Patents

Literature

90results about How to "Improve demulsification efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature sewage treatment reverse demulsifier of ultra-heavy oil

InactiveCN103086472ASimple technical routeMild reaction conditionsFatty/oily/floating substances removal devicesNon-miscible liquid separationCross-linkPotassium hydroxide

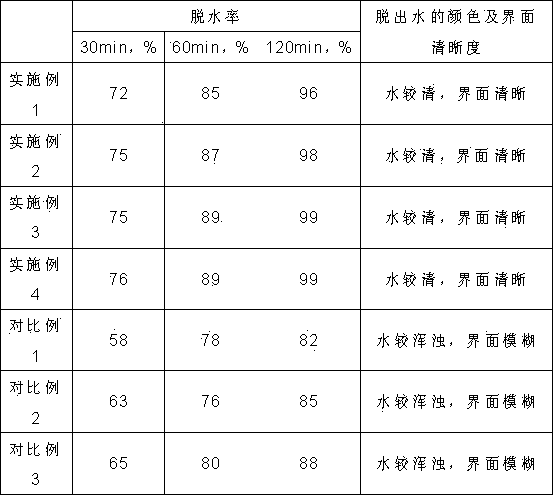

The invention discloses a high-temperature sewage treatment reverse demulsifier of ultra-heavy oil. The method comprises the following steps of preparing chlorinated polyether by taking propanetriol and epichlorohydrin as materials and boron trifluoride ether solution as an initiator; preparing cationic poly ether by placing the chlorinated polyether and trimethylamine in a high-pressure reactor; by taking carbinol as a solvent, and boron trifluoride diethyl etherate as the initiator, repeatedly and alternatively carrying out Michael addition reaction and amidation by ethanediamine, methyl acrylate and the like to prepare 3.0-generation dendritic macromolecule polyamide-amine; by taking polyethylene glycol and poly propylene glycol as materials, and potassium hydroxide powder as a catalyst, adding polypropylene glycol to prepare non-ionic polyether after the polyethylene glycol reacts a period of time; finally by taking 3.0-generation polyamide-amine as a cross-linking agent, preparing the modified composite polyamide-amine-polyether high-temperature sewage treatment reverse demulsifier of the ultra-heavy oil by compounding cationic polyether and non-ionic polyether.

Owner:KARAMAY SANDA NEW TECH +1

Fast emulsion breaking method

InactiveCN101121898AImprove dehydration rateImprove demulsification efficiencyHydrocarbon oil dewatering/demulsificationNon-miscible liquid separationMass ratioRadiation frequency

The invention relates to a rapid emulsion breaking method, including microwave radiation. Emulsion breaker is added according to the water content of the rolly oil (calculated by weight percent), the mass ratio of the water and emulsion breaker is 1:0.5*10-4 to 5*10-4, and microwave is adopted for emulsion breaking. The emulsion breaker is one or more than two types of mixtures of polyamine polyoxy-propylene polyoxyethylene ether, resin polyoxy-propylene polyoxyethylene ether, higher-alcohol initiator emulsion breaker or propylene glvcol emulsion breaker. The microwave radiation and microwave radiation frequency are 2450MHz or 915MHz. Under the synergistic reaction, water-in-oil emulsion liquid is broken within a relatively short period, a bigger anhydration rate is achieved, and the emulsion-breaking efficiency is improved. In the circumstance of a little emulsion breaker, microwave radiation breaking method can be adopted, and the emulsion breaking speed is increased by 1-2 orders of magnitude compared with the traditional emulsion breaking by heating. The method is easy to implement, energy efficient, rapid in emulsion breaking, and the emulsion breaking effect is good.

Owner:LIAONING UNIVERSITY

Dendritic reverse demulsifier and preparation method thereof

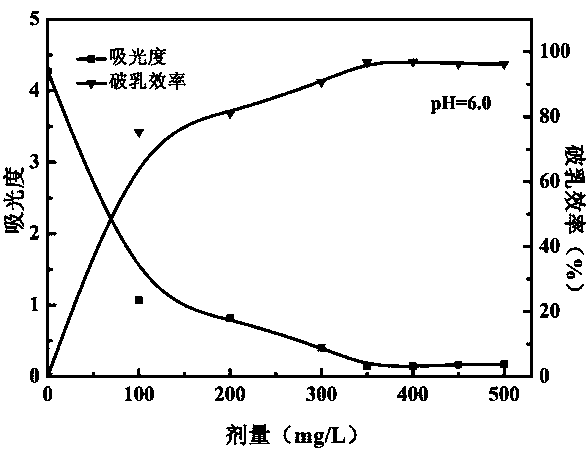

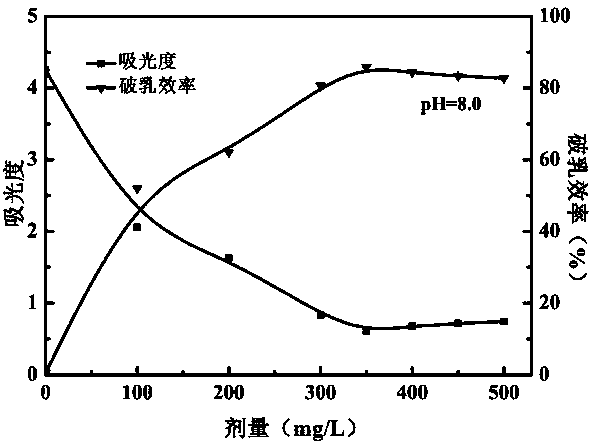

InactiveCN102233249AImprove demulsification efficiencyImprove water qualityTransportation and packagingMixingDemulsifierAqueous solution

The invention provides a dendritic reverse demulsifier used for demulsification of crude oil and a preparation method thereof. The dendritic reverse demulsifier is an aqueous solution with different concentration containing 10%-40% of composite composed of the following materials based on total weight of 100%: 0.1%-10% of dendritic polyamidoamine (PAMAM) from 1.0 to 3.0 generation, 10-45% of epichlorohydrin and 5-22% of dimethylamine (DMA). The preparation method comprises the following steps: firstly synthesizing the dendritic PAMAM from 1.0 to 3.0 generation; taking 1.0, 2.0 and 3.0 generation dendritic PAMAM based on different proportions, adding a proper amount of the epichlorohydrin for reacting at the temperature of below 40 DEG C for 2-4 hours, adding a certain amount of the DMA, adding the epichlorohydrin which accounts for 90% of total added amount to the obtained mixed solution, and heating to 85-95 DEG C for reacting for 1 hour; and adding 10% of the residual epichlorohydrin at three times (once every 20 minutes), and keeping the temperature of 85-95 DEG C until the reaction is completed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

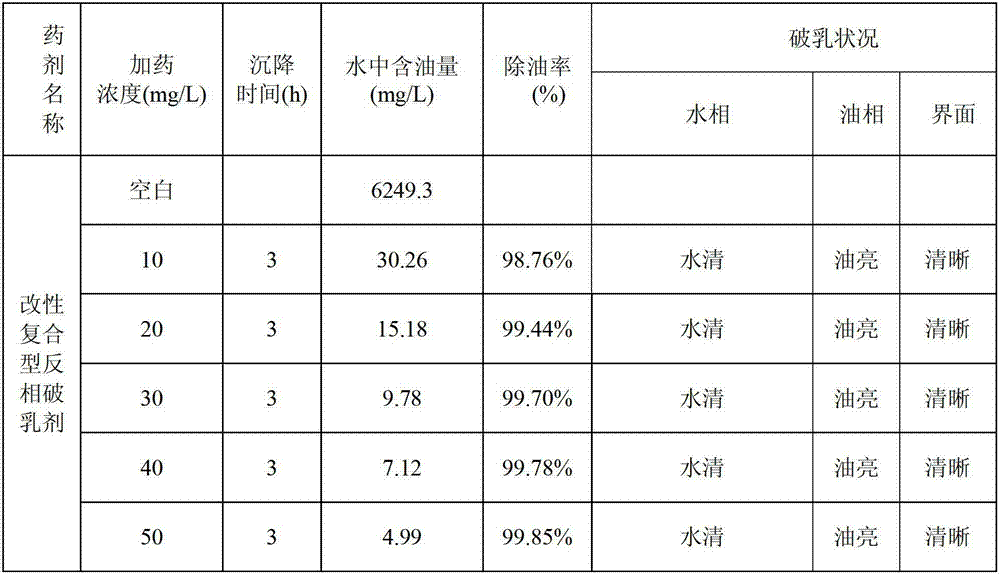

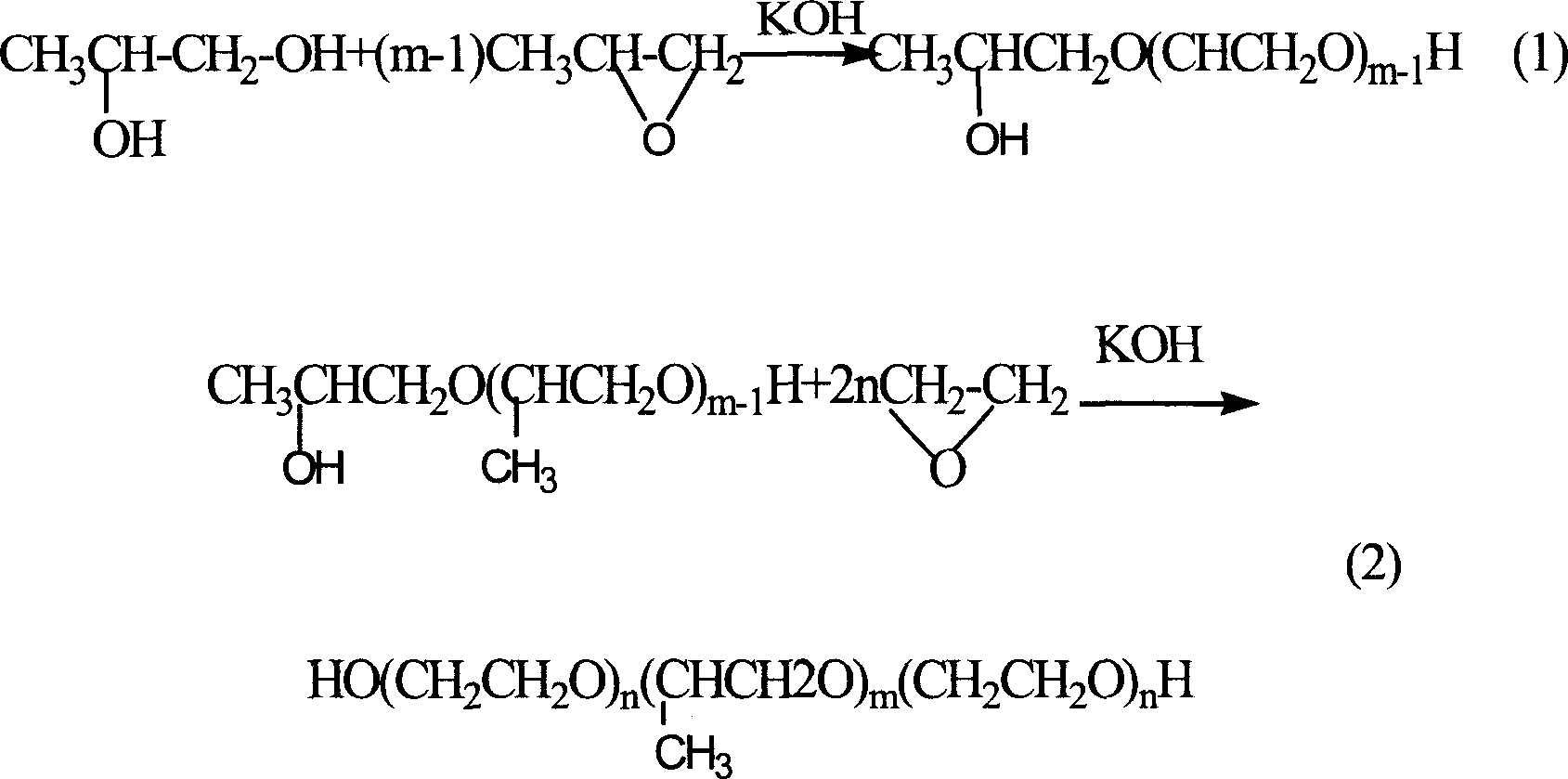

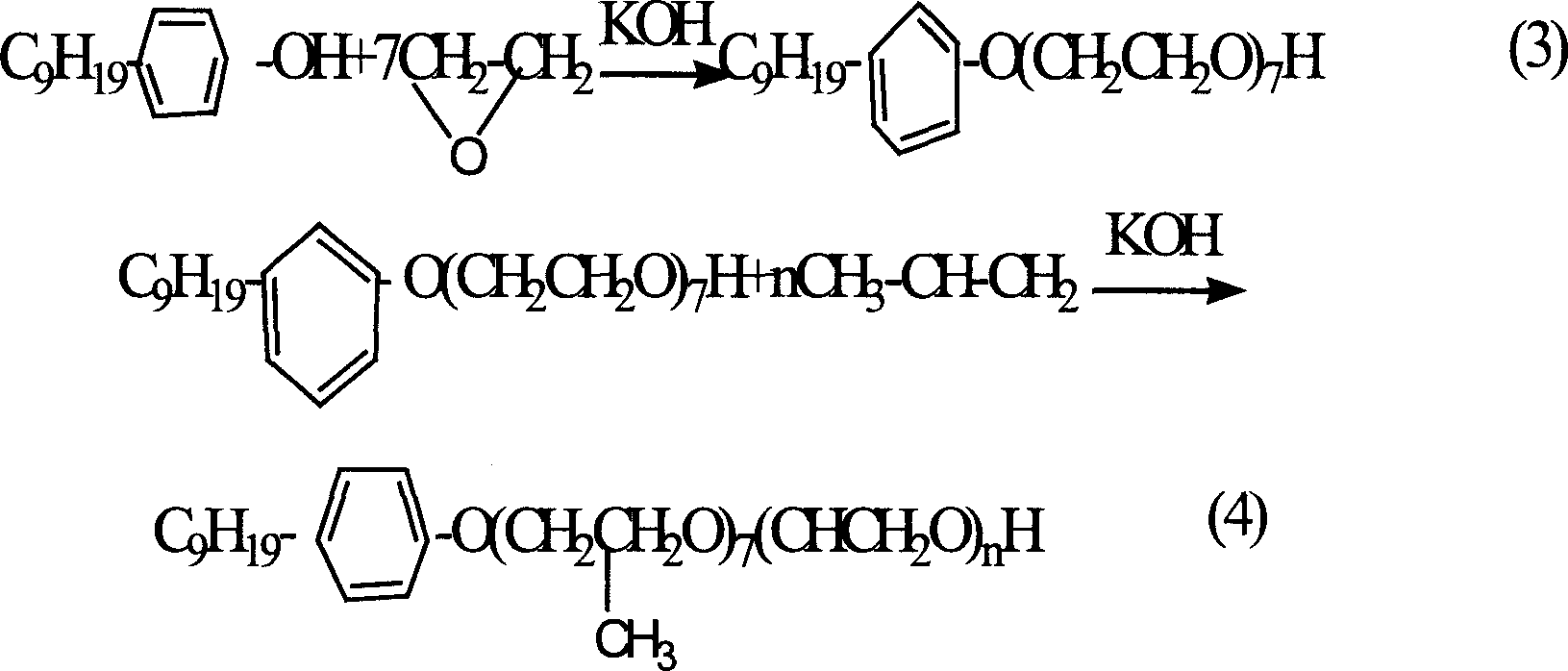

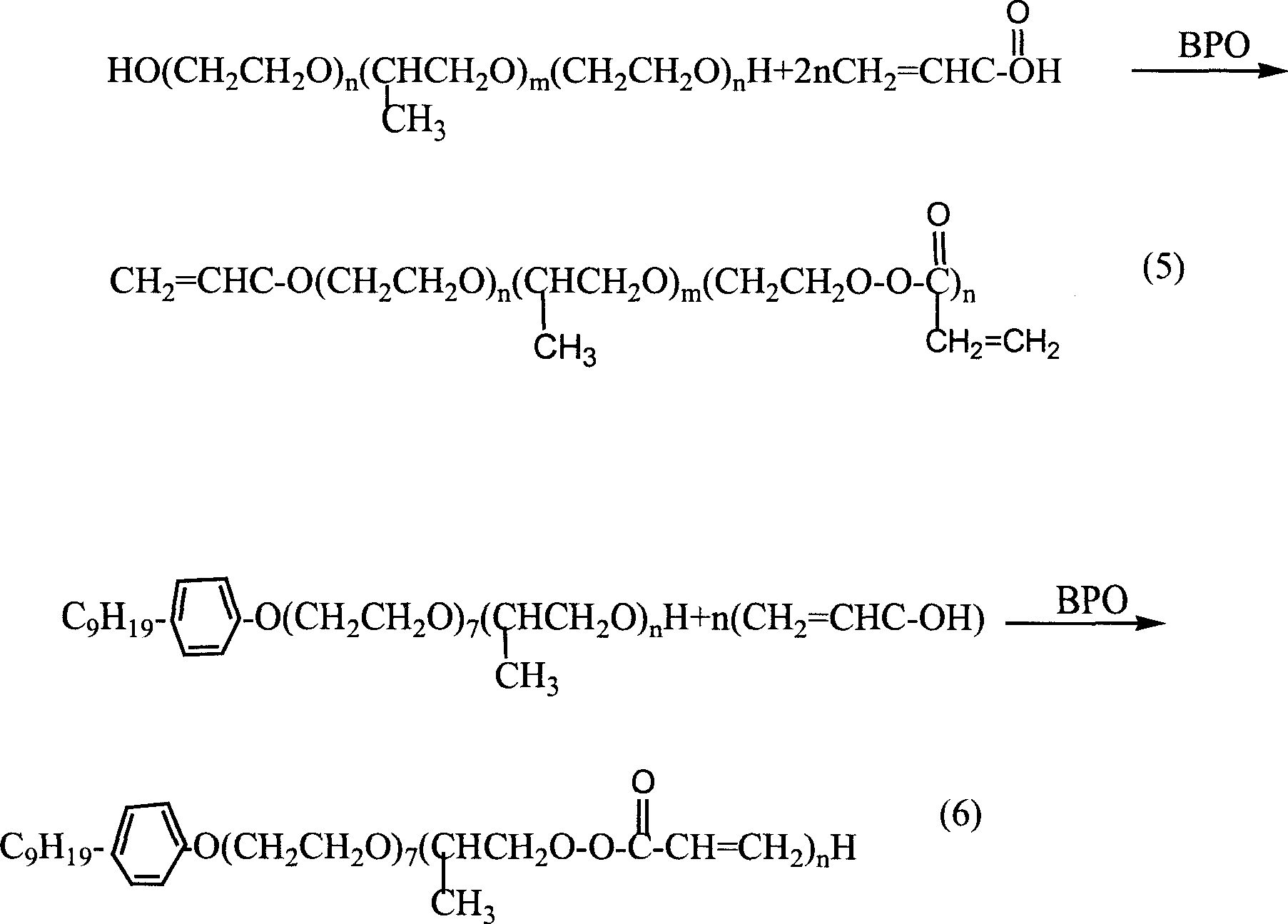

Highly efficient anti-phase emulsion breaker for thick oil pollution water processing

InactiveCN1966138AFast separationReduce oil contentTransportation and packagingMixingWater processingPhenol

The invention relates to a dense oil sewage treatment reverse-phase demulsifying agent, wherein the invention is characterized in that: it uses methyl glycol as initial agent, via catalyst, to process oxypropylation reaction, and process aggregation with epoxyethane, to generate methyl glycol polyether; uses nonyl phenol as initial agent, via catalyst, to react with epoxyethane to generate nonyl phenol ethoxy compound, then to be aggregated with epoxypropane, to generate alkyl phenol polyvinyl ether; then mixing two products, to process esterification with acroleic acid under acid condition, via initiator to process free group aggregation, to generate esterified product, then uses maleic acid to seal end, to generate acroleic acid modified macromolecule demulsifying agent. The invention has simple process, warm reaction, and high efficiency.

