Patents

Literature

34results about How to "Better behaved" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

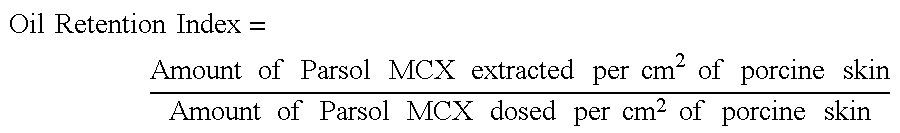

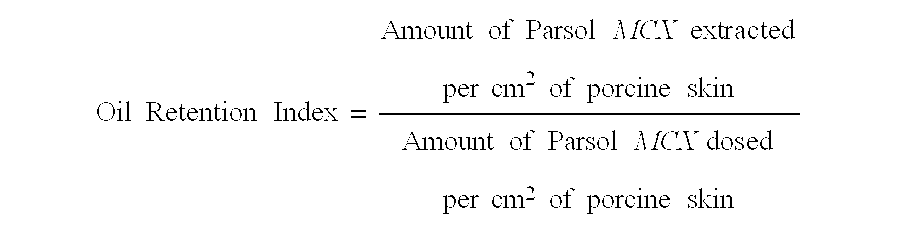

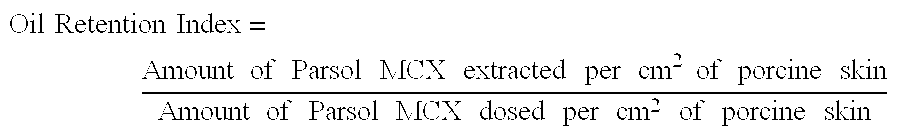

Wet-skin treatment compositions

InactiveUS6645511B2Better behavedFast absorptionCosmetic preparationsToilet preparationsSkin treatmentsDermatology

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

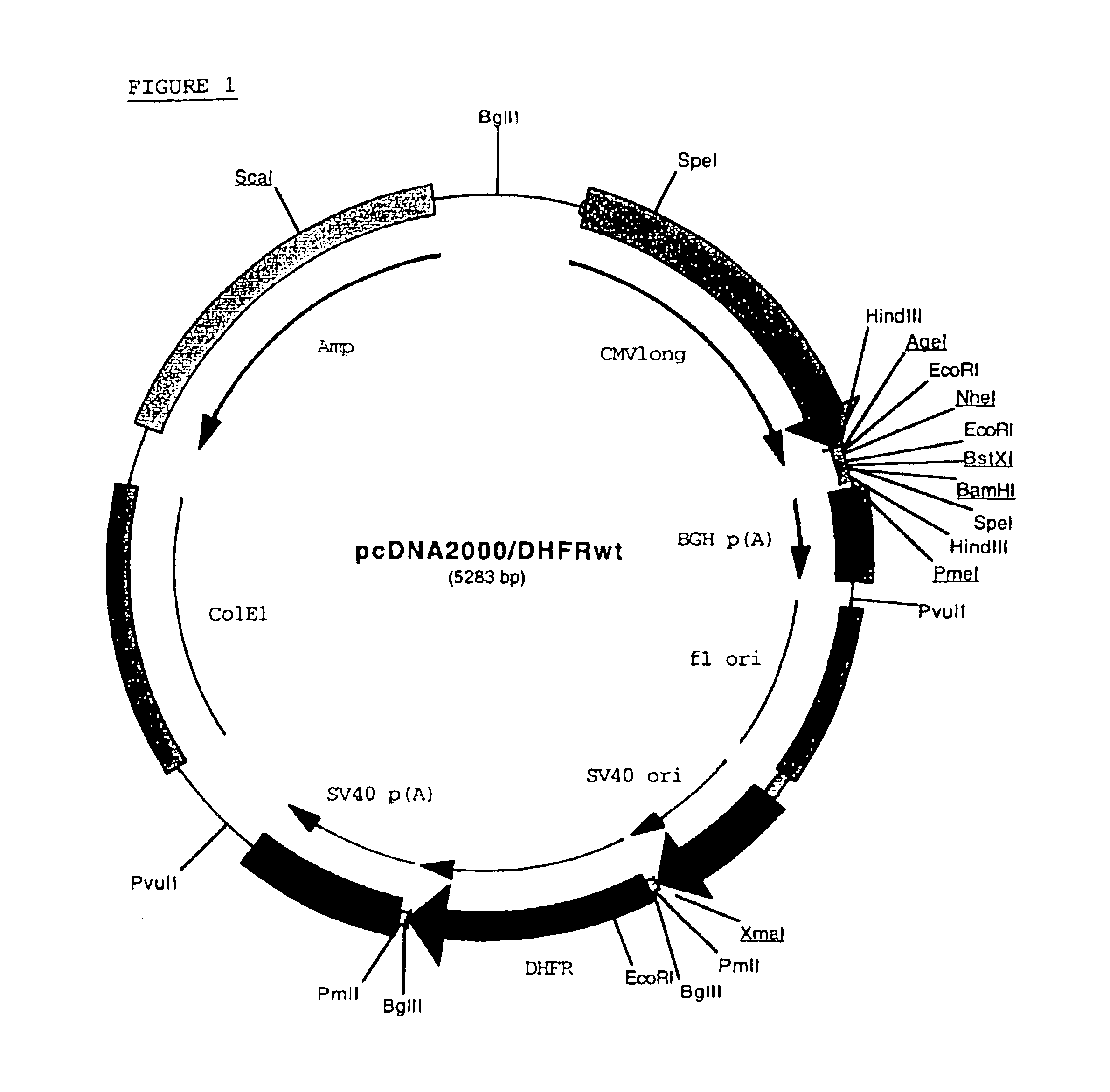

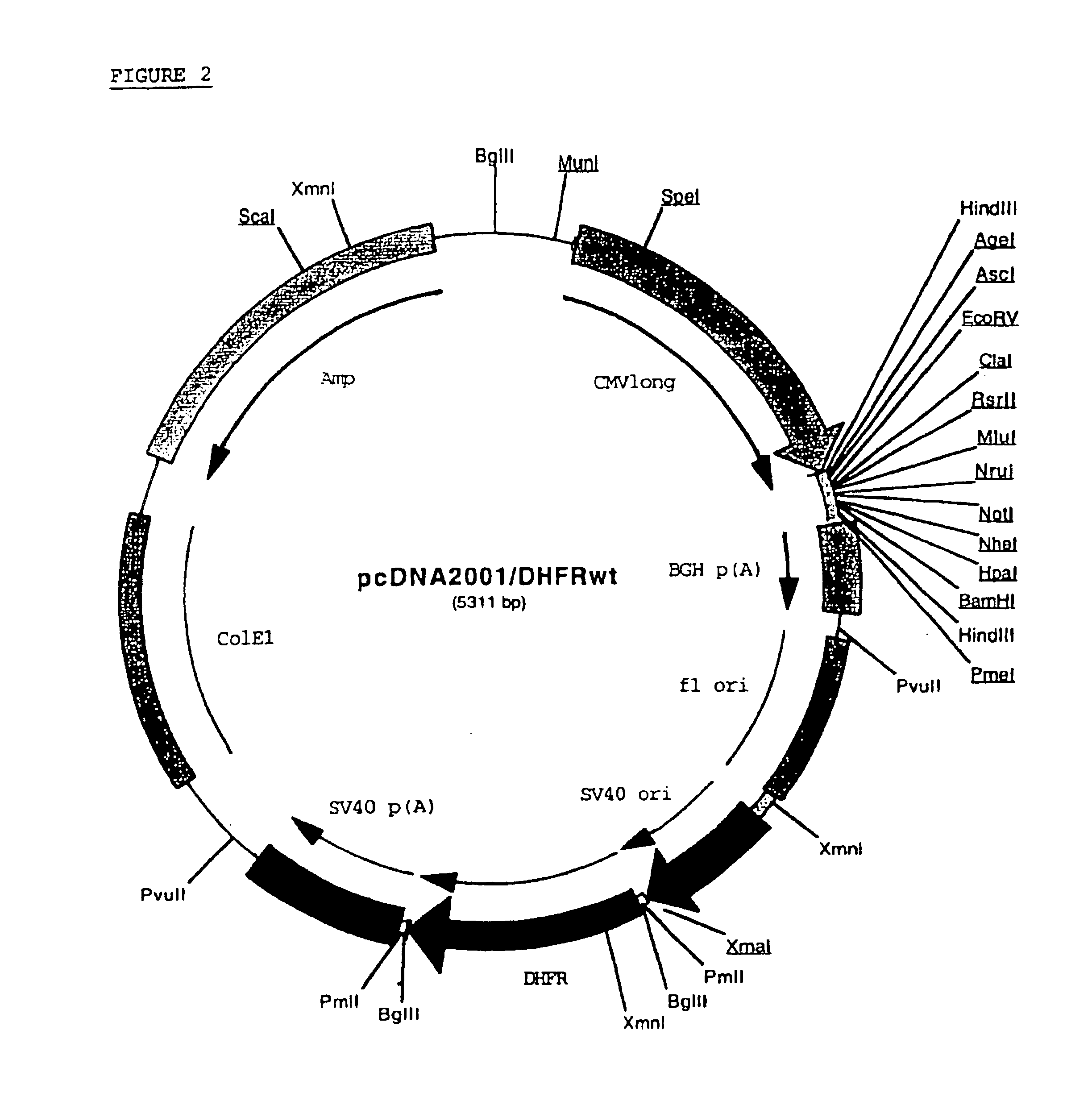

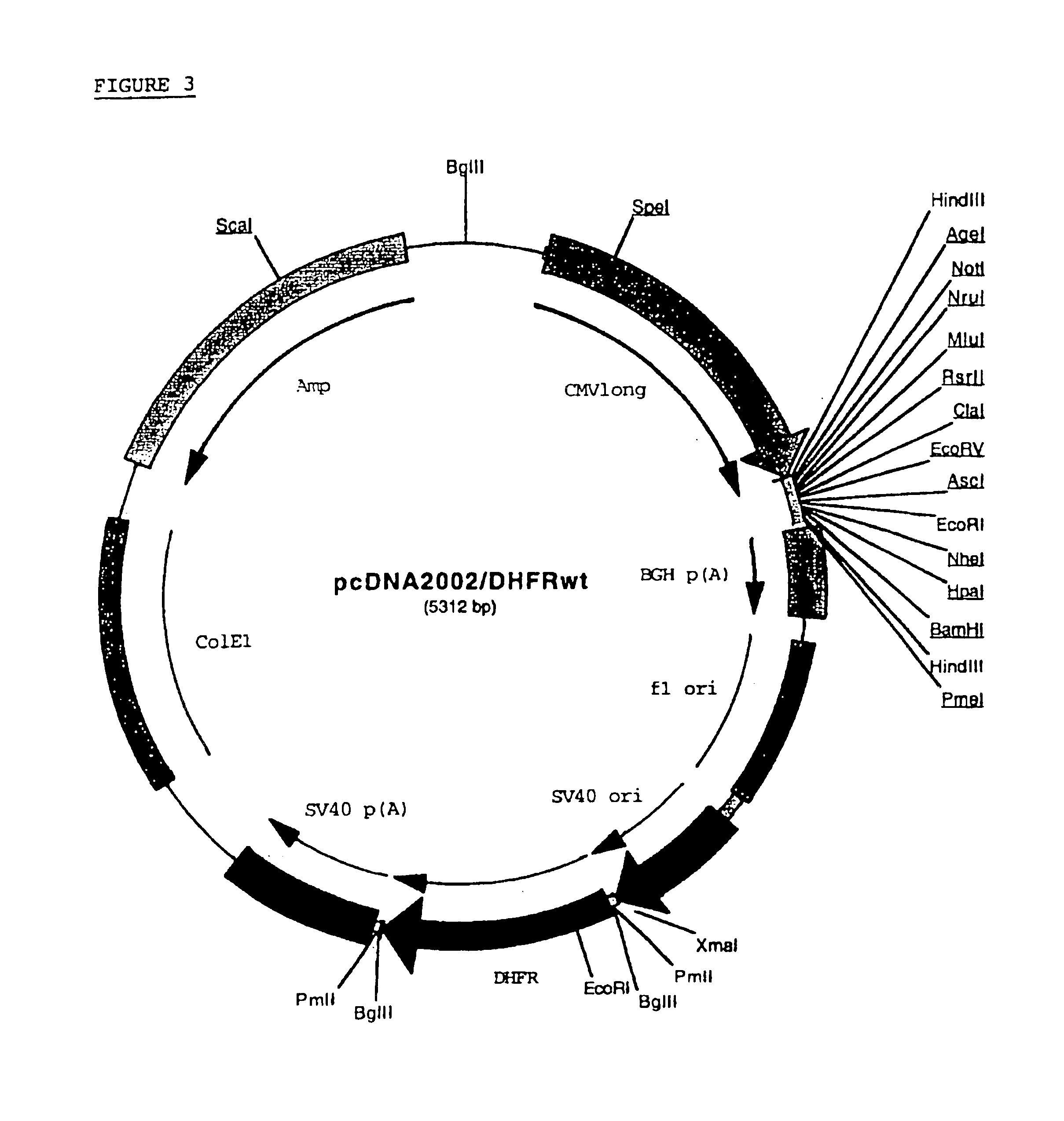

Recombinant protein production in a human cell

InactiveUS6855544B1Easy to handleLarge-scale (continuous) productionSsRNA viruses negative-senseSugar derivativesHamsterHuman cell

Methods and compositions for the production of recombinant proteins in a human cell line. The methods and positions are particularly useful for generating stable expression of human recombinant proteins of interest that are modified post-translationally, for example, by glycosylation. Such proteins may have advantageous properties in comparison with their counterparts produced in non-human systems such as Chinese Hamster Ovary cells.

Owner:JANSSEN VACCINES & PREVENTION BV

Method of enhanced moisture or reduced drying using wet-skin treatment compositions

InactiveUS20030049282A1Better behavedFast absorptionCosmetic preparationsToilet preparationsSkin treatmentsMoist skin

The invention provides methods of enhancing moisture or reducing drying using wet skin treatment composition. These compositions are activated by water and retained efficiently on skin. Thus, the compositions (and methods used) impart desirable benefits to skin, are perceived to absorb quickly on wet skin and leave the skin feeling clean, but non-greasy.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Wet-skin treatment compositions

InactiveUS20030054019A1Better behavedFast absorptionCosmetic preparationsHair cosmeticsSkin treatmentsDermatology

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Electrical, plating and catalytic uses of metal nanomaterial compositions

ActiveUS7820097B2Improve absorption rateReduce reflectivityOptical radiation measurementMangetographic processBiological activationElectroplating

