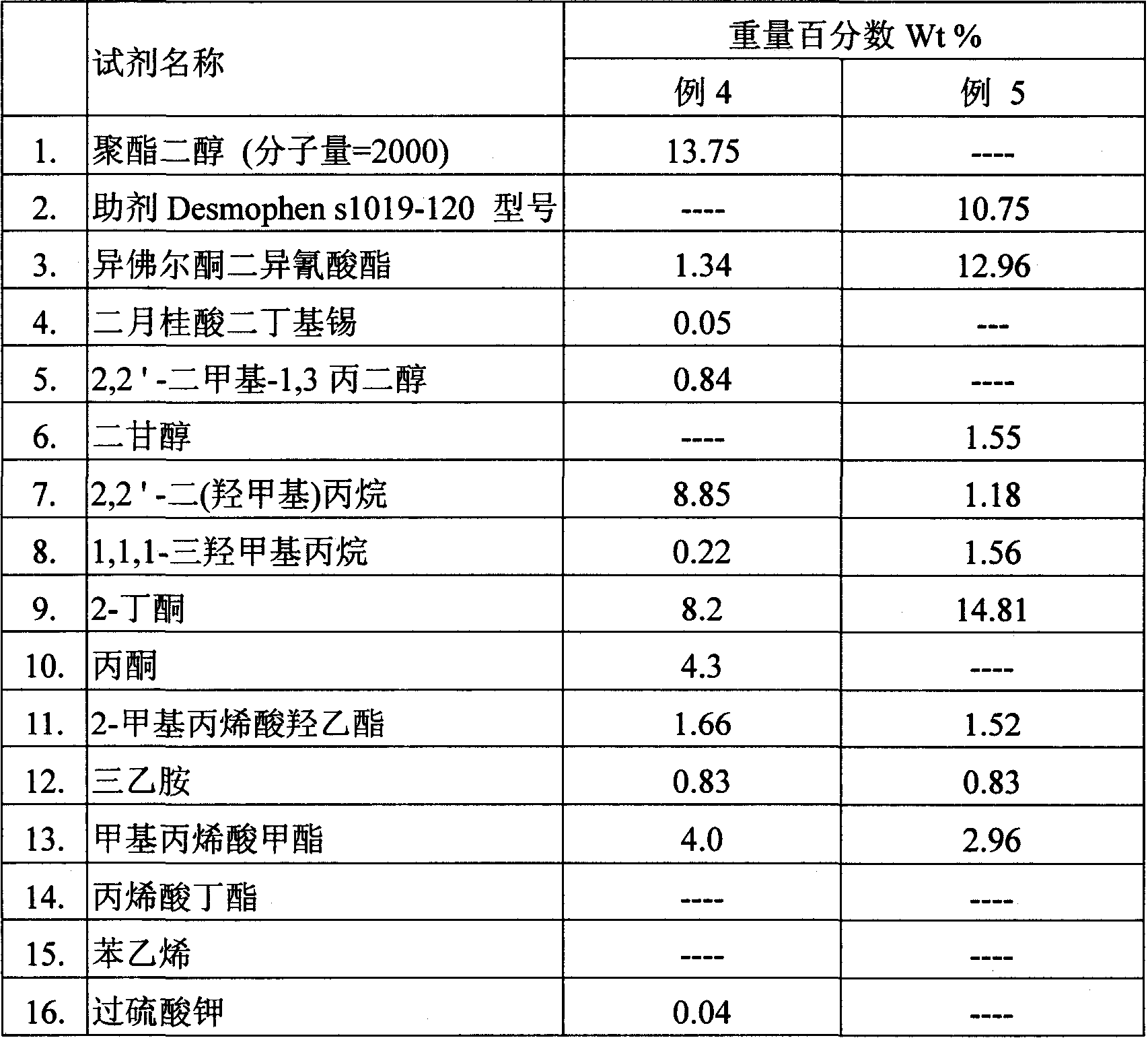

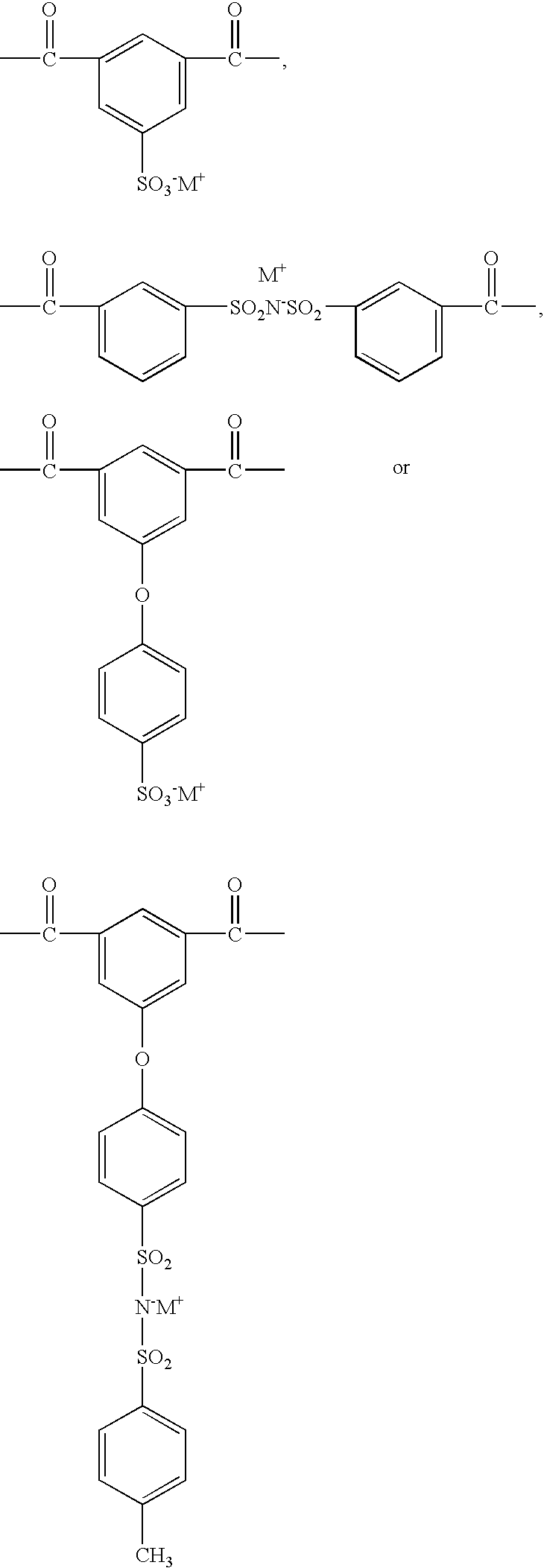

Polyurethane-acrylic ester composite emulsion and preparation method thereof

InactiveCN101165075AWide range of applicationsImprove water resistanceCoatingsCross-linkMethacrylate

The present invention provides one kind of polyurethane-acrylate composite emulsion and its preparation process. The preparation process includes preparing water soluble polyurethane seed emulsion, and adding methacrylate and cross-linking agent to the seed emulsion to prepare interpenetrating polymer network polyurethane-acrylate composite emulsion. The polyurethane-acrylate composite emulsion contains solid material in 20-60 wt%, and has particle diameter of 10-100 nm. The preparation process is simple, and the prepared polyurethane-acrylate composite emulsion has high quality, especially excellent water resistance, heat resistance, chemical resistance and wear resistance, and wide application range.

Owner:HONG KONG PRODUCTIVITY COUNCIL

Increased capacity sulfur recovery plant and process for recovering elemental sulfur

ActiveUS7501111B2Increasing sulfur recovery capacityLow costCombination devicesTeeth fillingPlate heat exchangerSingle stage

Owner:PHILLIPS 66 CO

Apparatus for separation of gas-liquid mixtures and promoting coalescence of liquids

ActiveUS8337603B2Promotes coalescenceEasy to separateLiquid degasificationReversed direction vortexChemical physicsOil separation

Provided herein is a conditioning apparatus that includes a geometrical configuration having an inlet flow deceleration conduit and a cyclonic tube to effectuate both liquid-gas separation and droplet coalescence. The apparatus is typically positioned at the inlet of a separator vessel used for removing water and gas from extracted crude oil containing entrained water and gas. The apparatus promotes droplet coalescence and gas separation for mixed fluids flowing into an existing water and oil separation device.

Owner:SAUDI ARABIAN OIL CO

Aqueous pigmented ink formulation containing polymer-encapsulated pigments, binder and smectite clay particles

An ink jet ink composition comprising from about 30 to about 90% by weight of water, from about 0.5 to about 30% by weight of a composite colorant, from about 0.1 to about 10% by weight of natural or synthetic smectite clay mineral, and from about 10 to about 50% by weight of a humectant comprising a polyhydric alcohol or a nitrogen-containing cyclic compound.