Owner:YANGTZE UNIVERSITY

Method for preparing dendrimer antiphase demulsifier

InactiveCN102234374AImprove demulsification efficiencyImprove water qualityFatty/oily/floating substances removal devicesLiquid separationDendrimerEpoxy

The invention discloses a method for preparing a dendrimer antiphase demulsifier used for demulsifying crude oil. Based on the total weight, 0.1 to 10 percent of 1.0 generation, 2.0 generation and 3.0 generation dendrimer polyamide-amine, 10 to 45 percent of epoxy chloropropane, and 5 to 22 percent of dimethylamine form an aqueous solution containing 10 to 40 percent of the composition at different concentrations. The method comprises the following steps of: synthesizing the 1.0 generation, 2.0 generation and 3.0 generation dendrimer polyamide-amine; taking 1.0 generation dendrimer polyamide-amine, 2.0 generation dendrimer polyamide-amine and 3.0 generation dendrimer polyamide-amine in different ratios, adding a proper amount of epoxy chloropropane at the temperature of below 40DEG C, reacting for 2 to 4 hours, adding a certain amount of dimethylamine, dripping epoxy chloropropane accounting for 90 percent of the total addition amount into the mixed solution, heating to the temperature of between 85 and 95DEG C, reacting for 1 hour; and adding the rest 10 percent of epoxy chloropropane by three times at time intervals of 20 minutes, and keeping the temperature of between 85 and 95DEG C until the reaction is fully carried out.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for preparing biological compound demulsifying agent

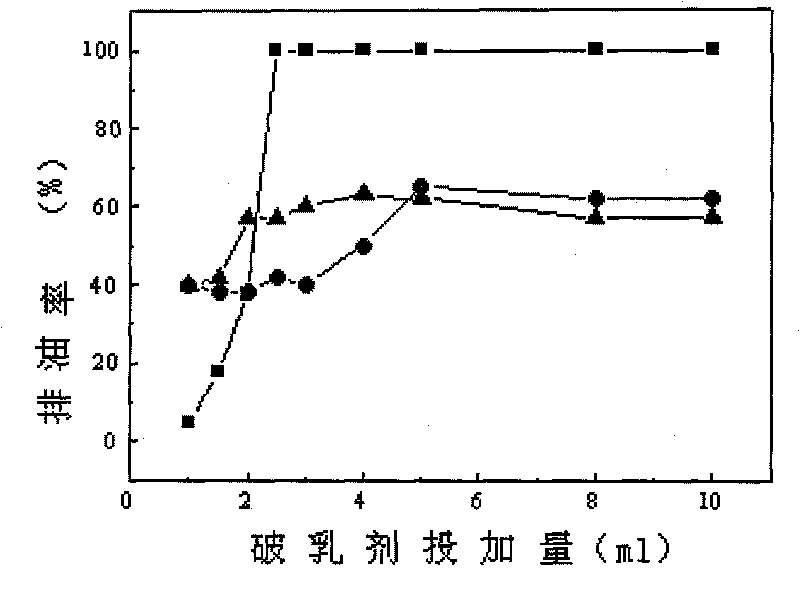

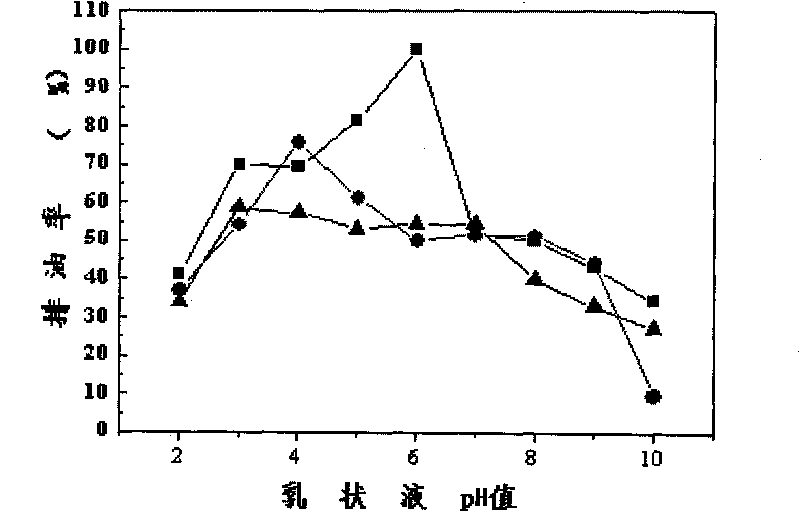

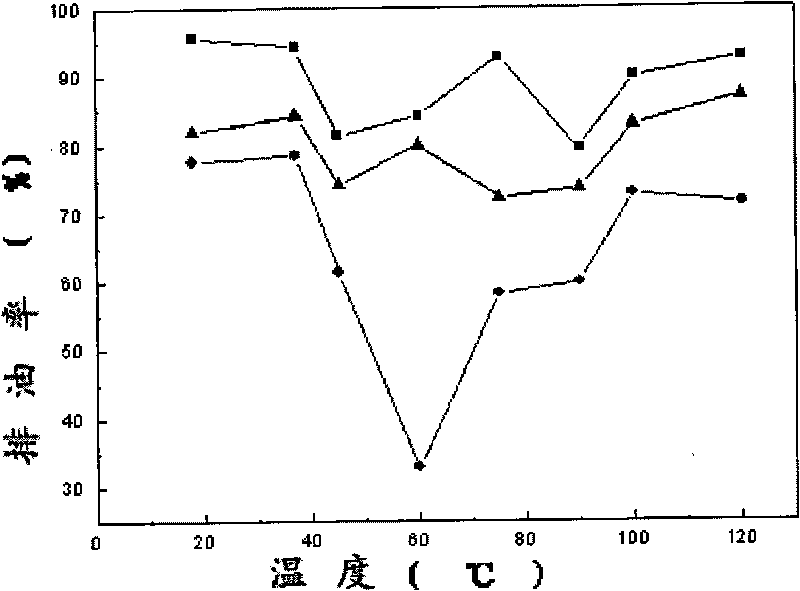

InactiveCN101709277AImprove demulsification efficiencyImprove stabilityBacteriaMicroorganism based processesEmulsionBacillus species

The invention discloses a method for preparing a biological compound demulsifying agent, which relates to a method for preparing a demulsifying agent. The method solves the problems that the harms to the environment caused by a chemical demulsifying agent still exist although the conventional biological demulsifying agent is compounded with the chemical demulsifying agent or auxiliary agents with other functions, and the biological demulsifying agent has low demulsifying efficiency, poor stability and high cost. The method comprises the following steps: firstly, preparing a bacillus mojavensis seed solution; secondly, preparing a bacillus subtillis seed solution; and finally, mixing the bacillus mojavensis seed solution and the bacillus subtillis seed solution, and inoculating the mixture into a culture medium for culture to obtain the biological compound demulsifying agent. The biological compound demulsifying agent has an oil expulsion rate up to 100 percent, reduces the addition and the cost, has high stability which is shown by good demulsifying effect on emulsions under the condition of the pH value of 3 to 9, and the change of the oil expulsion rate of not more than 10 percent when the temperature of the emulsions changes between 20 and 120 DEG C.

Owner:HARBIN INST OF TECH

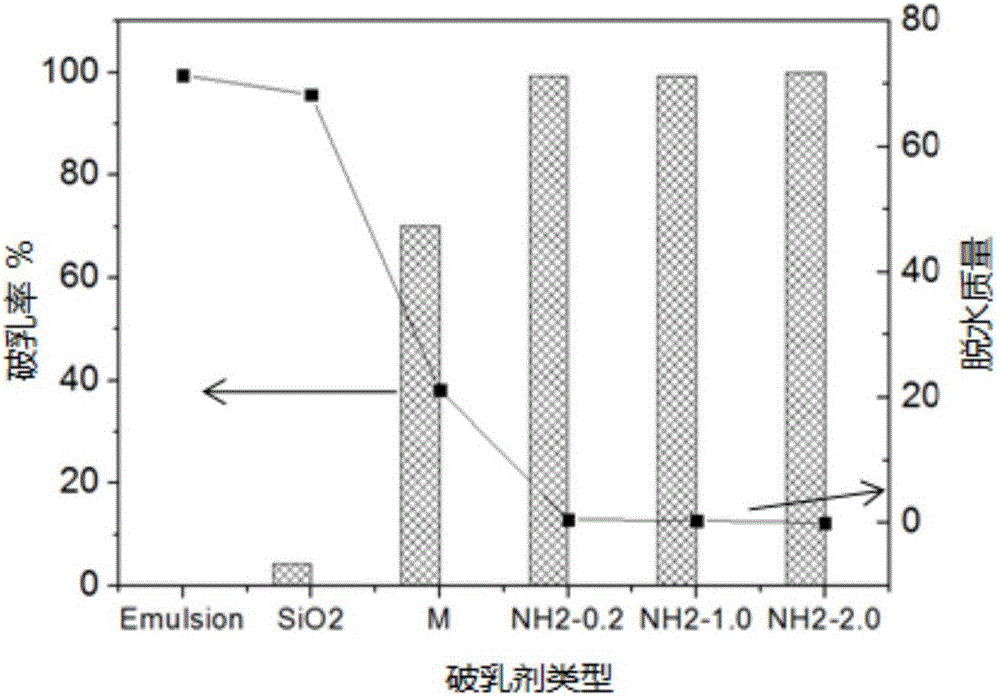

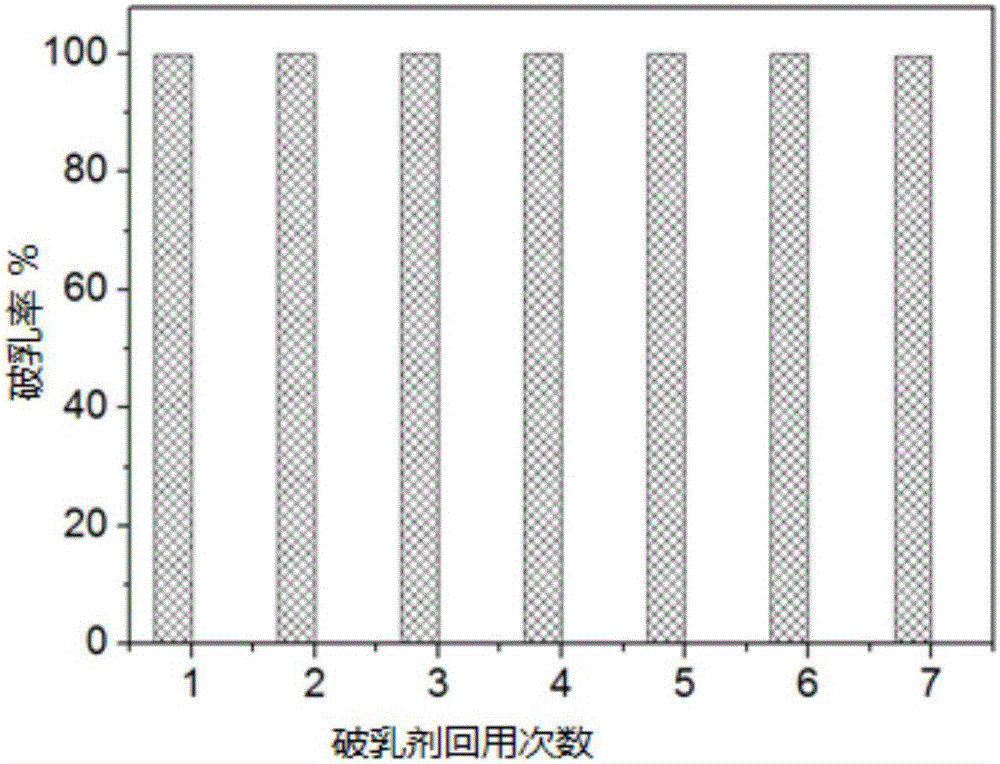

Demulsification method for oil-in-water system emulsion

InactiveCN106745505AEnable recyclingReduce the cost of demulsificationFatty/oily/floating substances removal devicesLiquid separationDemulsifierMagnetite Nanoparticles

The invention relates to a demulsification method for an oil-in-water system emulsion. The method comprises the following steps: (1) preparing Fe3O4 magnetic nanoparticles through a coprecipitation method and carrying out amino modification on the Fe3O4 magnetic nanoparticles to obtain charged Fe3O4@NH2 magnetic nanoparticles; and (2) putting the charged Fe3O4@NH2 magnetic nanoparticles into the oil-in-water system emulsion, applying an external magnetic field and carrying out demulsification on the oil-in-water system emulsion. Compared with the prior art, demulsification of 95% oil-in-water emulsion is completed within 2-10 minutes; the demulsification efficiency is high and the demulsification effect is good; recycling and reusing of a demulsifier are achieved; the oil-in-water system emulsion can be reused for 7 times on the basis of not affecting demulsification, so that the demulsification cost is reduced.

Owner:TONGJI UNIV

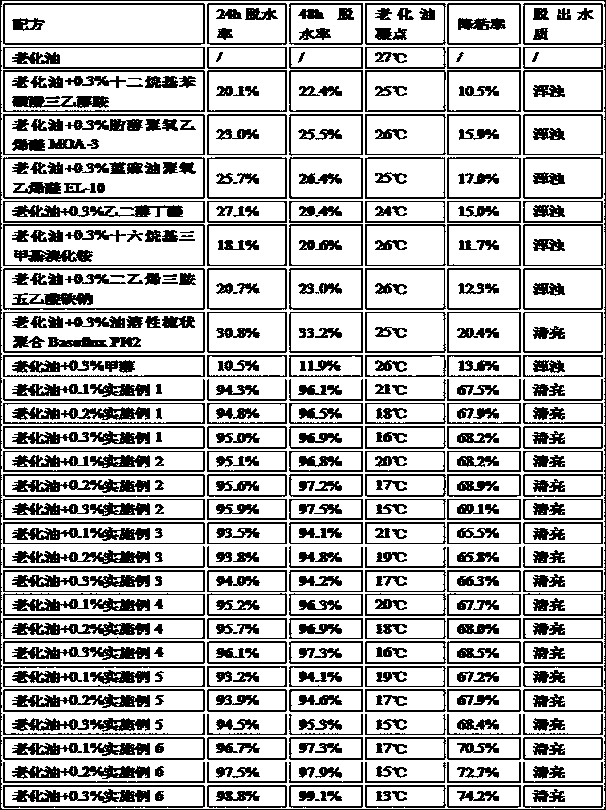

Ageing oil low-temperature demulsification viscosity reducer, preparation method thereof and application of viscosity reducer

ActiveCN109294548ALow viscosityLowering the freezing pointPipeline systemsDrilling compositionFatty alcoholPolymer

The invention discloses an ageing oil low-temperature demulsification viscosity reducer, a preparation method thereof and an application of the viscosity reducer. The viscosity reducer comprises, in weight percent, 5%-15% of triethanolamine dodecyl benzene sulfonate, 5%-10% of fatty alcohol-polyoxyethylene ether, 15%-30% of castor oil polyoxyethylene ether, 2%-8% butyl cellosolve, 5%-15% of cetyltrimethyl ammonium bromide, 5%-15% of sodium hydrogen ferric diethylenetriaminepentaacetate, 2%-8% of oil-soluble comb polymers, 15% of methanol and the balance water.

Owner:西安长庆化工集团有限公司

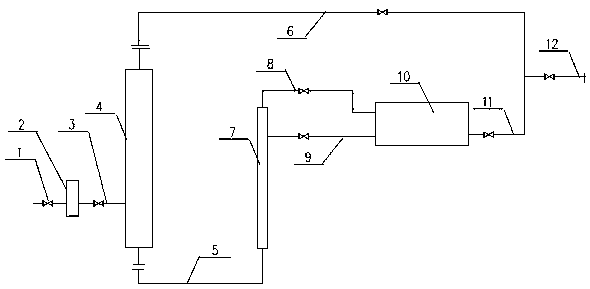

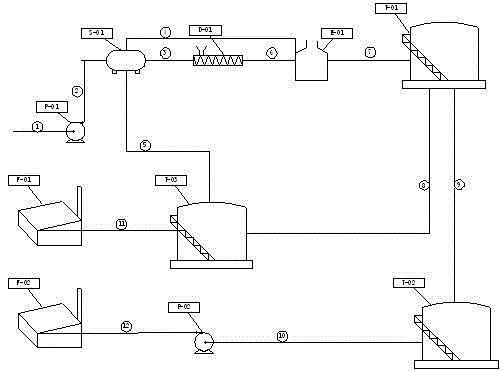

Water-in-oil demulsification method for oil field

PendingCN109337713AReduce water pressureImprove demulsification efficiencyDewatering/demulsification with chemical meansDewatering/demulsification with mechanical meansCyclonePetroleum

The invention relates to equipment applied to the oil and gas industry, wastewater treatment industry and the like, and in particular relates to a water-in-oil demulsification method for an oil field.The equipment is characterized by at least comprising a filter, a flow stabilizer, a cyclone emulsion breaker and a coalescing emulsion breaker. The method comprises the following steps: enabling water-in-oil emulsion to pass through a filter from a liquid inlet pipe, filtering impurities in the liquid, enabling the emulsion to enter the flow stabilizer via a connecting pipeline, stabilizing andbuffering the water-in-oil emulsion by the flow stabilizer, performing gas-liquid separation, and enabling the separated associated gas to enter a gas pipeline on the top of the flow stabilizer to output; enabling the separated oil water to enter the bottom inlet of the cyclone emulsion breaker via an emulsified oil water connecting pipeline; making a high-speed cyclone motion inside the cyclone emulsion breaker, enabling the emulsion to respectively enter the coalescing emulsion breaker via the oil outlet pipeline of the cyclone emulsion breaker and an oily wastewater outlet pipe, performingrectifier demulsification by the coalescing emulsion breaker, decomposing the water-in-oil emulsion into water and oil for the second time, gathering the decomposed water and oil to an oil-water mixing pipeline, merging with the gas pipeline, delivering to a separation device via a gas-liquid mixing pipeline so as to perform oil-water separation, thereby realizing oil and water demulsification.