Owner:NCC NANO LLC

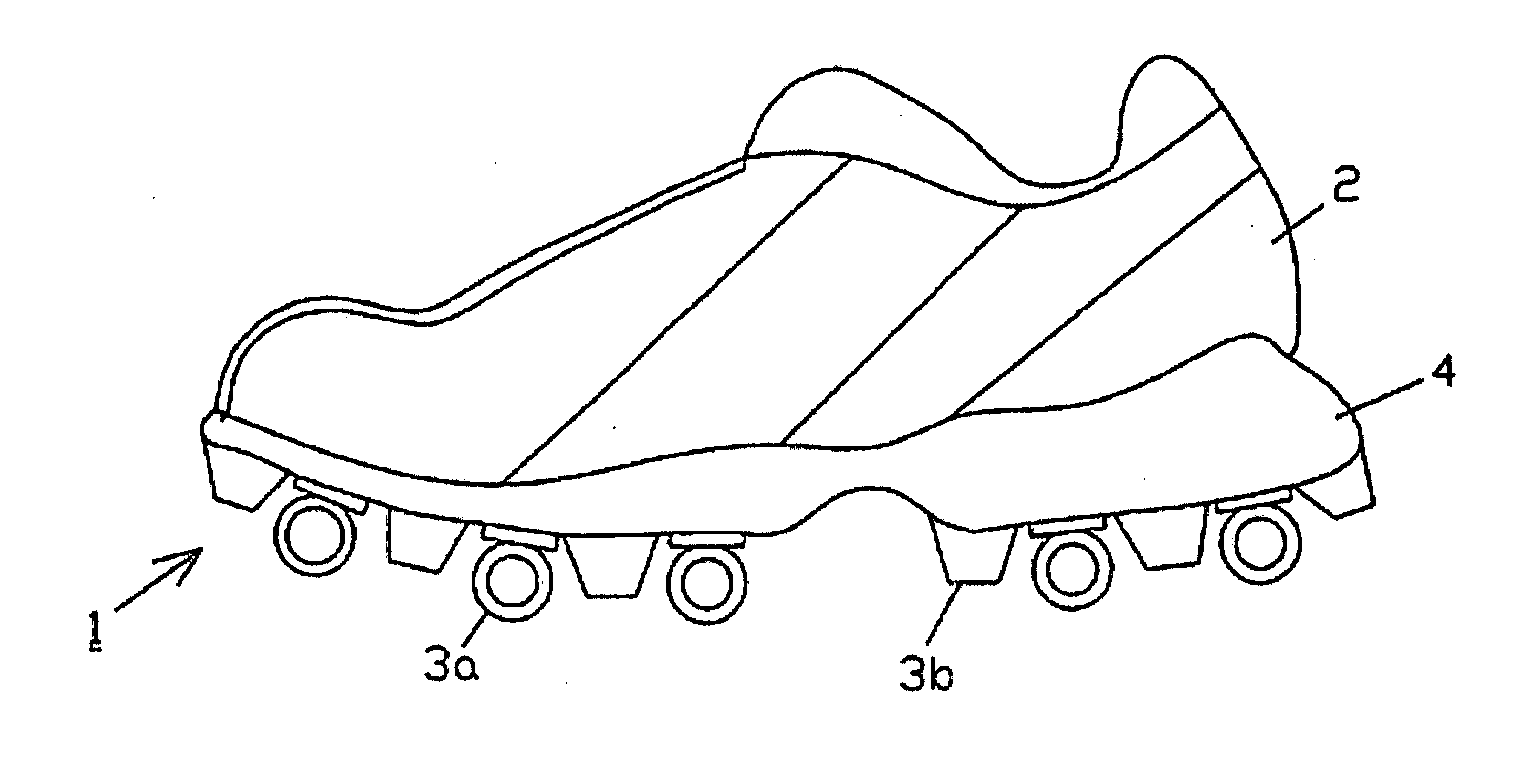

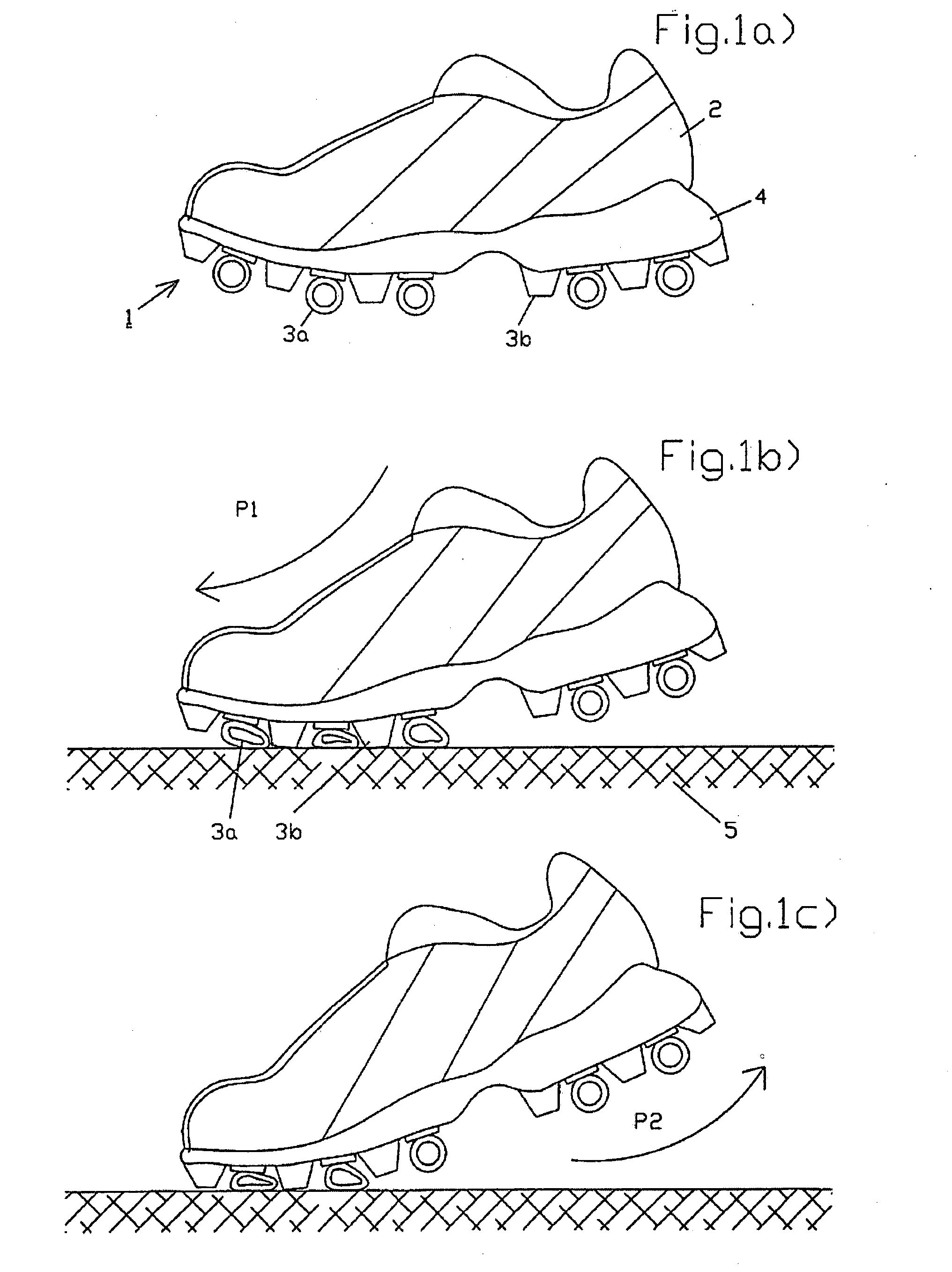

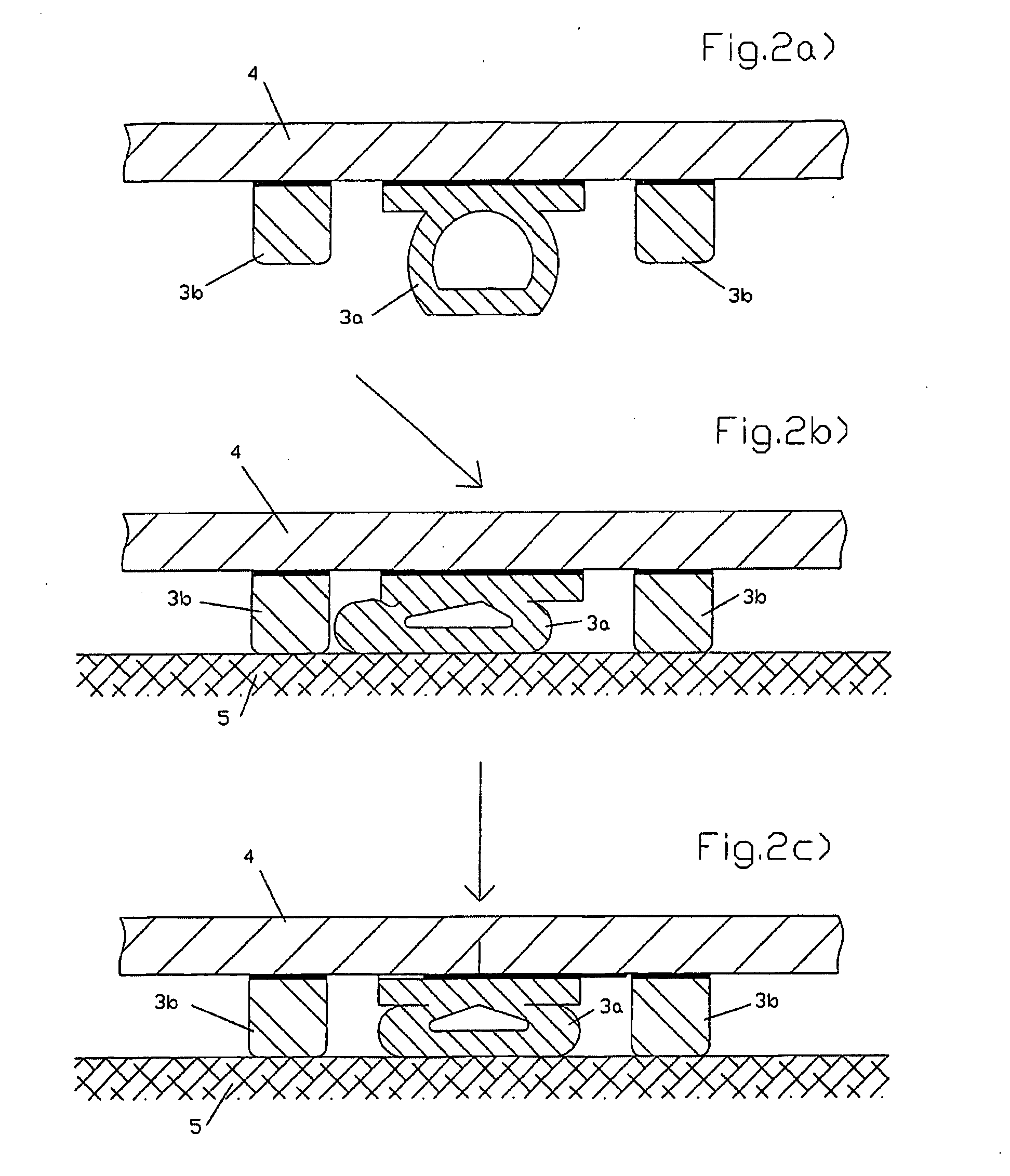

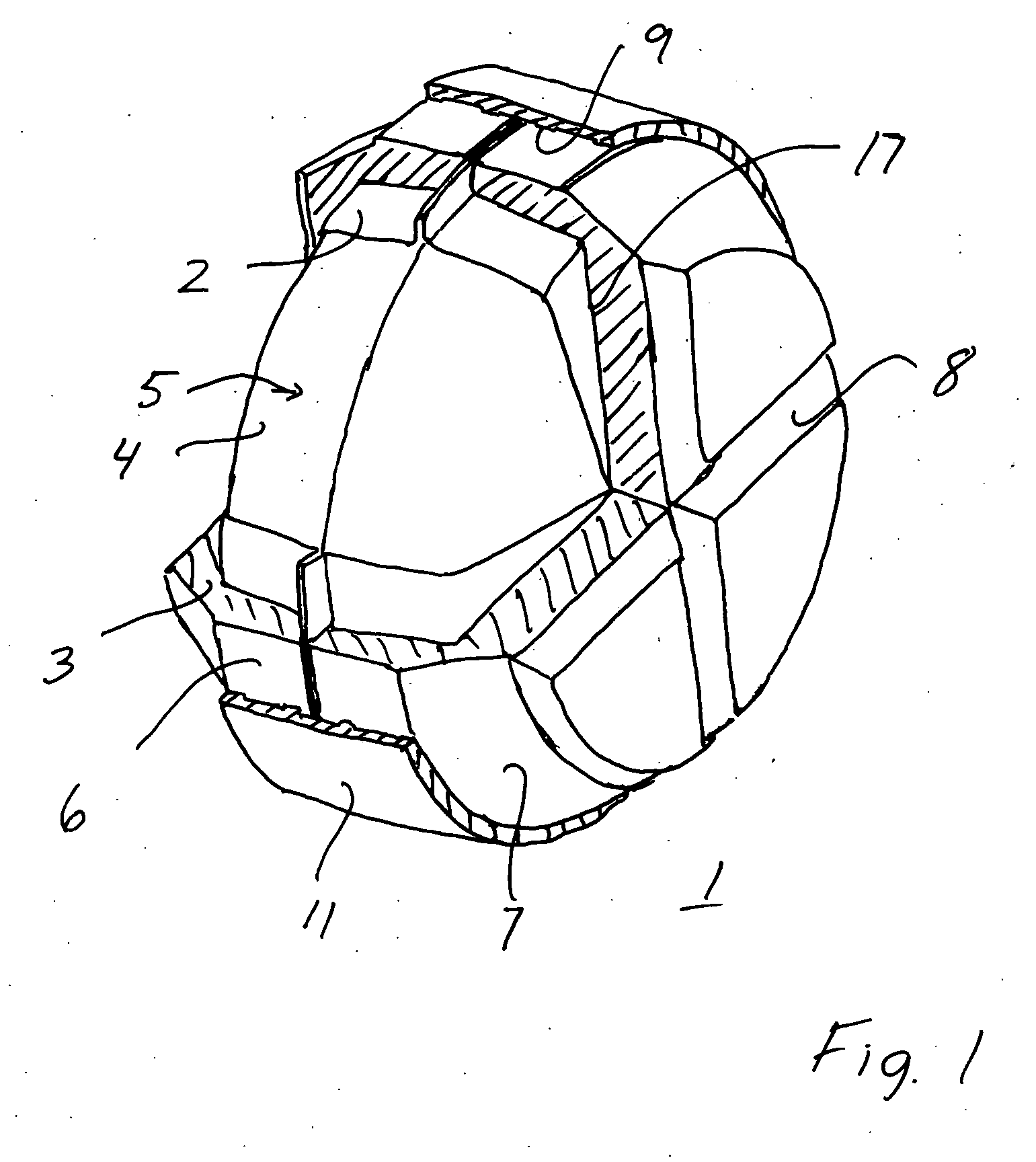

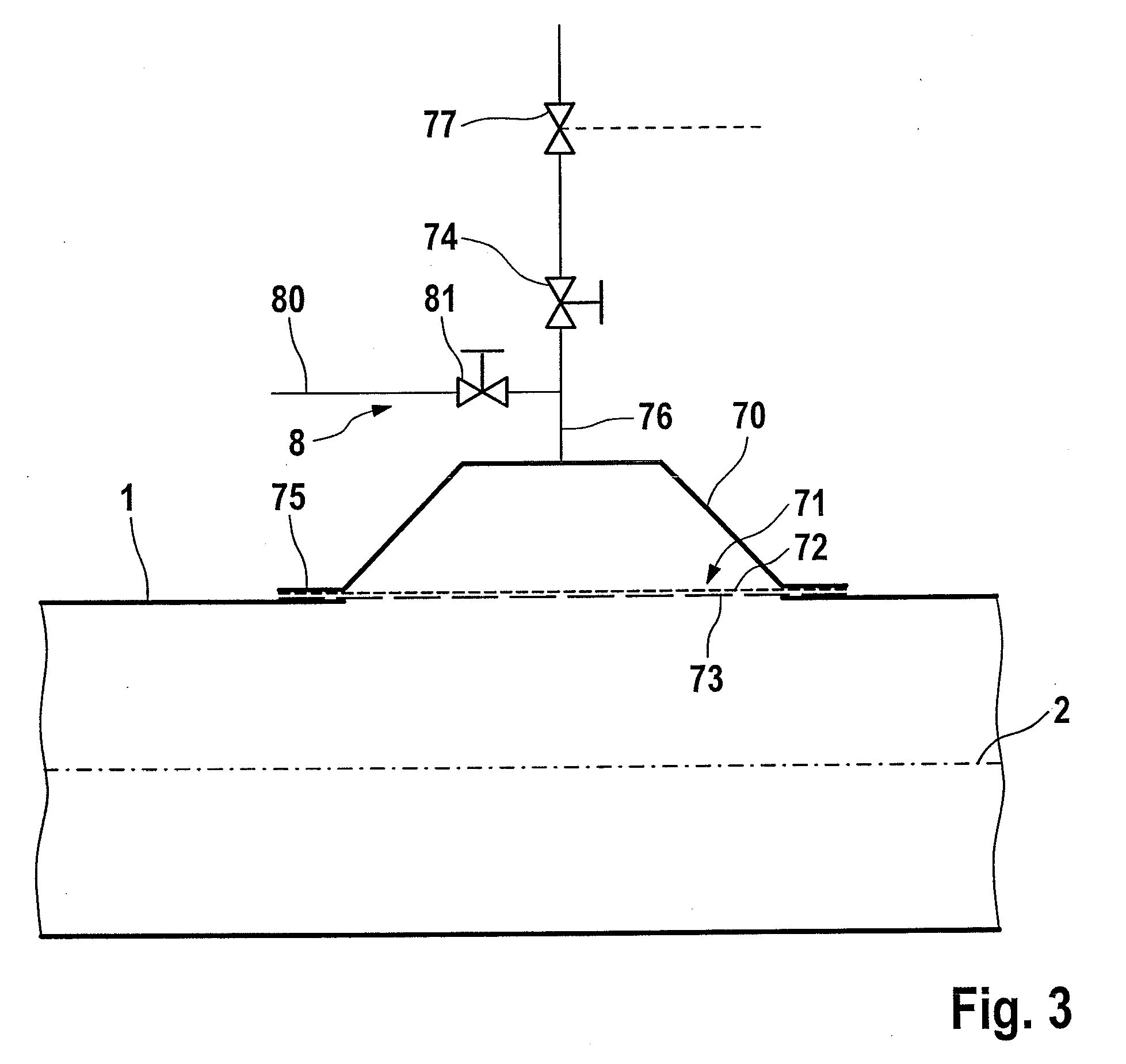

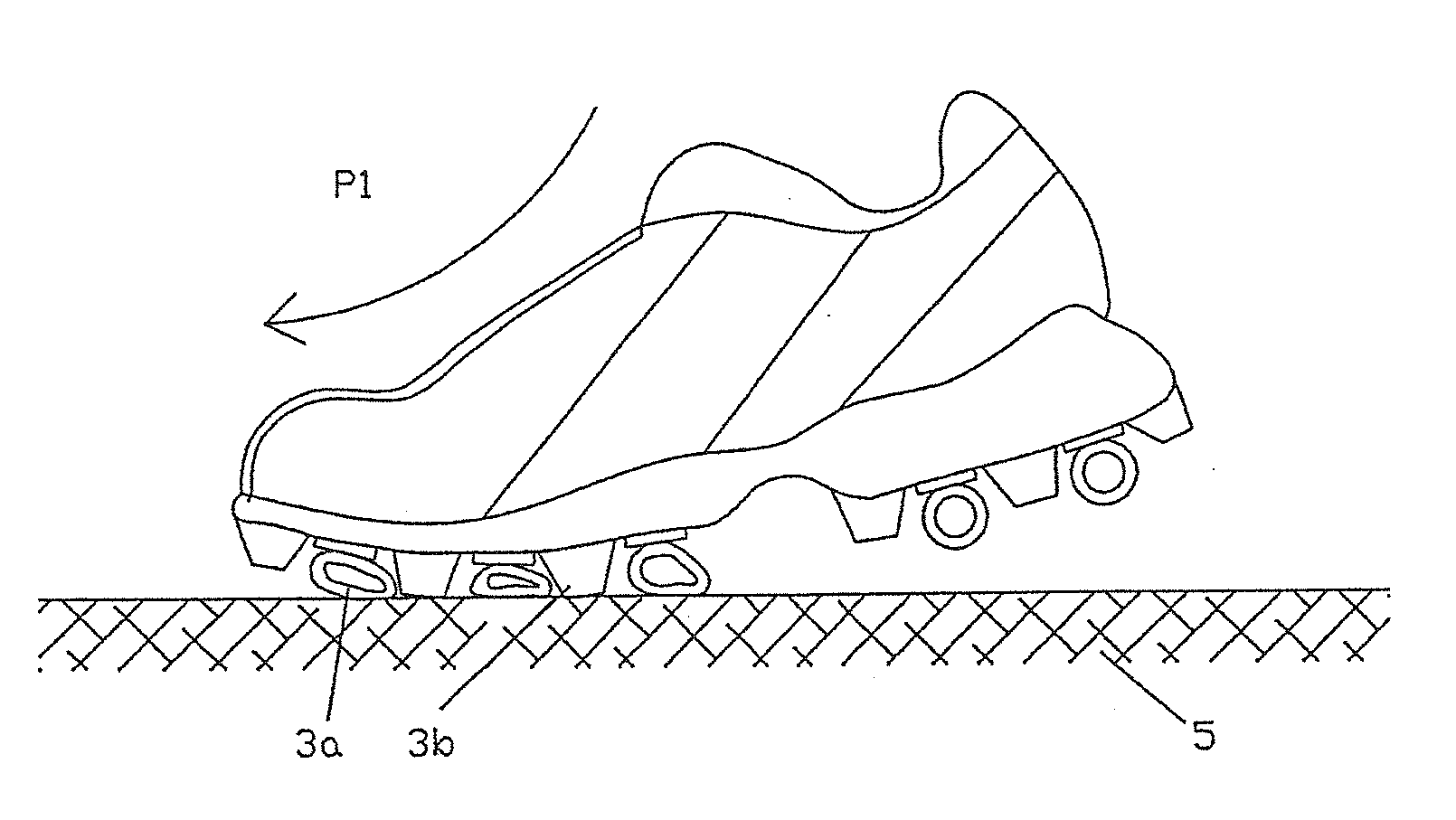

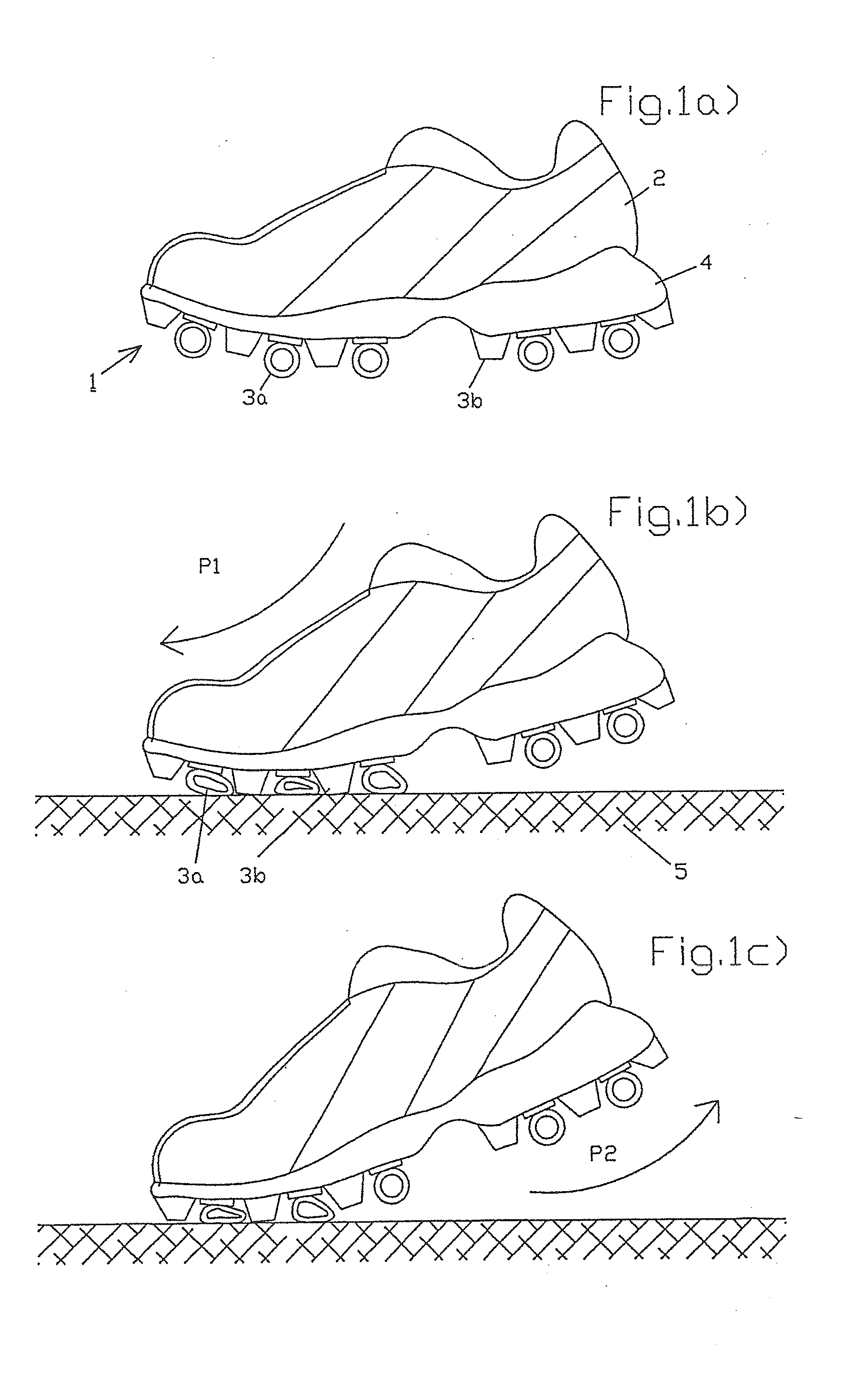

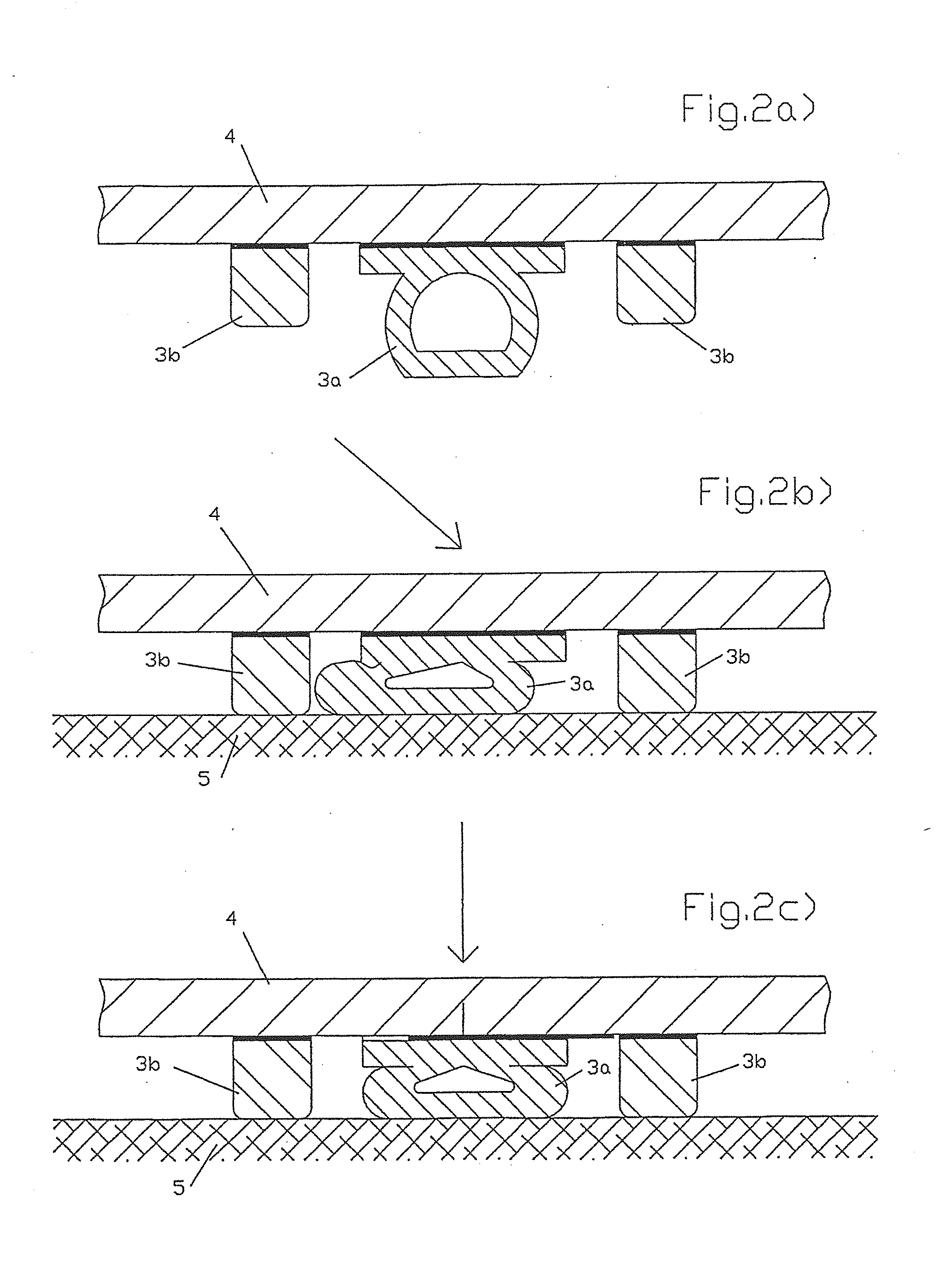

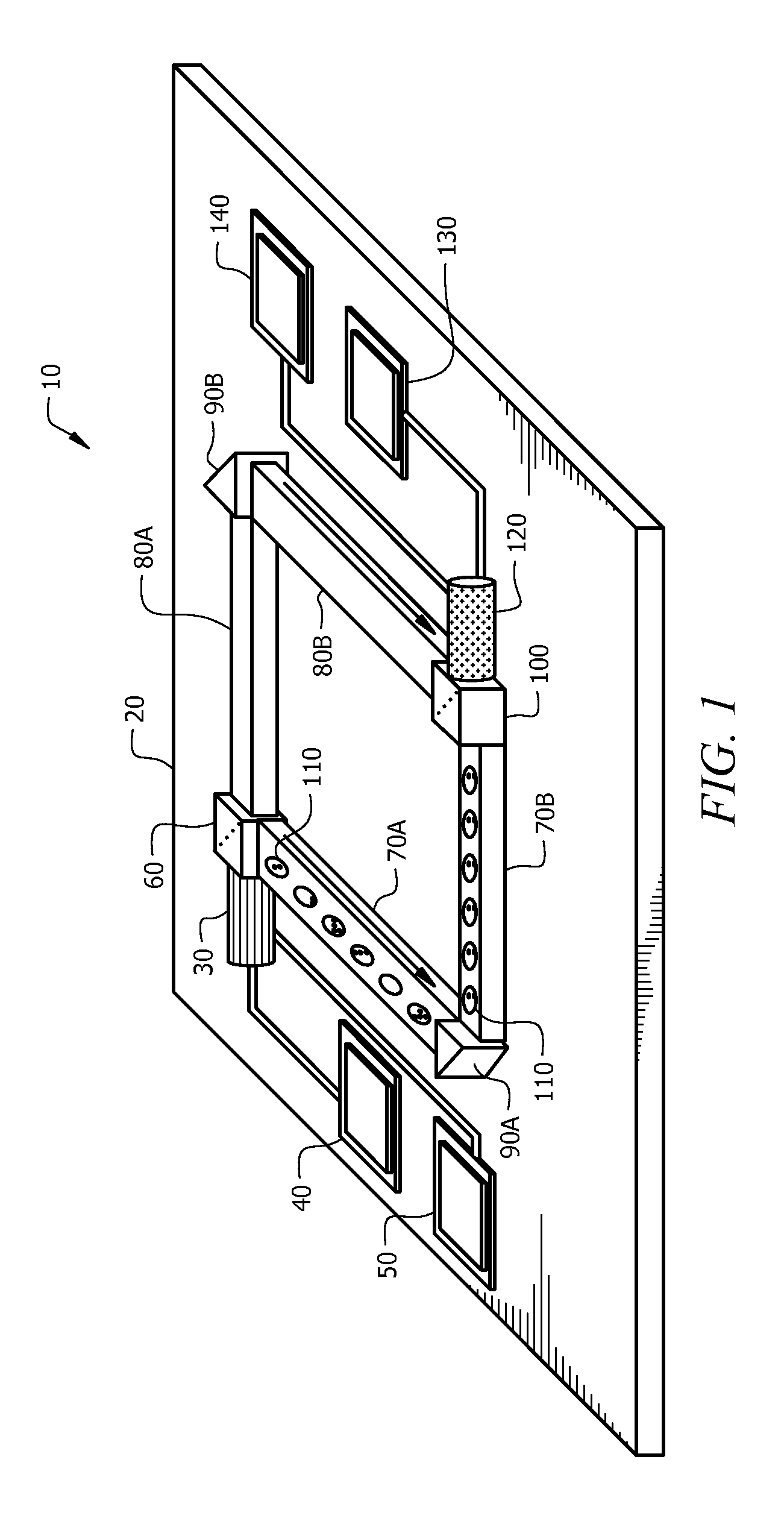

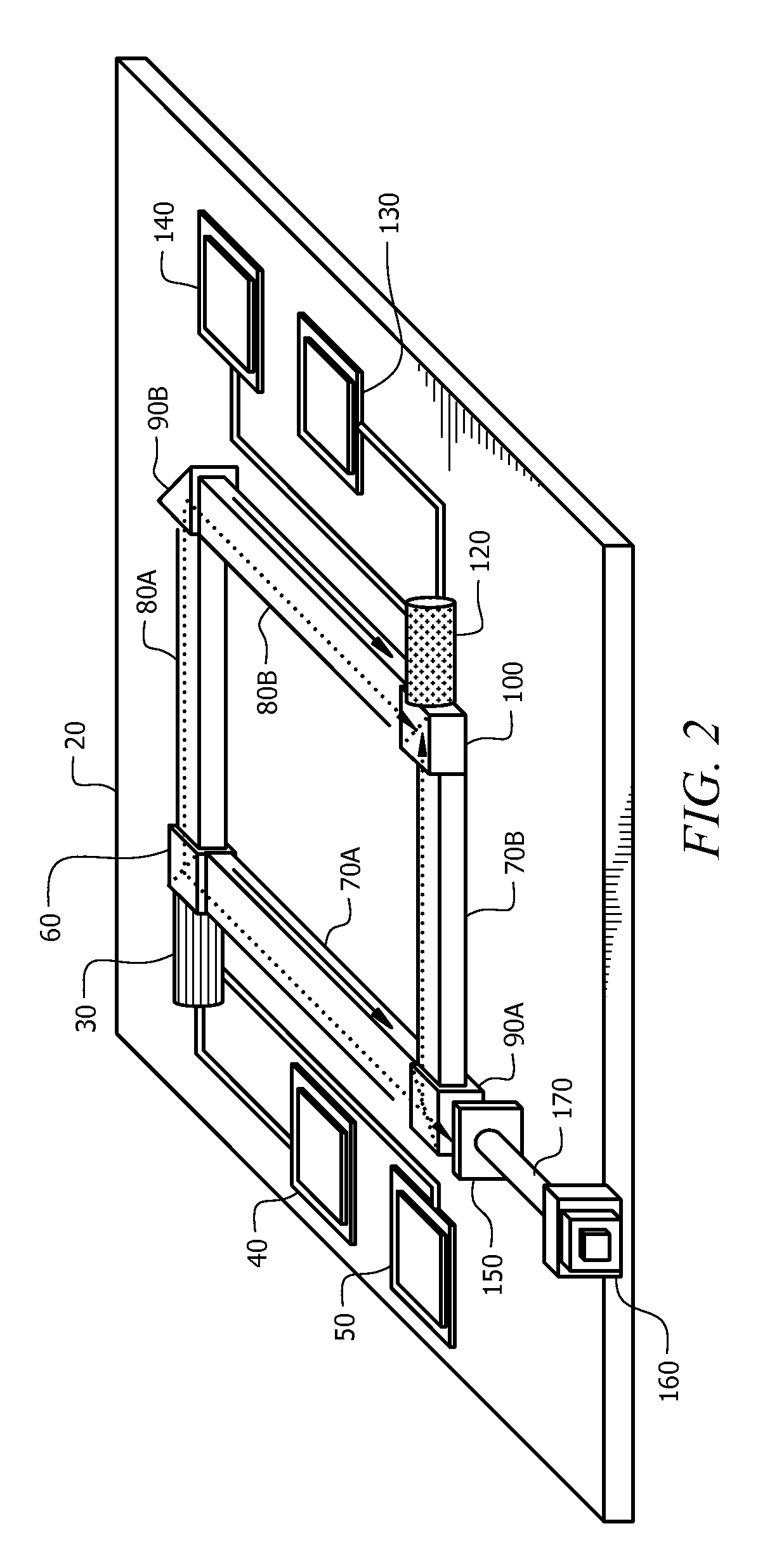

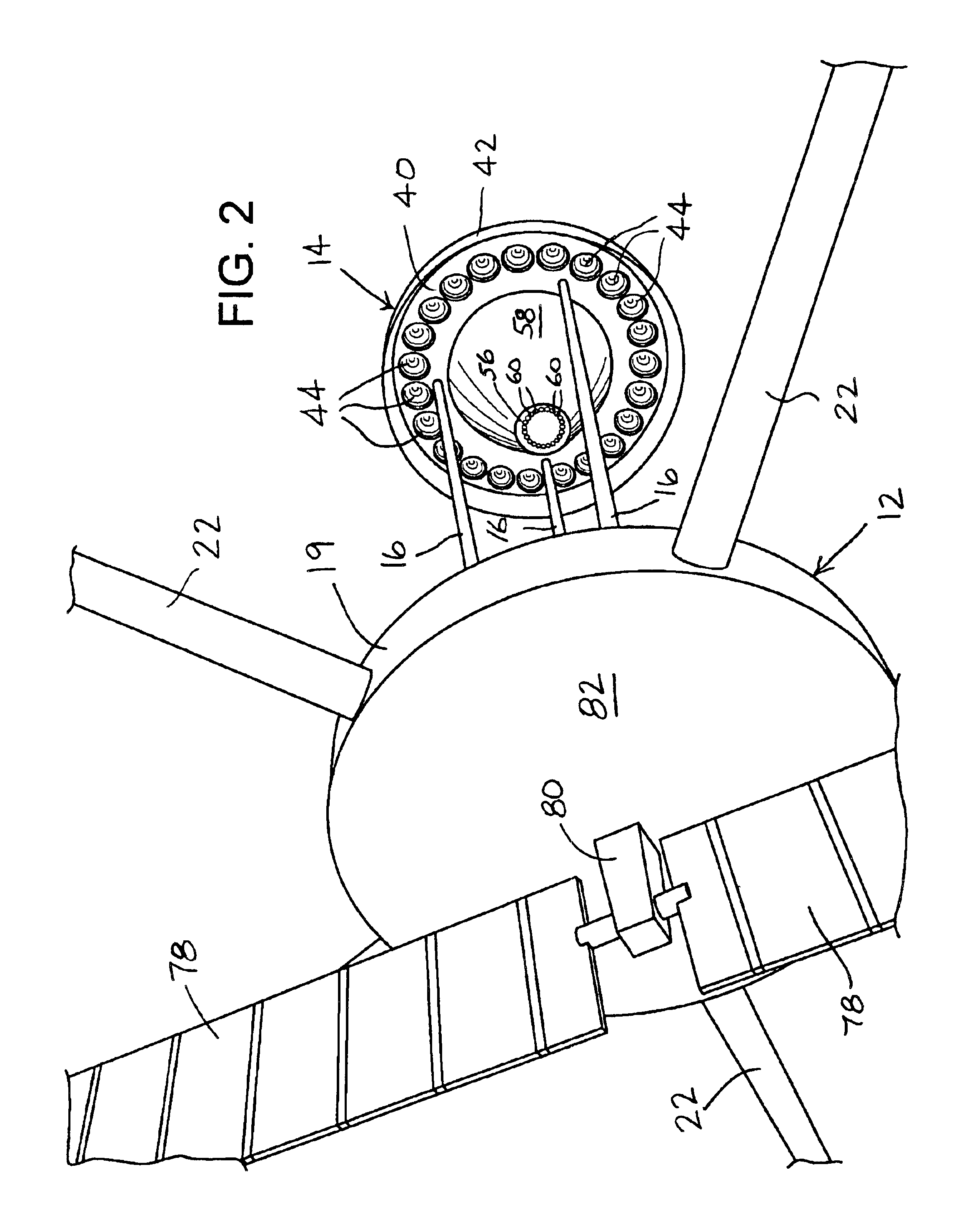

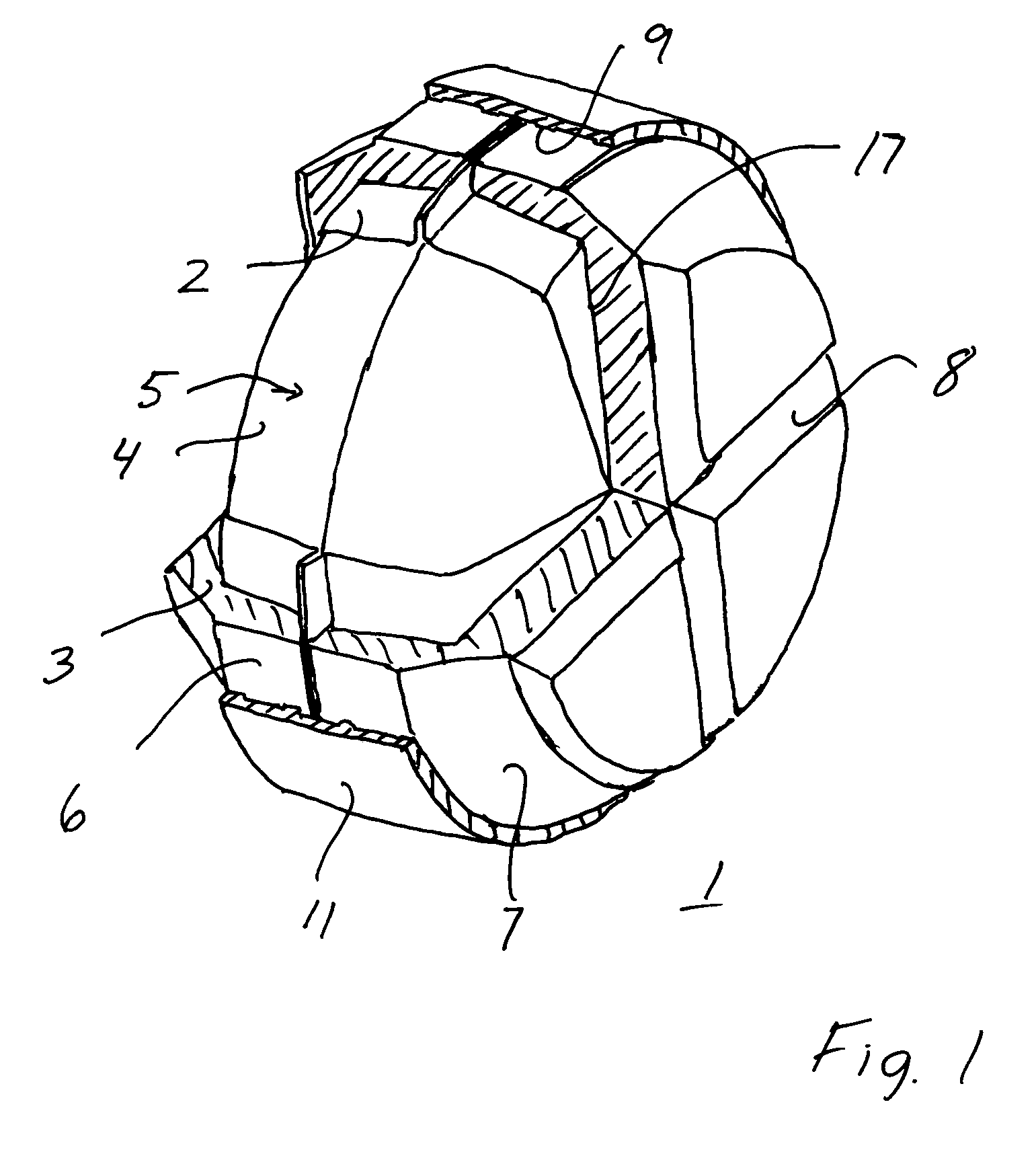

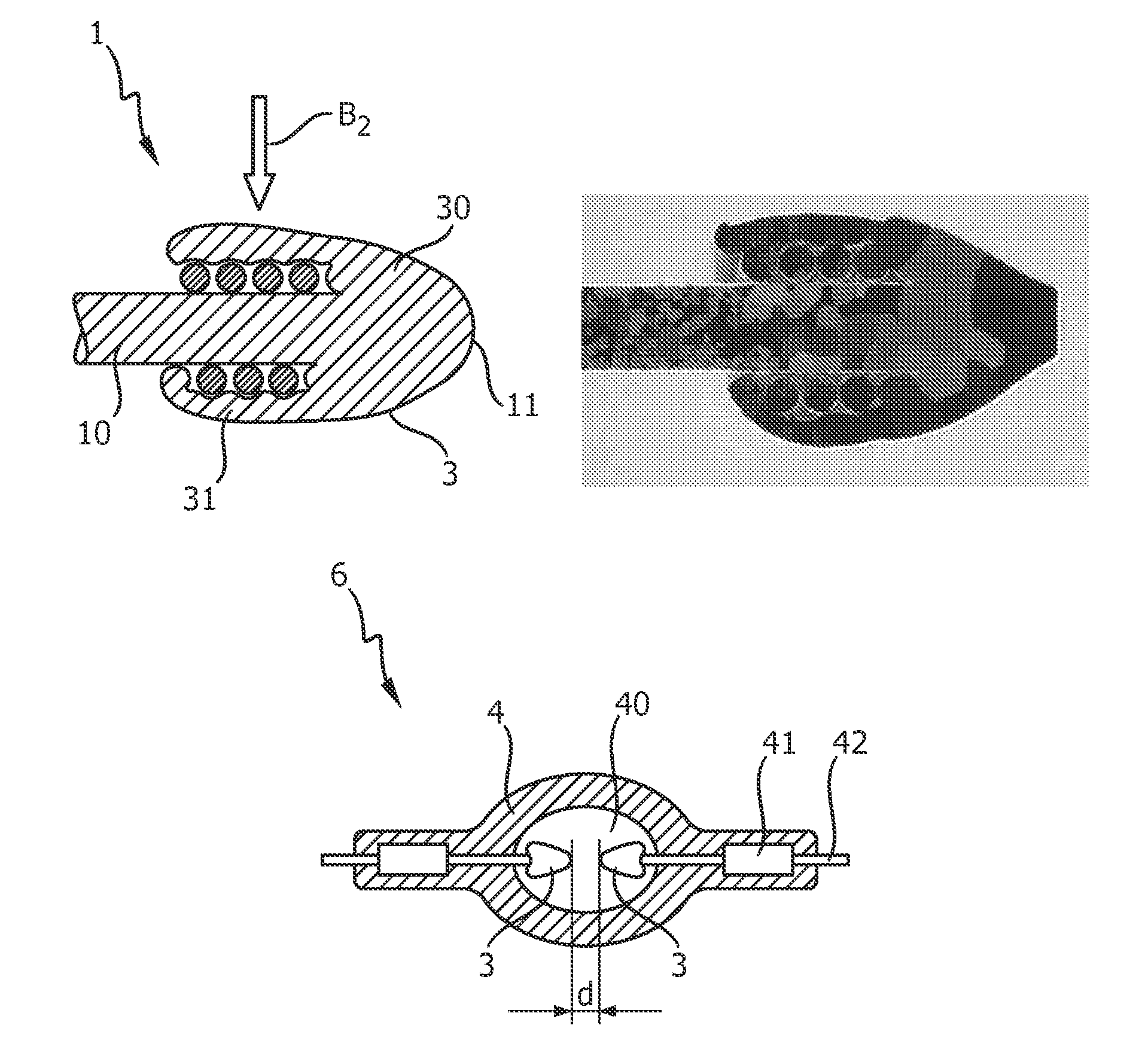

Outsole With Tangential Deformation

An outsole, especially for sports shoes, that can be formed with a large amount of elastic deformability even in the tangential direction towards the front and the back, enabling a good cushioning effect even when the tread of the foot is inclined and somewhat slipping. Beyond at least one critical deformation in the deformed region, the sole remains essentially rigid in relation to tangential deformation. In this way, the runner has a secure footing on the respective tread point. The runner can push off from the tread point without losing ground and a swimming effect on the sole is prevented. The elastic deformability of the sole also in the tangential direction is caused by at least one first element, and the rigidity of the sole in relation to tangential deformation beyond the at least one critical deformation, in addition to the degree of the at least one critical deformation in the deformed region is due to at least one second element. So that the first and second elements can be independently designed, dimensioned and produced, there are extensive structuring, formation and variation possibilities. Certain areas in the heel and / or the ball region of the sole can be varied by the at least one first element, and certain areas by the at least one second element, in the longitudinal direction.