Owner:MCCOVICK TAMMY A

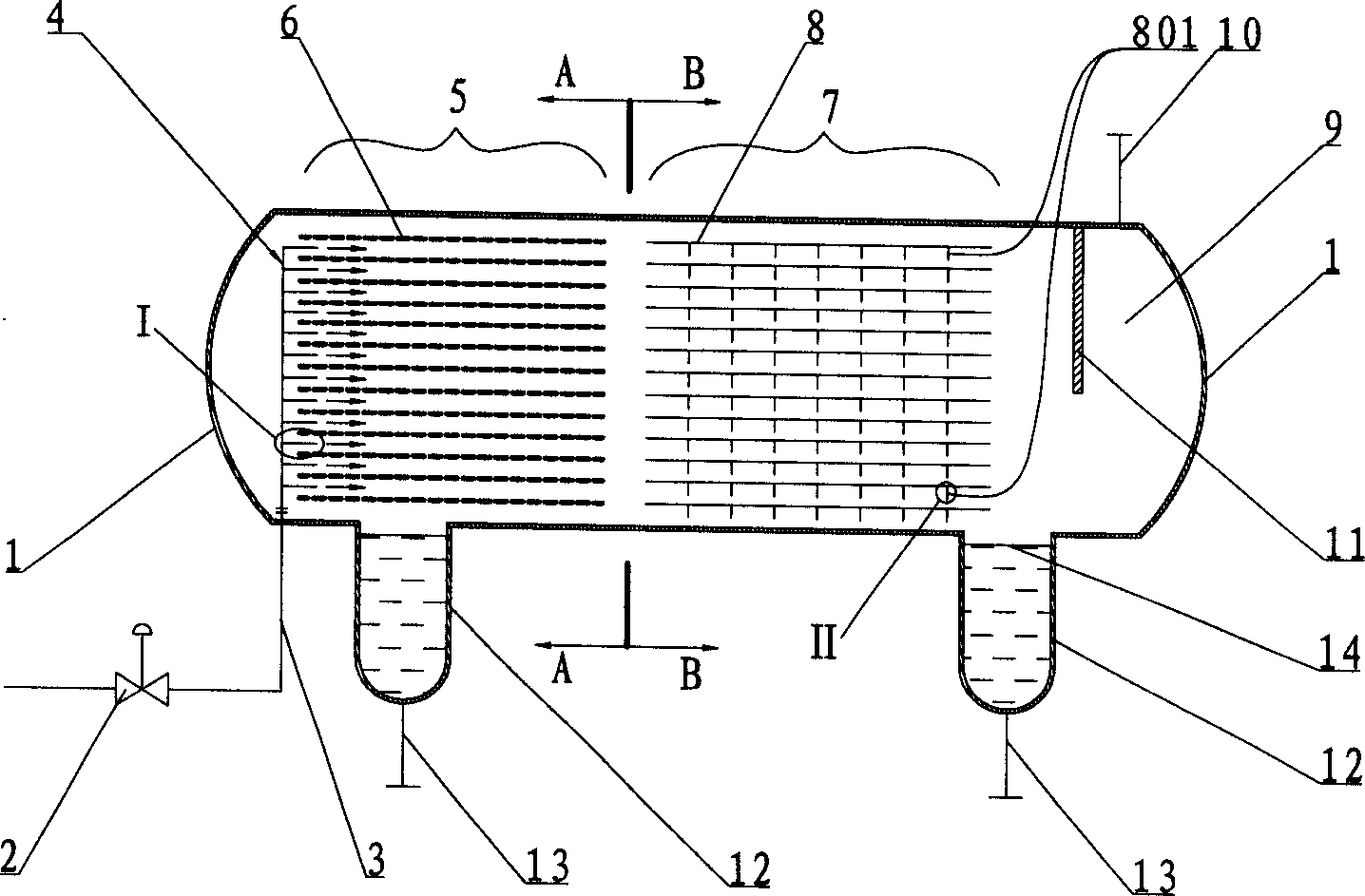

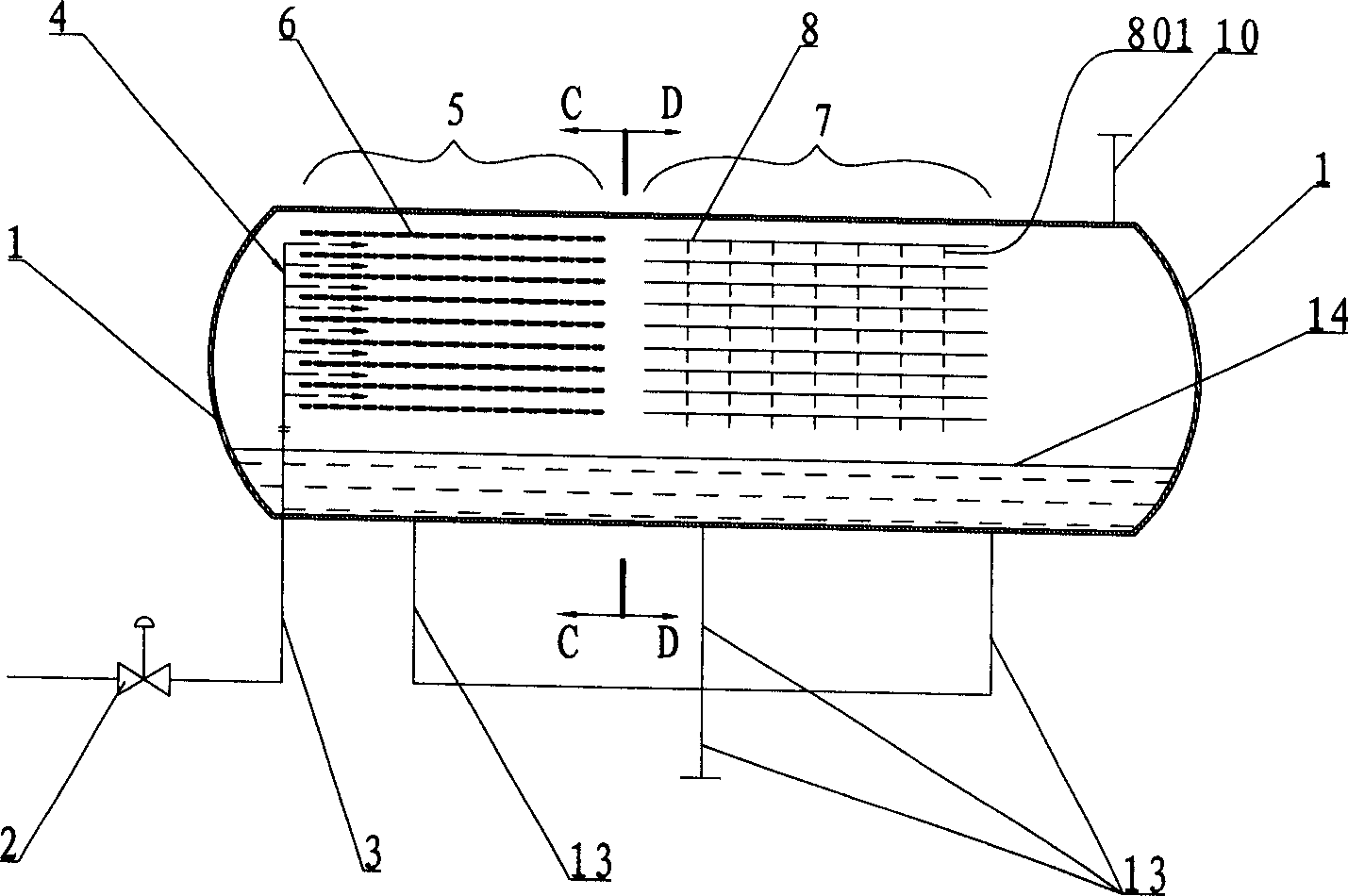

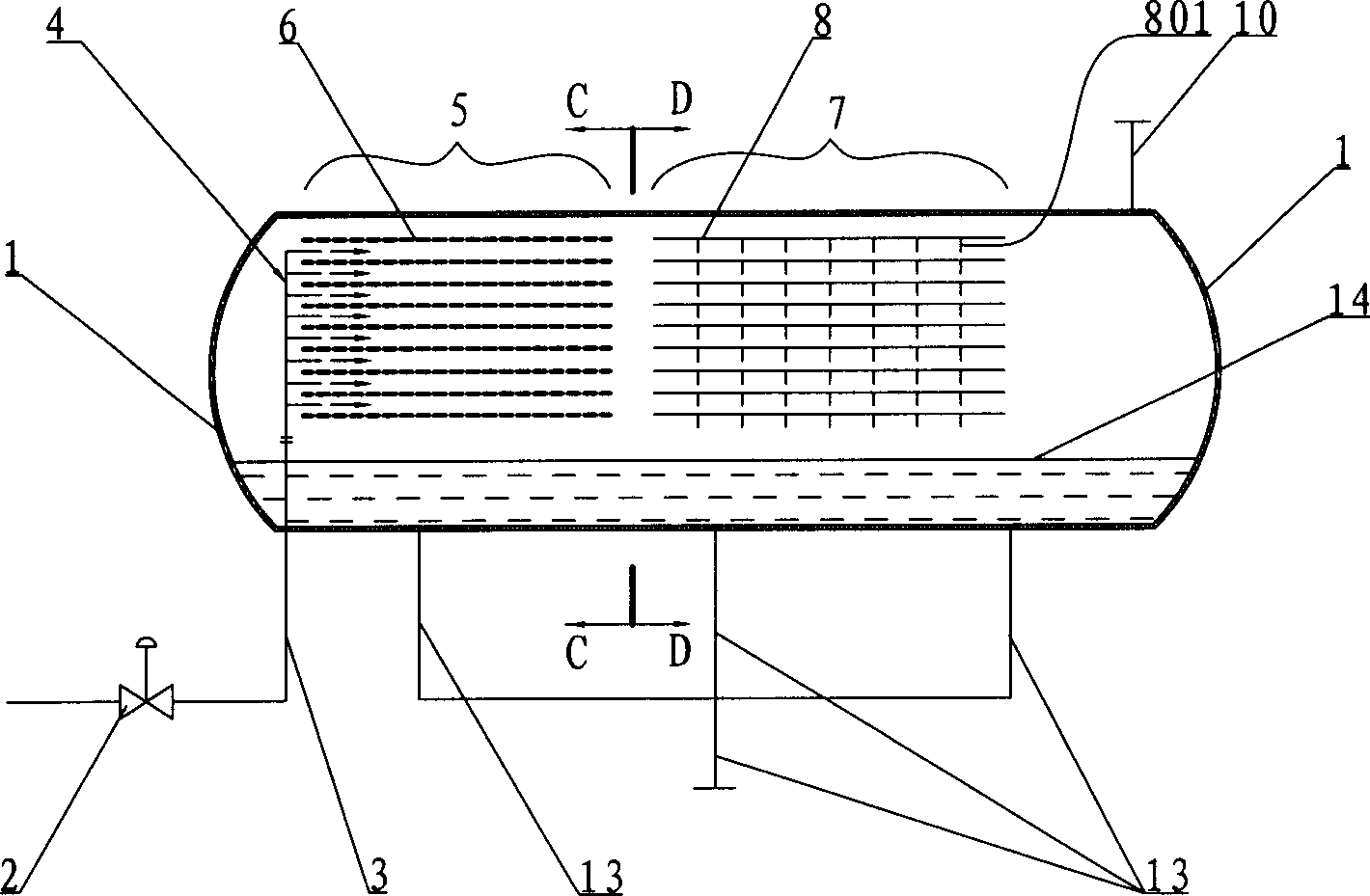

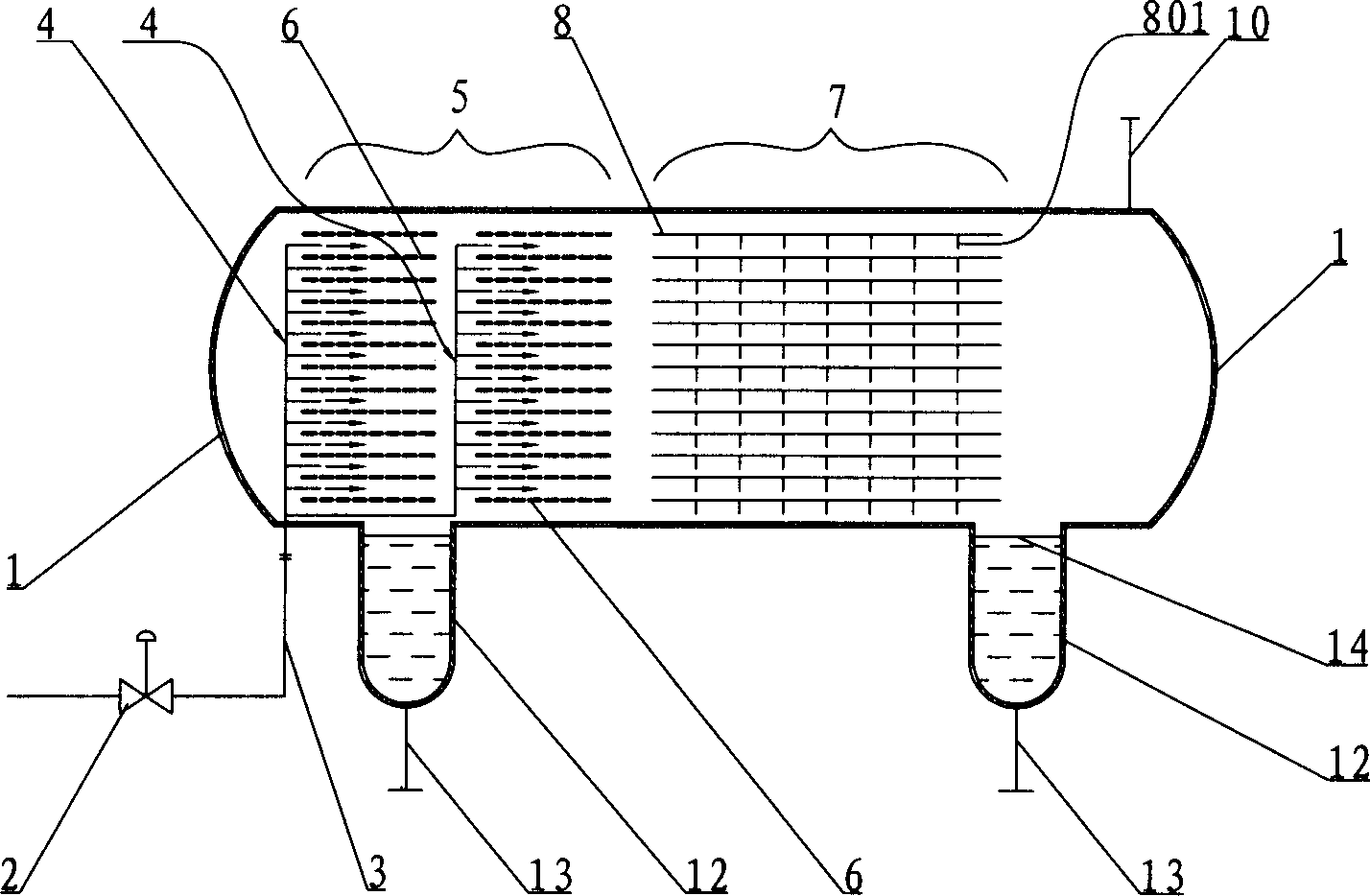

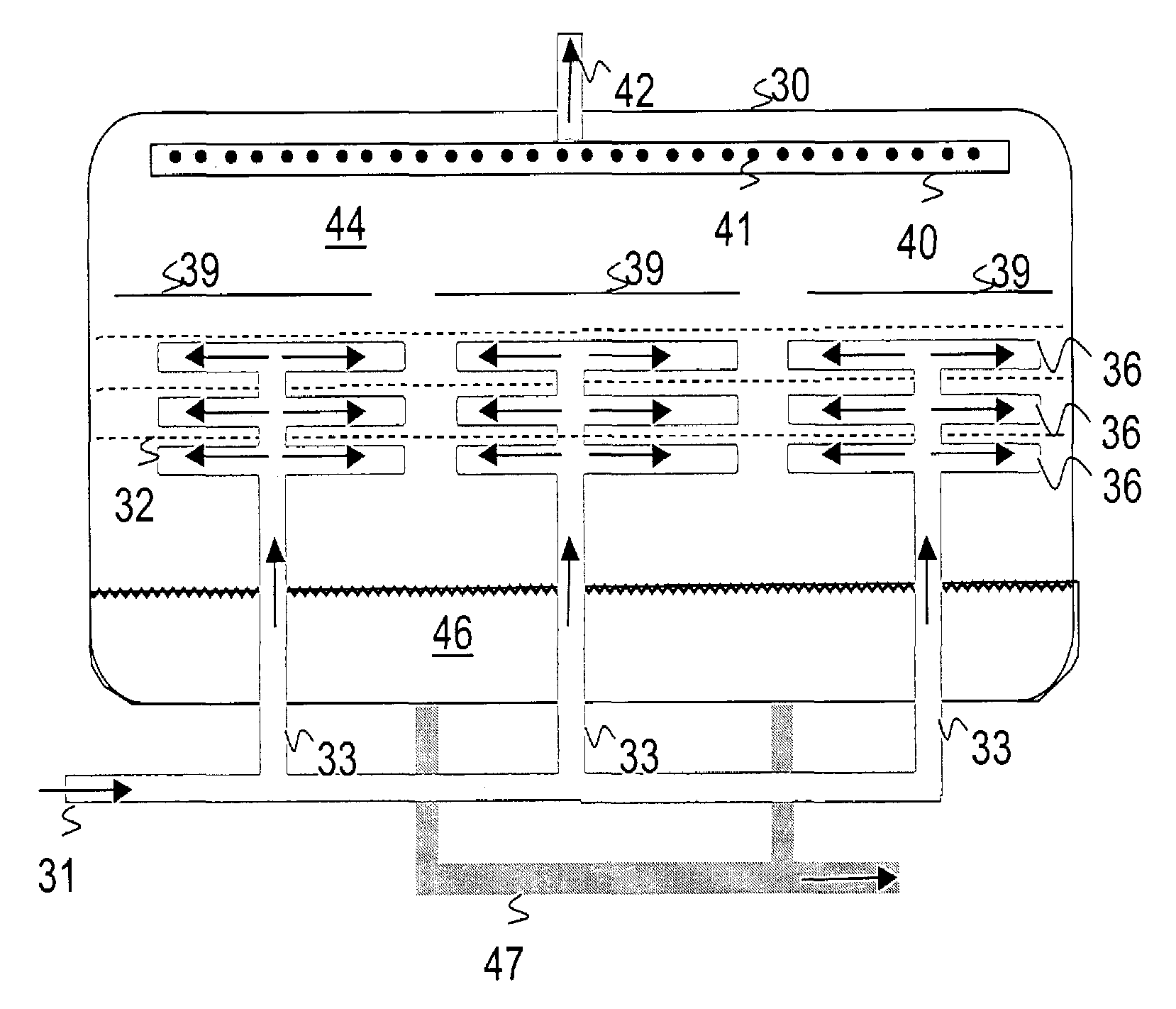

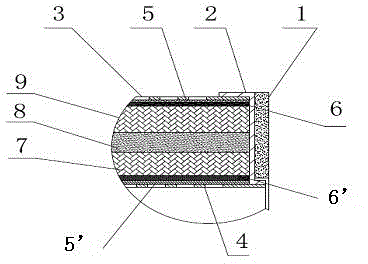

Electric dewatering and desalting appliance for crude oil

InactiveCN1482212AReduce moisture contentEnhanced electrical coalescenceLiquid separation by electricityDewatering/demulsification with electric/magnetic meansElectricityOil water

The electrical raw oil desalting and dewatering device for petrochemical industry features its direct material feeding in strong electric field and horizontal flow of raw oil. The electrical raw oildesalting and dewatering device of the present invention has material distributor and strong electric field coalescence area in tank axial direction and oil outlet pipe in the top of the raw oil purifying area, with the strong electric field coalescence area being provided with at least two layers of parallel electrode plates parallel to or perpendicular to the tank axis. The material distributor is provided with nozzles to spray mixed oil-water material into the strong electric field between two adjacent electrode plates. Between the strong electric field coalescence area and the purified raw oil outlet, deposit separating area may be set.

Owner:CHINA PETROCHEMICAL CORP +1

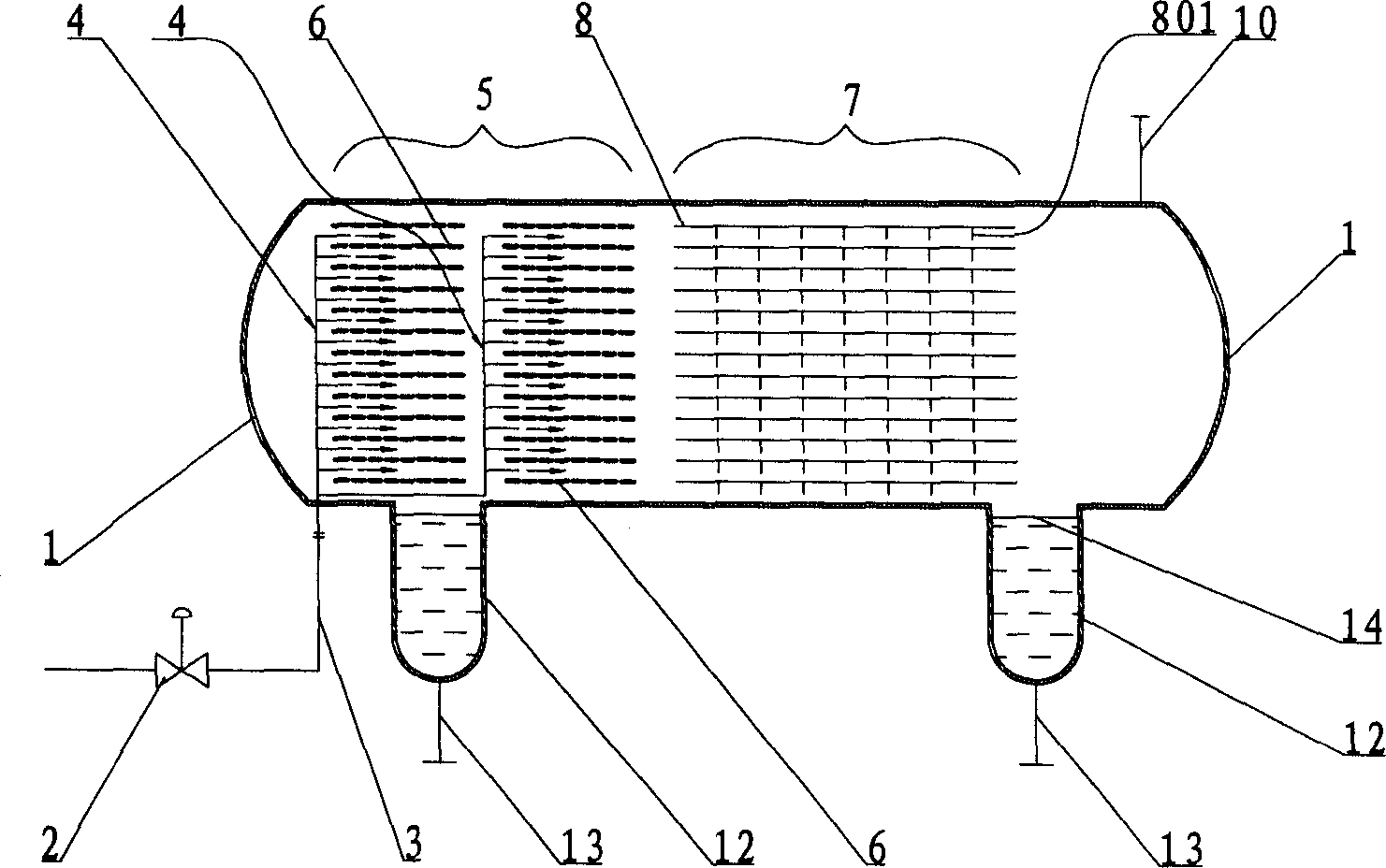

Treatment method of alkaline oily wastewater with demulsifier

InactiveCN102276072AImprove surface activityImprove wettabilityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationDemulsifierTreated water

The invention discloses a method for treating alkaline oily wastewater with a demulsifier, which adopts a secondary demulsification and two-stage air flotation treatment process. The main steps include: preparing a demulsifier, adding the demulsifier to a primary demulsification tank for Once fully stirred, through the first vortex air flotation treatment, the treated water enters the secondary demulsification tank for secondary demulsification, enters the air flotation tank for secondary dissolved air flotation treatment, and efficiently treats alkaline oily wastewater. The oil removal effect of the treatment method of the present invention can reach more than 95%; and the multifunctional agent of the present invention is low in price, easy to obtain on the market, easily soluble in water, simple to add, low in operating cost, obviously more stable in effect, and easy to use. practical use.