Owner:XIAN TIANXIANG ENERGY TECH

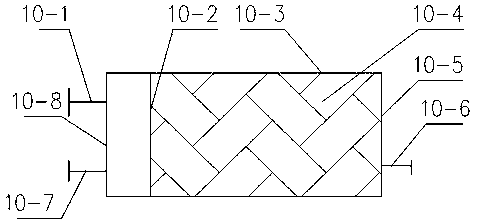

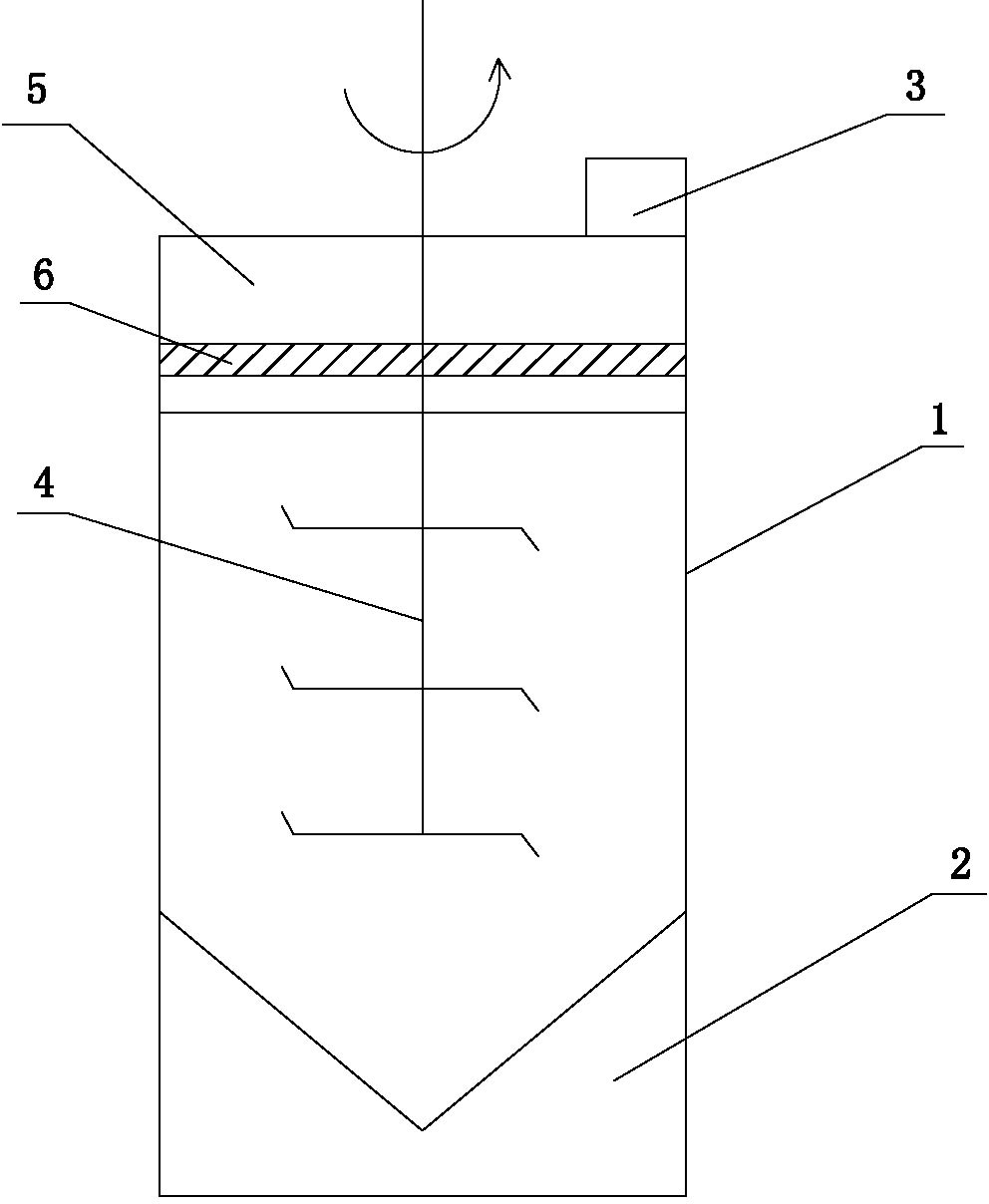

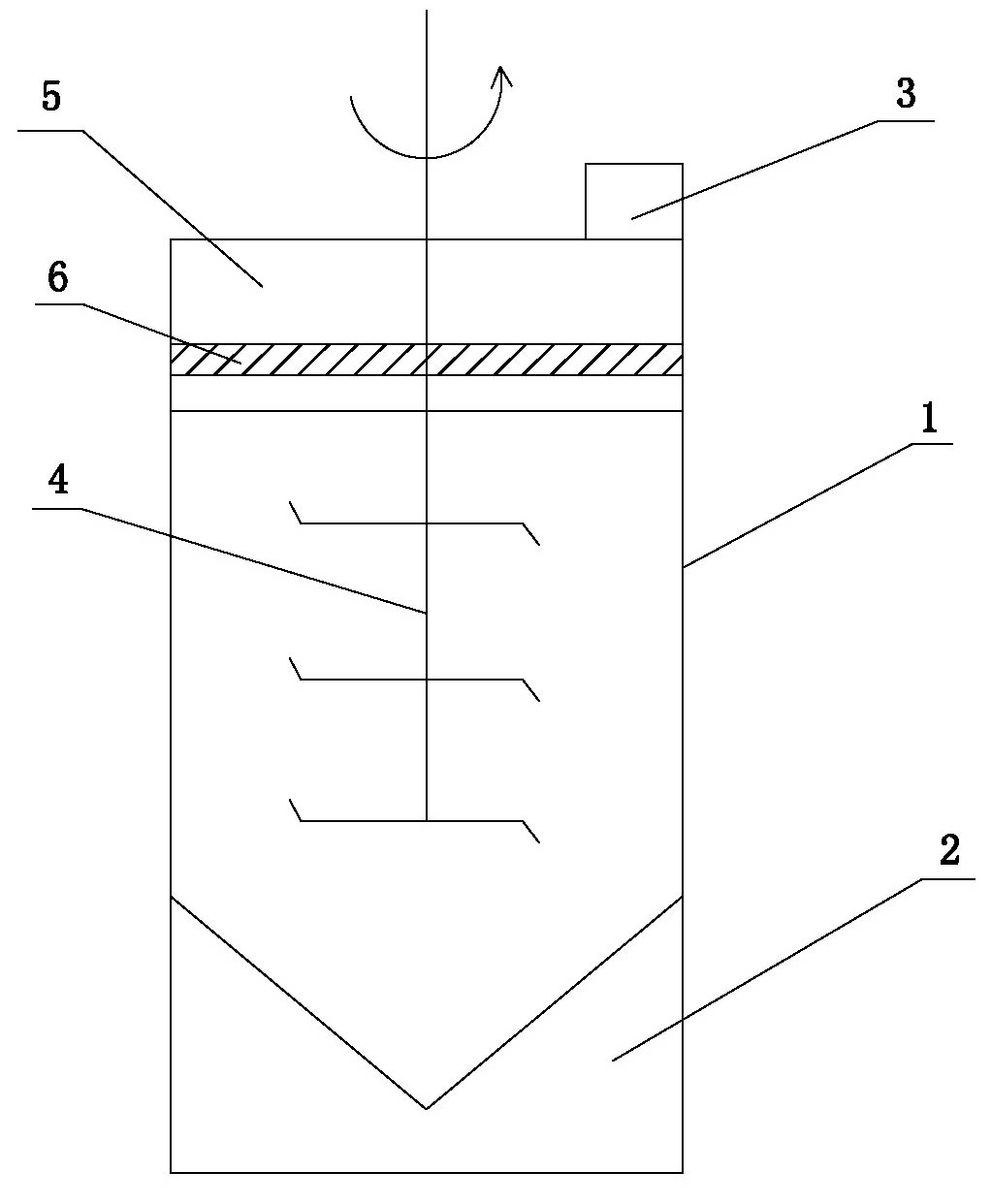

Novel high-concentration emulsified wastewater deemulsification device

InactiveCN102120630AReduce dosageReduce sludge volumeWater/sewage treatment by irradiationWater/sewage treatment by flocculation/precipitationDemulsifierHigh concentration

The invention discloses a novel high-concentration emulsified wastewater deemulsification device, which comprises a deemulsification groove (1) and a microwave generator (2) and is characterized in that the microwave generator (2) is arranged at the bottom of the deemulsification groove (1), the deemulsification groove (1) is provided with a charging pump (3) and is internally provided with a stirring mechanism (4), and the upper part of the deemulsification groove (1) is provided with an oil collecting cavity (5) which is internally provided with a rotary oil suction scraper (6). The novel high-concentration emulsified wastewater deemulsification device provided by the invention integrates the effects of chemical deemulsification and microwave deemulsification, is compact and occupies less flow area; and by means of the synergistic effect of the chemical deemulsification and the microwave deemulsification, the use level of a deemulsifier is decreased and the sludge quantity of oil and water is effectively reduced. The processing technology not only has the advantages of thoroughness in oil-water separation, good treatment effect and stability in long-term operation, but also has high deemulsification efficiency reaching above 90%.

Owner:JIANGSU JINSHAN ENVIRONMENTAL PROTECTION TECH

Preparation method and application of magnetic inorganic clay-graphene composite demulsifying material

InactiveCN110639240AEfficient separationReduce pollutionNon-miscible liquid separationSodium acetateFreeze-drying

The invention relates to a preparation method of a magnetic inorganic clay-graphene composite demulsifying material. The preparation method comprises the following steps: (1) dispersing graphene oxidein an aqueous polyethyleneimine solution, standing the obtained solution, stirring the solution, and carrying out suction filtration, washing and freeze drying to obtain a graphene oxide compound; (2) dispersing ferric chloride hexahydrate in ethylene glycol, sequentially adding sodium acetate, polyethylene glycol and silane coupling agent-modified inorganic clay, performing stirring, carrying out a reaction in a reaction kettle, and washing and drying the obtained reaction product to obtain a ferroferric oxide-inorganic clay compound; (3) dispersing the graphene oxide compound in deionized water to obtain a 10-100 mg / L solution; and (4) adding the ferroferric oxide-inorganic clay compound into the solution, and performing stirring, washing and drying to obtain the magnetic inorganic clay-graphene composite demulsifying material. The invention also discloses a separation application of the material in an oil-in-water crude oil emulsion. The method has the advantages of simplicity, andlow cost, and the obtained material can simultaneously realize efficient separation of oil-in-water crude oil emulsions with different pH values and recycling of demulsifying materials.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Crude oil demulsifier and production technology thereof

InactiveCN104946298AImprove demulsification efficiencyLow costDewatering/demulsification with chemical meansEpoxyAcetic acid

The invention relates to demulsifier, in particular to high-performance demulsifier for oil field crude oil dehydrating processing and a preparing method of the high-performance demulsifier. The crude oil demulsifier comprises, by mass, 12% of octyl phenol resin, 20% of xylene, 0.3% of potassium hydroxide, 40.5% of epoxypropane, 27% of ethylene oxide and the balance glacial acetic acid. According to the crude oil demulsifier production technology, the high molecular weight octyl phenol resin is prepared, double bonds are introduced in the high molecular weight octyl phenol resin, the polymerization reaction is carried out on the molecular weight octyl phenol resin and the epoxy compound, and the target product-crude oil demulsifier including the double-bond compound is prepared. Compared with the prior art, the demulsification efficiency of the crude oil demulsifier is high. The cost of the crude oil demulsifier is low. According to the crude oil demulsifier, the nonyl phenol is replaced with octyl phenol, and the pollution to the water is reduced.

Owner:万达集团股份有限公司

Raw petroleum demulsifying agent and preparation method thereof

InactiveCN104357081AReduce mining costsImprove demulsification efficiencyDewatering/demulsification with chemical meansPolypropyleneActive agent

The invention relates to a raw petroleum demulsifying agent and a preparation method thereof, and belongs to the technical field of petroleum additives. The raw petroleum demulsifying agent comprises the following components in parts by weight: 1-3 parts of parasitic loranthus, 0.1-0.4 part of stephania terandra, 10-15 parts of polypropylene oxide-polyoxyethylene segmented copolymer, 0.01-0.05 part of demulsifying strain XH-1, 2-5 parts of phosphorus oxychloride, 1-3 parts of sodium borate, 5-8 parts of an organic promoter, 0.1-0.2 part of a fluorocarbon surfactant, 5-7 parts of ethyl alcohol, 1-3 parts of pentaerythritol and 80-100 parts of water. The preparation method of the raw petroleum demulsifying agent is simple, the prepared raw petroleum demulsifying agent is high in demulsifying efficiency, wide in adaptability, small in using amount and low in demulsifying temperature, electric fields do not need to be added, the energy is economized, the extraction cost of raw petroleum is reduced, and the preparation method is easy for popularization and application.

Owner:淄博凯美可工贸有限公司

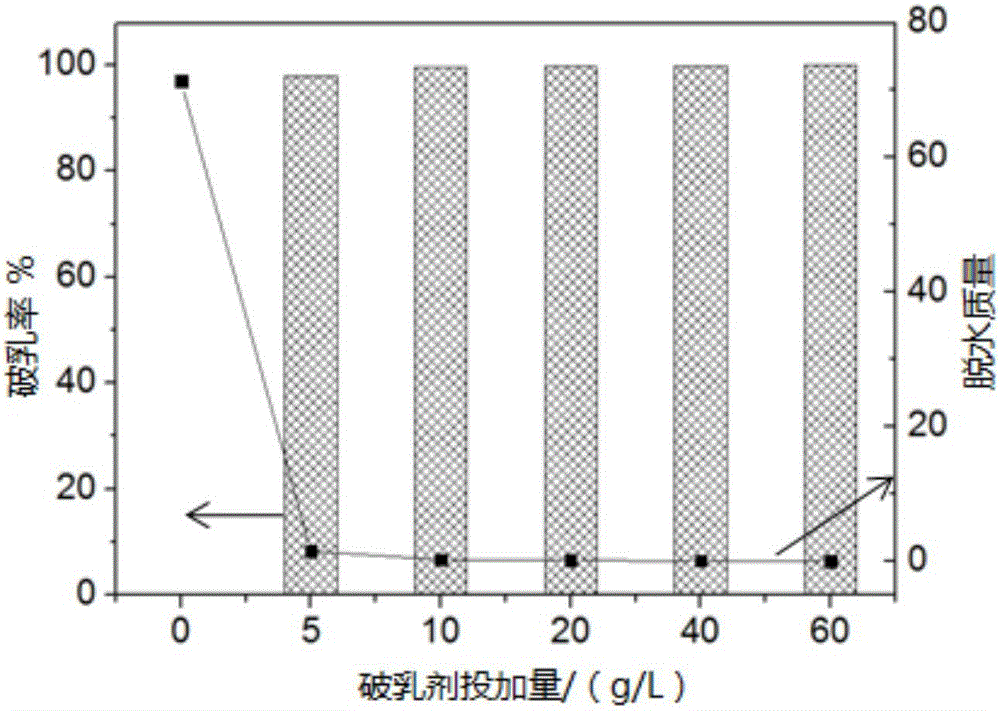

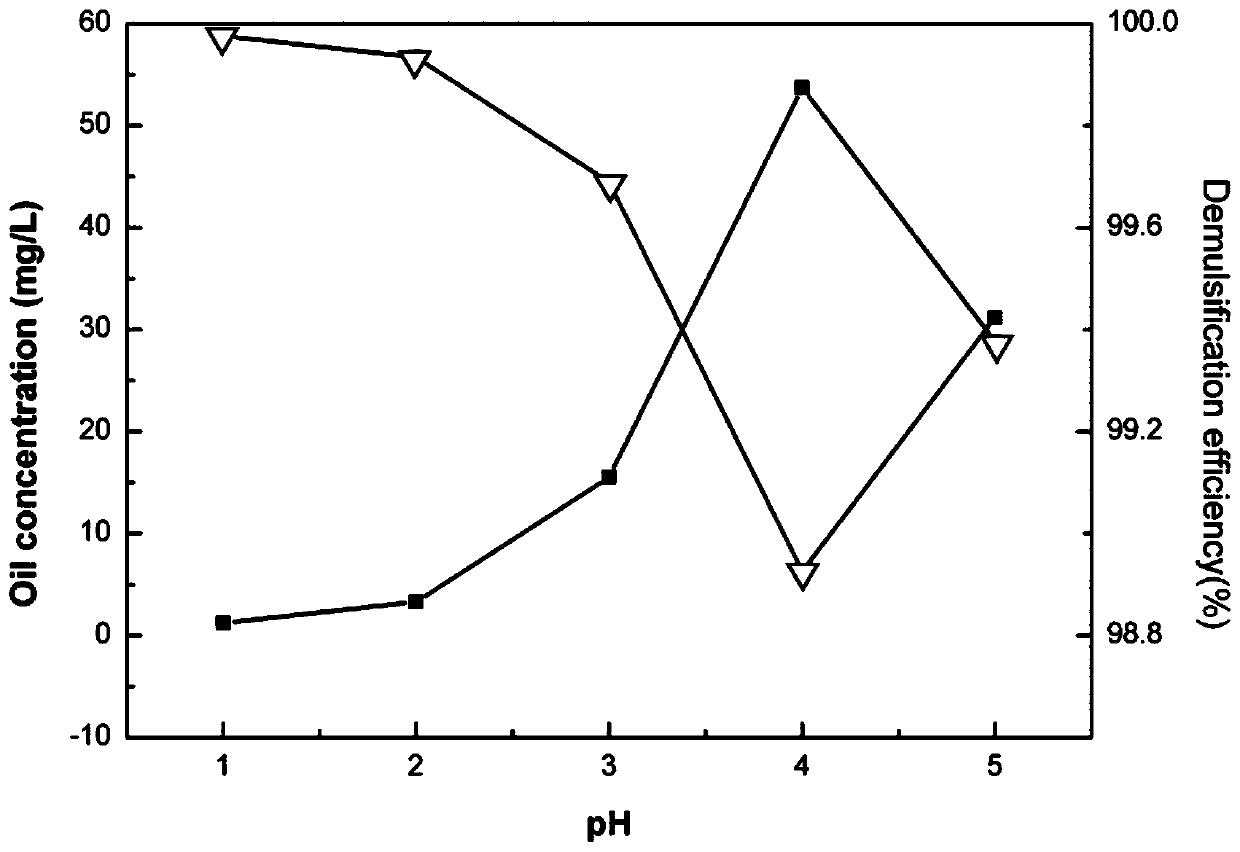

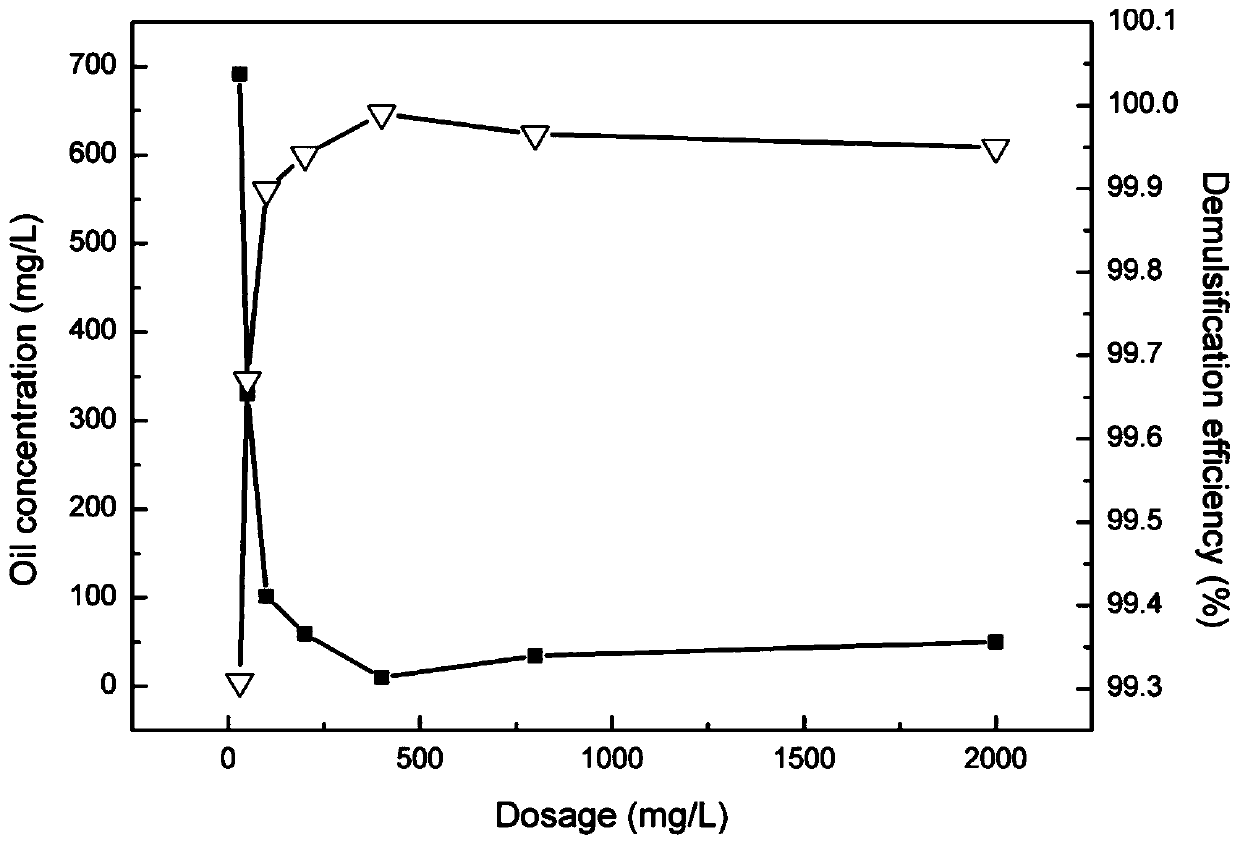

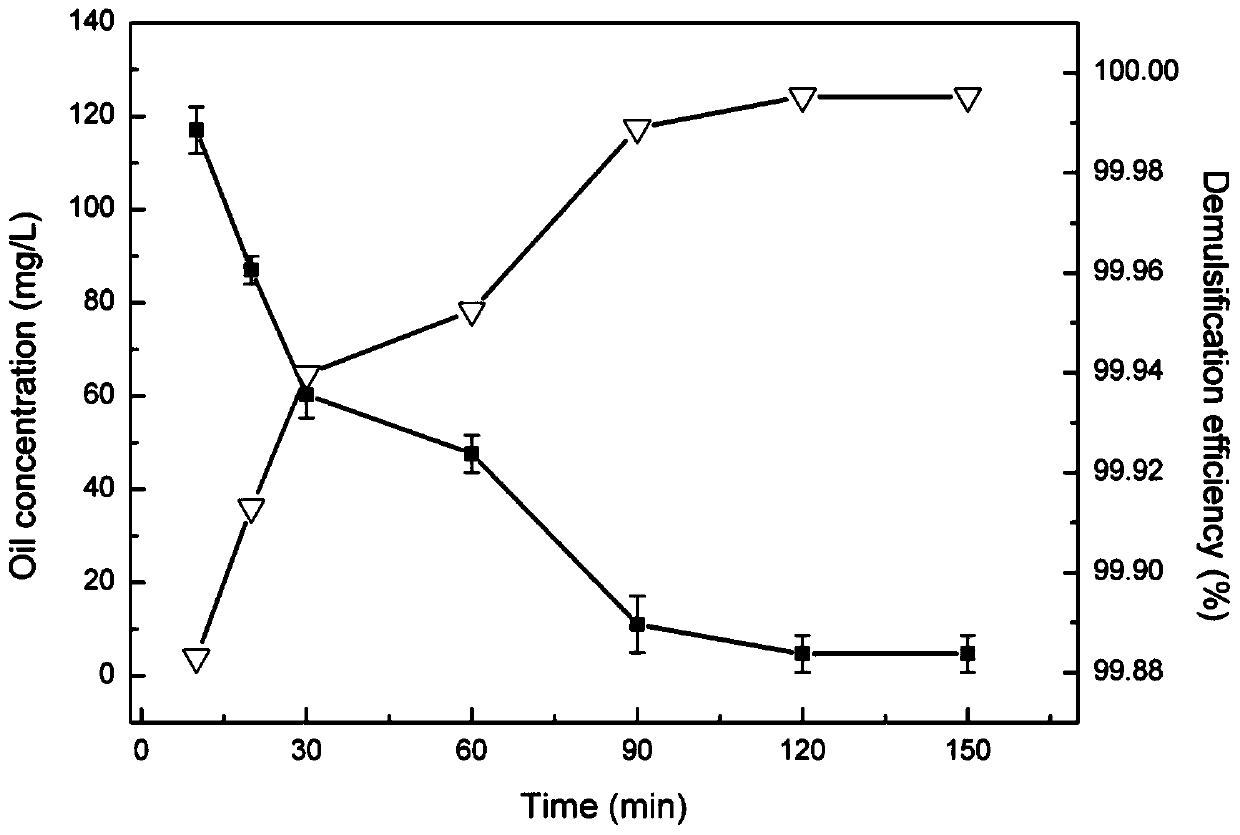

Novel clay mineral demulsifier, preparation method thereof, and method for demulsifying and recycling oil-in-water crude oil emulsion

