Method for assembling block copolymer for preparing gold nano array electrode in water phase

A technology of block copolymers and array electrodes, applied in the direction of electrochemical variables of materials, can solve the problems of limiting the promotion and application of electrodes, environmental pollution, etc., and achieve the effects of improving production efficiency, reducing costs, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

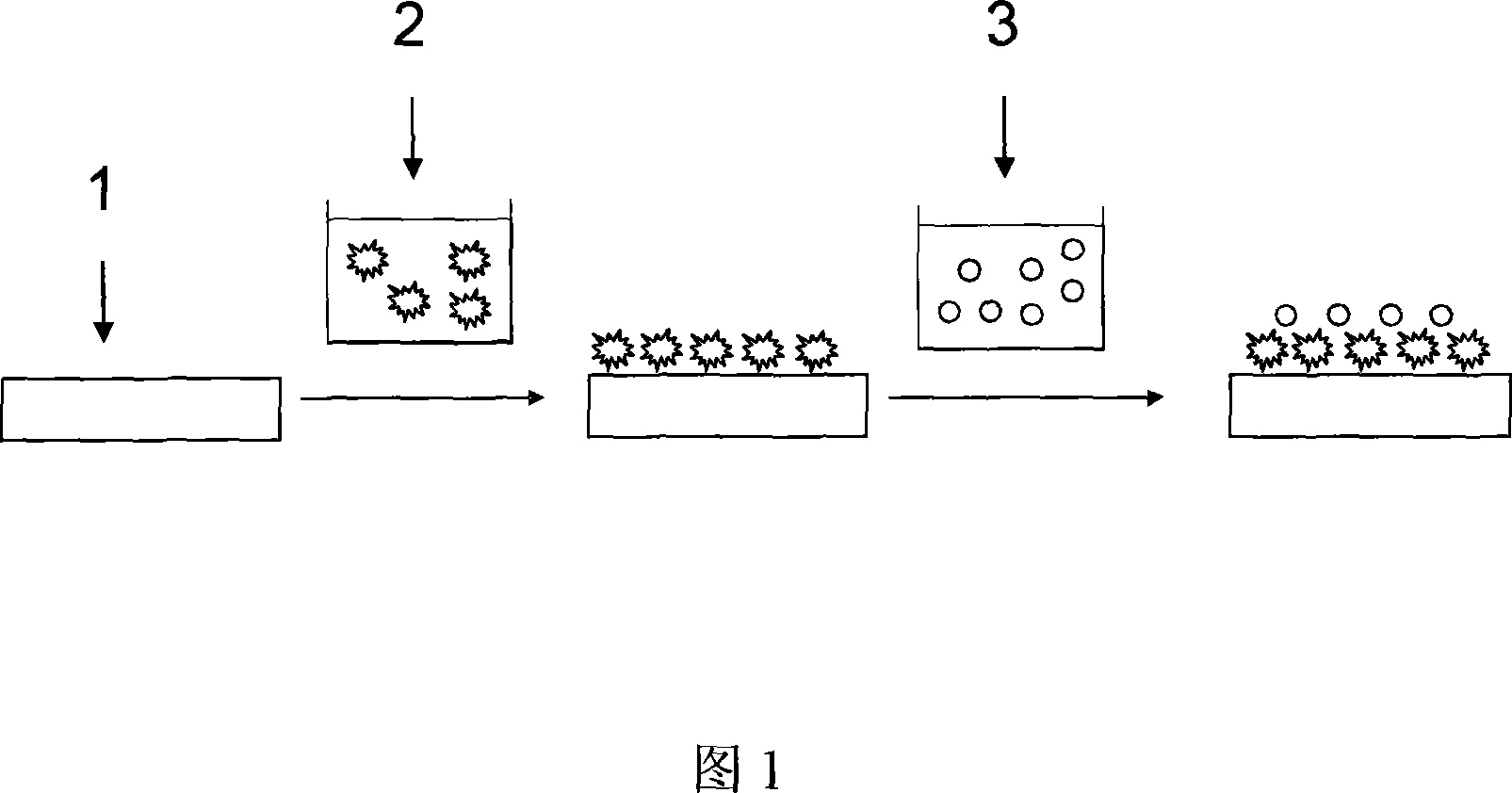

[0033] The preparation of embodiment 1 gold nanometer array electrode

[0034] 1. Preparation of cationic micelles

[0035] Dissolve the polytetravinylpyridine-polystyrene block copolymer in a HCl solution with a concentration of 0.1mol / L so that the concentration of the polytetravinylpyridine-polystyrene block copolymer is 3 mg / mL. Stir for 2 hours to form cationic micelles with polytetravinylpyridine as the shell and polystyrene as the core.

[0036] 2. Preparation of gold colloids

[0037] HAuCl with a concentration of 0.1mmol / L 4 The solution was heated while stirring, and after the solution boiled, the sodium citrate solution was added to the above-mentioned boiling HAuCl 4 In the solution, make the concentration of sodium citrate in the mixed solution be 30mmol / L, reflux 15 minutes. A gold colloid with a particle size of about 20 nm was obtained. Store the colloid in a refrigerator at 4°C when not in use.

[0038] 3. Electrostatic assembly

[0039] (1) Cut the ITO c...

Embodiment 2

[0050] Embodiment 2 Preparation of gold nano-array electrodes

[0051] 1. Preparation of cationic micelles

[0052] Dissolve the polytetravinylpyridine-polystyrene block copolymer in a HCl solution with a concentration of 0.1mol / L so that the concentration of the polytetravinylpyridine-polystyrene block copolymer is 3 mg / mL. Stir for 2 hours to form cationic micelles with polytetravinylpyridine as the shell and polystyrene as the core.

[0053] 2. Preparation of gold colloids

[0054] HAuCl with a concentration of 0.1mmol / L 4 The solution was heated while stirring, and after the solution boiled, the sodium citrate solution was added to the above-mentioned boiling HAuCl 4 In the solution, make the concentration of sodium citrate in the mixed solution be 30mmol / L, reflux 15 minutes. A gold colloid with a particle size of about 20 nm was obtained. Store the colloid in a refrigerator at 4°C when not in use.

[0055] 3. Electrostatic assembly

[0056] (1) Cut the ITO conduct...

Embodiment 3

[0067] The preparation of embodiment 3 gold nano-array electrodes

[0068] 1. Preparation of cationic micelles

[0069] Dissolve the polytetravinylpyridine-polystyrene block copolymer in a HCl solution with a concentration of 0.1mol / L so that the concentration of the polytetravinylpyridine-polystyrene block copolymer is 3 mg / mL. Stir for 2 hours to form cationic micelles with polytetravinylpyridine as the shell and polystyrene as the core.

[0070] 2. Preparation of gold colloids

[0071] HAuCl with a concentration of 0.1mmol / L 4 The solution was heated while stirring, and after the solution boiled, the sodium citrate solution was added to the above-mentioned boiling HAuCl 4 In the solution, make the concentration of sodium citrate in the mixed solution be 30mmol / L, reflux 15 minutes. A gold colloid with a particle size of about 20 nm was obtained. Store the colloid in a refrigerator at 4°C when not in use.

[0072] 3. Electrostatic assembly

[0073] (1) Cut the ITO con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com