Owner:JIANGSU BESITE WATER SCI & TECH

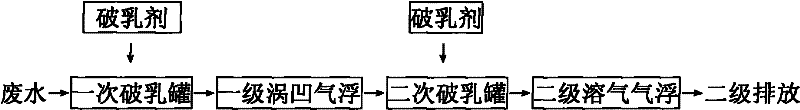

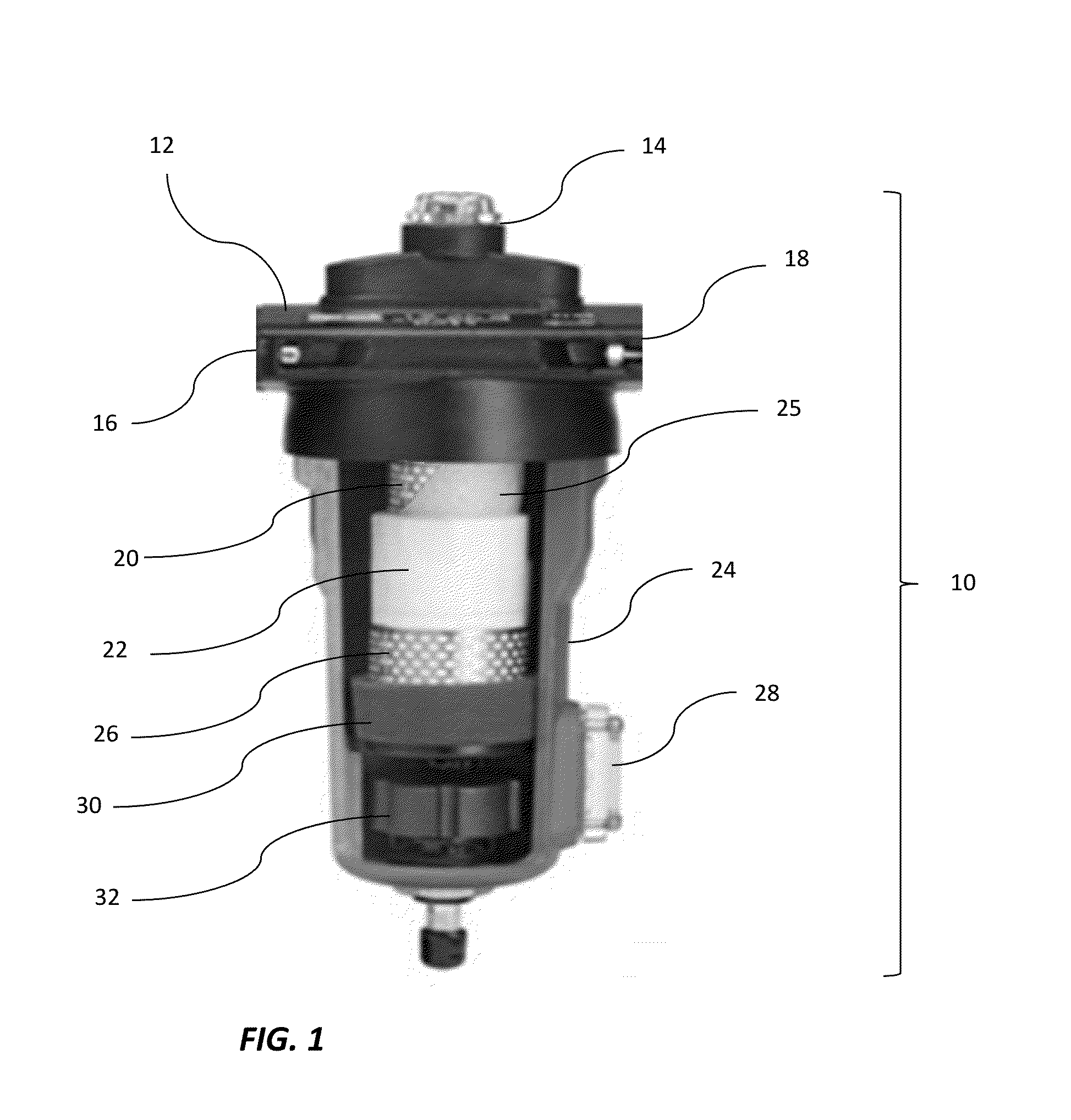

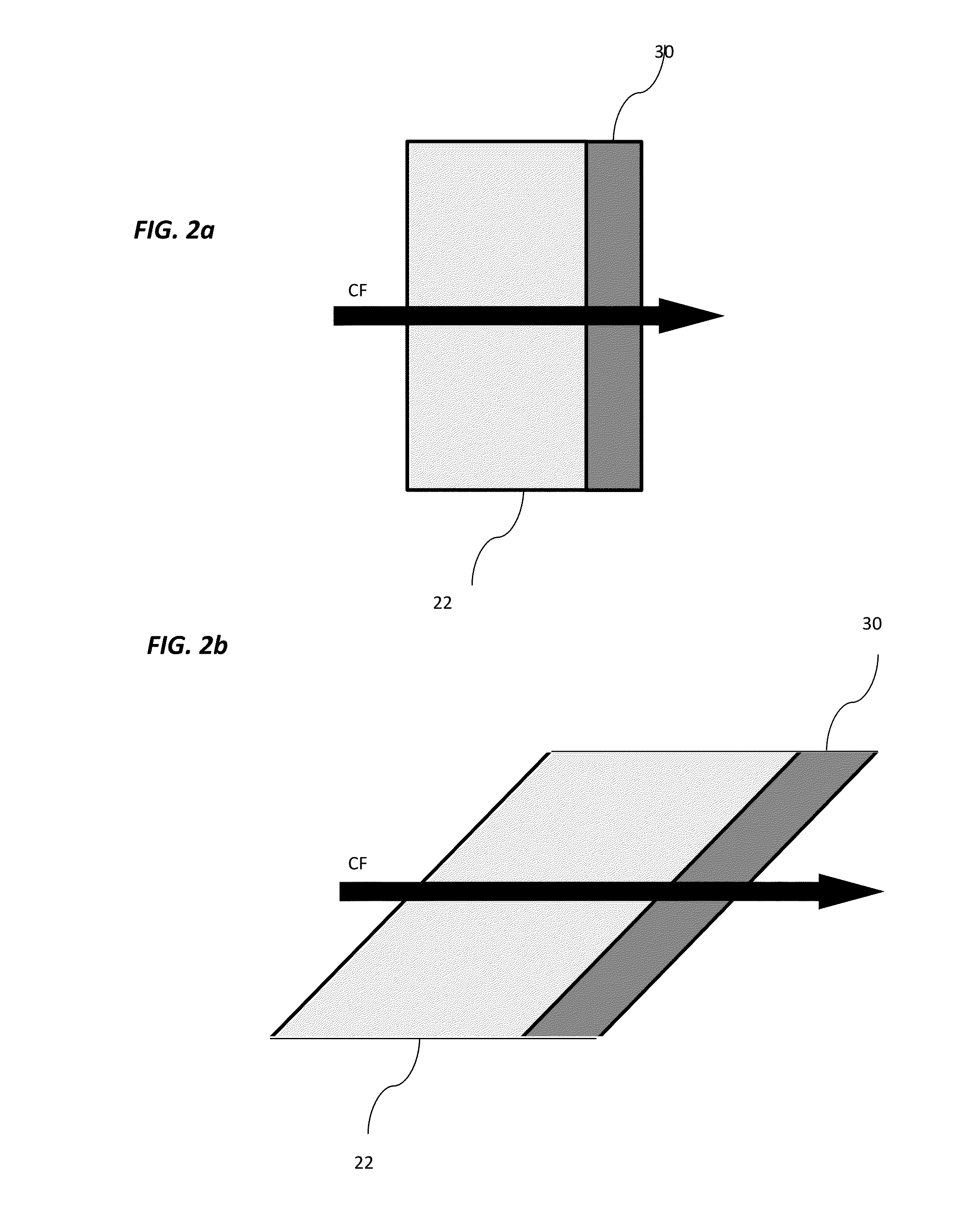

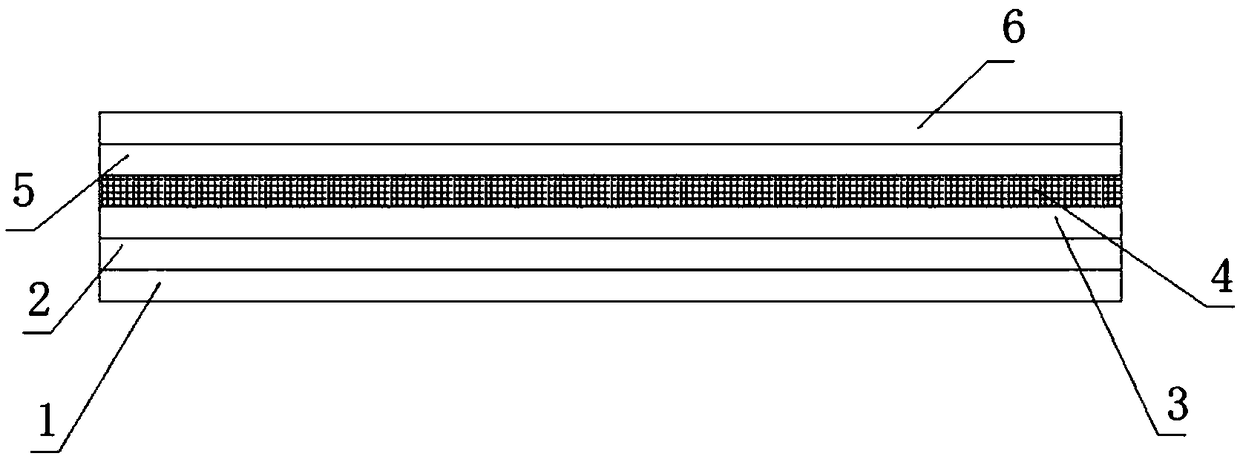

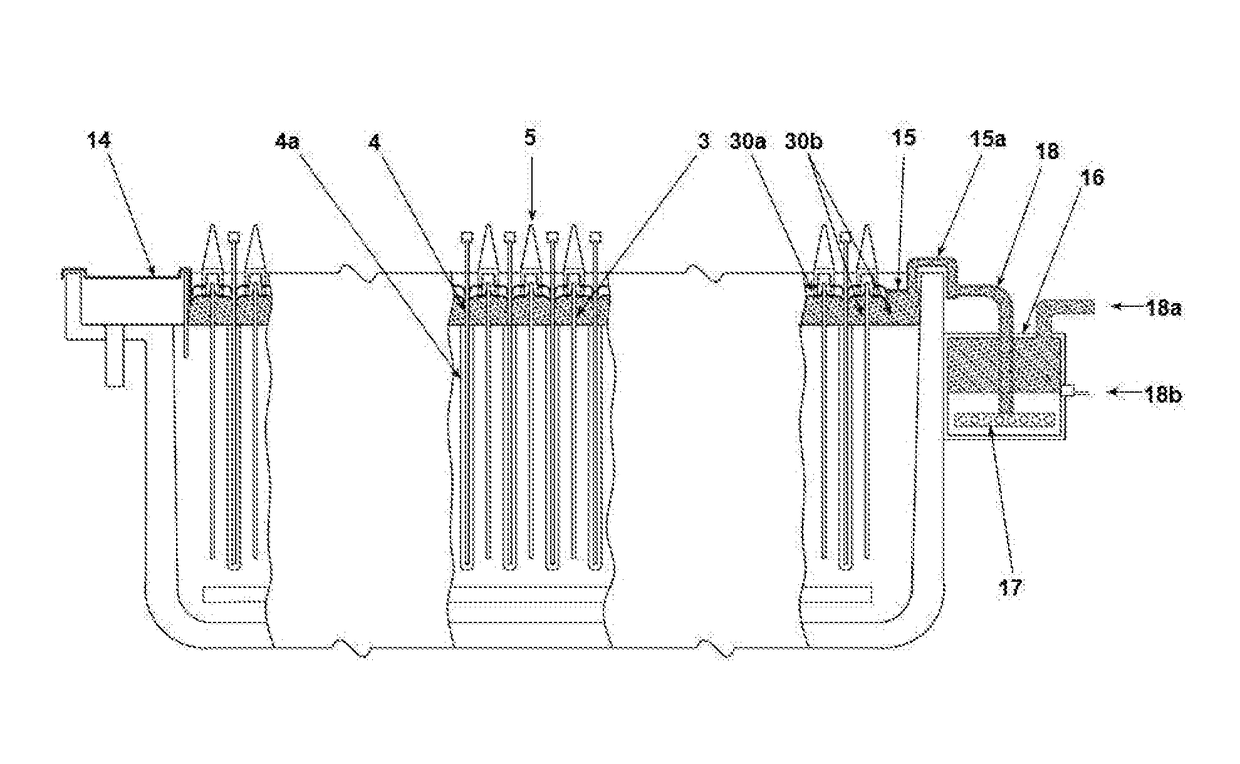

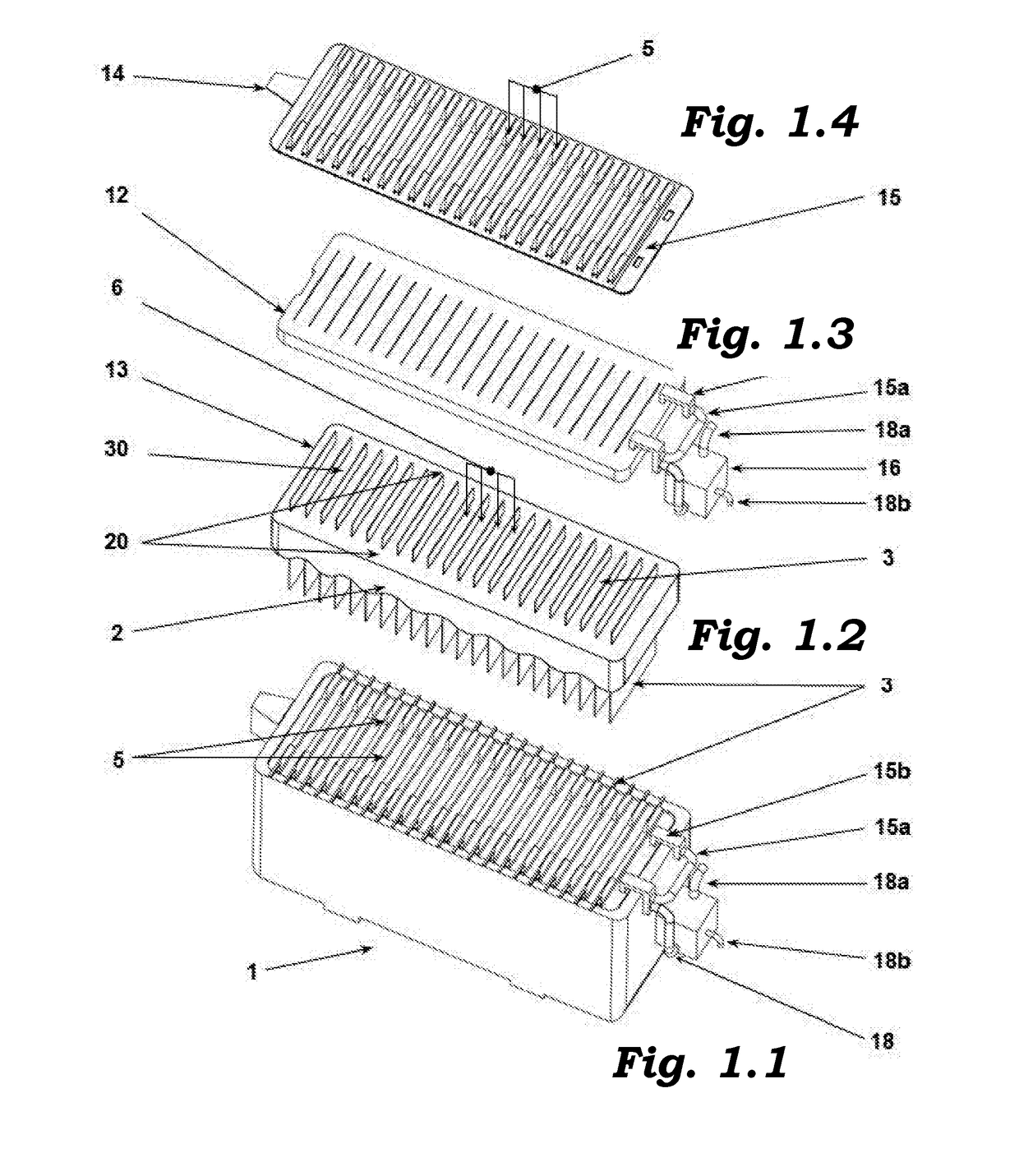

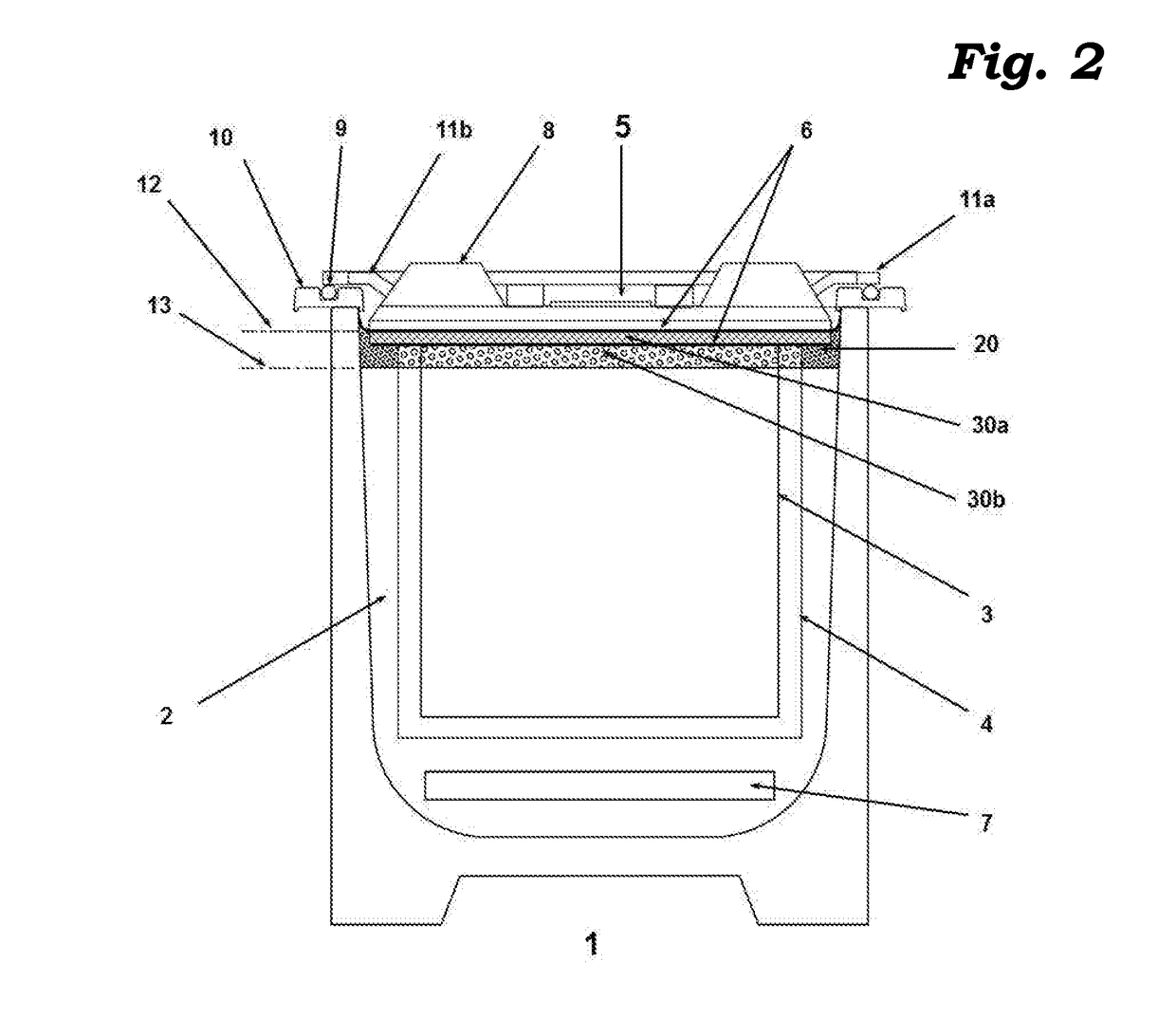

Coalescence filter and method for purifying a fluid

ActiveUS20150182878A1Improve filtering efficiencyImprove filtration efficiencyCombination devicesDispersed particle filtrationEnvironmental engineeringTotal thickness

The present invention relates to a coalescence filter for purifying a fluid which contains a carrier and at least one liquid contaminant, by coalescing of the at least one contaminant. The coalescence filter comprises an inlet for supplying the fluid to a filter element present in the coalescence filter. The filter element comprises a primary coalescence medium which is provided for coalescing of the at least one contaminant in the primary coalescence medium. The coalescence filter further comprises an outlet for discharging the coalesced contaminant from the filter element. The primary coalescence medium comprises at least one layer of a porous material, and has a total thickness of at least 3.5 mm, preferably at least 4 mm, preferably at least 5 mm, more preferably at least 6 mm, most preferably at least 7 mm, in particular at least 7.5 mm, measured at a pressure of 2N / cm2.