Owner:GLIDEN LOCK

Wet-skin treatment compositions

InactiveUS7192598B2Better behavedFast absorptionCosmetic preparationsToilet preparationsSkin treatmentsDermatology

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Wet-skin treatment compositions

InactiveUS20030190296A1Better behavedFast absorptionCosmetic preparationsHair removalSkin treatmentsDermatology

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Collagen Powder and Collagen-Based Thermoplastic Composition For Preparing Conformed Articles

ActiveUS20090226557A1Better behavedOther chemical processesSynthetic resin layered productsPolymer scienceCollagenan

The invention provides a new collagen based technology. The invention provides a dry collagen powder as a pre-cursor for the preparation of an homogeneous thermoplastic collagen-based composition, which may further comprise additives. The present invention relates also the use of said composition in the manufacturing of solid articles conformed according to plastic technology, and to the articles.

Owner:NATURIN GMBH & CO

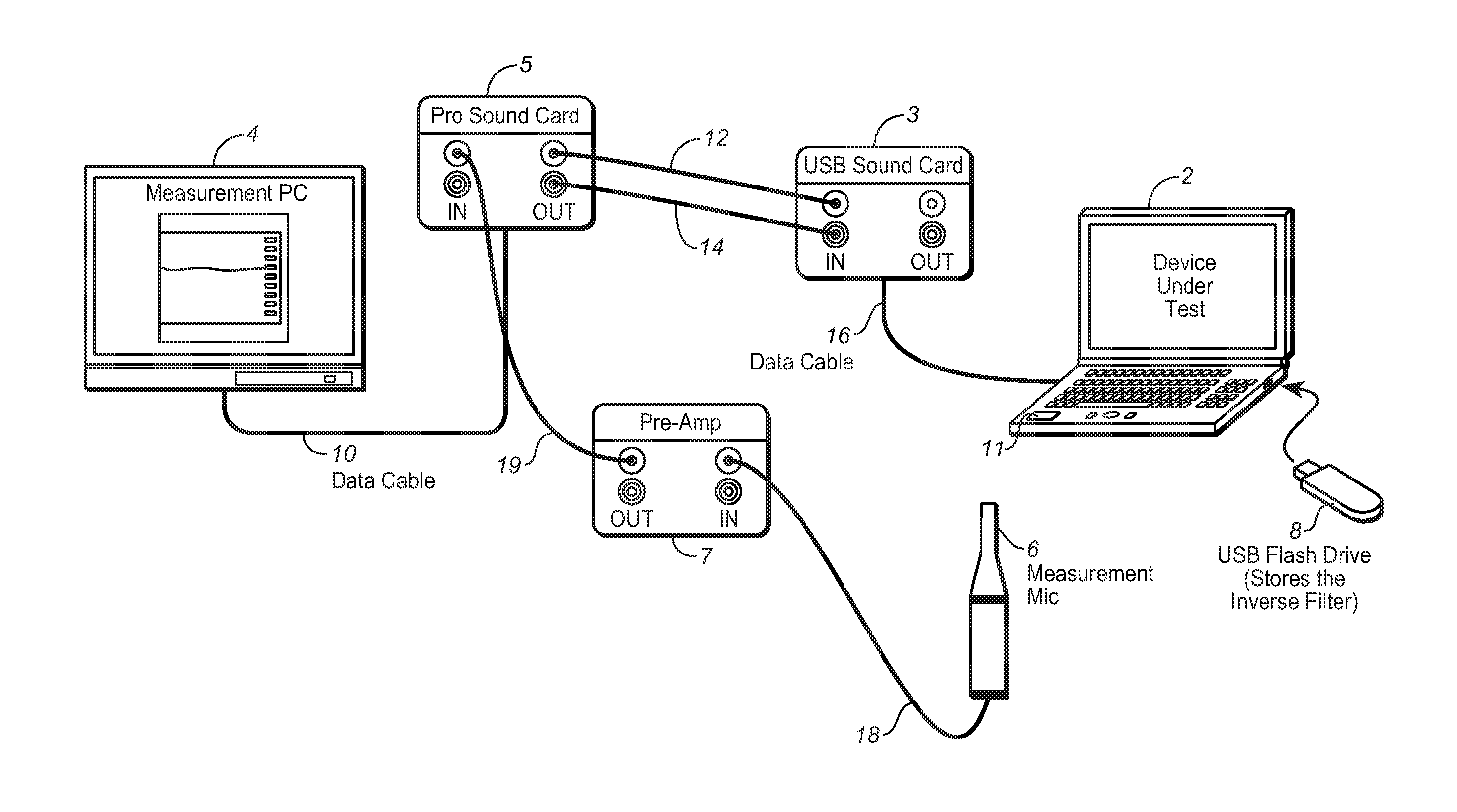

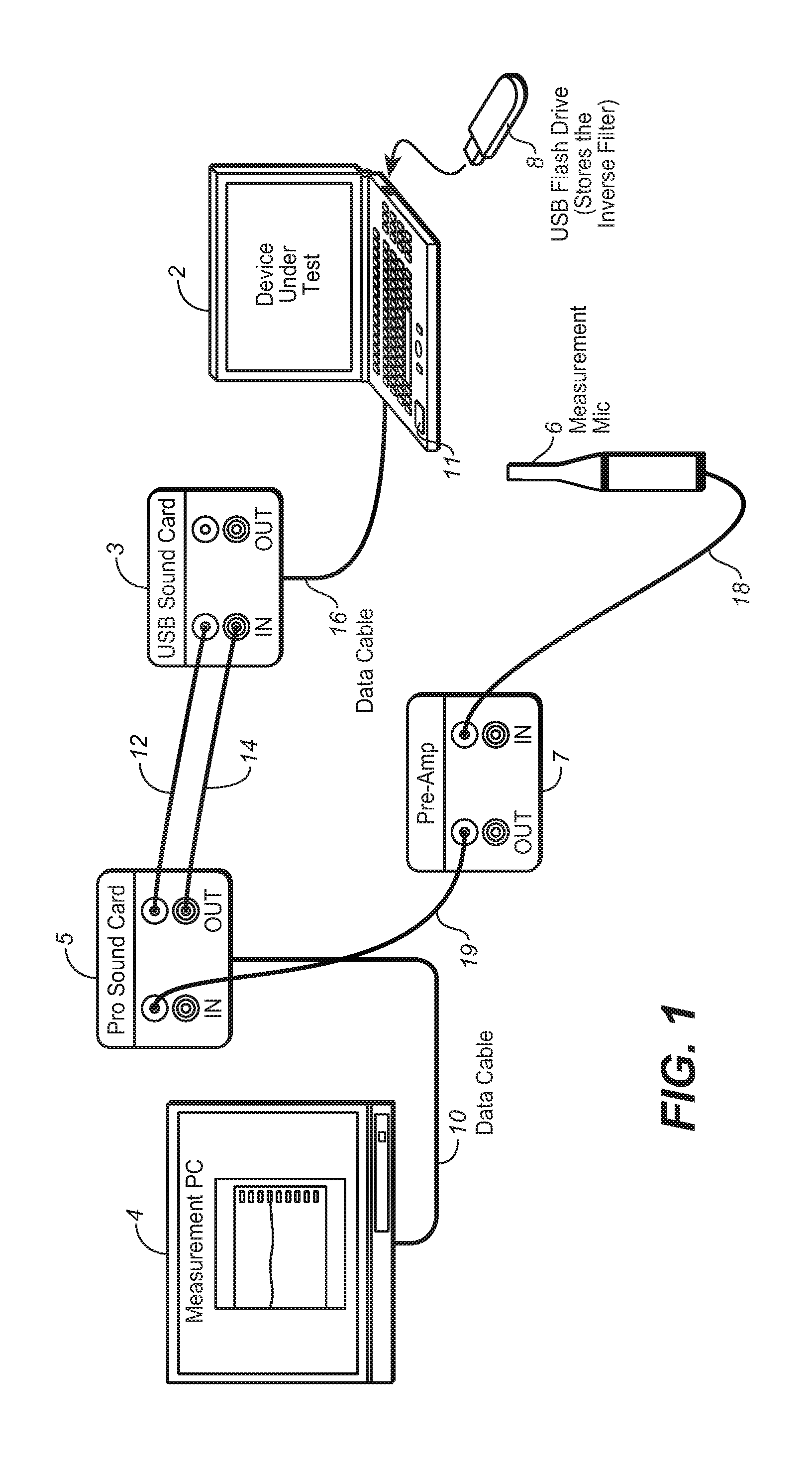

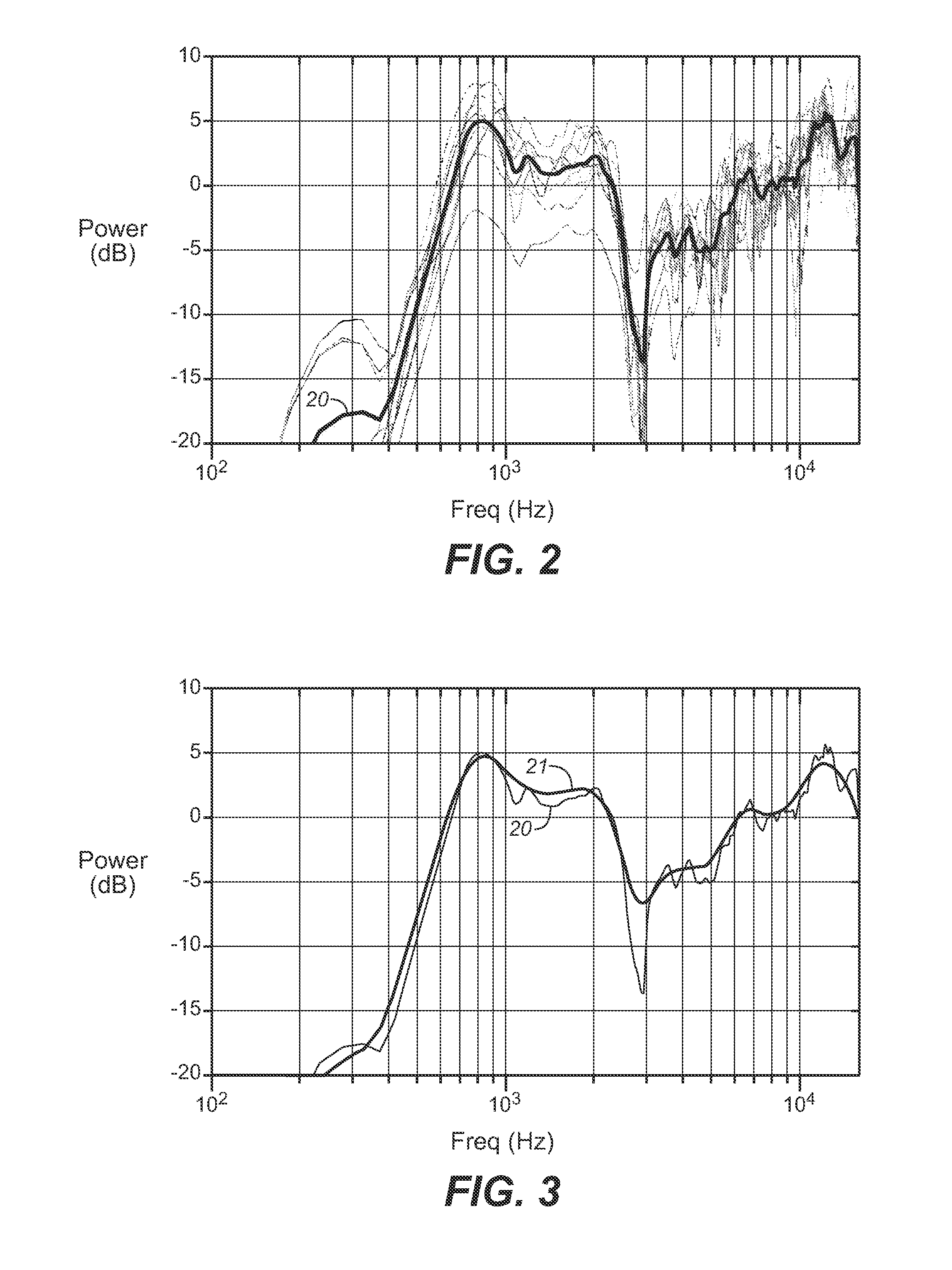

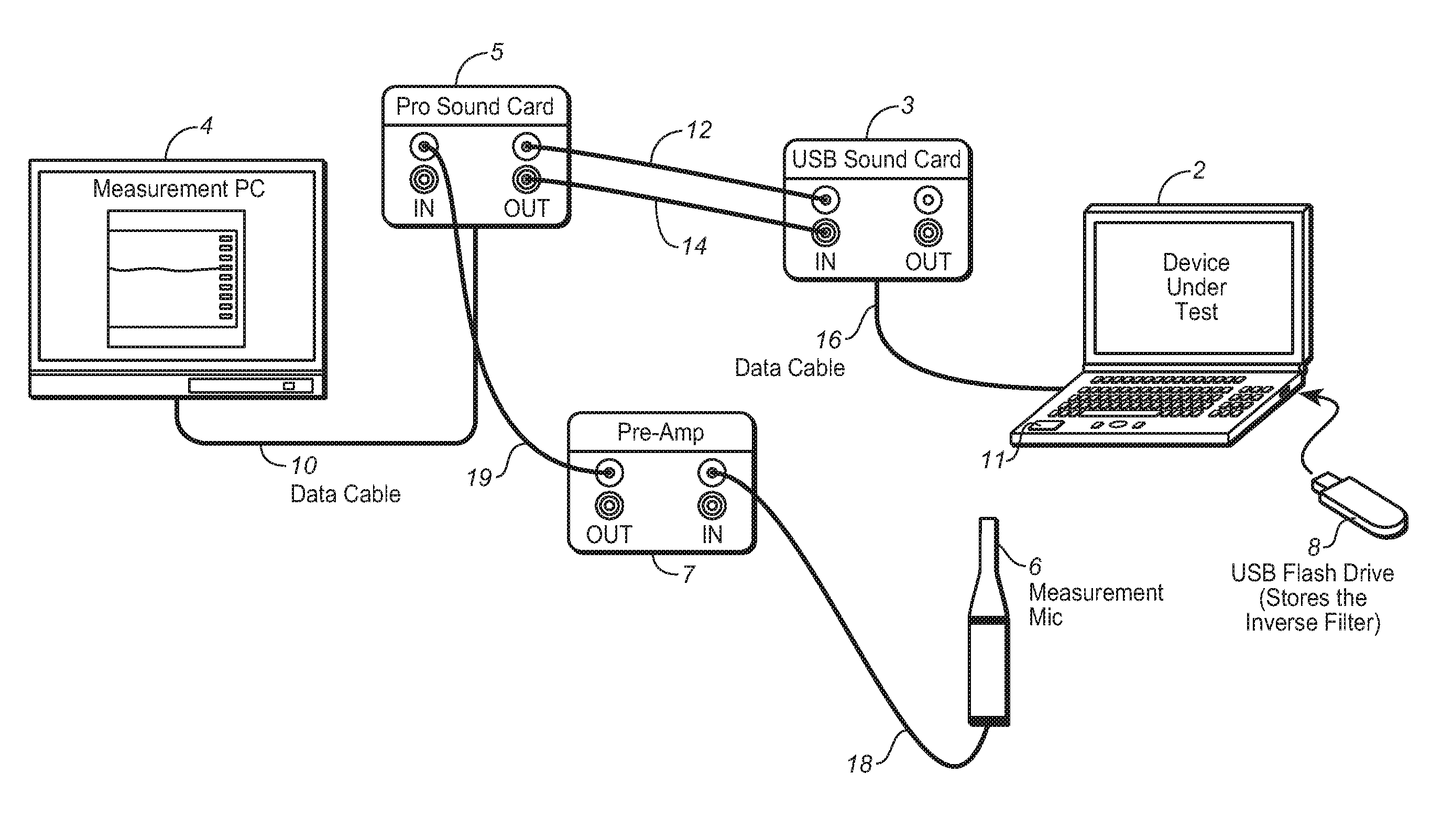

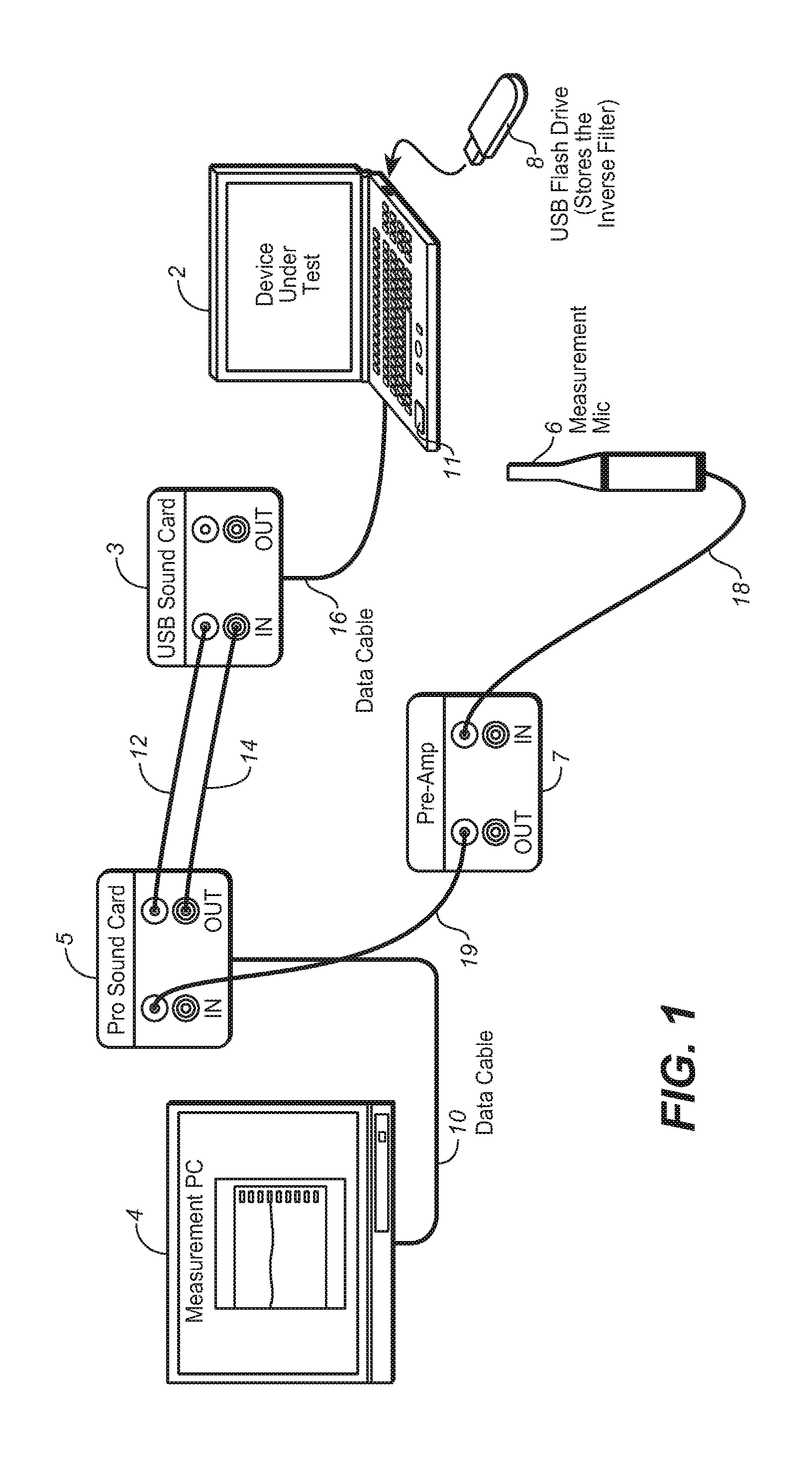

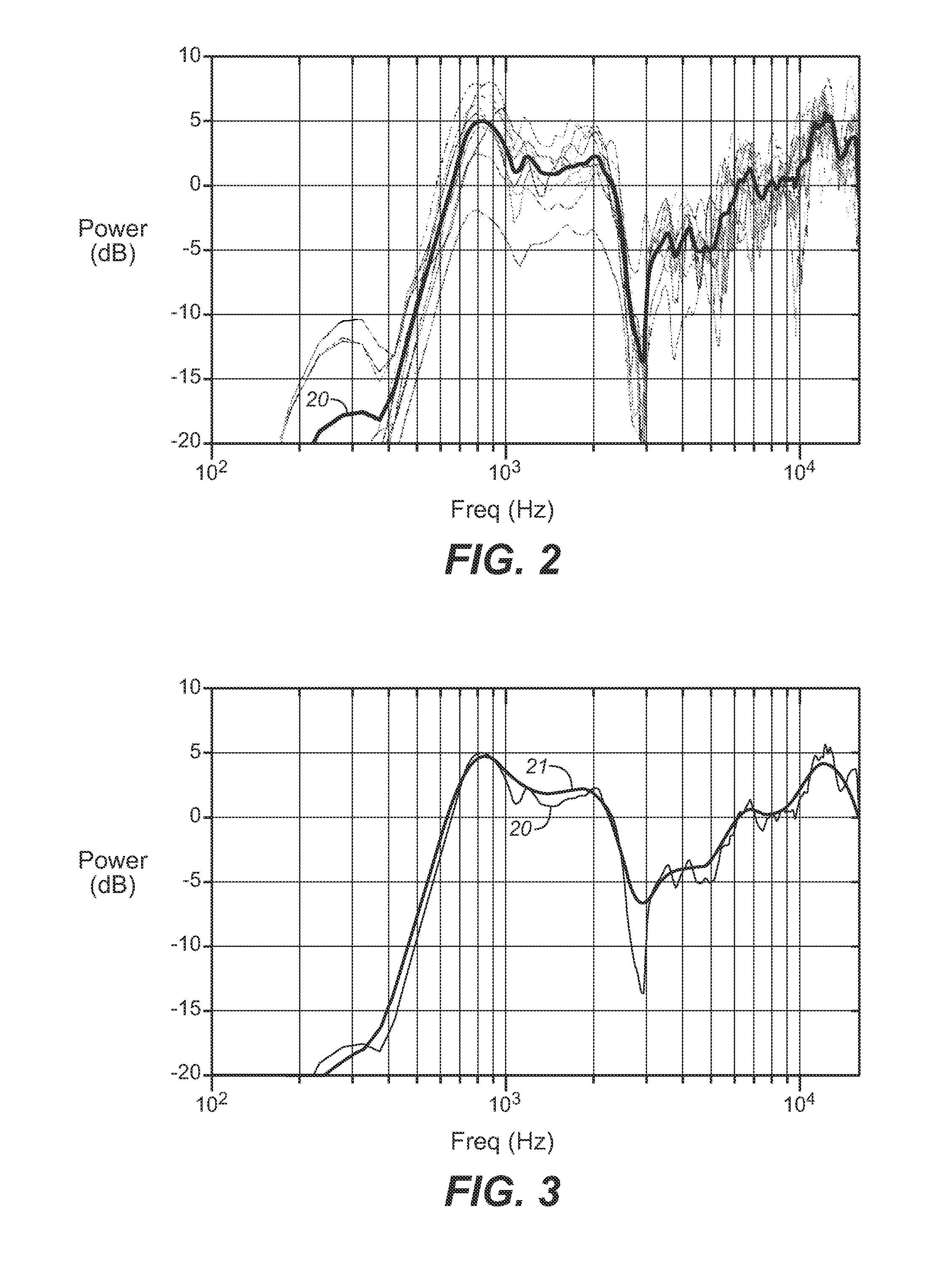

Method for Determining Inverse Filter from Critically Banded Impulse Response Data

ActiveUS20110274281A1Efficient executionEqual loudnessSignal processingFrequency response correctionMean squareEngineering

A method for determining an inverse filter for altering the frequency response of a loudspeaker so that with the inverse filter applied in the loudspeaker's signal path the inverse-filtered loudspeaker output has a target frequency response, and optionally also applying the inverse filter in the signal path, and a system configured (e.g., a general or special purpose processor programmed and configured) to determine an inverse filter. In some embodiments, the inverse filter corrects the magnitude of the loudspeaker's output. In other embodiments, the inverse filter corrects both the magnitude and phase of the loudspeaker's output. In some embodiments, the inverse filter is determined in the frequency domain by applying eigenfilter theory or minimizing a mean square error expression by solving a linear equation system.

