Patents

Literature

99results about How to "Fast dehydration rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite cationic starch and preparation method thereof, and method for making paper by using starch

InactiveCN102796202AImprove cohesionHigh tensile strengthNon-fibrous pulp additionPaper/cardboardStarch solutionChemistry

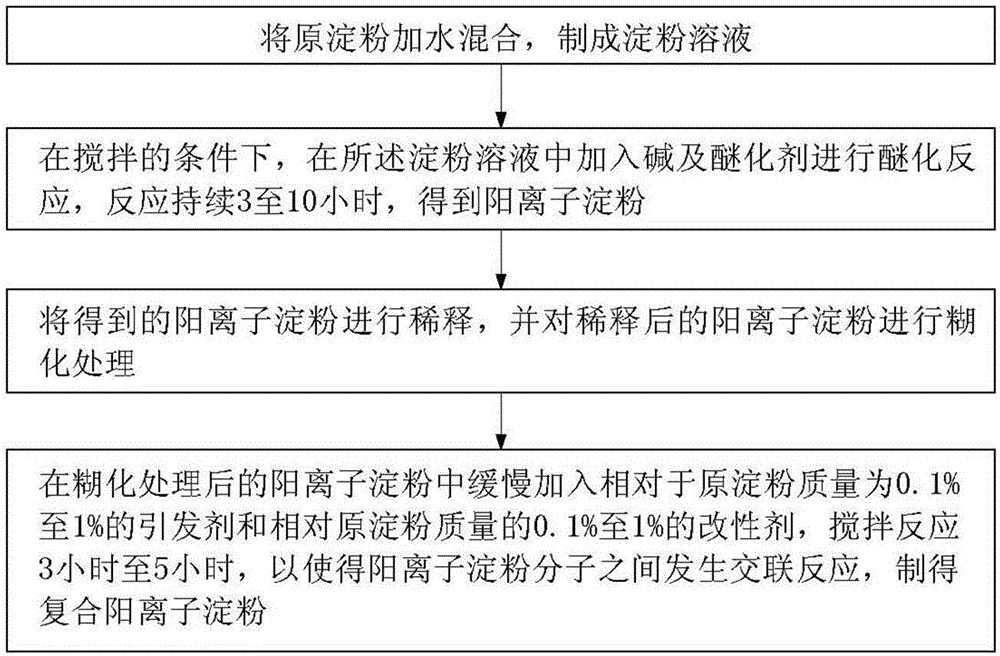

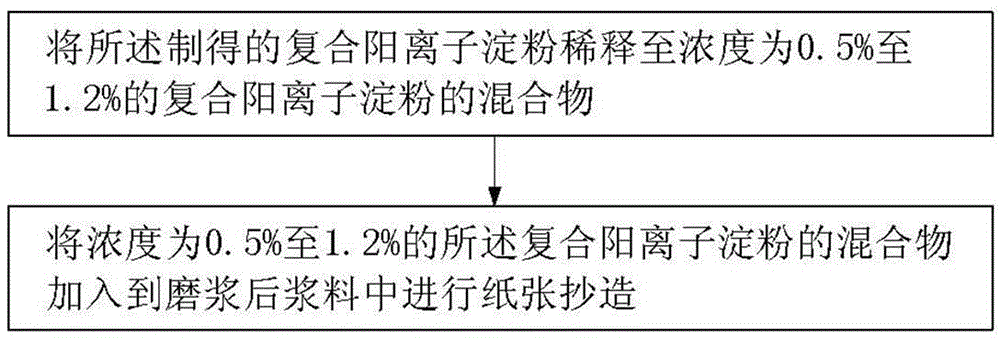

The invention provides a preparation method for composite cationic starch. The method comprises the following steps of: adding water into native starch, and mixing to obtain a starch solution; adding alkali and an etherifying agent into the starch solution with stirring, and reacting for 3 to 10 hours to obtain cationic starch; diluting a cationic starch solution, and gelatinizing; adding an initiator in an amount which is 0.1 to 1 percent based on the mass of the native starch and a modifier in an amount which is 0.1 to 1 percent based on the mass of the native starch into the gelatinized cationic starch, and reacting for 3 to 5 hours with stirring to make cationic starch molecules be subjected to cross-linking reaction so as to obtain the composite cationic starch. The invention also provides the composite cationic starch prepared by the method, and a method for making paper by using the composite cationic starch prepared by the method.

Owner:GOLD EAST PAPER JIANGSU

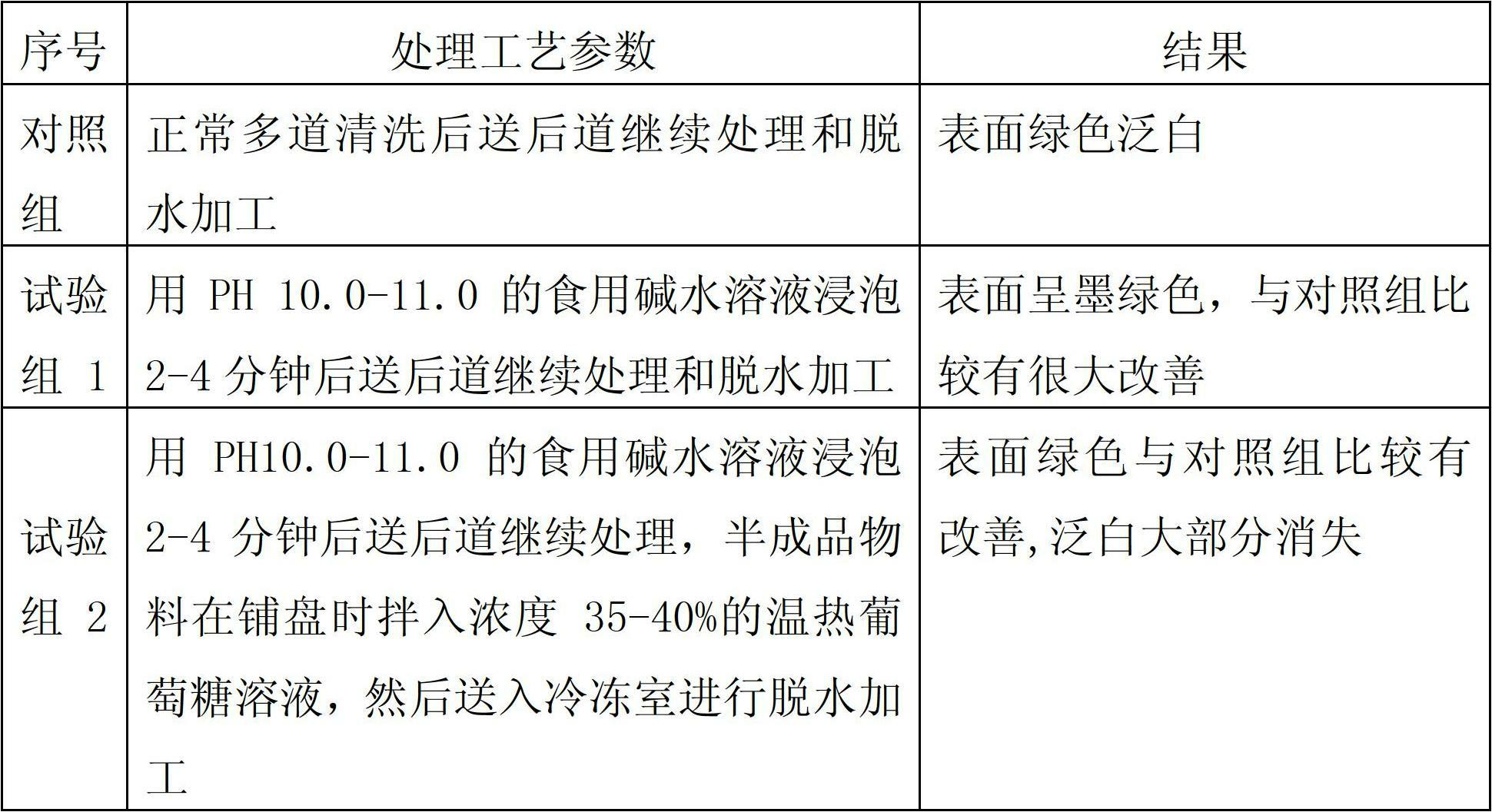

Color-protecting processing method of freeze drying onion

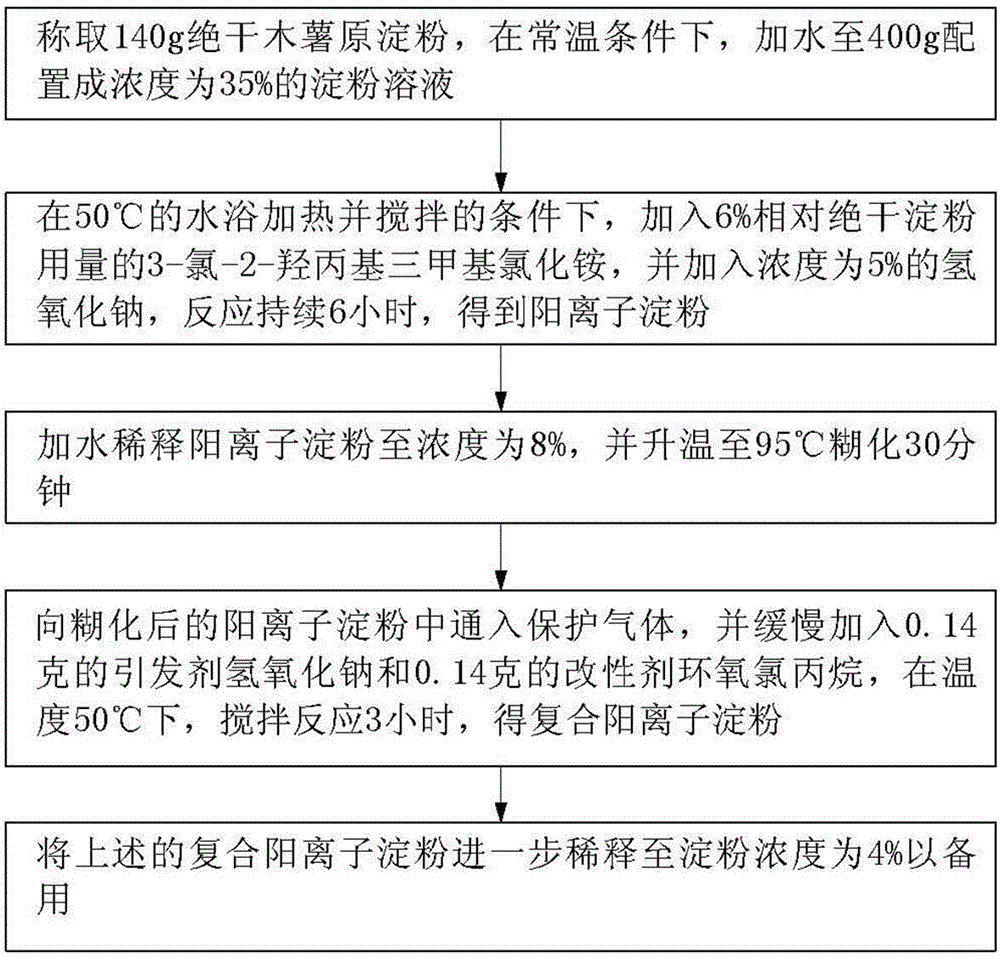

ActiveCN102640916AGreen stableDefects against green fadingFood preparationResidual volAlkaline water

The invention discloses a color-protecting processing method of freeze drying onion, wherein the method comprises the following steps of: immersing onion materials in an alkaline water solution firstly; then bleaching slightly in an alkaline warm water, cleaning, soaking by using a natural reducing sugar solution and draining; then freezing the onion materials by adopting a slow freezing mode; finally, freezing, drying, dehydrating and processing the frozen onion materials, wherein the slow freezing mode is that the total freezing time is not less than 5 hours, and the central temperature of the onion materials after freezing is less than and equal to minus 22 DEG C. After the scheme is adopted, according to the invention, the acid degree is regulated through the alkaline water solution firstly, and chlorophyll is prevented from being subjected to de-magging to lead to the defect of green fading of the materials, thus the green of the onion materials is kept to be stable, and the problem that the metal content of the materials in the prior art exceeds the standard is overcome. Moreover, according to the invention, a non-toxic natural reducing sugar solution is utilized as a processing auxiliary material for protecting the color, the problem that the sulfite residual quantity of the product after color-protection of the freeze drying onion exceeds the standard is overcome, and the product safety is ensured.

Owner:福建省新闽商业运营管理有限公司

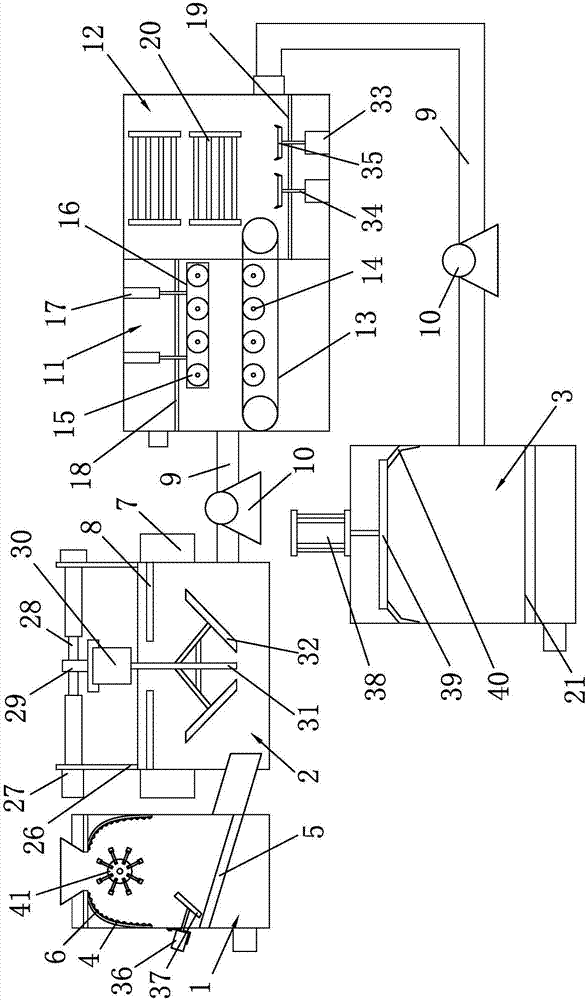

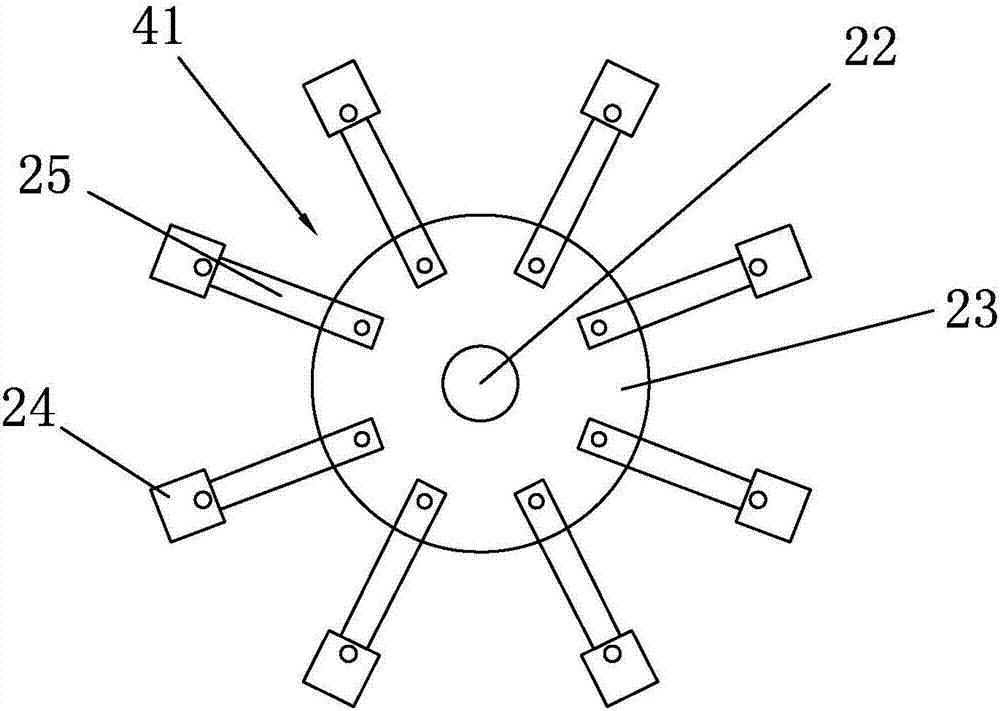

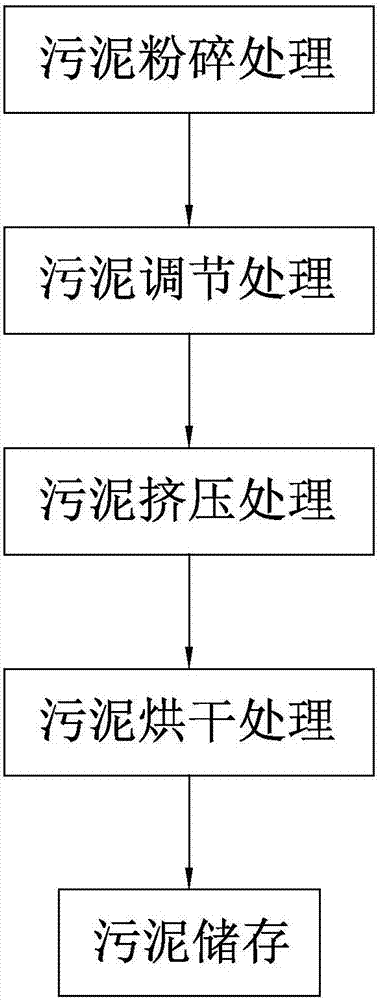

Sludge concentration and dewatering treatment method

ActiveCN107129127AEasy to dehydrateReduce moisture contentSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningMultiple treatmentsCapillary water

The invention discloses a sludge concentration and dewatering treatment method. The method comprises the following steps: (1) sludge pulverizing treatment; (2) sludge conditioning treatment; (3) sludge extrusion treatment; (4) sludge drying treatment; and (5) sludge storage. The method disclosed by the invention is simple in structure, high in practicality, convenient to use and remarkable in the sludge dewatering effect; through the multiple treatments of a pulverizing cavity, a conditioning tank and a dewatering cavity, void water, adsorbed water and capillary water in sludge are all separated out, so that the dewatering rate of the sludge is effectively improved, and the volume of the sludge is reduced, thereby facilitating subsequent recycling of the sludge; and the overall structure design is more reasonable and scientific.