Owner:ATLAS COPCO AIRPOWER NV

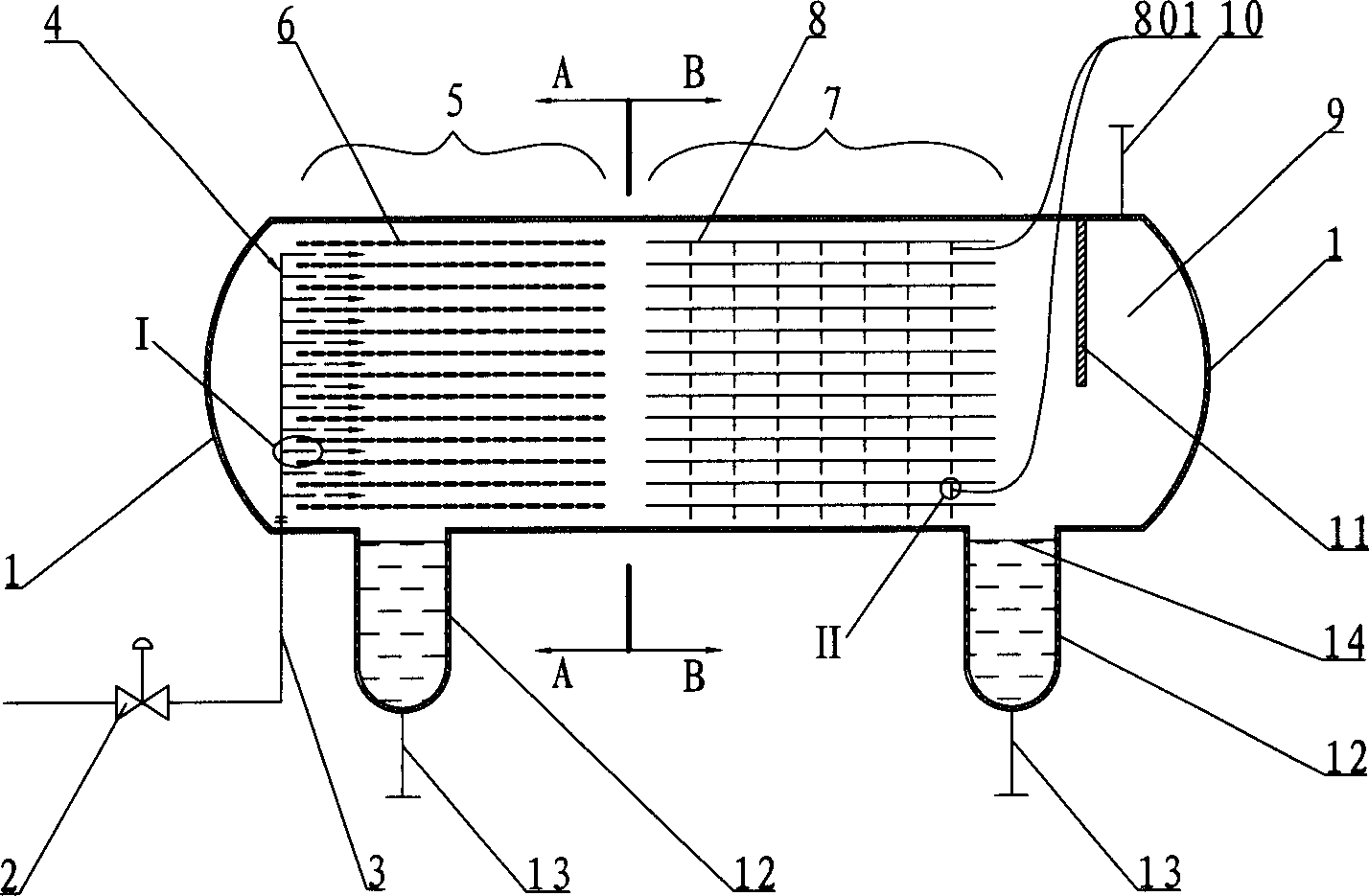

Electric desalting dewatering device for crude oil

InactiveCN1605615AReduce moisture contentEnhanced electrical coalescenceDewatering/demulsification with electric/magnetic meansElectricityPlanar electrode

The present invention is one electric raw oil desalting and dewatering apparatus for petrochemical industry. The present invention features the direct material feeding under strong electric field and the horizontal flow of raw oil. The electric raw oil desalting and dewatering apparatus has a tank with oil-water mixture inlet, axial strong electric field coagulation area with at least two layers of parallel planar electrode plates perpendicular to the axis of the tank, purified raw oil outlet with oil outlet pipe, material distributor inside the tank with nozzles to jet oil-water mixture into the strong electric fields between every two adjacent electrode plates, and depositing separation area set between the strong electric field coagulation area and the purified raw oil outlet.

Owner:CHINA PETROCHEMICAL CORP +1

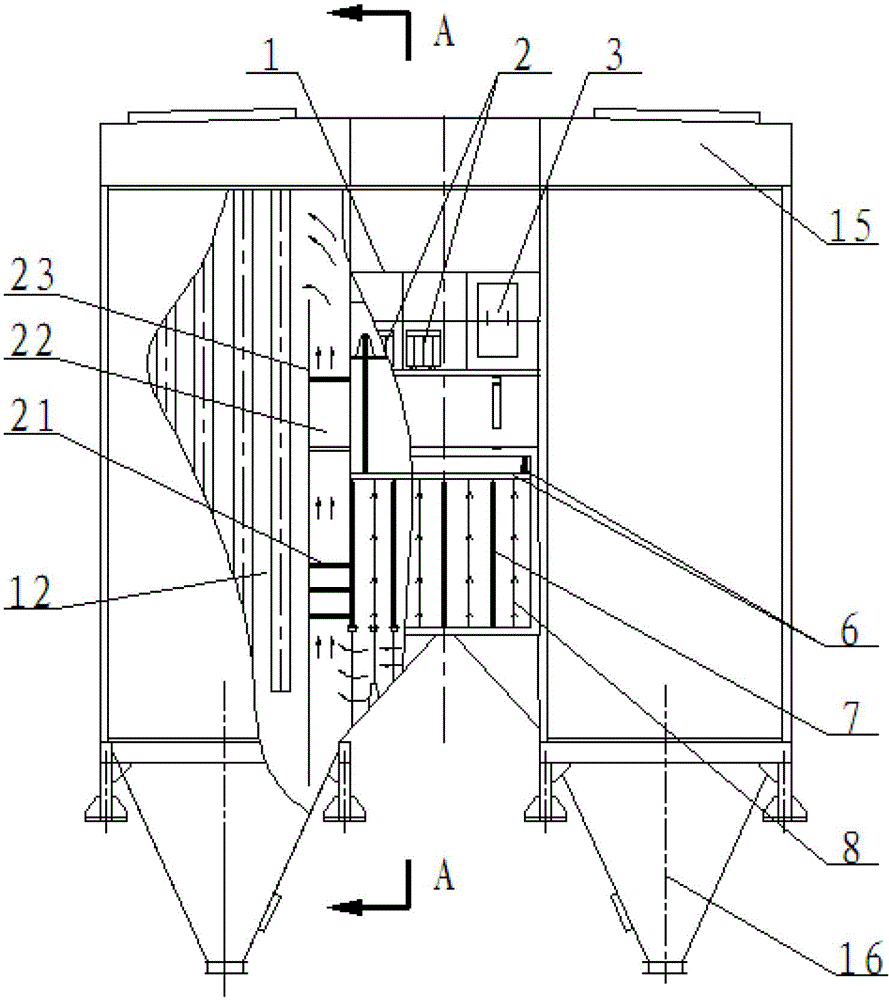

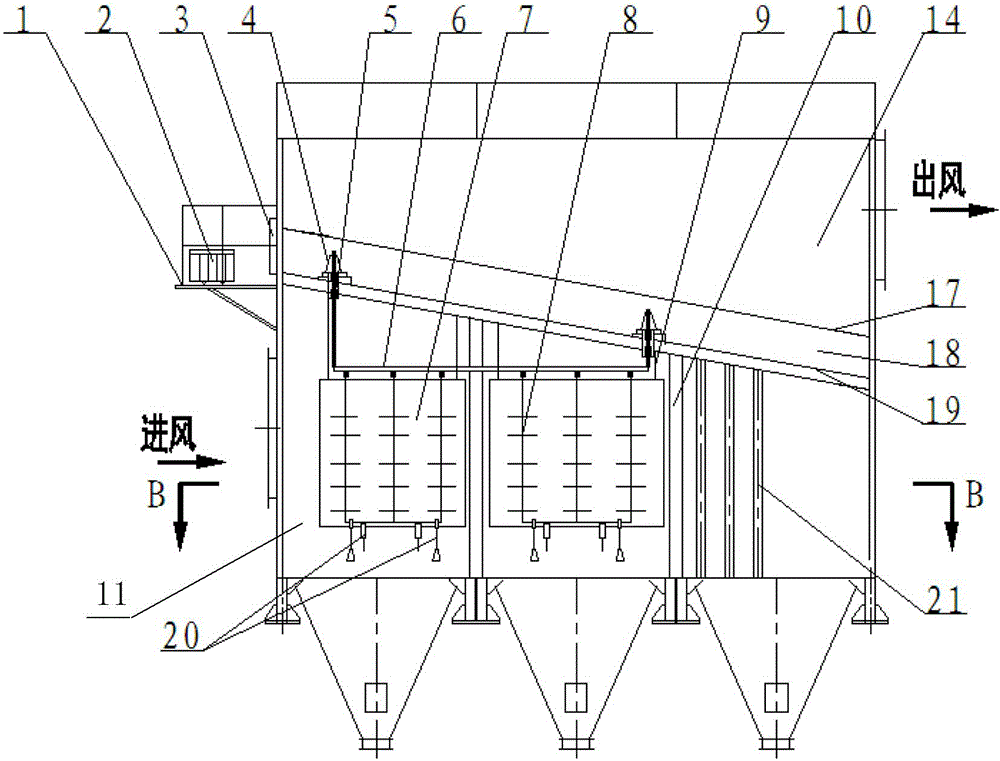

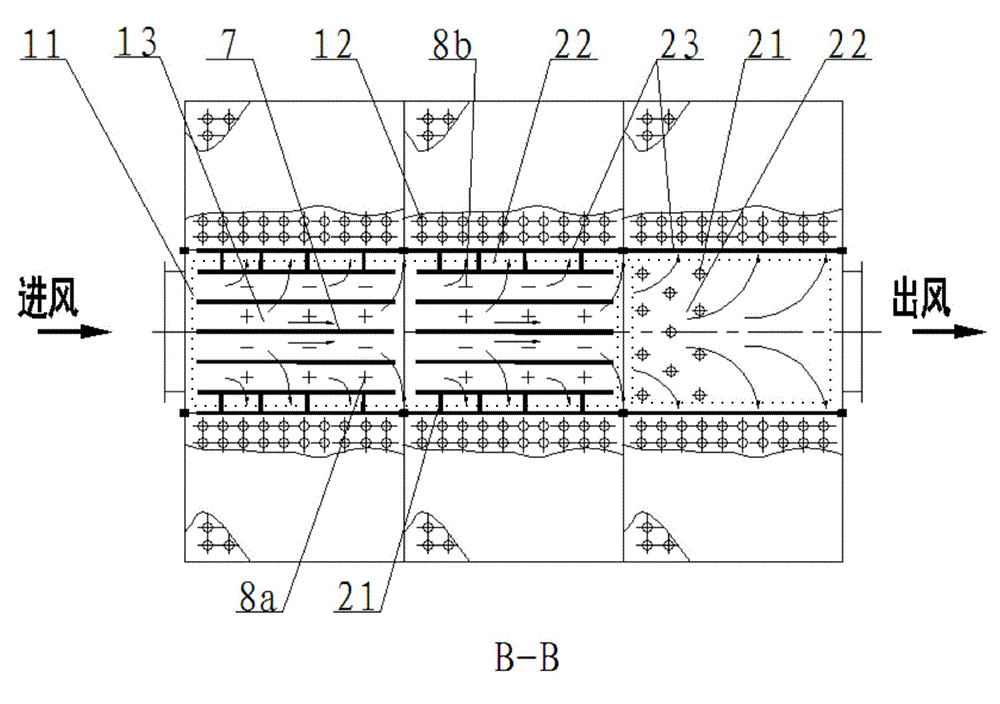

Pre-charging electrocoagulation bag type dust remover

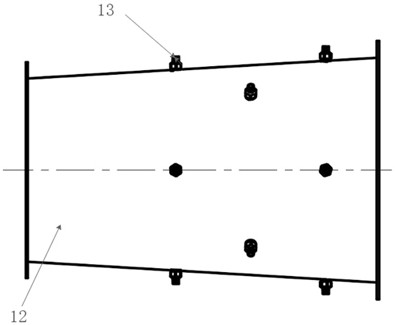

The invention relates to a pre-charging electrocoagulation bag type dust remover. A dual- pole charging device is arranged in an air inlet flue (11) and comprises a group of earth poles (7) arranged at intervals and positive and negative discharging poles (8), so that dual-pole charging regions (13) with positive and negative alternate electric fields are formed. A mixed coagulation region (22) is arranged in the tail space of the air inlet flue (11) and the buffering space of a filtering cabin, so that the coagulation efficacy of PM2.5 subparticles is observably improved. Coagulated large particles rapidly enter a filter bag filtering cabin (12) along with air currents, so that dust-air separation is performed by the filter bag. The dust remover disclosed by the invention utilizes a dual-pole charging electrocoagulation mechanism, and oversized PM2.5 subparticles are regularly arrayed on the surface of the filter bag and loosely stacked, so that the oversized PM2.5 subparticles are very liable to trap and remove. The dust remover has the significant characteristics of good coagulation effect on the subparticles, high trapping efficiency on the PM2.5 and the like, and is particularly suitable for reforming and improving a bag type dust remover adopting a traditional structure. The dust remover is economical, practical, convenient and high-efficiency.

Owner:ENELCO ENVIRONMENTAL TECH ANHUI

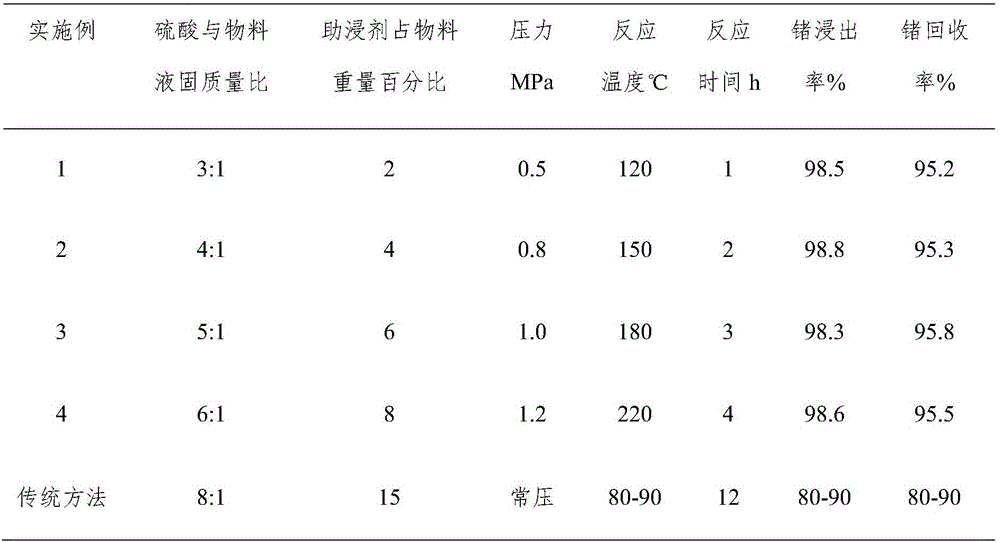

Method for extracting germanium from high-silicon high-iron low-grade germanium-containing material

InactiveCN106834753AIncrease the speed of diffusionEasy to addProcess efficiency improvementHydrometallurgyHigh pressure

The invention belongs to the technical field of wet metallurgy, and in particular, relates to a method for extracting germanium from a high-silicon high-iron low-grade germanium-containing material. The method comprises the steps: mixing the high-silicon high-iron low-grade germanium-containing material with sulfuric acid and a leaching aid agent, adding the mixture into a high pressure reaction kettle, introducing oxygen-containing gas, adjusting the oxygen partial pressure, carrying out oxygen pressure acid leaching, and carrying out solid-liquid separation of the obtained material, to obtain a germanium-containing acid leaching solution; adding an iron powder and gelatin, to obtain a purified solution; and extracting and carrying out back extraction, and finally, calcining to obtain a refined germanium ore with the germanium content of more than 30%. The method has the advantages of short flow, low energy consumption, high metal germanium leaching rate and recovery rate, low production cost, easy operation, and convenience in industrialized production.