Owner:DOLBY LAB LICENSING CORP +1

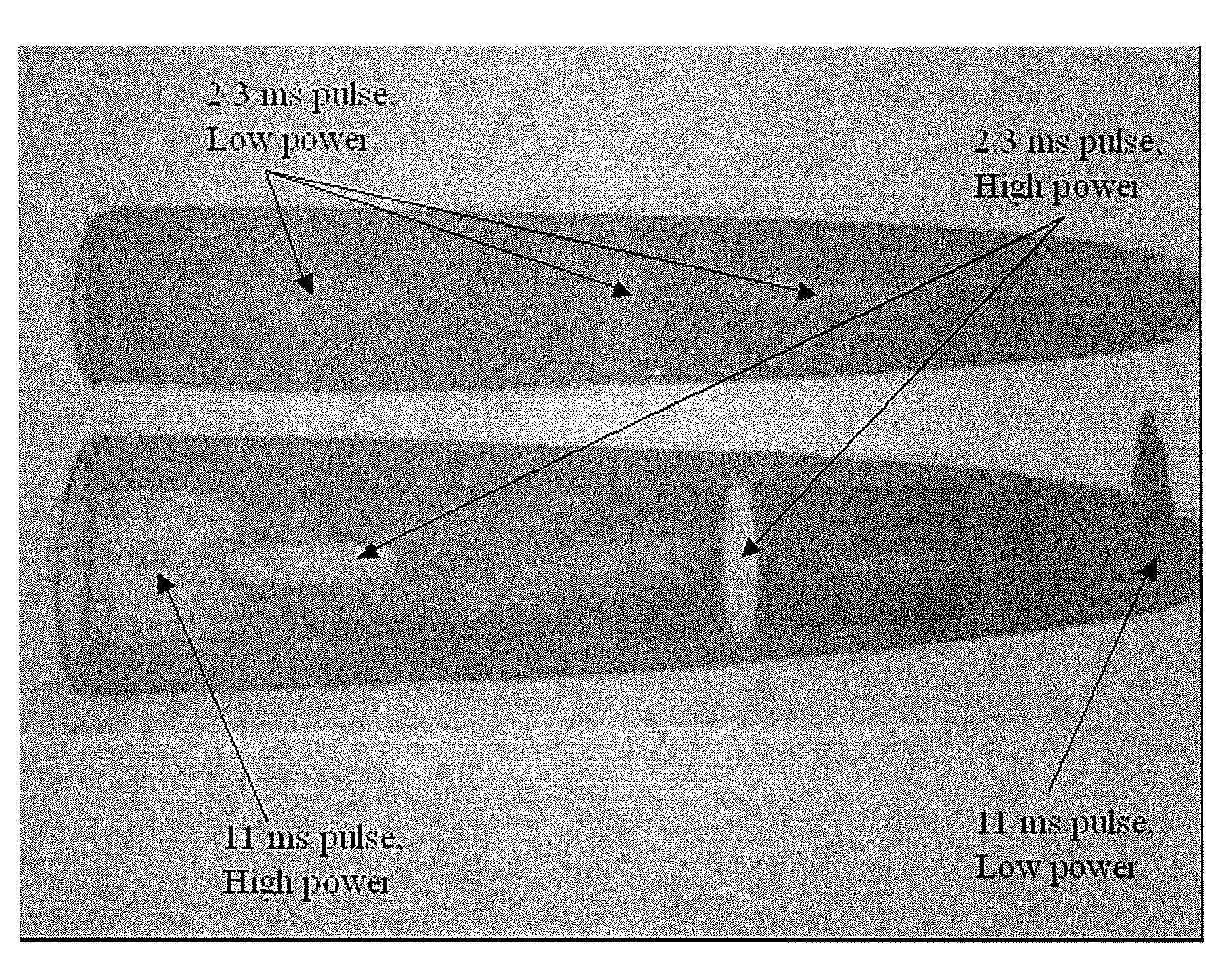

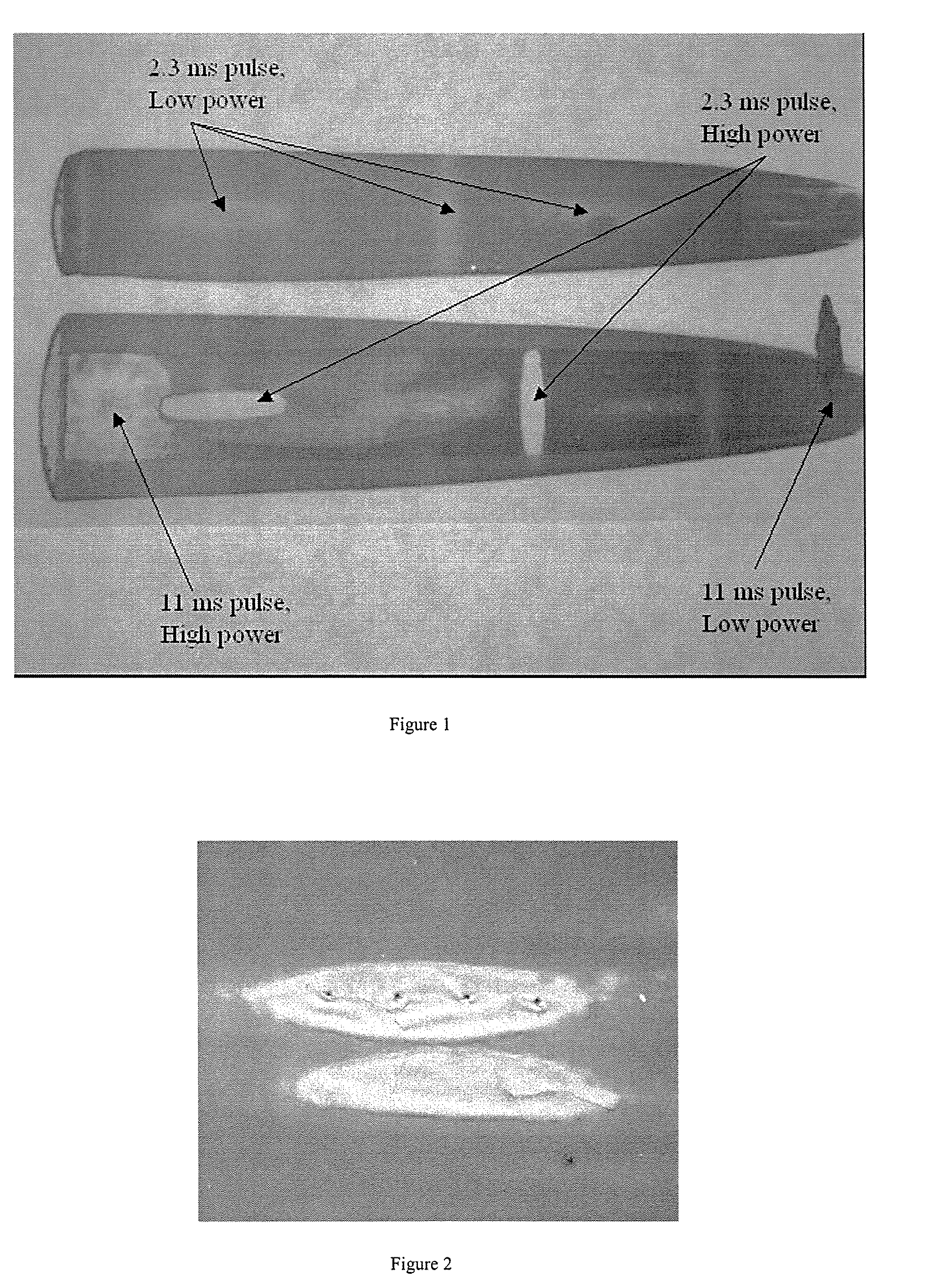

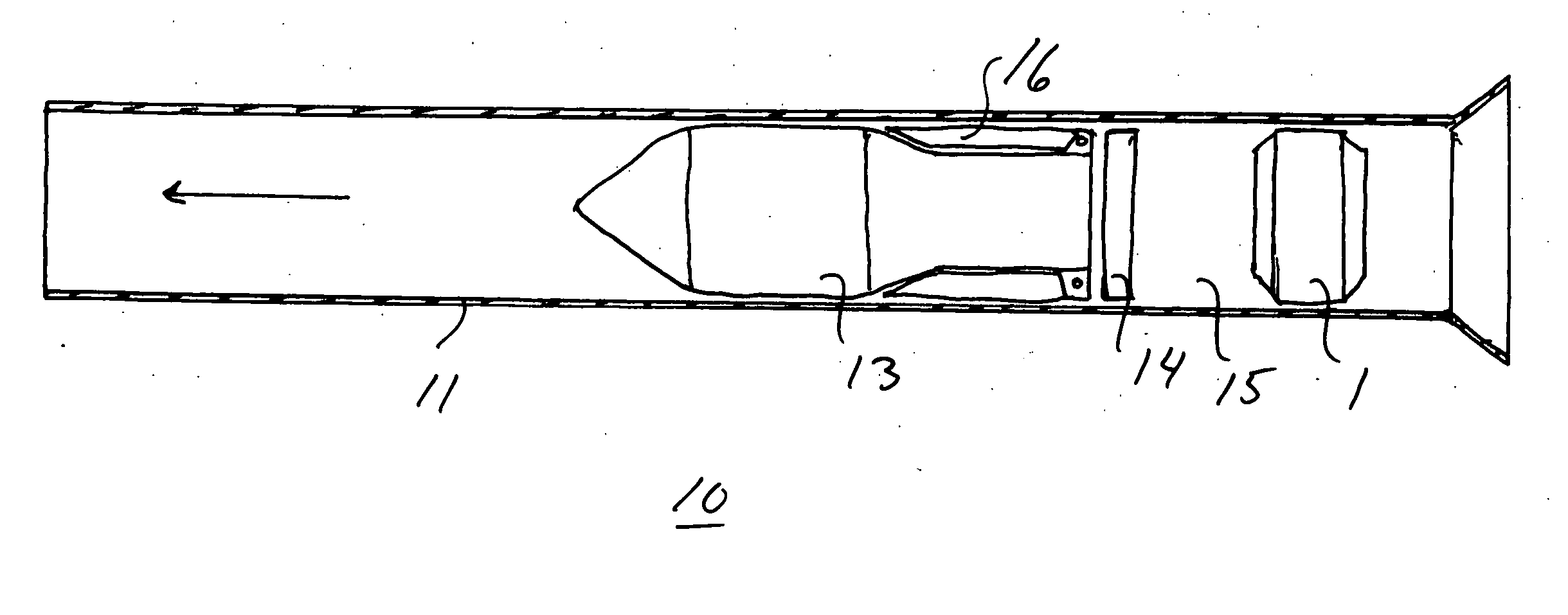

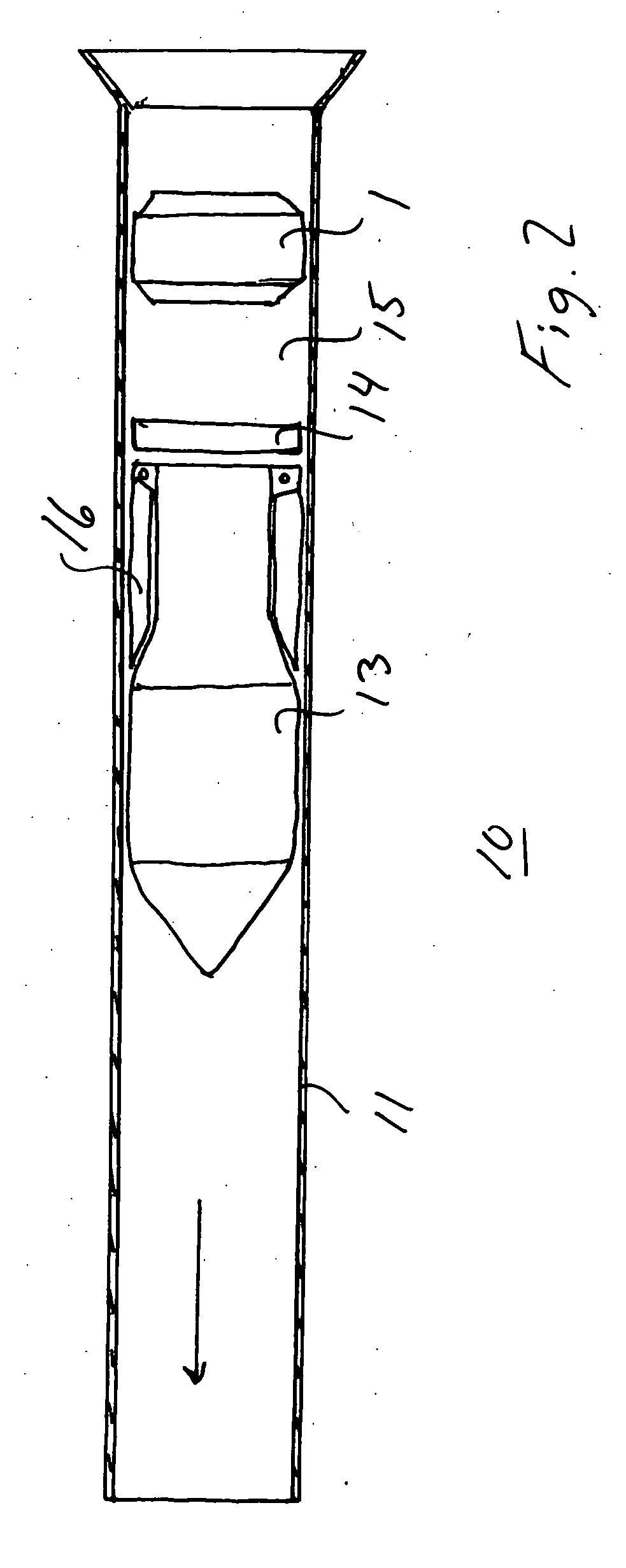

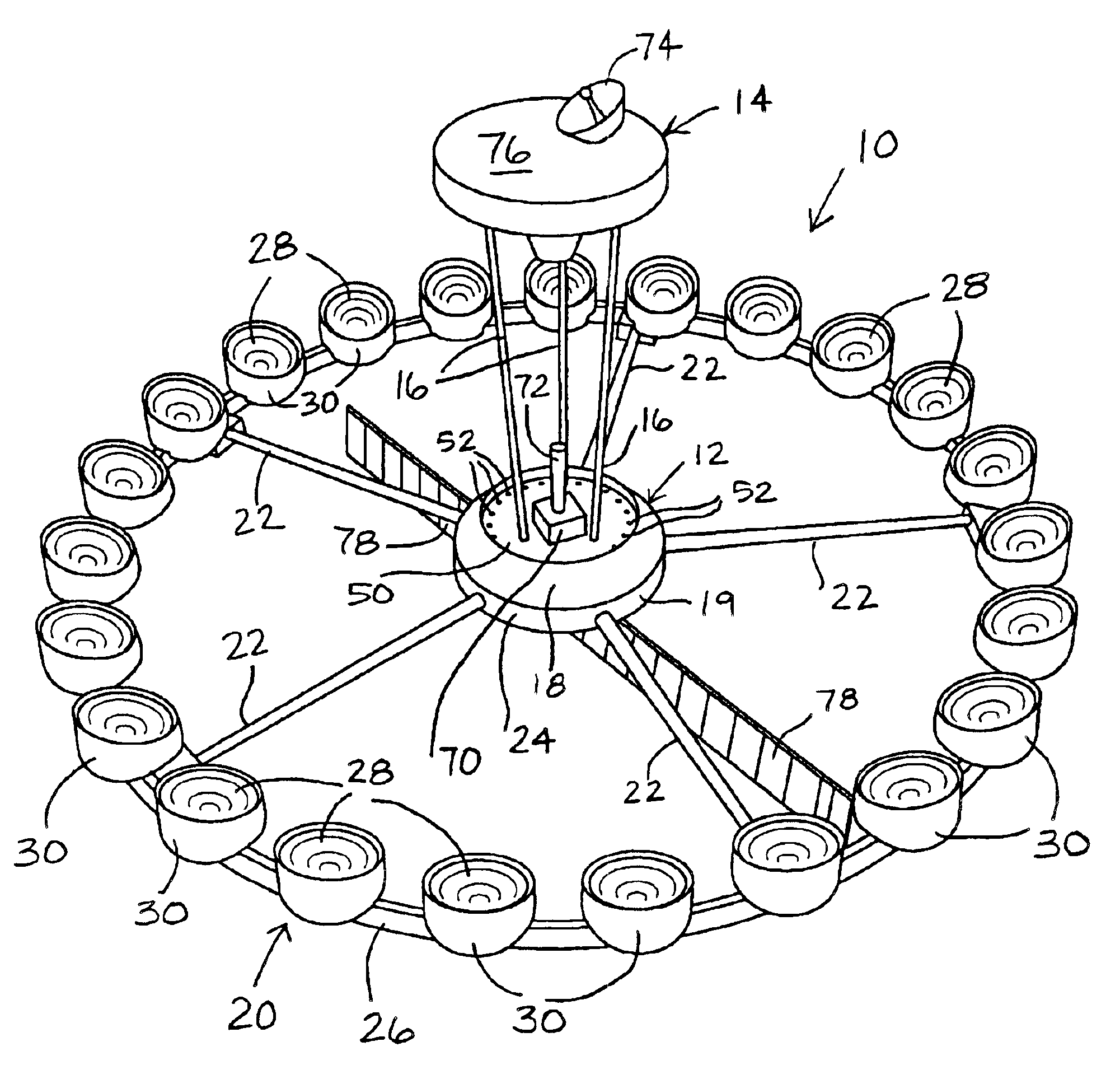

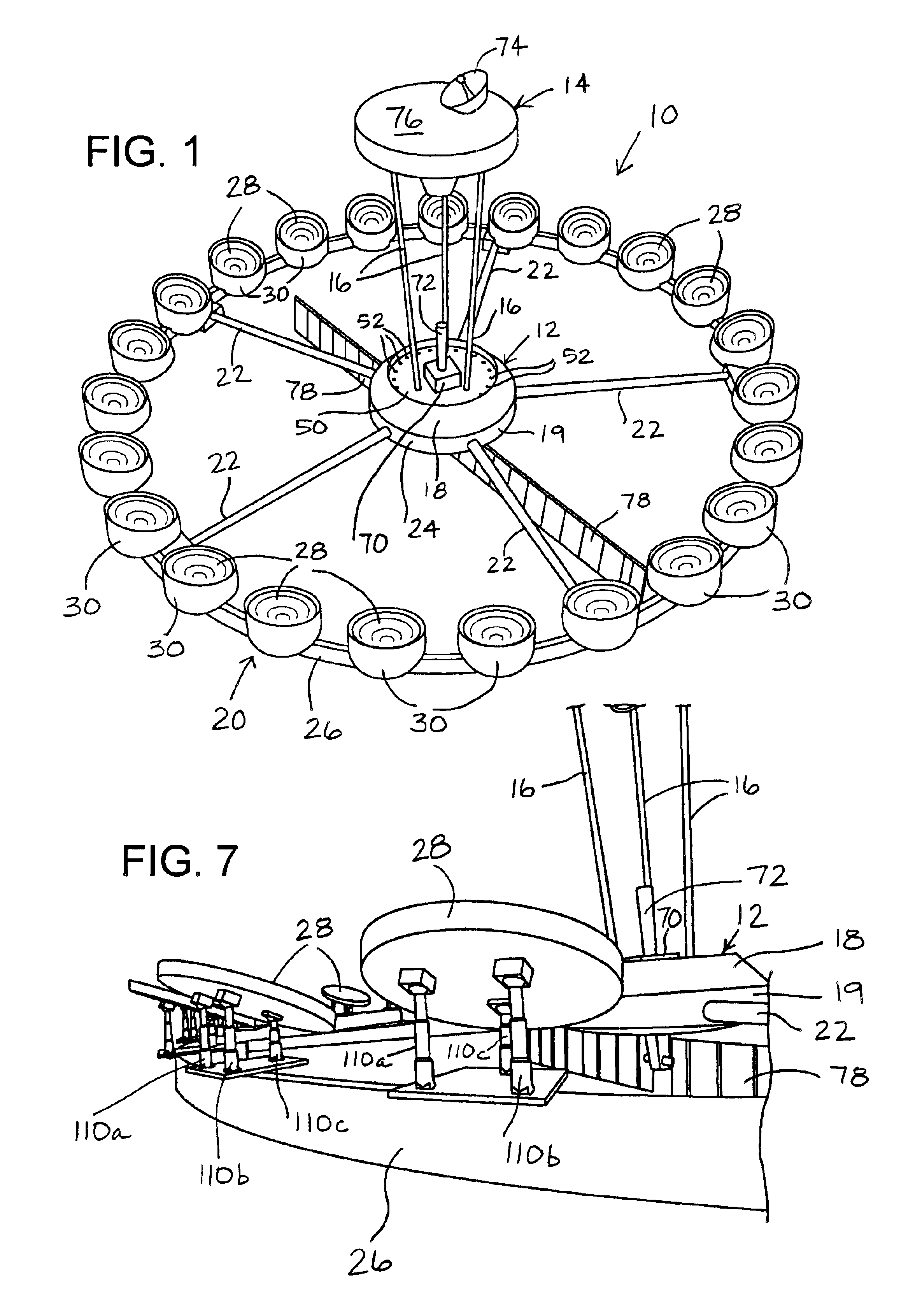

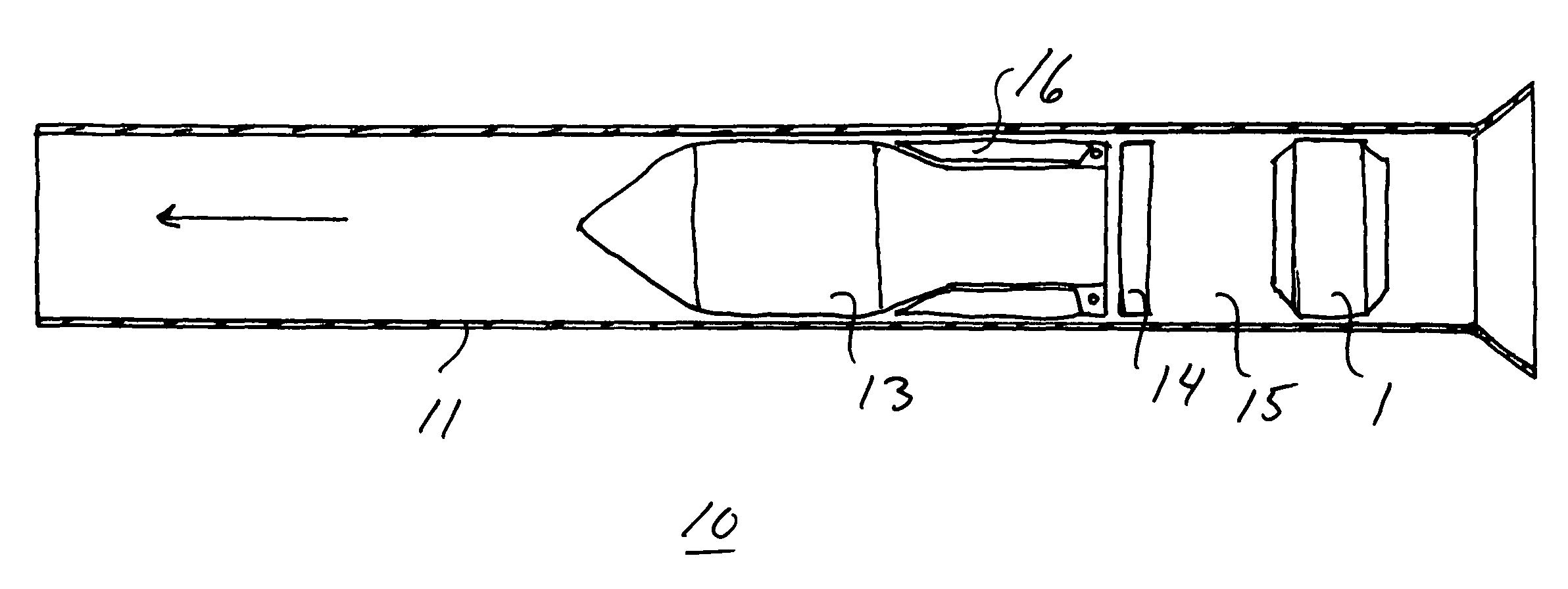

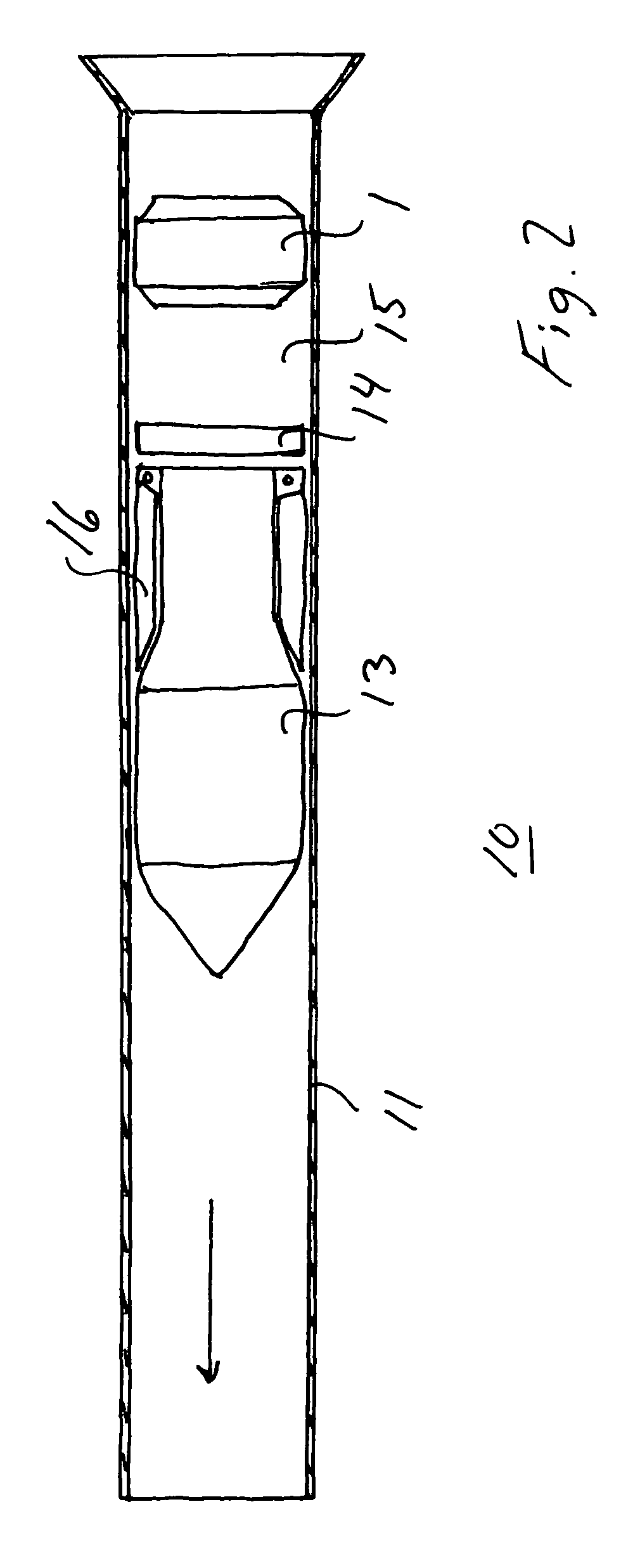

Countermass and countermass weapon

ActiveUS20070068374A1Facilitates enclosureEasy to solveRocket launchersFiring/trigger mechanismsCombustionEngineering

A countermass for use in a weapon to balance the forces arising when a launchable unit is launched from a launcher tube of the weapon. The countermass includes a first container enclosing a liquid. A countermass weapon includes a launcher tube open or openable in both ends. The launcher tube houses a launchable unit, a countermass including a first container enclosing a liquid, a pressure chamber, and a propellant charge that upon firing and combustion of the charge in cooperation with the pressure chamber and the countermass accelerates the launchable unit forwards in the tube at the same time as the countermass accelerates backwards in the tube. The first container is made of a non-rigid material. A second container is provided to cover or almost cover the first container. The second container is designed with damping characteristics.