ActiveCN109929584AImprove demulsification efficiencyReduce oil contentDewatering/demulsification with chemical meansClay mineralsPolyethylene glycol

The invention relates to a novel clay mineral demulsifier, a preparation method thereof, and a method for demulsifying and recycling an oil-in-water crude oil emulsion. The preparation method comprises the following steps: mixing pretreated clay mineral with iron chloride, sodium citrate, ethylene glycol and polyethylene glycol, performing ultrasonic dispersing to uniformity, placing the obtainedmixture in a reactor with a PTFE lining, raising the reaction temperature in the reactor to 200-240 DEG C, carrying out a constant temperature reaction for 20-28 h, and cooling the obtained reaction product to obtain the demulsifier. The novel clay mineral demulsifier prepared in the invention is used for the demulsification and dehydration treatment of the oil-in-water crude oil emulsion, the demulsification efficiency on the water-in-oil crude oil emulsion reaches up to 99.0% or more, and the water content of removed water is less than 10 mg / L, and basically meets the discharge standards ofsecondary water. The demulsifier provides an inexpensive and efficient method for the demulsification and dehydration treatment of the oil-in-water crude oil emulsion, and has an excellent applicationprospect.

Owner:JIANGXI UNIV OF SCI & TECH

Method for low temperature demulsification of thickened oil

InactiveCN104449812AGood for collision and coalescenceFacilitated DiffusionDewatering/demulsification with chemical meansDewatering/demulsification with mechanical meansEngineeringEnergy consumption

The invention relates to a method for low temperature demulsification of thickened oil. According to the method, a demulsifier is introduced, a demulsifying agent is effectively diffused in crude oil emulsion, and the aim of dehydrating the thickened oil at a low temperature is achieved by adopting a method for performing primary heating, performing primary demulsifying agent addition and performing primary sedimentation. The method disclosed by the invention is good in demulsification effect and is particularly suitable for demulsification of thickened oil at a low temperature. The method is simple in process, small in equipment number, easy and convenient to operate and high in demulsifying agent adaptability, and water in the thickened oil can be efficiently and rapidly removed at the low temperature, so that the aim of greatly reducing the energy consumption is achieved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

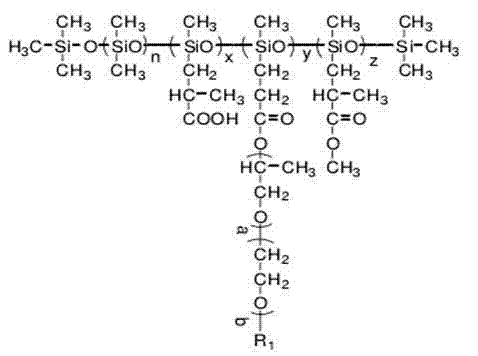

Oil-soluble condensate oil emulsion breaker and preparation method thereof

ActiveCN104498080ALow recovery rateFast demulsificationDewatering/demulsification with chemical meansHydrocarbon oils treatmentBetaineOil emulsion

The invention discloses an oil-soluble condensate oil emulsion breaker and a preparation method thereof. The oil-soluble condensate oil emulsion breaker is a compound formed by adding a cross-linking type block polyether emulsion breaker, a comb-type polysiloxane emulsion breaker and a glycine betaine type fluorocarbon surfactant to a solvent, and the compound comprises the following components in percentage by weight: 10%-25% of the cross-linking type block polyether emulsion breaker, 5%-15% of the comb-type polysiloxane emulsion breaker, 0.05%-0.2% of the glycine betaine type fluorocarbon surfactant and the balance of the solvent. The oil-soluble condensate oil emulsion breaker disclosed by the invention is suitable for the recovery of condensate oil contained in a produced fluid of a natural gas well foaming drainage gas recovery process, can achieve an ideal emulsion breaking effect of an condensate oil emulsion formed from different foaming drainage agents, has the characteristics of high emulsion breaking speed and high emulsion breaking efficiency at normal temperature, and can ensure the high-efficiency recovery of the condensate oil of a gas field.

Owner:成都华阳兴华化工有限公司

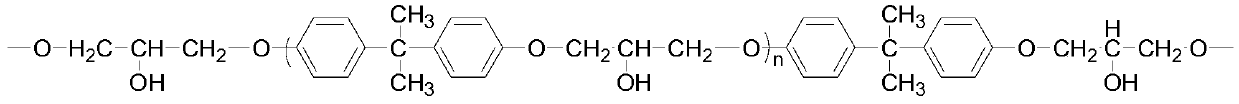

Solid type crude oil demulsifier and preparation method and application thereof

ActiveCN110343545AHigh molecular weightShorten Diffusion TimeDewatering/demulsification with chemical meansDemulsifierSolvent

The invention provides solid type crude oil demulsifier. The solid type crude oil demulsifier is prepared by adopting the following steps that (1) starting agent is prepared: polyethylene polyamine, phenol and methanol are mixed and then successively heated, refluxed and dehydrated from water and solvent, and cooled to obtain the starting agent; (2) an intermediate is prepared: alkali powder is added to the starting agent, epoxypropane and oxirane are successively added under vacuum, reaction is conducted under 120DEG C-140DEG C for 4-6h, and the intermediate is obtained by cooling; and (3) the demulsifier is prepared: bisphenol A type epoxy resin is added to the intermediate and reaction is conducted under 75DEG C-90DEG C for 4-6h, and the demulsifier is obtained by cooling. According tothe solid type crude oil demulsifier, a solid type structural final product can be obtained, the molecular weights of final demulsifier products are increased, at the same time, the penetration and diffusion of demulsifier molecule in heavy oil can be further enhanced, the diffusion time of the demulsifier is shortened, and the demulsification performance of demulsifier products is improved.

Owner:DESHI ENERGY TECH GRP CO LTD +1

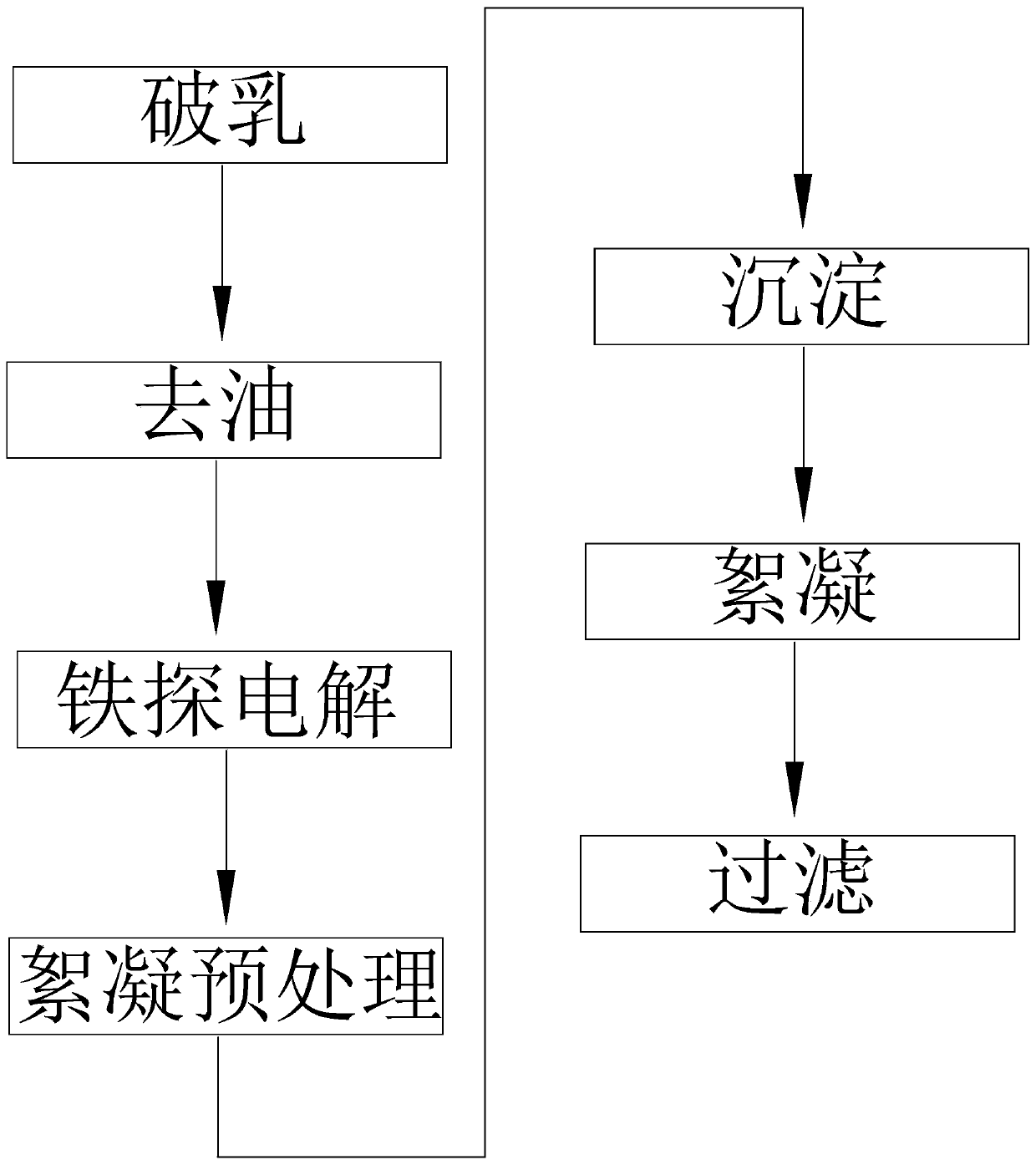

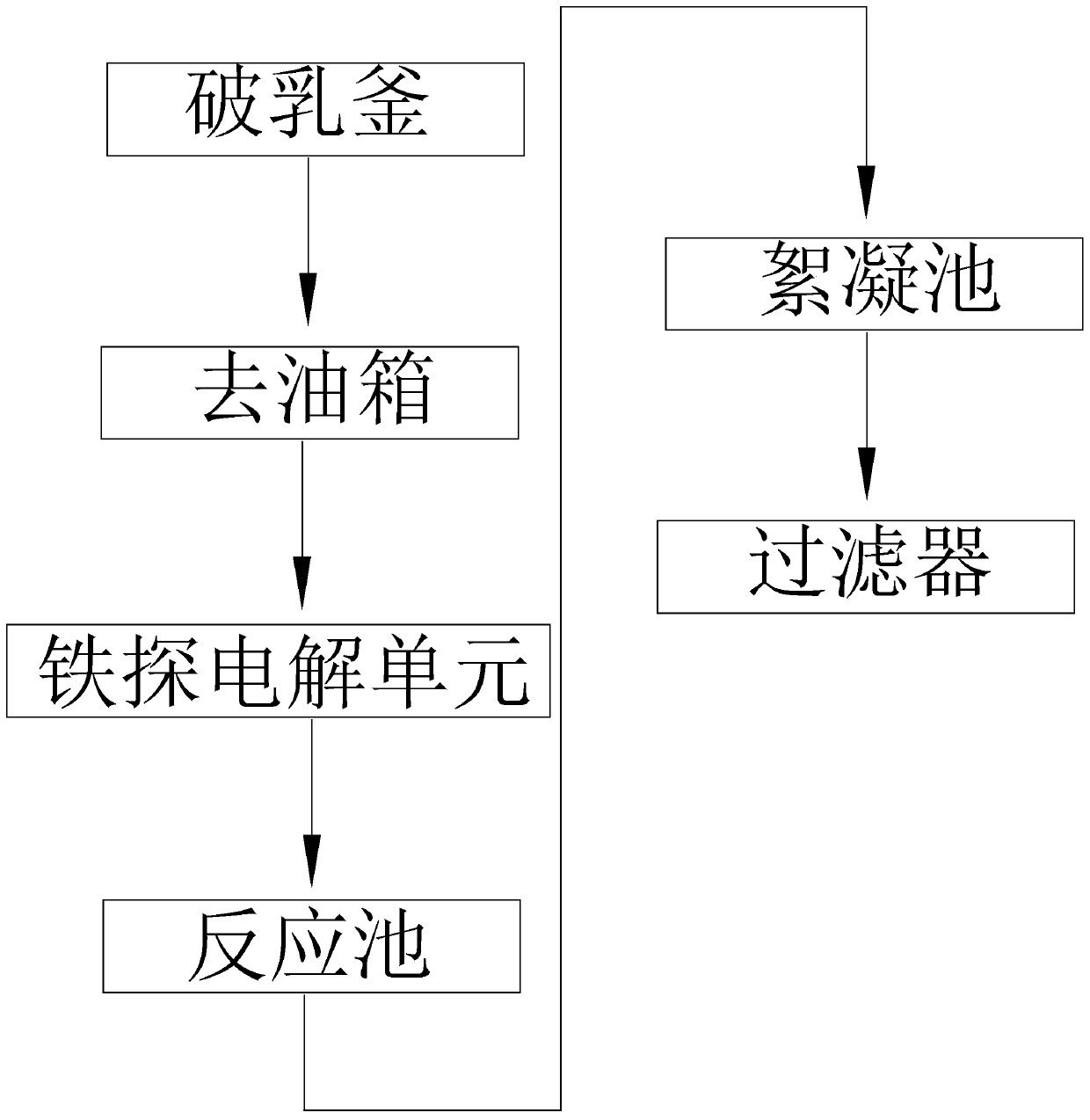

Treatment method and treatment system for emulsified liquid

ActiveCN111138018AReduce pollutionWell mixedFatty/oily/floating substances removal devicesTreatment involving filtrationFlocculationDemulsifier

The invention relates to an emulsified liquid treatment method which comprises the following steps: a, demulsification: heating and stirring an emulsified liquid, and adding a demulsifier into the emulsified liquid at the same time to separate oil from water in the emulsified liquid; b, oil removal: removing floating oil floating on the liquid level of the emulsified liquid; c, performing iron-carbon electrolysis; d, flocculation pretreatment: adding metal ions into the waste liquid to increase the concentration of metal ions in the waste liquid; e, precipitation: adding hydroxide base into the waste liquid and stirring to form water-insoluble metal hydroxide precipitate in the waste liquid; f, flocculation: adding PAM to the waste liquid so as to make the metal hydroxide and the PAM to beconnected to form coarse floccules; and g, filtering: making the wastewater pass through a filter to filter out floccules in the wastewater and remove metal ions in the wastewater. The method has theadvantages that the process is simple, metal ions can be removed, and environmental pollution is reduced.