Owner:GUIZHOU HONGDA ENVIRONMENTAL PROTECTION TECHNOLOGY CO LTD

Leaching method for increasing leaching rate of ionic adsorption type rare earth ore

ActiveCN106702181AReduce desorption processReduce the absolute valueProcess efficiency improvementClay mineralsRare earth

The invention discloses a leaching method for increasing the leaching rate of ionic adsorption type rare earth ore. According to the leaching method, a leaching aid agent is added into a leaching agent so that a leaching solution can be prepared, and then, the ionic adsorption type rare earth ore is leached; or the ionic adsorption type rare earth ore is subjected to drip washing through a leaching aid agent solution at first, after drip washing liquid of the ionic adsorption type rare earth ore is collected, a leaching agent is added so that a leaching solution can be prepared, and the ionic adsorption type rare earth ore subjected to drip washing through the leaching solution is leached; and the leaching aid agent is a mixture comprising one or more of succinic acid, sodium succinate, succinic acid and ammonium succinate. According to the leaching method, one or more of the succinic acid, the sodium succinate, the succinic acid and the ammonium succinate are adopted as the leaching aid agent, the aggregation of clay particles in ore is maintained, migration of the clay mineral particles in the leaching process is reduced, meanwhile, the ore penetrating quality can be improved moderately, and the leaching rate is increased.

Owner:JIANGXI UNIV OF SCI & TECH

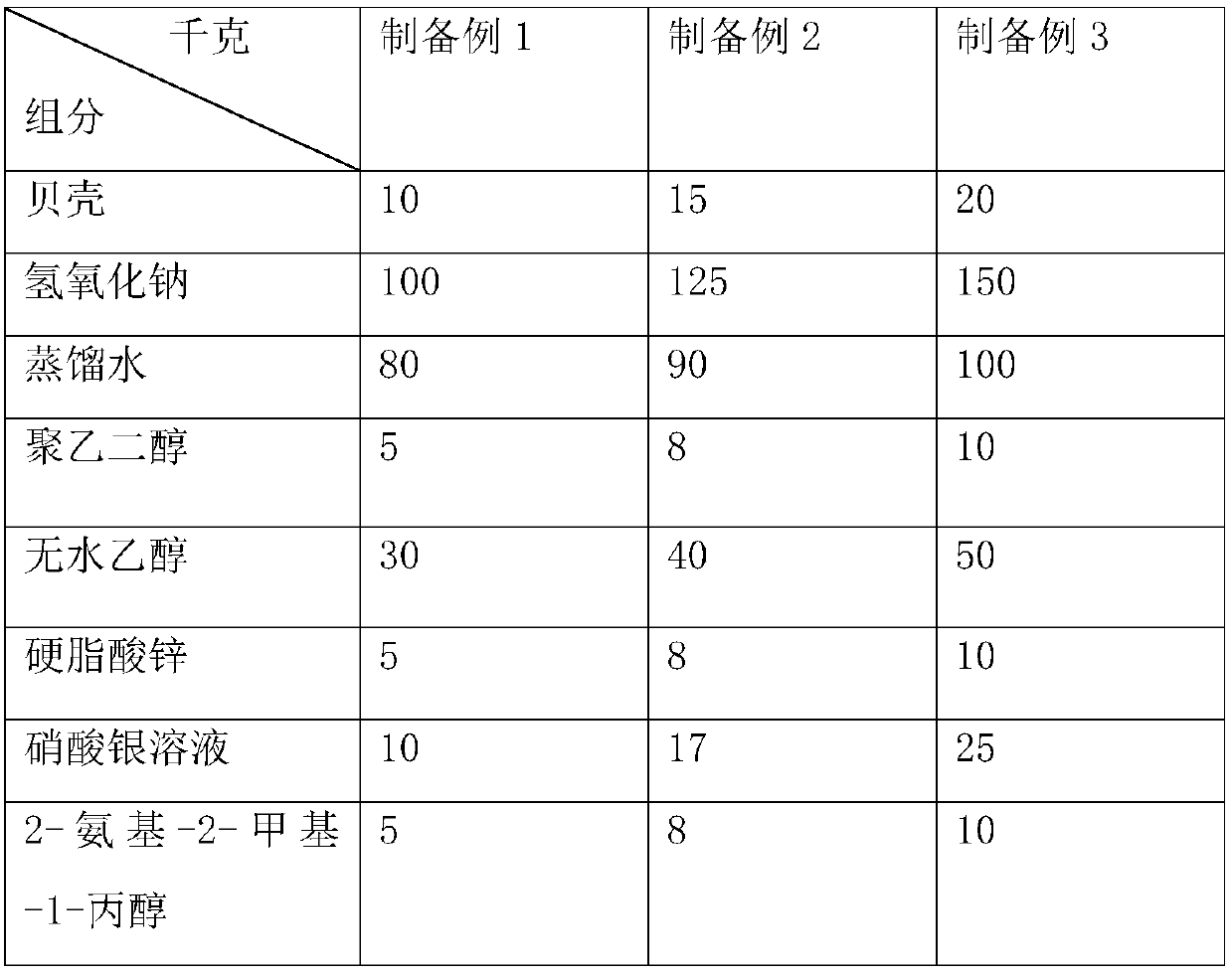

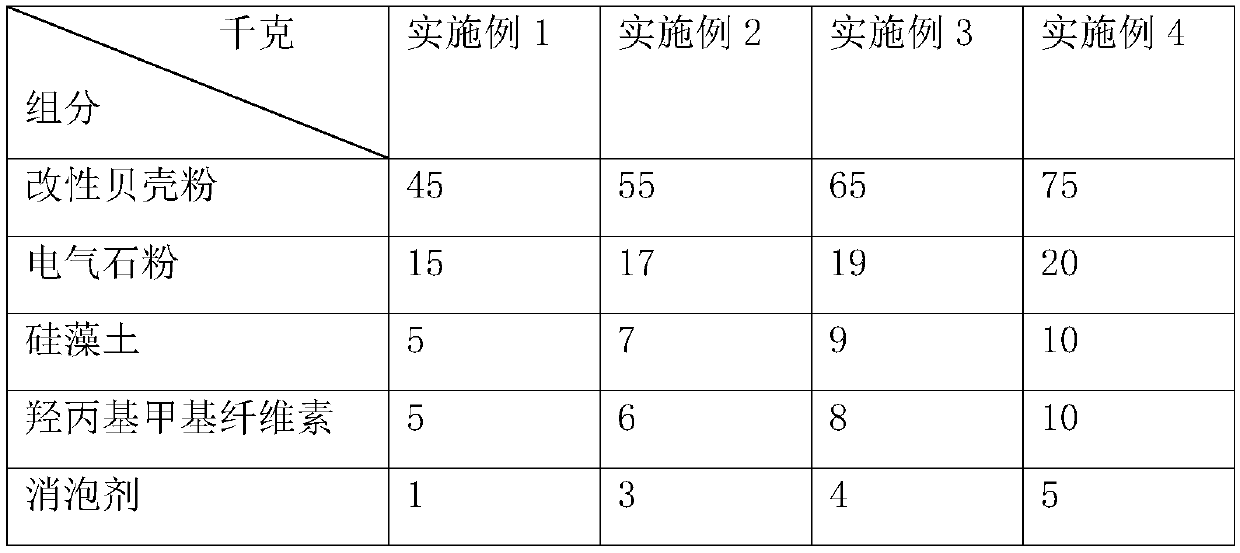

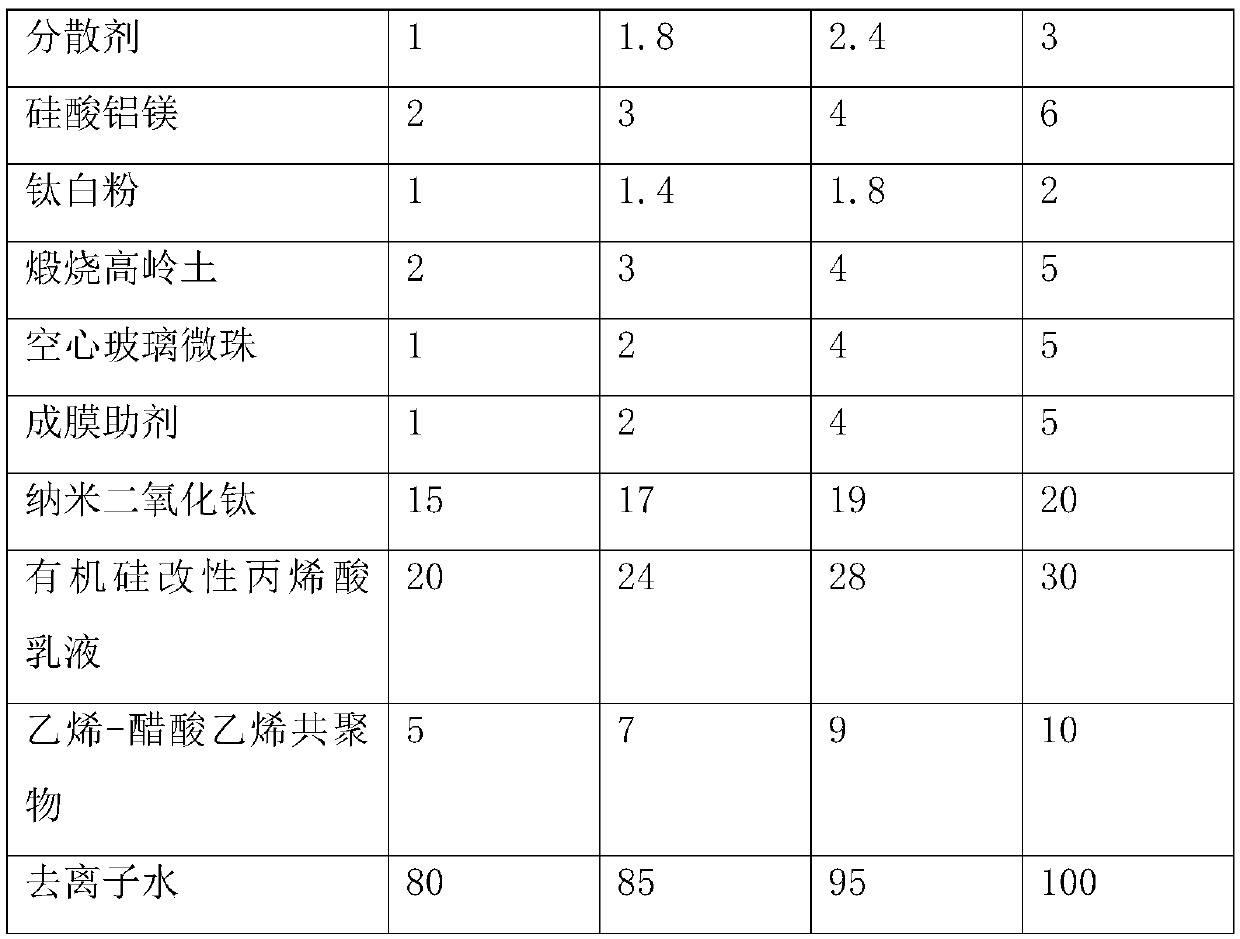

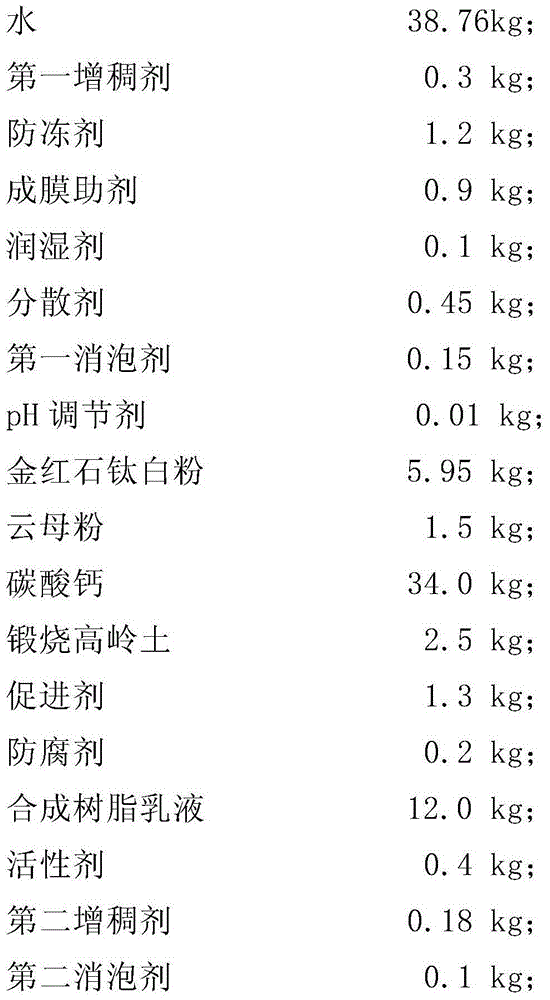

Environment-friendly interior wall paint and preparation method thereof

ActiveCN109575728AReduce volatilityImprove the bactericidal effectFireproof paintsAntifouling/underwater paintsCelluloseEmulsion

The invention discloses environment-friendly interior wall paint and a preparation method thereof. The environment-friendly interior wall paint comprises, by weight, 45-75 parts of modified shell powder, 15-20 parts of toumaline powder, 5-10 parts of diatomite, 5-10 parts of hydroxypropyl methyl cellulose, 1-5 parts of defoamer, 1-3 parts of dispersant, 26 parts of thixotropic agent, 1-2 parts oftitanium dioxide, 2-5 parts of calcined kaolin, 1-5 parts of hollow glass bead, 1-5 parts of film forming aid, 15-20 parts of nano titanium dioxide, 20-30 parts of organosilicon modified acrylic emulsion, 5-10 parts of ethylene-vinyl acetate copolymer and 80-100 parts of deionized water. The preparation method includes following steps: S1, dispersing cellulose; S2, mixing and grinding raw materials; S3, adding ingredients; S4, preparing the environment-friendly interior wall paint. The environment-friendly interior wall paint does not volatilize harmful gas, can adsorb and degrade harmful gaslike formaldehyde and is environment-friendly.

Owner:江西高雅科技新材料有限公司

Water-borne plastic paint and preparation method thereof

InactiveCN105885582AGood film formingImprove coalescenceFireproof paintsEpoxy resin coatingsEpoxyPolymer science

The invention relates to water-borne plastic paint and a preparation method thereof, and belongs to the technical field of paint processing. The water-borne plastic paint is prepared from the following components in a certain proportion: water-borne acrylic resin, water-borne epoxy resin, a coalescing agent, a water-borne color paste, hydroxyethyl cellulose, talc powder, a defoaming agent, a flatting agent, flame retardant, nano-silicon dioxide, dimethylethanolamine and deionized water. The paint film has strong adhesion, good glossiness and strong strength, has a certain flame retardant effect, and is safe and reliable.

Owner:杭州高思途实业有限公司

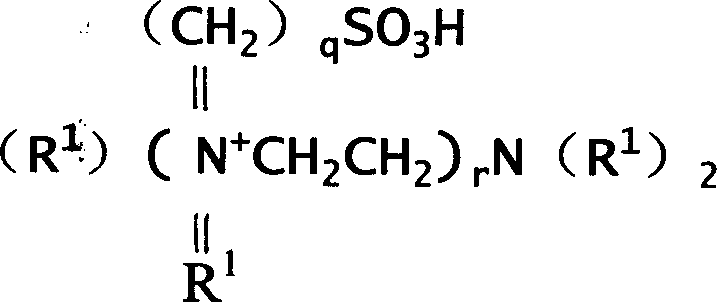

Multifunctional corrosion inhibitor and preparing method

This invention relates to a multi-functional corrosion-inhibitor used in parts of atmospheric vacuum tower top tube, and its prepn. method. The characteristic of the molecular structure of the inhibitor is that it is of betaine sulfonate type, being of amphoteric ion, having excellent corrosion inhibiting property. In this polymer, triethenyl teraamine is used as initiator, and introducing epoxy propane and epoxy ethane block polyether (excellent demulsification agent) having advantages of coalescence, quick de-water rate, the removed water being clear, less dosage, broad pH value range.