Owner:浙江金华德朗水务有限公司

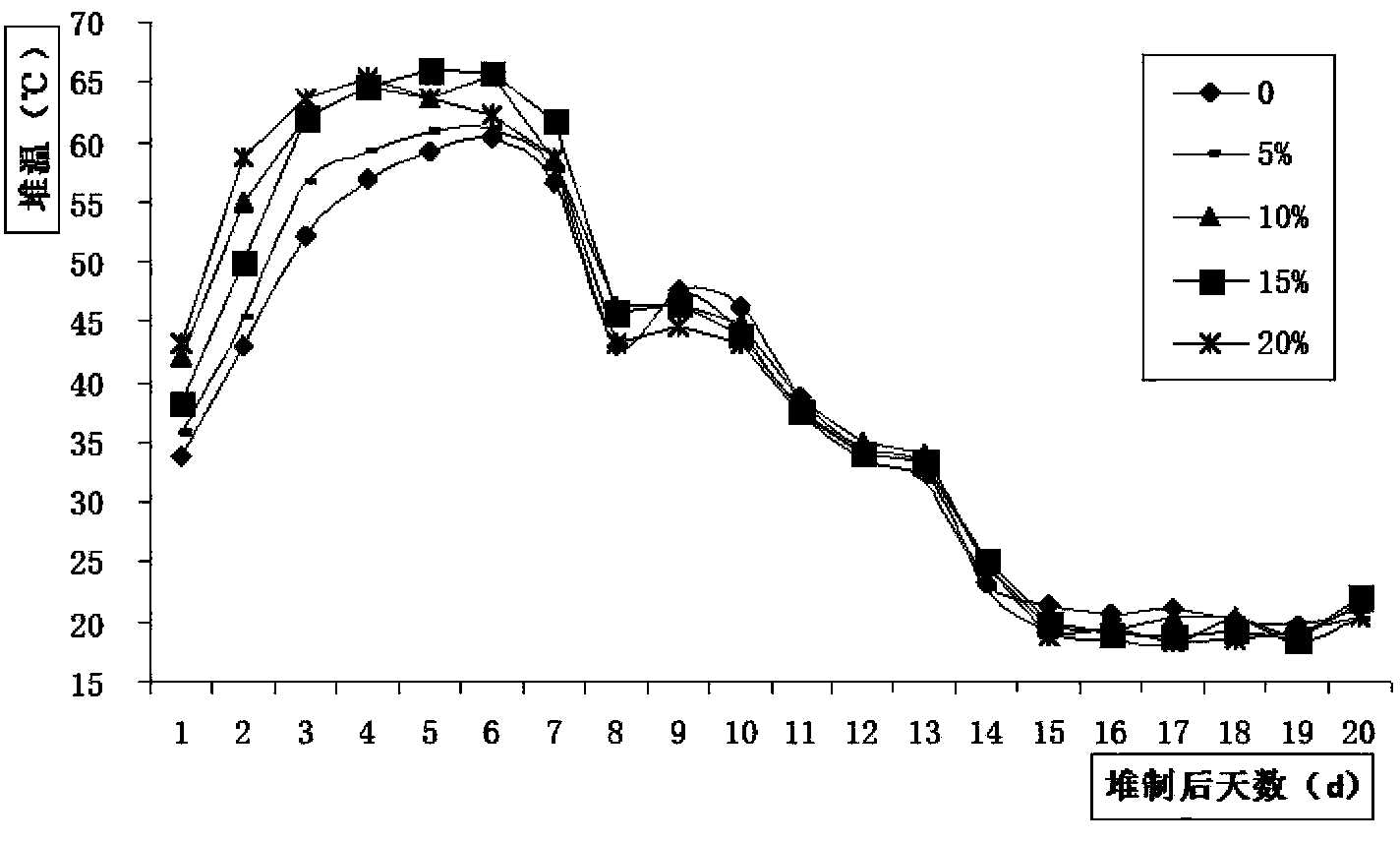

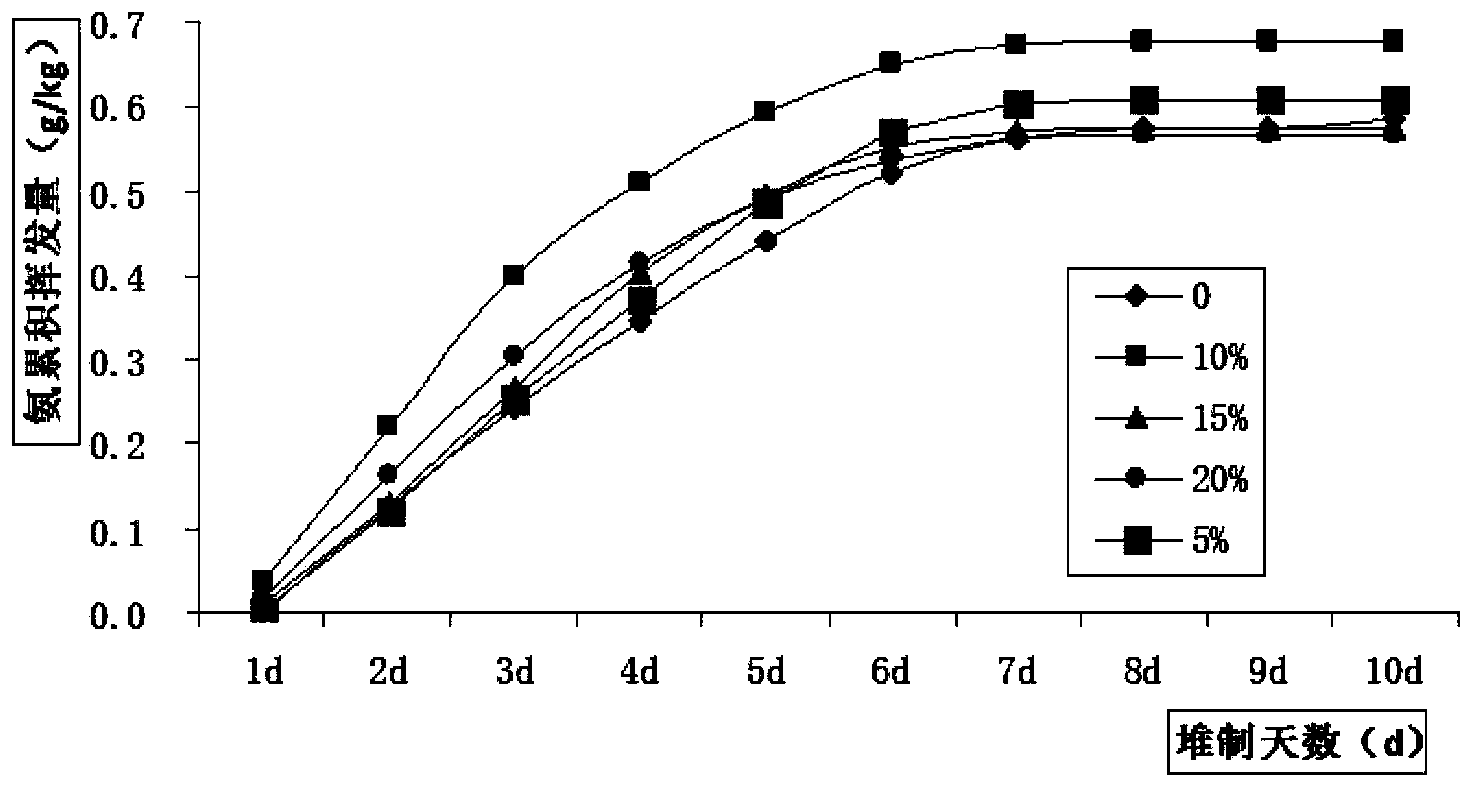

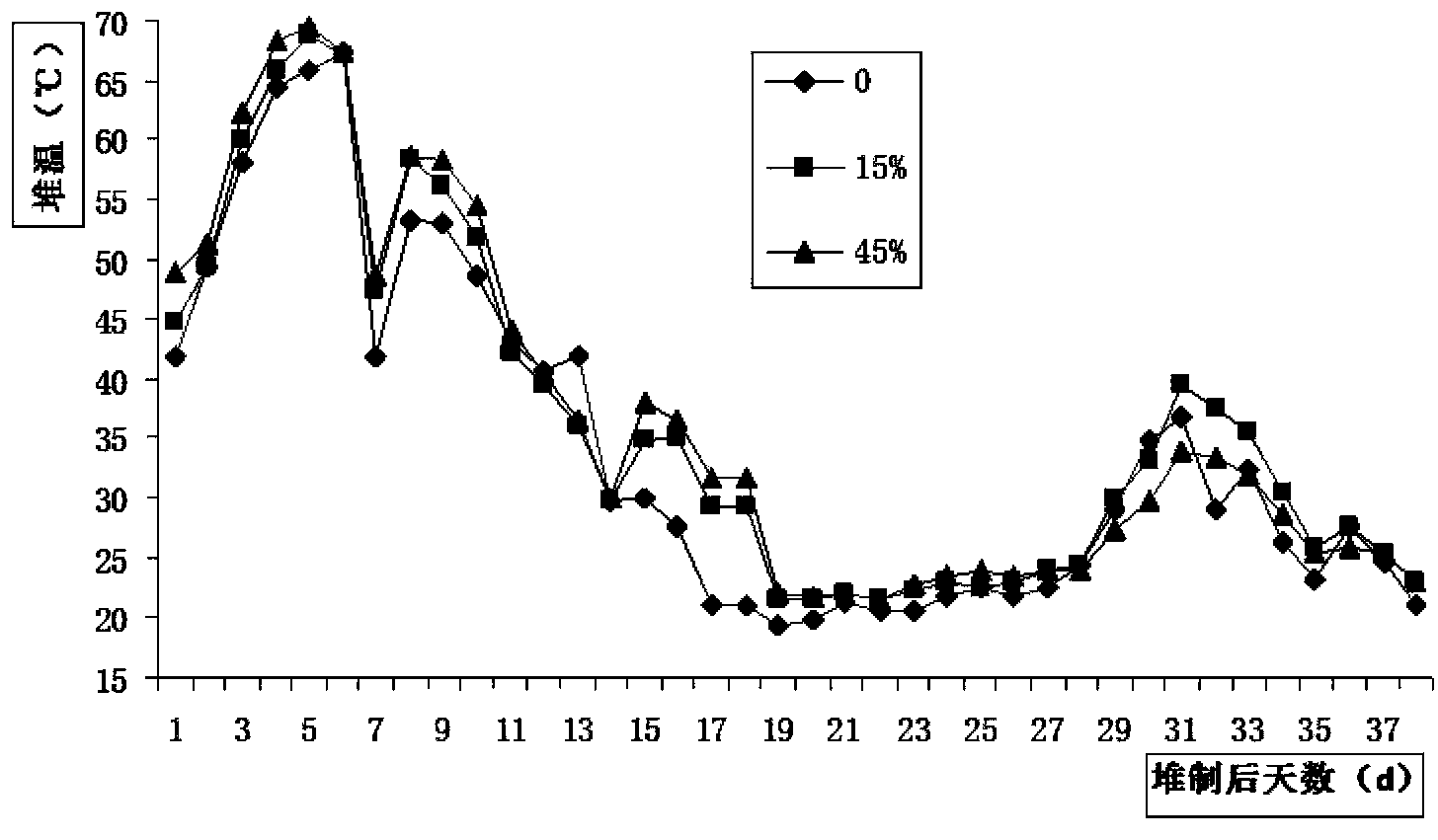

Rapid composting method of water plant by utilization of biomass charcoal

ActiveCN103396179AFast compostingReduce moisture contentBio-organic fraction processingOrganic fertiliser preparationMixed materialsHigh water content

A rapid composting method of a water plant by utilization of biomass charcoal is characterized by successively comprising the following steps: the first step, weighing raw materials: the raw materials comprises a base composting material and the biomass charcoal, the base composting material comprises a fresh water plant and air-dried straw, the ratio of the fresh water plant to the air-dried straw is configured based on that the range of the dry-basis carbon nitrogen ratio of the base composting material being 22-28, according to the actual water content, natural weight is obtained by conversion, an input amount of the biomass charcoal is 40%-50% of the dry-basis weight of the base composting material, and the water content after mixing of the three raw materials is controlled between 60% and 75%; the second step, evenly mixing the weighted three raw materials to produce a mixed material, and putting the mixed material to a composting place; and the third step, carrying out composting treatment of the mixed material until the mixed material forms a humic substance, namely a organic fertilizer product. Through use of the rapid composting method, a conventional dewatering volume-reduction pretreatment process of the high-water-content fresh water plant is omitted, and two-way synergy of rapid composting and ammonia emission reduction of the fresh water plant can be realized.

Owner:江苏太湖地区农业科学研究所

Demulsifier compounded from amido ionic liquid and polyether and preparation method thereof

InactiveCN102229814ALess componentsReduce dosageDewatering/demulsification with chemical meansOrganic acidDemulsifier

The invention discloses a demulsifier compounded from amido ionic liquid and polyether and a preparation method thereof. The demulsifier is prepared from 30-70 parts by weight of the polyether and 30-70 parts by weight of the amido ionic liquid. A synthesis method of the demulsifier comprises the following steps of: reacting one or more than one of C4-C12 organic amines with one or more than one of C2-C5 organic acids at 60-90 DEG C to produce the amido ionic liquid; and then compounding the polyether and the amido ionic liquid. The demulsifier prepared by using the method disclosed by the invention has the advantages of less use dosage, wide application range and low demulsifying temperature.