Owner:上海天成环境保护有限公司

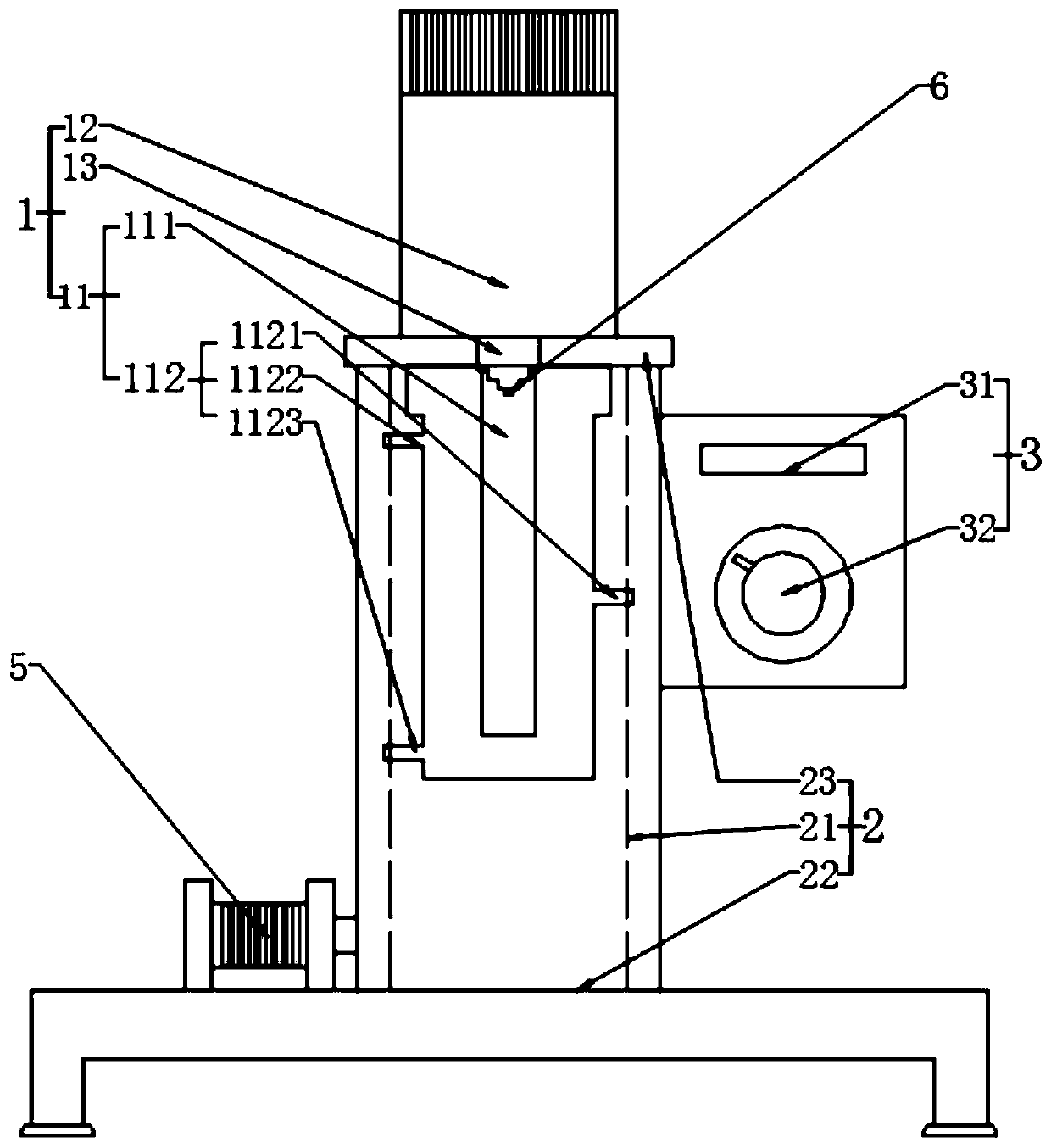

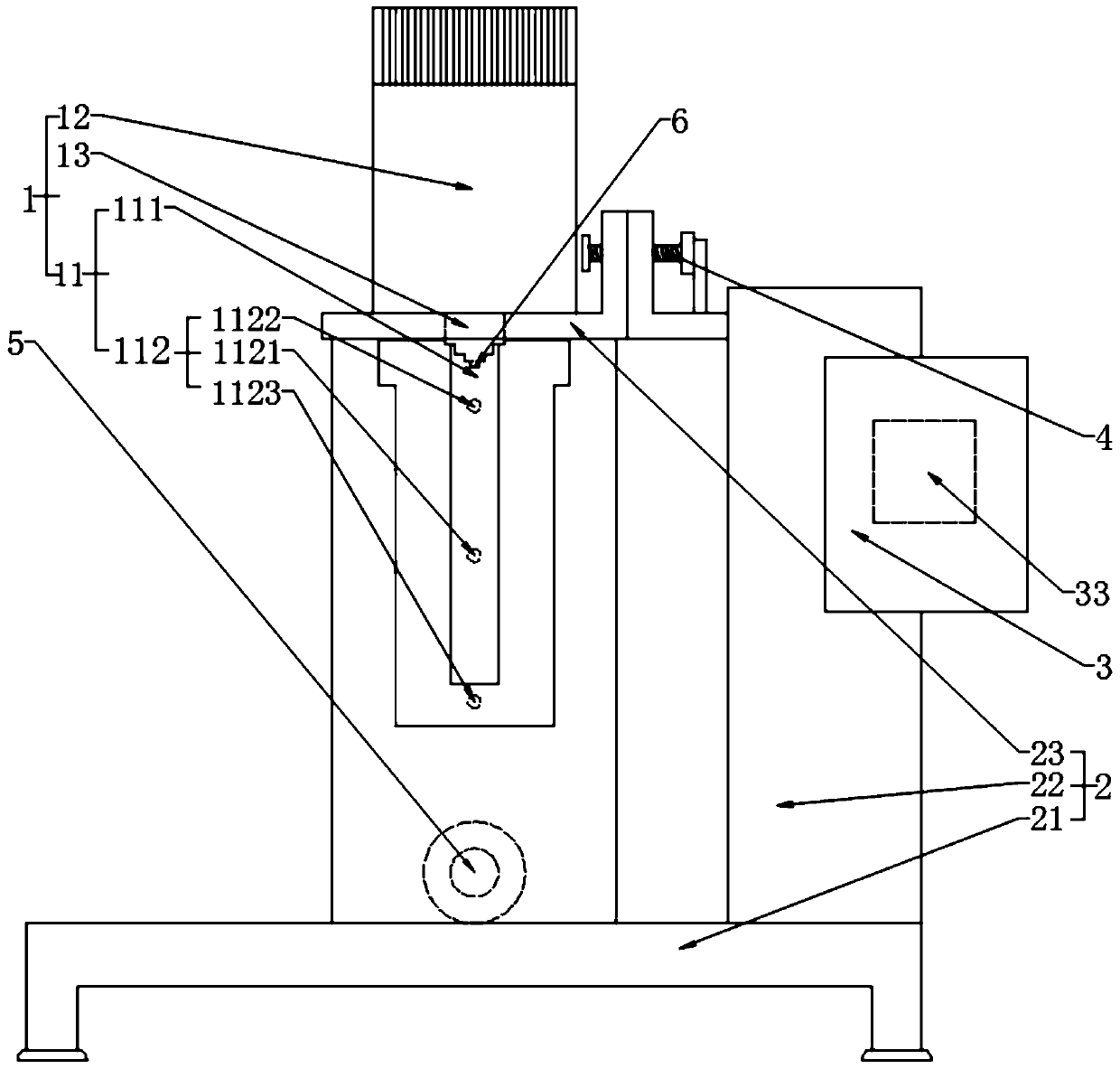

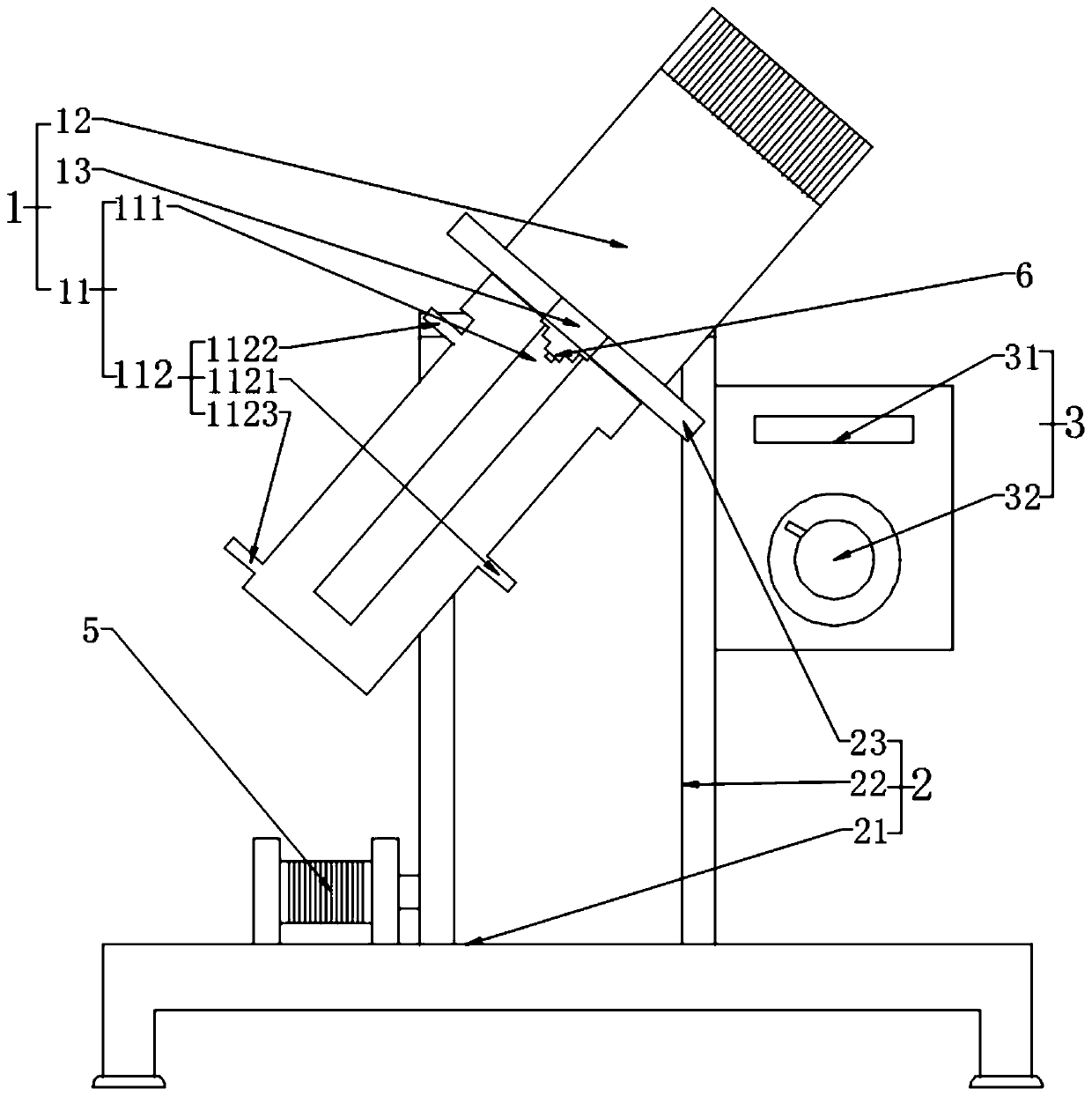

Rotary micro-channel demulsification method

ActiveCN110935198AEasy to separateFast separationNon-miscible liquid separationNumerical controlRotational axis

The invention discloses a rotary micro-channel demulsification method. A rotary demulsification part, a supporting part and a numerical control part are included. The rotary demulsification part comprises a demulsification cylinder, a rotary motor and a rotary shaft, the top of the demulsification cylinder is connected to the rotary motor through the rotary shaft, the demulsification cylinder comprises an inner demulsification cylinder and an outer demulsification cylinder, the outer demulsification cylinder is fixedly connected to the rotary motor through a glass plate, the inner demulsification cylinder is fixedly connected to the rotary shaft, the supporting part comprises a supporting base and a supporting rod, and the side face of the supporting rod is fixedly connected to the numerical control part. The method comprises the following steps: S1, preparing an emulsion, S2, adjusting the device, S3, demulsifying by the device and S4, collecting a demulsified liquid. The outer demulsification cylinder rotates, the demulsification part deflects, polytetrafluoroethylene and organic glass materials are adopted, rapid separation is achieved, efficient demulsification is achieved, andan emulsion feeding hole, an upper discharge hole and a lower discharge hole are limited, so that sufficient and stable demulsification is realized. Different demulsification requirements are met byutilizing an embedding mode.

Owner:SICHUAN UNIV

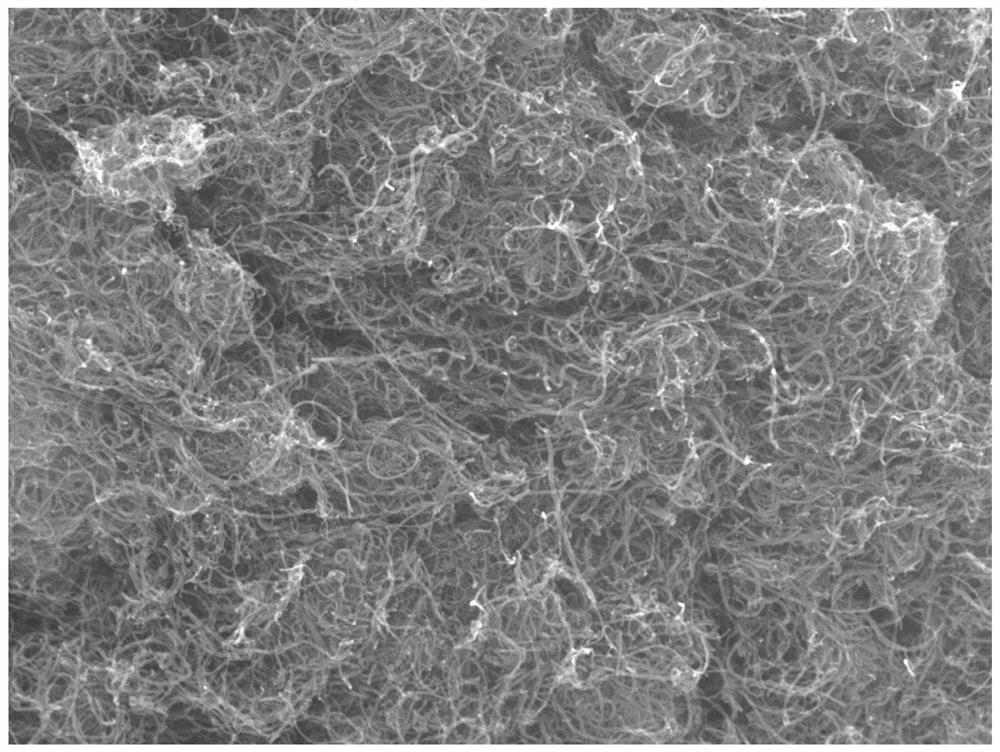

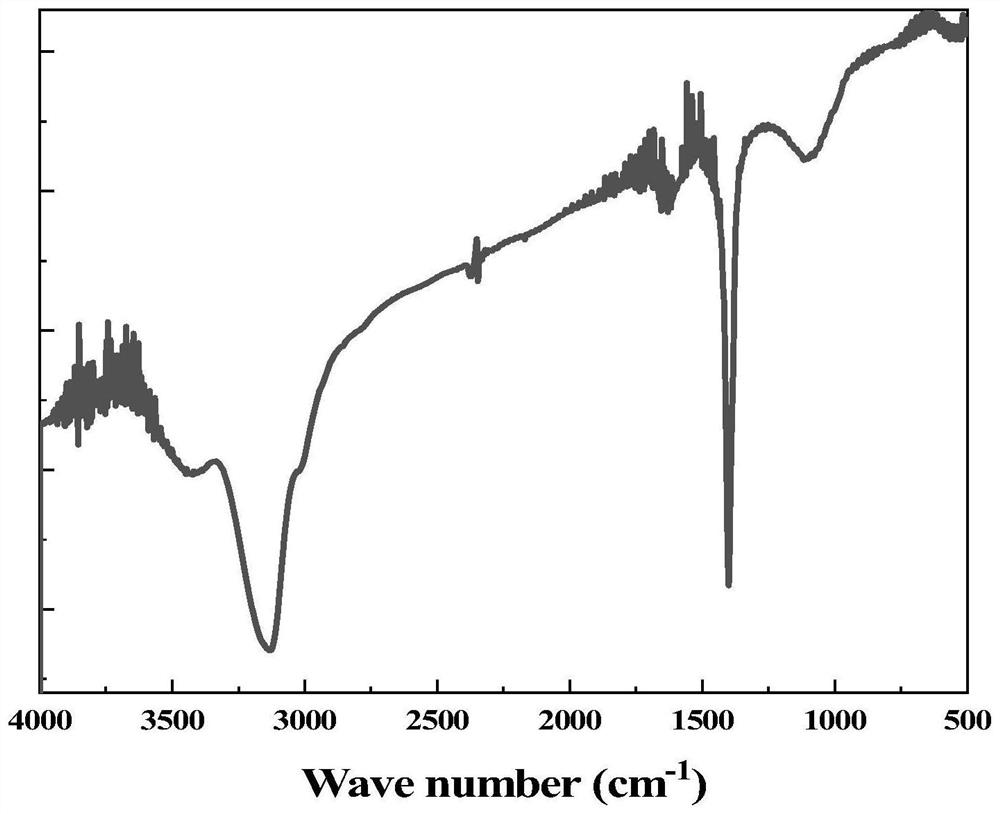

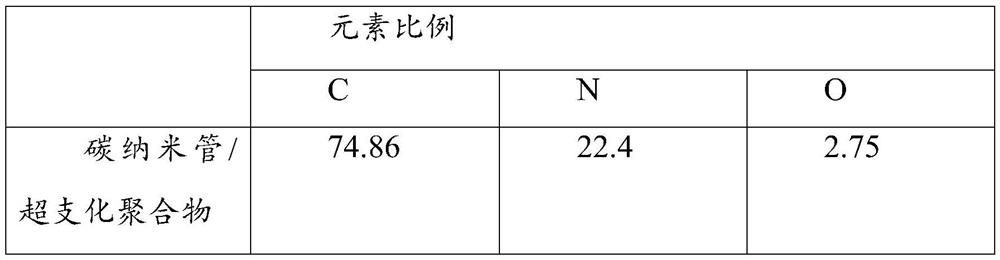

Demulsifying agent, carbon nanotube/hyperbranched polymer, preparation method of polymer and application of demulsifying agent

ActiveCN112430333APromote migrationReduce tensionNon-miscible liquid separationDemulsifierPolymer science

The invention relates to a demulsifier, a carbon nanotube / hyperbranched polymer, a preparation method of the polymer and application of the demulsifying agent. The method comprises the following steps: mixing amine modified carbon nanotubes, ethylenediamine and methyl acrylate, conducting reacting at 30-50 DEG C, gradually conducting heating, and carrying out reduced pressure distillation to obtain the carbon nanotube / hyperbranched polymer. The invention also provides the carbon nanotube / hyperbranched polymer prepared by the preparation method. In addition, the invention also provides the demulsifier which comprises the carbon nanotube / hyperbranched polymer. The invention also provides application of the demulsifier in separation of water-in-oil emulsion. The carbon nanotube / hyperbranchedpolymer can significantly reduce the oil-water interfacial tension and promote the occurrence of a demulsification process, and the demulsification efficiency of a water-in-oil emulsion is as high as93.1%.

Owner:YANGTZE UNIVERSITY

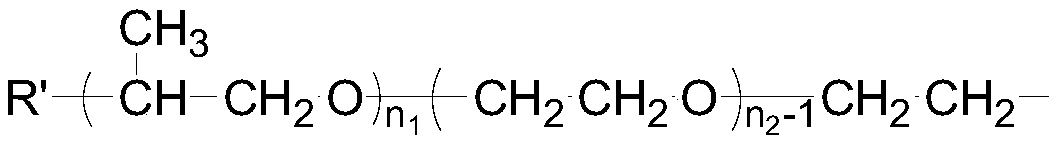

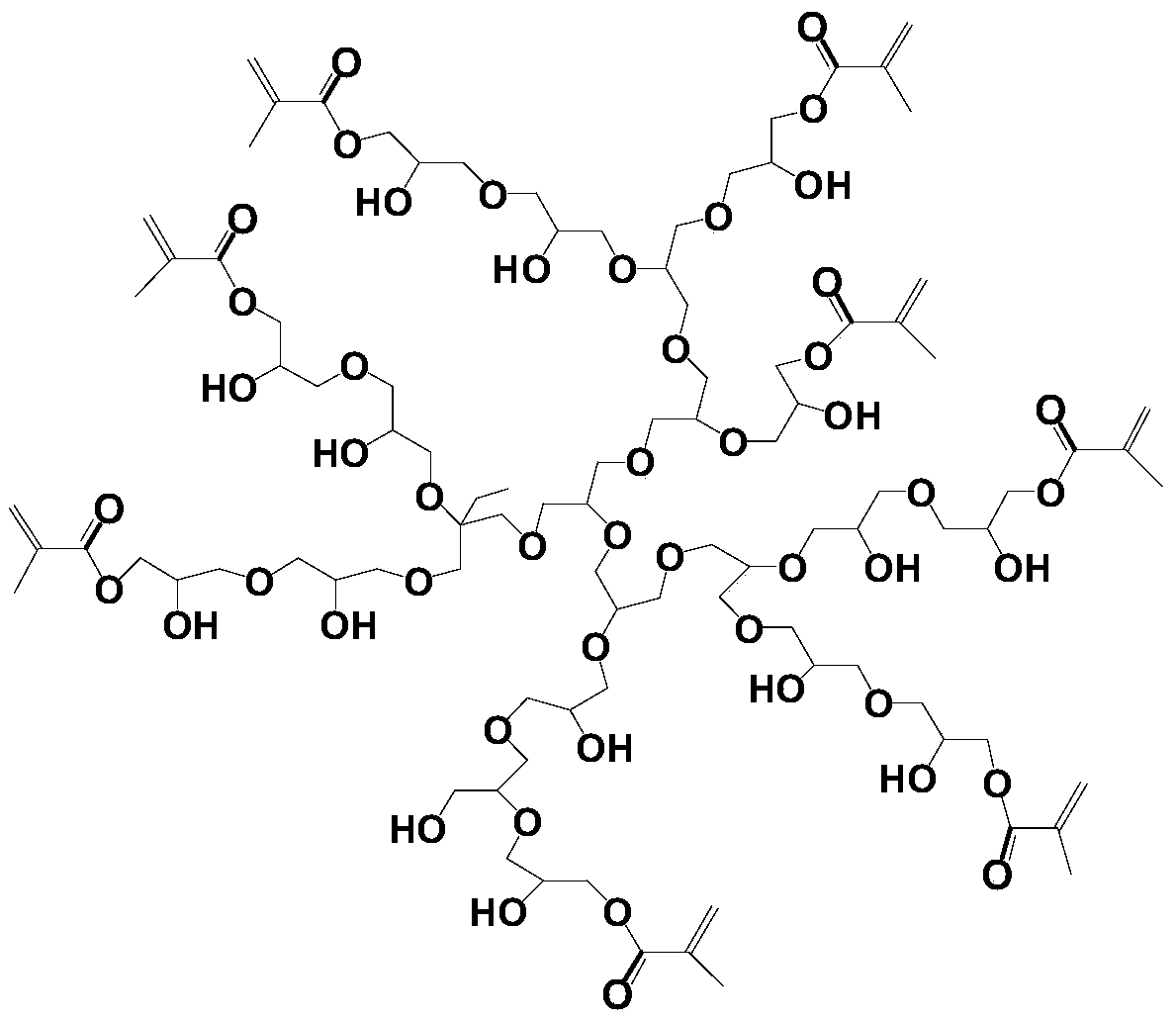

Application of polyether hyperbranched polymers as demulsifier

InactiveCN105504306AImprove demulsification efficiencyReduce interfacial tensionDewatering/demulsification with chemical meansEmulsionOil water

The invention relates to application of polyether hyperbranched polymers as a demulsifier. The center of the polyether hyperbranched polymers is a polyether structure, and the terminal group comprises hydrophilic hydroxy group and hydrophobic double bond. The number-average molecular weight distribution of the polyether hyperbranched polymers is 2000-8000. When the polyether hyperbranched polymers are used as the demulsifier, the oil-water separation rate of the emulsion is increased, the demulsification efficiency of the polyether hyperbranched polymers is enhanced, and the application range of the polyether hyperbranched polymers is widened.

