Ageing oil low-temperature demulsification viscosity reducer, preparation method thereof and application of viscosity reducer

A technology of aging oil and viscosity reducer, which is applied in the direction of chemical instruments and methods, mechanical equipment, drilling compositions, etc. It can solve the problem that the treatment effect is affected by the type and dosage of the agent, the aging oil treatment time is long, and the production capacity is improved. To solve problems such as operating costs, achieve the effect of reducing the dosage of chemicals, improving the efficiency of demulsification, and reducing the interfacial tension of oil and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

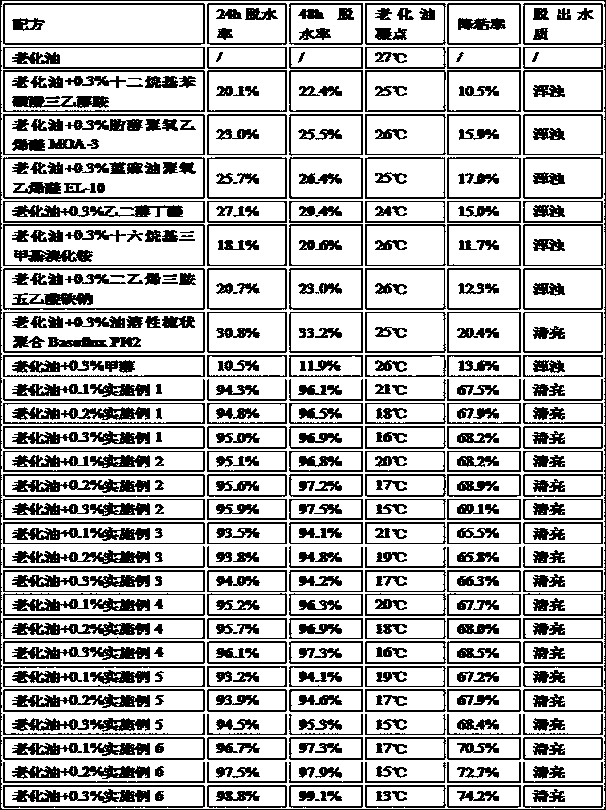

Examples

specific Embodiment approach

[0023] It should be noted that the structures, proportions, sizes, etc. shown in this specification are only used to cooperate with the content disclosed in the specification for the understanding and reading of those familiar with this technology, and are not used to limit the conditions for the implementation of the present invention , any modification of structure, change of proportional relationship or adjustment of size shall still fall within the scope covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. .

[0024] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without...

Embodiment 1

[0026] The invention discloses a low-temperature demulsification and viscosity-reducing agent for aging oil. The active ingredients include triethanolamine dodecylbenzenesulfonate, fatty alcohol polyoxyethylene ether, castor oil polyoxyethylene ether, ethylene glycol butyl ether, Hexaalkyltrimethylammonium bromide, sodium iron diethylenetriaminepentaacetate, oil-soluble comb polymer and methanol, wherein the weight percentage of each active ingredient is: triethanolamine dodecylbenzenesulfonate 5% ~15%, fatty alcohol polyoxyethylene ether 5%~10%, castor oil polyoxyethylene ether 15%~30%, ethylene glycol butyl ether 2%~8%, cetyltrimethylammonium bromide 5 %~15%, sodium iron diethylenetriaminepentaacetate 5%~15%, oil-soluble comb polymer 2%~8%, methanol 15%, water to make up the balance.

Embodiment 2

[0028] The invention discloses a low-temperature demulsification and viscosity-reducing agent for aging oil. The active ingredients include triethanolamine dodecylbenzenesulfonate, fatty alcohol polyoxyethylene ether, castor oil polyoxyethylene ether, ethylene glycol butyl ether, Hexaalkyltrimethylammonium bromide, sodium iron diethylenetriaminepentaacetate, oil-soluble comb polymer and methanol, wherein the weight percentage of each active ingredient is: triethanolamine dodecylbenzenesulfonate 5% ~15%, fatty alcohol polyoxyethylene ether 5%~10%, castor oil polyoxyethylene ether 15%~30%, ethylene glycol butyl ether 2%~8%, cetyltrimethylammonium bromide 5 %~15%, sodium iron diethylenetriaminepentaacetate 5%~15%, oil-soluble comb polymer 2%~8%, methanol 15%, water to make up the balance.

[0029] Preferably, the weight percent of each active ingredient is: triethanolamine dodecylbenzenesulfonate 5%~10%, fatty alcohol polyoxyethylene ether 8%~10%, castor oil polyoxyethylene ether...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com