Device and method for recovering acid from waste liquid containing low-concentration acid and high-concentration metal ions through hydrogen-ion selective electrodialysis

A metal ion, concentration acid technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., to achieve simple operation, good application value, and the effect of solving the problem of hydrogen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

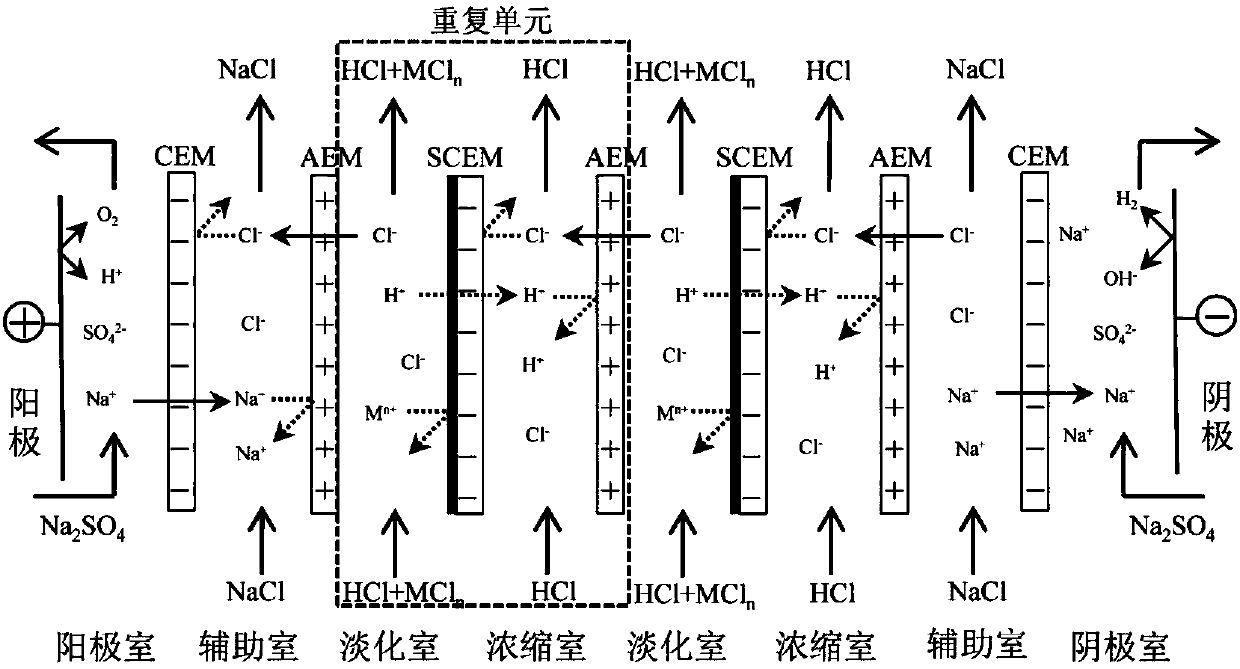

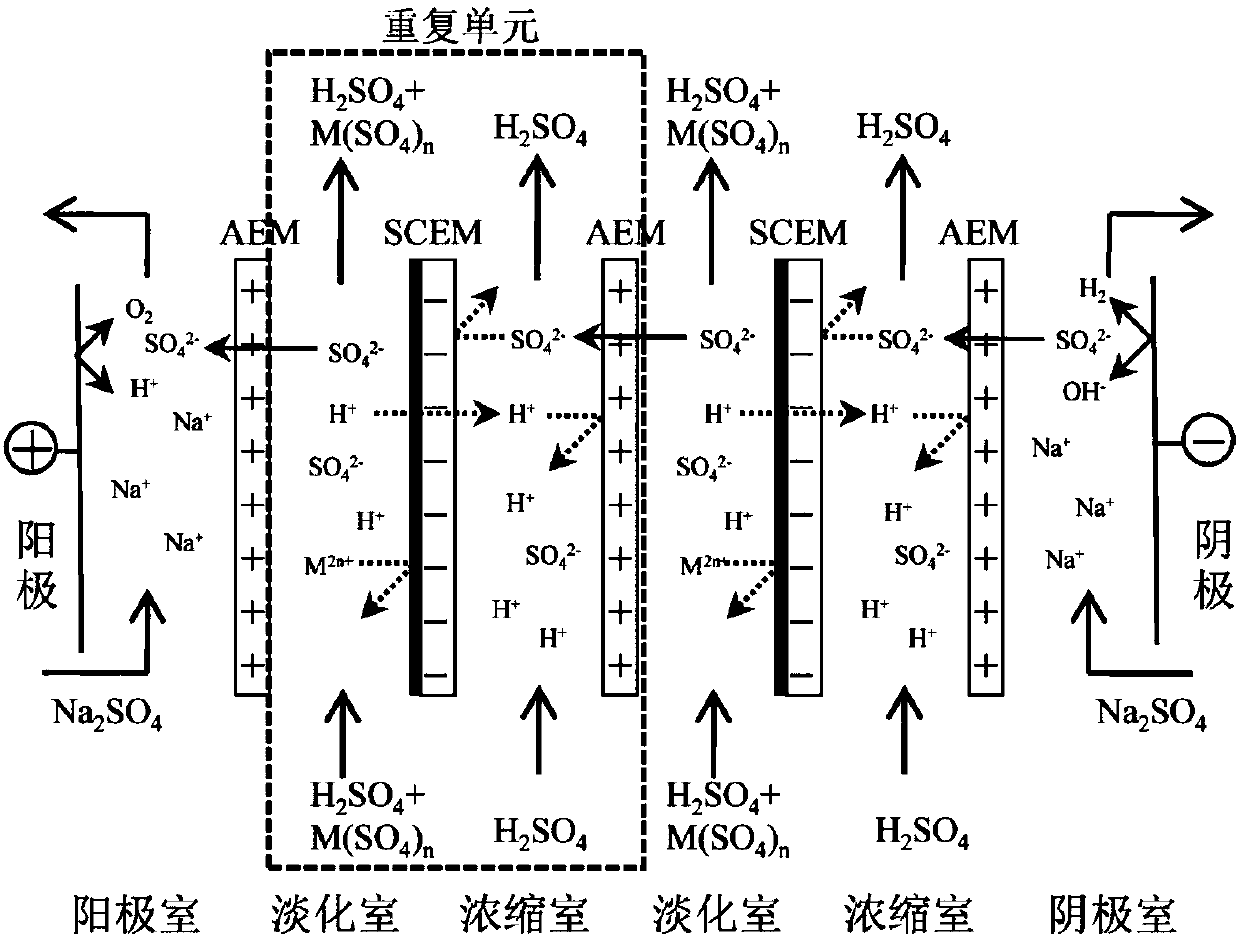

[0126] When the acid in the waste liquid containing low-concentration acid and high-concentration metal ions is hydrochloric acid, the hydrogen ion selective electrodialysis provided in this embodiment recovers acid from the waste liquid containing low-concentration acid and high-concentration metal ions. The device includes cathode, anode, membrane stack, waste liquid sampling device, deionized water sampling device, sodium chloride sampling device, strong electrolyte solution sampling device, and power supply;

[0127] Wherein, the cathode is connected to the negative pole of the power supply; the anode is connected to the positive pole of the power supply; the cathode and the anode are respectively arranged on both sides of the membrane stack; the material of the anode and the cathode is titanium Ruthenium coated.

[0128] The membrane stack includes a cation exchange membrane, an anion exchange membrane, a repeating unit membrane formed by a hydrogen ion selective membrane...

Embodiment 2

[0139] The hydrogen ion selective electrodialysis device used in this embodiment is the same as that in Embodiment 1.