Owner:ZHEJIANG UNIV

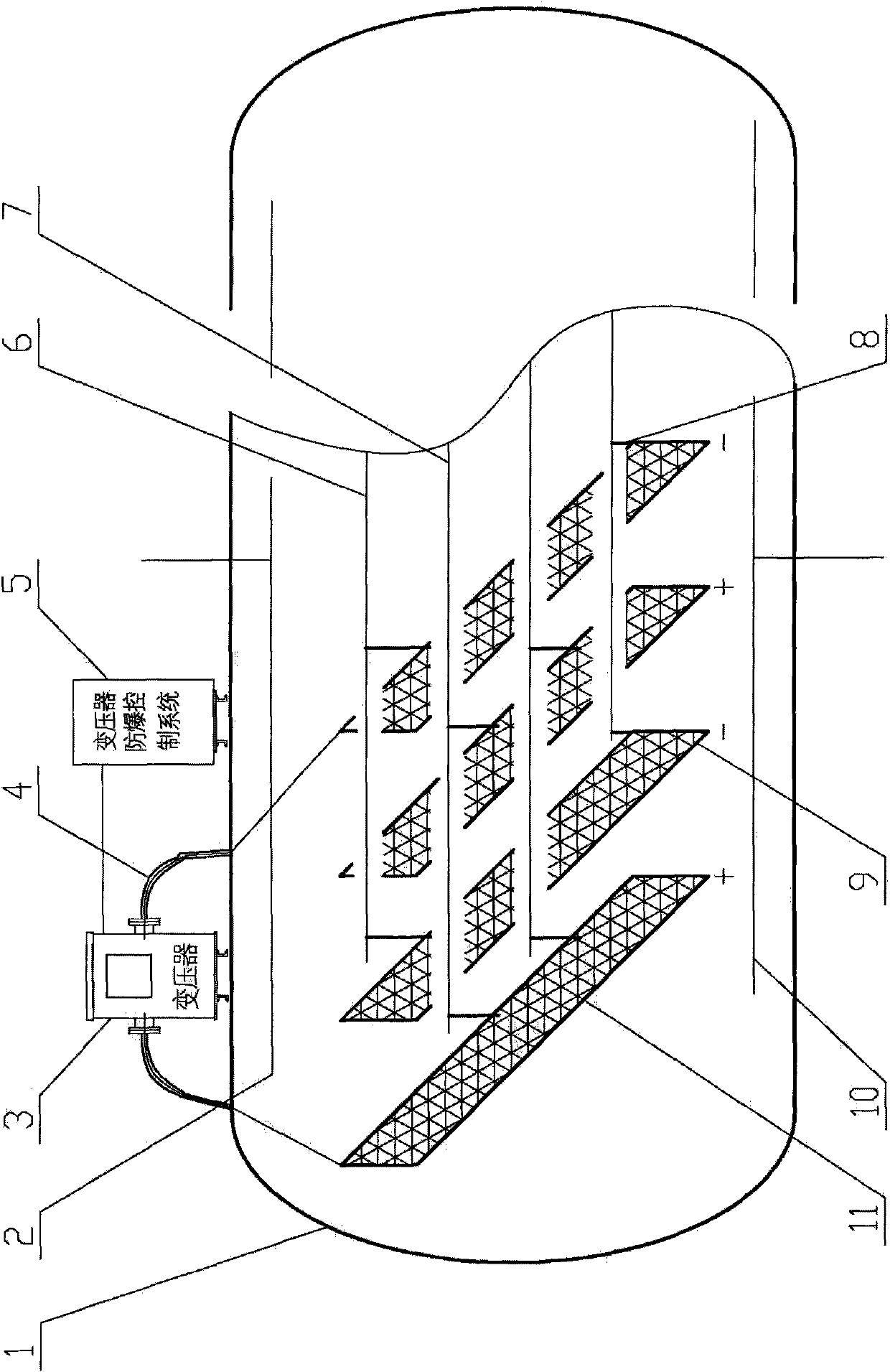

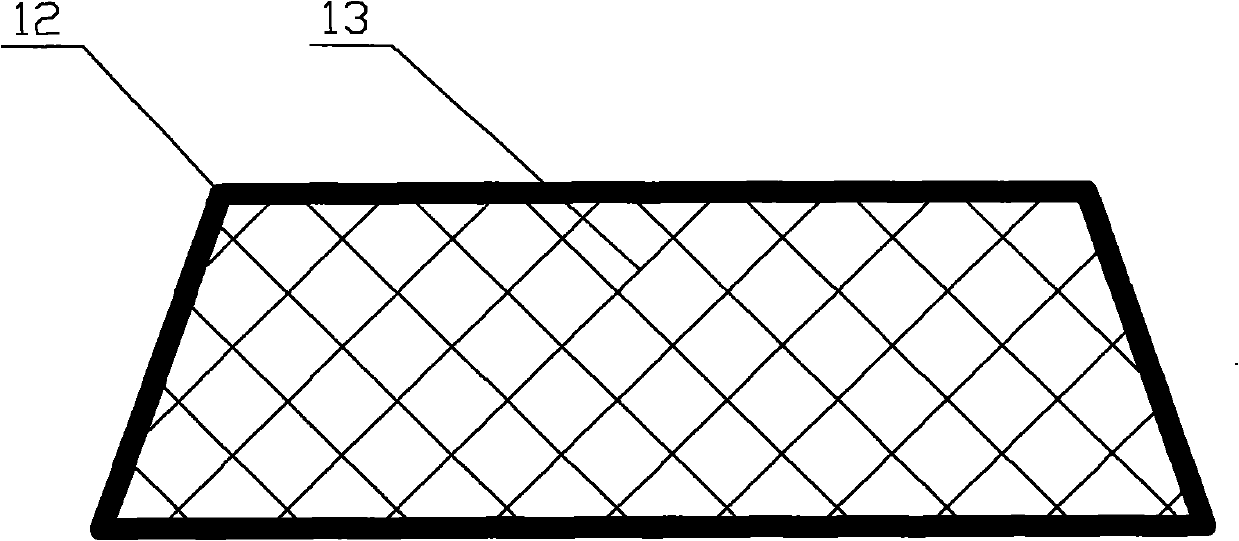

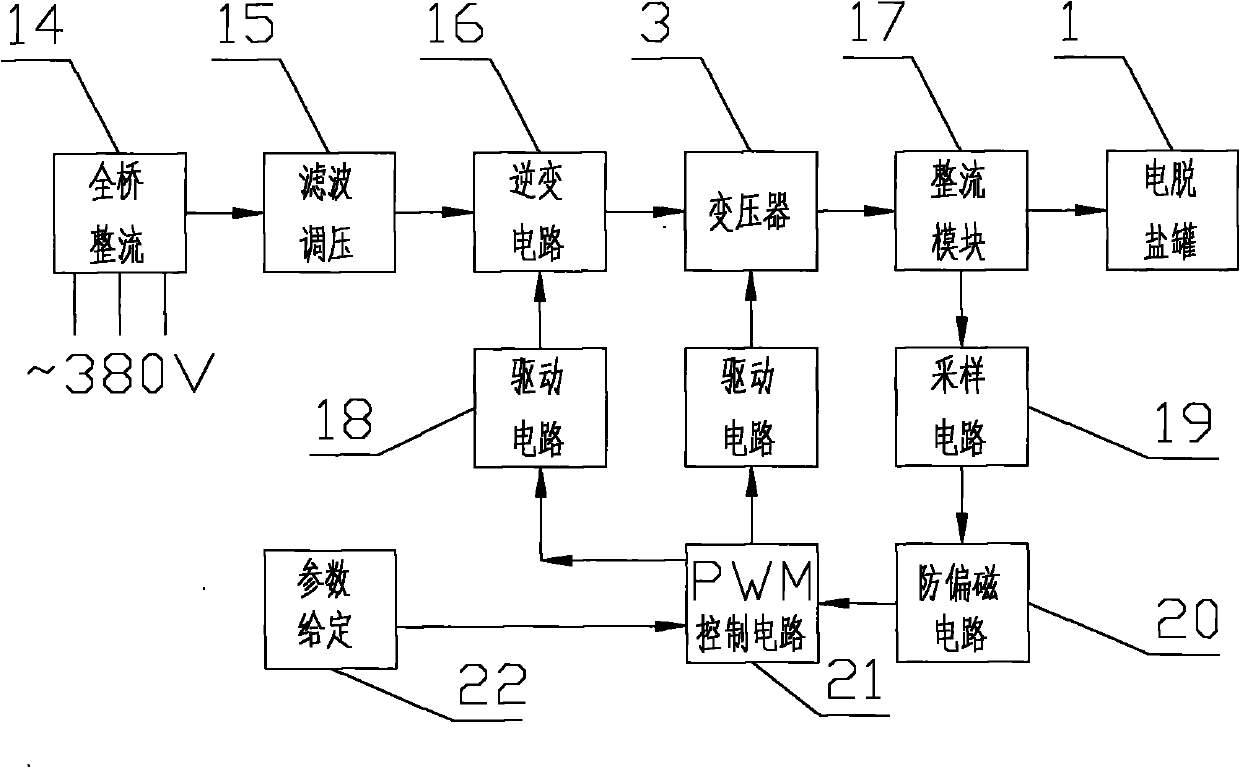

High-frequency intelligent response electro-desalting complete equipment

InactiveCN102086406AImprove demulsification efficiencyImprove the frequency adaptation rangeLiquid separation by electricityDewatering/demulsification with electric/magnetic meansBiochemical engineeringControl system

The invention discloses high-frequency intelligent response electro-desalting complete equipment, which comprises a horizontal electro-desalting tank body, wherein a transformer is arranged on the outer side of the top of the tank body, an outlet oil collecting pipe which is axially parallel to the tank body is arranged on the inner upper part of the tank body; an inlet oil distribution pipe axially parallel to the tank body is arranged on the lower part of the tank body; a suspended netty electrode plate is arranged in the tank body; a transformer explosion-proof control system is arranged on the side face of the outside of the tank body; the explosion-proof control system can monitor a current at one time of operation and at the same time intelligently regulate an output voltage according to current; and a frequency regulating button is arranged on the transformer explosion-proof control system.

Owner:江苏三星化工有限公司

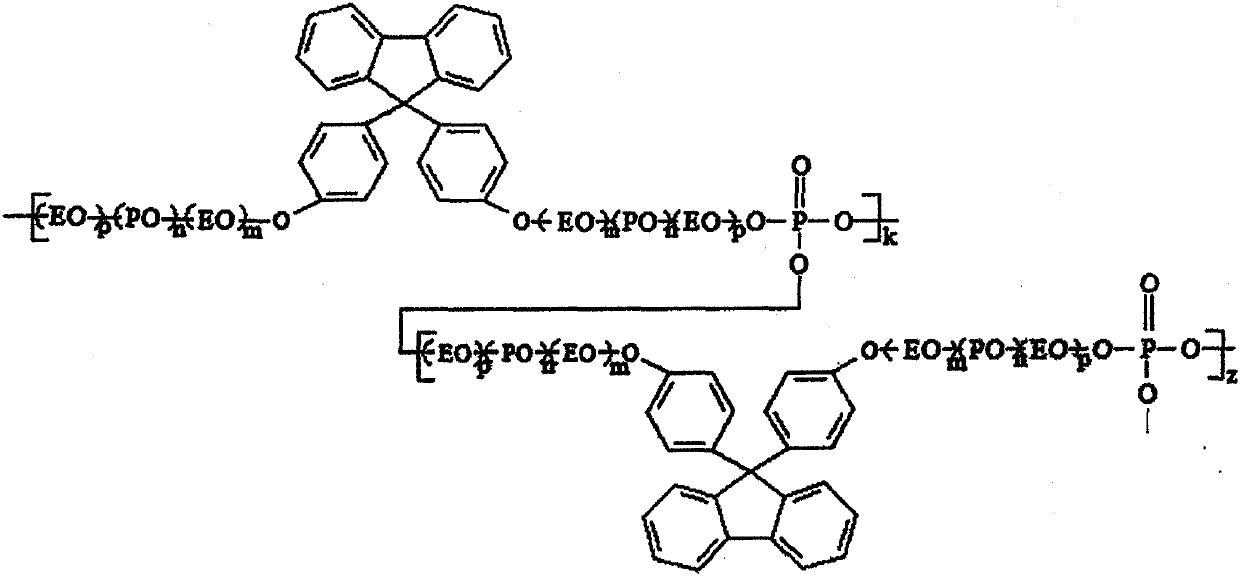

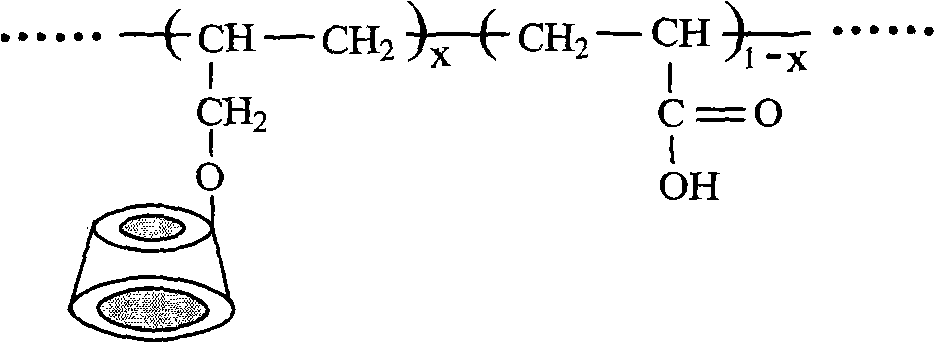

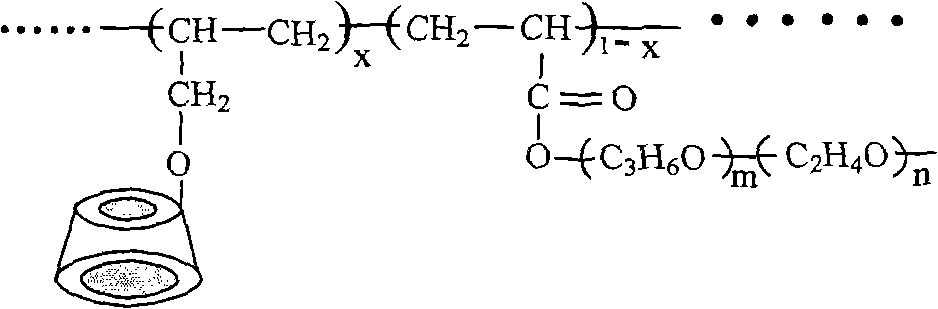

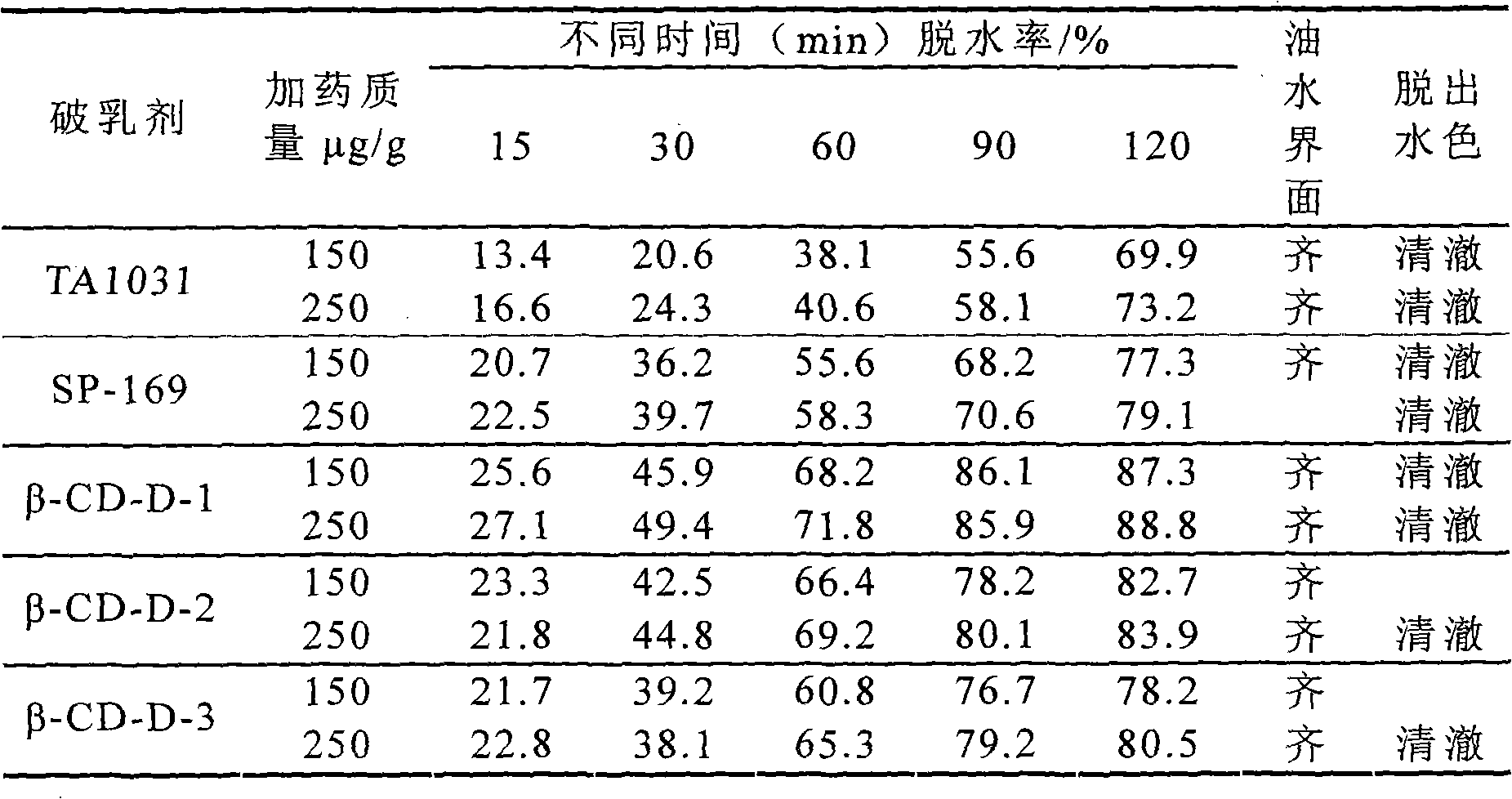

Preparation method and application of block polyether-beta-CD comb type demulsifying agent

InactiveCN101717518AHigh molecular weightEasy to prepareDewatering/demulsification with chemical meansNitrogen gasBeta-Cyclodextrins

The invention relates to a preparation method and an application of a block polyether-beta-CD comb type demulsifying agent for demulsifying and dewatering crude oil. The invention can improve the demulsifying and dewatering efficiency of a crude oil demulsifying agent and the molecular weight and the compounding capacity of the demulsifying agent. The preparation method comprises the following steps of: dissolving beta-cyclodextrin in dimethysulfoxide (DMSO), using NaOH as a catalyst and slowly dropping allylbromide to react for 48 hours at a temperature of 0-10 DEG C to obtain allyl-beta-cyclodextrin; dissolving the allyl-beta-cyclodextrin and acrylic acid raw materials in water, and under the protection of nitrogen, carrying out a polymerization reaction for 8 hours by using NaHSO3 and (NH4)2S2O7 as an initiating system so as to obtain a cyclodextrin / acrylic acid main chain polymer; and finally, putting the main chain polymer and polyoxy-ethylene block polyether in a reactor to react for 12-16 hours to obtain a product, and extracting and centrifugally separating the product to obtain the block polyether-beta-CD comb type demulsifying agent. The preparation method has simple operation, moderate condition, simple equipment and easy industrial production. After the block polyether-beta-CD comb type demulsifying agent is mixed with crude oil, the water yield of the crude oil is high, and the demulsifying time is short, thus the block polyether-beta-CD comb type demulsifying agent can be widely applied to oil fields and refineries for demulsifying and dewatering.