Owner:SAAB AB

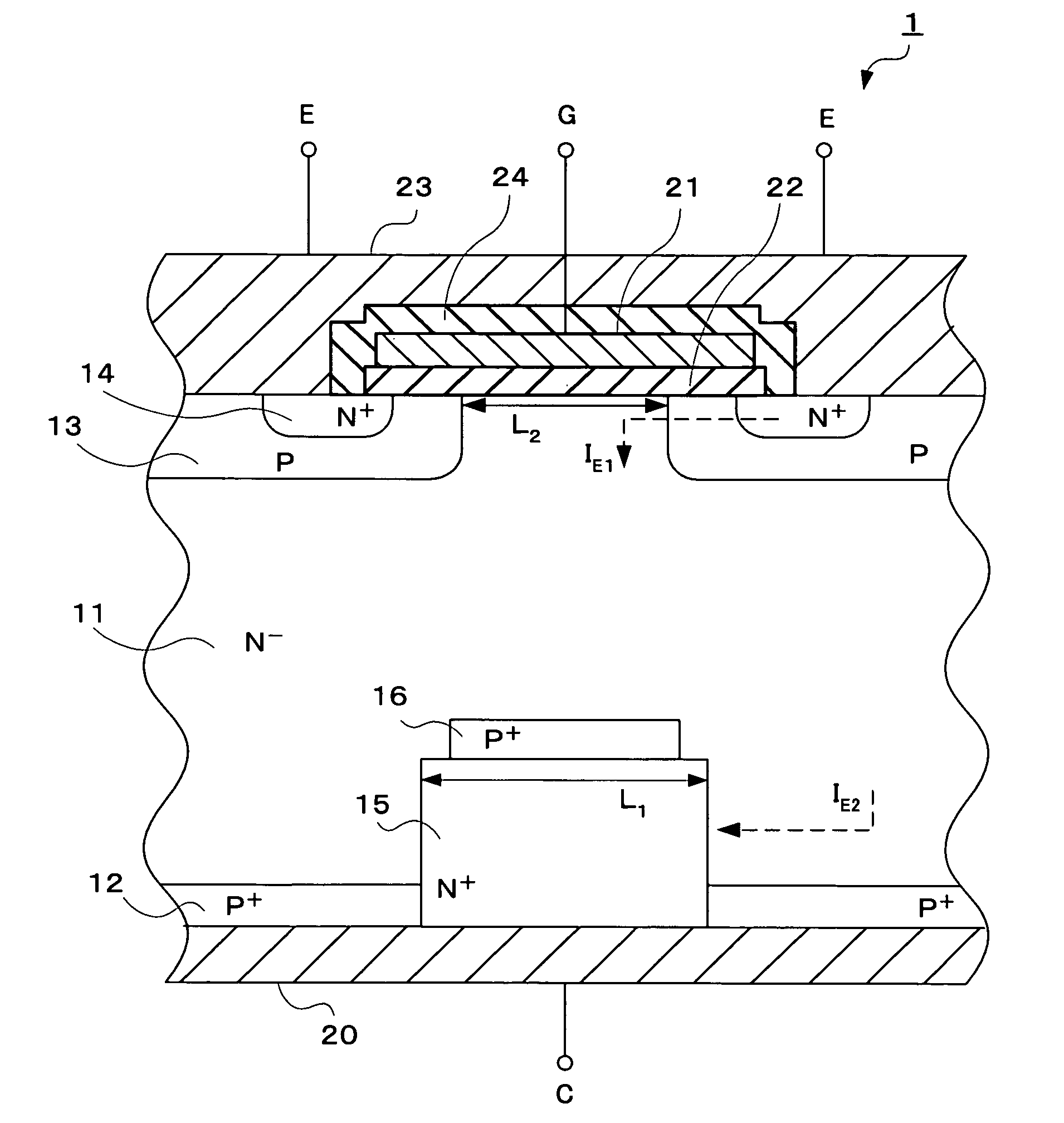

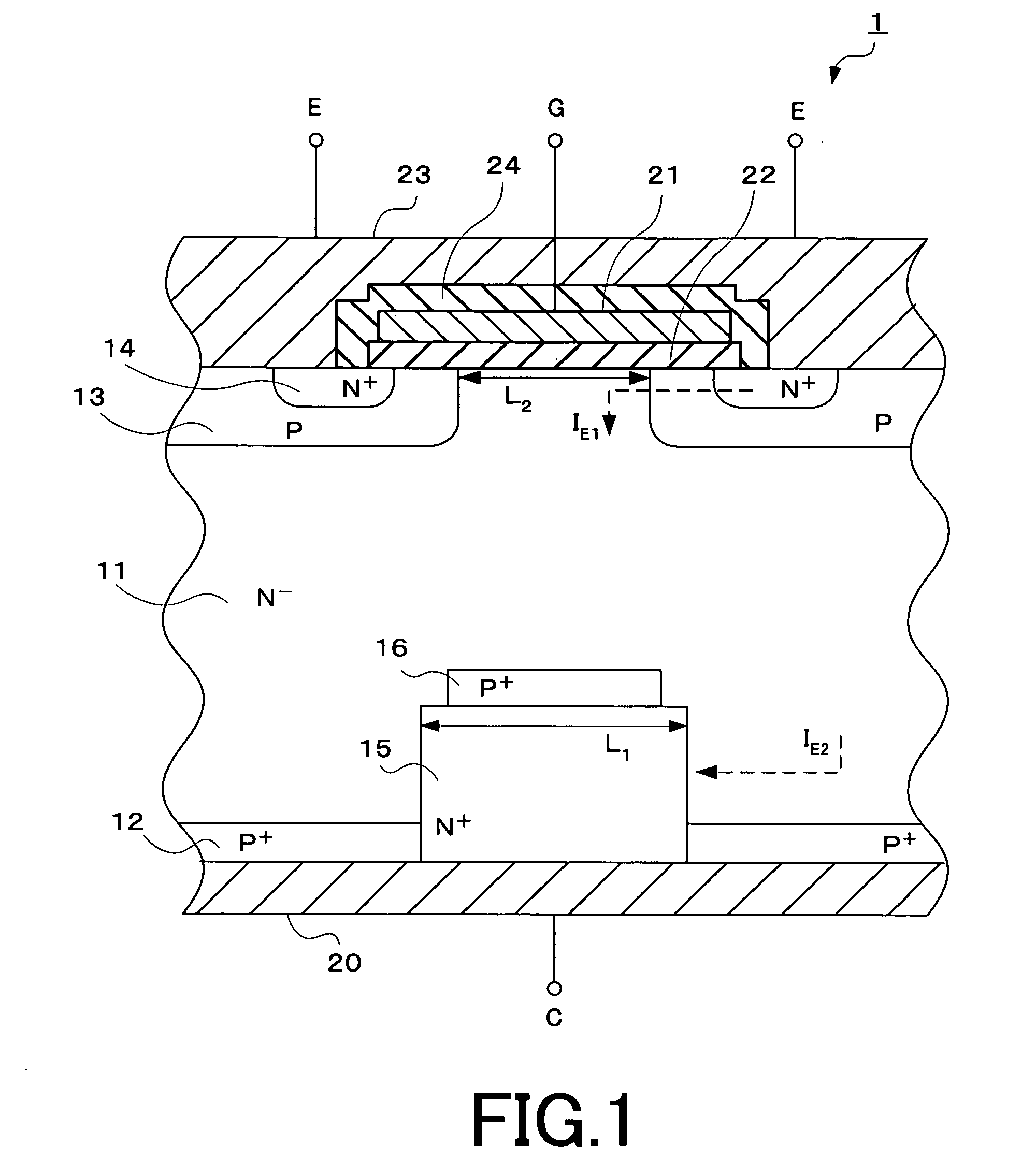

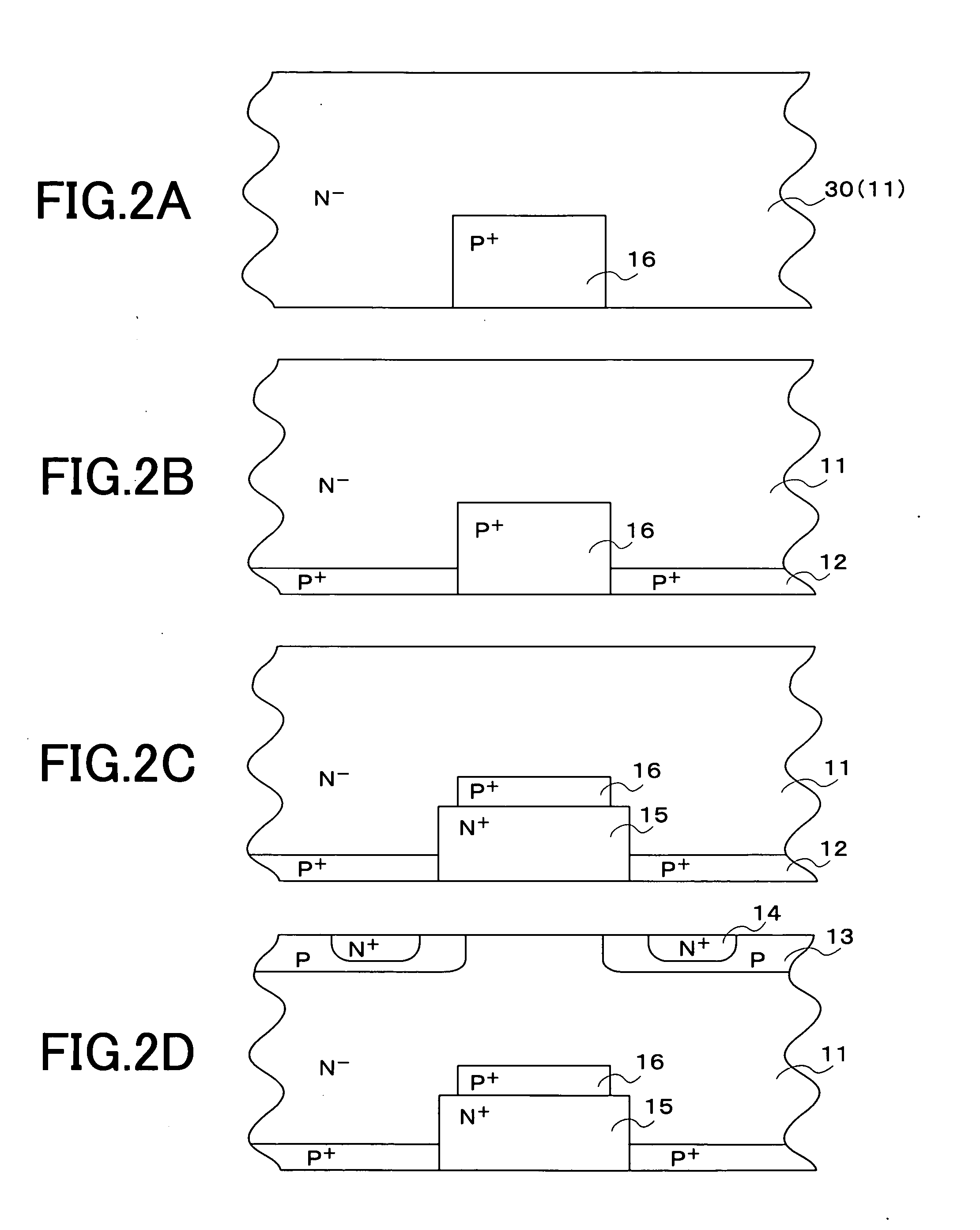

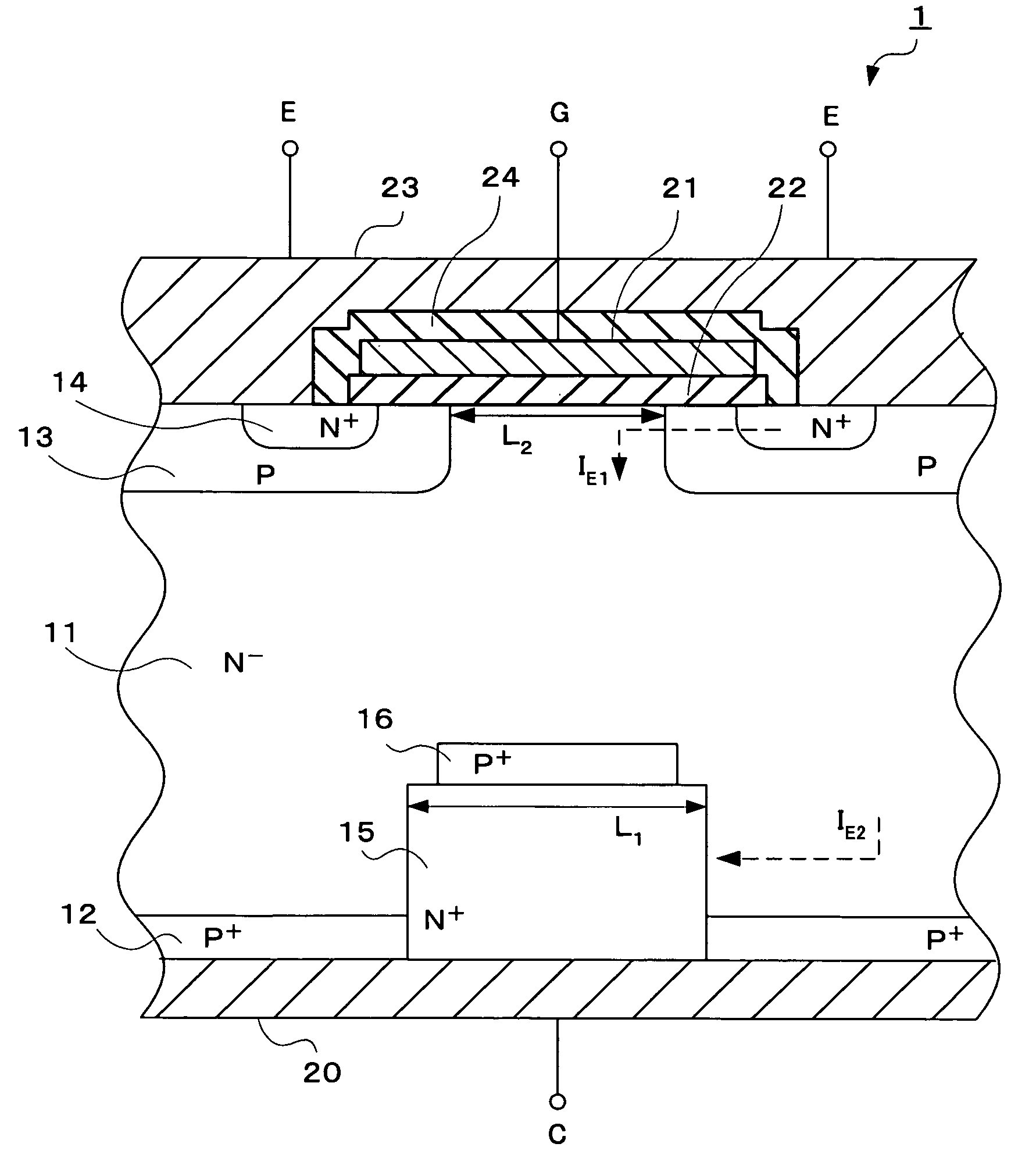

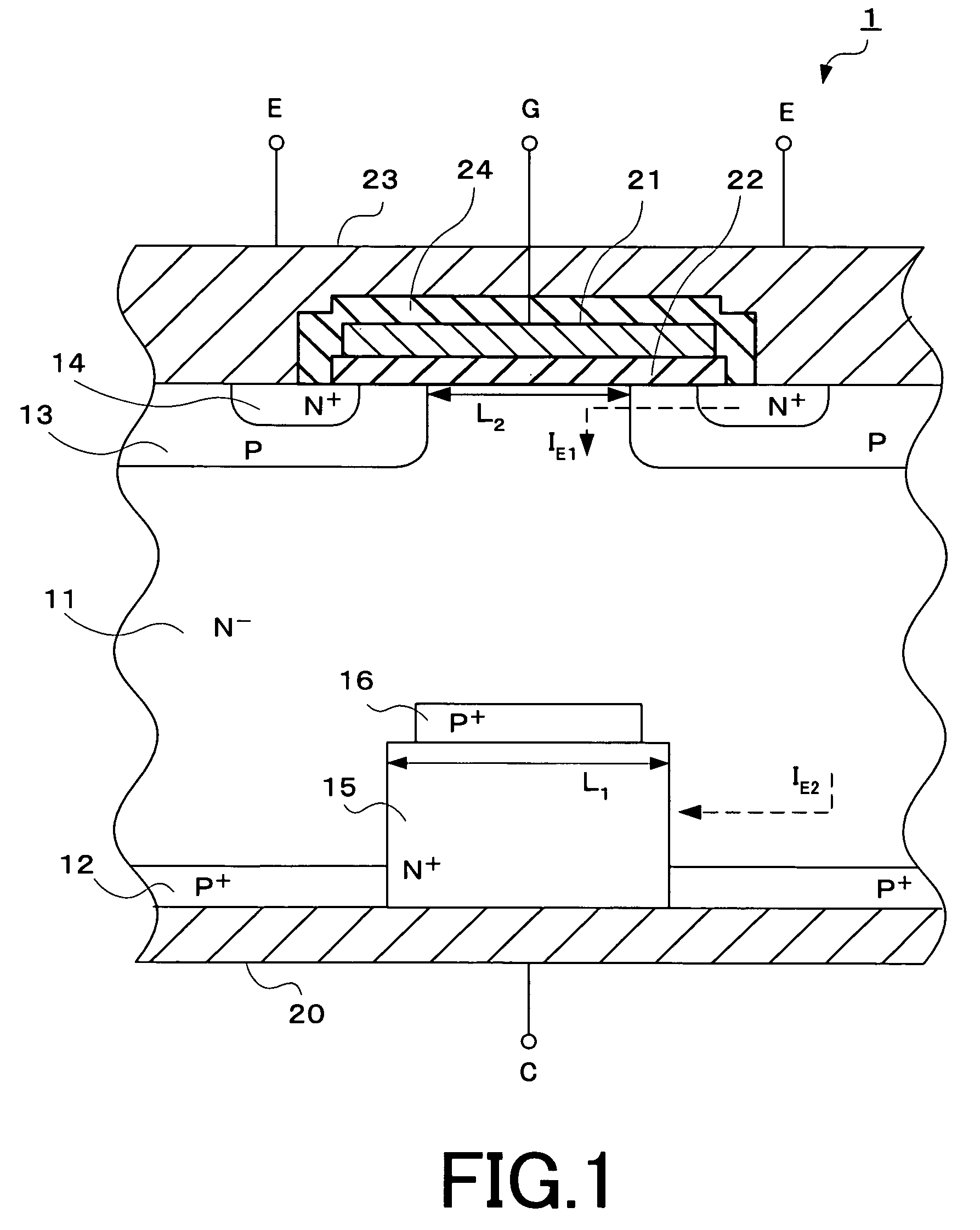

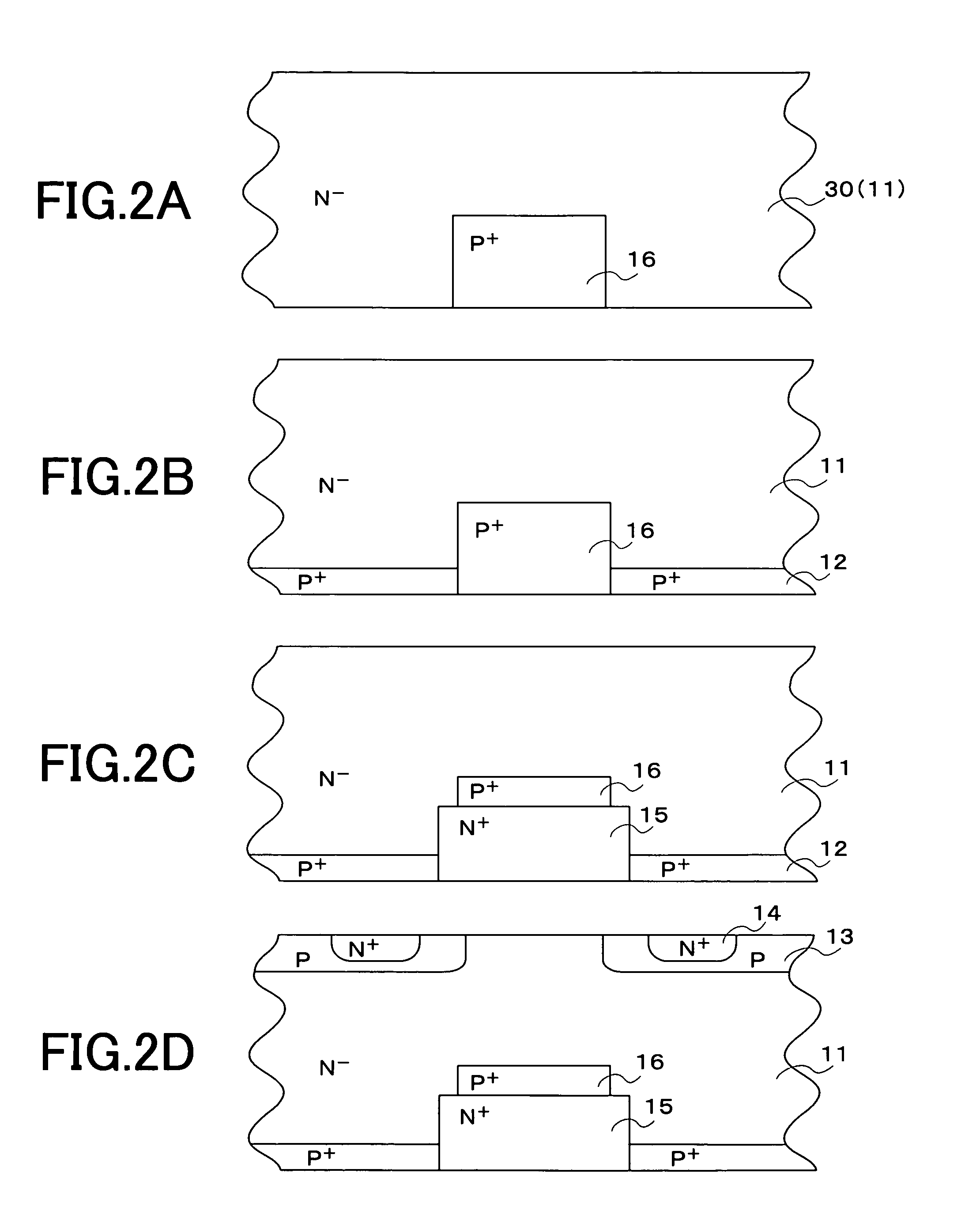

Insulated gate semiconductor device and method for manufacturing same

InactiveUS20080093623A1Better behavedReduce the amount requiredSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorSemiconductor device

In an insulated gate semiconductor device (1) having an N− type base region (11), P+ type collector regions (12), P type base regions (13), and N+type emitter regions (14), an N+ type collector-short region (15) which extends toward the N− type base region (11) farther than the P+ type collector regions (12) is formed in the lower surface of the N− type base region (11), and a P+ type semiconductor region (16) is formed between the N+ type collector-short region (15) and the N− type base region (11).

Owner:SANKEN ELECTRIC CO LTD

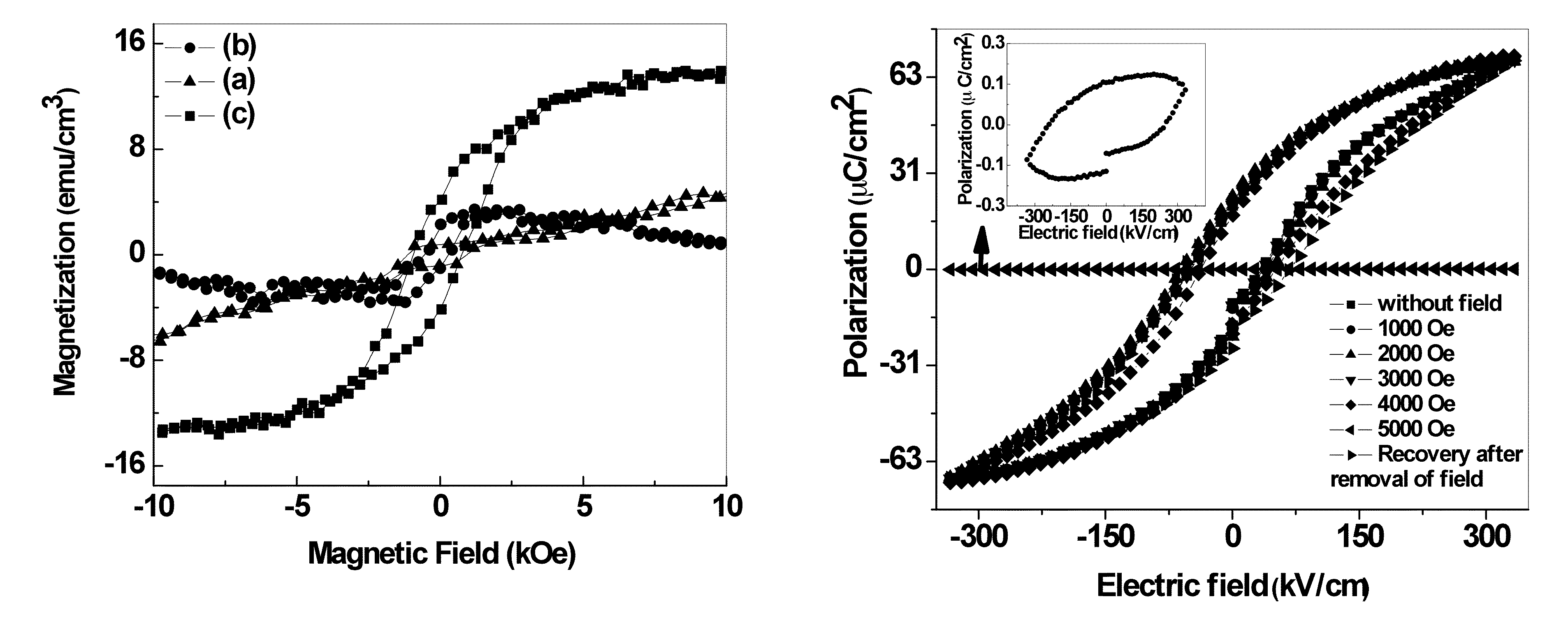

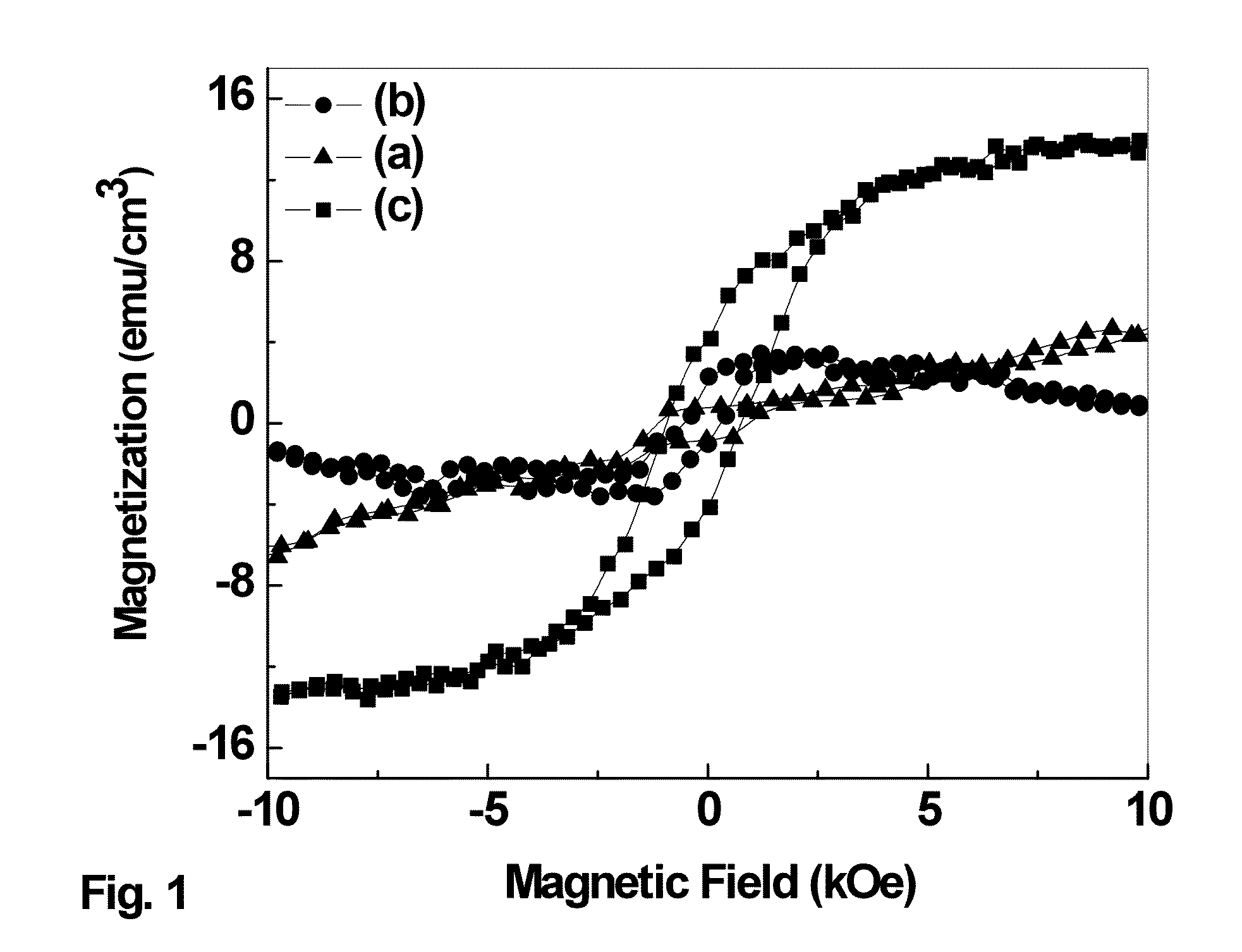

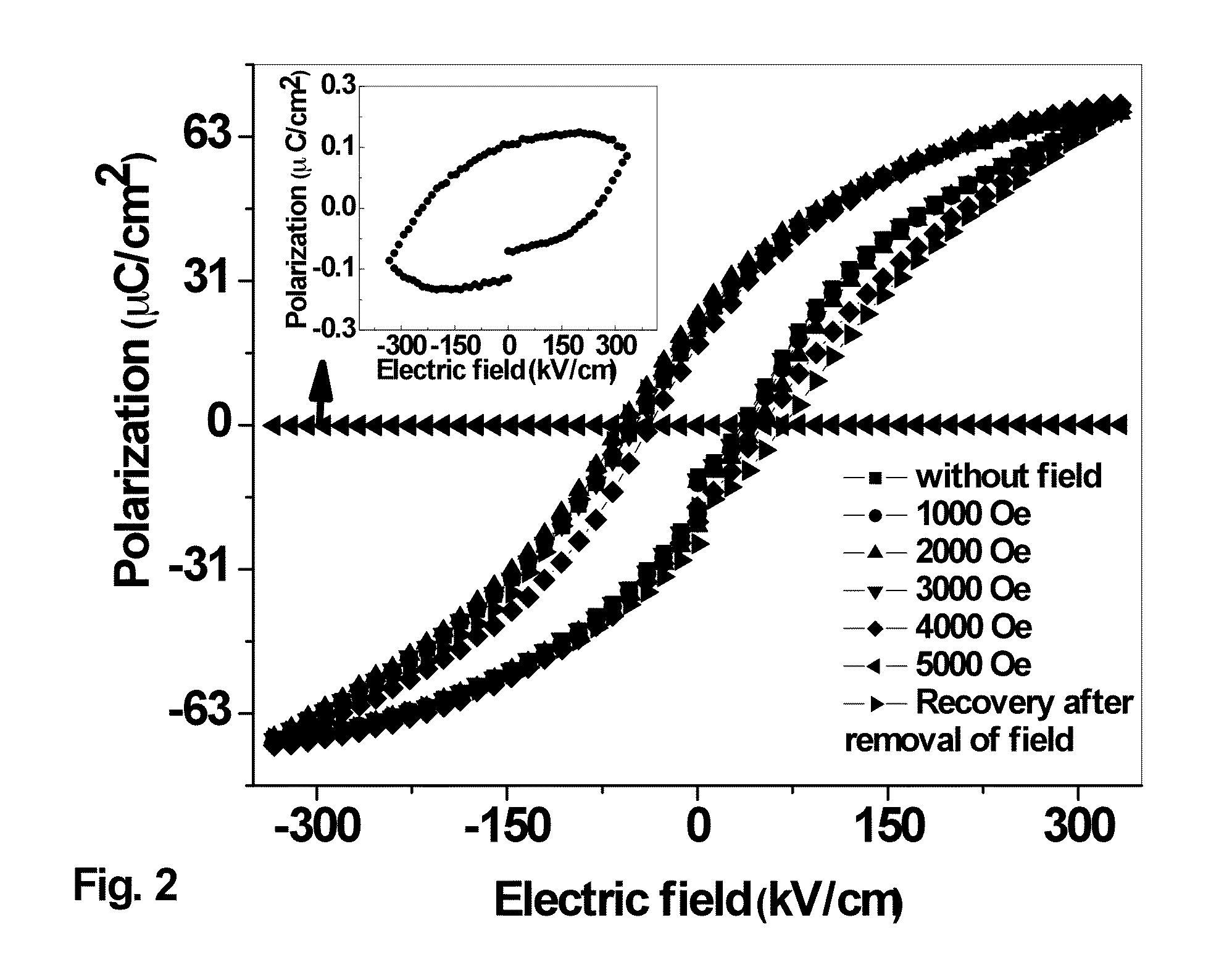

Room-temperature magnetoelectric multiferroic thin films and applications thereof

ActiveUS8803264B1Well behaved and saturated C(V) hysteresisReduce leakageTransistorDevice material selectionDielectric lossRoom temperature

The invention provides a novel class of room-temperature, single-phase, magnetoelectric multiferroic (PbFe0.67W0.33O3)x (PbZr0.53Ti0.47O3)1-x (0.2≦x≦0.8) (PFWx−PZT1-x) thin films that exhibit high dielectric constants, high polarization, weak saturation magnetization, broad dielectric temperature peak, high-frequency dispersion, low dielectric loss and low leakage current. These properties render them to be suitable candidates for room-temperature multiferroic devices. Methods of preparation are also provided.

Owner:UNIVERSITY OF PUERTO RICO

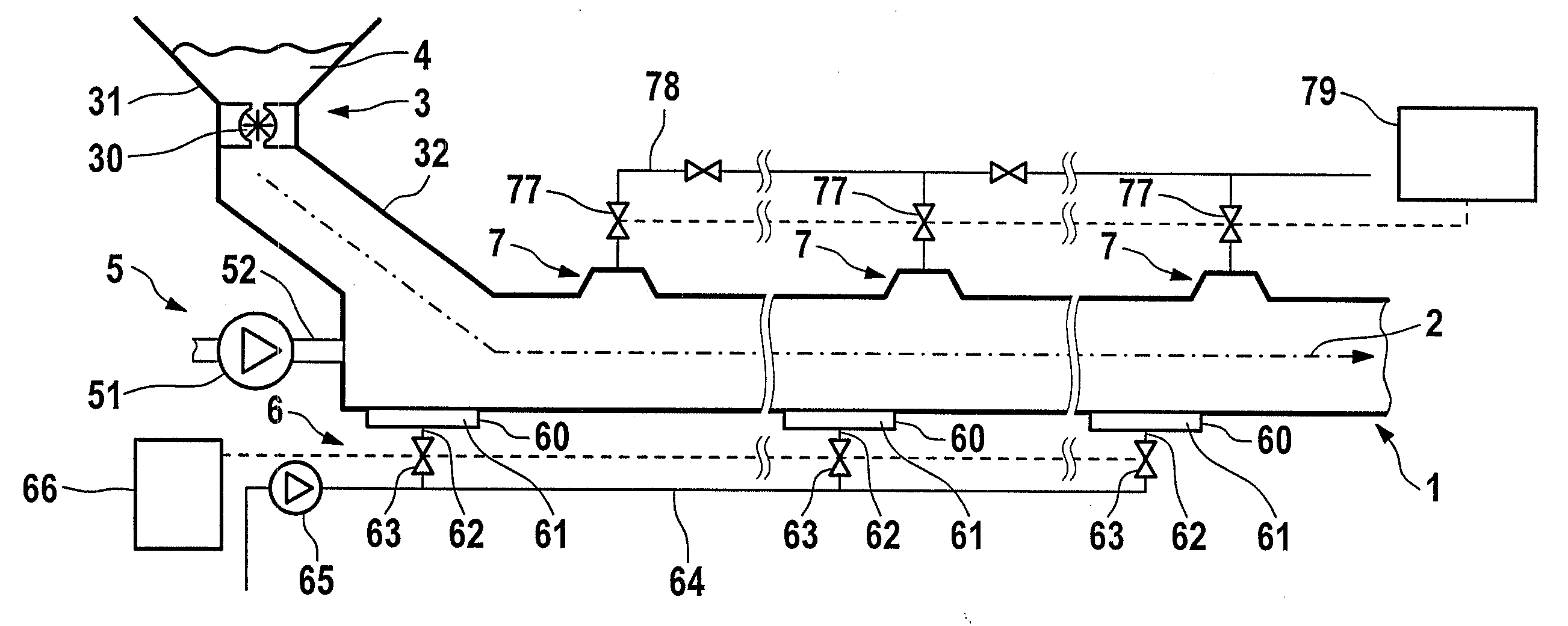

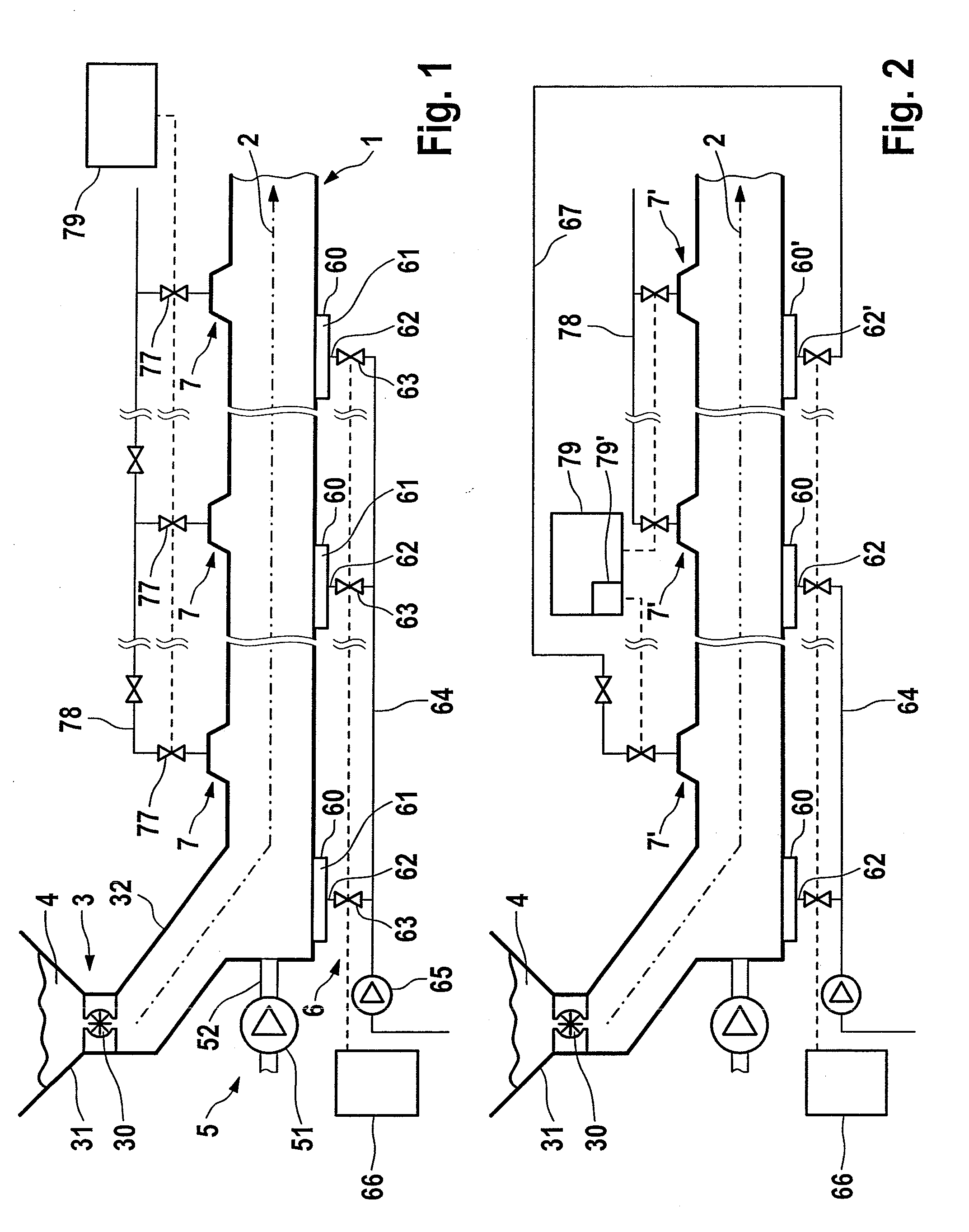

Conveyor device for powder materials

InactiveUS20090269149A1Reduce energy consumptionLarge gas consumptionBulk conveyorsEngineeringMechanical engineering

An apparatus for pneumatically conveying bulk material comprising a conveying pipe, a conveying gas source, and a plurality of removal points. The conveying pipe forms a conveying path for the bulk material. The conveying gas source is connected to the conveying pipe and is configured to supply conveying gas in the direction of the conveying path. The removal points allow gas to be removed from the conveying pipe. The removal points are arranged on the conveying pipe at a distance from one another along the conveying path, and are adjustable in terms of quantity of gas flow to be removed from the conveying pipe. Controlled removal of excess gas from the conveying pipe can therefore be achieved to reduce the gas velocity, such that the conveying remains steady and stable without a stepwise increase in the cross section of the conveying pipe along the conveying path.

