Demulsification method for oil-in-water system emulsion

An oil-in-water, system technology, applied in the field of demulsification, can solve the problems of difficult removal, high cost, increased processing difficulty and processing cost, etc., and achieve the effect of reducing the cost of demulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of magnetic nanoparticles: weigh 5.56g FeSO 4 ·7H 2 O and 11.6 g FeCl 3 ·6H 2 O, in N 2 Dissolve in 350 mL of ultrapure water at 500 rpm under stripping; quickly add 20 mL of concentrated ammonia water (25%), and stir for 6 hours. Wash three times with deionized water, and recover Fe by magnet 3 o 4 magnetic nanoparticles. will get Fe 3 o 4 The magnetic nanoparticles were dispersed into the mixed solution (120mL ethanol, 30mL ultrapure water, 2mL ammonia water), and ultrasonicated for 5min. Add 4mL tetraethyl orthosilicate to the above solution, then ultrasonicate for 5min, mechanically stir for 6h (500rpm); collect in an external magnetic field, and obtain silica-modified magnetic nanoparticles Fe 3 o 4 @SiO 2 .

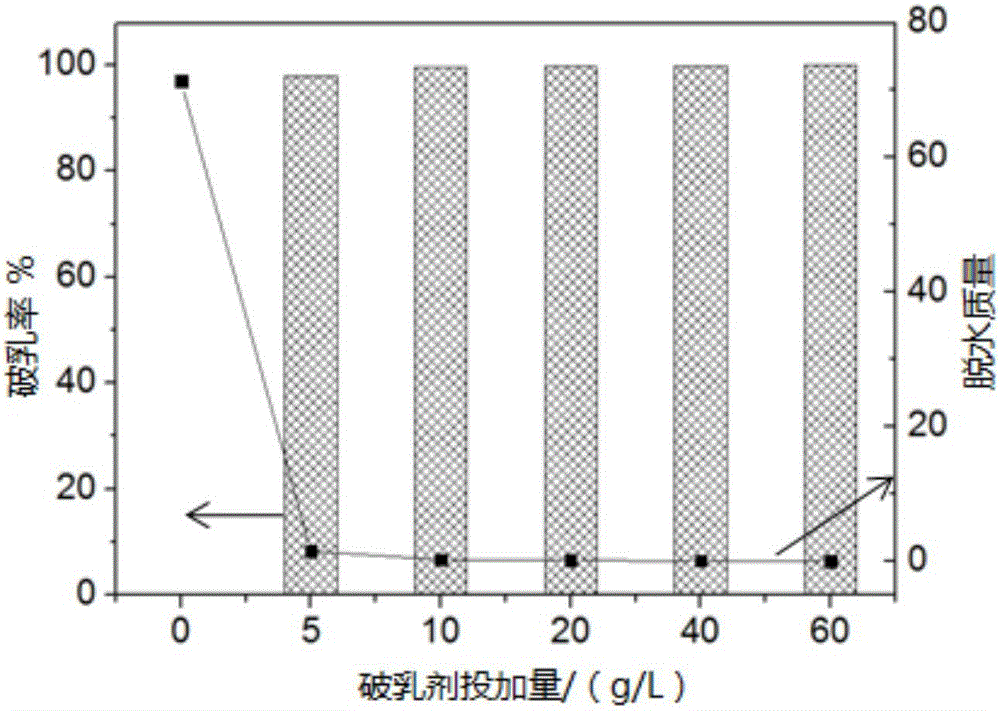

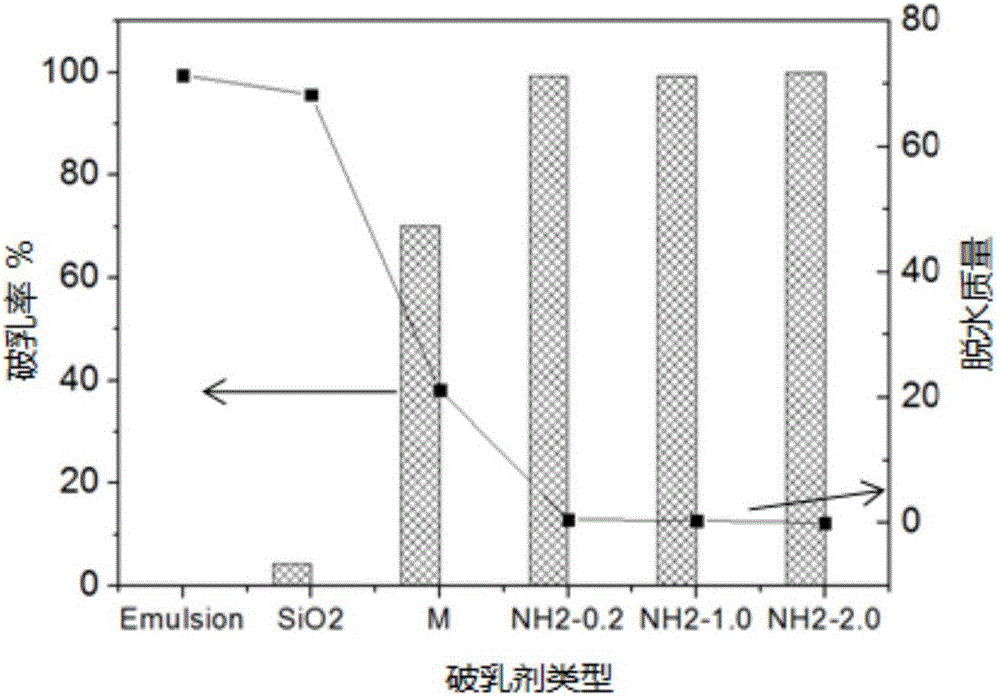

[0029] Modified synthesis of nanoparticles with different charge series: the Fe 3 o 4 @SiO 2 Disperse in 100mL toluene, add 4mL silylating reagent (KH560), and stir at 90°C for 6h. Wash with ethanol, recover the magnet and then dis...

Embodiment 2

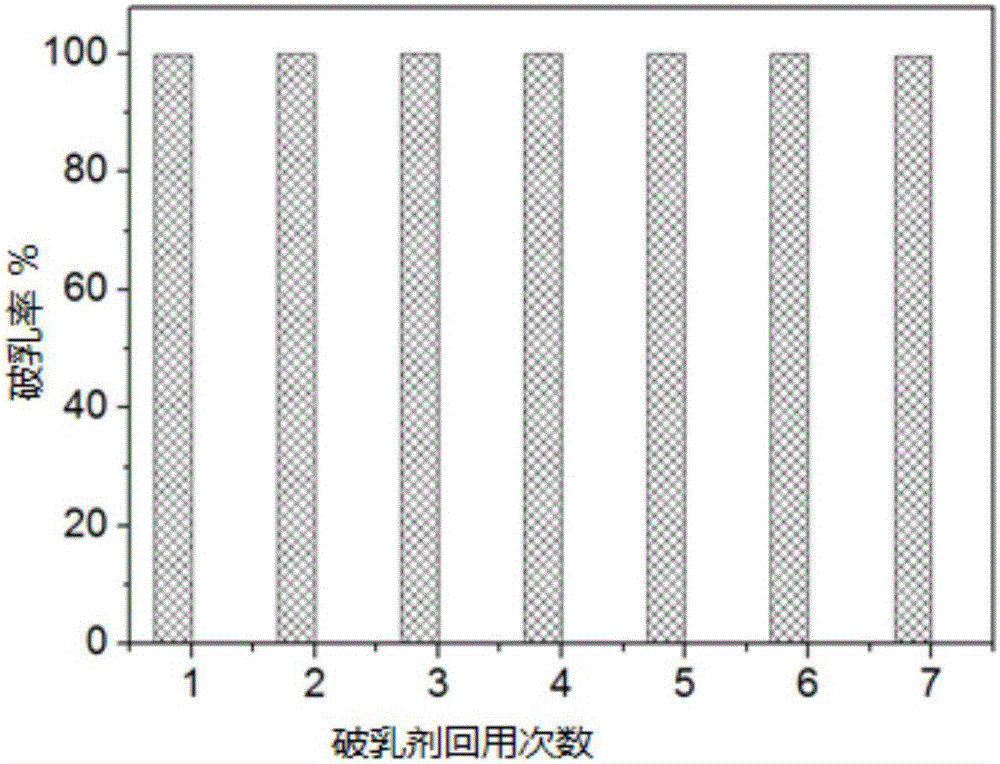