Owner:JURONG NINGWU CHEM +1

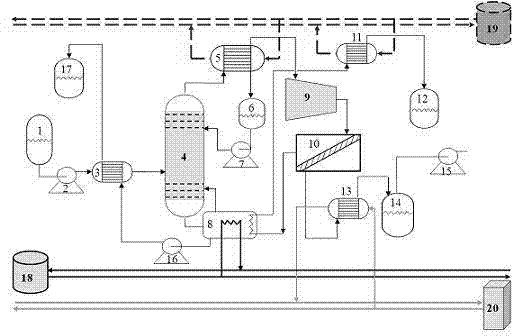

Method and device for dehydrating and refining biofuel

ActiveCN104262089AReduce energy consumptionAvoid Bloated and Complicated DefectsOrganic compound preparationChemical industryLiquid productReflux

The invention relates to a method for dehydrating and refining biofuel. The method comprises the following steps: carrying out normal-pressure rectification on fermentation liquor for preparing biofuel alcohol, wherein the tower bottom temperature is 95-105 DEG C, and the tower top temperature is 70-95 DEG C; separating waste water from the bottom of a rectifying tower, partially condensing the gas output from the rectifying tower top through a fractional condenser, and returning the condensate to the rectifying tower, wherein the reflux ratio is 1-3.5; pressurizing the uncondensed gas to be greater than 0.3Mpa and then introducing into a vapor permeation membrane separator, sucking with a vacuum pump at the permeation side, extracting water vapor from the permeation side of the vapor permeation membrane separator and cooling and collecting; and outputting anhydrous alcohol gas from the retentate side, and condensing to obtain an anhydrous alcohol liquid product containing water lower than 0.1wt%. The invention also provides a special device for the method. According to the method and device, normal-pressure rectification, a compressor and the novel efficient vapor permeation membrane separator are combined to be used for dehydrating biofuel alcohol, and the method and device have the advantages that energy-saving and efficient effects are achieved, the device is small in occupation area, environment-friendly and simple to operate, and the like.