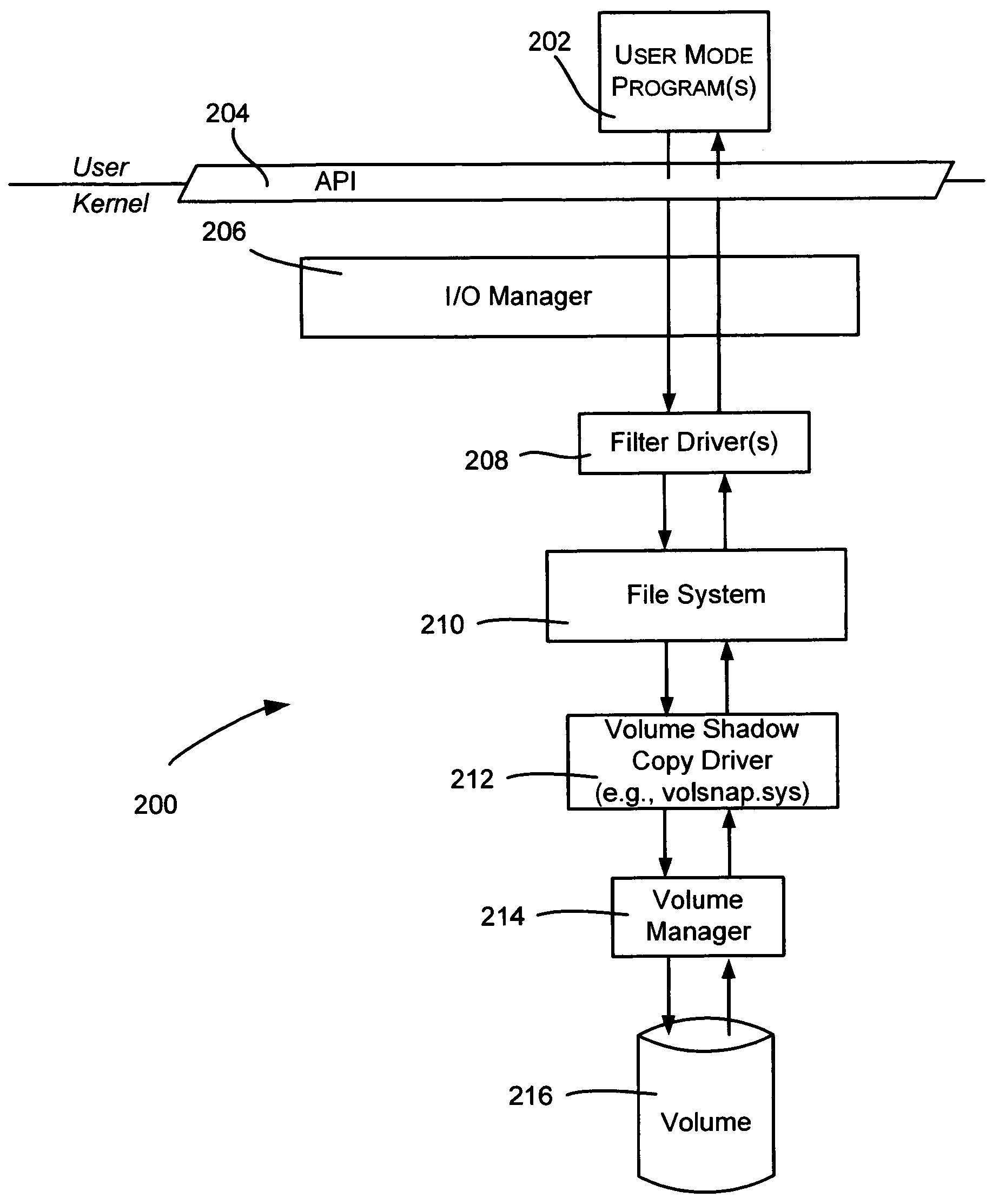

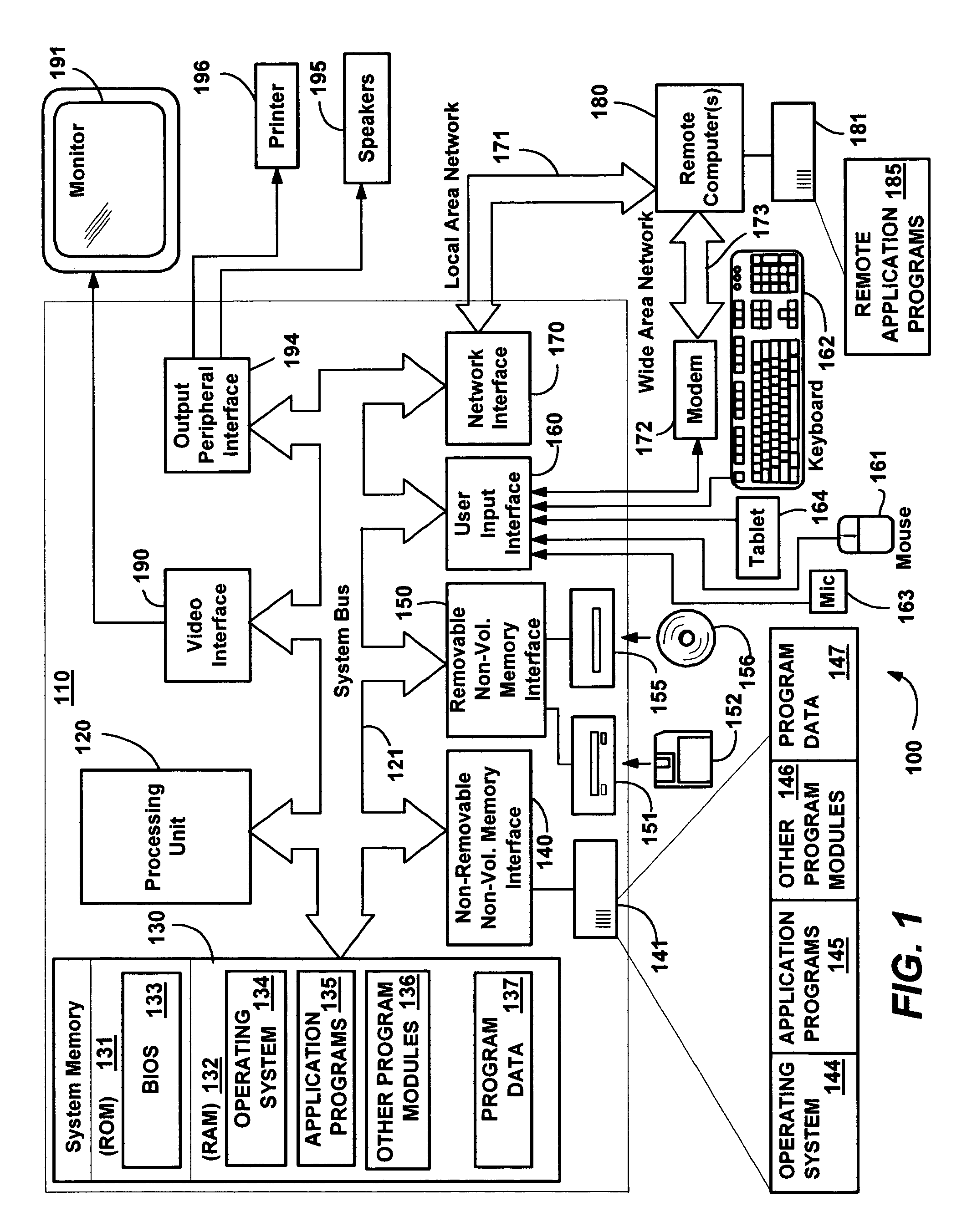

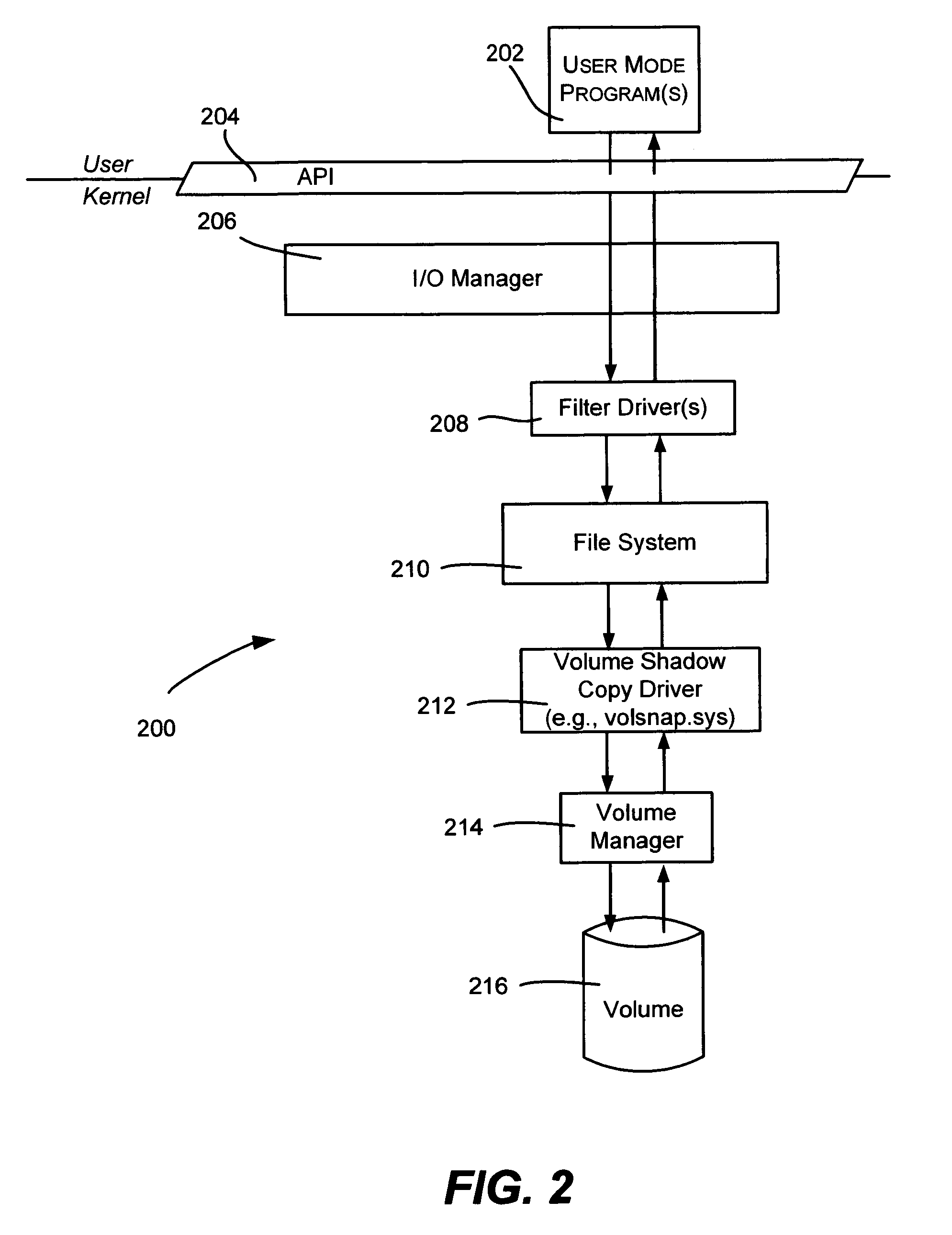

Method and system of previewing a volume revert operation

InactiveUS7383466B2Advanced technologyBetter behavedData processing applicationsError detection/correctionWindows RegistryTemporary storage

Described is a revert preview mechanism, which gives the user a chance to temporarily remount a storage volume with the contents of a shadow copy, and then evaluate the computer system as if reverted, including allowing full I / O read and write operations to the storage volume. A temporary storage location is provided to cache data writes. Read requests are read back from the temporary storage location if the corresponding volume location has been written, or are read back from the shadow copy of the volume if not written since the revert preview operation began. In the case of a revert preview of the boot volume, an API is used to specify a correct shadow copy instance of the system registry hive, which needs to be loaded following reboot, but before the shadow copy driver is loaded. Use of the API loads the correct instance on the next reboot.

Owner:MICROSOFT TECH LICENSING LLC

Outsole with tangential deformation

An outsole, especially for sports shoes, that can be formed with a large amount of elastic deformability even in the tangential direction towards the front and the back, enabling a good cushioning effect even when the tread of the foot is inclined and somewhat slipping. Beyond at least one critical deformation in the deformed region, the sole remains essentially rigid in relation to tangential deformation. In this way, the runner has a secure footing on the respective tread point. The elastic deformability of the sole also in the tangential direction is caused by at least one first element, and the rigidity of the sole in relation to tangential deformation beyond the at least one critical deformation, in addition to the degree of the at least one critical deformation in the deformed region is due to at least one second element.

Owner:GLIDEN LOCK

Wet-skin treatment compositions

InactiveUS20030180243A1Better behavedFast absorptionCosmetic preparationsHair cosmeticsSkin treatmentsDermatology