[0036] With the Fe that embodiment 1 obtains 3 o 4 @NH 2 It is applied to the treatment of an emulsion produced in a mechanical processing process, and the waste emulsion is produced in the process of mechanical processing of lubricating oil produced by Frank Chemical Co., Ltd. The magnetic nanoparticles with different surface charges have significant differences in the demulsification performance of the emulsion. When the Zeta potential of the magnetic nanoparticles is in the range of +32-+50mV, the oil removal rate of the magnetic nanoparticles can reach 90%. Therefore, the positively charged magnetic nanoparticles on the surface can not only deal with model emulsions with relatively simple components, but also can be used to deal with real emulsions with complex components. It is a potential high-efficiency demulsifier.

Embodiment 3

[0038] Adopt the operation step similar to embodiment 1, difference is:

[0039] (1) FeCl 3 and FeSO 4 The masses of are 8.115g and 5.56g respectively;

[0040] (2) Fe 3 o 4 Magnetic nanoparticles were mixed with tetraethyl orthosilicate at a ratio of 2g:0.5mL to obtain silica-modified magnetic nanoparticles Fe 3 o 4 @SiO 2 ;

[0041] (3) Fe 3 o 4 The mixing temperature of magnetic nanoparticles and tetraethyl orthosilicate is 20°C, the mixing time is 10h, and the stirring rate is 800rpm;

[0042] (4) Fe 3 o 4 @SiO 2 The mixing temperature with tetraethylenediamine is 20°C, the mixing time is 10h, and the stirring rate is 800rpm;

[0043] (5) Fe will be obtained 3 o 4 @NH 2 It is applied to the oil-in-water emulsion produced by the lubricating oil produced by Frank Chemical Co., Ltd. in the process of mechanical processing. A magnetic field with a magnetic field strength of 0.5T is applied for demulsification, and the demulsification time is 10 minutes.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com