Owner:NANJING UNIV OF TECH

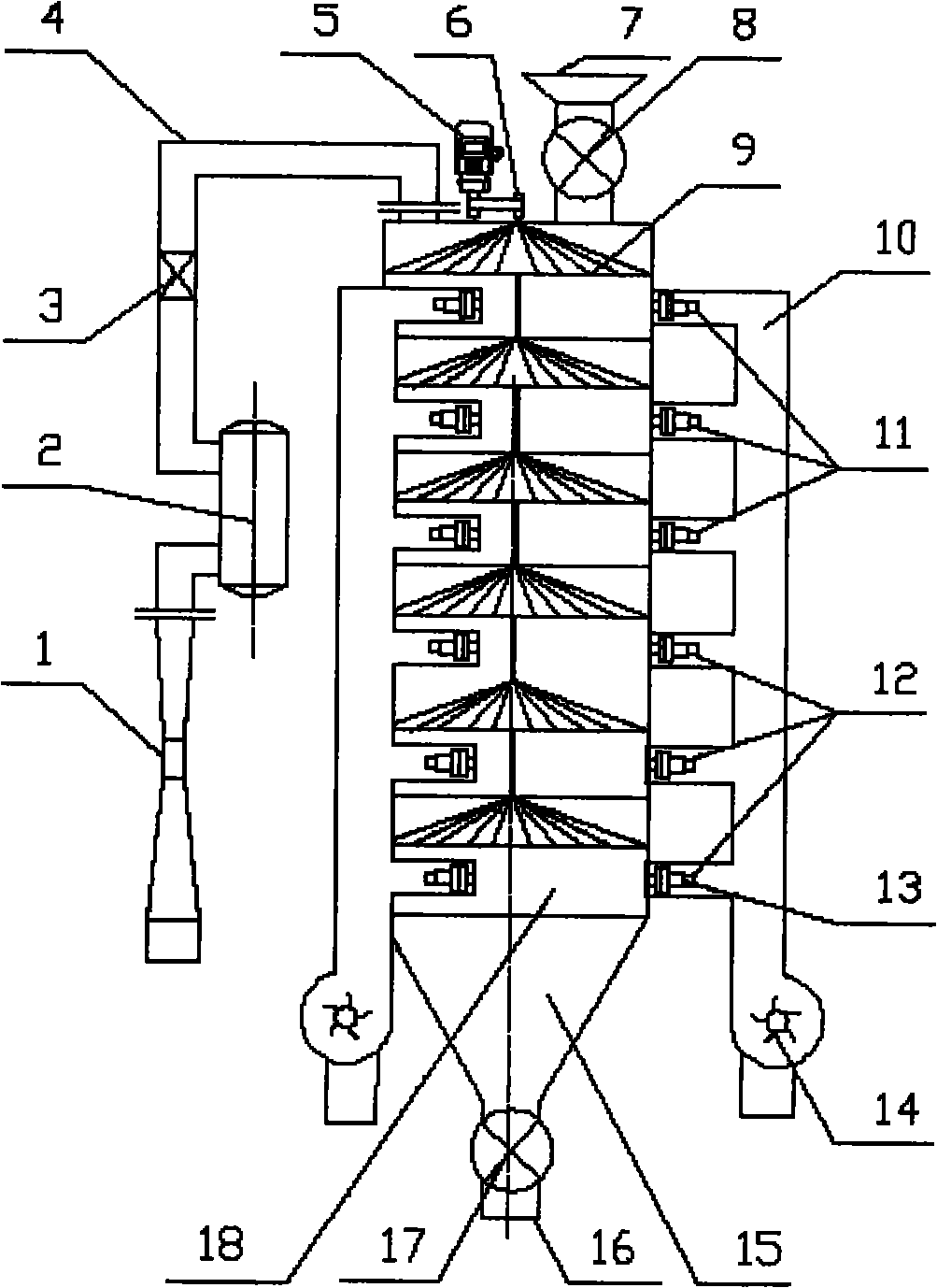

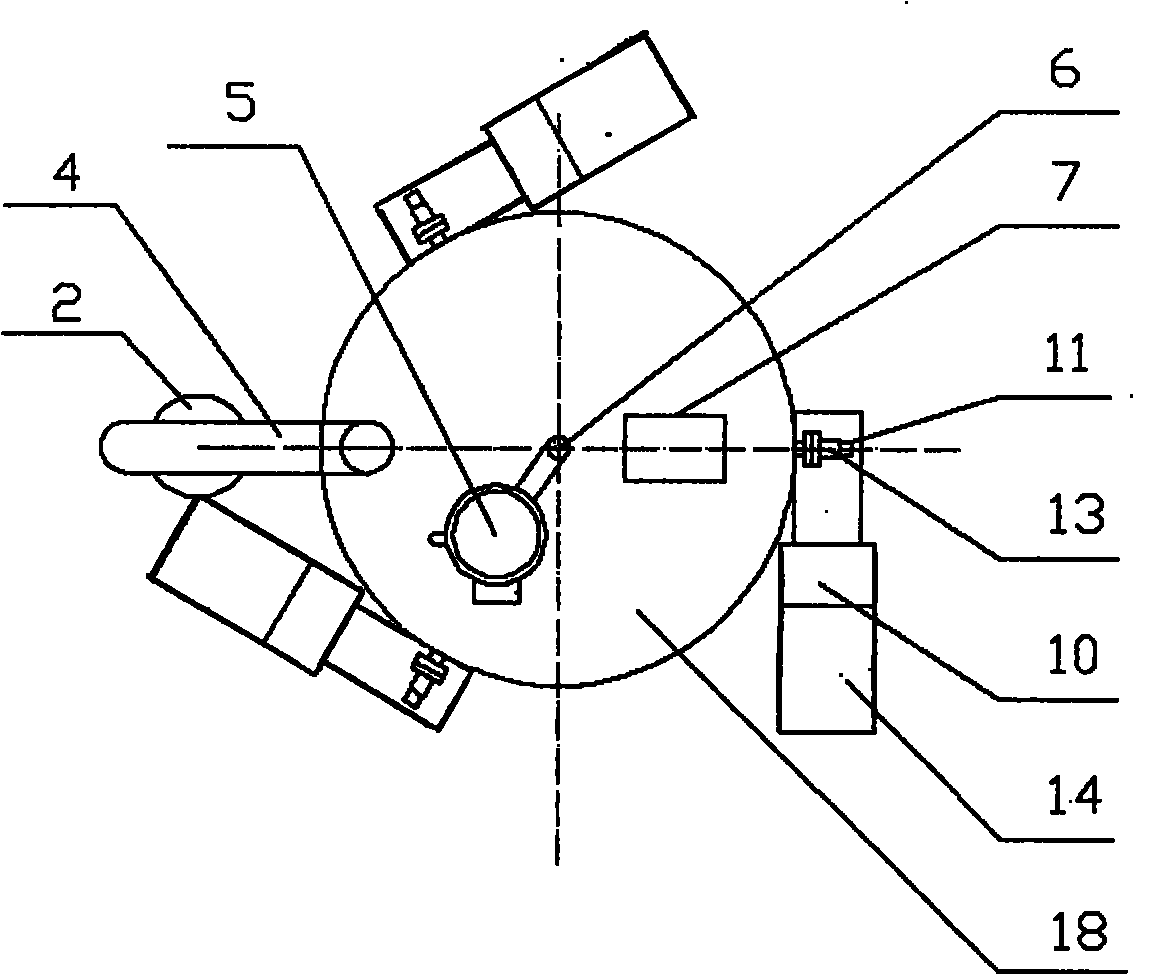

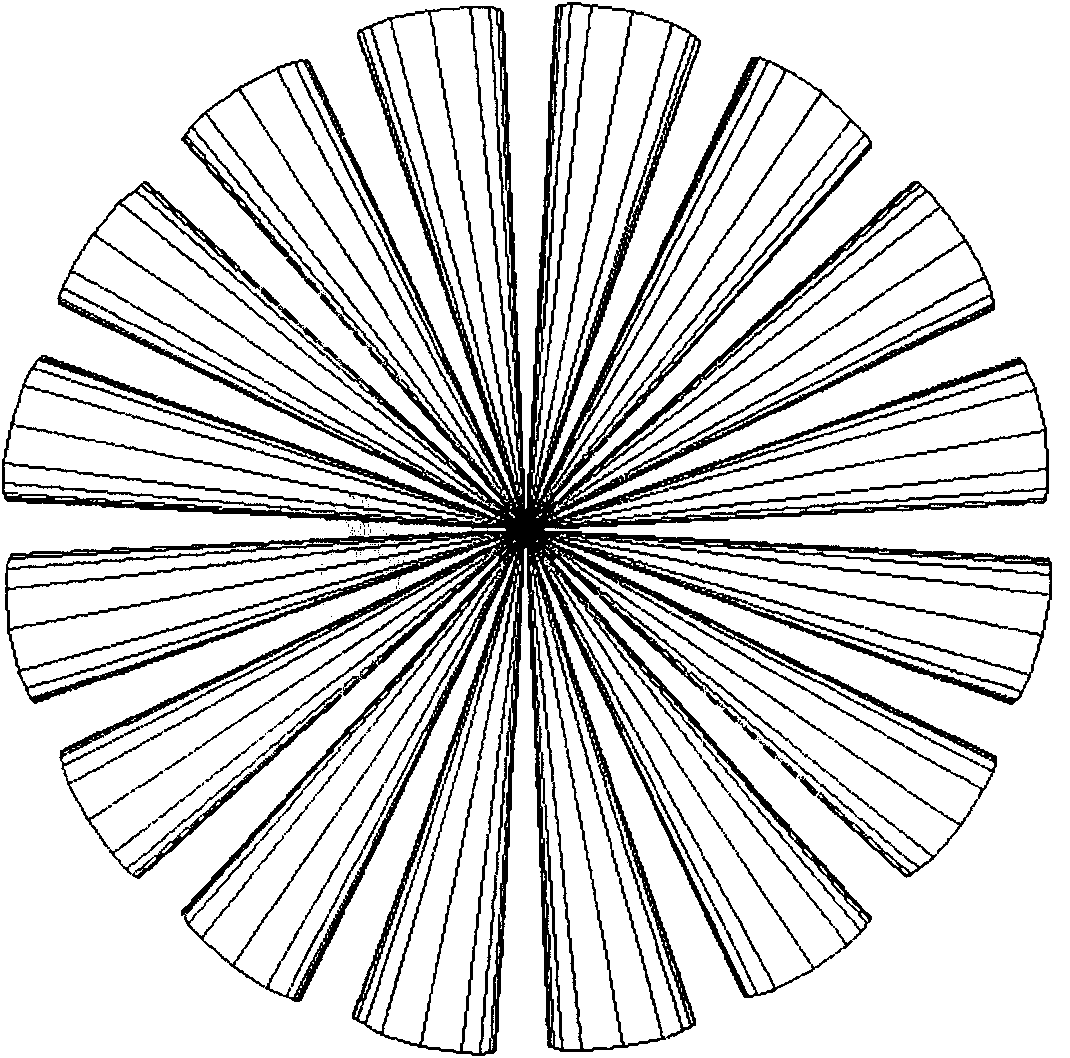

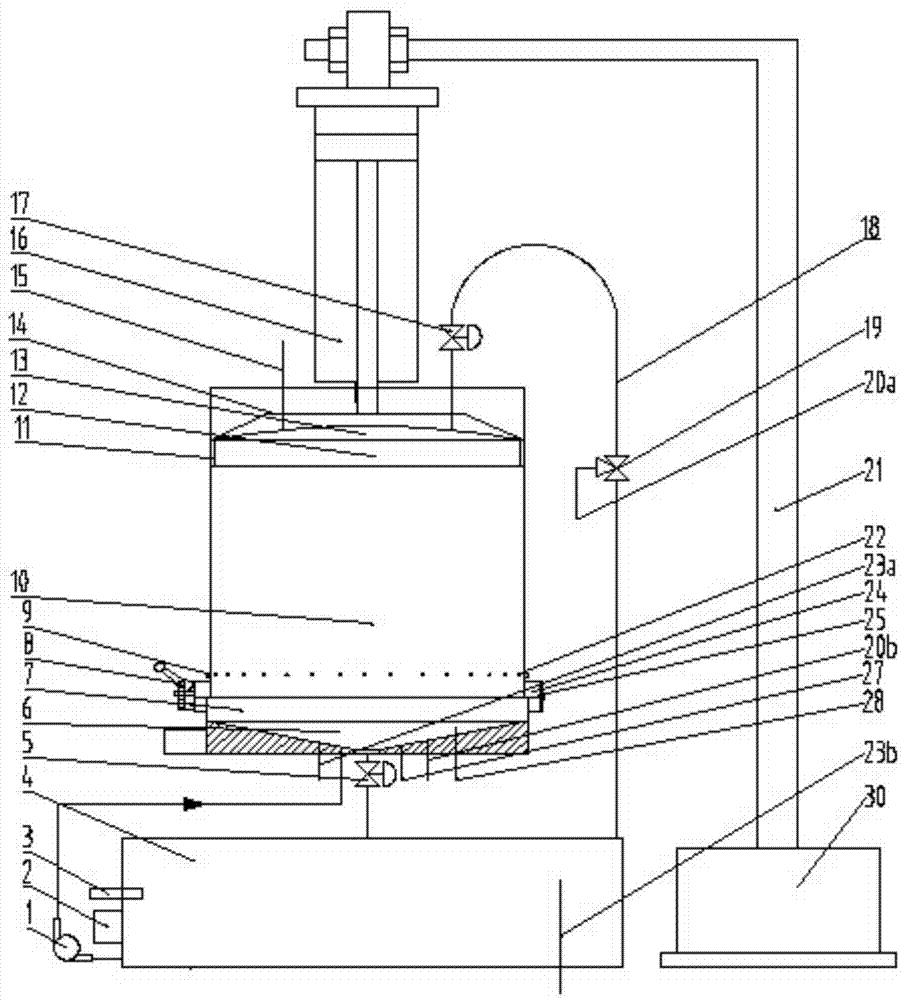

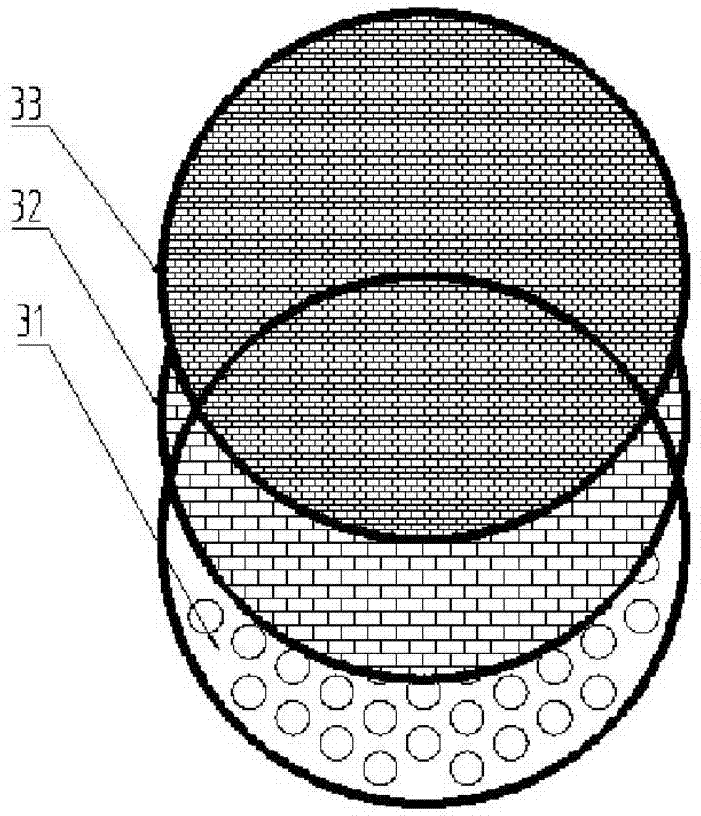

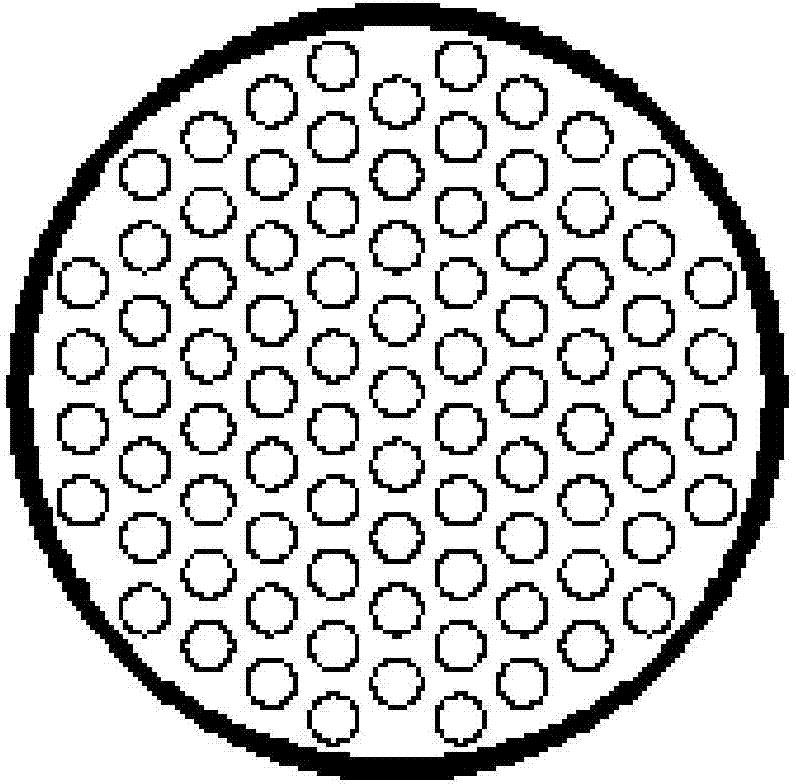

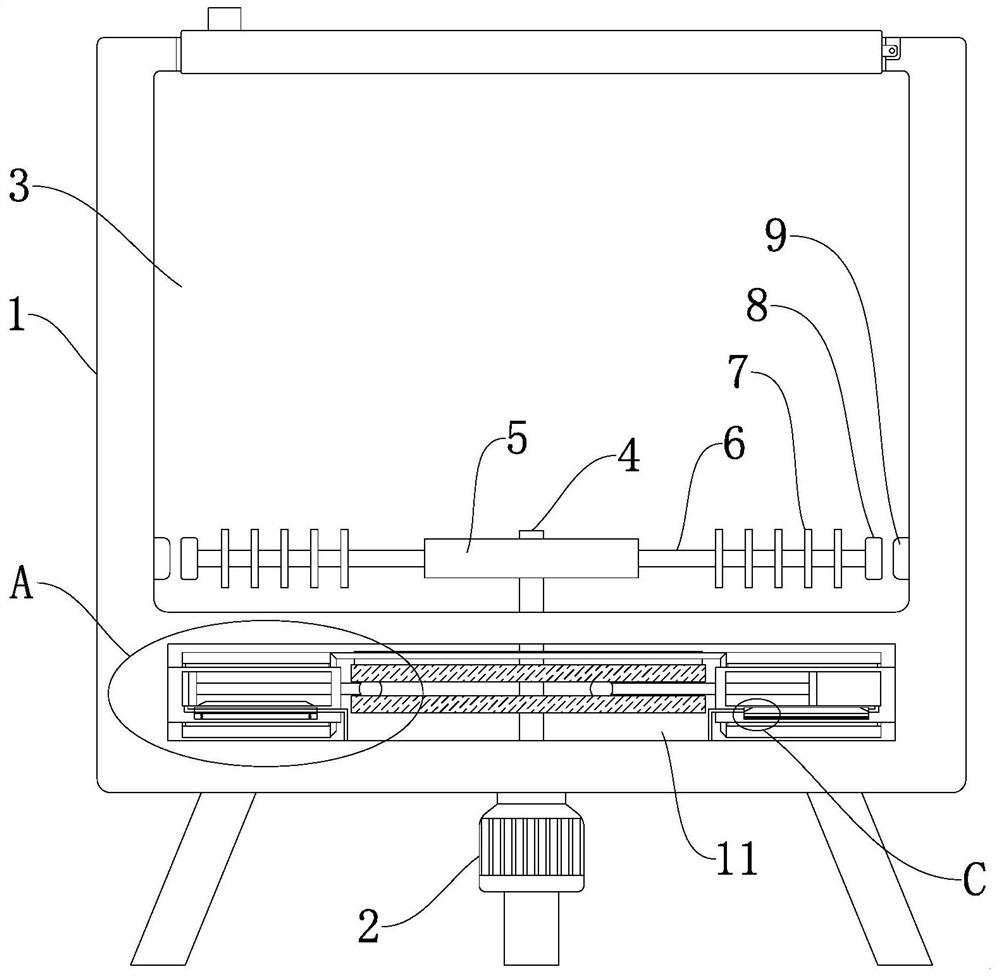

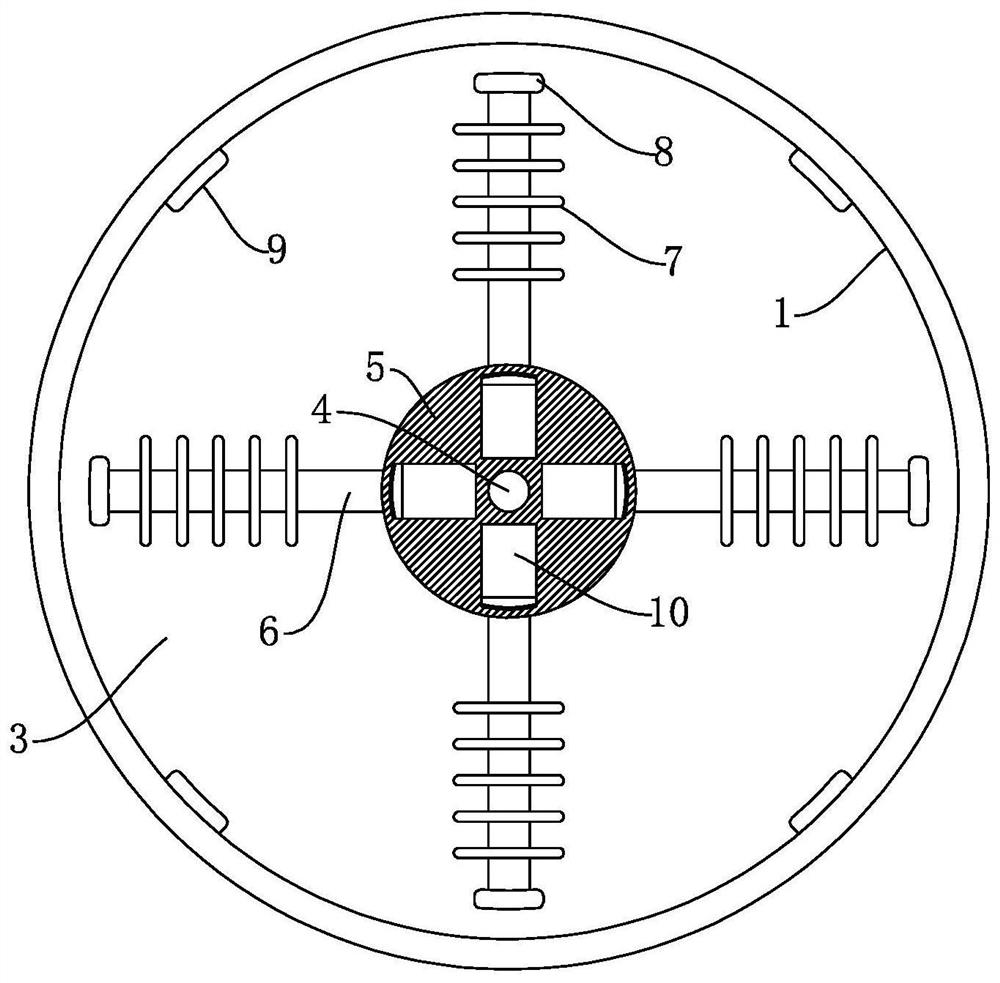

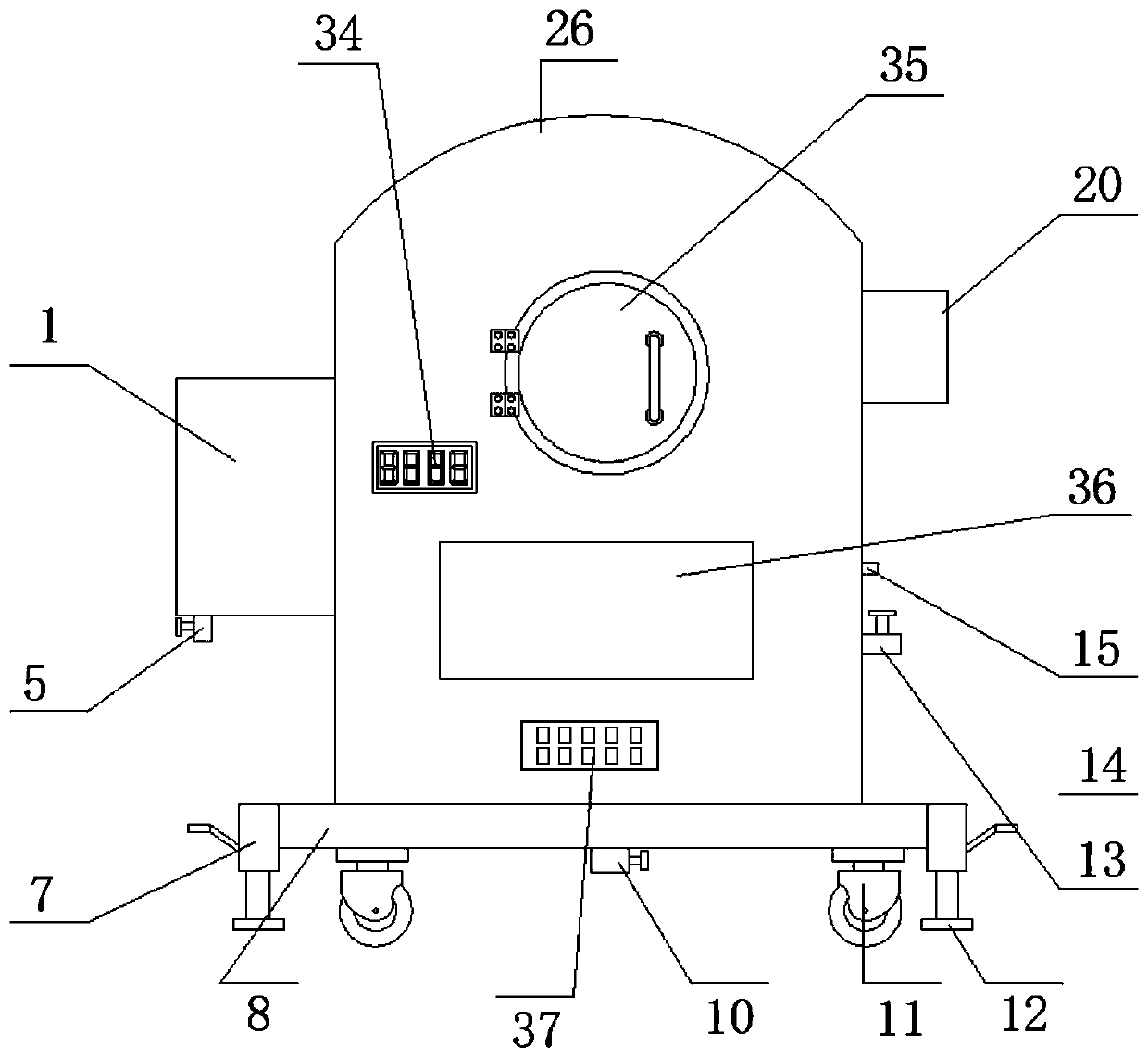

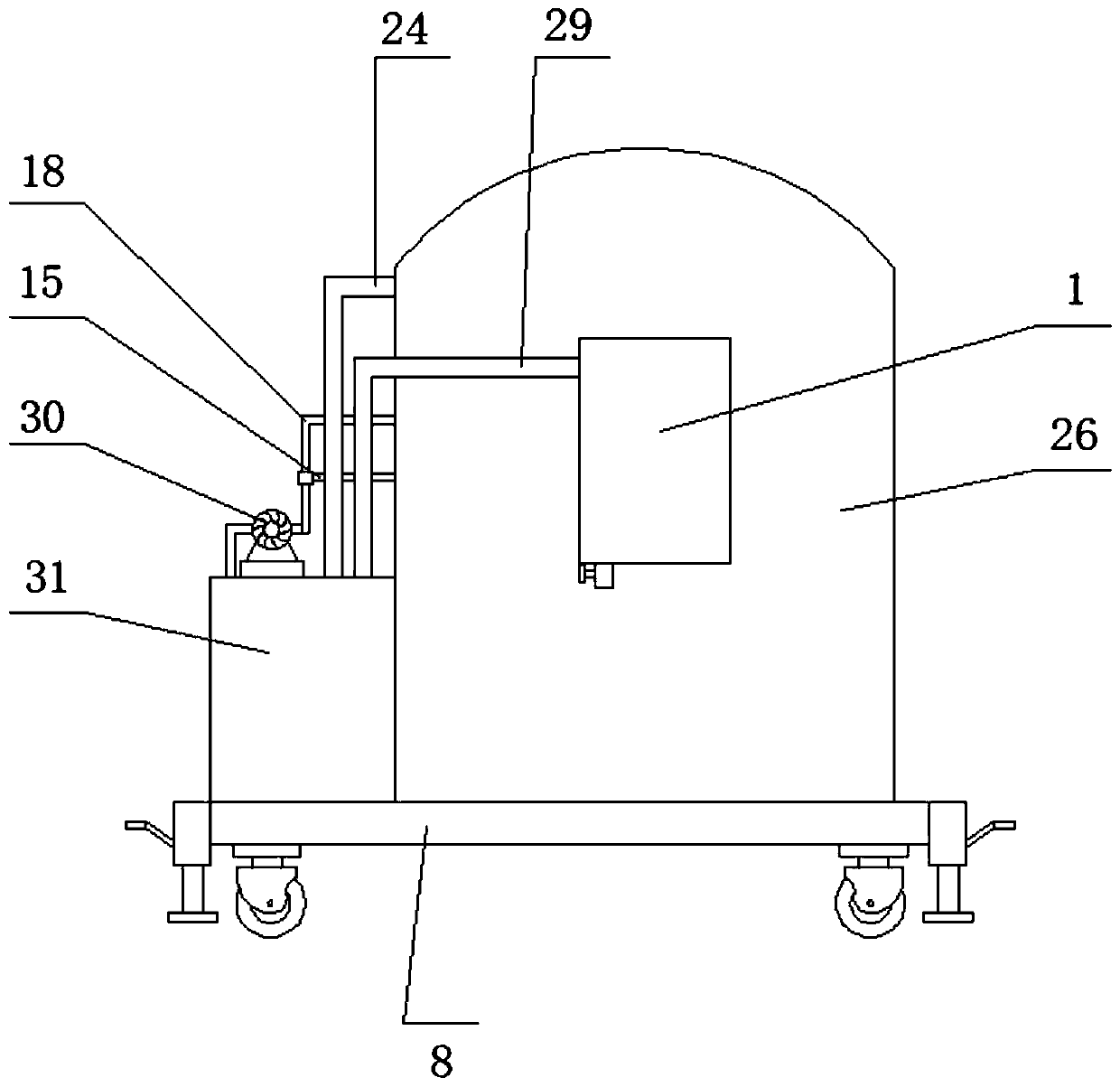

Cut leaf tobacco microwave vacuum drying equipment

ActiveCN101822415AImprove sensory qualityKeep the aromaTobacco preparationVacuum pumpingElectric machinery