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

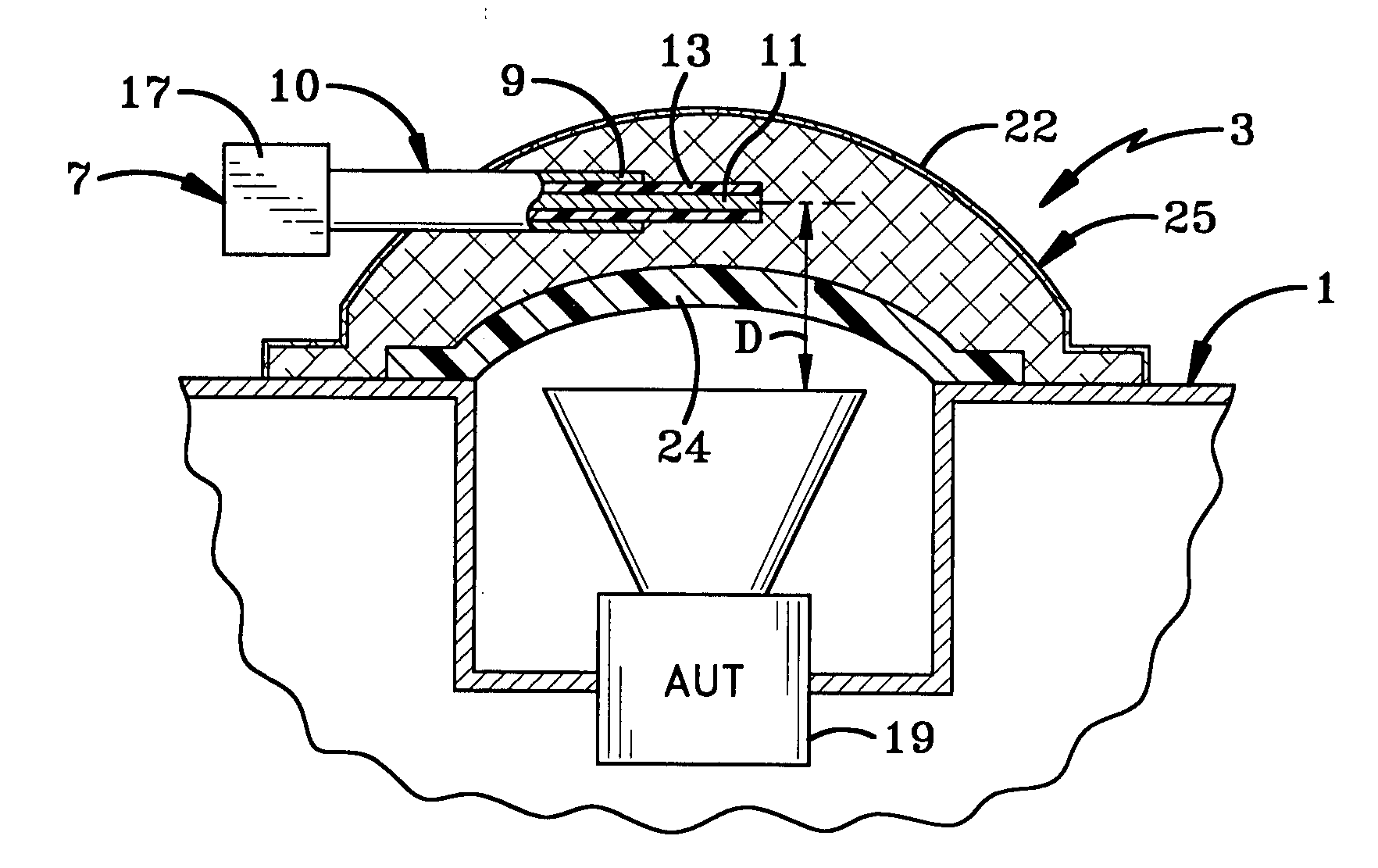

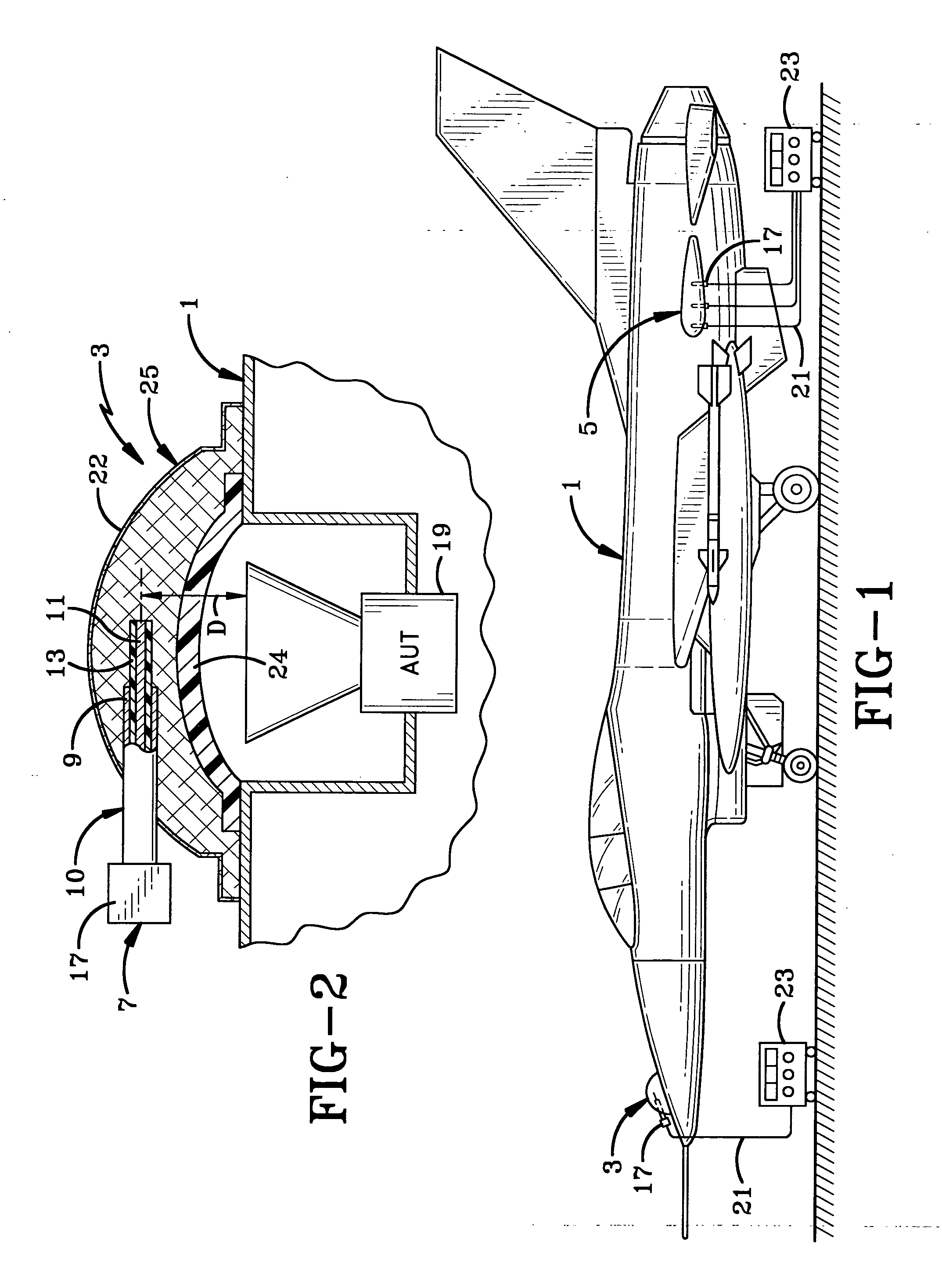

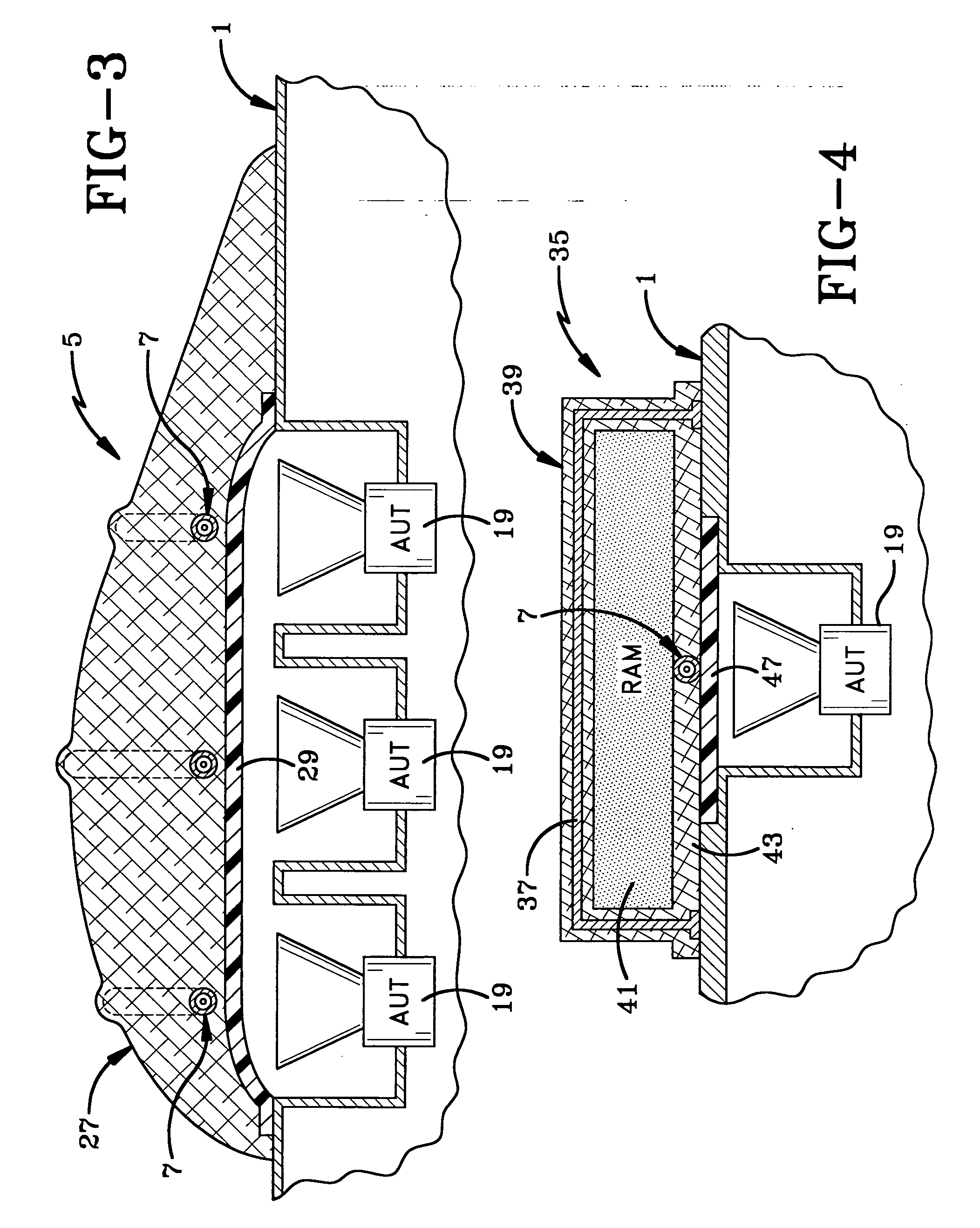

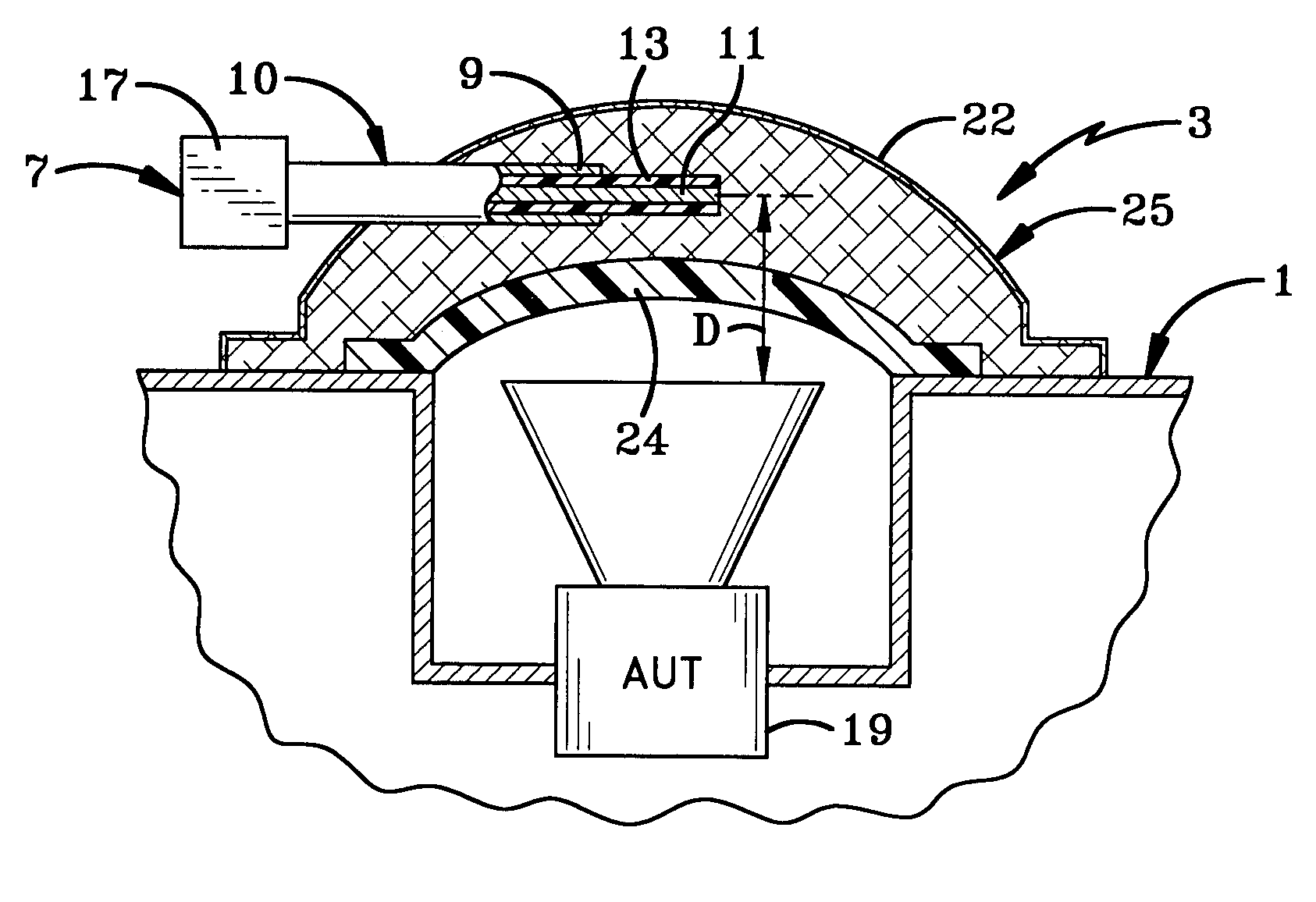

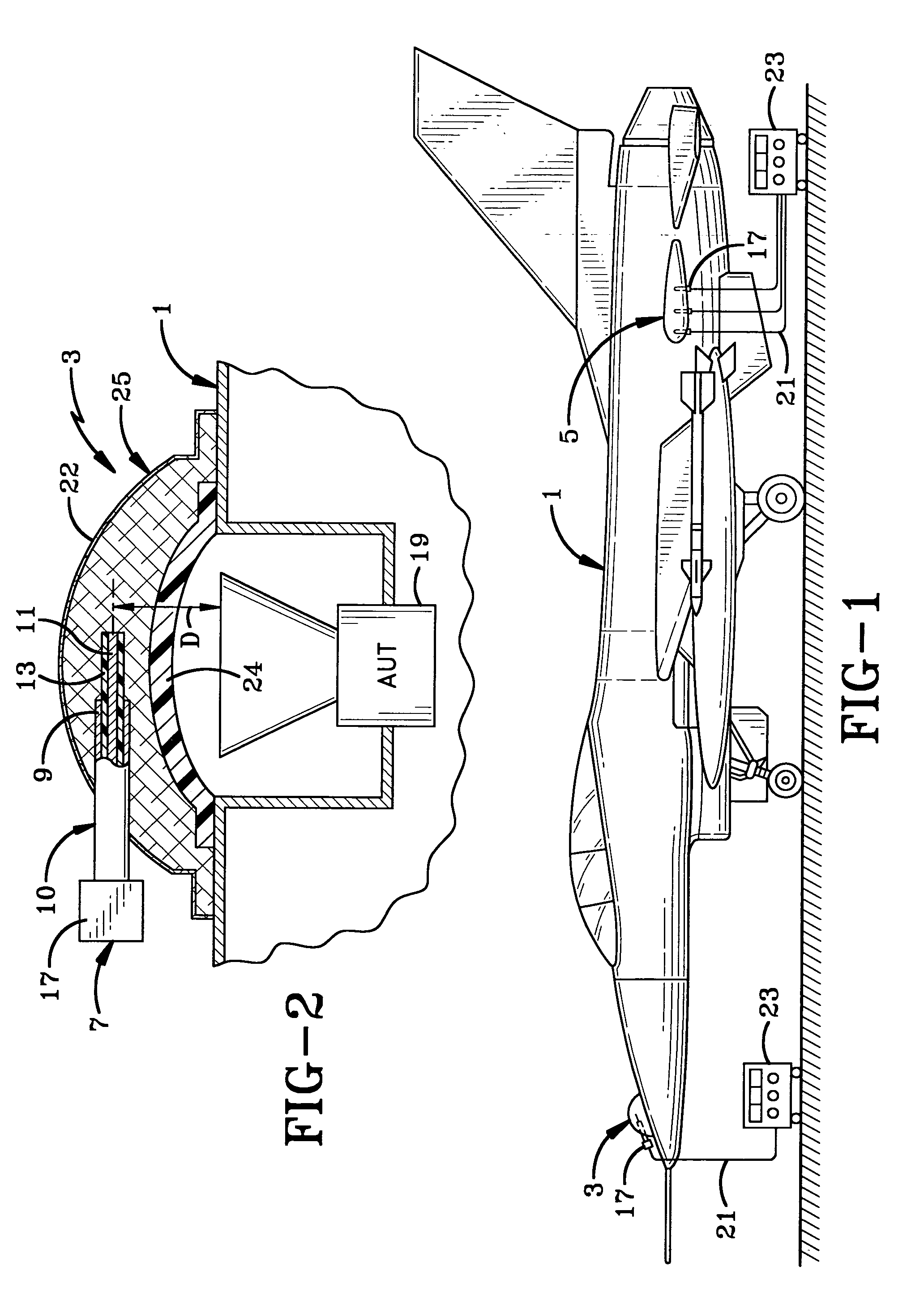

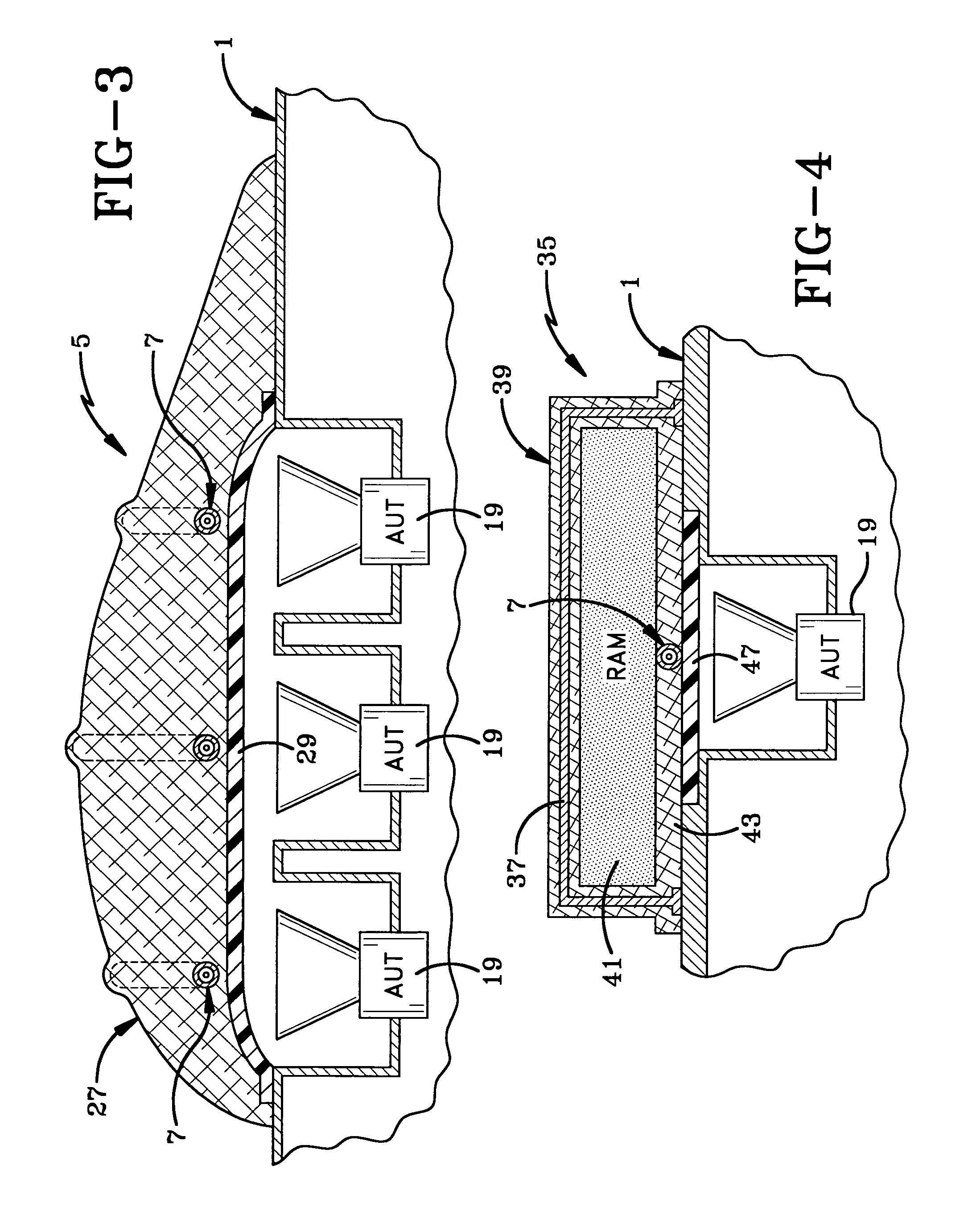

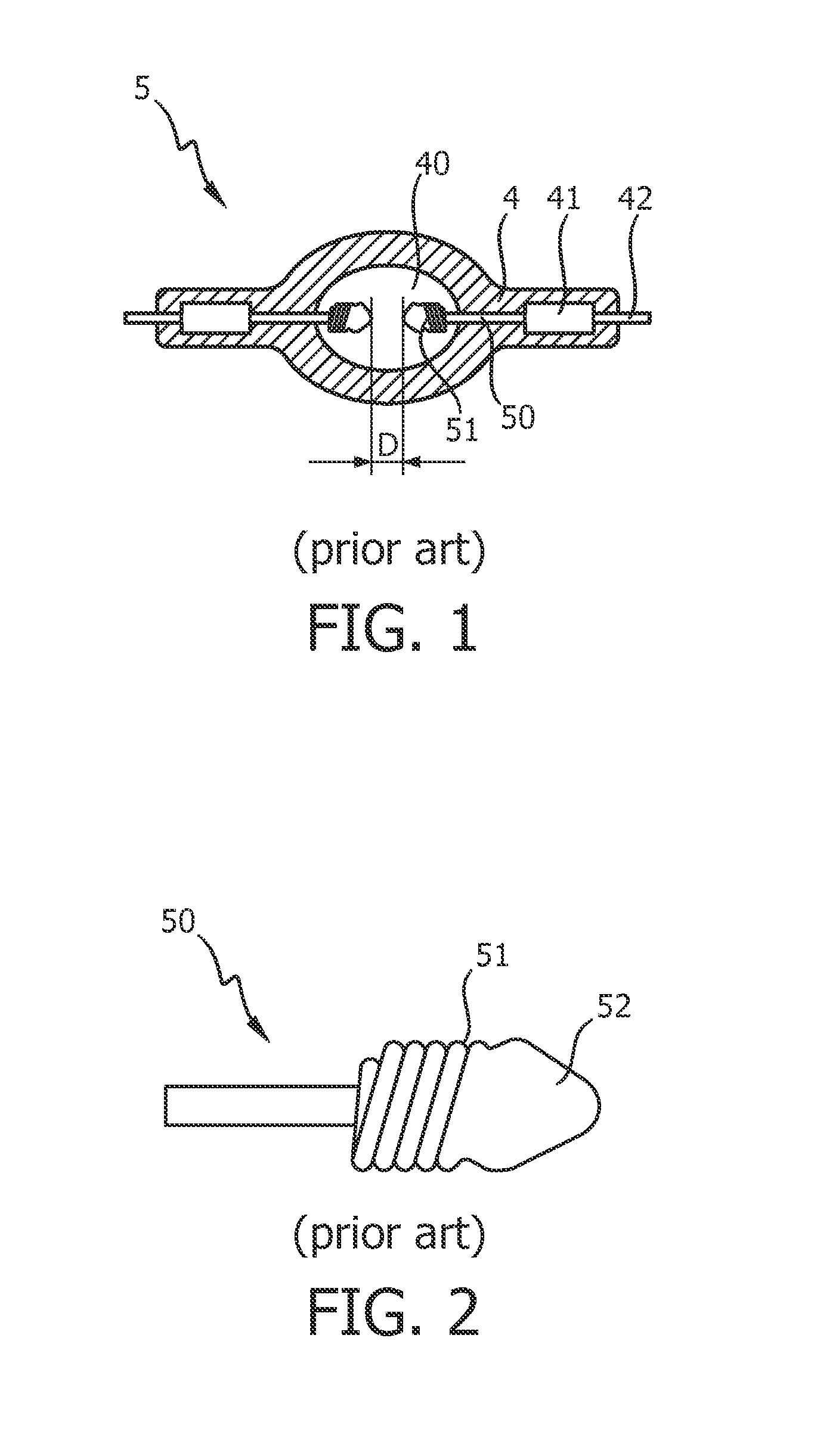

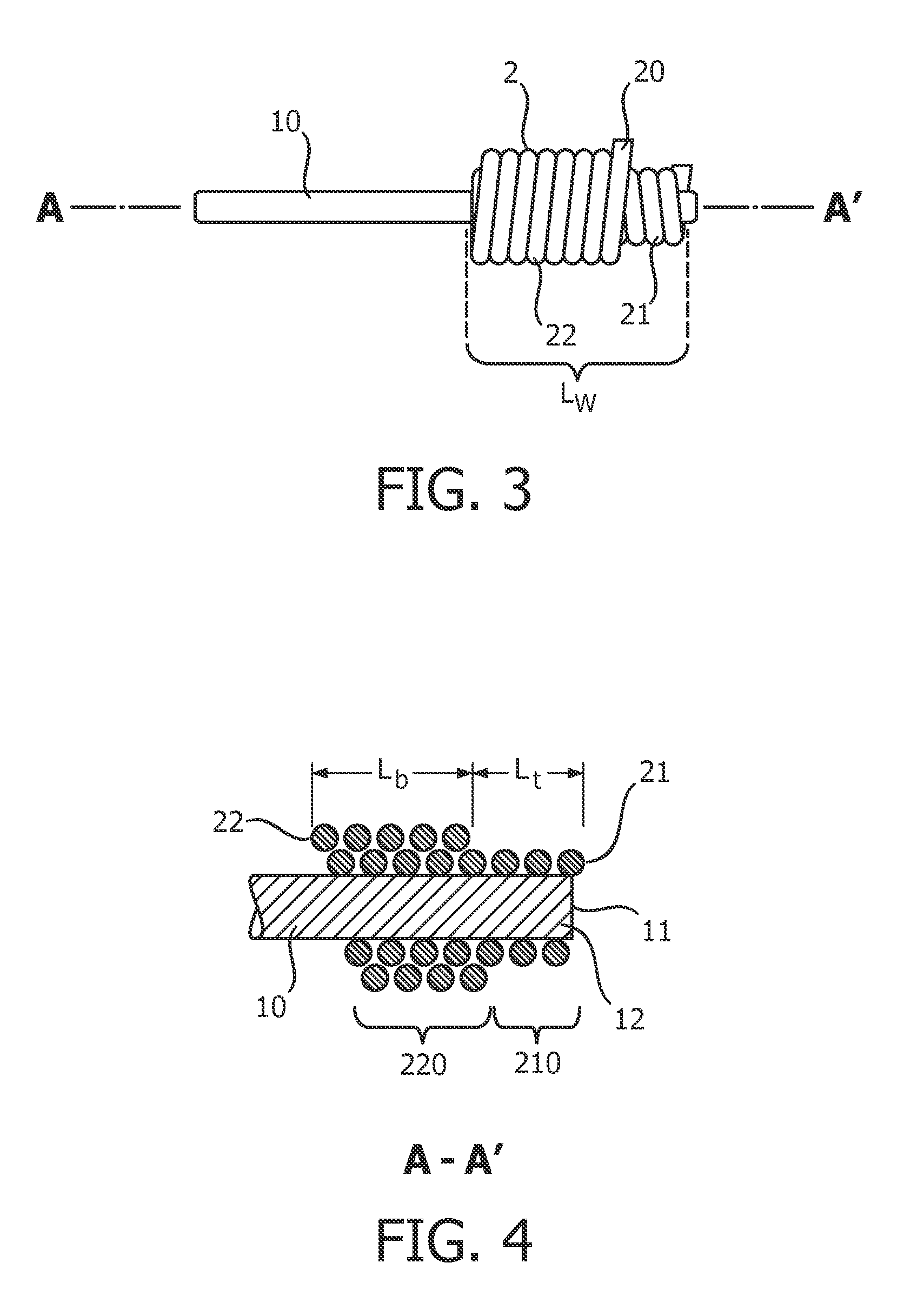

Antenna couplers and method of production

InactiveUS20070013607A1Low costReducing size and complexity and costAntenna adaptation in movable bodiesAntennas earthing switches associationSoftware engineeringMechanical engineering

A method of producing an antenna coupler for placement on an antenna under test (AUT) having an aperture. This method includes the steps of constructing a probe from a section of RF hard-line stock having a center conductor and an outer conductor. The outer conductor is removed to expose a portion of the center conductor having a length equal to or less than ¼ wavelength of the AUT. The probe is embedded within a fiberglass shell and has an exposed RF connector for connection to equipment for performing tests on the AUT. The probe is then positioned across the aperture of the Antenna Under Test (AUT).

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

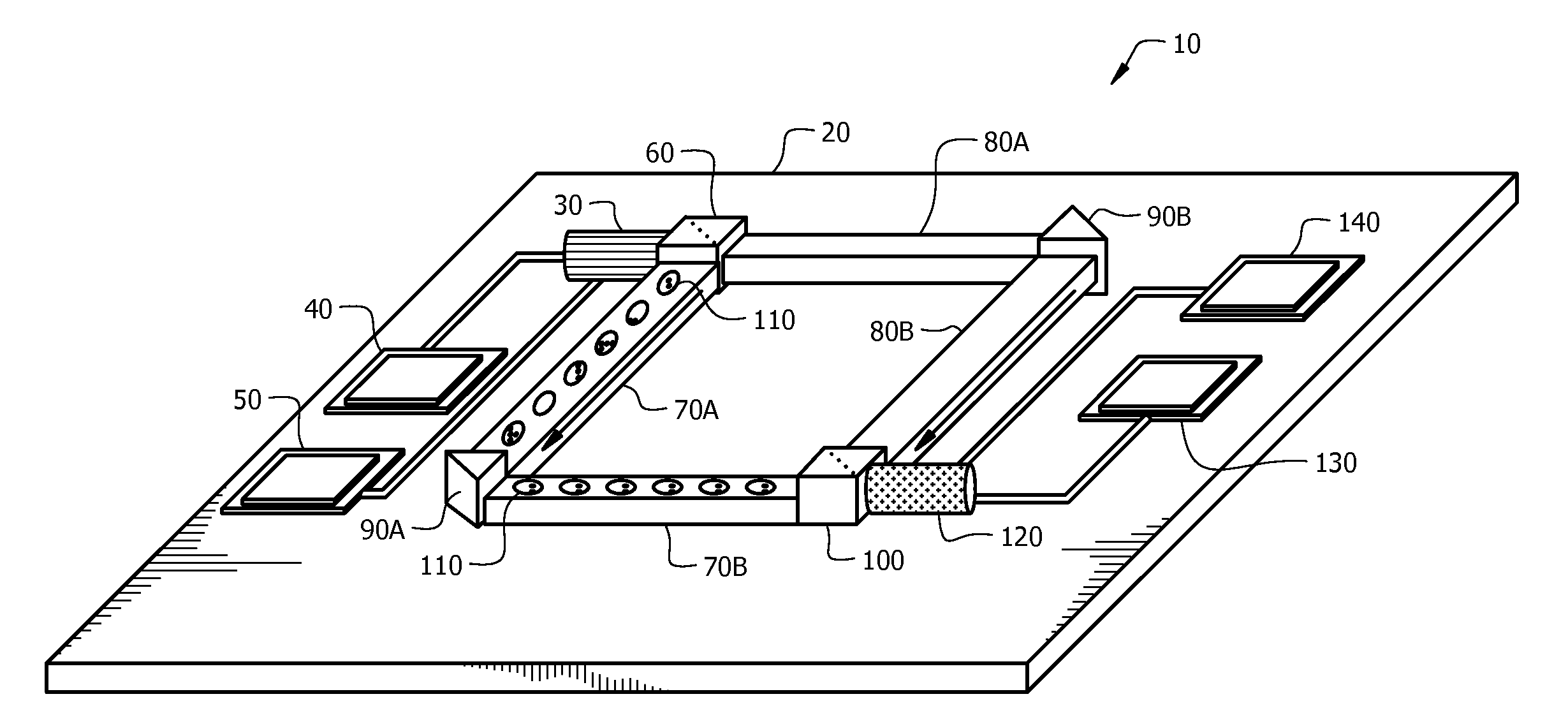

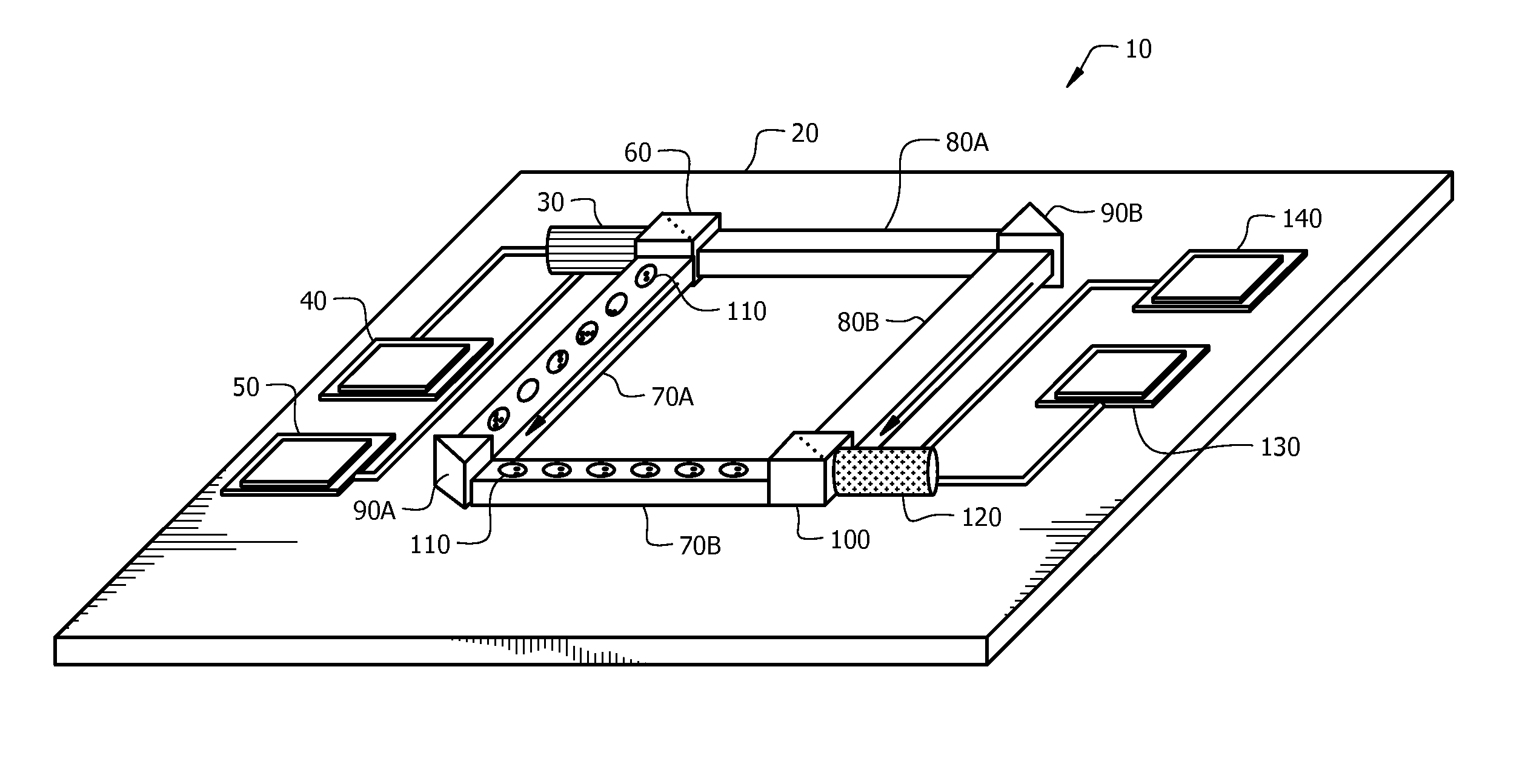

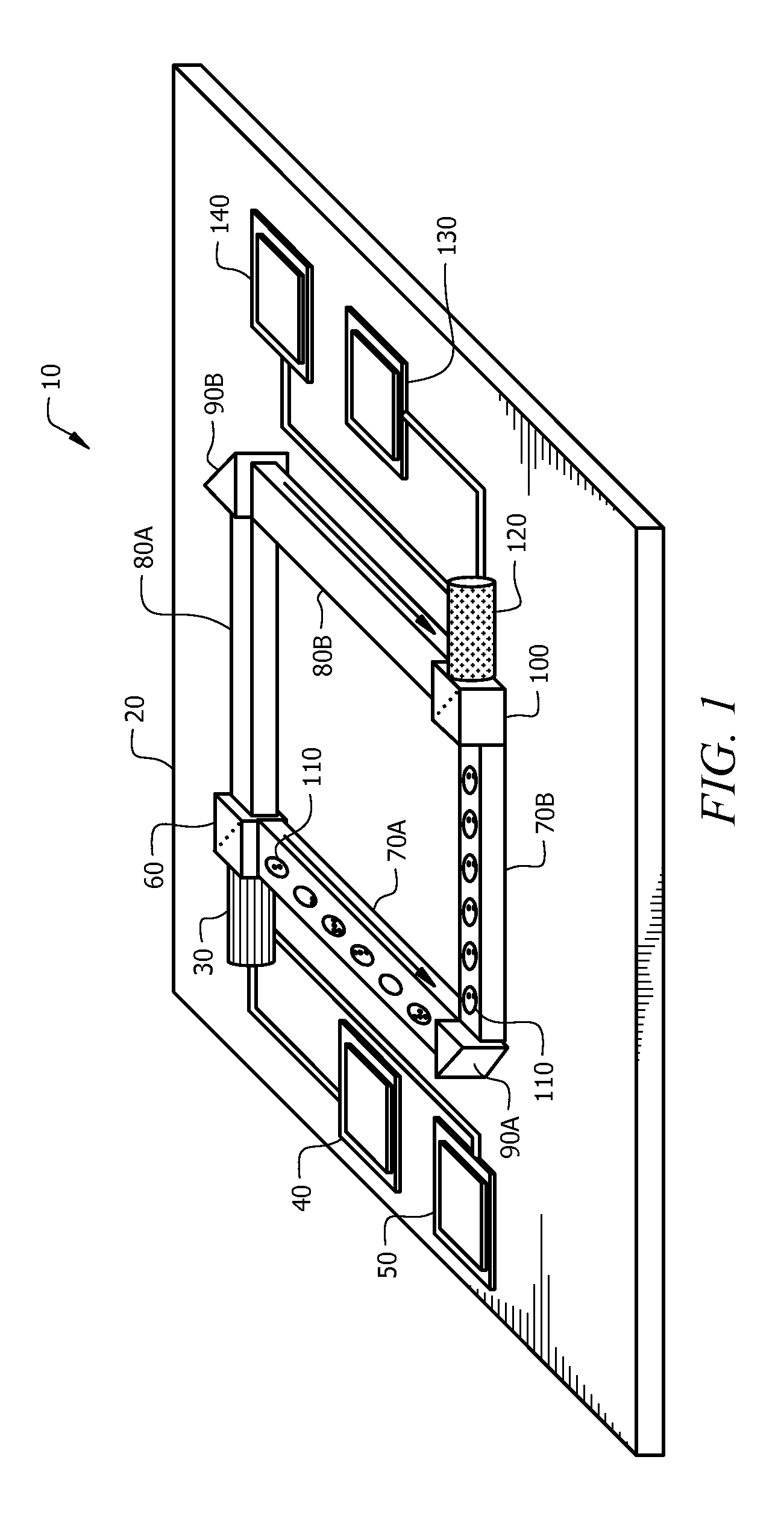

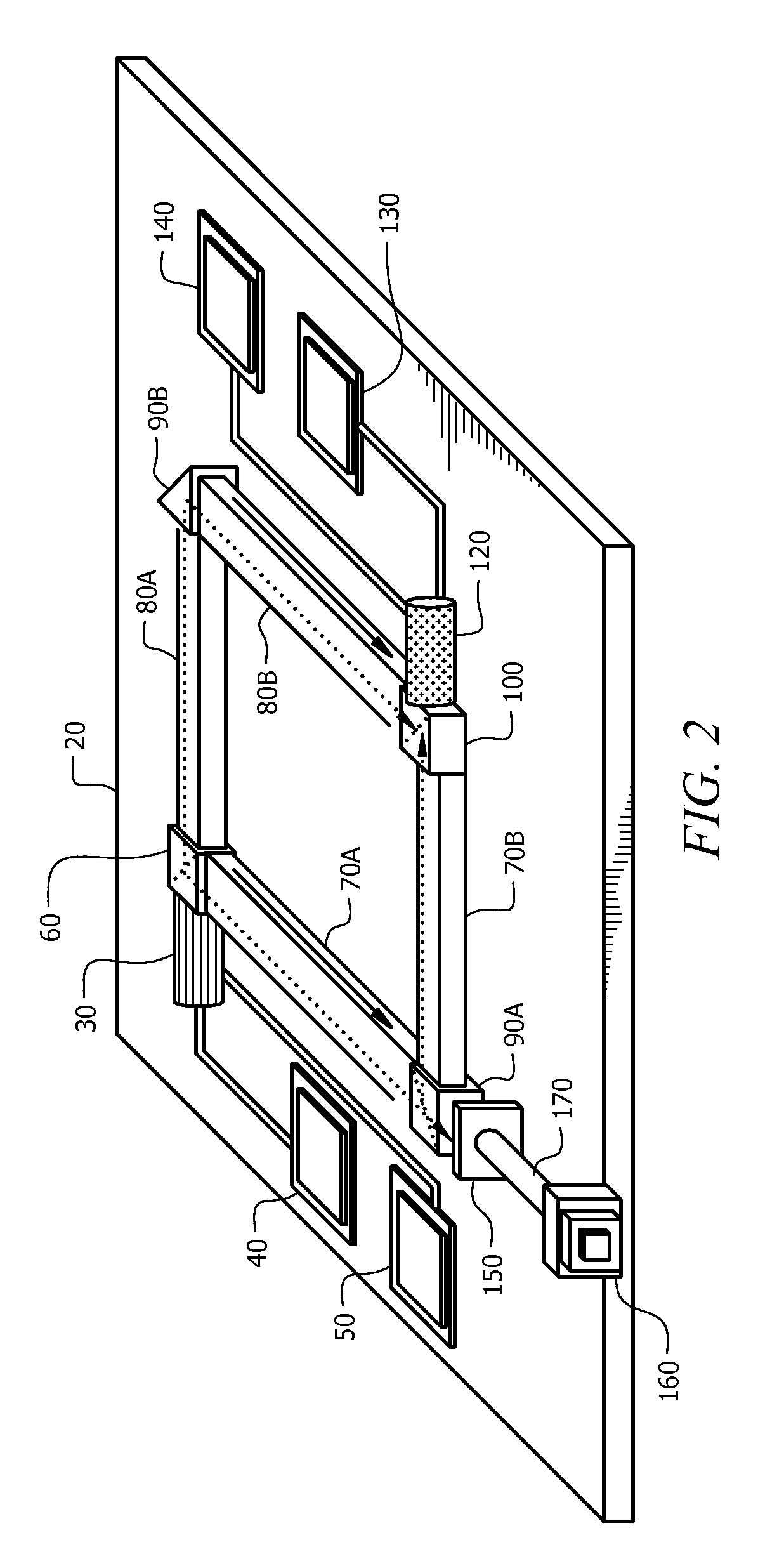

Interferometric Chemical Sensor Array

ActiveUS20090316158A1Increase power consumptionLarge power sourceRadiation pyrometryInterferometric spectrometryParticulatesCatoptrics

The device is a gas / vapor / aerosol / particulate sensor with a receiver / transmitter option. This optical MEMS device is designed to be a self-contained optical bench, integrating of an entire interferometer into a MOEMS ‘optical bench’ system-on-a-chip, and includes multiplexed optical path sensors. The sensing structures consist of laser sources, semiconductor photo detectors, refractive / reflective optical elements, and specialized optical transmission paths. Each individual laser source and photodiode is an optical path sensor with a particular ‘functionalization.’ These sensing arm functionalizations are sensitive to unique chemical signatures and as a result can recognize and report various chemical agents present in the ambient environment.

Owner:UNIV OF SOUTH FLORIDA

Ring optical interferometer

InactiveUS6837586B2Better behavedOptical measurementsPhotometry using reference valueOptical detectorsOptical detector

A multi-aperture interferometric optical system collects light propagating from a source of light and develops overlapping diffraction patterns on an optical detector that produces output signals for processing to form an image corresponding to the diffraction patterns. A preferred embodiment of the invention is a large aperture orbiting, earth-watching ring interferometric optical system configured such that there is no macro-structure pointing. Four mirror-ring structures direct incoming light to a multi-spectral primary optical detector that acquires light-pattern information from which an image can be derived.