Owner:SOUTHWEST PETROLEUM UNIV

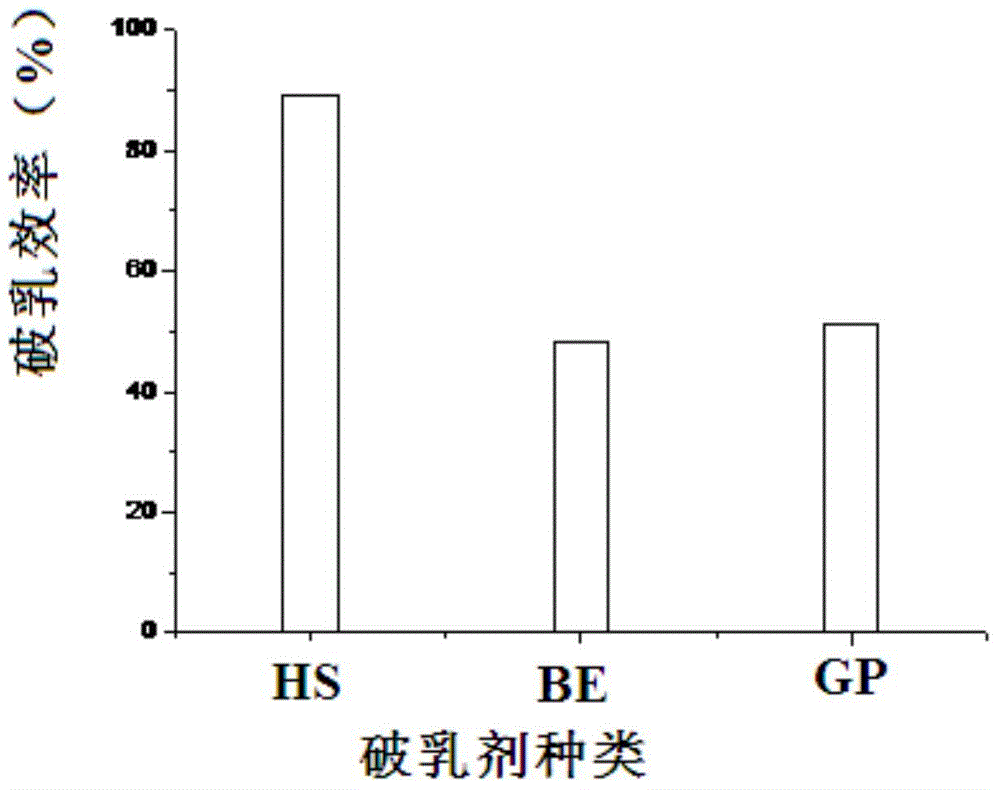

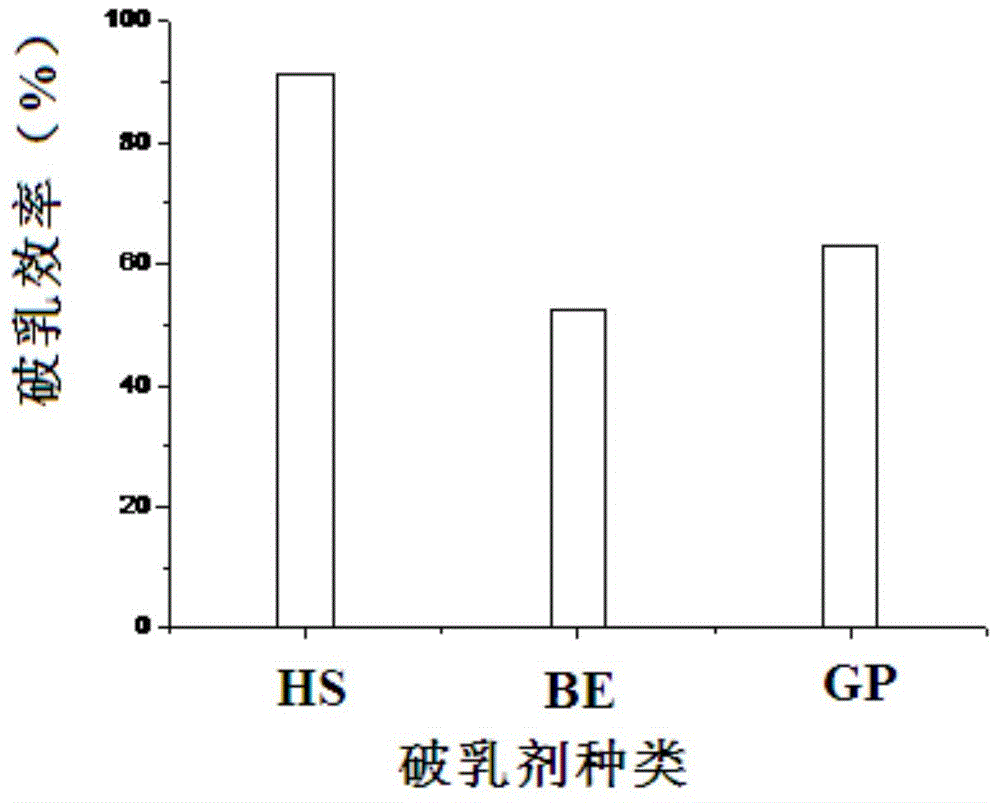

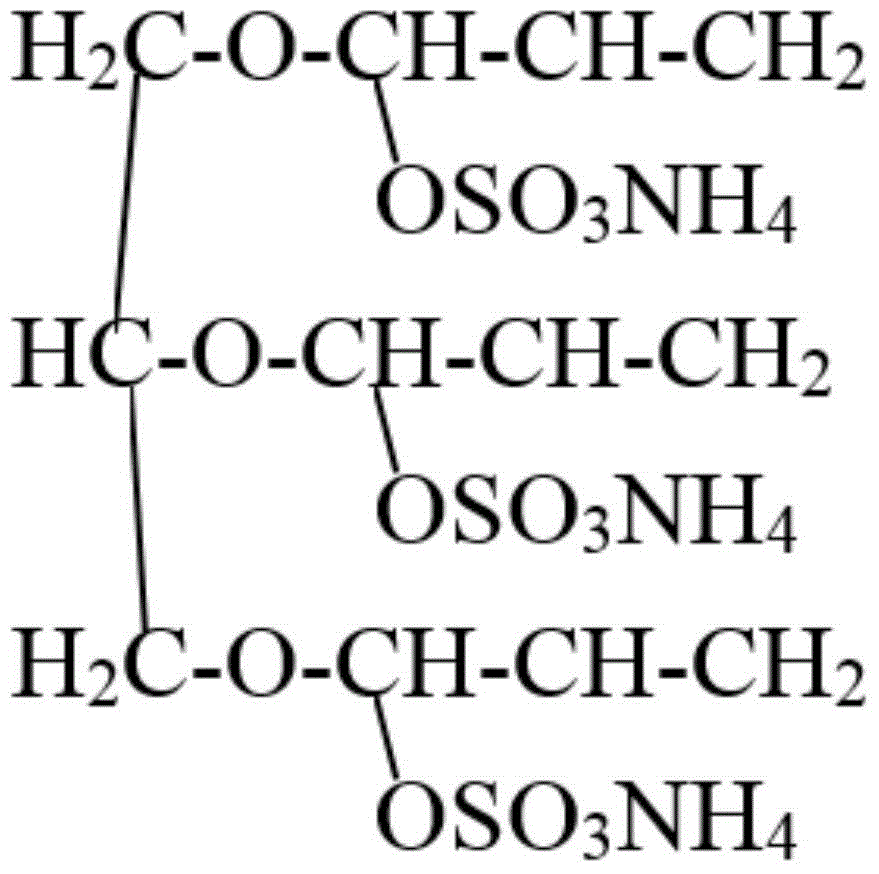

Ammonium sulfamate demulsifier, synthesis method thereof and application of ammonium sulfamate in cold rolling of waste emulsion

InactiveCN104447424AThe synthesis method is simpleHigh yieldDewatering/demulsification with chemical meansSulfuric acid esters preparationLiquid productSynthesis methods

The invention discloses an ammonium sulfamate demulsifier, a synthesis method thereof and application of ammonium sulfamate demulsifier in cold rolling of a waste emulsion. The ammonium sulfamate demulsifier is prepared according to the following steps: (1) carrying out etherification reaction, namely adding boron trifluoride etherate into glycerol, dropwise adding propylene oxide slowly to carry out reaction, dropwise adding solution of sodium hydroxide in ethanol, filtering, and carrying out reduced pressure distillation to obtain a viscous transparent liquid product of etherification reaction; (2) carrying out sulfation reaction, namely mixing sulfamic acid and urea uniformly, slowly adding the mixture of sulfamic acid and urea into the product of etherification reaction from the step (1), adding 200ml of water after the sulfation reaction is finished, and neutralizing the mixture with an alkali until the pH value is 7.0-8.5 so as to obtain a crude product; and (3) purifying the crude product to obtain the light-yellow waxy demulsifier. The synthesis method of the ammonium sulfamate demulsifier is simple, less side reaction is generated, and the yield and the demulsification efficiency of the ammonium sulfamate demulsifier are high.

Owner:武汉钢铁有限公司

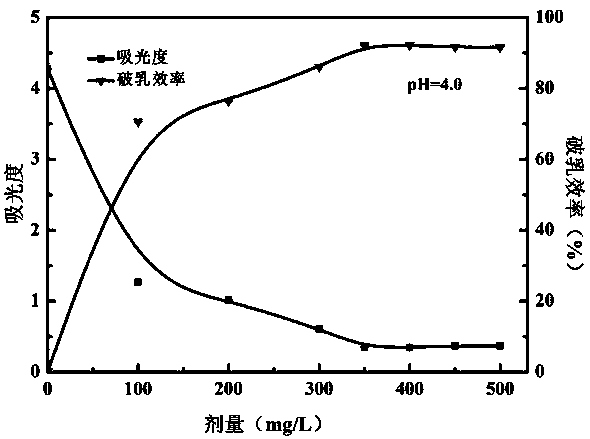

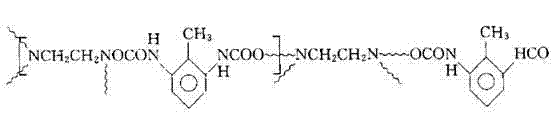

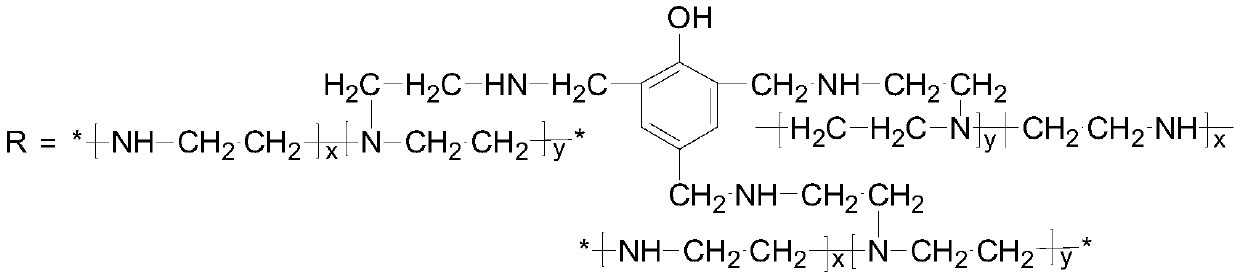

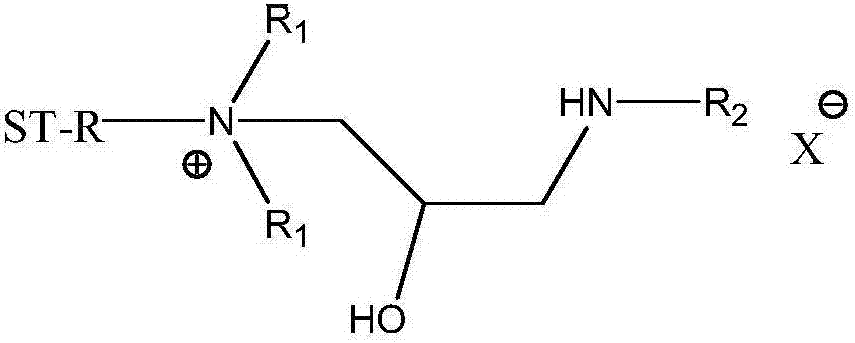

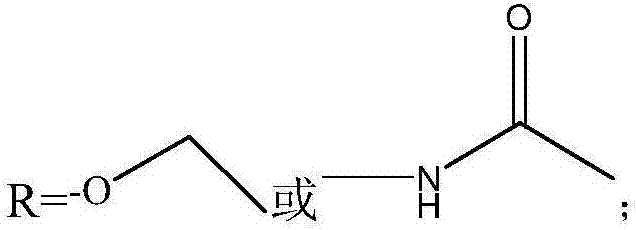

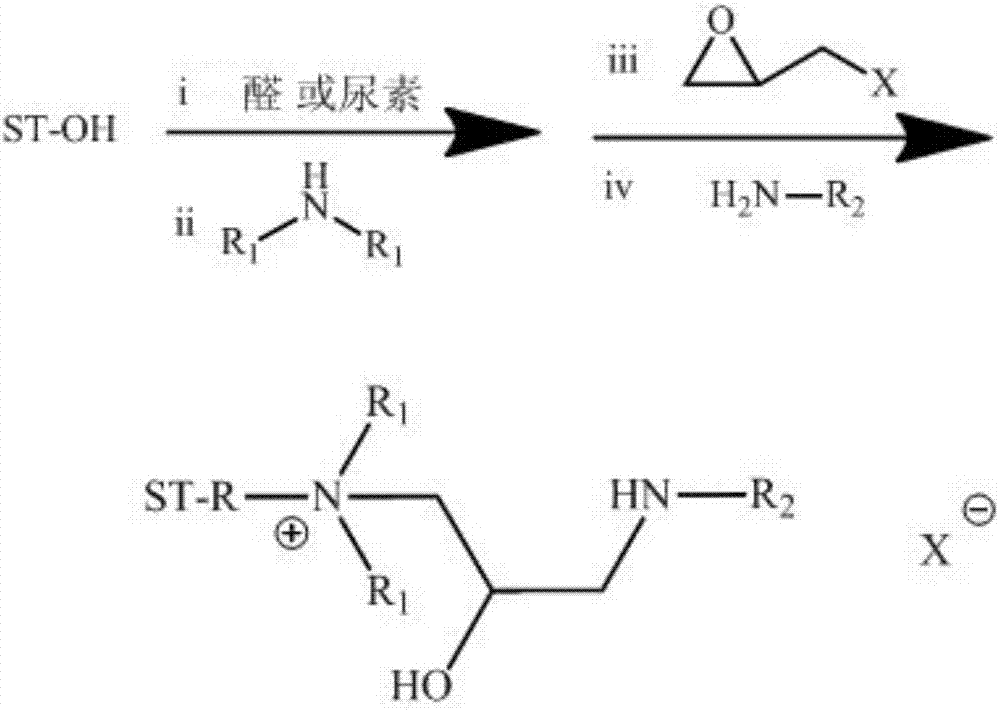

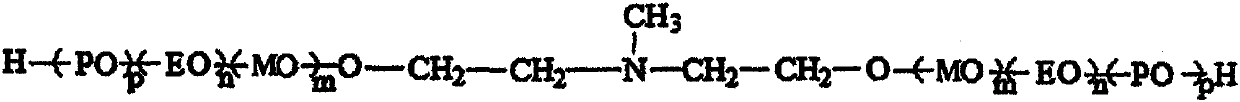

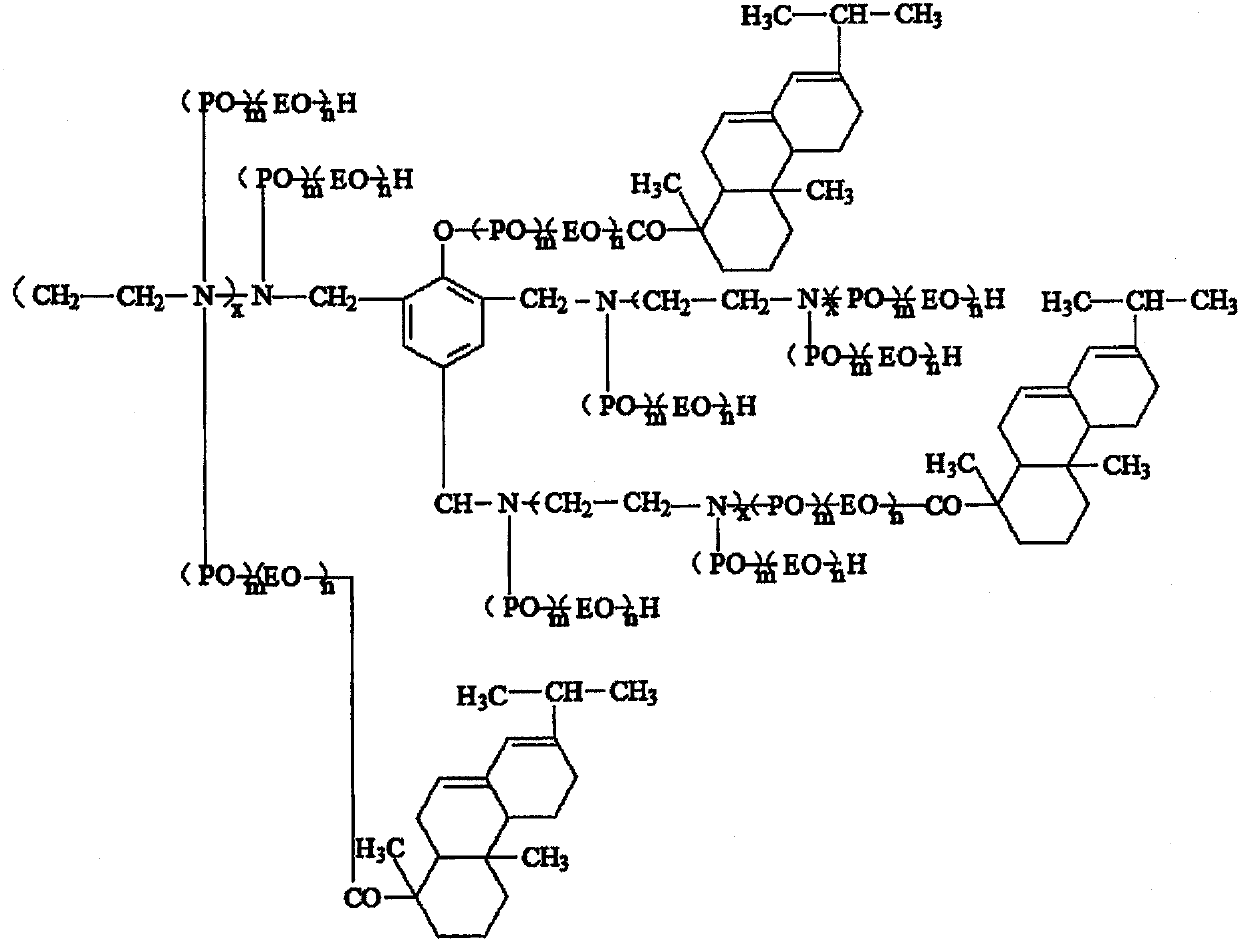

Branched low-temperature high-efficiency quaternary ammonium salt modified starch demulsifying agent and preparation method thereof

ActiveCN107188976AEfficient demulsificationLow priceNon-miscible liquid separationAldehydeBy-product

The invention relates to the technical field of oilfield sewage disposal demulsification flocculation, in particular to a branched low-temperature high-efficiency quaternary ammonium salt modified starch demulsifying agent and a preparation method thereof. The demulsifying agent has a general molecular formula as described in the description, and the preparation method comprises the following steps: (1) adding starch, aldehyde or urea, and dialkyl amine into a reactor one after another to carry out tertiary amine end capping grafting reaction; (2) adding halogeneated epoxyalkane in a reaction product to carry out quaternization grafting reaction; (3) adding a ring-opening reagent in the reaction product to carry out ring-opening grafting reaction to obtain the demulsifying agent. According to the demulsifying agent, under the condition of not using a catalyst, the starch which is low in price, rich in raw materials and can be regenerated is taken as a raw material, the production cost is low, the industrial production is conducive to being realized, the prepared demulsifying agent is characterized in that the dosage is less and the demulsifying efficiency is high, and has a very good demulsifying effect for sewage generated by the tertiary oil recovery technology. Water is the only by-product, the utilization rate of raw materials is high, and the discharge of three wastes does not exist.