Cut leaf tobacco microwave vacuum drying equipment is characterized by comprising a vertical cylinder-shaped drying cavity, a vacuum-pumping system communicated with the drying cavity, and a microwave heating system, wherein the top part and the bottom part of the drying cavity are respectively provided with a feed port and a discharge port, the drying cavity is internally provided with a material dispersion mechanism, the material dispersion mechanism comprises a spindle arranged on the axle center of the drying cavity, and multi-layer material dispersion plates arranged on the spindle, the spindle is driven to rotate by a motor, the microwave heating system is divided into a continuous microwave heating unit arranged on the upper part of the drying cavity and a pulsed microwave heating unit arranged on the lower part of the drying cavity, and the two heating units can respectively hierarchically arranged in multi groups along the shell of the drying cavity. Compared with the prior art, the invention has the advantages that the cut leaf tobacco microwave vacuum drying equipment can carry out the microwave drying in stages to the cut leaf tobacco under the a vacuum status, reduces the drying temperature of the cut leaf tobacco, keeps the fragrant of the cut leaf tobacco, improves the aesthetic quality of the cut leaf tobacco, at the same time, can realize the rapid dehydration and drying of the cut leaf tobacco, and improves the filling value of the cut leaf tobacco.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

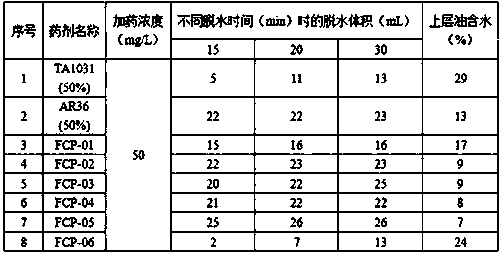

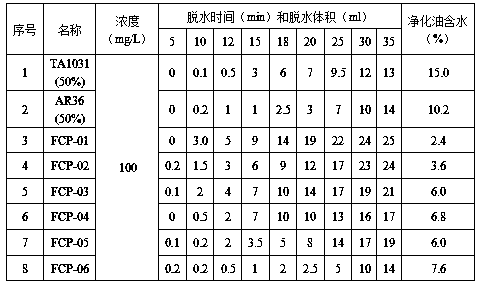

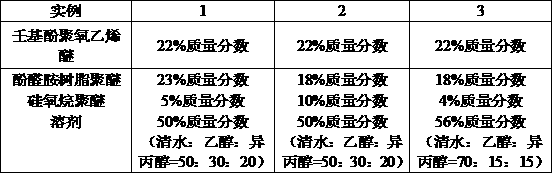

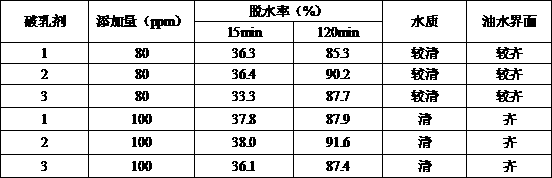

Compound demulsifying agent capable of improving demulsifying effect of polyether demulsifying agents

InactiveCN105771327AFast dehydration rateRapid dehydration effectNon-miscible liquid separationTemperature controlDemulsifier

The invention discloses a compound demulsifying agent capable of improving the demulsifying effect of polyether demulsifying agents. The compound demulsifying agent is prepared through the method which includes the following steps that firstly, polyether demulsifying agents with different initiators are prepared, the initiators and a basic catalyst are added into a reactor with a stirring and condensing device, heating is carried out, epoxypropane is introduced, the mixture is fully reacted with the temperature controlled to be 115-145 DEG C and the pressure controlled to be 0.4 MPa, vacuum pumping is carried out for 30 min, ethylene oxide is introduced under the same condition, and after the mixture is fully reacted, the polyether demulsifying agents are obtained, wherein with the raw materials of the initiators, epoxypropane and ethylene oxide 100% by weight, the initiators account for 0.4-6% of the total weight, epoxypropane accounts for 30-65.6% of the total weight, ethylene oxide accounts for 20-50% of the total weight, and the dosage of the basic catalyst accounts for 0.1-5% of the total weight; secondly, the prepared polyether demulsifying agents and a flocculating agent are dissolved with a solvent and then stirred evenly, and the compound demulsifying agent is obtained, wherein the polyether demulsifying agents account for 40-70%. The obtained flocculating agent-demulsifying agent has the advantages of being small in dosage, high in dewatering rate, ideal in dewatering effect and the like.

Owner:JURONG NINGWU CHEM

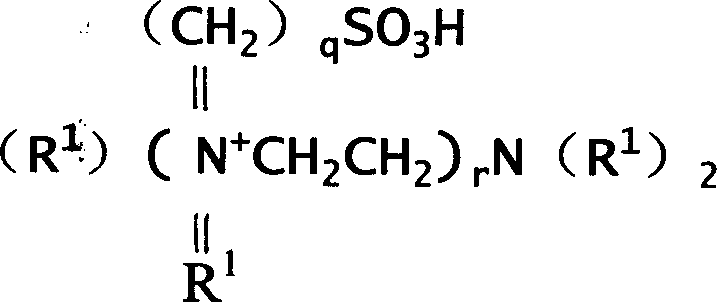

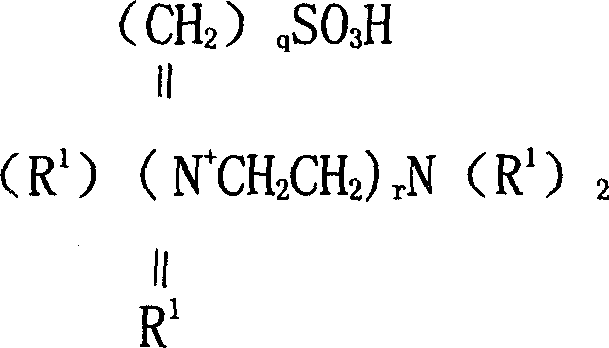

Multifunctional corrosion inhibitor and preparing method

This invention relates to a multi-functional corrosion-inhibitor used in parts of atmospheric vacuum tower top tube, and its prepn. method. The characteristic of the molecular structure of the inhibitor is that it is of betaine sulfonate type, being of amphoteric ion, having excellent corrosion inhibiting property. In this polymer, triethenyl teraamine is used as initiator, and introducing epoxy propane and epoxy ethane block polyether (excellent demulsification agent) having advantages of coalescence, quick de-water rate, the removed water being clear, less dosage, broad pH value range.

Owner:PETROCHINA CO LTD

Preparation method of hydrophobic anion flocculant

InactiveCN101899129AHigh molecular weightGood flocculation effectSludge treatment by de-watering/drying/thickeningFlocculationNitrogen

The invention relates to a preparation method of hydrophobic anion flocculant, which is characterized in that the method comprises the following processing steps: (1) taking a monomer for standby, wherein the monomer is acrylamide, 2-acrylamide group-2-methylpropanesulfonic acid and butyl acrylate; (2) successively adding acrylamide and 2-acrylamide group-2-methylpropanesulfonic acid into four flasks with a stirrer, a thermometer, an air guidance device and a feeding device, adding deionized water and introducing nitrogen to stir to obtain a system A; (3) adding an anion surfactant to the system A, continuously introducing nitrogen to obtain a system B by stirring; (4) adding butyl acrylate into the system B, and introducing the nitrogen to stir to obtain a system C; and (5) adding the initiator into a system C, and continuously introducing the nitrogen to react to obtain a finished product. The anion surfactant is lauryl sodium sulphate. The initiator is the mixture of ammonium persulfate and sodium hydrogensulfite. The hydrophobic anion flocculant prepared by the invention has high molecular weight and favourable flocculation effect.

Owner:JIANGSU JIANGDA ECOLOGICAL SCI & TECHCO +1

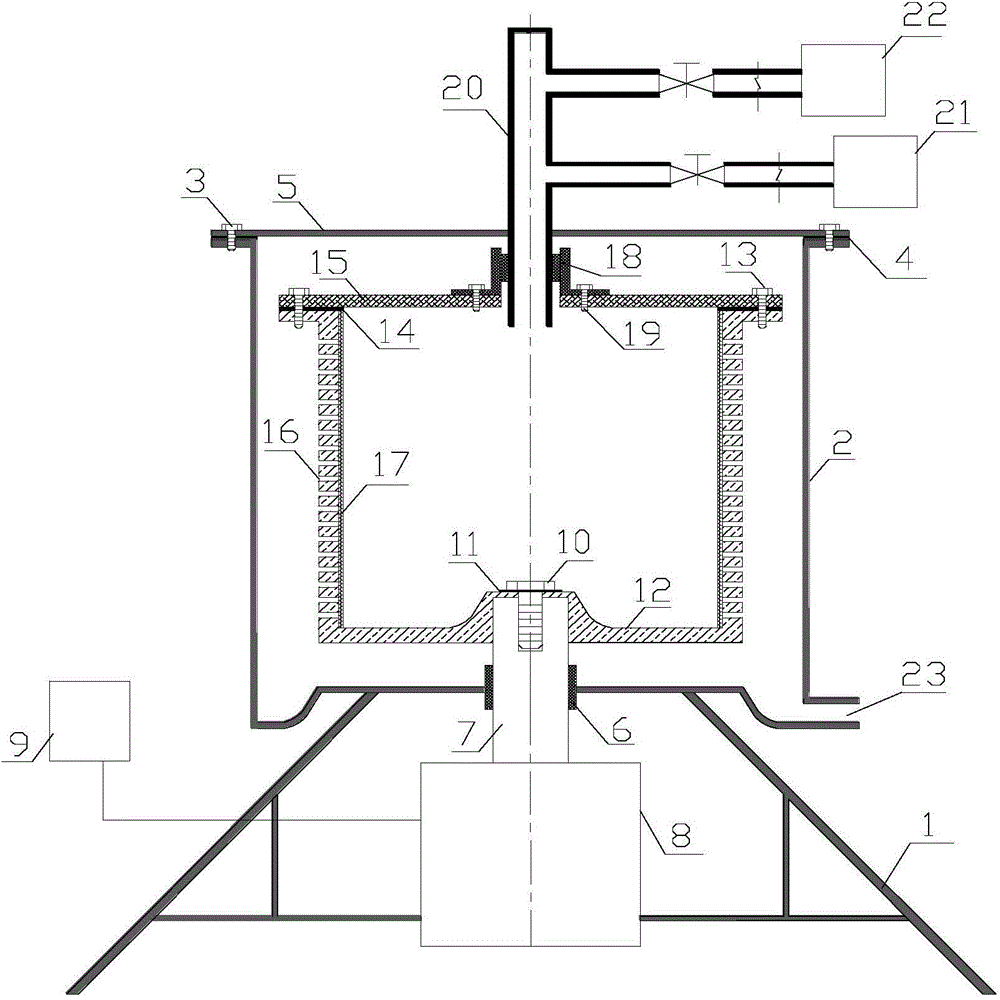

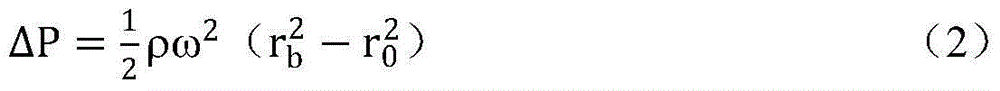

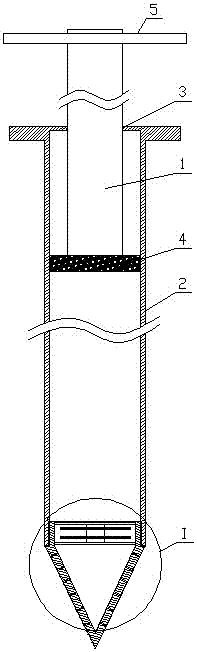

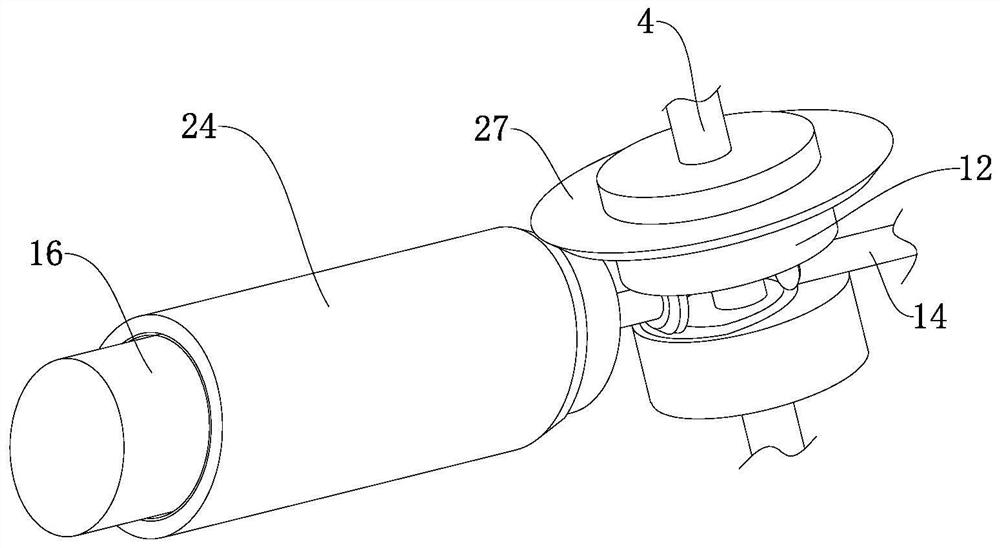

Fine-grain material centrifugal filtering and dewatering device

InactiveCN103977915AHigh centrifugal forceAdjustable centrifugal factorRotary centrifugesFilter mediaCentrifugal force

A fine-grain material centrifugal filtering and dewatering device comprises a frame, a housing, a motor, a drum and a speed regulator. A spindle of the motor penetrates the bottom of the housing to be connected with the drum, the spindle penetrates the housing to be provided with a sealing component, the upper portion of the housing is provided with an upper housing cover, the lower portion of the housing is provided with a liquid discharge outlet, the side wall of the drum is provided with a plurality of filtrate holes, and filter medium is attached to the inner wall of the drum. The upper portion of the drum is provided with an upper drum cover, the housing is provided with a feed pipe penetrating the upper housing cover and the upper drum cover to enter the drum, a mechanical sealing component is arranged at an inlet of the upper drum cover, the feed pipe is respectively provided with a suspension liquid feed system and an air feed system through pipelines, and the pipelines are provided with flow control valves. By coordinating pressurized filtering and centrifugal filtering, filtering speed can be accelerated by centrifugal force, dewatering speed is accelerated by compressed air, therefore dewatering process of a centrifugal filter is enhanced, solid-liquid separation efficiency is improved, residual water in centrifugal filter cakes is reduced and centrifugal dewatering effect of fine-grain materials is improved.