Owner:VENTURE ASTRA

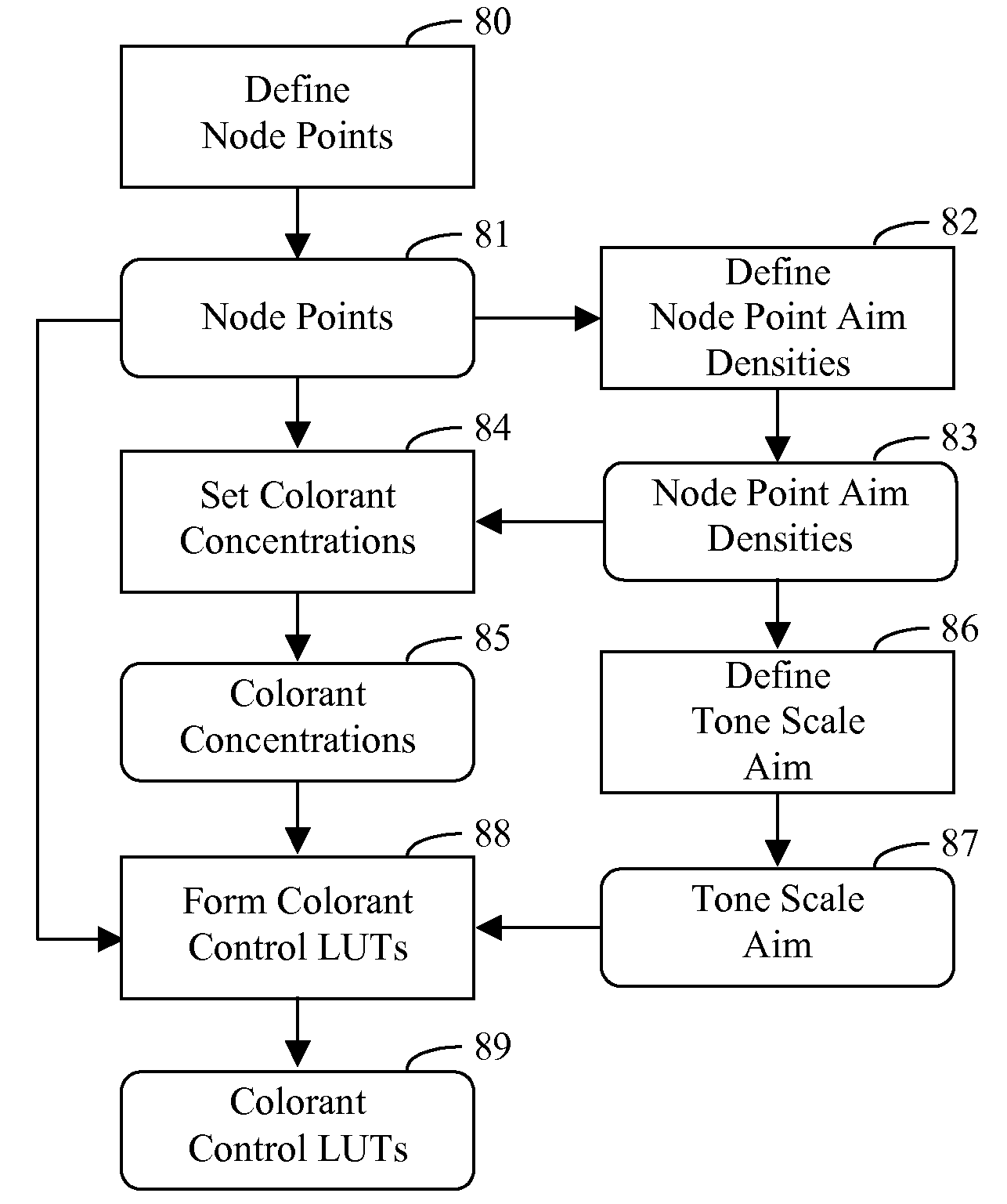

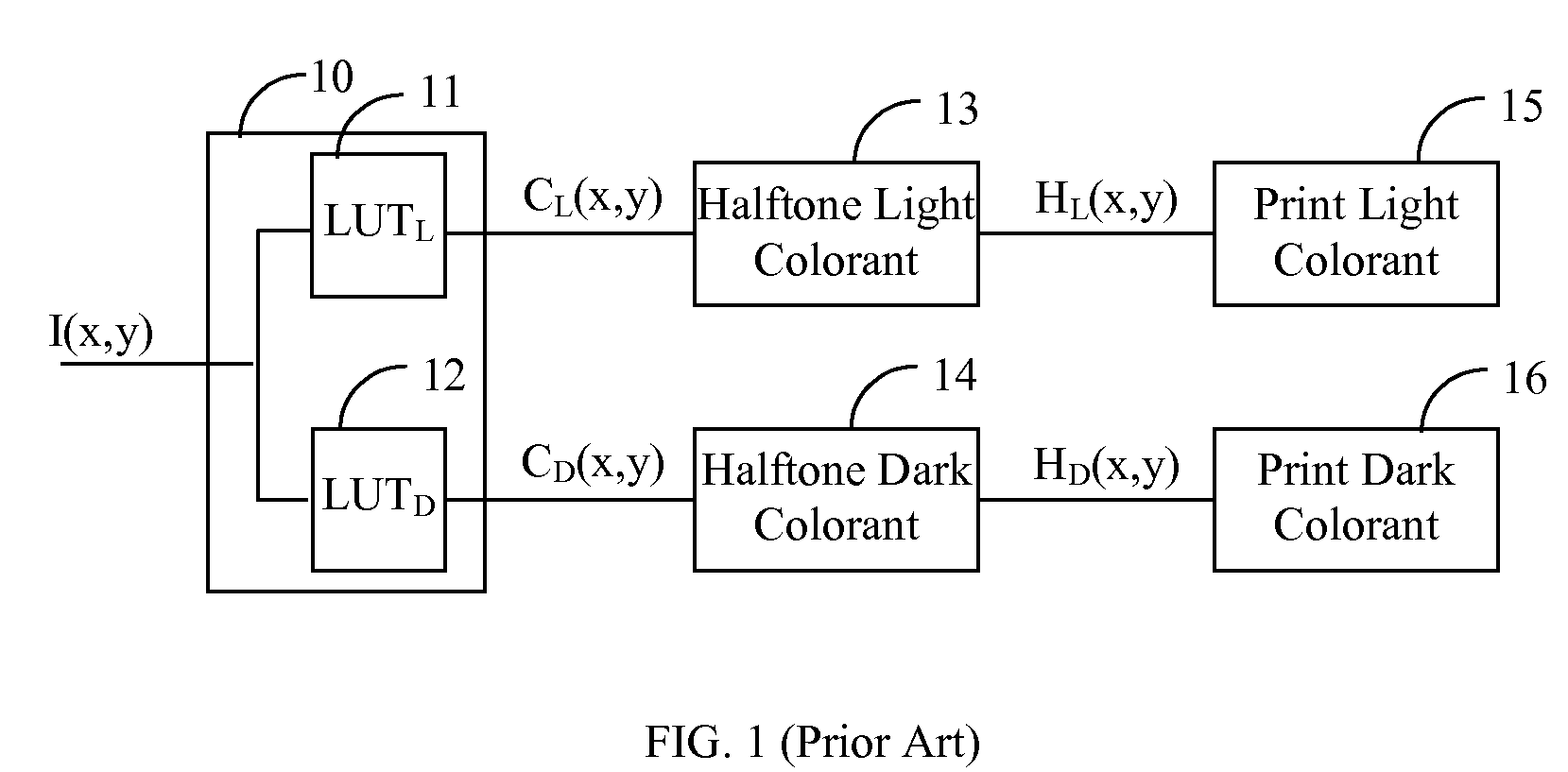

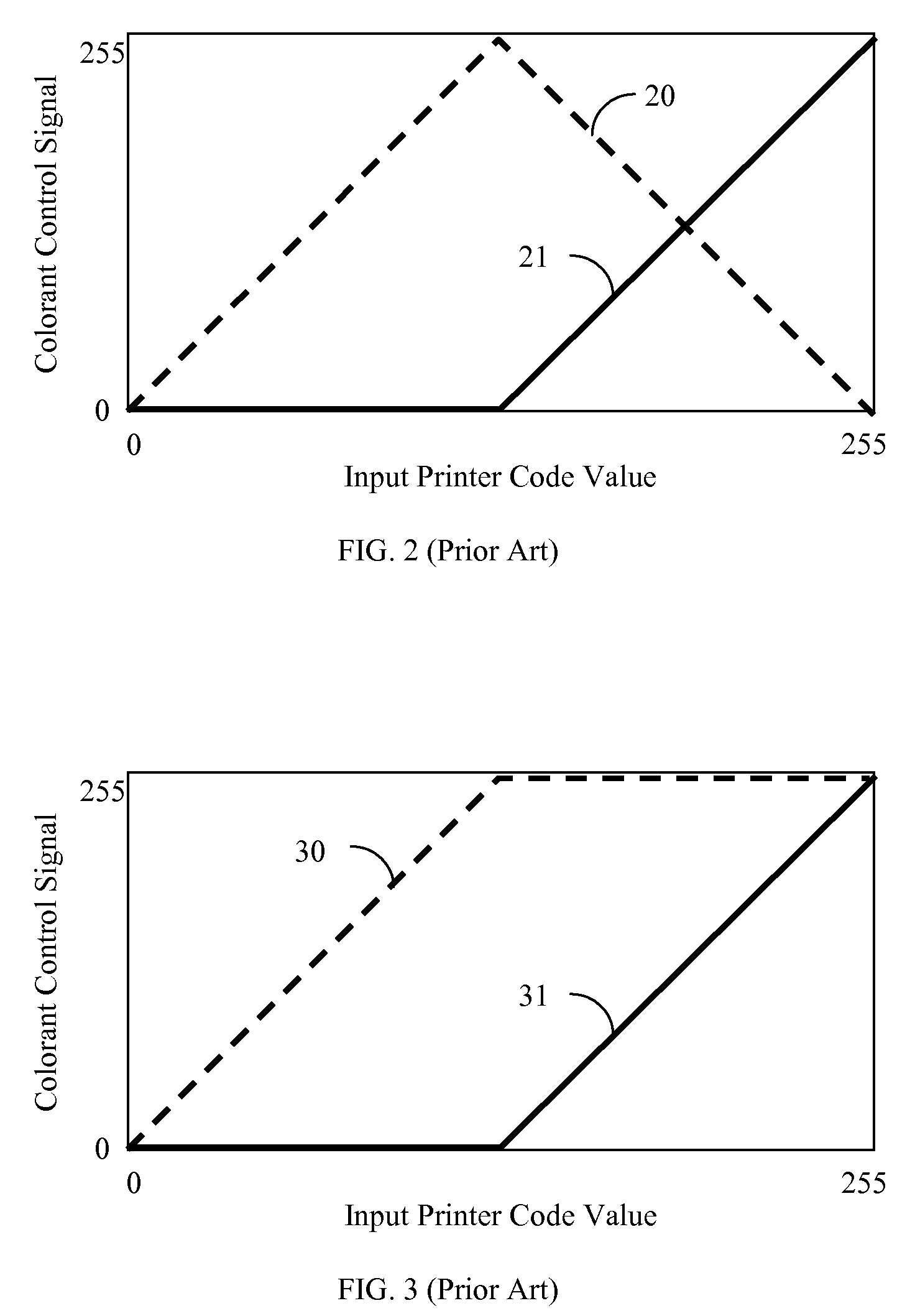

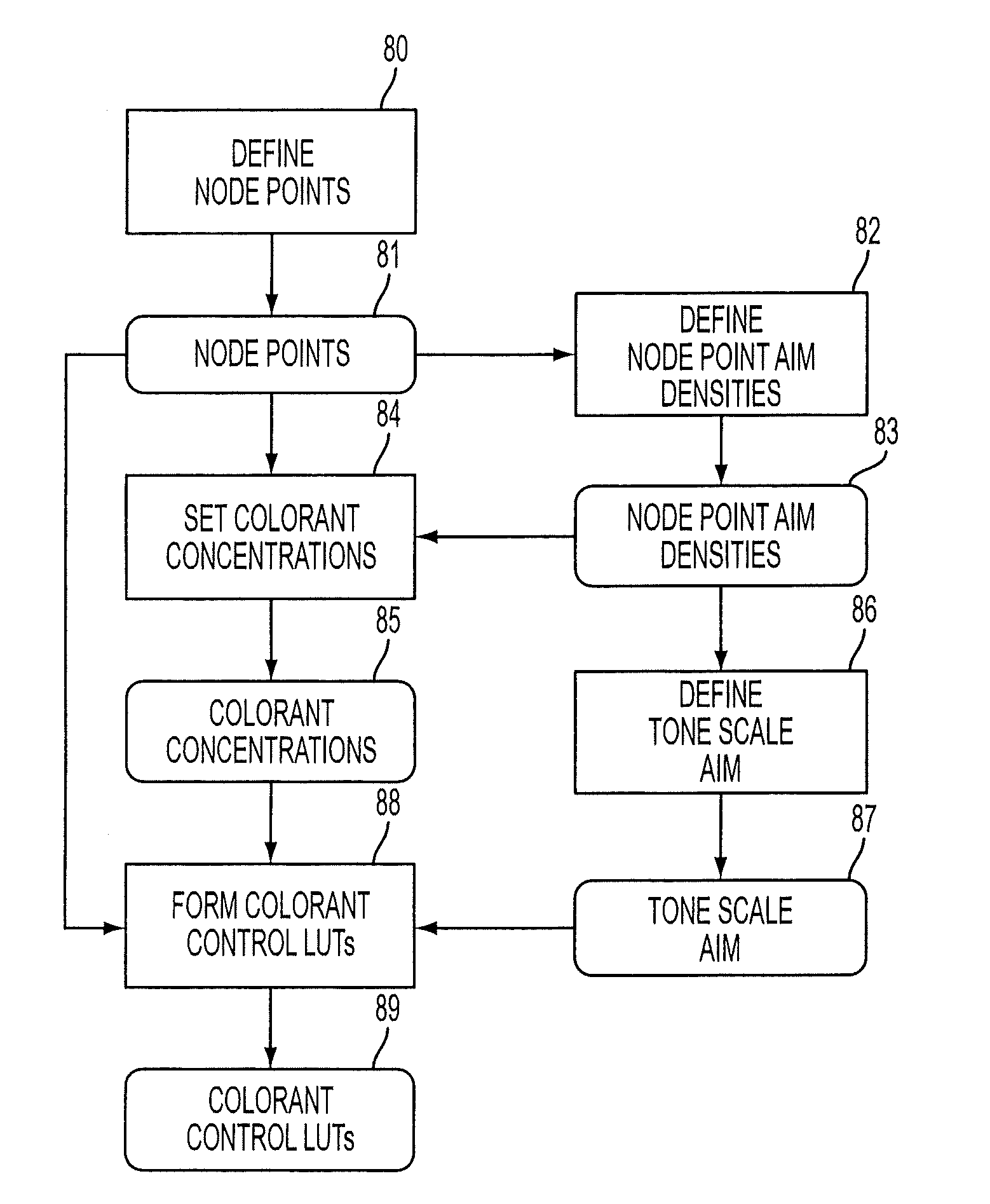

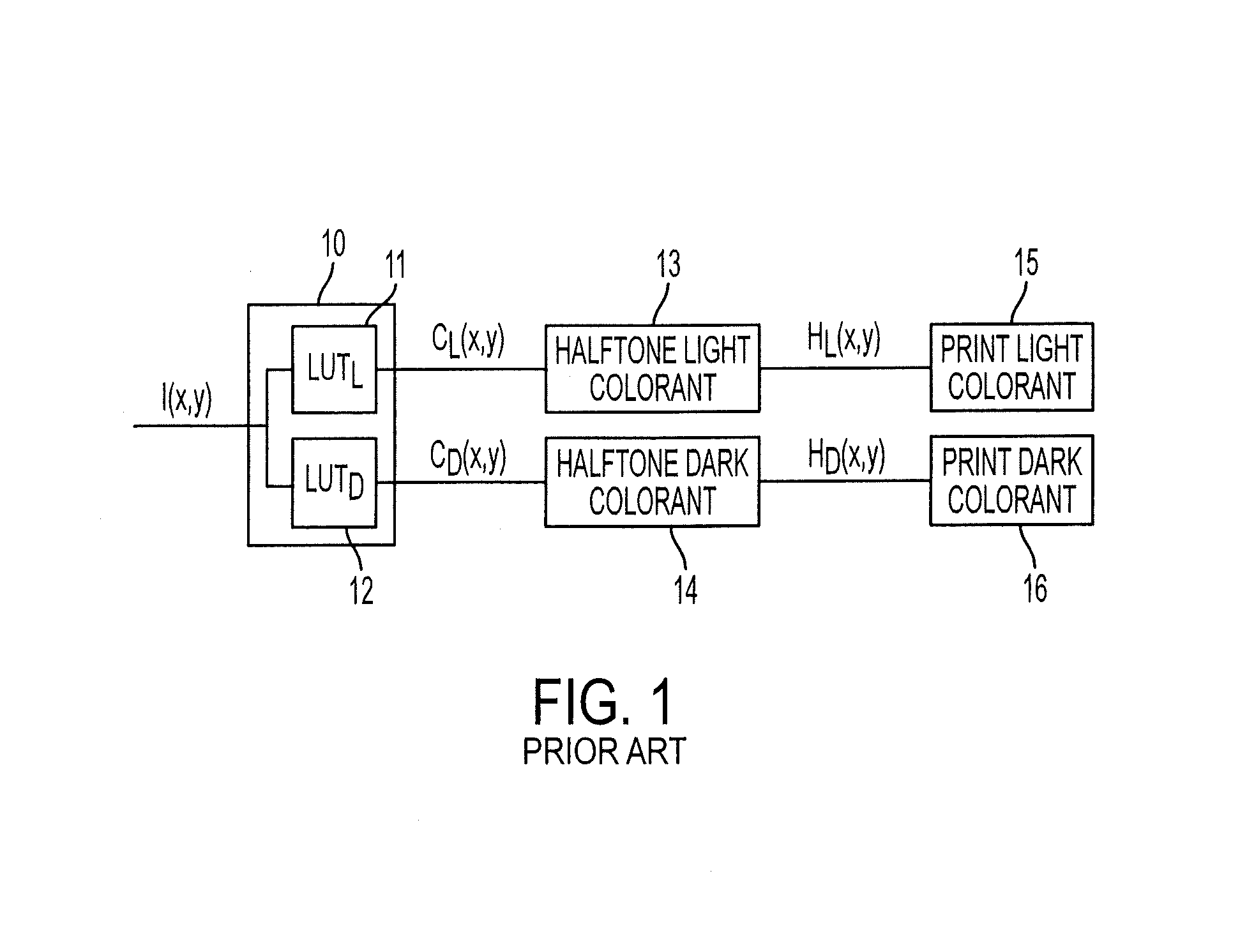

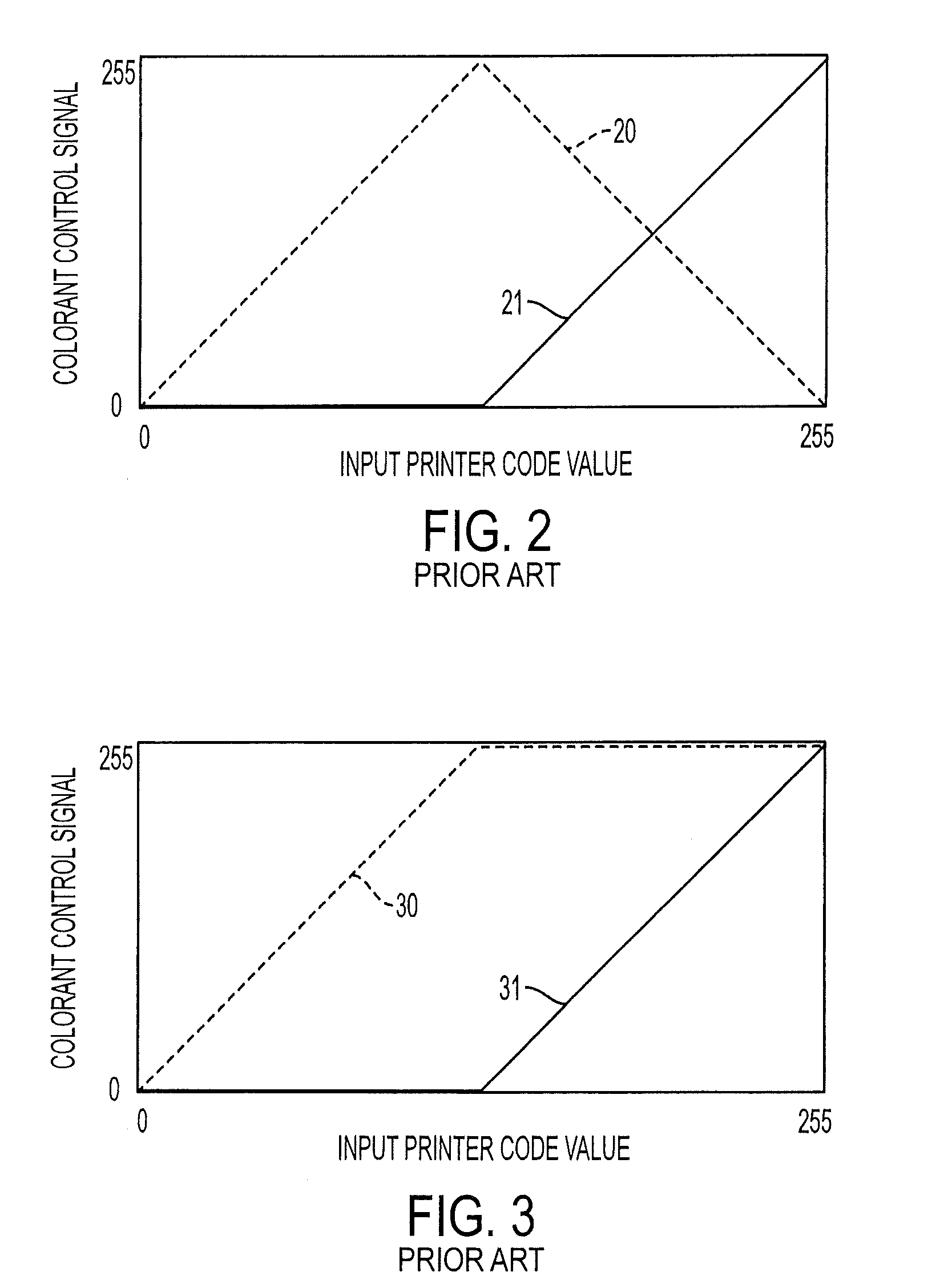

Digital printing using similar colorants

ActiveUS20100141970A1Stable changeAvoid contouring artifactDigitally marking record carriersDigital computer detailsComputer graphics (images)Computer printing

A method for printing an input digital image using a digital printer having a set of colorants with substantially the same color but different densities, including a sequence of node points where each of the two or more colorants are either at their maximum or minimum values, setting colorant concentrations such that the color channel output responses corresponding to the sequence of node points are substantially equally spaced in a visually uniform color space; forming colorant control look-up tables to provide smooth transitions in the color channel output response between the sequence of node points; addressing the colorant control look-up tables with the printer code value for each pixel of the input digital image to determine the colorant control signals for each of the two or more colorants; and controlling the digital printer using the colorant control signals to produce a print of the input digital image.

Owner:EASTMAN KODAK CO

Antenna couplers and method of production

InactiveUS7170467B1Low costReducing size and complexity and costAntenna adaptation in movable bodiesAntennas earthing switches associationGlass fiberElectrical conductor

A method of producing an antenna coupler for placement on an antenna under test (AUT) having an aperture. This method includes the steps of constructing a probe from a section of RF hard-line stock having a center conductor and an outer conductor. The outer conductor is removed to expose a portion of the center conductor having a length equal to or less than ¼ wavelength of the AUT. The probe is embedded within a fiberglass shell and has an exposed RF connector for connection to equipment for performing tests on the AUT. The probe is then positioned across the aperture of the Antenna Under Test (AUT).

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTEGRATION INC

Insulated gate semiconductor device and method for manufacturing same

InactiveUS7535040B2Better behavedTransistorSemiconductor/solid-state device manufacturingEngineeringSemiconductor

Owner:SANKEN ELECTRIC CO LTD

Countermass and countermass weapon

ActiveUS7823497B2Avoid it happening againDown costsRocket launchersFiring/trigger mechanismsCombustionMechanical engineering

A countermass for use in a weapon to balance the forces arising when a launch able unit is launched from a launcher tube of the weapon. The countermass includes a first container enclosing a liquid. A countermass weapon includes a launcher tube open or openable in both ends. The launcher tube houses a launch able unit, a countermass including a first container enclosing a liquid, a pressure chamber, and a propellant charge that upon firing and combustion of the charge in cooperation with the pressure chamber and the countermass accelerates the launch able unit forwards in the tube at the same time as the countermass accelerates backwards in the tube. The first container is made of a non-rigid material. A second container is provided to cover or almost cover the first container. The second container is designed with damping characteristics.

Owner:SAAB AB

Cosmetic/dermatological compositions formulated as supple doughs

Transfer-resistant cosmetic / dermatological compositions (e.g., lipcolors) formulated as supple and homogeneous doughs, advantageously via extrusion, include a fatty phase which comprises at least one volatile oil, at least one phenylated silicone oil and at least 12% by weight of at least one wax.

Owner:LOREAL SA

Interferometric chemical sensor array

ActiveUS8269974B2Increase power consumptionSolve the power is smallRadiation pyrometryInterferometric spectrometryParticulatesOptical table

The device is a gas / vapor / aerosol / particulate sensor with a receiver / transmitter option. This optical MEMS device is designed to be a self-contained optical bench, integrating of an entire interferometer into a MOEMS ‘optical bench’ system-on-a-chip, and includes multiplexed optical path sensors. The sensing structures consist of laser sources, semiconductor photo detectors, refractive / reflective optical elements, and specialized optical transmission paths. Each individual laser source and photodiode is an optical path sensor with a particular ‘functionalization.’ These sensing arm functionalizations are sensitive to unique chemical signatures and as a result can recognize and report various chemical agents present in the ambient environment.

Owner:UNIV OF SOUTH FLORIDA

Digital printing using similar colorants

ActiveUS8085436B2Stable changeAvoid contouring artifactDigitally marking record carriersDigital computer detailsControl signalDigital image

A method for printing an input digital image using a digital printer having a set of colorants with substantially the same color but different densities, including a sequence of node points where each of the two or more colorants are either at their maximum or minimum values, setting colorant concentrations such that the color channel output responses corresponding to the sequence of node points are substantially equally spaced in a visually uniform color space; forming colorant control look-up tables to provide smooth transitions in the color channel output response between the sequence of node points; addressing the colorant control look-up tables with the printer code value for each pixel of the input digital image to determine the colorant control signals for each of the two or more colorants; and controlling the digital printer using the colorant control signals to produce a print of the input digital image.

Owner:EASTMAN KODAK CO

Method of manufacturing an electrode for a gas discharge lamp

InactiveUS9053922B2Extended service lifeReduce the possibilityVacuum tubesDischarge tube/lamp detailsGas-discharge lampMaterials science

Owner:KONINK PHILIPS ELECTRONICS NV +1

Method for determining inverse filter from critically banded impulse response data

ActiveUS8761407B2Equal loudnessBetter behavedSignal processingPicture reproducers using cathode ray tubesLoudspeakerImpulse response

A method for determining an inverse filter for altering the frequency response of a loudspeaker so that with the inverse filter applied in the loudspeaker's signal path the inverse-filtered loudspeaker output has a target frequency response, and optionally also applying the inverse filter in the signal path, and a system configured (e.g., a general or special purpose processor programmed and configured) to determine an inverse filter. In some embodiments, the inverse filter corrects the magnitude of the loudspeaker's output. In other embodiments, the inverse filter corrects both the magnitude and phase of the loudspeaker's output. In some embodiments, the inverse filter is determined in the frequency domain by applying eigenfilter theory or minimizing a mean square error expression by solving a linear equation system.

Owner:DOLBY LAB LICENSING CORP +1

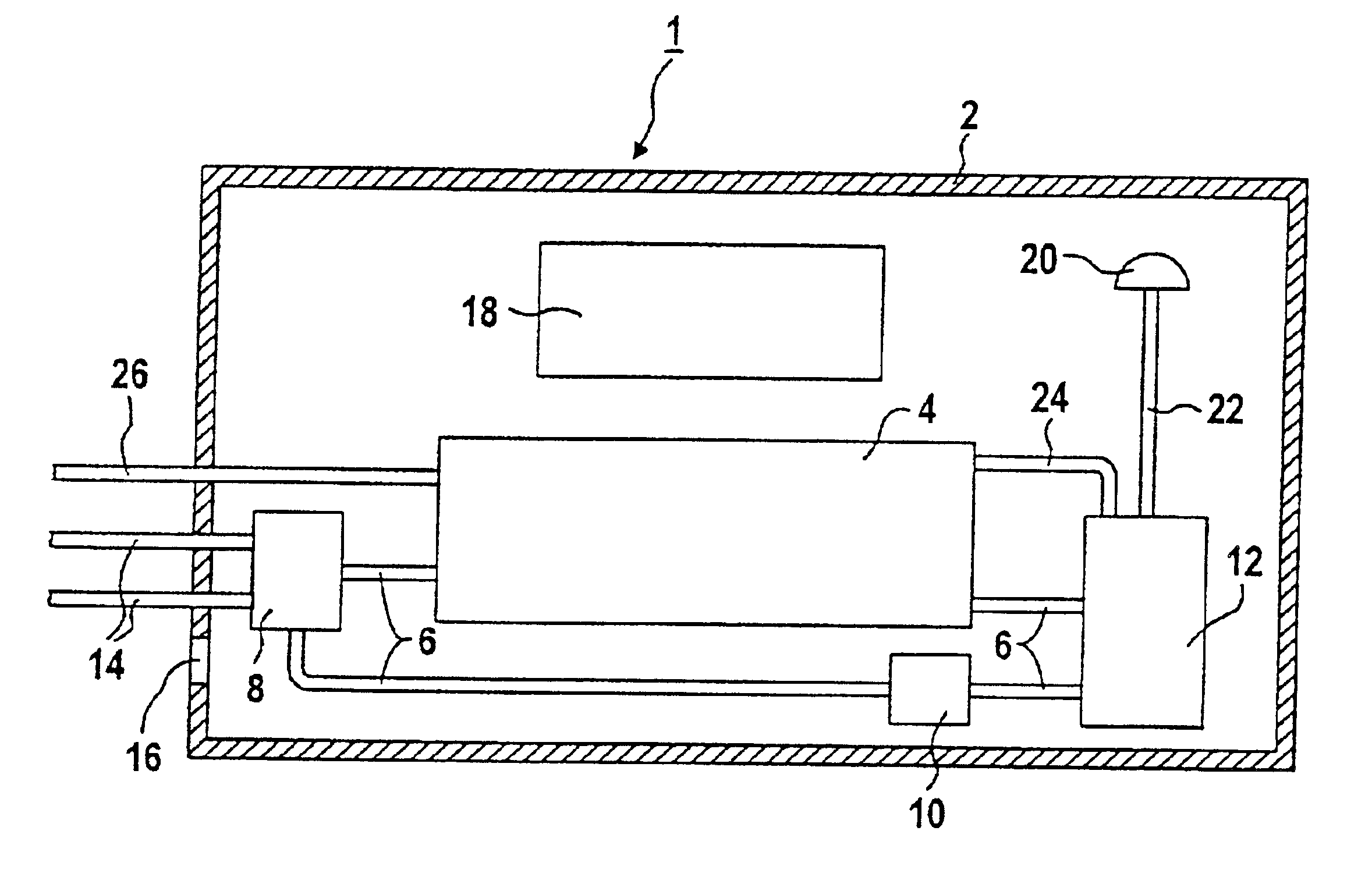

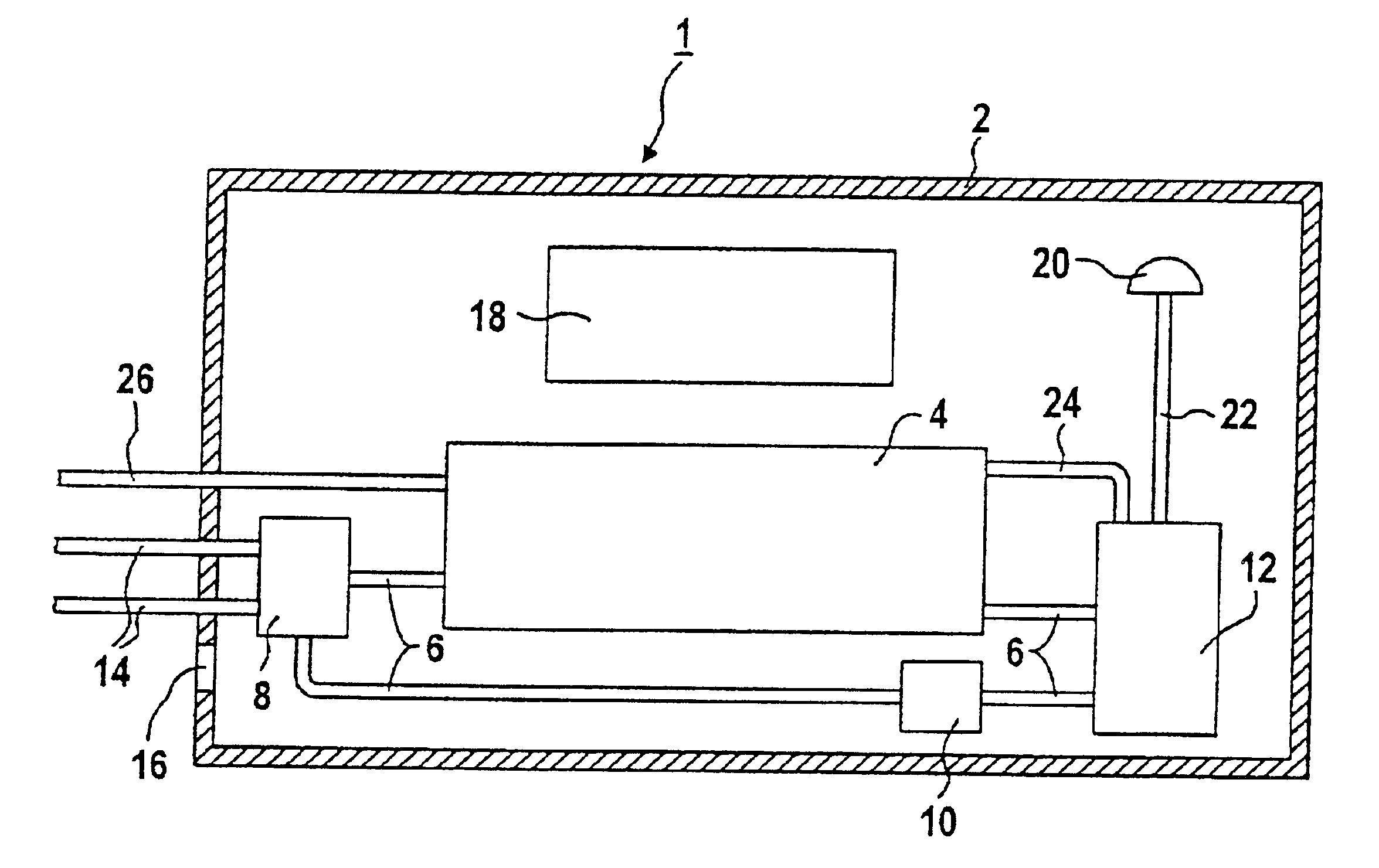

Method for operating a fuel cell plant and fuel cell plant

InactiveUS6841277B2Easy constructionAvoid heatSolid electrolytesHeating fuelFuel cellsThermal radiation

A method for operating a fuel cell plant and a fuel cell plant are provided. The thermal efficiency of a fuel cell plant results from the useful heat which is generated per quantity of fuel. Heat which is radiated from the fuel cell plant into the environment is lost and cannot be utilized. The method minimizes the radiation of heat from the fuel cell plant. Air for operation of the fuel cells is passed into a housing which surrounds heat-radiating components of the fuel cell plant. The air flows around the components, absorbs the heat which is radiated and delivers it to the fuel cell block, where the heat is emitted to cooling water that cools the fuel cell block and transfers the heat to water of a heating-water circuit.

Owner:SIEMENS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com