Owner:PETROCHINA CO LTD

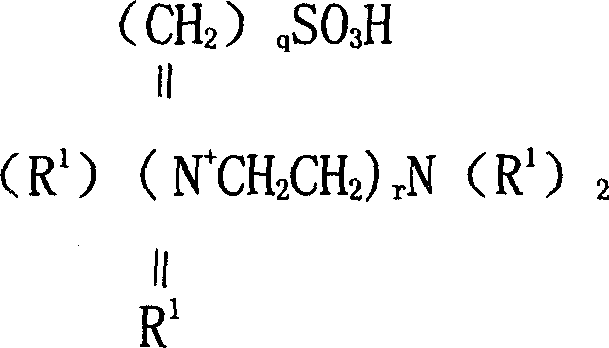

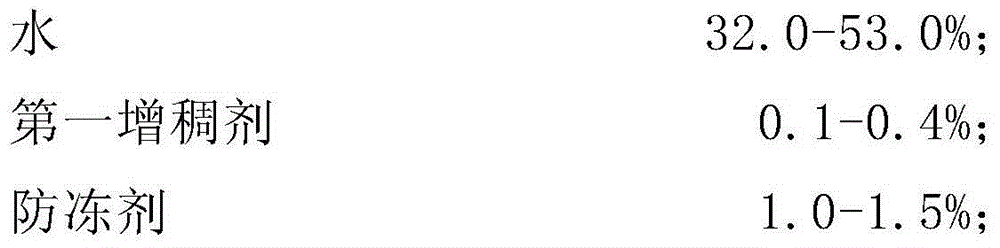

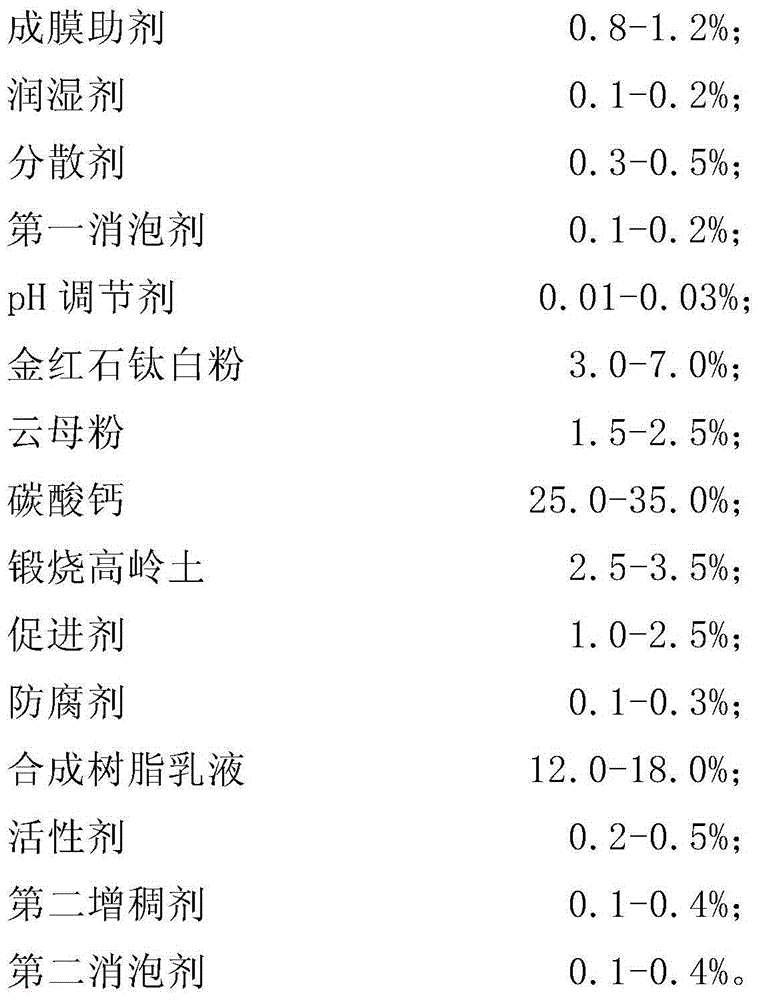

Alkali-resistant interior wall primer and preparation method for same

ActiveCN104962141ASmall particle sizeImprove permeabilityCoatingsEnvironmental resistancePolymer science

The invention provides an alkali-resistant interior wall primer and a preparation method for the same. The alkali-resistant interior wall primer is a synthetic resin emulsion coating, commonly known as emulsion paint, prepared by adding a pigment, a filler and various auxiliaries into a substrate synthetic resin emulsion. The alkali-resistant interior wall primer comprises 12.0 to 18.0 weight percent of synthetic resin emulsion, wherein the synthetic resin emulsion is a styrene and acrylic copolymer. The alkali-resistant interior wall primer is economical and environment-friendly, and has partial covering force, and the adhesion of finish paint can be improved; high sealing property on a concrete building substrate can be achieved, open holes of the substrate can be effectively sealed, alkali in the substrate can be effectively isolated, a coating can be prevented from being damaged by seeping alkali, and a function of strengthening and reinforcing the substrate can be realized.

Owner:SHANGHAI CARPOLY PAINT

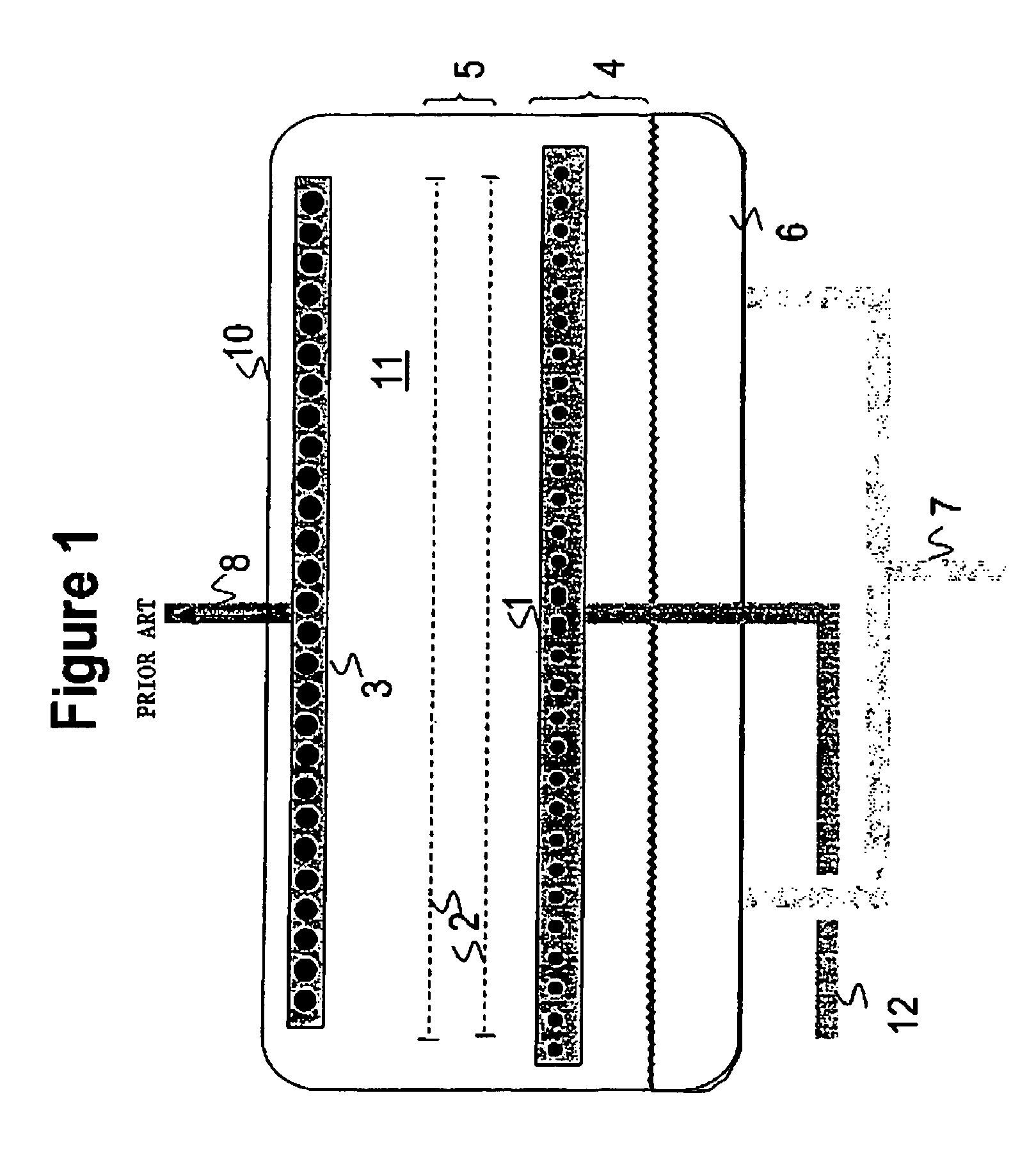

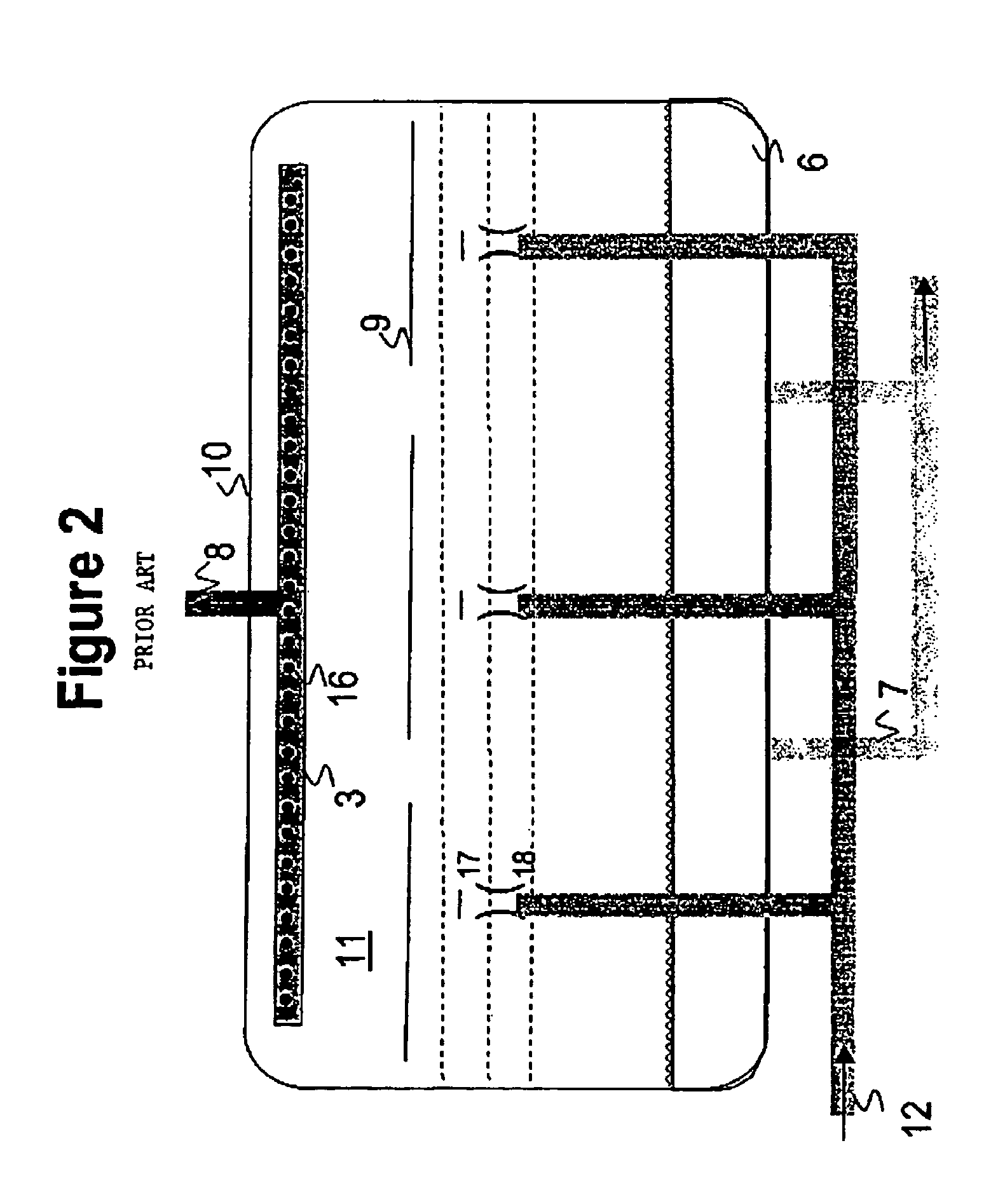

Oil desalting and dewatering

InactiveUS7008536B2Improve coalescenceDewatering/demulsification with chemical meansLiquid separation by electricityEngineeringWater in oil emulsion

The invention includes a method for dewatering and / or desalting a water-in-oil emulsion comprising introducing a plurality of streams of the emulsion into the electrostatic field under opposed flow whereby the water coalescence is enhanced. The invention also includes an improved electrostatic apparatus for dewatering and / or desalting a water-in-oil emulsion comprising a plurality of horizontally directed nozzles positioned to introduce a plurality of streams of the emulsion into the electrostatic field under opposed flow conditions.

Owner:EXXON RES & ENG CO

Low shearing plunger type throttling valve used for oil production gathering and transporting

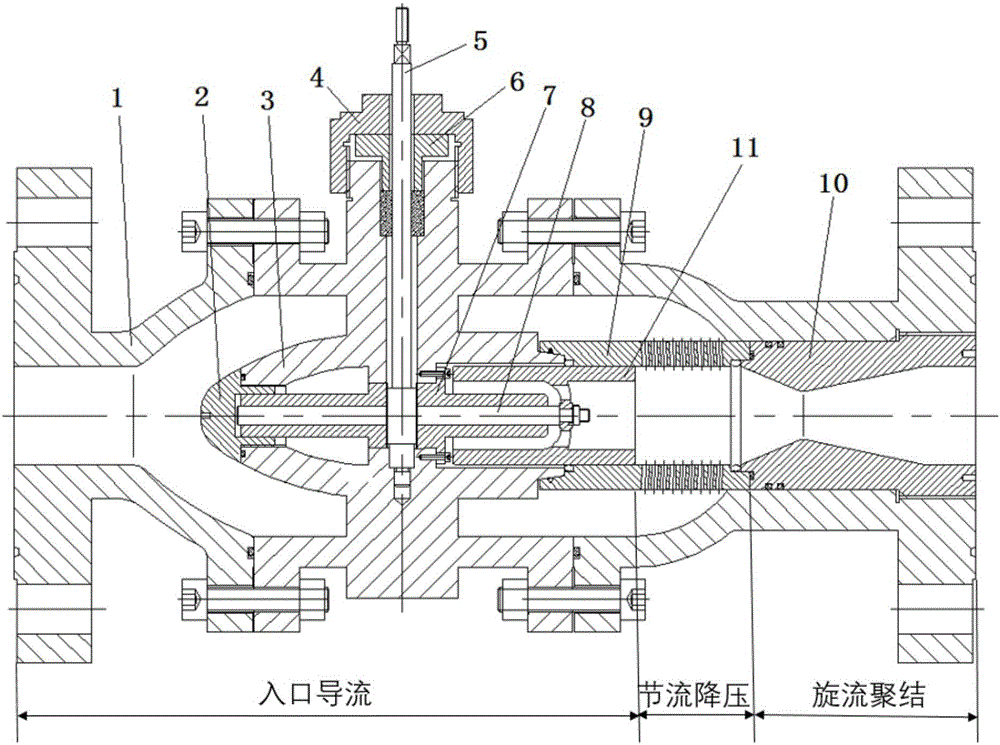

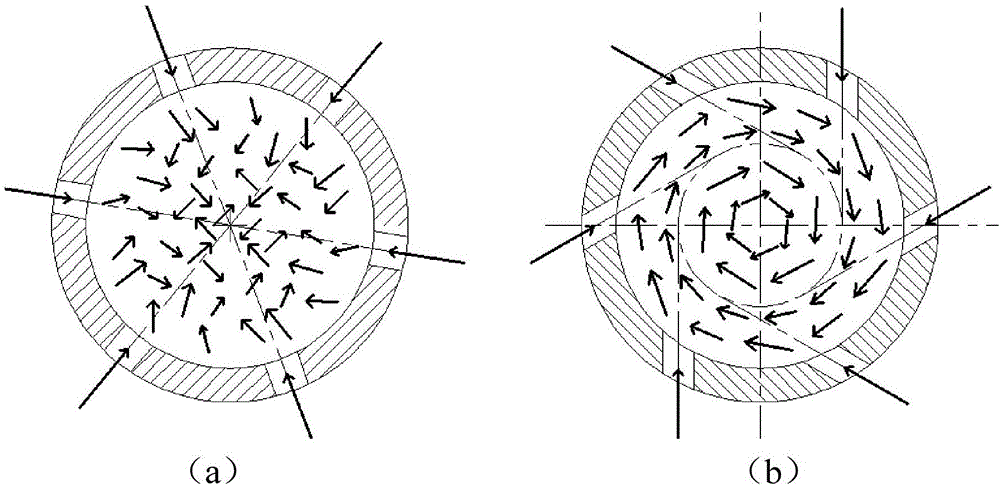

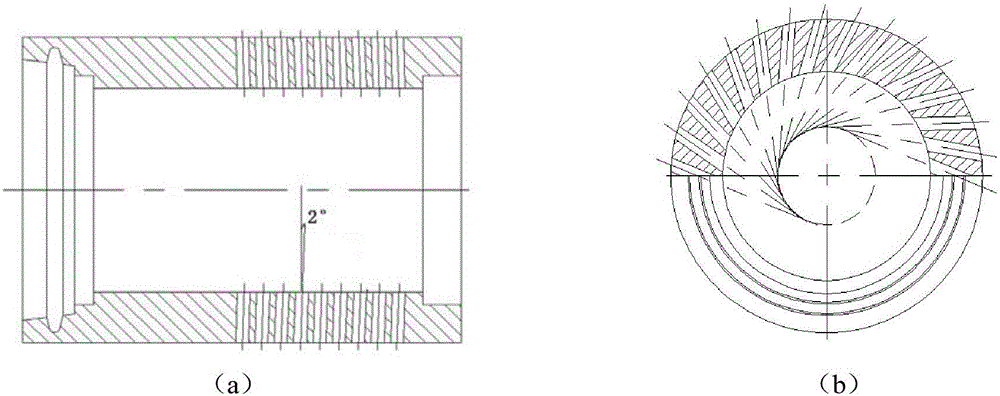

InactiveCN106439137AEnhance swirl effectReduce random vortex motionEqualizing valvesSafety valvesBase functionOil water