Owner:CHINA UNIV OF MINING & TECH

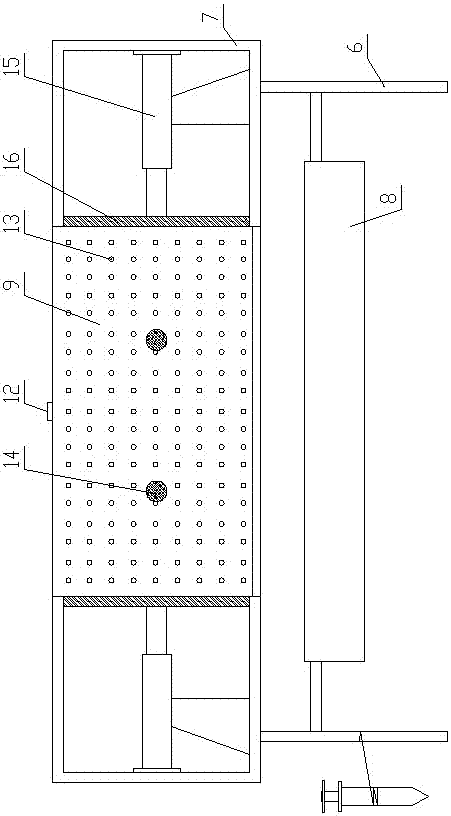

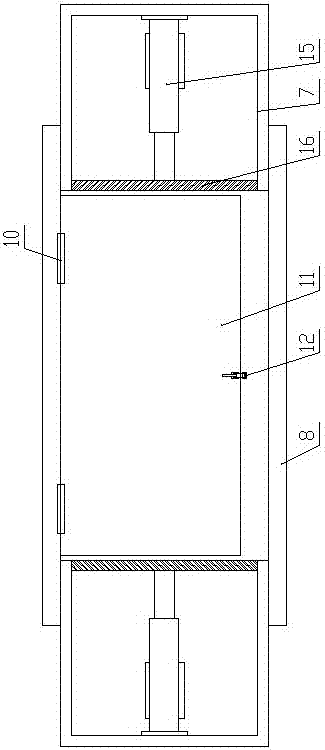

Laboratory paper sheet making machine

The invention discloses a laboratory paper sheet making machine, and belongs to the field of paper making experimental equipment. The laboratory paper sheet making machine comprises a transmission device, a swing arm, an air cylinder and a pulp storage tank, the bottom of the pulp storage tank is connected with a buffer tank in a sealed mode, and a manual opening device is arranged. A lower filter device is arranged at the position, closely attached to the bottom of the pulp storage tank, in the buffer tank, the bottom of the buffer tank is connected with a white water tank through a pipeline with a bottom regulating valve, and an upper filter device capable of moving along the inner wall of the pulp storage tank is arranged in the pulp storage tank. A plurality of air blowing holes are evenly formed in the bottom of the pulp storage tank, and are connected with an air blowing pipe. The transmission device is connected with the swing arm, the air cylinder is fixed to the swing arm, and a piston rod of the air cylinder is connected with the upper filter device. According to the laboratory paper sheet making machine, single-face dehydration and double-face dehydration of the laboratory paper sheet making machine can be achieved, the distribution condition of fine fibers and fillers in the paper thickness direction of top mesh forming and clamping mesh forming is simulated well, the structure is simple, manufacturing cost is low, use is convenient, and the laboratory paper sheet making machine has good use prospects.

Owner:SHAANXI UNIV OF SCI & TECH

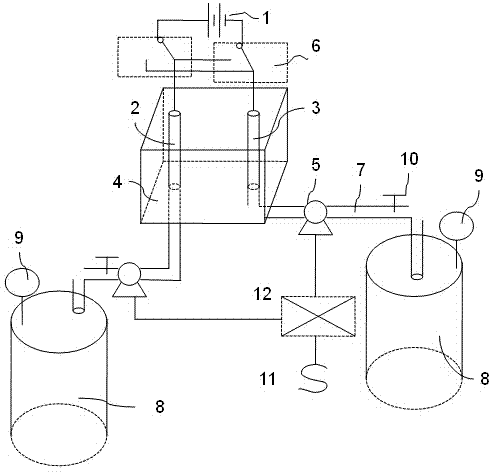

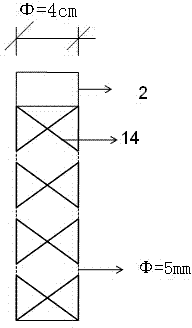

Transfer-electron type electroosmosis-advanced oxidation sludge dewatering system and dewatering method thereof

ActiveCN106904803AReduce moisture contentImprove uniformitySludge treatment by oxidationWater/sewage treatment apparatusConvertersProcess engineering

A transfer-electron type electroosmosis-advanced oxidation sludge dewatering system and a dewatering method thereof are disclosed. The system of the invention comprises a power supply, a positive and negative convertor and an underframe. A mounting rack is arranged above the underframe. An electroosmosis liquid collecting bin which is positioned below the mounting rack is installed on the underframe. A rectangular electroosmosis reactor is installed on the mounting rack. The mounting rack is connected to a dosing injection device through a rope. The length direction of the electroosmosis reactor is the horizontal direction. Width and length of the electroosmosis liquid collecting bin are both greater than width and length of the electroosmosis reactor. The left side and right side of the electroosmosis reactor are both opened. The top of the electroosmosis reactor is provided with a sludge opening, the rear side of which is hinged to a cover plate through a hinge. The front side of the cover plate is connected to the top wall of the electroosmosis reactor through a buckle. In conclusion, sludge is dewatered through combination of electroosmosis and advanced oxidation without addition of lots of advanced oxidizing agents, heavy metal pollution will not be caused due to excessive corrosion of a plate electrode, and the technological process is simple.

Owner:HENAN INST OF ENG

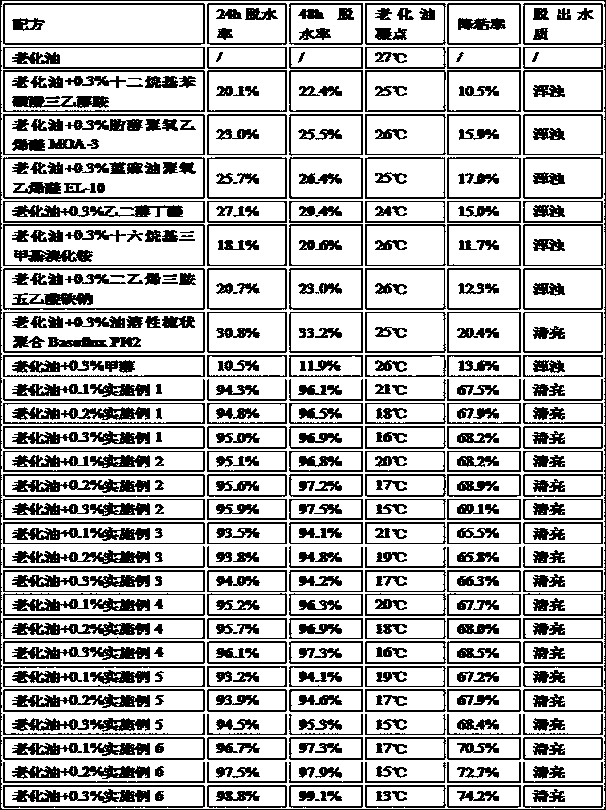

Ageing oil low-temperature demulsification viscosity reducer, preparation method thereof and application of viscosity reducer

ActiveCN109294548ALow viscosityLowering the freezing pointPipeline systemsDrilling compositionFatty alcoholPolymer

The invention discloses an ageing oil low-temperature demulsification viscosity reducer, a preparation method thereof and an application of the viscosity reducer. The viscosity reducer comprises, in weight percent, 5%-15% of triethanolamine dodecyl benzene sulfonate, 5%-10% of fatty alcohol-polyoxyethylene ether, 15%-30% of castor oil polyoxyethylene ether, 2%-8% butyl cellosolve, 5%-15% of cetyltrimethyl ammonium bromide, 5%-15% of sodium hydrogen ferric diethylenetriaminepentaacetate, 2%-8% of oil-soluble comb polymers, 15% of methanol and the balance water.

Owner:西安长庆化工集团有限公司

Fluoride-contained crosslinked polyether demulsifier and preparation method thereof

ActiveCN107641523AReduce usageFast dehydration rateDewatering/demulsification with chemical meansDemulsifierPotassium hydroxide

The invention discloses a fluoride-contained crosslinked polyether demulsifier and a preparation method thereof. The fluoride-contained crosslinked polyether demulsifier is prepared by adding an initiator and potassium hydroxide to a high-temperature and high-pressure reaction vessel, heating and dehydrating in vacuum, charging propylene epoxide and ethylene oxide, performing anion block polymerizing to obtain fluoride-contained polyether, and then reacting the fluoride-contained polyether and unsaturated acid in an alkylbenzene solvent under the effects of an esterifying catalyst and the initiator. The fluoride-contained crosslinked polyether demulsifier has the characteristics of a plurality of aromatic nucleuses, a plurality of branches, and high molecular weight, is capable of effectively reducing the oil-water interface strength and achieving the purpose of completely separating oil and water, and can also be independently used as or compounded with other demulsifiers to be used as the demulsifier for dehydrating liquid produced by an oilfield and dehydrating and desalting of an oil refinery.

Owner:CHINA NAT OFFSHORE OIL CORP +2

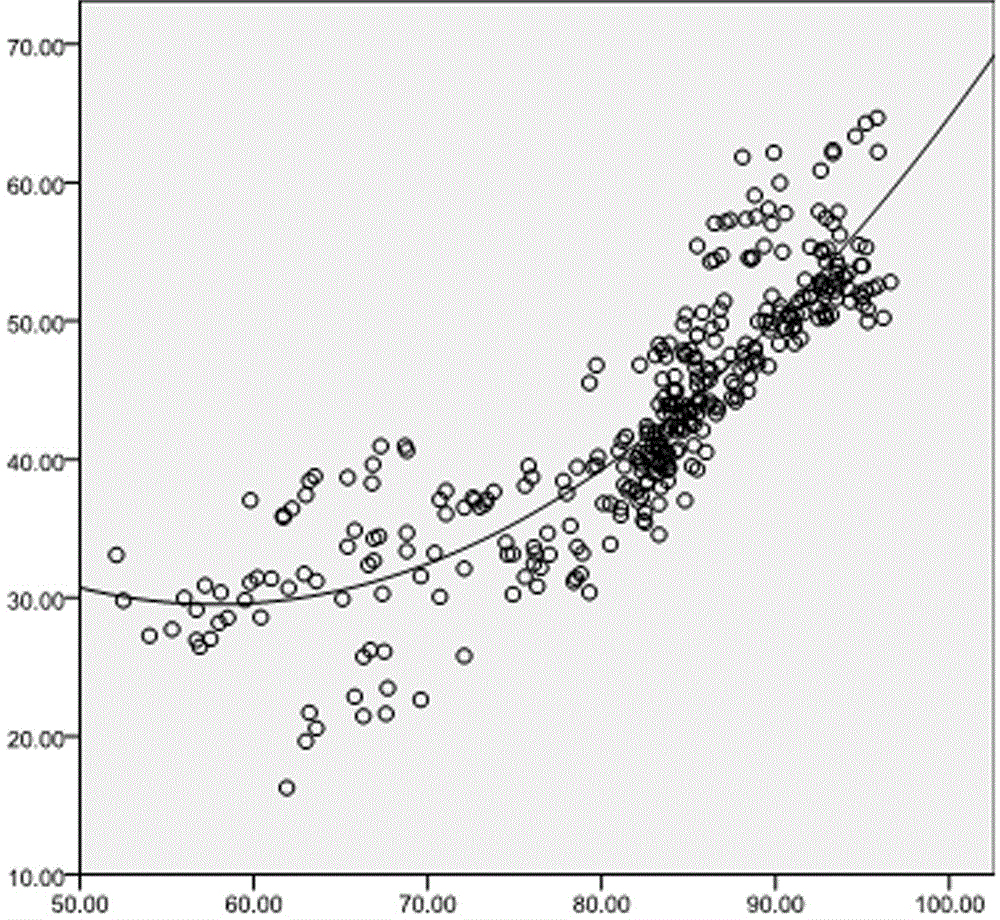

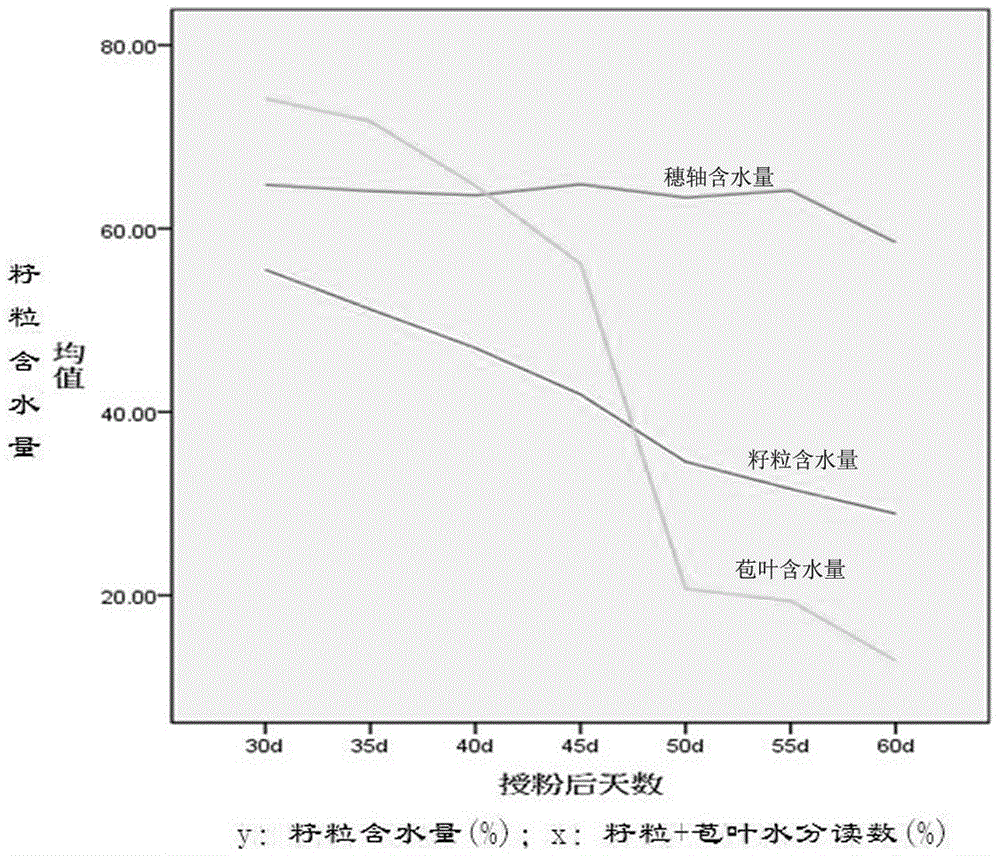

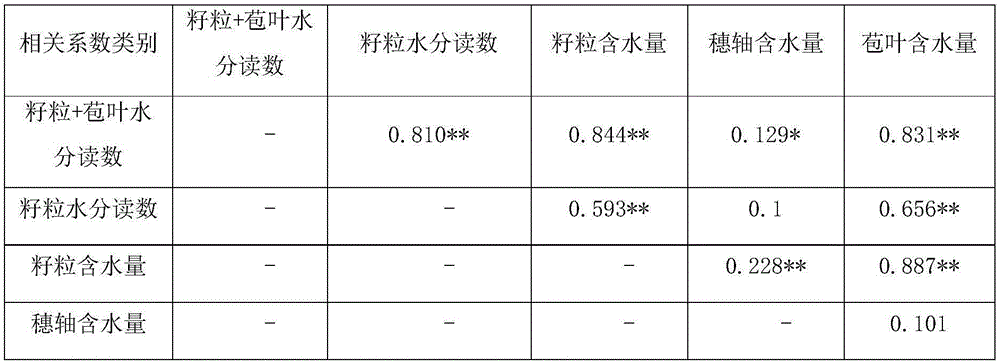

Method for fast measuring corn kernel water loss rate based on regression model and application

InactiveCN106370551AFast dehydration rateImportant breeding valueTesting starch susbtancesWeighing by removing componentLoss rateMeasuring instrument

The invention belongs to the field of crop breeding, and relates to a method for fast measuring the corn kernel water loss rate based on a regression model and application. The method comprises the following steps of building a regression model of corn kernel water content yn; calculating the corn kernel water loss rate V=(yn-y1) / n; determining the correlation between the water content measured by an oven drying method and readings of a water measuring instrument through SPSS (statistic package for social science) software according to the regression model of the corn kernel water content yn; drawing a scatter diagram; building a regression model y=95.709-2.29x+0.02x<2>, wherein the x is the reading of the water measuring instrument on the corn kernels and bracteal leaves, and the y is the corn kernel water content. The method for fast measuring the corn kernel water loss rate provided by the invention has very important breeding values, and particularly in nowadays that mechanical harvest becomes the major trend of corn industry development; the importance of the method is increasingly shown.