Owner:WEIHAI CY DENDRIMER TECH

A kind of super heavy oil demulsifier and preparation method thereof

ActiveCN107474873BImprove Diffusion BehaviorSolve uneven defectsDewatering/demulsification with chemical meansDemulsifierActive agent

Owner:盘锦富隆化工有限公司

Aqueous enzymatic method for extracting zanthoxylum seed oil

InactiveCN105018212AHigh extraction rateImprove qualityFatty-oils/fats refiningFatty-oils/fats productionOil and greaseZanthoxylum bungeanum

The invention discloses an aqueous enzymatic method for extracting zanthoxylum seed oil. The method comprises the following steps: drying and smashing zanthoxylum seeds, performing enzymolysis, filtering, performing centrifugal separation, performing demulsification in combination with an electrolyte and membrane separation, and then merging an oil fluid to obtain a finished zanthoxylum seed oil product. The zanthoxylum seed oil prepared by adopting the method is yellowish-brown, clear and transparent, and has zanthoxylum seed fragrance; and the extraction rate is 90% to 93%. The adopted method meets the safe and green requirements of oil and fat production, the adopted enzymatic method damages plant cell walls, the reaction condition is mild, the energy consumption is low, the extraction rate is high, the electrolyte is adopted to be combined with membrane separation for demulsification, the operation is simple, the demulsification efficiency is high, the produced zanthoxylum seed oil is high in quality, the oil and fat extraction rate is high, the pollution is little, and the method is beneficial for large-scale production.

Owner:QINGDAO UNIV OF SCI & TECH

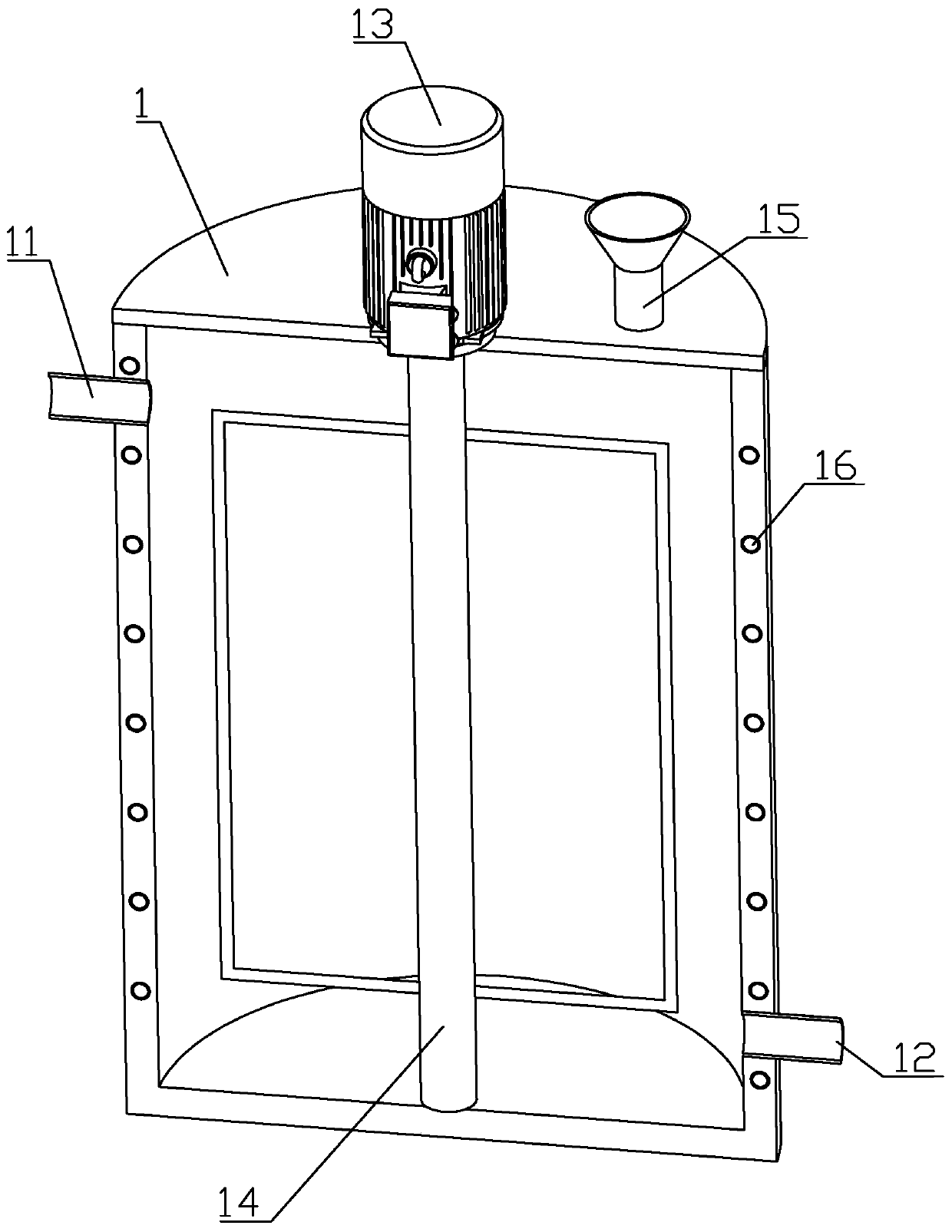

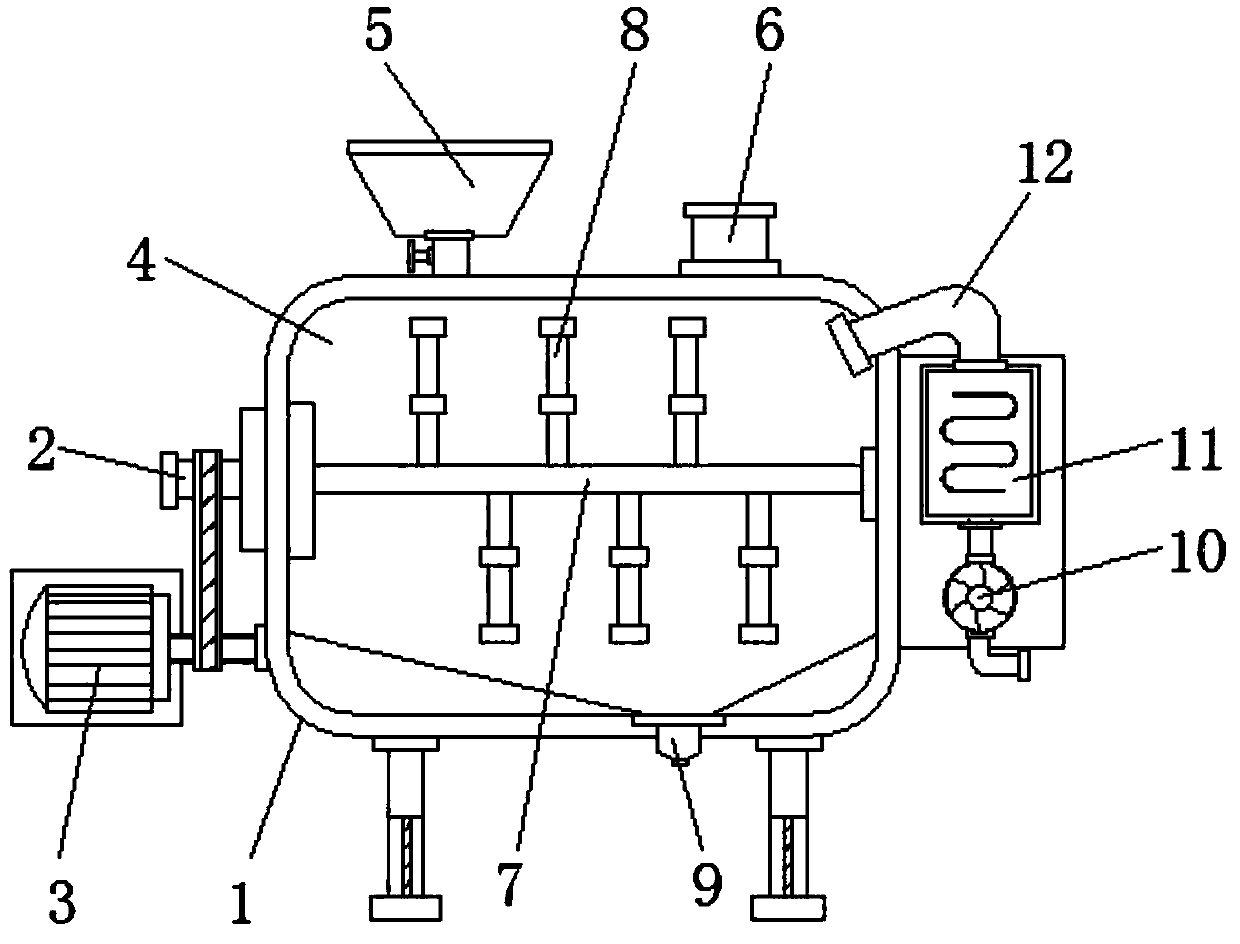

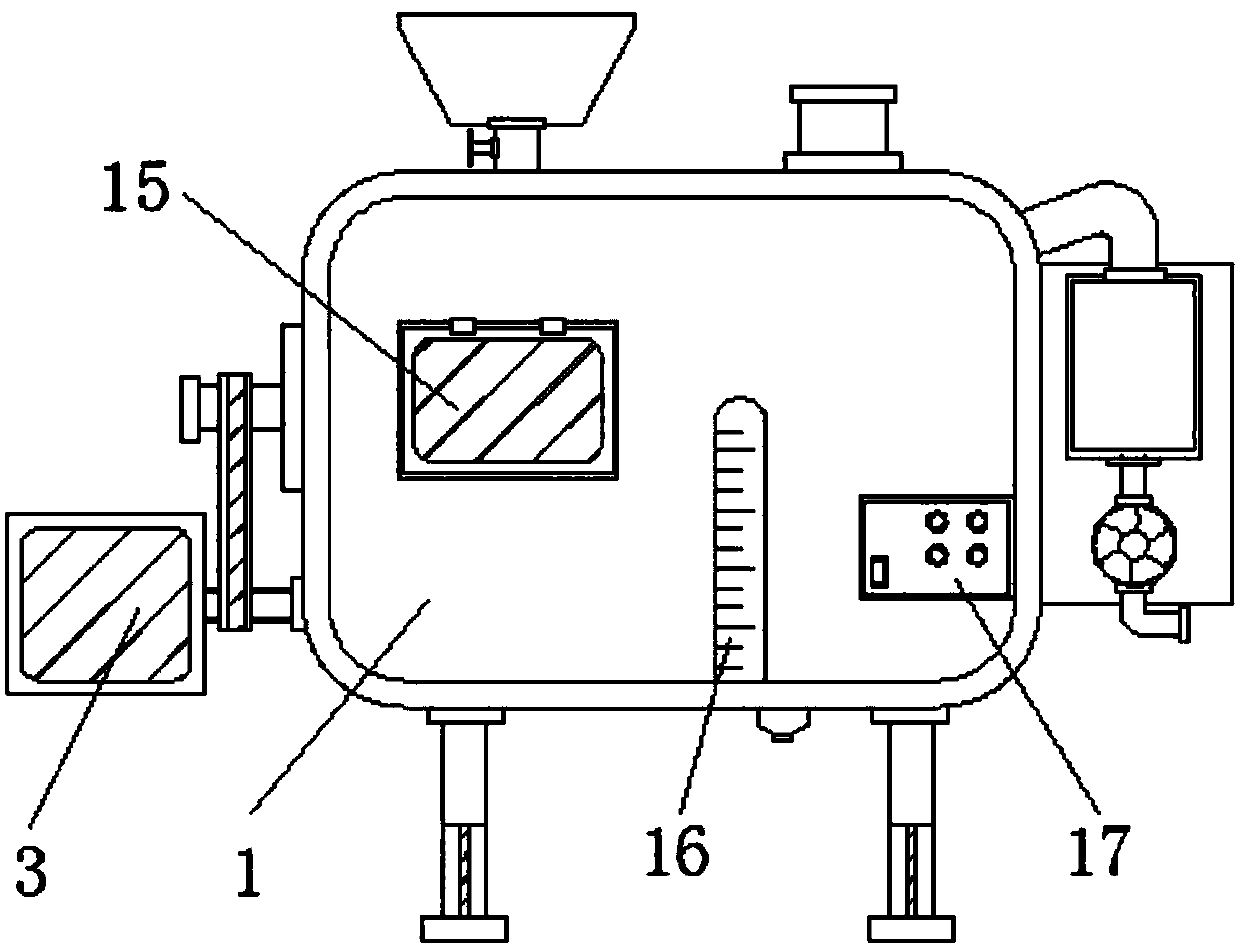

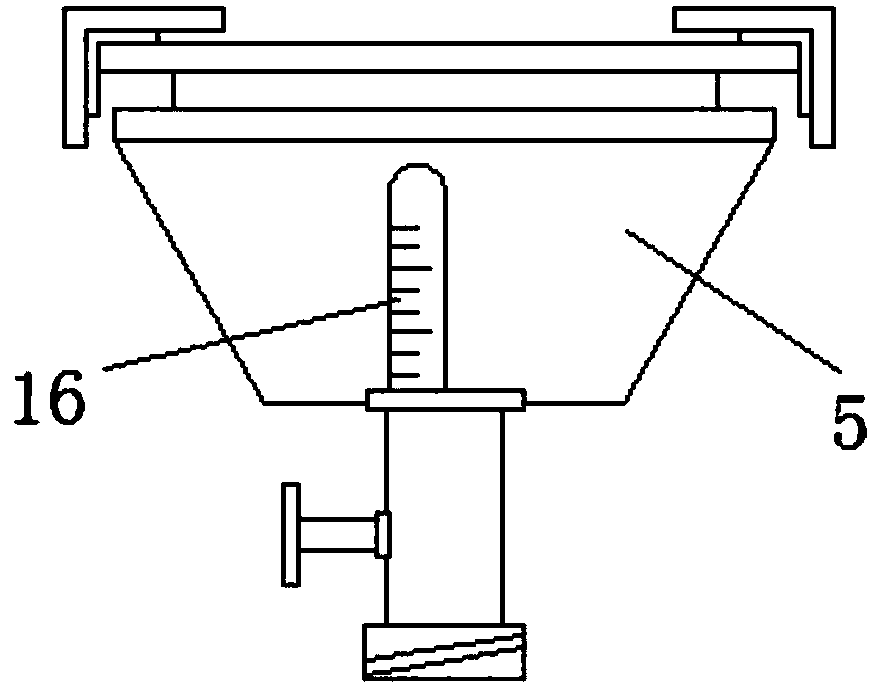

Special demulsification device for PVDF (polyvinylidene fluoride) emulsion

InactiveCN107648885AEasy to viewStir wellChemical/physical/physico-chemical stationary reactorsNon-miscible liquid separationEmulsionPolyvinylidene difluoride

The invention discloses a special demulsification device for PVDF (polyvinylidene fluoride) emulsion, which comprises an external tank, agitating blades and an observation window, the external tank isconnected to an electromotor through a transmission mechanism mounted on the left side, an internal tank is arranged inside the external tank, a storage hopper is arranged on the top of the externaltank, a feed inlet is mounted on the right side of the storage hopper, the internal tank is connected to the transmission mechanism through a connecting shaft mounted inside the internal tank, the agitating blades are mounted on both sides of the connecting shaft, an exhaust nozzle is mounted at the left end of an air supply pipe, the observation window is located on the surface of the external tank, a scale bar is arranged by the right side of the observation window, and a control cabinet is mounted by the right side of the scale bar. The agitating blades of the special demulsification devicefor PVDF emulsion sufficiently stir emulsion and chemical agents, the design of a heating barrel plays the role of heating the internal tank, so that the overall speed of demulsification reaction iseffectively increased, and because the air supply pipe is downwardly inclined, the emulsion is prevented from getting into the air supply pipe to cause the damage of the heating barrel.

Owner:HANGZHOU TELAISI CHEM EQUIP

Preparation method and application of block polyether-beta-CD comb type demulsifying agent

InactiveCN101717518BHigh molecular weightEasy to prepareDewatering/demulsification with chemical meansPolymer sciencePtru catalyst

The invention relates to a preparation method and an application of a block polyether-beta-CD comb type demulsifying agent for demulsifying and dewatering crude oil. The invention can improve the demulsifying and dewatering efficiency of a crude oil demulsifying agent and the molecular weight and the compounding capacity of the demulsifying agent. The preparation method comprises the following steps of: dissolving beta-cyclodextrin in dimethysulfoxide (DMSO), using NaOH as a catalyst and slowly dropping allylbromide to react for 48 hours at a temperature of 0-10 DEG C to obtain allyl-beta-cyclodextrin; dissolving the allyl-beta-cyclodextrin and acrylic acid raw materials in water, and under the protection of nitrogen, carrying out a polymerization reaction for 8 hours by using NaHSO3 and (NH4)2S2O7 as an initiating system so as to obtain a cyclodextrin / acrylic acid main chain polymer; and finally, putting the main chain polymer and polyoxy-ethylene block polyether in a reactor to react for 12-16 hours to obtain a product, and extracting and centrifugally separating the product to obtain the block polyether-beta-CD comb type demulsifying agent. The preparation method has simple operation, moderate condition, simple equipment and easy industrial production. After the block polyether-beta-CD comb type demulsifying agent is mixed with crude oil, the water yield of the crude oil ishigh, and the demulsifying time is short, thus the block polyether-beta-CD comb type demulsifying agent can be widely applied to oil fields and refineries for demulsifying and dewatering.

Owner:SOUTHWEST PETROLEUM UNIV

Demulsification treatment method for waste oil agent for acrylic fiber spinning

ActiveCN105800827AEffective in demulsificationEasy to recycleWater/sewage treatment by centrifugal separationWater treatment compoundsDemulsifierSorbent

The invention relates to a demulsification treatment method for a waste oil agent for acrylic fiber spinning.The method comprises the steps that a demulsifying agent and water are prepared into an aqueous solution to be added into a waste oil agent, efficient stirring is conducted, standing is conducted till the mixture is completely flocculated, and filtration is conducted; the filtered aqueous solution is subjected to adsorption treatment through an adsorbing agent, solid-liquid separation is conducted, an aqueous phase of which the COD value is lower than 500 PPm and organic matter is obtained, the aqueous phase meets the discharge standards and can be directly discharged or recycled, and the organic matter serves as fuel for generating electricity or heating.The demulsification treatment method for the waste oil agent for acrylic fiber spinning has the advantages of being low in cost, simple in treatment process and economically feasible.

Owner:中国科学院山西煤炭化学研究所扬州碳纤维工程技术中心 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com