The invention discloses a low shearing plunger type throttling valve used for oil production gathering and transporting. Based on a rotational flow agglomeration and unit mass energy dissipation rate control technology, orifices of a valve cage are designed to be in the tangential direction, a rotational flow chamber which is converged firstly and expanded afterwards is connected behind the orifices, the basic function of flow and pressure adjustment can be achieved on the plunger type throttling valve, meanwhile, the velocity gradient and the turbulence energy dissipation rate in a flow field are reduced, the shearing force of the orifices for fluid is reduced, the liquid drop breaking degree is lowered, and the subsequent oil water separation difficulty is lowered.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

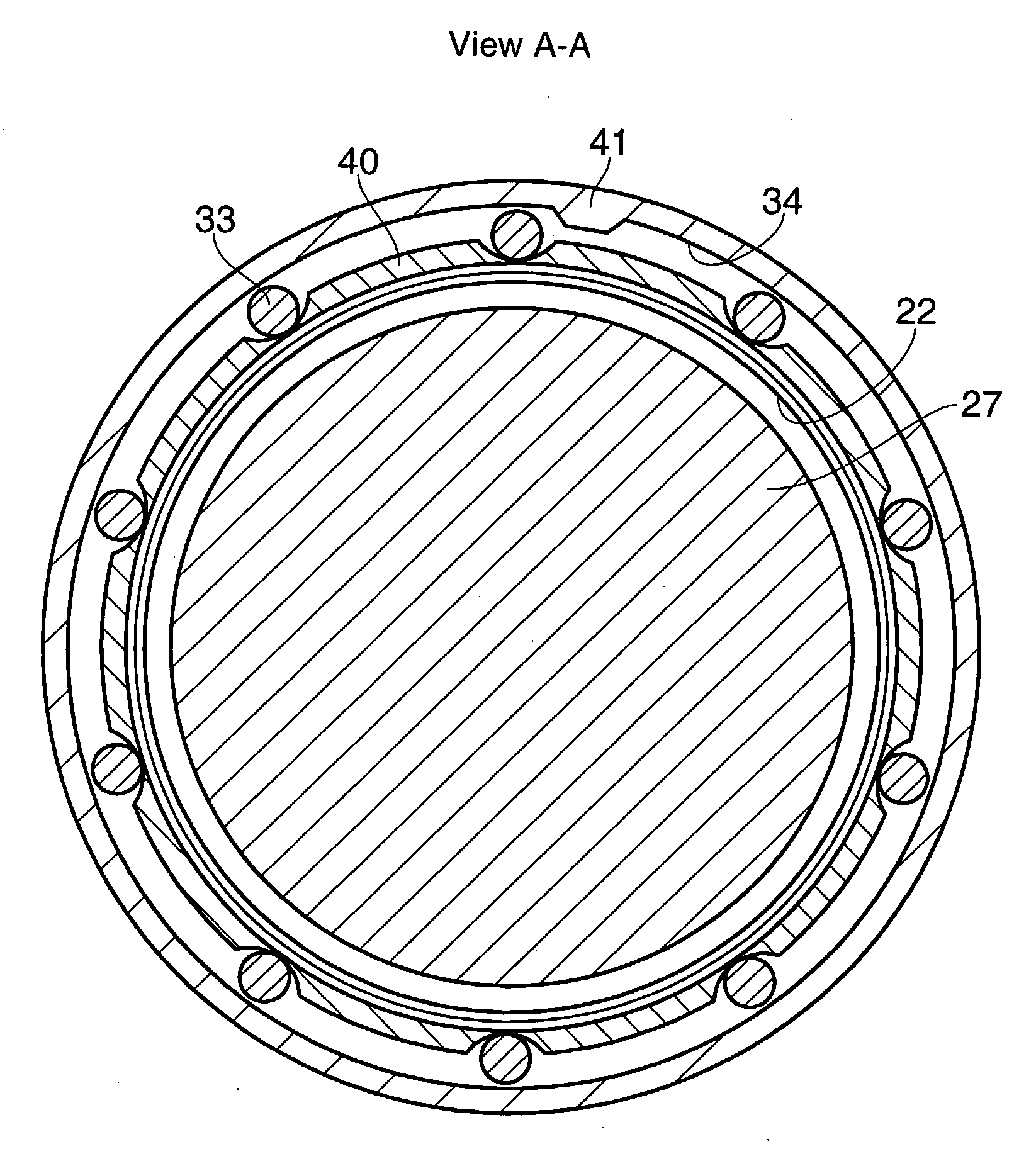

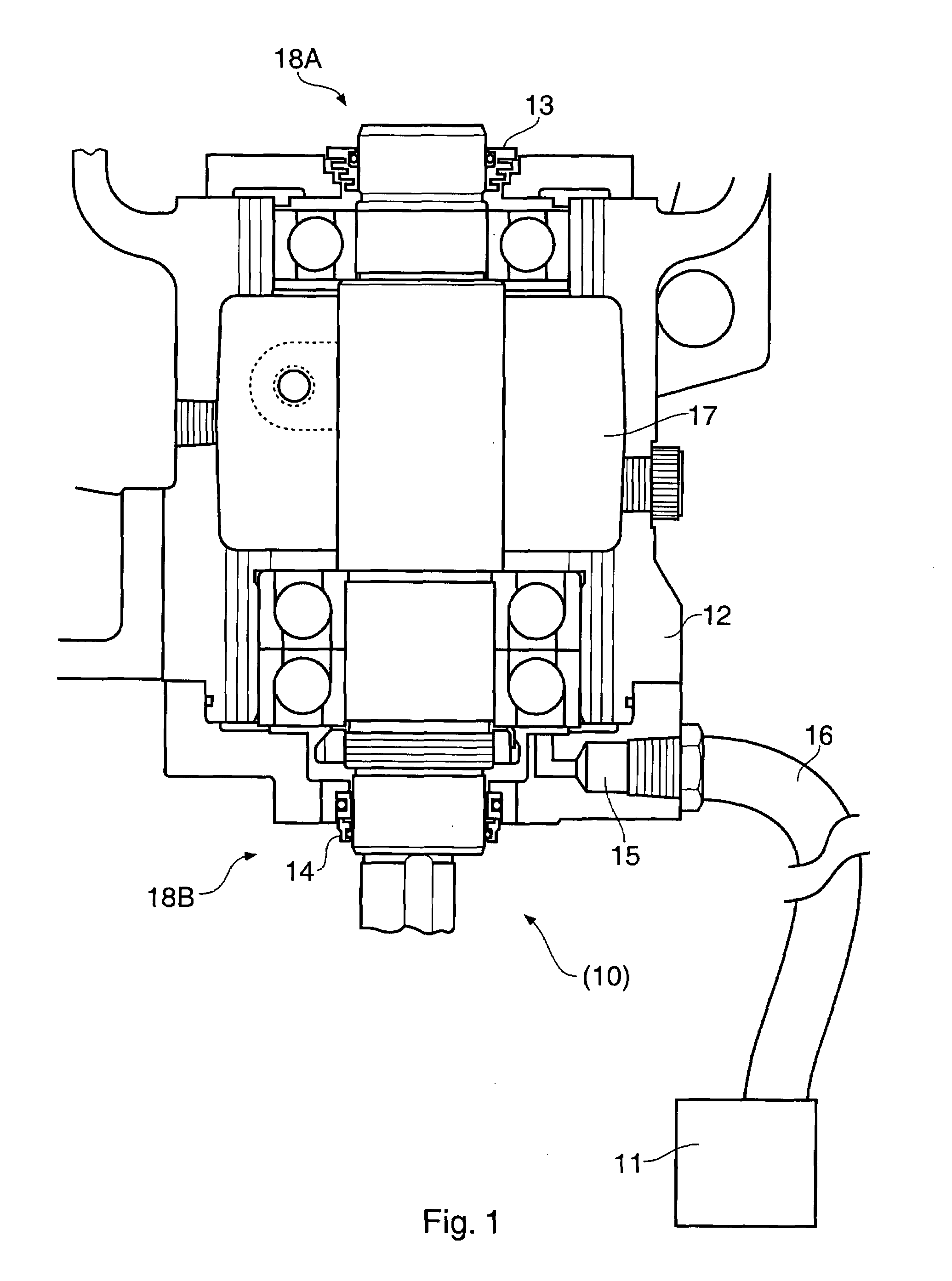

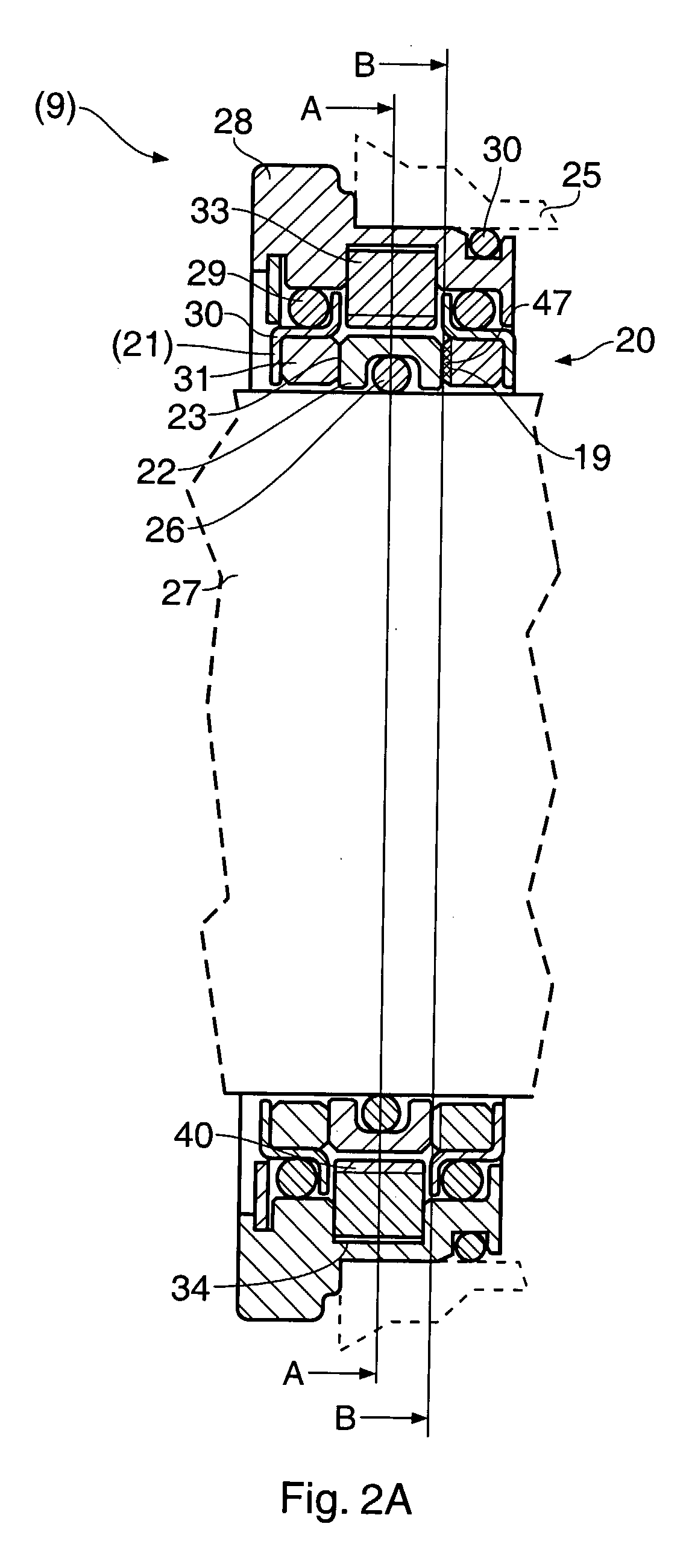

Rotary Seal

A rotary seal has a floating seal face in a sealing relationship with a stationary seal face, and a fluid collection cavity adjacent the floating seal face and the stationary seal face. The seal further includes a device for introducing a lubricant into the vicinity of the fluid collection cavity and a device for promoting coalescence of the lubricant, so that the lubricant accumulates in the fluid collection cavity and lubricates the seal faces.

Owner:AES ENG

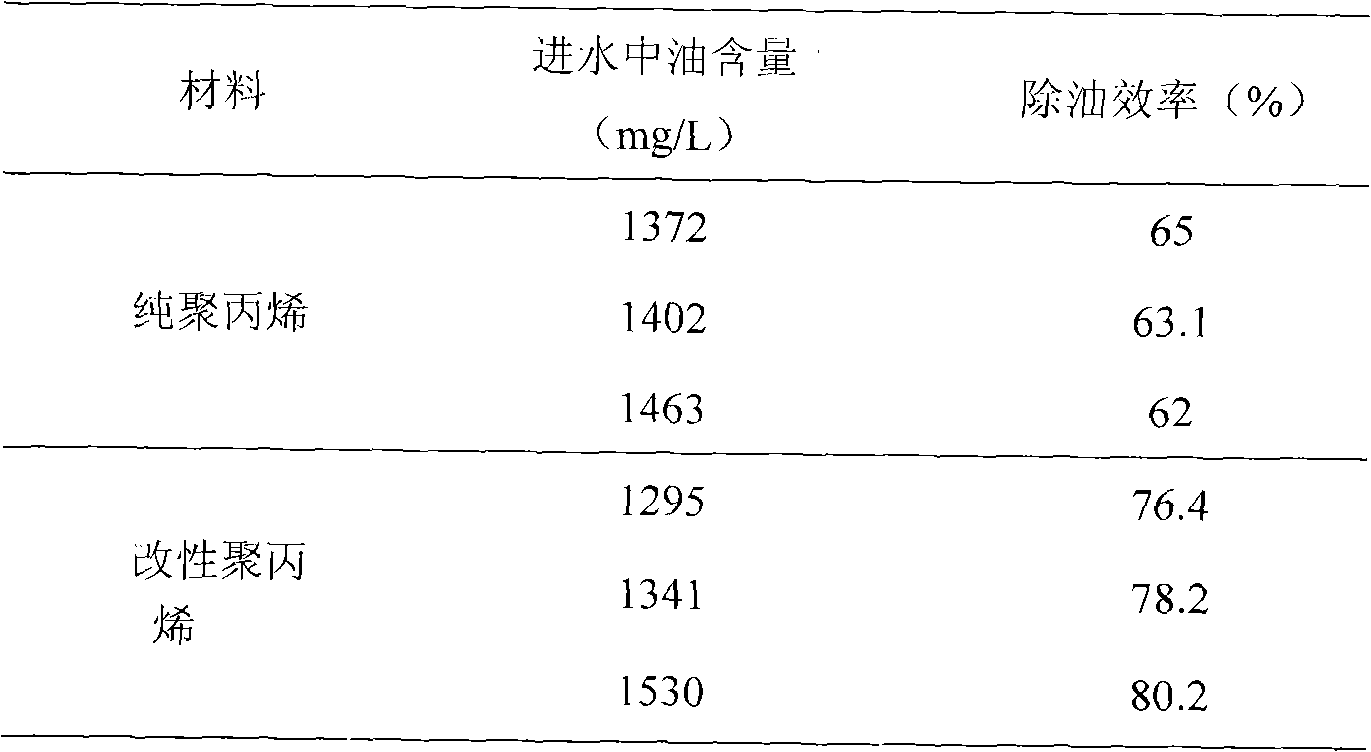

Coalescence material and preparation method

ActiveCN101838419AImprove lipophilic and hydrophilic balanceImprove coalescenceFatty/oily/floating substances removal devicesLiquid separationGlass fiberPolymer science

The invention relates to a coalescence material. The technical scheme is that: a polypropylene coalescence material is modified by polyvinylidene fluoride, nano-calcium carbonate, glass fibers and a 1010-antioxidant and the modified formula is formula a or formula b. According to the formula a, the mass part ratio of polypropylene, polyvinylidene fluoride, nano-calcium carbonate, glass fibers and 1010-antioxidant is 71.5%: 4%: 3%: 20%: 1.5%. According to the formula b, the mass part ratio of polypropylene, polyvinylidene fluoride, nano-calcium carbonate, glass fibers and 1010-antioxidant is 77.5%: 6%: 5%: 10%: 1.5%. According to the above formula a or formula b, the coalescence material is prepared by the steps of mixing the above components according the mass part ratio in the above formula a or formula b; mixing the raw materials uniformly at the temperature of between 50 and 80 DEG C; granulating the raw materials in a granulation machine; and drying at the temperature of between 50 and 95 DEG C after granulating so as to prepare a granular master batch of a polypropylene-modified coalescence material, wherein the working temperature of the granulation machine is between 165 and 185 DEG C; and the grain size is less than 3 mm. The coalescence material is better in balance between hydrophilic and lipophilic performances and is beneficial to the coalesce separation of oil droplets in the water.

