Environment-friendly interior wall paint and preparation method thereof

An interior wall coating, environmental protection technology, applied in the field of coatings, can solve the problems of no adsorption and degradation, achieve the effect of improving coalescence, improving coalescence performance, and excellent elimination of harmful gases such as formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

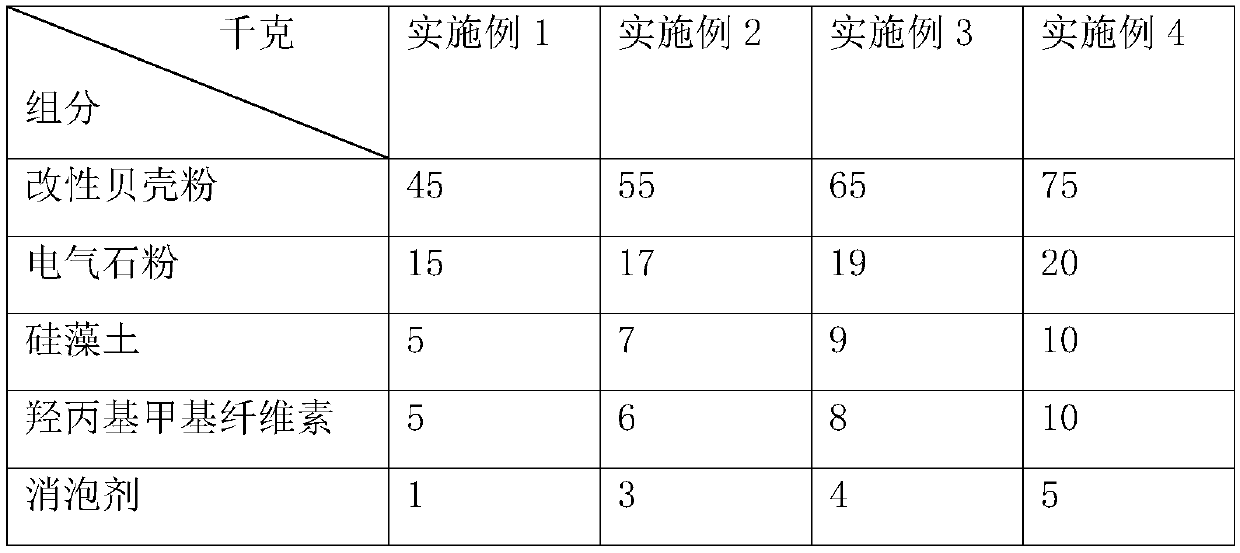

Examples

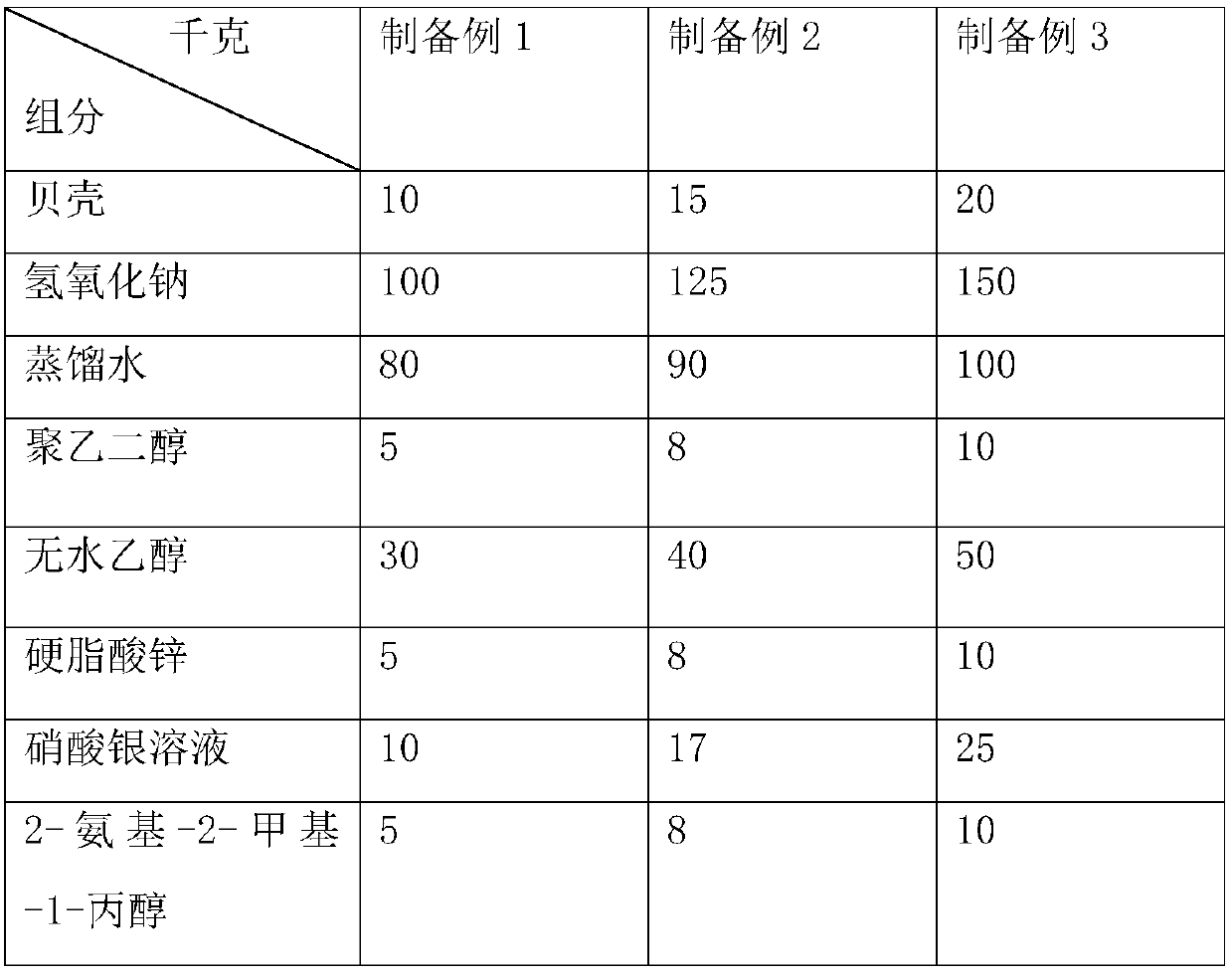

preparation example 1

[0042] Preparation Example 1: (1) According to the ratio in Table 1, 10 kg of shells were soaked in 100 kg of 4% sodium hydroxide solution for 18 hours, ultrasonically cleaned several times, then placed in an oven, and dried at 100°C for 20 hours , taken out, ground, and passed through a 100-mesh sieve to obtain shell powder; the ultrasonic cleaning frequency was 25kHz, the single cleaning time was 5min, the grinding time was 10h, the grinding medium was zirconia balls, the ball-to-material ratio was 4:1, and the ball mill speed 30r / min;

[0043] (2) Take the shell powder, add 80 kg of distilled water and 5 kg of polyethylene glycol, heat it in a water bath to 95 °C after ultrasonic oscillation and dispersion, add 5 kg of zinc stearate, mix and stir for 1.5 hours, suction filter, and use 30 kg of anhydrous Suction filtration after washing with ethanol; the ultrasonic oscillation frequency is 40kHz, and the oscillation time is 20min;

[0044] (3) Take the result of step (2), a...

preparation example 2