[0140] The anode chamber and the cathode chamber are connected in series, and 500mL 0.3mol / L Na 2 SO 4 The aqueous solution is used as a strong electrolyte, and 500mL of 0.5mol / L NaCl aqueous solution is passed into the auxiliary chamber, and 500mL of waste liquid containing low-concentration acid and high-concentration metal ions is passed into the desalination chamber, and the components are 0.3mol / L HCl and 0.5mol / L FeCl 2 , 500mL of water was passed into the concentration chamber. During the experiment, the linear flow velocity of each compartment solution flowing in the membrane stack was 5 cm / s, and the current density was kept constant at 5 mA / cm 2 .

[0141] The hydrogen ion selective electrodialysis device was operated for 55 minutes, and the experiment was stopped. The acid concentration in the wastewater in the desalination chamber could be red...

Embodiment 3

[0143] The hydrogen ion selective electrodialysis device used in this embodiment is the same as that in Embodiment 1.

[0144] The anode chamber and the cathode chamber are connected in series, and 500mL 0.3mol / L Na 2 SO 4 The aqueous solution is used as a strong electrolyte, and 500mL of 0.5mol / L NaCl aqueous solution is passed into the auxiliary chamber, and 500mL of waste liquid containing low-concentration acid and high-concentration metal ions is passed into the desalination chamber, and the components are 0.6mol / L HCl and 0.75mol / L FeCl 2 , 500mL of water was passed into the concentration chamber. During the experiment, the linear flow velocity of each compartment solution flowing in the membrane stack was 4cm / s, and the current density was kept constant at 20mA / cm 2 .

[0145] The hydrogen ion selective electrodialysis device runs for 30 minutes, stops the experiment, the acid concentration in the wastewater in the desalination chamber can be reduced to 0.050mol / L, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com