Electric dewatering and desalting appliance for crude oil

A technology of electric desalination and dehydration, crude oil, applied in the direction of electric/magnetic dehydration/emulsification, electric liquid separation, etc., can solve the problem of reducing the efficiency of oil-water separation, retarding the settlement of crude oil, and uneven radial distribution of the electric field intensity of the ring electric field, etc. problems, to achieve the effect of improving the dehydration efficiency of electric desalination, coalescence effect and sedimentation separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

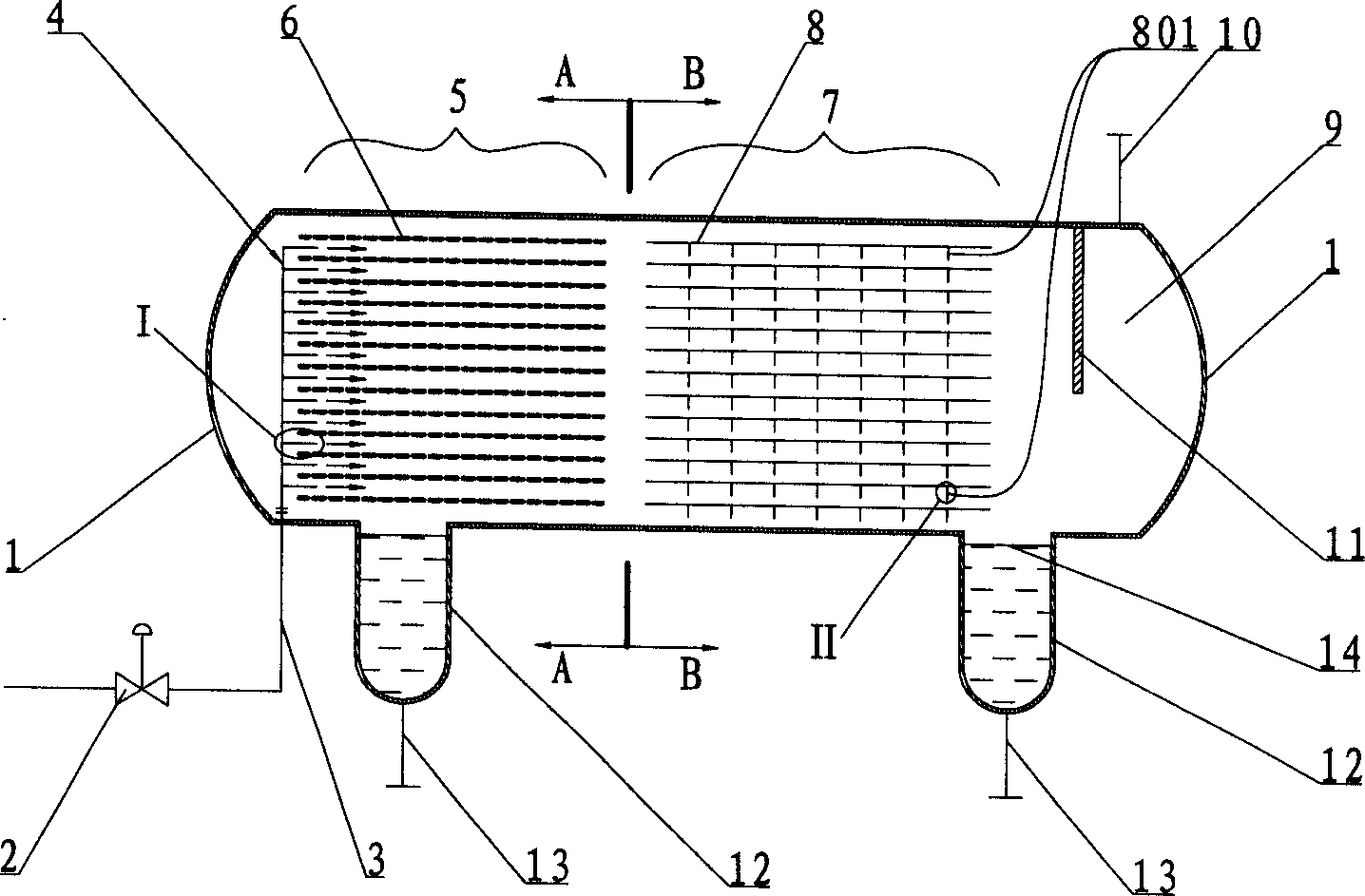

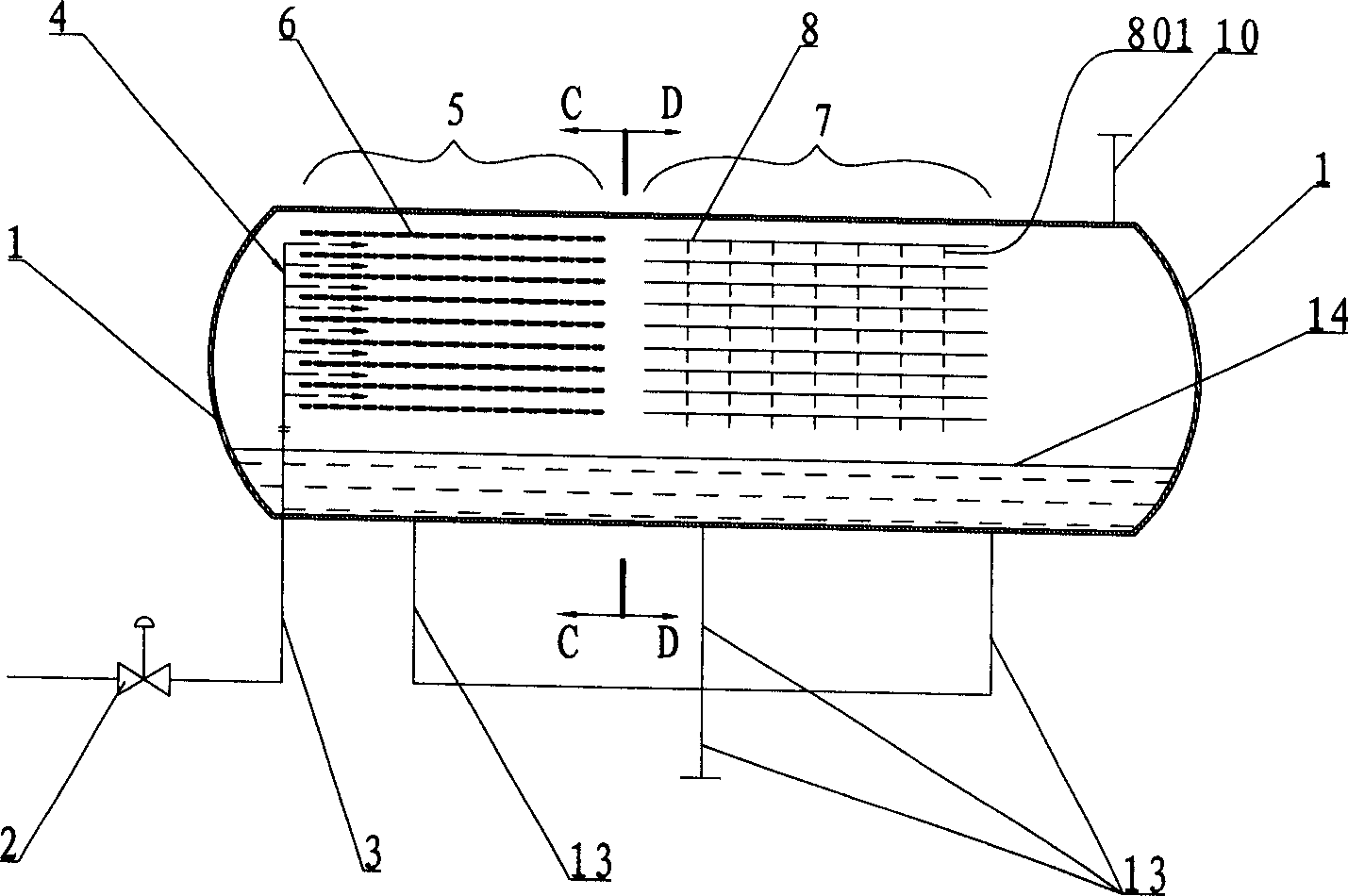

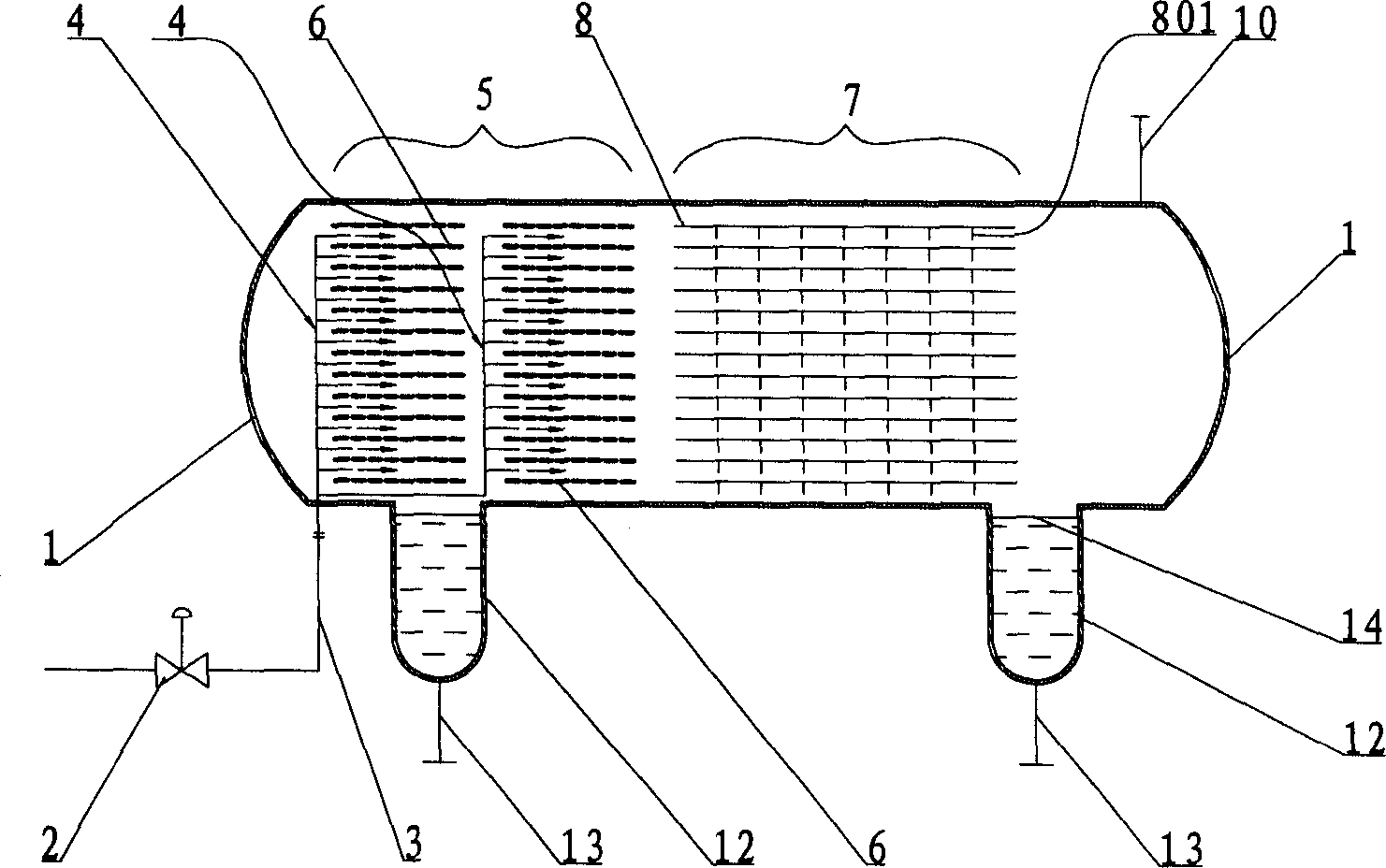

[0040] Such as figure 1 Shown is a kind of crude oil electric desalination dehydrator of the present invention. It includes a horizontal cylindrical tank body 1, one end of the tank body 1 is the inlet port of the oil-water mixture (hereinafter referred to as the inlet port), and the other end is the outlet port of purified crude oil (hereinafter referred to as the outlet port). The bottom of the tank body 1 is provided with two water bags 12, and the bottoms of the water bags 12 are respectively provided with outlet pipes 13. Inside the tank body 1, a feed distributor 4, a strong electric field coalescence zone 5 and a sedimentation separation zone 7 are sequentially arranged along the axial direction of the tank body 1 from the inlet end, and an oil outlet pipe 10 is arranged on the top of the outlet end of the tank body 1. The outlet end of the tank body 1 is also provided with a baffle plate 11 and an oil collection chamber 9 .

[0041] The strong electric field coalesci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com