[0045] Preparation Example 2: (1) According to the proportioning in Table 1, 15 kg of shells were soaked in 125 kg of 6% sodium hydroxide solution for 25 hours, ultrasonically cleaned several times, then placed in an oven, and dried at 115°C for 22 hours , taken out, ground, and passed through a 100-mesh sieve to obtain shell powder; the ultrasonic cleaning frequency is 35kHz, the single cleaning time is 8min, the grinding time is 11h, the grinding medium is zirconia balls, the ball-to-material ratio is 5:1, and the ball mill speed 35r / min;

[0046] (2) Take the shell powder, add 90 kg of distilled water and 8 kg of polyethylene glycol, heat it in a water bath to 98 ° C after ultrasonic oscillation and dispersion, add 8 kg of zinc stearate, mix and stir for 1.8 hours, suction filter, and use 40 kg of anhydrous Suction filtration after washing with ethanol; the ultrasonic oscillation frequency is 45kHz, and the oscillation time is 25min;

[0047] (3) Take the result of step (2...

preparation example 3

[0048] Preparation Example 3: (1) According to the proportioning in Table 1, 20 kg of shells were soaked in 150 kg of 8% sodium hydroxide solution for 28 hours, ultrasonically cleaned several times, then placed in an oven, and dried at 130°C for 24 hours , taken out, ground, and passed through a 100-mesh sieve to obtain shell powder; the ultrasonic cleaning frequency is 40kHz, the single cleaning time is 10min, the grinding time is 12h, the grinding medium is zirconia balls, the ball-to-material ratio is 6:1, and the ball mill speed 40r / min;

[0049] (2) Take the shell powder, add 100 kg of distilled water and 10 kg of polyethylene glycol, heat it in a water bath to 100 ° C after ultrasonic oscillation and dispersion, add 10 kg of zinc stearate, mix and stir for 2 hours, filter with suction, and use 50 kg of absolute ethanol Suction filtration after washing; wherein the ultrasonic oscillation frequency is 50kHz, and the oscillation time is 30min;

[0050] (3) Take the result ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com