Owner:鹤壁市农业科学院

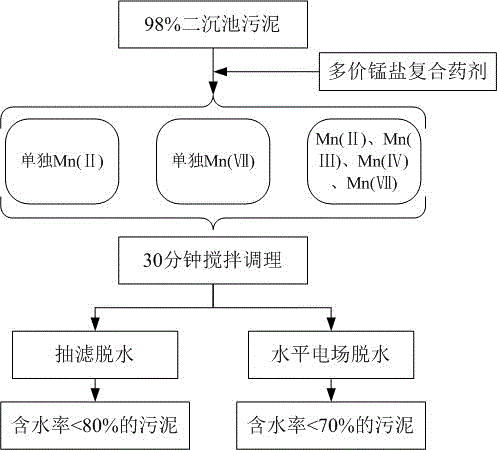

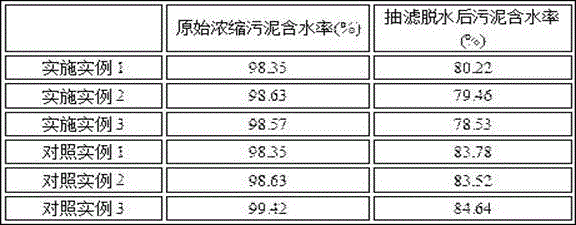

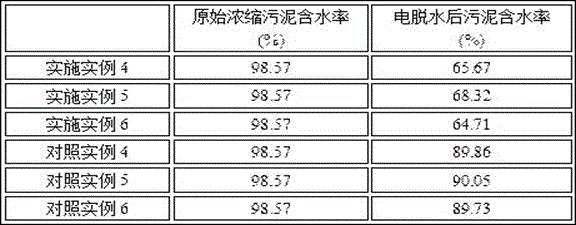

Manganese salt sludge conditioner and sludge dewatering method

InactiveCN106242242AImprove dehydration effectFast dehydration rateSludge treatment by de-watering/drying/thickeningElectrochemical sludge treatmentBound waterFiltration

The invention provides a manganese salt sludge conditioner and a sludge dewatering method. The manganese salt sludge conditioner comprises compounds of bivalent, trivalent, tetravalent and heptavalent manganese; the manganese salts can cause sludge floc flocculation or extracellular organic matter damage; partial bound water is released; in addition, a sludge framework and a dewatering passage can be built. The method for conditioning and dewatering the sludge by using the sludge conditioner comprises the following steps that (1) sludge pretreatment is performed; (2) manganese slat, including single Mn(II) salts or Mn(VII) salts and KMnO4 and NaHSO3(Na2SO3) are added; oxidation-reduction reaction is performed to produce Mn(III) and reaction products of Mn(II), Mn(IV) and Mn(VII) in situ; (3) sludge dewatering is performed; suction filtration or horizontal electric field is used for water removal. The manganese salt sludge conditioner and the sludge dewatering method provided by the invention have the advantages that the dewatering time is short; the operation is simple; pathogenic microorganisms in the sludge are killed in an auxiliary way; the water content of the sludge can be effectively reduced; the safe and sanitation performance of the sludge can be improved.

Owner:BEIJING FORESTRY UNIVERSITY

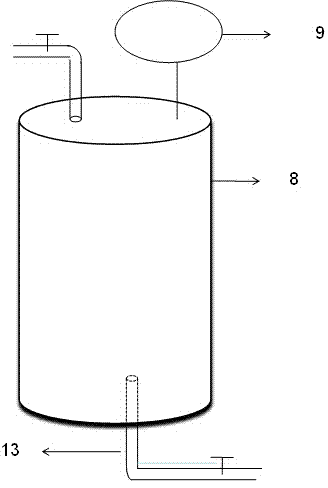

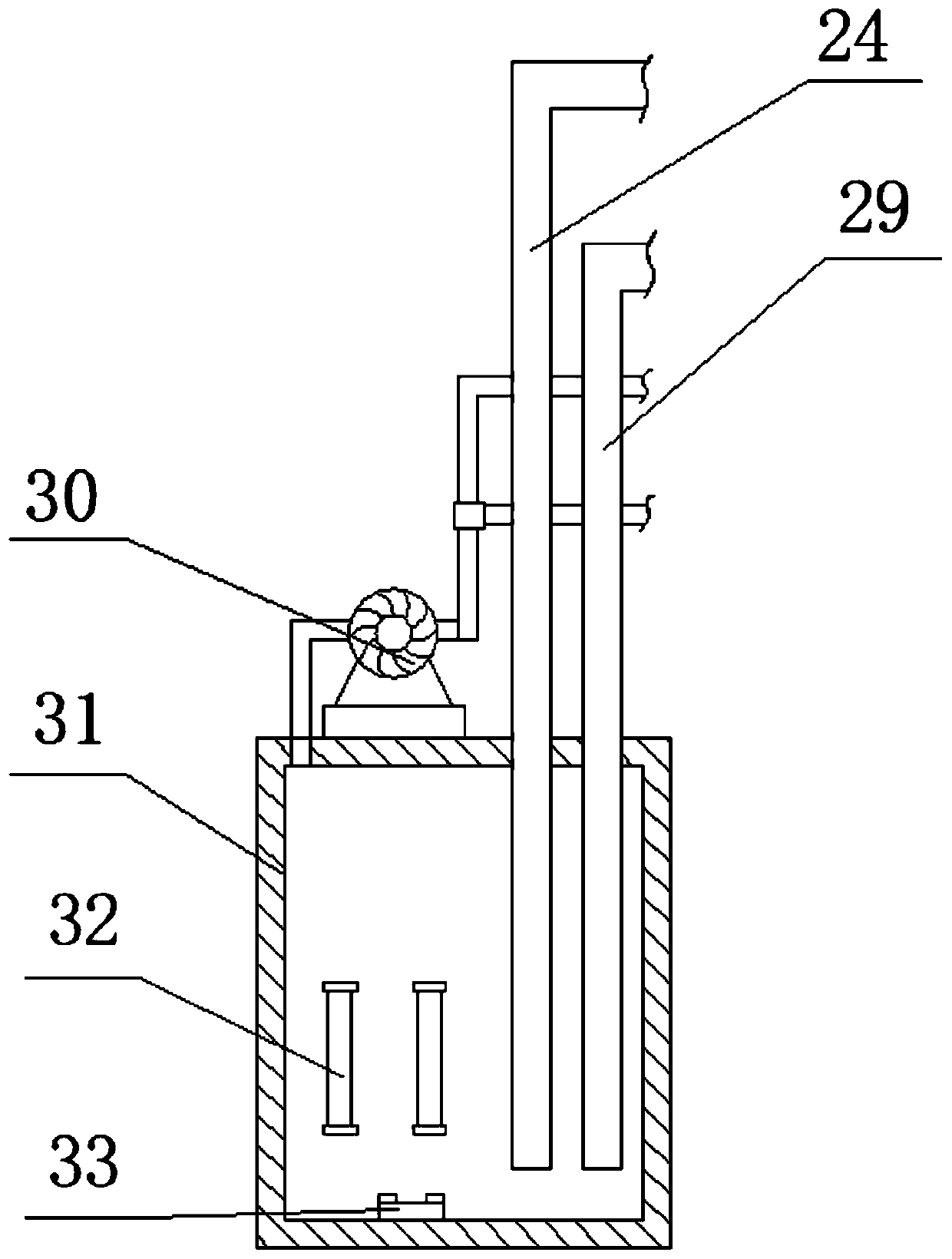

Vacuum electroosmosis curing water supply plant sludge device and use method thereof

ActiveCN104496149AImprove dehydration effectReduce electroosmosis timeSludge treatment by de-watering/drying/thickeningIonEngineering

The invention discloses a vacuum electroosmosis curing water supply plant sludge device and a use method thereof. The positive electrode and the negative electrode of a direct-current power supply of the device are respectively connected with negative electrode metal and positive electrode metal inside a sludge tank; the other ends of the negative electrode metal and the positive electrode metal are respectively connected with vacuum tanks through drain tubes; vacuum pumps and valve are arranged on the drain tubes; the vacuum pumps are both connected with a timing switch. According to the method, curing is performed firstly and electroosmosis is performed secondly, and the timing switch is adopted to control the vacuum pumps to be opened or closed. The vacuum electroosmosis curing water supply plant sludge device is good in water supply sludge curing effect, the sludge obtained after metal ions are removed meets the national soil reuse discharge standard, and the operation cost is low when being compared with that of a conventional vacuum combined electroosmosis device.

Owner:江苏海壹环境科技有限公司

Dialdehyde extender chain type demulsifier and preparation method thereof

InactiveCN103421534AThe synthesis process is simpleReduce manufacturing costDewatering/demulsification with chemical meansDemulsifierDistillation

The invention discloses a dialdehyde extender chain type demulsifier and a preparation method thereof. The raw materials for preparing the demulsifier comprises, by weight, 50-90% industrial polyether, 0.5-15% dialdehyde, and good solvents of industrial polyether and dialdehyde. Moreover, the raw materials comprise acid catalyst, and the utilization amount of the acid catalyst is 0.05-2% that of the industrial polyether. According to the preparation method, dialdehyde or industrial polyether is reacted with a plurality kinds of mixtures under the action of acid catalyst of 80-100 oC, then, sodium hydroxide solution is added for neutralization, and finally solvents are removed through reduced pressure distillation, so that the dialdehyde extender chain type demulsifier is obtained. The demulsifier obtained through the method is simple in synthetic technology, small in utilization amount and low in demulsification temperature.

Owner:JIANGSU UNIV +1

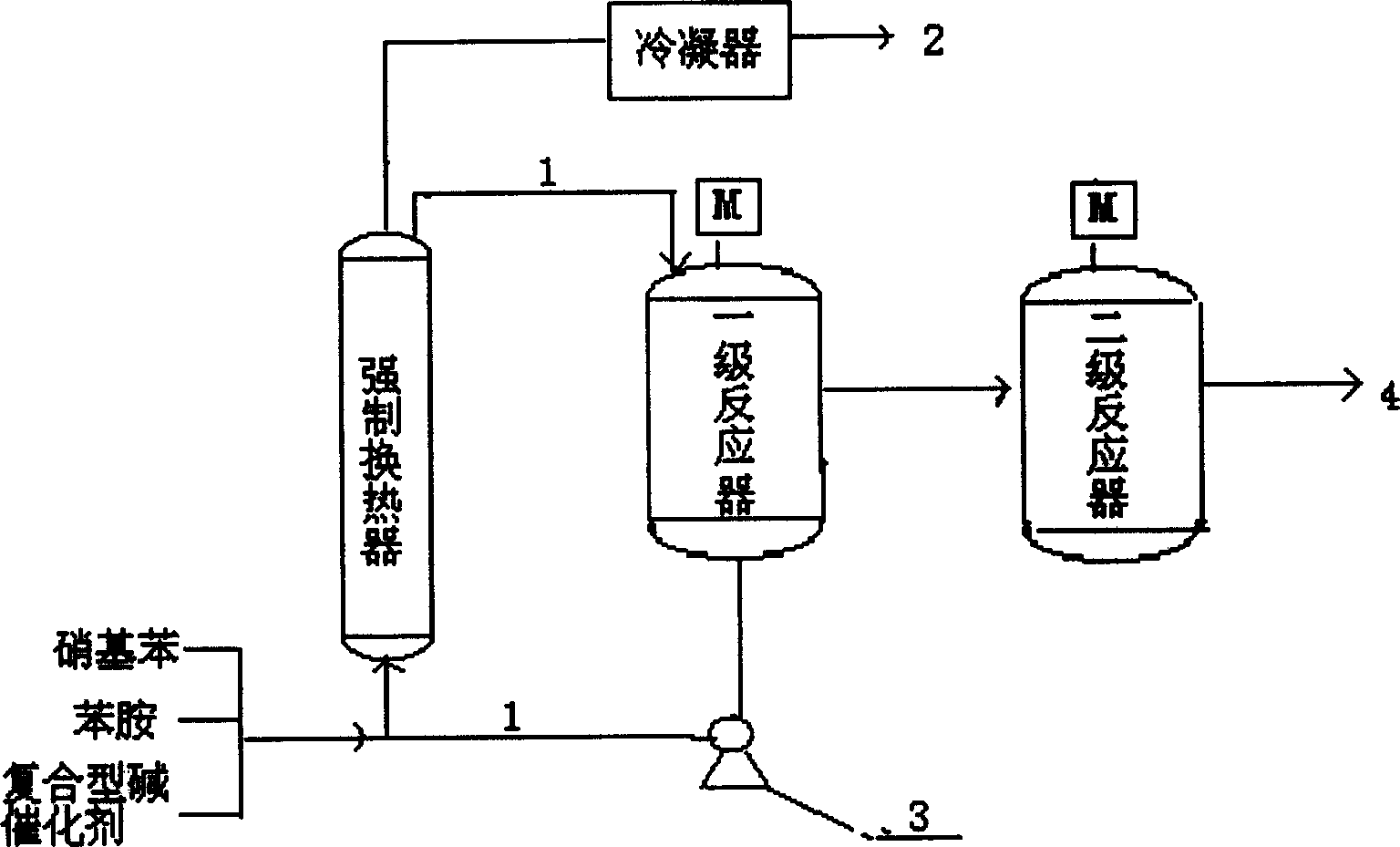

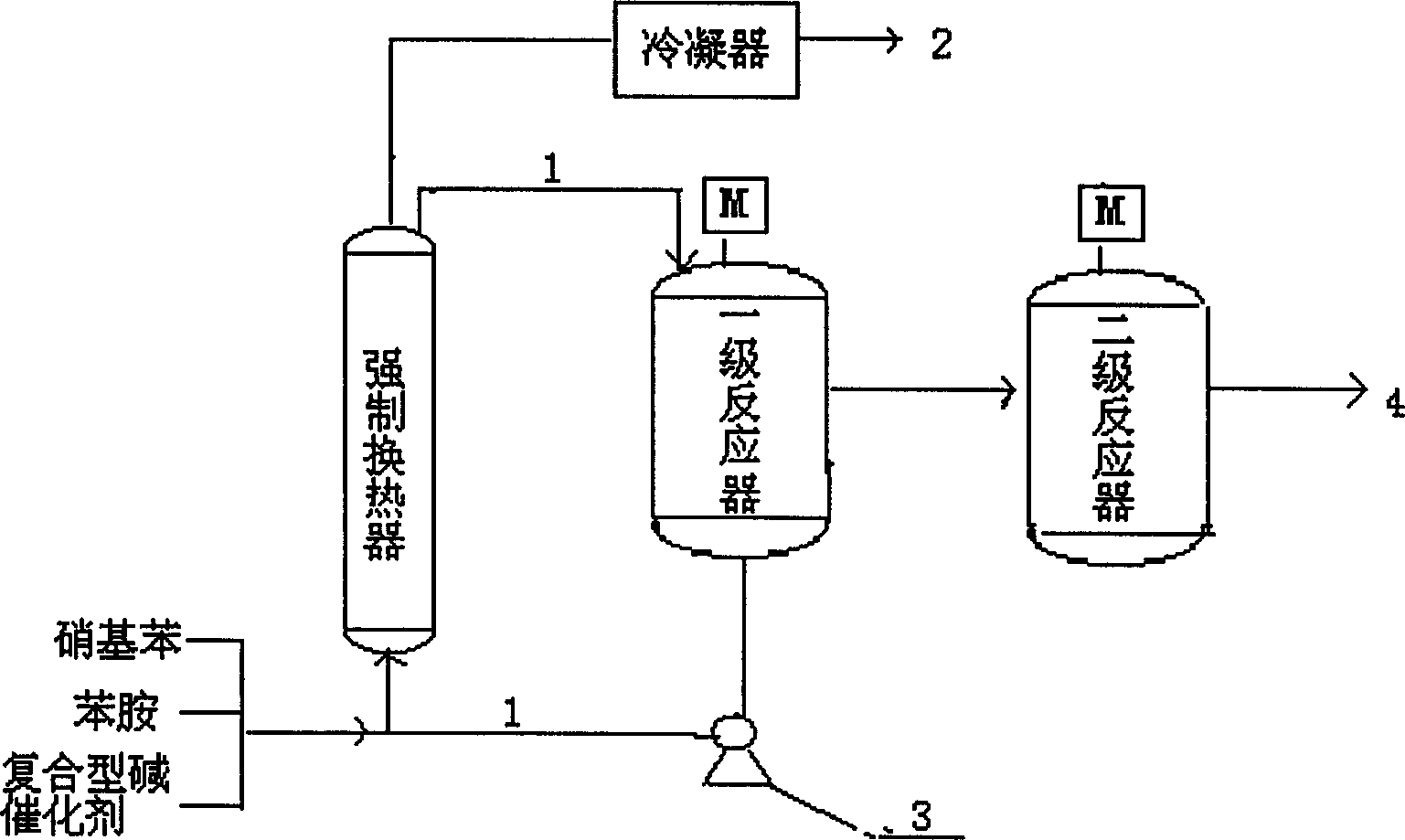

Method for synthesizing 4-nitro diphenylamine and 4-nitroso diphenylamine or/and their salts

InactiveCN1470500ALow priceEasy to operateOrganic-compounds/hydrides/coordination-complexes catalystsAmino compound preparation by condensation/addition reactionsNitrosoNitrobenzene

The present invention relates to a method for making continuous condensation reaction to synthesize 4-nitrodiphenylamine and 4-nitrosodiphenylamine or / and their salts by using phenylamine and nitrobenzol as raw material in the presence of compound catalyst. Said invention selects and uses the cheap compound alkali catalyst, phenylamine and nitrobenzol, and places them into a reactor according to a certain proportion, and makes them pass throu gh one-stage or multistage reactor and forced heat exchanger at a certain pressure and temp., and utilizes forced circulation pump to make said materialimplement locak circulation and reaction while dewatering. Said invented reaction condition is moderate, conversion rate of nitrobenzol is greater than 99%, and its selectivity is greater than 97%.