Owner:CHINA PETROCHEMICAL CORP +2

Preparation method of zero-VOC high-performance alcoholic acid emulsion

The invention discloses a preparation method of a zero-VOC high-performance alcoholic acid emulsion. The preparation method comprises the following steps: firstly, performing alcoholysis on a drying oil or a semi-drying oil and a polyhydric alcohol under the action of a high temperature and an alcoholysis catalyst, and then performing an esterification reaction with polybasic acid to obtain an air-drying alkyd resin; next, moving the alkyd resin to a reaction kettle with a circulating water jacket, heating the circulating water in the jacket of the reaction kettle until an emulsification temperature, controlling the rotating speed to the range of 170rpm to 180rpm, adding a neutralizer to the reaction kettle and mixing thoroughly and evenly; keeping the temperature unchanged, and adding a proper amount of emulsifier to the reaction kettle, adjusting the rotating speed to the range of 250rpm to 270rpm, and stirring for 30 to 45 minutes; heating deionized water equivalent to the resin by mass until an emulsification temperature and slowly and dropwise adding the deionized water to the reaction kettle at a constant speed in about 3-5 hours; and furthermore, cooling in water bath under stirring until a room temperature, regulating the pH value of the emulsion by use of a pH regulator to the range of 5-7, and filtering to obtain the zero-VOC high-performance alcoholic acid emulsion. According to the preparation method, zero VOC emission is really realized in the production and application processes.

Owner:青岛乐化科技有限公司 +3

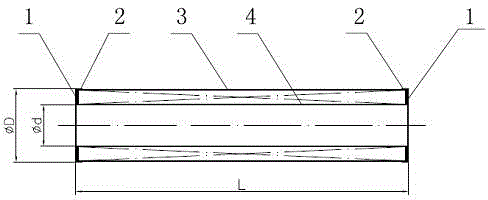

Composite metal coalescent filter element

InactiveCN103550987AImprove coalescenceEasy to replaceFiltration separationLiquid separationChemical industryEngineering

The invention relates to a composite metal coalescent filter element for separation and collection in the fields of environmental protection, chemical industry, foods, light industry, automobiles and the like. The composite metal coalescent filter element is provided with an internal framework and an external framework. the outer circumference of the internal framework is coated with a coalescent filter element material and is sleeved with the external framework, and both ends of the material are sealed through a seal pad and an end cover, wherein the coalescent filter element material sequentially comprises a silk screen, a flow distribution layer, a demulsification layer, an oleophylic stainless steel coalescent layer, a gathering layer, a flow distribution layer and a silk screen from the internal framework to the external framework. The composite metal coalescent filter element provided by the invention has the characteristics of high temperature resistance, corrosion resistance, wide using range, convenience for element replacement and maintenance and the like.

Owner:SHANGHAI FINETAC PRECISION TECH CO LTD

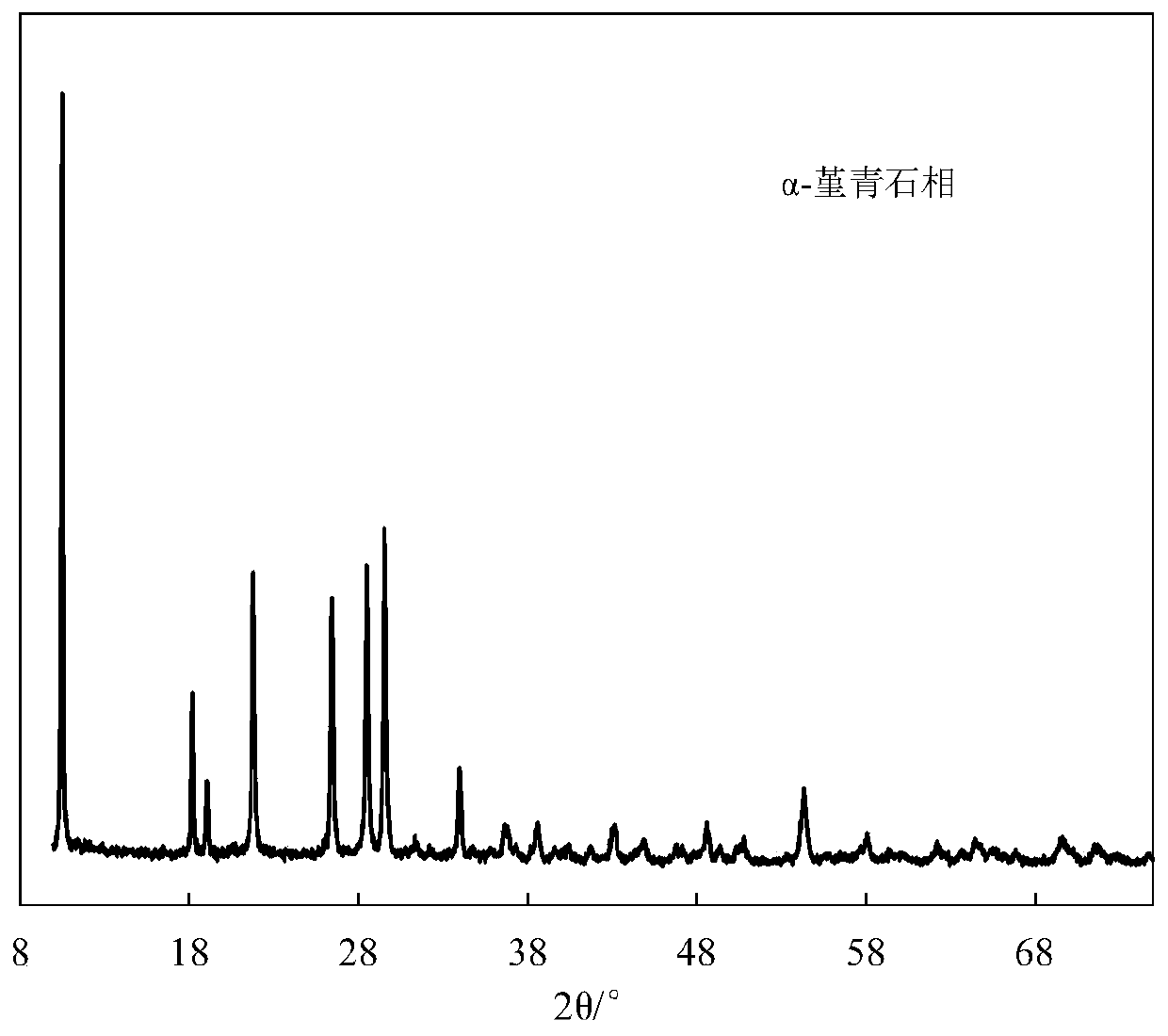

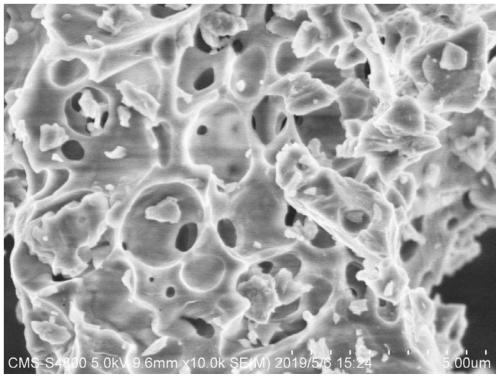

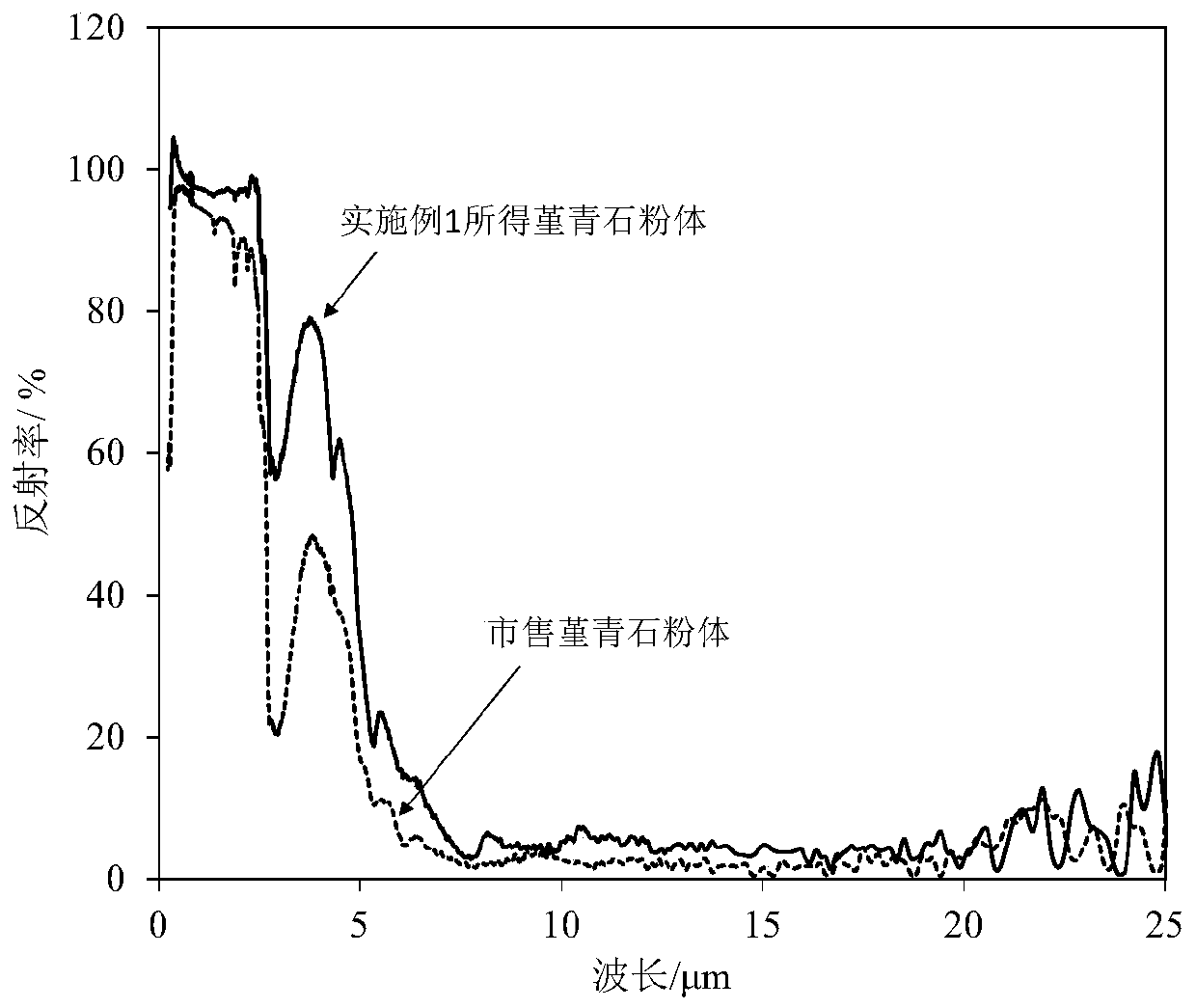

Radiation refrigeration coating and preparation method and application thereof

ActiveCN111303709AIncrease surface tensionReduce surface tensionAluminium silicatesReflecting/signal paintsAcrylic resinEthylic acid

The invention discloses a radiation refrigeration coating as well as a preparation method and application thereof. The radiation refrigeration coating is prepared from the following raw material components in percentage by mass: 4%-8% of porous cordierite, 10%-18% of titanium dioxide, 22%-35% of acrylic resin, 0.5%-1.5% of a silane coupling agent, 0.1%-1% of a coalescing agent, 0.1%-1% of a leveling agent, 0.1%-1% of a dispersing agent, 0.2%-1% of an antifoaming agent, 0.1%-2% of a thickener, 0.1%-2% of an anti-flash rust agent and the balance of dipropylene glycol methyl ether acetate, and the radiation refrigeration coating is prepared by mixing the raw materials. The radiation refrigeration coating disclosed by the invention has high sunlight reflectivity and high selectivity and radiance in an atmospheric window, the preparation method has the advantages of simplicity, feasibility, low cost and the like, and meanwhile, a radiation refrigeration coating layer prepared from the coating can realize all-weather refrigeration, has a good refrigeration effect, and has very high use value and application prospect.

Owner:NAT UNIV OF DEFENSE TECH

Water-based environmental-friendly sandpaper and production method thereof

ActiveCN109290971AImprove water resistanceReduce cloggingAbrasion apparatusSandpaperFolding endurance

The invention provides water-based environmental-friendly sandpaper. The water-based environmental-friendly sandpaper comprises a base paper layer (1), a waterproof treatment layer (2), a bottom gluelayer (3), an abrasive layer (4), a compound glue layer (5) and an anti-blocking treatment layer (6) which are sequentially arranged from bottom to top. The waterproof treatment layer in the sandpaperimproves the waterproof capability, tensile strength, softness, folding endurance and smoothness of the base paper layer and effectively prevents base glue and compound glue from penetrating to the back of the base paper layer. The anti-blocking treatment layer in the sandpaper can make abrasive dust fall off and be not adhered to the sandpaper, so that the blocking phenomenon generated during the grinding of the sandpaper is reduced effectively, the service life of the sandpaper is greatly prolonged, and the grinding efficiency is improved.

Owner:湖北重泰研磨工具有限公司

Coking demulsifier and preparation method thereof

InactiveCN103951009AReduce oil contentPromote stratificationFatty/oily/floating substances removal devicesNon-miscible liquid separationDemulsifierInorganic ions

The present invention discloses a coking demulsifier, which comprises, by weight, 25-40% of a cationic surfactant, 5-10% of a dispersant, 5-10% of a wetting agent, 10-20% of a corrosion inhibitor, and the balance of water. The present invention further discloses a preparation method for the coking demulsifier. According to the present invention, rapid demulsification of the delayed coking apparatus oil-water separation tank can be achieved, and the oil content in the discharged water can be significantly reduced; the water is clear after demulsification; corrosion of the water body on equipment is reduced; and the coking demulsifier does not contain inorganic ions, and does not affect the existing water system.

Owner:宜兴汉光高新石化有限公司

Method and System for Precluding Air Pollution in Industrial Facilities

InactiveUS20180142368A1Reduced Power RequirementsReduce heat lossElectrolysis componentsAtmospheric airPower usage

A holistic system for sustained capture, confinement and depuration of acid mist generated in nonferrous metal electrodeposition processes utilizing lead anodes, for precluding zero release of gaseous fluid pollutants in the atmospheric air surrounding electrodeposition processes, providing an assured solution to acid mist control and total abatement in an effective, efficient manner and sustainable in time by immediate recovery and recycling back in the source generating the contaminant effluents as there are produced, according to a “cell by cell” strategy, and directly connecting each cell to a system for depuration, recovery and recycling the contaminants gaseous fluid flow extracted from each cell reducing them to innocuous levels in the discharge to the open atmosphere; complying the condition of “100% Null escape of acid mist” from each individual cell to the working environment, simultaneously with minimum power usage, and substantial global gaseous fluid contaminant reduction, far exceeding present minimum sustainability standards, in terms of human health, energy usage and environmental protection.

Owner:VIDAURRE HEIREMANS VICTOR EDUARDO

High-temperature-resistant coating containing hydantoin epoxy resin and preparation method of high-temperature-resistant coating

InactiveCN104673092ALow viscosityImprove insulation performanceAnti-corrosive paintsEpoxy resin coatingsChemistrySilicone resin

The invention discloses a high-temperature-resistant coating containing hydantoin epoxy resin. The coating comprises a component I and a component II, wherein the component I is blended by a component A and a component B, the component A comprises ingredients as follows: the hydantoin epoxy resin, filler, a dispersing agent, an auxiliary, a coalescing agent, a thickening agent and a defoaming agent, and the component B comprises ingredients as follows: grafted organic silicon resin, a thixotropic agent, a matting agent, antimonous oxide, an auxiliary and a mildew preventive; the component II comprises components as follows: a curing agent, a coupling agent and a solvent. The invention further designs a preparation method of the high-temperature-resistant coating containing the hydantoin epoxy resin. The preparation method is simple to operate and low in cost, and the prepared coating has excellent high temperature resistance and high adhesive force, and is non-poisonous and pollution-free.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

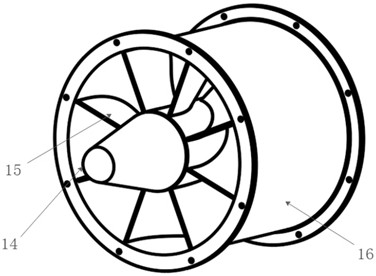

Coal mine dust removal system and dust removal method

ActiveCN111878153AReasonable matchingReduce volumeHuman health protectionCombination devicesMining engineeringSlag

The invention discloses a coal mine dust removal system and dust removal method. The coal mine dust removal system comprises a trapping device, a pneumatic suction device, an entrainment dust removaldevice, a cyclone separation device, a multi-phase flow division device and a dust exhauster which are connected in sequence, wherein the trapping device, the pneumatic suction device, the entrainmentdust removal device, the cyclone separation device and the multi-phase flow division device are all of tubular structures, every two adjacent devices are integrally connected through a flange, and the pneumatic suction device is connected with a coal mine ventilation pipe through a telescopic hose; a slag discharge port of the multi-phase flow division device is connected with a coal mine slag discharge system through a telescopic pipeline, the entrainment dust removal device is connected with a coal mine water supply system through a hose, and stop valves are arranged on the telescopic hoseand a pipeline of the hose. The coal mine dust removal system is reasonable in unit combination design and small in size, and has the advantages of being small in investment, small in occupied area, low in energy consumption, high in dust removal rate and the like, and the coal mine dust removal method has the advantages of being short in process, low in operation cost and the like.

Owner:DALIAN EAST REFRIGERATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com