Owner:JIANGSU SINORGCHEM TECH CO LTD

Method for preparing silicon-containing polyether demulsifier

InactiveCN106047397AImprove dehydration effectReduce usageDewatering/demulsification with chemical meansHydrocarbon oils treatmentMethacrylateDistillation

The invention discloses a method for preparing a silicon-containing demulsifier. The method comprises the steps of adopting a fractional step method to first perform alcoholysis on gamma-trimethoxysilyl propyl methacrylate, alcohol and deionized water for 2-4 h at the pH of 3-5, performing stirring reaction for 1-3 h at a temperature of 60-80 DEG C, and obtaining an oligosiloxane product A containin Si-OH; adding a polyether demulsifier, a basic catalyst and calcium oxide into a reactor with a stirring and dropwise adding device and a condensing pipe, controlling the temperature to be 60-130 DEG C, adding the product A dropwise, continuing to performing stirring reaction for 3-6 h after the dropwise adding and then adding a solvent dissolution crude product, performing stirring for 1-3 h and then standing, filtering out solid matter, and performing reduced pressure distillation to remove a solvent to obtain the silicon-containing demulsifier. The obtained demulsifier has the advantages of being good in dehydration effect, small in usage amount and low in demulsification temperature.

Owner:JURONG NINGWU CHEM

Epoxy resin chain extension type polyether demulsifying agent and preparation method thereof

InactiveCN103421536AThe synthesis process is simpleReduce manufacturing costDewatering/demulsification with chemical meansEpoxyDistillation

The invention discloses an epoxy resin chain extension type polyether demulsifying agent and a preparation method of the epoxy resin chain extension type polyether demulsifying agent. Raw materials for preparation of the demulsifying agent comprise 50wt% to 90wt% of industrial polyether, 0.1wt% to 7wt% of epoxy resin, basic catalysts with the dosage being 0.01wt% to 3wt% of industrial polyether, 0.01wt% to 2wt% of triethanolamine, and good solvents of industrial polyether and epoxy resin. The synthetic method includes the steps of enabling one or more types of epoxy resin mixtures to react with one or more types of industrial polyether mixtures under the temperature ranging from 80 DEG C to 130 DEG C, adding a defined amount of triethanolamine, stirring the mixture and enabling the mixture to react for 2 hours, and obtaining the epoxy resin chain extension type polyether demulsifying agent by conducting reduced pressure distillation to remove the solvent. The epoxy resin chain extension type polyether demulsifying agent is simple in synthetic process, small in usage amount and low in demulsifying temperature.

Owner:JIANGSU UNIV +1

Environment puricant and using method thereof

InactiveCN109809544AWell-developed pore structureExcellent physicochemical adsorption functionWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationMechanical propertySolid matter

The invention discloses an environment puricant and a using method thereof. Aluminum sulfate in the environment puricant is used for settlement of suspended matters in sewage, a polyacrylamide hydrolysis product is used for flocculation of impurities, ferrous sulfate is used as a settling promoter, the polyacrylamide hydrolysis product has a stronger nucleation function, and then the aluminum sulfate and the ferrous sulfate are matched, so that not only the nucleation effect is increased, but also the dehydration speed during a flocculation process is greatly increased, and quick dehydration of sludge and other suspended particles in the sewage can be effectively promoted; a water treatment aid is prepared from anhydrite, slaked lime, sodium carbonate, cement, sodium thiosulfate, silicon dioxide and sodium hypochlorite, so that not only bacteria and viruses in the sewage and solid matters can be effectively killed, but also rapid moisture absorption, dehydration and separation can be carried out on water in concentrated sludge, the water can be conveniently separated from the solid matters, the solid matters obtained through separation have stronger hydrophobicity, the separated solid matters are in dry pasty shapes, the solid matters are low in water content and very good in mechanical performance.

Owner:桂林新竹大自然生物材料有限公司

Riverway sludge treatment method

ActiveCN107814474AVolatileImprove dehydration rateSludge treatment by de-watering/drying/thickeningBiological sludge treatmentSludgeShore

The invention discloses a riverway sludge treatment method. The riverway sludge treatment method comprises the following steps: firstly catching or hydraulic filling sludge at river bottom to a barge,a tugboat or a shore sludge piling region by a grab dredger or dredger, and then treating the accumulated sludge according to the following steps: (1) carrying out mechanical dehydration until watercontent of the sludge is lower than 15%; (2) adding microorganisms into the sludge treated in the step (1), stirring and carrying out reaction, carrying out air blast and ventilation until the water content of sludge is lower than 5%; and (3) taking the sludge treated in the step (2), and carrying out electroosmotic dehydration to constant weight. The method disclosed by the invention has the effect of improving dehydration rate.

Owner:浙江山海建设有限公司

Crude oil demulsifier for low temperature

InactiveCN109679681AHigh molecular weightImprove lipophilicityDewatering/demulsification with chemical meansHydrocarbon oils treatmentPolyesterDemulsifier

The invention relates to a crude oil demulsifier for the low temperature. The crude oil demulsifier is prepared from the following components: nonylphenol polyoxyethylene ether, phenolic aldehyde amine resin polyether, siloxane polyether and a solvent. The nonylphenol polyoxyethylene ether in the compositions of the crude oil demulsifier can achieve a good basic dehydration effect on conventionalcrude oil produced fluid, the phenolic aldehyde amine resin polyether is high in molecular weight and high in lipophilicity, the dissolved quantity in an oil phase is greater than the dissolved quantity in a water phase, the phenolic aldehyde amine resin polyether has the good wetting ability and the flocculation and coalescence abilities, the siloxane polyether can achieve demulsification at thelow temperature of 25-30 DEG C, compared with the mode of separately using a polyester surfactant, the additive amount is decreased by 50% or above, the dehydration rate is high, the demulsification effect is good, and the comprehensive cost is lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nonionic-cationic copolymer containing polyether branched chain and preparation method thereof

ActiveCN112300340AReduce usageFast dehydration rateWaste water treatment from quariesDewatering/demulsification with chemical meansDemulsifierPolymer science

The invention discloses a nonionic-cationic copolymer containing a polyether branched chain and a preparation method thereof. The preparation method comprises the following steps of: adding maleic anhydride and polyether polyol into a container according to a certain sequence, carrying out a reaction at a certain temperature, adding a water-soluble cationic monomer, water and an initiator according to a certain ratio, and carrying out a polymerization reaction under a certain condition to obtain non-ionic cationic copolymer containing a polyether branched chain. The nonionic-cationic amphoteric copolymer disclosed by the invention can be used as a reverse demulsifier for oil-water separation of oilfield produced liquid, has demulsification and flocculation functions, and has the advantagesof high separation rate and good dehydrated water quality for high-water-content or ultrahigh-water-content crude oil emulsion.

Owner:中海油(天津)油田化工有限公司 +2

Chemical textile fiber dehydrator

InactiveCN113503709AIncrease confusionFast dehydration rateDrying gas arrangementsDrying chambers/containersTextile fiberElectric machinery

The invention relates to the technical field of chemical production, in particular to a chemical textile fiber dehydrator. The chemical textile fiber dehydrator comprises a machine shell, a dewatering chamber used for dehydrating textile fibers is arranged in the machine shell, a rotating mechanism used for scattering the textile fibers is arranged at the bottom of the dewatering chamber, and a device cavity is further formed in the machine shell; two cylinder bodies are symmetrically and fixedly connected to the inner walls of the two sides of the device cavity, and air pumping mechanisms which are matched with the rotating mechanism and used for spraying gas into the dewatering chamber are arranged in the two cylinder bodies; and friction mechanisms which are matched with the rotating mechanisms and are used for heating gas in the two cylinder bodies are further arranged outside the two cylinder bodies. According to the chemical fiber dehydrator, a motor drives a disc in the dewatering chamber to rotate, then drives chemical fiber raw materials in the dewatering chamber to move ceaselessly, drives compressed gas to be sprayed into the dewatering chamber and heats gas in a sliding cavity, and the dewatering rate of the materials is increased.

Owner:唐文燕

Method for synthesizing 4-nitro diphenylamine and 4-nitroso diphenylamine or/and their salts

InactiveCN1253428CLow priceEasy to operateOrganic-compounds/hydrides/coordination-complexes catalystsAmino compound preparation by condensation/addition reactionsNitrosoNitrobenzene

The invention relates to a method for synthesizing 4-nitrodiphenylamine and 4-nitrosodiphenylamine and / or their salts through continuous condensation reaction using aniline and nitrobenzene as raw materials in the presence of a composite catalyst. That is to choose a cheap composite alkali catalyst, aniline, nitrobenzene and composite alkali catalyst enter the reactor in a certain proportion, and under a certain pressure and temperature, pass through one-stage or multi-stage reactors and forced heat exchangers, using a forced circulation pump The material is partially circulated, dehydrated and reacted at the same time. The invention has mild reaction conditions, few by-products, the conversion rate of nitrobenzene is greater than 99%, and the selectivity is greater than 97%. No corrosive substances are produced, the requirements for equipment are not high, the production is stable, it is easy to realize automatic control, and the production cost is reduced.

Owner:JIANGSU SINORGCHEM TECH CO LTD

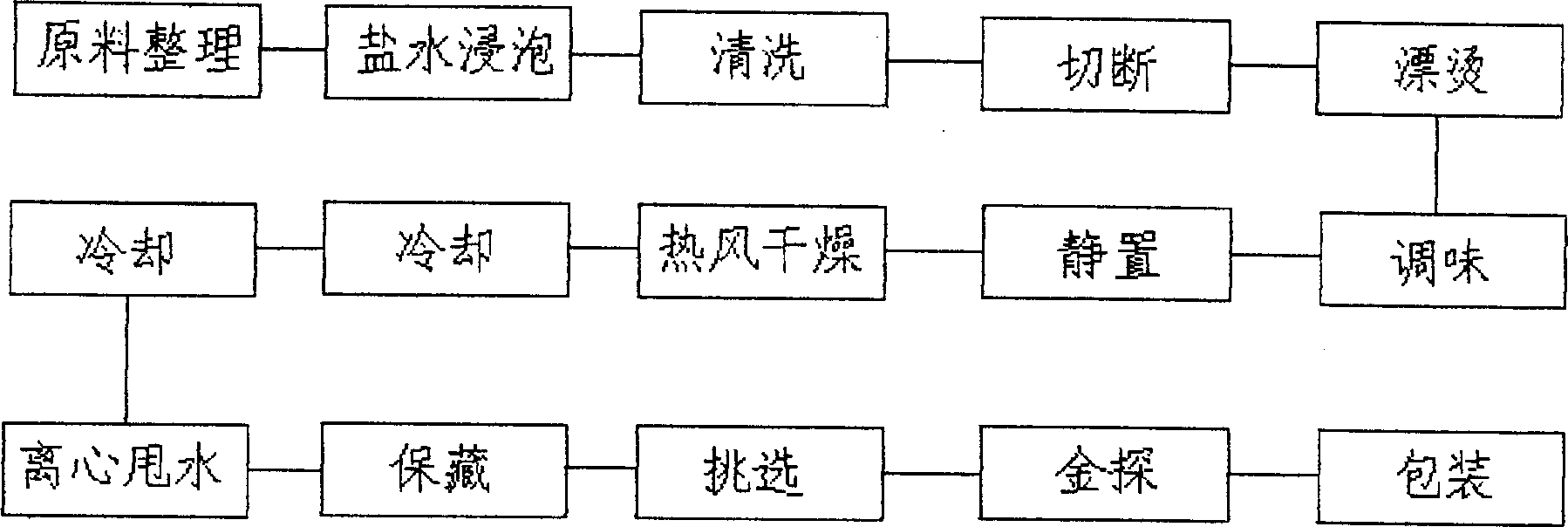

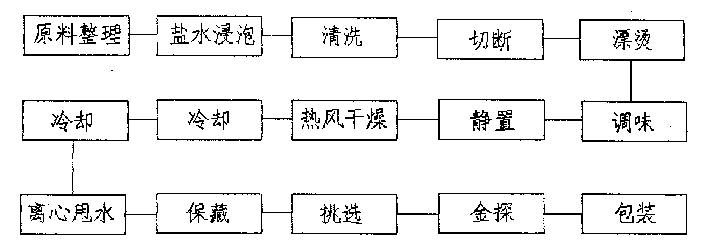

Method for preparing vegetable core clear soup

InactiveCN1449680AWeight increaseIncrease profitFood preservationFood preparationSaline waterThree stage

The production method of vegetable core clear soup includes the following steps: preparing raw material, soaking is salt water, cleaning, cutting, scalding, cooling, centrifugal drying, flavouring, standing still, hot air drying, cooling, preservation, selecting, metal detection and packing so as to obtain the invented finished product. It is characterized by that A flavouring procedure: according to weight percentage of rape bolt after centrifugal drying respectively adding 1.5-2% of edible salt and 3-5% of lactose, and stirring and standing still for 20 min.; B. hot air drying procedure is divided into three stages: first stage, temp. is 80-85 deg.C and time is 1-2 hr; second stage, temp. is 60-70 deg.C and time is 1-1.5 hr; and third stage, temp. is 40-50 deg.C and time is 3 hr.; and C. preservation method, dried vegetable core is sealed and placed into low-temp. cold storage at 0-10 deg.C to make storage.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD

Grain dehydration device for agricultural scientific research

InactiveCN109855410AExpand the scope of useFast dehydration rateSievingScreeningAgricultureEngineering

The invention belongs to the technical field of agriculture, in particular to a grain dehydration device for agricultural scientific research. The following scheme is provided for solving the problemof use inconvenience of a current grain dehydration device. The grain dehydration device comprises a dehydration shell, the top inner walls of the two sides of the dehydration shell are connected withthe same horizontally-arranged drying shell through bolts, the inner walls of the two sides of the drying shell are rotatably connected with the same horizontally-arranged rotating shaft through a bearing, the rotating shaft extends to the exterior of the dehydration shell, stirring blades distributed at the equal intervals are connected with the circumference outer wall of the rotating shaft through bolts, and through holes distributed at equal intervals are formed in the outer wall of each stirring blade. According to the grain dehydration device, by arranging an air extracting pump, a heating rod and a second intake pipe, hot air blowing and drying can be conducted on the grain in a drying shell, the dehydration rate of the grain is increased, and by arranging an electro motor, the rotating shaft and the stirring blades, the grain can be stirred, so that the surface of the grain can be heated evenly, and the dehydration rate of the grain is further increased.

Owner:湖南全望信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com